A method of processing fir tree-shaped arc tenon with forming milling cutter

A technology for forming milling cutters and fir-tree shapes, which is applied in milling cutters, metal processing equipment, milling machine equipment, etc., can solve the problems of high tool cost, low processing efficiency of fir-tree-shaped arc tenons, and low product qualification rate. The effect of improving processing efficiency, reducing tool consumption and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

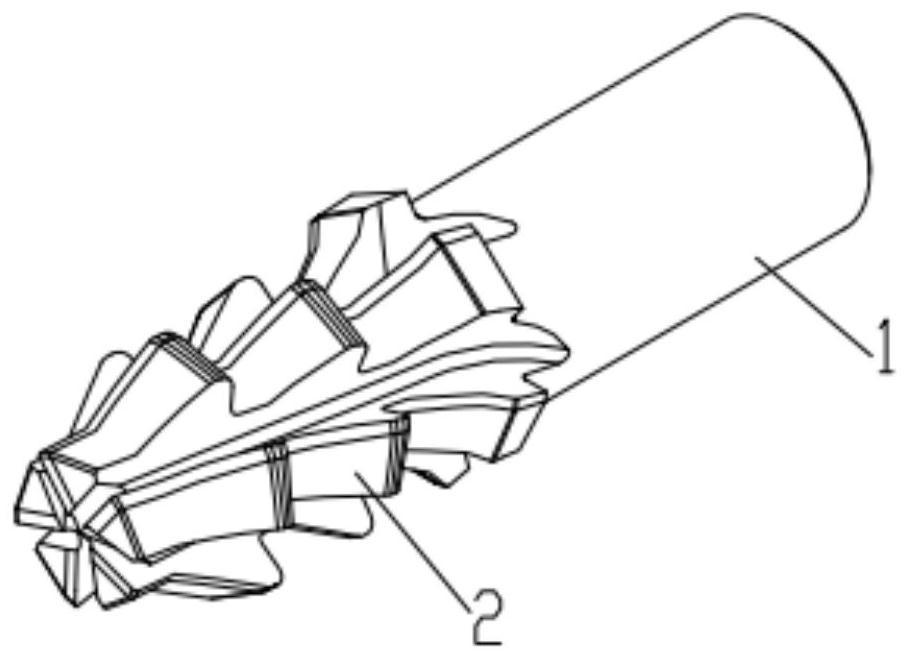

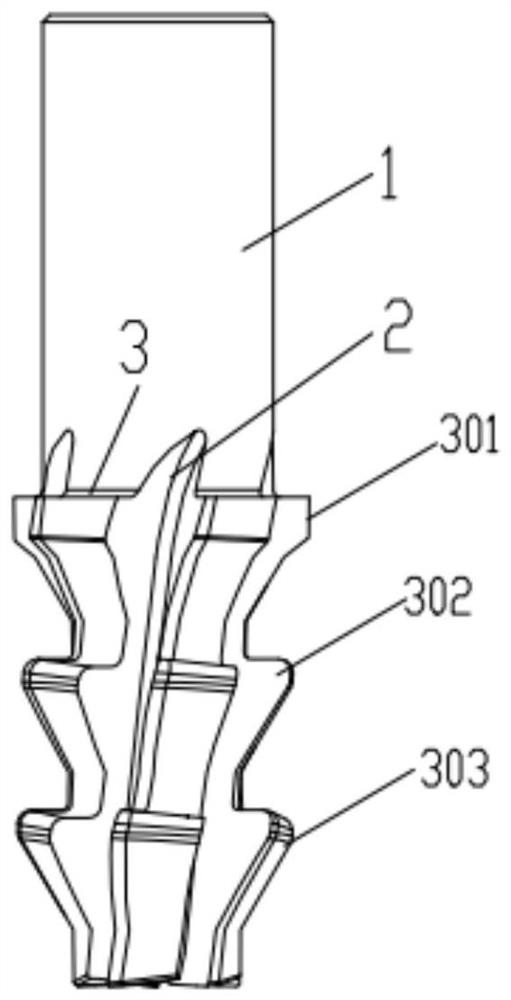

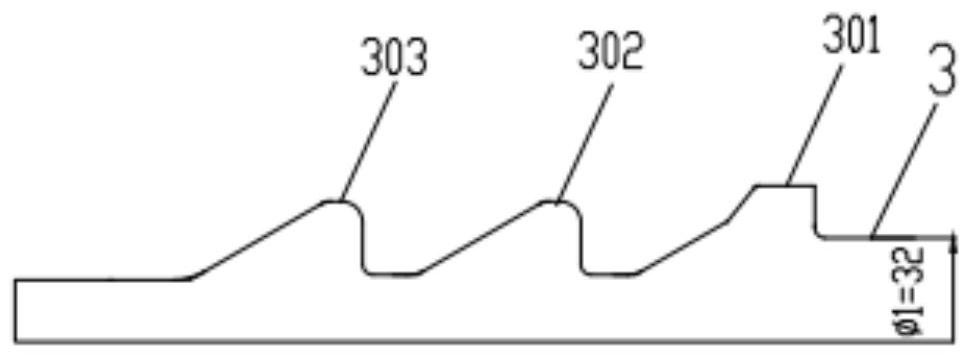

[0046] Please refer to Figure 1-3 , in order to process the fir tree-shaped arc tenon, a special forming milling cutter is made, including a cutter bar 1, a cutter tooth 2 and a blade support seat 3, and the blade support seat 3 is installed on one end of the cutter bar 1, The blade supporting seat 3 is provided with a reference step surface 301, a first step surface 302 and a second step surface 303 from the end of the knife bar 1 to the tip of the knife, and the tool bar 1, the reference step surface 301, the first step surface 302 and the center line of the second stepped surface 303 are on the same straight line, and the said reference stepped surface 301, the first stepped surface 302 and the second stepped surface 303 are provided with five said cutter teeth 2, five said The cutter teeth 2 have the same structure, and the five cutter teeth 2 of each layer are distributed equiangularly to the center line of the cutter bar 1, and the connecting line of the cutting edge pr...

Embodiment 2

[0053] In this embodiment, the fir tree-shaped arc tenon is processed on a CNC milling machine of the model TMH-630. First, rough milling is carried out to the wool 5 with a disc cutter, and then the basin pressure of the fir tree arc tenon is obtained by fine milling with a rod knife. surface and back pressure surface, and then use the forming milling cutter to process the air inlet surface 402 of the blade tenon and the air outlet surface 401 of the blade tenon.

[0054] The fir tree-shaped arc tenon of this embodiment is processed with wool 5 made of stainless steel, and the material of the forming milling cutter used is cemented carbide K40UF.

[0055] The method for processing the fir tree-shaped arc tenon by using the forming milling cutter mainly includes the following steps:

[0056] The first step is to roughly process the wool 5 to form a preliminary wool with tenon profile: fix the wool 5 on the fixture of the machine tool turntable 6, make the central axis 406 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com