Salt-free low-alkali cellulose fiber dyeing process

A cellulose fiber and process technology, applied in the field of textile dyeing, can solve the problems of inapplicability to large-scale production, high chroma of dyeing residual liquid, and difficult treatment of waste water, etc., and achieve the effect of not easy hydrolysis, uniform dyeing, difficult diffusion and penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

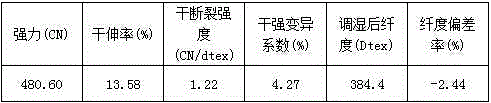

Embodiment 1

[0078] Cellulose fiber dyeing process:

[0079] A salt-free and low-alkali dyeing process for cellulose fibers, comprising the following process steps:

[0080] A. Cellulose fiber modification treatment

[0081] Put the cellulose fiber into the container, add water to the container, and then modify the cellulose fiber with two cationic modifiers, the small molecule quaternary ammonium salt cationic modifier and the high molecular quaternary ammonium salt cationic modifier , modified cellulose fibers are obtained after the modification treatment is completed; the small molecule quaternary ammonium salt cationic modifier is the epichlorohydrin parent derivative of the epoxy quaternary ammonium salt, and the high molecular quaternary ammonium salt cationic modified The main chain type polyepichlorohydrin dimethylamine;

[0082] B. Washing treatment

[0083] Washing the modified cellulose fibers obtained through the modification treatment in step A;

[0084] C. Dyeing

[0085...

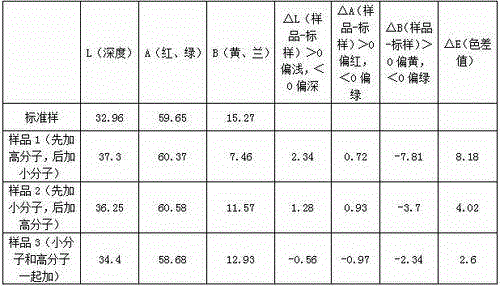

Embodiment 2

[0090] Cellulose fiber dyeing process:

[0091] A salt-free and low-alkali dyeing process for cellulose fibers, comprising the following process steps:

[0092] A. Cellulose fiber modification treatment

[0093] Put the cellulose fiber into the container, add water to the container, and then modify the cellulose fiber with two cationic modifiers, the small molecule quaternary ammonium salt cationic modifier and the high molecular quaternary ammonium salt cationic modifier , modified cellulose fibers are obtained after the modification treatment is completed; the small molecule quaternary ammonium salt cationic modifier is the epichlorohydrin parent derivative of the epoxy quaternary ammonium salt, and the high molecular quaternary ammonium salt cationic modified The main chain type polyepichlorohydrin dimethylamine;

[0094] B. Washing treatment

[0095] Washing the modified cellulose fibers obtained through the modification treatment in step A;

[0096] C. Dyeing

[0097...

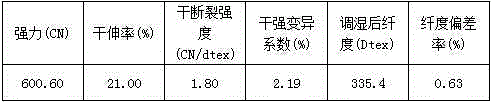

Embodiment 3

[0103] The small molecule quaternary ammonium salt cationic modifier of the present invention is the epichlorohydrin parent derivative of epoxy quaternary ammonium salt;

[0104] The polymer quaternary ammonium salt cationic modifier of the present invention is a main chain type polyepichlorohydrin dimethylamine.

[0105] Epichlorohydrin parent derivatives of epoxy quaternary ammonium salts:

[0106]

[0107] Main chain polyepichlorohydrin dimethylamine:

[0108]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com