Patents

Literature

240results about How to "Waste time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

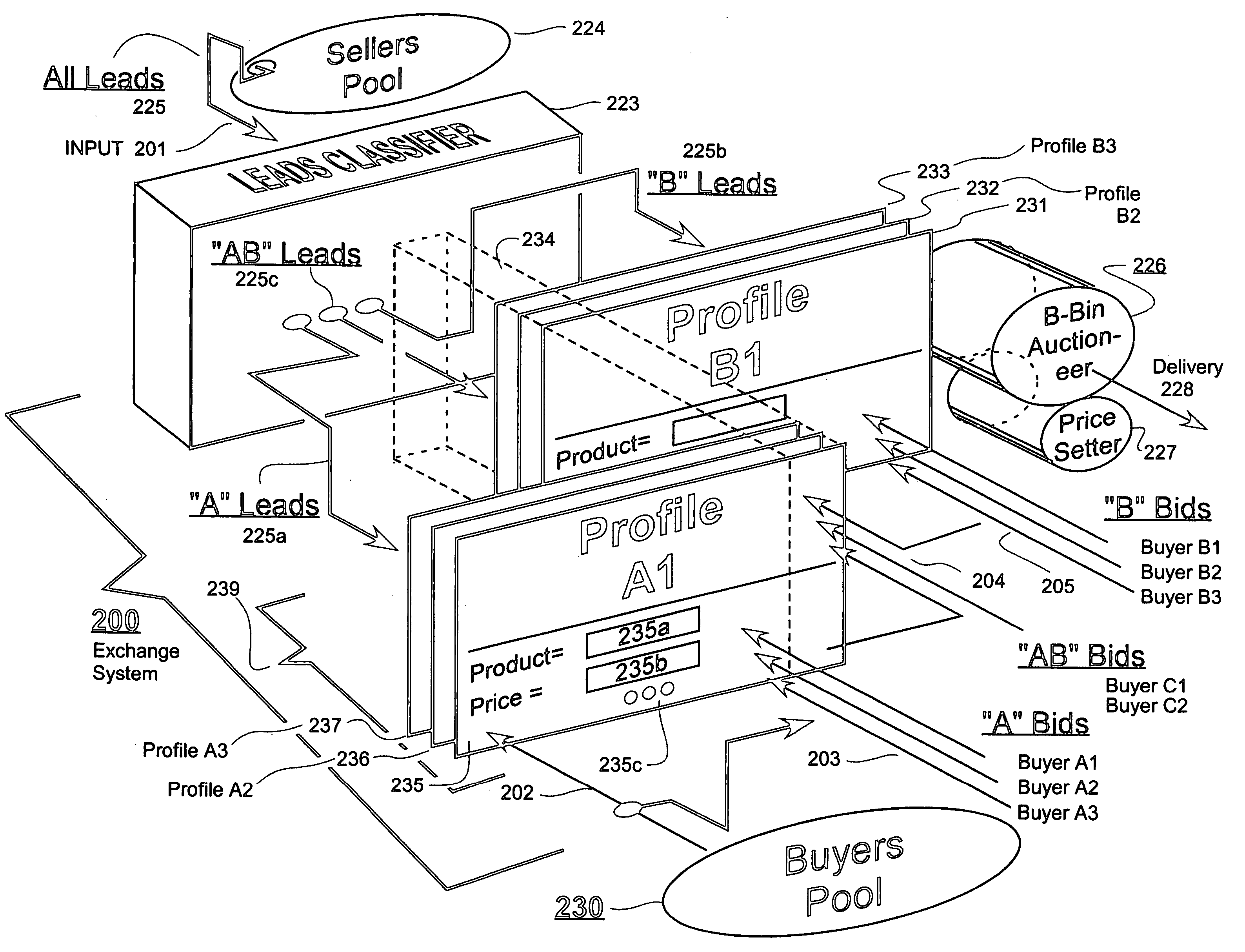

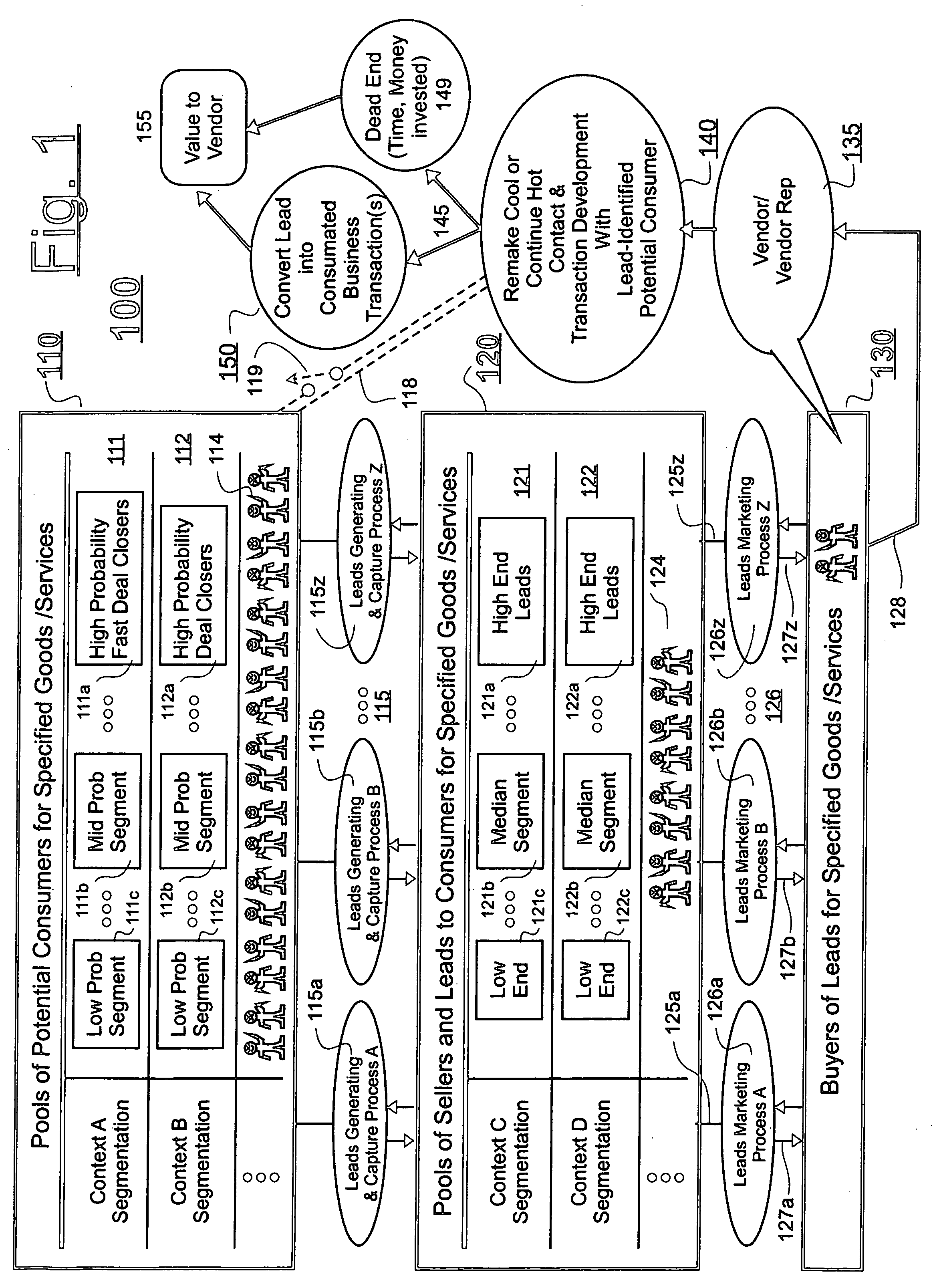

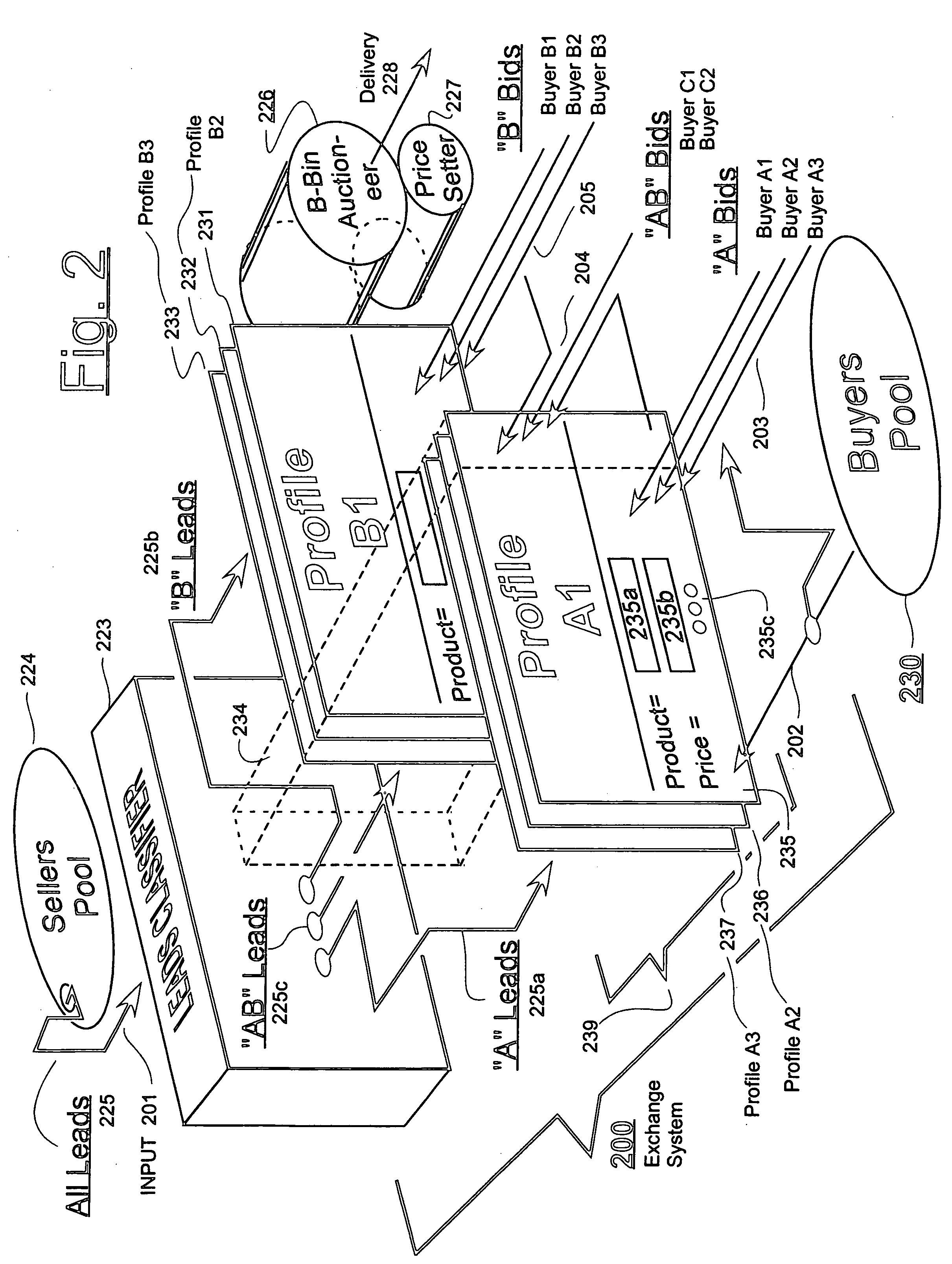

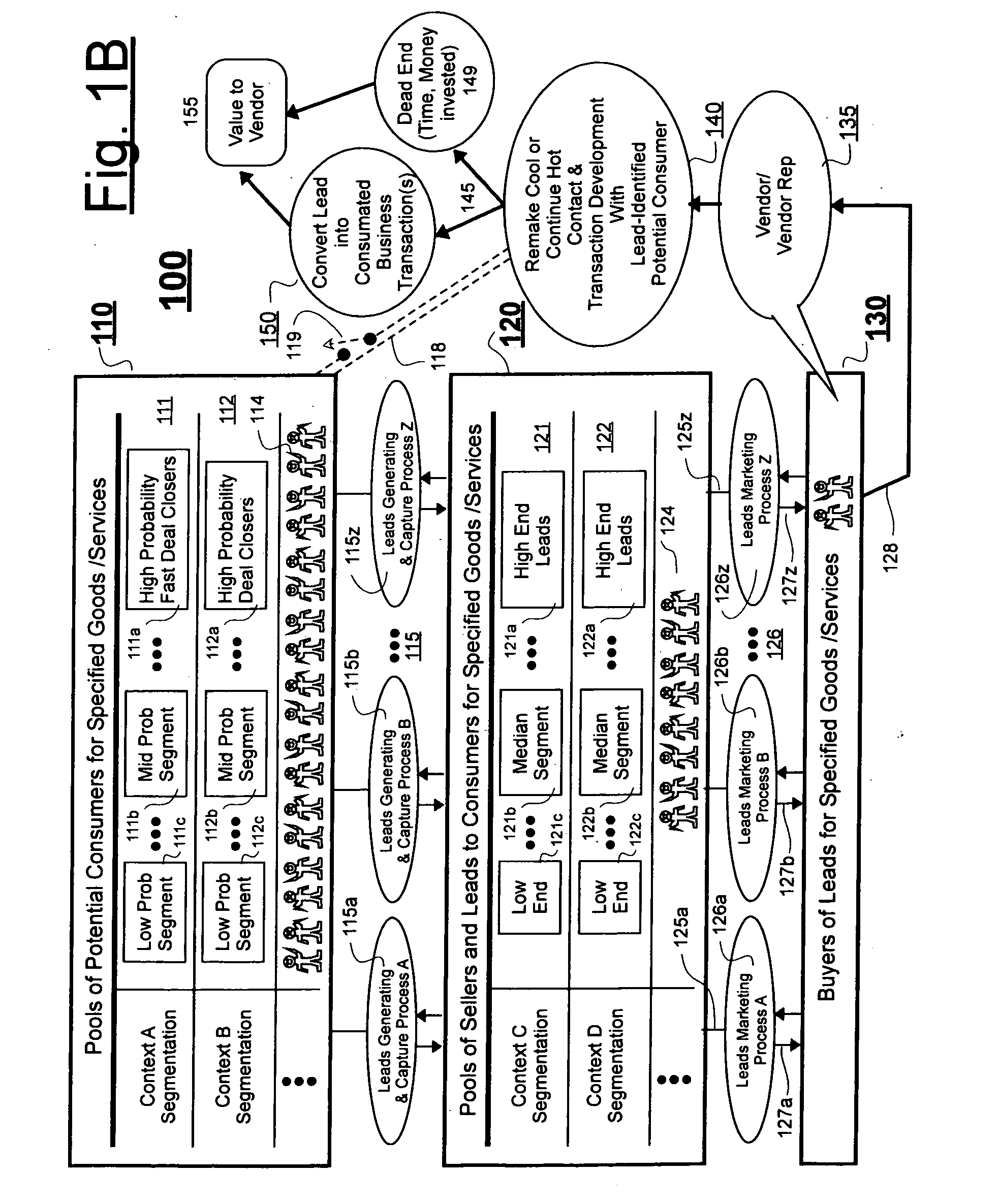

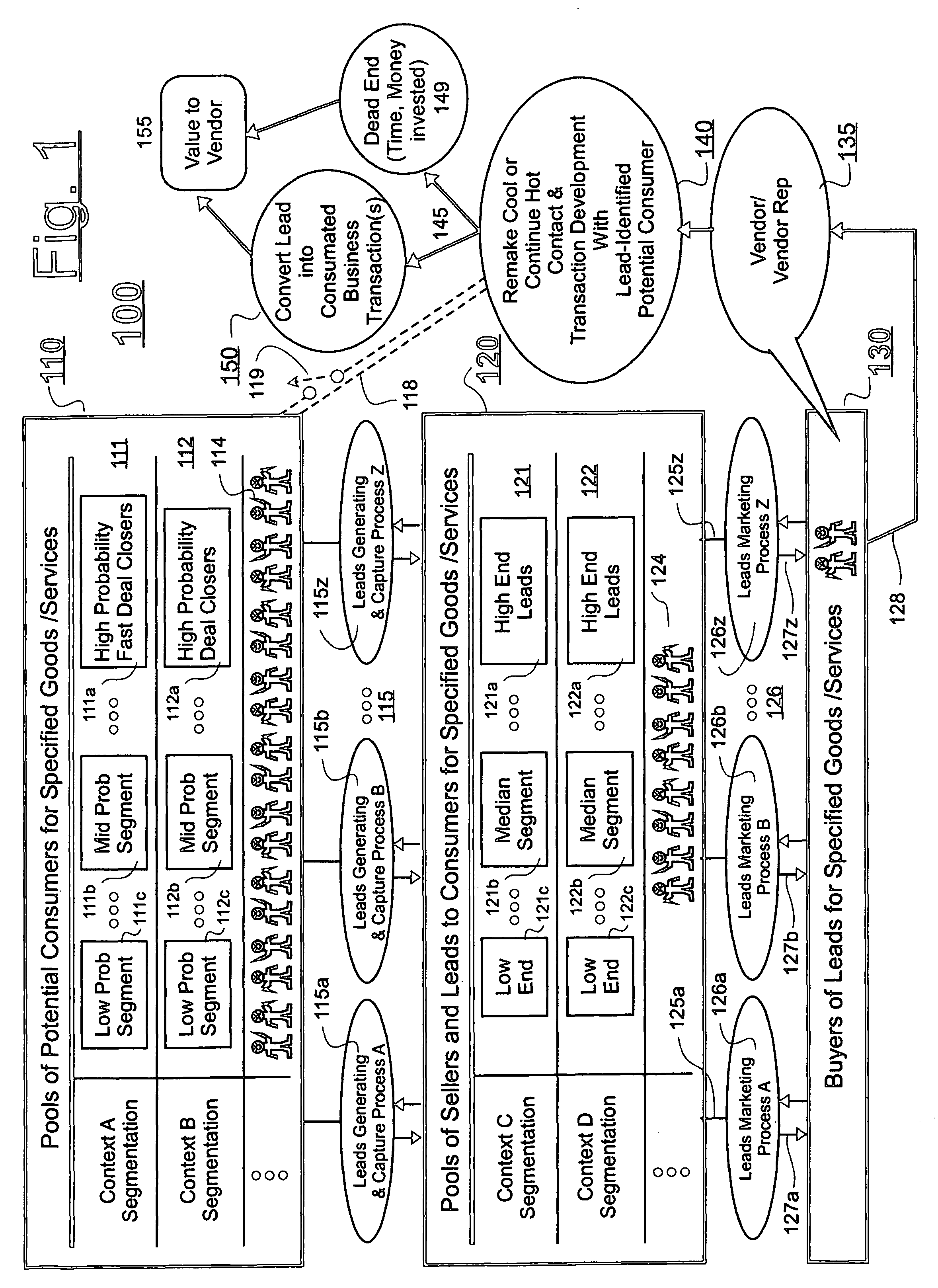

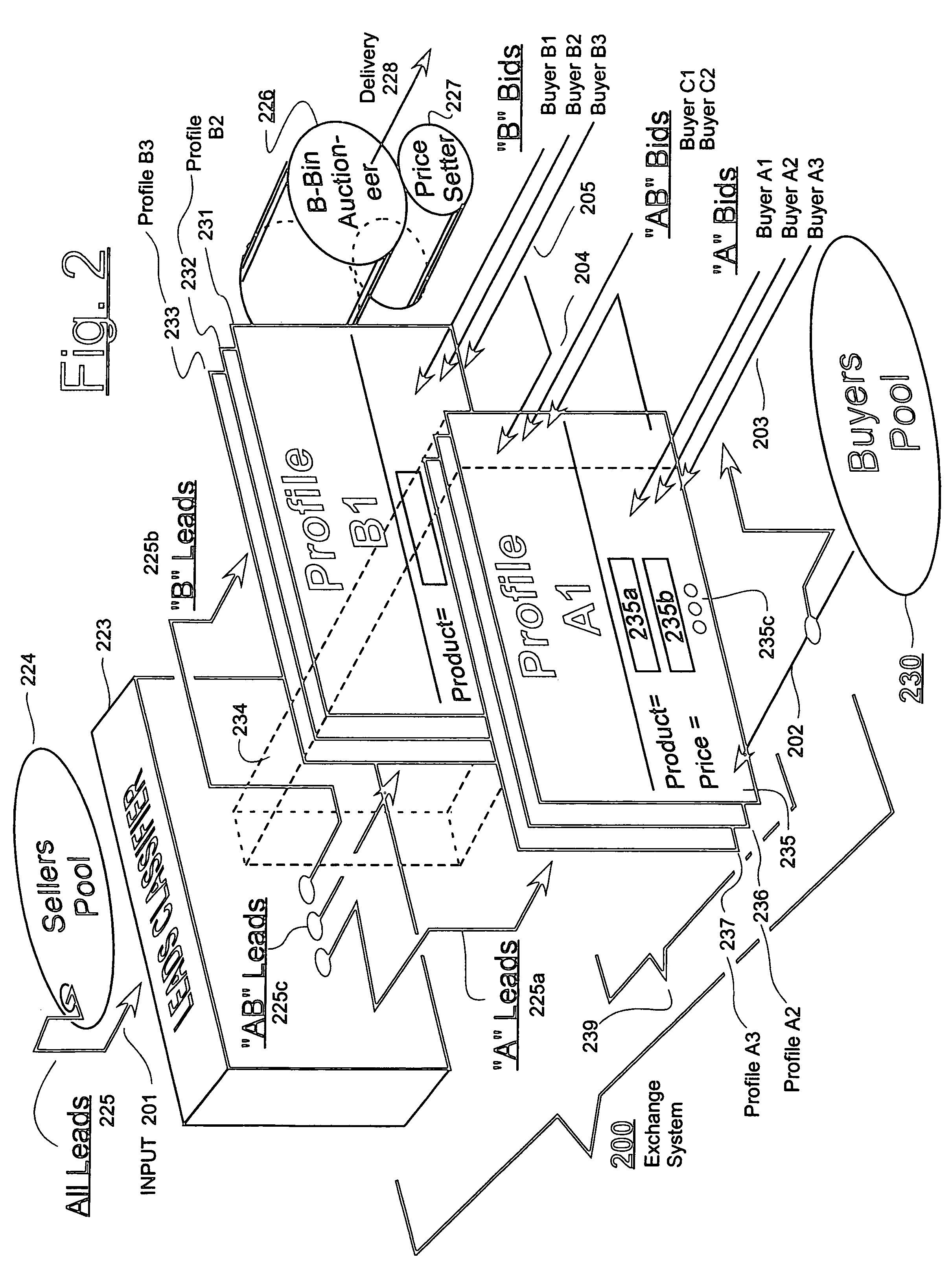

System for implementing automated open market auctioning of leads

ActiveUS20060041500A1Reduce probabilityMaximize auction-generated revenueFinanceCommerceQuality ratingEngineering

In an automated leads-and-bids exchange system, bid profiles are defined to describe desires of lead buyers. Received leads are matched to active ones of the bid profiles whose specifications the leads substantially match. An auctioning subsystem finds the highest one or group of bids for each given lead. A quality rating database rates the quality of leads provided by different sellers. A price discounting engine discounts the amount paid to sellers who are rated as inferior sources of leads.

Owner:LEADPOINT

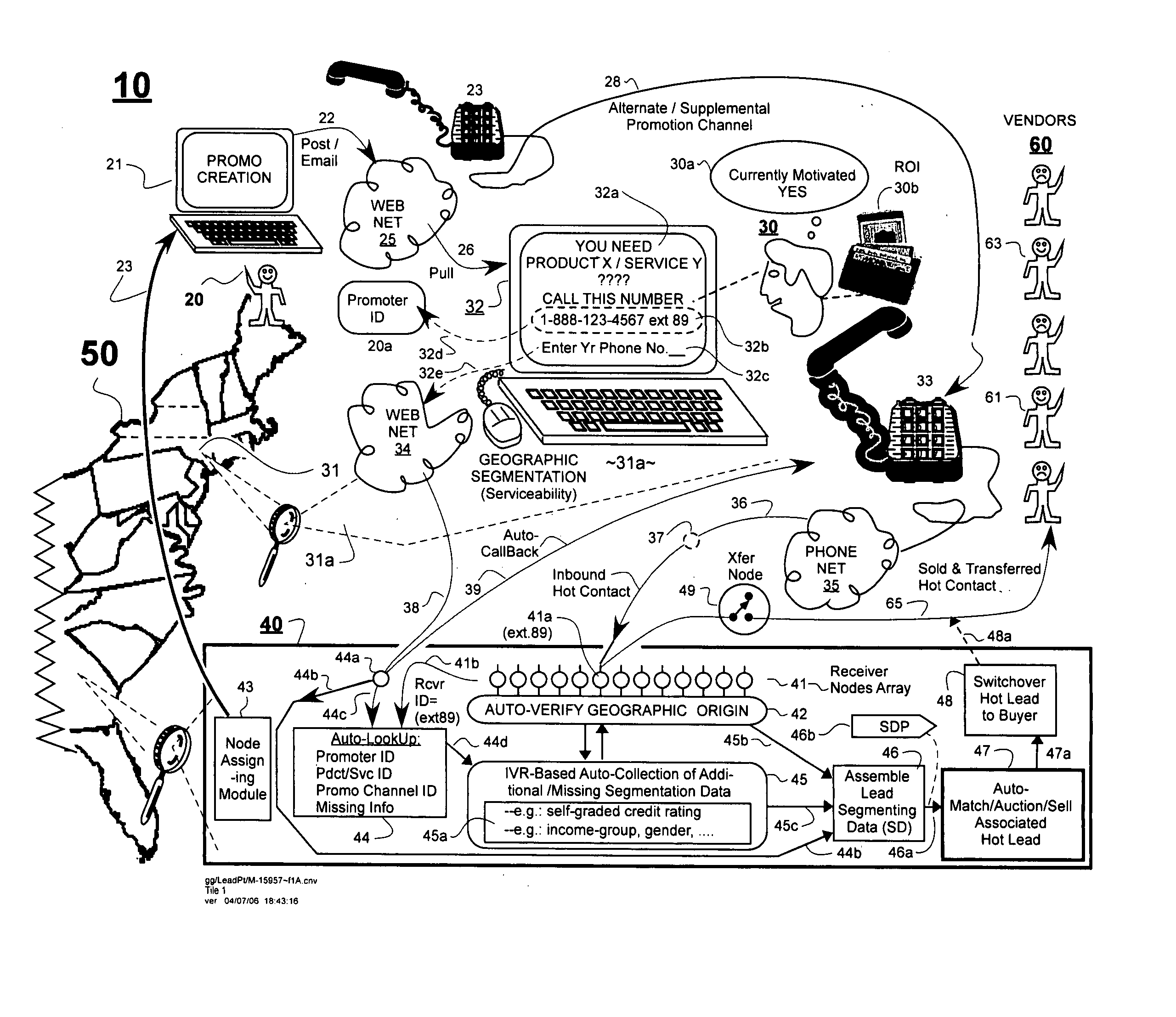

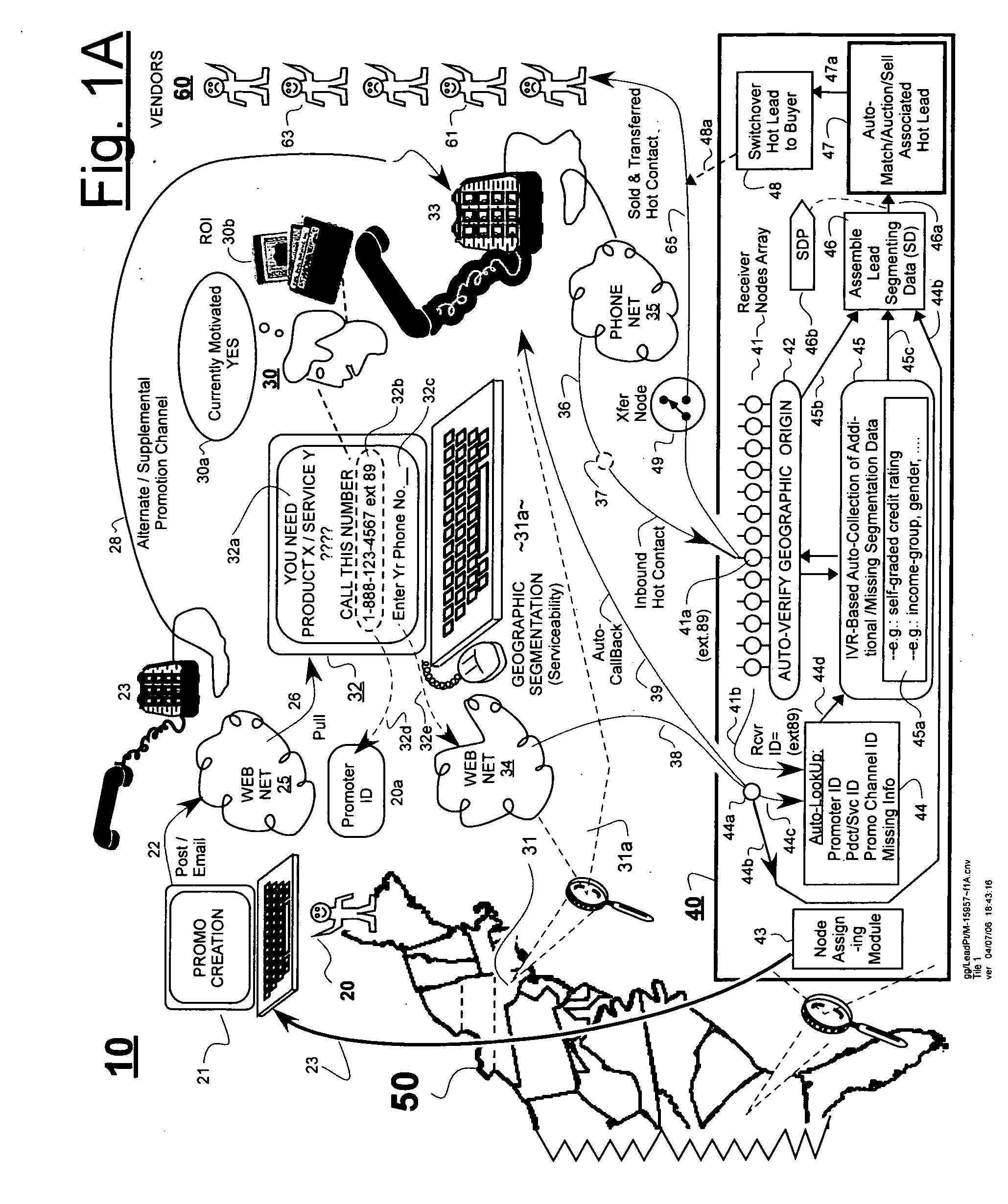

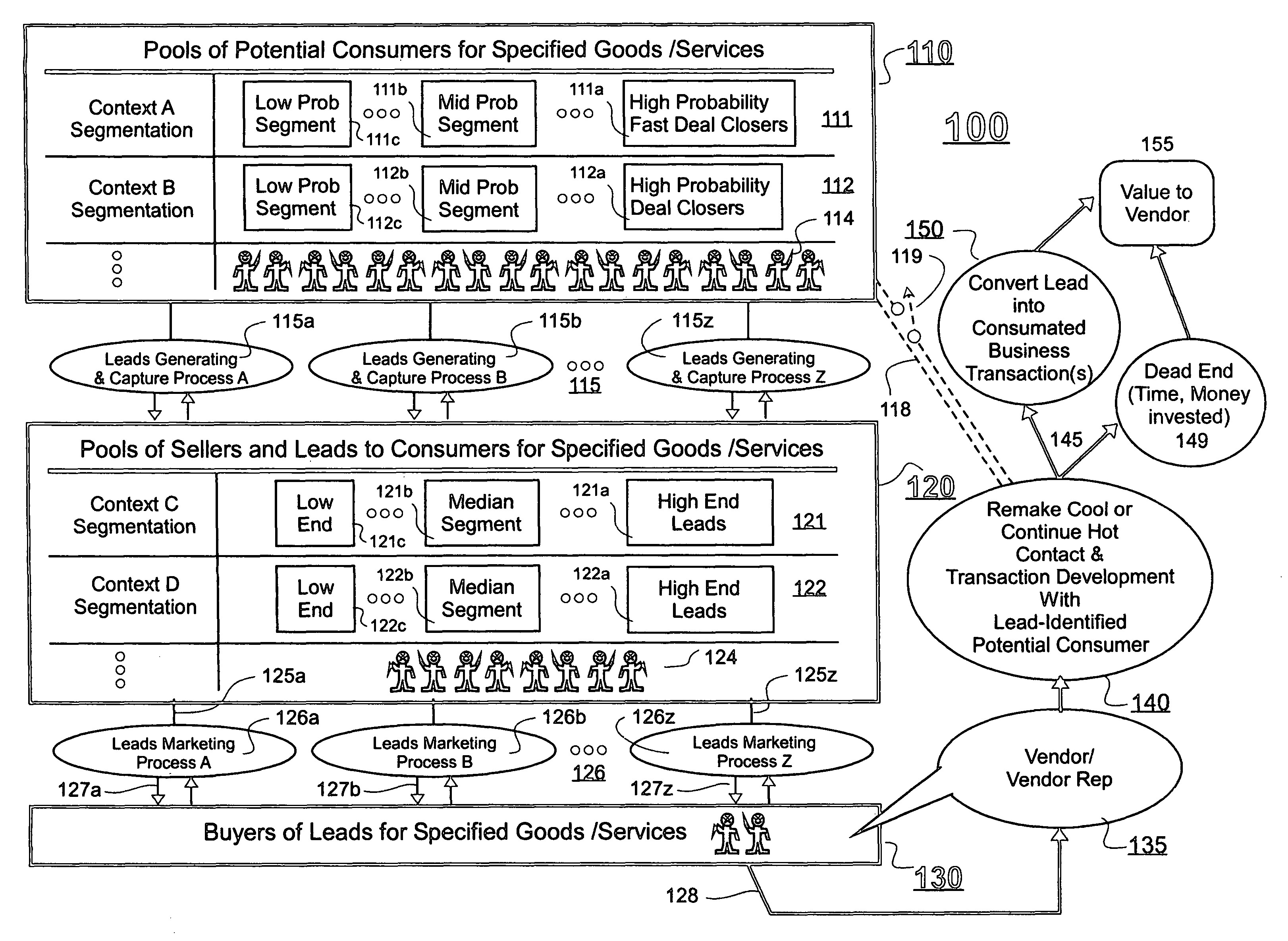

Automated attachment of segmentation data to hot contact leads for facilitating matching of leads to interested lead buyers

ActiveUS20060265259A1Reduce probabilityWaste timeFinanceSpecial data processing applicationsLive voiceWeb site

In an automated leads-and-bids matching system, bid profiles are defined to describe desires of lead buyers. Received leads are matched to active ones of the bid profiles whose specifications the leads substantially match. Lead segmentation data is captured on-the-fly for example by inducing potential consumers to navigate their way through tree-organized web sites that categorize the consumers according to their geographic location, income / revenue range, class of products desired and / or other attributes. Live voice or other telecommunication connections to the pre-classified consumers are coupled to corresponding, pre-classified telecommunication nodes of a call processing system. The call processing system deduces the segmentation data of the consumers from the identities of the pre-classified nodes through which their connections pass. The deduced segmentation data is passed to an automated matching system or auctioning subsystem that finds the highest bids for each given lead. A quality rating database rates the quality of leads provided by different sellers. A price discounting engine discounts the amount paid to sellers who are hot-rated as sources of inferior leads.

Owner:LEADPOINT

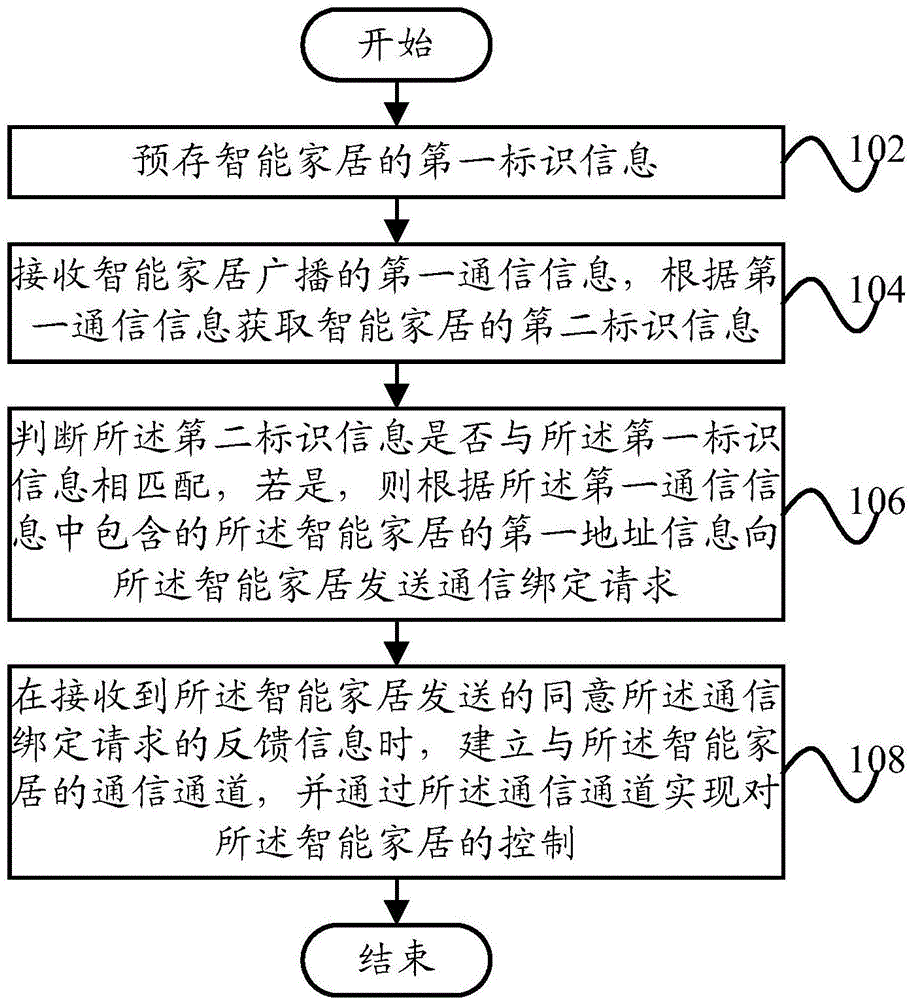

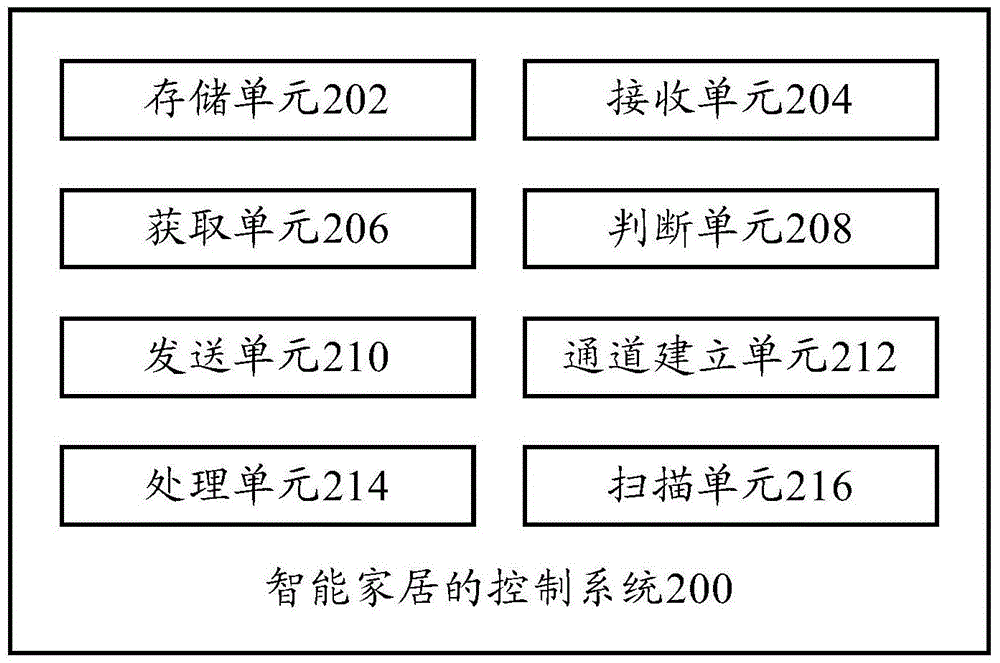

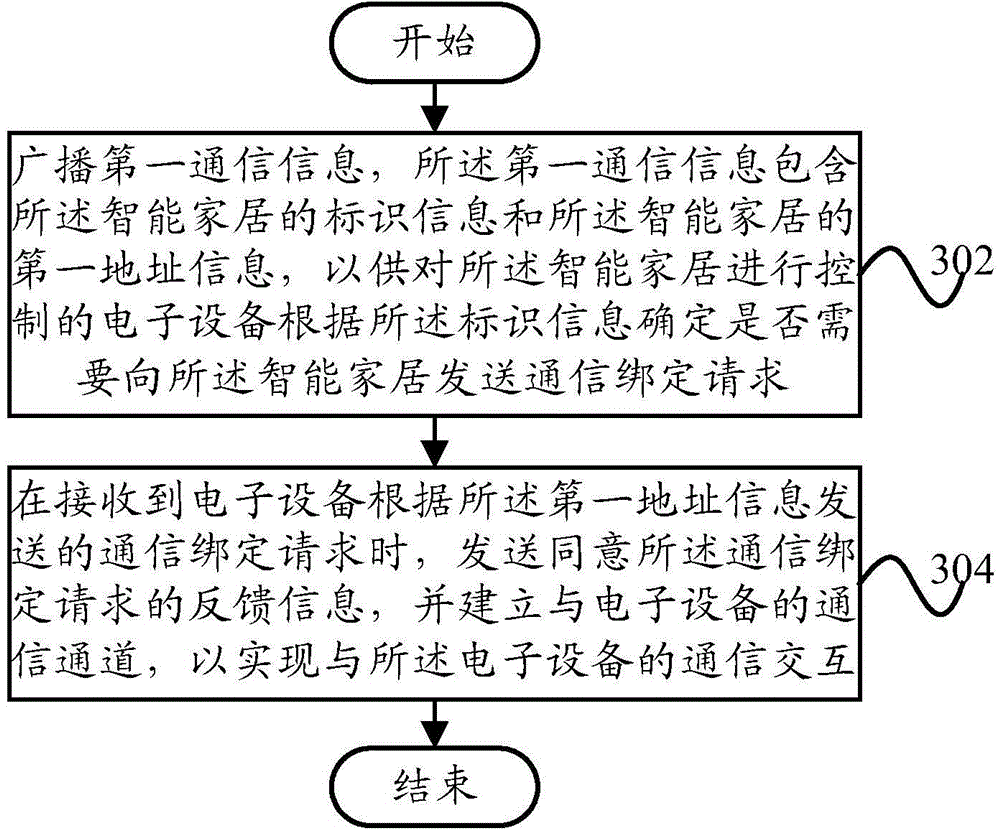

Smart home, smart home control method, control system and electronic equipment

ActiveCN104375497AAffect normal workAffect user experienceTotal factory controlProgramme total factory controlControl systemElectric equipment

The invention provides a smart home, a smart home control method, a control system and electronic equipment. The smart home control method includes: prestoring first identification information of the smart home; receiving first communication information of smart home broadcast, and acquiring second identification information of the smart home according to the first communication information; judging whether the second identification information is matched with the first identification information or not, and if yes, sending a communication binding request to the smart home according to first address information, contained in the first communication information, of the smart home; when feedback information, consenting to the communication binding request, sent by the smart home is received, setting up a communication channel with the smart home, and controlling the smart home through the communication channel. The smart home, the smart home control method, the control system and the electronic equipment have the advantages that safety in communication between a smart terminal and the smart home can be improved, time consumption for searching in each-time connection setup between the smart terminal and the smart home is avoided, and the fact that the smart home can report the information to the smart terminal smoothly is guaranteed.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

System for implementing automated open market auctioning of leads

ActiveUS7970690B2Reduce probabilityMaximize auction-generated revenueFinanceCommerceQuality ratingEngineering

In an automated leads-and-bids exchange system, bid profiles are defined to describe desires of lead buyers. Received leads are matched to active ones of the bid profiles whose specifications the leads substantially match. An auctioning subsystem finds the highest one or group of bids for each given lead. A quality rating database rates the quality of leads provided by different sellers. A price discounting engine discounts the amount paid to sellers who are rated as inferior sources of leads.

Owner:LEADPOINT

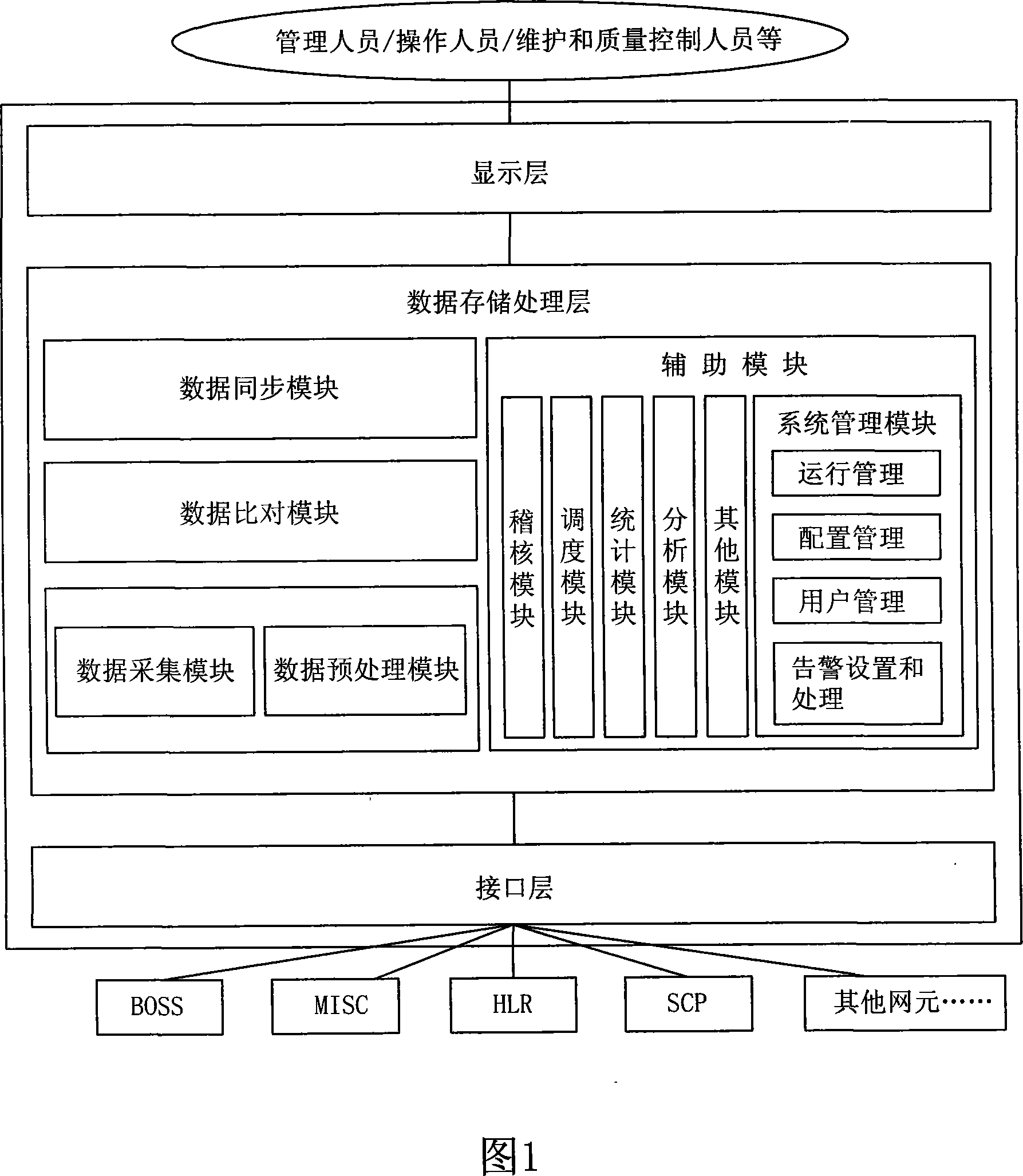

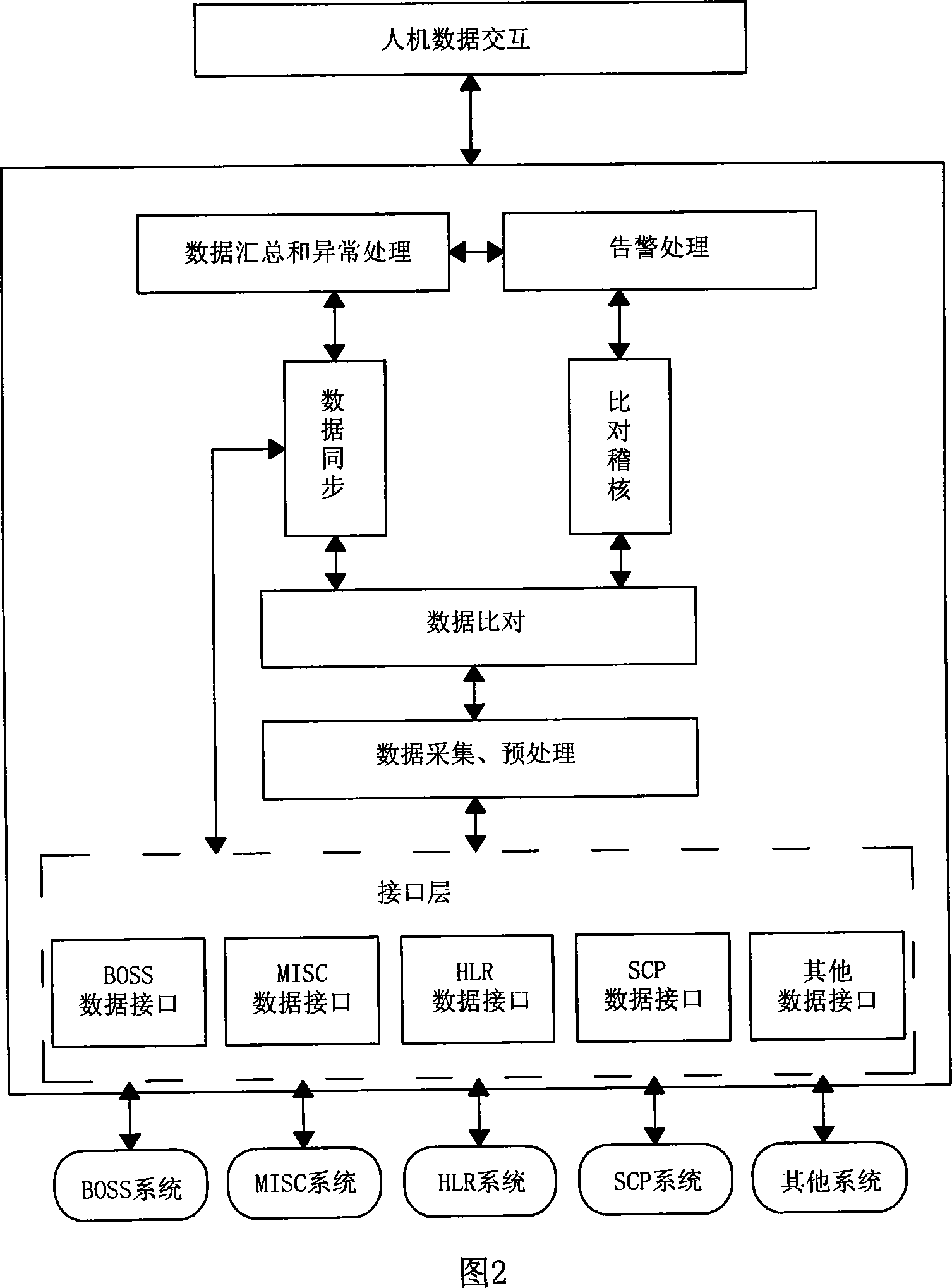

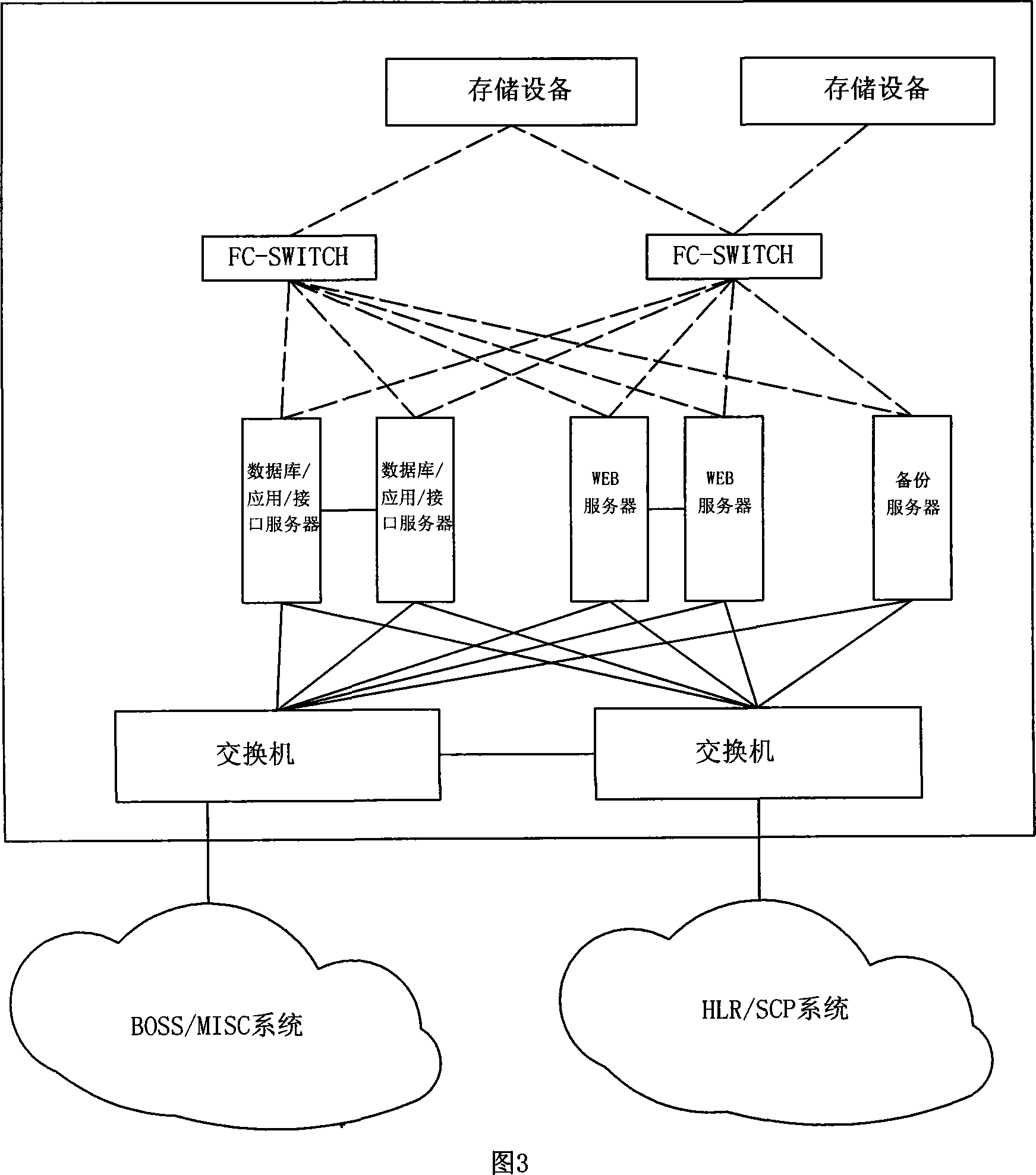

System and method for synchronizing comparison of data consistency

ActiveCN101094051AAvoid complaintsImprove effectivenessSynchronisation signal speed/phase controlData switching networksData synchronizationDifference list

It includes display layer, data storage / procession layer (SP) and system interface layer (SI). SP includes data collect module (DL), data pre-processing module (DP), data comparison module (DM), data sync, module (DS) and assistant module. Via SI, the business backup and bearing nets (BBB) realize mutual comm. between net elements (NE). From BBB, DL collects NE data requiring keeping coincident. DP / DM pre-processes and compares these data. Non-coincident data are recorded in the error list. According to availability test rule, DS verifies availability of data difference, generates corresponding synchronization data against valid data difference base on sync. rule and sends to related NE to keep coincidence of data between NEs. This invention raises data comparison synchronization level, system running efficiency and resource utilization. It ensures accuracy and coincidence of system data. It extensively is applied in multi-NE cooperation fields, such as comm., insurance and banking.

Owner:CHINA MOBILE GROUP SICHUAN

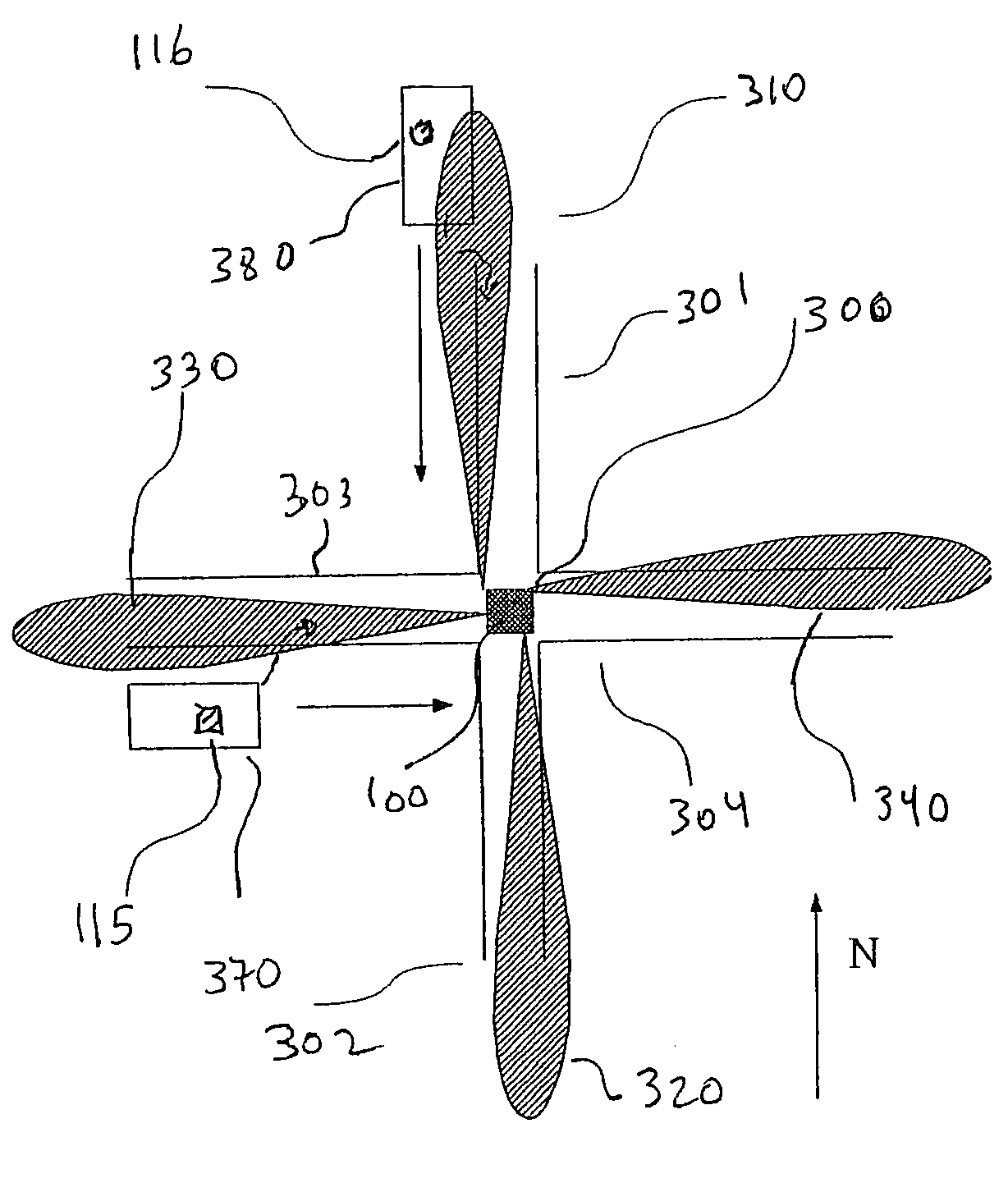

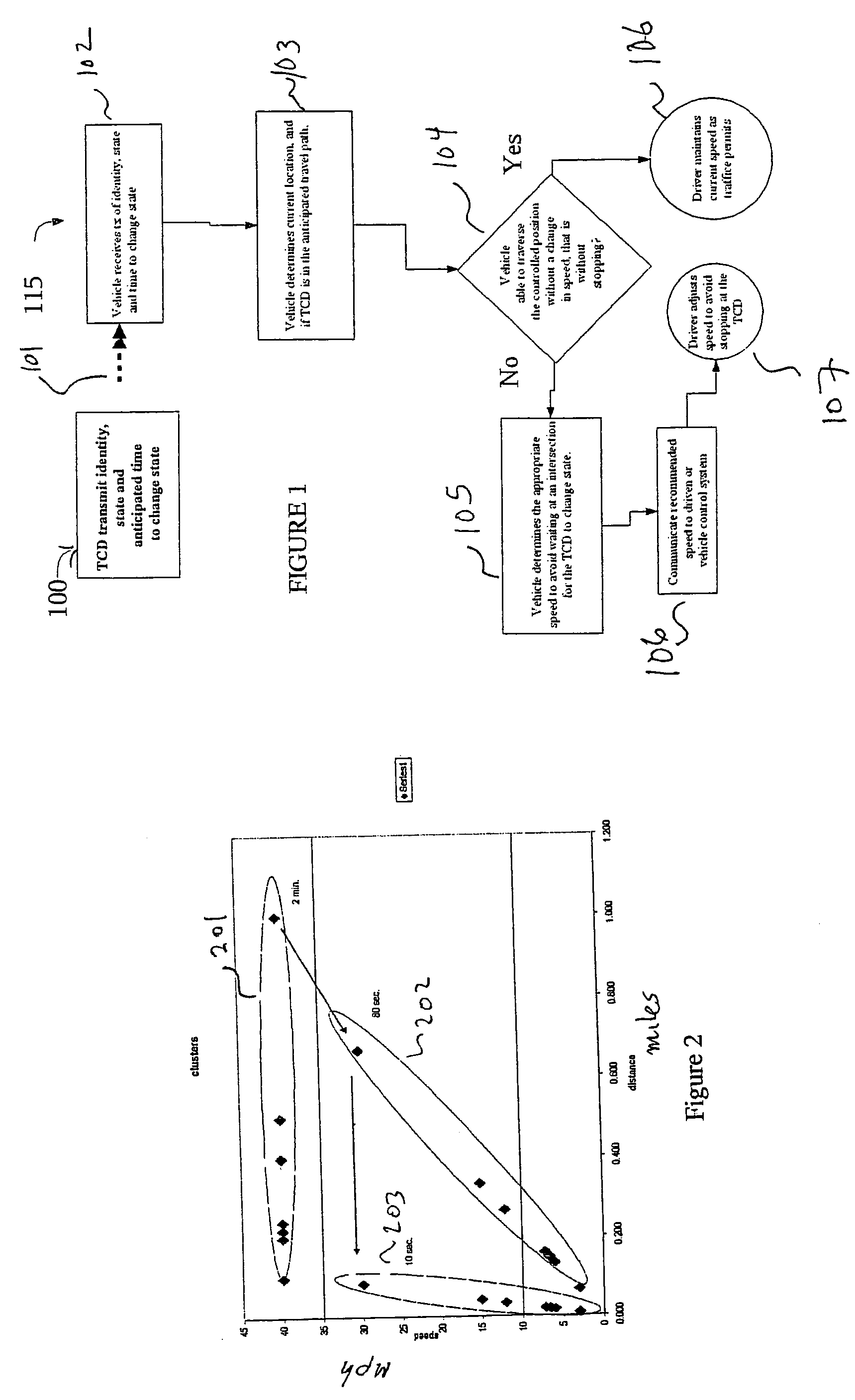

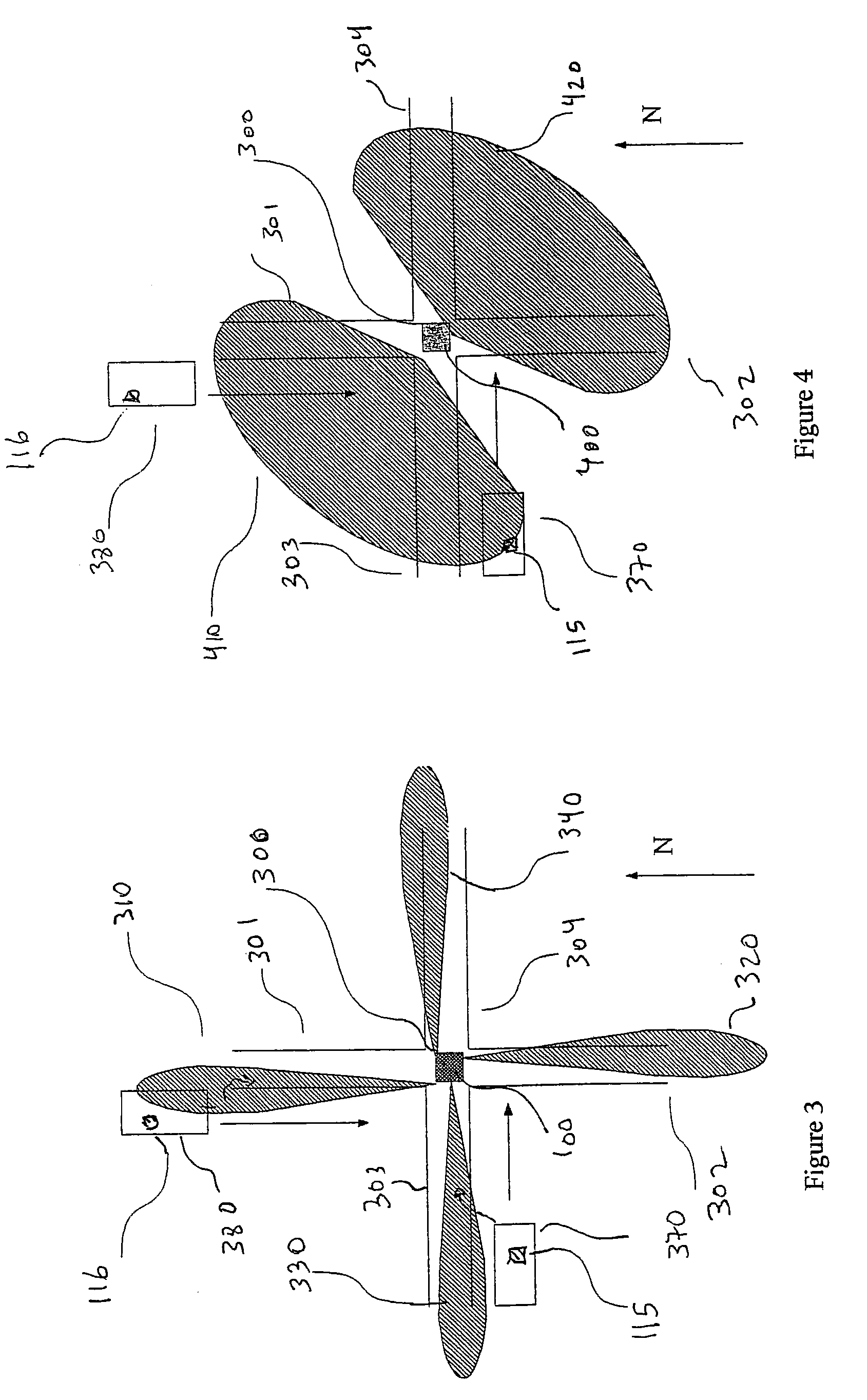

Traffic management device and system

ActiveUS7274306B2Efficient managementImprove fuel efficiencyControlling traffic signalsAnalogue computers for vehiclesEngineeringControl equipment

Owner:PUBLICOVER MARK W

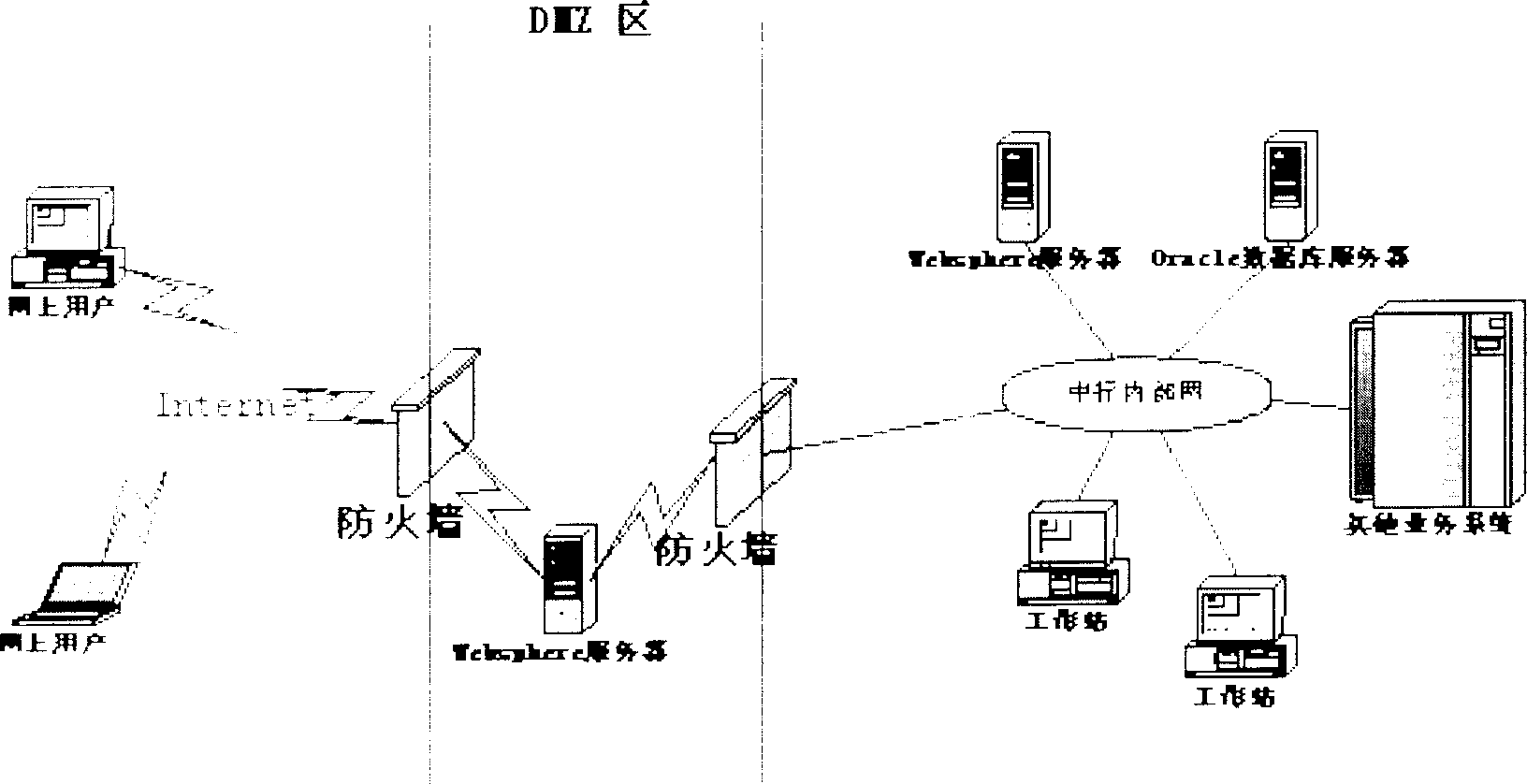

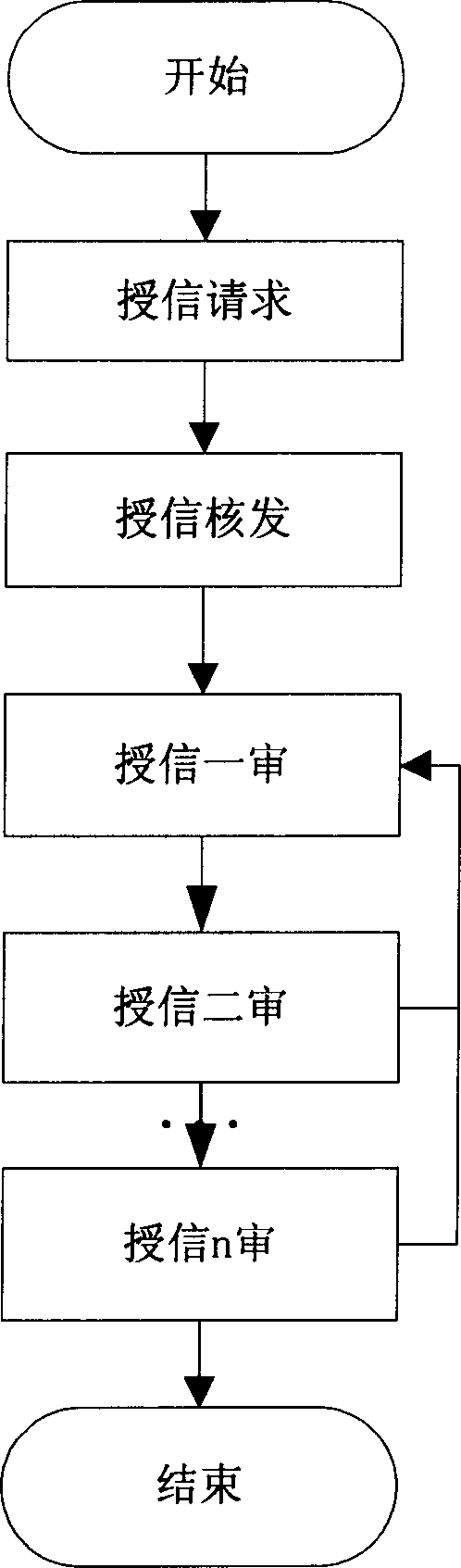

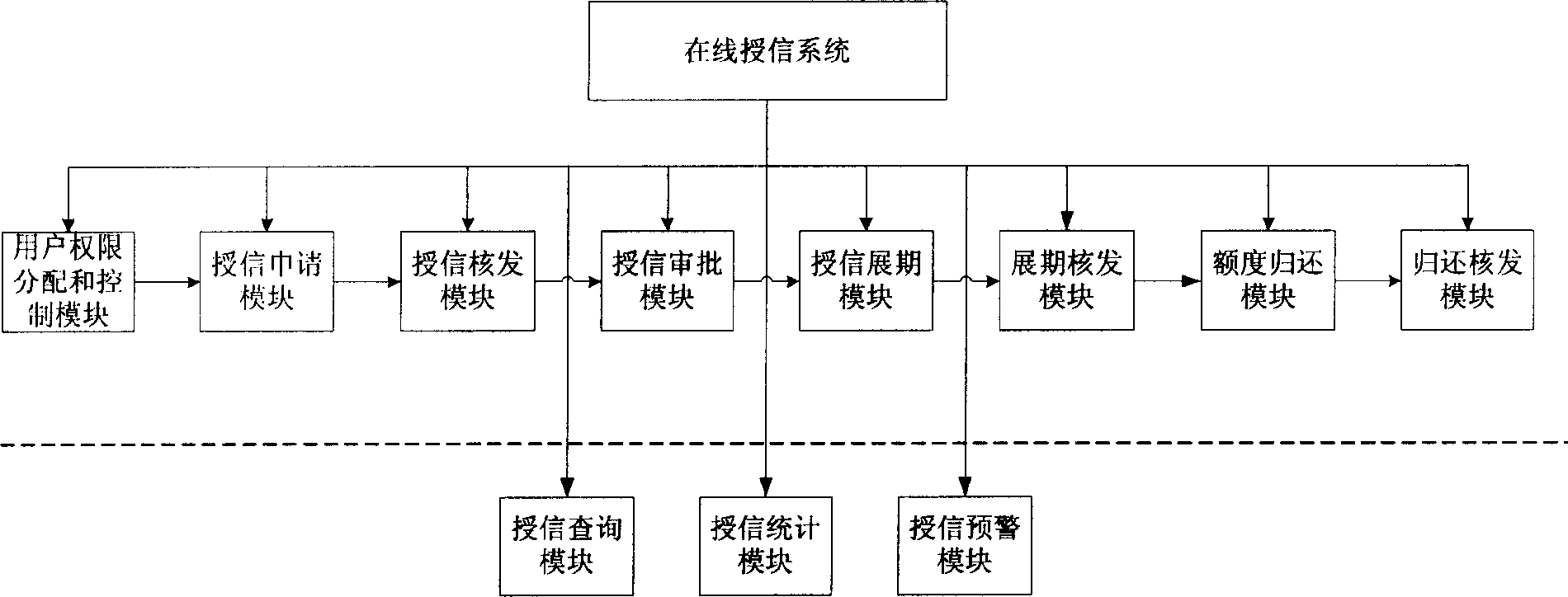

System and method for online user authorization for banks

A system of granting credit to the client on line by financial enterprise comprises user power distribution and control module, credit application module, credit checking and issuing module, credit approval module, credit extending module, extension period approval module, ceiling return module, return back checking and issuing module, credit inquiry module, credit statistic analysing module and credit prewarning module. The system can be used as control system of credit approval operation within financial enterprises.

Owner:BANK OF CHINA

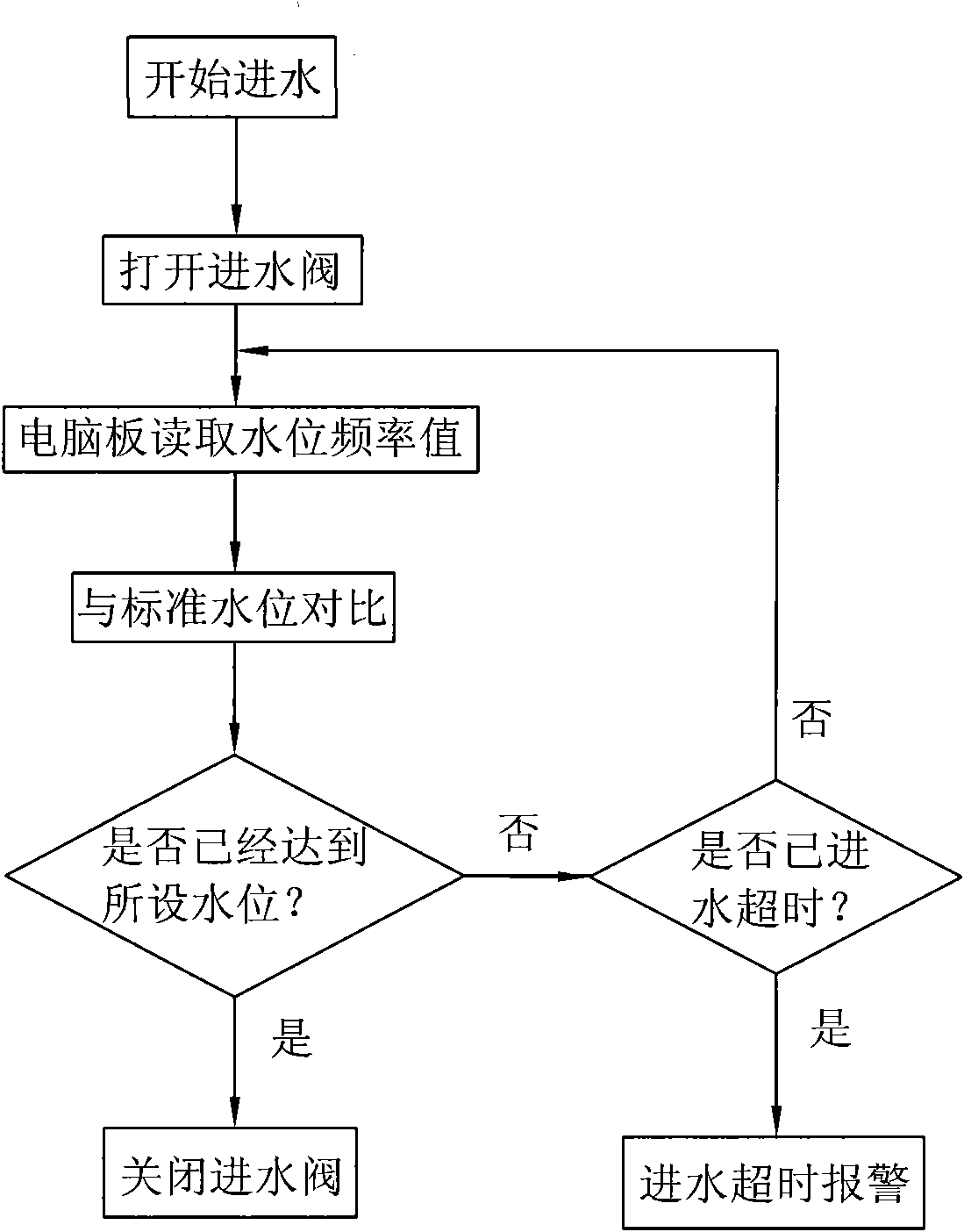

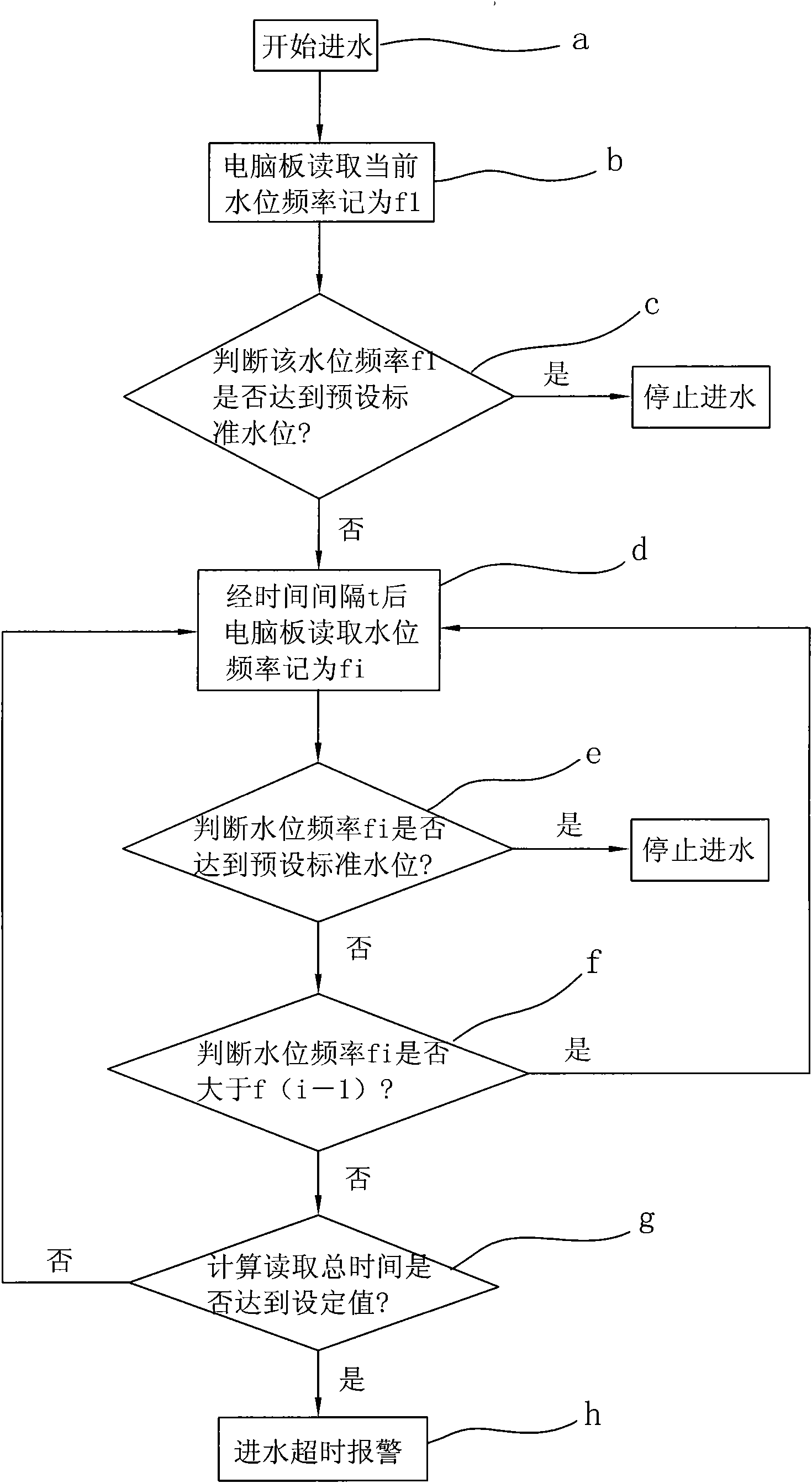

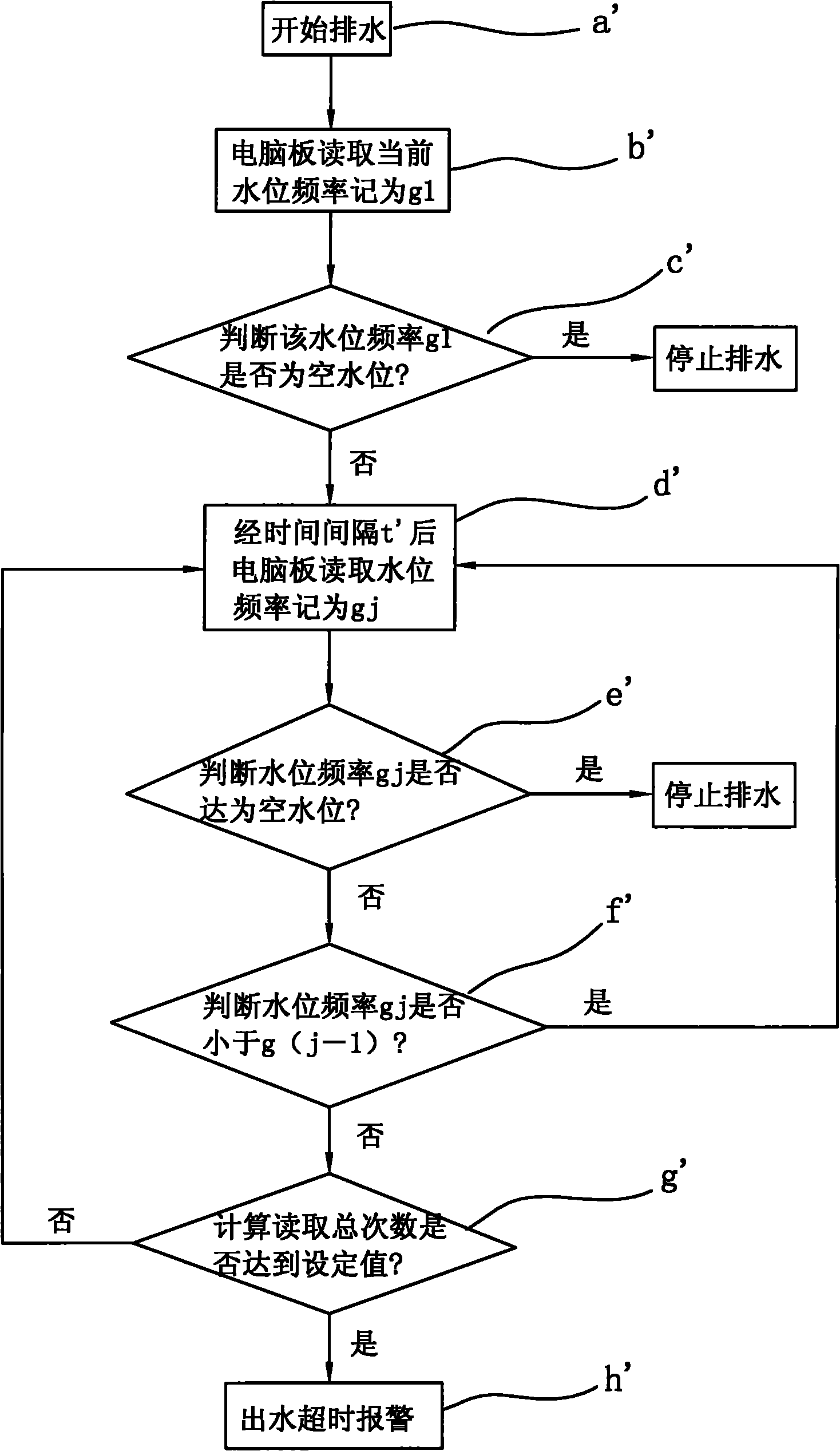

Method for monitoring water-charging process and water-discharging process of washing machine

InactiveCN101929056AAvoid wastingAvoid security issuesOther washing machinesControl devices for washing apparatusWater dischargeEngineering

The invention discloses a method for monitoring the water-charging process and water-discharging process of a washing machine. The method comprises the following steps: in the water-charging process or water-discharging process, a computer board reads the water level frequency once after a set period of time; and if the water level frequency is not changed compared with the last water level frequency and the set total times of reading and the total time water level frequency are not changed, a water-charging overtime alarm or the water-discharging overtime alarm is executed. Every time when the computer board reads the water level frequency, the water level is compared with a preset water level to judge whether to reach the preset water level; if so, the water-charging process is stopped or the water-discharging process is started; if not, the water level frequency is compared with the next water level frequency to judge whether the water level frequency is charged; and the preset water level is the washing water level or empty water level. By adopting the method of the invention, the changes of the water level can be detected dynamically in the water-charging process or water-discharging process to judge whether the water-charging or water-discharging state is normal; and when the water-charging or water-discharging state is abnormal, the water-charging process or water-discharging process is stopped and the user is informed through the alarm.

Owner:HAIER GRP CORP +1

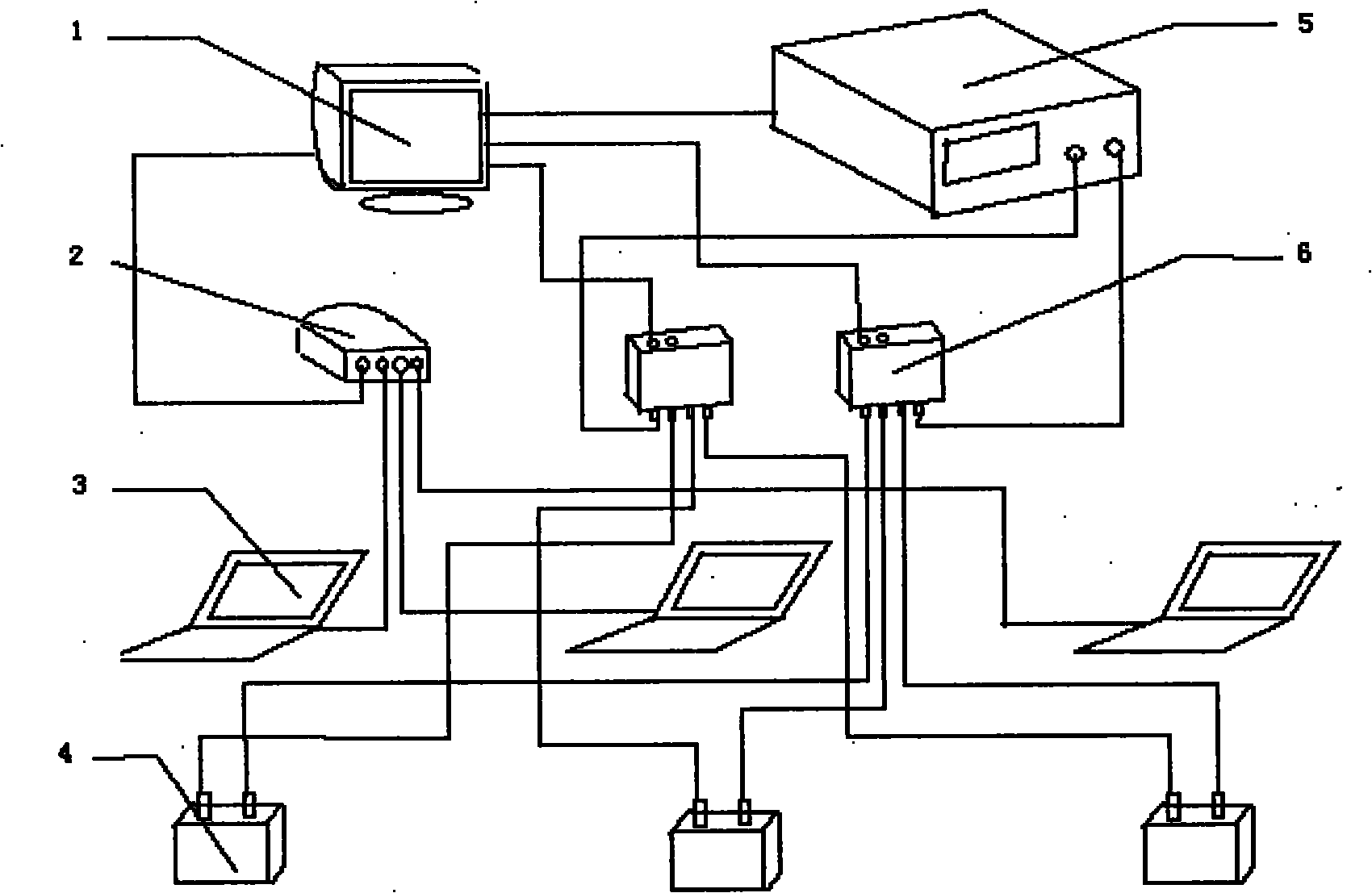

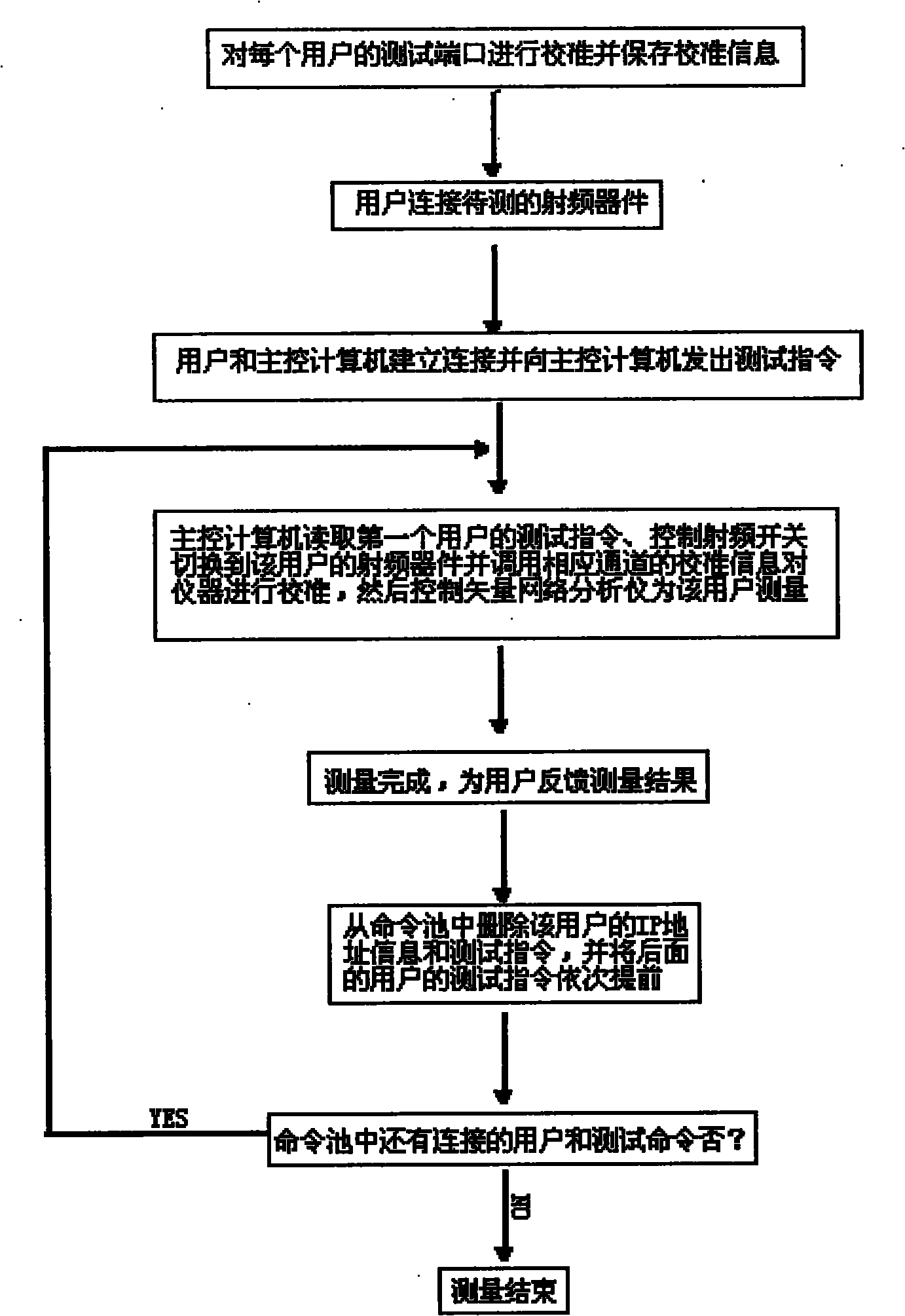

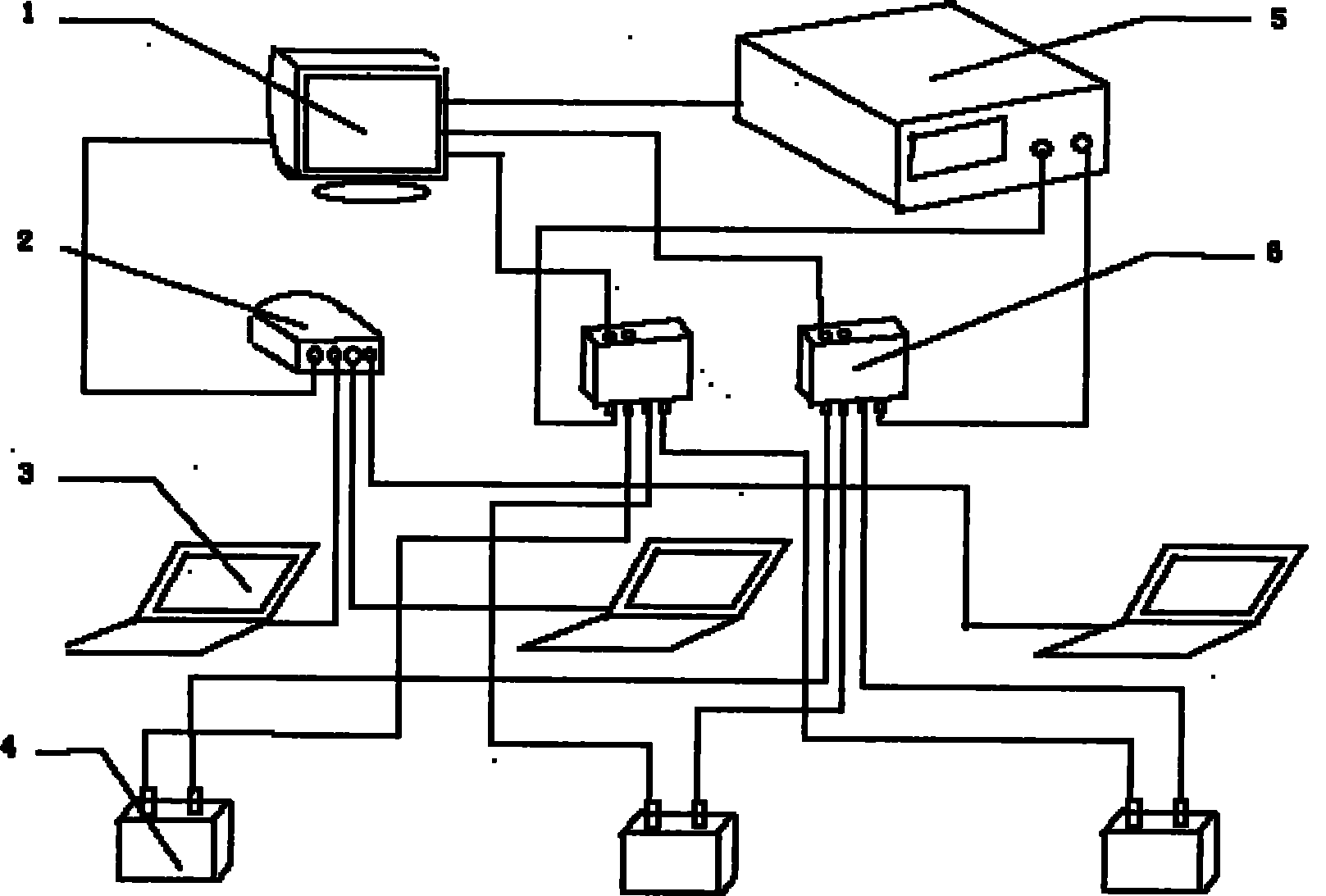

Time sharing multiplex measurement system and method based on vector network analyzer

InactiveCN101871973ALow costAchieve sharingResistance/reactance/impedenceProduction lineTime-sharing

The invention discloses time sharing multiplex measurement system and method based on a vector network analyzer, mainly solving the problems of high configuration cost and low efficiency of the prior art. The measurement system realizes multi-user sharing of one vector network analyzer through a vector network analyzer, a main control computer, a router, two radio-frequency multi-way switches and a plurality of user PCs. The measurement method comprises the steps of: firstly, grouping output ends of the radio-frequency multi-way switches; secondly, establishing a connection between the main control computer and the user PCs; thirdly, realizing the control on the main control computer by operating the PCs to ensures that the main control computer firstly controls the radio-frequency multi-way switches to be switched into a radio-frequency element of the user; fourthly, controlling the vector network analyzer to feed measurement data for the user; and fifthly, after the measurement is finished, carrying out corresponding processing on the data on the PCs by the user. Compared with the prior art, the invention reduces the cost of configuring production line apparatus, reasonably utilizes traditional resources, shortens the time, and improves the efficiency.

Owner:XIDIAN UNIV

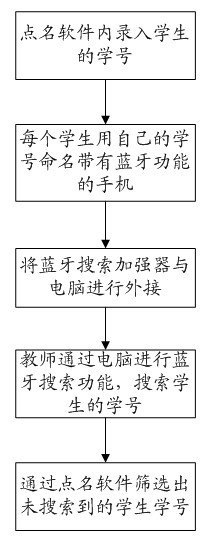

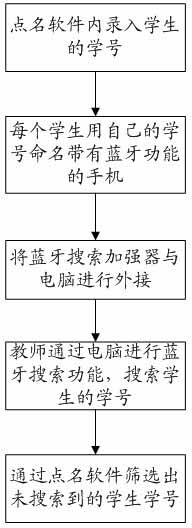

Operation method for roll-call system with bluetooth

InactiveCN102693564AReduce the burden onSave attendanceNear-field transmissionRegistering/indicating time of eventsBluetoothComputer science

The invention discloses an operation method for a roll-call system with bluetooth. The roll-call system with bluetooth comprises a mobile phone with bluetooth, a bluetooth searching intensifier and roll-call software installed in a computer. The operation method includes steps of a, inputting student numbers into the roll-call software; b, denominating bluetooth mobile phones with own numbers of students; c, externally connecting the bluetooth searching intensifier with the computer; d, searching for the student numbers by a bluetooth searching function via the computer; and e, sifting the unsearched student numbers via the roll-call software. The operation method for the roll-call system with bluetooth is simple in operation, free of time wasting and capable of realizing quick roll call, releasing burdens including voice-using burden of teachers, storing attendance conditions of the students each time and calculating at the end of a semester.

Owner:苏州奇可思信息科技有限公司

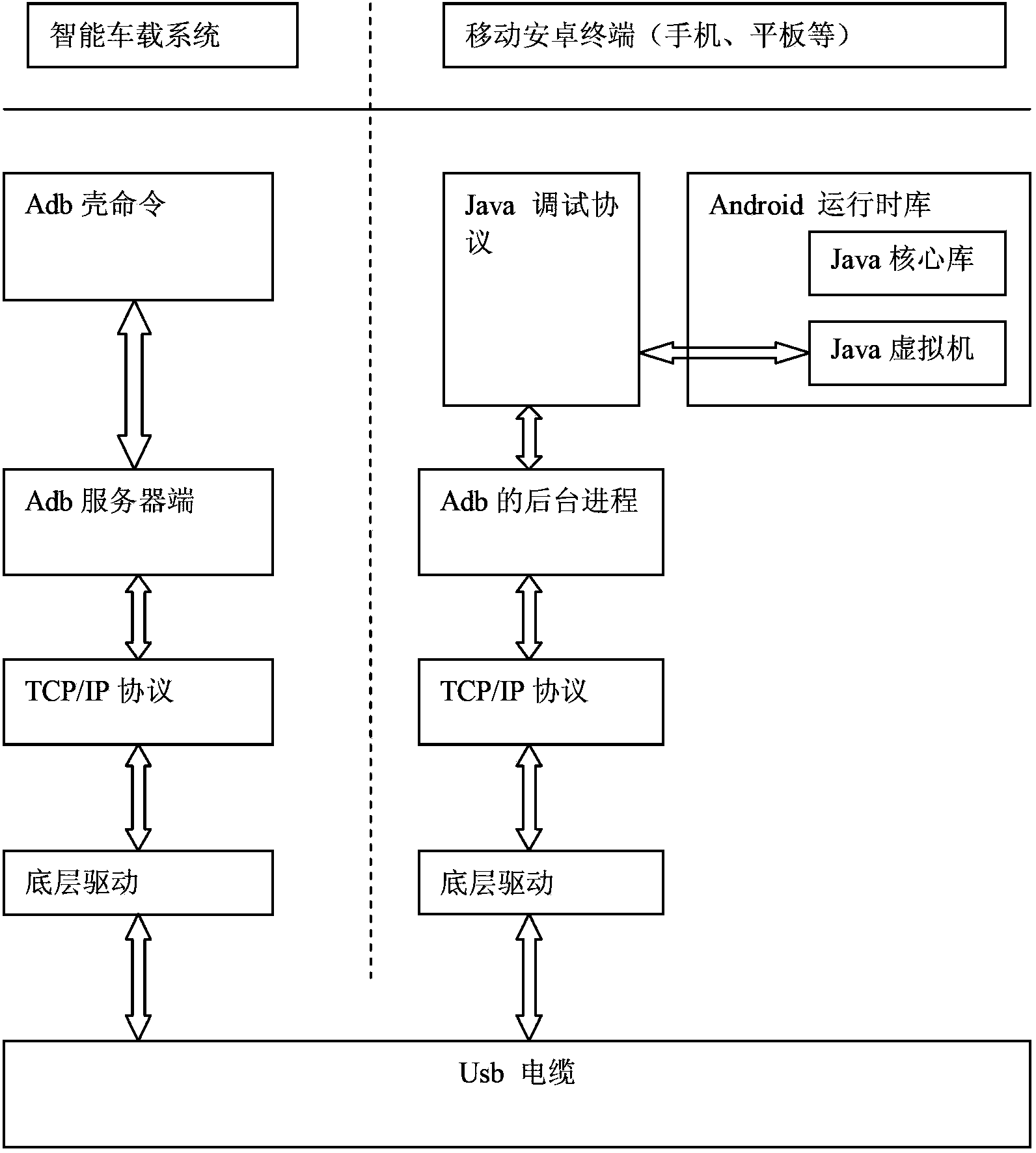

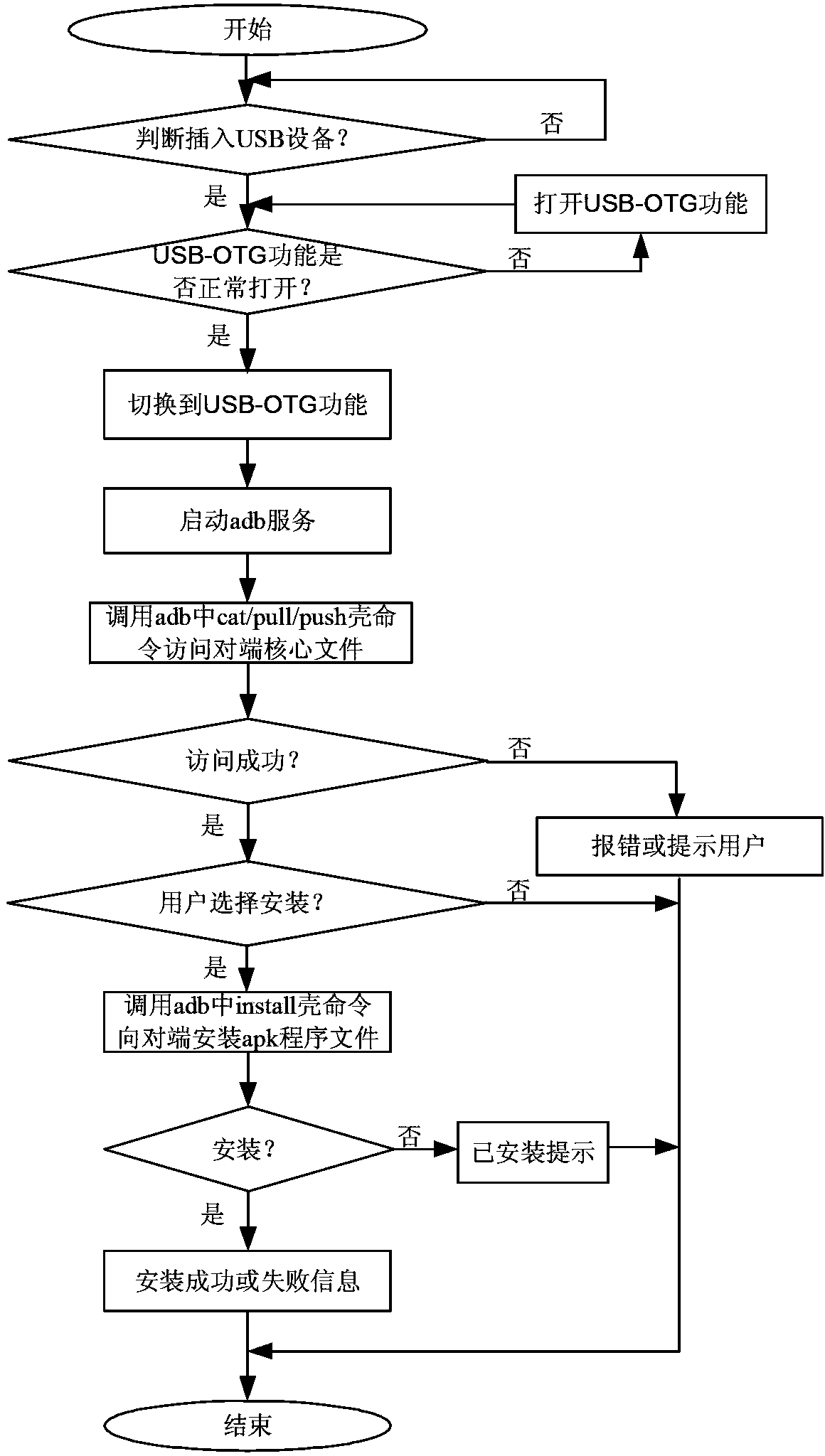

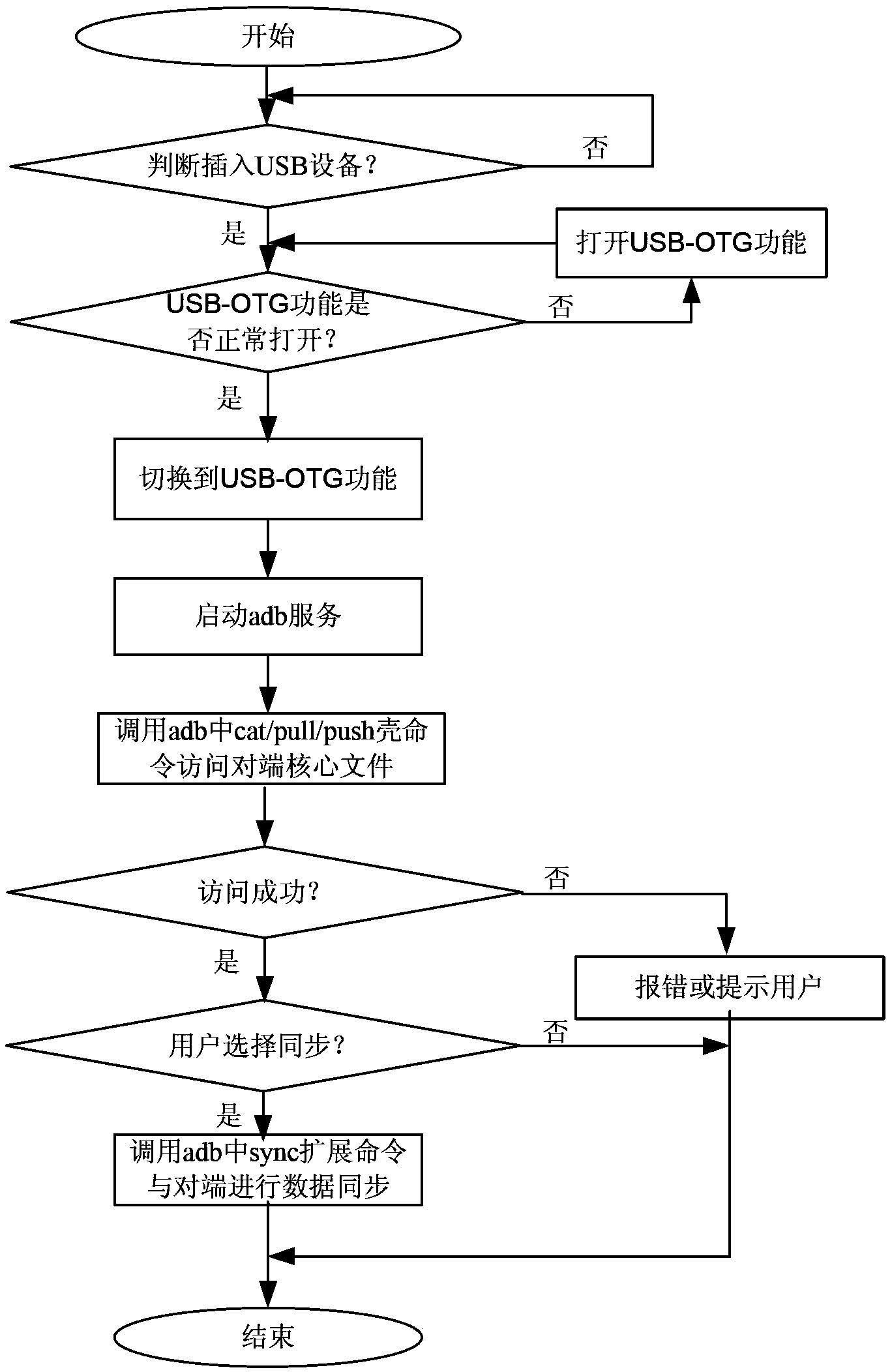

Method for automatic installation and synchronization of software between Android intelligent devices

ActiveCN103365688AAdvantage Automatic InstallationAdvantage methodProgram synchronisationProgram loading/initiatingSoftware engineeringUSB

The invention relates to a method for automatic installation and synchronization of software between Android intelligent devices. Main equipment for starting USB-OTG is used and a slave unit for an adbd process is run. The method comprises the followings: 101), the main equipment detects whether USB equipment is accessed or not, if yes, moving to 102), otherwise, returning to 101); 102) an adb service is started; 103), shell inside the adb is called to access an appointed document; 104), whether the access is successful or not is judged, if yes, moving to 105), otherwise, moving to 108); 105), install shell inside the adb is called to send an appointed APK to the slave unit for software installing; 106), the slave unit executes the install shell, if software is installed, the slave unit withdraws and sends installed respond to the main equipment, otherwise, the slave unit continues to execute installing and sends install success or install failure information to the main equipment; 107), results of being installed or install success / failure are sent to users for promoting through the main equipment; 108) ending.

Owner:AUTOLINK ELECTRONICS

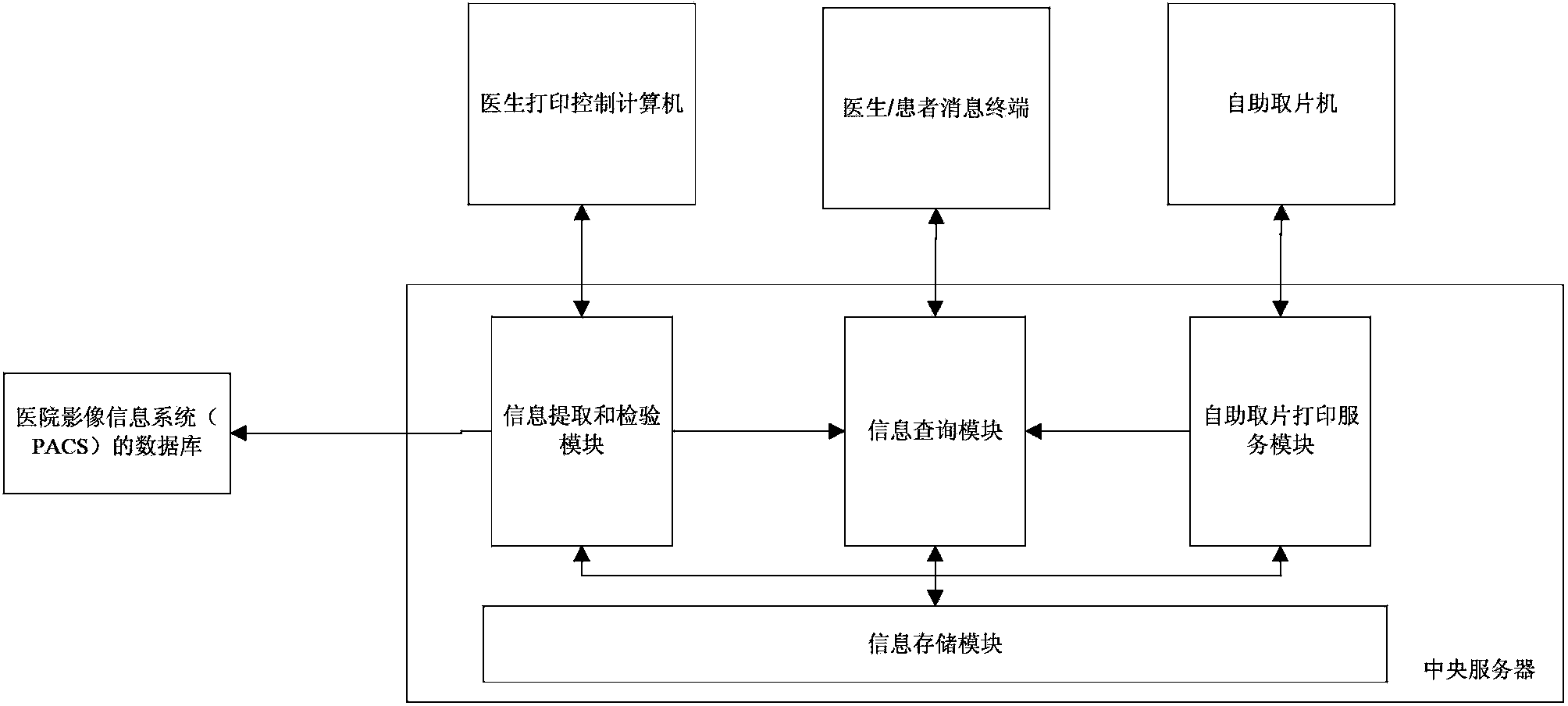

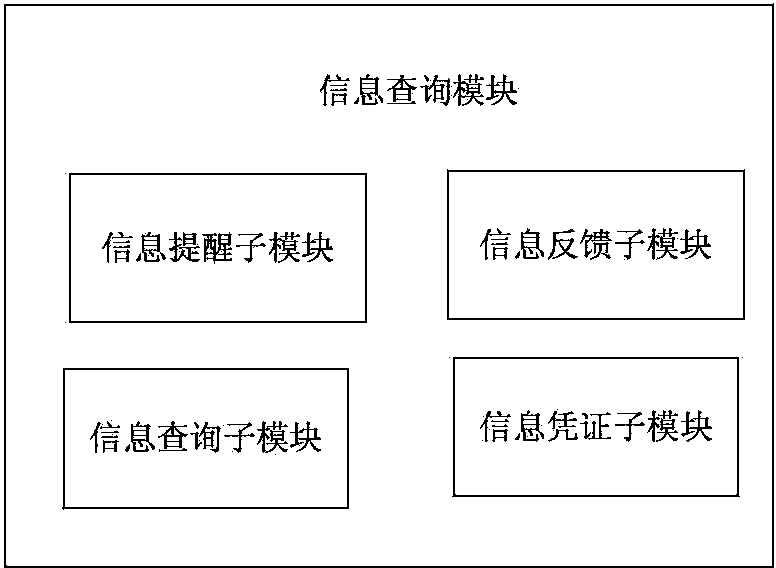

Medical printing system and achieving method thereof

InactiveCN103543966ASave medical resourcesWaste timeDigital output to print unitsTelecommunications networkEngineering

The invention provides a medical printing system and an achieving method thereof. The medical printing system comprises a doctor printing control computer, a self-service film taking machine and a center server, wherein the doctor printing control computer submits information to be printed to the center server through the generalized network, the center server stores the information to be printed and transmits the information to be printed to the self-service film taking machine based on a printing request, and the self-service film taking machine is used for submitting the printing request to the center server and printing the received information to the printed. The generalized network is a local area network or a telecommunication network. By means of the system, a patient can take a film, a report and the like through the self-service film taking machine by himself, there is no need for a medical worker to participate in the whole process, and the valuable medical care resources are saved.

Owner:北京美智医疗科技有限公司

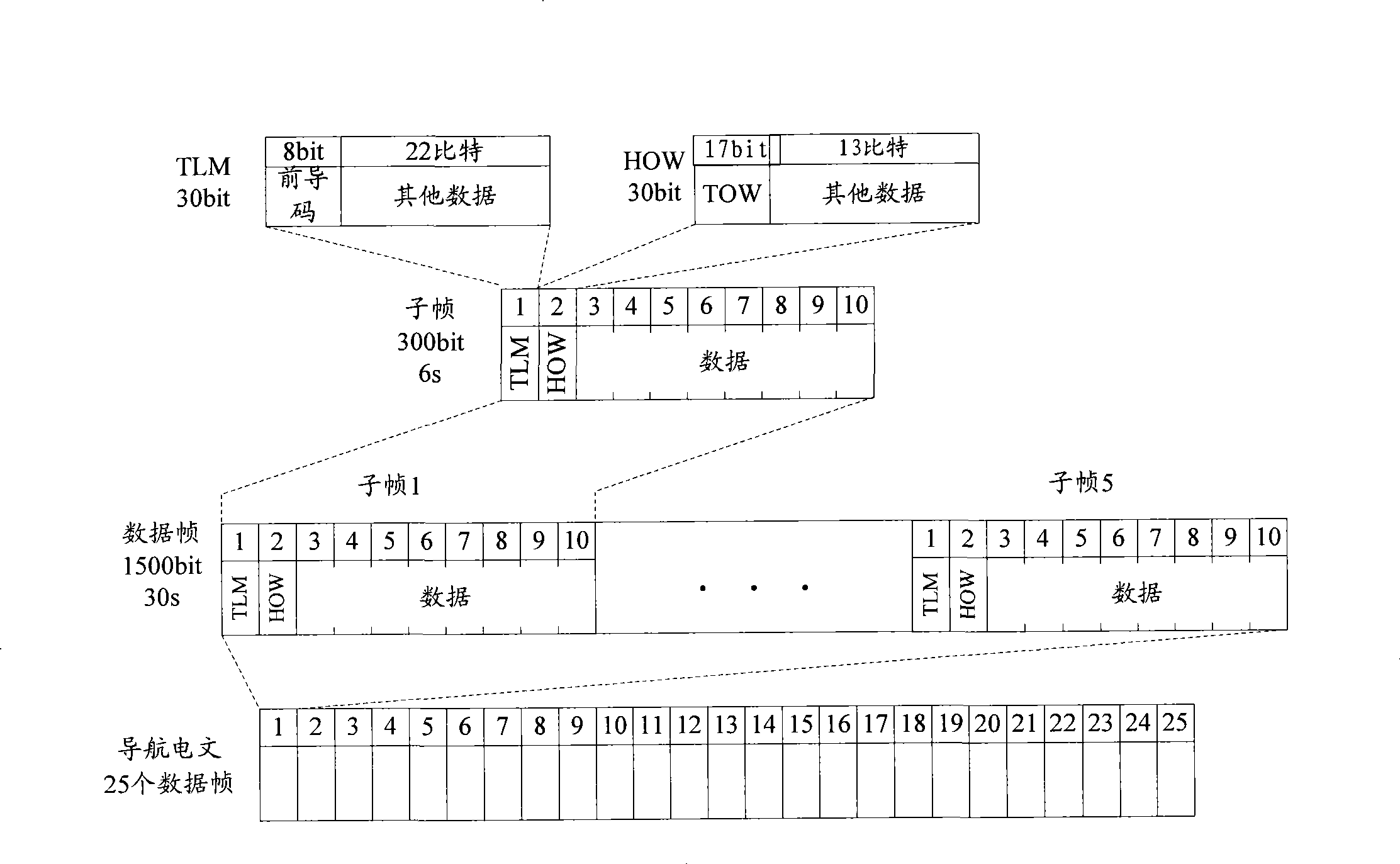

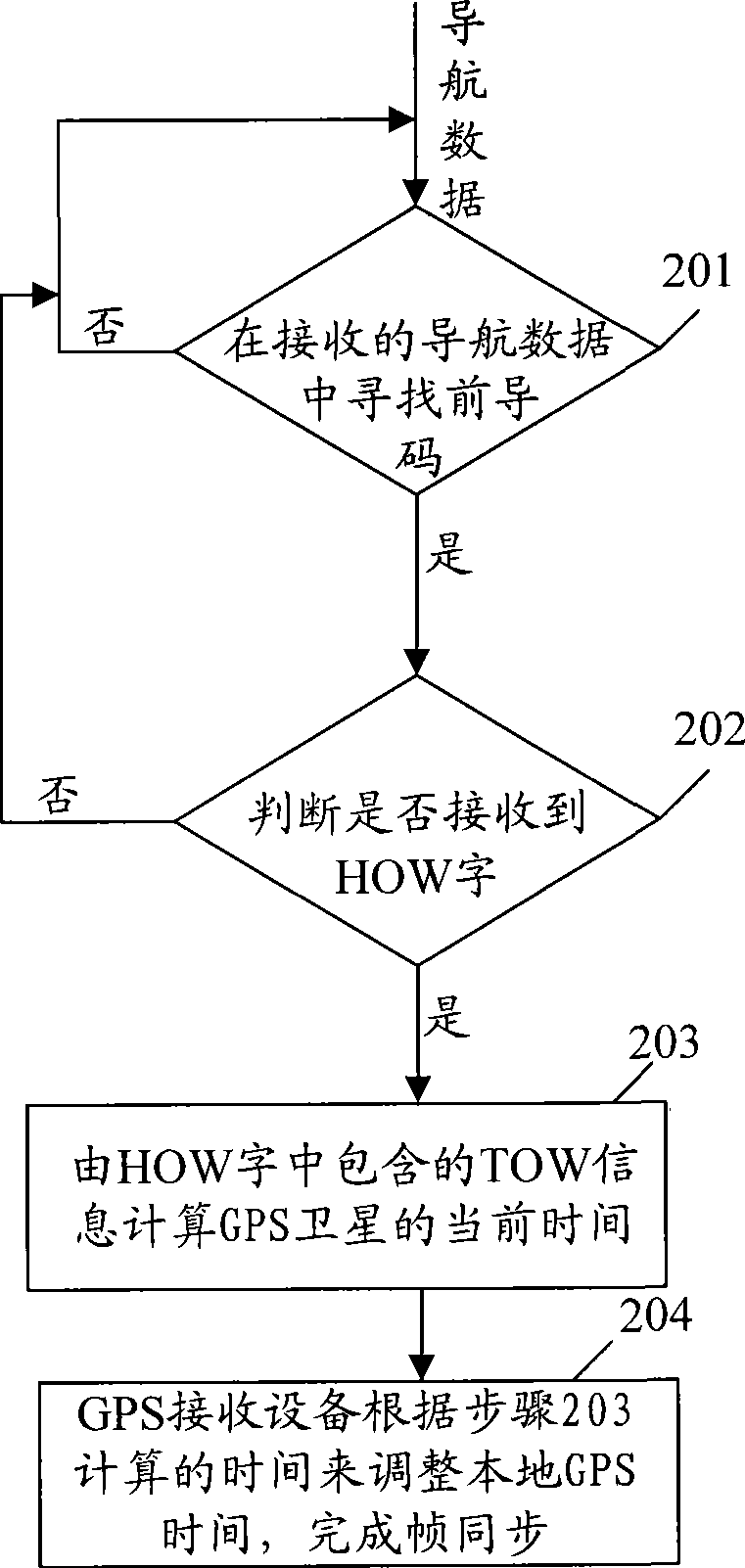

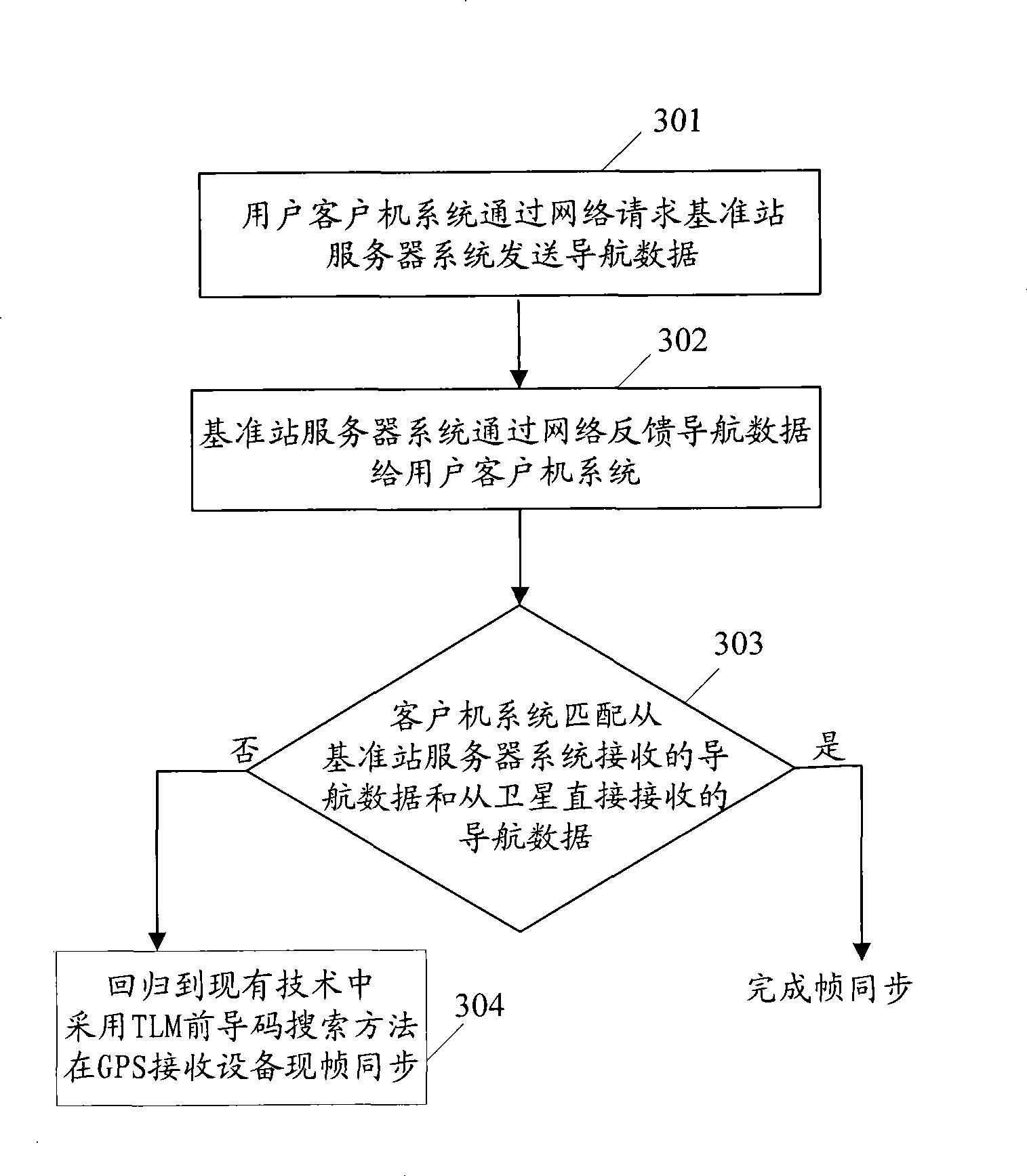

Frame synchronization method and device

ActiveCN101420259AWaste timeReduce workloadPosition fixationRadio transmission for post communicationMarine navigationSatellite

The present invention discloses a method for realizing the frame synchronization. The key of the method comprises forecasting navigation data that is being transmitted; matching the forecasted navigation data with the navigation data received from a GPS satellite directly; modifying the local time of the GPS receiving device to complete the frame synchronization under the condition that the matching is successful. The present invention also discloses a frame synchronization device realizing the frame synchronization method. According to the present invention, the time of achieving the frame synchronization for a GPS receiving device can be shortened.

Owner:RDA MICROELECTRONICS SHANGHAICO LTD

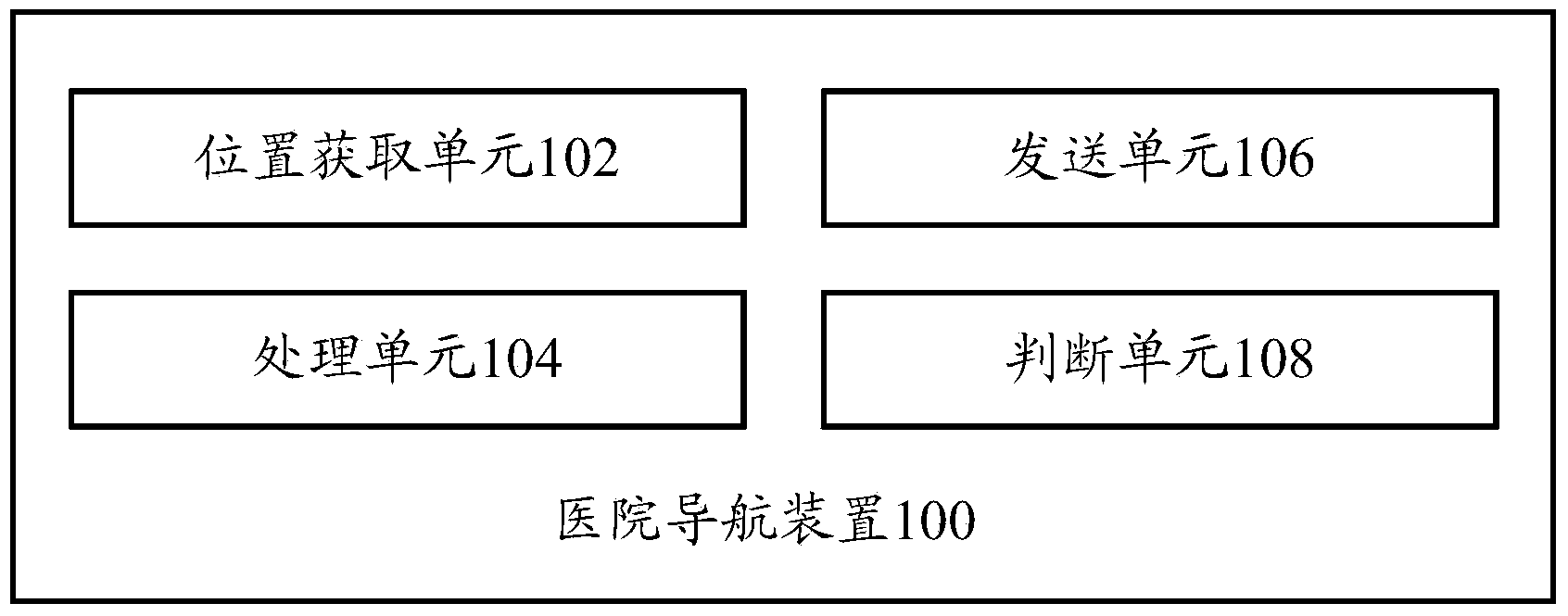

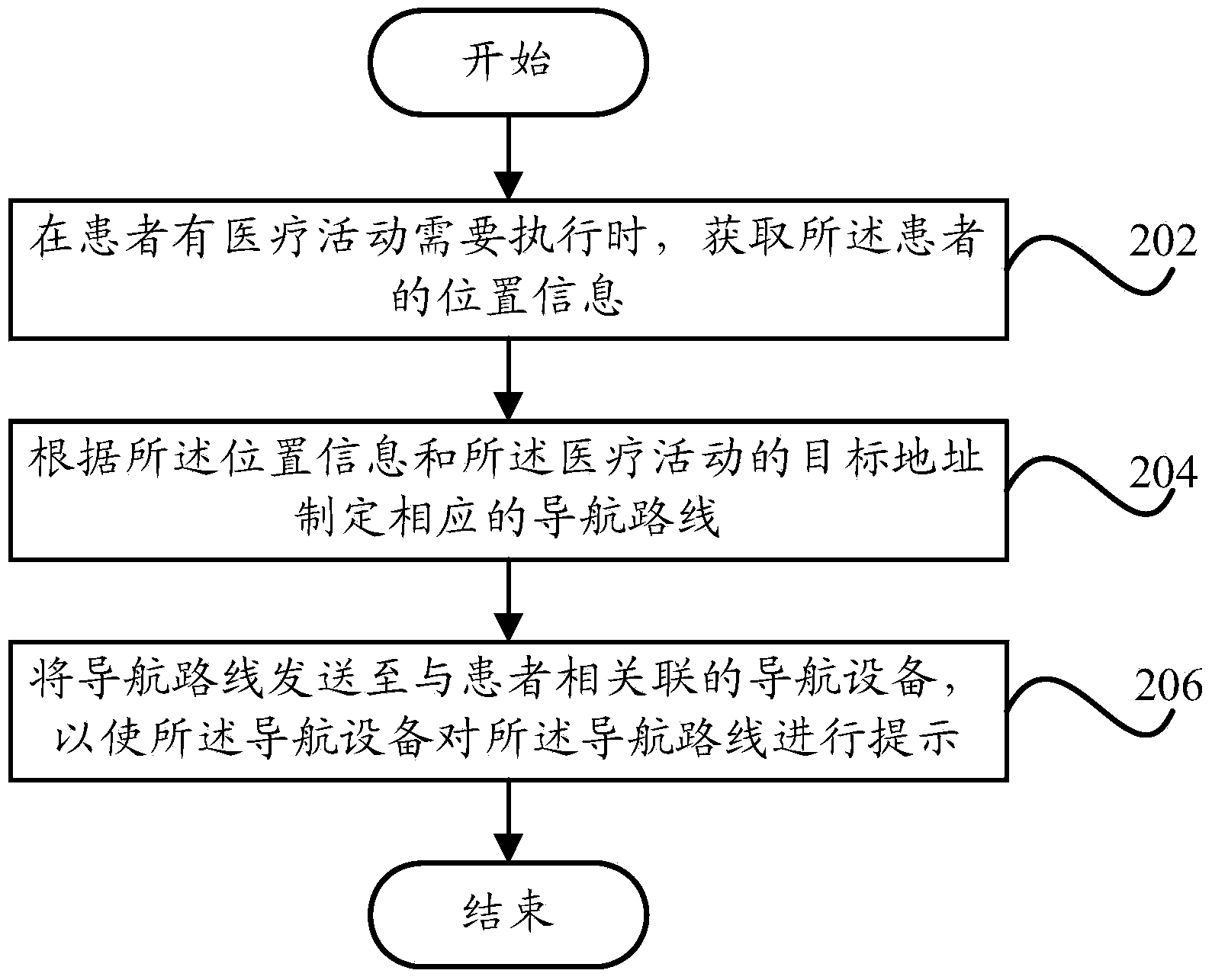

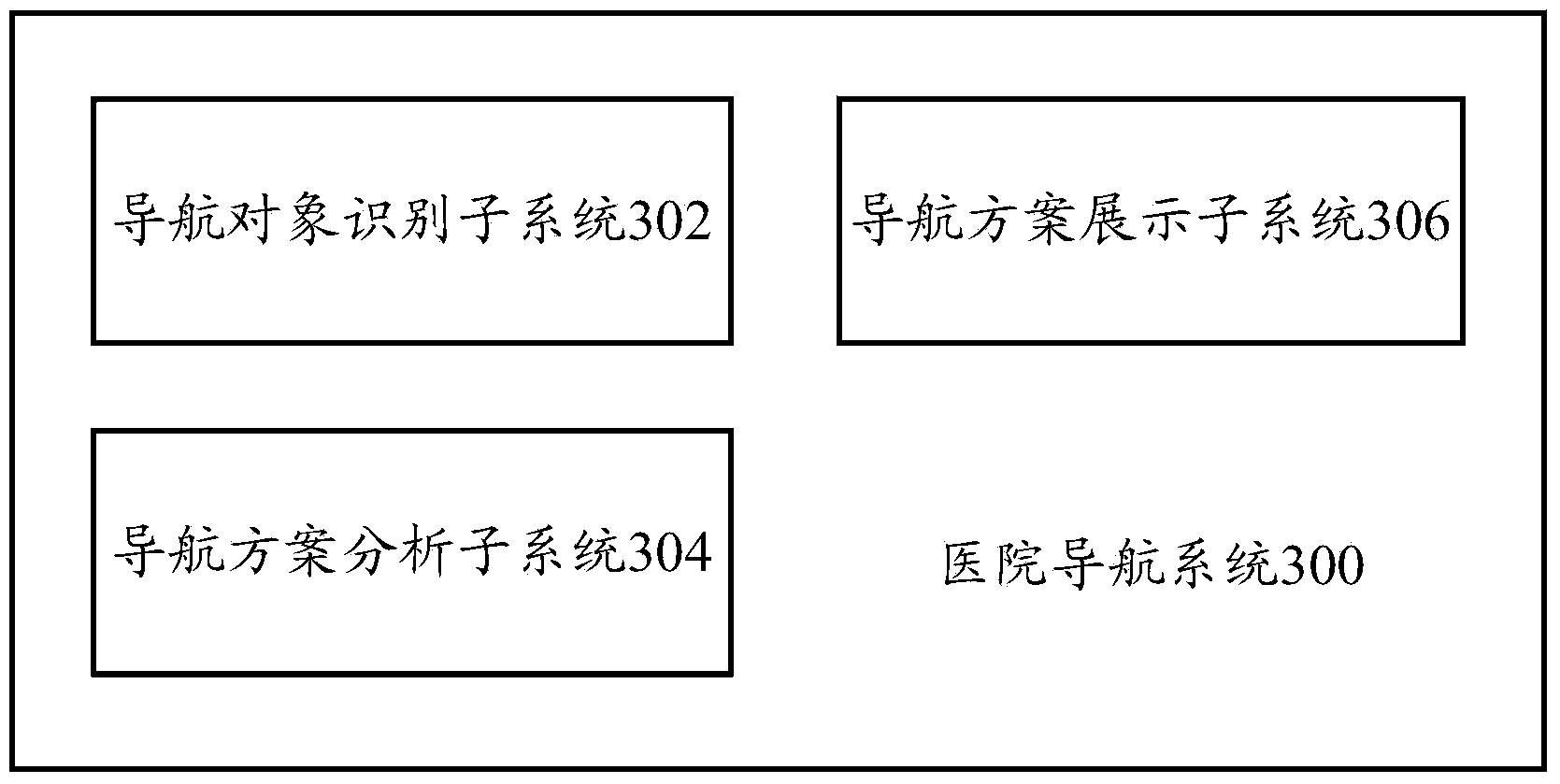

Hospital navigation device and hospital navigation method

The invention provides a hospital navigation device and a hospital navigation method. The hospital navigation device comprises a position acquiring unit, a processing unit and a sending unit, wherein the position acquiring unit is used for acquiring position information of a patient when a patient has medical activities to be executed; the processing unit is used for making corresponding navigation route according to the position information and the destination address of the medical activity; the sending unit is used for sending the navigation route to a navigation apparatus associated with the patient, so that the navigation apparatus can prompt the navigation route. According to the technical scheme, the patient can head to the destination address according to the received navigation route to execute corresponding medical activities when the patient has medical activities to be executed.

Owner:PKU HEALTHCARE IT

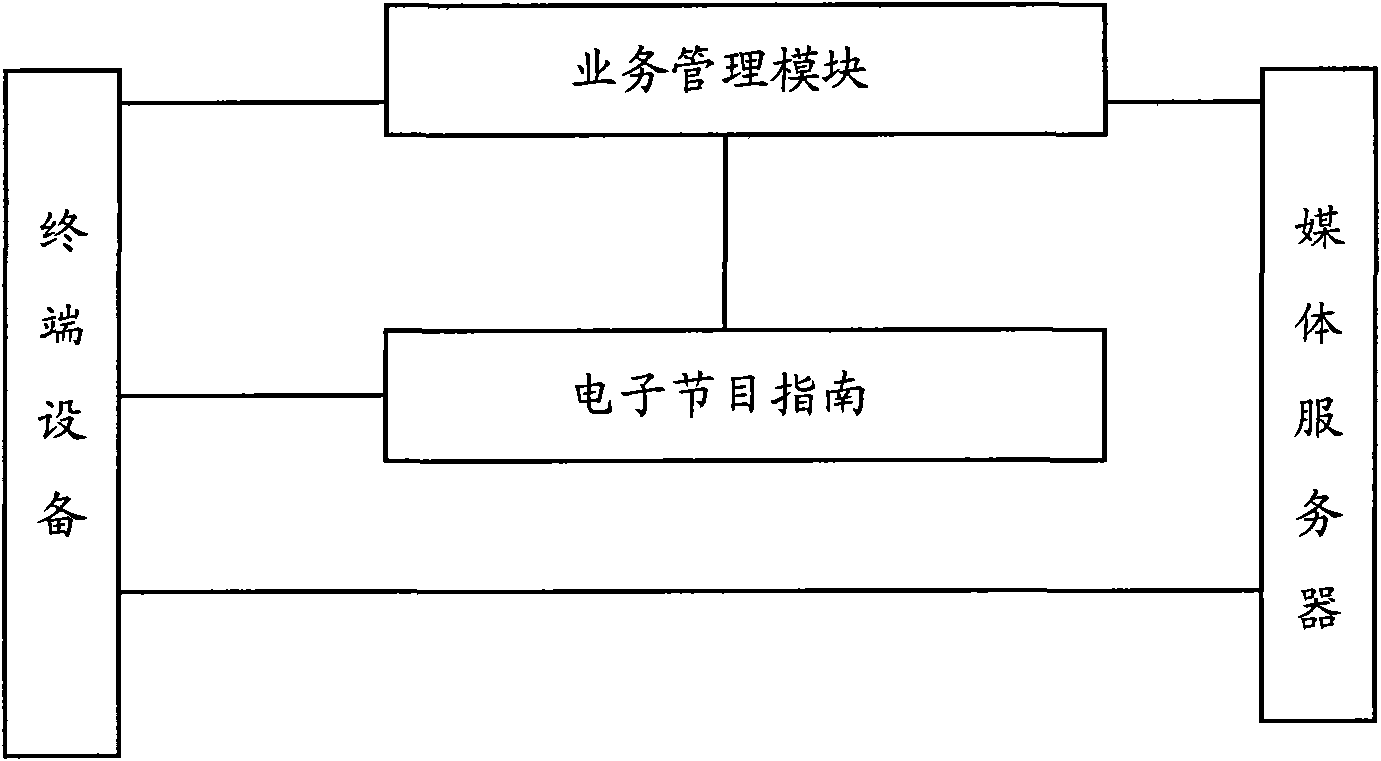

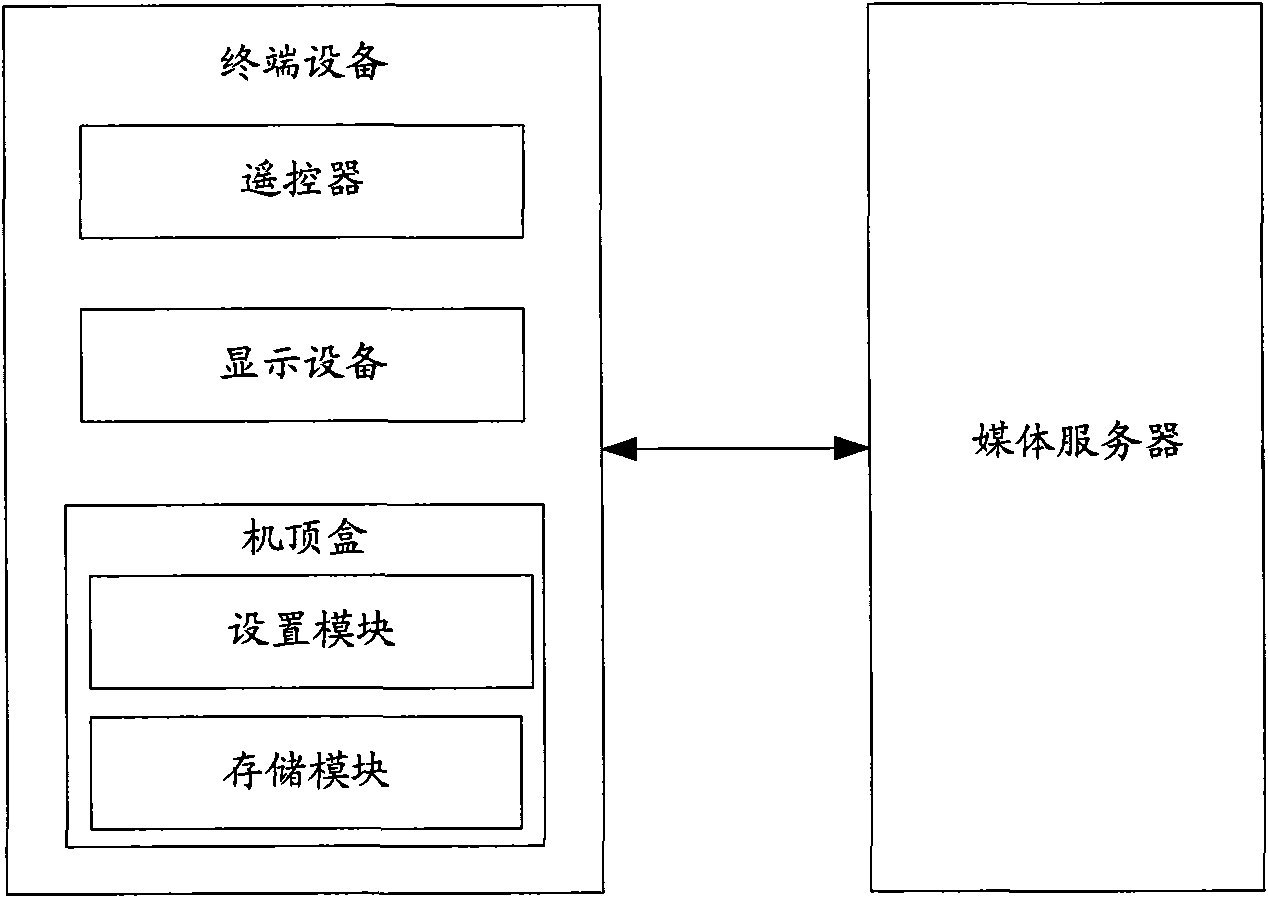

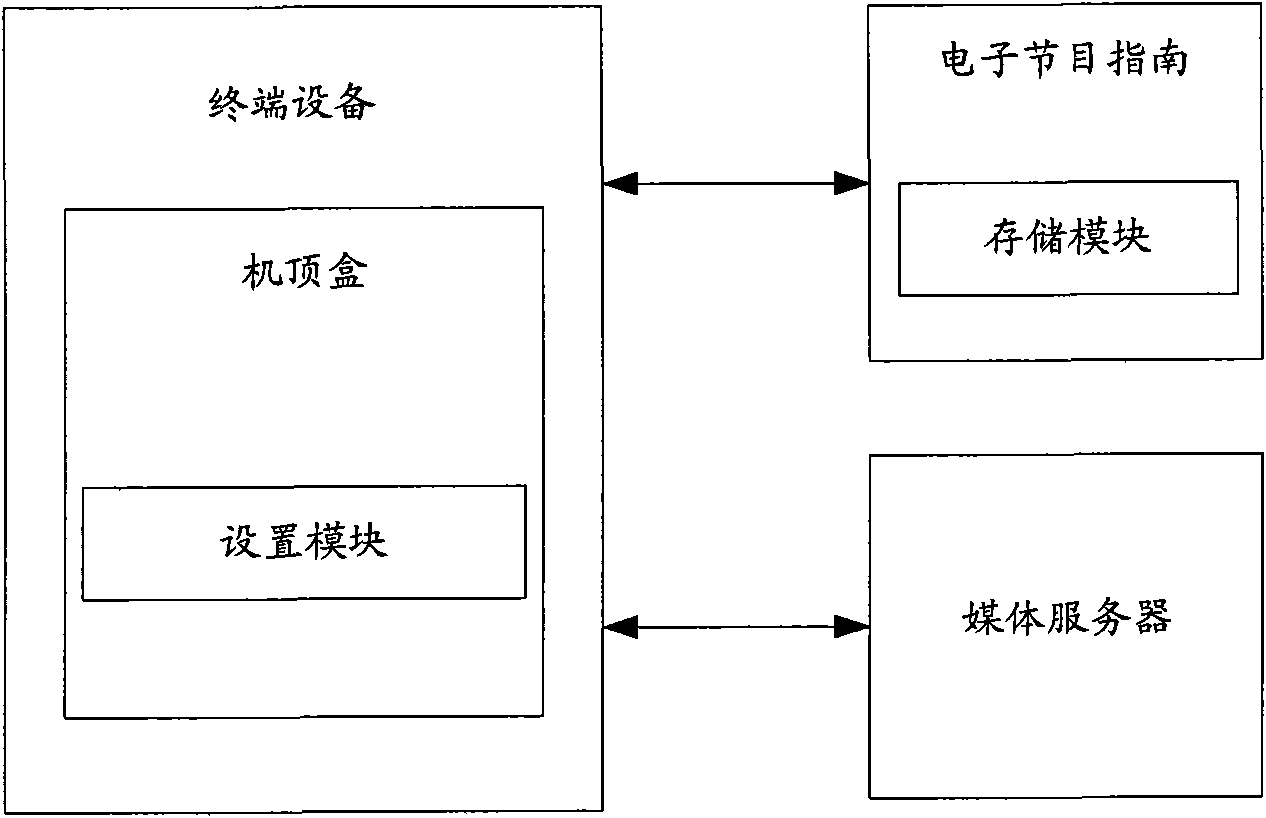

Method and system for hiding channel

InactiveCN101568015AImprove user experienceWaste timeTelevision system detailsColor television detailsTerminal equipmentComputer science

The invention discloses a method for hiding channels, which includes the following steps: A. a channel need to be hidden is selected, and then setting the channel as a hidden channel; B. the hidden channel is restricted to be watched by a terminal equipment based on set in step A. The invention also discloses a system for hiding channels. By setting a hidden channel, the method and system provided by the invention can restrict watching of the hidden channel, thereby avoiding browsing a great amount of uninterested channels to waste time, and improving the using experience of user.

Owner:ZTE CORP

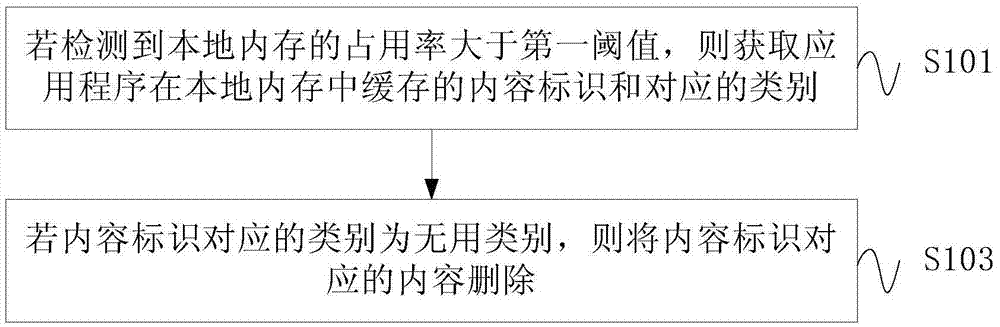

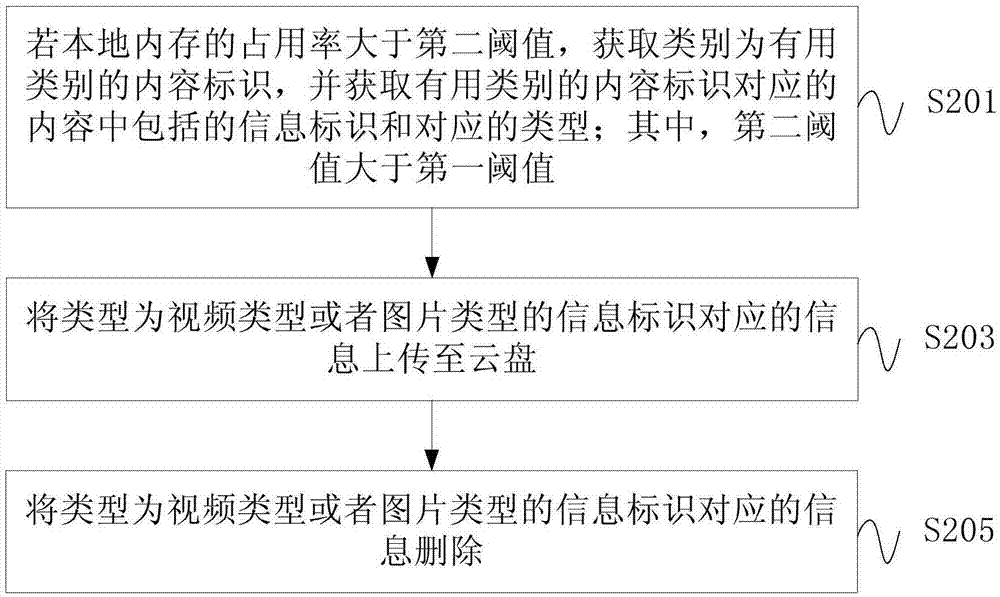

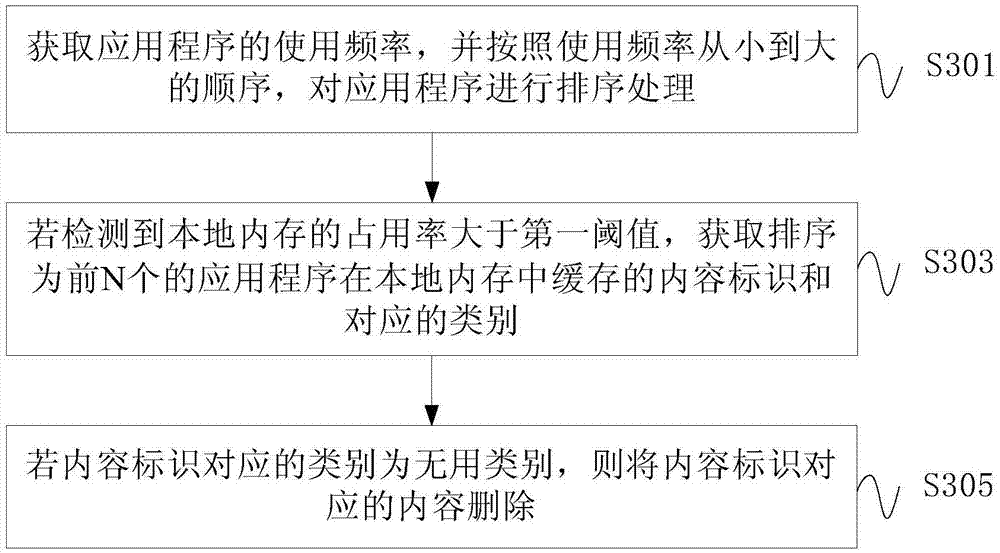

Information processing method and apparatus

The invention provides an information processing method and apparatus. The method comprises the steps of obtaining the identifier of the content in a local memory, of an application and a corresponding type if it is detected that an occupation rate of the local memory is greater than a first threshold; and if the type corresponding to the content identifier is a useless type, deleting contents corresponding to the content identifier. According to the information processing method and apparatus, useless information cached in the local memory can be automatically deleted, so that a current task process is not influenced, the useless information cleaning process is carried out in a background without user operation, and waste of user time is avoided.

Owner:BEIJING QIHOO TECH CO LTD +1

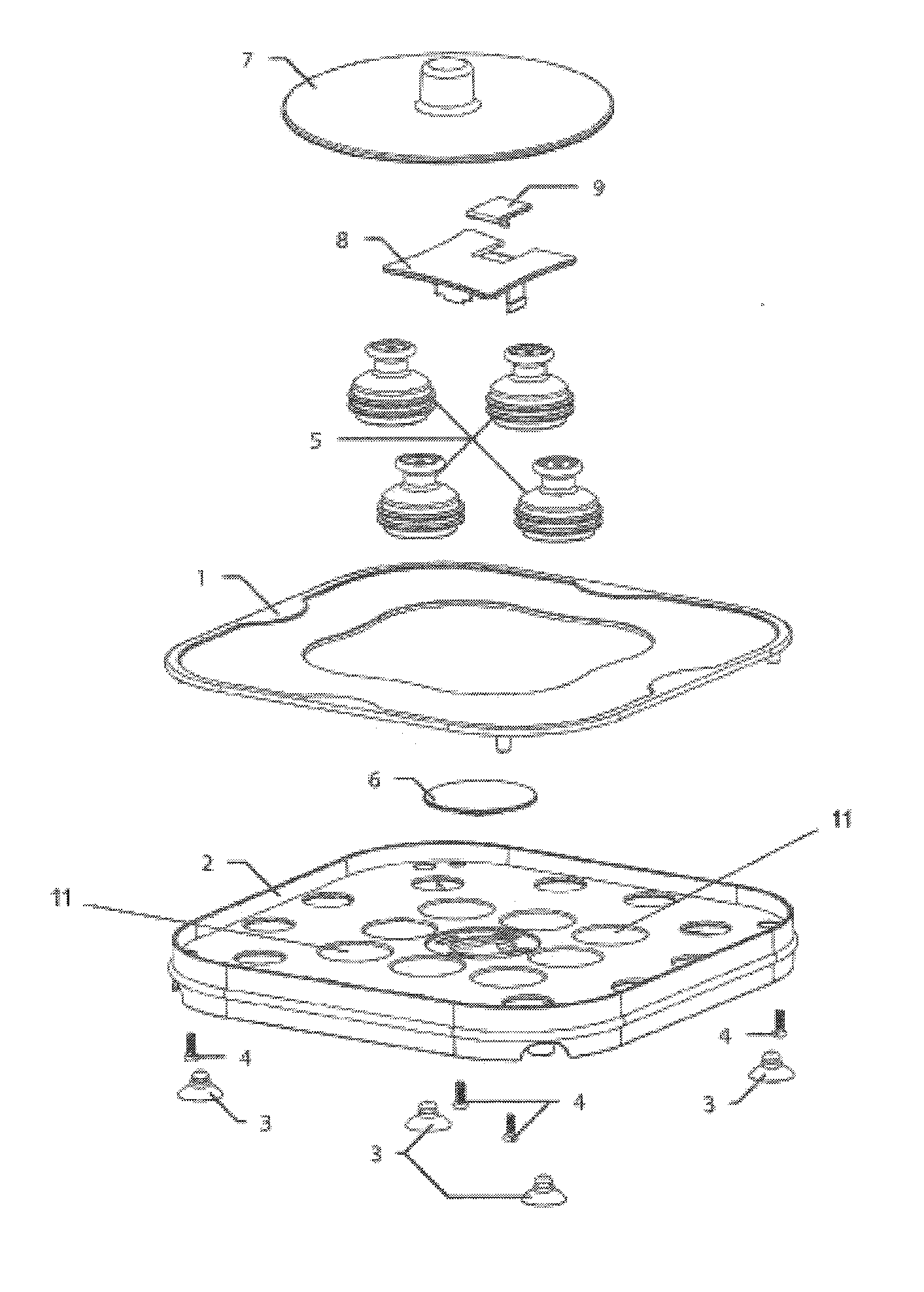

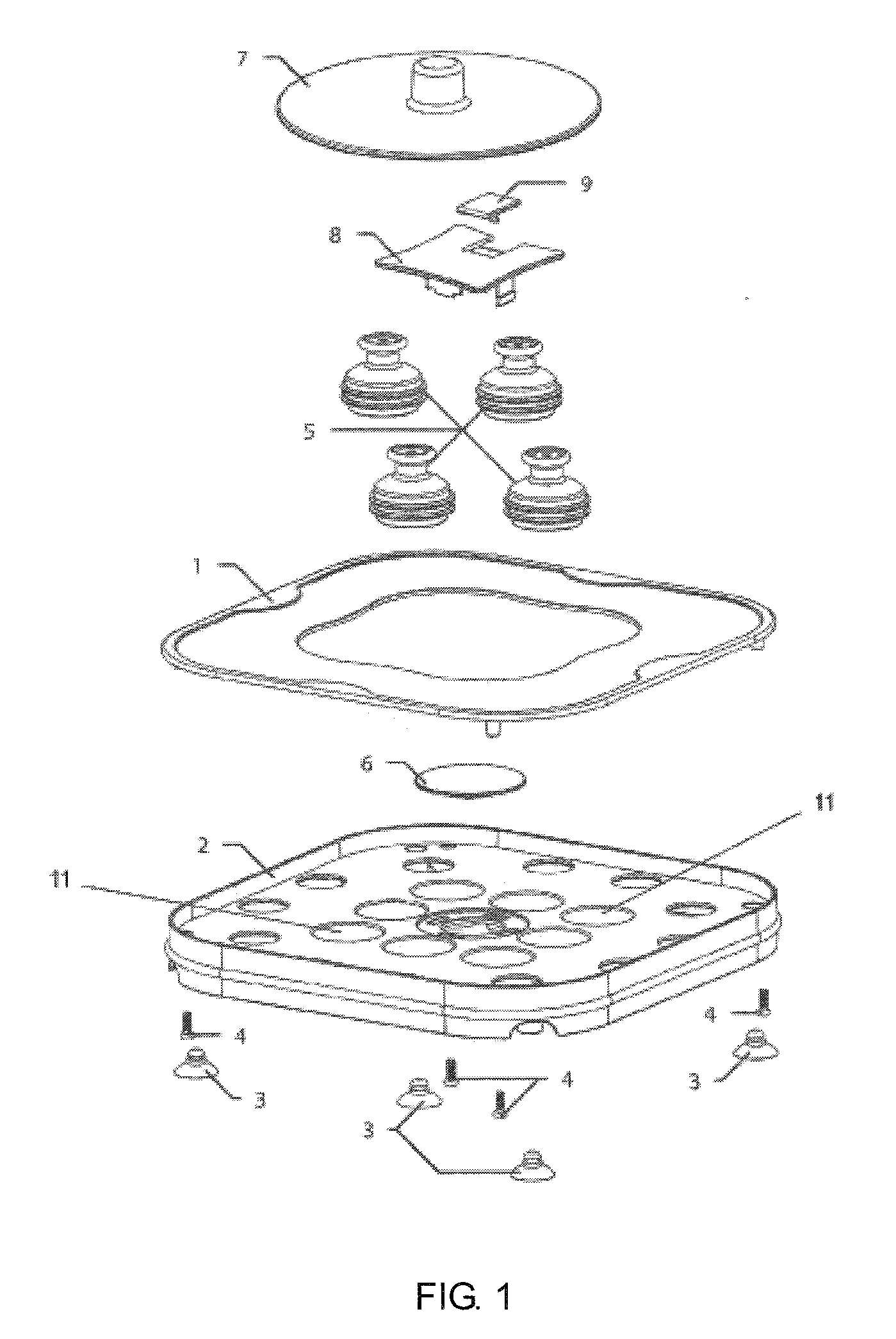

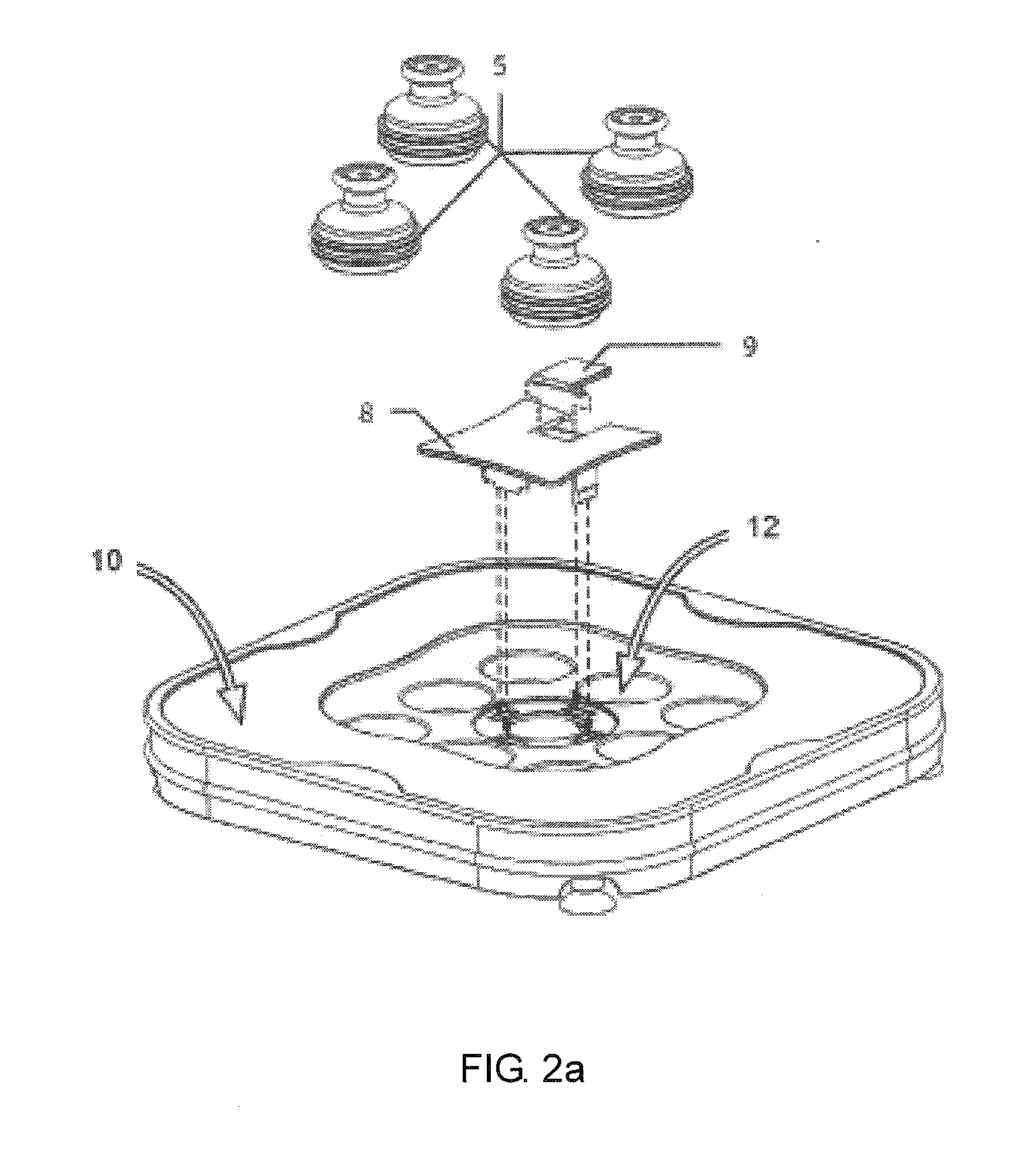

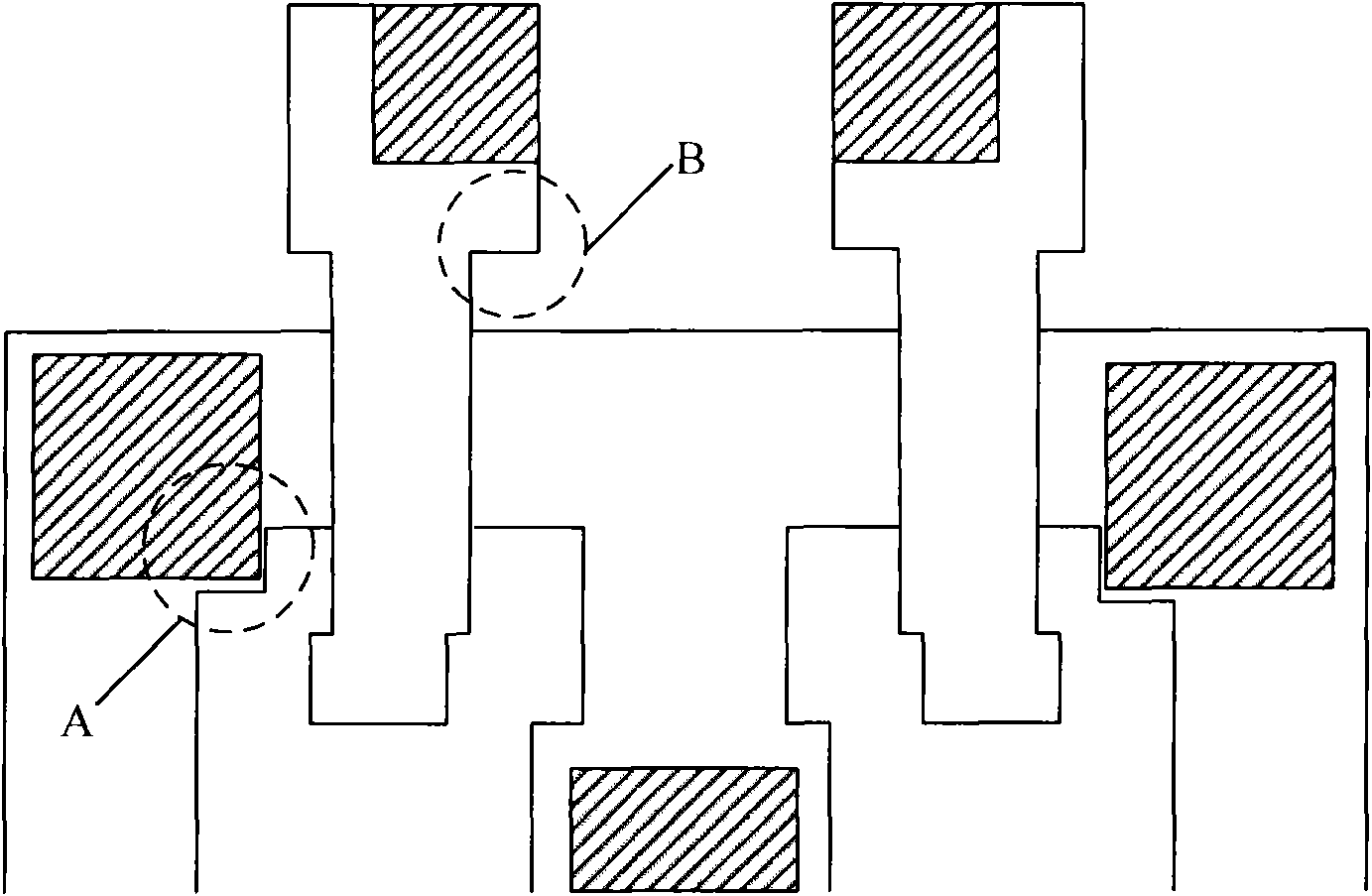

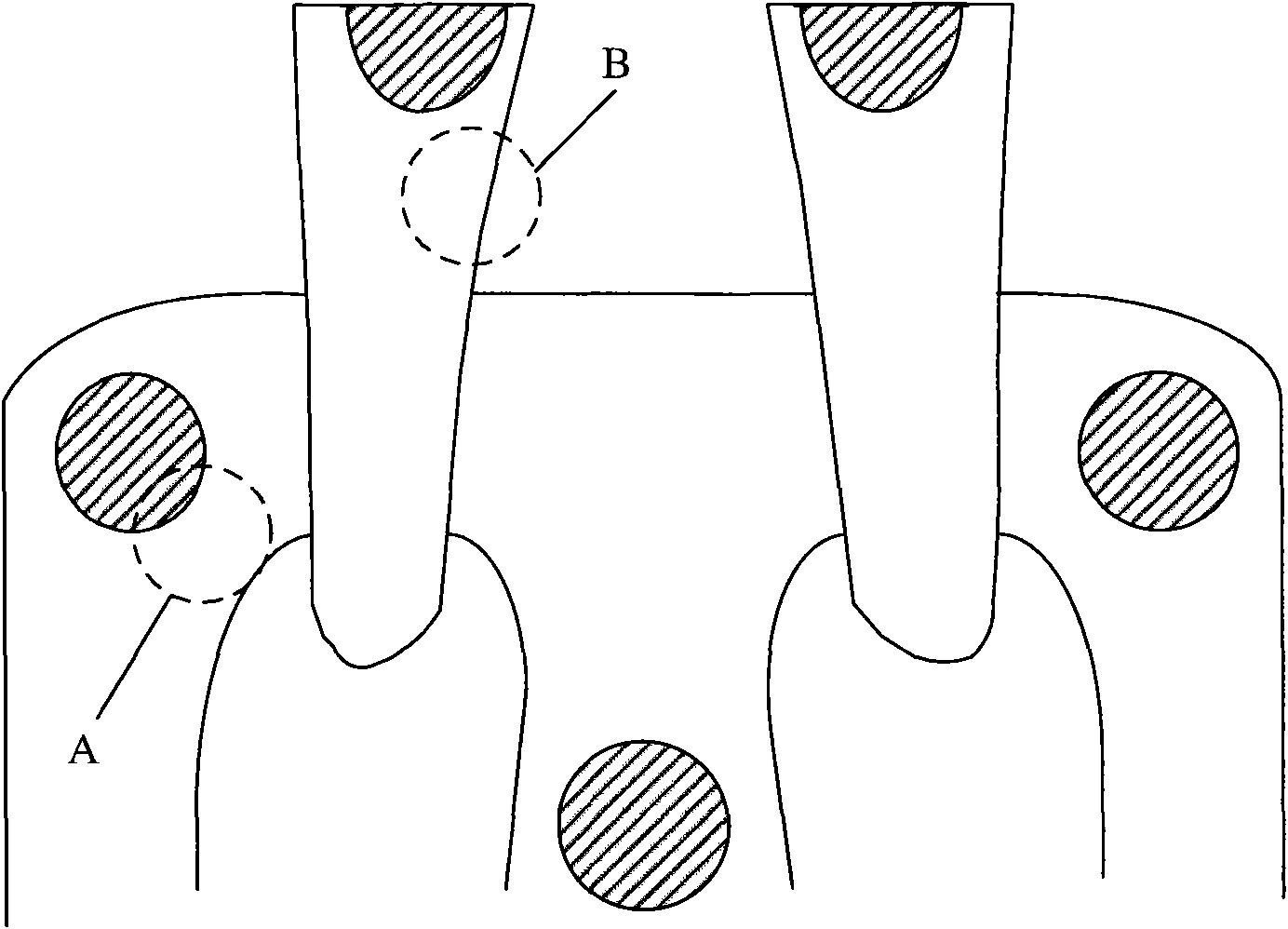

Multi-Function Pets Training Tool

This invention involves a multi-function pets training tool, in particular, it could allow pets to maintain vitality, a tool both enhancing training and entertainment, and to utilize different designs and purpose-made accessories for different results, users could use these accessories in making out different training tools. The training aim of this invention is mainly through a hide-and-seek process to find out the hiding articles as may be pre-concealed by the trainer in the base platform, and the training pets have to use skills of topple over, drive and pull to find out these articles, through these trainings to enhance the agility of pets' muscle, concentration and smelling capabilities. This invention is structurally simple, change of accessories is flexible, which makes the functional training more fun, versatile and varied in fashions, to meet with the pets' psychology of fun inducing and to satisfy fully the curiosity of training pets, meanwhile, it enhances pets' vitality and to keep the pets entertained.

Owner:WONG KUN BONG

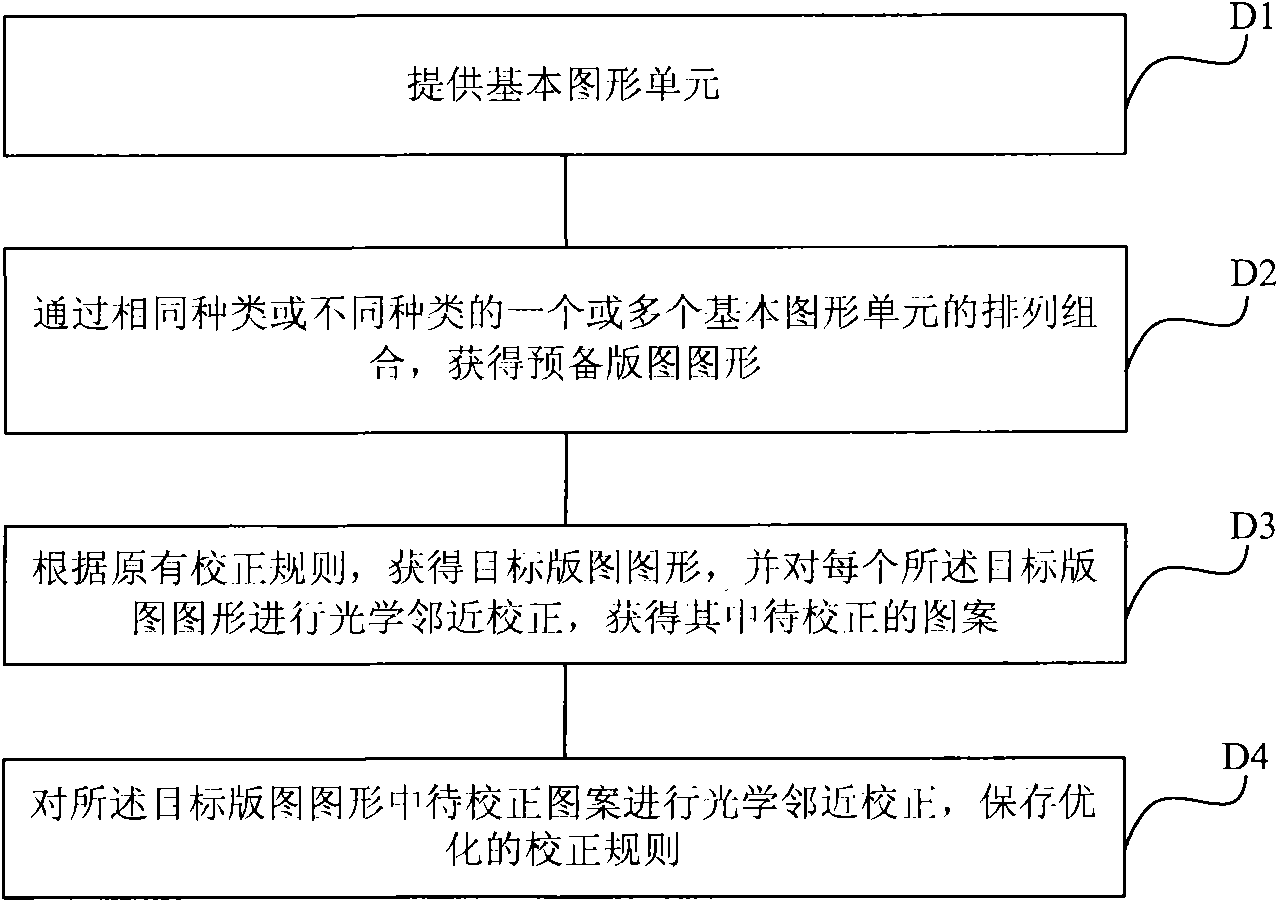

Optimization method of optical proximity correction rule

ActiveCN101788760ACalibration rules are simpleWaste timeOriginals for photomechanical treatmentGraphicsComputer science

The invention discloses an optimization method of an optical proximity correction rule, comprising the following steps of: providing a basic graphics unit; arranging and combining one or a plurality of basic graphics units of the same kind or different kinds, and acquiring a preliminary domain graphics; acquiring the target domain graphics according to the traditional correction rule, carrying out the optical proximity correction on each target domain graphics and acquiring a pattern to be corrected; and correcting the pattern to be corrected in the target domain graphics and storing the optimized correction rule. The invention provides a large number of patterns with variety and randomness by the preliminary domain graphics consisting of the basic graphics unit and acquires the set of the correction rule corresponding to various patterns based on the optical proximity correction of the preliminary domain graphics; therefore, the optimization of the traditional correction rule is realized, and the time and the labor in the actual correction course are greatly saved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

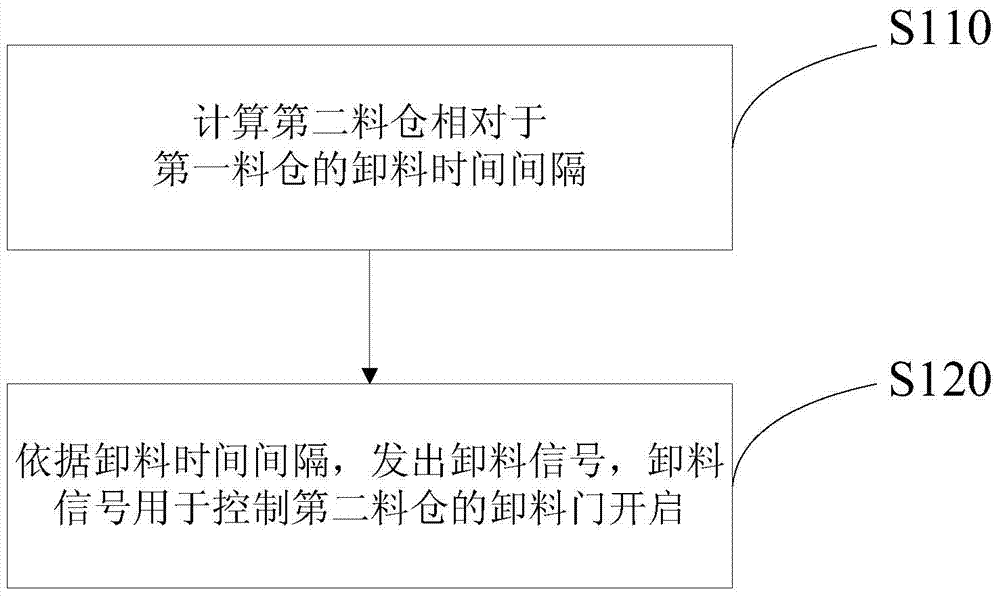

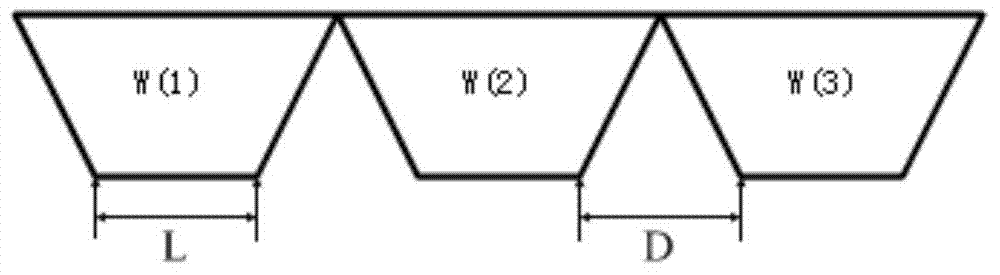

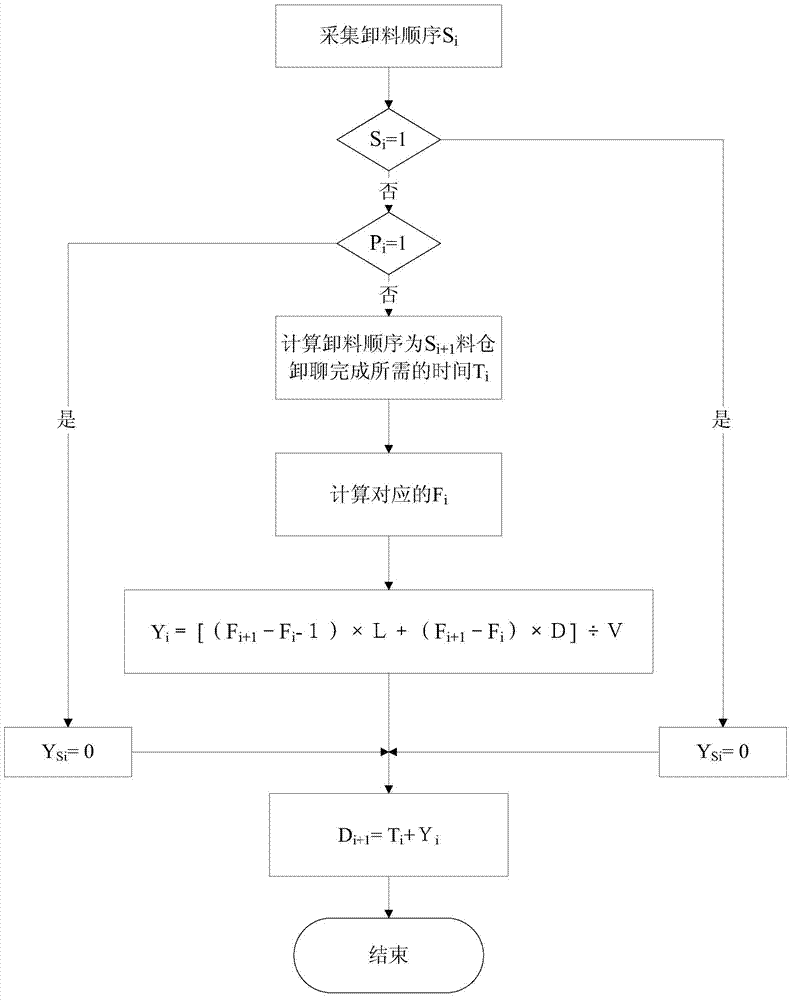

Unloading control method and system for storage bins of concrete mixing station

The invention discloses an unloading control method and an unloading control system for storage bins of a concrete mixing station. The unloading control method for the storage bins of the concrete mixing station comprises the following steps of calculating an unloading time interval of a second storage bin relative to a first storage bin, wherein the second storage bin is adjacent to the first storage bin; sending an unloading signal according to the unloading time interval, wherein the unloading signal is used for controlling an unloading door of the second storage bin to be opened. According to the unloading control method for the storage bins of the concrete mixing station, the phenomenon that materials are stacked on a conveyer belt or the materials are broken can be avoided as possible, and the production efficiency and the quality in the concrete mixing station can be improved.

Owner:SANY AUTOMOBILE MFG CO LTD

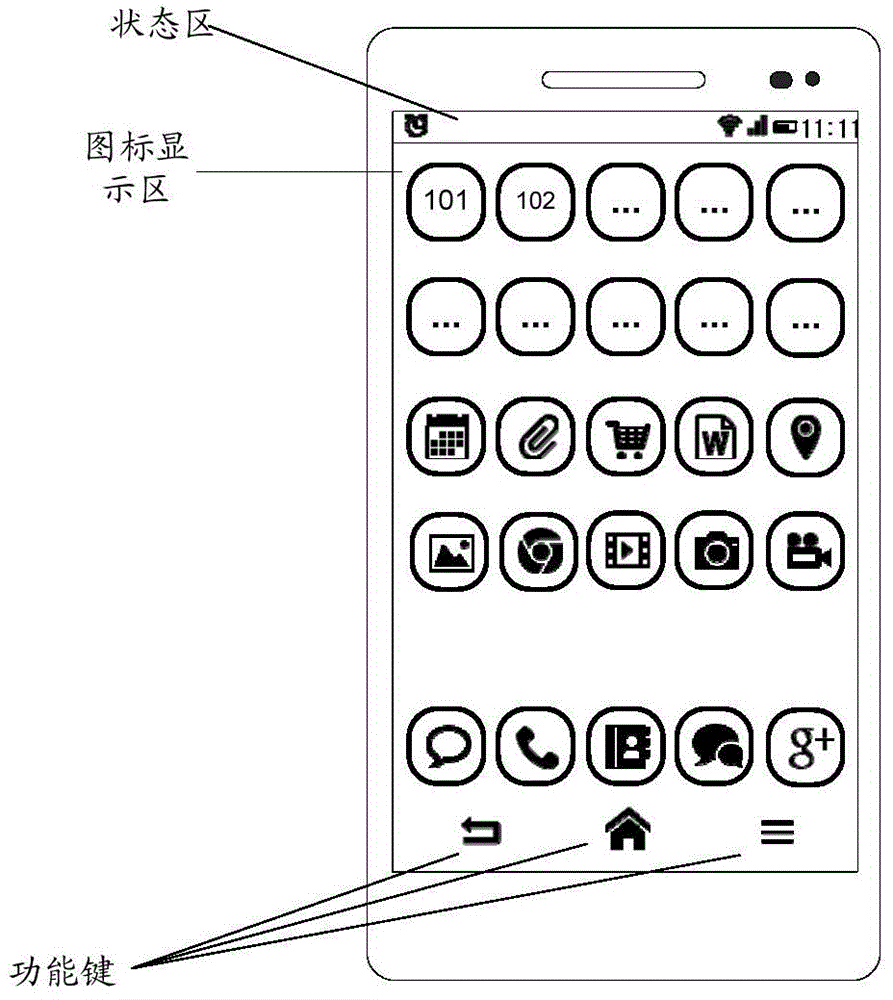

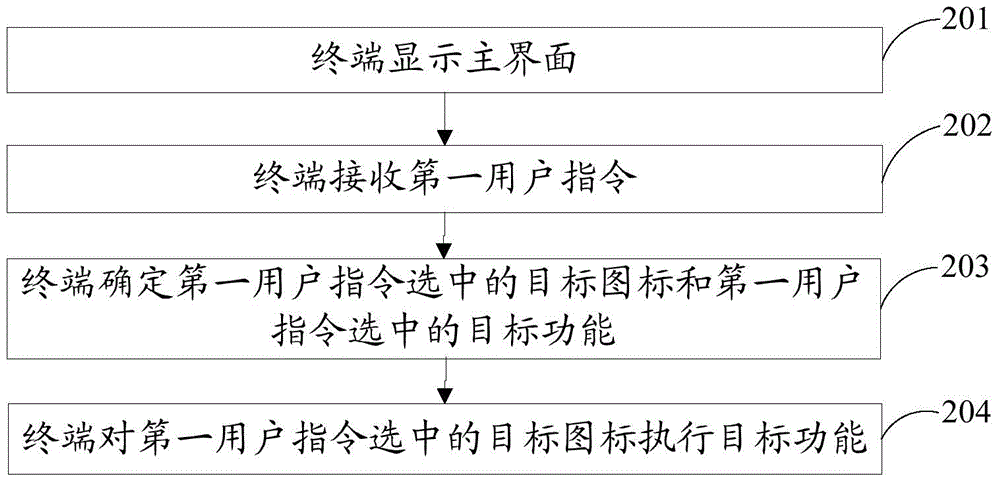

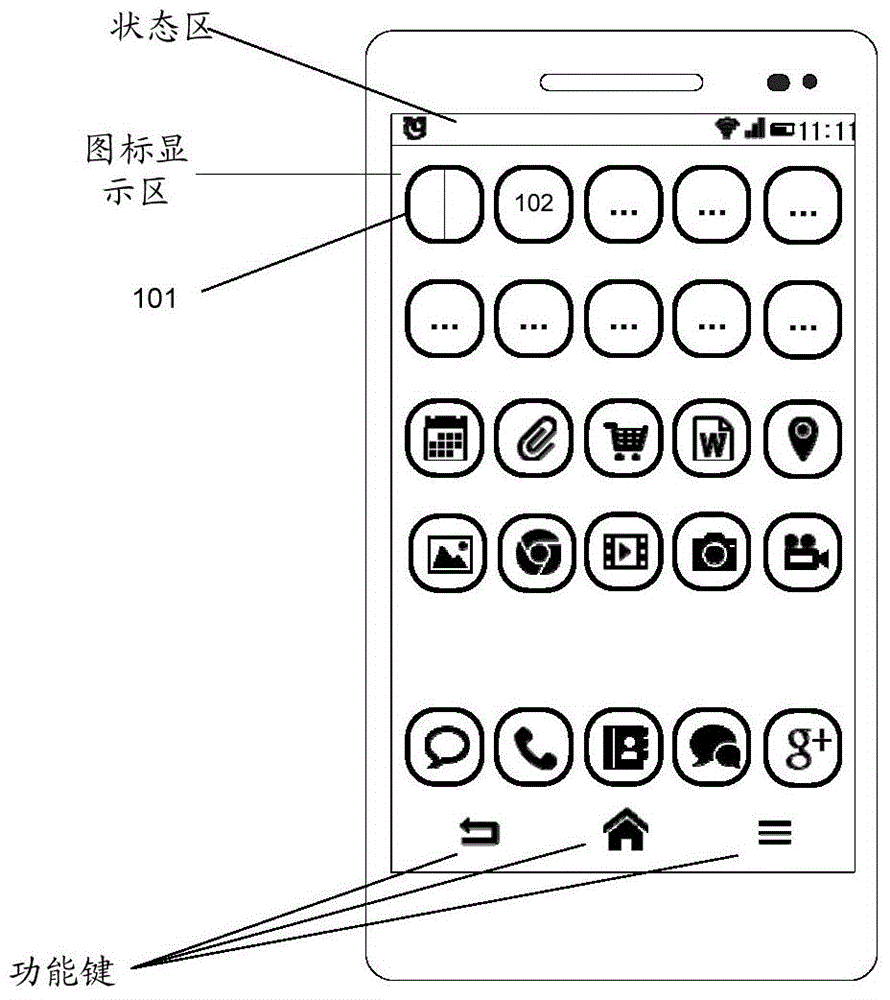

Icon management method, device and terminal

ActiveCN105677305AWaste timeImprove accuracySpecific program execution arrangementsInput/output processes for data processingComputer terminalHuman–computer interaction

The invention discloses an icon management method, device and terminal, relates to the electronic equipment field, and solves the problems that the terminal frequently makes misoperation when the icon is adjusted by user operation, thus reducing icon adjustment accuracy; the method comprises the following steps: displaying a main interface, wherein the main interface comprises at least one target icon, the target icon comprises at least two non-overlapping function areas matched with different functions, and the functions are used for adjusting the icon; receiving a first user order; determining the target icon selected by the first user order and the target function selected by the first user order, wherein the target function is function corresponding to the function area of the target icon selected by the first user order; executing the target function on the target icon selected by the first user order. The method and device are suitable for the terminal.

Owner:HUAWEI DEVICE CO LTD

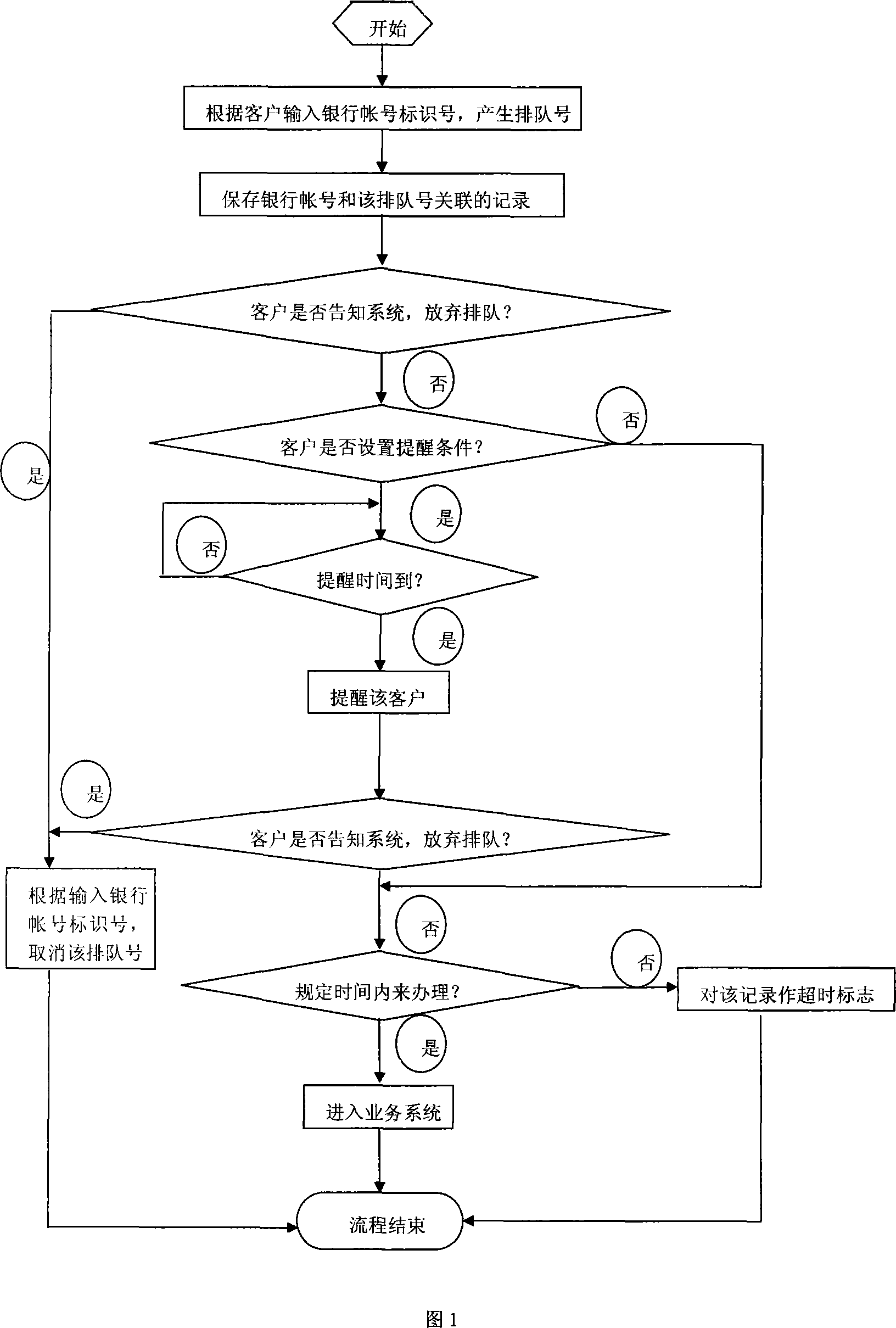

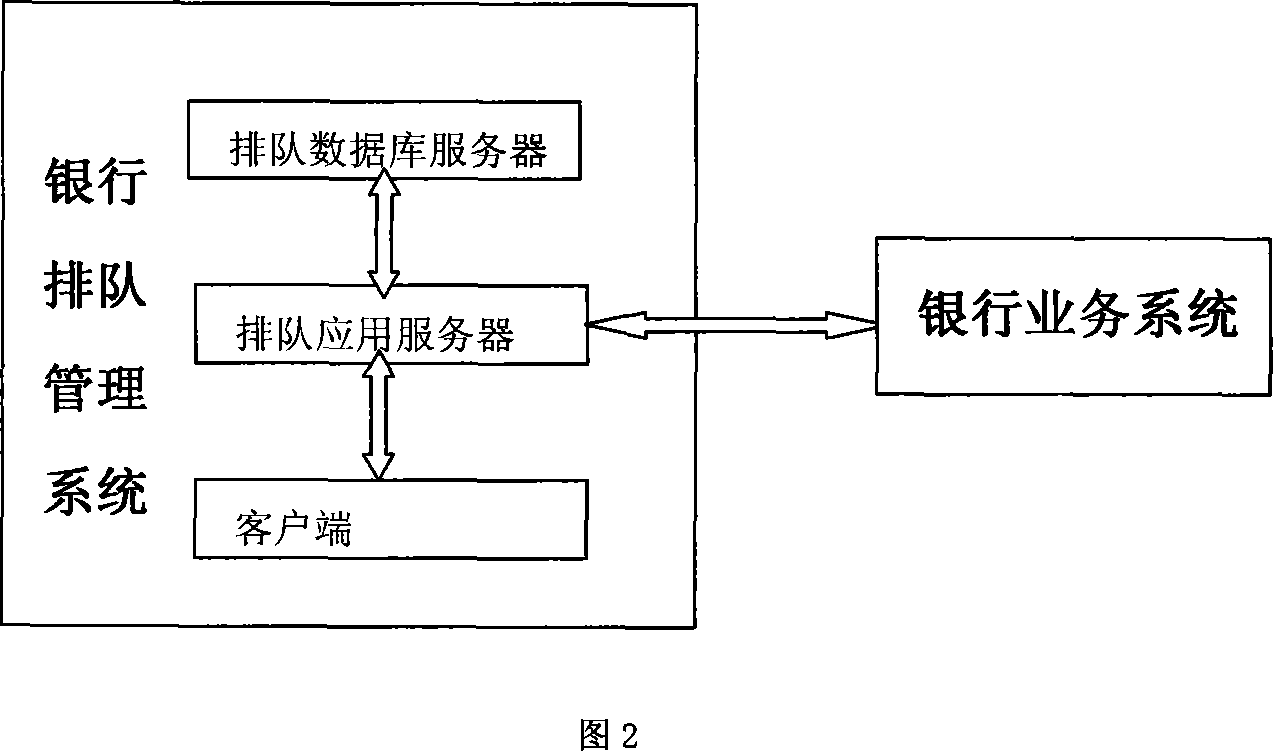

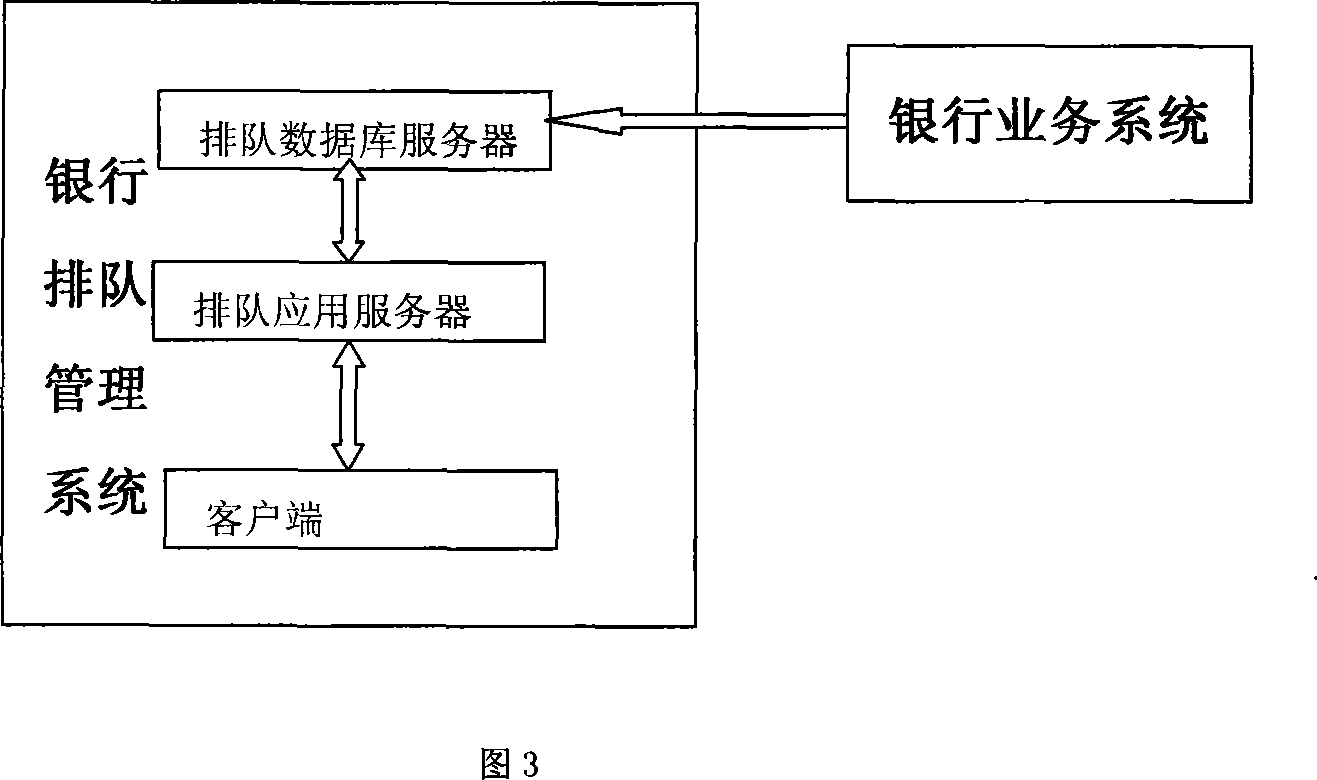

A service account number-based queue method

A queue method based on back account uses bank account mark number as reference of the queue number, to generate a queue number according to the account mark number input by client, wherein the account mark number is relative to the bank account, which can be positioned to one unique back account. A queue manage system stores the record of the relation between the bank account and the queue number, and when client withdraws the queue, the client can based on the account mark number inform the queue manage system to eliminate the queue number, and when client is delay, the queue information can be changed to move back the real serial number in the queue, to save time. And client can set a plurality of prompts, to be processed in met condition by the system. And when the client without eliminated queue dose not process relative service, the queue manage system records an overtime mark on the record between the bank account and the queue number, to accelerate the queue elimination of client to inform the queue manage system.

Owner:郑志豪

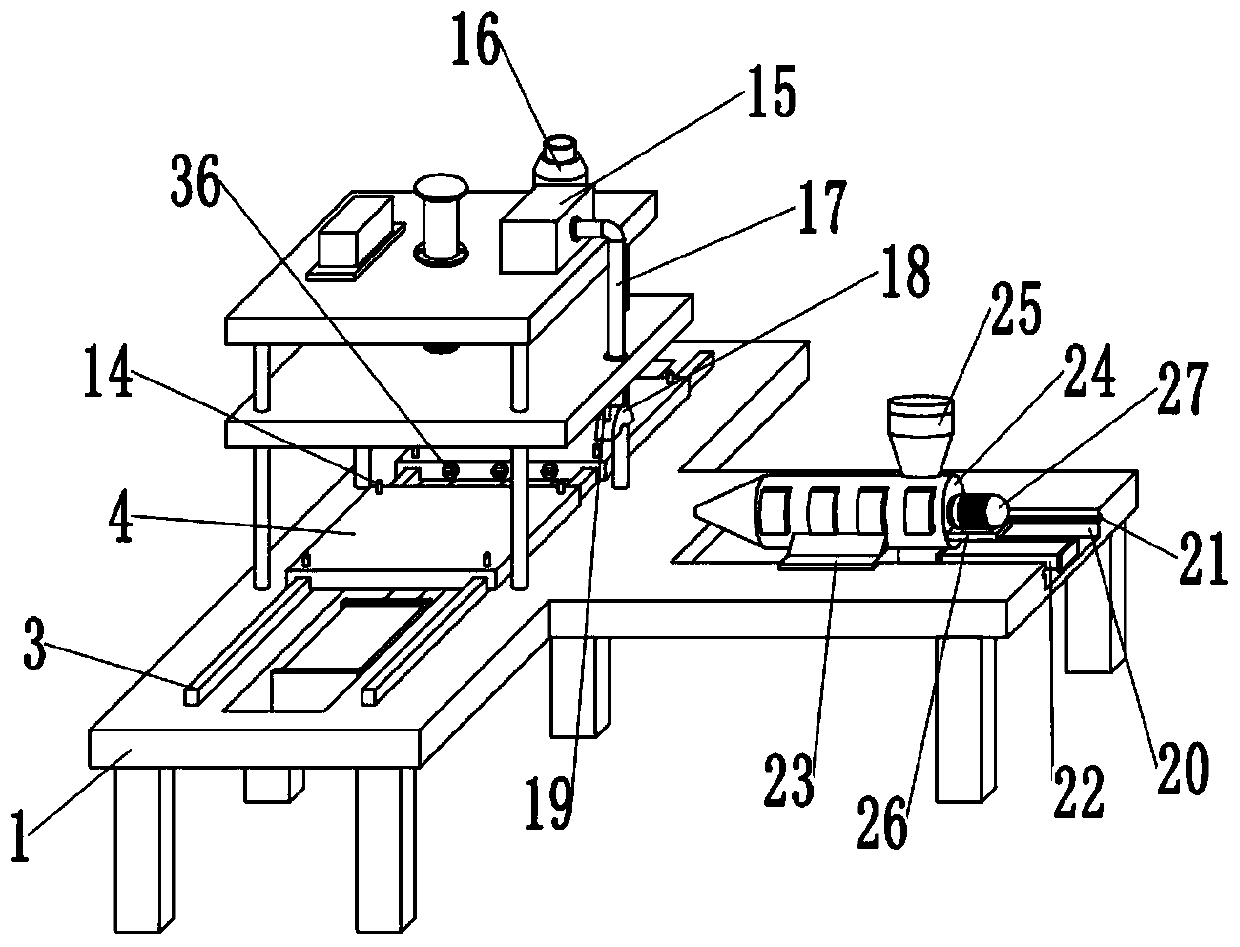

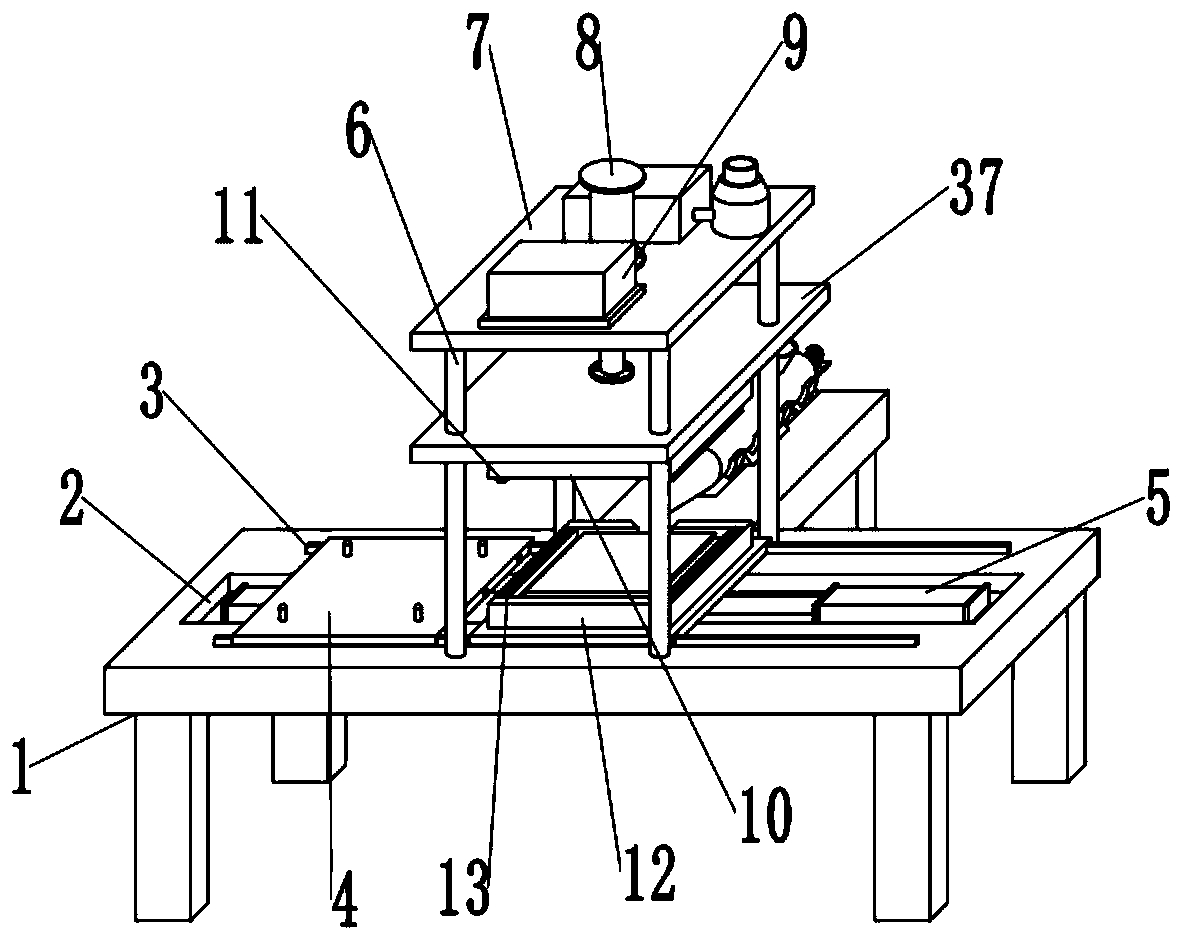

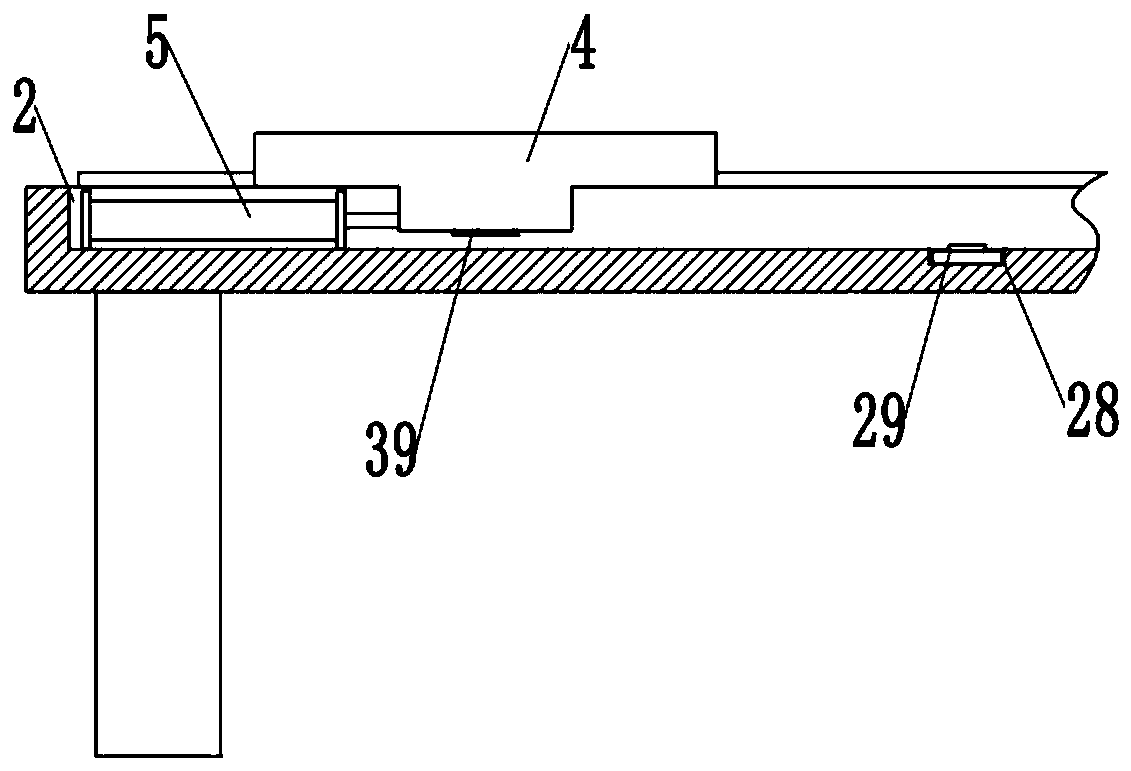

Injection molding equipment for refrigerator glass partition plate machining and production

InactiveCN111391232AImprove injection molding efficiencyAffect healthDispersed particle separationDirt cleaningIceboxInjection moulding

The invention relates to the technical field of glass partition plate production, in particular to injection molding equipment for refrigerator glass partition plate machining and production. The injection molding equipment comprises a worktable, wherein a first groove is formed in one side of the outer wall of the top of the worktable, and first cylinders are arranged on the two sides of the inner wall of the bottom of the first groove through bolts; sliding rails are arranged on the two sides of the outer wall of the top of the workbench through screws, and two lower mold bases distributed in a horizontal structure are connected to the outer walls of the tops of the two sliding rails in a sliding mode; the lower mold bases are fixedly connected with the first air cylinders through screws, and the outer walls of the tops of the lower mold bases are sleeved with lower molds; and two stand columns distributed in a horizontal structure are welded to each of the two sides of the outer wall of the top of the workbench. The injection molding equipment for refrigerator glass partition plate machining and production has the beneficial effects that the injection molding efficiency of a glass partition plate can be improved, and when upper molds and the lower molds are adjusted or replaced, through cooperation of limiting blocks and limiting grooves, a worker can rapidly align the uppermolds with the lower molds, so that a large amount of time is prevented from being wasted.

Owner:滁州克莱帝玻璃科技有限公司

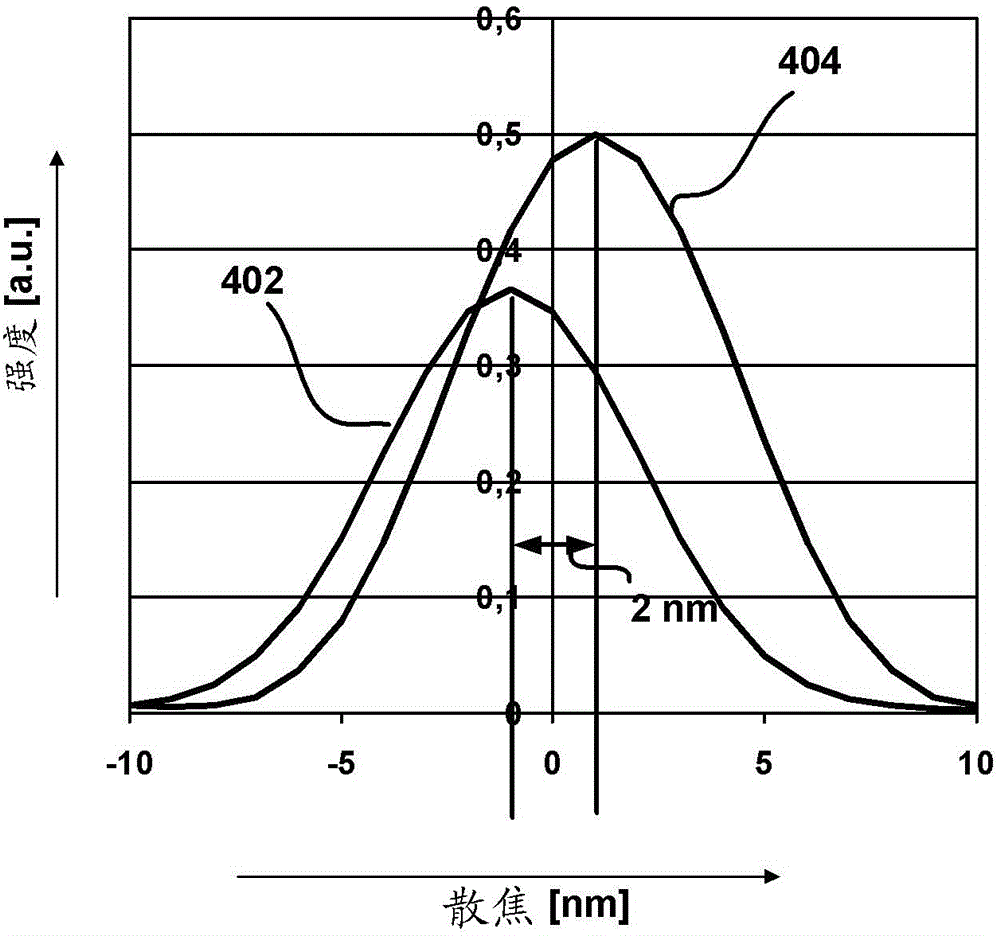

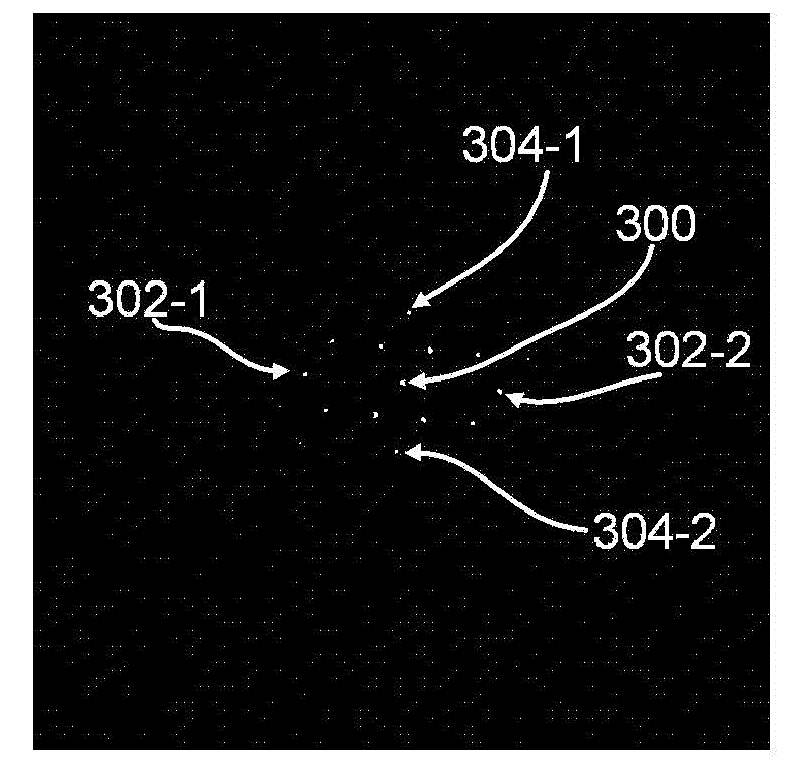

Method for adjusting a stem equipped with an aberration corrector

ActiveCN103065917AWaste timeElectric discharge tubesMaterial analysis using radiation diffractionImage conversionMaterials science

The invention relates to a method for adjusting a C s corrector in a STEM using a crystalline sample. The method comprises recording a through-focus series, converting the obtained images to Fourier space, thus forming a set of images alike diffraction images. By then determining the symmetry of the Fourier images, the corrector can be tuned for better symmetry, and the transfer limit can be determined by determining the maximum distance of the spots from the centre. By repeatedly performing these steps, the corrector can be tuned to its optimum performance.

Owner:FEI CO

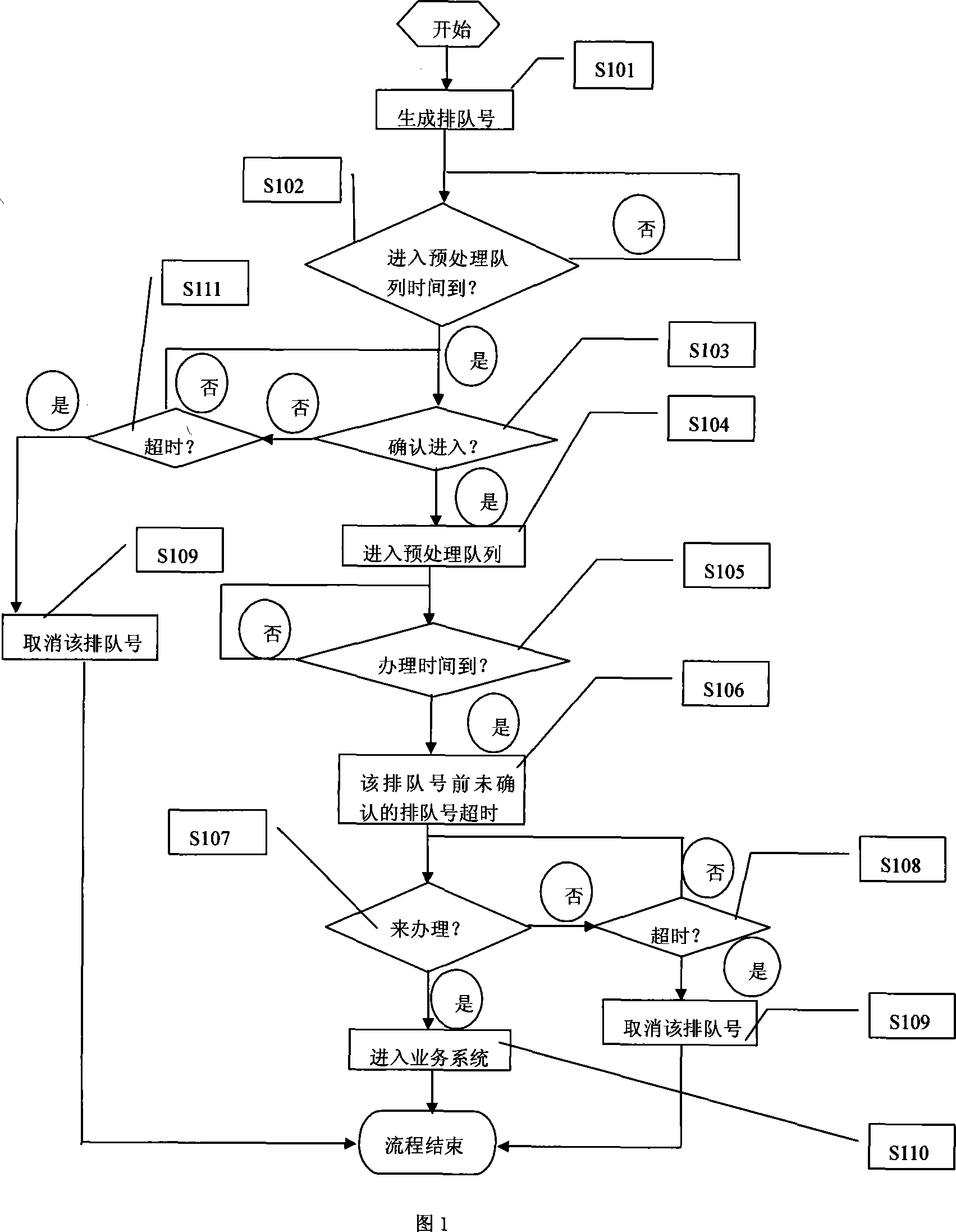

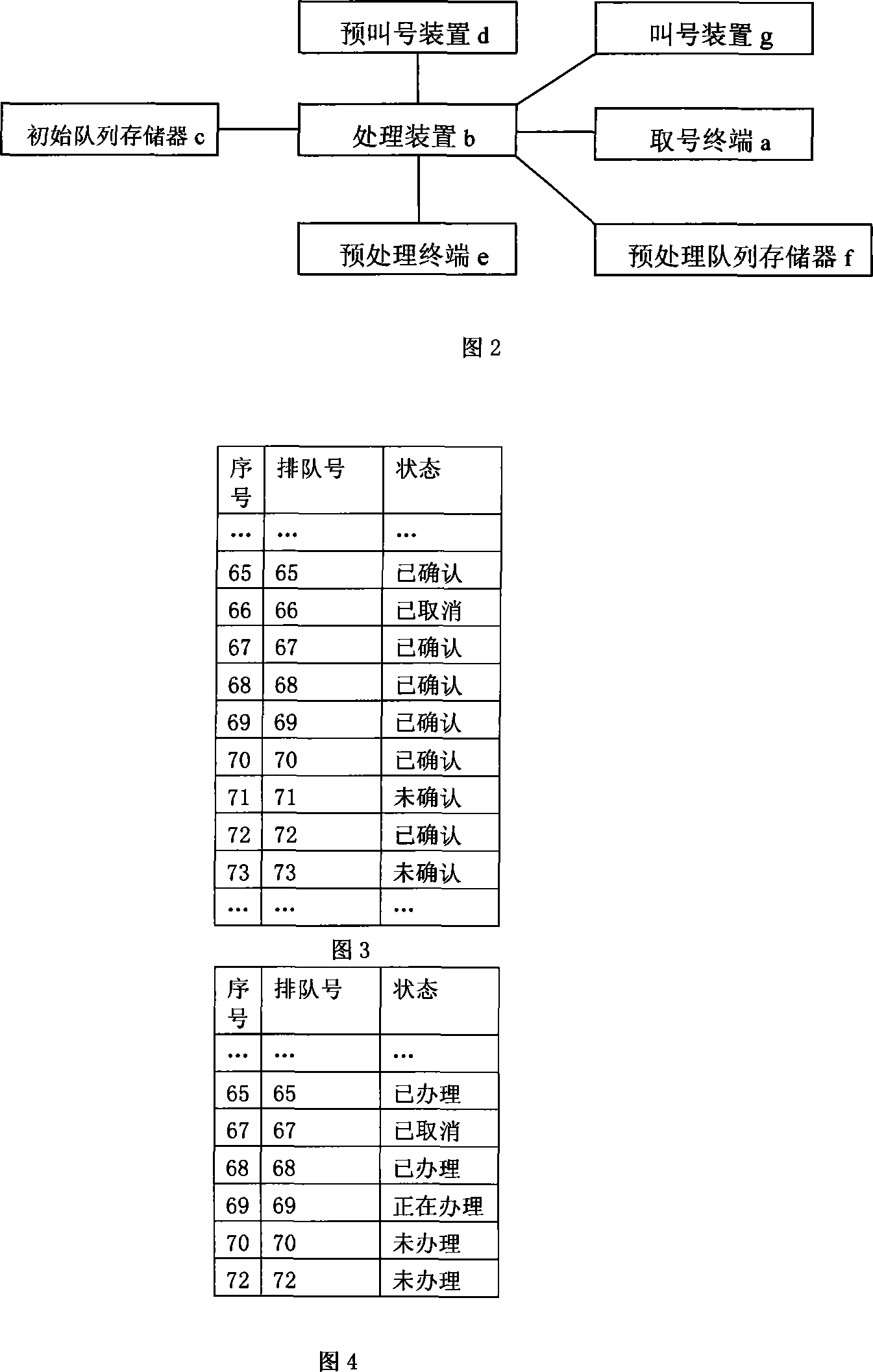

Method and system for managing queueing

InactiveCN101206775AAvoid calling empty numbersWaste timeChecking apparatusDistributed computingSystem call

The invention relates to a queue administrating method and a system which are used for solving the problems that a vacant number is called by a queue administrating system and the time of the customer waiting on site and the staff is wasted. The provided method comprises the following steps: a queue number is generated and outputted according to the customer applying; when the queue number of which the turn is the next is N, the queue administrating method in advance informs the customer of which the queue number is N plus K going off to an appointed device to confirm, wherein, K is an integer number not smaller than 0; the customer informed is confirmed that the customer still queues in schedule time, and then the customer goes into a pretreatment queue; the queue administrating system calls a number according to the queue number in the pretreatment queue. A system used for realizing the method is also provided. The method has the advantages that the customer not being on queue site cannot go into the pretreatment queue if not being confirmed, and solves the problem of calling the vacant number.

Owner:郑志豪

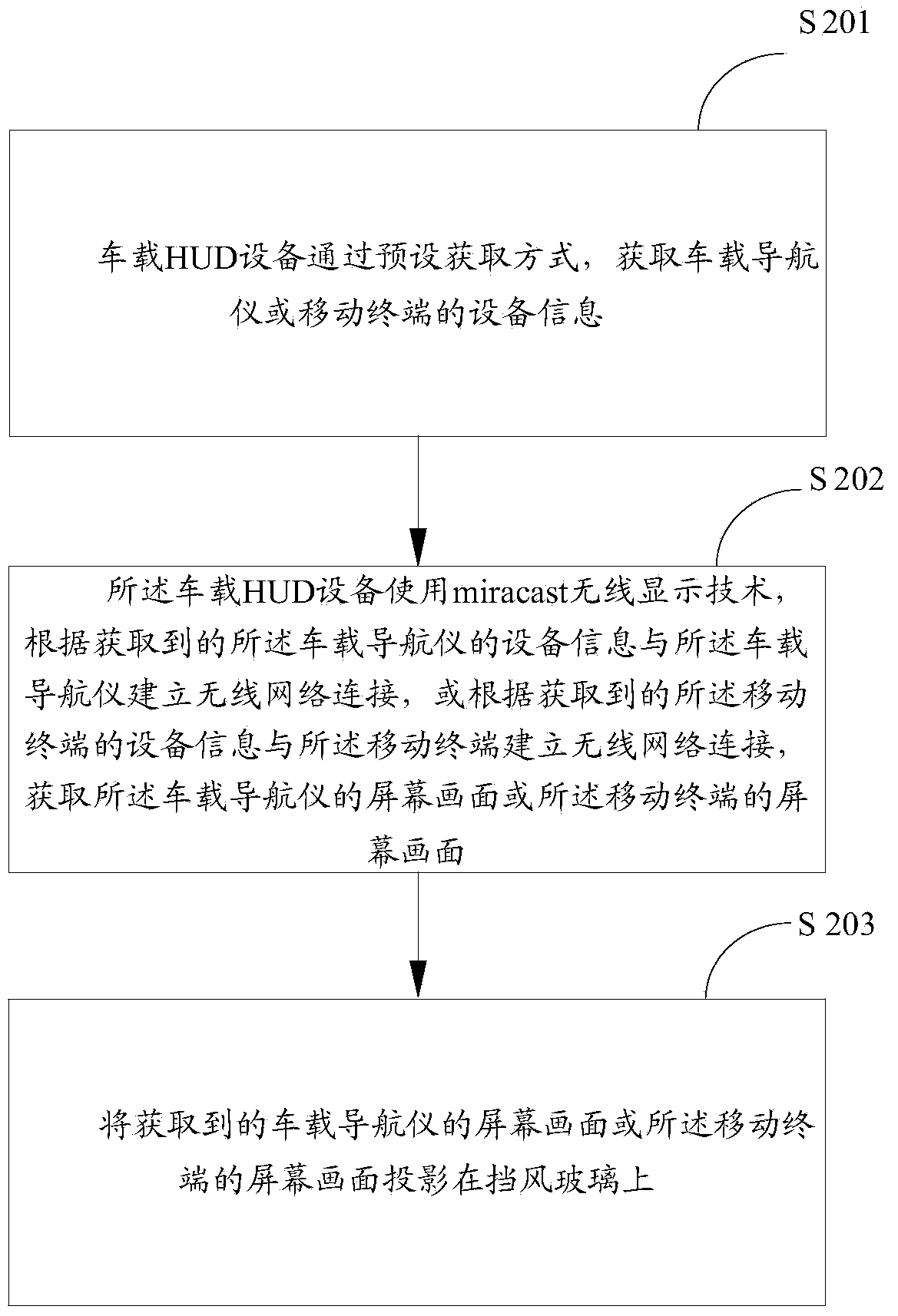

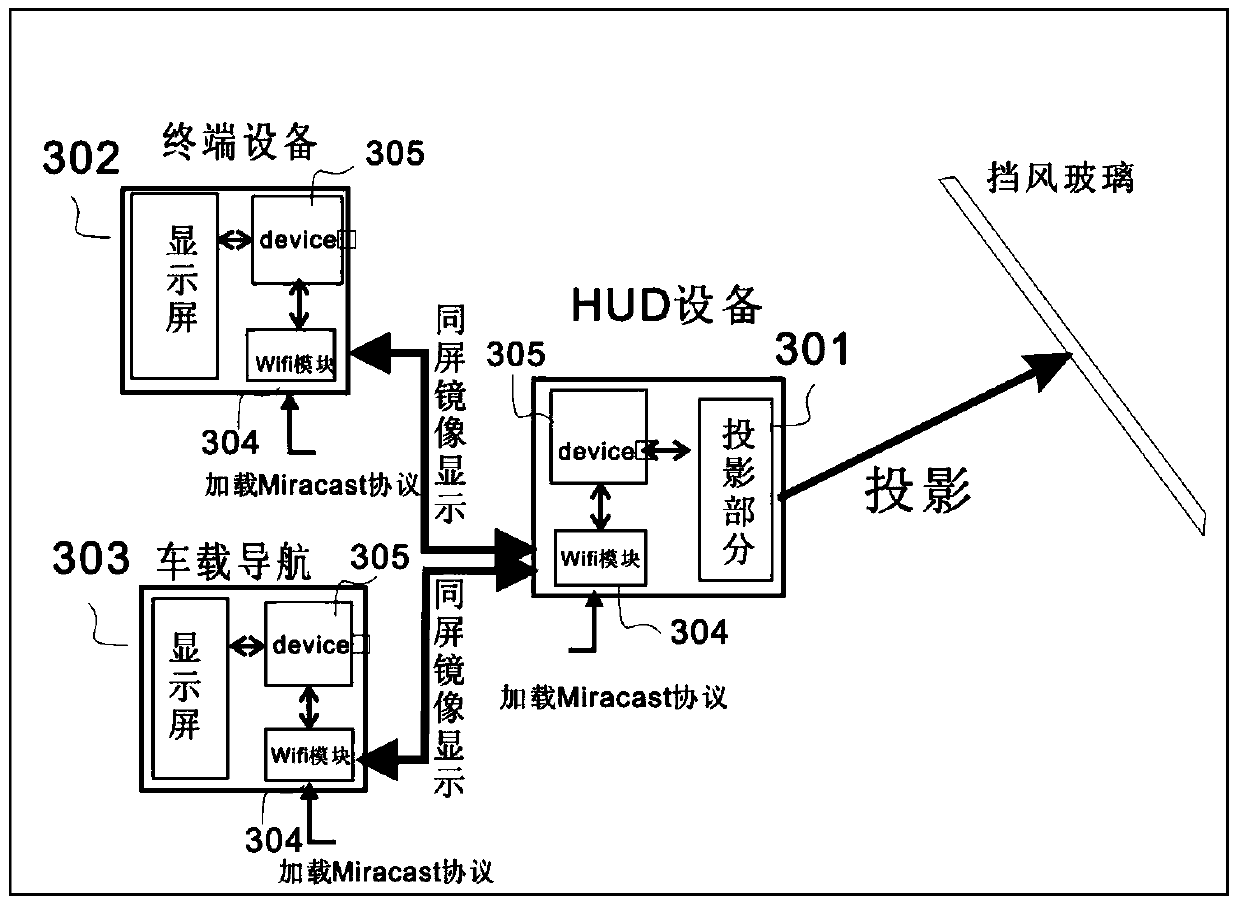

HUD (head-up display) device display method, device and system

ActiveCN103786655AAvoid Limiting SituationsWaste timeVehicle componentsHead-up displayComputer terminal

The invention applies to the technical field of HUD devices and provides an HUD (head-up display) device display method, device and system. The method includes: allowing an HUD device to acquire device information of a vehicular navigator or mobile terminal in a preset acquisition manner; allowing the vehicular HUD device to establish wireless network connection with the vehicular navigator according to the device information of the vehicular navigator or establish wireless network connection with the mobile terminal according to the device information of the mobile terminal, by the Miracast wireless display technology, and acquiring a screen image of the vehicular navigator or a screen image of the mobile terminal; projecting the acquired screen image of the vehicular navigator or the acquired screen image of the mobile terminal to a windshield. The screen image of the vehicular navigator of the screen image of the mobile terminal is projected to the windshield, so that projection contents are no longer limited and operating efficiency of users is improved.

Owner:SHENZHEN DIANSHI INNOVATION TECH CO LTD

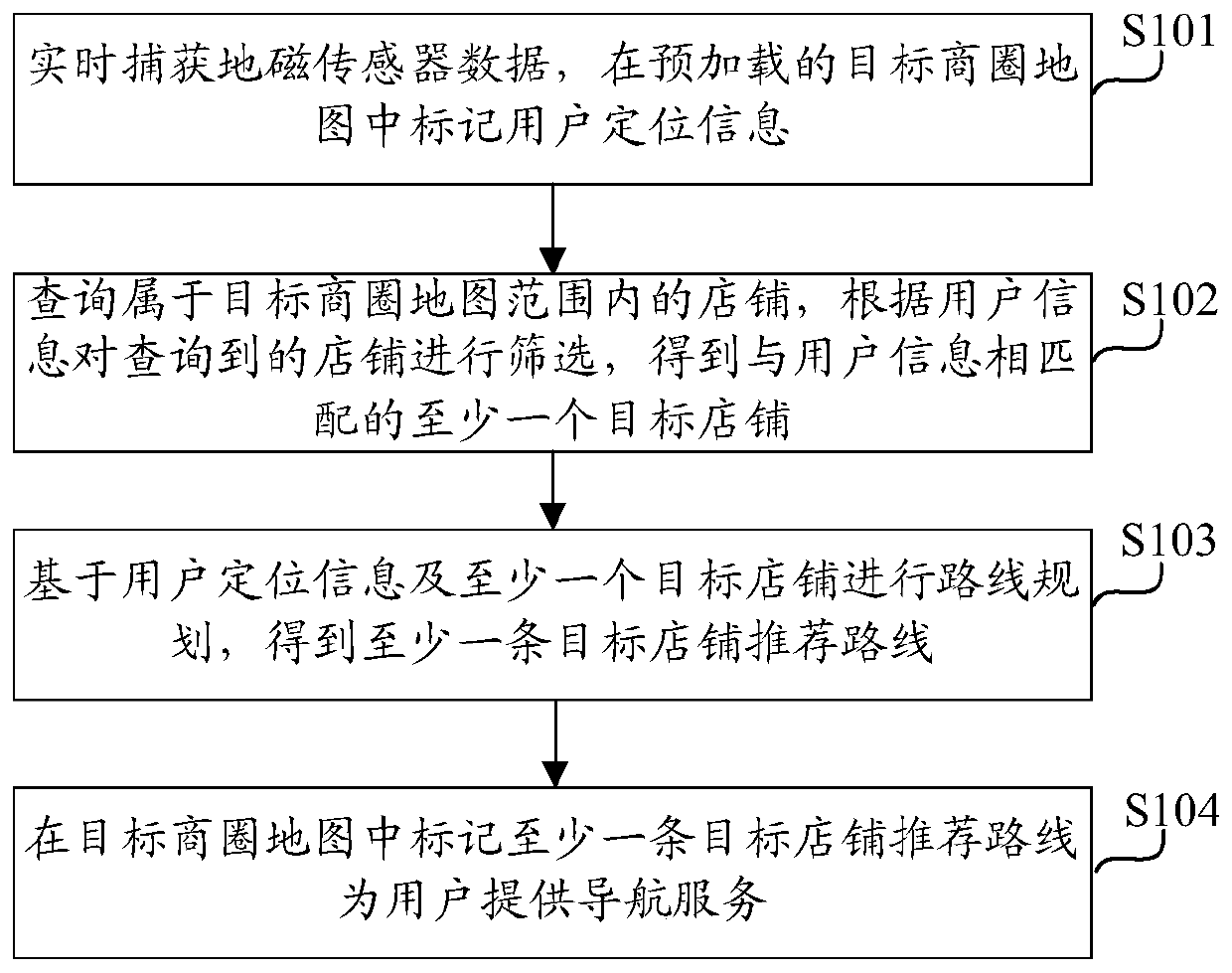

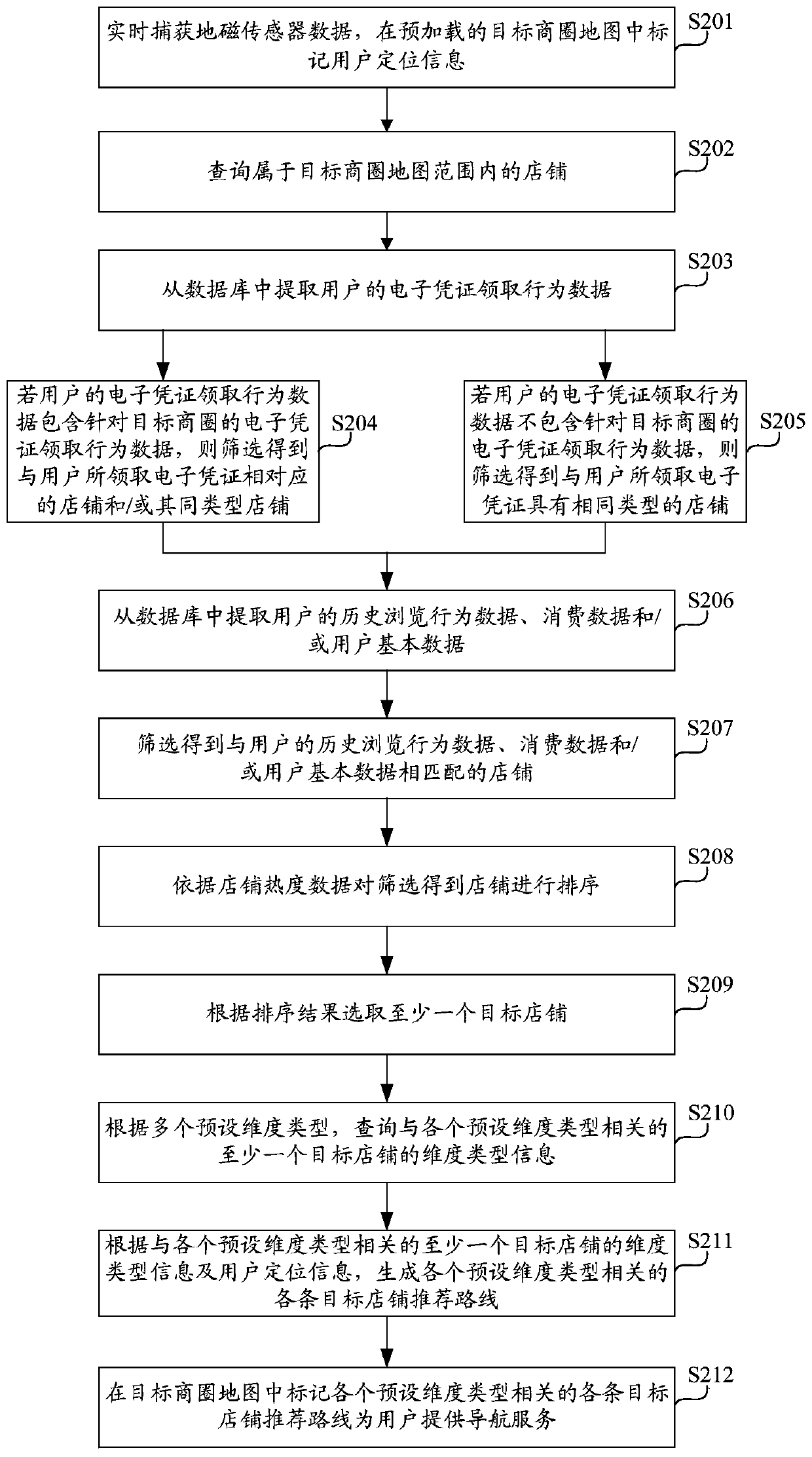

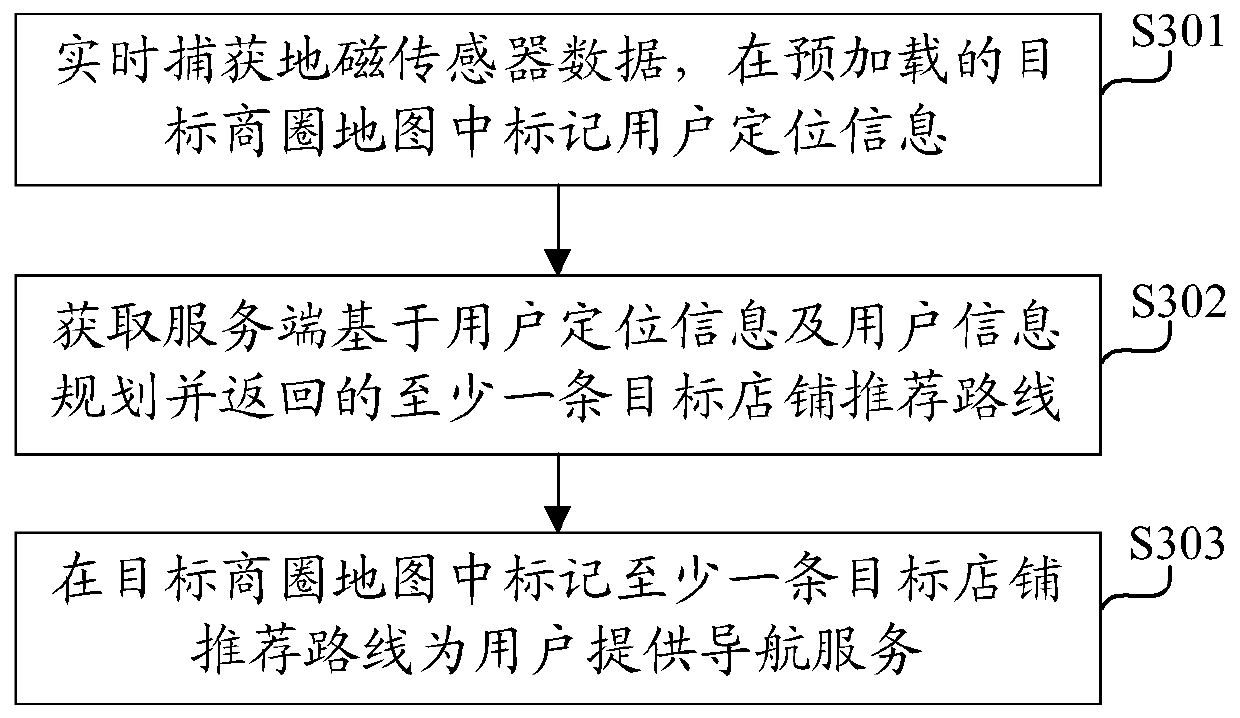

Positioning information-combined store route recommendation method and device

ActiveCN110231026ARaise the possibilityIncrease turnoverNavigational calculation instrumentsNavigation by terrestrial meansRoute planningSensing data

The invention discloses a positioning information-combined store route recommendation method and device. The method comprises the steps of capturing geomagnetic sensing data in real time and labellinguser positioning information in a preloaded target business area map; querying stores belonging to a range of the target business area map and screening the queried stores according to user information so as to obtain at least one target store matched with the user information; and carrying out route planning on the basis of the user positioning information and the at least one target store so asto obtain at least one target store recommendation route. According to the method, the at least one target store recommendation route is labelled in the target store map to provide a navigation service for the user, and the stores are screened according to the user information, so that the screened stores are stores in which the user is interested, thereby enhancing the possibility that the userenters the stores, enhancing the purchasing possibility of the user, enhancing the turnover of the business area and avoiding the user from purposelessly walking in the business area to waste the timeof the user.

Owner:ZHEJIANG KOUBEI NETWORK TECH CO LTD

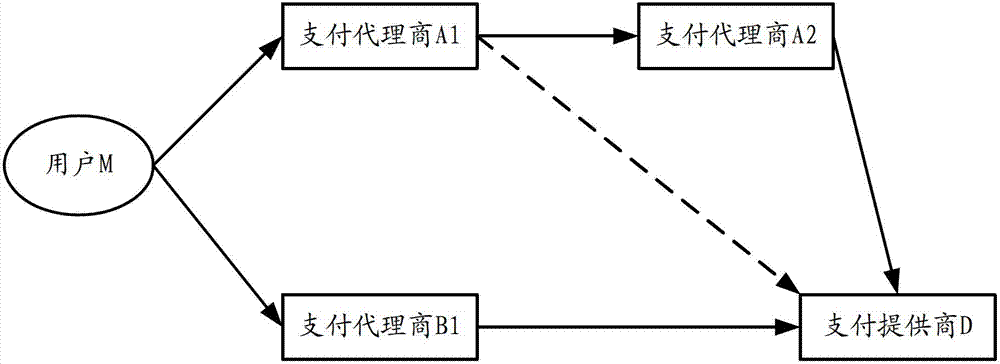

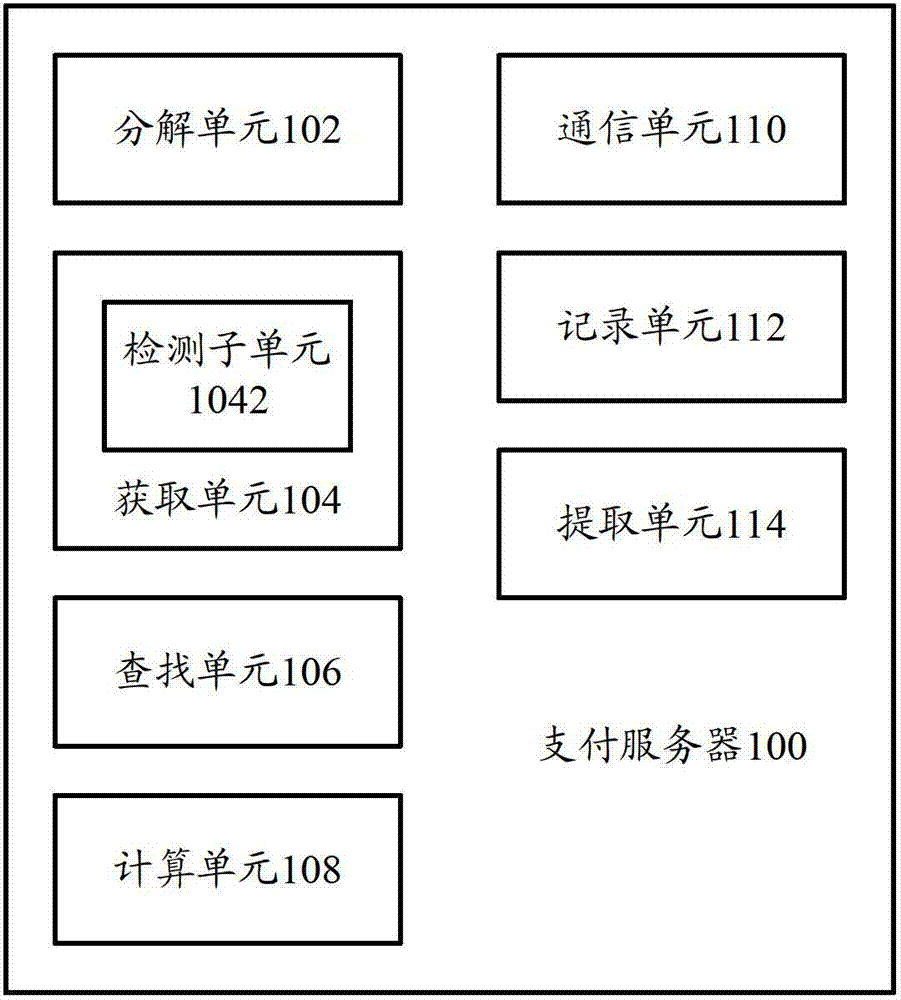

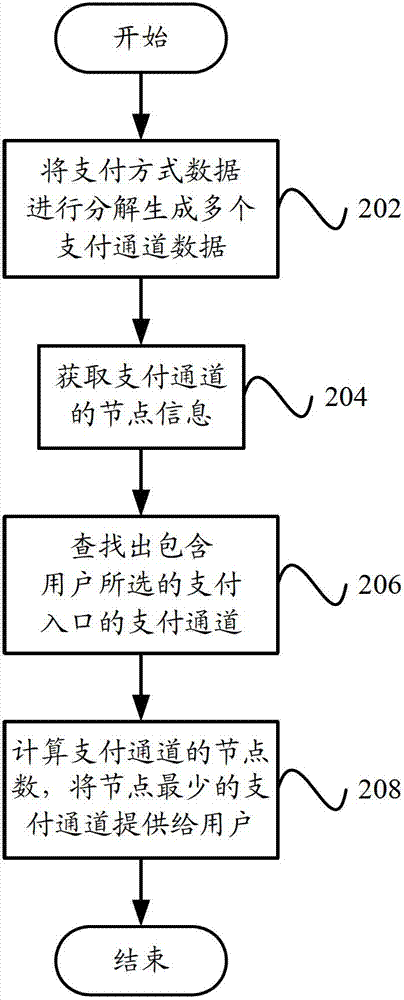

Payment server and payment channel acquisition method

ActiveCN102903043AAvoid wasting timeReduce the number of nodesPayment architectureTransmissionChannel dataPayment order

The invention provides a payment server which comprises a decomposing unit, an acquiring unit, a searching unit, a calculating unit and a communicating unit, wherein the decomposing unit is used for decomposing payment mode data provided by a plurality of proxy servers to generate a plurality of payment channel data and storing the payment channel data to a database; the acquiring unit is used for acquiring and storing the node information experienced by each payment channel; the searching unit is used for finding out the payment channel belonging to the selected payment entrance type according to the payment entrance type selected by the client; the calculating unit is used for calculating the node number experienced by each found-out payment channel; and the communicating unit is used for sending the payment channel data with the least node number to the client. The invention further provides a payment channel acquisition method. According to the technical scheme provided by the invention, a payment channel with the least payment node can be provided to a user automatically in the payment process of the user, thereby reducing the transitional skipping process, reducing expenses in payment, and ensuring the payment rapidness and stability.

Owner:DONGGUAN YULONG COMM TECH +1

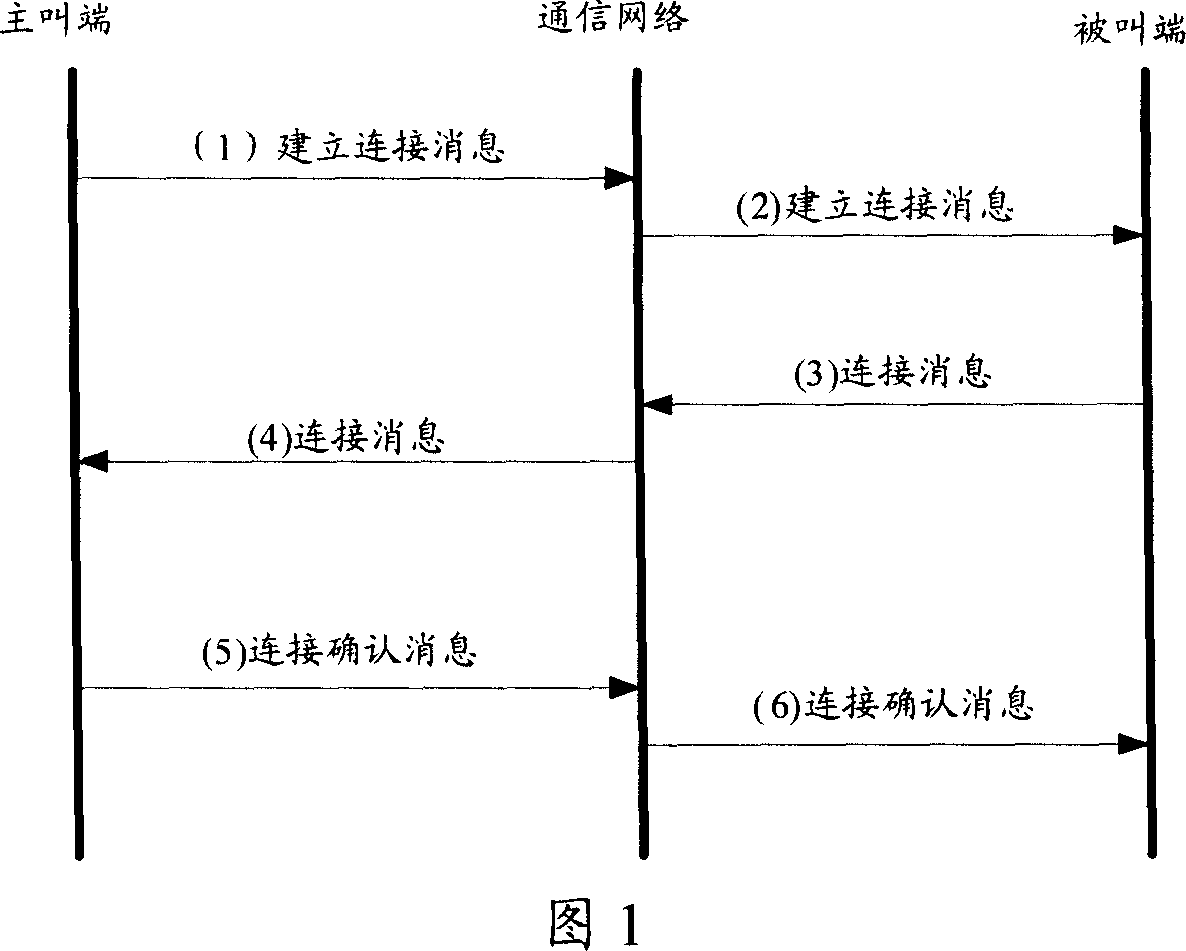

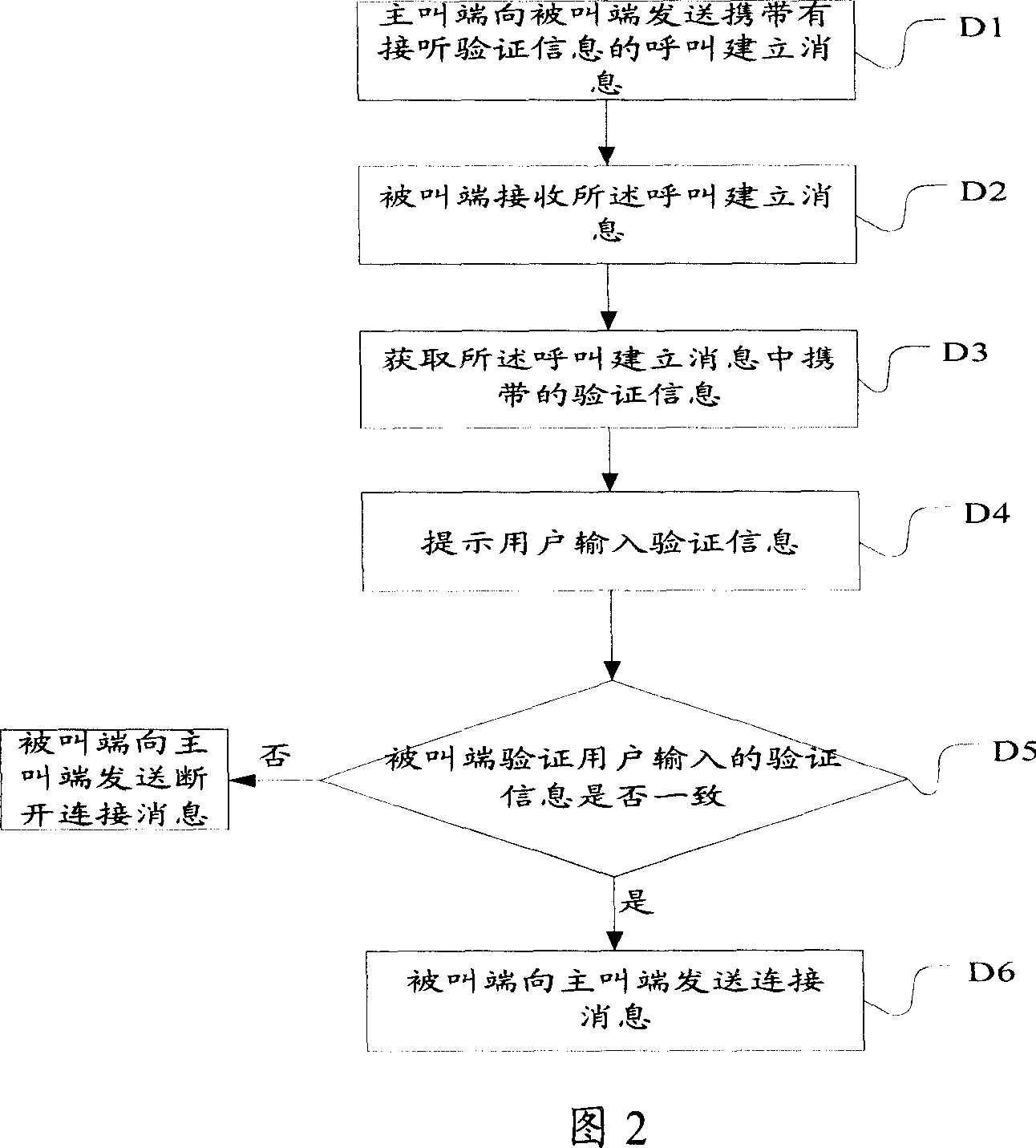

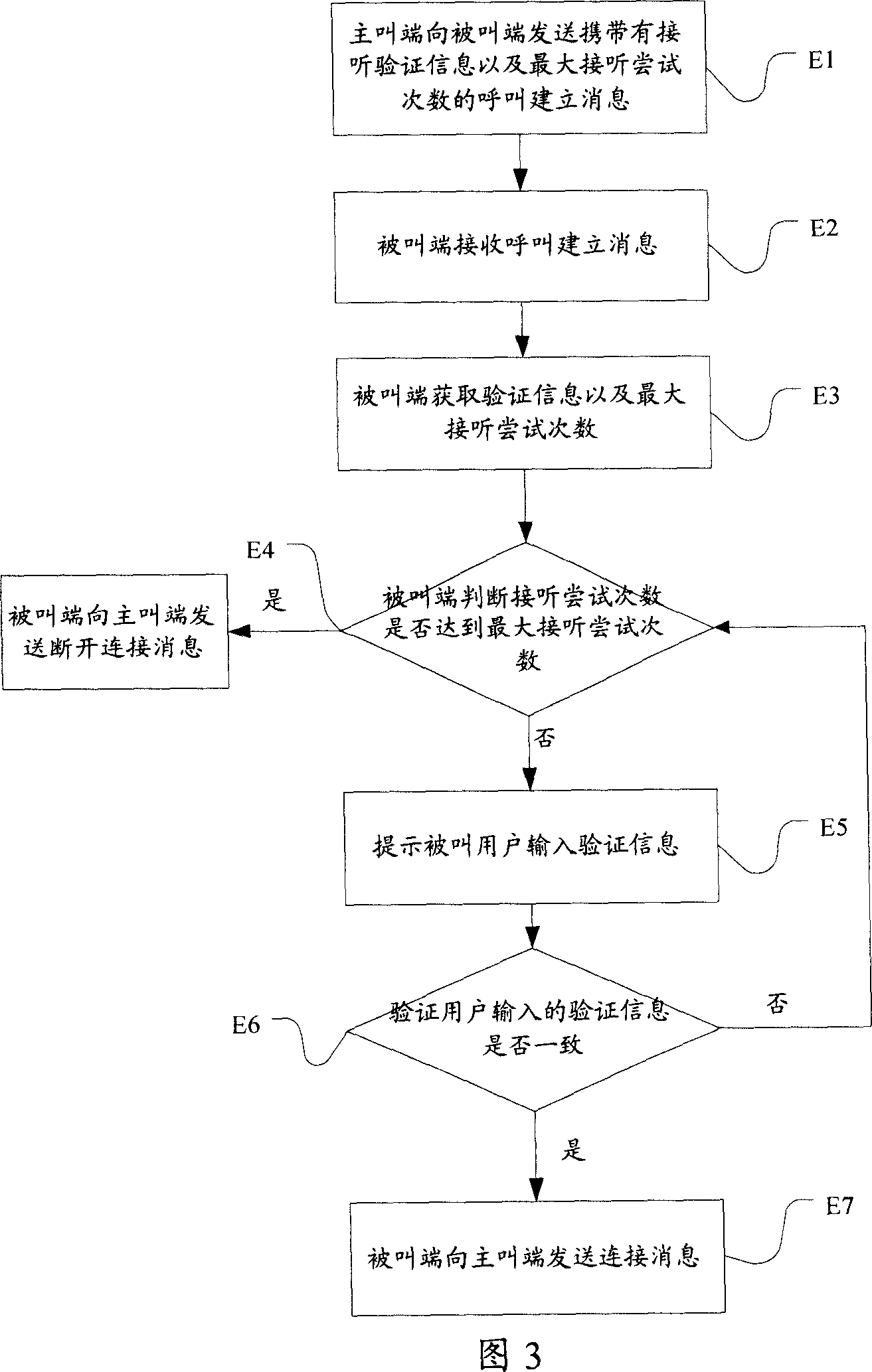

Telephone call method and telephone terminal

InactiveCN1925519AAchieve securityEnsure safetySupervisory/monitoring/testing arrangementsSubstation equipmentUser inputTelephone terminal

This invention discloses phone call method, system and terminal in call process, wherein the method comprises the following steps: main call end sends call establishing information with validation information; the called end receives call establishing information to get the information with validation information to indicate user input validation information; the called validation user tests user input validation information and establishing information to send connection information of main call end. This invention also discloses one phone terminal.

Owner:HUAWEI TECH CO LTD

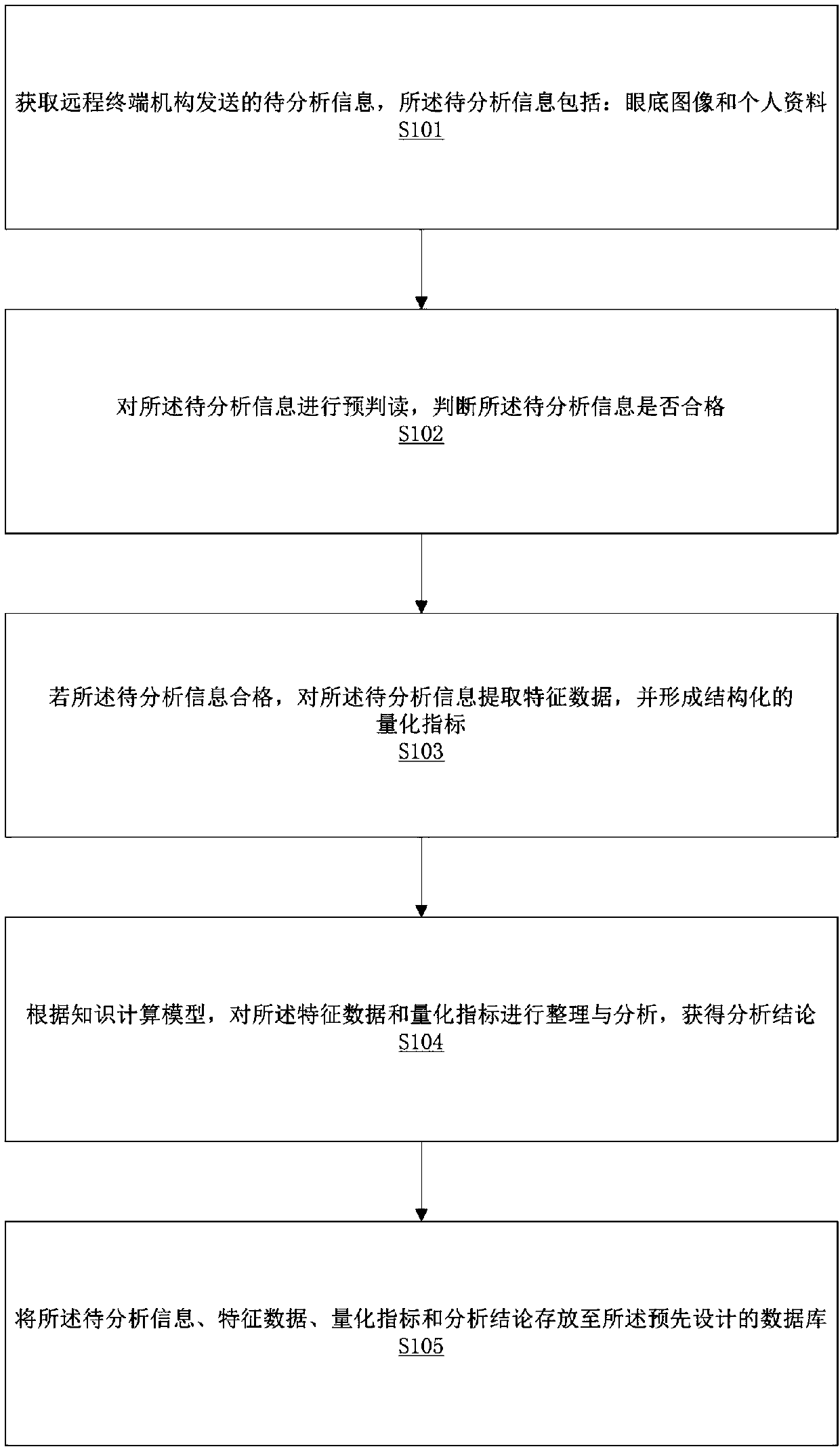

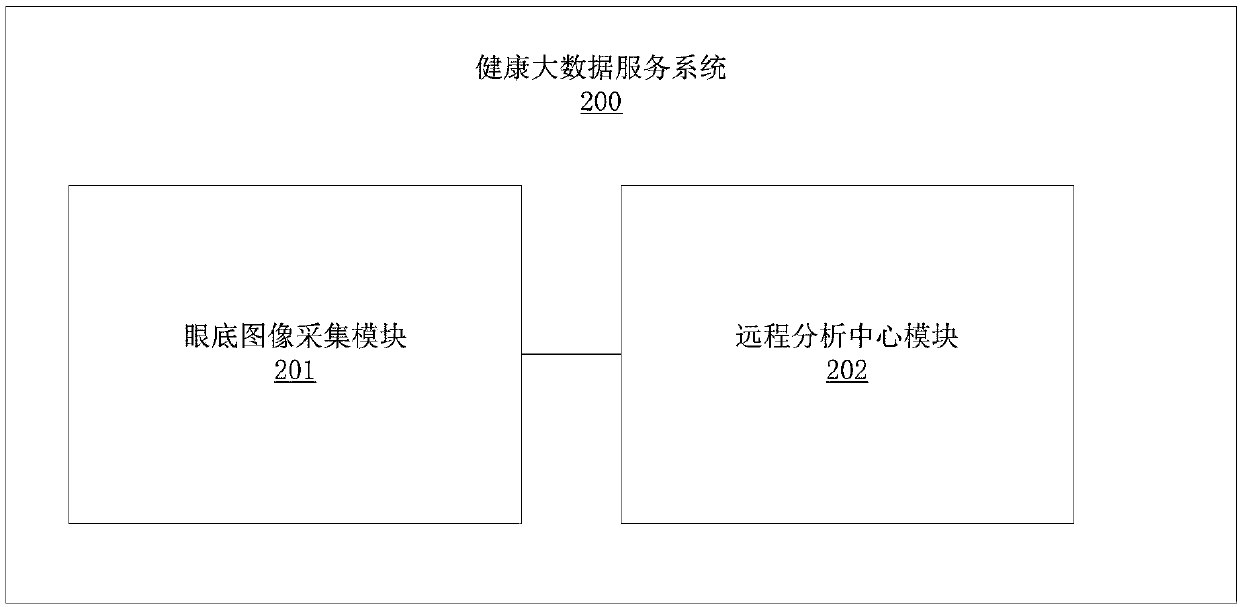

Health big data service method and system based on remote fundus screening

ActiveCN110875092AImprove experienceAids in disease interpretationImage enhancementMedical data miningPersonalizationFundus camera

The invention relates to the field of health big data, in particular to a health big data service method and system based on remote fundus screening. The health big data service method based on remotefundus screening comprises the steps: obtaining information to be analyzed sent by a remote terminal mechanism; carrying out pre-interpretation on the information to be analyzed, and judging whetherthe information to be analyzed is qualified or not; if the information is qualified, extracting feature data from the information to be analyzed, and forming a structured quantitative index; sorting and analyzing the feature data and the quantitative index according to a knowledge calculation model to obtain an analysis conclusion; and storing the information to be analyzed, the feature data, thequantitative index and the analysis conclusion in a database. Through the above steps, no matter what types of fundus cameras and what working modes are, the finally obtained fundus images can have comparability-unified quantitative indexes and feature data after being processed; and a whole big data service platform is established, and implementation of personalized health big data services and the like is greatly facilitated.

Owner:FUZHOU YIYING HEALTH TECH CO LTD

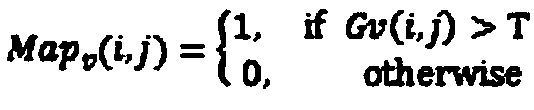

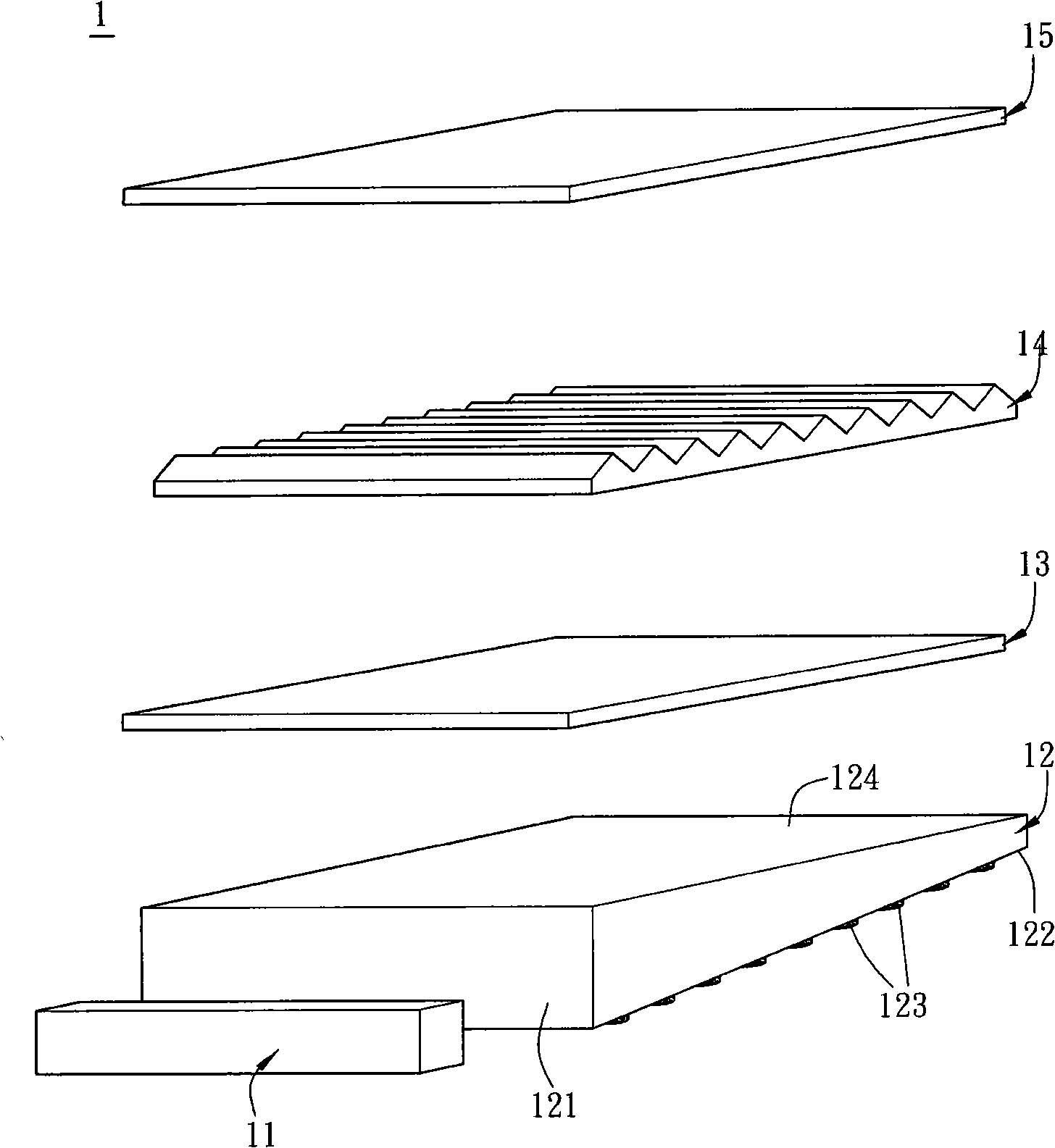

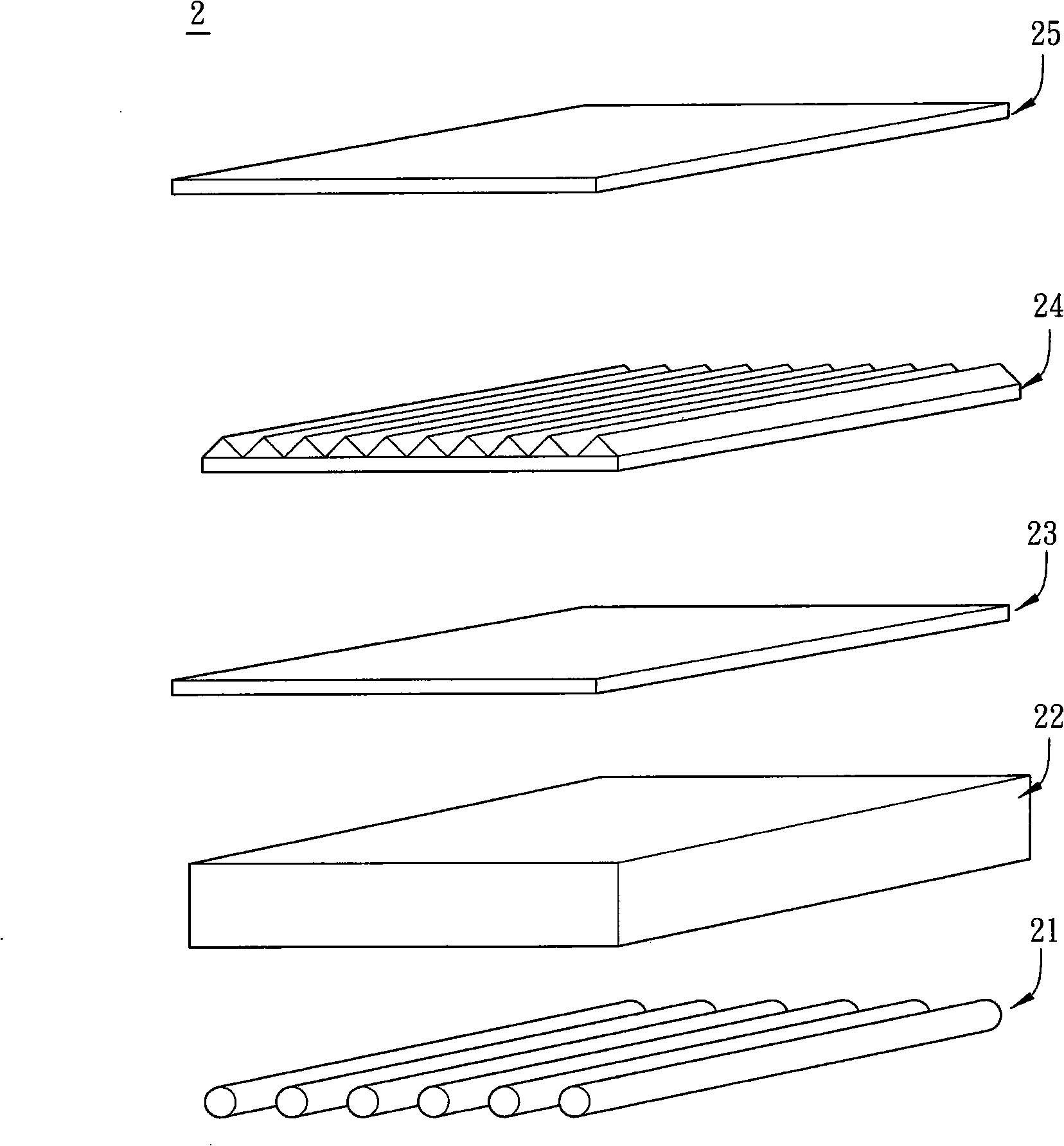

Light-collecting compound sheet

InactiveCN101329414AWaste timeReduce manufacturing costDiffusing elementsNon-linear opticsDiffusionPrism

A collection complex piece comprises a first optical element, a second optical element and a plurality of cavities. The first optical element is provided with a first surface, a second surface which is opposite to the first surface and a plurality of first prisms which are positioned at the first surface. The second optical element is provided with a diffusion material and combined with at least one part of the first prisms. A plurality of cavities are formed between the first optical element and the second optical element. The collection complex piece can solve the problems of a plurality of optical elements, thicker thickness and long assembly time, etc., in the prior art, thereby reducing the production cost of the product.

Owner:GIGNO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com