Kitchen wastewater treatment method

A treatment method, a technology for kitchen waste water, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve difficult organic components and ammonia nitrogen degradation, poor biochemical properties, salt content, Solve problems such as difficulty in reaching the standard, and achieve the effect of less equipment, high degree of automation, and short aeration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

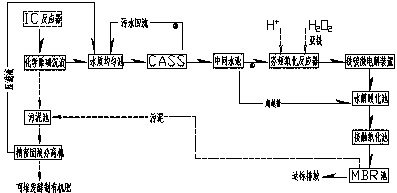

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] (1) Step 1, chemical phosphorus removal: add 500-1000ppm phosphorus removal agent to the kitchen wastewater from the IC reactor for chemical phosphorus removal and precipitation for 30-90 minutes, such as adding 1000ppm phosphorus removal agent for chemical precipitation for 30 minutes minute. (2) Step 2, water quality uniformity and CASS reaction: the effluent after chemical phosphorus removal passes through the water quality uniform pool, and then the water flow uniformly enters the CASS reactor. In the biological selection area of the CASS reactor, react with microbial strains under anaerobic or facultative oxygen conditions for 30-60 minutes to remove soluble substrates and further remove phosphorus. Then to the main reaction area of the CASS reactor, water is fed, aerated, sedimented, decanted and idled in sequence for 2-8 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com