Biogas fermentation tank heating system

A biogas fermentation and fermenter technology, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, gas production bioreactor, etc. Problems such as large investment and high maintenance and management costs are achieved to reduce equipment and operating costs, facilitate maintenance and management, and facilitate maintenance and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

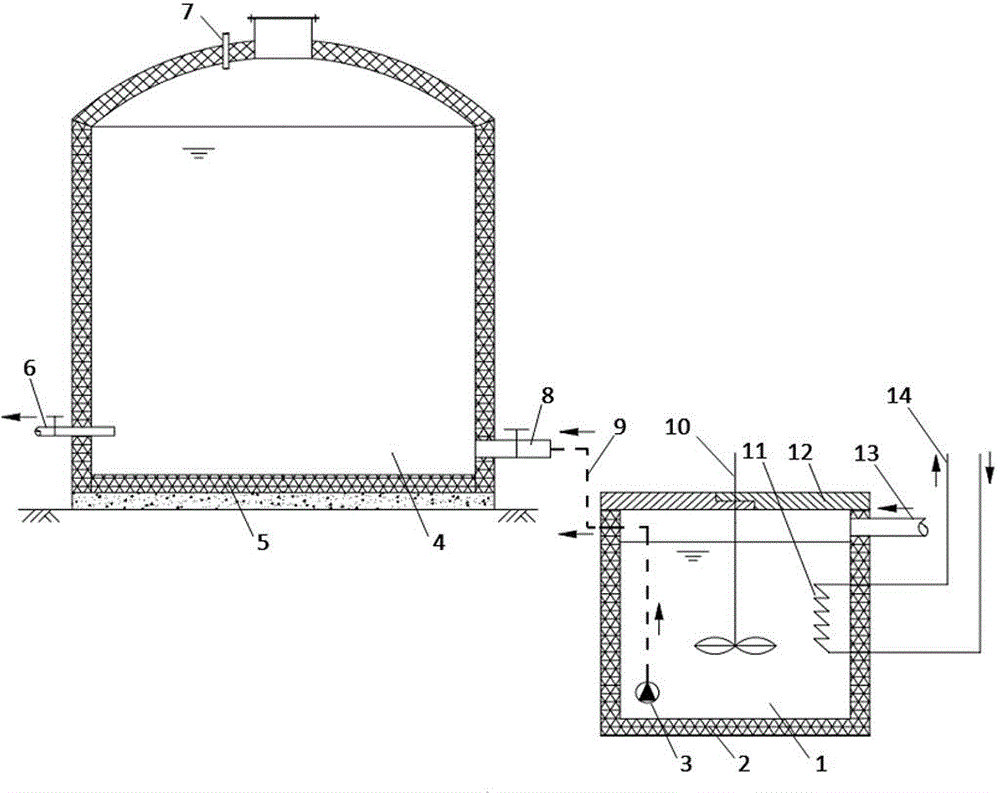

[0015] The heating system of the biogas fermentation tank in this example is as follows: figure 1 As shown, it is mainly composed of a regulating pool 1 and a heat exchanger 11. The heat exchanger 11 is evenly arranged in the regulating pool 1, and the heat exchanger 11 is connected with the hot water circulation pipe 14; , the top of the regulating tank 1 is provided with a thermal insulation cover 12; the regulating tank 1 is provided with a feed pump 3, and the feed pump 3 is connected to the fermenter feed port 8 through the fermenter feed pipe 9; the upper part of the regulating tank 1 is provided with a regulating Pool inlet 13. A stirrer 10 is arranged in the adjustment tank 1 .

[0016] The feed port 8 of the fermenter is set at the bottom of the fermenter 4, the outer side of the fermenter 4 is provided with a fermenter insulation layer 5, the bottom of the fermenter 4 is provided with a discharge port 6 of the fermenter, and the top of the fermenter 4 is provided wi...

Embodiment 2

[0021] The biogas fermentation tank warming system of this example is the same as the first embodiment except that the agitator 10 is not provided.

[0022] In the operation of this example, after the fermentation material enters the adjustment tank 1 from the feed port 13 of the adjustment tank, it is connected to the hot water circulation pipe 14, and the heat exchange medium passes through the hot water circulation pipe 14 to bring heat to the heat exchanger 11 for heating with the fermentation liquid. exchange. All the other are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com