Patents

Literature

378results about How to "Improve injection molding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

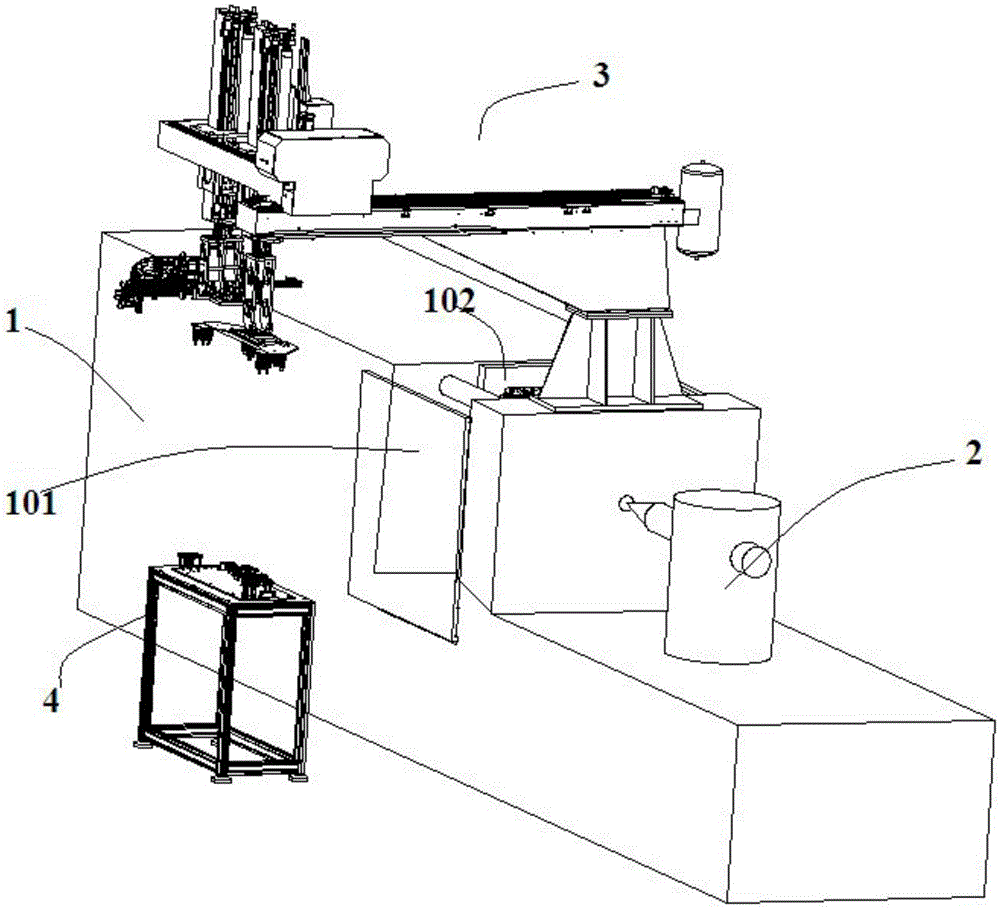

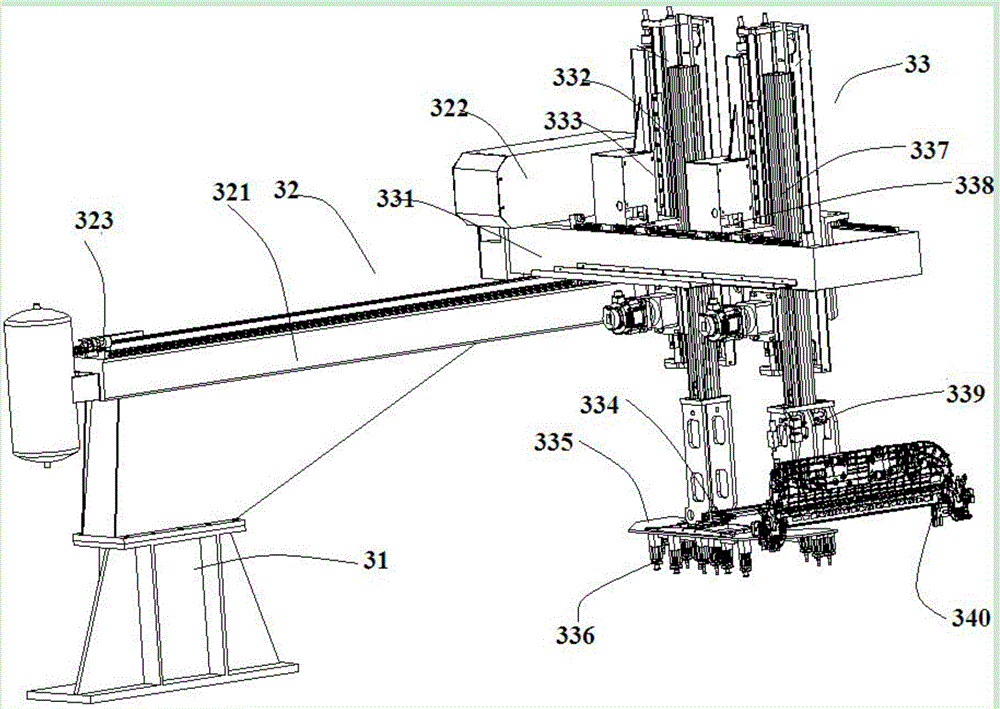

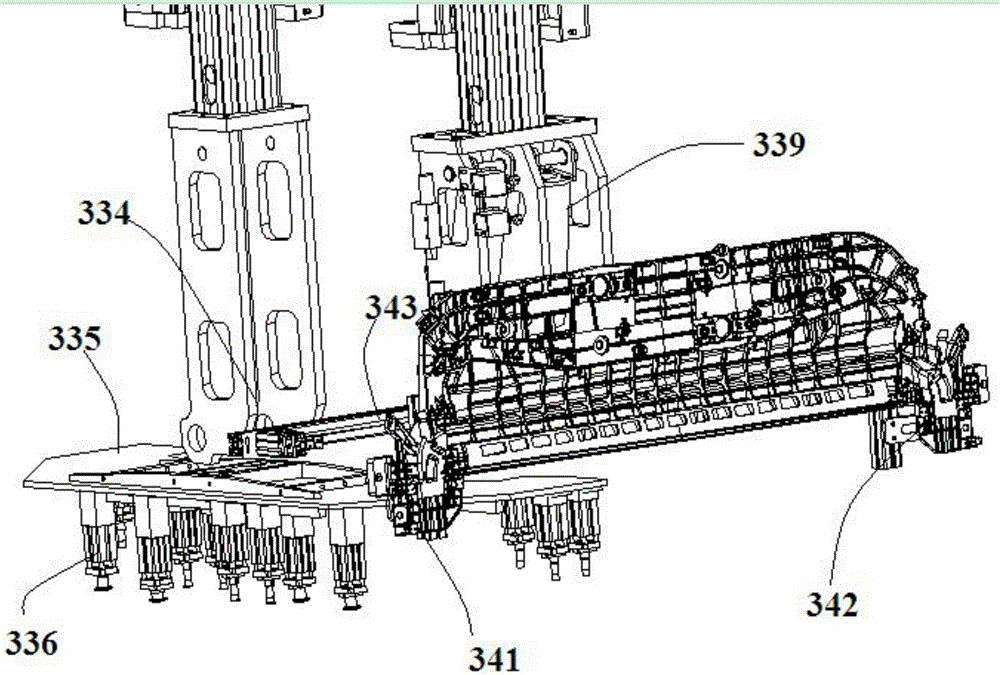

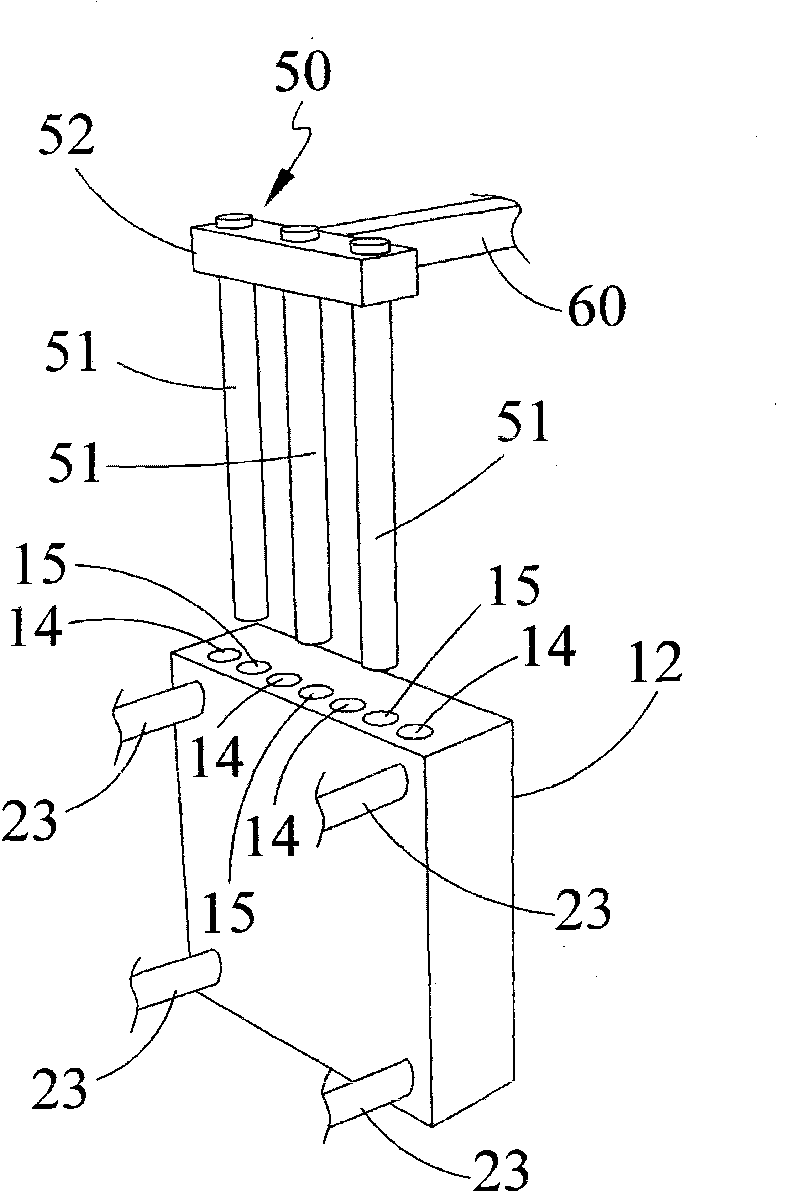

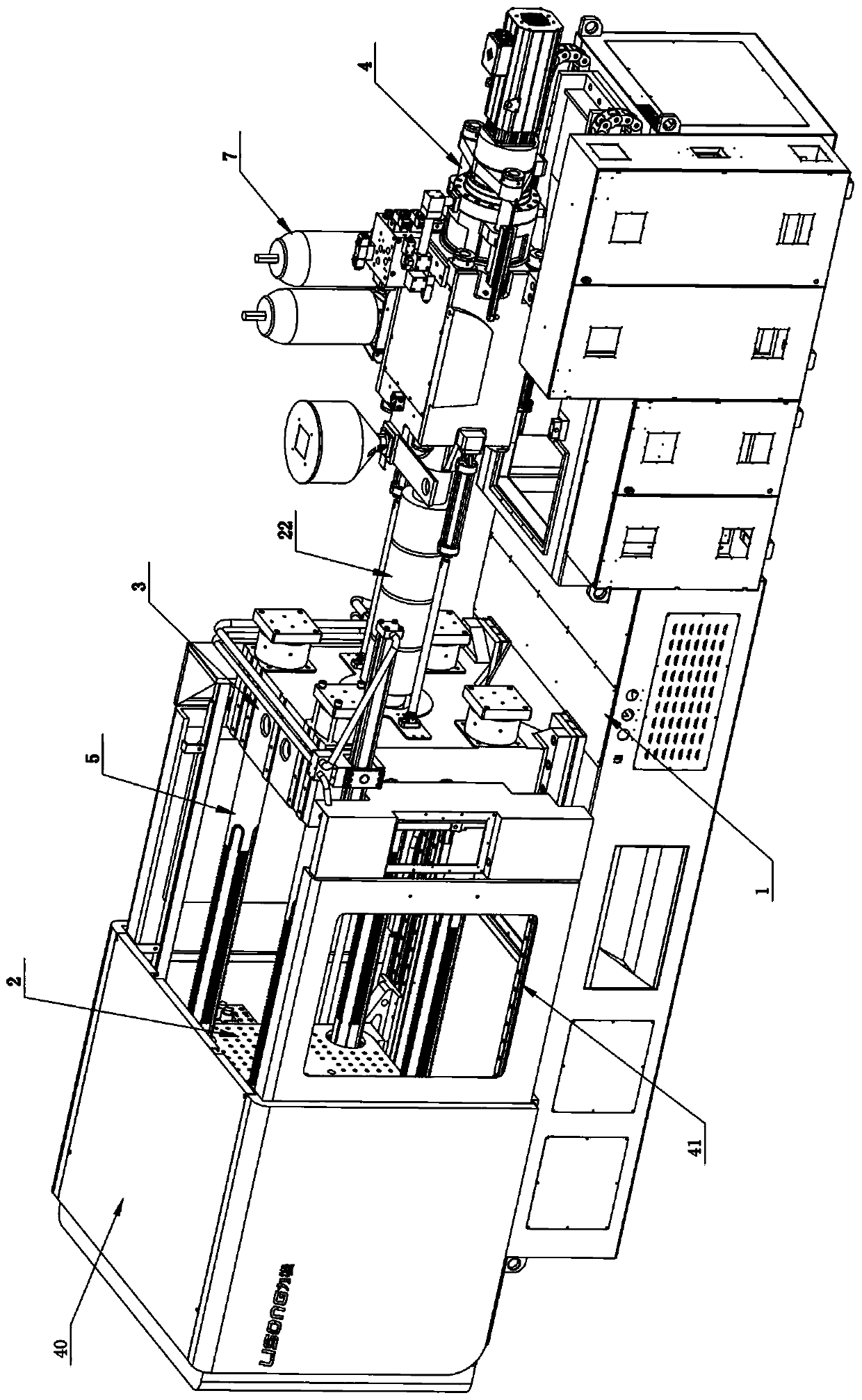

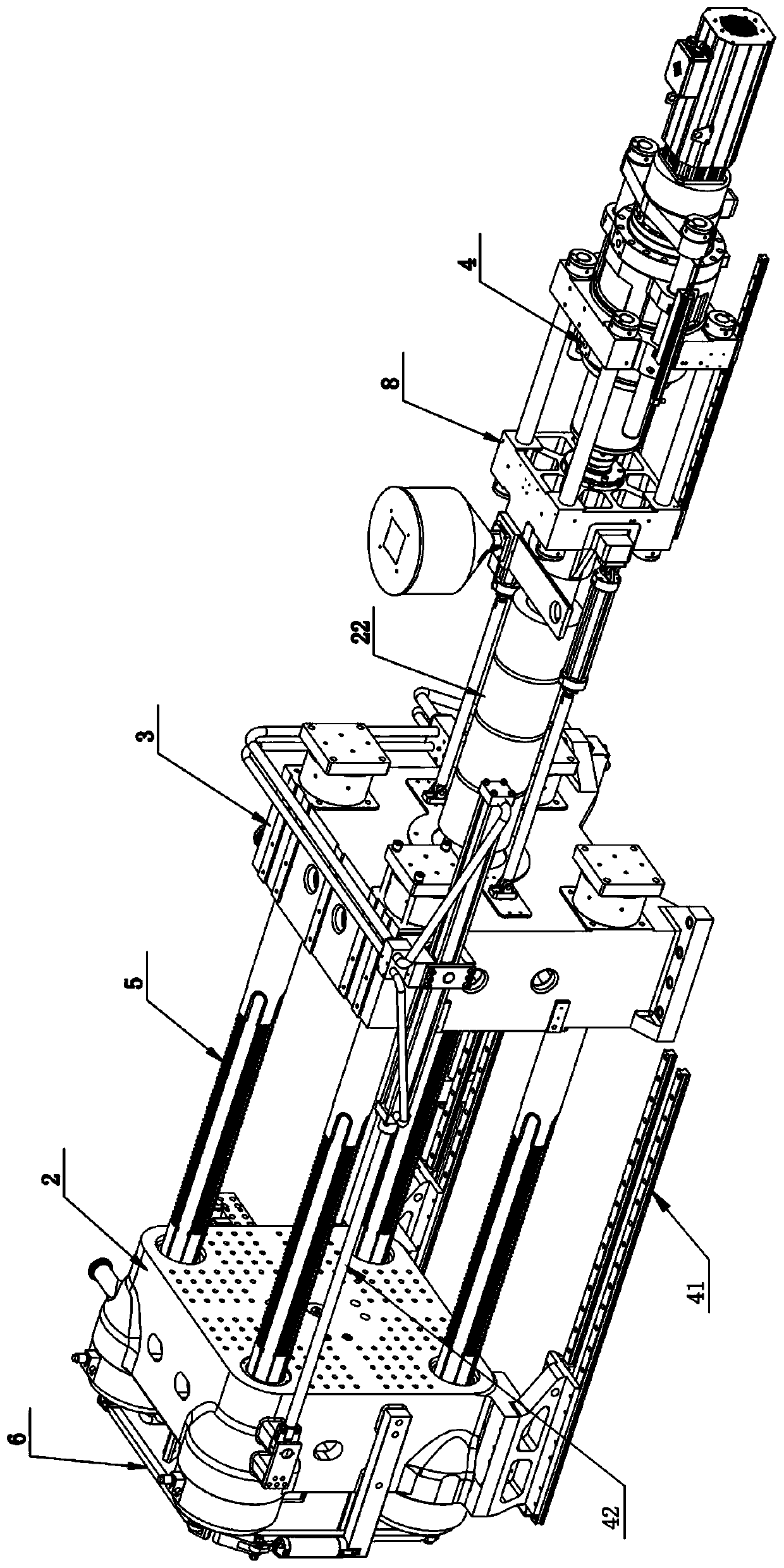

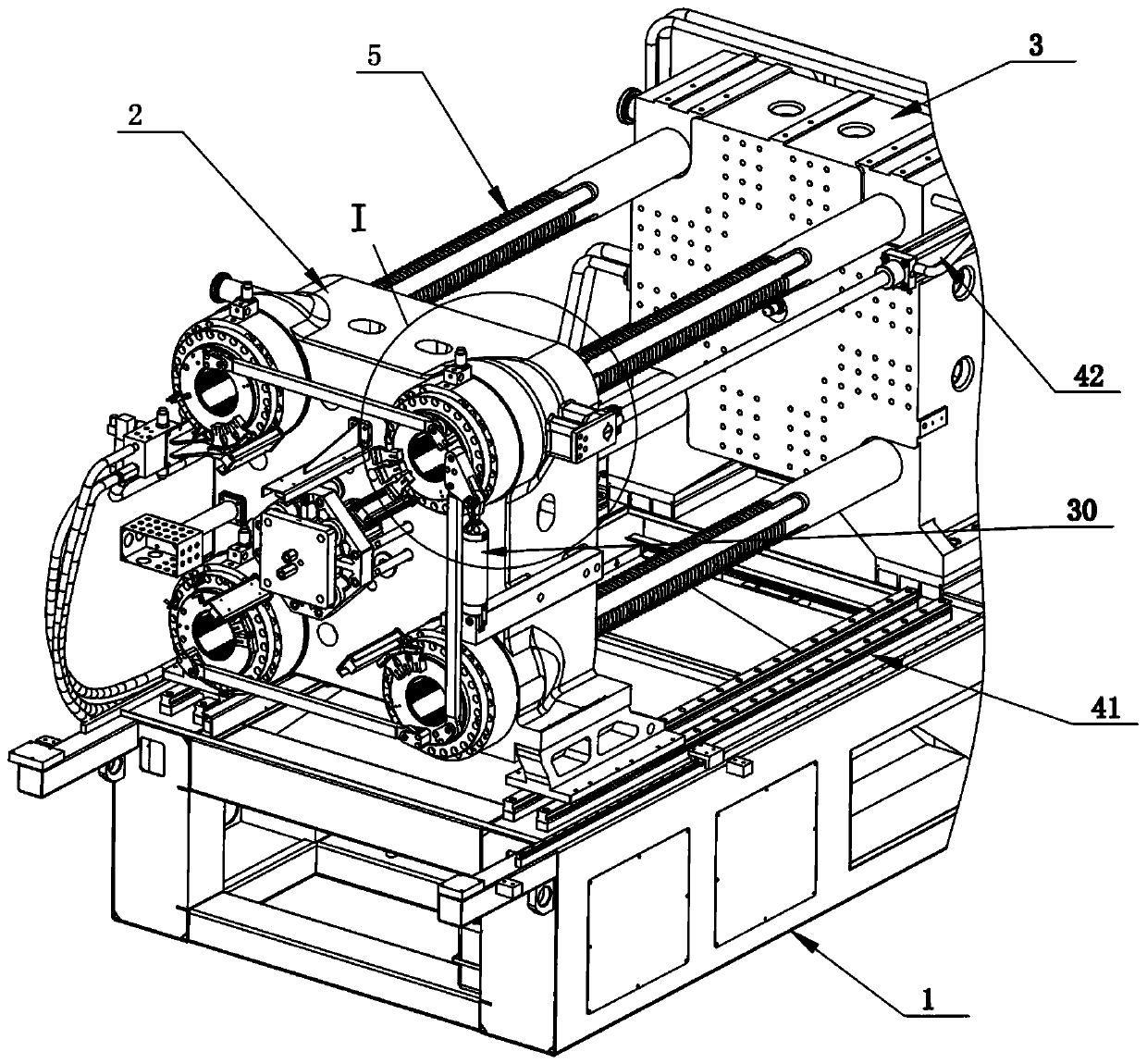

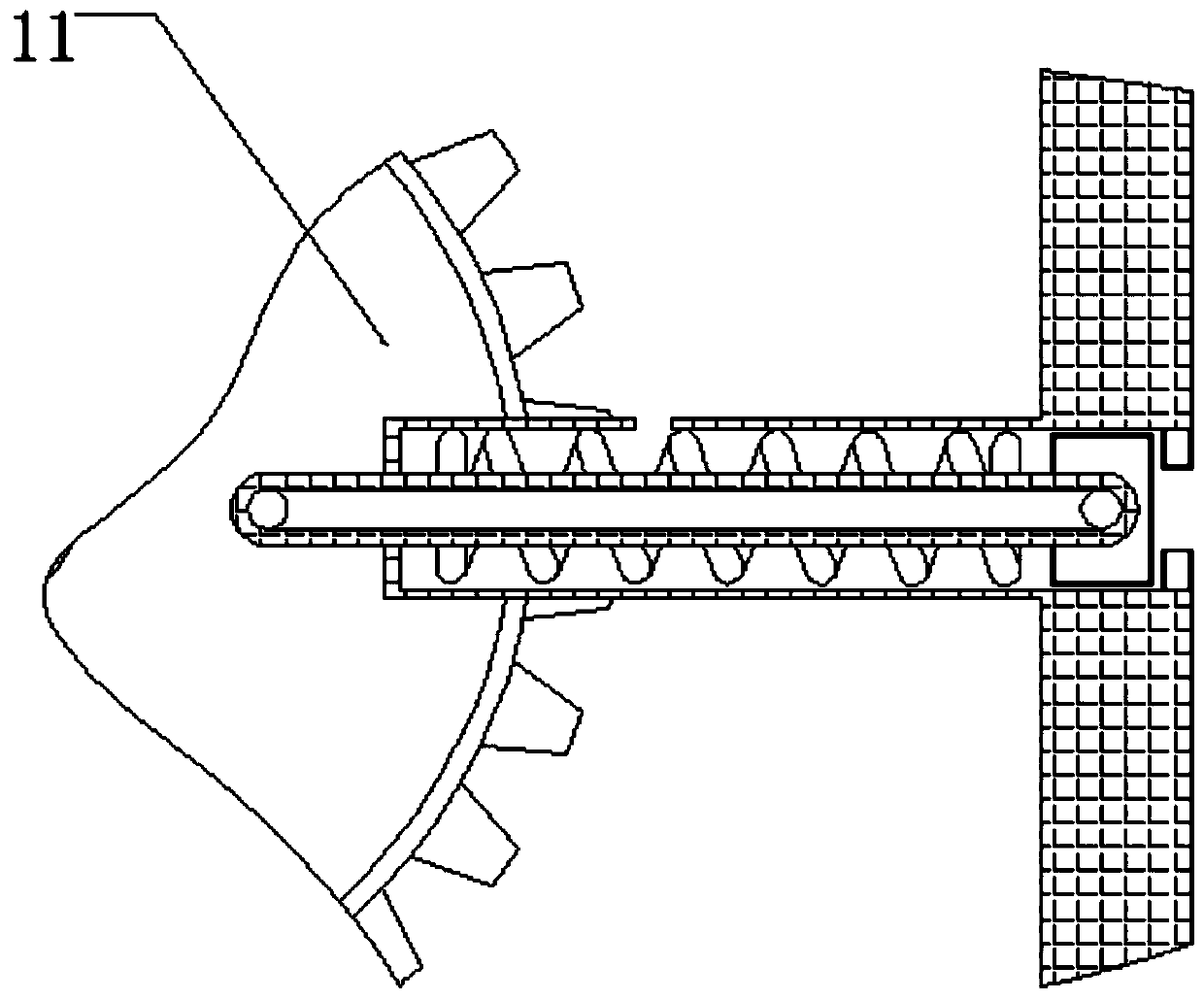

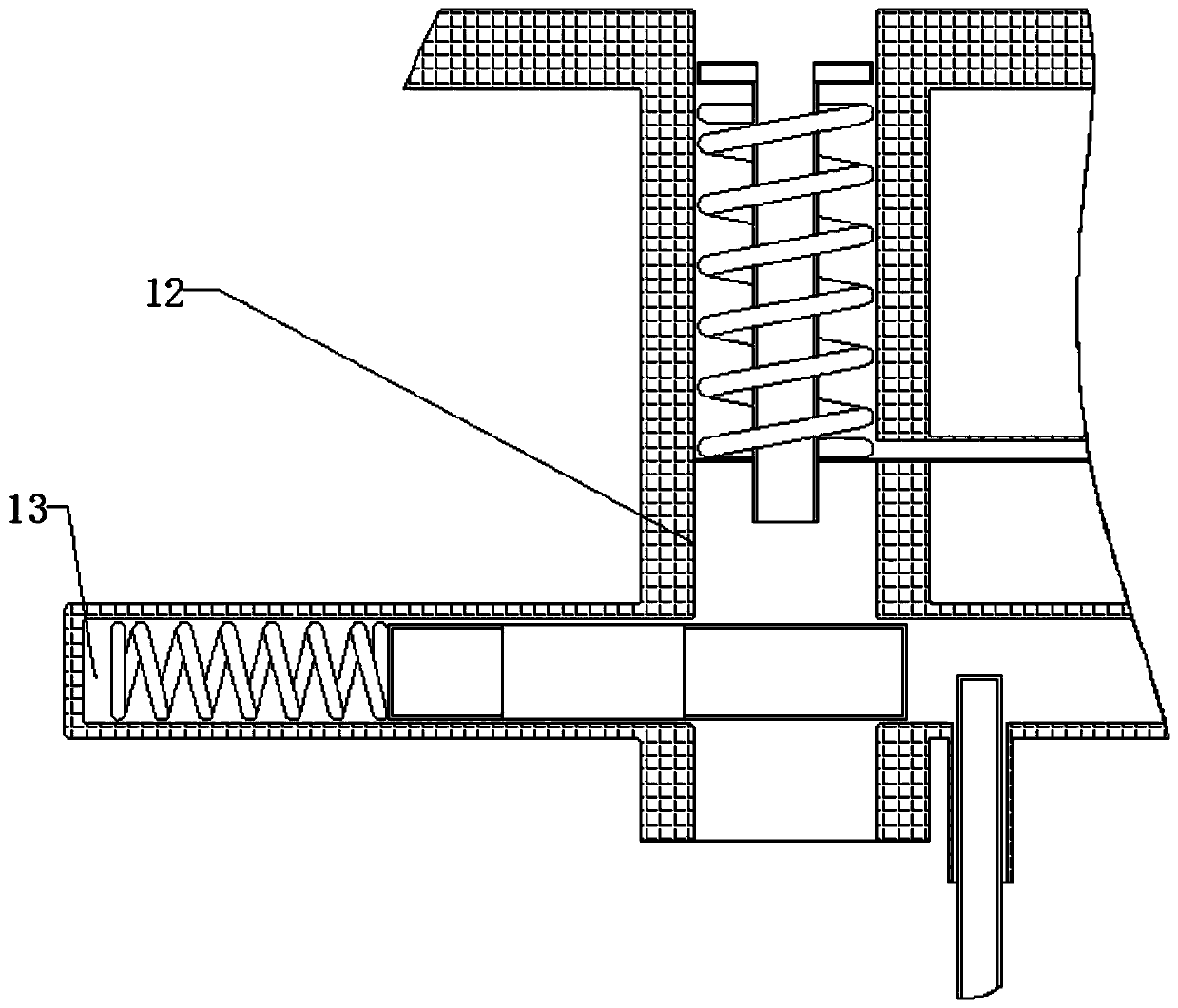

Automatic embedding injection molding equipment for iron parts and injection molding method

ActiveCN105538597AHigh degree of automationImprove injection molding efficiencyProgramme-controlled manipulatorGripping headsRobotic armEngineering

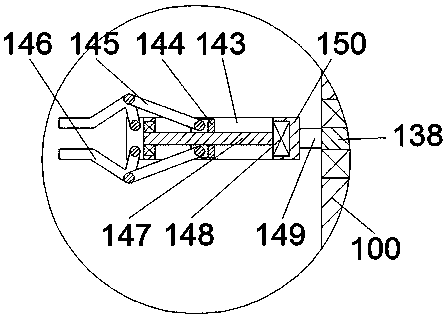

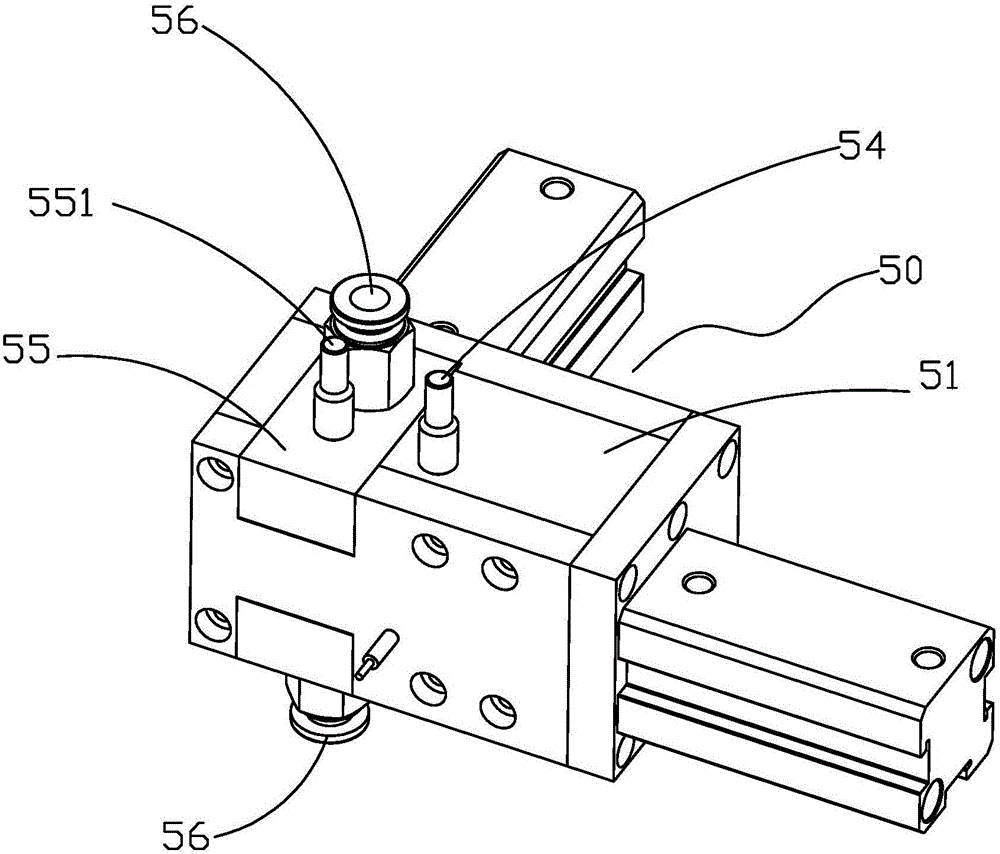

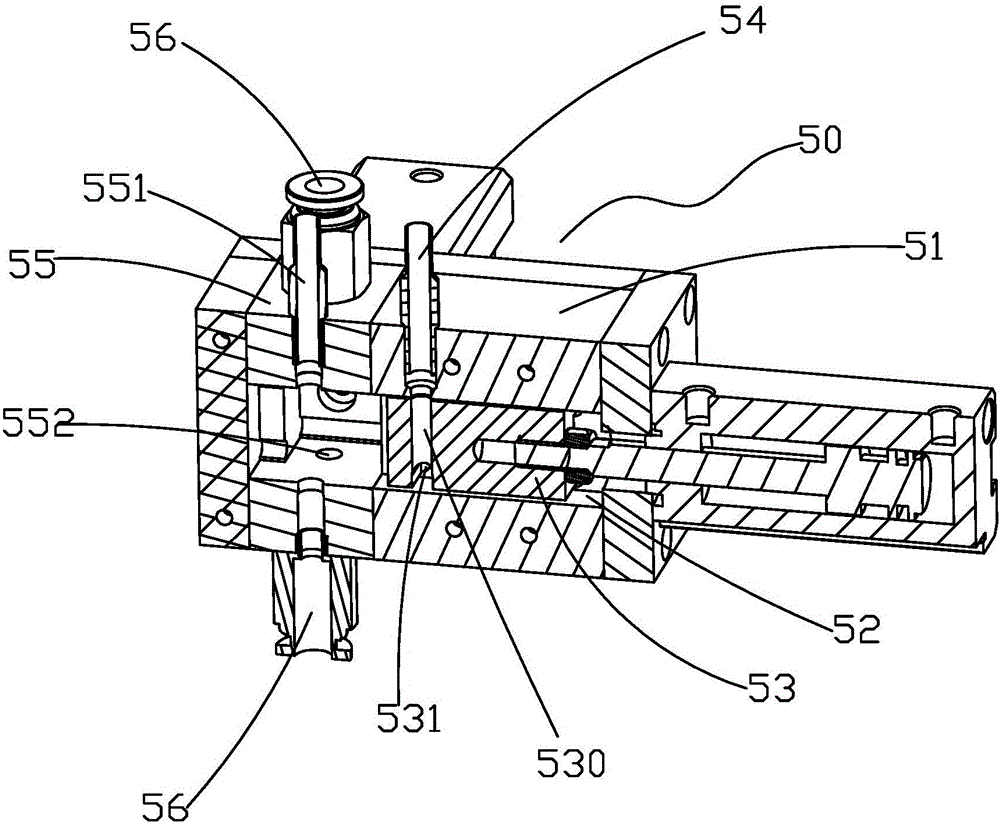

The invention discloses automatic embedding injection molding equipment for iron parts. The automatic embedding injection molding equipment comprises an injection molding machine board, a manipulator and a worktable, wherein the manipulator comprises a manipulator base, a transverse moving assembly and a mechanical arm module; the manipulator base is used for supporting the manipulator and assembling the manipulator in the injection molding equipment; the transverse moving assembly is fixed on the manipulator base and is used for driving mechanical arms to transversely move; the mechanical arm module comprises a first mechanical arm and a second mechanical arm; a suction tooling is arranged at the tail end of the first mechanical arm and is used for sucking workpieces; a clamping jaw is arranged at the tail end of the second mechanical arm and is used for grabbing an injection molding product; a plurality of sucking discs are arranged on the end face of the suction tooling; and the arrangement mode of the sucking discs is consistent with the positions where the iron parts are embedded into injection molding parts. The automatic embedding injection molding equipment disclosed by the invention has the advantages that high automatic degree is realized, and the injection molding efficiency is improved; and in addition, labor input is reduced, so that the cost is relatively reduced.

Owner:SUZHOU HENGYUANSHENG MOLDING CO LTD

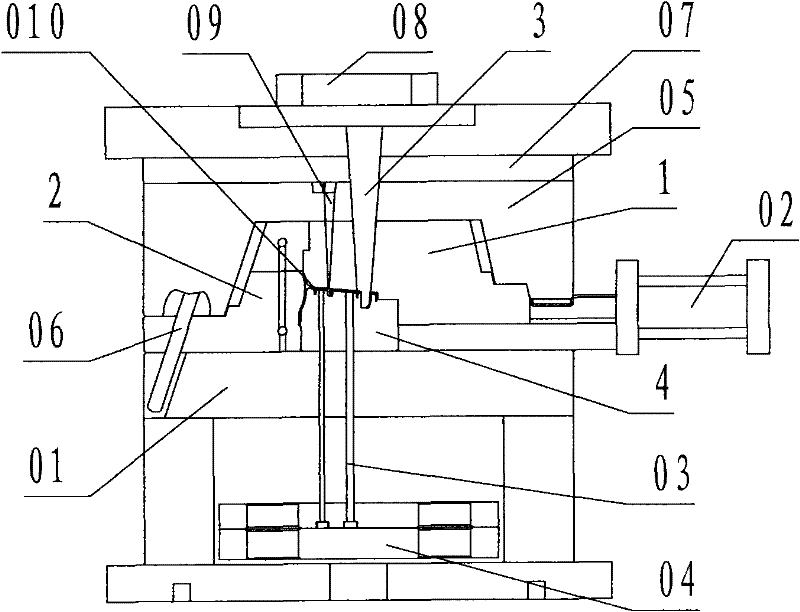

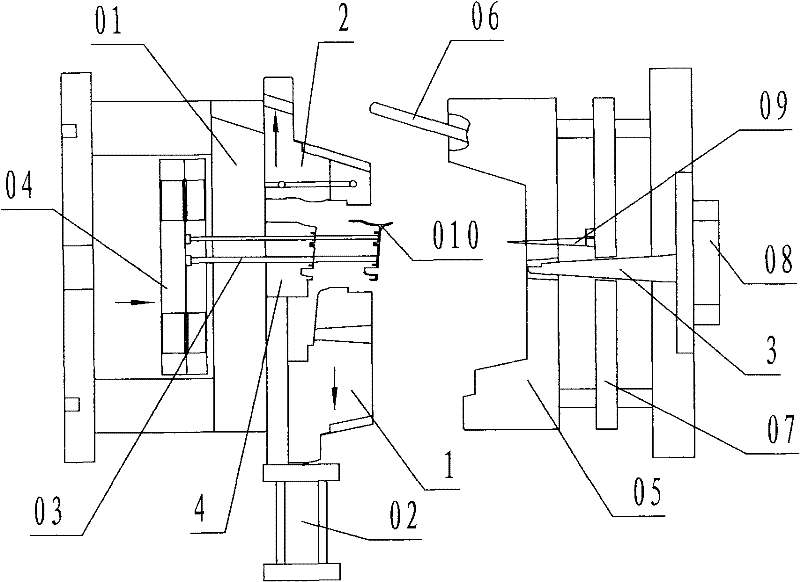

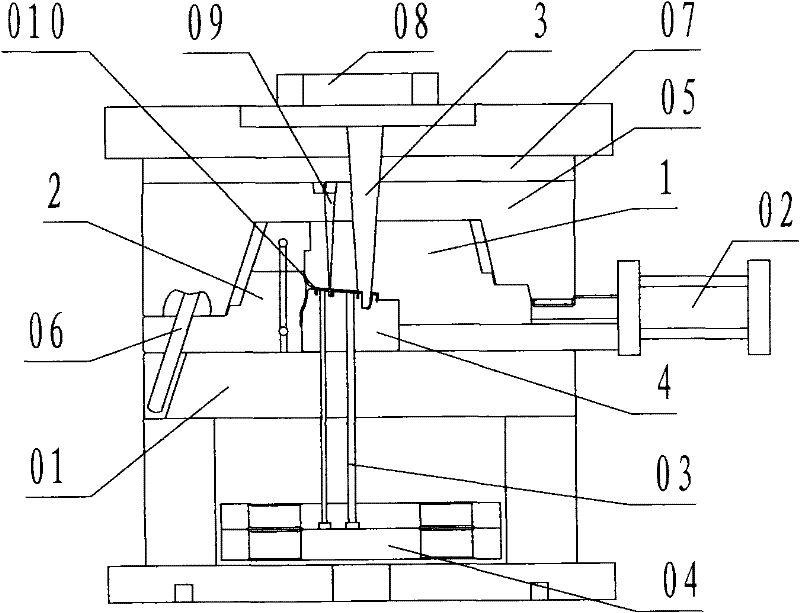

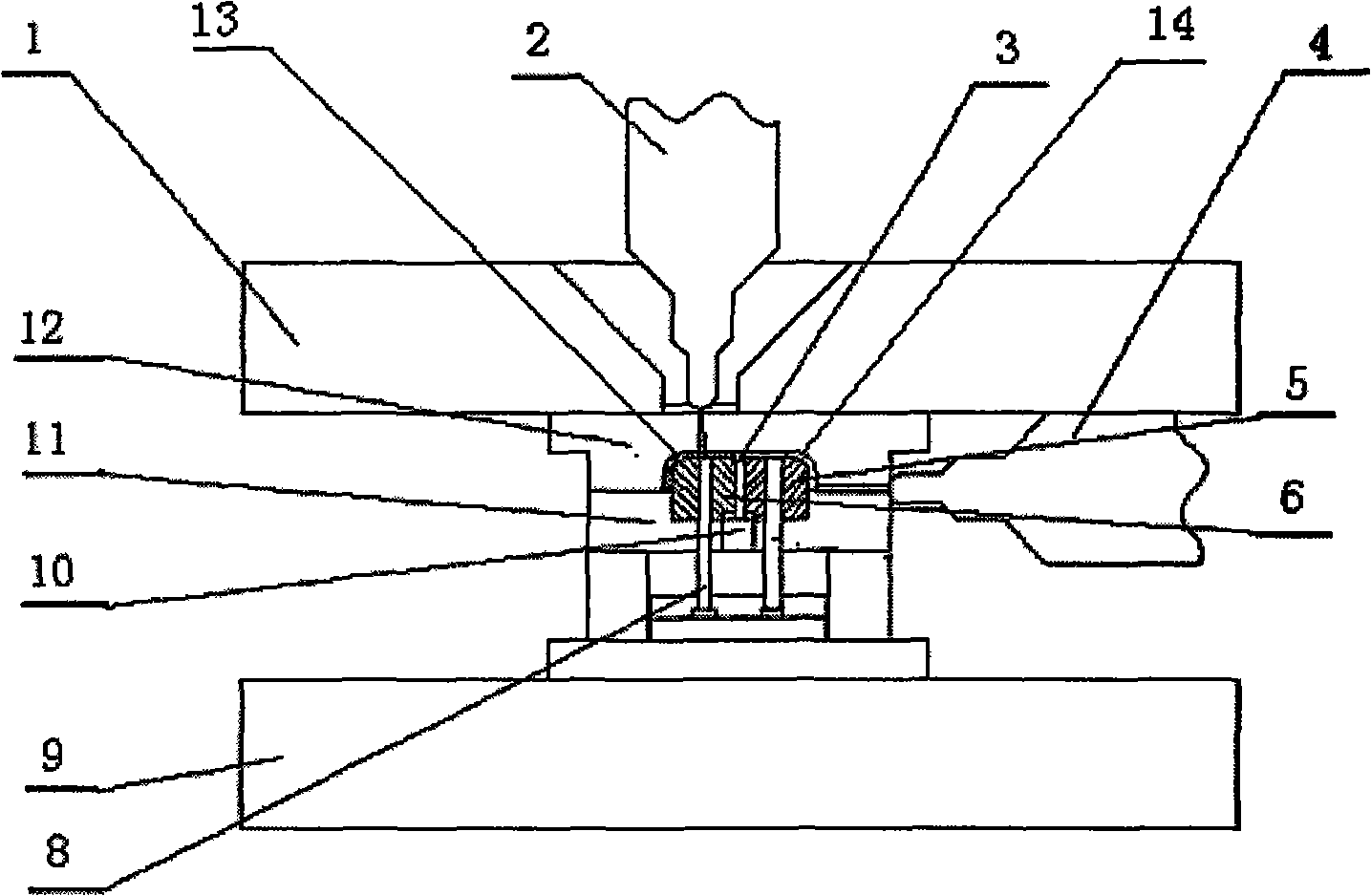

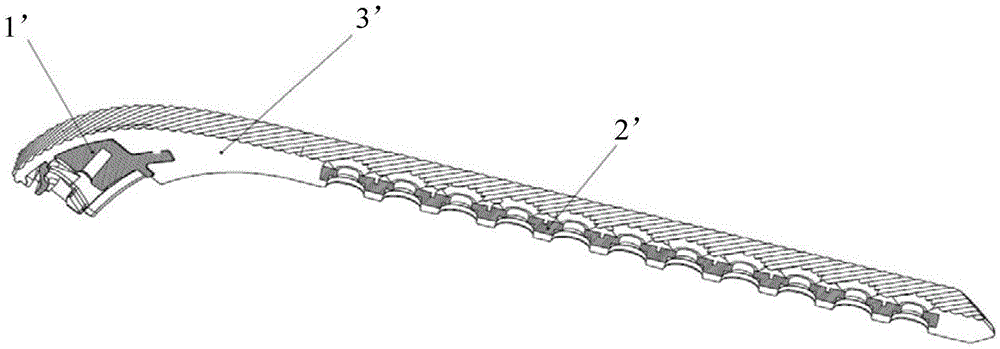

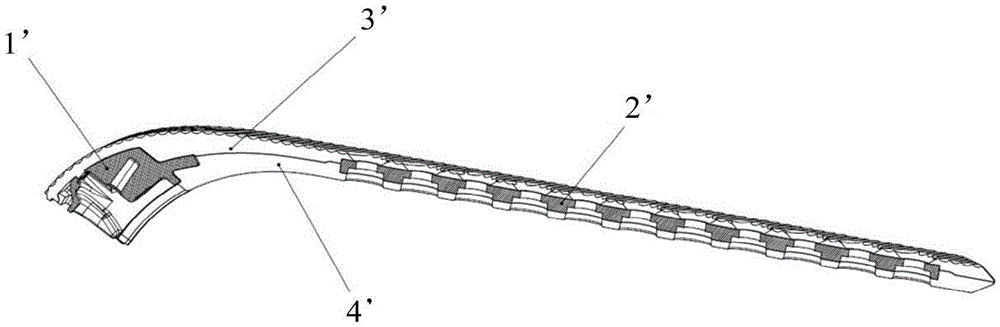

Core pulling mechanism of Audi car door cover plate injection mold

The present invention discloses a core pulling mechanism of an Audi car door cover plate injection mold. The core pulling mechanism comprises a first cavity slider (1), a second cavity slider (2), a top hole core slider (3), a moving mold core (4) and a fixed mold (05). The core pulling mechanism of the present invention adopts the following technical scheme that: the cavities are arranged on thefirst cavity slider and the second cavity slider, wherein the cavities provide the outer shaped surface for the shaped product, and the outer shaped surface of the shaped product requires the transverse core pulling; the first cavity slider and the second cavity slider are arranged on the moving mold; the top hole core slider of the top hole of the shaped product is arranged on the fixed mold; with mold opening and oblique guide pillar driving, the top hole core slider is longitudinally pulled while the second cavity slider is transversely pulled, then the first cavity slider is transversely pulled with the oil cylinder; finally the product is ejected from the moving mold core by an ejection rod. With the technical scheme of the present invention, the problems and the defects of complex mechanism, large volume, high cost, more failures and low efficiency are overcome, the purposes of mechanism simplifying, volume reducing, cost reducing, reliable operation and efficiency improving of the Audi car door cover plate injection mold are achieved.

Owner:宁波宇升模塑有限公司

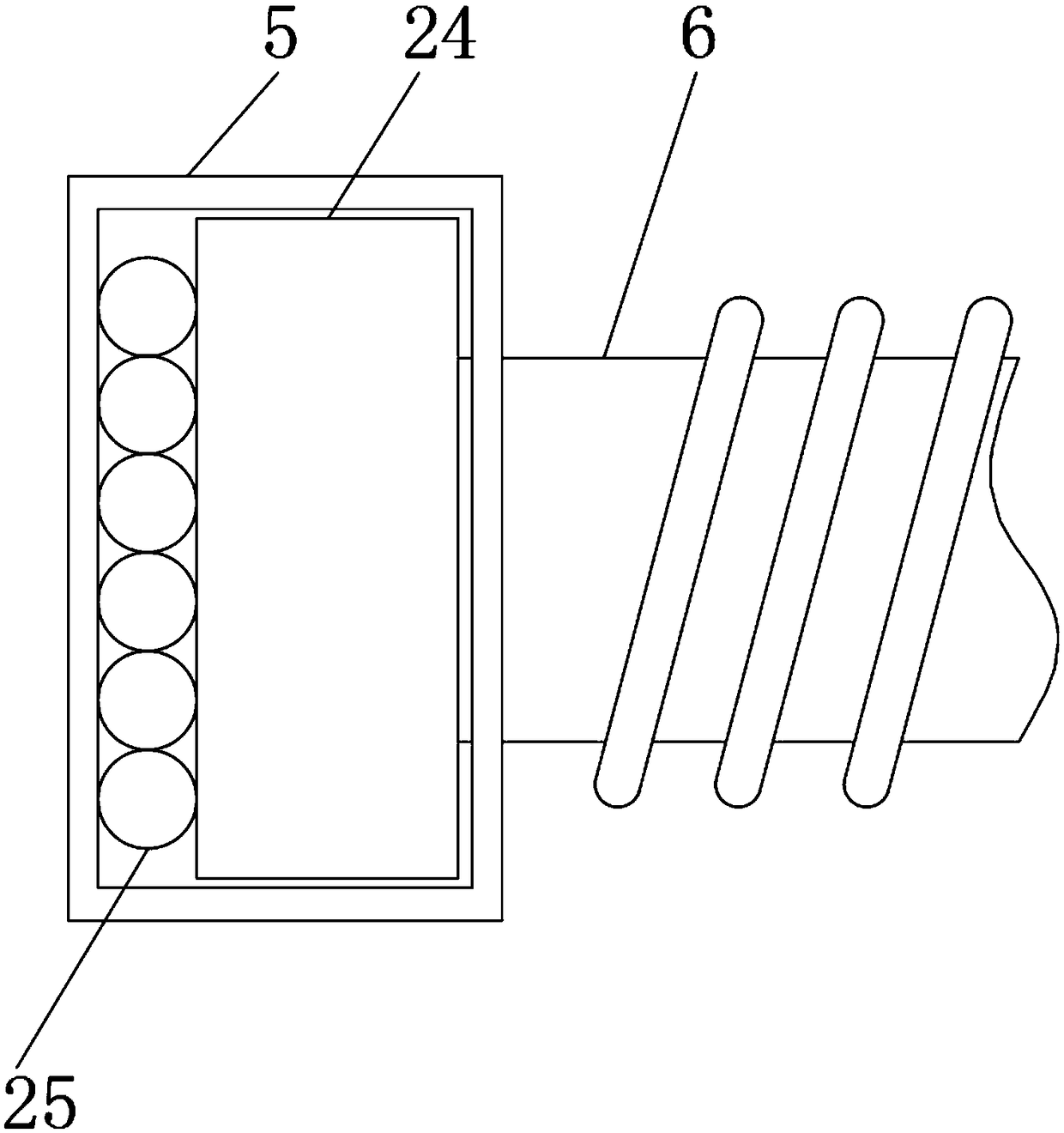

Injection molding machine nozzle with self-cleaning function

The invention discloses an injection molding machine nozzle with a self-cleaning function. The injection molding machine nozzle comprises a nozzle body and a piston, a piston is arranged inside the nozzle body, and a conical plug is welded to one end of the piston, and the other end of the conical plug is connected with an inserting block in a welded mode. According to the maching nozzle, the conical plug and the piston are located inside the nozzle body, the size of the piston is equal to the internal size of the nozzle body, a remaining injection molding material inside the nozzle body can be pushed out of the nozzle body in a forward propelling process of the piston, the effect of scraping residual materials inside the nozzle body is achieved, and a self-cleaning function of the nozzlebody is enabled to be finished; the size of the conical plug is equal to the internal size of one end of the nozzle body, when the piston is conveyed to an end part, the conical plug is attached to the inner wall of one end of the nozzle body, the materials inside the nozzle body can be completely extruded out, so that no material is left in the nozzle body, blockage is avoided, the workload of manual cleaning of the nozzle is reduced, and the production efficiency is improved.

Owner:肖尧

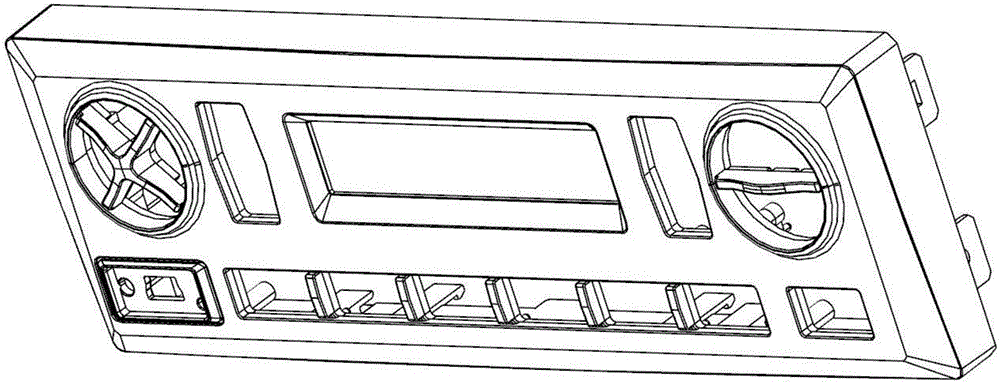

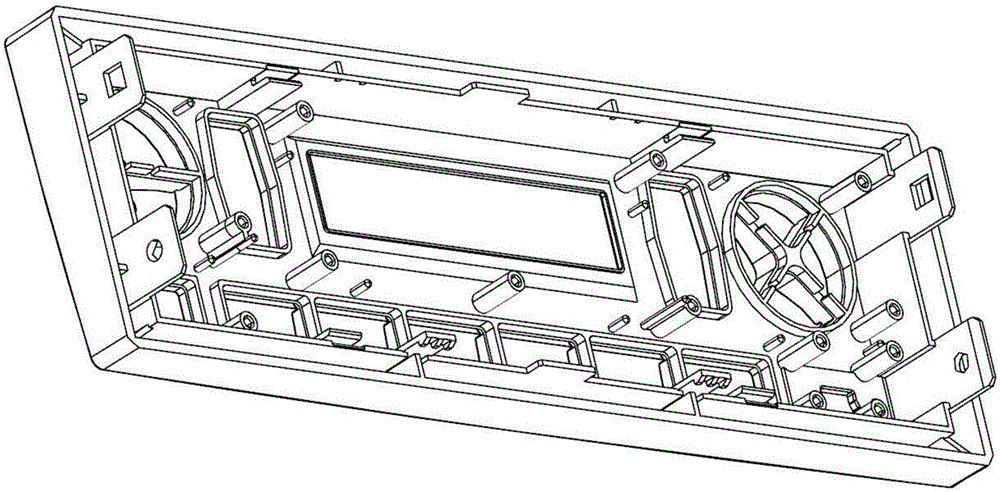

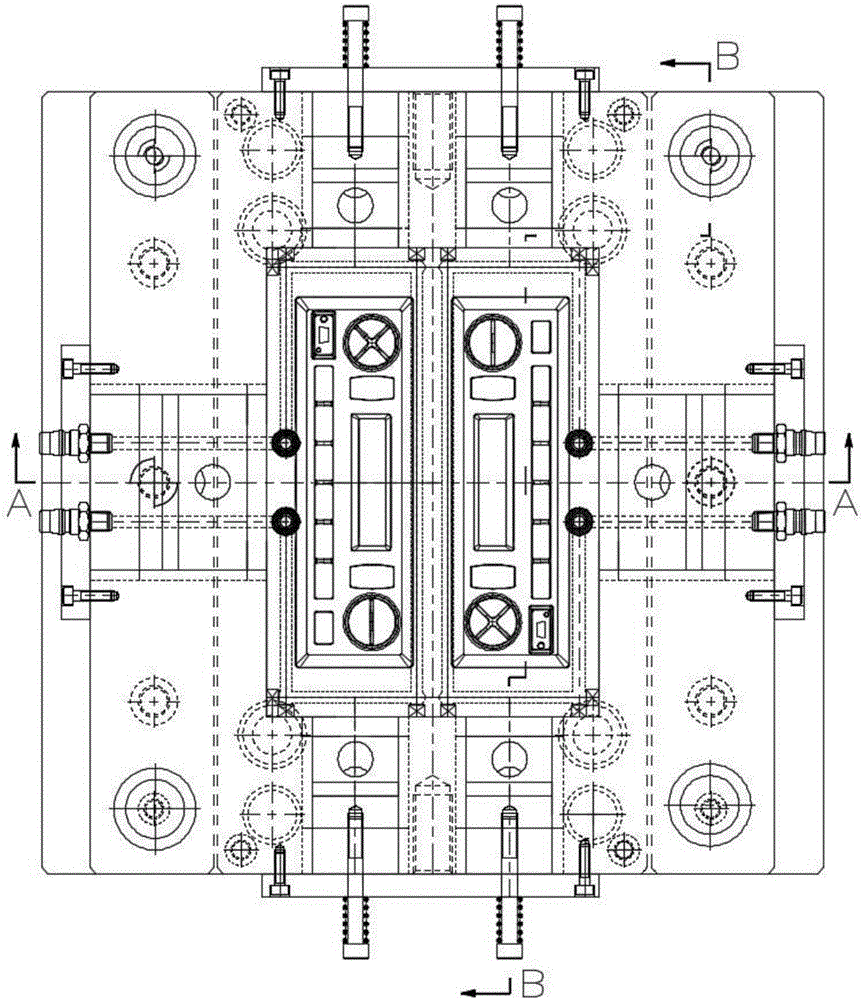

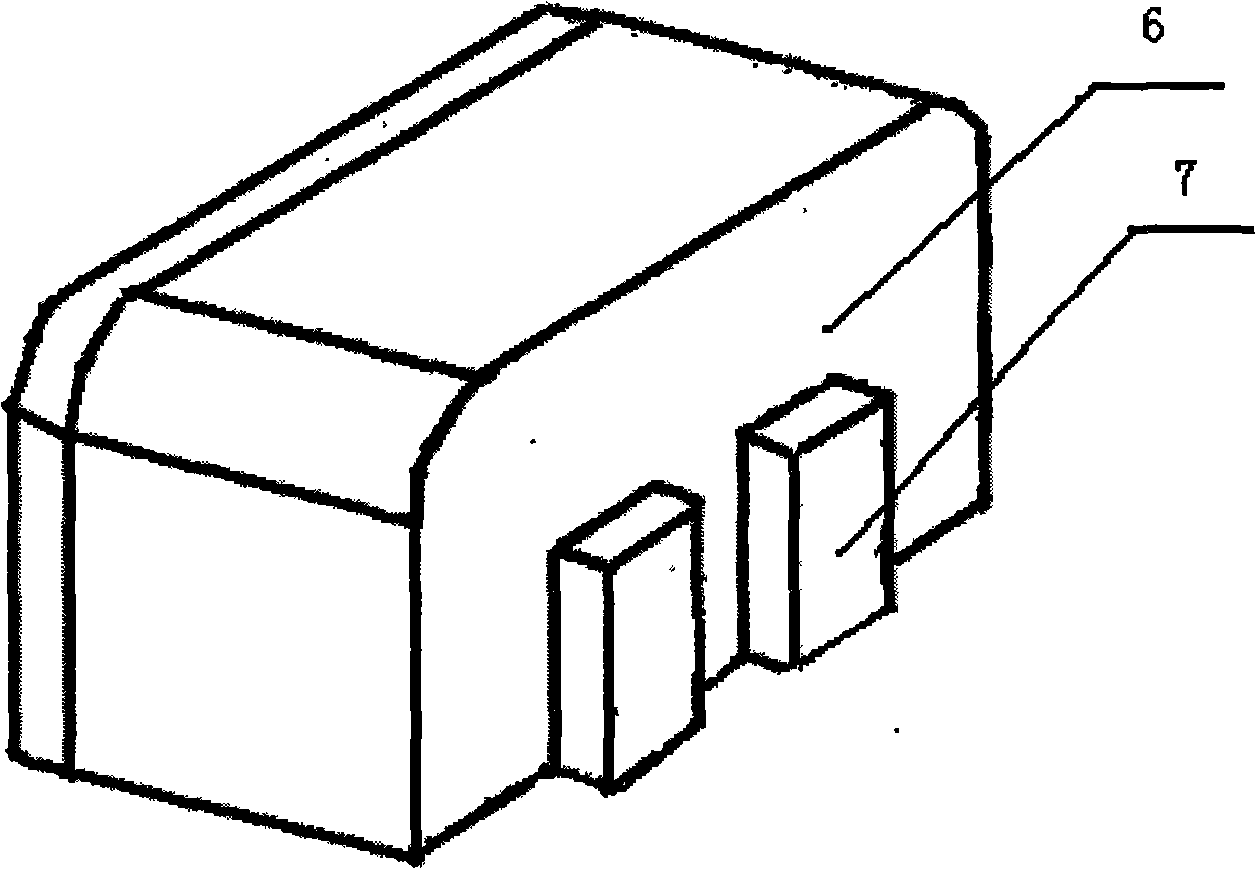

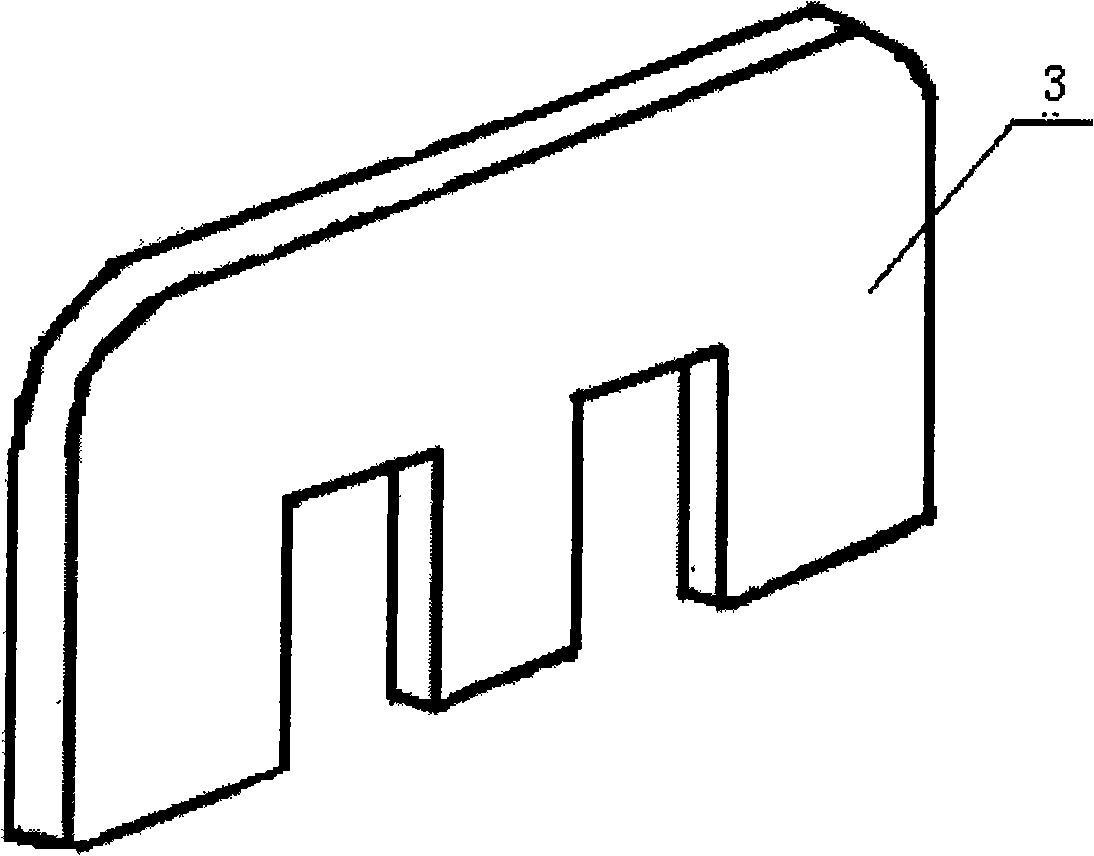

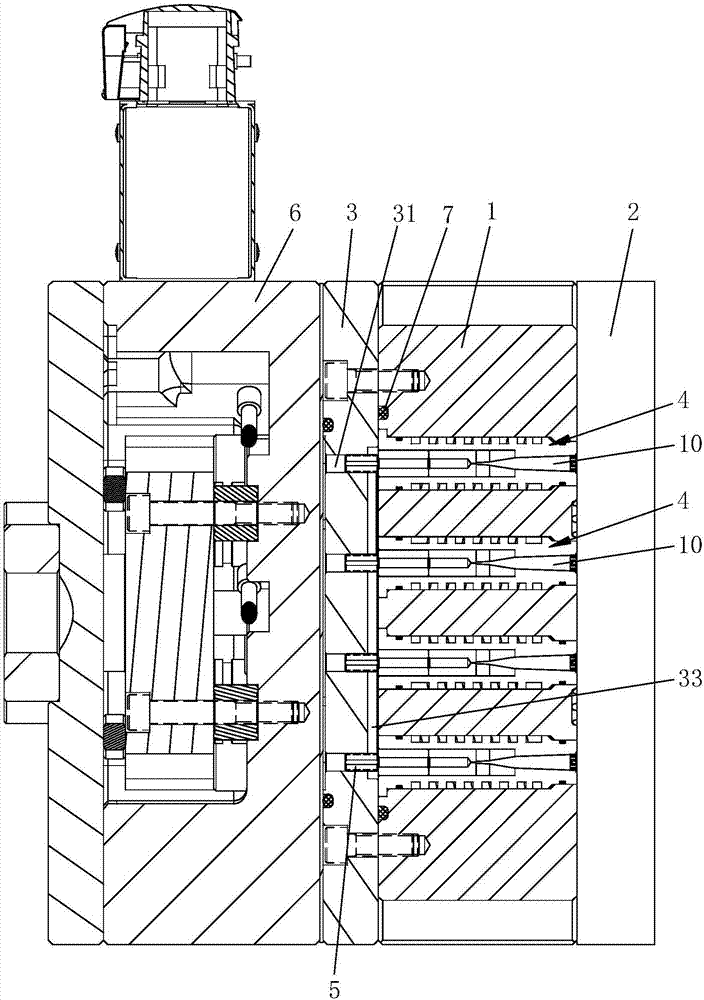

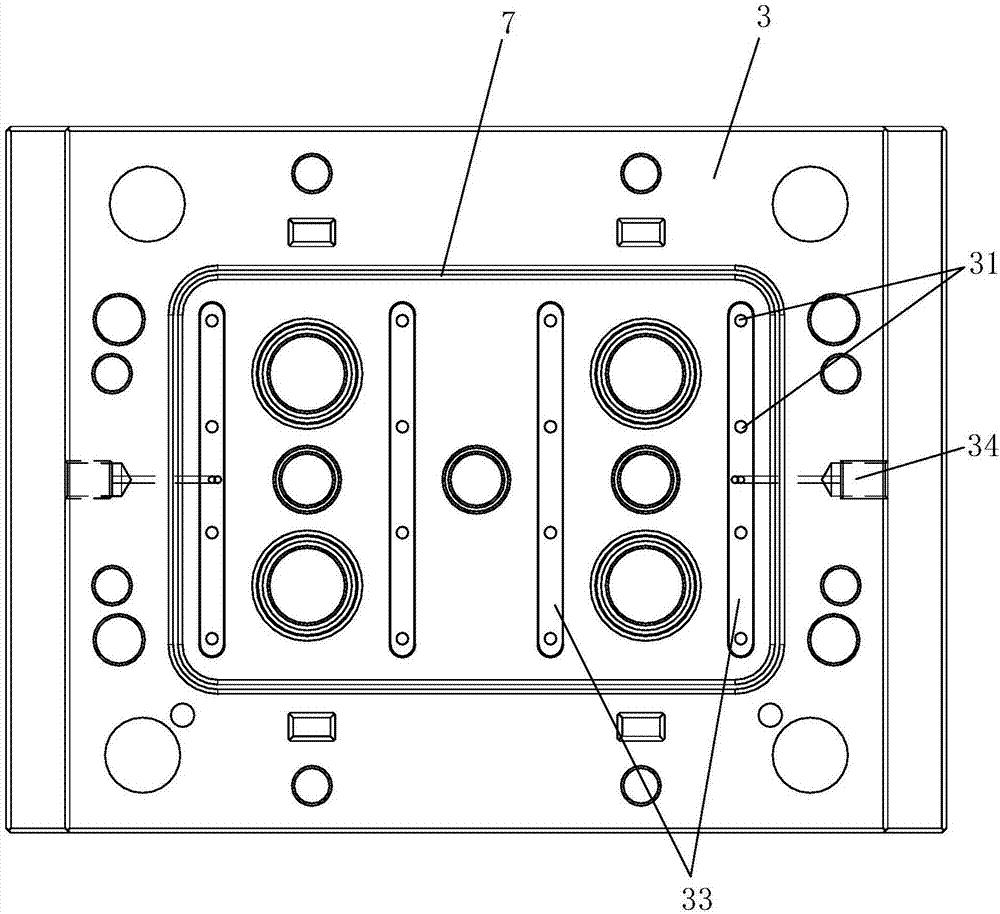

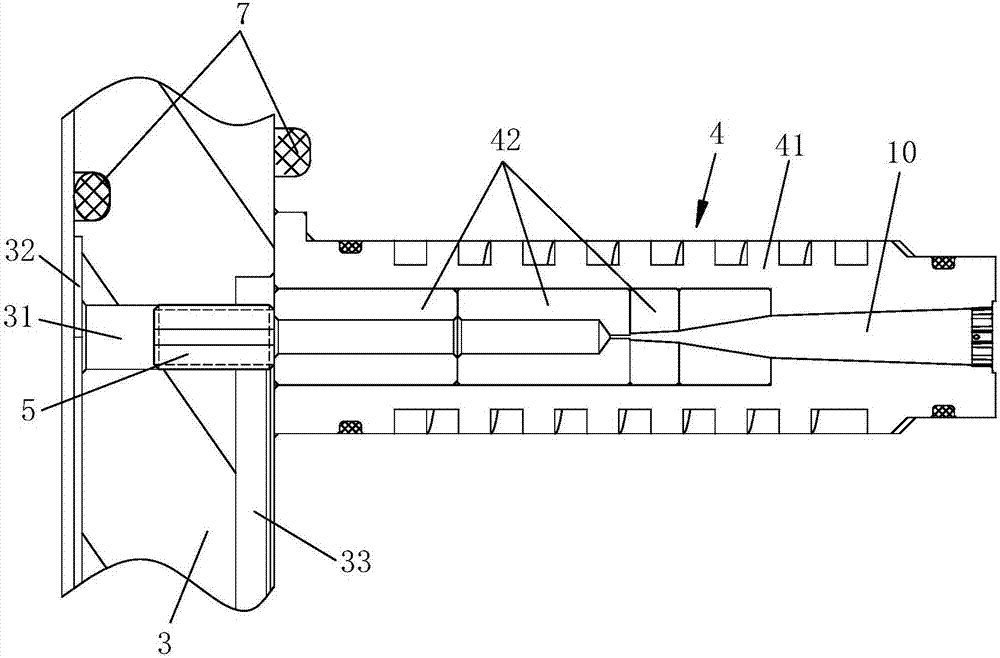

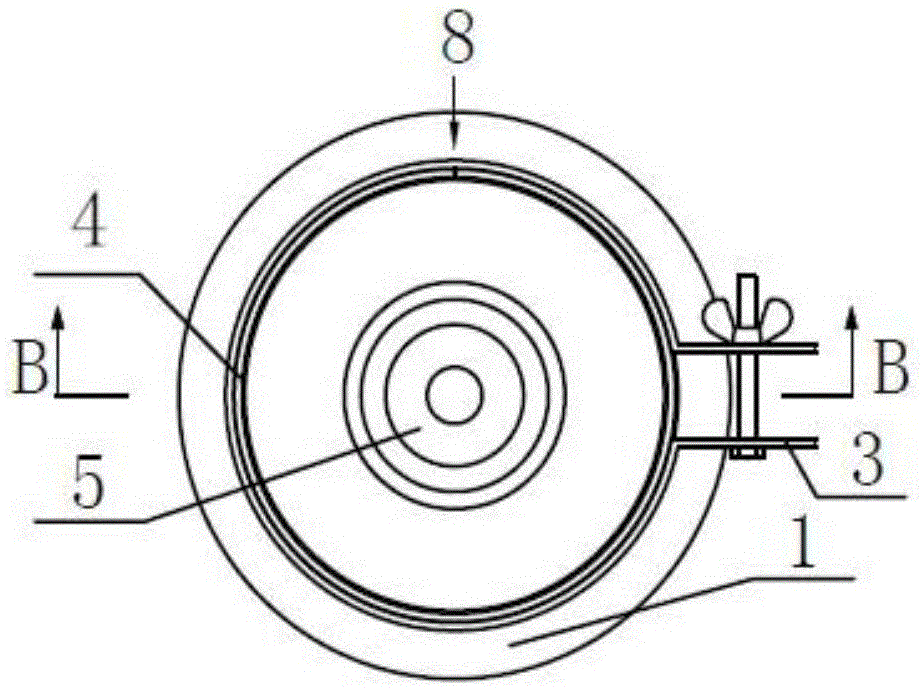

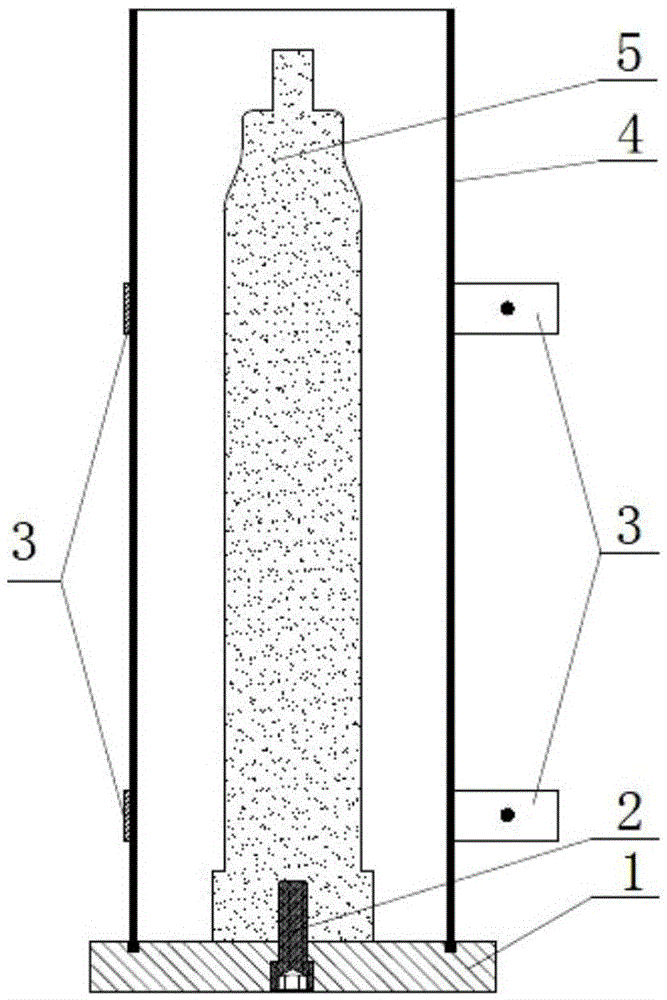

Car audio panel injection mold

InactiveCN106827396ASuitable for mass productionExtended service lifeDomestic articlesHot runnerHigh volume manufacturing

The invention discloses a car audio panel injection mold. The car audio panel injection mold adopts a layout of one-mold and two-cavity, and comprises a fixed mold module (1), a hot runner module (2), a lateral core pulling device (3), a movable mold module (4) and a mold ejecting module (5); a mold cavity (14) of the fixed mold module, a mold core (44) of the movable mold module and a side mold core (36) of the lateral core pulling device are all provided with one part of plastic part bodies, are combined mold cores and jointly define an injection molding body cavity of a car audio panel plastic part; and the pulled cores can be separated from the mold cavity (14) and the mold core (44) in the core pulling direction. The car audio panel injection mold can realize no waste of injection molding materials in runners and reduction of the cost, further guarantees the quality and the precision of the car audio panel plastic part, reduces the probability of the plastic part for generating such defects as warping and burrs, can realize improvement of the injection molding efficiency of the car audio panel plastic part, and in particular, is suitable for large-batch production of car audio panels.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

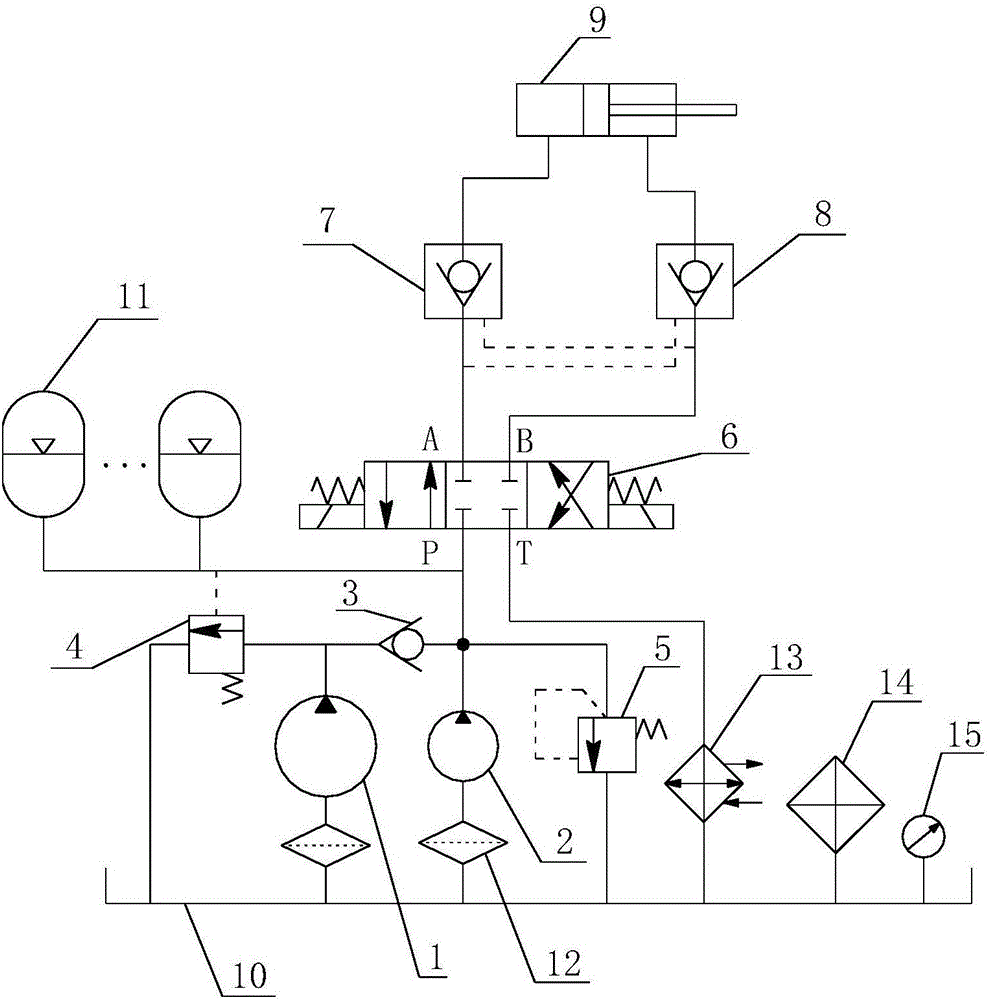

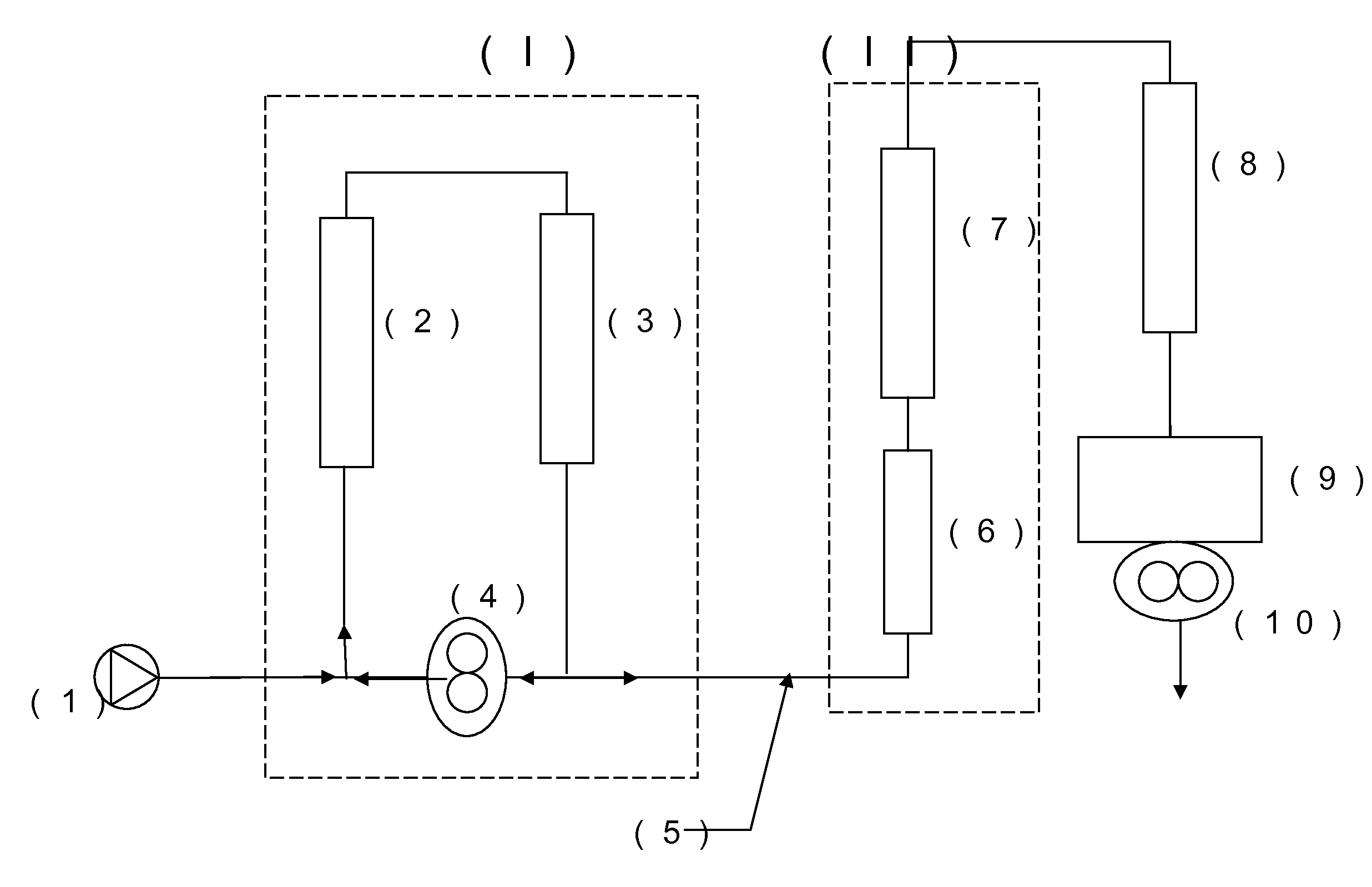

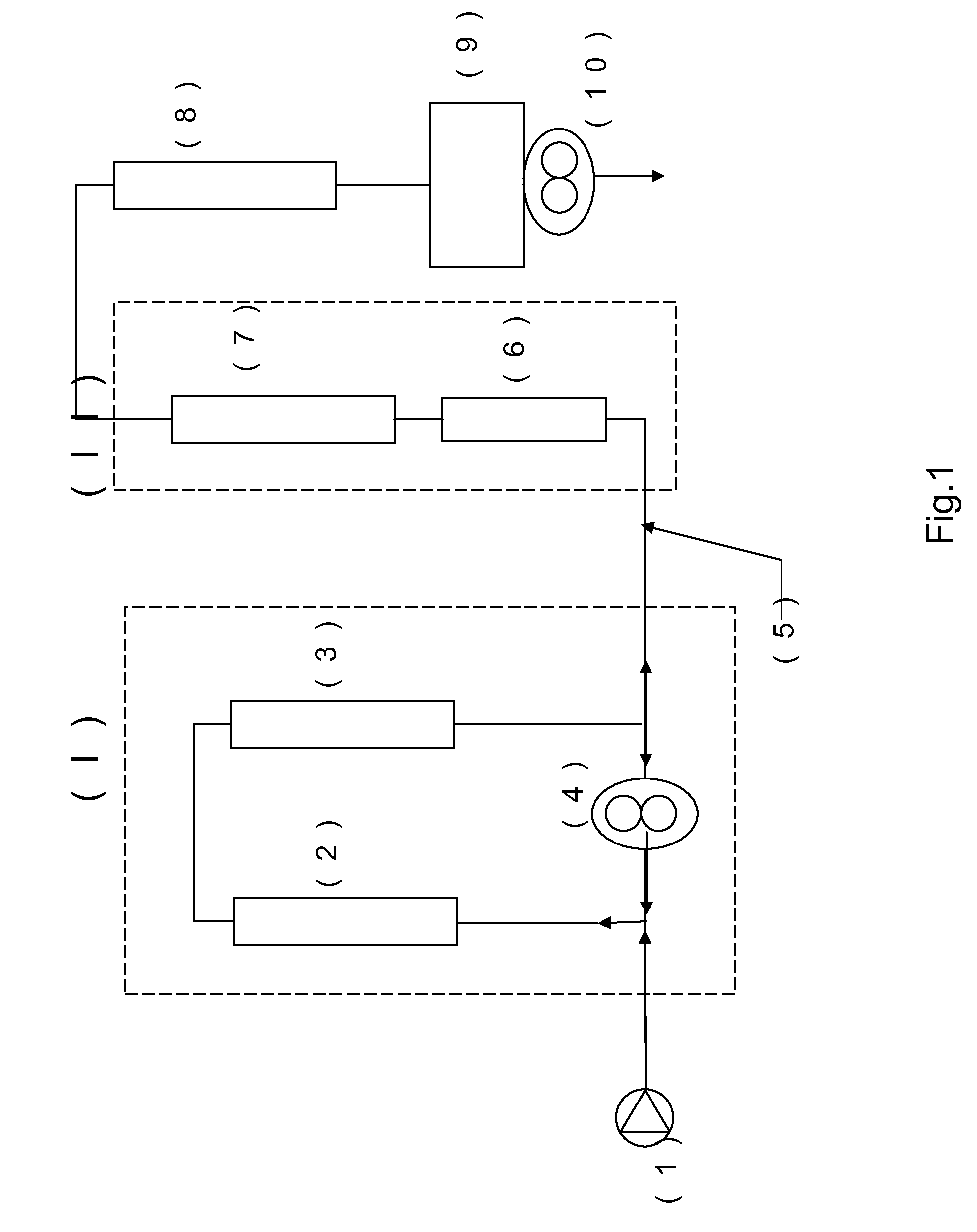

Hydraulic control system of high-speed injection molding machine

InactiveCN106378915AMove quicklySimple structureFluid-pressure actuator componentsHydraulic cylinderControl system

The invention relates to the technical field of high-speed injection molding machines, in particular to a hydraulic control system of a high-speed injection molding machine. The hydraulic control system of the high-speed injection molding machine comprises a low-pressure large-flow pump, a high-pressure small-flow pump, a check valve, a hydraulic control sequence valve, an overflow valve, a three-position four-way reversing valve, a first hydraulic control check valve, a second hydraulic control check valve, a hydraulic cylinder, an oil groove and multiple energy accumulators. The hydraulic control system of the high-speed injection molding machine is simple in structure and convenient to operate, lowers cost and improves the work efficiency. Through the double-pump oil supply manner, the injection molding time can be shortened, and the injection molding efficiency is improved. Besides, through cooperative use of the small-flow hydraulic pump and the energy accumulators, rapid movement of an executing element can be achieved.

Owner:成都源云机械有限公司

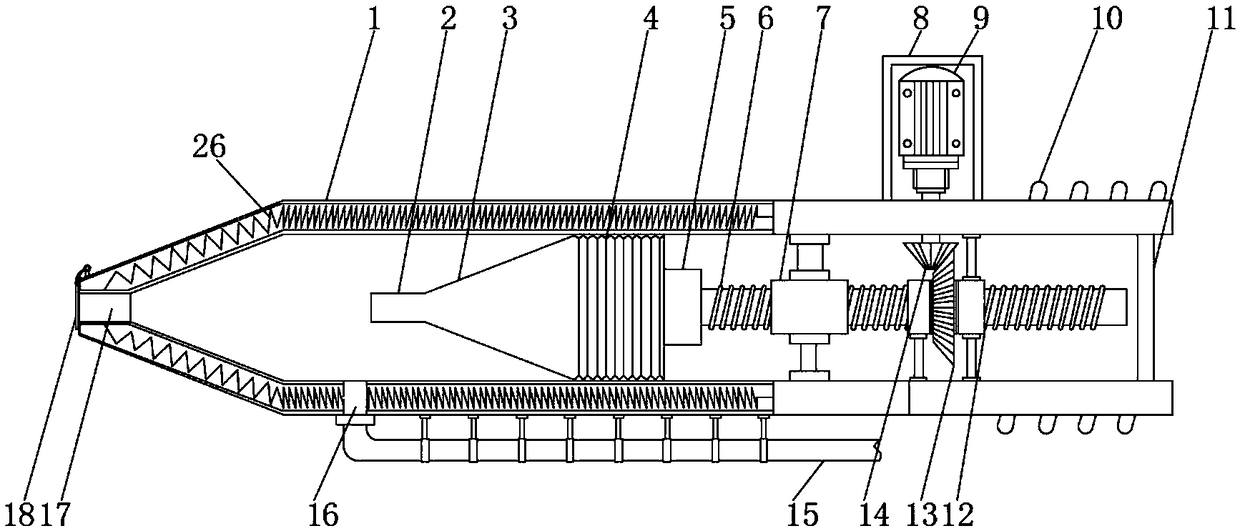

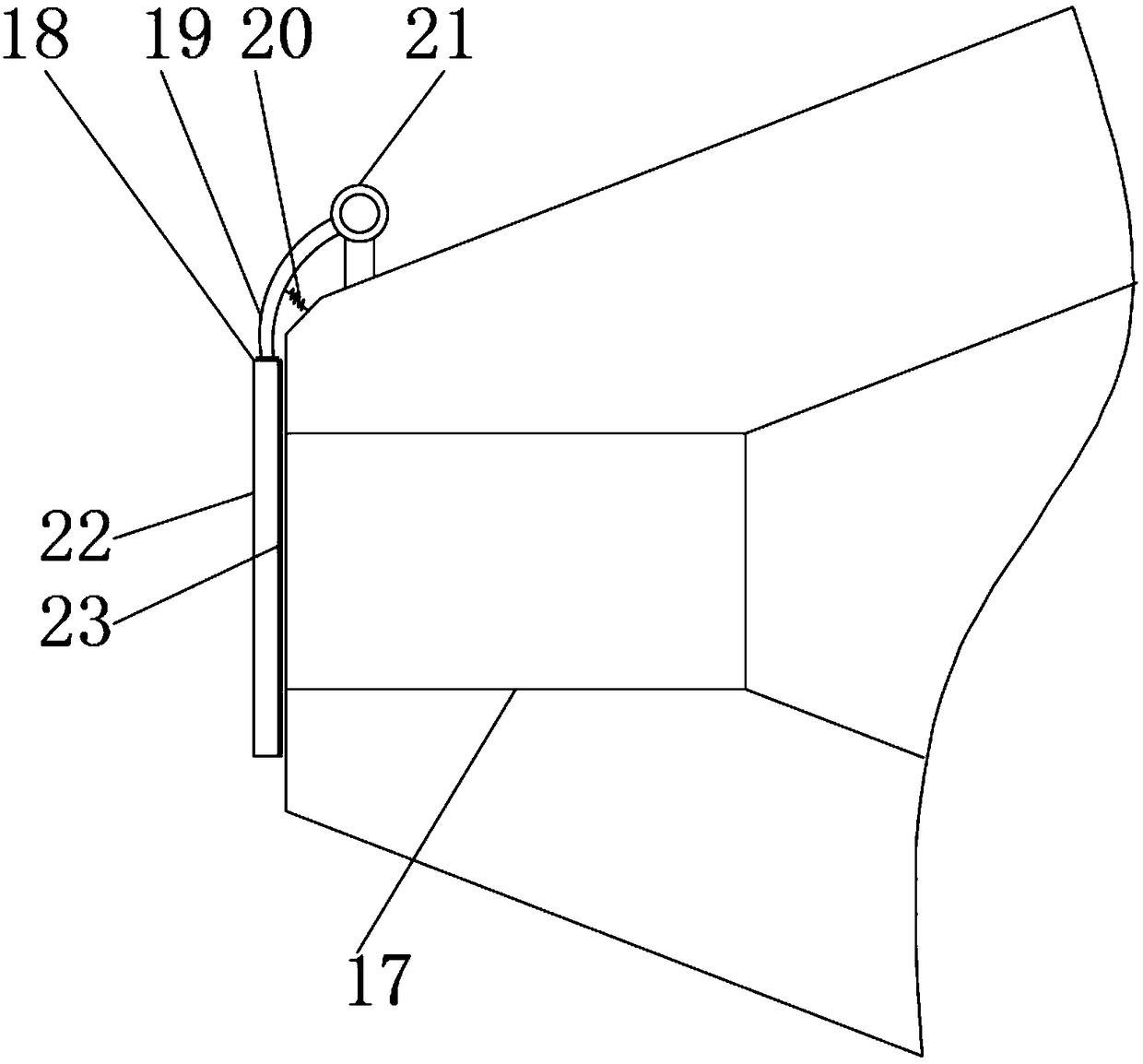

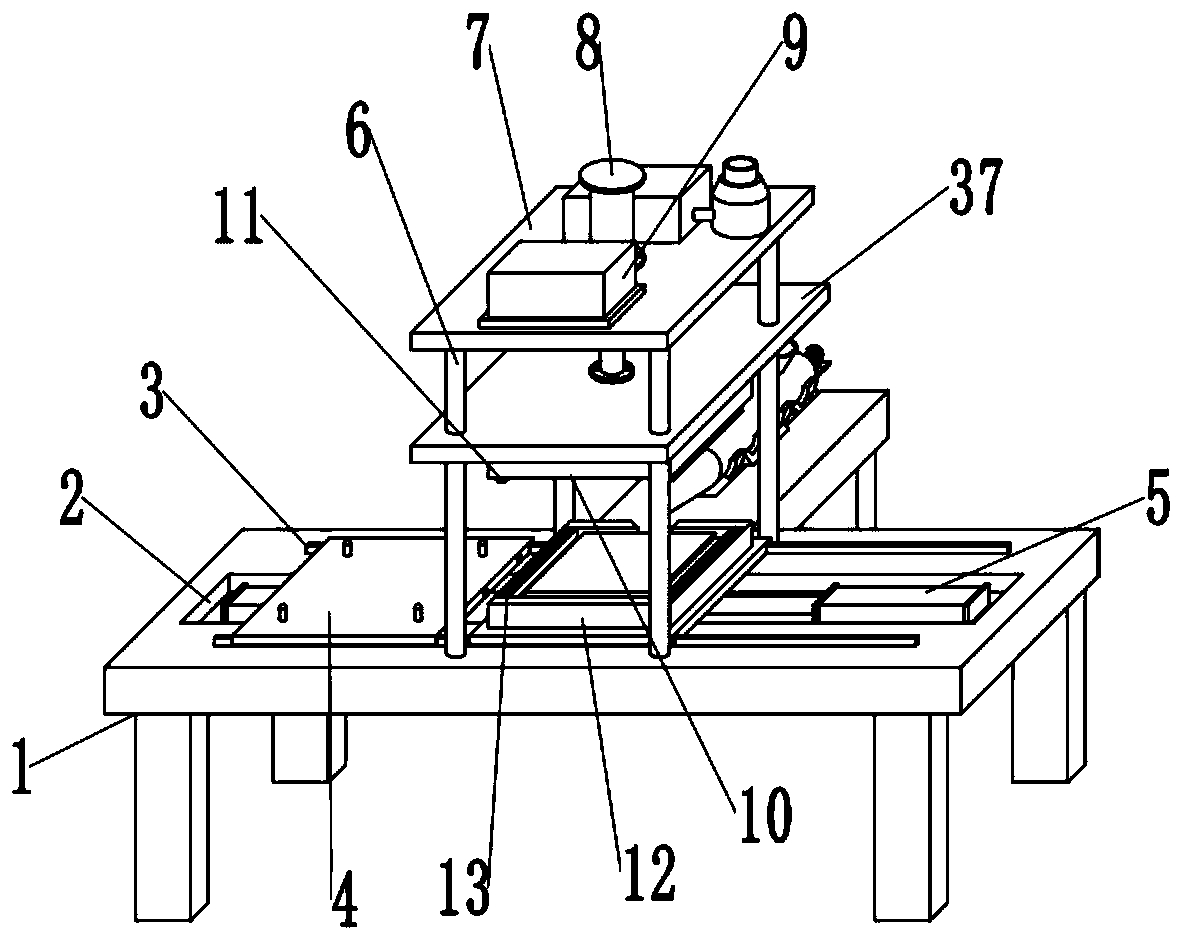

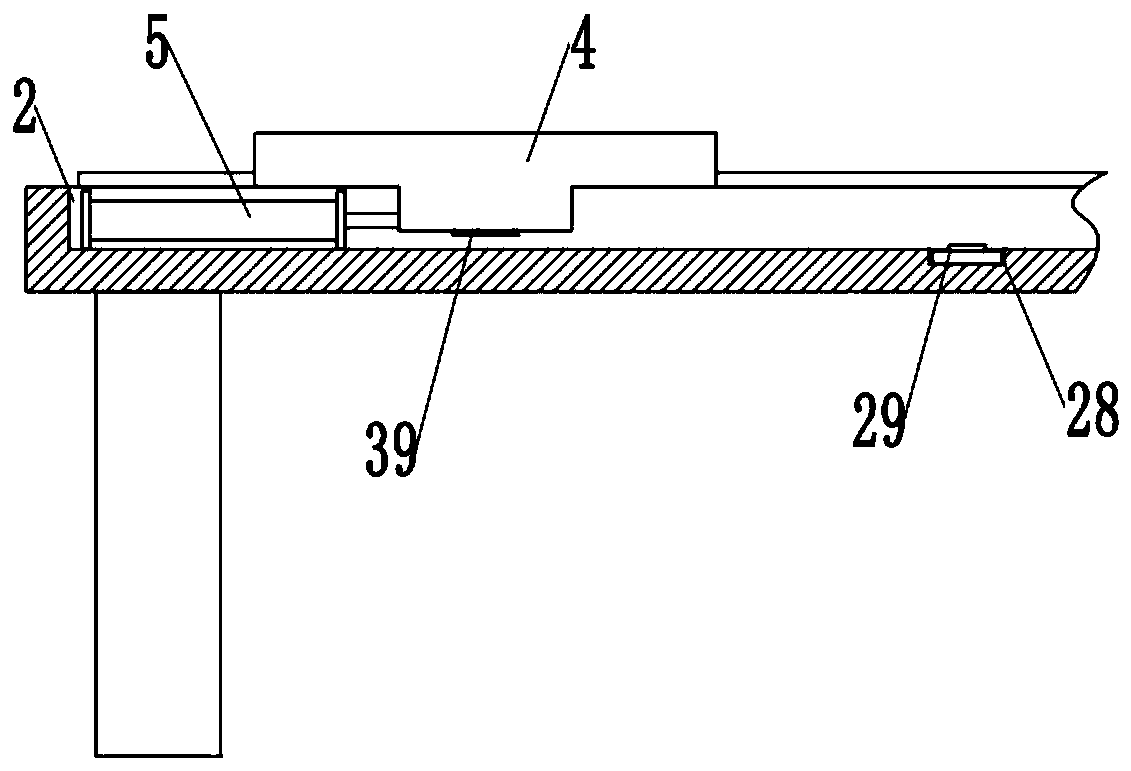

Injection molding equipment for refrigerator glass partition plate machining and production

InactiveCN111391232AImprove injection molding efficiencyAffect healthDispersed particle separationDirt cleaningIceboxInjection moulding

The invention relates to the technical field of glass partition plate production, in particular to injection molding equipment for refrigerator glass partition plate machining and production. The injection molding equipment comprises a worktable, wherein a first groove is formed in one side of the outer wall of the top of the worktable, and first cylinders are arranged on the two sides of the inner wall of the bottom of the first groove through bolts; sliding rails are arranged on the two sides of the outer wall of the top of the workbench through screws, and two lower mold bases distributed in a horizontal structure are connected to the outer walls of the tops of the two sliding rails in a sliding mode; the lower mold bases are fixedly connected with the first air cylinders through screws, and the outer walls of the tops of the lower mold bases are sleeved with lower molds; and two stand columns distributed in a horizontal structure are welded to each of the two sides of the outer wall of the top of the workbench. The injection molding equipment for refrigerator glass partition plate machining and production has the beneficial effects that the injection molding efficiency of a glass partition plate can be improved, and when upper molds and the lower molds are adjusted or replaced, through cooperation of limiting blocks and limiting grooves, a worker can rapidly align the uppermolds with the lower molds, so that a large amount of time is prevented from being wasted.

Owner:滁州克莱帝玻璃科技有限公司

Multi-station injection molding machine

The invention discloses a multi-station injection molding machine which is suitable for the technical field of injection molding machines. The multi-station injection molding machine comprises a rack, a lower die plate arranged on the rack, a rotating mechanism for driving the lower die plate to rotate, an upper die plate located above the lower die plate, a lifting mechanism for driving the upper die plate to ascend and descend and multiple injection devices arranged above the upper die plate. The upper die plate is provided with multiple fixed die mounting positions. The lower die plate is provided with multiple movable die mounting positions corresponding to the fixed die mounting positions in rotation respectively. According to the multi-station injection molding machine, the injection devices are arranged above the upper die plate, products in different colors made of different materials can be obtained in an injection molding manner; and multiple movable dies can be mounted at the same time through the movable die mounting positions, and multiple processes can be conducted at the same time, so that the whole injection molding period is shortened, injection molding efficiency is improved, a great amount of time and manpower and a great number of material resources are saved, injection molding cost is lowered greatly, input cost is reduced, and the competitiveness of the products in the market can be improved.

Owner:MODERN PRECISION PLASTIC & MOLD SHENZHEN CO LTD

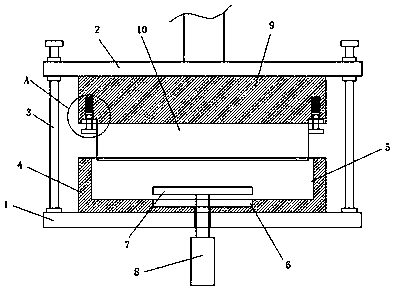

Double-color injection-molding die with active spacing block and preparation method thereof

The invention relates to a double-color injection moulding mould with a movable separator and a method for preparing the same. Compared with two forms of convex mould translation and convex mould rotation of the prior double-color injection moulding mould, the double-color injection moulding mould is a single-cavity double-injection mould and comprises a convex mould and a concave mould. The moulding surface of the concave mould and the moulding surface of the convex mould form an injection moulding cavity; the convex mould comprises a first convex mould and a second convex mould between which a gap exists; and the gap is provided with a movable separating slice inside, and the movable separating slice extends into the injection moulding cavity and divides the injection moulding cavity into a first injection moulding cavity and a second injection moulding cavity which are not communicated. The mould has the advantages of simple structure, small volume, small ground occupying range, small investment, low energy consumption and high injection moulding efficiency.

Owner:JIANGSU CHANGSANJIAO MOLD CITY DEV +2

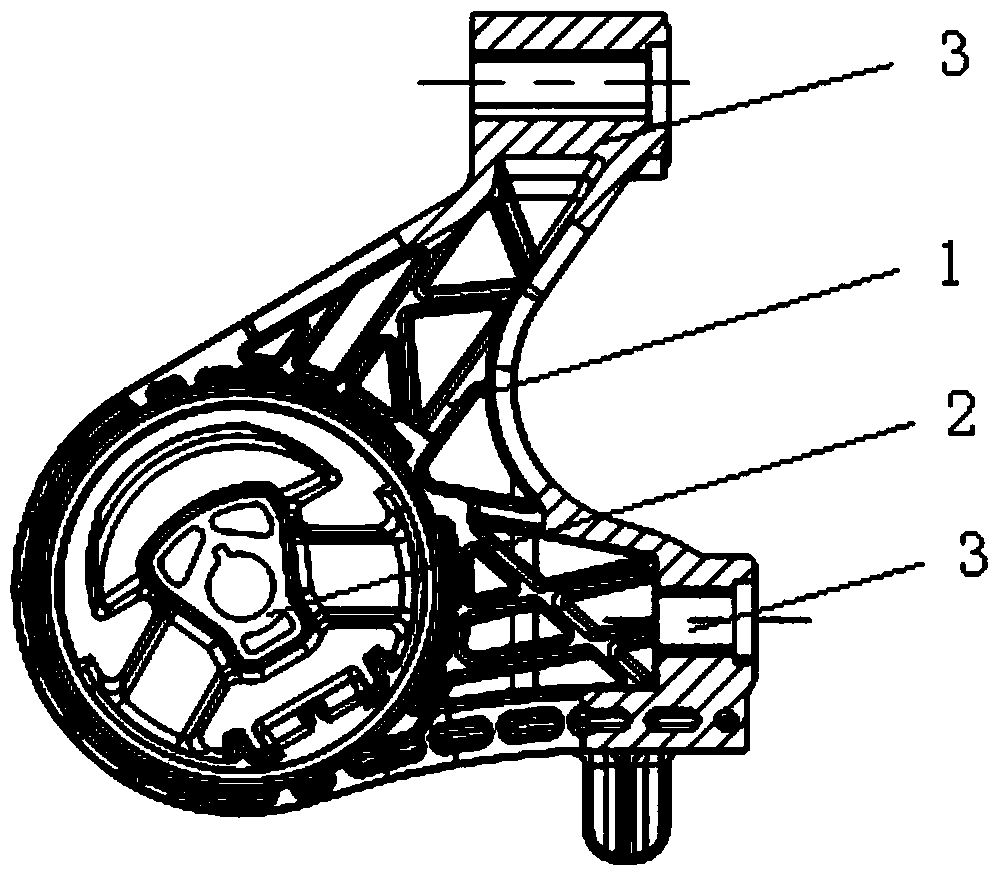

Making method of lightweight rubber shock absorption member for automobile

ActiveCN103640143AAvoid degradationAvoid morphological changesDomestic articlesVulcanizationEngineering

The invention discloses a making method of a lightweight rubber shock absorption member for an automobile. The rubber shock absorption member is characterized in that the rubber shock absorption member is composed of a rubber mainspring, a plastic support and a metal insert, and the making method comprises the steps of vulcanization, gluing, drying, assembling, injection molding, cooling and moisture absorption. The method has the advantages of simple technology and low cost, and the lightweight rubber shock absorption member made through the method has a good performance and a long service life.

Owner:NINGBO TUOPU GROUP CO LTD

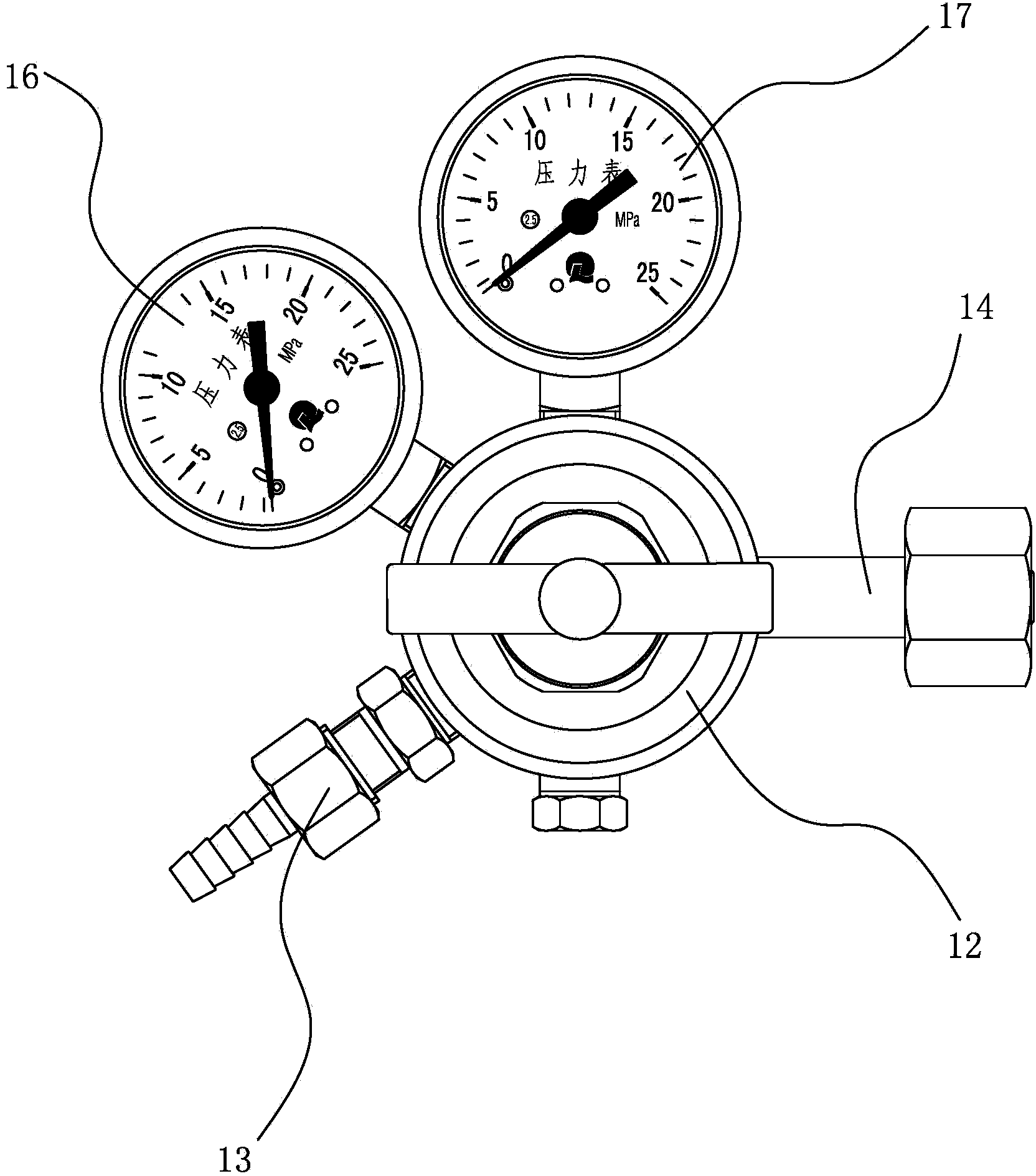

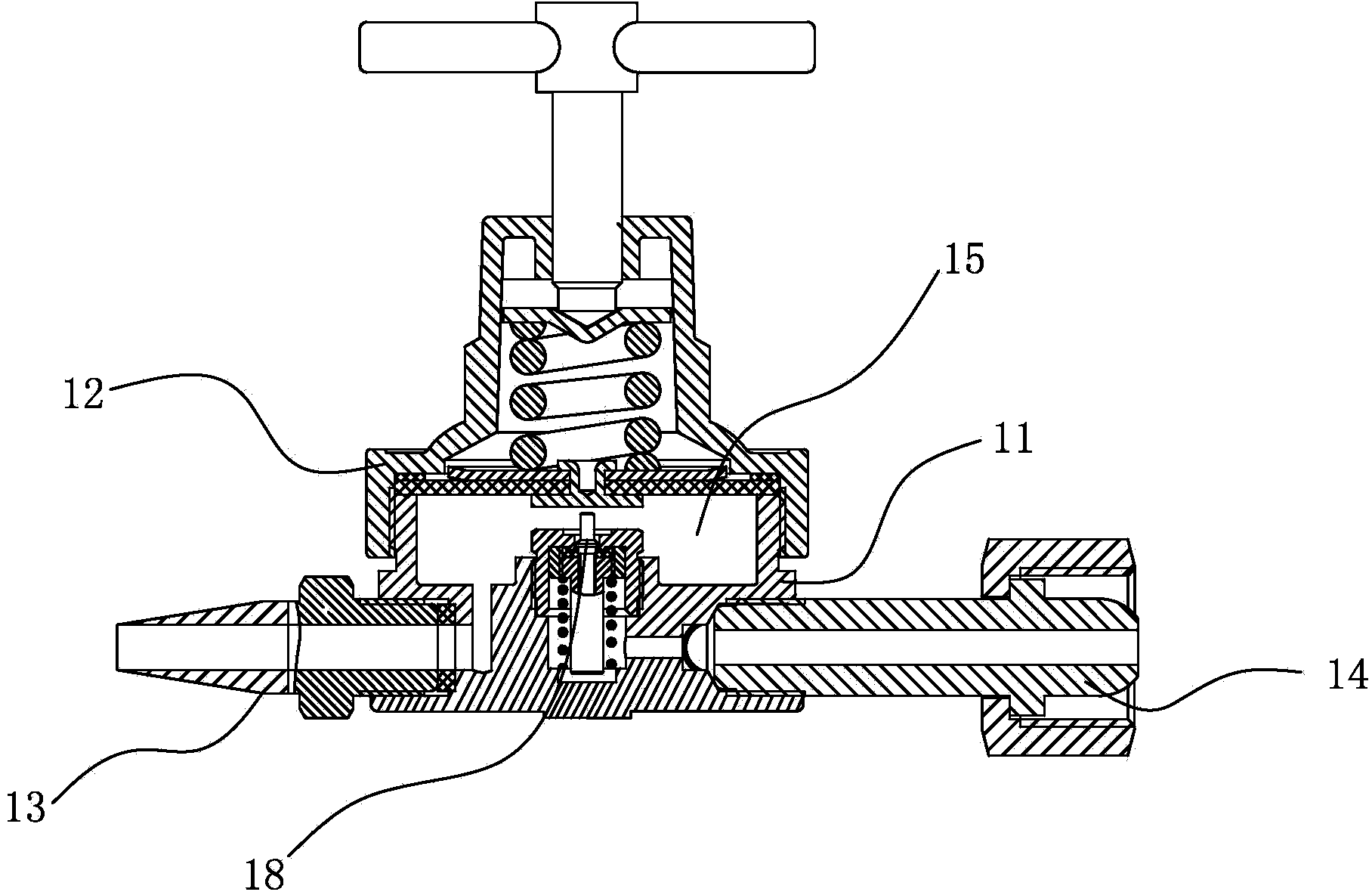

Plastic pressure reducer and manufacturing method of plastic pressure reducer

ActiveCN103672095AReduce weightLow costValve housingsGas flame welding apparatusHot runnerAntistatic agent

The invention relates to a plastic pressure reducer which comprises a shell, a cover, an air inlet pipe, an air outlet pipe and a throttling valve. The shell and the cover are made of modified polyformaldehyde engineering plastic which comprises, by weight, 80-100 parts of polyformaldehyde, 5-15 parts of flexibilizers, 3-5 parts of wear-resisting agents, 5-8 parts of compatilizers, 3-5 parts of fire retardants, 3-5 parts of antistatic agents and 5-10 parts of stabilizing modifying agents. The manufacturing method includes the steps of firstly weighing the raw materials, drying the polyformaldehyde, evenly mixing the raw materials, adding the raw materials into a pre-heated charging barrel of a high-speed injection molding machine, heating the raw materials to be in the fusing state, injecting the fused raw materials into hot moulds of the shell and the cover in two times through nozzles of hot runners, manufacturing the shell and the cover after pressure maintaining, cooling molding and mould opening are carried out, and finally conducting assembling to form the plastic pressure reducer. The shell and the cover of the manufactured plastic pressure reducer are made of the modified polyformaldehyde engineering plastic, the modified polyformaldehyde engineering plastic is low in cost and easy to obtain, and the plastic pressure reducer is easy to machine, light in weight, low in cost, good in performance and long in service life.

Owner:NINGBO LONGXING WELDING CUTTING TECH STOCK

Process for production of thermoplastic copolymer

Disclosed is a process for producing a thermoplastic copolymer, which comprises step of supplying a monomer mixture (a) to a loop reactor continuously to produce a copolymer (A), the monomer mixture (a) comprising an aromatic vinyl monomer (a1), a vinyl cyanide monomer (a2) and an N-substituted maleimide monomer (a3). The process enables the production of a thermoplastic copolymer which has an excellent balance among physical properties such as heat resistance, color and flow property, reduces the amount of bleeding that may cause mold staining during molding processing and has excellent handleability and productivity.

Owner:TORAY IND INC

Spray molding equipment

The invention discloses spray molding equipment. The spray molding equipment comprises a machine body. The machine body is internally provided with an spray cavity. The spray cavity is internally provided with a supporting plate. The supporting plate is internally provided with a groove with an upward opening. A carrying plate is rotatably arranged in the groove. An article to be sprayed is placedon the carrying plate. The lower end face of the carrying plate is fixedly provided with a spline shaft in spline connection with a rotating device. Lifting grooves with opposite openings are formedin the spray cavity in bilateral symmetry in a communication mode. The spray molding equipment is simple in structure and convenient to operate, completes rotary spray through lifting components whilemaking the article to be sprayed to rise so that the whole body of the article to be sprayed can be sprayed comprehensively. A horizontal spraying device moves horizontally while conducting sprayingfront and back so as to achieve the uniform spraying effect; secondly, through comprehensive rotary spraying and horizontal spraying on the upper surface, the spraying time can be shortened, and the spraying molding efficiency of the spray molding equipment can be improved. The spray molding equipment is small in occupied area and convenient to operate and overhaul.

Owner:余连平

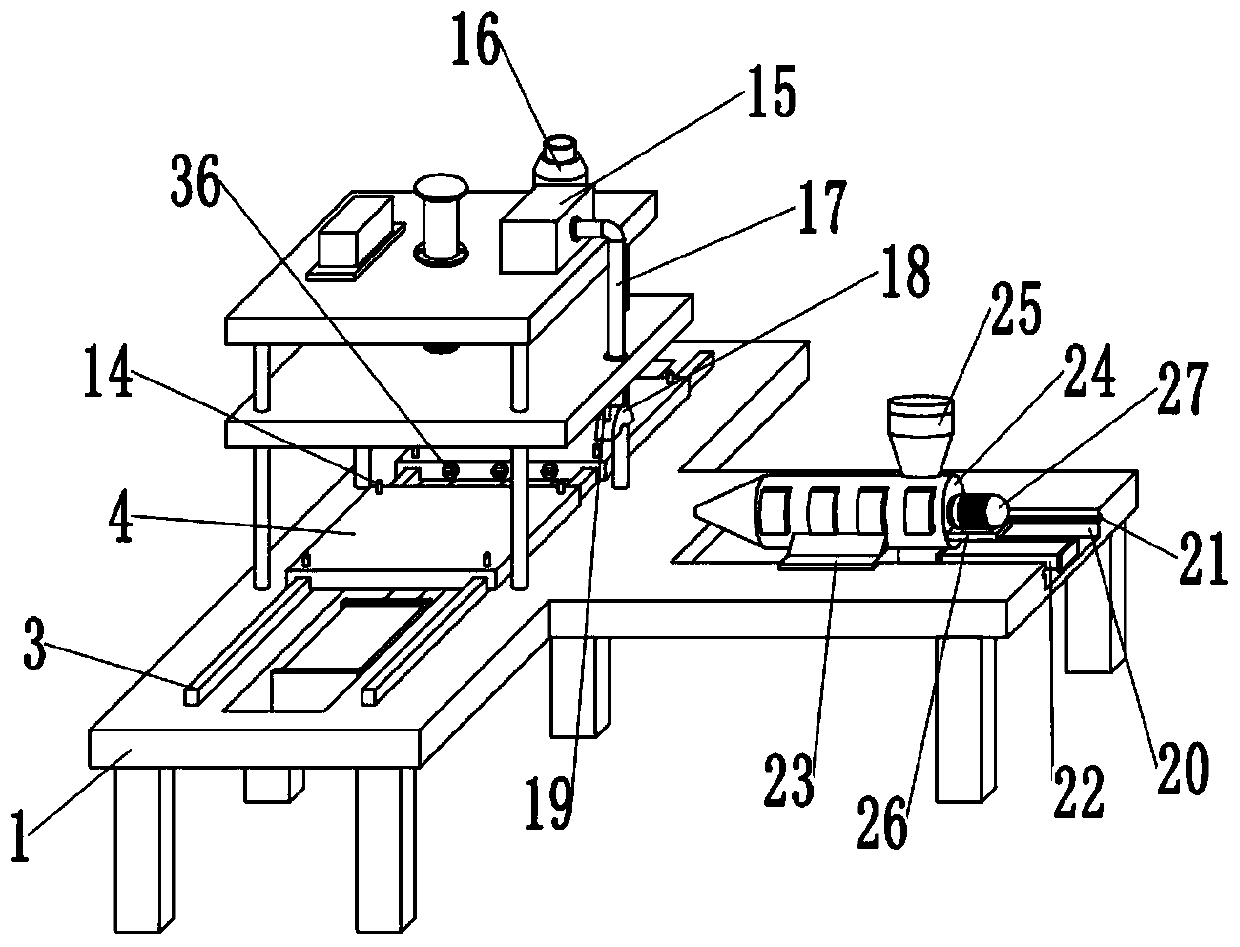

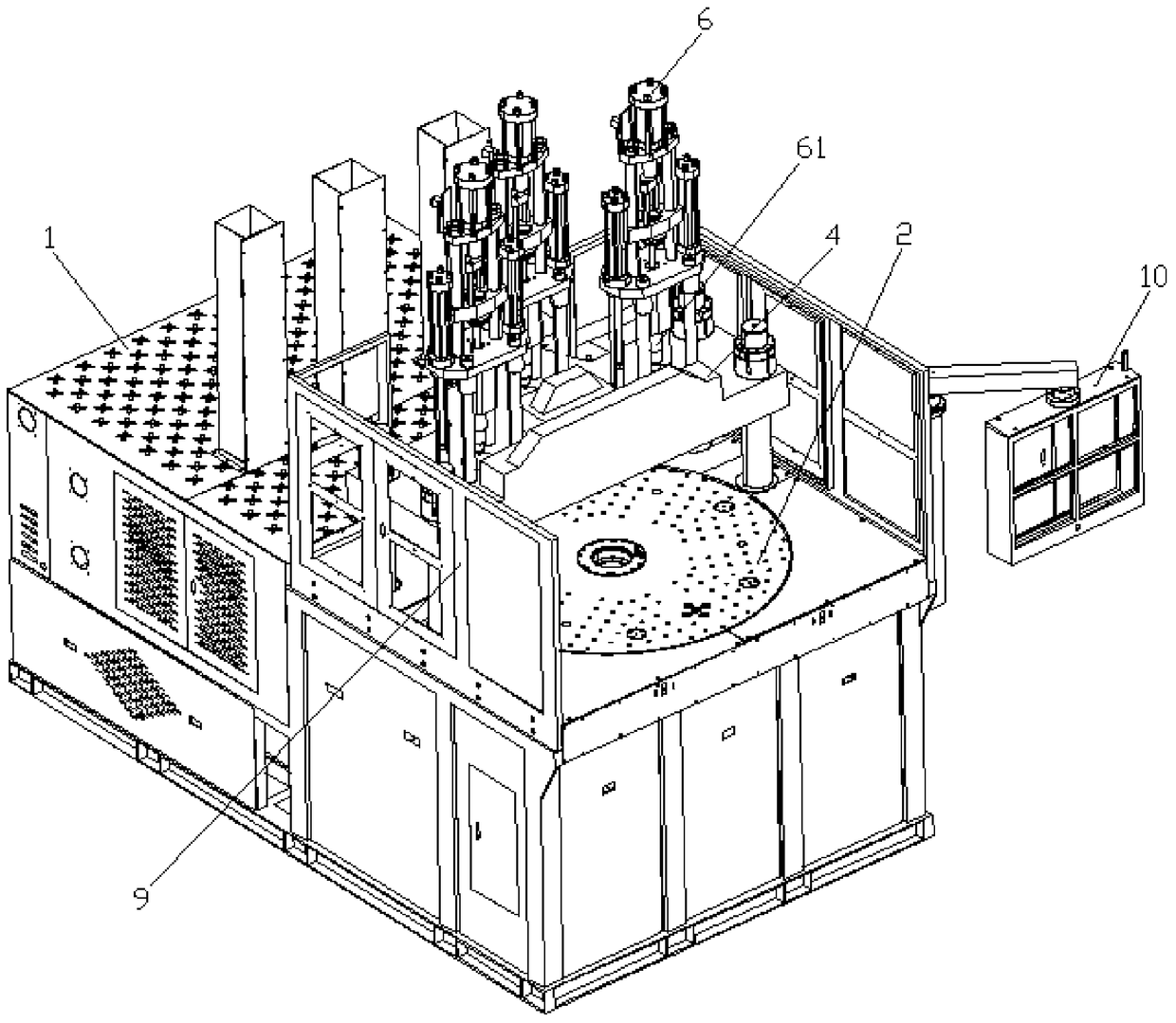

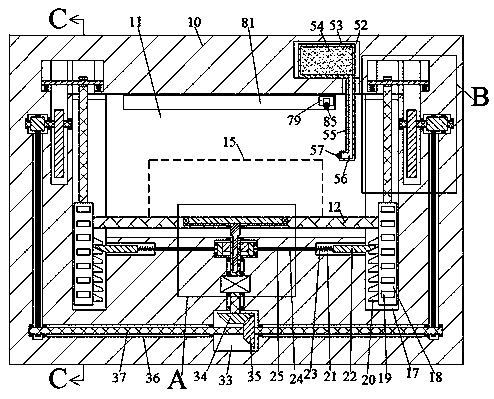

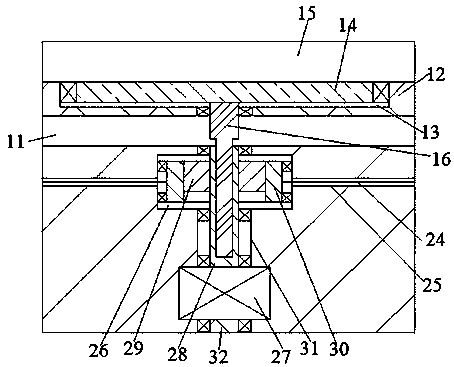

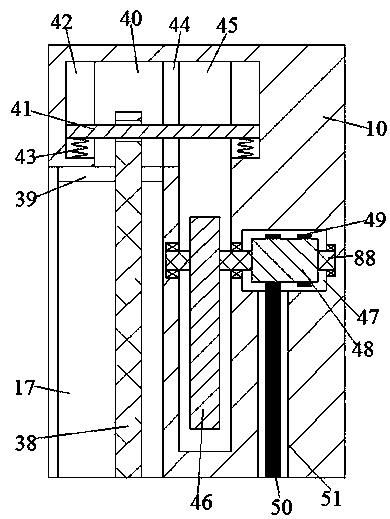

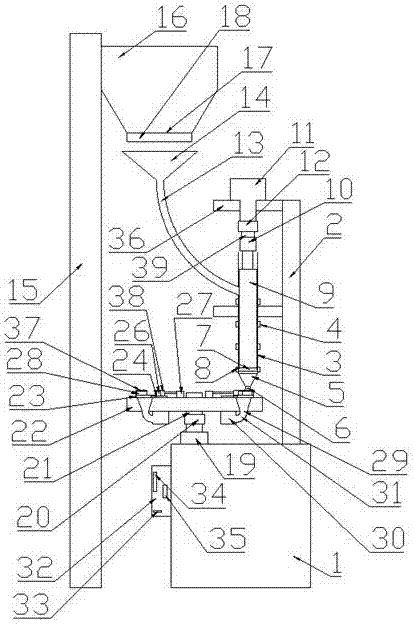

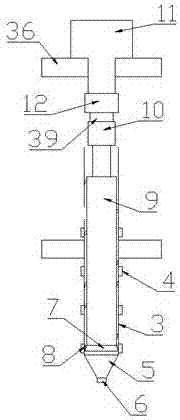

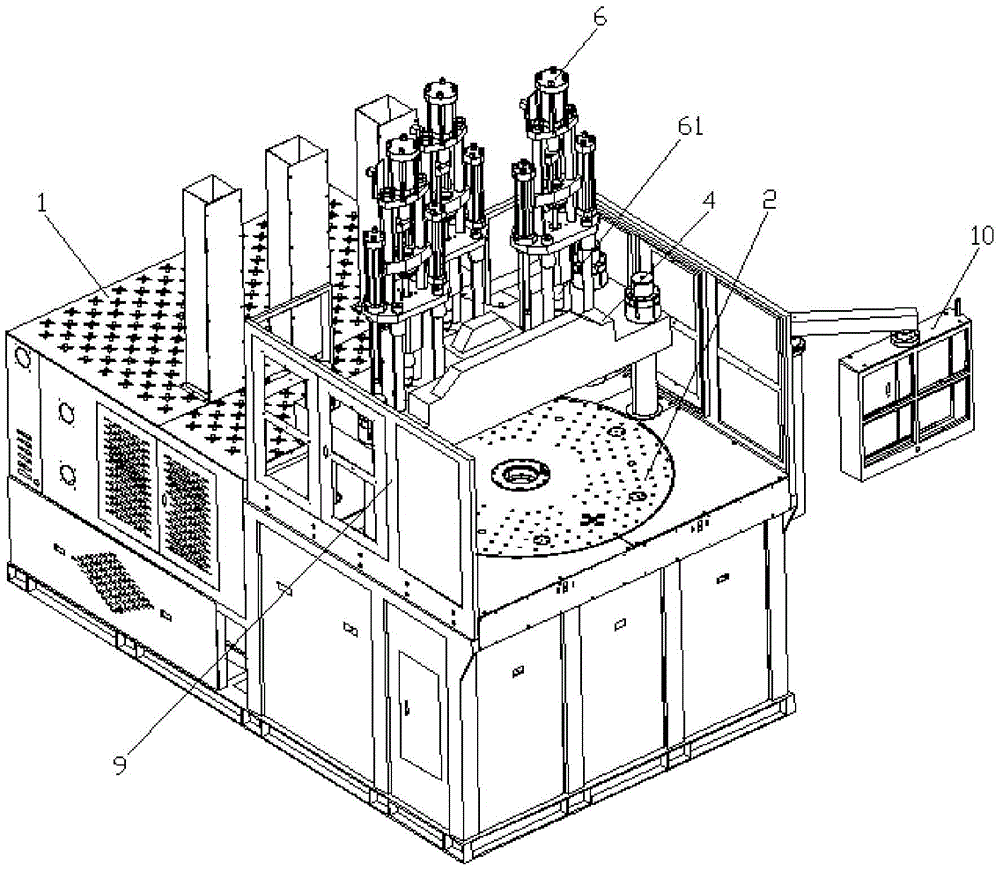

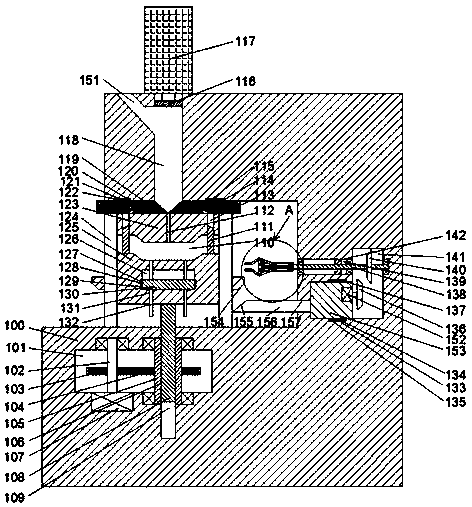

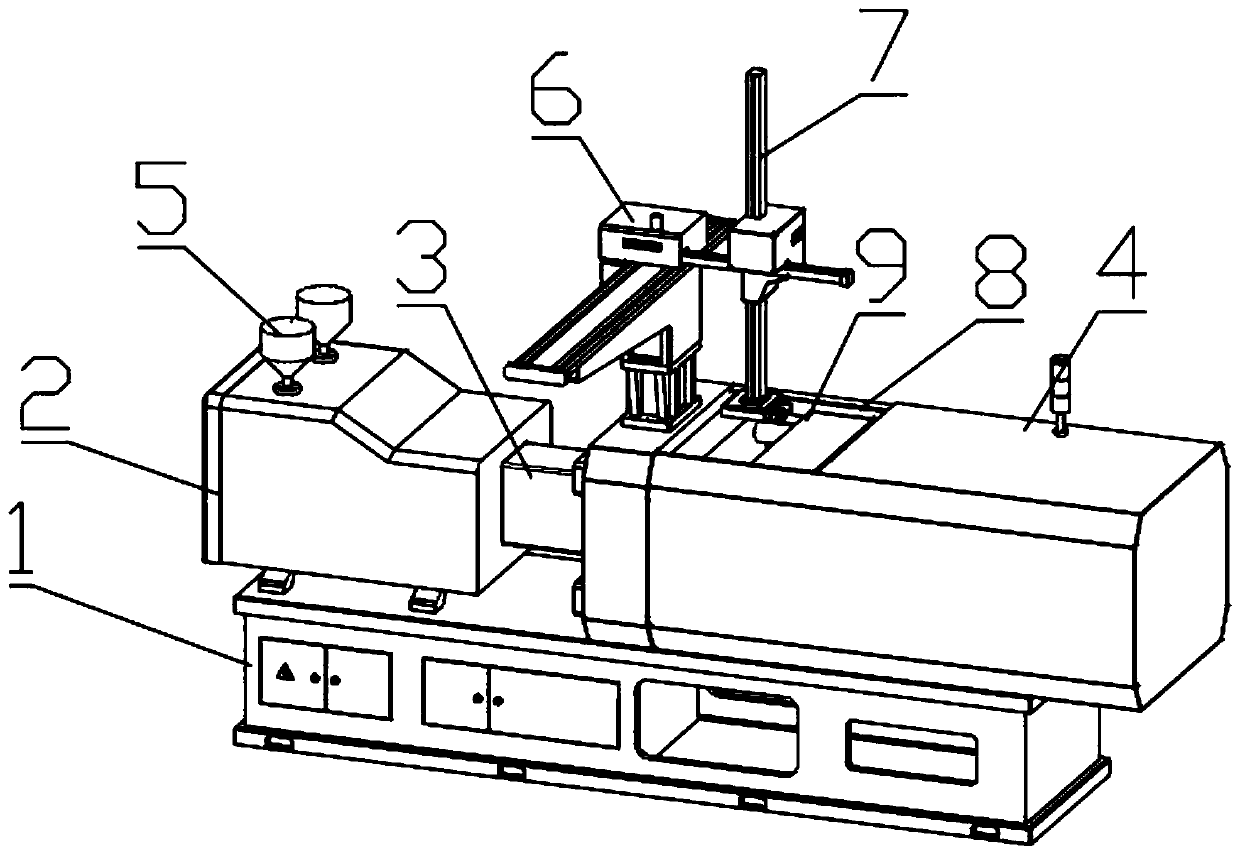

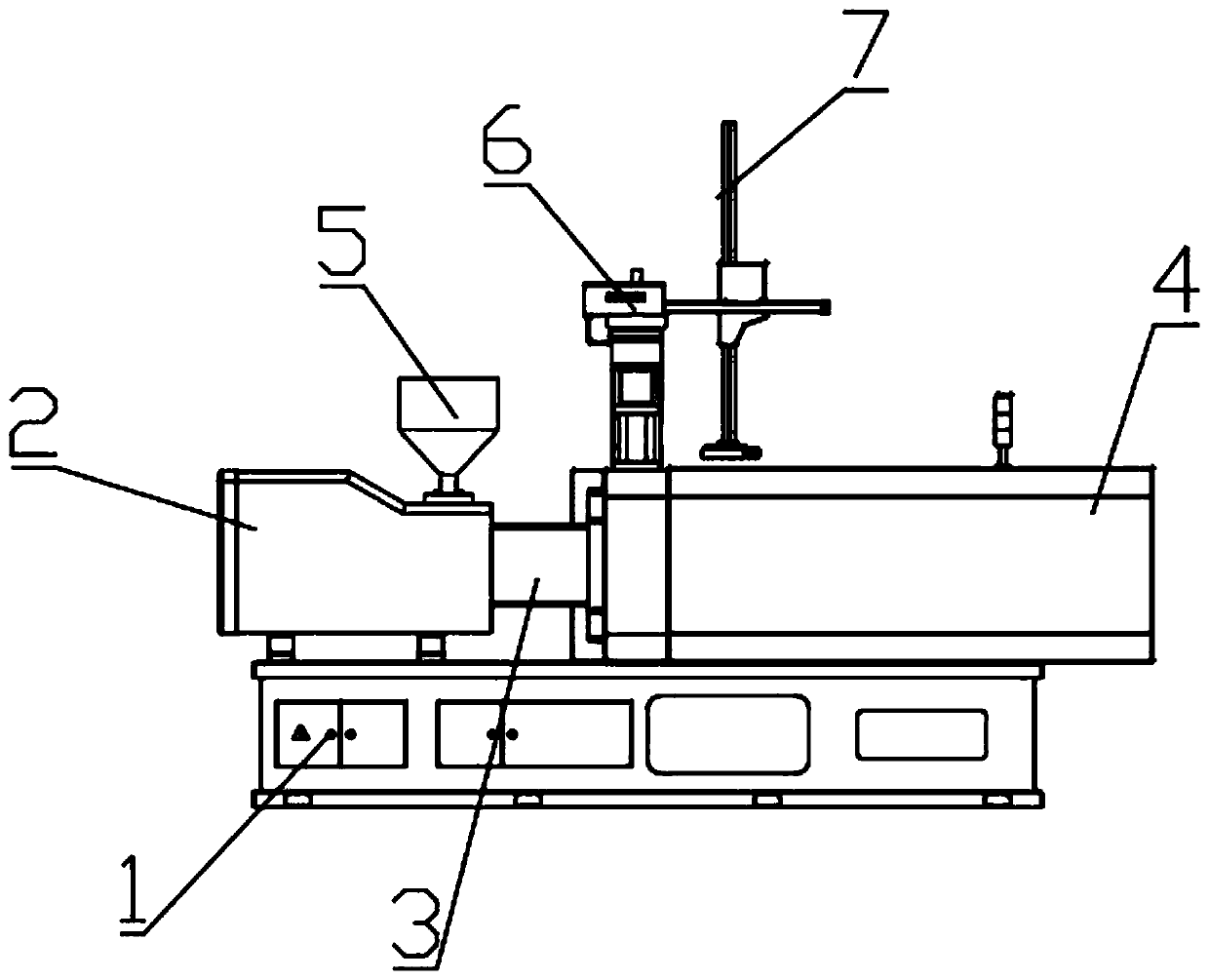

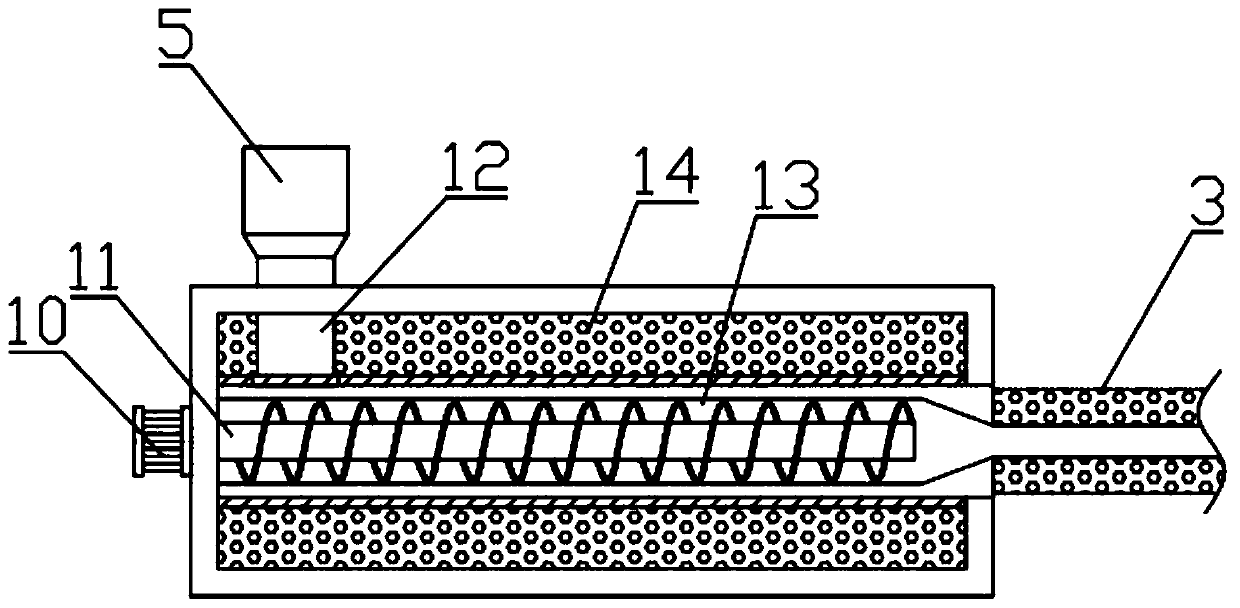

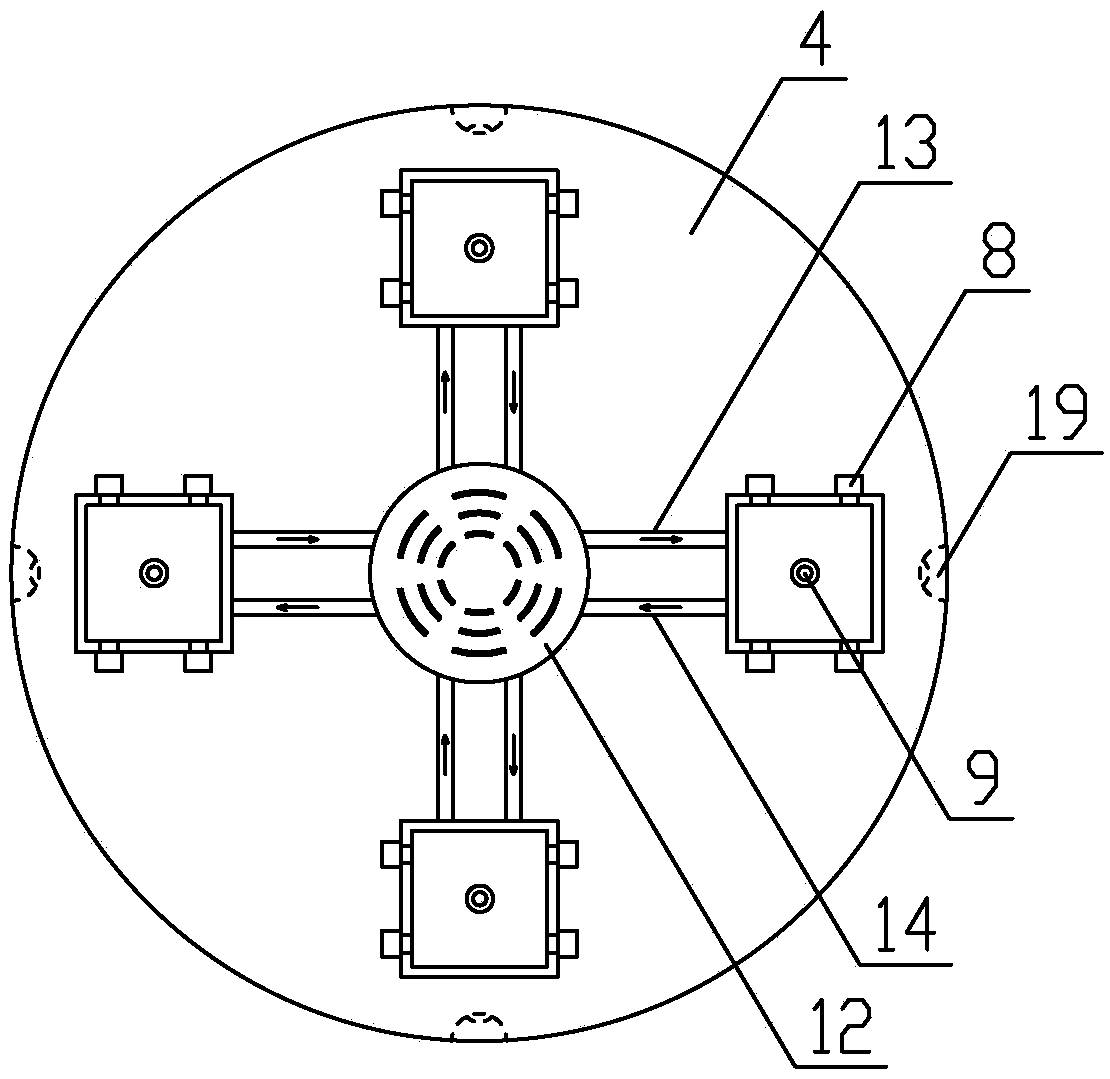

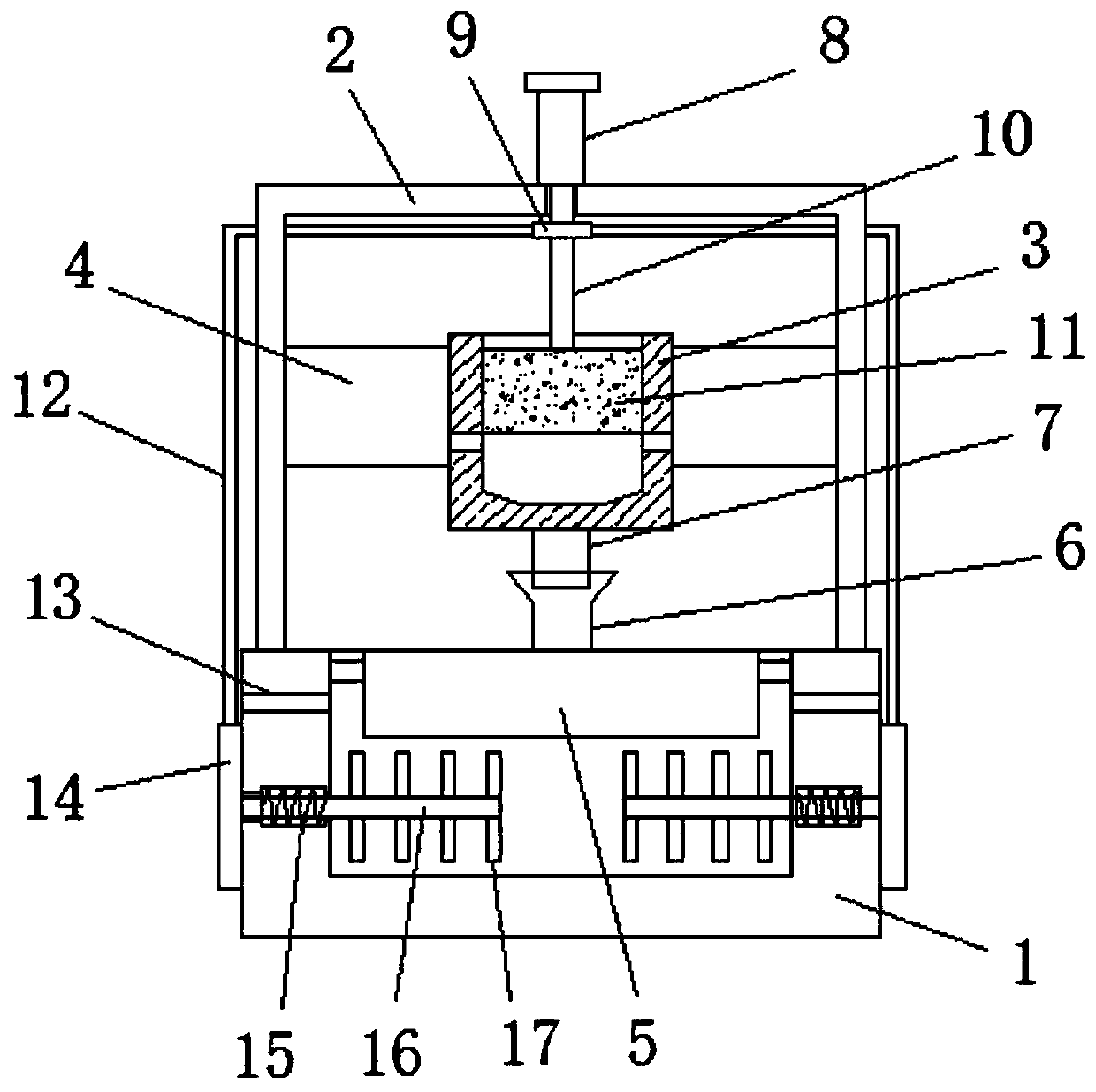

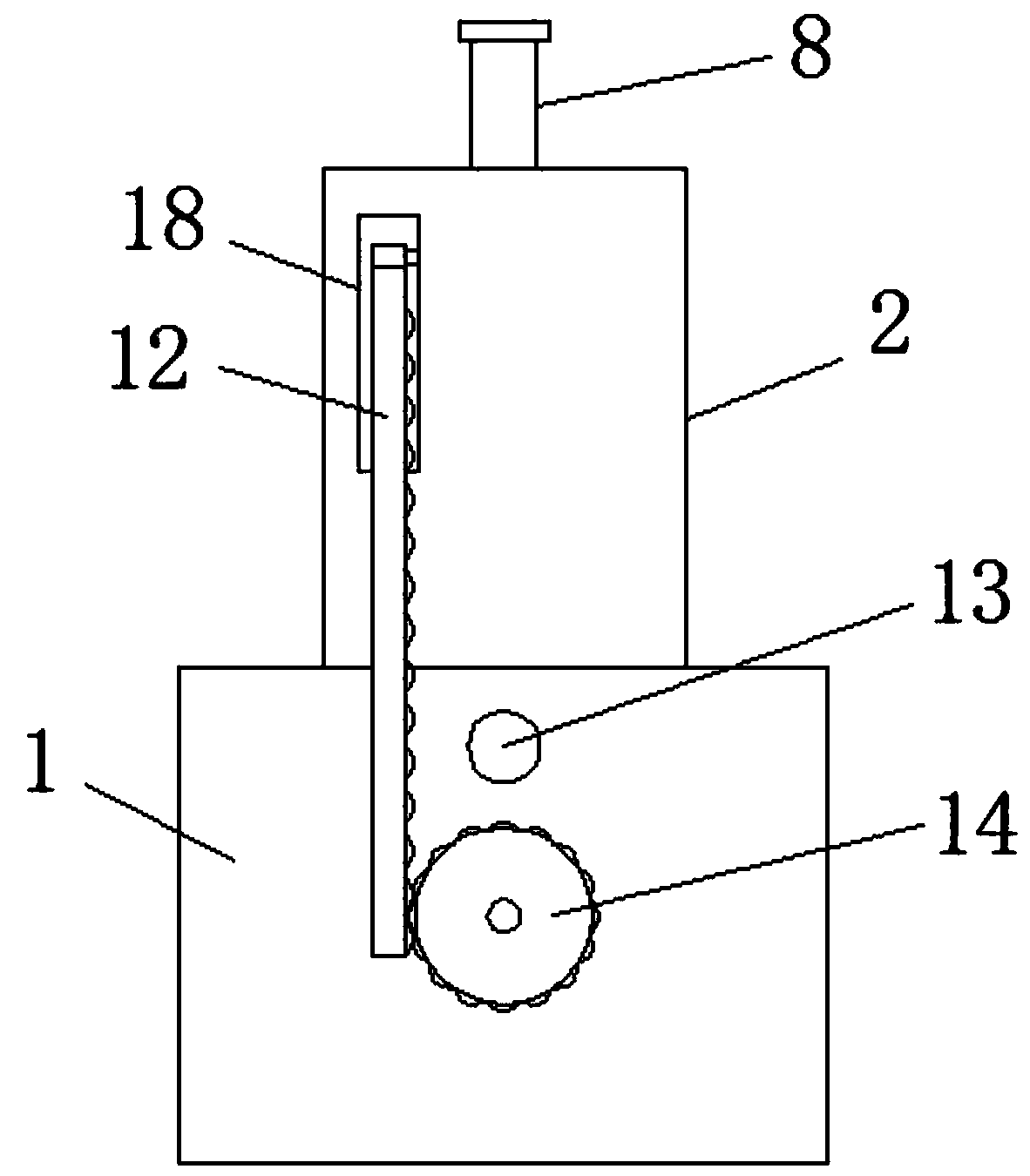

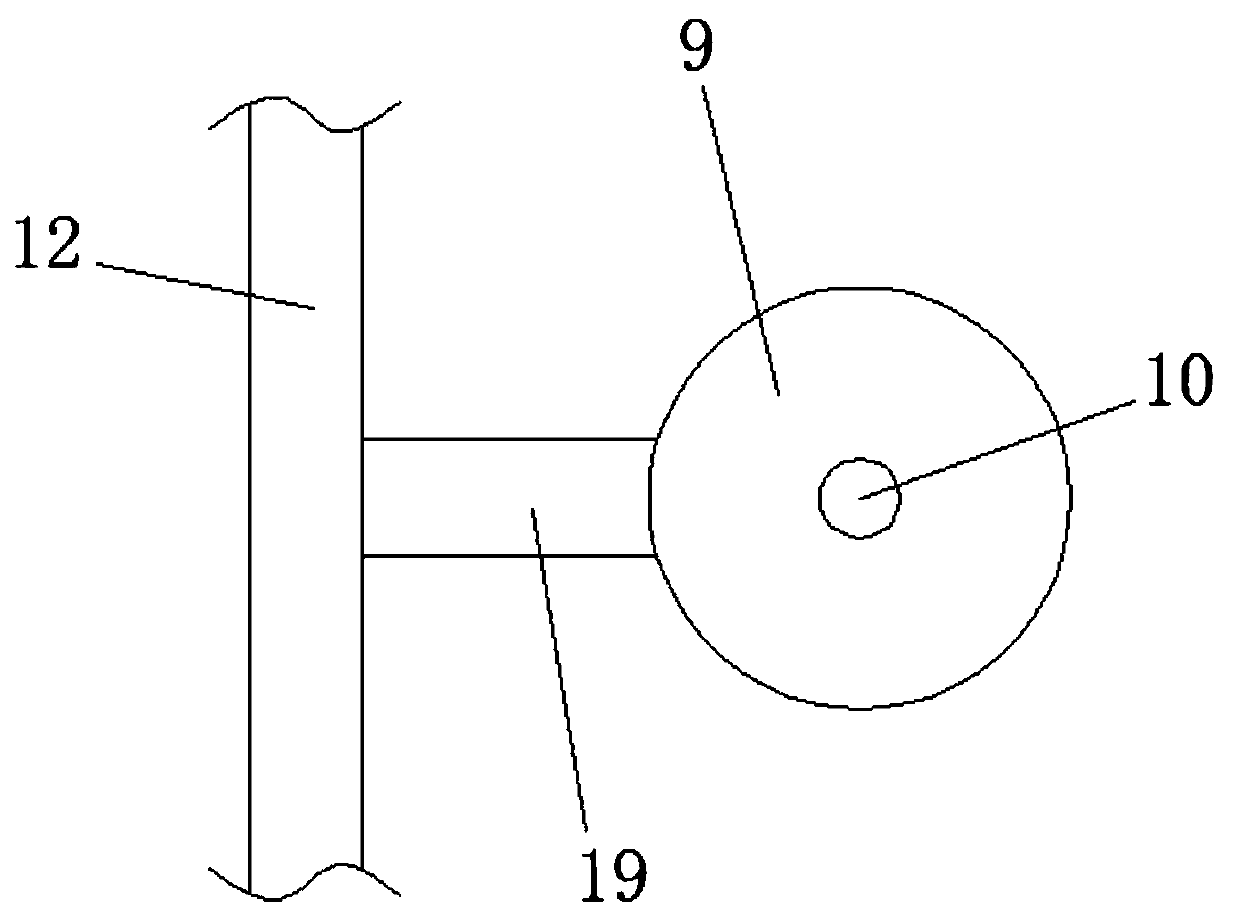

Wheel disc type injection mold containing vertical screw injection molding machine

InactiveCN107263795AImprove injection molding efficiencyImprove business efficiencyAutomatic controlManipulator

The invention discloses a wheel disc type injection mold containing vertical screw injection molding machine. The wheel disc type injection mold containing vertical screw injection molding machine comprises an injection molding machine base. The injection molding machine base is fixedly installed on the ground and provided with a material pushing heating mechanism, a feeding mechanism and an injection mold containing mechanism. The injection mold containing mechanism is provided with an injection mold cooling mechanism and a manipulator for automatically controlling blanking of a finished injection mold. The injection molding machine base is provided with a controller. The controller is provided with an industrial electricity socket, a capacitive display screen and a PLC system. The wheel disc type injection mold containing vertical screw injection molding machine has the beneficial effects of being simple in structure and high in practicability.

Owner:杨淑兰

Multi-station injection molding machine

The invention discloses a multi-station injection molding machine which is suitable for the technical field of injection molding machines. The multi-station injection molding machine comprises a rack, a lower die plate arranged on the rack, a rotating mechanism for driving the lower die plate to rotate, an upper die plate located above the lower die plate, a lifting mechanism for driving the upper die plate to ascend and descend and multiple injection devices arranged above the upper die plate. The upper die plate is provided with multiple fixed die mounting positions. The lower die plate is provided with multiple movable die mounting positions corresponding to the fixed die mounting positions in rotation respectively. According to the multi-station injection molding machine, the injection devices are arranged above the upper die plate, products in different colors made of different materials can be obtained in an injection molding manner; and multiple movable dies can be mounted at the same time through the movable die mounting positions, and multiple processes can be conducted at the same time, so that the whole injection molding period is shortened, injection molding efficiency is improved, a great amount of time and manpower and a great number of material resources are saved, injection molding cost is lowered greatly, input cost is reduced, and the competitiveness of the products in the market can be improved.

Owner:MODERN PRECISION PLASTIC & MOLD SHENZHEN CO LTD

Injection mold

The invention discloses an injection mold. The injection mold comprises a machine body and a first cavity with a leftward opening, wherein the first cavity is arranged in the machine body; a lower sub-mold capable of sliding up and down is arranged in the first cavity, and first through holes with the upper part communicating with the lower part is formed in the lower sub-mold in a left-right symmetry and front-back symmetry mode, and first sliding rods which extend up and down are installed in the first through holes in a sliding fit mode; and the upper ends and the lower ends of the first sliding rods are fixedly connected to the upper end wall and the lower end wall of the first cavity correspondingly, a first sliding cavity is formed in the lower sub-mold, and a first sliding block isarranged in the first sliding cavity in an up-down sliding mode. According to the injection mold, structure is simple, the problem that mold stripping of the device is difficult is solved through an ejection mechanism, the automatic mold taking of the device is realized by utilizing a clamping device, the working procedures are coordinated with one another and are not affected by one another, labor cost is reduced, and meanwhile, the safety of the device is improved; and the device is automatic in the whole process, operation errors are reduced, the injection molding efficiency and the qualityare improved, and the practical performance of the device is improved.

Owner:宁波美丁模塑有限公司

Negative pressure precision injection molding method for mobile phone plastic parts

The invention relates to the technical field of plastic injection molding, in particular to a negative pressure precision injection molding method for mobile phone plastic parts. The method includes the steps that air in a forming mold cavity is sucked out to form negative pressure through an air compression system at first, and then a plastic raw material in the molten state is injected to the cavity to form a product; and in the demolding process, gas is blown into the forming mold cavity through the air compression system, and thus the product can be separated from a fixing mold plate. By means of the negative pressure precision injection molding method for the mobile phone plastic parts, injection molding can be conducted on the cavity in the negative pressure state, the cavity can be filled with the injection molding plastic raw material quickly, and injection molding efficiency is high; moreover, the phenomenon that oxygen in the cavity is reacted with the plastic raw material to burn the plastic raw material is avoided, the performance, surface quality and precision of the mobile phone plastic parts are improved, and injection molding of small-size precision thin-walled products can be achieved; and the products can be blown out in a positive pressure gas blowing mode, the products can be prevented from being attached to the fixing mold plate, product deformation and damage are also prevented, and demolding is easy.

Owner:东莞市中萃模具塑胶科技有限公司

Multicolor injection molding mold and injection molding method thereof

InactiveCN110978386APlay a role in heat preservationPromote circulationElectric machineryEngineering

The invention discloses a multicolor injection molding mold. The mold comprises a base, a feeding box and an injection molding box, wherein the feeding box and the injection molding box are arranged on the base, the feeding box is located on one side of a top face of the base, the injection molding box is located on the other side of the top face of the base, the feeding box communicates with theinjection molding box through a communicating pipe, multiple sets of storage cylinders are arranged on the side, away from the injection molding box, of the top face of the feeding box side by side, afeeding mechanism is arranged in the feeding box, an injection molding mechanism is arranged in the injection molding box, an injection molding pipe is arranged in the injection molding box, a screwrod is arranged in the injection molding pipe, the screw rod is connected with an output end of the motor, a storage barrel communicates with a feeding end of the injection molding pipe through a feeding pipe, a discharging end of the injection molding pipe is connected with a feeding end of the injection molding mechanism through an injection molding communicating pipe, and the injection moldingcommunicating pipe is located in the communicating pipe. The mold can be formed through one-time injection molding step by step according to materials of different colors, the formed mold is automatically ejected out, the mold is convenient to replace, and mold products of different structures and sizes are formed through injection molding.

Owner:HANGZHOU JIATONG MACHINERY

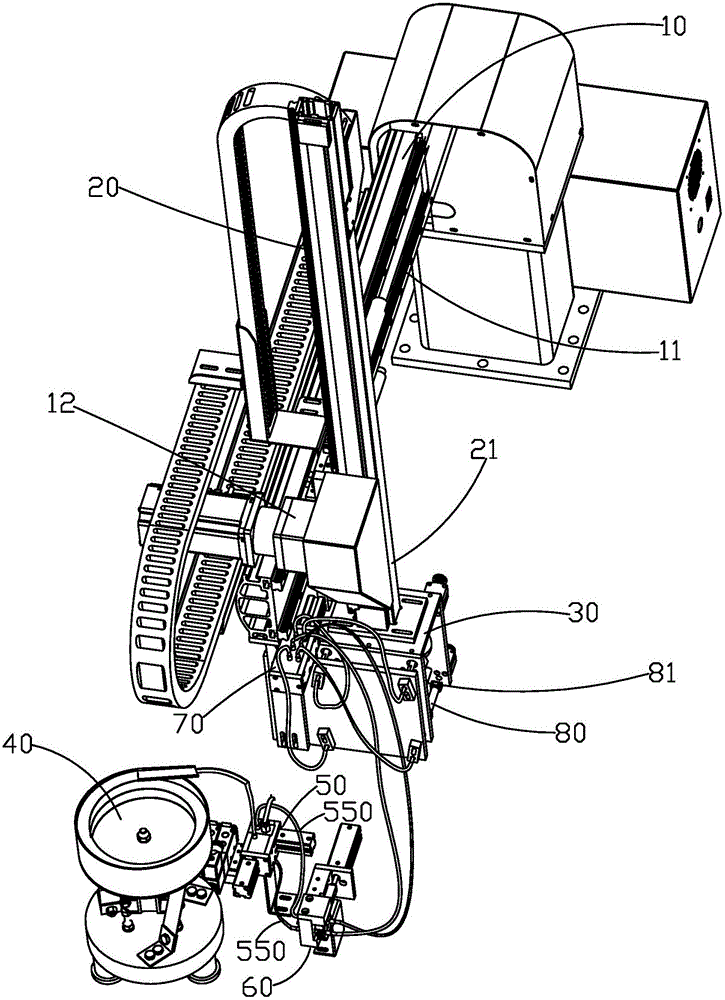

Automatic insert manipulator for injection molding machine

InactiveCN106003563AReduce labor intensityAvoid pinchingCoatingsEngineeringInjection molding machine

The invention discloses an automatic insert manipulator for an injection molding machine. The automatic insert manipulator comprises a rack. A horizontal guide rail, a horizontal moving platform, a horizontal drive mechanism, a lifting guide rail, a lifting platform and a lifting drive mechanism are arranged on the rack. Meanwhile, a jig used for mounting an insert on an injection molding die of the injection molding machine is arranged on the lifting platform. According to the automatic insert manipulator for the injection molding machine, by the adoption of the structure, the lifting platform can drive the jig to move freely along the horizontal guide rail and the lifting guide rail, so that the jig can be used for mounting the insert on the die of the injection molding machine instead of workers; and the labor intensity of the workers is lowered greatly, meanwhile it can be avoided that the workers are clamped by the injection molding machine and hurt, and the personnel safety of the workers is guaranteed.

Owner:中山市德城电器有限公司

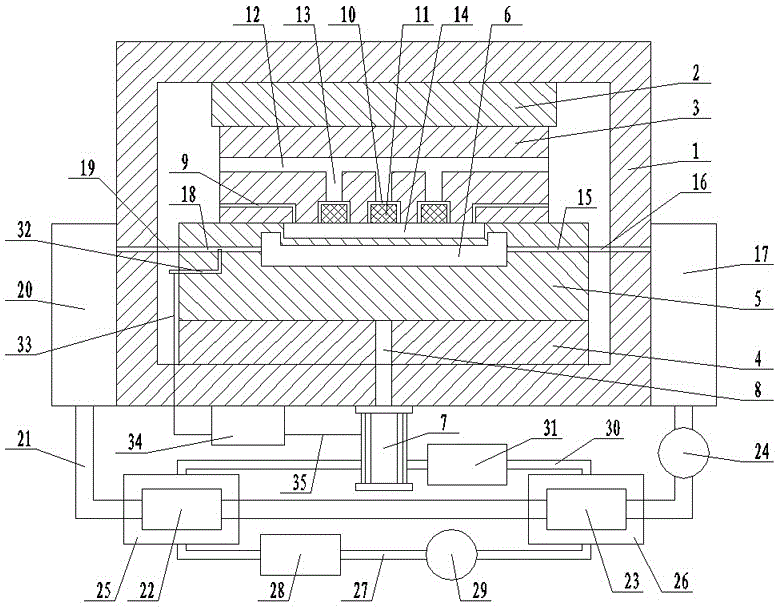

Efficient injection molding machine

InactiveCN109605658AImprove injection molding efficiencyShorten molding cycleTemperature controlCold air

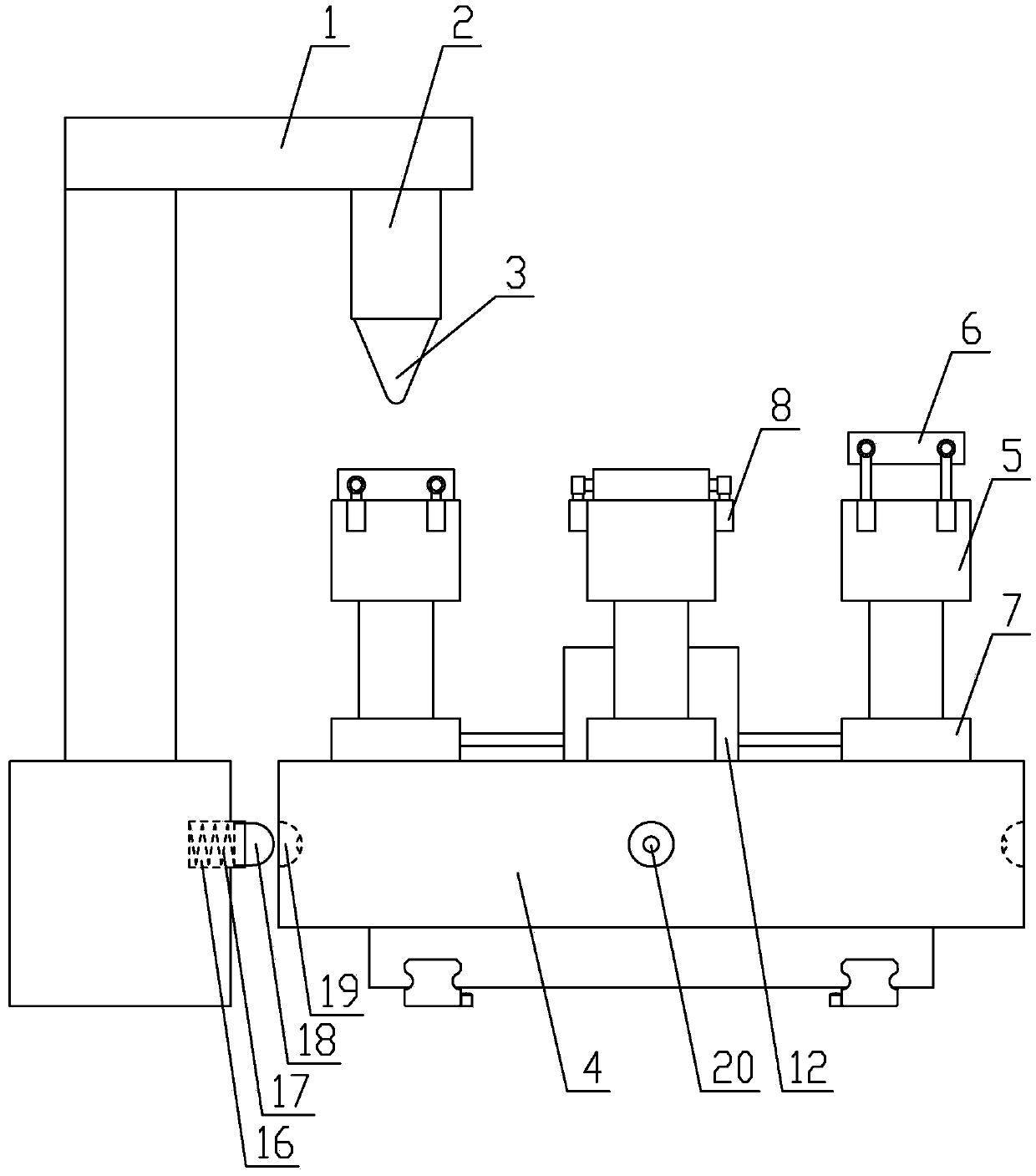

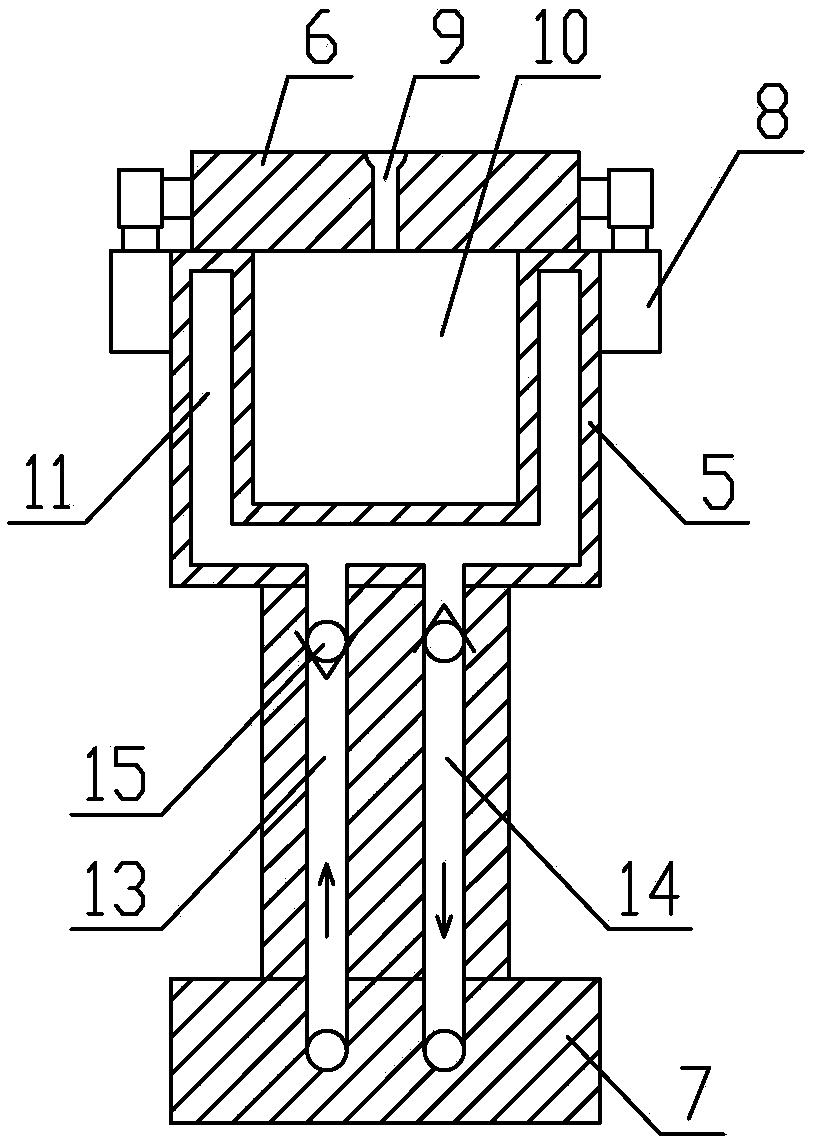

The invention provides an efficient injection molding machine. The efficient injection molding machine comprises an injection molding unit and a mold unit. The injection molding unit comprises a fixedframe, a telescopic piece and an injection molding head; and the mold unit comprises a rotary table, a plurality of forming molds and temperature control assemblies. Each forming mold comprises a lower mold and an upper mold, wherein the lower mold is fixedly connected with the rotary table, and the upper mold is movably connected with the lower mold; and each upper mold is provided with an injection molding hole, and each lower mold is provided with an injection molding cavity and a temperature control cavity for preheating and cooling the injection molding cavity. Each temperature control assembly comprises a cool-warm air heating radiator, an air inlet pipe and an air outlet pipe, and the air inlet pipes and the air outlet pipes communicate the cool-warm air heating radiators with thetemperature control cavities. The fixed frame is further provided with a positioning assembly for ensuring the alignment of the injection molding holes and the injection molding head. According to theefficient injection molding machine, the forming molds are arranged on the rotary table, so that the injection molding head can continuously work, and the injection molding efficiency is improved; and the forming molds communicate with the cool-warm air heating radiators correspondingly, hot air or cold air is conveyed into the molds through the cool-warm air heating radiators, so that the multiple forming molds are preheated or cooled at the same time, the forming period is shortened, and the forming efficiency is improved.

Owner:江苏东弘塑业有限公司

Automobile grille machining mold

The invention discloses an automobile grille machining mold which comprises a machine frame. An upper mold base is arranged at the upper end inside the machine frame. A fixed forming mold is arranged on the upper mold base. A lower mold base is arranged at the lower end of the machine frame. A movable forming mold mutually matched with the fixed forming mold is arranged on the lower mold base. A grille cavity is formed between the movable forming mold and the fixed forming mold. A jacking air cylinder is arranged at the lower end of the machine frame. A piston rod of the jacking air cylinder penetrates through the machine frame and the lower mold base and is connected with the movable forming mold. Injection molding channels are symmetrically arranged in the portions, at the upper ends of the two sides of the grille cavity, inside the fixed forming mold. The injection molding channels are connected with an injection molding device. A plurality of sintered metal block storage grooves are evenly formed in the portion, at the upper end of the grille cavity, of the fixed forming mold. Sintered metal blocks are embedded in the sintered metal block storage grooves. A main exhaust channel is arranged at the upper end of the fixed forming mold in a penetrating mode.

Owner:JIANGSU YUYAN MOLD IND

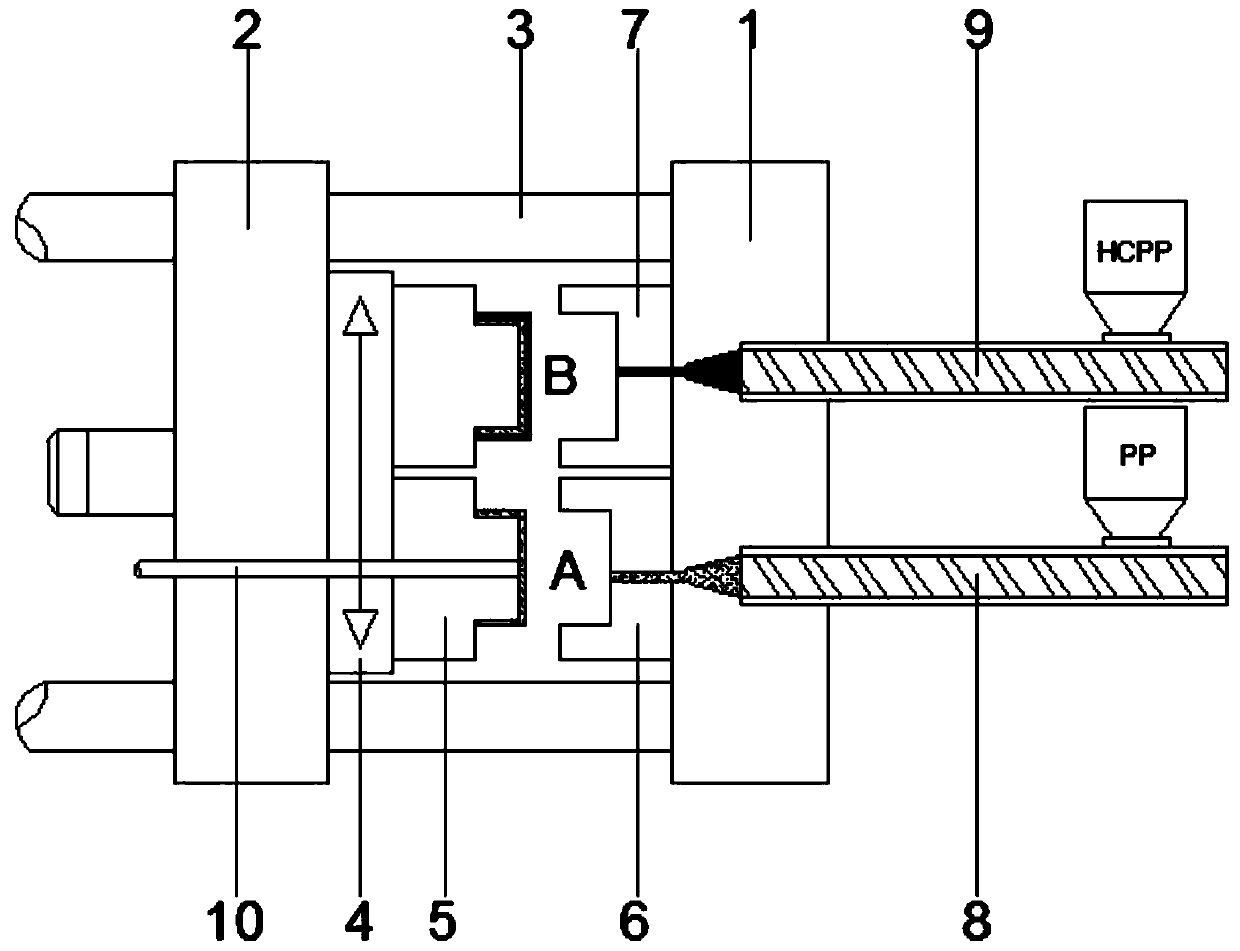

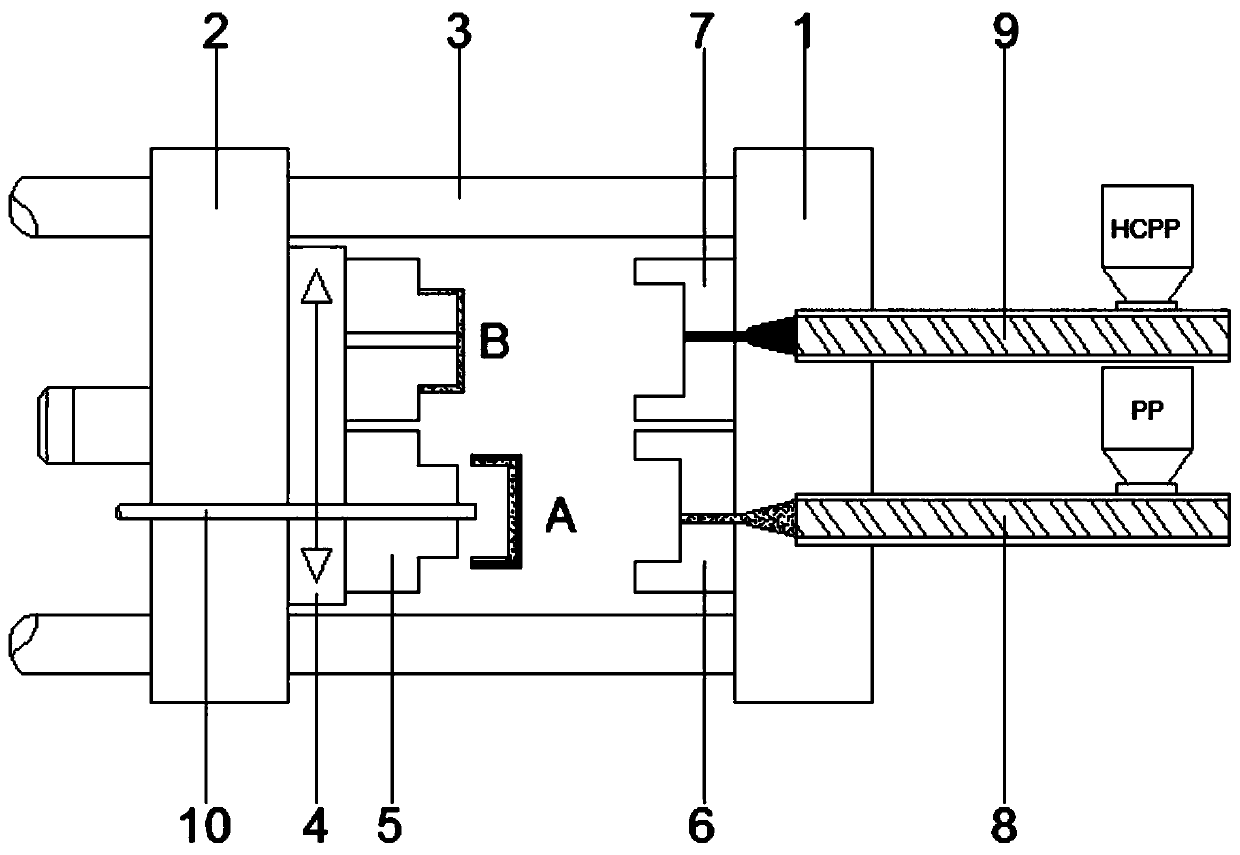

Rotary disc type double-color injection mold forming process

InactiveCN109732843AContinuous injection molding processImprove injection molding efficiencyCoatingsInjection mouldingInjection molding machine

The invention provides a rotary disc type double-color injection mold forming process. A rotary disc, a male mold core, a first female mold core and a second female mold core are involved; movable mold bases which are symmetrically installed along the central axis of a double-color injection molding machine is combined with a fixed mold base through the forward movement of a guide column, a firstinjection pipe is used for injecting a PP material into a first mold cavity A, the material temperature is controlled to be 235 DEG C, the injection molding time is 17.5-20 seconds, then the mold is opened, after the rotary disc is rotated by 180 degrees, the mold is closed again, the first injection pipe is used for injecting the PP material into the first mold cavity A, the material temperatureis controlled to be 235 DEG C, and the injection molding time is 17.5-20 seconds. Through the improvement of a structure, the rotary disc type injection mold forming process is provided, and has the advantages that the process is continuous, the injection molding efficiency is improved, the connectivity among product melts is high, and the product quality is improved, so that the problems and defects brought in the prior art are effectively solved.

Owner:苏州敏煌精密电子科技有限公司

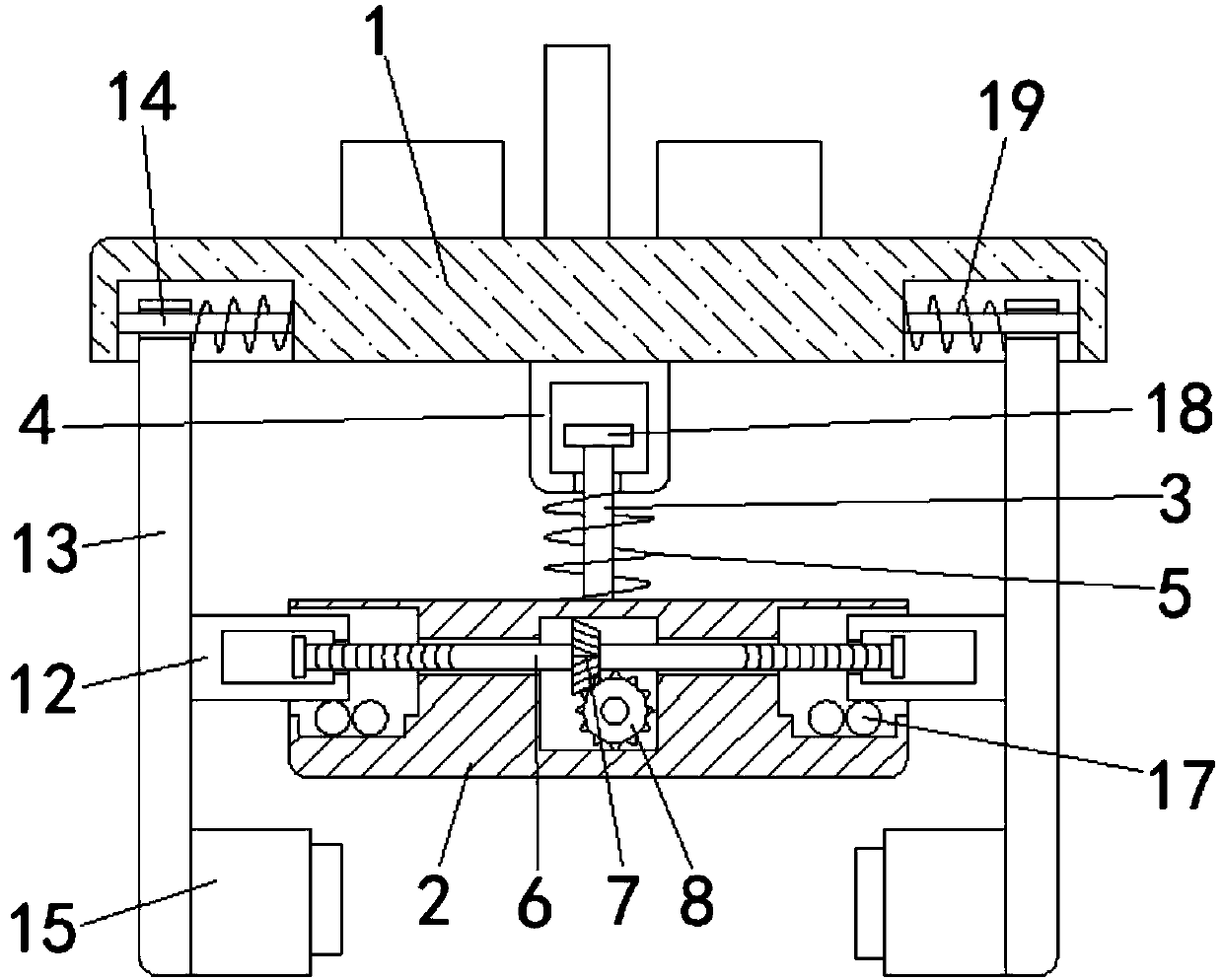

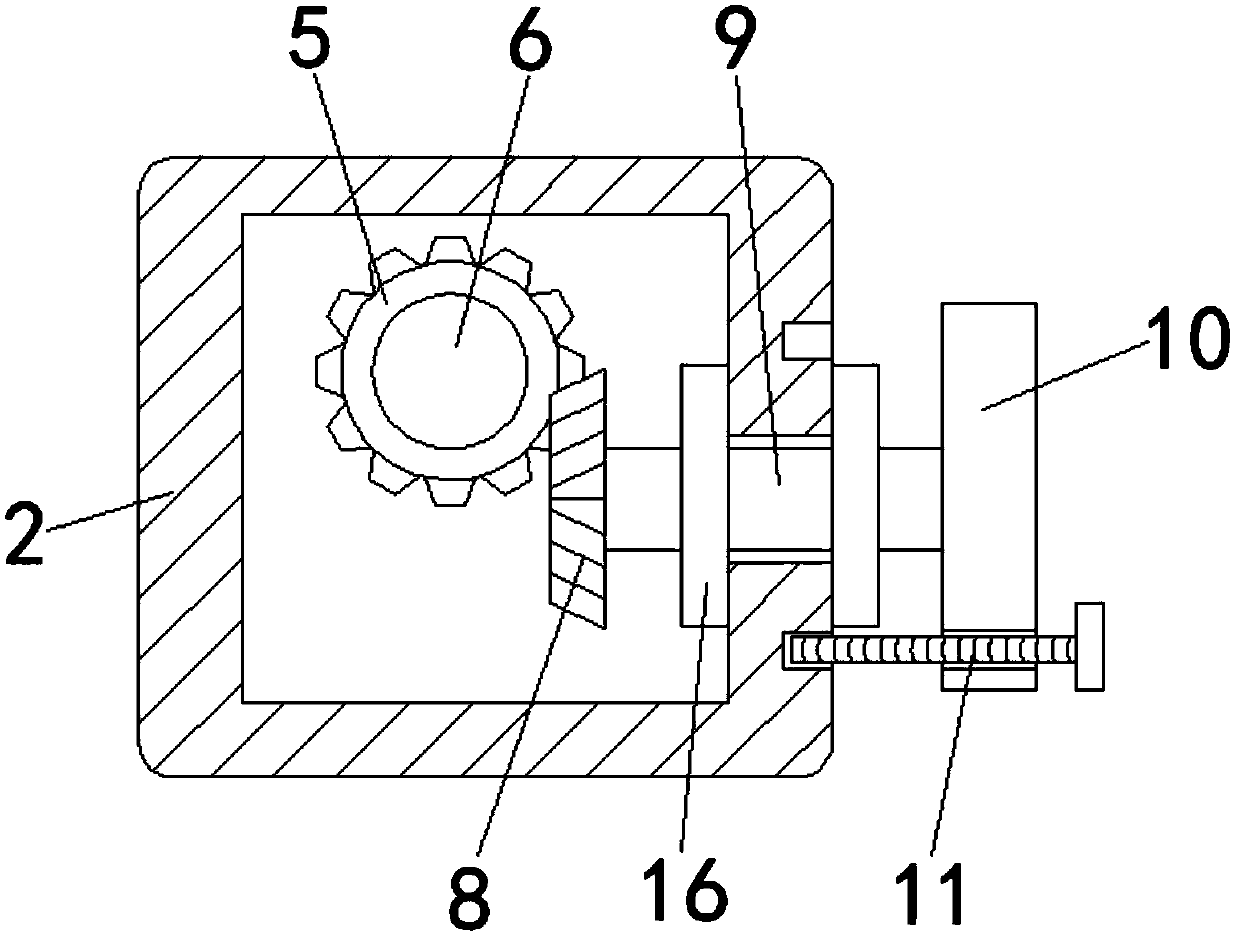

Toy buckle plate mold

InactiveCN107738405AImprove injection molding efficiencyEasy to fixDomestic articlesArchitectural engineeringThreaded rod

The invention discloses a toy gusset mold, which comprises a mold body and a base. The mold body is arranged in parallel above the base. The top of the base is fixedly connected with a support rod, and the top of the support rod is slidably sleeved with a sliding sleeve. The end of the sliding sleeve away from the support rod is fixedly connected to the bottom of the mold body, the support rod is covered with a first spring, the two ends of the first spring are respectively fixedly connected to the sliding sleeve and the base, and the inside of the base A cavity is provided, and a threaded rod is rotatably connected to the cavity, and a first gear is fixedly sleeved on the threaded rod, and a second gear meshed with the first gear is provided in the cavity, and the first gear is fixedly sleeved on the threaded rod. The two gears are rotatably connected with the inner wall of the cavity through the rotating rod. The present invention makes the installation and fixing of the mold and the mold base easier when the mold performs injection molding through the arrangement of multiple transmission mechanisms, thereby improving the injection molding efficiency of the mold.

Owner:肇庆高新区进化论科技有限公司

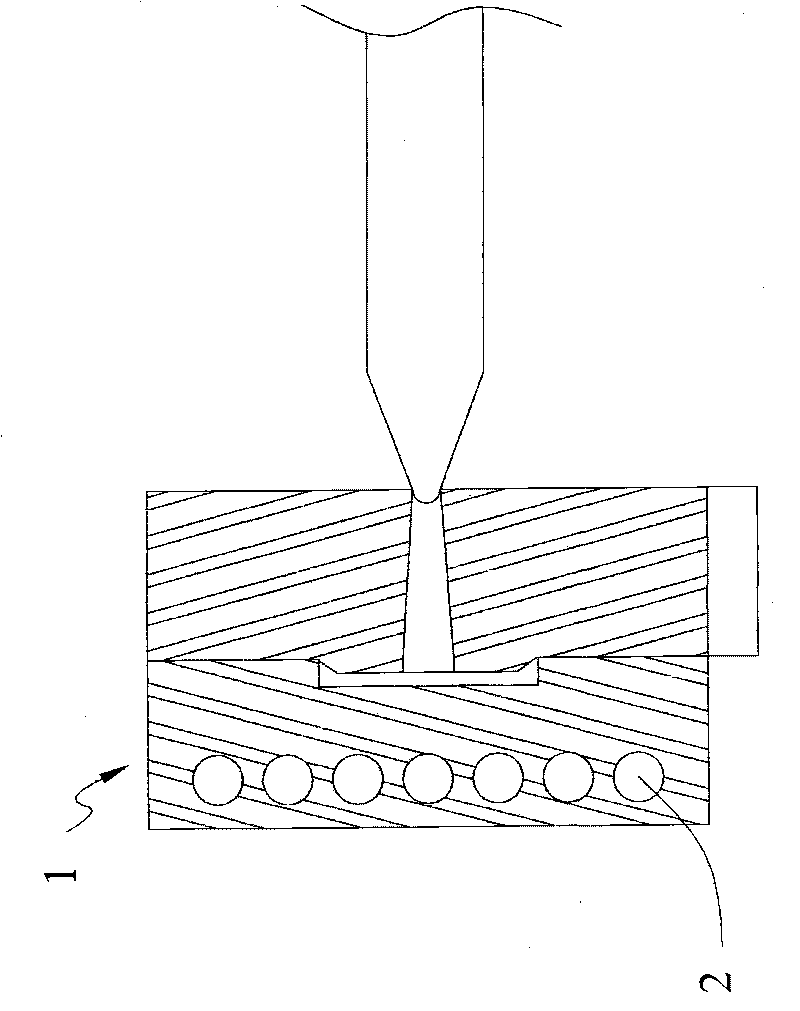

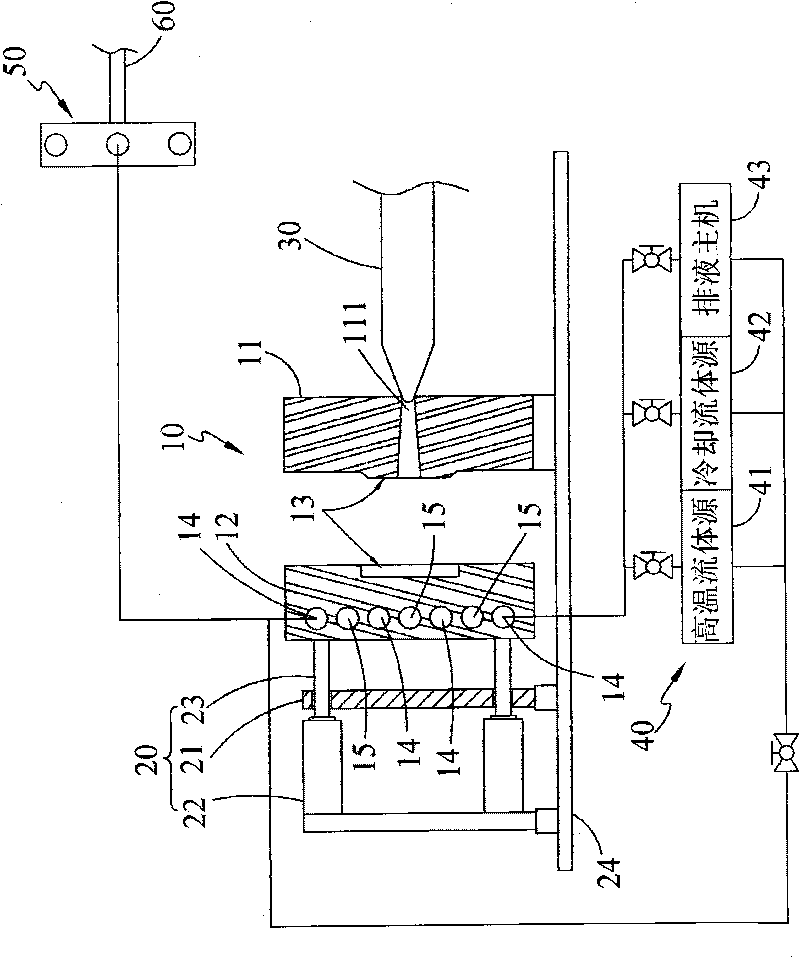

Fast injection molding system

ActiveCN101733915AAvoid heatingNo need to consider the problem of high temperature affecting cooling efficiencyWorking temperatureEngineering

The invention relates to a fast injection molding system, used for manufacturing an injection molding part so as to heat a die by a movable heating element. Before injection liquid is injected into a die cavity of the die, the heating element is moved and contacted with the die, thereby heating the die to a working temperature. After the temperature of the die achieves the working temperature, the heating element is moved and detached from the die so as to enable high temperature of the heating element to continuously heat the die. When a cooling fluid source cools the die, high temperature of the heating element can not influence the cooling efficiency. Because the heating element can not influence the subsequent cooling process, the heating power of the heating element can also be dramatically promoted, thereby accelerating the velocity of injection molding.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

Injection mold provided with cooling mechanism and used for producing mobile phone shell

InactiveCN111300778AAvoid wastingUniform cooling forming operationDomestic articlesCooling effectProcess engineering

The invention discloses an injection mold provided with a cooling mechanism and used for producing a mobile phone shell, relates to the field of production of mobile phone shells and aims to solve theproblem that the cooling effect is poor when an existing injection mold for mobile phone shell production finishes injection molding. According to the scheme, the injection mold comprises a cooling box and an injection mold body, wherein the injection mold body is mounted in the cooling box; a feeding pipe is arranged at the top end of the injection mold body; a U shaped mounting rack is fixedlyconnected with the top end of the cooling box; aggregating boxes are fixedly mounted between the inner walls on the two sides of the mounting rack; and an injection molding box is fixedly mounted between the two aggregating boxes. The injection mold is novel in structure, can inject quantitative raw material in the injection mold body to avoid material waste, and can carry out uniform cooling forming operation on the injection molding raw material in the injection mold body at the same time to shorten the cooling forming time and improve the injection molding efficiency, thereby improving themobile phone shell production efficiency and being suitable for popularization.

Owner:龙门县华信高新科技有限公司

High-precision and high-efficiency injection molding machine

The invention provides a high-precision and high-efficiency injection molding machine. The high-precision and high-efficiency injection molding machine comprises a machine body and further comprises amovable mold plate, a fixed mold plate and an injection mechanism. A plurality of pull rods are mounted between the movable mold plate and the fixed mold plate. A combined contracting brake mechanismcorresponding to the pull rods is mounted on the movable mold plate. A nitrogen auxiliary injection device connected with the injection mechanism is mounted at the side end of the machine body. During mold closing, the combined contracting brake mechanism locks the pull rods. the combined contracting brake mechanism comprises a contracting brake cylinder and a plurality of mold locking pistons. The contracting brake cylinder is connected with one mold locking piston. A piston linkage connecting rod is eccentrically hinged between the two adjacent mold locking pistons. The high-precision and high-efficiency injection molding machine provided by the invention is high in mold replacing speed, good in combined mold locking effect and high in reliability and safety coefficient. The whole high-precision and high-efficiency injection molding machine is high in starting speed, stable in injection rate, high in repeating precision, large in mold containing space, high in production efficiencyand stable and reliable in operation.

Owner:宁波力松注塑科技有限公司

Refrigerator drawer injection mold

The invention discloses a refrigerator drawer injection mold. The refrigerator drawer injection mold comprises a fixed bottom plate and a movable top plate. Guide columns are welded to the four corners of the fixed bottom plate correspondingly. The movable top plate is movably mounted on the four guide columns. A lower mold body is arranged on the fixed bottom plate. An injection mold cavity is formed in the middle of the lower mold body. A first storage groove is formed in the center of the bottom of the injection mold cavity. A top extension plate is movably mounted in the first storage groove. A piston rod of a top extension air cylinder is fixedly connected with the bottom of the top extension plate. The top extension air cylinder is fixedly mounted to the outer side of the bottom of the fixed bottom plate. An upper mold body is arranged at the position, over the lower mold body, of the movable top plate. An inner mold body is arranged at the position, close to the lower mold body,of the upper mold body. The refrigerator drawer injection mold is novel in design, simple in structure and convenient to use, products can be demolded rapidly, deformation and cracking caused by bonding of the products and the mold are avoided, and the injection efficiency of the mold is improved.

Owner:滁州市润达机械科技有限公司

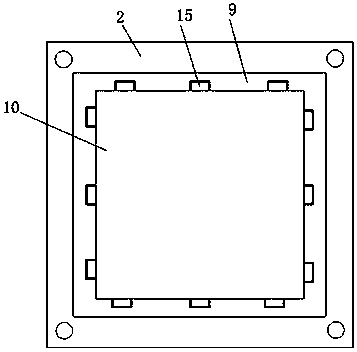

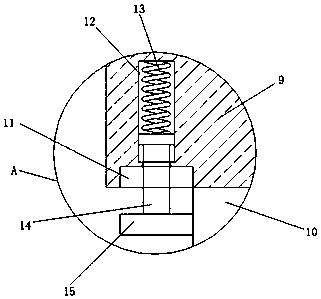

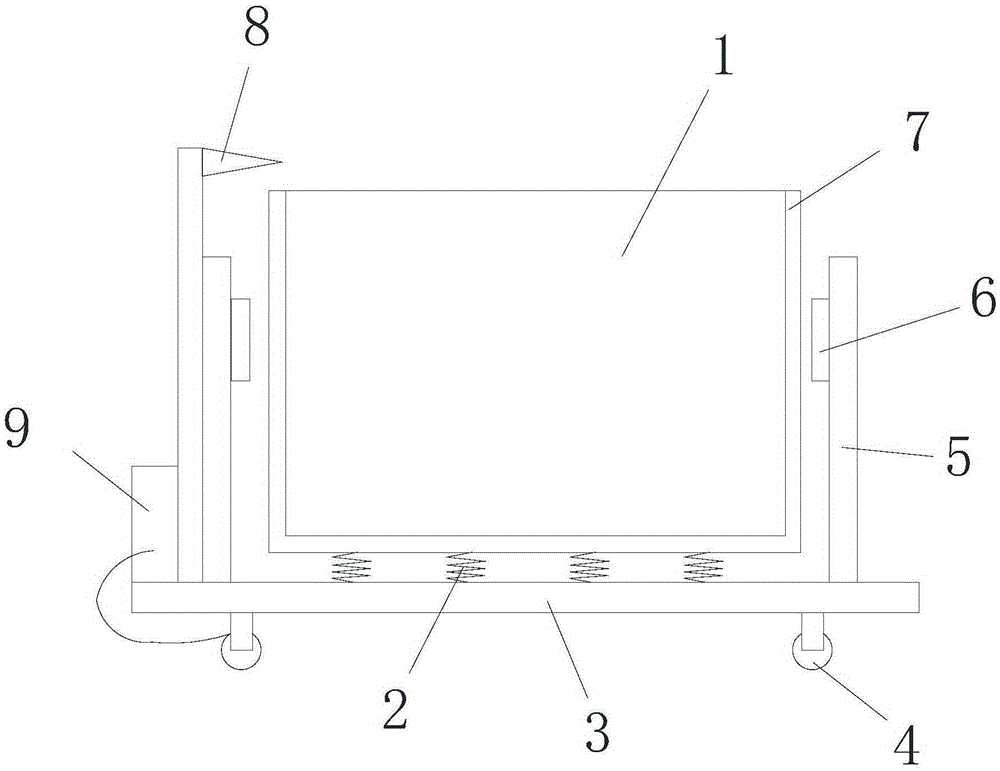

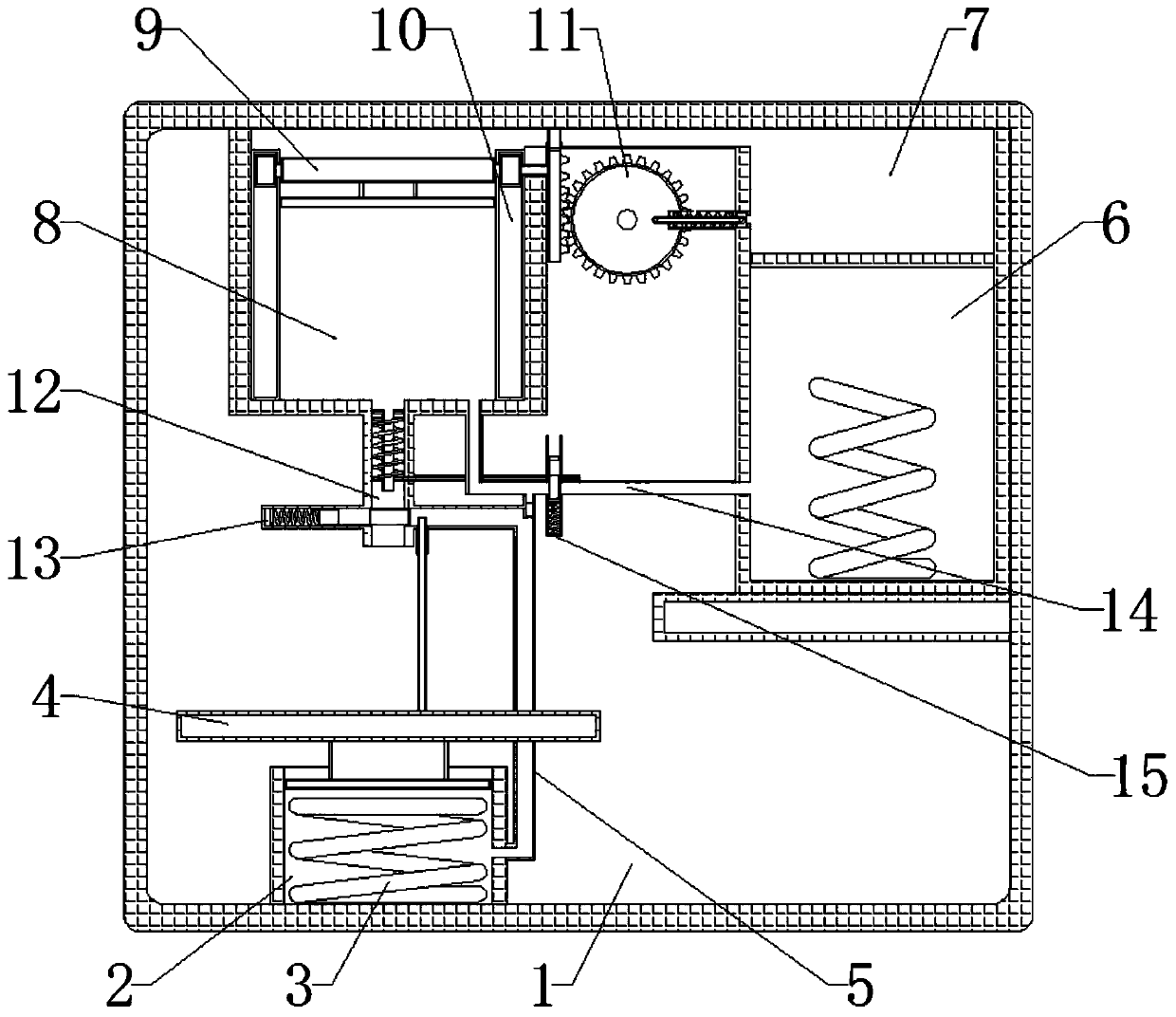

Automatic collection device for injection products

The invention discloses an automatic collection device for injection products. The automatic collection device comprises a collection box, a base plate and a plurality of springs, wherein one end of each of the multiple springs is detachably arranged on the bottom end face of the collection box at intervals, and the other end of each spring is fixedly connected to the top surface of the base plate; sliding rollers are arranged on the bottom surface of the base plate; a supporting column is vertically arranged on the base plate; a sensor is arranged at the top end of the supporting column, is electrically connected with driving equipment, and can sense the injection product falling into the collection box and switch on the driving equipment to drive the sliding rollers to roll; meanwhile, a timer connected with the sensor starts to count the time; and when the timer reaches a preset time value, the driving equipment is switched on so as to drive the sliding rollers to roll towards the opposite direction. The device can uniformly distribute and stack the injection products falling into a plastic box quickly and conveniently, so that damage, which is caused by falling, to the products can be avoided, and the production cost is saved.

Owner:WUHU DEXIN AUTO PARTS

Injection molding device using plastic melting for continuous pressure applying

InactiveCN110900997AControl the effect of plastic fillingReduce generationInjection molding machineMechanical engineering

The invention relates to the technical field of plastic processing, and discloses an injection molding device using plastic melting for continuous pressure applying. The injection molding device comprises a processing machine, the bottom of the interior of the processing machine is fixedly connected with an air pressure base, the interior of the air pressure base is movably connected with a returnspring, an injection molding table is movably connected above the return spring, an air pipe is movably connected to the right side of the air pressure base, a plastic melting machine is movably connected to the upper right portion of the interior of the processing machine, a pressurizing chamber is movably connected above the plastic melting machine, and an injection molding machine is movably connected to the upper left portion of the interior of the processing machine. When a locking lever is moved out of a plastic filling valve, a plastic filling slider moves upwards under the elastic force effect of the plastic filling spring, a plastic filling tube is blocked, and plastic filling is prevented from being continuously carried out, so that the effect of controlling plastic filling of the plastic filling tube is achieved, and the condition that plastic filling is carried out in the process of avoiding plastic filling, and consequently melted plastic flows back into the plastic melting machine is avoided.

Owner:陆聆聆

Device and method for manufacturing plaster mold

InactiveCN105599118AImprove production efficiencyImprove injection molding efficiencyMouldsMould fastening meansCeramicManufacturing efficiency

The invention discloses a device and method for manufacturing a plaster mold. The device comprises a mold core, a mold sleeve sleeving the mold core, a chassis and a banding device, wherein a molding cavity is formed between the mold sleeve and the mold core, both the bottom of the mold sleeve and the bottom of the mold core are fixed on the chassis, a longitudinal opening is formed in the mold sleeve from the axial direction of the mold core, and the banding device is used for banding the mold sleeve. The method sequentially comprises the steps of smearing a mold releasing agent, assembling the device for manufacturing the plaster mold, blocking up periphery gaps of the device for manufacturing the plaster mold, preparing calcium plaster, and molding the plaster mold. By using the device and the method, the manufacturing efficiency of the plaster mold can be increased, the use level of plaster powder can be lowered, and the manufactured plaster mold can be used for greatly increasing the grouting molding efficiency of ceramics and reducing subsequent workloads of production of the ceramics.

Owner:湖北朗驰新型材料有限公司

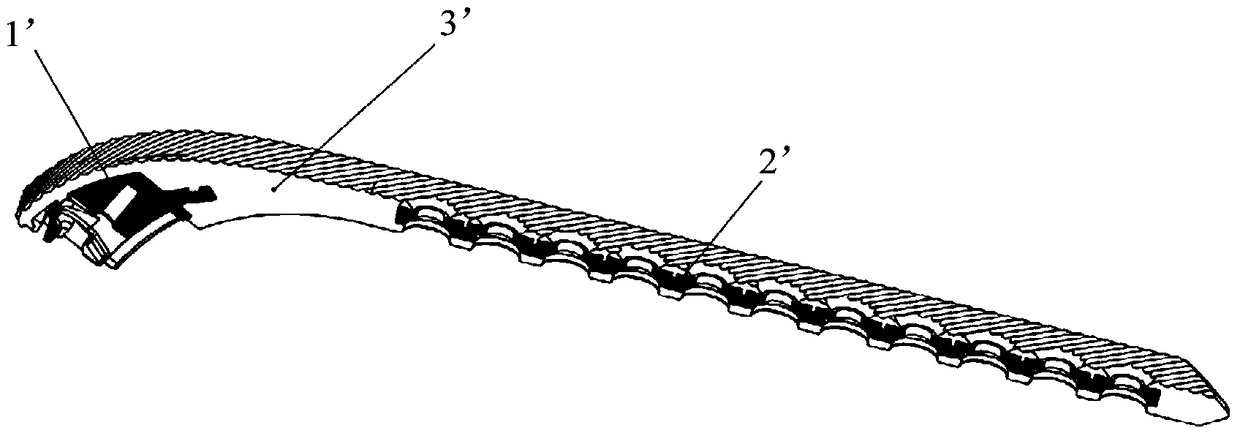

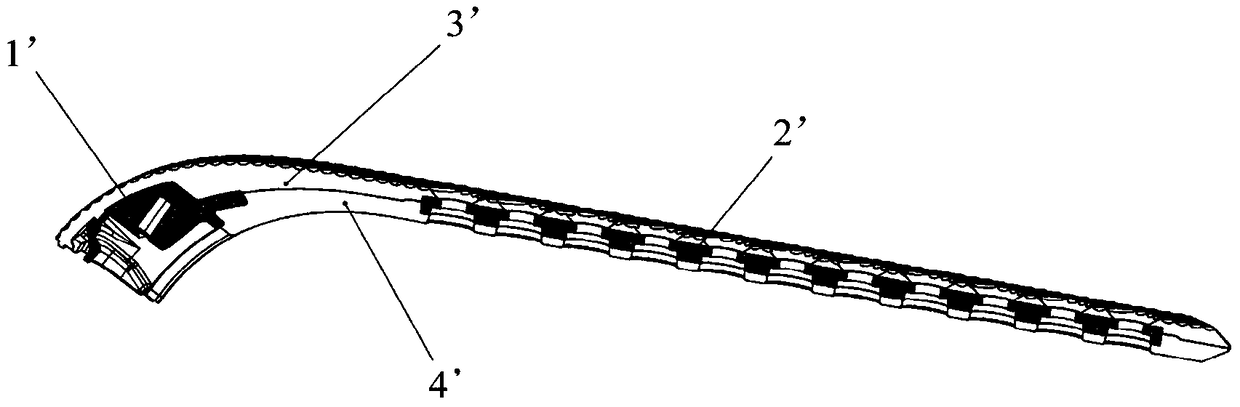

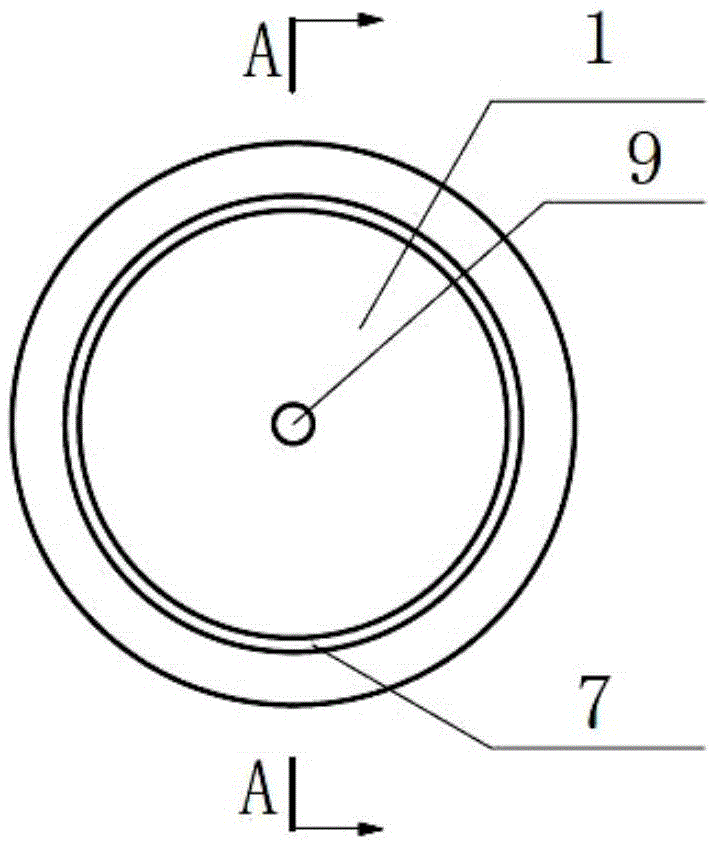

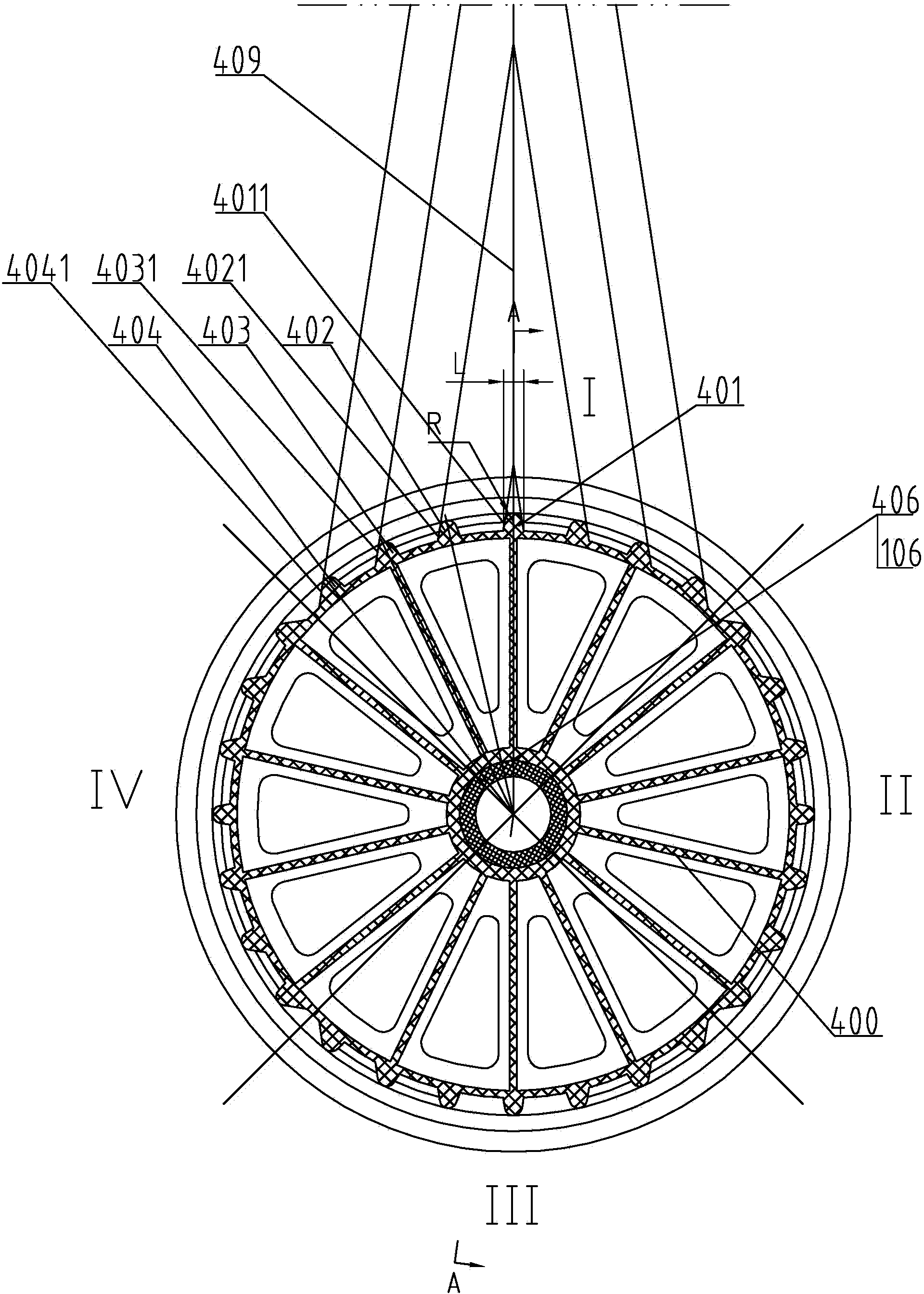

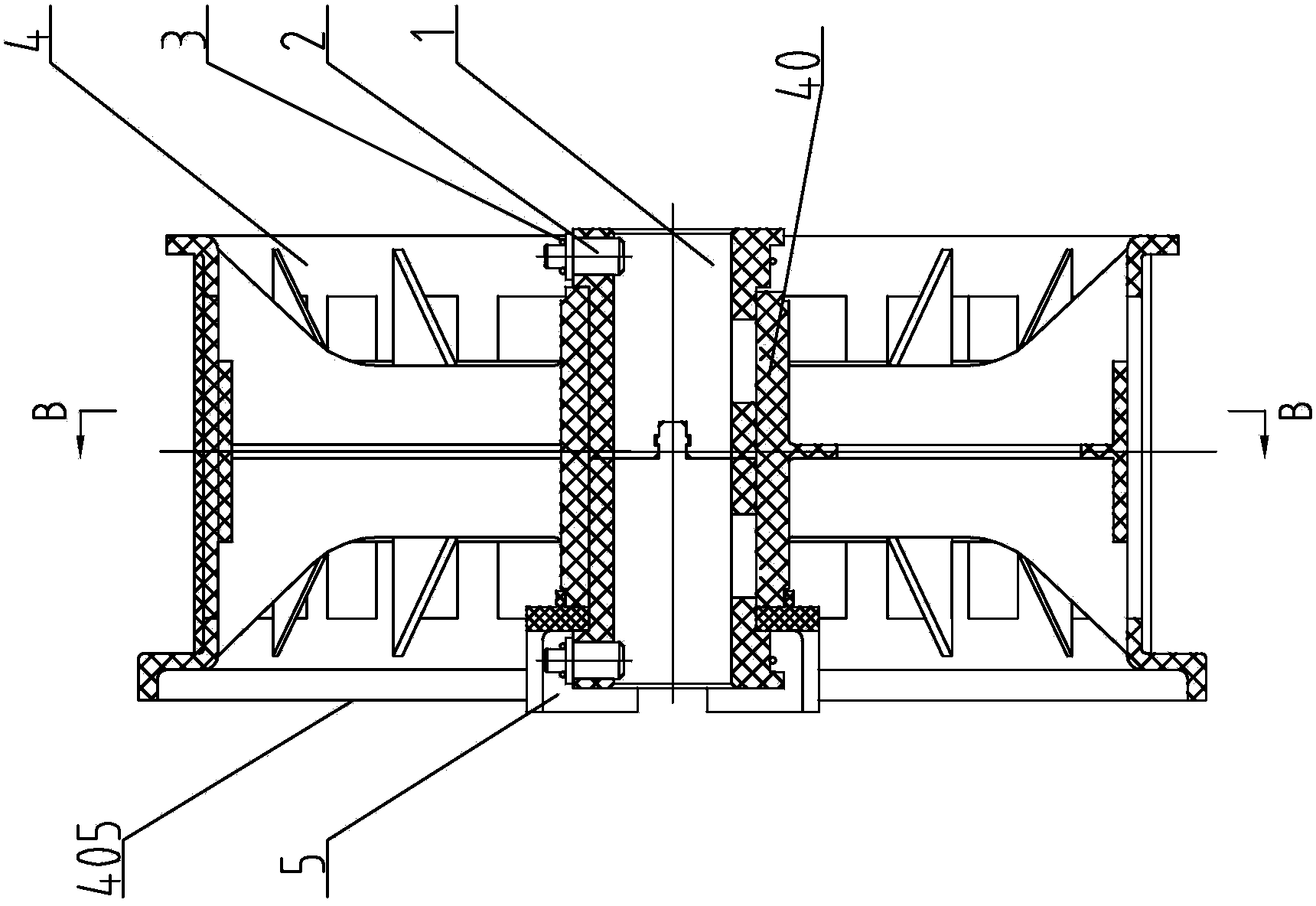

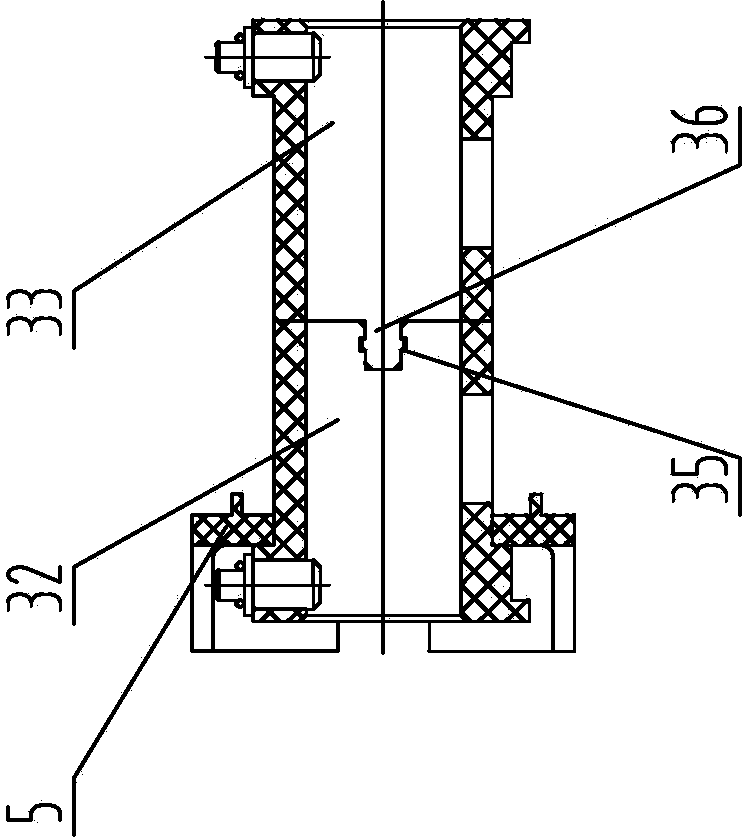

Combined type small reel device

ActiveCN104005101AGuarantee working reliabilityDimensionally stableSilk reelingEngineeringOuter Cannula

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com