Patents

Literature

87 results about "Feeding self" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

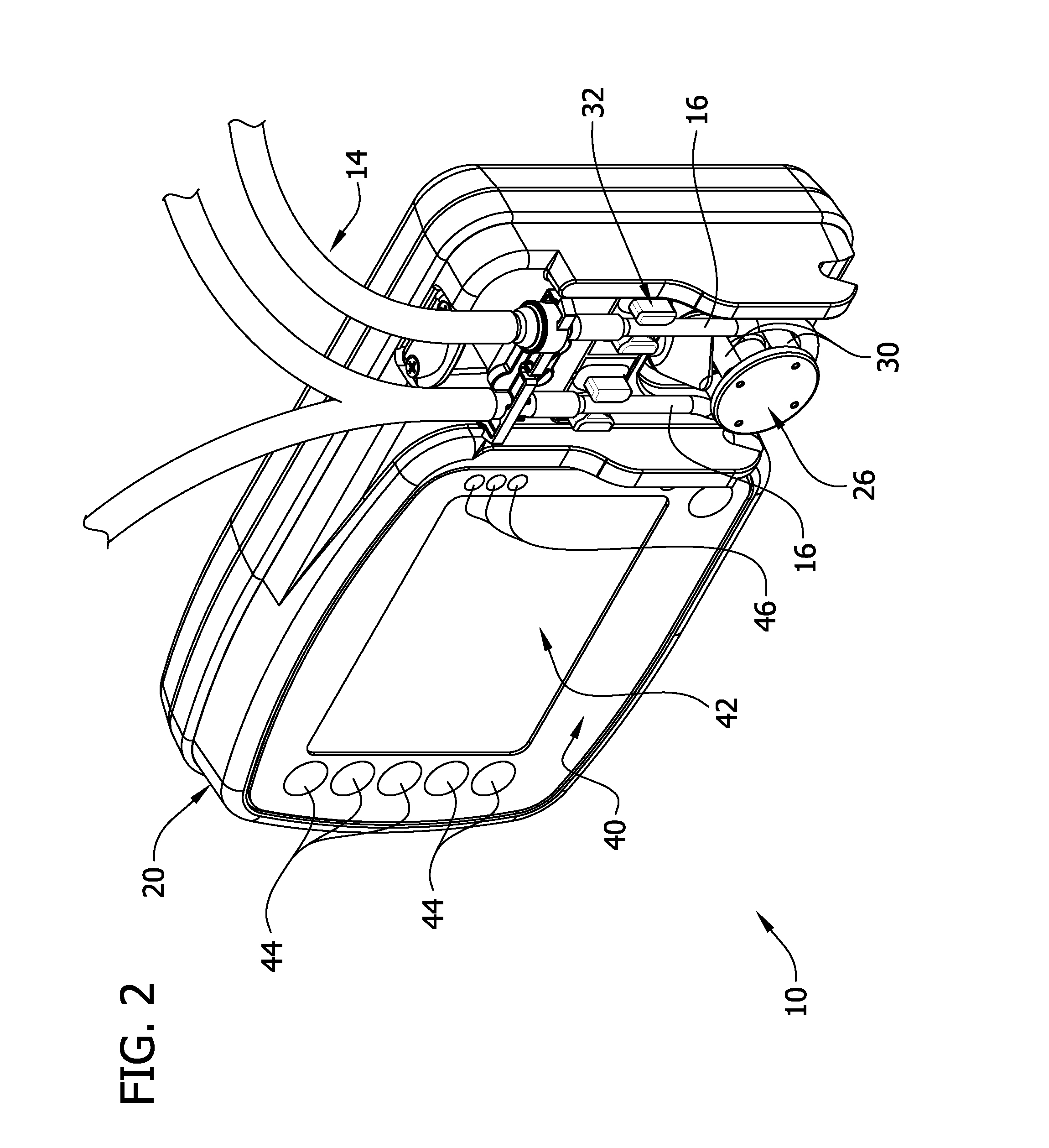

Disposable wild bird feeder

InactiveUS20100089330A1Easy to useResistant being reusedPisciculture and aquariaAvicultureBird feederEngineering

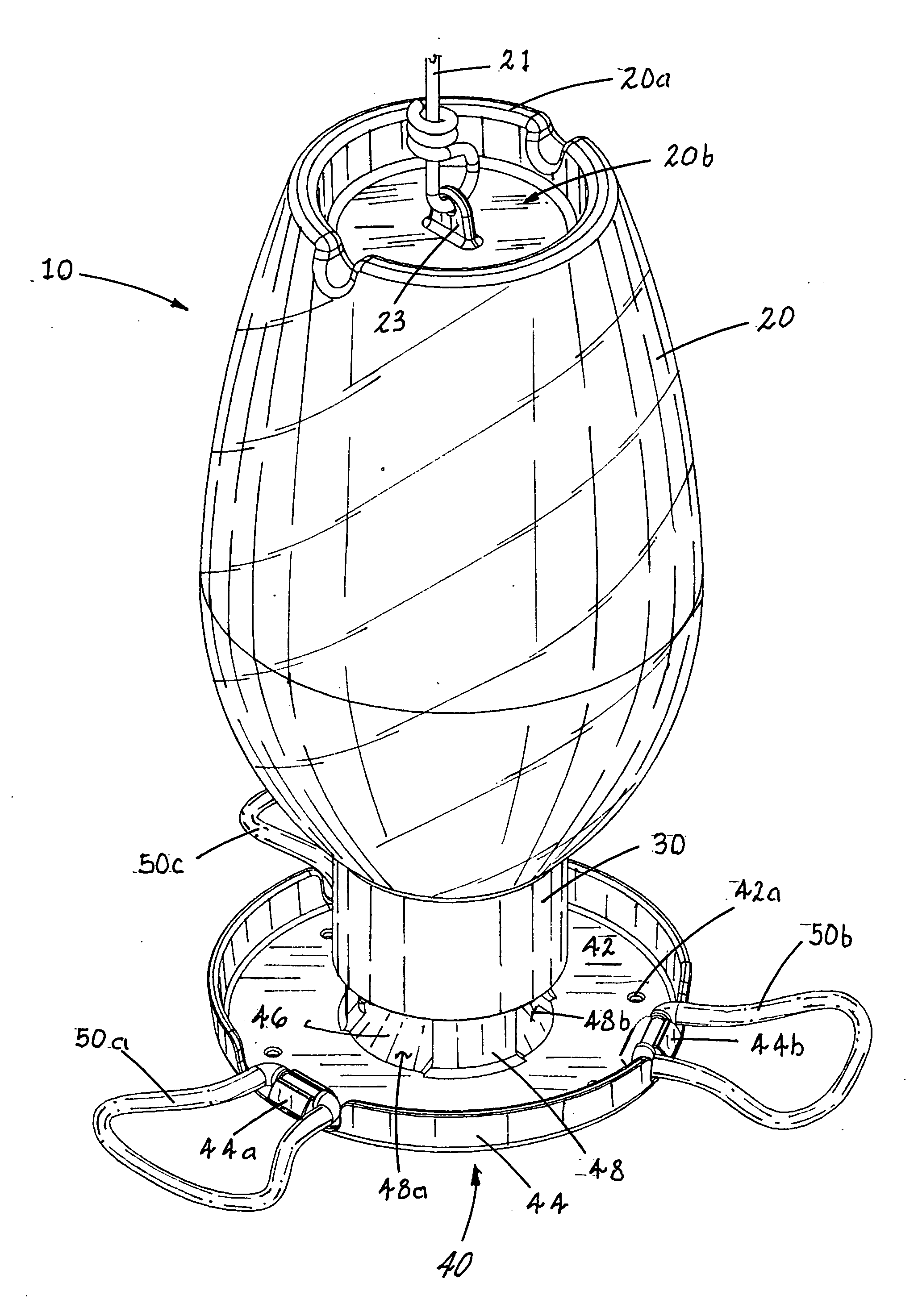

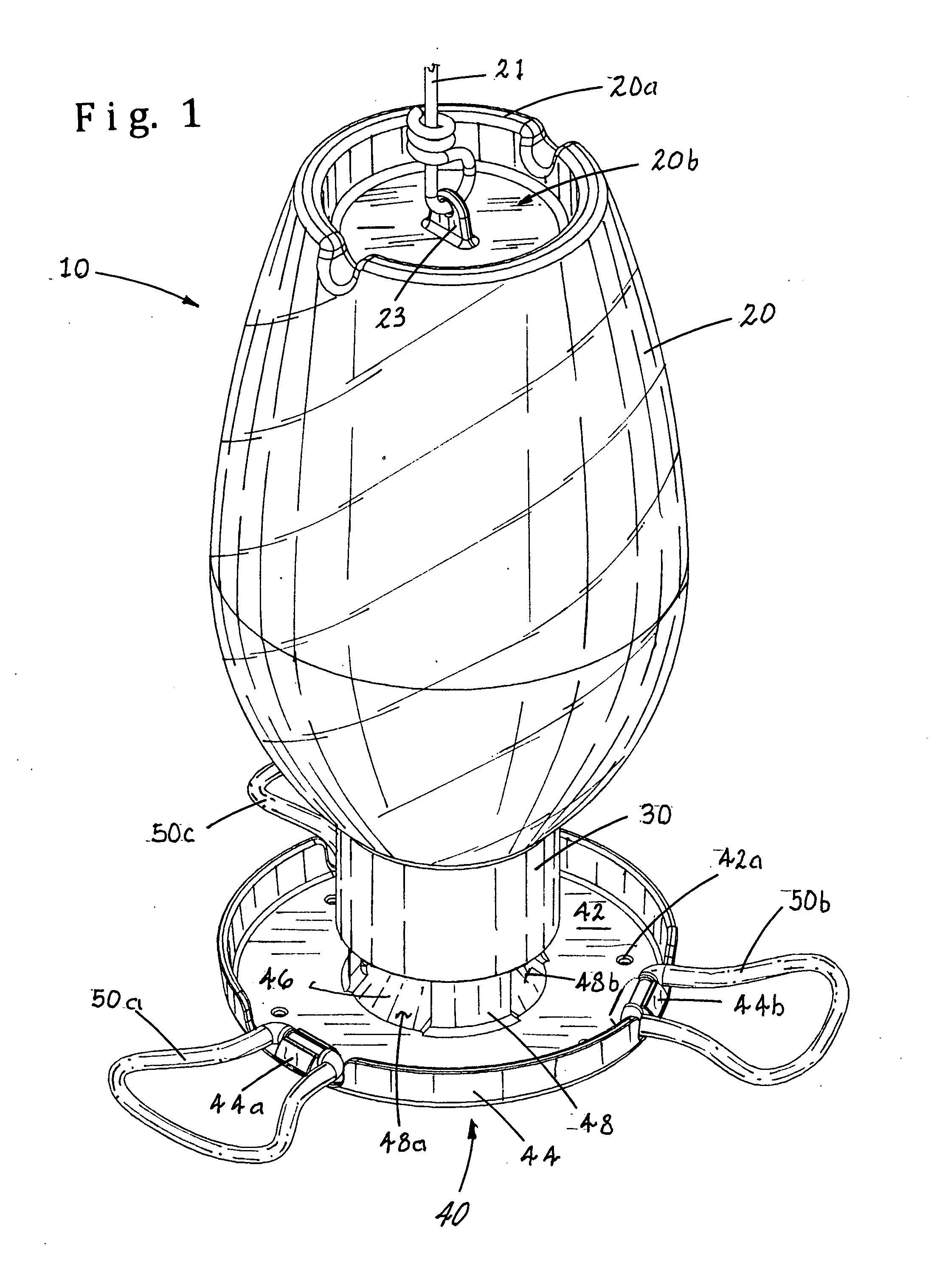

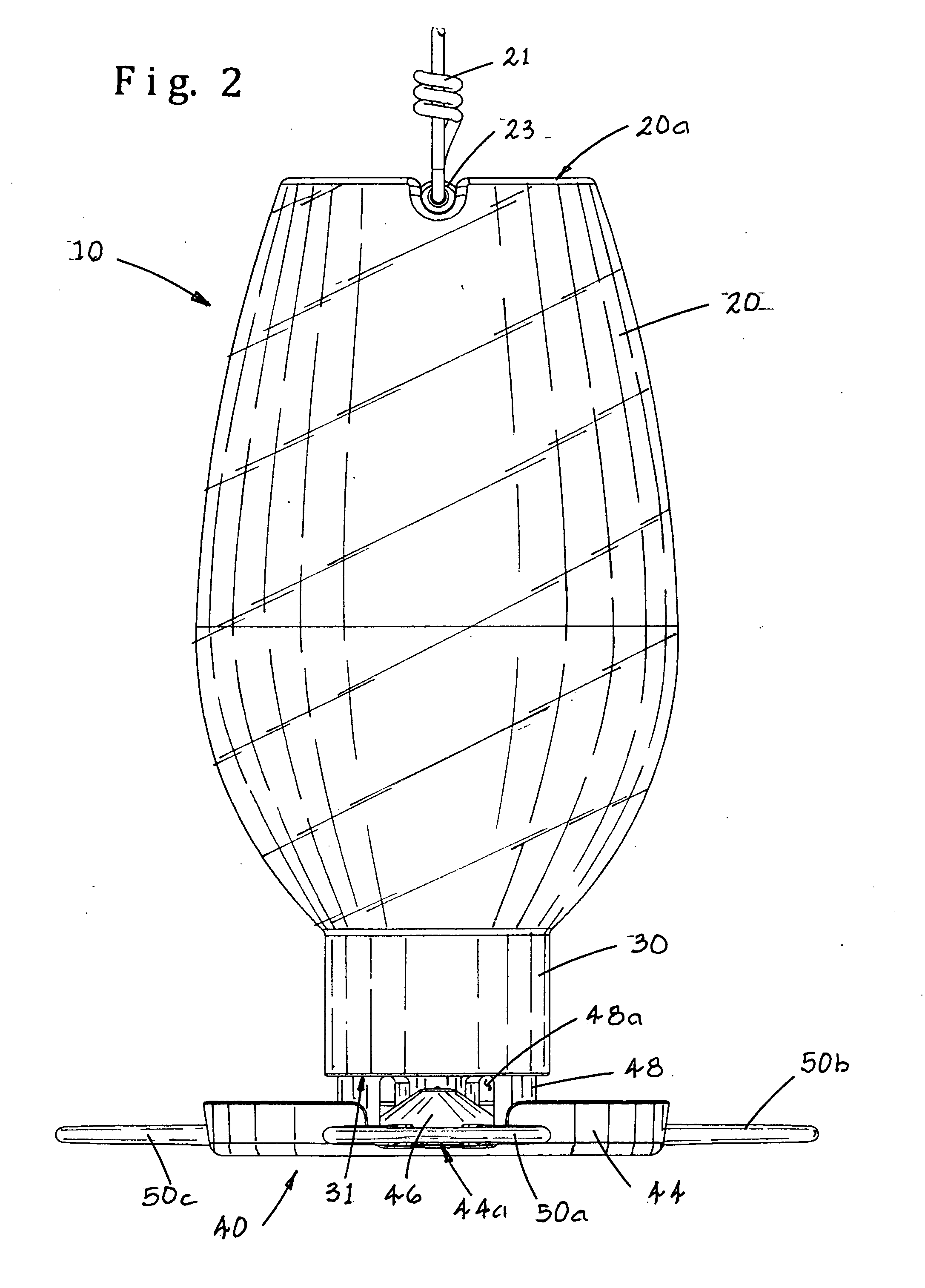

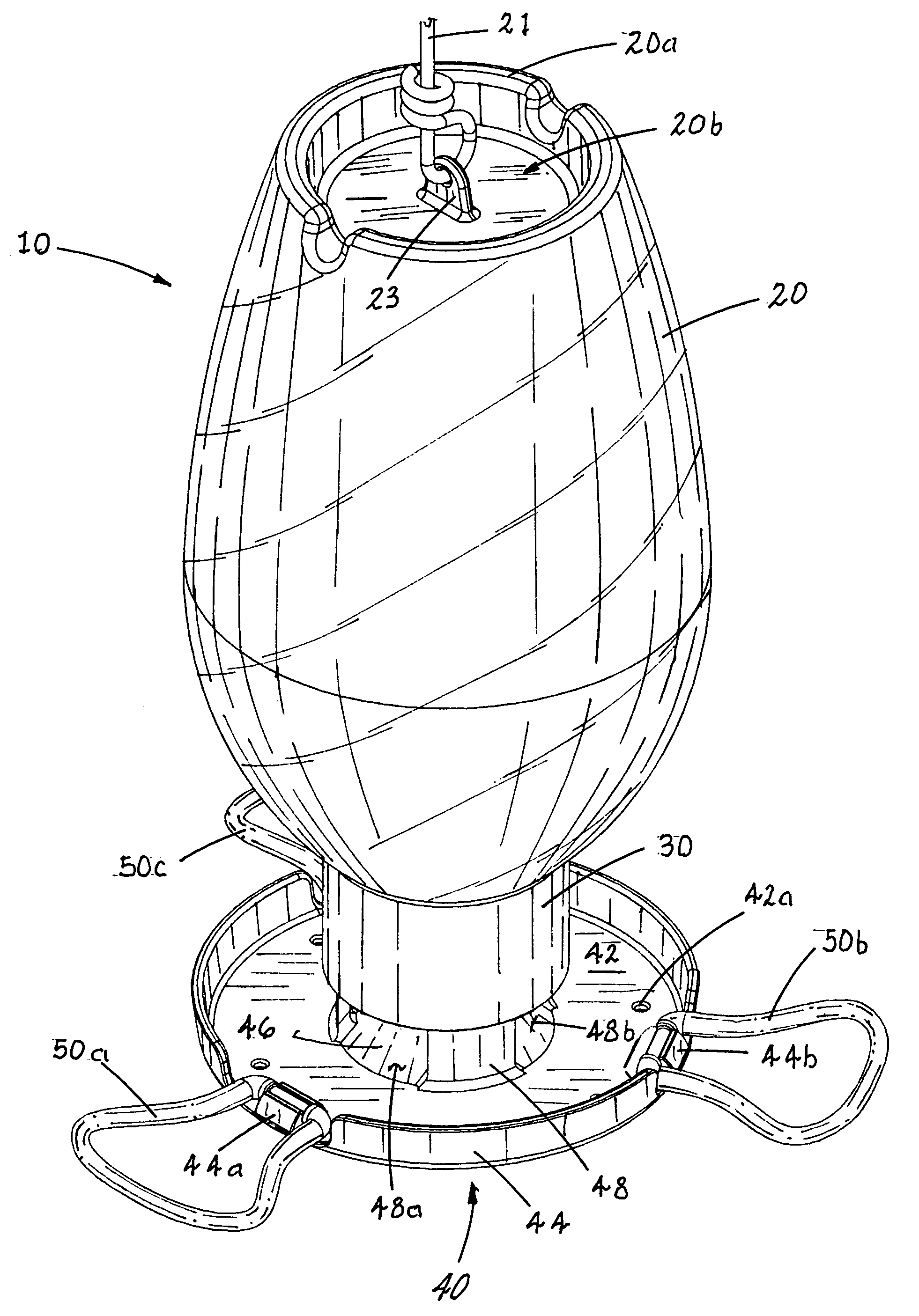

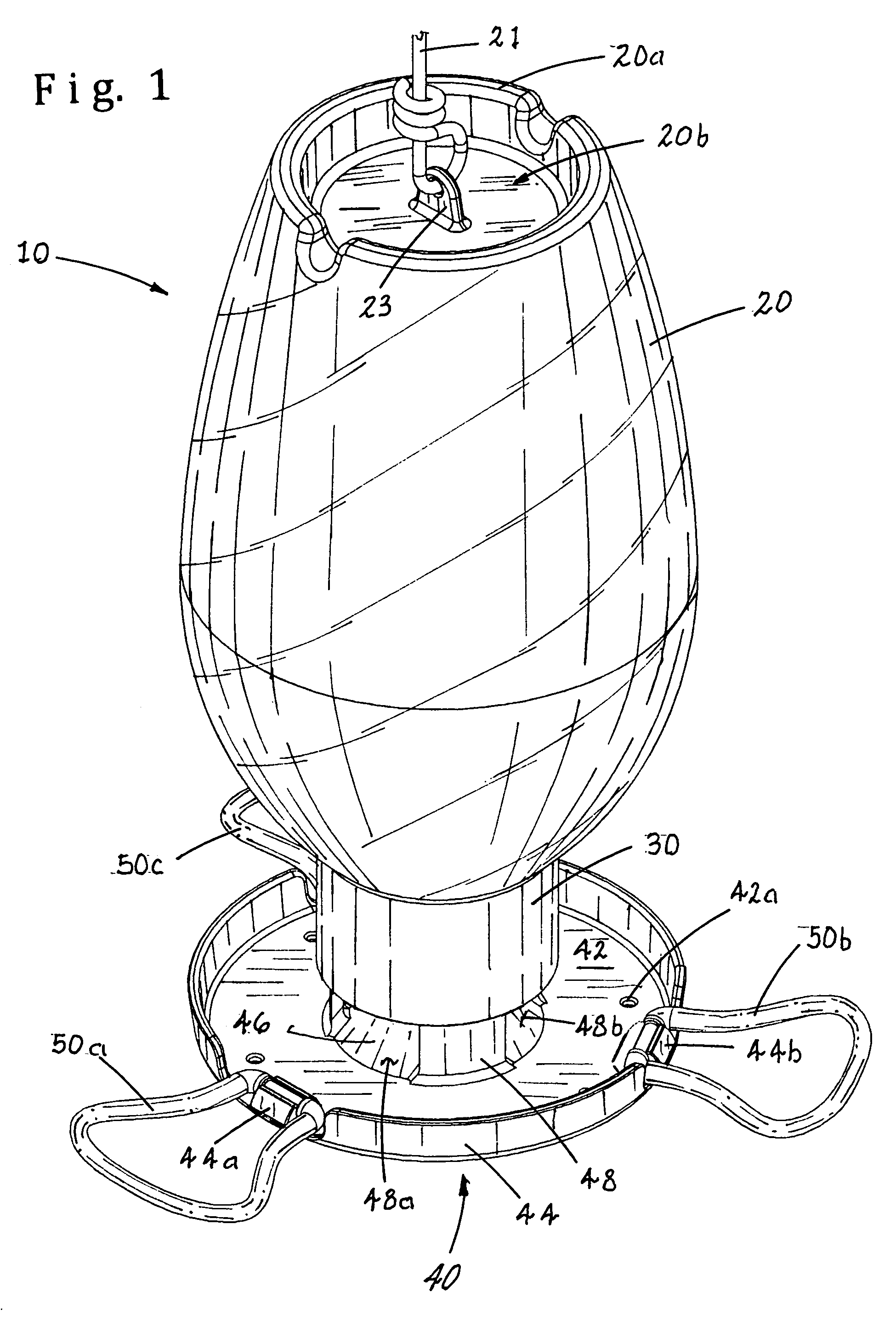

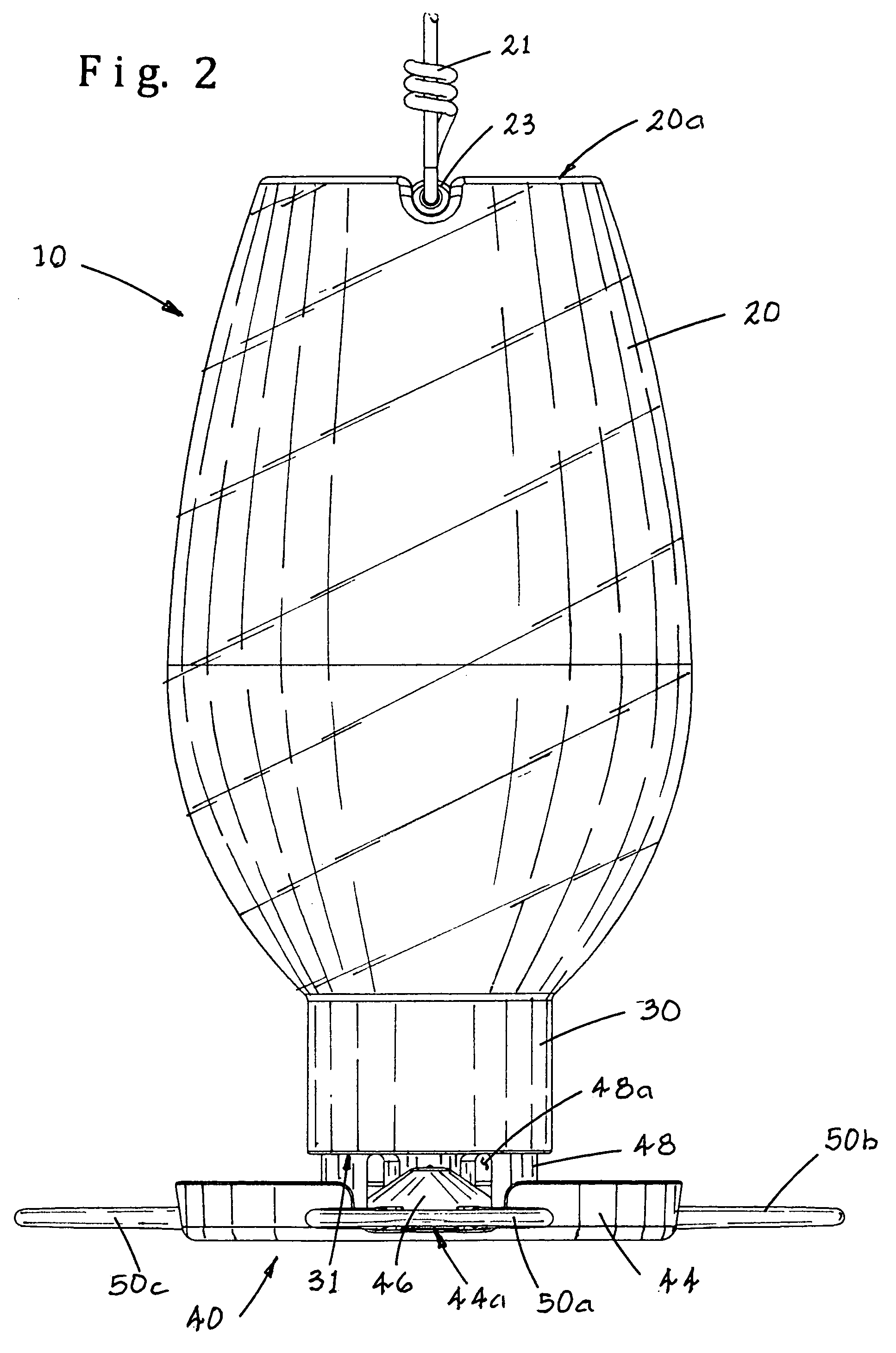

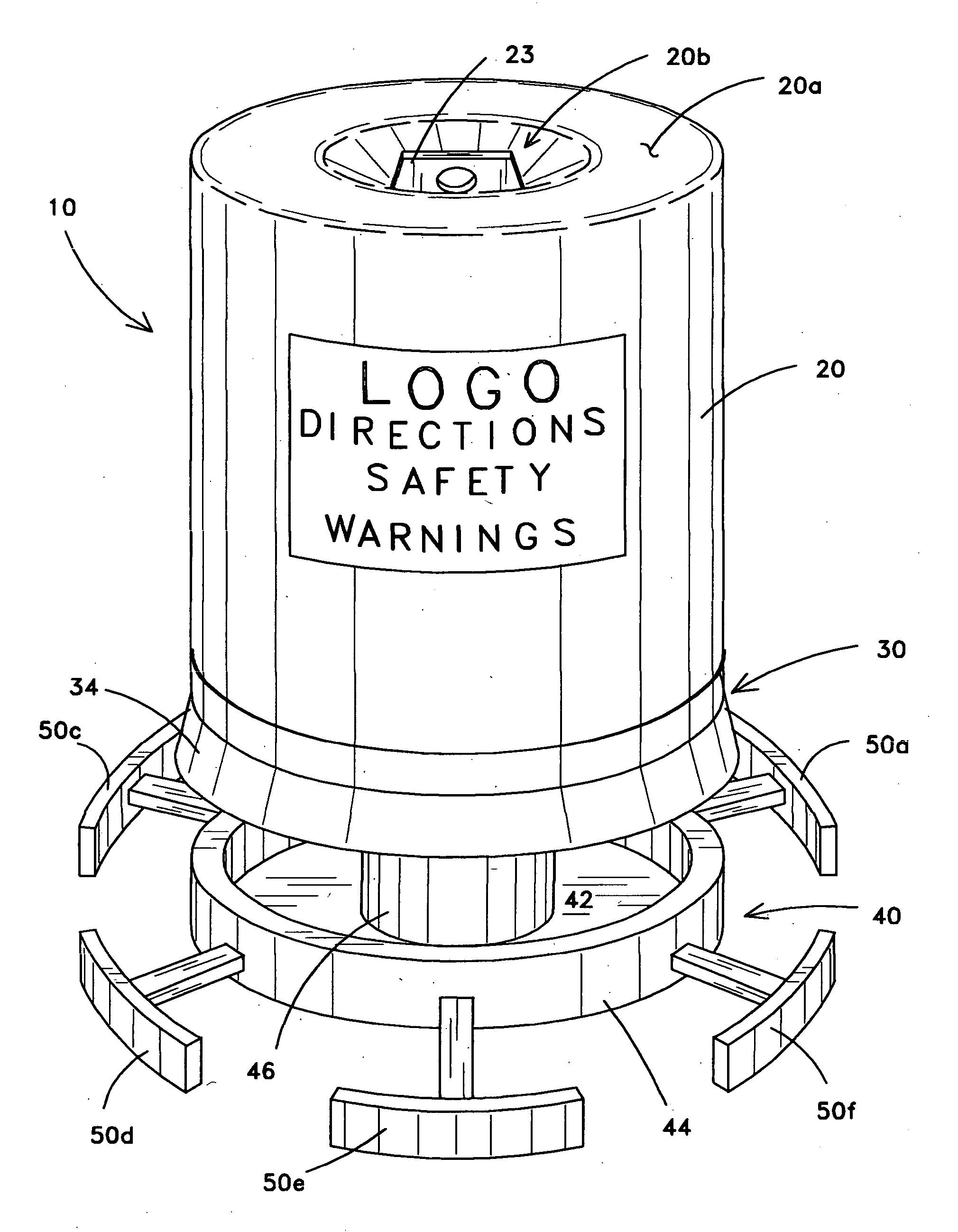

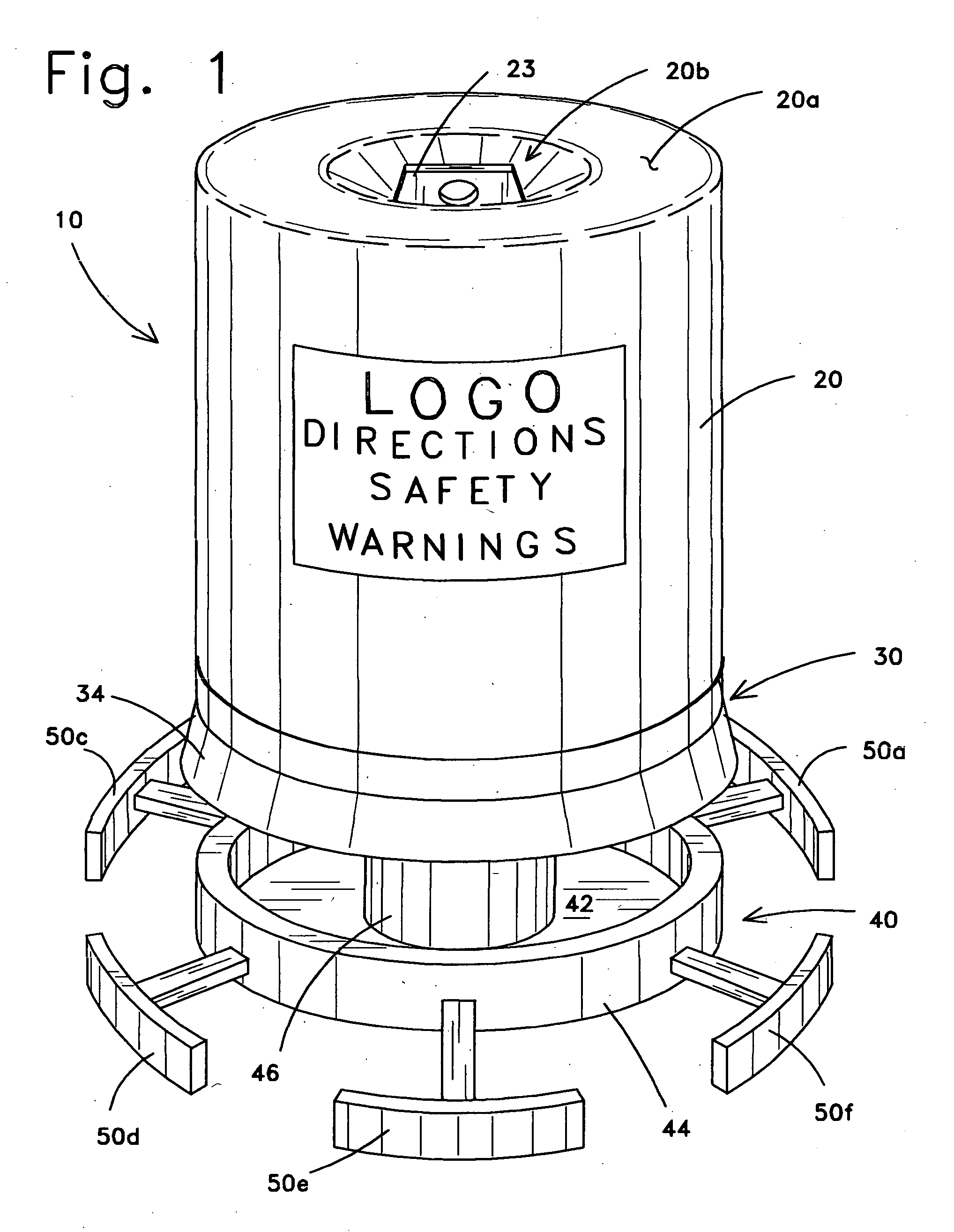

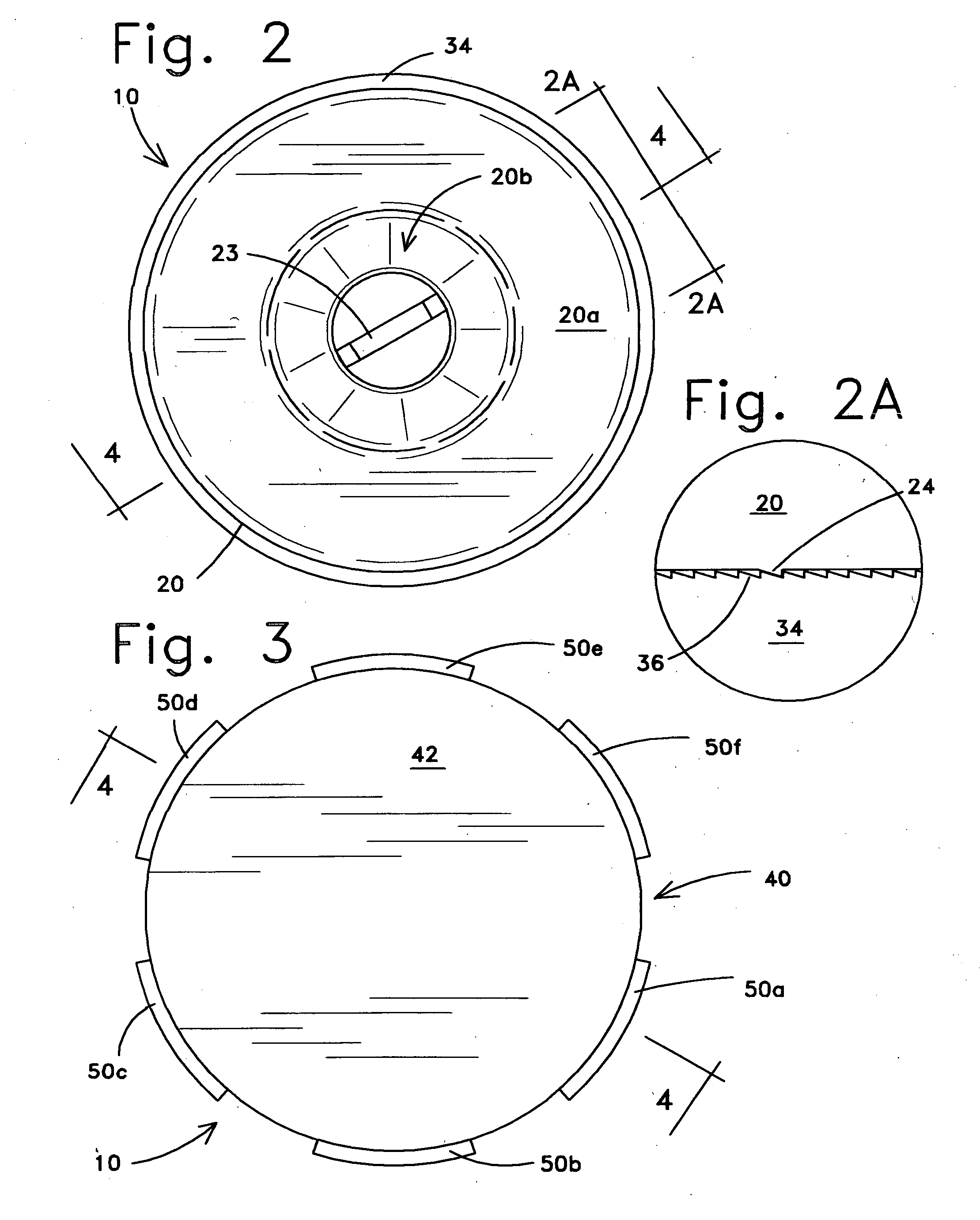

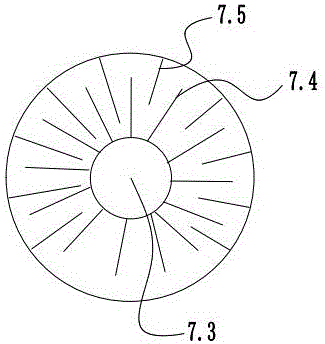

The present invention is a disposable wild bird feeder with the features that make it safe and easy to use but protected from being reused. A transparent reservoir containing bird seed is connected with a feeding base. The feeding base is threaded to an adaptor portion of the reservoir. A locking means between the internal threads of the adaptor portion and the external threads of the feeding base discourages the assembled wild bird feeder from being taken apart and refilled. The wild bird feeder converts from a first storage and shipping configuration to a second feeding configuration by partially unthreading the feeding base from the adaptor so bird seed is supplied to the bottom portion of the feeding base. A plurality of perches are supported by the feeding base. The perches are moved from a stored position to approximately a horizontal deployed position when the second feeding configuration is realized. A removable label is placed on the reservoir to provide a logo, directions for safe use and bird seed data.

Owner:MCMULLEN JOSEPH E

Disposable wild bird feeder

InactiveUS7874264B2Easy to useResistant being reusedPisciculture and aquariaAvicultureBird feederEngineering

The present invention is a disposable wild bird feeder with the features that make it safe and easy to use but protected from being reused. A transparent reservoir containing bird seed is connected with a feeding base. The feeding base is threaded to an adaptor portion of the reservoir. A locking means between the internal threads of the adaptor portion and the external threads of the feeding base discourages the assembled wild bird feeder from being taken apart and refilled. The wild bird feeder converts from a first storage and shipping configuration to a second feeding configuration by partially unthreading the feeding base from the adaptor so bird seed is supplied to the bottom portion of the feeding base. A plurality of perches are supported by the feeding base. The perches are moved from a stored position to approximately a horizontal deployed position when the second feeding configuration is realized. A removable label is placed on the reservoir to provide a logo, directions for safe use and bird seed data.

Owner:MCMULLEN JOSEPH E

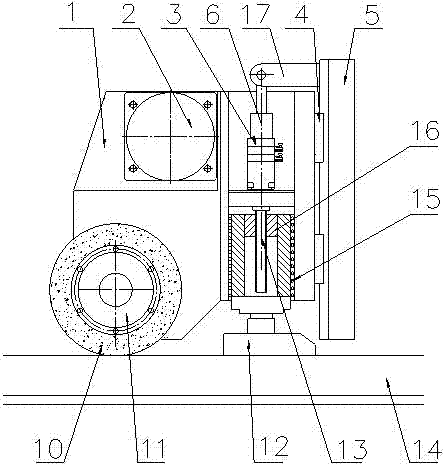

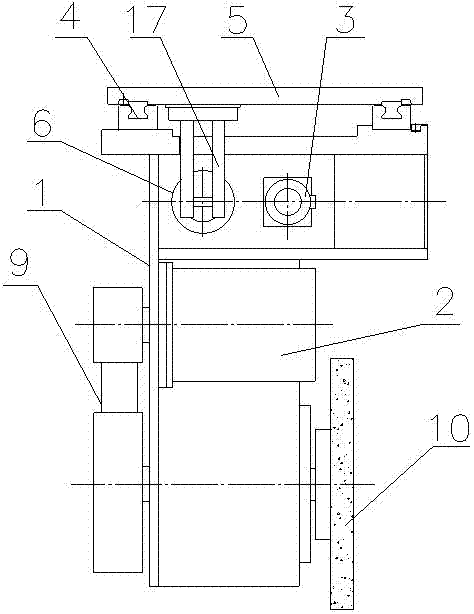

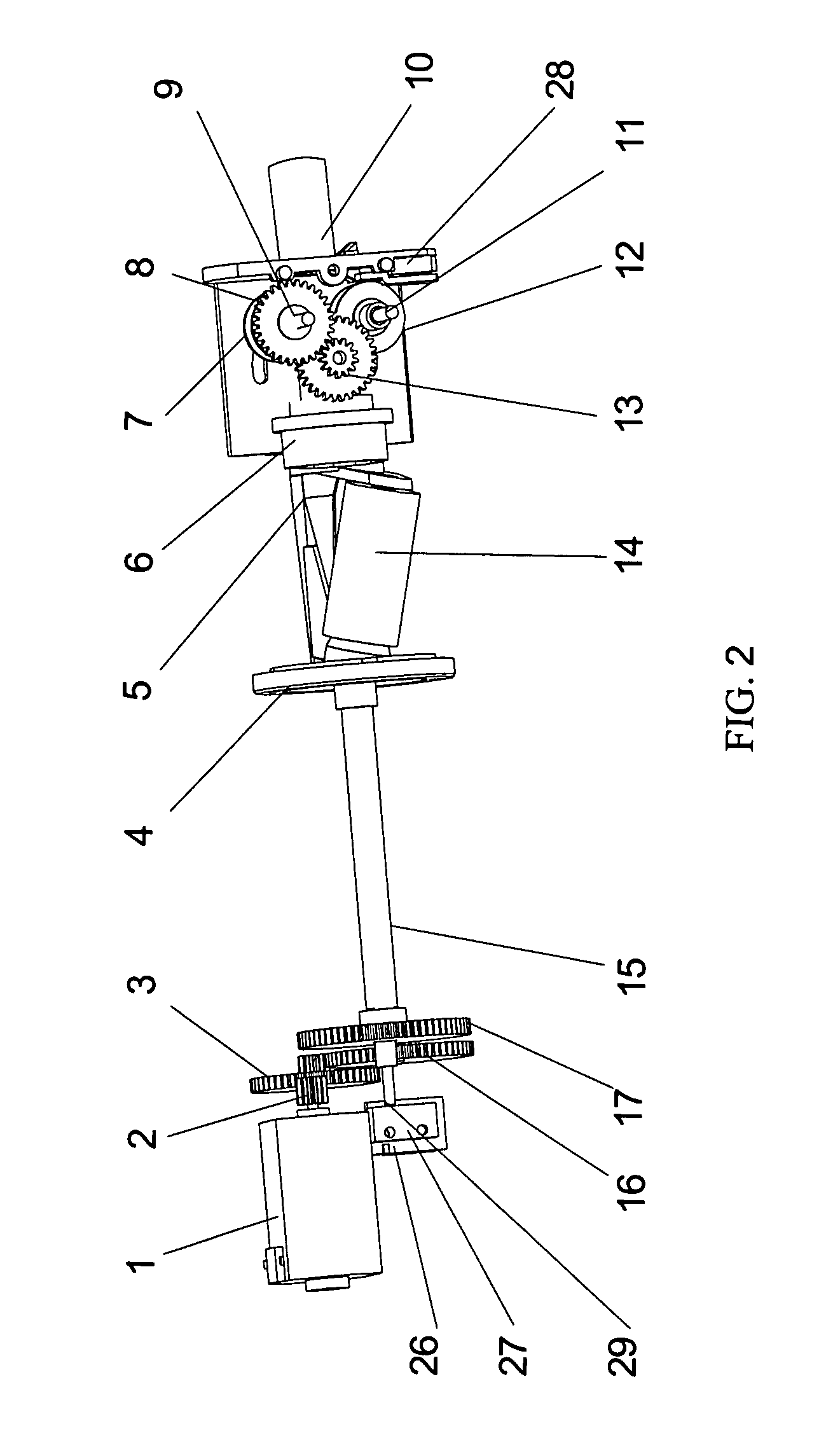

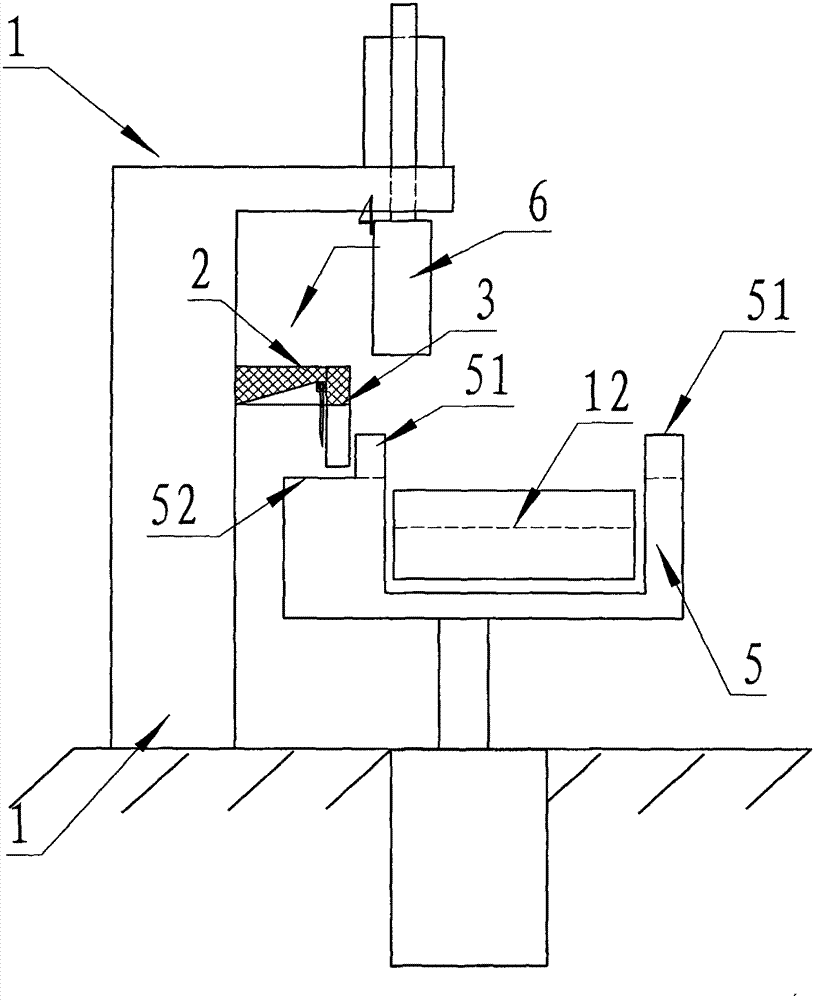

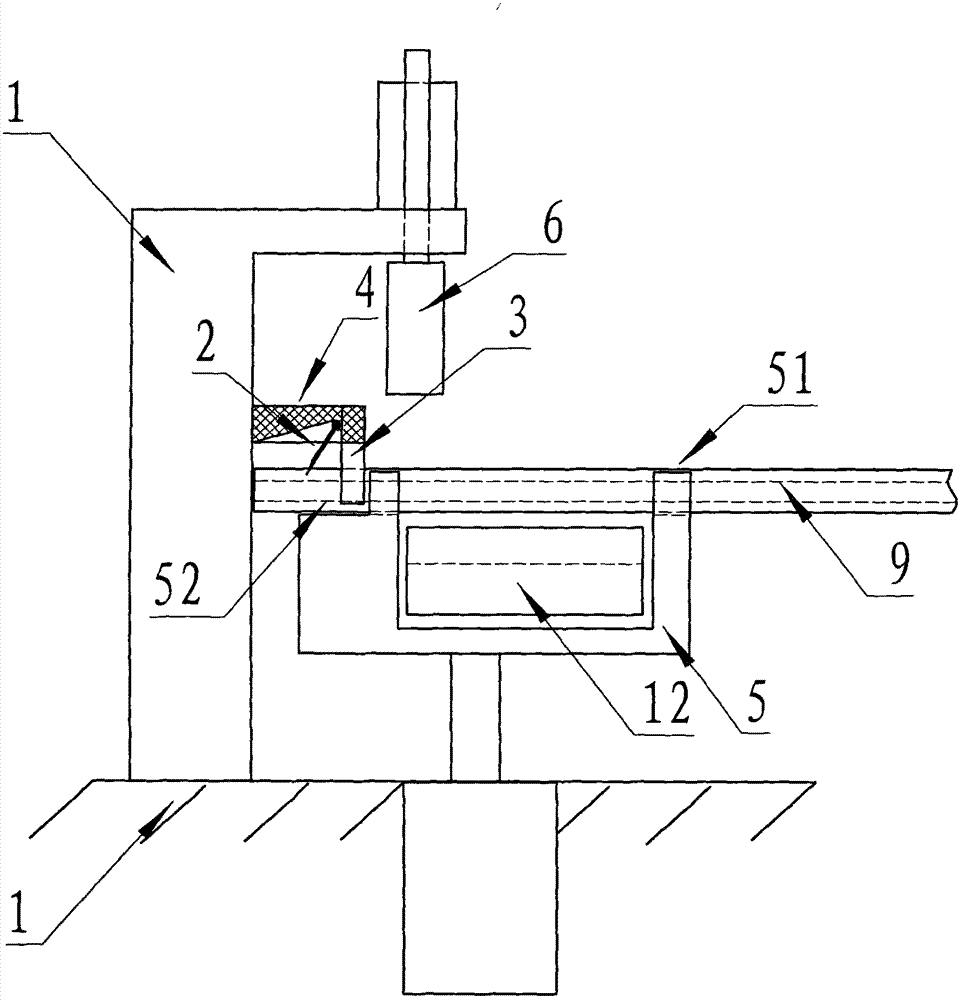

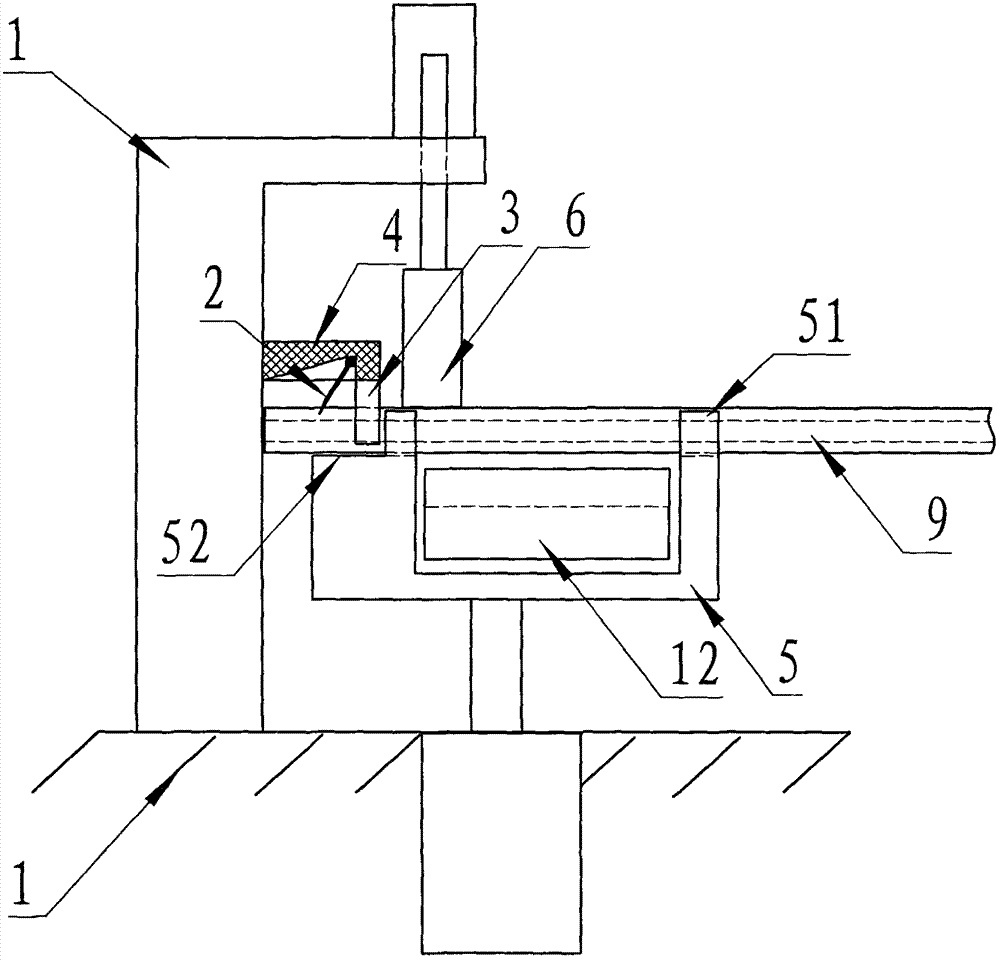

Drilling machine provided with automatic feeding device

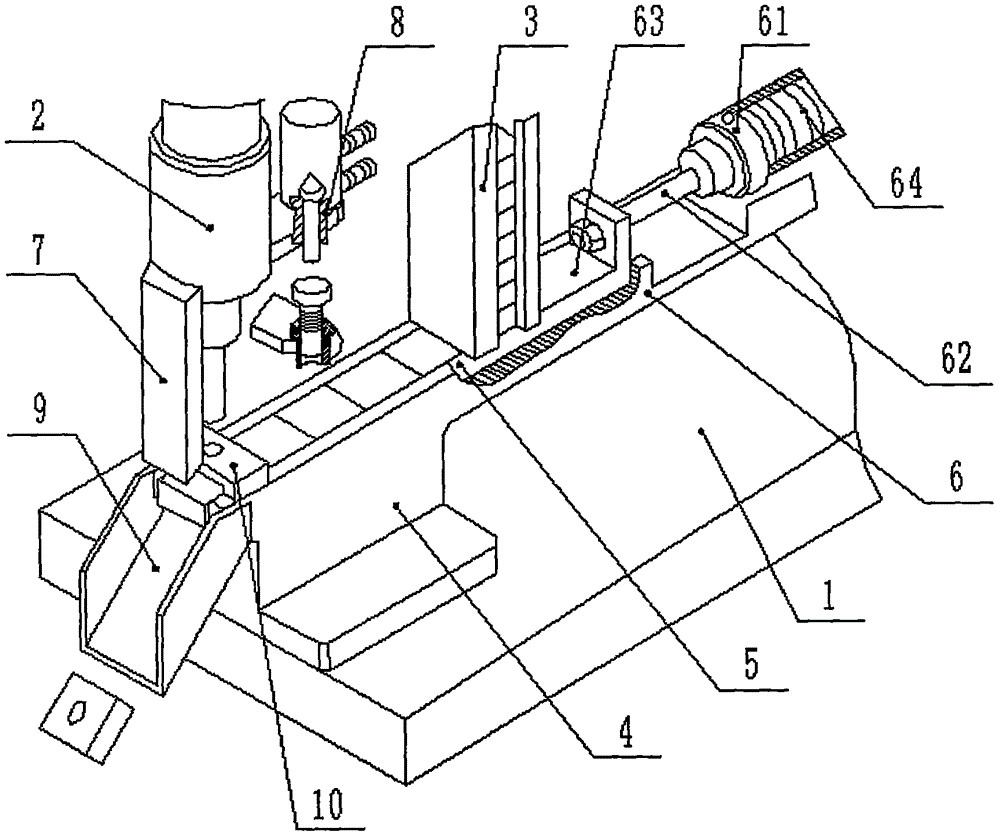

InactiveCN105798689ARealize automatic feedingImprove clamping efficiencyMetal working apparatusEngineeringDrilling machines

The invention discloses a drilling machine provided with an automatic feeding device, belongs to the field of automatic drilling machines and solves problems that existing drilling machines cannot feed materials automatically and are low in drilling efficiency. The technical scheme is as follows: the drilling machine comprises a workbench and a drilling machine spindle, wherein a storage tank is fixedly arranged on one side of the drilling machine spindle, a feeding base is fixedly mounted on the workbench below the storage tank, a delivery guiding groove is formed in the feeding base in advance, a discharging port of the storage tank directly faces the delivery guiding groove, one side of the delivery guiding groove extends right below the drilling machine spindle, a push device is mounted on the other side of the delivery guiding groove, and a workpiece stop block is fixedly arranged on the drilling machine spindle, can slide up and down along the outer side surface of the drilling machine spindle and is located at the tail end of the delivery guiding groove after vertically falling.

Owner:WUXI INST OF COMMERCE

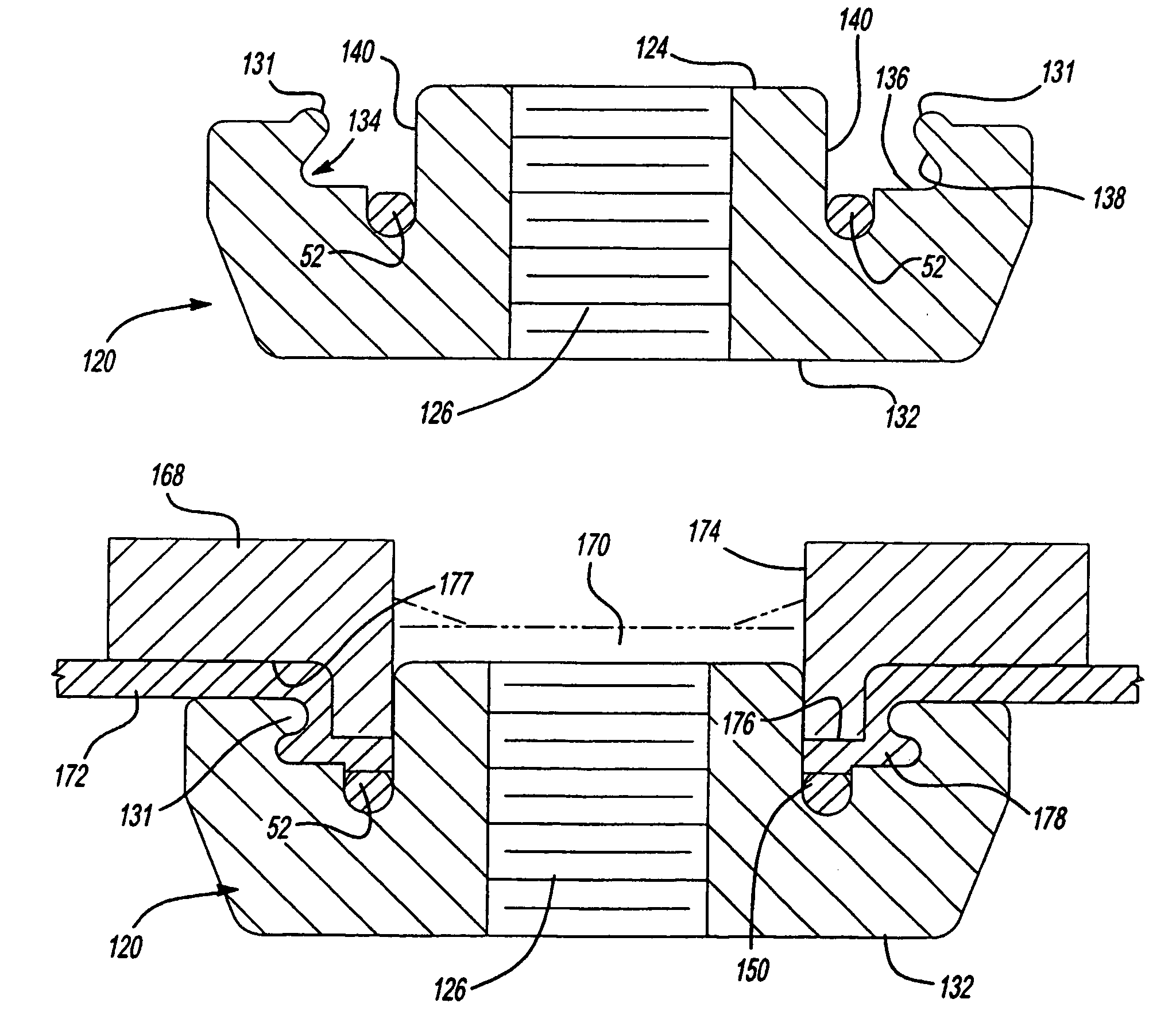

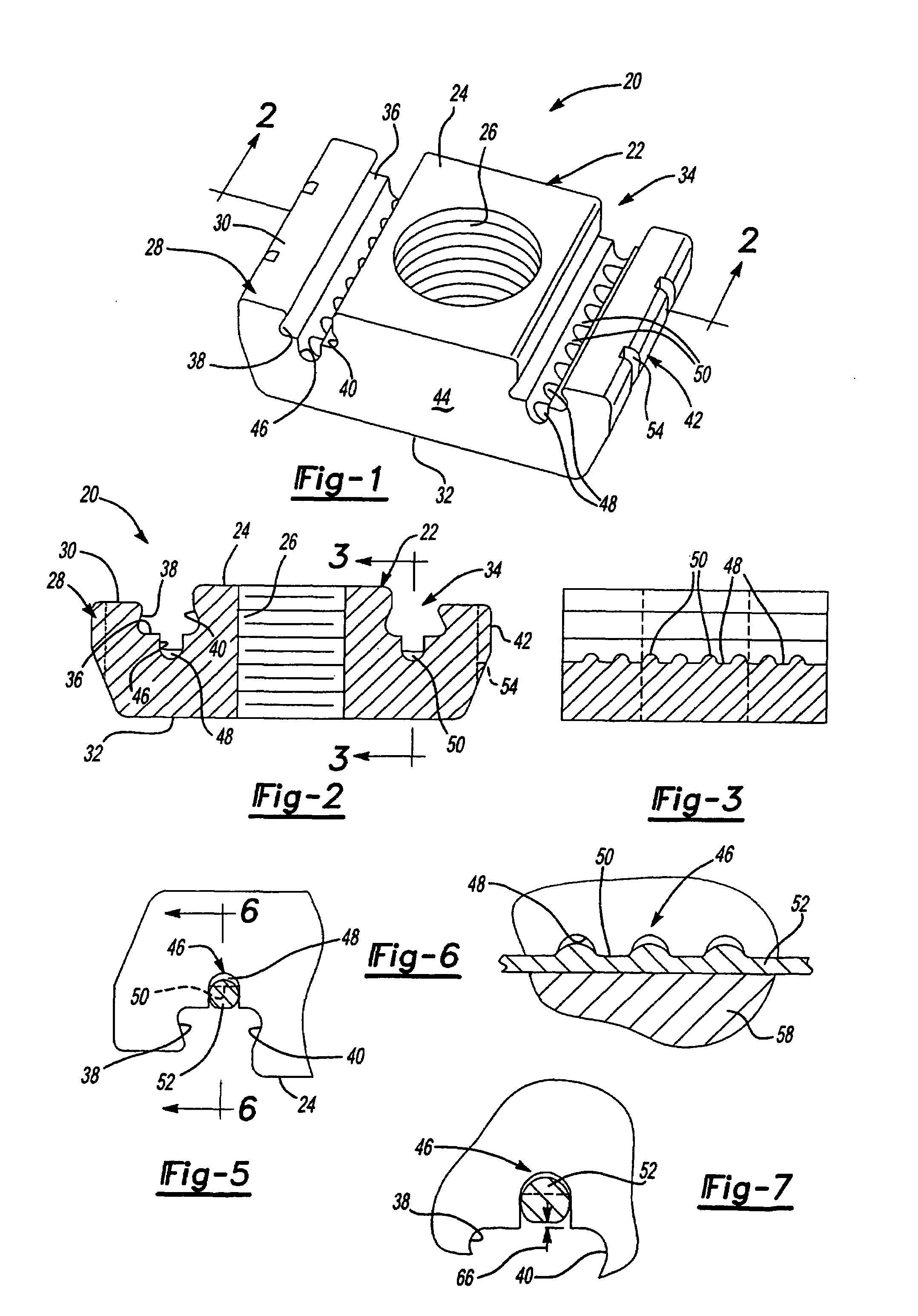

Self-attaching fastener systems

Methods of forming and feeding self-attaching fasteners are disclosed wherein the strip includes a plurality of spaced abutment surfaces, preferably notches, which may be used both during the manufacturing process and feeding of a strip of fasteners to an installation head. Where the fasteners are interconnected in a strip, by frangible wires, the wires are located in the bottom wall of the panel receiving grooves in the flange portions on opposed sides of the projecting pilot portion. A self-attaching fastener having deformable inclined lip portions which extend upwardly and toward the pilot portion from the flange portions which are deformed during installation to provide further securement for the panel when deformed in the grooves.

Owner:PENN AUTOMOTIVE INC

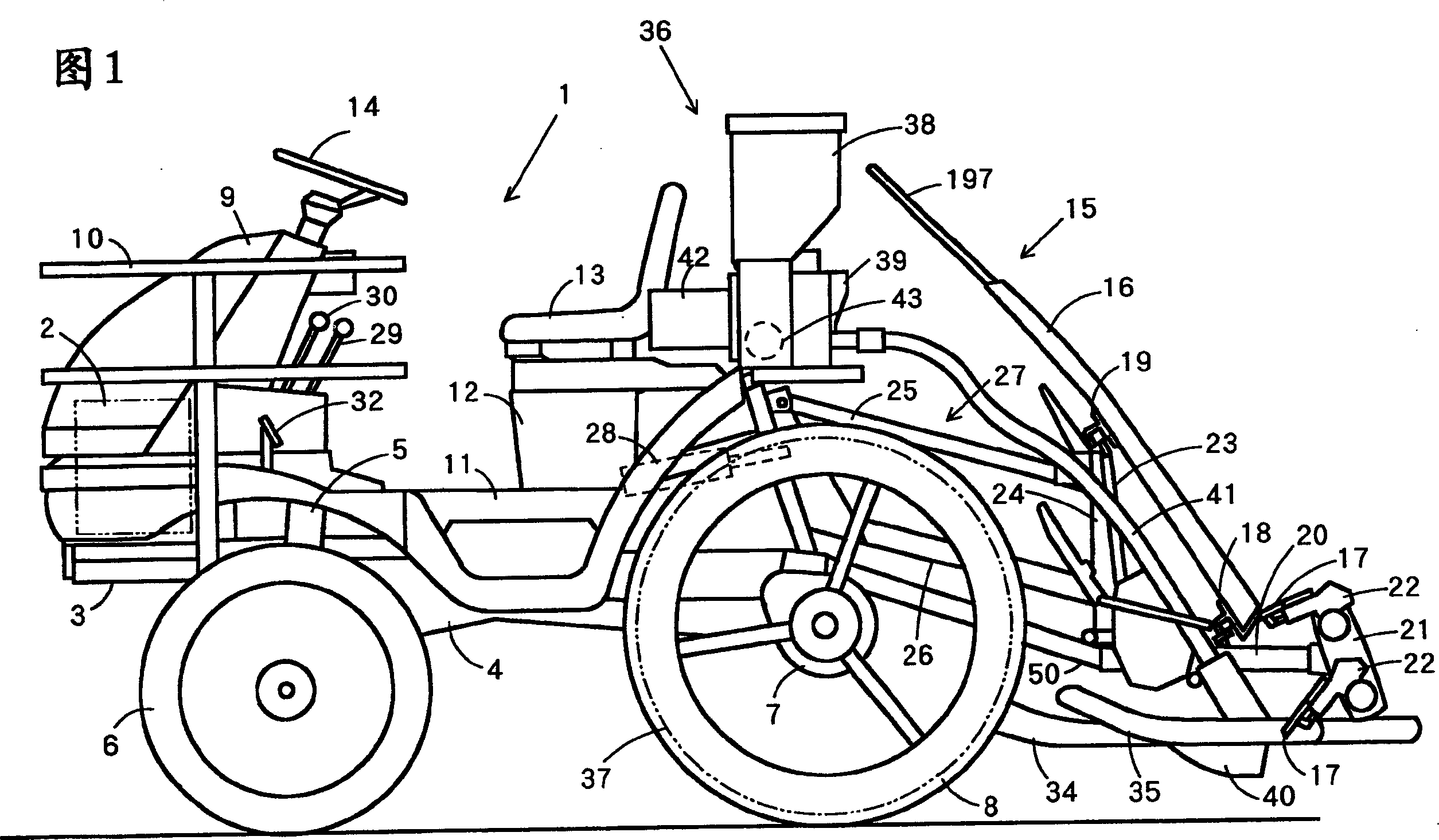

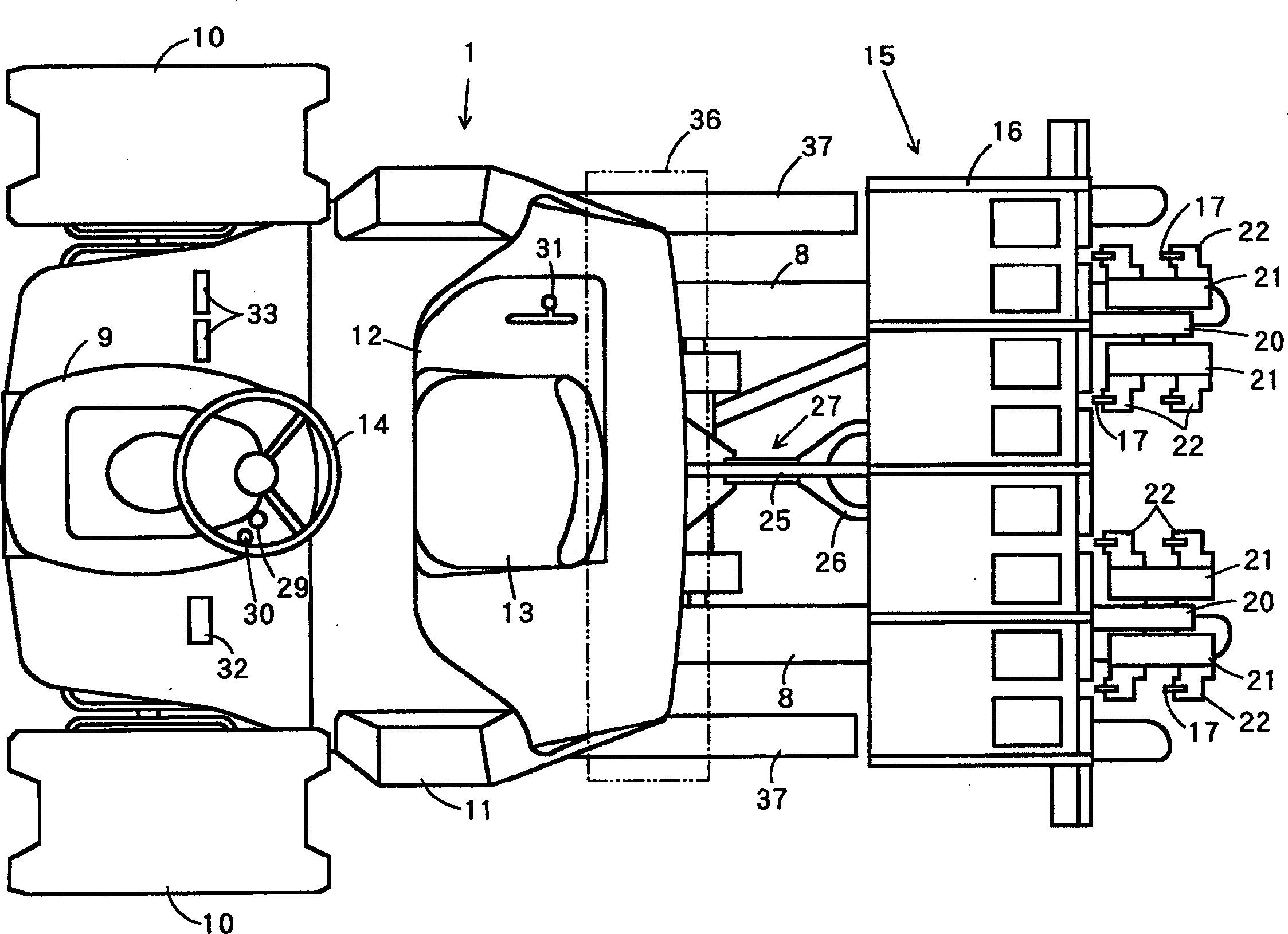

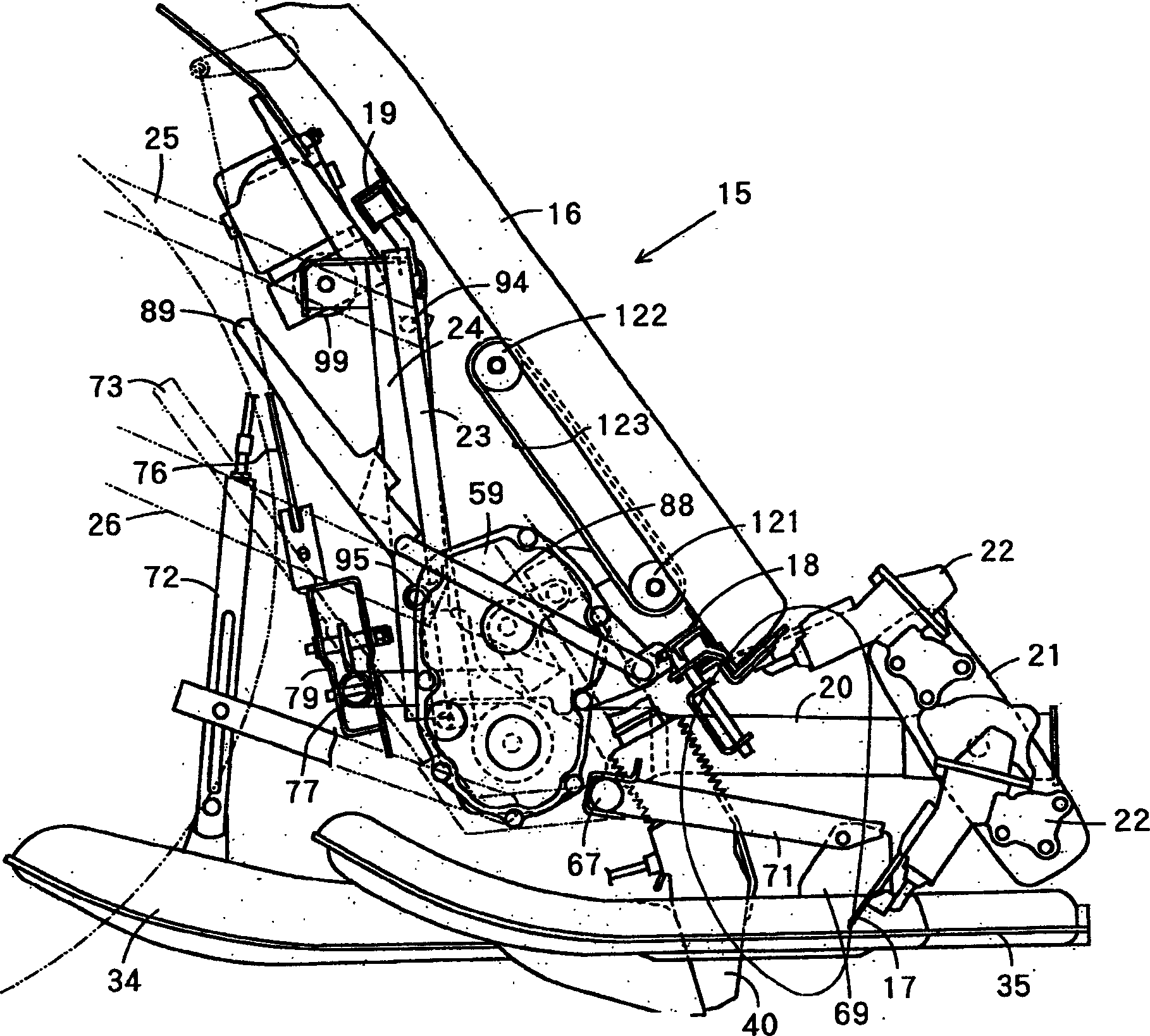

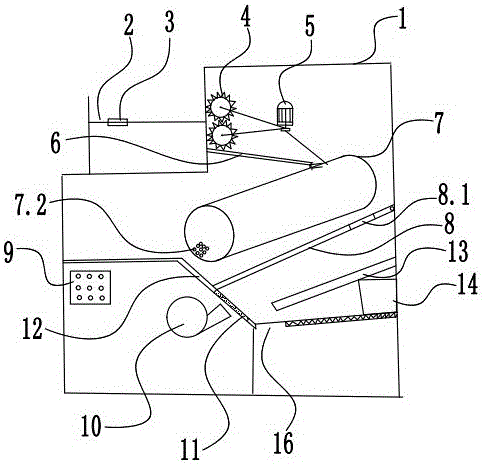

Rice transplanter

This invention relates to a rice transplanter comprising: a transplanting frame 20 for driving rice transplanting pawls 17; and a seedling feeding member 58 connected to the transplanting frame 20 through a seedling feeding case 59. The seedling feeding member 58 has a longitudinal feed camshaft 65 formed on one side and a transverse feed threaded shaft 66 formed on the other side, and the camshaft 65 and threaded shaft 66 are arranged on the right and left sides across the center of the transplanter body, to improve two side weight balances of a transplanting portion 15 thereby keeping the transplanting precision stable. The longitudinal feed cams 116 of the longitudinal feed camshaft 65 and the slide blocks 114 of the transverse feed threaded shaft 66 are arranged on the right and left sides across the body center to facilitate their maintenances.

Owner:YANMAR POWER TECHNOLOGY CO LTD

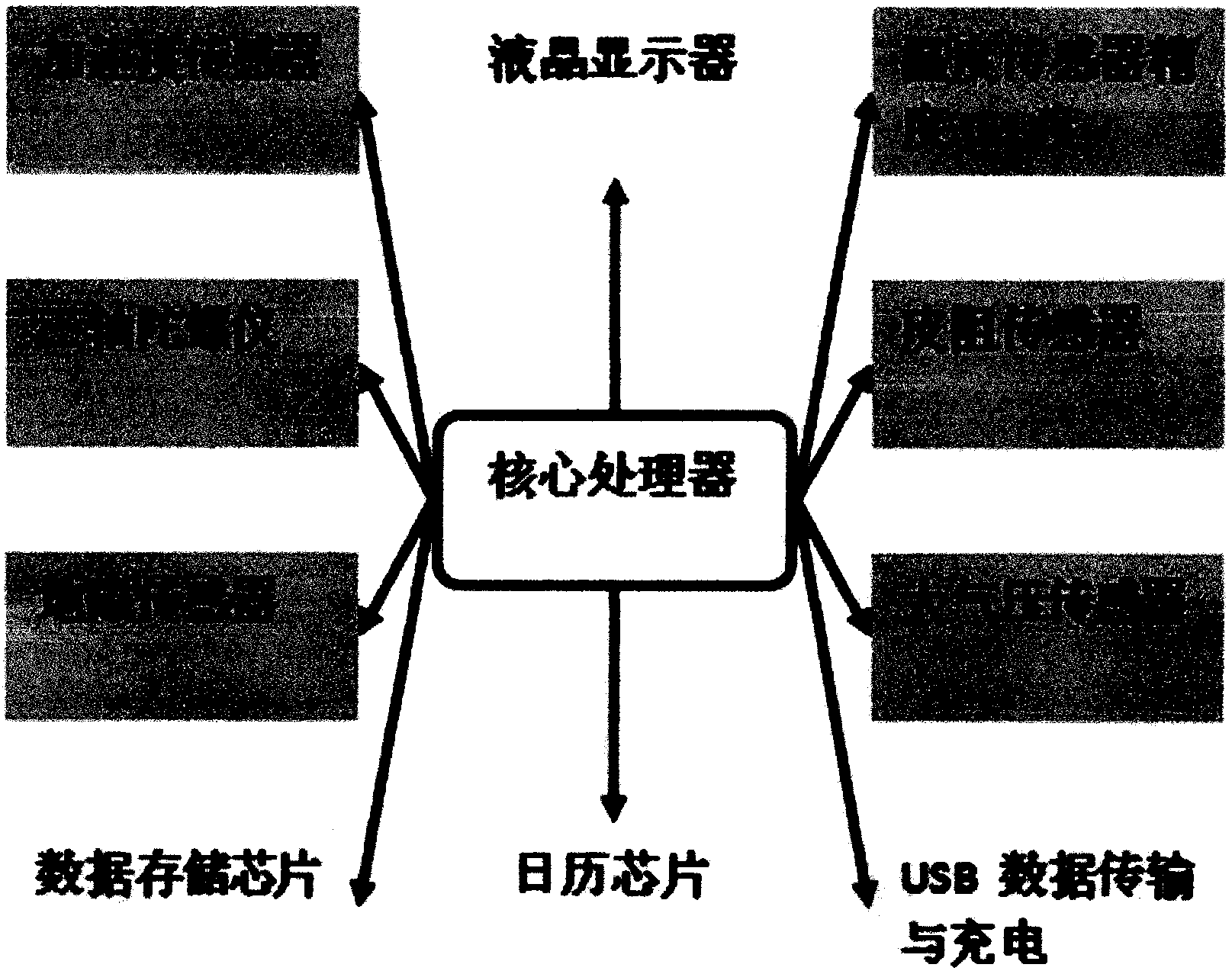

Monitoring method implemented by aid of sleep and fatigue monitoring watch device and sleep and fatigue monitoring normalized small devices

ActiveCN103445777AGuarantee the safety of life and propertyEasy to monitorDiagnostic recording/measuringSensorsLife qualityOriginal data

The invention relates to a monitoring method implemented by the aid of a sleep and fatigue monitoring watch device and sleep and fatigue monitoring normalized small devices. The technical scheme includes that the monitoring method is implemented by the aid of a skin resistance sensor, a temperature sensor, a barometric pressure sensor, an acceleration sensor and a data storage chip; the sensors are connected with a core processor, and the data storage chip is connected with the core processor. The monitoring method implemented by the aid of the sleep and fatigue monitoring normalized small devices is characterized by comprising steps of continuously monitoring the skin resistance, the skin temperature, the acceleration and the barometric pressure by the aid of the personal small devices and storing original data; computing the measured data, judging computation results and outputting fatigue results and indexes. According to the technical scheme, the monitoring method has the advantages that human fatigue and sleep conditions can be continuously detected for a long time under the condition that normal work and life are unaffected, and the monitoring method brings convenience for timely monitoring and effectively feeding self conditions of people, improving the health level and the life quality of people and guaranteeing the personal life and property safety of people.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

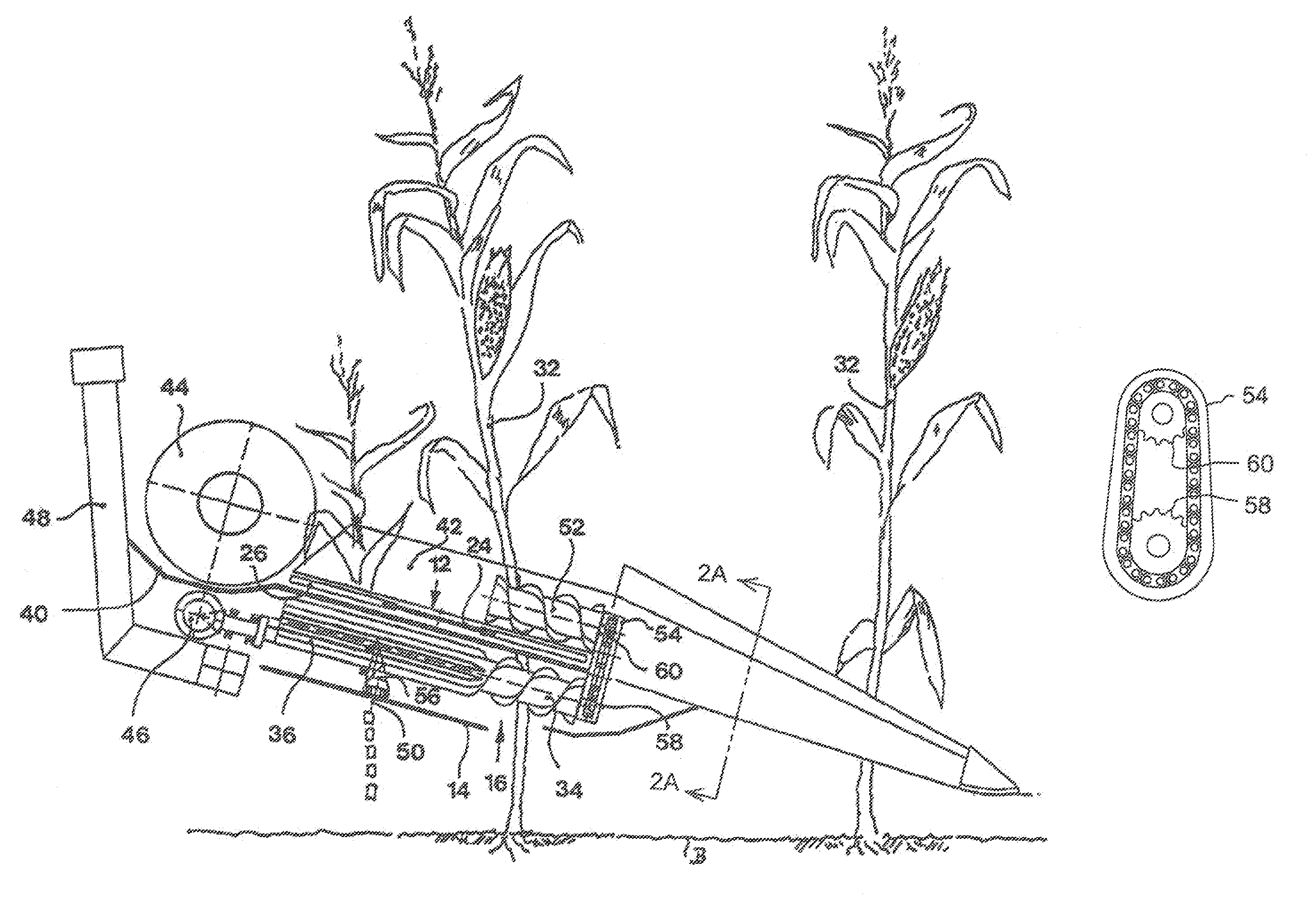

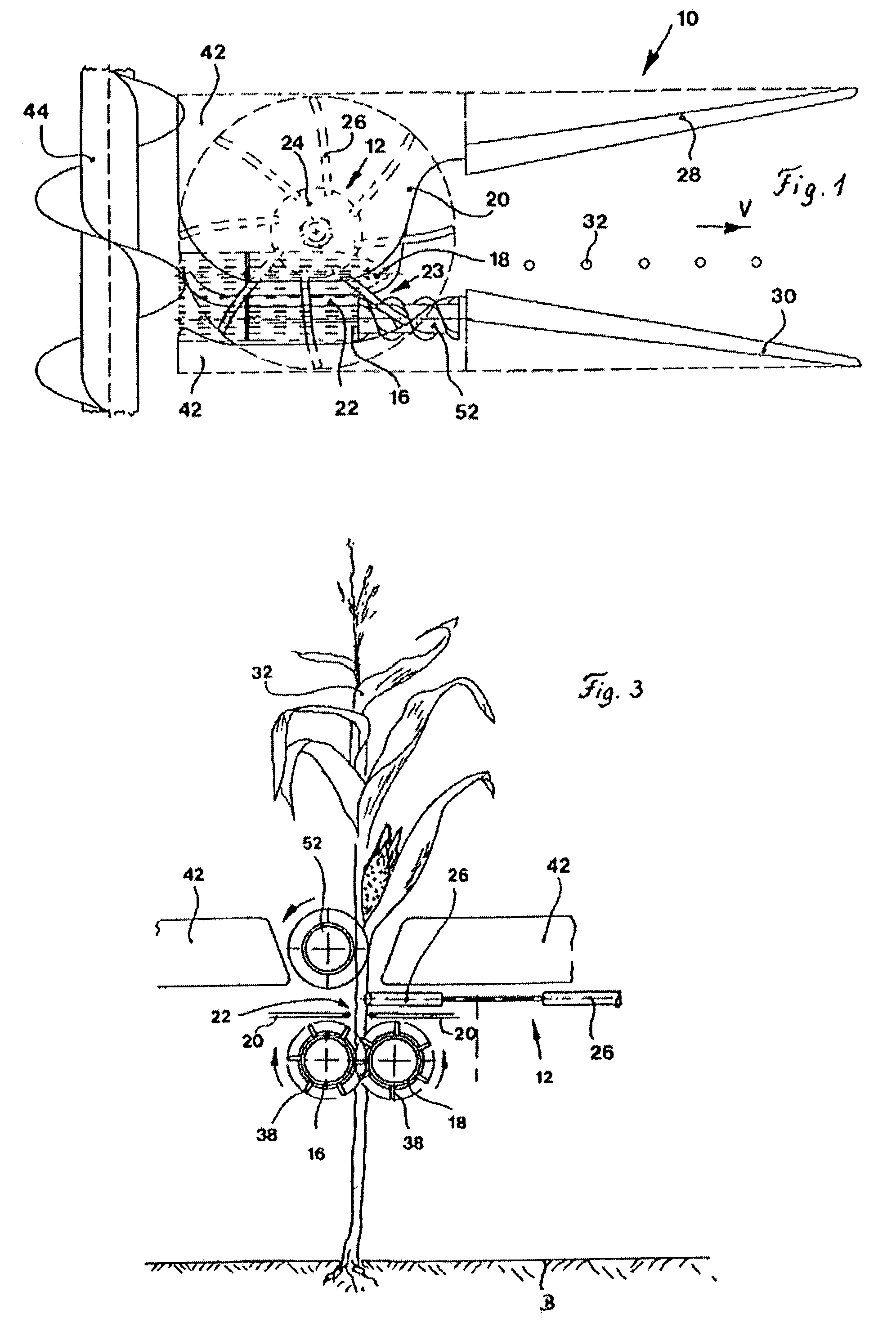

Gathering and picking device

Owner:MASCHFAB KEMPER

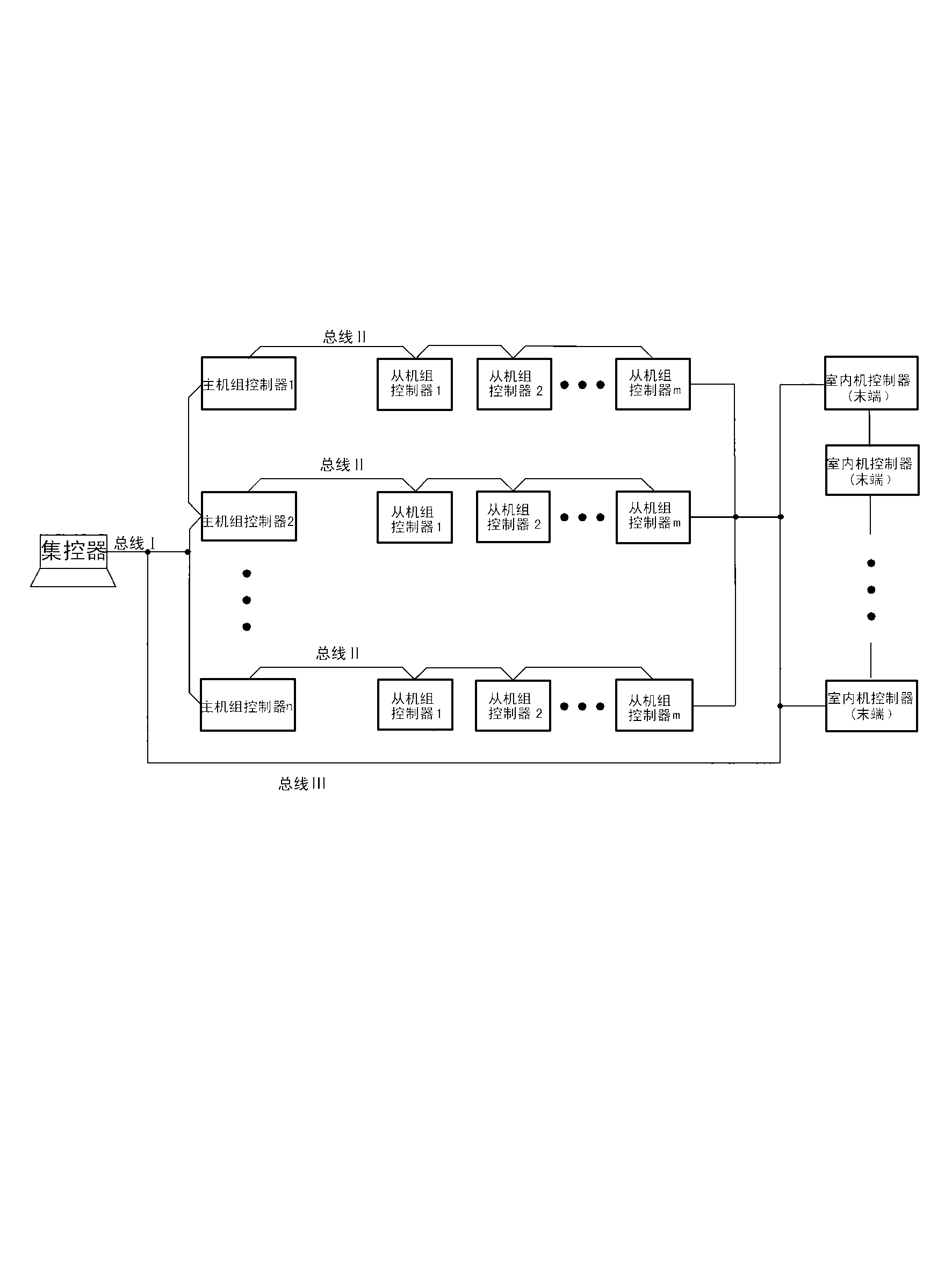

Group control system and control method for module type central air-conditioners

InactiveCN103062869AImprove anti-interference abilityMeet the requirements of centralized control managementSpace heating and ventilation safety systemsLighting and heating apparatusControl systemState parameter

The invention discloses a group control system for module type central air-conditioners. The group control system comprises n groups of machine set sub-control systems and a plurality of indoor unit controllers. Each group of machine set sub-control system comprises a main machine set controller and m auxiliary machine set controllers and further comprises a centralized control device, wherein the centralized control device is respectively connected with input ends of the main machine set controllers through first buses, and output ends of each group of main machine set controller are in series connection with the auxiliary machine set controllers through second buses. The invention further discloses a control method of the group control system for the module type central air-conditioners. The centralized control devices set switches and operating parameters of the main machine set controllers and transmit control instructions to a main controller, the main controller receives the control instructions and sets switches of the auxiliary machine set controllers according to air-conditioner load parameters so as to control running of an air-conditioner machine set, the auxiliary machine set controllers feed self running state parameters back to the main machine set controller, and the main machine set controller feeds self running state parameters and the running state parameters of the auxiliary machine set controllers back to the centralized control devices to perform display.

Owner:江苏春兰空调设备有限公司

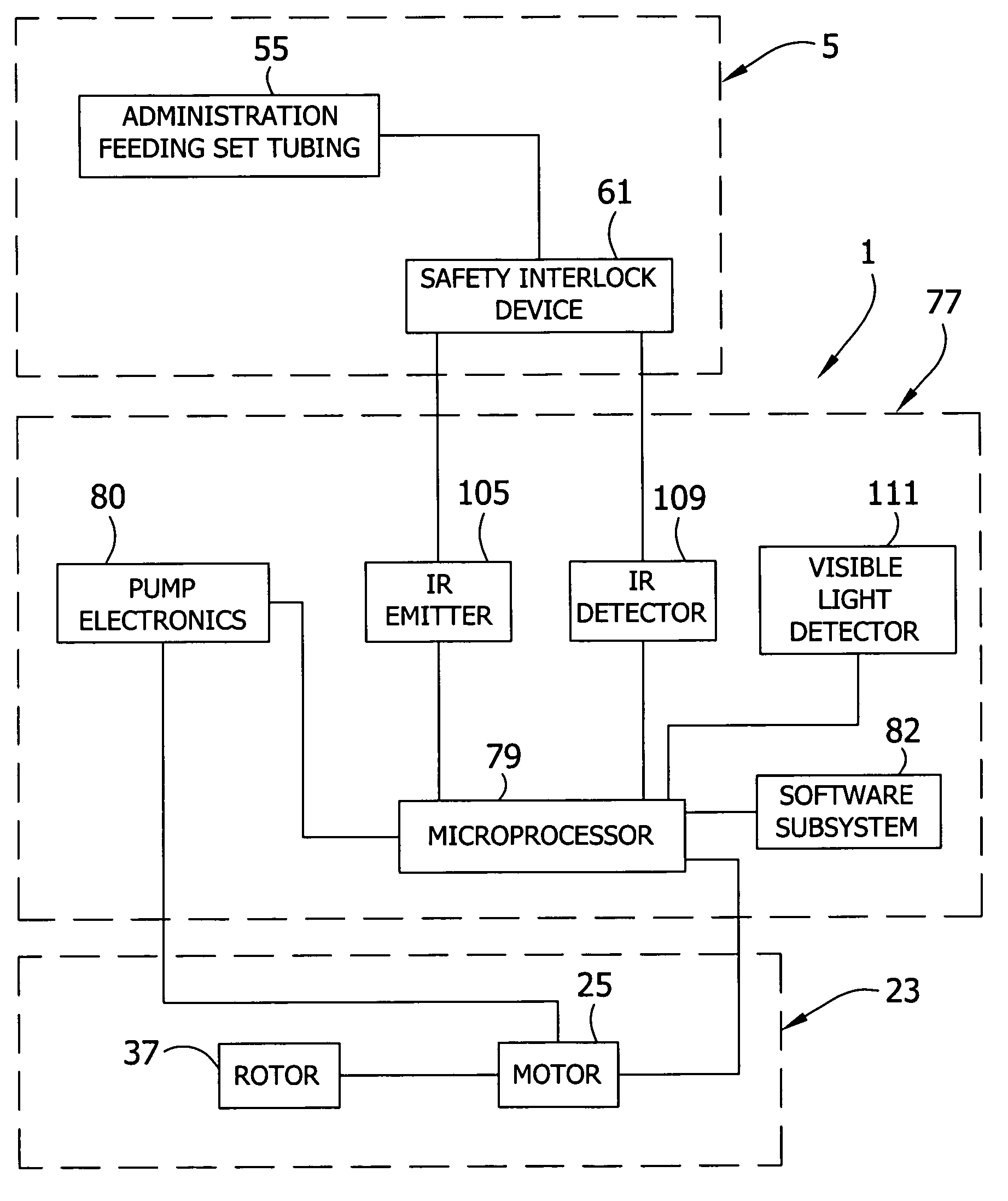

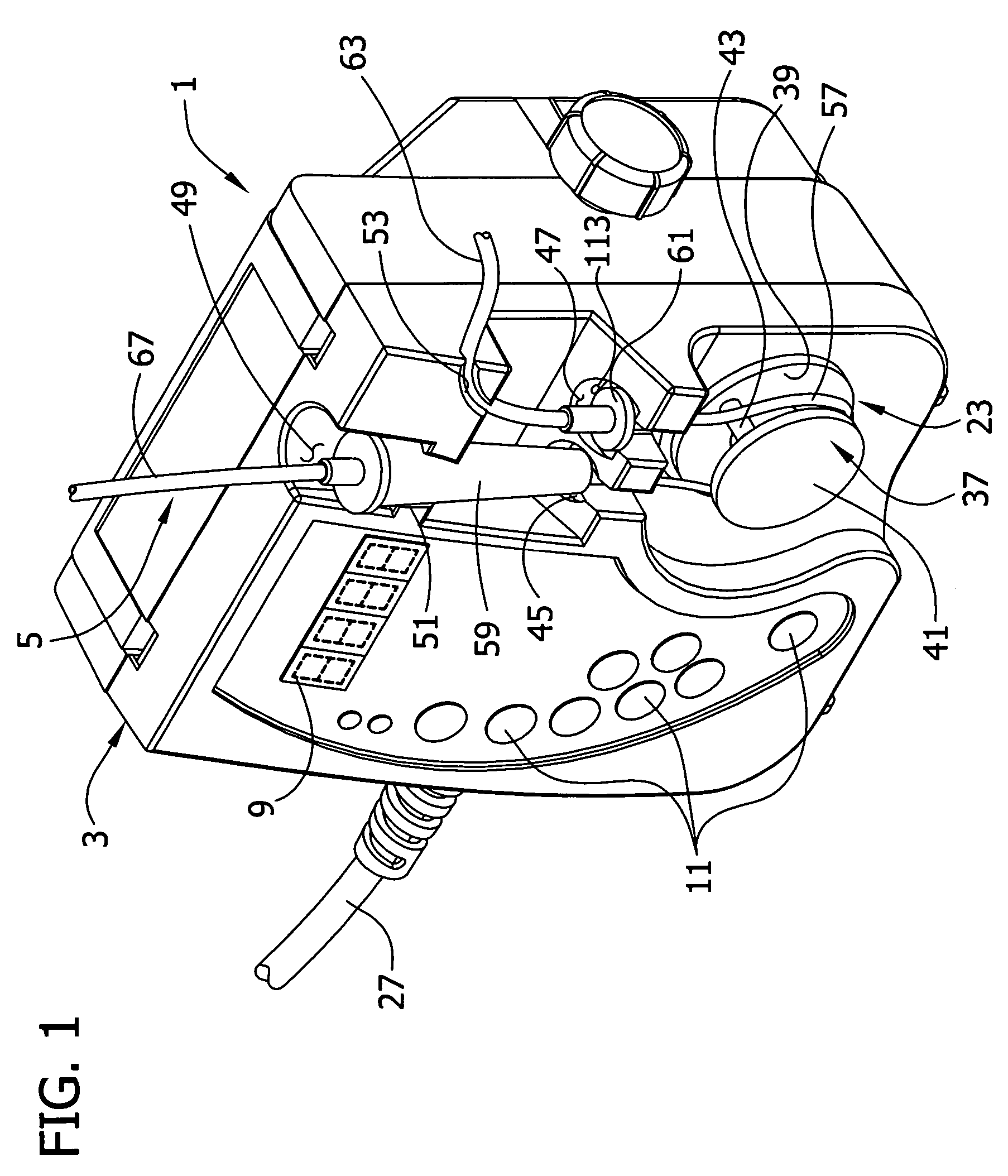

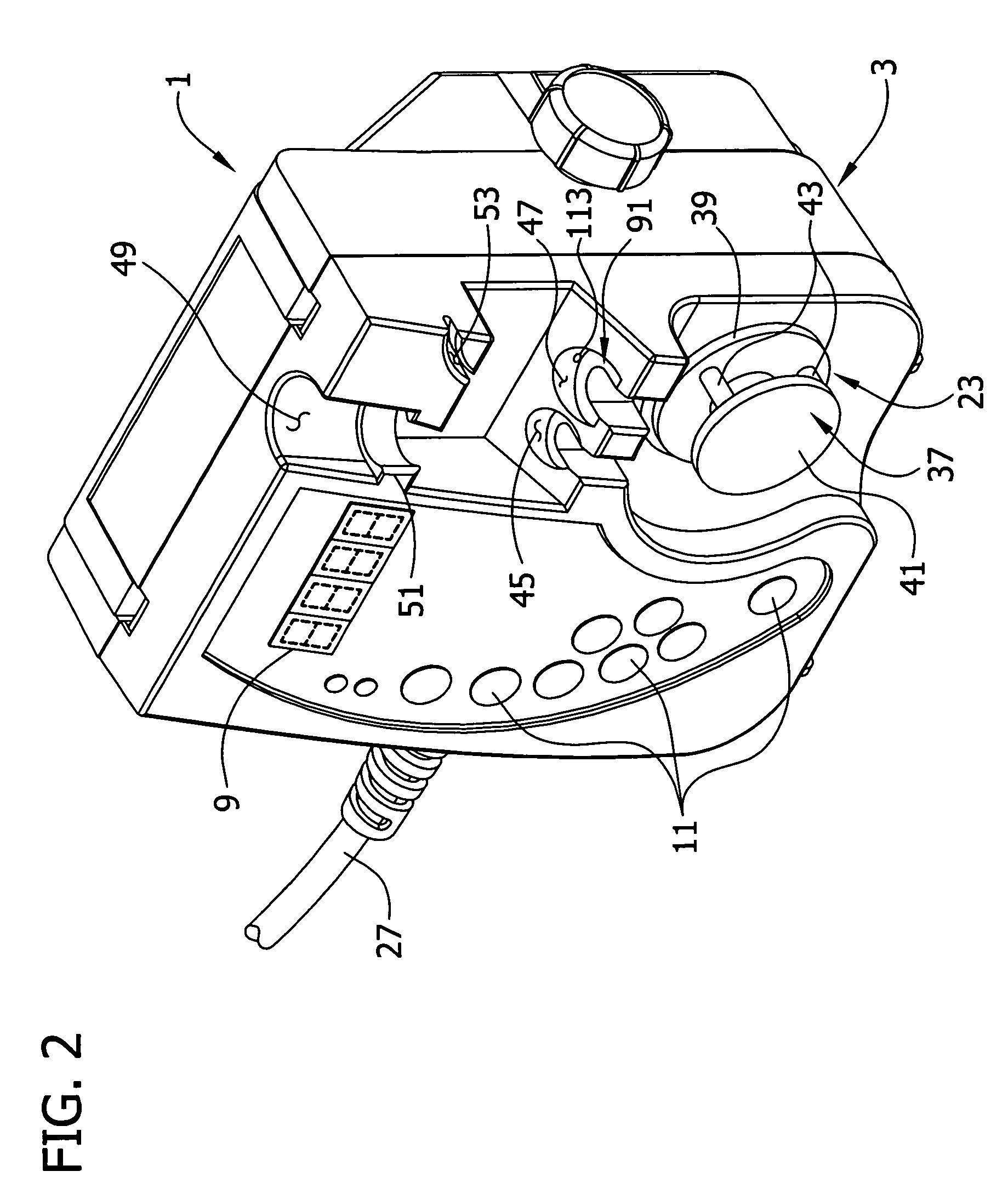

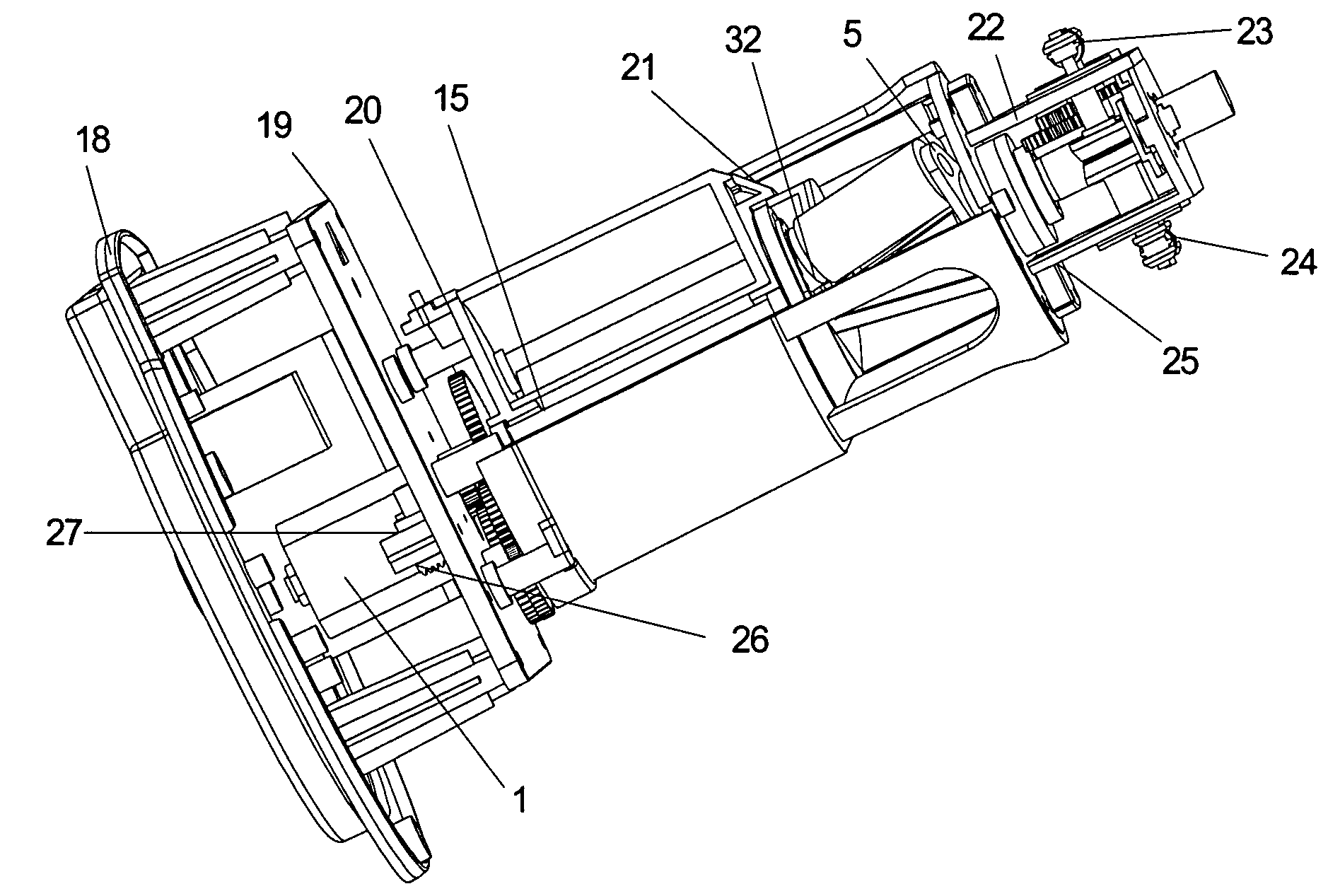

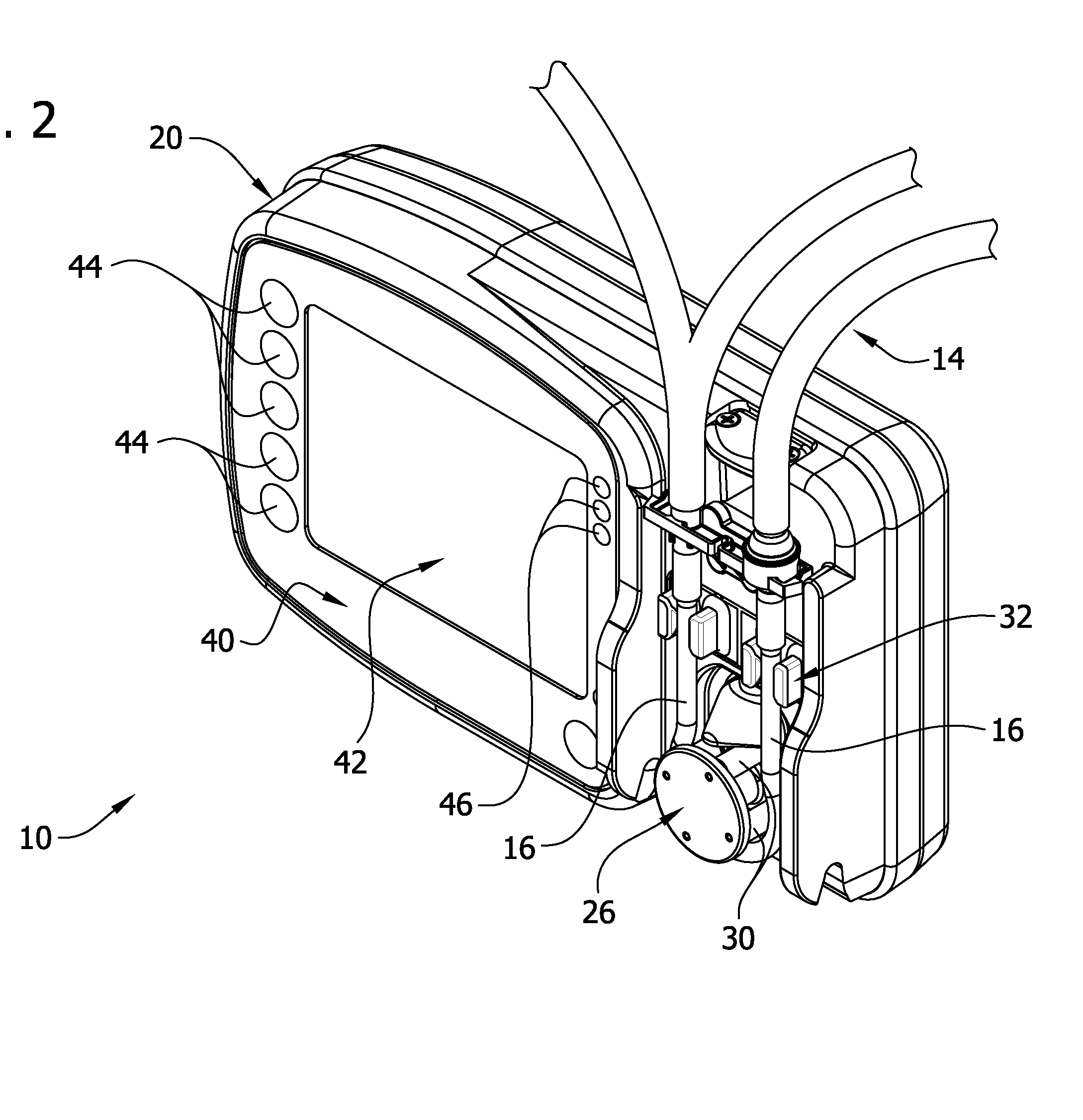

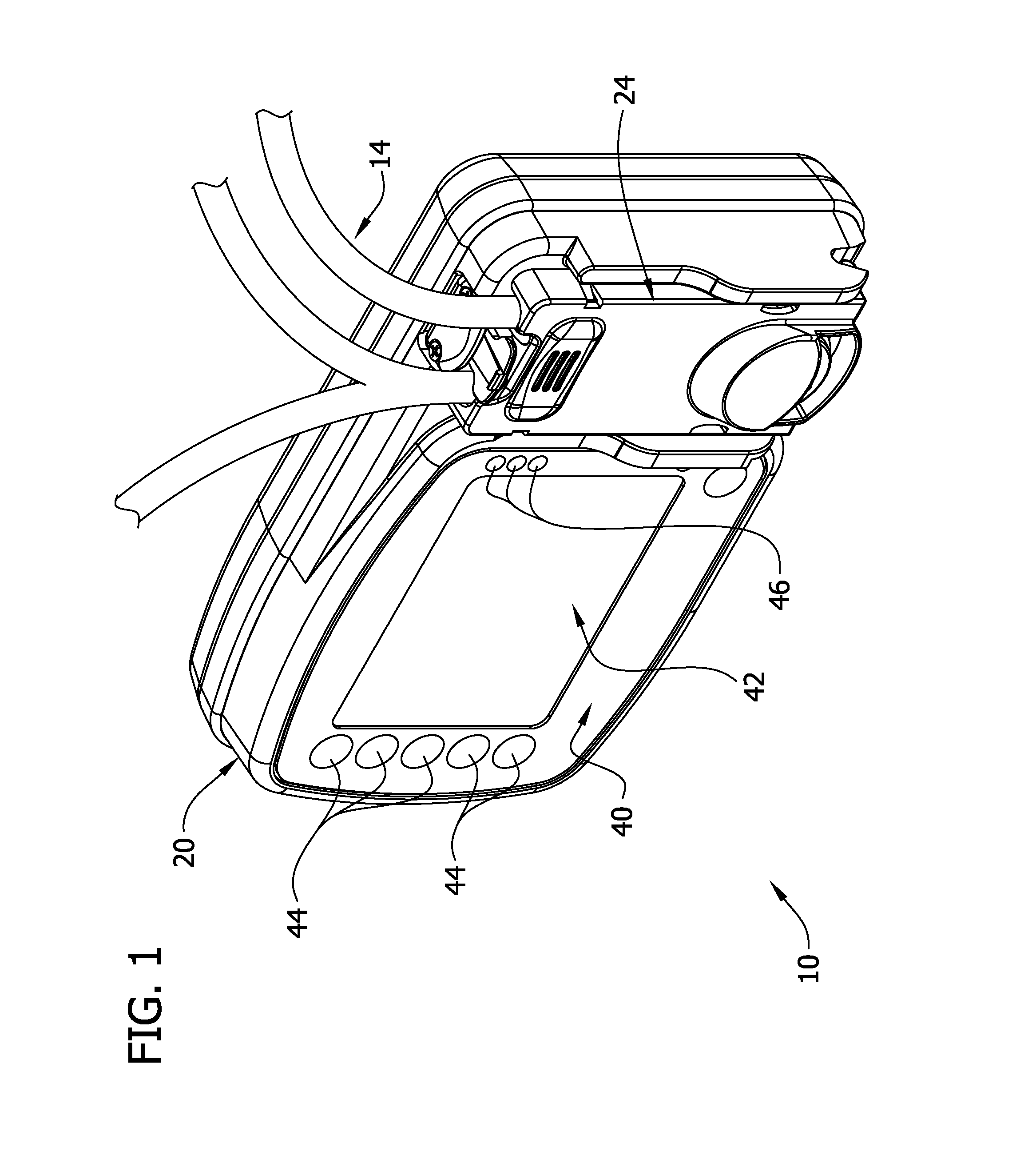

Pump set with secure loading features

ActiveUS7758551B2Load accuratelyMedical devicesPressure infusionControl systemElectromagnetic radiation

Owner:KPR U S LLC

Disposable wild bird feeder

InactiveUS20090188432A1Easy to useResistant being reusedPisciculture and aquariaAvicultureBird feederEngineering

The present invention is a wild bird feeder with the features that make it safe and easy to use but protected from being reused. A reservoir containing bird seed is connected with a feeding base using an adaptor. The feeding base is threaded to the adaptor which in turn is threaded to the reservoir. A stop attached to the feeding base and a locking adaptor seat keeps the assembled wild bird feeder from being taken apart and refilled. The wild bird feeder converts from a first storage position to a second feeding position by partially unthreading the feeding base from the adaptor so bird seed is supplied to the bottom portion of the feeding base. A plurality of perches are supported by the feeding base. The perches are moved from a stored position to a properly deployed position when second feeding position is realized. A label is placed on the reservoir to provide a logo, directions for use and bird seed data.

Owner:NATRIUM

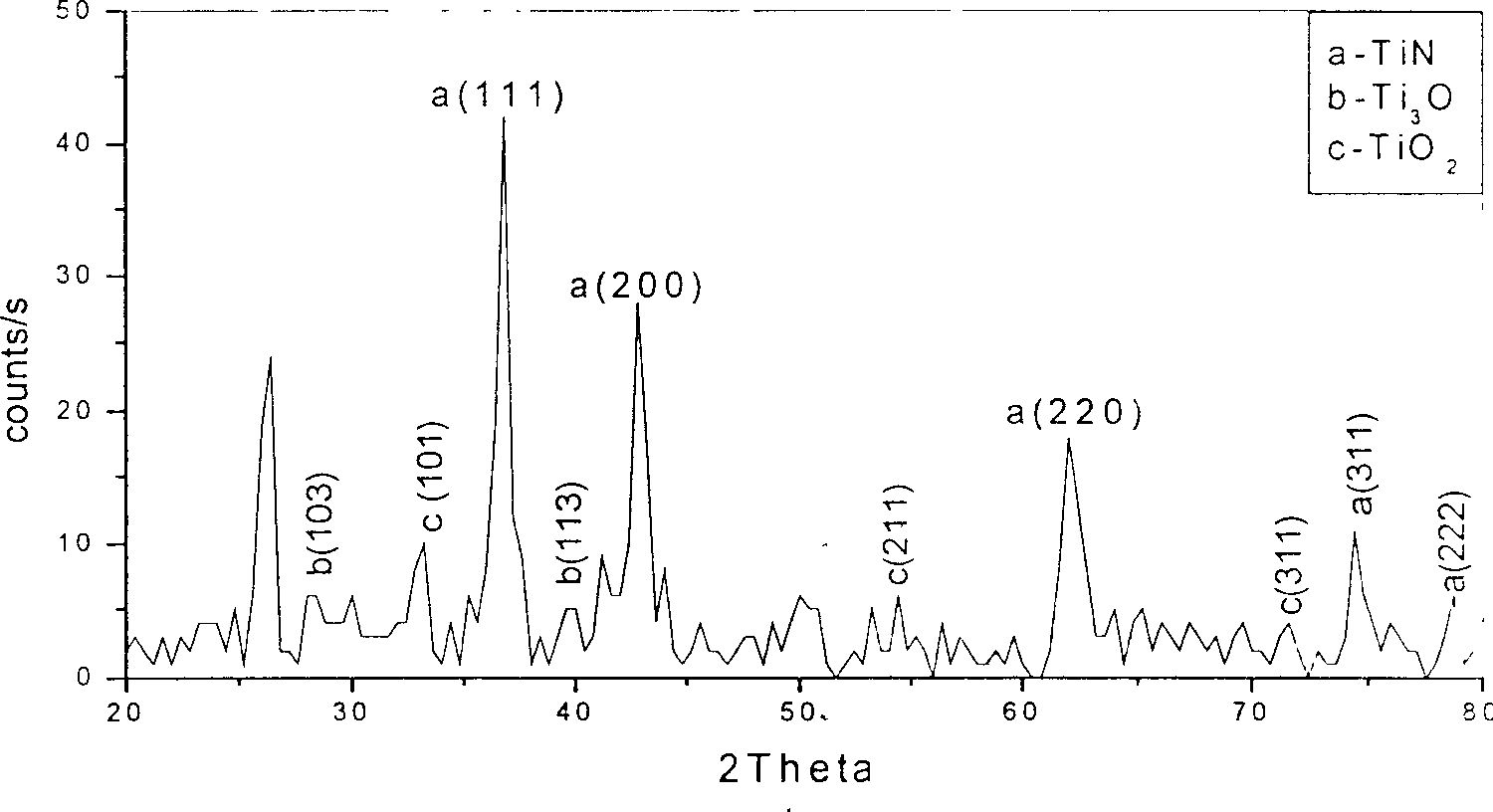

Method for reaction plasma spraying nano crystal titanium nitride coating

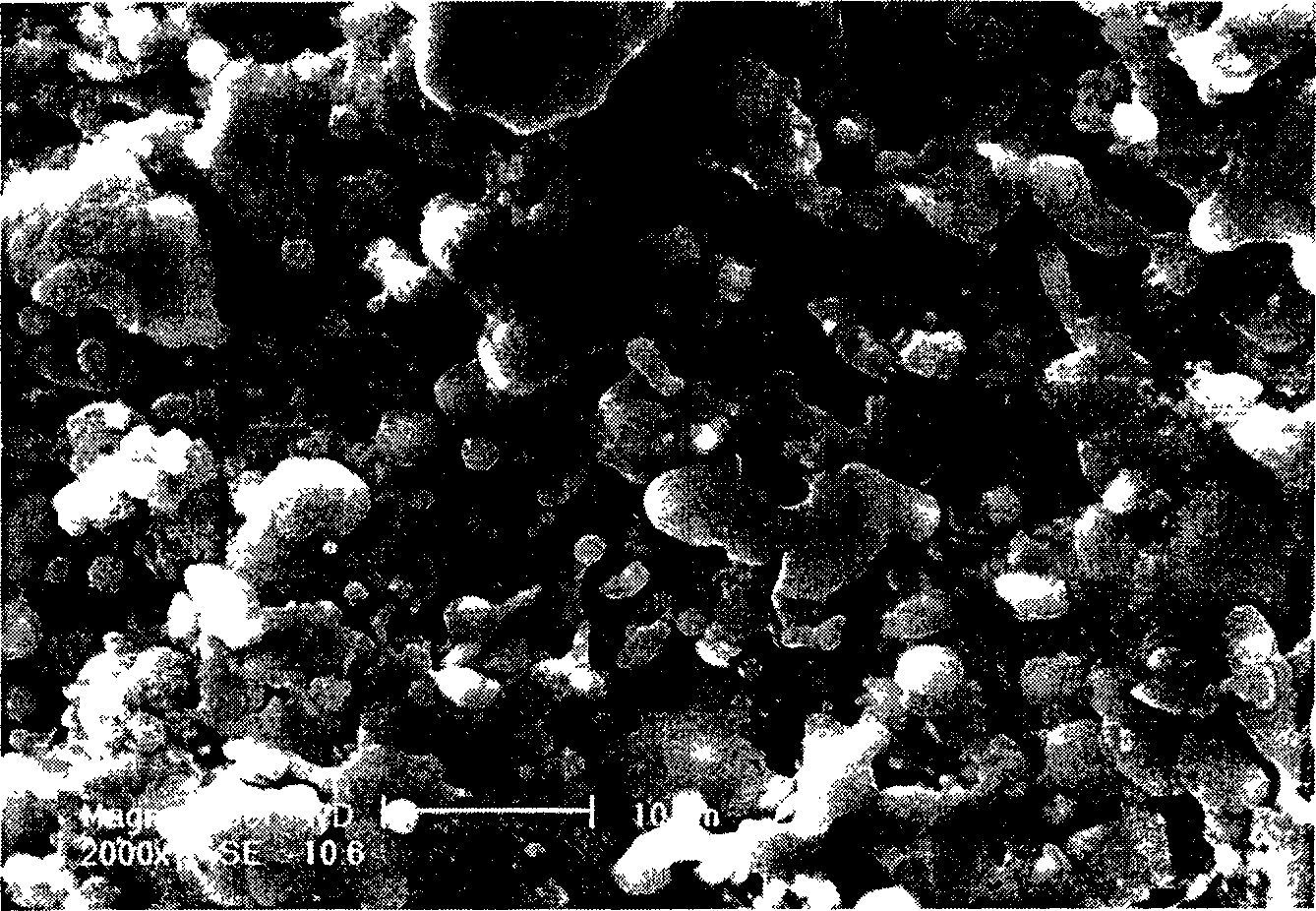

InactiveCN1616712AImprove production efficiencySimple methodMetallic material coating processesCeramic coatingTitanium nitride

The reaction and plasma spraying process of preparing nano crystal titanium nitride coating on alloy base layer in metal or ceramic substrate includes the main steps of: pre-treating substrate, feeding mixed ion gas to start arc, feeding self-melting alloy powder into plasma flow for spraying to form the alloy base layer; and feeding nitrogen-containing reacting gas into the reaction chamber and feeding metal powder into the flame flow for spraying to form nano crystal titanium nitride coating on the alloy base layer. The process can form coating with raised toughness, wear resistance, friction reducing property and heat shock resistance, as well as thickness up to 600 microns, high smelting point, high hardness and excellent chemical stability. The present invention is mainly used in preparing high smelting point nano nitride ceramic coating.

Owner:HEBEI UNIV OF TECH

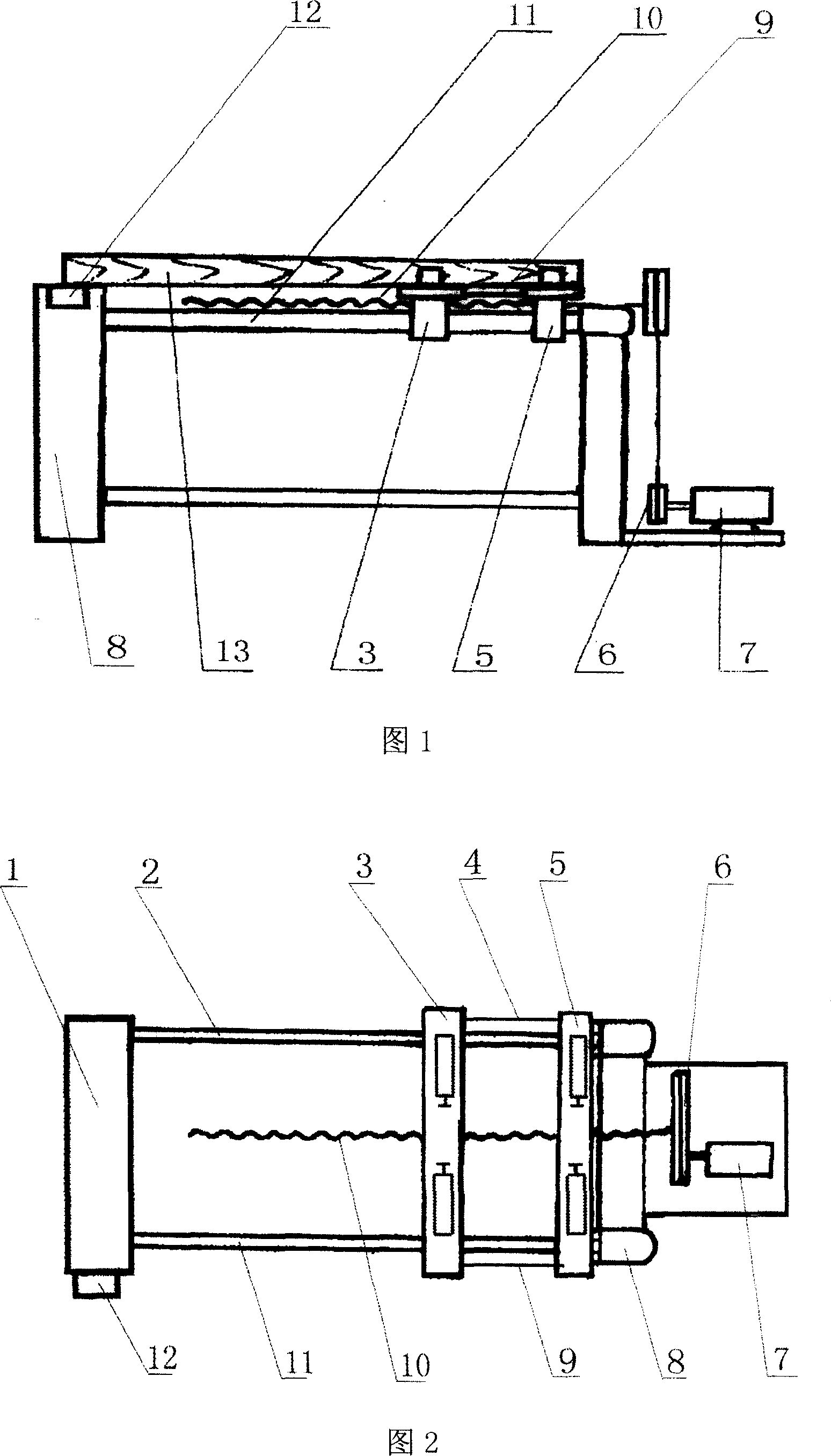

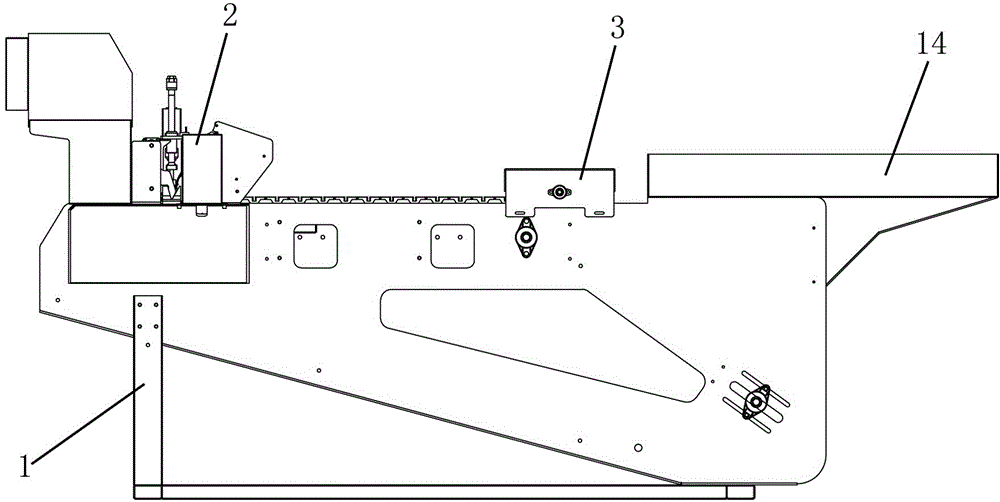

Lumber feeding mechanism

InactiveCN100999282AReduce volumeReliable horizontal conveyingConveyorsManipulatorReciprocating motionEngineering

The present invention discloses a log feeding mechanism. Said log feeding mechanism includes machine frame and power mechanism. Said machine frame possesses working table surface for placing log end portion and slideway along log axial direction. On the slideway are set first feeding self-body and second feeding self-body which can be reciprocally-moved along said slideway. The second feeding self-body is positioned between first feeding self-body and working table surface, said first feeding self-body is connected with a drive mechanism for controlling its reciprocating movement, and between first feeding body and second feeding self-body a connecting component is set, their space along slideway direction can be regulated. On the first feeding self-body and on the second feeding self-body are respectively set log-clamping mechanisms for clamping log or releasing said log.

Owner:冯士祥

Electric pencil sharpener

Owner:WAN CHUNG PAK

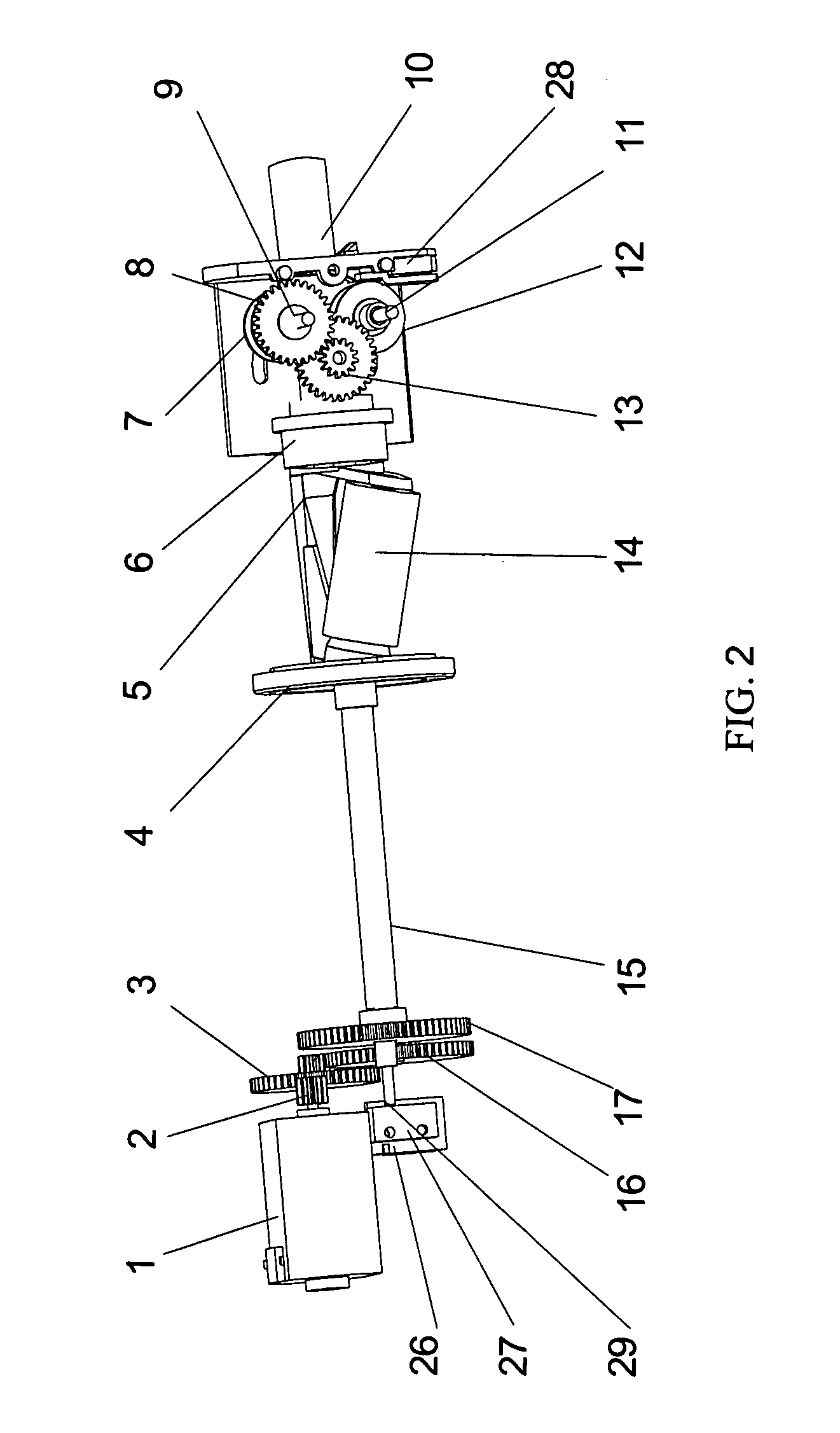

Longitudinal feed self-adaptation device for steel rail milling and grinding machine

ActiveCN102848316ARealize adaptive feed functionHigh feed accuracyGrinding drivesClosed loopTorque motor

The invention discloses a longitudinal feed self-adaptation device for a steel rail milling and grinding machine. The device comprises a carriage, a machine body, a grinding wheel and a locating boot, wherein the carriage is vertically provided with a linear guide rail; the machine body is driven by a vertical oil cylinder to vertically move along the linear guide rail on the carriage; the machine body is fixedly provided with a servo motor for vertically driving the locating boot; the machine body is further provided with a torque motor; and the grinding wheel is arranged on the machine body through a main shaft. According to the longitudinal feed self-adaptation device for the steel rail milling and grinding machine disclosed by the invention, hydraulic pressure detection control over the vertical oil cylinder and the grinding torque detection control over the torque motor are simultaneously applied to one feed device, and a multi-closed-loop control loop is formed, so that a self-adaptive feed function in various working conditions is realized; and a hydraulic feed system of the vertical oil cylinder and a servo feed system of the servo system are simultaneously applied to the feed device, and coarse feed and fine feed at different levels, as well as safety protection at different levels, are realized, so that the feed precision and safety performance of the feed systems are improved.

Owner:长沙海捷智能科技有限公司

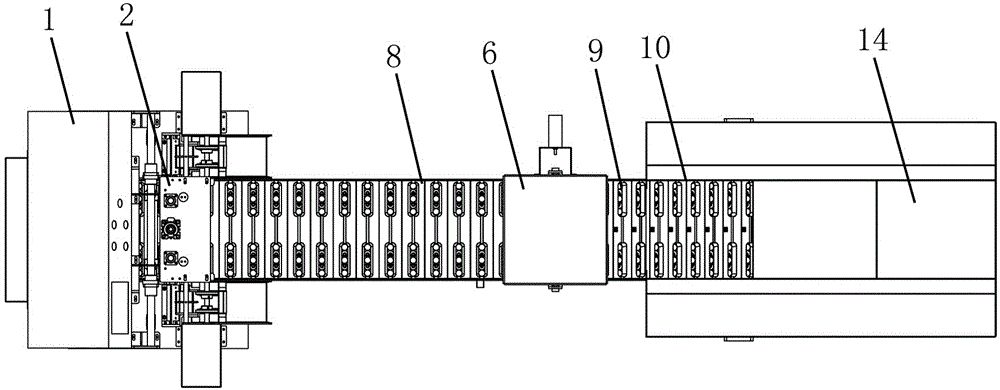

Automatic tally method based on automatic tally system

InactiveCN109607128AReduce repetitive loopsEasy to processConveyor partsStart stopComputer engineering

The invention relates to an automatic tally method capable of automatically sorting batched materials in the staggered, overlapped and stacked states into a single line arrangement on-line output way.The automatic tally method includes the steps that feeding is conducted; initial sorting is conducted, single line arrangement sorting is conducted; elimination sorting is conducted; transverse separation is conducted; longitudinal separation is conducted; the flow rate is detected to adjust the feeding speed or start-stop; and different speed differences are adopted to detect the material spacing. According to the automatic tally method, finished goods are automatically sorted.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

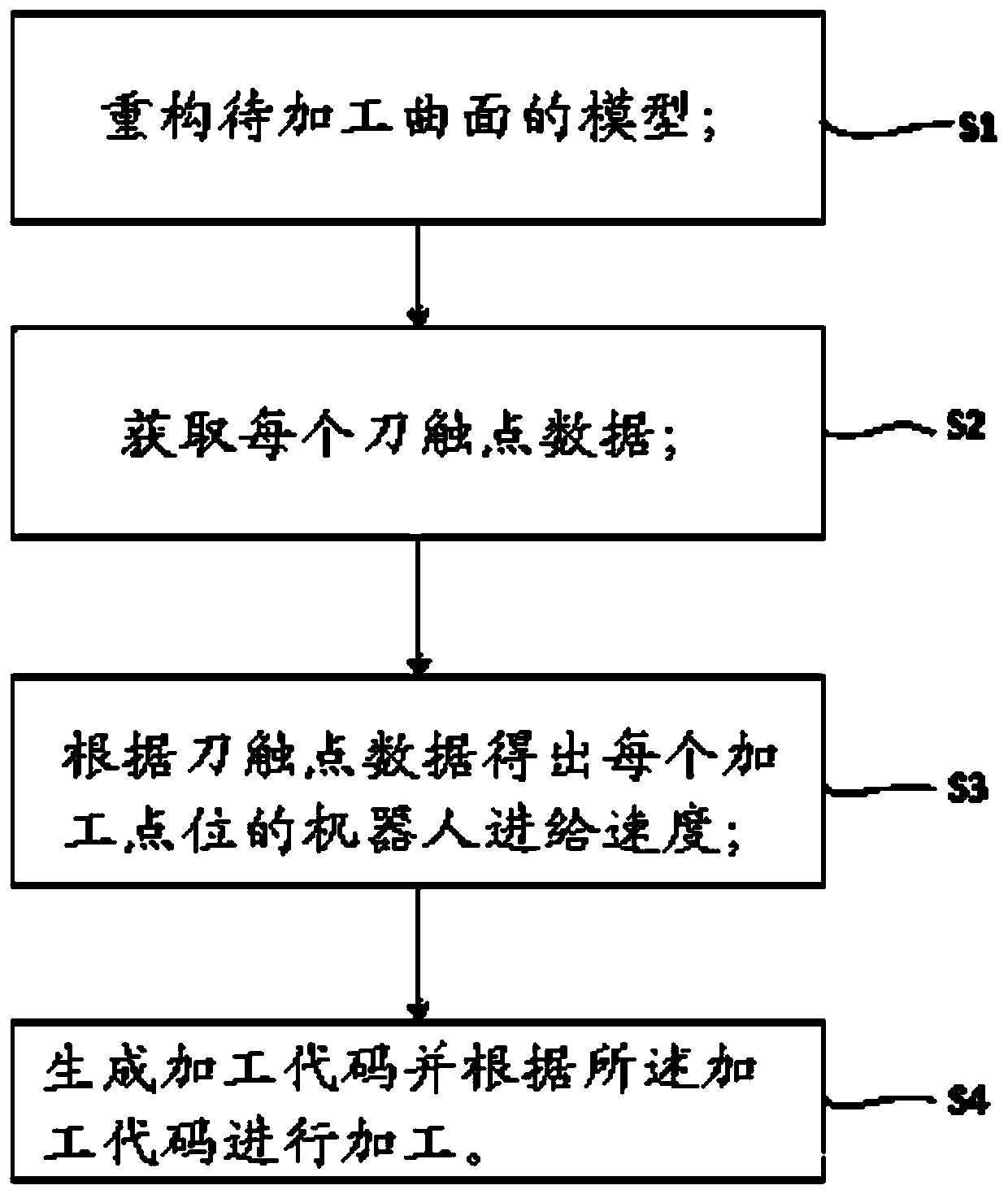

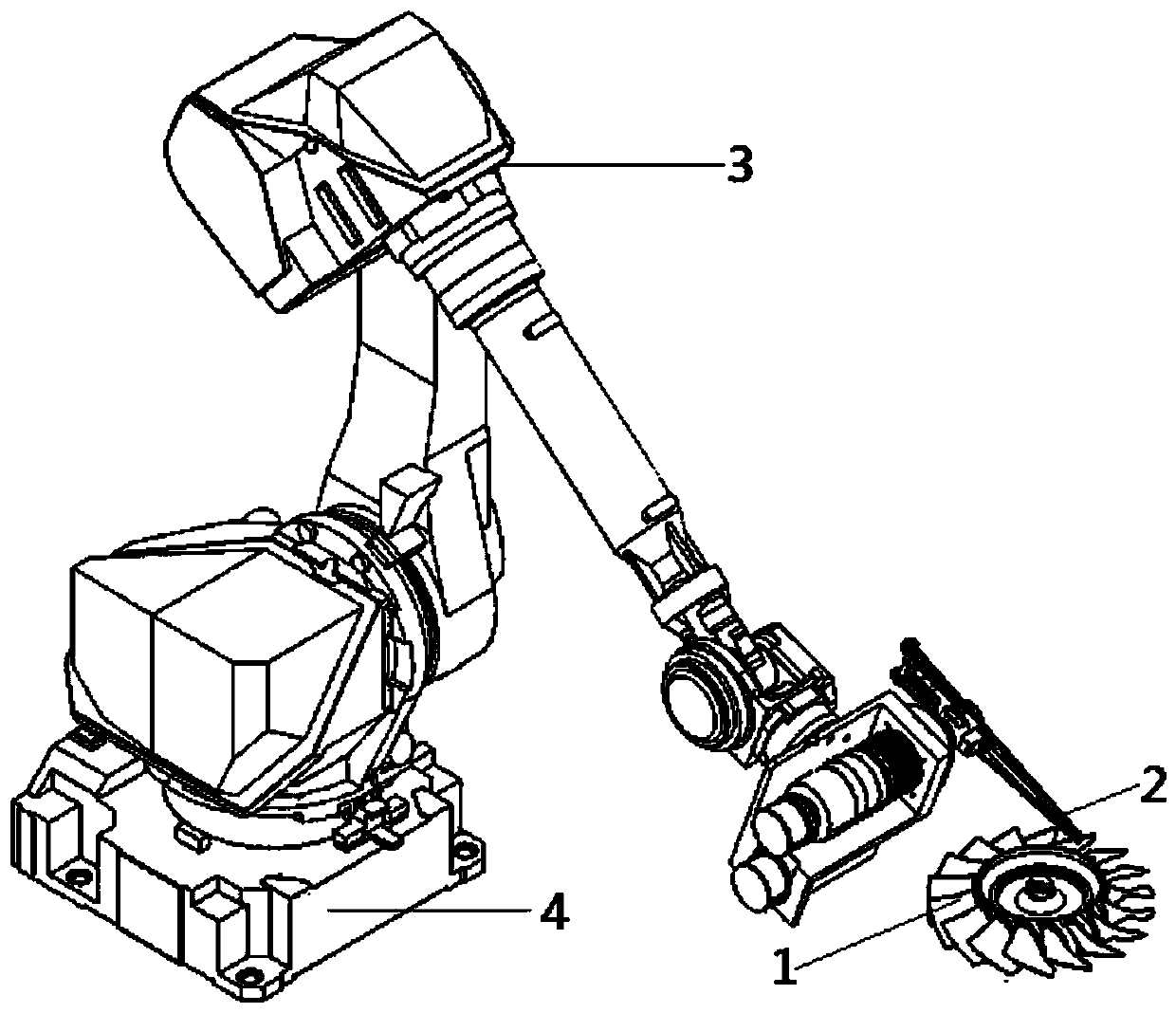

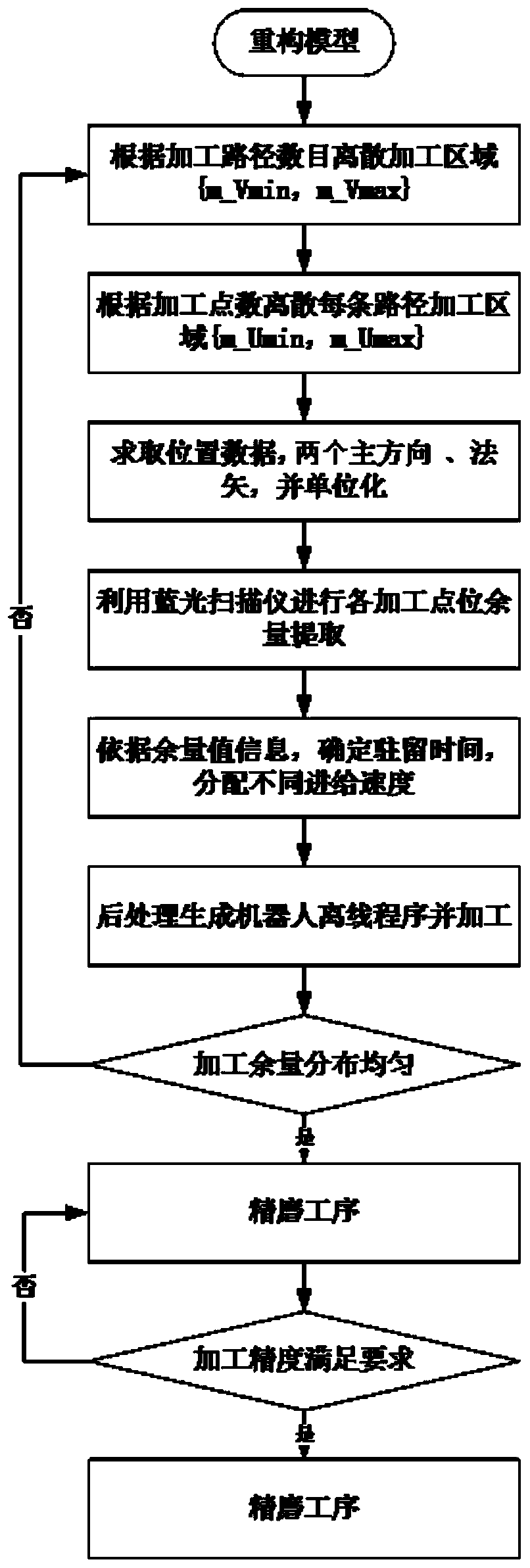

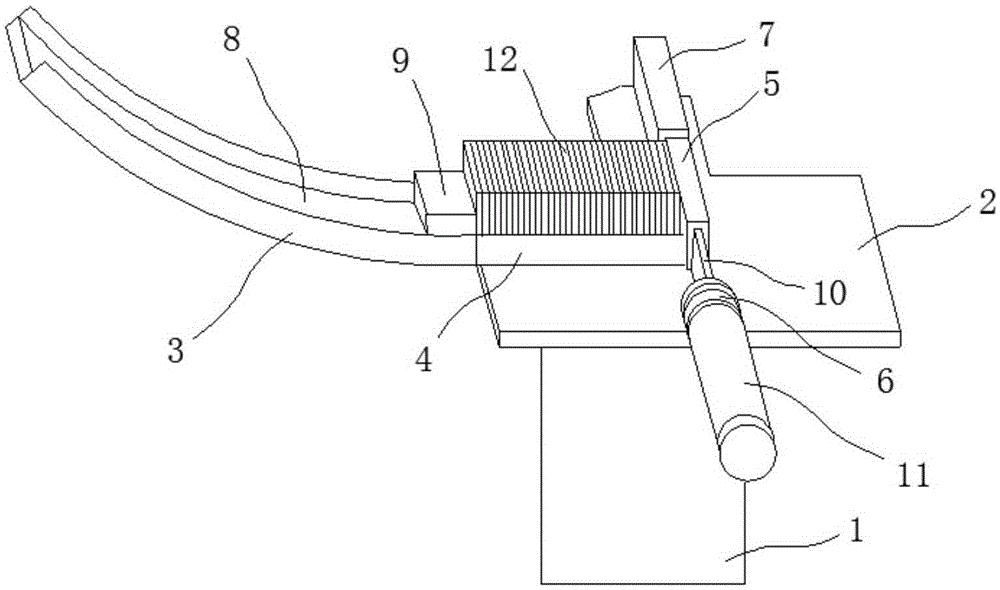

Complex curved surface robot abrasive belt variable feeding self-adaptive grinding method and equipment

InactiveCN111300208AAvoid overcuttingHigh precisionGrinding drivesGrinding machinesEngineeringSelf adaptive

The invention discloses a complex curved surface robot abrasive belt variable feeding self-adaptive grinding method. The method comprises the following steps that a model of a to-be-machined curved surface is reconstructed; data of cutter contact points are acquired; the robot feeding speed of machining point positions is obtained according to the cutter contact data; and a machining code is generated and machining is conducted according to the machining code. The invention further discloses complex curved surface robot abrasive belt variable feeding self-adaptive grinding equipment applying the complex curved surface robot abrasive belt variable feeding self-adaptive grinding method. According to the complex curved surface robot abrasive belt variable feeding self-adaptive grinding method, a robot contact wheel can be attached to the blade profile in the optimal posture, different robot feeding speeds can be further distributed according to the allowance value information of all the machining point positions, and therefore the accurate removal amount of the allowance of all the machining point positions can be guaranteed, and therefore, the self-adaptive grinding machining precision and quality of the complex curved surface part robot can be comprehensively improved.

Owner:CHONGQING UNIV +1

Efficient feeding mechanism

InactiveCN105236122AConvenient statisticsEasy to generate arrangementsConveyor partsEngineeringFeeding self

Owner:GUILIN UNIV OF AEROSPACE TECH

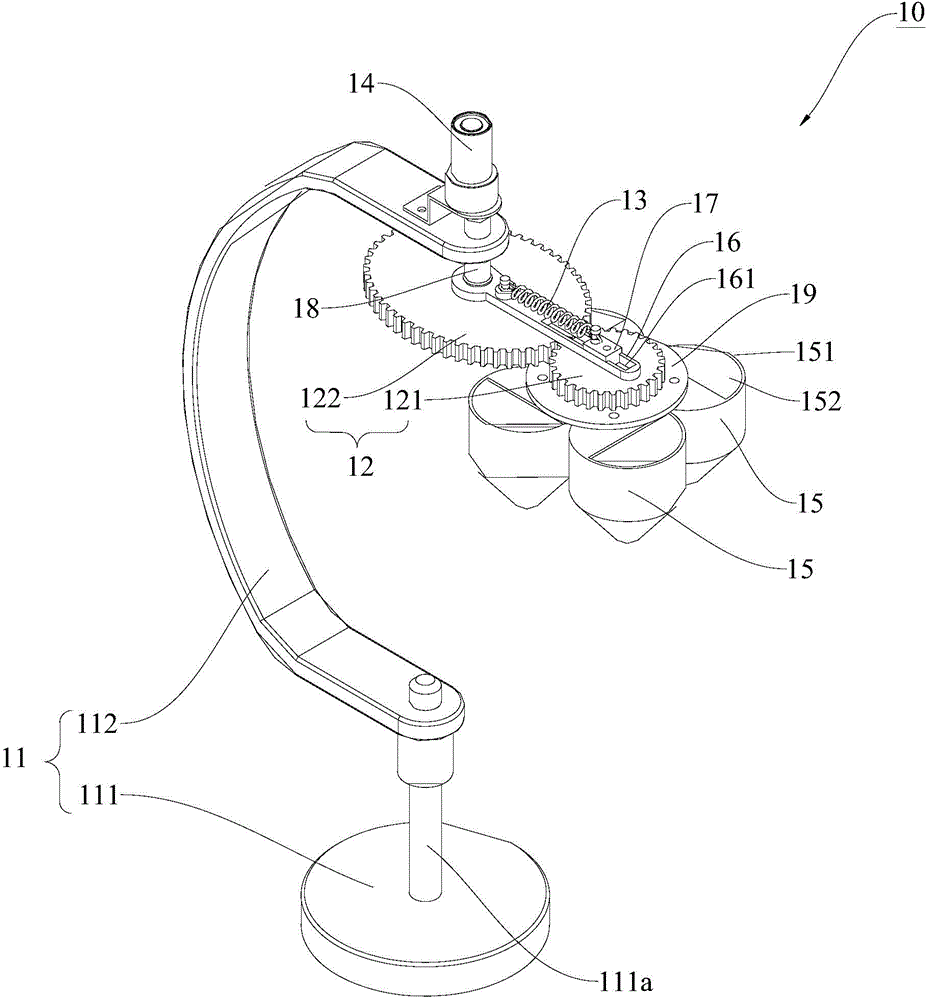

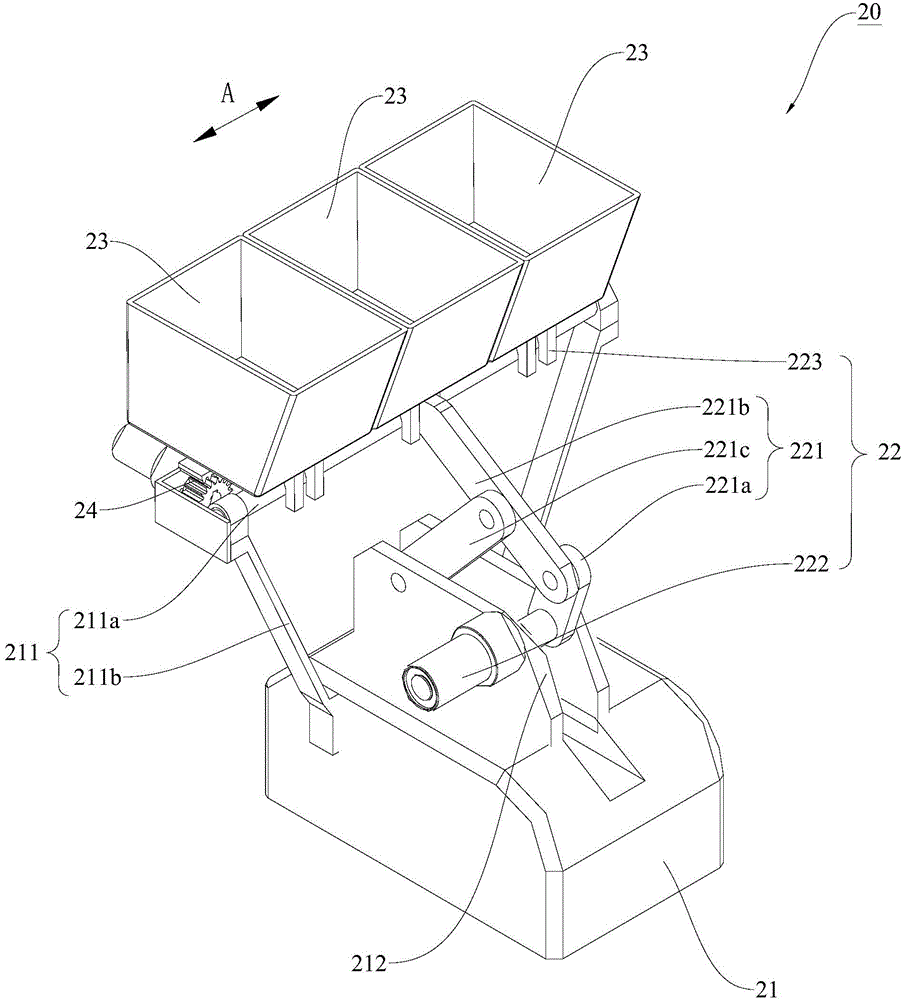

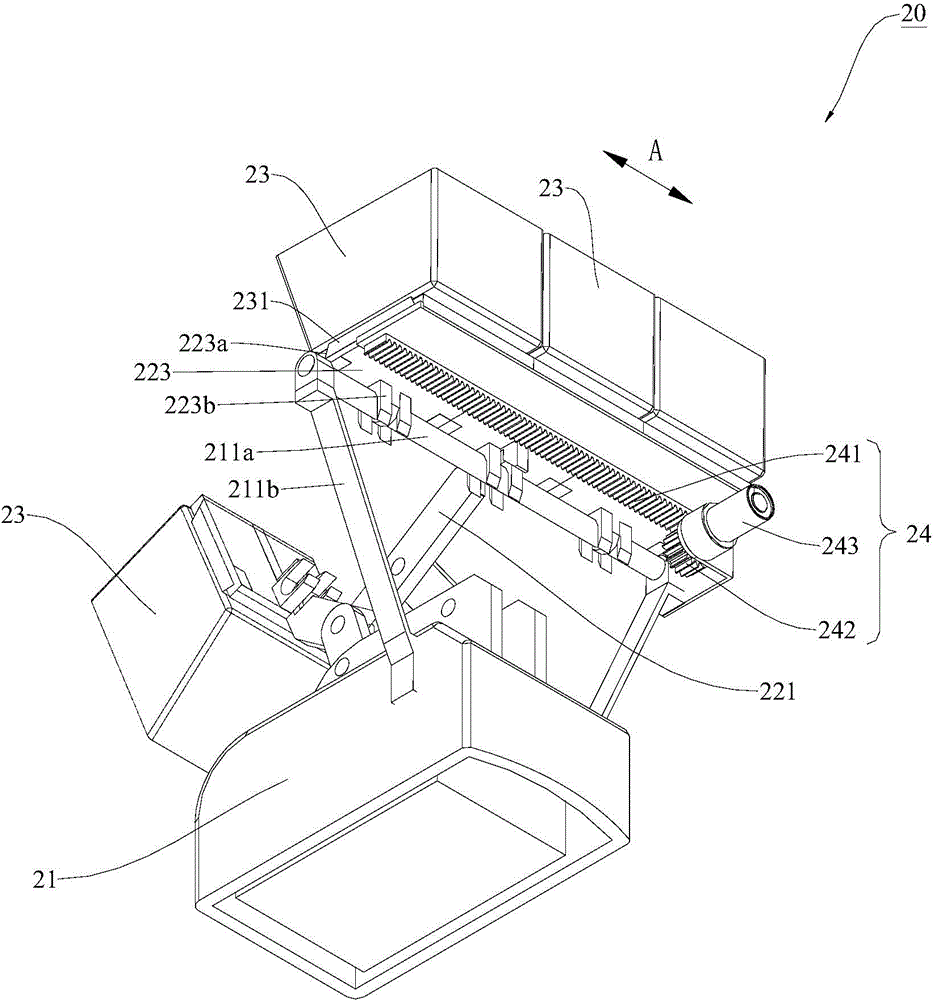

Main cooking material feeder and automatic cooking machine

ActiveCN105768832ARealize time-segmented feedingReasonable stir fry timeCooking vesselsElectric machineryDrive motor

The invention discloses a main cooking material feeder and an automatic cooking machine. The main cooking material feeder comprises a base, a feeding mechanism, multiple feeding boxes and a feeding box drive structure, wherein a supporting frame structure is disposed on the base; the feeding mechanism comprises a connecting rod structure, a first drive motor and multiple feeding bases, one of the multiple feeding bases is connected to the connecting rod structure, the multiple feeding bases are supported on the supporting frame structure, and the first drive motor is connected to the connecting rod structure and used to drive the connecting rod structure so as to drive the feeding base connected to the connecting rod structure to feed materials; the multiple feeding boxes can be positioned on the multiple feeding bases; and the feeding box drive structure is disposed to drive the multiple feeding boxes to move along a length direction of the multiple feeding boxes so as to switch the feeding box on the feeding base connected to the connecting rod structure. The main cooking material feeder disclosed by the invention has the advantages that different food materials can be fed in different periods, so that stirring and frying time of the different food materials becomes rational.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

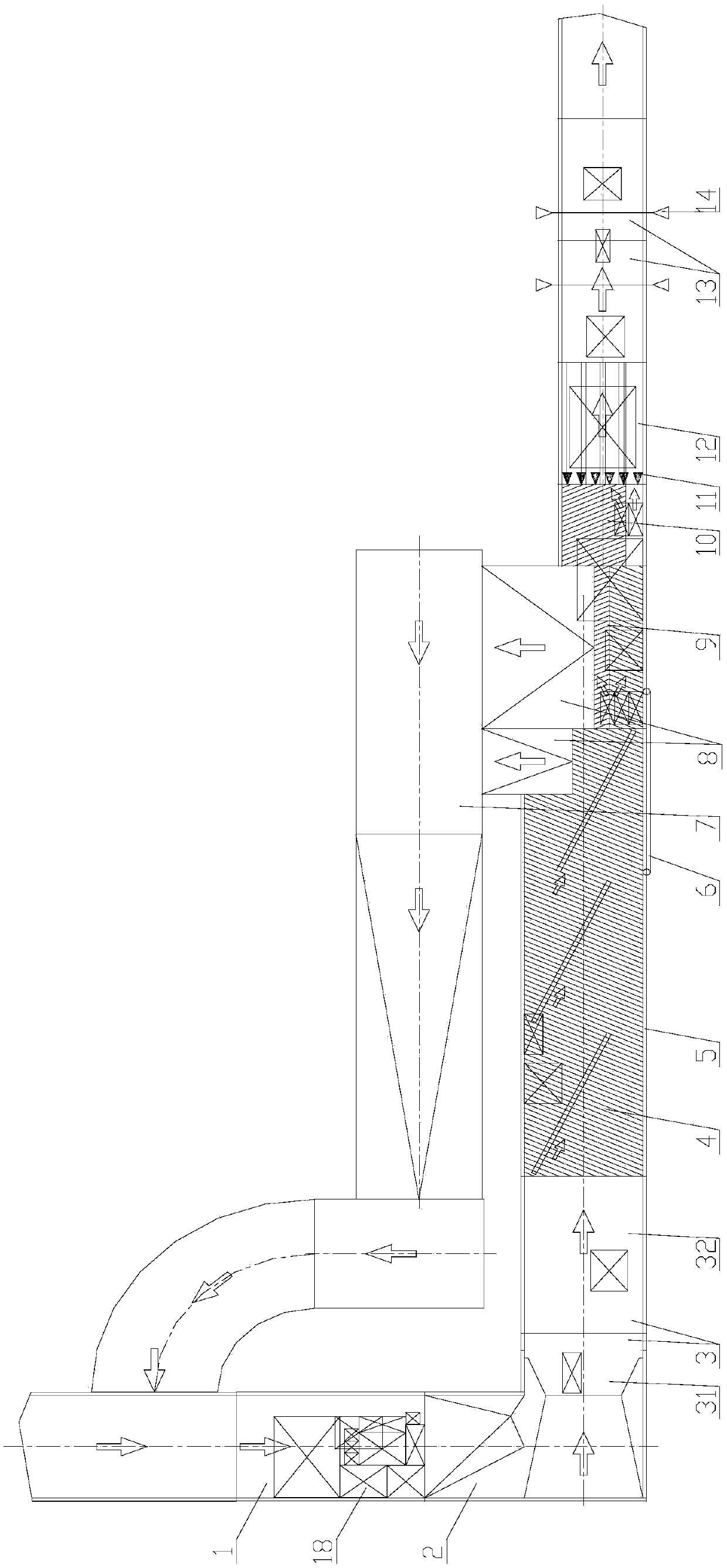

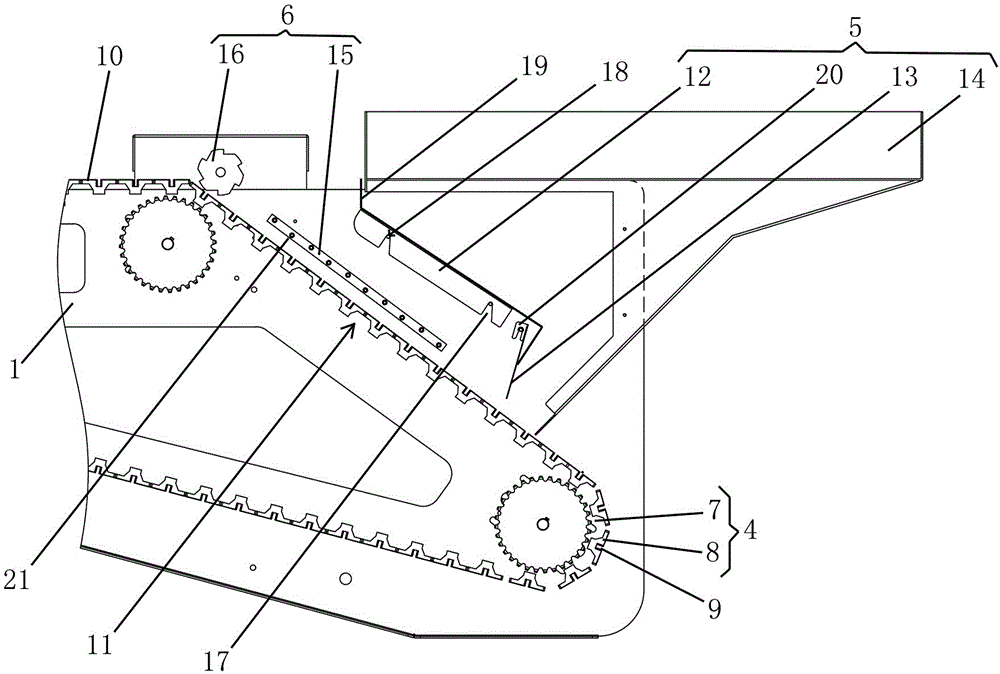

Whole-feed self-cleaning soybean picker

The invention relates to a whole-feed self-cleaning soybean picker, belongs to the technical field of agricultural machinery, and mainly solves the problem that an existing soybean picker has single functionality and complex structure. The whole-feed self-cleaning soybean picker comprises a frame, a feeding device positioned at the top end of the frame, a first separator for separating pods and stalks, a conveyer for conveying the separates, a rotary baking barrel for separating pods, a second separator for separating beans and pod residue, and a vibrator device for cleaning. The whole-feed self-cleaning soybean picker provides mechanized operations from picking and shelling, working efficiency is greatly improved, and damage of manual soybean shelling to human bodies is also reduced.

Owner:CHONGQING SUTENG MACHINERY MFG

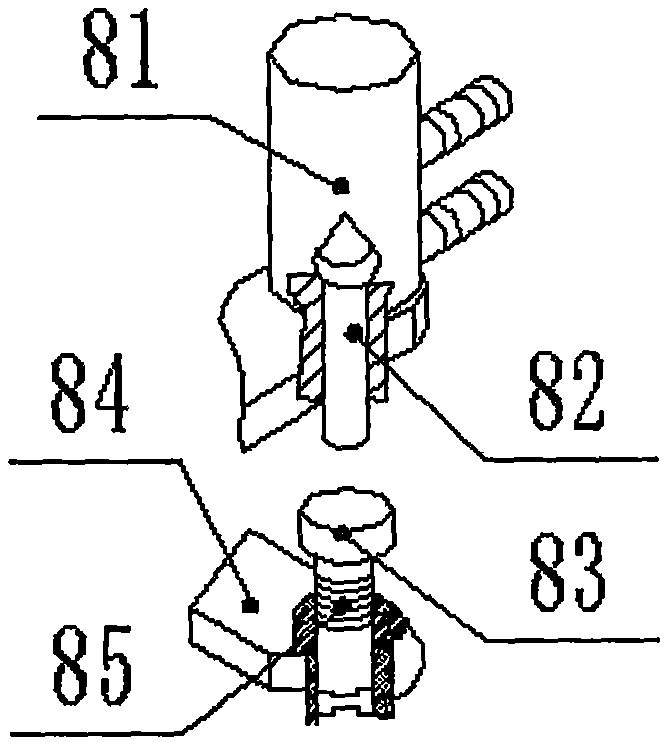

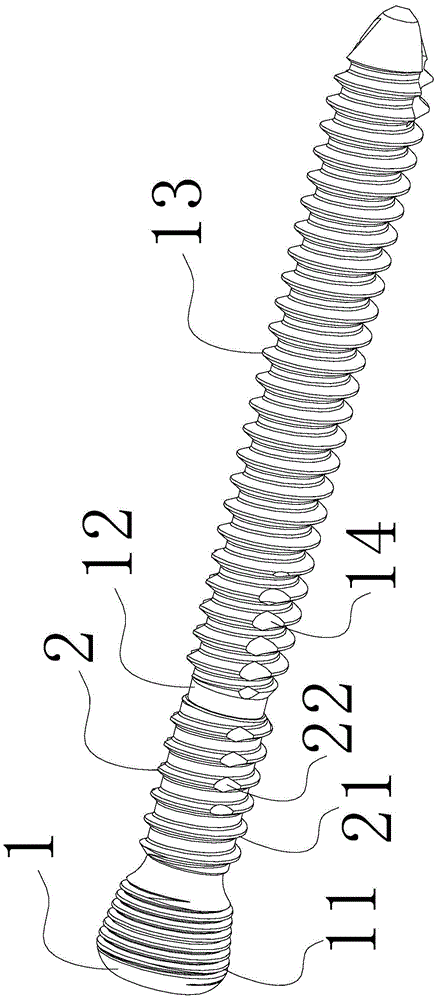

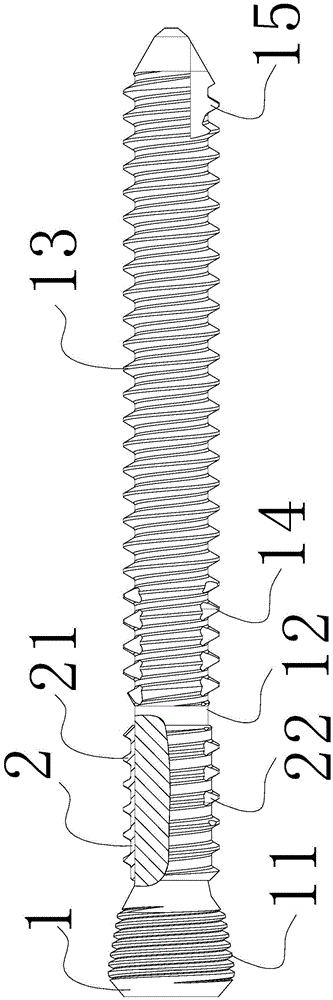

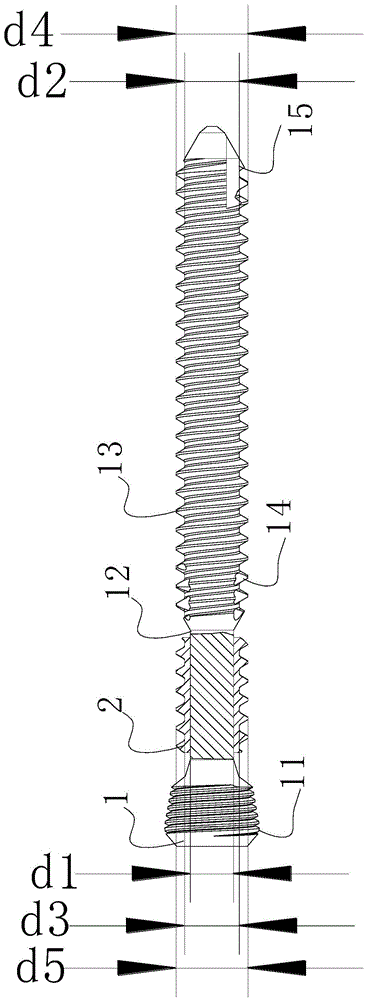

Micro-motion locking screw

The invention relates to a micro-motion locking screw which comprises a screw body made of a non-biodegradable material; the screw body is fixedly provided with a screw sleeve made of a degradable material; the screw body is composed of a locking thread, a connection rod, a screw bone thread, screw returning self tapping slots and screw feeding self-tapping slots which are sequentially connected; the screw sleeve is provided with the screw bone thread. According to the micro-motion locking screw, pressurizing operation can be conducted in surgery, the screw sleeve can be degraded within 1-15 months, a bone close to the side of a locking bone connection plate can conduct micro motion after the screw sleeve is degraded, and thus growth of the bone is promoted under stimulus of force.

Owner:CHUANGHUI MEDICAL EQUIP JIANGSU

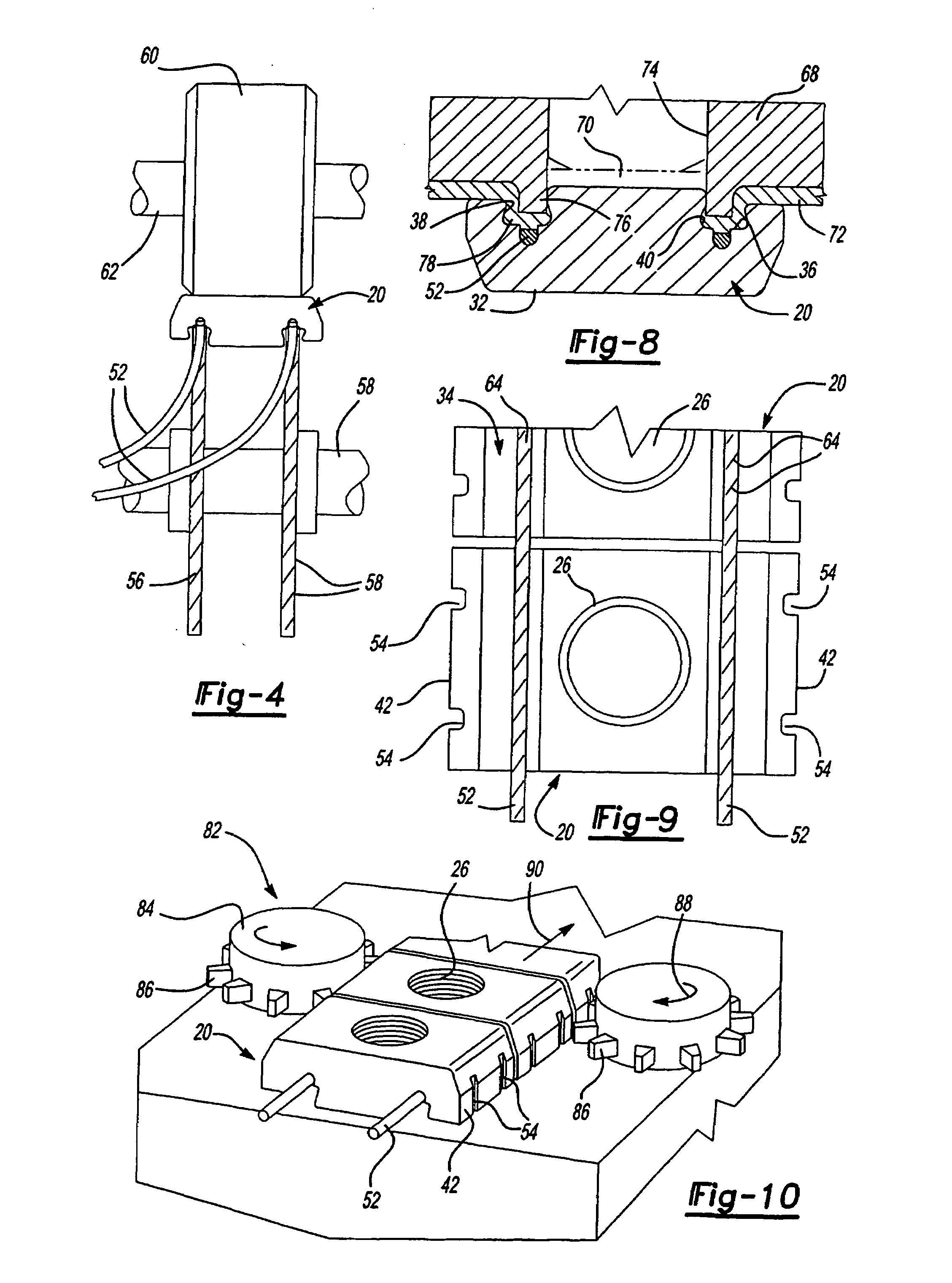

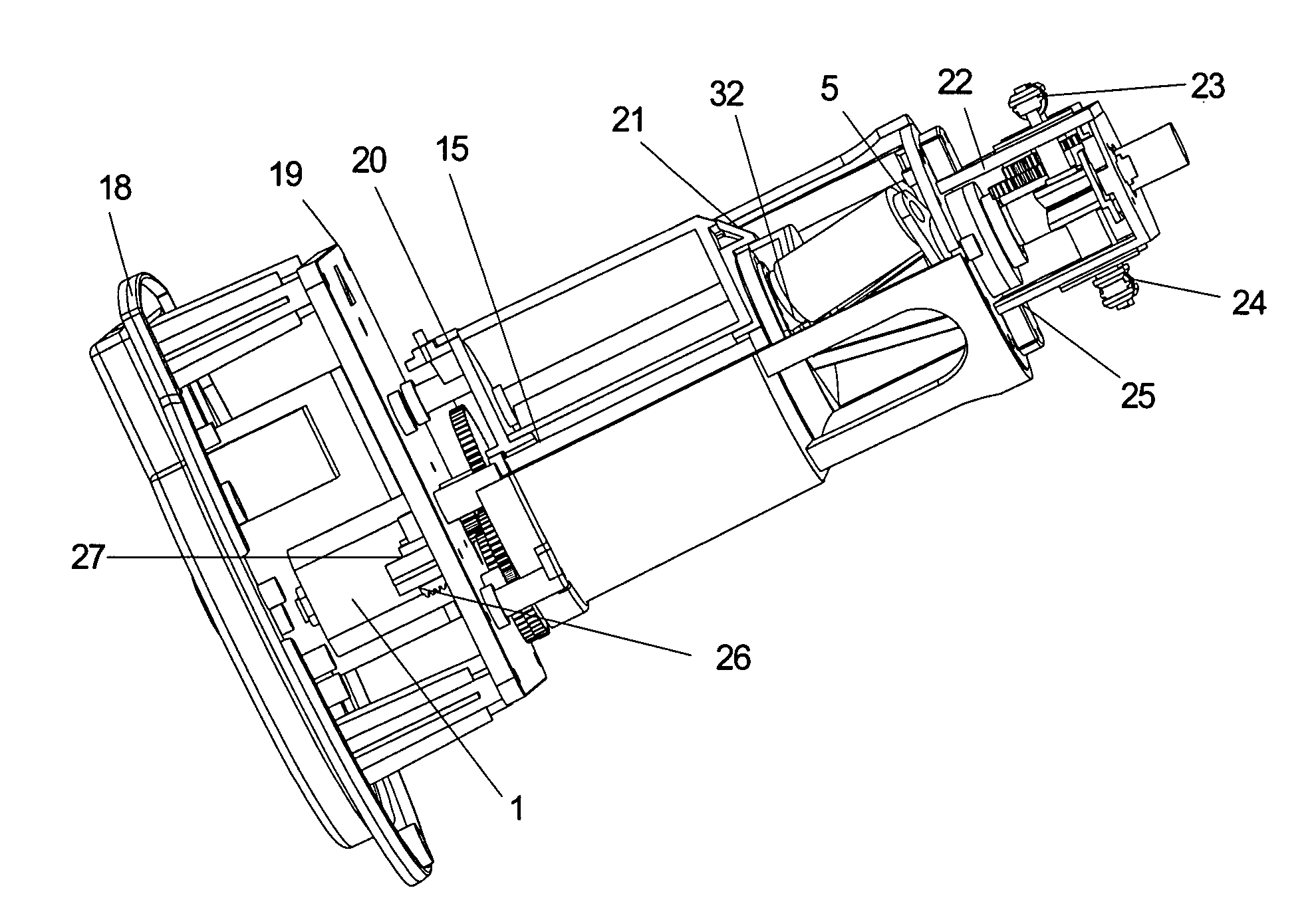

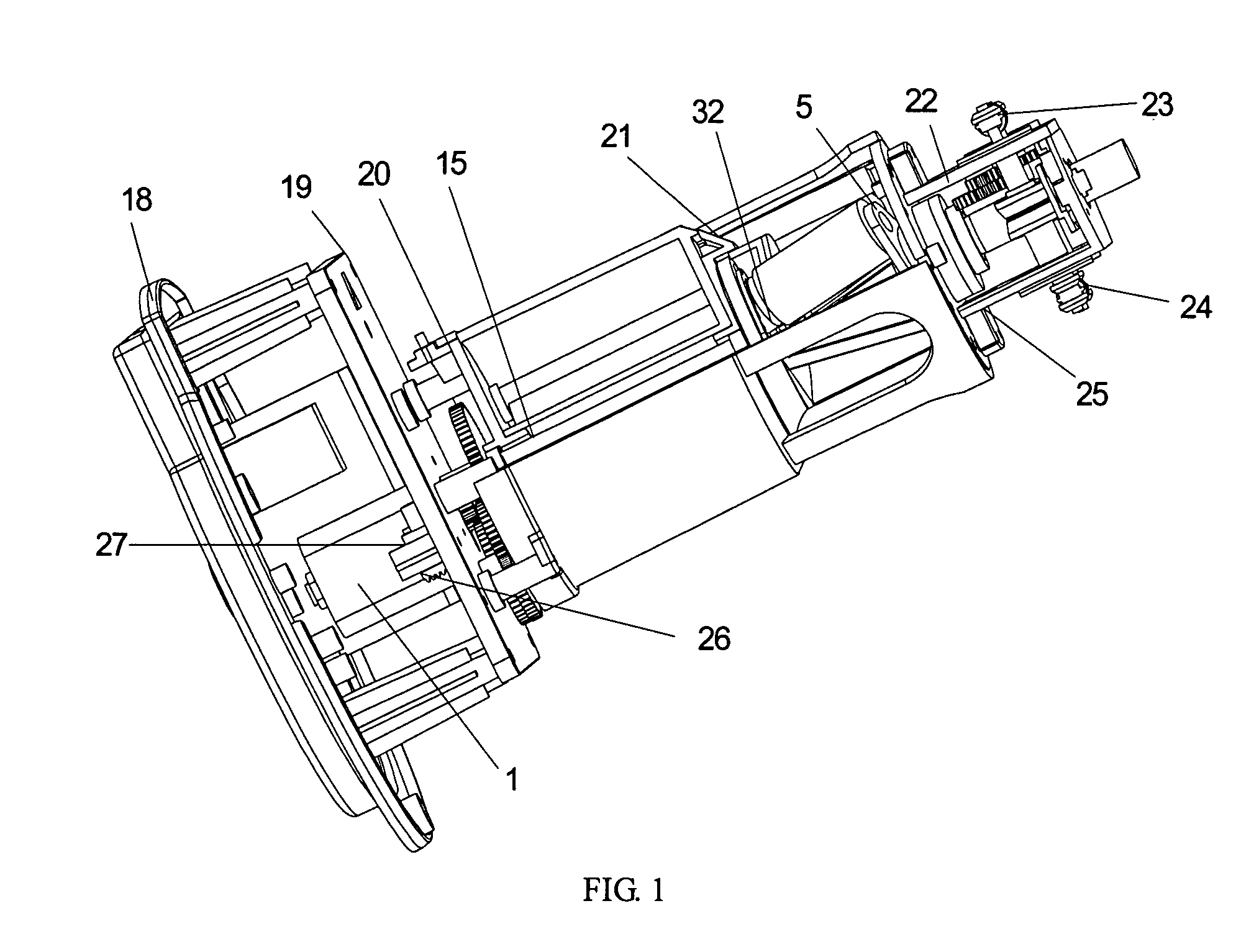

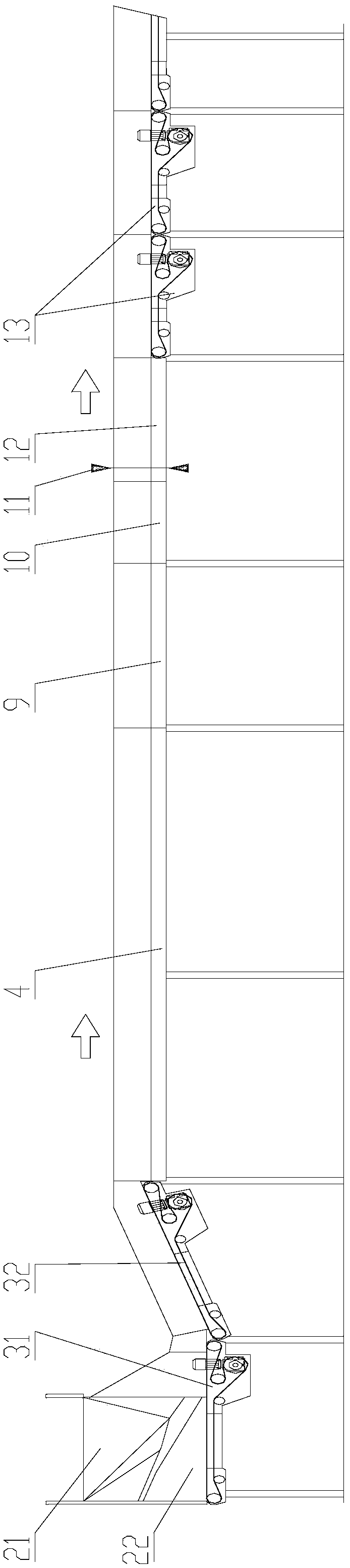

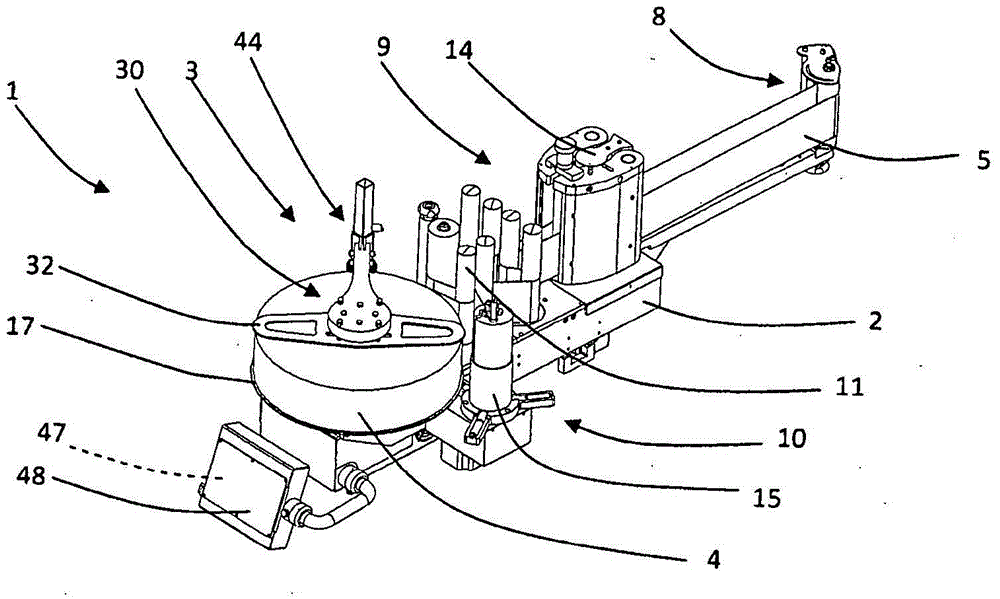

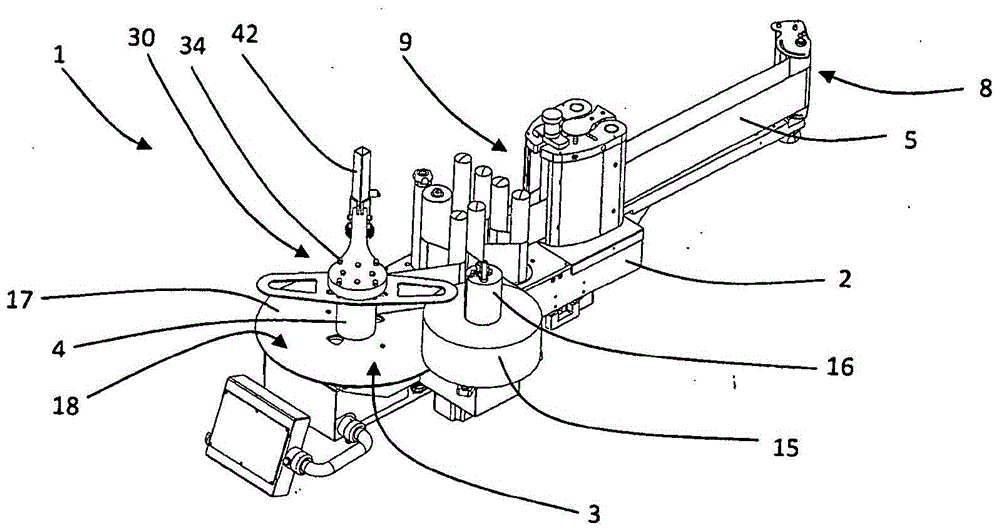

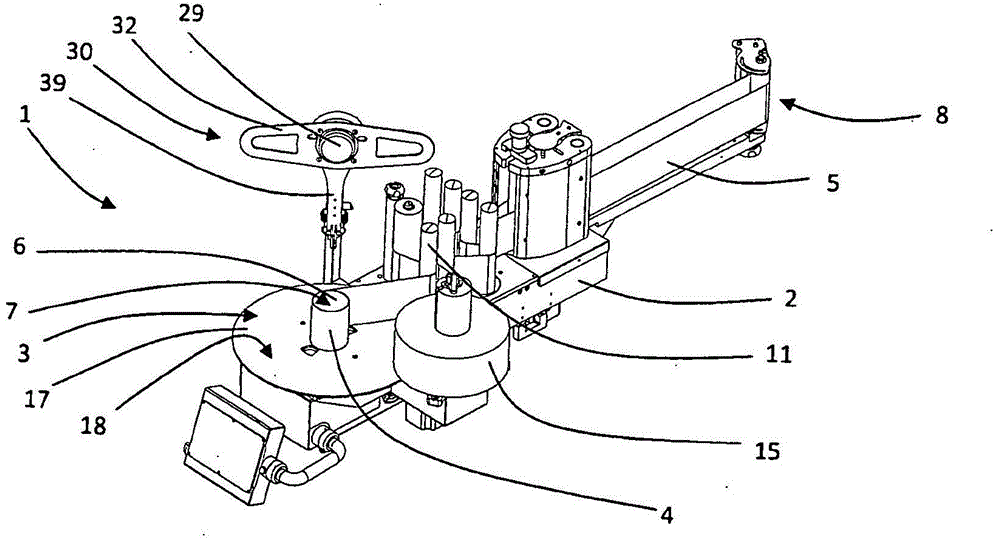

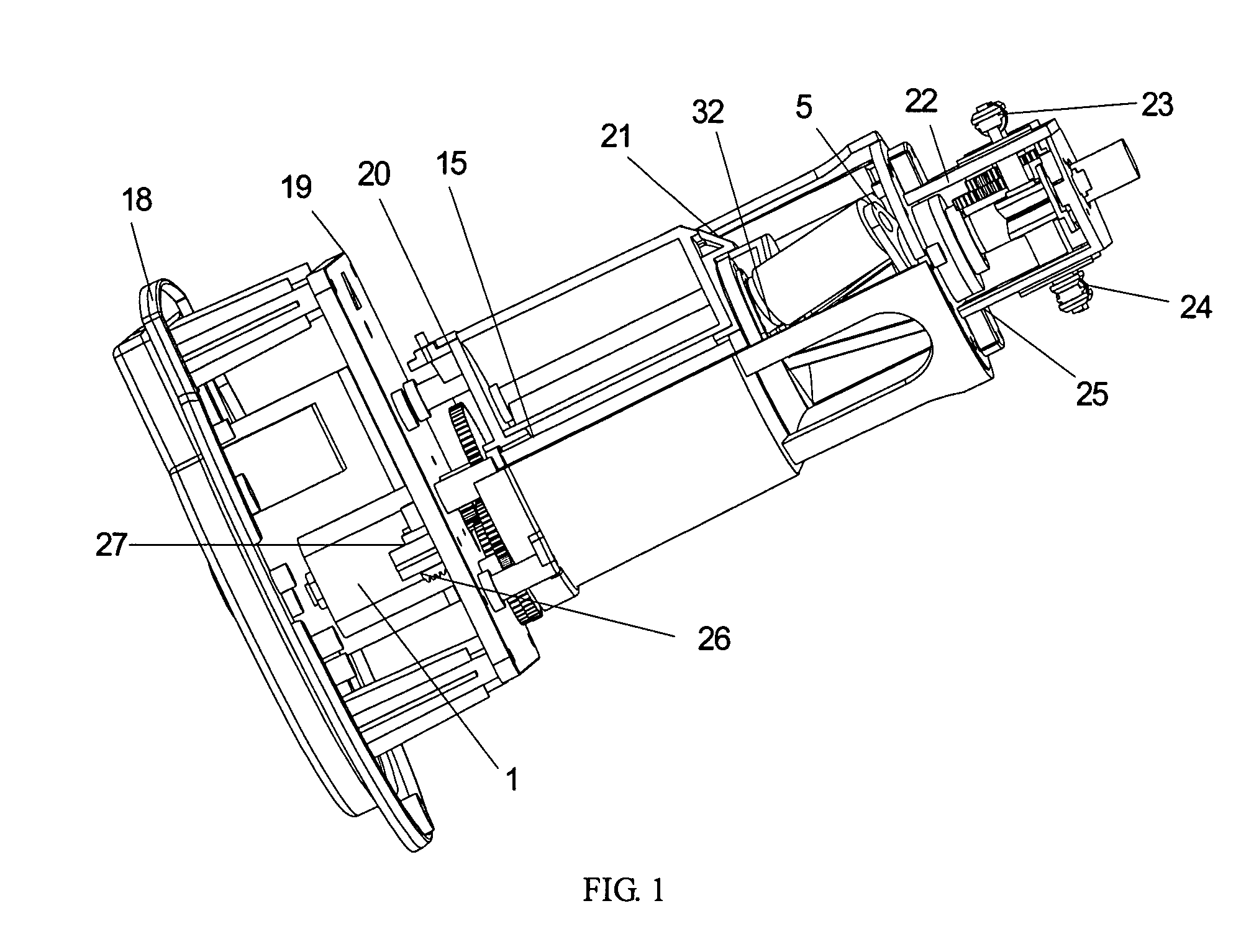

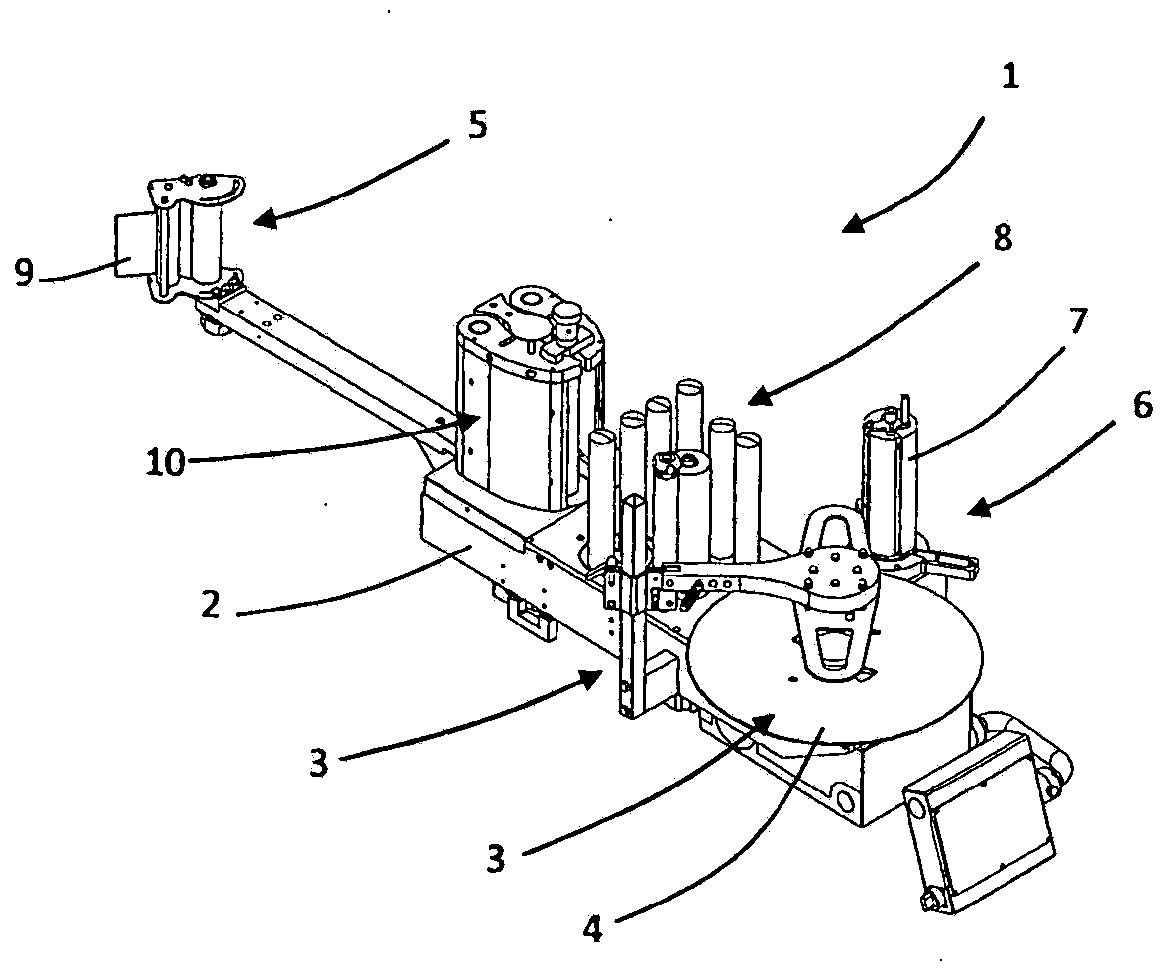

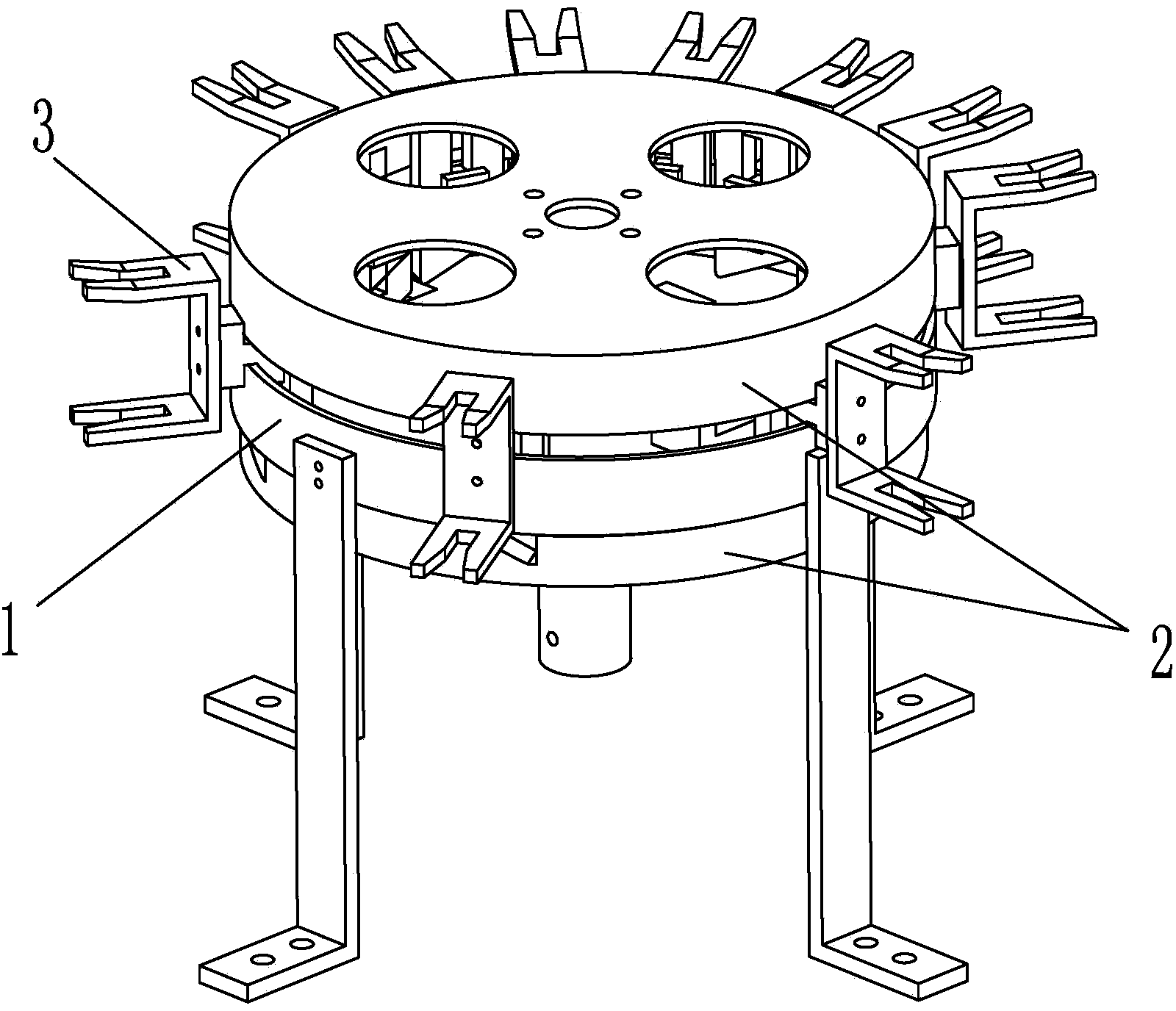

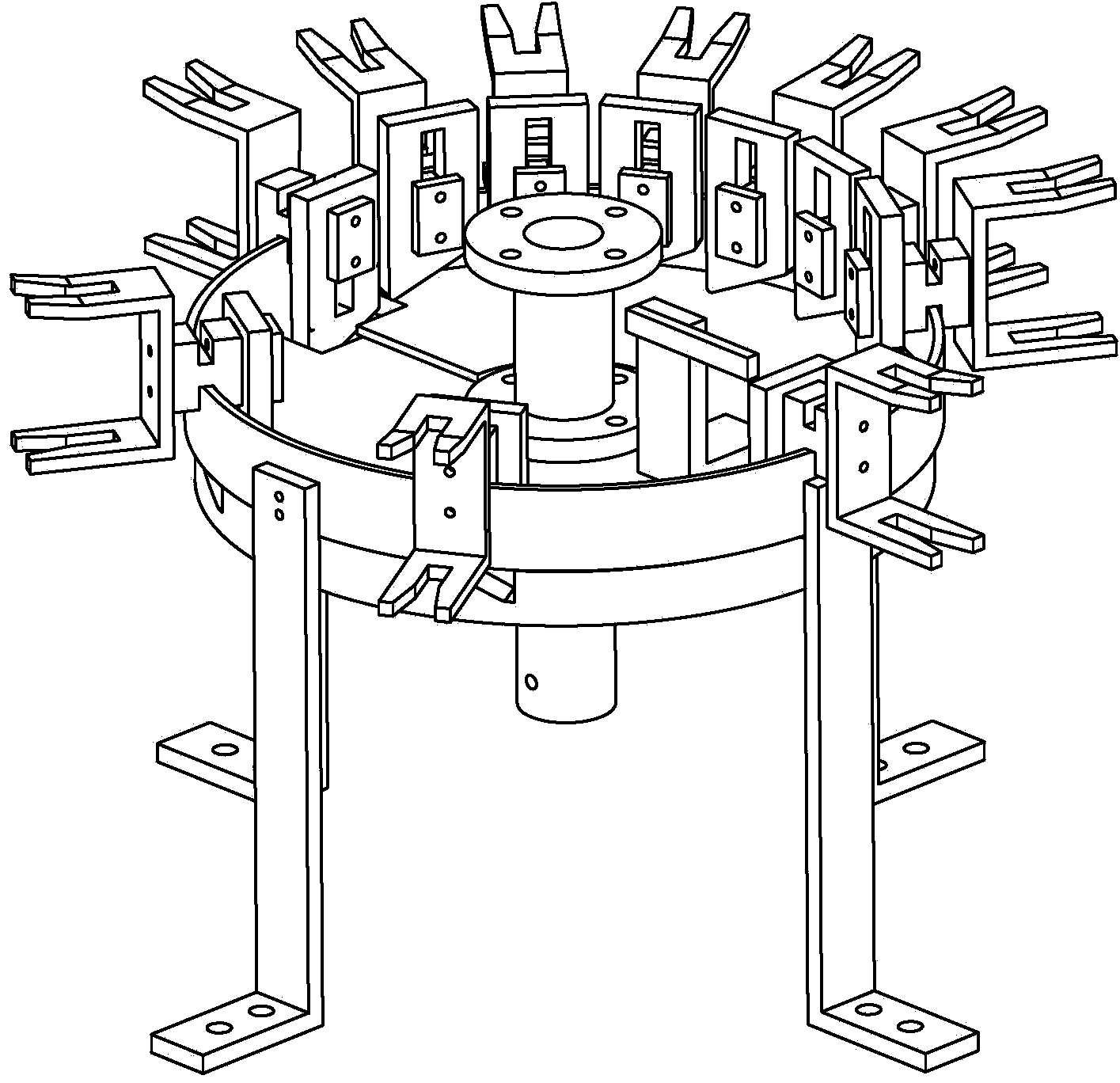

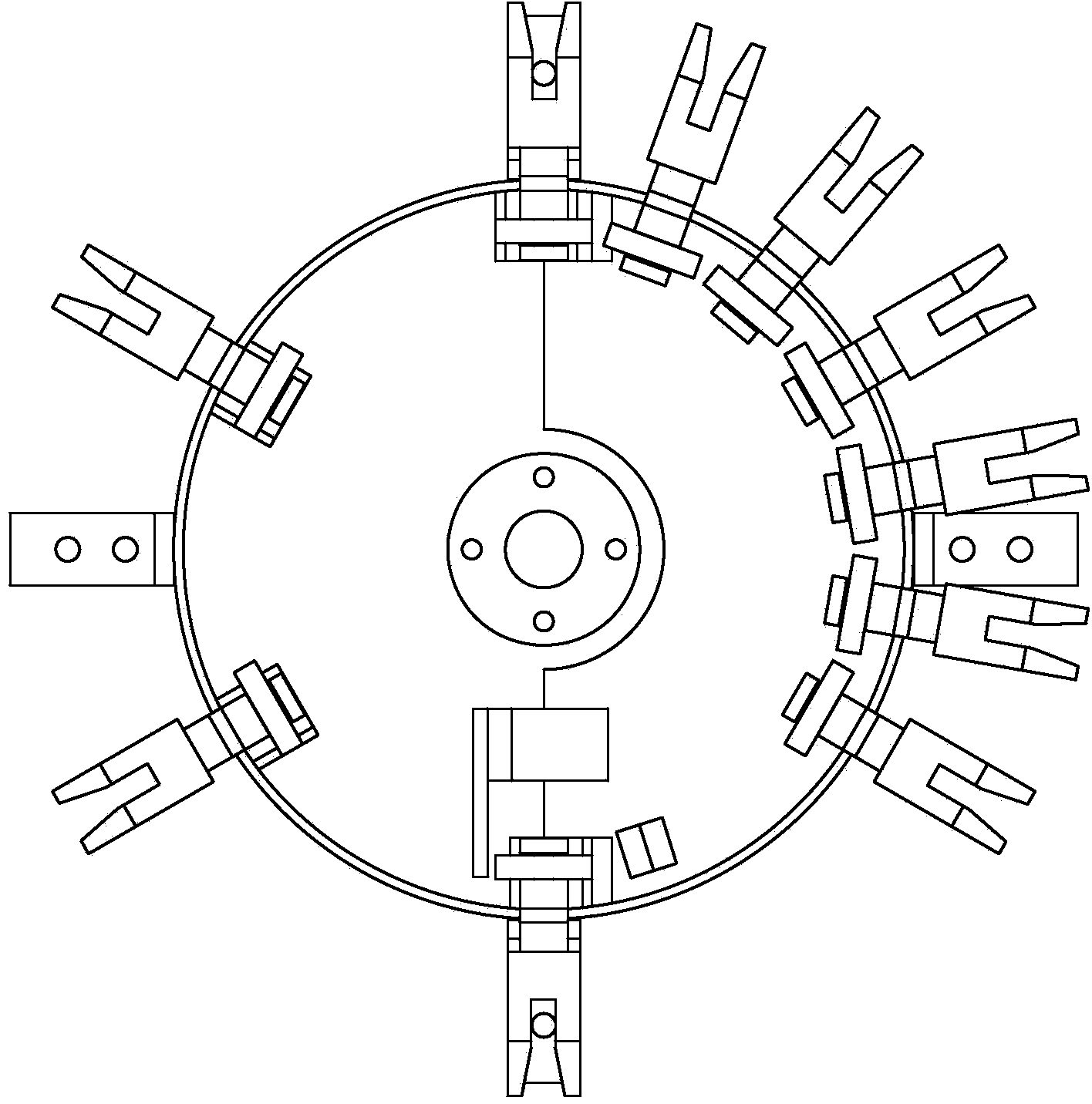

Device for feeding self-adhesive or "pressure sensitive" labels to a labelling machine

ActiveCN104470813AHelp replaceReduces risk of accidental releaseLamination ancillary operationsFilament handlingCouplingEngineering

A device (1) for feeding self-adhesive or "pressure sensitive" labels to a labelling machine comprises a frame (2) and supporting means (3) comprising a supporting plate (17) for supporting a reel (4) of web (5) with labels applied to it, and also comprises at least one guide element (28, 29) designed to be at least partly inserted in a central hole (7) of the reel (4) which can rotate about it. The device (1) also comprises a detaching station (8) for detaching the labels from the web (5), feeding means (9) for feeding the web (5) to the detaching station (8) and recovery means (10) for recovering the web (5) without labels. The supporting plate (17) is removably associated with the frame (2) and the supporting means (3) also comprise a containment head (30) switchable between an open configuration, in which it allows the coupling with and uncoupling from the frame (2) of the supporting plate (17), with the reel (4) placed on it, and an operating configuration, in which it allows the reel (4) to be held between itself and the supporting plate (17), allowing reel (4) rotation.

Owner:KOSME S R L UNIPERSONALE

Electric pencil sharpener

Owner:WAN CHUNG PAK

Flow detection system for flow control apparatus

ActiveUS20160022546A1Eliminate deformationBuildDrug and medicationsMedical devicesEngineeringControl circuit

A flow control apparatus and method for accurate detection of occlusion conditions in a feeding set. A sensor is arranged with respect to a pumping device to produce a signal indicative of pressure in the feeding set. A control circuit that may receive the sensor signal from the sensor indicative of the pressure in the feeding set may also control operation of the pumping device. The control circuit is configured to operate the pumping device in an operational state, and in a reset state subsequent to the operational state in which the pumping device does not produce a pumping action and the pumping device is moved to a position in which the pumping device does not block the feeding set to permit fluid flow in a backflow direction opposite to the patient direction thereby relieving any built up pressure in the feeding set downstream of the pumping device.

Owner:KPR U S LLC

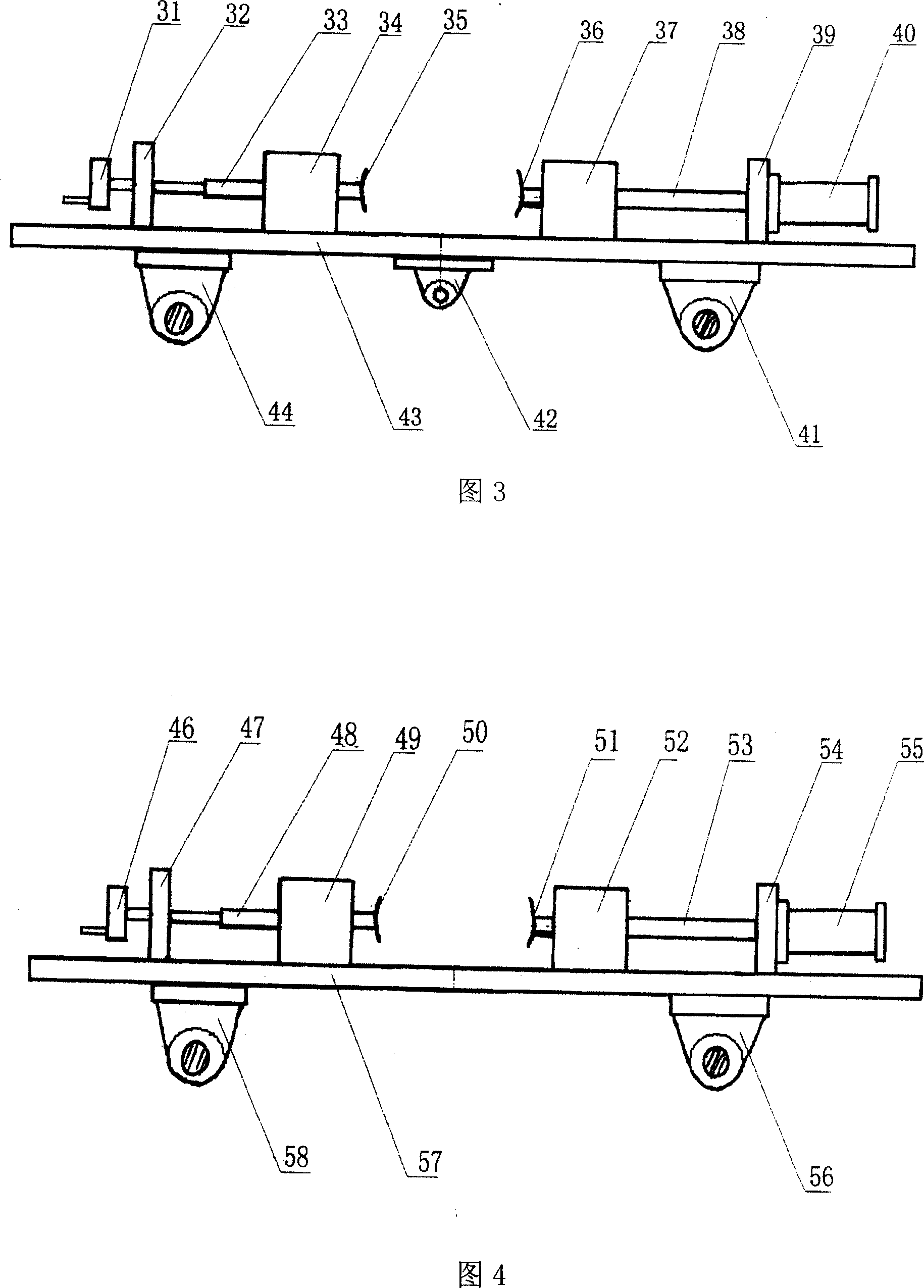

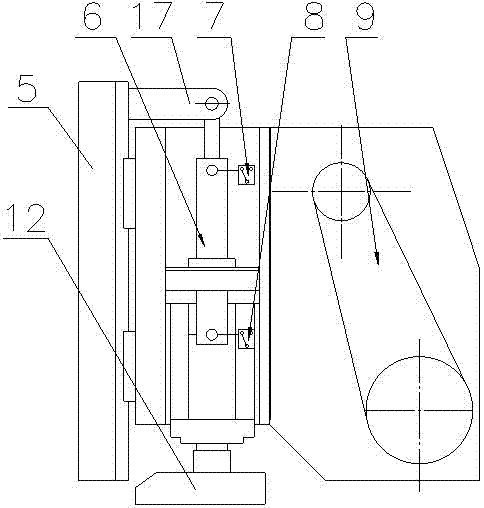

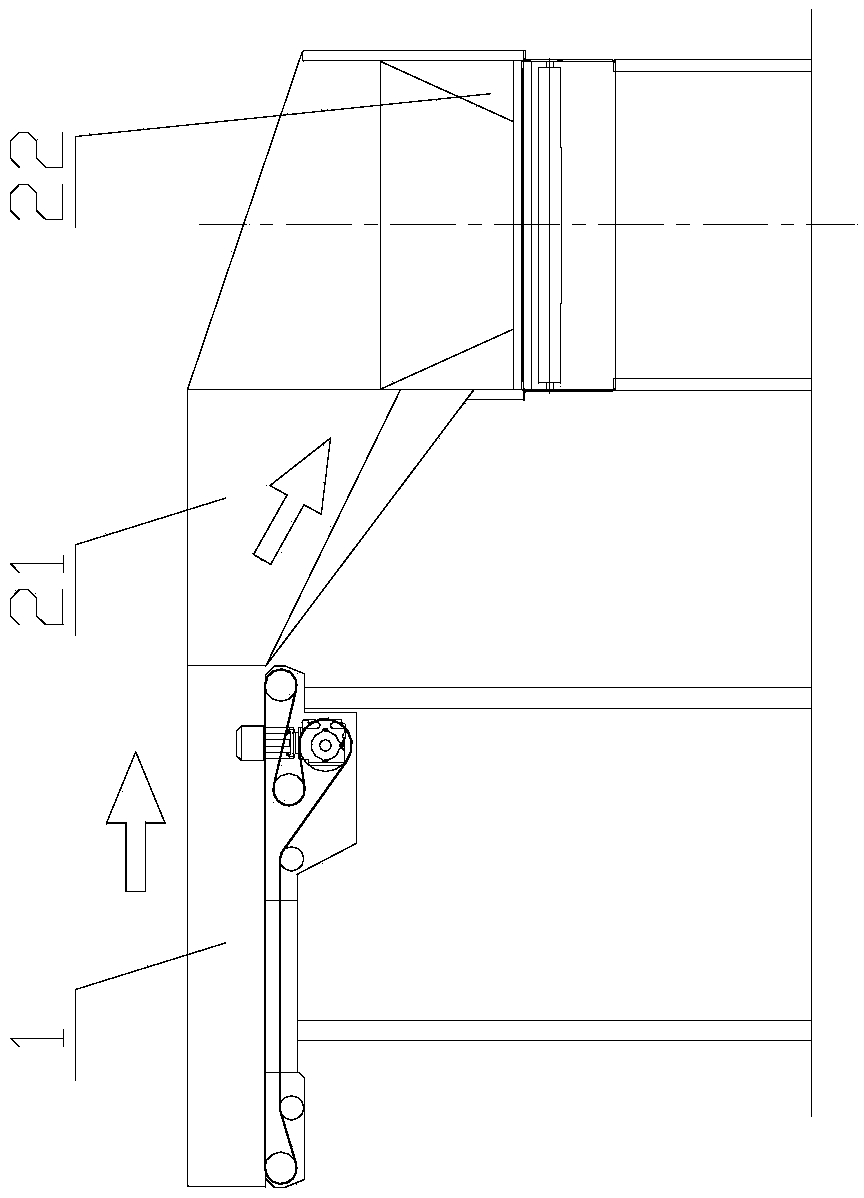

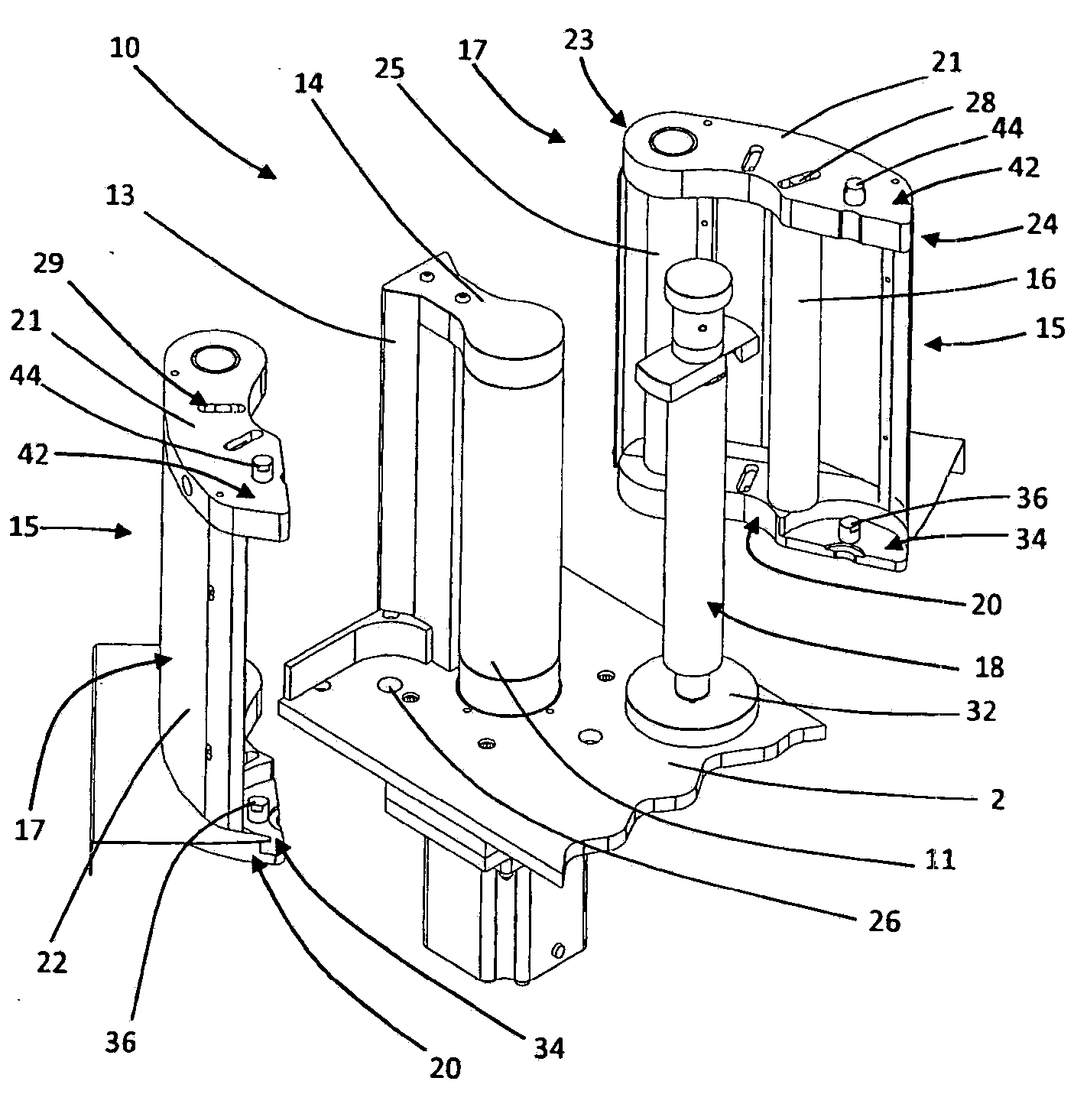

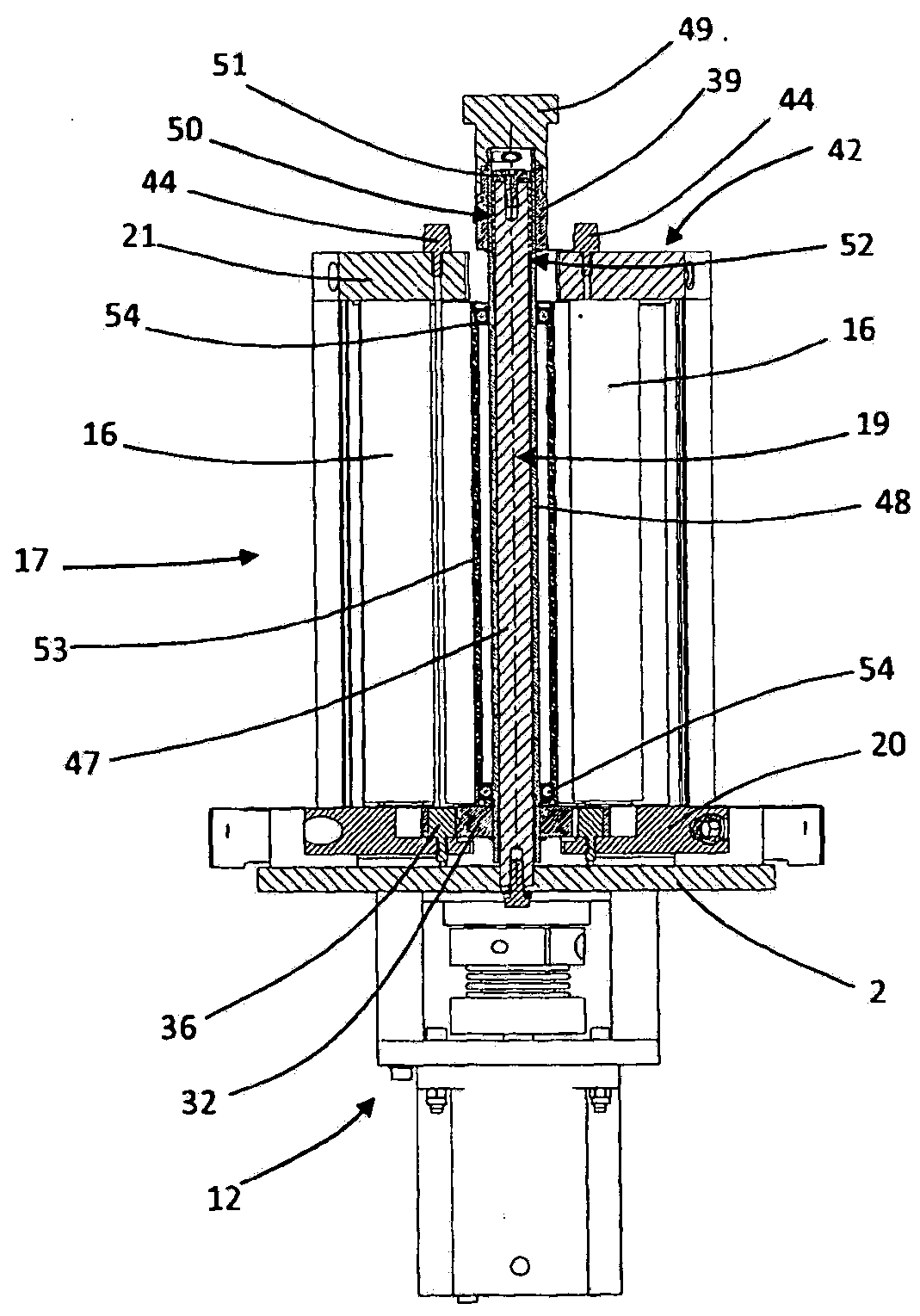

Hose feeding self-locking and conveying device of hose assembling machine

ActiveCN102814636AReasonable structureIncrease production capacityMetal working apparatusEngineeringLocking plate

The invention relates to a hose feeding self-locking and conveying device of a hose assembling machine. The hose feeding self-locking and conveying device is arranged at upper ends of hoses on lateral upper sides of feed inlets of a hose conveying mechanism on a cabinet rack of the hose assembling machine. The hose feeding self-locking and conveying device is characterized by comprising a plurality of socket parts, a feeding movable mechanism, a plurality of locking plates, fixing parts and a pressing device; more than one hose is inserted in the socket parts; the locking plates are used for automatically locking the hoses; the fixing parts are used for fixing the locking plates, and the pressing device is used for pressing the hoses to prevent the hoses from slipping. The hose feeding self-locking and conveying device solves difficult problems that multiple hoses cannot be simultaneously placed in both hands of a worker, and if the hoses are placed in the hose assembling machine sequentially, the hoses placed in the hose assembling machine previously can slip out of the hose assembling machine. By the hose feeding self-locking and conveying device, the hoses only need to be placed into the feeding positions and then can be automatically locked and do not slip off again without holding by hands of workers, the automatic conveying device can realize feeding self-locking and can automatically convey the hoses to assembling positions, assembling time is effectively shortened, and assembling efficiency is improved.

Owner:广西自由贸易试验区良维电子有限公司

Feeding mechanism of string forming machine and feeding method of feeding mechanism

ActiveCN105883359AEasy to roll inAvoid defects that affect the processing processConveyorsConveyor partsEngineeringSieve

The invention relates to a feeding mechanism of a string forming machine and a feeding method of the feeding mechanism. The feeding mechanism comprises a rack and a string forming device and a feeding device which are arranged on the rack respectively; the feeding device comprises a feeding mechanism body, a material storing mechanism and a material distributing mechanism, the material storing mechanism comprises a material retaining plate, a turning plate and a hopper, the material retaining plate is detachably installed on the rack, the material retaining plate and the rack form the hopper with a certain containing space, the turning plate is arranged at the end of the material retaining plate, one end of the turning plate is detachably installed on the rack, the other end of the turning plate is suspended in the rack, and the material distributing mechanism comprises a feeding sieve and a material pushing rolling wheel. The feeding mechanism of the string forming machine and the feeding method of the feeding mechanism have the advantages that the turning plate is arranged in a traditional feeding mechanism, the feeding amount can be adjusted automatically according to the material piling condition, the defect that the processing process is affected due to material piling is avoided, and the production efficiency is improved effectively; due to the fact that the feeding sieve is arranged, the piled materials can be rolled into a string forming mold more conveniently by means of the feeding sieve, use is very convenient, the structure is simple, the cost is low, and the practicability is high.

Owner:CLOUDFOCUS DONGGUAN AUTOMATION EQUIP CO LTD

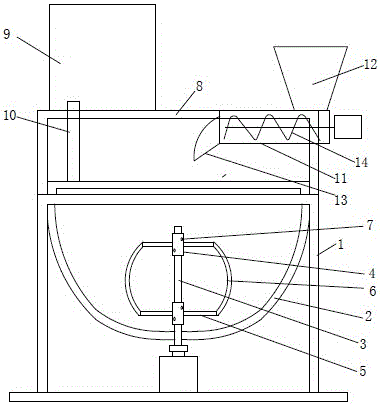

Detachable dough mixer

InactiveCN106212581AEasy to cleanMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsEngineeringCounterbore

The invention discloses a detachable dough mixer and belongs to the field of food processing equipment. The detachable dough mixer comprises a frame, a stirring barrel arranged on the frame, a stirring mechanism arranged in the stirring barrel and a stirring motor under the stirring barrel, wherein the stirring mechanism comprises a stirring shaft and stirring cutters mounted on the stirring shaft; each stirring cutter comprises two sleeves which are arranged at an interval in an axial direction; a cutter body is connected between the two sleeves; vertical posts are arranged along the axial directions of the sleeves; counterbore holes are formed in the side walls of the sleeves; locking screws are arranged in the counterbore holes; the lower end of the stirring shaft stretches out of the stirring barrel and is in transmission connection with the stirring motor; a bracket located above the stirring barrel is fixed on the frame; a water tank and a dough feeding mechanism are mounted on the bracket; the dough feeding mechanism comprises a horizontal dough discharging cylinder, a dough feeding hopper arranged at one end of the dough discharging cylinder and a dough discharging plate arranged at the other end of the dough discharging cylinder; a feeding screw is arranged in the dough discharging cylinder; one end of the feeding screw stretches out of the dough discharging cylinder and is connected with a feeding motor. Through the detachable dough mixer, the dough can be simply and rapidly taken out; and the detachable dough mixer is convenient to clean.

Owner:CHENGDU FANXINJIA TECH

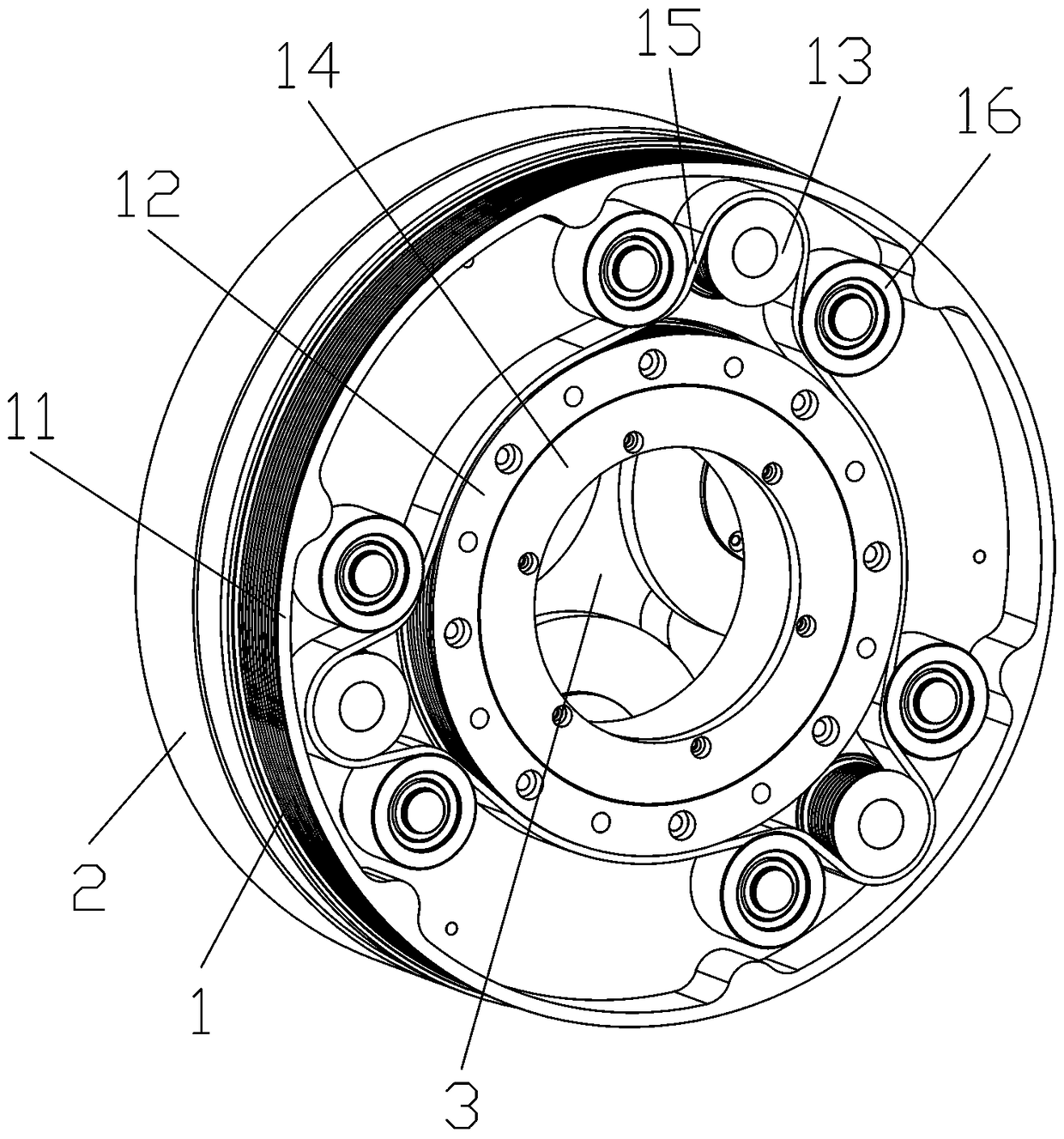

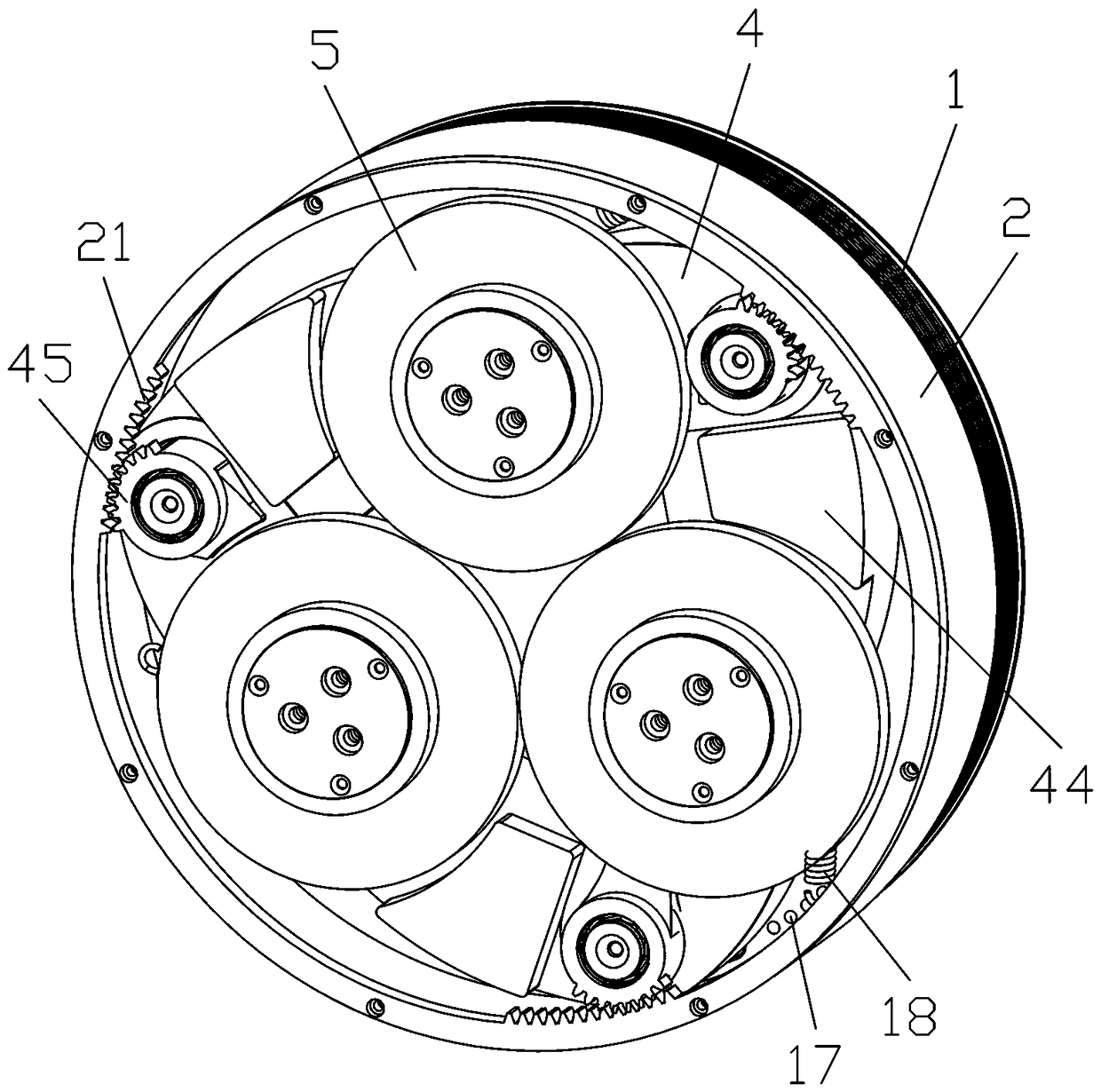

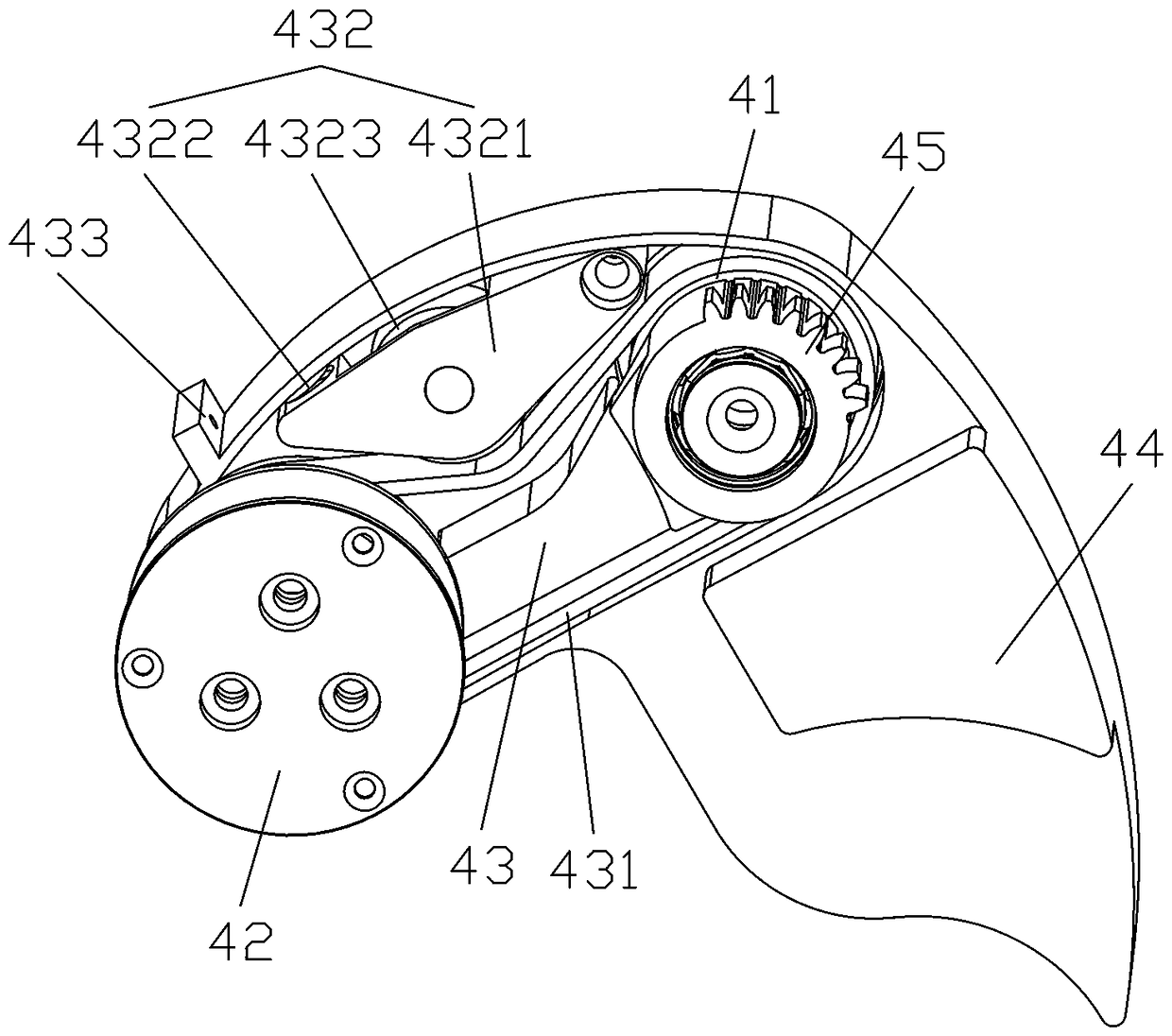

Feeding self-adaptive cleaning device

PendingCN108568711AImprove covering powerEasy loadingRevolution surface grinding machinesGrinding/polishing safety devicesDrive wheelEngineering

The invention relates to a feeding self-adaptive cleaning device which comprises a main wheel and a synchronizing wheel mounted in parallel, wherein the main wheel and the synchronizing wheel are coaxially connected through a bearing; the main wheel comprises a transmission wheel and a mounting wheel which are concentrically arranged and are fixedly connected; the transmission wheel is driven by amotor to rotate so as to drive the main wheel to rotate, a driven wheel is connected to the outer side of the mounting wheel through a bearing in a matched manner, the driven wheel is fixedly mounted, driven wheels of a circumferential array are mounted in match around the driven wheel in the periphery on the driving wheel disc surface, and the driving wheel rotates along with rotation of the transmission wheel; and a cleaning unit is mounted on the side, located on the synchronizing wheel, of the driving wheel, the cleaning unit swings, so that the cleaning wheel can be folded or separated,and the cleaning wheel transfers power by the cleaning unit to rotate along with rotation of the driven wheel and revolves along with rotation of the driving wheel.

Owner:杭州同悦自动化设备有限公司

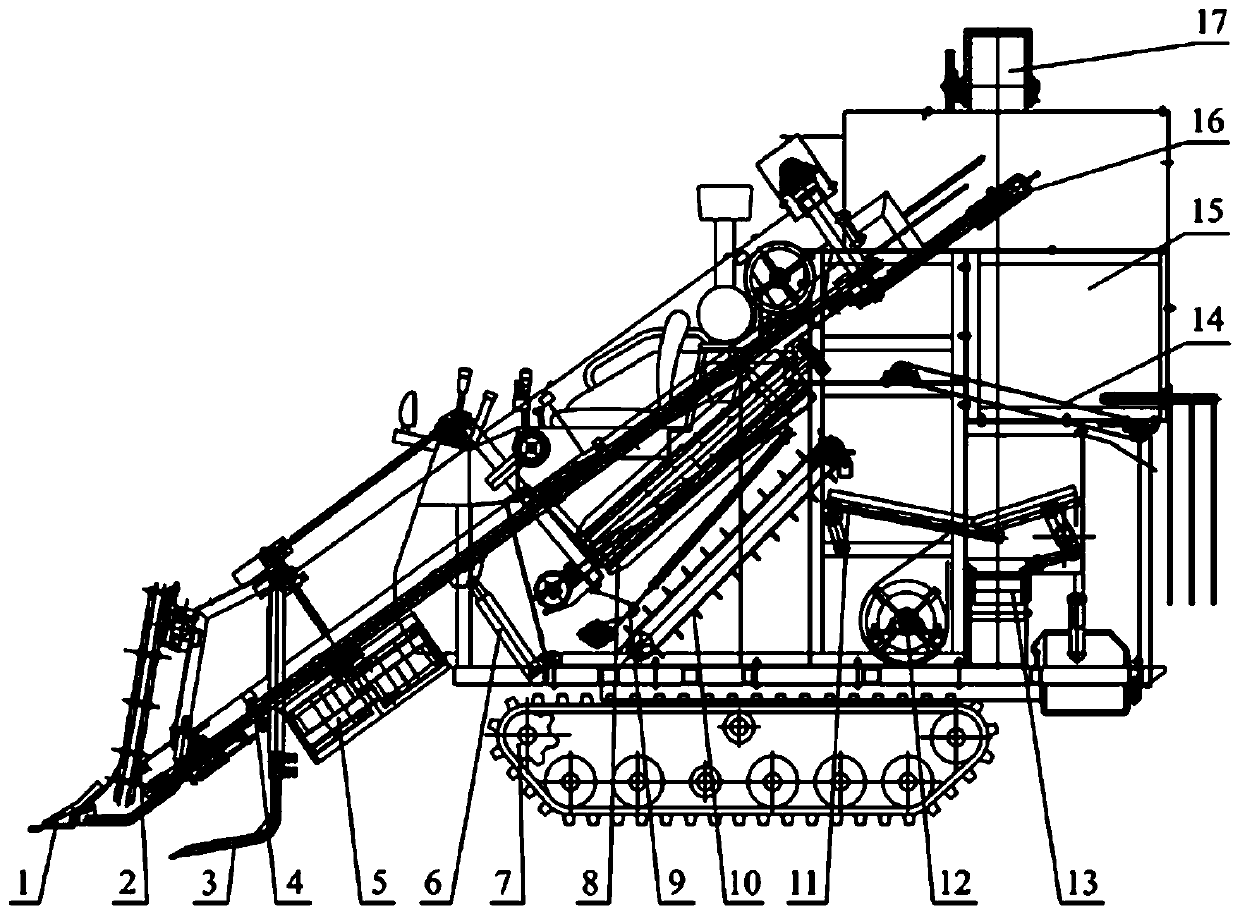

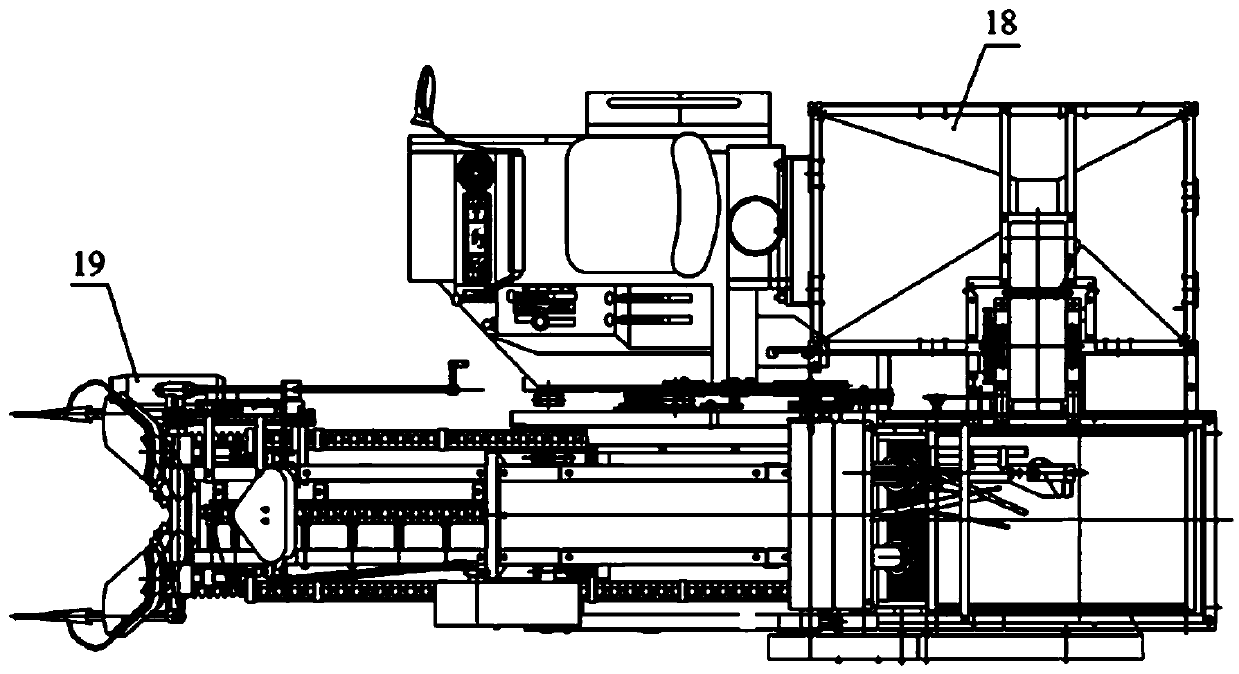

Semi-feeding self-propelled peanut combined harvester

InactiveCN107637254AReduce manufacturing costSimple and fast operationDigger harvestersEngineeringDepth limit

The invention relates to a semi-feeding self-propelled peanut combined harvester capable of finishing combined operation of peanut digging, soil removing, fruit picking, sorting, fruit collecting andseedling vine spreading. The harvester mainly comprises a grain divider, a grain lifter, a digging shovel, a grain pulling and conveying chain, a soil cleaning device, a hydraulic lifting cylinder, arubber crawler chassis, a fruit picking roller, an elastic blocking curtain, a scraper conveyer belt, a sorting screen, a draught fan, a transverse conveying belt, a vine conveying belt, a main machine frame, a vine throwing chain, a vertical lifting machine, a fruit collecting box and a depth limiting device; the grain divider and the grain lifter separate plants and lift the plants up, the digging shovel cuts off peanut roots and loosens soil, and the plants enter the grain pulling and conveying chain to be pulled up; a counter-roller fruit picking device brushes off fruit pods, and impurities such as stems, leaves and sandy soil are separated out under the action of a vibrating screen and the draught fan; selected peanut fruits are sent to the fruit collecting box; and peanut vines after the pods are removed are discharged out of the harvester. The semi-feeding self-propelled peanut combined harvester has the characteristics of simple and convenient operation, high efficiency, low labor intensity of workers and the like.

Owner:刘铮

Device for feeding self-adhesive or "pressure sensitive" labels to a labelling machine

A device (1) for feeding self-adhesive or "pressure sensitive" labels to a labelling machine comprises a frame (2), supporting means (3) for a reel of a web with the labels attached to it, a station (5) for detaching the labels from the web, recovery means (6), return means (8), and means (10) for moving the web comprising: a motor-driven roller (11) and at least one unit (15) for pressing the web against the motor-driven roller (11) comprising at least one contact roller (16), mounted on a support (17), for clamping the web against the motor-driven roller (11). The support (17) being movable relative to the frame (2) between an operating position, with the contact roller (16) pressed against the motor-driven roller (11), and an insertion position, with the contact roller (16) distanced from the motor-driven roller (11). There being a switching element (18) associated with the support (17) which in their first configuration is in the operating position, in a second configuration is in an insertion position and in a third configuration is able to move between the insertion position and a maintenance position in which the contact roller (16) is further from the motor-driven roller (11) than in the insertion position.

Owner:KOSME S R L UNIPERSONALE

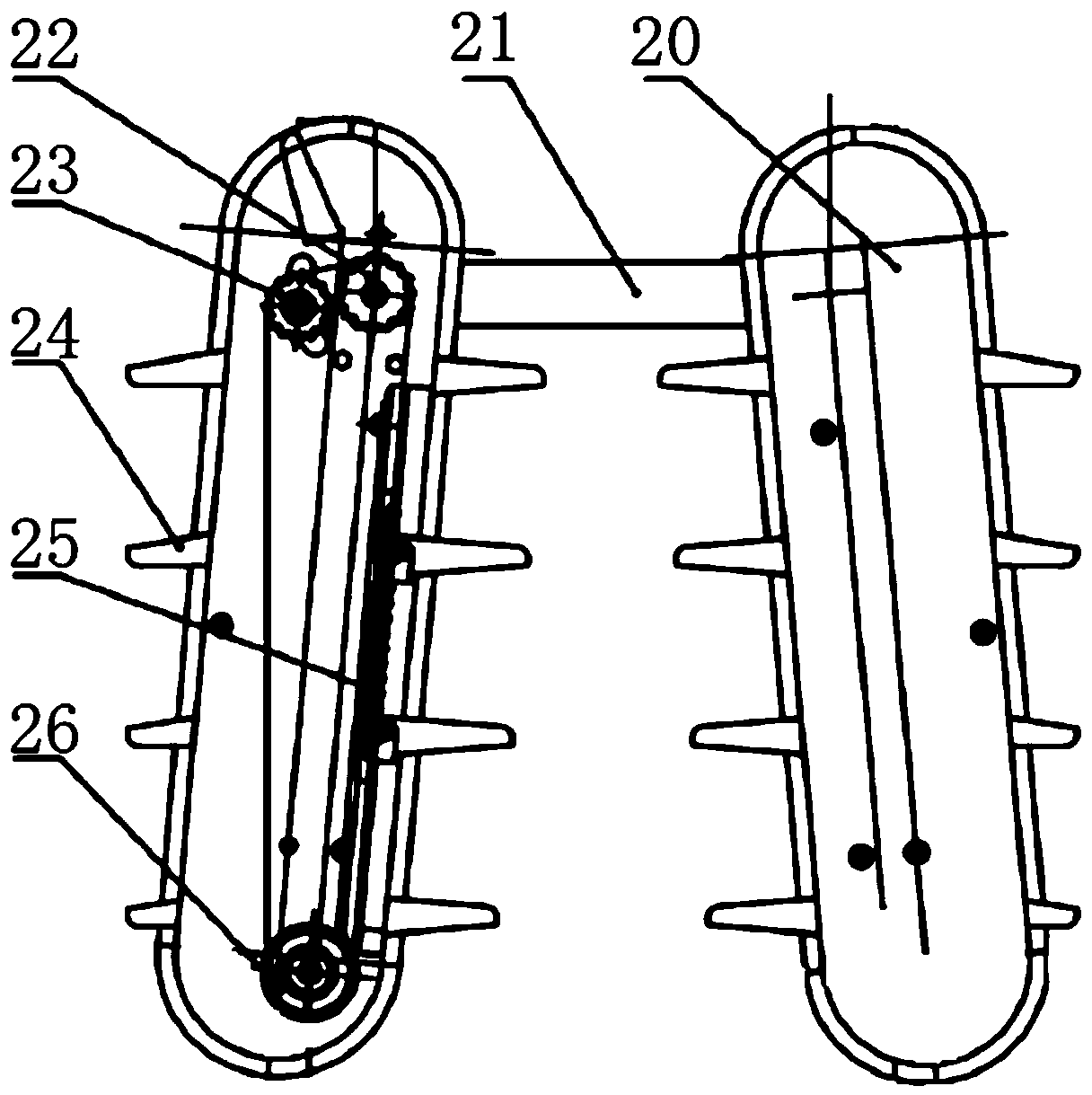

Free seedling feeding self-positioning grafting machine seedling holder

The invention relates to a free seedling feeding self-positioning grafting machine seedling holder and aims to provide a device with the advantages that manually free seedling feeding and machine seedling taking are simultaneously realized, the seedling feeding speed can be manually freely handled, the operation is simple and accurate, and the grafting efficiency is improved. The technical scheme is that the free seedling feeding self-positioning grafting machine seedling holder is characterized in that the free seedling feeding self-positioning grafting machine seedling holder comprises a bearing assembly mounted above a worktable, a driving assembly wrapping the bearing assembly from two directions up and down, and a plurality of seedling holding assemblies mounted between the bearing assembly and the driving assembly.

Owner:HUZHOU ZHILI CHILDRENS CLOTHING DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com