Patents

Literature

297results about How to "Reduce COD content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technique and system for zero discharging treatment of electroplating effluent

ActiveCN105271622AReduce processing costsAvoid wastingSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processSludgeWastewater

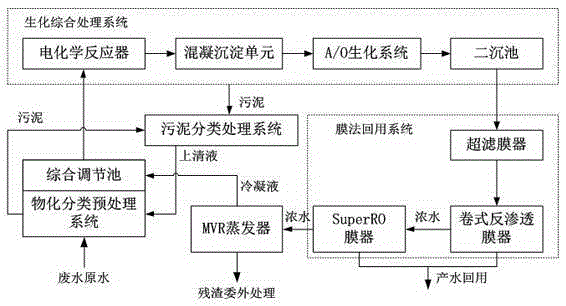

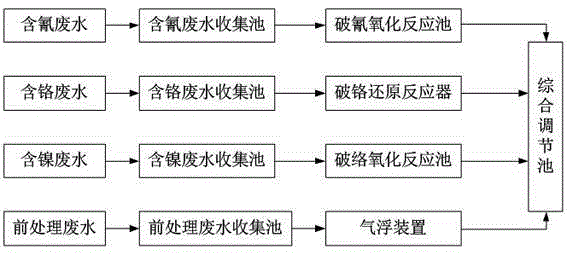

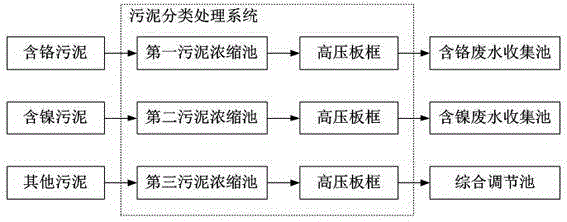

The invention discloses a technique and a system for zero discharging treatment of electroplating effluent. The system comprises a material classifying pre-treatment system, a biochemical comprehensive treatment system, a membrane method system, a membrane concentrated liquor vaporization system and a sludge classifying treatment system which are connected with each other in turn, wherein the sludge classifying treatment system is connected with the material classifying pre-treatment system and the biochemical comprehensive treatment system; the raw wastewater enters into the material classifying pre-treatment system; water generated by the membrane method system is recycled; the condensed liquid from the membrane concentrated liquor vaporization system is re-injected into the material classifying pre-treatment system. According to the technique provided by the invention, the wastewater is firstly treated in classifying form, so that the heavy pollution ions, such as, chromium, cyanogen, nickel, and the like, and the oily matters in the wastewater are effectively removed, and then the biochemical comprehensive treatment system is used for further treating, and lastly, the RO+SuperRo two-level combination mode is utilized to achieve the gross recovery at 94%, and meanwhile, the liquid amount for evaporation treatment is less than 6% of the gross wastewater quantity, the cost of the evaporation treatment is saved, the sludge is recycled, the waste of resources is avoided and the sludge treating cost is saved.

Owner:CHENGDU MEIFUTE MEMBRANE TECHNOLOGY CO LTD

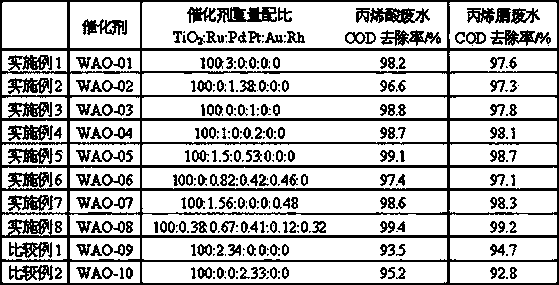

Wet oxidation catalyst and preparation method thereof

ActiveCN105080540AReduce COD contentReduce organic contentWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsRare earthOxidative treatment

The present invention relates to a preparation method of a wet oxidation catalyst, and a wet oxidation treatment method of industrial acrylic acid wastewater, and aims to solve the problem of low wastewater COD reduction efficiency of a catalyst in the prior art. The wet oxidation catalyst adopts a rare earth doped noble metal catalyst, and comprises the following components: (1) 96 to 99.8 parts of a carrier; (2) 0.1 to 2 parts of a rare earth oxide; and ( 3) 0.1 to 2 parts of at least one noble metal selected from the platinum group, by the technology scheme, the problem is better solved, and the wet oxidation catalyst is used for treatment of industrial acrylic acid wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

Efficient paint mist coagulating agent and preparation thereof

InactiveCN101407353AImprove working environmentExtended service lifeWater/sewage treatment by flocculation/precipitationIron saltsWastewater

The invention relates to a highly-efficient paint mist coagulant and an application method thereof. The paint mist coagulant includes an A reagent and a B reagent, the A reagent is a water solution mainly prepared by a modified macromolecule polymerization metal salt, the macromolecule polymerization metal salt is aluminium salt or iron salt; the B reagent is a water solution mainly prepared by a polymerization amide-type substance with molecular weight of 9 millions to 12 millions. When in application, the paint waste water is blended with the A reagent and the B reagent according to volume ratio of 500:2:1, thus leading the paint in the paint waste water to cake and float, the paint and the water are separated, clear water is obtained to reuse. The usage is firstly adding the A reagent, and adding the B reagent after even blending. The processed paint waste water is fat-soluble paint waster water and water-soluble paint waste water. The highly-efficient paint mist coagulant has a wide reagent source, effectively overcomes the disadvantages of the trivial preparation process, many and complex additional reagents and high price of the traditional paint mist coagulant, can reduce common paint waste water treatment cost to 0.25 yuan / ton and can be widely used in circulating water treatment in a wet-typed paint mist removing system.

Owner:WUHAN UNIV OF TECH

Improved paper pulp bleaching process

The invention discloses an improved pulp bleaching technique for reed pulp paper-making, which comprises: first, using deoxylignin for bleaching, wherein, slurry concentration 8-20%, temperature 85-130Deg, oxygen consumption quanity 1-4.5Kg per ton slurry, NaOH consumption quanity 1-4Kg per ton slurry, and MgSO4 consumption quantiy 0.1-1.0%; second, using biological enzyme for bleaching, wherien, enzyme adding quanity 20-80g per ton slurry, temperature 30-80Deg, slurry concentration 5-16%, pH value 5-12, slurry hardness 2-8(KMnO4), and time 0.5-4h; third, adding hypochlorite for bleaching. This invention can reduce bleachability and back-yellow value, improves yield and slurry hardness, and decreases pollution to environment.

Owner:XINJIANG BOHU REED IND

Method for realizing catalytic wet oxidation of wastewater containing organic substances

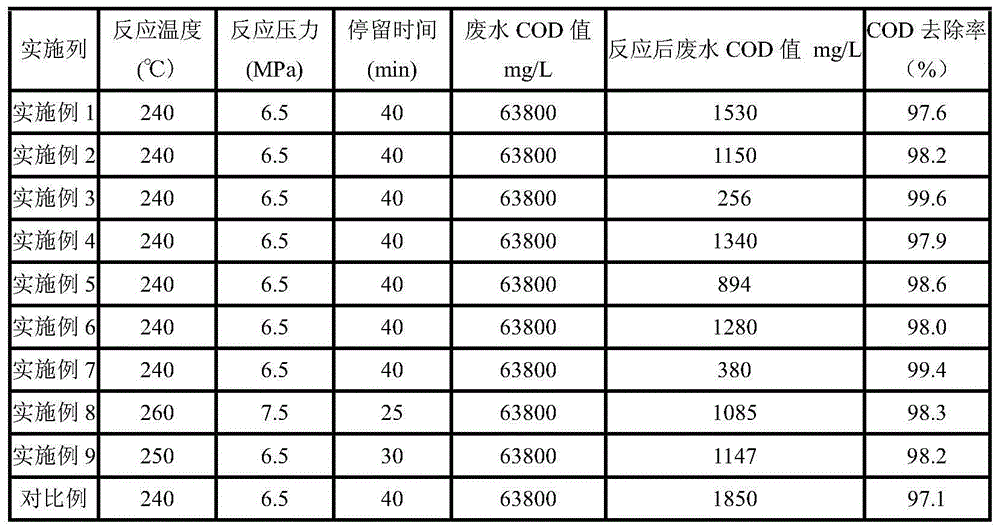

ActiveCN103523891AHigh activityReduce COD contentCatalyst carriersWater contaminantsHigh concentrationReaction temperature

The invention relates to a method for realizing catalytic wet oxidation of wastewater containing organic substances, which mainly solves the problem that high-concentration organic wastewater is difficult to treat in the prior art. The technical scheme of the method comprises the following step: by taking noble metal loaded nano titanium dioxide as a catalyst, enabling organic wastewater to be in contact with the catalyst in a high-pressure reaction kettle for 30-120 minutes under the conditions that the reaction temperature is 120-260 DEG C and the oxygen gas pressure is 1-10 MPa, wherein the used catalyst comprises the following components in parts by weight: A) 97-99.8 parts of titanium dioxide nanotube, and B) 0.2-3 parts of at least one of Ru, Pd, Pt, Au or Rh loaded on the nanotube. Thus, the problem is well solved; and the method can be used for industrial production of organic wastewater treatment.

Owner:CHINA PETROLEUM & CHEM CORP +1

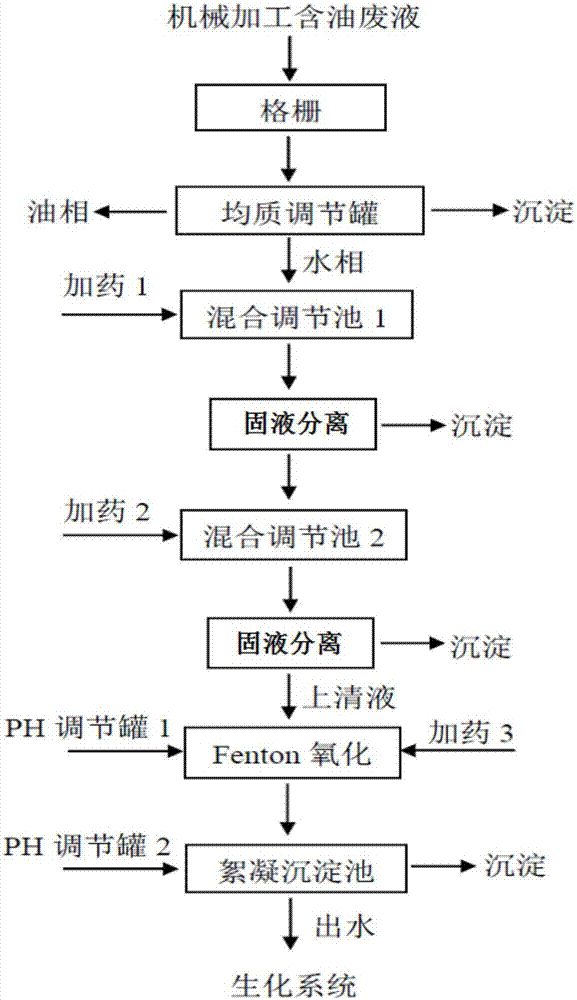

Pretreatment method for waste emulsion

InactiveCN107082526AGood effectReduce COD contentWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesGratingPretreatment method

The invention discloses a pretreatment method for oil-containing waste liquid from machining. The method comprises the following steps: firstly, oil-containing waste liquid from machining passes a grating, in order to remove pollutants of large particles; the waste liquid passes a homogenizing and adjusting pot in order to realize three-phase separation of oil, water and sand; two-stage demulsification is carried out for separated water phase in order to destroy an emulsion, and solid-liquid separation is carried out; supernatant is separated after demulsification, the pH value is adjusted, and fenton oxidation is carried out; after the fenton reaction ends, the pH value is adjusted for deposition, and effluent enters a biochemical system. The oil-containing waste liquid with high COD from machining is directly subjected to simple two-stage demulsification and the fenton oxidation process, COD content is greatly reduced, turbidity is obviously reduced, B / C ratio is obviously increased, and biochemical treatment conditions are created. The method has the advantages of very low treatment cost, and simple operation without secondary pollution.

Owner:安徽汇泽通环境技术有限公司

Photo resist film removing agent

InactiveCN101071278AReduce COD contentImprove protectionPhotosensitive material processingResistCompound organic

A photoresist stripping of the membrane, which is composed of the percentage of weight: Composite organic base 10% - 30%; polyether active agent 1% to 5%; broken film of 1% to 5% copper Corrosion Inhibitor 0.1% -1%; deionized water 60 percent to 70 percent above base is a complex organic chemical-XR-NH2 organic amines in at least two, X is H, OH or NH2, R-n - base; polyether active agent for ethylene oxide and ethylene oxide to block copolymer or inorganic in at least one copolymer; broken film for the long carbon chain aliphatic amines, copper corrosion inhibitor for benzo triazole and its derivatives in at least one. The present invention retreat film properties, and its high rate of retreat membrane, the membrane of the retreat, the use of low-cost, Wuxi migration, copper corrosion, do not contaminate pure tin, gold, silver surface membrane retire at the metal layers with superior protection and particularly suitable for flexible lines and fine lines, and other high-end PCB manufacturing, production safety and environmental protection are used.

Owner:HUNAN SCI & TECH RES & DEV CENT

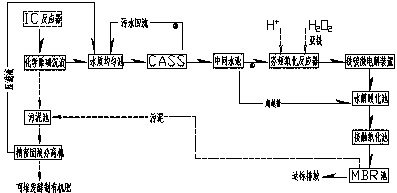

Kitchen wastewater treatment method

InactiveCN103739173AInhibition of bloomsInhibition of reproductionMultistage water/sewage treatmentChemical oxygen demandElectrolysis

The invention discloses a kitchen wastewater treatment method which comprises the following steps: 1, chemical phosphorus removal is performed on kitchen wastewater flowing out from an IC (internal circulation) reactor; 2, after passing through a water quality equalization tank, the wastewater enters a CASS (Cyclic Activated Sludge System) to react, so that soluble substrates, organisms, phosphorus and an synchronous nitrification and denitrification effect are removed; 3, after the wastewater flows into an intermediate water tank to be subjected to volume regulation, the wastewater enters a Fenton oxidation reactor and an iron-carbon micro-electrolysis device so as to improve biodegradability of the wastewater; 4, after passing through the Fenton oxidation reactor and the iron-carbon micro-electrolysis device, the wastewater directly enters a hydrolysis acidification pool from the intermediate water tank, suspended matter and iron ions are removed and sludge is separated, hydrolyzed and acidified; 5, the wastewater is subjected to aerated oxidation to remove COD (Chemical Oxygen Demand) content; 6, the wastewater enters an MBR (Meane Biological Reactor) pool and hardly degradable substances are degraded, so that the drained wastewater reaches the take-over standard of a sewage treatment plant; 7, after the sludge discharged from a chemical phosphorus removal pool and the MBR pool is processed by a precision solid-liquid separator, solids are prepared into an organic fertilizer and filter-pressing liquid enters the water quality equalization tank.

Owner:HUNAN HAISHANG ENVIRONMENTAL PROTECTION INVESTMENT CO LTD

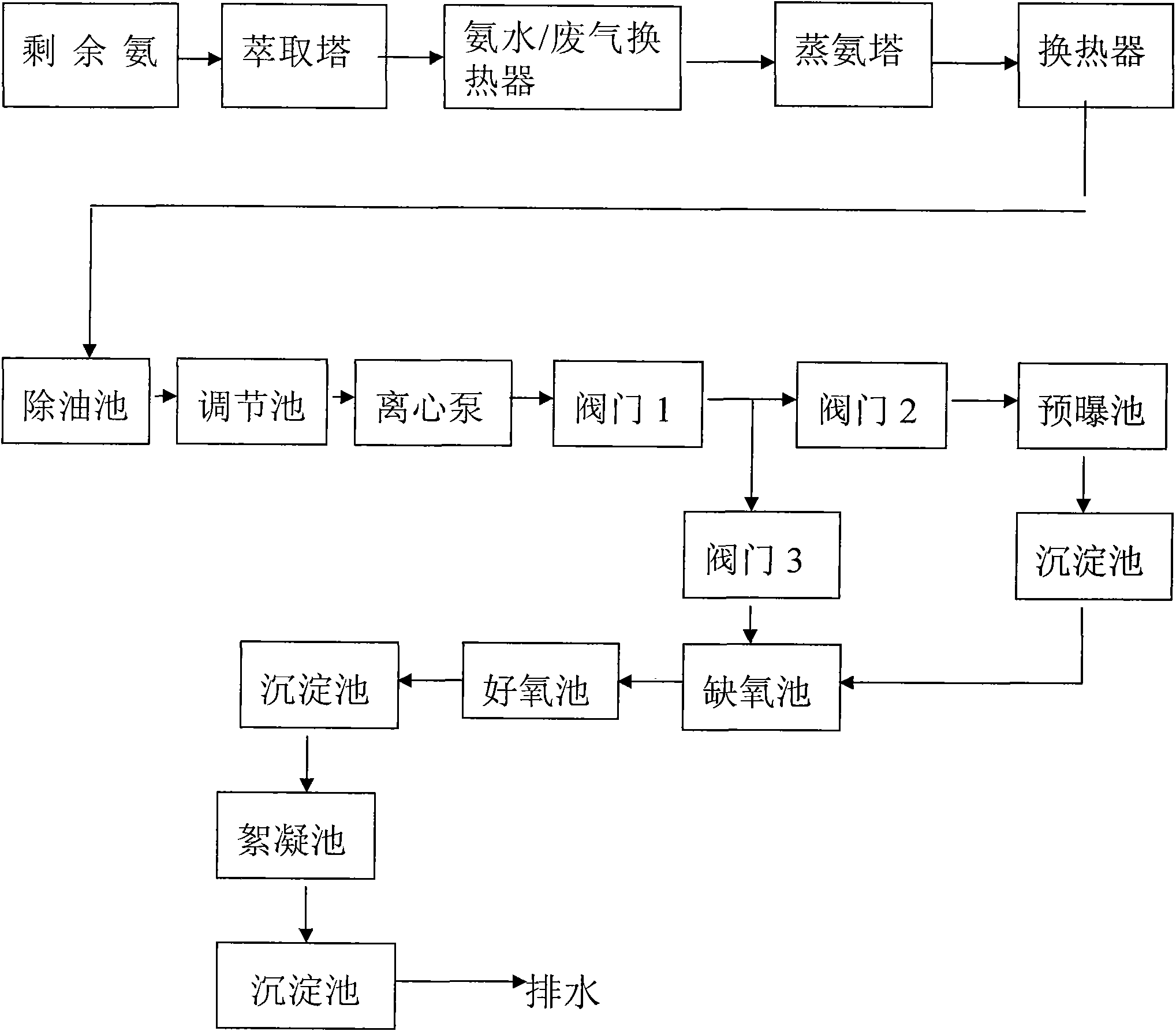

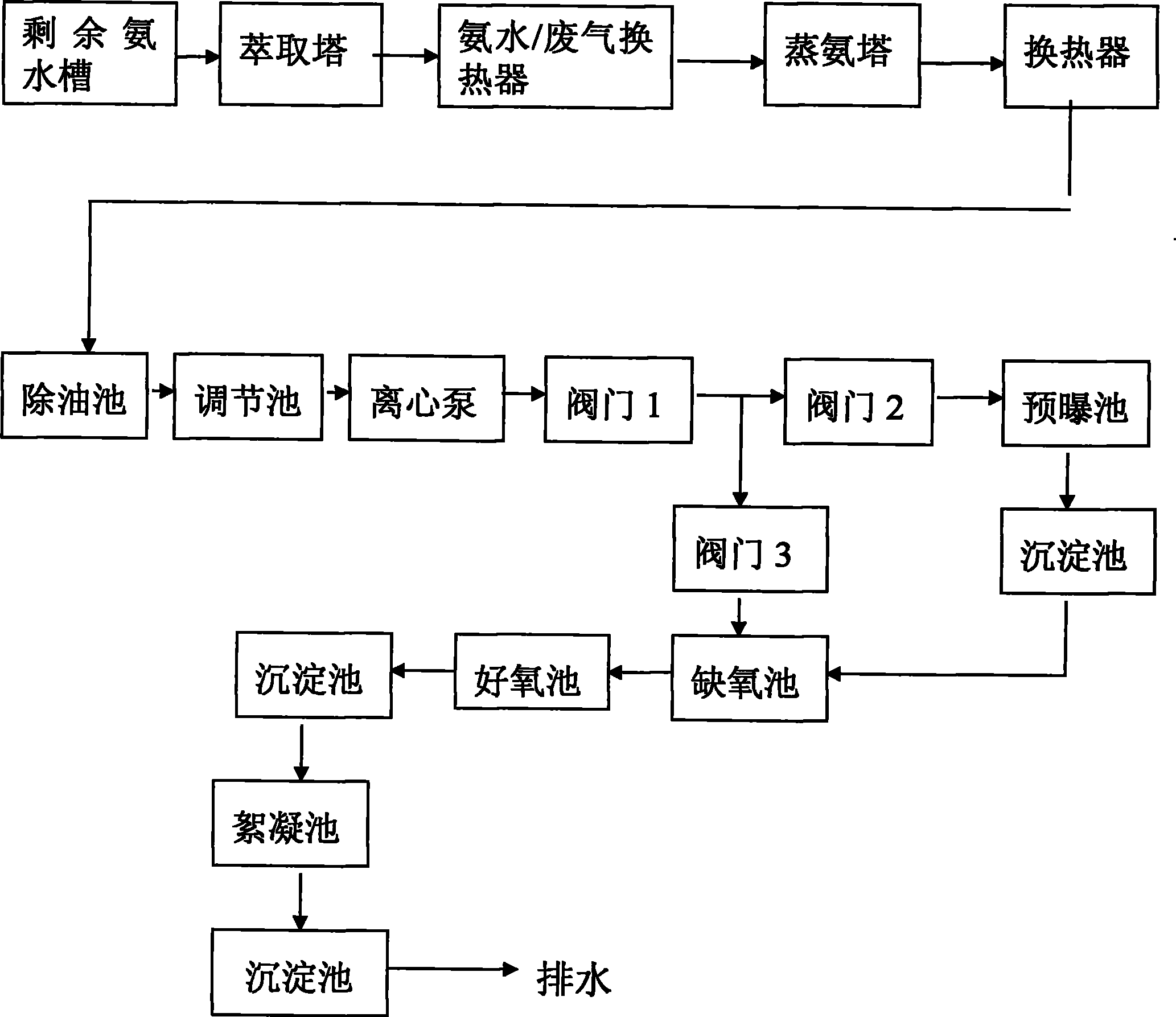

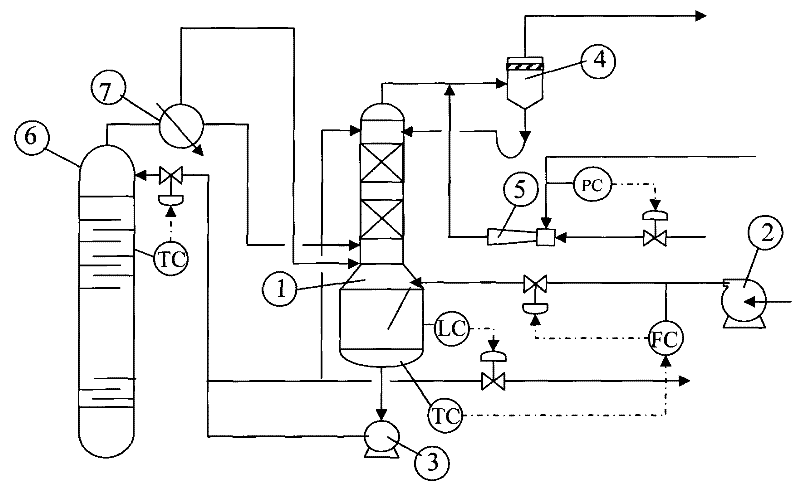

Coking wastewater treatment process

InactiveCN101880112APromote escapeReduce COD contentTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentWater qualityEmission standard

The invention discloses a coking wastewater treatment process, which comprises the steps of extraction separation, heating, ammonia still, oil removal, water quality and water quantity regulation, biochemical treatment, flocculating settling and the like. Wastewater after the extraction separation is sent to the ammonia still step to be treated after being heated, and the ammonia still step is carried out under the condition of negative pressure. The noxious compounds such as ammonia, phenol and the like can be perfectly escaped from the ammonia, and the biochemical treatment load can be lightened. The biochemical treatment step is realized through a preaeration tank, an anoxic tank and an aerobic tank, a regulation tank is respectively communicated with the preaeration tank and the anoxic tank through a centrifugal pump and pipelines, pipelines communicated with the preaeration tank and the anoxic tank are respectively provided with a valve, the A / O process, the O / A / O process and the simultaneous proceeding of the A / O process and the O / A / O process can be switched according to different water qualities, and the invention can adapt to the coking wastewater with large water quality fluctuation. Through the treatment by the process, the wastewater reaches the first grade discharge standard specified by Discharge Standard of Water Pollutants for Iron and Steel Industry (GB 13456-92).

Owner:WUHAN IRON & STEEL (GROUP) CORP

Method for removing pollutants from water by using action of biochar strengthened oxidant

InactiveCN110015745AHigh reactivityExtended half-lifeWater/sewage treatment by sorptionWater/sewage treatment by reductionPersulfateSewage

The invention discloses a method for removing pollutants from water by using action of a biochar strengthened oxidant and relates to water treatment methods. The method is used for solving the problems that when oxidants frequently-used for water treatment at present, i.e., ferrate, permanganate, ozone and persulfate are applied to treatment on the pollutants in the water, the removal effect is poor, and the efficiency of removal of total organic matters is low. The method for removing the pollutants from the water comprises the steps: (1) adding biochar into the water to be treated, so as toobtain biochar containing water; (2) stirring the biochar containing water, and meanwhile, adding an oxidant for a reaction; and (3) filtering the treated water after the reaction ends up, thereby completing removal of the pollutants from the water. According to the method, based on a strengthened oxidation action and improved adsorption performance, after a combined action of the biochar and theoxidant, the rate of removal of typical organic pollutants from untreated water can reach 90% or more, the removal rate of TOC can reach 50% or more, or the content of COD in sewage can be lowered by60% to 90%.

Owner:HARBIN INST OF TECH

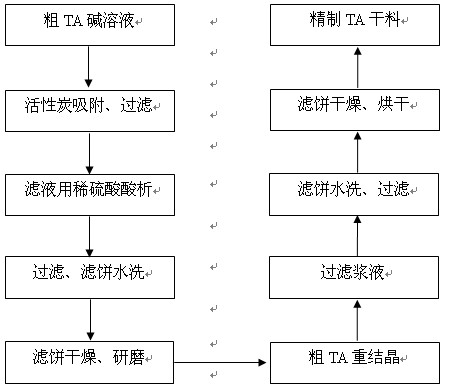

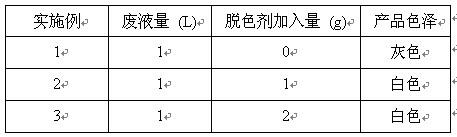

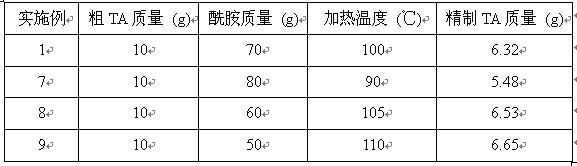

Method for recovering and purifying terephthalic acid in alkali-minimization waste liquor

InactiveCN102234226AReduce COD contentEasy to operatePreparation from carboxylic acid saltsCarboxylic compound separation/purificationActivated carbonChemical oxygen demand

The invention relates to a method for purifying terephthalic acid in alkali-minimization waste liquor through acidolysis and crystallization, which comprises the following steps of: adsorbing to remove organic impurities and colored substances from the alkali-minimization waste liquor by using active carbon; adding a dilute acid solution into filtrate for acidolysis, and extracting the terephthalic acid from the waste liquor; drying and grinding a filter cake to obtain coarse terephthalic acid; dissolving and crystallizing the terephthalic acid by using a strong polar organic solvent, and performing recrystallization for multiple times to more effectively improve the purity of the terephthalic acid; and washing with water, filtering, drying, and refining the terephthalic acid to make the purity more than 99.8 percent, so that the terephthalic acid can be polymerized with glycol to produce polyester. By the method, the chemical oxygen demand (COD) of discharged wastewater can be effectively reduced, high-purity terephthalic acid can be obtained through recovery and purification, and waste materials can be reutilized.

Owner:EAST CHINA UNIV OF SCI & TECH

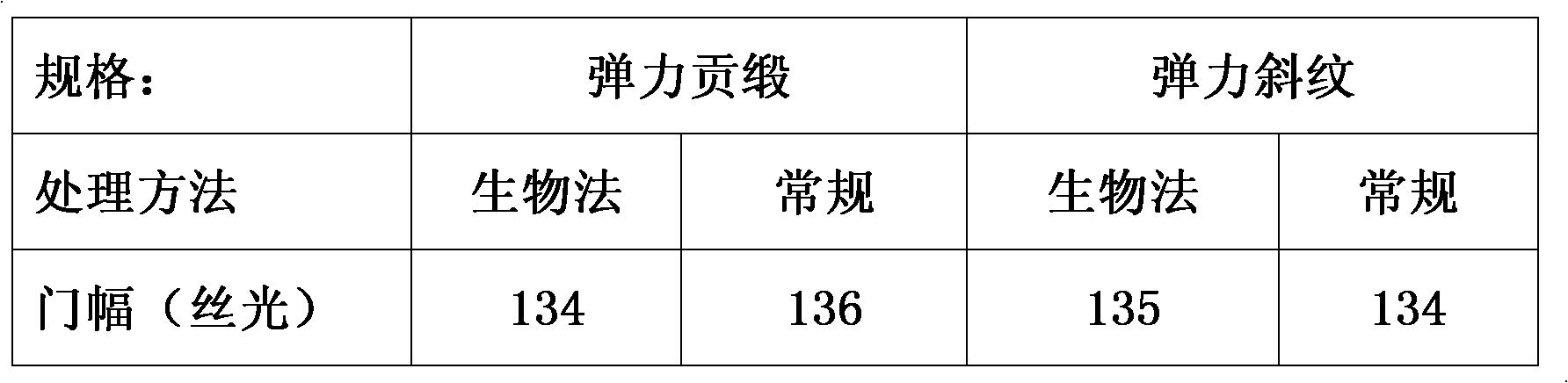

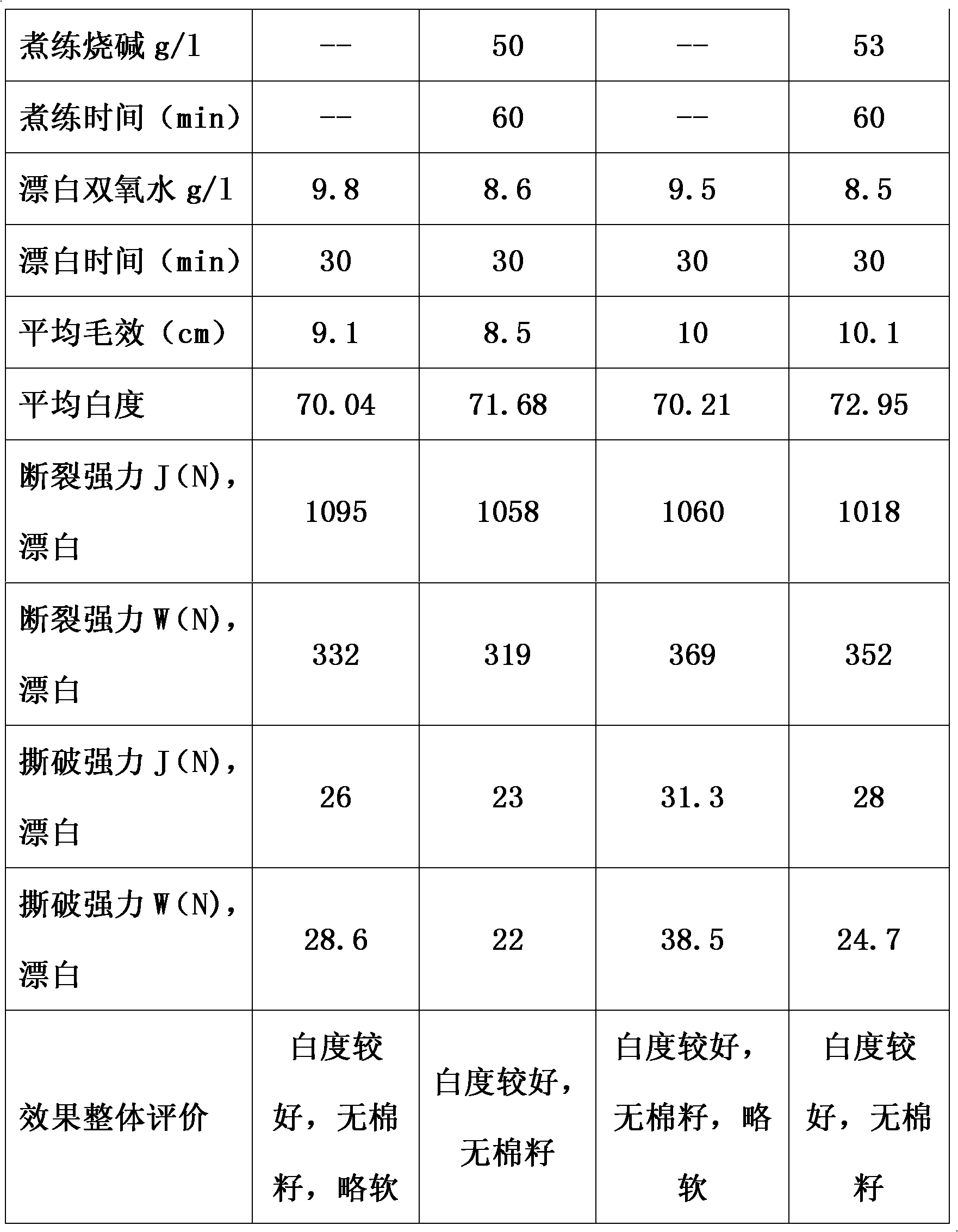

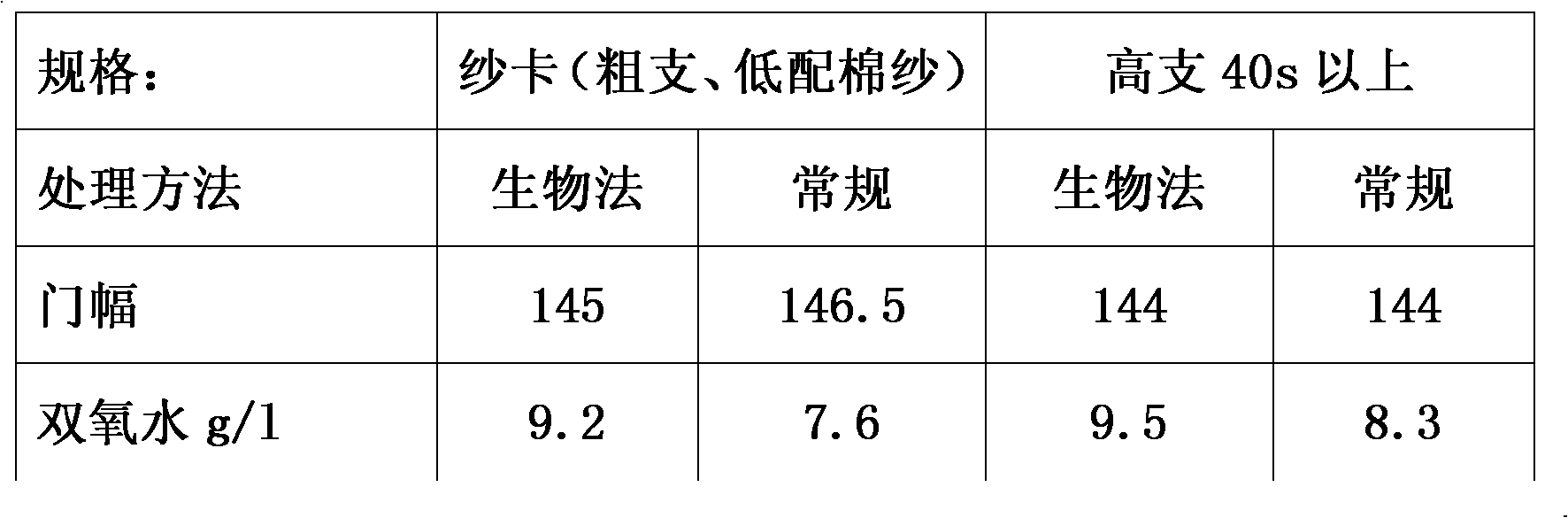

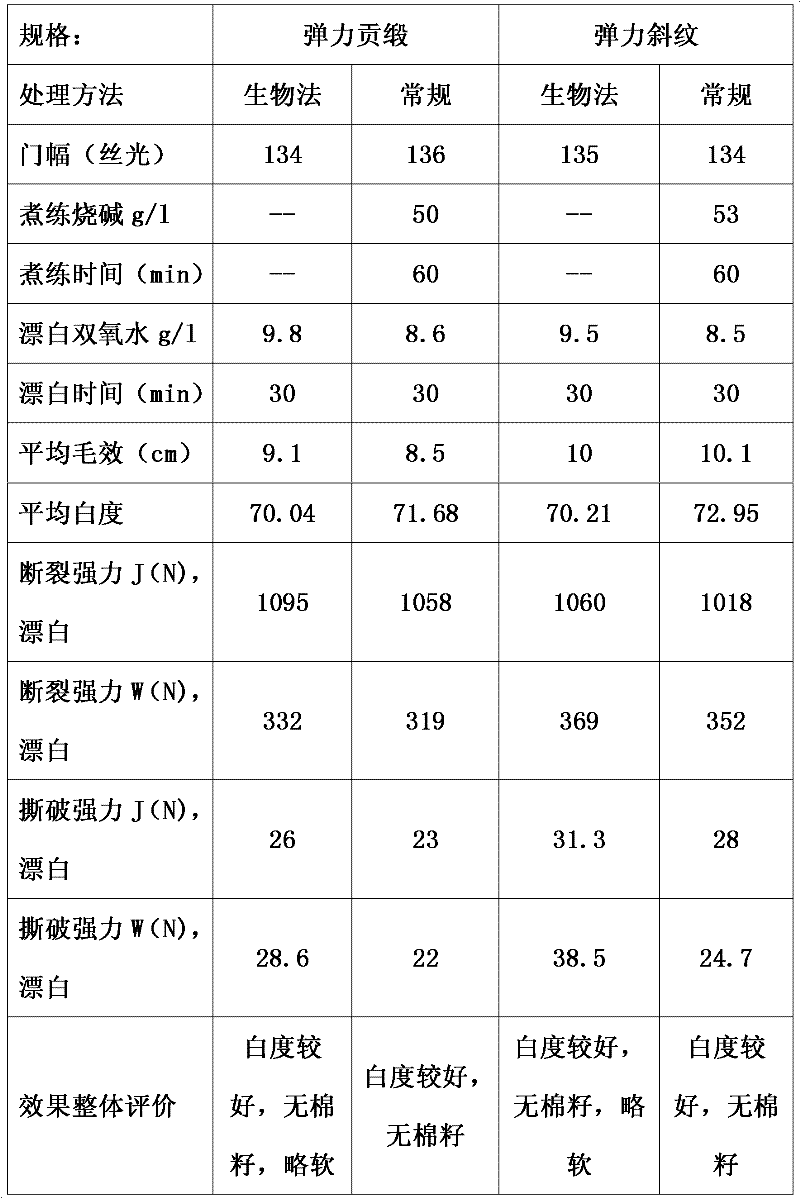

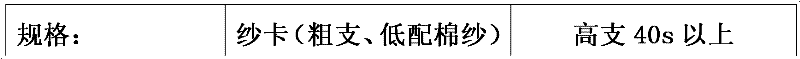

Enzyme preparation and application thereof

The invention discloses an enzyme preparation. The enzyme preparation is characterized in that: one liter of the enzyme preparation comprises 0.5 to 20g of cotton seed hull removal enzyme, 0.2 to 20g of amylase, 0.5 to 10g of cellulose, and 1 to 100g of complex enzyme preparation of emulsifiable penetrant, wherein the pH of the complex enzyme preparation is 4 to 7. By applying the enzyme preparation, the conventional desizing and scouring process can be replaced. The defects of complex steps, high steam consumption, and electric power and sewage discharge value in the conventional fabric pretreatment processing are overcome, the damage to the fabric is reduced, the processing difficulty of pretreatment on cotton blend fabric and mixed fabric is reduced, and energy consumption, sewage and the chemical oxygen demand (COD) content in the sewage can be reduced.

Owner:HUZHOU MEIXINDA BIOLOGICAL TECH

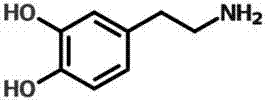

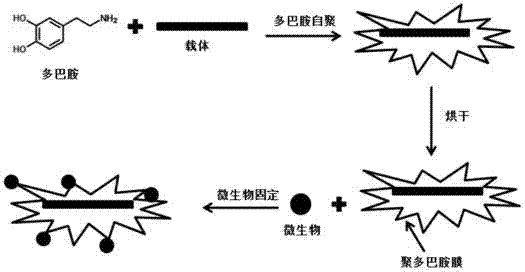

Polyurethane carrier with polydopamine hydrophilic layer attached to surface thereof and preparation method and application of polyurethane carrier

InactiveCN107478790ASimple processEasy to operateTesting waterBiological water/sewage treatmentRoom temperaturePetrochemical

The invention relates to a polyurethane carrier with a polydopamine hydrophilic layer attached to the surface thereof and a preparation method and application of the polyurethane carrier. The preparation method comprises: 1) dissolving dopamine in a buffer, and adding an oxidant to prepare a dopamine-modified solution; 2) soaking a polyurethane carrier in the dopamine-modified solution at the room temperature; and 3) taking the treated polyurethane carrier obtained from the step 2) out, cleaning the obtained polyurethane carrier, and performing drying to obtain the polyurethane carrier with a polydopamine hydrophilic layer attached to the surface thereof. The method is simple in process and easy to operate. The polyurethane carrier is beneficial for industrial application and has bright application prospects in the fields of water treatment, biology, medicine, petrochemical and energy.

Owner:CHINA PETROLEUM & CHEM CORP +1

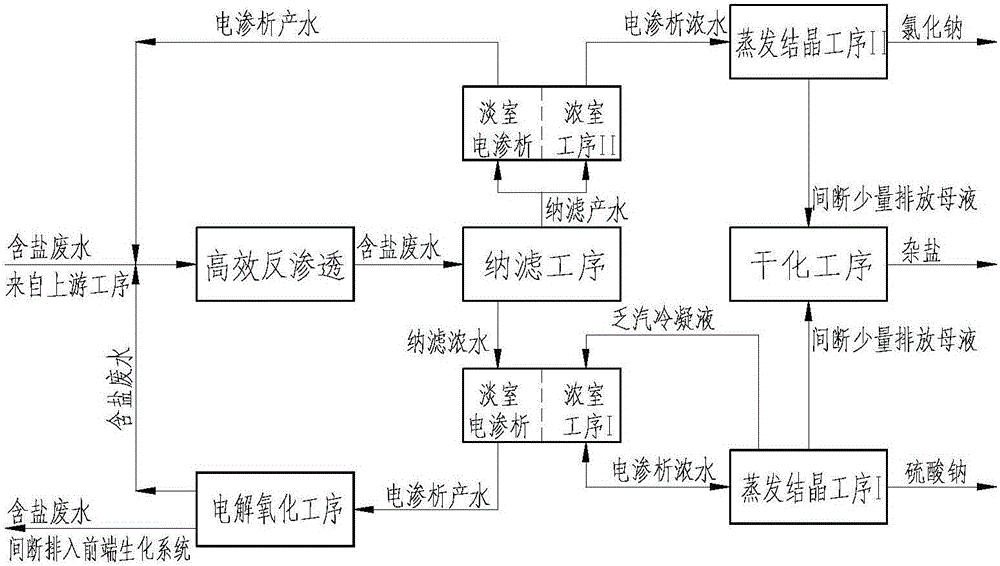

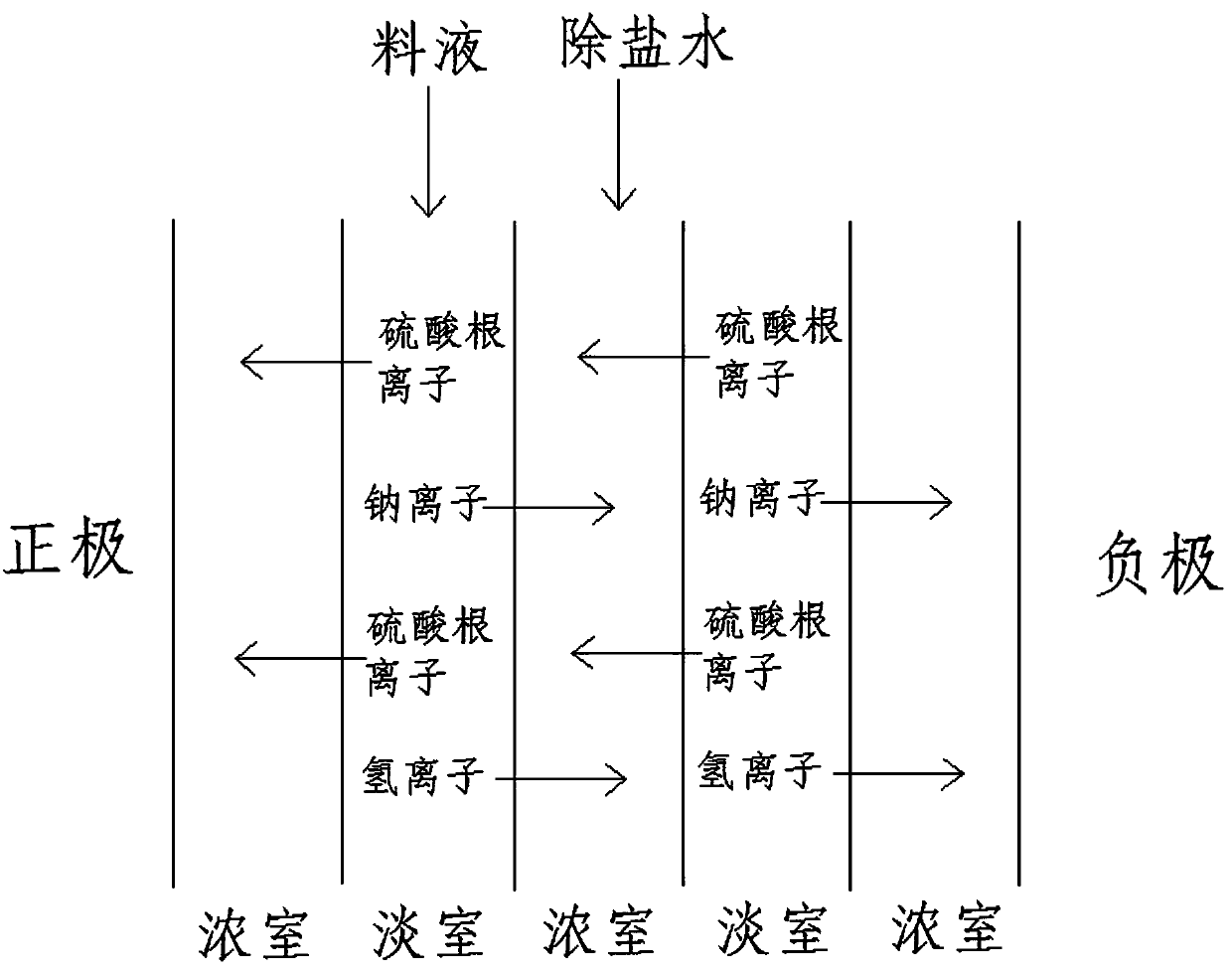

Method for separating organic matter impurities from brine waste of coal chemical industry and separating salt by utilizing membrane method

InactiveCN106830481AAchieve separationAvoid disadvantages such as low purityWater treatment parameter controlMultistage water/sewage treatmentReverse osmosisWater quality

The invention discloses a method for separating organic matter impurities from brine waste of a coal chemical industry and separating salt by utilizing a membrane method. The method comprises the following steps: (1) efficient reverse osmosis process; (2) nanofiltration process; (3) electroosmosis process I; (4) evaporative crystallization process I; (5) electrolytic oxidation process; (6) electroosmosis process II; and (7) evaporative crystallization process II. The invention abandons the traditional scheme for separating the salt in the manner of high-quality crystal separation through freezing crystallization or thermal method at the rear end and adopts a nanofiltration membrane process for separating the salt. The selective permeability of the nanofiltration membrane for ions under different valence states is utilized to separate the two main components, namely, sodium chloride and sodium sulfate in the waste water. The defects that the water quality change cannot be coped with and the product purity is low in the traditional salt niter separation hot-process crystallizing scheme can be overcome.

Owner:EAST CHINA ENG SCI & TECH

Method for preparing cation type composite flocculant for treating waste drilling fluid

ActiveCN102167431AWide variety of sourcesLow costWater/sewage treatment by flocculation/precipitationFlocculationCollagenan

The invention relates to a composite flocculant for treating waste drilling fluid generated in the petroleum drilling process, and a preparation method thereof. The preparation method comprises the following steps of: extracting gelatin with larger relative molecular mass from waste skin collagen through alkaline hydrolysis; further hydrolyzing the extracted gelatin into collagen with moderate relative molecular mass by using different hydrolytic reagents; and loading proper metal ions on the collagen by using a tanning mechanism in tanning chemistry to obtain a cation type composite flocculant, and performing flocculation on anionic waste drilling fluid. The composite flocculant prepared by the method has the advantages of low cost, simple operation, high flocculating efficiency, safety and nontoxicity for a human body and the like, and is an environment-friendly product. Meanwhile, the waste skin collagen is reutilized, waste is used to treat contamination, and secondary pollution on the environment is avoided.

Owner:江苏肇方智能装备有限公司

Paint mist coagulant and preparation method thereof

InactiveCN102502935AImprove working environmentImprove circulating water qualityWater/sewage treatment by flocculation/precipitationEnvironmental engineeringAqueous solubility

The invention discloses a paint mist coagulant and a preparation method thereof. The paint mist coagulant comprises an agent A and an agent B, wherein the agent A is an aqueous solution which is prepared by taking a macromolecular polymeric metal salt as a main component; the macromolecular polymeric metal salt is aluminum salt or ferric salt; and the agent B is an aqueous solution which is prepared from a polyamide substance with the molecular weight of 9000000-12000000. In the application, paint wastewater, the agent A and the agent B are mixed according to a volume ratio of 500: 2: 1, paint in the paint wastewater agglomerates and floats upwards, the paint is separated from water to obtain clear water, and the clear water is reused; the application method is that the agent A is added and uniformly mixed firstly and then the agent B is added; and the treated paint wastewater is fat-soluble treated paint wastewater and water-soluble treated paint wastewater. The chemicals used in the invention are wide in source; the defects that the conventional process of preparing the paint mist coagulant is complicated and many complicated and expensive chemicals are added are overcome; the treatment cost of the ordinary paint wastewater can be reduced to 0.25 Yuan per ton; and the paint mist coagulant can be widely applied to circulating water treatment of a wet-type paint mist removing system.

Owner:CHANGSHA GUTERUI NOVEL MATERIAL SCI & TECH

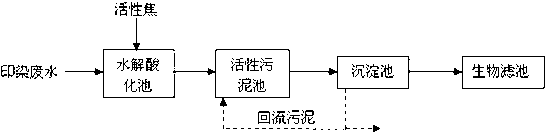

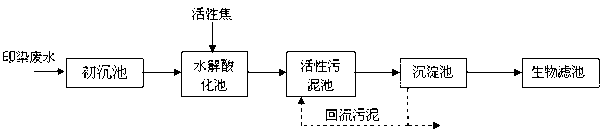

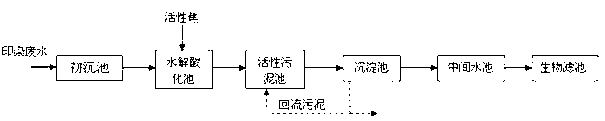

System for treating printing and dyeing wastewater with activated coke adopted and process thereof

ActiveCN103058455AExtended stayImprove removal efficiencyMultistage water/sewage treatmentActivated sludgeBiological filter

The invention provides a system for treating printing and dyeing wastewater with activated coke adopted. The system comprises a hydrolytic acidification device, an activated sludge pool, a settling pool and a biological filter pool, wherein the hydrolytic acidification device, the activated sludge pool, the settling pool and the biological filter pool are arranged in a sequentially connected mode, activated coke is added into the hydrolytic acidification device, and discharging water with the activated coke and from the hydrolytic acidification device enters the activated sludge pool again. According to the system, the activated coke is added into the hydrolytic acidification device, the activated coke is fully mixed with the wastewater in the hydrolytic acidification device, so that standing time of recalcitrant molecules in the wastewater on the hydrolytic acidification device is improved, and efficiency of hydrolytic acidification is improved. The wastewater with the activated coke and from the hydrolytic acidification device enters the activated sludge pool again, the activated coke continues to have the function of absorption and degradation, and removal efficiency on sludge concentration and organic matter in the activated sludge pool is improved.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

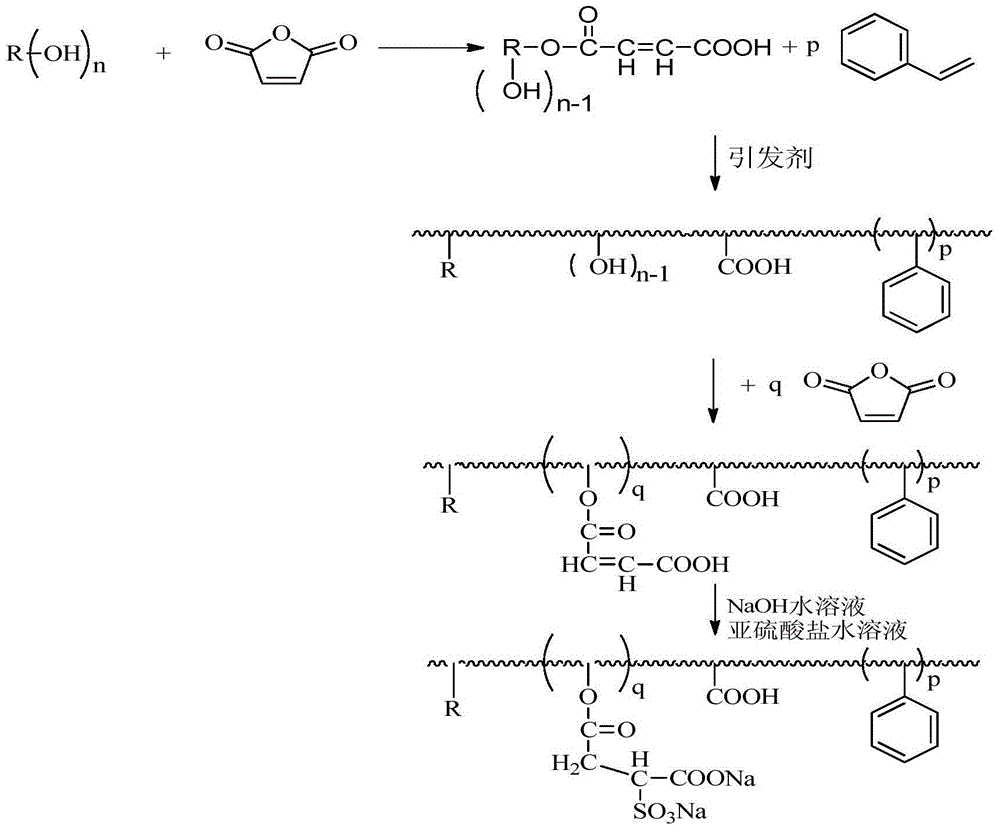

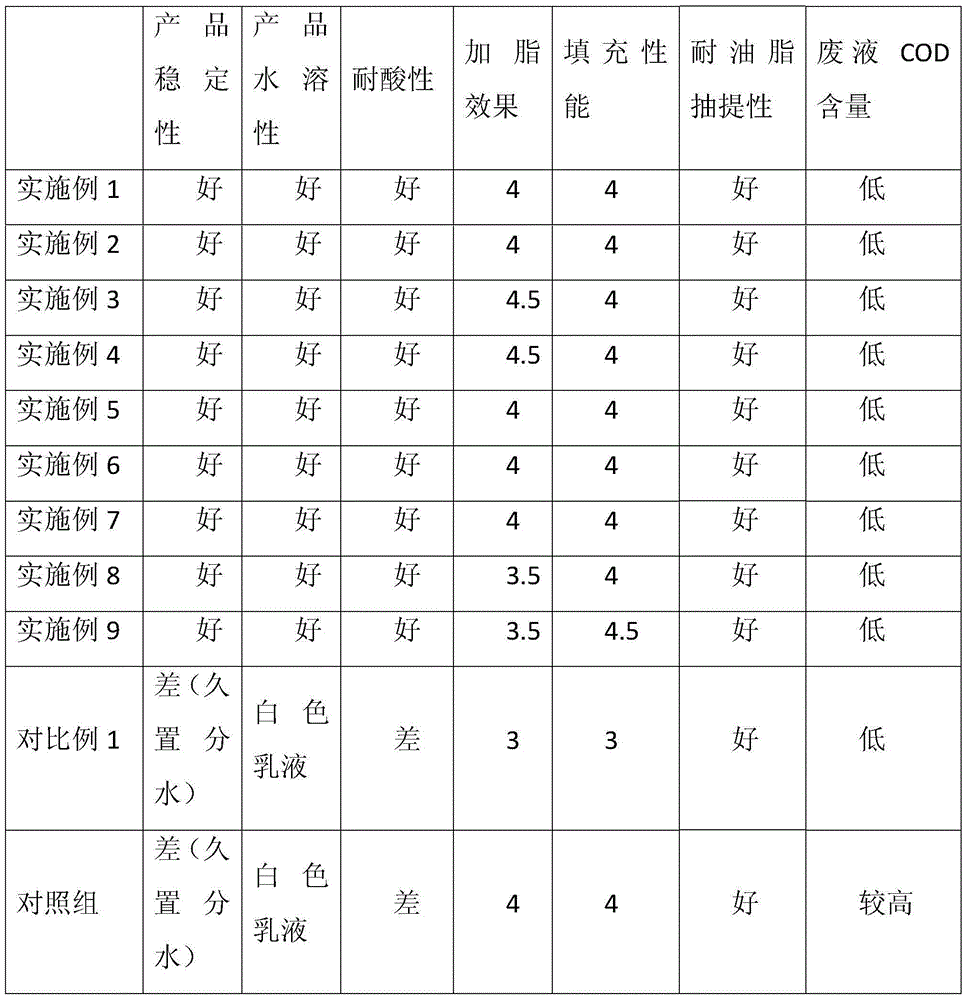

Preparation method for polymer fat-liquoring agent containing sulfosuccinate salt structure

The invention discloses a preparation method for a polymer fat-liquoring agent containing a sulfosuccinate salt structure. The preparation method comprises the following specific steps of performing mono-esterification reaction on poly-hydroxy compound and unsaturated anhydride so as to prepare an intermediate A; performing reaction on the intermediate A, a vinyl monomer and an initiator, so as to prepare a polymer B containing active hydroxyls; further esterifying the polymer B by use of maleic anhydride; sulfonating by sulfite after regulating the pH, thereby obtaining the polymer fat-liquoring agent. The polymer fat-liquoring agent is obviously improved in aspects of stability, water solubility, acid resistance, fat liquoring effect, filling property and fat extraction resistance, and further can be used for reducing the COD (Chemical Oxygen Demand) content of waste liquid.

Owner:四川德赛尔新材料科技有限公司

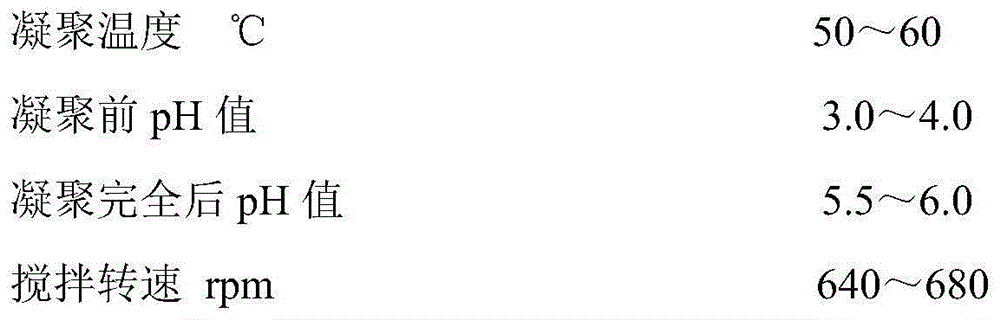

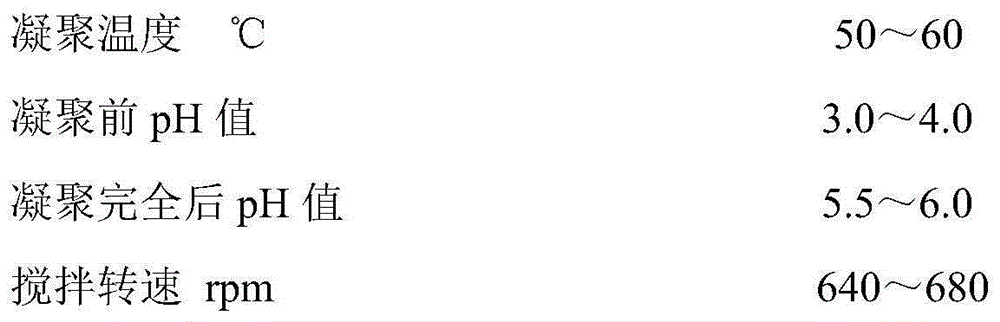

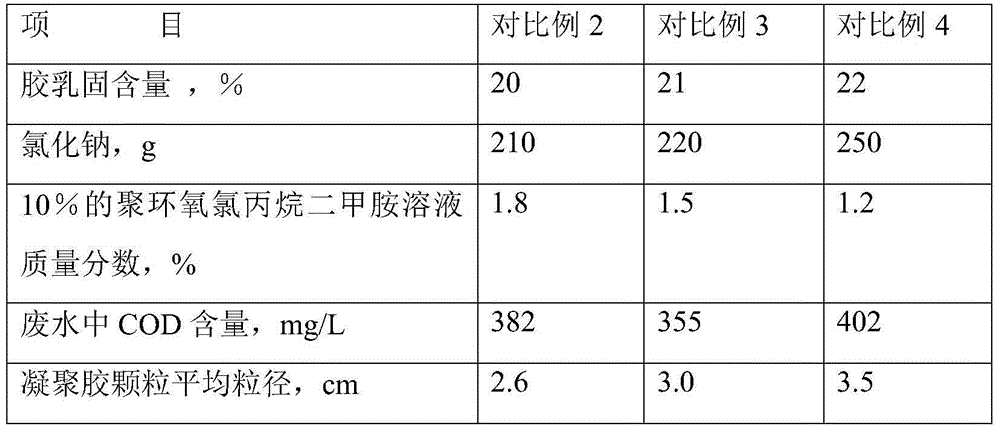

Ternary integrated rubber latex agglomeration process

The present invention relates to a ternary integrated rubber latex agglomeration process, and belongs to the technical field of synthetic rubbers. According to the agglomeration process, a ternary integrated rubber latex is adopted as a raw material, sulfuric acid is adopted as a pH value adjusting agent, an ammonium sulfate aqueous solution is adopted as an agglomeration mother liquor, and a poly epichlorohydrin-dimethylamine and cellulose derivative complex is adopted as an agglomeration agent; and the steps comprise: adding the agglomeration agent to the agglomeration mother liquor, adding the raw material, adding the pH value adjusting agent, and carrying out agglomeration. According to the present invention, the composite agglomeration agent is used, such that the COD content in the production wastewater can be reduced during the ternary integrated rubber production; the composite agglomeration agent has good water solubility, and can be used within a wide pH value range; the particle size of the colloidal particles after the agglomeration is moderate, the average particle size is 0.5-2 cm, and the drying is easily achieved; and the metal-ion-free ammonium sulfate electrolyte is adopted as the agglomeration mother liquor, such that the ternary integrated rubber with characteristics of low metal ion content and low corrosion on metals can be produced.

Owner:CHINA PETROLEUM & CHEM CORP

Recycling and pretreatment methods of raw materials containing benzene thiazole alcohol pesticide industrial wastewater

InactiveCN101973660APromote regenerationReduce COD contentOrganic chemistryMultistage water/sewage treatmentBenzeneChemical oxygen demand

The invention discloses recycling and pretreatment methods of raw materials containing benzene thiazole alcohol pesticide industrial wastewater. The treatment method comprises the following steps of: regulating a pH value of wastewater, and filtering and removing a suspended matter in the wastewater; enabling a filtering liquid to pass through an absorption column filled with macroporous resins; stopping absorption when the absorption reaches to a leakage point, and using ethanol as a desorprtion agent for desorption and regeneration to obtain an ethanol solution containing benzene thiazole alcohol; rectifying a desorption liquid, using the evaporated ethanol as the desorption liquid for recycling and using the obtained benzene thiazole alcohol as the raw material, and returning to the original production process. The invention is simple in operation, can recycle the benzene thiazole alcohol in the wastewater and effectively reduces COD (Chemical Oxygen Demand) of the wastewater, and the absorption resins have good regeneration performance and can be repeatedly used.

Owner:ZHEJIANG UNIV

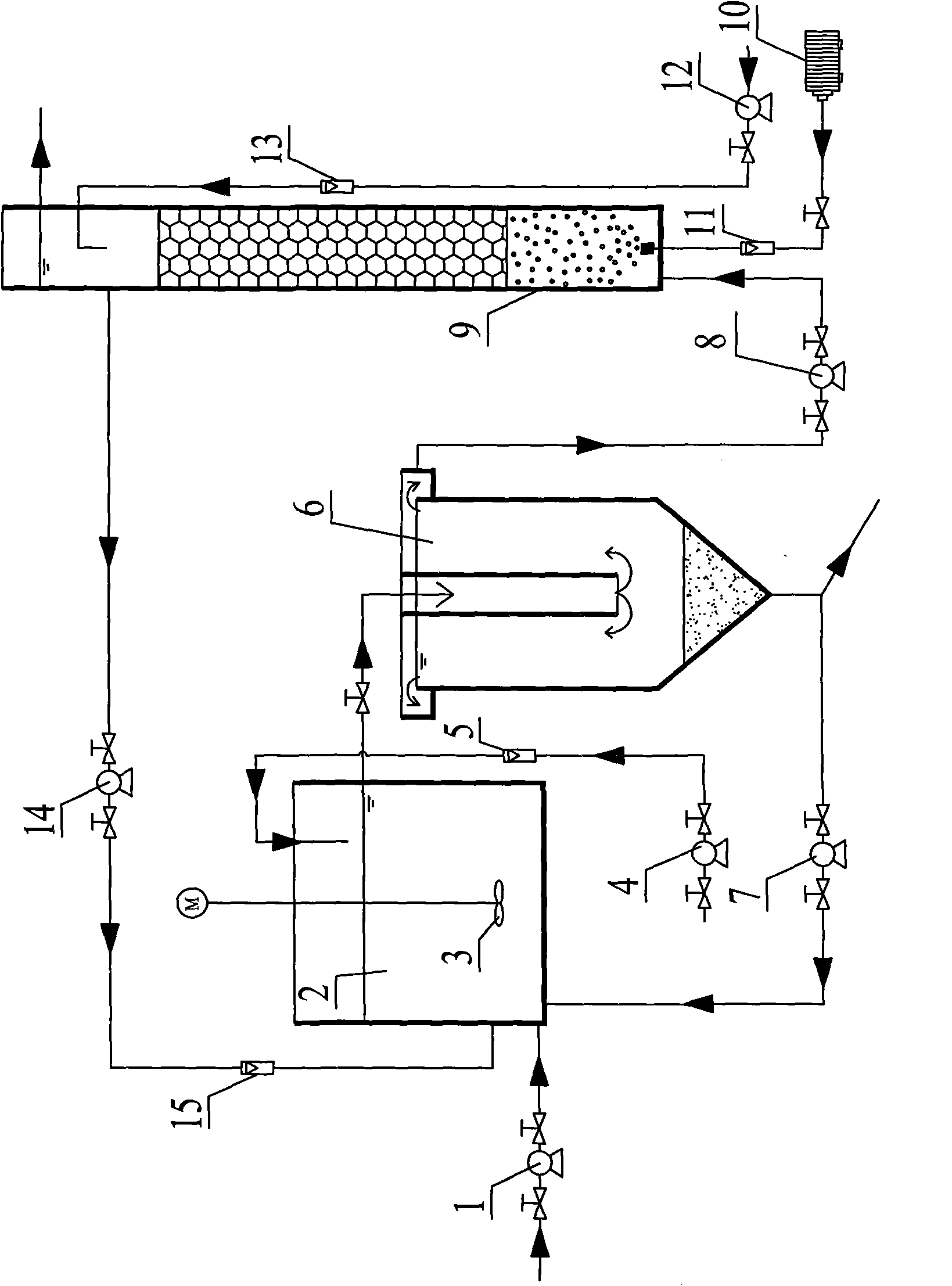

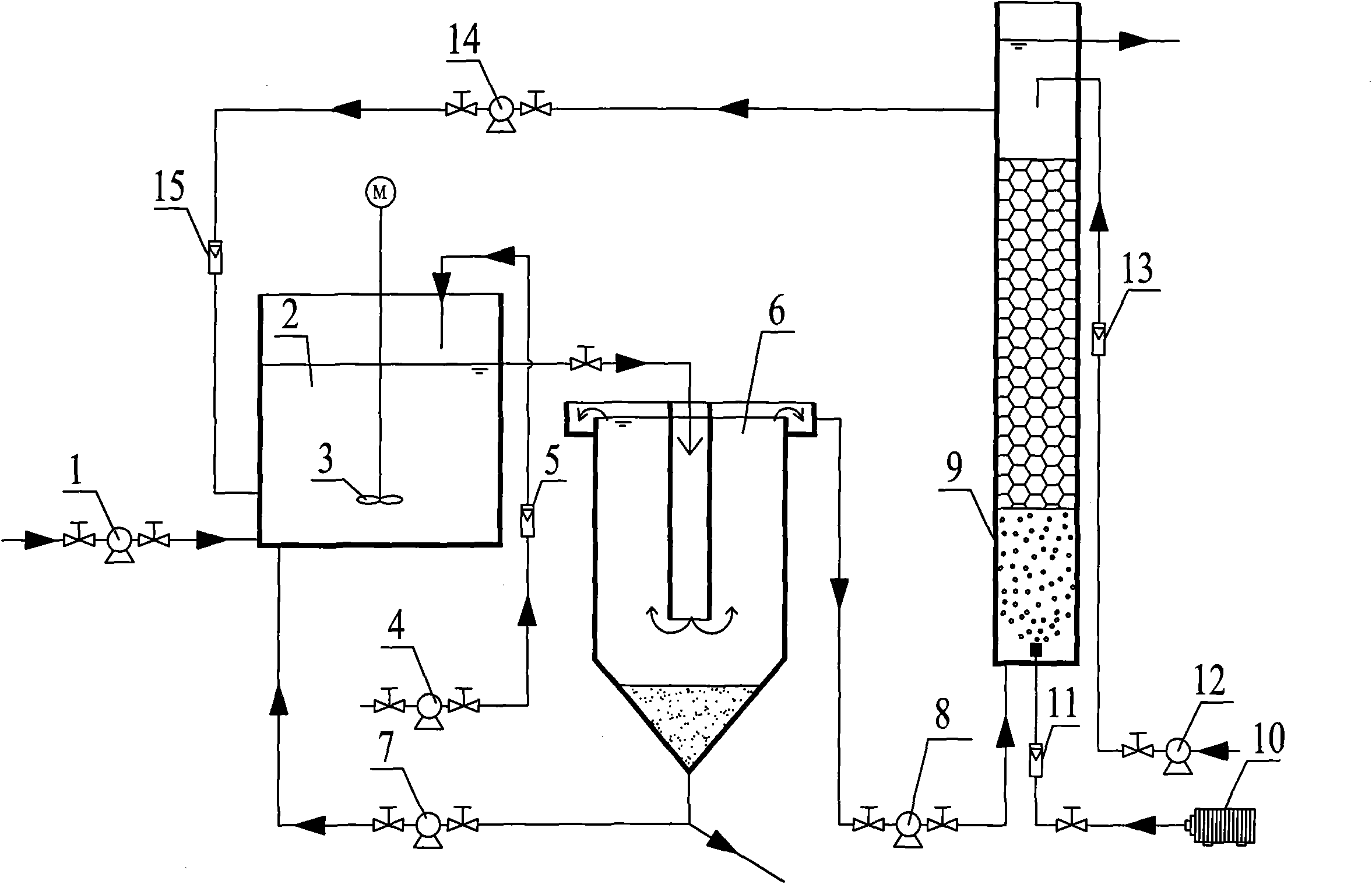

Aeration biological filter pool device and process for efficiently denitrifying and dephosphorizing

InactiveCN101857345ASimple processEmission reductionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationActivated sludgeBiological filter

The invention relates to an aeration biological filter pool device and a process for efficiently denitrifying and dephosphorizing in the sewage treatment and provides an aeration biological filter pool device for efficiently denitrifying and dephosphorizing. The aeration biological filter pool device comprises water feeding pumps which are connected and arrayed according to water feeding sequence, a synchronous denitrification dephosphorizing pool for synchronously denitrifying and dephosphorizing water from the water feeding pumps, a settling pond for settling the water from the synchronous denitrification dephosphorizing pool, an aeration biological filter pool water feeding pump and an aeration biological filter pool, wherein the synchronous denitrification dephosphorizing pool adopts a activated sludge process. The invention also provides an aeration biological filter pool process for efficiently denitrifying and dephosphorizing. The invention has the beneficial effects of solving the problems of complicated pretreatment, frequent back flush and insufficient utilization on a raw water carbon source of the conventional aeration biological filter pool, reducing the emission of carbon dioxide, improving the utilization rate of structures and reducing the occupied area and the cost by optimizing a process flow and being beneficial to wide application of the aeration biological filter pool process.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Biological pulp and paper making wastewater zero discharge technique

InactiveCN101824766ALess extractablesReduce COD contentPulp liquor regenerationSludge treatment by de-watering/drying/thickeningFiberBlack liquor

The invention relates to a biological pulp and paper making wastewater zero discharge technique, which belongs to the technical field of paper making. The invention mainly improves the procedures of cooking and middle section water treatment. The cooking procedure adjusts the cooking technique, reduces the cooking pressure and shortens the cooking time, thereby effectively reducing the pulp extract and reducing the COD content in middle section water; and the middle section water treatment procedure modifies the rotary mixing type aerator in the bioaeration pool into a suspension-type aeration chain device, thereby enhancing the oxygen conversion efficiency by 5-10%, increasing the dissolved oxygen content in wastewater and enhancing the organic matter removal rate in wastewater on the premise of not increasing the power. The invention breaks through the normal procedure for the middle section water treatment, and treats the middle section water twice, so that all the treated water can be recycled. The invention realizes cyclic utilization of black liquor and zero discharge of middle section water, solves the problem of large amount of clear water of the paper machine, saves the water resources, reduces the environmental pollution and provides successful experience for non-xylogen paper making.

Owner:HUIXIN BIOLOGICAL PULP PAPER

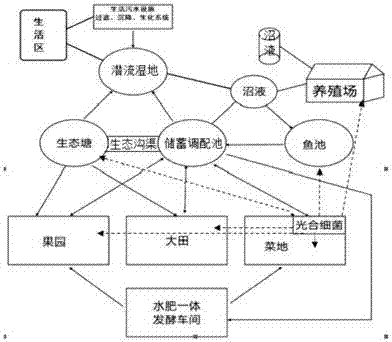

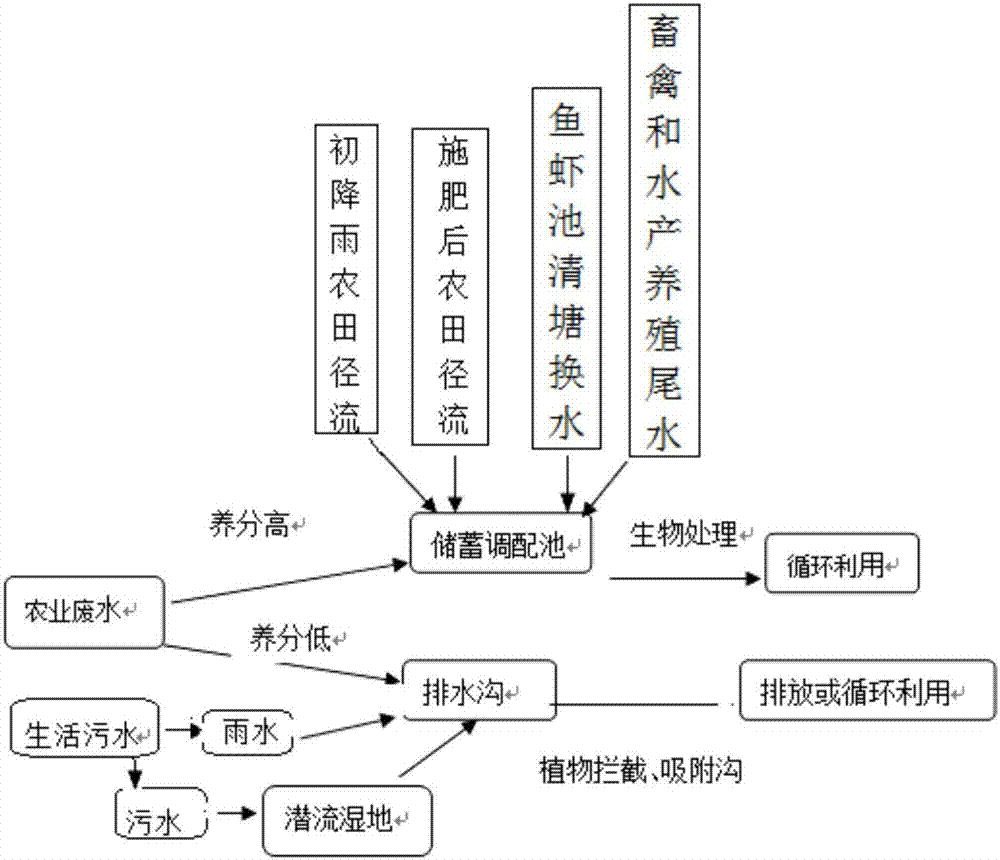

Emission reduction and cyclic utilization method for agricultural tail water and rural domestic sewage

InactiveCN107381826AReduce nitrogen and phosphorus nutrient contentShorten the residency periodWaste based fuelSustainable biological treatmentEutrophicationWater quality

The invention discloses an emission reduction and cyclic utilization method for agricultural tail water and rural domestic sewage. The emission reduction and cyclic utilization method comprises the following steps: 1) collecting eutrophic runoff tail water by utilizing a storage and blending tank and carrying out temporary storage and aeration; 2) discharging the tail water which exceeds the capacity into an ecological channel pond; 3) culturing photosynthetic bacteria by utilizing one part of the tail water and utilizing the photosynthetic bacteria to improve the water quality and a feed additive; 4) discharging domestic sewage into a subsurface flow wetland and treating the domestic sewage; 5) temporarily storing biogas slurry by utilizing the storage and blending tank. According to the emission reduction and cyclic utilization method disclosed by the invention, the agricultural tail water with high nutrients is selected and is cyclically utilized after being temporarily stored and treatment pressure of the ecological intercepting channel pond is alleviated; eutrophic agricultural wastewater is cyclically utilized to the greatest extent; in a non-agricultural tail water water-draining season, the disadvantages of a current rural domestic sewage treatment facility can be made up by utilizing a nitrogen and phosphorus intercepting facility and sufficient utilization can be realized; the emission reduction and cyclic utilization method has the advantages of investment saving, high efficiency and less manpower needed by management and protection; meanwhile, the problem that a previous sewage collection and treatment process has many intermediate links is also solved.

Owner:SUZHOU WUJIANG DISTRICT SOIL FERTILIZER TECH GUIDANCE STATION

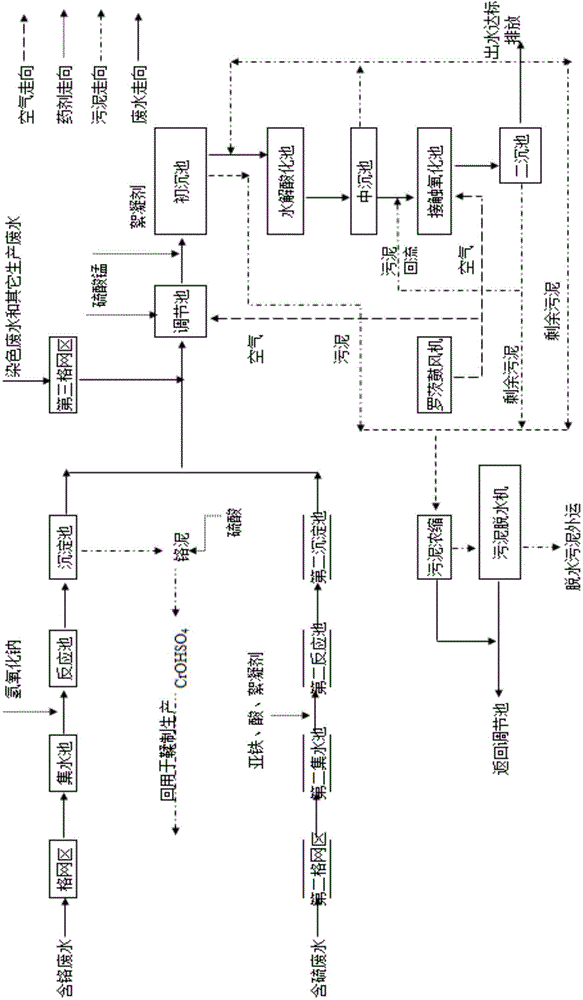

Treatment technology and treatment system of leather waste water

ActiveCN104787960AReduce COD contentReduce ammonia nitrogen contentWaste water treatment from animal processingMultistage water/sewage treatmentFlocculationSulfate

The invention provides treatment technology of leather waste water. The treatment technology comprises the following steps: 1, firstly, filtering sulfur-containing waste water and chromium-containing waste water of leather waste water to remove foreign materials, respectively; performing homogenizing treatment, then performing reaction, and finally performing precipitation treatment to obtain sulfur-containing waste water and chromium-containing waste water; 2, performing homogenizing treatment and aeration treatment to other production waste water and the obtained sulfur-containing waste water and chromium-containing waste water, reacting the obtained waste water with manganese sulfate, adding a flocculating agent; and performing flocculation precipitation treatment to obtain mixed treated water and primary precipitation mud; 3, performing hydrolytic acidification treatment to the mixed treated water, and performing intermediate precipitation treatment to obtain intermediate treated water and intermediate precipitation mud; and 4, performing bio-contact oxidation treatment to the intermediate treated water, and performing intermediate precipitation treatment to obtain treated leather waste water and secondary precipitation mud.

Owner:CHONGQING LONGFA LEATHER PROD

Method for treating acidic dye printing and dyeing wastewater

InactiveCN102531226AReduce COD contentSolve the contact area problemMultistage water/sewage treatmentWater/sewage treatment by neutralisationMicro nanoChemical oxygen demand

The invention discloses a method for treating acidic dye printing and dyeing wastewater, which belongs to the field of wastewater treatment. The method comprises the steps of (1) filtering collected acidic printing and dyeing wastewater through a screen, then enabling the acidic printing and dyeing wastewater to enter a regulation tank, and using alkali waste to regulate the pH value of the acidic printing and dyeing wastewater to be 6.0-8.0; (2) feeding anionic surfactants into the regulation tank, and performing aeration decoloring treatment through a micro-nano aeration device; (3) enabling wastewater after aeration decoloring treatment to flowing through a sepiolite device of immobilized catalysts from bottom to top, wherein chemical oxygen demand (COD) in processed outlet water is lower than 100mg / L, the chromaticity is lower than 40mg / L, and the COD and the chromaticity both reach level 1 emission standards in Discharge standard of water pollutant for dyeing and finishing of textile industry. By means of combination of the anionic surfactants and the micro-nano aeration device, the method performs the aeration decoloring treatment on the acidic dye printing and dyeing wastewater, and absorption-catalysis is performed through the sepiolite device of the immobilized catalysts to further reduce the COD content in the wastewater. The method has the advantages of being simple in process flow, small in floor area, remarkable in effect of treatment on the COD and the chromaticity in the acidic dye printing and dyeing wastewater, and the like.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

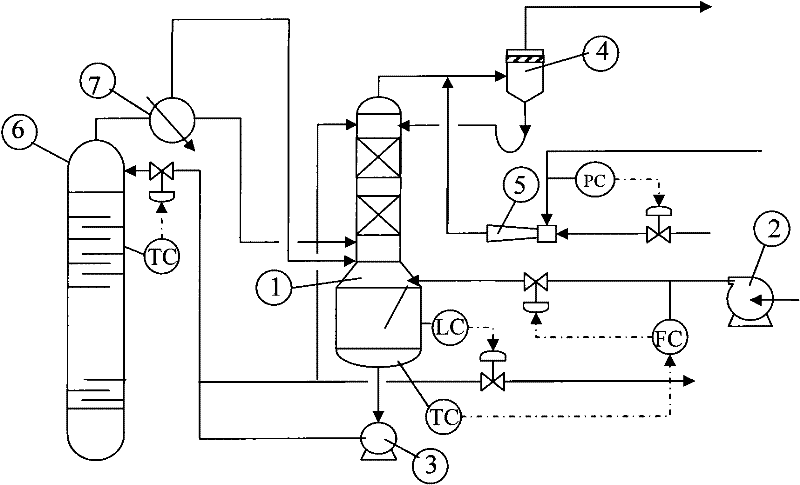

Process for cooling and separating gas phase mixture on top of polyester process column

ActiveCN101575122BReduce COD contentImprove separation efficiencyDispersed particle separationVapor condensationPolyesterGas phase

Owner:SINOPEC YIZHENG CHEM FIBER

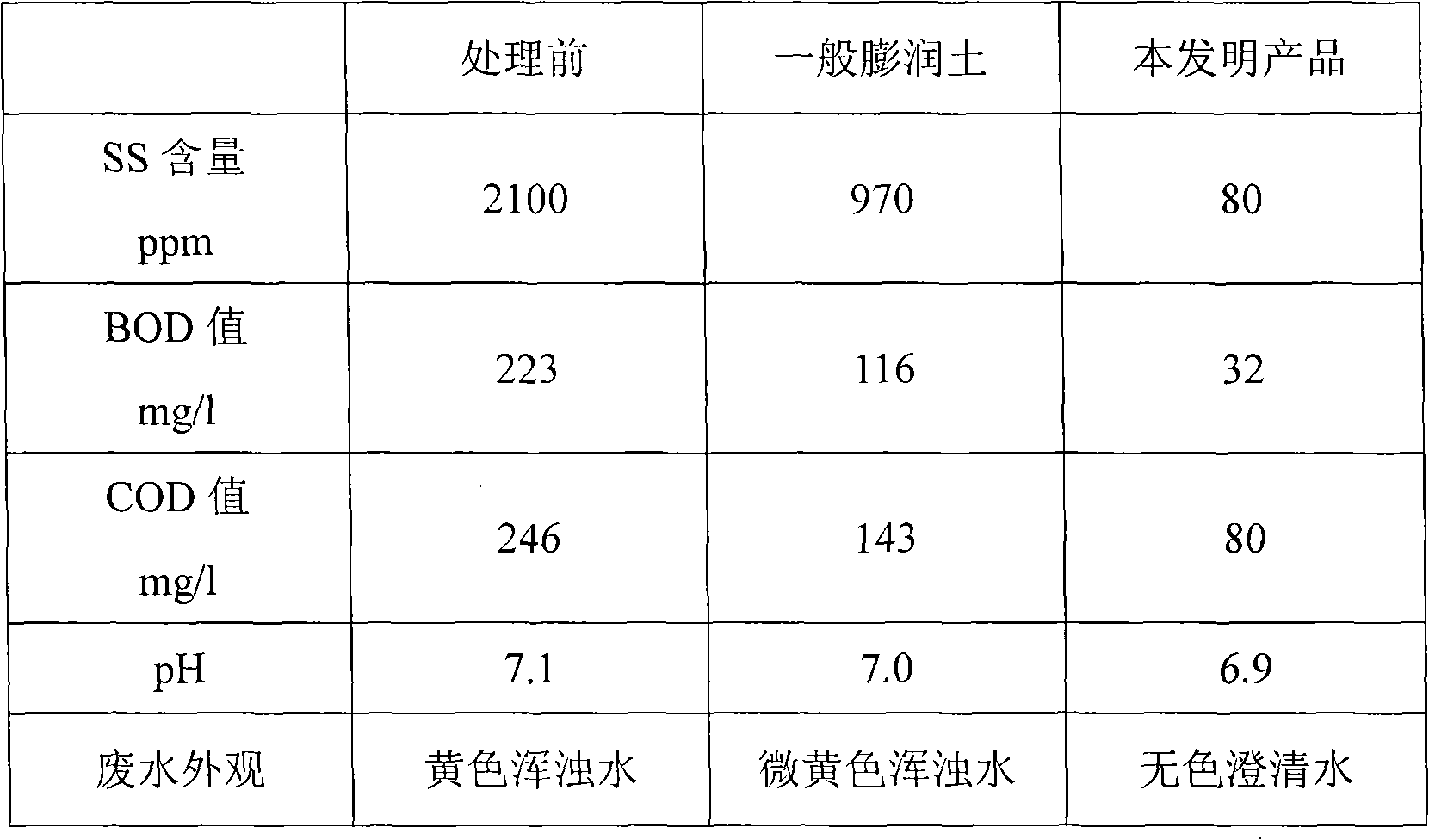

Method for preparing organic pollutant adsorbent for papermaking wastewater

ActiveCN101961642ALarge specific surface areaImprove adsorption capacityOther chemical processesWater contaminantsFiberSodium Bentonite

The invention relates to a method for preparing an adsorbent, and aims to provide a method for preparing an organic pollutant adsorbent for papermaking wastewater. The method comprises the following steps of: (1) firing bentonite to form firing bentonite; (2) sprinkling alkyl ammonium salt solution on the firing bentonite uniformly for reacting, and drying or airing; and (3) mixing the bentonite obtained in the step (2) with diatomite uniformly, and grinding to obtain the organic pollutant adsorbent. The adsorbent of the invention has high specific surface area which can reach over 900 m<2> / g, has excellent adsorption performance for organic pollutants such as fine fibers, sticky matter, starch, gum rosin and the like in the papermaking wastewater, can reduce the COD content of the papermaking wastewater effectively, and is convenient to use and low in equipment investment.

Owner:ZHEJIANG RENHENG CHEM

Treatment method of anthraquinone dye waste acid

InactiveCN110759545AEfficient recyclingReduce COD contentWater treatment parameter controlSpecific water treatment objectivesAnthraquinonesSpecific adsorption

The invention discloses a treatment method of anthraquinone dye waste acid. The treatment method comprises the following steps: preparing resin balls and carrying out sulfonation modification; washingwith ammonia water to be neutral, filling a resin column with the adsorption resin balls, performing adsorption decolorization on the filtered anthraquinone dye waste acid through an adsorption column, adding potassium permanganate into the adsorption decolorized waste acid, filtering and separating to obtain a colorless sulfuric acid solution, desorbing the resin by adopting a desorbing agent, and recycling the desorbed resin to the step S2. According to the invention, a recovery process of combining specific adsorption resin with adsorption treatment and deep oxidation treatment is adopted;according to the method, the anthraquinone dye waste acid is efficiently recycled, the recovery rate of sulfuric acid can be close to about 90%, the removal rate of the COD content of the waste acidcan reach 99% or above, and the method can be used for treating the anthraquinone sulfate waste acid with the COD content of 5,000 ppm to 20,000 ppm.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

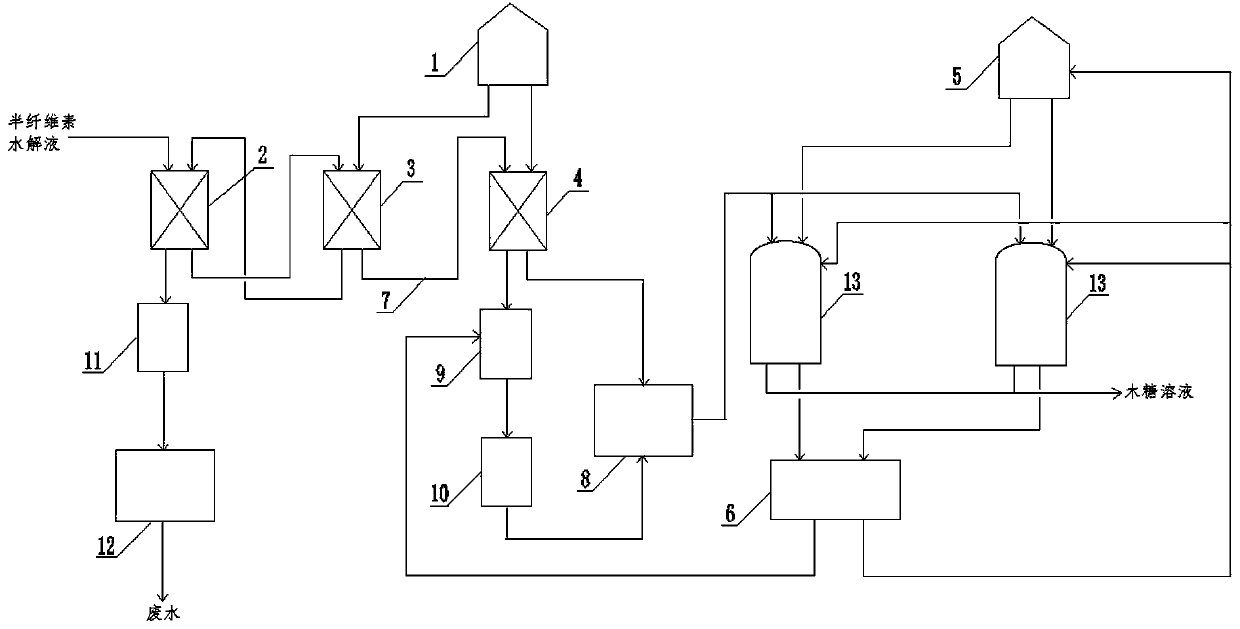

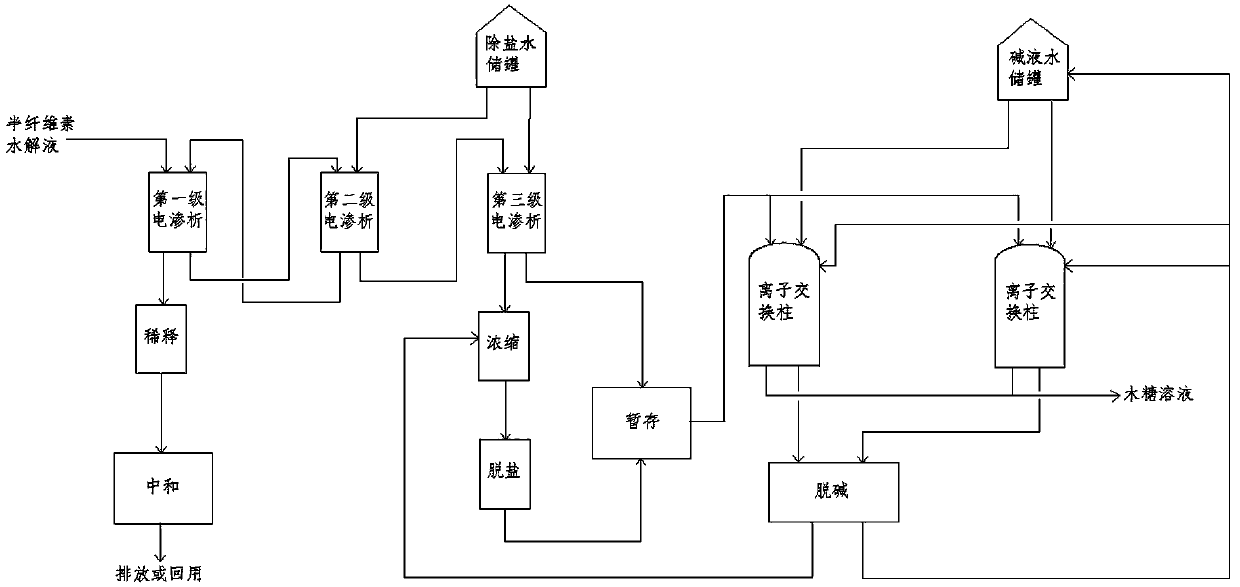

Electrodialysis and chromatography combined process for preparing xylose

The invention discloses an electrodialysis and chromatography combined process for preparing xylose, and belongs to the technical field of xylose production. The process comprises: carrying out three-stage electrodialysis on hemicellulose hydrolysate to finally obtain a first-stage high-salt solution, a third-stage high-salt solution and a third-stage high-sugar solution; concentrating and desalting the third-stage high-salt solution, and making the concentrated and desalted third-stage high-salt solution and the third-stage high-sugar solution co-enter an ion exchange column chromatography process; and regenerating the ion exchange column to obtain a regenerated solution (containing alkali and sugar), carrying out dealkalization on the regenerated solution to obtain an alkali liquid and asugar liquid, recycling the alkali liquid in regeneration of the ion exchange column, concentrating and desalting the sugar liquid and the third-stage high-salt liquid, and carrying out chromatography again. According to the present invention, with the process, the removal rate of the impurities in a xylose solution is increased so as to improve the quality of the product, the third-stage high-salt solution and the regenerated solution are recycled so as to reduce the sugar loss and improve the economic benefits, and on the premise of improving of the quality of the xylose solution and the production efficiency, the COD content in sewage is reduced so as to reduce the environmental protection pressure.

Owner:四川雅华生物有限公司 +1

Enzyme preparation and application thereof

InactiveCN102251405AImprove permeabilityNon-toxicBiochemical fibre treatmentVegetal fibresElectricityAmylase

The invention discloses an enzyme preparation which is characterized by being a compound enzyme preparation with a pH value ranging from 6 to 10 and comprising 3-50g / L compound refining enzyme, 0.2-20g / L amylase and 1-100g / L emulsifiable penetrant. The application of the enzyme preparation can replace the traditional desizing and scouring processes. The invention can overcome the disadvantages of complicated procedures, high steam and electricity consumption and large sewage discharge amount in the pretreatment process of the traditional textile, can reduce the damage to the textile and the pretreatment difficulty of the cotton blended / mixed texture, decreases energy consumption and sewage, and lowers the COD (Chemical Oxygen Demand) content in the sewage.

Owner:ZHEJIANG MIZUDA PRINTING & DYEING GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com