Chlorine dioxide gas generating apparatus

A gas generating device, chlorine dioxide technology, applied in the direction of chlorine oxidation, etc., can solve the problems of low conversion rate of sodium chlorate, low purity of chlorine dioxide, increased reaction cost, etc., to achieve complete reaction, high conversion rate, and improved conversion rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

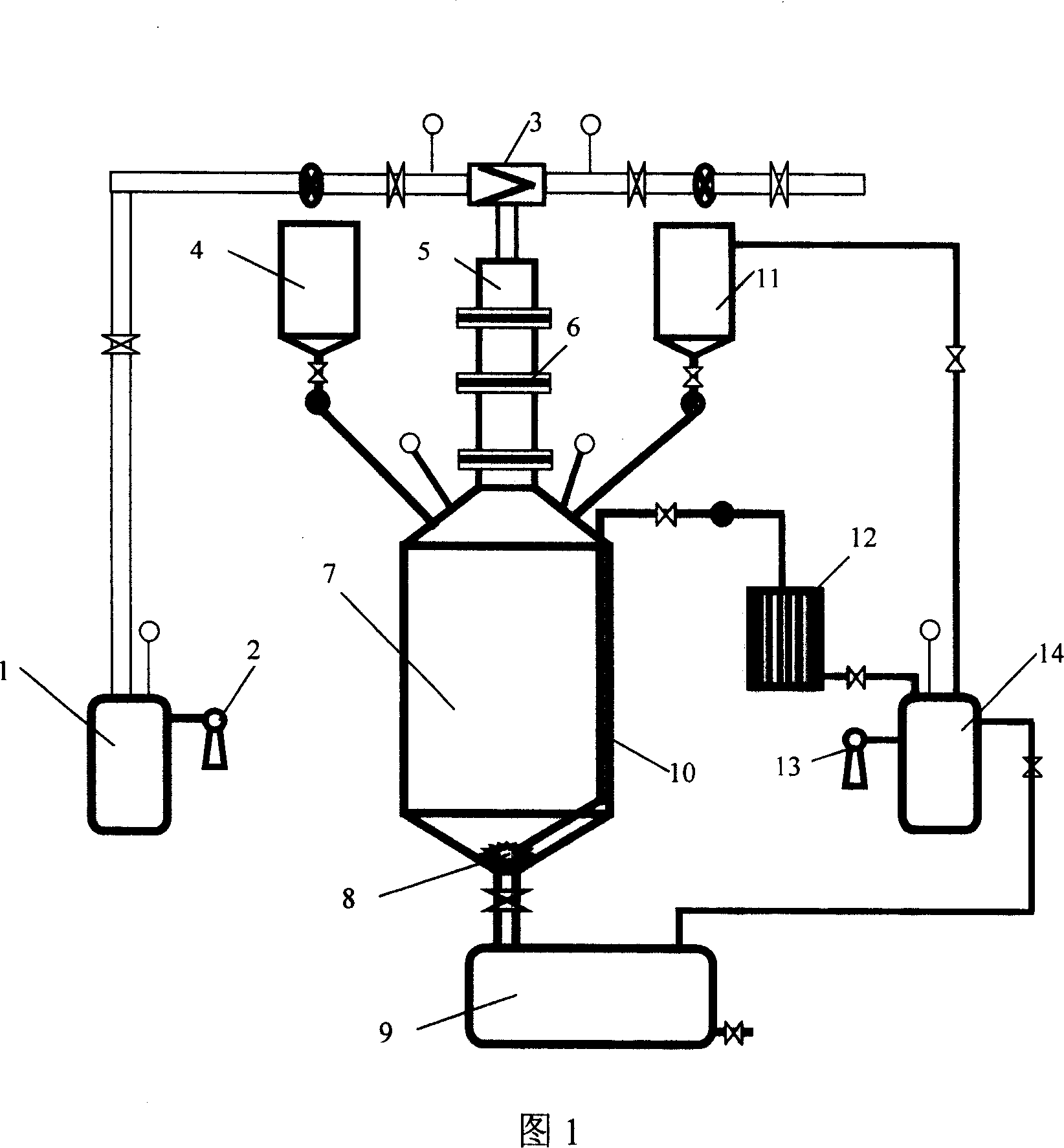

[0043] The structure of chlorine dioxide gas generating device of the present invention is as shown in Figure 1, comprises reactor 7, scrubber 5, sodium chlorate solution storage tank 4, hydrochloric acid storage tank 11, air aeration head 8, aeration pipe 10, Heating device 12, air pumps 2, 13, air ejector 3 and waste liquid tank 9 and other components.

[0044] Sodium chlorate solution storage tank 4 and hydrochloric acid storage tank 11 are connected with reactor 7 by pipeline, valve and flow meter, make sodium chlorate solution and hydrochloric acid control enter in reactor 7. An air aeration head 8 is placed at the bottom of the reactor 7, and is connected with an air pump 13 through an aeration pipe 10 and an air buffer tank 14 for introducing air into the reaction system in the reactor 7. A heating device 12 is installed on the aeration tube 10 for heating the air in the aeration tube 10 . A part of the air in the air buffer tank 14 enters the hydrochloric acid storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com