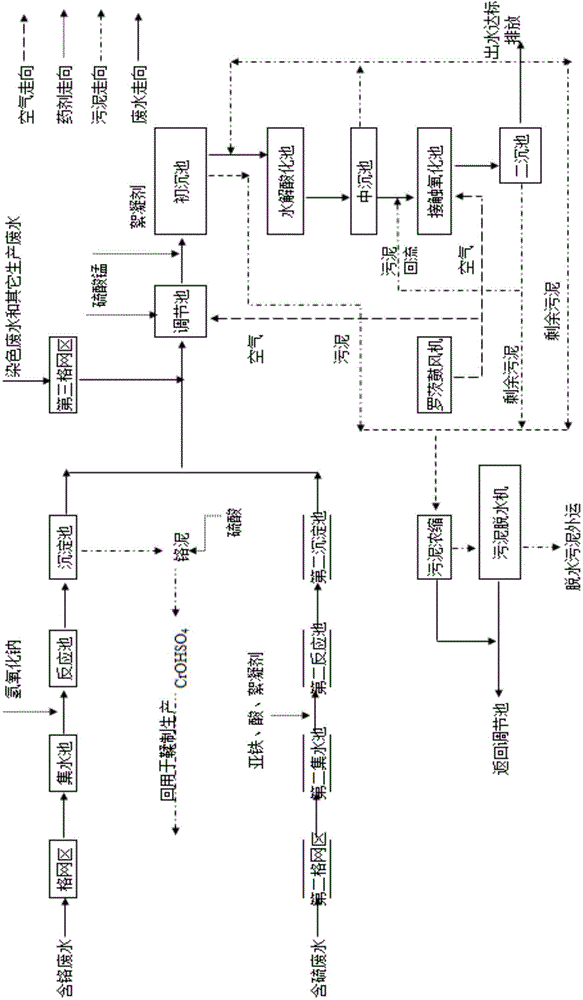

Treatment technology and treatment system of leather waste water

A technology of leather wastewater and treatment process, which is applied in animal processing wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problems of non-compliance with production requirements, long processing time and difficulty in comprehensive treatment major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The content of COD in the untreated leather waste water of the present invention is 3000mg / l, NH 4+ -N is 250mg / l, suspended solids is 1000mg / L and the pH value is 8.1, the amount of wastewater is 1000m3 / d.

[0082] First, the sulfur-containing wastewater in the leather wastewater is filtered through the grid area to remove impurities, then enters the sump for homogeneous treatment, and then enters the reaction tank, adding ferrous sulfate, sulfuric acid and inorganic polymer flocculant for reaction , and finally enter the sedimentation tank for sedimentation treatment to obtain sulfur-containing treated water;

[0083] The chromium-containing wastewater in the leather wastewater first passes through the second grid area to filter out impurities, then enters the second sump for homogeneous treatment, and then enters the second reaction pool, adds sodium hydroxide for reaction, and finally enters the Sedimentation treatment is carried out in the second sedimentation tan...

Embodiment 2

[0089] The content of COD in the untreated leather waste water of the present invention is 3000mg / l, NH 4+ -N is 250mg / l, suspended solids is 1000mg / L and the pH value is 8.1, the amount of wastewater is 1000m3 / d.

[0090] First, the sulfur-containing wastewater in the leather wastewater is filtered through the grid area to remove impurities, then enters the sump for homogeneous treatment, and then enters the reaction tank, adding ferrous sulfate, sulfuric acid and inorganic polymer flocculant for reaction , and finally enter the sedimentation tank for sedimentation treatment to obtain sulfur-containing treated water;

[0091] The chromium-containing wastewater in the leather wastewater first passes through the second grid area to filter out impurities, then enters the second sump for homogeneous treatment, and then enters the second reaction pool, adds sodium hydroxide for reaction, and finally enters the Sedimentation treatment is carried out in the second sedimentation tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com