Screen printing device for storage battery packaging line

A technology of screen printing device and storage battery, which is applied to screen printing machines, printing machines, printing machines, etc., which can solve the problems of screen cleaning and disassembly restrictions, unreliable clamping mechanism, and decline in screen printing quality, so as to achieve increased space and work efficiency. Guaranteed reliability and fast driving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below through specific examples.

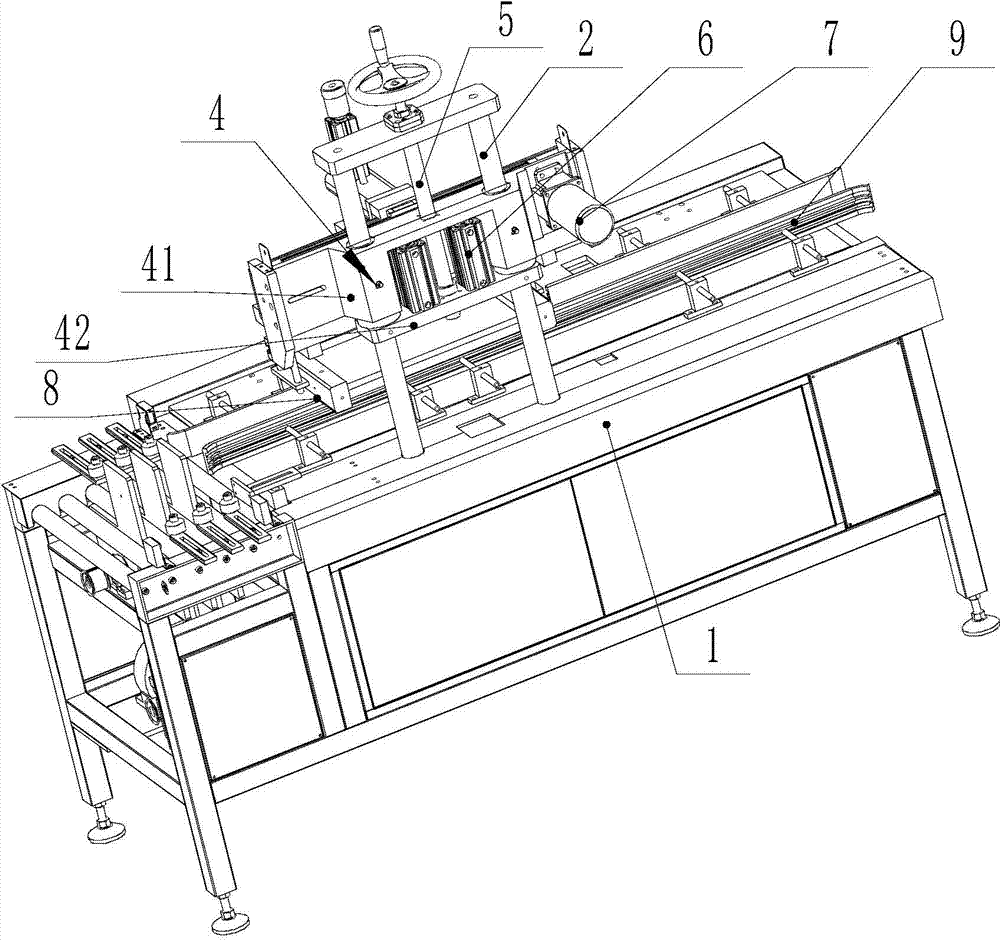

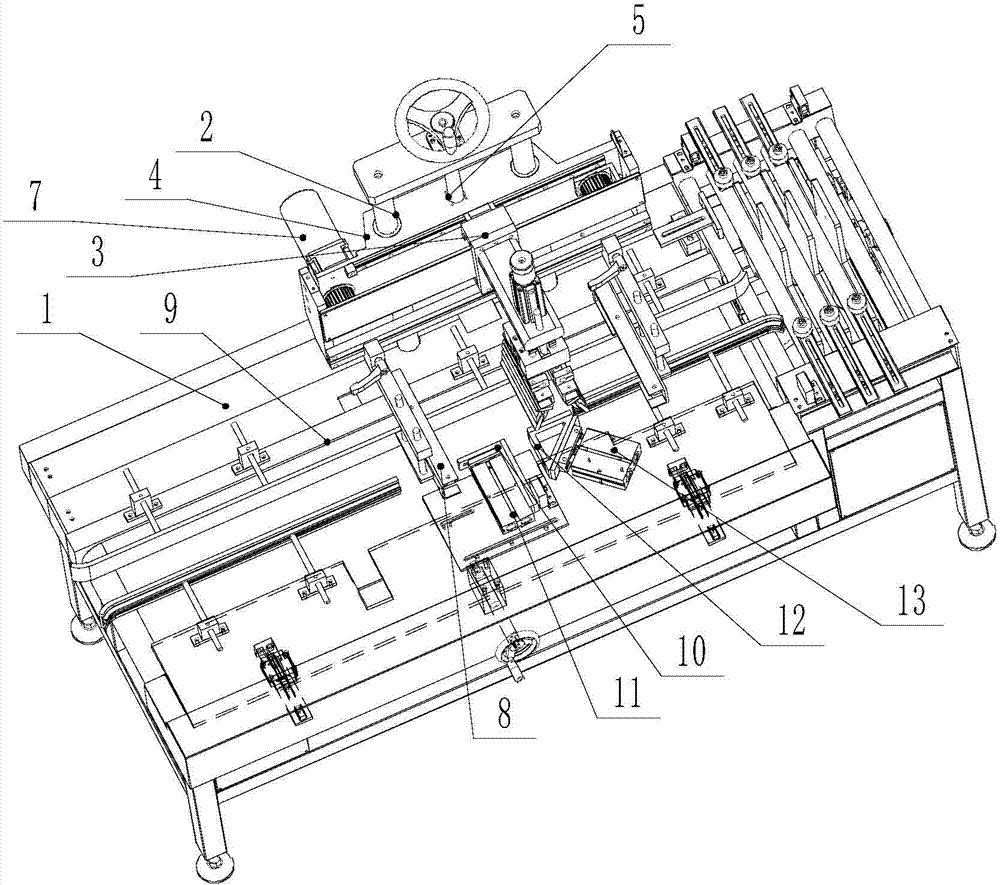

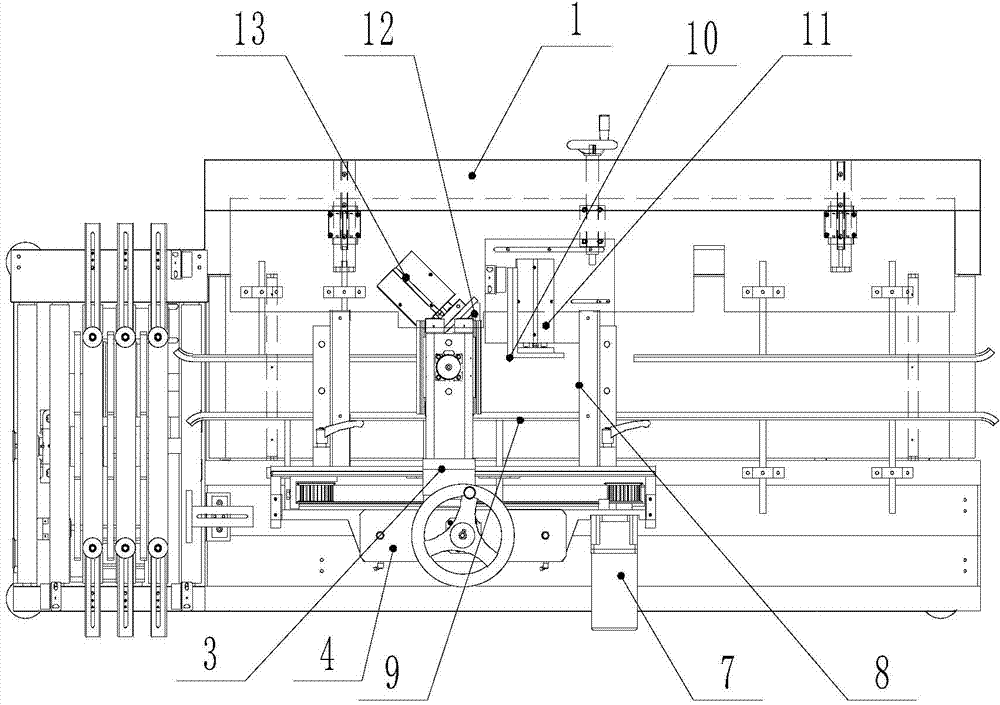

[0020] like figure 1 , 2 As shown in .3, a screen printing device on a storage battery packaging line includes a frame 1 on which a column 2 is fixed. The vertical sliding seat 4 on the top, the vertical sliding seat 4 includes a bottom plate 42 slidably installed on the column 2, a sliding seat body 41 vertically slidably installed on the column 2, and the sliding seat body 41 is located above the bottom plate 42 The bottom plate 42 is connected with the first vertical adjustment mechanism installed on the frame 1, the first vertical adjustment mechanism is a screw nut mechanism 5, and the top of the leading screw is equipped with an adjustment handwheel, and the slide body 41 and the base plate 42 are connected by a second vertical adjustment mechanism 6, which can drive the slide body 41 to vertically lift relative to the base plate 42; the horizontal slide mounted on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com