Combined type small reel device

A combined and assembled technology, applied in the direction of silk reeling, etc., can solve the problems of complex overall structure, scrapping of small units, and increase of enterprise use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

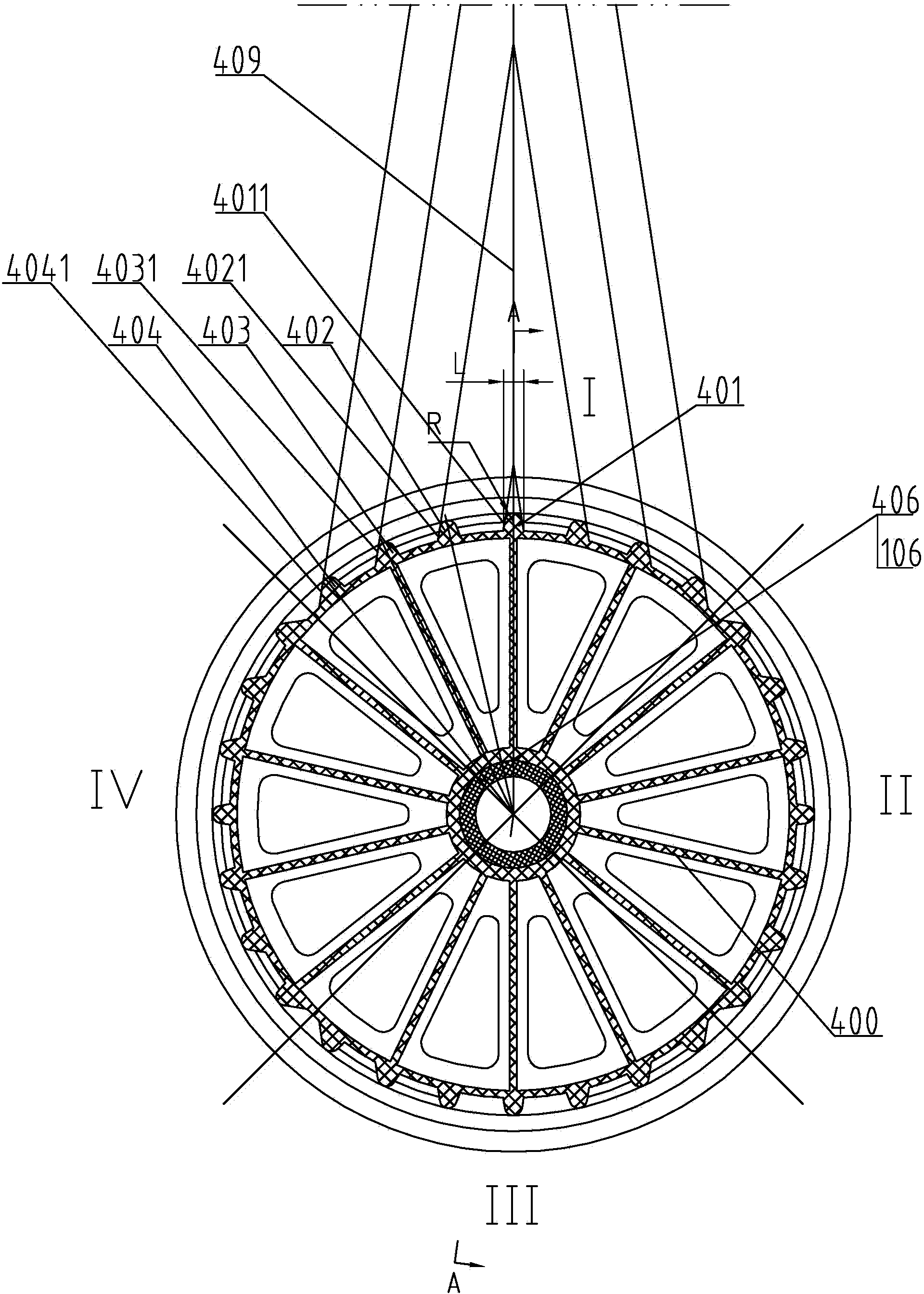

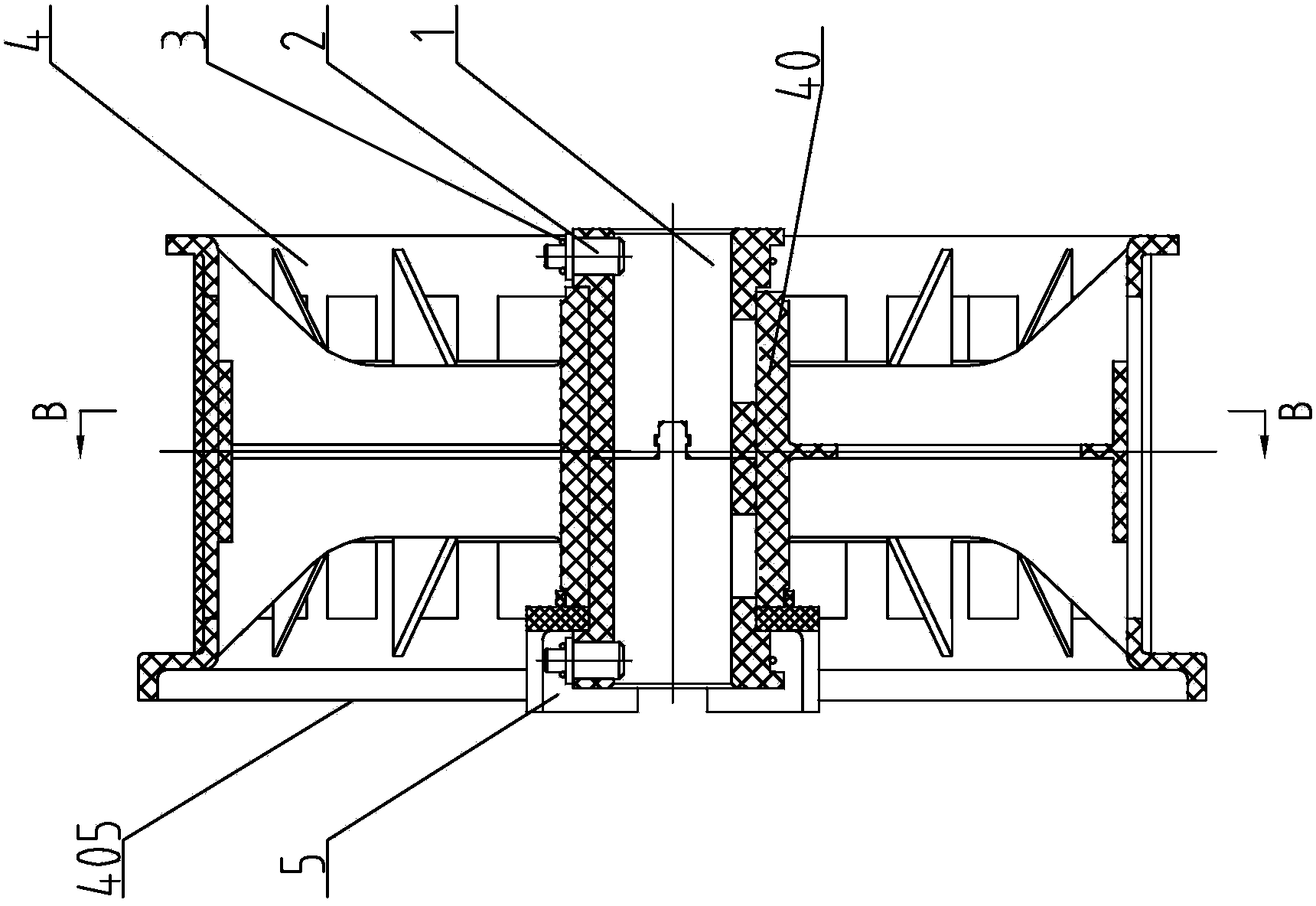

[0033] Embodiment 1, with reference to attached Figure 1-8 .

[0034] Refer to attached picture. A combined small valve device provided by the present invention includes a small valve 4, the center of the small valve has an outer sleeve 40, and the small valve device also has an inner shaft sleeve assembly 1, and the outer sleeve 40 is sleeved on the inner shaft Outside the sleeve assembly 1, the aperture of the inner shaft sleeve assembly 1 is matched with the small shaft, so that the inner shaft sleeve assembly 1 can allow the small shaft to pass through, and the inner shaft sleeve assembly 1 and the outer sleeve 40 can be Detachable connection and synchronous rotation, the inner shaft sleeve assembly 1 has a friction part, and the friction part is used to generate friction fit with the small shaft, so that the inner shaft sleeve assembly 1 can be driven by the small shaft by virtue of the friction fit Drive the rotation and then drive the small yoke 4 to rotate, and can ...

Embodiment 2

[0045] Embodiment 2, with reference to attached figure 1 , 3 -4, 9-14.

[0046] In this embodiment, the structure of the small yoke is the same as that of Embodiment 1, but the inner sleeve assembly adopts another embodiment, which has two left and right sleeves 1a.

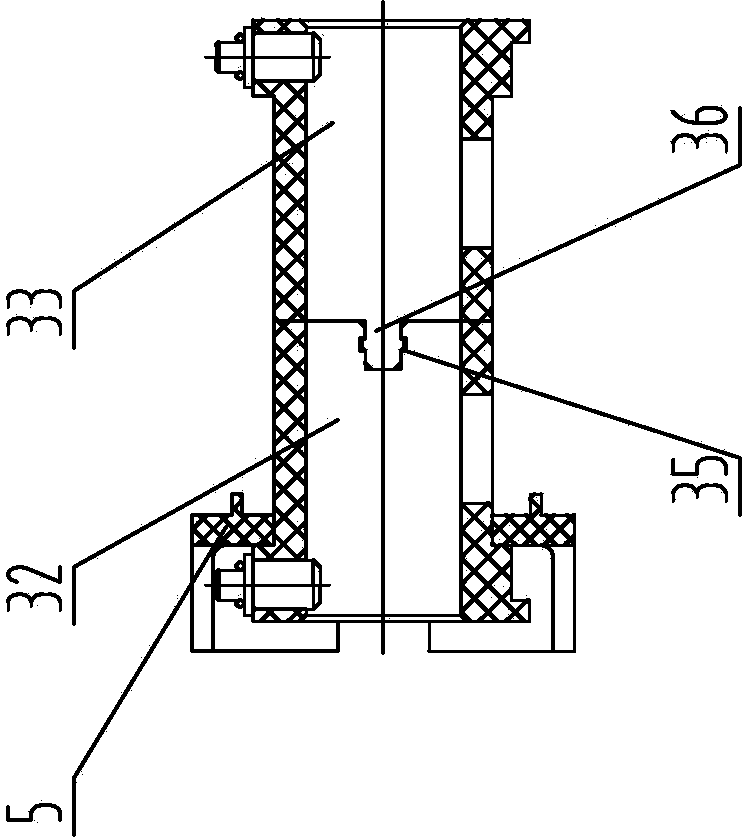

[0047] Such as Figure 9 As shown, the sleeve body 1a of the inner shaft sleeve assembly pressed in left and right symmetrically in the outer sleeve 40 of Xiaoyu 4, the sleeve body 1a is provided with a friction pin 2, and the outside of the friction pin 2 is pressed by a spring 3, and the friction pin 2 The inside protrudes through the sleeve body 1a, and frictionally fits with the small yoke shaft (the matching effect is the same as that of embodiment 1), so as to drive the small yoke 4 to rotate. At the same time, it also cooperates with Xiaoyu 4 as an axial positioning component of the inner shaft sleeve assembly.

[0048] On the outer circle of the sleeve body 1a, there are inner sleeve circumferential p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com