Mobile Express Bucket

A mobile, shell technology, applied in rigid containers, locking equipment, bottle/can parts, etc., can solve the problems of wasting time, unable to walk away, short customer time period, etc., saving human resources, simple structure, The effect of easy pickup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

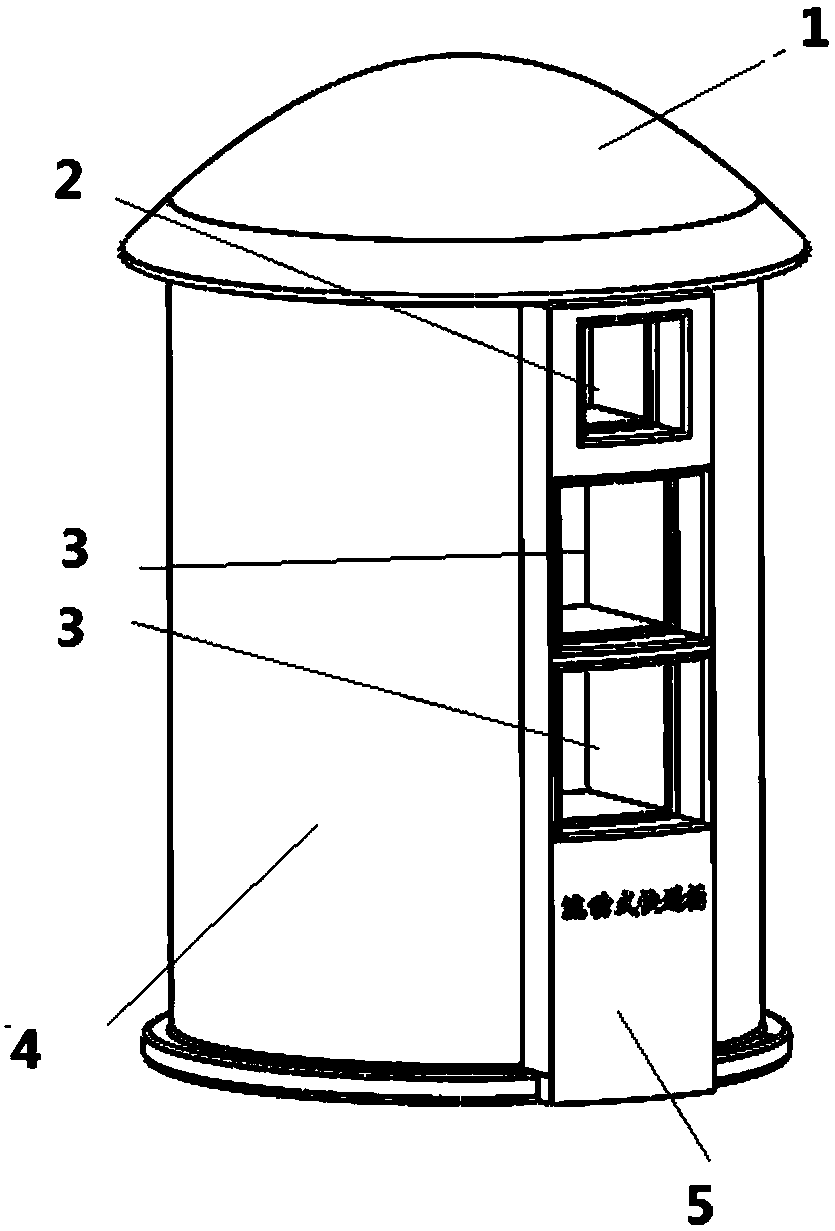

[0025] The preferred embodiment of the mobile express barrel of the present invention is:

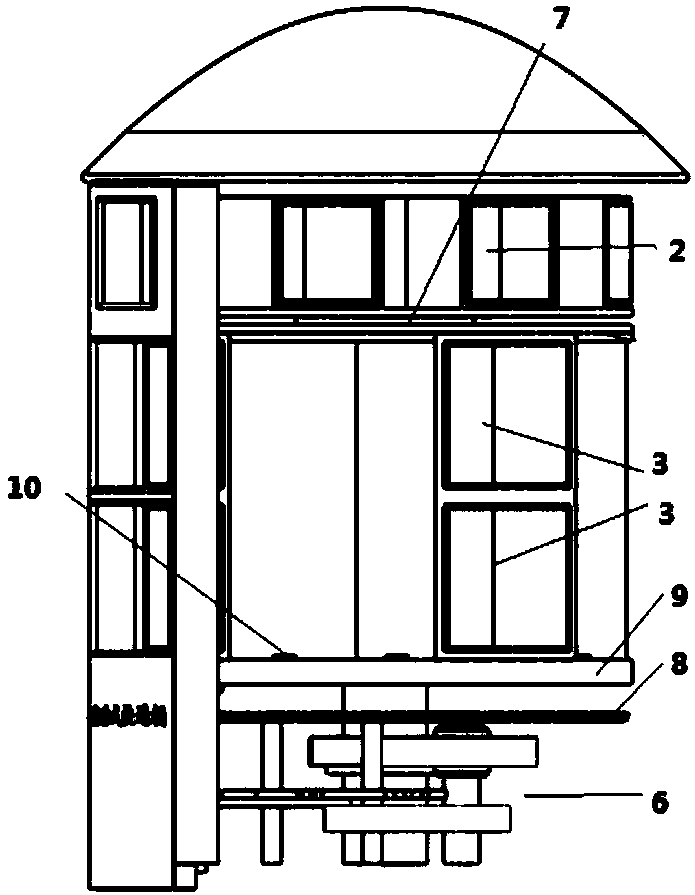

[0026] It includes a casing and a top cover, a door is provided on one side of the casing, a rotating chassis is arranged inside the casing, a large object box is arranged on the rotating chassis, and a small object box is arranged above the large object box. The rotating chassis is connected to the motor through a transmission system, and the small object box is connected to the large object box through a planetary gear reducer.

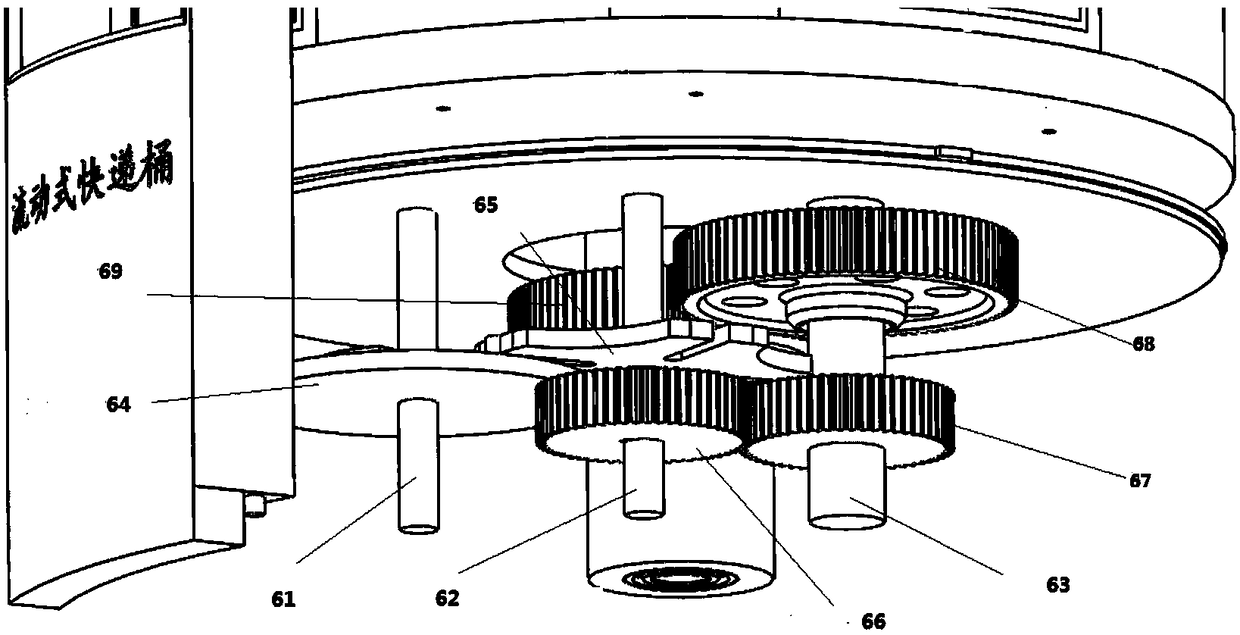

[0027] The motor is connected to the input shaft, and the input shaft is connected to the No. 2 shaft through a sheave mechanism at an angular velocity of 4:1, and the No. 2 shaft is connected to the No. 3 shaft at an angular velocity of 1:1 through gear transmission. The shaft is connected to the rotating chassis at an angular velocity of 1:1 through gear transmission. There are four large object boxes distributed evenly on the circumference. When the input ...

specific Embodiment

[0039] A mobile express bucket is composed of a top cover 1, a small item box 2, a large item box 3, a casing 4, a door 5, a transmission system 6, a planetary gear reducer 7, a shaft plate 8, and a rotating chassis 9, etc. Courier final delivery process. The motor is connected to the input shaft 61, and the input shaft 61 and the second shaft 62 have a sheave mechanism. Using the characteristics of this mechanism, the input shaft 61 rotates once, and the second shaft 62 rotates 90 degrees. The second shaft 62 is driven by gears, and the The angular velocity is transmitted to the No. 3 shaft 63 by 1:1, and the No. 3 shaft 63 is also transmitted to the rotating chassis 9 by 1:1 through gear transmission. Like this, input shaft 61 turns a circle, and rotating chassis 9 turns 90 degrees, and large object box 3 is installed on rotating chassis 9 by 90 degrees (using bolt connection) just in time, and 4 large object boxes are arranged around rotating chassis 9 circumferences, No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com