Patents

Literature

32results about How to "Reduce COD index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

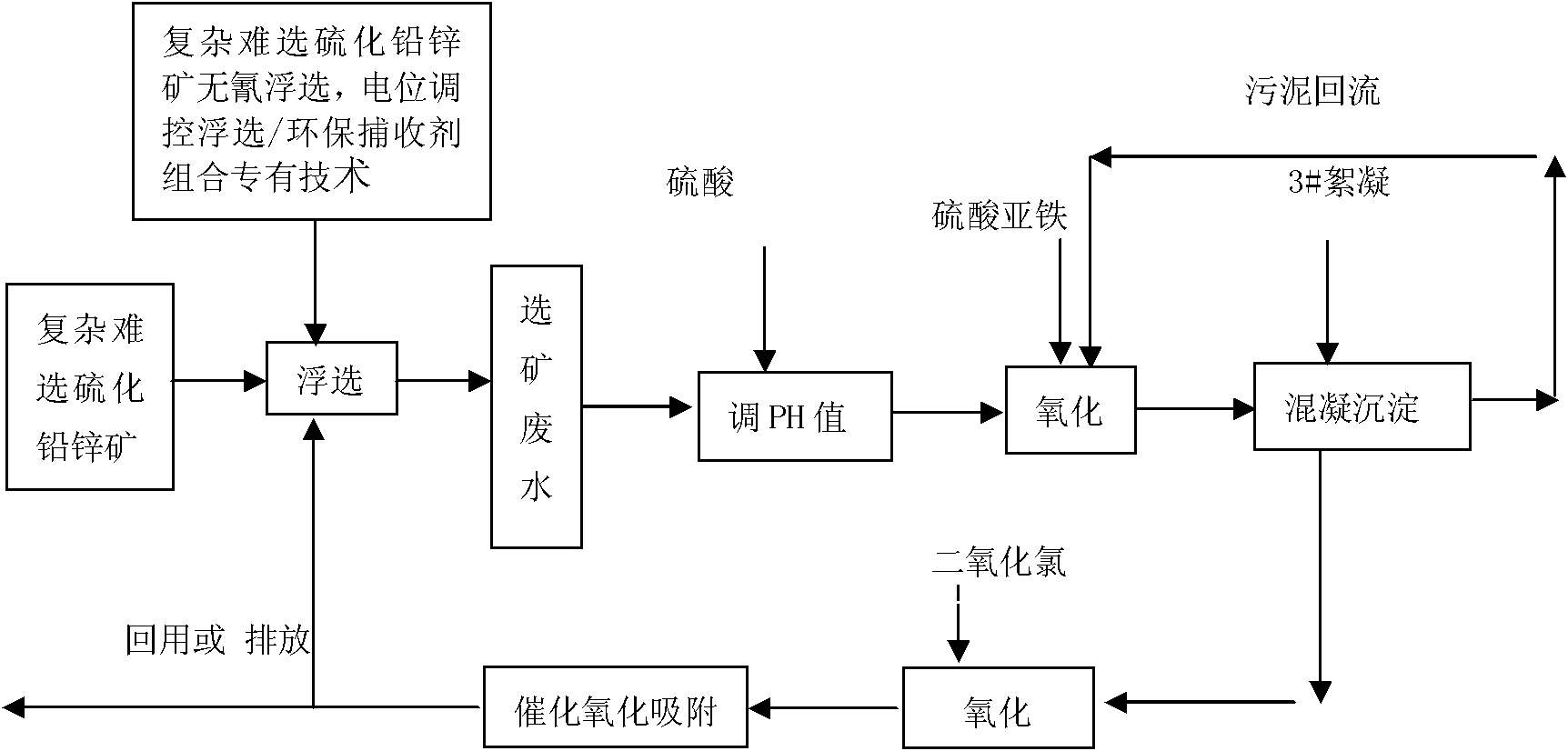

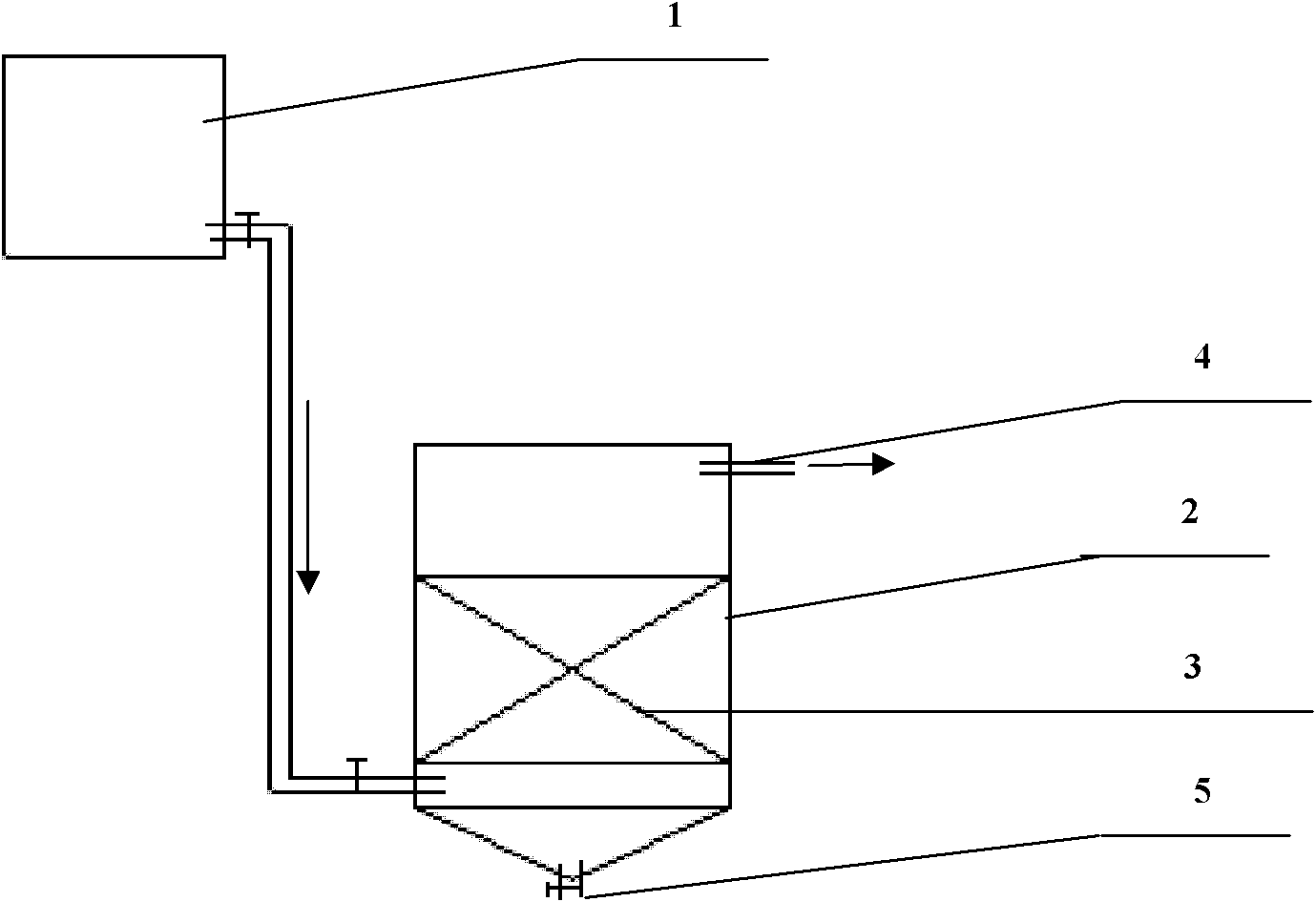

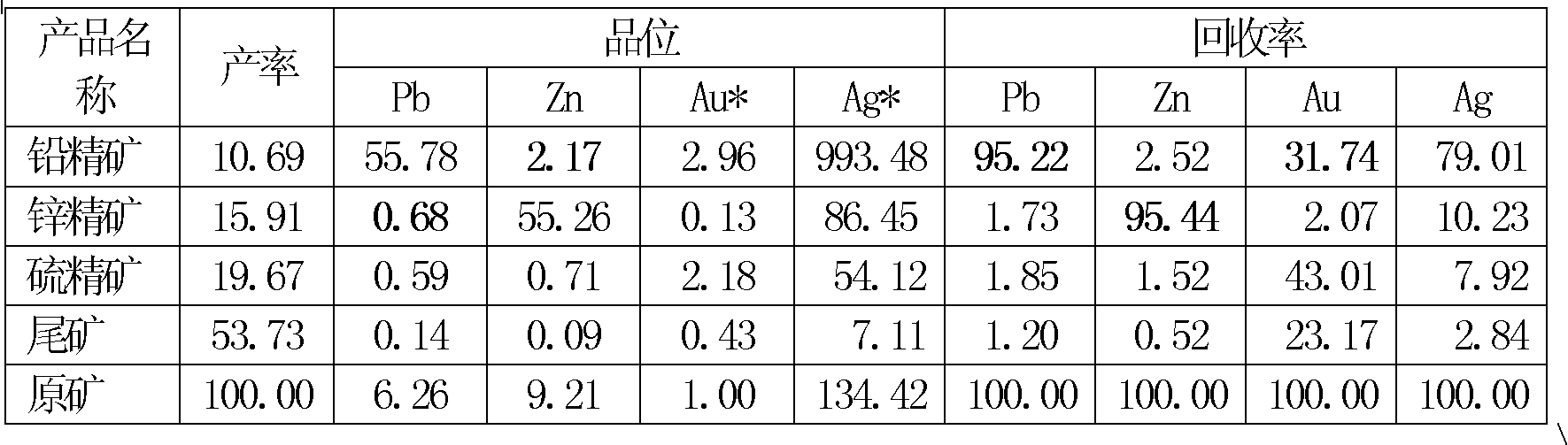

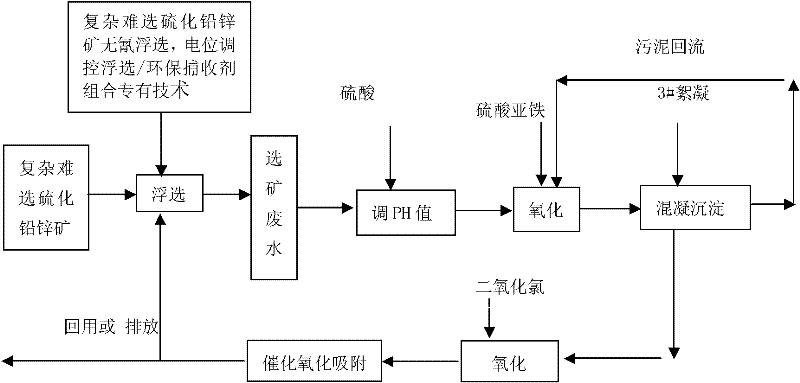

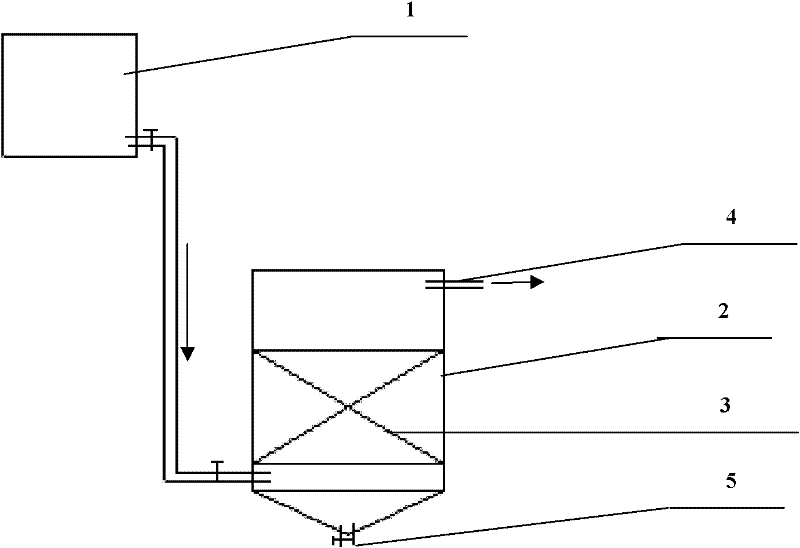

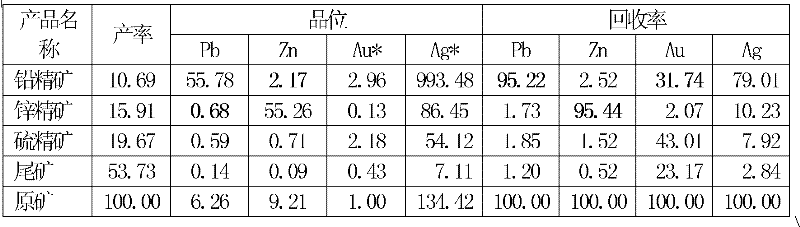

Method for treating and recycling lead-zinc sulfide ore dressing wastewater

ActiveCN101913720AEliminate the effects ofExtended service lifeWaste water treatment from quariesMultistage water/sewage treatmentActive carbonNovel technique

The invention provides a technique for treating and recycling lead-zinc ore dressing wastewater and aims to solve the problems of influence on the ore dressing index due to the recycling of the ore dressing wastewater for production and environmental pollution caused by drainage. The novel technique for treating and recycling the lead-zinc sulfide ore dressing wastewater comprises the steps of: adjusting the pH value of the total wastewater of an ore dressing plant; adding ferrous sulfate and flocculant into the wastewater to perform oxidation-coagulation treatment; and oxidizing the treated water by using chlorine dioxide, and performing catalytic oxidation and adsorption by using an active carbon bed, so that the treated water reaches the relevant discharge standard of China; and totally recycling the treated water by adopting the combined application of potential-controlled flotation and an environmental-protection collector. Compared with the field process technique, the method saves the cyanide flotation process and improves the recovery rates of lead, zinc and gold. The method provides whole technical integration of the combined application technique of the potential-controlled flotation and the environmental-protection collector and the wastewater treatment technique for the treatment and recycling of the lead-zinc ore dressing wastewater, and realizes recycling of the ore dressing wastewater.

Owner:HUNAN HERMES SAFE ENVIRONMENT PROTECTION SCI

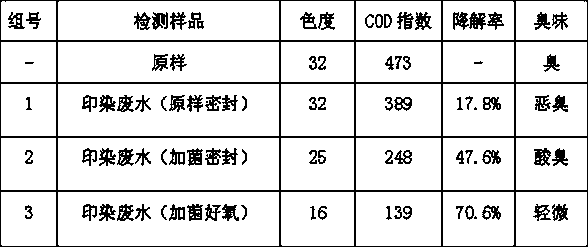

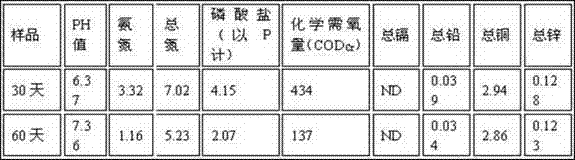

Biological treatment method for waste mud in petroleum and natural gas exploration drilling work

ActiveCN101830614AEasy to handleThe role and effect are obviousBiological sludge treatmentWell drillingWater source

The invention discloses a biological treatment method for waste mud in petroleum and natural gas exploration drilling work, which is characterized by comprising the following steps of: a, forming a microbial treatment layer, namely inoculating special microbial strains to the waste mud in a weight ratio of 3-5: 100, mixing the strains and the waste mud uniformly, stirring the mixture and natural soil with water content of 10 to 10 percent and grain diameter of less than 0.5 centimeter uniformly according to the density condition of the waste mud in a following mode to form the microbial treatment layer, adding the natural soil in an amount which is 2.5 to 3 times that of the waste mud into the waste mud with density of 1 to 1.5kg / L, adding the natural soil in an amount which is 2 to 2.5 times that of the waste mud into the waste mud with density of 1.5 to 2.5kg / L, and controlling the water content of the microbial treatment layer to be between 25 and 30 percent; b, treating the soil; and c, treating plants. The method can solve the technical problem that effusion enters underground water to pollute a water source because the natural soil with high water content and large grain diameter is easily scoured by hard rain under the condition that pollutants in a pretreatment mixture are not yet effectively degraded in the prior art.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Acrylic fiber waste water treatment method

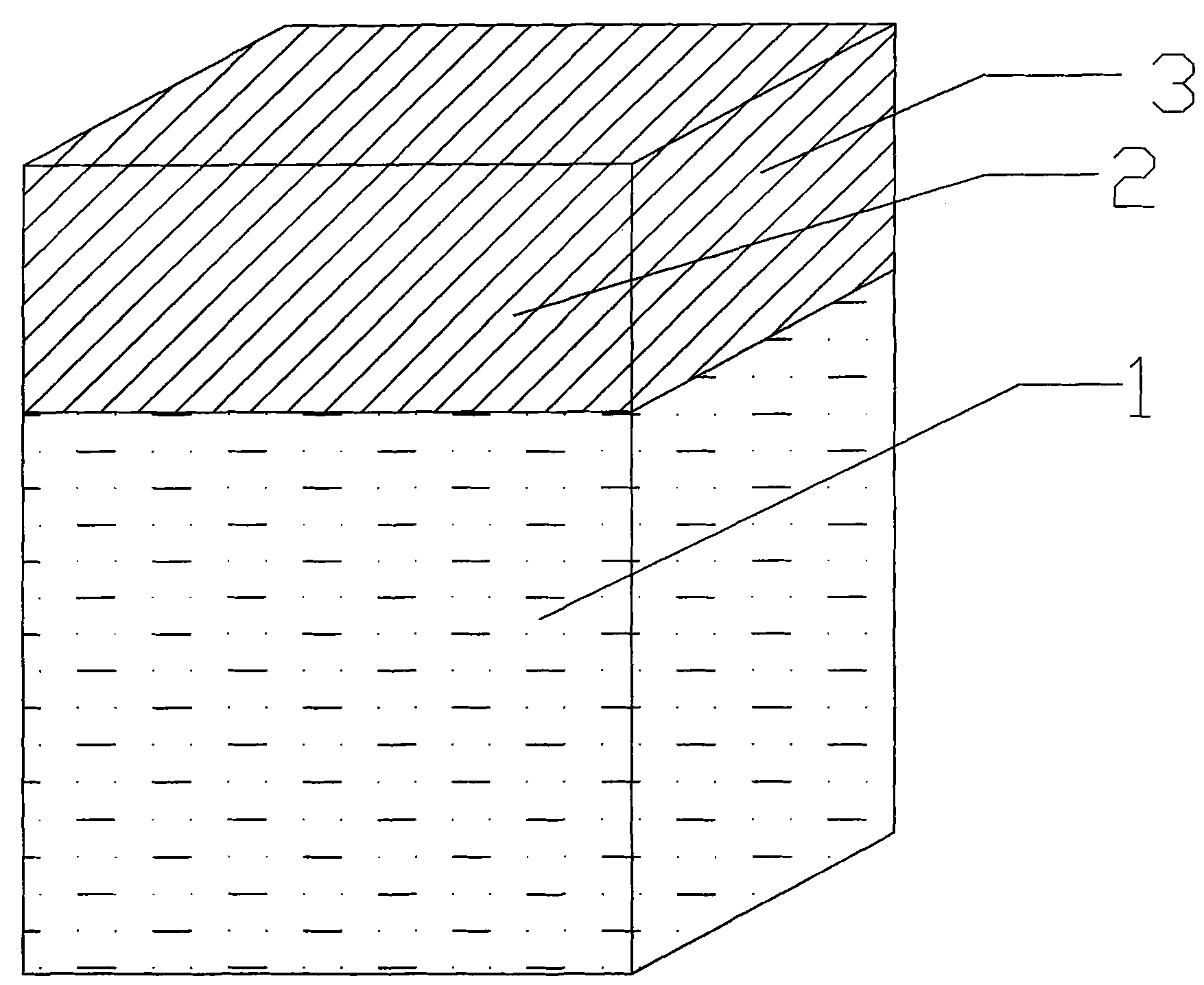

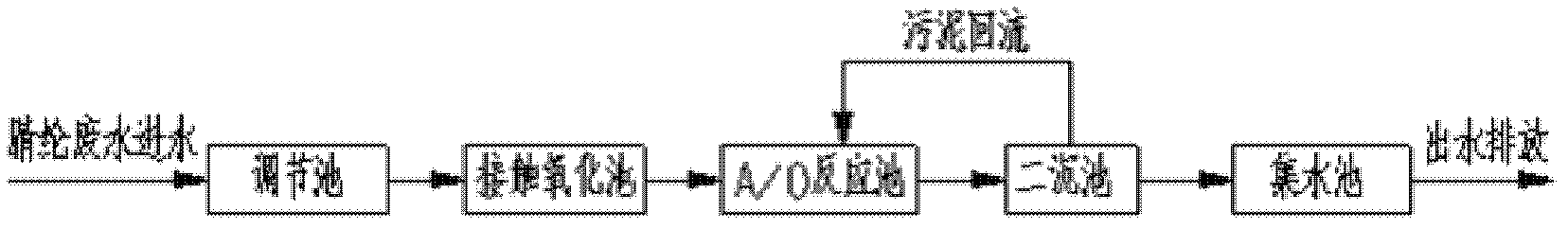

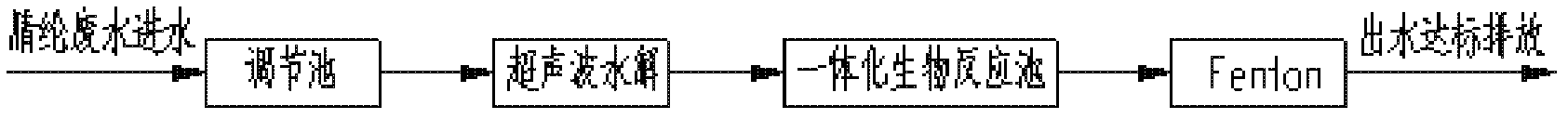

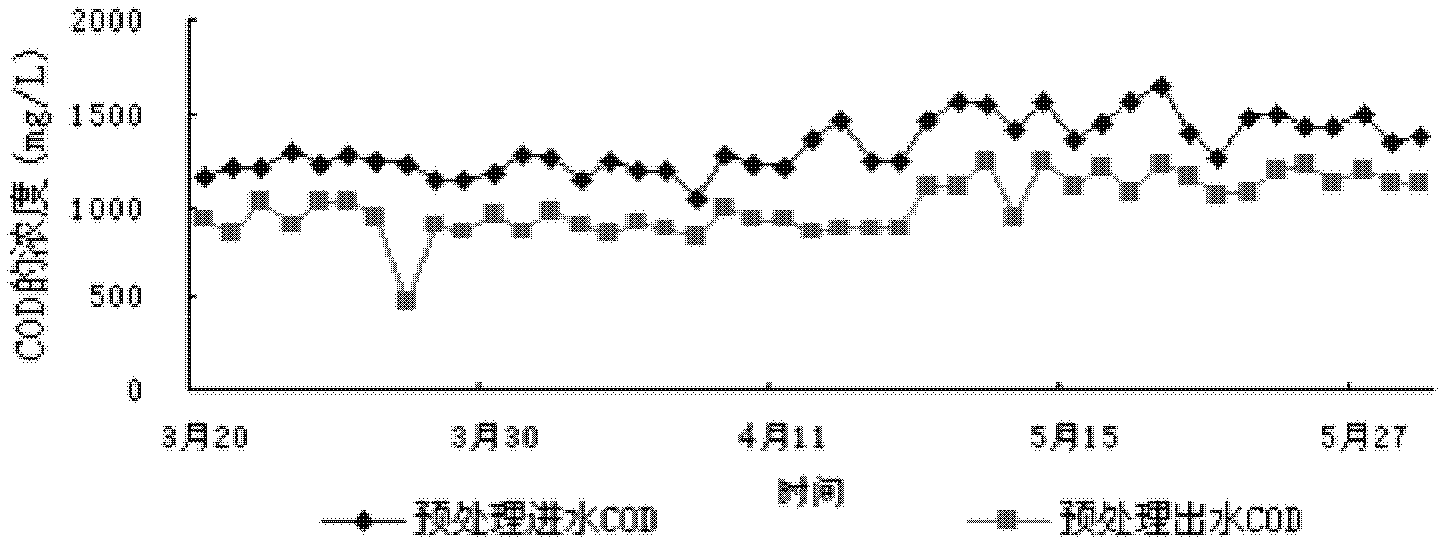

InactiveCN103043846AReduce COD indexImprove biodegradabilityWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentWater qualityHydrolysis

An acrylic fiber waste water treatment method. An acrylic fiber waste water treatment method is provided which comprises the following steps: (a) performing ultrasonic hydrolysis treatment of acrylic fiber waste water; (b) treating the acrylic fiber waste water treated by ultrasonic hydrolysis in step (a) in a biological reaction tank; and (c) performing Fenton treatment of the acrylic fiber waste water obtained in step (b). Through ultrasonic hydrolysis pretreatment of the acrylic fiber waste water, oligomers and long-chain macromolecules which are difficult to bio-degrade in the waste water are decomposed and degraded; the COD index of the waste water is decreased obviously; and the biodegradability is improved. Effluent from ultrasonic hydrolysis flows into the integrated biological reaction tank for biological reactions such as denitrification and decarbonization so as to remove most COD and ammonia nitrogen. Effluent from the integrated biological reaction tank is subjected to the Fenton process to remove residual organic matter difficult to degrade so as to ensure the effluent quality.

Owner:CHINA PETROLEUM & CHEM CORP +3

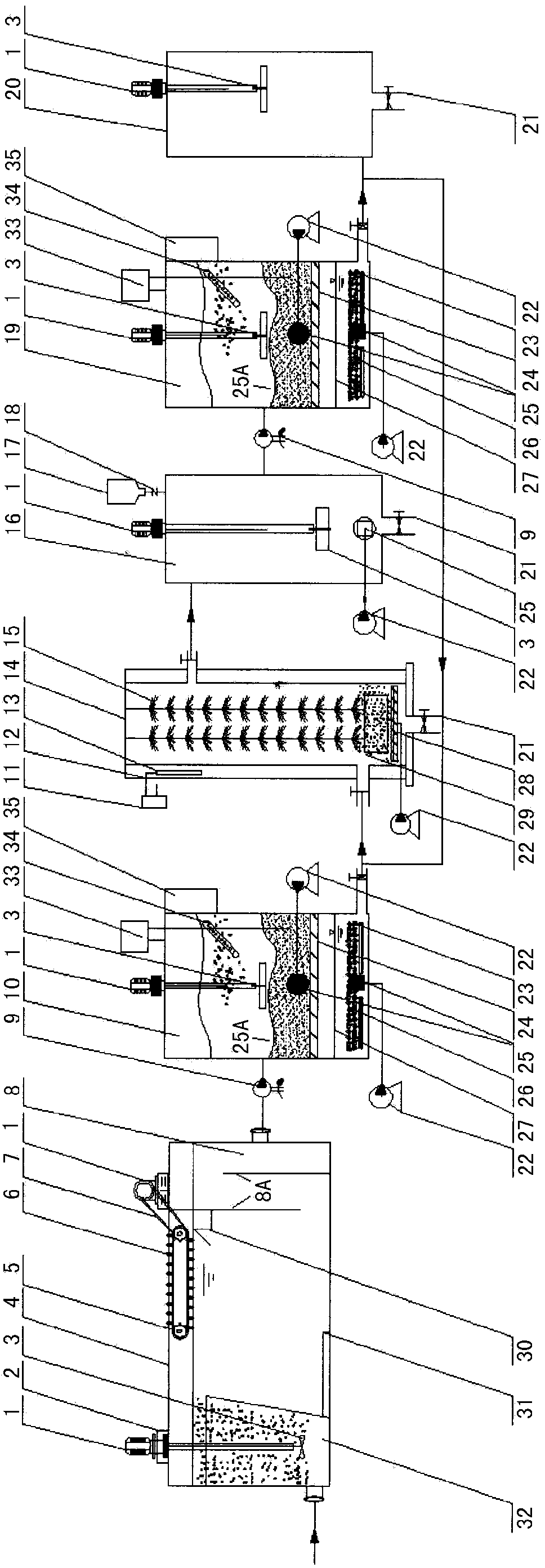

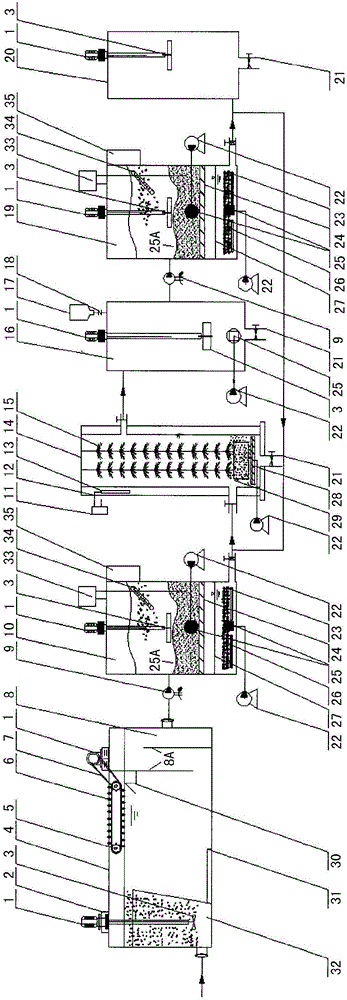

Device and method for rapidly treating kitchen waste wastewater

ActiveCN104193082APrevent rotReduce processing timeMultistage water/sewage treatmentFlocculationCavitation

The invention discloses a device for rapidly treating kitchen waste wastewater. The device mainly comprises a cavitation air floatation device, a first-stage turbulent flow nano-aeration backwash filter, a bio-membrane reactor, a flocculation tank, a second-stage turbulent flow nano-aeration backwash filter and a girt chamber. The invention also discloses a method for treating kitchen waste wastewater by using the device. The problems of high kitchen waste wastewater output, high treatment difficulty and long reaction period are effectively solved by mainly using a mechanical method and accessorily using a biological method according to the concept that the kitchen waste wastewater is rapidly treated, the wastewater treatment time is shortened, the generated wastewater can be rapidly discharged up to the standard, and the aims of reduction, harmlessness and recycling of the kitchen waste wastewater are realized.

Owner:张列宇

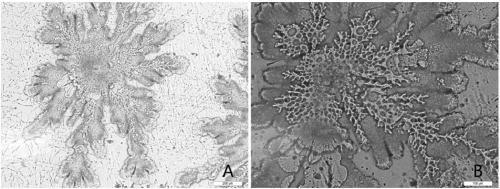

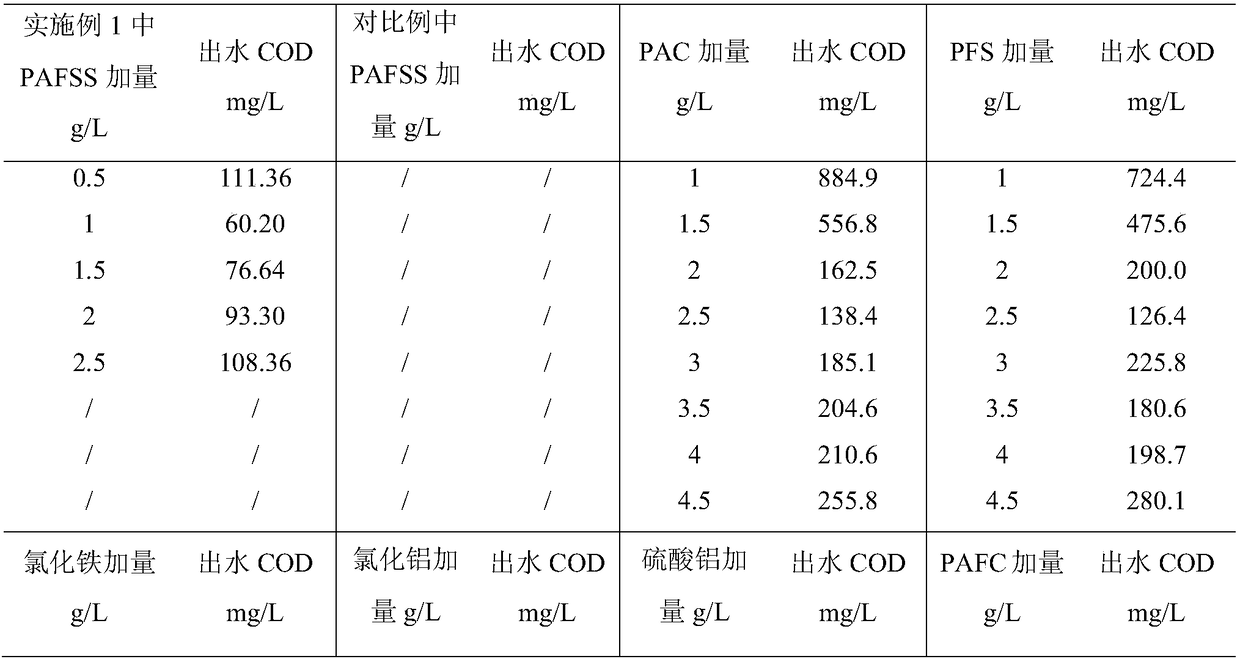

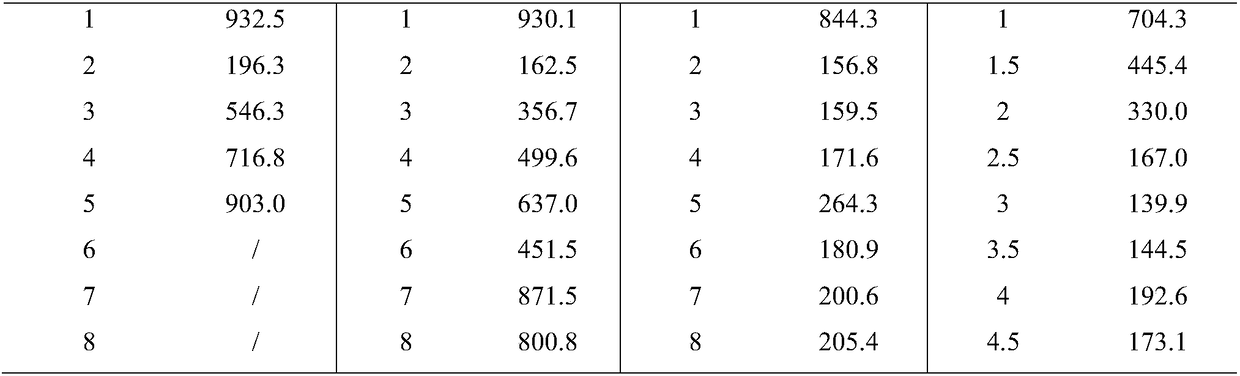

Polysilicic acid aluminum sulfate flocculating agent, preparation method and application

InactiveCN109095572AGood flocculation and sedimentation effectSmall dosageWaste water treatment from quariesWater treatment parameter controlAluminium sulfateAfter treatment

The invention discloses a polysilicic acid aluminum sulfate flocculating agent, a preparation method and application, and belongs to the technical field of purification of waste water in an oil and gas field. The preparation method for the polysilicic acid aluminum sulfate flocculating agent comprises the steps that 1) sodium silicate is dissolved in water to obtain a solution with the concentration of 0.2-0.5 mol / L, the p H value of the solution is 2.1-5, and the solution is stirred for polymerization for 10-30 minutes at the indoor temperature to obtain polysilicic acid; 2) according to molar ratio, aluminum sulfate and ferrous sulfate are added, (Al+Fe) / Sl=0.5-2.2, Al / Fe=0.5-2.2, the mixture is stirred for polymerization for 10-30 minutes at the indoor temperature and subjected to standing for curing for 20-28 hours, and the polysilicic acid aluminum sulfate flocculating agent is obtained. The flocculating agent is specially applied to waste liquid treatment for drilling wells in the oil and gas field, the flocculent precipitate effect is good, single dosage is added, the addition amount is small, the COD removing rate is high, and after treatment, the COD index of waste water is below the national emission standard.

Owner:CHINA PETROLEUM & CHEM CORP +1

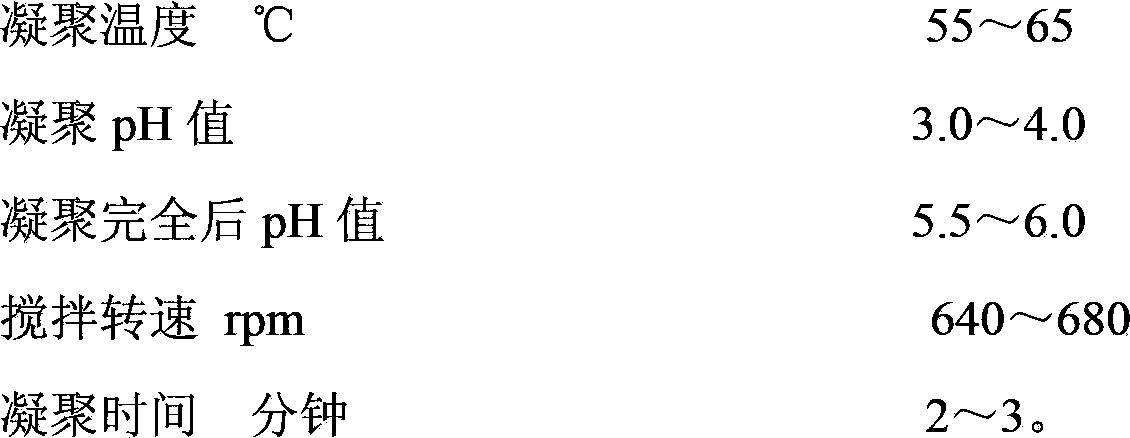

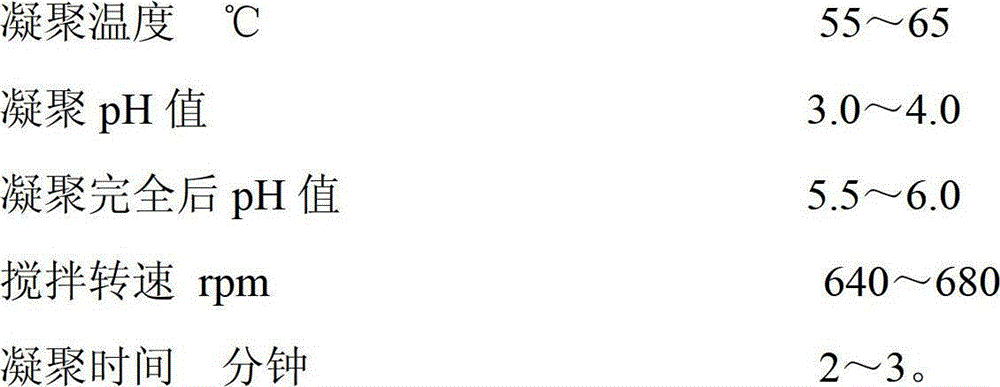

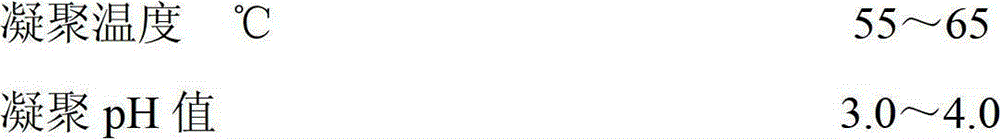

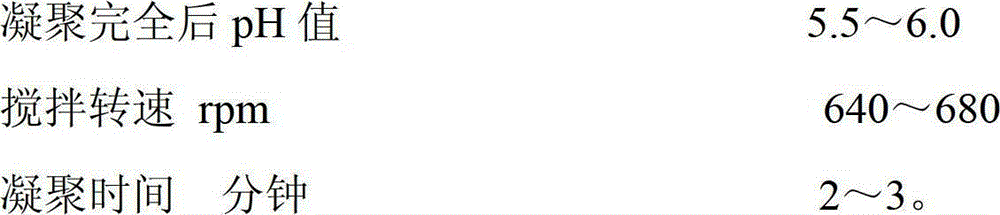

Nitrile butadiene rubber latex coagulation technology

The invention relates to a nitrile butadiene rubber latex coagulation technology, and belongs to the treatment of a rubber latex characterized by a used coagulation agent. The technology is characterized in that polyepichlorohydrin dimethylamine is adopted as a coagulation agent, an aqueous solution of sodium chloride is adopted as a coagulation mother liquor, and sulfuric acid is adopted as a pH adjusting agent, and the technology comprises the following steps: 1, preparing the coagulation mother liquor, 2, preparing a solution of the coagulation agent, 3, preheating a nitrile butadiene rubber latex, 4, preparing a pH adjusting solution, and 5, coagulating the latex. The nitrile butadiene rubber latex coagulation technology has the advantages of coarse colloidal particles in the coagulation process, small crushed colloid loss, less consumption of the coagulation agent, small consumption of the pH adjusting agent, low COD index in discharged wastewater, simple use, short coagulation time and low production cost. The COD content in wastewater is 266.48mg / L, and accounts of 40% of the COD content in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of high-adsorption-capacity water treatment agent

InactiveCN107029678AEfficient releaseSimple processOther chemical processesWater/sewage treatment by sorptionWater bathsFiltration

The invention discloses a preparation method of a high-adsorption-capacity water treatment agent. The preparation method comprises the following steps that corncob powder is fed into tartaric acid for soaking, microwave irradiation treatment is performed, and filtration is performed to obtain a first pre-prepared material; vermiculite power, lauryl sodium sulfate, cocamidopropyl betaine and water are mixed evenly, heating is performed in a water bath, ultrasonic dispersion is performed, a succinimide solution is added, the pH value of a system is regulated with hydrochloric acid to 7.1-7.4, microcrystalline cellulose is added for stirring, suction filtration is performed, washing is performed to reach a neutral state, and drying and grinding are performed to obtain a second pre-prepared material; absolute ethyl alcohol and toluene are evenly stirred, the first pre-prepared material, the second pre-prepared material and methyltriethoxysilane are added, heating and stirring are performed, centrifugation is performed, flushing is performed with deionized water to make pH value neutral, and drying and smashing are performed to obtain the high-adsorption-capacity water treatment agent. The obtained high-adsorption-capacity water treatment agent is large in adsorption capacity and good in hydrophilcity.

Owner:HEFEI LYUJIE ENVIRONMENTAL PROTECTION TECH

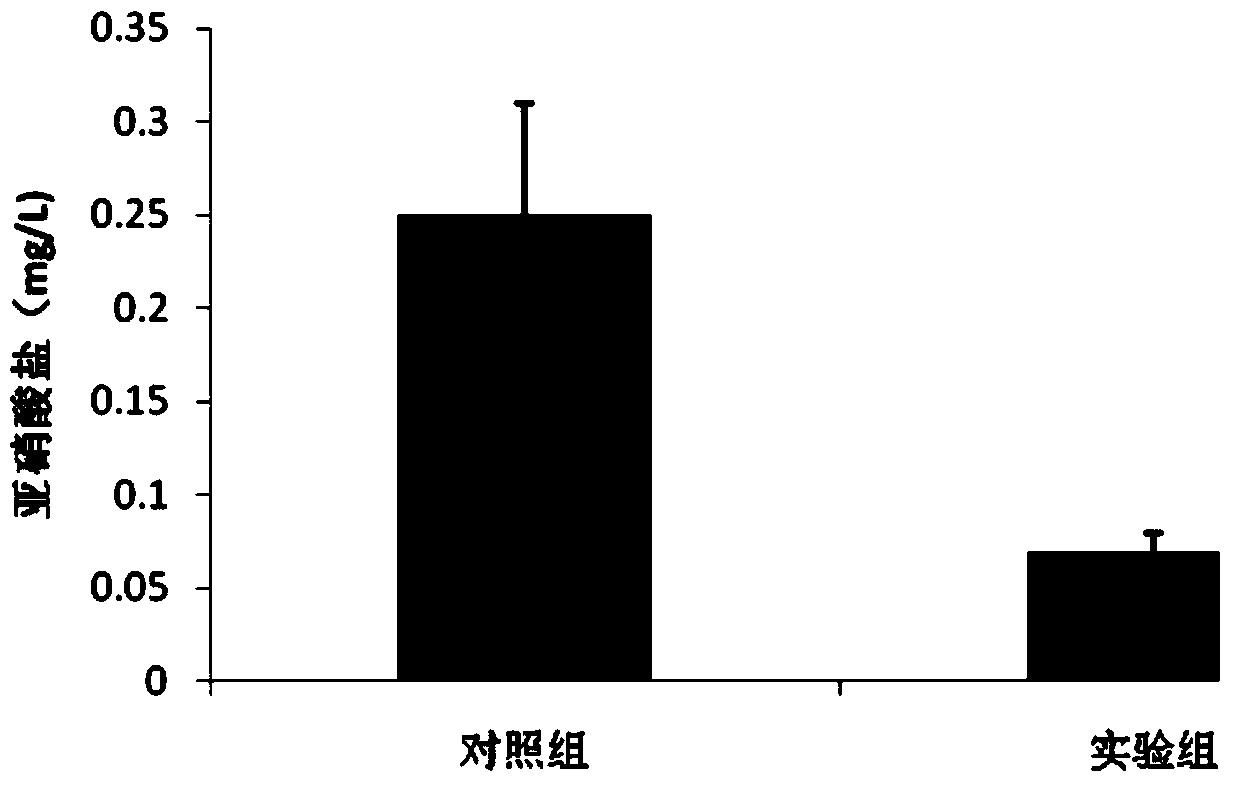

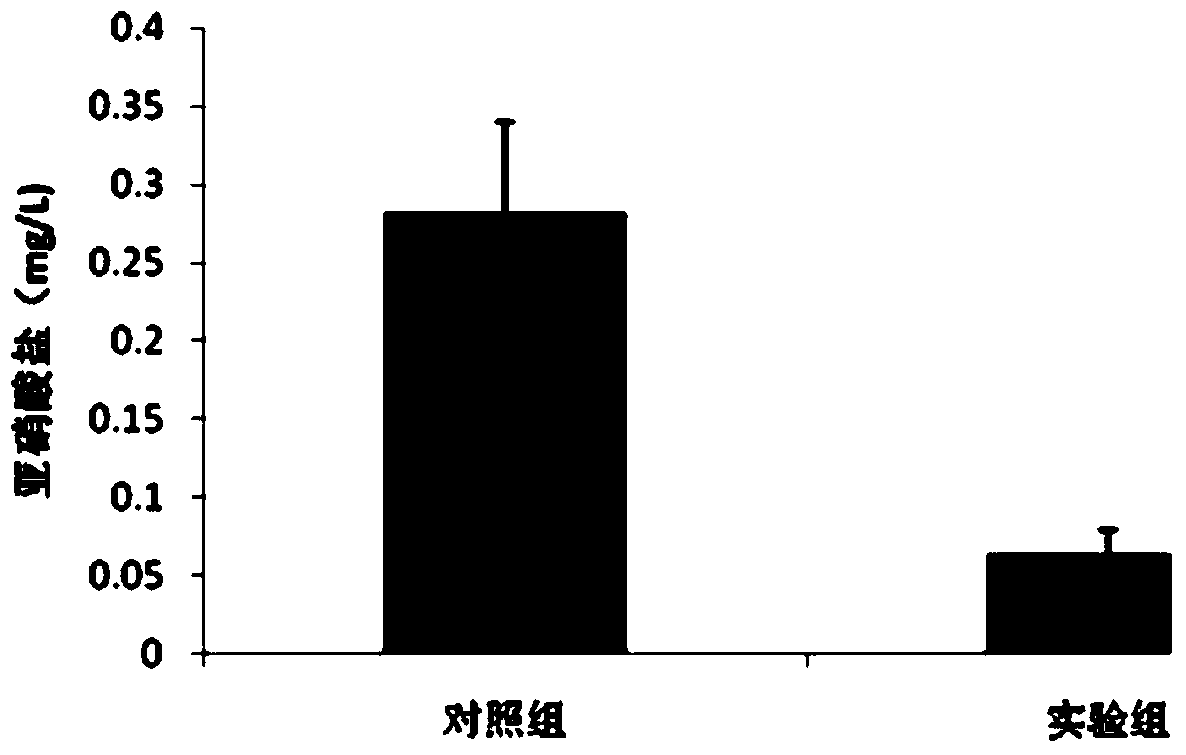

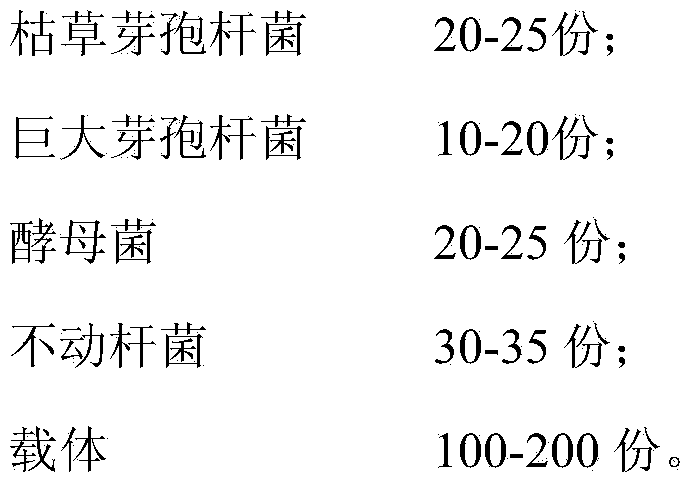

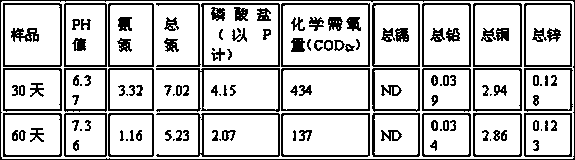

Microbial preparation for brackish water aquaculture, and preparation method and application thereof

InactiveCN104030459APromote reproductionPromote growthBiological water/sewage treatmentBacillus megateriumWater quality

The invention relates to a microbial preparation for brackish water aquaculture, which comprises the following components in parts by weight: 20-25 parts of Bacillus subtilis, 10-20 parts of Bacillus megaterium, 20-25 parts of microzyme, 30-35 parts of Acinetobacter and 100-200 parts of carrier. The preparation method comprises the following steps: sequentially inoculating Bacillus subtilis, Bacillus megaterium, microzyme and Acinetobacter seed culture solutions into a culture medium, fermenting, and mixing the obtained bacterium solution with the carrier substance to obtain the microbial preparation. The microbial preparation is applicable to a culture water body with the salinity range of 0.2-1%. The microbial preparation can obviously improve the water quality of the brackish water aquaculture water body, especially obviously lowers the nitrite content in the water body, and can enhance the flesh texture of the cultured animals.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-concentration nonionic surfactant wastewater treatment device and method

InactiveCN110357357AReduce CODLow costSludge treatmentWater treatment compoundsChemistryHigh concentration

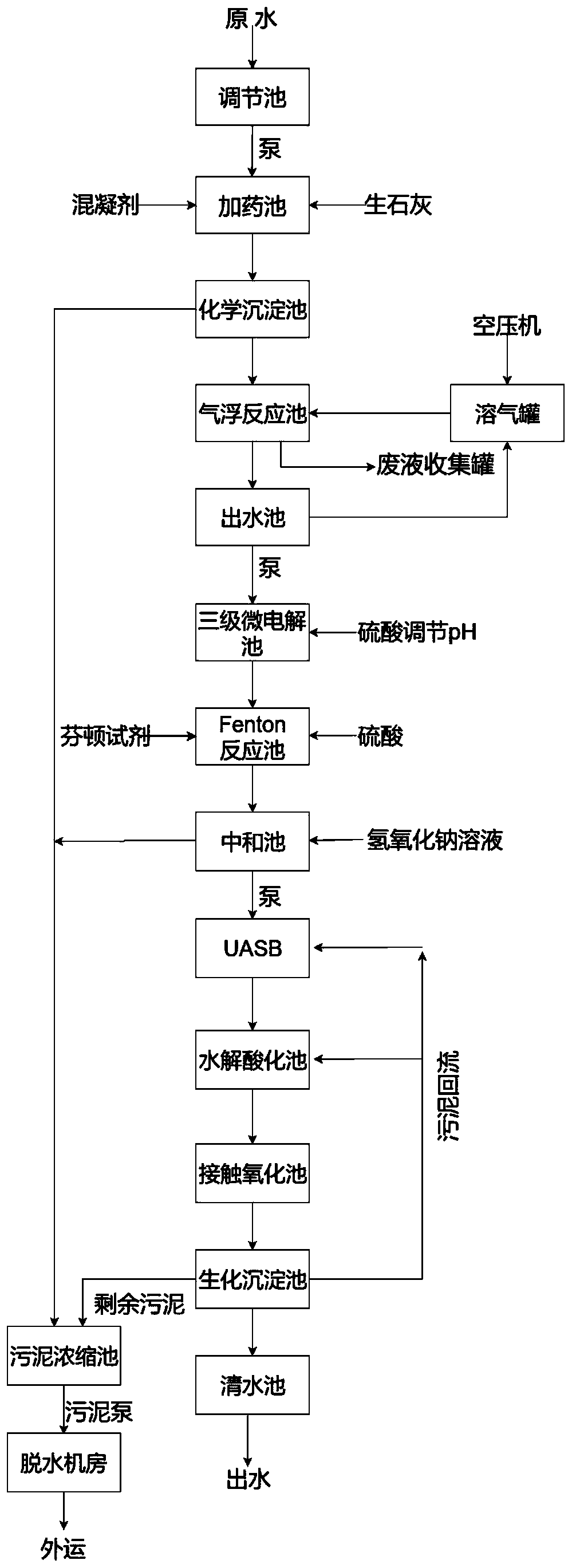

The invention relates to the field of surfactant wastewater treatment, particularly to a high-concentration nonionic surfactant wastewater treatment device and method. According to the invention, a physicochemical combined process of coagulation chemical precipitation, dissolved air flotation, three-stage microelectrolysis, Fenton oxidation and the like is adopted, so nonionic surfactants in wastewater are effectively removed, the content of COD is also greatly reduced, and the requirements of a biochemical pool on inflow water are met; and a combined process of treatment with a UASB anaerobicsludge bed reactor, hydrolysis acidification and aerobic contact oxidation is performed subsequently, so the content of CODs in a water body is significantly reduced, and effluent meets national andlocal water quality emission standards.

Owner:JIANGSU UNIV

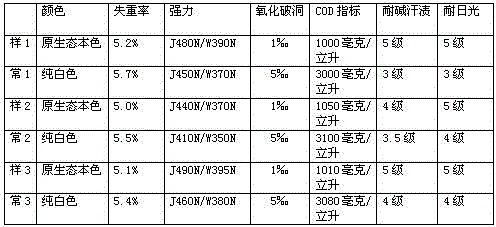

Original natural color processing technology for fabric

ActiveCN104805686ADelay decayStable working fluidSucessive textile treatmentsFibre treatmentFiberWastewater

The invention discloses an original natural color processing technology for a fabric. The original natural color processing technology comprises the following steps: (1) washing the fabric for the first time after the fabric is woven; (2) processing the washed fabric by using tea saponin; (3) washing the processed fabric for the second time; (4) pickling the fabric washed for the second time; (5) softening the pickled fabric. The fabric processed by the original natural color processing technology disclosed by the application presents original natural color, and is environment-friendly and healthy; the processing technology is simplified, fiber is broad in adaptation range, and the fabric does not generate the phenomena of oxidation and broken holes; compared with a conventional oxygen bleaching technology, the COD index of waste water generated after cooking, bleaching, printing and dyeing can be reduced by about 50%.

Owner:JIANGSU CANASIN WEAVING

Advanced treatment method for heavy alkylbenzene sulfonate (HABS) industrial wastewater

InactiveCN101921031AReduce COD indexReduce processing costsMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationAutomatic controlSludge

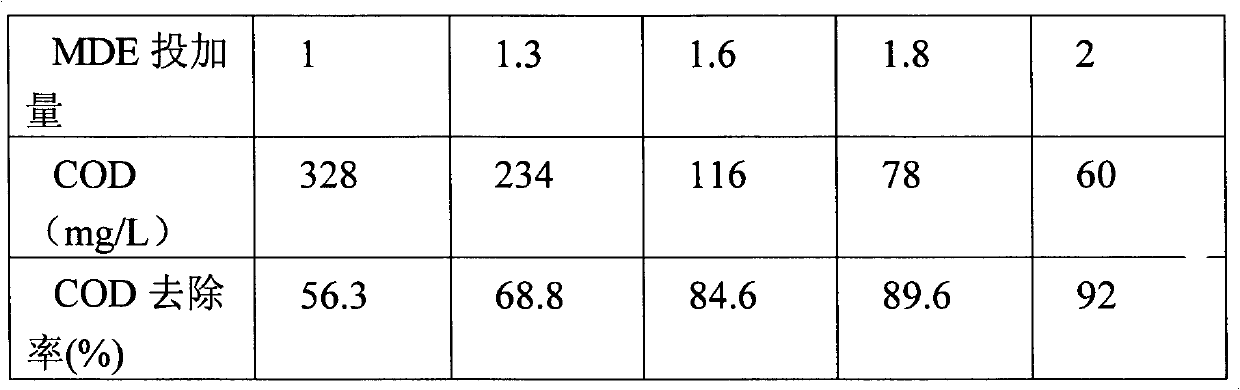

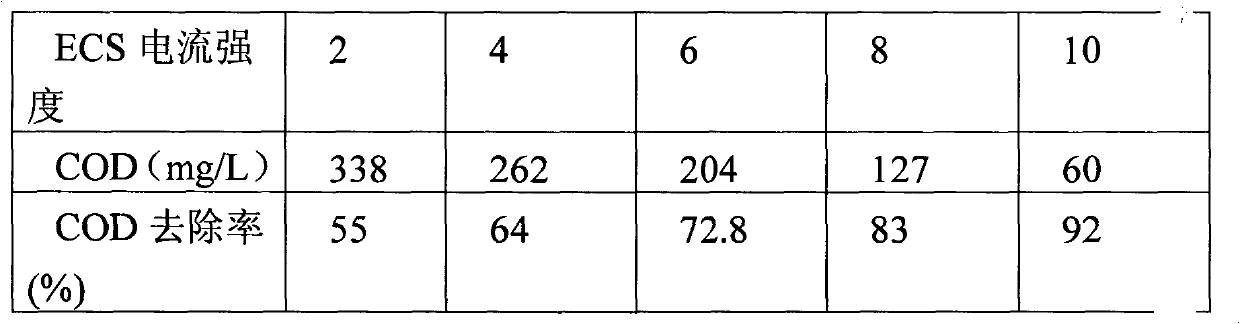

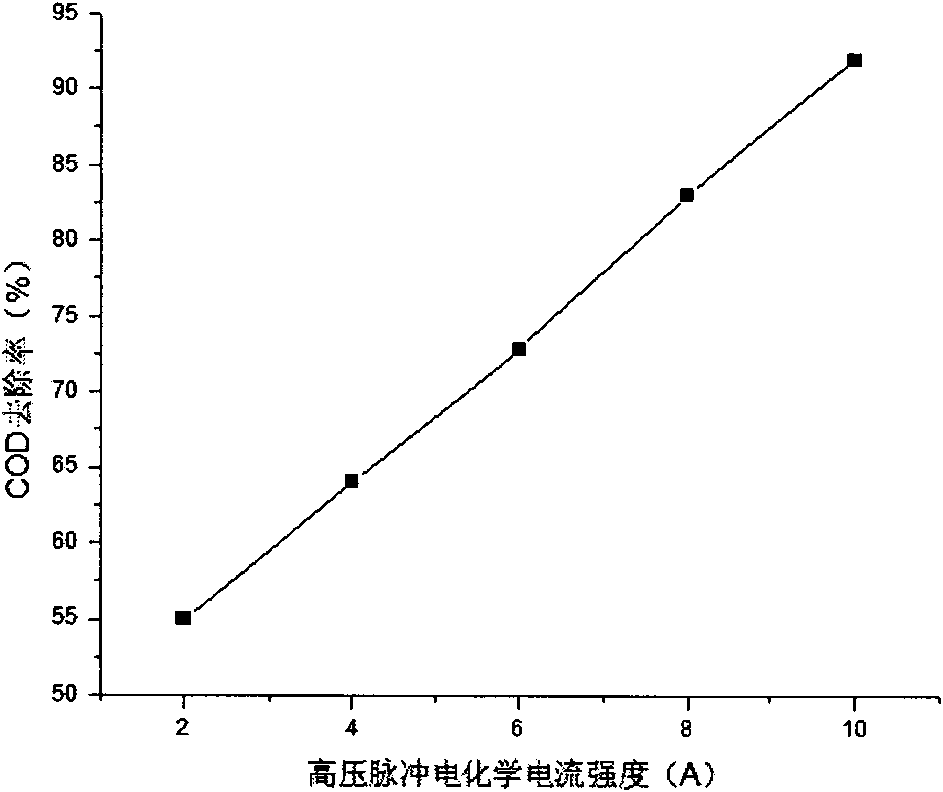

The invention discloses an advanced treatment method for heavy alkylbenzene sulfonate (HABS) industrial wastewater, belonging to the technical field of water treatment and comprising the following steps: regulating the pH value of the HABS industrial wastewater to be 2-4 firstly, feeding the HABS industrial wastewater after pH value regulation in a container, and putting at least two polar plates in the container, wherein the two polar plates are respectively connected with the positive and negative poles of a DC regulated power supply; regulating the current intensity of the DC regulated power supply to 2-10A, and processing for 2-10min, wherein the used polar plates are iron polar plates; standing and settling for 30min, taking supernate, regulating the pH value of the supernate to be 7.5-9.5, pouring a composite water treatment agent based on the mass ratio of 1-2g / L, stirring, and standing and settling for 1h, wherein the composite water treatment agent is prepared by compounding diatomite with aluminum polychloride, ferrous sulphate heptahydrate, aluminum sulfate aluminium sulfate octadecahydrate or polymerized aluminium ferric sulfate based on the mass ratio of 3:1-6. the advanced treatment method in the invention lowers COD index, has simple operation and is easy to realize automatic control, and the generated sludge can be used as an auxiliary material for subgrade and brickmaking, and has relative low cost.

Owner:BEIJING UNIV OF TECH +2

Biological treatment method for waste mud in petroleum and natural gas exploration drilling work

ActiveCN101830614BEasy to handleThe role and effect are obviousBiological sludge treatmentWater sourceWell drilling

The invention discloses a biological treatment method for waste mud in petroleum and natural gas exploration drilling work, which is characterized by comprising the following steps of: a, forming a microbial treatment layer, namely inoculating special microbial strains to the waste mud in a weight ratio of 3-5: 100, mixing the strains and the waste mud uniformly, stirring the mixture and natural soil with water content of 10 to 10 percent and grain diameter of less than 0.5 centimeter uniformly according to the density condition of the waste mud in a following mode to form the microbial treatment layer, adding the natural soil in an amount which is 2.5 to 3 times that of the waste mud into the waste mud with density of 1 to 1.5kg / L, adding the natural soil in an amount which is 2 to 2.5 times that of the waste mud into the waste mud with density of 1.5 to 2.5kg / L, and controlling the water content of the microbial treatment layer to be between 25 and 30 percent; b, treating the soil; and c, treating plants. The method can solve the technical problem that effusion enters underground water to pollute a water source because the natural soil with high water content and large grain diameter is easily scoured by hard rain under the condition that pollutants in a pretreatment mixture are not yet effectively degraded in the prior art.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

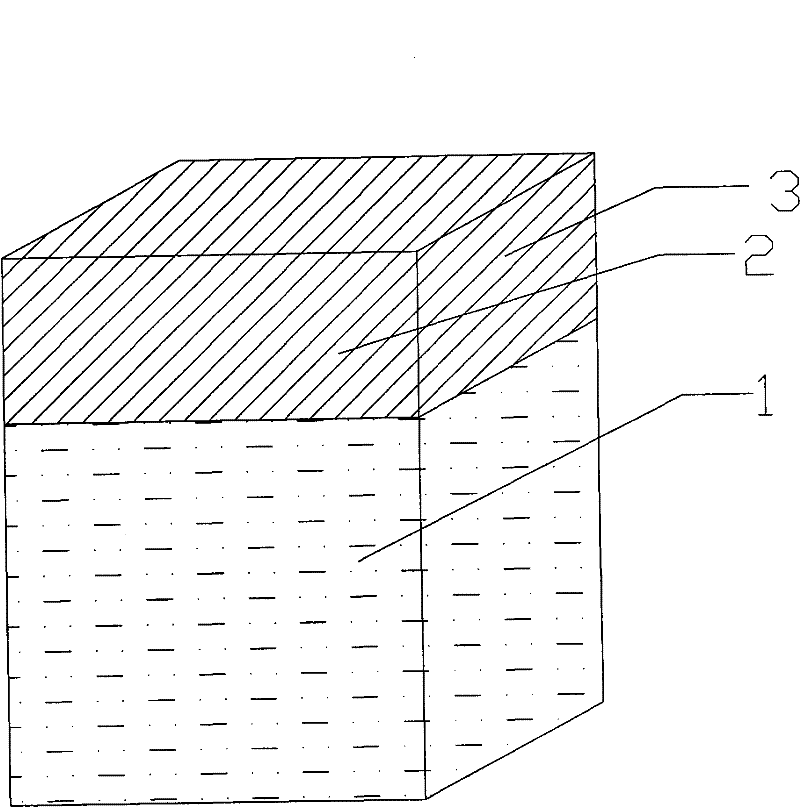

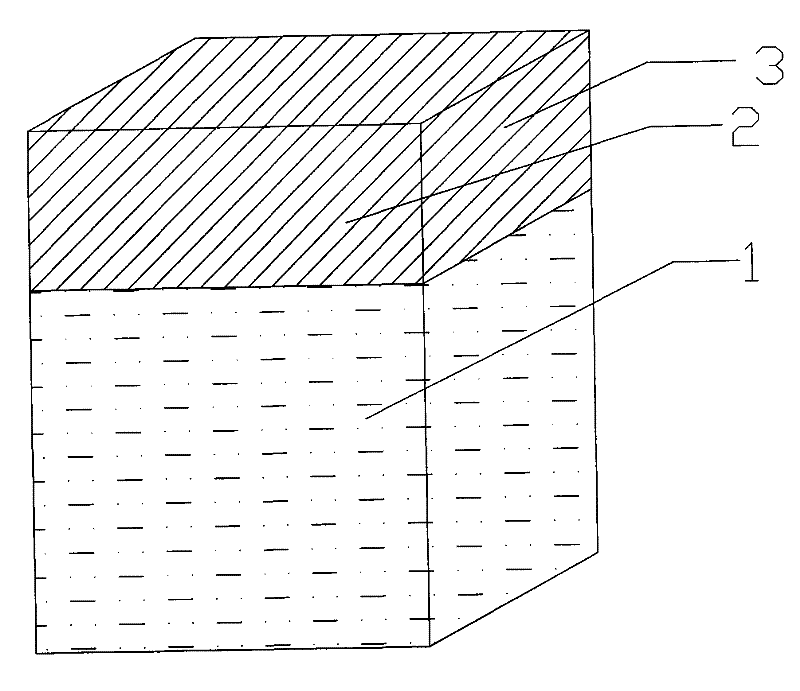

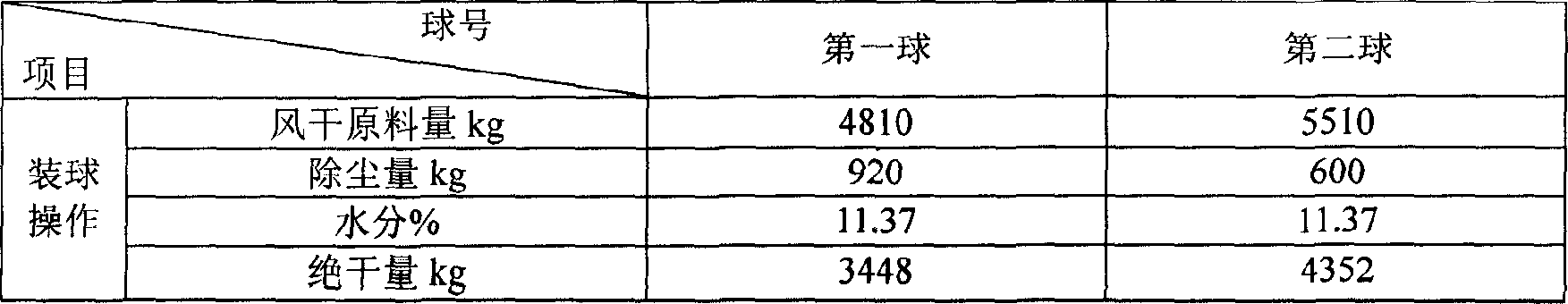

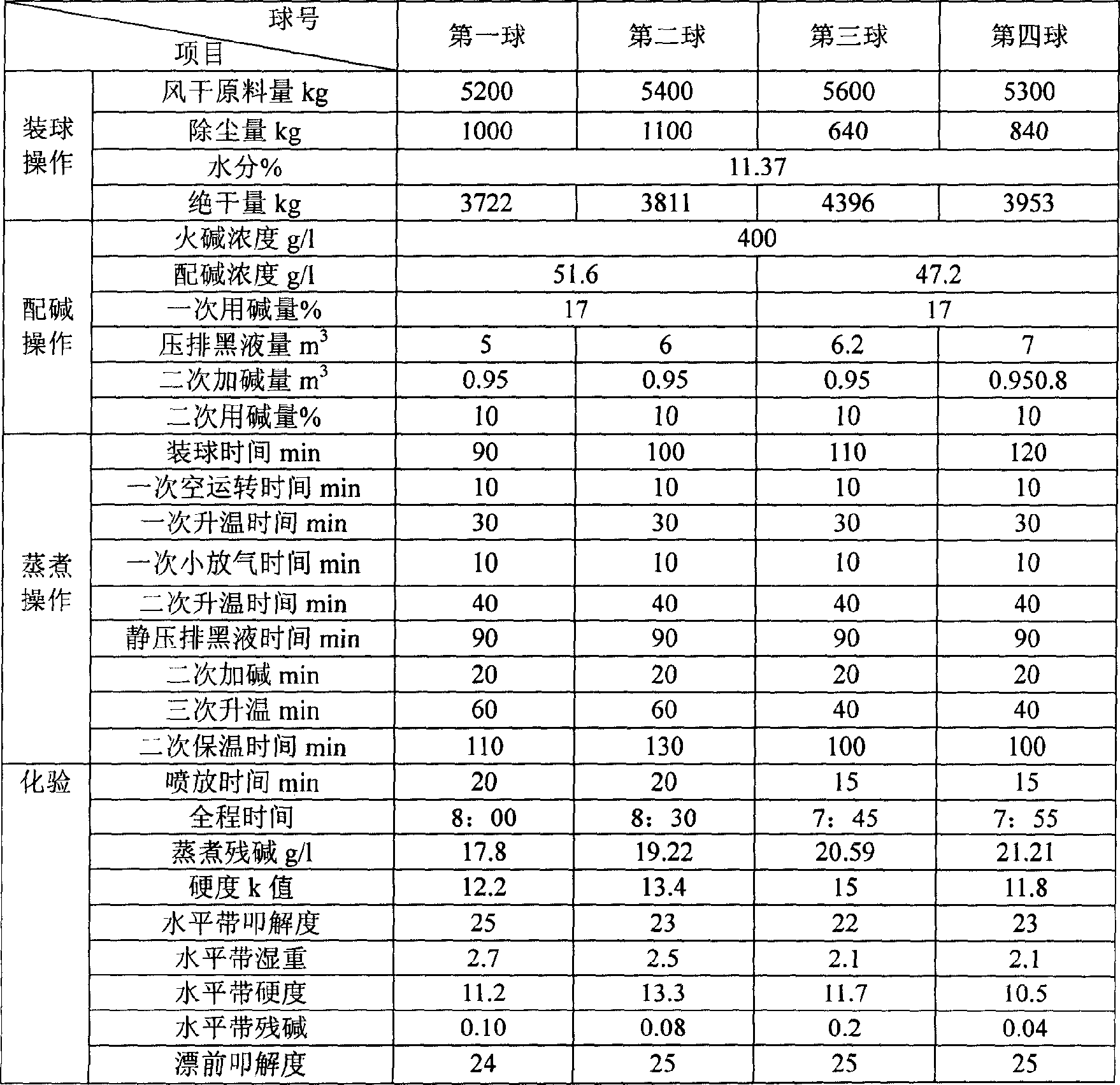

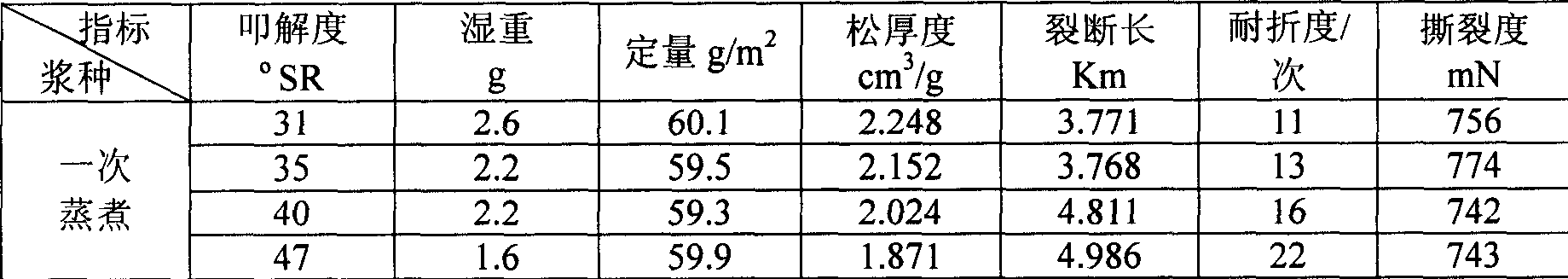

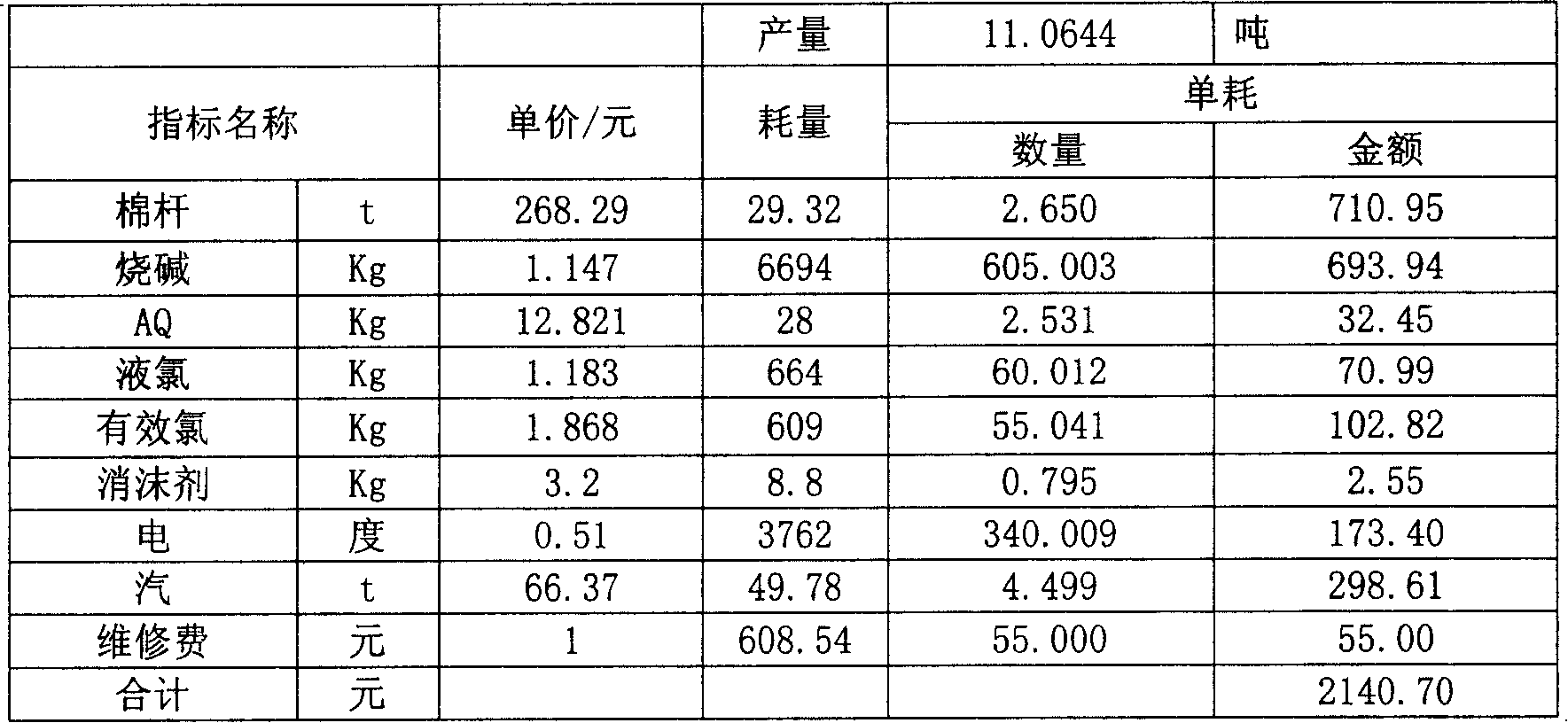

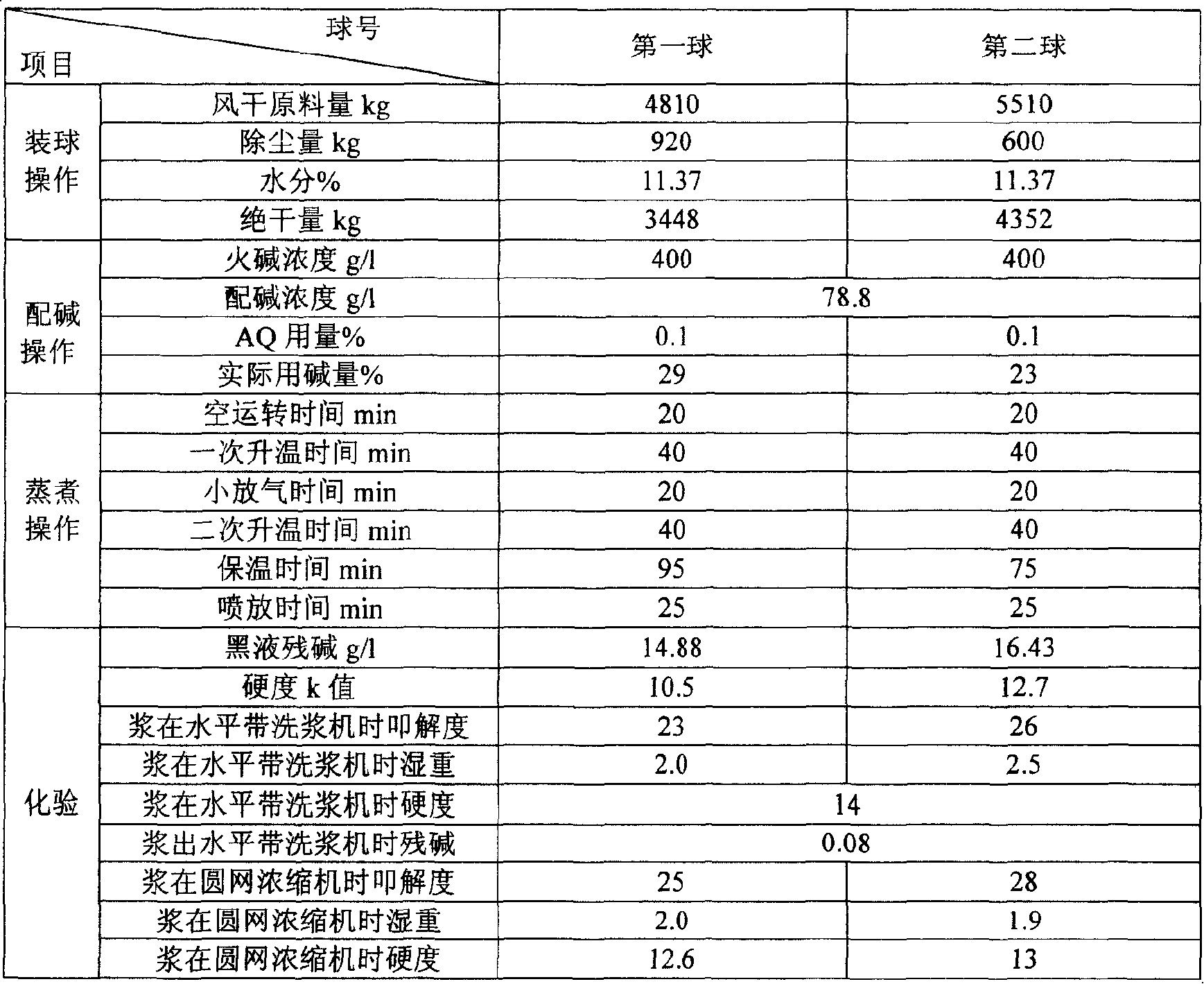

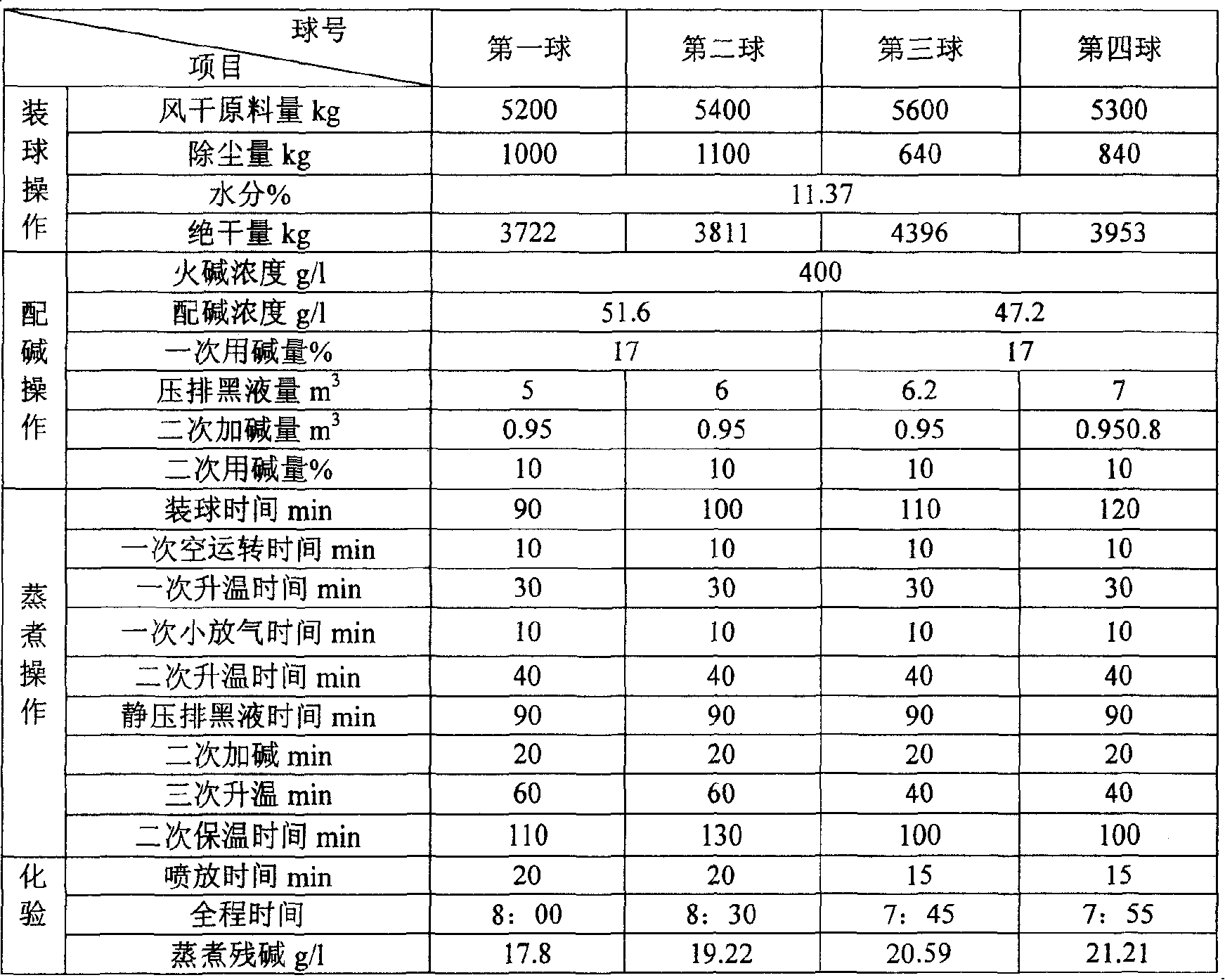

Method of preparing bleached chemical pulp using cotton stalk

ActiveCN1718919AIdeal qualityQuality improvementPulp bleachingPulping with inorganic basesPre treatmentChemical pulp

The present invention discloses a method for preparing bleached chemical pulp by using cotton stalk. The described method is an alkaline process, and includes the following steps: preparing material, impregnating treatment, first cooking or secondary cooking to obtain crude pulp, then washing pulp, bleaching so as to obtain the finished paper.

Owner:SHANDONG TRALIN PAPER

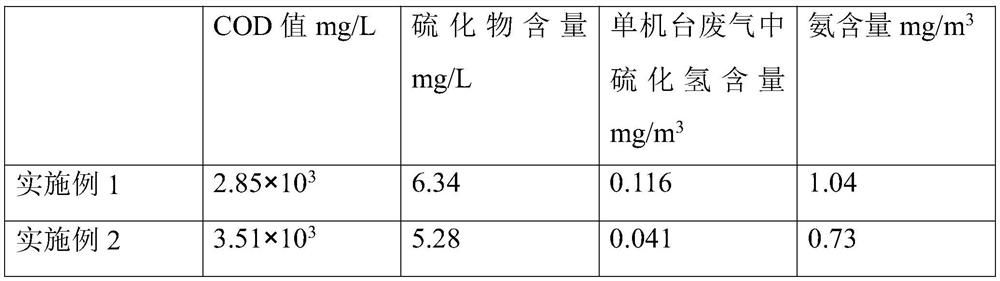

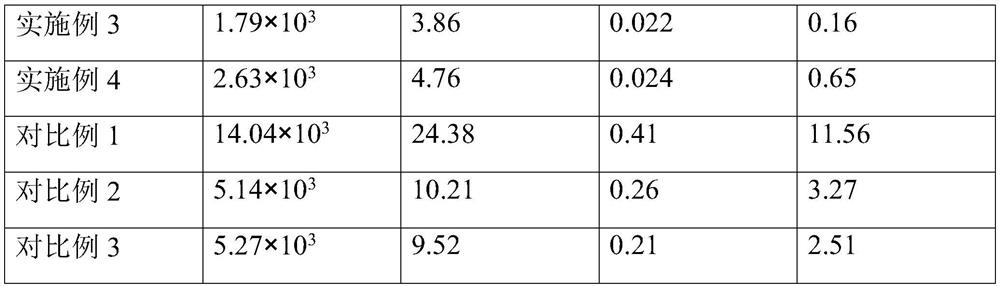

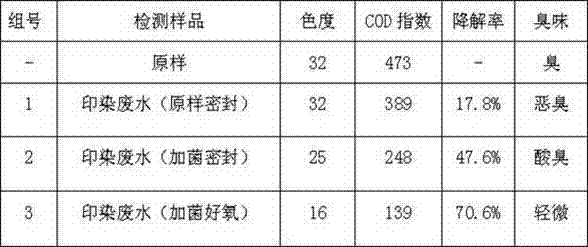

Non-stink black denim dyeing technology

The invention discloses a non-stink black denim dyeing technology. The non-stink black denim dyeing technology includes a basic yarn beam wetting step, a dyeing step, a water washing step, a color fixing step, a brittleness preventing step, a drying sizing step and a lease reeling step which are continuously completed in one step through a sizing and drying combined machine. According to the dyeing step, under the condition that the temperature ranges from 90 DEG C to 98 DEG C, warp yarn is subjected to dip dyeing through a dyeing base solution, and the dyeing base solution includes the following components of 95 g / L-105 g / L of sulfur black, 25 g / L-35 g / L of a novel composite reducing agent, 1 g / L-5 g / L of an alkali-resisting penetrating agent, 1 g / L-5 g / L of Turkey red oil and 25 g / L-35 g / L of caustic soda. In the denim dyeing technology, the novel composite reducing agent is adopted for replacing sodium sulfide, free sulfides of black denim fabric can be greatly reduced, people cannot smell the stink smell on the fabric, the COD index of sewage generated by subsequent production of clothes manufacturing, water washing and the like is reduced by 76% or higher, the content of the sulfides is reduced by 74% or higher, the content of hydrogen sulfide in waste gas of a single machine is reduced by 72% or higher, the ammonia content is reduced by 91% or higher, the free sulfides ofthe fabric are obviously reduced, and people cannot smell the stink smell completely.

Owner:佛山市南海德耀翔胜纺织有限公司

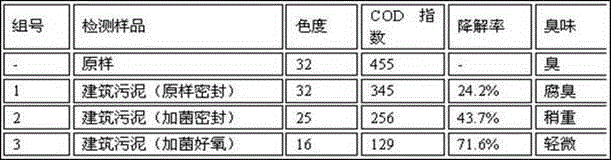

Sludge activating ball and manufacture method thereof

InactiveCN104591513AControl secondary pollutionEliminate bad odorWater treatment compoundsSpecific water treatment objectivesMicroorganismPoterium sanguisorba

The invention provides a sludge activating ball and a manufacture method thereof; the sludge activating ball is mainly prepared from the following raw materials: garden burnet, field pennycress, lumbricus, sargentgloryvine stem, fructus cnidii, old ginger, sea salt, distillation wood vinegar liquid, brown sugar, wheat bran, trass and environment-friendly YangSu; the manufacture method comprises the following steps: mixing garden burnet, field pennycress, lumbricus, sargentgloryvine stem, fructus cnidii, old ginger and sea salt for the same ratio, grinding the mixture, mixing the mixture with the trass in a ratio of 1:1, mixing the brown sugar with the mixture in a ratio of 1:1.5 and pouring the obtained mixture into the mixed liquid composed of the distillation wood vinegar liquid and the environment-friendly YangSu in a ratio of 1:1, adding the wheat bran the weight percentage of which is 10%, kneading into the clump, placing the clump in the moist, cool and lucifugal environment or on a wood shelf, the environment temperature is about 37 DEG C, cultivating for 15 days, and if the surface of the clump turns white, finishing fermentation for use. The sludge activating ball is slowly dissolved and released during the using process, so as to increase the beneficial microorganism of the sludge, improve and activate the sludge and remove the soil odor.

Owner:SHANTOU ZHENGNENGLIANG HERBACEOUS PLANTS RES INST

Fabric printing and dyeing pretreatment method

InactiveCN107217465AHigh energy consumptionImprove pollutionDry-cleaning apparatus for textilesPretreatment methodEnvironmental engineering

The invention relates to the chemical field and discloses a fabric printing and dyeing pretreatment method, which comprises the following steps: S1: washing: washing a fabric for 10-20min under the condition with a bath ratio being 1 to (5.5 to 6.5), and then draining water; S2: tea saponin washing: washing the fabric obtained in the step S1 for 75-85min under the condition with a bath ratio being 1 to (4.5 to 5.5), and then draining water; S3: washing: washing the fabric obtained in the step S2 for 10-20min under the condition with a bath ratio being 1 to (5.5 to 6.5), and then draining water; and S4: pickling neutralization: performing pickling neutralization on the fabric obtained in the step S3 for 10-20min under the condition with a bath ratio being 1 to (4.5 to 5.5), and then draining water. The fabric printing and dyeing pretreatment method is simple, clean and safe and does not generate pollution; and the treated fabric is relatively strong in comfort feeling.

Owner:江苏卡曼卡纺织有限公司

Device and method for rapid treatment of kitchen waste wastewater

ActiveCN104193082BPrevent rotReduce processing timeMultistage water/sewage treatmentFlocculationCavitation

The invention discloses a device for rapidly treating kitchen waste wastewater. The device mainly comprises a cavitation air floatation device, a first-stage turbulent flow nano-aeration backwash filter, a bio-membrane reactor, a flocculation tank, a second-stage turbulent flow nano-aeration backwash filter and a girt chamber. The invention also discloses a method for treating kitchen waste wastewater by using the device. The problems of high kitchen waste wastewater output, high treatment difficulty and long reaction period are effectively solved by mainly using a mechanical method and accessorily using a biological method according to the concept that the kitchen waste wastewater is rapidly treated, the wastewater treatment time is shortened, the generated wastewater can be rapidly discharged up to the standard, and the aims of reduction, harmlessness and recycling of the kitchen waste wastewater are realized.

Owner:张列宇

Sludge activation ball and its production method

InactiveCN104591513BControl secondary pollutionEliminate bad odorBiological sludge treatmentActivated sludgeCnidium monnieri

Provided in the present invention are a sludge activating ball and a preparation method therefor. The ball is prepared primarily from the following constituents: Sanguisorba officinalis, Patrinia scabiosaefolia, Pheretima aspergillum, Sargentodoxa cuneata, Cnidium monnieri, raw aged ginger, sea salt, a distilled wood vinegar solution, brown sugar, wheat bran, volcanic soil, and an environmentally friendly male agent. During preparation, aliquot parts of Sanguisorba officinalis, Patrinia scabiosaefolia, Pheretima aspergillum, Sargentodoxa cuneata, Cnidium monnieri, raw aged ginger, and sea salt are mixed and crushed and then mixed with volcanic soil at a ratio of 1:1, brown sugar and the mixture are mixed at a ratio of 1:1.5, a mixture prepared from the distilled wood vinegar solution and the environmentally friendly male agent at a ratio of 1:1 is poured in, wheat bran at a percentage by mass of 10% is sprinkled in and kneaded into a dough, which is placed in a moist, cool, and dark environment or placed onto a wooden rack at an ambient temperature of roughly 37 degrees, and, after 15 days of culturing, turns white on the surface, thus indicating the completion of fermentation and being ready for use. During use, the present invention dissolves slowly for sustained release, thus increasing the amount of beneficial microorganisms in the sludge, improving and activating the sludge, and removing foul odors of contaminated soil.

Owner:SHANTOU ZHENGNENGLIANG HERBACEOUS PLANTS RES INST

Sewage activation ball and manufacturing method thereof

InactiveCN104496040BEliminate bad odorControl secondary pollutionWater treatment parameter controlWater treatment compoundsMicroorganismTribulus terrestris

The invention provides a sewage activation ball and a production method thereof, which is mainly prepared from the following raw materials: honeysuckle, Cnidium mongolica, Guanzhong, sea salt, Kochia scoparia, Tribulus terrestris, old ginger, brown sugar, wheat bran, volcanic soil, Distilled wood vinegar, environmental protection Yin element; when making, take honeysuckle, cnidium fruit, Guanzhong, sea salt, Kochia scoparia, Tribulus terrestris, old ginger, brown sugar, mix well, pour in distilled wood vinegar, environmental protection Yin element Add the volcanic soil filtered through a 200-mesh sieve to the mixed clarified liquid, stir evenly, and finally sprinkle wheat bran, knead it into a ball, place it on a wooden frame, and keep the ambient temperature at about 37 degrees. After 15-30 days, the surface of the sphere is white and ready to use. During use, the present invention reaches various parts of rivers through the action of water flow, and slowly dissolves and releases, effectively increasing beneficial microorganisms in sewage, improving and activating sewage, and effectively eliminating sewage odor.

Owner:SHANTOU ZHENGNENGLIANG HERBACEOUS PLANTS RES INST

Sewage activated ball and manufacture method thereof

InactiveCN104496040AEliminate bad odorControl secondary pollutionWater treatment parameter controlWater treatment compoundsEngineeringSea salt

The invention discloses a sewage activated ball and a manufacture method thereof. The sewage activated ball is mainly prepared by the raw materials as follows: honeysuckle, fructus cnidii, cyrtomium fortune, sea salt, fructus kochiae, caltrop, mature ginger, brown sugar, wheat bran, volcanogenic soil, distilled pyroligneous acid and environmental protection Yinsu; the manufacture method is as follows: taking the honeysuckle, fructus cnidii, cyrtomium fortune, sea salt, fructus kochiae, caltrop, mature ginger and brown sugar, crushing and mixing, pouring the mixture into the clear liquor mixed by the distilled pyroligneous acid and environmental protection Yinsu, adding the volcanogenic soil screened by the screen of 200 meshes, blending evenly, adding the wheat bran, kneading into the shape of ball and locating the ball on a wood rack, keeping for 15 to 30 days at the temperature of 37 DEG C, the ball can be used while the ball surface is white. The sewage activated is transported to any part of the rivers through the function of the water flow and is slowly dissolved and released for effectively increasing the beneficial microorganism in the sewage, improving and activating the sewage and effectively eliminating the sewage foul smell.

Owner:SHANTOU ZHENGNENGLIANG HERBACEOUS PLANTS RES INST

A kind of agglomeration process of nitrile rubber latex

The invention relates to a nitrile butadiene rubber latex coagulation technology, and belongs to the treatment of a rubber latex characterized by a used coagulation agent. The technology is characterized in that polyepichlorohydrin dimethylamine is adopted as a coagulation agent, an aqueous solution of sodium chloride is adopted as a coagulation mother liquor, and sulfuric acid is adopted as a pH adjusting agent, and the technology comprises the following steps: 1, preparing the coagulation mother liquor, 2, preparing a solution of the coagulation agent, 3, preheating a nitrile butadiene rubber latex, 4, preparing a pH adjusting solution, and 5, coagulating the latex. The nitrile butadiene rubber latex coagulation technology has the advantages of coarse colloidal particles in the coagulation process, small crushed colloid loss, less consumption of the coagulation agent, small consumption of the pH adjusting agent, low COD index in discharged wastewater, simple use, short coagulation time and low production cost. The COD content in wastewater is 266.48mg / L, and accounts of 40% of the COD content in the prior art.

Owner:CHINA PETROLEUM & CHEM CORP

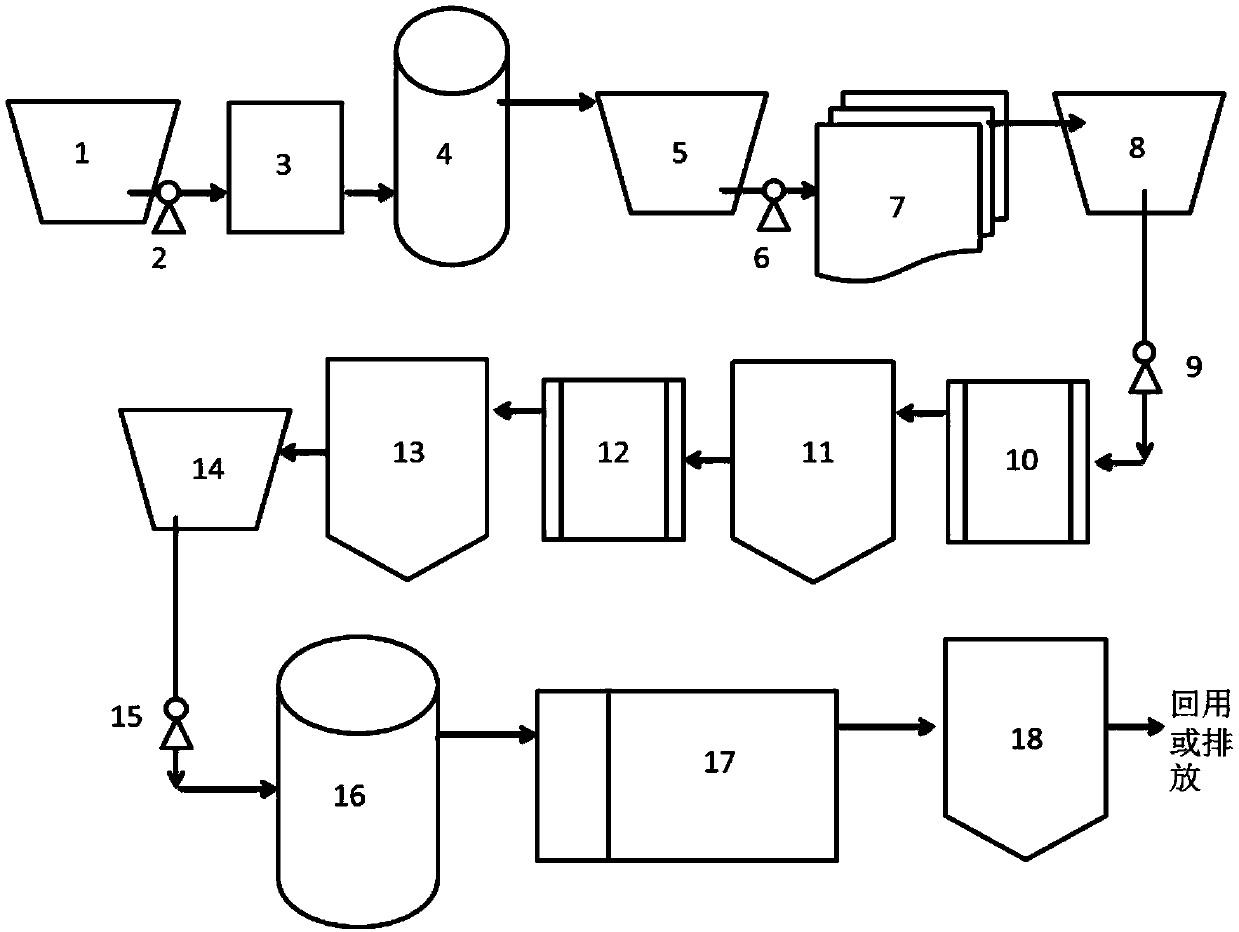

Diversified integrated processing process and device of high-concentration bamboo product wastewater

PendingCN109650671ABiochemical improvementWith ion exchange functionTreatment involving filtrationWater/sewage treatment by ion-exchangeHigh concentrationWastewater

The invention discloses a diversified integrated processing process and device of high-concentration bamboo product wastewater. The diversified integrated processing device comprises a water collecting pond, an aeration and oxidization device, a microelectrolysis device, an adjusting pond, a press-filtering device, a middle water pond, a first-stage diversified electrolysis device, a reaction andprecipitation pond A, a second-stage diversified electrolysis device, a reaction and precipitation pond B, a homogenizing pond, a UASB, an A2 / O pond and a solid-liquid separating device. Various processing means are integrated for processing low-water-amount high-concentration bamboo product processing wastewater, all the processing means cooperate with one another, and the processing effect is improved.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

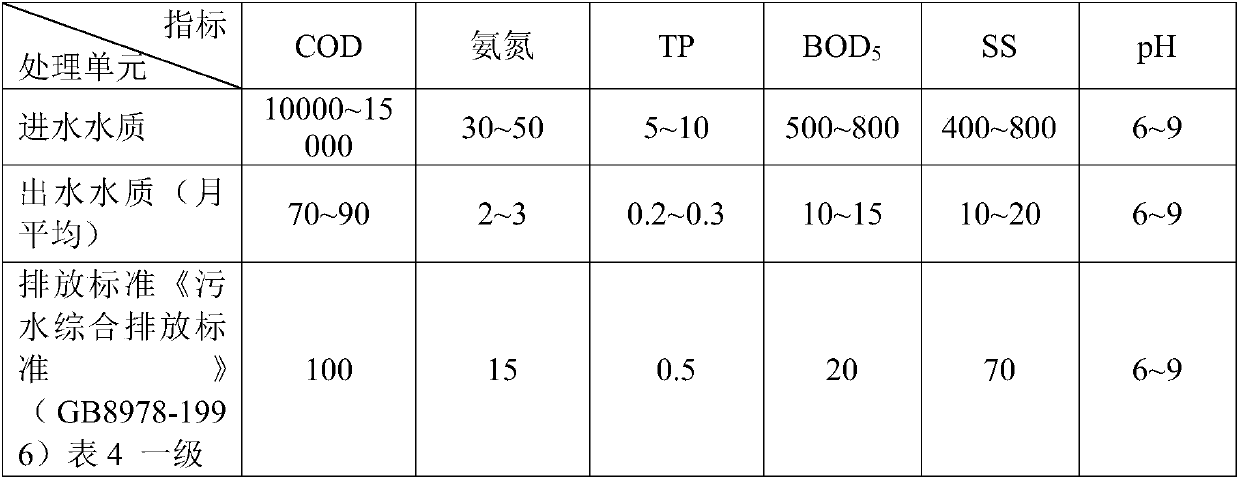

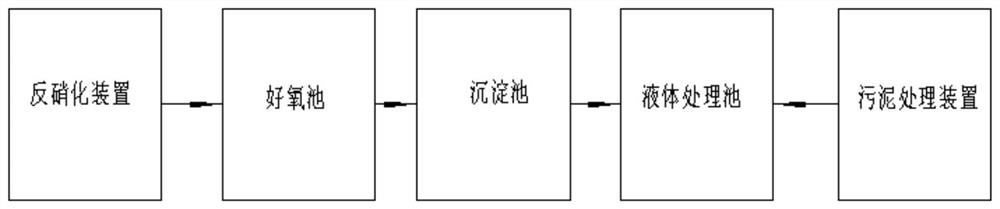

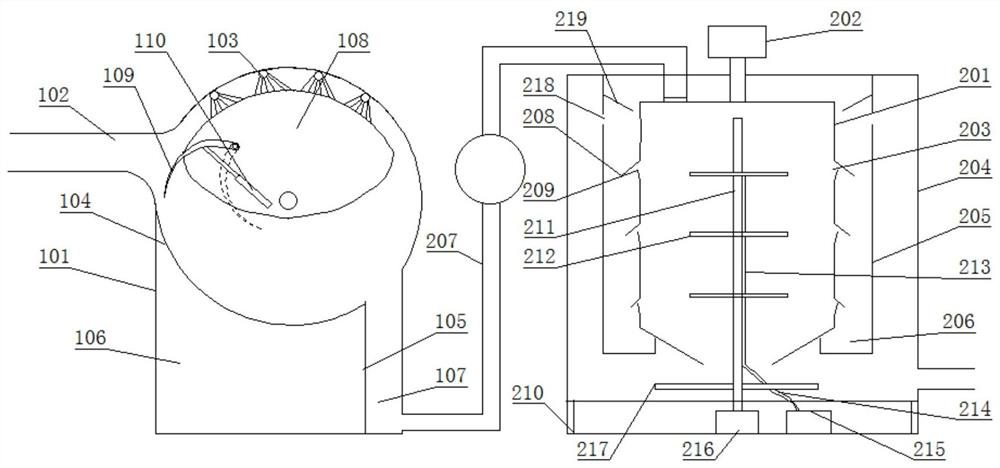

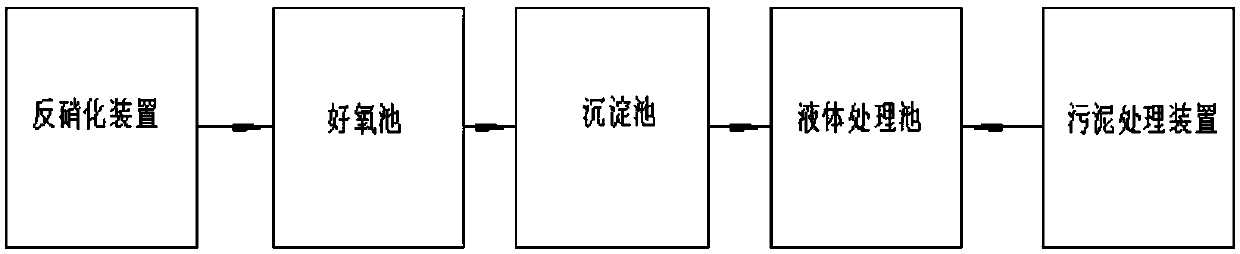

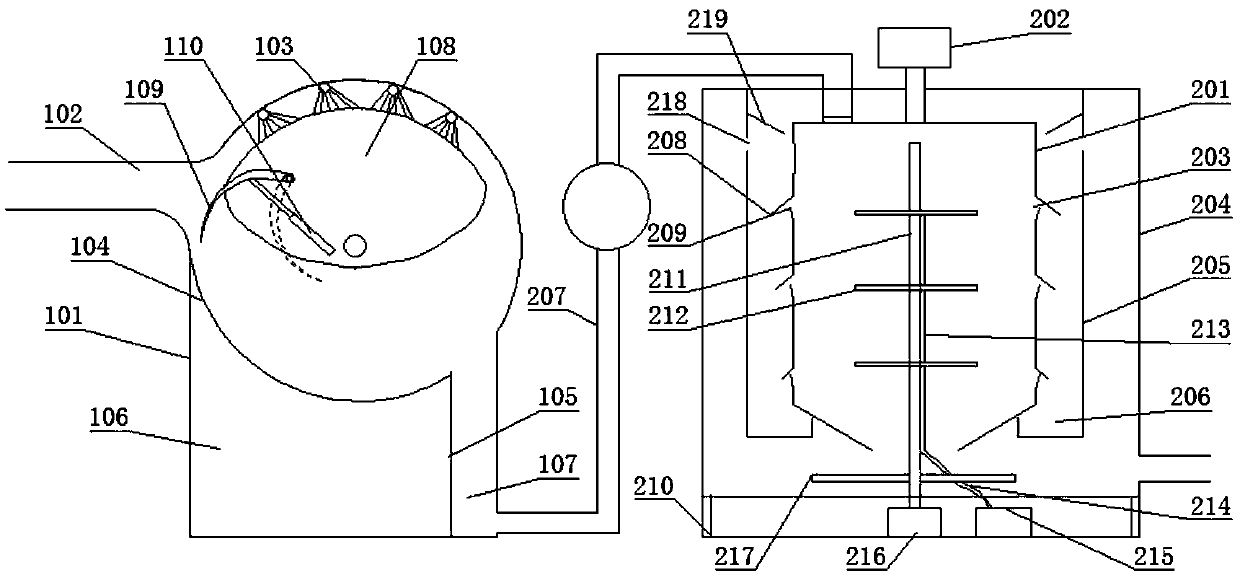

Large-scale chemical sewage treatment device and method

ActiveCN109607949BReduce COD indexEfficient removalSludge treatmentMultistage water/sewage treatmentSludgeSewage

The invention discloses a large-scale chemical sewage treatment device, which includes a denitrification device, an aerobic tank, a sedimentation tank, a liquid treatment tank and a sludge treatment device connected in sequence; wherein, the sludge treatment device includes: a first-level sludge treatment unit , which includes: a first shell, the upper side wall of which is provided with a mud inlet, the top of the first shell is an arc-shaped structure, and a plurality of hard brush strips are arranged at intervals on the top of the first shell; the first filter plate, which is arranged in the middle of the first shell in the form of an arc-shaped belt, one end of the first filter plate is connected to the side wall of the first shell, the other end of the first filter plate is fixed to the vertical plate, and the first filter plate The two plates are vertically fixed in the first housing to separate the lower part of the first housing into a liquid storage space and a mud outlet space which are independent of each other, the mud outlet space communicates with the upper space of the first housing, and the storage The liquid space communicates with the upper space of the first housing through the filter holes of the first filter plate. The invention effectively dehydrates the sludge while treating the sewage.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

Method of preparing bleached chemical pulp using cotton stalk

ActiveCN100381635CPoor qualityQuality improvementPretreatment with alkaline reacting compoundsPulp bleachingPre treatmentChemical pulp

The present invention discloses a method for preparing bleached chemical pulp by using cotton stalk. The described method is an alkaline process, and includes the following steps: preparing material, impregnating treatment, first cooking or secondary cooking to obtain crude pulp, then washing pulp, bleaching so as to obtain the finished paper.

Owner:SHANDONG TRALIN PAPER

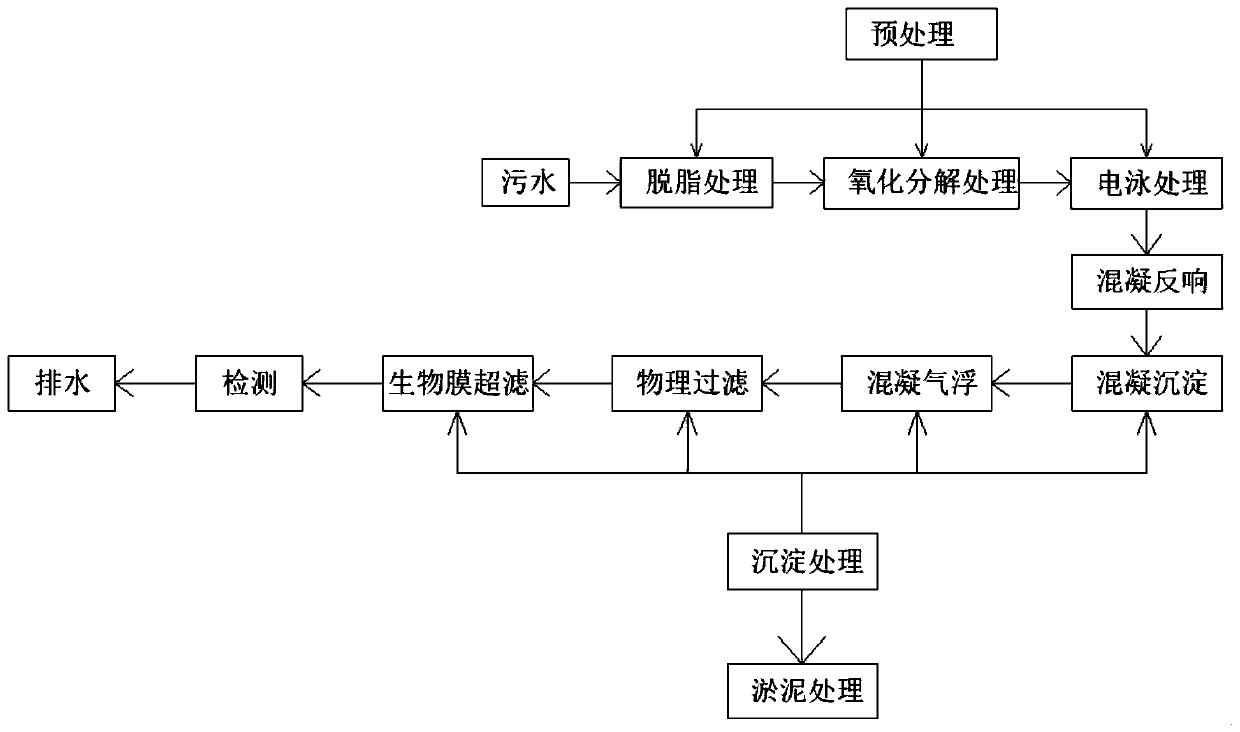

Immersed ultrafiltration process for automobile factory common sewage treatment

InactiveCN110981076AImprove the effect of sediment filtrationReduce COD indexFatty/oily/floating substances removal devicesSpecific water treatment objectivesElectrophoresesBiofilm

The invention discloses an immersed ultrafiltration process for automobile factory common sewage treatment. The immersed ultrafiltration process comprises degreasing treatment, oxygenolysis treatment,electrophoresis treatment, coagulation reaction, coagulation precipitation, coagulation air floatation, physical filtration, biofilm ultrafiltration, detection and sludge treatment. According to theinvention, by adding the biofilm ultrafiltration system after the traditional first-stage precipitation treatment and the second-stage precipitation treatment, sewage filtered by the traditional filtering mode is further filtered so as to improve the precipitation filtering effect in the sewage and reduce the COD index of the sewage, so that the standard reaching rate of sewage treatment is improved; and the ultrafiltration membrane used by the biofilm ultrafiltration can be repeatedly used through backwashing so as to reduce the sewage treatment cost.

Owner:江苏特立智能装备科技有限公司

The original ecological natural color treatment process of the fabric

ActiveCN104805686BDelay decayStable working fluidSucessive textile treatmentsFibre treatmentFiberEngineering

The invention discloses an original natural color processing technology for a fabric. The original natural color processing technology comprises the following steps: (1) washing the fabric for the first time after the fabric is woven; (2) processing the washed fabric by using tea saponin; (3) washing the processed fabric for the second time; (4) pickling the fabric washed for the second time; (5) softening the pickled fabric. The fabric processed by the original natural color processing technology disclosed by the application presents original natural color, and is environment-friendly and healthy; the processing technology is simplified, fiber is broad in adaptation range, and the fabric does not generate the phenomena of oxidation and broken holes; compared with a conventional oxygen bleaching technology, the COD index of waste water generated after cooking, bleaching, printing and dyeing can be reduced by about 50%.

Owner:JIANGSU CANASIN WEAVING

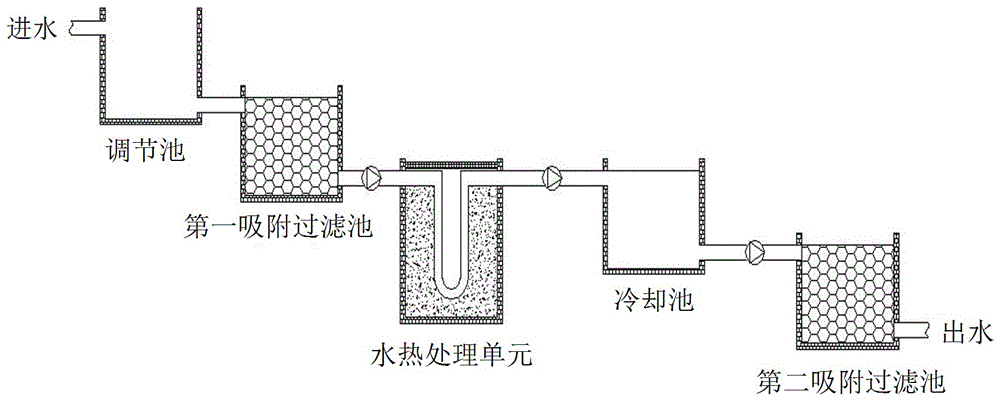

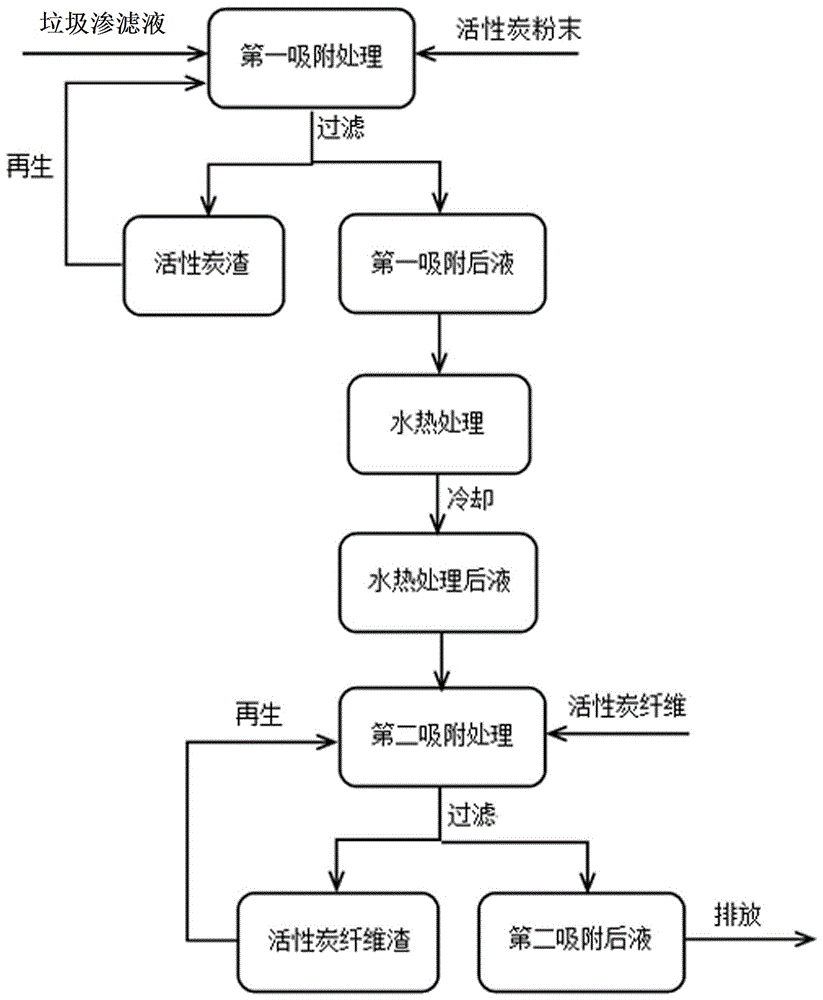

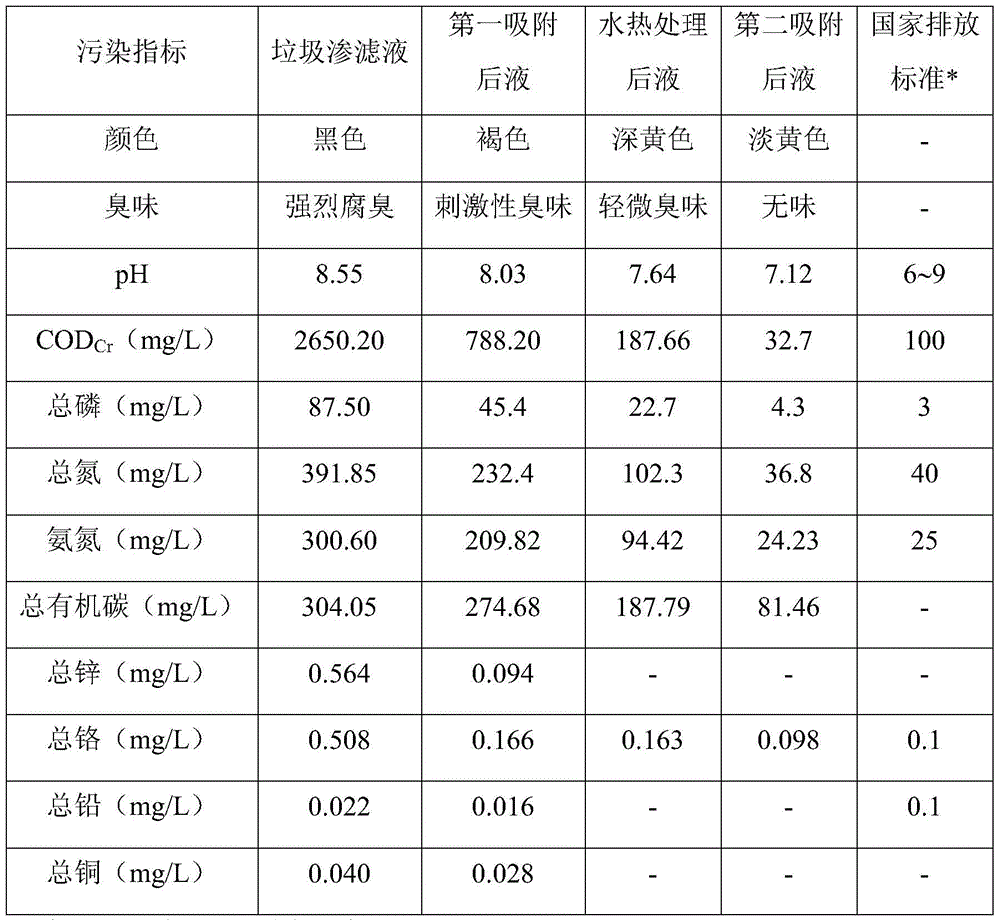

Method and device for treating landfill leachate

ActiveCN104787956BSmall footprintCompletely occupiedMultistage water/sewage treatmentActivated charcoal powderChemical treatment

The invention discloses a treatment method of landfill leachate and a device of the treatment method. The treatment method sequentially comprises the following steps: (1) carrying out first adsorption treatment on the landfill leachate by using active carbon powder to obtain a first post-adsorption liquid; (2) carrying out hydro-thermal treatment on the first post-adsorption liquid in a hydrothermal reaction kettle and cooling the liquid to obtain a hydrothermal post-treatment liquid; and (3) carrying out second adsorption treatment on the hydrothermal post-treatment liquid by using active carbon fibers to obtain a second post-adsorption liquid which can be directly discharged. The treatment device comprises a first adsorption filter tank, a hydrothermal treatment unit, a cooling pool and a second adsorption filter tank which are sequentially connected. The treatment method and device disclosed by the invention combine physical and chemical treatment methods and can economically and efficiently remove various toxic and harmful components in the landfill leachate, so that the landfill leachate is met.

Owner:POWERCHINA ZHONGNAN ENG

Preparation method of efficient waste paper de-inking agent

InactiveCN102277031BImprove wettabilityGood emulsificationChemical paints/ink removersActive agentBeef Tallow

The invention belongs to the technical field of de-inking and in particular discloses a preparation method of an efficient waste paper de-inking agent. The preparation method comprises the following steps: putting the beef tallow serving as a raw material into a reaction kettle; adding water and sodium hydroxide; performing steam heating until boiling; continuously stirring until saponification is finished to obtain transparent liquid soap; precipitating and cooling the liquid soap in the reaction kettle; after soap and water are separated, putting separated soap into an agitation tank; adding a surfactant and auxiliary materials into the agitation tank; and after evenly stirring, pelleting and drying to obtain the de-inking agent. The product disclosed by the invention has good compatibility with other chemical additives, is energy-efficient and environmentally-friendly and completely meets the waste paper de-inking requirements of Europe, America, Japan and the like; and the whiteness of the finished product paper can be improved by 2-5%, and the ink removal rate can be improved by 10-15%.

Owner:SHANXIAN TIANYUAN CHEM CO LTD

Large-scale chemical industry wastewater treatment device and method

ActiveCN109607949AReduce COD indexEfficient removalSludge treatmentMultistage water/sewage treatmentChemical industrySludge

The invention discloses a large-scale chemical industry wastewater treatment device, which comprises a denitrification device, an aerobic tank, a sedimentation tank, a liquid treatment tank and a sludge treatment device which are sequentially communicated; the sludge treatment device comprises a first-stage sludge treatment unit and a second-stage sludge treatment unit, wherein the first-stage sludge treatment unit comprises a first shell, wherein the upper side wall of the first shell is provided with a sludge inlet, the top of the first shell is of an arc-shaped structure, and a plurality ofhard brush strips are arranged at intervals at the top of the first shell; a first filter plate, wherein the structure of the first filter plate, in an arc-shaped strip structure, is arranged at themiddle part of the first shell, one end of the first filter plate is connected with the side wall of the first shell, the other end of the first filter plate is fixedly connected with a vertical plate, a second plate body is vertically fixed in the first shell so as to divide the lower part of the first shell into a liquid storage space and a sludge discharge space which are mutually independent,wherein the sludge discharge space is communicated with the upper space of the first shell, and the liquid storage space is communicated with the upper space of the first shell through filter holes ofthe first filter plate. According to the invention, the sludge is effectively dewatered while the sewage is treated.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

Method for treating and recycling lead-zinc sulfide ore dressing wastewater

ActiveCN101913720BIncrease in sizeHigh densityWaste water treatment from quariesMultistage water/sewage treatmentChlorine dioxideCyanide

The invention provides a technique for treating and recycling lead-zinc ore dressing wastewater and aims to solve the problems of influence on the ore dressing index due to the recycling of the ore dressing wastewater for production and environmental pollution caused by drainage. The novel technique for treating and recycling the lead-zinc sulfide ore dressing wastewater comprises the steps of: adjusting the PH value of the total wastewater of an ore dressing plant; adding ferrous sulfate and flocculant into the wastewater to perform oxidation-coagulation treatment; and oxidizing the treated water by using chlorine dioxide, and performing catalytic oxidation and adsorption by using an active carbon bed, so that the treated water reaches the relevant discharge standard of China; and totally recycling the treated water by adopting the combined application of potential-controlled flotation and an environmental-protection collector. Compared with the field process technique, the method saves the cyanide flotation process and improves the recovery rates of lead, zinc and gold. The method provides whole technical integration of the combined application technique of the potential-controlled flotation and the environmental-protection collector and the wastewater treatment technique for the treatment and recycling of the lead-zinc ore dressing wastewater, and realizes recycling of the ore dressing wastewater.

Owner:HUNAN HERMES SAFE ENVIRONMENT PROTECTION SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com