Nitrile butadiene rubber latex coagulation technology

A nitrile-butadiene rubber and process technology, which is applied in the field of coagulation process of nitrile-butadiene rubber latex, can solve the problems of increased production cost, fine particles of nitrile-butadiene rubber latex, large loss of broken rubber, etc., and achieves the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Coagulate the nitrile rubber latex according to the following process steps:

[0042] ① Preparation of coagulation mother liquor

[0043] Accurately weigh 250 grams of sodium chloride, dissolve it in 20 parts by weight of desalted, deoxygenated water, and make it into a condensed mother liquor for subsequent use;

[0044] ② Preparation of coagulant solution

[0045] Dilute commercially available polyepichlorohydrin dimethylamine with desalted and deoxygenated water to a coagulant solution with a solid content of 10%, and set aside;

[0046] ③Nitrile rubber latex preheating

[0047] 500 grams of industrial nitrile rubber latex with a solid content of 20% equivalent to 100 grams of dry glue, preheated at 52 ° C. Standby;

[0048] ④Preparation of pH adjustment solution

[0049] Preparation weight percentage concentration is the sulfuric acid solution of 20%, standby;

[0050] ⑤ Coagulation of latex

[0051] Add the coagulation mother liquor prepared in step ① into th...

Embodiment 2~ Embodiment 6

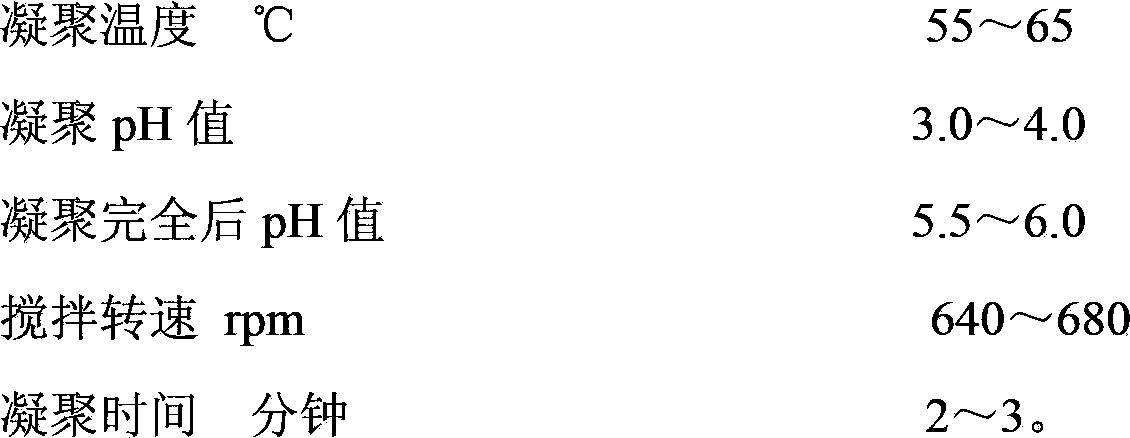

[0058] According to the method and step of embodiment 1, acrylonitrile-butadiene rubber latex is carried out coagulation treatment, and the technical index that raw material proportioning and coagulation treatment process reaches is listed in table 1,

[0059] Table 1

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com