Combined machine tool for drilling oil hole of connecting rod and cutting big-head hole of connecting rod

A combined machine tool and big head hole technology, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, can solve the problems of difficult product accuracy requirements and low processing efficiency, so as to save time and human resources, improve production efficiency, and avoid multiple The effect of secondary clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

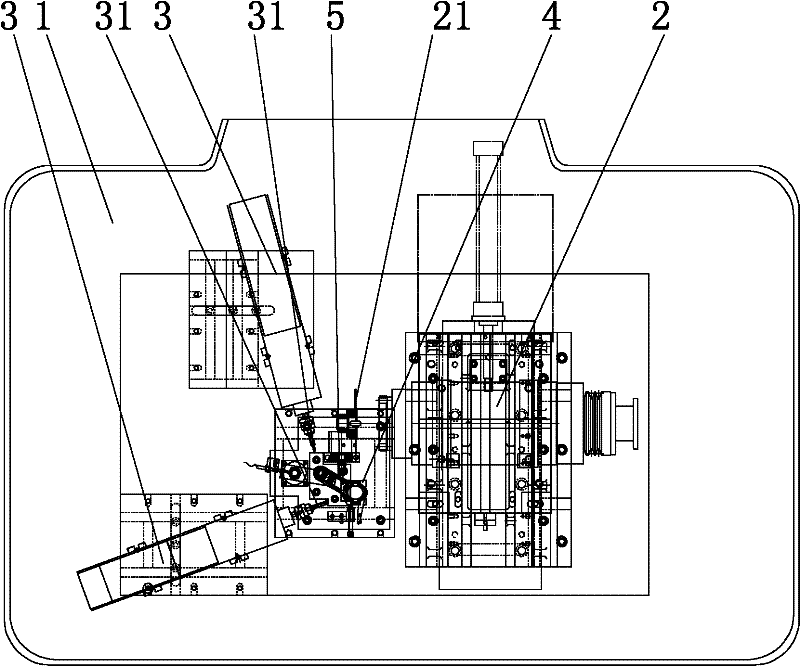

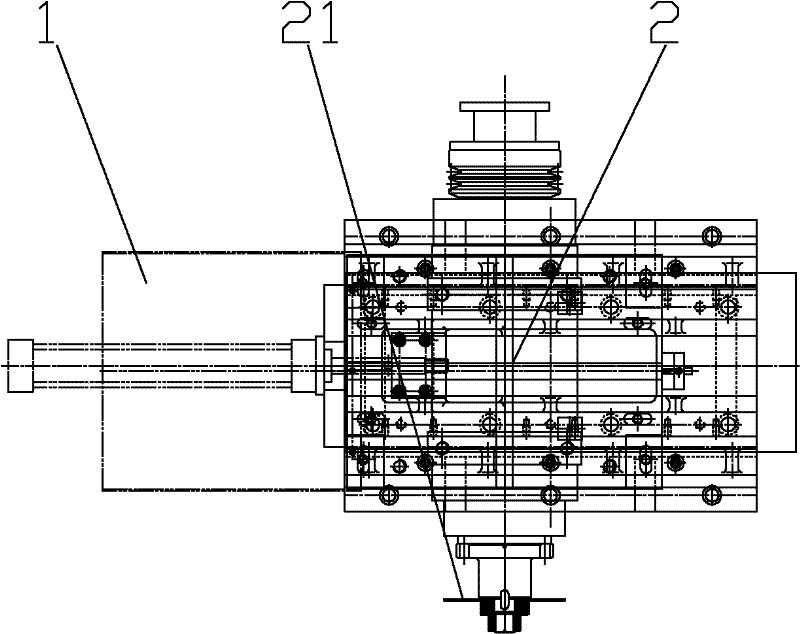

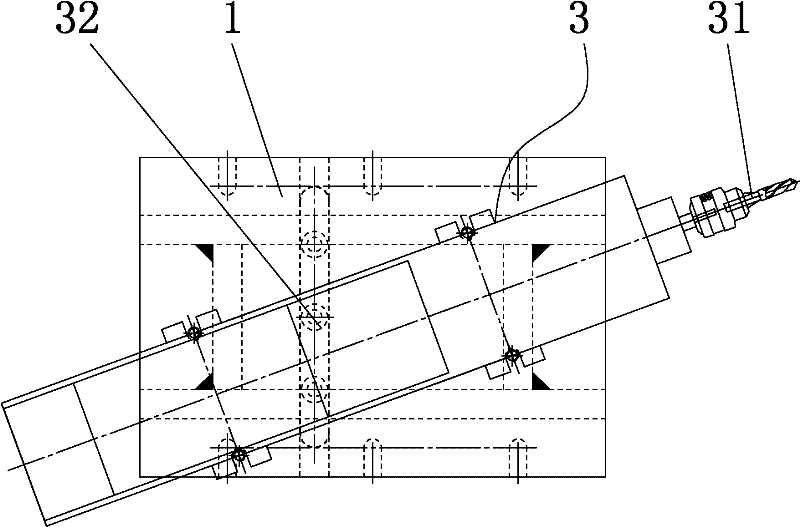

[0015] like Figures 1 to 3 As shown, the combined machine tool of the present invention includes a machine platform 1, a cutting mechanism 2, two sets of drilling mechanisms 3, and a positioning fixture 4; the positioning fixture 4 and the drilling mechanism 3 are arranged on the machine platform, and the cutting mechanism 2 and the machine platform Sliding connection, the sliding of the cutting mechanism 2 on the machine table is driven and controlled by the oil cylinder, the connecting rod 5 to be processed is fixed on the positioning fixture 4; the rotating head of the cutting mechanism 2 is fixed with a saw blade 21, and the saw blade 21 is aligned with the connecting rod 5 The cutting position of the big head hole, the cutting mechanism 2 drives the saw blade 21 to cut and move along the set cutting position of the big head hole; the drilling mechanism 3 is provided with a drill bit 31, and the drill bit 31 is pre-opened along the connecting rod 5 big head holes and small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com