Method for preparing ZnO thin films with buffer layers

A buffer layer and composite buffer layer technology, applied in chemical instruments and methods, from chemically reactive gases, single crystal growth, etc., can solve problems such as large mismatch of thermal expansion coefficients, and achieve improved crystallization quality, high repeatability, and The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

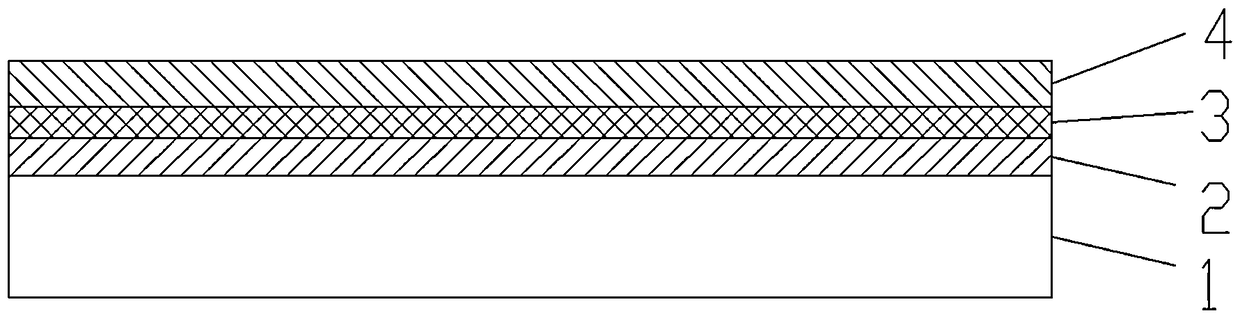

[0013] Such as figure 1 Shown, the invention provides a kind of preparation method with the ZnO thin film of buffer layer, comprises the following steps:

[0014] S1, cleaning the monocrystalline silicon substrate 1 to remove oil stains and impurities on the surface of the monocrystalline silicon substrate 1;

[0015] S2. Using magnetron sputtering equipment, using Al target as the target material, place the single crystal silicon substrate in the vacuum chamber of the magnetron sputtering equipment, and the vacuum degree reaches 3.0*10 -4 At Pa, the sputtering gas Ar is introduced for 5 minutes of pre-sputtering to make the Al target glow, so as to achieve the purpose of activating the target and removing the oxide on the target surface: after the pre-sputtering, the reaction gas N is introduced 2 , sputtering AlN buffer layer 2 on the surface of single crystal silicon substrate, sputtering power 100W, Ar flow rate 20sccm, N 2 The flow rate is 5sccm, the working pressure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com