Patents

Literature

45results about How to "Avoid multiple clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

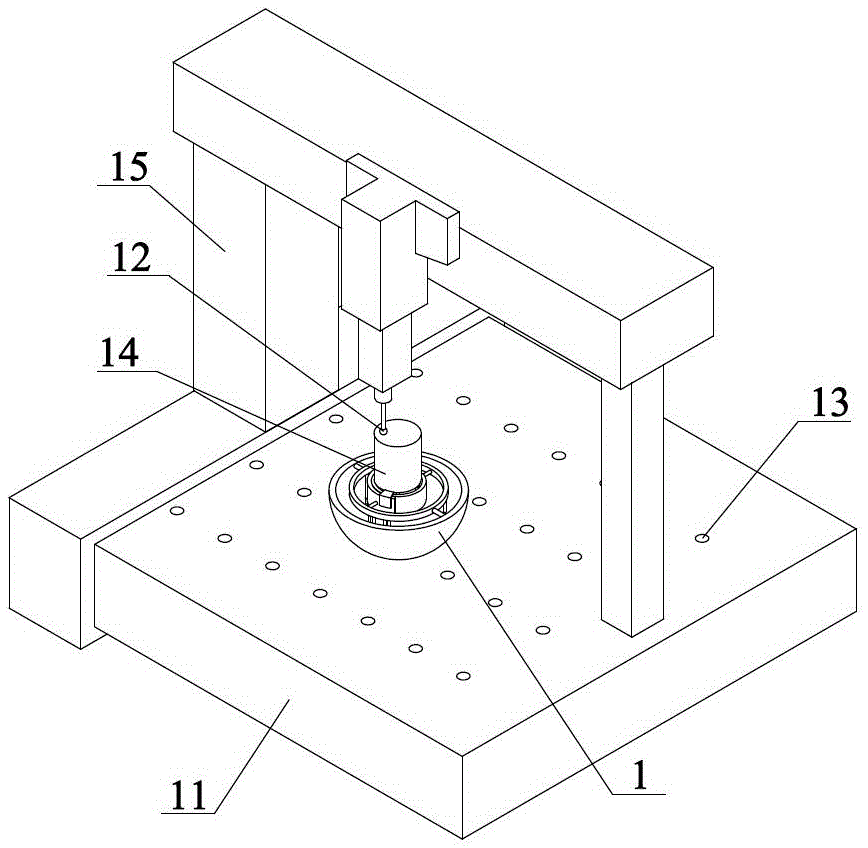

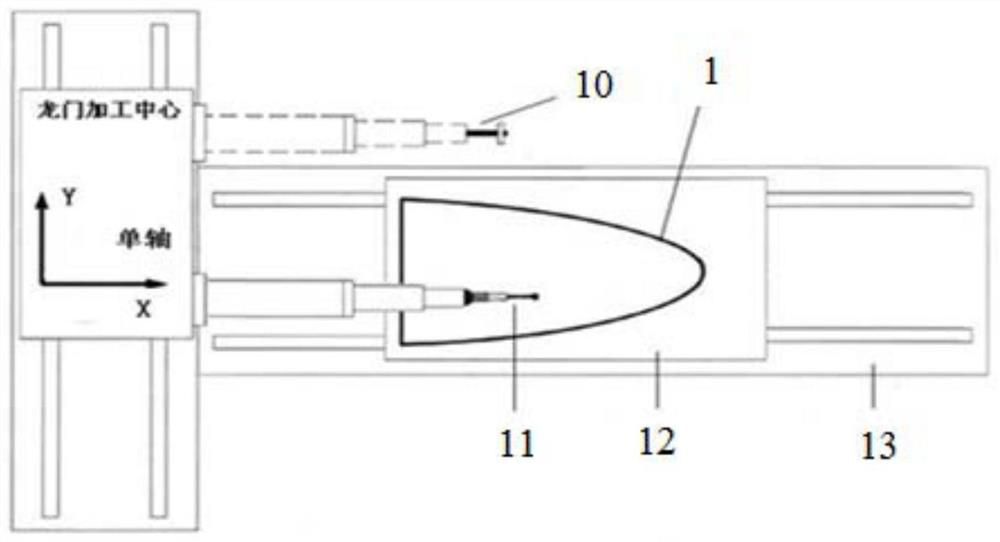

In-machine roundness detection method

InactiveCN106289145ALarge clamping rangeAvoid multiple clampingMeasurement devicesMeasurement pointThree dimensional measurement

The invention relates to the field of machining and detection, in particular to an in-machine roundness detection method. The in-machine roundness detection method involves a base, a first rotating shaft, a second rotating shaft, a circular hoop, a clamping buckle, a first half ring and a second half ring, wherein the first half ring is arranged on the circular hoop through the first rotating shaft; the second half ring is connected with the first half ring through the clamping buckle; the circular hoop is arranged on the base through the second rotating shaft; supporting legs are arranged on the lower end surfaces of the circular hoop and the first half ring. According to the in-machine roundness detection method, a three-dimensional measurement point, acquired by a three-coordinate measurer, on a cylinder is projected to a plane, and a circle center of a circle with the minimum area is searched by an iteration method, so that the calculated amount of searching is greatly simplified; an initial value of the circle center is determined by the least square method according to the projected measurement point, so that the search process under a determined attitude is quicker; by the selection of a center moving direction and a center moving step length, the number of searching times is reduced, and the searching precision is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

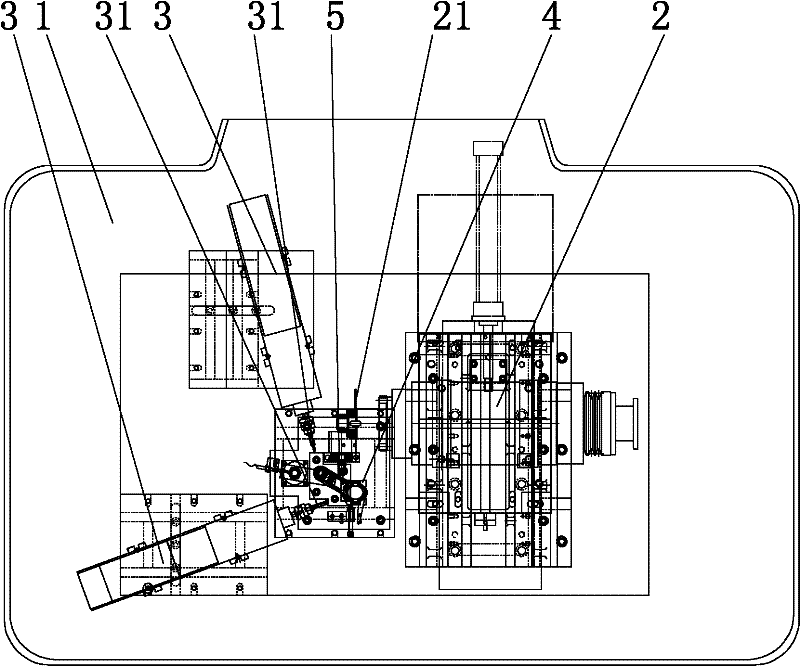

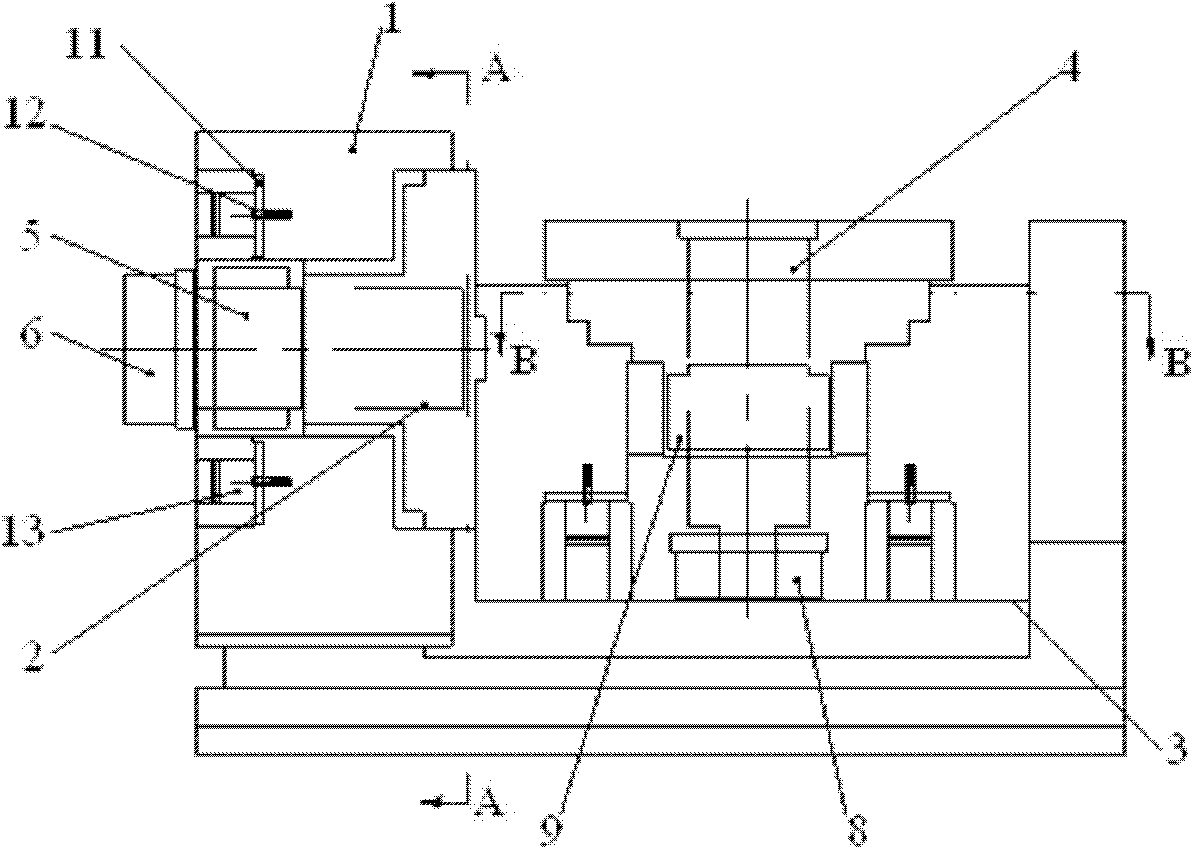

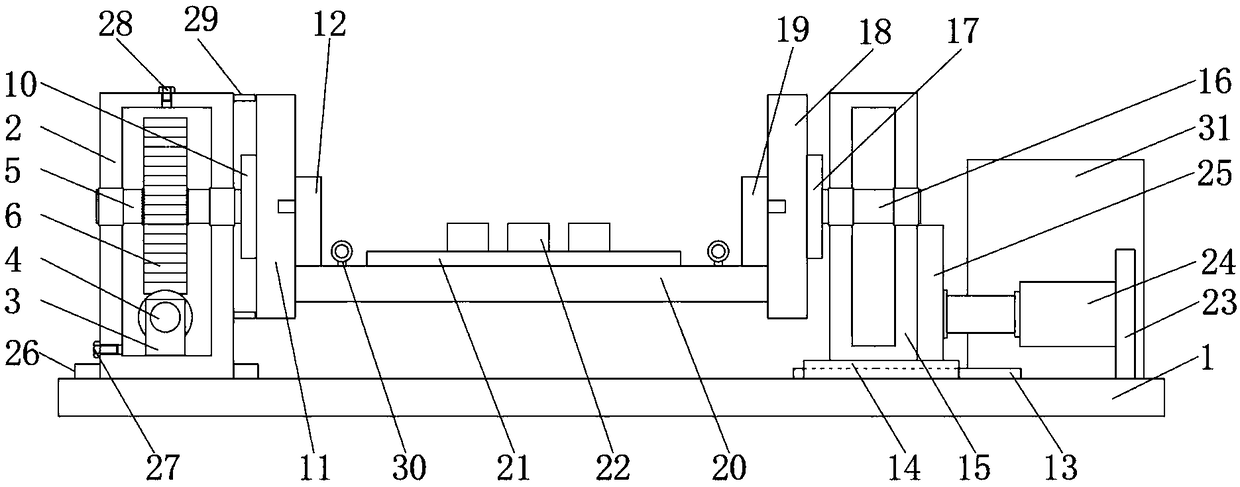

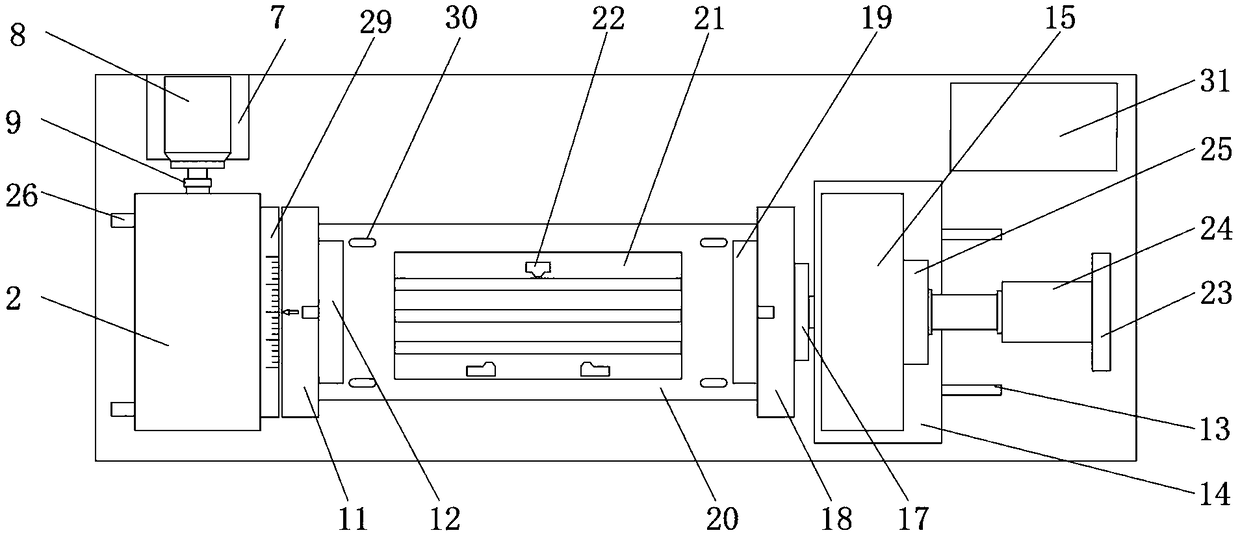

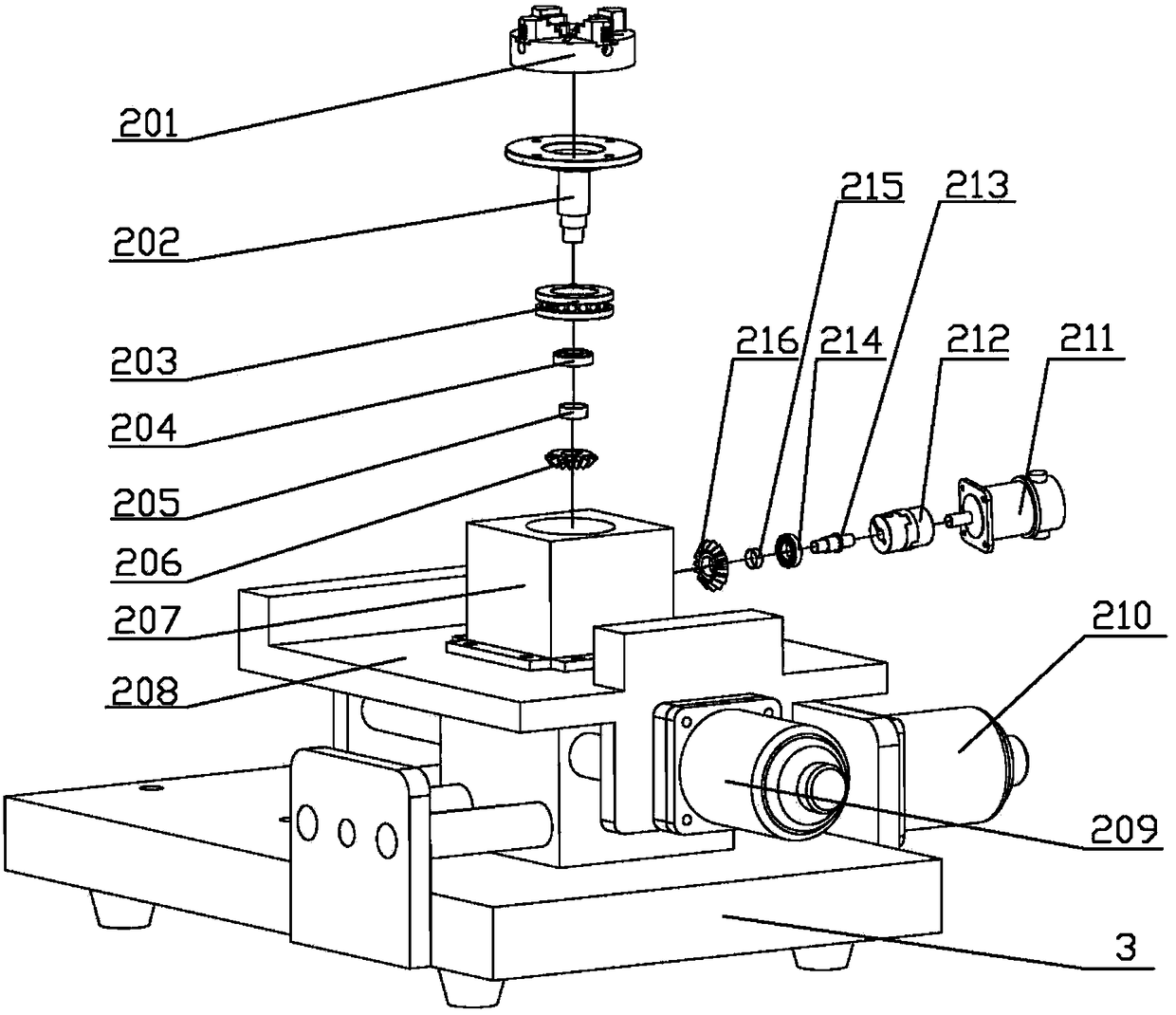

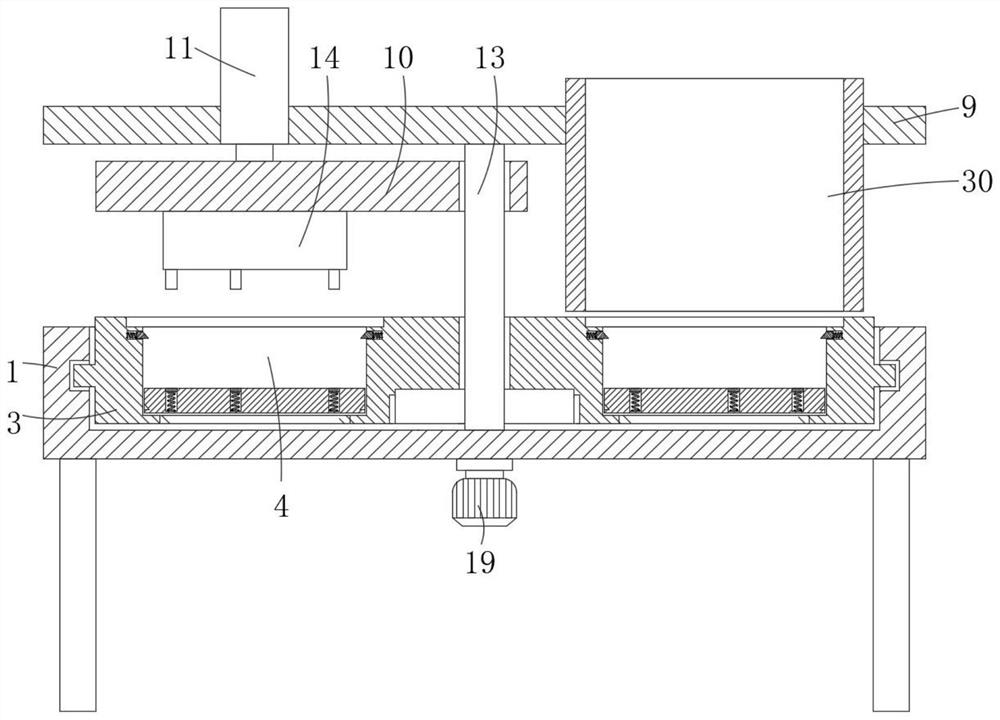

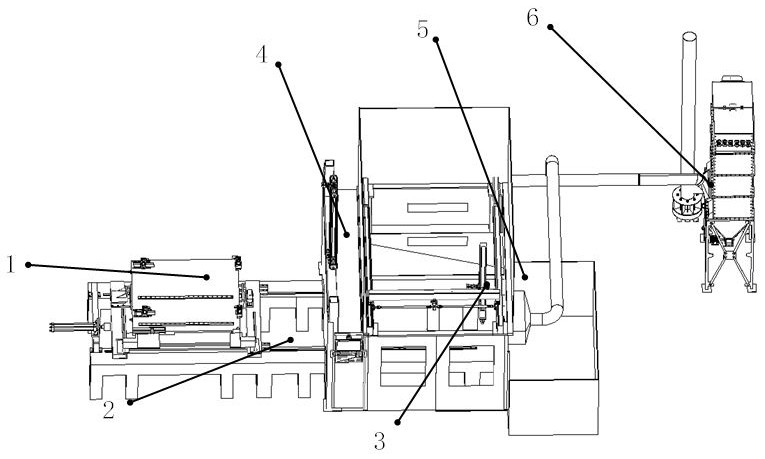

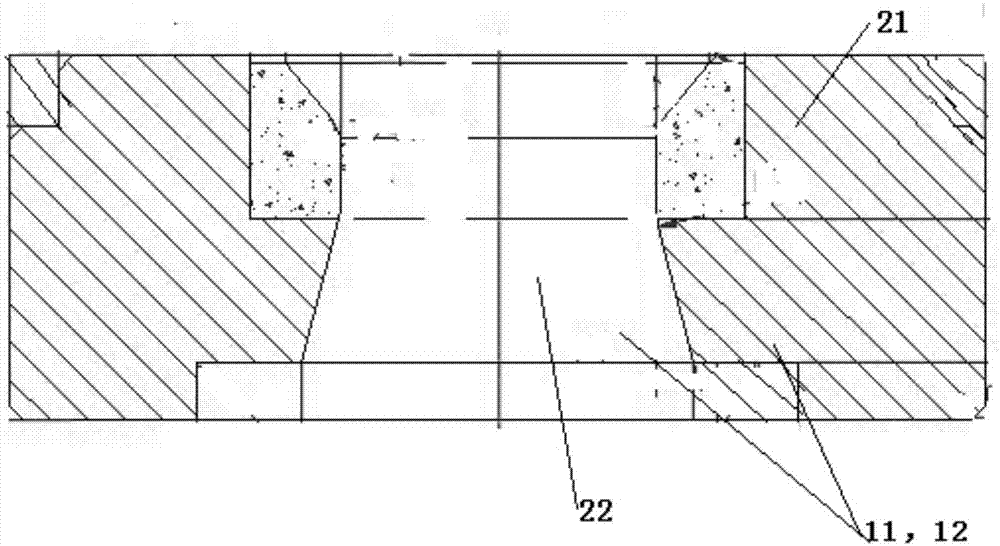

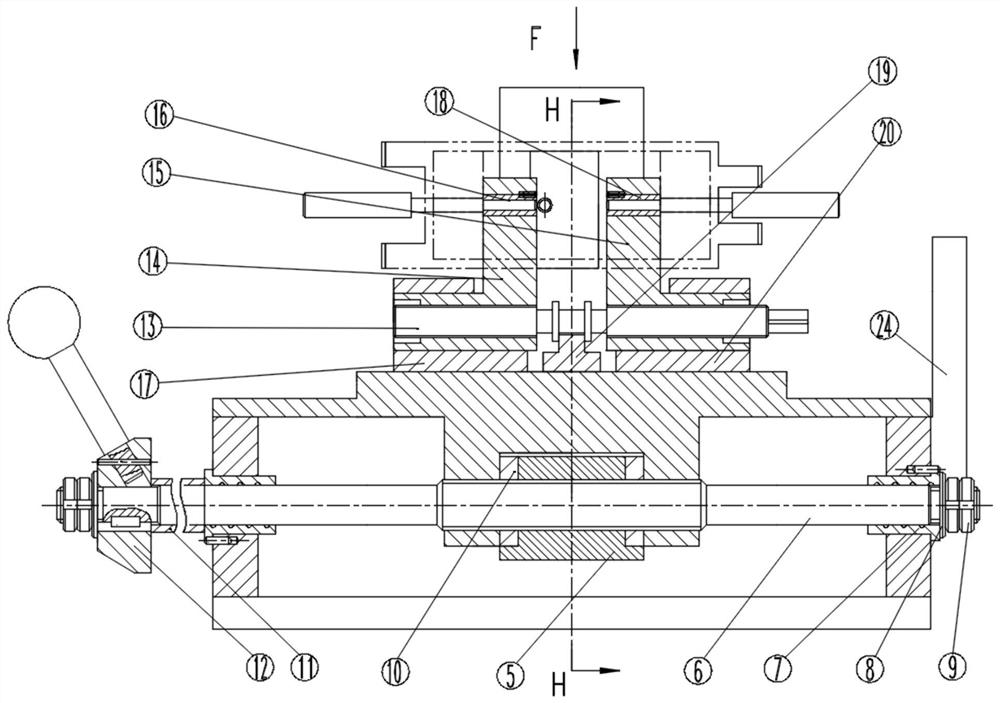

Combined machine tool for drilling oil hole of connecting rod and cutting big-head hole of connecting rod

ActiveCN102476280AAvoid multiple clampingEasy to operateOther manufacturing equipments/toolsEngineeringRelative stability

The invention discloses a combined machine tool for drilling an oil hole of a connecting rod and cutting a big-head hole of the connecting rod, and the machine tool comprises a machine platform, a cutting mechanism, two sets of drilling mechanisms and a positioning fixture, wherein the positioning fixture and the drilling mechanisms are arranged on the surface of the machine platform; the cutting mechanism is in sliding connection with the surface of the machine platform; an oil cylinder is used for driving and controlling the cutting mechanism to slide on the surface of the machine platform; a to-be-processed connecting rod is fixed on the positioning fixture; a rotating head of the cutting mechanism is fixed with a saw bit; the saw bit is aligned with a cutting position of a big-head hole of the connecting rod; the cutting mechanism is used for driving the saw bit to cut and move along the preset cutting position of the big-head hole; drilling bits are arranged on the drilling mechanisms; and the drilling bits respectively do feed motion along preset oil hole drilling positions on the big-head hole and a small-head hole of the connecting rod. The invention provides a device combined with two processes of drilling the oil hole for the connecting rod and cutting the connecting rod; the operation of repeatedly clamping the connecting rod during a processing process is avoided; the relative stability of the position of the oil holes on the connecting rod is realized; the device is convenient in operation; and the production efficiency of products is increased.

Owner:福建华威钜全精工科技有限公司

Double-laser composite cutting high-precision drilling method

ActiveCN110814544ASolve the vertical pitSolve ridge (along the direction of optical axis) defectsLaser beam welding apparatusLaser processingOptical axis

The invention provides a double-laser composite cutting high-precision drilling method. The drilling method comprises the following steps: installing a laser cutting head at the position of a machining head of a laser machining machine tool, wherein the laser cutting head can output double laser beams, one laser beam is a high-power hot melting cutting laser beam, and the other laser beam is an ultra-fast pulse precision trimming laser beam; adjusting the relative orientation of the laser cutting head and a workpiece so as to enable the two laser beams output by the laser cutting head to be perpendicular or incident on the surface of the workpiece at a certain deviation angle and to focus on the surface of the workpiece, wherein the optical axes of the two focused laser beams are coaxial or parallel; and starting the composite cutting process in any one of three ways. By means of the double-laser composite cutting high-precision drilling method, a surface hardening layer cannot be generated, therefore, traditional machining methods such as milling, boring, drilling, turning and the like do not needed for removing the surface hardening layer, and the method can be directly used fordrilling important metal parts, such as bolt holes, pin holes and other holes with impact or fatigue loads.

Owner:WENZHOU UNIVERSITY

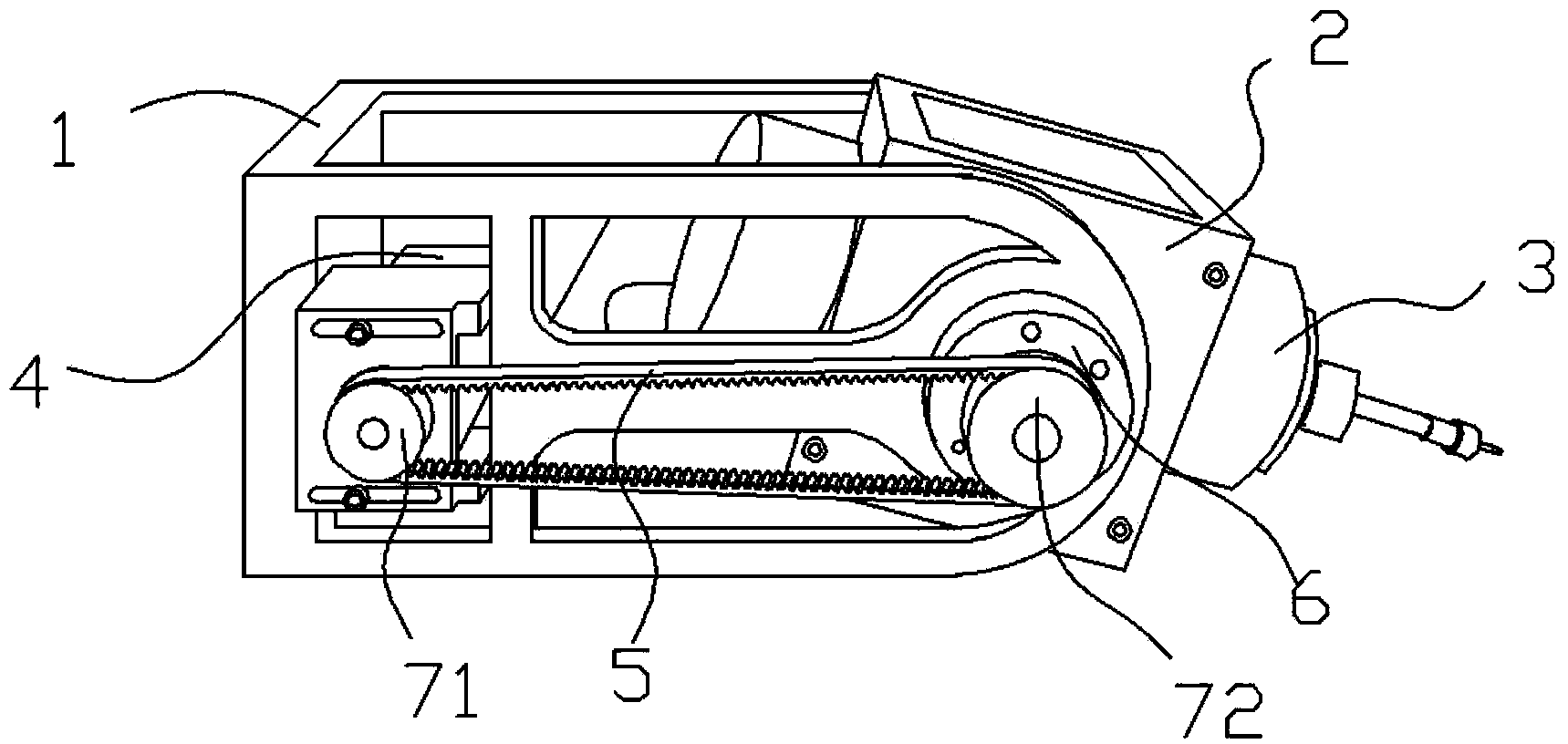

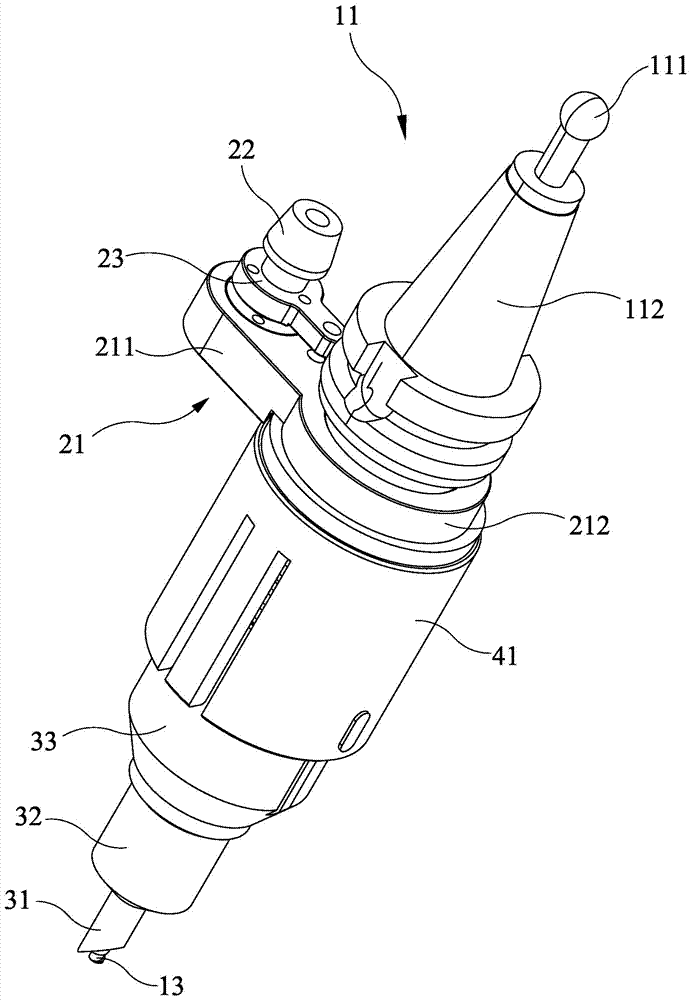

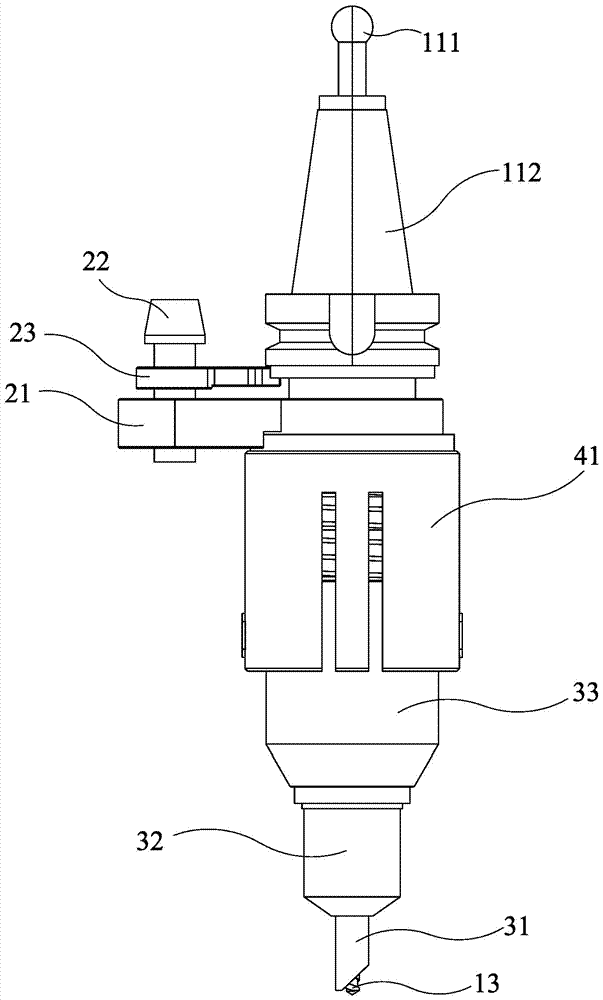

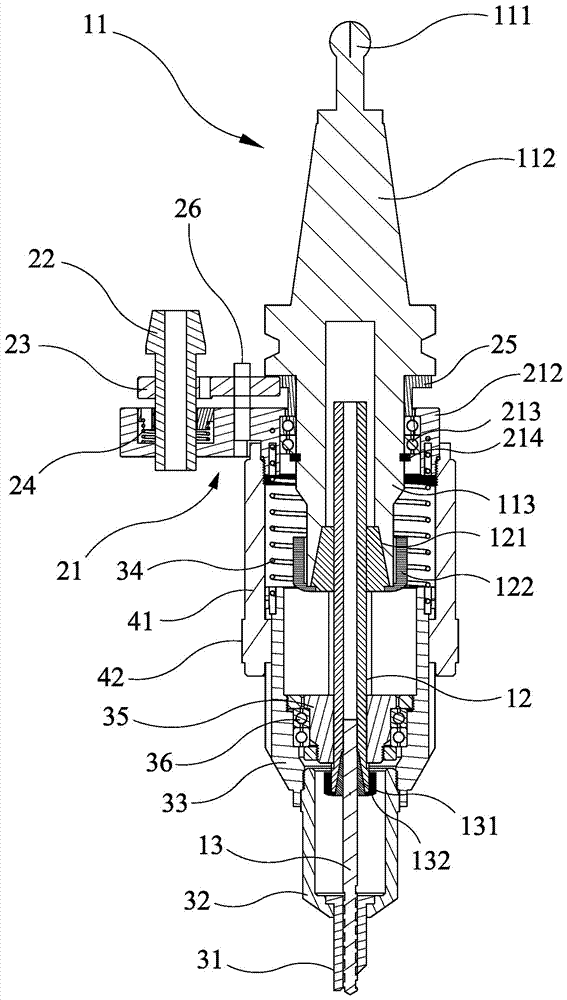

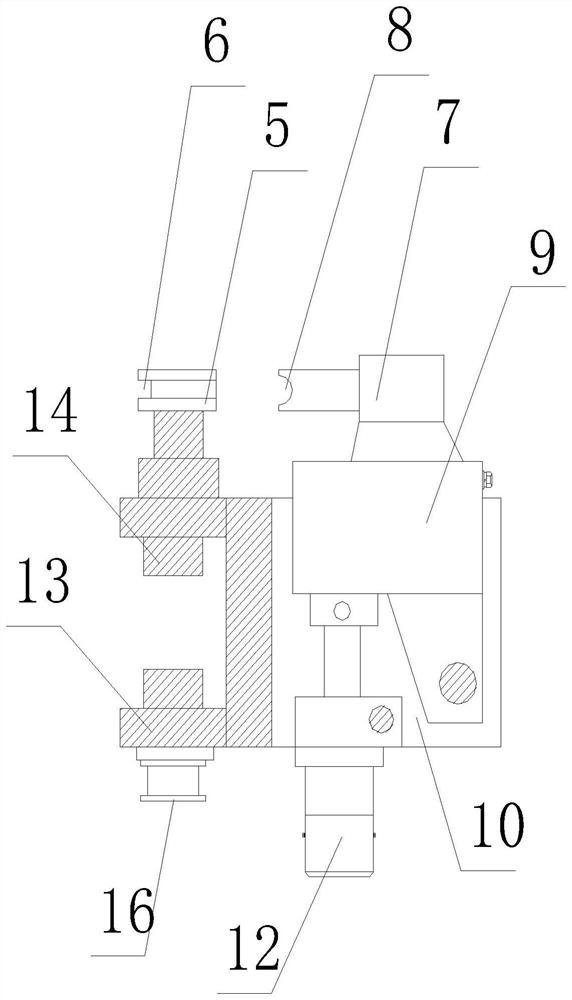

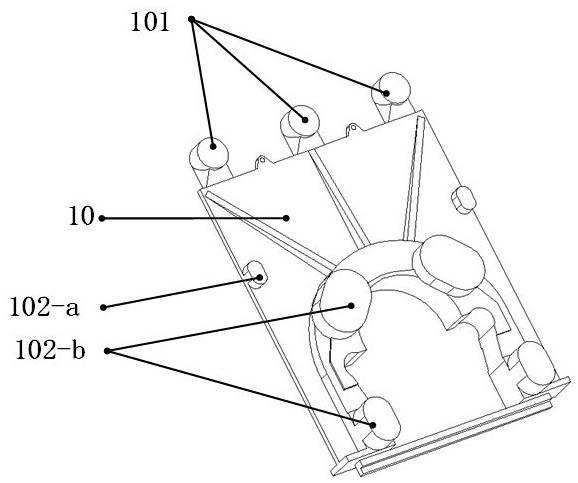

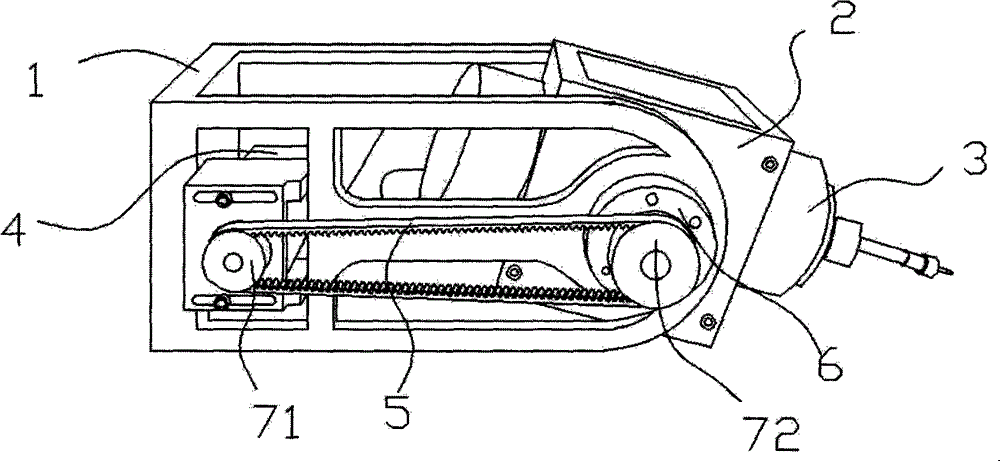

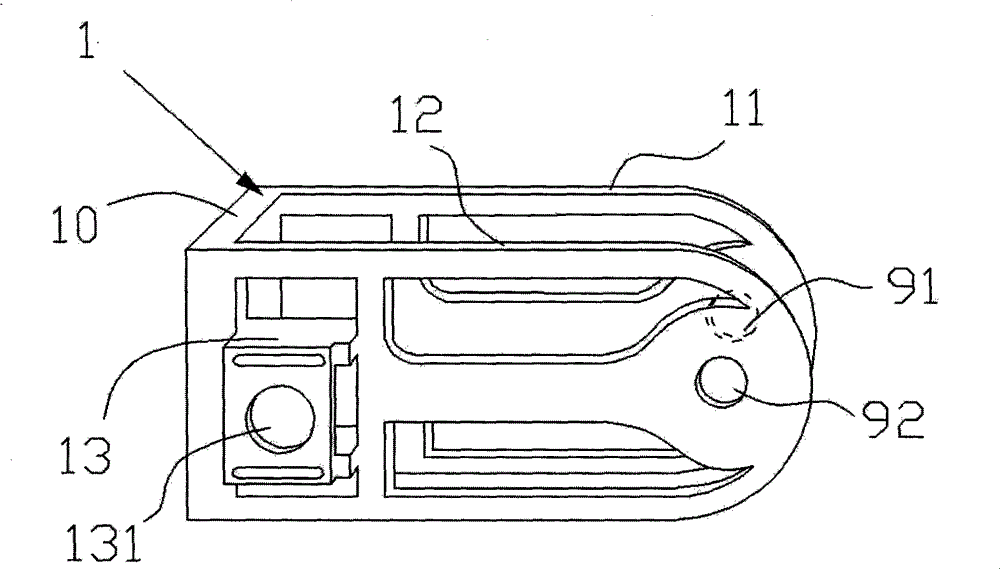

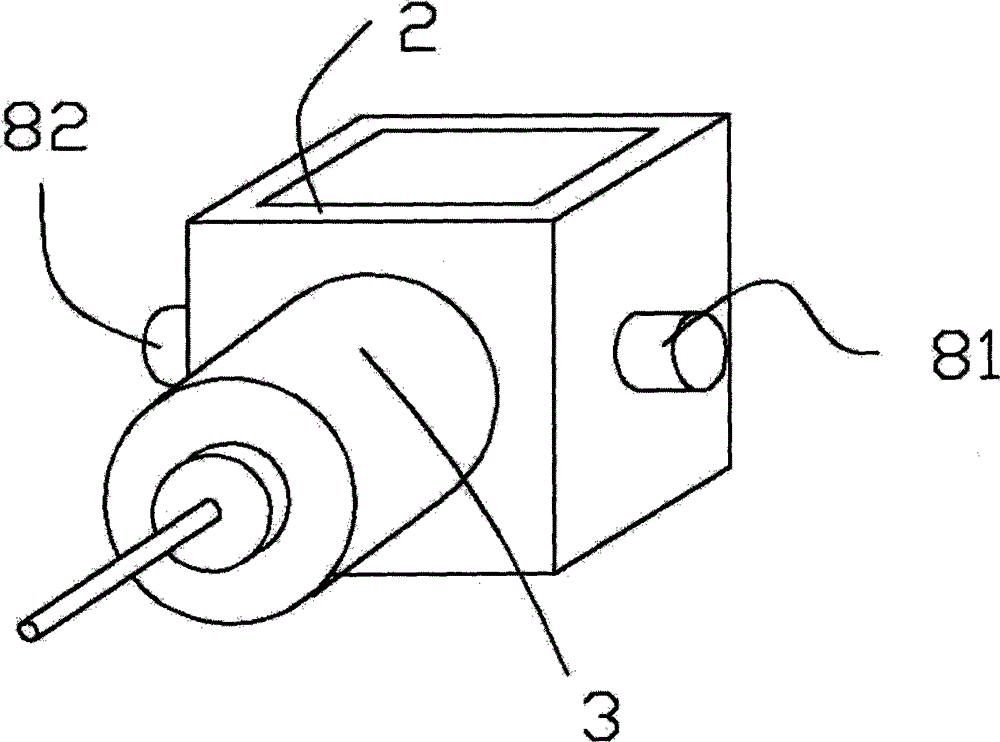

Five-axis numerical control carving machine swinging head

The invention provides a five-axis numerical control carving machine swinging head, which comprises a fixed frame, a grinding head mounting bracket connected with the fixed frame, and a grinding head connected with the grinding head mounting bracket, wherein a servo motor is arranged on the fixed frame, a synchronous belt is arranged between the servo motor and the grinding head, and the servo motor drives the grinding head through the synchronous belt. According to the five-axis numerical control carving machine swinging head, the servo motor drives the grinding head through the synchronous belt, and clamping for multiple times can be avoided. The five-axis numerical control carving machine swinging head can be applied to more precise operation. The swinging head has a simple structure, and is easy to use and maintain. The original cutting tool of a four-axis numerical control carving machine can be replaced, and the four-axis numerical control carving machine can be converted into the five-axis numerical control carving machine.

Owner:陶冬波

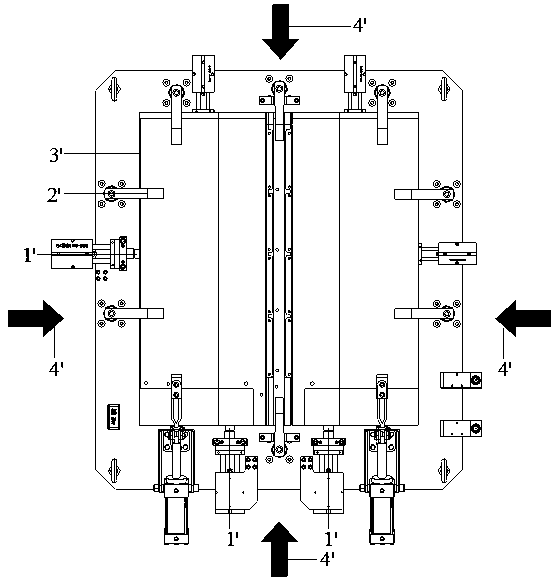

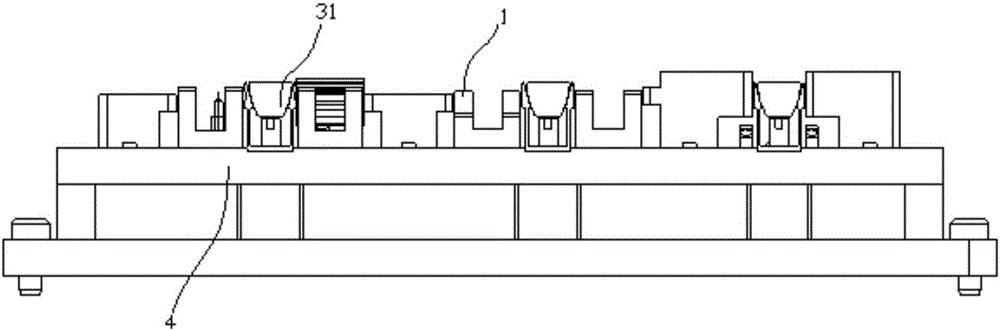

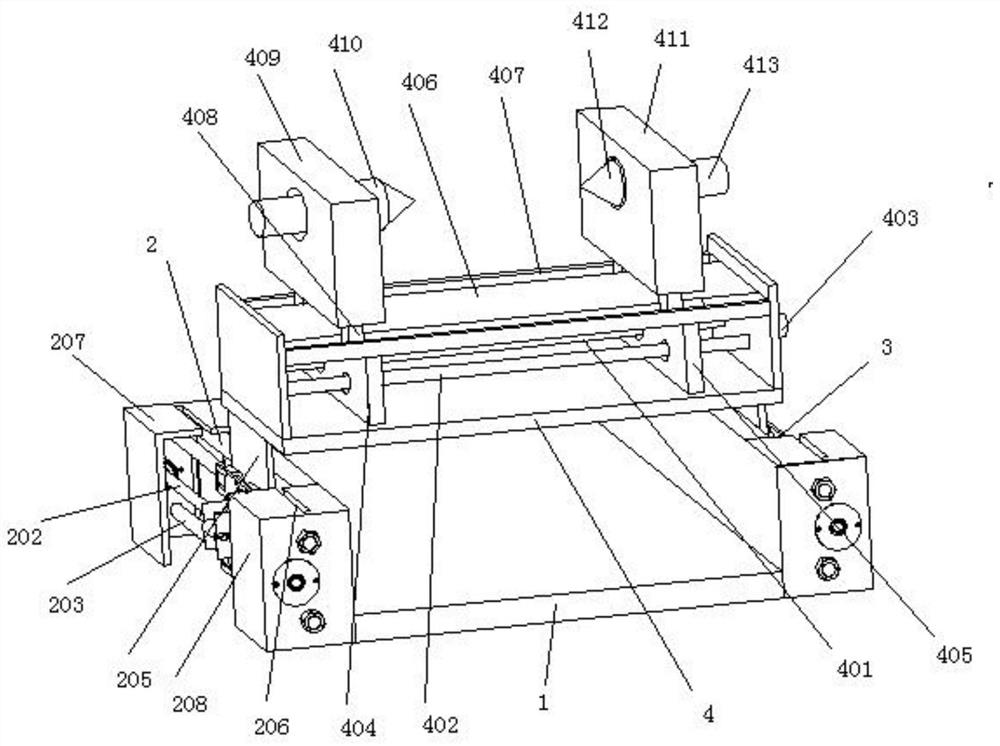

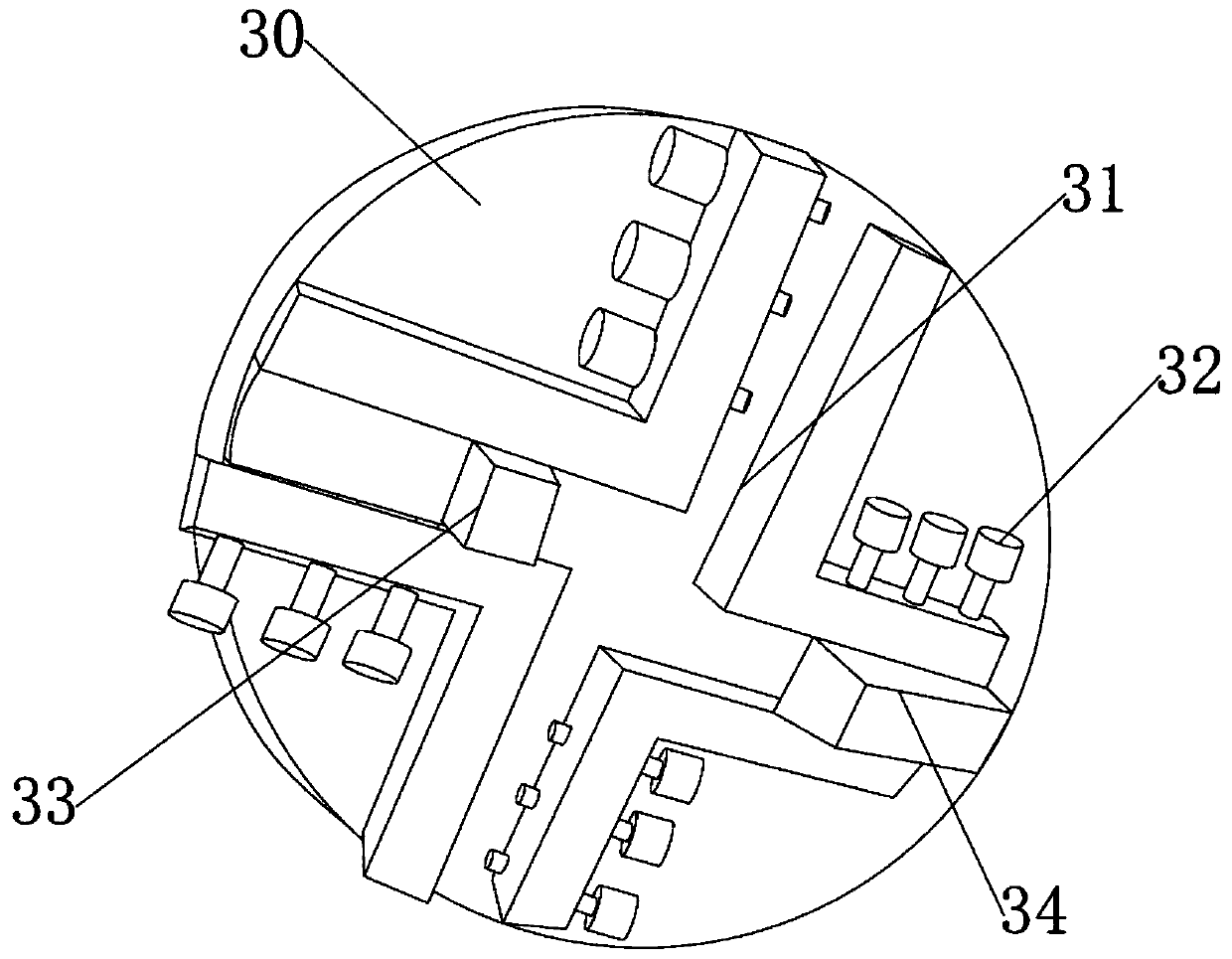

Battery tray bottom plate CNC finish machining fixing tool

PendingCN111283457AGuaranteed positioning requirements in the horizontal directionGuaranteed Position RequirementsWork clamping meansPositioning apparatusElectrical batteryStructural engineering

The invention discloses a battery tray bottom plate CNC finish machining fixing tool. The battery tray bottom plate CNC finish machining fixing tool comprises a tool body, and the tool body comprisesan air pressure structure plate, a horizontal positioning mechanism and a negative pressure acupoint adsorption mechanism; and a to-be-machined product is arranged on the air pressure structure plate,clamped in the horizontal positioning mechanism, positioned in the X and Y directions through the horizontal positioning mechanism, attached to all contact points in the vertical direction of the negative pressure acupoint adsorption mechanism 400 in a floating mode, and adsorbed in the Z direction through the negative pressure acupoint adsorption mechanism. In this way, according to the batterytray bottom plate CNC finish machining fixing tool, positioning requirements of the product in the horizontal direction can be effectively met, it can be guaranteed that all the contact points in thevertical direction are attached to the product in the floating mode through negative pressure acupoints, the periphery and hole positions can be machined at a time, thus multiple times of clamping isavoided, and the machining time is shortened.

Owner:纽维科精密制造江苏有限公司

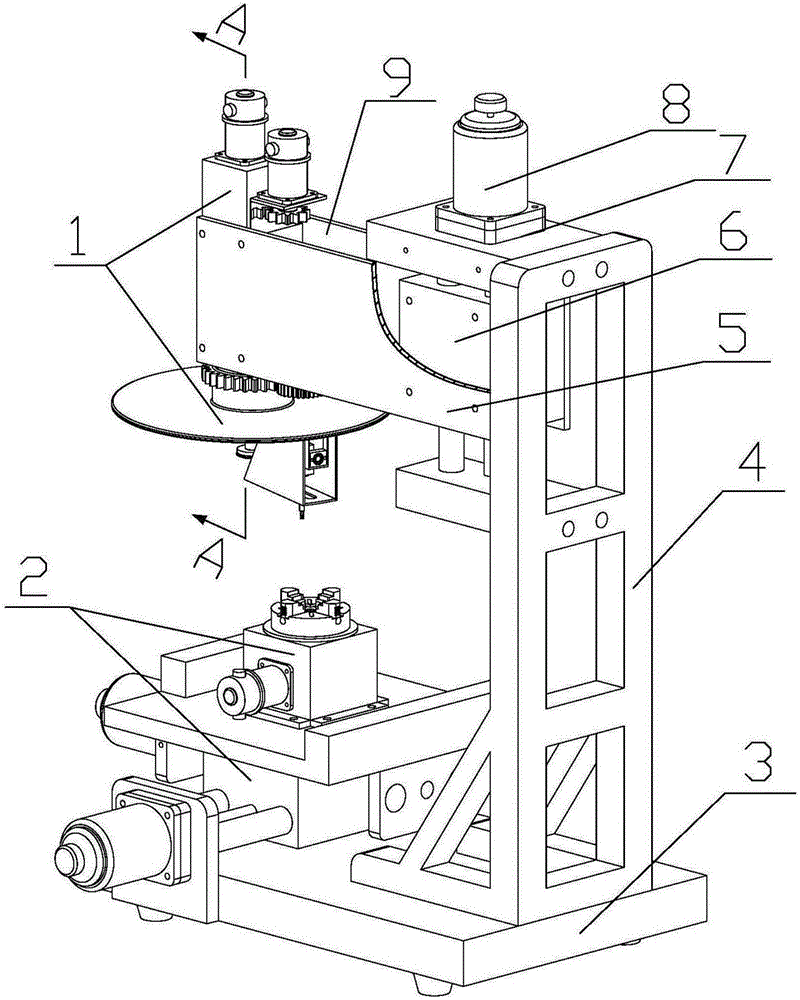

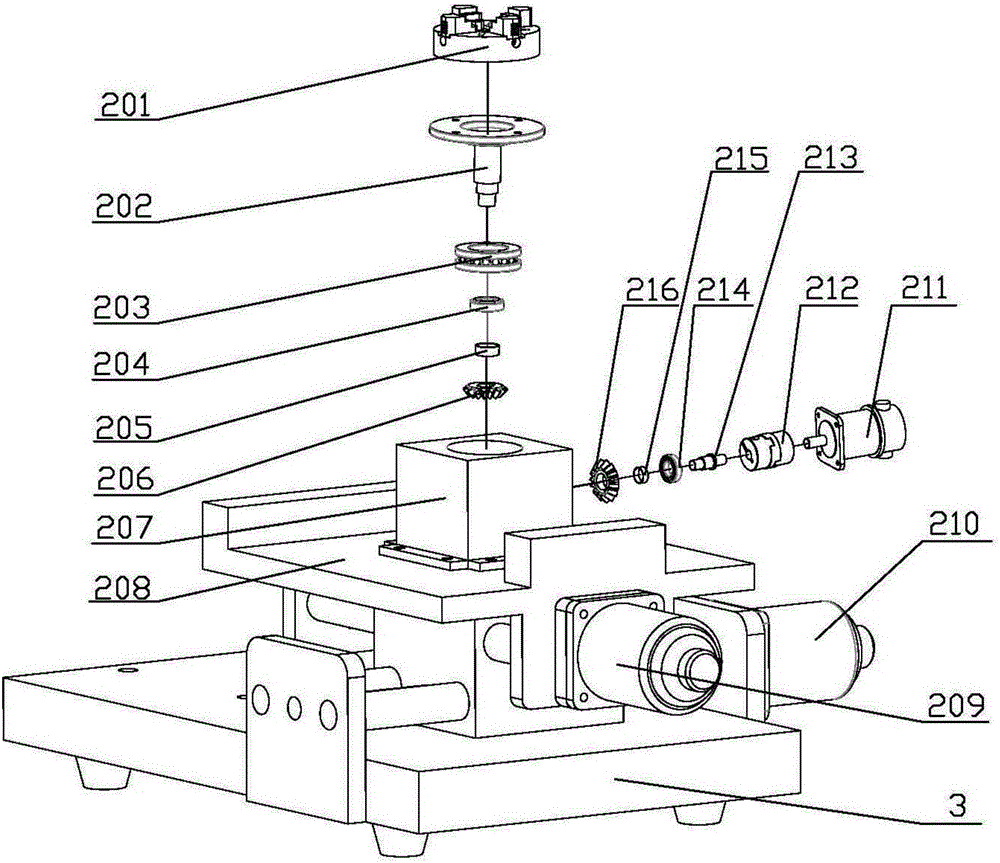

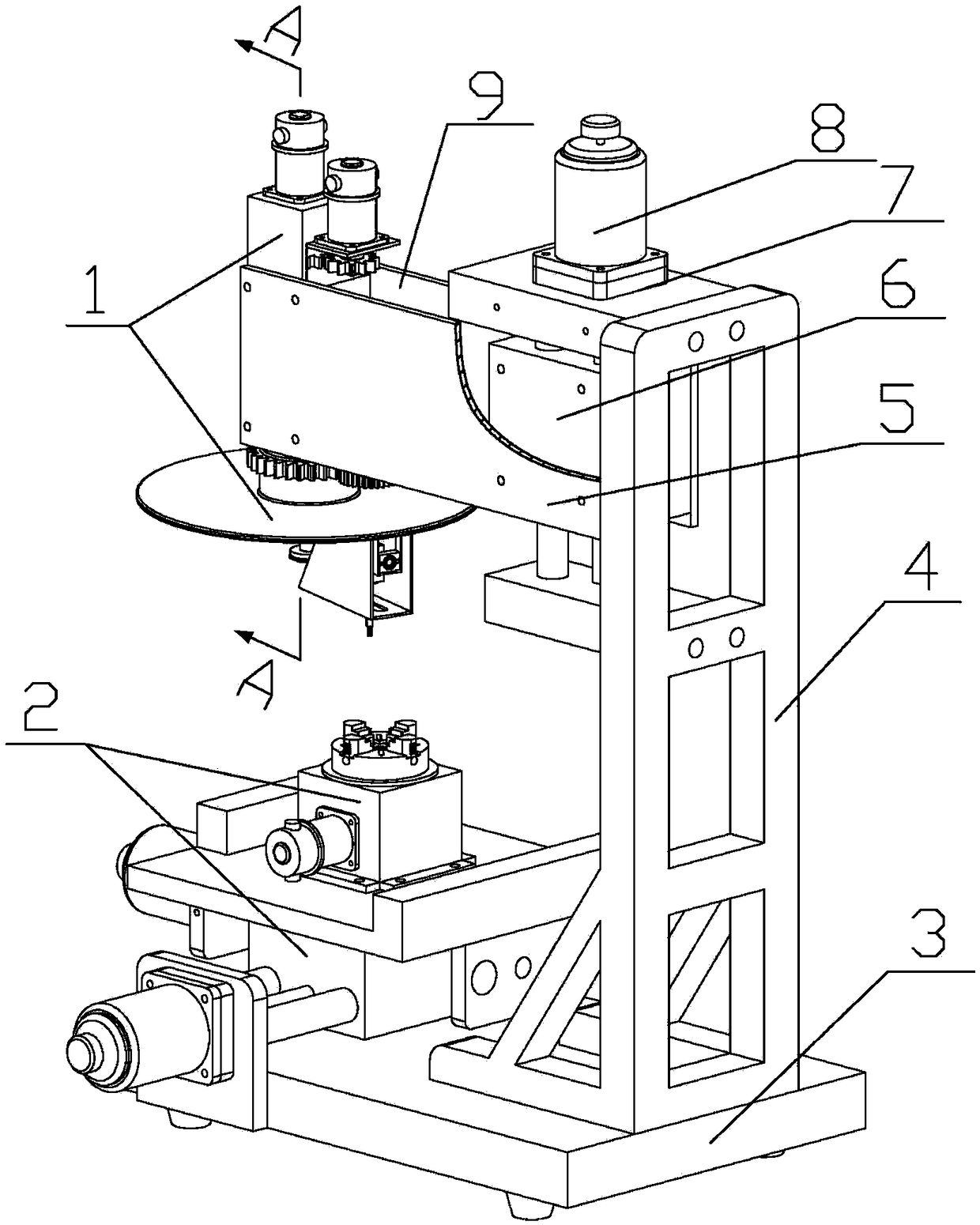

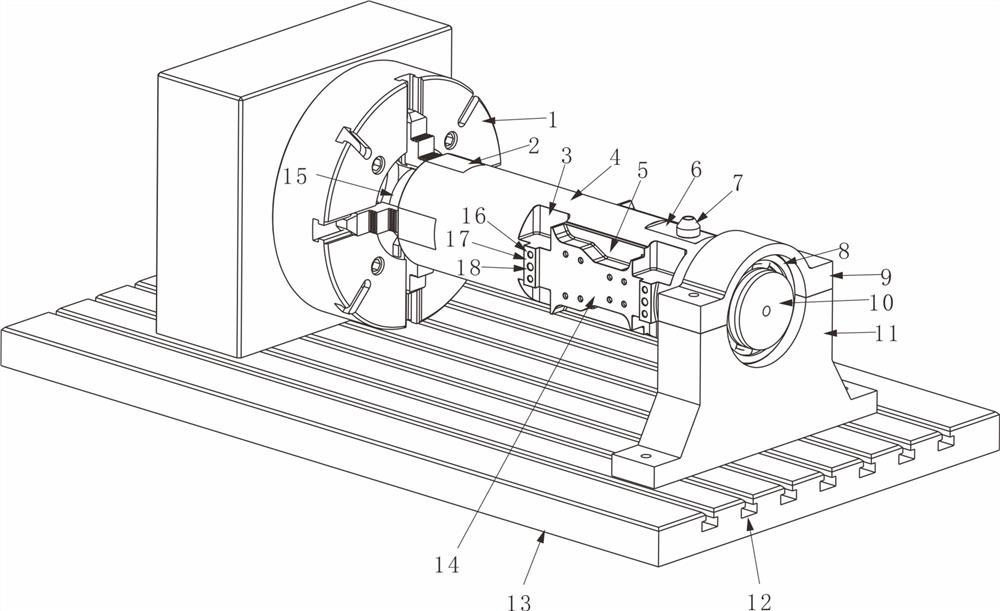

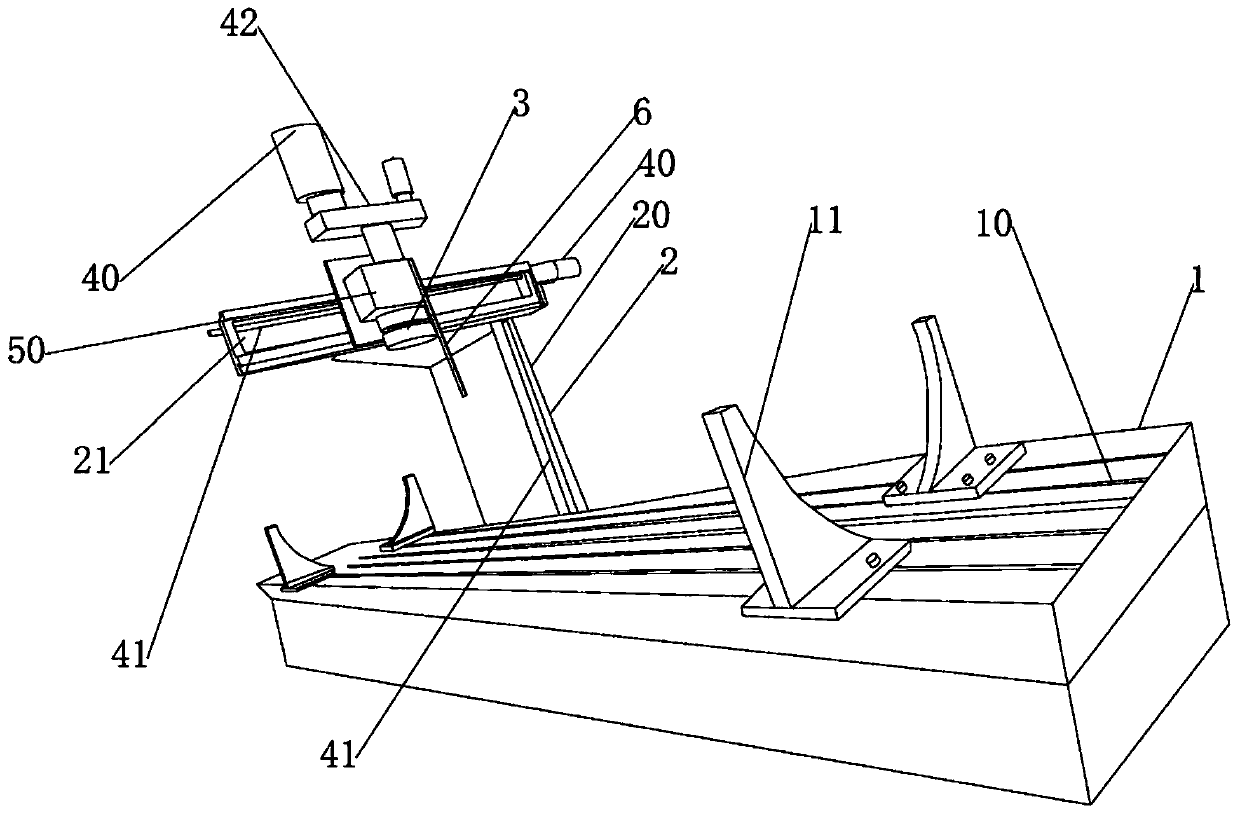

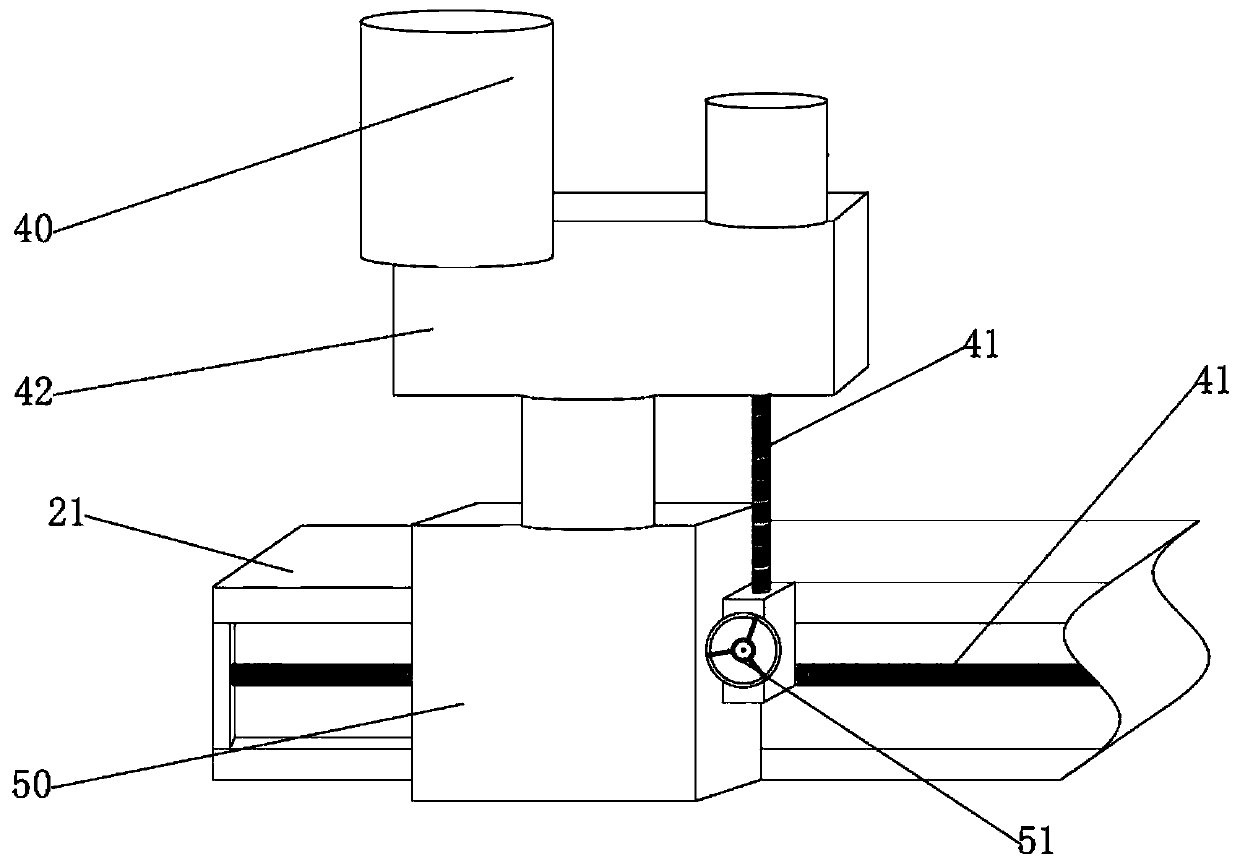

Cycloid rotational indexing-based novel vertical milling machine

ActiveCN106424867ALow costAvoid multiple clampingLarge fixed membersMilling equipment detailsEngineeringMilling cutter

The invention relates to vertical milling machines and belongs to the field of machining. A cycloid rotational indexing-based novel vertical milling machine is characterized by comprising a machine body mechanism, a milling head mechanism and a worktable mechanism. The cycloid rotational indexing-based novel vertical milling machine comprises two working modes: rotational indexing machining and milling by an eccentric milling cutter. In the rotational indexing machining mode, the milling cutter in compound movements of rotation and revolution is matched with two-dimensional translation of a to-be-machined workpiece and a vertical movement of the milling head mechanism to form a special movement track of the milling cutter relative to the to-be-machined workpiece so as to machine a special part in a complex shape. The milling mode by the eccentric milling cutter is as follows: the milling cutter is fixed in an expected position relative to the rotary center of a spindle box to form the eccentric milling cutter, and the rotation movement of the eccentric milling cutter is combined with two-dimensional translation of the to-be-machined workpiece and a vertical movement of the milling head mechanism. The cycloid rotational indexing-based novel vertical milling machine provided by the invention retains the functions of a conventional milling machine and increases a mode of efficiently machining the part in the special shape by cycloid rotational indexing. The two modes can be freely switched, so that the cycloid rotational indexing-based novel vertical milling machine is of certain universality.

Owner:SHANGHAI UNIV OF ENG SCI

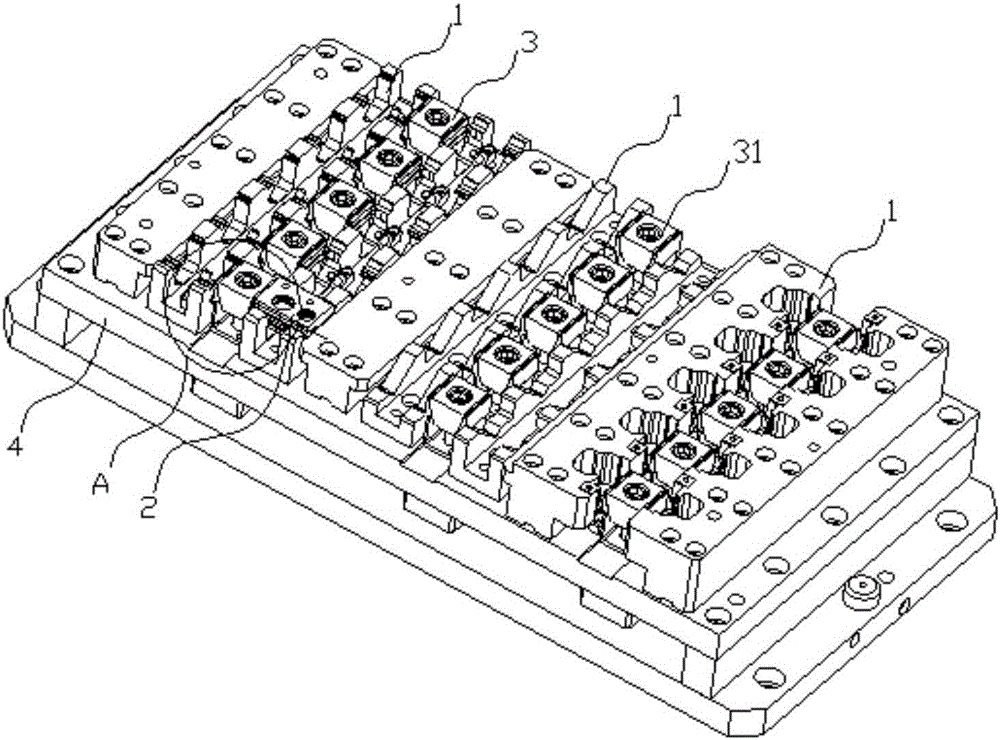

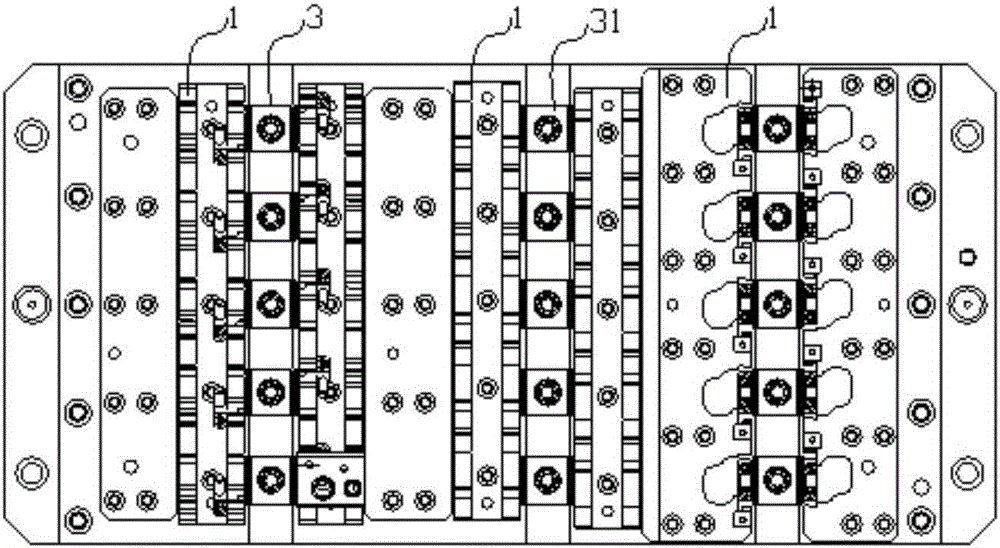

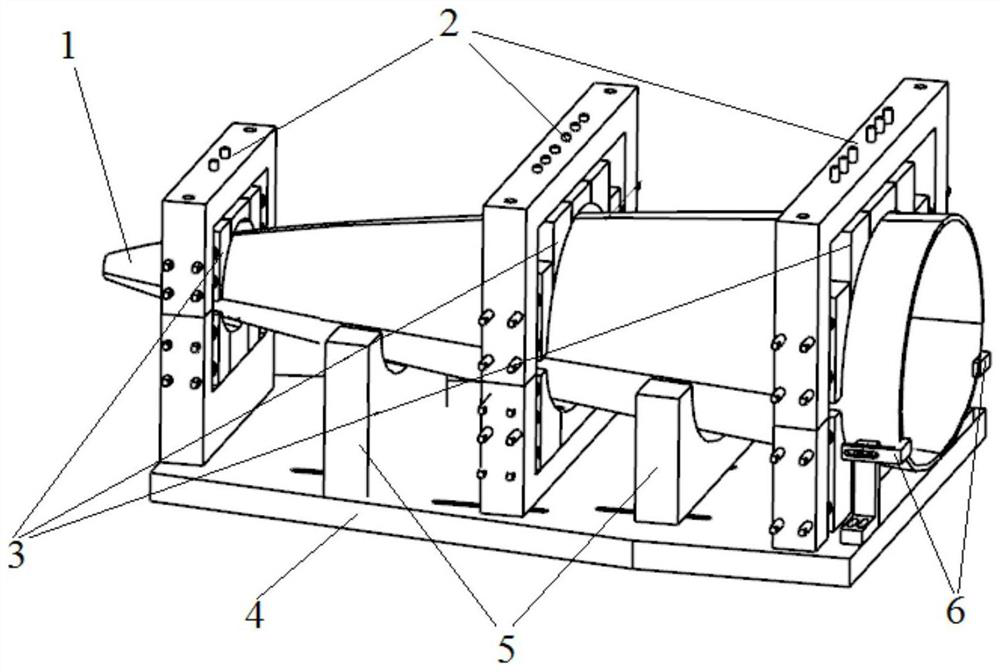

Multi-station processing fixture

InactiveCN106584161ALess equipmentIncrease productivityPositioning apparatusMetal-working holdersMachining processMechanical engineering

The invention relates to a multi-station processing fixture, which comprises a base plate and at least two processing stations fixedly arranged on the base plate in parallel. The at least two processing stations are used for processing one same parts in at least two directions; each processing station comprises a hold-down device which is used for fixing the parts placed on the corresponding station. Multiple stations are arranged in parallel, so that the parts can be prevented from being clamped for multiple times during a processing process of the parts, equipment is saved, and the production efficiency is effectively improved.

Owner:JIANGSU HAOFENG AUTO PARTS

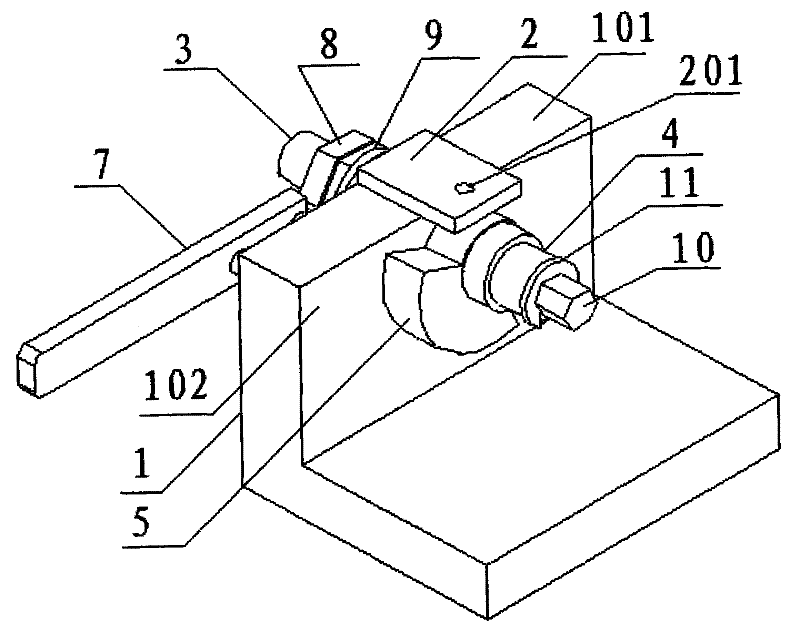

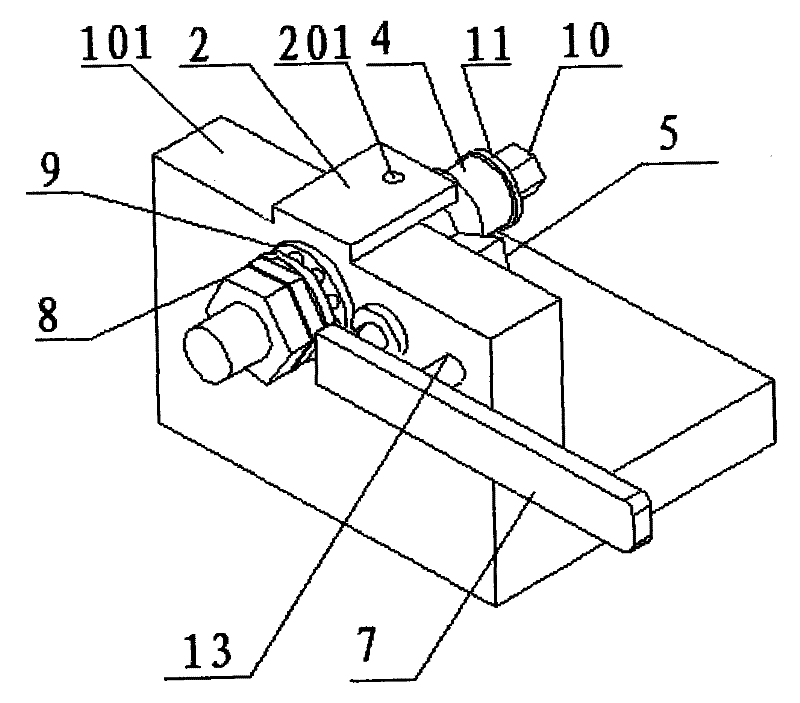

Special fixture for radial porous parts

InactiveCN102528492AAvoid multiple clampingAvoid timePositioning apparatusMetal-working holdersFree stateEngineering

The invention relates to a special fixture for radial porous parts, and the special fixture comprises a base, wherein the base comprises a first plane and a second plane which are vertical to each other, a drilling template is arranged on the first plane, a hole site is formed on the drilling template, and a screw hole and a draw bar hole are formed on the second plane, a screw is rotatably arranged in the screw hole, one end, positioned below the drilling template, of the screw is provided with a locating shaft for installing a part to be processed, the screw is also fixedly provided with a locating block, the locating block is arranged between the locating shaft and the base, a panel, opposite to the base, of the locating block is provided with a plurality of locating pits, a draw bar is rotatably arranged in the draw bar hole, one end of the draw bar is connected to a draw bar handle, the other end of the draw bar is provided with a draw bar contact head which can retract under external action and extend in a free state, the draw bar contact head is arranged at one side, which is provided with the locating block, of the base, and the draw bar contact head is positioned in the locating pits when in the free state. After the fixture is used, the processing efficiency is greatly improved and the product quality is stable.

Owner:JIANGSU WANGONG TECH GRP CO LTD

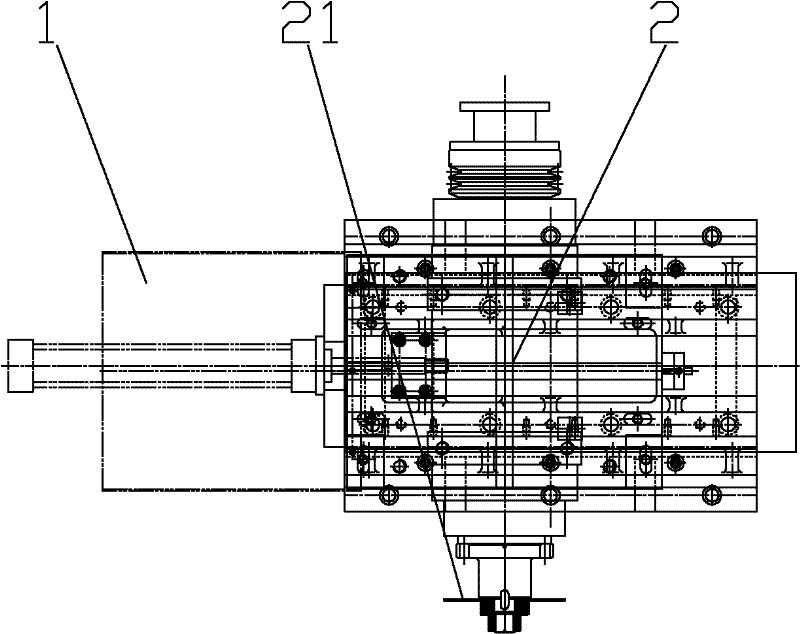

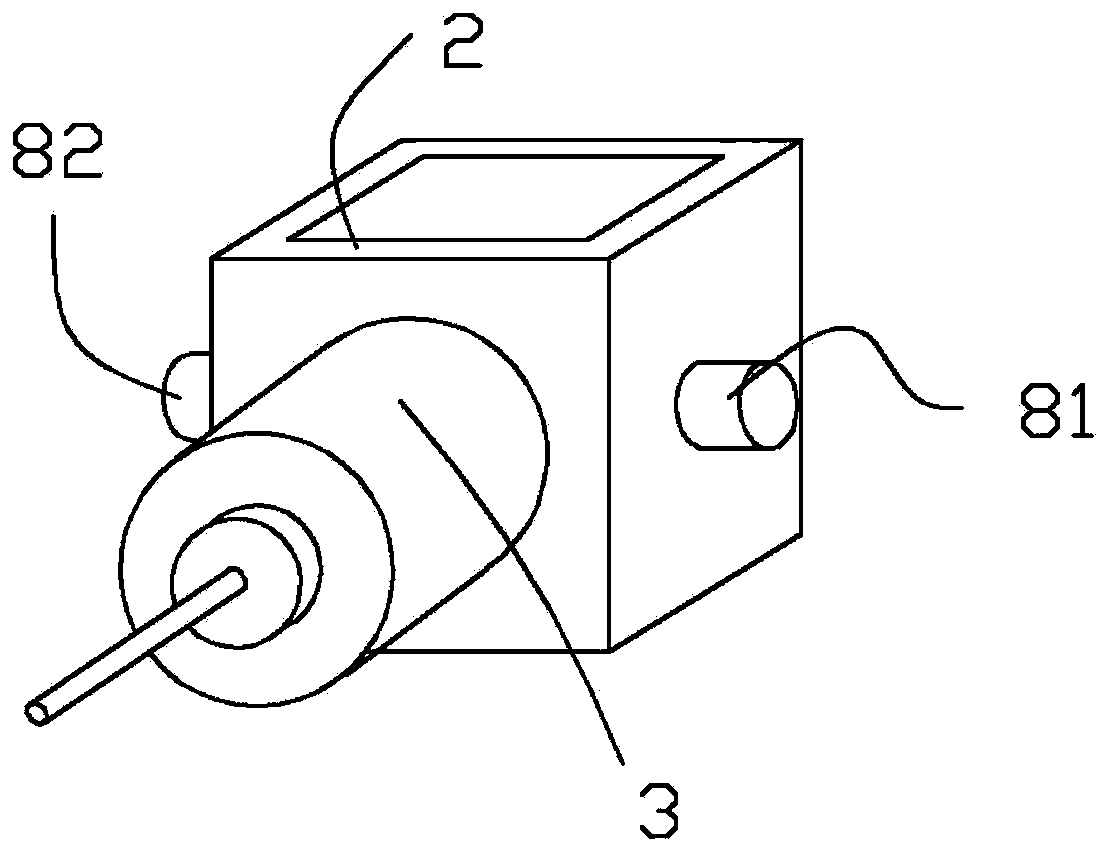

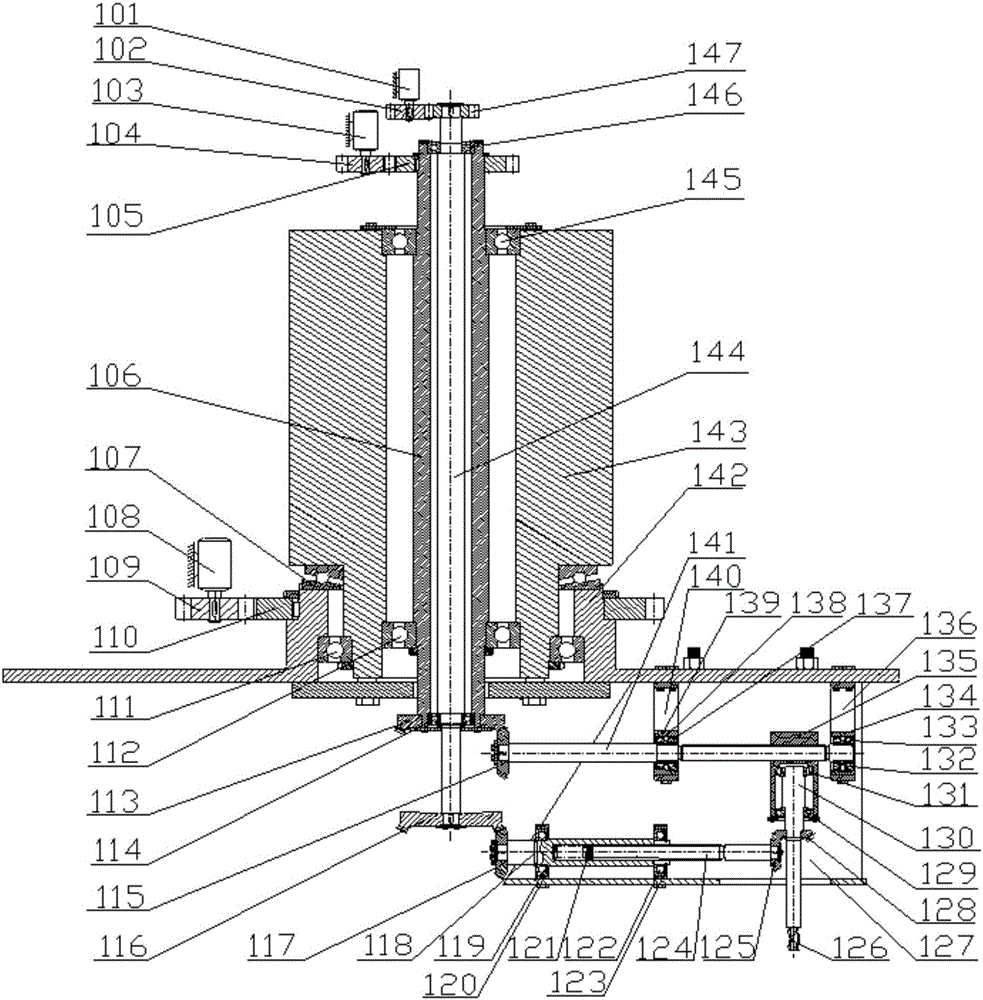

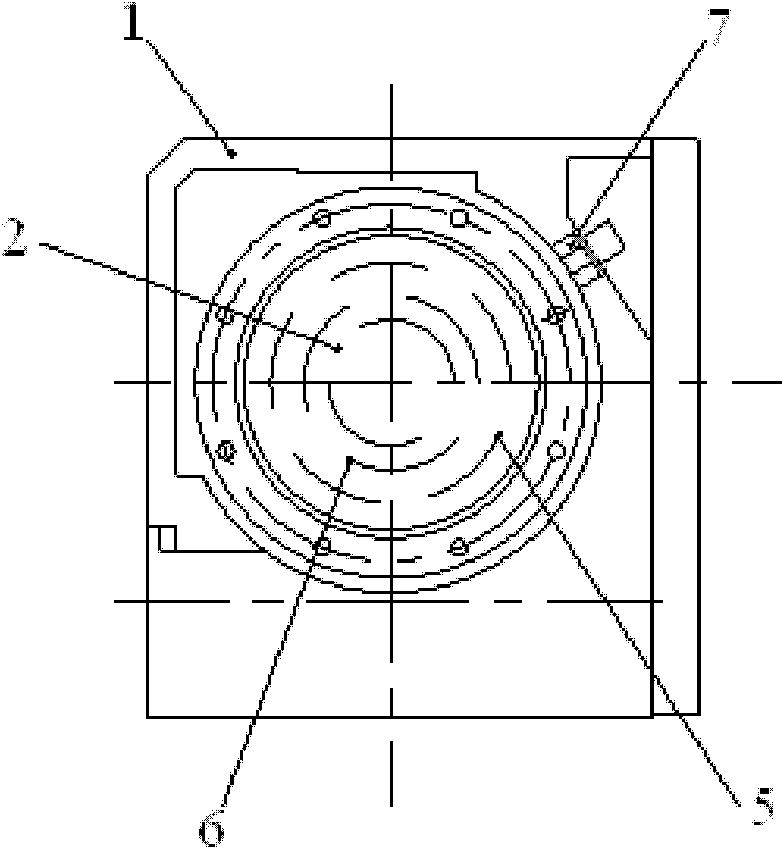

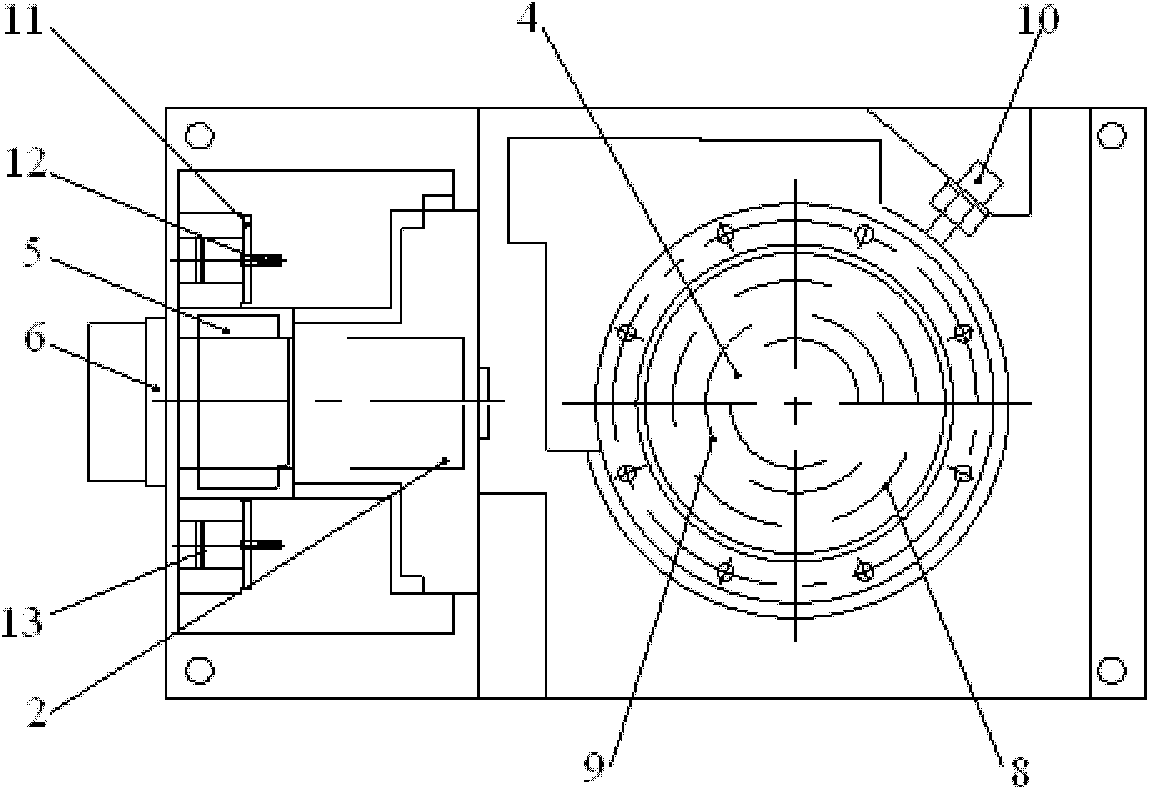

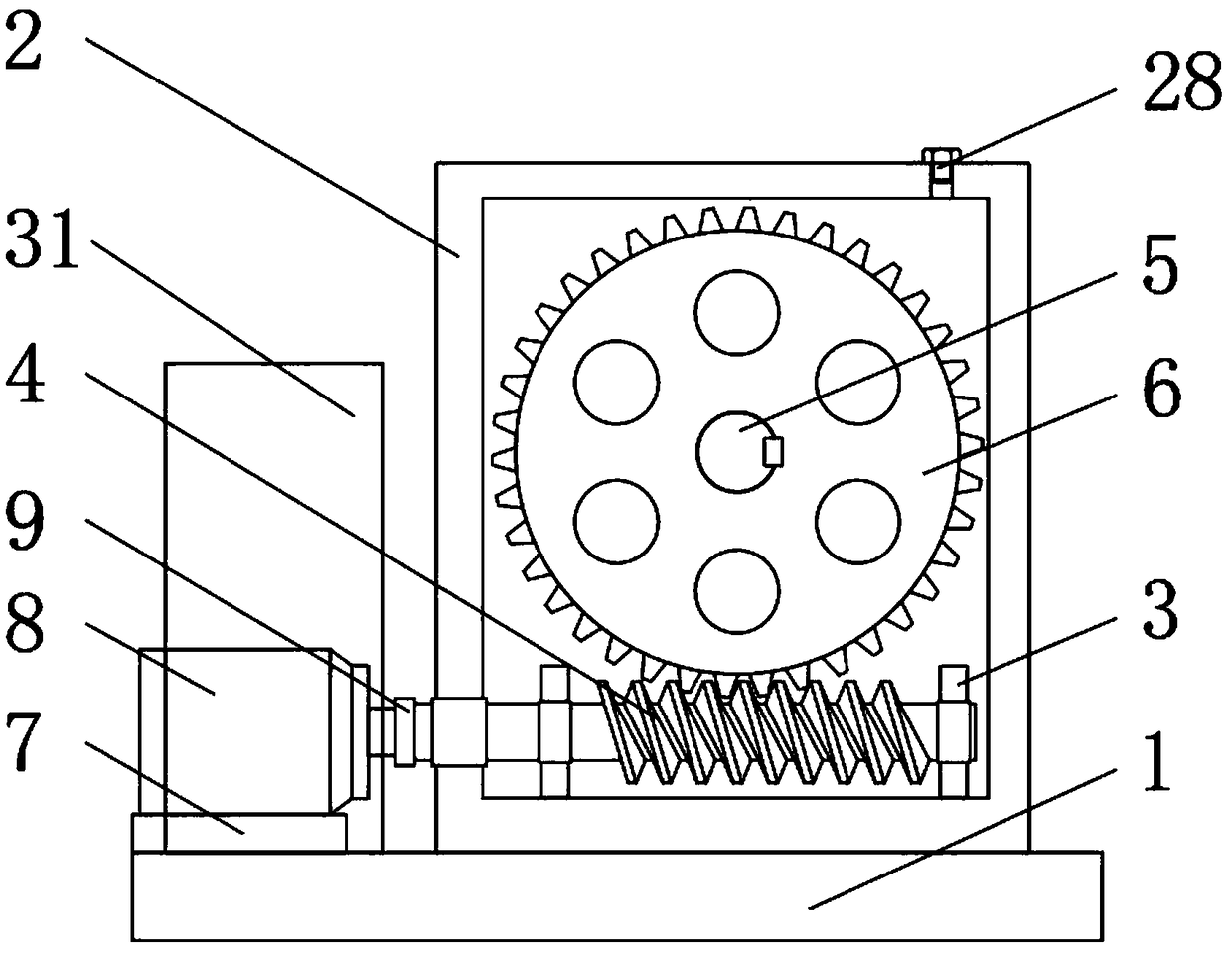

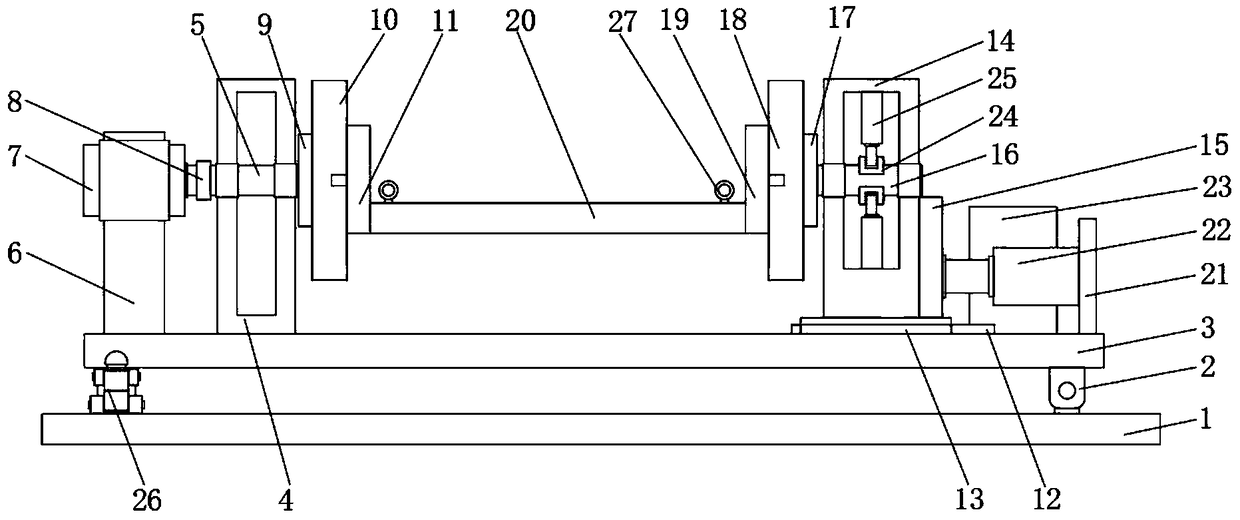

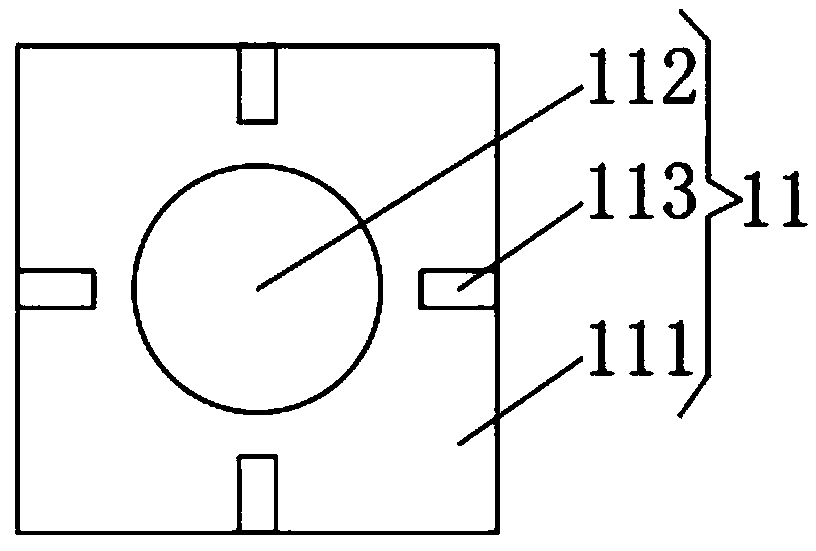

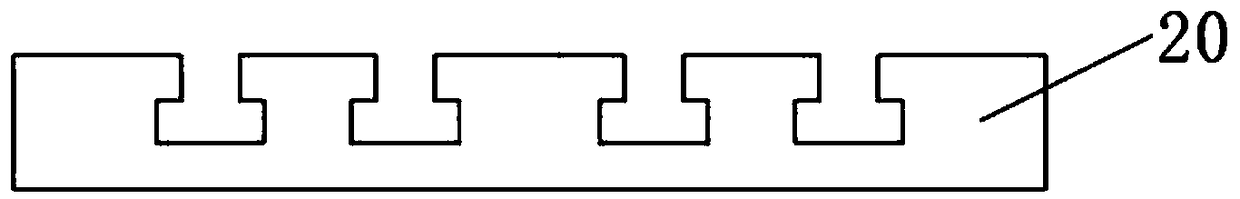

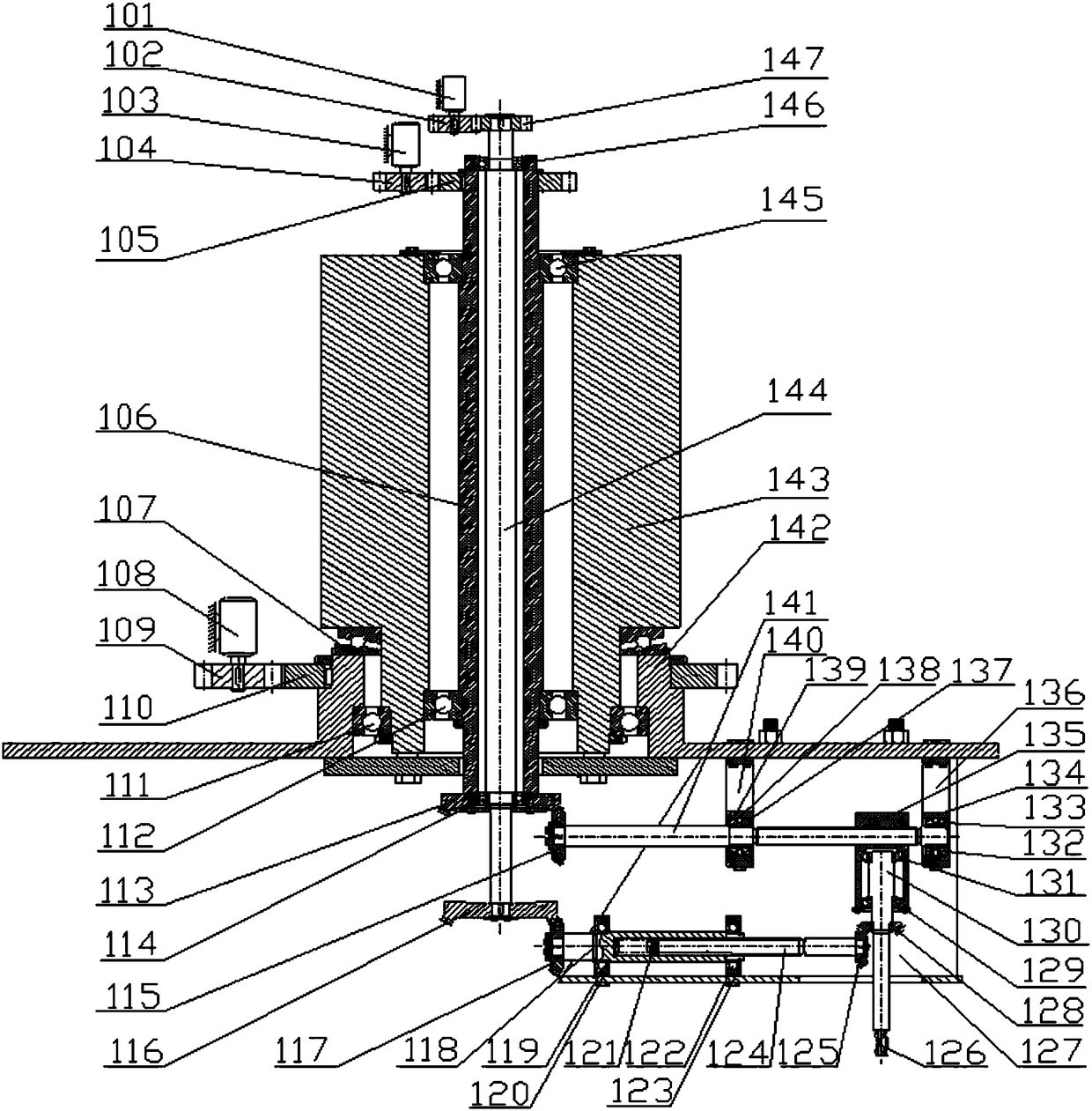

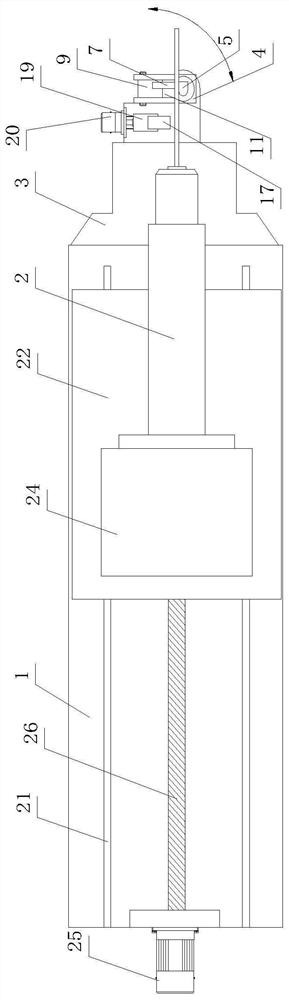

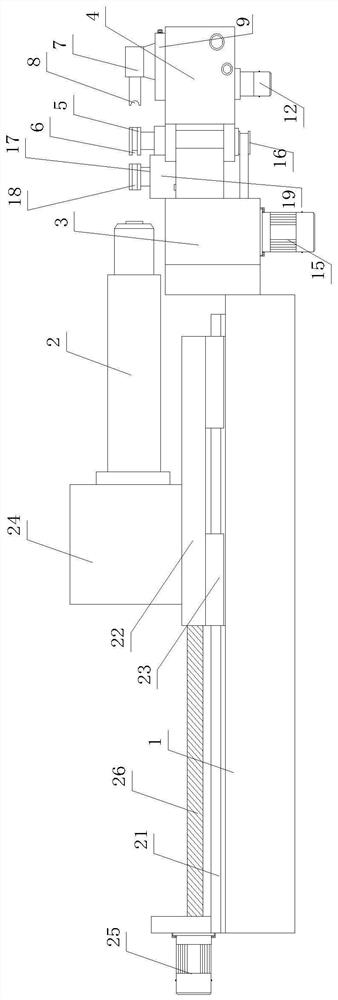

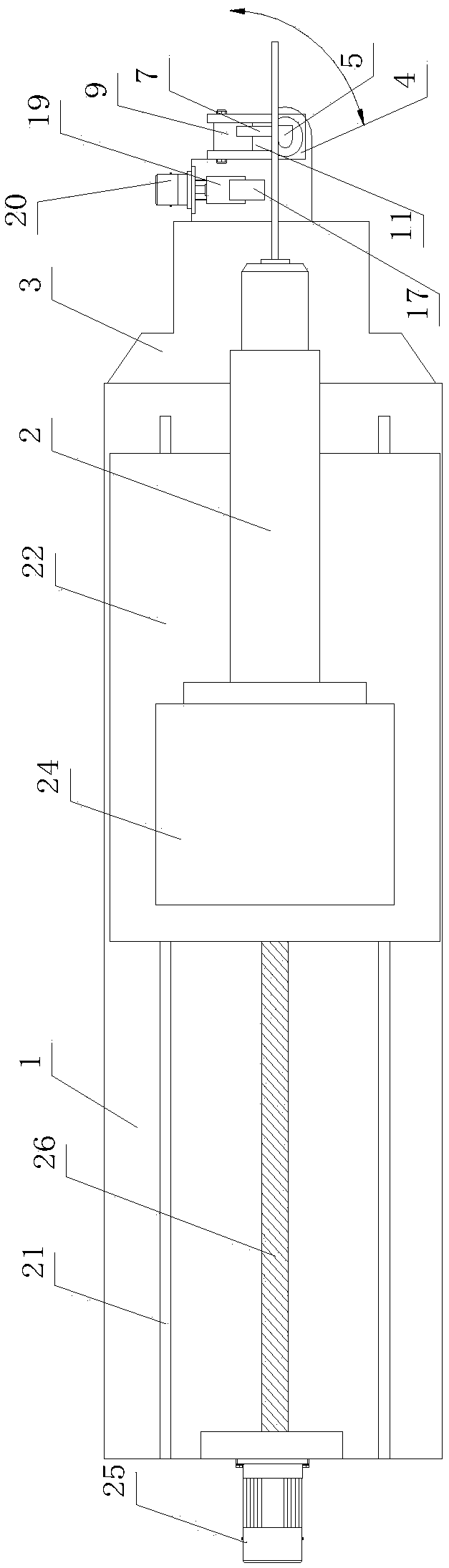

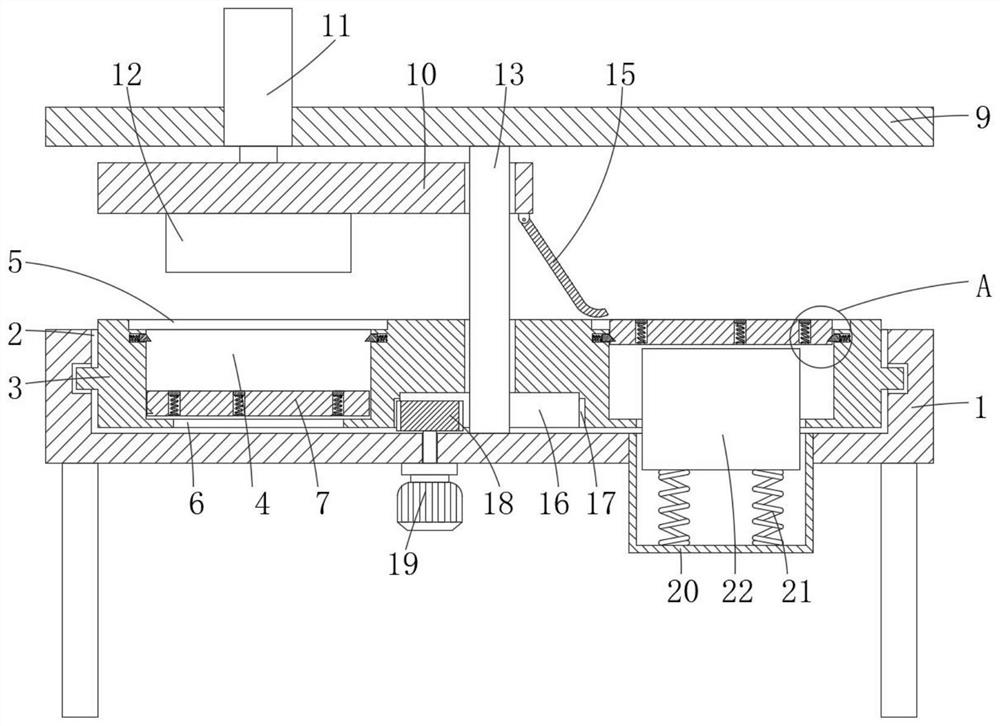

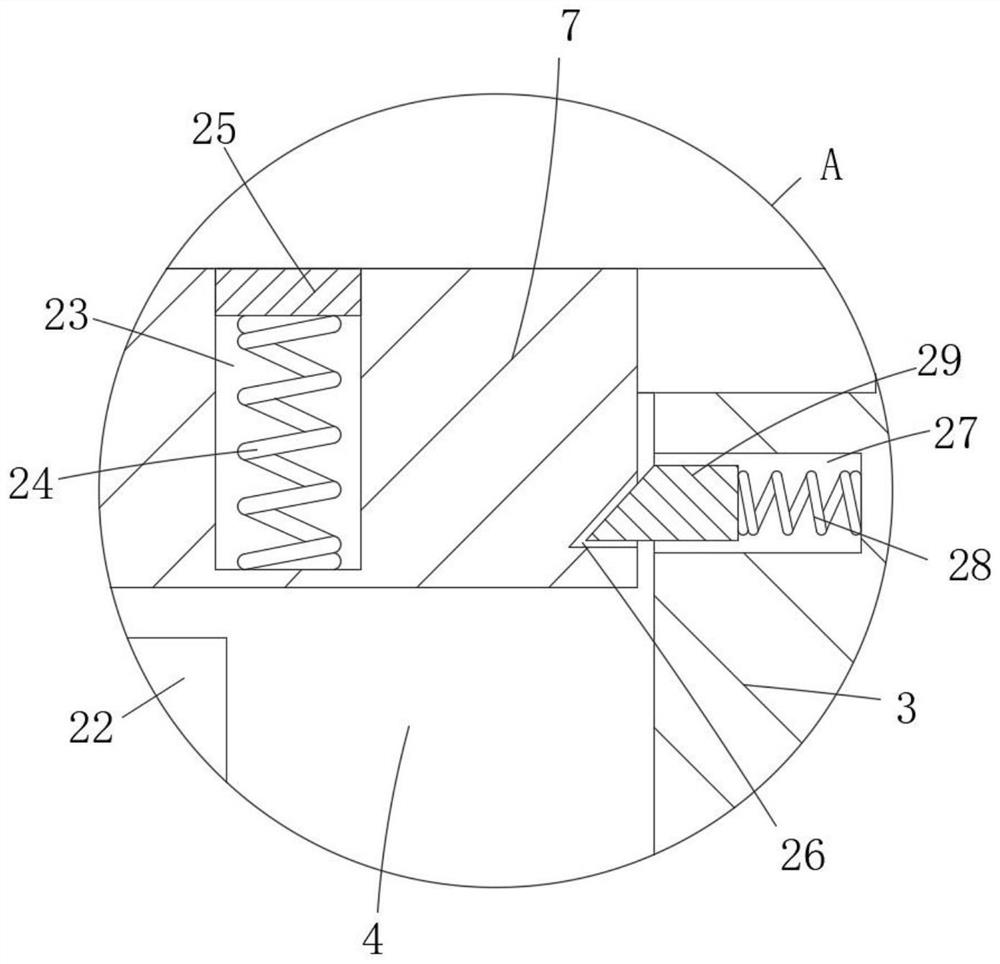

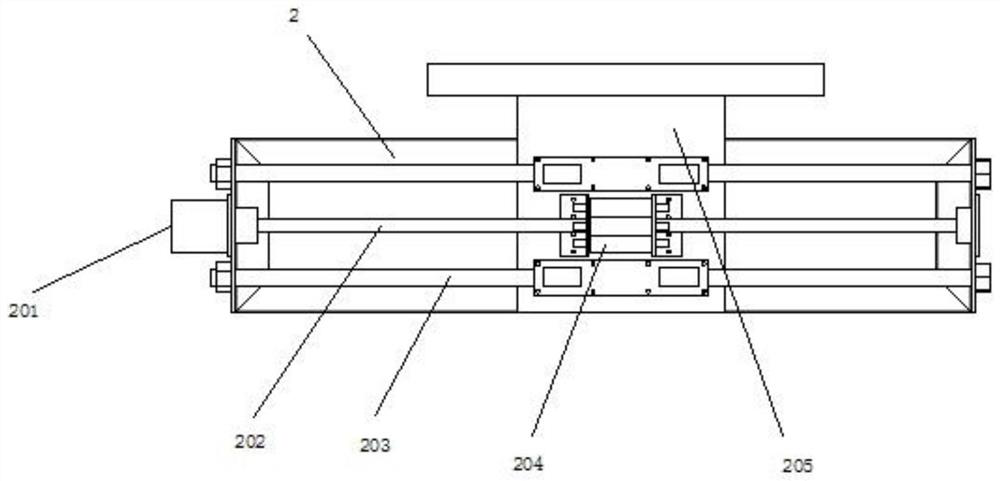

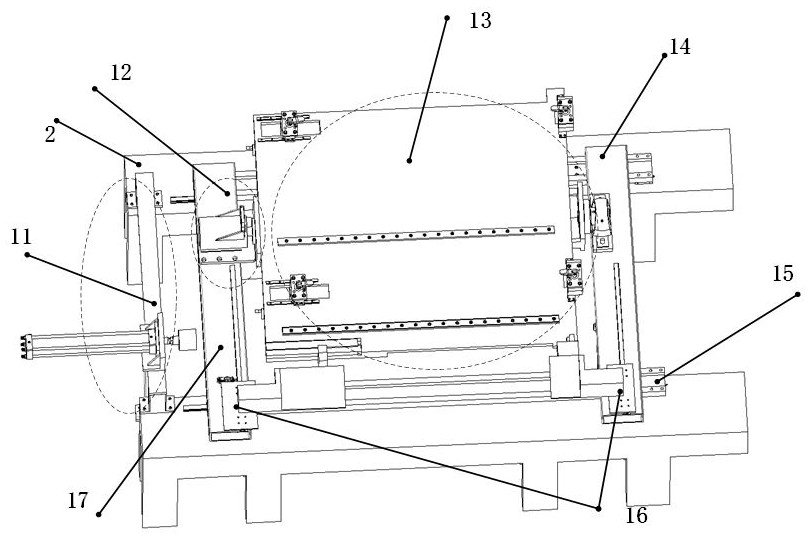

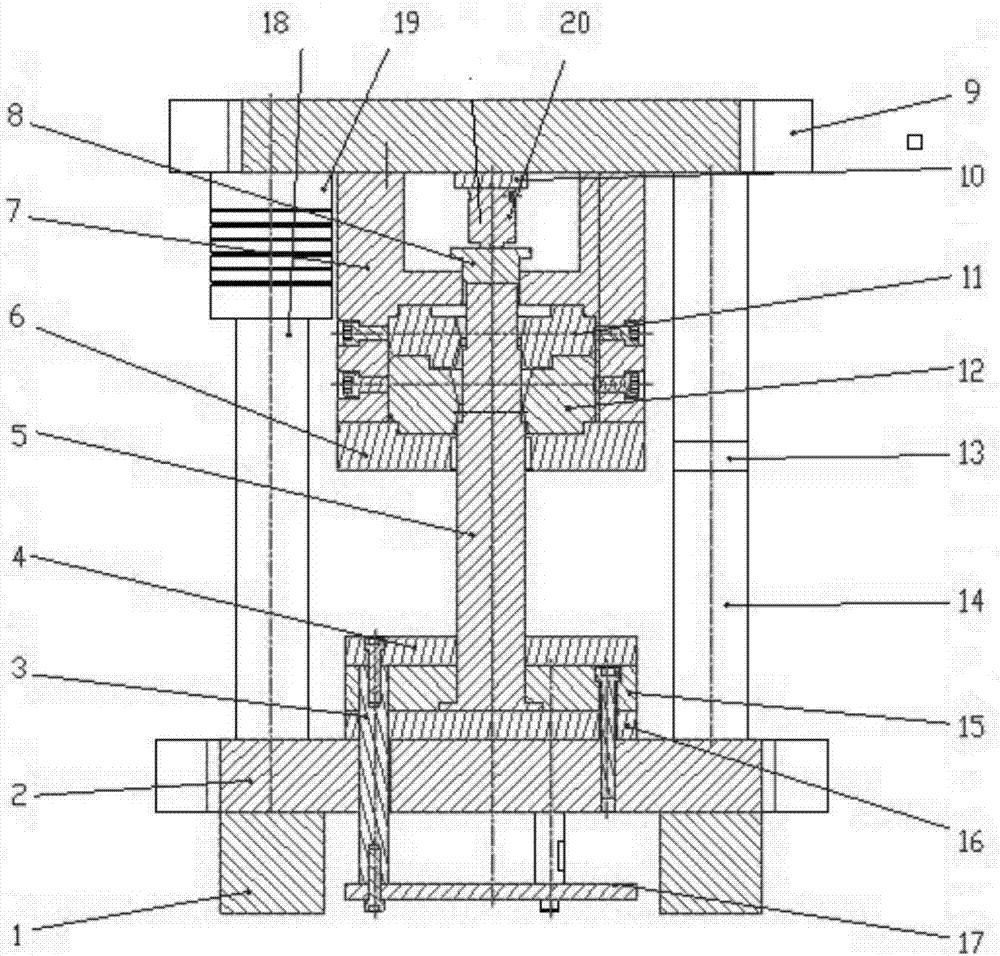

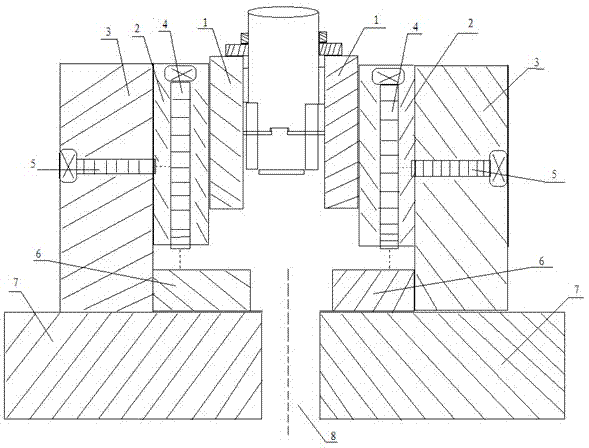

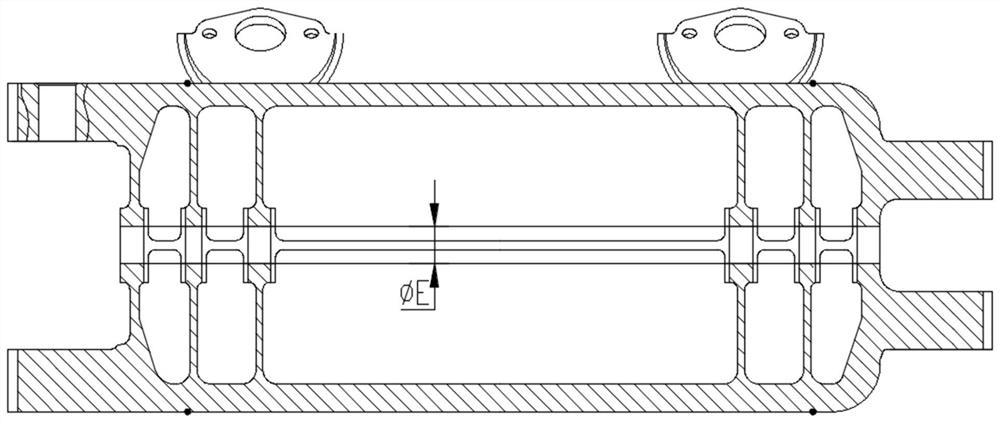

Two-shaft linked rotating workbench for numerical control machine tool

ActiveCN102490023AHigh positioning accuracyLow costLarge fixed membersNumerical controlRotational axis

The invention discloses a two-shaft linked rotating workbench for a numerical control machine tool. The workbench comprises an inclined shaft seat (1), a main shaft (2), a rotating seat (3) and a rotating shaft (4), wherein a main shaft moment servo motor (5) is arranged on the inclined shaft seat (1) and directly connected with the main shaft (2); an interference scanning coder (6) with the average pitch of 4mu m is arranged on the main shaft (2); a rotating shaft moment servo motor (8) is arranged on the rotating seat (3) and directly connected with the rotating shaft (4); and an interference scanning coder (9) with the average pitch of 4mu m is arranged on the rotating shaft (4). The workbench is directly driven by high-performance moment servo motors, and dynamic and static errors are reduced to a certain extent; and a workpiece is more easily clamped, the workbench has enough rotating angles, repeated clamping can be avoided, an accumulated error generated by repeated clamping is reduced, and machining accuracy is improved.

Owner:安徽新诺精工股份有限公司

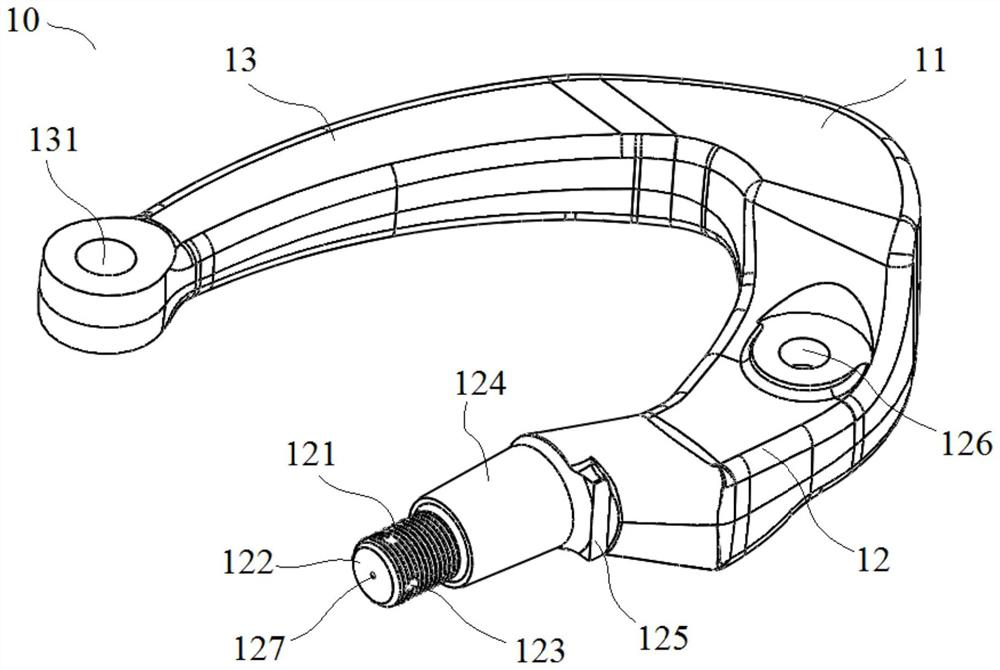

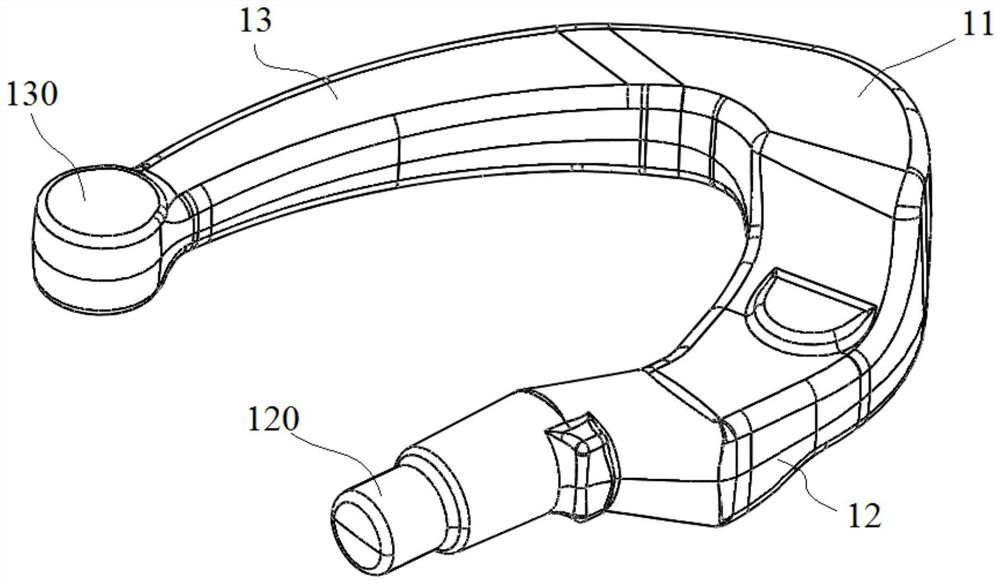

Machining process of steering knuckle arm

ActiveCN113843582AGuaranteed dimensional accuracyImprove processing efficiencyMachining processScrew thread

The invention relates to a machining process of a steering knuckle arm. The machining process comprises the following steps of S1, providing a steering knuckle arm blank; S2, machining a shaft end center hole, a bottom hole and upper and lower end faces of a first taper hole, a second taper hole and upper and lower end faces of the second taper hole; S3, conducting auxiliary supporting on the front side blank face of a to-be-machined conical shaft, and turning the conical shaft and a shaft end thread; S4, machining a cross hole, a step surface and the front end face of the conical shaft; S5, machining the first taper hole. According to the machining process of the steering knuckle arm, efficient machining of the steering knuckle arm is achieved through fewer times of positioning and clamping and fewer machining procedures; and due to the fact that the number of clamping times is fewer, the overall accumulated error is smaller, and the machined steering knuckle arm structure better meets the actual design requirement.

Owner:HUBEI TRI RING FORGING

Special fixture for engine support bracket

InactiveCN108705339AAchieve rotationAvoid multiple clampingLarge fixed membersPositioning apparatusEngineeringFlange

The invention discloses a special fixture for an engine support bracket, and relates to the technical field of fixtures. The special fixture for the engine support bracket comprises a base, a first box body is fixedly connected to one side of the top of the base, a first rotating shaft is rotatably connected to the inner wall of the first box body, a first flange is fixedly connected to one end ofthe first rotating shaft, and a first fixed plate is fixedly connected to the first flange through a first hydraulic chuck. A fixed base is slidably connected to the side, away from the first box body, of the top of the base through a sliding rail, a second box body is fixedly connected to the top of the fixed base, a second rotating shaft is rotatably connected to the inner wall of the second box body, a second flange is fixedly connected to one end of the second rotating shaft, a second fixed plate is fixedly connected to the surface of the second flange through a second hydraulic chuck, and a bottom plate is fixedly connected to the bottoms of the first fixed plate and the second fixed plate. The special fixture for the engine support bracket solves the problem of repeated clamping when machining the support bracket, improves working efficiency, and guarantees machining accuracy.

Owner:安徽永泰汽车零部件有限公司

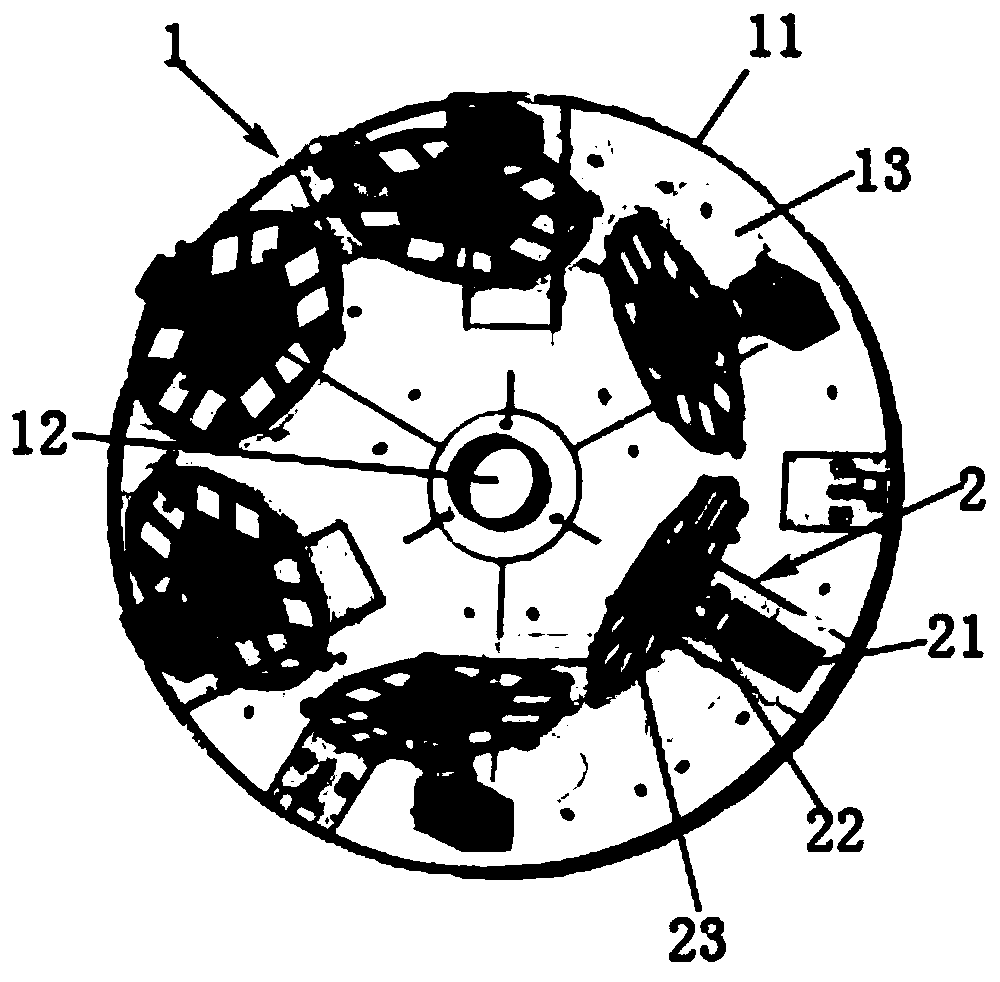

Film coating fixture

PendingCN110423993AReduce coating uniformity variationAvoid multiple clampingVacuum evaporation coatingSputtering coatingFilm coatingEngineering

The present invention relates to a film coating fixture, comprising a revolution system, a rotation system and a turnover system; the revolution system comprises a revolution support, a revolution shaft located on the central position of the revolution support and connected with the revolution support, and a guard plate supported on the revolution support; the rotation system is fixed on the guardplate, and comprises a fixing base, a rotating shaft connected to the fixing base and a workpiece plate that is connected to and rotatable with the rotating shaft; the revolution shaft drives the rotation system to rotate, meanwhile the rotating shaft drives the workpiece plate to rotate; the turnover system is connected with the workpiece plate and used for driving the workpiece plate to turn by180 degrees. The film coating fixture of the present invention can effectively improve the effect of film coating, and also can increase the efficiency of film coating.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Hydraulic rotary machining table for automobile metal part machining center

InactiveCN108942832AEasy to processImprove processing efficiencyWork benchesEngineeringMachining process

The invention discloses a hydraulic rotary machining table for an automobile metal part machining center. The hydraulic rotary machining table comprises a mounting bottom plate, one side of the top ofthe mounting bottom plate is connected with a fixing bottom plate in a rotating mode through a rotating piece, one side of the top of the fixing bottom plate is fixedly connected with a first box body, the inner wall of the first box body is connected with a first rotating shaft in a rotating mode, the top of the fixing bottom plate is fixedly connected with a rotating oil cylinder through a fixing frame, the side, far away from the first box body, of the top of the fixing bottom plate is fixedly connected with a sliding track, a sliding base is connected with the surface of the sliding trackin a sliding mode, the top of the sliding base is sequentially and fixedly connected with a second box body and a push plate, and the inner wall of the second box body is connected with a second rotating shaft in a rotating mode. The invention relates to the technical field of automobile machining equipment. According to the hydraulic rotary machining table for the automobile metal part machiningcenter, problems that final precision of the parts is difficult to control due to the fact that the appearances of some metal parts are in irregular shapes, thus machining process is complicated andrepeated clamping and changing machining positions are required to be carried out, and machining efficiency is low are solved.

Owner:ANHUI TIANYU AUTO PARTS MFG

A New Vertical Milling Machine Based on Cycloid Rotation

ActiveCN106424867BAvoid multiple clampingLow costLarge fixed membersMilling equipment detailsMilling cutterEngineering

The invention relates to vertical milling machines and belongs to the field of machining. A cycloid rotational indexing-based novel vertical milling machine is characterized by comprising a machine body mechanism, a milling head mechanism and a worktable mechanism. The cycloid rotational indexing-based novel vertical milling machine comprises two working modes: rotational indexing machining and milling by an eccentric milling cutter. In the rotational indexing machining mode, the milling cutter in compound movements of rotation and revolution is matched with two-dimensional translation of a to-be-machined workpiece and a vertical movement of the milling head mechanism to form a special movement track of the milling cutter relative to the to-be-machined workpiece so as to machine a special part in a complex shape. The milling mode by the eccentric milling cutter is as follows: the milling cutter is fixed in an expected position relative to the rotary center of a spindle box to form the eccentric milling cutter, and the rotation movement of the eccentric milling cutter is combined with two-dimensional translation of the to-be-machined workpiece and a vertical movement of the milling head mechanism. The cycloid rotational indexing-based novel vertical milling machine provided by the invention retains the functions of a conventional milling machine and increases a mode of efficiently machining the part in the special shape by cycloid rotational indexing. The two modes can be freely switched, so that the cycloid rotational indexing-based novel vertical milling machine is of certain universality.

Owner:SHANGHAI UNIV OF ENG SCI

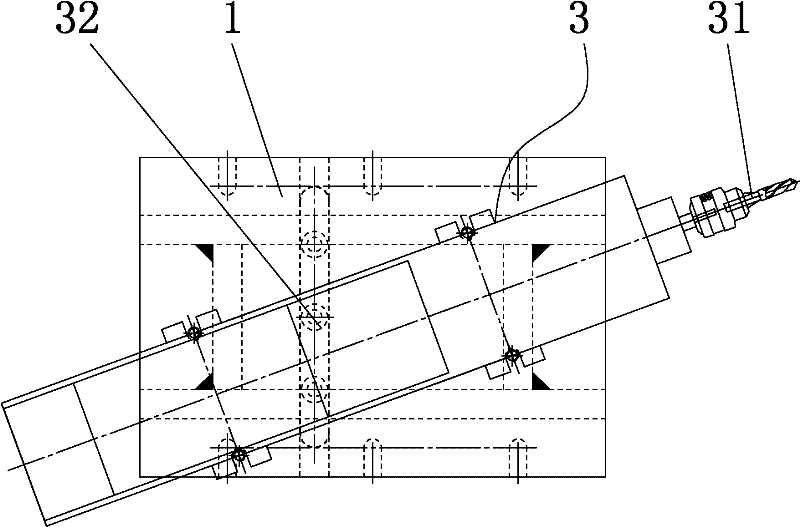

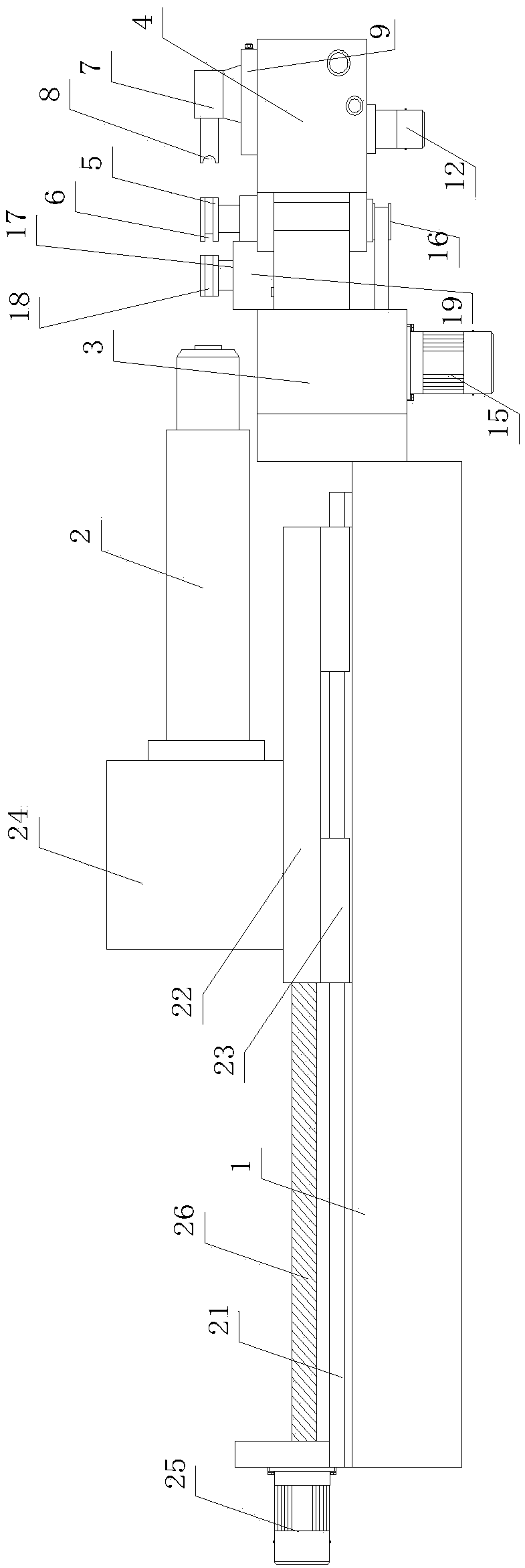

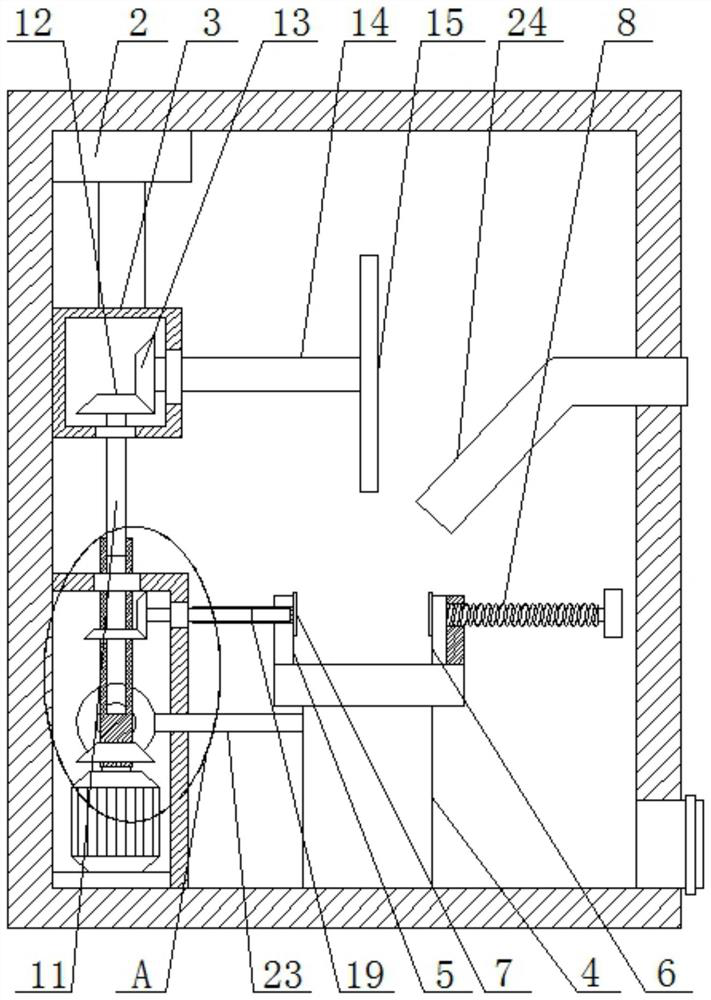

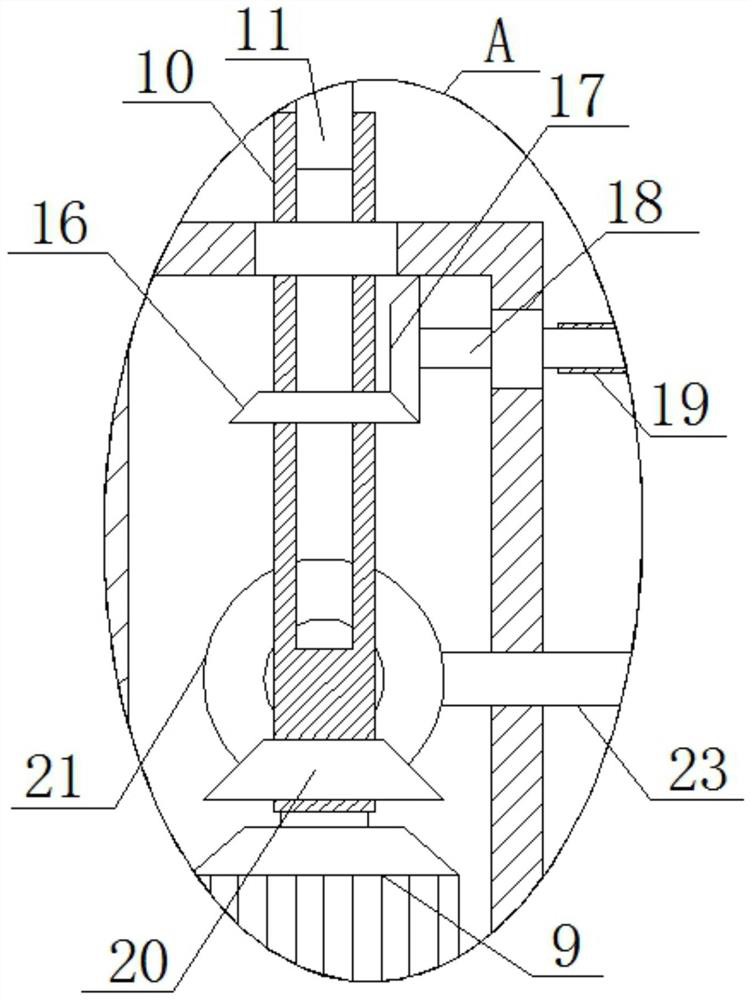

Numerically controlled inclined hole machining device

ActiveCN107457436AFully automatedAvoid multiple clampingDrilling/boring measurement devicesBoring/drilling machinesTool bitStructural engineering

The invention relates to a numerically controlled inclined hole machining device which is arranged on machining center equipment. The numerically controlled inclined hole machining device comprises a drilling mechanism, a sliding mechanism, a guiding mechanism and a positioning mechanism. The drilling mechanism comprises a tool bit and a drill. The sliding mechanism comprises a drill holder which can slide relative to the drill and an elastic piece. One end of the drill is connected to a spindle of the machining center equipment while the other end of the spindle is connected to a drill. The drill holder sleeves the periphery of the drill, the upper end of the drill holder is connected to the elastic piece, and the elastic piece is connected in an accommodating space formed by a fixed outer cover and the spindle. According to the numerically controlled inclined hole machining device provided by the invention, the drill holder is arranged to move relative to the drill and the drill holder is matched with and connected to one side of the drill, so that the drill holder and a clamp seat are separated, and the clamp seat for machining an inclined hole can be universally used as clamp seat for other machining. Therefore, all machining of a product can be achieved on the machining center equipment, the product is prevented from being clamped for many times, and the machining efficiency of the product machining is increased.

Owner:XIAMEN LOTA INT CO LTD

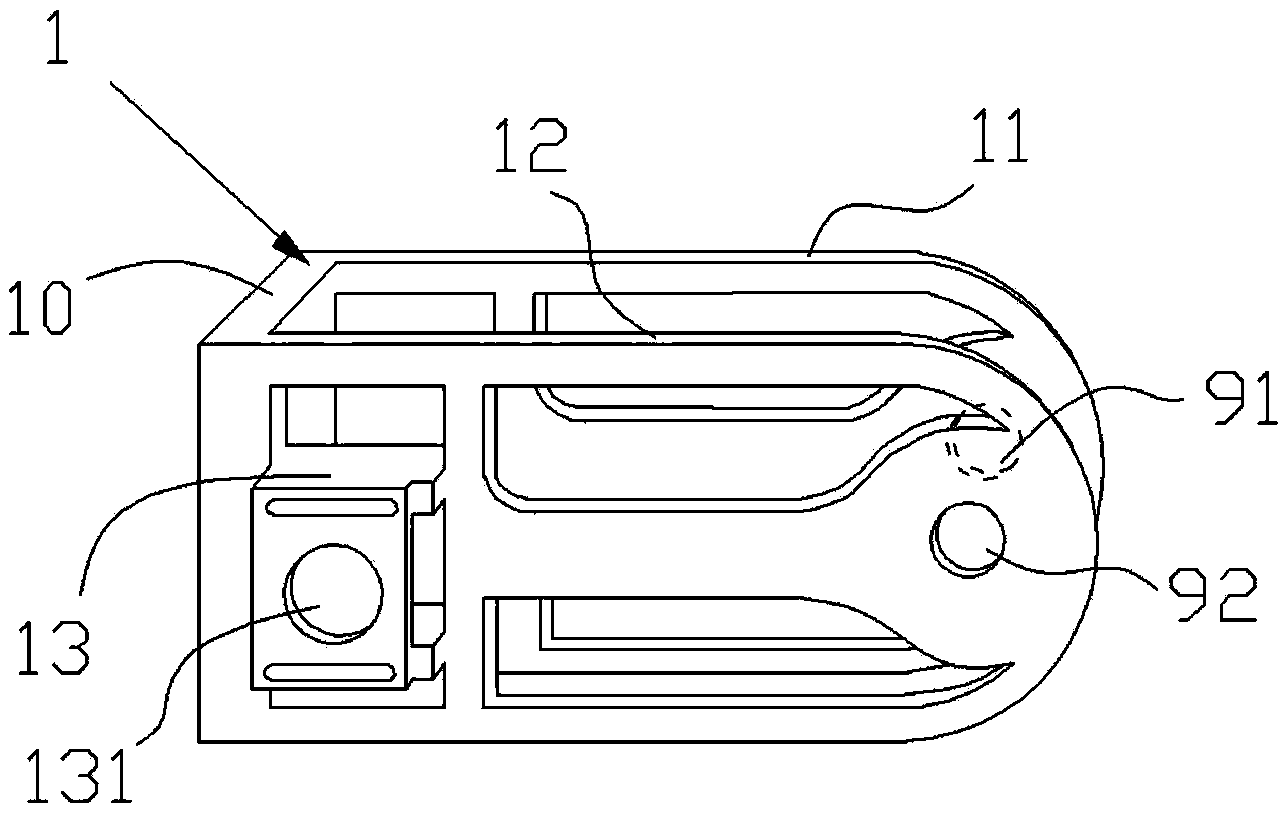

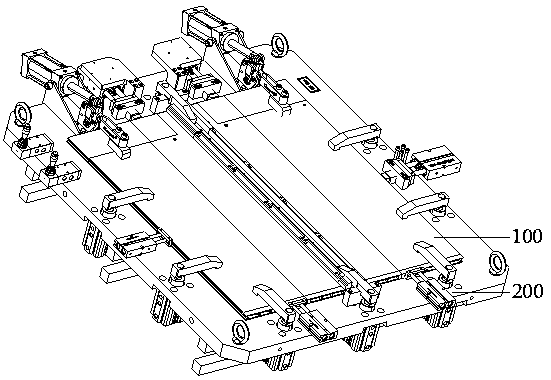

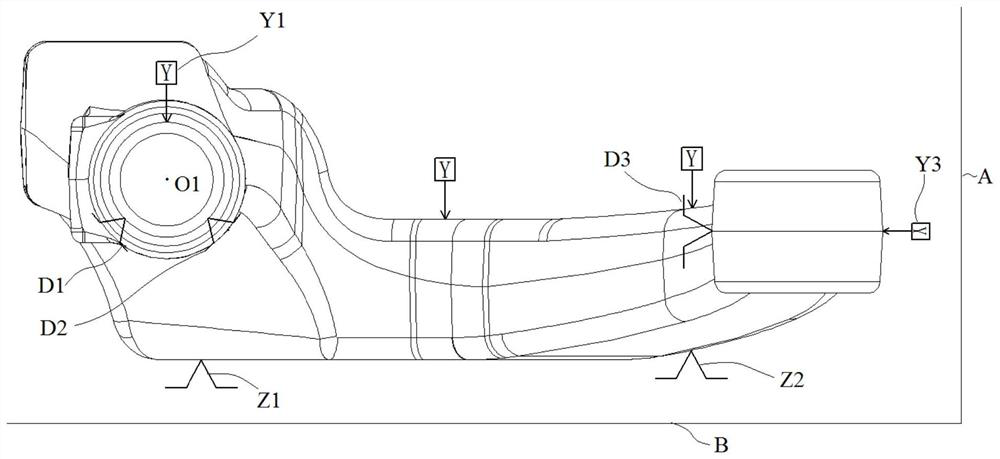

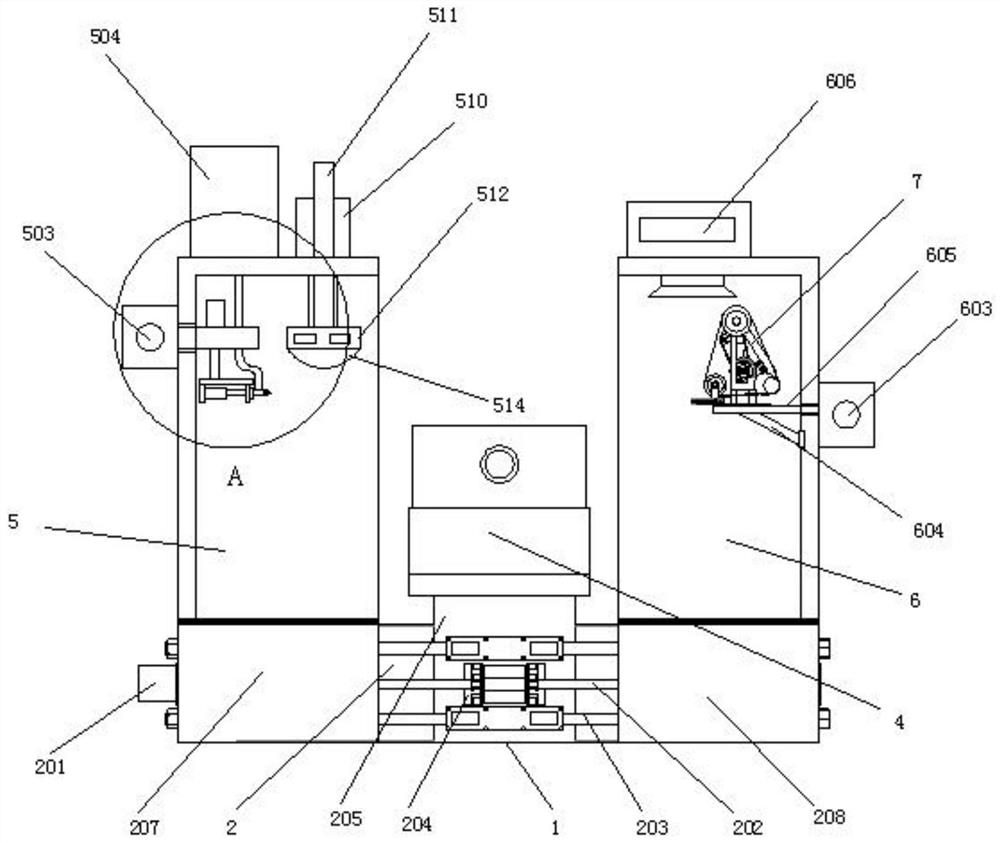

Continuous automatic bending and forming device for air-conditioning pipe fittings

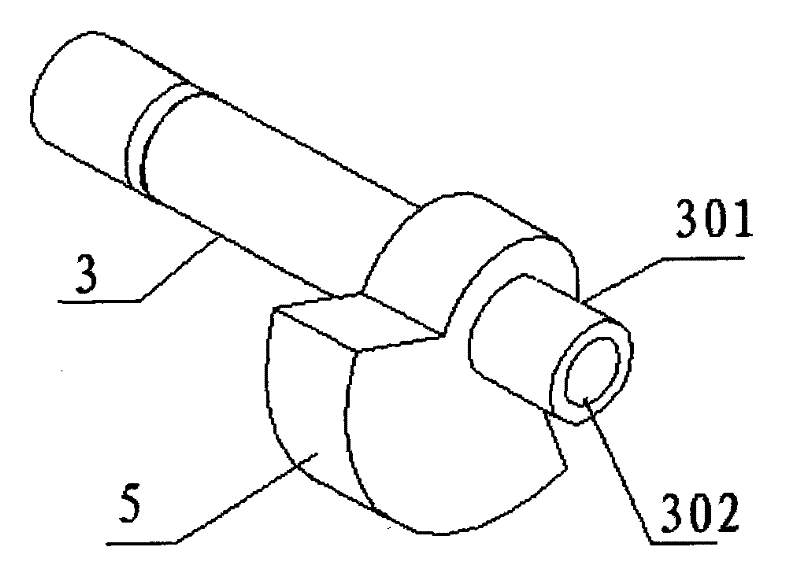

ActiveCN108906932BAchieve mechanized bending processingAvoid multiple clampingPipe fittingStructural engineering

The invention discloses a continuous and automatic air conditioner pipe fitting bending and forming device. The continuous and automatic air conditioner pipe fitting bending and forming device comprises a rack and a pneumatic clamp for fixing an air conditioner pipe fitting. The pneumatic clamp is slidingly arranged on the rack, the end of the rack is provided with a support, the support is rotatably provided with a bending mechanism, the bending mechanism comprises a bending base and a bending assembly arranged on the bending base, the bending base is in swinging connection with the support,the bending base is provided with a limiting die externally lined on one side of the air conditioner pipe fitting, the limiting die is provided with a limiting groove corresponding to the air conditioner pipe fitting in diameter and can swing with the bending base, the bending assembly is in misplaced connection with the limiting ide, the bending assembly is liftably arranged on the bending base and is externally lined on the other side of the air conditioner pipe fitting through lifting. Compared with the prior art, the continuous and automatic air conditioner pipe fitting bending and formingdevice achieves mechanical bending machining and improves the production efficiency.

Owner:ZHEJIANG CHUANGXIN AUTO AIR CONDITIONER

Continuous and automatic air conditioner pipe fitting bending and forming device

ActiveCN108906932AAchieve mechanized bending processingAvoid multiple clampingPipe fittingEngineering

The invention discloses a continuous and automatic air conditioner pipe fitting bending and forming device. The continuous and automatic air conditioner pipe fitting bending and forming device comprises a rack and a pneumatic clamp for fixing an air conditioner pipe fitting. The pneumatic clamp is slidingly arranged on the rack, the end of the rack is provided with a support, the support is rotatably provided with a bending mechanism, the bending mechanism comprises a bending base and a bending assembly arranged on the bending base, the bending base is in swinging connection with the support,the bending base is provided with a limiting die externally lined on one side of the air conditioner pipe fitting, the limiting die is provided with a limiting groove corresponding to the air conditioner pipe fitting in diameter and can swing with the bending base, the bending assembly is in misplaced connection with the limiting ide, the bending assembly is liftably arranged on the bending base and is externally lined on the other side of the air conditioner pipe fitting through lifting. Compared with the prior art, the continuous and automatic air conditioner pipe fitting bending and formingdevice achieves mechanical bending machining and improves the production efficiency.

Owner:ZHEJIANG CHUANGXIN AUTO AIR CONDITIONER

High-precision adjustable lock machining equipment

PendingCN114346069AImprove machining accuracy and machining efficiencyImprove processing efficiencyMetal-working feeding devicesStripping-off devicesProcessing accuracyMachining

The invention relates to the technical field of lock machining, in particular to high-precision adjustable lock machining equipment, and aims to solve the problems that in the prior art, a lock panel is poor in machining precision and low in machining efficiency, the high-precision adjustable lock machining equipment comprises an operation plate, a mounting groove is formed in the top face of the operation plate, and a rotating plate is mounted on the inner side of the mounting groove; a driving assembly used for driving the rotating plate to rotate is installed on the operation plate, four cavities are formed in the top of the rotating plate, four through holes communicated with the cavities are correspondingly formed in the bottom of the rotating plate, bottom plates are installed on the inner sides of the four cavities, and a top plate is installed on the top of the operation plate; a lifting plate is mounted at the bottom of the top plate through a lifting assembly. The device is reasonable and stable in structure and easy to operate, the machining precision of the lock panel is effectively improved, the machining efficiency of the lock panel is improved, the labor intensity of operators is reduced, and the device is easy to popularize and use.

Owner:贵州华禾制锁有限公司

A high-strength corrosion-resistant aluminum plate recoiling machine carbon roll production device

ActiveCN111890189BAchieve clamping and fixingPracticalGrinding carriagesGrinding drivesPolishingEngineering

The invention discloses a carbon roll production device for a high-strength corrosion-resistant aluminum plate recoiling machine, which includes a base, a left guide cavity and a right guide cavity are respectively arranged on both sides of the base, the left guide cavity and the right guide cavity The structure is exactly the same, a clamping platform is fixedly arranged between the vertical plates of the left guide chamber and the right guide chamber, and a coating chamber is fixedly arranged on the L-shaped support frame at the same end of the left guide chamber and the right guide chamber. The L-shaped supporting frame two at the other end of the left guide chamber and the right guide chamber is fixedly provided with a polishing chamber, the inside of the coating chamber is provided with a spray gun, and the inside of the polishing chamber is provided with a grinding frame. The polishing chamber is integrated into the same equipment, so that the coating and polishing of the carbon roller during the production process can be carried out on the same equipment, avoiding multiple clamping of the carbon roller during the coating and polishing process, saving time and effort , It also improves the processing efficiency of the enterprise on carbon rolls and reduces the production cost of the enterprise.

Owner:马鞍山欧凯新材料科技有限公司

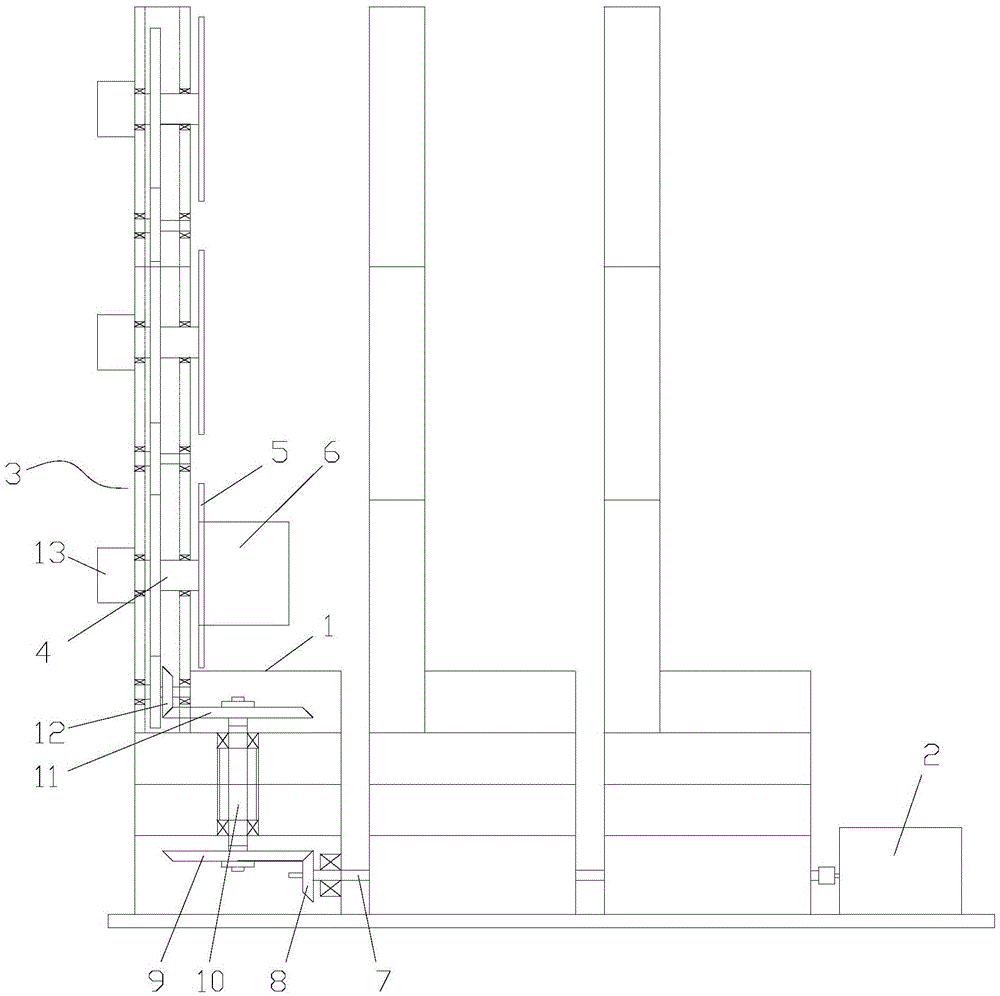

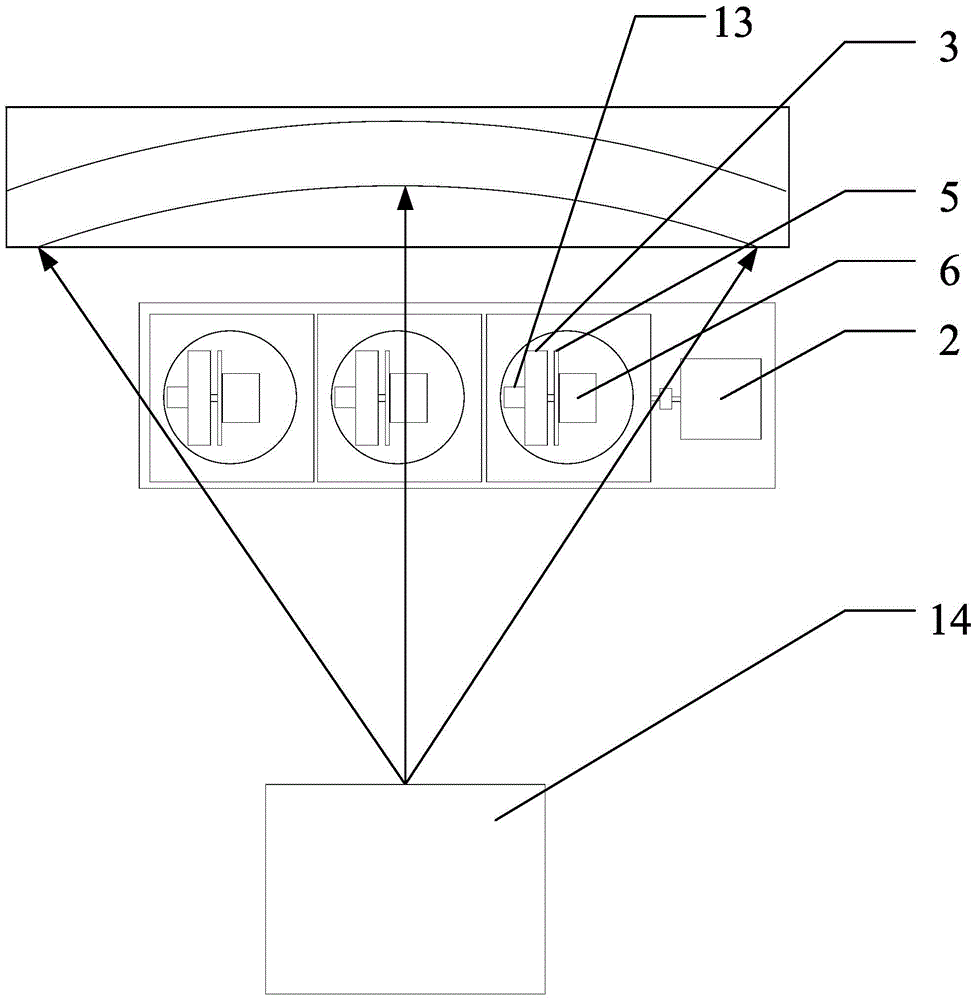

Multi-degree-of-freedom, multi-angle rotating device

ActiveCN103983650BSimple structureRapid positioningMaterial analysis by transmitting radiationAssembly lineMulti degree of freedom

The invention discloses a multi-degree-of-freedom and multi-angle rotating device which comprises a horizontal rotary working table and a vertical rotary working table, wherein the vertical rotary working table comprises a power source, a gear box and a transmission mechanism, the gear box is fixedly arranged on the horizontal rotary working table, the transmission mechanism is used for connecting the power source with the gear box, the gear box comprises at least one power output shaft which is horizontally arranged, the power output shafts are parallel in a vertical direction, and a piece carrying platform which is perpendicular to each power output shaft is fixedly arranged on the power output shaft. Workpieces can be rotated on a horizontal surface and a vertical surface by using the horizontal rotary working table and the vertical rotary working table of the multi-degree-of-freedom and multi-angle rotating device, so that parts can be scanned at different azimuth angles by a radiation source, comprehensive scanning detection data are acquired, and the detection accuracy is good. By adopting the rotating device, the scanning cost can be reduced, additionally, multiple workpieces can be scanned at a time, large-batch and assembly-line operation is facilitated, and the detection efficiency can be greatly improved.

Owner:CHONGQING UNIV

A device and method for automatically removing pouring riser of diesel engine bearing seat

ActiveCN112536504BImprove versatilityTo achieve the effect of automatic positioningGas flame welding apparatusHydraulic cylinderRotary stage

The invention discloses a device and method for automatically removing the pouring riser of a diesel engine bearing seat. The linear track is composed of two guide rails that are the same on the left and the right. Above the front end of the linear track is a special clamp mechanism. The special clamp mechanism includes a positioning device, a rotary table, and a flexible clamp body. , the rear support plate, the base and the front support plate, the positioning device is directly above the front end of the linear track, and the flexible clamping body is connected in the middle of the rotating base; the flexible clamping body includes a clamping plate, a mobile clamping hydraulic cylinder, a fixed clamping hydraulic cylinder, Positioning pins and sliding positioning blocks, the rear end of the linear track is the processing plant, and the gas cutting riser removal device is installed in the processing plant; the flexible clamp body can be adjusted according to the size of the blank, and the diesel engine bearing seat can be automatically positioned and the station can be changed during processing to improve the roughness. The generality of clamping, the clamping plate rotates at a certain angle, the blank slides to the bottom by gravity, and then sticks to the positioning pin with the help of thrust, so as to achieve the effect of automatic positioning and improve the efficiency of clamping.

Owner:JIANGSU UNIV OF SCI & TECH

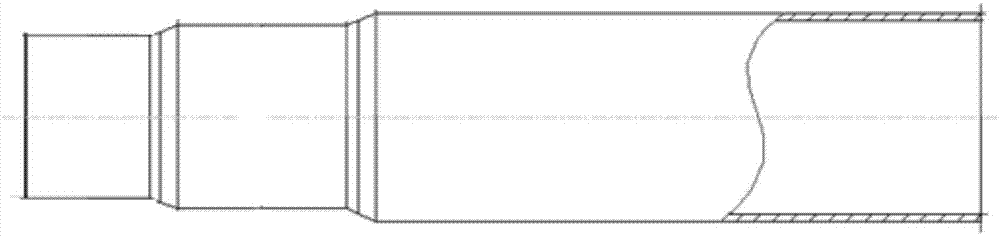

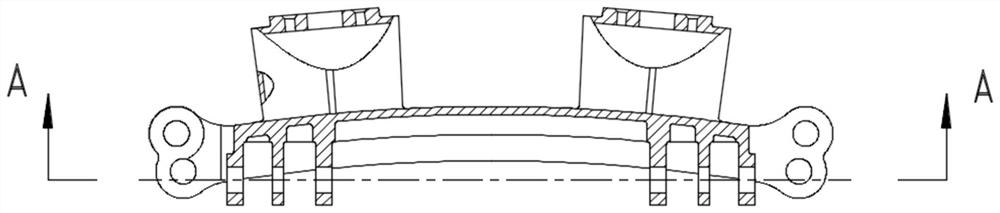

Tubular product multi-section one-time closing-in forming die and forming method

PendingCN107952809AEasy to masterMold manufacturing is easy to guaranteeExtrusion diesPalletBiochemical engineering

Owner:隆昌山川机械有限责任公司

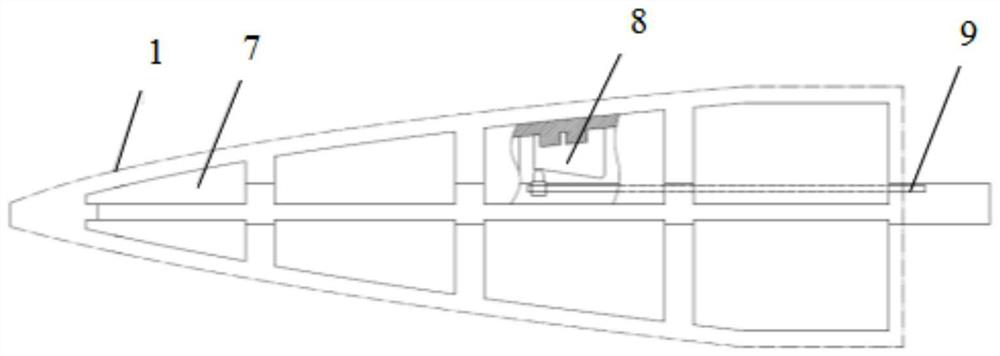

A kind of aircraft special-shaped parts clamping auxiliary device and clamping method

ActiveCN114633133BGuaranteed dimensional accuracyGuaranteed shape and position accuracyWeight reductionPositioning apparatusNumerical controlMachine parts

The invention discloses an auxiliary device for clamping special-shaped parts of an aircraft and a clamping method thereof, which comprises a cylindrical rotating body, two ends of the rotating body are respectively provided with cylindrical clamping ends and fixed ends; The surface on one side of the end is provided with two planes. The two planes are symmetrical with the axis of the revolving body. The clamping surface is provided with several screw holes, and both ends of the clamping surface are provided with fixed bosses. Two bolt holes are provided on the fixed boss, and pin holes are set between the two bolt holes. The clamping method includes steps S1-S14. By designing different stations on the same rotary body, the invention can assist CNC machine tools to process aircraft special-shaped and difficult-to-machine parts, avoid multiple clamping and the use of special tooling in the processing process, improve processing efficiency, and ensure the size of the parts. Accuracy and Geometric Accuracy.

Owner:四川仨川航空科技股份有限公司

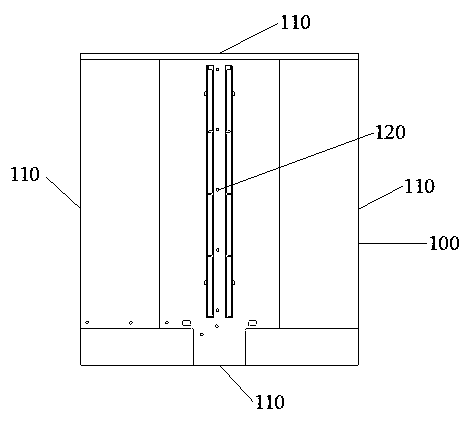

Machining method for large-size thin-wall special-shaped cover body

ActiveCN114054813AIn situ axial flipAvoid multiple clampingMilling equipment detailsReverse modelingMachine

The invention relates to a machining method for a large-size thin-wall special-shaped cover body. The machining method comprises the following steps: a tool special for cutting machining is designed and manufactured; 3D reverse modeling is carried out after the blank is scanned; the relative position relation between the blank and the product is determined; according to the comparison relation between the allowance and the removal amount, a machining tool is replaced with a measuring module, the machining profile tolerance and precision of an inner chamber are detected under the condition that a product is not disassembled through online in-situ measurement, and error compensation coping machining is conducted according to a deviation value; and a 90-degree adapter on a vertical milling machine is detached, a spindle of the vertical milling machine is used for milling a second outer profile of the product by taking the end face of the large end of the finish-machined blank as a reference face. The machining method meets the cutting machining requirements of the large-size thin-wall special-shaped ceramic cover body, is simple, convenient and reliable in clamping, high in positioning precision and suitable for popularization and application.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

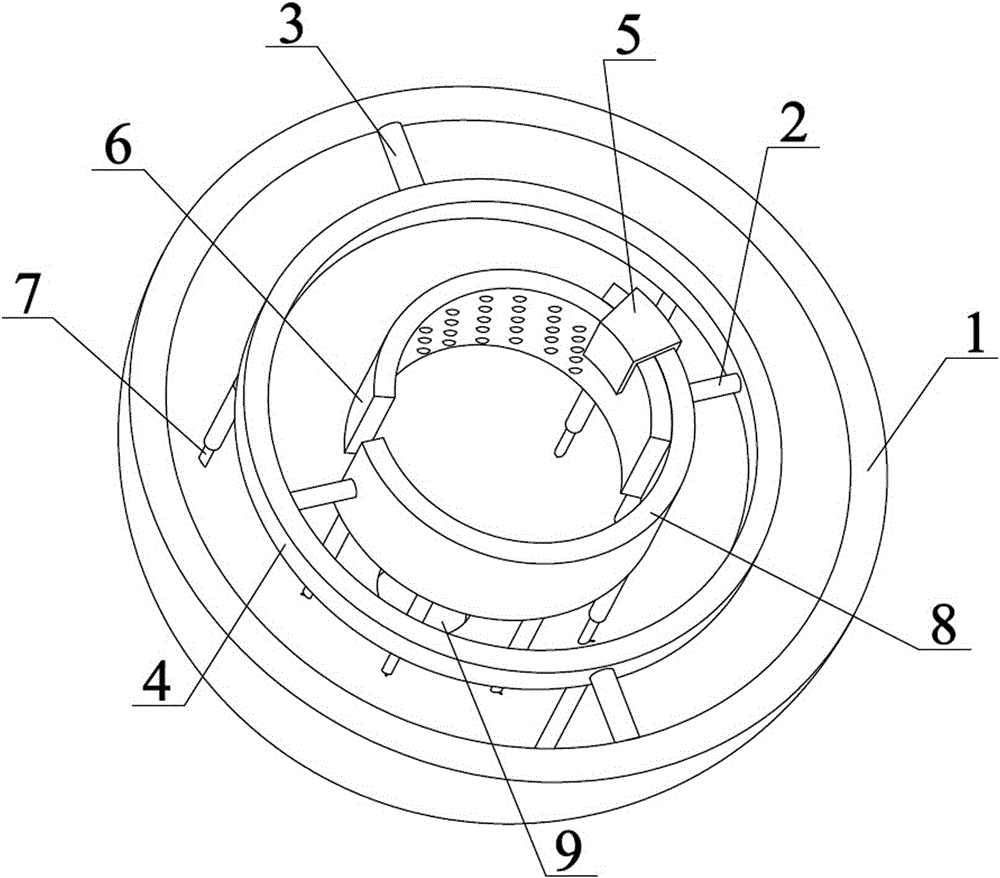

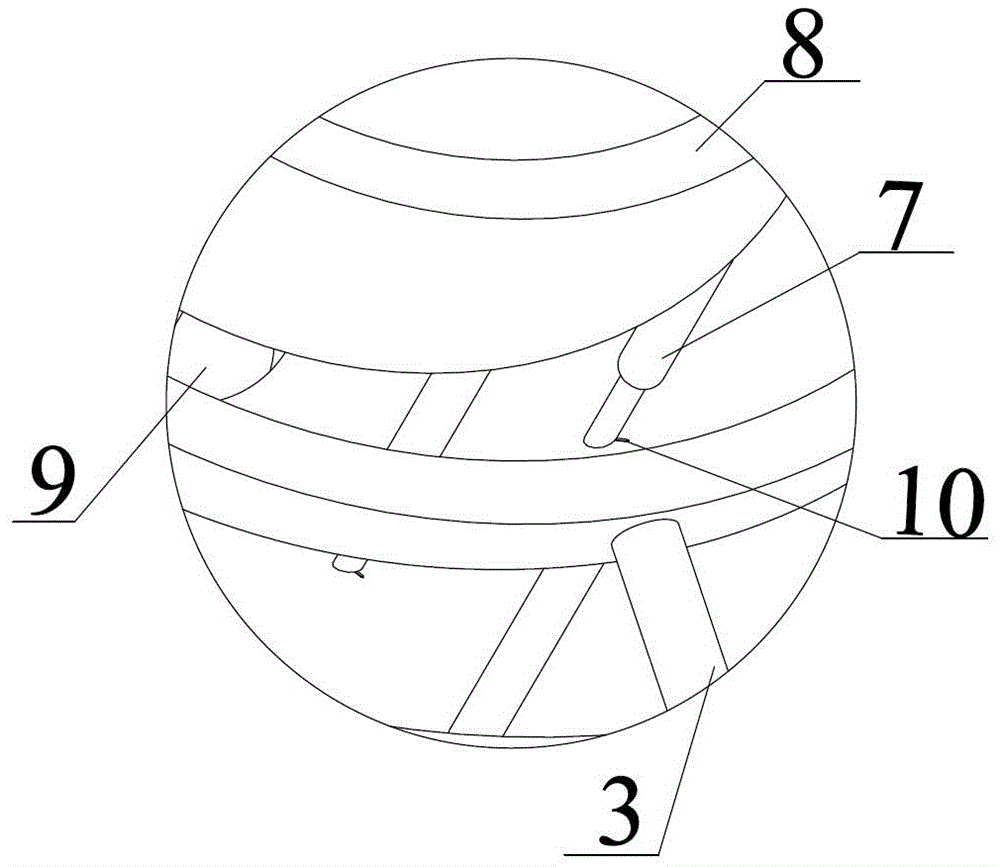

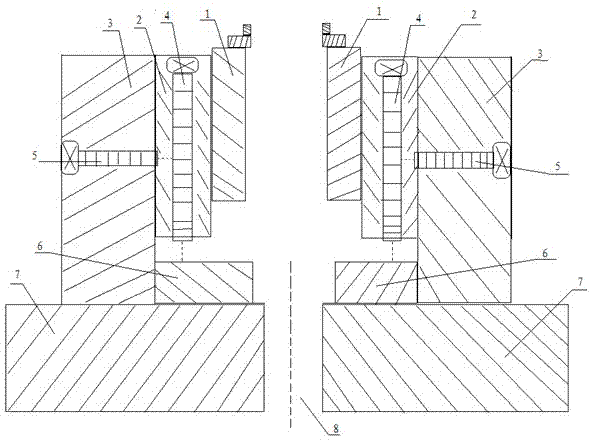

Clamping tool for punching equipment pipe shell

InactiveCN102825481ASmall toleranceLight in massPositioning apparatusMetal-working holdersPunchingClassical mechanics

The invention discloses a clamping tool for a punching equipment pipe shell. The clamping tool comprises an open sleeve (1), an inner ring (2) and an outer ring (3), wherein the inner ring (2) is positioned on the periphery of the open sleeve (1); the outer ring (3) is positioned on the periphery of the inner ring (2); the inner ring (2) is provided with an axial adjusting screw (4); the outer ring (3) is provided with a radial adjusting screw (5); a gasket (6) is arranged below the inner ring (2); a clamp (7) is arranged below the gasket (6); and the centers of the gasket (6) and the clamp (7) are provided with circular holes (8). The clamping tool for the punching equipment pipe shell provided by the invention is reasonable in structural design, and is convenient to use; after clamping, the planeness and coaxiality can be adjusted, the assembling and processing standards can be ensured, and the position tolerance is small; moreover, after one-time clamping, step processing treatment and through hole treatment can be performed on the punching equipment pipe shell simultaneously, so that processing is very convenient, and the working efficiency is high; and moreover, the punching equipment pipe shell obtained by processing has small tolerance and high quality.

Owner:WUJIANG WUHUA HARDWARE PROD

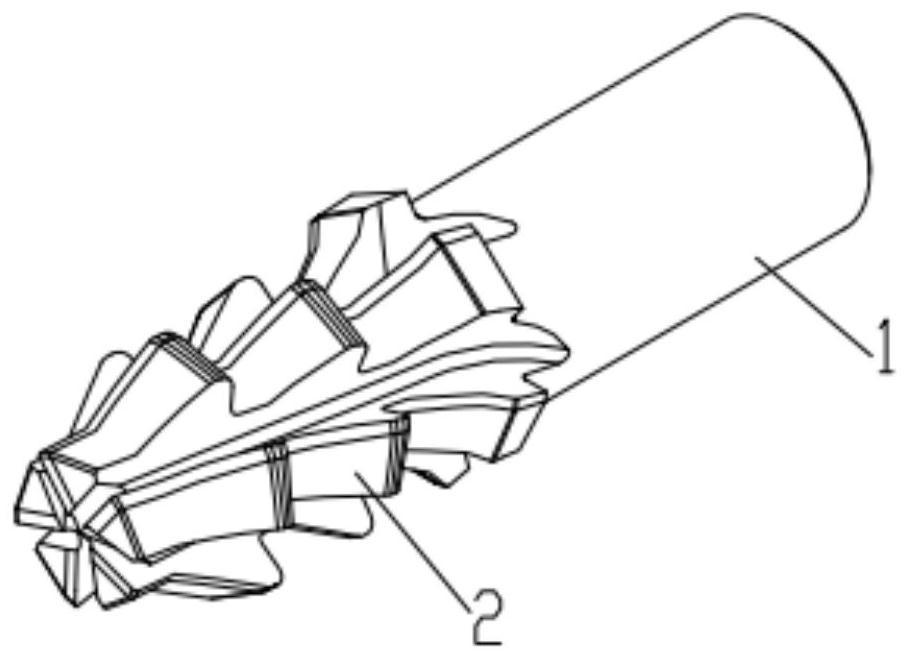

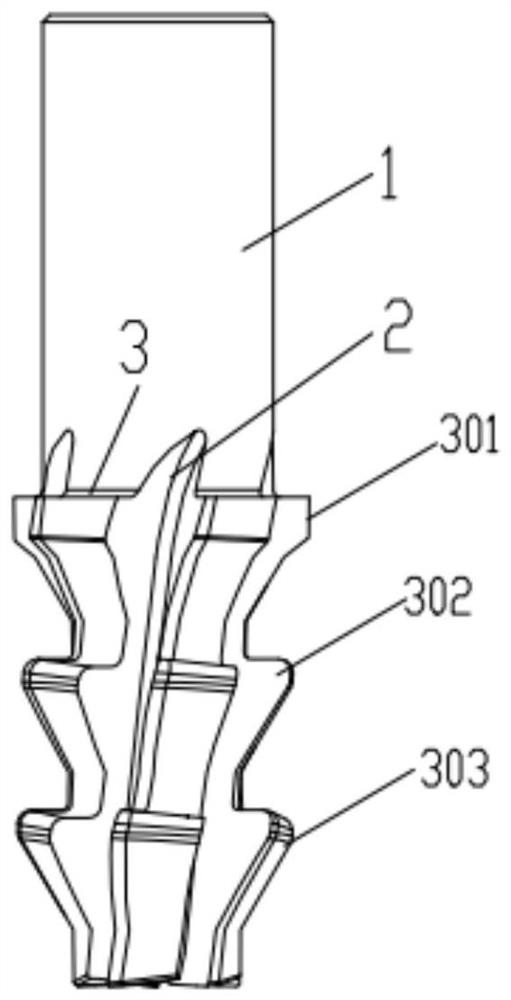

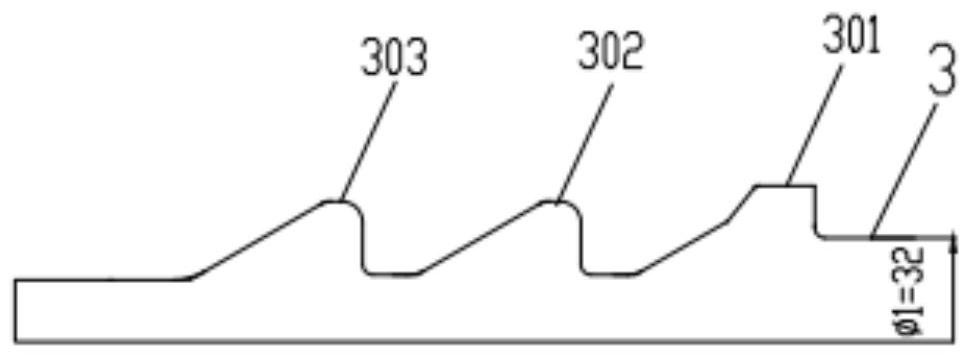

A method of processing fir tree-shaped arc tenon with forming milling cutter

ActiveCN110405266BAvoid multiple clampingReduce consumptionMilling cuttersMilling equipment detailsMilling cutterStructural engineering

The invention discloses a method for processing a fir tree-shaped arc tenon with a forming milling cutter. The forming milling cutter includes a cutter bar, cutter teeth and a blade support seat, and the blade support seat is installed at one end of the cutter bar. , the blade supporting seat is provided with a reference step surface, a first step surface and a second step surface sequentially from the end of the tool bar to the tip of the knife, and the reference step surface, the first step surface and the second step surface are all provided with Five described cutter teeth, the five described cutter teeth have the same structure, and the five described cutter teeth of each layer are distributed equiangularly to the center line of the cutter bar, and the connecting line of the cutting edge profile line of the described cutter teeth is The fir tree-shaped arc surface of the workpiece to be processed matches and is a helical line; processing the fir tree-shaped arc tenon with the forming milling cutter does not require multiple clamping, and the joint rotation of the tenon, machine tool turntable and forming milling cutter can avoid machining overcut , to solve the problems of low processing efficiency, low product qualification rate and high tool cost of the existing fir tree arc tenon.

Owner:AECC AERO SCI & TECH CO LTD

Automatic high-pressure washing and deburring equipment for automobile parts

ActiveCN114193259AEasy to fixImprove grinding efficiencyEdge grinding machinesGrinding drivesElectric machineryMechanical engineering

The invention belongs to the technical field of deburring equipment, particularly relates to automatic high-pressure flushing deburring equipment for automobile parts, and aims to solve the problems of low grinding efficiency and need of independent flushing in the prior art, the following scheme is provided: the automatic high-pressure flushing deburring equipment comprises a shell, an air cylinder is arranged in the shell, and a limiting box is fixedly mounted on a telescopic rod of the air cylinder; a base is slidably mounted in the shell, a fixing plate is fixedly mounted on the base, a clamping plate is slidably mounted on the base, circular plates are rotatably mounted on the fixing plate and the clamping plate, a screw is in threaded connection with the base, the screw is rotatably connected with the clamping plate, and a grinding mechanism is arranged in the shell and comprises a rotating rod. According to the grinding device, the grinding efficiency can be improved, automatic flushing can be achieved, time is saved, the machining efficiency is improved, use is easy, and operation is convenient.

Owner:润斯普瑞超声科技(苏州)有限公司

A kind of branch beveling equipment for drawing manifold

ActiveCN106624809BLower life cycle costsFunction increaseOther manufacturing equipments/toolsBiochemical engineering

The invention discloses a set of pulling opening collecting tube support groove equipment. The collecting tube support groove equipment comprises a worktable, an upright post, a power device, a fine-tuning device and a cutter disk; a plurality of parallel installation rails are arranged on the worktable, a group of supporting seats is arranged at two ends of the worktable, a cambered surface matched with the side radian of the collecting tube is arranged at the inner side of the supporting seat; the upright post is fixed at one side of the worktable, and comprises a backer and a walking beam, the rail is arranged on the side of the backer, the walking beam is matched with the rail and slidingly installed on the backer; a waste shaping machine is improved to obtain the new equipment, the equipment is used for performing the groove processing on the collecting tube, the cost is saved, and the product quality is improved.

Owner:合肥实华管件有限责任公司

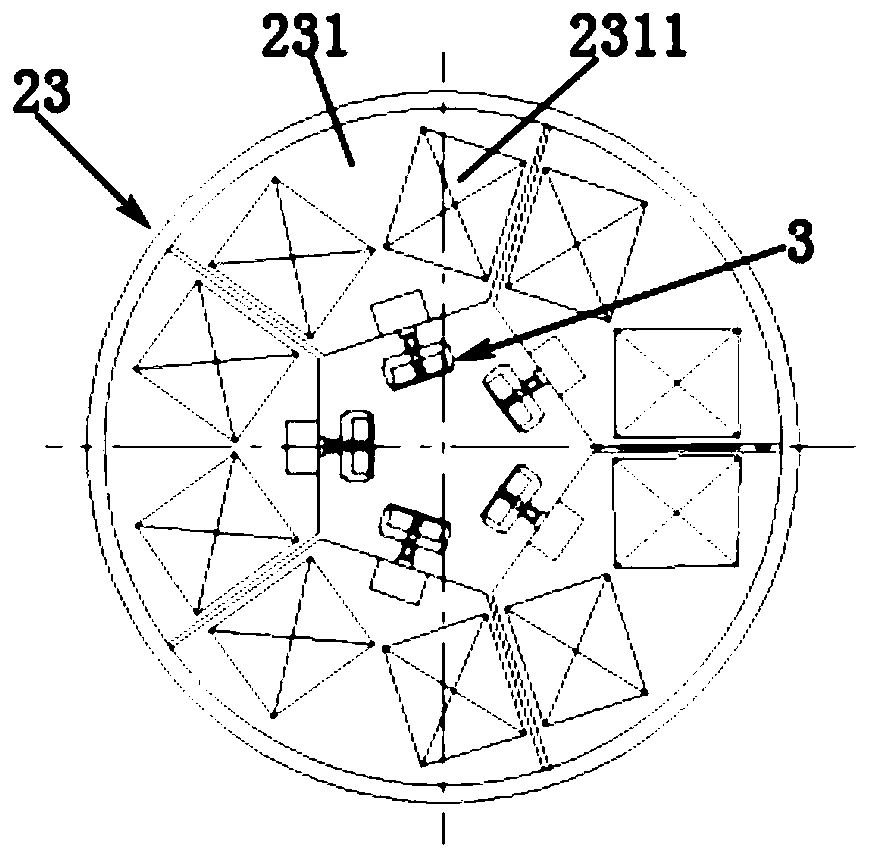

A Dovetail Indexing and Self-Centering Device Based on Radial Boring of Irregular Rings

ActiveCN110977516BAvoid multiple clampingCompact structurePositioning apparatusMetal-working holdersAbnormal shapedIndustrial engineering

The invention relates to a dovetail type indexing and self-centering device based on radial boring of a special-shaped ring member. The device comprises a dovetail type stepless indexing mechanism, anautomatic centering and clamping mechanism, a tool setting mechanism and a pressing mechanism; the automatic centering clamping mechanism and the pressing mechanism are used for positioning and clamping a part. The dovetail type indexing mechanism comprises a base, a rotary disc, a lead screw nut, an indexing lead screw, a sleeve and a hand wheel assembly; the base is a dovetail type female die,the rotary disc is a dovetail type male die, the base and the rotary disc form an arc-shaped sliding rail pair, the rotary disc rotates on the base through the indexing lead screw, and the rotating angle is controlled through a positioning plug pin assembly and an indexing hole in the base. According to the invention, the machining problem of the special-shaped ring member is solved, the part position and size precision requirements are met, and the working efficiency is improved; meanwhile, the defect that the indexing center must be located at the arc center during large-diameter indexing isovercome, the size of the corresponding tool is reduced, the manufacturing cost of the tool is reduced, the manufacturing period of the tool is shortened, and the tool has very high reference significance for similar parts and has very good generalization performance.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

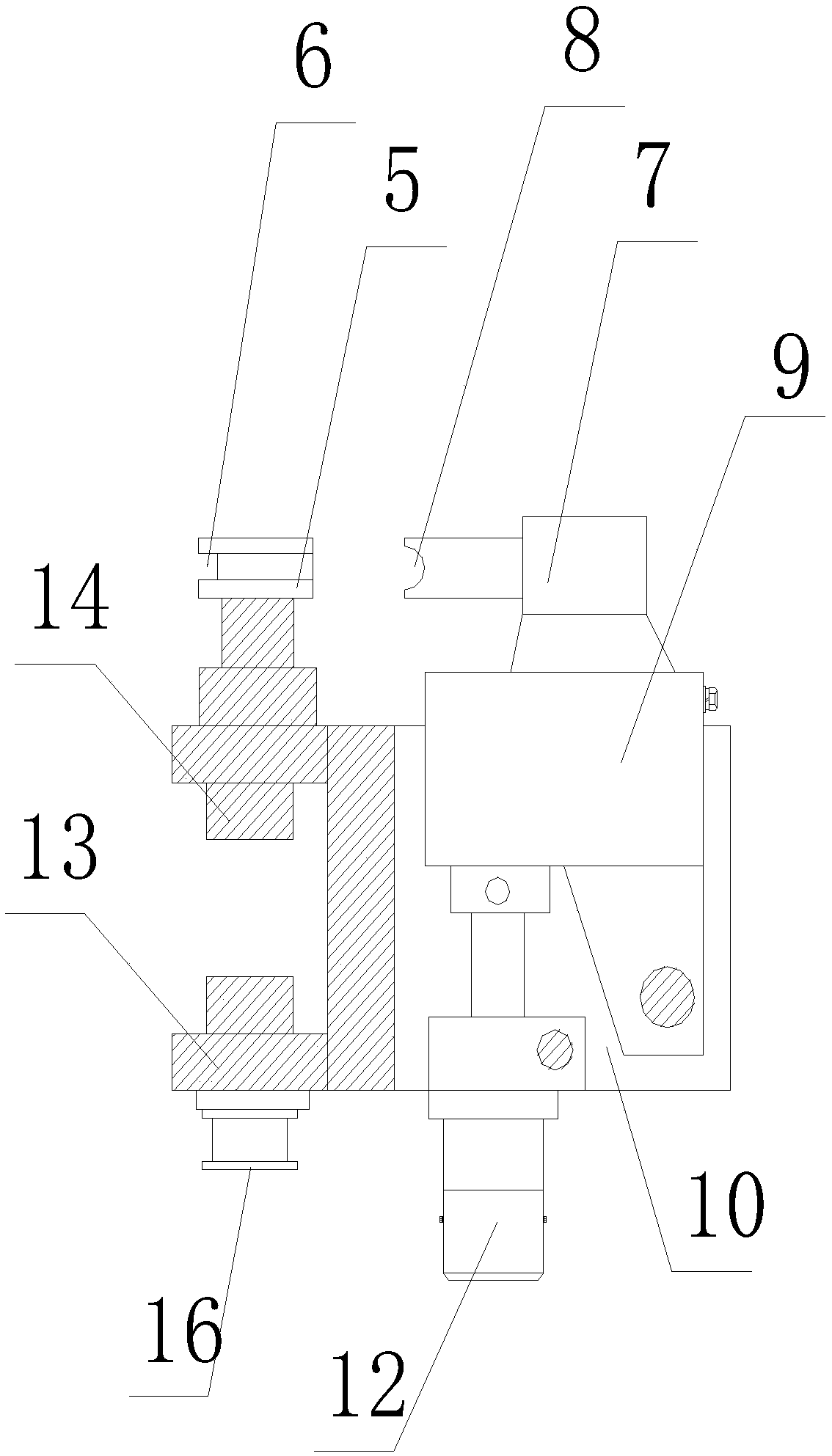

New type tilting mechanism of five-axis numerical control non-metallic material-dedicated machine tool

The invention provides a new type tilting mechanism of a five-axis numerical control non-metallic material-dedicated machine tool. The new type tilting mechanism of the five-axis numerical control non-metallic material-dedicated machine tool comprises a fixed frame, a grinding head mounting bracket fixedly connected with the fixed frame, and a grinding head connected with the grinding head mounting bracket, wherein a servo motor is arranged on the fixed frame; a synchronous belt is arranged between the servo motor and the grinding head; the servo motor drives the grinding head through the synchronous belt. By applying the new type tilting mechanism of the five-axis numerical control non-metallic material-dedicated machine tool, the grinding head is driven through the synchronous belt, clamping for many times is avoided, the tilting mechanism can be used for more sophisticated operations, the tilting head has a simple structure, and is convenient to use and maintain, the original cutting tool of a four-axis numerical control carving machine can be replaced, and the four-axis numerical control carving machine can be converted into a five-axis numerical control engraving machine.

Owner:JINAN SINGHUI CNC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com