Patents

Literature

78results about How to "Expanded size range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

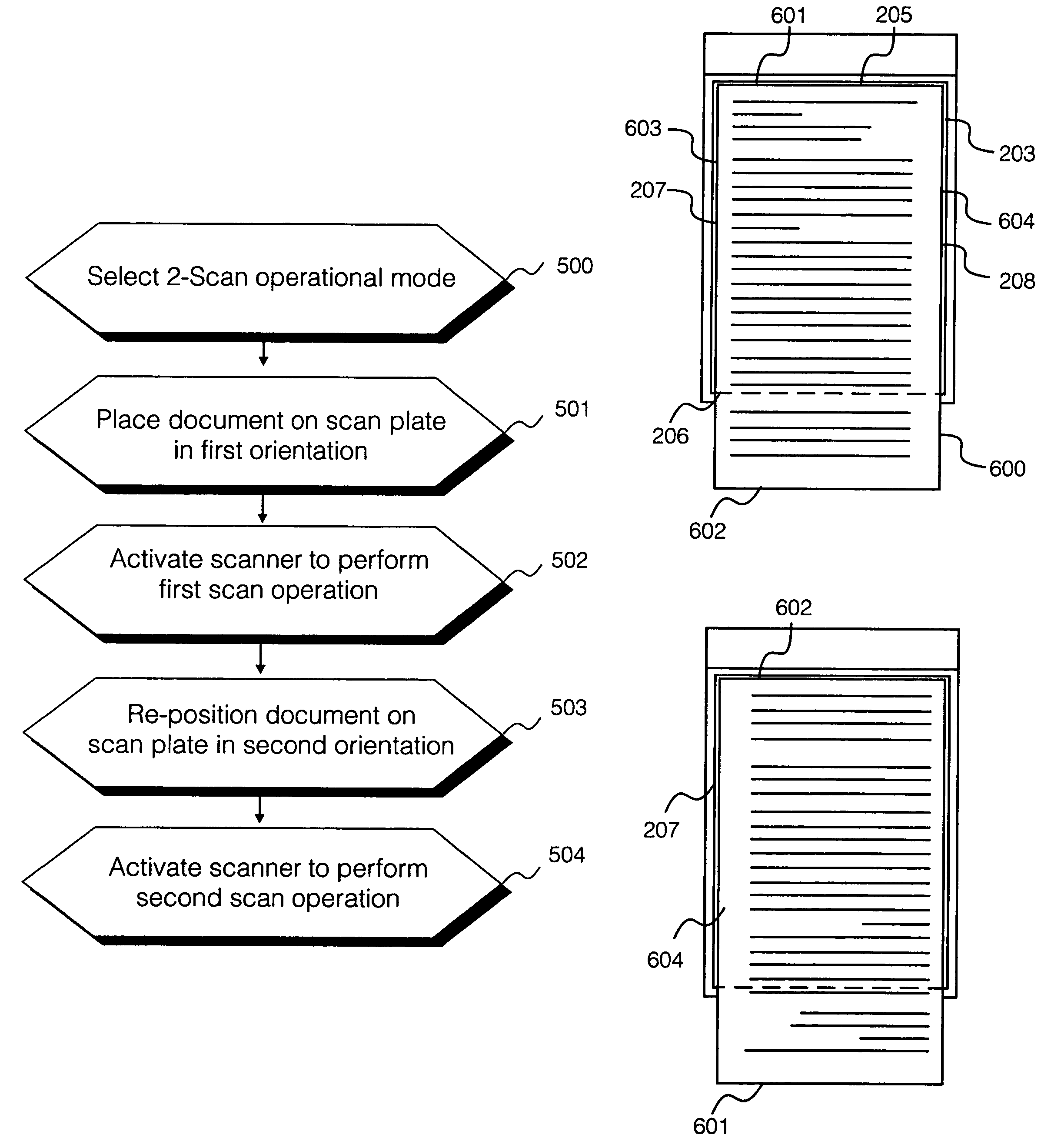

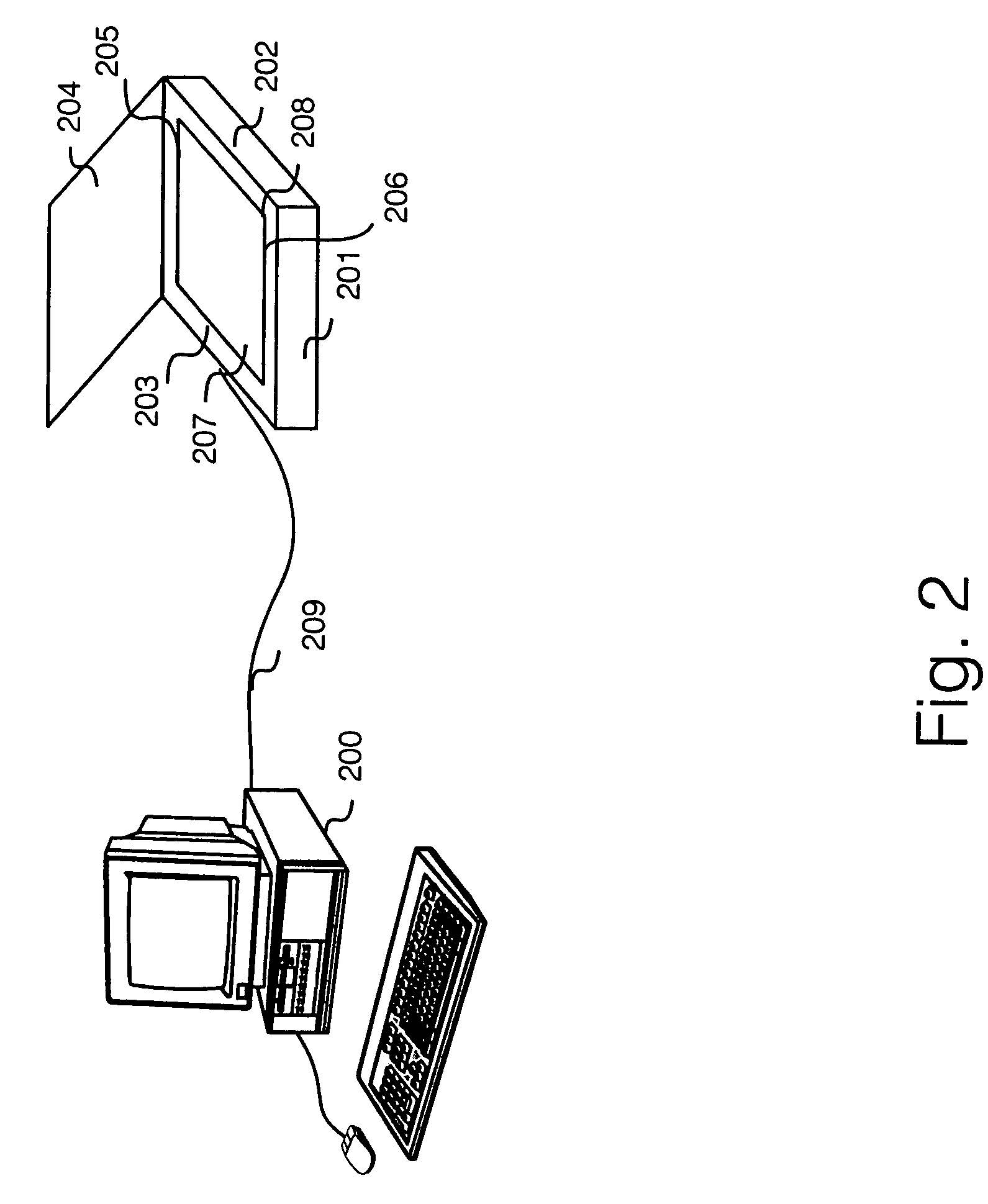

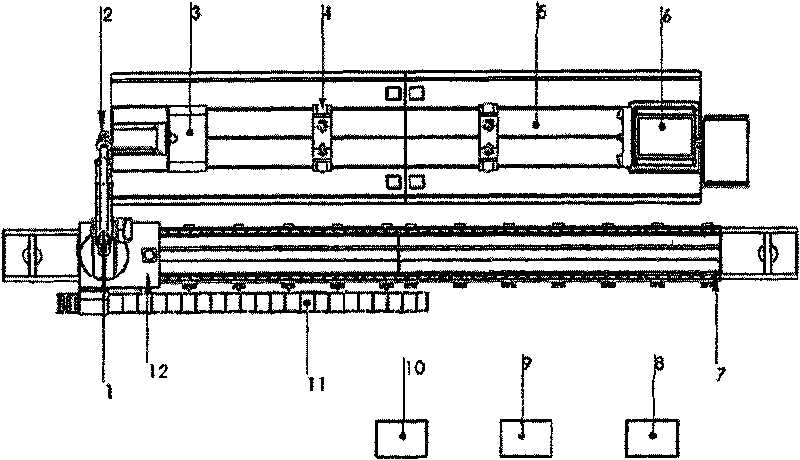

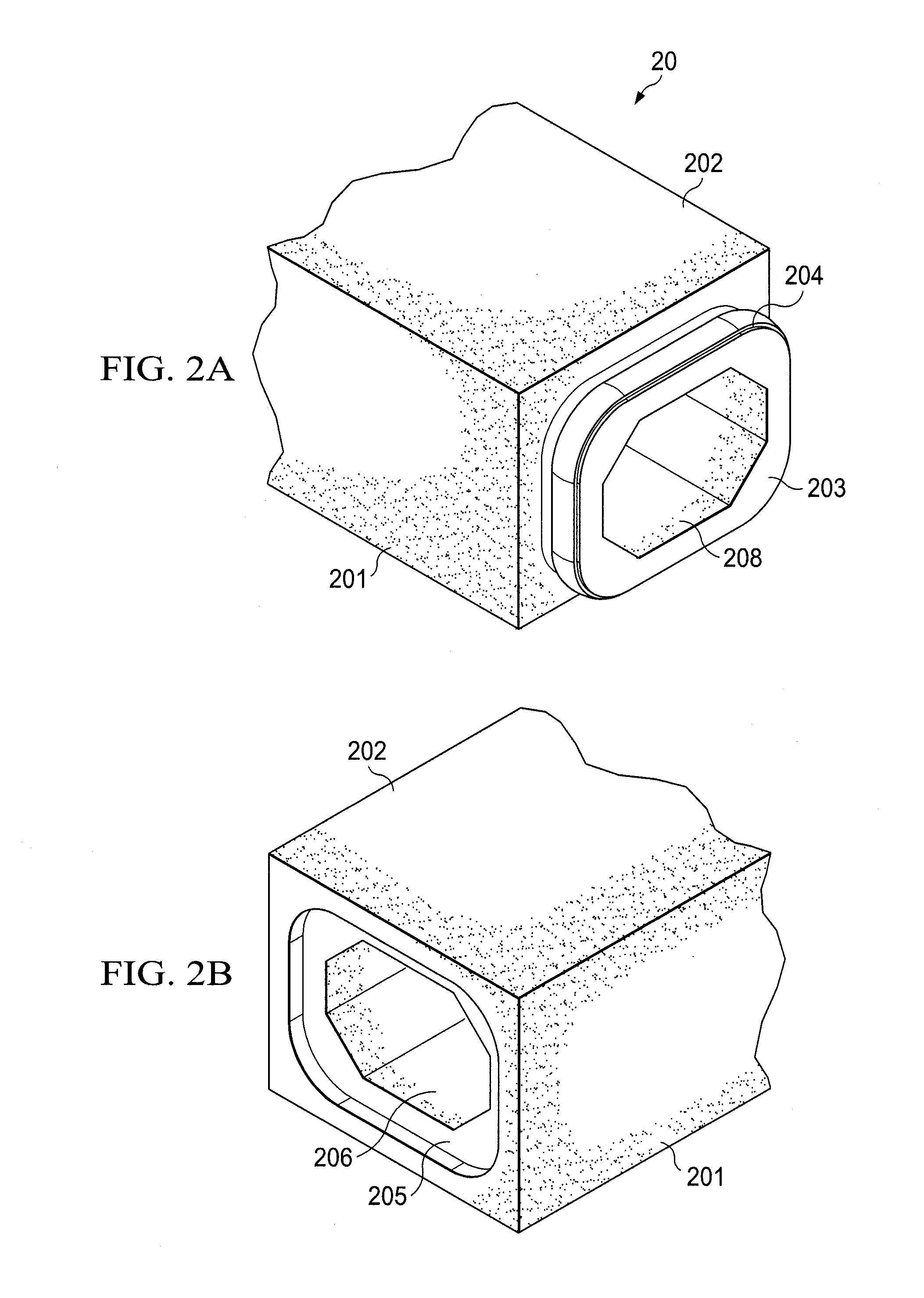

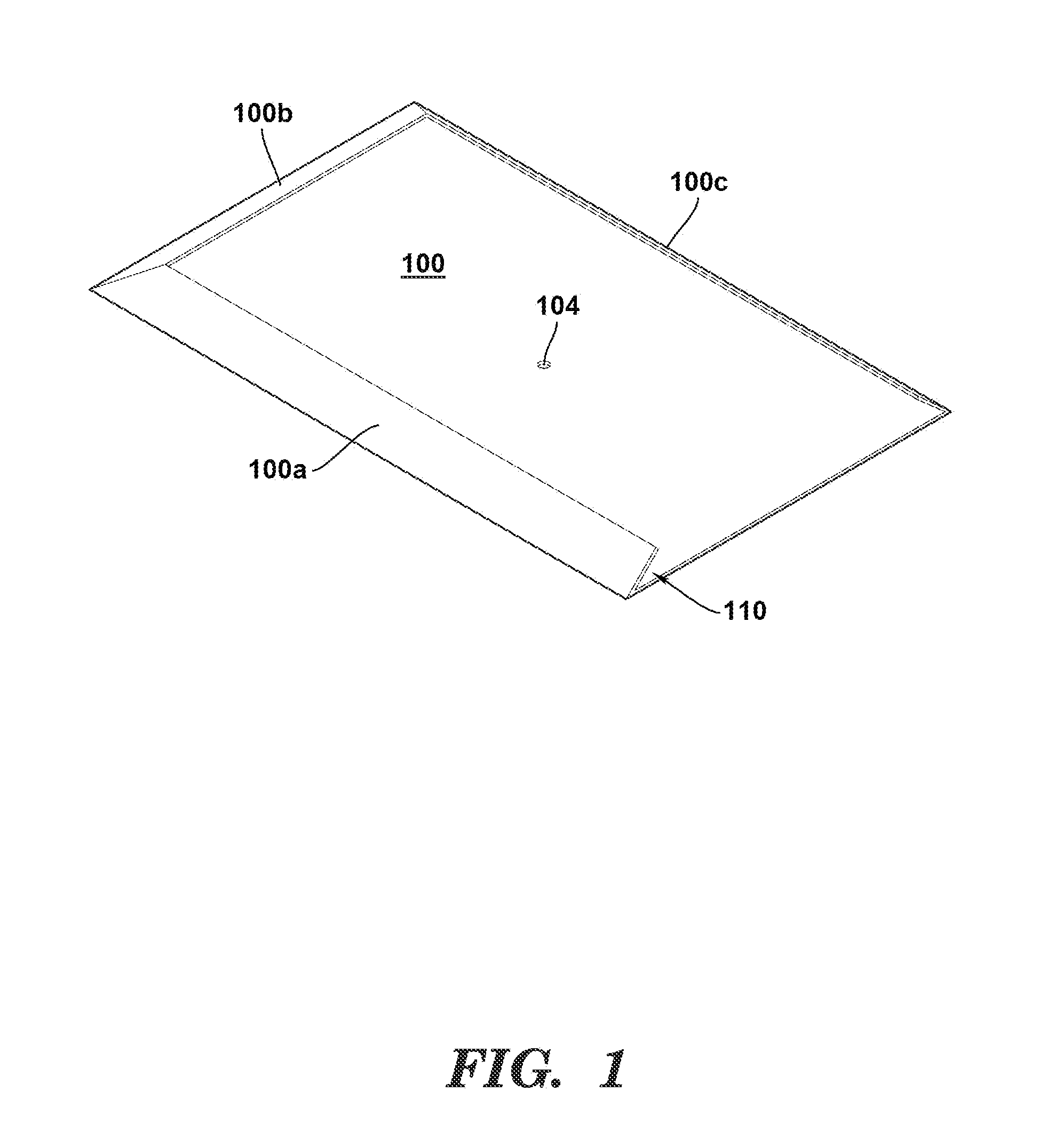

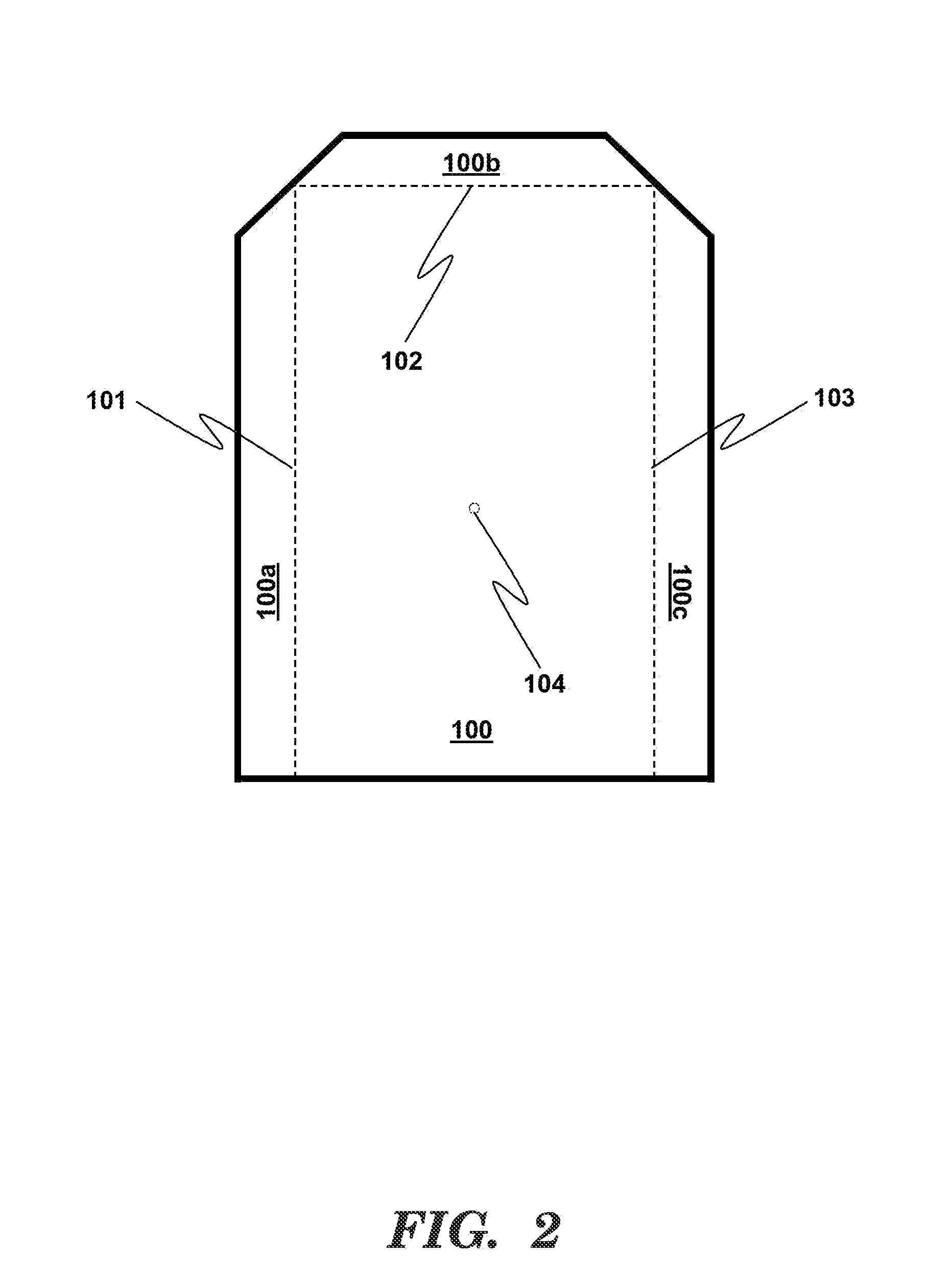

Method and apparatus for scanning oversized documents

InactiveUS6975434B1Expanded size rangeQuick matchCharacter and pattern recognitionPictoral communicationPersonal computerTwo step

An image capture apparatus comprises a computer device, for example a personal computer, and a scanning device, for example a flat bed scanning device, configured to operate a two-scan image capture process followed by data processing for combining first and second images obtained in said two-step image capture process, and a three-step image capture process followed by data processing for combining first, second and third images obtained in said three-step image capture process for obtaining a combined full image of a document. Algorithms are disclosed for stitching first and second images together to obtain a combined image data. In both the two-step and three-step image capture operation and subsequent data processing, a document having a size larger than an image capture area of said image capture device can be combined to produce a combined image data representing the whole of the document in a fully automated manner without the need for user intervention in matching images.

Owner:HEWLETT PACKARD DEV CO LP

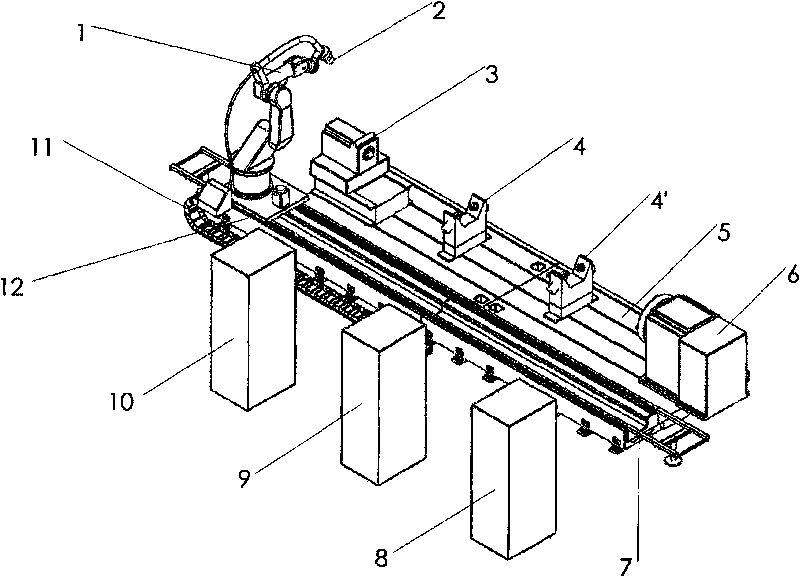

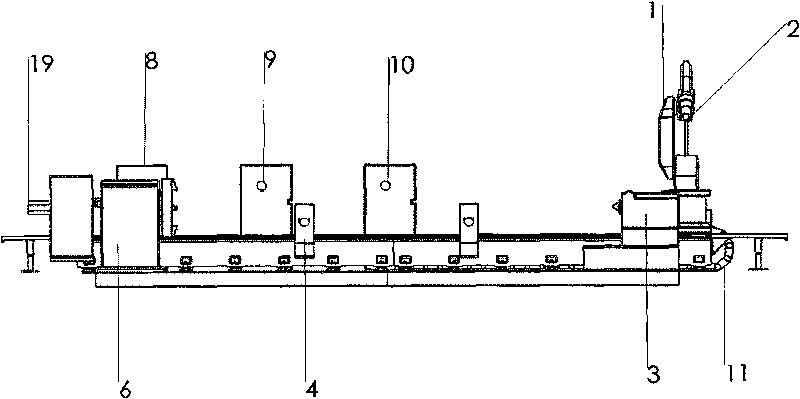

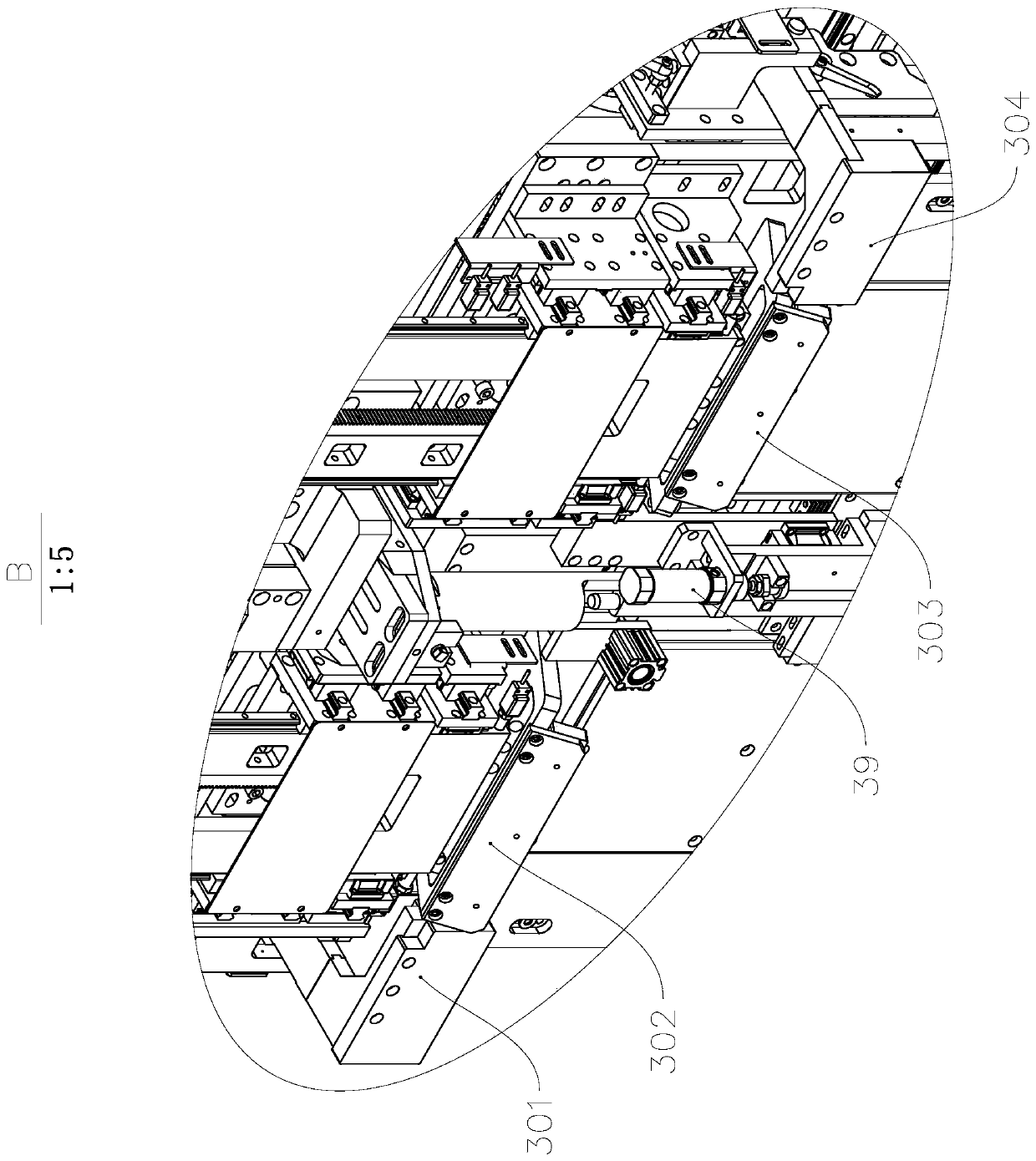

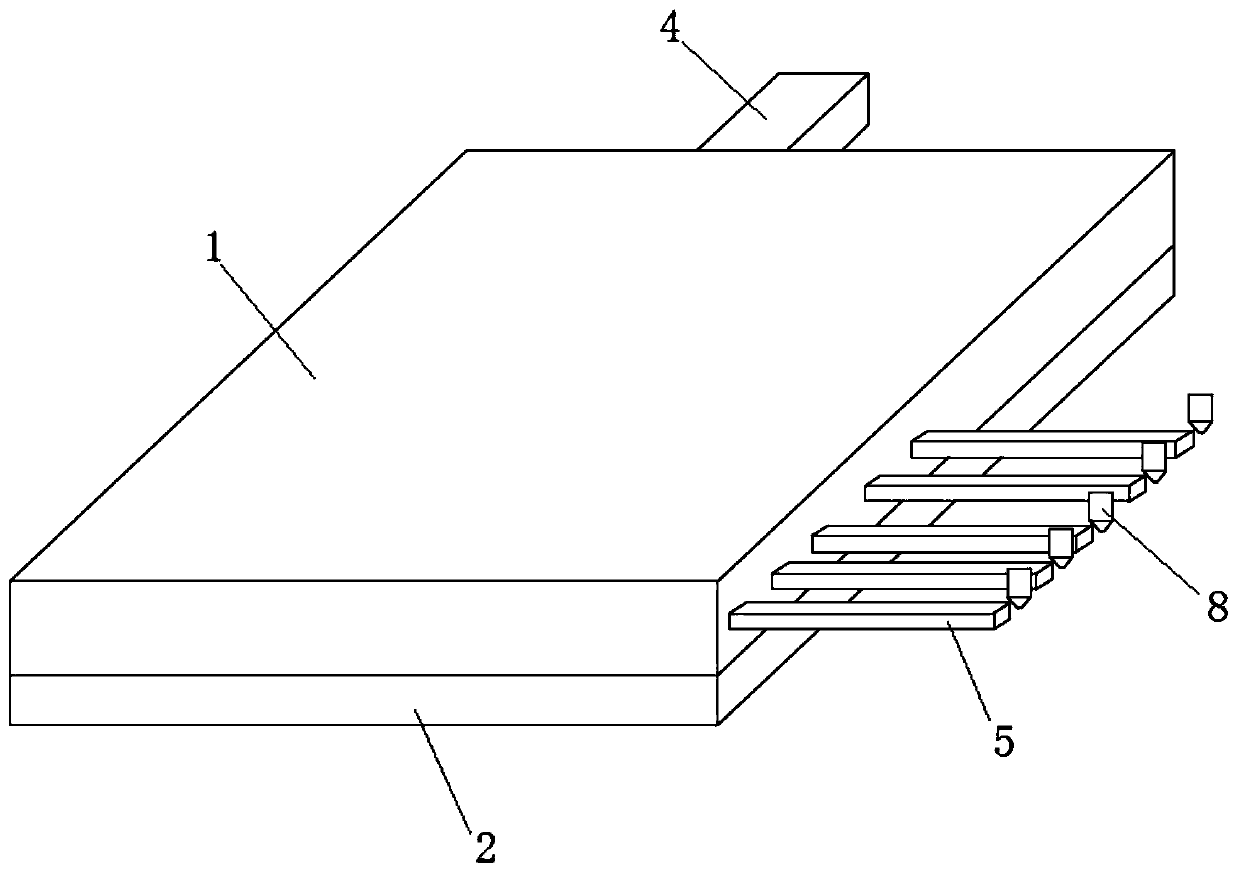

Multi-axis linkage numerical control laser processing system

InactiveCN101690993AOvercoming complexityDifficult to overcome controlLaser beam welding apparatusNumerical controlLaser processing

The invention provides a multi-axis linkage numerical control laser processing system, which is structurally characterized in that a workbench is provided with a linear guide rail, two ends of the guide rail are provided with a workbench tail seat and a headstock respectively, and two open center brackets are movably arranged on the guide rail and are positioned between the workbench tail seat and the headstock; a guide rail stand is arranged beside the workbench, the guide rail stand is provided with another parallel guide rail, and a movable sliding stand is movably arranged on the guide rail; a robot is fixed on the movable sliding stand, and a laser processing head is arranged at the tail end of a last joint of the robot; and a controller is connected with the robot and the movable sliding stand through control wires respectively so as to control the robot and control the movable sliding stand to drive the robot to move on the guide rail stand. The system solves the problem that a joint robot laser processing system has a small processing range, and can meet the numerical control laser processing requirements of parts of large size and super-large size.

Owner:HUAZHONG UNIV OF SCI & TECH

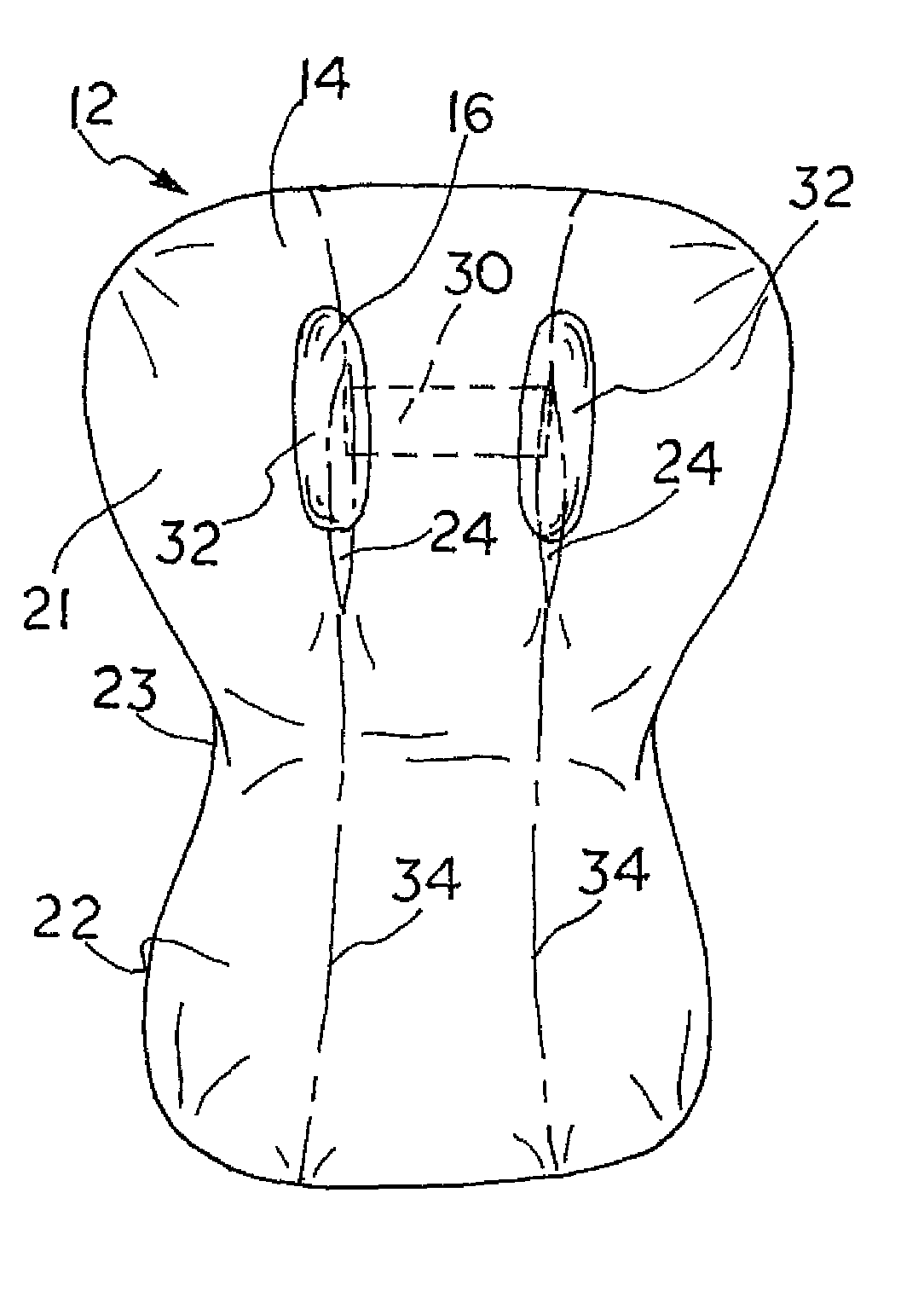

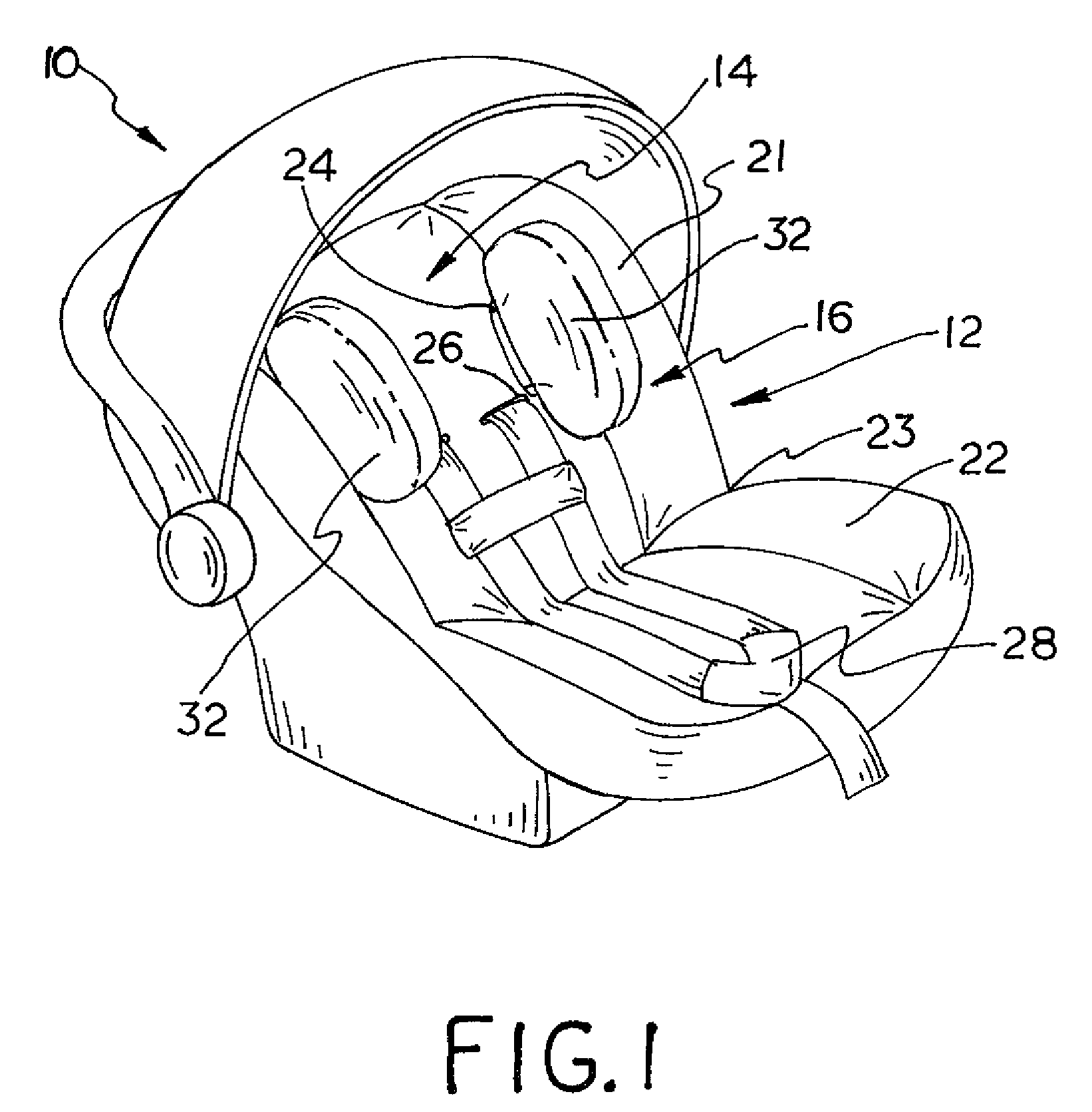

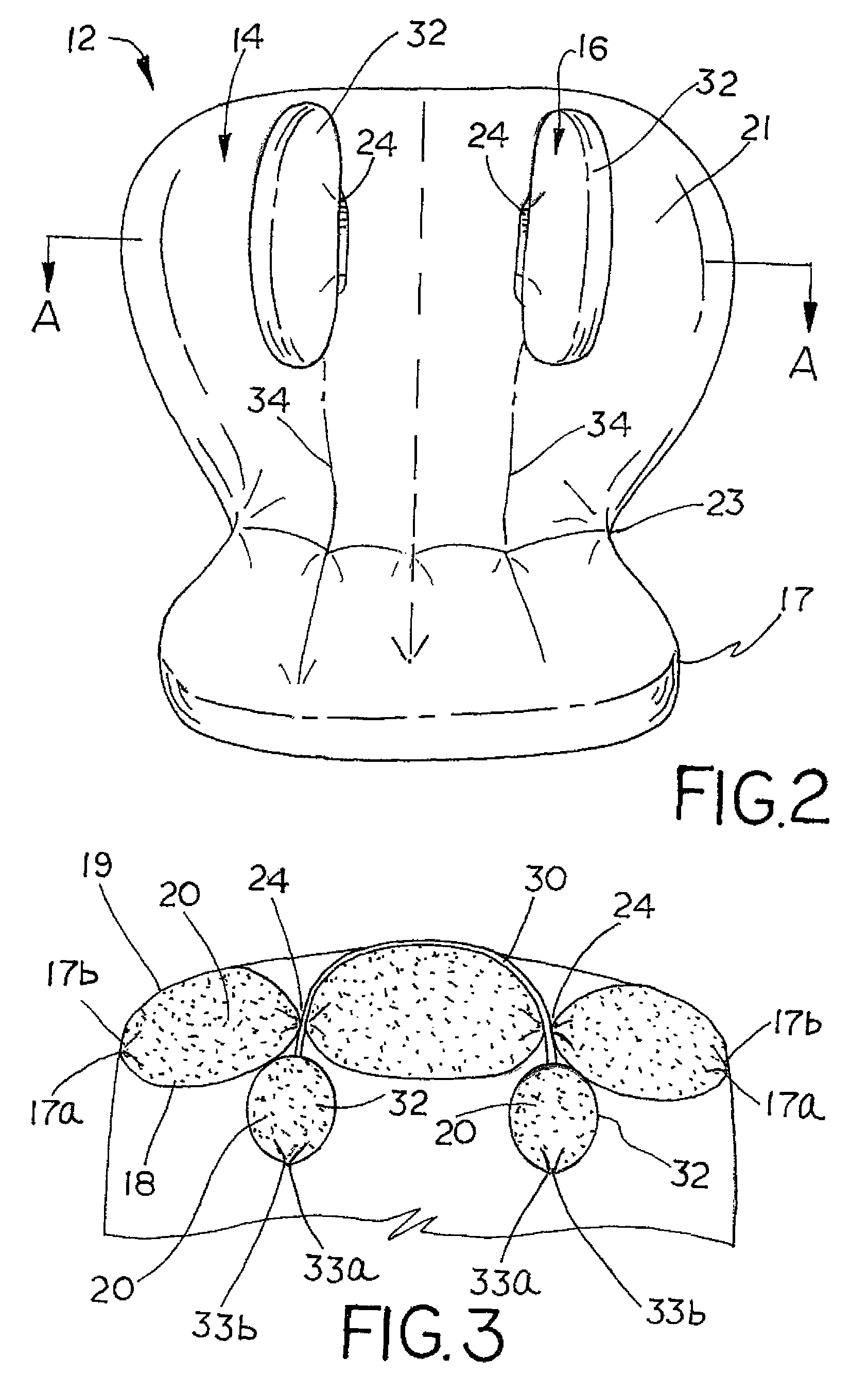

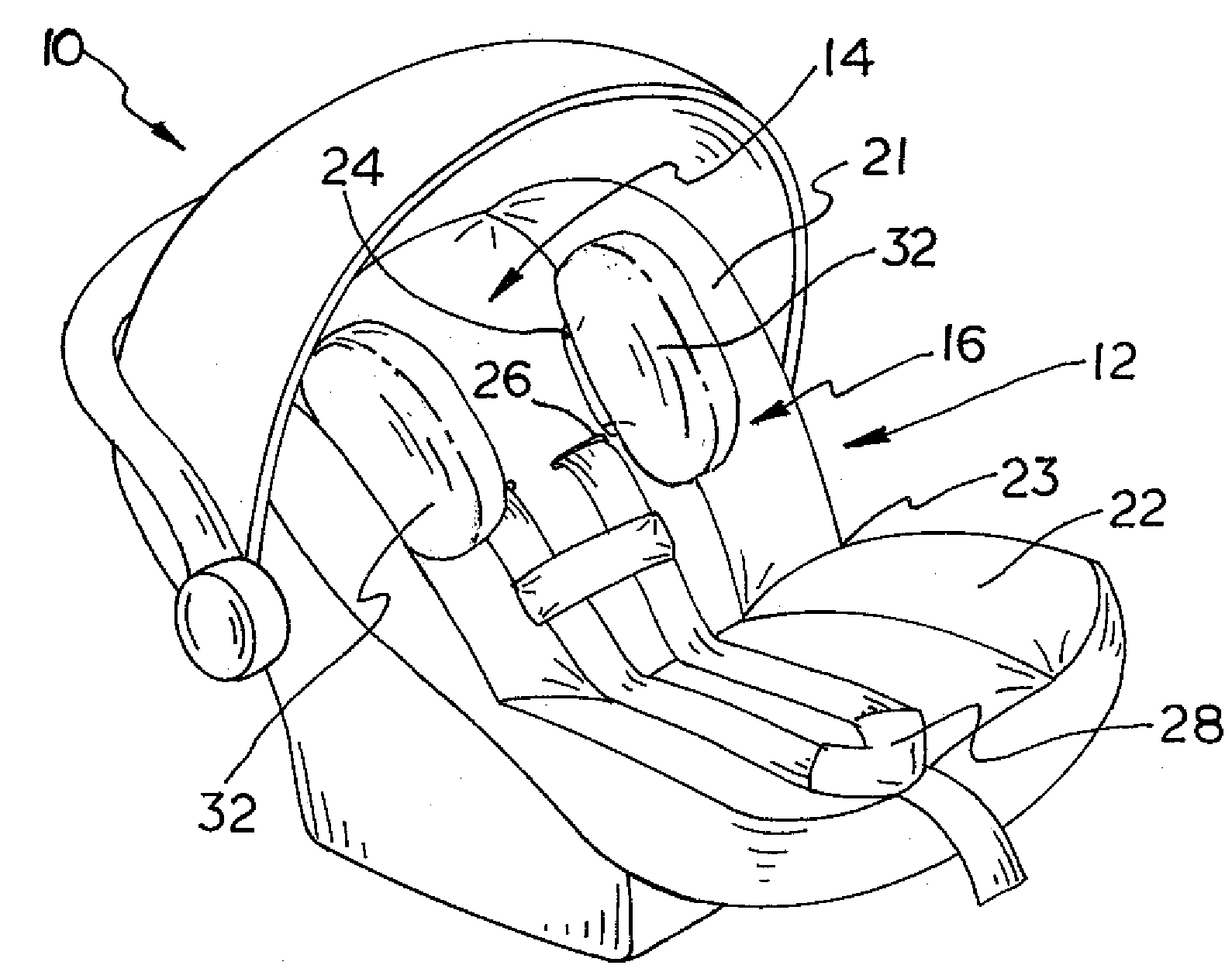

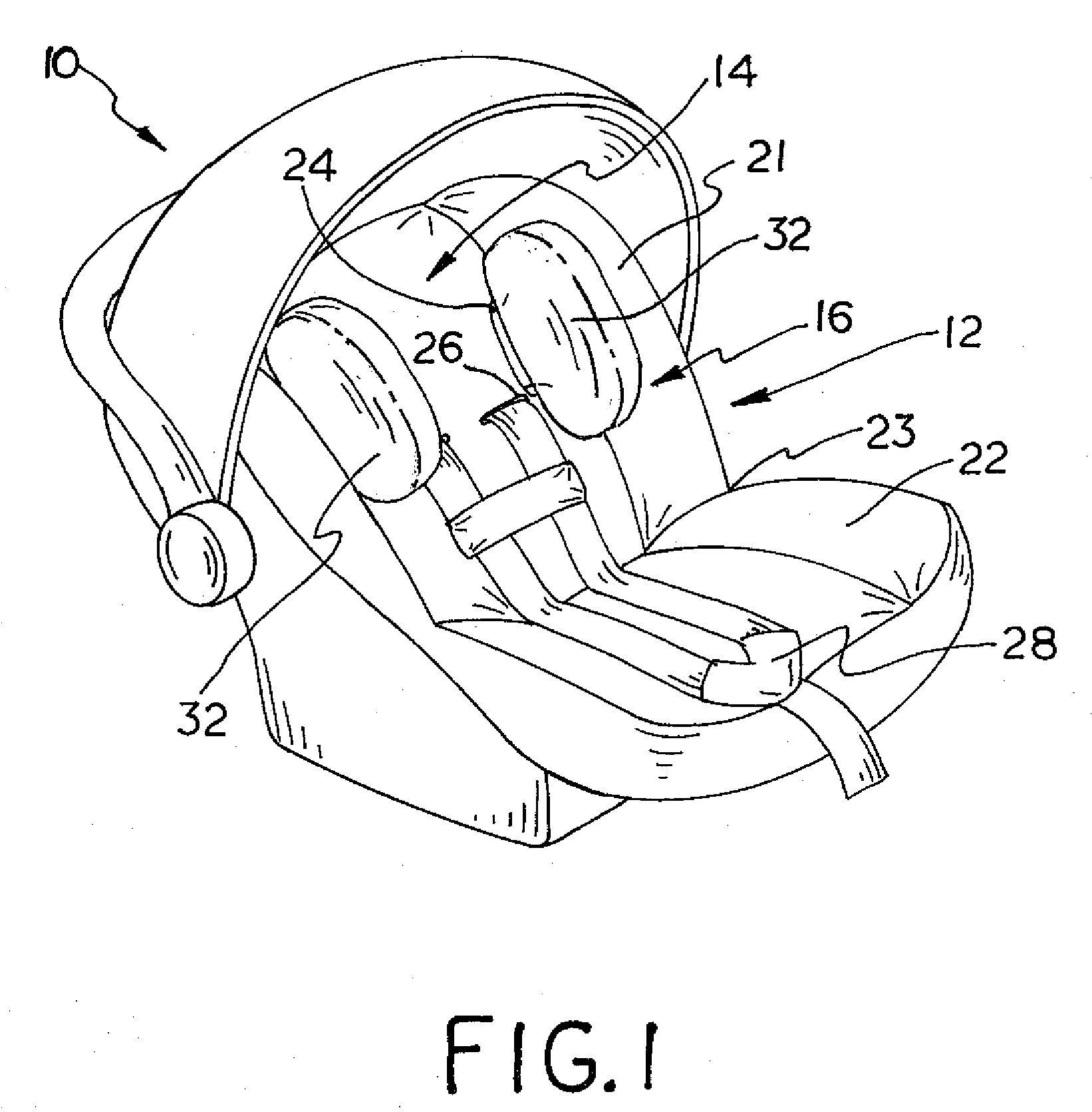

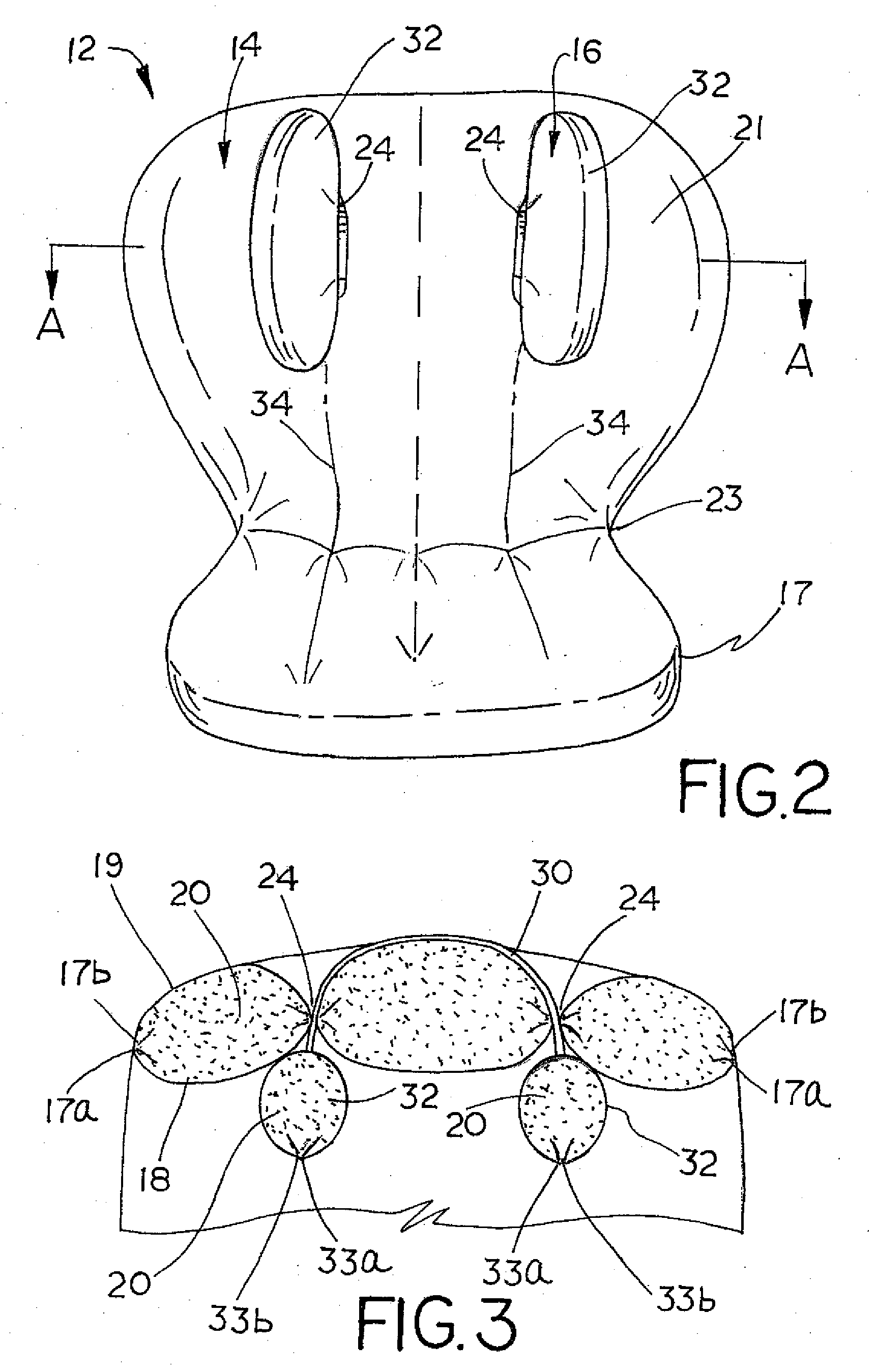

Head support and seat pad assembly for a child seat

ActiveUS7806472B2Expanded size rangeWide range of sizesVehicle seatsStuffed mattressesCar seatEngineering

A seat pad assembly is disclosed including a body pad for placement on the seating surface of a child seating device. The body pad has a front side, a back side, and two spaced apart vertical slots through the pad. The seat pad assembly has a head support with a connecting strip extending between a pair of laterally spaced apart cushions. The head support is generally H-shaped and installed on the pad through the slots with the pair of cushions on one side of the pad and the connecting strip on the other side. The head support is slidable along the slots to adjust the vertical position of the cushions. The seat pad assembly can be used on a child seating device such as a children's car seat, an infant carrier, a stroller, an infant swing, or the like.

Owner:GRACO CHILDRENS PROD INC

A high-performance cooper-coated aluminum rectangle section compound conductive bus bar and its making technology

ActiveCN101241778AMeet the requirements of multiple specificationsGreat widthSingle bars/rods/wires/strips conductorsMeasuring devicesCopperAluminum composites

The present invention provides a high-performance copper-clad aluminum cross section composite conductive bus-bar and the preparing technique thereof, and the invention relates to a rectangle-cross section bimetal composite material and the preparation thereof. The copper-clad aluminum rectangular cross section composite conductive bus-bar is compounded by the core-part aluminum and the coating layer copper. The area proportion of the coating copper layer is 15to 50 The technique comprises the following procedures: Adopting horizontal continuous casting for directly compounding and forming the copper-clad aluminum composite blank. Commonly flat-roller rolling and finish drawing-pulling the copper-clad aluminum blank according to requirement or rolling with the flat roller provided with a vertical roller, the range of the rolling speed is 3-50m / min, and the single-pass relative reduction is between 15and 40 The speed range of finish drawing-pulling is 1-20m / min and the single-pass cross section scalage is 10%. When the multiple-pass relative reduction is up to 70%, the low-temperature intermediate annealing is executed to the copper-clad aluminum composite conductive bus-bar. The annealing temperature is between 250 and 450 DEG C and the annealing time is between 0.5 and 3h. The annealed composite conductive bus-bar is executed with hole-form rolling or drawing. The invention not only can produce the high-performance copper-clad aluminum cross section composite conductive bus-bar, but also has the advantages of short process flow and high efficiency of the producing method.

Owner:UNIV OF SCI & TECH BEIJING

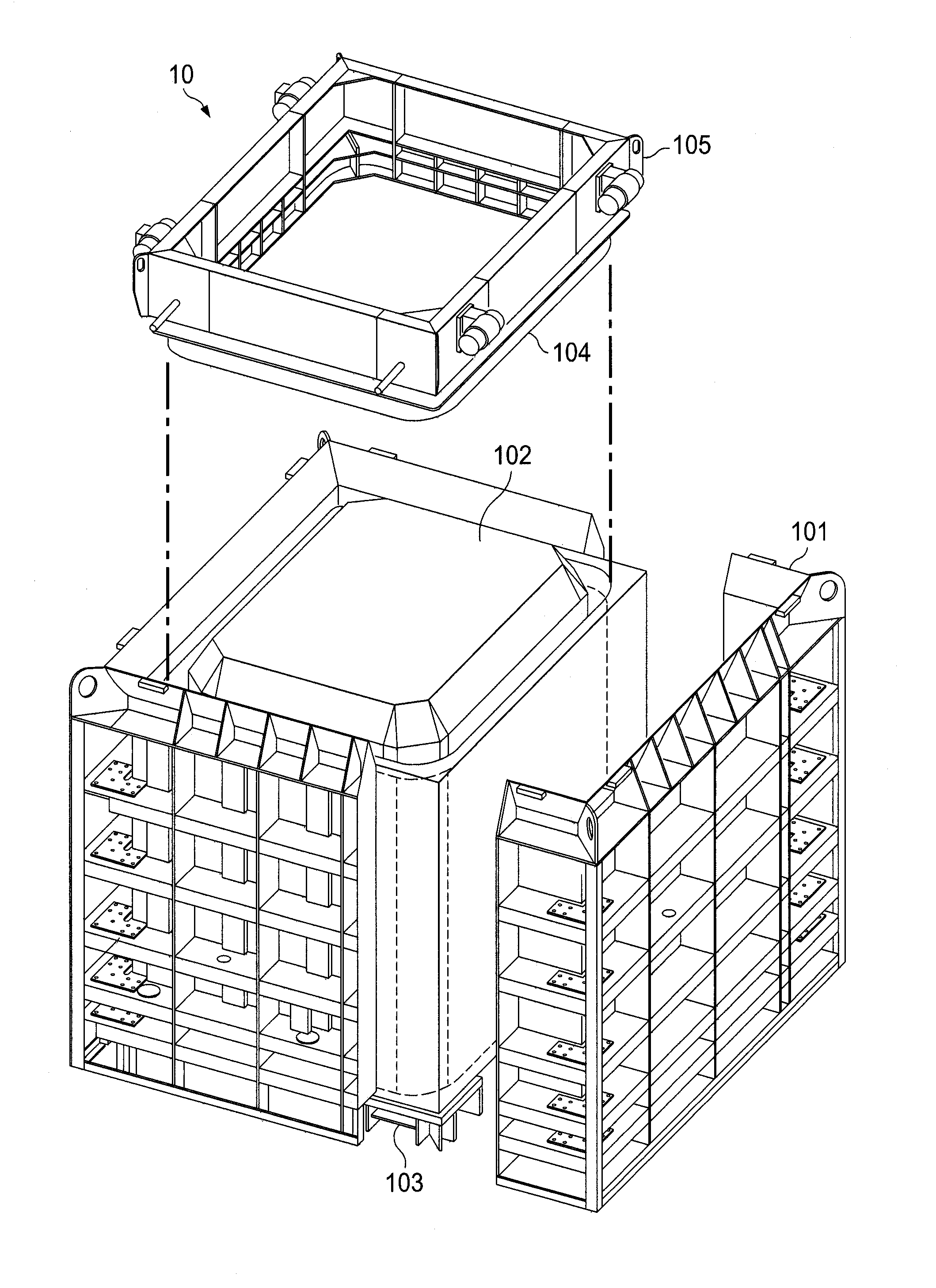

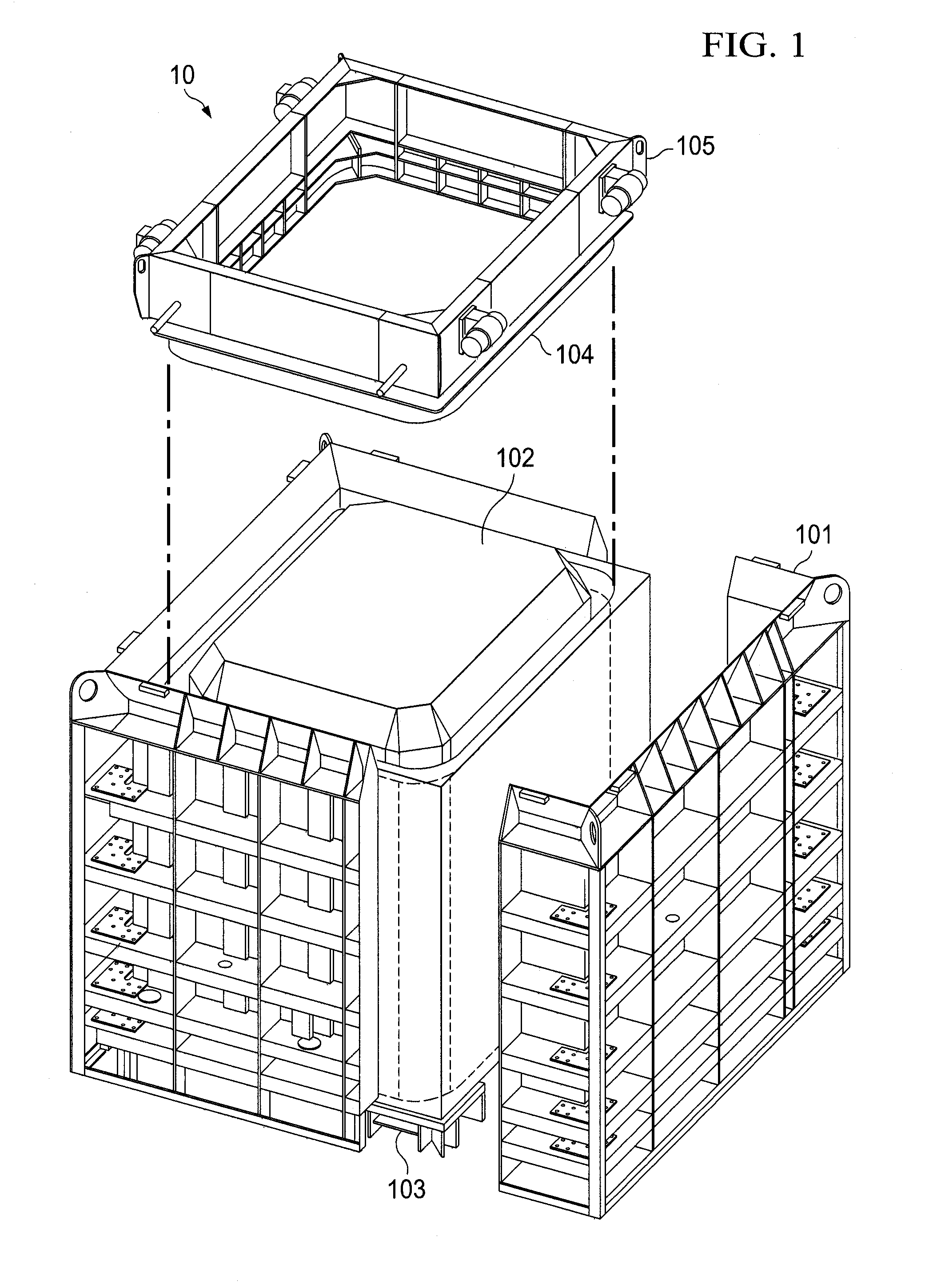

System and method for constructing modular concrete ducts

Modular mold equipment for producing concrete culverts with tight tolerances. Modular mold equipment having a coupling plate is used to align and interconnect components of the mold. The components being aligned may have recesses for receiving the coupling plate. Modular mold equipment system with an extended size range to cover all standard concreted duct product sizes. Modular mold equipment having a pallet guide adjustment mechanism adapted for setting the pallet at a desired location in relation to a form. The desired location is based on a wall thickness of a concrete culvert to be produced. Modular mold equipment having a core that includes a core corner and another core component adapted to be coupled to the core corner, and locking apparatus adapted to lock the core corner to the other core component via a mechanism that extends outside the core.

Owner:SOUTHERN CAST PRODS

Head Support and Seat Pad Assembly for a Child Seat

ActiveUS20100148543A1Expanded size rangeGreat size rangeVehicle seatsStuffed mattressesCushionCar seat

A seat pad assembly is disclosed including a body pad for placement on the seating surface of a child seating device. The body pad has a front side, a back side, and two spaced apart vertical slots through the pad. The seat pad assembly has a head support with a connecting strip extending between a pair of laterally spaced apart cushions. The head support is generally H-shaped and installed on the pad through the slots with the pair of cushions on one side of the pad and the connecting strip on the other side. The head support is slidable along the slots to adjust the vertical position of the cushions. The seat pad assembly can be used on a child seating device such as a children's car seat, an infant carrier, a stroller, an infant swing, or the like.

Owner:GRACO CHILDRENS PROD INC

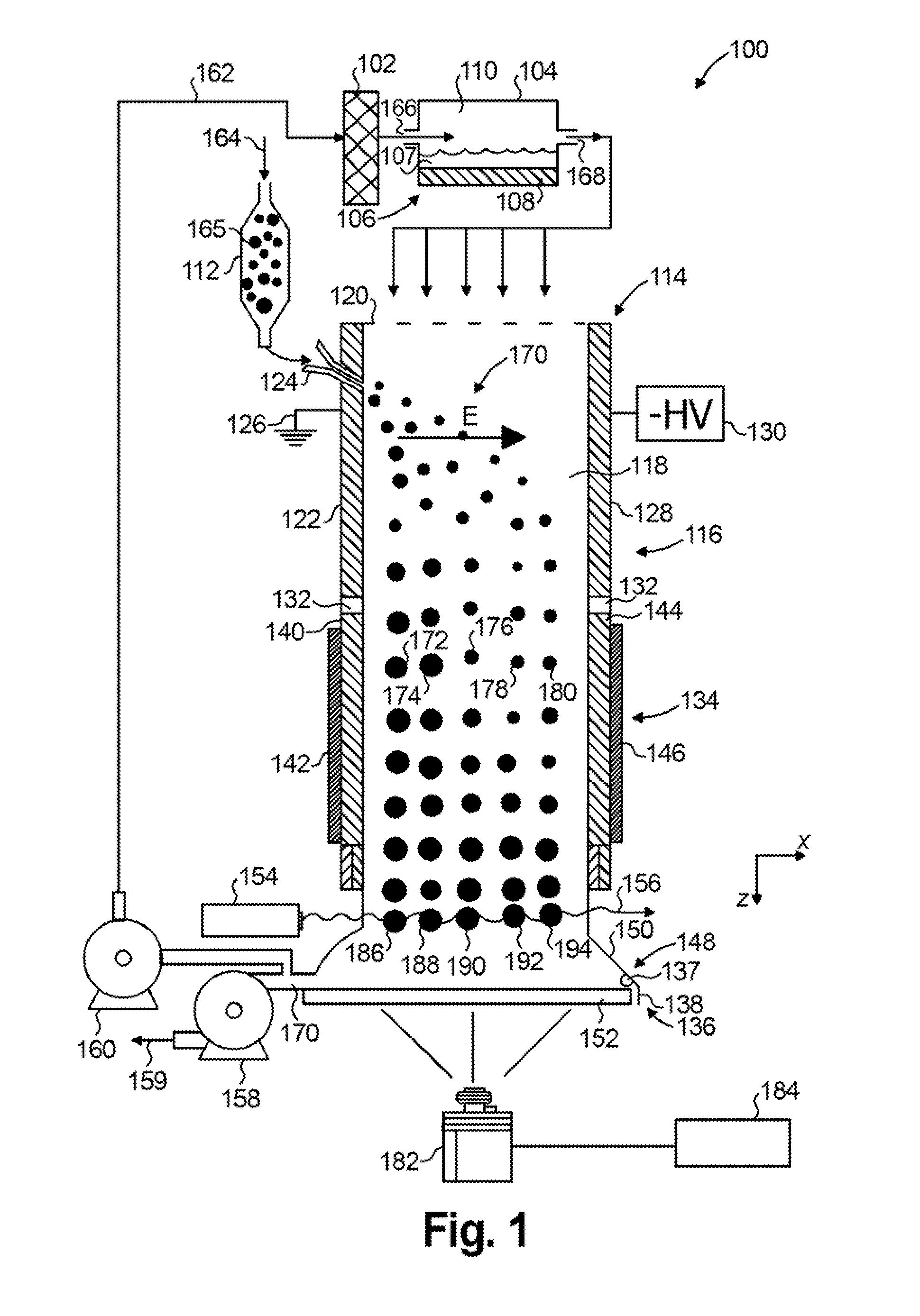

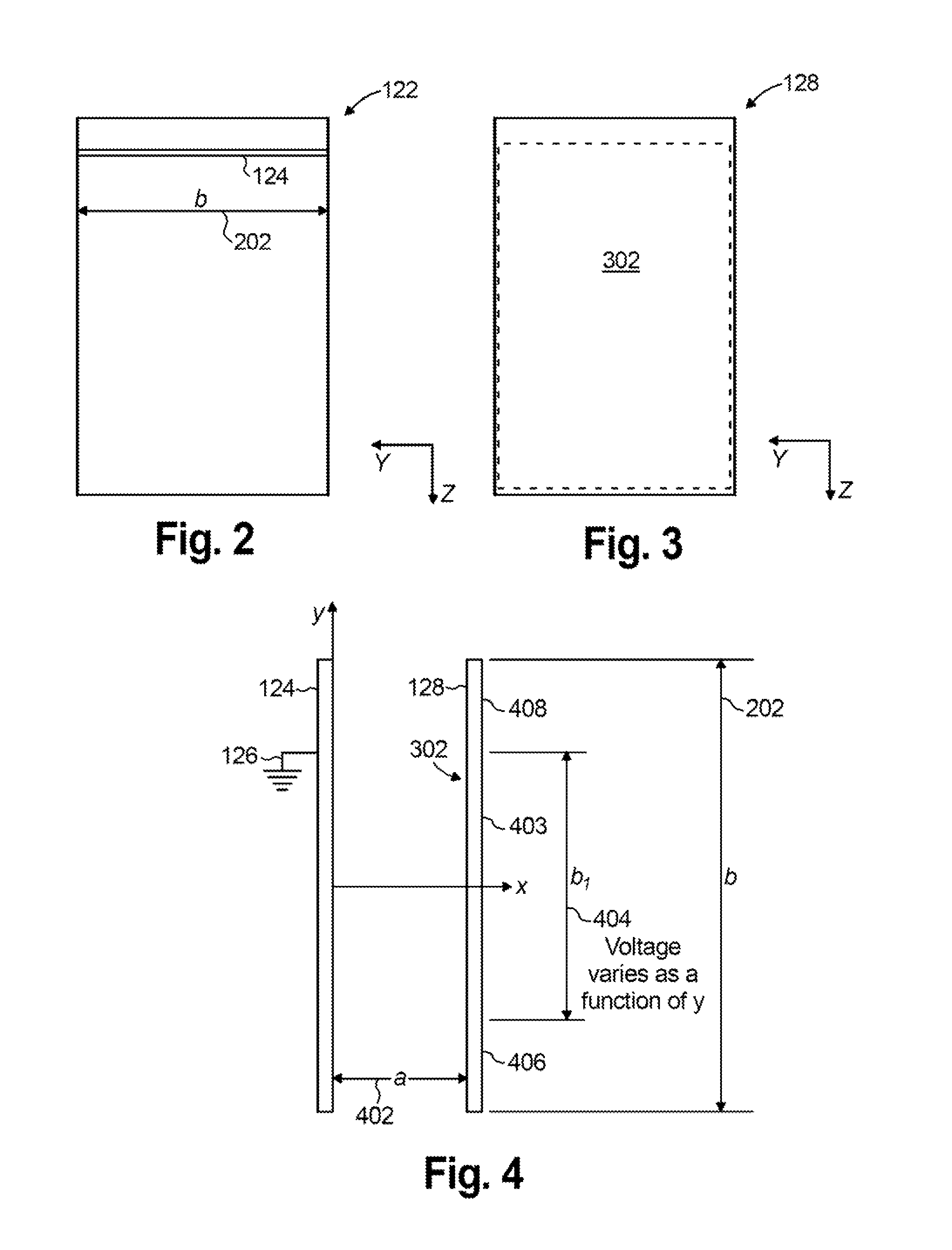

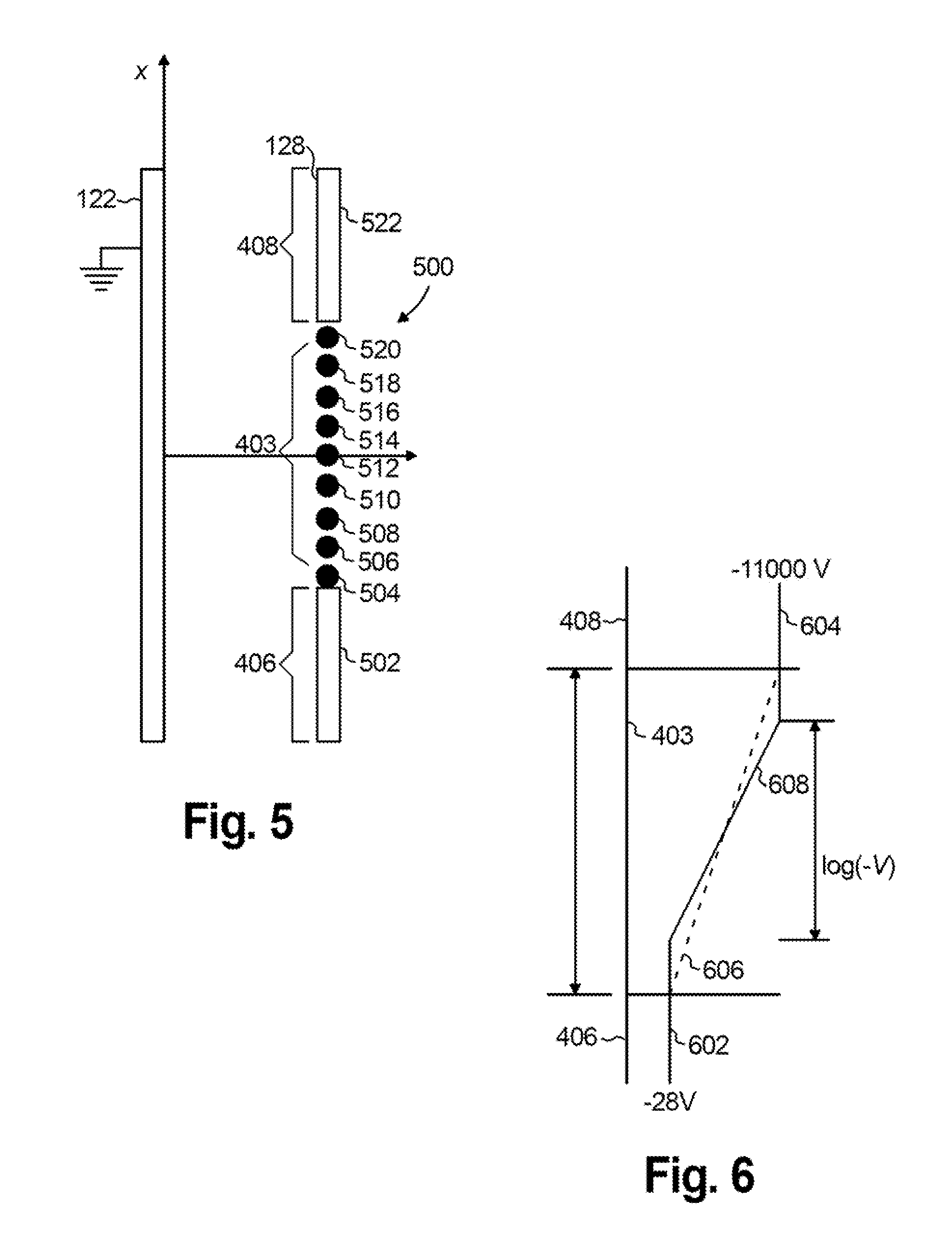

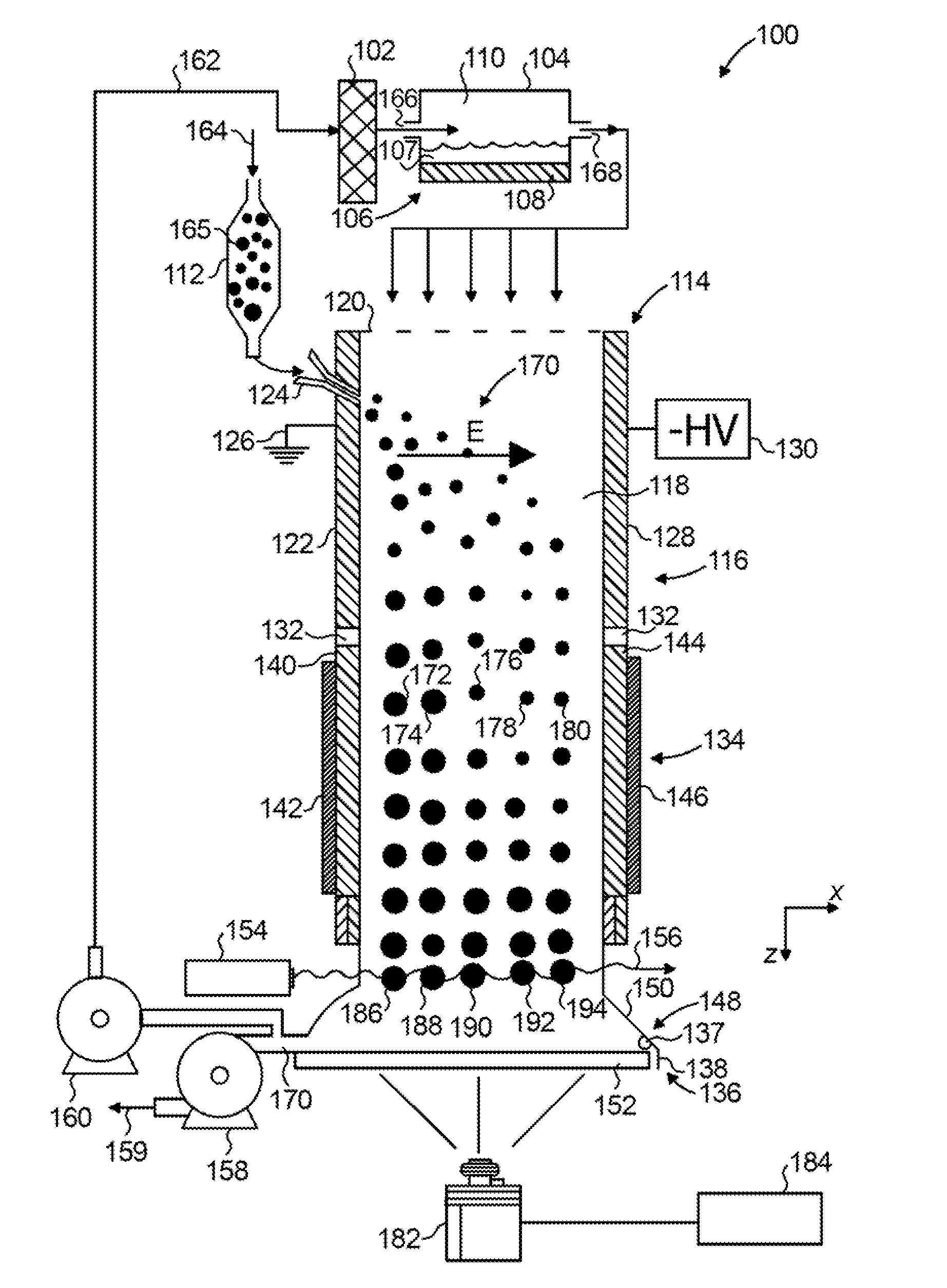

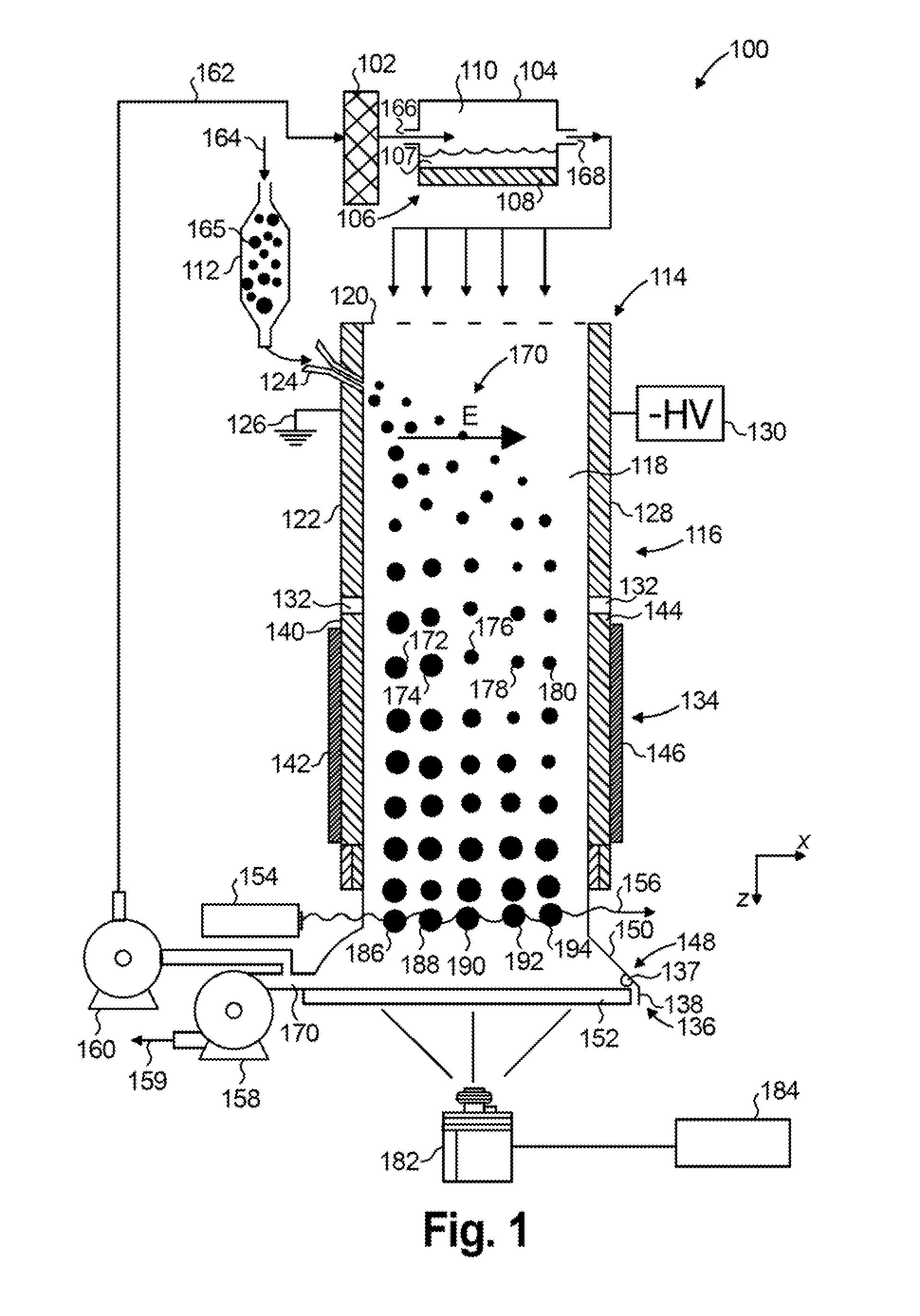

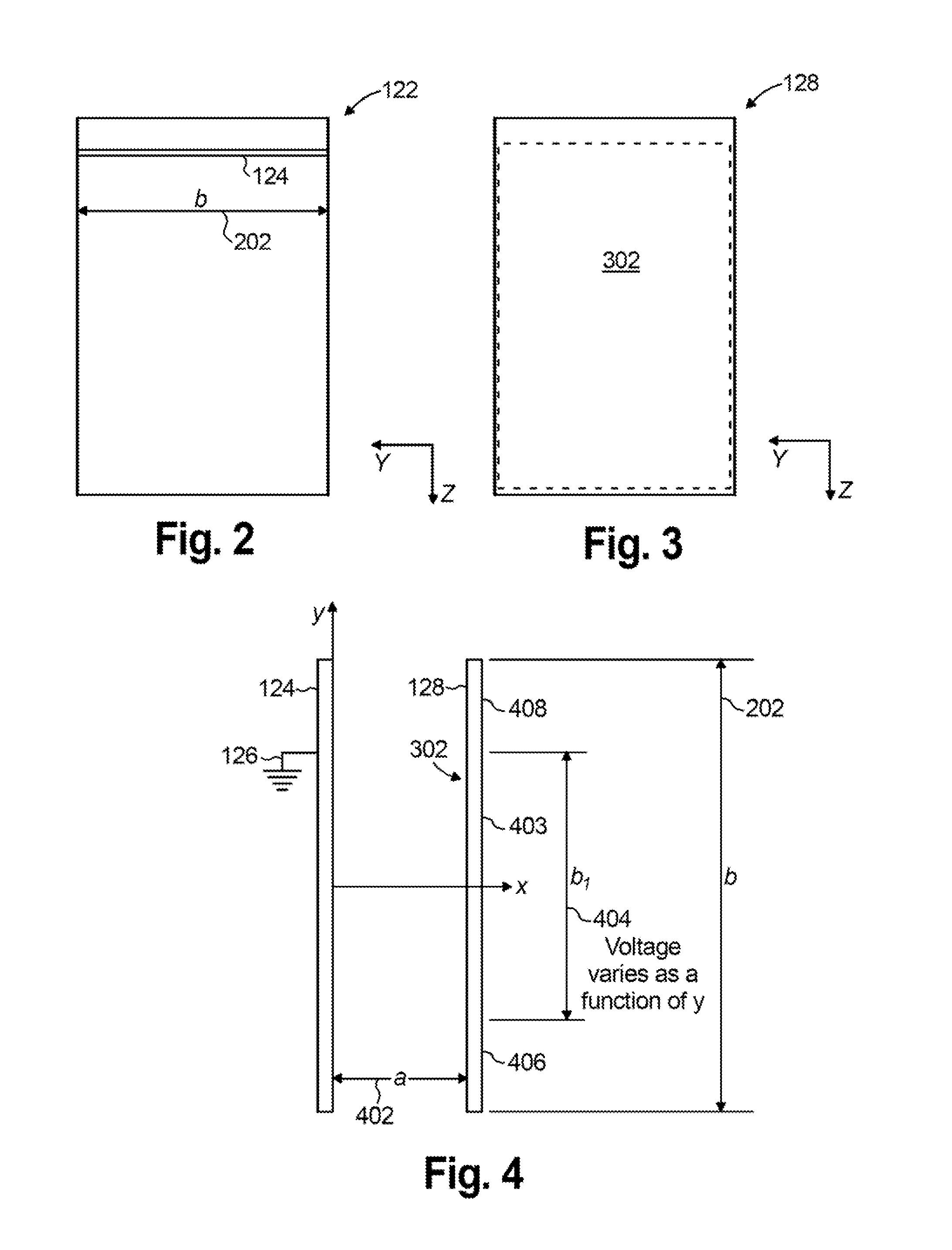

Wide size range fast integrated mobility spectrometer

ActiveUS8570511B2Expanded size rangeReduce necessityParticle size analysisNanoparticleParticle physics

A mobility spectrometer to measure a nanometer particle size distribution is disclosed. The mobility spectrometer includes a conduit and a detector. The conduit is configured to receive and provide fluid communication of a fluid stream having a charged nanometer particle mixture. The conduit includes a separator section configured to generate an electrical field of two dimensions transverse to a dimension associated with the flow of the charged nanometer particle mixture through the separator section to spatially separate charged nanometer particles of the charged nanometer particle mixture in said two dimensions. The detector is disposed downstream of the conduit to detect concentration and position of the spatially-separated nanometer particles.

Owner:BROOKHAVEN SCI ASSOCS

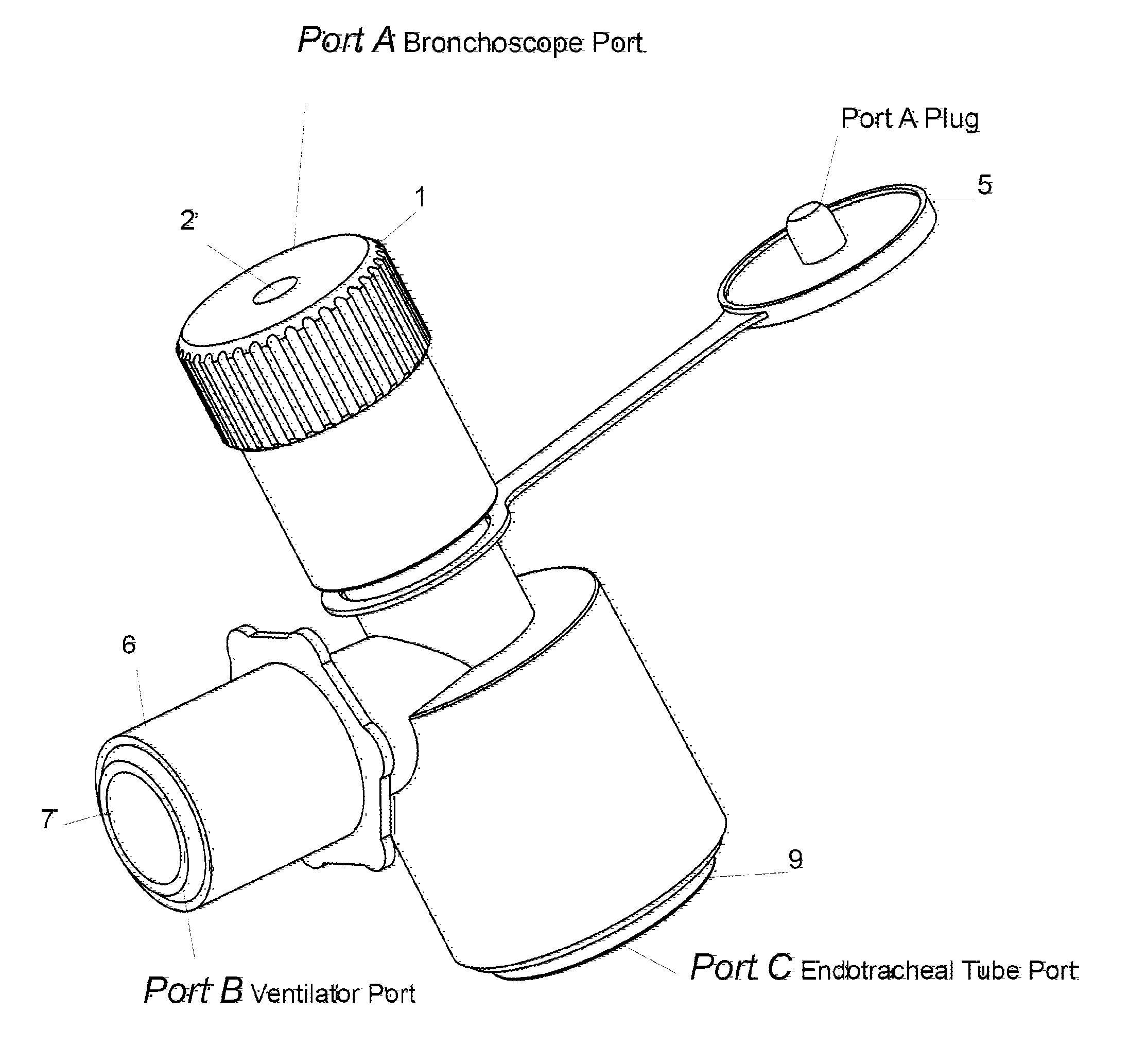

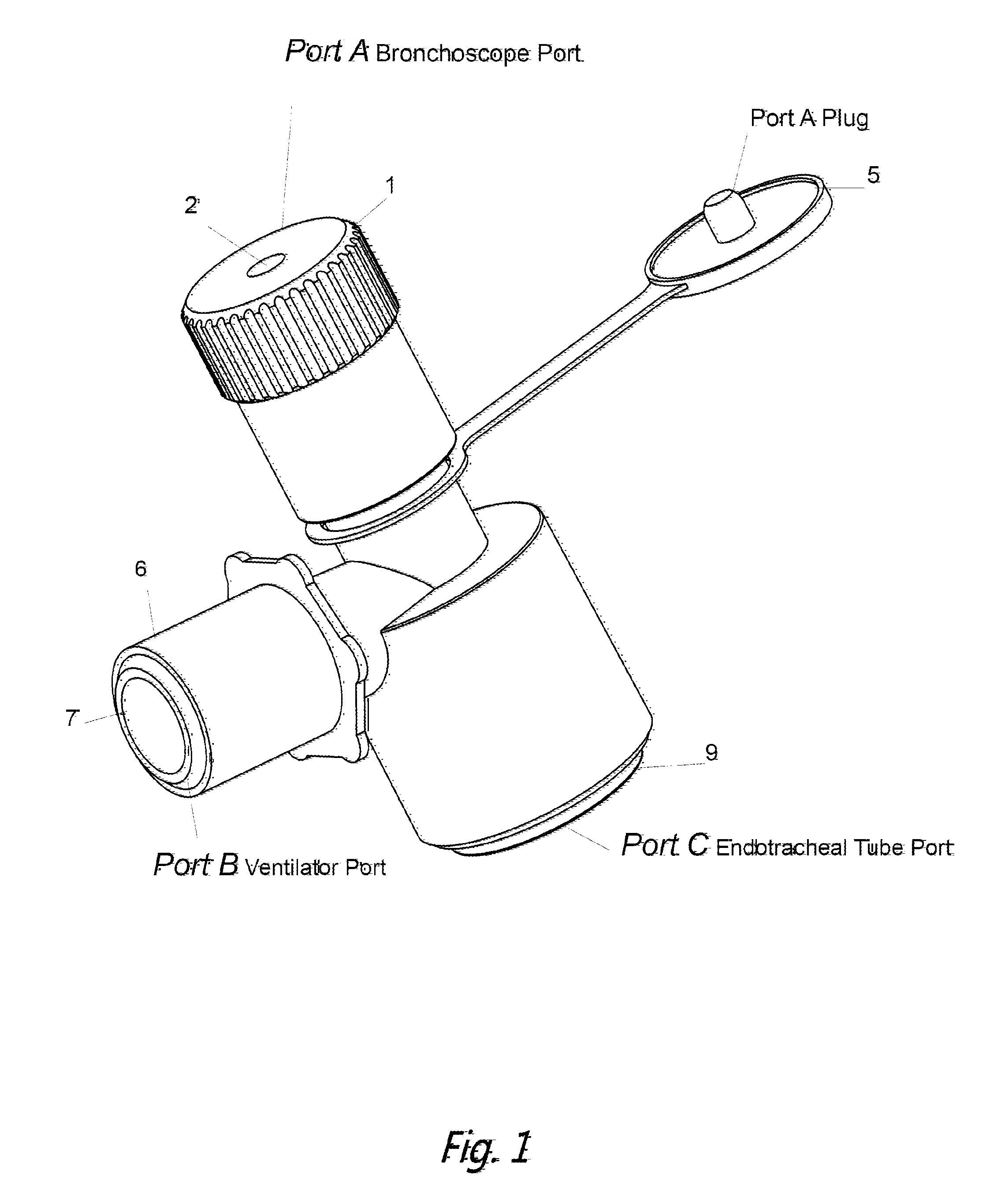

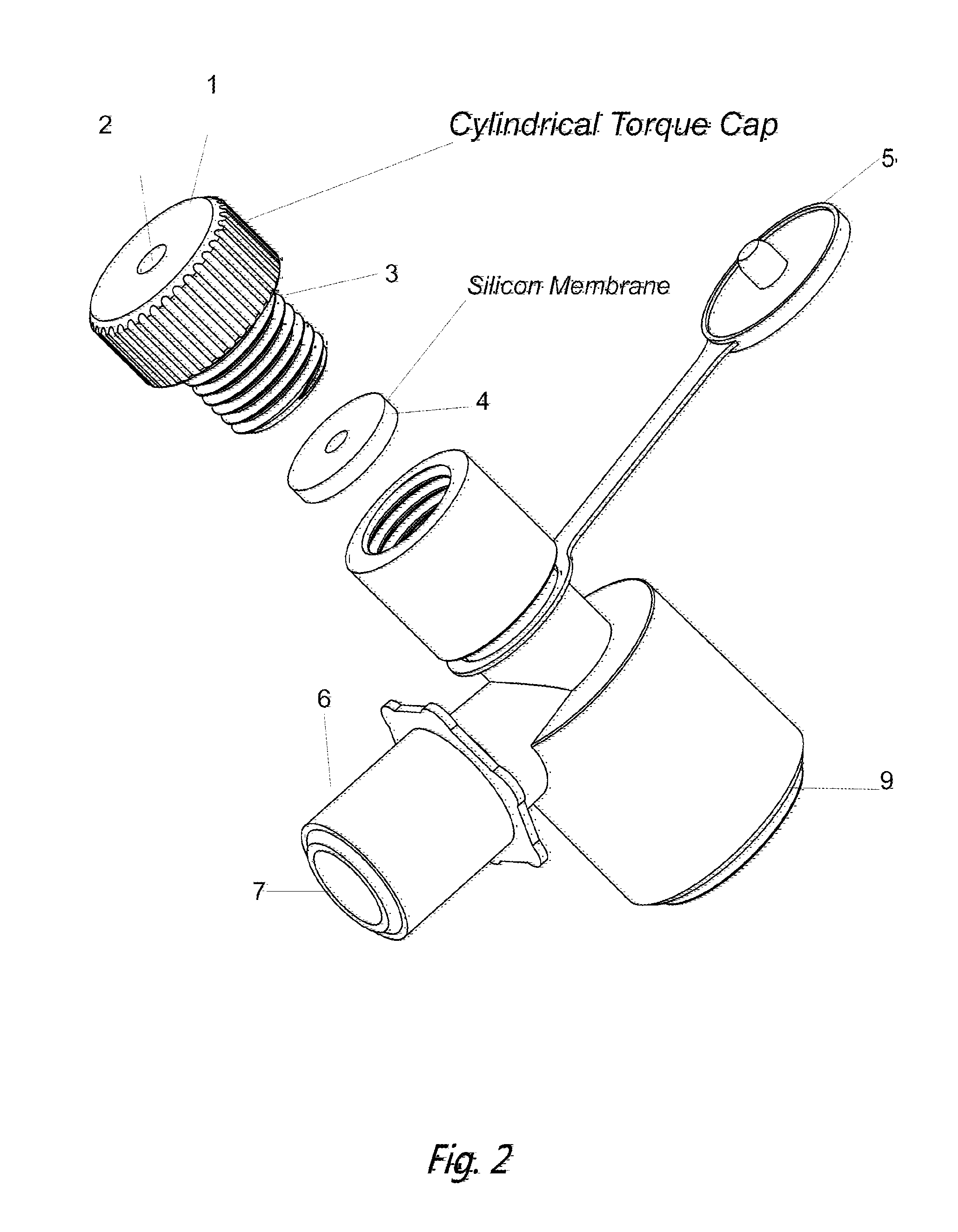

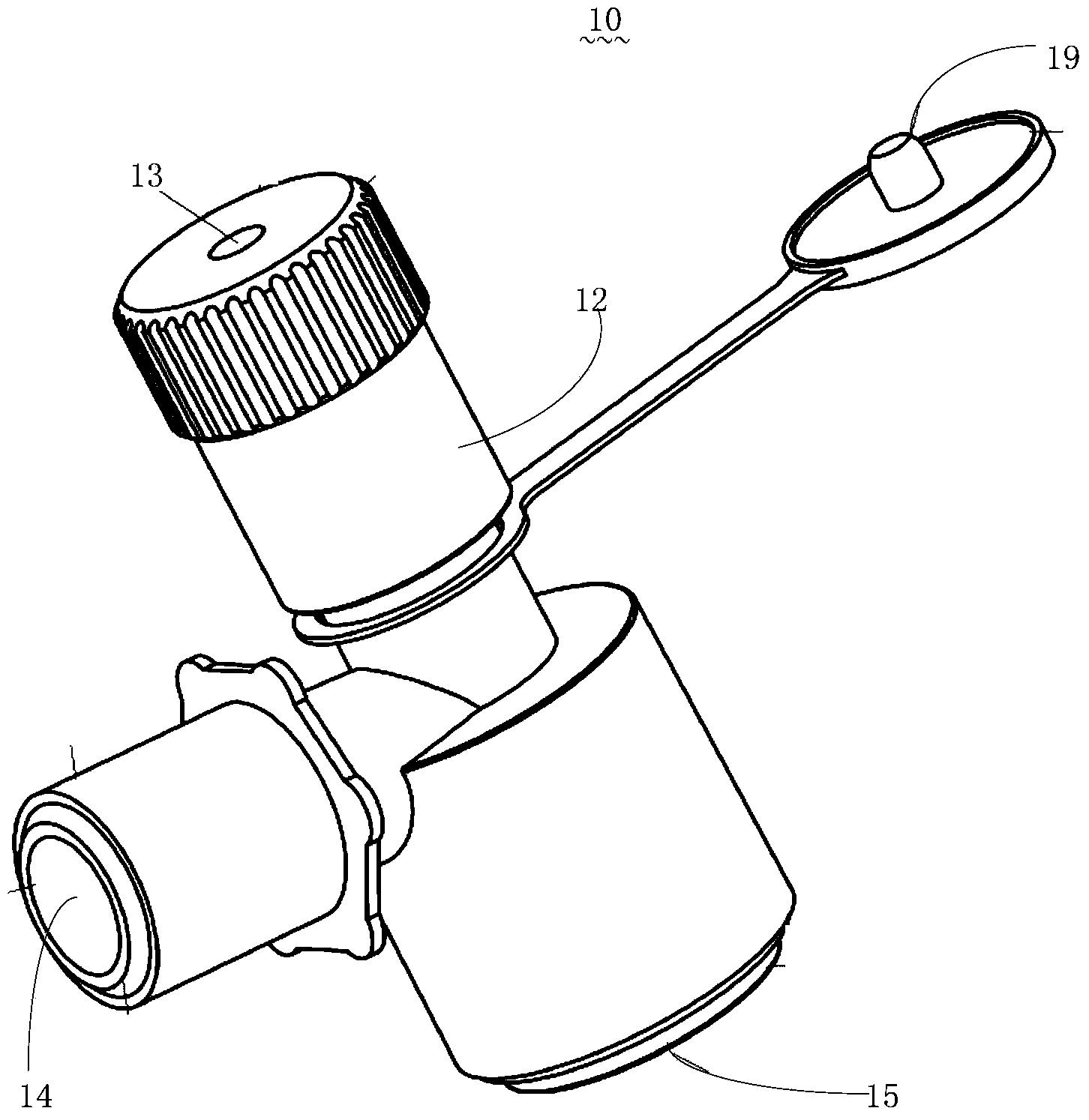

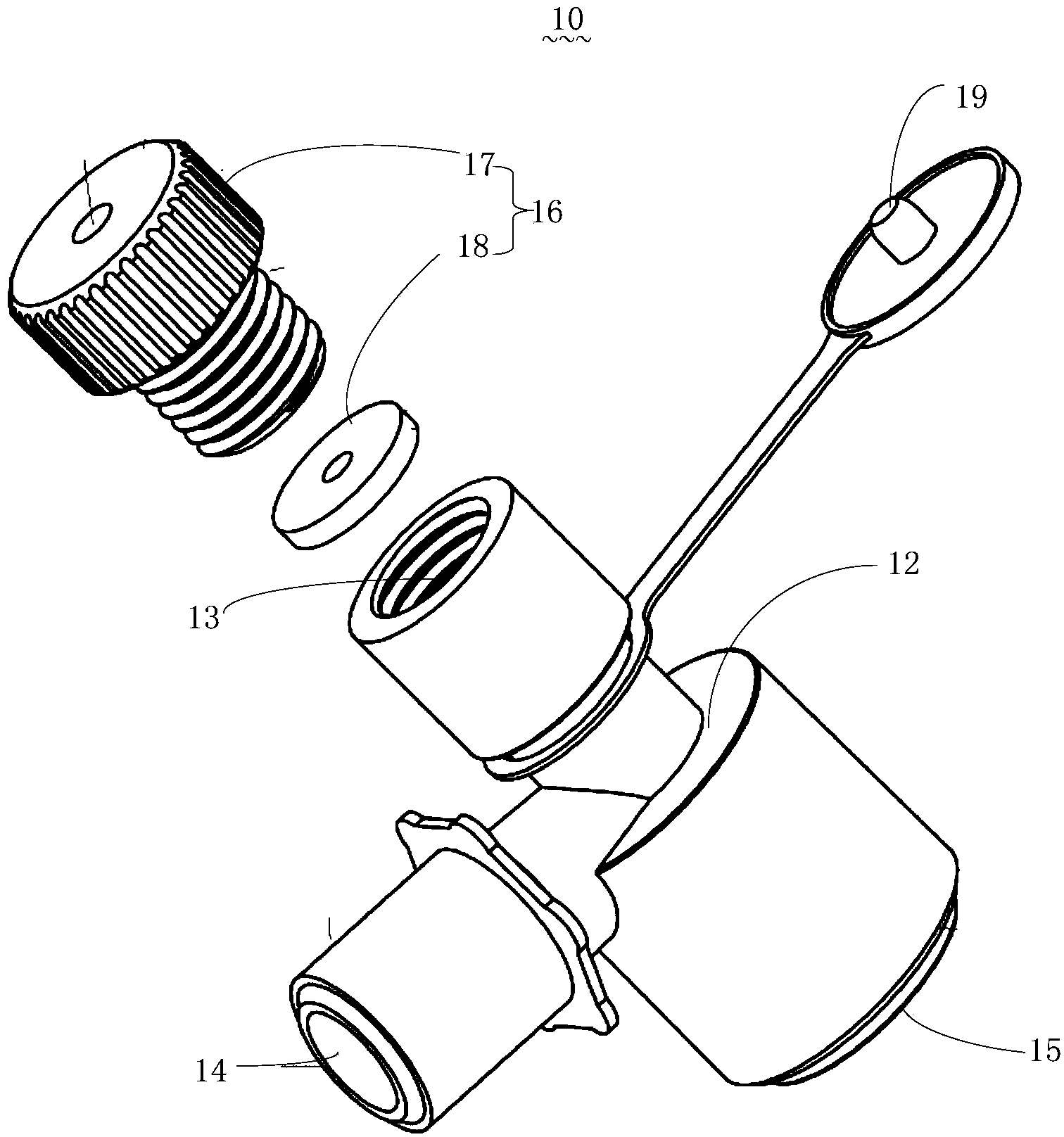

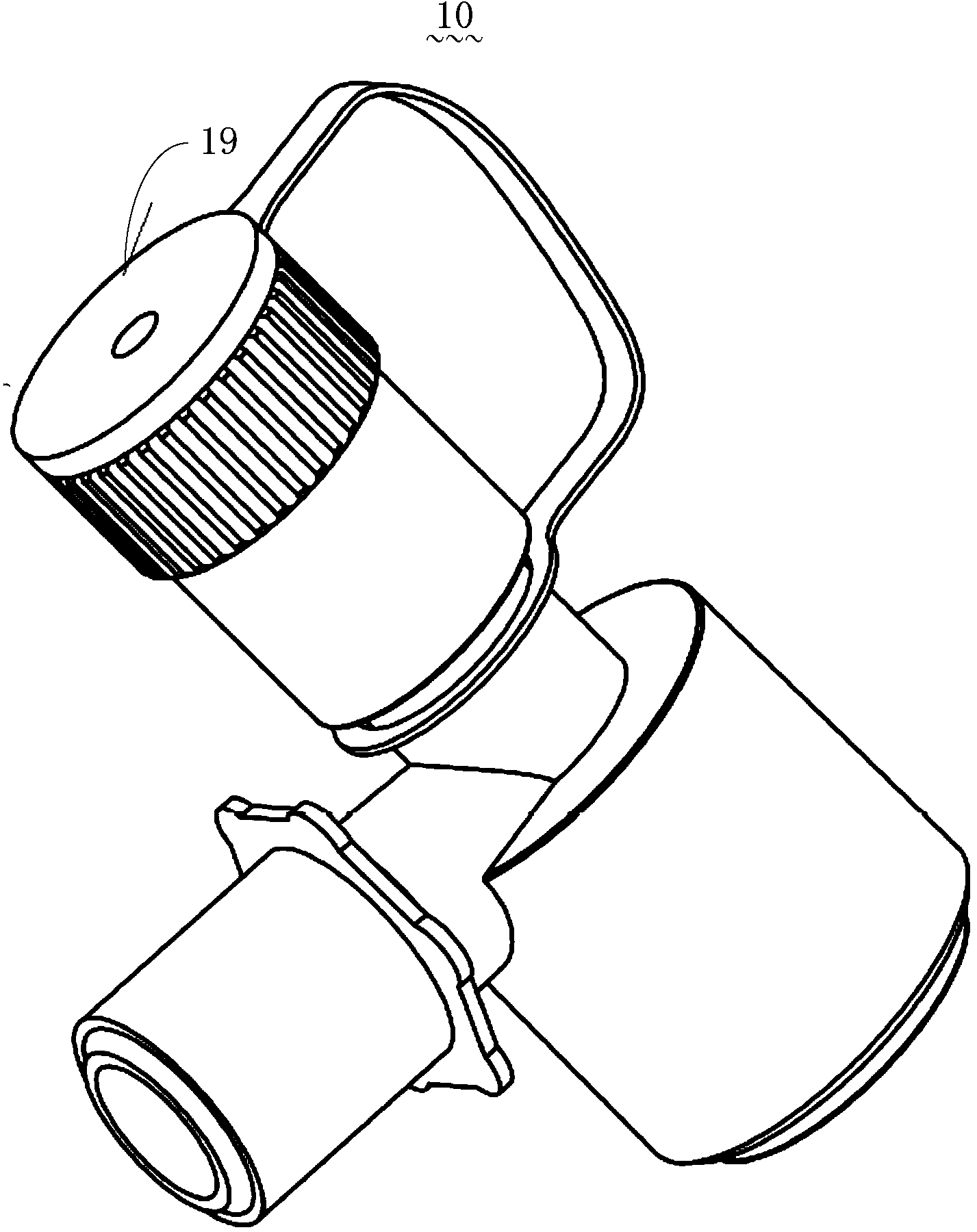

Bronchoscope Adapter and Methods for Using the Same

ActiveUS20150335228A1Reduce decreaseFacilitate and secure lockingBronchoscopesTracheal tubesMechanical ventilatorsEngineering

Bronchoscope adapters and methods of using the same are provided. Aspects of the adaptors include a body having a passageway, a mechanical ventilator access port, a bronchoscope access port configured to receive a bronchoscope into the passageway, and an exit port. The bronchoscope access port comprises a reversibly adjustable inner diameter component that provides locking of the bronchoscope at desired position. The adaptors find use in a variety of different applications.

Owner:LEI THOMAS DINGHUA +2

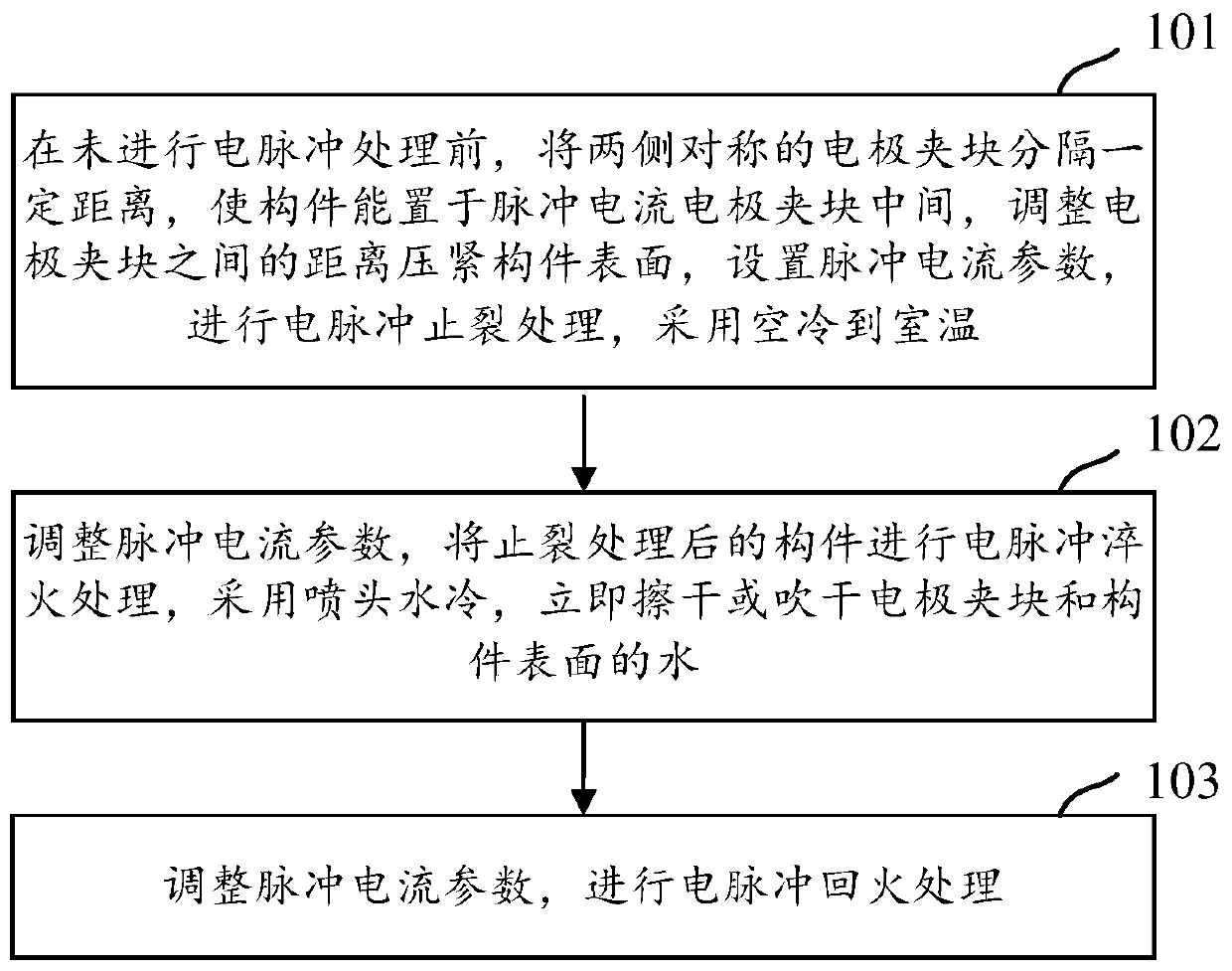

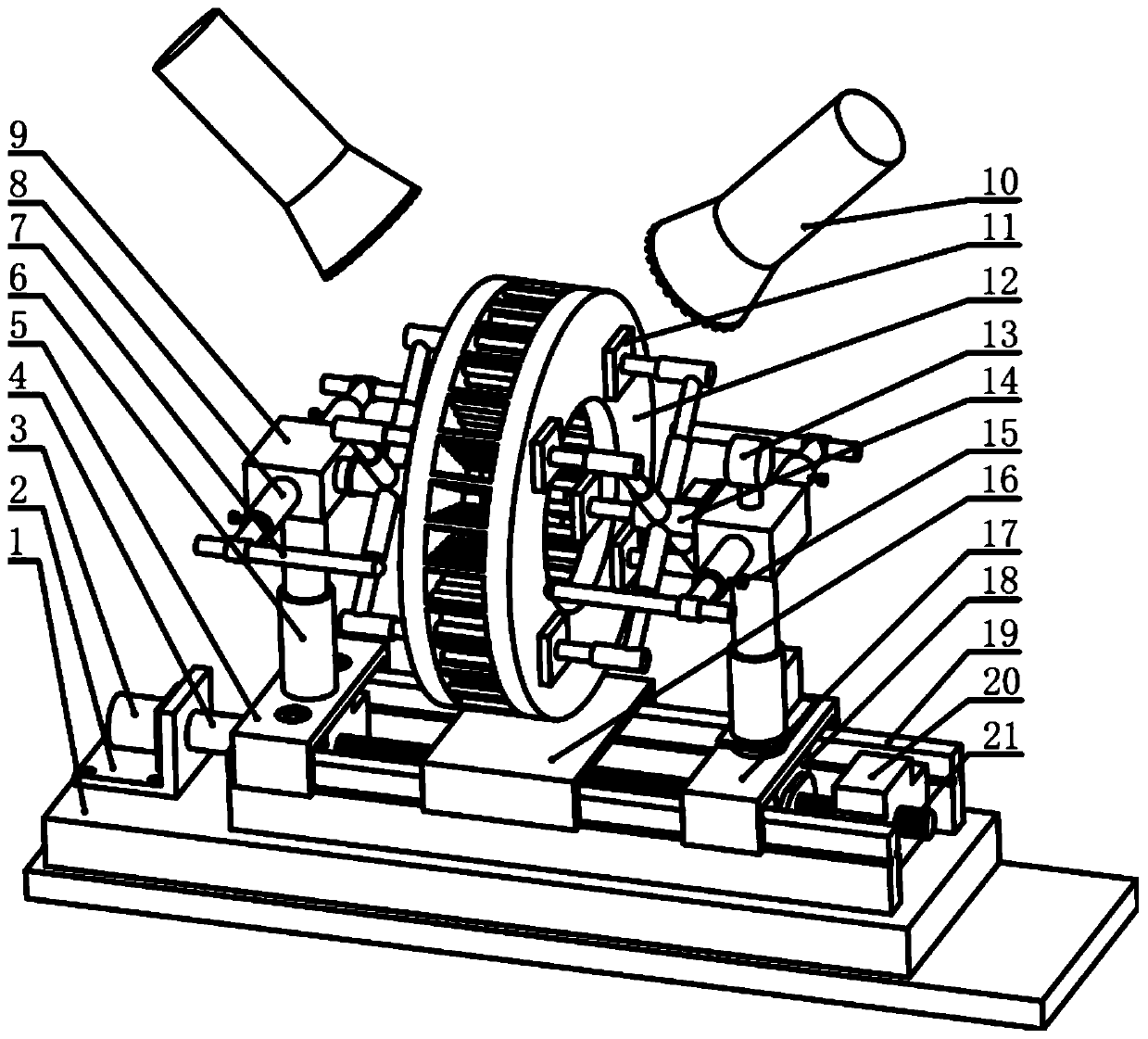

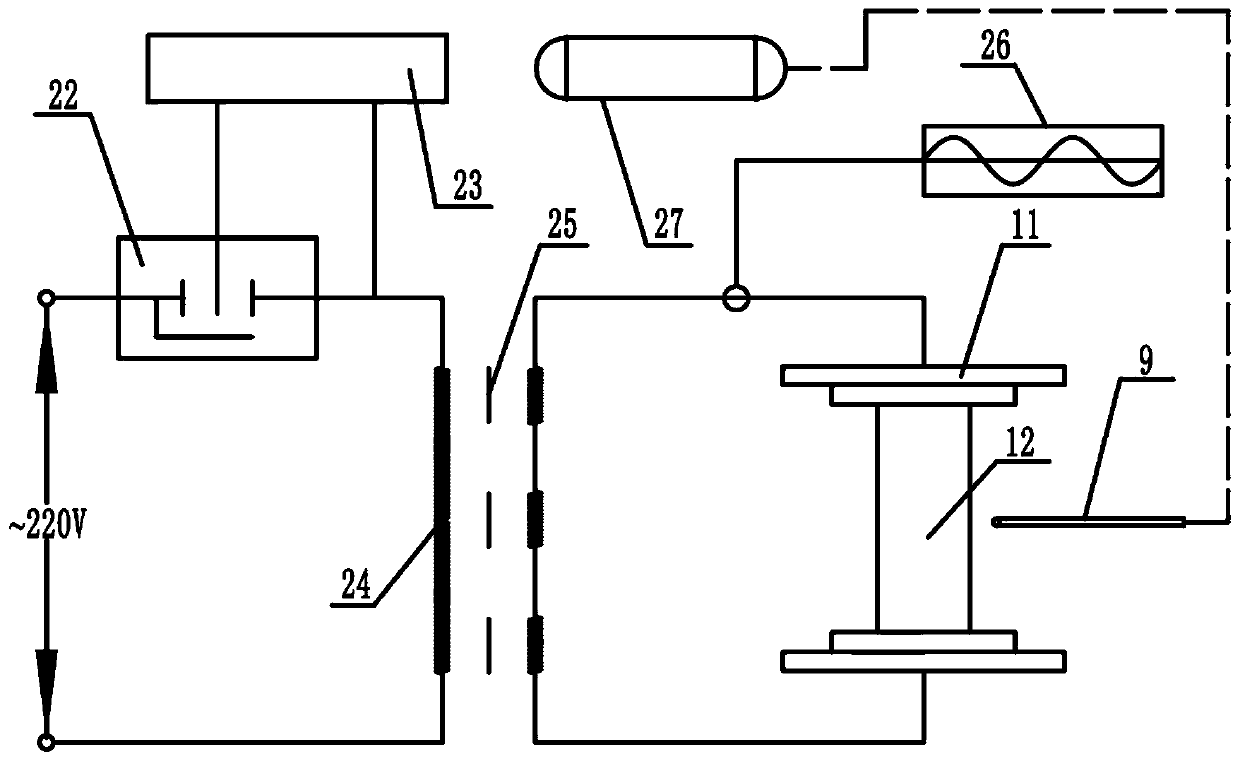

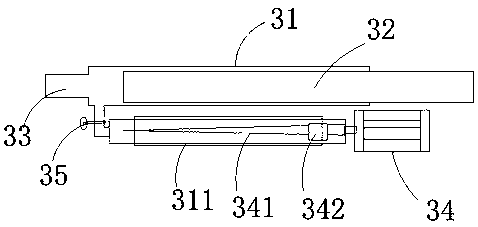

Electric pulse aftertreatment method and device for improving performance of metal component

The invention relates to an electric pulse aftertreatment method and device for improving the performance of a metal component. The method comprises the steps that electric pulse crack arresting treatment is carried out on an initial component, then electric pulse quenching treatment is carried out, and finally two times of electric pulse tempering are carried out. The device comprises a telescopic multi-head electrode support, multiple electrode clamp blocks distributed at the vertexes and the center in a square shape, a lead screw and nut transmission mechanism and a dual spray head quenching device. By means of the electric pulse device, the problems that traditional electric pulse aftertreatment equipment has limitations to large-size components, and quenching of the surfaces of the components is not even are solved. By means of the electric pulse aftertreatment process, a low-defect, even and ultrafine isometric crystal structure is obtained, the residual stress is reduced under the situation that crystals are not grown up, and the comprehensive performance of the laser additive manufacturing metal component is improved. According to the electric pulse aftertreatment method and device, traditional heat treatment equipment such as a resistance furnace is not needed, aftertreatment procedures and energy consumption are reduced, the aftertreatment process is more environment-friendly and is simple and easy to do, and the manufacturing cost is reduced.

Owner:JILIN UNIV

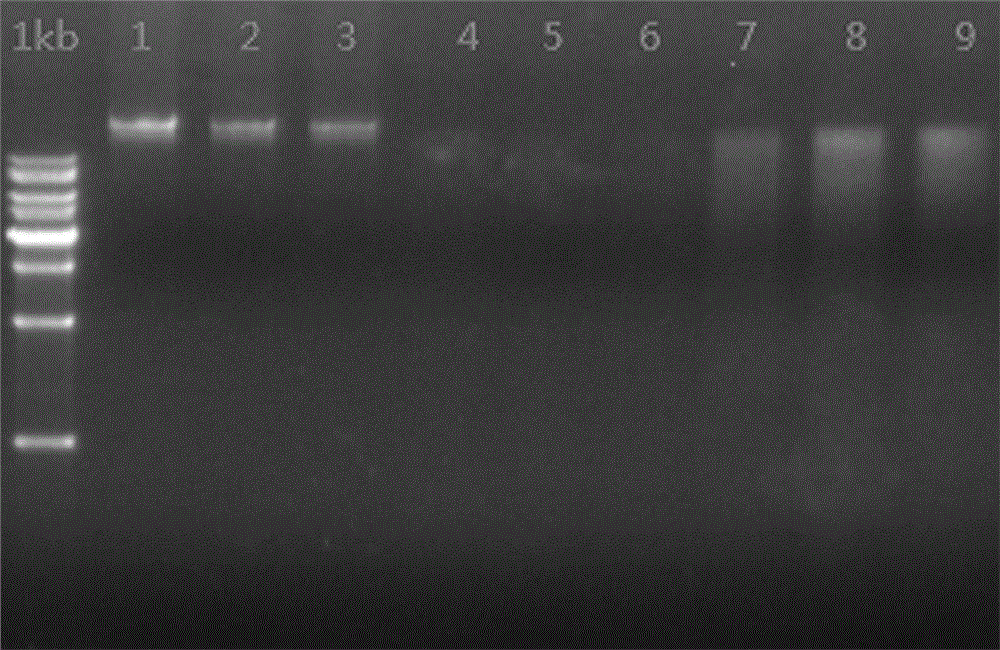

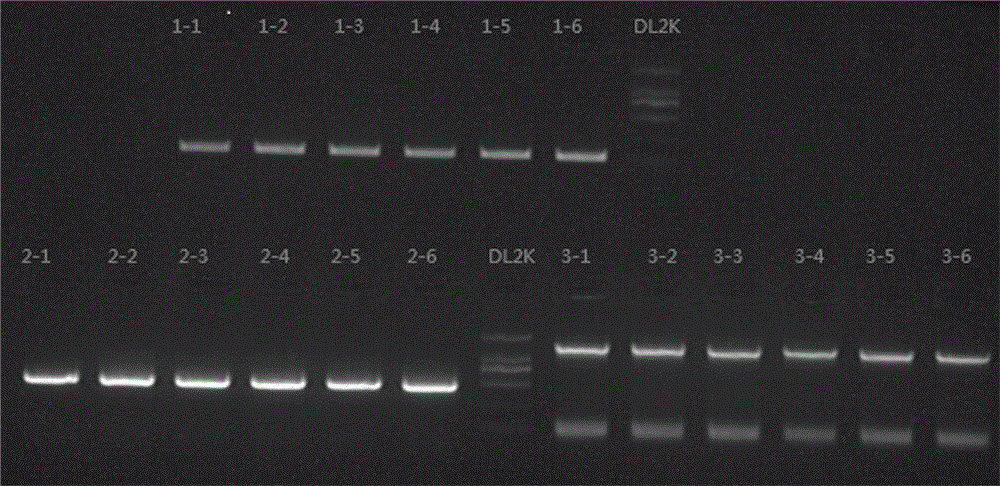

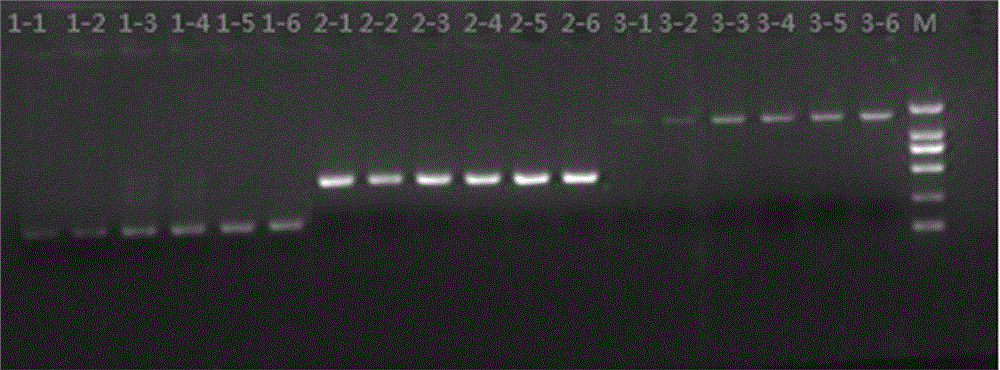

Nucleic acid recovery and purification kit and method

InactiveCN104975003AShorten the timeRelax conditionsDNA preparationPurification methodsMagnetic bead

The invention relates to a nucleic acid recovery and purification kit which comprises a sol solution, a magnetic bead solution and a combination solution. The sol solution contains 3-4 mol / L guanidine isosulfocyanate, 20-30 mol / L Tris-HCl buffer solution and the balance of water. The magnetic bead solution contains 0.2-3 mg / mL hydroxy magnetic bead and the balance of water. The combination solution contains 40-60% isopropanol, 1-2 mol / L sodium chloride and the balance of water. The invention also relates to a nucleic acid recovery and purification method using the kit. The nucleic acid recovery and purification kit and method can quickly and efficiently recover and purify large-segment nucleic acids in a sepharose gel.

Owner:SHANGHAI MAJORBIO BIO PHARM TECH

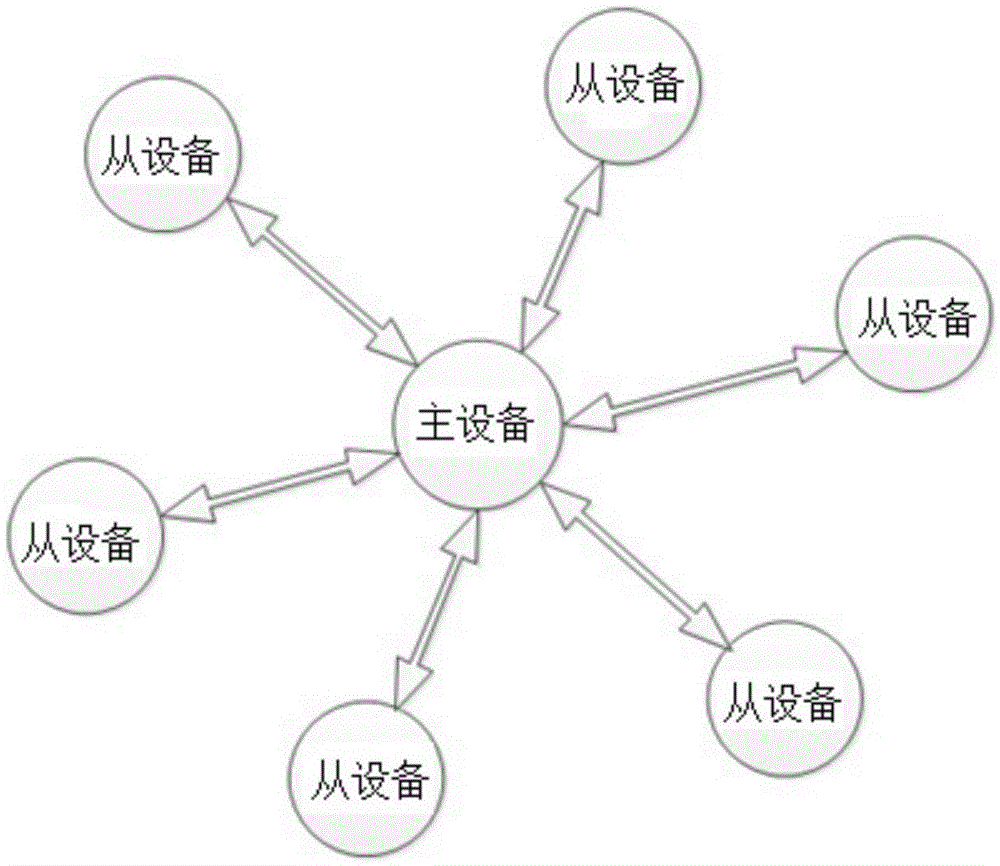

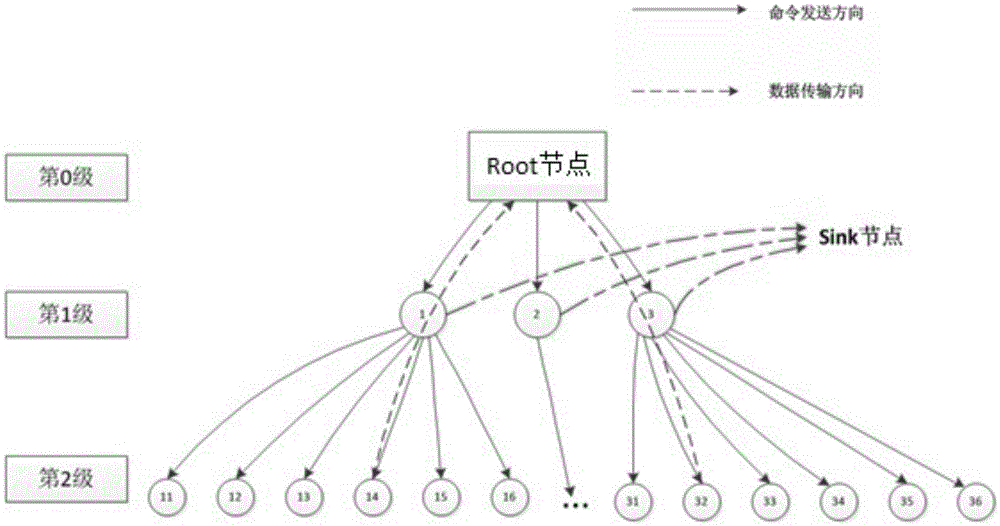

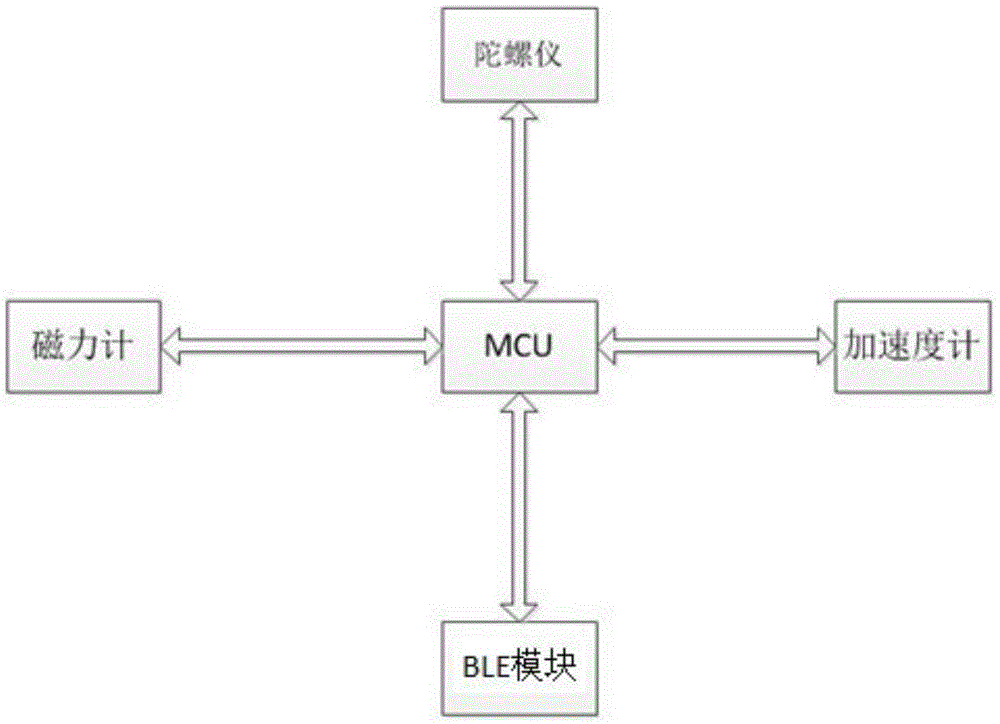

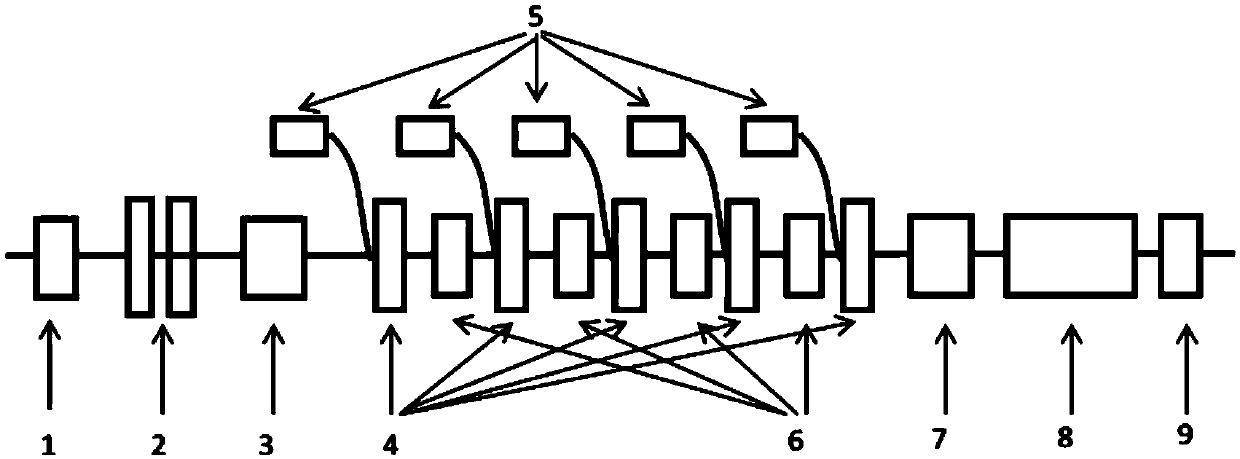

Bluetooth 4.0-based inertia motion capturing system used for realizing low-power wireless data transmission, and data transmission method thereof

InactiveCN105592535AImprove experienceGet rid of the bondagePower managementTransmission systemsTree shapedMotion capture

The invention relates to a Bluetooth 4.0-based inertia motion capturing system used for realizing low-power wireless data transmission, and a data transmission method thereof. A BLE (Bluetooth Low Energy) module is arranged at each joint of a collection object, allowing each joint to employ the Bluetooth technology to communicate with a sink node; all joints are divided into a plurality of sets, and each set is in connection with a sink node; the joint in each set can transmit data with an own sink node; the sink node performs data transmission with a Root node through a serial port, thereby forming a tree-shaped transmission network. The tree-shaped transmission network based on Bluetooth effectively overcomes the deficiency of the WiFi and Zigbee wireless technology in a motion capturing system, emancipates users from data line constraints, improves user experience and reduces the power consumption of a whole system.

Owner:SHANDONG UNIV

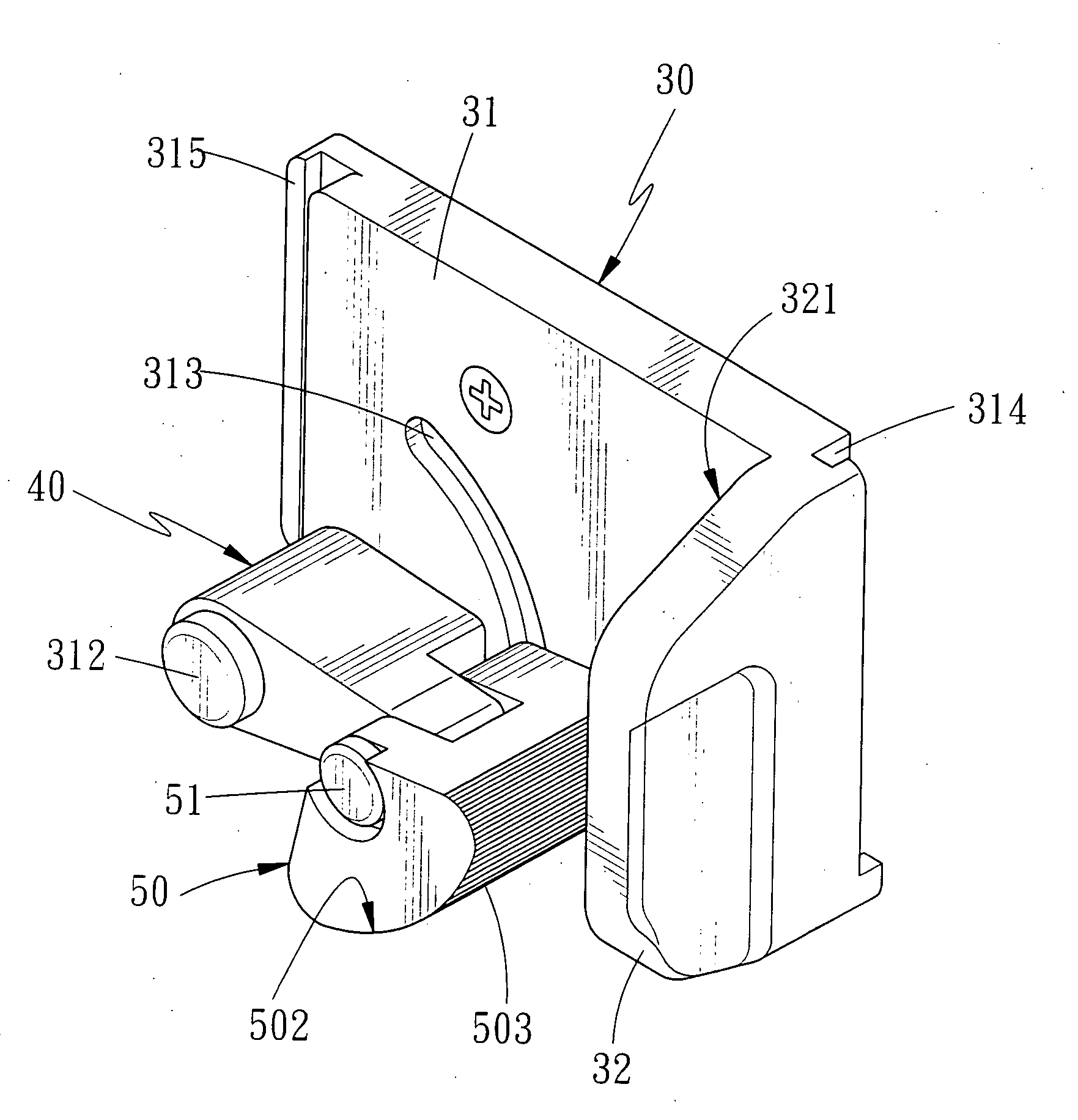

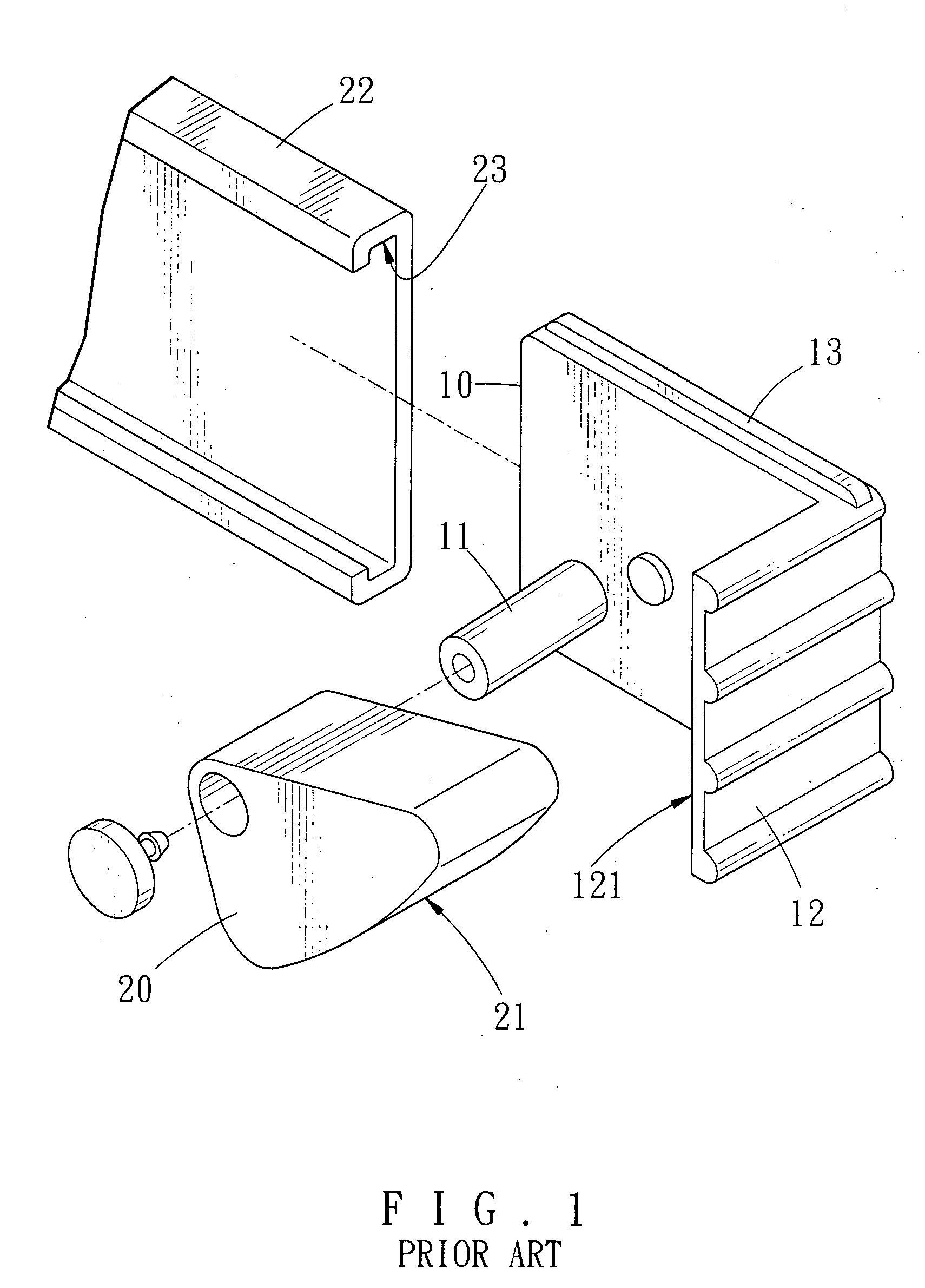

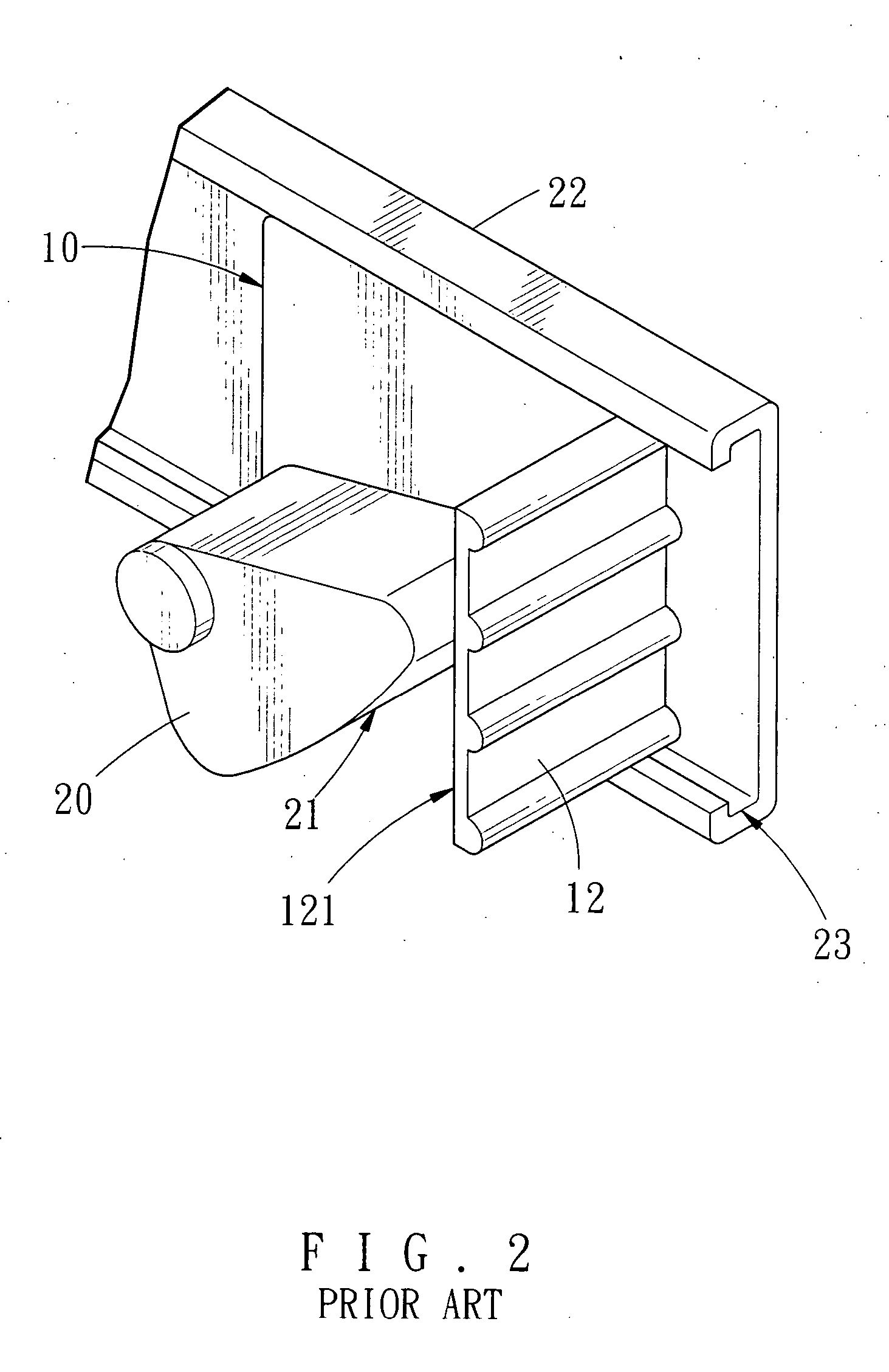

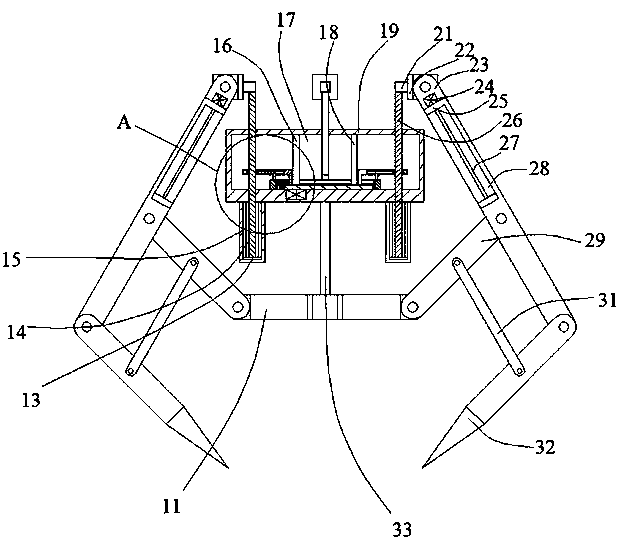

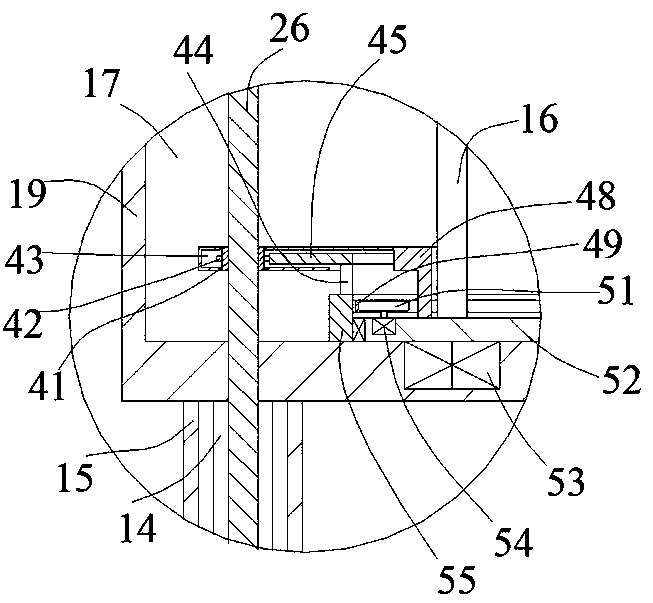

Clamping device

ActiveCN101798908AExpanded size rangeThe device is compactDrilling rodsDrilling casingsBiomedical engineeringAutomation

The invention discloses a clamping device comprising hanging ears, an arm support and clamping mechanisms. The hanging ears are arranged on the arm support; the clamping mechanisms are respectively arranged on two ends of the arm support; each clamping mechanism comprises two clamping parts, a mounting bracket and a clamping driving device; one clamping part is connected with the mounting bracket, and the other clamping part is articulated with the clamping driving device; and the clamping part which is articulated with the clamping driving device is also articulated with the mounting bracket. Because the clamping mechanisms are designed, when clamping, the clamping device can not interfere with drilling tools which are arrayed adjacently and can not be restricted by the gaps formed due to the array of the drilling tools. In addition, because the clamping device is supported on three points by supporting mechanisms which are matched with the clamping mechanisms, the clamping device greatly improves the drilling tool clamping size range. The clamping device has compact structure and high work efficiency, can clamp the drilling tools reliably and can realize the automation.

Owner:宏华油气工程技术服务有限公司

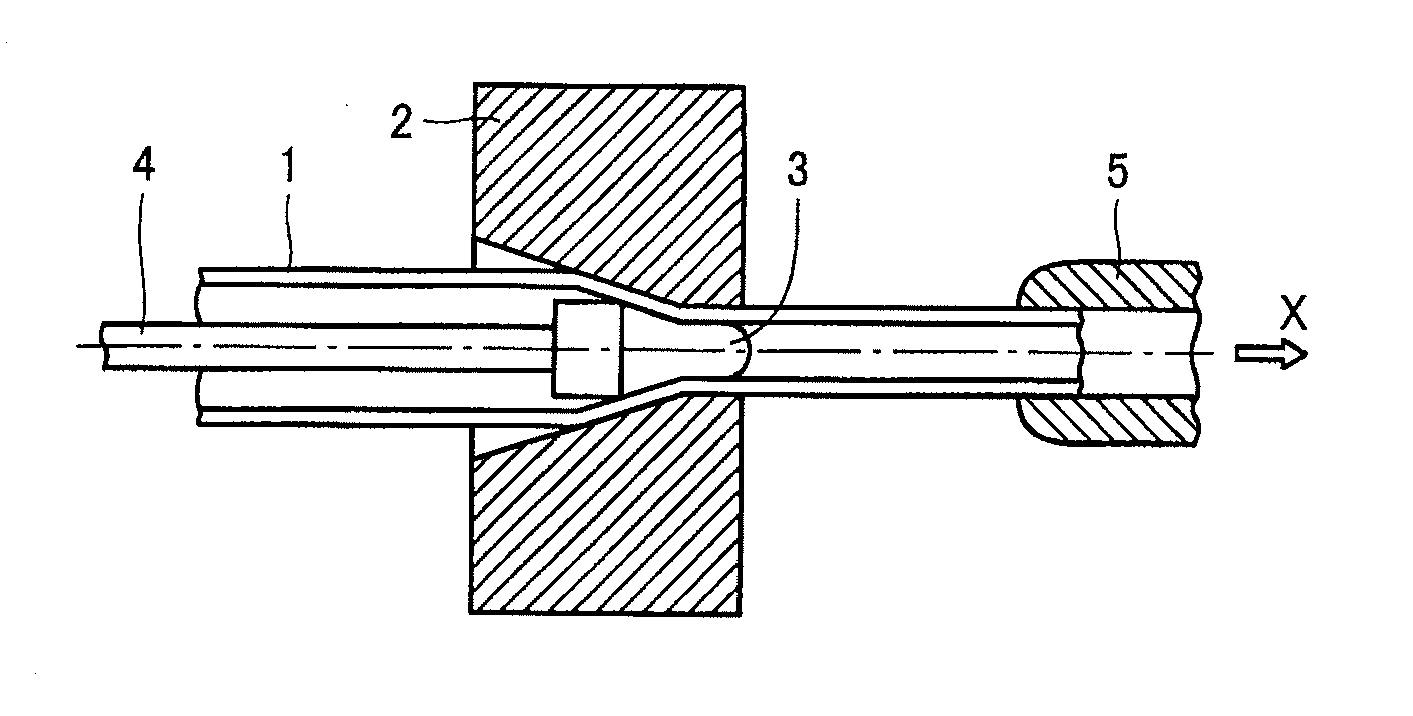

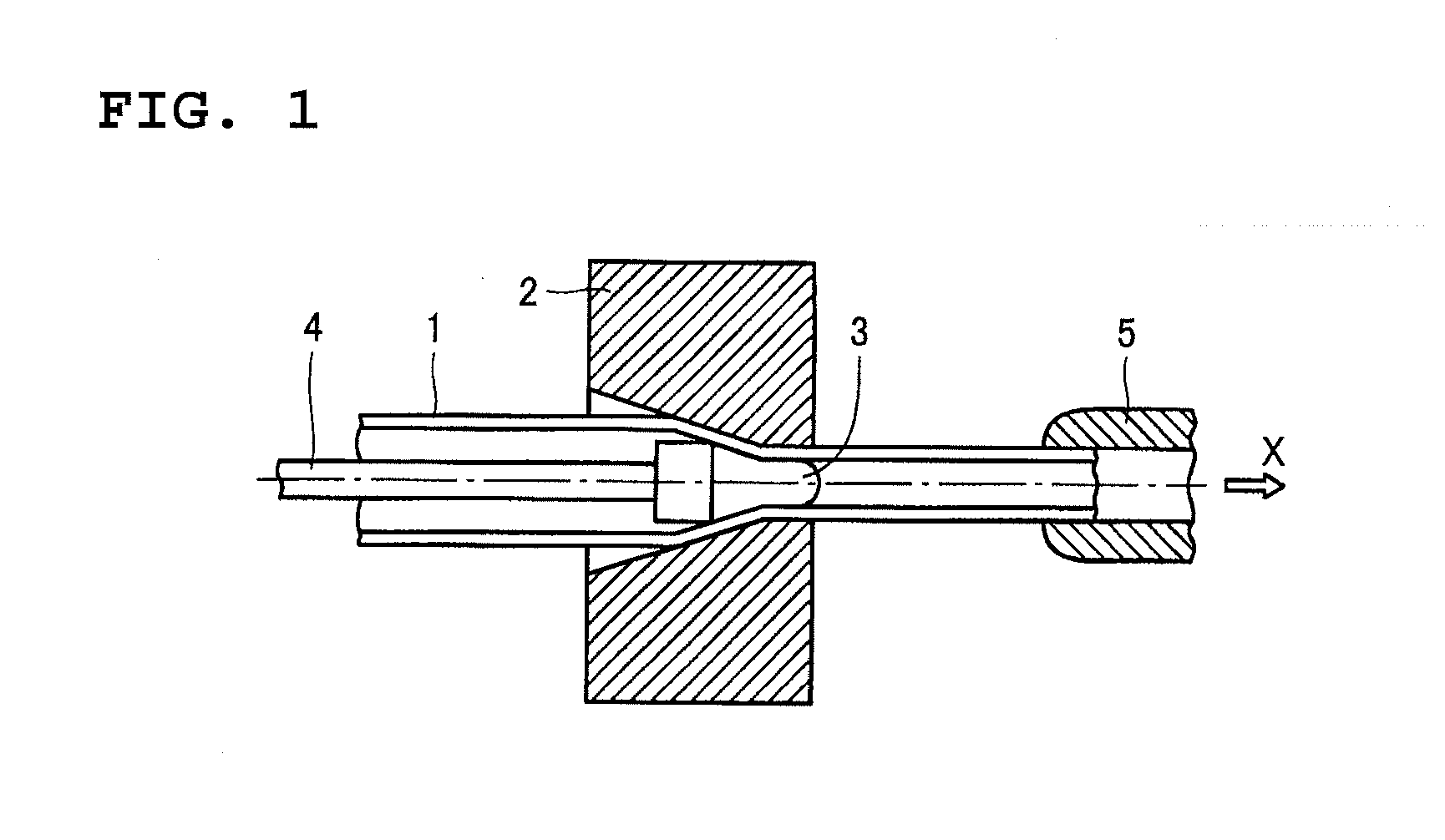

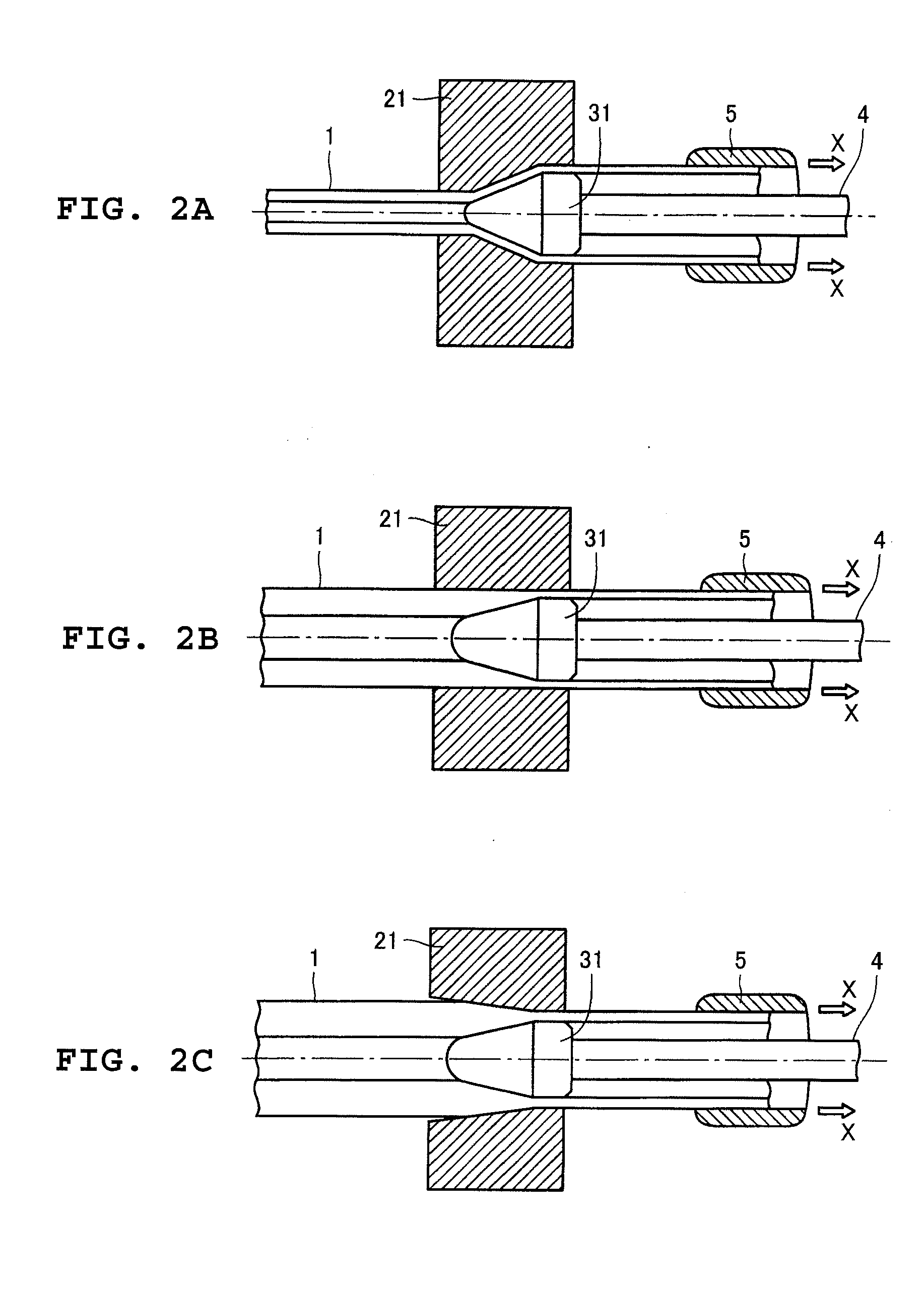

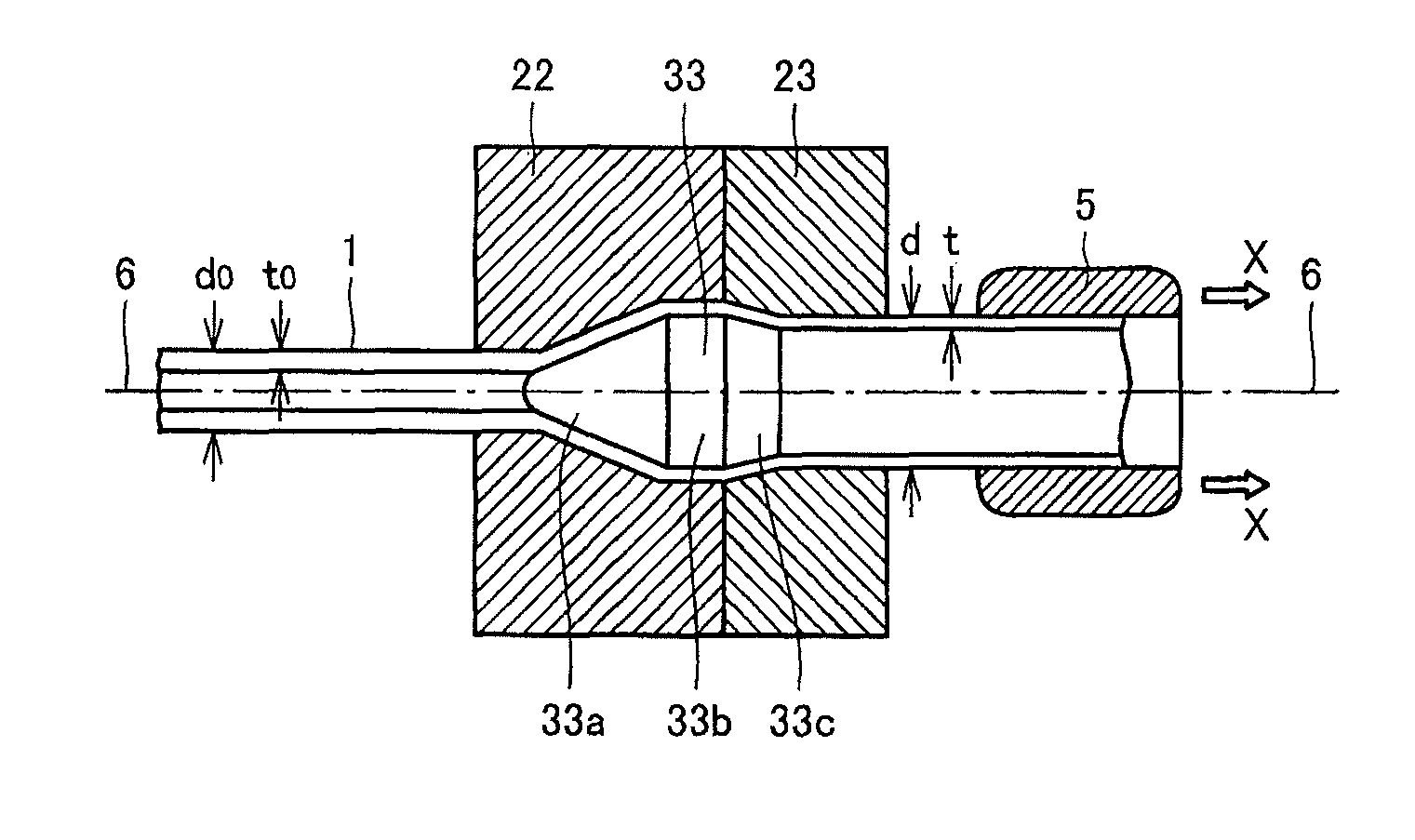

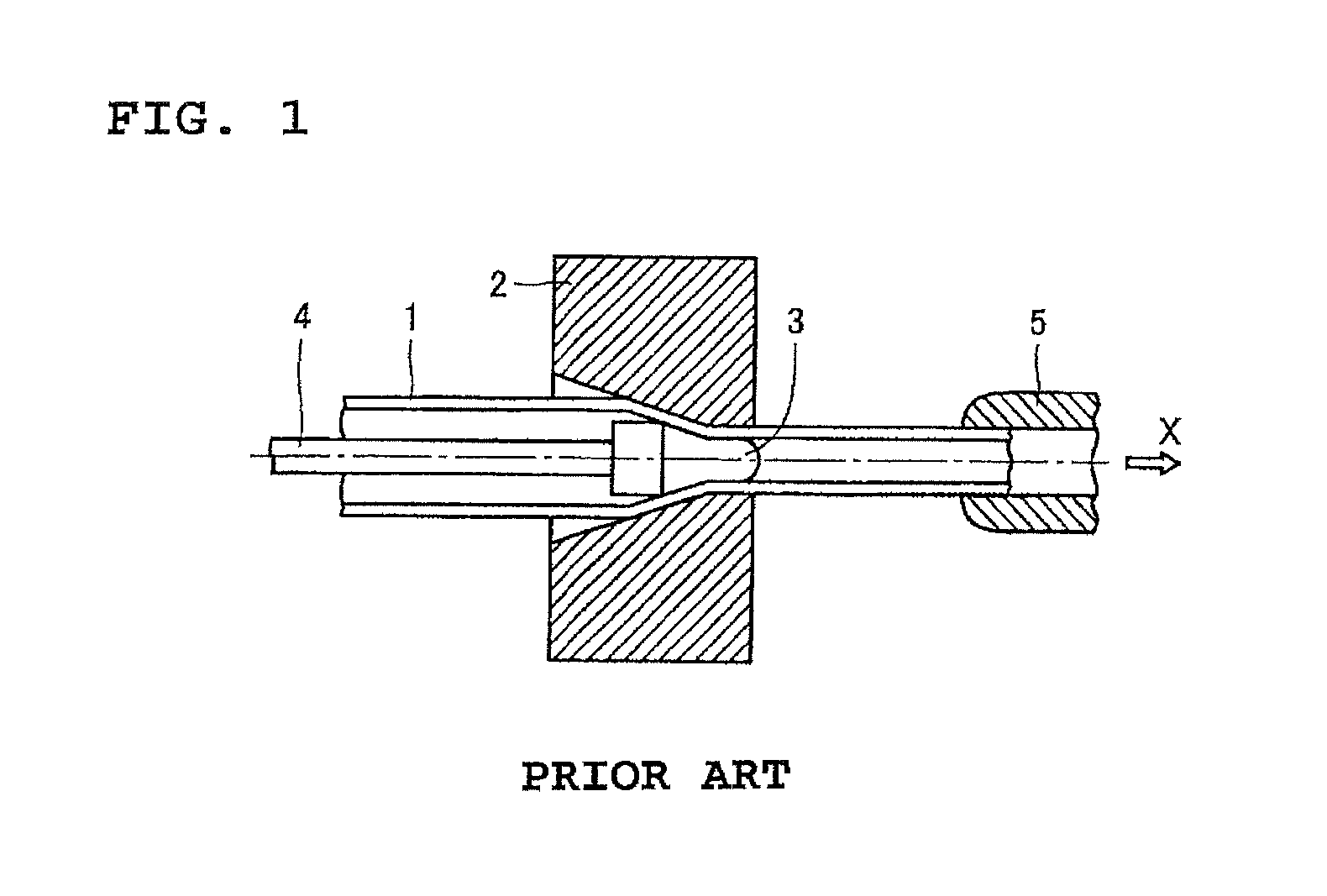

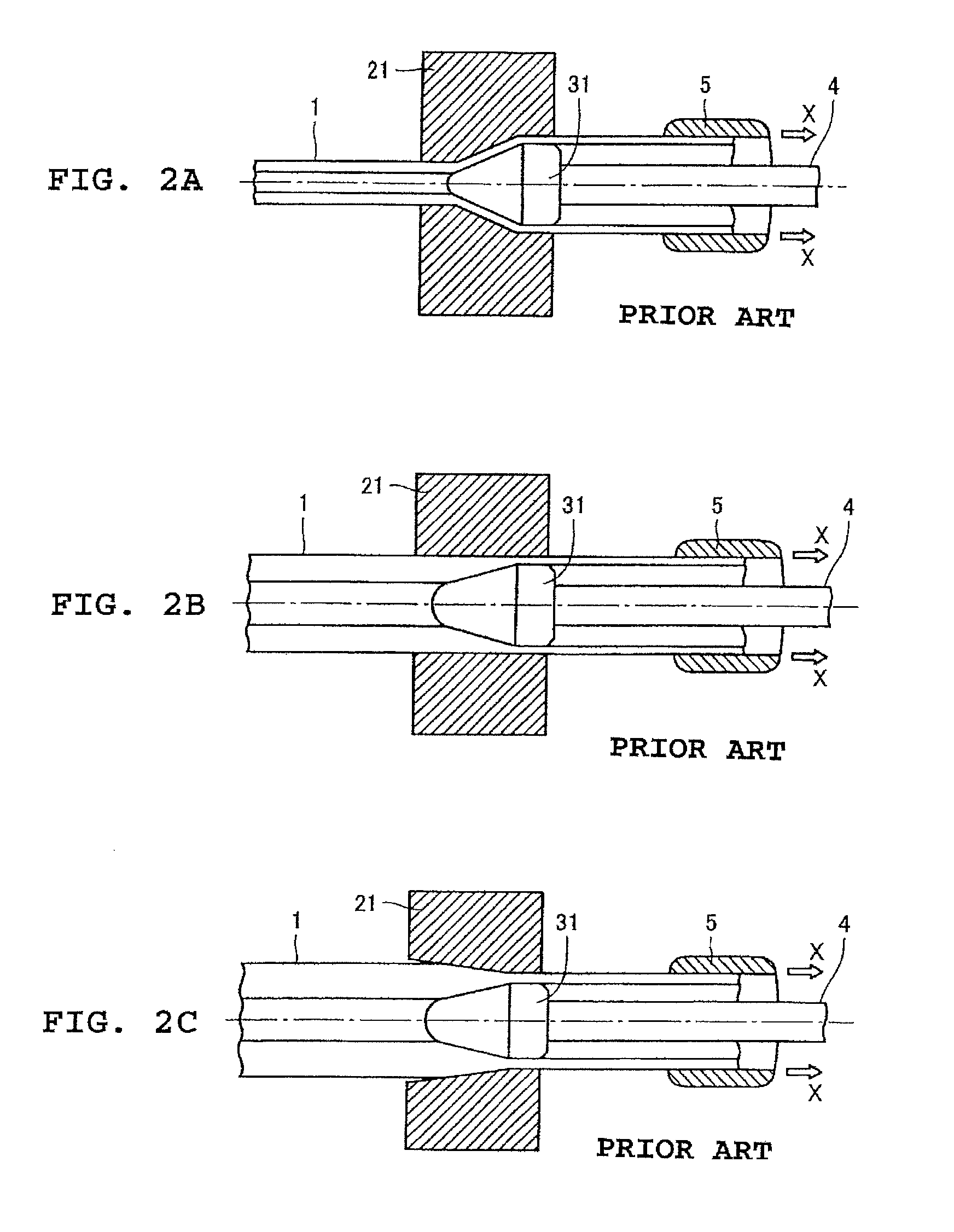

Method of producing ultrathin-wall seamless metal tube using floating plug

Proposed is a method of producing an ultrathin-wall metal tube by a cold drawing method capable of drastically expanding an available size range toward much thinner side with respect to wall thickness of metal tubes. This is a diameter-expanding drawing method, in which an entry solid die, the diameter of which increases, remains constant or decreases from the engaging entry side toward the finishing exit side, and a delivery solid die, the diameter of which decreases at least in the vicinity of the engaging entry, are arranged in series and in an abutting relation on the same pass line, and a tapered plug, the diameter of which increases from the engaging entry side toward the finishing exit side, is caused to float along the pass line, whereby in the entry solid die region, the wall thickness is reduced while the mid-wall diameter of a hollow shell is being expanded between the solid die and the plug, and in the delivery solid die region, the tapered plug is caused to float by performing reduction working of the outside diameter. This method offers tremendously great economic advantages, because it is possible to produce ultrathin-wall seamless metal tubes and to make longer length tubes, and to realize the rationalization of processes in terms of yield, efficiency and the like.

Owner:NIPPON STEEL CORP

Bronchoscopy adaptor

InactiveCN104107027AHigh precisionImprove diagnosis rateSuture equipmentsBronchoscopesTracheal tubeCatheter

The invention provides a bronchoscopy adaptor. The bronchoscopy adaptor comprises a body, a mechanical breathing machine join-up end opening, a bronchoscope join-up end opening and an outlet. A channel is arranged in the body. The mechanical breathing machine join-up end opening is arranged on the body and connected with the channel, and the mechanical breathing machine join-up end opening is used for enabling a mechanical breathing machine to be connected with the channel. The bronchoscope join-up end opening is arranged on the body and connected with the channel, and the bronchoscope join-up end opening is used for receiving a bronchoscope and enabling the bronchoscope to enter the channel. The outlet is formed in the body and connected with the channel, and the outlet is used for being connected with a tracheal catheter so as to enable the tracheal catheter to be connected with the channel. The bronchoscopy adaptor further comprises a component with the inner diameter capable of being adjusted in two ways, and the component is detachably arranged in the bronchoscope join-up end opening. The bronchoscopy adaptor can reduce human errors and improve the diagnostic rate.

Owner:汤马斯·定华·雷 +1

Hanging clamp for different size rods

InactiveUS20070120021A1Expanded size rangeReduce manufacturing costPipe supportsStands/trestlesBiomedical engineering

Owner:LIN YU SHEN +1

Bending equipment

ActiveCN109985941AImprove yield rateExpanded size rangeMetal-working feeding devicesHeat exchange apparatusPetroleum engineeringHeat exchanger

The invention relates to bending equipment, and belongs to the technical field of bending machining. The bending equipment comprises a rack, a clamping unit, a core rod unit, a shifting unit and a bending unit, wherein the clamping unit, the core rod unit, the shifting unit and the bending unit are arranged on the rack, and the bending unit comprises a left bending arm and a right bending arm which are hinged through a bending rotating shaft; and the clamping unit comprises a transverse floating mounting frame which can be transversely arranged on one bending arm in a floating and sliding mode, and a clamping device which is arranged on the transverse floating mounting frame and is used for clamping a to-be-bent workpiece. The clamping unit is arranged to comprise the transverse floating mounting frame and the clamping device, so that the clamping device can freely move in the transverse direction in a floating mode relative to the correspondingly bending arm in the bending process, sothat restriction of a heat exchanger in the floating transverse direction can be reduced, the position change in the bending process can be better matched, so that the product yield can be improved,and the bending equipment can be widely applied to the field of manufacture of evaporators and the like.

Owner:浙江长兴和良智能装备有限公司

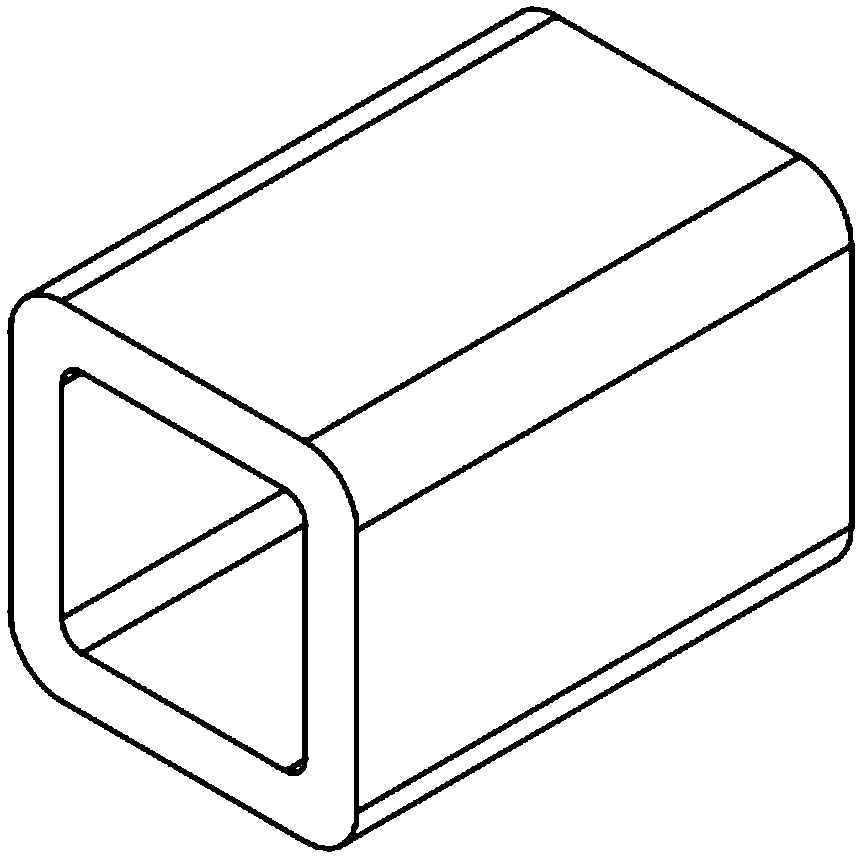

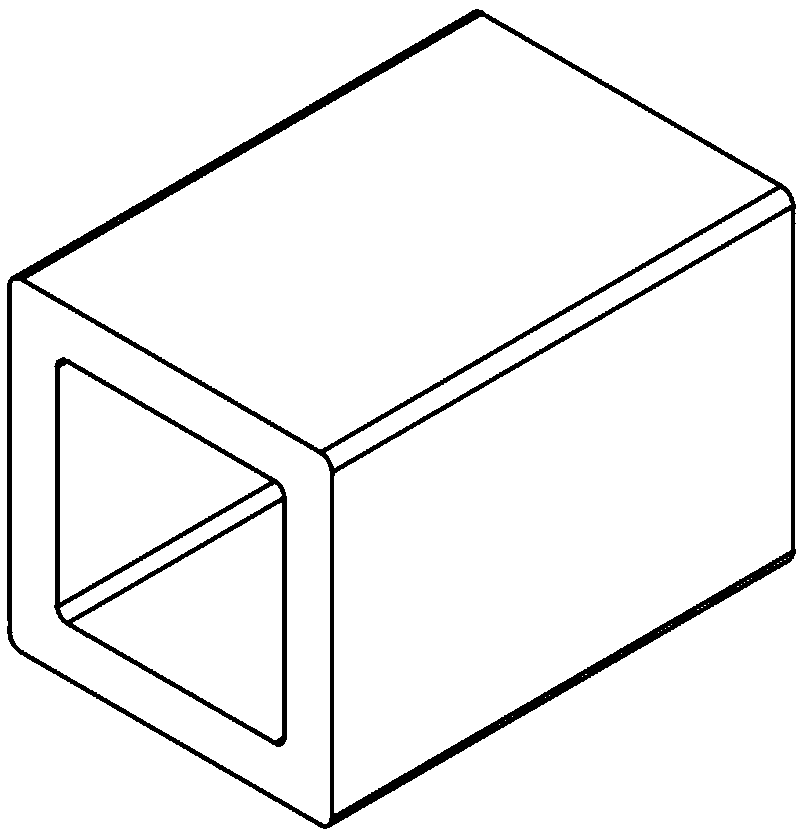

Square rectangular steel pipe with corner thickening and cold-heat composite molding and preparation method thereof

PendingCN110726064AIncrease productivityScale upElongated constructional elementsTemperature control deviceStraight tubeEngineering

The invention discloses a square rectangular steel pipe with corner thickening and cold-heat composite molding and a preparation method thereof. The outer corner radius of the square rectangular steelpipe satisfies the following conditions: when t is less than or equal to 6mm, R is greater than 0 and less than 2.0t; when t is greater than 6 and less than or equal to 10mm, R is greater than 0 andless than 2.5t; and when t is greater than 10mm, R is greater than 0 and less than 3.0t, wherein t is the wall thickness of the straight pipe section of the square rectangular steel pipe, R is the outer corner radius of the four corners of the square rectangular steel pipe, and the corner wall thickness of the square rectangular steel pipe is between 1.0t and 1.8t. According to the square rectangular steel pipe with corner thickening and cold-heat composite molding and the preparation method thereof, the hot forming technology is introduced into a traditional roll-bending forming process, thatis, the local induction heating technology. High temperatures can reduce the forming force of materials and improve the forming performance of the materials; and meanwhile, the phenomena of the residual stress caused by work hardening and cracking which is possibly caused can be eliminated, a corner profile of the square rectangular steel pipe subjected to cold-heat composite molding is dense, the radii of an inner corner and an outer corner are small, the angle of the corner is close to 90 degrees, and the corner is thickened.

Owner:SINO RES INST OF ROLL FORMING IND CAOFEIDIAN CO LTD

Wide Size Range Fast Integrated Mobility Spectrometer

ActiveUS20110116092A1Expanded size rangeReduce necessityParticle size analysisNanoparticleParticle physics

A mobility spectrometer to measure a nanometer particle size distribution is disclosed. The mobility spectrometer includes a conduit and a detector. The conduit is configured to receive and provide fluid communication of a fluid stream having a charged nanometer particle mixture. The conduit includes a separator section configured to generate an electrical field of two dimensions transverse to a dimension associated with the flow of the charged nanometer particle mixture through the separator section to spatially separate charged nanometer particles of the charged nanometer particle mixture in said two dimensions. The detector is disposed downstream of the conduit to detect concentration and position of the spatially-separated nanometer particles.

Owner:BROOKHAVEN SCI ASSOCS

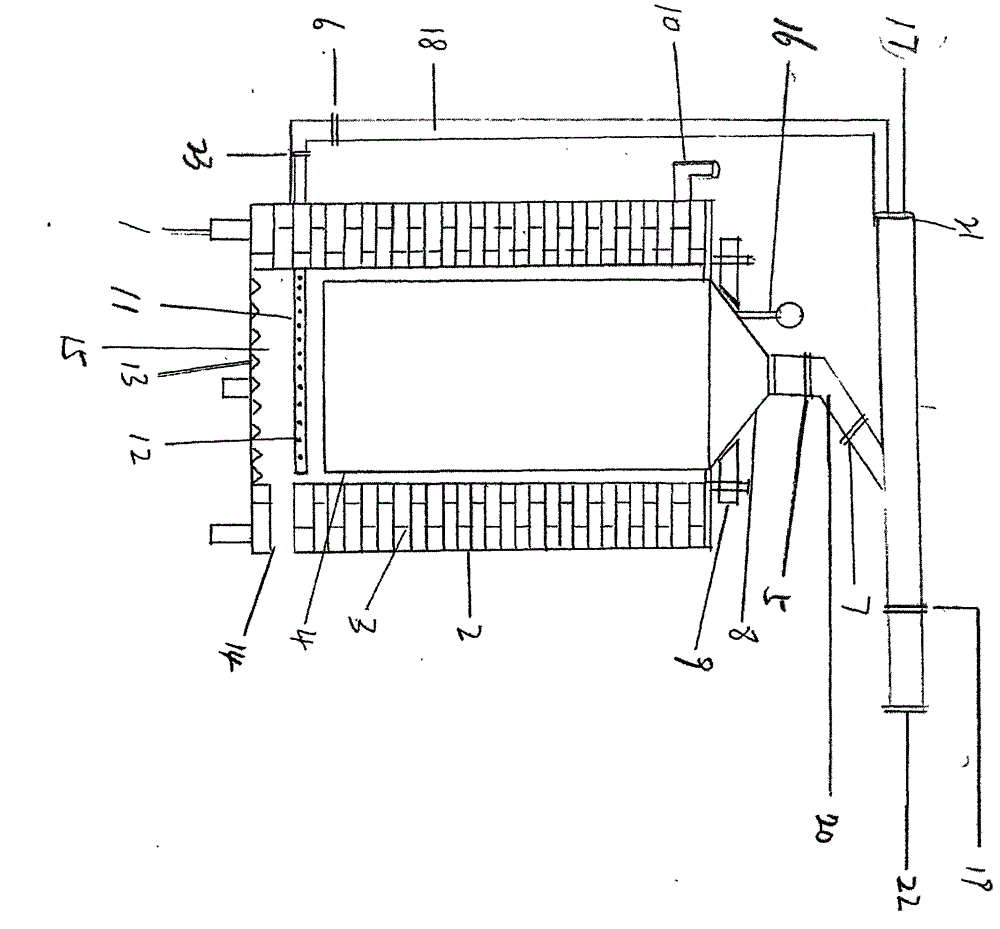

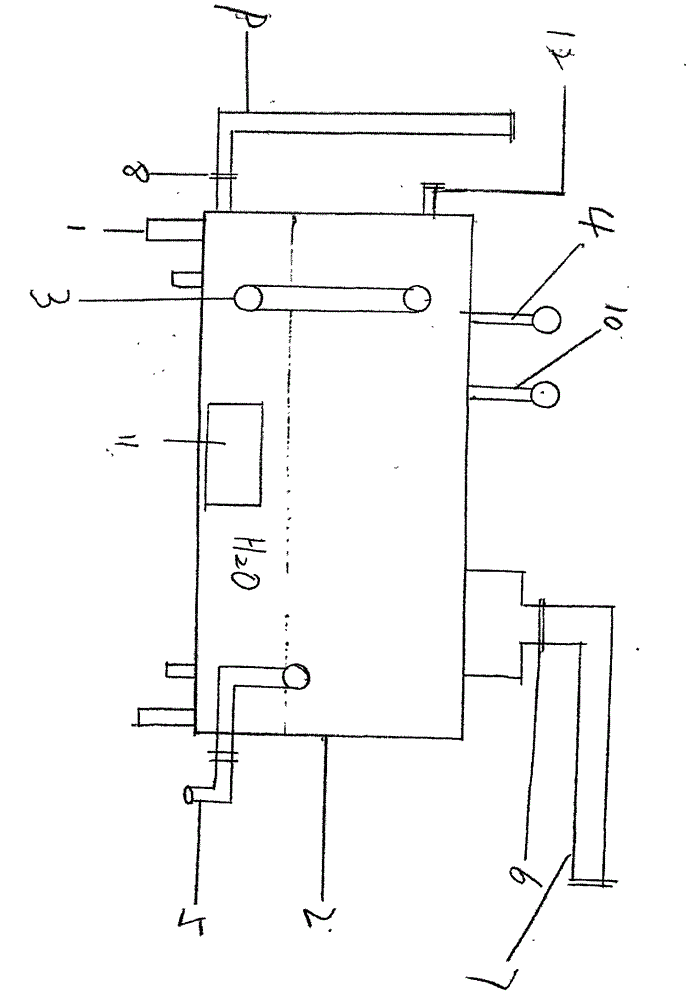

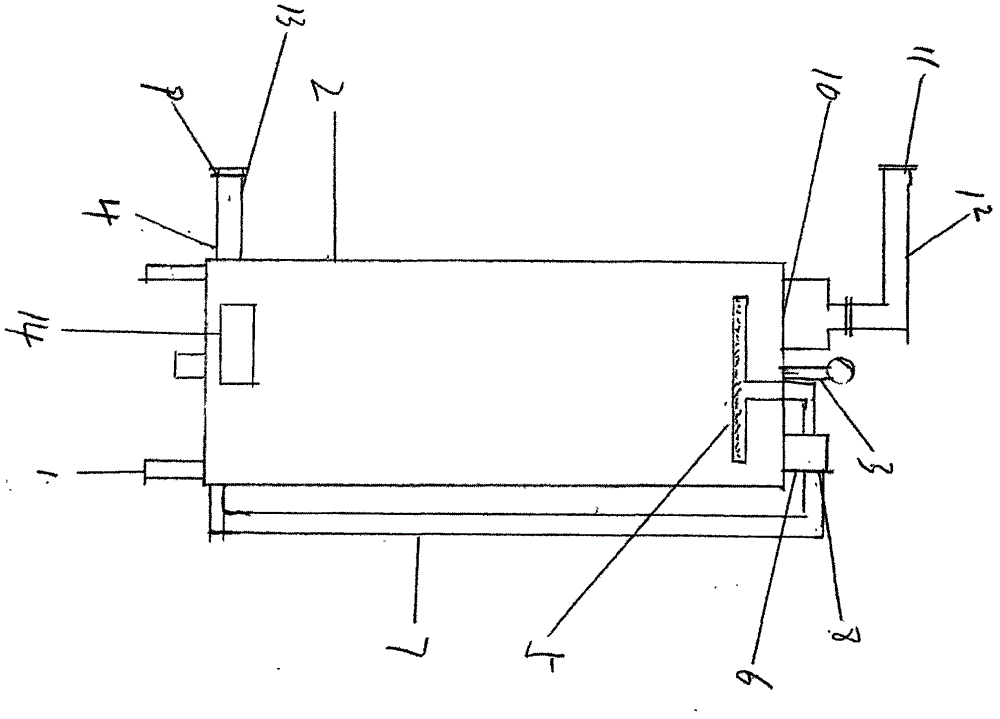

Method and device for co-production of coal, fuel gas and tar

InactiveCN104673336ASolve the investmentSolve the problem of desulfurizationWorking-up tarSpecial form destructive distillationEcological environmentTar

The invention relates to a method and device for producing coal, fuel gas and tar, used for solving the problems that coal and fuel gas are mainly formed naturally; the period is long; the cost is high, etc. The invention provides a co-production process and a device, used for solving the above problems and simultaneously producing the tar. According to the scheme provided by the invention, combustible raw material is put in the liner of a reaction kettle and heated to generate gas through high-temperature fission; a small part of gas flows back into a combustion pipe to continuously heat the liner; the remained gas enters a separator; fuel gas and tar are automatically separated through water; the separated fuel gas enters a purifier; the tar flows into a tar tank; after reaching use standards through water-fog dedusting and purifying, the fuel gas entering the purifier is conveyed into a gas storage tank to be used; and, after being subjected to complete fission, the combustible raw material is taken out and can be prepared into the coal by adding lime or soil. The co-production process and the device disclosed by the invention have the benefits that the problem that coal and fuel gas are only formed naturally for a long period is solved; the cost is saved; and the ecological environment is protected.

Owner:苏改平

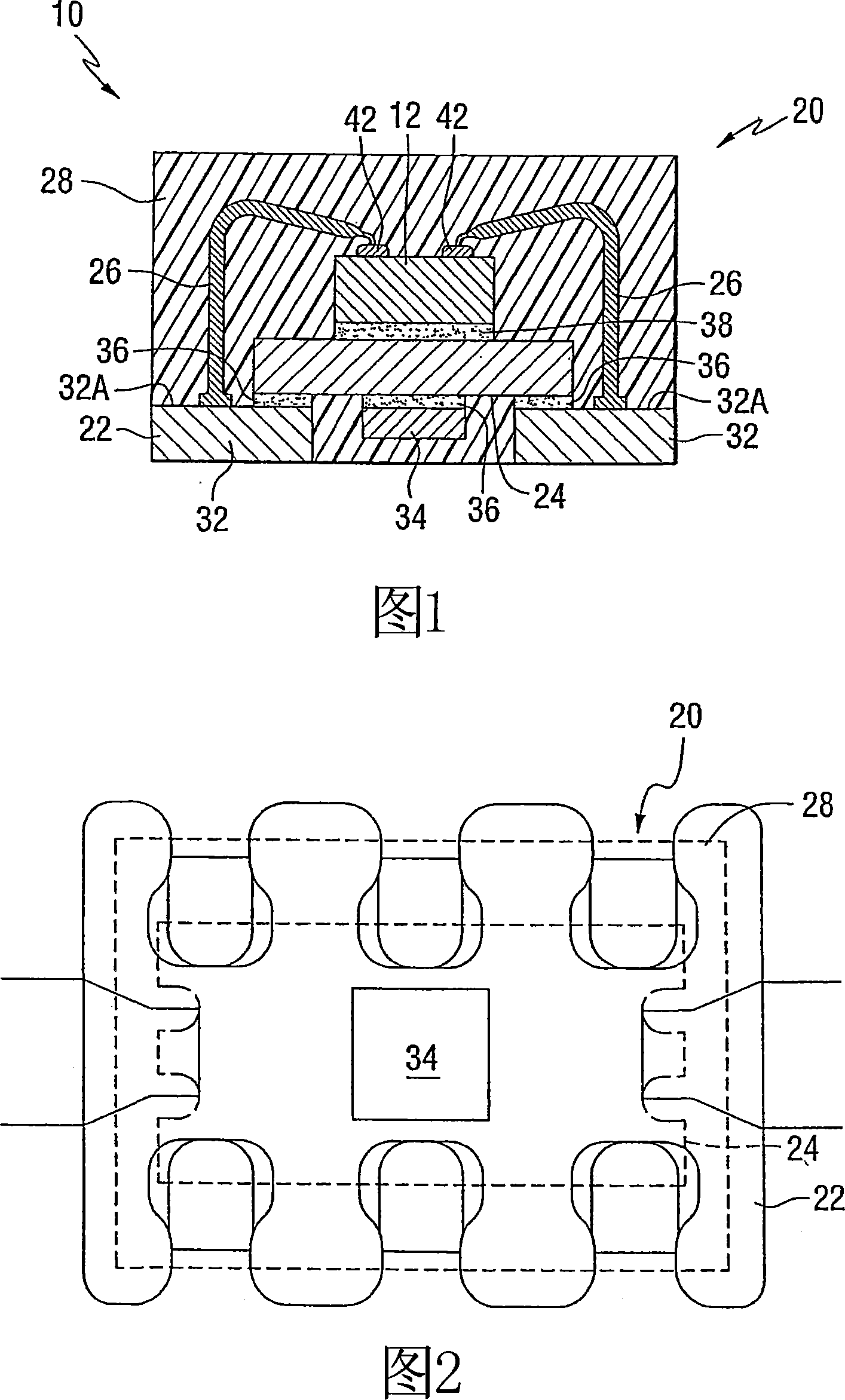

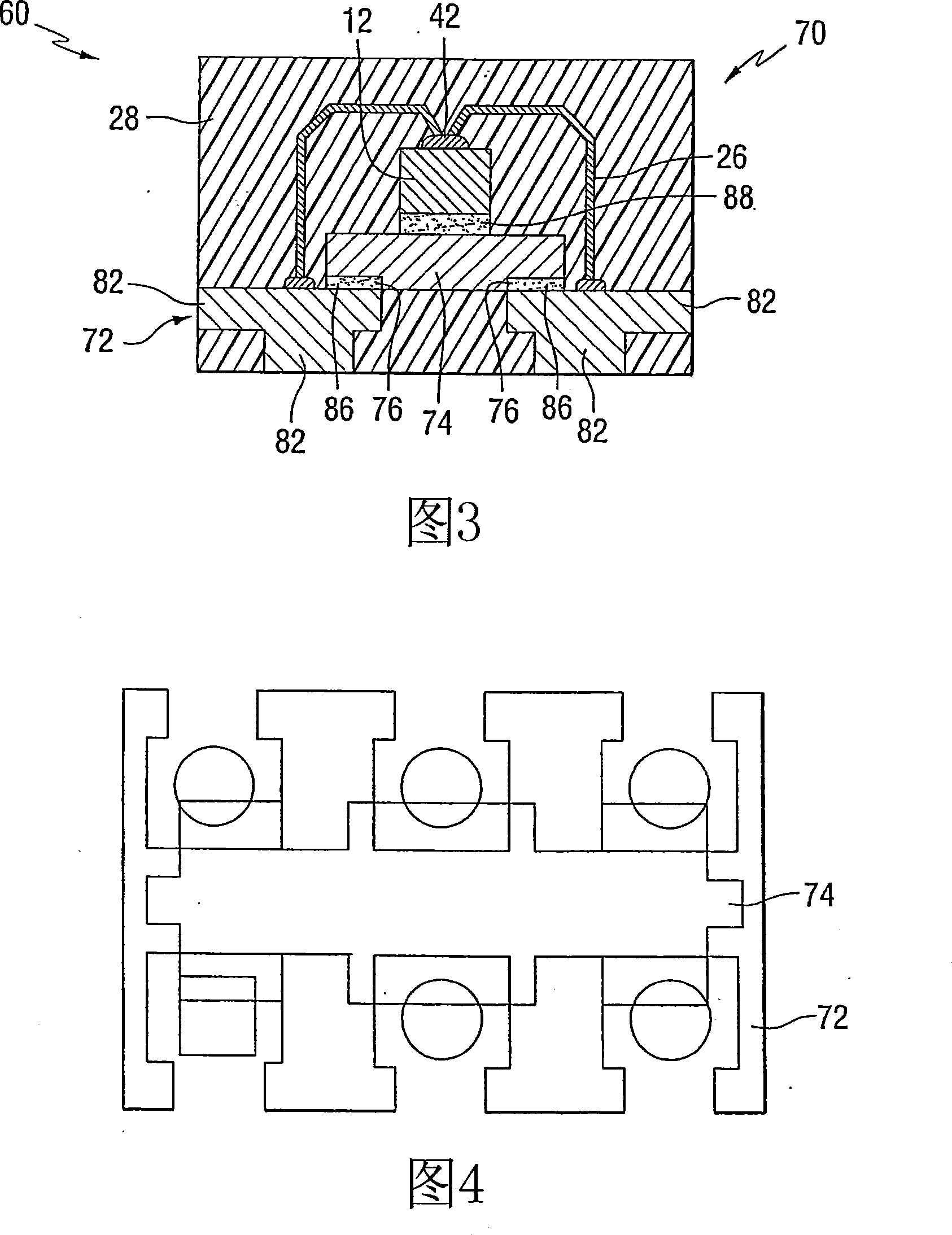

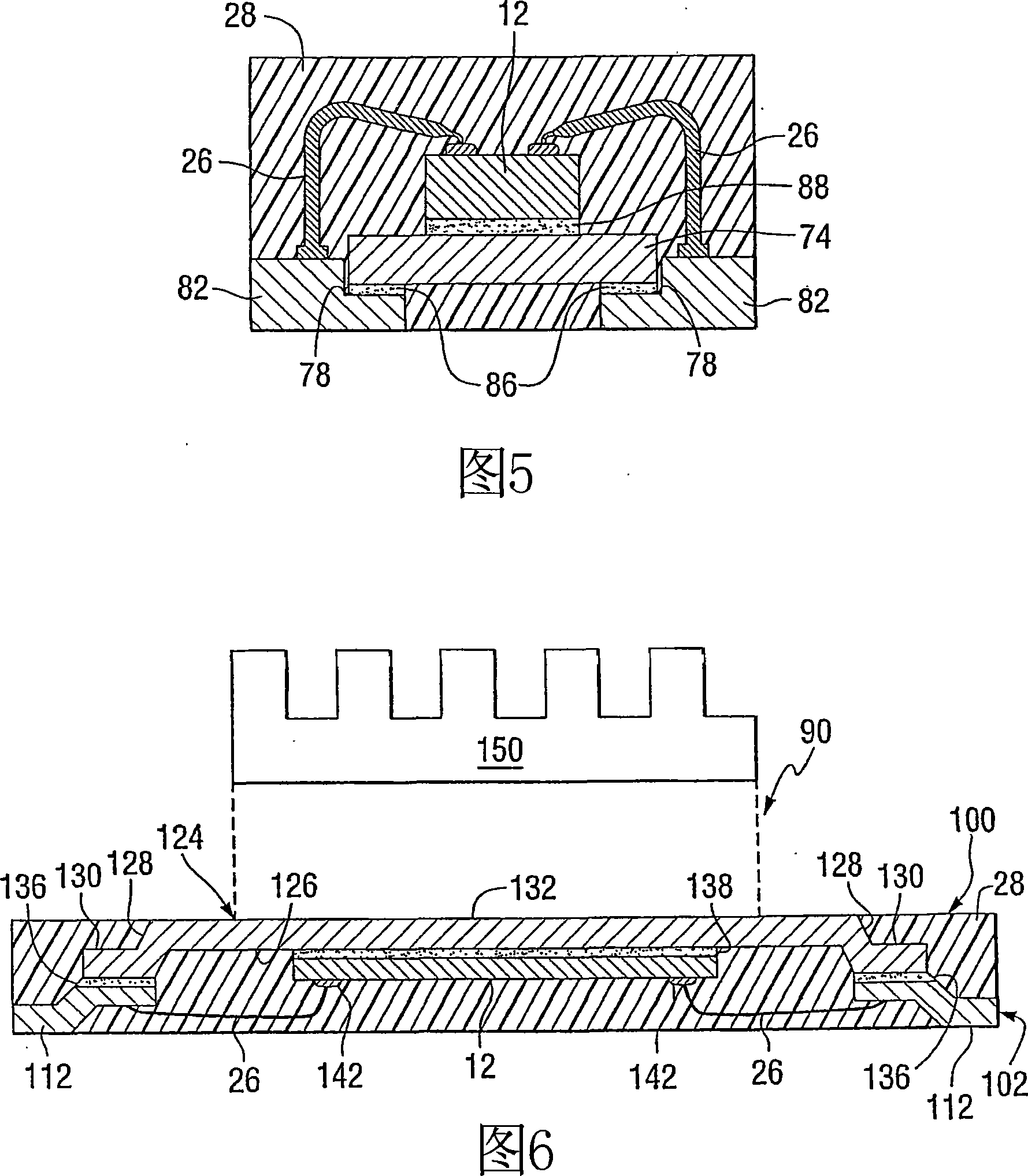

Package and method for packaging an integrated circuit wafer

InactiveCN101015054AExpanded size rangeImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

An integrated circuit assembly includes a lead frame having a plurality of leads with inner portions. A thermally-conductive clip member is bonded to the inner portions of the leads such that the clip member is electrically isolated from yet thermally coupled to the lead frame. An integrated circuit die is bonded and thereby thermally coupled to the clip member. The die is electrically connected to the wire die by wire bonds. Encapsulant material is disposed over the inner portions of the leads and at least a portion of the clip member, and encapsulates the die and the wire bonds.

Owner:FAIRCHILD SEMICON CORP

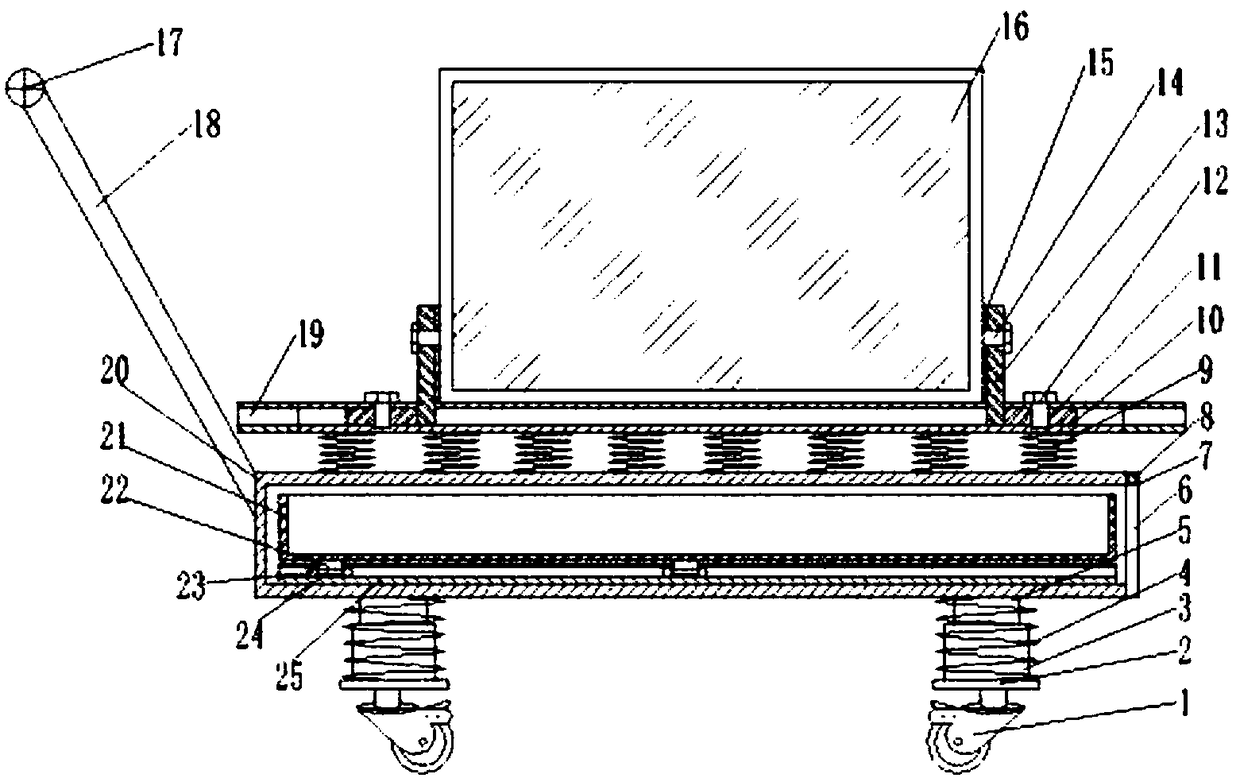

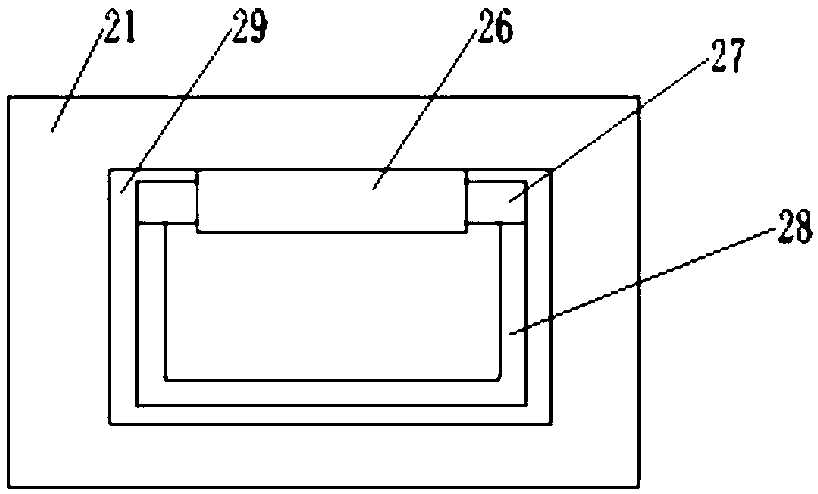

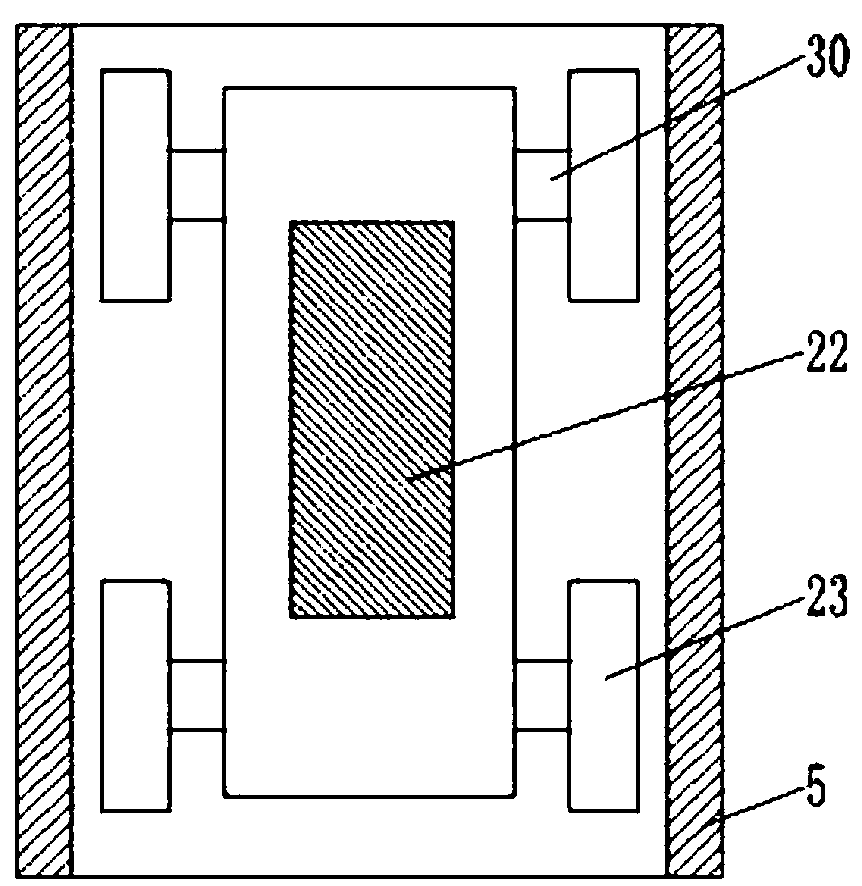

Simple cart with good stability for transporting liquid chemical materials

InactiveCN108909783APrevent overflowOffset the impactHand carts with multiple axesHand cart accessoriesChemical industryCompound (substance)

The invention belongs to the technical field of chemical industry, in particular to a simple cart with good stability for transporting liquid chemical materials. Aiming at the problems that the transportation device is complex in structure, large in volume, low in safety during transportation and failure in satisfying transportation needs, the following scheme is put forward: a bottom box is provided, wherein four corners of the outer wall of the bottom of the bottom box are connected with a movable rod through bolts; the outer wall of the movable rod is sleeved with a sleeve; the outer wall of the bottom of the sleeve is connected with a baffle through the bolt; the outer wall of the bottom of the baffle is connected with a universal wheel through the bolt; the outer wall of the sleeve and the movable rod are sleeved with a same first damping spring. The storage box of the invention is more stable in the transportation process, prevents the liquid chemical material inside the storagebox from overflowing due to violent shaking, improves the safety of the device, does not slide when the storage box is above the mounting plate, improves the stability of the device, the diluent or neutralizing agent which needs to be used is taken out from the storage box in time, and the safety of the device is effectively improved.

Owner:郑州莉迪亚医药科技有限公司

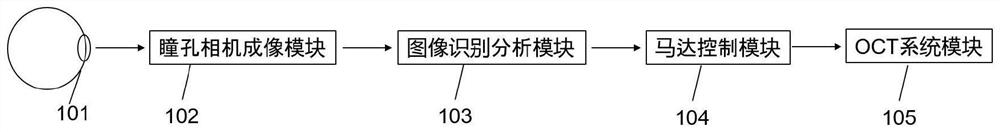

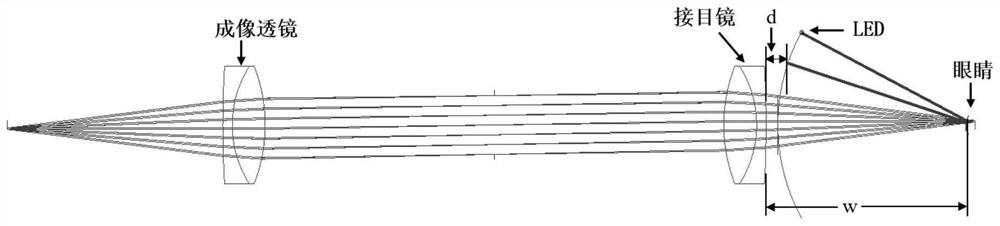

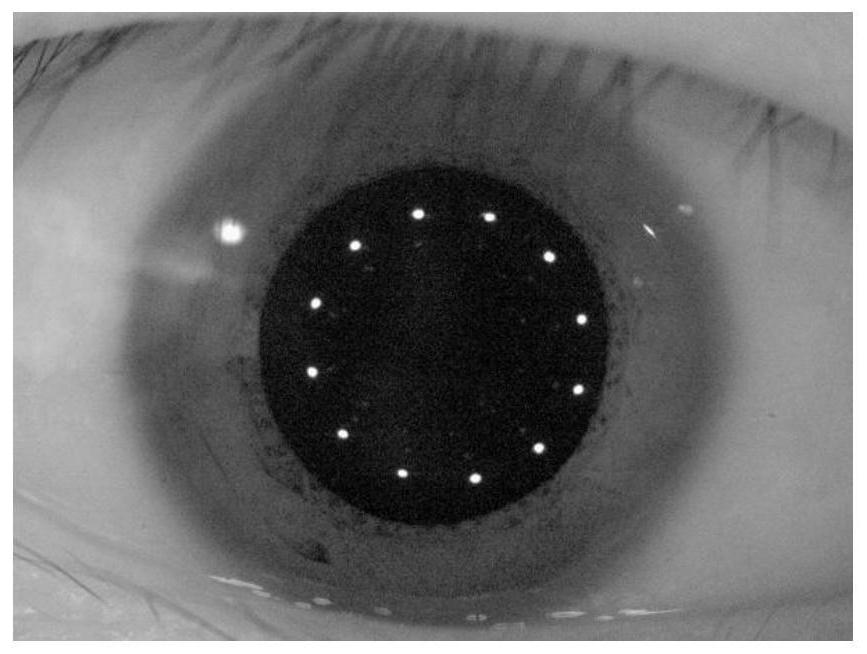

Three-dimensional eye movement tracking system and tracking method thereof

The invention discloses a three-dimensional eye movement tracking system, which comprises a pupil camera imaging module, an image recognition and analysis module, a motor control module and an OCT (Optical Coherence Tomography) system module which are connected in sequence. The tracking method of the system comprises the following steps that: continuous real-time imaging on an object to be detected is carried out through the pupil camera module at first; when the object to be detected, namely the eyes, moves along the eye axis or the transverse direction, namely the horizontal direction, or the longitudinal direction, namely the vertical direction, the sizes of the eye movements along the eye axis, the horizontal direction and the vertical direction can be respectively calculated through the image recognition and analysis module; then, the displacement amounts deltaZ, deltaX and deltaY of corresponding motors in the three directions are calculated; a corresponding motor is adjusted to move according to the calculated displacement of the motor, so that the object to be detected always keeps an accurate working distance and is aligned with the centre of an eyepiece; and three-dimensional imaging on an anterior segment or posterior segment of the eye of the object to be detected is carried out through the OCT system module. The invention can perform real-time tracking on three-dimensional eye movement and calculates the size and direction of the eye movement; the eye movement in diagnosis can be compensated in real time through the motor control module; high-quality system imaging is achieved; the complexity of a diagnosis system is reduced; and the diagnosis success rate and efficiency are improved.

Owner:SVISION IMAGING LTD

Quenching method of thin steel plate

ActiveCN110117708ASolve the problem of quenching warping deformationQuenching flatness is stable and controllableFurnace typesHeat treatment furnacesNitrogenQuenching

The invention relates to a quenching method of a thin steel plate. The thickness of the steel plate is 4-80 mm. The quenching method comprises the production steps of the heating stage and the water spray cooling stage, wherein a quenching normalizing furnace is adopted at the heating stage; the quenching normalizing furnace adopts a continuous roller hearth type; nitrogen is introduced into the furnace, the heating temperature of the quenching normalizing furnace is 890-910 DEG C, the quenching normalizing furnace conducts heating through upper and lower rows of radiant tubes, and the furnacetemperature fluctuation amplitude of the quenching normalizing furnace is less than 5 DEG C; at the water spray cooling stage, a quenching machine is adopted and is internally provided with pressingrollers in an up-down mode, and the quenching machine operates in a continuous rolled quenching mode; the water spray cooling stage is divided into a winter quenching mode and a summer quenching mode;a medium adopted at the water spray cooling stage belongs to circulating cooling water, and the water temperature of the circulating cooling water is less than 35 DEG C. Through the quenching method,the problem that buckling deformation occurs to the thin steel plate in the quenching process is solved, and the thin steel plate is stable and controllable in quenching straightness.

Owner:冀南钢铁集团有限公司

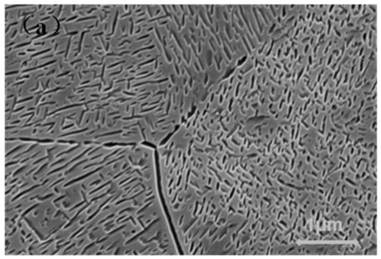

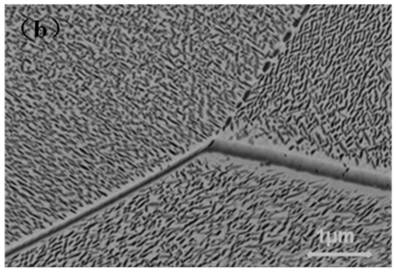

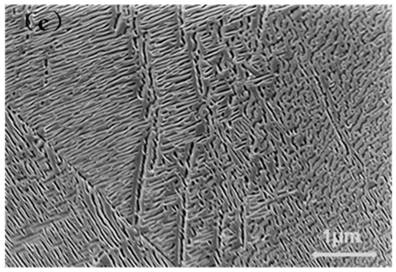

Heat treatment method for regulating and controlling microstructure and microhardness of near-beta titanium alloy

The invention relates to a heat treatment method for regulating and controlling a microstructure and a microhardness of a near-beta titanium alloy, which comprises the following steps: S1, selecting heat treatment raw materials, and carrying out cogging forging treatment on an alloy cast ingot to form a bar; S2, performing solid solution treatment, specifically, after a heat treatment furnace is heated to + / -50 DEG C near a titanium alloy beta phase transformation temperature of the bar, putting the bar in the heat treatment furnace to be subjected to heat preservation, then quenching the bar,thereby obtaining a sample with a large number of metastable beta phases; and S3, performing subsequent heat treatment, specifically, slowly heating the sample from the room temperature, introducingexternal elastic tensile stress or compressive stress in the heating process, and quenching after the sample reaches the preset temperature. Elastic stress fields act on the Ti-7333 alloy in the heattreatment process, so that refined regulation and control over the microstructure of the Ti-7333 alloy can be achieved, i.e., preferred orientation of an alpha precipitated phase is formed, and the effect of enhancing the microhardness of the near-beta titanium alloy Ti-7333 is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method of producing ultrathin-wall seamless metal tube using floating plug

A method of producing an ultrathin-wall metal tube by a cold drawing method includes a diameter-expanding drawing method, in which an entry solid die, the diameter of which increases, remains constant or decreases from the engaging entry side toward the finishing exit side, and a delivery solid die, the diameter of which decreases at least in the vicinity of the engaging entry, are arranged in series and in an abutting relation on the same pass line. A tapered plug, the diameter of which increases from the engaging entry side toward the finishing exit side, floats along the pass line, whereby in the entry solid die region, the wall thickness is reduced while the mid-wall diameter of a hollow shell is being expanded between the solid die and the plug, and in the delivery solid die region, the tapered plug floats by performing reduction working of the outside diameter.

Owner:NIPPON STEEL CORP

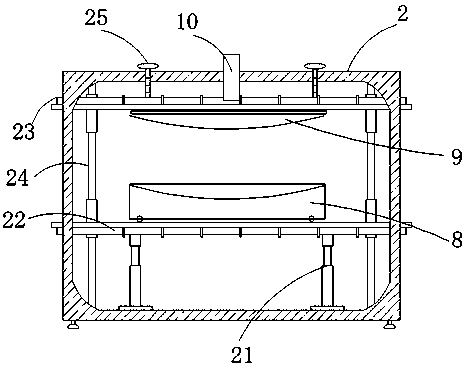

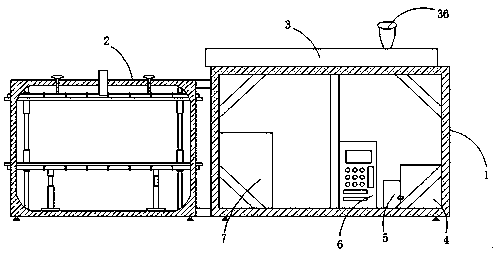

Plastic boat injection molding machine and preparation method of single-layer plastic boat

PendingCN109466016AEasy loading and unloadingEasy to cool and formDomestic articlesSource materialEngineering

The invention relates to the technical field of injection molding, in particular to a plastic boat injection molding machine and a preparation method of a single-layer plastic boat. The problems thatthe efficiency of injection molding production of injection-molded boats is poor, the steps of injection molding production of the injection-molded boats are tedious, and inconvenience is caused during production of the injection-molded boats in the prior art are solved. The plastic boat injection molding machine comprises a main control box and an auxiliary frame; a barrel is arranged on one sideof the interior of the main control box; a loading machine is arranged on one side of the barrel; a hydraulic machine is arranged on the other side of the interior of the main control box; and a console is arranged inside the main control box. The final forming quality of the plastic boat can be improved from the source by screening the source materials, the loading and unloading in the whole production process are convenient, and the amount of extruded solution can be adjusted with a computer according to different demands; cooling water is available on the edge of a mold, so that cooling molding is facilitated; in addition, different products can be produced by changing the mold; the machine is convenient to use as a whole; and the preparation method of the plastic boat is efficient, simple and convenient to implement.

Owner:湖南虹旭塑业有限公司

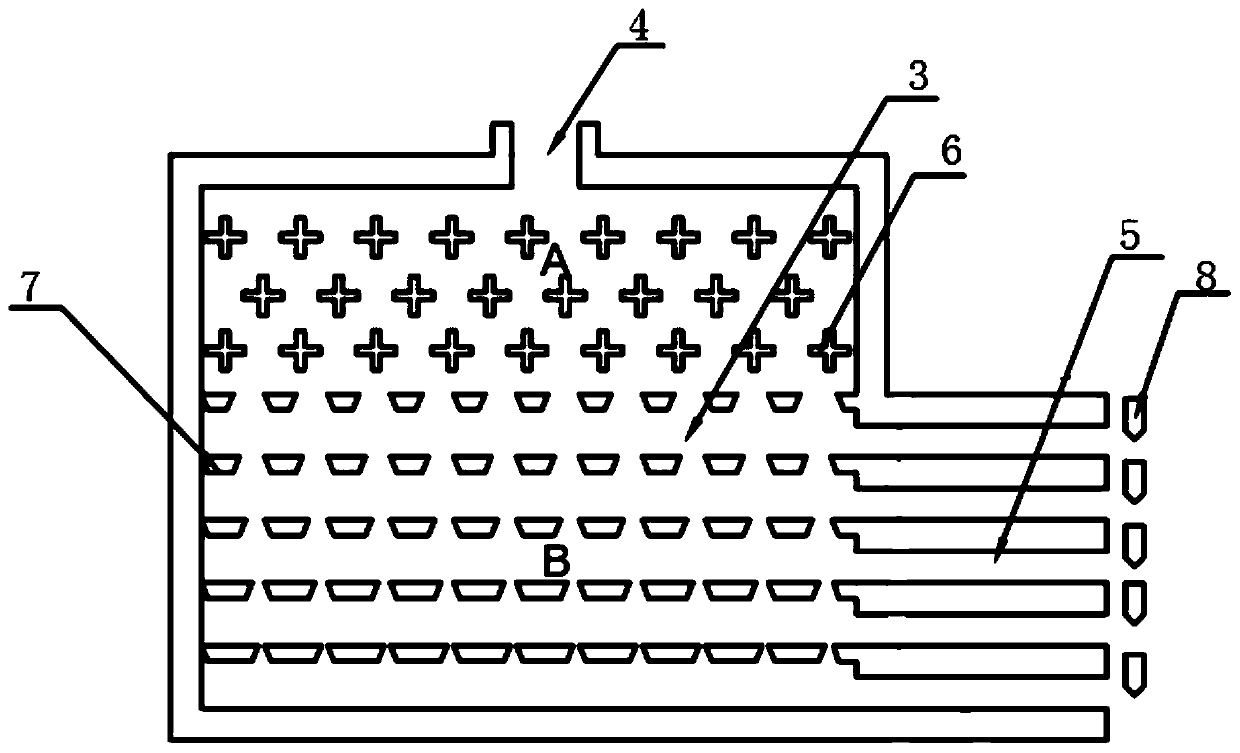

Microfluidic device for cell sorting and detection and method thereof

ActiveCN110835596AImplement extractionExpanded size rangeBioreactor/fermenter combinationsBiological substance pretreatmentsMicroscopic imageGlass chip

The invention discloses a microfluidic device for cell sorting and detection and a method thereof, the device comprises a chip and a glass sheet, one side of the chip in contact with the glass sheet is engraved with a flow channel, the flow channel is divided by a plurality of fences, and the tops of the fences are in close contact with the glass sheet; wherein the chip is divided into a region Aand a region B, the region A is close to a flow channel inlet, a plurality of cross-shaped fences are distributed on the region A, the region B is close to a flow channel outlet, a plurality of trapezoidal or triangular fences are distributed on the region B, and the left-right spacing of the trapezoidal or triangular fences on the region B is gradually reduced row by row according to the flowingdirection of a sample; and a flow channel outlet is correspondingly formed between two adjacent rows of fences in the region B, and a microscopic image acquisition device is arranged above each flow channel outlet. According to the device and the method disclosed by the invention, cells with different sizes can be automatically and accurately sorted, classification and identification are carried out by combining an image identification algorithm, the cell activity can be retained, and the flux is extremely high.

Owner:SHANDONG UNIV

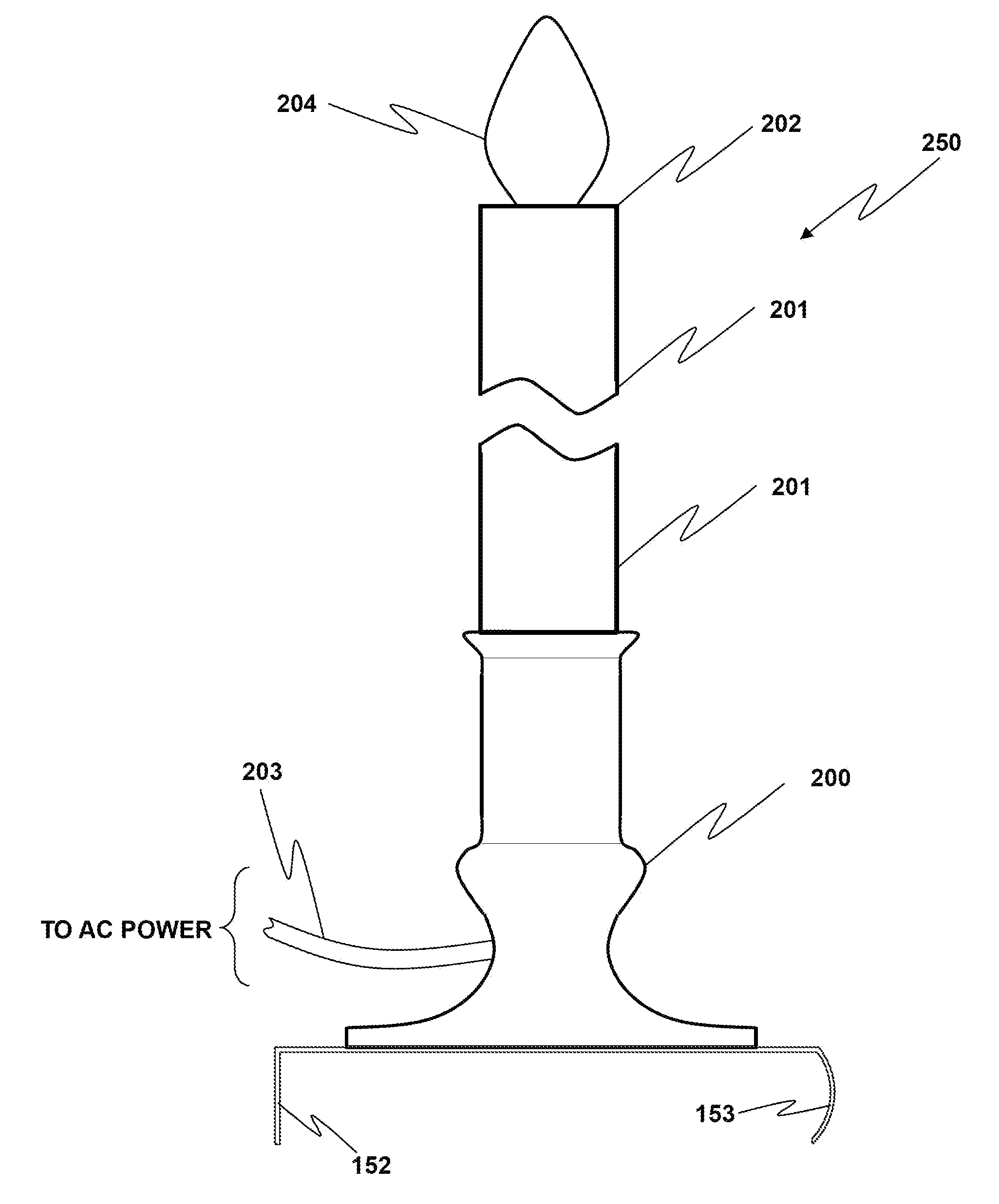

Candle Holder Mount

InactiveUS20120328998A1Expanded size rangeEasily and economically manufacturedCandle holdersLighting support devicesWindow sillCandelabrum

A candle holder mount is provided for holding electrical candle simulations firmly to a window sill of a home without the simulated candle being dragged off the sill by the weight of the electrical cord used to power the simulating device. The candle holder mount is affixable to window sills of various materials either in a permanent or removable fashion.

Owner:STANZIONE MARY ANN

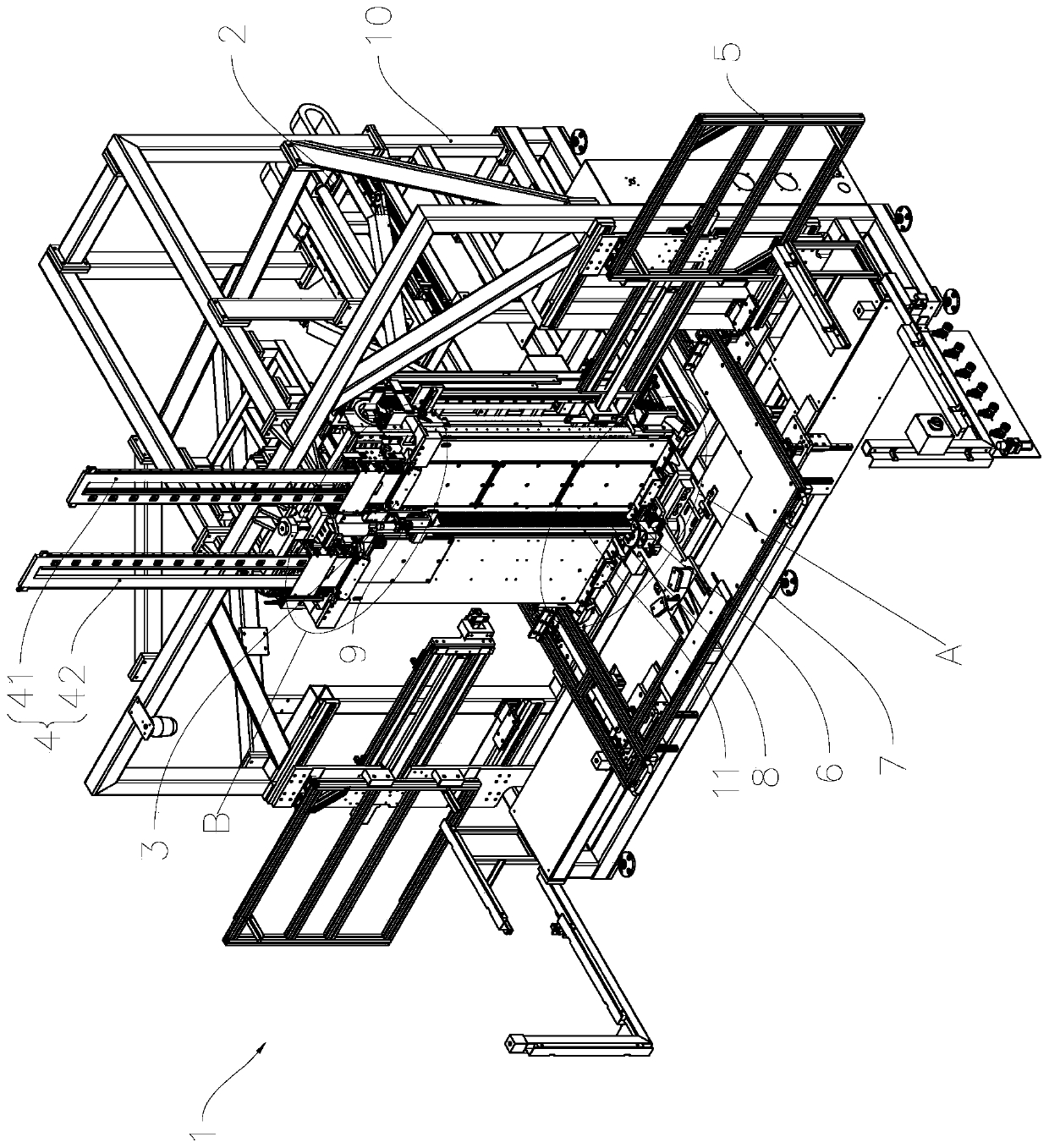

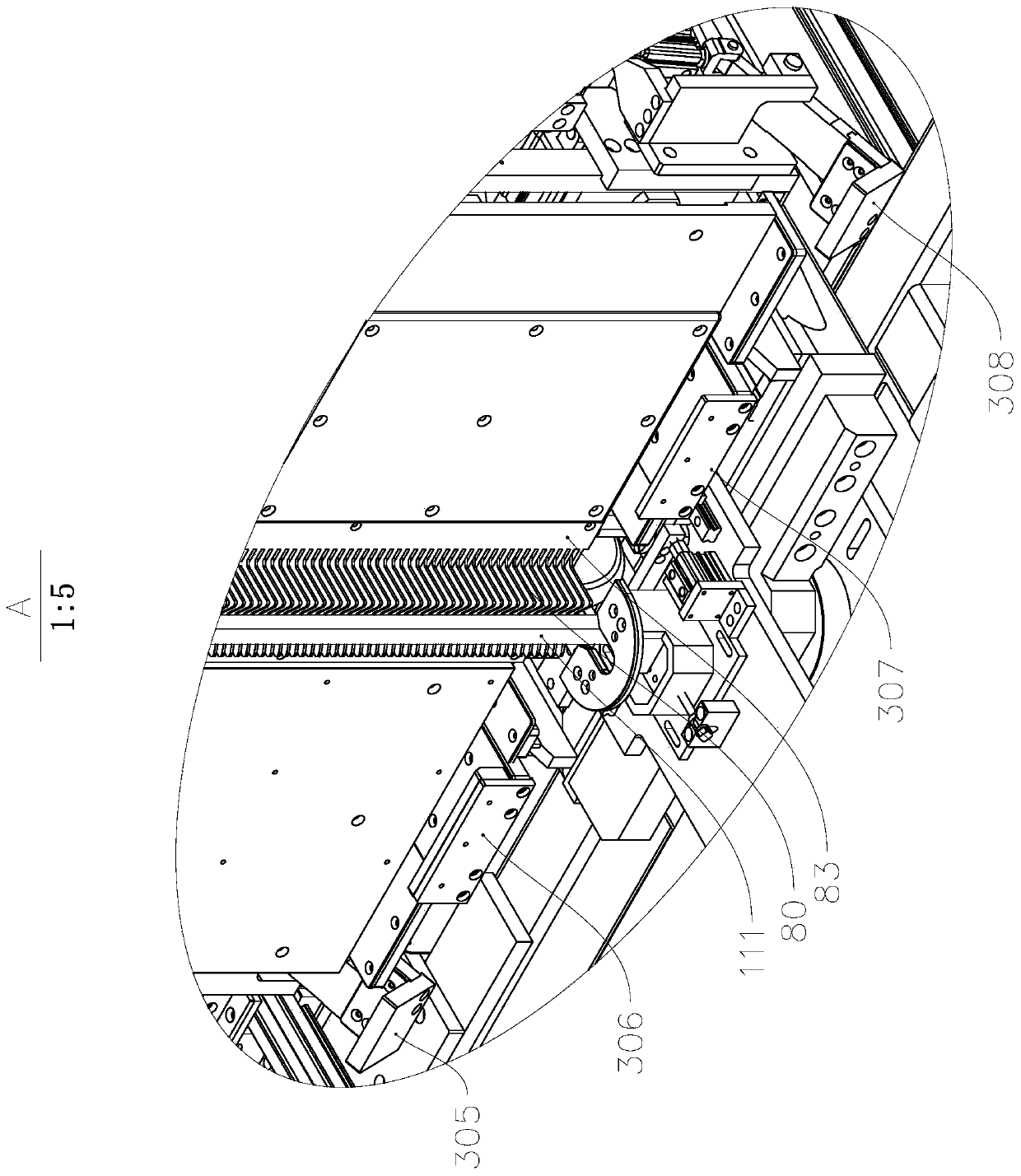

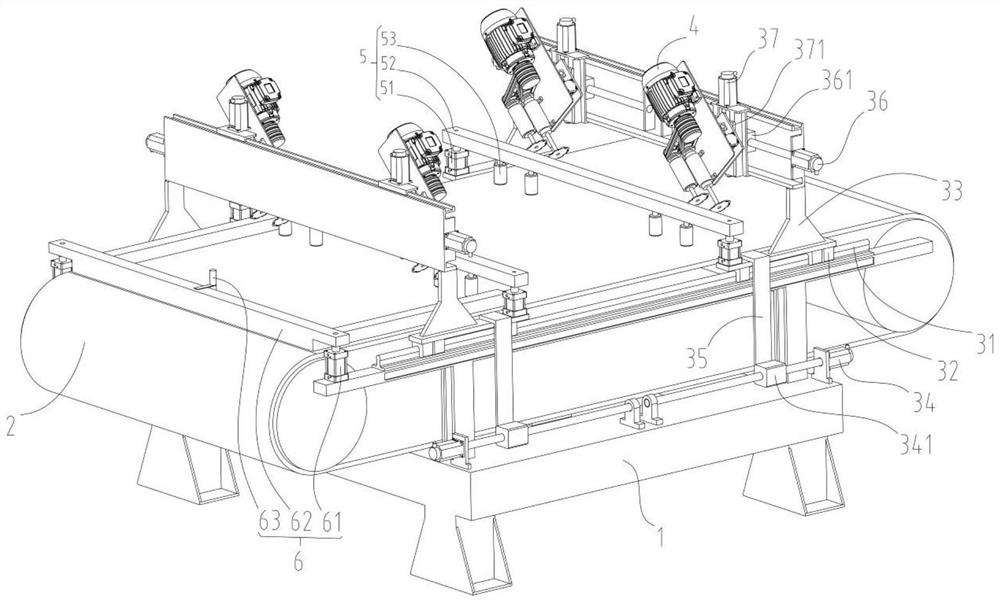

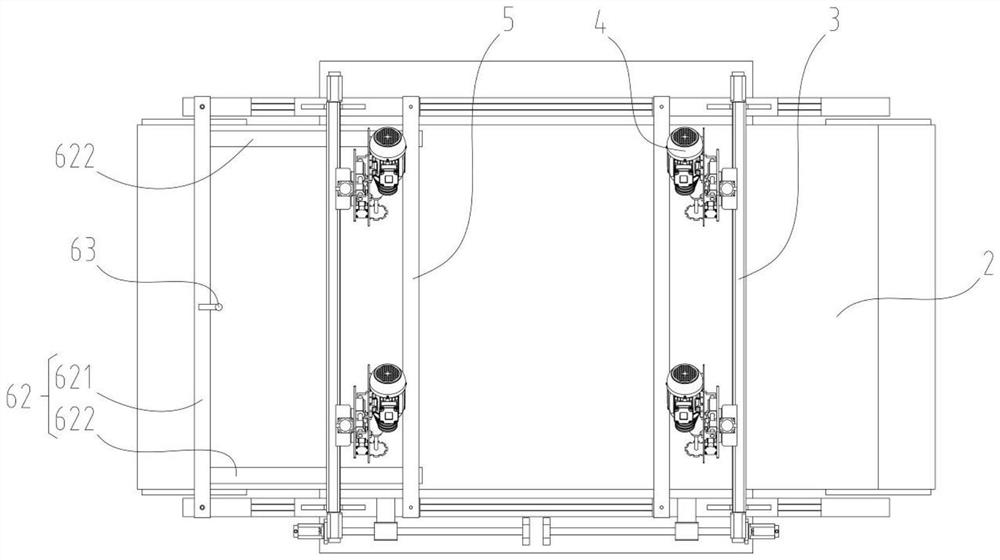

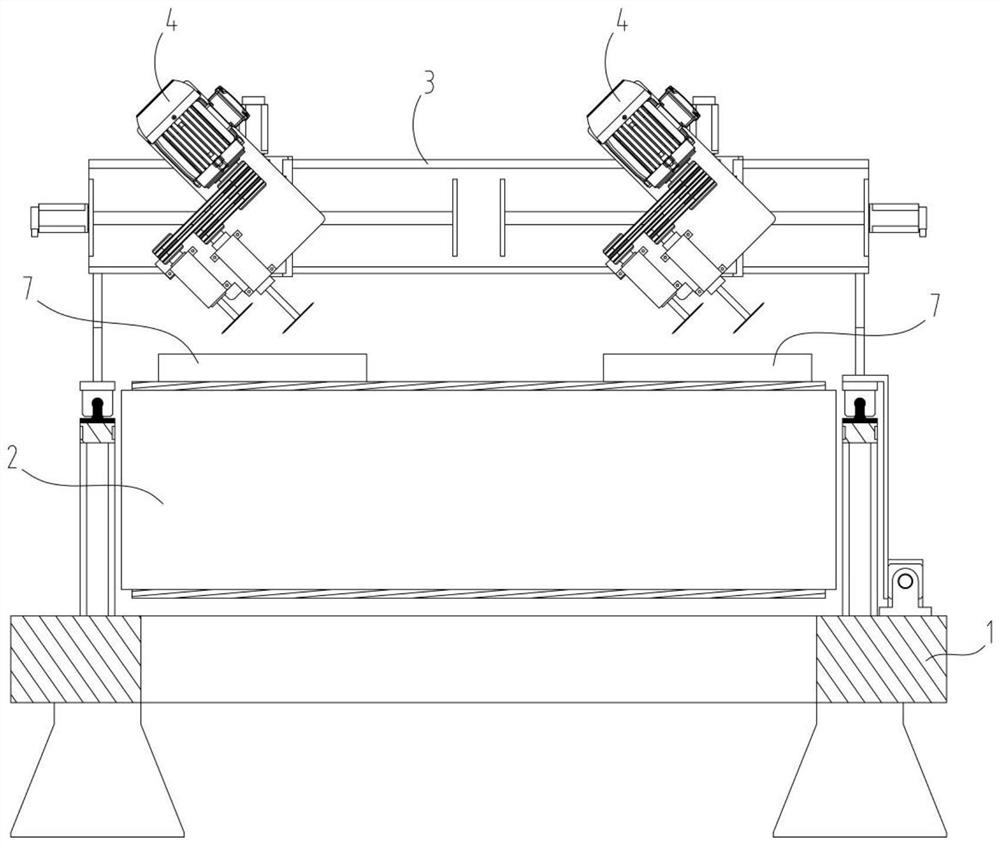

Curtain wall panel grooving machine

ActiveCN111775350ARealize fully automatic slottingExpanded size rangeWorking accessoriesStone-like material working toolsElectric machineryPortal frame

The invention relates to curtain wall panel processing equipment, and provides a curtain wall panel grooving machine. The curtain wall panel grooving machine comprises a machine frame, a conveying mechanism, portal frames arranged on the machine frame, grooving mechanisms arranged on the portal frames, pressing mechanisms arranged on the portal frames and used for pressing curtain wall panels, anda limiting mechanism arranged on the machine frame and used for limiting the movement of the curtain wall panels on the conveying mechanism. Each grooving mechanism comprises a base plate connected to the corresponding portal frame, a first air cylinder arranged on the base plate in parallel, a connecting plate connected to the output end of the first air cylinder and parallel to the base plate,a first motor arranged on the side, away from the base plate, of the connecting plate, and grooving pieces fixed to the connecting plate and driven by the first motor to rotate.

Owner:厦门思合科技有限公司

Milling machining clamping device

ActiveCN111546098ASimple equipment structureEfficiency and work efficiencyPositioning apparatusMetal-working holdersStructural engineeringManufacturing engineering

The invention discloses a milling machining clamping device. The device comprises a matching box, wherein a transmission inner cavity is arranged in the matching box, a middle fixing shaft is fixedlyarranged on the lower end face of the matching box, the lower end face of the middle fixing shaft is fixedly provided with a bottom plate, the bottom plate is internally provided with a plurality of side swinging rods in a rotational mode, one sides of the side swinging rods are rotatably provided with movable matching rods, the movable matching rods are internally provided with clamping ejector rods in a rotational mode, and connecting power rods are rotatably arranged between the clamping ejector rods and the side swinging rods. The device is simple in structure, the device adopts the mode through which a clamping arm can be increased, so that the range in which a workpiece can be clamped by the device is expanded, the size range of a machined workpiece clamped by the device is expandedwhile clamping force of the device is improved, so that the efficiency and the working efficiency during milling machining are facilitated, and the clamping feeding and clamping machining are achieved.

Owner:湖北宏胜机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com