Ternary integrated rubber latex agglomeration process

A technology of integrating rubber and latex, which is applied in the field of synthetic rubber, can solve the problems of undisclosed ternary integrated rubber latex coagulation process, etc., and achieve the effects of low metal corrosion, easy drying, and low metal ion content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

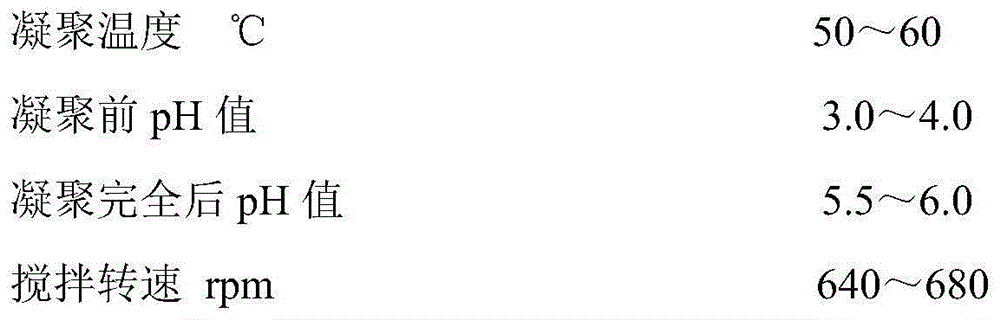

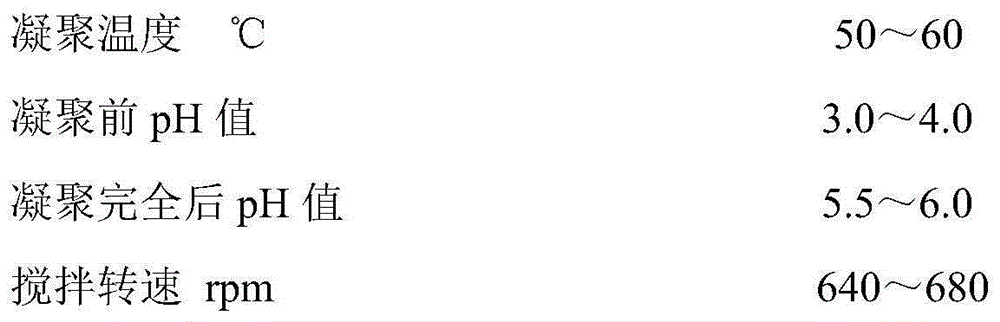

[0031] Coagulate the ternary integrated rubber latex according to the following process steps:

[0032] ① Preparation of condensed mother liquor:

[0033] Accurately weigh 50 grams of ammonium sulfate, dissolve it in 20 parts by weight of desalted, deoxygenated water, and make it into a condensed mother liquor, which is set aside;

[0034] ② Preparation of coagulant solution:

[0035] After mixing 98 parts by mass of commercially available polyepichlorohydrin dimethylamine and 2.0 parts by mass of methyl lignin, dilute it with desalted and deoxygenated water to a solution with a solid content of 10%, and set aside;

[0036] ③ Preparation of raw materials:

[0037] Preheat 500 grams of ternary integrated rubber latex equivalent to 100 grams of dry glue with a solid content of 20% to 55°C and set aside;

[0038] ④ Preparation of pH regulator:

[0039] Preparation weight percentage concentration is the sulfuric acid solution of 20%, standby;

[0040] ⑤ Coagulation of latex: ...

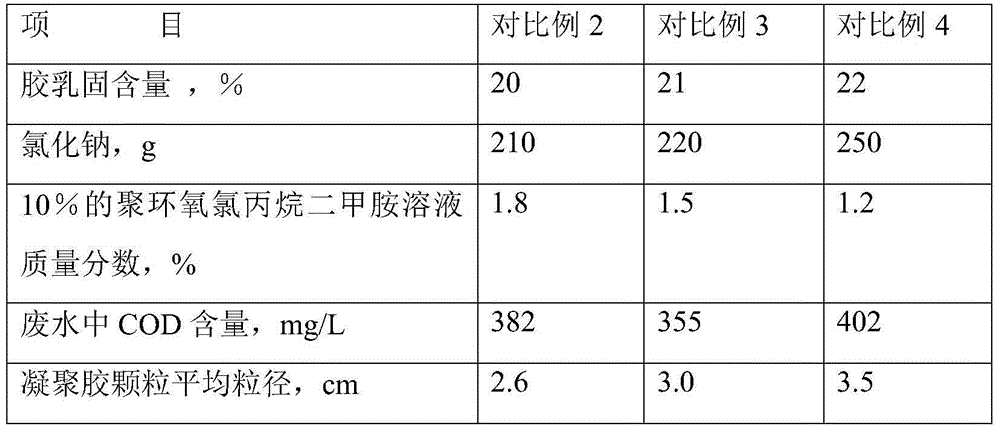

Embodiment 2-6

[0048] According to the steps of Example 1, the ternary integrated rubber latex was subjected to coagulation treatment, and the raw material ratio and the technical indicators achieved by the coagulation treatment process are listed in Table 1.

[0049] Table 1 Embodiment 2-6 raw material ratio and product technical index table

[0050] project

[0051] Latex solid content, %

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com