Patents

Literature

95results about How to "Avoid overcutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

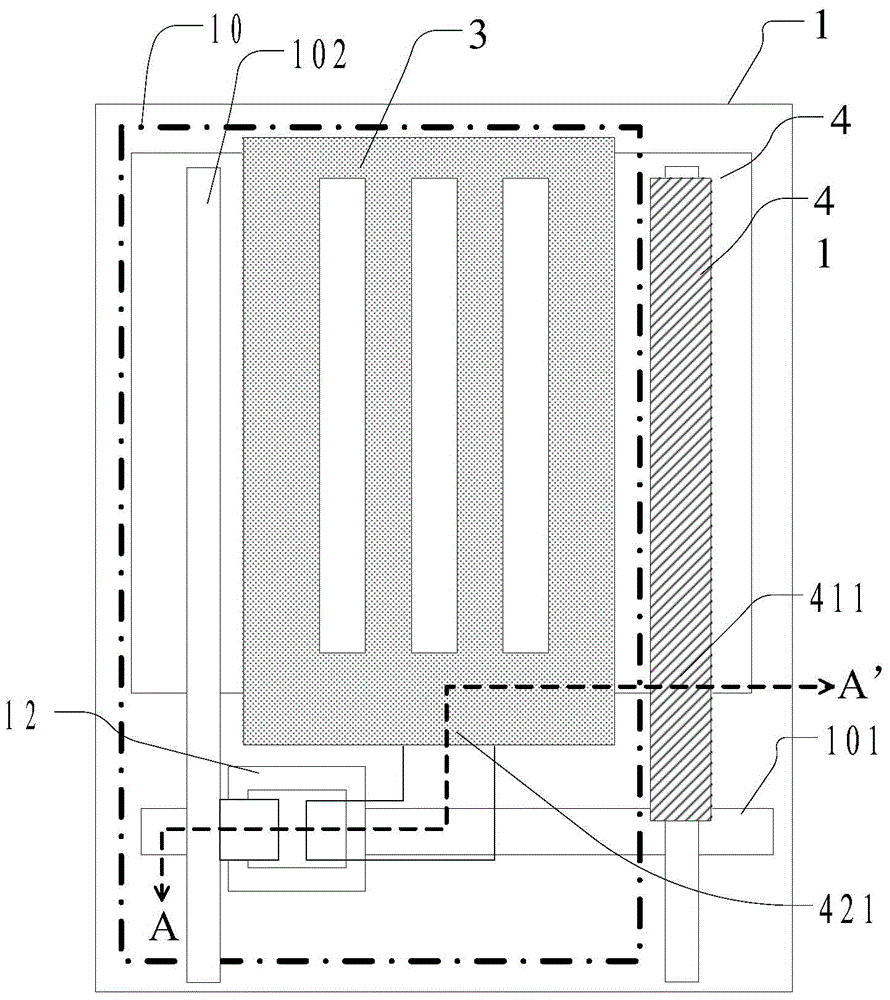

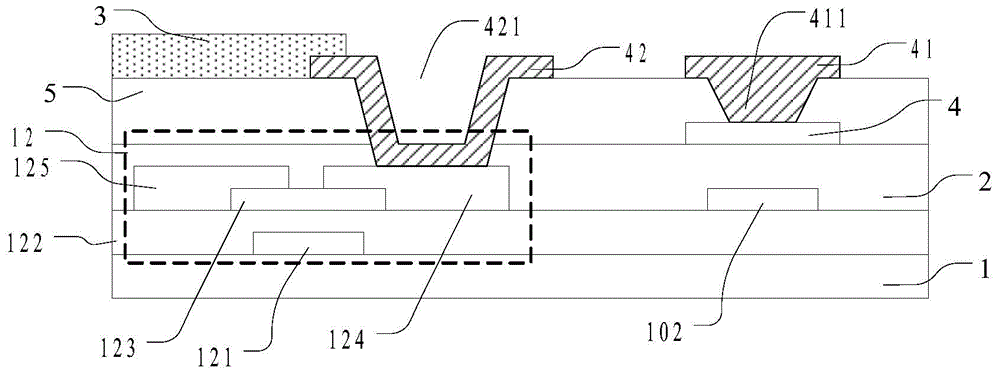

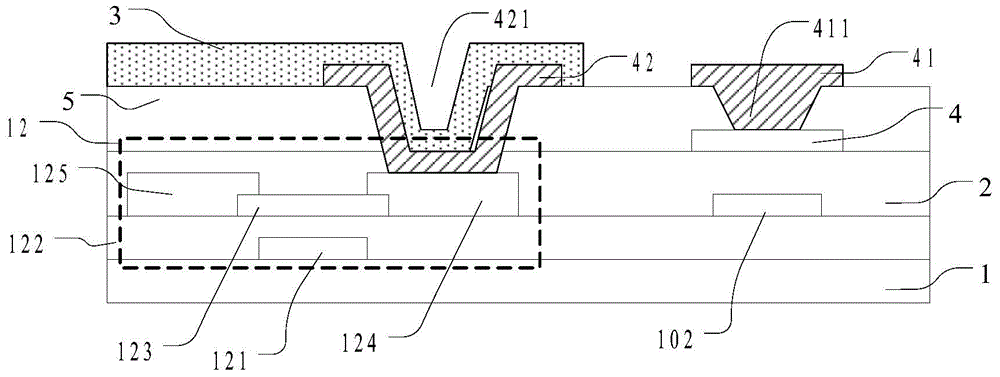

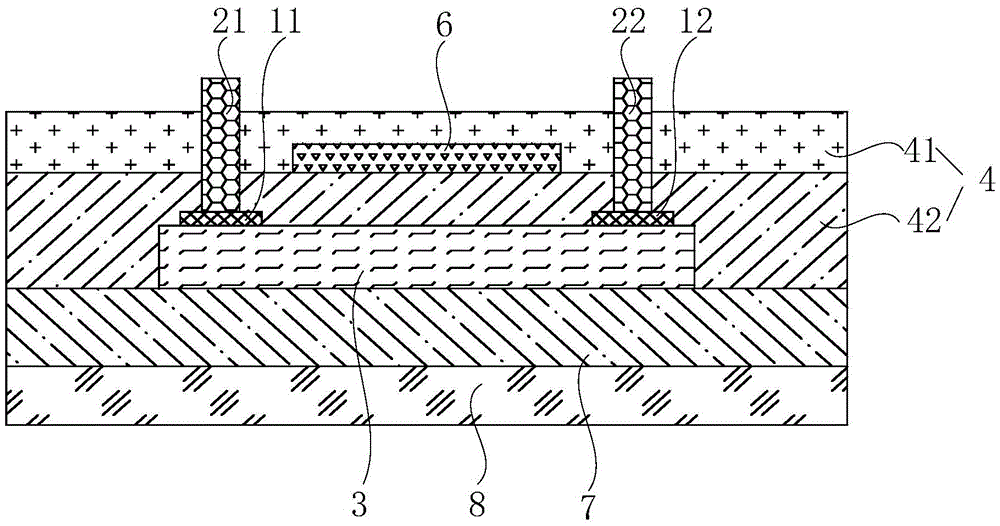

Array substrate and preparation method thereof, and display device

ActiveCN108376672AImprove voltage compensation capabilityIncrease pixel capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComposition process

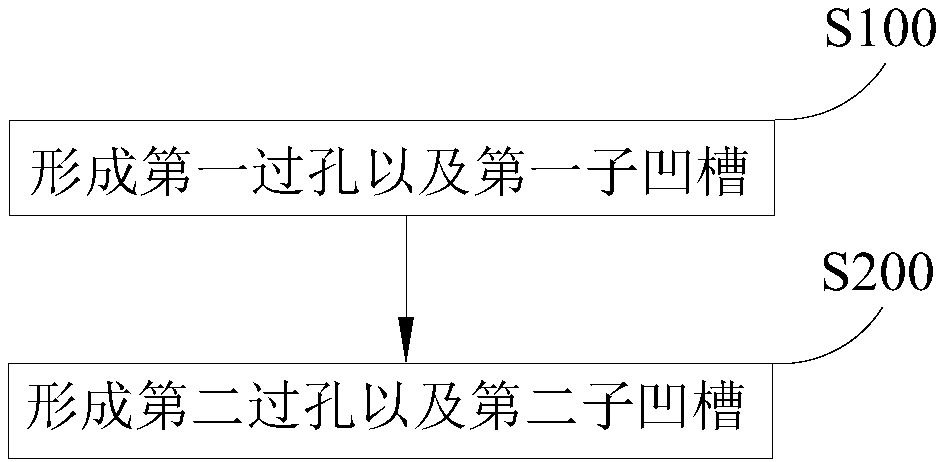

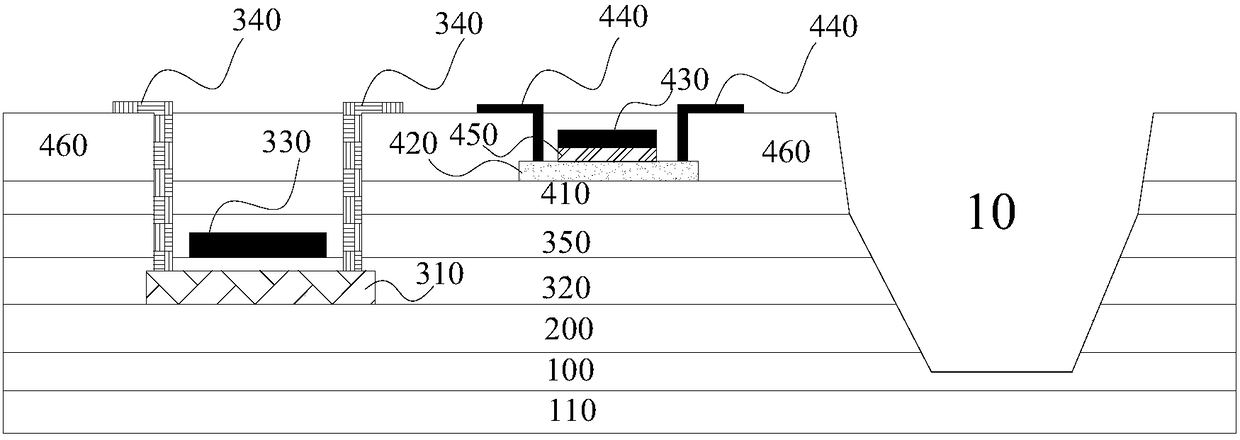

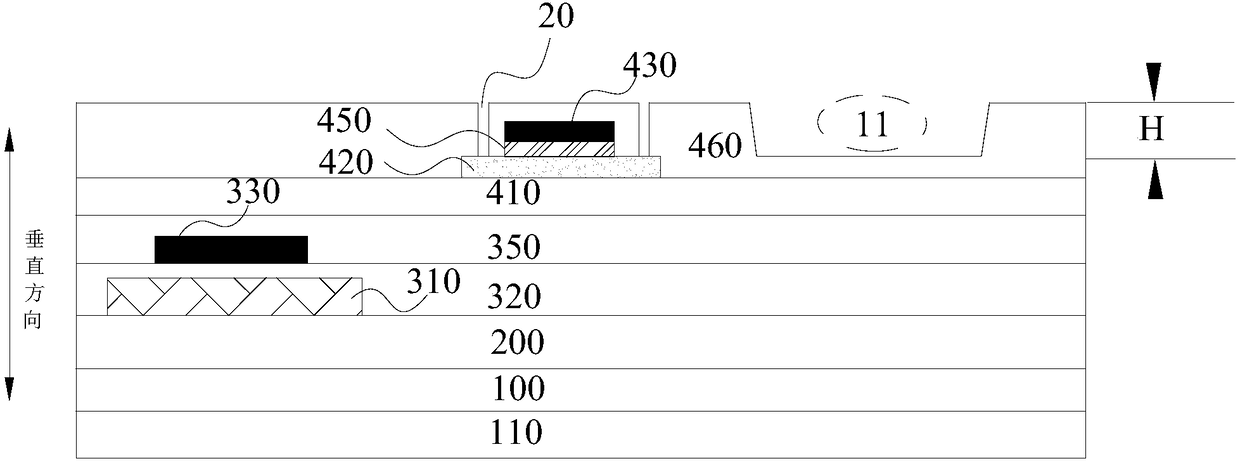

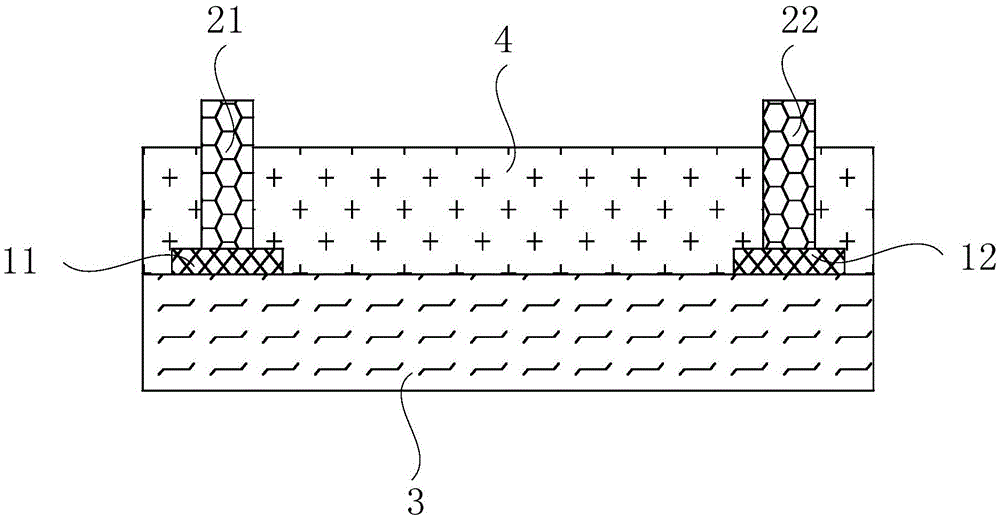

The invention discloses an array substrate and a preparation method thereof, and a display device. A base of the array substrate is provided with a first film transistor and a second film transistor and a groove arranged in a wiring region, wherein the groove comprises a first sub groove and a second sub groove. The method comprises steps that a first through hole and the first sub groove are formed through employing the one-time picture composition process; the second through hole and the second sub groove are formed through employing the one-time picture composition process. The method is advantaged in that a problem of active layer over-etching due to difference in depth of the two through holes when the two through holes are formed synchronously is solved, and prolongation of the production process is avoided.

Owner:BOE TECH GRP CO LTD

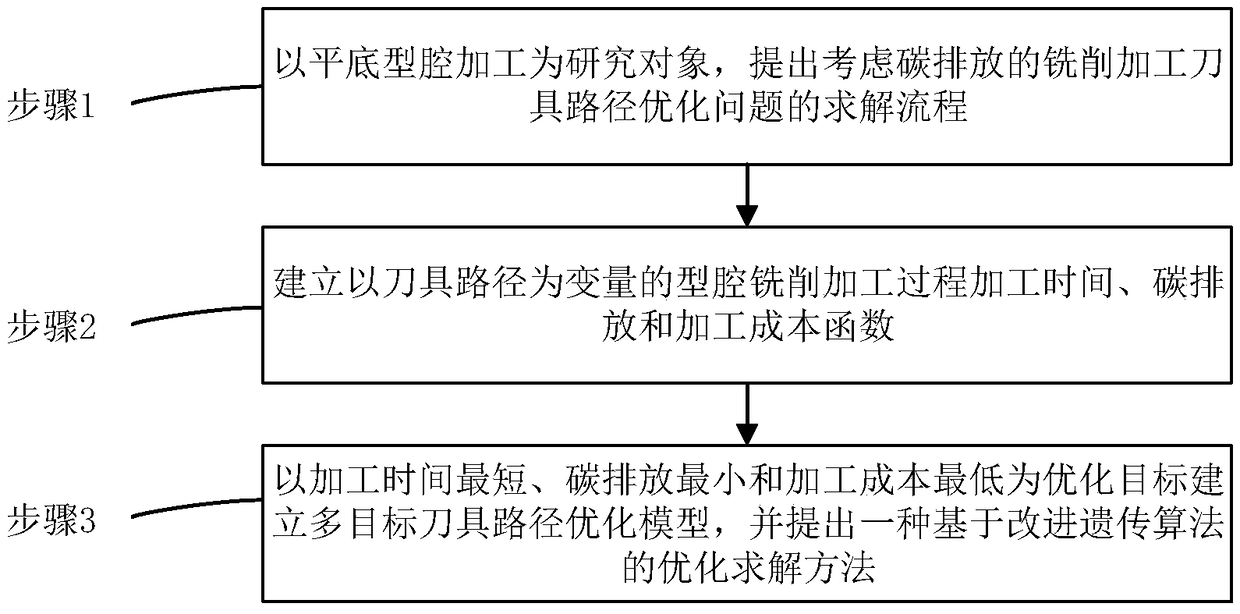

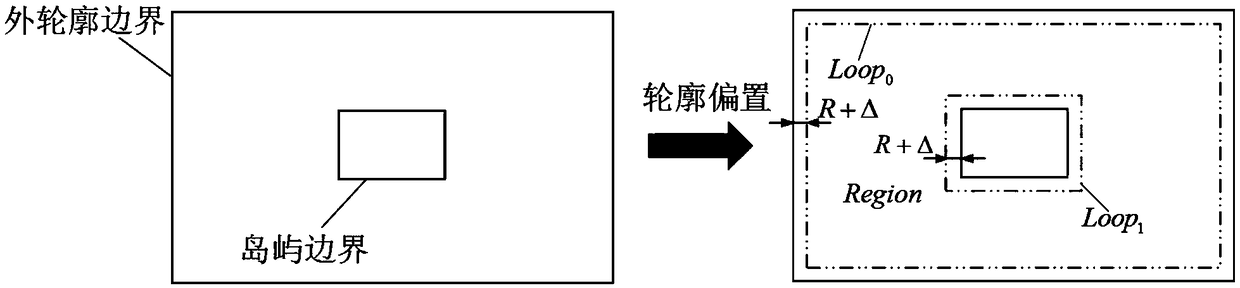

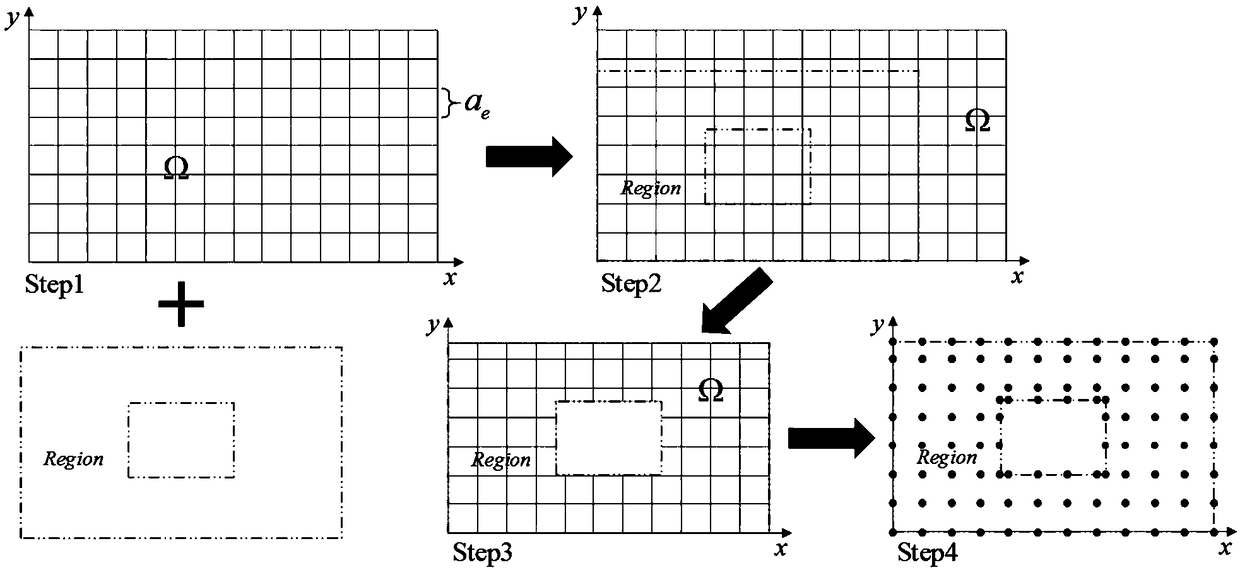

Milling tool path optimization method for low carbon

ActiveCN109240202AGuaranteed surface qualityEmission reductionNumerical controlLocal optimumResearch Object

The invention discloses a milling tool path optimization method for low carbon. The milling tool path optimization method comprises the steps of firstly, building solving process of milling tool pathoptimization problem considering carbon emission by taking flat cavity processing as a research object; secondly, building processing time, carbon emission and a processing cost function of cavity milling process taking a tool path as a variable; and finally, building a multi-target tool path optimization model taking shortest processing time, minimum carbon emission and lowest processing as optimization targets, and optimizing the multi-target tool path optimization model by an improved genetic algorithm-based optimization solution method. The method comprehensively considers the targets of the processing time, the carbon emission and the processing cost, the actual application demand of an enterprise is satisfied, the tool path optimization solving process is simple and effective and iseasy to implement, the population convergence speed is rapid during path optimization solving by the proposed improved genetic algorithm, and the algorithm can be effectively prevented from being sunken to local optimal solution.

Owner:XI AN JIAOTONG UNIV

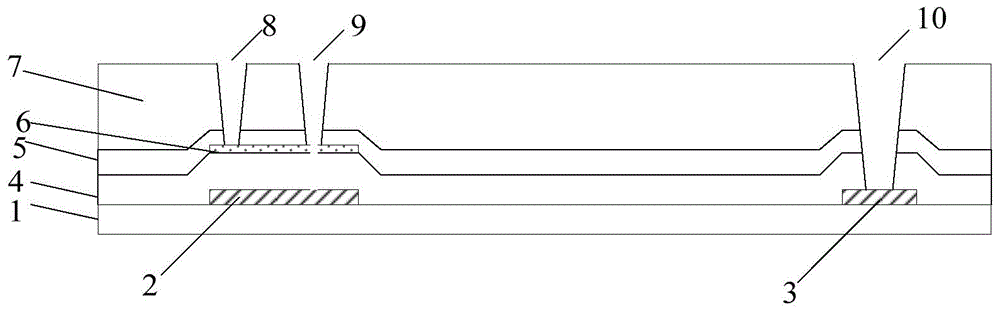

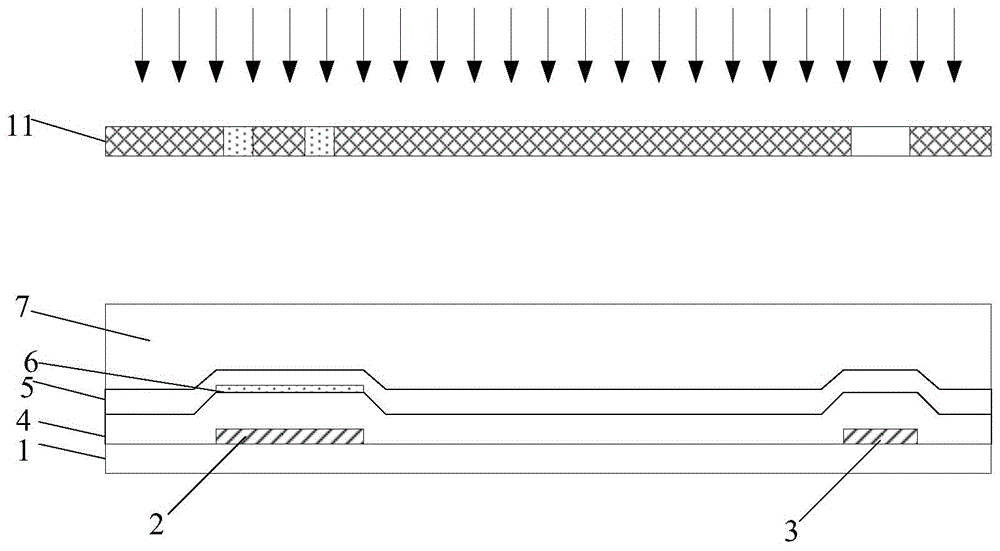

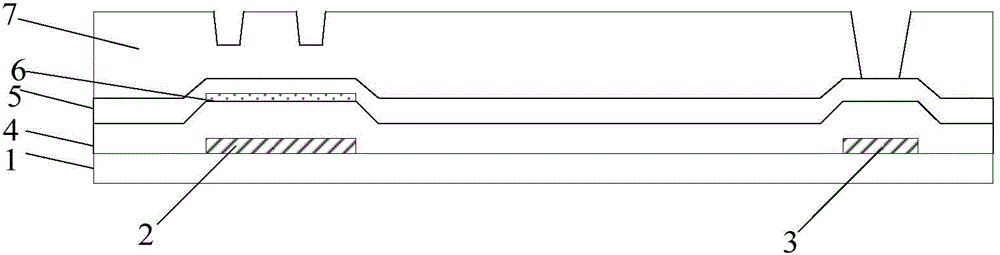

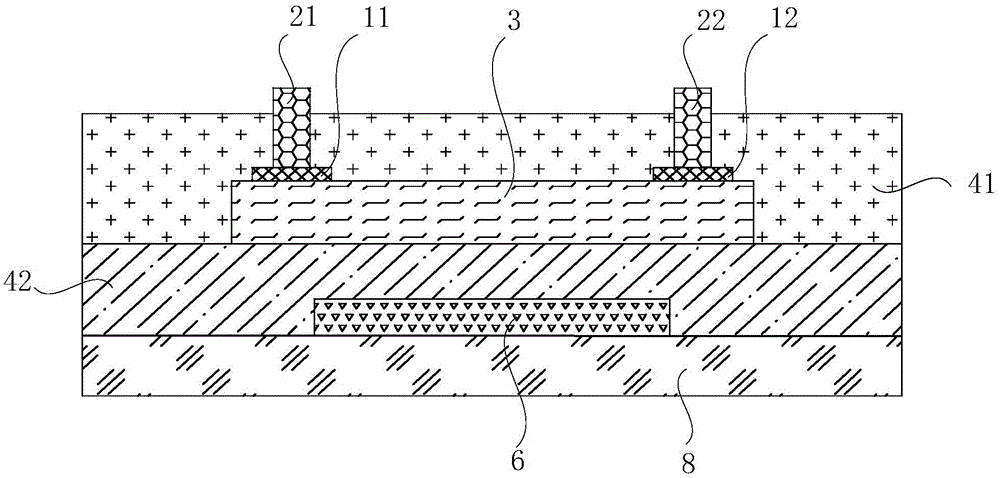

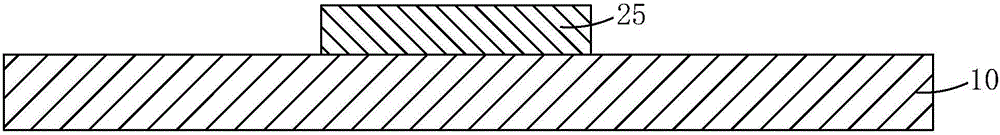

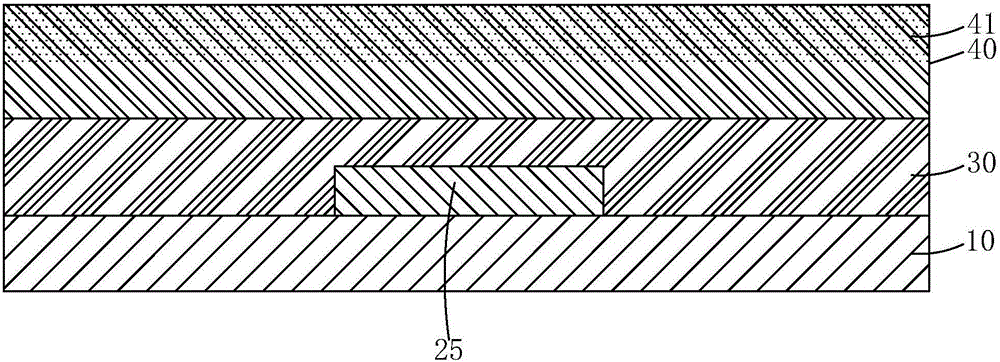

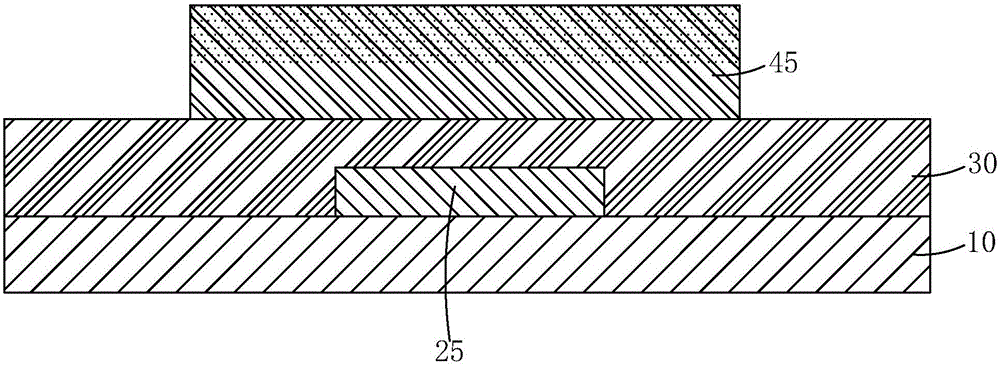

Array substrate, manufacturing method of array substrate and display device

ActiveCN104576542AAvoid overcuttingAvoid short circuit problemsSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceComposition process

The invention provides an array substrate, a manufacturing method of the array substrate and a display device. The manufacturing method includes the steps that photoresist is coated to an insulating layer covering a conductive pattern or a semiconductor pattern; exposing is carried out to at least form a photoresist partial reserving area and a photoresist complete removing area; etching is carried out to at least partially remove the portion, corresponding to the photoresist complete removing area, of the insulating layer so as to form a middle hole; etching is carried out again to form a first via hole, a second via hole is formed in the position of the middle hole, and the portions, where the first via hole and the second via hole are formed, of the conductive pattern or the semiconductor pattern are exposed, wherein the depth of the first via hole is smaller than the depth of the second via hole. By means of the array substrate, the manufacturing method of the array substrate and the display device, on the premise that the number of times of composition processes of the array substrate is not increased, the condition that when a shallow hole and a deep hole are etched at the same time, an oxide semiconductor layer and a gate insulating layer at the position of the shallow hole are punctured through etching due to long-time etching, so that a single line and a gate line are in short circuit is avoided.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

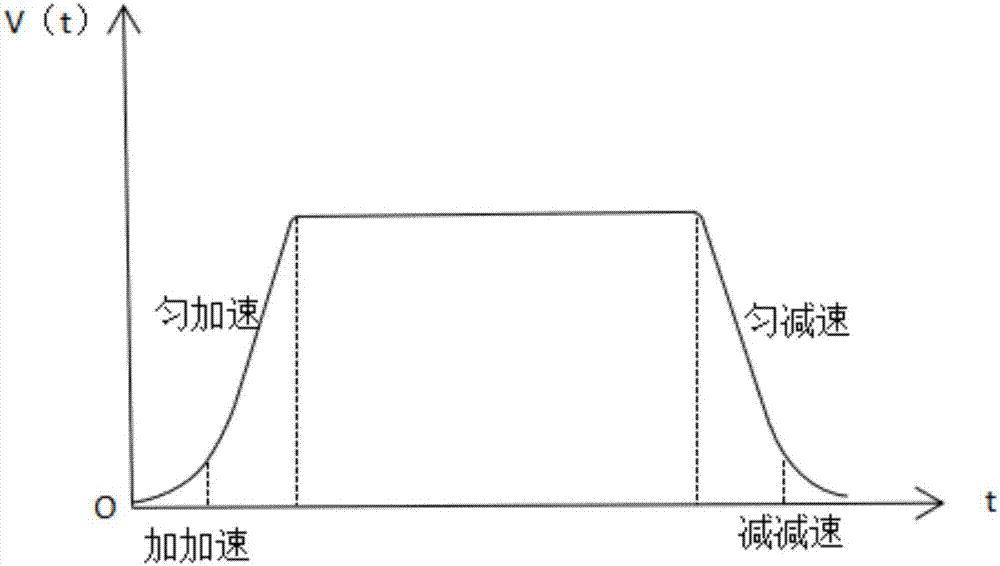

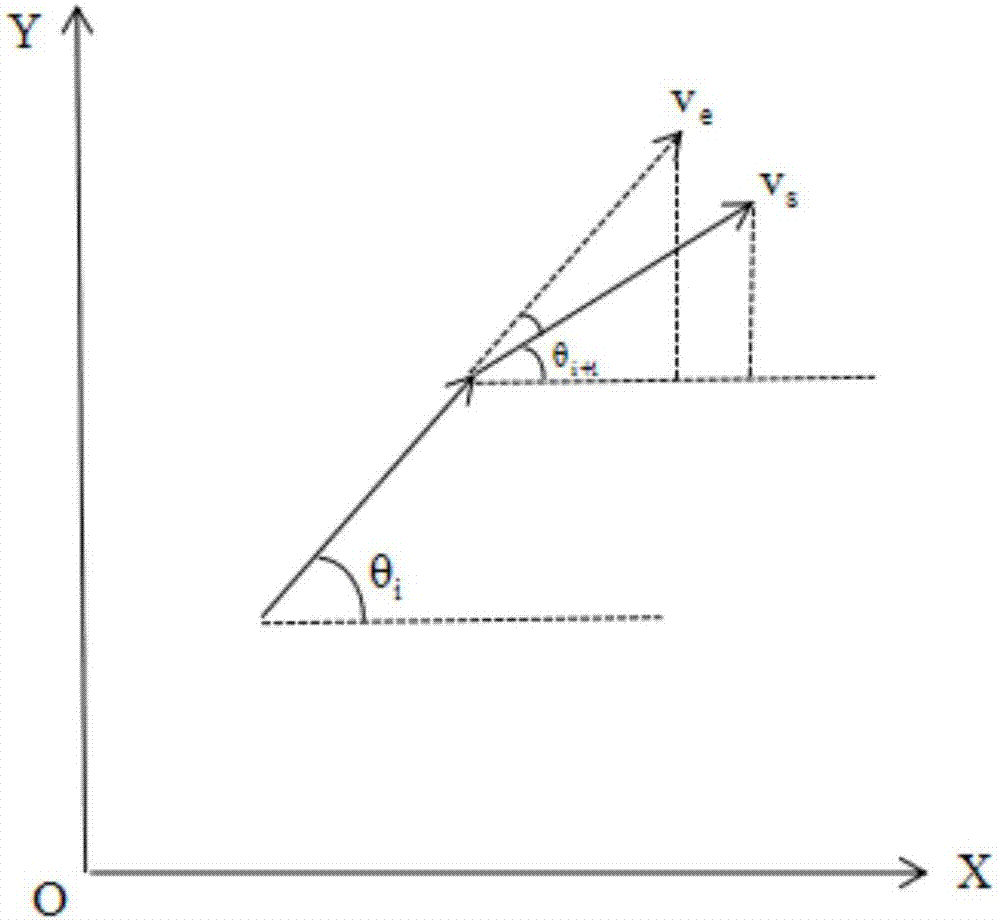

Speed planning method of cutting machine

ActiveCN107505918AAcceleration and deceleration time is shortGuaranteed uptimeNumerical controlAngular velocityEngineering

The invention discloses a speed planning method of a cutting machine. The speed planning method comprises the steps of: 1) determining a corresponding ladder step length table by adopting an S-like five-stage acceleration and deceleration control method; 2) implementing variable acceleration by determining relations among an inflection point speed, a corner size and an acceleration, and adjusting the acceleration according to a current real-time speed when passing through different corners of a track; 3) calculating a self-adaptive inflection point speed, and determining a final corner speed according to an angular velocity solution formula and a speed reverse derivation method. The speed planning method of the cutting machine provided by the invention effectively shortens the motion acceleration and deceleration time and increases the corner speed in the cutting process.

Owner:宁波永石精密工具有限公司

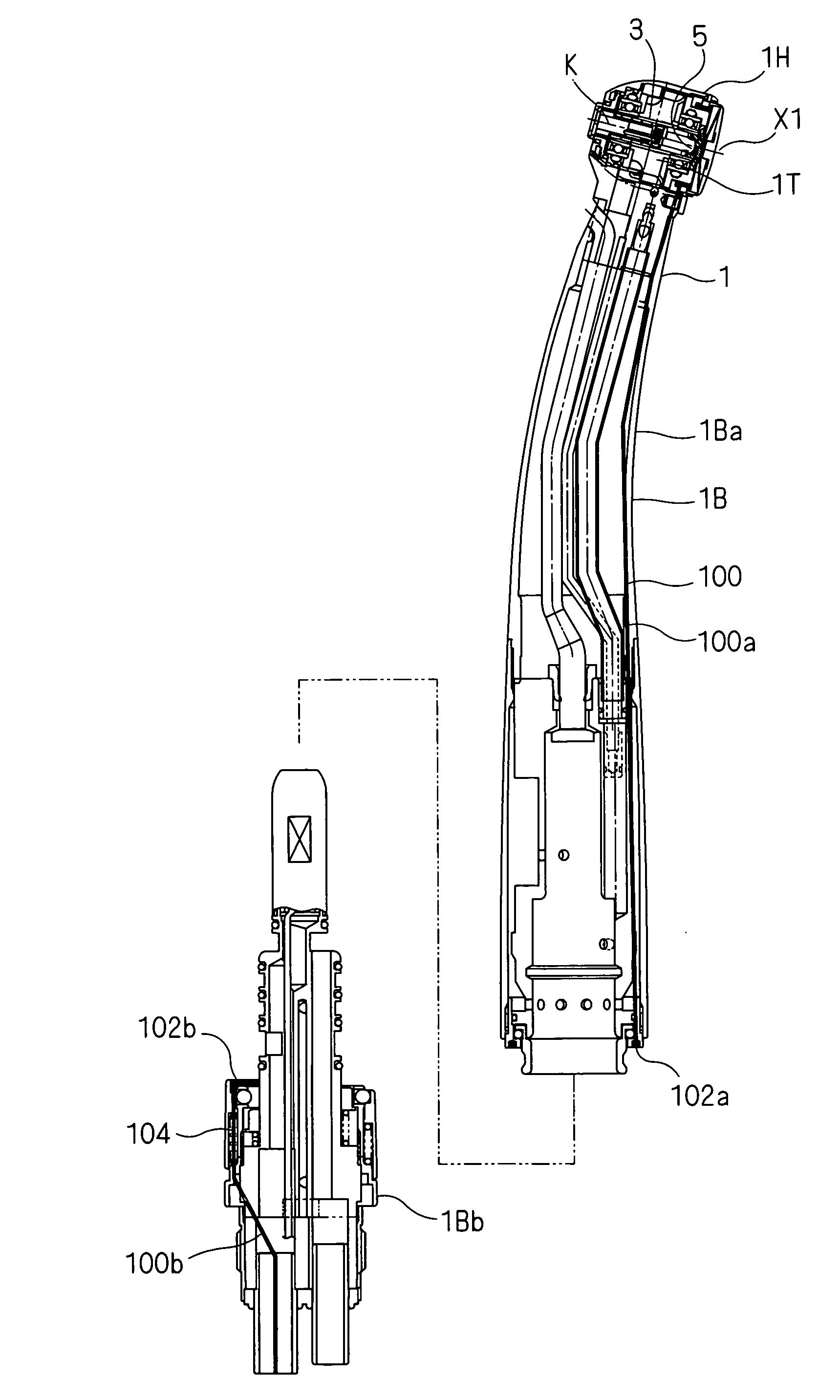

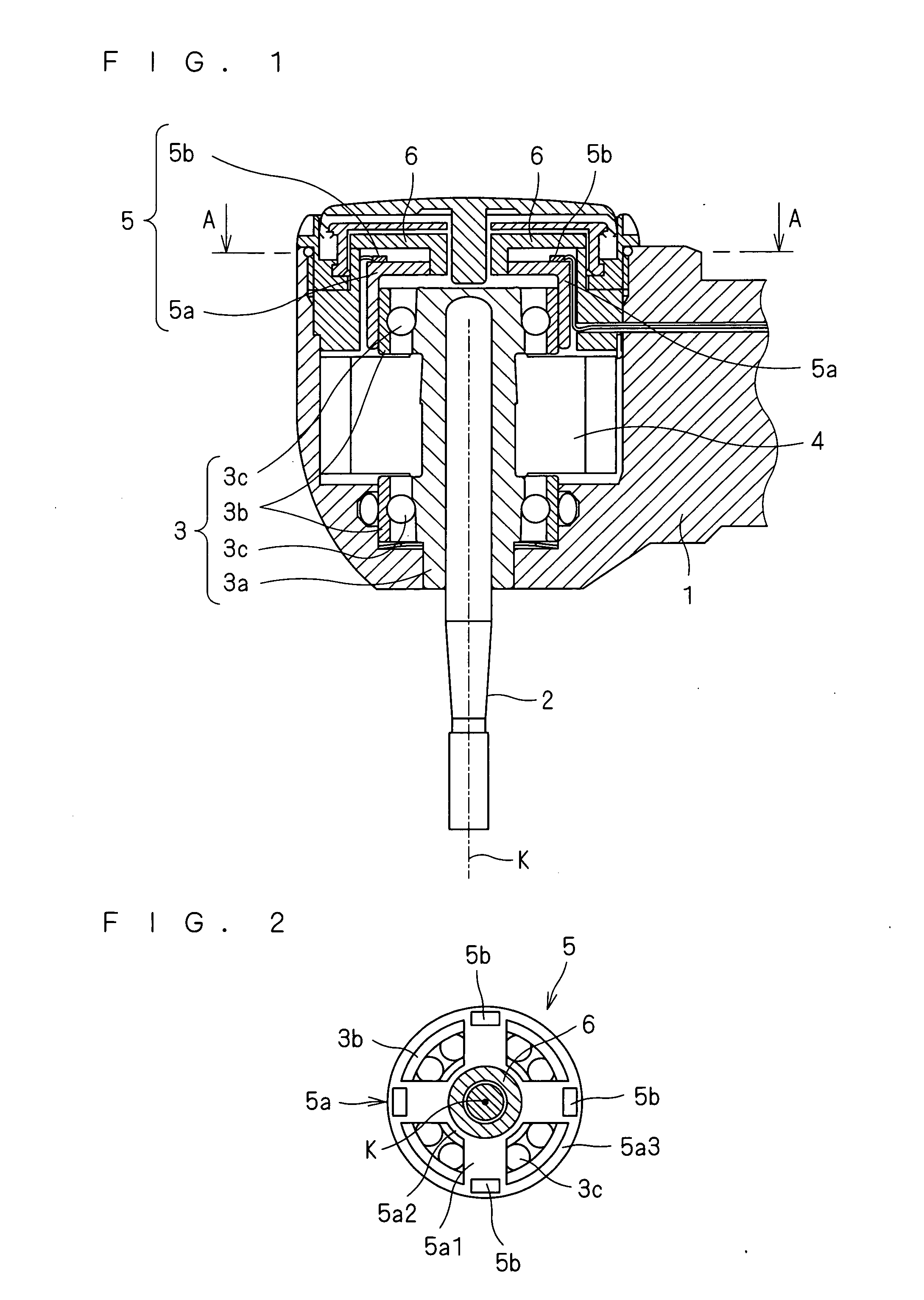

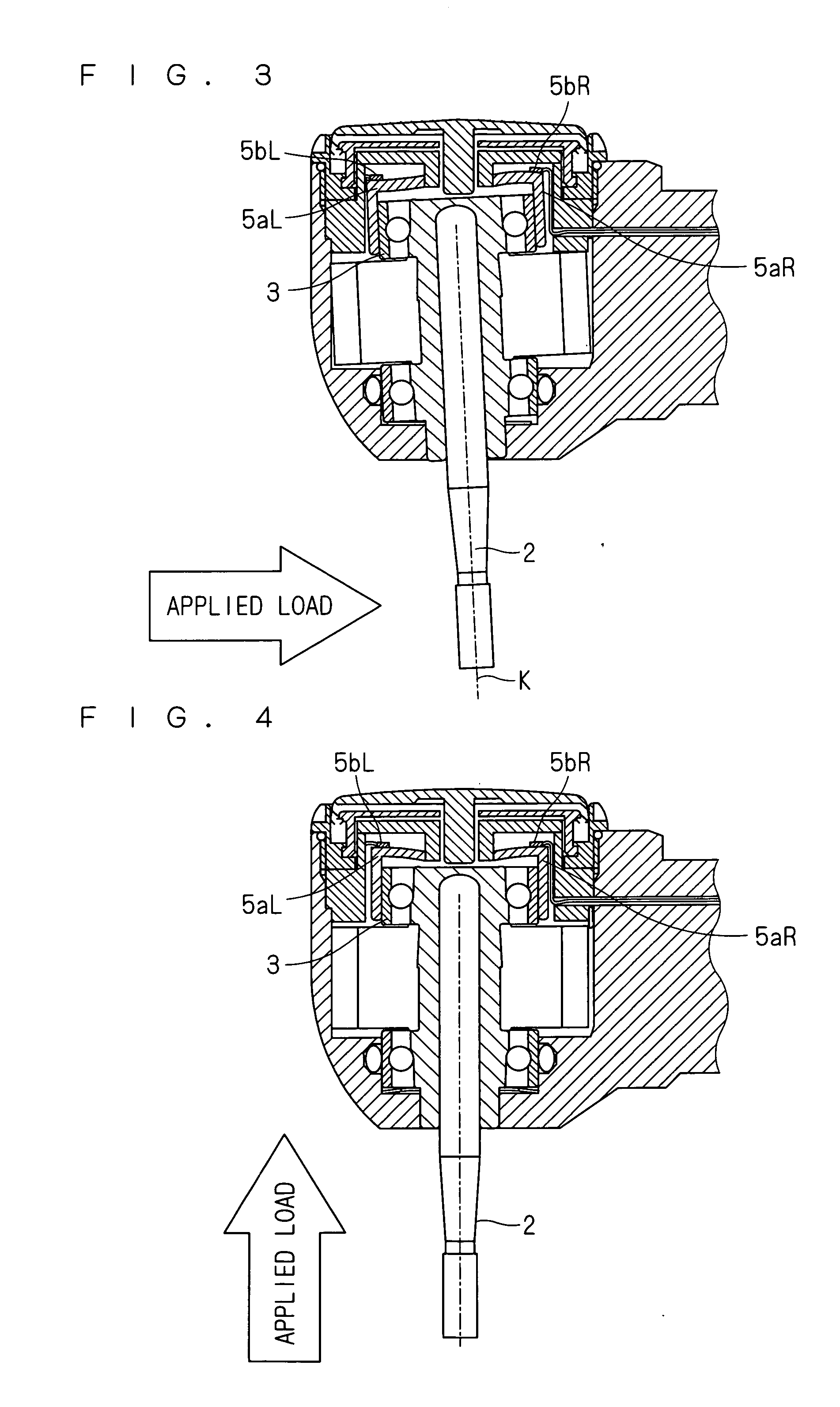

Medical cutting device and medical cutting training device

Provided is a medical cutting device including a housing, a cutting tool, a tool supporting unit and a load detecting unit. The housing supports the tool supporting unit and the load detecting unit. The tool supporting unit supports the cutting tool. The load detecting unit detects a load applied to the cutting tool.

Owner:MORITA MFG CO LTD

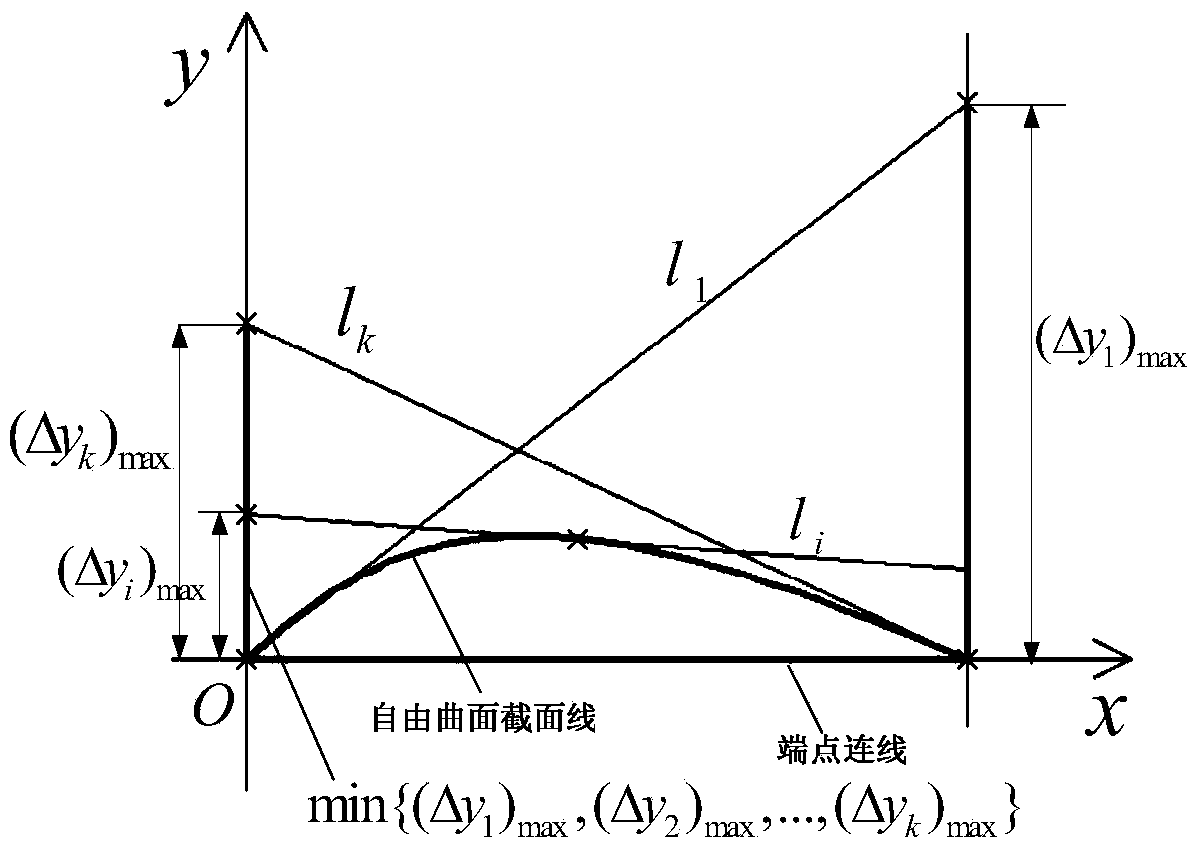

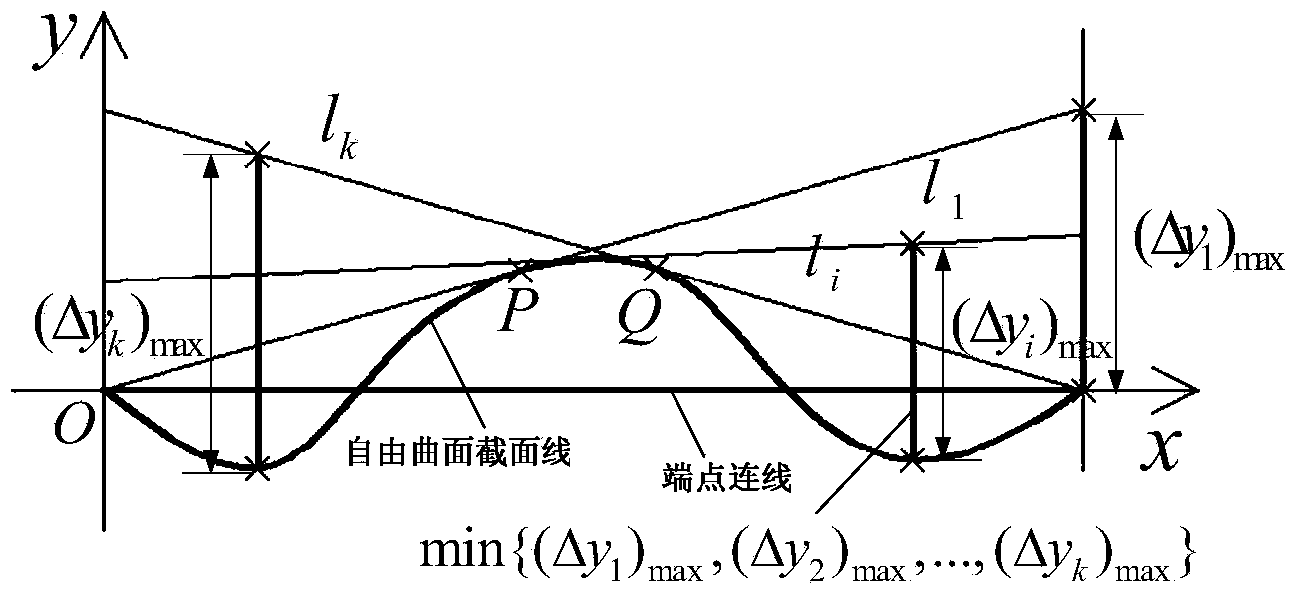

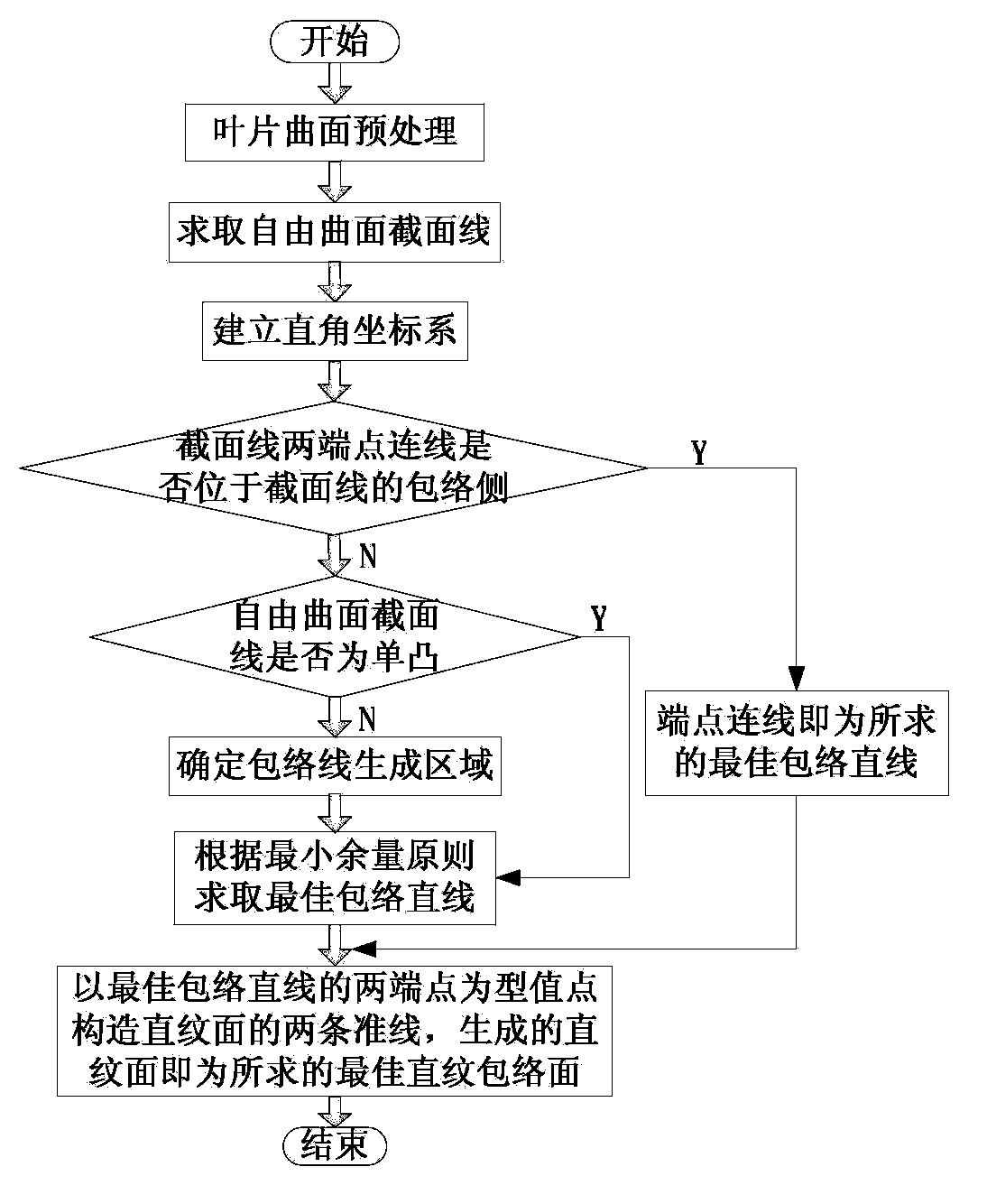

Method for generating optimal straight-line enveloping surface of free-form surface blade

InactiveCN103513606AGuaranteed uniformitySolve the problem of efficient roughingMilling equipment detailsNumerical controlImpellerFree form

The invention discloses a method for generating an optimal straight-line enveloping surface of a free-form surface blade. The method for generating the optimal straight-line enveloping surface of the free-form surface blade comprises the steps of (1) carrying out offset on the blade, carrying out preprocessing on the blade through the method that shortening is carried out and then tangential extending is carried out so as to obtain a curved surface to be enveloped; (2) cutting out the curved surface to be enveloped through a plurality of planes to obtain free-form surface section lines, wherein the planes are arranged at equal intervals and are perpendicular to the axial direction of an impeller or a blade disk; (3) according to the free-form surface section lines, generating optimal enveloping straight lines of the free-form surface section lines through the residual allowance maximum minimizing method according to the position relation between endpoint connecting lines of the free-form surface section lines and the free-form surface section lines, and concavity and convexity of the free-form surface section lines; (4) using two endpoints of each of all the optimal enveloping straight lines as data points to generate two splines, using the two generated splines as directrixes to generate the optimal straight-line enveloping surface of a free-form surface. When the optimal straight-line enveloping surface generated through the method for generating the optimal straight-line enveloping surface of the free-form surface blade serves as a tool drive surface, uniformity of the working allowance can be ensured, the overcutting phenomenon can be avoided in the process of machining, and efficiency of rough machining is remarkably improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

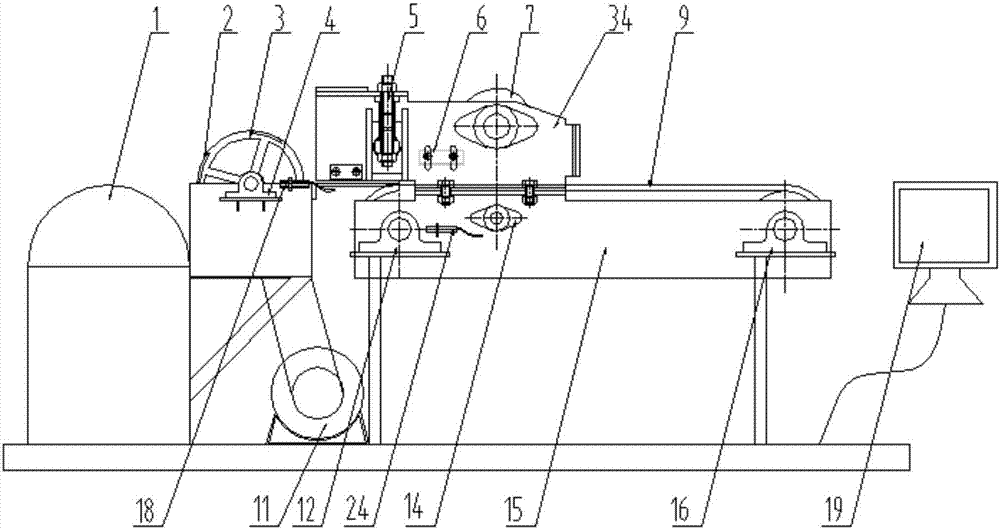

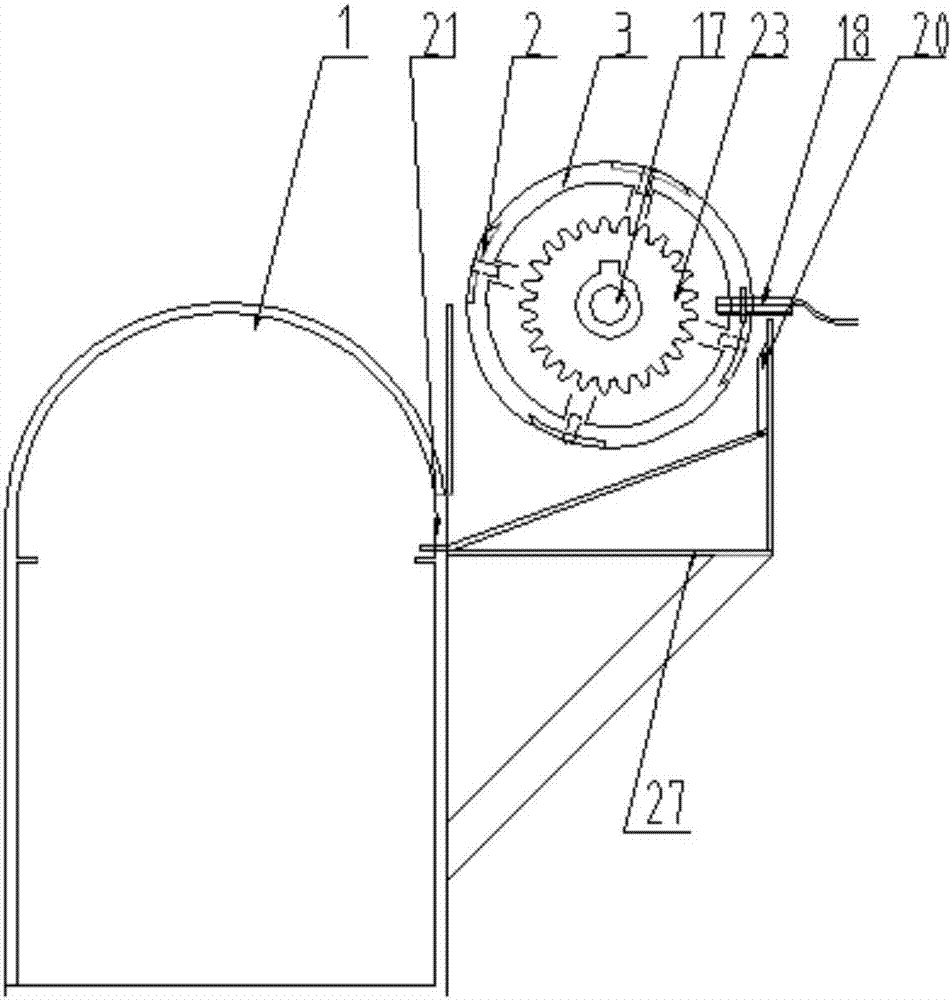

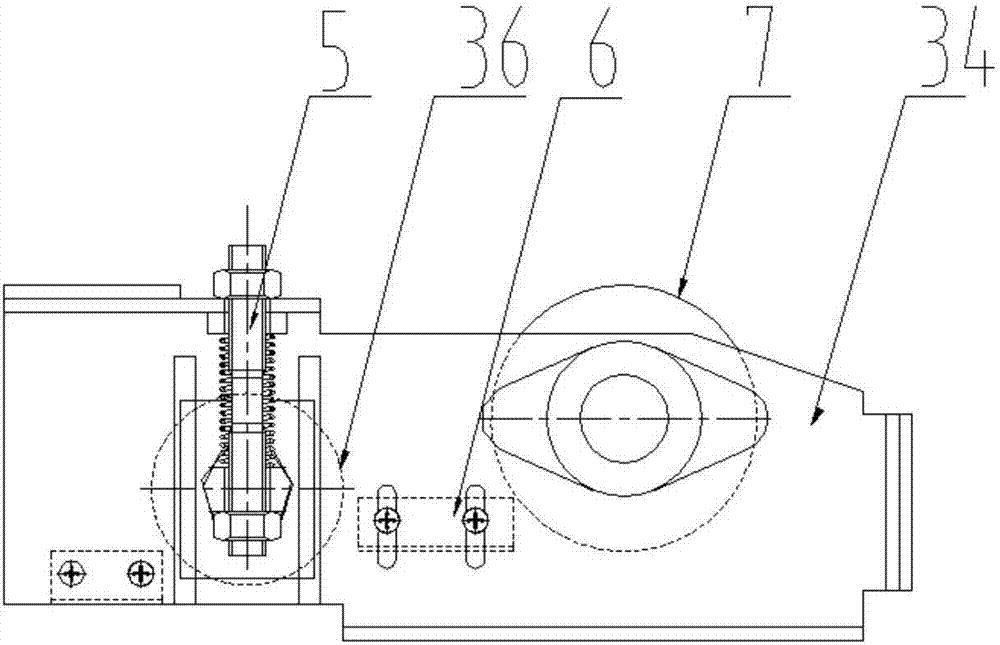

Straw cutting speed and length adjustable cylinder cutter

ActiveCN107046962AAdjust the speed in real timeControllable cutting speedCuttersControllers with particular characteristicsHelical lineResource utilization

The invention discloses a straw cutting speed and length adjustable cylinder cutter, belongs to the technical field of a straw resource utilization device, and is mainly used for rapidly and efficiently cutting a straw according to the required cutting length at the low power consumption. The cylinder cutter comprises a cylinder cutting device, a material pressing type feed device and a control display unit. The cylinder cutting device comprises a helical line type cutting moving blade, a horizontal cutting stationary blade and a rotating cylinder for installing the moving blade; the material pressing type feed device comprises an upper floating type material pressing roller, an upper fixing material pressing roller and a belt conveying platform; the cutting length is controlled through the belt conveying speed, and the cutting speed and the cutting efficiency are controlled through the belt conveying speed and the rotating speed of the rotating cylinder together. A controller acquires data through an acquisition test unit, the belt conveying speed and the rotating speed of the rotating cylinder are respectively controlled through calculation according to the set cutting length and the set cutting speed, and the straw is accurately efficiently cut at the low power consumption.

Owner:JIANGSU UNIV

Array substrate, preparation method thereof, and display device

ActiveCN104656332AImprove the display effectAvoid disconnectionSemiconductor/solid-state device detailsSolid-state devicesElectricityEtching

The invention discloses an array substrate, a preparation method thereof, and a display device comprising the array substrate. A first through hole through which part of a first electrode is exposed is arranged in a pixel switch; a first protective layer is arranged in the first through hole; a pixel electrode is electrically connected with the first electrode through the first protective layer; the protective layer and a first signal line are of the same metal layer; the first signal line provides an electric signal to a common electrode. Through the structural design, the drain metal in the first through hole can be effectively prevented from over-etching, so that the pixel electrode on the upper layer of a drain is prevented from being broken; therefore, the display effect of the display device is improved; moreover, the preparation method of forming the first signal line and the first protective layer on a third insulating layer in which the first through hole and a second through hole are formed is adopted, wherein the first protective layer is formed in the first through hole; in addition, the preparation method is easy to operate.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

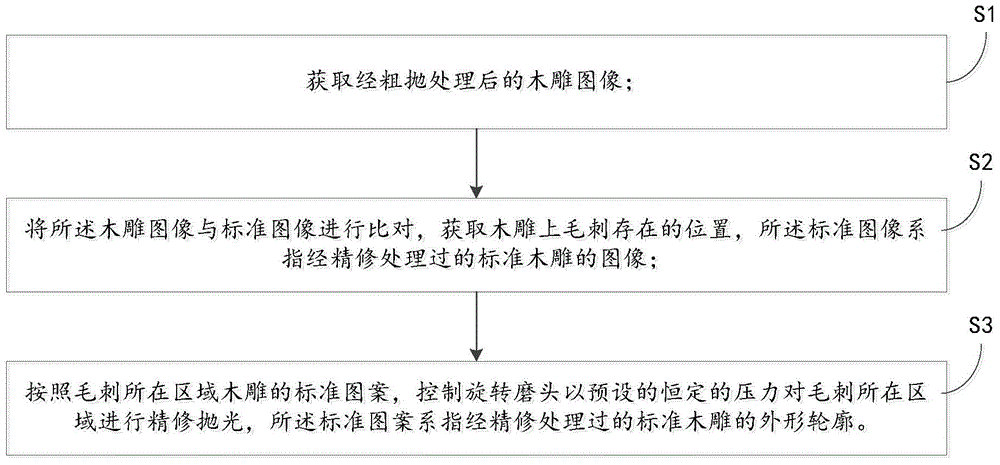

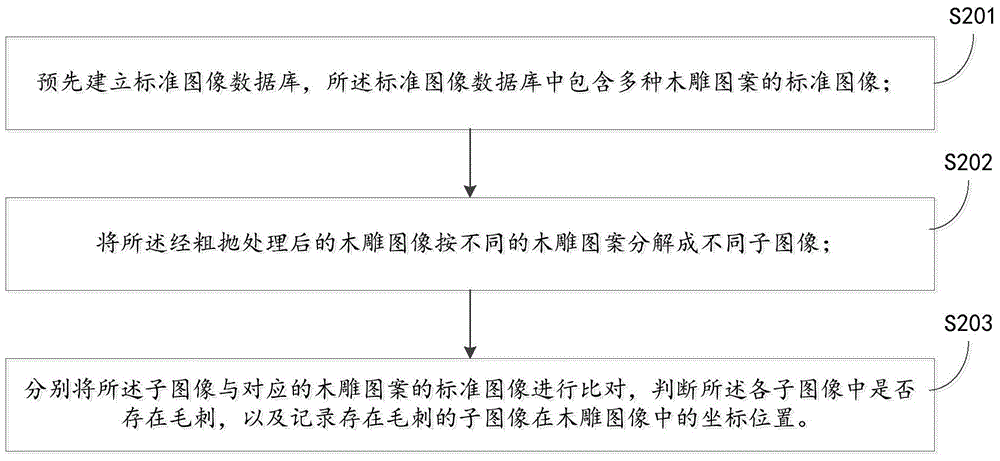

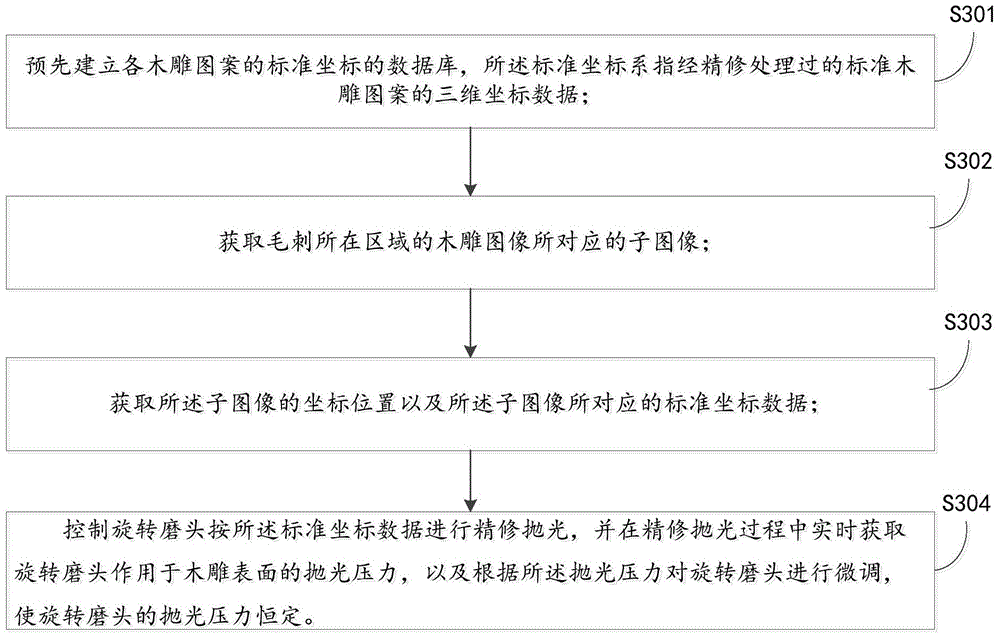

Woodcarving refine method and device based on image processing and force feedback

InactiveCN104959891AImprove search efficiencyQuality improvementEdge grinding machinesImaging processingDigital image processing

The invention discloses a woodcarving refine method based on image processing and force feedback; the method comprises the following steps: obtaining a woodcarving image after rough polishing; comparing the woodcarving image with a standard image so as to obtain burr positions on the woodcarving, and the standard image refers to a standard woodcarving image after refine process; controlling a rotary grinding head to carry out refine polishing on the burr positions with a preset constant pressure according to the woodcarving standard image of the burr positions, wherein the standard image refers to a layout of the standard woodcarving after refine treatment. The invention also discloses a woodcarving refine device based on image processing and force feedback, thus realizing high precision and high efficiency woodcarving refine by a machine.

Owner:福建省天大精诺信息有限公司

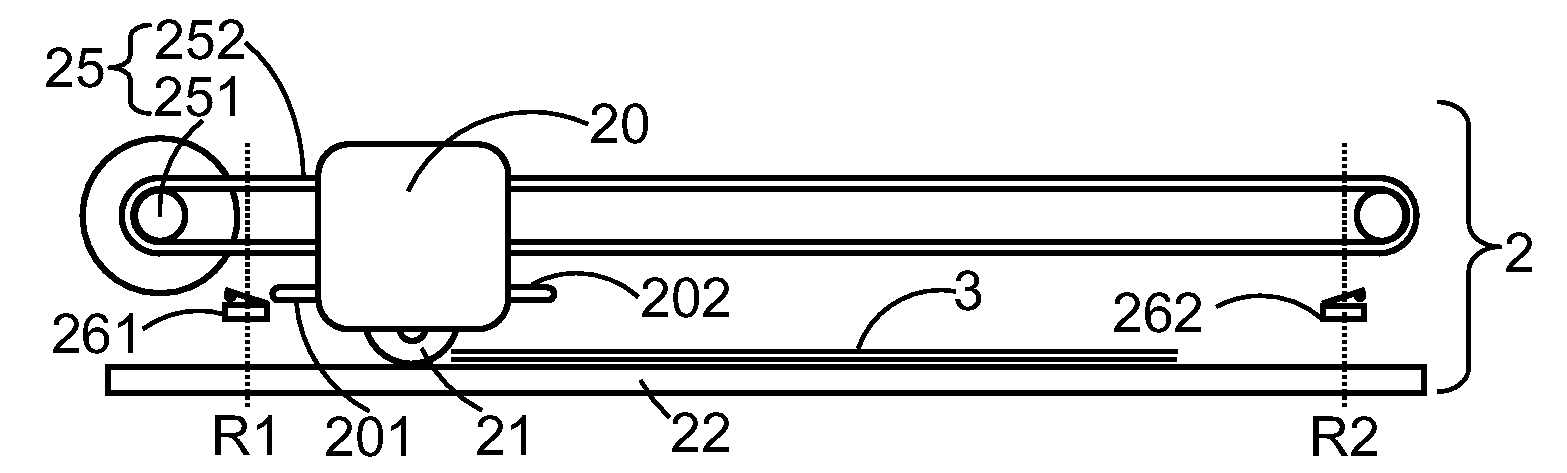

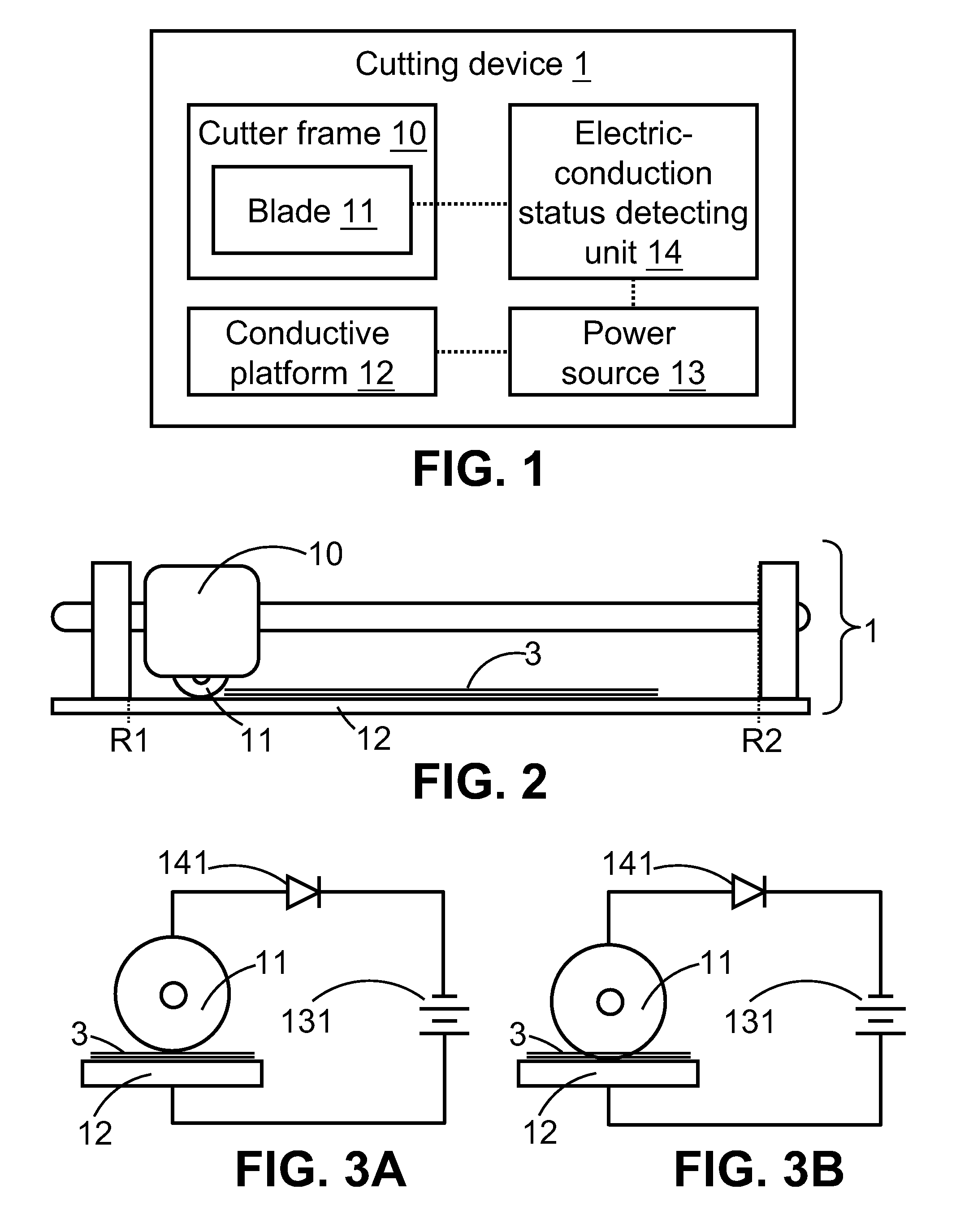

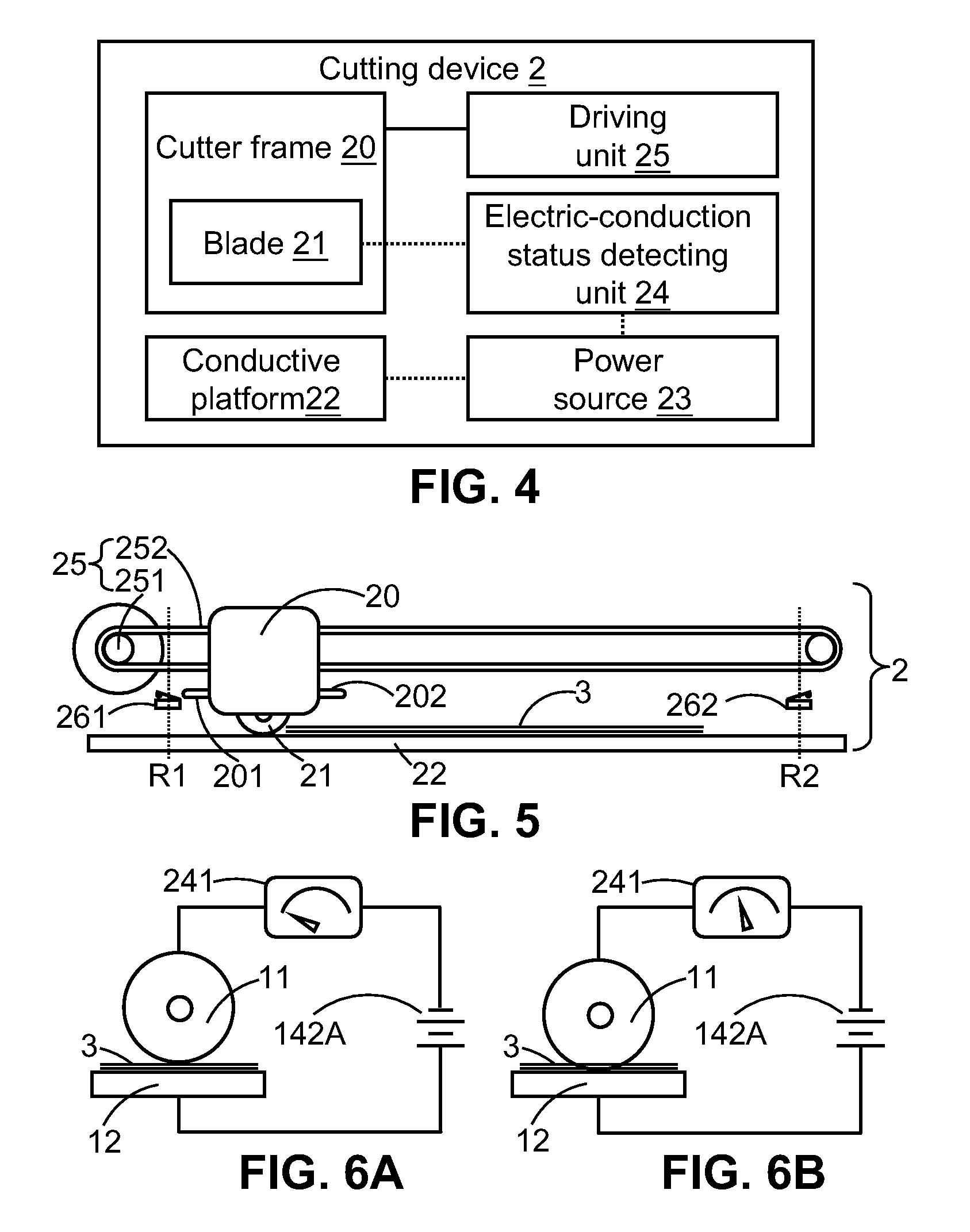

Method for detecting whether object is completely cut off and cutting device using such method

InactiveUS20090133554A1Avoid overcuttingPrevent under-cuttingAutomatic control devicesFeeding apparatusEngineering

The present invention relates to a method for detecting whether an object is completely cut off and a cutting device using such a method. The cutting device includes a cutter frame, a blade, a conductive platform and an electric-conduction status detecting unit. The electric-conduction status detecting unit can detect the electric-conduction status between the blade and the conductive platform to discriminate whether the object on the conductive platform is completely cut off by the blade.

Owner:PRIMAX ELECTRONICS LTD

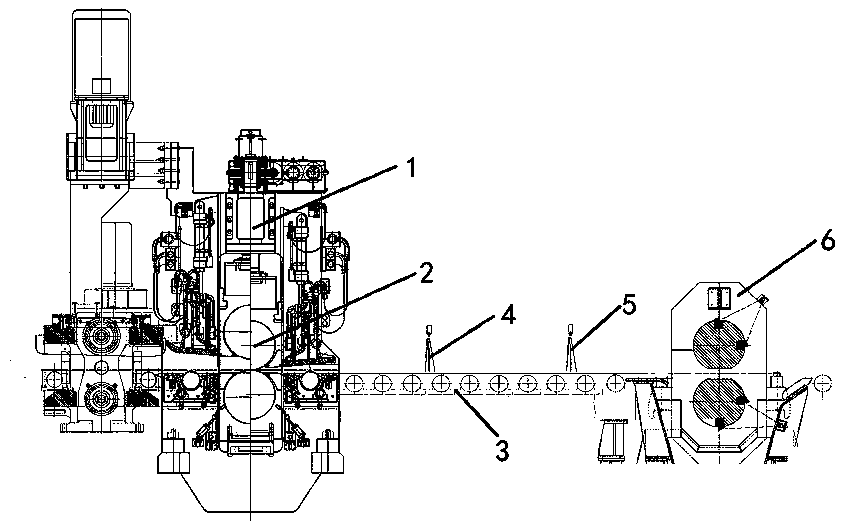

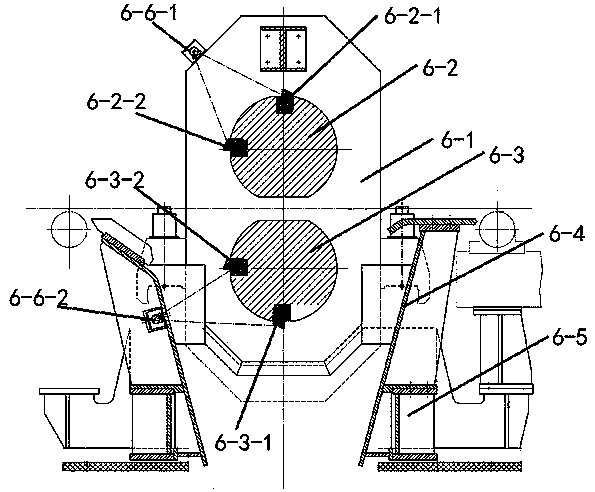

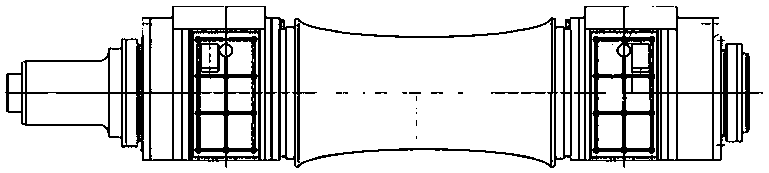

Device and method for preventing head and tail cutting amounts of flying shear from being excessively large

ActiveCN109807179AAvoid overcuttingReduce consumptionMetal rolling arrangementsAerospace engineeringControl system

The invention discloses a device and method for preventing the head and tail cutting amounts of a flying shear from being excessively large and belongs to the technical field of metallurgical steel rolling. The device comprises a roughing mill, a conveying rail, a flying shear mechanism and a flying shear control system. A roughing roll is arranged on the rough mill. One end of the conveying railis connected with the roughing mill, and the other end of the conveying rail is connected to the flying shear mechanism. The upper end of the conveying rail is provided with a thermal detection deviceI and a thermal detection device II in sequence, and the thermal detection device I and the thermal detection device II are both connected with the flying shear control system. The flying shear mechanism comprises a flying shear frame, an upper rotating drum and a lower rotating drum, wherein the upper rotating drum and the lower rotating drum are arranged on the flying shearing frame, the upperrotating drum is provided with an upper head cutting shear blade and an upper tail cutting shear blade, the lower rotating drum is provided with a lower head cutting shear blade and a lower tail cutting shear blade, and the upper head cutting shear blade, the upper tail cutting shear blade, the lower head cutting shear blade and the lower tail cutting shear blade are all connected to the flying shear control system. The device and method for preventing the head and tail cutting amounts of the flying shear from being excessively large reduce the head cutting length and tail cutting length of amiddle blank, avoids the head and tail cutting lengths of the middle blank from being excessively large, reduces the consumption of the middle blank, improves the outturn percentage and reduces production cost.

Owner:HEBEI PUYANG IRON & STEEL

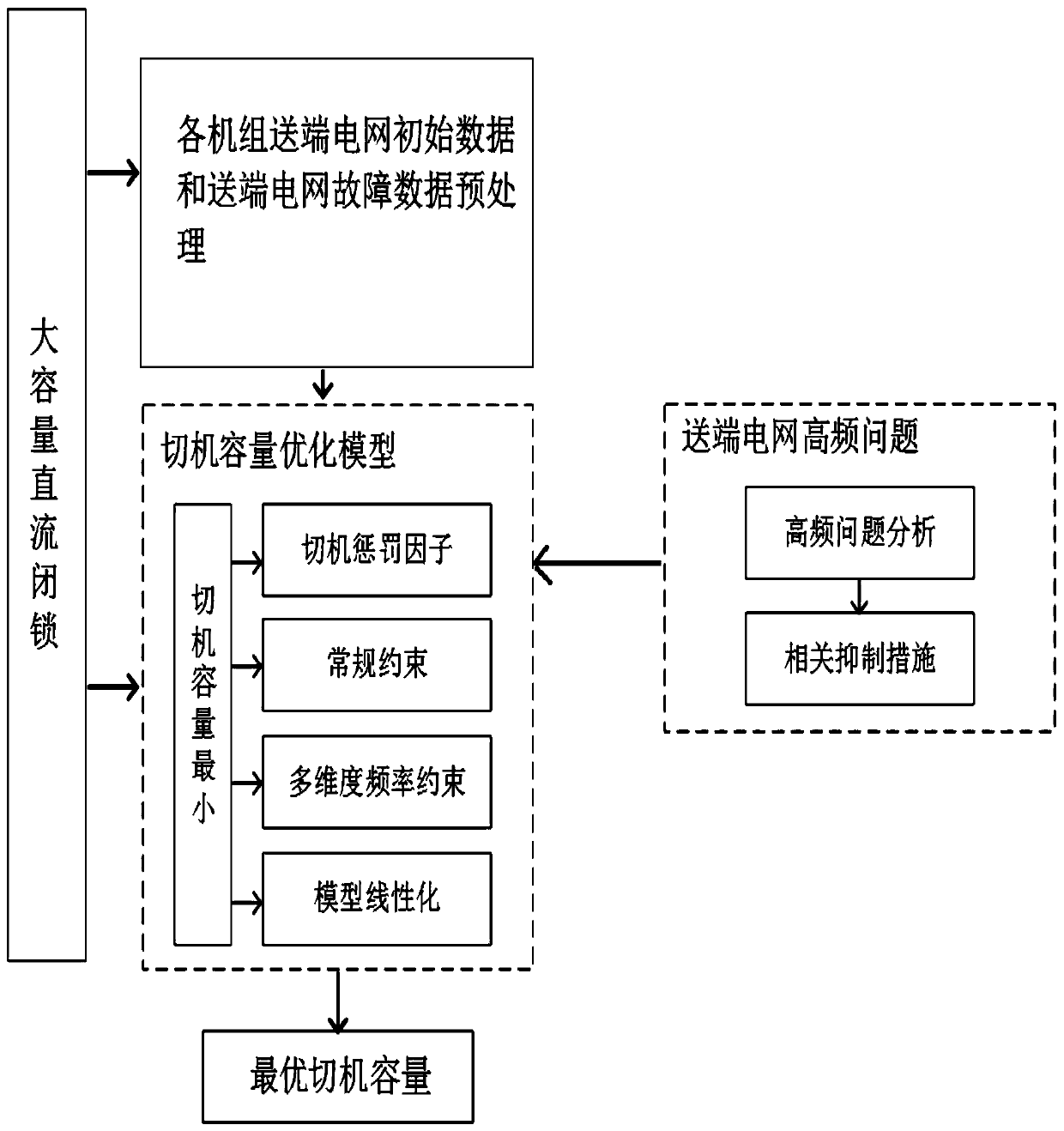

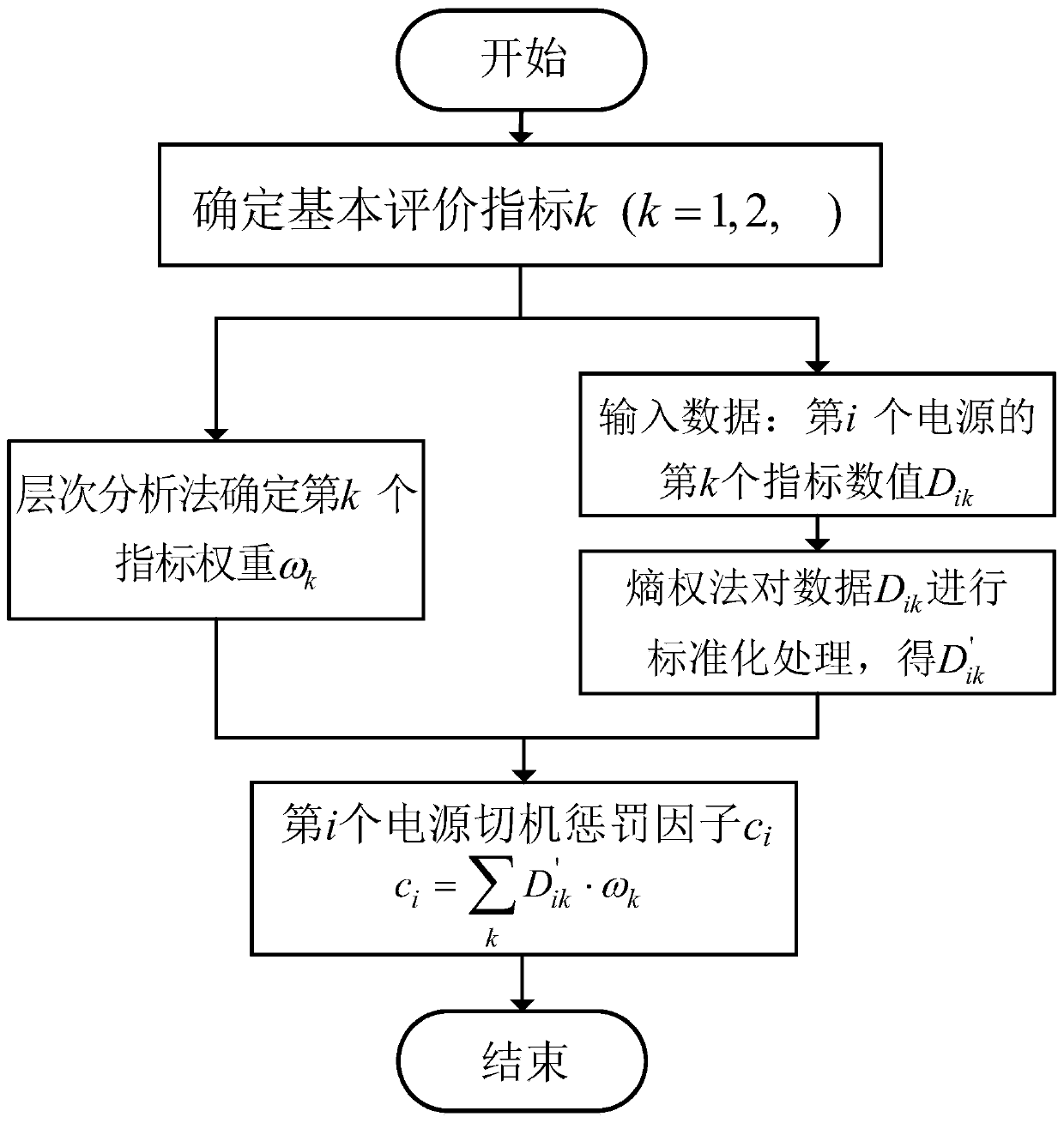

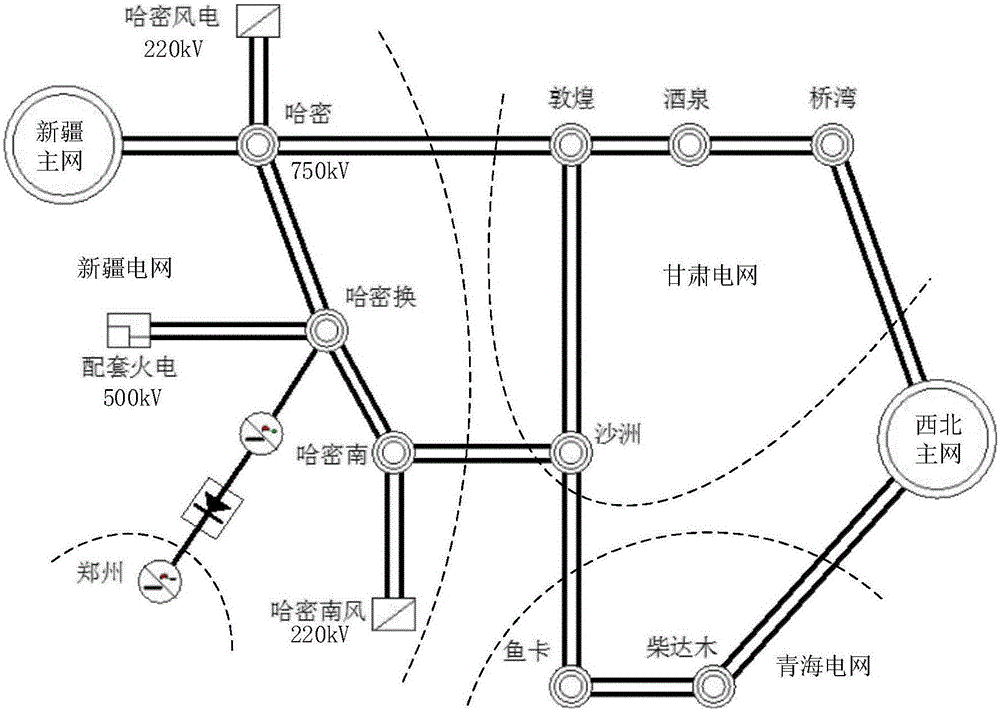

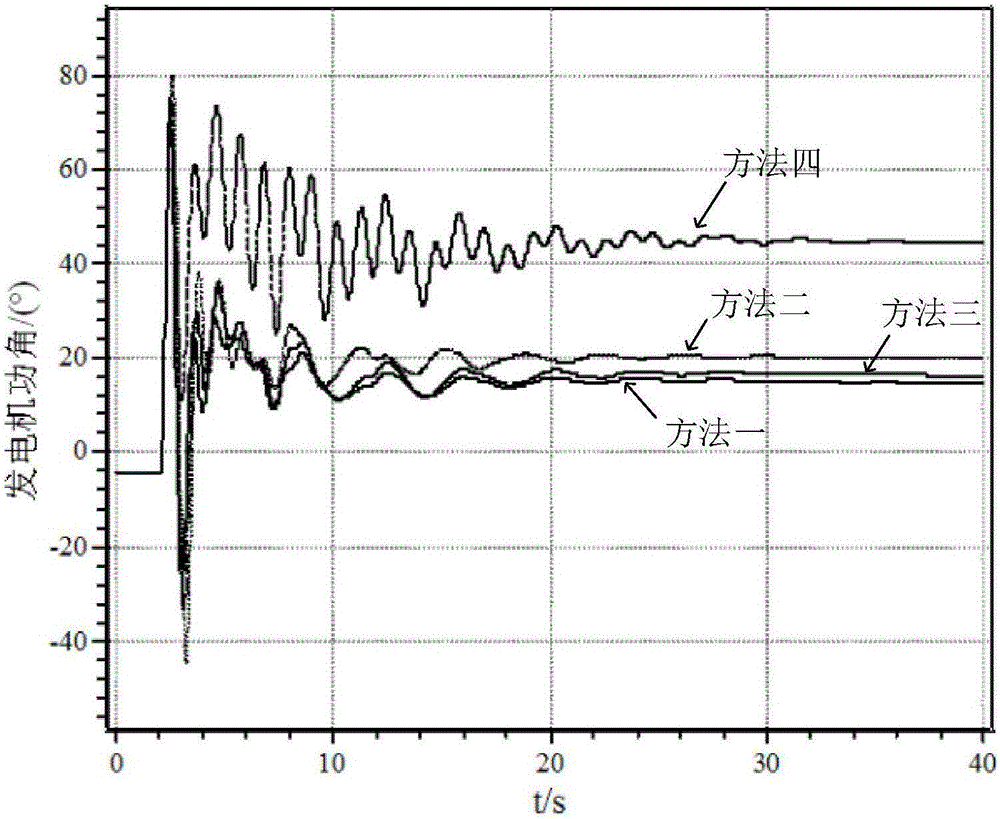

Optimized generator tripping capacity acquisition method for suppressing high-frequency problem of sending-end power grid

ActiveCN111525598AGood frequency adaptabilityPrecise control of cutting capacityPower oscillations reduction/preventionAc networks with different sources same frequencyPower gridControl theory

The invention discloses an optimized generator tripping capacity acquisition method for suppressing a high-frequency problem of a sending-end power grid. The method comprises the steps of firstly analyzing a sending-end power grid high-frequency problem and a related suppression strategy under a high-capacity direct-current blocking accident; and then constructing a power grid generator tripping capacity optimization model, calculating generator tripping penalty factors of each power supply in the sending-end power grid, and finally substituting the generator tripping penalty factors into thepower grid generator tripping capacity optimization model considering the system frequency stability requirement to solve to obtain the sending-end power grid generator tripping optimization mode andthe corresponding generator tripping capacity under the direct-current blocking accident. According to the scheme, the global power supply of the sending-end power grid is brought into a removal alternative, the difference of generator tripping effects among different types of power supplies is considered, and the removal effects of different regions and different parameter performance units are quantitatively quantified through generator tripping penalty factors; the related suppression strategy of the high-frequency problem of the sending-end power grid under the impact of the large-capacitydirect-current locking anticipated accident is coordinated and optimized, the active surplus in the sending-end power grid is remarkably reduced, the total generator tripping capacity is kept withina reasonable range, and undertripping and overtripping phenomena are effectively avoided.

Owner:STATE GRID SICHUAN ECONOMIC RES INST

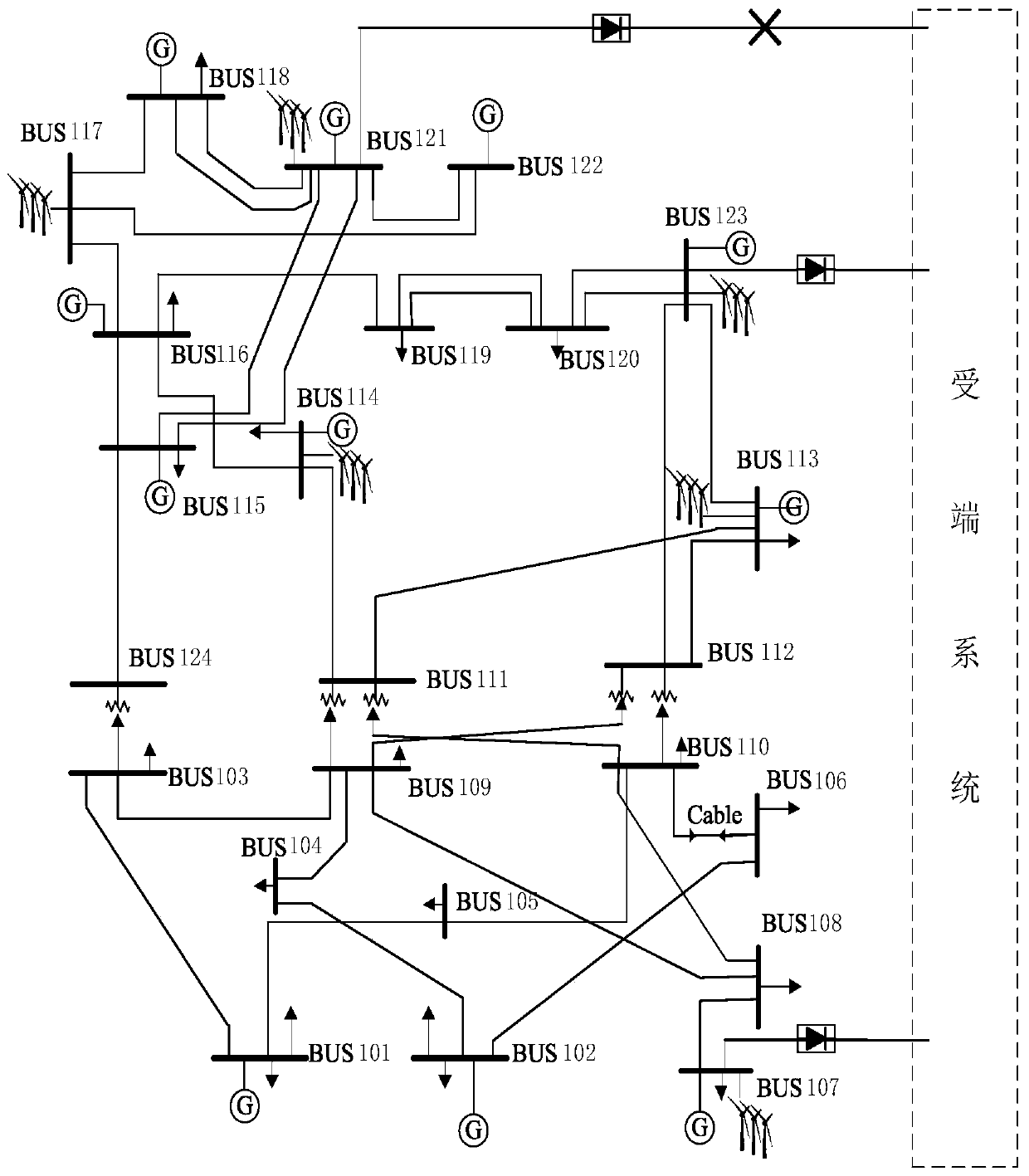

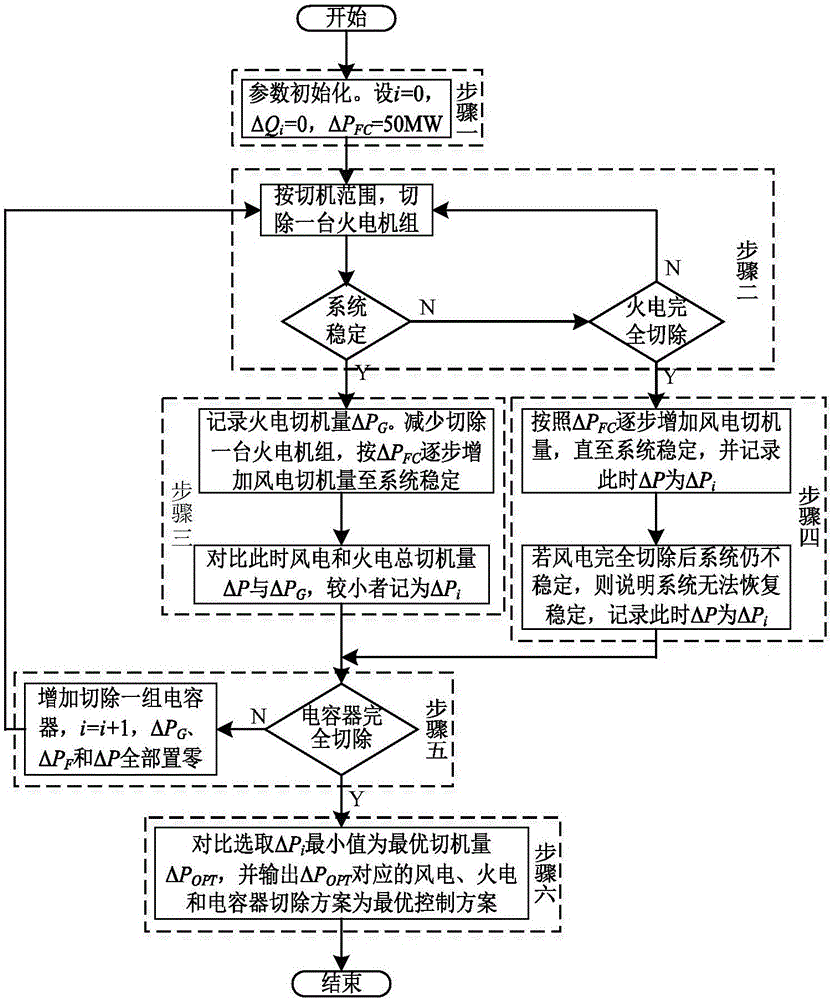

Control method for wind power, thermal power and capacitor coordinated wind and thermal bundling system after direct current block

ActiveCN106786727AOptimizing the ratio of wind-fired electrical cutting machinesRaise the voltage levelElectric power transfer ac networkSingle network parallel feeding arrangementsElectricityEngineering

The invention relates to a control method for a wind power, thermal power and capacitor coordinated wind and thermal bundling system after direct current block. The control method for the wind power, thermal power and capacitor coordinated wind and thermal bundling system after direct current block is characterized by comprising the following steps: initializing parameters at first, and switching off thermal power units one by one in a switch-off range until the system is stable or the thermal power units are switched off completely; if the system is stable, then remaining a thermal power unit, and switching off wind power units one by one until the system is stable; if the thermal power units are switched off completely, switching off the wind power units one by one until the system is stable or the wind power units are switched off completely; switching off a capacitor, switching off the thermal power units and the wind power units in the switch-off range until the system is stable or the wind power units and the thermal power units are switched off completely, recording optimal switch-off amount delta Pi of the wind power units and the thermal power units when recording different capacitor switch-off numbers until the capacitors are switched off completely; and taking a minimum amount of delta Pi as an optimal switch-off amount by comparison, and outputting the switch-off scheme at the time as an optimal control scheme. By coordination of wind power, thermal power and the capacitors, the switch-off amount of wind power and thermal power is reduced effectively, and the method can be widely applied to emergency control after direct current block of the wind and thermal bundling system.

Owner:HEFEI UNIV OF TECH

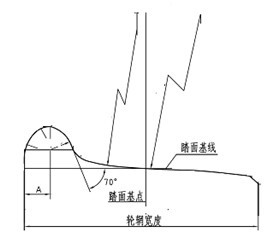

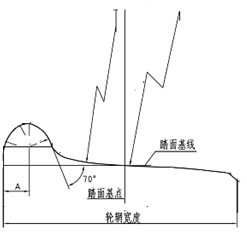

Wheel rotary cutting method of rail wagon

The invention relates to a wheel rotary cutting method of a rail wagon. Firstly a wheel set tread shape of a wheel set needing economic cutting is measured and scanned from a 1:8 straight line portion to a flange peak portion or the whole flange, an appearance curve of a wheel set tread is obtained, abrasion flange thickness and wheel diameter size are obtained through calculation. Therefore, thewheel rotary cutting method of the rail wagon has the advantages of achieving accuracy of machining parameters of the wheel set tread, avoiding excessive cutting, using old wheel to the greatest extend, improving wheel set repairing rate and reducing car repairing cost.

Owner:CRRC YANGTZE CO LTD

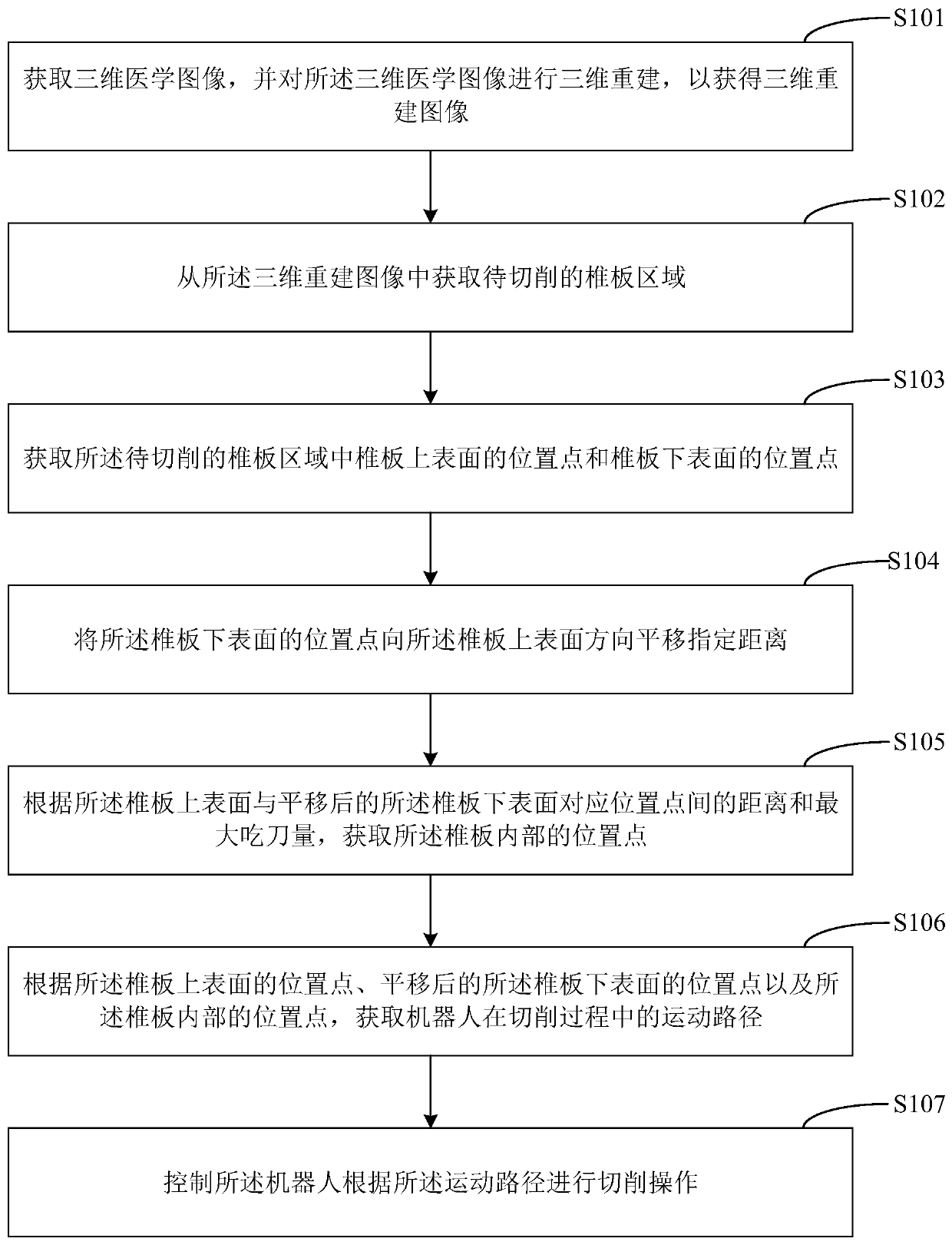

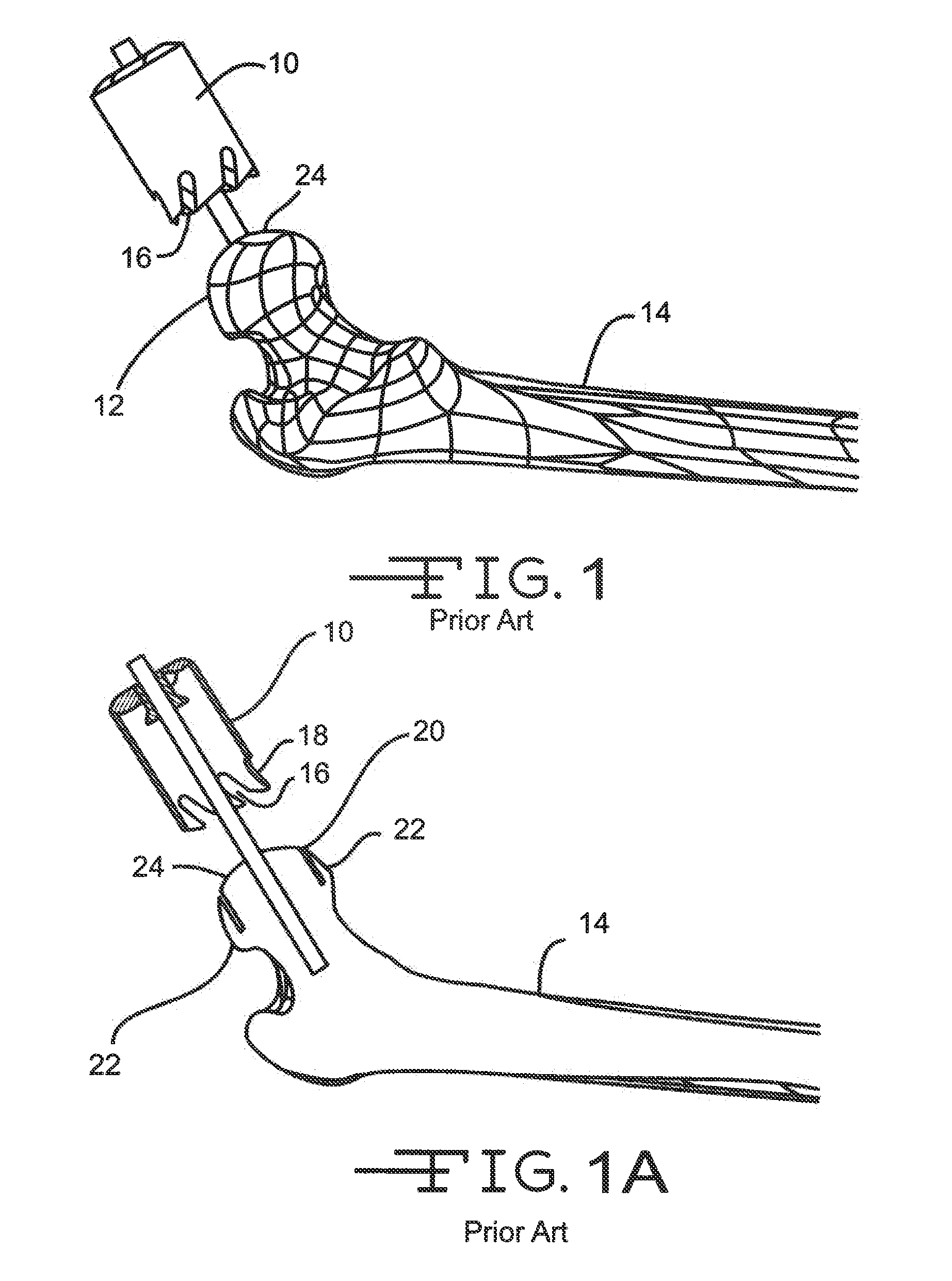

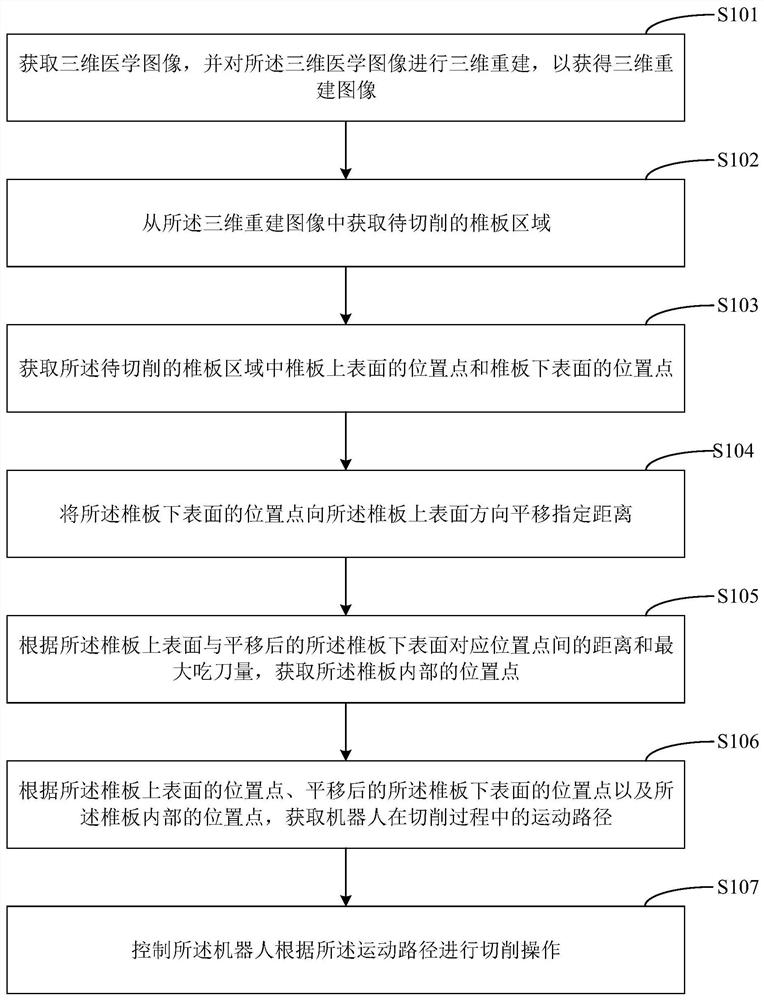

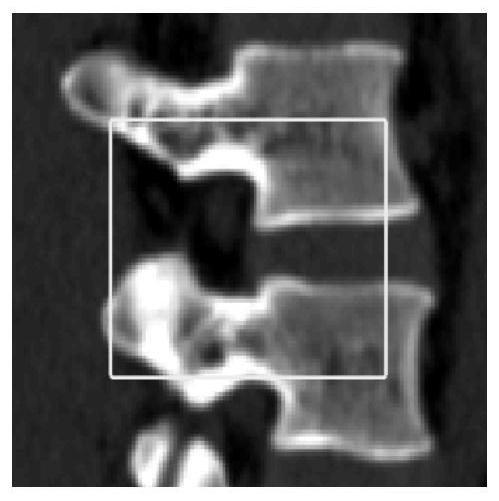

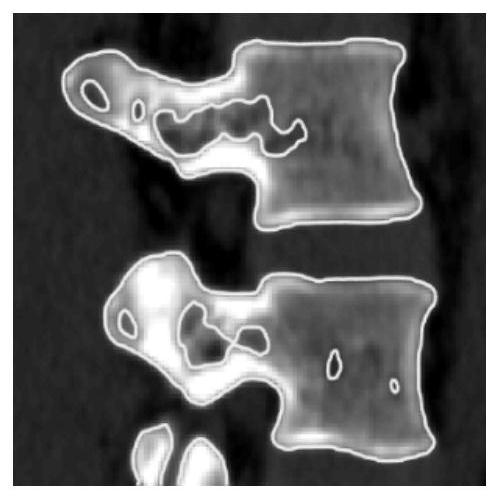

Robot control method, robot control device and robot

InactiveCN110154019ARealize the cutting operationAvoid overcuttingProgramme-controlled manipulatorPhysical medicine and rehabilitationLaminectomy procedure

The invention is suitable for the technical field of robots and provides a robot control method, a robot control device, a robot and a computer readable storage medium. The robot control method comprises the steps that a three-dimensional medical image is obtained, and three-dimensional reconstruction is performed on the three-dimensional medical image to obtain a three-dimensional reconstructionimage; a vertebral plate area to be cut is obtained from the three-dimensional reconstruction image; position points of the upper surface of the vertebral plate and the position points of the lower surface of the vertebral plate are obtained; the position points of the lower surface of the vertebral plate are translated a specified distance towards the direction of the upper surface of the vertebral plate; the position points inside the vertebral plate are obtained according to the distances between the corresponding position points of the upper surface of the vertebral plate and the translated lower surface of the vertebral plate and the maximum engagement of the cutting edge; a moving path of the robot in the cutting process is obtained according to all the position points of the vertebral plate; and the robot is conteolled to perform cutting operations according to the moving path. By means of the robot control method, the robot control device, the robot and the computer readable storage medium, the robot can be conteolled to perform vertebral plate laminectomy, the cutting quality is improved, and spinal nerve injury caused by overcutting and other risks are reduced.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

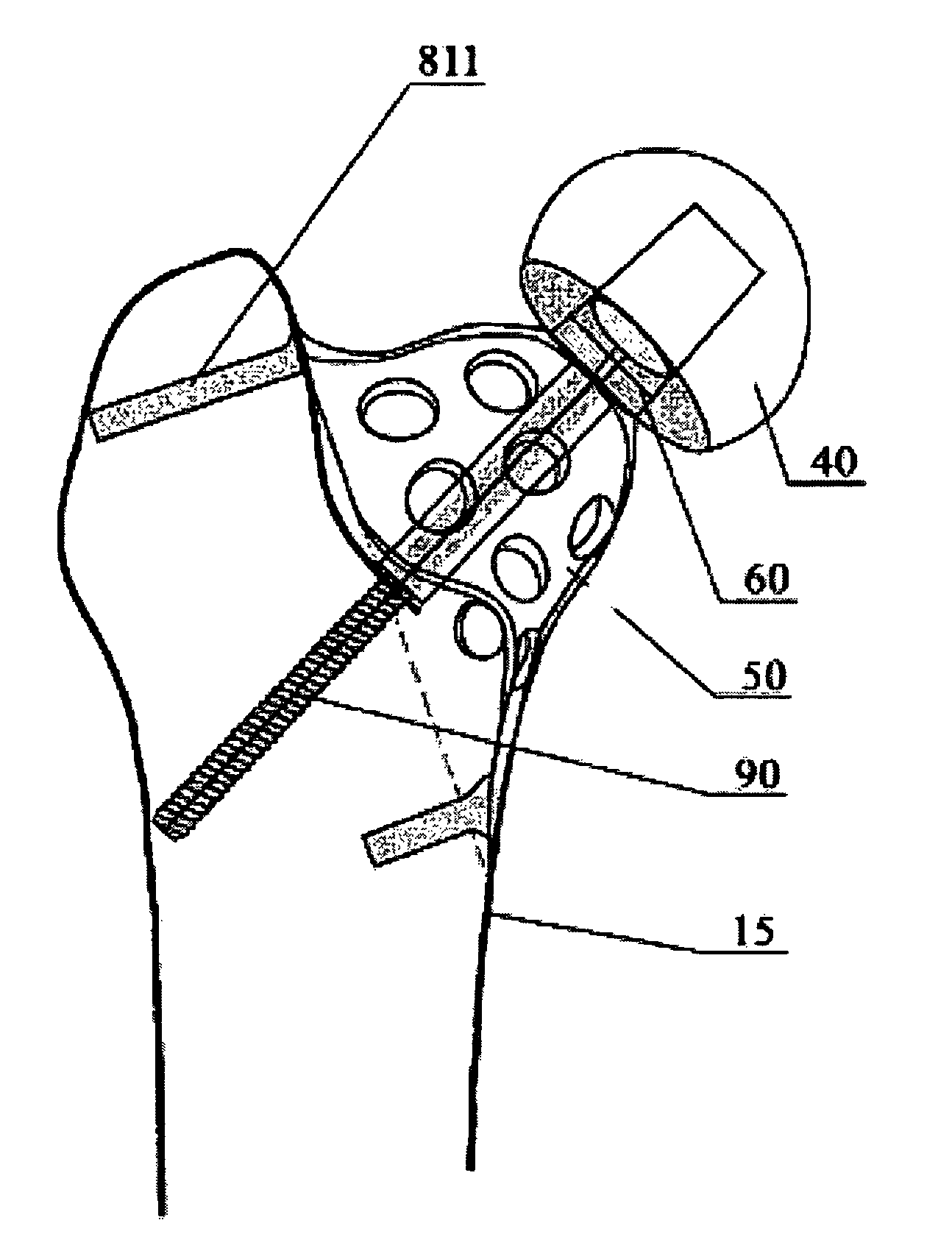

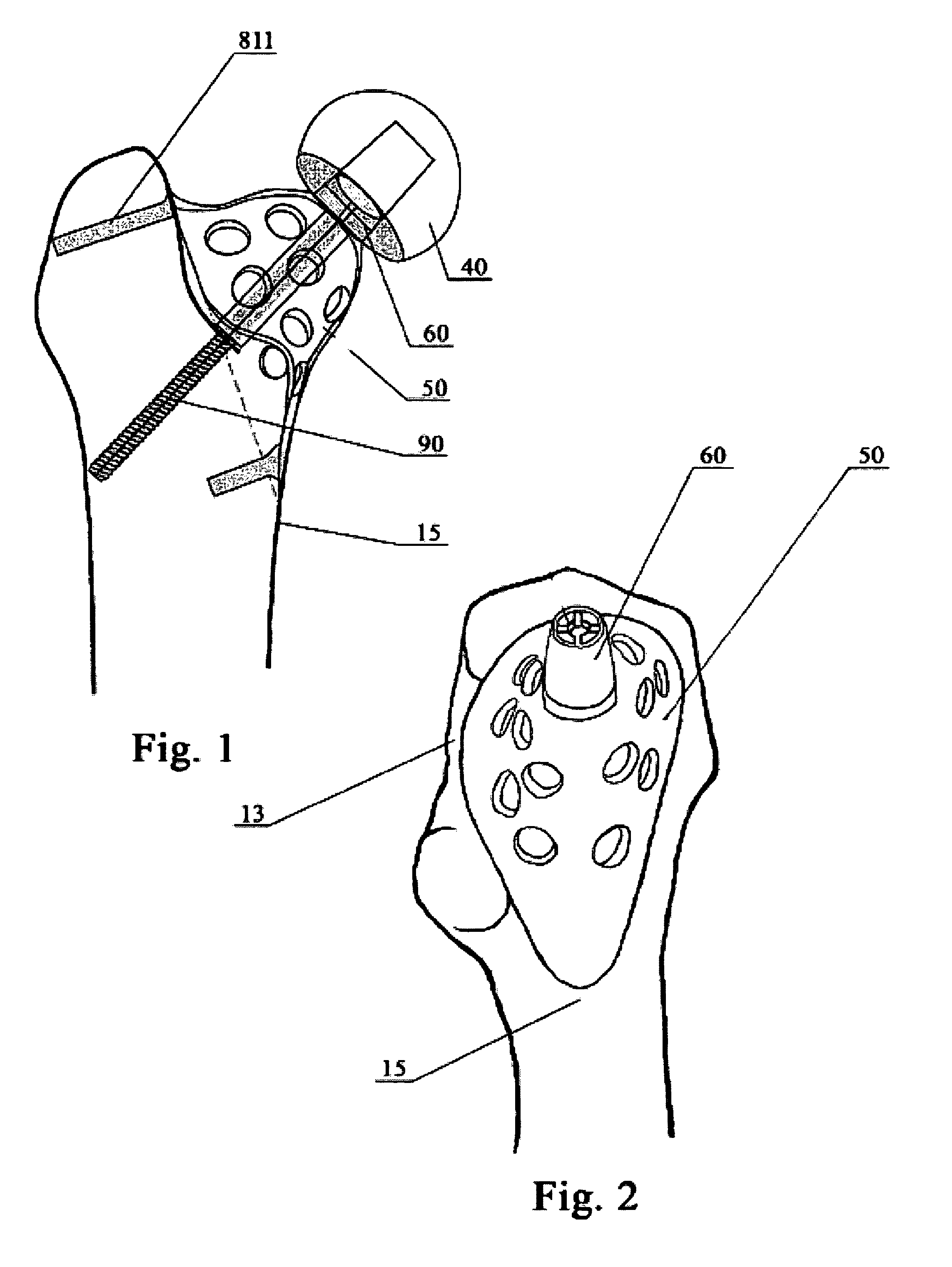

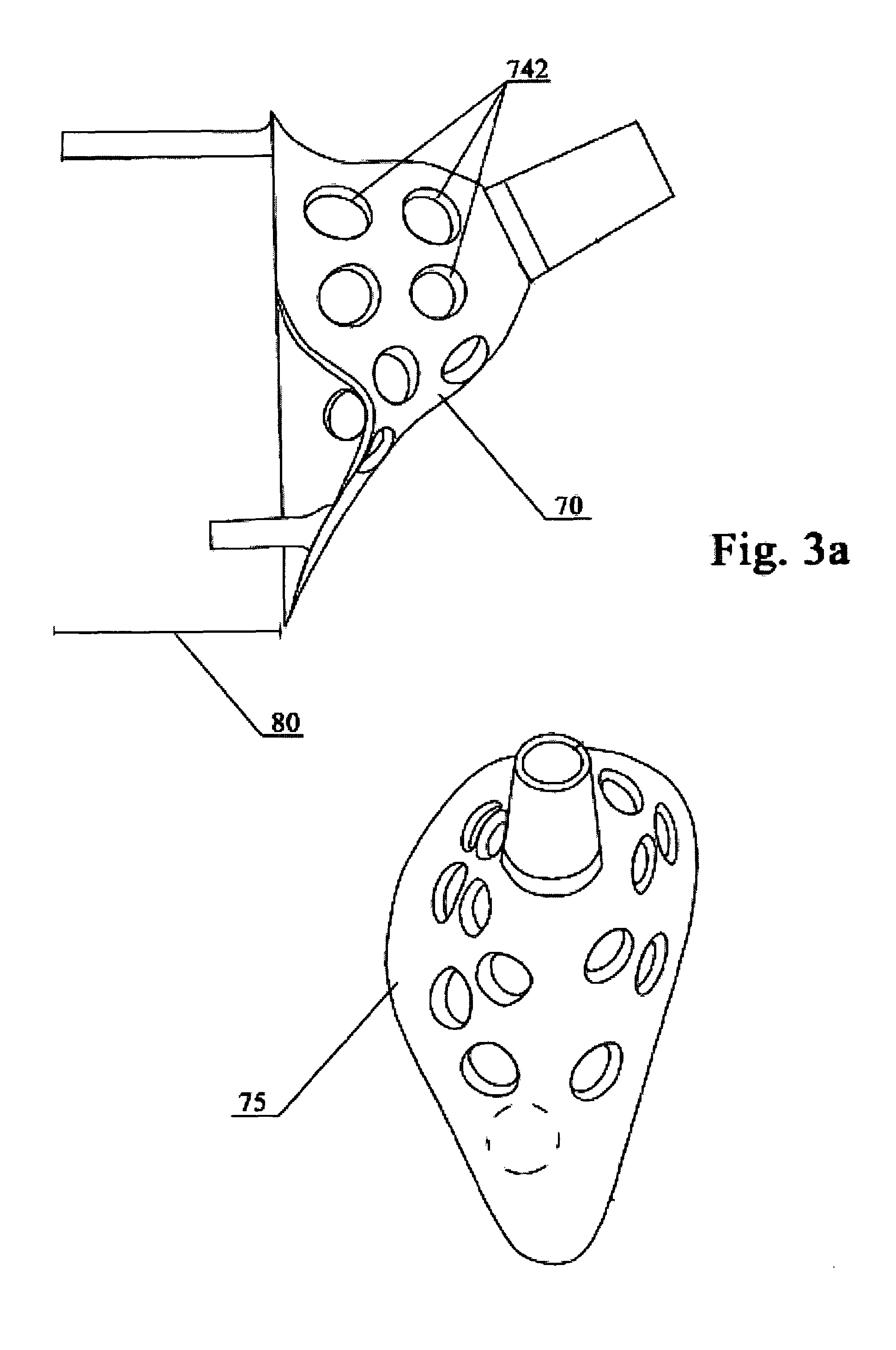

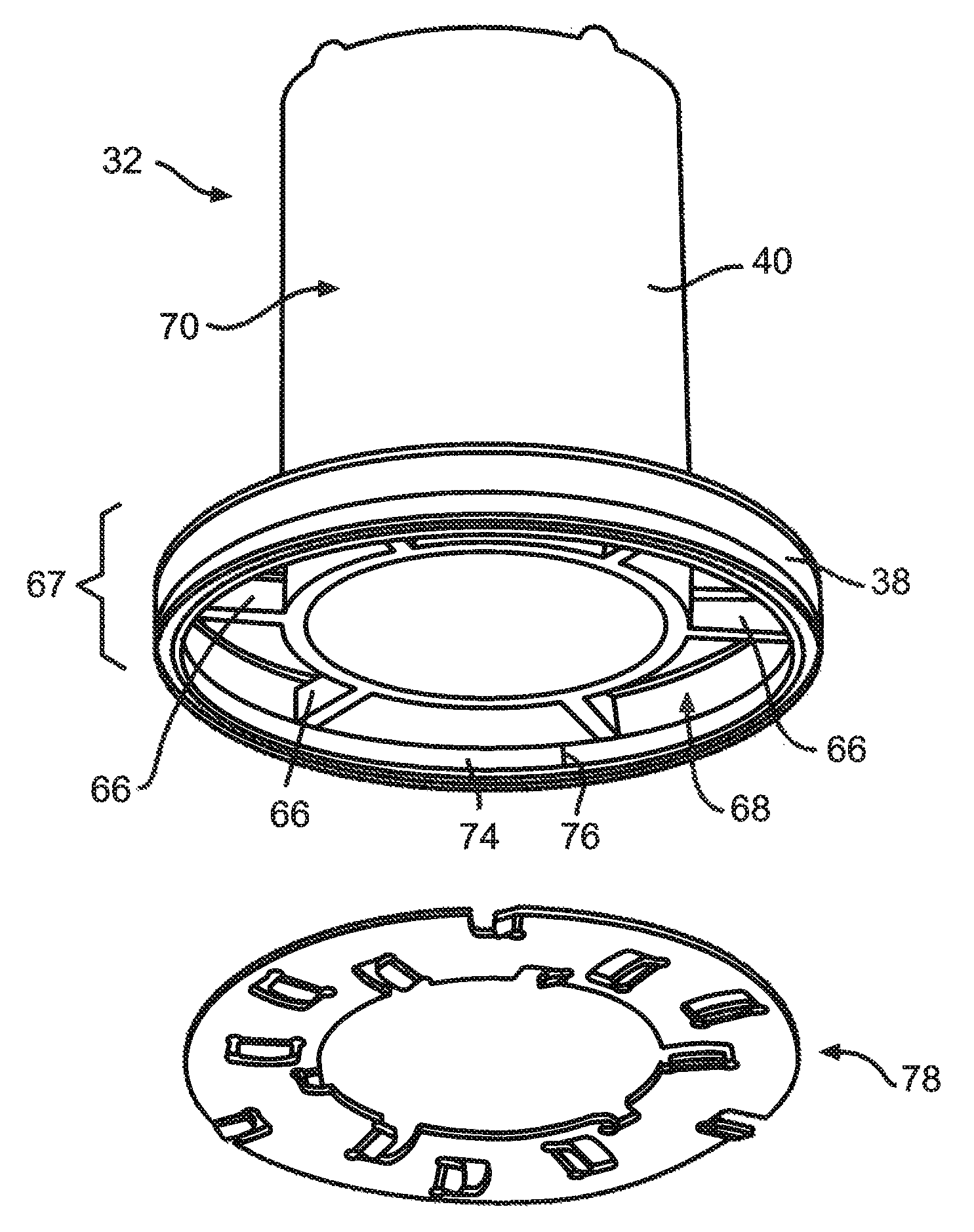

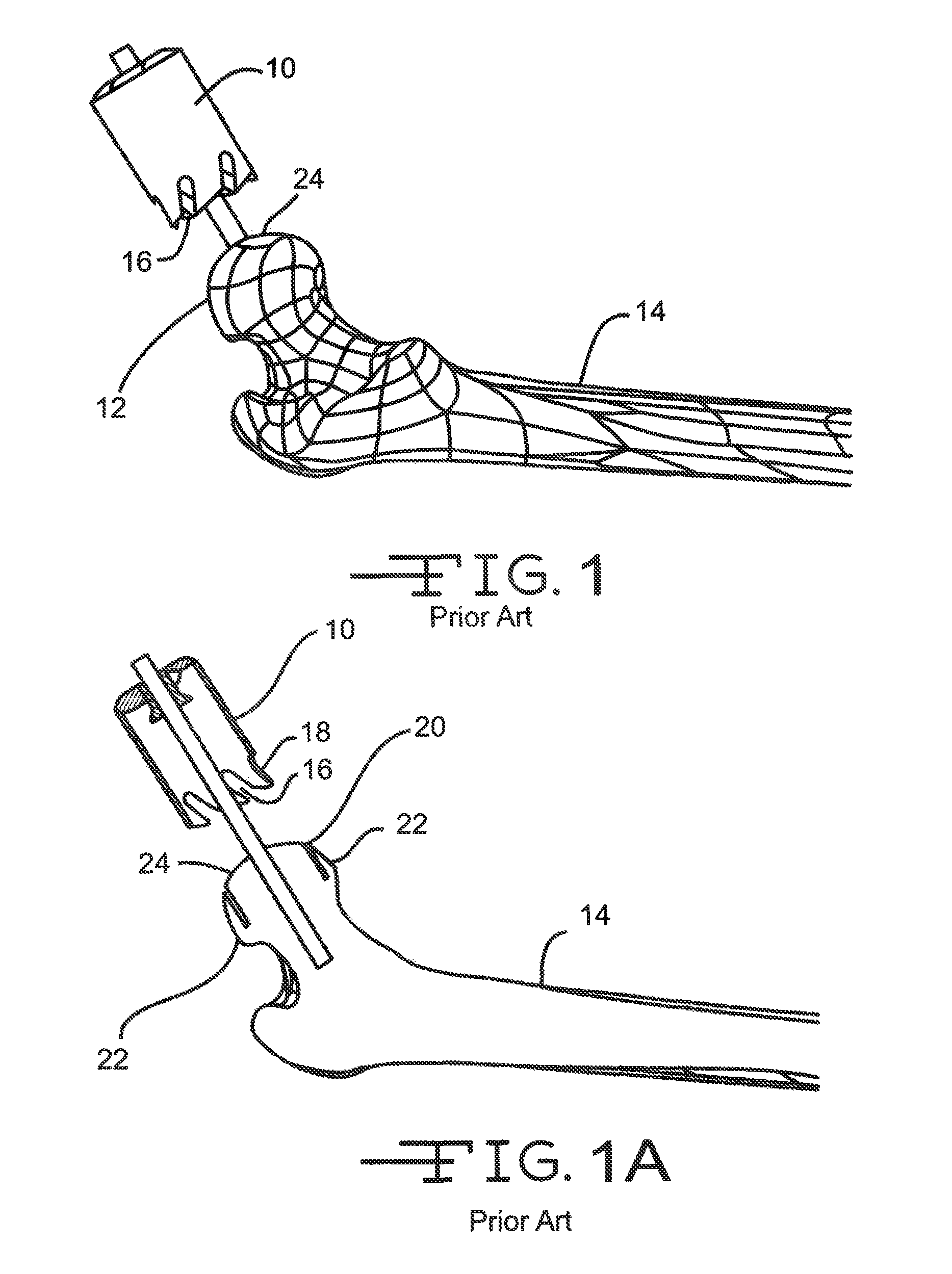

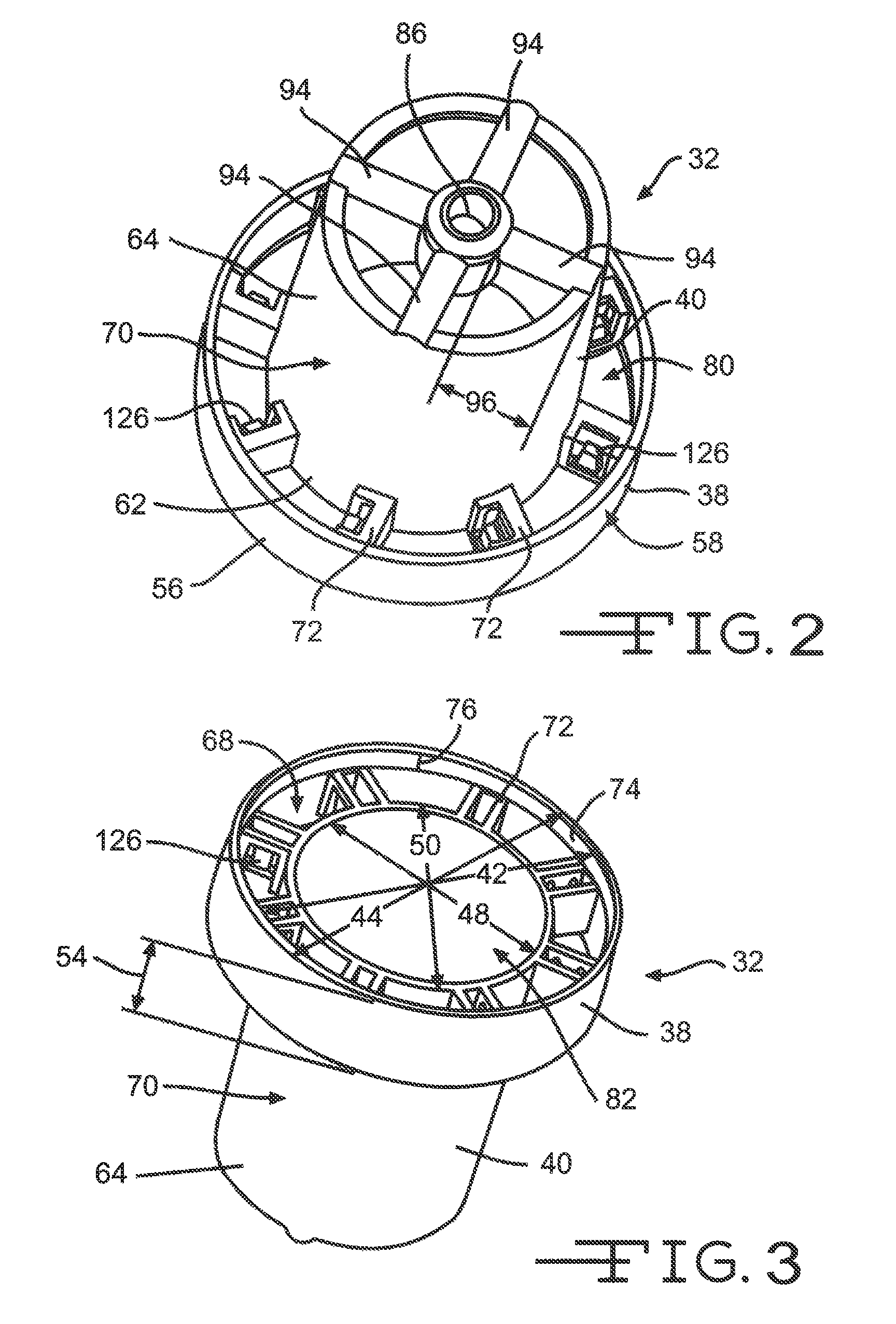

External proximal femoral prosthesis for total hip arthroplasty

InactiveUS7931691B2Improve abilitiesImprovement effortsInternal osteosythesisJoint implantsTotal hip arthroplastyFemoral component

A external femoral component for mechanically housing onto exterior remnant of natural femur and coupling with articulation elements in order to use in total hip arthroplasty defines as a hollow shell comprised of asymmetrically bell shaped cup, at least one rigid elongated stem downwardly extended from the lower rim of the cup and a plurality of an cylindrical object upwardly protruded from top of the cup for pairing with articulation elements and coupling with anchoring means and the tension anchoring means fixes the hollow shell on the bone surface through an interlocking mechanisms.

Owner:LI XUE +2

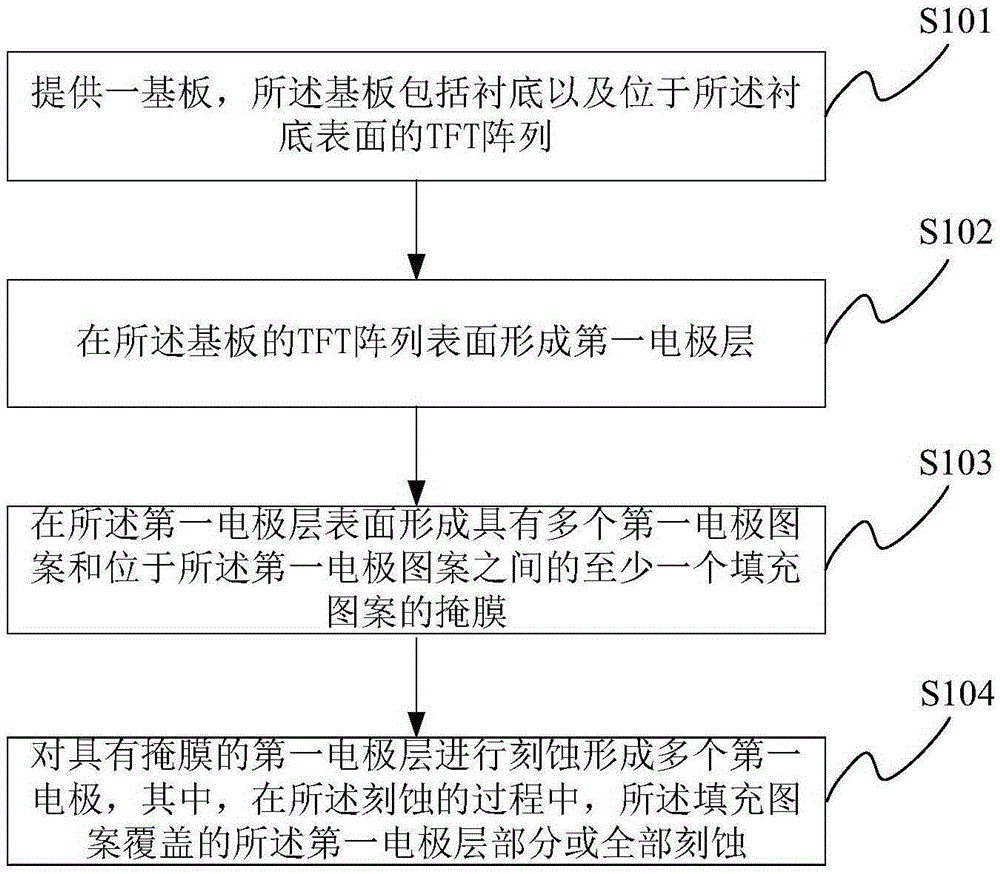

Display device, array substrate and manufacturing method thereof

ActiveCN105390506AAvoid overcuttingAvoid uniformitySolid-state devicesSemiconductor/solid-state device manufacturingDark spotDisplay device

The invention provides a display device, an array substrate and a manufacturing method thereof. The manufacturing method comprises the following steps: providing a substrate, wherein the substrate includes a base and a TFT array disposed on the surface of the base; forming a first electrode layer on the surface of the TFT array of the base; forming a mask on the surface of the first electrode layer, wherein the mask is provided with multiple first electrode patterns and at least one filling pattern disposed between the first electrode patterns; and etching the first electrode layer with the mask to form multiple first electrodes, wherein the first electrode layer covered by the filling patterns is partially or fully etched in the etching process. According to the invention, the pattern density of the first electrode patterns is increased through the filling patterns between the first electrode patterns, and therefore, the problem that the first electrodes are over-etched or etched unevenly in the etching process is avoided, and dark spots and other defects of the display caused thereby are overcome.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

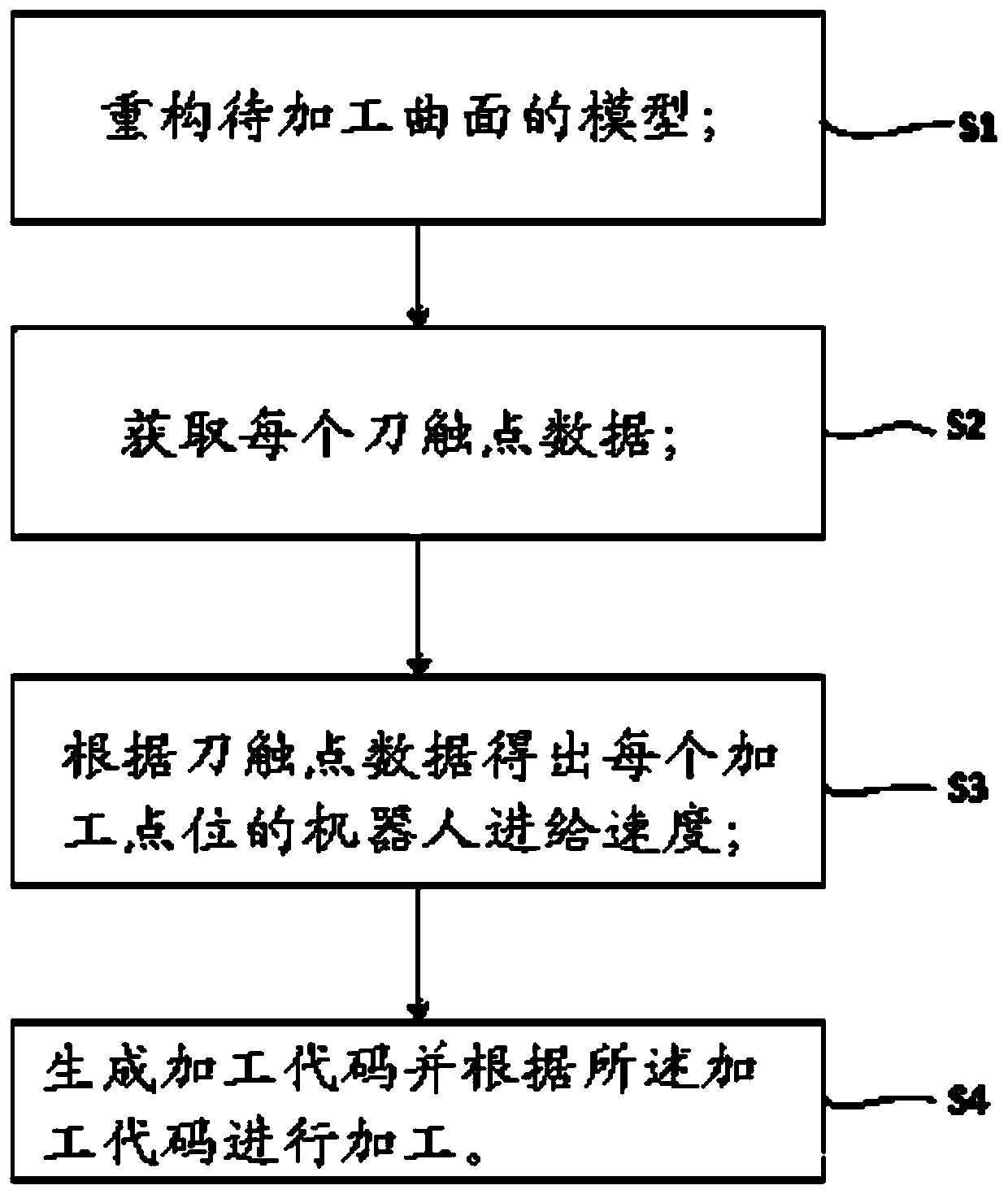

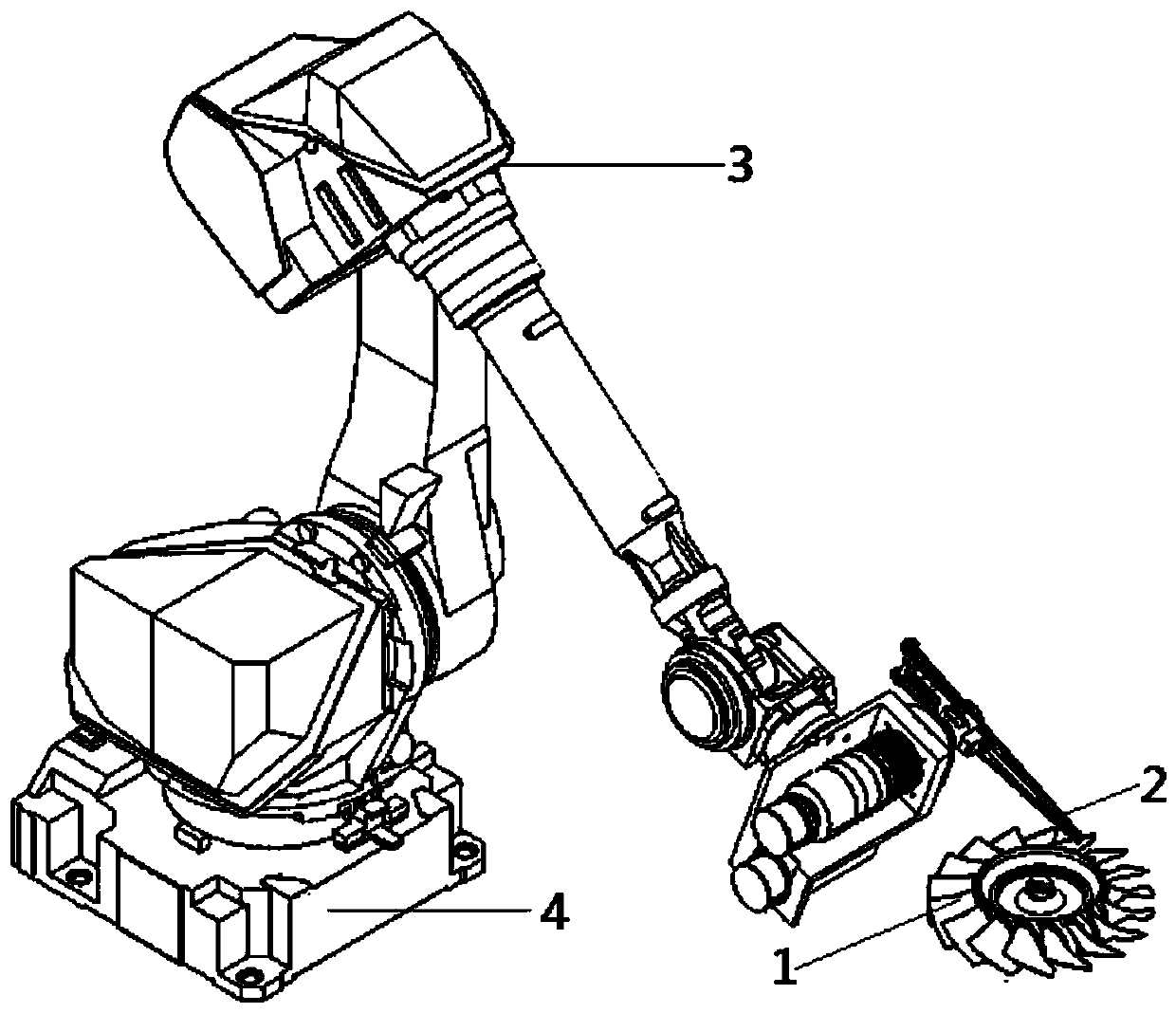

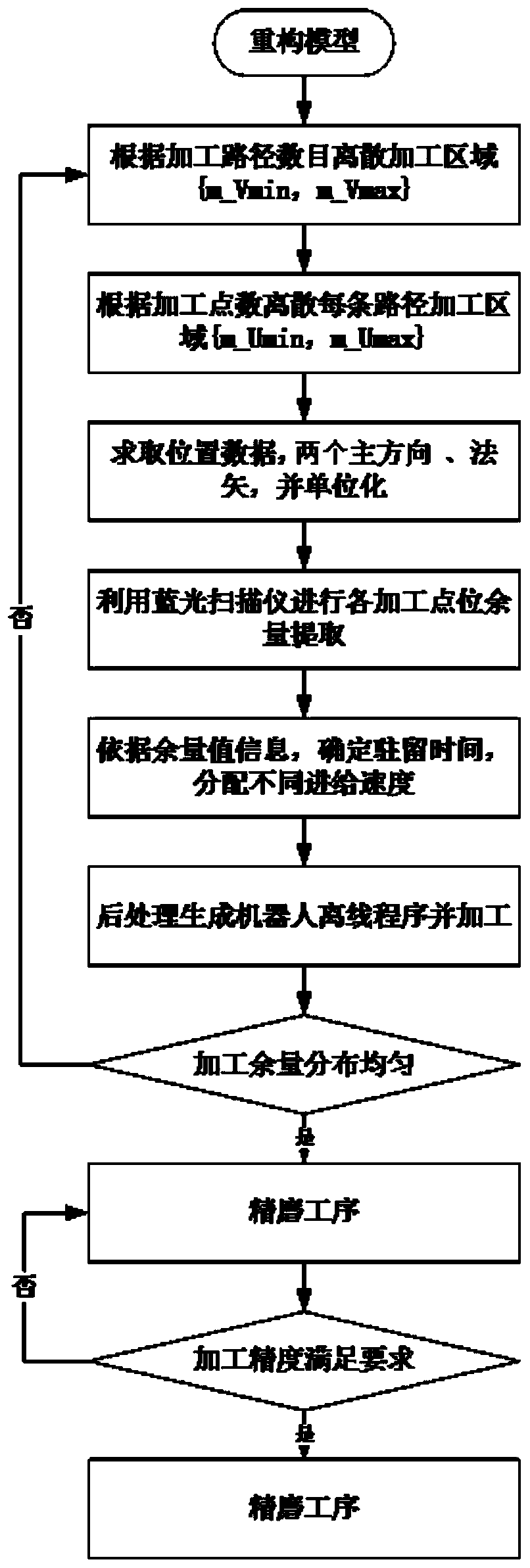

Complex curved surface robot abrasive belt variable feeding self-adaptive grinding method and equipment

InactiveCN111300208AAvoid overcuttingHigh precisionGrinding drivesGrinding machinesEngineeringSelf adaptive

The invention discloses a complex curved surface robot abrasive belt variable feeding self-adaptive grinding method. The method comprises the following steps that a model of a to-be-machined curved surface is reconstructed; data of cutter contact points are acquired; the robot feeding speed of machining point positions is obtained according to the cutter contact data; and a machining code is generated and machining is conducted according to the machining code. The invention further discloses complex curved surface robot abrasive belt variable feeding self-adaptive grinding equipment applying the complex curved surface robot abrasive belt variable feeding self-adaptive grinding method. According to the complex curved surface robot abrasive belt variable feeding self-adaptive grinding method, a robot contact wheel can be attached to the blade profile in the optimal posture, different robot feeding speeds can be further distributed according to the allowance value information of all the machining point positions, and therefore the accurate removal amount of the allowance of all the machining point positions can be guaranteed, and therefore, the self-adaptive grinding machining precision and quality of the complex curved surface part robot can be comprehensively improved.

Owner:CHONGQING UNIV +1

Thin film transistor and manufacturing method, array substrate and display device

InactiveCN105609567AImprove yieldAvoid etchingTransistorSolid-state devicesDisplay deviceActive layer

The invention discloses a thin film transistor and a manufacturing method, an array substrate and a display device, and belongs to the field of display processing technology. The thin film transistor comprises a first etching barrier layer, a second etching barrier layer, a source, a drain, an insulating layer and an active layer; the insulating layer is arranged on the active layer, the first etching barrier layer and the second etching barrier layer, and the insulating layer is provided with a first contact hole and a second contact hole; the source is electrically connected with the active layer via the first contact hole, and the drain is electrically connected with the active layer via the second contact hole; the first etching barrier layer is positioned between the active layer and the source; and the second etching barrier layer is positioned between the active layer and the drain. When the insulating layer is etched with the contact holes, the contact holes can be directly etched onto the first etching barrier layer and the second etching barrier layer to prevent under-etching, and the first etching barrier layer and the second etching barrier layer block the active layer to prevent the active layer from being etched and prevent over-etching, so that the yield of the thin film transistor is improved.

Owner:BOE TECH GRP CO LTD

Numerical control machining method of annular hiding groove in arc-shaped surface

InactiveCN102689044ASolve the problem of overtravelReduce the amount of cuttingMilling equipment detailsNumerical controlEngineering

The invention relates to a numerical control machining method of an annular hiding groove in an arc-shaped surface. The method comprises the following steps of: 1) sewing the arc-shaped surface serving as an integral body, namely the hiding groove, performing rough milling, and then performing finish milling in all dimensions in place; 2) machining the sewn hiding groove, equally dividing the hiding groove into two parts along the axis direction, and machining one part in a five-shaft linkage layering mode in advance; and 3) moving a tool to the other side of a machine tool, centering, and machining the other part of the hiding groove similar to that of the step 2). By the method, the problems of large machining ranges and the excess of travel of the machine tool are effectively solved, and the phenomena of high cutter bending possibility, high excessive cutting possibility and the like in the machining process are prevented by a reasonable method, so that the integral tool is high in machining accuracy, and the production efficiency is improved.

Owner:SHENYANG AIRCRAFT CORP

Halftone mask plate and fabrication method of thin film transistor (TFT) substrate

ActiveCN105892221AAvoid too muchAvoid overcuttingSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentProduction rateActive layer

The invention provides a halftone mask and a fabrication method of a thin film transistor (TFT) substrate. The halftone mask comprises a first light-proof region, a second light-proof region, a U-shaped semi-transparent region, two semi-transparent extension regions and a remaining all-transparent region, wherein the first light-proof region and the second light-proof region are used for being in correspondence to a source position and a drain position of a TFT respectively, the U-shaped semi-transparent region is used for being in correspondence to a U-shaped channel region position of an active layer of the TFT, the two semi-transparent extension regions are located at an opening of the U-shaped semi-transparent region and extend towards the outside of the opening, and a fringe effect can be prevented from being generated to cause over-development and over-etching in the semi-transparent extension regions when a source region, a drain region and a channel region are formed through composition, so that the problems of low yield and too low production rate in the prior art are eliminated. According to the fabrication method of the TFT substrate, provided by the invention, the halftone mask plate is adopted, and the fringe effect can be prevented from being generated to cause over-development and over-etching when the channel region is formed through composition, so that the problems of low yield and too low production rate in the prior art are eliminated.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

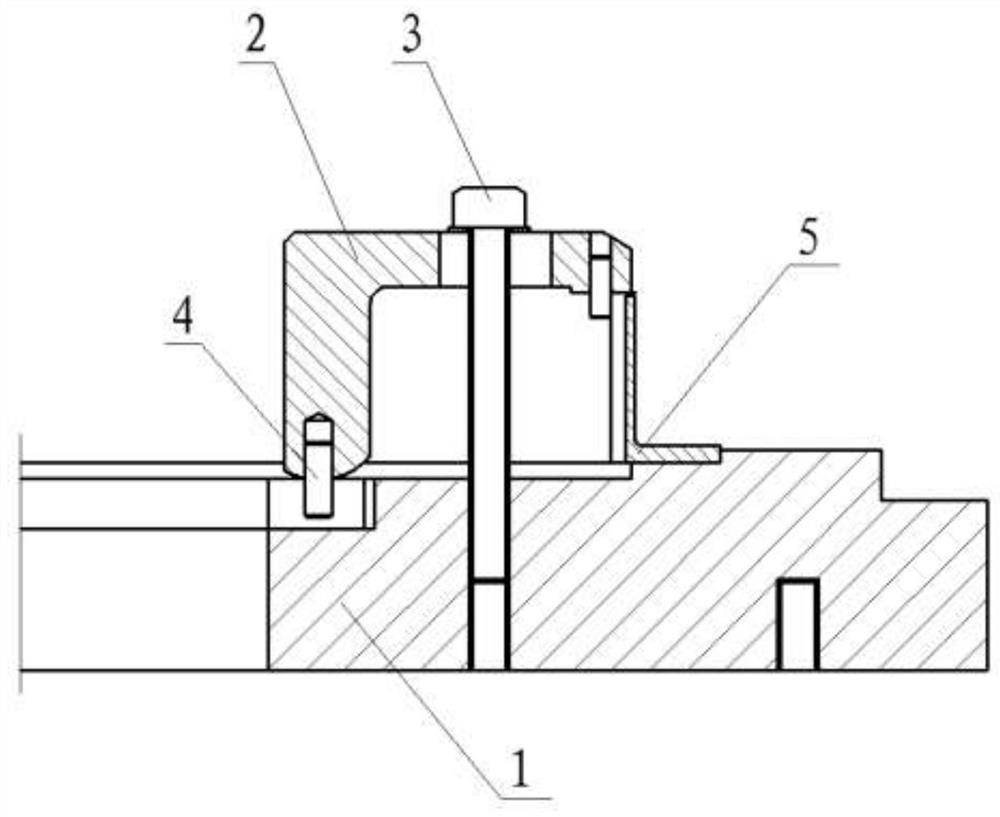

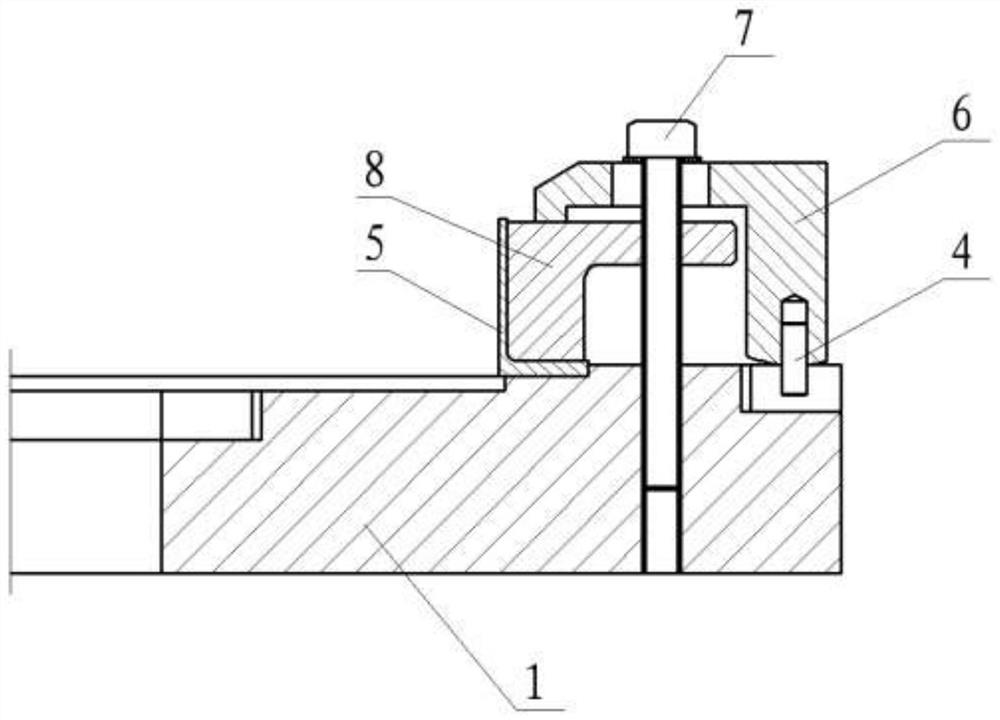

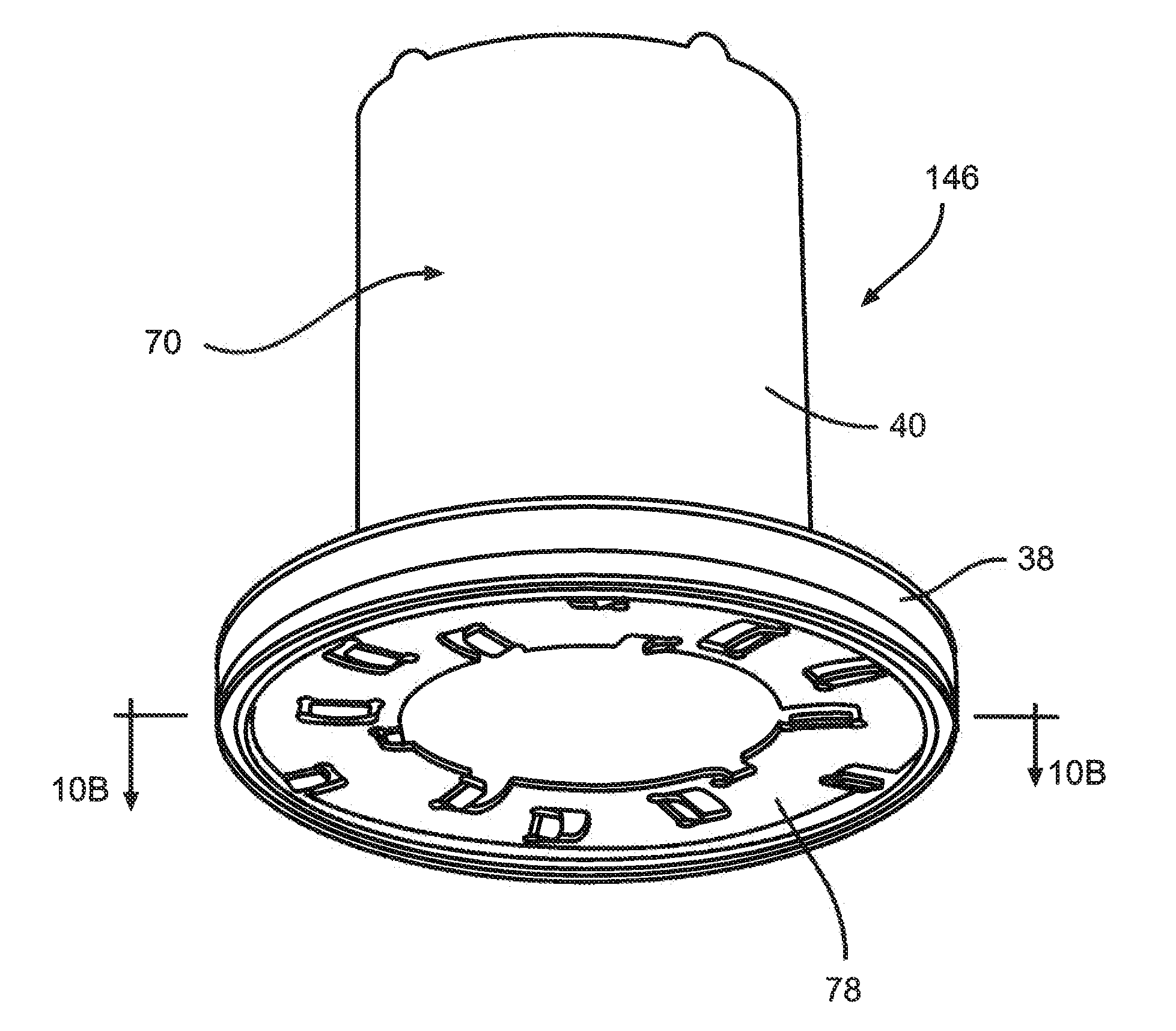

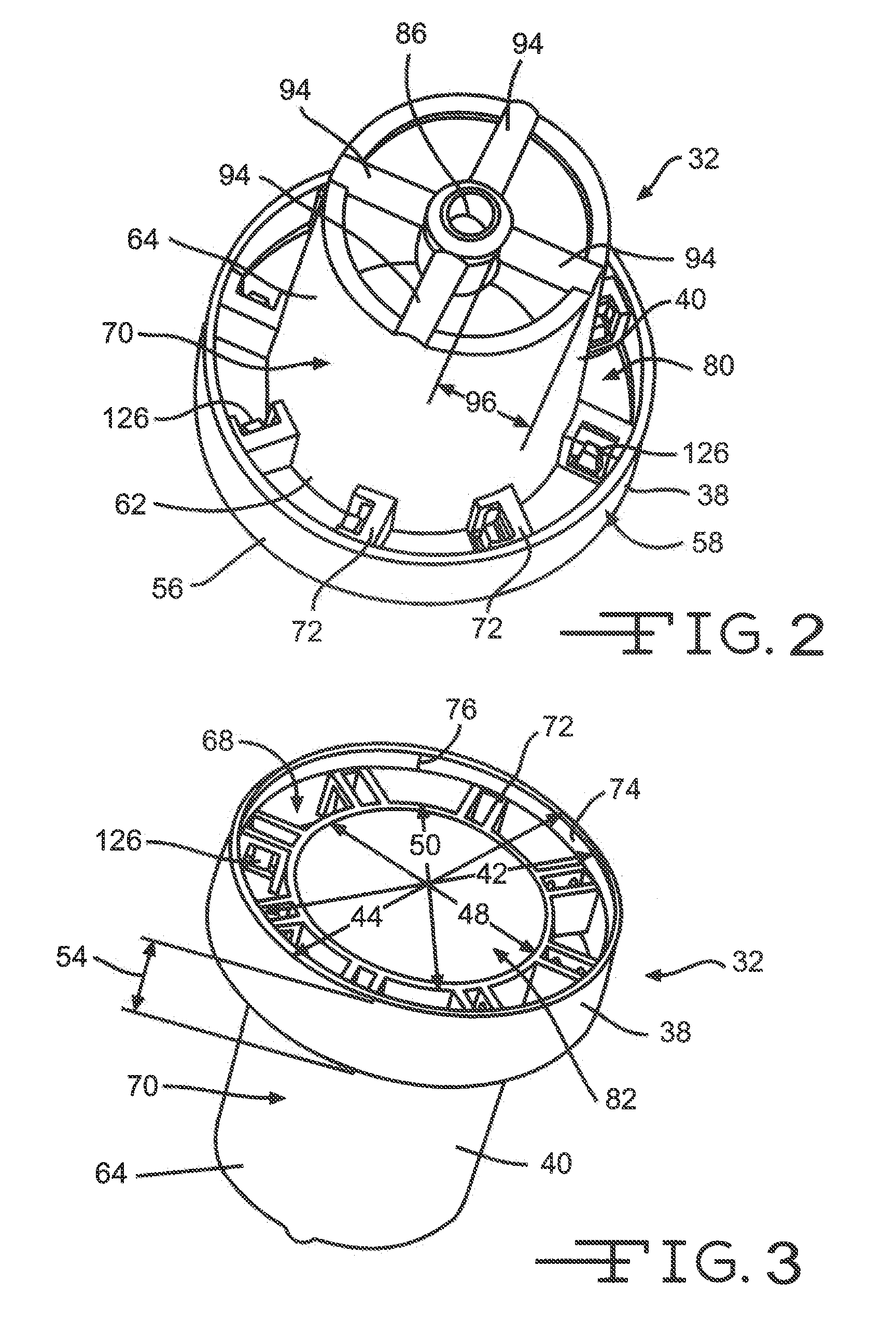

Disposable cylindrical cutter

ActiveUS8876825B2Avoid accidental damageAvoid overcuttingBone drill guidesConcentric cylinderMechanical engineering

A single use bone cutter comprised of two concentric cylinders and a series of insert blades or cutter disc is described. The cutter blades or cutter disc is preferably positioned at the distal end of the cutter. The bone cutter also comprises a guide rod that aids in the line of sight when using the cutter device.

Owner:WILSON GREATBATCH LTD

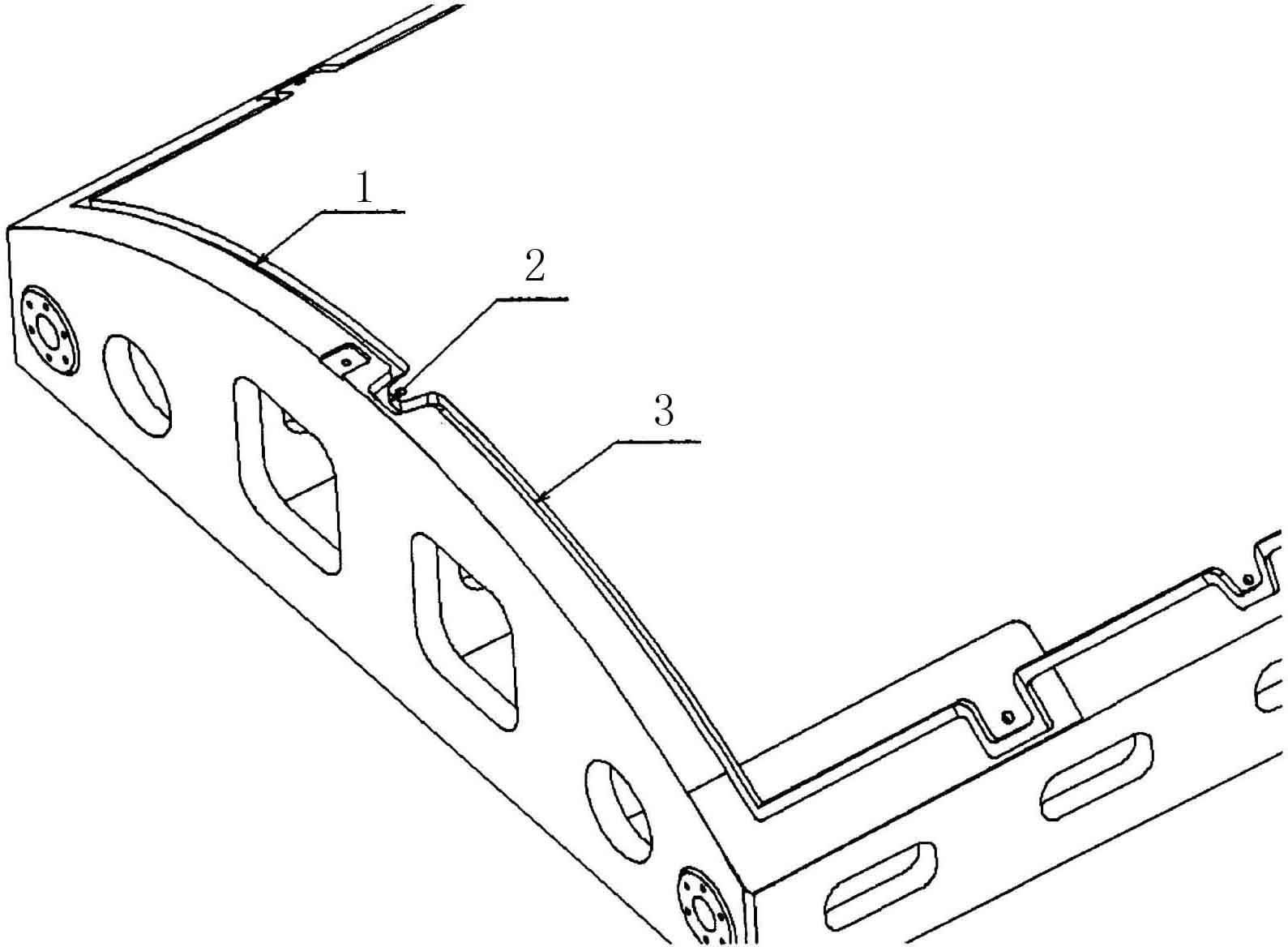

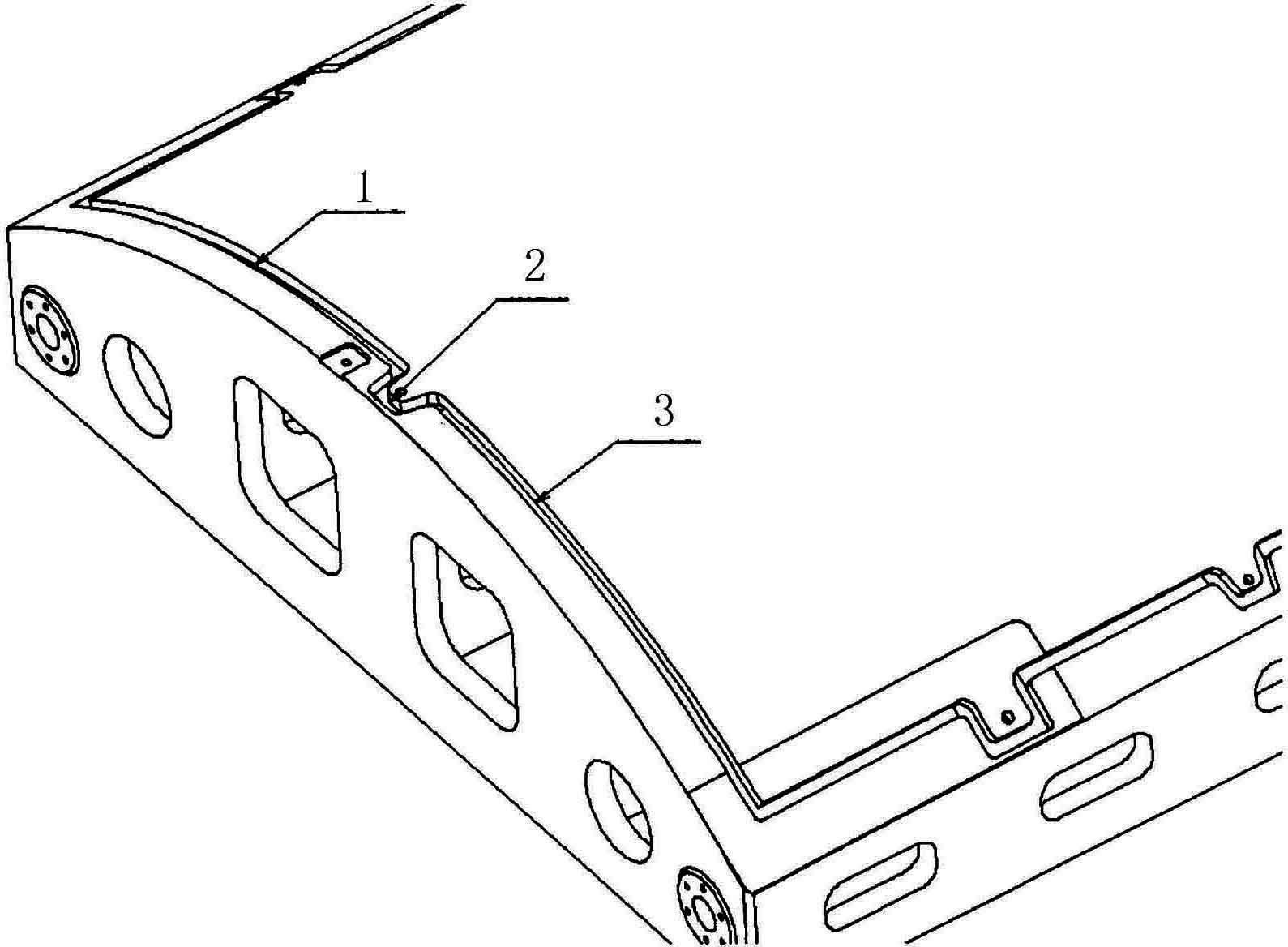

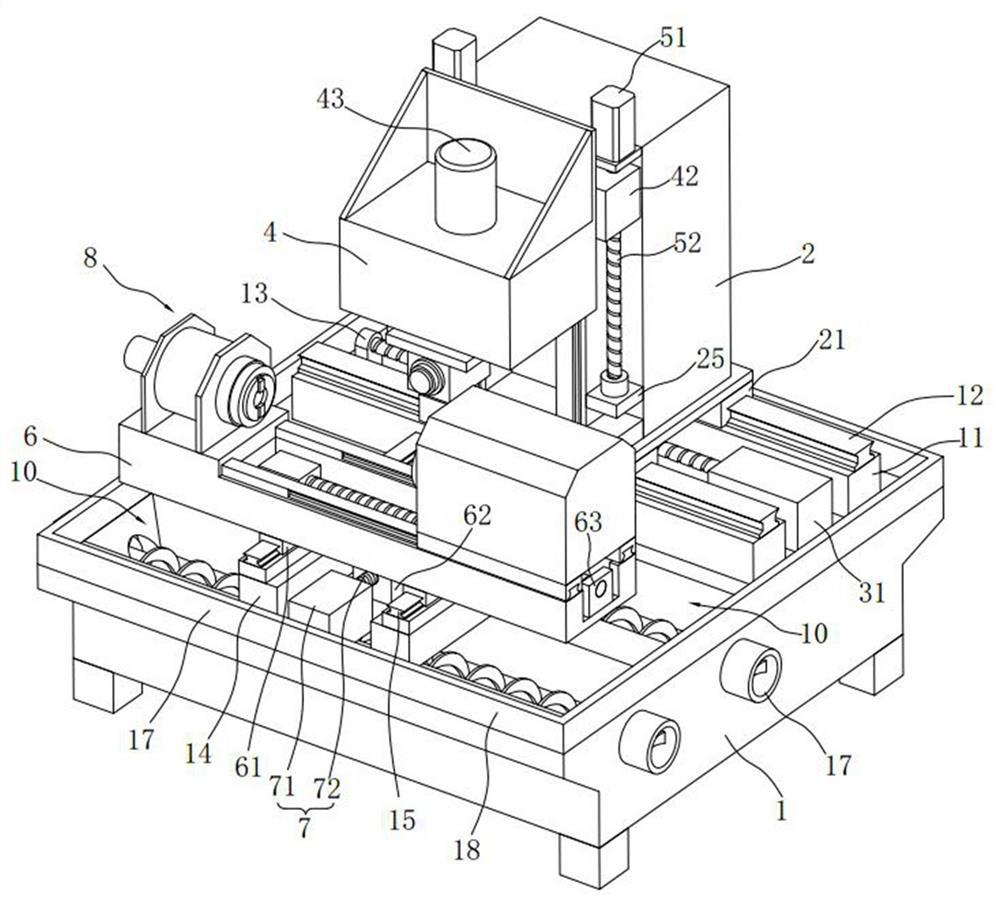

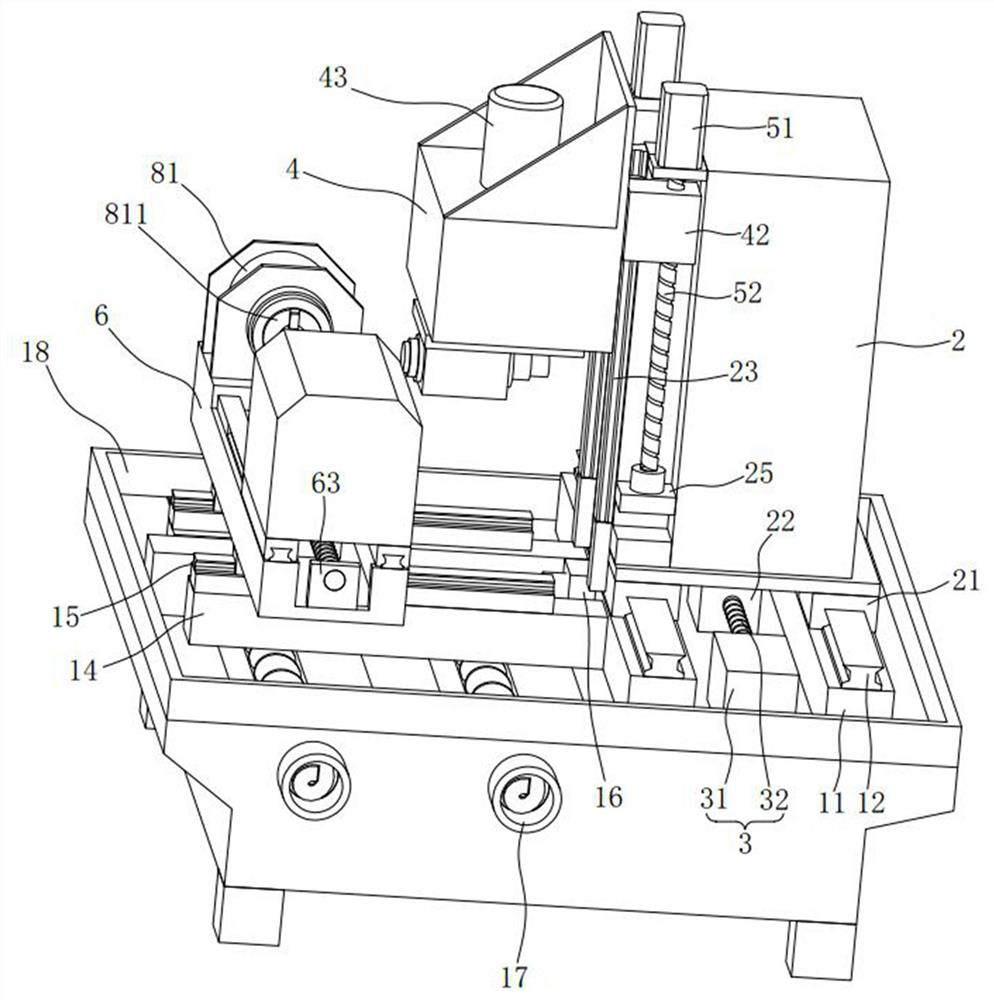

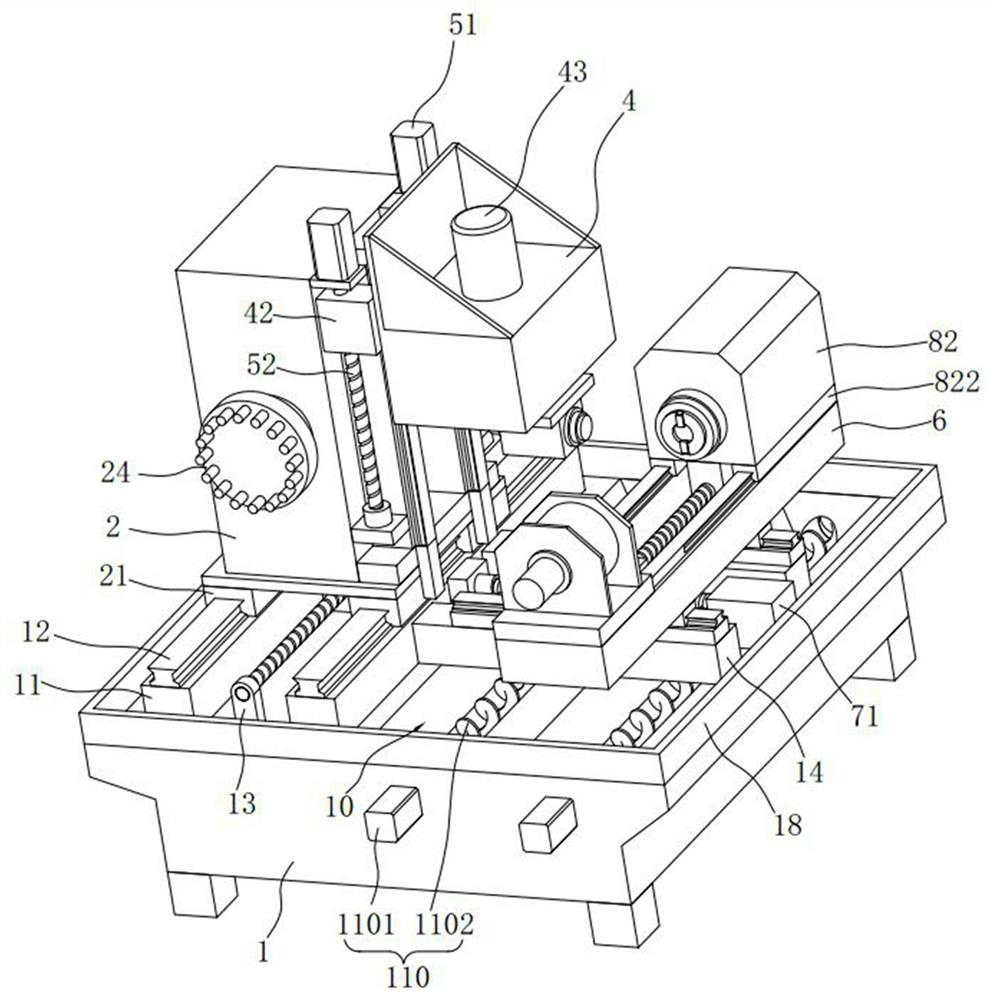

High-speed precise horizontal five-axis linkage aero-engine blade numerical control milling center

InactiveCN113560644AGood dynamic performanceLow power consumptionWorkpiecesFeeding apparatusEngineeringStructural engineering

The invention relates to a high-speed precise horizontal five-axis linkage aero-engine blade numerical control milling center, and belongs to the technical field of metal milling equipment, the high-speed precise horizontal five-axis linkage aero-engine blade numerical control milling center comprises a lathe bed and a stand column, the lathe bed is in sliding connection with the stand column, and a sliding seat is arranged on one side of the stand column; two parallel Z-axis guide rails are fixed to the side, close to the sliding seat, of the stand column, the Z-axis guide rails are arranged in the vertical direction, and two Z-axis sliding blocks which are in sliding connection with the two Z-axis guide rails correspondingly are fixed to the side, close to the stand column, of the sliding seat; and the stand column is provided with two Z-axis driving assemblies for driving the sliding seat to move up and down, a spindle box is arranged on the side, close to the lathe bed, of the sliding seat, a tool spindle is installed on the side, close to the lathe bed, of the spindle box, and a driving part for driving the spindle box to rotate is fixed to the side, away from the spindle box, of the sliding seat. The high-speed precise horizontal five-axis linkage aero-engine blade numerical control milling center has the effect of improving the overall rigidity of the milling center.

Owner:BEIJING PROSPER PRECISION MACHINE TOOL CO LTD

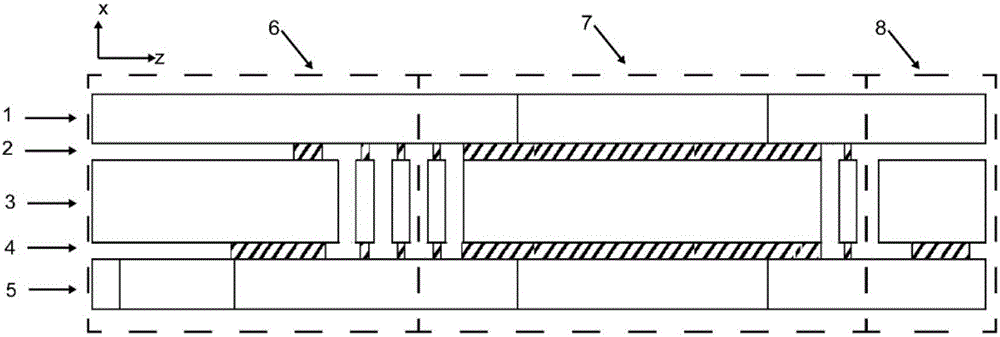

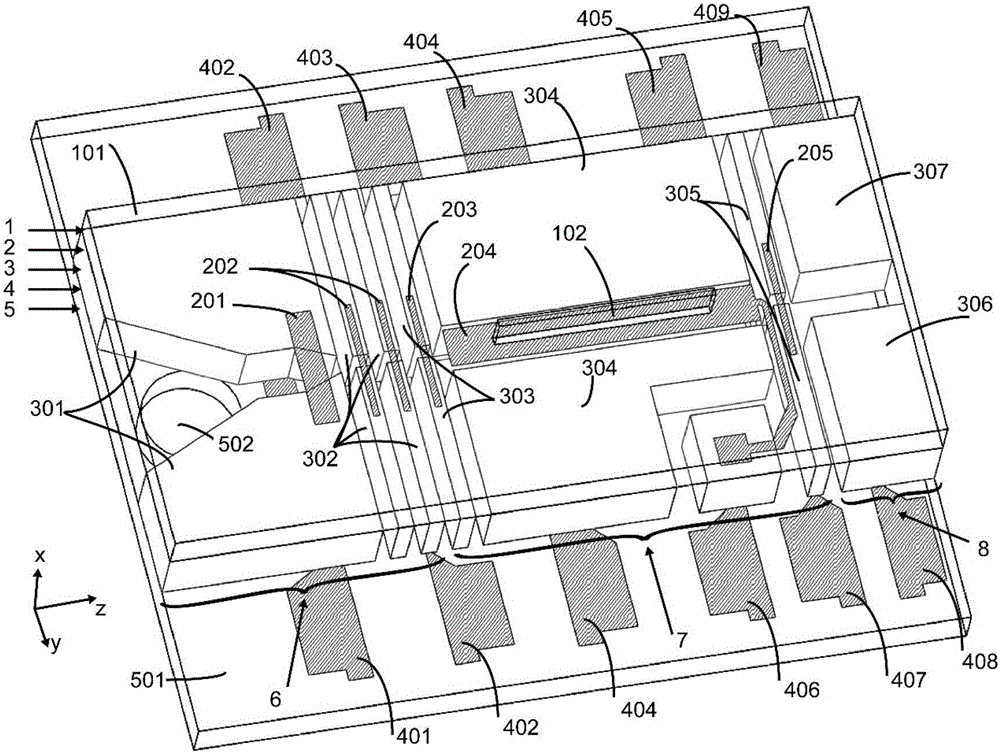

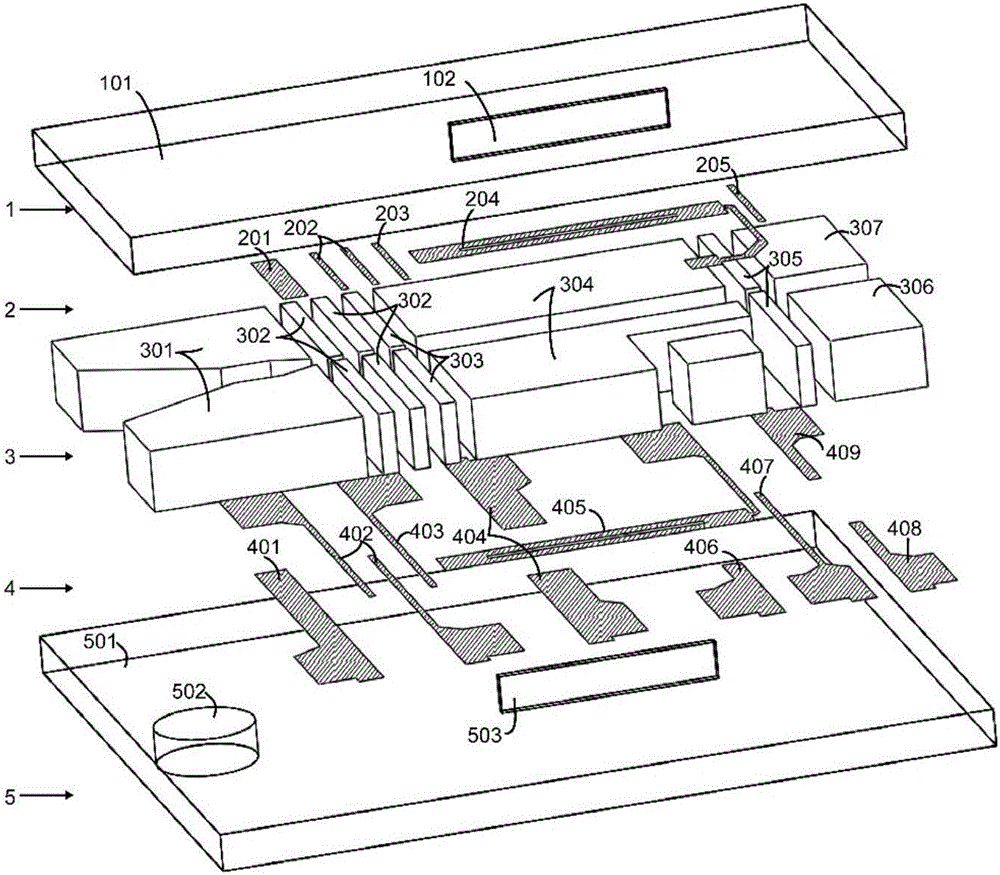

MEMS technology based multilayer structured rectangular ion trap and preparation method thereof

ActiveCN106024575AReduce volumeReduce weightStability-of-path spectrometersMicrominiaturised spectromotorsIon currentMass Spectrometry-Mass Spectrometry

The invention provides an MEMS technology based multilayer structured rectangular ion trap and preparation method thereof. The rectangular ion trap comprises an upper glass layer, a lower glass layer, an upper electrode layer grown on the lower surface of the upper glass layer, a lower electrode layer grown on the upper surface of the lower glass layer, as well as a silicon layer bonded between the lower surface of the upper glass layer and the upper surface of the lower glass layer. With such a design, a multilayer bonding structure featuring glass-metal-silicon-metal-glass is formed wherein the upper electrode layer, the silicon layer and the lower electrode layer are enclosed to form an ion flow channel. The ion flow channel is successively divided into an ion focal area and an ion analyzing area in the direction of ion current. The preparation method of the invention adopts MEMS technology, has low energy consumption, high processing precision, high yield, strong bonding strength and good long-term stability; in addition, the rectangular ion trap is advantageous in that its size is small and its weight is light. It has wide application prospects in the field of micro-mass spectrometry analysis and detection.

Owner:TSINGHUA UNIV

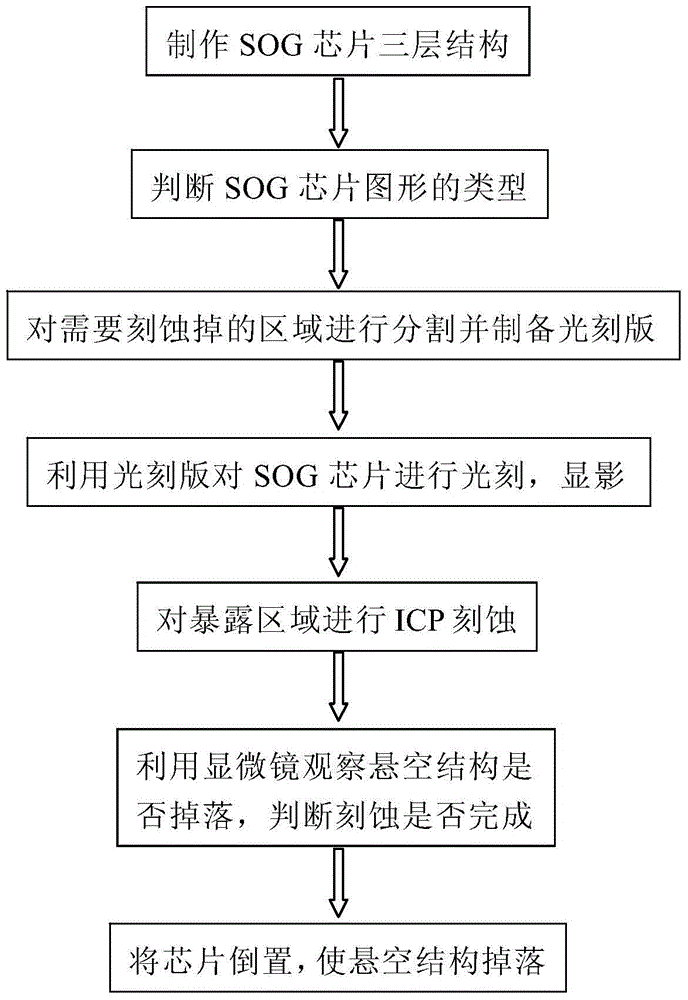

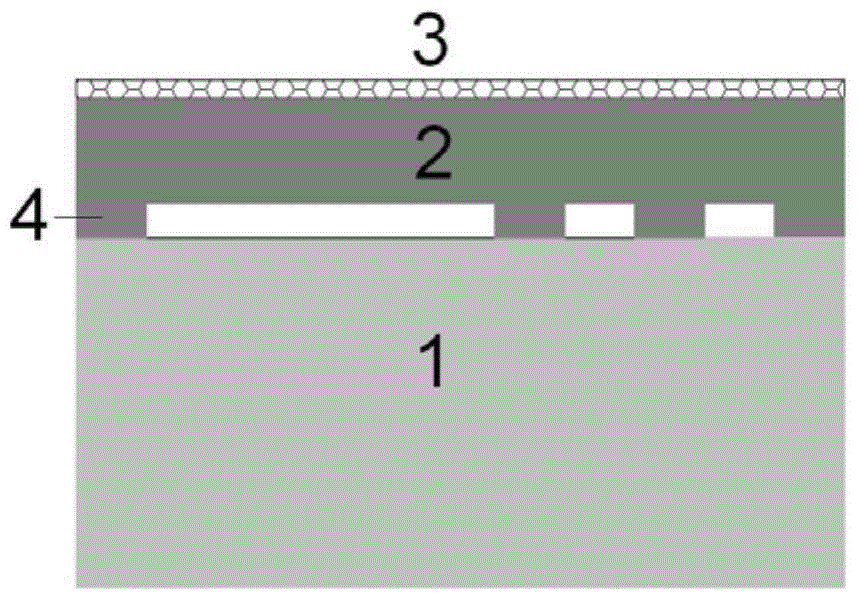

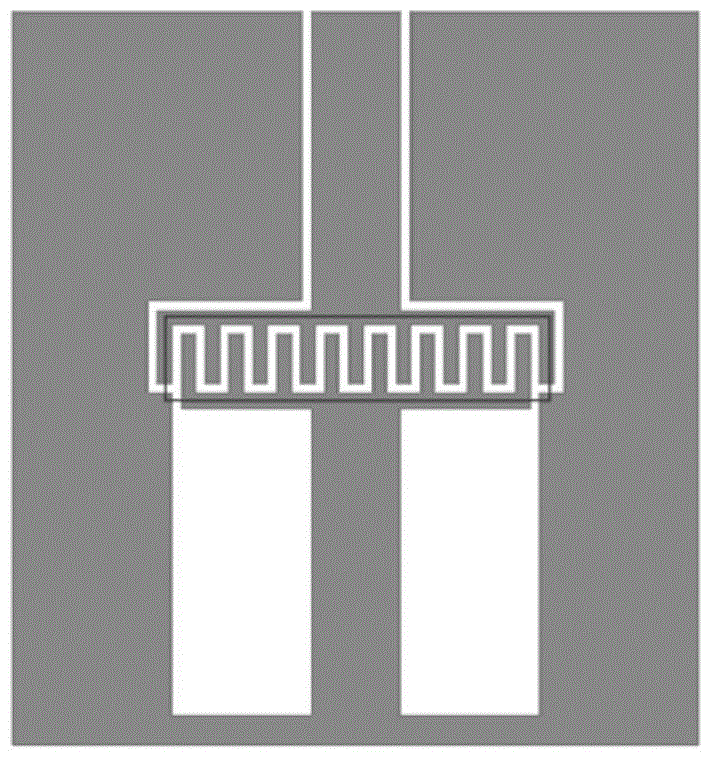

A method for preventing excessive etching of ICP in a sog-mems chip

ActiveCN105253853BAvoid overcuttingAvoid over etchingDecorative surface effectsChemical vapor deposition coatingEtchingLine width

The invention provides a method for preventing ICP excessive etching in an SOG-MEMS chip. For simultaneously etching multiple rectangles and through etching multiple line shapes with the same line width or different line widths, a central non-exposed area (12) is arranged in each rectangle needing to be etched on a photoetching board and forms a to-be-etched exposed area with the middle of the frame, that is, an external non-exposed area (11) of the rectangle, and the width of the to-be-etched exposed area is equal to the line width of the minimum line shape to be through etched; the uniform of the etching strip width is guaranteed, and the problem of an Lag effect in the etching process of the structure with the different strip widths is solved; meanwhile, when etching is completed, the central non-exposed areas (12) fall onto supporting layers (1) under the central non-exposed areas (12), and therefore the fact that etching is completed can be accurately judged. The method has the advantages that seriously excessive etching of the MEMS structure with the different etching strip width in ICP etching can be effectively prevented from being caused.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

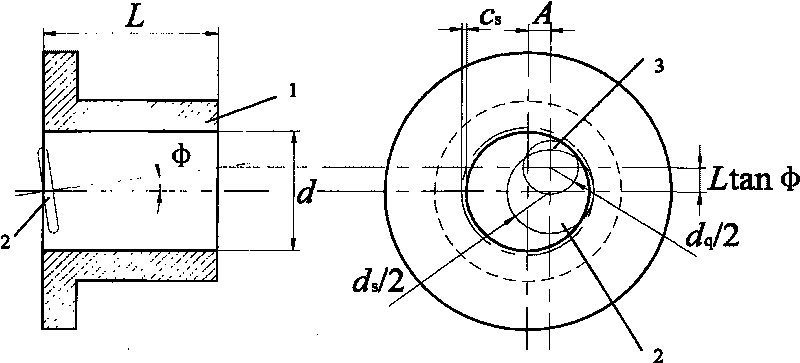

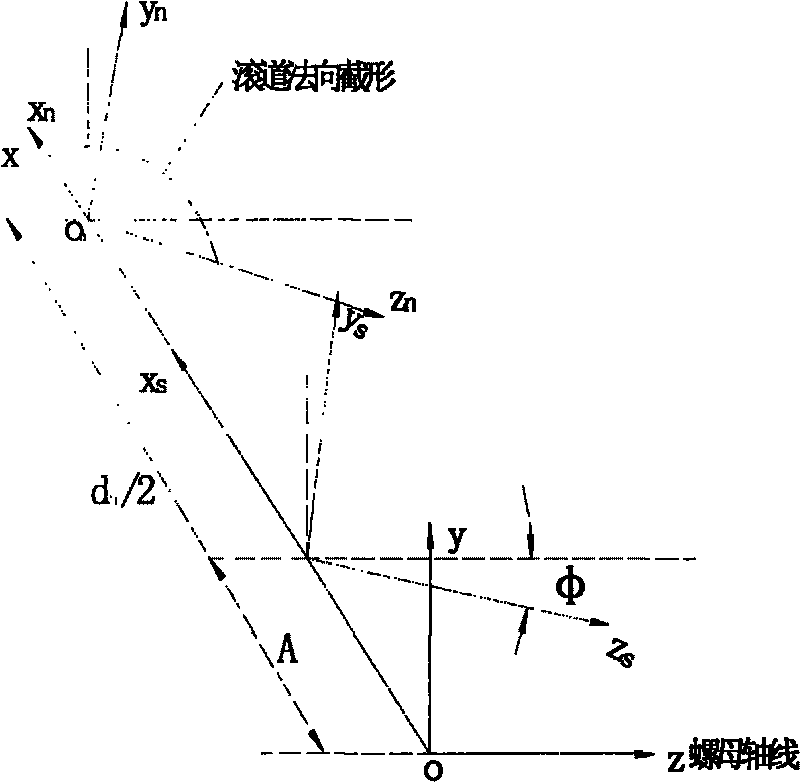

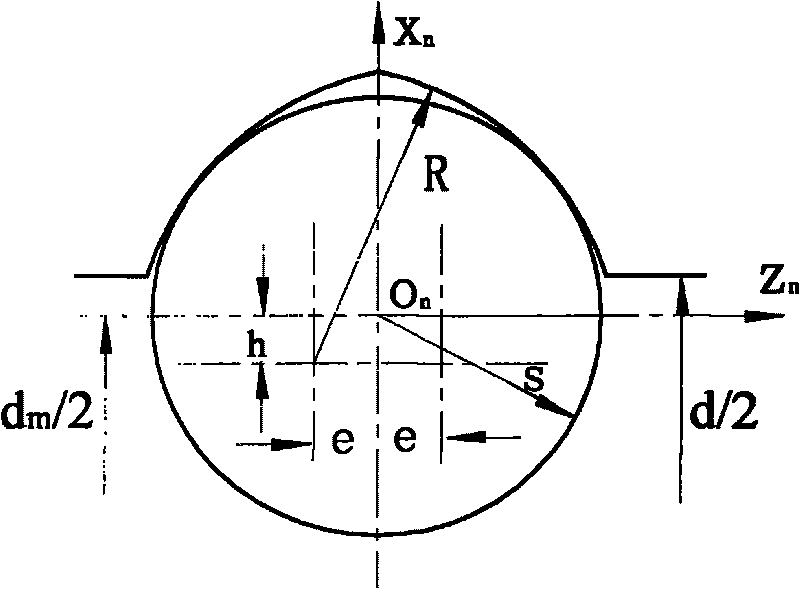

Method for grinding installation angle of grinding wheel through inner roller path of ball nut and designing accurate profile

The invention discloses a method for grinding an installation angle of a grinding wheel through an inner roller path of a ball nut and designing an accurate profile, comprising the following steps of: giving the cross section of the roller path and the length of the roller path of the ball nut, as well as the diameter of a grinding wheel and the diameter of a grinding rod, and calculating a center distance between the grinding wheel and an axial line of the nut. Because of the geometrical position relation among the grinding wheel, the grinding rod and the ball nut, a constraint equation exists between the installation angle of the grinding wheel and geometrical parameters, and the constraint equation is solved to obtain the installation angle of the grinding wheel which is not collided in grinding. A space contact line is formed between a rotary surface of the grinding wheel and an interior screw roller path surface of the processed ball nut; according to double circular arc cross section parameters and the installation angle of the grinding wheel, a roller path curve equation is established according to the method of the roller path of the ball screw; and a series of contact points between the grinding wheel and the roller path surface are solved to obtain a profile curve of the grinding wheel, and the profile curve of the rotated rotate around the axial line of the grinding wheel to obtain the grinding wheel profile. The invention can avoid the phenomenon of collision and undercutting in the grinding process of the ball screw cap, the grinding wheel profile is simple to calculate, the installation angle of the grinding wheel is designed according to the technique, and the grinding profile is correspondingly finished.

Owner:ZHEJIANG UNIV

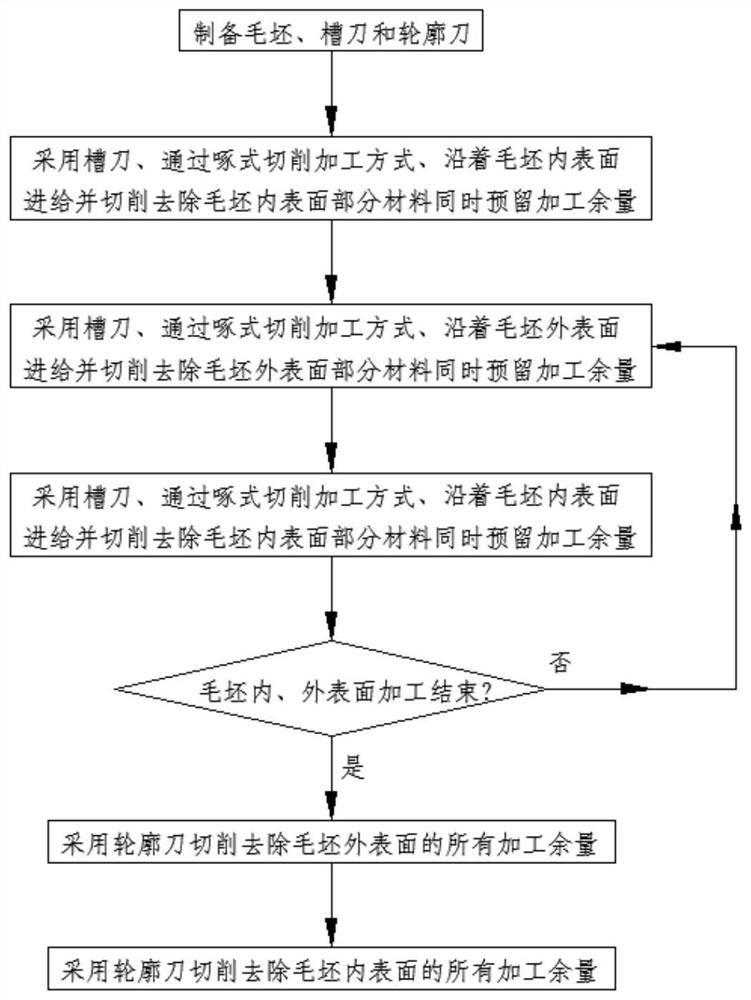

Cutting machining forming method for L-shaped thin-wall ring piece

The invention provides a cutting machining forming method for an L-shaped thin-wall ring piece. The cutting machining forming method comprises the following steps of preparing a blank, a groove cutter and a contour cutter; feeding along the inner surface of the blank by adopting the groove cutter, cutting to remove partial material on the inner surface of the blank and reserving machining allowance; feeding along the outer surface of the blank by adopting the groove cutter, cutting to remove partial material on the outer surface of the blank and reserving machining allowance; feeding along the inner surface of the blank by adopting the groove cutter, cutting to remove partial material on the inner surface of the blank and reserving machining allowance; repeating the steps for a plurality of times; cutting and removing all machining allowances on the outer surface of the blank by adopting the contour cutter; and cutting and removing all machining allowances on the inner surface of the blank by adopting the contour cutter. According to the technical scheme, the inner surface and the outer surface of the blank are cut in a staggered alternating mode, the feeding direction of a cutter is corrected, the rigidity of a workpiece is improved, deformation of the workpiece is reduced, over-cutting phenomenon during machining is avoided, and machining precision and machining quality are improved.

Owner:GUIZHOU LIYANG INT MFG

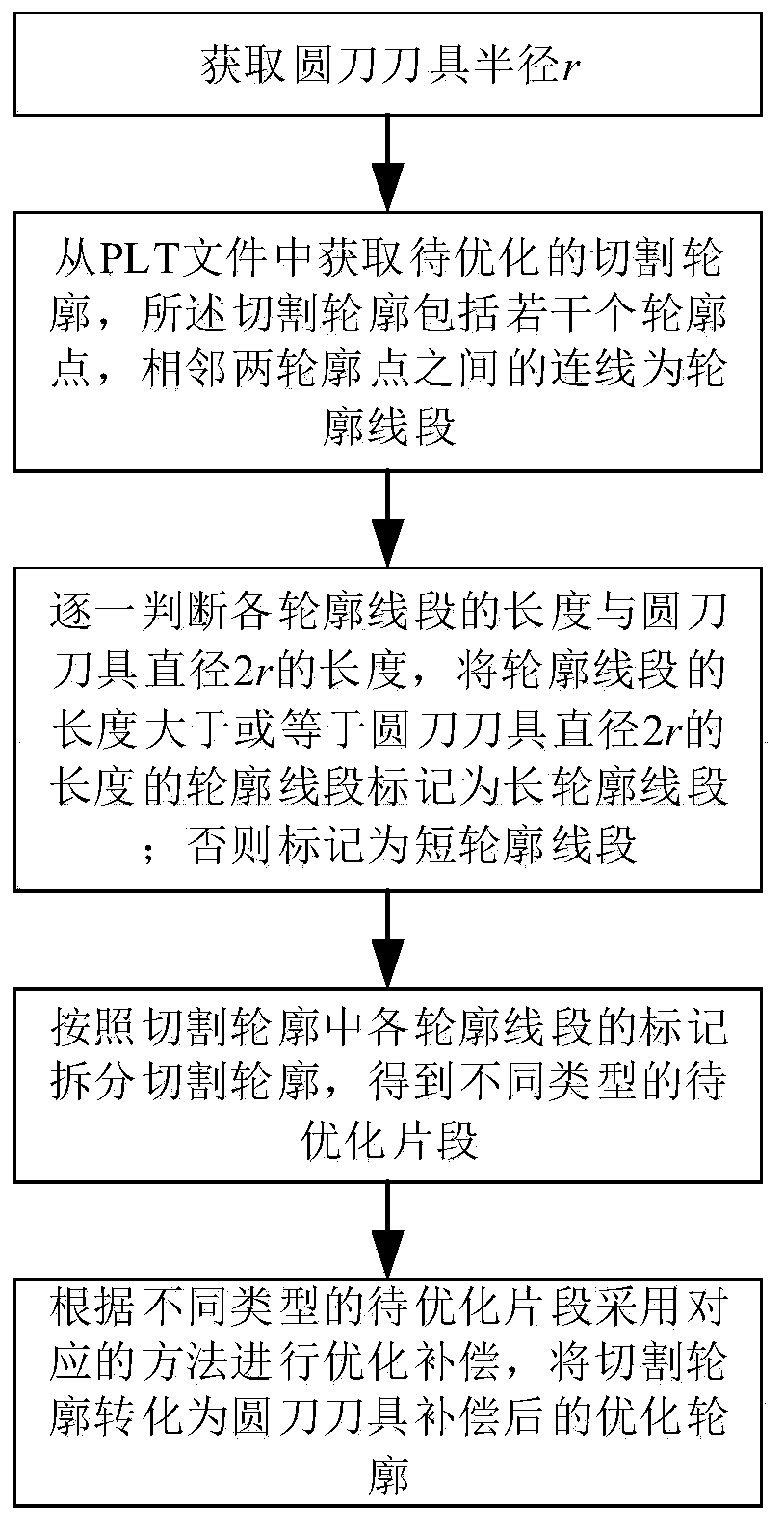

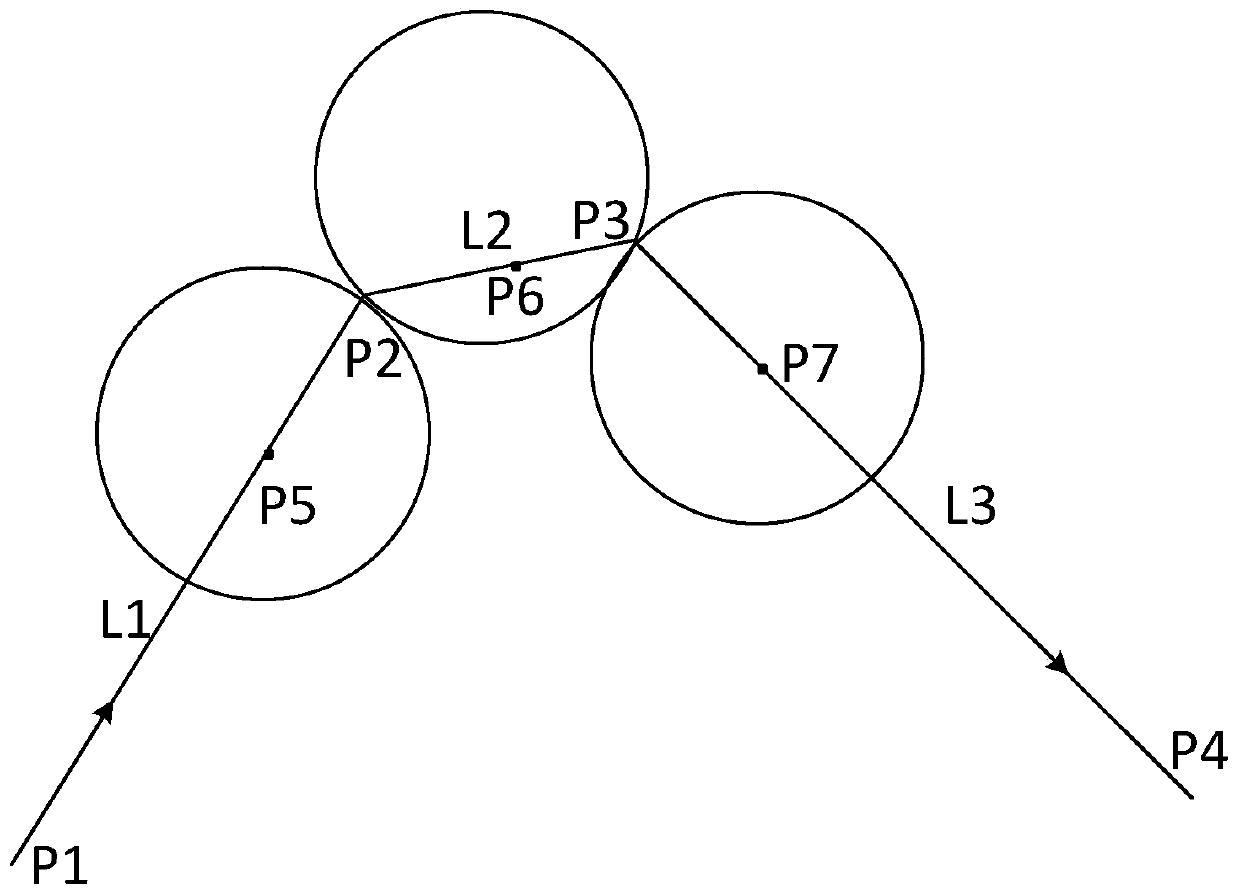

Cutting optimization method based on circular cutter compensation

InactiveCN111274654AAvoid overcuttingImprove cropping accuracyGeometric CADImage analysisAlgorithmStructural engineering

The invention discloses a cutting optimization method based on circular cutter compensation. The cutting optimization method comprises the steps: obtaining the radius r of a circular cutter; obtaininga to-be-optimized cutting contour from the PLT file, the cutting contour comprising a plurality of contour points, and a connection line between two adjacent contour points being a contour line segment; judging the length of each contour line segment and the length of the diameter 2r of the circular cutter one by one, and marking the contour line segment with the length greater than or equal to the length of the diameter 2r of the circular cutter as a long contour line segment; otherwise, marking as a short contour line segment; splitting the cutting contour according to the mark of each contour line segment in the cutting contour to obtain different types of to-be-optimized segments; and carrying out optimization compensation by adopting a corresponding method according to different types of to-be-optimized fragments, and converting the cutting contour into an optimized contour after circular cutter compensation. According to the method, the cutting contour is optimized according tothe radius of the circular knife, the over-cutting situation in the cutting process is avoided, the cutting precision is improved, and the optimization efficiency is high.

Owner:ZHEJIANG UNIV OF TECH

Disposable Cylindrical Cutter

A single use bone cutter comprised of two concentric cylinders and a series of insert blades or cutter disc is described. The cutter blades or cutter disc is preferably positioned at the distal end of the cutter. The bone cutter also comprises a guide rod that aids in the line of sight when using the cutter device.

Owner:WILSON GREATBATCH LTD

Robot control method, robot control device and robot

ActiveCN110936379BRealize the cutting operationAvoid overcuttingProgramme-controlled manipulatorSpinal nerveComputer vision

This application is applicable to the field of robot technology, and provides a robot control method, a robot control device, a robot and a computer-readable storage medium, including: acquiring a three-dimensional medical image, and performing three-dimensional reconstruction on the three-dimensional medical image to obtain a three-dimensional reconstruction image; Obtain the lamina area to be cut from the three-dimensional reconstruction image; obtain the position point of the upper surface of the lamina and the position point of the lower surface of the lamina; translate the position point of the lower surface of the lamina to the direction of the upper surface of the lamina for a specified distance; according to the The distance between the upper surface of the plate and the corresponding position point on the lower surface of the lamina after translation and the maximum cutting amount are used to obtain the position points inside the lamina; according to all the position points of the lamina, the movement path of the robot during the cutting process is obtained; the control The robot performs cutting operations according to the motion path. Through this application, the robot can be controlled to decompress the laminae, improve the cutting quality, and reduce the risk of spinal nerve injury caused by over-cutting.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com