Pipe gallery box culvert pouring mould

A technology for pouring molds and box culverts, which is applied in the direction of molds, mold fixing devices, mold auxiliary parts, etc., which can solve the problems of time-consuming and material-consuming, unfavorable mass-production pouring, and cumbersome steps of pouring mold demoulding operations, etc., to achieve convenient use and saving resources, the effect of easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

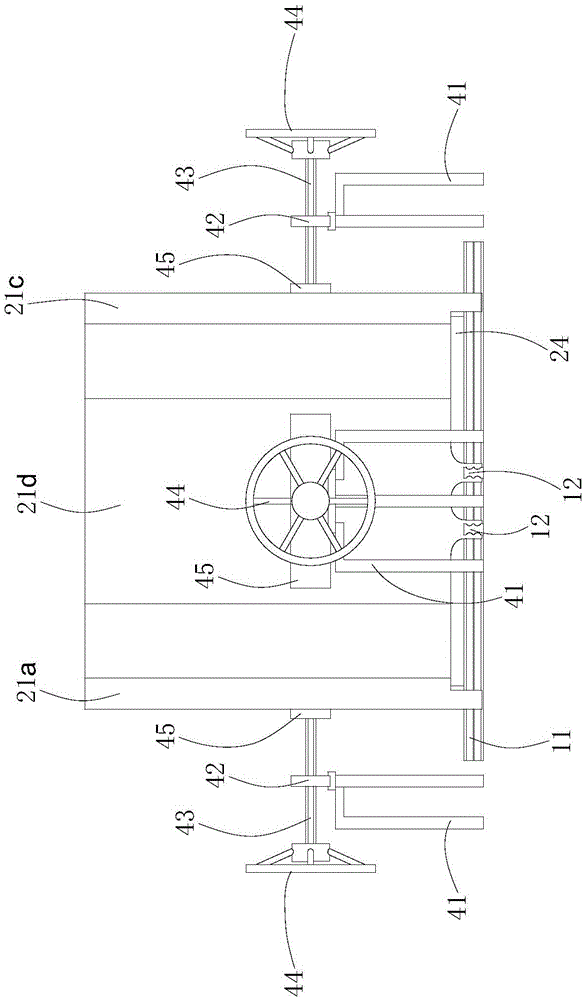

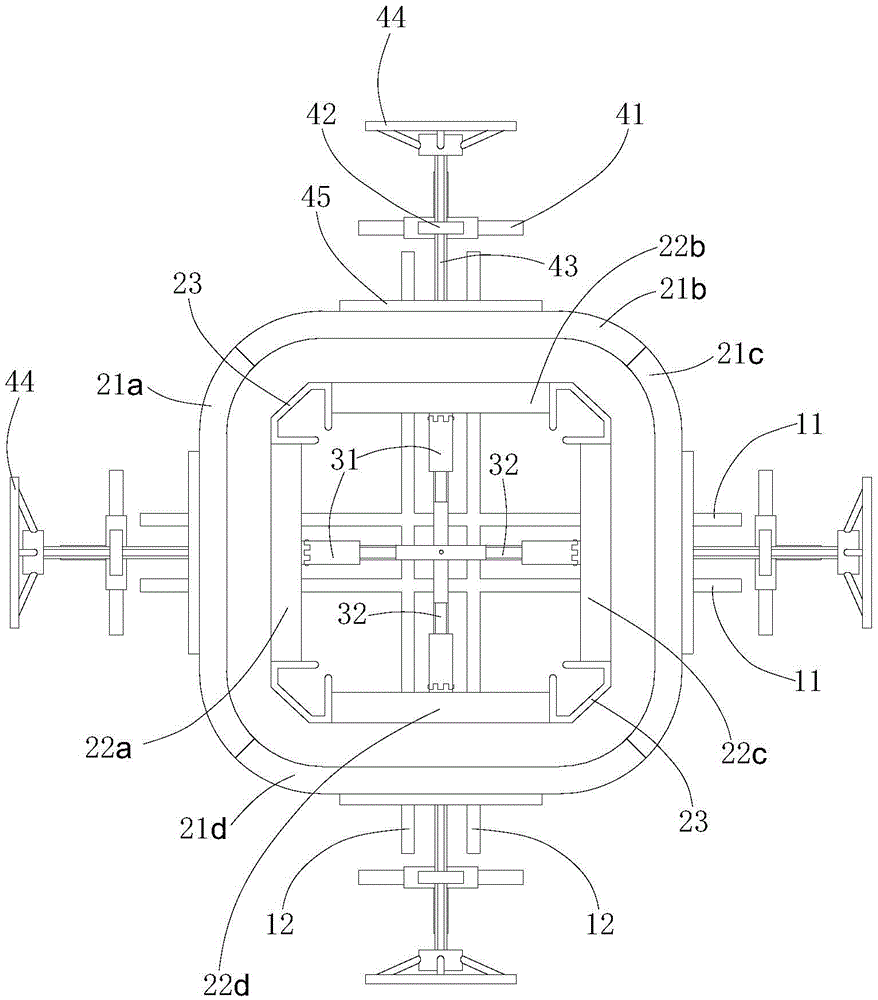

[0017] Such as Figures 1 to 2 shown

[0018] The casting mold for the box culvert of the pipe gallery includes mold components, guide rail components, four external demoulding components and two internal demoulding components;

[0019] The guide rail assembly includes two horizontal rails 11 and two vertical rails 12. The two horizontal rails 11 and the two vertical rails 12 are laid on the ground. The two horizontal rails 11 and the two vertical rails 12 are on the same water surface. The horizontal rails 11 The trend of the vertical rail 12 is perpendicular to the trend;

[0020] The mold assembly includes at least four outer templates, four inner templates, four inner mold columns 23, a lower template 24 and an upper template;

[0021] The four outer templates are respectively the first outer template 21a, the second outer template 21b, the third outer template 21c and the fourth outer template 21d, and the first outer template 21a and the third outer template 21c are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com