Patents

Literature

30results about How to "Avoid waiting for each other" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

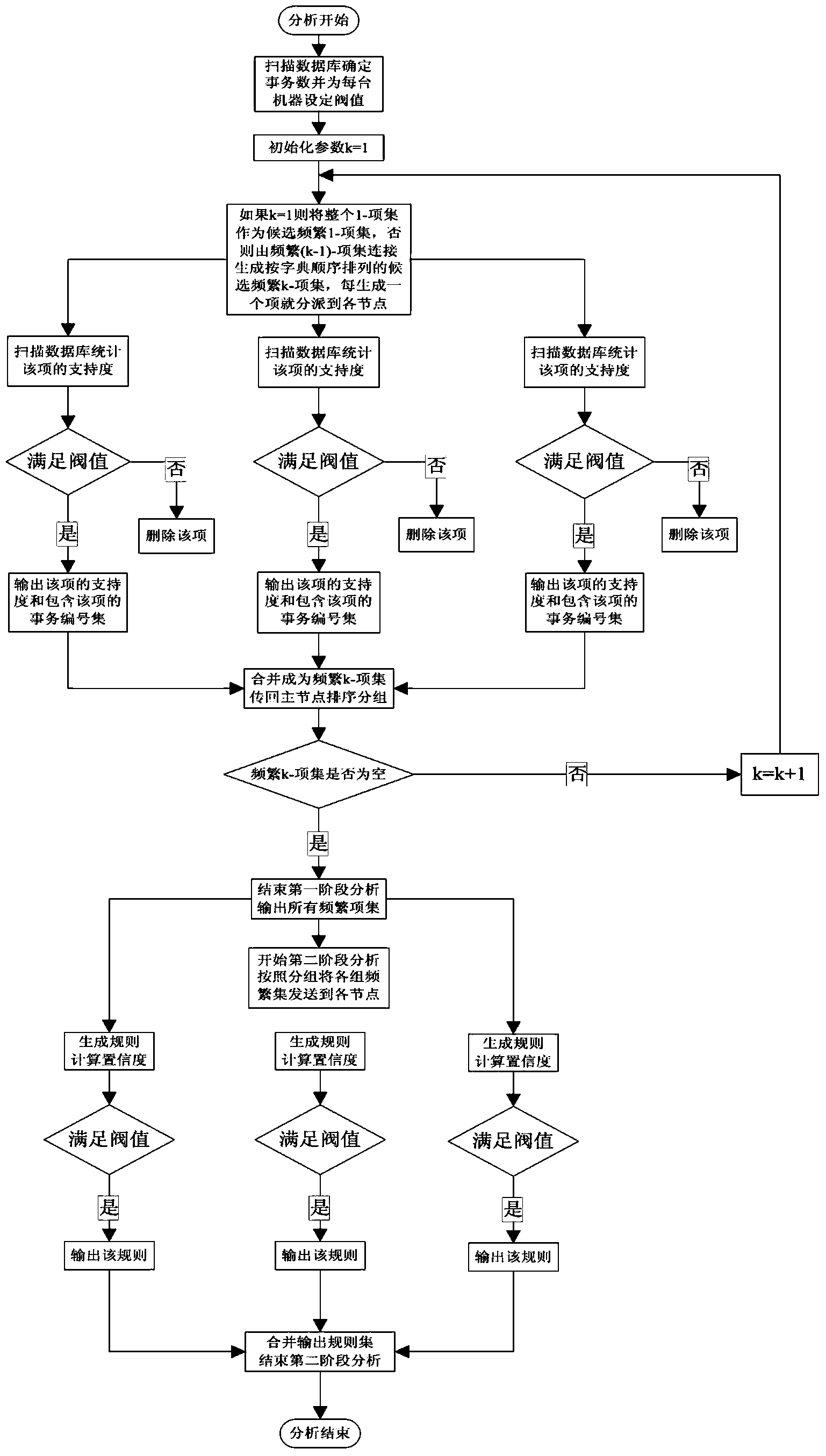

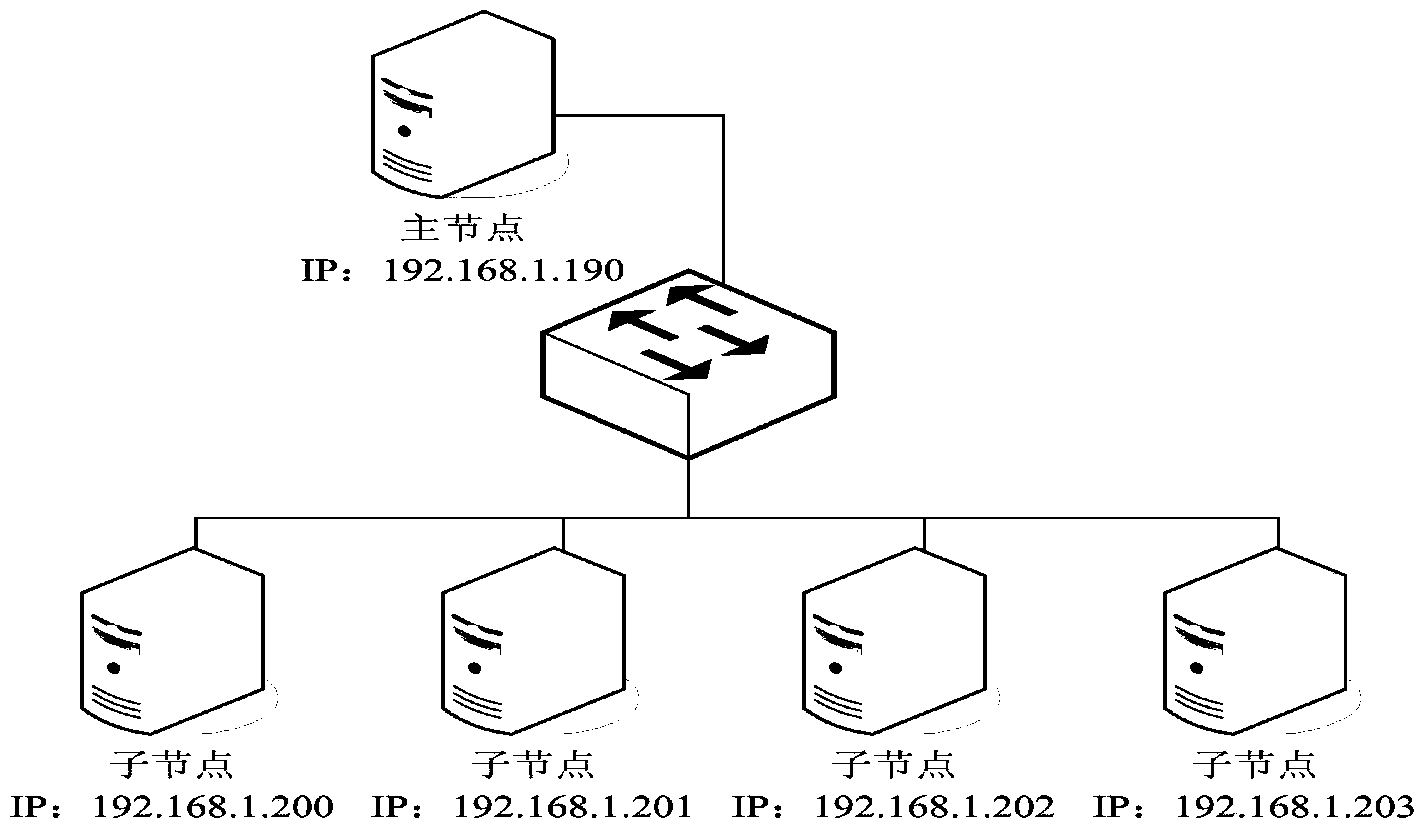

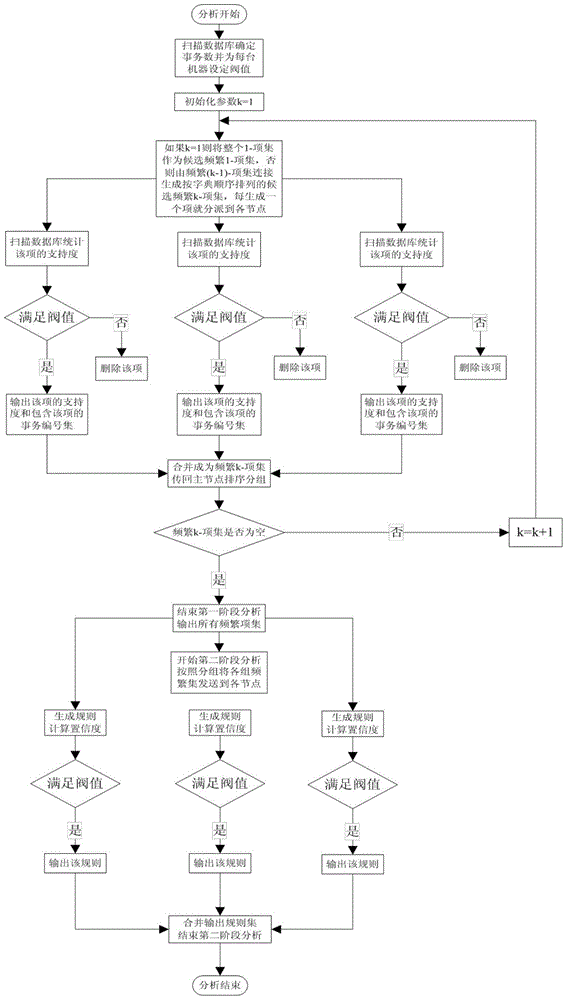

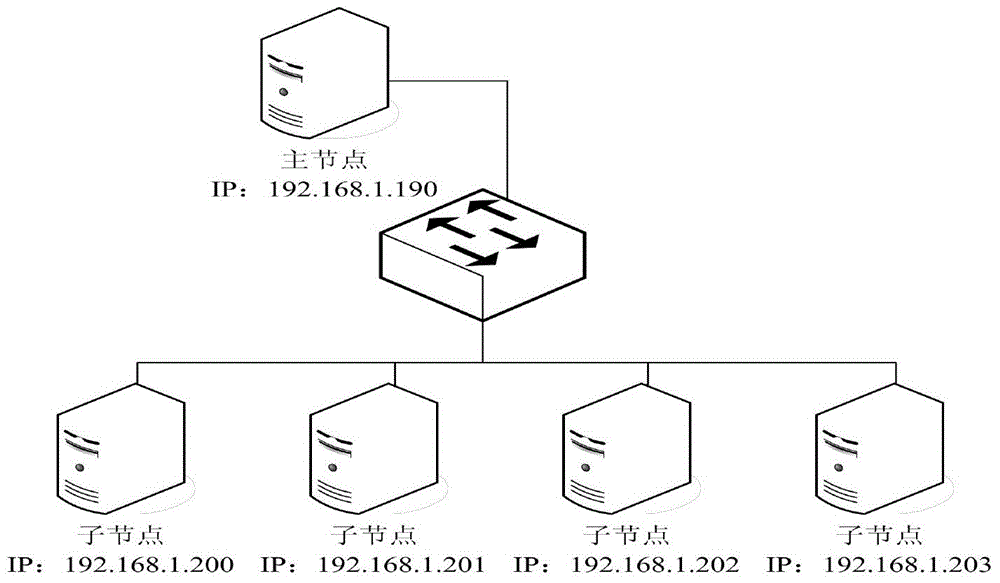

Parallelizing method of association analytical algorithm

ActiveCN103914528AIncrease generation speedRelieve pressureSpecial data processing applicationsTheoretical computer scienceComputation process

The invention designs a novel parallelization scheme, particularly relates to a parallelizing method of association analytical algorithm in order to overcome the defect that a conventional association rule analysis algorithm Apriori cannot well adapt to parallelization. The parallelizing method includes blocking computation tasks via a master control node, allocating and distributing to various subsidiary computation nodes; parallelly computing via the various subsidiary computation nodes to screen frequent item sets, finally combining the nodes and returning results for statistics, and generating the frequent item sets; distributing the frequent item sets again and generating rules via various nodes. Since each computation node only processes a part of computation tasks, the problem that massive data cannot be processed by being read into an internal storage by one machine and processing speed is too slow is solved; the various nodes can be parallelly involved in processing, and processing efficiency is effectively improved; synchronous dependence, network communication overload, high frequency in I / O (input / output) operation among the nodes during computation are correspondingly improved, and scanning and computing speed of a database are improved.

Owner:NANJING UNIV OF POSTS & TELECOMM

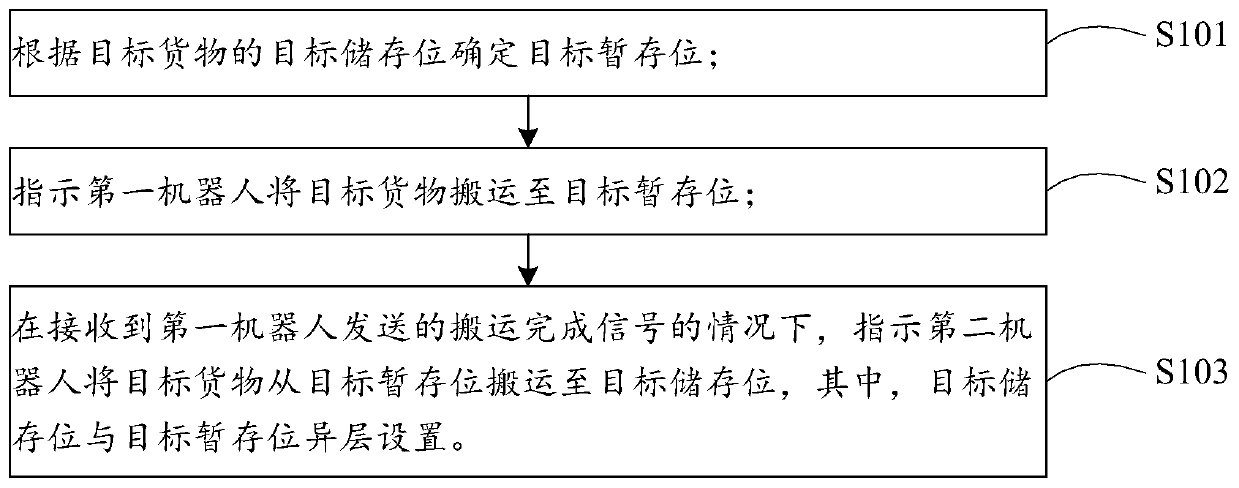

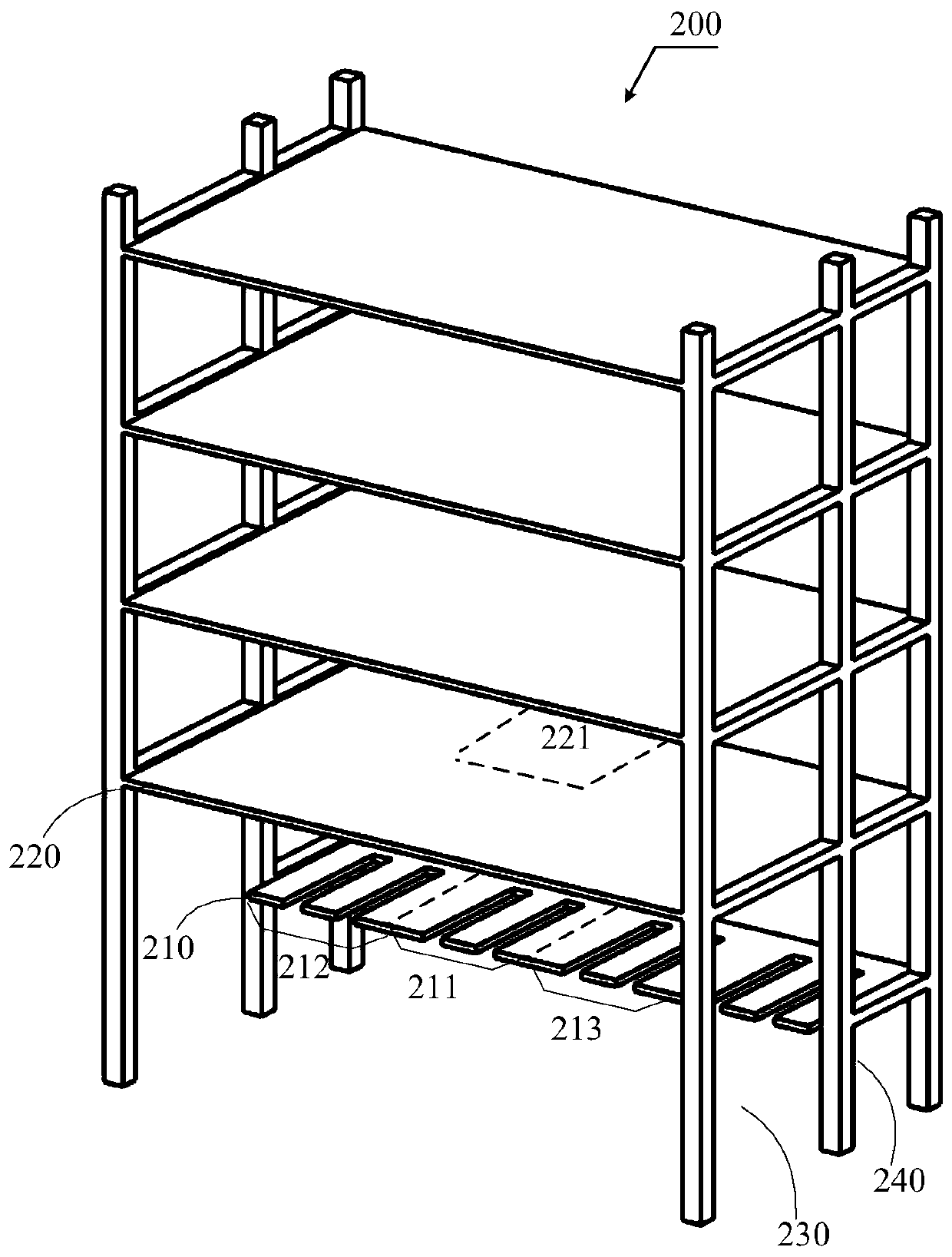

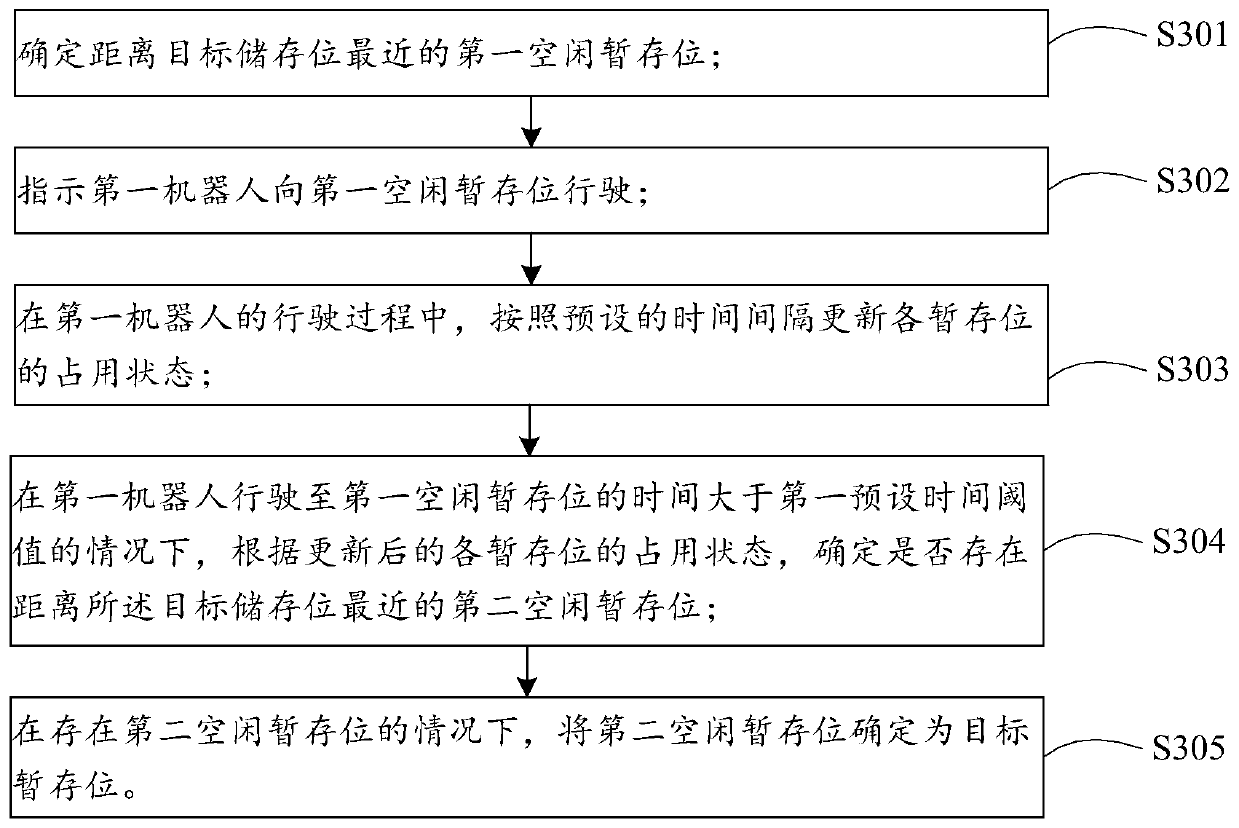

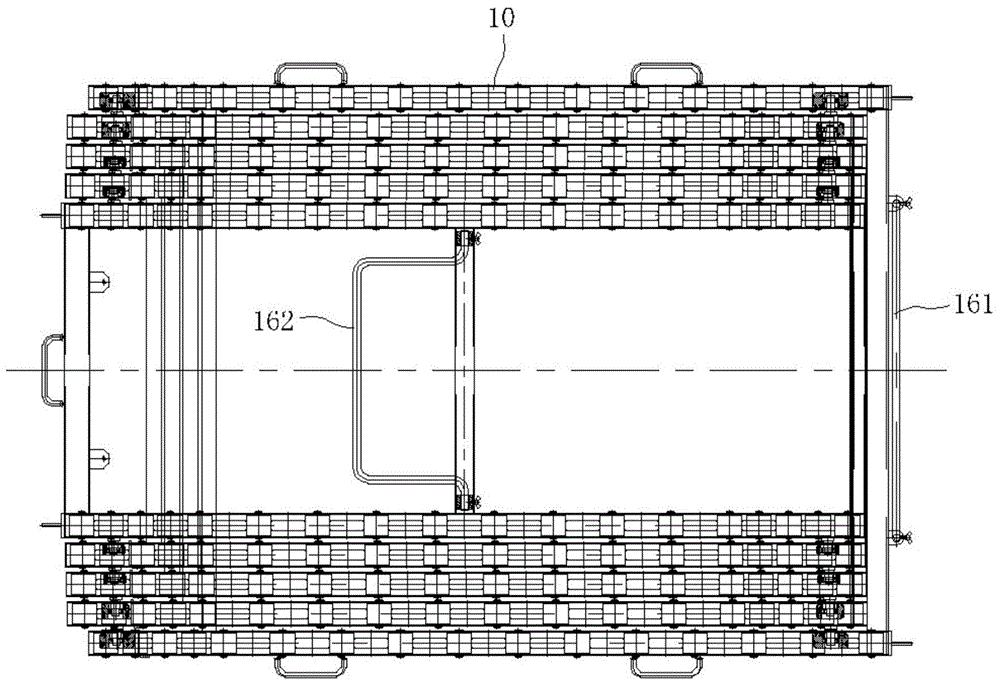

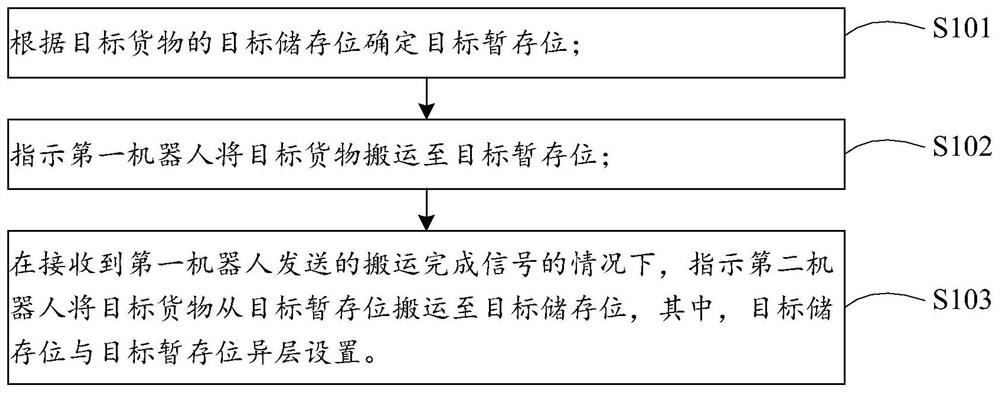

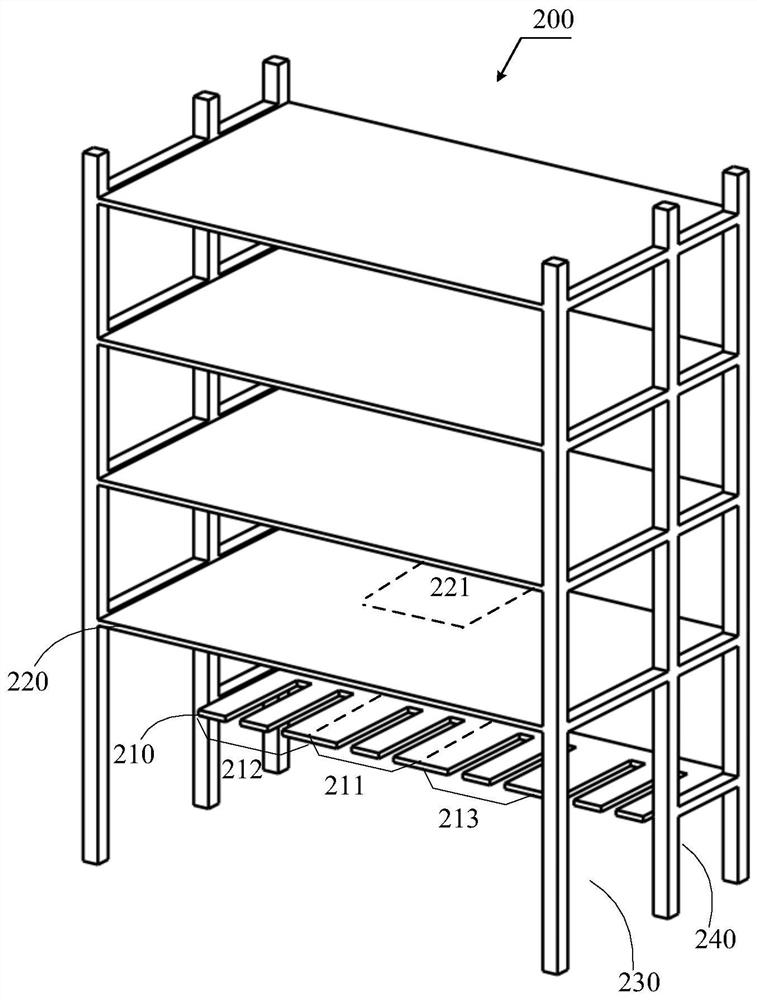

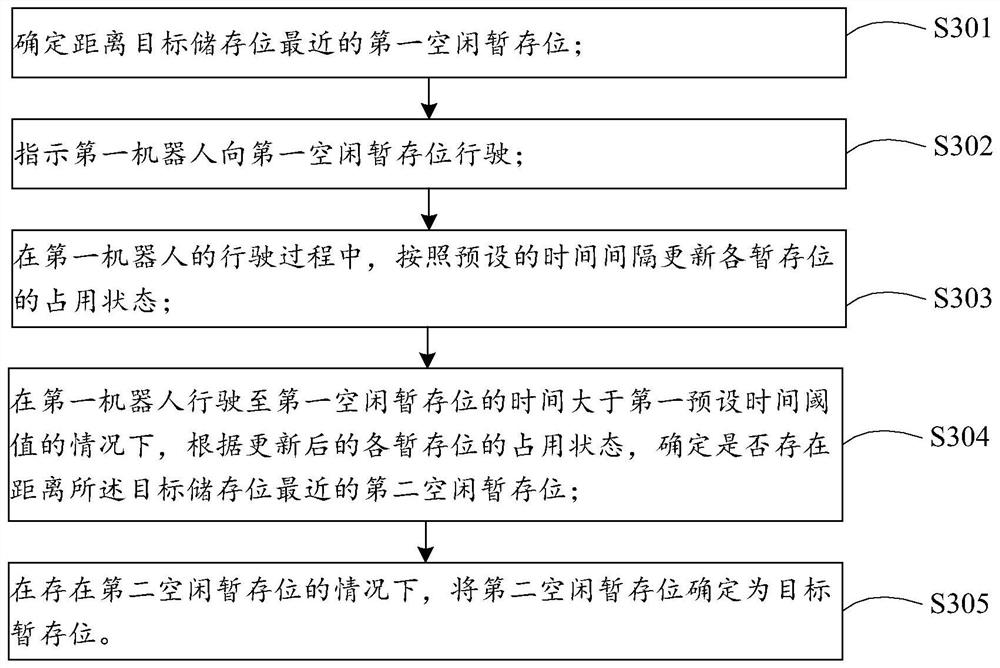

Warehouse-in and warehouse-out control method, device and equipment and readable storage medium

ActiveCN111453275AImprove storage efficiencyAvoid waiting for each otherStorage devicesDatabaseIndustrial engineering

The invention provides a warehouse-in and warehouse-out control method, device and equipment and a readable storage medium. The warehouse-in and warehouse-out control method comprises the steps of determining a target temporary storage position according to a target storage position of target goods; instructing a first robot to carry the target goods to the target temporary storage position; and on the condition that a carrying completion signal sent by the first robot is received, instructing a second robot to carry the target goods from the target temporary storage position to the target storage position, wherein the target storage position and the target temporary storage position are arranged at different layers. By means of the technical scheme, the warehouse-in and warehouse-out efficiency of goods can be effectively improved.

Owner:SHANGHAI QUICKTRON INTELLIGENT TECH CO LTD

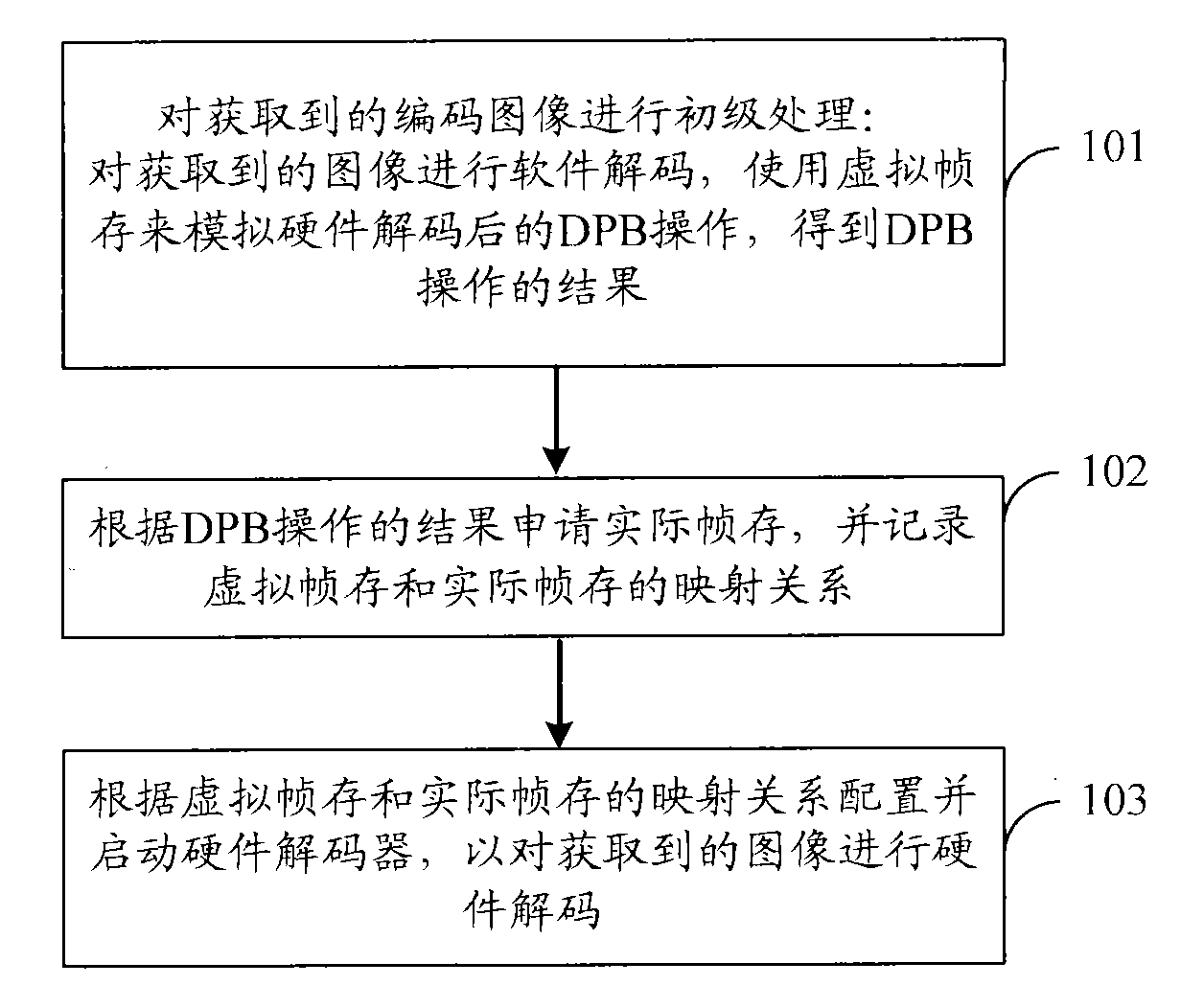

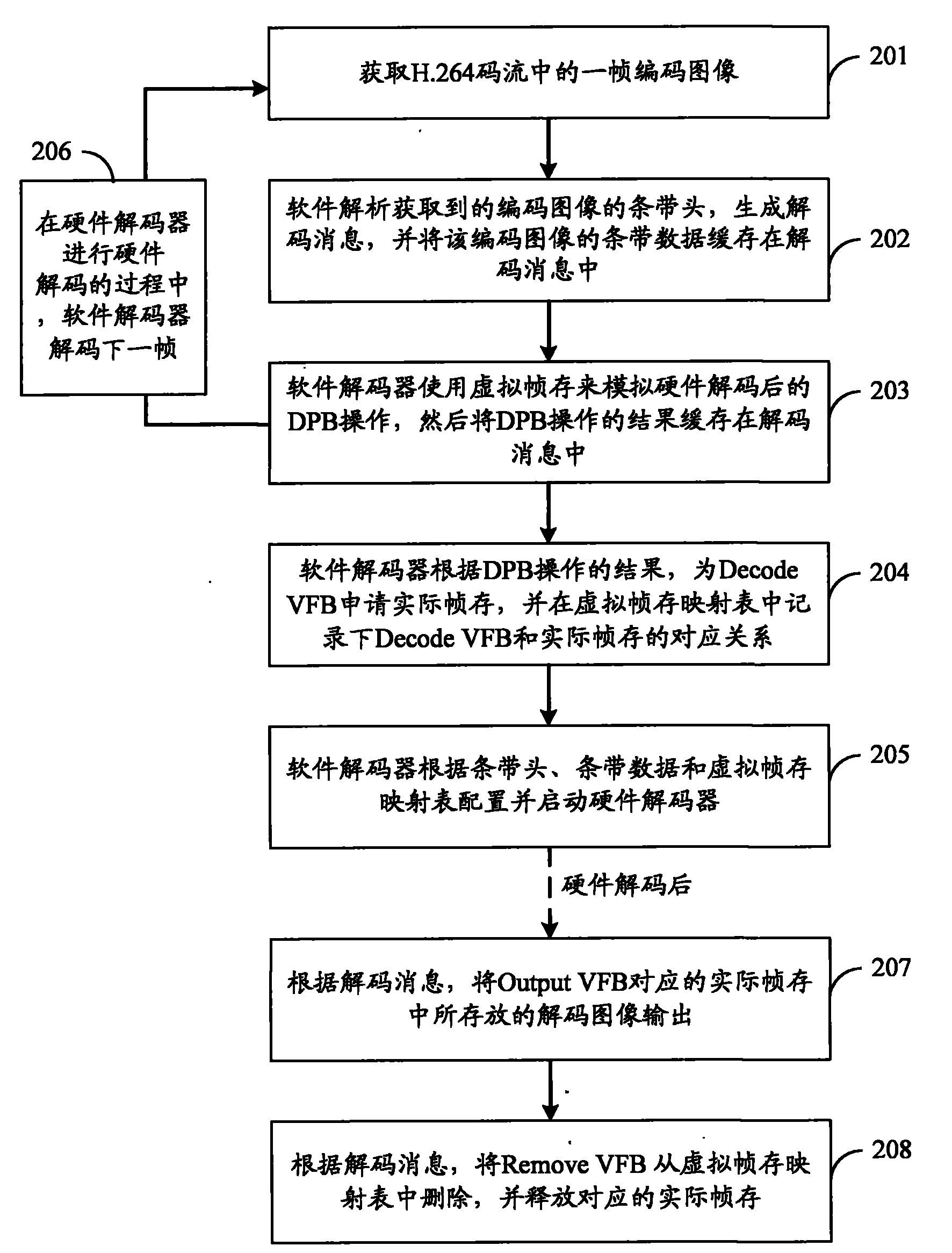

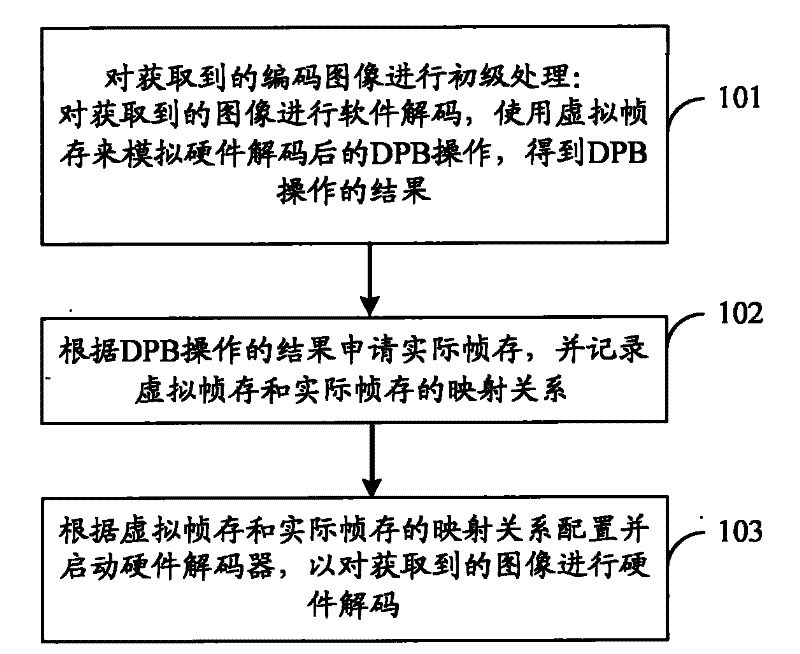

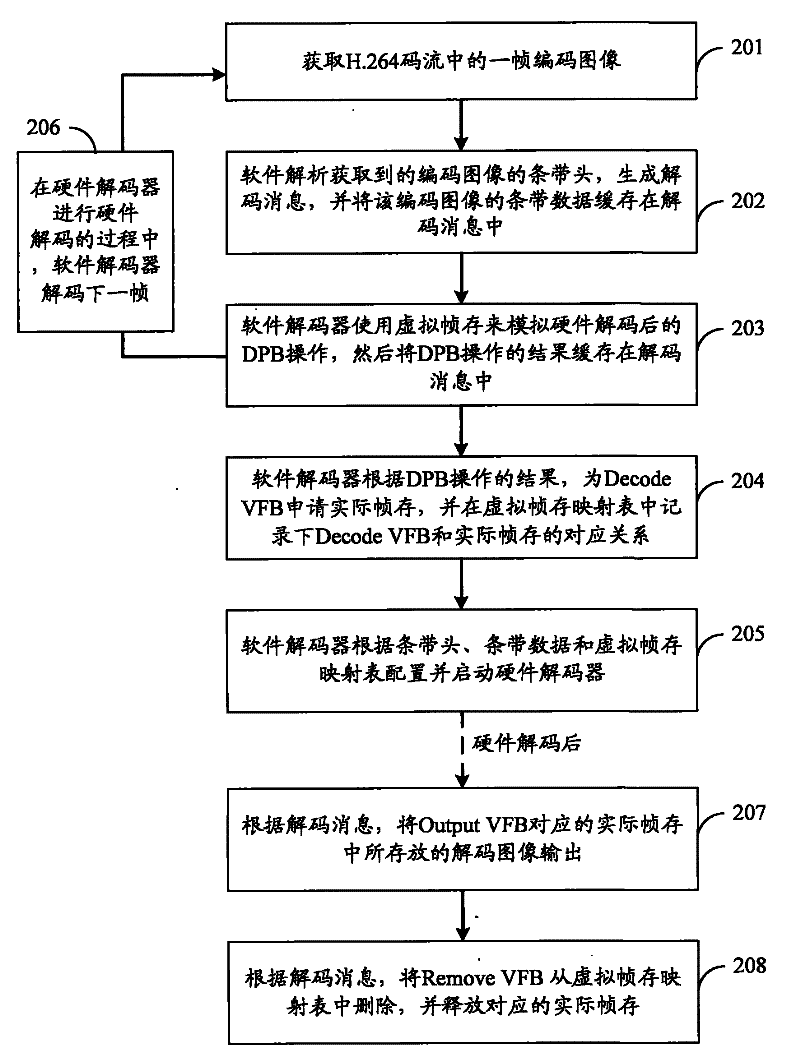

Method for realizing decoding, software decoder and decoding device

InactiveCN101841717AAvoid waiting for each otherImplement parallel processingTelevision systemsDigital video signal modificationSoftwareComputer engineering

The invention discloses a method for realizing decoding, a software decoder and a decoding device. When used for decoding an encoded image, the software decoder of the embodiment of the invention adopts virtual frame storage to imitate DPB operation of a hardware decoder after decoding the encoded image of a frame to ensure that the encoded image of the next frame can be decoded without waiting the finish of the decoding of the hardware decoder so as to avoid the situations that the software decoder and the hardware decoder wait for each other because the DPB operation is performed only after the finish of the decoding of the hardware decoder in the prior art. The method, the software decoder and the decoding device can well realize parallel processing of the software decoder and the hardware decoder, and improve the decoding efficiency.

Owner:李晶晶

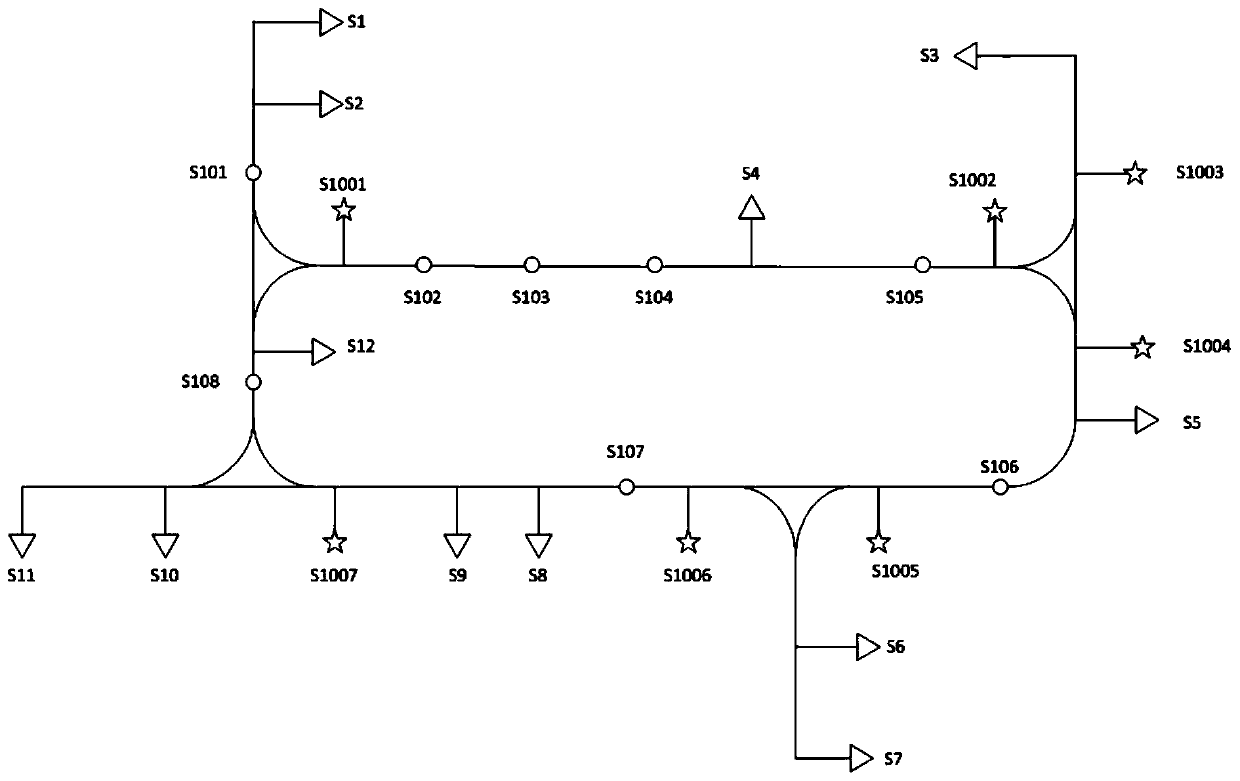

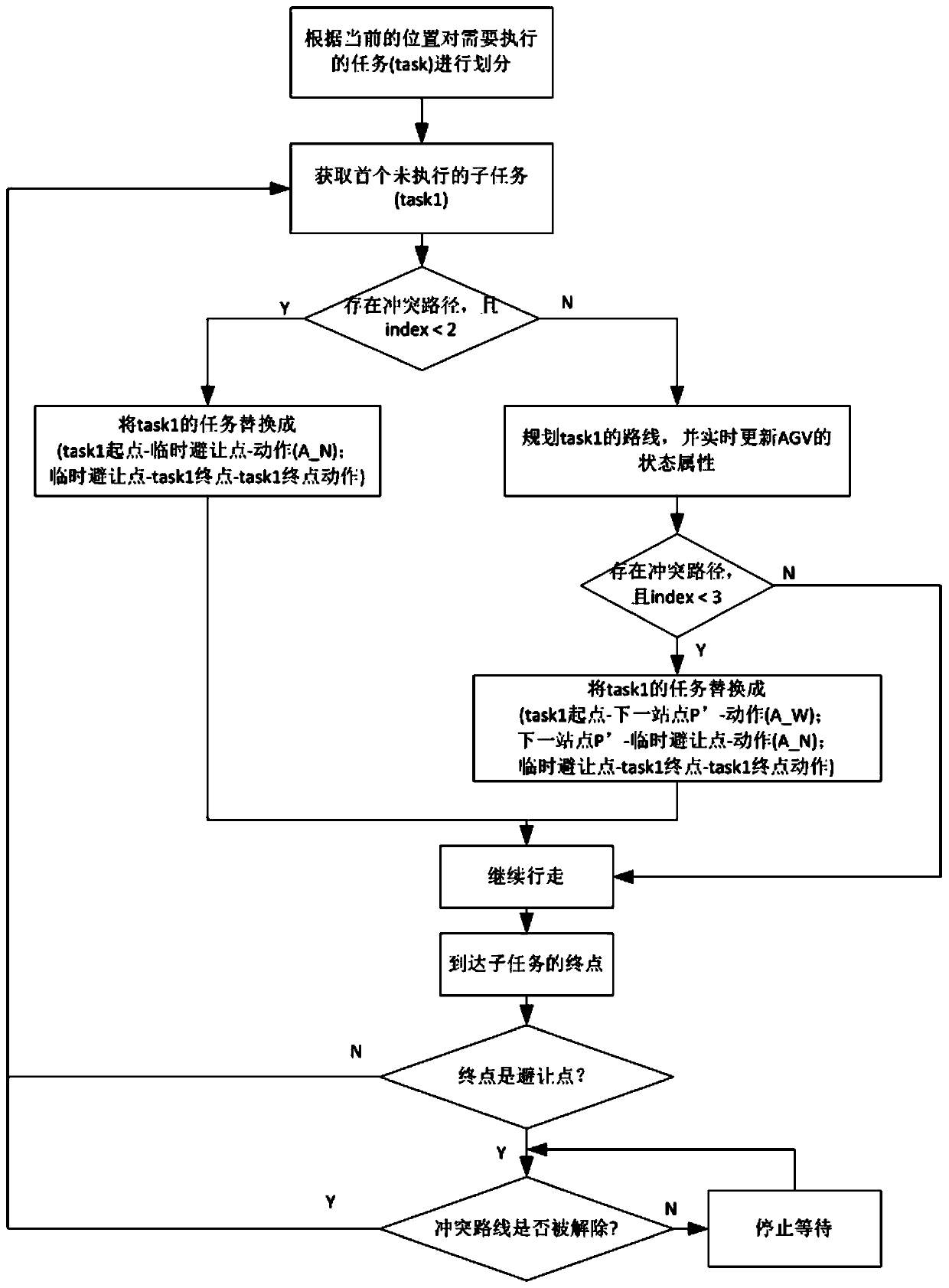

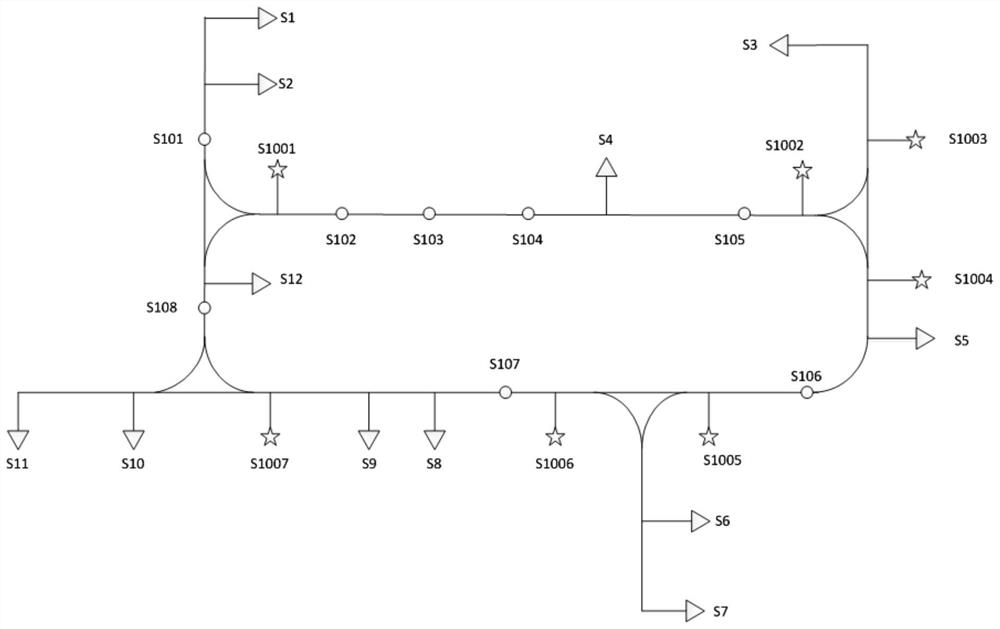

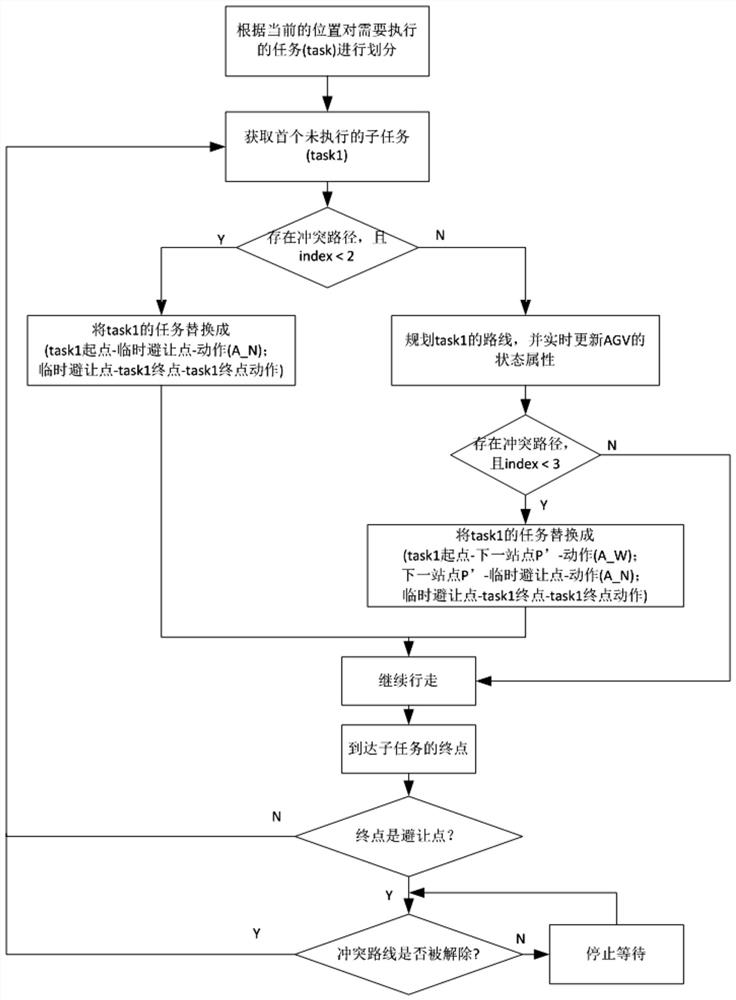

Multi-laser AGV avoidance method

ActiveCN111026128AImprove operational efficiencyGuaranteed reliabilityPosition/course control in two dimensionsVehiclesCollision domainOperations research

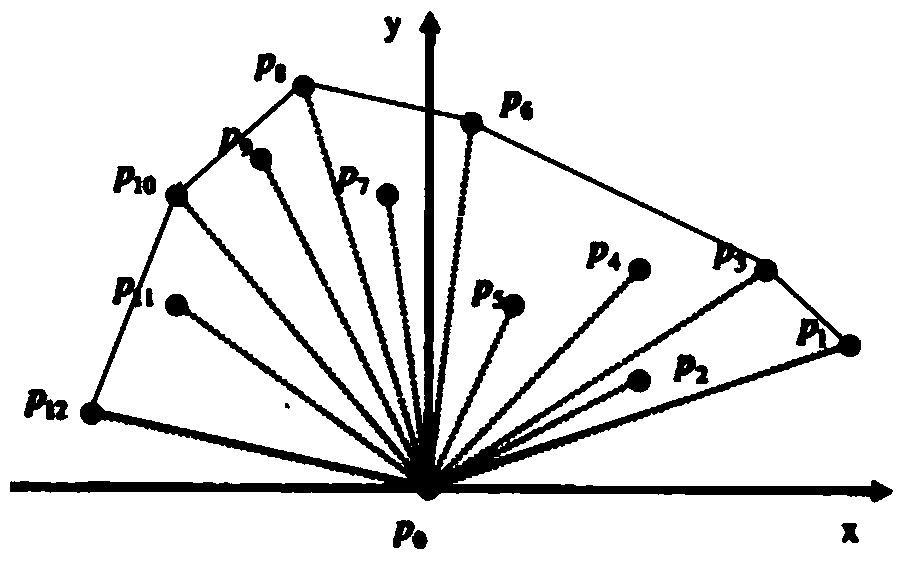

The invention discloses a multi-laser AGV avoidance method. The method comprises steps of constructing an environment model, and setting stations and operation routes of laser AGVs; subdividing tasksand adding the subdivided tasks to a task attribute table of the laser AGVs; planning a route of a first unexecuted task in the task attribute table according to the path planning strategy, and updating t attributes of the AGV; in the driving process of the laser AGV, updating the information attribute of the laser AGV in real time,comparing the information attribute with task attributes of otherlaser AGVs, and determining whether the laser AGV needs to be driven to a temporary avoidance point or not; if so, changing a task attribute table of the AGV; if not, continuing to execute the tasks;if the AGV drives to a temporary avoidance point, determining whether a conflict domain is removed or not. The method is advantaged in that the situation that vehicles wait for each other or get stuckin opposite directions is avoided; the subtasks are redivided in real time according to the running state, the waiting time of the laser AGV is shortened, and the dynamic avoiding function is achieved.

Owner:WUHU HIT ROBOT TECH RES INST

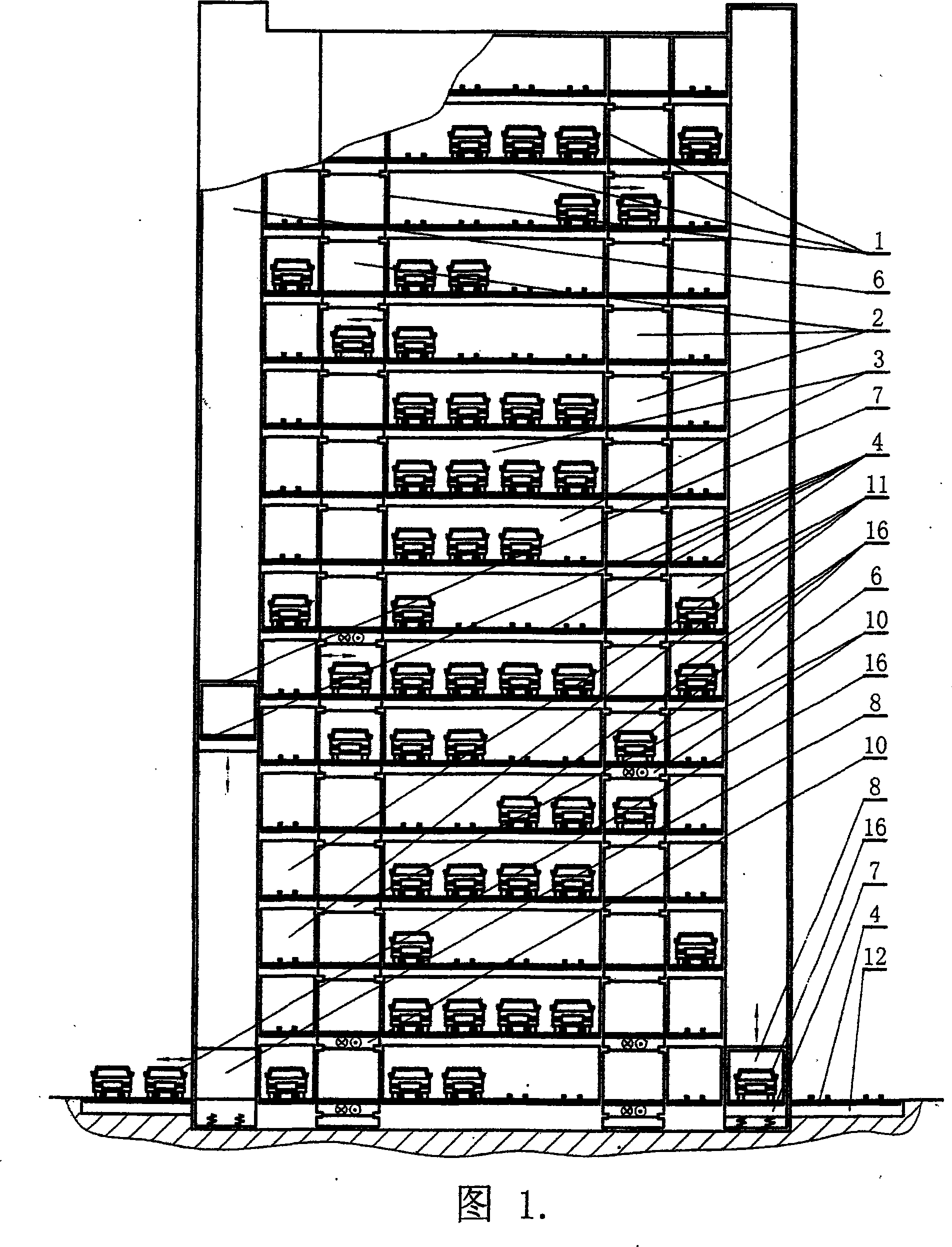

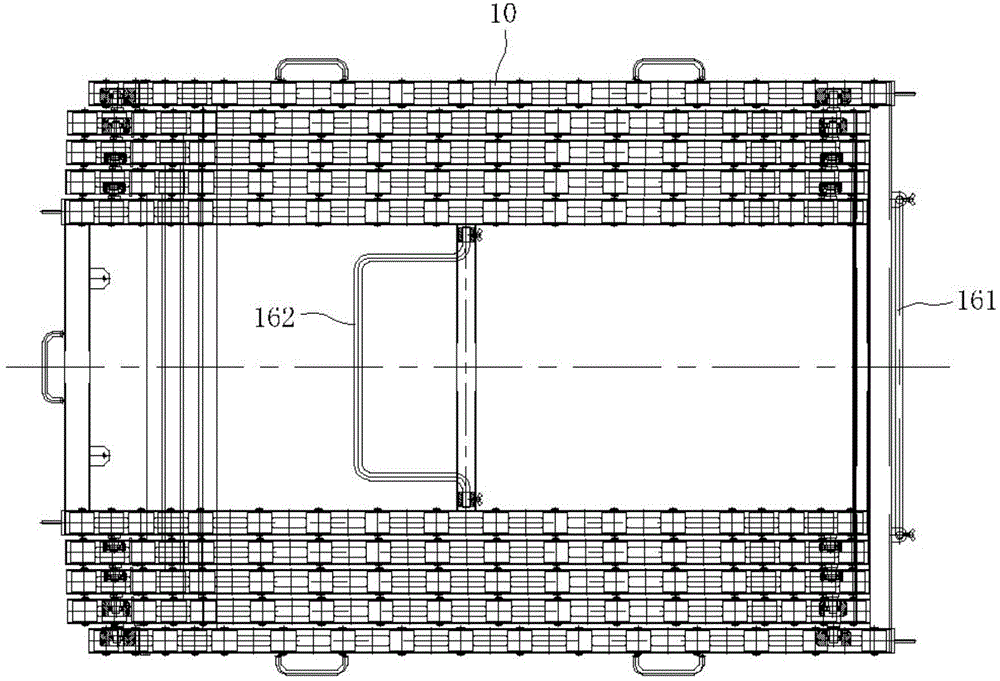

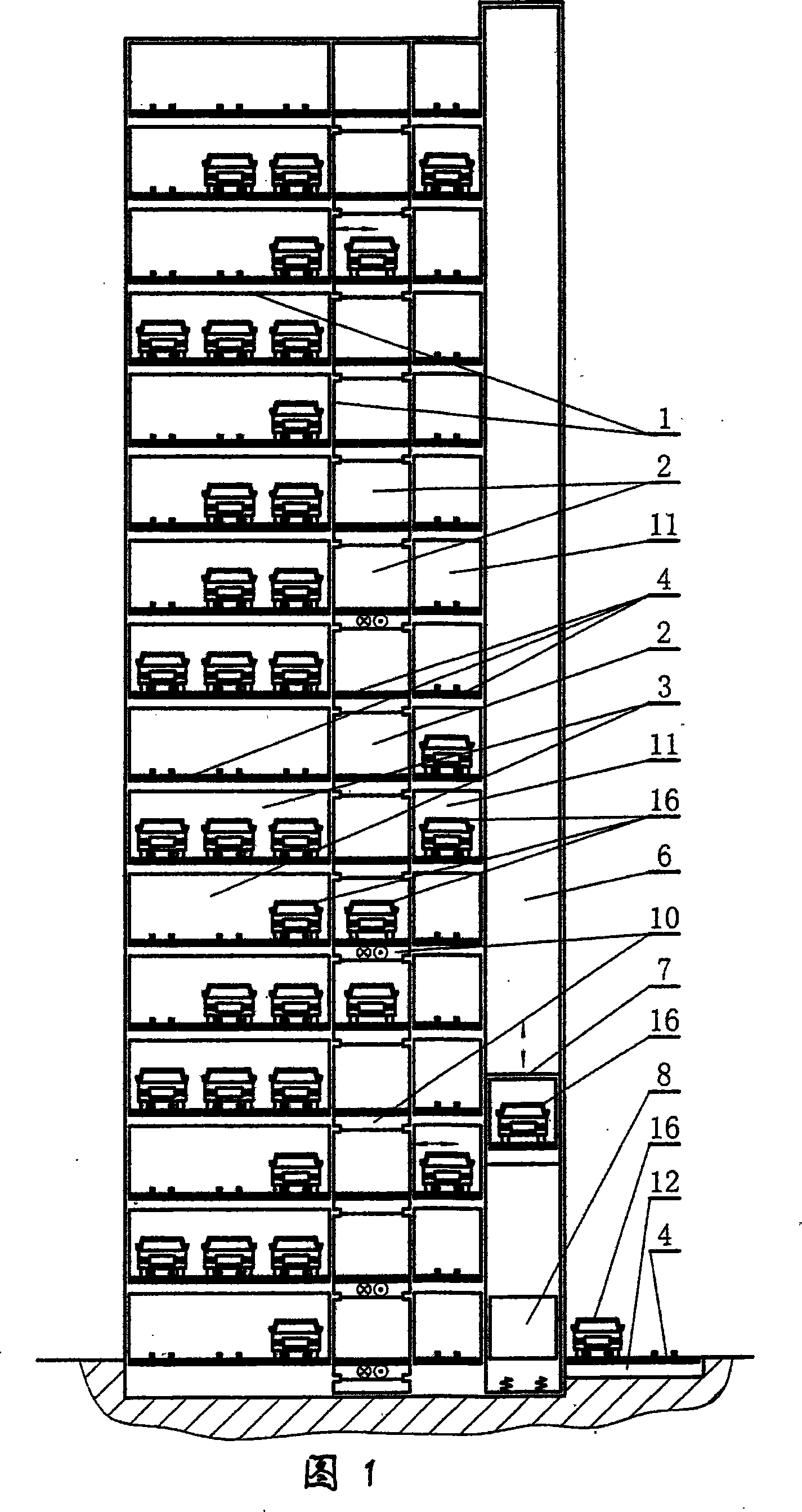

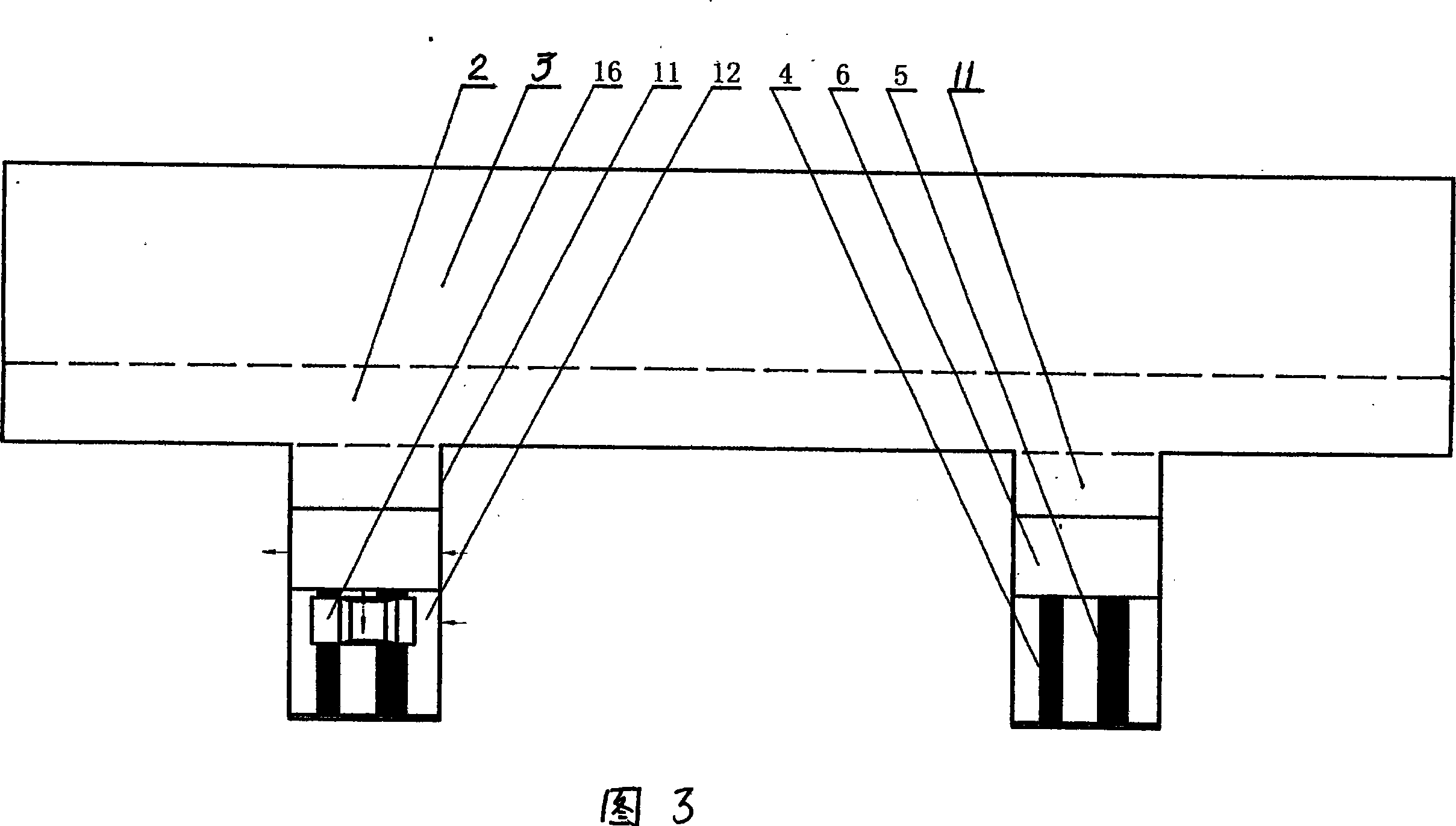

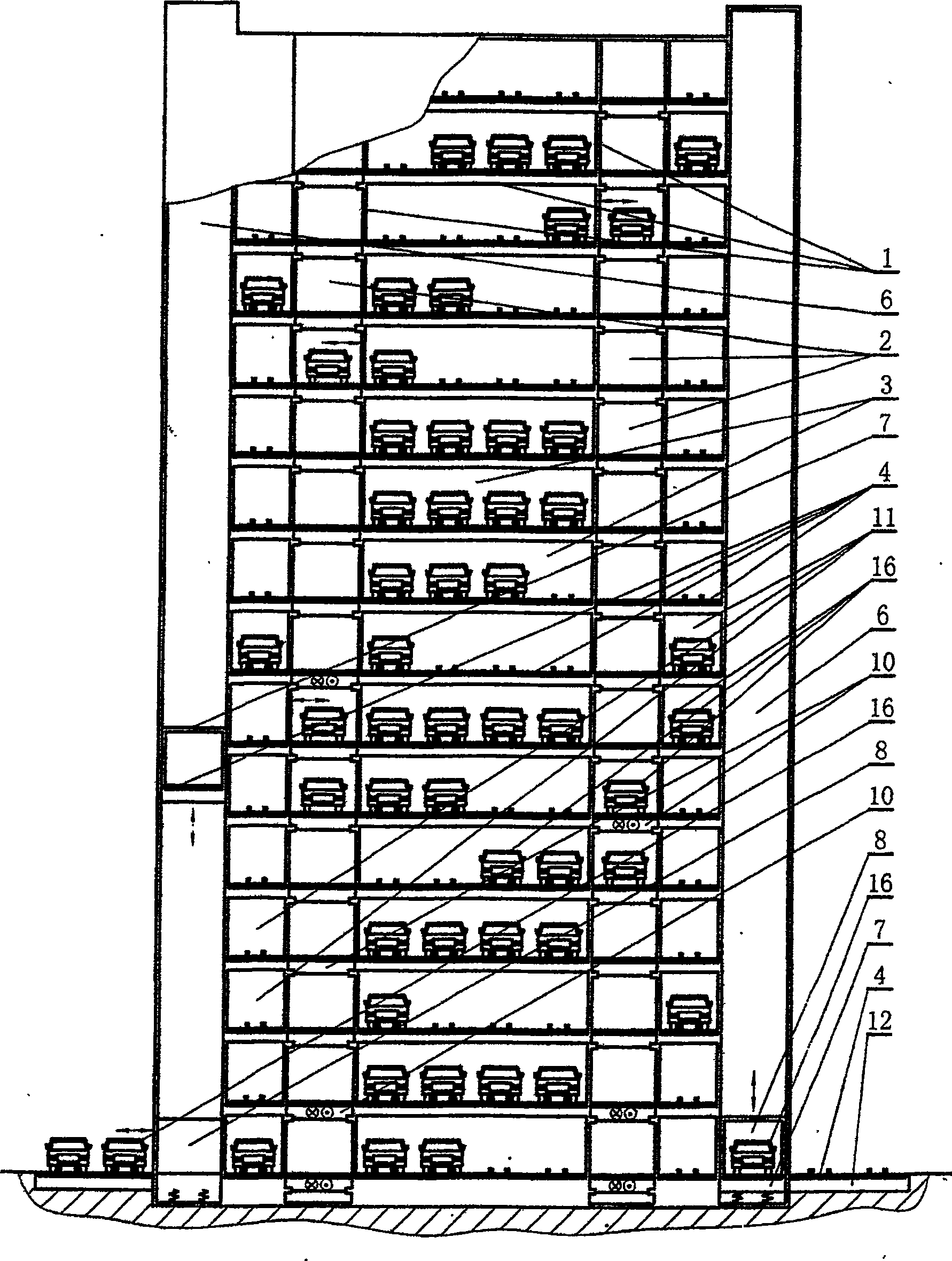

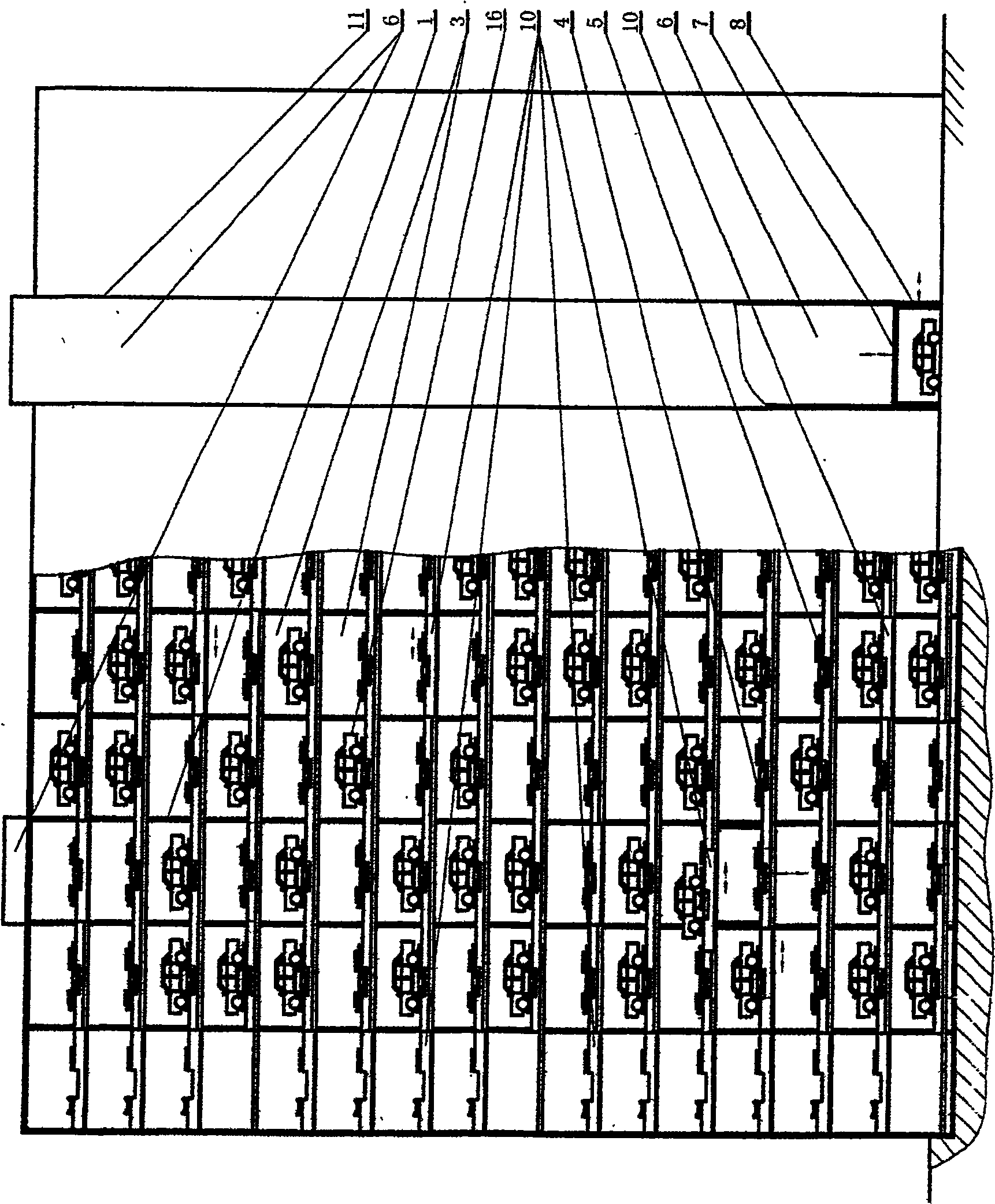

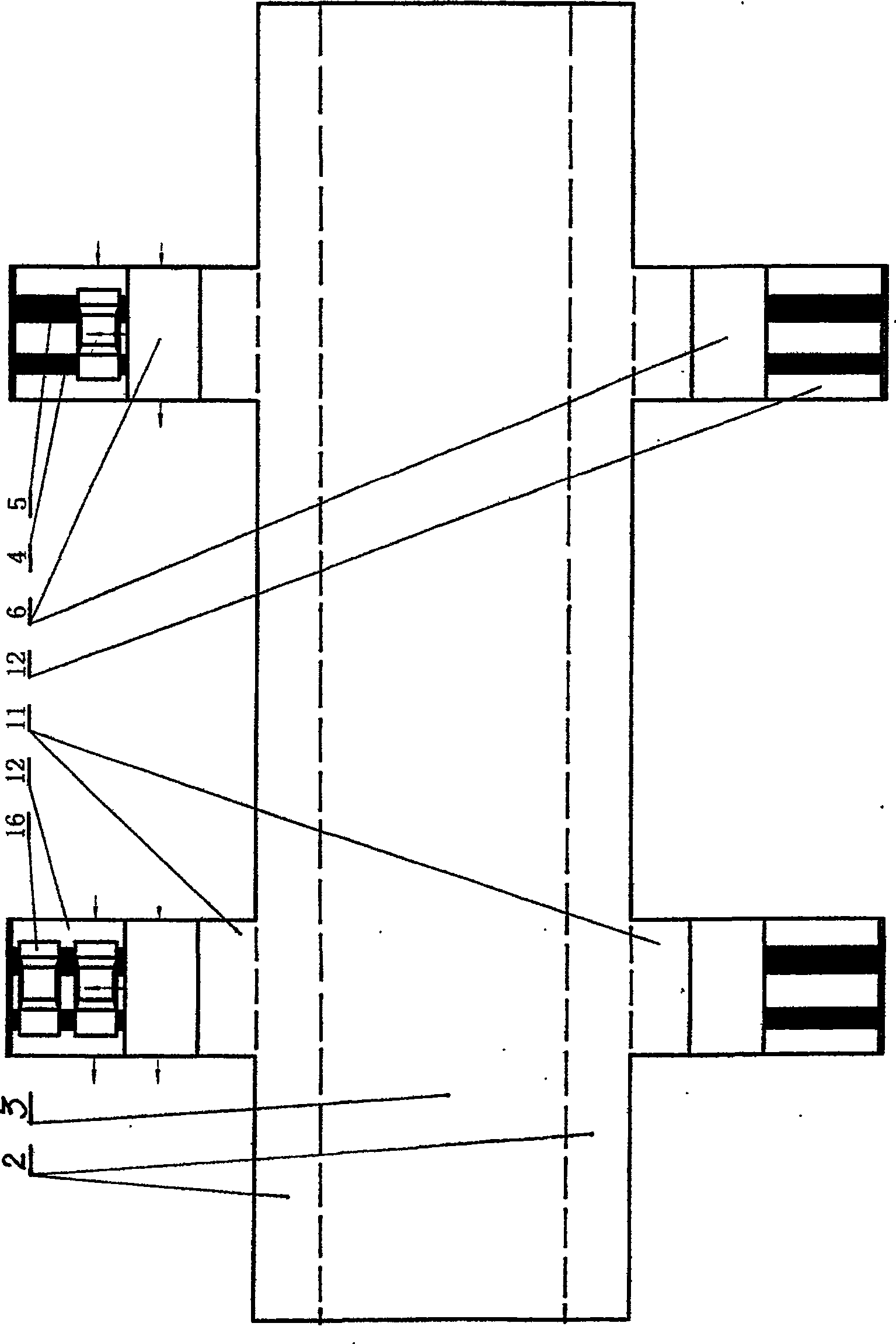

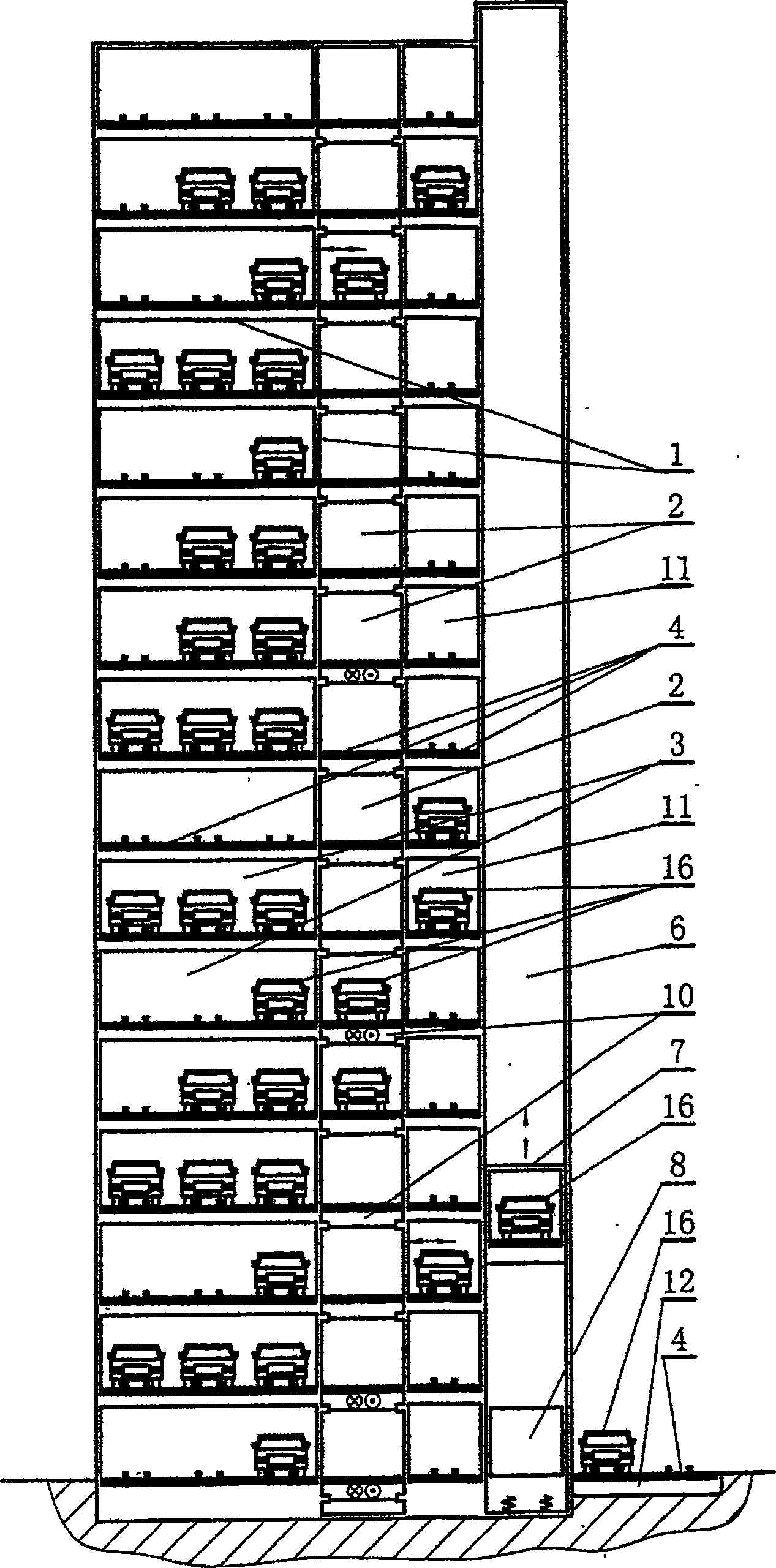

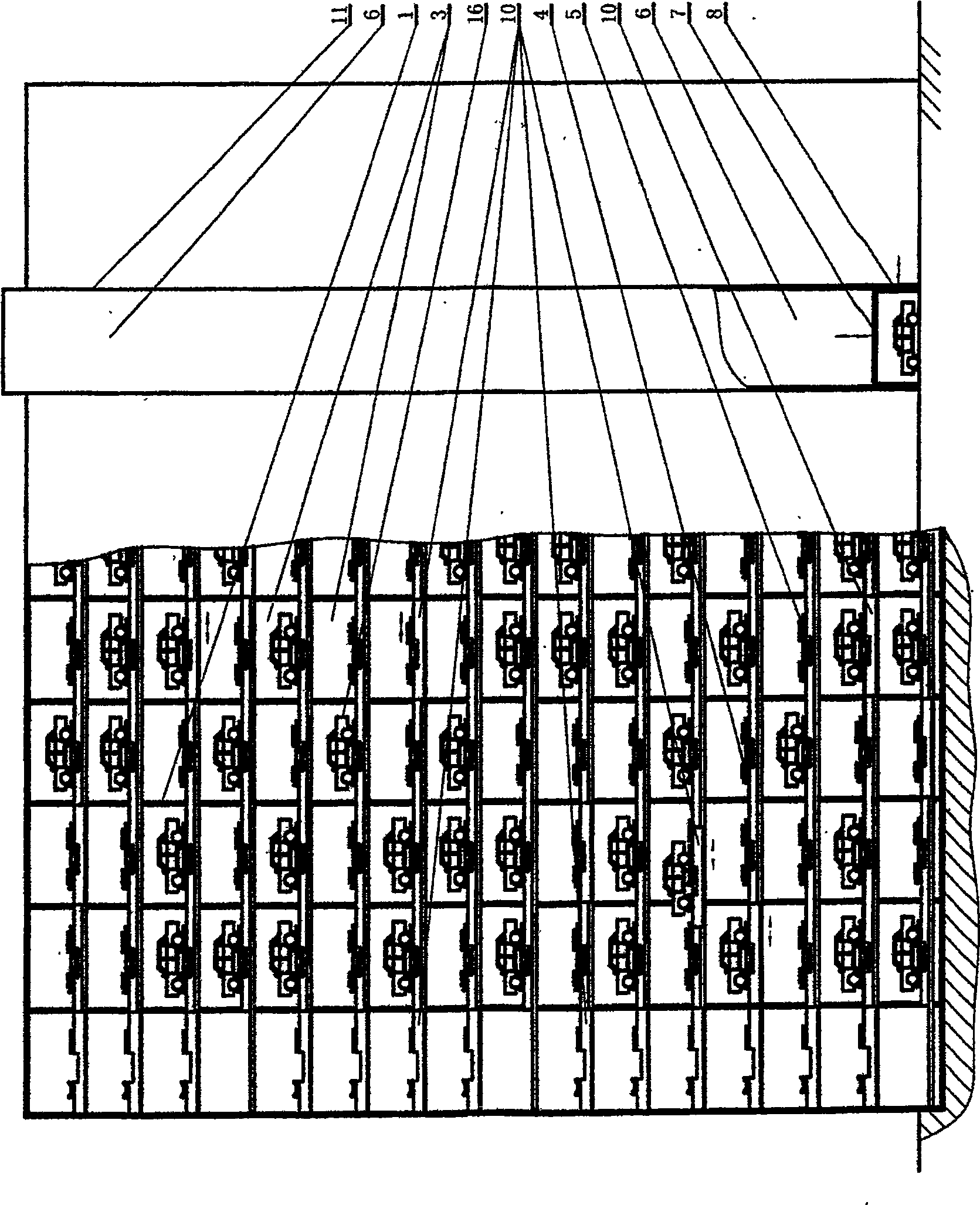

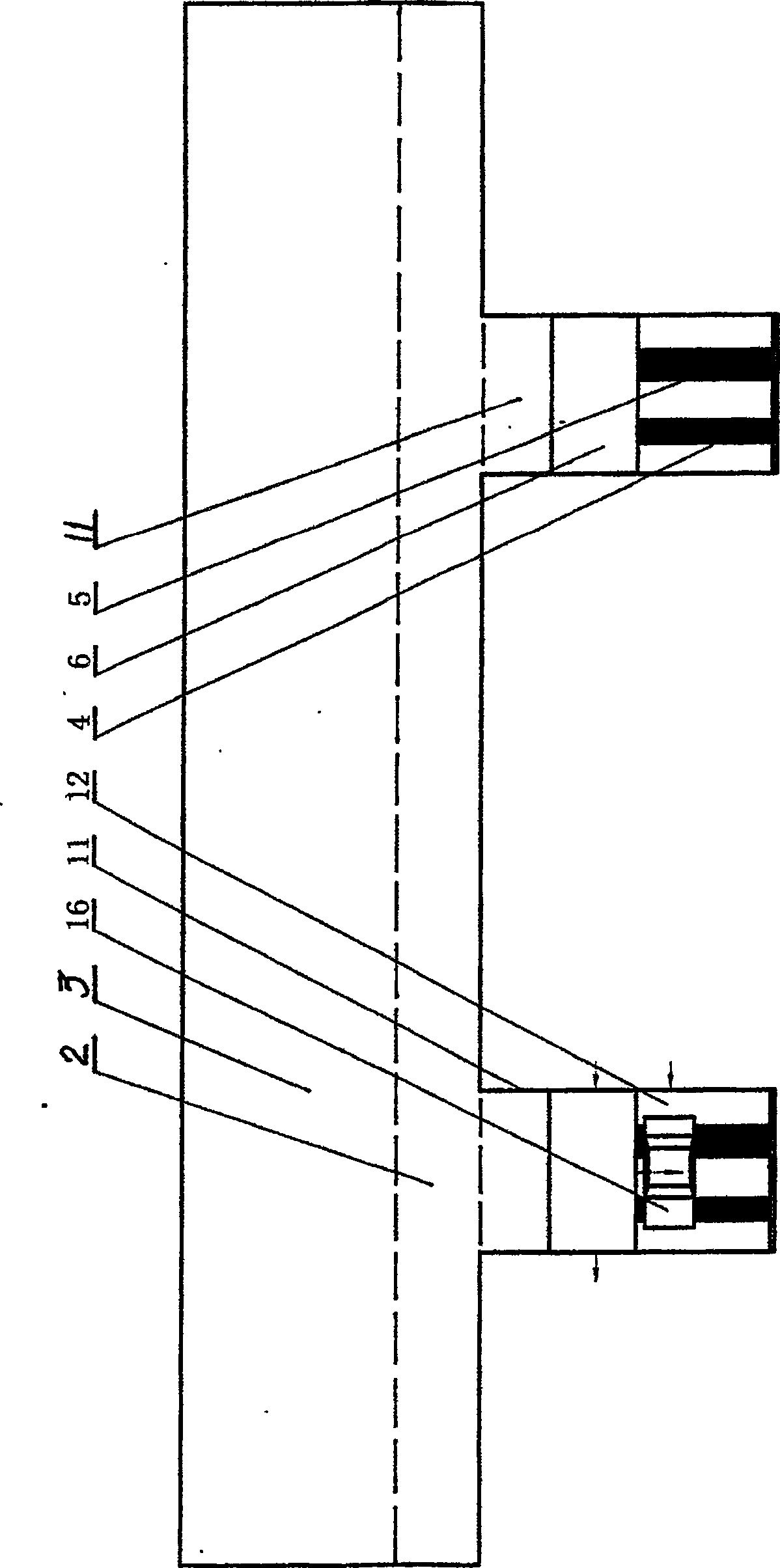

Double laneway transition passage layered transportation rolling way parallel parking type mechanical parking system

A bi-transitional road way removal tiered raceway side-by-side storage-mechanical parking system used in the unilateral roadway, which belongs to the traffic and transportation field, comprises stockroom-type frames, a roadway, parking areas, wheel holding raceways, external well roads, lifting handlings, vertical shift handlings, a separating and positioning horizontally moved delivery device, a storage and taking out transitional area; on the stockroom-type frame between two road ways, each layer is provided vertically with the parking area along the road way, the wheel holding raceway is arranged horizontally thereabove to hold many cars side by side; in the bi-road way, a vertical shift handling carries out the separating work; well roads with lifting handlings and the storage and taking out transitional area are arranged along the external side of the road way; lifting handlings, vertical shift handlings and the storage and taking out transitional area are also provided with the same wheel holding race ways; on the storage area and the storage and taking out transitional area, the separating and positioning horizontally moved delivery device, which can move horizontally and extend into the vertical shift handling and is arranged between the front wheel holding race way and the back wheel holding race way, can be used to storage, take out and move horizontally cars. The invention has a large capacity of bikes and is high in working efficiency.

Owner:SHANGHAI JIAO TONG UNIV

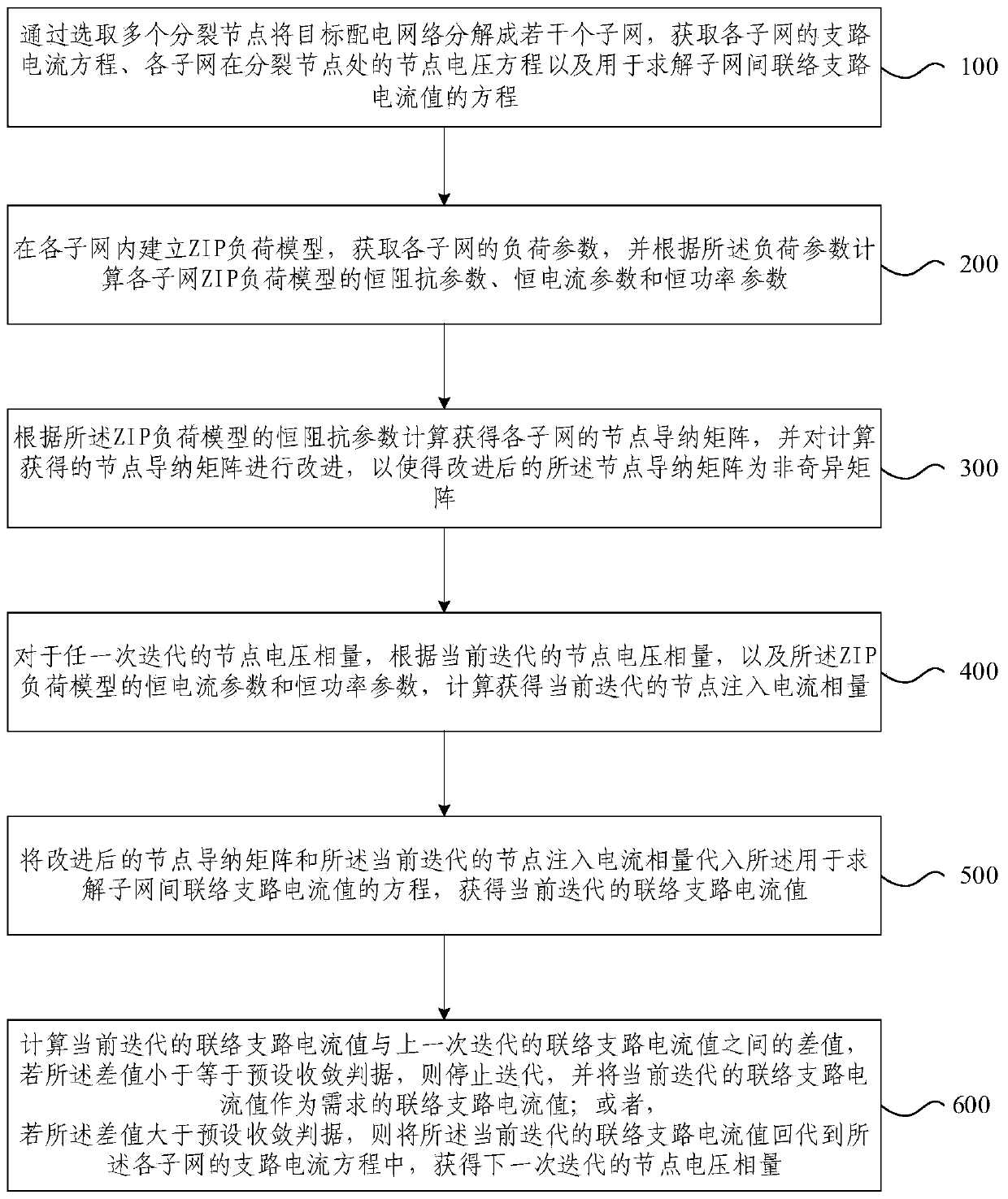

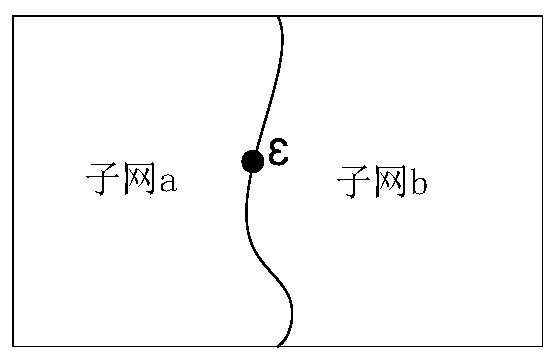

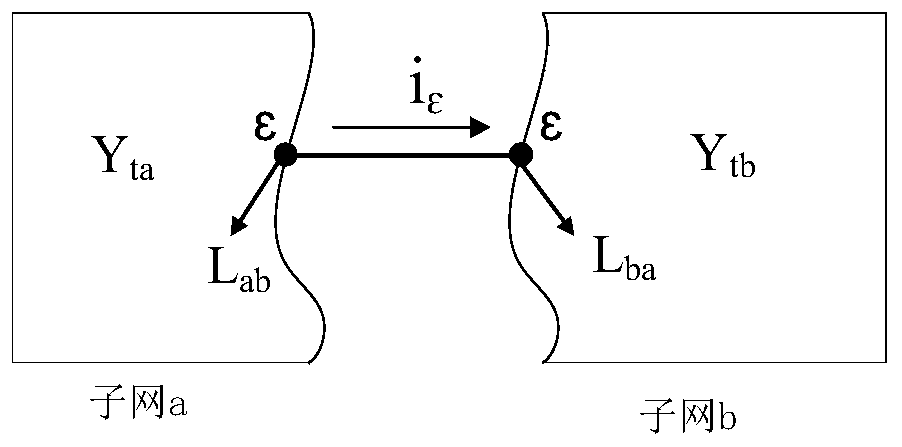

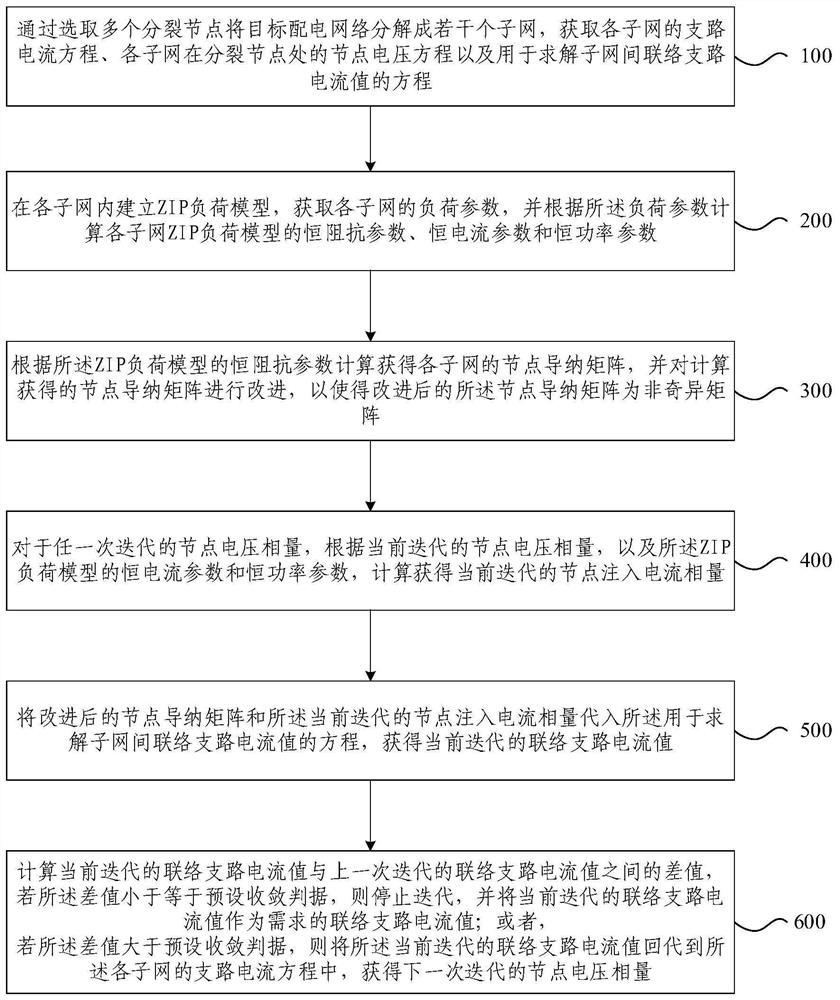

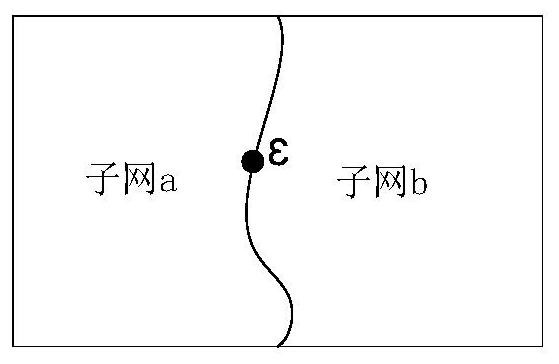

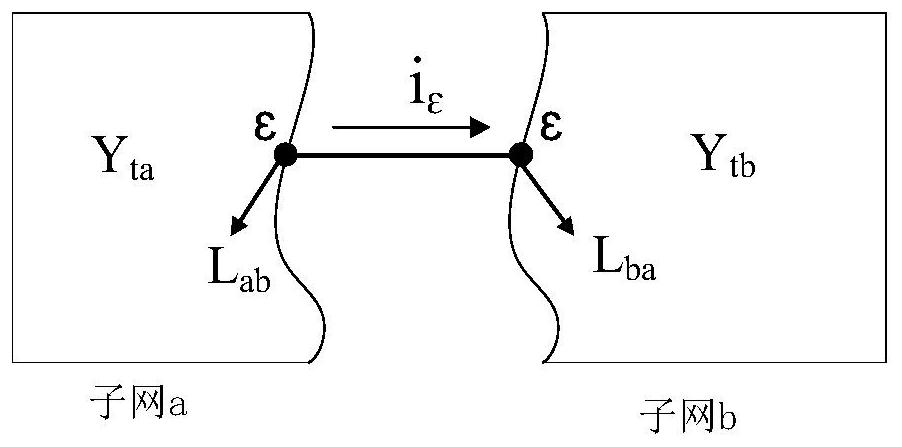

Load flow calculation method and device for large-scale power distribution network

ActiveCN109802392AIn line with actual operating conditionsFast convergenceAc networks with different sources same frequencyConstant powerConstant impedance

The embodiment of the invention provides a load flow calculation method and device for a large-scale power distribution network, and the method comprises the steps: decomposing a target power distribution network into a plurality of sub-networks, and obtaining an equation for solving a contact branch current value between the sub-networks; calculating constant impedance, constant current and constant power parameters of each subnet ZIP load model; calculating a node admittance matrix of each subnet according to the constant impedance parameters, and improving the node admittance matrix; calculating the node injection current of the current iteration according to the node voltage of the current iteration and the constant current and constant power parameters; obtaining the current iterationcontact branch current according to the improved node admittance matrix, the current iteration node injection current and an equation used for solving the contact branch current between the subnets;obtaining the node voltage phasor of the next iteration according to the contact branch current of the current iteration if the difference value between the contact branch current of the previous iteration and the next iteration is greater than the convergence criterion. According to the embodiment of the invention, the efficiency and flexibility of load flow parallel computing are considered.

Owner:CHINA AGRI UNIV

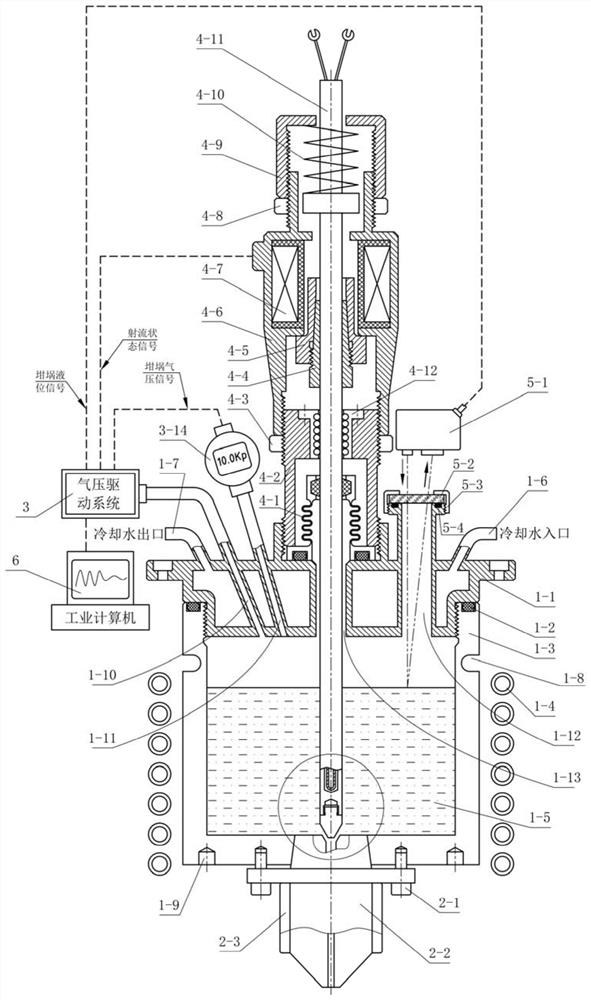

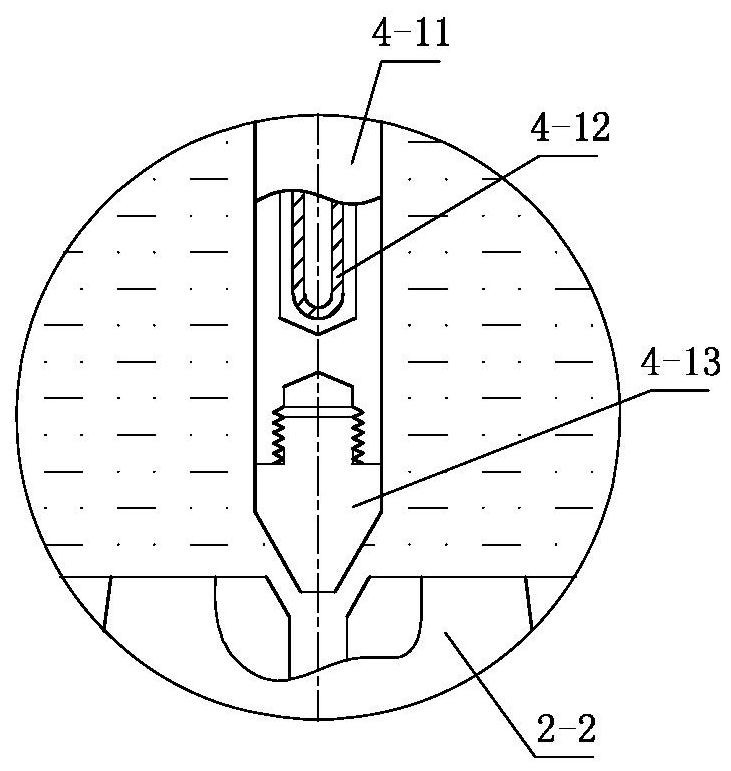

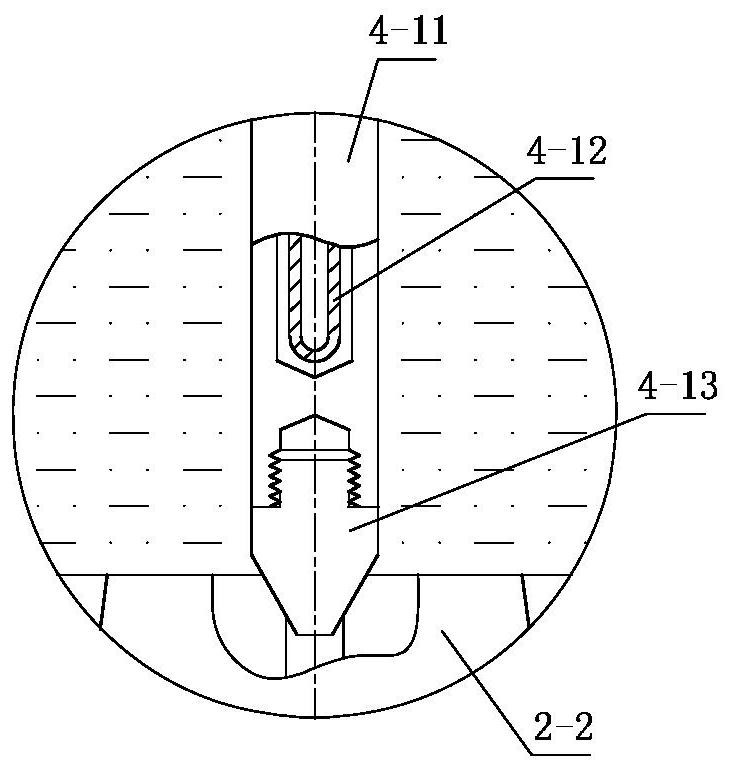

Melt flow control device and method for melting coating forming process

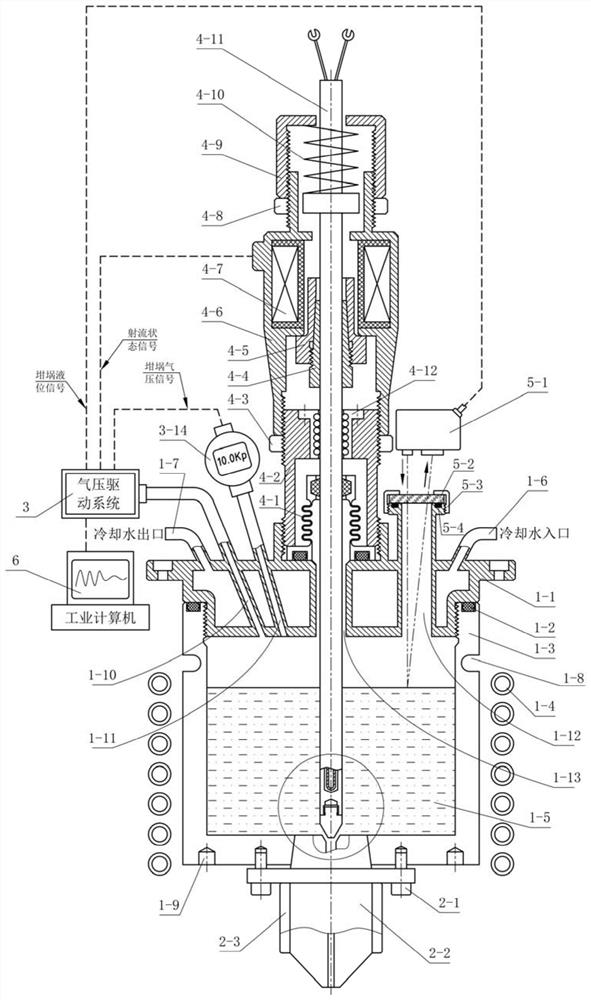

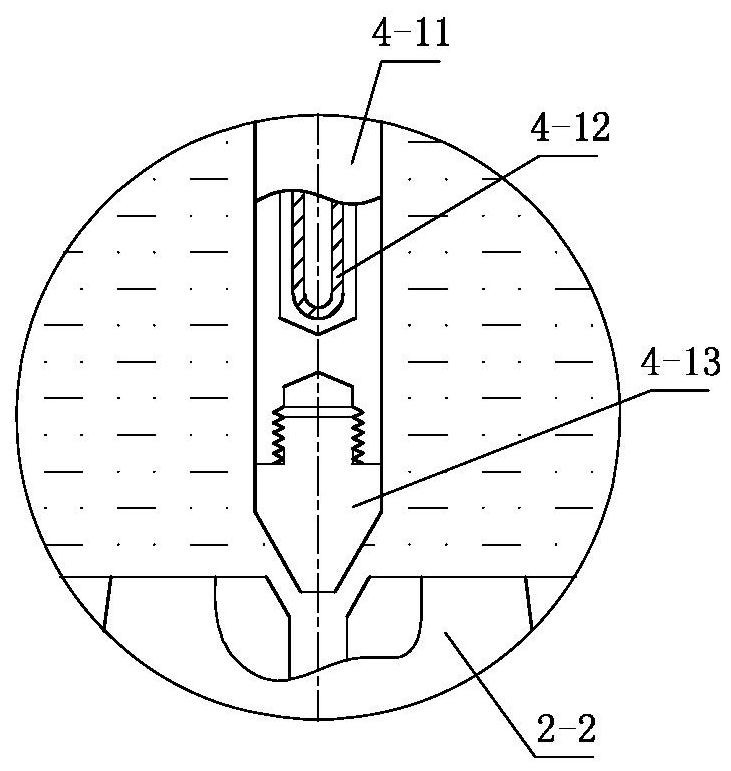

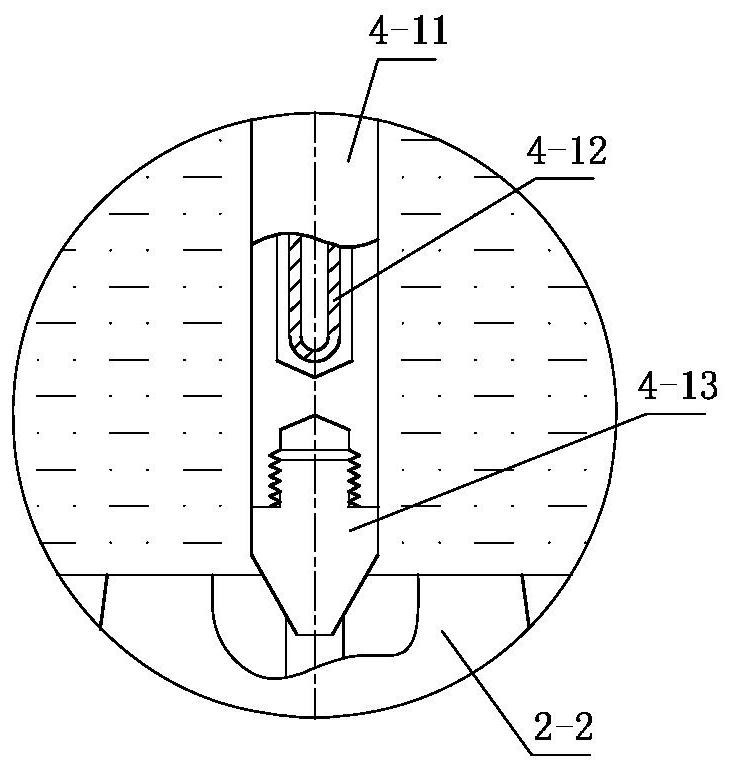

ActiveCN113084202AHigh precisionImprove responsivenessAdditive manufacturing apparatusIncreasing energy efficiencyIndustrial engineeringFlux control

The invention discloses a melt flow control device and method for a melting coating forming process. The melt flow control device comprises a crucible smelting unit, a melting coating head, an air pressure driving unit, a jet flow starting and stopping apparatus, a crucible liquid level ranging module and an industrial computer. A water-cooling top cover is positioned above a smelting crucible, and the melting coating head is arranged below the smelting crucible; the crucible smelting unit communicates with the air pressure driving unit; and the jet flow starting and stopping apparatus drives a starting and stopping control rod to press downwards or lift upwards so as to start and stop jet flow. Pressure control adopts three stages: a computer sends spraying pressure to a PLC according to a pressure-flow function relationship, the PLC receives a melt liquid level signal from a laser ranging module and the spraying pressure of the industrial computer at the same time and sends an air pressure control instruction to a pressure controller, the pressure controller realizes real-time control over the air pressure in a crucible, therefore, accurate control over the jet flow in the forming process is achieved, and high-precision and high-efficiency coating forming of a target part is completed.

Owner:XI AN JIAOTONG UNIV

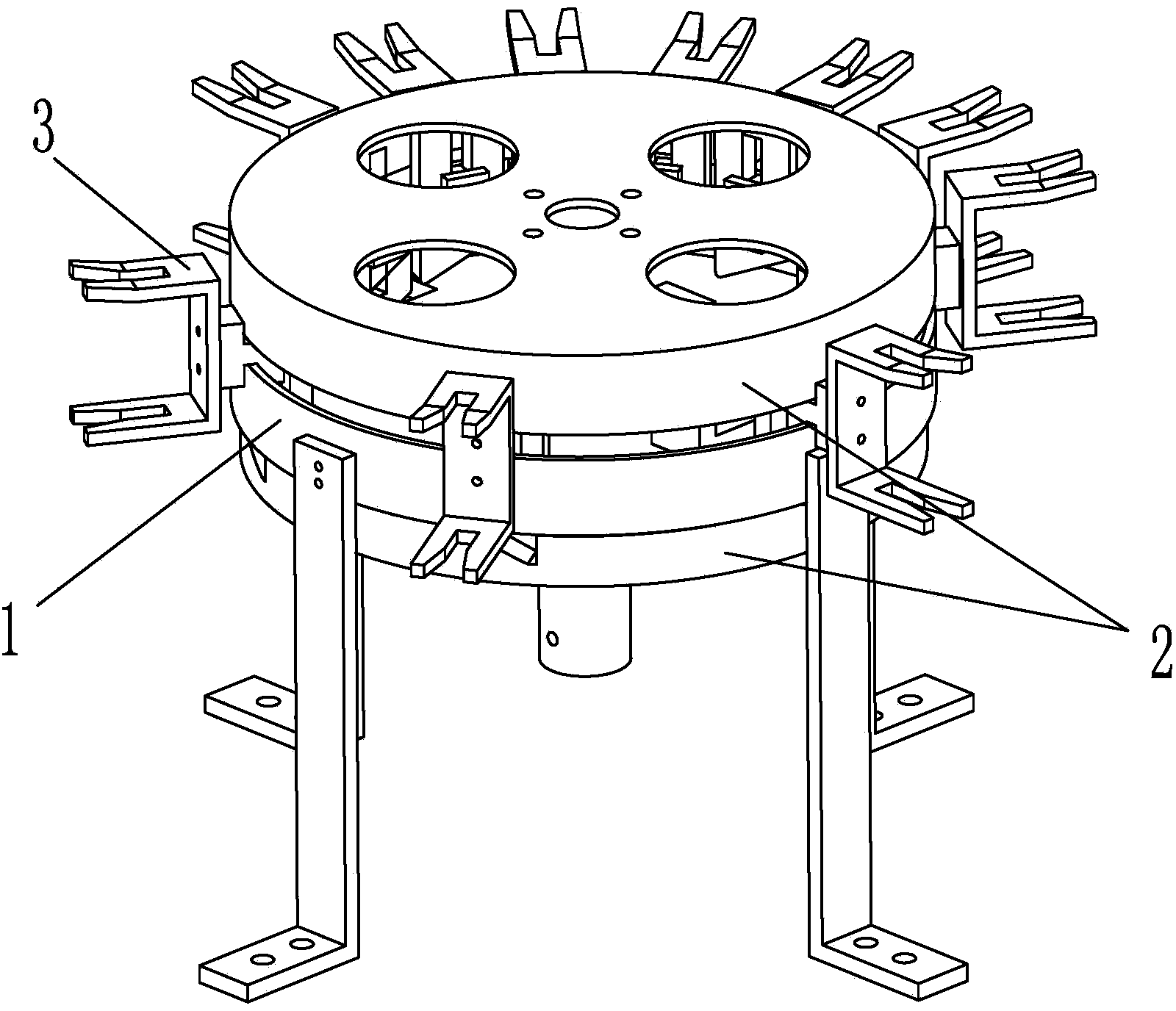

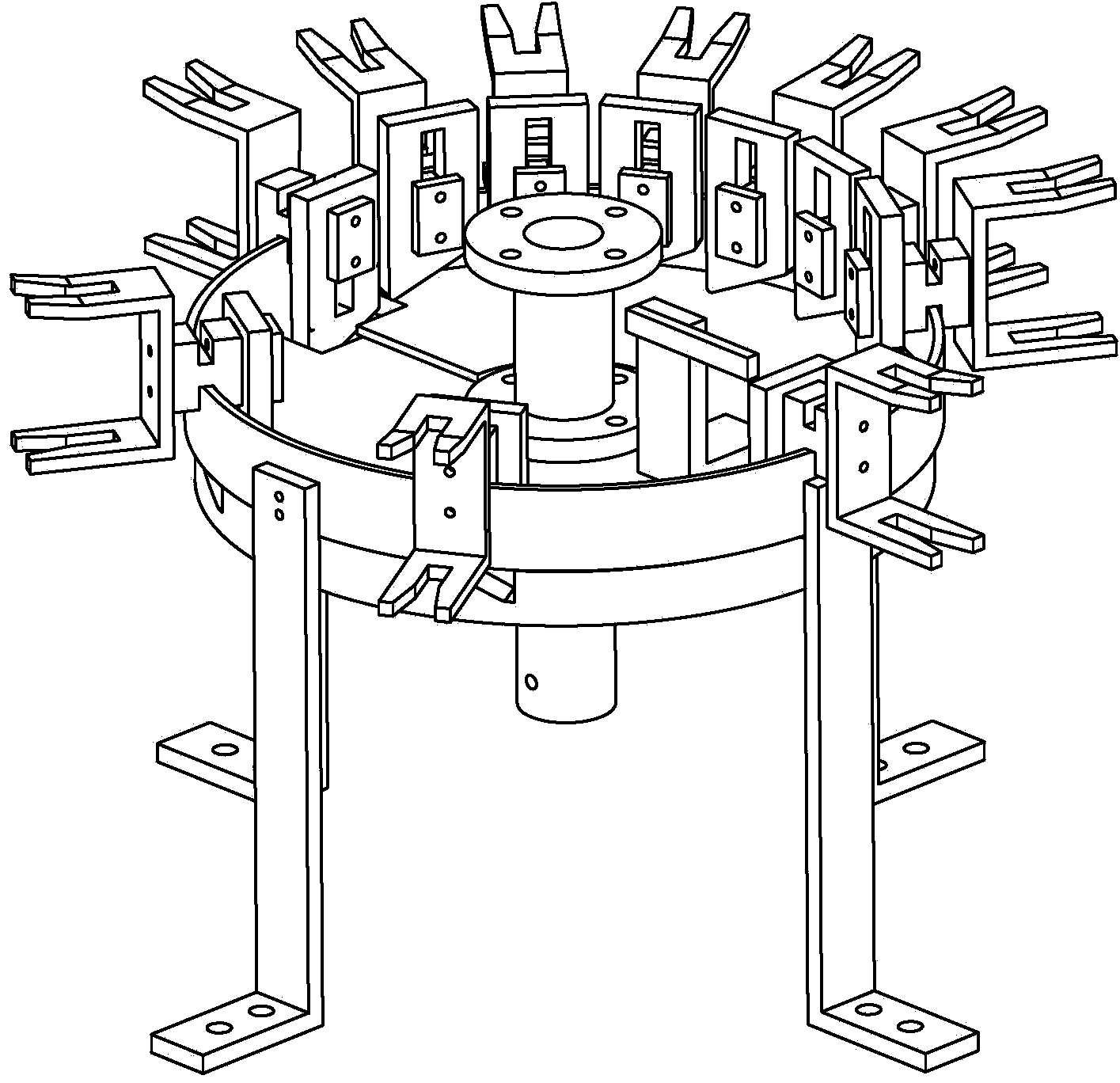

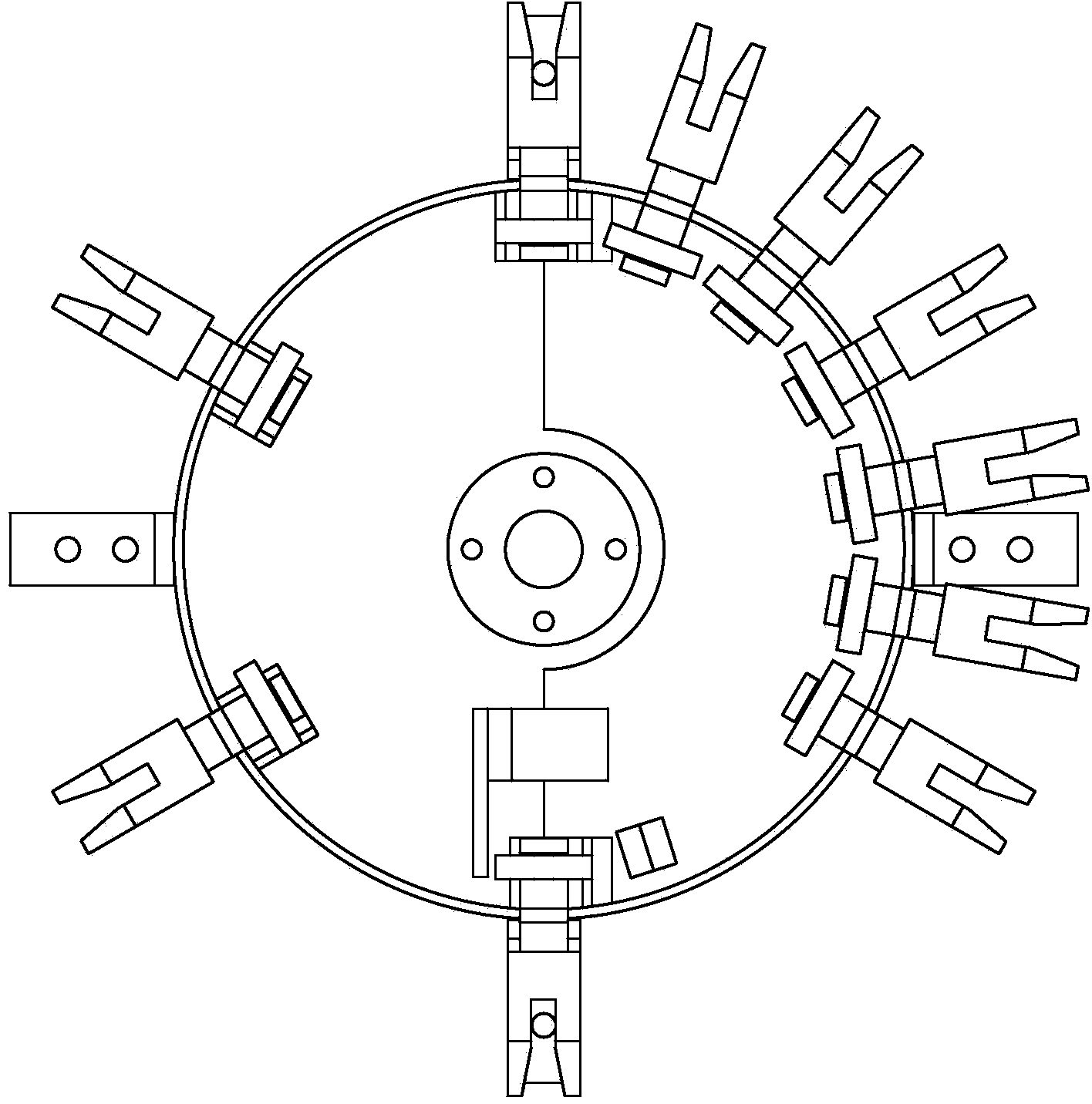

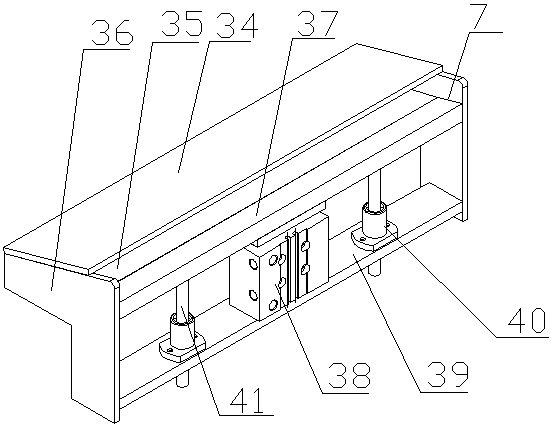

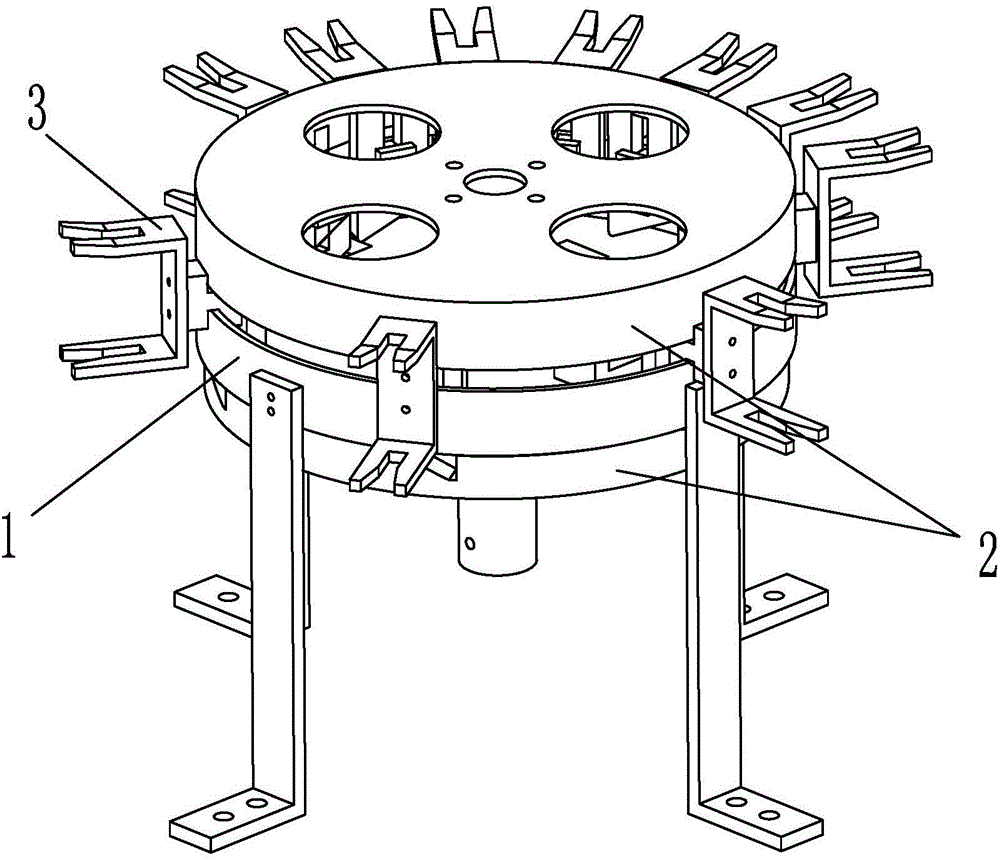

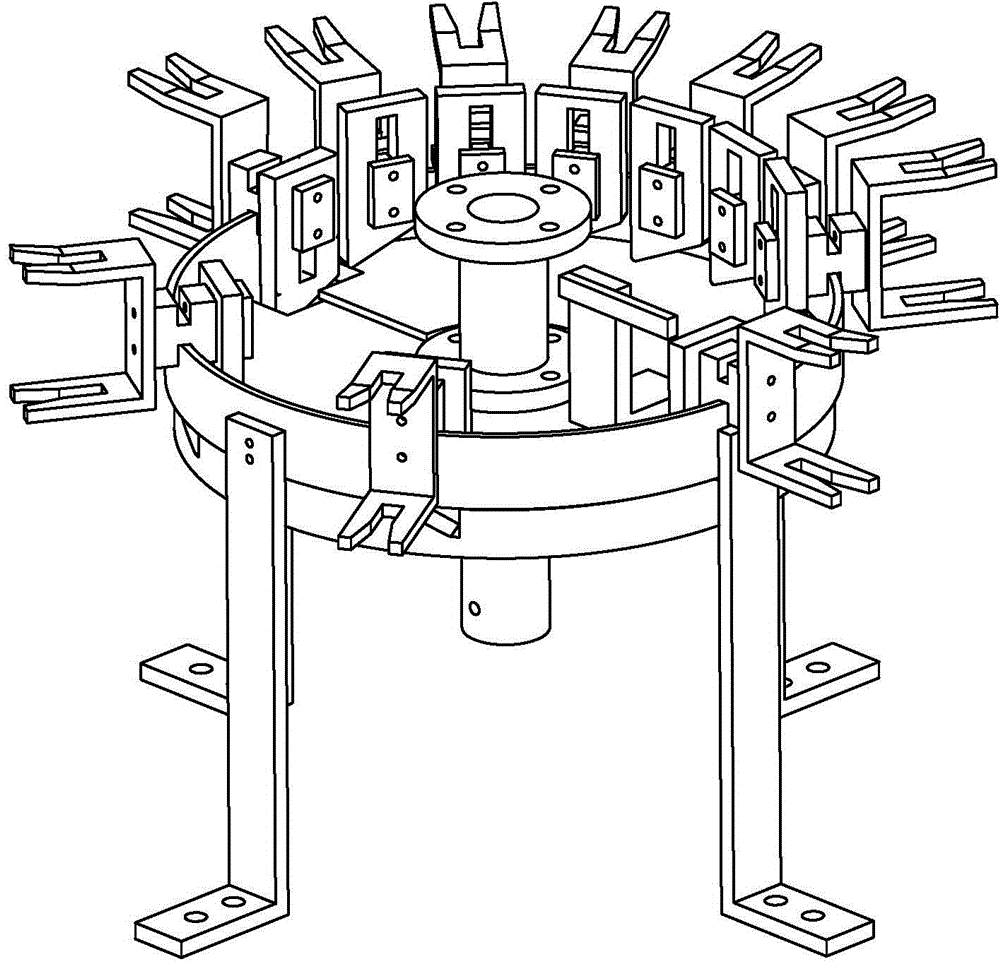

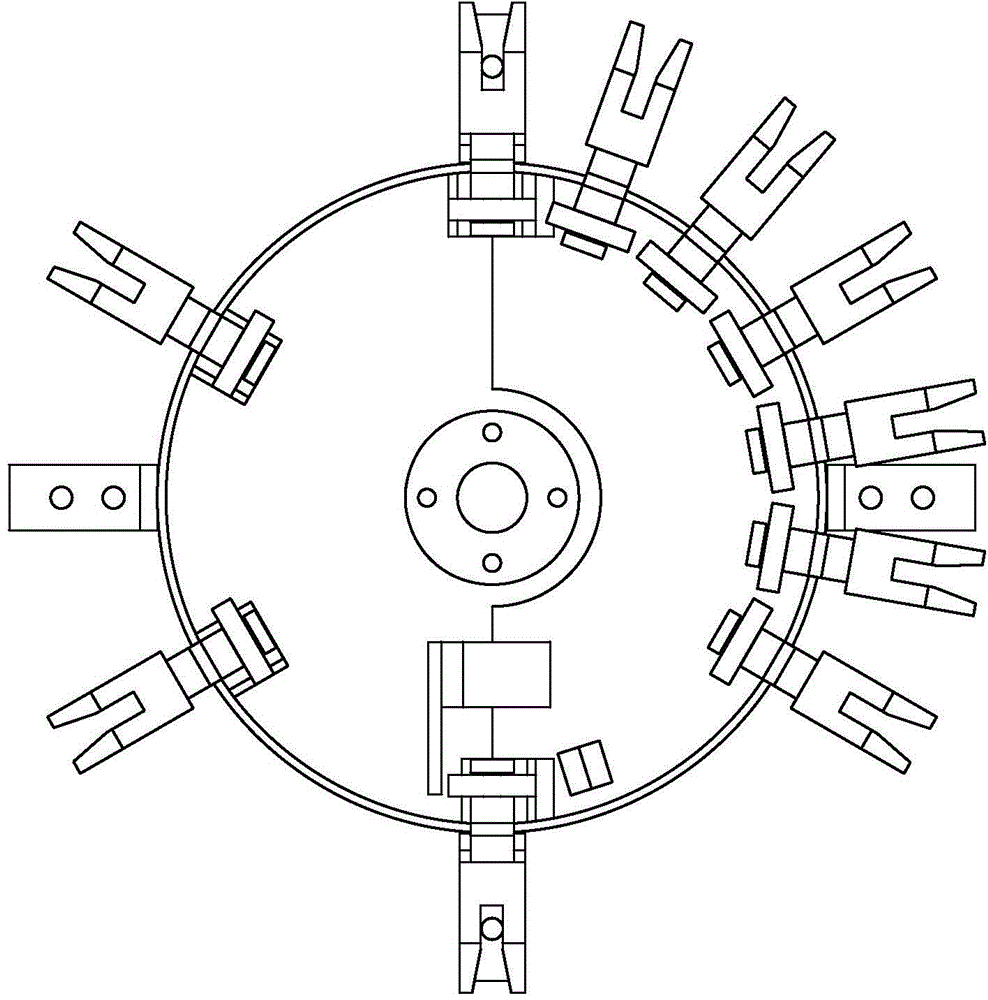

Free seedling feeding self-positioning grafting machine seedling holder

The invention relates to a free seedling feeding self-positioning grafting machine seedling holder and aims to provide a device with the advantages that manually free seedling feeding and machine seedling taking are simultaneously realized, the seedling feeding speed can be manually freely handled, the operation is simple and accurate, and the grafting efficiency is improved. The technical scheme is that the free seedling feeding self-positioning grafting machine seedling holder is characterized in that the free seedling feeding self-positioning grafting machine seedling holder comprises a bearing assembly mounted above a worktable, a driving assembly wrapping the bearing assembly from two directions up and down, and a plurality of seedling holding assemblies mounted between the bearing assembly and the driving assembly.

Owner:HUZHOU ZHILI CHILDRENS CLOTHING DEV

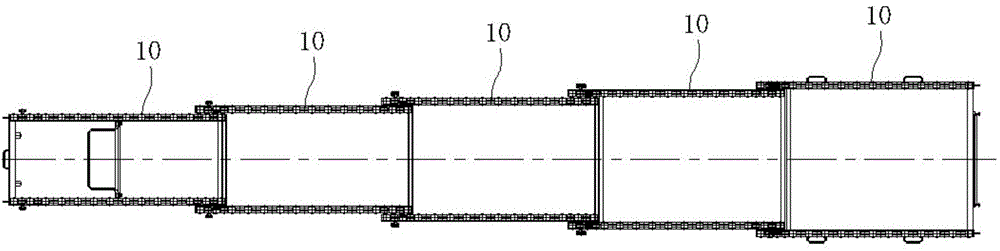

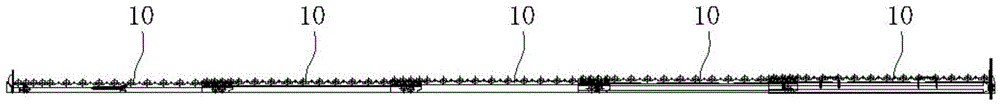

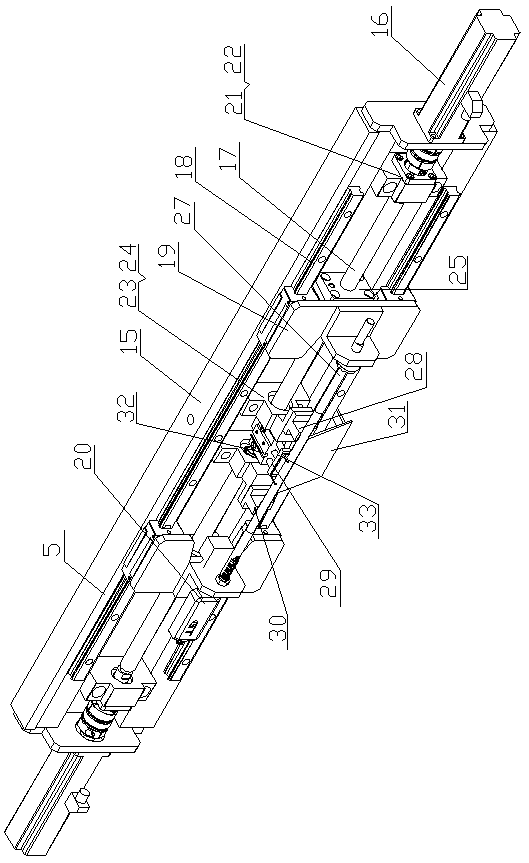

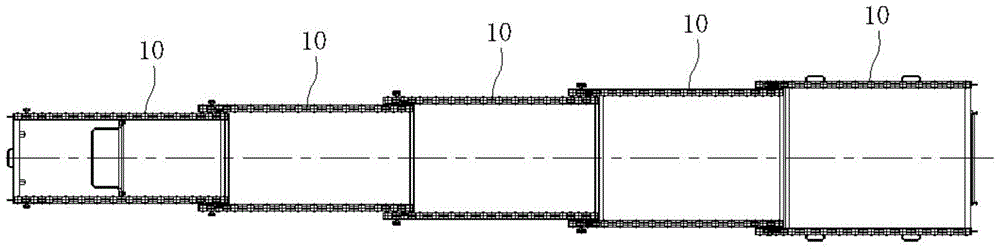

Ground rail car

InactiveCN104960942AReduce labor intensityAvoid duplicationLoading/unloadingMechanical conveyorsMechanical engineeringEngineering

The invention discloses a ground rail car. The ground rail car comprises multiple roller guide rail units serially connected together, wherein the multiple roller guide rail units are the same in length; the widths of the multiple roller guide rail units are gradually decreased one by one in the length direction of the ground rail car; single roller guide rail unit comprises a bracket, a conveying roller and a limiting roller; roller grooves are formed in the inner side walls of the brackets; stop pieces are arranged in the roller grooves; and the limiting roller of single roller guide rail unit is mounted in the roller grooves of the adjacent roller guide rail units. Through the technical scheme, the ground rail car can be stretched according to the carriage length demand to form a horizontal rail at the bottom of a carriage. Forked products can be directly put on the ground rail car without needing the coordination of loading and unloading persons, have no need to wait a trolley for loading and unloading, and also have no need to be renewedly forked on the car after being placed at the car tail, so that the repeated operation and the mutual waiting are prevented, and the improvement of carrying efficiency is facilitated.

Owner:SHANGBAOTAI MACHINERY TECH KUNSHAN

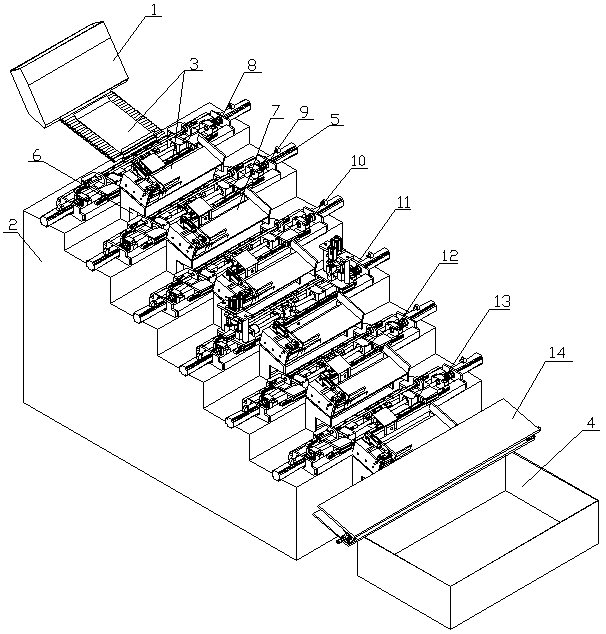

Step slope type circular pipe automatic detection equipment

The invention discloses step slope type circular pipe automatic detection equipment which comprises a feeding bin, a step base, a slope material conveying system and a storage bin. The feeding bin isarranged on the feeding side of the step base, the storage bin is arranged on the discharge side of the step base, the slope material conveying system is arranged on the step base, and the slope material conveying system is arranged along the slope of the step base. The step base is provided with detection units correspondingly from the topmost step to the bottommost step, and each step is provided with a waste recycling box of the previous step. The slope material conveying system comprises multiple material screening devices, the material screening devices are arranged on the rear end sidesof the second step to the last step, one outlet of each material screening device corresponds to the detection unit on the current step, and the other outlet of each material screening device corresponds to an inlet of the waste recycling box on the current step. The detection efficiency is high, and material conveying is efficient.

Owner:南通睿驰智能科技有限公司

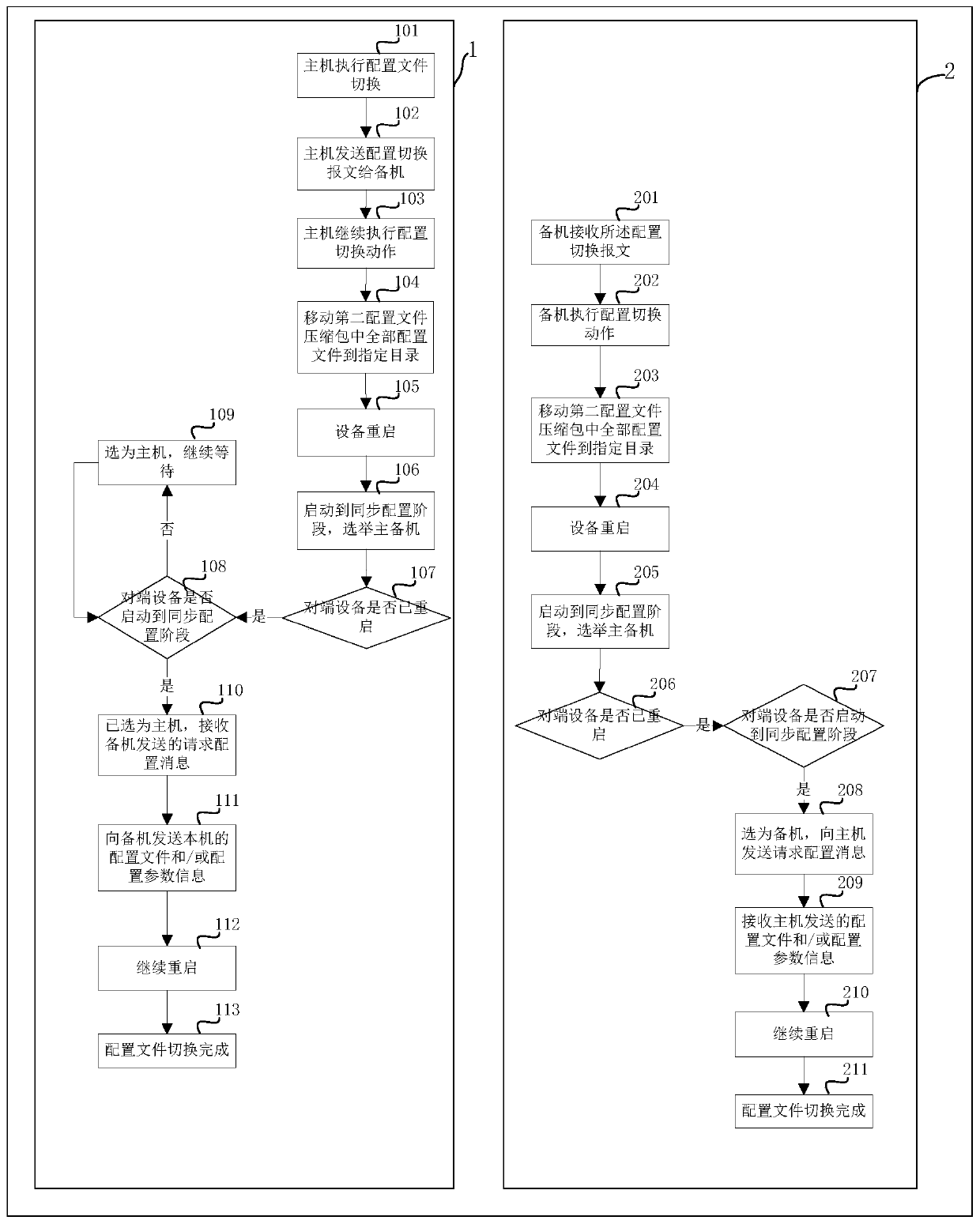

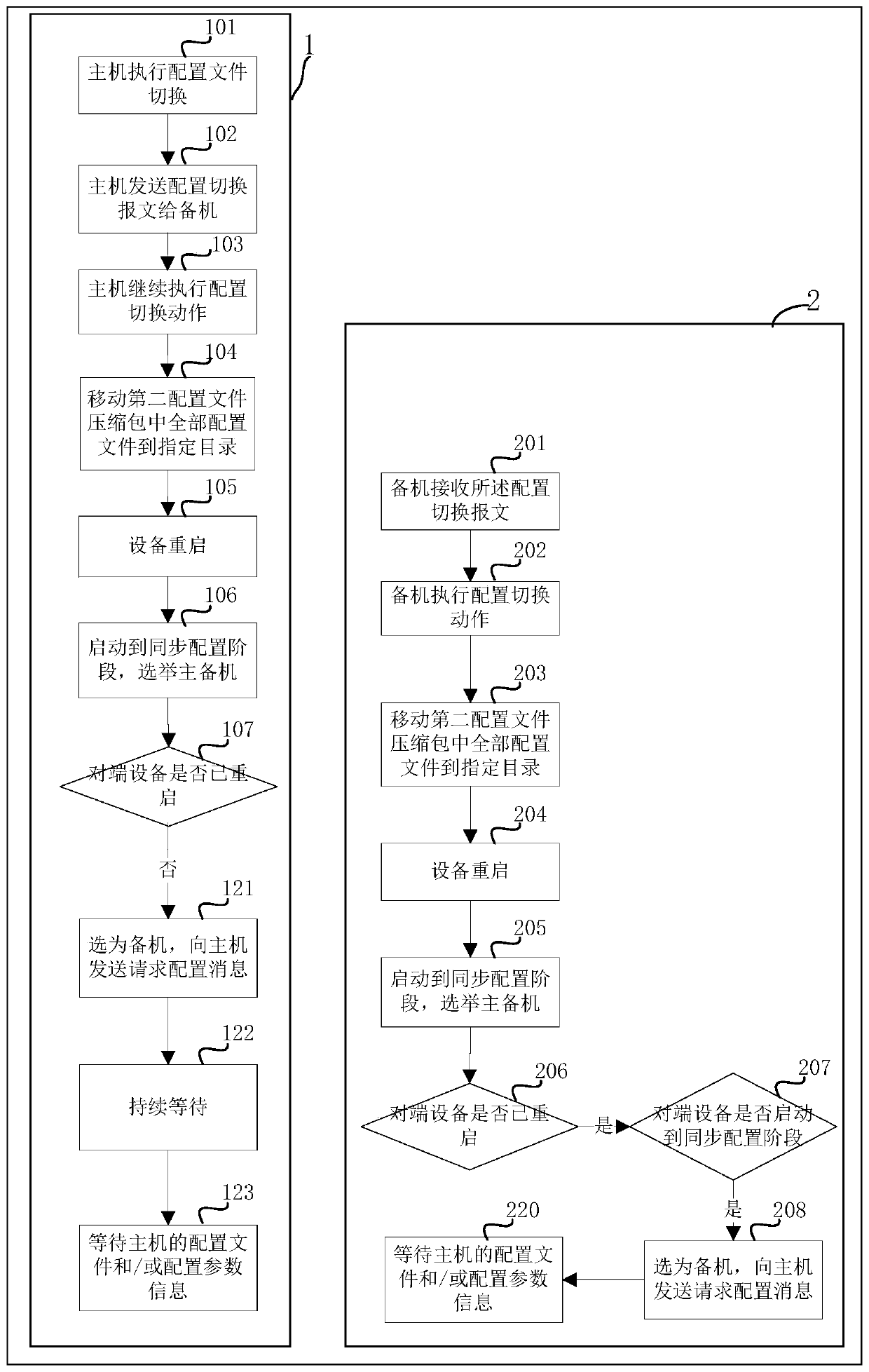

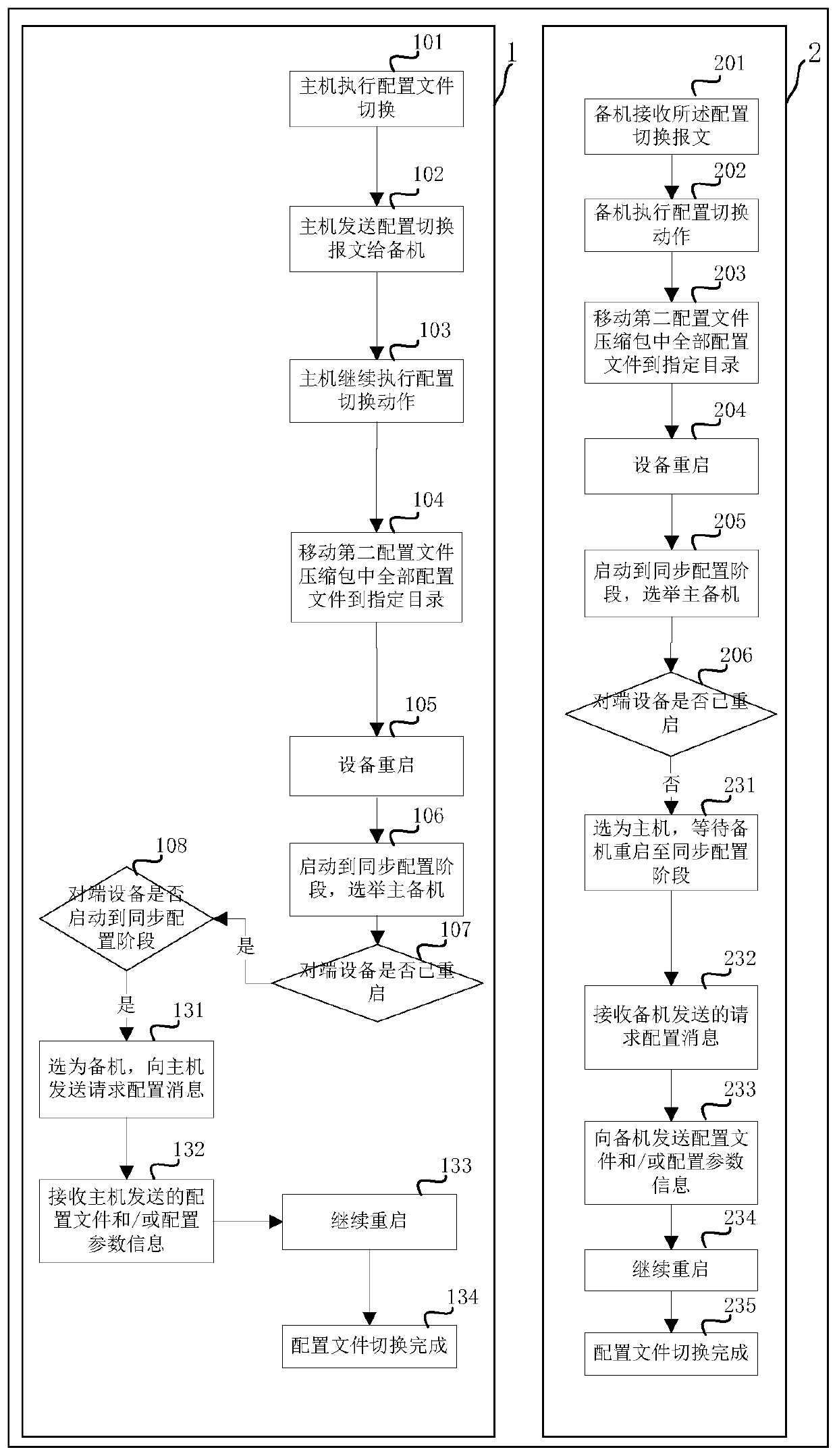

Configuration file switching method and system

ActiveCN110086668AAvoid lossAvoid problems such as damageData switching networksFile synchronizationOperating system

The invention provides a configuration file switching method. The method is applied to a first device in a double-master-control environment, the first device is switched from a first configuration toa second configuration, and the double master control environment comprises the first device and a second device, the first device is configured as a host, and the second device is configured as a standby machine. The method comprises the following steps of before restarting, using the first device to set a configuration file switching mark; after restarting, according to the configuration file switching mark, moving all configuration files in a second configuration file compression package to an appointed directory, wherein the second configuration file compression package corresponds to thesecond configuration; and starting to a synchronous configuration stage, selecting the host and the standby machine based on a preset strategy and executing the synchronous switching of the configuration files. According to the technical scheme provided by the invention, the problems of configuration file loss or damage and the like caused by transferring the configuration files before the deviceis restarted can be avoided.

Owner:HANGZHOU DPTECH TECH

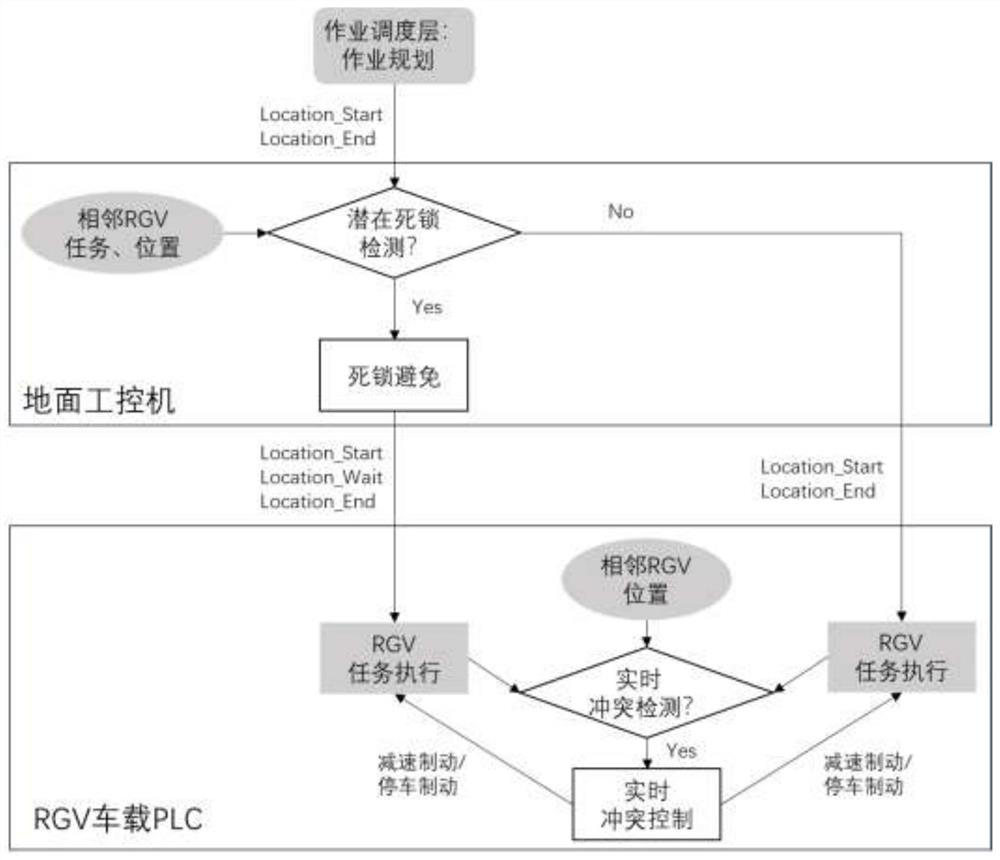

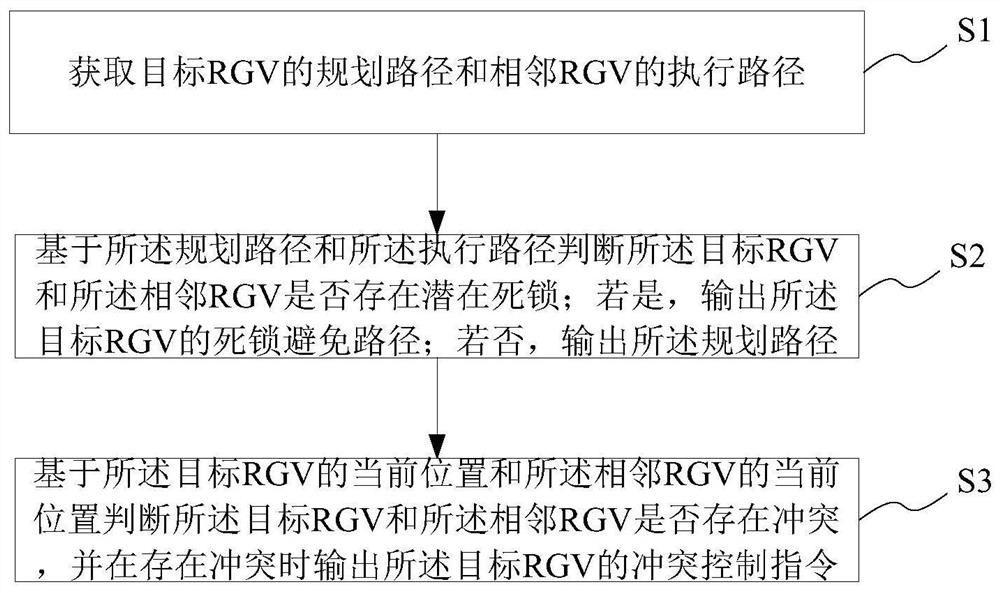

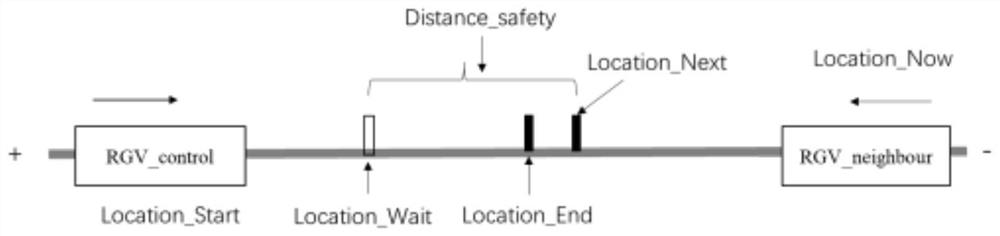

Linear reciprocating type multi-RGV deadlock avoidance and conflict real-time control method and system, medium and terminal

PendingCN112214013AAvoid waiting for each otherAvoid collision situationsPosition/course control in two dimensionsPathPingEngineering

The invention provides a linear reciprocating type multi-RGV deadlock avoidance and conflict real-time control method and system, a medium and a terminal. The method comprises the following steps: obtaining a planned path of a target RGV and an execution path of an adjacent RGV; judging whether the target RGV and the adjacent RGV have potential deadlocks or not based on the planned path and the execution path; if so, outputting a deadlock avoidance path of the target RGV; if not, outputting the planned path; and judging whether a conflict exists between the target RGV and the adjacent RGV based on the current position of the target RGV and the current position of the adjacent RGV, and outputting a conflict control instruction of the target RGV when the conflict exists. According to the linear reciprocating type multi-RGV deadlock avoiding and conflict real-time control method and system, the medium and the terminal, the problems of deadlock and conflict of multiple RGVs on a linear reciprocating type rail are effectively avoided by detecting and controlling potential deadlocks and conflicts of RGVs, and the running efficiency of the RGVs is guaranteed to the maximum extent.

Owner:SHANGHAI HI TECH CONTROL SYST

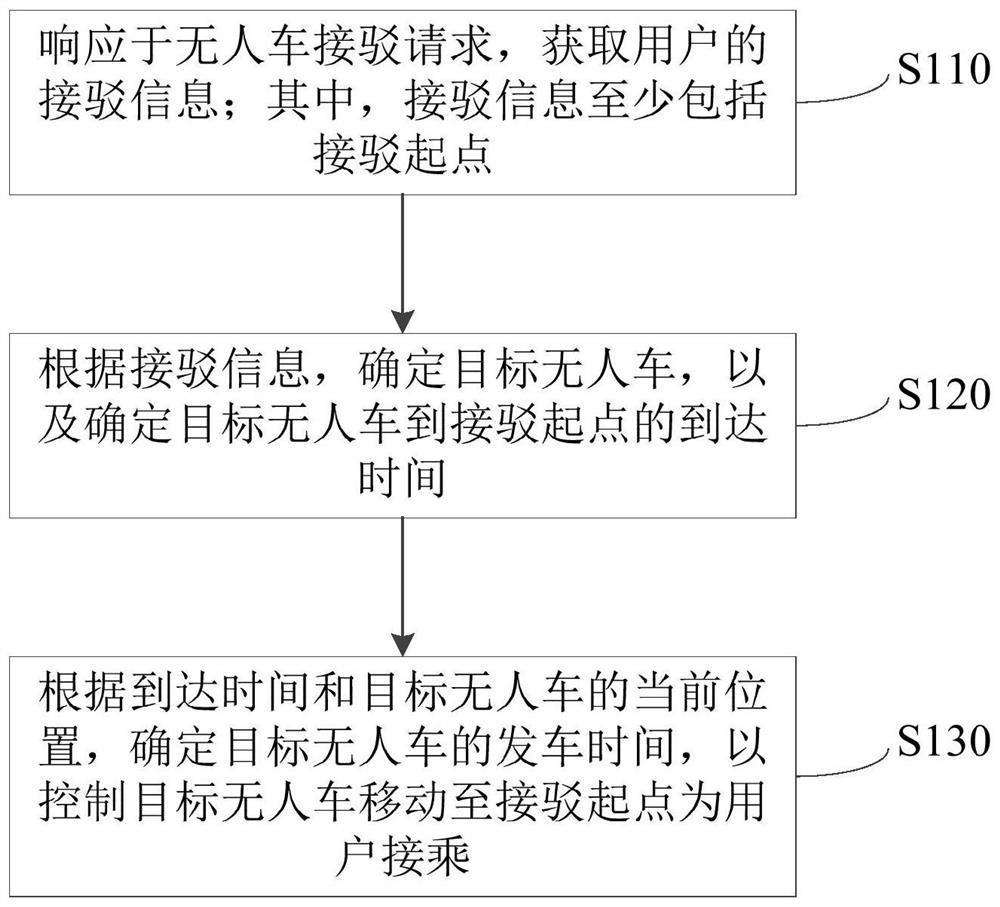

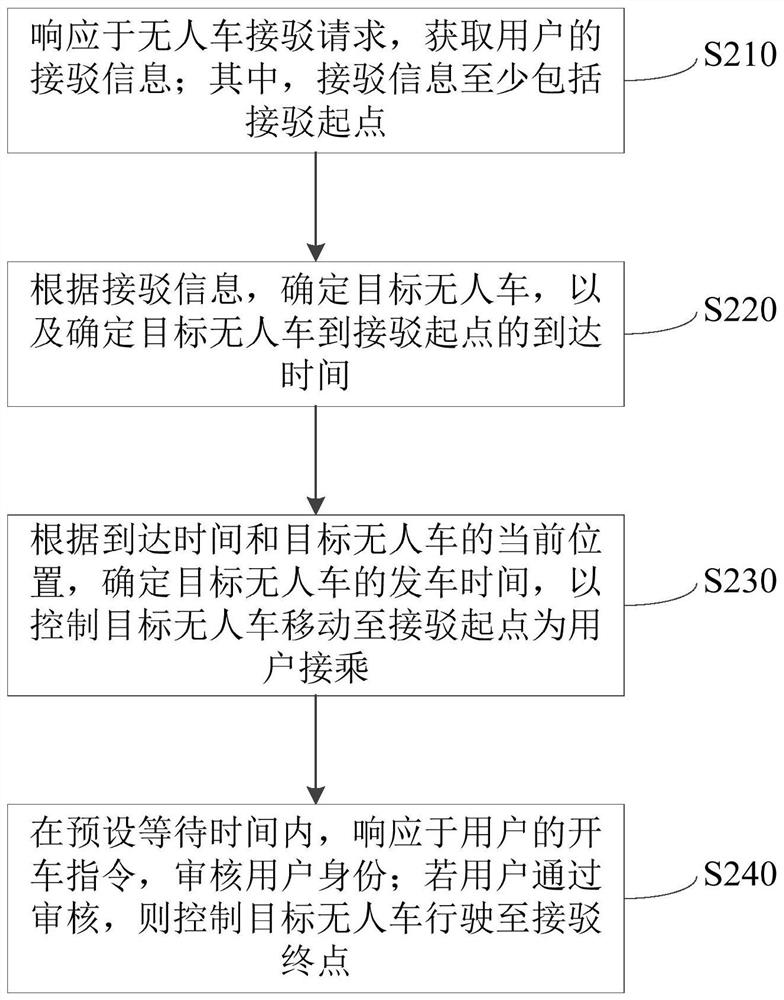

Unmanned vehicle connection method and device, equipment and storage medium

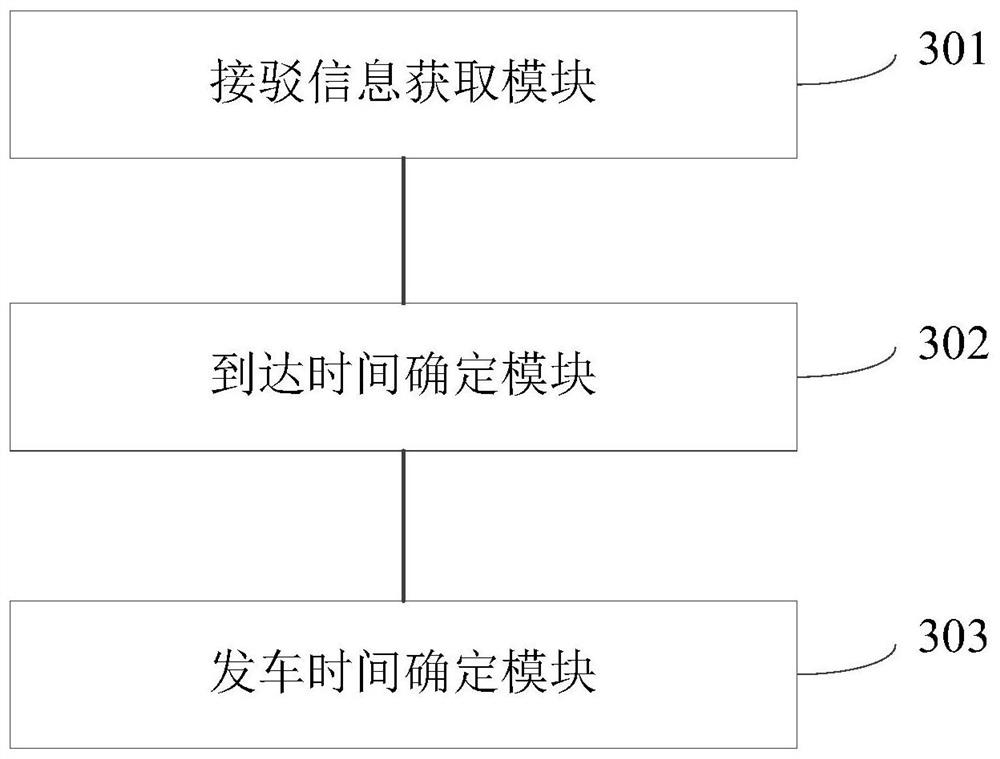

PendingCN111898832AImprove connection efficiencyImprove experienceForecastingArrival timePublic transport

The embodiment of the invention discloses an unmanned vehicle connection method and device, equipment and a storage medium. The method comprises the following steps: acquiring connection information of a user in response to an unmanned vehicle connection request, the connection information at least comprising a connection starting point; determining a target unmanned vehicle according to the connection information, and determining arrival time from the target unmanned vehicle to the connection starting point; and determining departure time of the target unmanned vehicle according to the arrival time and the current position of the target unmanned vehicle so as to control the target unmanned vehicle to move to the connection starting point to be taken by the user. According to the embodiment of the invention, connection information of the user is obtained; the target unmanned vehicle for connection is determined; the target unmanned vehicle automatically drives to pick up the user according to the proper time, the user is prevented from waiting for the unmanned vehicle for a long time, the problem that in the prior art, public transport cannot go deep into a residential district ora narrow street to travel is solved, accurate collection of the traffic start and stop amount is achieved, and the user experience is improved through unmanned driving of the unmanned vehicle.

Owner:NEOLIX TECH CO LTD

Manufacturing method of large steel box girder

InactiveCN112719795AEffectively control welding deformationAvoid cross assignmentCantileverWelding deformation

The invention relates to a manufacturing method of a large steel box girder. The manufacturing method comprises the following steps of: manufacturing a unit piece, assembling and pre-splicing girder sections, hoisting a steel box girder on a construction site, and performing welding, wherein the step of manufacturing the unit piece comprises: designing a drawing by using AUTOCAD software, performing modeling, determining a theoretical size, and determining welding and processing compensation amounts; and the step of manufacturability analysis comprises: A, welding manufacturability test, B, manufactured bridge actual measurement data and C, part machining requirements. Compared with the prior art, the manufacturing method disclosed by the invention has the advantages that a forward mounting method and a reverse mounting method are adopted, namely, bottom plate unit pieces are firstly assembled, then web unit pieces, diaphragm plate unit pieces, panel unit pieces and cantilever unit pieces are sequentially assembled, and the cantilever unit pieces adopt the reverse mounting method. The method has the advantage that most of weld joints are welded in a horizontal or climbing position. During welding, welding deformation is effectively controlled by utilizing the principles of constraint, self-constraint, strong constraint and flexible constraint, so that various geometric dimension deviations of all steel box girders are within a very small range.

Owner:江苏恒睿杰钢结构工程有限公司

Melt flow control device and method for melt coating forming process

ActiveCN113084202BHigh precisionImprove responsivenessAdditive manufacturing apparatusIncreasing energy efficiencyPressure.driveIndustrial engineering

The invention discloses a melt flow control device and method for a fusion coating forming process, comprising a crucible melting unit, a fusion coating head, an air pressure drive unit, a jet flow start-stop device, a crucible liquid level ranging module and an industrial computer . The water-cooled top cover is located above the melting crucible, and the molten coating head is placed below the melting crucible; the melting unit of the crucible is connected with the air pressure drive unit; the jet start-stop device drives the start-stop control lever to press down or lift up to realize the start and stop of the jet flow. stop. The pressure control adopts three-level division of labor: the computer sends the injection pressure to the PLC according to the pressure-flow function relationship, and the PLC simultaneously receives the melt level signal from the laser ranging module and the injection pressure of the industrial computer, and sends the air pressure control command to the pressure The controller, the pressure controller realizes the real-time control of the gas pressure in the crucible, so as to realize the precise control of the jet flow during the forming process, so as to complete the high-precision and high-efficiency coating forming of the target parts.

Owner:XI AN JIAOTONG UNIV

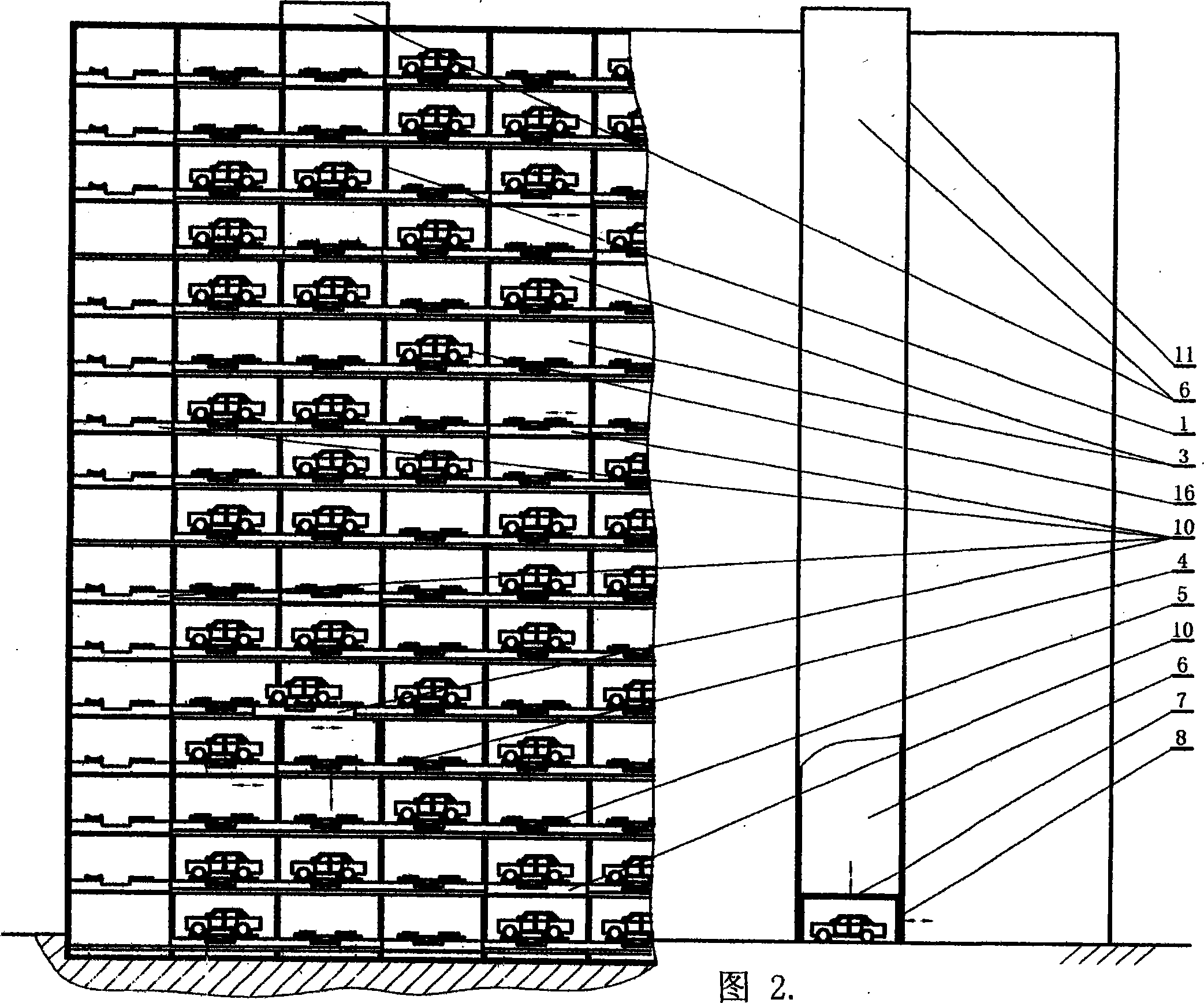

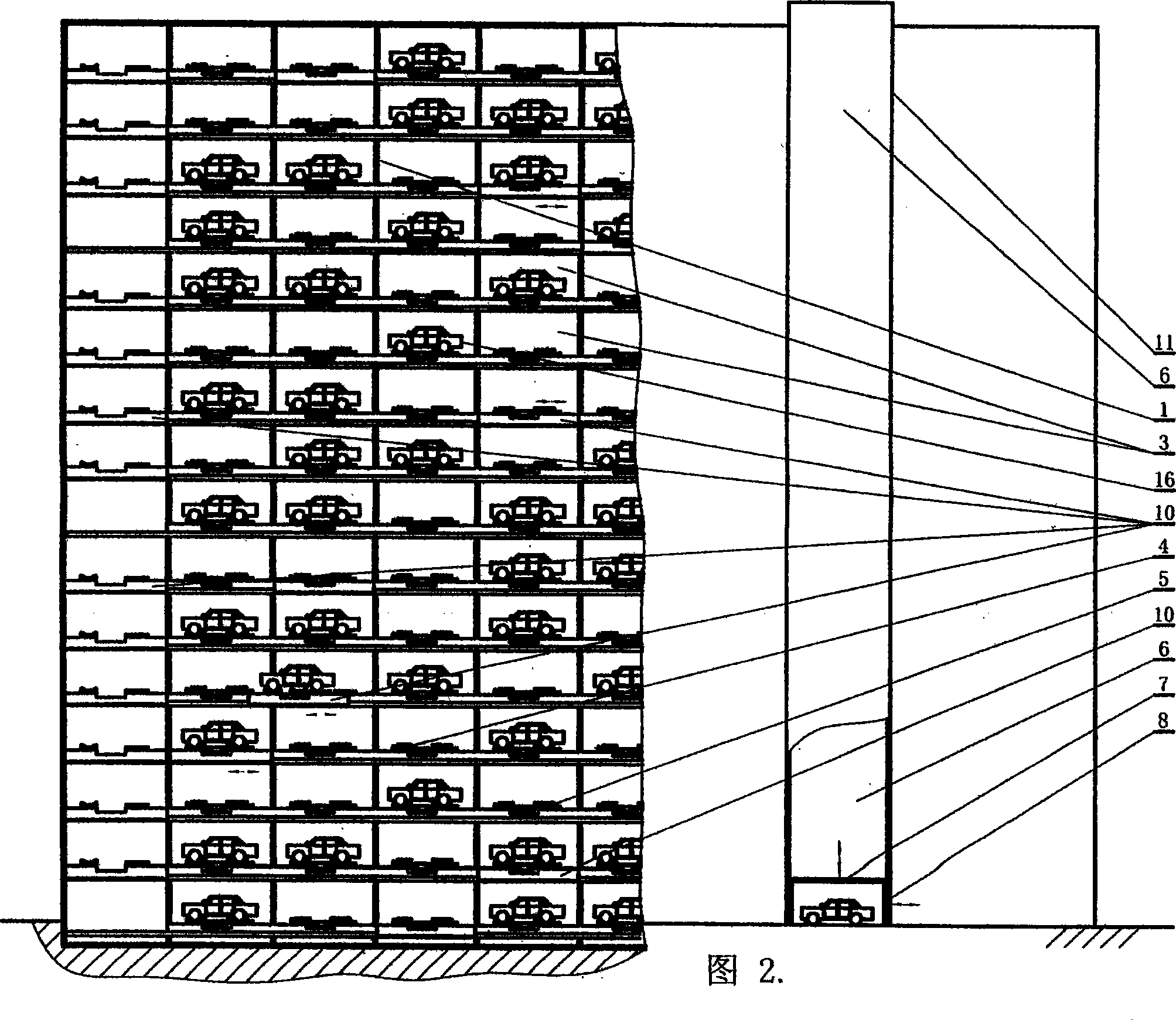

One-sided laneway external passage layered transportation rolling way parallel parking type mechanical parking system

A external road way removal tiered raceway side-by-side storage-mechanical parking system used in the unilateral roadway, which belongs to the traffic and transportation field, comprises stockroom-type frames, a roadway, parking areas, wheel holding raceways, external well roads, lifting handlings, vertical shift handlings, a separating and positioning horizontally moved delivery device, the storage and taking out transitional area; the road way are positioned in the middle of the stockroom-type frames. each layer of the stockroom-type frame is provided vertically with the parking area along the road way, the wheel holding raceway is arranged horizontally thereabove to hold many cars side by side; each layer in the road way on one side of the stockroom-type frame is provided with a vertical shift handling to carry out separating work; well roads with lifting handlings and the storage and taking out transitional area are arranged along the external side of the road way; lifting handlings, vertical shift handlings and the storage and taking out transitional area are also provided with the same wheel holding race ways; on the parking area and the storage and taking out transitional area, the separating and positioning horizontally moved delivery device, which can move horizontally and extend into the vertical shift handling and is arranged between the front wheel holding race way and the back wheel holding race way, can be used to storage, take out and move horizontally cars. The invention has a large capacity of bikes and is high in working efficiency.

Owner:SHANGHAI JIAO TONG UNIV

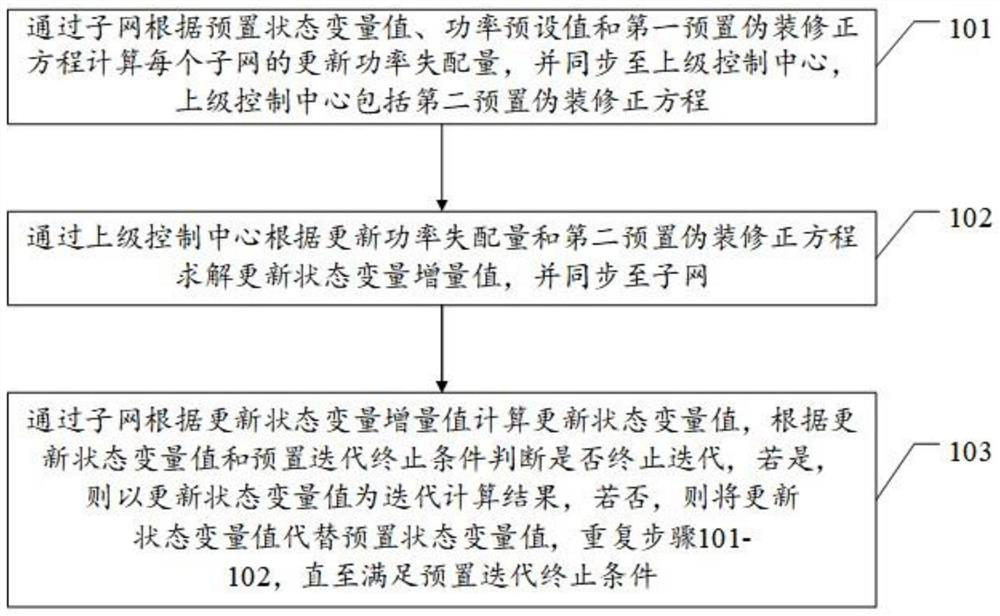

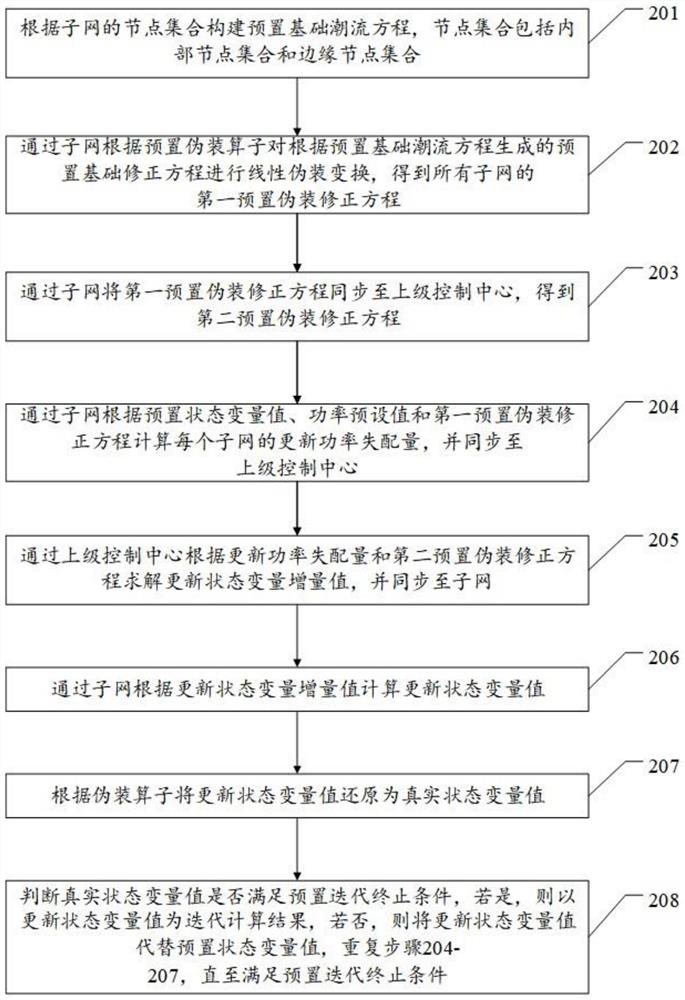

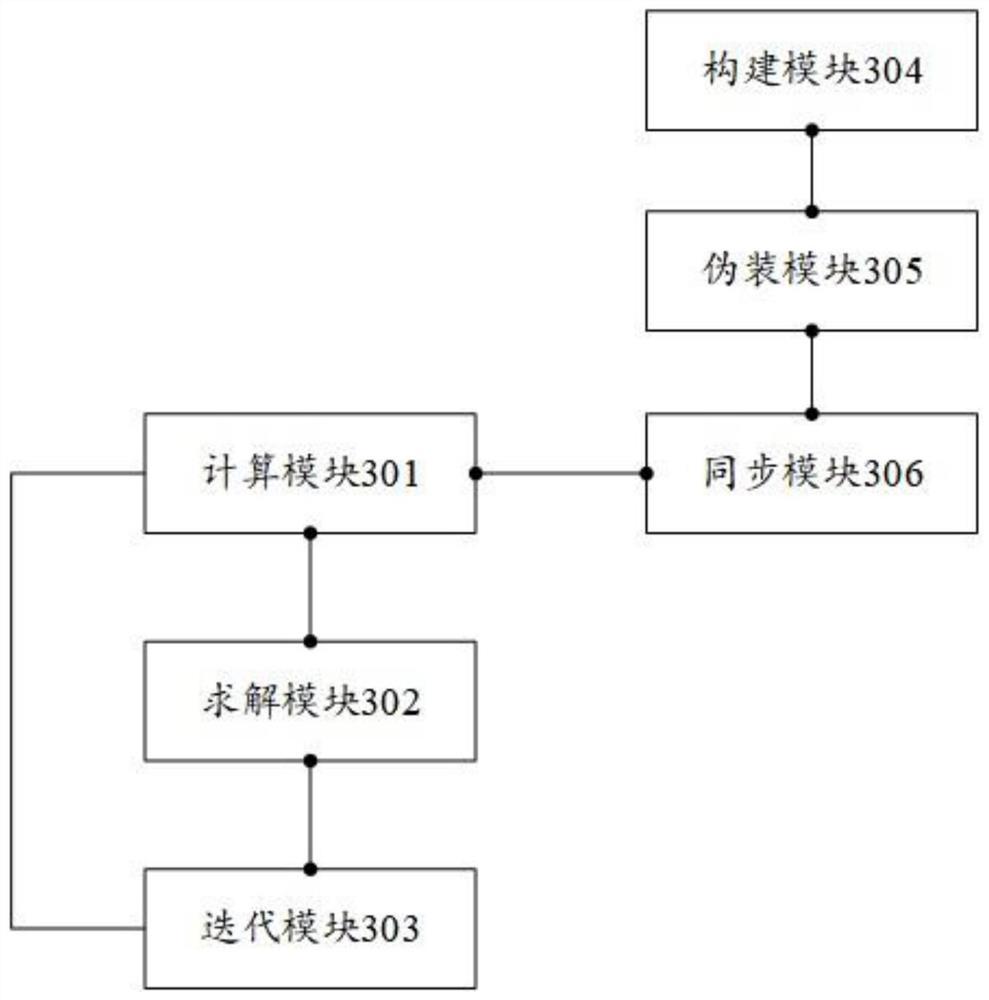

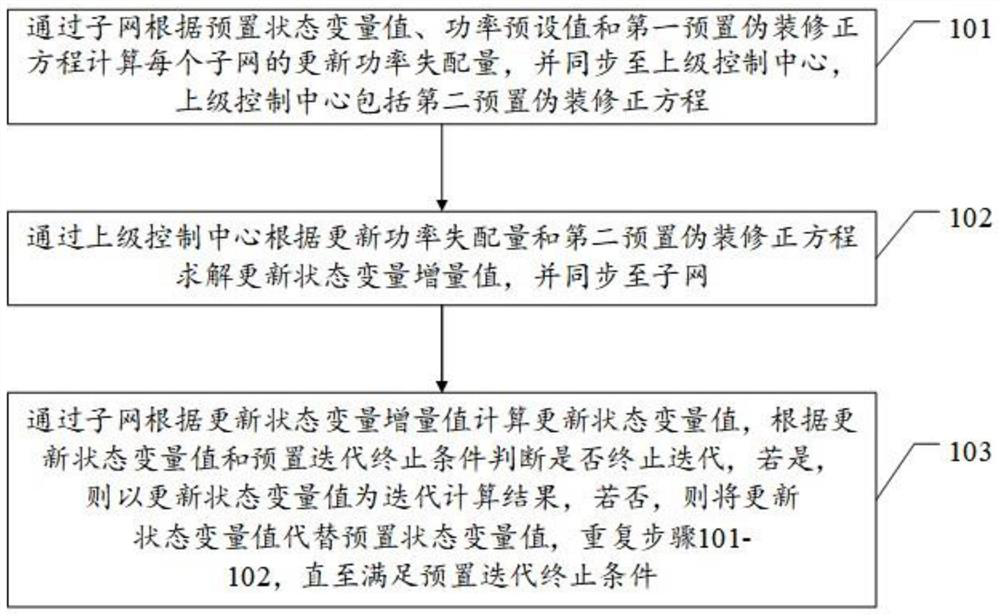

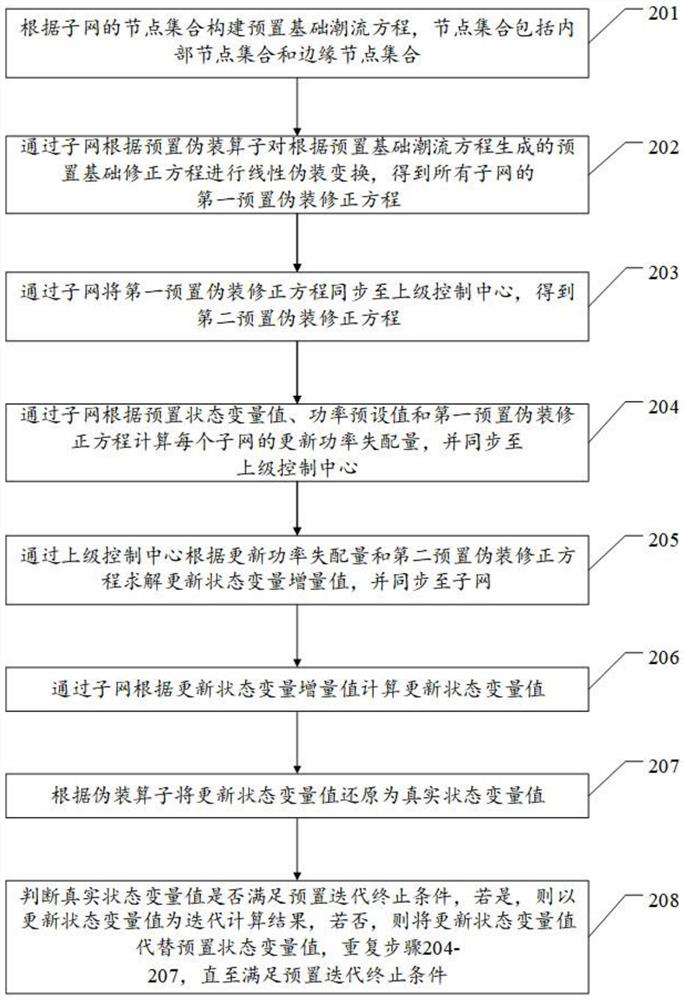

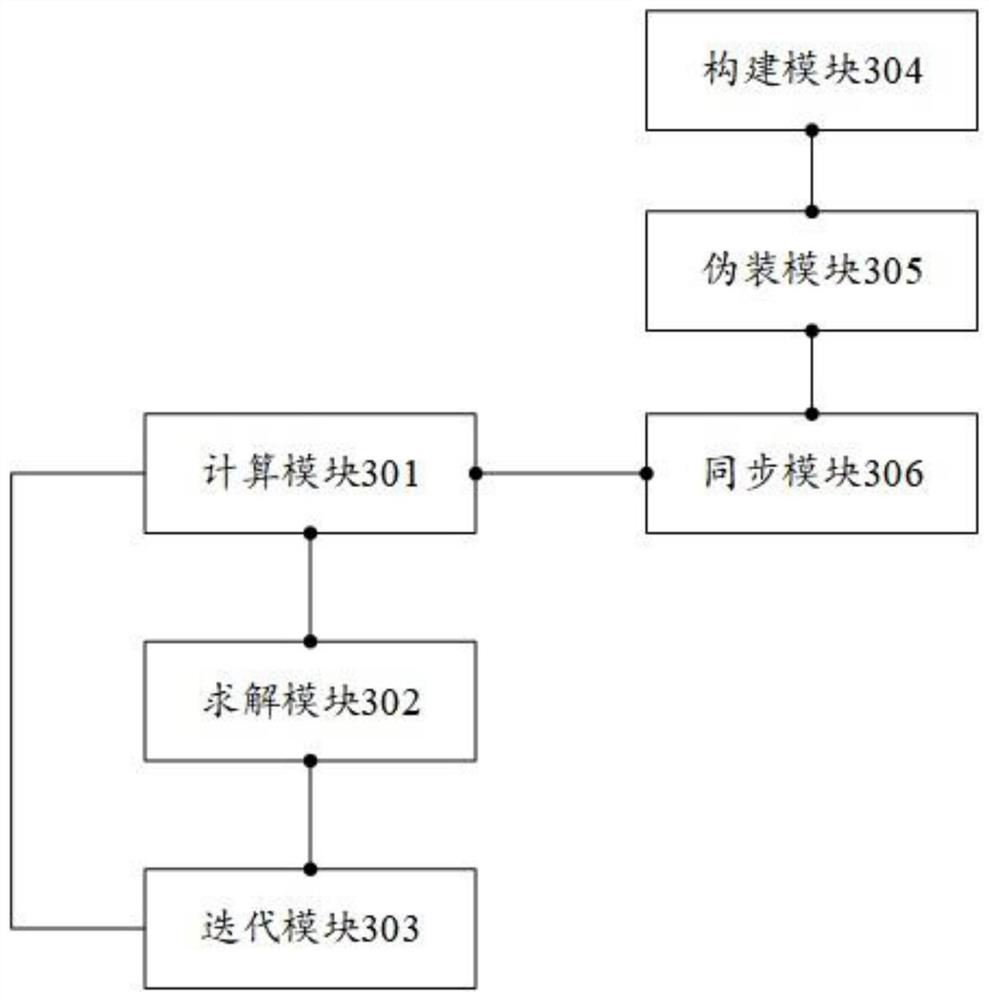

Interconnected power grid power flow synchronous iterative computation method and related device

ActiveCN111641210ASmall amount of calculationEliminate the effects of synchronous iterationsAc networks with different sources same frequencyPower flowSimulation

The invention discloses an interconnected power grid power flow synchronous iterative calculation method and a related device. The method comprises the steps of S1, calculating the updated power mismatch amount of each subnet through the subnets according to a preset state variable value, a power preset value and a first preset camouflage correction equation, and synchronizing the updated power mismatch amount to a superior control center; S2, solving an updated state variable increment value through the superior control center according to the updated power mismatch amount and a second presetcamouflage correction equation, and synchronizing the updated state variable increment value to the subnet; S3, calculating an updated state variable value through the subnet according to the updatedstate variable increment value, judging whether iteration is terminated or not according to the updated state variable value and a preset iteration termination condition, if so, taking the updated state variable value as an iterative calculation result, and if not, replacing the preset state variable value with the updated state variable value, and repeating the steps S1-S2 until the preset iteration termination condition is met. The technical problems that an existing synchronous iteration technology is poor in calculation efficiency and low in applicability can be solved.

Owner:GUANGDONG POWER GRID CO LTD

Method for realizing decoding, software decoder and decoding device

InactiveCN101841717BAvoid waiting for each otherImplement parallel processingTelevision systemsDigital video signal modificationParallel processingComputer engineering

The invention discloses a method for realizing decoding, a software decoder and a decoding device. When used for decoding an encoded image, the software decoder of the embodiment of the invention adopts virtual frame storage to imitate DPB operation of a hardware decoder after decoding the encoded image of a frame to ensure that the encoded image of the next frame can be decoded without waiting the finish of the decoding of the hardware decoder so as to avoid the situations that the software decoder and the hardware decoder wait for each other because the DPB operation is performed only afterthe finish of the decoding of the hardware decoder in the prior art. The method, the software decoder and the decoding device can well realize parallel processing of the software decoder and the hardware decoder, and improve the decoding efficiency.

Owner:李晶晶

Free seedling feeding self-positioning grafting machine seedling holder

ActiveCN103621322BAvoid waiting for each otherImprove work efficiencyHorticultureBiologyFeeding self

The invention relates to a free seedling feeding self-positioning grafting machine seedling holder and aims to provide a device with the advantages that manually free seedling feeding and machine seedling taking are simultaneously realized, the seedling feeding speed can be manually freely handled, the operation is simple and accurate, and the grafting efficiency is improved. The technical scheme is that the free seedling feeding self-positioning grafting machine seedling holder is characterized in that the free seedling feeding self-positioning grafting machine seedling holder comprises a bearing assembly mounted above a worktable, a driving assembly wrapping the bearing assembly from two directions up and down, and a plurality of seedling holding assemblies mounted between the bearing assembly and the driving assembly.

Owner:HUZHOU ZHILI CHILDRENS CLOTHING DEV

A Parallelization Method of Correlation Analysis Algorithm

ActiveCN103914528BIncrease generation speedRelieve pressureSpecial data processing applicationsParallel algorithmTheoretical computer science

Owner:NANJING UNIV OF POSTS & TELECOMM

A method for synchronous iterative calculation of power flow in an interconnected power grid and related devices

ActiveCN111641210BSmall amount of calculationEliminate the effects of synchronous iterationsAc networks with different sources same frequencyAlgorithmPower grid

Owner:GUANGDONG POWER GRID CO LTD

A method of avoiding multi-laser agv

ActiveCN111026128BImprove operational efficiencyGuaranteed reliabilityPosition/course control in two dimensionsVehiclesCollision domainIndustrial engineering

Owner:WUHU HIT ROBOT TECH RES INST

a rail car

InactiveCN104960942BReduce labor intensityAvoid duplicationLoading/unloadingMechanical conveyorsEngineeringMechanical engineering

The invention discloses a ground rail car. The ground rail car comprises multiple roller guide rail units serially connected together, wherein the multiple roller guide rail units are the same in length; the widths of the multiple roller guide rail units are gradually decreased one by one in the length direction of the ground rail car; single roller guide rail unit comprises a bracket, a conveying roller and a limiting roller; roller grooves are formed in the inner side walls of the brackets; stop pieces are arranged in the roller grooves; and the limiting roller of single roller guide rail unit is mounted in the roller grooves of the adjacent roller guide rail units. Through the technical scheme, the ground rail car can be stretched according to the carriage length demand to form a horizontal rail at the bottom of a carriage. Forked products can be directly put on the ground rail car without needing the coordination of loading and unloading persons, have no need to wait a trolley for loading and unloading, and also have no need to be renewedly forked on the car after being placed at the car tail, so that the repeated operation and the mutual waiting are prevented, and the improvement of carrying efficiency is facilitated.

Owner:SHANGBAOTAI MACHINERY TECH KUNSHAN

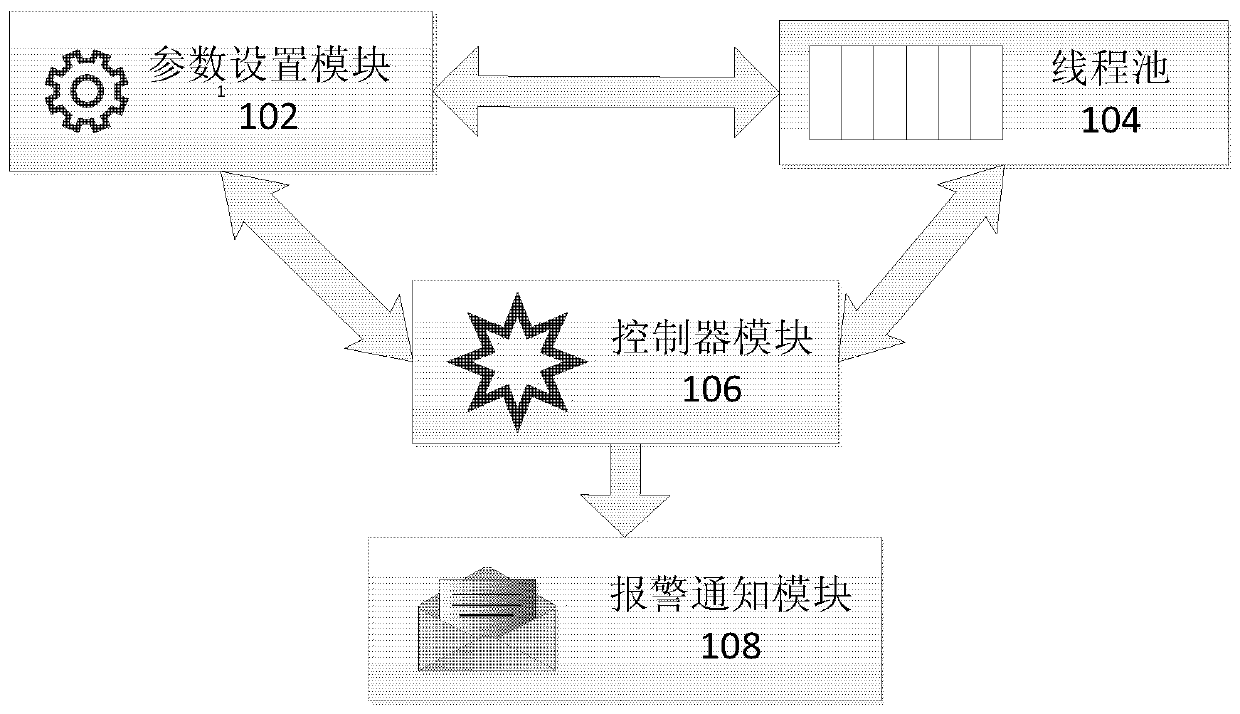

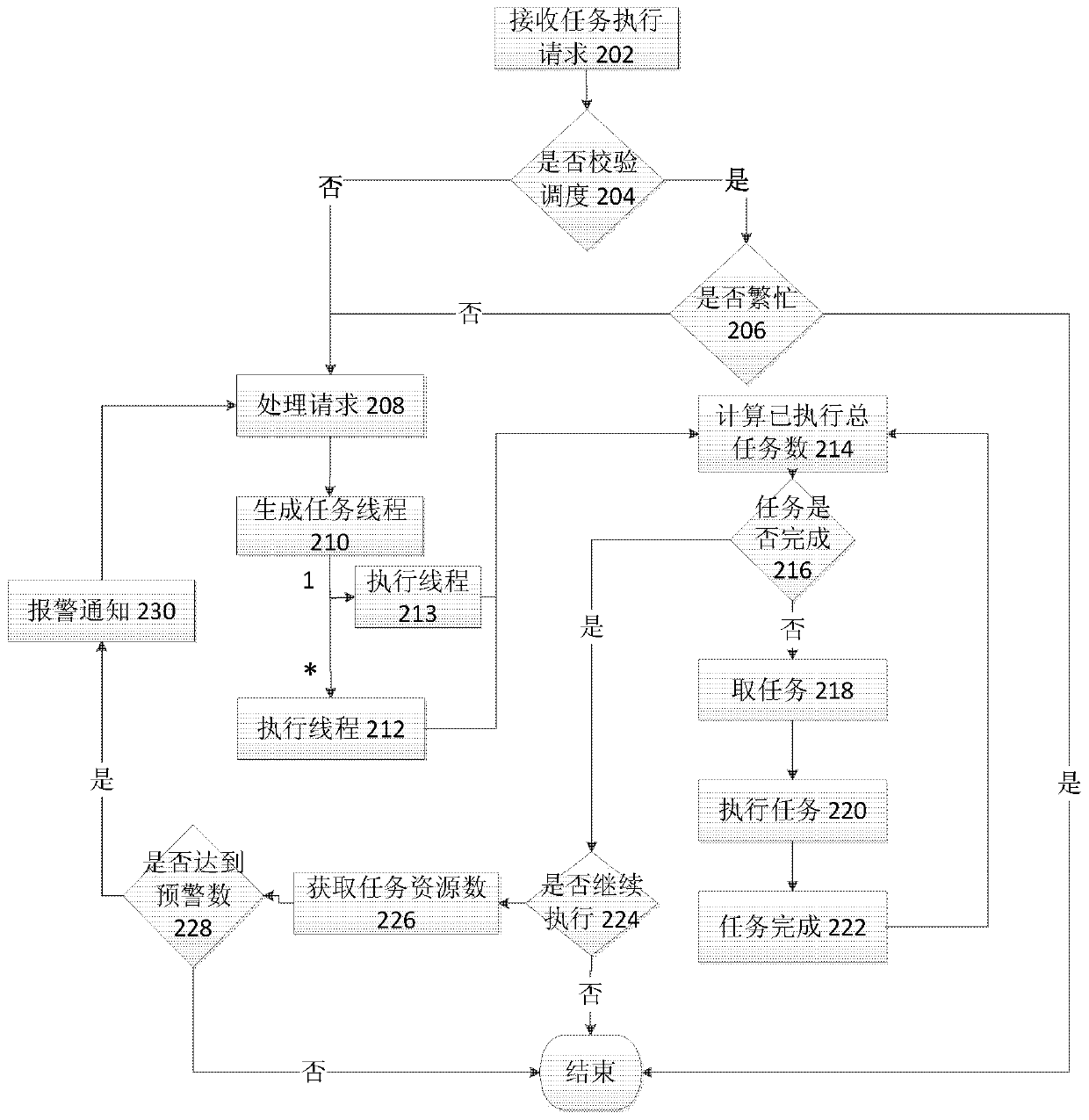

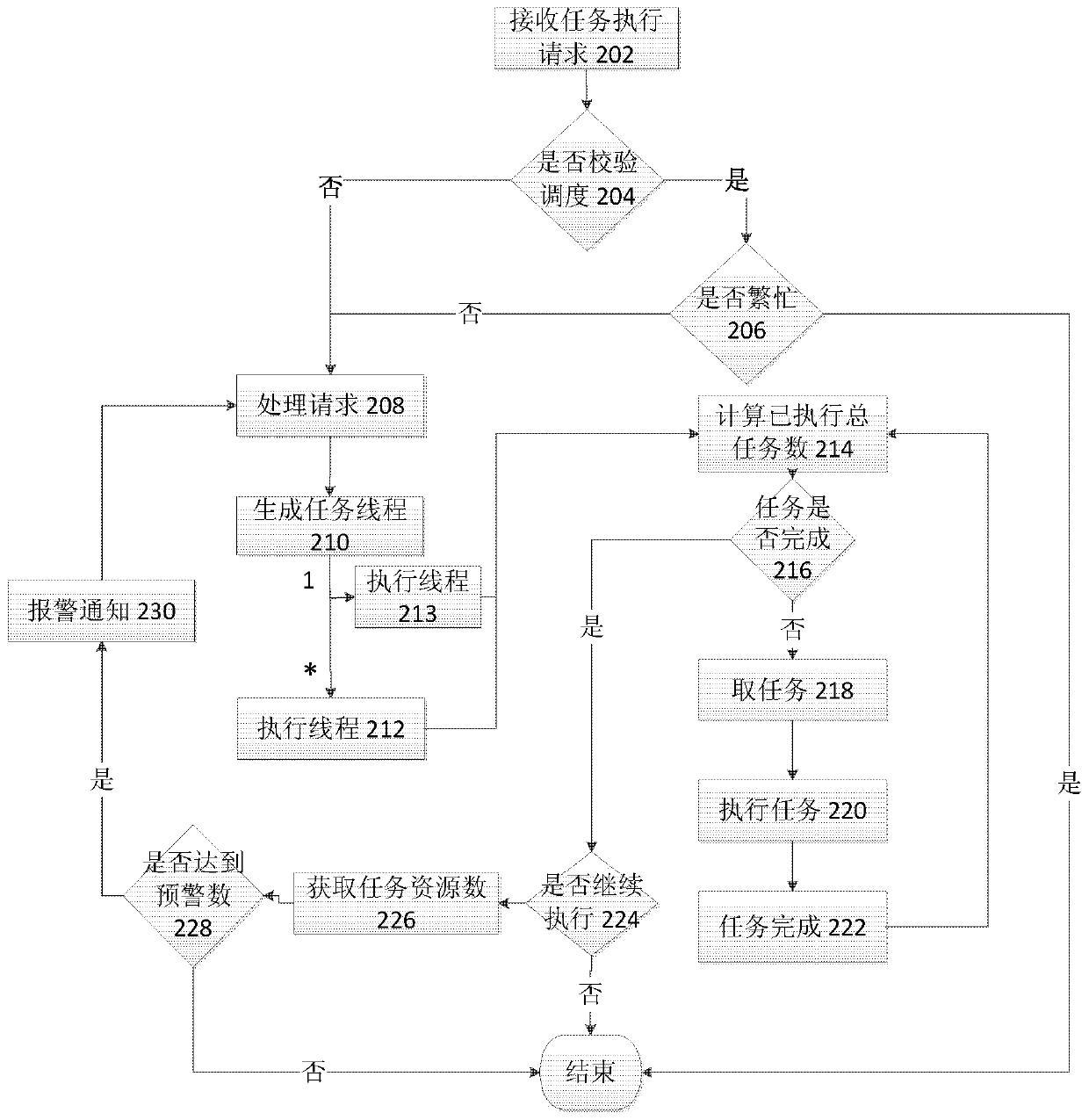

Method and device for distributed task scheduling

ActiveCN104915258BEasy to handleAvoid waiting for each otherProgram initiation/switchingParallel computingEngineering

The invention discloses a distributed task scheduling method and device. The method includes: a discloses a distributed task scheduling device receives a task executing request; the control module of the discloses a distributed task scheduling device determines whether a thread pool is busy or not; if not, the control module process the received task executing request and generate a task thread for the thread pool; the thread pool executes the generated task thread; the parameter setting module of the discloses a distributed task scheduling device determines whether to continue executing the executing thread generated by the thread pool or not after the task is completed.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

Warehousing control method, device, equipment, and readable storage medium

ActiveCN111453275BImprove storage efficiencyAvoid waiting for each otherStorage devicesIndustrial engineeringReal-time computing

The present application proposes a method, device, equipment, and readable storage medium for inbound and outbound control. The inbound control method includes: determining the target temporary storage location according to the target storage location of the target goods; instructing the first robot to carry the target goods to the target temporary storage location; Storage: Instructing the second robot to transport the target goods from the target temporary storage position to the target storage position upon receiving the transport completion signal sent by the first robot, wherein the target storage position and the target temporary storage position are arranged in different layers. The technical solutions provided in the embodiments of the present application can effectively improve the efficiency of goods in and out of storage.

Owner:SHANGHAI QUICKTRON INTELLIGENT TECH CO LTD

Method and device for power flow calculation of large-scale distribution network

ActiveCN109802392BIn line with actual operating conditionsFast convergenceAc networks with different sources same frequencyConcurrent computationConstant power

Owner:CHINA AGRI UNIV

Double laneway transition passage layered transportation rolling way parallel parking type mechanical parking system

A mechanical parking system in the field of transportation and parking equipment, which is a double-lane transition channel layered transport rollway side-by-side storage type, including: warehouse-style warehouse racks, laneways, car storage areas, wheel support raceways, external wells, lifting and transporting Vehicle storage device, longitudinal moving carrier, vehicle separation and positioning lateral movement pick-up and delivery device, and access vehicle transition area; each layer of the warehouse-style warehouse rack in the middle of the two lanes is provided with a storage area along the lane longitudinally, and a wheel support is placed horizontally on it. The raceway can support multiple vehicles side by side, and the longitudinal moving carriers in the double lanes work in layers. The transition zone for accessing vehicles and the external shaft with lifting carriers inside are set on the outer side of the roadway. The lifting carrier, longitudinal moving carrier and The same wheel support raceway is placed on the access car transition area, and a vehicle that can move in both directions into the lifting carrier and the longitudinal transfer carrier is provided between the car storage area and the front and rear wheel support raceways on the access car transition area. Separate positioning and traversing pick-and-feed devices are used for accessing traversing vehicles. The vehicle of the invention has large storage capacity and high operating efficiency.

Owner:SHANGHAI JIAO TONG UNIV

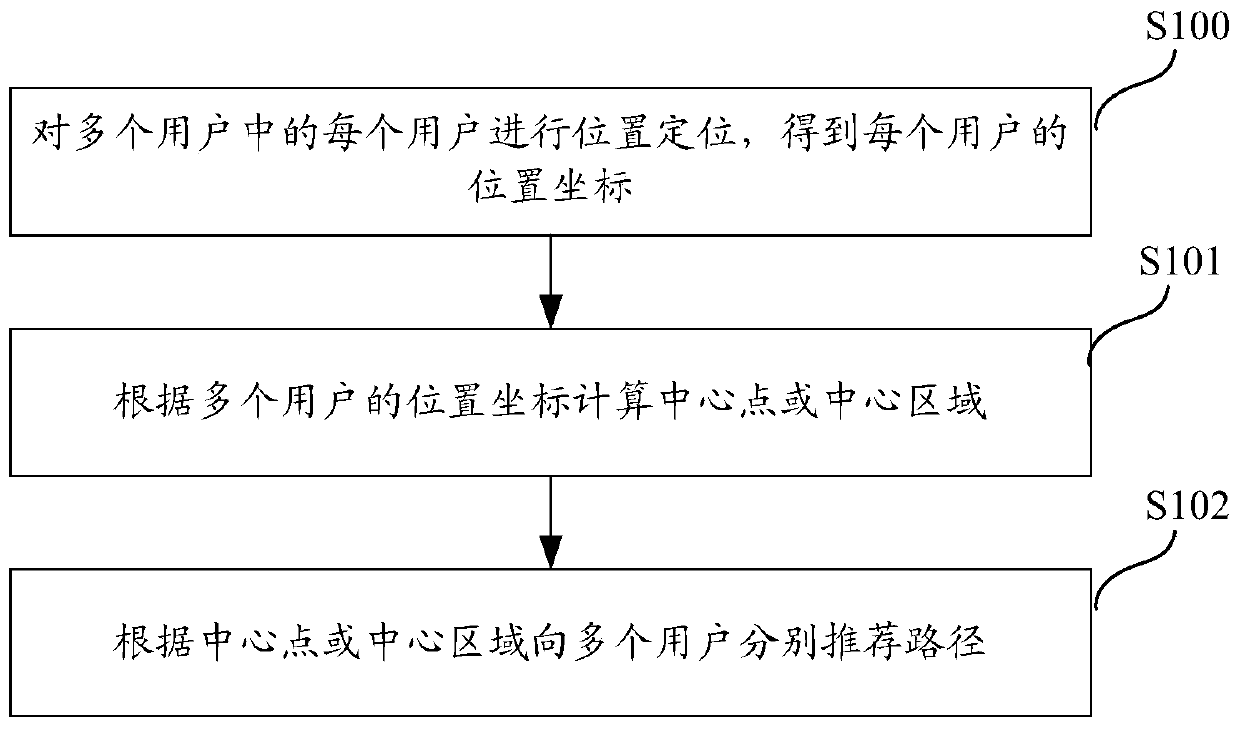

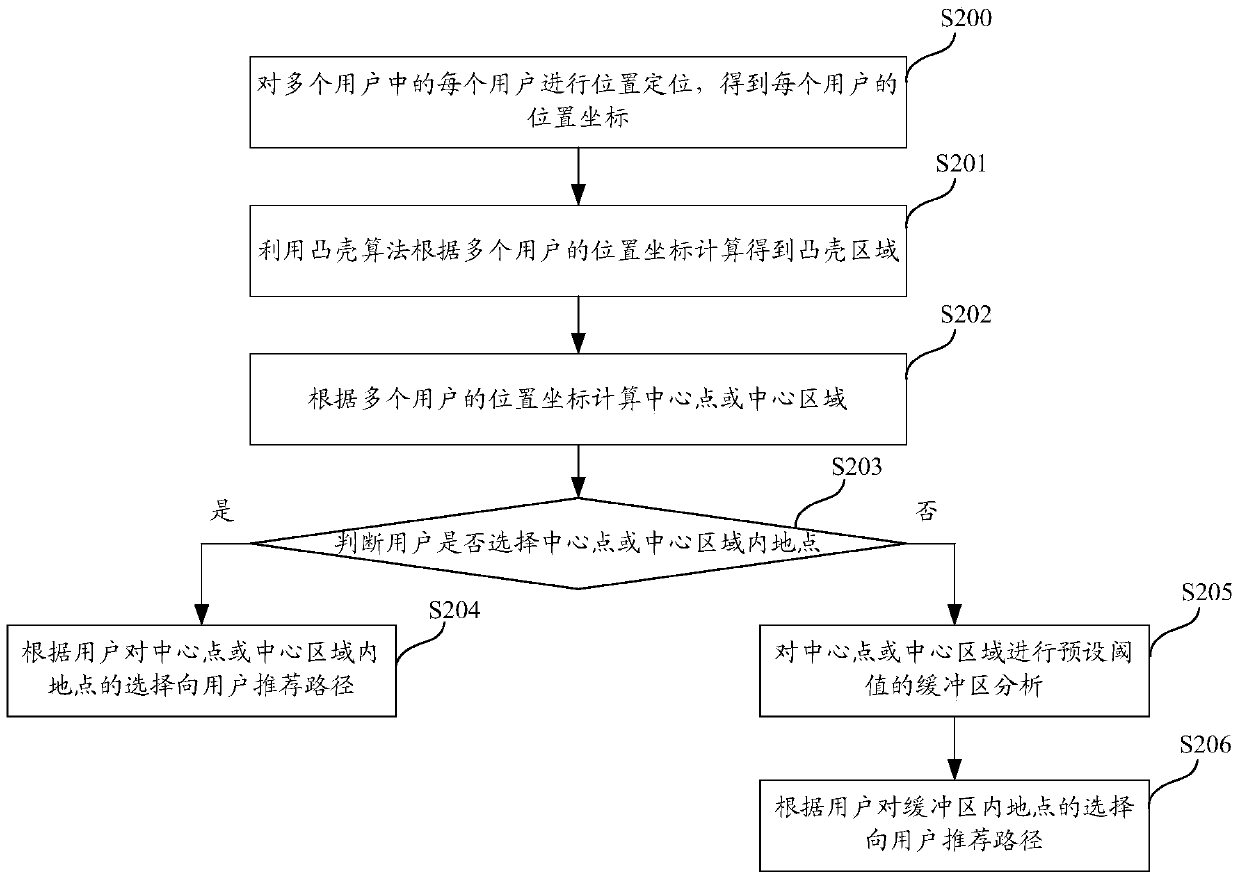

Route calculation method and device for travel by multiple users

ActiveCN105871969BAlmost timeWaste timeInstruments for road network navigationLocation information based serviceHuman–computer interactionCalculation methods

Owner:FAFA AUTOMOBILE (CHINA) CO LTD

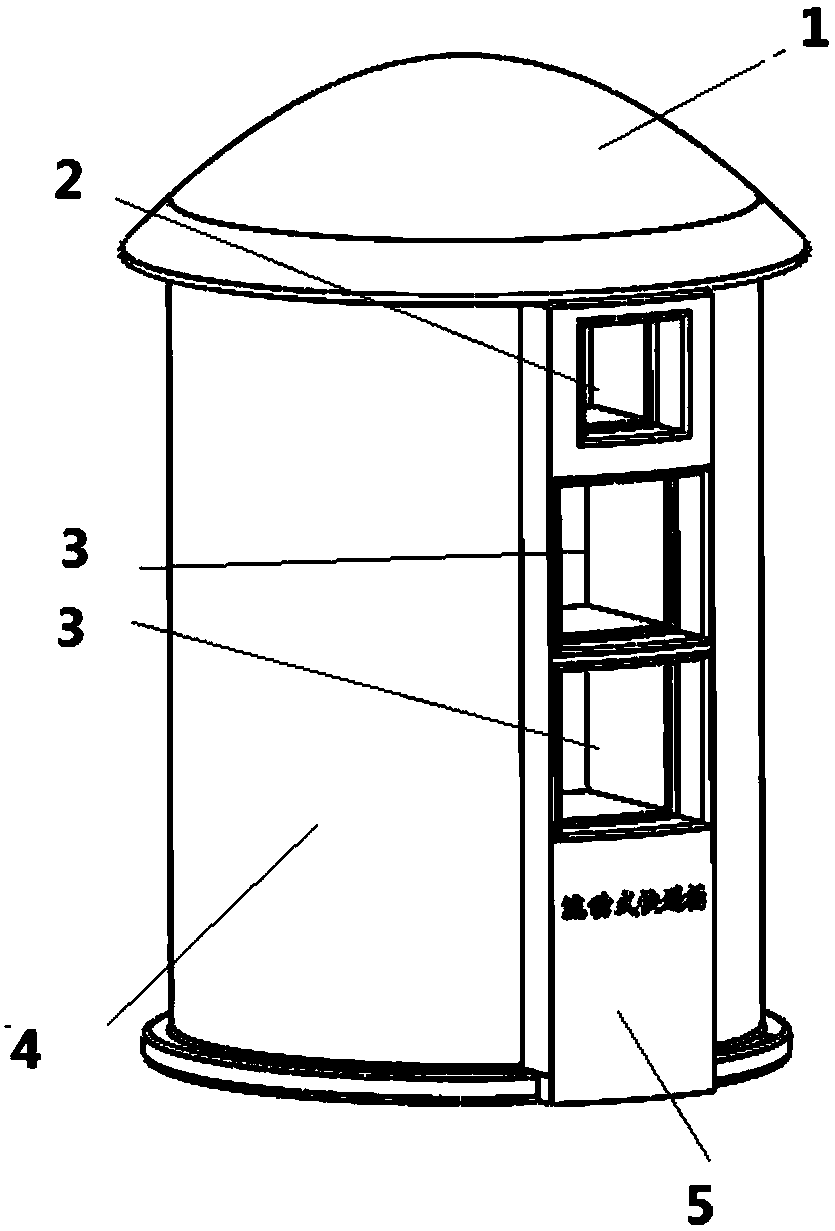

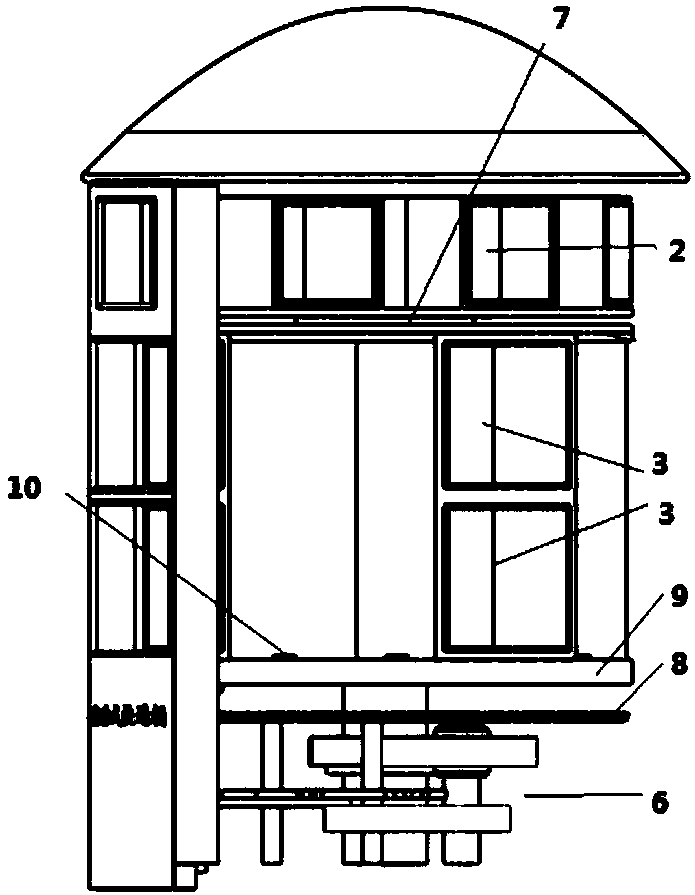

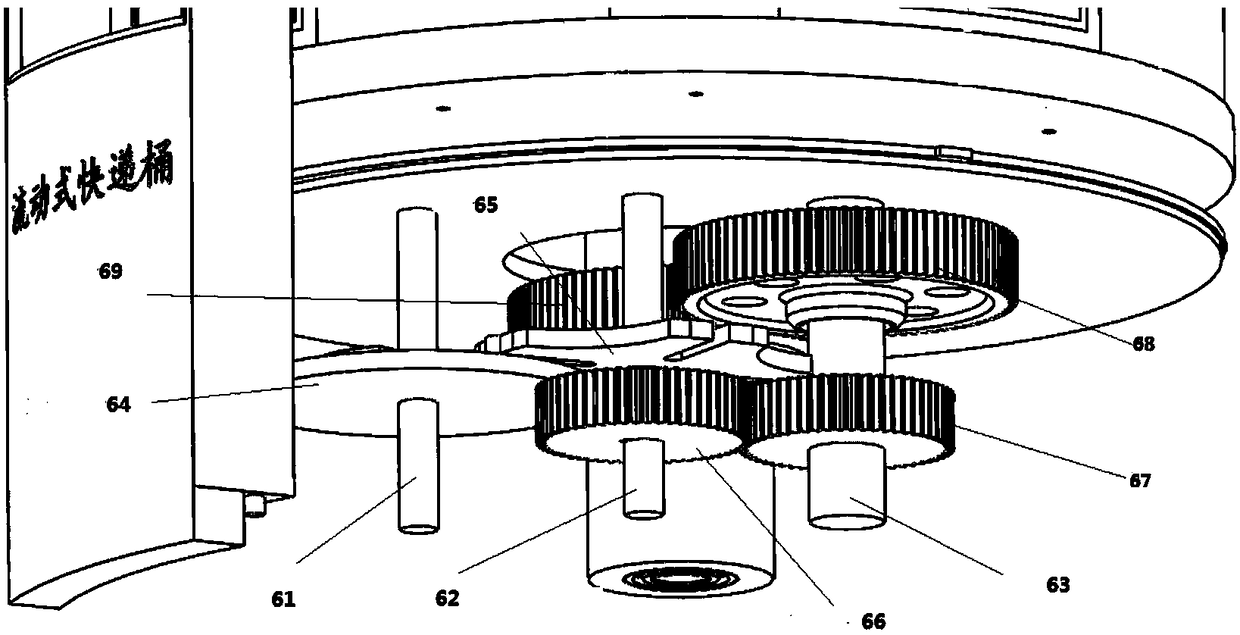

Mobile Express Bucket

InactiveCN105730820BSimple structureEasy PickupContainer/bottle contructionRigid containersResting timePassword

The invention discloses a mobile express delivery box. The mobile express delivery box comprises a shell and a top cover, one side of the shell is provided with a door, a rotary bottom plate is arranged in the shell, eight small article containers are arranged above four large article containers which are arranged on the rotary bottom plate, the rotary bottom plate is connected with a motor through a transmission system, and the small article containers are connected with the large article containers through planetary gear reducers. The four large article containers are uniformly and circumferentially distributed, and when an input shaft rotates by one circle and the rotary bottom plate rotates by 90 degrees, one of the large article containers faces the door; the eight small article containers are uniformly and circumferentially distributed, and when the large article containers rotate by 90 degrees and the small article containers rotate by 45 degrees, one of the small article containers face the door. A slide groove and a lock are arranged between the shell and the door, and the door is provided with small doors which are provided with password unlocking devices respectively. The mobile express delivery box is simple in structure, delivered articles can be fetched conveniently, clients are allowed to freely arrange time for fetching the delivered articles, occupancy of working and resting time is avoided, and manpower resources are greatly saved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com