Automatic high-pressure washing and deburring equipment for automobile parts

A technology for auto parts and high-pressure flushing, which is applied in metal processing equipment, grinding machine parts, grinding/polishing equipment, etc., can solve the problem of low grinding efficiency, improve grinding efficiency, improve efficiency, and avoid multiple times clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

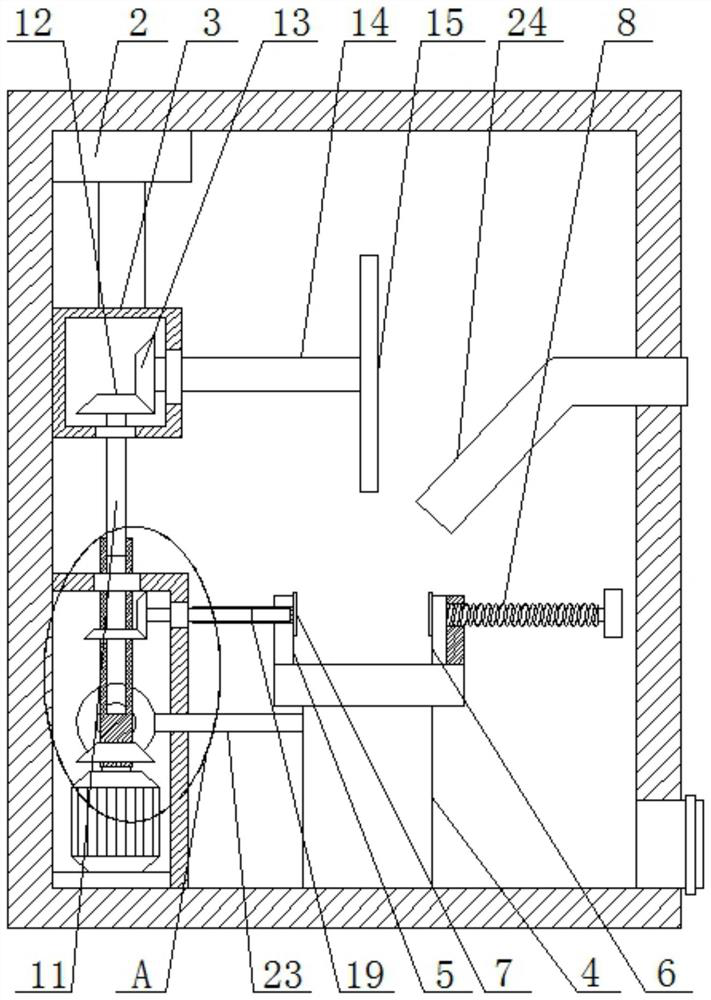

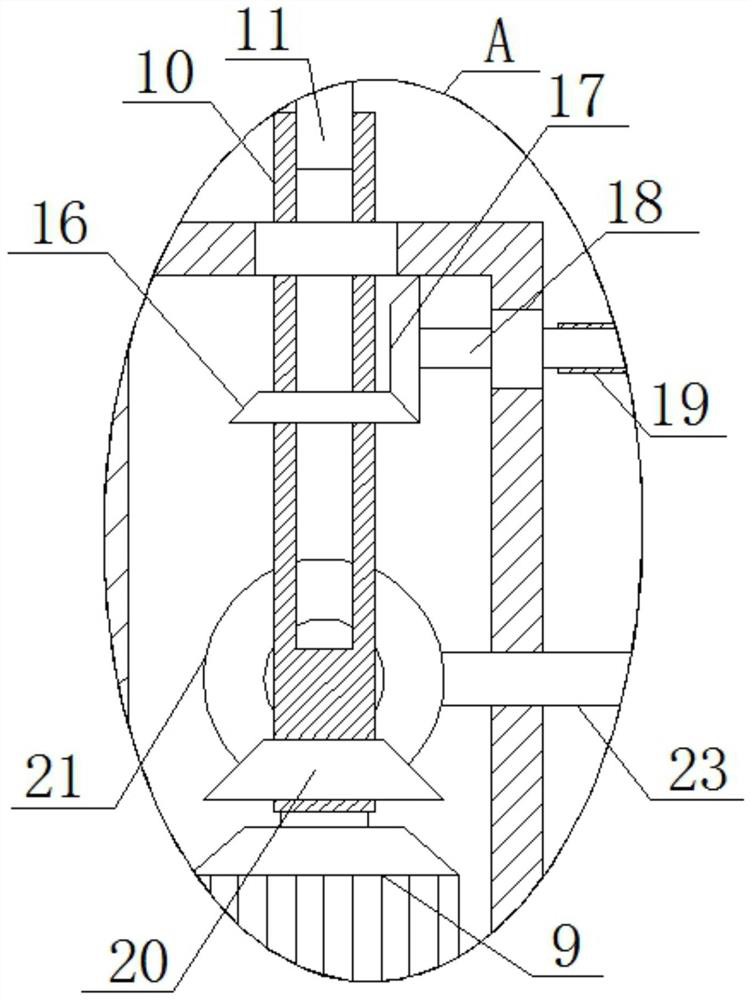

[0026] refer to Figure 1-4 , an automatic high-pressure flushing and deburring equipment for auto parts, comprising a housing 1, a cylinder 2 is arranged in the housing 1, a limit box 3 is fixedly installed on the telescopic rod of the cylinder 2, a base 4 is slidably installed in the housing 1, A fixed plate 5 is fixedly installed on the base 4, a splint 6 is slidably installed on the base 4, a circular plate 7 is rotatably installed on the fixed plate 5 and the splint 6, and a screw 8 is threaded on the base 4, and the screw 8 is connected to the splint 6 in rotation , the housing 1 is provided with a grinding mechanism, the grinding mechanism includes a rotating rod 10, the rotating rod 10 is fixedly connected with the output shaft of the motor 9, a first rectangular rod 11 is slidably mounted on the rotating rod 10, and the first rectangular rod 11 is fixedly installed First bevel gear 12 is arranged, and second bevel gear 13 is engaged with on the first bevel gear 12, an...

Embodiment 2

[0036] refer to Figure 5-6, the difference from Embodiment 1 is that the motion mechanism includes a third bevel gear 16, the third bevel gear 16 is fixedly connected with the rotating rod 10, the third bevel gear 16 is meshed with a fourth bevel gear 17, and the fourth bevel gear 17 is A second rectangular rod 18 is fixedly installed, and a rotary rod 19 is slidably installed on the second rectangular rod 18. The rotary rod 19 is fixedly connected with one of the two circular plates 7, and the first gear is fixedly installed on the rotary rod 10. 26. A second gear 27 is meshed with the first gear 26, and a round shaft 28 is fixedly installed on the second gear 27. A center plate 23 is slidably installed in the housing 1, and the round shaft 28 is slidingly connected with the inner wall of the center plate 23. The plate 23 is fixedly connected with the base 4 .

[0037] Working principle: when in use, open the warehouse door 25, start the cylinder 2 to control the limit box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com