Polyurethane carrier with polydopamine hydrophilic layer attached to surface thereof and preparation method and application of polyurethane carrier

A technology of polydopamine affinity and polyurethane, which is applied in chemical instruments and methods, test water, biological water/sewage treatment, etc., can solve the problems of polydopamine, improve the hydrophilicity of polyurethane carrier, etc., and achieve the improvement of fixed biomass, Stable mechanical properties and high universal applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

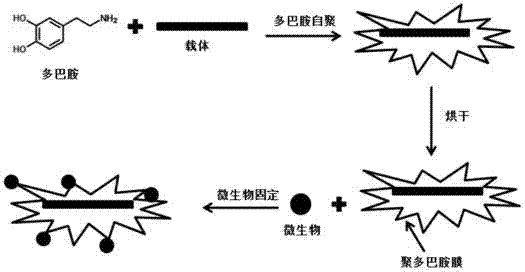

[0040] 1. Preparation of polyurethane carrier with polydopamine hydrophilic layer on the surface

[0041] 1) Prepare a 10mmol / L Tris-HCl buffer solution, adjust the pH to 8, add dopamine and ammonium persulfate, the initial concentration is 1mg / mL, and make a dopamine modified solution;

[0042] 2) Immerse a square polyurethane carrier with a side length of 20 mm in the dopamine modification solution, and soak for 4 hours at room temperature;

[0043] 3) After soaking, take out the carrier, clean it with deionized water, and dry it in an oven at 40°C for 2 hours to complete the hydrophilic modification process of the polyurethane carrier, and obtain a polyurethane carrier with a polydopamine hydrophilic layer attached to the surface.

[0044] 2. Immobilization of microorganisms

[0045] Put the polyurethane carrier with polydopamine hydrophilic layer on the surface obtained in step 1 into the aerobic reaction tank to carry out the biofilm-hanging experiment. The sludge concen...

Embodiment 2

[0051] 1. Preparation of polyurethane carrier with polydopamine hydrophilic layer on the surface

[0052] 1) Prepare a 15 mmol / L barbiturate buffer solution, adjust the pH to 8.5, add dopamine and sodium persulfate, the initial concentration is 3 mg / mL, and make a dopamine modified solution;

[0053] 2) Immerse a square polyurethane carrier with a side length of 30 mm in the dopamine modification solution, and soak for 2 hours at room temperature;

[0054] 3) After soaking, take out the carrier, clean it with deionized water, and dry it at 50° C. for 1 hour to complete the hydrophilic modification process of the polyurethane carrier, and obtain a polyurethane carrier with a polydopamine hydrophilic layer attached to the surface.

[0055] 2. Immobilization of microorganisms

[0056] Put the polyurethane carrier with the polydopamine hydrophilic layer on the surface obtained in step 1 into the aerobic reaction tank to carry out the biofilm-hanging experiment. The sludge concent...

Embodiment 3

[0063] 1. Preparation of polyurethane carrier with polydopamine hydrophilic layer on the surface

[0064] 1) Prepare a 20mmol / L Tris-HCl buffer solution, adjust the pH to 8.3, add dopamine and ammonium persulfate, the initial concentration is 2mg / mL, and make a dopamine modified solution;

[0065] 2) Immerse a square polyurethane carrier with a side length of 25 mm in the dopamine modification solution, and soak at room temperature for 3 hours;

[0066] 3) After soaking, take out the carrier, clean it with deionized water, and dry it at 45° C. for 1.5 hours to complete the hydrophilic modification process of the polyurethane carrier, and obtain a polyurethane carrier with a polydopamine hydrophilic layer attached to the surface.

[0067] 2. Immobilization of microorganisms

[0068] Put the polyurethane carrier with polydopamine hydrophilic layer on the surface obtained in step 1 into the aerobic reaction tank to carry out the biofilm-hanging experiment. The sludge concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com