Device and method for manufacturing plaster mold

A gypsum mold and mold sleeve technology, applied in mold fixtures, molds, manufacturing tools, etc., can solve problems such as deformation of ceramic products, and achieve the effect of reducing dosage and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

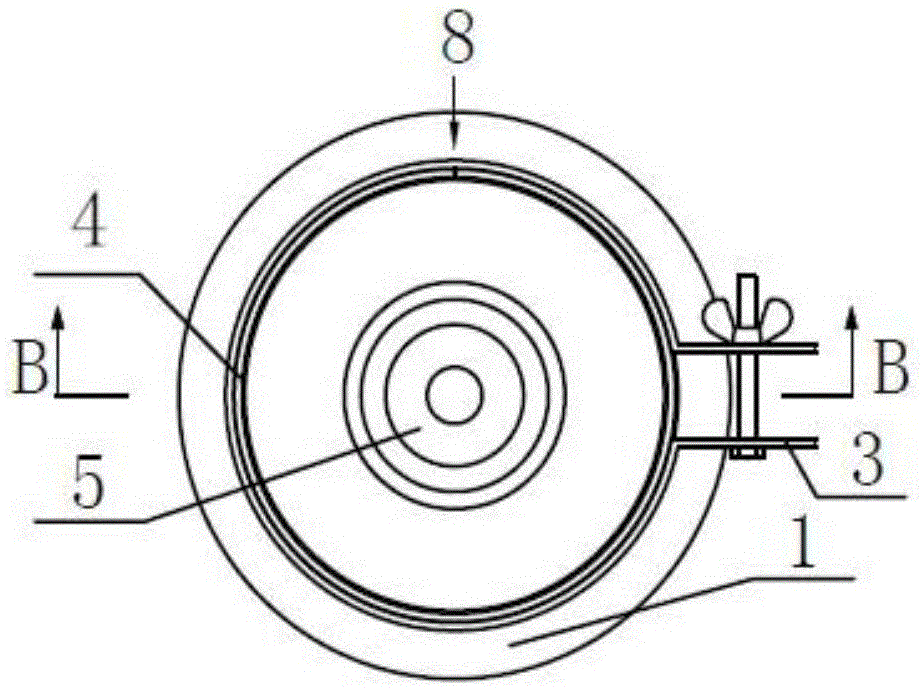

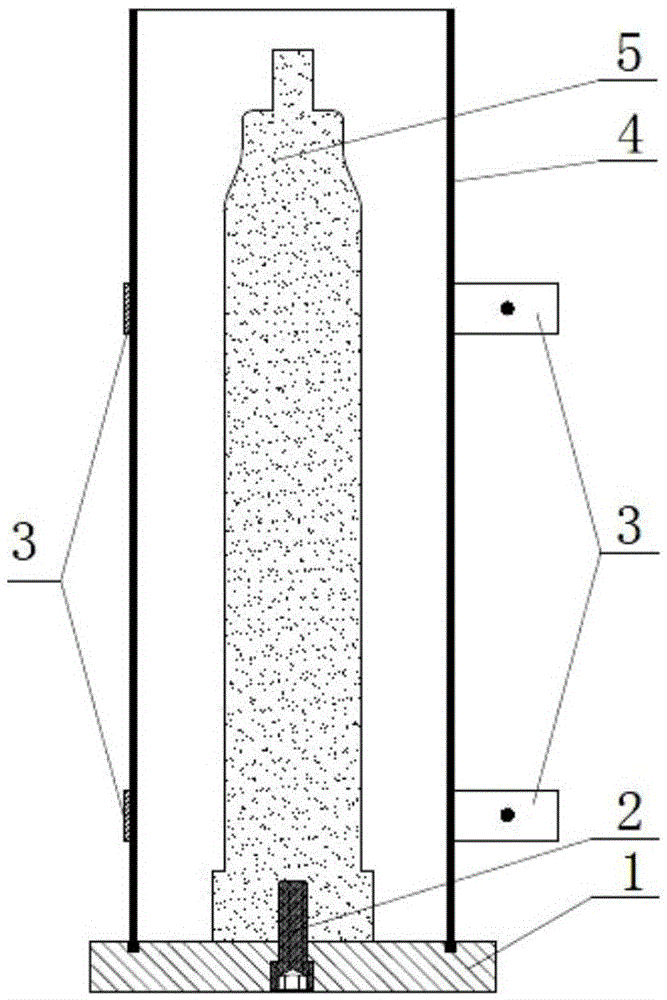

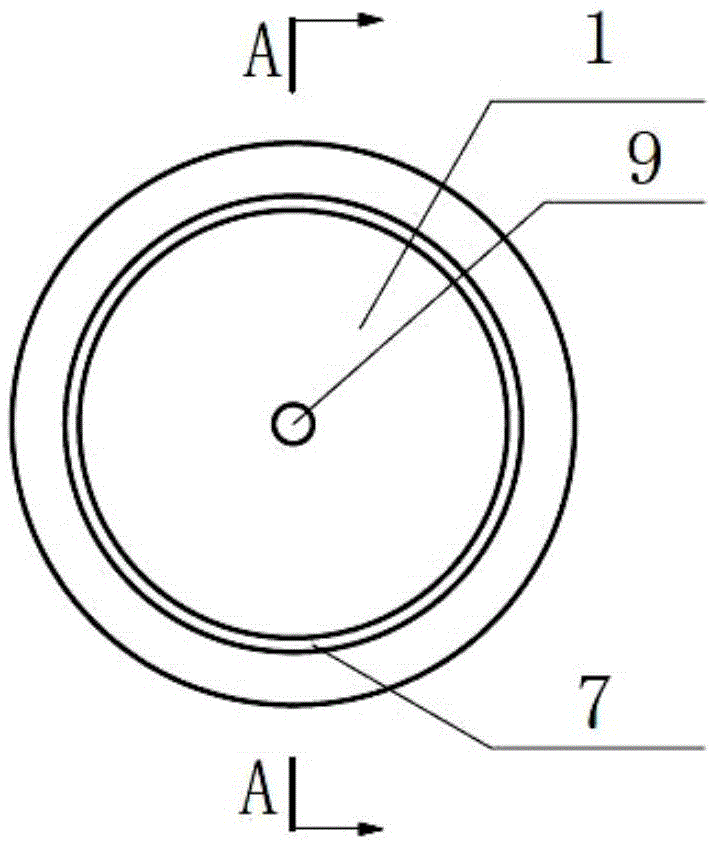

[0041] Such as Figure 1 to Figure 7 As shown, it is a device for making plaster molds provided by the embodiment of the present invention, which includes a mold core 5, a mold sleeve 4 sleeved outside the mold core 5, a chassis 1 and a clamping device. There is a molding cavity 31 between the mold cover 4 and the mold core 5 (such as Figure 9 shown). The bottoms of the mold casing 4 and the mold core 5 are all fixed on the chassis 1 . Die cover 4 is provided with a longitudinal opening 8 from the axial direction of mold core (such as Image 6 shown). The clamping device is used for clamping the mold cover 4. Both the inner surface of the mold casing 4 and the outer surface of the mold core 5 are provided with a release agent layer.

[0042] The mold core 5 includes a main body portion and a discharge port forming portion from bottom to top along its axial direction, and the width of the main body portion is greater than that of the discharge port forming portion. The c...

Embodiment 2

[0054] This embodiment is roughly the same as Embodiment 1, the difference is:

[0055] 1) if Figure 10 As shown, the total height of the mold core 19 of this embodiment is 800mm, and its main body includes a first mold core 20, a second mold core 21, and a third mold core 22 connected in sequence from bottom to top along its axial direction. , and the pulp opening forming part 23. The diameter of the first mold core 20 is d 7 . The diameter of the third mold core 22 is d 9 . The diameter of the pulp opening forming part 23 is d 10 . d 7 、d 9 、d 10 is a certain value and d 7 >d 9 >d 1 . The diameter d of the second mold core 21 8 gradually decreases from bottom to top. The maximum diameter of the second core 21 and the diameter of the first core d 7 Same, the minimum diameter of the second mold core 21 is the same as the third mold core diameter d 9 same. The outer wall 20 of the first mold core is provided with external threads.

[0056] 2) According to th...

Embodiment 3

[0059] This embodiment is roughly the same as Embodiment 1, the difference is:

[0060] 1) if Figure 11 As shown, the total height of the mold core 24 of this embodiment is 1100 mm, and its main body includes a first mold core 25, a second mold core 26, and a third mold core 27 connected in sequence from bottom to top along its axial direction. , the fourth mold core 28 and the slurry opening forming part 29 . The diameter of the first mold core 25 is d 11 . The diameter of the second mold core 26 is d 12 . The diameter of the fourth mold core 28 is d 14 . The diameter of the pulp opening forming part 2329 is d 15 . d 11 、d 12 、d 14 、d 15 is a certain value and d 11 >d 12 >d 14 >d 15 . The diameter d of the third mold core 27 13 gradually decreases from bottom to top. The maximum diameter of the third core 27 and the second core diameter d 12 Same, the minimum diameter of the third mold core 27 is the same as the fourth mold core diameter d 14 same. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com