Patents

Literature

57results about How to "Solve the investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Centralized remote electric power system

InactiveCN101299517ASolve space problemsSolve the problem of hotspot areas where the website cannot be opened due to mass disputesOverhead installationDistribution substationsElectric power transmissionElectric power system

The invention relates to a centralization remote power feeding system including a primary device machine room arranged with wireless primary devices and power supply primary devices, which include an inverter and a transmission primary device for converting the external electricity 380 V industrial electricity into the -48 to 24 V DC to access to the wireless primary devices to cause the wireless primary devices operate normally; the -48 to 24 V DC is converted to the 220-380V AC through the inverter of the power supply primary devices, then the power is transmitted to the farend unit of the farend covering system of the base station part newly built through the common rod transmission mode of the power transmission line and the optical fiber transmission line, providing the stable power to the farend unit, thereby completing the construction of the whole base station. The invention reduces the building size of the base station, saves the project invest and advances the net operation safety reliability, which is applied in the signal covering of the road, the subway , the tunnel of the city and the small countryside base station.

Owner:CHINA MOBILE GRP GUANGDONG CO LTD

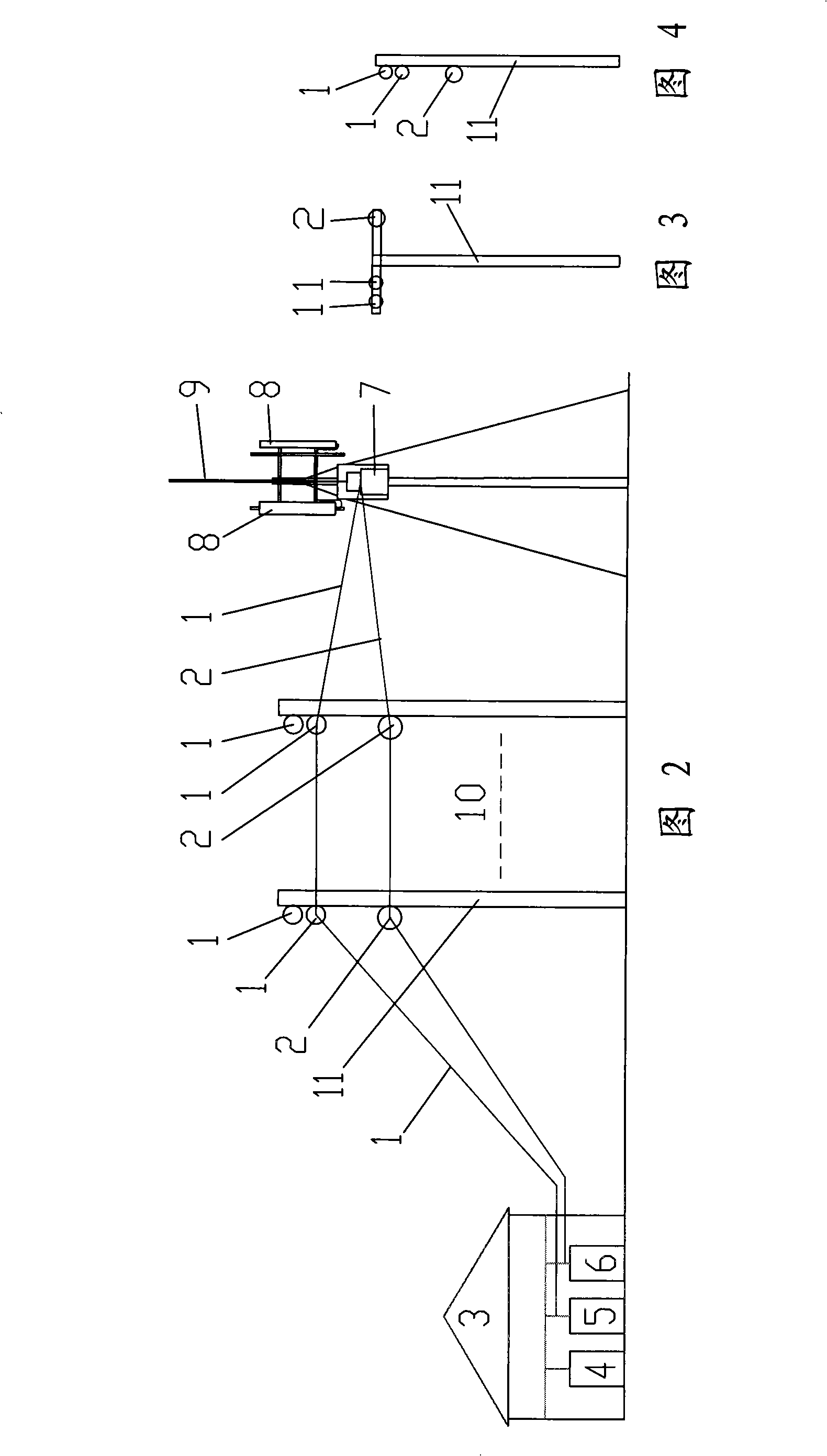

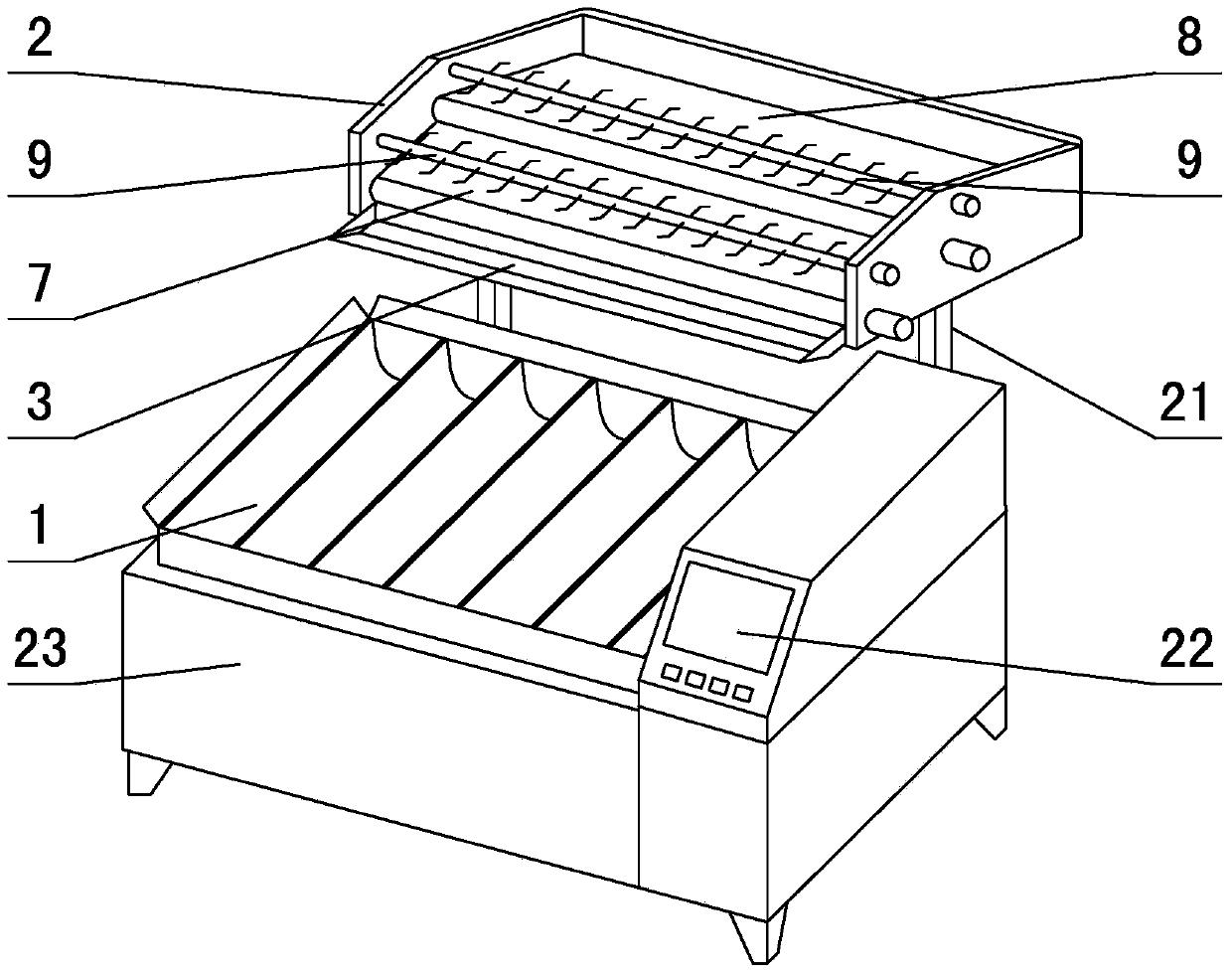

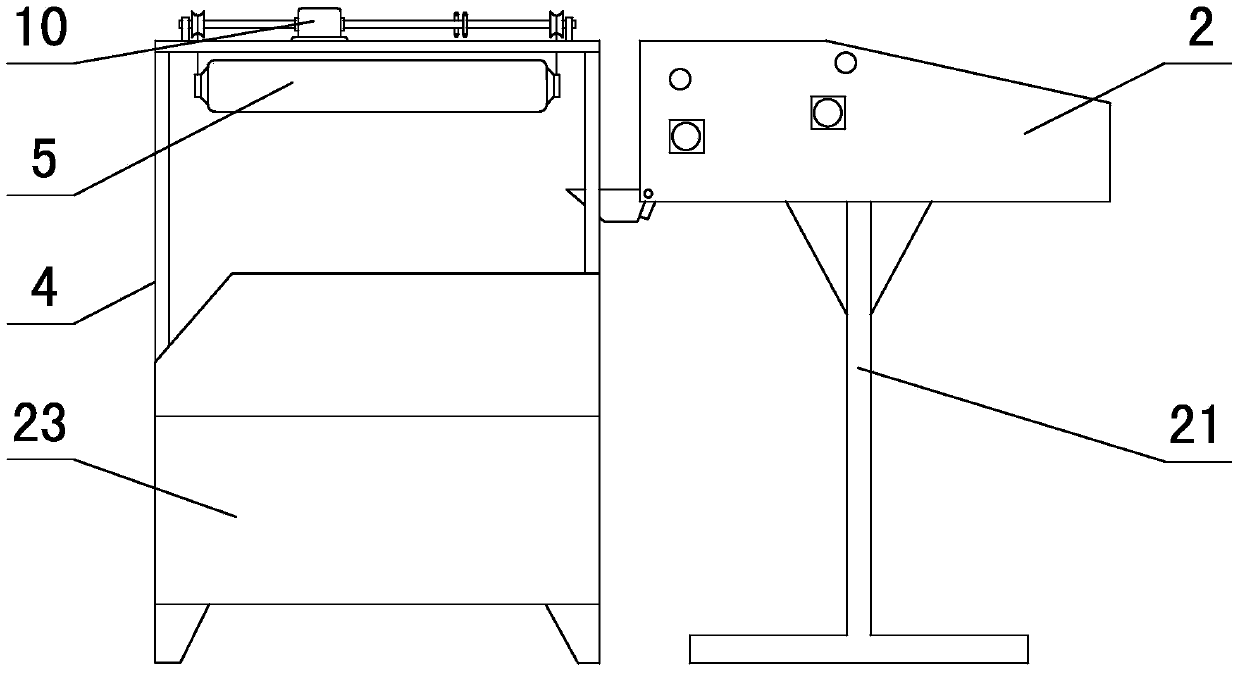

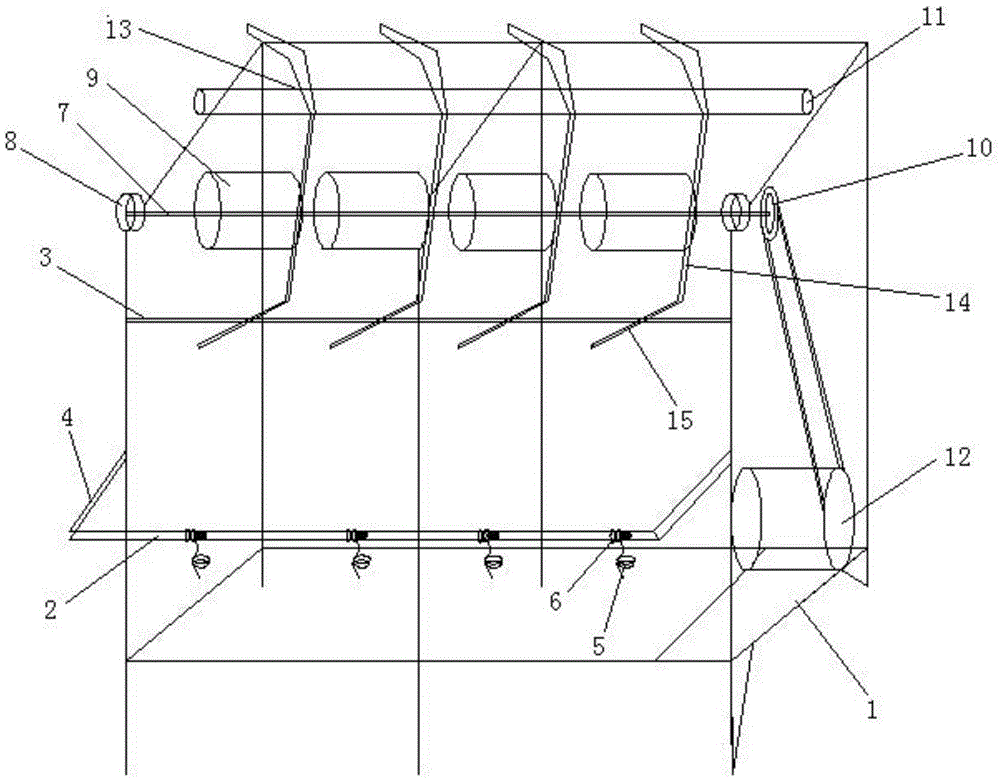

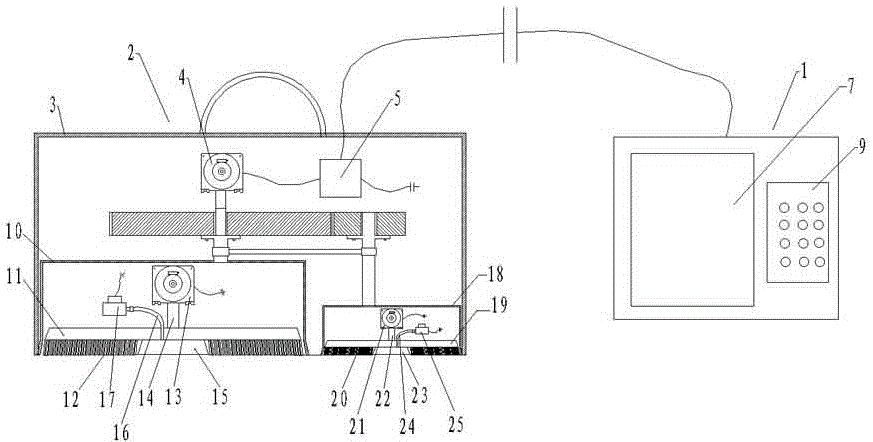

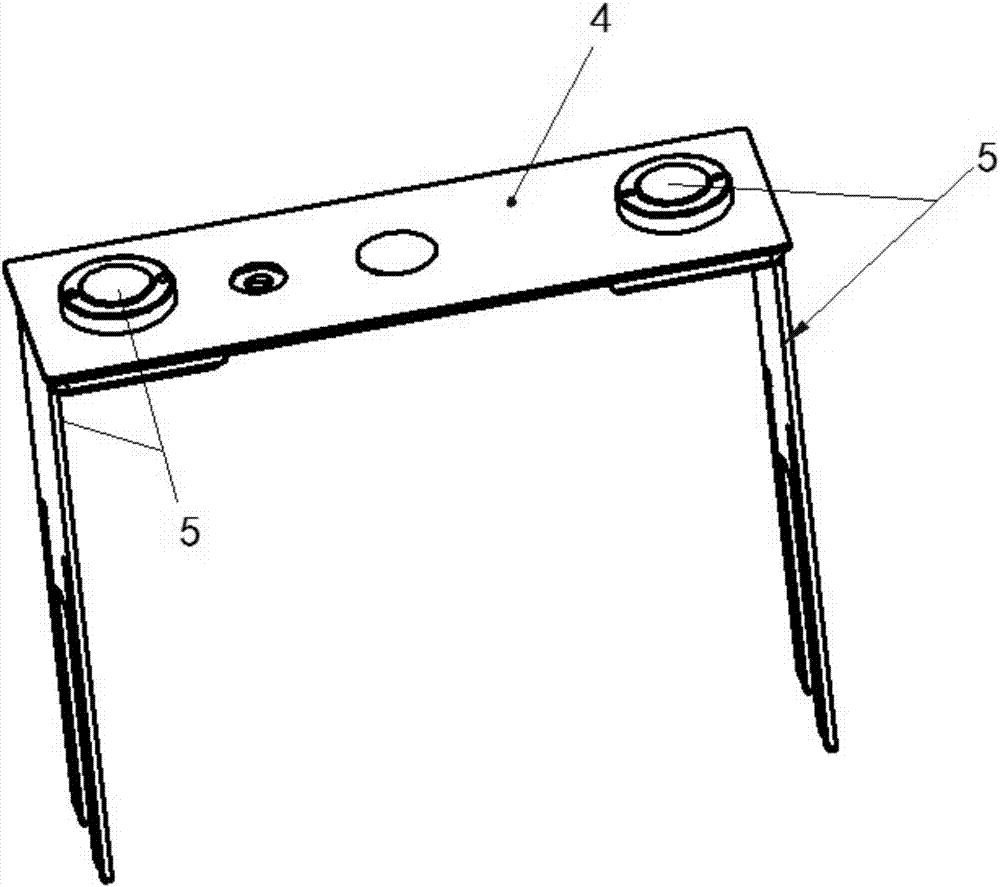

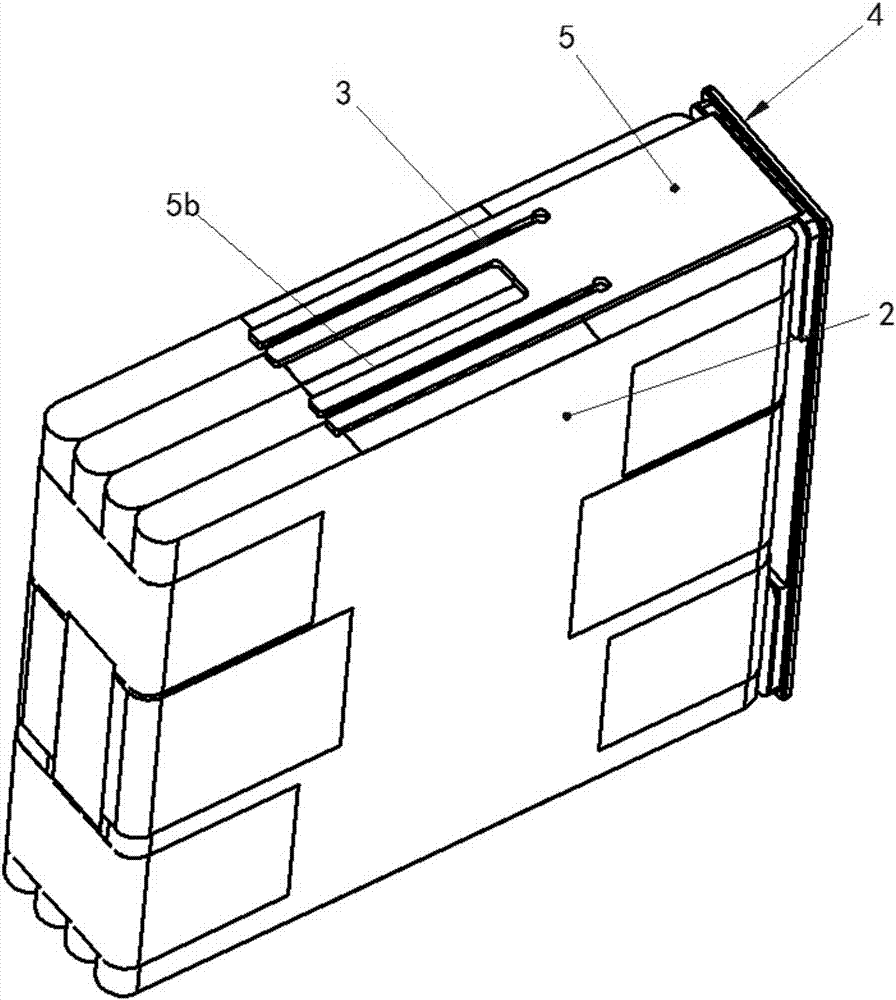

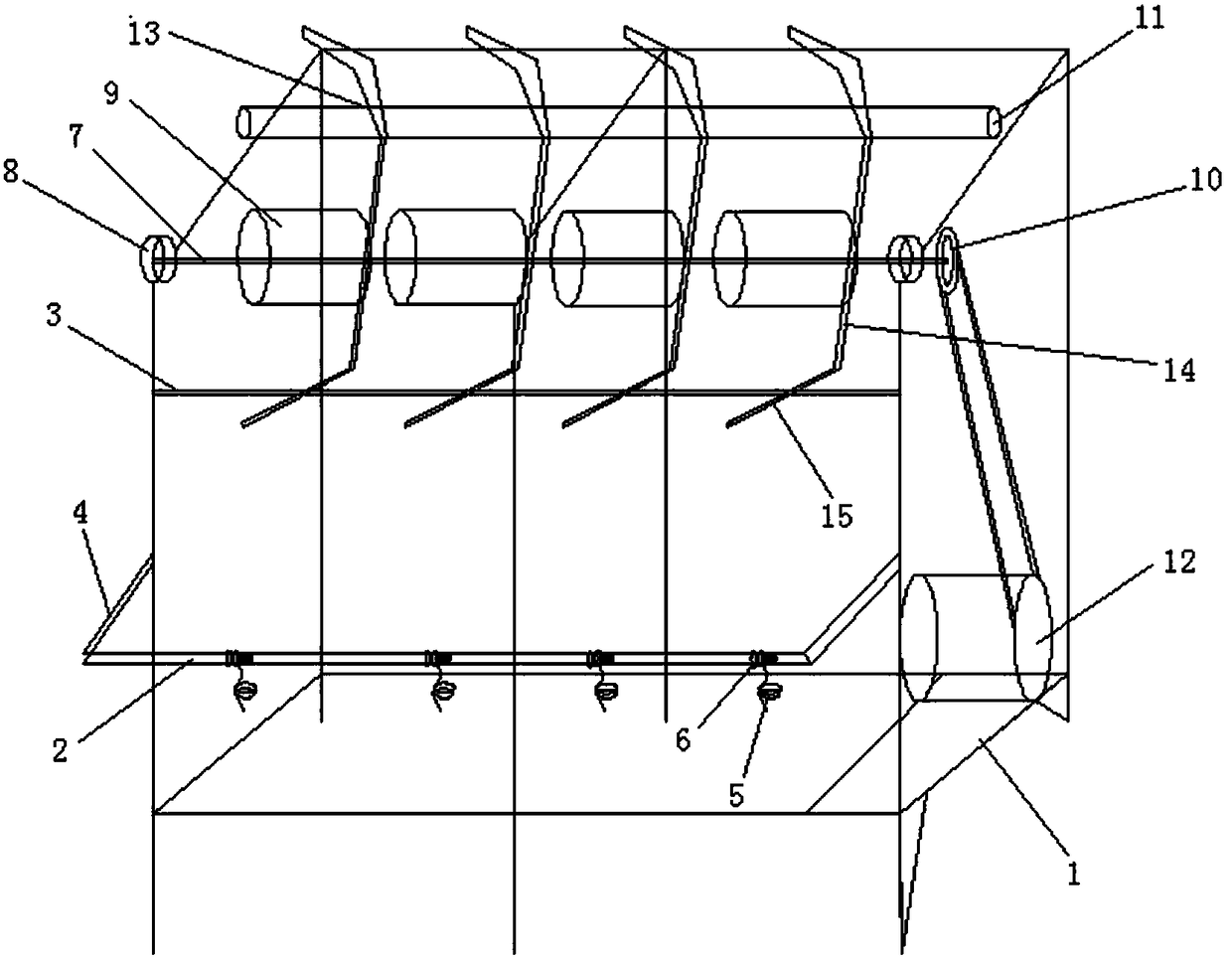

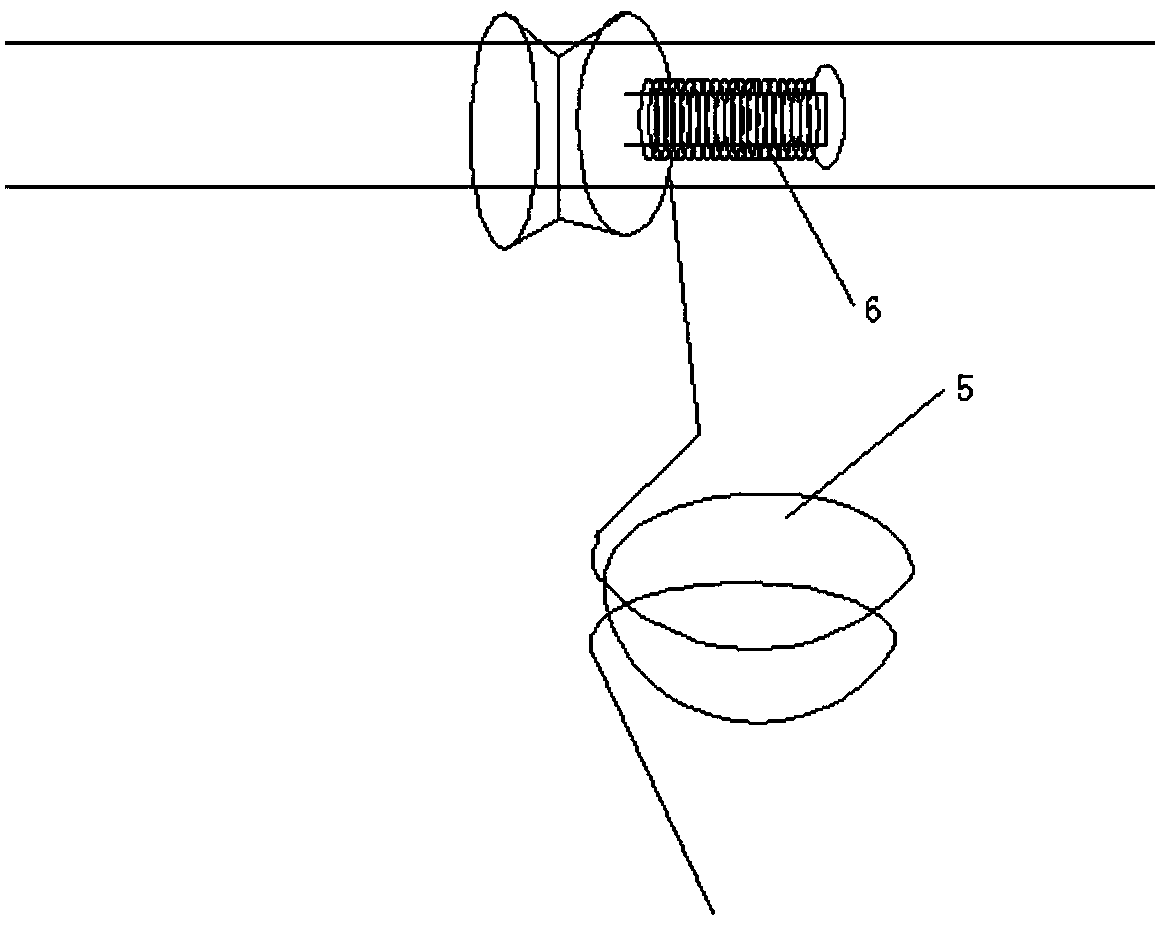

Full-automatic multifunctional carding machine and tea processing method

ActiveCN104186713ASolve the investmentReduce investmentPre-extraction tea treatmentFlavorCompression molding

The invention discloses a full-automatic multifunctional carding machine and a tea processing method. One side of a main machine body is provided with a tea leaf supplying platform; the tea leaf supplying platform is provided with a tea leaf transmission mechanism; a rotatable tea leaf weighing storage slot is disposed below a discharging opening of the tea leaf supplying platform; a compression roller rack is provided with compression rollers with the number corresponding to the number of trough pots; the compression rollers are in cylindrical shapes; the lengths of the compression rollers are adaptive to the lengths of the trough pots; the diameters of the compression rollers is smaller than opening widths of the trough pots; the compression roller rack is provided with a compression roller lifting mechanism; two ends of the compression rollers are connected to the compression roller lifting mechanism through a flexible connecting rope; and the full-automatic multifunctional carding machine is also provided with a control device. The full-automatic multifunctional carding machine can finish all stir-frying processes of deactivating bar-type tea, carding, compression molding, drying and improving the flavor only by one device, is low in device investment, small in required production place, and has very high practical values.

Owner:浙江丰凯机械股份有限公司

Three-dimensional greening mesh bag seedling method

The invention discloses a three-dimensional greening mesh bag seedling method comprising the following steps: preparing nutritional soil, disinfecting, preparing a mesh bag, filling the nutritional soil, sowing, culturing seedlings and the like. In the three-dimensional greening mesh bag seedling technology of the invention, the traditional seedling container is replaced by the mesh bag; after cultured, nursery stocks are integrally used for three-dimensional greening; on the one hand, the shape of the container can be changed according to modelling requirements so as to build the three-dimensionalgreening landscape with various forms; and on the other hand, watering and fertilization can be carried out in the mode of spraying so as to avoid nutritional soil loss and environment pollution. The invention is used for reducing the working procedure of three-dimensional greening, improving efficiency and bringing easy and convenient processes of watering and fertilizing in the conservation process. Thus, the problems of large input, poor effect, complex management, great possibility of secondary environment pollution and the like in the existing three-dimensional greening mode are solved.

Owner:SHANGHAI INST OF TECH

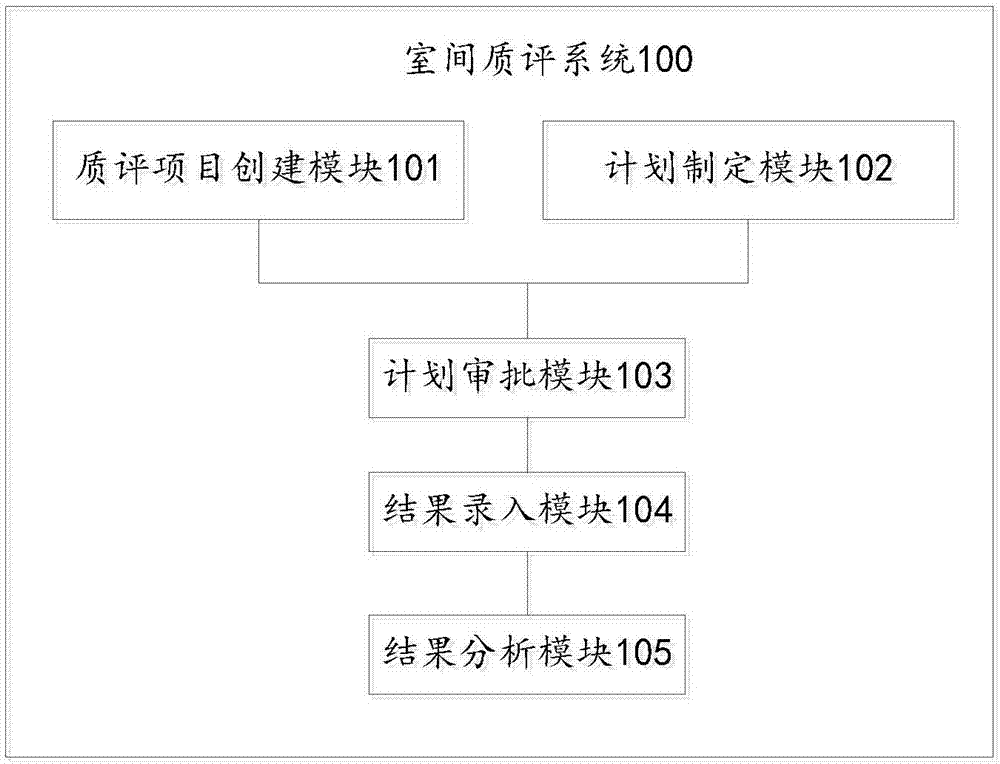

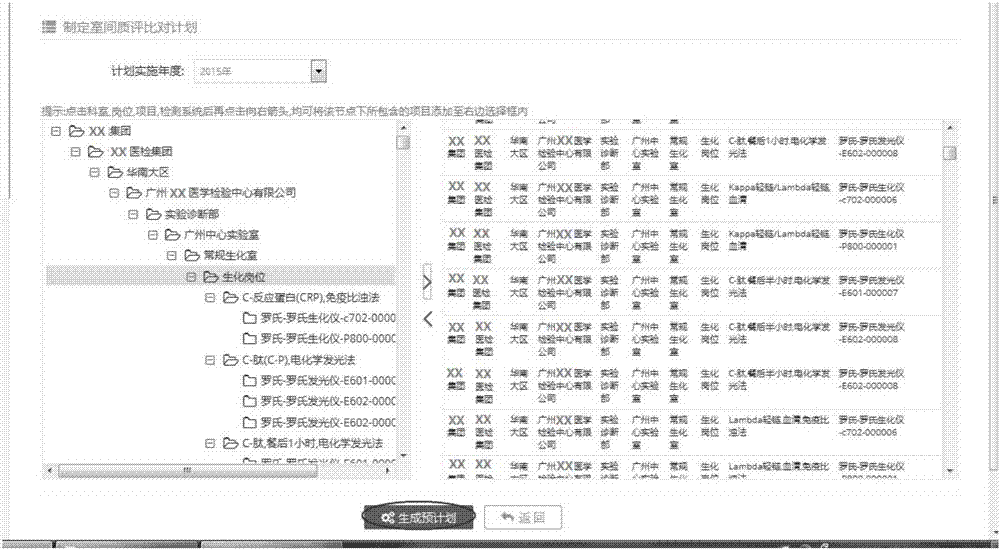

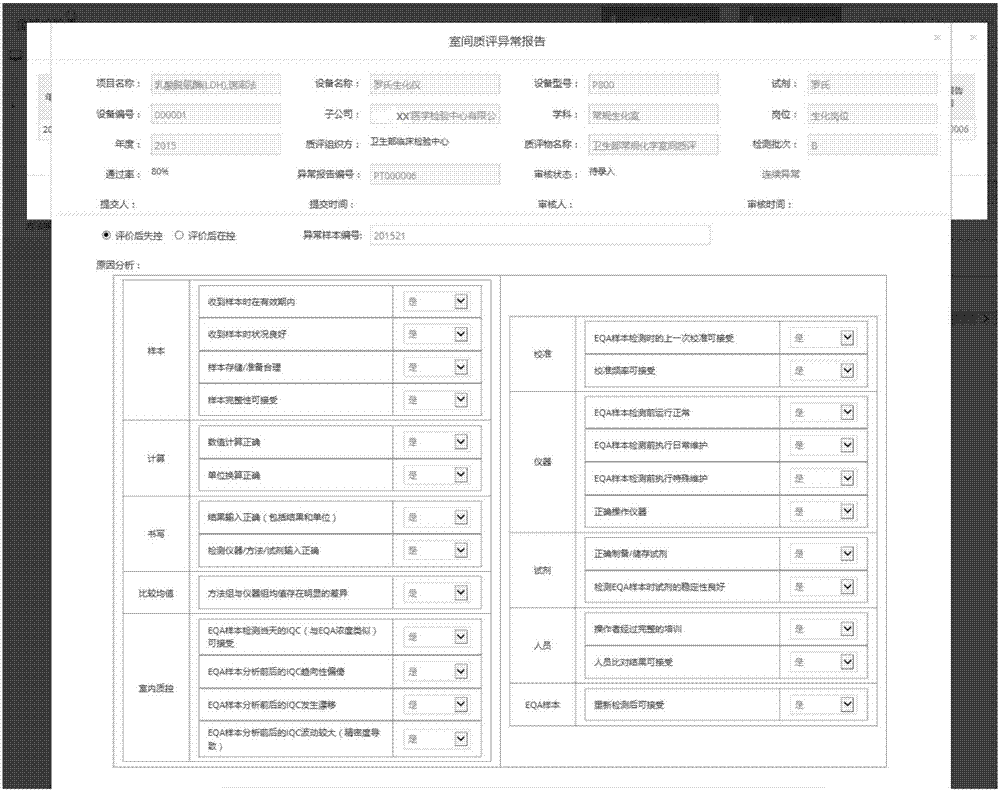

Interlaboratory comparison system and method

ActiveCN107545361ATime-consuming to solveSolve the investmentResourcesSpecial data processing applicationsProgram planningPass rate

The invention discloses an interlaboratory comparison system and method. By creating a quality assessment project firstly, check items are added to the quality assessment project; an interlaboratory comparison plan is established for a detection system of the check items; by matching the check items corresponding to the interlaboratory comparison plan with check items in any quality assessment project, the corresponding quality assessment project is allocated to the detection system of the check items; a quality assessment result of the detection system of the check items is input; and according to the quality assessment result of the detection system of the check items, a ratio of a correct quality assessment number to a total quality assessment number is calculated to obtain a quality assessment passing rate of the detection system. The organization and execution of an interlaboratory comparison project are facilitated; the data processing efficiency is higher; the problems of long consumed time, high input and high data error rate of existing interlaboratory comparison can be effectively solved; and laboratorial error reasons can be guided to be analyzed, so that the time for sorting quality assessment reports is effectively shortened and the interlaboratory comparison efficiency is improved.

Owner:广西金域医学检验实验室有限公司

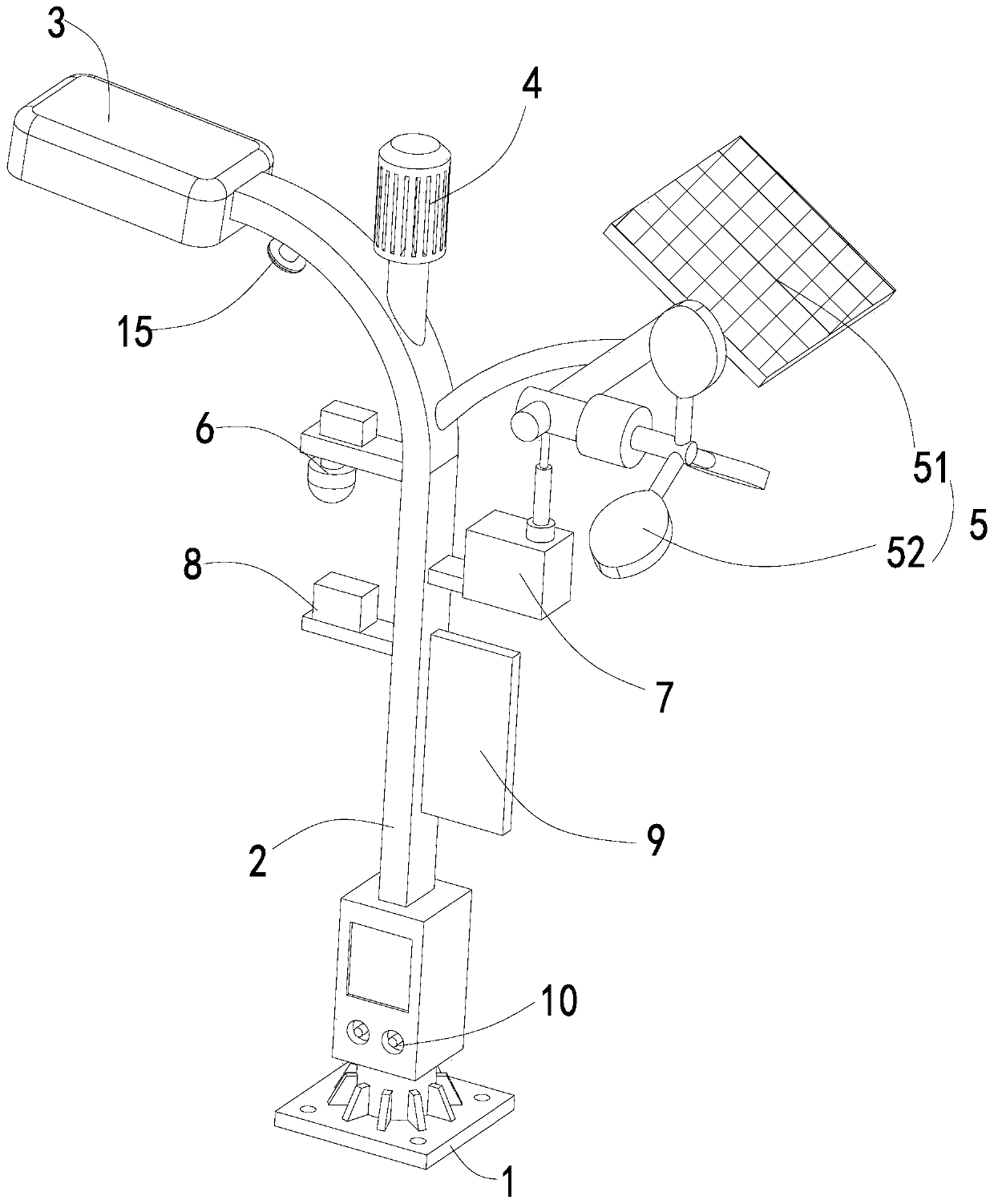

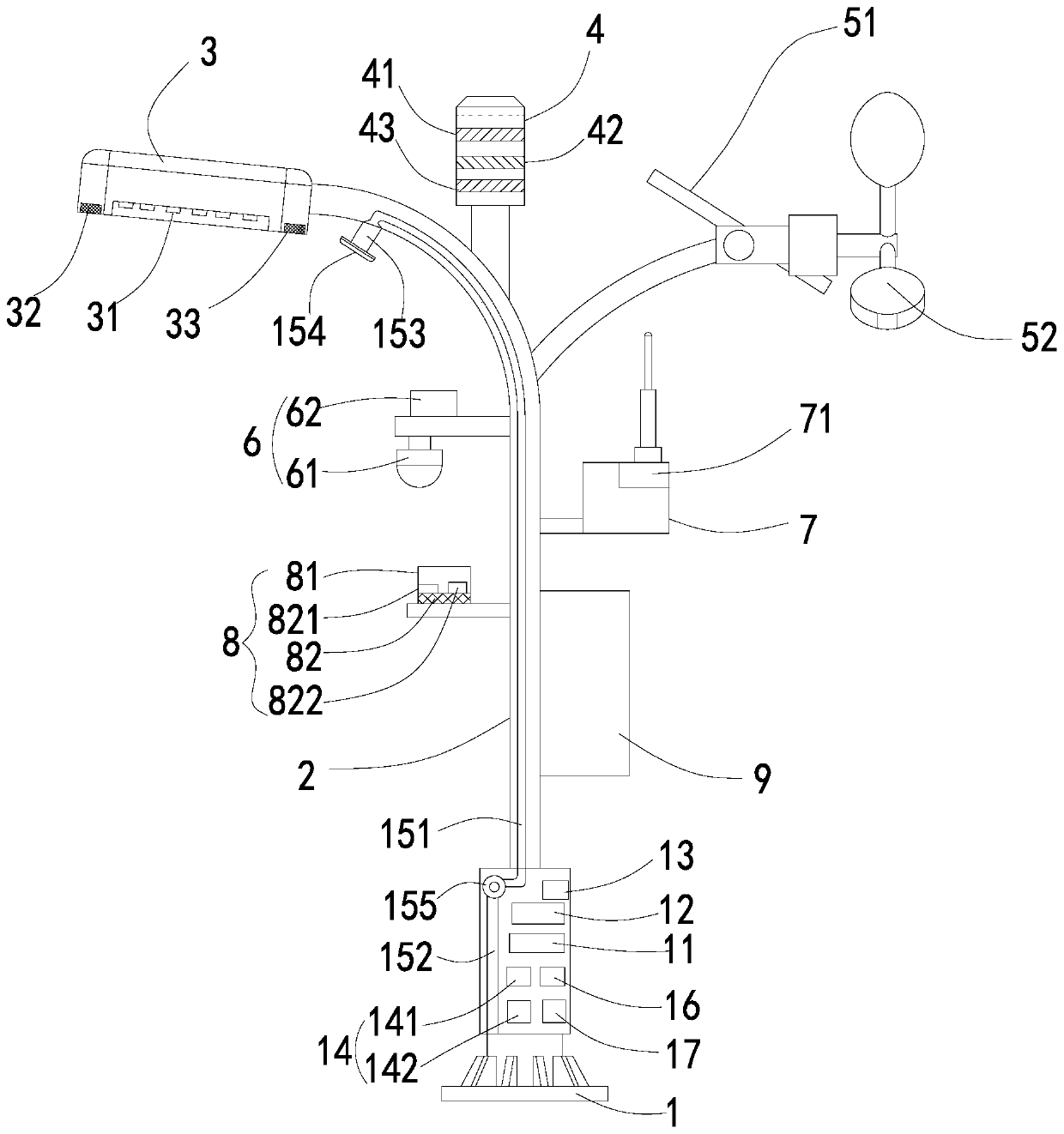

Multifunctional intelligent street lamp

InactiveCN111511065ARealize comprehensive utilizationIncrease profitTelevision system detailsMeasurement devicesVideo monitoringMonitoring system

The invention provides a multifunctional intelligent street lamp. The street lamp comprises a base, a street lamp pole and a lamp holder, wherein an LED light source is arranged in the lamp holder; anenvironment monitoring system is arranged at the top of the streetlamp pole; the upper end of the streetlamp pole is connected with an auxiliary power generation module; the upper end of the street lamp pole is provided with a video monitoring system, a micro base station and an RFID radio frequency identification module; a multimedia display screen is also arranged on the street lamp pole; a charging pile is arranged at the lower end of the streetlamp pole; a control module, a storage battery and an energy charging conversion module are arranged in the street lamp pole; the storage battery is respectively connected with the control module and the energy charging conversion module; the energy charging conversion module is electrically connected with the auxiliary power generation module;and the control module is respectively connected with the environment monitoring system, the video monitoring system, the micro base station, the RFID radio frequency identification module, the multimedia display screen and the charging pile. The street lamp disclosed by the invention realizes monitoring and control in the fields of illumination, traffic, security and protection, environment and the like while meeting the reasonable utilization of electric energy resources, so that the life of people is more intelligent and diversified.

Owner:李金枝

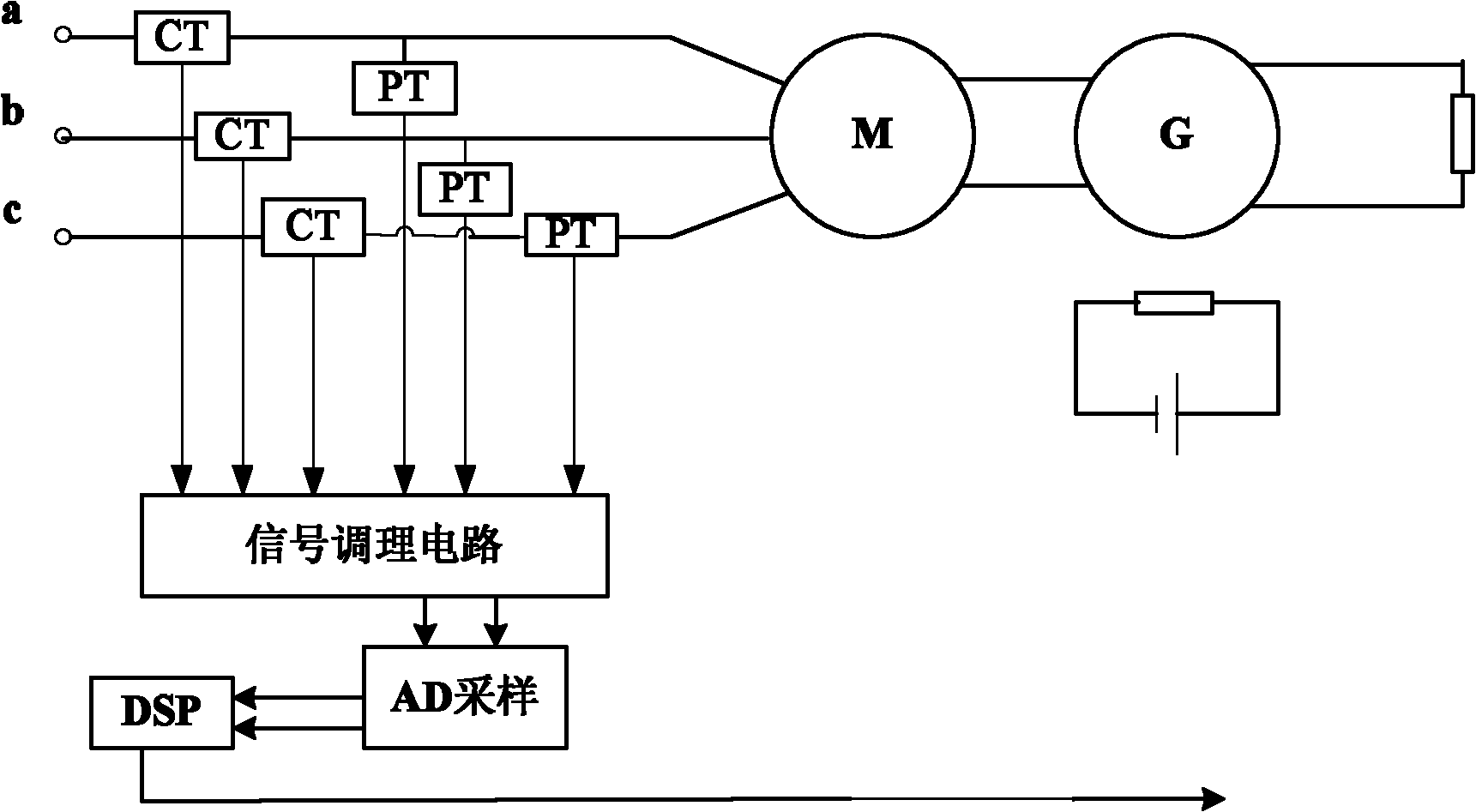

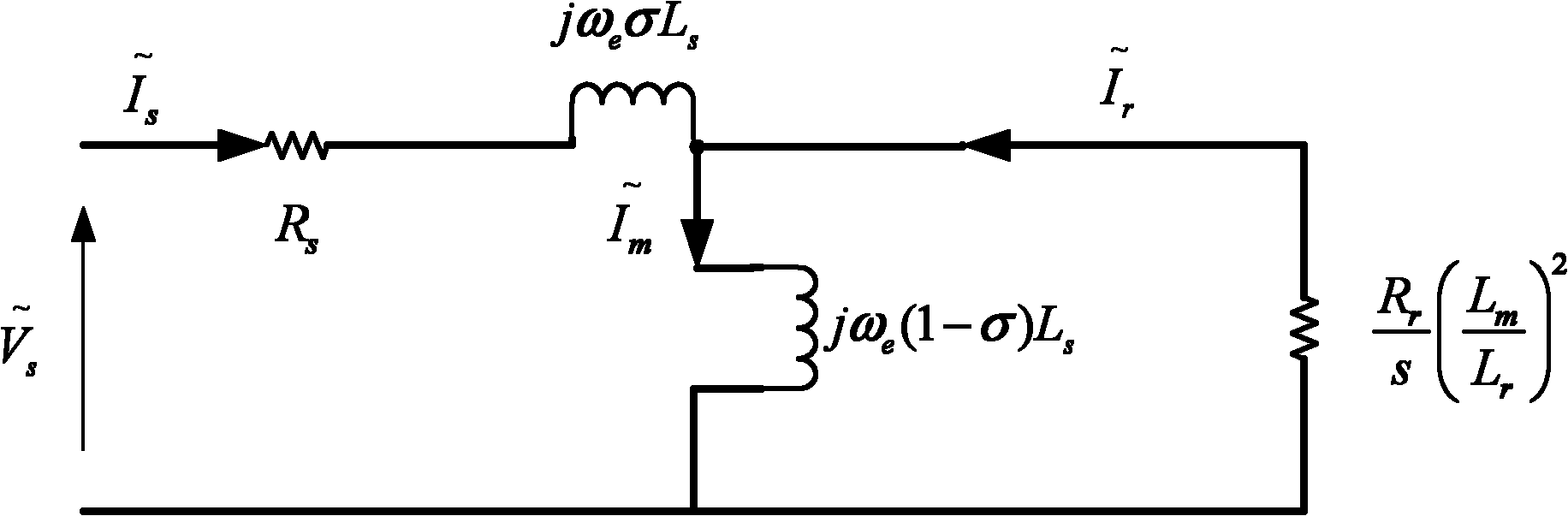

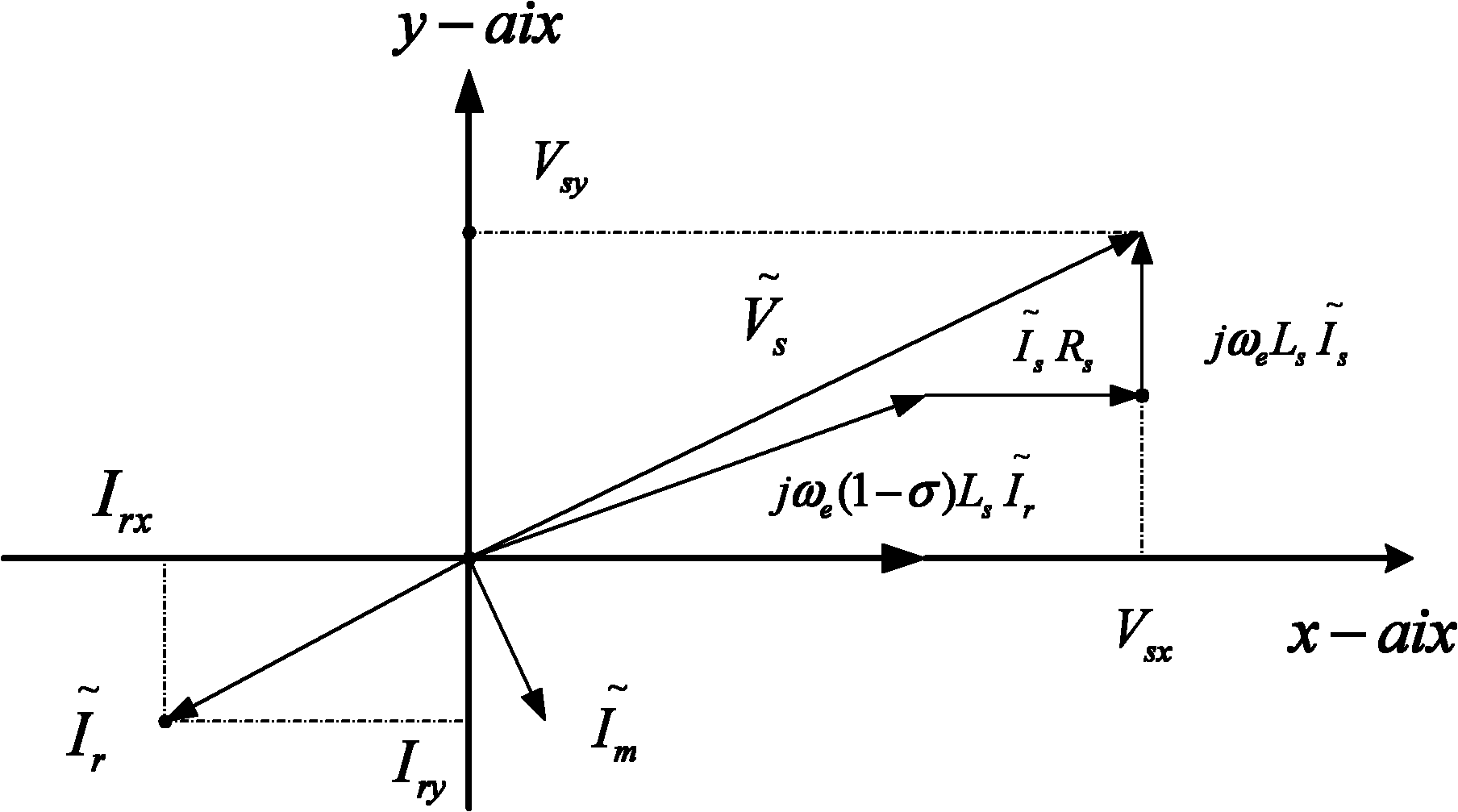

Rotor-groove harmonic analysis based method for identifying temperature of sensorless rotor for submersible motor

InactiveCN102072779AHigh working reliabilityWorking temperature real-time controlThermometers using electric/magnetic elementsUsing electrical meansStator voltageSignal conditioning circuits

The invention relates to a rotor-groove harmonic analysis based method for identifying the temperature of a sensorless rotor for a submersible motor, which belongs to the technical field of fundamental application combining power electronics modeling with motor control and solves the problem that the temperature identification of a rotor for a submersible motor greatly depends on motor parameters in the prior art. The method comprises the following steps of: firstly, acquiring the three-phase stator voltage and the three-phase stator current of the submersible motor; secondly, respectively processing the three-phase stator voltage and the three-phase stator current through a signal conditioning circuit, wherein processed signals are used as original stator current input signals and original stator voltage input signals; thirdly, converting frequency spectra of the original stator current input signals through a DSP (Digital Signal Processor), so as to obtain the harmonic frequency fseh of the rotor and further obtain the rotary speed s of the rotor; and fourthly, simultaneously calculating the inductance of the motor through an original one-phase stator voltage input signal vector and an original one-phase stator current input signal vector, so as to further obtain the temperature value of the rotor. The method provided by the invention is suitable for measuring the temperature of the rotor for the submersible motor.

Owner:HARBIN INST OF TECH

Diskless rice seedlingraising method

The invention belongs to the technical field of rice planting, in particular to a diskless rice seedlingraising method. The method comprises the following steps: evenlymixing nutritious soil andhydrosol, then laying on a degradable non-woven fabric, after the hydrogel in the bottom layer is dried and bonded with the non-woven fabric, sprinkling rice seeds on the surface layer of the nutrition soiland hydrosol mixture by a printing seeding method, spraying a small amount of water to weta straw pulp paper, and then evenly spreading a layer of nutrient soil to cover the seeds; carrying out conventional seedbed management, whenseedlings are 17-21cm high and grow 4.2-4.8 leaves, pulling outthe seedlings and planting by a machine. The method uses the mixture of nutritious soil and hydrosol as adiskless seedling raising substrate, which not only can meet the nutrient requirement for seed growth, but also has the advantages of loose substrate structure, good air permeability and good benefits forroot growth. And the diskless rice seedlingraising methodeffectively solves the problems of high cost and heavy investmentof disk seedling raising method, and is easy to operate, labor-saving, time-saving and capable of improving the utilization of rice seedling beds.

Owner:安仁县鑫亮粮油发展有限公司

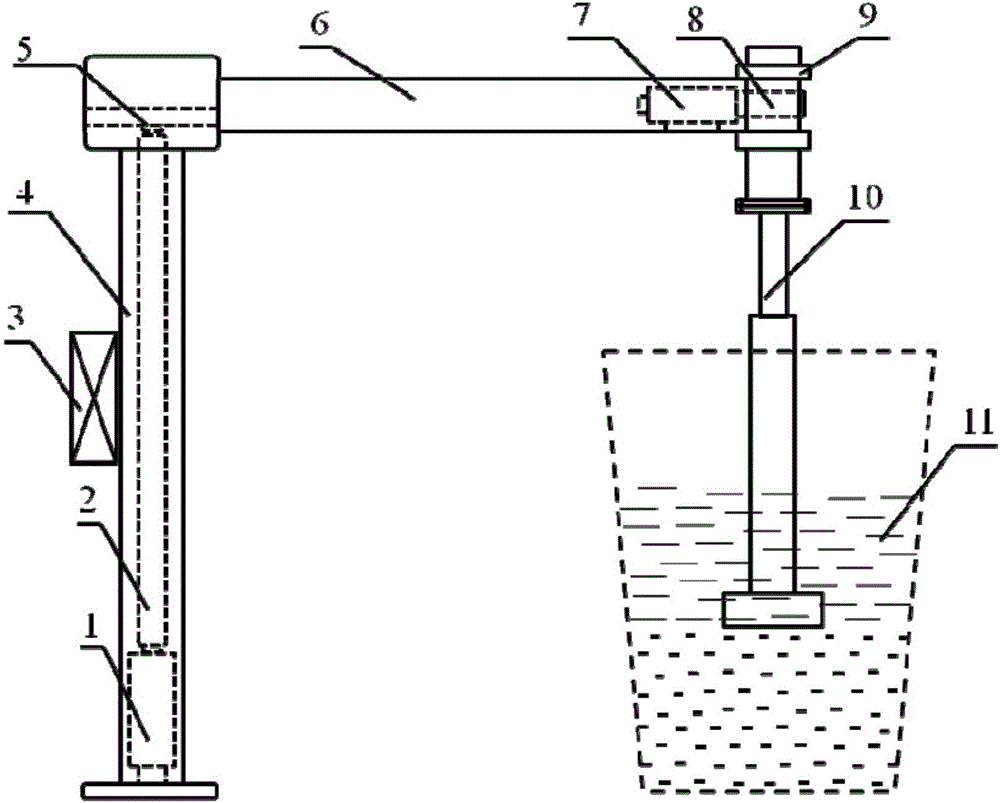

Mechanical stirring device for production of manganese-iron alloy

ActiveCN106756026AImprove reaction efficiencyHigh recovery rateRotary stirring mixersTransportation and packagingSlagManganese oxide

The invention relates to a mechanical stirring device for production of manganese-iron alloy, and belongs to the technical field of iron alloy and casting production. The mechanical stirring device comprises a lifting motor, a lifting guide rod, an electric cabinet, a guide rail vertical column, a lifting wheel group, a lifting cross arm support, a rotating motor, a rotating guide wheel, a rotating frame and a stirring paddle, wherein the lifting cross arm support is arranged on the guide rail vertical column; the lifting system composed of the lifting motor, the lifting guide rod, the electric cabinet, the lifting wheel group, the lifting cross arm support and the like can lift the cross arm support so as to drive the stirring paddle to be lifted and lowered in a alloy liquid and a slag liquid; the rotating system composed of the electric cabinet, the rotating motor, the rotating guide wheel, the rotating frame, the stirring paddle and the like can enable the stirring paddle to rotate in the alloy liquid and the slag liquid. The mechanical stirring device has the advantages that the stirring paddle can accurately fall on the interface of the alloy liquid and the slag liquid, thus the solution stirring can be directly completed, the reaction efficiency is higher than that of the shaking ladle process, the power consumption is reduced, the recovery rate of manganese in the alloy is high, the mass fraction of manganese oxide in the final slag is far lower than that produced by using the shaking ladle process.

Owner:CENT IRON & STEEL RES INST

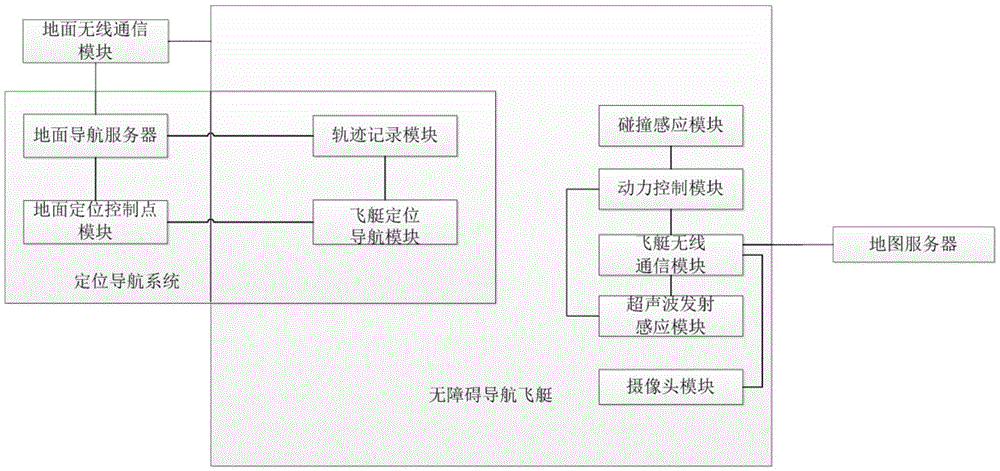

Barrier-free navigation airship based three-dimensional map automatic mapping system

InactiveCN105628004ASolve the manual cumbersome surveying and mappingSolve the investmentSurveying instrumentsSpacetimeMarine navigation

The invention relates to a barrier-free navigation airship based three-dimensional map automatic mapping system. The automatic mapping system comprises a rotor wing airship, a positioning navigation system, a wireless communication system for an airship and a map server, wherein the positioning navigation system is connected with the map server by the wireless communication system for the airship for acquiring and recording the movement locus of the barrier-free navigation airship, forming a whole-course movement locus file of the barrier-free navigation airship according to the space-time coordinate series and sending the movement locus file to the map server; and the map server is used for automatically generating a three-dimensional map of the flight environment according to the whole-course movement locus file. The system can realize indoor (outdoor) three-dimensional omnibearing data acquisition and generate the three-dimensional map by automatic and intelligent flight performance of the barrier-free navigation airship, can solve the problems of artificial indoor (outdoor) mapping complexity, high investment, long period and difficulty in updating maintenance, and adopts automatic mapping to replace artificial behavior, therefore, the cost is reduced and the efficiency is improved.

Owner:SHENZHEN INST OF ADVANCED TECH

A method for near-solid pressure forming of train wheels

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

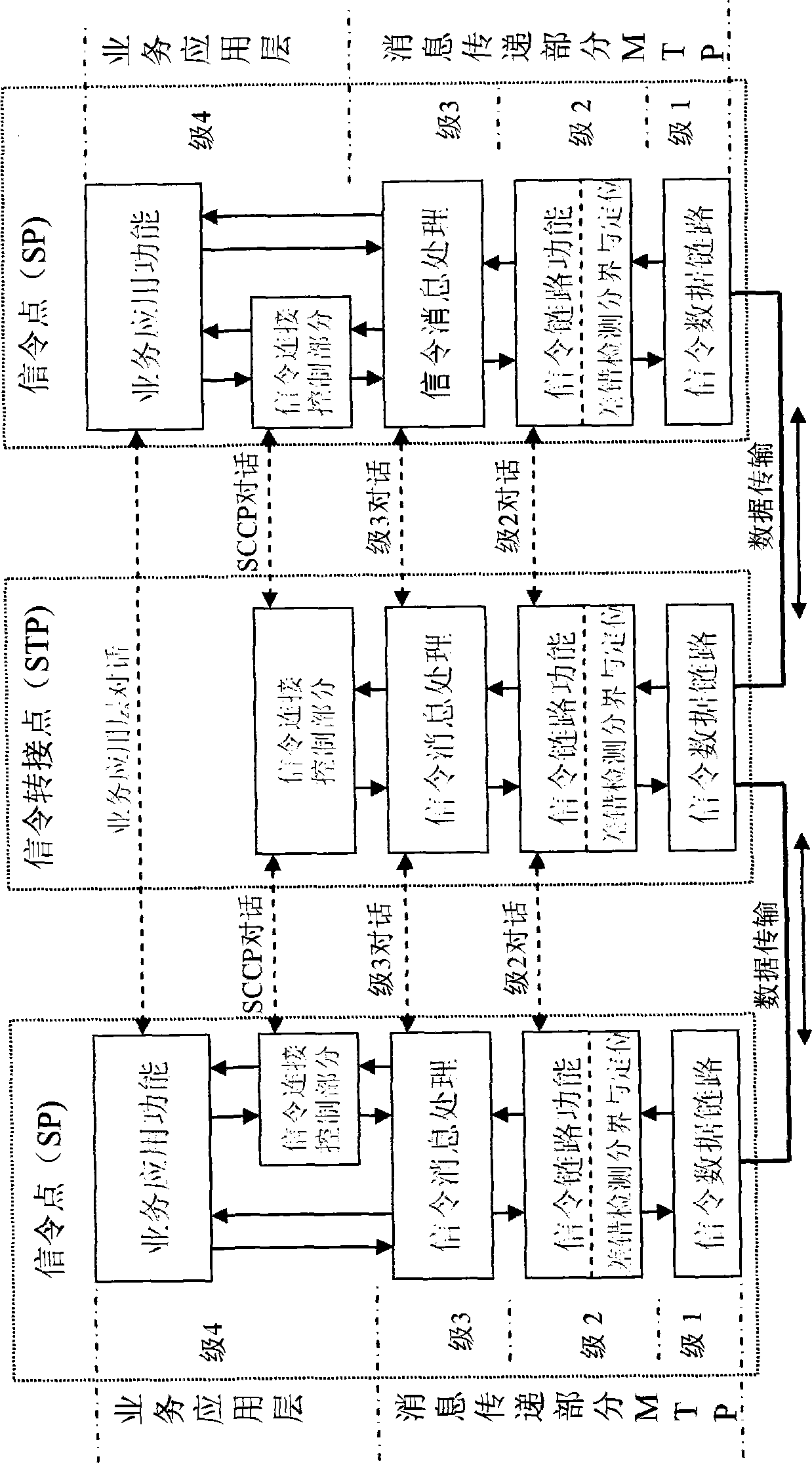

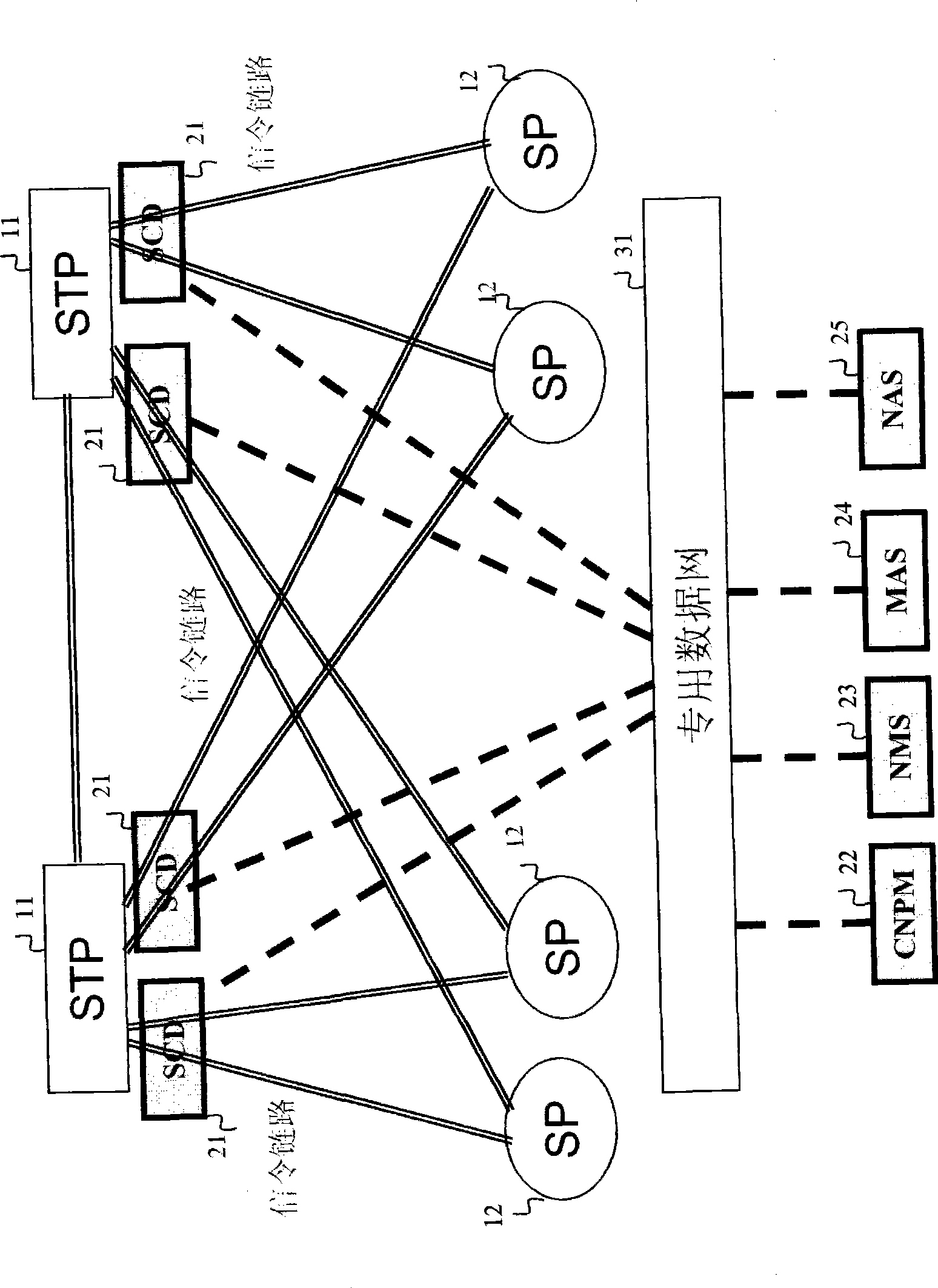

System for implementing telecom value added business based on signaling processing technology

InactiveCN101472197AEfficient handlingEfficient deliverySpecial service for subscribersSelection arrangementsIntelligent NetworkService control

The invention relates to a system based on the signaling processing art for realizing the telecom value-added service. The system comprises a plurality of service control devices accessed in a No 7 signaling network and a service management server. The service control device organically applies the processor art and the decentralized data table art to a communication network, and ingeniously utilizes the message-passing ability and the internal high-reliability characteristics of the No 7 signaling network, and provides two signaling link access modes to realize the query about a memory service data sheet and the execution service logic, wherein, the access modes are a signaling terminal mode with signaling points and a signaling transfer mode without signaling points, so that the high-effective processing and transferring of the signaling information are realized. The invention breaks the confines of the traditional exchange and the intelligent network art, implements the services, such as the user service authentication, the number portability, the signaling monitoring, and the like, in a large scale, effectively solves the contradictions between investment and benefit, and technology and development, and is dependent of the prior communication network.

Owner:SHANGHAI LIANGJIANG COMM SYST

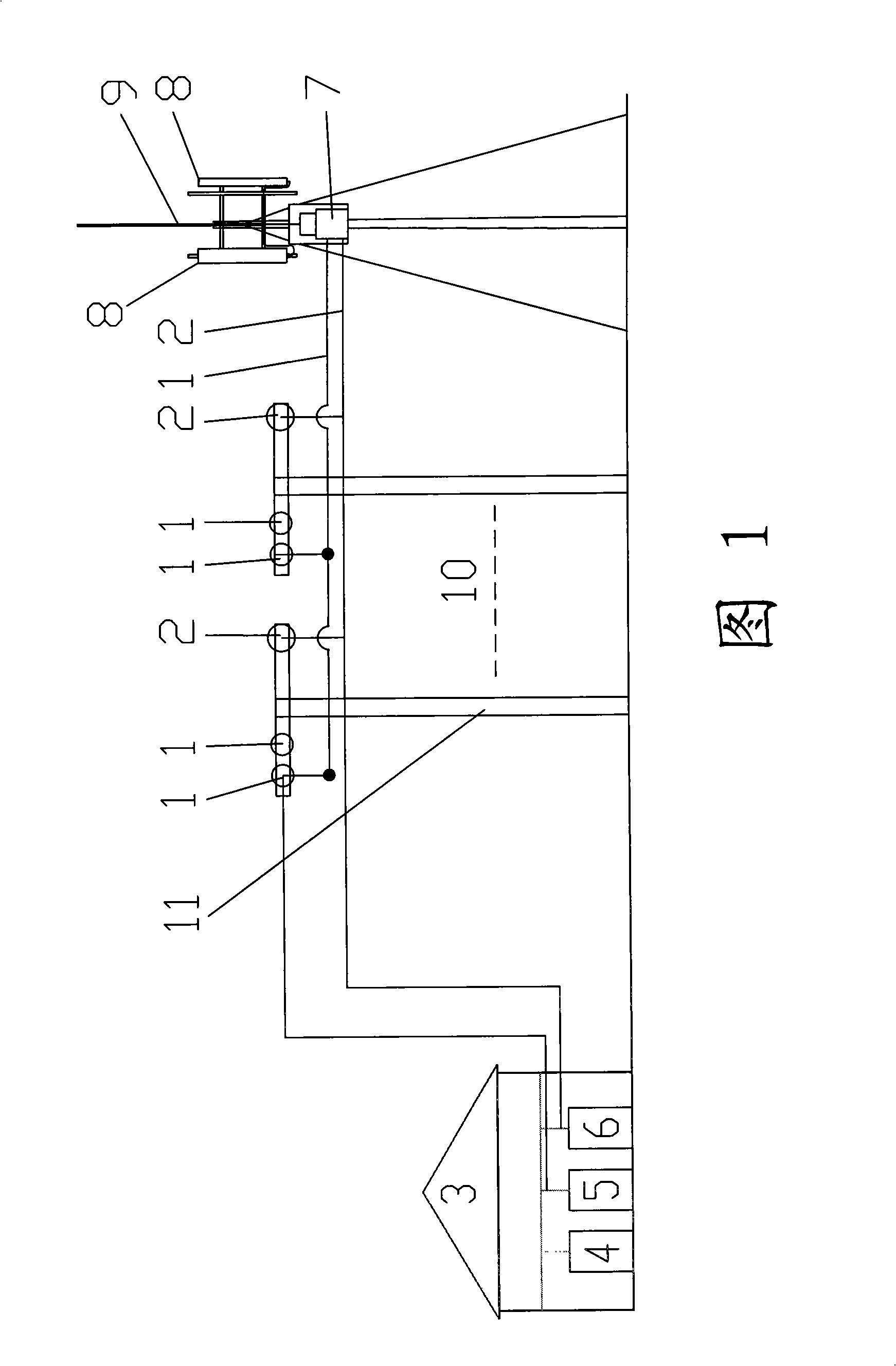

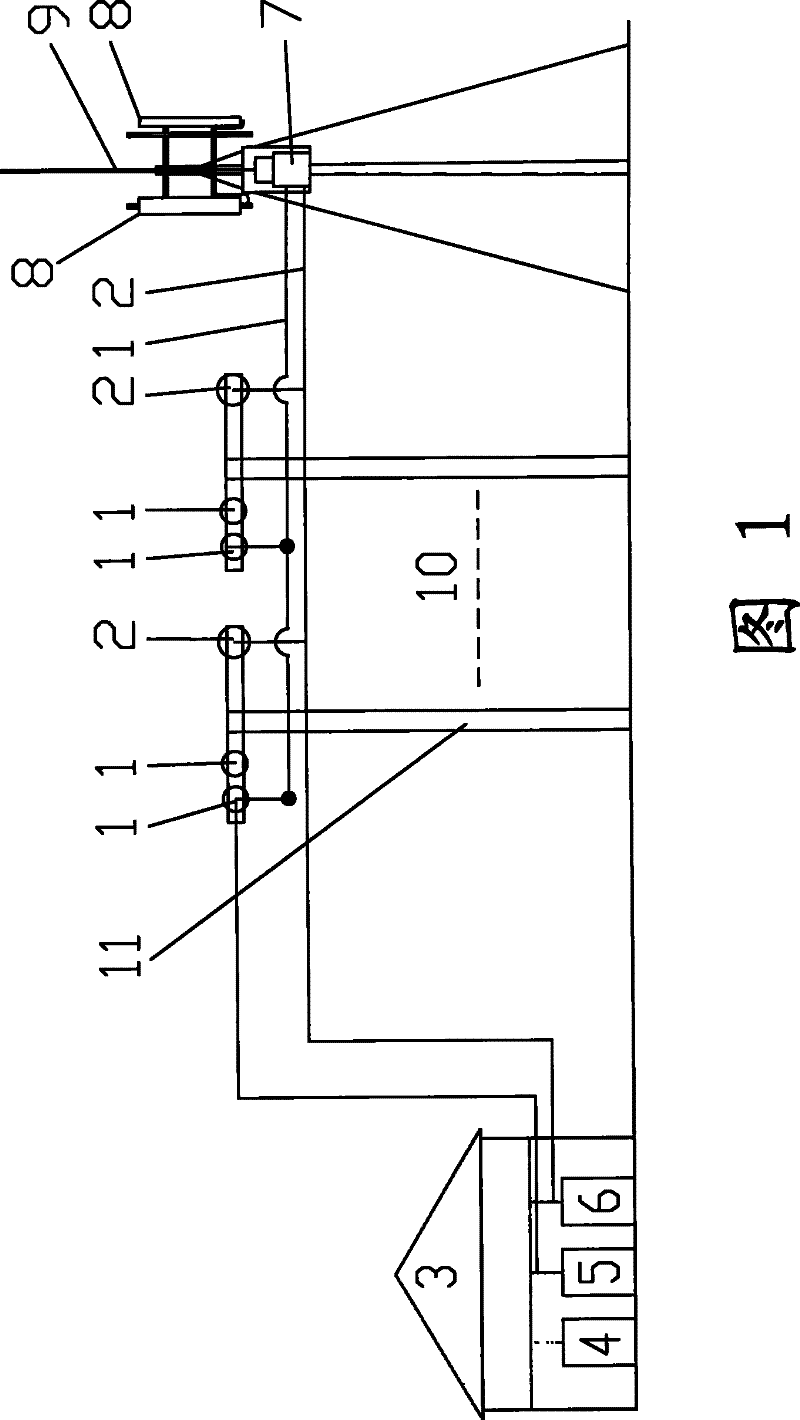

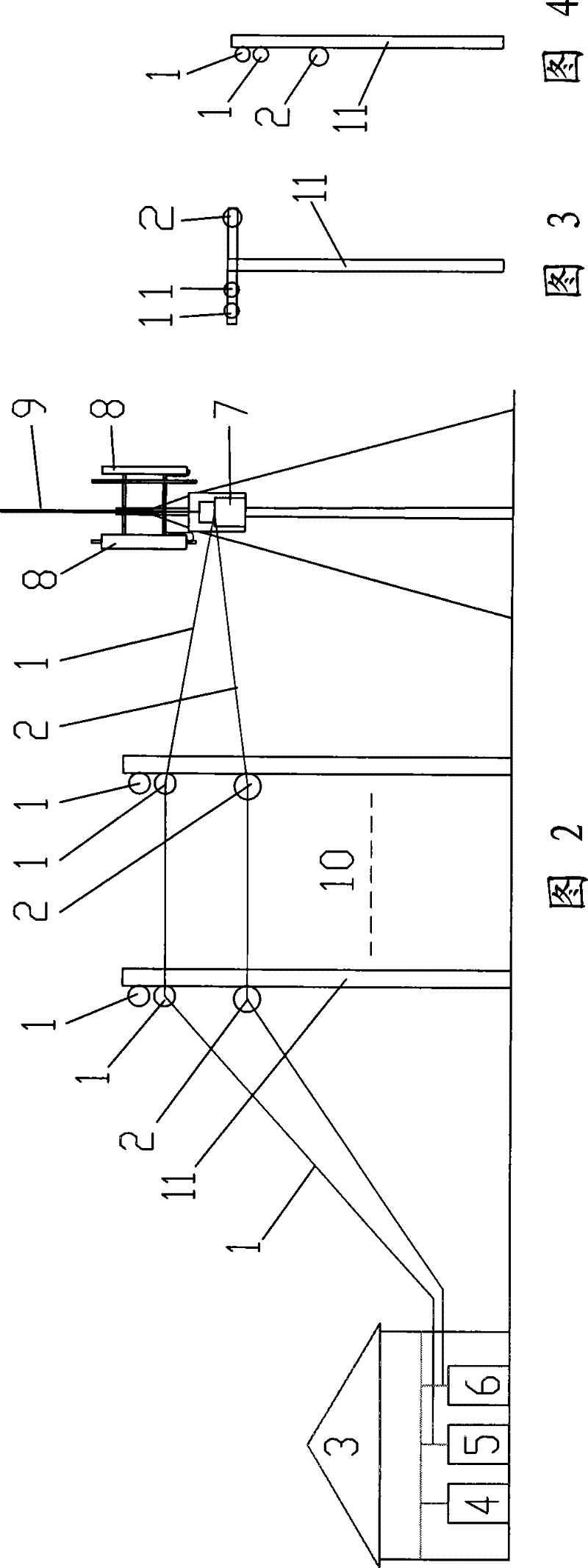

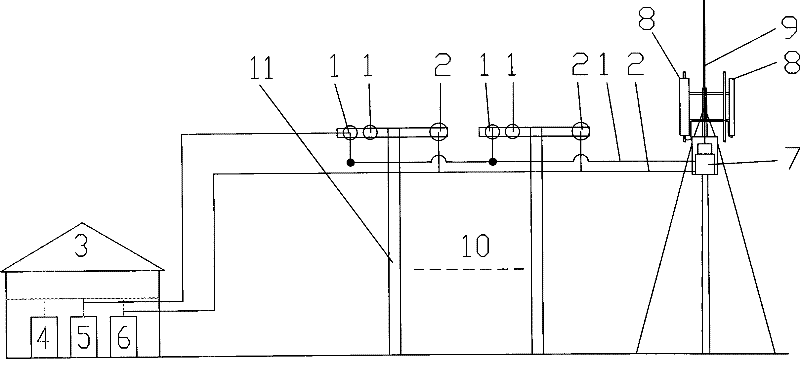

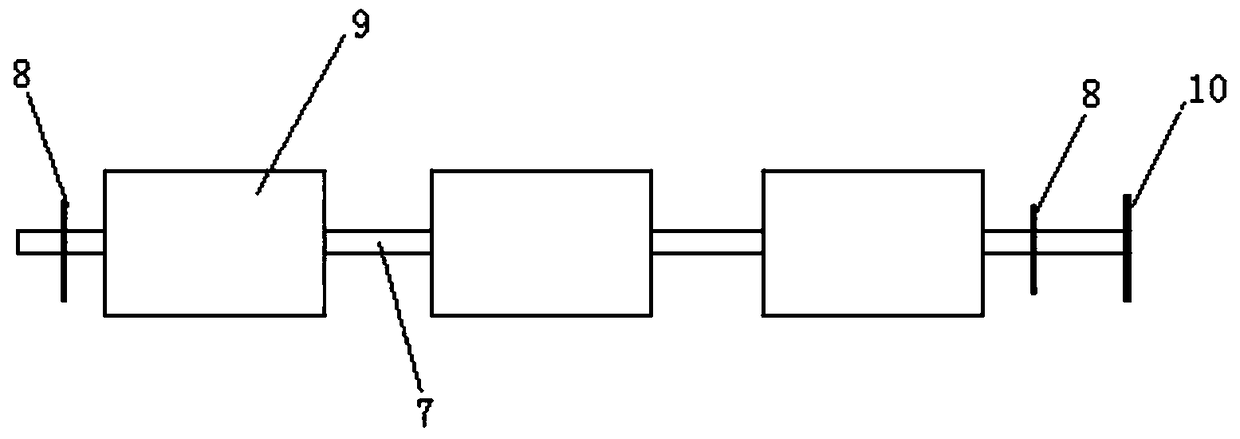

Centralized remote power supply system

InactiveCN101299517BSolving Power Quality IssuesSolve the problem of multi-point coverageOverhead installationDistribution substationsElectric power transmissionEngineering

The invention relates to a centralized remote power supply system, which includes a main equipment room, where a wireless main equipment and a power main equipment are installed in the main equipment room. The power main equipment includes an inverter and a transmission main equipment. The electricity is converted into direct current with a voltage of -48V~24V and connected to the wireless main device to make the wireless main device operate normally; Then, the power transmission line and the optical fiber transmission line are used to transmit the power to the remote unit of the remote coverage system of the newly built base station to provide stable power for the operation of the remote unit, thus completing the construction of the entire base station. The invention reduces the construction scale of base stations, saves engineering investment and improves the safety and reliability of network operation, and can be applied to the signal coverage of urban roads, subways, tunnels and small rural base stations.

Owner:CHINA MOBILE GRP GUANGDONG CO LTD

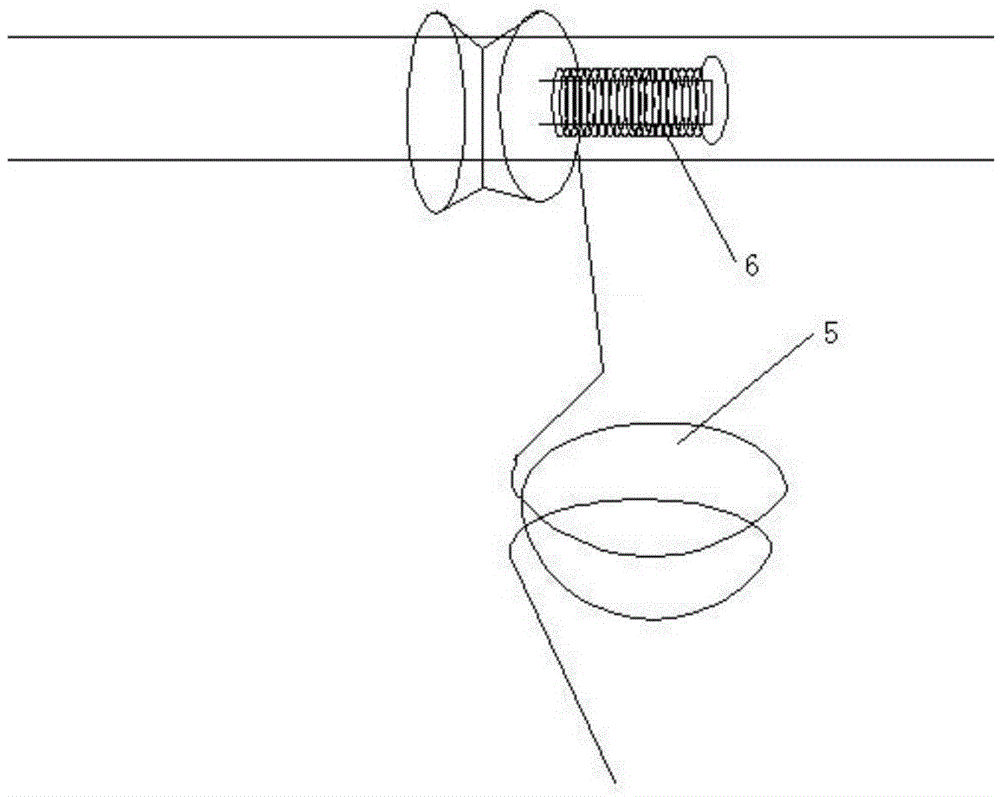

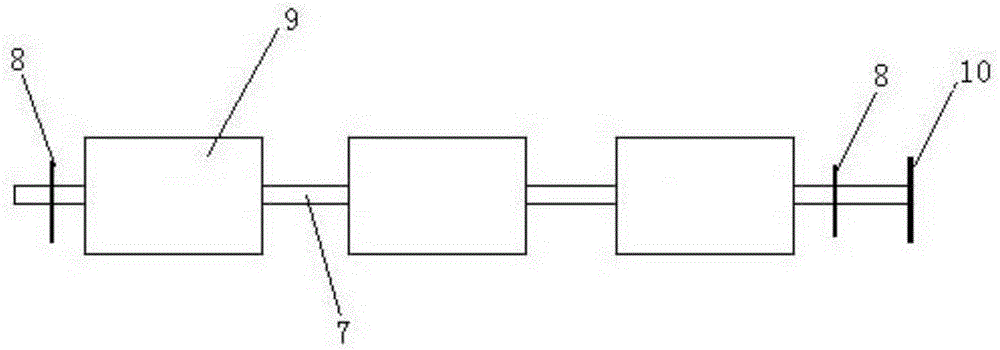

Domestic simple bobbin winder and production method thereof

The invention discloses a domestic simple bobbin winder and a production method thereof. The domestic simple bobbin winder comprises a machine frame part, a yarn guiding part, a pressurizing winding part, a breakage stopping part and a transmission part. The domestic simple bobbin winder is specially used for enterprises small in production scale, and the enterprises specializes in external processing and production; due to the fact that the number of winding tasks is small, if a special bobbin winder is arranged, the occupied area is large, the use efficiency is low, and the investment is large; due to the fact that the use frequency of the bobbin winder is low, equipment breaks down more easily, professional maintainers are required for maintenance, and the burden of the enterprises is large. The domestic simple bobbin winder is specially used for solving the problem of difficult winding by family type small enterprises, and the price of the equipment is only 800-1000 yuan; due to the fact that the structure is extremely simple, no professional maintainer is needed; the domestic simple bobbin winder is small and exquisite, and only 4-5 square meters of area is occupied; operation is extremely convenient, a user can use the domestic simple bobbin winder without being trained, and the production problem of difficult winding by the small enterprises is solved.

Owner:IANGSU COLLEGE OF ENG & TECH

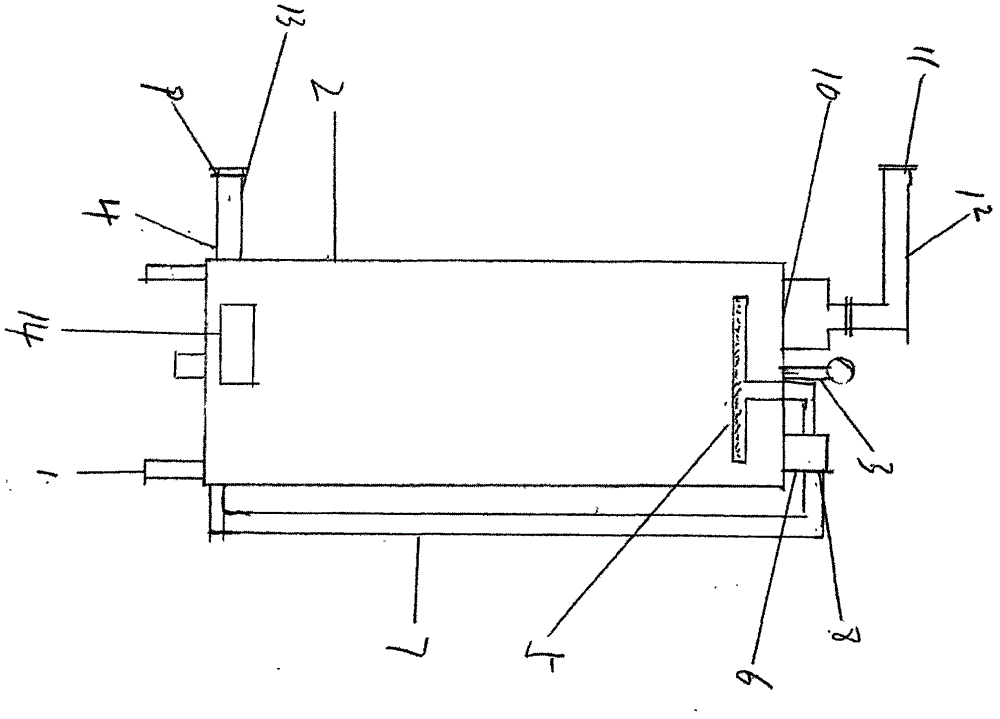

Method and device for co-production of coal, fuel gas and tar

InactiveCN104673336ASolve the investmentSolve the problem of desulfurizationWorking-up tarSpecial form destructive distillationEcological environmentTar

The invention relates to a method and device for producing coal, fuel gas and tar, used for solving the problems that coal and fuel gas are mainly formed naturally; the period is long; the cost is high, etc. The invention provides a co-production process and a device, used for solving the above problems and simultaneously producing the tar. According to the scheme provided by the invention, combustible raw material is put in the liner of a reaction kettle and heated to generate gas through high-temperature fission; a small part of gas flows back into a combustion pipe to continuously heat the liner; the remained gas enters a separator; fuel gas and tar are automatically separated through water; the separated fuel gas enters a purifier; the tar flows into a tar tank; after reaching use standards through water-fog dedusting and purifying, the fuel gas entering the purifier is conveyed into a gas storage tank to be used; and, after being subjected to complete fission, the combustible raw material is taken out and can be prepared into the coal by adding lime or soil. The co-production process and the device disclosed by the invention have the benefits that the problem that coal and fuel gas are only formed naturally for a long period is solved; the cost is saved; and the ecological environment is protected.

Owner:苏改平

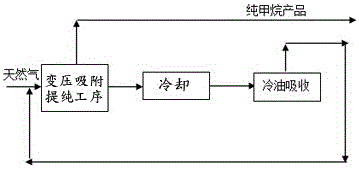

Full-temperature process pressure swing adsorption method for preparing pure methane from natural gas

InactiveCN105777471AExtended service lifeRealize continuous productionHydrocarbonsAdsorption purification/separationChemistryHeat torch

The invention discloses a full-temperature process pressure swing adsorption method for preparing pure methane from natural gas and relates to the technical field of methane purification. The method comprises a full-temperature process pressure swing adsorption purifying process and a desorbed gas recycling process; in the full-temperature process pressure swing adsorption purifying process, the adsorption pressure is 0.05-3.5Mpa, and the operation temperature is 60-150 DEG C; after evacuation and desorption, the CH4 not adsorbed is discharged from the top of an adsorption tower and used as a pure methane product; the hydrocarbon components of C2 and above are concentrated by a full-temperature process pressure swing adsorption device and then evacuated and desorbed by a vacuum pump before entering the desorbed gas recycling process; for recycling, a hydrocarbon recycling unit is adopted, which consists of first-level cooling, second-level cooling and a shallow cold oil absorption unit; heavy hydrocarbons are separated out after the second-level cooling, and the rest C2 and C3 hydrocarbon components are absorbed by cold oil, wherein the operation temperature of the cold oil absorption is (-10)-10 DEG C; and if the hydrocarbon components of C2 and above are not recycled, the desorbed gas is directly introduced into a combustion system or flare system.

Owner:SICHUAN TECHAIRS

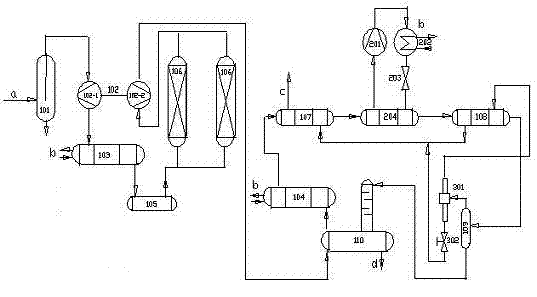

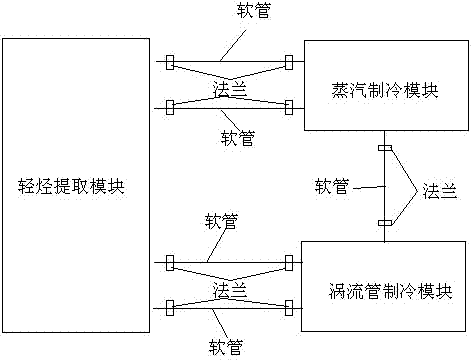

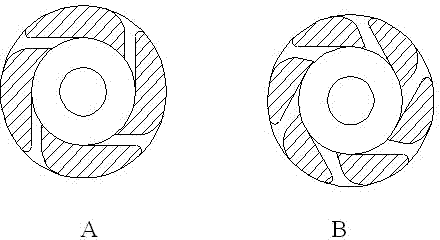

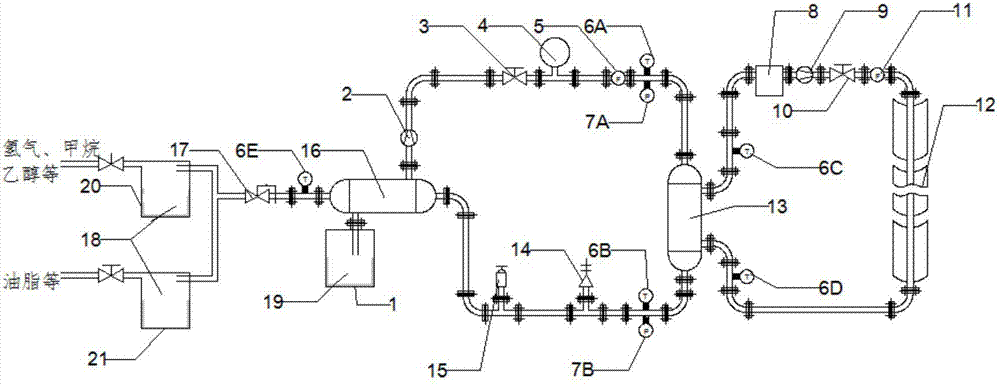

Skid-mounted small and medium-sized light hydrocarbon extraction system by using secondary refrigeration of vortex tube

ActiveCN102229811AHigh extraction rateSolve the problem that the extraction rate is difficult to improveLiquid hydrocarbon mixture recoveryRefrigeration compressorEngineering

The invention discloses a skid-mounted small and medium-sized light hydrocarbon extraction system by using a secondary refrigeration of a vortex tube. The invention is characterized in that the system is composed of a light hydrocarbon extraction module, a steam refrigeration cyclic module and a vortex tube refrigeration module by a braid connection; an inlet centrifugation separator of the lighthydrocarbon extraction module is successively connected with a raw material gas compressor one-stage compression section, a first cooler, a liquid separation tank, drying towers, a raw material gas compressor two-stage compression section, a stabilizer, a second cooler, a first heat exchanger, an evaporator, a second heat exchanger, a low temperature separator and a stabilizer through pipes; a refrigeration compressor of the steam refrigeration cyclic module is successively connected with a condenser, a throttle valve and the evaporator through pipes, then returned to the refrigeration compressor for compositing a cycle; the vortex tube refrigeration module comprises the vortex tube and a heat valve block. According to the invention, the one-stage compression steam refrigeration and the vortex tube refrigeration (the secondary refrigeration) enable the device to obtain a higher light hydrocarbon recovery rate without increasing energy consumption.

Owner:HANGZHOU YUEQIANG LOW TEMPERATURE MACHINE EQUIP

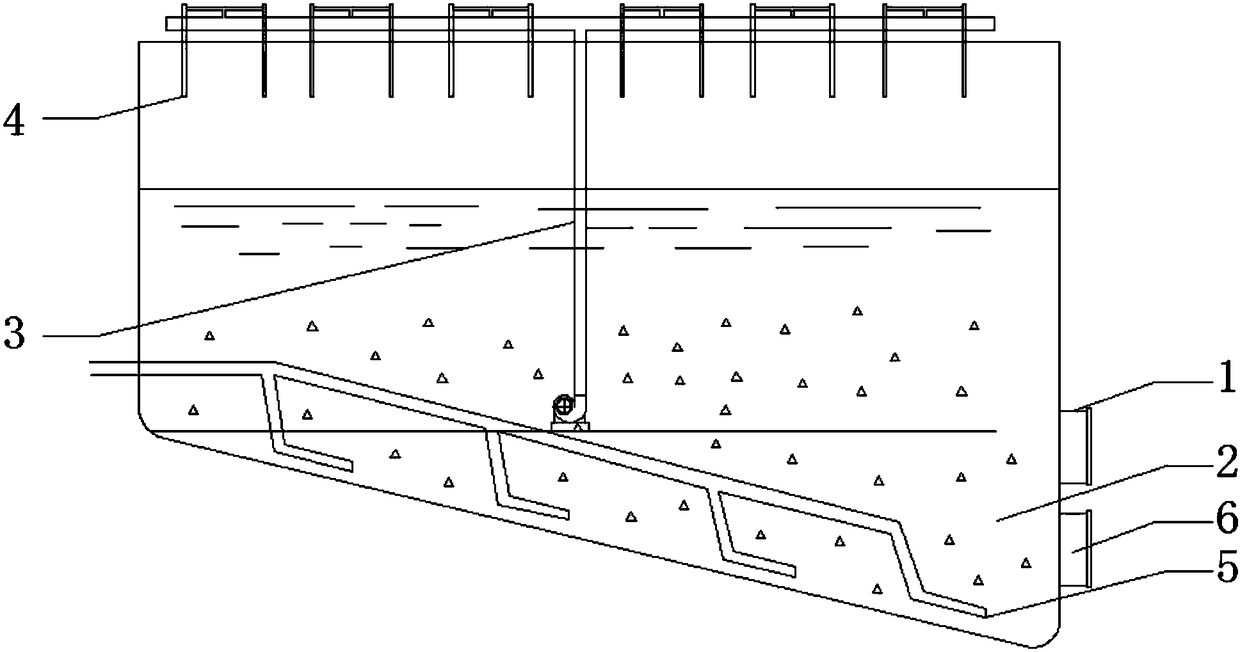

Oxidation system for semi-dry desulfurization waste ash

The invention provides an oxidation system for semi-dry desulfurization waste ash, and belongs to the technical field of environmental engineering. The system comprises a desulfurization waste ash inlet, a slurry area, a spray pipe, oxidant nozzles, spray guns and a desulfurization gypsum outlet; the desulfurization waste ash inlet is positioned at the right lower side of the outside of the systemand is positioned at the one-quarter part from the bottom; the slurry area is positioned at the lower part of the system and occupies two-thirds of the internal space of the system; the oxidant nozzles are positioned at the top of the inner side of the system for spraying an oxidant; the spray guns are used for providing an oxygen source, so that CaSO3 is oxidized to CaSO4, and meanwhile the spray guns are used to blow bottom sludge, so that the deposition phenomenon of the desulfurization waste ash at the bottom of the system is effectively prevented; and the bottom surface of the slurry area is designed as a slope, so that the deposition of the desulfurization waste ash at the bottom is effectively avoided. The system has the advantages of low investment, small land occupation, low energy consumption, simple operation, high oxidation efficiency and the like.

Owner:BEIJING BEIKE ENVIRONMENTAL ENG CO LTD

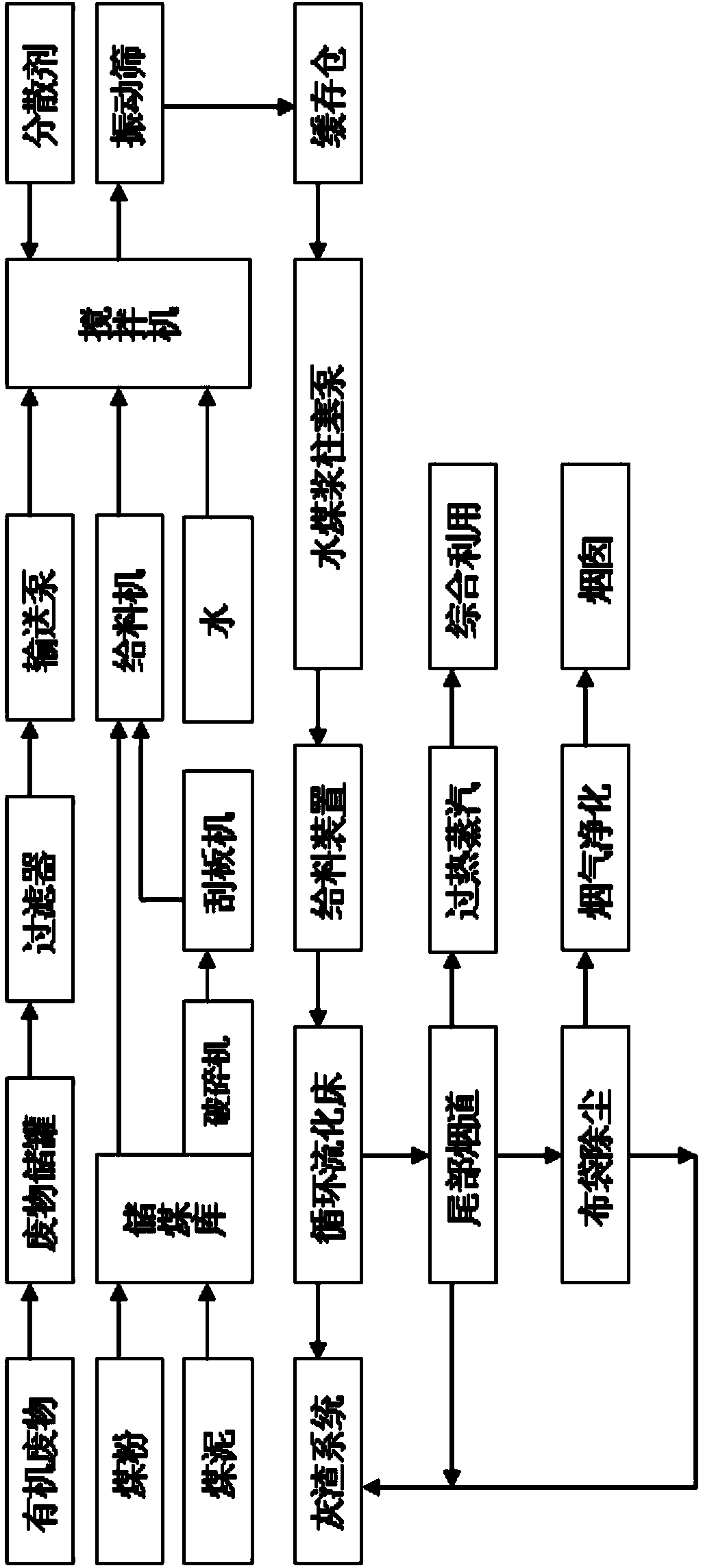

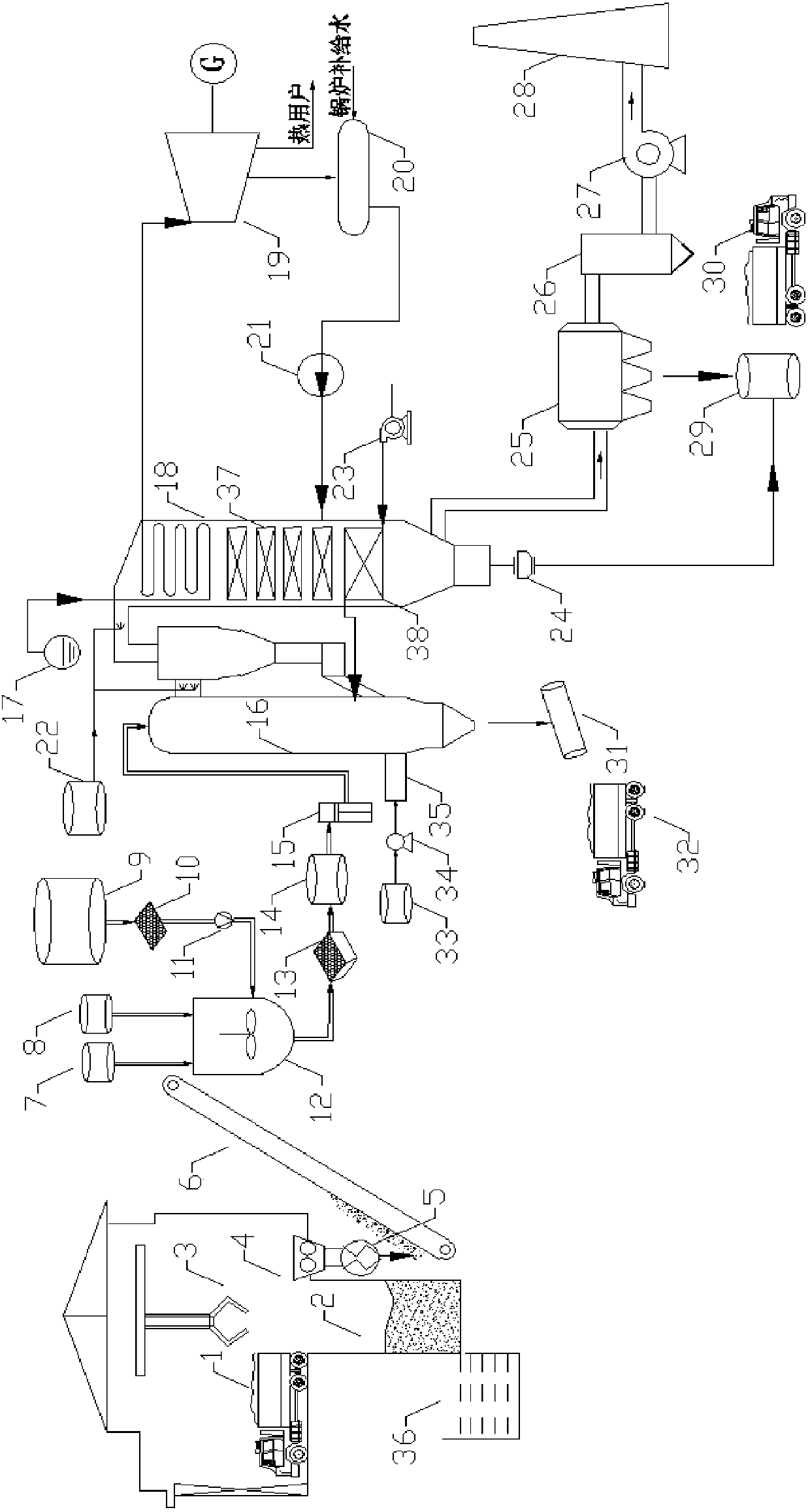

High-concentration organic waste innocent treatment system and process

InactiveCN103776037ASimple pulping processLess investmentIncinerator apparatusLump/pulverulent fuel feeder/distributionFluidized bedEnvironmental engineering

The invention provides a high-concentration organic waste innocent treatment system and process. High-concentration organic waste discharged from industrial production is mixed with coal slime or fine particle clean coal to proportionally produce coal water slurries, the water content of the coal water slurries is controlled through a slurry ability experiment, and a coal water slurry plunger pump is used to continuously and stably convey the coal water slurries to a circulating fluidized bed boiler for burning to produce superheated steam for comprehensive utilization of enterprises, so that effects of energy conservation and environmental protection are achieved. Combustion tail gases are subjected to desulfurization, denitrification and dedusting through a flue gas cleaning system and discharged until the combustion tail gases meet the requirement of environment protection, and ashes left in the production process can be used as building materials or brick-making raw materials. According to the high-concentration organic waste innocent treatment system and process, the high-concentration organic waste discharged from industrial production and coal slime or fine particle clean coal is used as raw materials of the coal water slurries, and by means of a water coal slurry clean combustion technology, the high-concentration organic waste is used as production water for the water coal slurries, so that treatment costs of high-concentration organic waste and waste water are saved, industrial production waste is absorbed, and production costs of enterprises are reduced.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

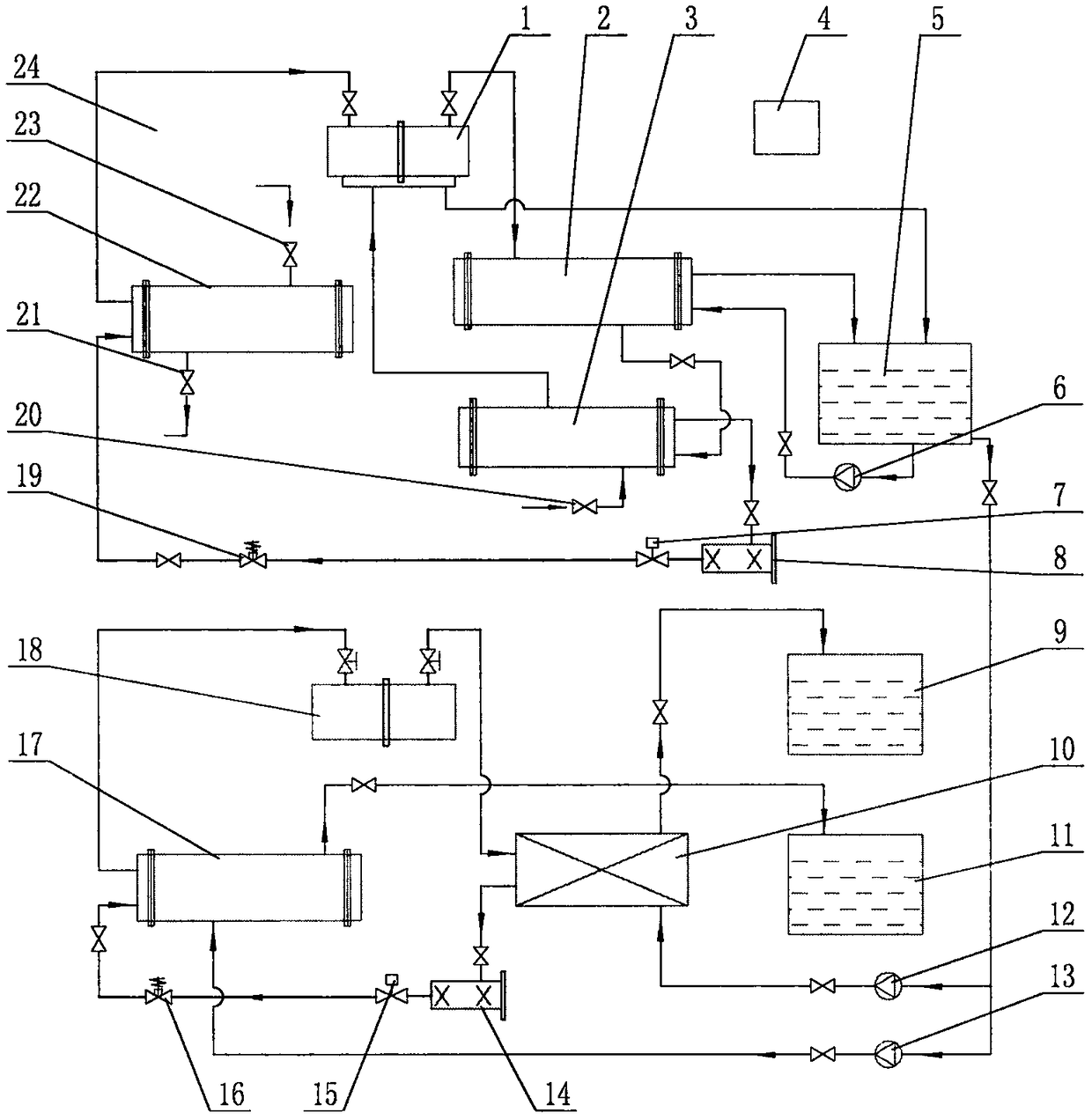

Unit for converting waste heat in refrigerating into environmentally-friendly new energy

InactiveCN108204693ASolve the retrofit problemSolve pollutionRefrigeration safety arrangementHeating and refrigeration combinationsCold chainCooling tower

The invention provides a unit for converting waste heat in refrigerating into environmentally-friendly new energy, and belongs to the technical field of cold chain freezers and slaughtering and meat processing heat pumps. The unit is characterized in that the waste heat of a refrigerating system is completely recycled, thus coal-fired boilers of the slaughtering and meat processing industry and the food processing industry and a cooling tower and a cooling water pump of the refrigerating system can be replaced, and thus a completely novel technology for converting the waste heat in refrigerating into the environmentally-friendly new energy is provided to the slaughtering and meat processing industry and the food processing industry. The unit comprises a screw compressor (1), a horizontal condenser (2), a subcooler (3), a controller (4), a heat preserving type heat storing box (5), a hot water pump (6), a first-grade throttling device (7), a first-grade drying filtering device (8), a slaughtering and livestock scalding hot water tank (9), a guide tube condenser (10), a slaughtering and livestock washing hot water tank (11), a condensing hot water pump (12), an evaporating hot waterpump (13), a second-grade drying filtering device (14), a second-grade throttling device (15), a second-grade expansion valve (16), a dry evaporator (17), a semi-closed piston machine (18), a first-grade expansion valve (19), a supplemented water inlet control valve (10), a supplied refrigerating liquid outlet control valve (21), an evaporating condensing device (22), a refrigerating waste heat inlet control valve (23) and a prying body (24).

Owner:重庆翔源制冷设备股份有限公司

Train wheel casting-forging composite forming method

A train wheel casting-forging composite forming method aims at solving the technical problems that an existing rolled steel train wheel producing method has many procedures, is large in device investment and high in production cost, wastes materials and is high in energy consumption. The method includes the following steps of conducting alloy smelting, wherein metal raw materials are heated till the temperature ranges from 1655 DEG C to 1685 DEG C to be smelted, and molten steel formed after smelting is cooled in a furnace; casting a train wheel ingot blank, wherein the molten steel is poured into a metal die after the temperature of the molten steel falls to the range of 1540 DEG C to 1560 DEG C, and the train wheel ingot blank is obtained after cooling is conducted; heating the obtained train wheel ingot blank; conducting rolling, wherein the heated train wheel ingot blank is placed on a rolling machine to be rolled, the feed amount of a main roller ranges from 0.5 mm / s to 3.0 mm / s, the pressure ranges from 300 KN to 900 KN, the radial diameter of a hub reaches the diameter of a hot forging part, and the hub, a rim and a step face are formed; conducting bending, wherein after rolling is completed, the temperature falls to the range of 980 DEG C to 1000 DEG C, and hot bending forming is conducted on a train wheel disk through a bending machine. The method has the advantages of being short in technological process, simple in procedure, small in device investment, high in raw material utilization rate and capable of saving energy.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

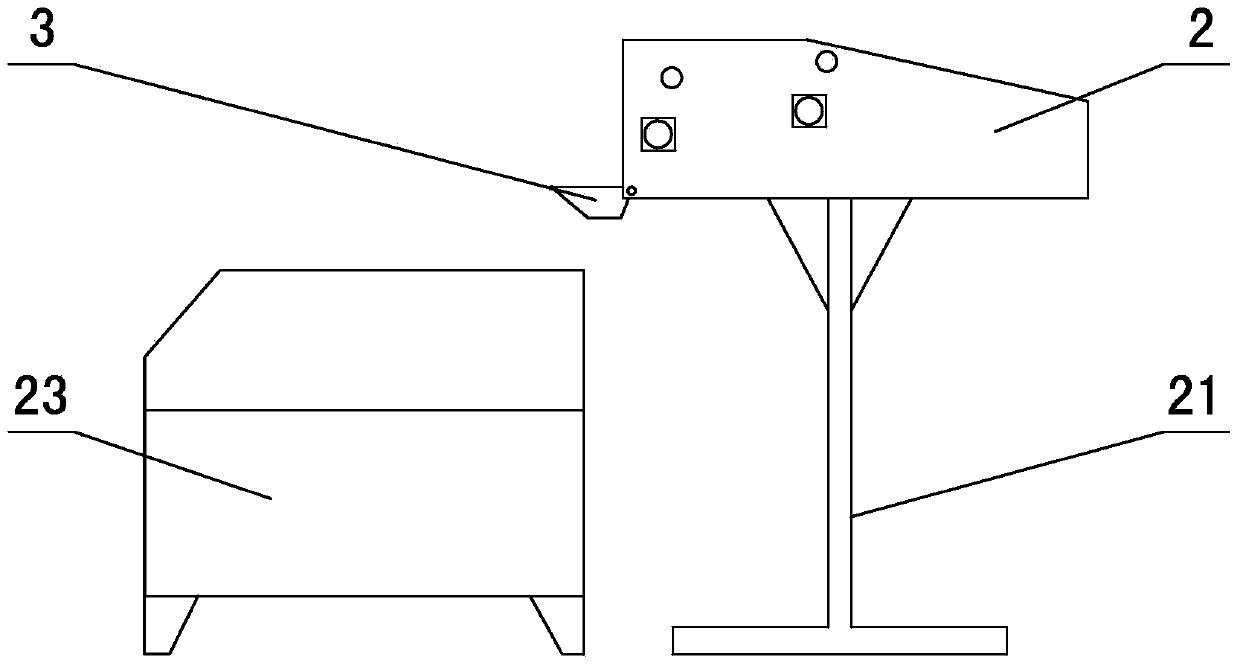

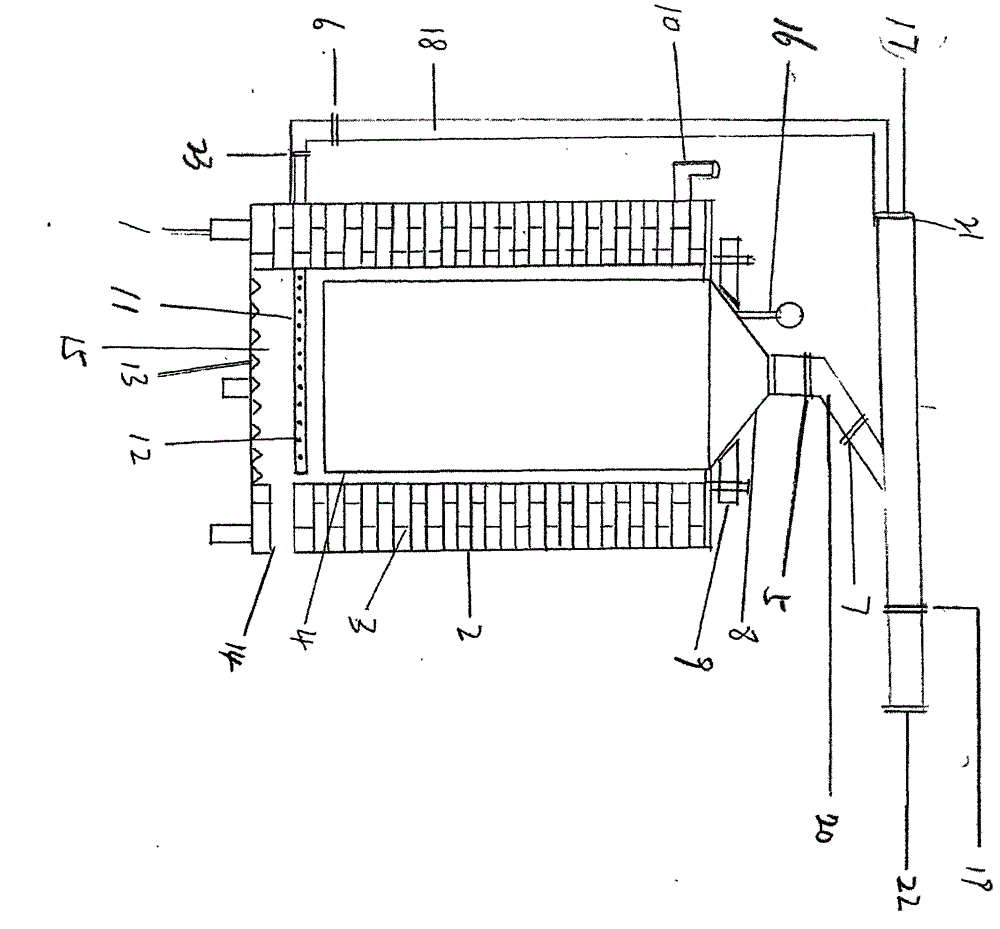

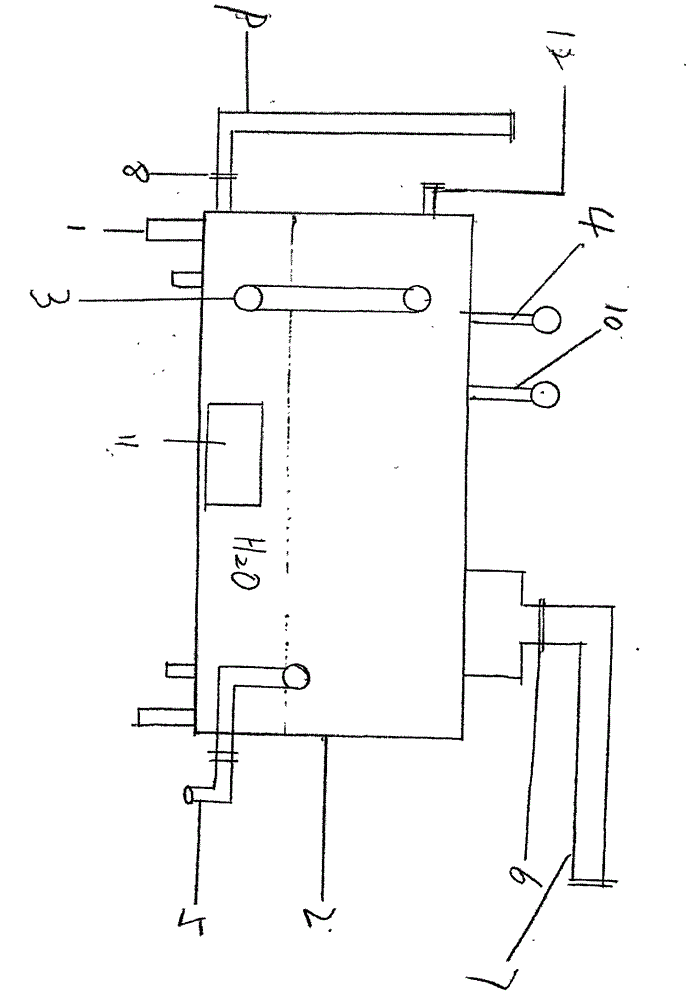

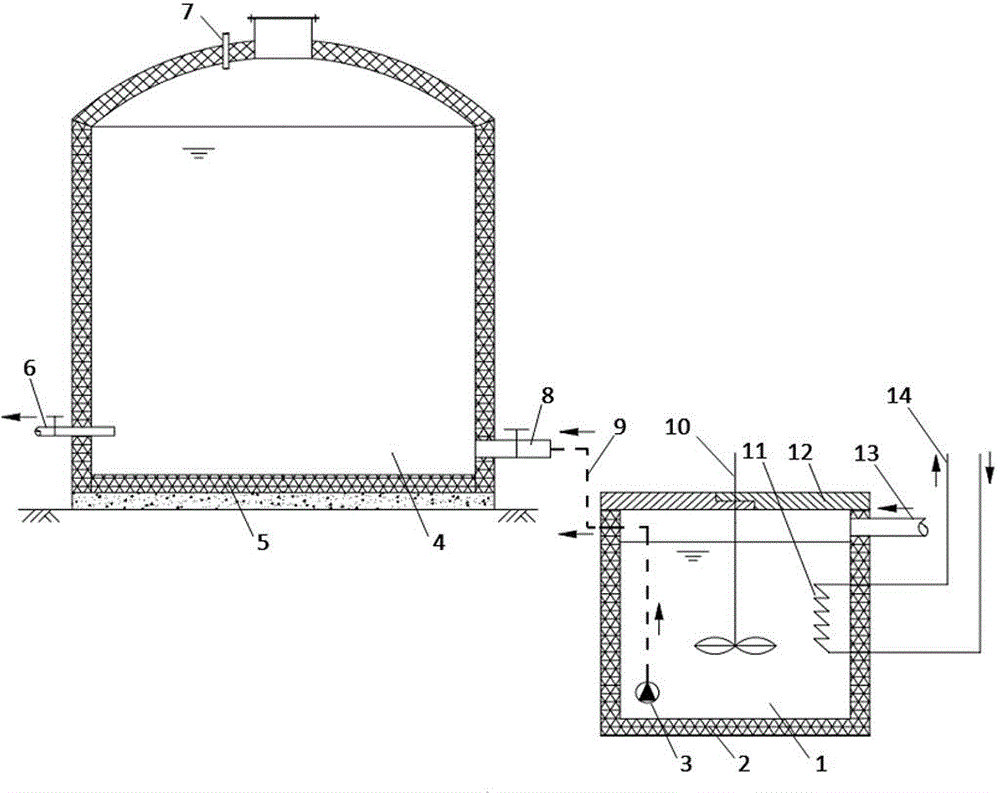

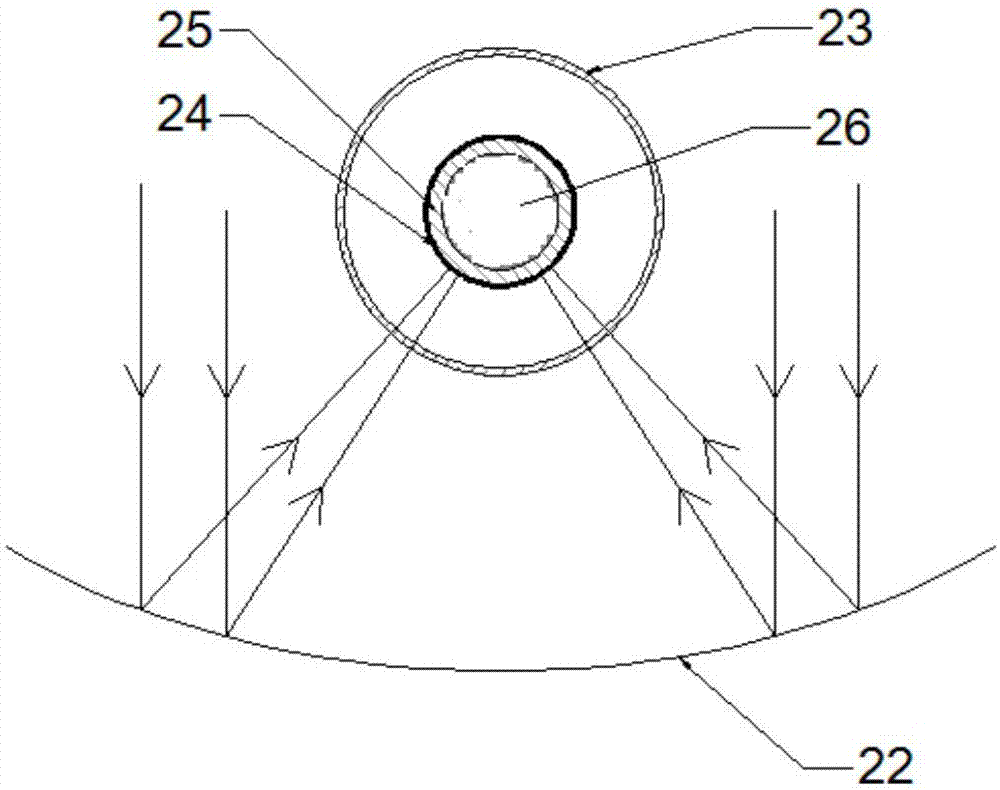

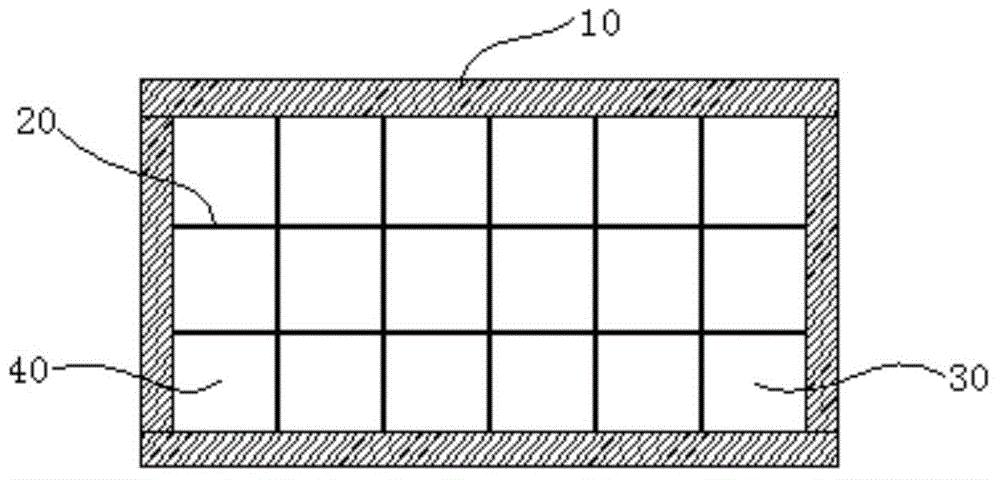

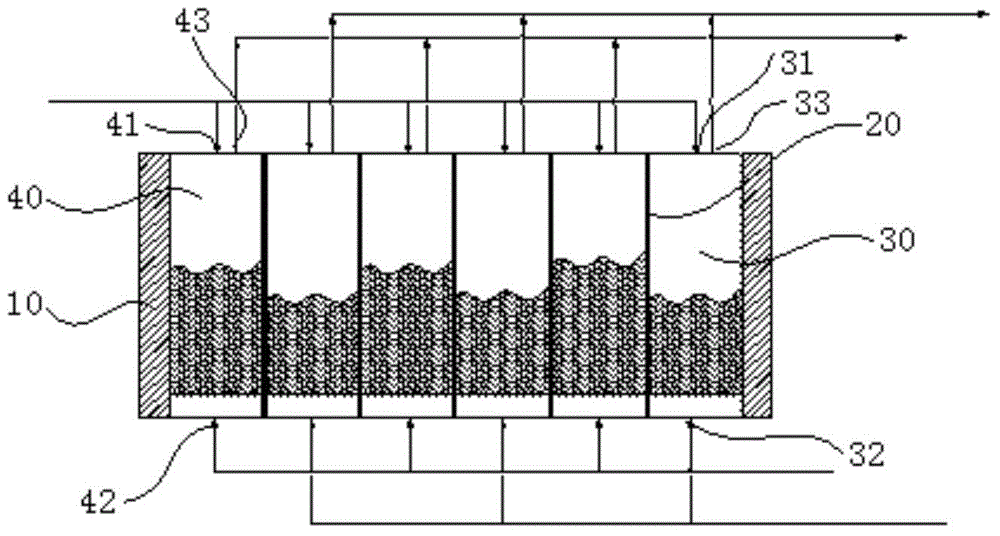

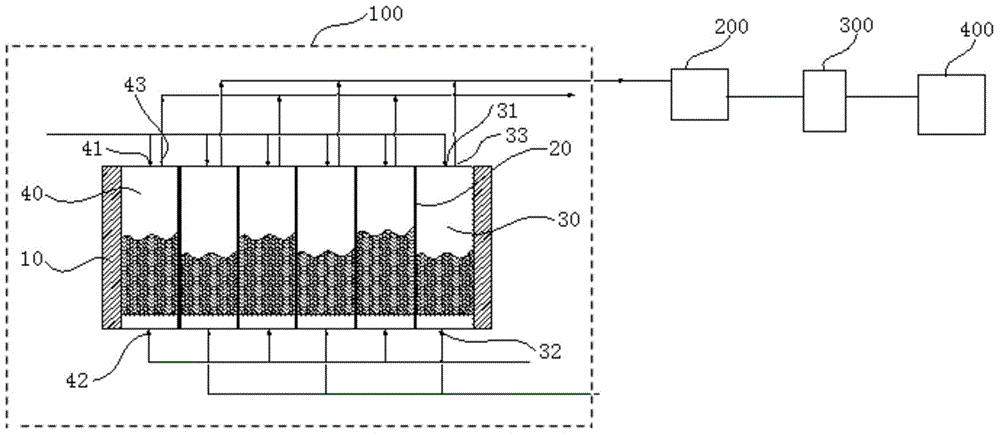

Biogas fermentation tank heating system

InactiveCN104877903AReduce heat dissipationReduce investmentBioreactor/fermenter combinationsBiological substance pretreatmentsInsulation layerMaintenance management

The invention relates to a biogas fermentation tank heating system, belonging to the field of development of renewable energy sources. The biogas fermentation tank heating system comprises a regulation tank (1) and heat exchangers (11), wherein the heat exchangers (11) are uniformly distributed in the regulation tank (1) and are connected with a hot water circulating pipe (14); insulation layer (2) is arranged on the outer side of the regulation tank (1), and an insulation cover plate (12) is arranged on the top of the regulation tank (1); a feeding pump (3) is arranged in the regulation tank (1) and is connected with a fermentation tank feeding hole (8) through a fermentation tank feeding pipe (9); a regulation tank feeding hole (13) is formed in the upper part of the regulation tank (1). According to the biogas fermentation tank heating system, the defects of weak heating purpose, high heat exchange equipment investment, low heating efficiency and high maintenance management cost in the prior art are overcome; the heating efficiency and the reliability are high, a heat exchanger is convenient to maintain and manage, the equipment cost and the operation cost of the heating system can be lowered, and the fermentation temperature in a fermentation tank can be effectively guaranteed.

Owner:BIOGAS SCI RES INST MIN OF AGRI

Full-intelligent numerical control window cleaning device

InactiveCN105120140ASolve the inconvenience of wipingSolve the investmentTelevision system detailsColor television detailsNumerical controlComputer module

The invention relates to a full intelligent numerical control window cleaning device, comprising a window scanner and a scrubbing device, wherein the scrubbing device consists of a protective shell and a big contact, a small contact, an executing connecting rod mechanism, an either-rotation motor and a control chip which are mounted in the protective shell, the window scanner consists of a camera module, a display screen, a processing module and a control module; the camera module is used for acquiring the size data of glass on a window, and transmitting the size data to the processing module; the processing module converts the received size data into real size of the glass, displays the real size on the display screen, and meanwhile transmits the data to the control chip, and the control module is used for controlling the movements of the big contact, the small contact, the executing connecting rod mechanism and the either-rotation motor. A form of combining the big and small contacts is adopted, and corners of the glass can be thoroughly cleaned by using the small contact, thus saving trouble greatly and realizing convenience.

Owner:杨卫东

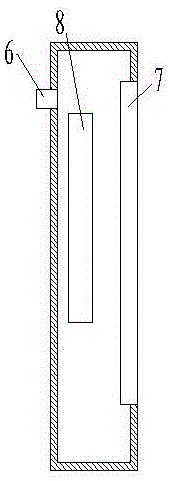

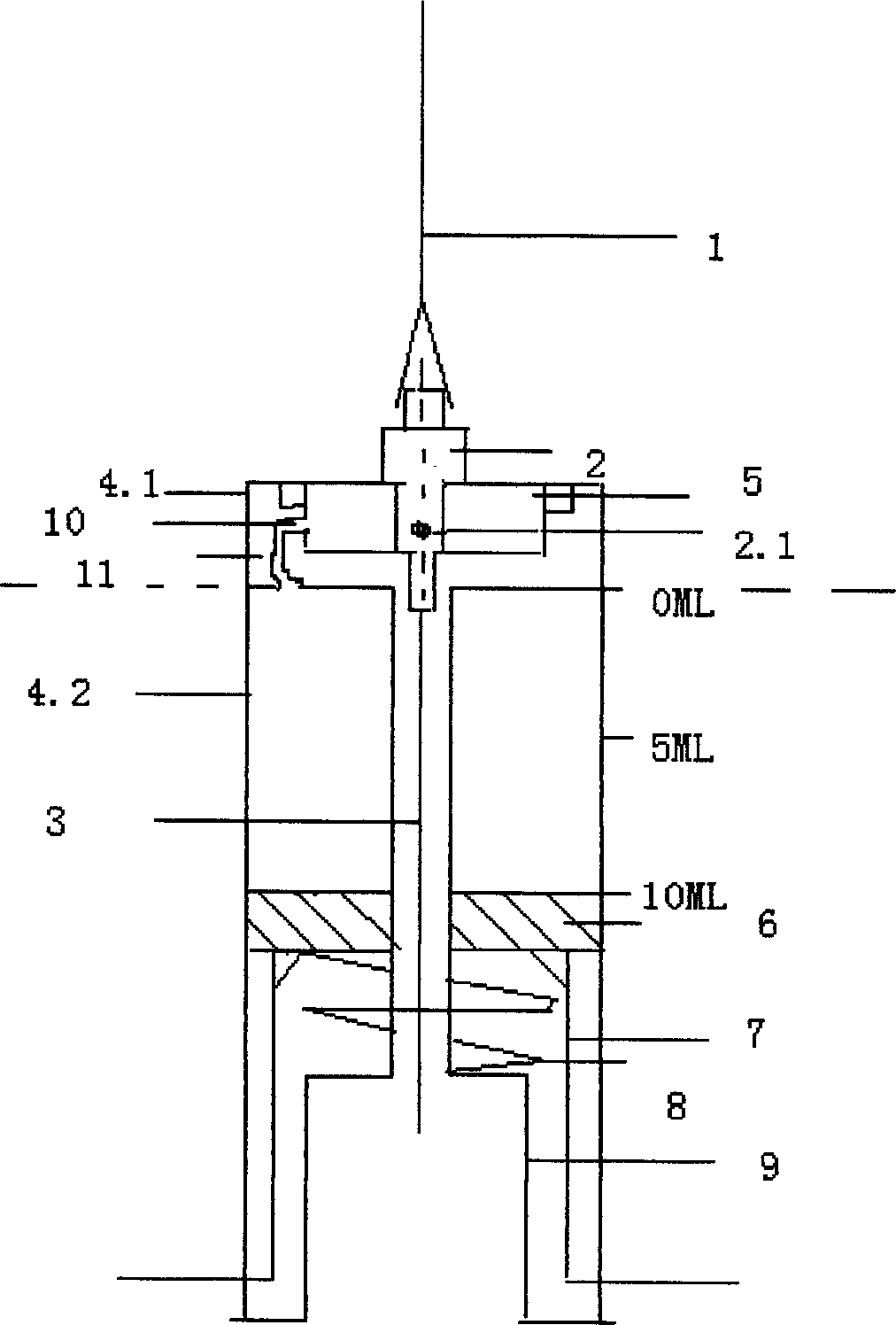

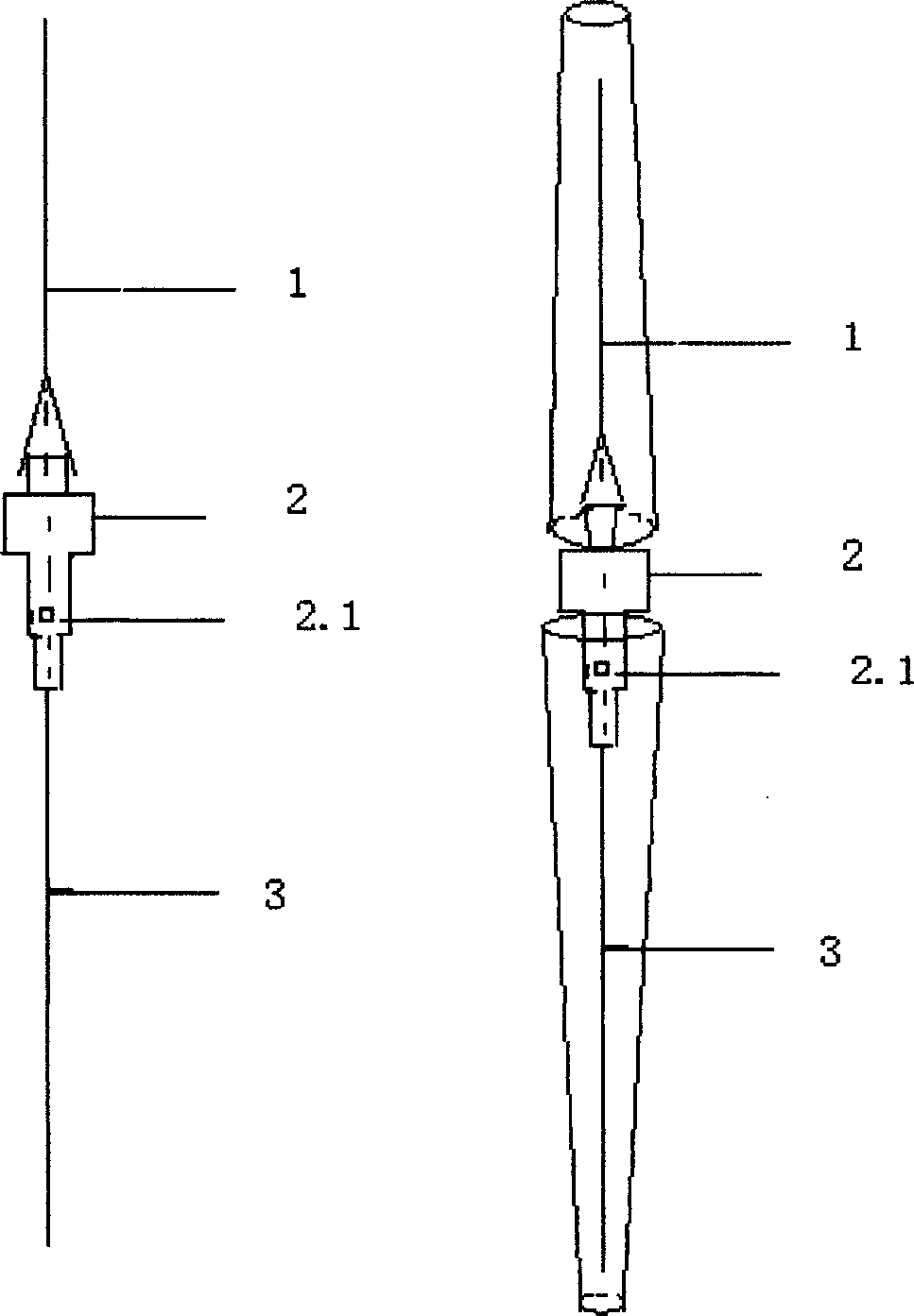

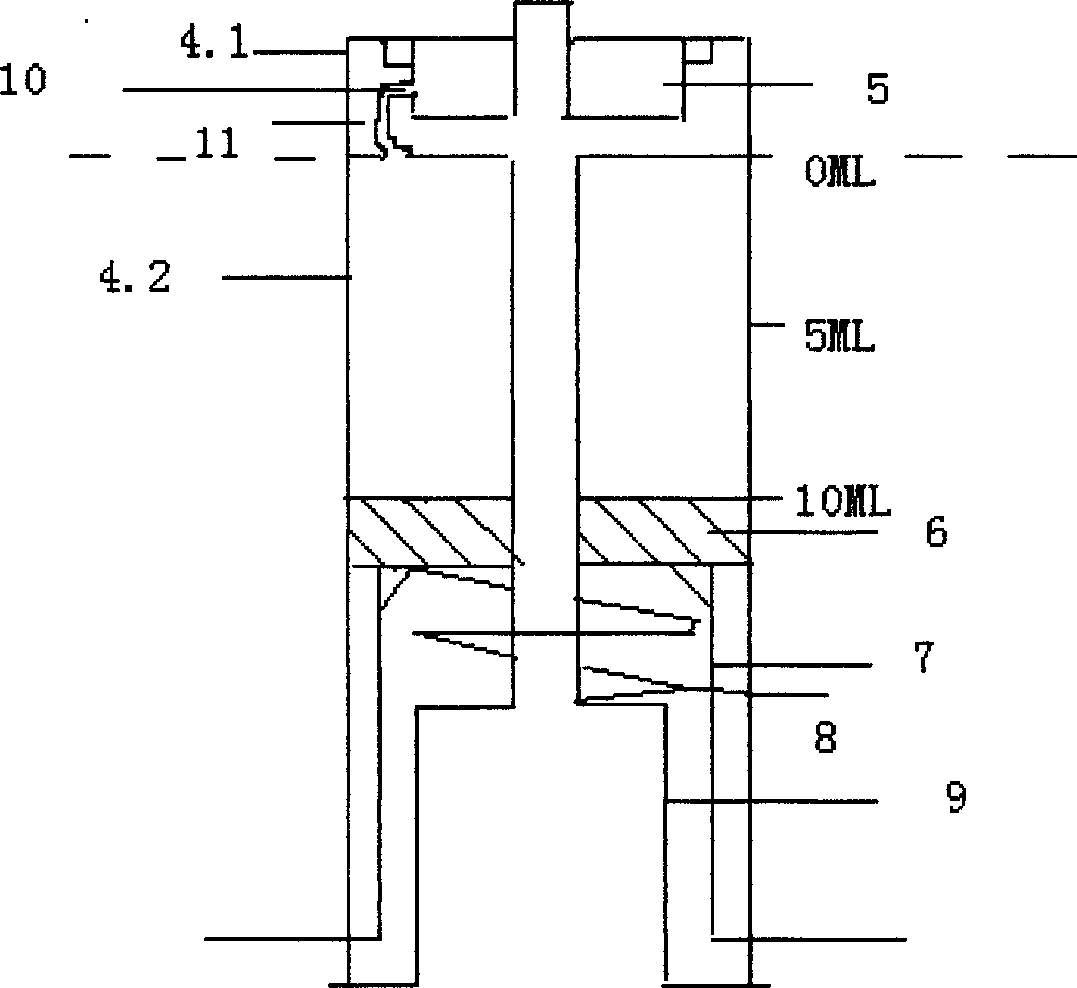

Automatic quantitative vein blood sampling needle device

InactiveCN1788678ASolve the investmentSolve the problems of high cost and cumbersome processBlood sampling devicesVeinBlood Collection Tube

The present invention discloses one automatic rationing venous blood taking needle device and relates to clinical blood sampling device. The automatic rationing venous blood taking needle device consists of one bi-directional taking needle and one hand-held syringe. The bi-directional taking needle consists of a 7# venous puncture needle, a needle seat, a bolt and a 8# venous puncture needle. The hand-held syringe consists of a sleeve, a switch unit, a piston, a pull rod, a spring, a positioning tube, a ventilating port and a hose. The bi-directional taking needle is fixed via thread onto the switch unit of the hand-held syringe. The present invention is one disposable device operating on vacuum negative pressure principle, and has the features of automatic rationing venous blood taking, raised vacuum accuracy, high vacuum maintaining capacity, etc.

Owner:徐双苗

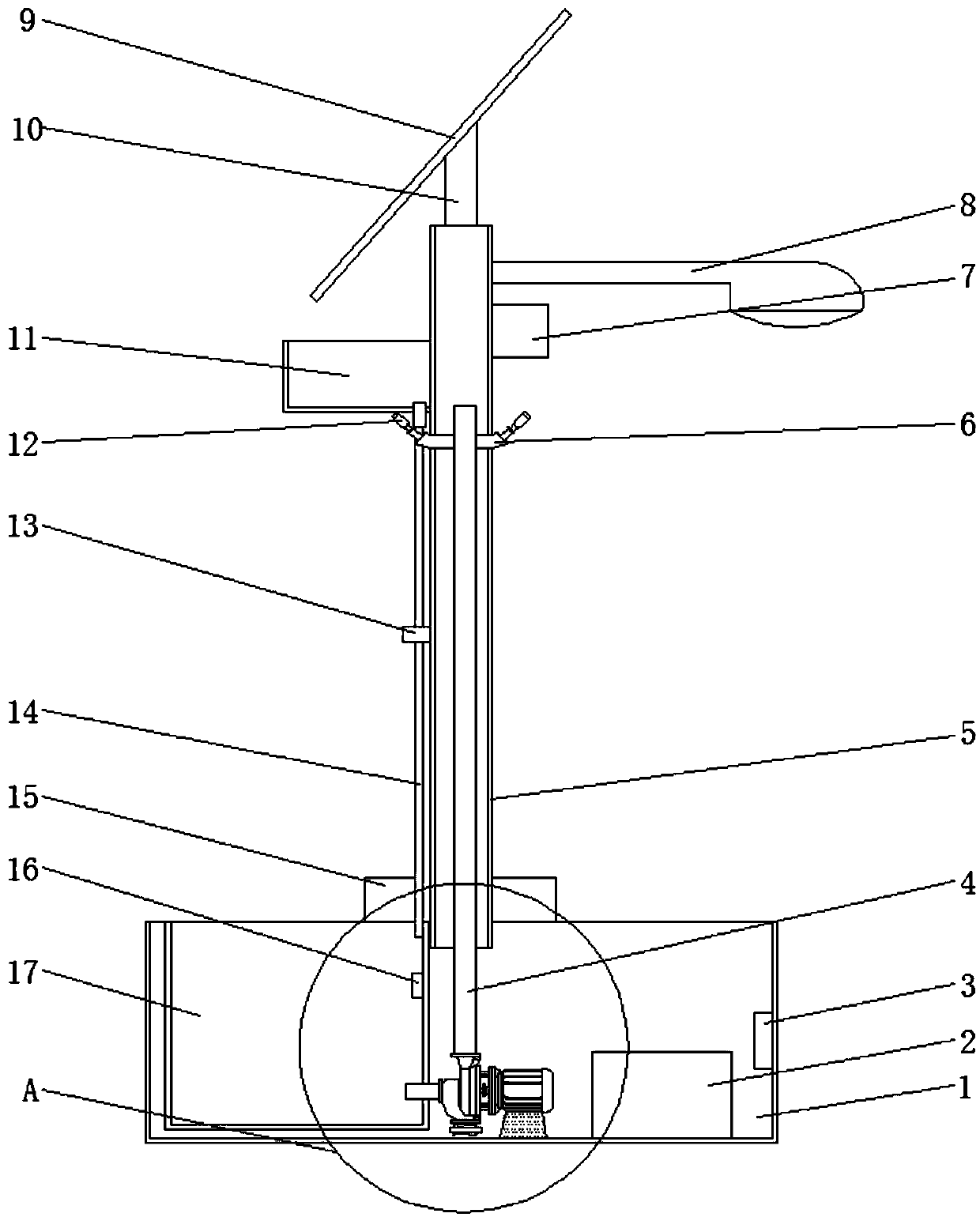

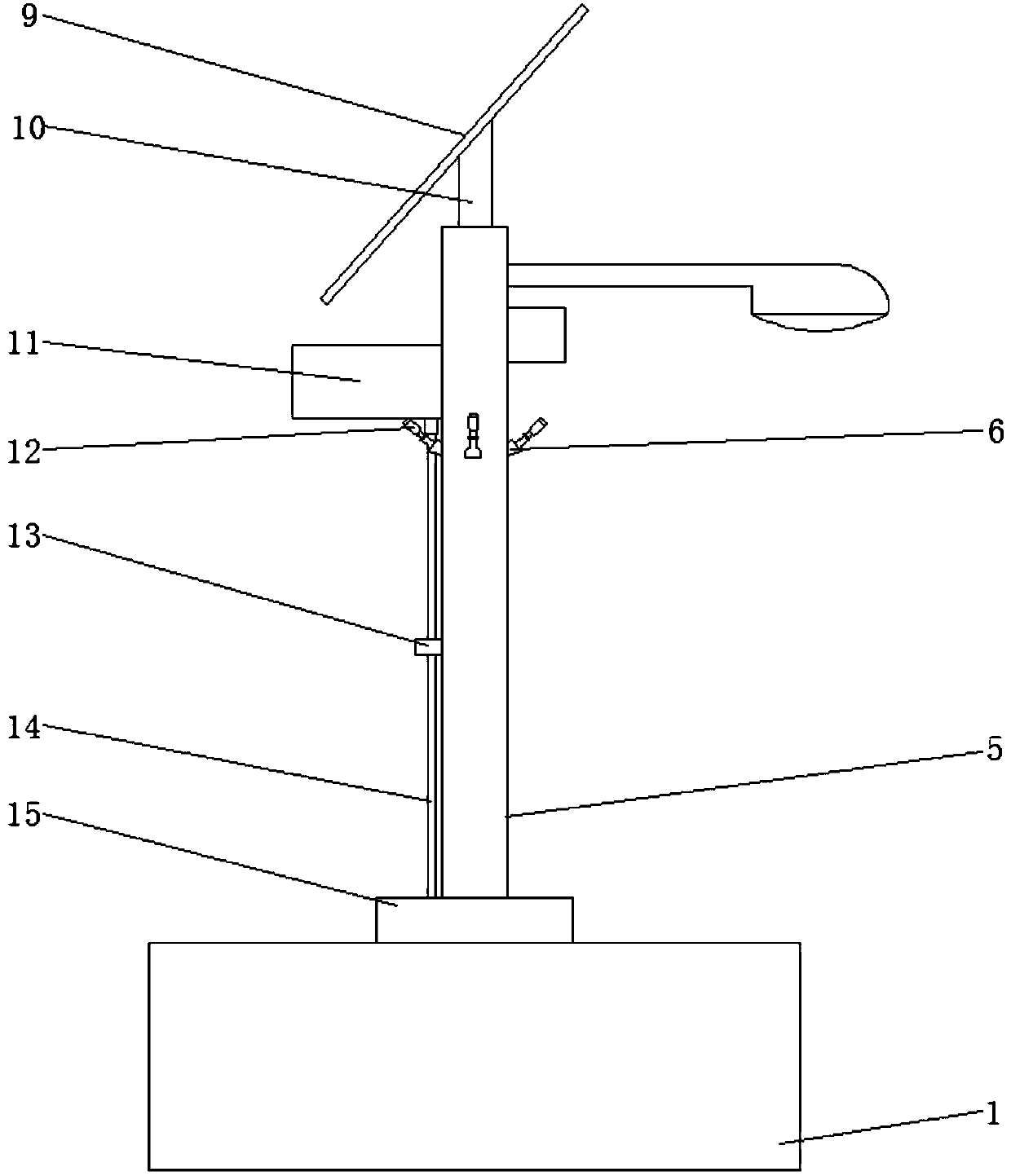

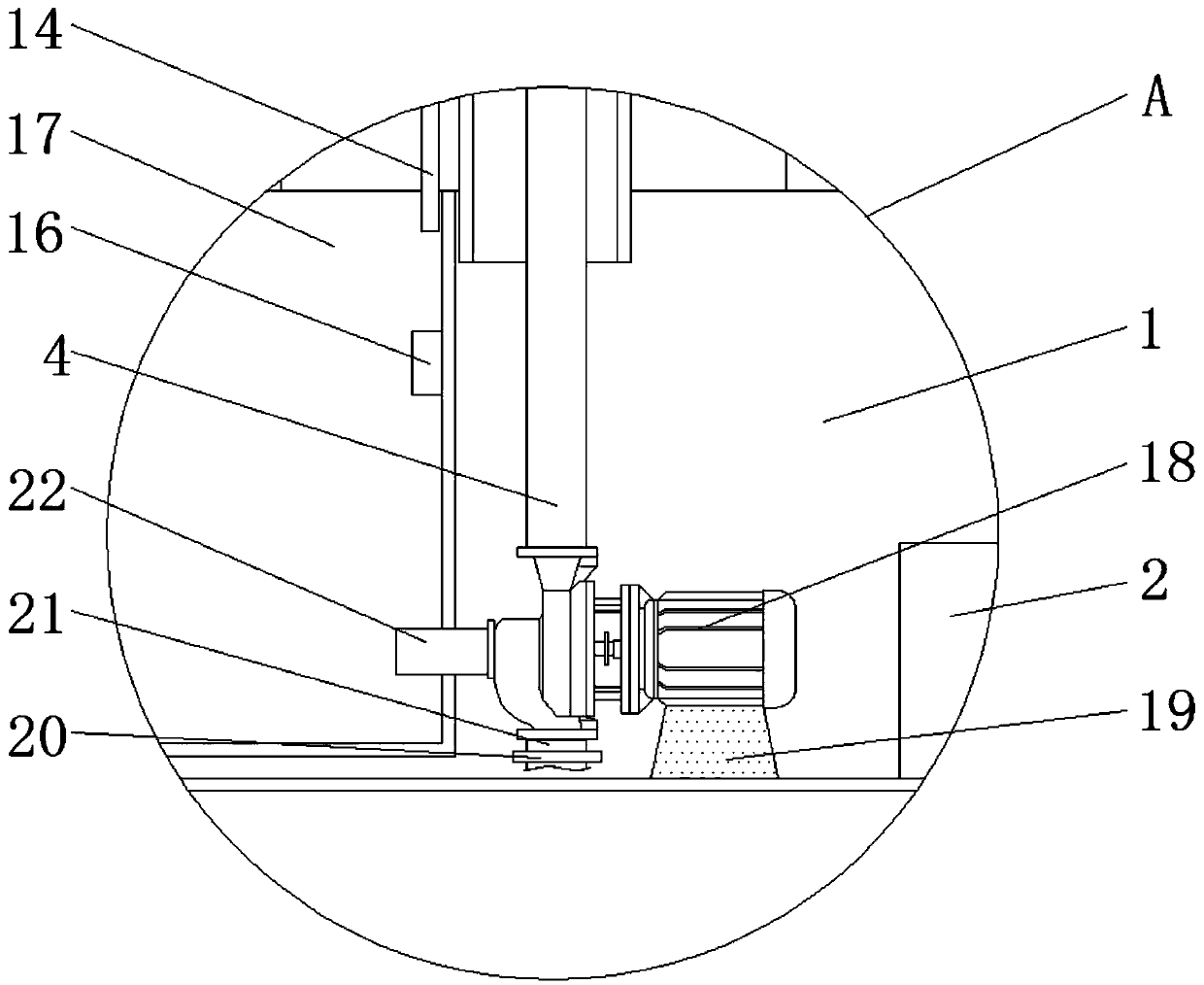

Multifunctional street lamp with spraying system

InactiveCN109519833AWide area of smog removalImprove functionalityMechanical apparatusElectric circuit arrangementsEngineeringSolar cell

The invention relates to the technical field of environment engineering, and discloses a multifunctional street lamp with a spraying system. The multifunctional street lamp comprises an installation cavity, a controller is fixedly installed on the right side face of an inner cavity of the installation cavity, a storage battery is fixedly installed at the bottom of the inner cavity of the installation cavity, a water storage box is fixedly installed at the bottom of the inner cavity of the installation cavity, a liquid level sensor is fixedly installed on the right side face of an inner cavityof the water storage box, and an installation base is fixedly installed at the bottom of the inner cavity of the installation cavity. According to the multifunctional street lamp with the spraying system, rainwater is collected through a water collection box, rainwater recycling is achieved, water resources are saved, rainwater collected in the water collection box is filtered through a filter device to prevent the problem that water entering a booster pump is not pure enough to block the booster pump, electric energy can be supplied through cooperated of a solar cell panel and the storage battery, electric energy consumption is reduced, and an environment monitoring device is used for detecting environment to determine whether mist spray is needed for haze removal.

Owner:北京依途网络科技有限公司 +1

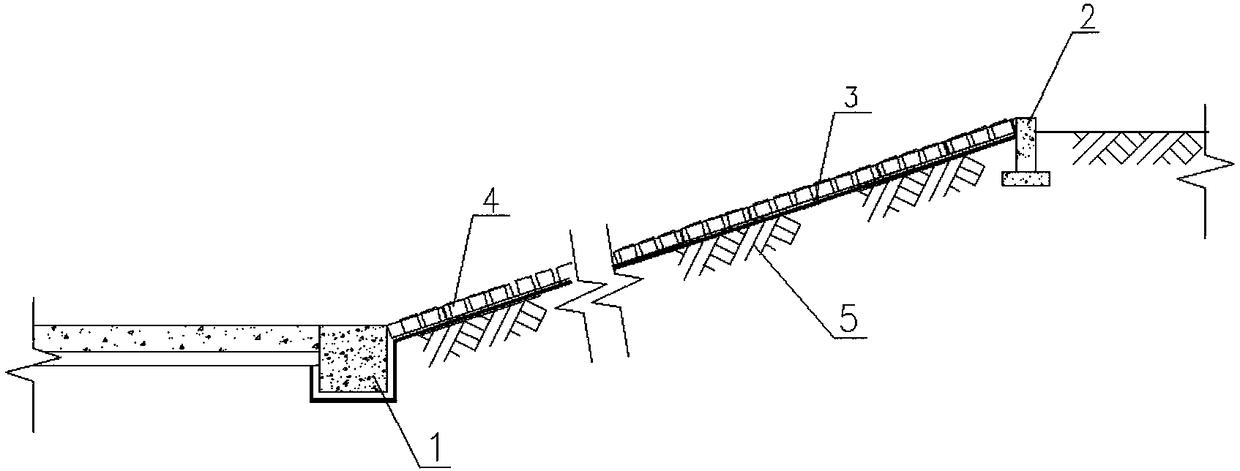

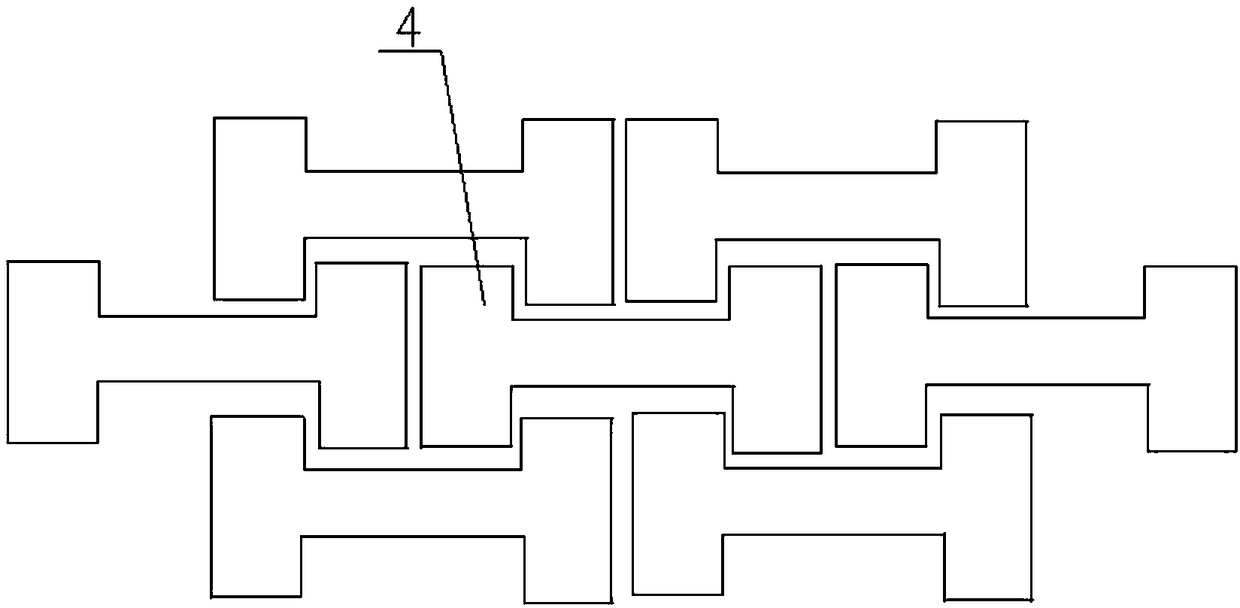

Combined protective slope and construction method thereof

InactiveCN108457247ALow costLight weightCoastlines protectionCultivating equipmentsFiltrationEngineering

The invention discloses a combined protective slope. The combined protective slope mainly comprises a lower blanket zone positioned at a river embankment blanket and an upper blanket zone positioned on a river embankment slope top as well as a protective slope main body which spreads along the river embankment slope surface and is used for connecting the upper blanket zone to the lower blanket zone, wherein reverse-filtration non-woven geotechnical cloth spreads between the protective slope main body and the river embankment slope surface. The invention further discloses a construction methodof the combined protective slope, and the construction method comprises the following steps of: pouring the lower blanket zone on the site on the bottom of the river embankment slope surface, and pouring the upper blanket zone on the site on the top of the river embankment slope surface; spreading the reverse-filtration non-woven geotechnical cloth from the river embankment blanket to the river embanked slope top on the river embankment slope surface; spreading the protective slope main body; and planting green plants. The combined protective slope adopts an interlocking block as the protective slope main body, plants green plants to assist slope protection, is environmentally friendly, is low in cost, and is relatively simple in daily maintenance and management.

Owner:WUHAN YIYE CONSTR ENG

Granulation method of zinc leaching residues, zinc leaching residue material and application of zinc leaching residue material

ActiveCN111118283ALow costEasy to operateRotary drum furnacesProcess efficiency improvementPhysical chemistryMixed materials

The invention discloses a granulation method of zinc leaching residues, a zinc leaching residue material and application of the zinc leaching residue material. The granulation method of the zinc leaching residues comprises the steps that the zinc leaching residues are obtained; the zinc leaching residues and lime are mixed to obtain mixed materials; the mixed materials are stacked; and the stackedmixed materials and fuel are mixed to obtained a fuel mixed mixture, crude zinc oxide powder is mixed into the fuel mixed mixture to carry out granulation, and granulation of the zinc leaching residues is completed. According to the granulation method of the zinc leaching residues, a drying kiln does not need to be adopted for drying the leaching residues, water of materials before granulation can meet the requirements of a granulation system, and the problems that in the prior art, a drying kiln needs to be adopted for drying the zinc leaching residues, and consequently the investment and running cost is large are solved.

Owner:云南云铜锌业股份有限公司

System and method for indirectly thermo-chemically converting biomass slurry by using solar energy

ActiveCN107034133ASolve the investmentReduce investmentBioreactor/fermenter combinationsBiological substance pretreatmentsSlurryProcess engineering

The invention discloses a system and method for indirectly thermo-chemically converting biomass slurry by using solar energy. The system for indirectly thermo-chemically converting biomass slurry by using solar energy comprises a material storage box, a plunger pump, a heat exchanger, a heat conduction oil tank, a heat conduction oil pump solar heat collector, a vent valve and a waste heat recovery heat exchanger, and is characterized in that frustule suspension liquid is charged into the material storage box; the liquid storage box is connected with a first inlet of the waste heat recovery heat exchanger via a pipeline, a first outlet of the waste heat recovery heat exchanger is connected with a first inlet of the heat exchanger via the plunger pump and a second pipeline, a first outlet of the heat exchanger is connected with the heat conduction oil tank via a third pipeline, and the heat conduction oil tank is connected with the solar heat collector via the heat conduction oil pump and a fourth pipeline; the solar heat collector is connected with a second inlet of the heat exchanger via a fifth pipeline, and a second outlet of the heat exchanger is connected with a second inlet of the waste heat recovery heat exchanger via a sixth pipeline and the vent valve. The system and method provided by the invention can be widely applied to the fields of environmental protection, energy, biology, chemical engineering and the like.

Owner:CHONGQING UNIV

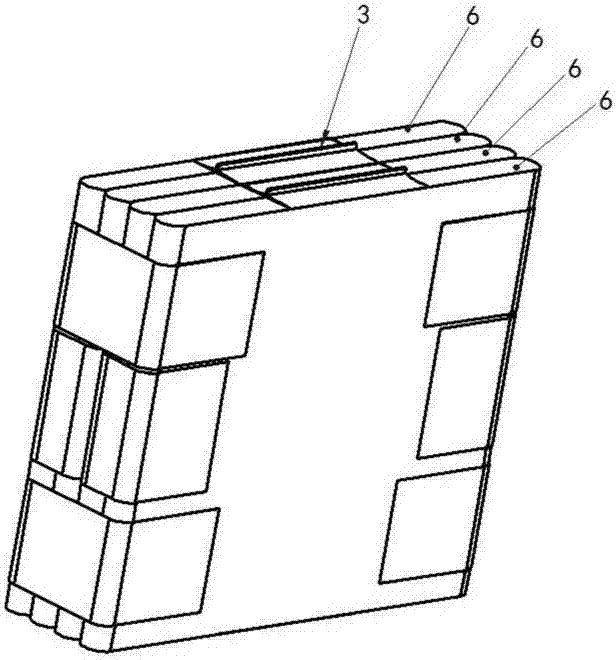

Reaction equipment and system and method for preparing reducing gas for gas-base shaft furnace

The invention provides reaction equipment, and a system and a method for preparing a reducing gas for a gas-base shaft furnace. The reaction equipment comprises a housing and partitions, wherein a cavity is formed in the housing; the partitions are arranged in the cavity and divide the cavity into a plurality of sub-cavities including a plurality of gasification cavities and a plurality of combustion cavities; the gasification cavities and the combustion cavities are alternately arranged in a first direction and alternately arranged in a second direction orthogonal with the first direction. The reaction equipment is utilized for gasification, gasification reaction and combustion reaction can be independently carried out, equipment investment for pure oxygen or rich oxygen preparation are saved, restriction on selecting gasification raw coal is omitted, and accordingly, the gasification cost can be remarkably lowered.

Owner:SHENWU TECH GRP CO LTD

Lithium ion battery with positive electrode and negative electrode in same-side arrangement and manufacturing method thereof

PendingCN107195957ASolve Welding ProblemsHigh capacity densityFinal product manufactureElectrolyte accumulators manufactureEngineeringLithium-ion battery

The application discloses a lithium ion battery with a positive electrode and a negative electrode arranged at the same side and a manufacturing method thereof. The lithium ion battery comprises a shell with an opening structure at an upper end, a naked cell held in the shell and provided with lugs at the left side and the right side, and a shell cover arranged at the upper opening of the shell and provided with poles at the left side and the right side; one end of the pole extends into the shell, and a lug connecting seam corresponding to the lug is formed on the pole extending into the shell; the lug extends into the lug connecting seam on the pole, and the lug is connected with the pole through the friction-stir welding process; the shell cover and the shell are connected together through the friction-stir welding process. By using the lithium ion battery disclosed by the application, the battery production efficiency and yield are improved, the battery capacity and the energy density are improved, the welding quality and the battery rate discharge performance are promoted, and the equipment input cost in the battery production process is lowered.

Owner:GEESUN AUTOMATION TECH

A simple household winder and its production method

The invention discloses a domestic simple bobbin winder and a production method thereof. The domestic simple bobbin winder comprises a machine frame part, a yarn guiding part, a pressurizing winding part, a breakage stopping part and a transmission part. The domestic simple bobbin winder is specially used for enterprises small in production scale, and the enterprises specializes in external processing and production; due to the fact that the number of winding tasks is small, if a special bobbin winder is arranged, the occupied area is large, the use efficiency is low, and the investment is large; due to the fact that the use frequency of the bobbin winder is low, equipment breaks down more easily, professional maintainers are required for maintenance, and the burden of the enterprises is large. The domestic simple bobbin winder is specially used for solving the problem of difficult winding by family type small enterprises, and the price of the equipment is only 800-1000 yuan; due to the fact that the structure is extremely simple, no professional maintainer is needed; the domestic simple bobbin winder is small and exquisite, and only 4-5 square meters of area is occupied; operation is extremely convenient, a user can use the domestic simple bobbin winder without being trained, and the production problem of difficult winding by the small enterprises is solved.

Owner:IANGSU COLLEGE OF ENG & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com