Patents

Literature

30 results about "Polyepichlorohydrin-dimethylamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

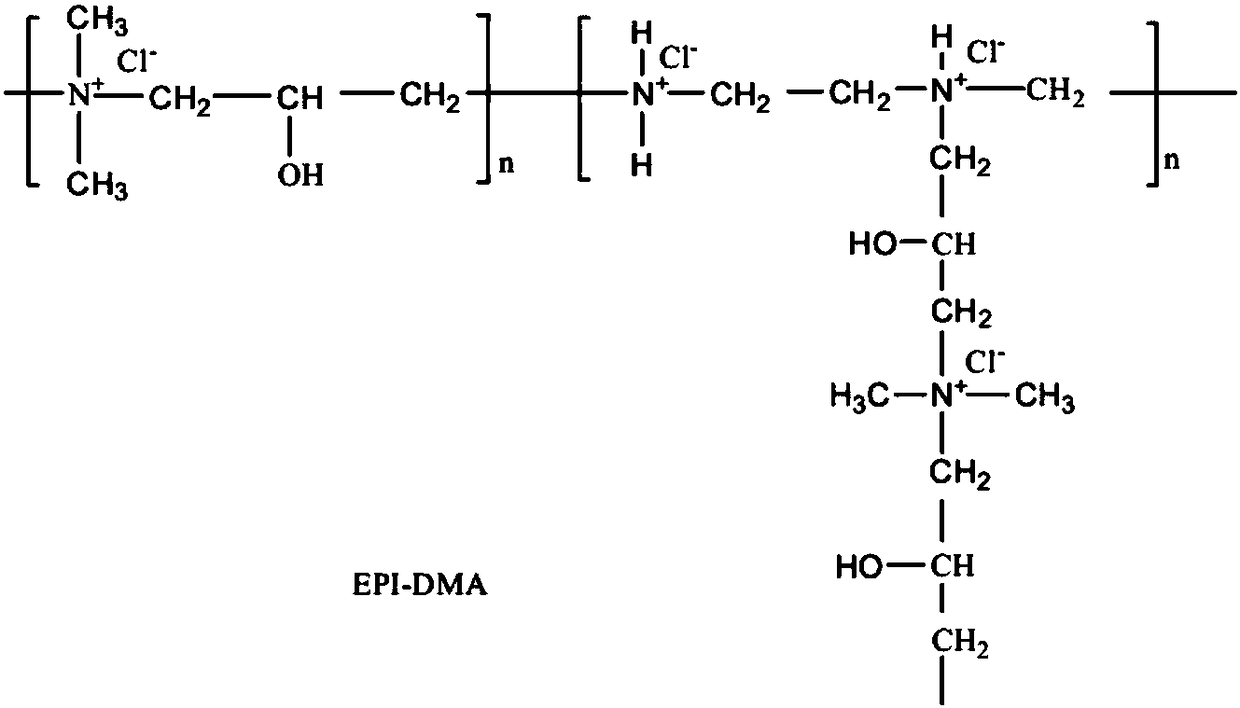

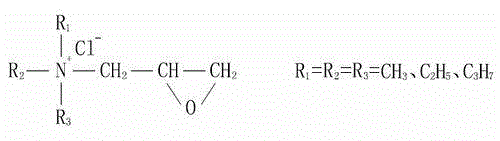

Polyepichlorohydrin-dimethylamine organic polymer coargulator and its preparation technology

InactiveCN1868911AGood effectSimple production processWater/sewage treatment by flocculation/precipitationEpoxyCross-link

An organic high-molecular flocculant with high flocculating effect for decoloring the printing and dyeing sewage in textile industry is prepared from epoxy chloropropane, dimethylamine and 1,6-hexyldiamine as cross-linking agent. Its preparing process is also disclosed.

Owner:SHANDONG UNIV

Ferric salt-polyepichlorohydrin-dimethylamine composite flocculant as well as preparation method and application thereof

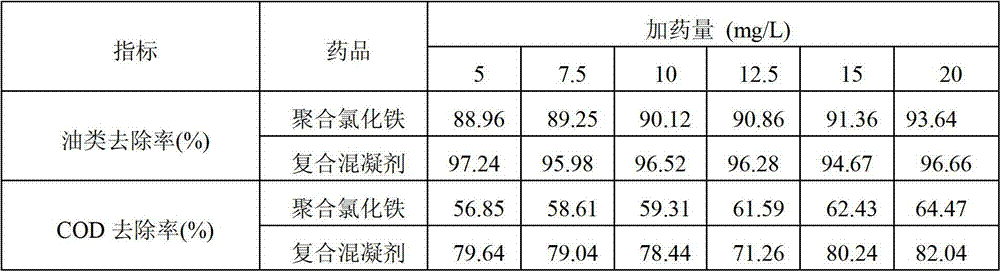

InactiveCN103043766AReduce processing costsEasy to dehydrateWater/sewage treatment by flocculation/precipitationChemical industryPapermaking

The invention relates to a ferric salt-polyepichlorohydrin-dimethylamine composite flocculant. The composite flocculant is prepared by mixing a ferric chloride solution or a polyferric chloride solution and polyepichlorohydrin-dimethylamine at a normal temperature; the mass concentration of Ferrum in the ferric chloride solution or the polyferric chloride solution is 5-15 g / L; and the mass ratio of the Ferrum in the ferric salt-polyepichlorohydrin-dimethylamine composite flocculant to the polyepichlorohydrin-dimethylamine is (1-10):1. The invention further relates to a preparation method and an application of the ferric salt-polyepichlorohydrin-dimethylamine composite flocculant. The preparation method provided by the invention is simple, convenient, economic and practical, can be widely applied to water supply and waste water treatment in the fields such as dye waste water, surface water, refinery processing wastewater, papermaking, mining and daily-use chemical industry, and has the advantages of simple and fast treatment process as well as good coagulation effect.

Owner:SHANDONG UNIV

Poly-ferric chloride-polyepichlorohydrin-dimethylamine composite coagulant

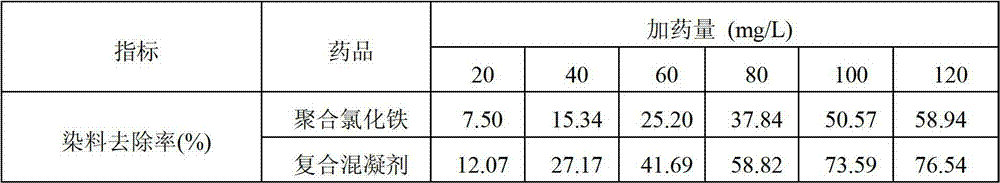

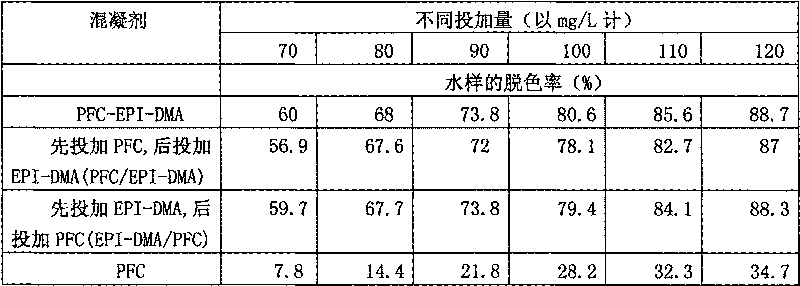

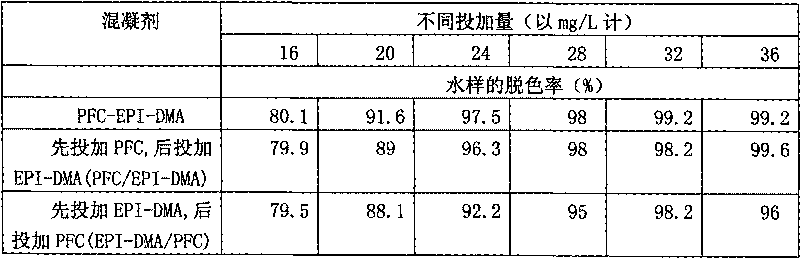

InactiveCN101693562AImprove the coagulation effectReduce dosageWater/sewage treatment by flocculation/precipitationTurbidityWastewater

The invention discloses a poly-ferric chloride-polyepichlorohydrin-dimethylamine composite coagulant, which is characterized in that poly-ferric chloride-polyepichlorohydrin-dimethylamine composite coagulants with different alkalization degree B values, different polyepichlorohydrin-dimethylamine mass fractions and viscosity eta values are prepared by compositing the poly-ferric chloride, the polyepichlorohydrin and the dimethylamine. The composite coagulant with fine decolorizing effect can be applied to decolorizing treatment of textile dyeing waste water and simultaneously has fine effects of removing turbidity and organics for simulated natural surface water.

Owner:SHANDONG UNIV

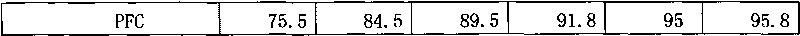

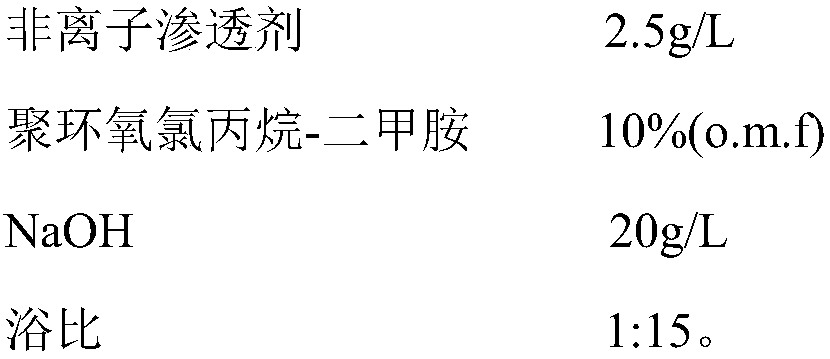

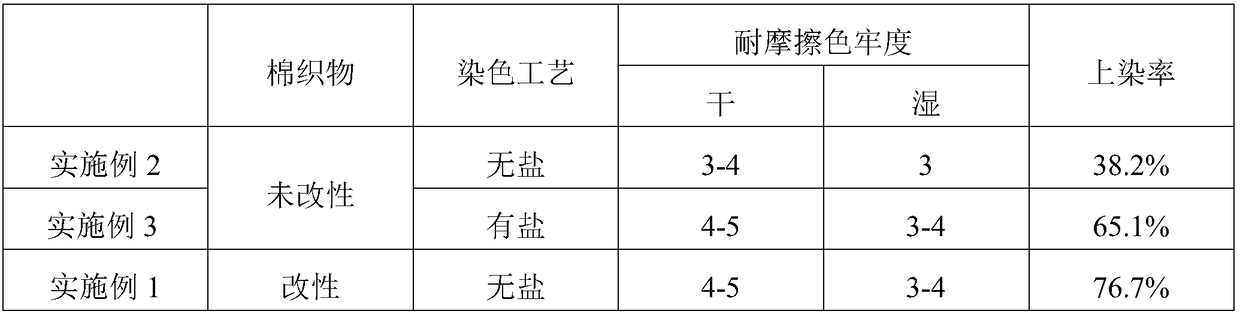

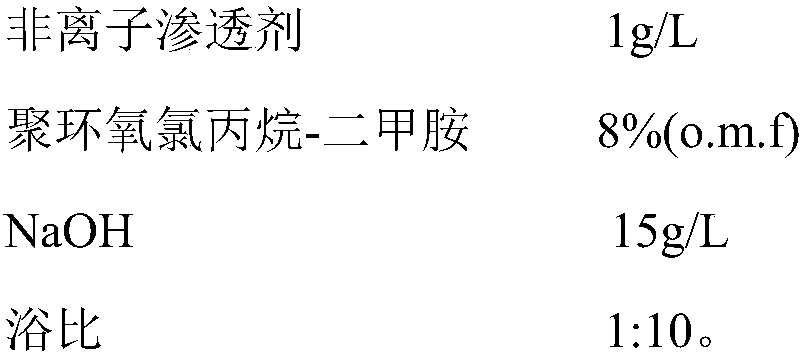

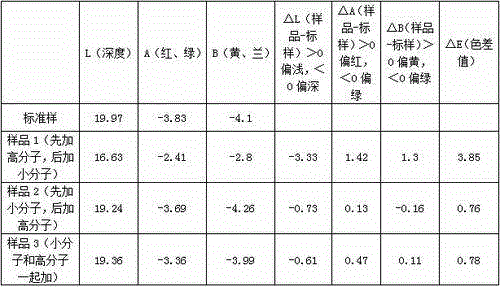

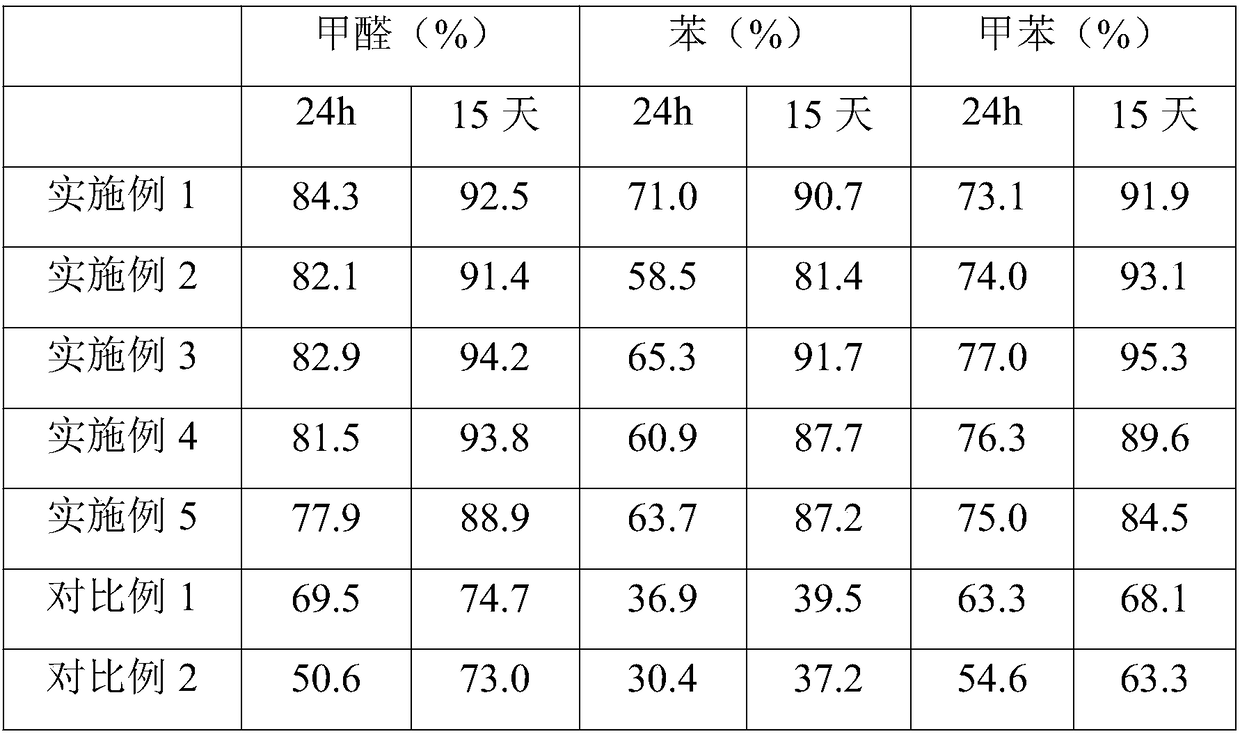

Salt-free dyeing method of cationic modified cotton fabric

InactiveCN108166258AImprove dye uptakeAvoid pollutionDyeing processVegetal fibresSalt freeEngineering

The invention provides a salt-free dyeing method of a cationic modified cotton fabric. The salt-free dyeing method comprises the steps of carrying out cationic modification treatment of a cotton fabric firstly and then carrying out salt-free dyeing; the cationic modification treatment comprises the steps of carrying out impregnation treatment on the cotton fabric in the cationic modification liquid. Through the cold pad batch method, a polyepichlorohydrin-dimethylamine cationic modifier is finished onto the cotton fabric, the working fluid can be recycled, and energy saving and environmental protection are achieved. The modified cotton fabric is dyed under the salt-free condition, the dyeing rate is higher than that of dyeing under a conventional cotton fabric salt condition, and a reactive dye is saved; at the same time, the pollution of salt dyeing Na2SO4 sewage to the environment is avoided.

Owner:LUOLAI LIFESTYLE TECH CO LTD +2

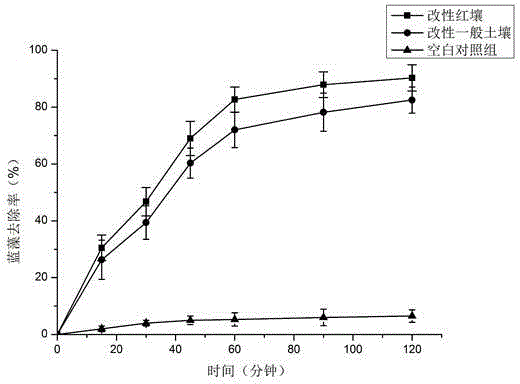

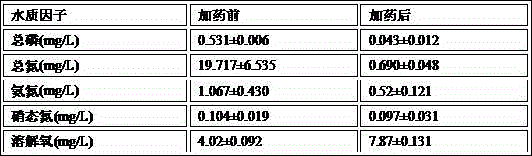

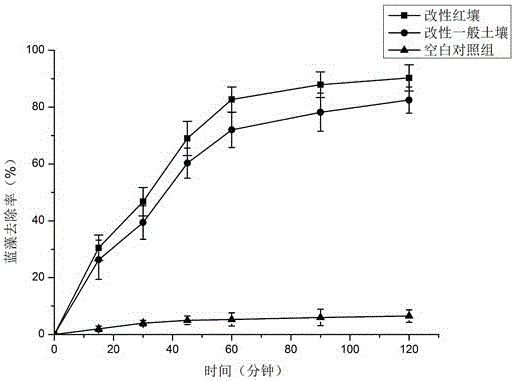

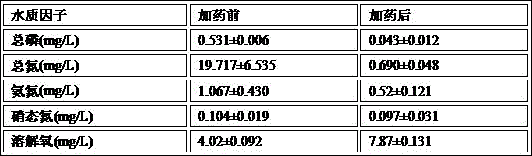

Modified red soil for removing cyanobacteria and preparation method

ActiveCN104445554AHigh removal rateHigh densityWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationPhylum CyanobacteriaCyanobacteria

The invention discloses modified red soil for removing cyanobacteria. The modified red soil comprises raw materials in percentage as follows: red soil, polyepichlorohydrin-dimethylamine, polymeric ferric sulfate and water. A preparation method of the modified red soil comprises steps as follows: 1, weighing out the polyepichlorohydrin-dimethylamine, and diluting the polyepichlorohydrin-dimethylamine with water through stirring to obtain a polyepichlorohydrin-dimethylamine mother solution; 2, weighing out the polymeric ferric sulfate, and diluting the polymeric ferric sulfate with water to obtain a polymeric ferric sulfate mother solution; 3, weighing out the red soil, and dissolving the red soil after drying and grinding to obtain a red soil mother solution; 4, adding the polyepichlorohydrin-dimethylamine mother solution and the polymeric ferric sulfate mother solution to the red soil mother solution, and diluting the mixture with water to obtain the modified red soil. According to the modified red soil, the polyepichlorohydrin-dimethylamine and the polymeric ferric sulfate are used as flocculating agents, the red soil is used as a flocculation aid, and active aluminium and active iron, which are higher in content, of the red soil are used as coagulants, so that the cyanobacteria removal rate is increased, and secondary pollution cannot be caused after the cyanobacteria are removed. The preparation method is simple, low in cost and simple to operate.

Owner:江西省水利科学研究院

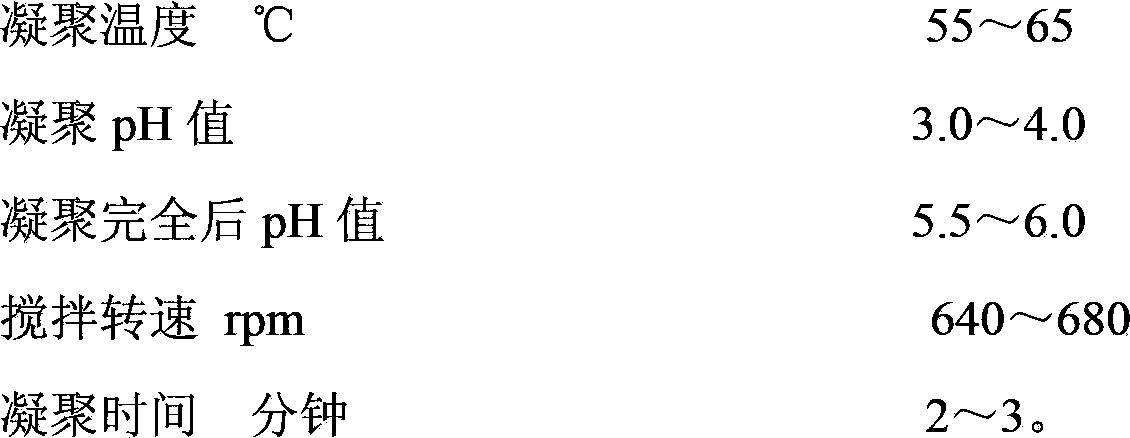

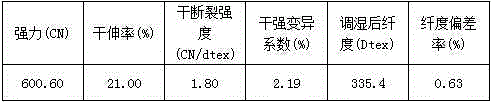

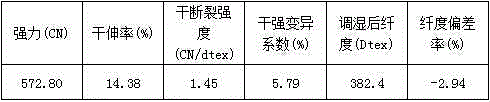

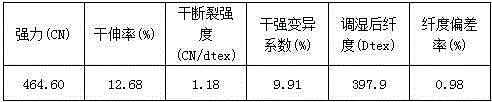

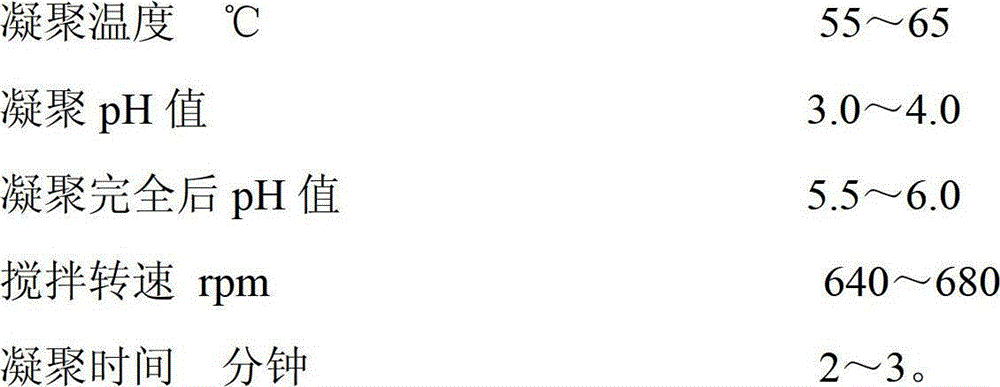

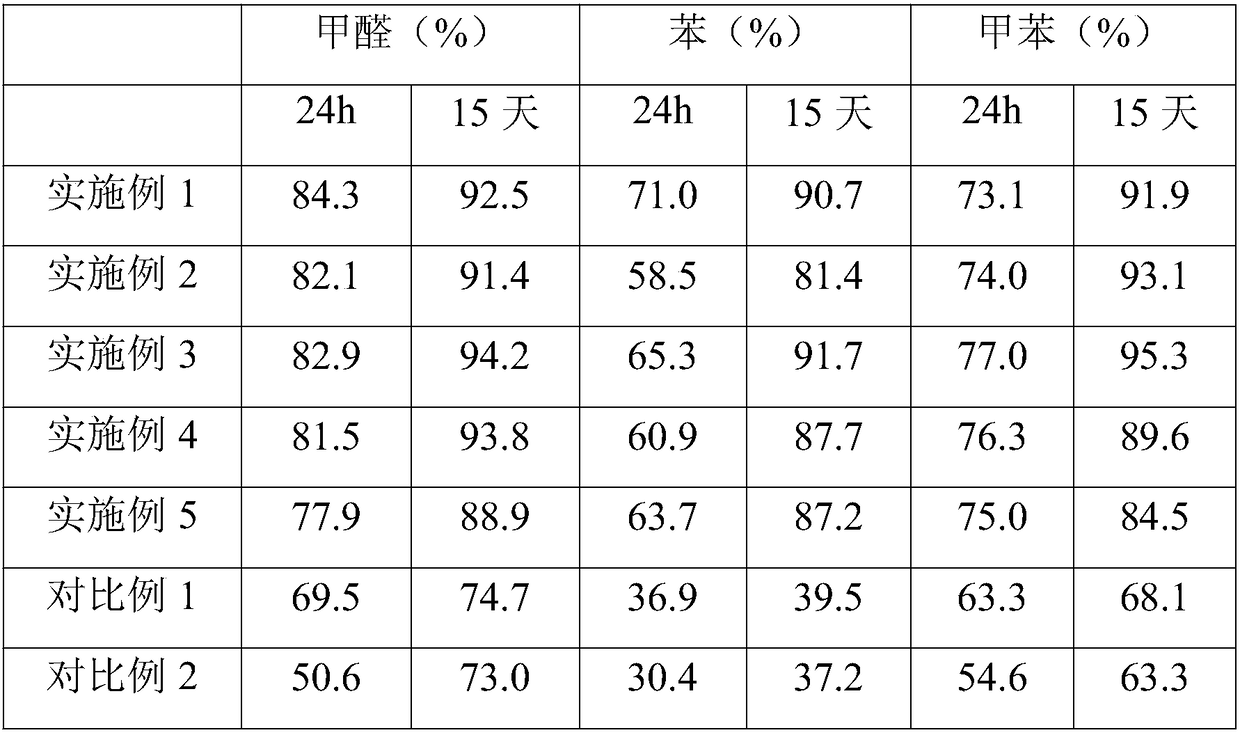

Nitrile butadiene rubber latex coagulation technology

The invention relates to a nitrile butadiene rubber latex coagulation technology, and belongs to the treatment of a rubber latex characterized by a used coagulation agent. The technology is characterized in that polyepichlorohydrin dimethylamine is adopted as a coagulation agent, an aqueous solution of sodium chloride is adopted as a coagulation mother liquor, and sulfuric acid is adopted as a pH adjusting agent, and the technology comprises the following steps: 1, preparing the coagulation mother liquor, 2, preparing a solution of the coagulation agent, 3, preheating a nitrile butadiene rubber latex, 4, preparing a pH adjusting solution, and 5, coagulating the latex. The nitrile butadiene rubber latex coagulation technology has the advantages of coarse colloidal particles in the coagulation process, small crushed colloid loss, less consumption of the coagulation agent, small consumption of the pH adjusting agent, low COD index in discharged wastewater, simple use, short coagulation time and low production cost. The COD content in wastewater is 266.48mg / L, and accounts of 40% of the COD content in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP

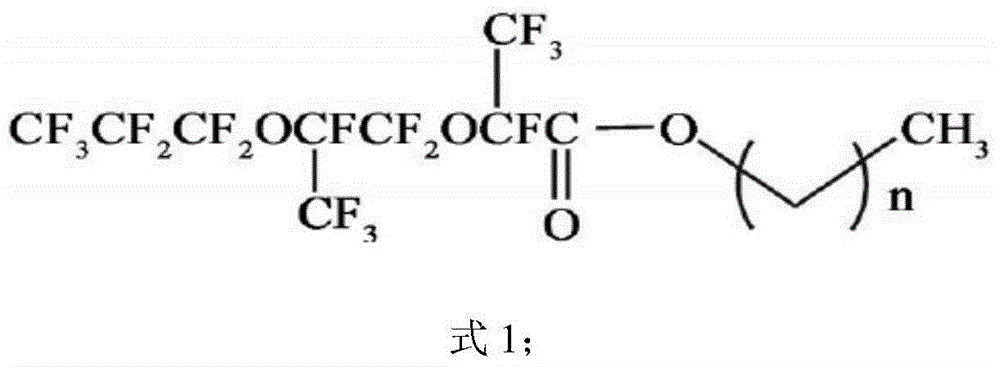

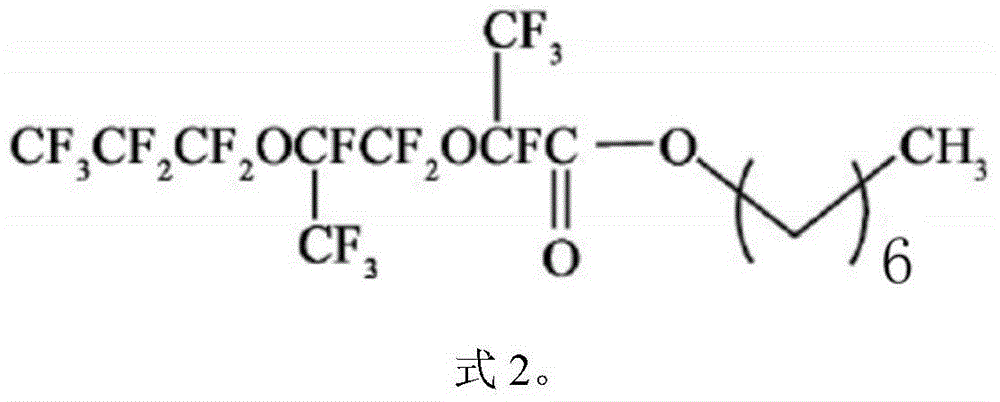

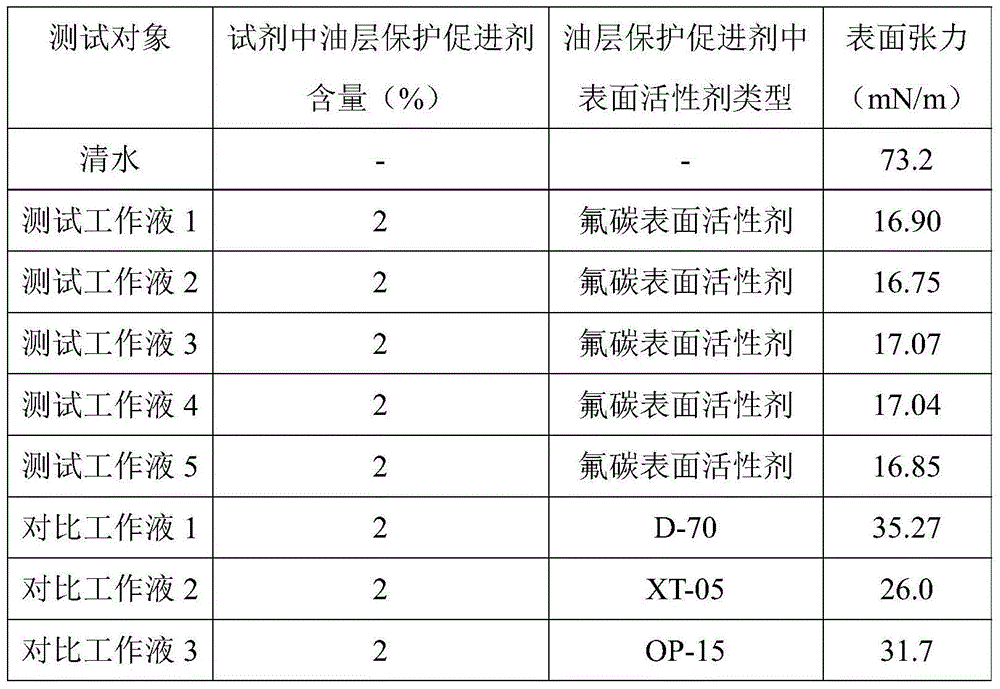

Oil reservoir protection accelerator and preparation method thereof

ActiveCN104449627AStable and long-lastingInhibits clay swellingDrilling compositionPorosityFiltration

The invention discloses an oil reservoir protection accelerator and a preparation method of the oil reservoir protection accelerator. The oil reservoir protection accelerator comprises the following components in percentage by weight: 0.1-1.0 percent of polyepichlorohydrin-dimethylamine, 0.5-2.0 percent of ammonium chloride, 0.1-0.5 percent of a surfactant, 5-15 percent of ethanol, and the balance of water. The oil reservoir protection accelerator is relatively-high in anti-swelling rate and anti-scouring degree, and can reduce the surface tension of working solutions and increase the filtration capacity of the working solutions; the water sensitivity and water blocking damages of a reservoir are greatly reduced, the aim that the protective reservoir is prevented from being damaged due to invasion of the working solutions is fulfilled, and the requirement of oil reservoir protection in a construction operation process of low-porosity and low-permeability reservoirs is met. The oil reservoir protection accelerator can be used in various measure working solutions in an oil field production process, can also be used as an addictive of the measure working solutions such as acidification, crushing, water plugging and profile control, and has functions of protecting stratum and preventing the stratum from being damaged in an operation process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing polyepichlorohydrin-dimethylamine-modified porous magnetic glucan microspheres

InactiveCN106268692AGood physical and chemical stabilityHigh mechanical strengthOther chemical processesWater contaminantsMicrosphereSorbent

The invention discloses a method for preparing polyepichlorohydrin-dimethylamine-modified porous magnetic glucan microspheres. The method is characterized by including the steps that mineral ether, dichloromethane and octacosane serve as organic phases; glucan and nanometer Fe3O4 magnetic particles serve as water phases; the water phases are sprayed to the organic phases, epoxy chloropropane is added, the mixture is frozen and dried for 24 h, and the porous magnetic glucan microspheres are obtained; 64%-70% by mass of acetone, 2%-8% by mass of ethanediamine and 8%-14% by mass of polyepichlorohydrin dimethylamine are added into a reactor and dissolved, 12%-20% by mass of the porous magnetic glucan microspheres are added, the sum of all the components are 100%, and all the components are stirred and subjected to a reflux reaction for 4 h to 6 h at the constant temperature of 50 DEG C+ / -2 DEG C, cooling is carried out, then the product is washed with deionized water and acetone, subjected to solid-liquid separating and dried, and the polyepichlorohydrin-dimethylamine-modified porous magnetic glucan microspheres are obtained; an adsorbent has the quite-high adsorption capacity for bisphenol A and is repeatedly used, the cost is low, environmental protection is achieved, and meanwhile magnetism is easy to separate.

Owner:UNIV OF JINAN

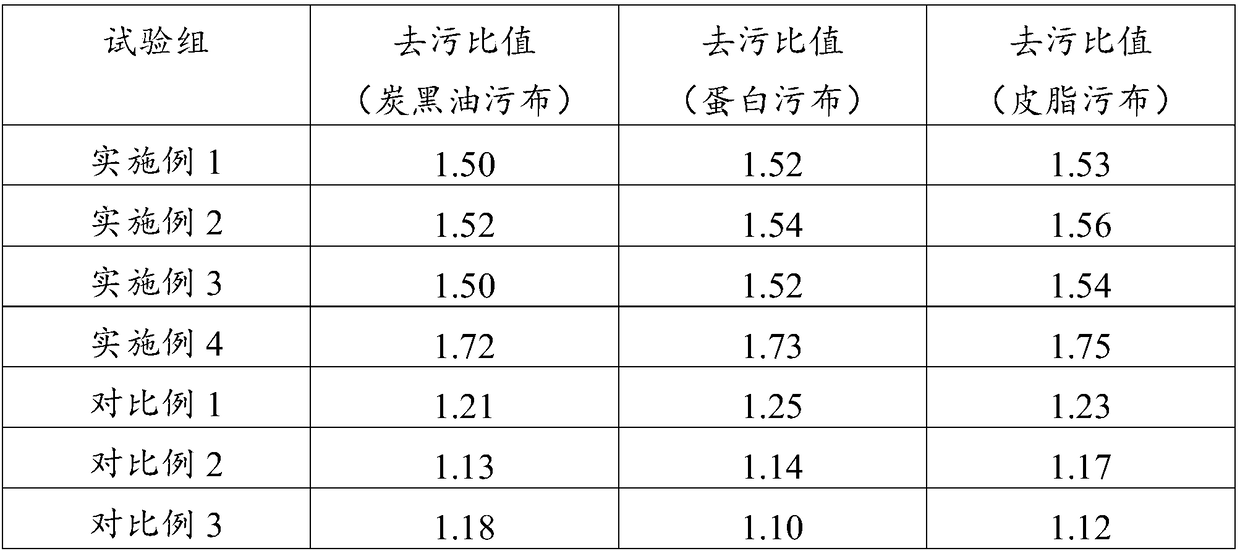

Color-protecting laundry detergent

InactiveCN108441342AGood color protectionImprove sterilization effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsCellulaseColor mixing

The invention discloses a color-protecting laundry detergent. The laundry detergent is prepared from the following components in parts by weight: 5 to 10 parts of anionic surfactant, 10 to 20 parts ofnon-ionic surfactant, 0.5 to 2.0 parts of cellulase, 0.01 to 1.5 parts of enzyme stabilizing agent, 0.1 to 1.0 part of polyepichlorohydrin dimethylamine, 2.0 to 5.0 parts of co-solvent, 1.0 to 5.0 parts of essential oil and 30 to 70 parts of de-ionized water. The laundry detergent provided by the invention can be used for effectively preventing a color fading or color mixing problem of clothes and also has a relatively good sterilization effect.

Owner:SHENZHEN LINGDU INTELLIGENT CONTROL TECH CO LTD

Cement-based water permeable brick with wear resistance enhanced by EVA resin and steel slag micropowder

The invention discloses a cement-based water permeable brick with wear resistance enhanced by EVA resin and steel slag micropowder. The cement-based water permeable brick is prepared form the following raw materials in parts by weight: 40-43 parts of granite scrap, 30-32 parts of waste concrete, 20-22 parts of 42.5-level ordinary Portland cement, 2-2.5 parts of polyester-cotton fabric scrap, 0.1-0.12 part of polyepichlorohydrin dimethylamine, 0.3-0.4 part of early strength polycarboxylate water reducer, an appropriate amount of water, 3-4 parts of EVA resin emulsion, 6-7 parts of steel slag micropowder, 3-4 parts of silica fume and 2-3 parts of silica sol. The cement-based water permeable brick disclosed by the invention has excellent water permeability; with a large number of ventilation pores in the brick body, the surface water can quickly permeate to underground, and the adjustment of surface humidity is promoted; the cement-based water permeable brick is firm and wear-resistant and has high compressive strength and is suitable for park roads, stadiums and the like; and moreover, the raw materials are conveniently available, and the technology facilitates batch production.

Owner:闻承岳

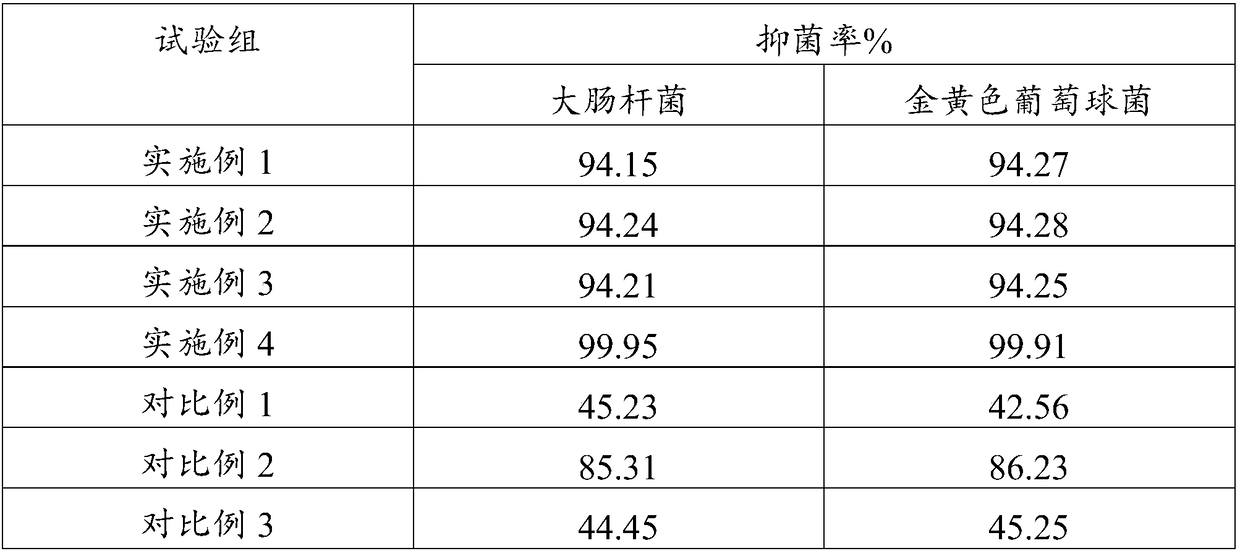

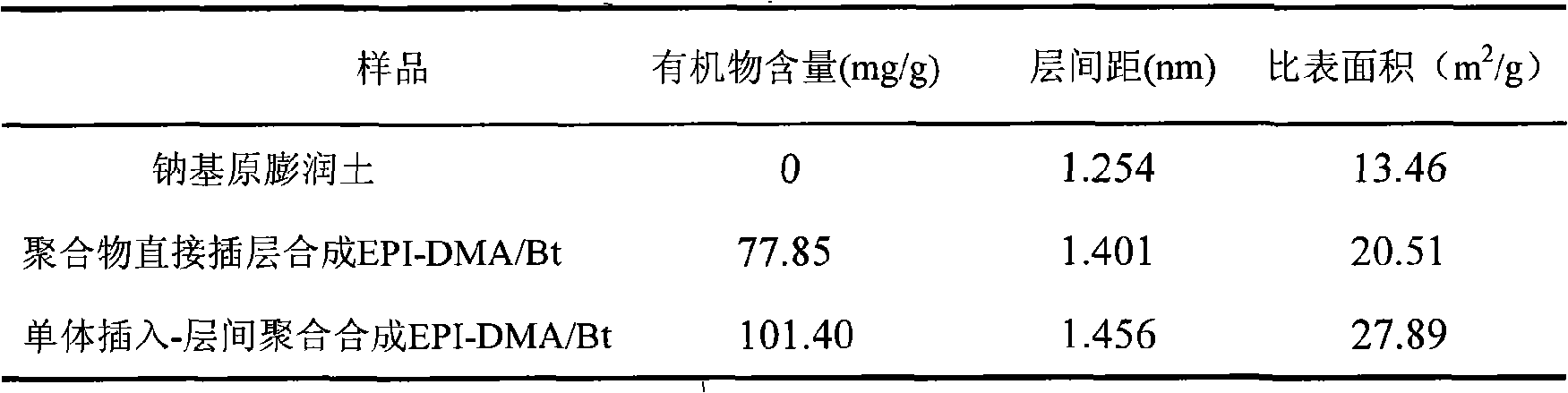

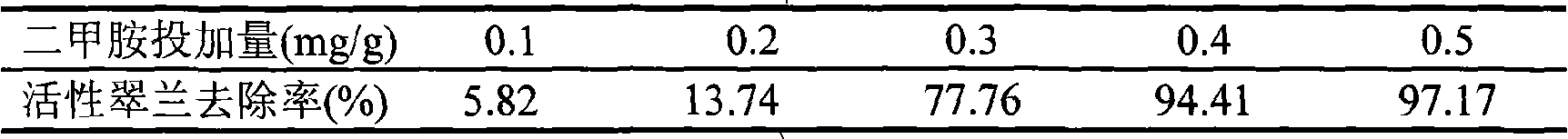

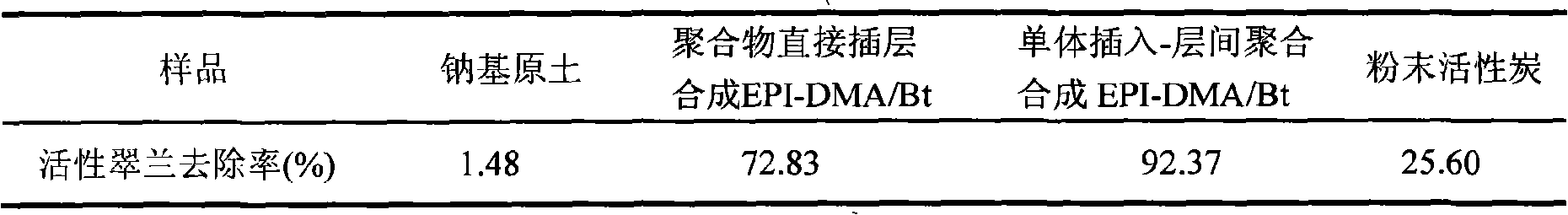

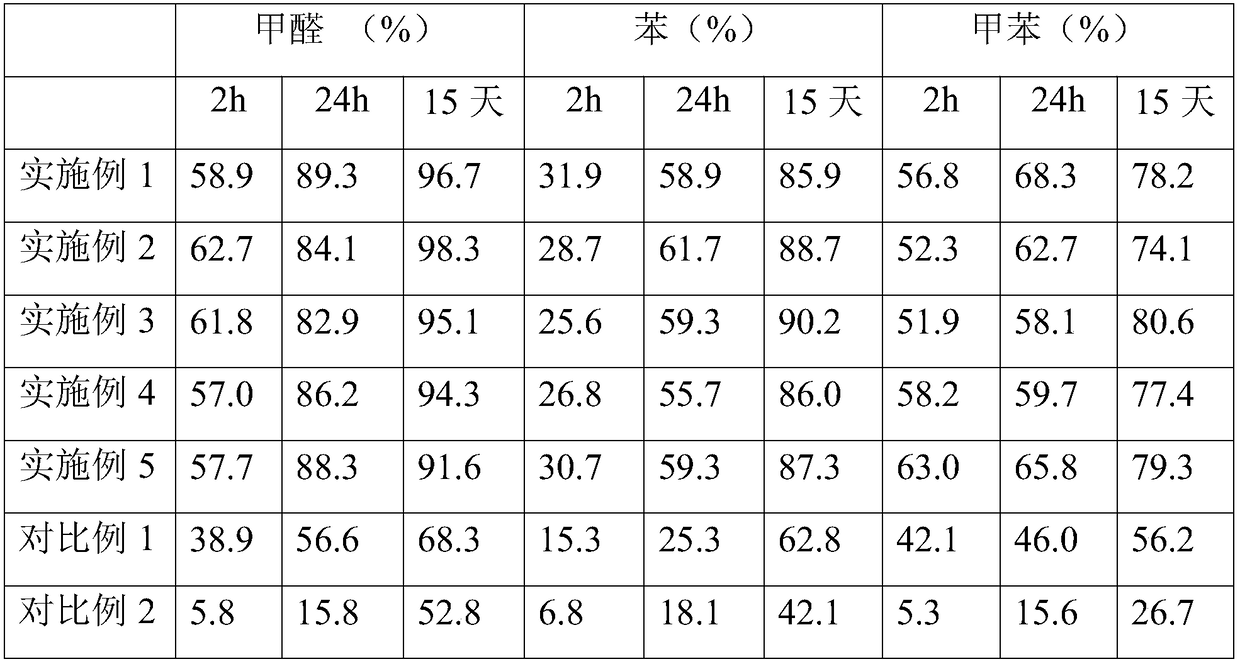

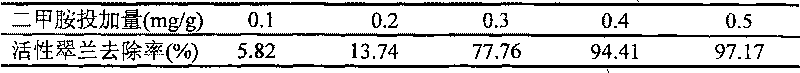

Method for preparing poly-epoxychloropropane dimethylamine cation alta-mud

InactiveCN101318125AQuality improvementUniform appearanceOther chemical processesSodium BentoniteDyeing wastewater

The invention relates to a preparation method for polyepichlorohydrin dimethylamine cation bentonite, belonging to the technical field of environmental protection; the preparation method prepares the polyepichlorohydrin dimethylamine / bentonite by taking sodium bentonite as the raw material, dimethylamine, epichlorohydrin and quadrol as intercalation agents and adopting a monomer insertion-interlayer polymerization method. The product is milky white solid powder, which has around100mg / g of organic loading capacity, 1.456nm of interlayer spacing, 27.89m<2> / g of specific surface and more than 90 percent of decoloration rate to reactive turquoise blue. The method of the invention has the advantages of reasonable design, simple technique, low cost, etc. The prepared polyepichlorohydrin dimethylamine cation bentonite has the advantages of stable product quality and excellent adsorption performance, which has high application value in the decoloration treatment of printing and dyeing wastewater.

Owner:SHANDONG UNIV

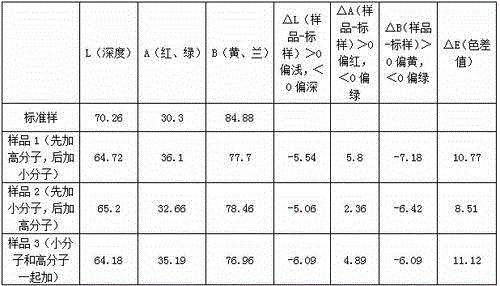

Salt-free low-alkali cellulose fiber modified dyeing process

The invention relates to a salt-free low-alkali cellulose fiber modified dyeing process, belonging to the technical field of textile dyeing. The process comprises the steps of cellulose fiber modification treatment, water washing treatment, dyeing and after-treatment, wherein in the step of cellulose fiber modification treatment, epoxy quaternary ammonium salt compounds and branched polyepichlorohydrin dimethylamine are adopted for modification treatment of cellulose fibers. The salt-free low-alkali cellulose fiber modified dyeing process has the beneficial technical effects that two kinds of specific modifiers are adopted, the synergistic effects of the modifiers are given play to and the specific dyeing steps are provided, so that the cellulose fibers achieve salt-free low-alkali dyeing in dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and dyeing effects, and are suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Mouth mask filter disc for efficiently purifying air, and preparation method thereof

InactiveCN108914245AEfficient purificationImprove adsorption capacityDispersed particle filtrationMonocomponent synthetic polymer artificial filamentFiberHazardous substance

The invention belongs to the field of public environmental protection and health, and concretely relates to a mouth mask filter disc for efficiently purifying air, and a preparation method thereof. The preparation method comprises the following steps: (1) dissolving tetraisopropyl titanate and tin tetrachloride in anhydrous ethanol, adding ammonium fluoride and a ZIF-8 material, performing ultrasonic dispersion, and carrying out a sealing reaction to obtain an intermediate product A; (2) dispersing polyepichlorohydrin-dimethylamine water, adding the intermediate product A, performing ultrasonic treatment, adding polyol and glyceryl ether to obtain a reaction mixture, dropwise adding a precipitant, filtering the obtained solution, and adding an organic solvent to obtain a composite fiber stock solution; (3) electrospinning the composite fiber stock solution to obtain composite fibers, and weaving the composite fibers to obtain the mouth mask filter disc. Tin-fluorine co-doped titanium dioxide is generated in the pores of the ZIF-8 material in an in-situ manner by introducing tetraisopropyl titanate, tin tetrachloride and ammonium fluoride into the ZIF-8 material, so harmful substances in air are adsorbed and catalytically degraded in order to achieve the purpose of efficiently purifying the air.

Owner:ANHUI ZHIBO NEW MATERIAL TECH CO LTD

Polyepichlorohydrin-dimethylamine organic polymer coargulator and its preparation technology

InactiveCN100343183CGood effectSimple production processWater/sewage treatment by flocculation/precipitationEpoxyCross-link

An organic high-molecular flocculant with high flocculating effect for decoloring the printing and dyeing sewage in textile industry is prepared from epoxy chloropropane, dimethylamine and 1,6-hexyldiamine as cross-linking agent. Its preparing process is also disclosed.

Owner:SHANDONG UNIV

Viscose fiber fabric finishing agent and method for applying same

InactiveCN108708169AImprove breathabilityGood moisture permeabilityGrip property fibresVegetal fibresEpoxyAlcohol

The invention discloses a viscose fiber fabric finishing agent and a method for applying the same. The viscose fiber fabric finishing agent comprises, by weight, 5-15 parts of silkworm pupa proteins,5-10 parts of epoxy cross-linking agents, 2-8 parts of polyepichlorohydrin dimethylamine, 1.0-1.5 parts of magnesium chloride, 5-10 parts of absolute ethyl alcohol, 2-5 parts of sodium citrate and 50-60 parts of deionized water. According to the technical scheme, the viscose fiber fabric finishing agent and the method have the advantage that the viscose fiber fabric finishing agent is good in environmental friendliness, softness and antibacterial property.

Owner:SHENZHEN LINGDU INTELLIGENT CONTROL TECH CO LTD

Salt-free low-alkali cellulose fiber dyeing process

The invention relates to a salt-free low-alkali cellulose fiber dyeing process, belonging to the technical field of textile dyeing. The process comprises the steps of cellulose fiber modification treatment, water washing treatment, dyeing and after-treatment, wherein in the step of cellulose fiber modification treatment, an epichlorohydrin parent derivative of epoxy quaternary ammonium salt and branched polyepichlorohydrin dimethylamine are adopted for modification treatment of cellulose fibers. The salt-free low-alkali cellulose fiber dyeing process has the beneficial technical effects that two kinds of specific modifiers are adopted, the synergistic effects of the modifiers are given play to and the specific dyeing steps are provided, so that the cellulose fibers achieve salt-free low-alkali dyeing in dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and dyeing effects, and are suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

Environment-friendly water-based paint and preparation method thereof

InactiveCN114196312AStem shrinkReduce crackingPolyurea/polyurethane coatingsLignin material coatingsFiberAmmonium bromide

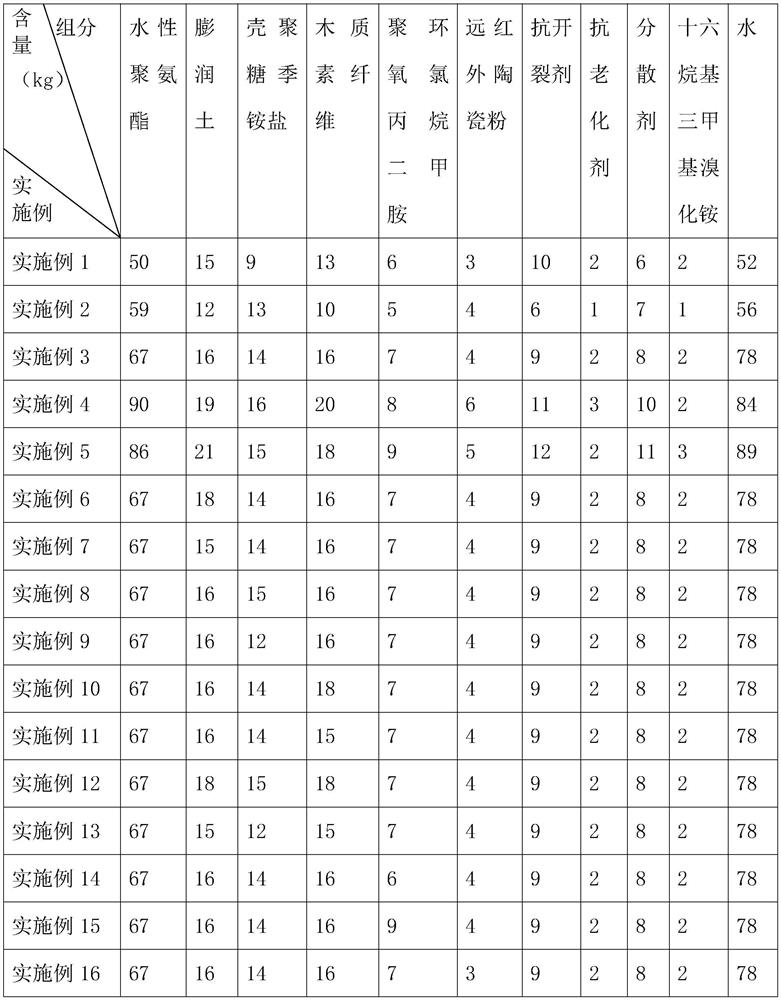

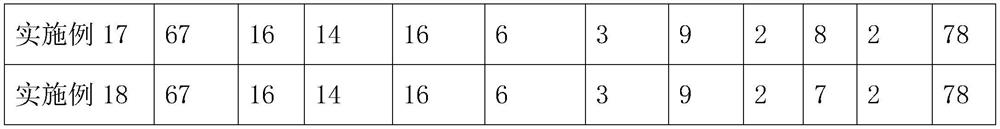

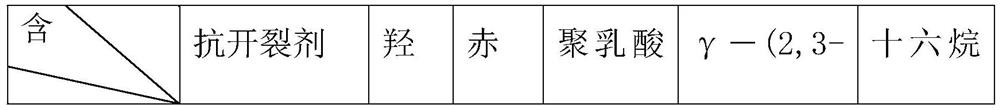

The invention relates to the field of water-based paint, and particularly discloses environment-friendly water-based paint and a preparation method thereof.The environment-friendly water-based paint is prepared from, by weight, 50-90 parts of waterborne polyurethane, 12-21 parts of bentonite, 9-16 parts of chitosan quaternary ammonium salt, 10-20 parts of lignin fiber, 5-9 parts of polyepichlorohydrin dimethylamine and 3-6 parts of far-infrared ceramic powder. 1-3 parts of hexadecyl trimethyl ammonium bromide, 6-12 parts of an anti-cracking agent, 5-11 parts of a dispersing agent, 1-3 parts of an anti-aging agent and 52-89 parts of water. Therefore, the cracking phenomenon after the coating is dried can be effectively reduced.

Owner:SUZHOU COLOR WAY ENTERPRISE DEV

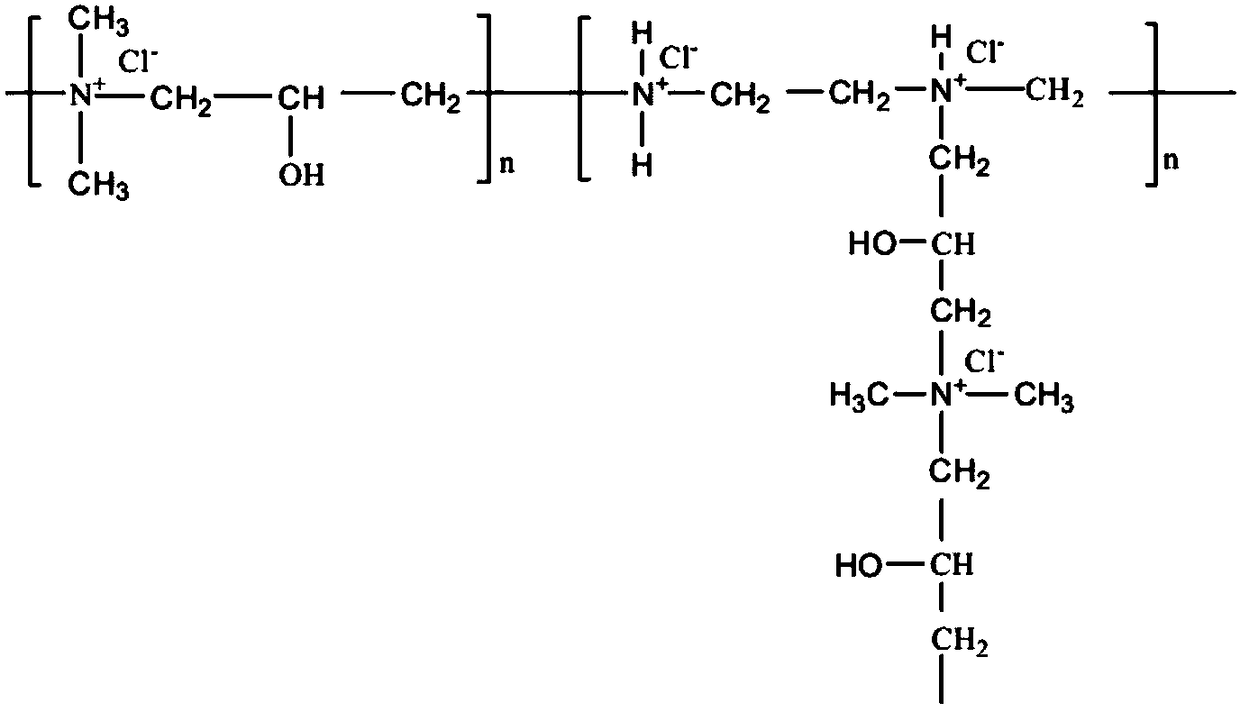

Cationic modified cellulose fibers

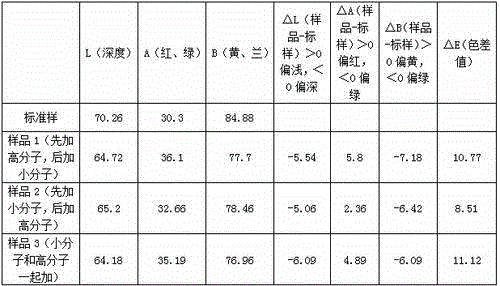

The invention relates to cationic modified cellulose fibers, belonging to the technical field of textile dyeing. The modified cellulose fibers are obtained by carrying out modification treatment on cellulose fibers with low molecular quaternary ammonium salt cationic modifiers and a high molecular quaternary ammonium salt cationic modifier as cationic modifiers and have Zeta electrode potential values of 10-30mV when the pH values are 6.5-8.5, wherein the low molecular quaternary ammonium salt cationic modifiers are epoxy quaternary ammonium salt compounds; the high molecular quaternary ammonium salt cationic modifier is branched polyepichlorohydrin dimethylamine. The cationic modified cellulose fibers have the beneficial technical effects that the two kinds of specific modifiers are adopted and the synergistic effects of the modifiers are given play to, so that the modified cellulose fibers achieve salt-free low-alkali dyeing in subsequent dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and subsequent dyeing effects, and are suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

A kind of method for preparing solid polyferric sulfate

ActiveCN108483597BHigh removal ratePH effect is smallWater/sewage treatment by flocculation/precipitationIron sulfateAluminium chloride

A method for preparing solid polyferric sulfate, the invention belongs to the field of water treatment, the present invention adopts the following technical scheme, adopts ferrous sulfate heptahydrate, sodium chlorate and concentrated sulfuric acid to react to prepare polyferric sulfate liquid, and then by adding The viscosity is 200-10000Pa·s polyepichlorohydrin dimethylamine and white cement, and then placed and solidified to obtain polyferric sulfate solid. Due to the adoption of the above technical scheme, the present invention has the following advantages: (1) Compared with the existing production process of solid polyferric sulfate, the present invention does not need drying and heating equipment, saving 1 / 3 of the production cost; (2) Compared with polyferric sulfate and polyaluminum chloride produced by other methods, the product obtained by the invention has larger alum flowers and faster sedimentation; (3) the product obtained by the invention has good decolorization effect, total phosphorus and COD removal rate High, little impact on water pH and so on.

Owner:SHENZHEN CHANGLONG TECH CO LTD

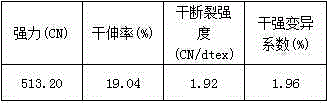

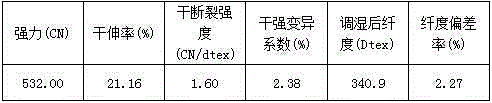

Cellulose fiber cationic modification process

The invention relates to a cellulose fiber cationic modification process, belonging to the technical field of textile dyeing. The cellulose fiber modification process comprises the following steps: putting cellulose fibers in a container, then adding water to the container, and then carrying out modification treatment on the cellulose fibers with two kinds of cationic modifiers, namely low molecular quaternary ammonium salt cationic modifiers and a high molecular quaternary ammonium salt cationic modifier, thereby obtaining modified cellulose fibers after modification treatment is completed, wherein the low molecular quaternary ammonium salt cationic modifiers are epoxy quaternary ammonium salt compounds; the high molecular quaternary ammonium salt cationic modifier is branched polyepichlorohydrin dimethylamine. The cellulose fiber cationic modification process has the beneficial technical effects that the two kinds of specific modifiers are adopted and the synergistic effects of the modifiers are given play to, so that the modified cellulose fibers achieve salt-free low-alkali dyeing in subsequent dyeing, have the effects of reducing pollution, saving the cost, simplifying the process and reducing the difficulty, have good modification and subsequent dyeing effects, and are suitable for large-scale industrial production.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN +1

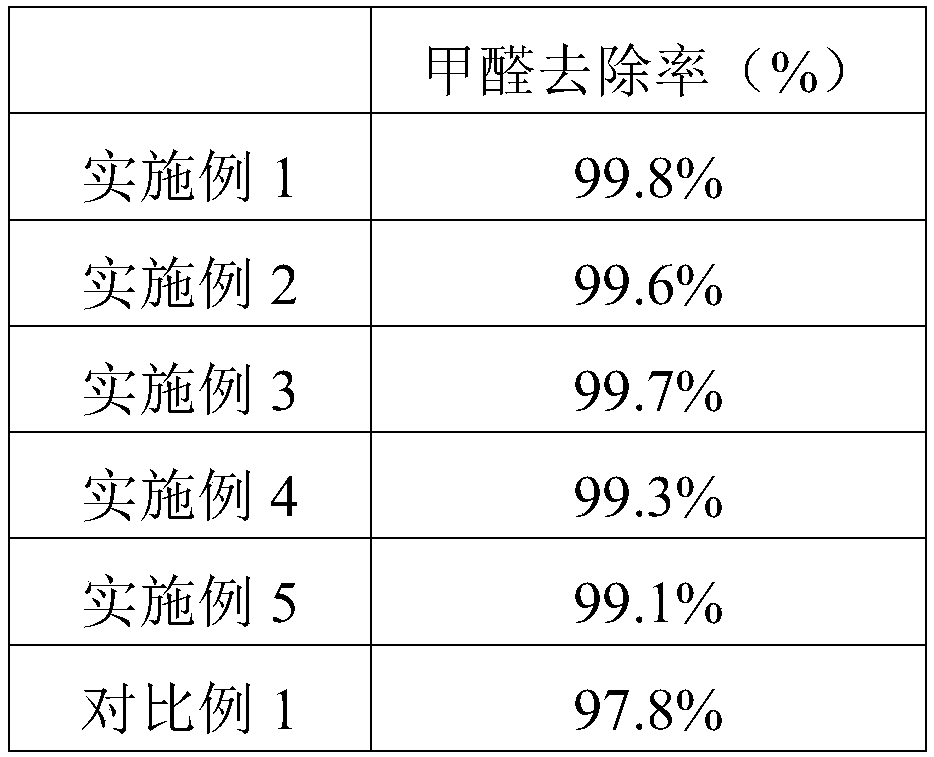

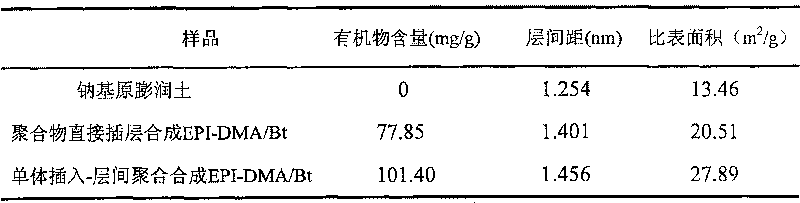

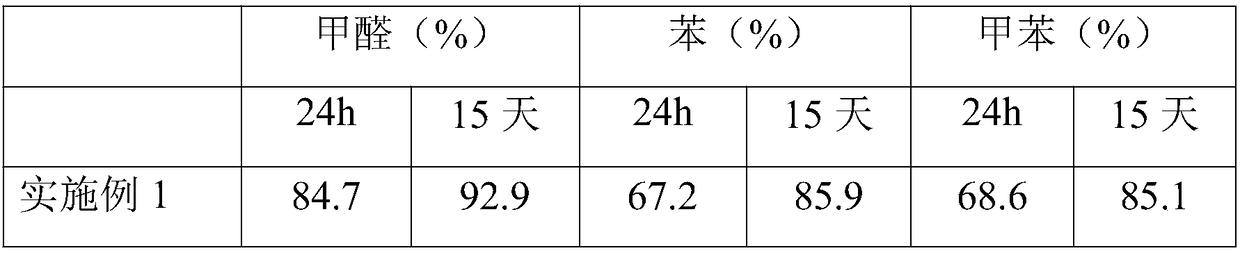

Photocatalyst-based composite air purifying agent and preparation method thereof

InactiveCN109012146ALarge specific surface areaExcellent Surface Catalytic ActivityOther chemical processesDispersed particle separationCompound organicSpare part

The invention relates to the technical field of automobile spare parts, in particular to a photocatalyst-based composite air purifying agent and a preparation method thereof. The preparation method comprises the steps of: compounding organic silicate ester, organic titanate and IRMOFs to obtain an intermediate product 1; dispersing polyepichlorohydrin dimethylamine in water evenly, then adding theintermediate product 1 and redox graphene, carrying out ultrasonic reaction for 15-25min, then carrying out stirring reaction for 3-12h, and then performing centrifugal washing and drying to obtain an intermediate product 2; and roasting the intermediate product 2 in an inert gas atmosphere at 300-500DEG C for 2-6h, thus obtaining the photocatalyst-based composite air purifying agent. The photocatalyst-based composite air purifying agent provided by the invention has excellent catalytic performance, can effectively adsorb pollutants in the air and degrade pollutants in situ, and has broad application prospects in the air purification field.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

A kind of modified red soil for removing cyanobacteria and preparation method thereof

ActiveCN104445554BHigh removal rateHigh densityWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by flocculation/precipitationPhylum CyanobacteriaIron sulphate

The invention discloses modified red soil for removing cyanobacteria. The modified red soil comprises raw materials in percentage as follows: red soil, polyepichlorohydrin-dimethylamine, polymeric ferric sulfate and water. A preparation method of the modified red soil comprises steps as follows: 1, weighing out the polyepichlorohydrin-dimethylamine, and diluting the polyepichlorohydrin-dimethylamine with water through stirring to obtain a polyepichlorohydrin-dimethylamine mother solution; 2, weighing out the polymeric ferric sulfate, and diluting the polymeric ferric sulfate with water to obtain a polymeric ferric sulfate mother solution; 3, weighing out the red soil, and dissolving the red soil after drying and grinding to obtain a red soil mother solution; 4, adding the polyepichlorohydrin-dimethylamine mother solution and the polymeric ferric sulfate mother solution to the red soil mother solution, and diluting the mixture with water to obtain the modified red soil. According to the modified red soil, the polyepichlorohydrin-dimethylamine and the polymeric ferric sulfate are used as flocculating agents, the red soil is used as a flocculation aid, and active aluminium and active iron, which are higher in content, of the red soil are used as coagulants, so that the cyanobacteria removal rate is increased, and secondary pollution cannot be caused after the cyanobacteria are removed. The preparation method is simple, low in cost and simple to operate.

Owner:江西省水利科学研究院

A kind of agglomeration process of nitrile rubber latex

The invention relates to a nitrile butadiene rubber latex coagulation technology, and belongs to the treatment of a rubber latex characterized by a used coagulation agent. The technology is characterized in that polyepichlorohydrin dimethylamine is adopted as a coagulation agent, an aqueous solution of sodium chloride is adopted as a coagulation mother liquor, and sulfuric acid is adopted as a pH adjusting agent, and the technology comprises the following steps: 1, preparing the coagulation mother liquor, 2, preparing a solution of the coagulation agent, 3, preheating a nitrile butadiene rubber latex, 4, preparing a pH adjusting solution, and 5, coagulating the latex. The nitrile butadiene rubber latex coagulation technology has the advantages of coarse colloidal particles in the coagulation process, small crushed colloid loss, less consumption of the coagulation agent, small consumption of the pH adjusting agent, low COD index in discharged wastewater, simple use, short coagulation time and low production cost. The COD content in wastewater is 266.48mg / L, and accounts of 40% of the COD content in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP

Photocatalyst-based composite air purifying agent

InactiveCN109012148ALarge specific surface areaMultiple reactive sitesOther chemical processesDispersed particle separationHazardous substanceGraphene

The invention relates to the technical field of air purification, in particular to a photocatalyst-based composite air purifying agent. The photocatalyst-based composite air purifying agent is prepared from the following substances by weight: 20-50 weight parts of an IRMOFs material, 3-12 weight parts of organic titanate, 1-5 weight parts of organic silicate, 6-20 weight parts of polyepichlorohydrin dimethylamine, 5-15 weight parts of cetyl trimethyl ammonium bromide, 5-15 weight parts of reduced graphene oxide, 1-10 weight parts of a pH regulator, and 10-50 weight parts of a solvent. The photocatalyst-based composite air purifying agent provided by the invention has excellent catalytic performance, has catalytic degradation effect on a variety of toxic and harmful substances existing in the air, and has broad application prospects in the air purification field.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

Automotive air purifying filter element

InactiveCN108722179AReach enrichmentEfficient degradationGas treatmentDispersed particle separationFoaming agentSolvent

The invention relates to the technical field of parts of automobiles, in particular to an automotive air purifying filter element. The automotive air purifying filter element is prepared from the following substances in parts by weight: 1-5 parts of organic titanate, 3-12 parts of organic silicate ester, 0.005-0.02 part of soluble metal salt, 6-20 parts of polyepichlorohydrin dimethylamine, 5-15 parts of hexadecyl trimethyl ammonium bromide, 1-5 parts of a foaming agent, 10-50 parts of a polymer emulsion, 1-10 parts of a pH regulator, 1-3 parts of a chain extender and 10-50 parts of a solvent.The automotive air purifying filter element can enrich and effectively degrade the harmful gas in the automobile, and the purpose of purifying air in the automobile is achieved.

Owner:WUHU DEXIN AUTO PARTS

Method for preparing poly-epoxychloropropane dimethylamine cation alta-mud

InactiveCN101318125BQuality improvementUniform appearanceOther chemical processesSodium BentoniteDyeing wastewater

The invention relates to a preparation method for polyepichlorohydrin dimethylamine cation bentonite, belonging to the technical field of environmental protection; the preparation method prepares thepolyepichlorohydrin dimethylamine / bentonite by taking sodium bentonite as the raw material, dimethylamine, epichlorohydrin and quadrol as intercalation agents and adopting a monomer insertion-interlayer polymerization method. The product is milky white solid powder, which has around100mg / g of organic loading capacity, 1.456nm of interlayer spacing, 27.89m<2> / g of specific surface and more than 90percent of decoloration rate to reactive turquoise blue. The method of the invention has the advantages of reasonable design, simple technique, low cost, etc. The prepared polyepichlorohydrin dimethylamine cation bentonite has the advantages of stable product quality and excellent adsorption performance, which has high application value in the decoloration treatment of printing and dyeing wastewater.

Owner:SHANDONG UNIV

Activated composite absorption air filter core and preparation method thereof

InactiveCN109012147ALarge specific surface areaExcellent Surface Catalytic ActivityOther chemical processesDispersed particle separationFiberAir filter

The invention relates to the technical field of automobile spare parts, in particular to an activated composite adsorption air filter core and a preparation method thereof. The activated composite adsorption air filter core is prepared from the following substances by weight: 200-500 weight parts of wood pulp fiber, 20-50 weight parts of a zeolite-like imidazole framework material, 3-12 weight parts of organic titanate, 1-5 weight parts of organic silicate ester, 6-20 weight parts of polyepichlorohydrin dimethylamine, 5-15 weight parts of cetyltrimethylammonium bromide, 1-10 weight parts of apH regulator and 10-50 weight parts of a solvent. The activated composite adsorption air filter core provided by the invention has excellent catalytic performance, can effectively adsorb pollutants inthe air and achieve in situ degradation on pollutants, thus having broad application prospects in the air purification field.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

Activated composite absorption air purifying agent and preparation method thereof

InactiveCN109012145ALarge specific surface areaExcellent Surface Catalytic ActivityOther chemical processesDispersed particle separationCompound organicIn situ degradation

The invention relates to the technical field of automobile spare parts, in particular to an activated composite absorption air purifying agent and a preparation method thereof. The preparation methodcomprises the steps of: compounding organic silicate ester, organic titanate and the zeolite-like imidazole skeleton material to obtain an intermediate product 1; dispersing polyepichlorohydrin dimethylamine in water evenly, then adding the intermediate product 1, carrying out ultrasonic reaction for 15-25min, then performing centrifugal washing and drying to obtain an intermediate product 2; androasting the intermediate product 2 at 300-500DEG C for 2-6h, thus obtaining the activated composite absorption air purifying agent. The activated composite absorption air purifying agent provided bythe invention has excellent catalytic performance, can effectively adsorb pollutants in the air and achieve in situ degradation on pollutants, thus having broad application prospects in the air purification field.

Owner:WUHU SAUNAKING ELECTRONICS TECH CO LTD

Preparation method of polyepichlorohydrin dimethylamine modified porous magnetic dextran microspheres

InactiveCN106268692BGood physical and chemical stabilityHigh mechanical strengthOther chemical processesWater contaminantsMicrosphereSorbent

The invention discloses a method for preparing polyepichlorohydrin-dimethylamine-modified porous magnetic glucan microspheres. The method is characterized by including the steps that mineral ether, dichloromethane and octacosane serve as organic phases; glucan and nanometer Fe3O4 magnetic particles serve as water phases; the water phases are sprayed to the organic phases, epoxy chloropropane is added, the mixture is frozen and dried for 24 h, and the porous magnetic glucan microspheres are obtained; 64%-70% by mass of acetone, 2%-8% by mass of ethanediamine and 8%-14% by mass of polyepichlorohydrin dimethylamine are added into a reactor and dissolved, 12%-20% by mass of the porous magnetic glucan microspheres are added, the sum of all the components are 100%, and all the components are stirred and subjected to a reflux reaction for 4 h to 6 h at the constant temperature of 50 DEG C+ / -2 DEG C, cooling is carried out, then the product is washed with deionized water and acetone, subjected to solid-liquid separating and dried, and the polyepichlorohydrin-dimethylamine-modified porous magnetic glucan microspheres are obtained; an adsorbent has the quite-high adsorption capacity for bisphenol A and is repeatedly used, the cost is low, environmental protection is achieved, and meanwhile magnetism is easy to separate.

Owner:UNIV OF JINAN

A kind of laminated thick steel paper and preparation method thereof

ActiveCN109518530BImprove adsorption capacityImprove uniformityPlastic/resin/waxes insulatorsSpecial paperPolymer sciencePolyethylene oxide

The invention relates to a steel paper, in particular to a laminated thick steel paper and a preparation method thereof, comprising the following raw materials in parts by weight: 25-30 parts of cotton fiber, 50-70 parts of phenylenediamide fiber, Mongolian 0.1-1 part of soil removal, 0.1-1 part of polyepichlorohydrin dipotassium amine, 0.1-1 part of polyethylene oxide, 0.01-0.1 part of carboxylated styrene-butadiene latex, and 0.01-0.3 part of graphene oxide. The addition of polyepichlorohydrin dimethylamine modified montmorillonite to the slurry improves the adsorption capacity of the steel paper to the flame retardant, and the addition of polyethylene oxide reduces the flocculation between fibers and improves the paper quality. uniformity, thereby improving the strength of the paper, and then using the positive charge on the polyepichlorohydrin dimethylamine, the negatively charged graphene oxide is adsorbed on the base paper, and the base paper is formed through layer-by-layer adsorption. The film layer makes the steel paper have higher flame retardancy.

Owner:杭州特种纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com