Method for preparing poly-epoxychloropropane dimethylamine cation alta-mud

A polyepichlorohydrin, epichlorohydrin technology, applied in chemical instruments and methods, other chemical processes, etc., achieves the effects of low cost, uniform appearance and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The steps of preparing polyepichlorohydrin dimethylamine cationic bentonite by monomer insertion-interlayer polymerization method are as follows:

[0024] (1) Weigh 2.00g of dried sodium bentonite in a three-necked round-bottomed flask filled with 100mL of deionized water, and stir and disperse in a JJ-1 booster electric stirrer for 1h;

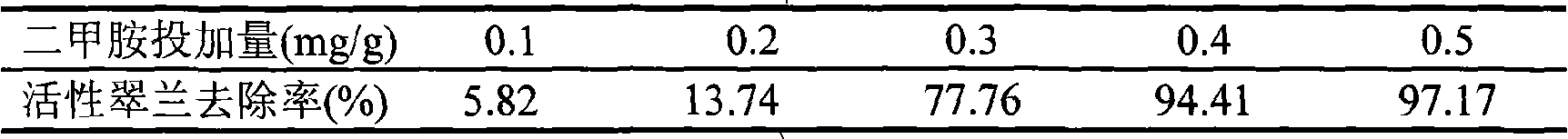

[0025] (2) Add 0.800 g of intercalation agent dimethylamine (dimethylamine is 2 / 5 of the mass of sodium bentonite used) to the above suspension, control the temperature and stir at 20°C for 2 hours to make it fully exchanged;

[0026] (3) Add epichlorohydrin quantitatively at a molar ratio of epichlorohydrin: dimethylamine=1:1, and ethylenediamine by mass ratio: (epoxychlorohydrin+dimethylamine)=2% quantitatively Add ethylenediamine and stir for 3h at a temperature of 65°C;

[0027] (4) Suction filter the reaction solution, wash the above-mentioned cationized bentonite with distilled water until the filtrate does not contain chloride ...

Embodiment 2

[0028] Embodiment 2: As described in Example 1, the difference is that the consumption of dimethylamine is 1 / 5 of the quality of sodium bentonite used, and the mol ratio of epichlorohydrin to dimethylamine is 1.25: 1, and ethylenediamine is added The amount is 1% of the total mass of epichlorohydrin and dimethylamine.

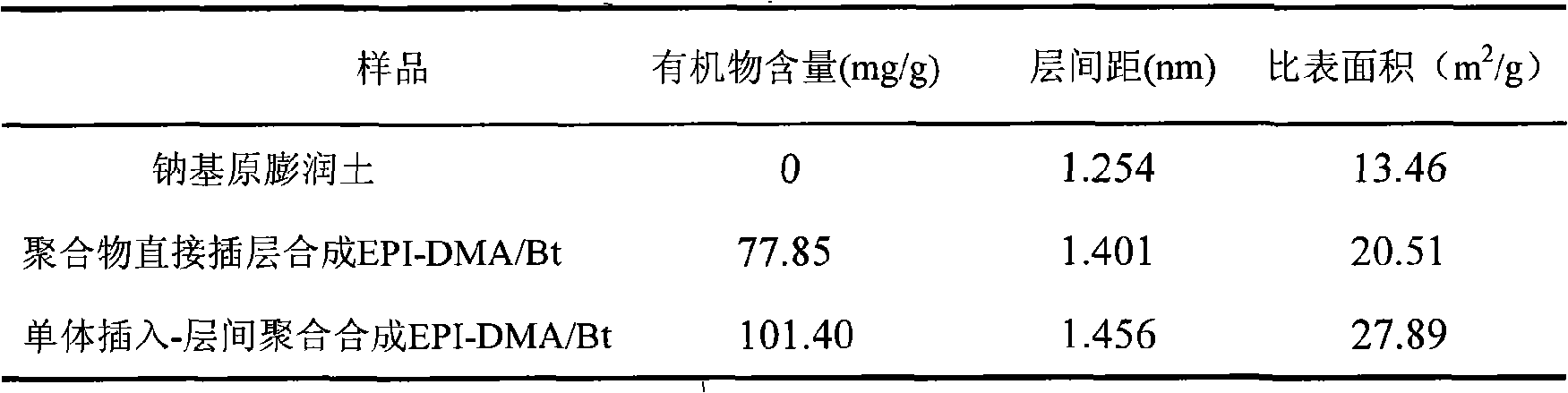

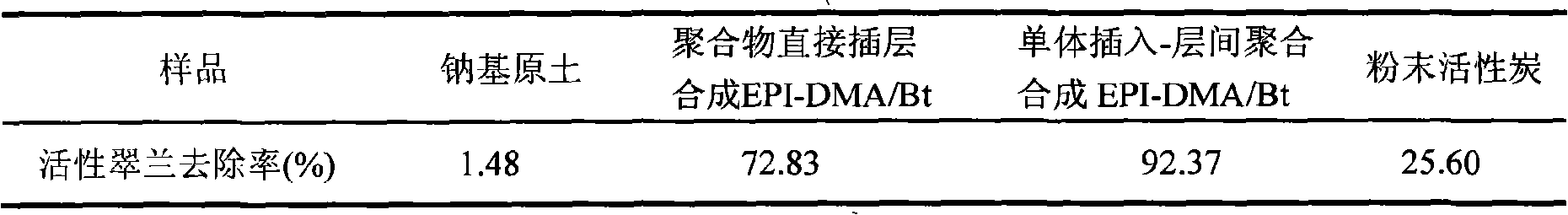

[0029] The polyepichlorohydrin dimethylamine polymer / bentonite prepared by the above steps is characterized, and the results are shown in table 1:

[0030] Table 1 Comparison of structural characteristics of bentonite and polyepichlorohydrin dimethylamine cationic bentonite

[0031]

[0032] From the above results, it can be seen that the interlayer spacing of polymer direct intercalation EPI-DMA / Bt is 1.4.1nm, which is 0.147nm larger than the 1.254nm of the original soil; the interlayer spacing of monomer insertion-interlayer polymerization EPI-DMA / Bt It is 1.456nm, which is 0.202nm larger than the original soil, and 0.055nm larger than the polymer solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com