Patents

Literature

1329results about "Mould fastening means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

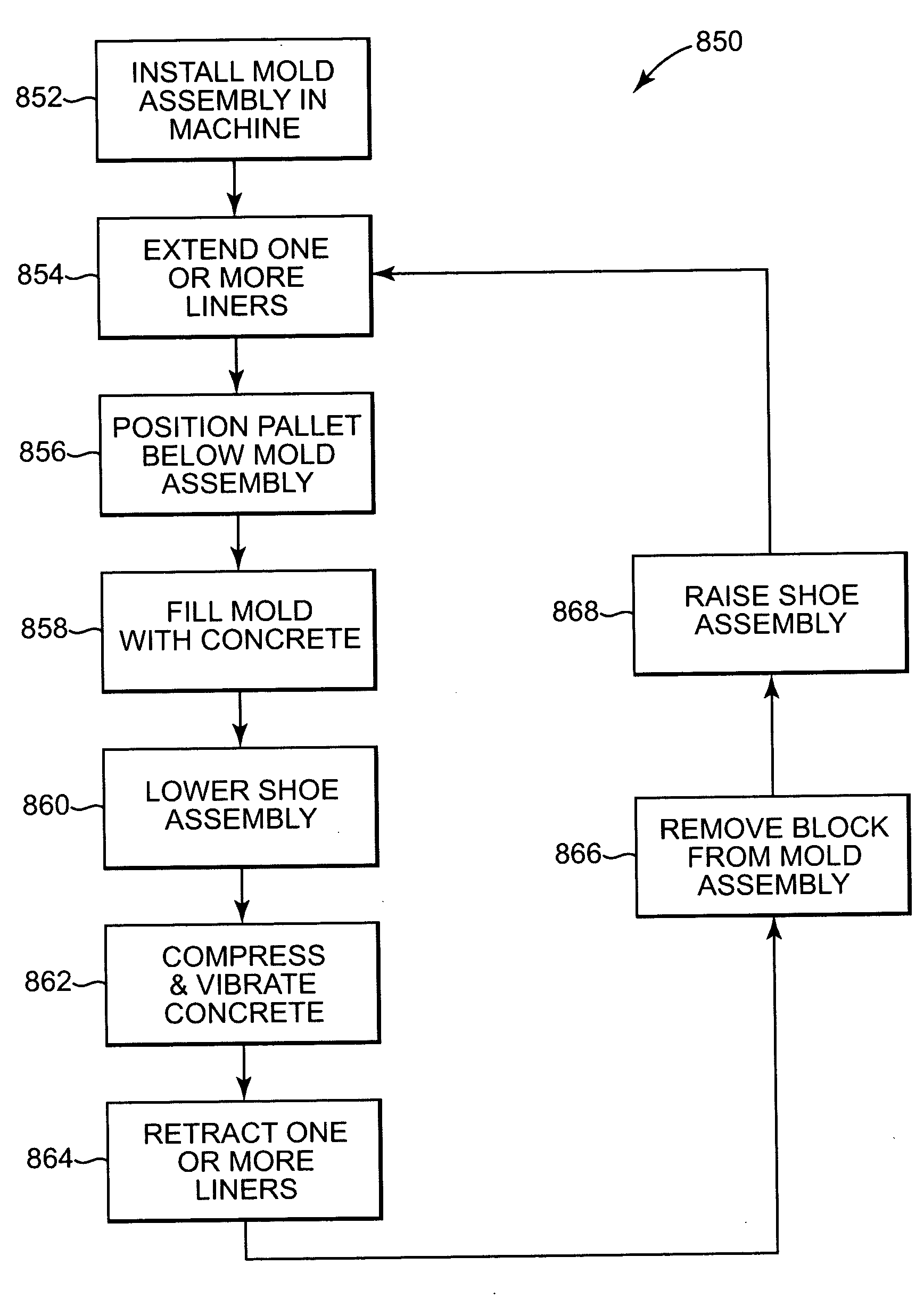

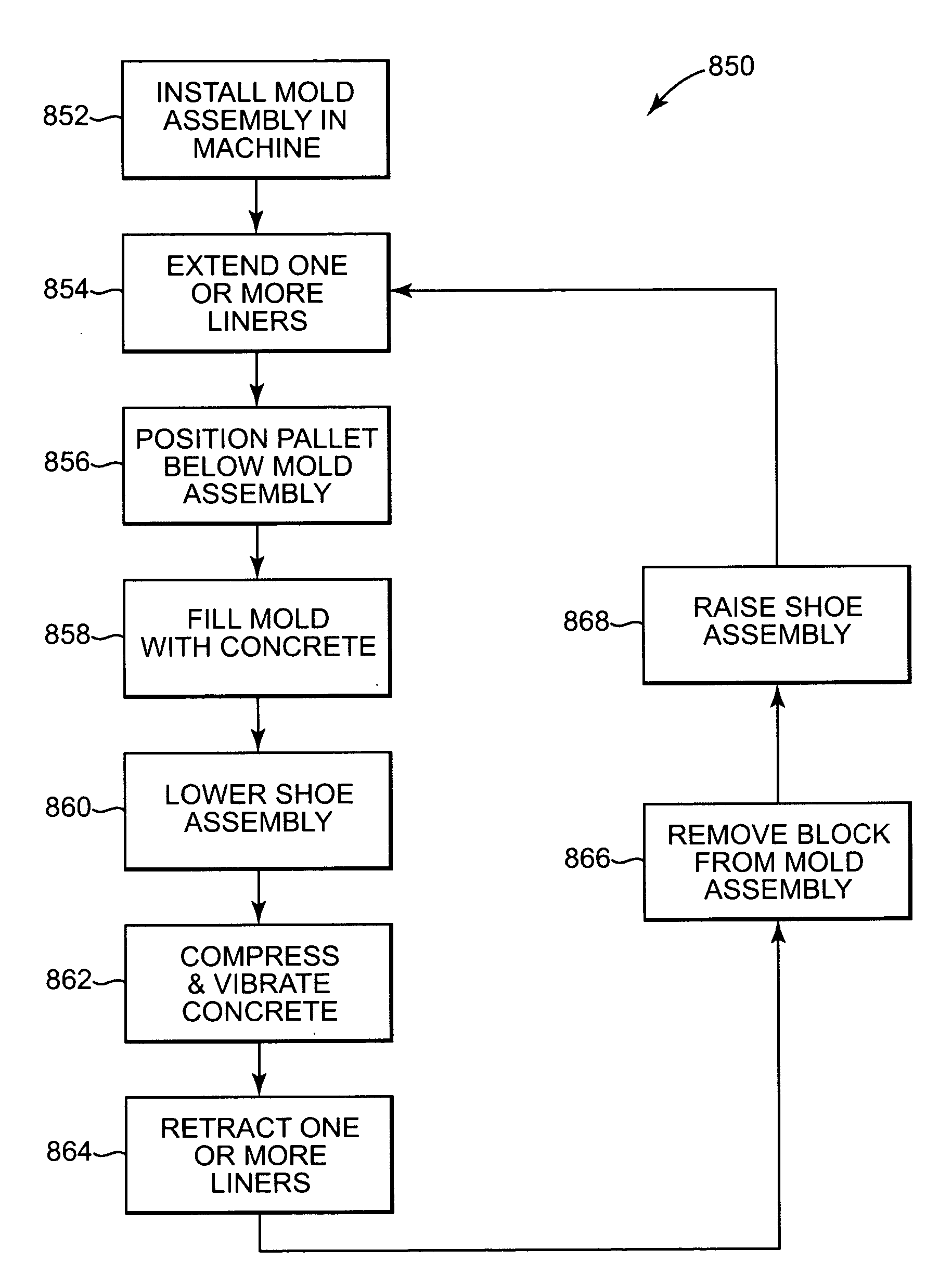

Masonry blocks and method and system of making masonry blocks

A method of producing a masonry block including providing a mold assembly having a plurality of liner plates that together form a mold cavity having an open top and an open bottom, wherein at least one of the liner plates is moveable between a retracted position and a desired extend position relative to an interior of the mold cavity with a gear drive assembly. The at least one moveable liner plate is moved to the desired extended position, the bottom of the mold cavity is closed with a pallet, dry cast concrete is placed in the mold cavity via the open top, the top of the mold cavity is closed with a moveable head shoe assembly, and the dry cast concrete is compacted to form a pre-cured masonry block. The at least one moveable liner plate is moved to the retracted position, the pre-cured masonry block is expelled from the mold cavity and cured.

Owner:NESS INVENTIONS

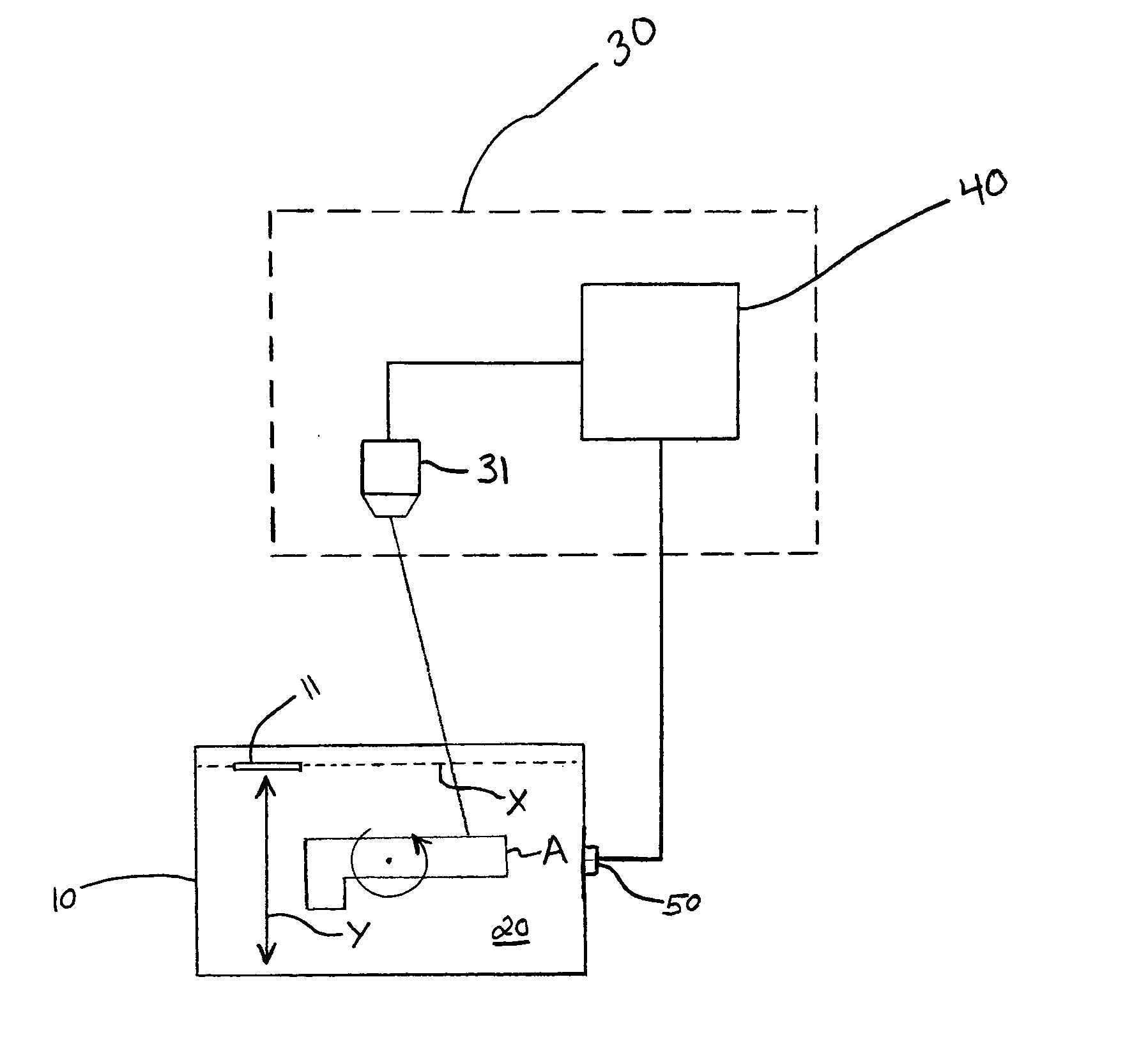

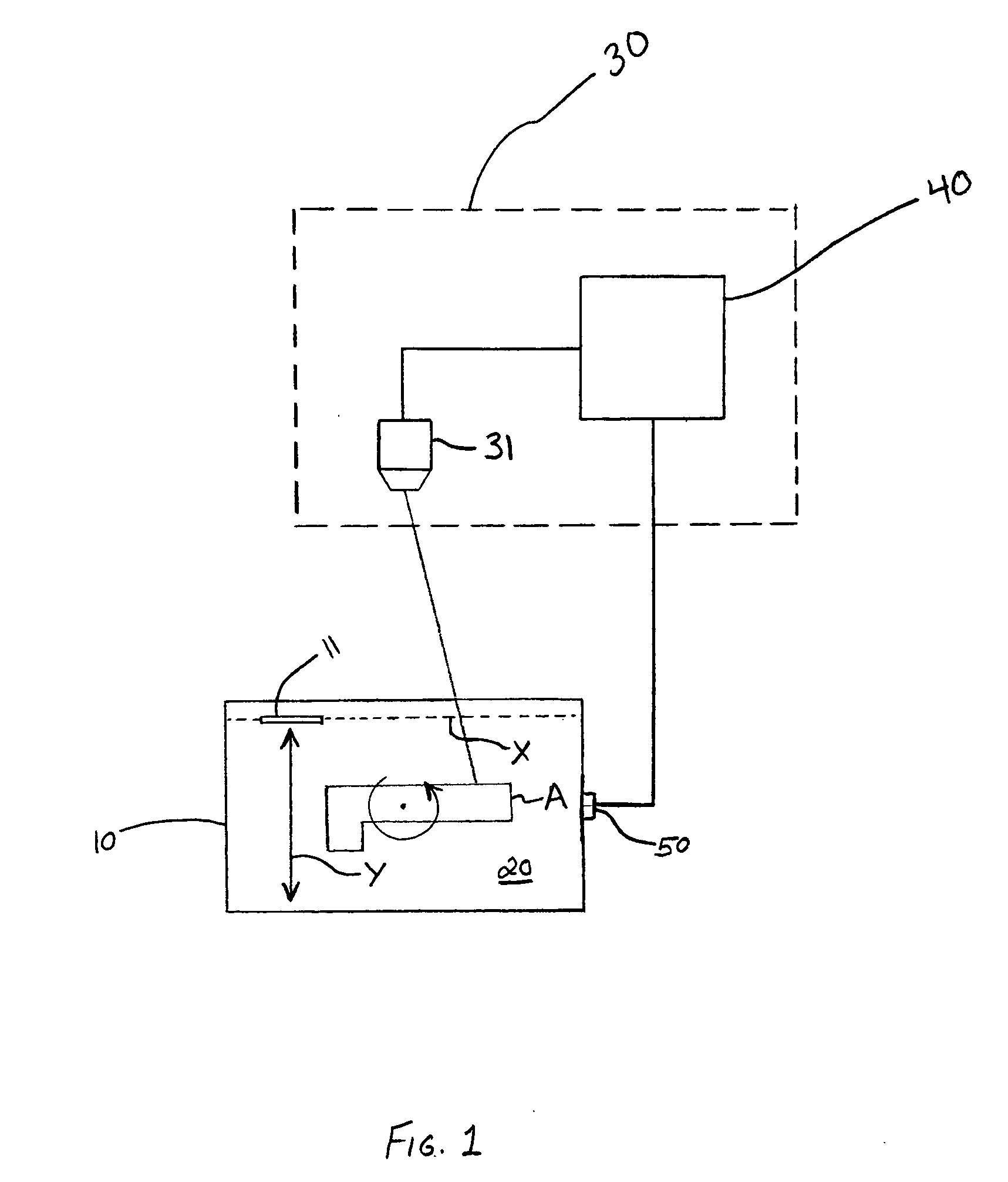

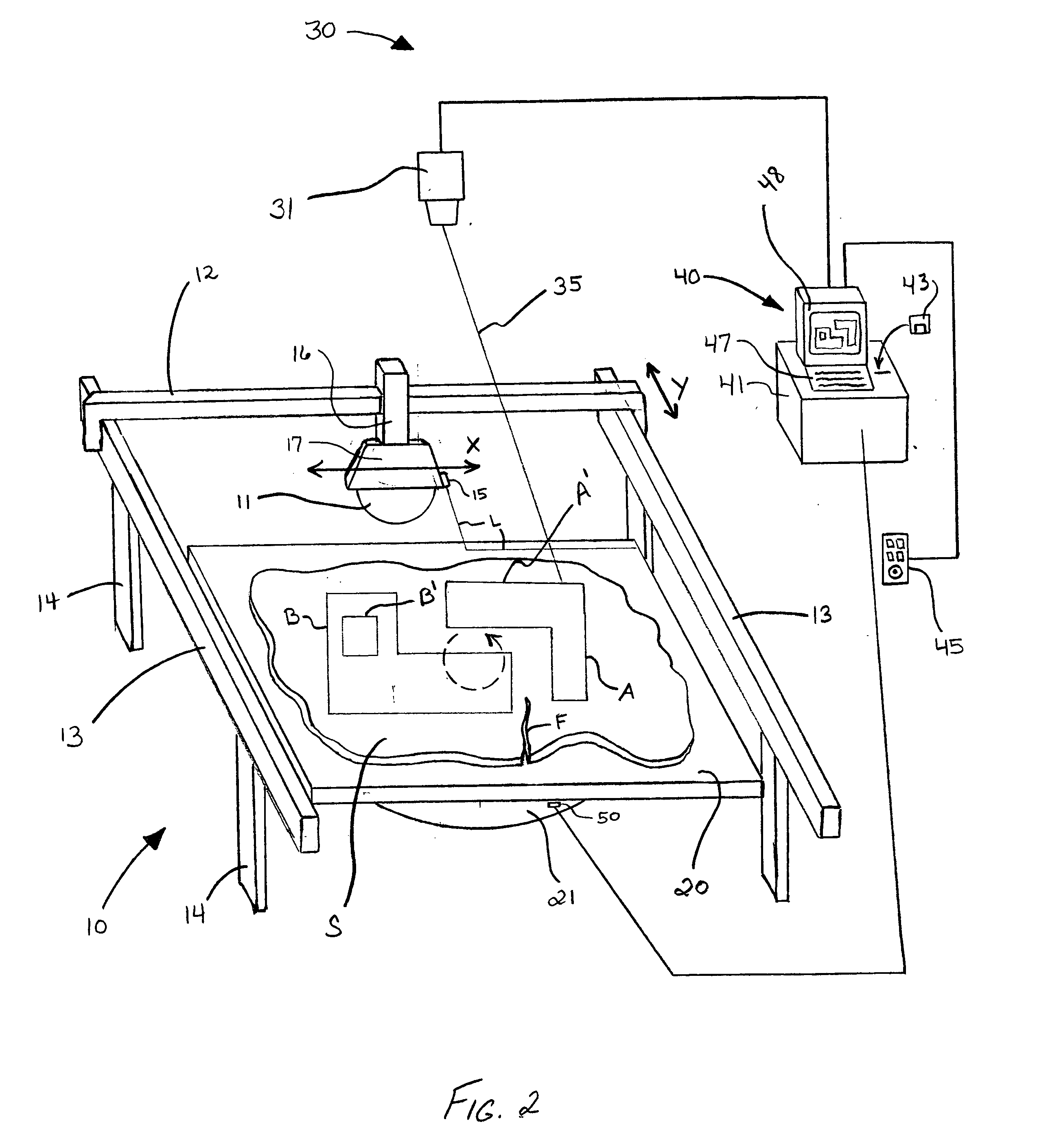

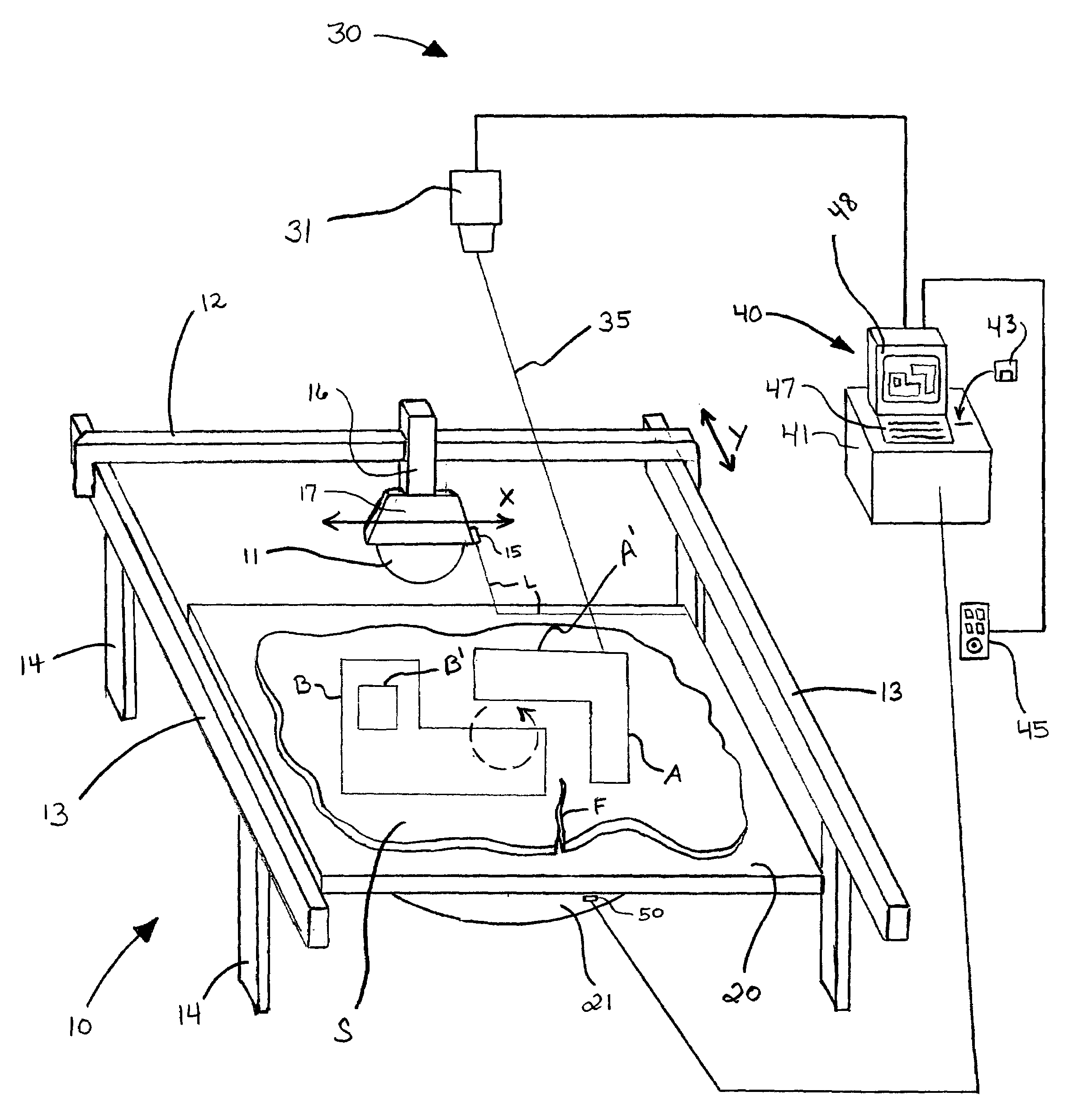

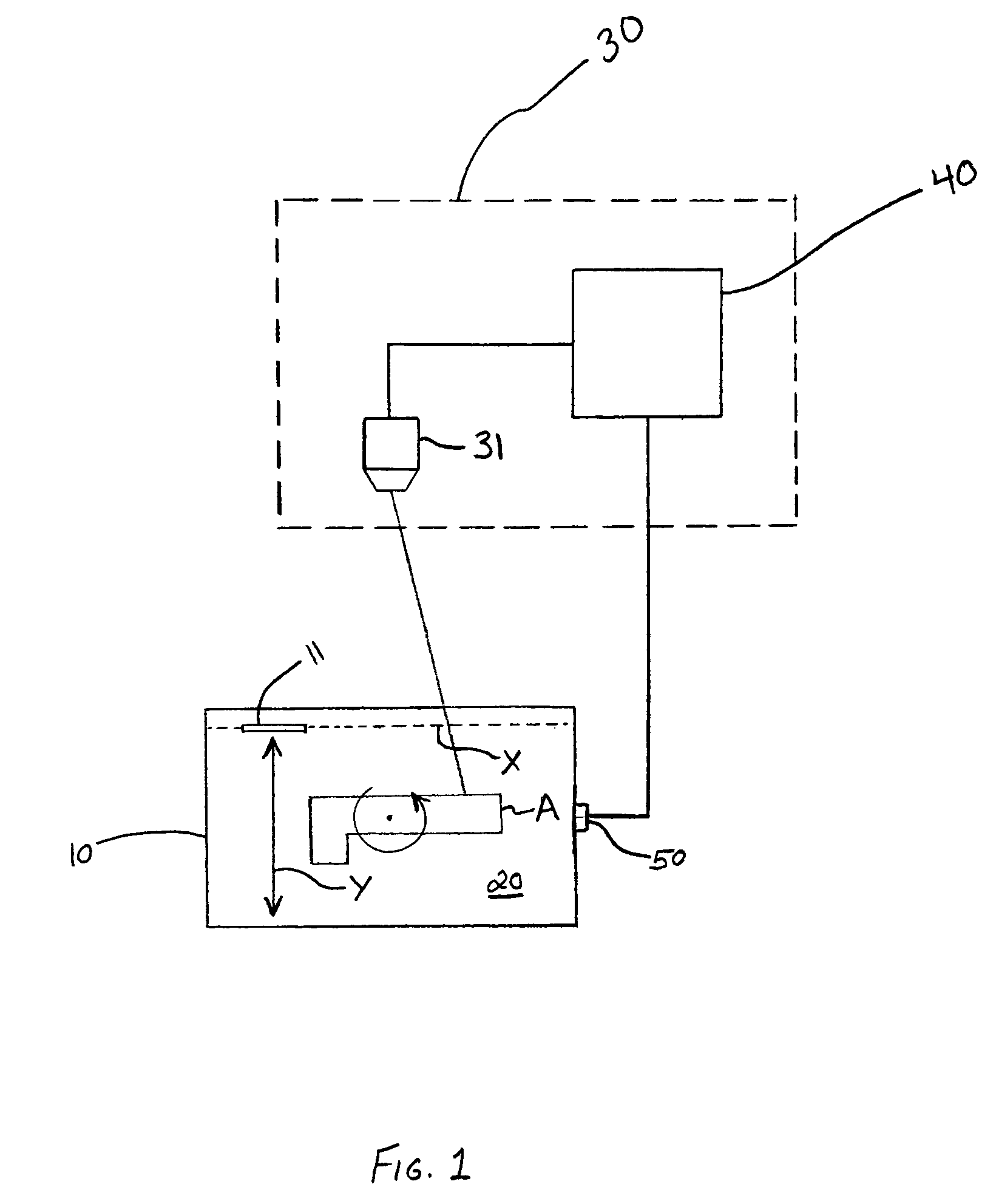

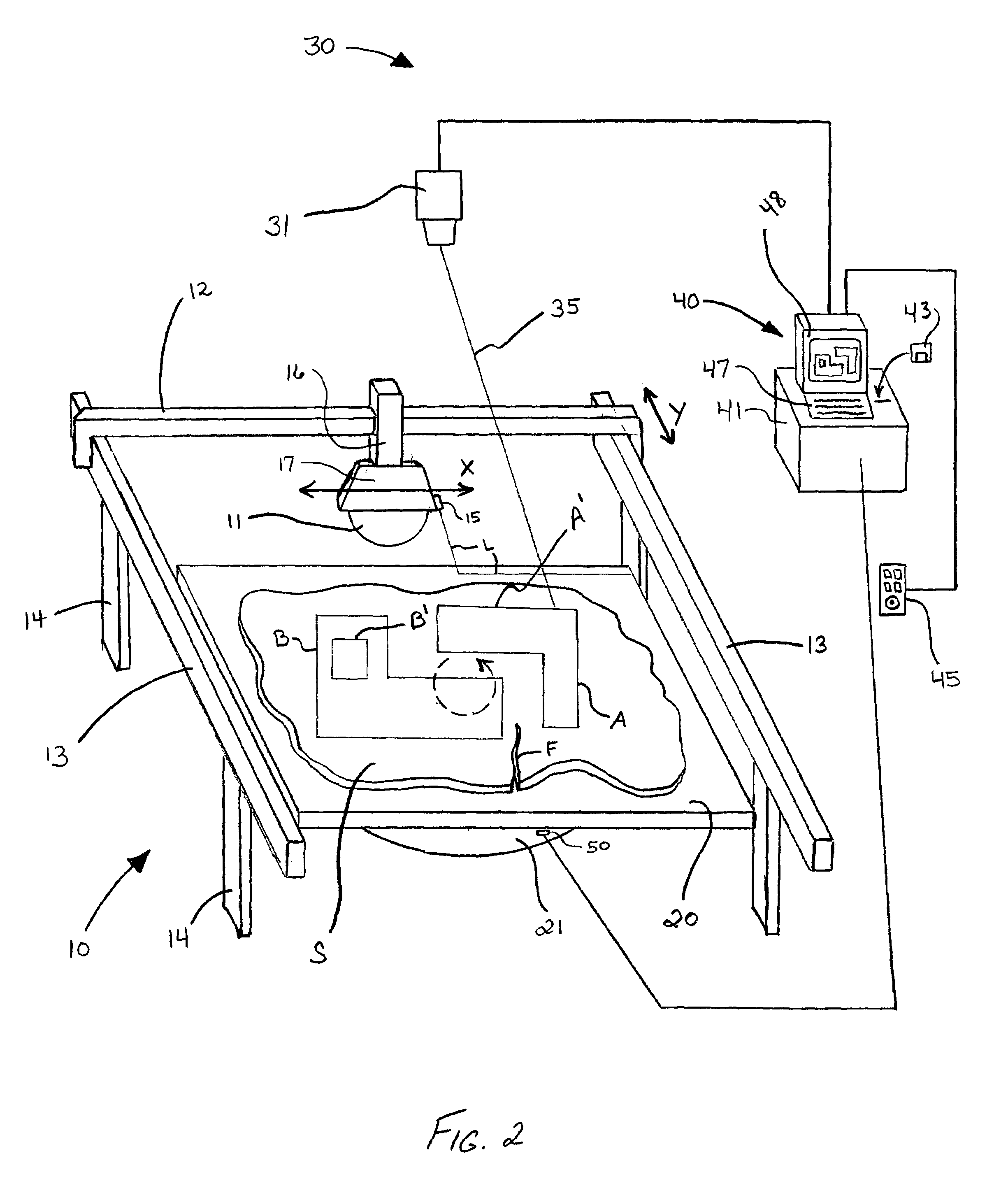

Systems and methods for displaying images and processing work pieces

A method of displaying an image on a work piece positioned on a movable work surface. A method of processing a work piece, as well as a method of displaying an image on a moveable work surface, is also provided. A system for machining a work piece in accordance with one or more images projected onto the work piece is also provided.

Owner:LAP LASER

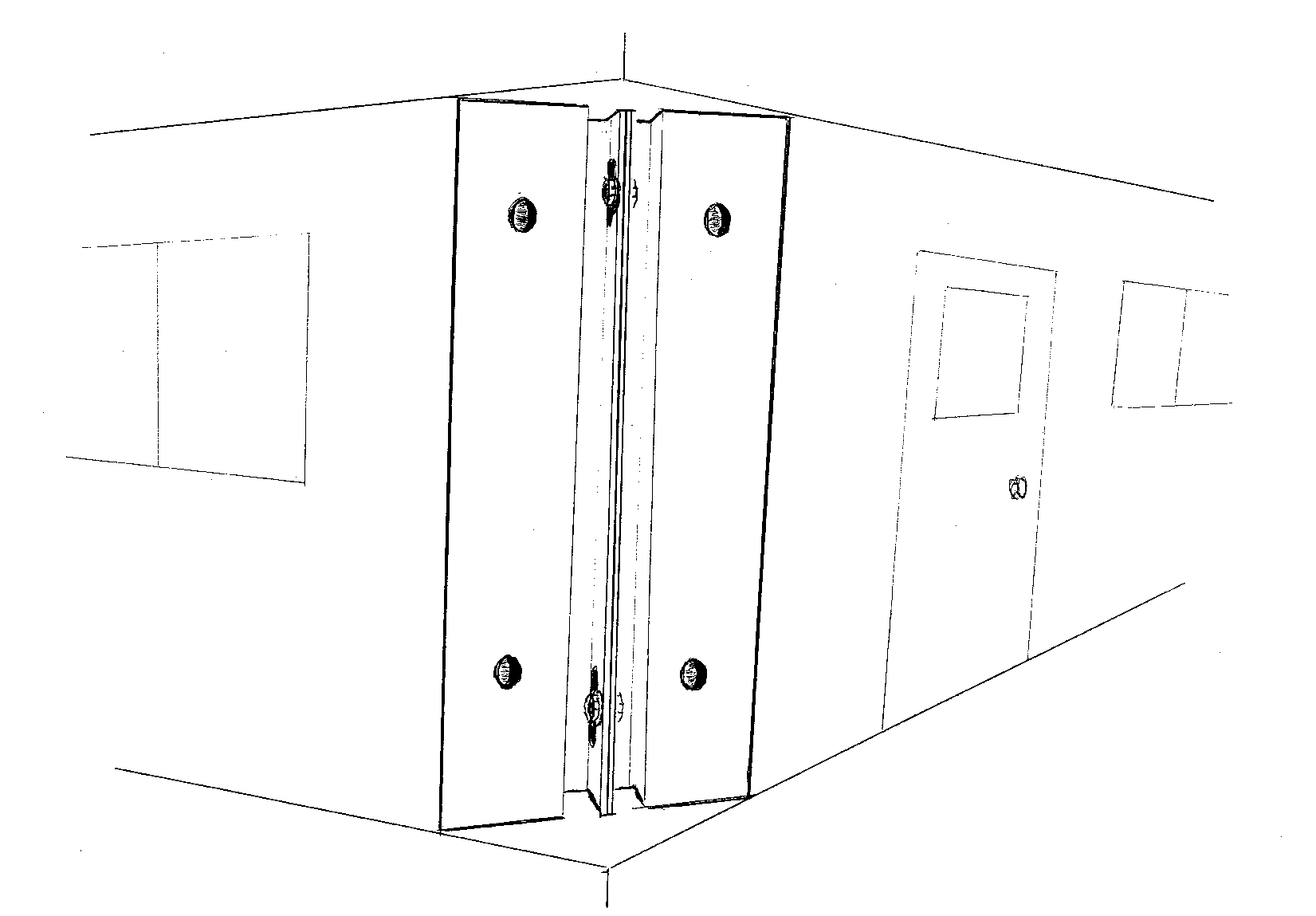

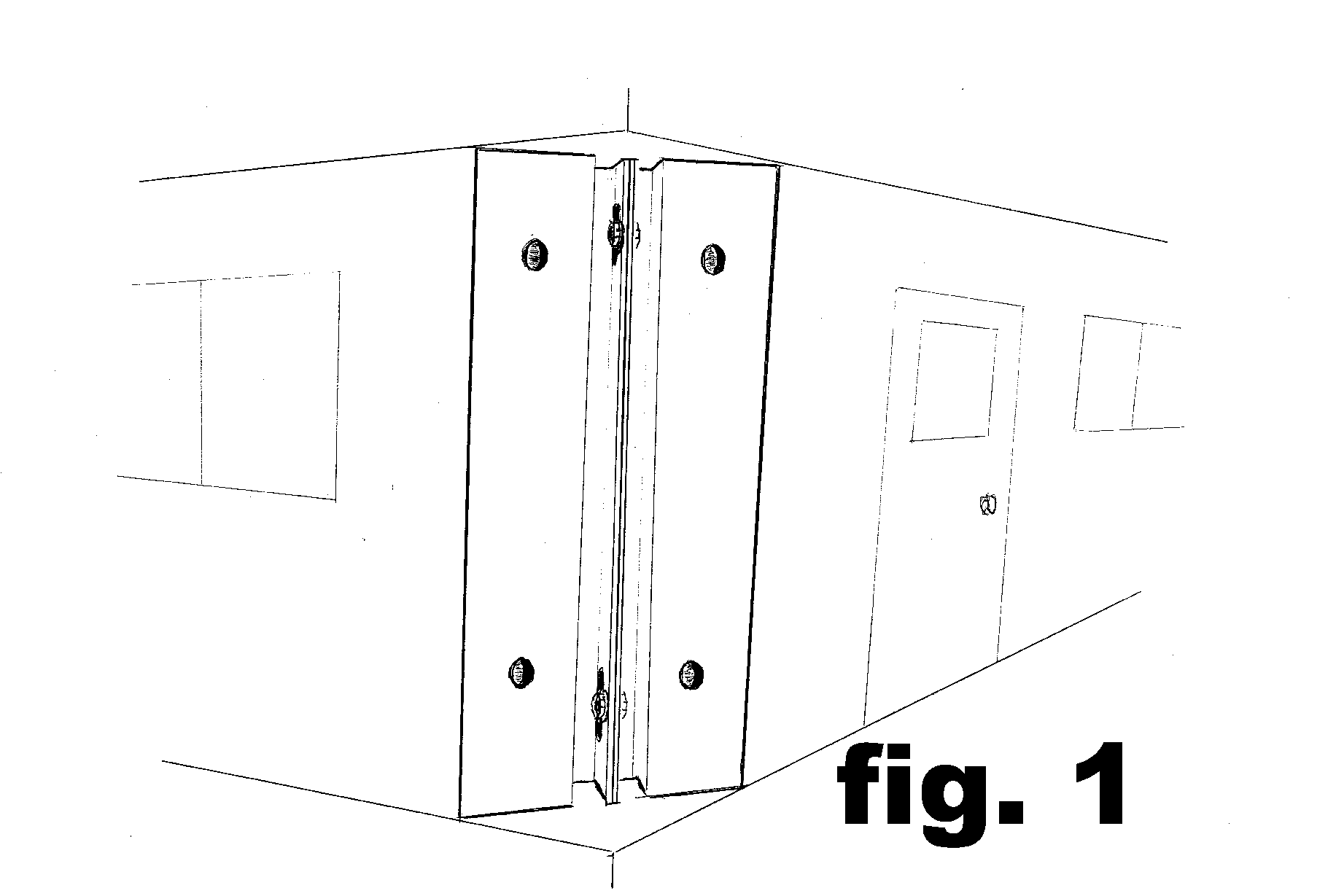

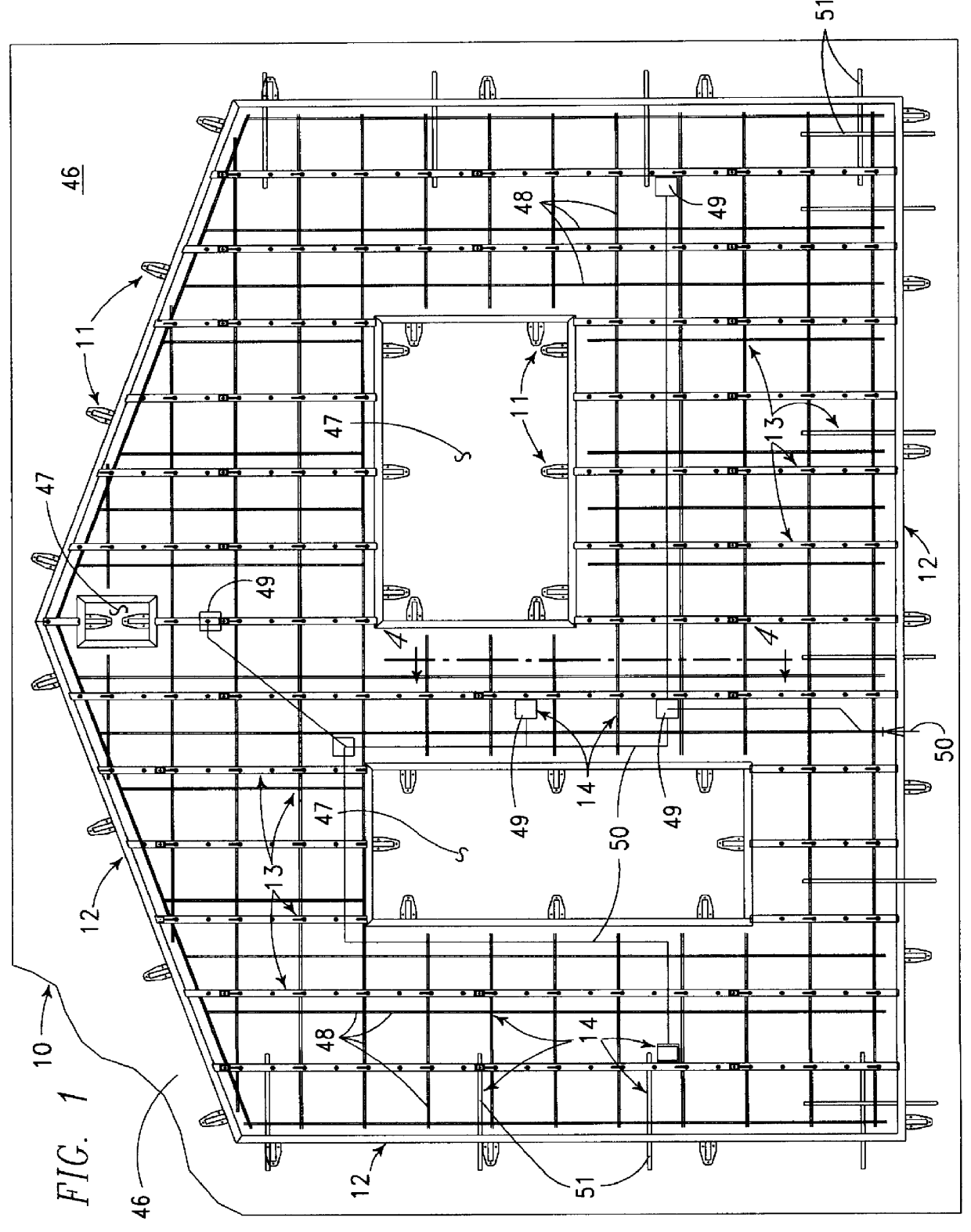

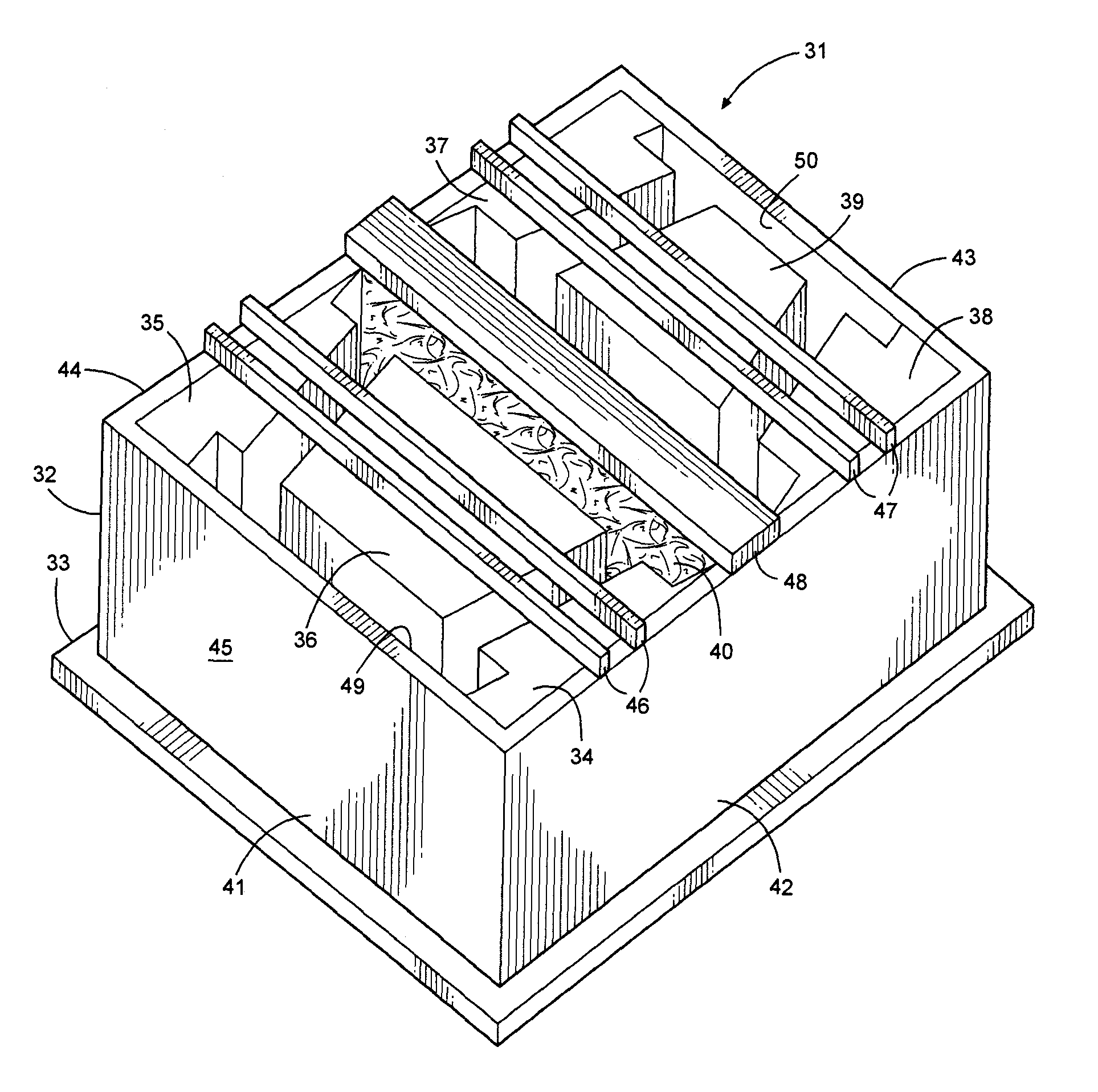

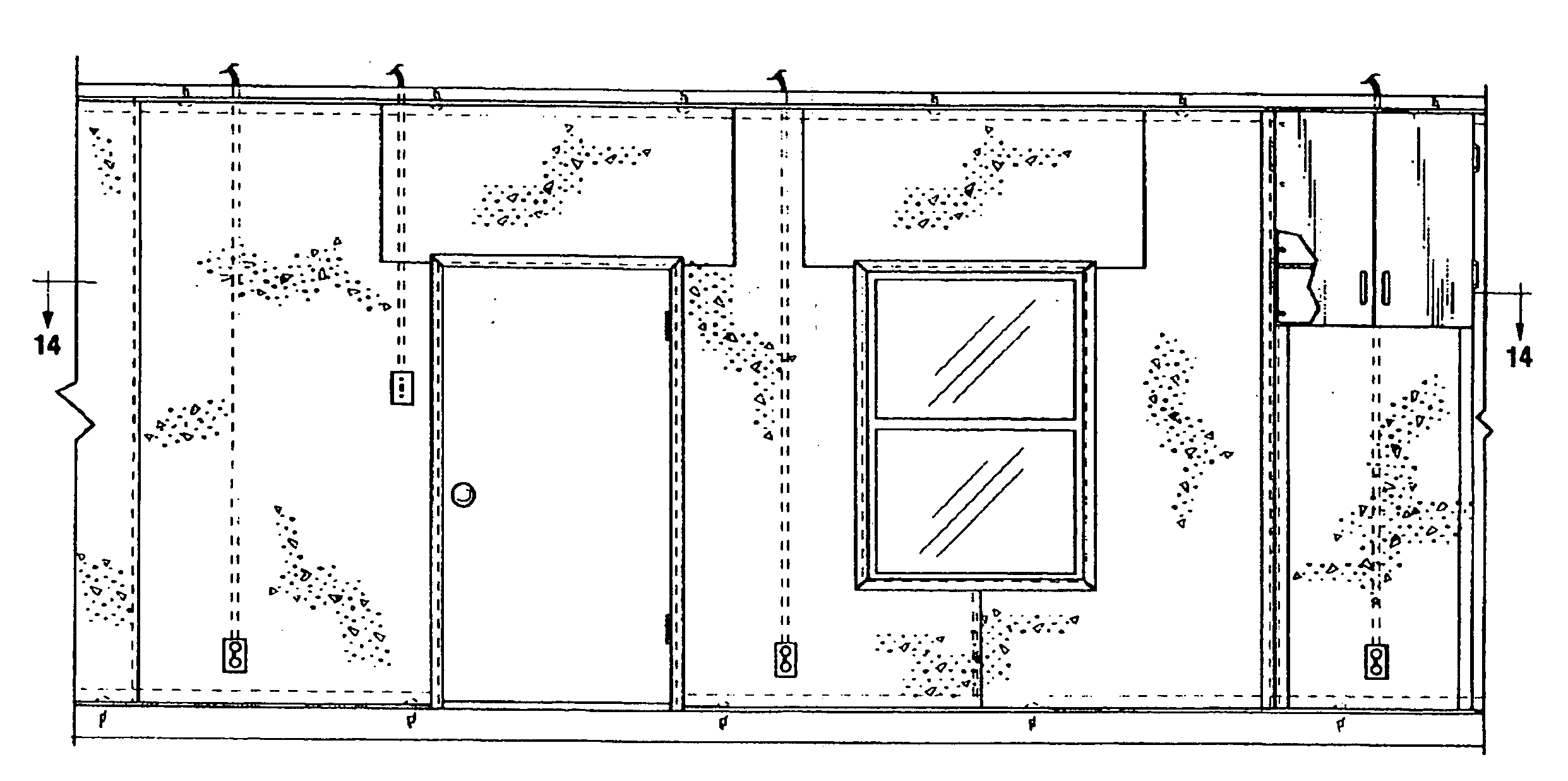

Connectors and Methods of Construction for a Precast Special Concrete Moment Resisting Shear Wall and Precast Special Concrete Moment Resisting Frame Building Panel System

InactiveUS20080098676A1Saving environment protectionThermally efficientMoulding surfacesBuilding roofsComposite constructionInternational Building Code

A precast concrete wall panel molding system for fabricating a wall shell and a plurality of ribs and beams. A precast concrete wall panel molding system with facilities for incorporating door and window frames. A ductile panel end connector for attaching panels one to another whether in parallel or angled as in inside or outside corners. A ductile panel end connector for attaching panels to columns. A wall anchor / shear plate with post-tensioning brace plate. A hybrid precast / cast-in-place special moment resisting shear wall / special moment resisting frame reinforced concrete building system for regions of potential seismic activity. A prescriptive method building system for composite structural building assemblies with conventional wood and light-gauge steel framing, structural steel, and other building code approved and tested building systems, building components, building panel systems, building roofing systems, modular and manufactured buildings, and building electrical, mechanical, and plumbing systems. A precast concrete wall panel system conforming to industry practices and standards as published by the Precast / Prestressed Concrete Institute, (PCI) in it's “PCI Design Handbook” (fifth edition, 1999), the American Concrete Institute “Building Code Requirements for Structural Concrete” (ACI 318-05), The “International Building Code 2006” and the “Uniform Building Code”.

Owner:HUTCHENS JOHN FRANCIS

Method of producing unitary multi-element ceramic casting cores and integral core/shell system

A method for producing ceramic articles having a complex geometry. Temporary tooling is provided having cavities corresponding in shape to the desired ceramic article. The cavities are filled with a ceramic slurry which is solidified by freezing or gelation of a polymer. The ceramic is treated to remove the original liquid portion of the slurry and the temporary tooling is removed. The ceramic is then sintered. The ceramic article thus obtained may be used to investment cast a metal article.

Owner:UNITED TECH CORP

Support device

InactiveUS20050116131A1Reduce the possibility of damageEasy to adjustPicture framesDomestic mirrorsEngineeringMechanical engineering

Owner:RETAIL & COMML PROPERTIES PTY

System and method for constructing modular concrete ducts

Modular mold equipment for producing concrete culverts with tight tolerances. Modular mold equipment having a coupling plate is used to align and interconnect components of the mold. The components being aligned may have recesses for receiving the coupling plate. Modular mold equipment system with an extended size range to cover all standard concreted duct product sizes. Modular mold equipment having a pallet guide adjustment mechanism adapted for setting the pallet at a desired location in relation to a form. The desired location is based on a wall thickness of a concrete culvert to be produced. Modular mold equipment having a core that includes a core corner and another core component adapted to be coupled to the core corner, and locking apparatus adapted to lock the core corner to the other core component via a mechanism that extends outside the core.

Owner:SOUTHERN CAST PRODS

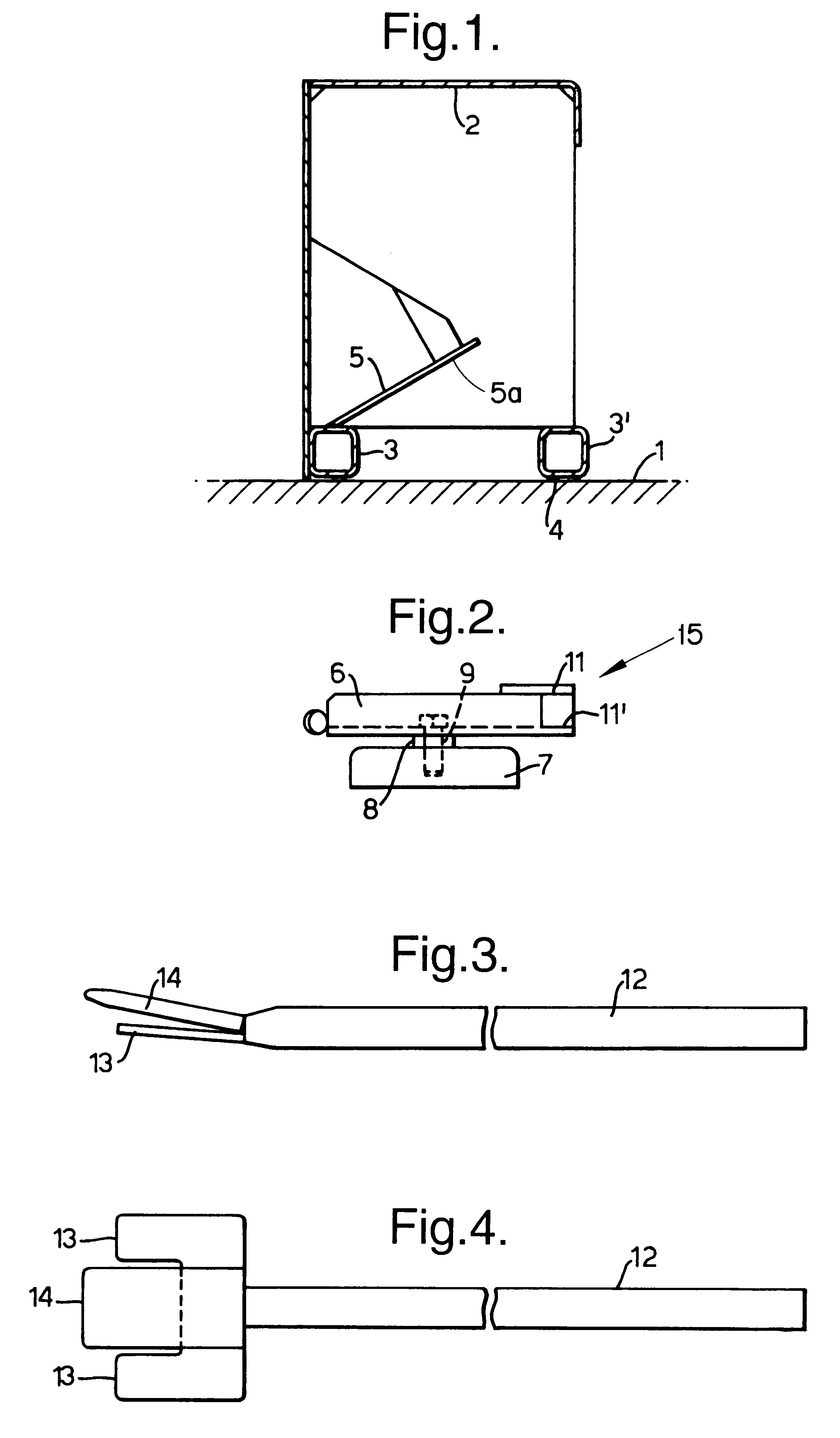

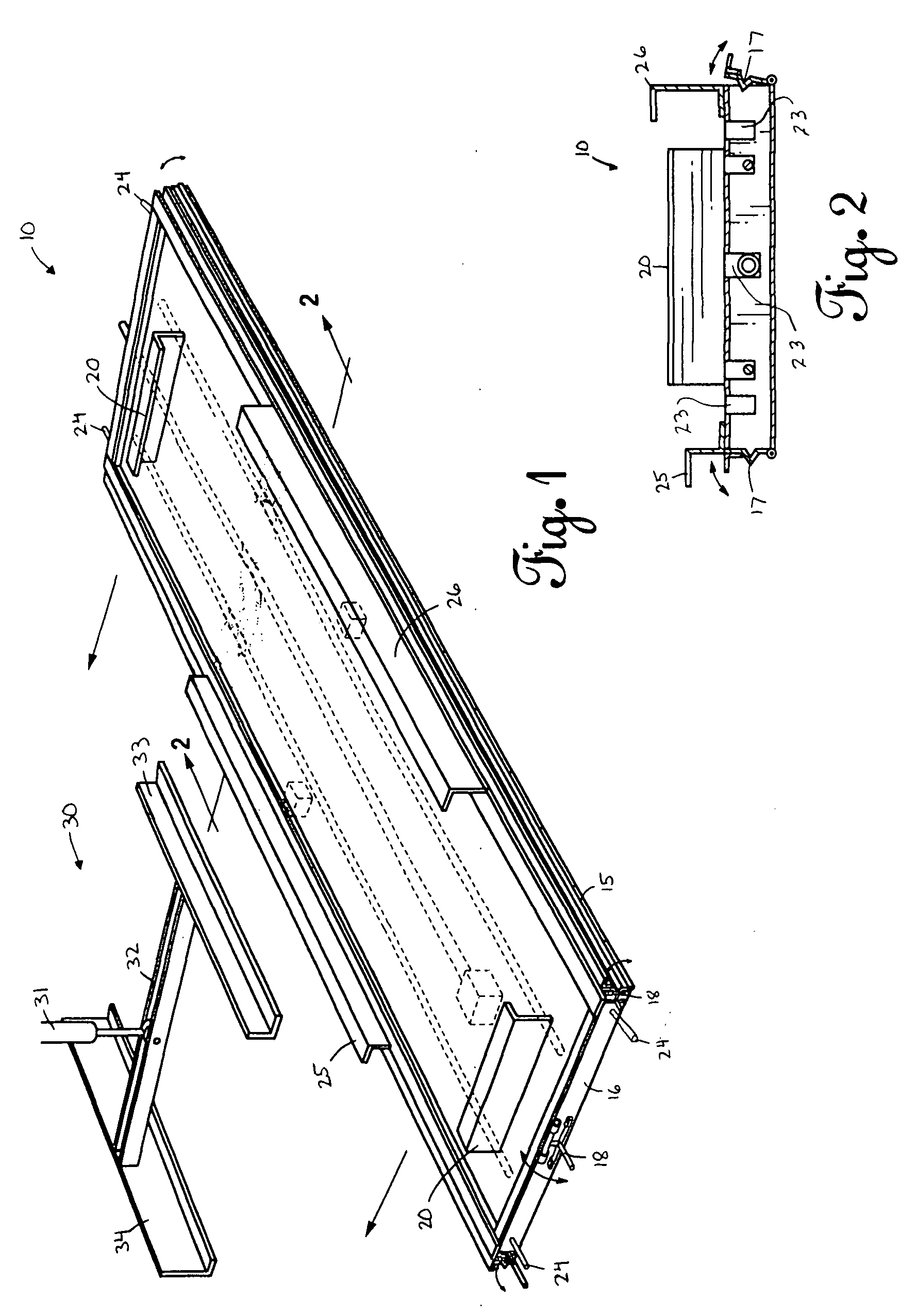

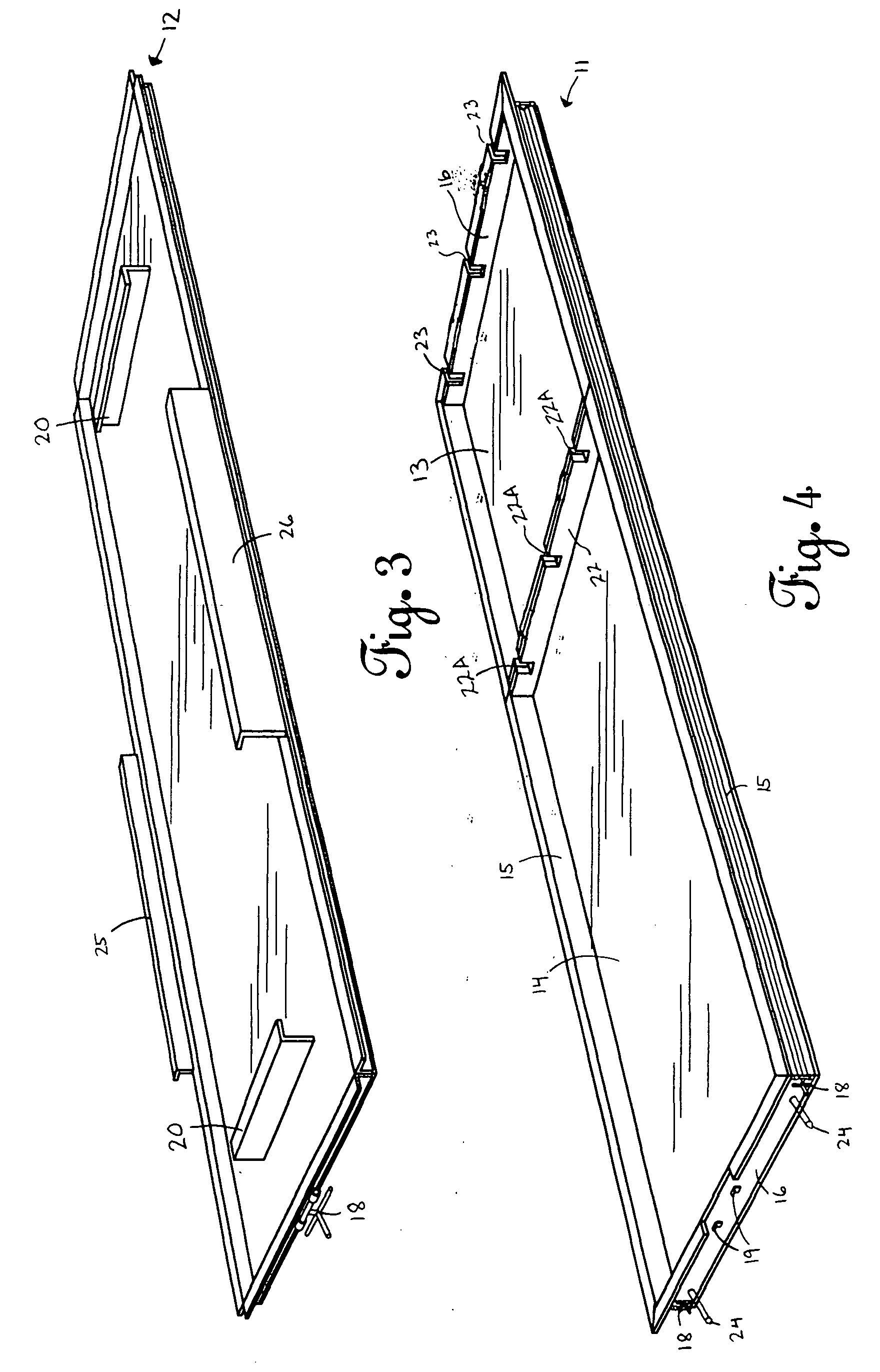

Tilt-up concrete panel and forming system therefore

A concrete wall panel for tilt-up construction provides polymeric peripheral elements defining panel and orifice edges and medial fastening strips extending in the panel between the peripheral elements, all of which remain as part of the finished panel to accept traditional self-penetrating nail, screw and staple fasteners historically used in wood construction. The peripheral elements are of solid configuration to provide a form for pouring plastic concrete that forms the panel embodying them. The fastening strips extend through the panel between opposed panel surfaces and are formed by two initially releasably interconnected elements defining voids therebetween to allow thickness adjustment and convenient placement and support of structural components within the panel. The fastening strips define spaced areas to receive traditional wood fasteners and may carry index strips on opposed exposed surfaces to visually indicate strip location and fastening areas. The peripheral elements allow joinder of adjacent panels with each other and both the peripheral elements and the fastening strips allow joinder of structural elements on one or both panel surfaces by self-penetrating fasteners of wood construction.

Owner:OLSON TIMOTHY +1

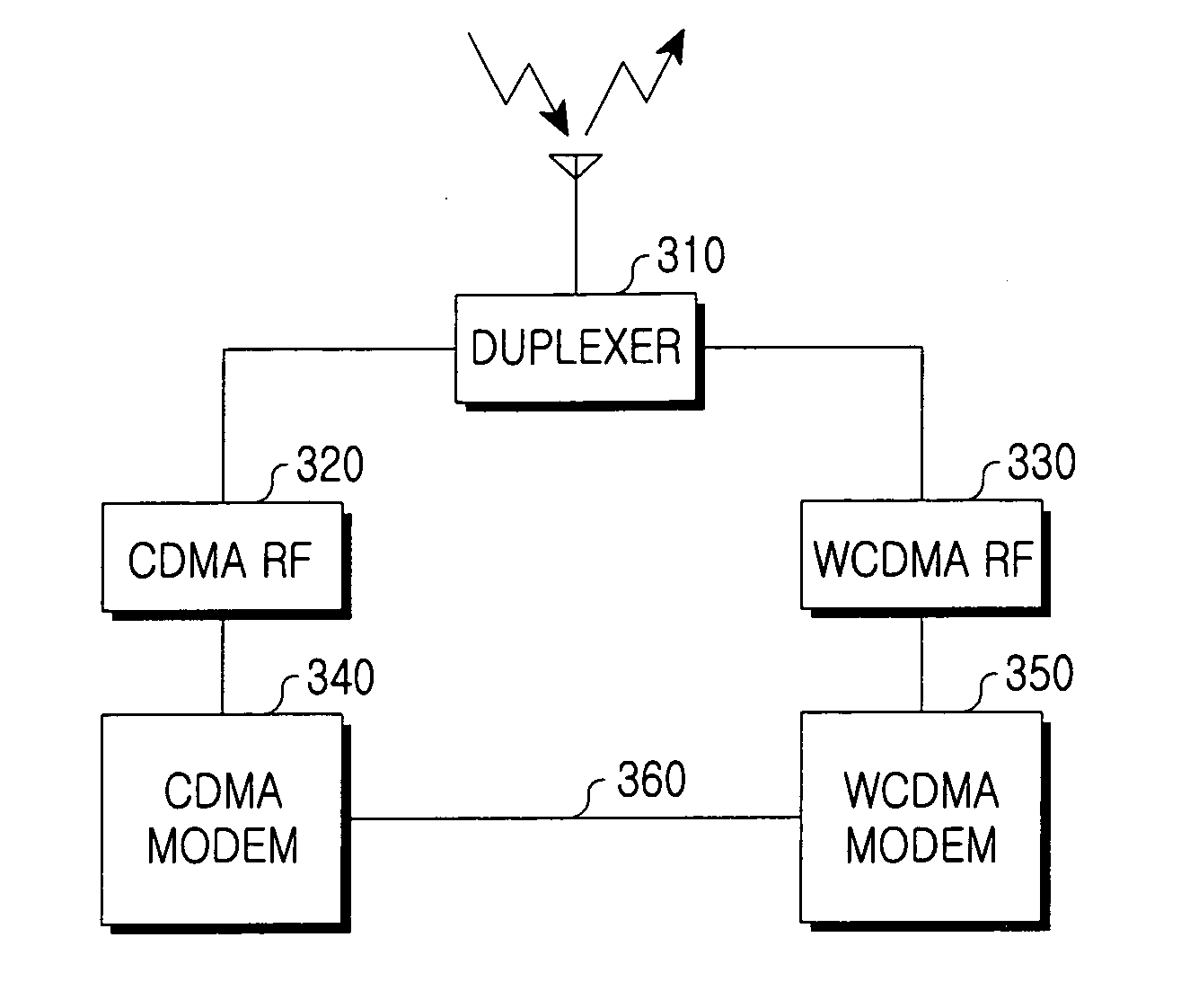

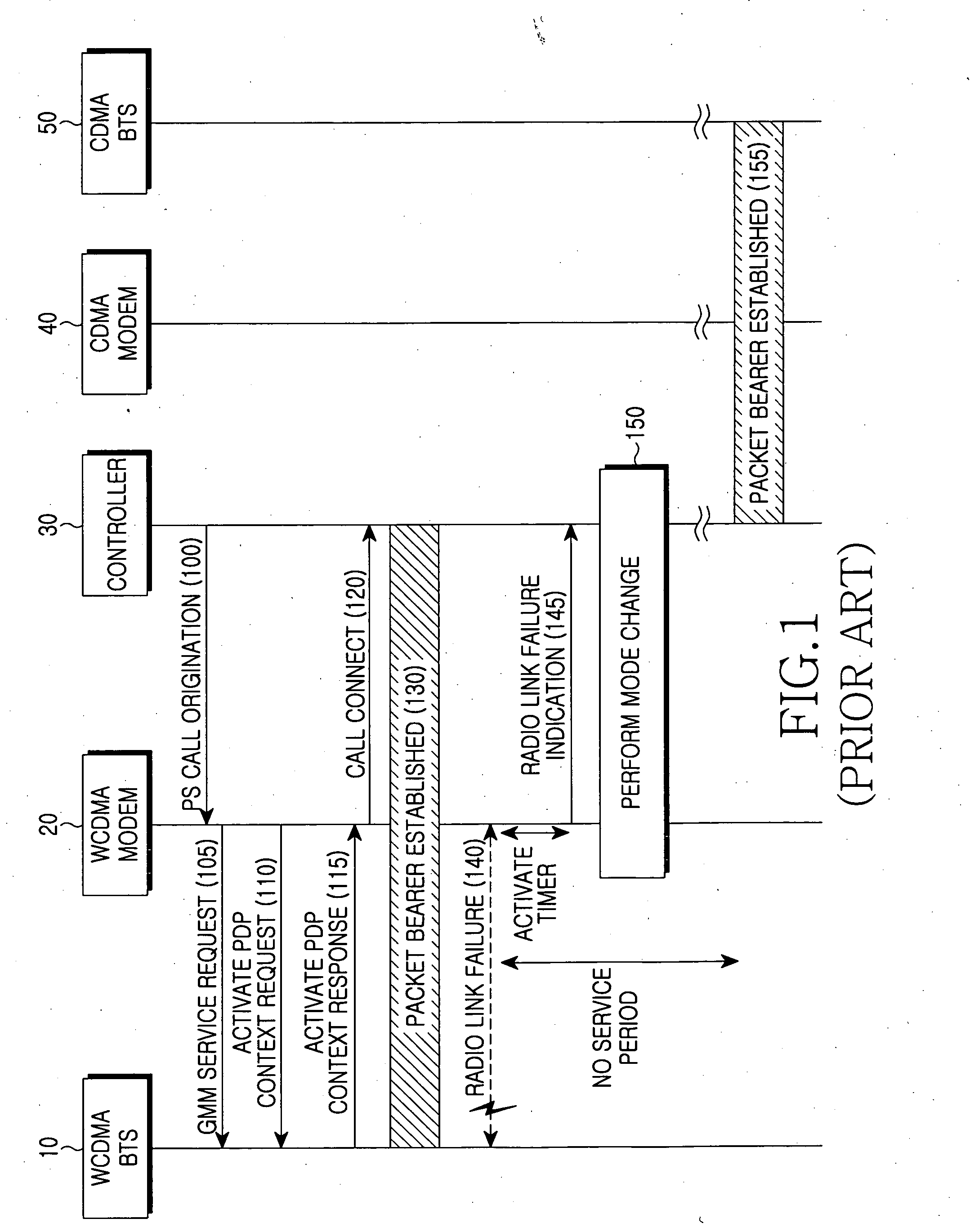

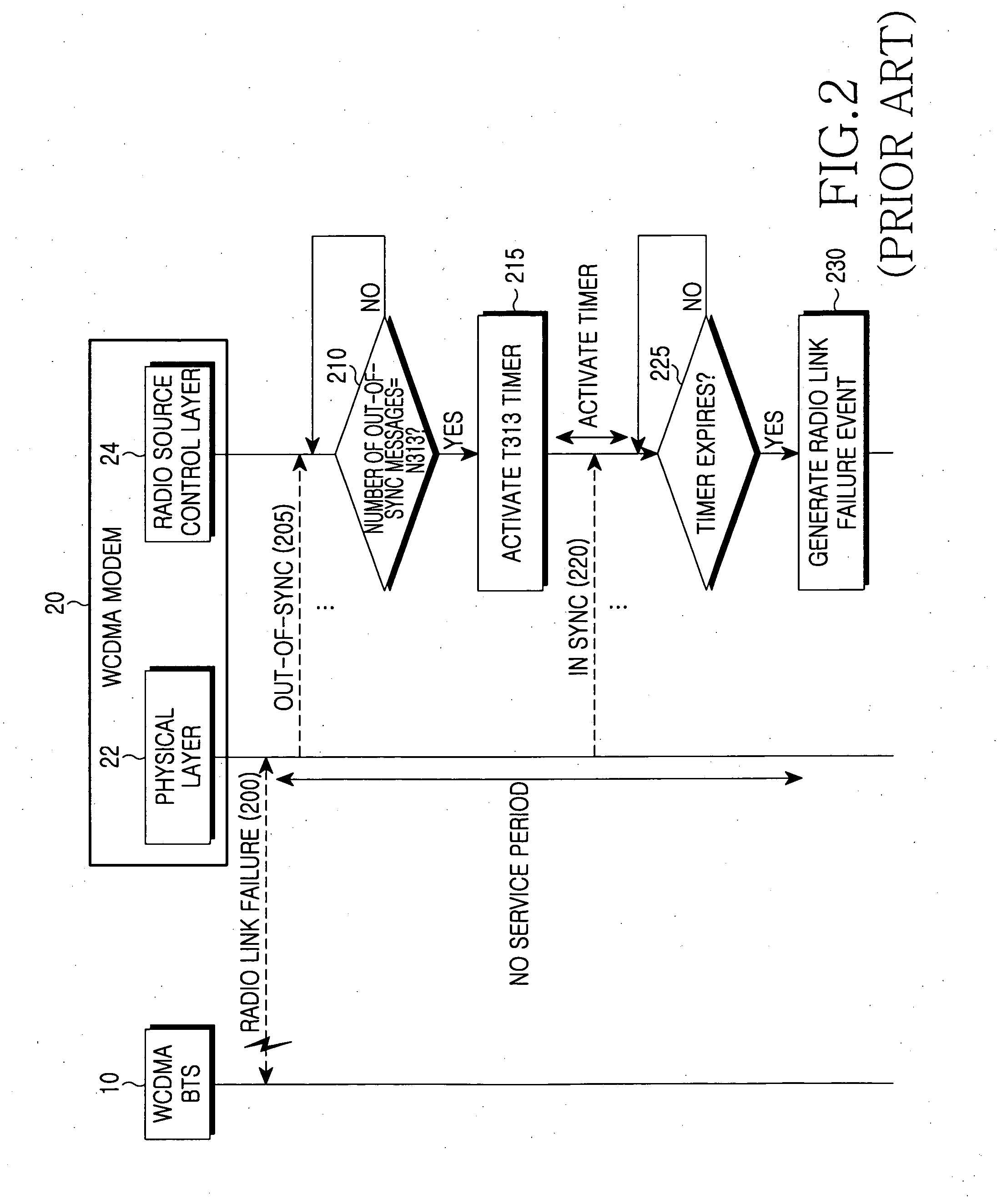

Handover method for minimizing packet call reconnection delay time between different mobile communication schemes and multi-mode terminal for the same

InactiveUS20070195733A1Minimize delay timeMinimize timeMould separation apparatusMouldsDelayed timeMode change

Provided is a function of minimizing a delay time of a packet call disconnect due to a handover between communication networks providing a communication service using different mobile communication technologies. To do this, even though a handover situation is generated during a packet service, the packet service is continuously provided by maintaining a current mode and performing a mode change after registration in a handover target network succeeds. Accordingly, since the packet service is not provided only while a packet call connecting process is performed, a delay time according to a packet call reconnection can be minimized.

Owner:SAMSUNG ELECTRONICS CO LTD

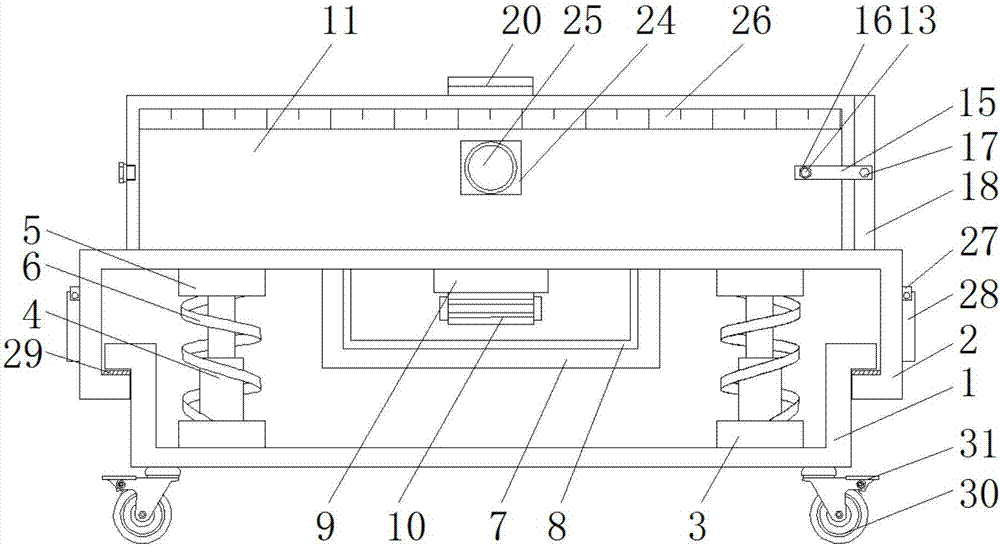

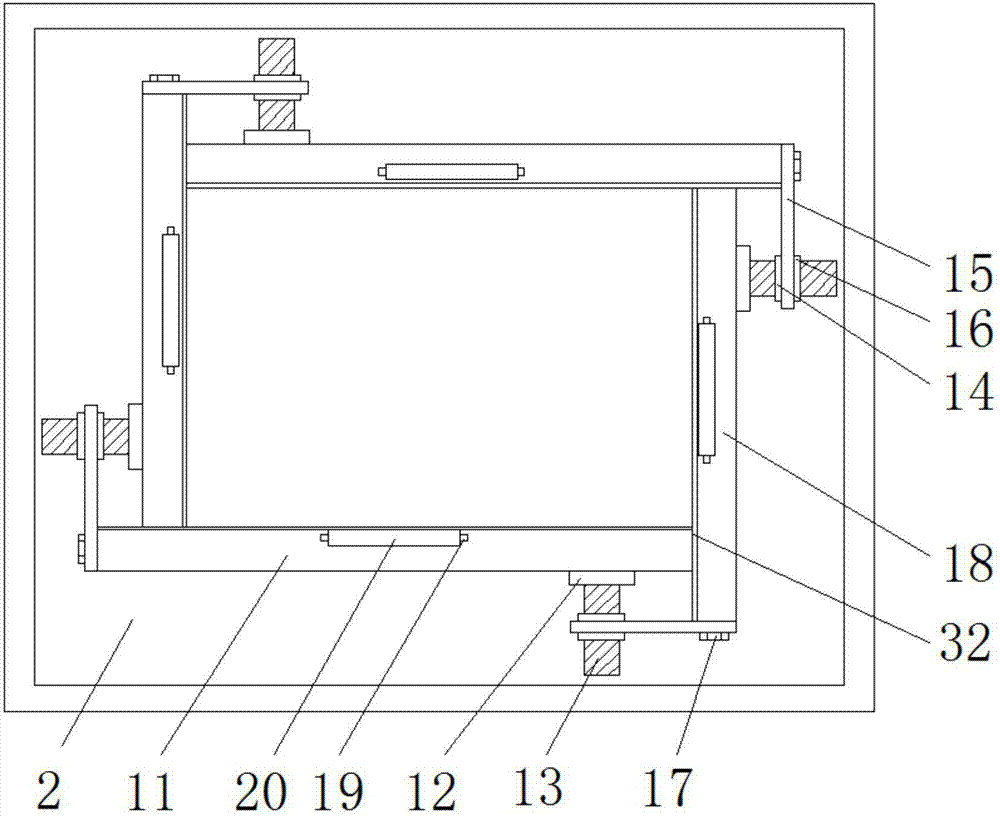

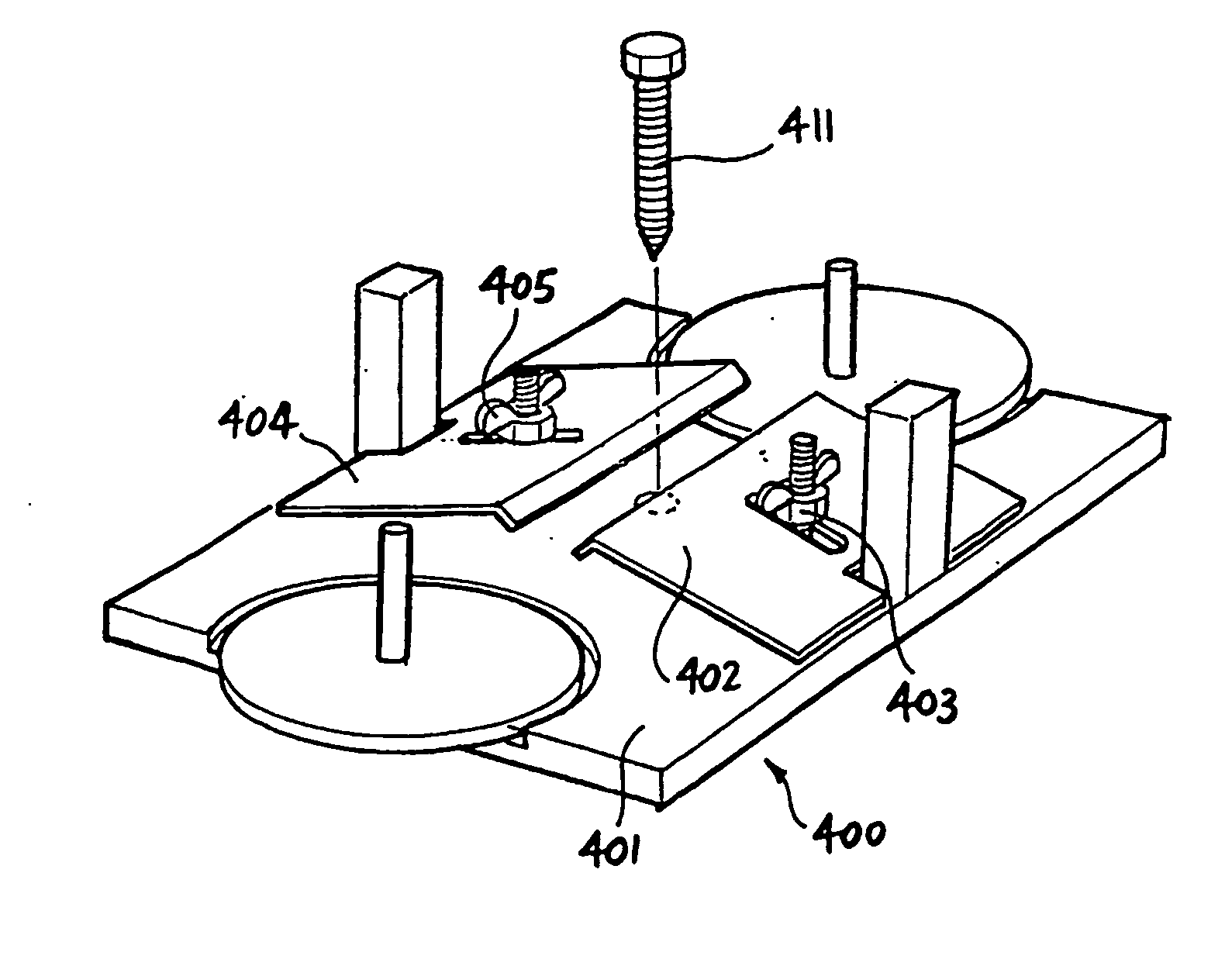

Adjustable concrete fabricated part mold

ActiveCN107457889AIncrease diversityAvoid wastingMouldsMould fastening meansArchitectural engineeringMaterial resources

The invention relates to the technical field of concrete molds, and discloses an adjustable concrete prefabricated part mold. The mold comprises a lower base; first positioning blocks are fixedly connected to the top of the lower base; telescopic rods are fixedly connected to the tops of the first positioning blocks; second positioning blocks are fixedly connected to the tops of the telescopic rods; compression springs are movably arranged on the surfaces of the telescopic rods in a sleeving mode; the bottoms of the compression springs are fixedly connected to the tops of the first positioning blocks; the tops of the compression springs are fixedly connected to the bottoms of the second positioning blocks; and the tops of the second positioning blocks are fixedly connected to the bottom of an upper base. According to the adjustable concrete prefabricated part mold, the size of first mold bodies and the size of second mold bodies can be freely changed so as to form a large or small concrete mold so that the diversity of the mold can be realized, the concrete mold can produce prefabricated parts with different specifications, and therefore the manpower and material resources can be saved, and the waste of the resources can be avoided.

Owner:广州桃园建筑工程有限公司

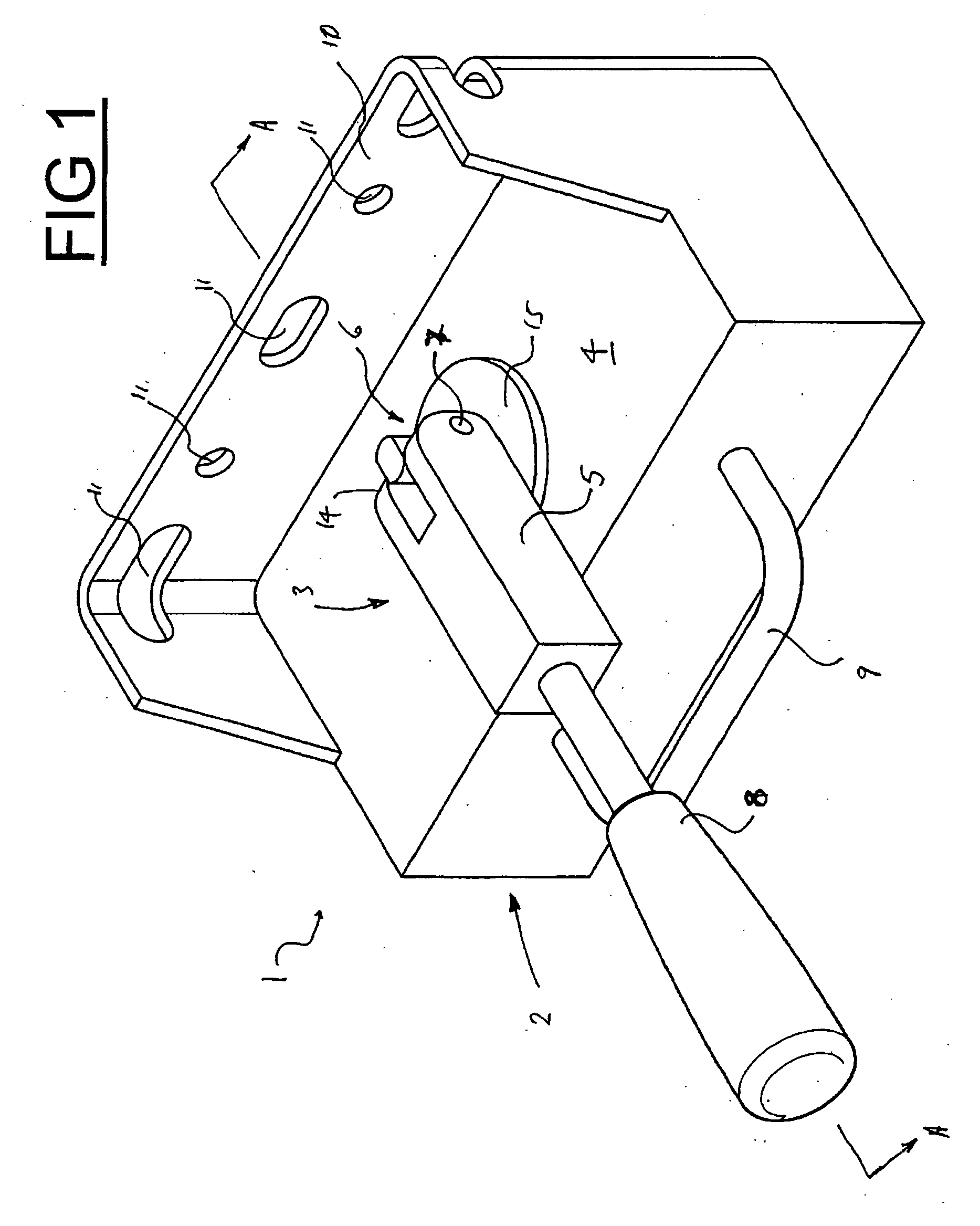

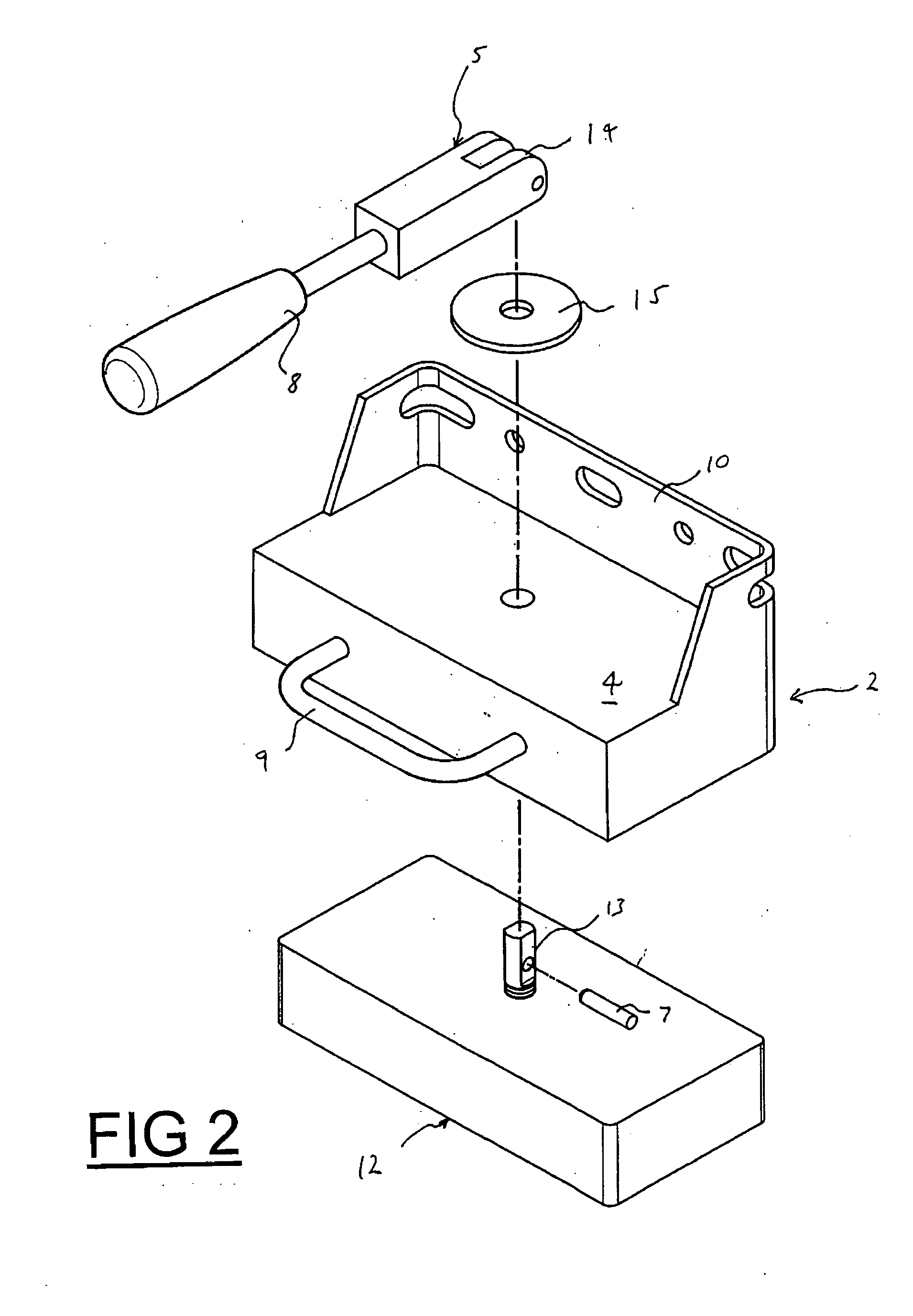

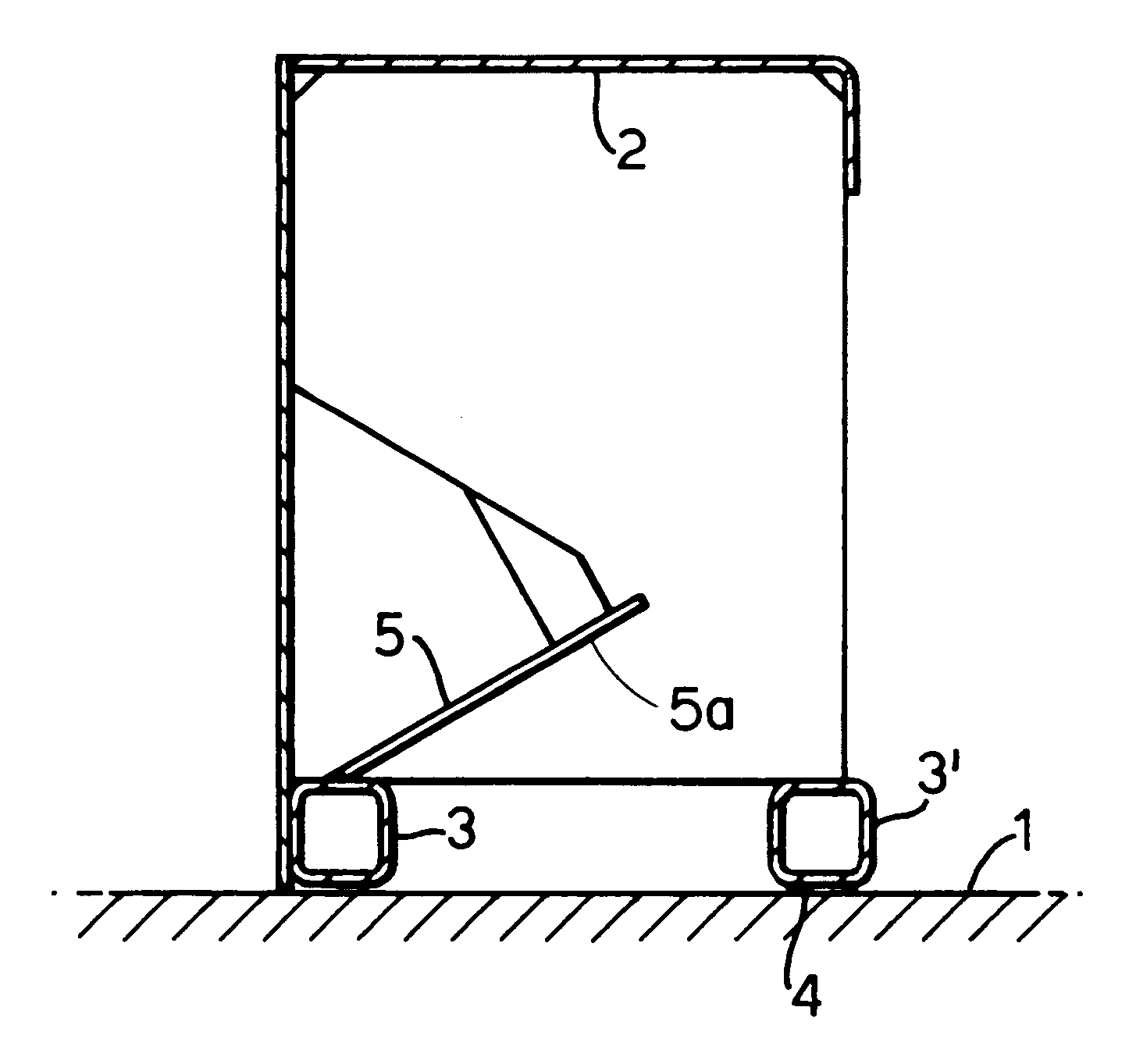

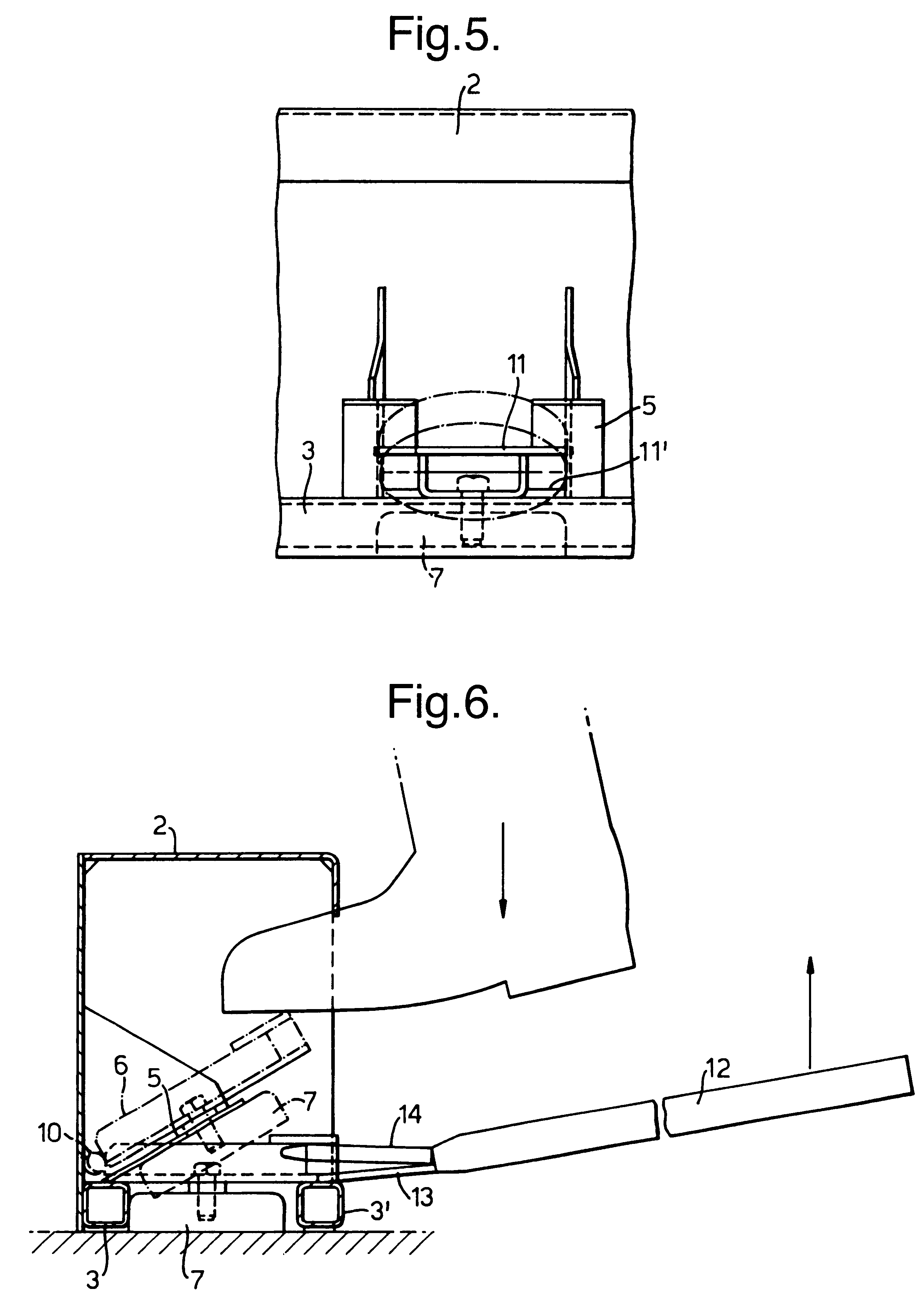

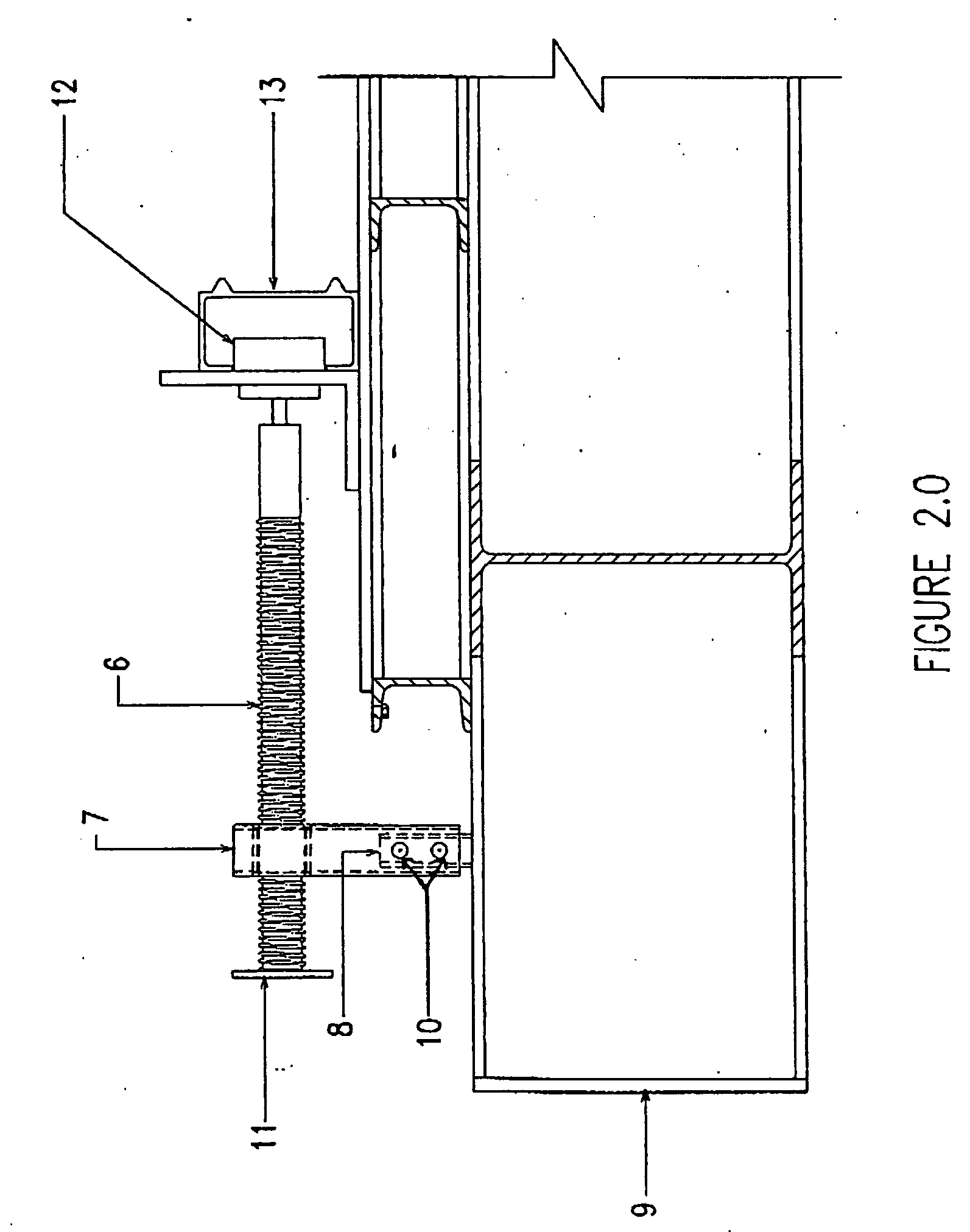

Removable side wall system for a casting mould

InactiveUS6202978B1Easy to useEasy to removeForms/shuttering/falseworksForming/stuttering elementsEngineeringLower upper

A side wall system for a concrete casting mould, including a side part (2, 3) which is removably attachable to a casting bed (1) by means of one or several magnets (7). The body (6) of the magnet part that carries the magnet (7) includes a pivoting shaft (10) about which the magnet part (6, 7) can be pivoted into a lower position wherein the magnet (7) is fastened to the casting bed (1) and into an upper position wherein the magnet is spaced from the casting bed. The side part (2, 3) includes a holder (5) on which the pivoting shaft (10) of the magnet part can be hung so that it can be pivoted between its lower and upper positions. The holder (5) has a mounting face to which the upper surface of the magnet (7) can be fastened by means of the magnetic force when the magnet is pivoted into its upper position about its pivoting shaft.

Owner:ELEMATIC GROUP

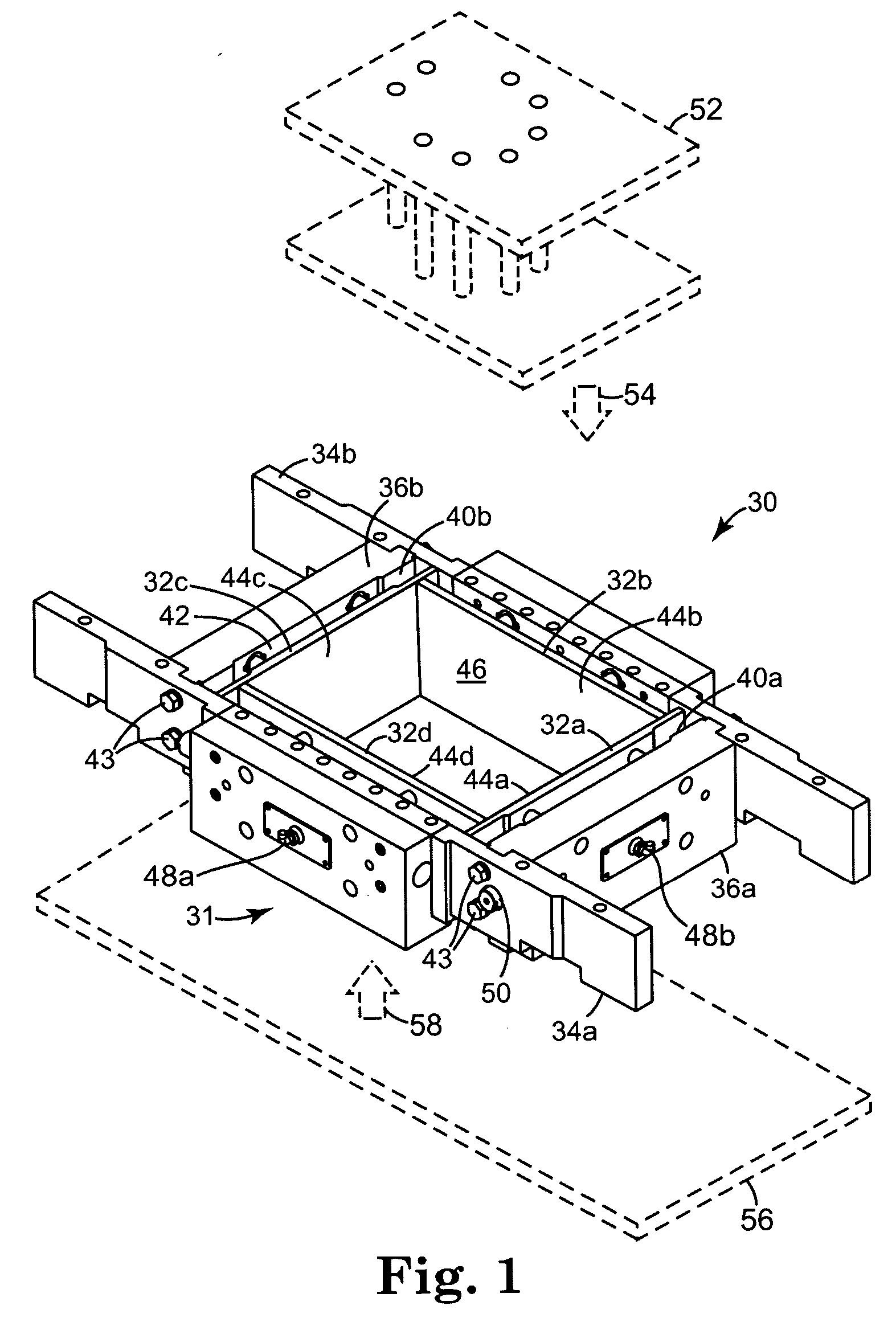

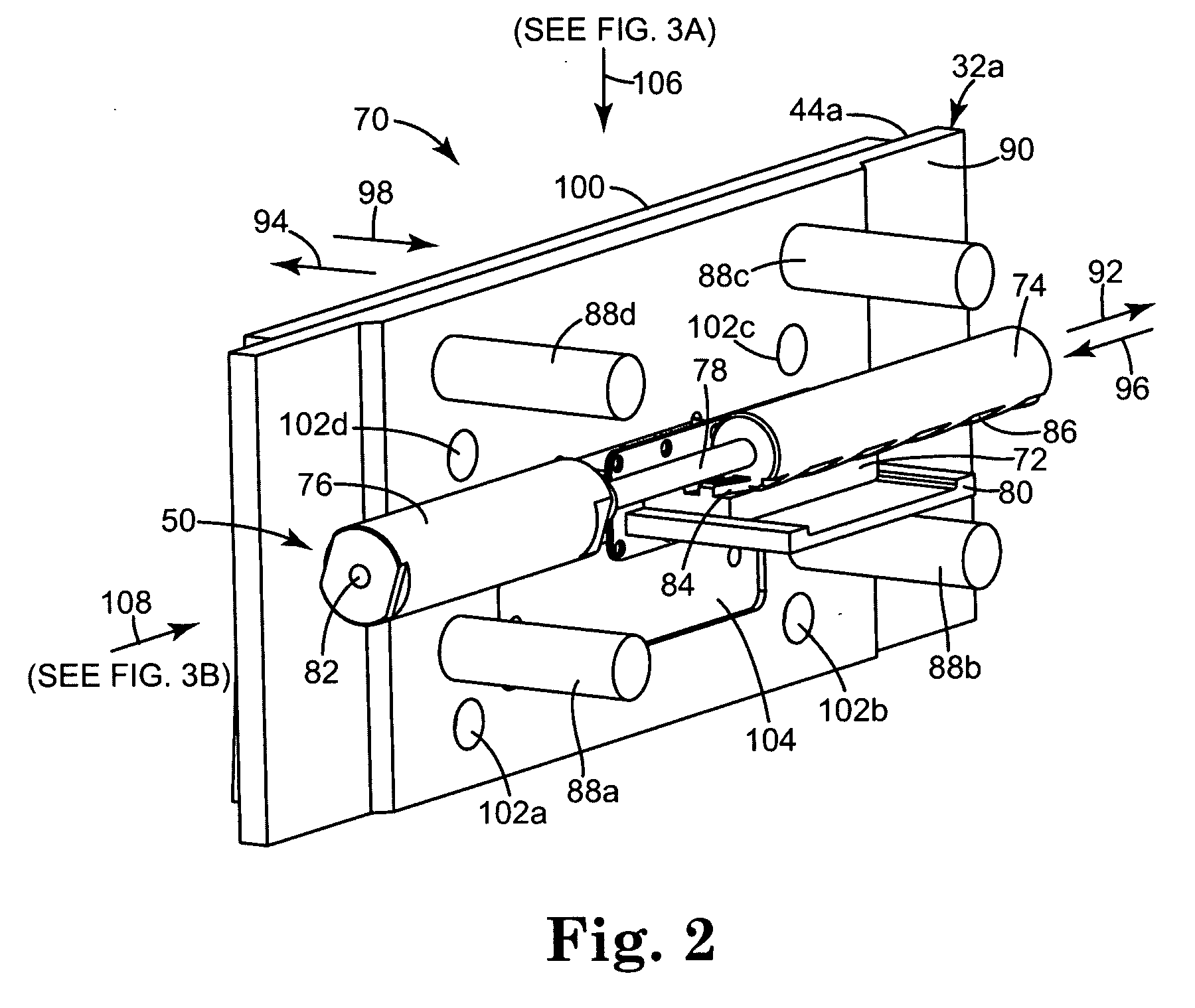

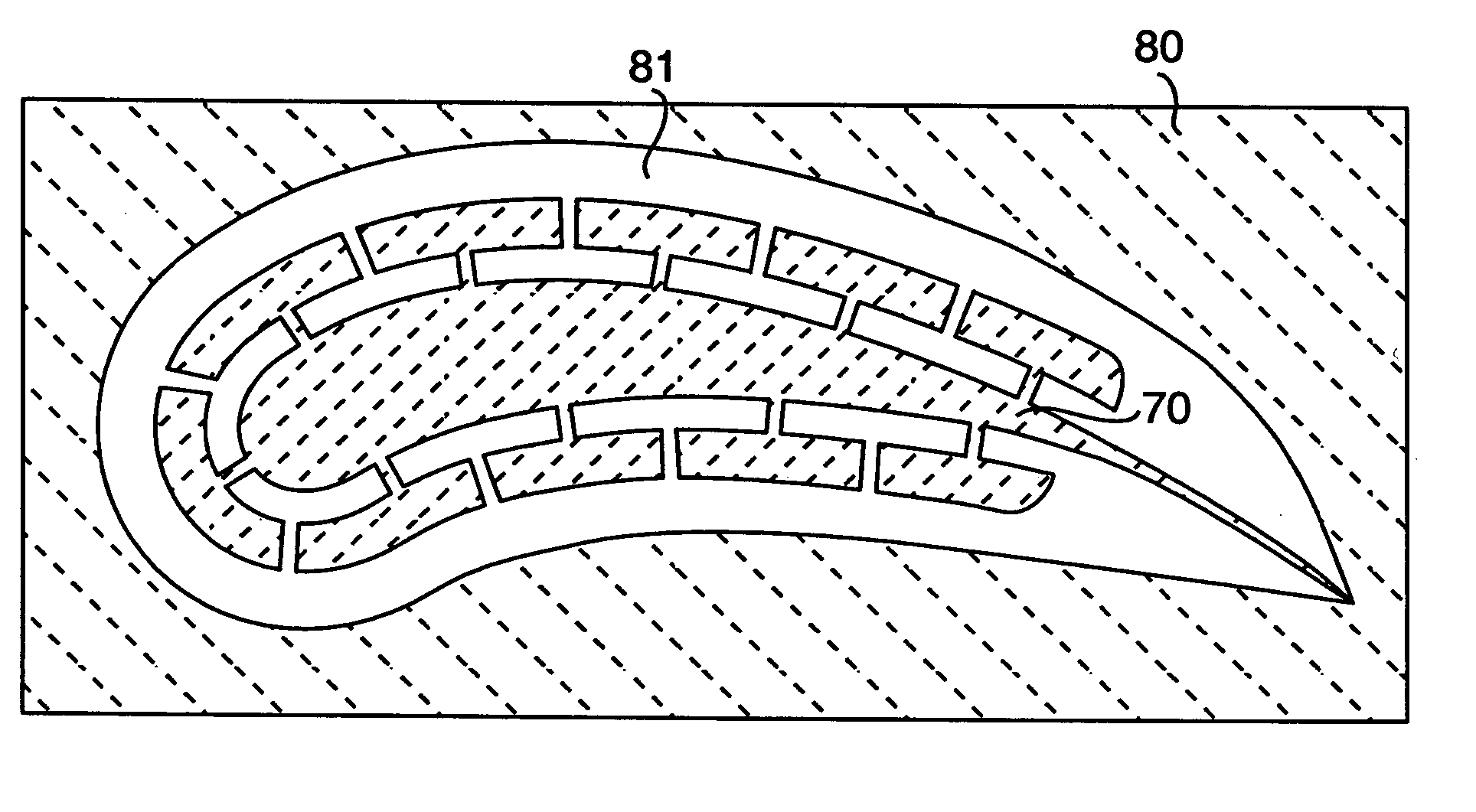

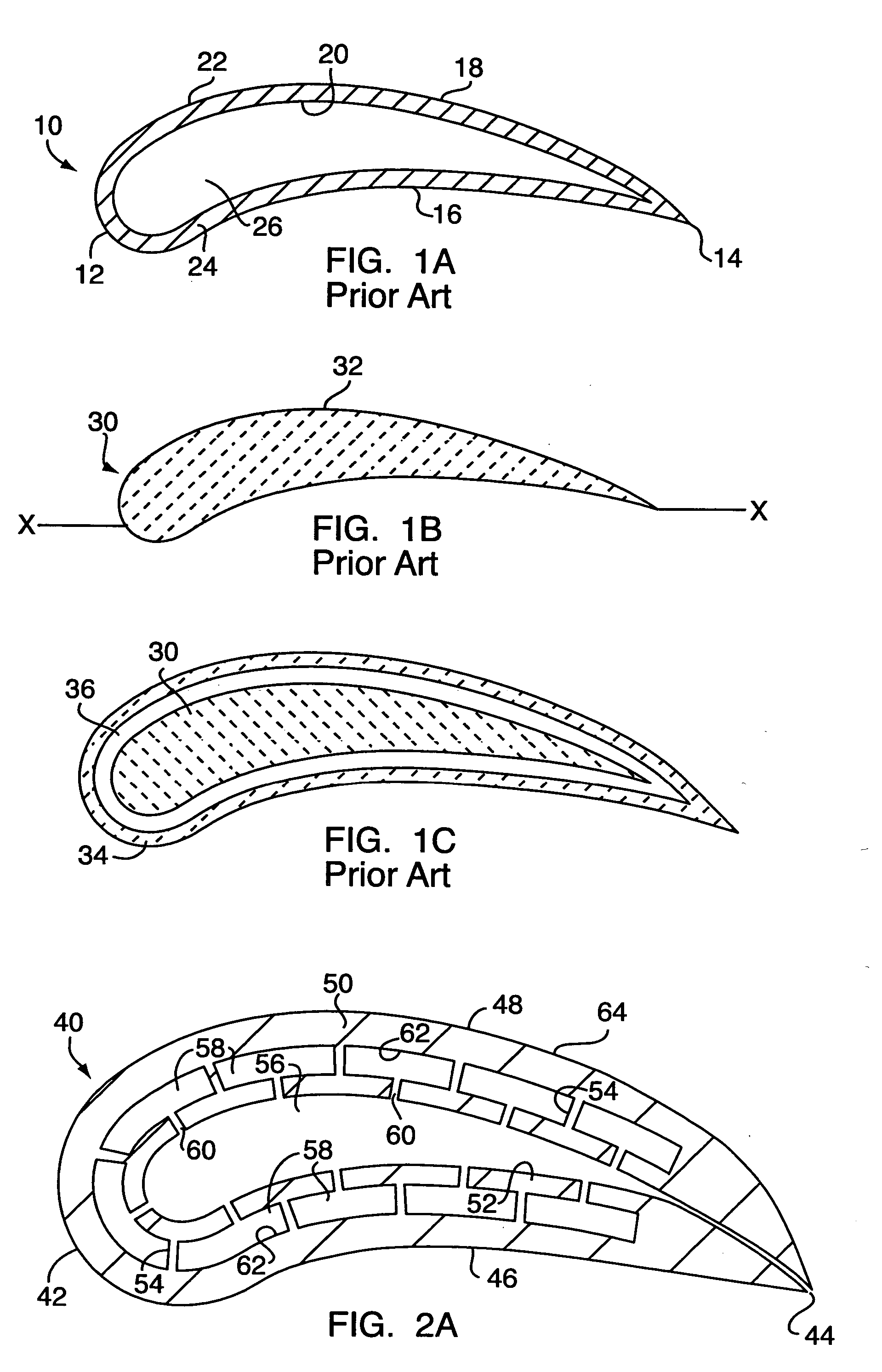

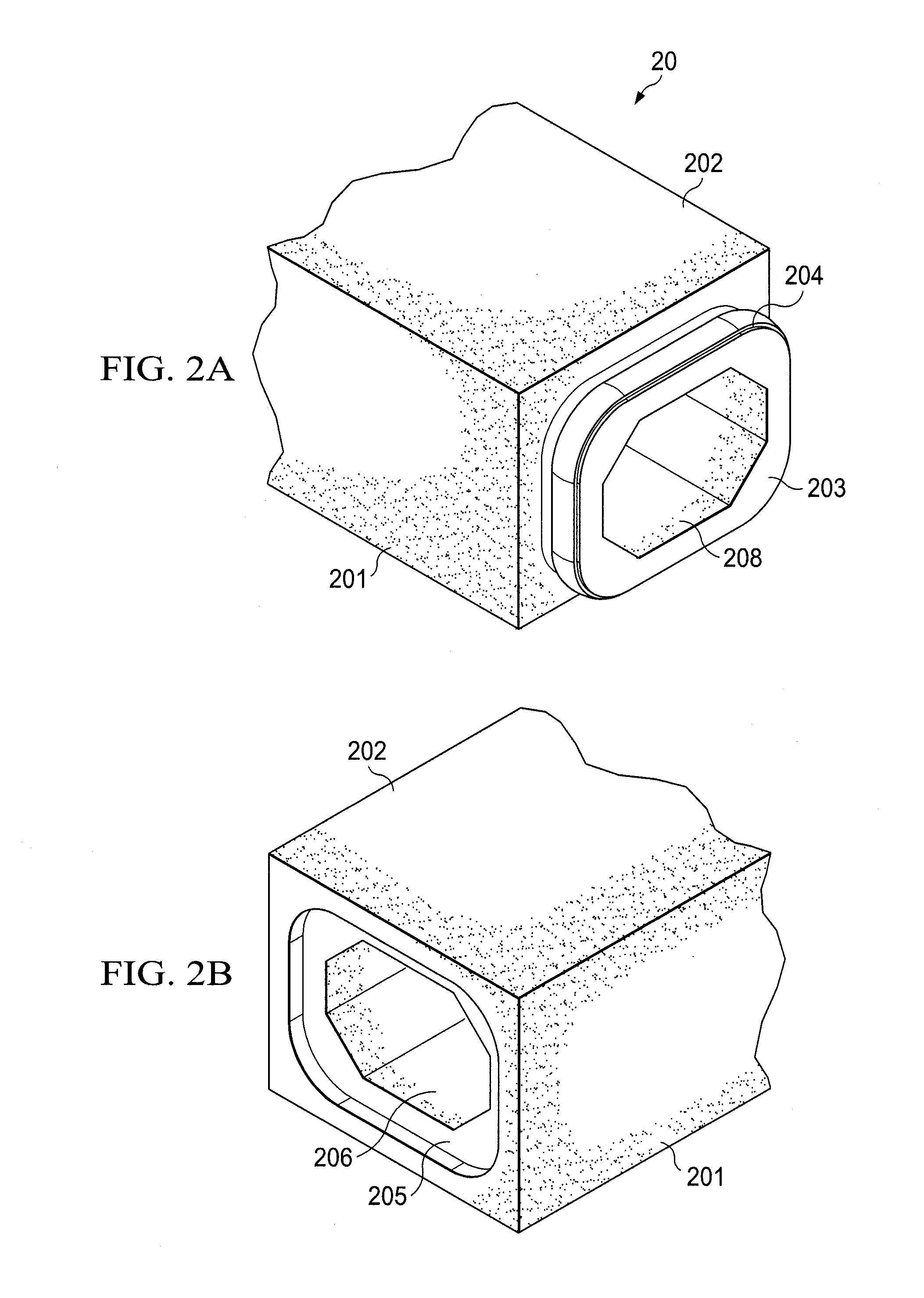

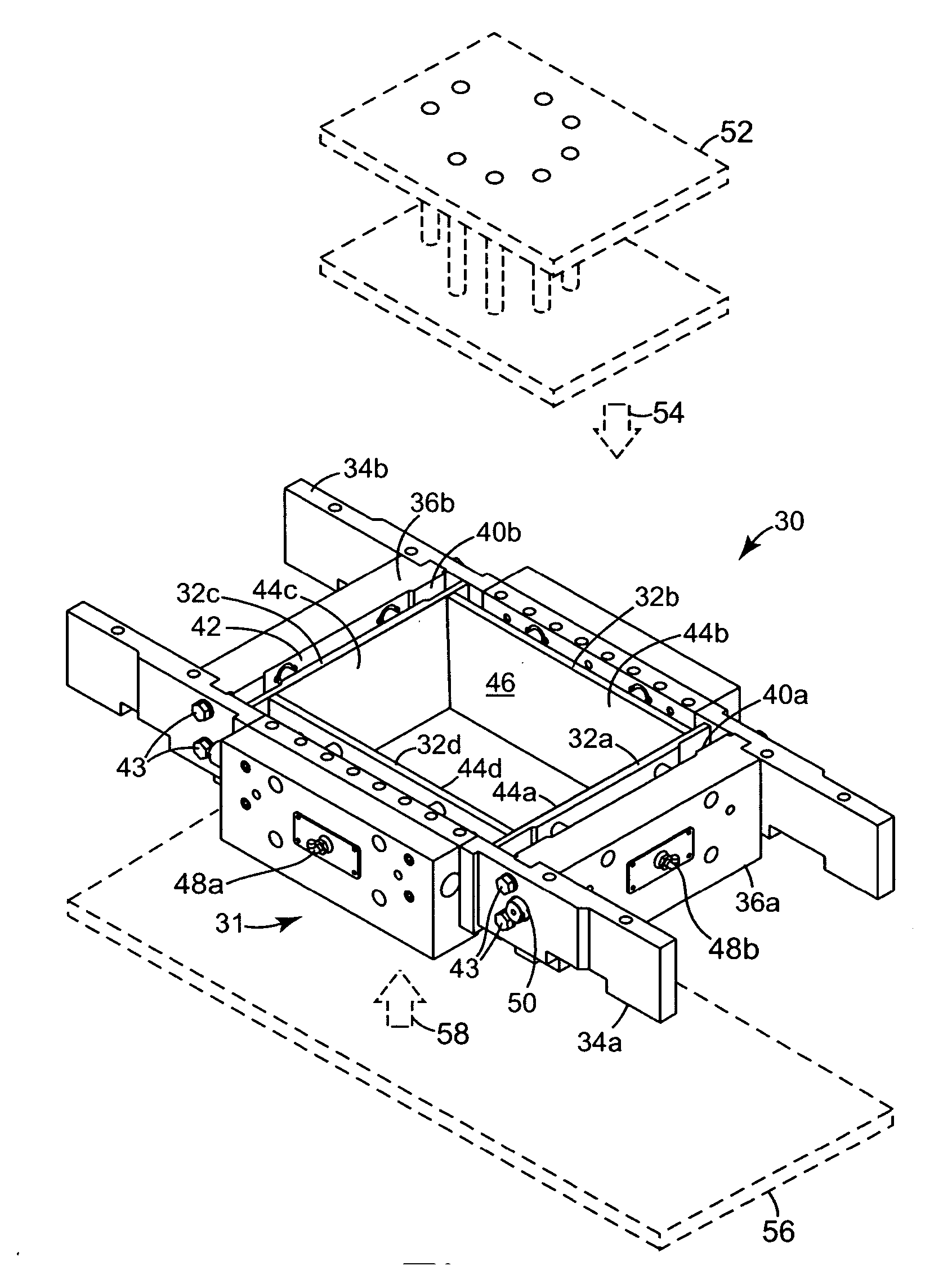

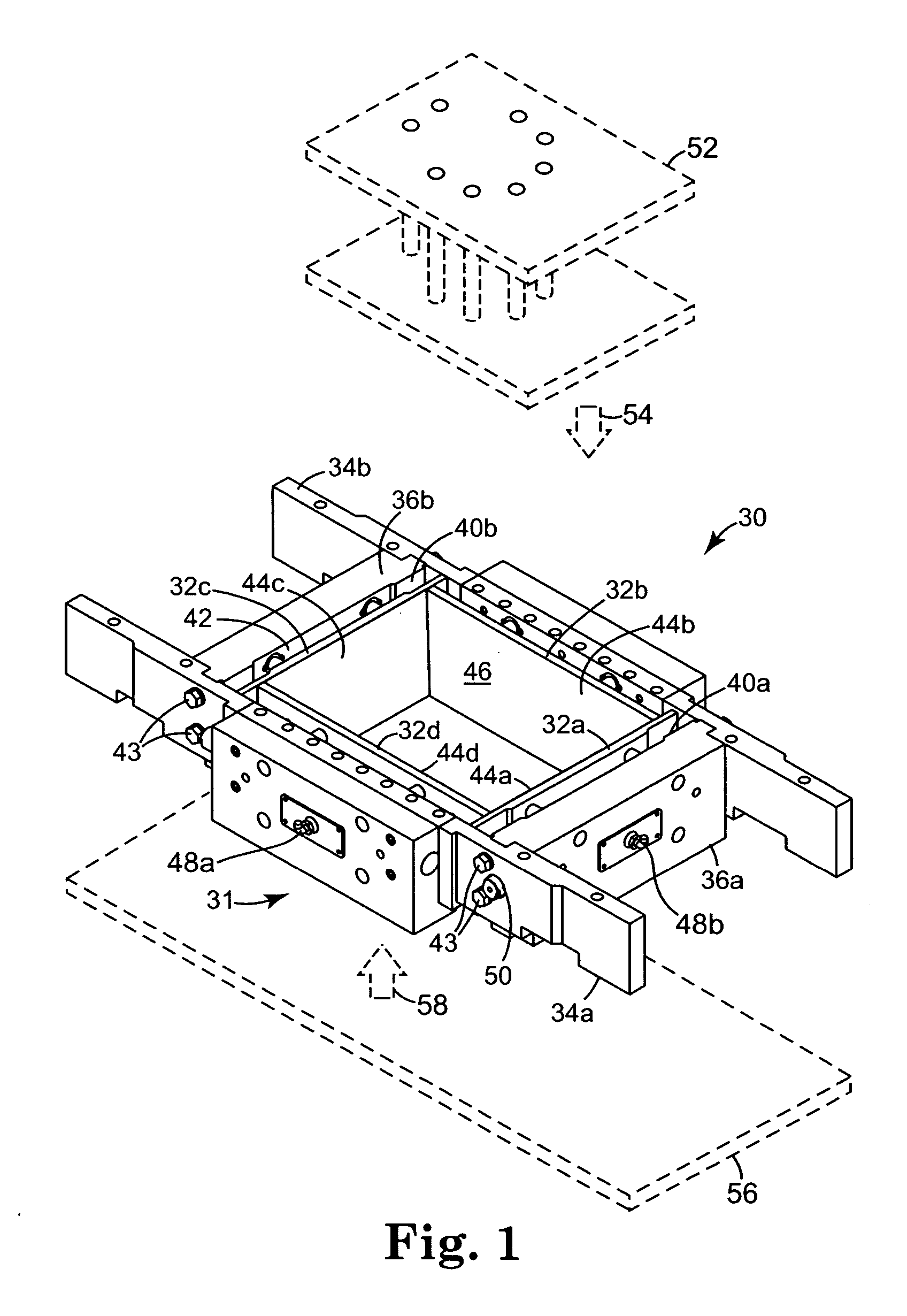

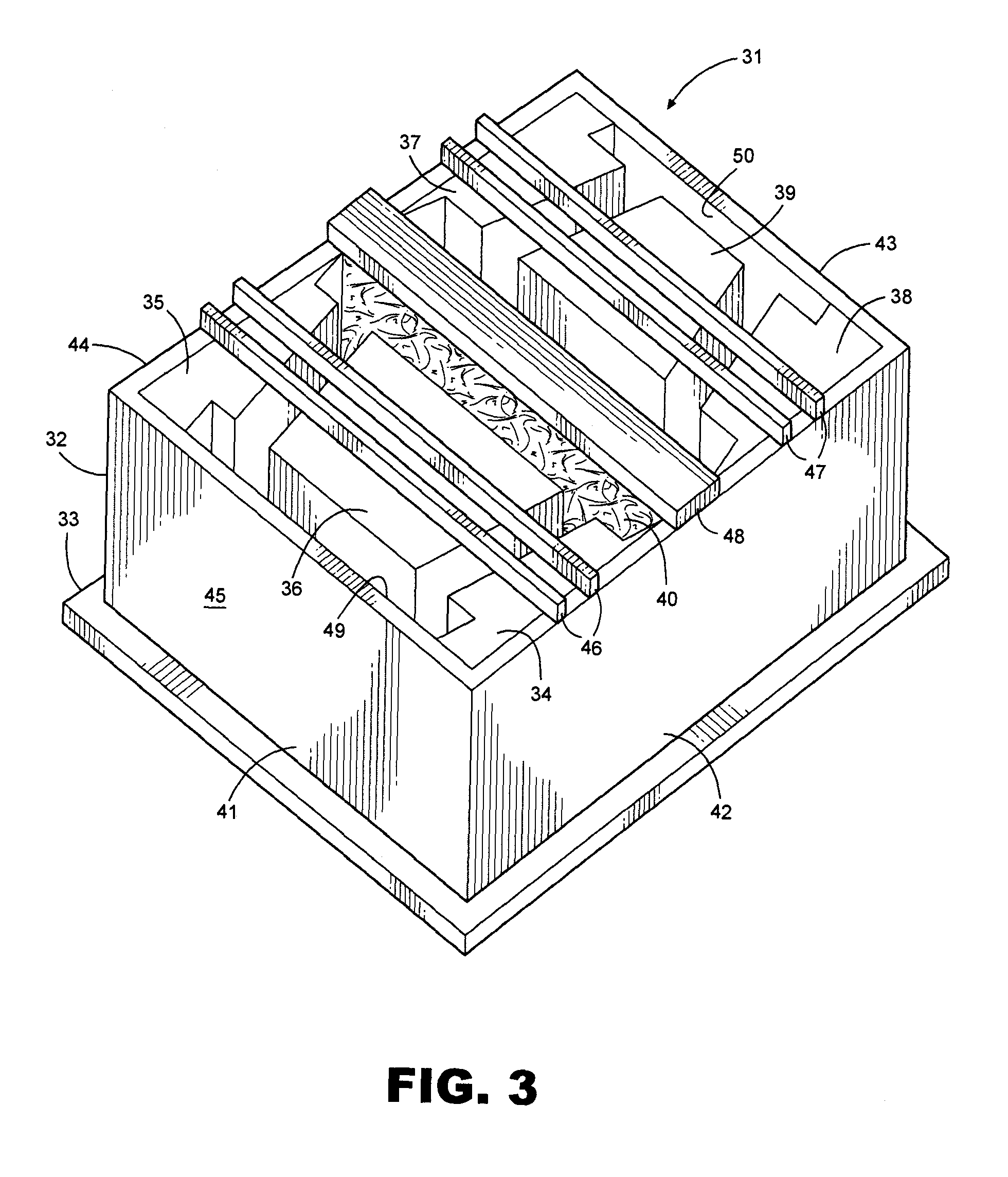

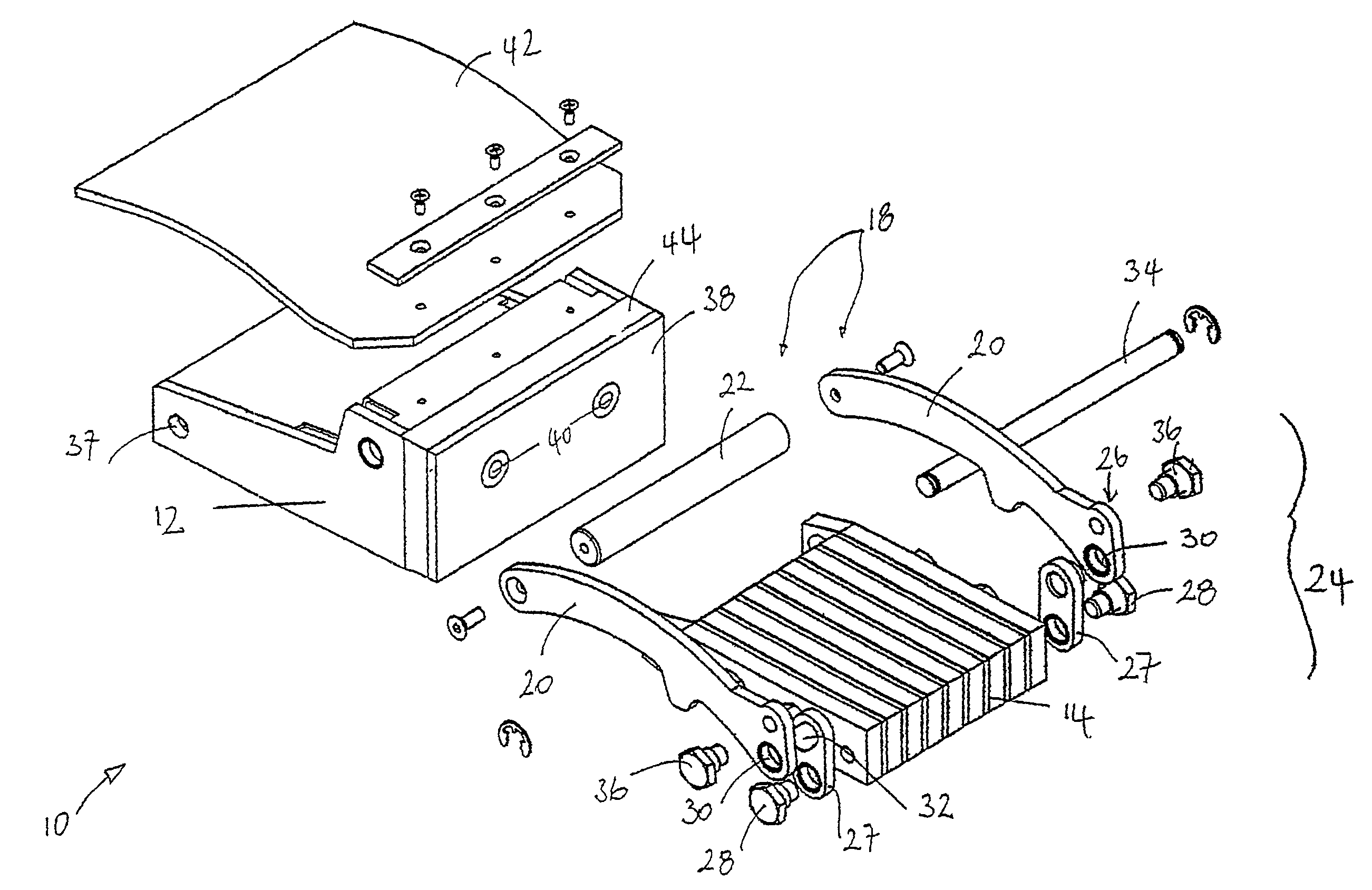

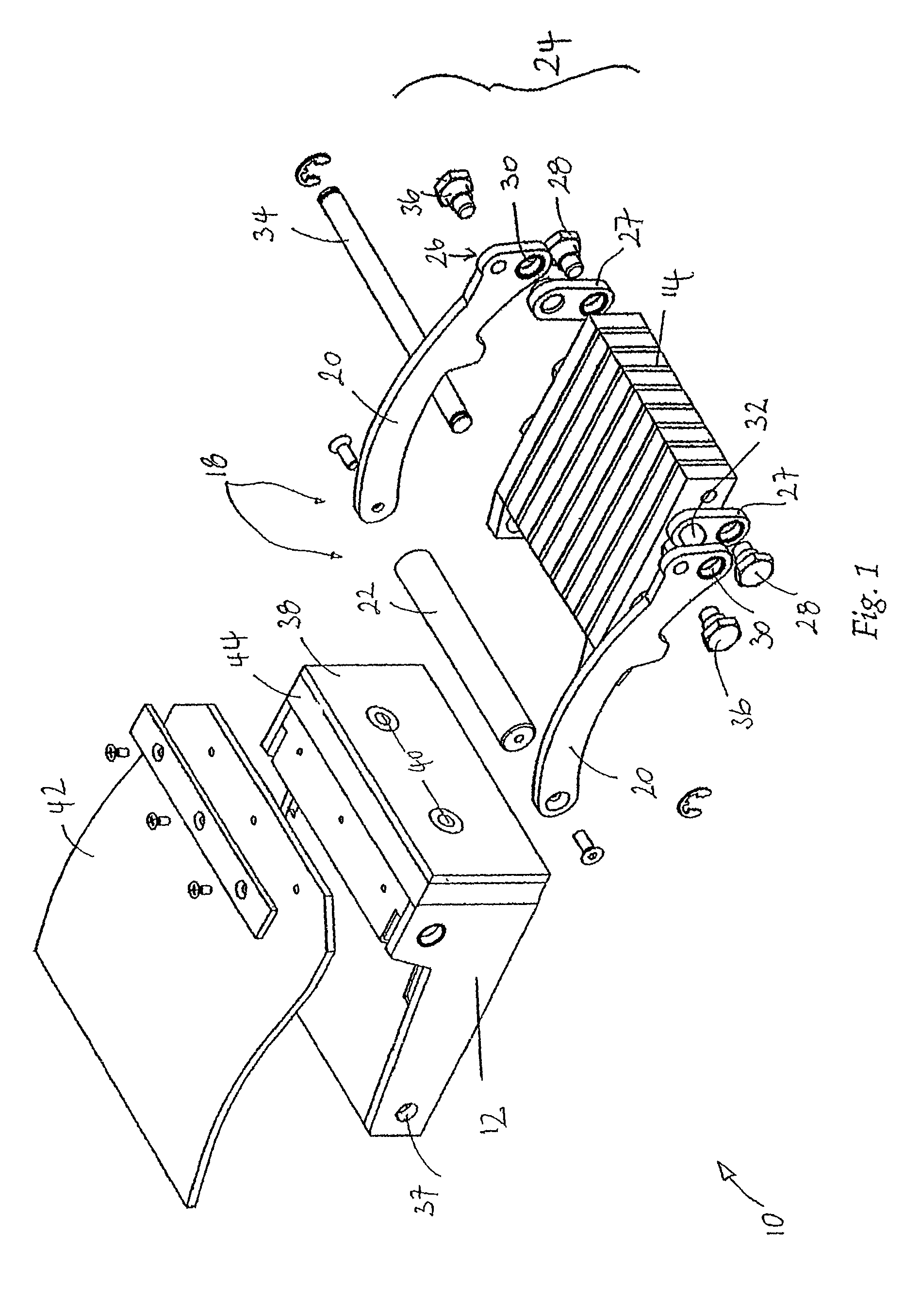

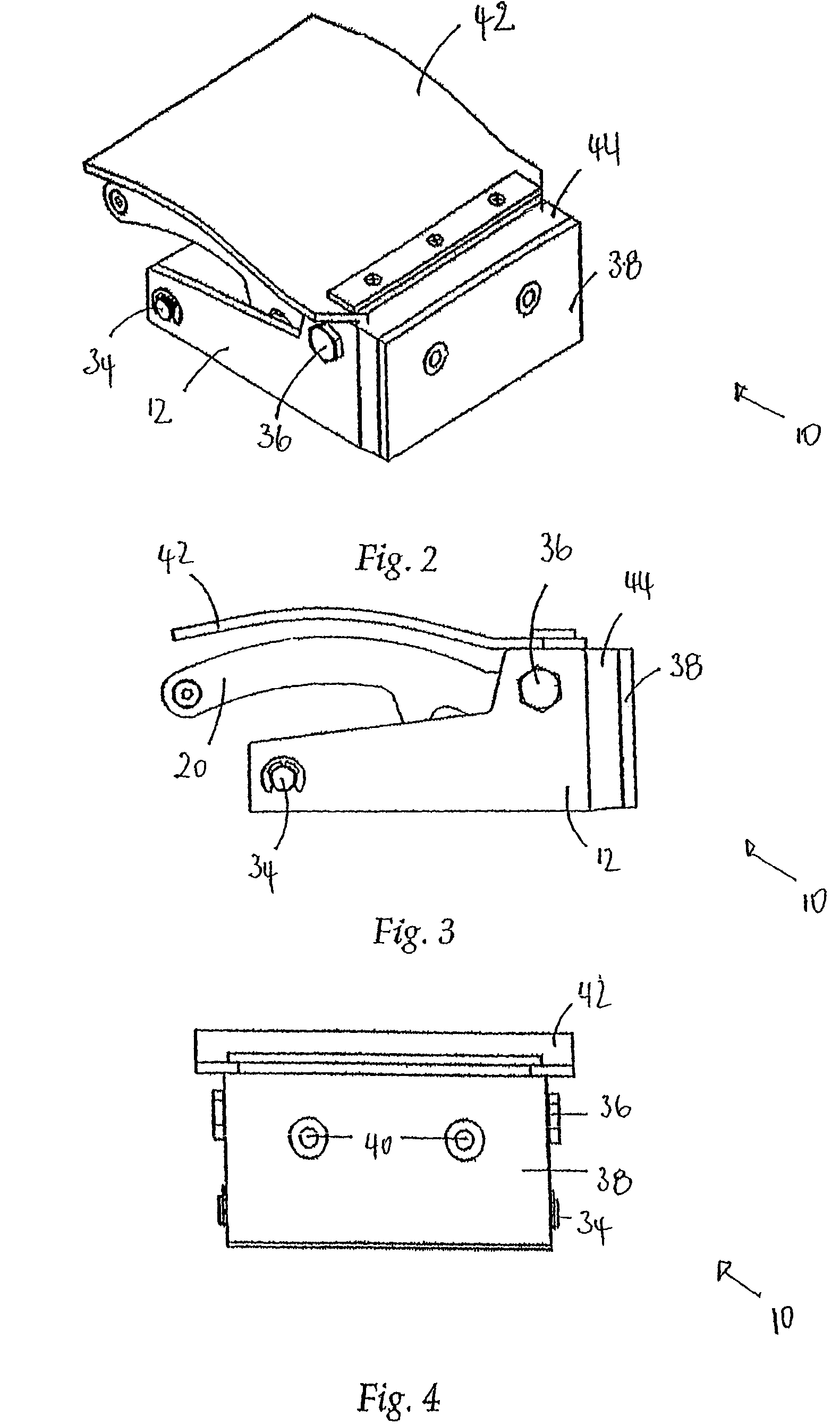

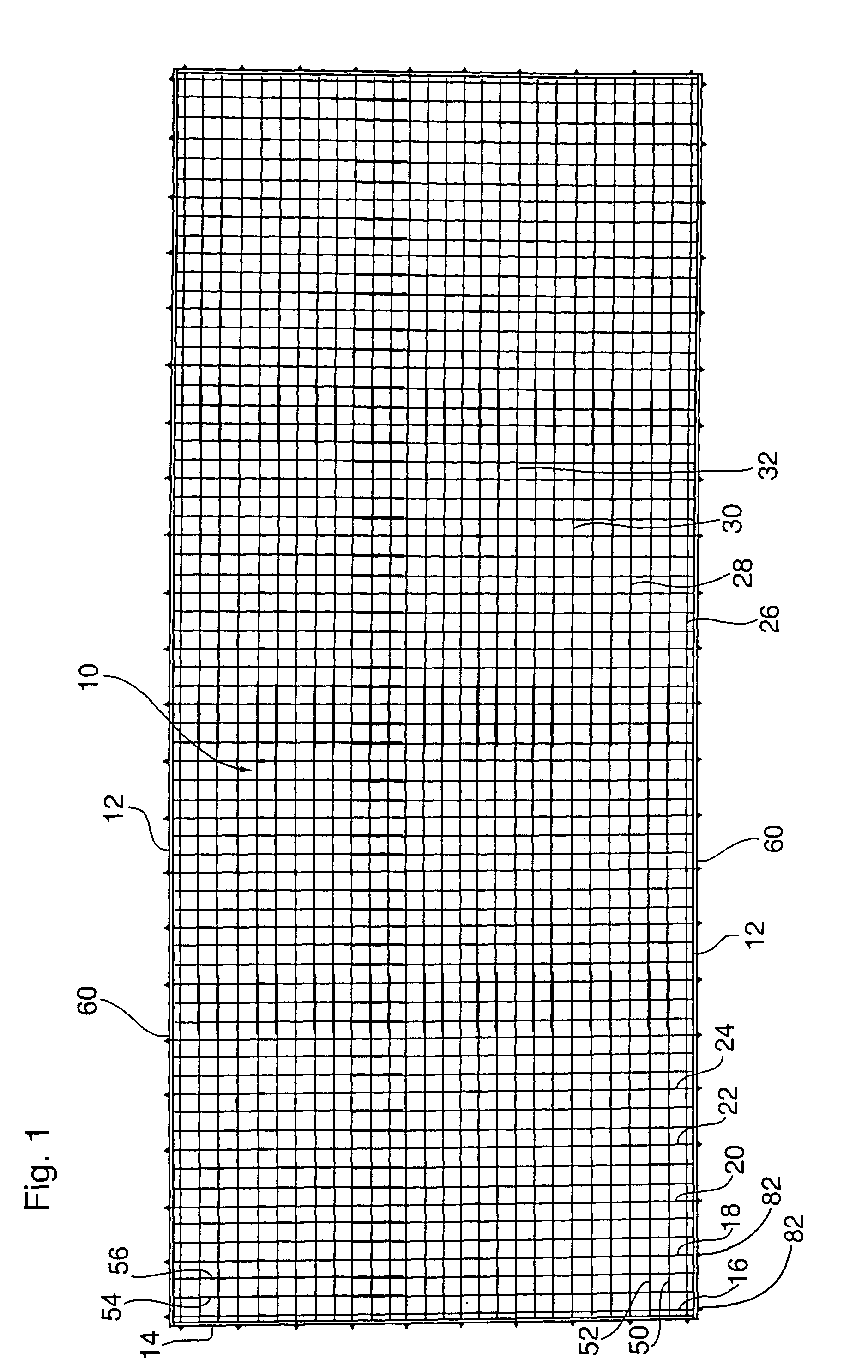

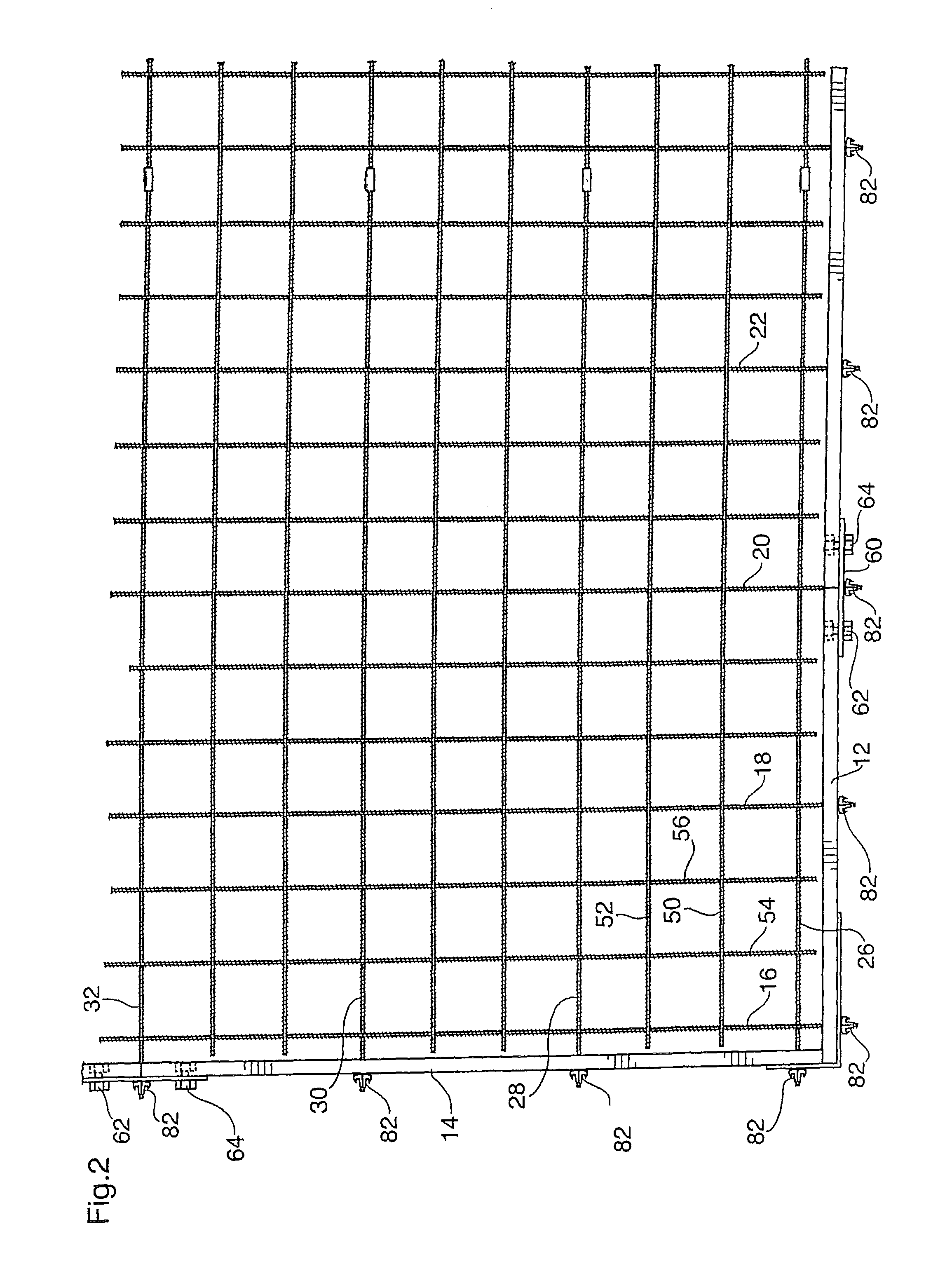

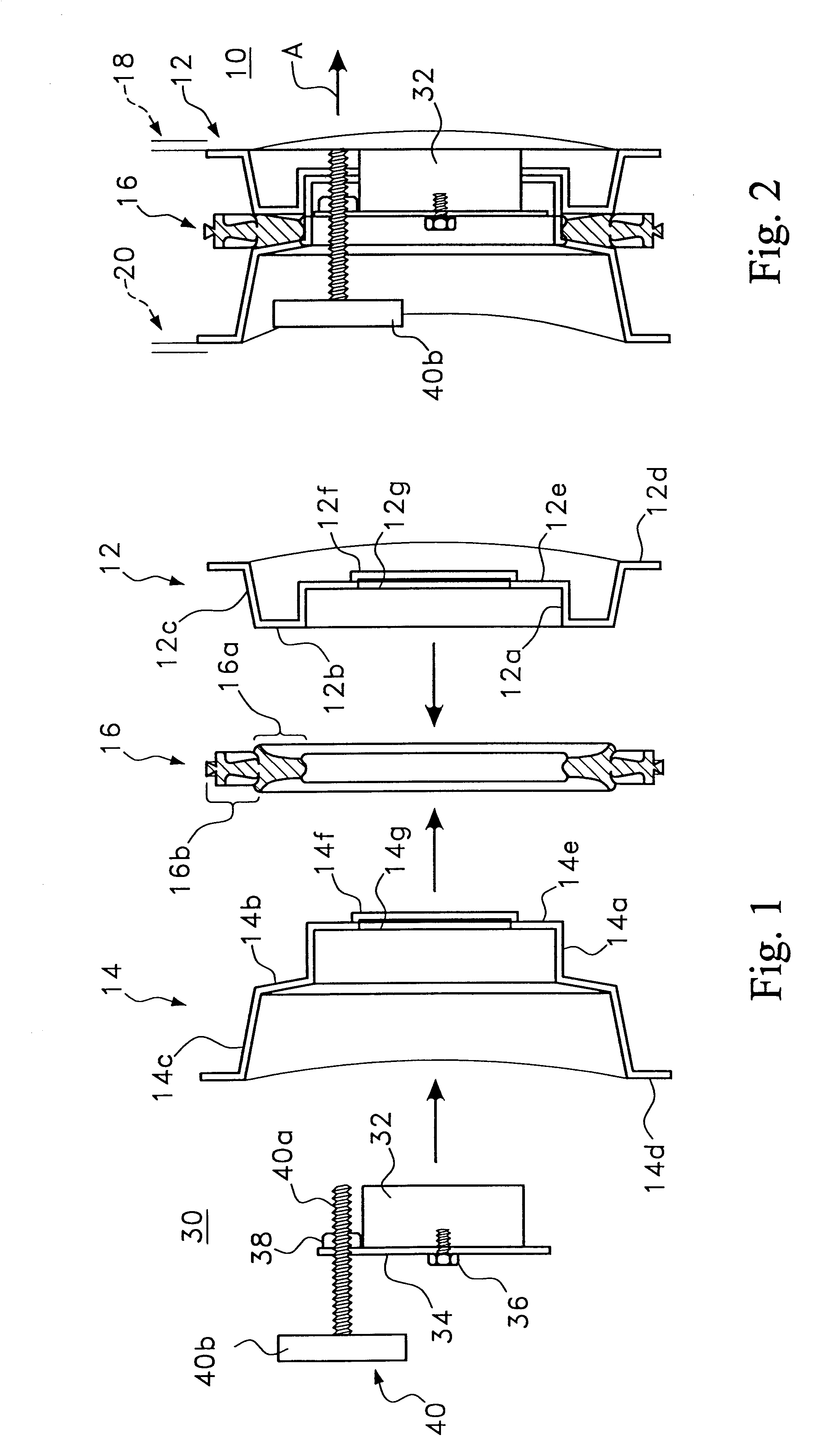

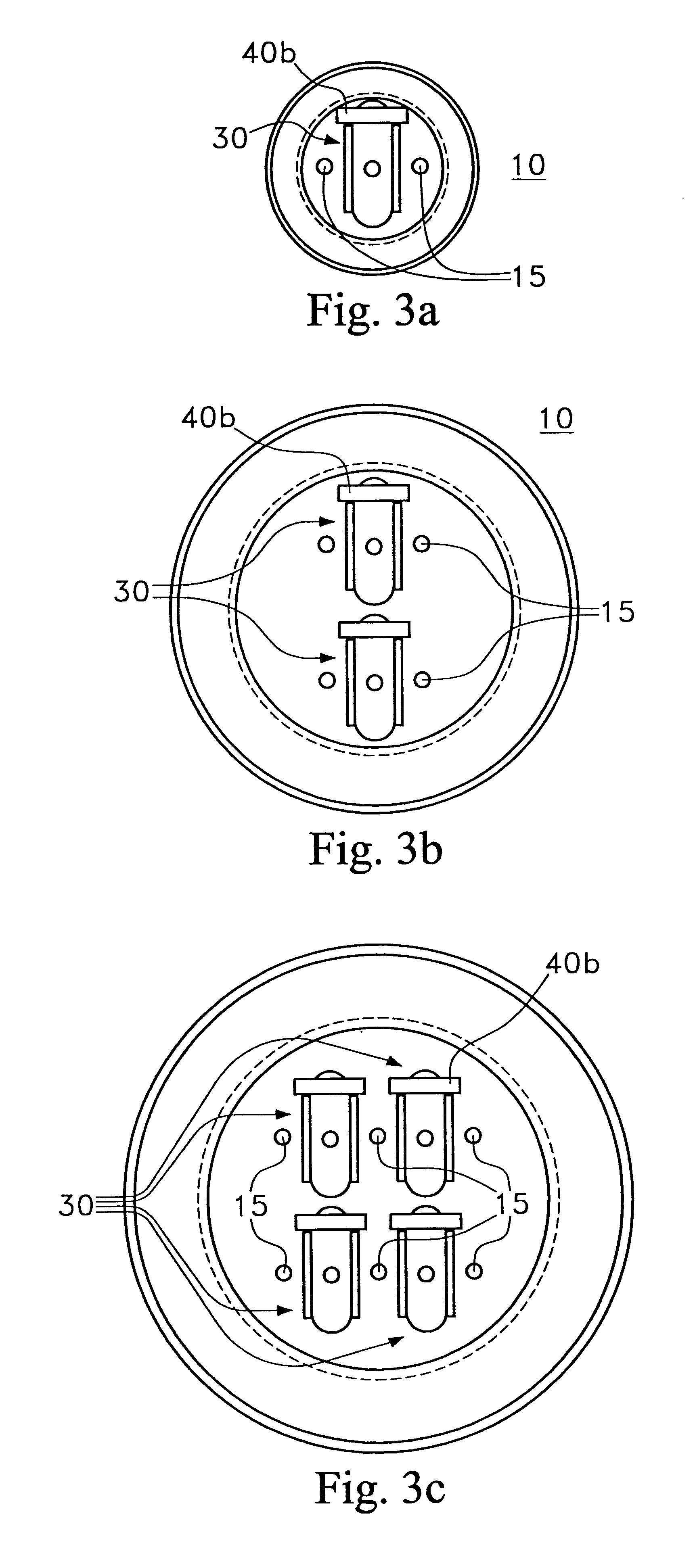

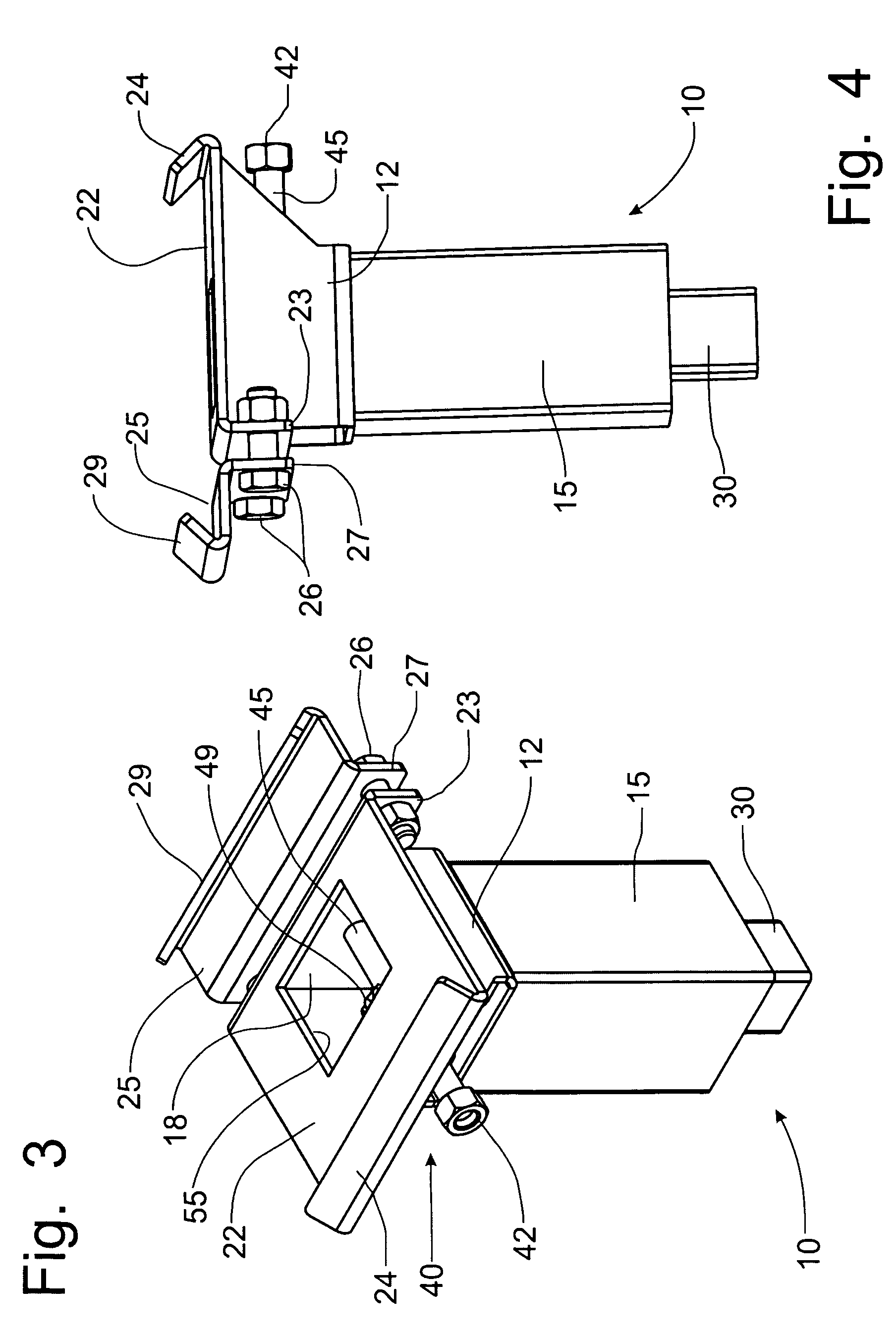

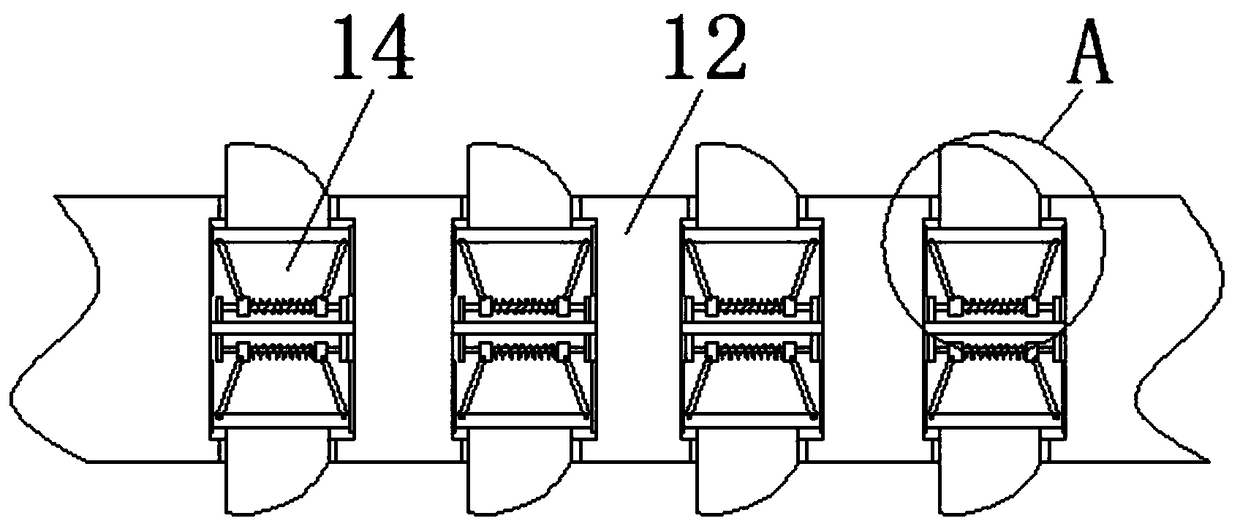

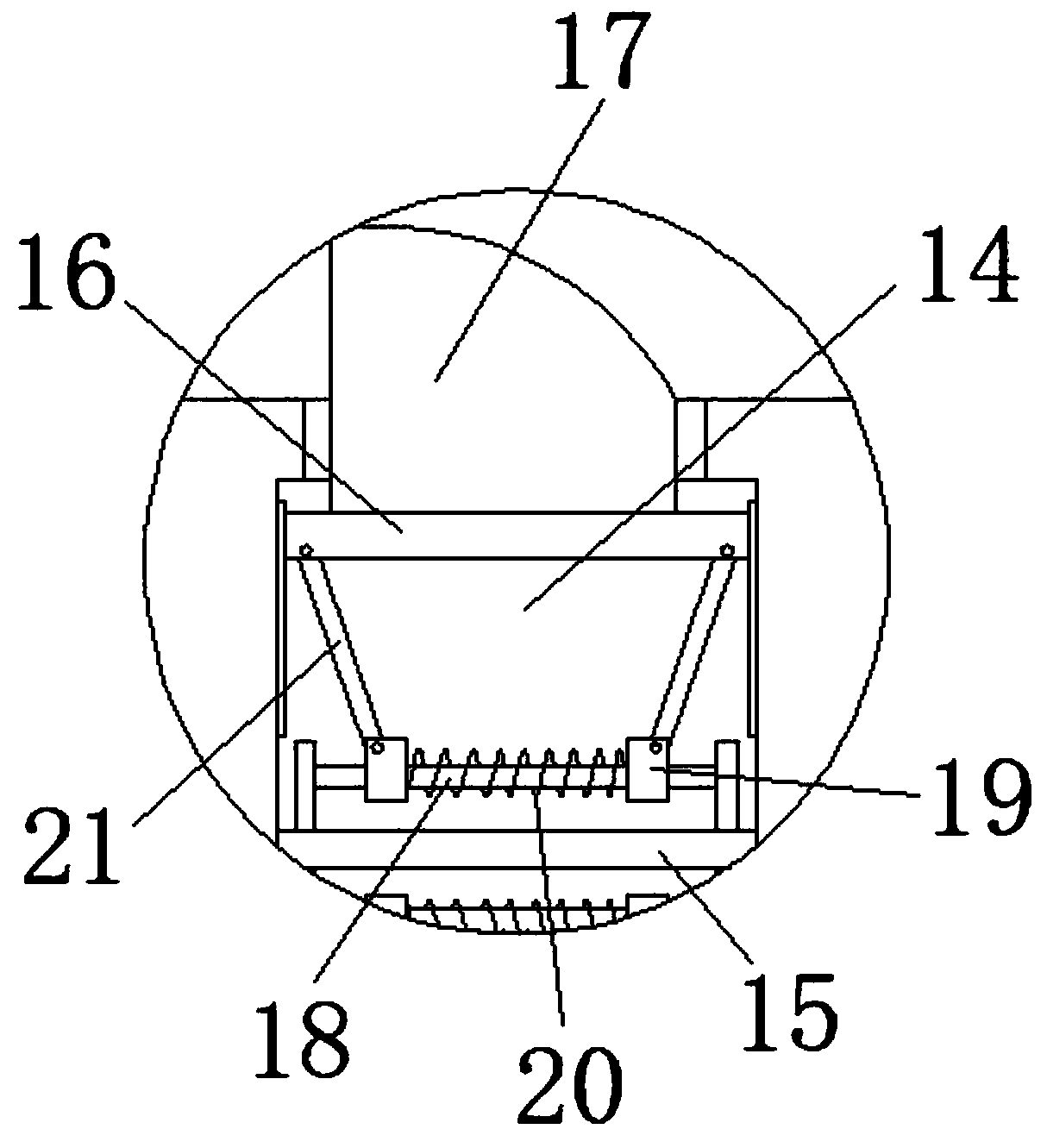

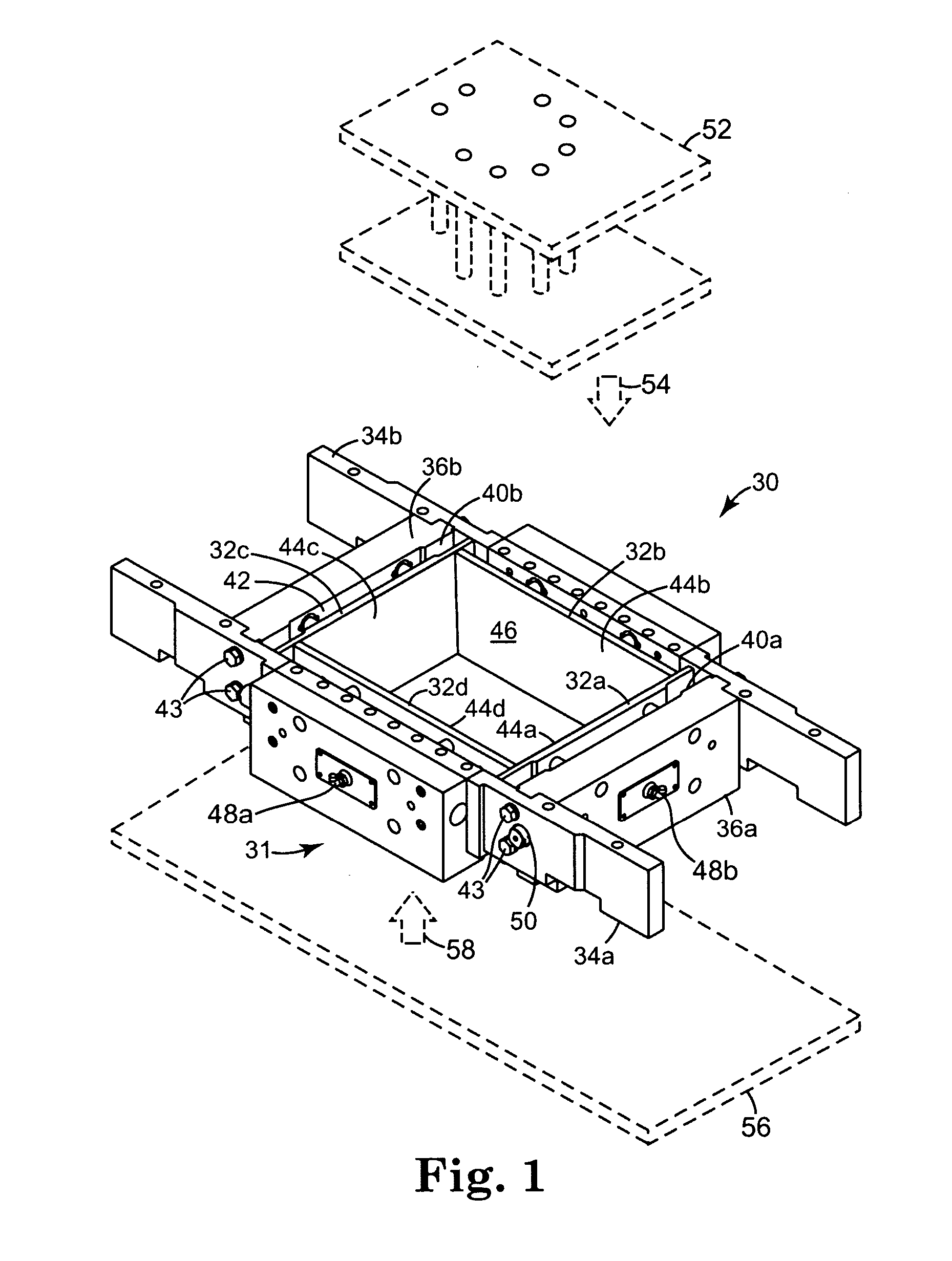

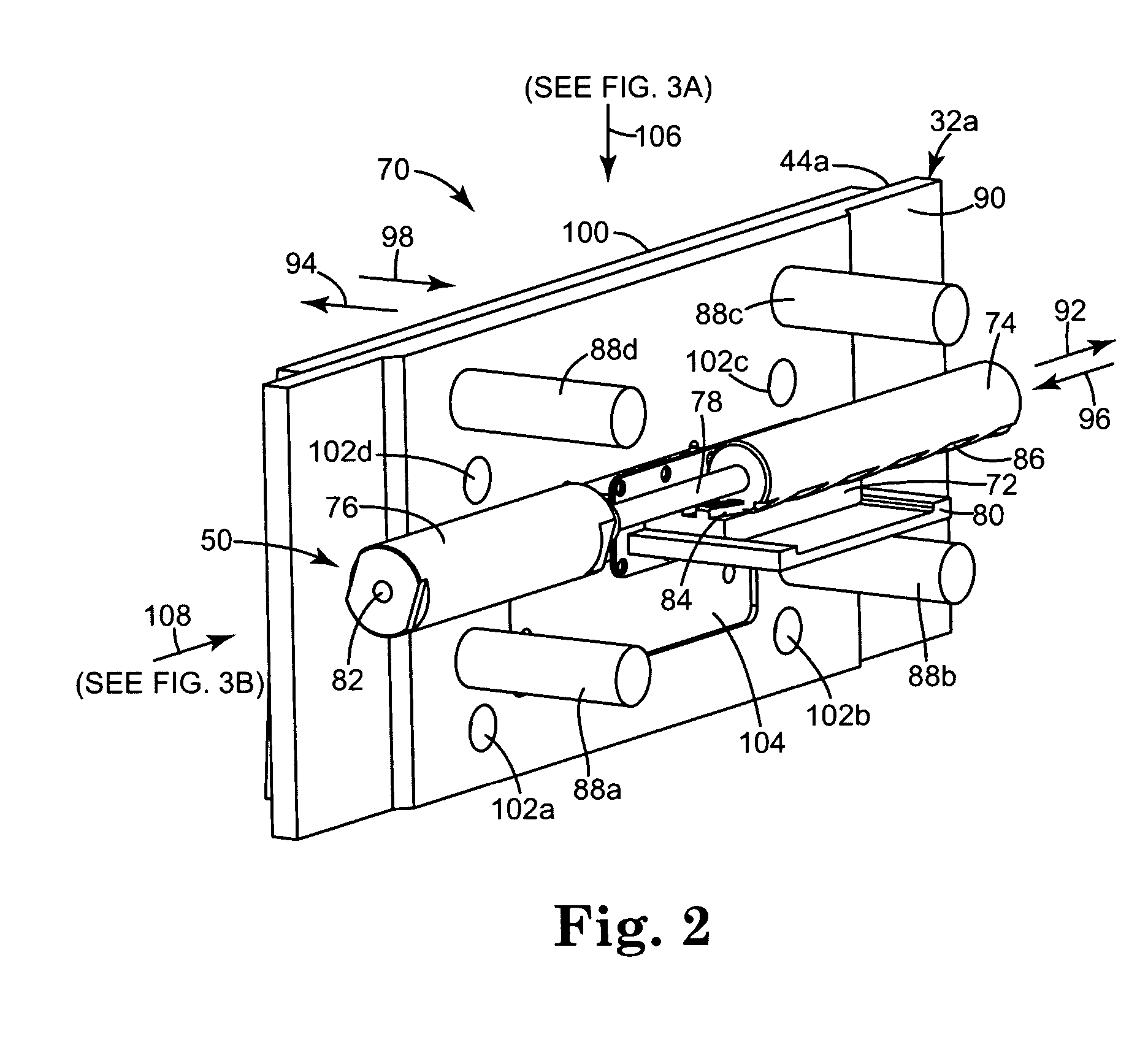

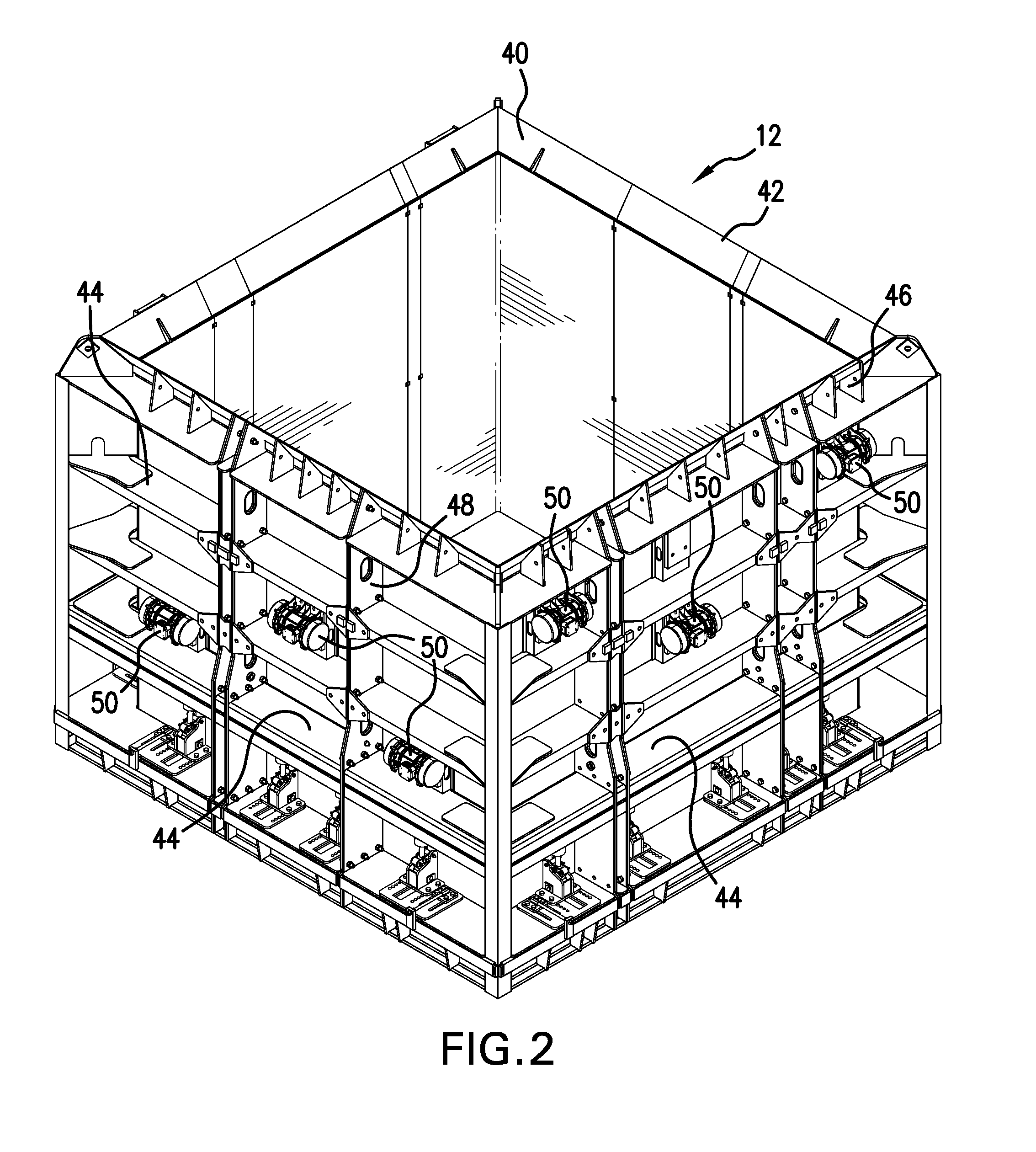

Concrete block mold with moveable liner

A mold assembly for manufacturing concrete blocks that is adapted for use in a concrete block machine. The mold assembly includes a plurality of liner plates, each having a major surface, the liner plates configured such that the major surfaces form a mold cavity having a desired form, and wherein at least one of the liner plates is moveable. A gear drive assembly is selectively coupled to the at least one moveable liner plate and configured to move the at least one moveable liner plate toward and away from an interior of the mold cavity. A stabilizer assembly is operatively coupled to the gear drive assembly and is configured to support the gear drive assembly as it moves the at least one moveable liner plate.

Owner:NESS INVENTIONS

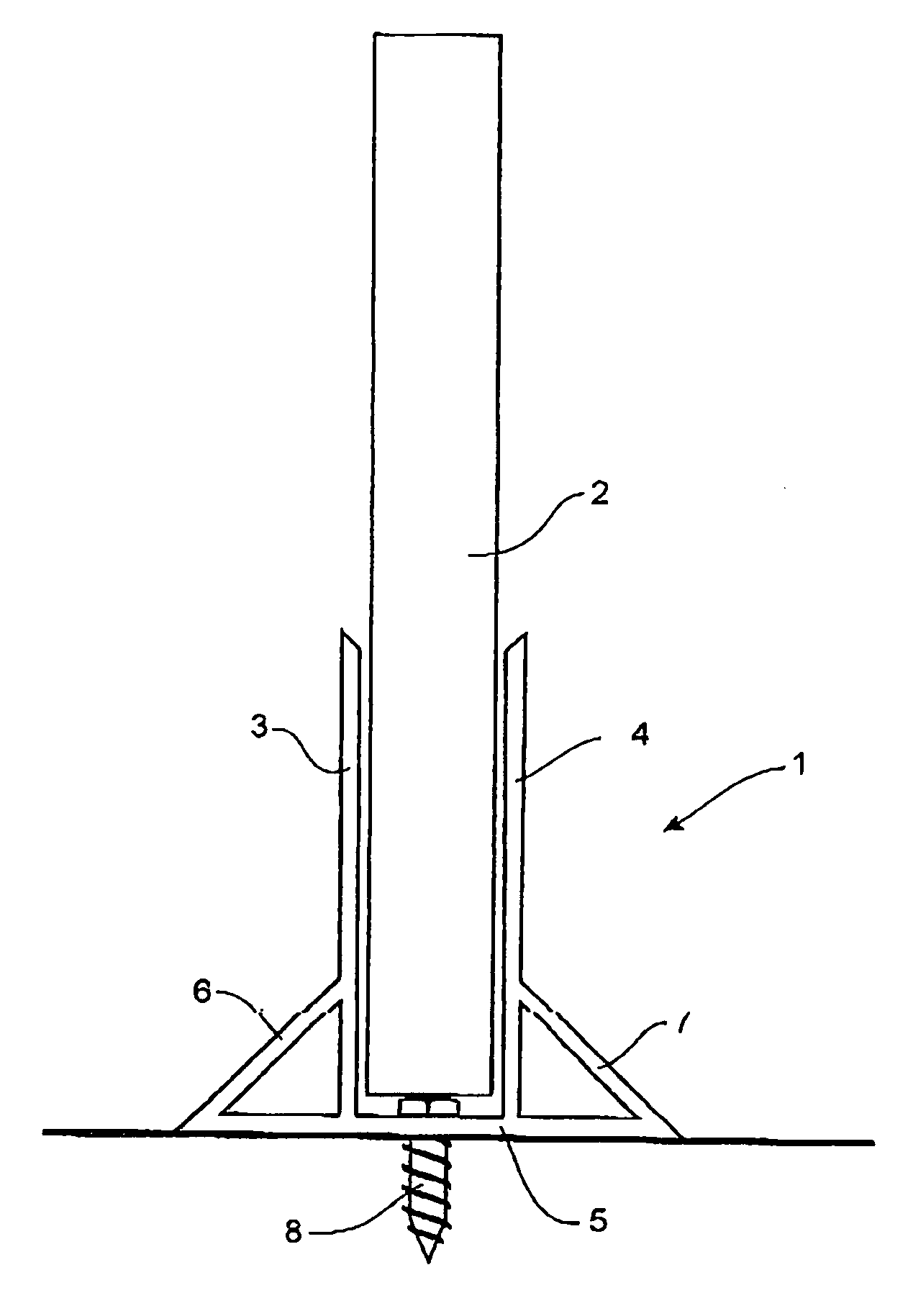

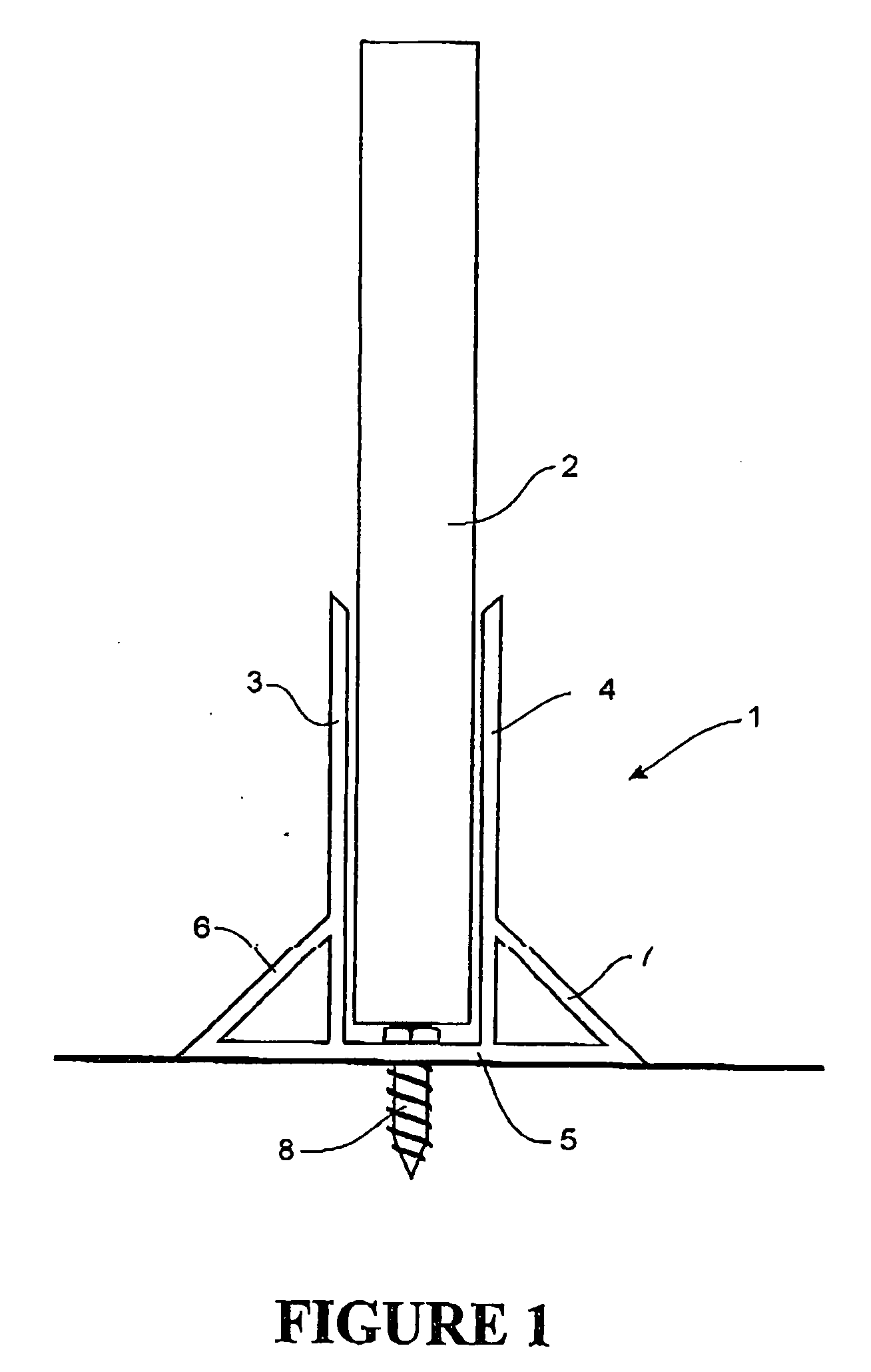

Method and apparatus for forming construction panels and structures

InactiveUS20050061948A1Low costEasy to useMouldsForms/shuttering/falseworksEngineeringFixed position

The present invention includes a formwork structure located on supporting surface, the structure having a side form perimeter including side form members, the perimeter defining a curable non-solid material retaining area; the formwork including side form support members that support the side form members, at least one of the side form support members being held in a fixed position relative to the supporting surface by a surface-to-member releasable securing device fixed to the supporting surface and which engages the side form support member, characterised in that the secured side form support member is adapted to permit another side form support member to be secured thereto by one or more releasable inter-member securing devices, which are separate to the surface-to-member securing device.

Owner:NICOLO ASSUNTA

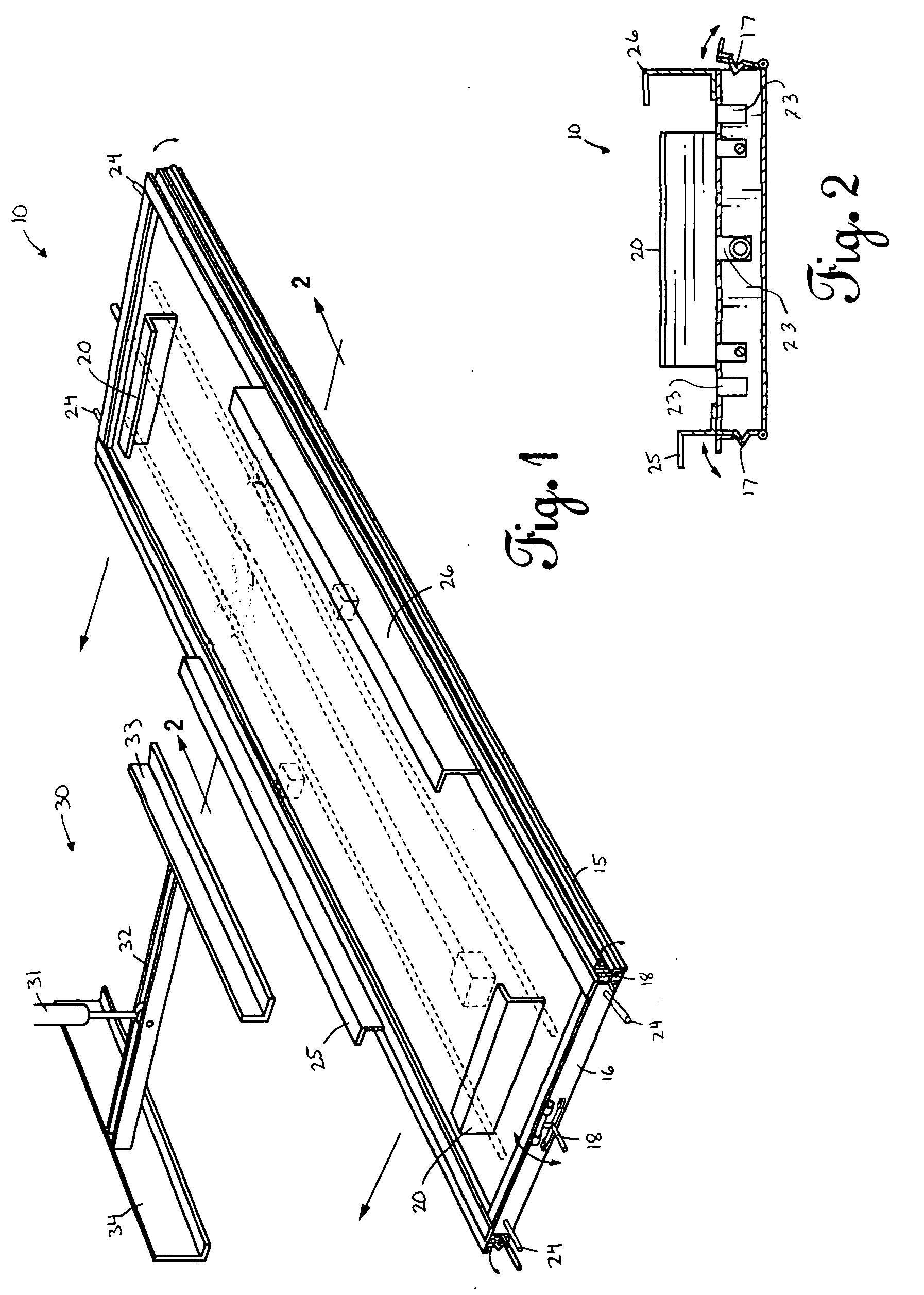

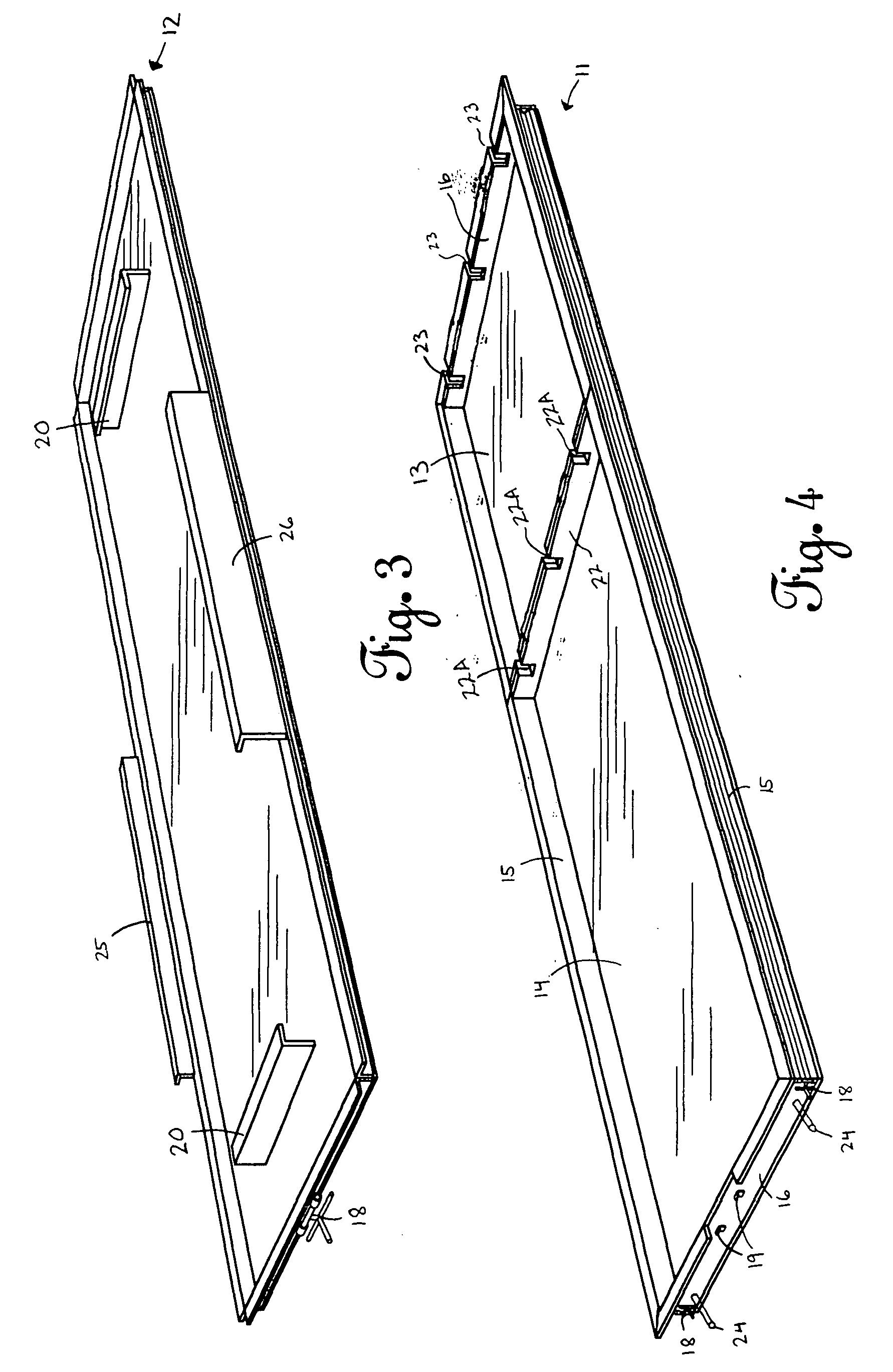

Panel formwork system

Formwork system for the process of casting prefabricated wall and slab panels that is flexible in width and height is provided. This formwork system includes two types of retractable bracing structures that are located on the sides and ends of mould structure. The height and width of panels can be varied by moving the linear retractable bracing structure, while the lever retractable bracing structure holds the side form firmly by clamping down the side form to the platform of the support structure. The thickness of the panel to be cast can be varied by using different modules of side form that are designed to produce a series of modules of various heights. Various patterns on the wall can be designed by incorporating specially designed channels in the mould.

Owner:HC PRECAST SYST

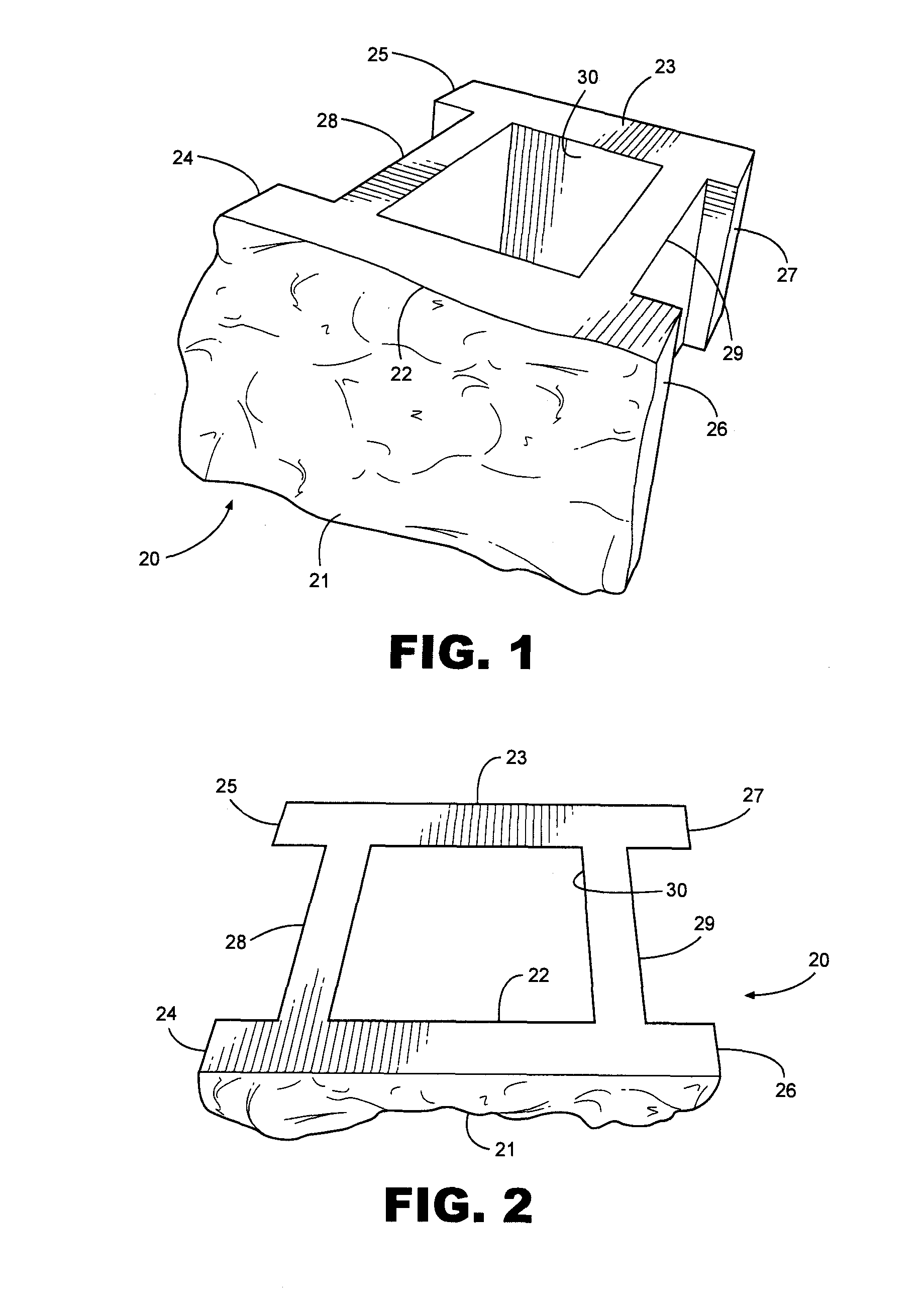

Method And Apparatus For Dry Casting Concrete Blocks Having A Decorative Face

A method and apparatus for dry casting concrete wall blocks having a decorative face. The blocks are cast in a mold including a form, a flexible insert and a steel pallet. Magnets hold the insert on the pallet while permitting the insert to slide on the pallet into alignment with the form when the form and pallet are moved together. The insert creates a decorative face on one or more simultaneously cast blocks. After the blocks are cast, the uncured blocks and the insert are moved together from the form and transferred to a curing area. After the blocks cure, they are separated from the insert. Preferably, additional concrete mix is provided adjacent the insert prior to compacting to avoid voids in the block face. Optionally, the shoe which compacts the concrete mix may be shaped to impart a lip adjacent a back edge of the block.

Owner:ROSETTA HARDSCAPES

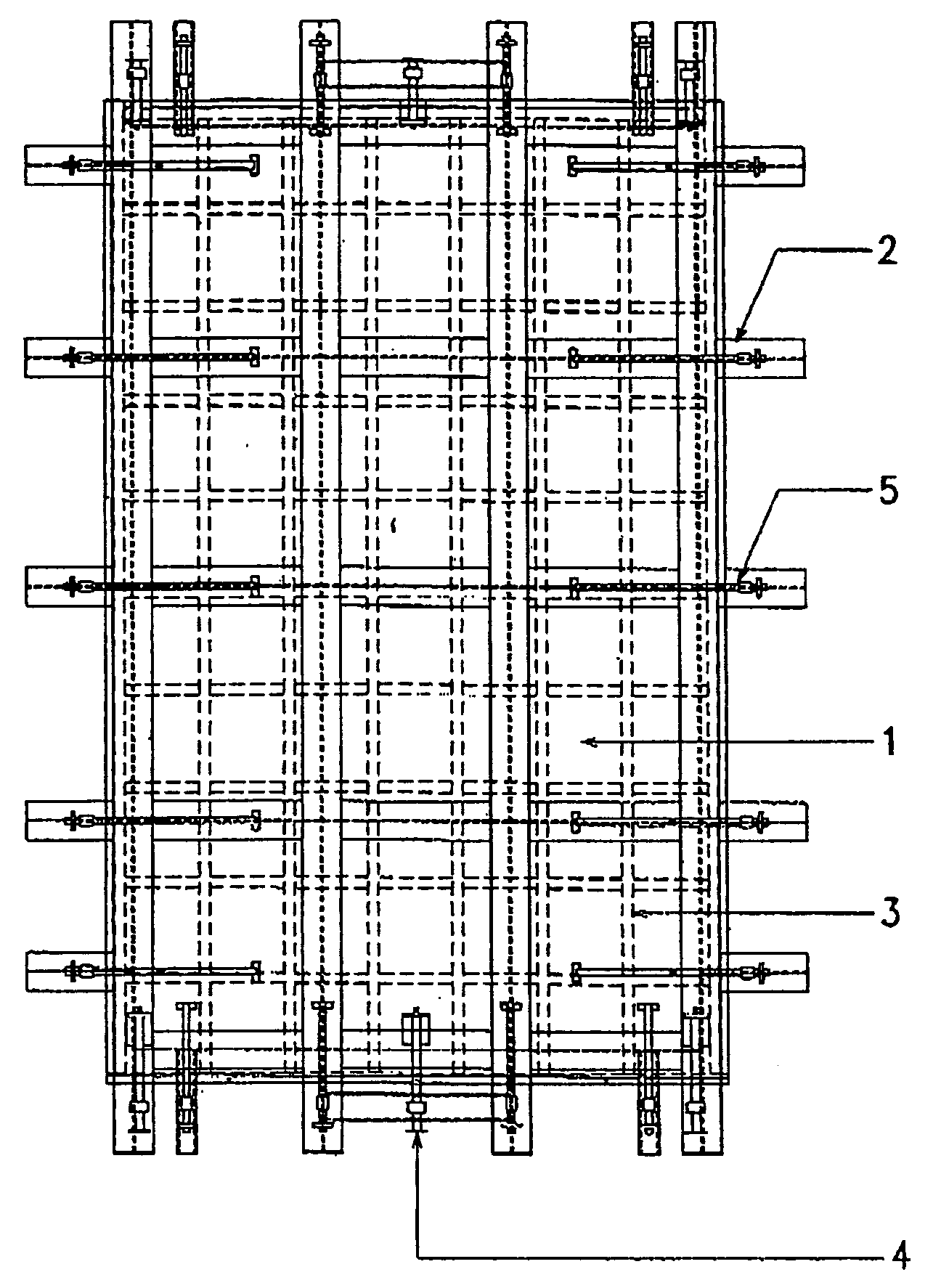

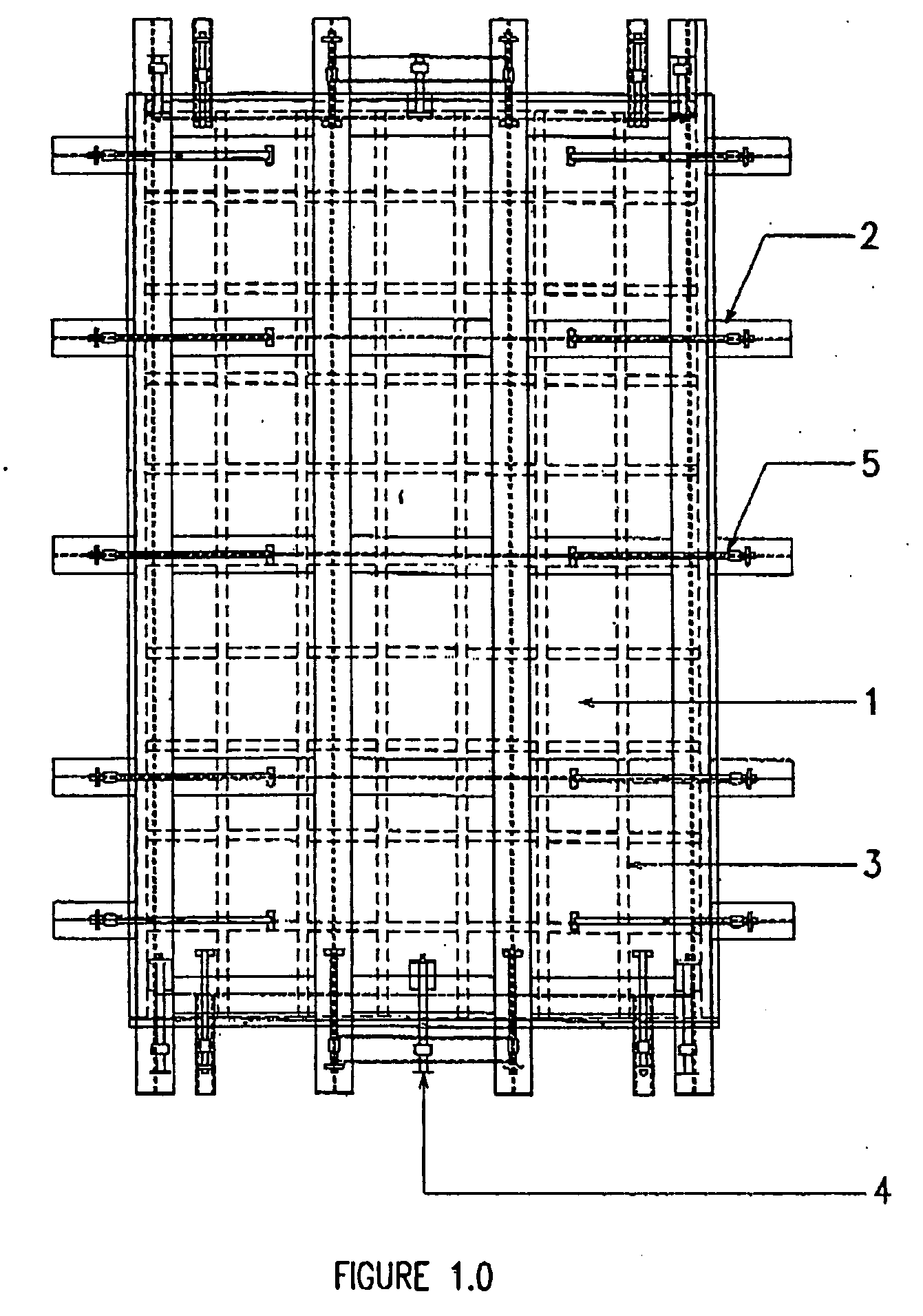

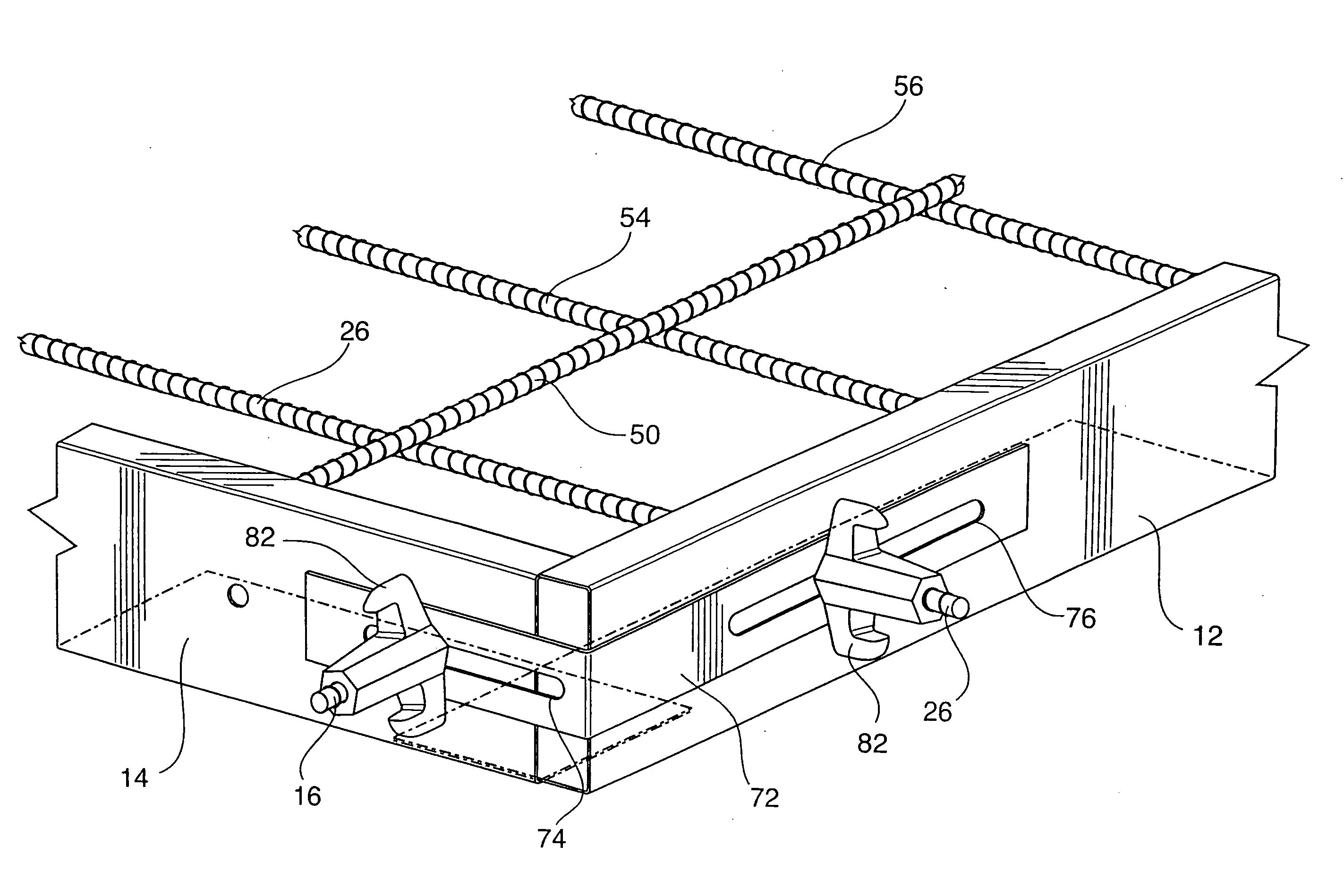

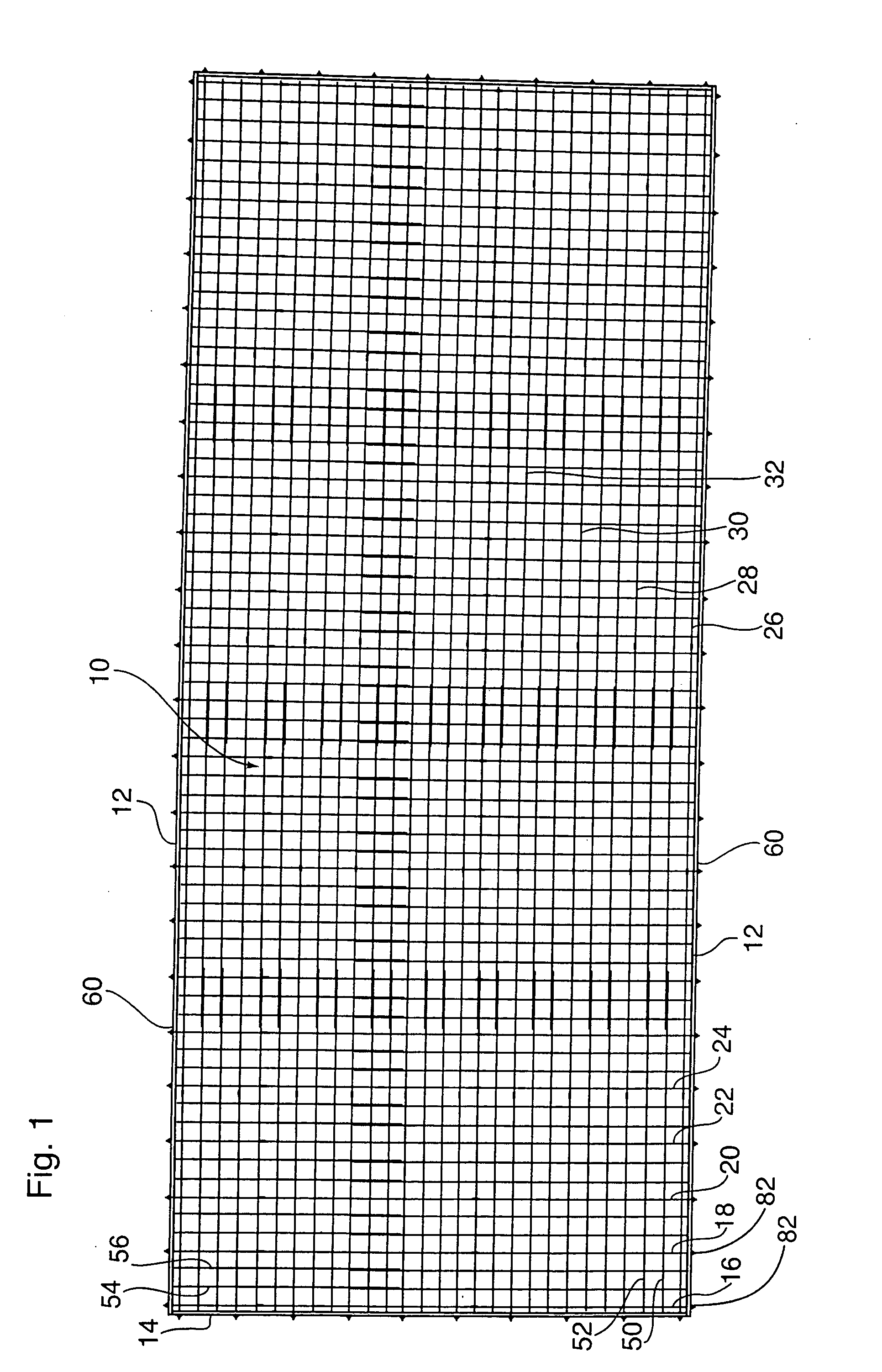

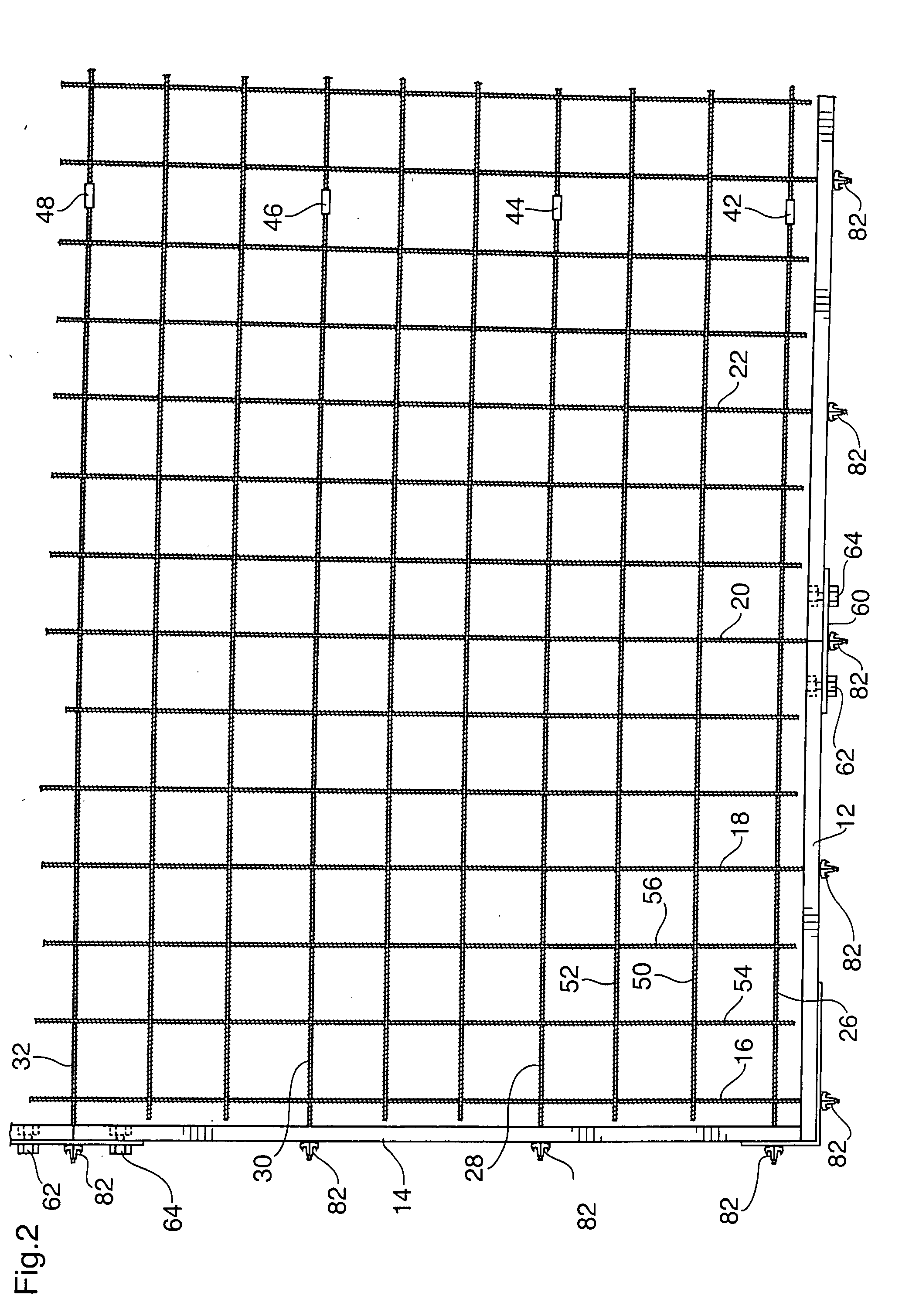

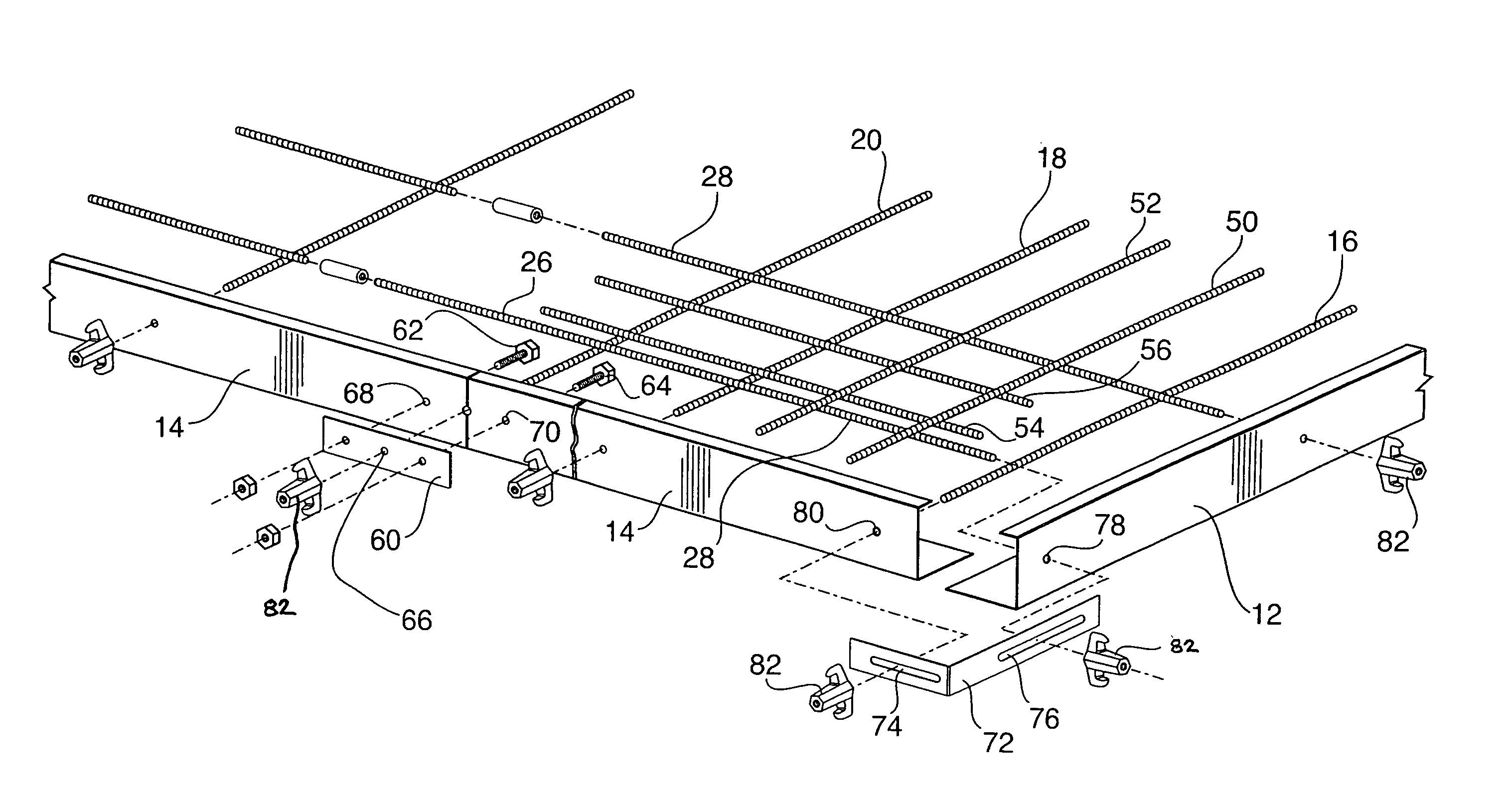

Concrete slab forming apparatus

A form for a concrete slab which consists of a series of similarly shaped steel plates that are held in predetermined spaced relationship by a series of special rebars, (special nuts are provided) before the slab is poured. The slab is criss-crossed by rebars which extend through the form to accurately locate the remaining steel plates as well as to prevent excessive cracking of the slab.

Owner:DRYBURGH RICHARD J +2

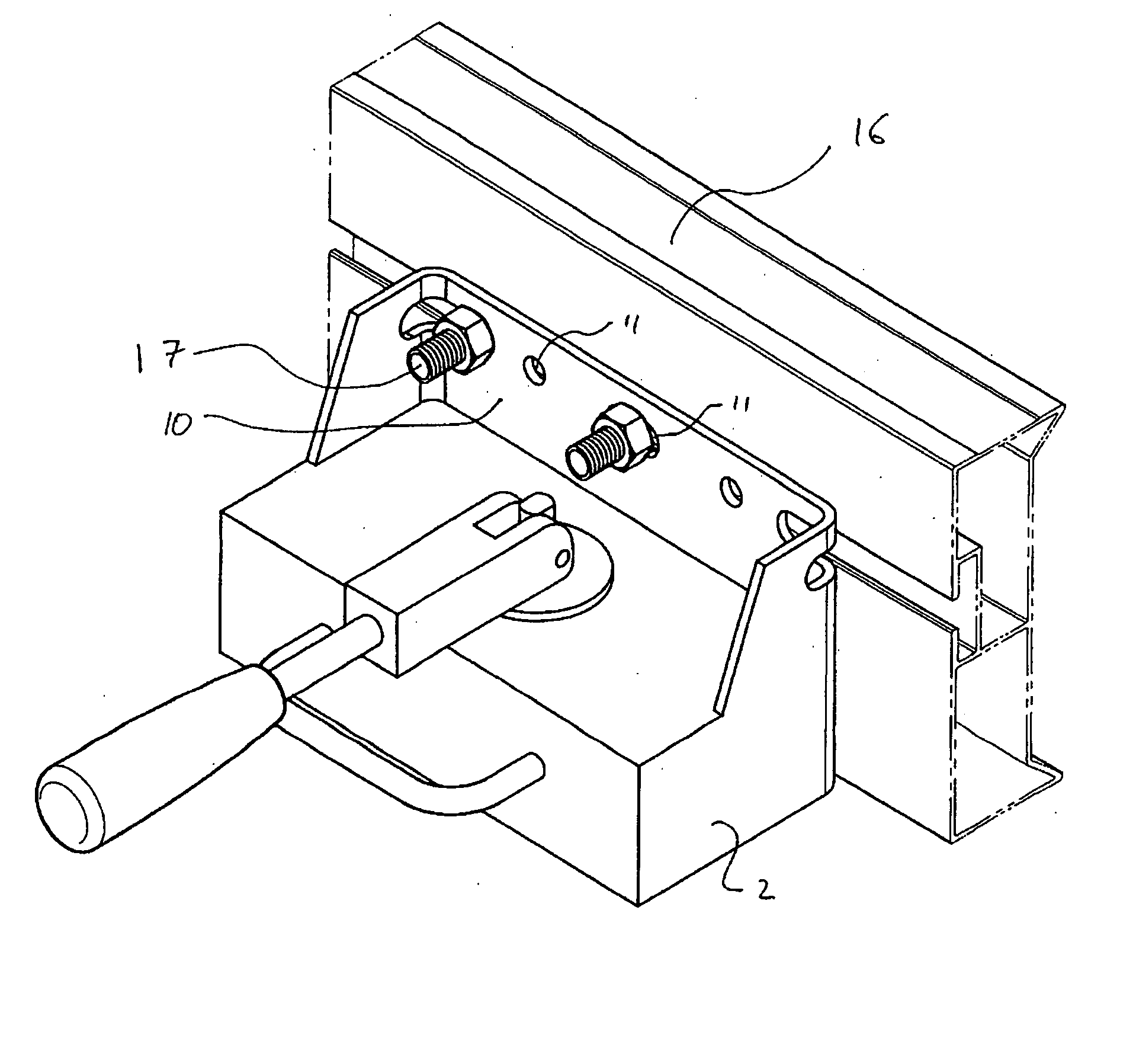

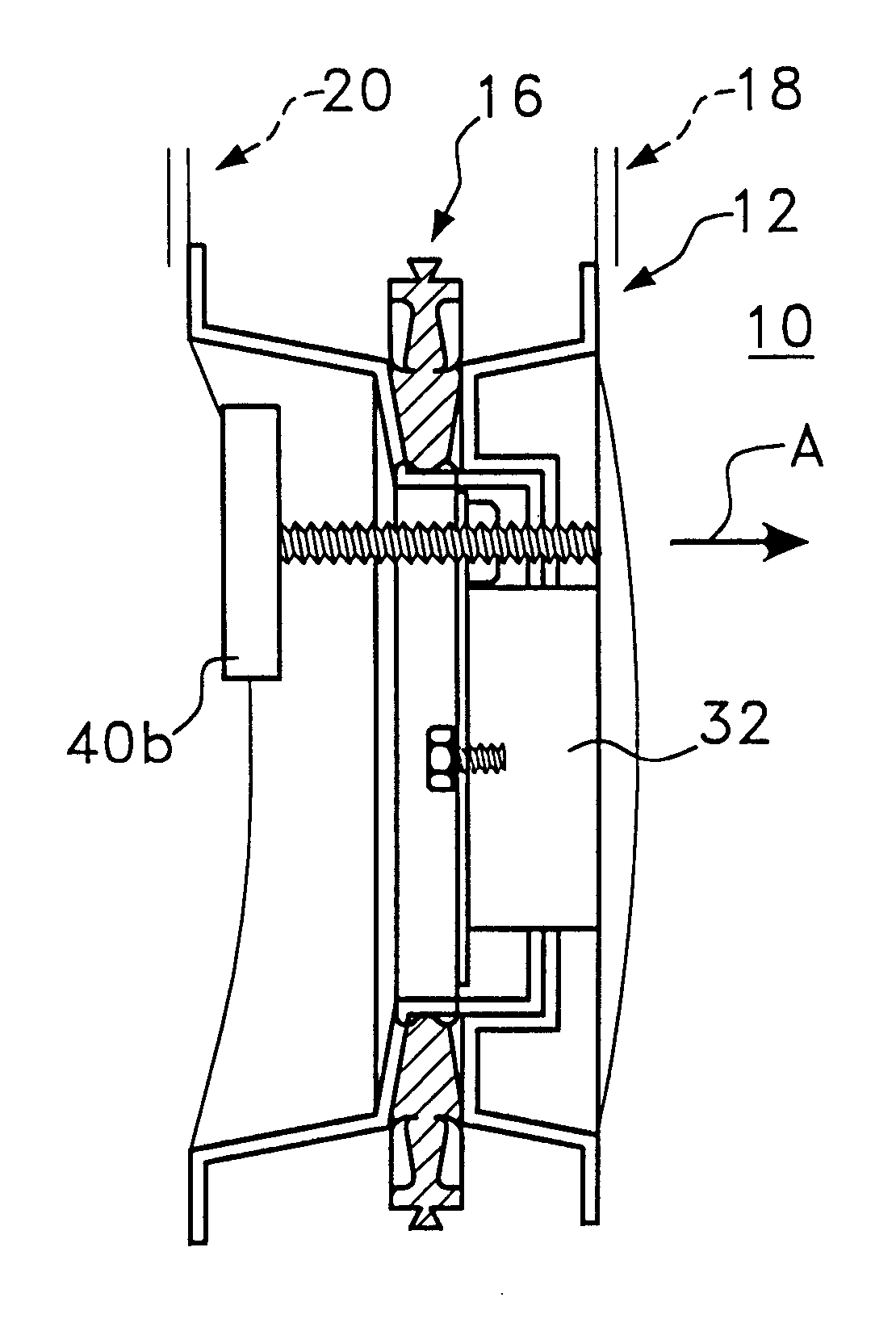

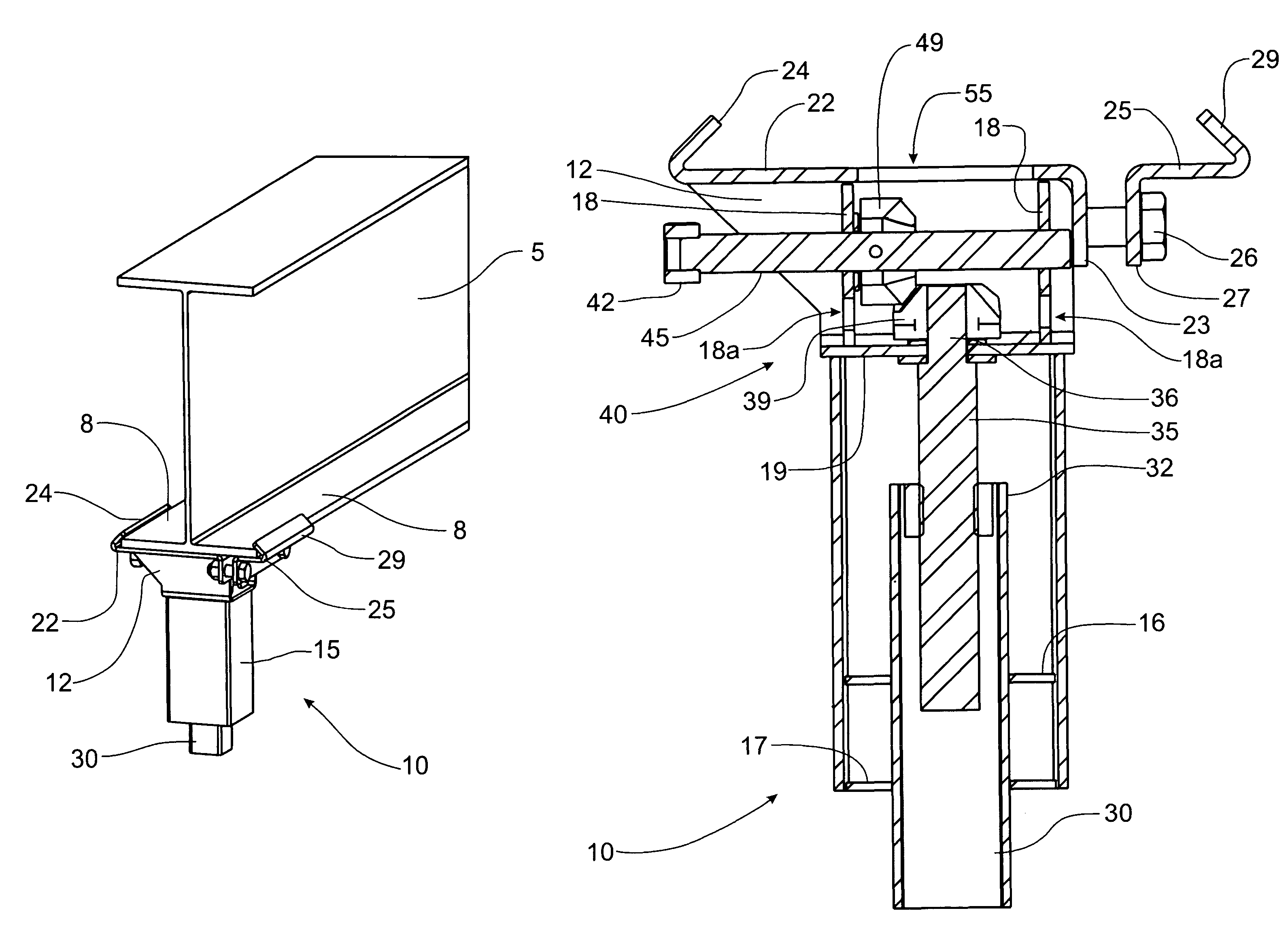

Magnetic clamp

ActiveUS7850142B2Increase coefficient of frictionImprove clippingElectromagnets without armaturesPermanent magnetsEngineeringPrecast concrete

A magnetic clamp (10) for use in clamping metal formwork in precast concrete manufacture includes a housing (12). A magnet (14) is displaceably arranged within the housing (12). A displacement mechanism (18) is displaceably arranged on the housing (12) to displace the magnet (14) relative to the housing (12). A force amplification mechanism (24) is connected to the magnet (14) and at least a portion of the force amplification mechanism (24) is interposed between the displacement mechanism (18) and the magnet (14).

Owner:SRB CONSTR TECH

Concrete slab forming apparatus

A form for a concrete slab which consists of a series of similarly shaped steel plates that are held in predetermined spaced relationship by a series of special rebars, (special nuts are provided) before the slab is poured. The slab is criss-crossed by rebars which extend through the form to accurately locate the remaining steel plates as well as to prevent excessive cracking of the slab.

Owner:DRYBURGH RICHARD J +2

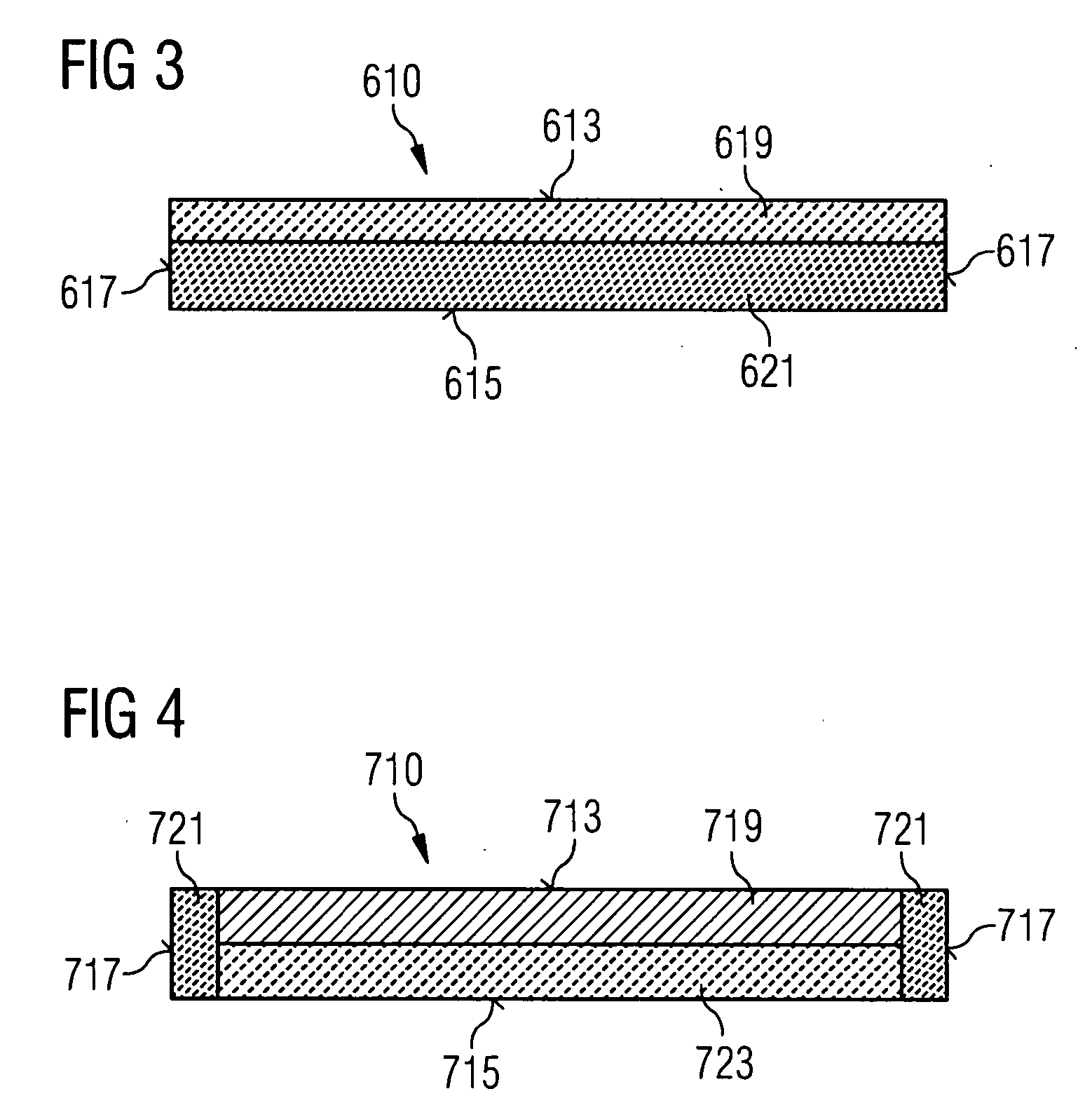

Heat Shield Element, Method and Mold for the Production Thereof, Hot-Gas Lining and Combustion Chamber

InactiveUS20070289307A1Easy to disassembleLittle effortMould separation apparatusMouldsElectrical resistance and conductanceCold side

There is described a heat shield element comprising a hot side which is turned towards the hot medium, a cold side which is turned away from the hot medium, peripheral sides which connect the hot side to the cold side and a material volume which is defined by the hot side, the cold side and the peripheral sides, wherein the material volume comprises at least two material areas which are made of different materials. The materials are different from each other at least in respect of their resistance and / or thermal expansion coefficient.

Owner:SIEMENS AG

Placement ring assembly having magnetic securing means

InactiveUS6371436B1Eliminate needEasy to separateForms/shuttering/falseworksCoatingsCushioningEngineering

A placement ring assembly has inside and outside mandrels releasably fastened together to secure and align a pipe connector gasket therebetween. A permanent magnet of a magnet assembly is inserted through co-aligned openings in the mandrels and is magnetically attracted to an inner-core of a casting assembly. When the cast member is set, a mechanical release is rotated to release the magnetic attraction between the permanent magnet and the mold core. One of the mandrels may be provided with shock absorbing knockout pads while the other mandrel has openings aligned with the knockout pads to enable the knockout pads to be struck with a hammer to separate the mandrels. Rubber cushioning members absorb the shock of the impacts, protecting the mandrel from permanent damage. One-piece hole formers may likewise be provided with a magnetic assembly having a mechanic release as well as knock-out pads.

Owner:WESTHOFF JAMES A +1

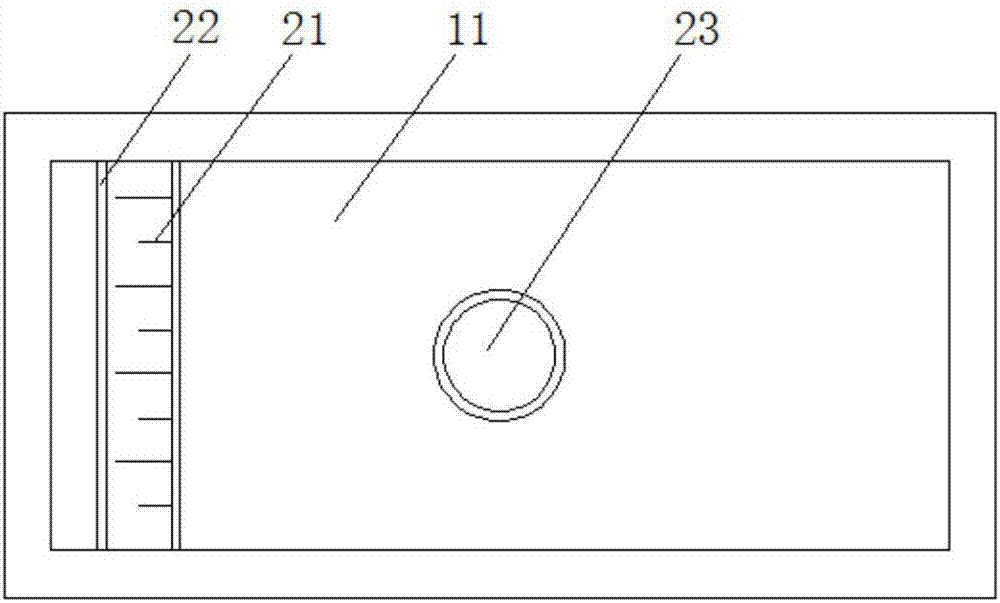

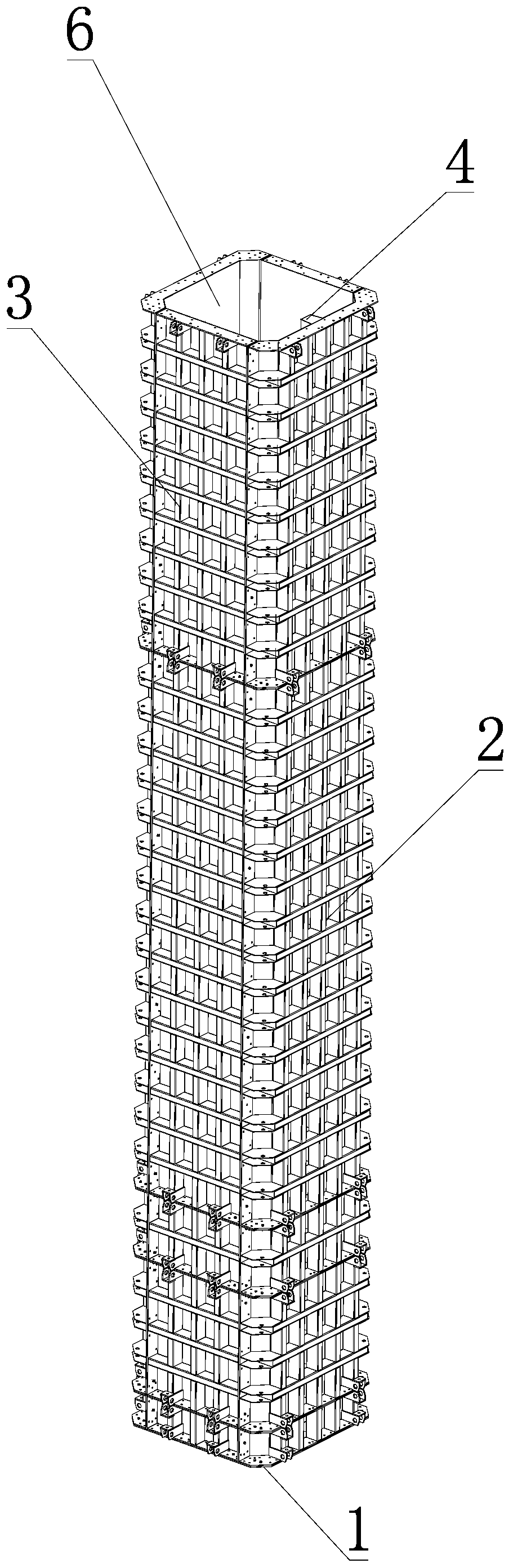

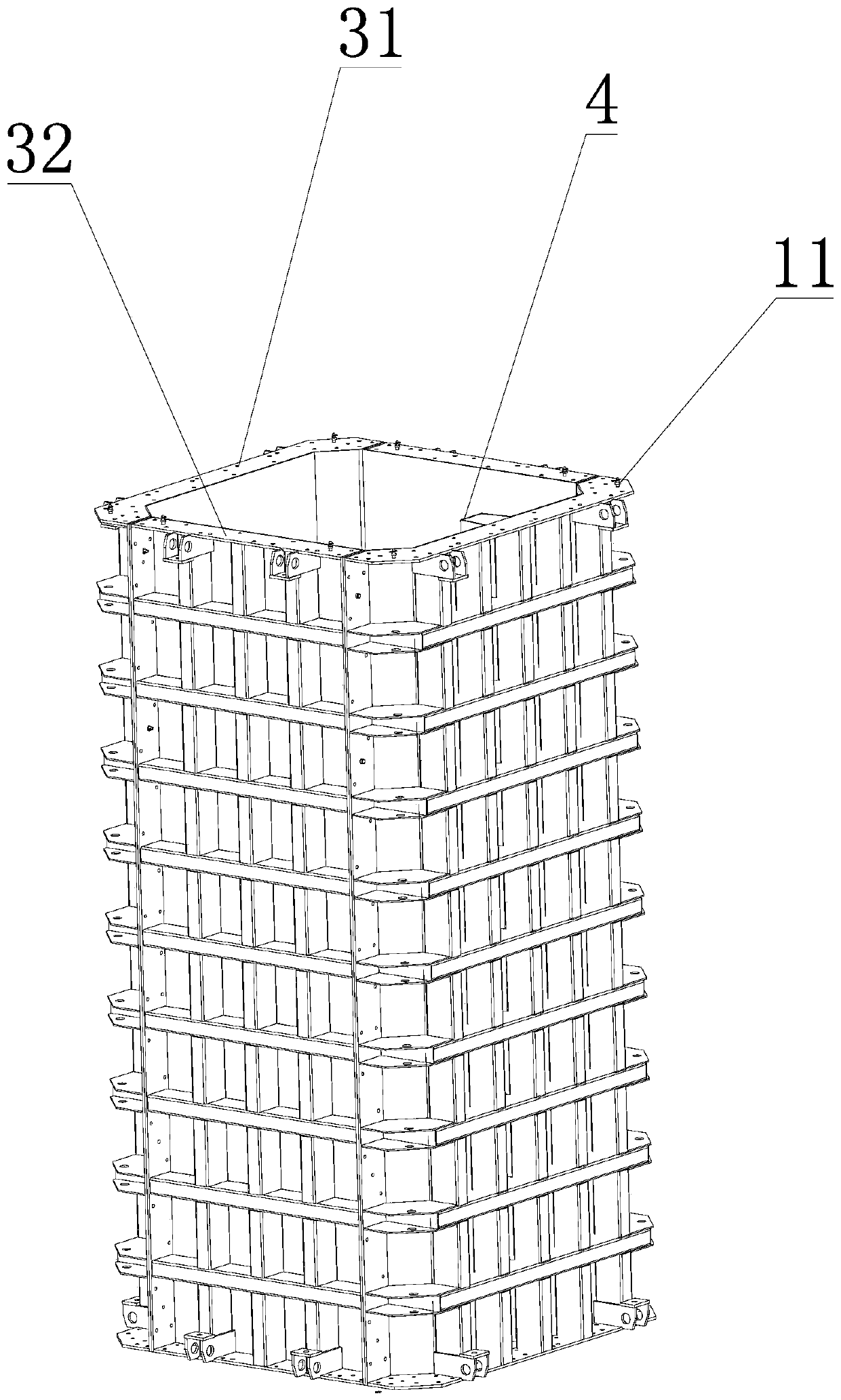

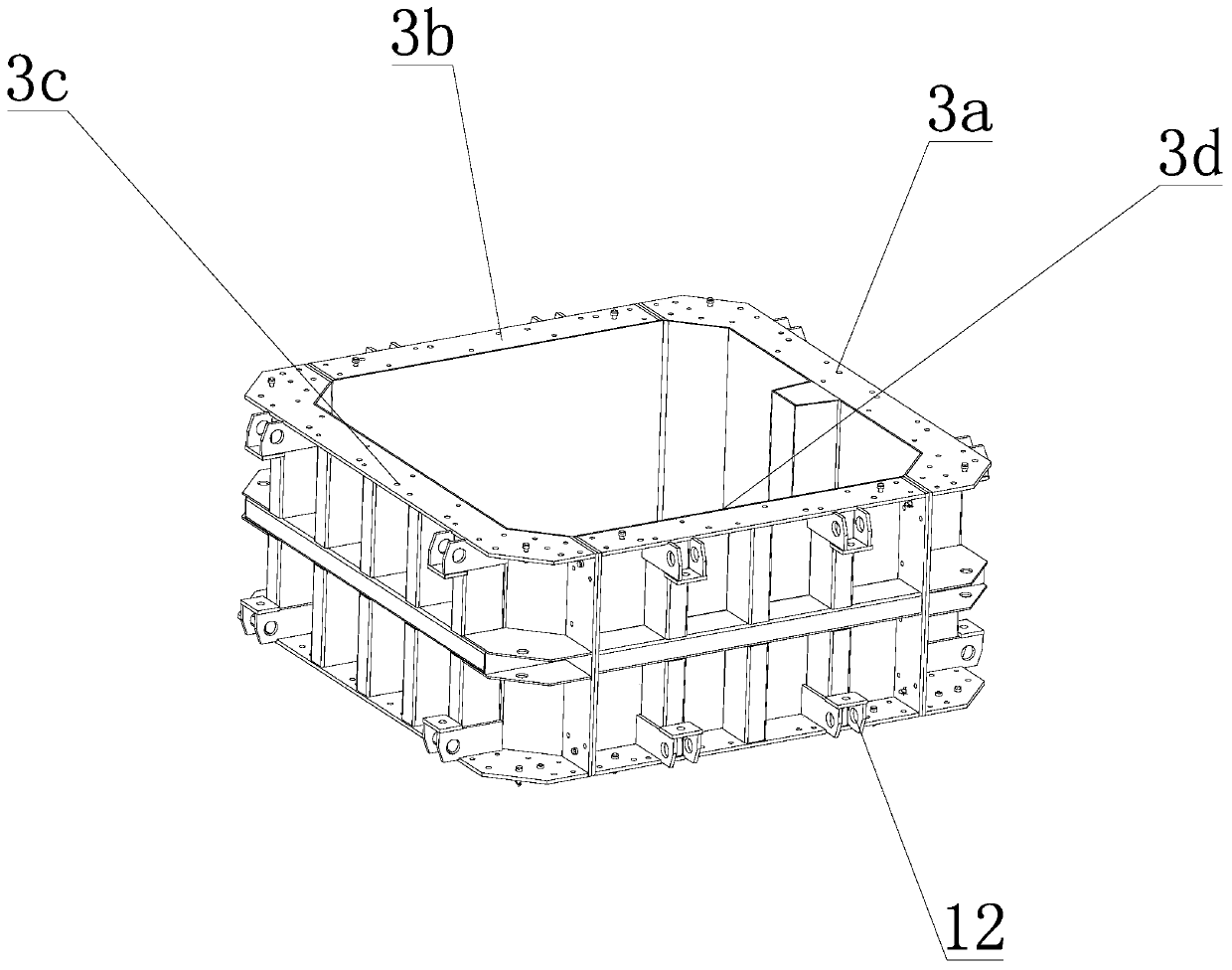

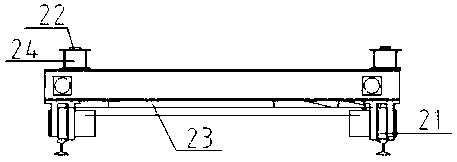

Modular mold for prefabricated upright post pouring

ActiveCN110774421AGuaranteed to meet the strength standardQuick fixMouldsMould fastening meansStructural engineeringMachining

The invention discloses a modular mold for prefabricated upright post pouring. The modular mold aims to solve the technical problem that in the prior art, a mold for machining prefabricated upright posts needs to be customized according to the size of upright posts, and a number of molds is discarded after the upright posts are subjected to one-time grouting machining. The modular mold comprises abottom mold and a side mold detachably connected with the bottom mold, wherein the side mold of the modular structure is formed by splicing side mold sections with unequal lengths, the inner wall surfaces of the side mold sections are provided with rain grooves in the thickness direction of the side mold sections, the side mold sections comprise wide mold plates and narrow mold plates, the side mold sections are formed by staggered splicing of the wide mold plates and the narrow mold plates, a positioning assembly for positioning a reinforcement skeleton is arranged on the bottom mold connected with one end surface of the side mold, a complete machining mold is formed after the side mold and the bottom mold are installed, a grouting groove along the length direction of the machining moldis formed in the middle of the machining mold, and the reinforcement skeleton is located in the grouting groove and is tightly attached to the inner wall surface of the side mold. According to the modular mold for prefabricated upright post pouring, a group of modular side mold can be used for machining the upright posts with different sizes, so that the production cost is reduced.

Owner:绍兴市城投建筑工业化制造有限公司 +1

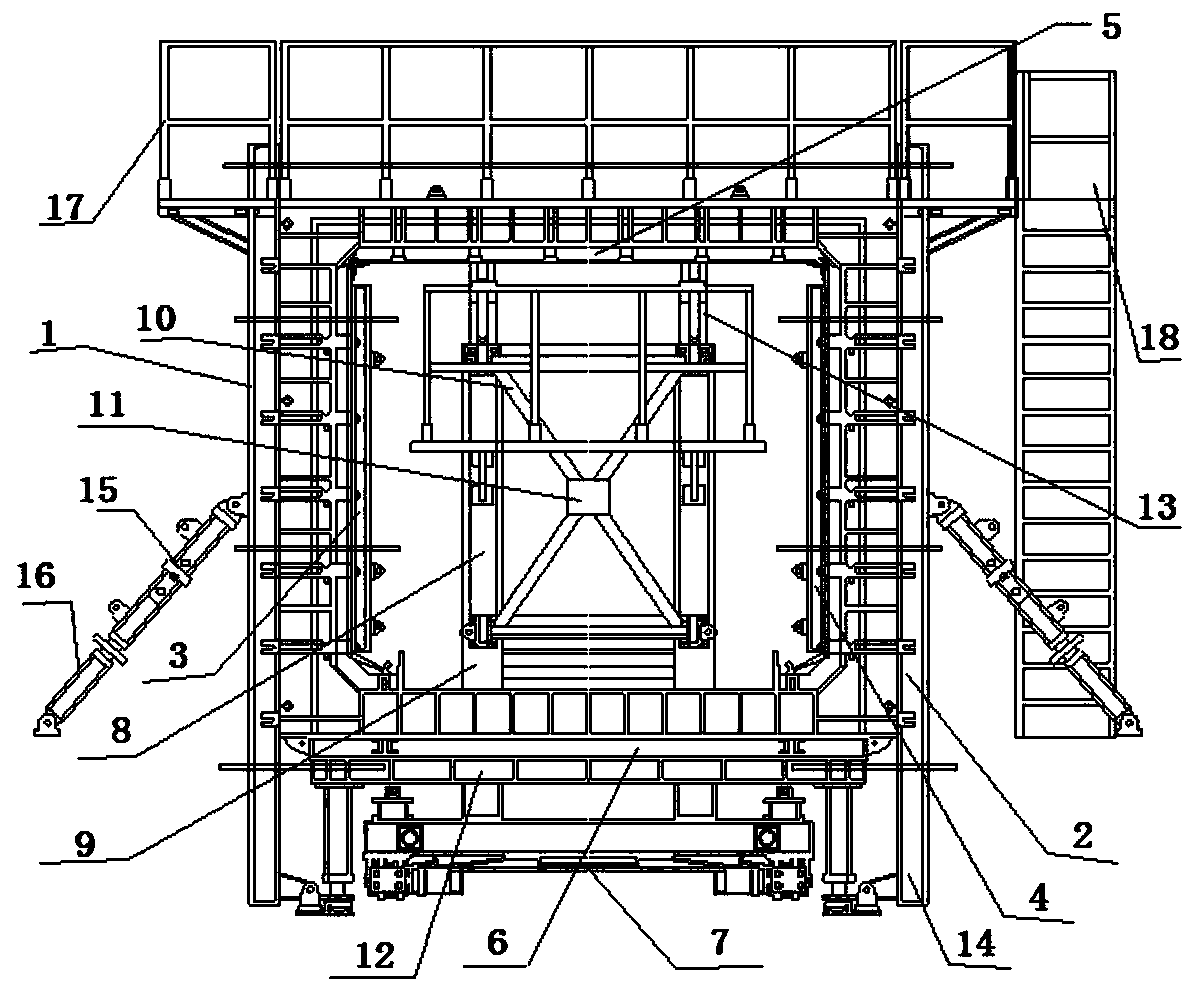

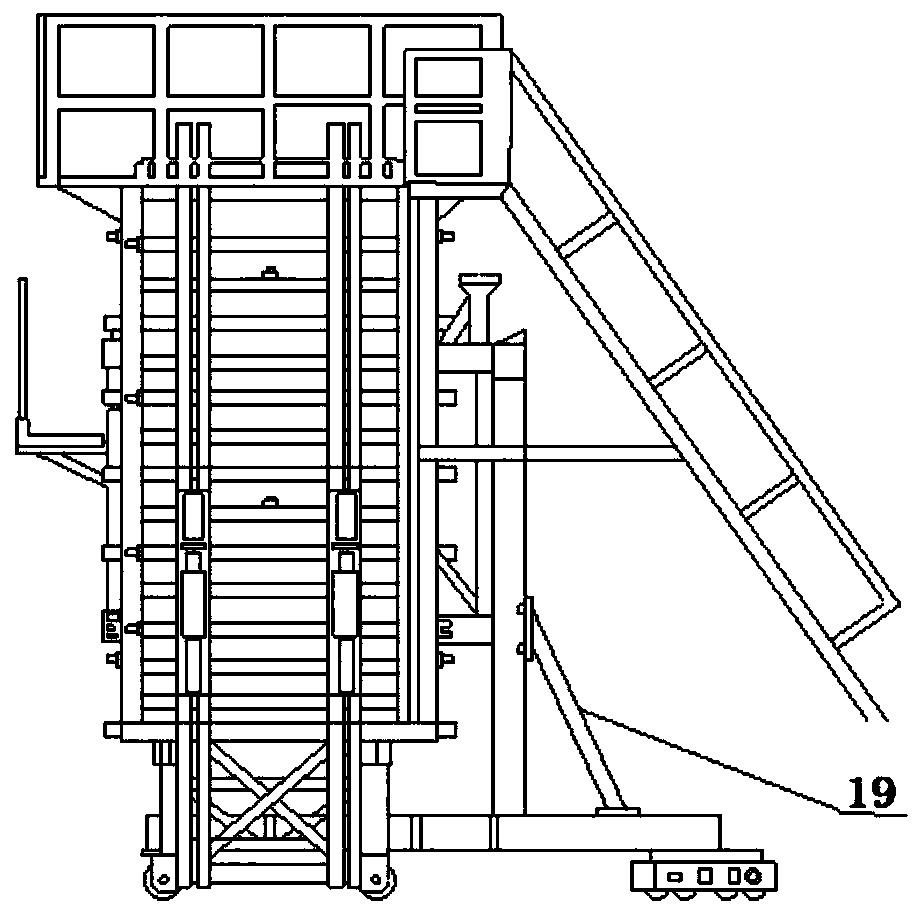

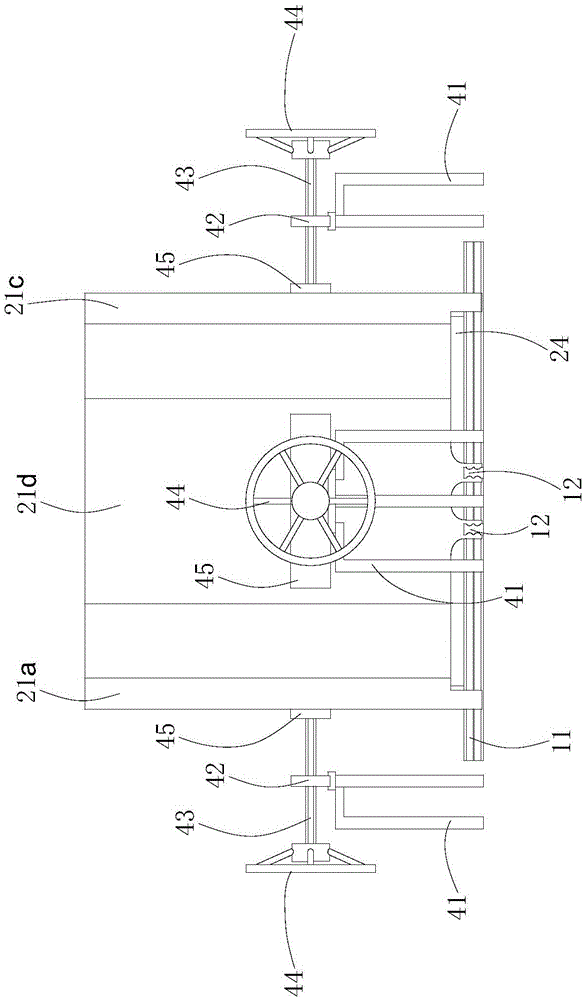

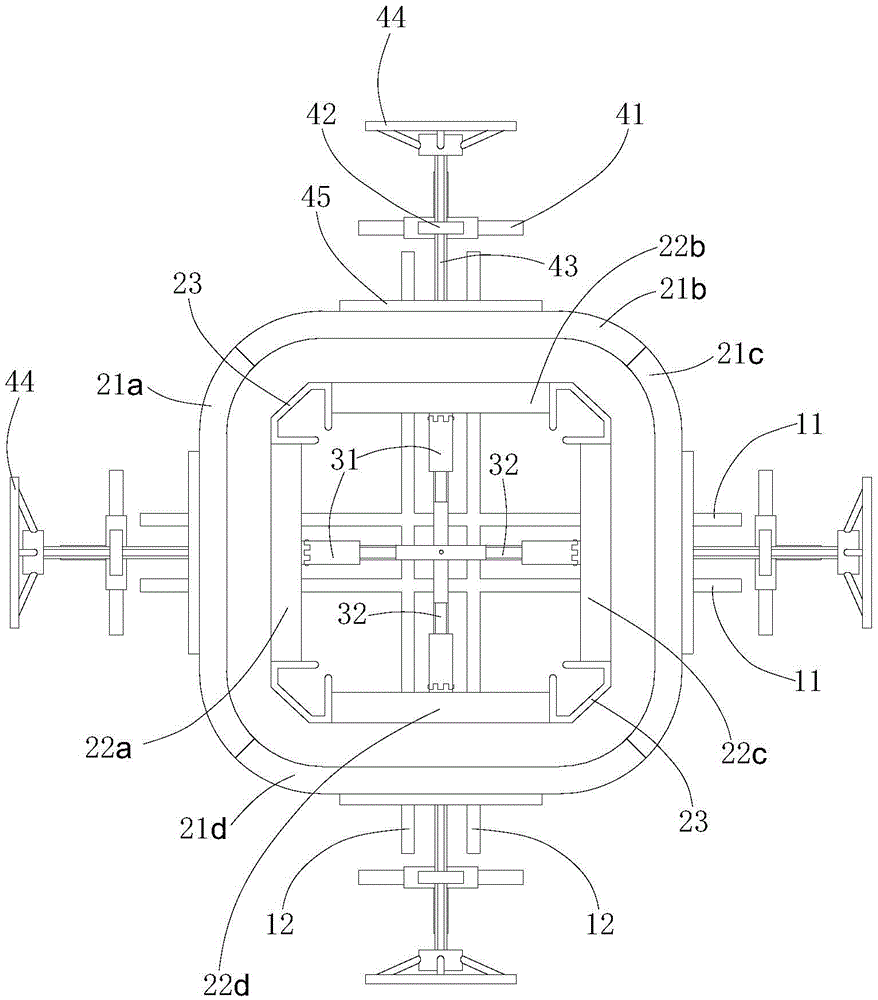

Integral hydraulic formwork applied to box culvert prefabrication

ActiveCN110394885AGuaranteed installation qualityQuick demolitionMouldsAuxillary shaping apparatusHigh surfacePrefabrication

The invention belongs to the field of box culvert pouring, and provides an integral hydraulic formwork applied to box culvert prefabrication. The integral hydraulic formwork comprises an internal formwork component, a bottom formwork component, an external formwork component, an end formwork component and a retaining formwork component; the internal formwork component includes internal formworks and an internal top formwork; the internal formworks include the first internal formwork and the second internal formwork; the bottom formwork component includes a bottom formwork; the external formwork component includes external formworks; the external formworks include the first external formwork and the second external formwork; the retaining formwork component includes a first retaining formwork and a second retaining formwork; the end formwork component includes a convex end formwork and a concave end formwork; and the space enclosed by the first external formwork, the second external formwork, the first internal formwork, the second internal formwork, the internal top formwork, the bottom formwork, the first retaining formwork, the second retaining formwork, the convex end formwork and the concave end formwork is used for pouring concrete. By mean of the integral hydraulic formwork applied to box culvert prefabrication, the prefabrication quality is high and stable, the adopted set shaped steel formwork has high surface rigidity, is not prone to deforming, and has good flatness.

Owner:INNER MONGOLIA ROAD & BRIDGE

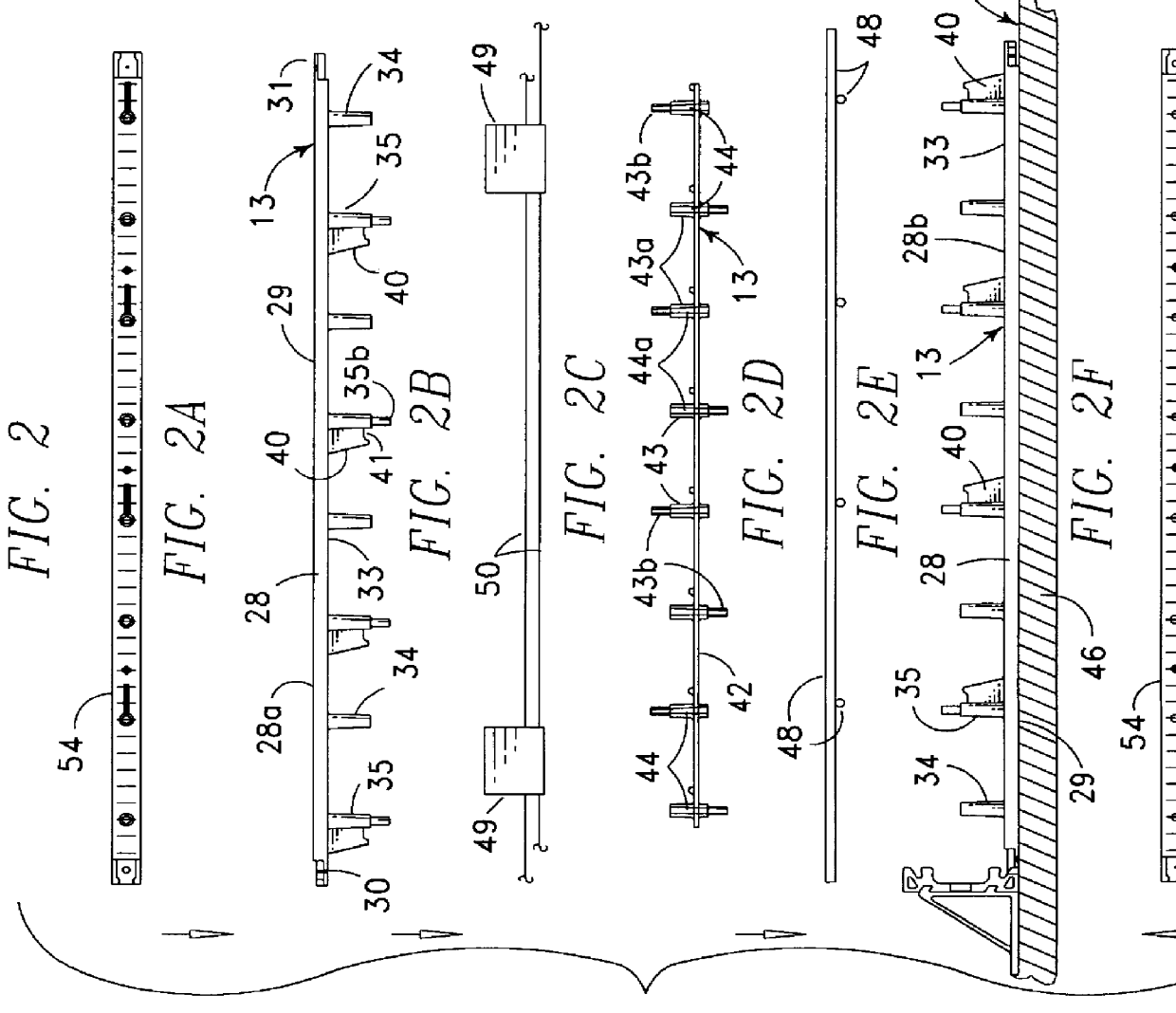

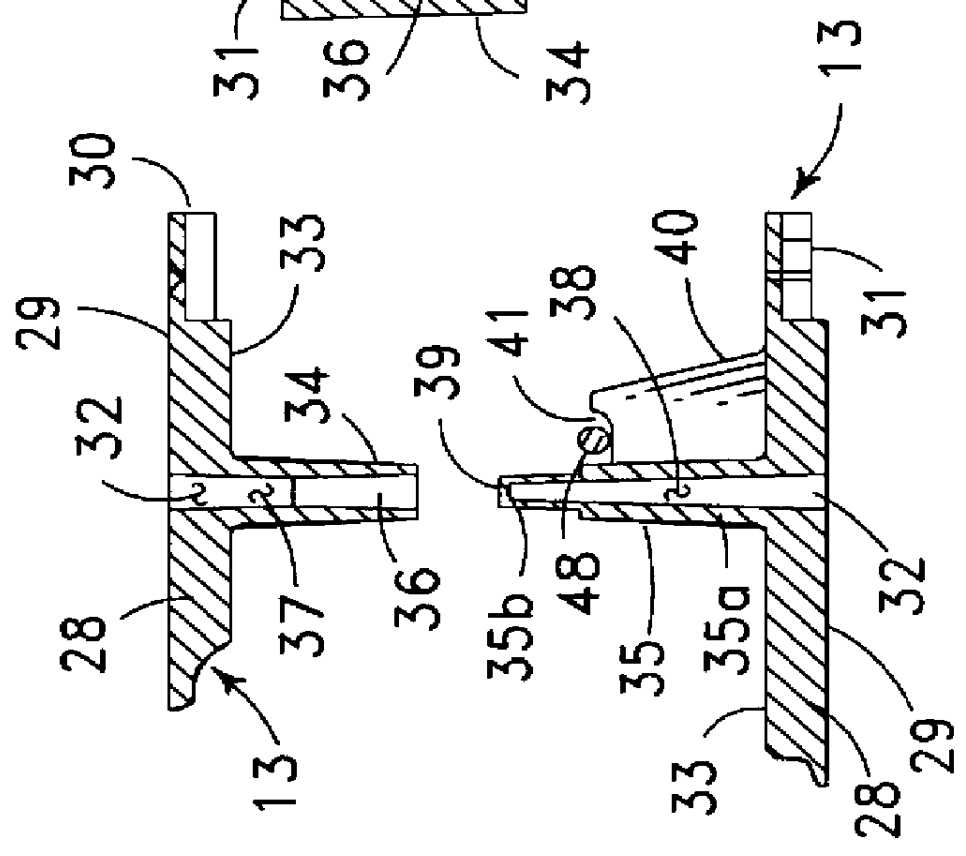

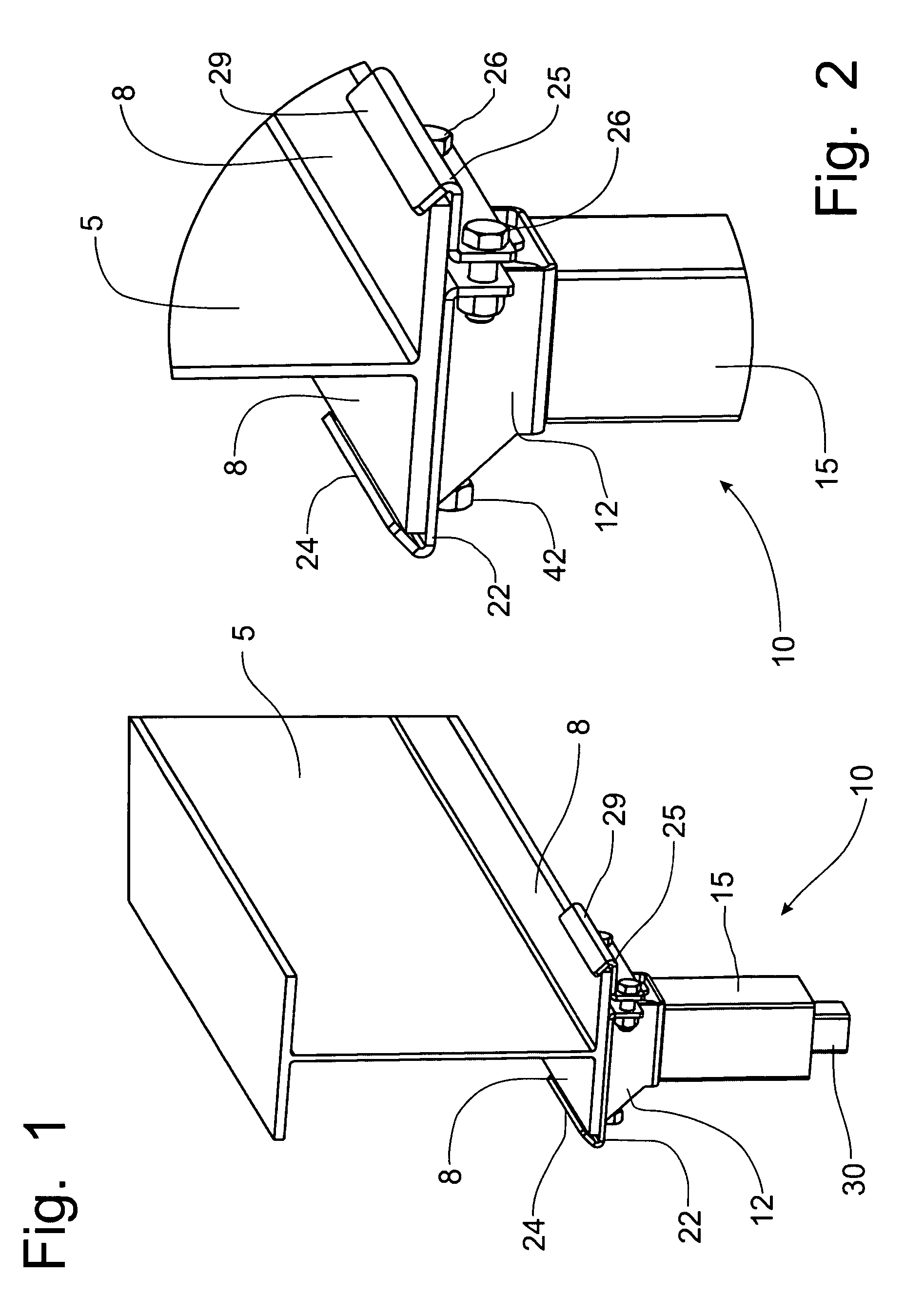

Adjustable support stand for pre-cast concrete wall forms

ActiveUS7922145B2Durable in constructionReduce manufacturing costMoulding surfacesMould separation apparatusDrive shaftEngineering

An adjustable support stand is mounted on a pre-cast concrete wall panel form to facilitate the leveling of the form and the support of the form about the production plant floor. The adjustable support stand includes a frame portion that houses a threaded rod positional fixed for rotation within the frame portion to drive a vertical movement of the leg member in response to rotation of the threaded rod. The adjustable support stand further includes a clamping apparatus that detachably mounts the frame portion to the flanges of a steel beam frame member. The actuator member can be a nut welded to the top of the threaded rod to affect movement of the engaged leg member in response to manipulation with a powered or manually operated hand tool, or a gear set and an orthogonal drive shaft that transfers rotation from a hand tool to the threaded rod.

Owner:SUPERIOR WALLS OF AMERICA

Pipe gallery box culvert pouring mould

The invention provides a pipe gallery box culvert pouring mould. A guide rail assembly comprises cross rails and longitudinal rails; four outer mould plates of a mould assembly are respectively arranged on the cross rails and the longitudinal rails; screw rod supporting seats are fixed on the outer side of the every outer mould plate; four inner mould plates are respectively arranged on the cross rails and the longitudinal rails; four inner mould columns and outer walls of the four inner mould plates accord with an inner wall of the box culvert; lower mould plates are fixedly connected to the cross rails and the longitudinal rails; supporting frames of every outer demoulding assembly are fixed on the outer side of the mould assembly; screw nuts are fixed on the supporting frames and handles are fixed on the outer ends of screw rods; the screw rods are matched with the screw rod supporting seats of the outer module plates; double-thread screws of every inner demoulding assembly are respectively matched with two connecting sleeves through threads; the two connecting sleeves are respectively connected with two inner mould plates. An outer side surface of the box culvert is formed by the outer mould plates; an inner side surface of the box culvert is formed by the inner mould columns and the inner mould plates; a lower end surface of the box culvert is formed by lower mould plates; assembling reinforcements are positioned in the mould and concrete grout is poured into the mould, so that the pipe gallery box culvert is obtained; the mould can be used repeatedly.

Owner:ANHUI WATER RESOURCES DEV

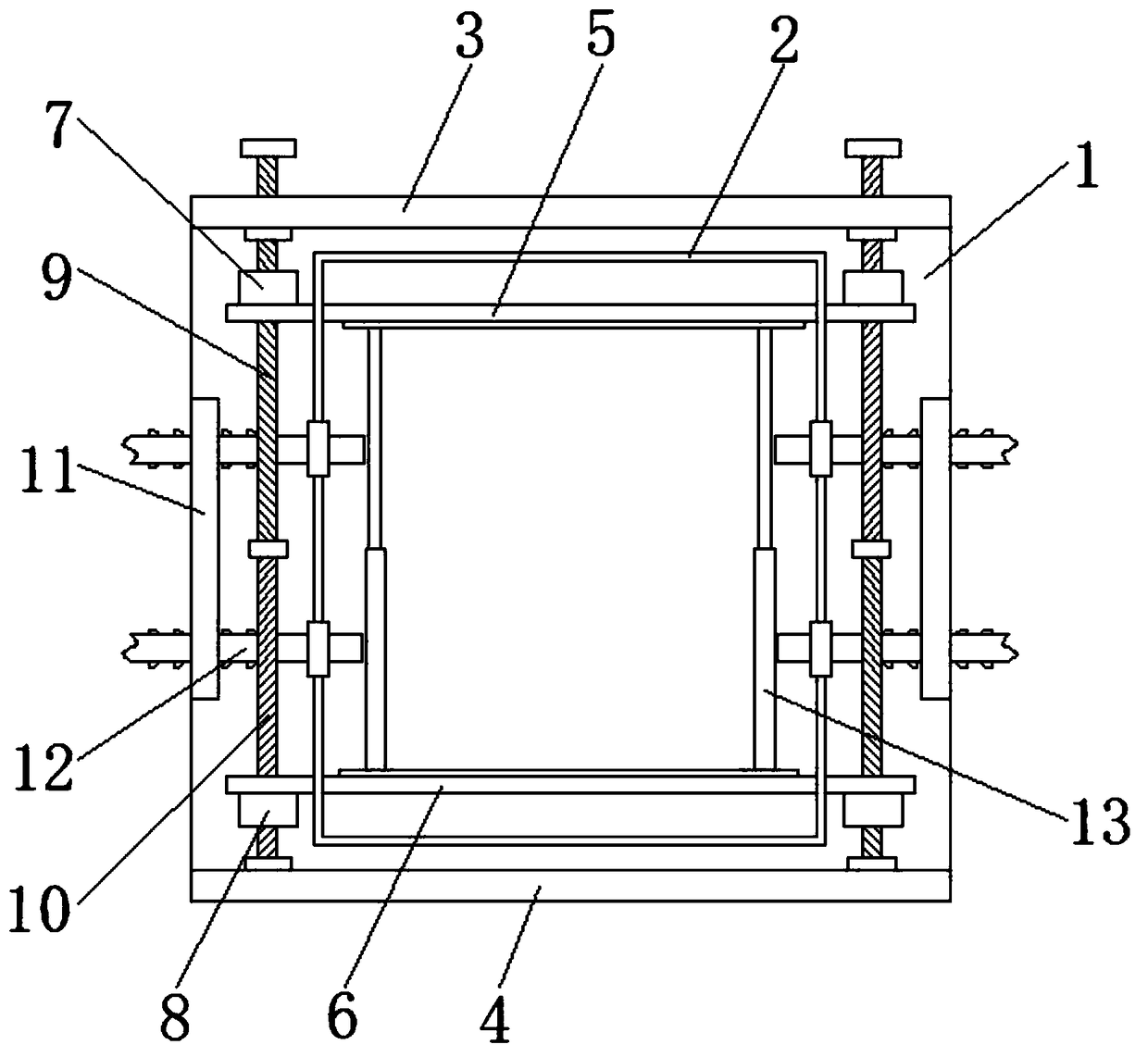

Framework with adjustable size for reinforced concrete stone plate

InactiveCN108908659AEasy to useChange lengthMouldsMould fastening meansReinforced concreteEngineering

The invention discloses a framework with adjustable size for a reinforced concrete stone plate, and relates to the technical field of reinforced concrete of buildings. The framework comprises a fixedplate, wherein the front side of the fixed plate is fixedly connected with a formwork; the top part and bottom part of the fixed plate are respectively fixedly connected with a first installation plate and a second installation plate; both sides of the inner wall of the formwork are respectively glidingly connected with a first formwork and a second formwork from top to bottom; both sides of the top part of the second formwork are respectively glidingly connected with telescopic plates; the top part of each telescopic plate is glidingly connected with the bottom part of the first formwork; both sides of the first formwork penetrate through the formwork and extend to both sides of the formwork. The framework with adjustable size for the reinforced concrete stone plate has the advantages that the good size adjusting function is realized; the size can be conveniently adjusted, the adjusting time is shortened, and the labor intensity in adjusting is decreased; the production requirements of the reinforced concrete stone plates with different sizes can be met, and the usability of the framework for the reinforced concrete stone plate is greatly improved.

Owner:芜湖青悠静谧环保科技有限公司

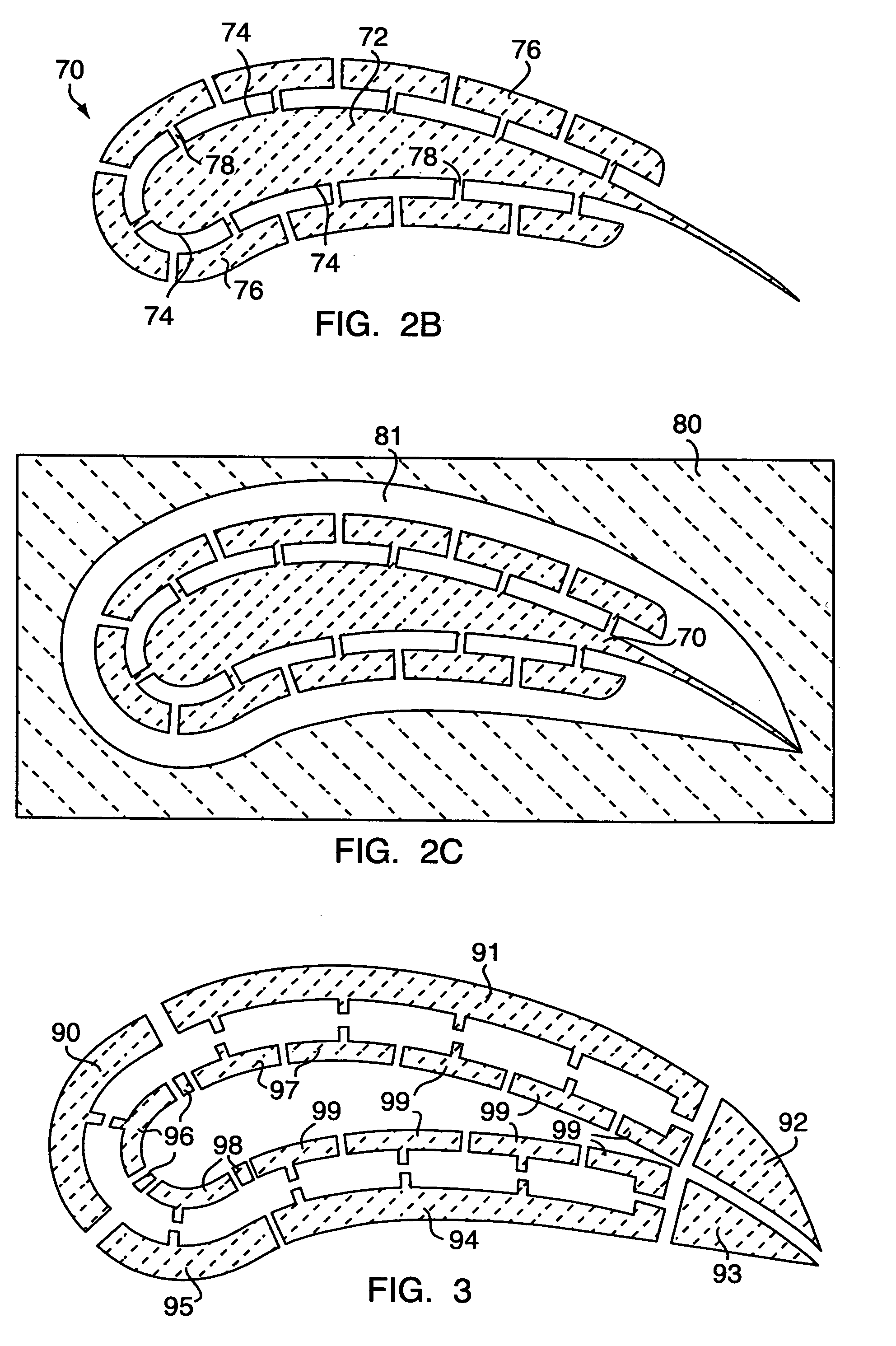

Masonry blocks and method and system of making masonry blocks

A method of producing a concrete block having a front face, a rear face, an upper face, a lower face, and a pair of opposed side faces. The method includes providing a mold assembly having a plurality of liner plates that together form a mold cavity having an open top and an open bottom, wherein at least a first liner plate is moveable between a retracted position and an extended position with a gear drive assembly, and wherein the first liner plate is angled such that when the first liner plate is in the extended position the bottom of the mold cavity is narrower than the top by a predetermined distance. The first liner plate is moved to the extended position, a pallet is positioned below the mold to close the bottom of the mold cavity, dry cast concrete is placed in the mold cavity via the open top, a shoe assembly is positioned into the mold cavity via the open top, and the dry cast concrete is compacted to form a pre-cured concrete block with the rear face resting on the pallet, the front face contacting the shoe assembly, and one side face of the pair of opposed side faces contacting the first liner plate. The first liner plate is moved to the retracted position such that the bottom of the mold cavity is narrower than the top by the predetermined distance and at least as wide as the top when first liner plate is in the extended position, the pre-cured concrete block is expelled from the mold cavity and cured.

Owner:NESS INVENTIONS

Lightweight concrete composite blocks

An apparatus for manufacturing lightweight concrete composite blocks includes a form, a station conveyor, a form-loading station, a form assembly station, a curing oven, and a block removal station. The station conveyor conveys the form or a multitude of forms around the apparatus in a continuous loop to produce a desired rate of production of lightweight concrete composite blocks. The form-loading station fills the form with a lightweight concrete composite. The form assembly station assembles the form to seal the composite within the form. The curing oven cures the lightweight concrete composite into a lightweight concrete composite block. The block removal station removes the lightweight concrete composite block from the form prior to the return of the form to the form-loading station for re-use.

Owner:AMAZON FORMS ONE

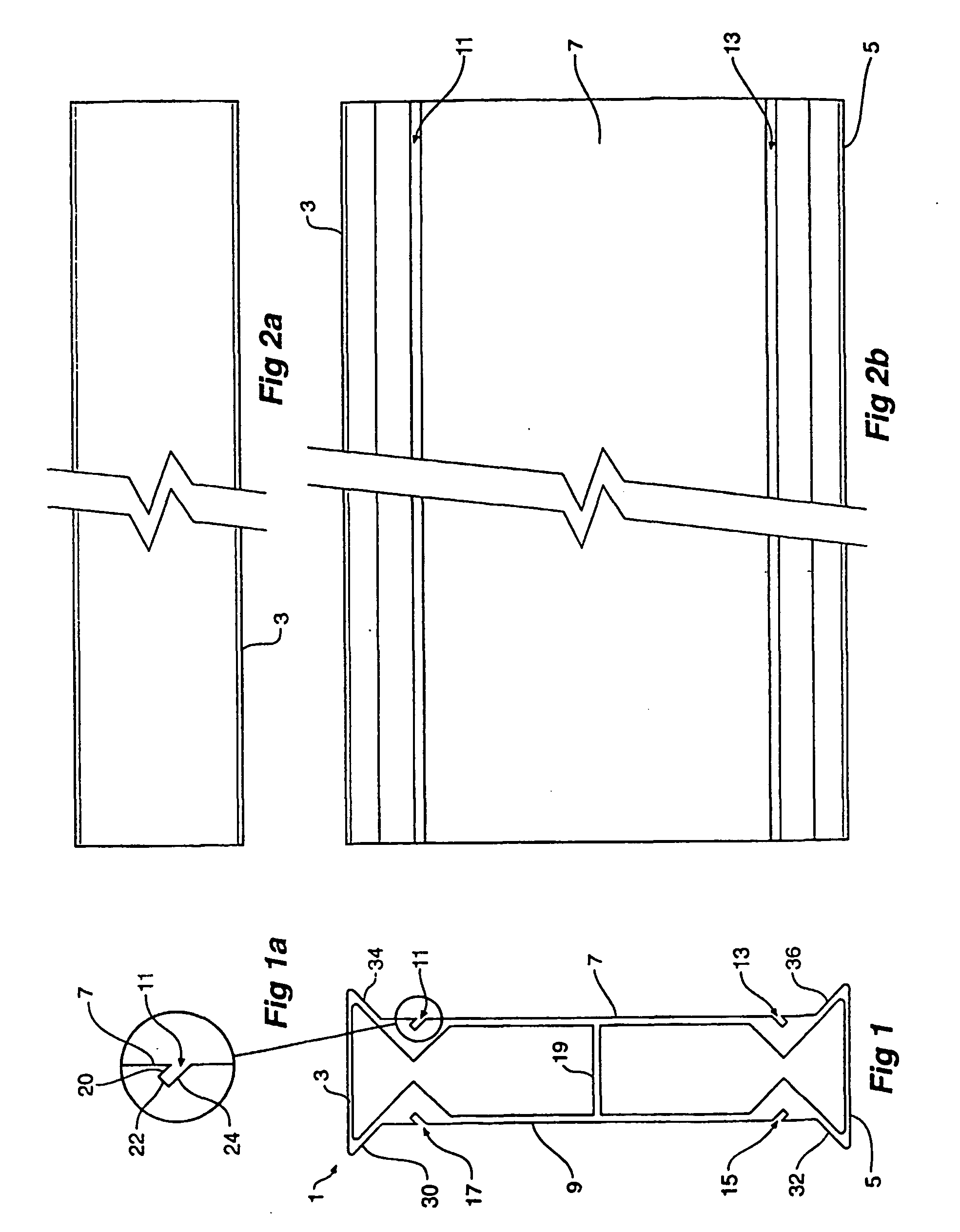

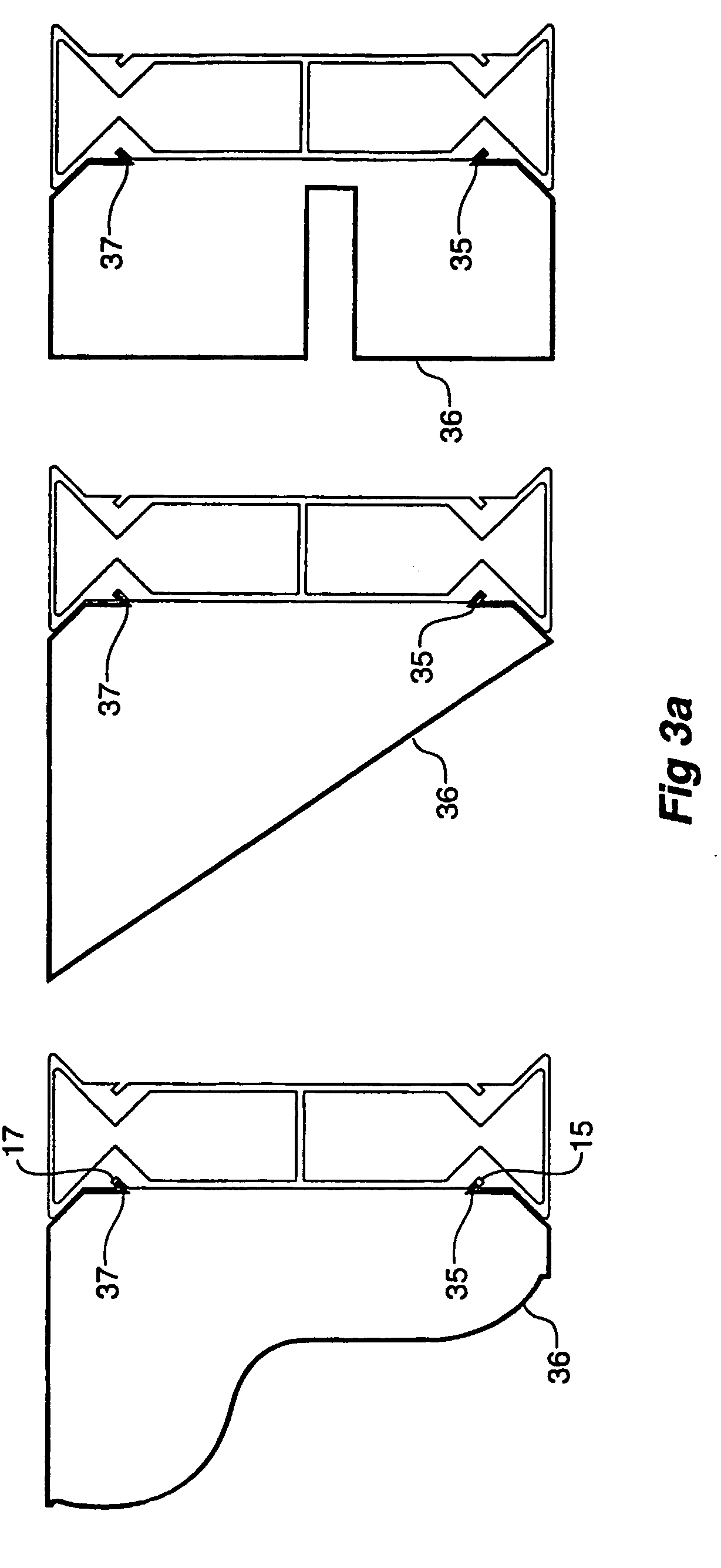

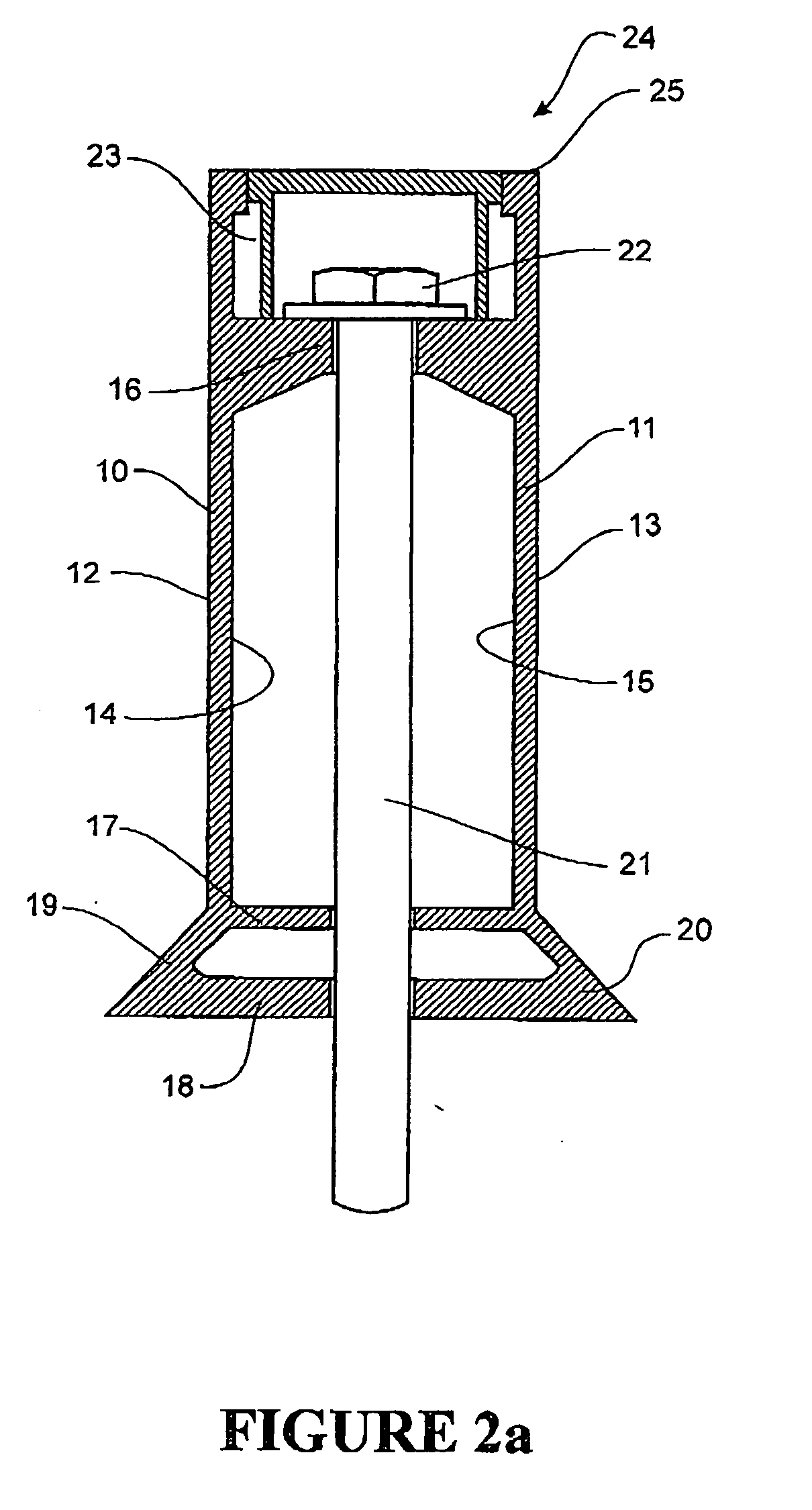

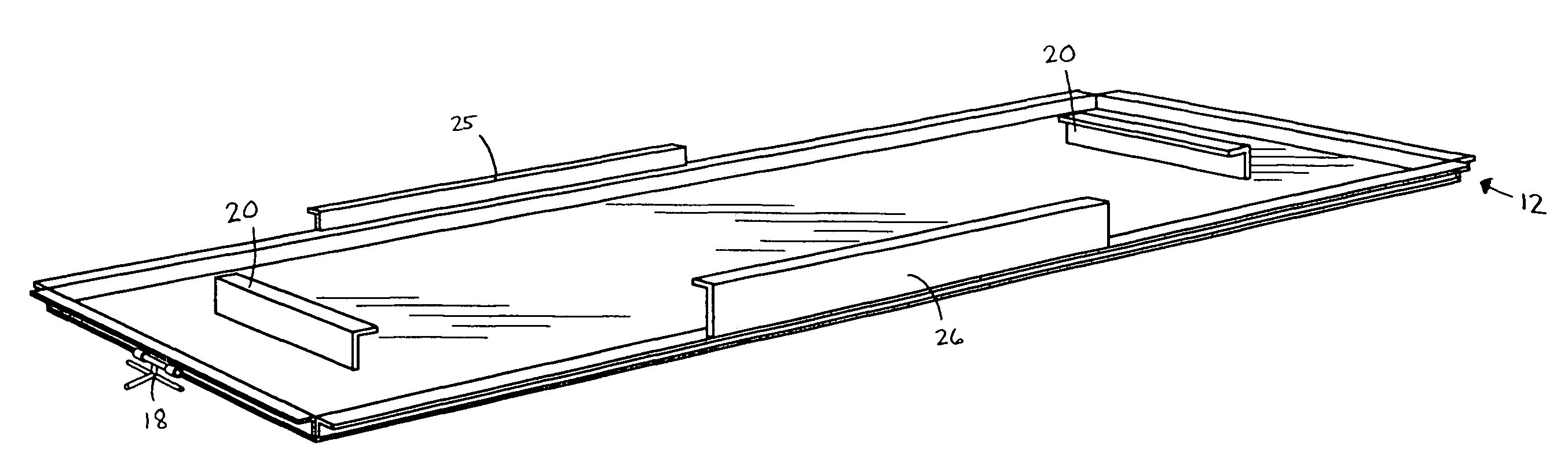

Apparatus and method for forming concrete panels

The invention provides a form member for use in forming concrete panels comprising a pair of upright walls connected by a plurality of ribs. Each of the ribs includes an aperture for allowing a fastener through. The fastener passes through each of the ribs into a casting floor to fix the form member to the floor. A plurality of form members can be arranged to define enclosures, concrete is then poured into the enclosures to the level of the upright walls, smoothed and allowed to cure to form concrete panels. The form members of the present invention allow a number of panels to be formed at the same time, with some form members common to more than one concrete panel. The invention provides easy of use and savings in space, time and labour.

Owner:SPEEDLINE PANEL FORMERS

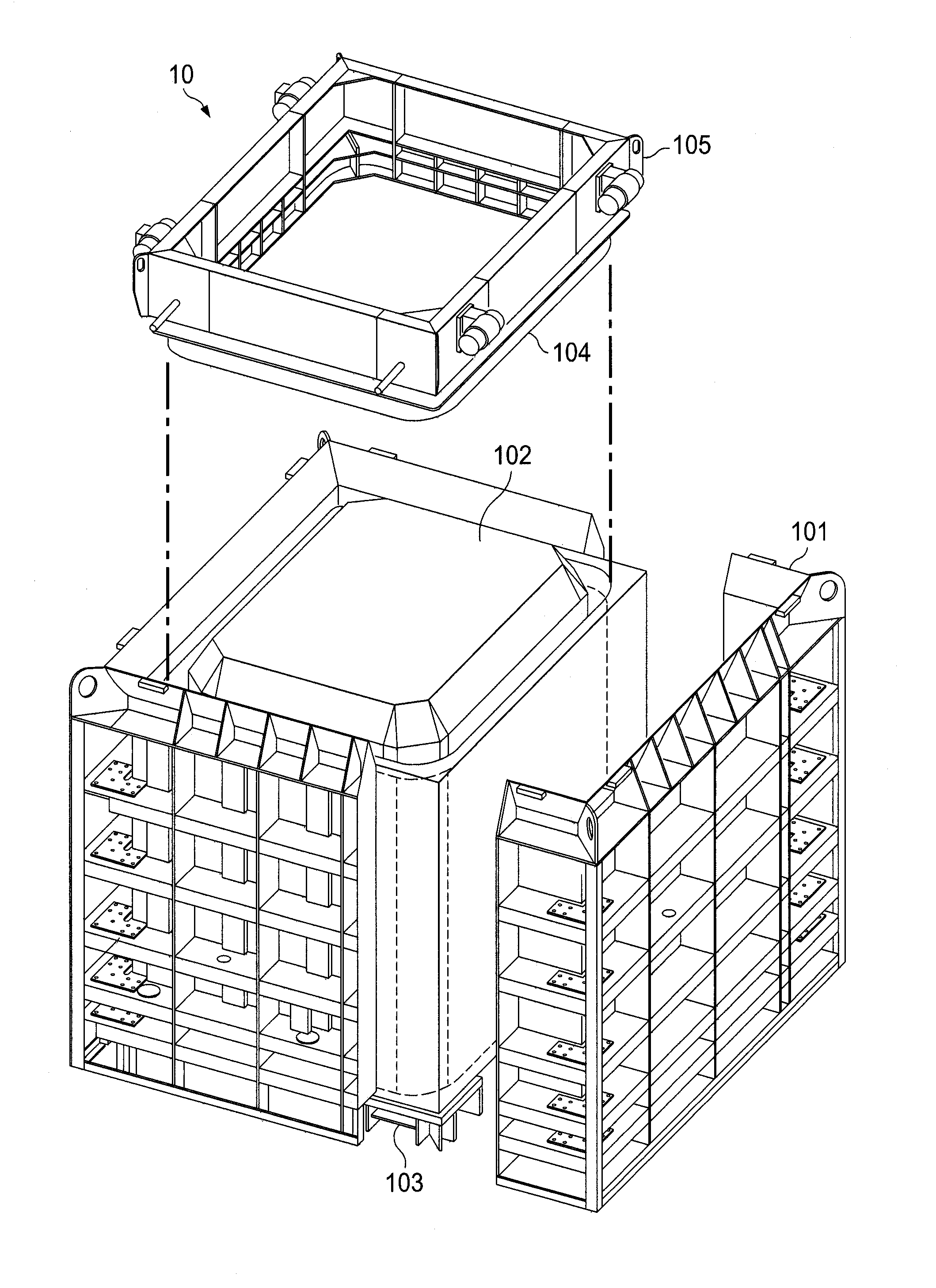

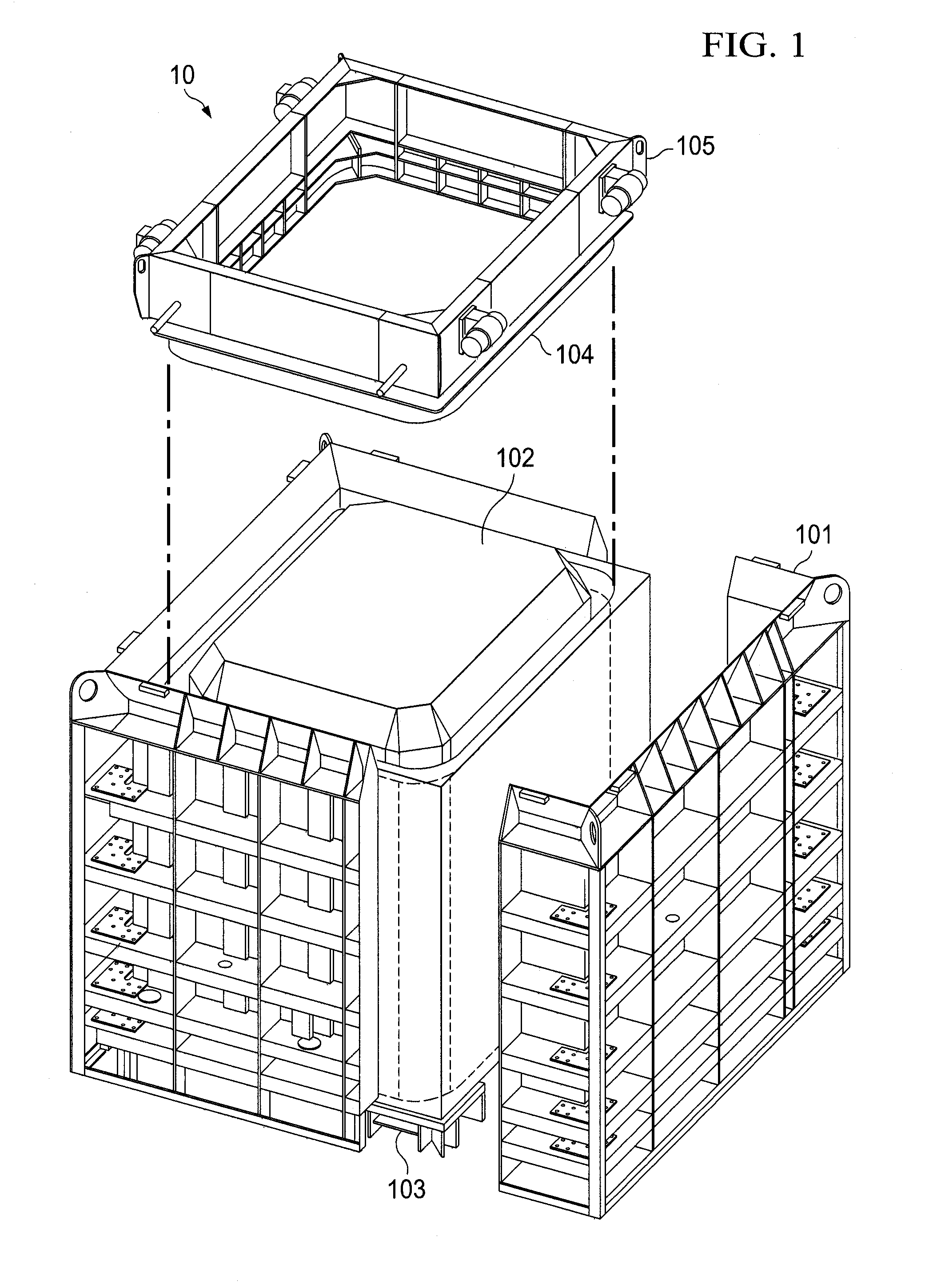

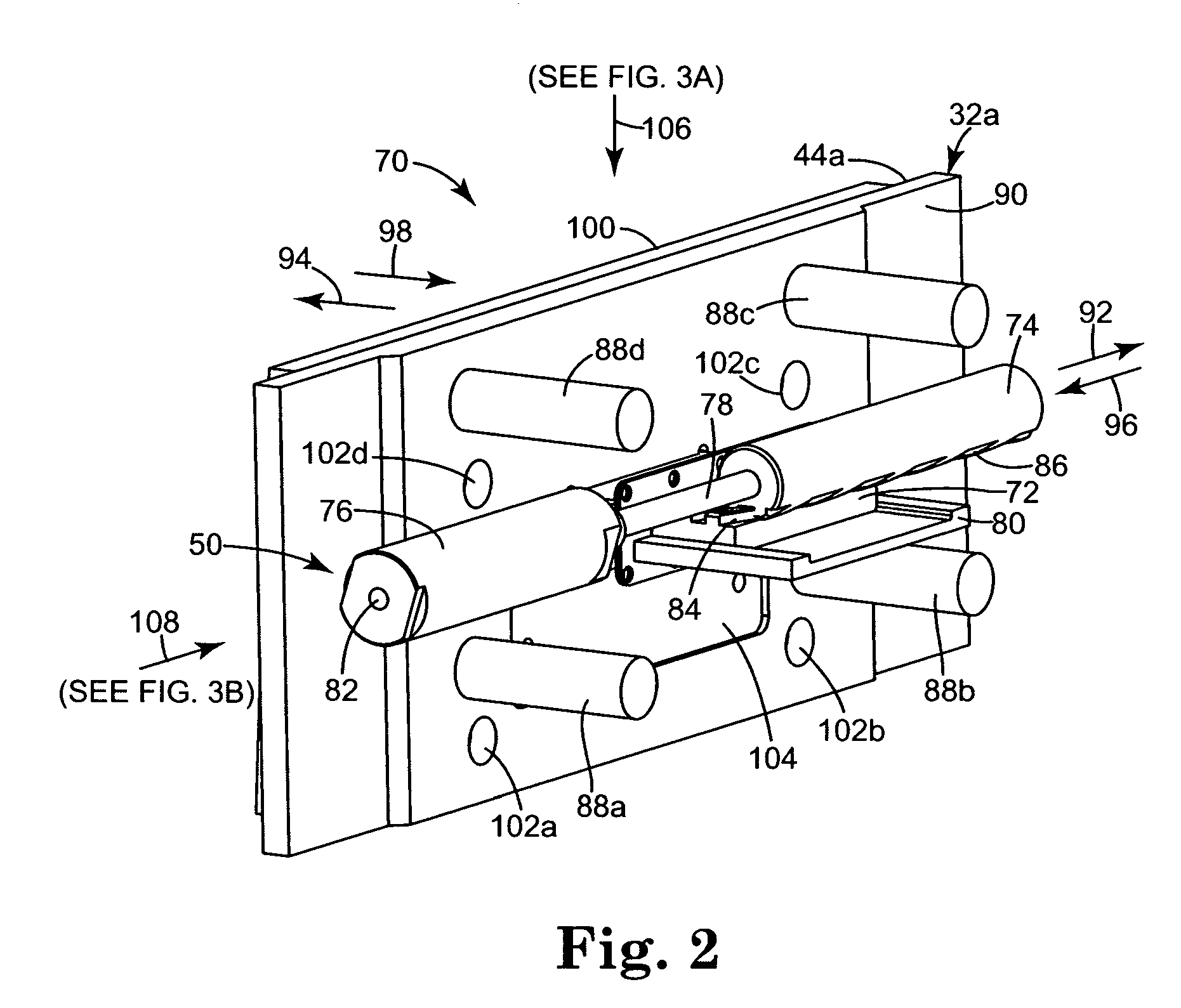

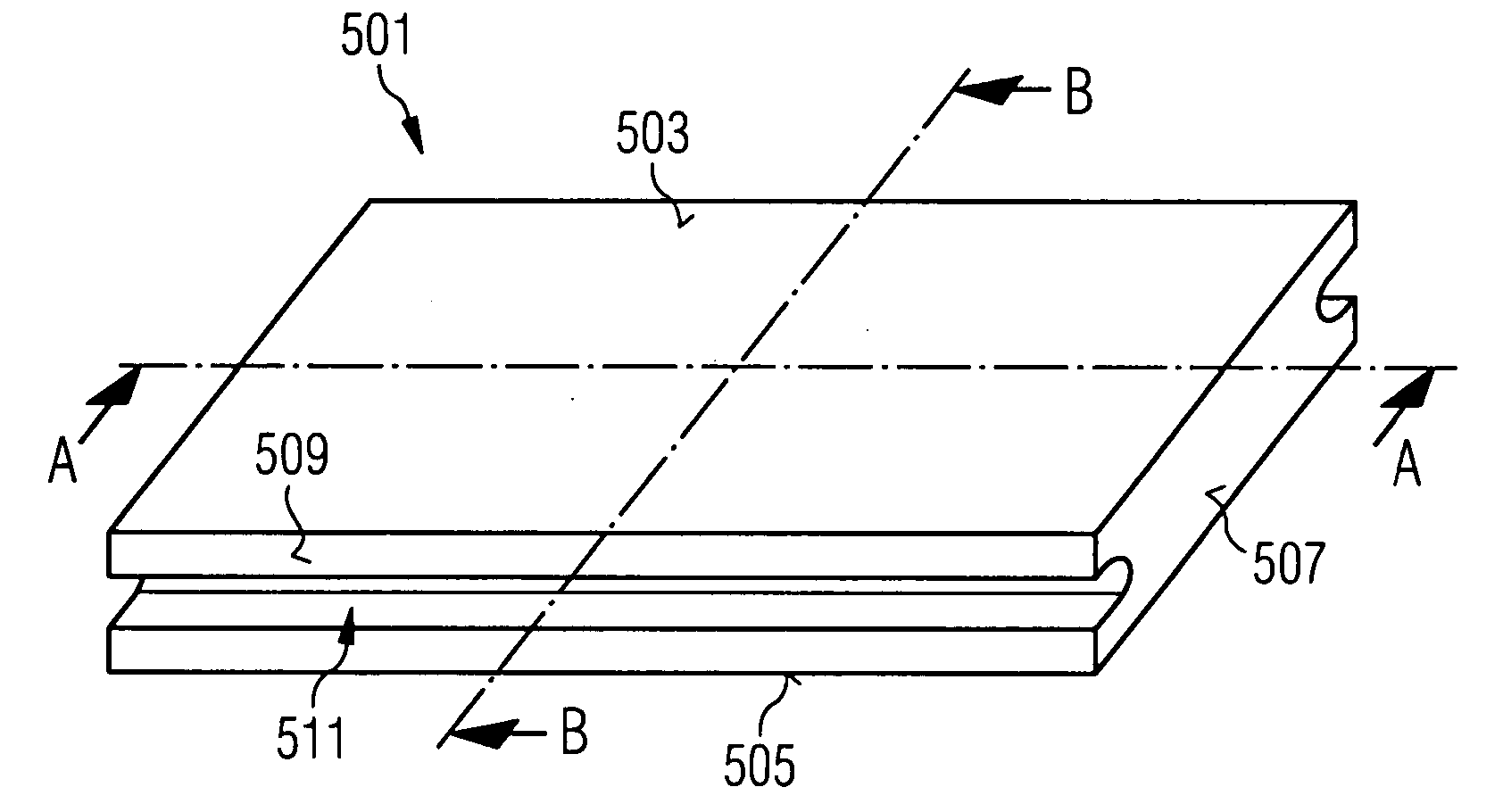

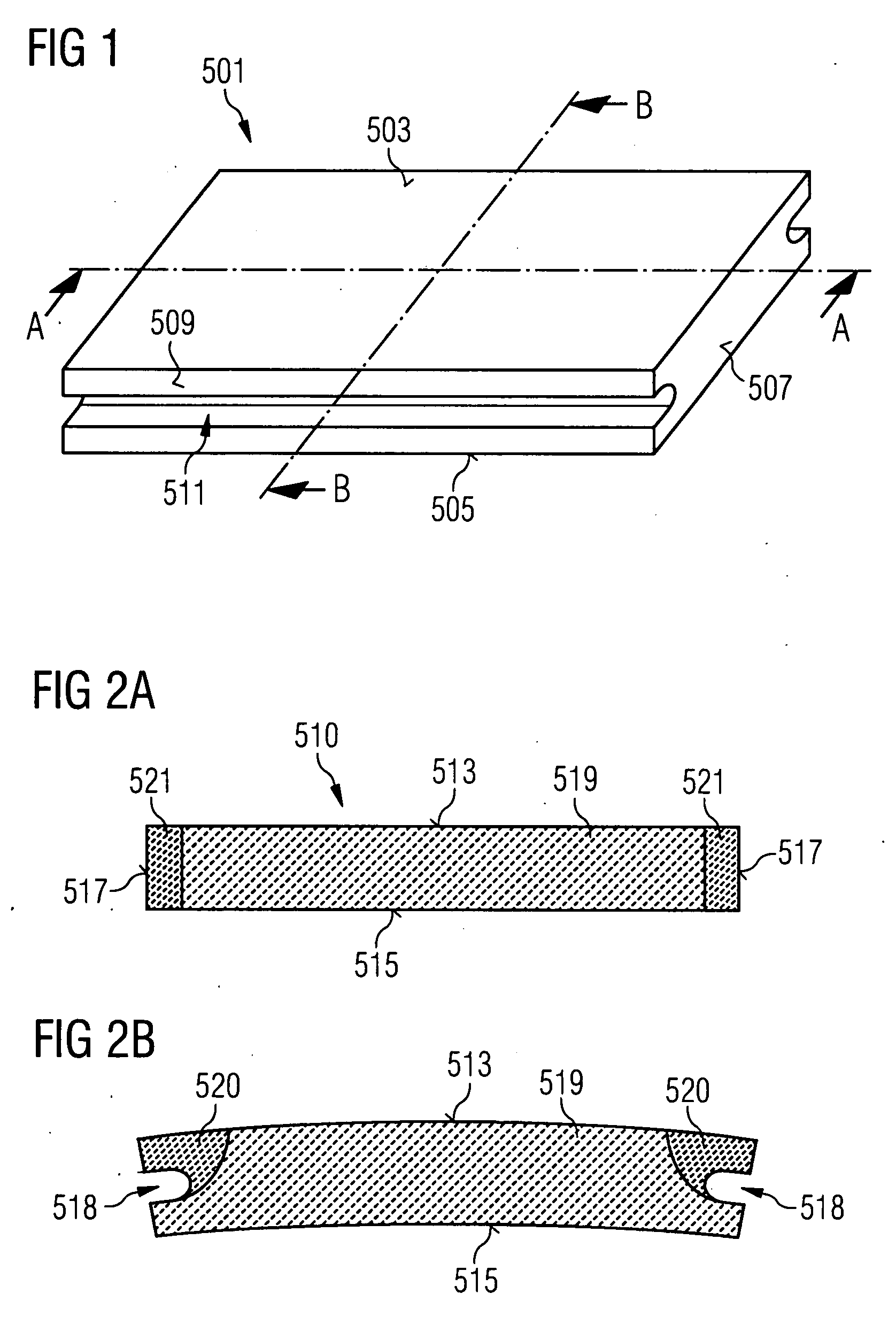

Lightweight concrete composite blocks

InactiveUS20050257458A1Easy to assembleMouldsCeramic shaping plantsEngineeringMechanical engineering

An apparatus for manufacturing lightweight concrete composite blocks includes a form, a station conveyor, a form-loading station, a form assembly station, a curing oven, and a block removal station. The station conveyor conveys the form or a multitude of forms around the apparatus in a continuous loop to produce a desired rate of production of lightweight concrete composite blocks. The form-loading station fills the form with a lightweight concrete composite. The form assembly station assembles the form to seal the composite within the form. The curing oven cures the lightweight concrete composite into a lightweight concrete composite block. The block removal station removes the lightweight concrete composite block from the form prior to the return of the form to the form-loading station for re-use.

Owner:AMAZON FORMS ONE

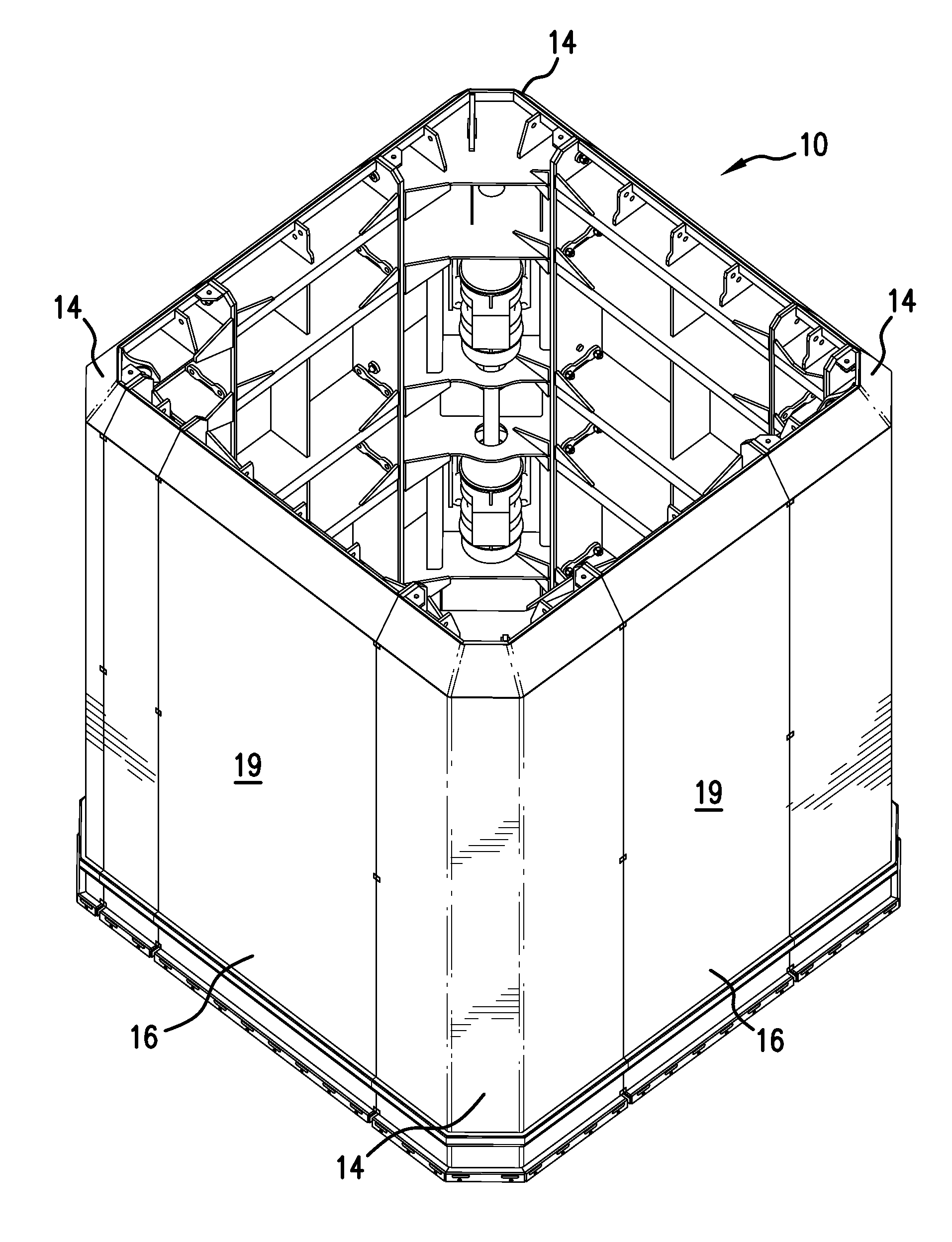

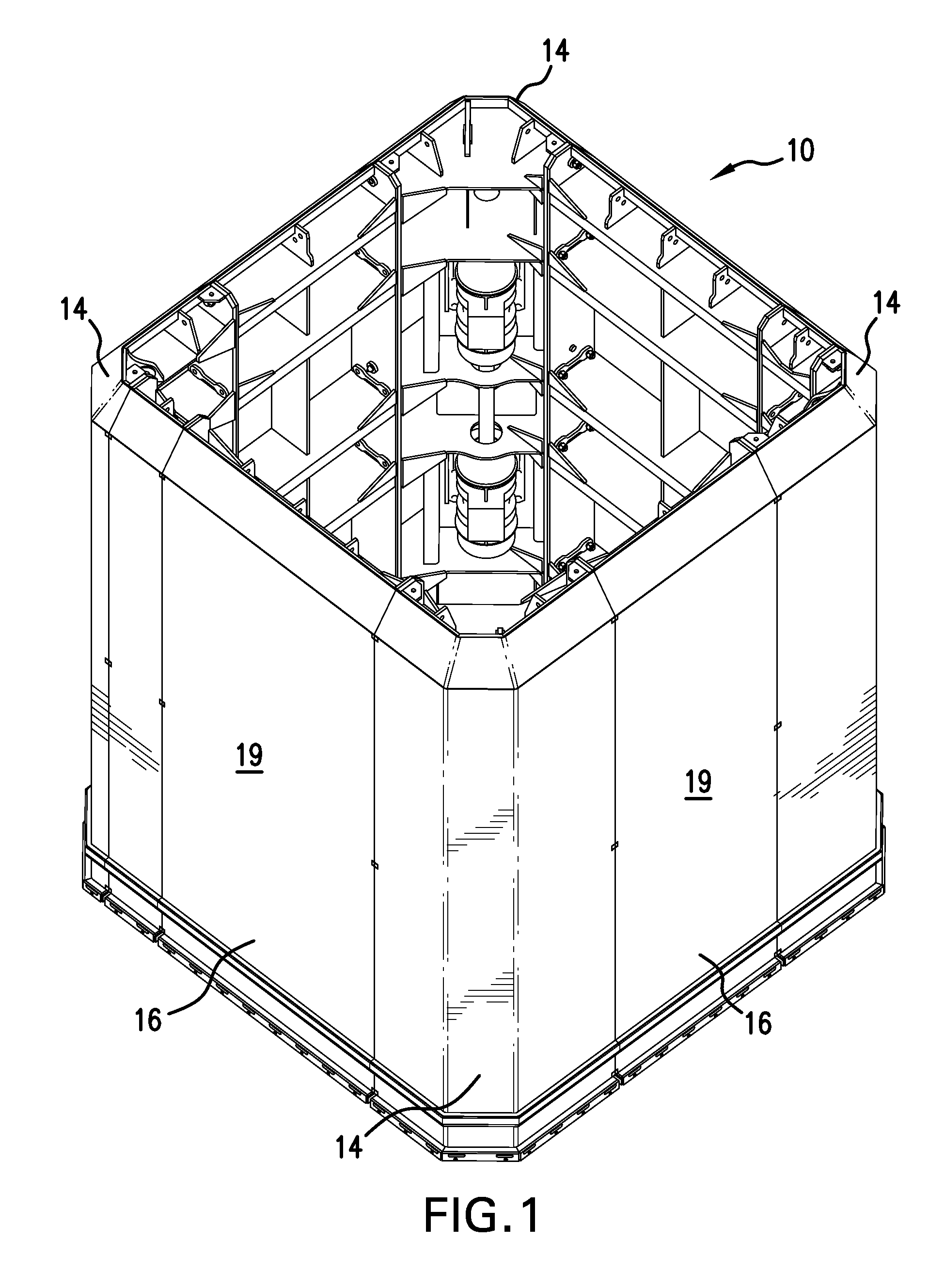

Vibration system for concrete pipe making machines

ActiveUS8926311B1Superior uniform vibration systemSmooth vibrationMouldsConfectioneryRigid coreEngineering

A vibration system for concrete pipe making machines using the dry cast method and which employ adjustable molds comprised of corner panels joined to intermediate panels. Two coupled vertically spaced-apart vibrators are mounted in two opposite corner panels of the mold core. The vibrators are mounted on shelves welded to the interior of the walls that form the mold surface. The shelves are also welded to vertical end walls that extend inwardly to form the box-like corner panel. The corner panels and intermediate panels are secured together by removable fasteners that join the vertical end walls of the corner panels to the corresponding vertical end walls of the side panels. The joined corner panels and side panels provide a rigid core structure similar to a solid core and allow the entire core to become the vibration structure.

Owner:HAWKEYEPEDERSHAAB CONCRETE TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com