Lightweight concrete composite blocks

a composite block and lightweight technology, applied in the direction of mould fastening, building components, food shaping, etc., can solve the problems of high cost of wood, low structural safety of other building materials, and high cost of concr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

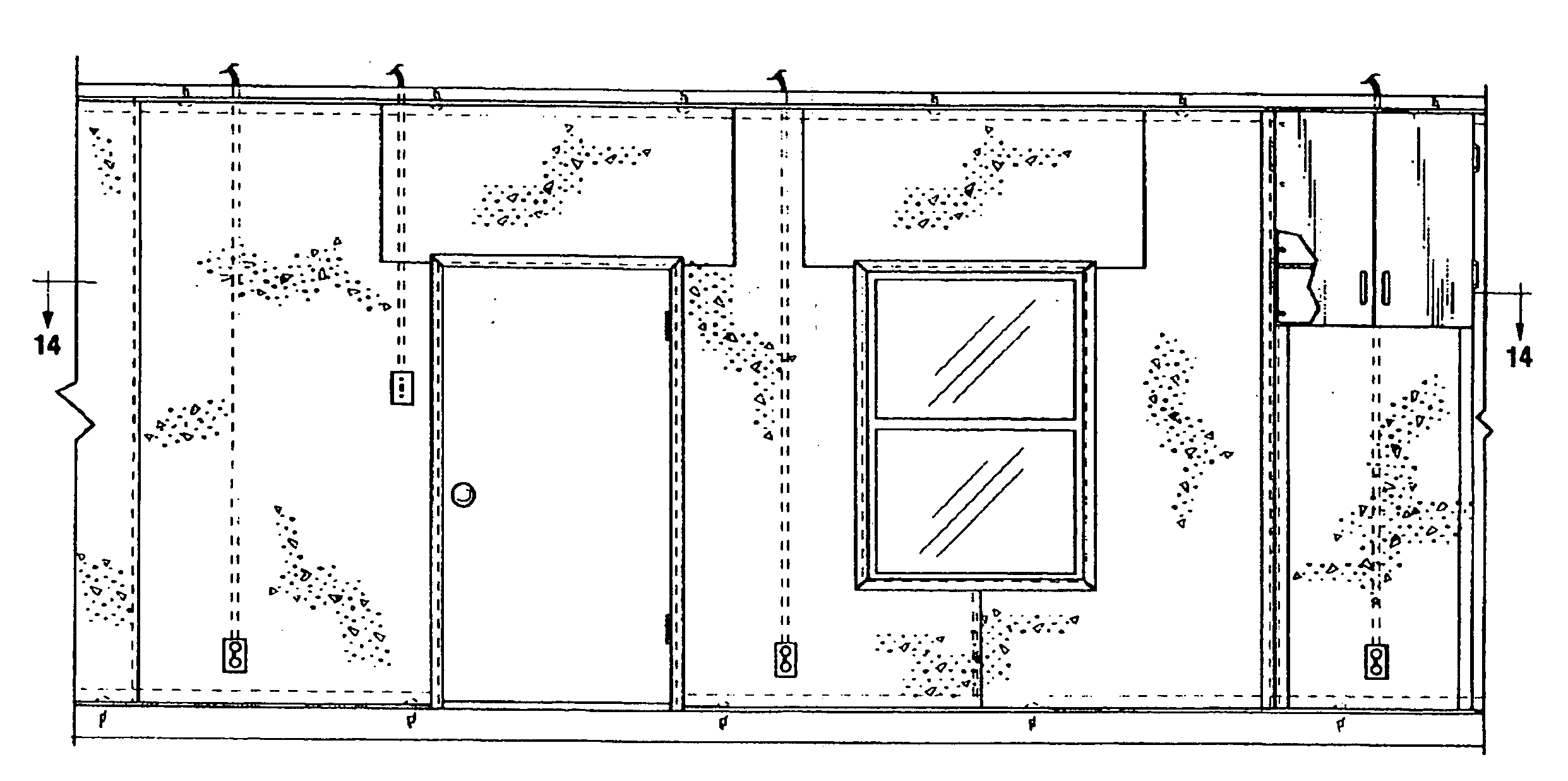

[0034] As illustrated in FIG. 11, the preferred embodiment of the block 10A discloses a rectangular block with a top end, a bottom end, and two sides. One side defines a raised tongue 106 while the opposite side defines a recessed groove 107, whereby blocks can be assembled in a successive fashion by fitting a tongue side into a groove side. In addition, the block 10A includes electrical conduit 200 and electrical boxes 201 for running electrical wire and making electrical connections. While the preferred embodiment discloses electrical conduit 200 and electrical boxes 201, those of ordinary skill in the art will recognize that any multitude of items normally used inside building walls may be substituted, such as plumbing piping, air ducts, and the like. The ability of the block 10A to contain electrical conduit and electrical boxes makes it ideal for use as an interior wall in buildings.

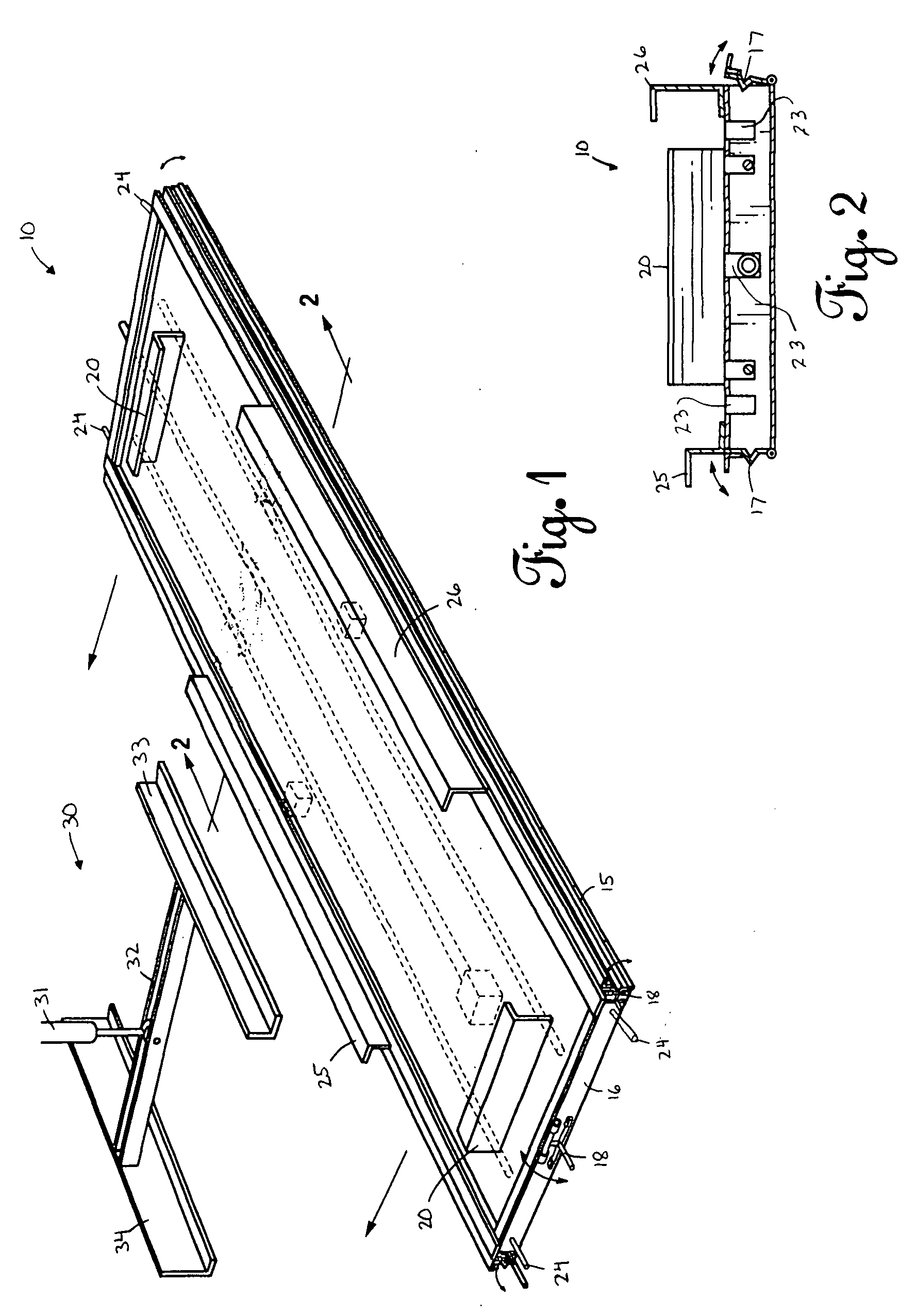

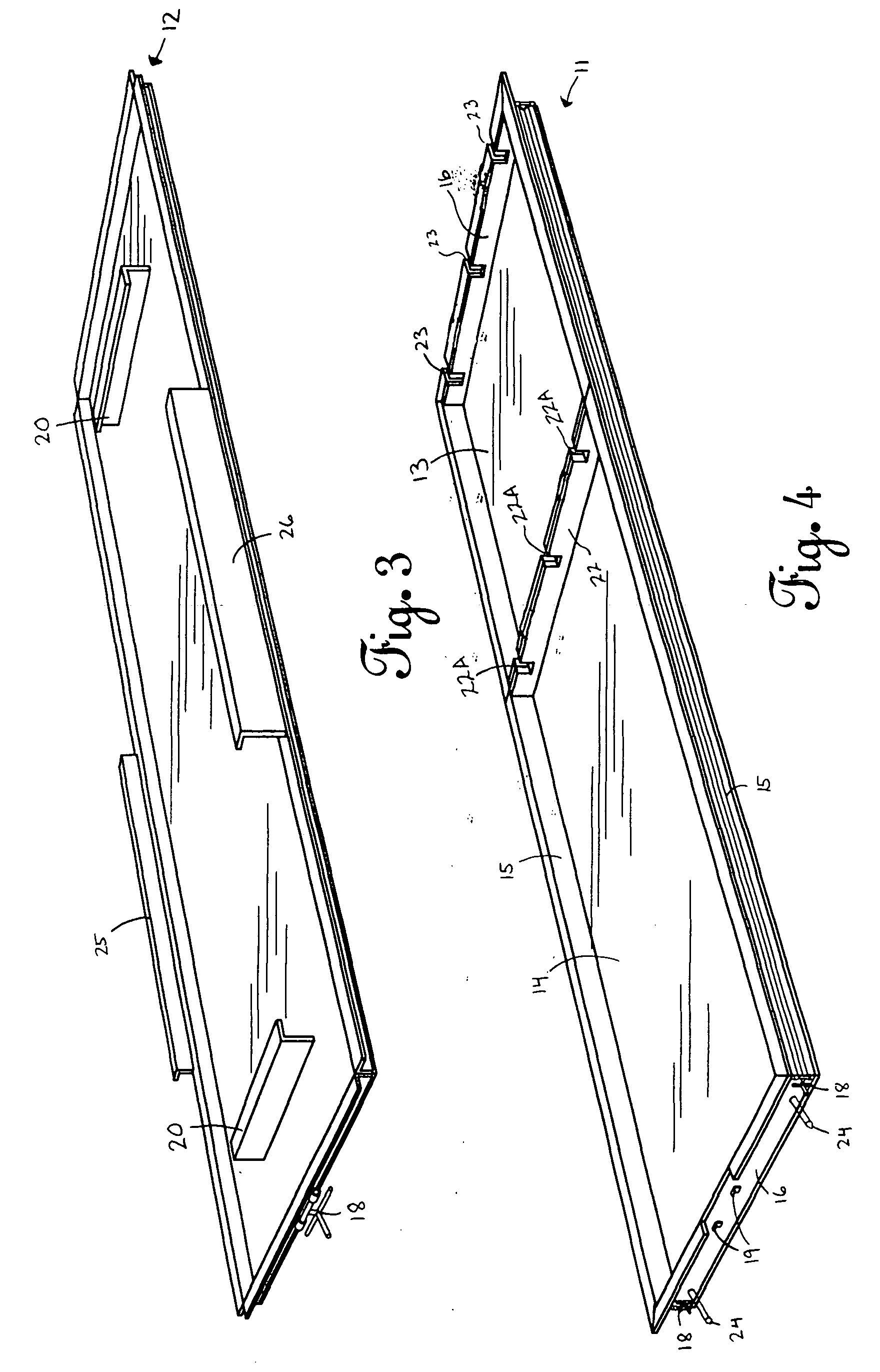

[0035] As illustrated in FIG. 10, an apparatus 1 for manufacturing unitary lightweight concrete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com