Process for cooling and separating gas phase mixture on top of polyester process column

A technology of tower top gas and process tower, which is applied in the direction of separation method, dispersed particle separation, steam condensation, etc., can solve the problems of high water content in waste gas, high energy consumption, and no contribution to efficiency, so as to reduce COD content and improve separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

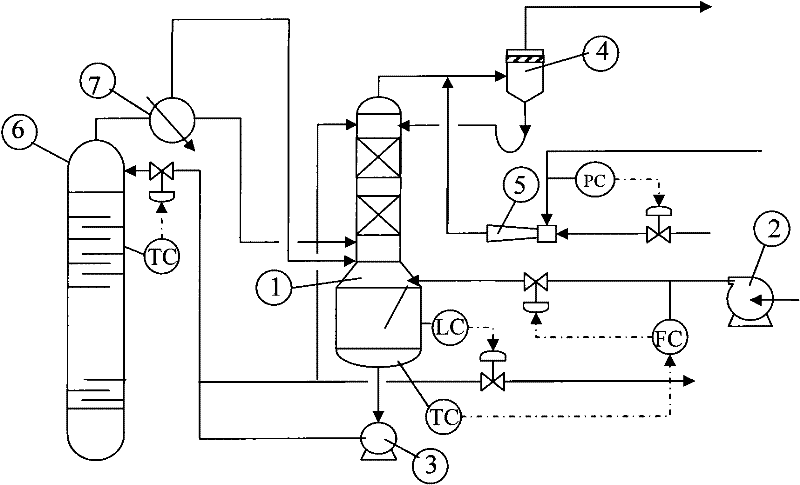

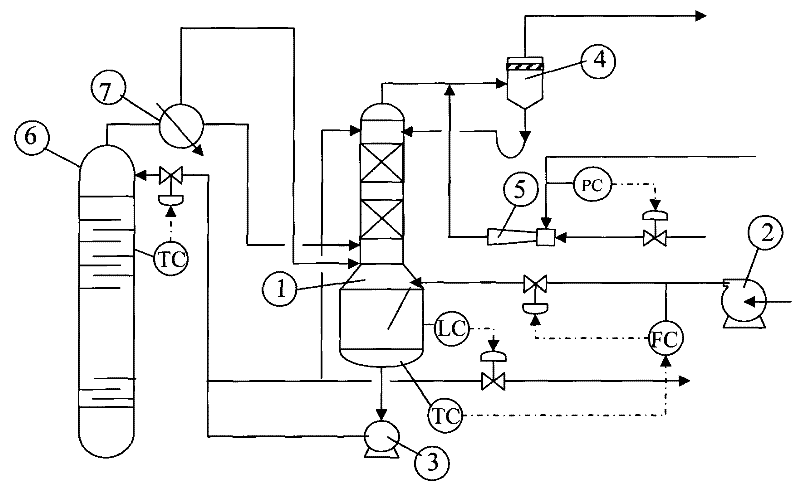

[0013] The invention is a new process for directly separating organic matter waste gases such as acetaldehyde, which is a by-product of polyester, from waste water, which is closely combined with the esterification process tower of a polyester plant. Its feature is to cool the gas phase mixture at the top of the esterification process tower of the polyester plant, and all the condensate is introduced into the stripping tower to carry out stripping and separation of volatile organic compounds such as acetaldehyde. The stripper is combined with the top condenser and reflux tank of the process tower, and one device performs multiple different process operations: a blower is used to send air into the bottom of the stripper for stripping waste water Acetaldehyde waste gas, using compressed air as the power of the jet pump, sucks the tail gas discharged from the gas phase pipe of the vacuum system of the polyester plant, and discharges it to the stripping tower system to form a cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com