Method of preparing bleached chemical pulp using cotton stalk

A chemical pulping and pulping technology, which is applied in pulp bleaching, pulping with inorganic alkali, pretreatment with alkaline compounds, etc., can solve problems such as unsatisfactory effects, and alleviate the shortage of wood resources, low COD index, reduce The effect of water dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

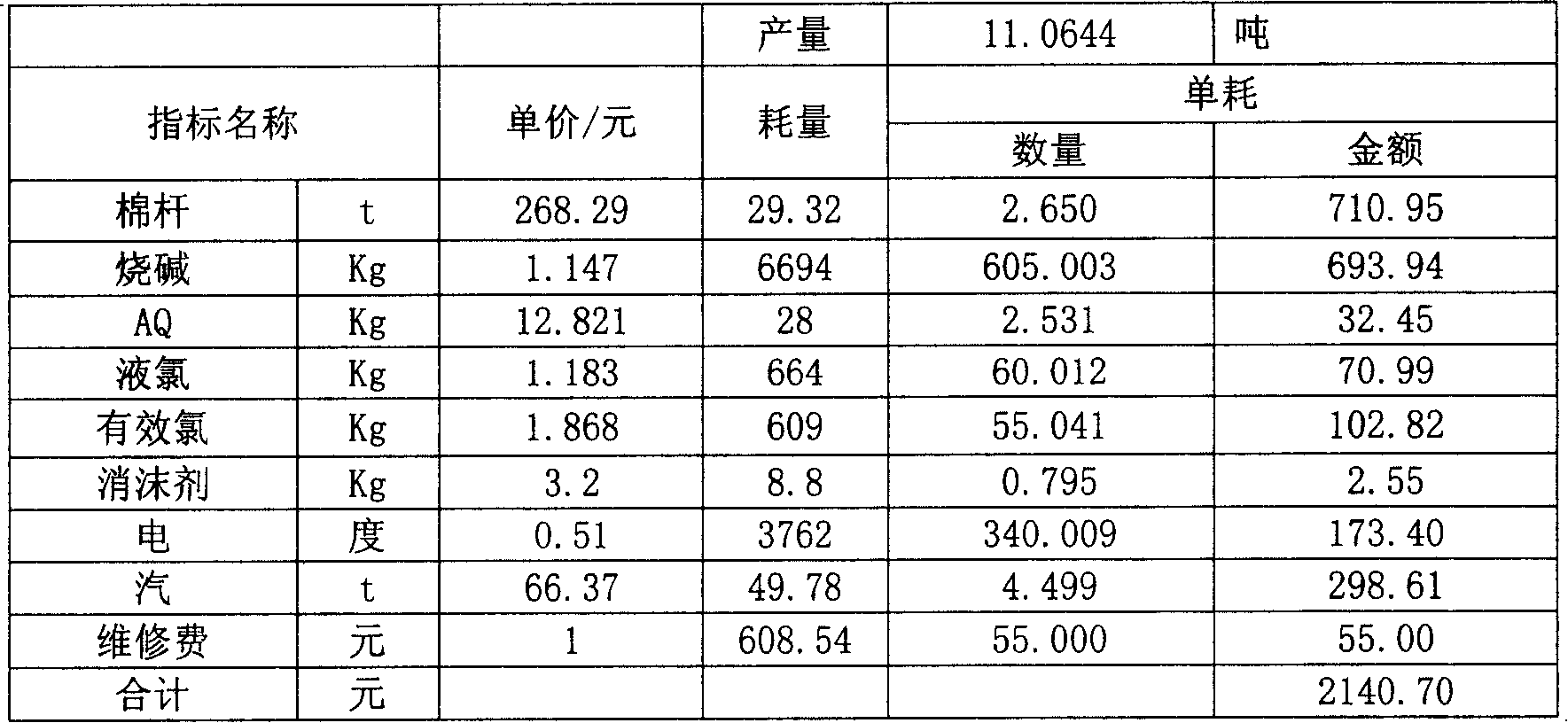

[0039] Cotton stalk pulp cooking cost analysis:

[0040]

[0041] A total of 7 balls were produced in the test, with an output of 11.0644 tons, a dry cotton stem consumption of 29.32 tons, and a harvest rate of 37.74%.

experiment example 1

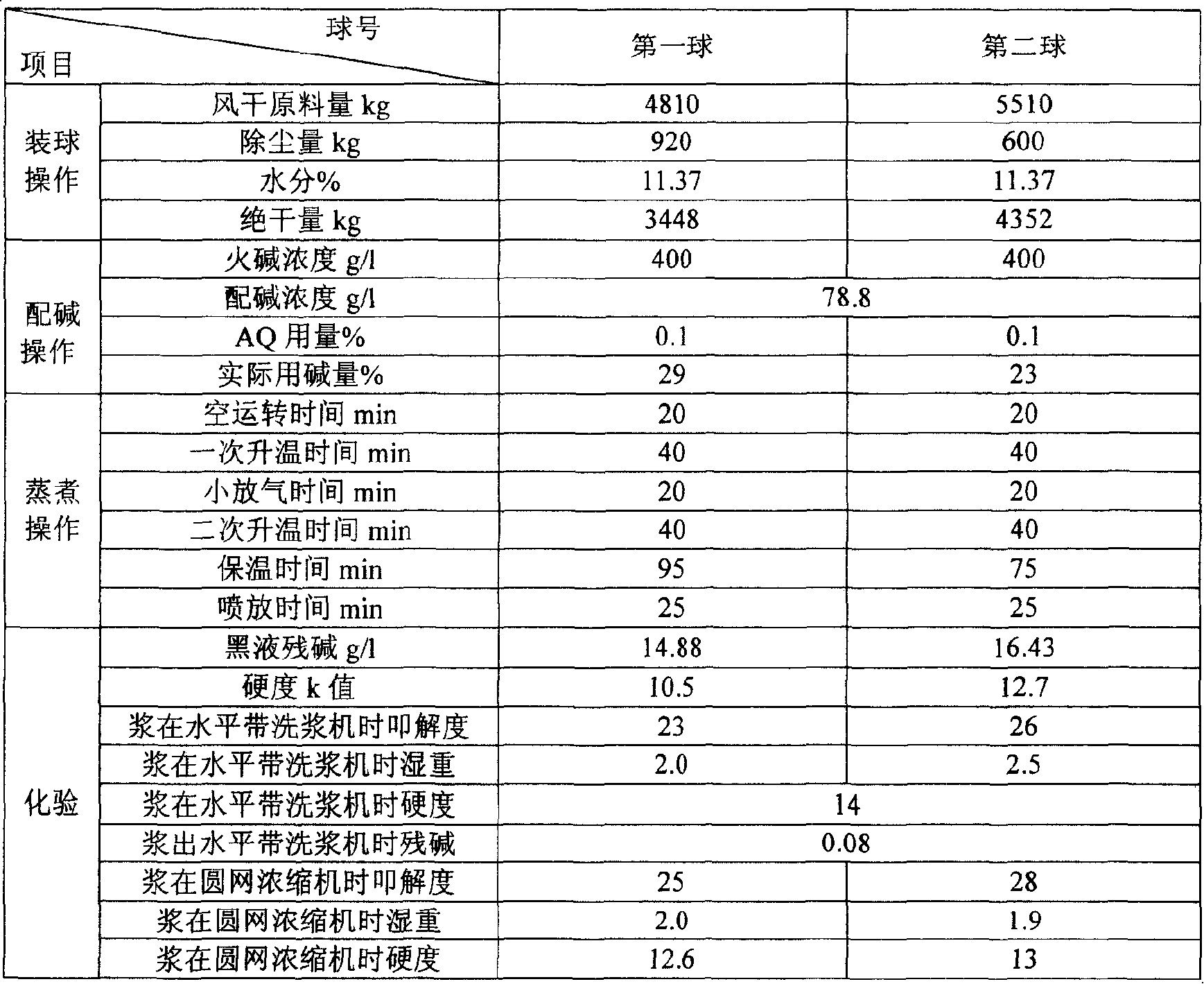

[0043] Cotton stalk cooking operation record data sheet:

[0044]

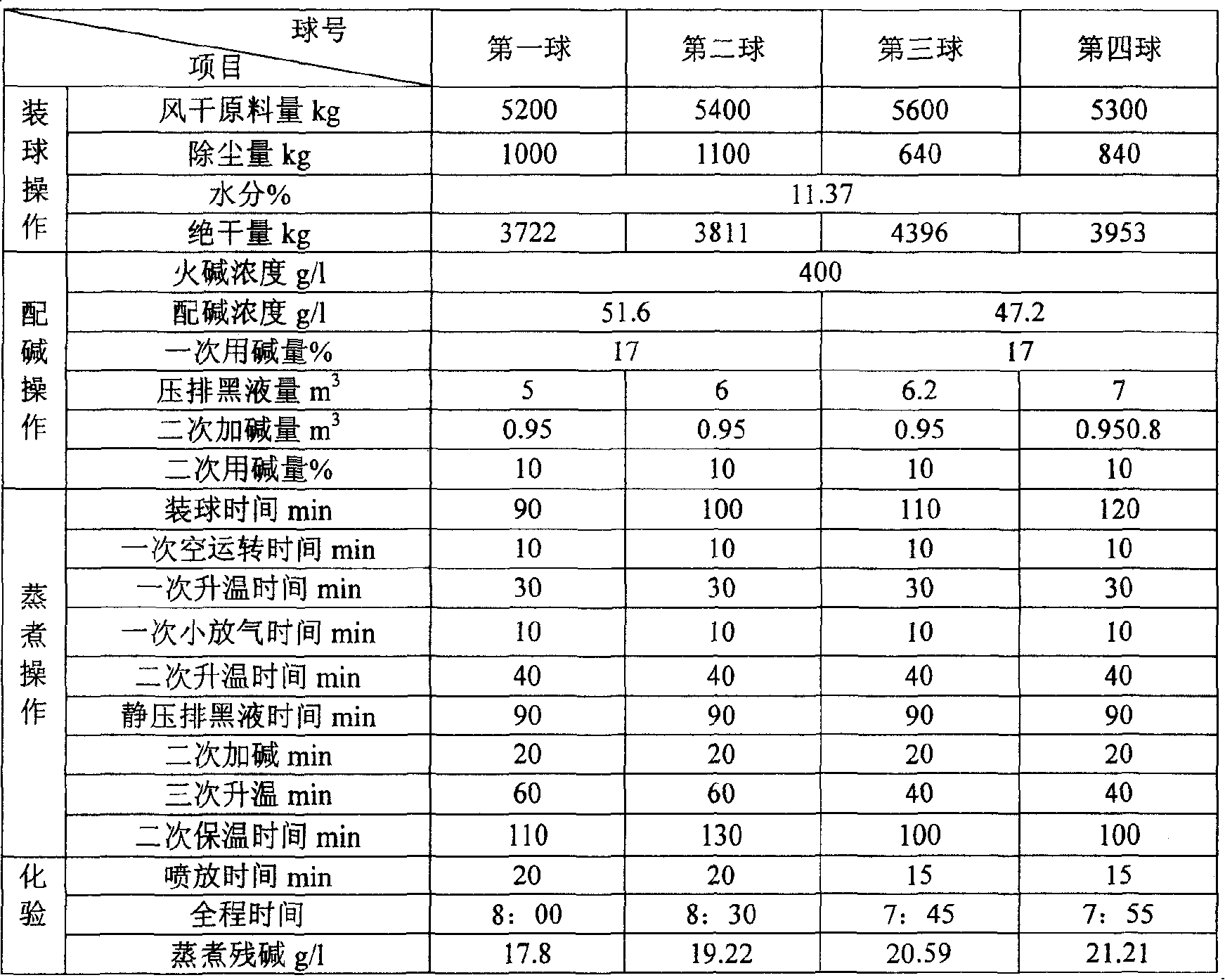

[0045] Cotton stalk secondary cooking operation record data sheet:

[0046]

[0047]

[0048] The average length of the cotton stalk fiber is 2.0mm, and the average diameter is 20um; the average length of the woody core fiber is 0.74mm, and the average diameter is 16um; the phloem of the cotton stalk contains more pectin, and it can be seen in the process that the pectin is degraded There is a large amount of starch in the slurry, and there is no need to add starch indicator when testing the hardness; therefore, it is best to store the cotton stalks for more than half a year before use, so as to facilitate natural fermentation and save cooking alkali.

[0049] When the cotton stalks are directly cooked, the lye is not easy to penetrate, and the raw materials should be crushed or crushed, which is conducive to improving the lye’s penetration ability, making the cooking more uniform, and greatly reducing ...

experiment example 2

[0051] Bleach data:

[0052]

[0053] Pool No. 1 is primary cooking slurry, and the rest are secondary cooking slurry. In order to ensure the whiteness and color stability of slurry, the amount of bleaching liquid in the next few pools has increased; under laboratory conditions, the bleached slurry has a large amount of Dust, therefore, bleaching is the focus of this test, and the hardness is also intentionally reduced during cooking. From the results, cotton stalk pulp is easier to bleach than expected. After chlorine treatment, the final whiteness can reach more than 78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com