Patents

Literature

295 results about "Real size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

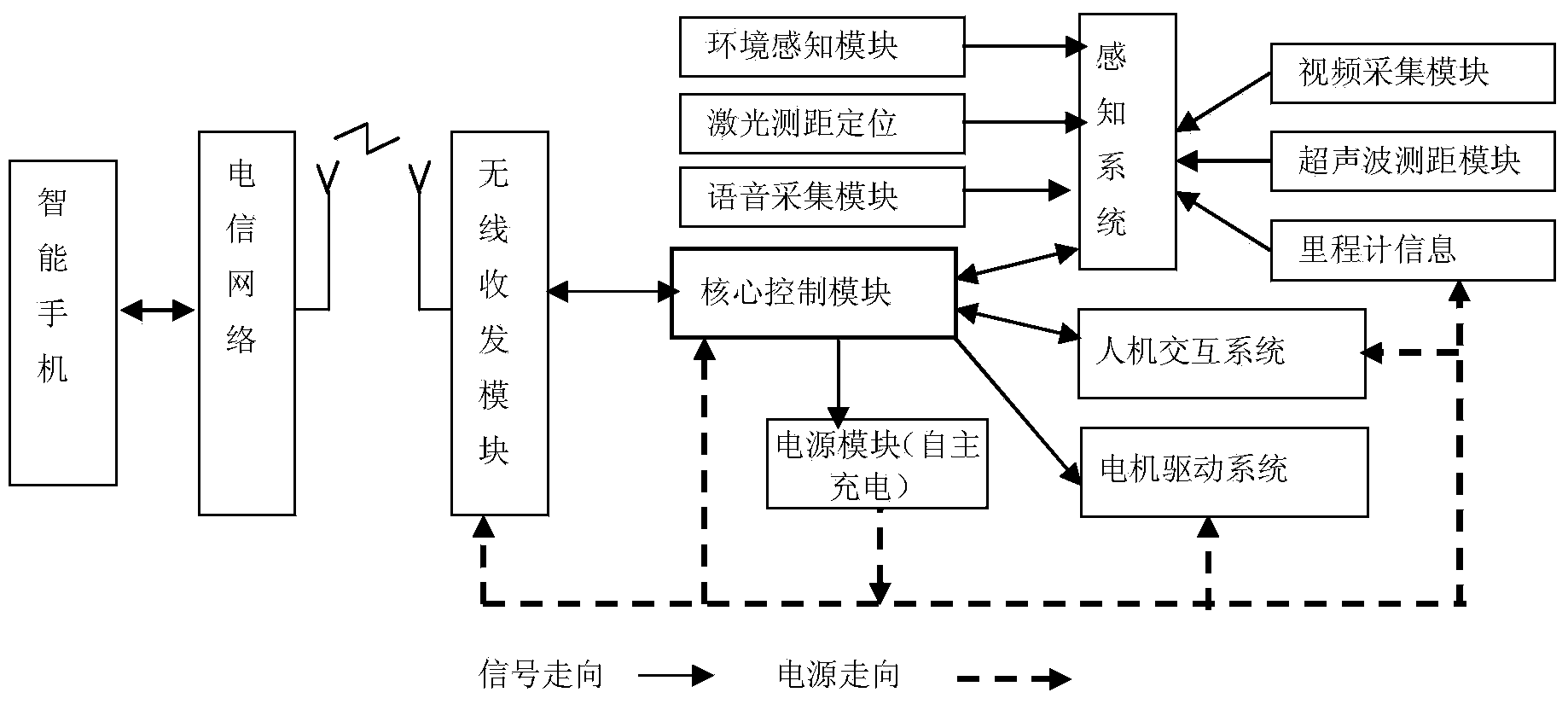

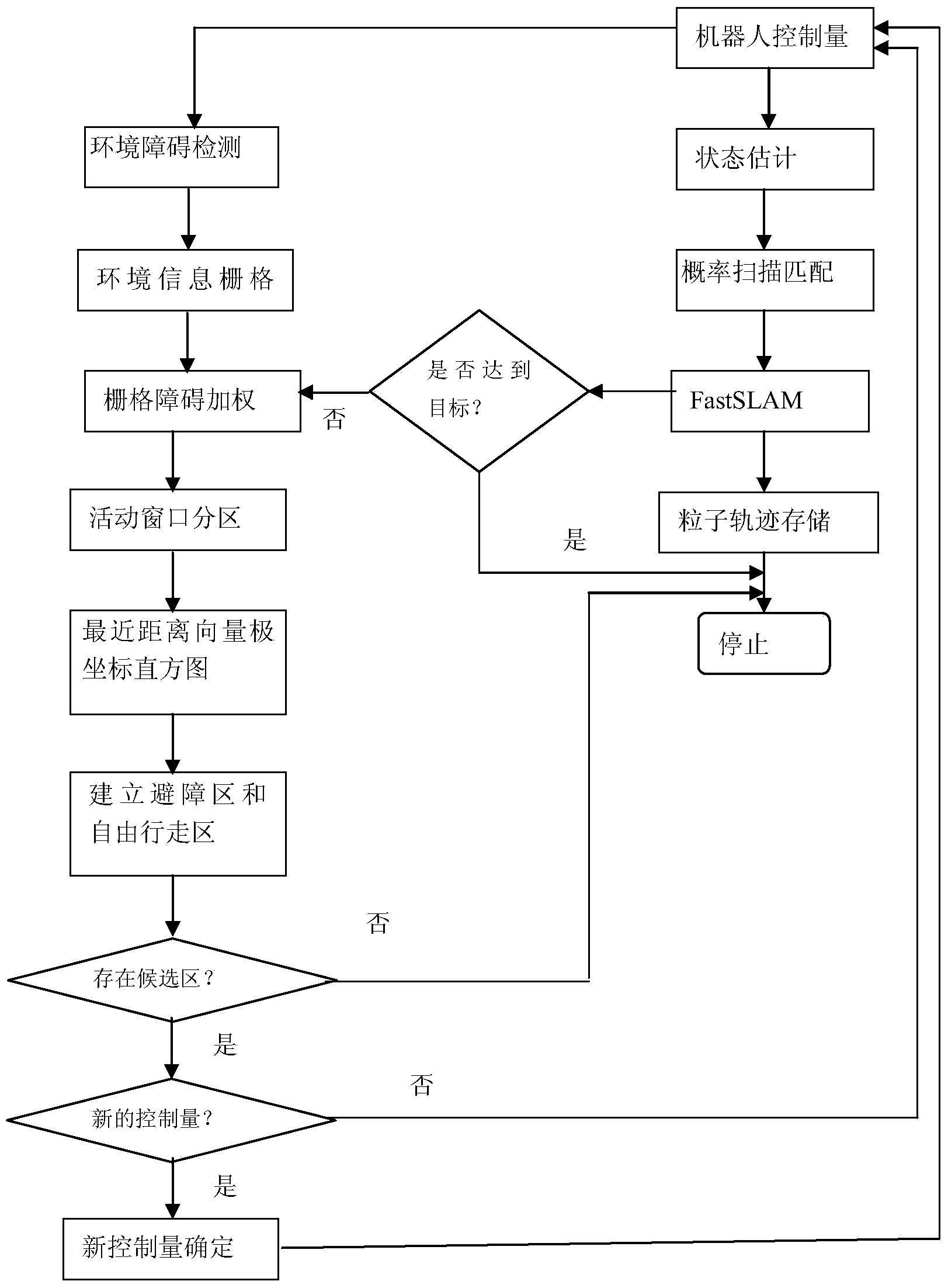

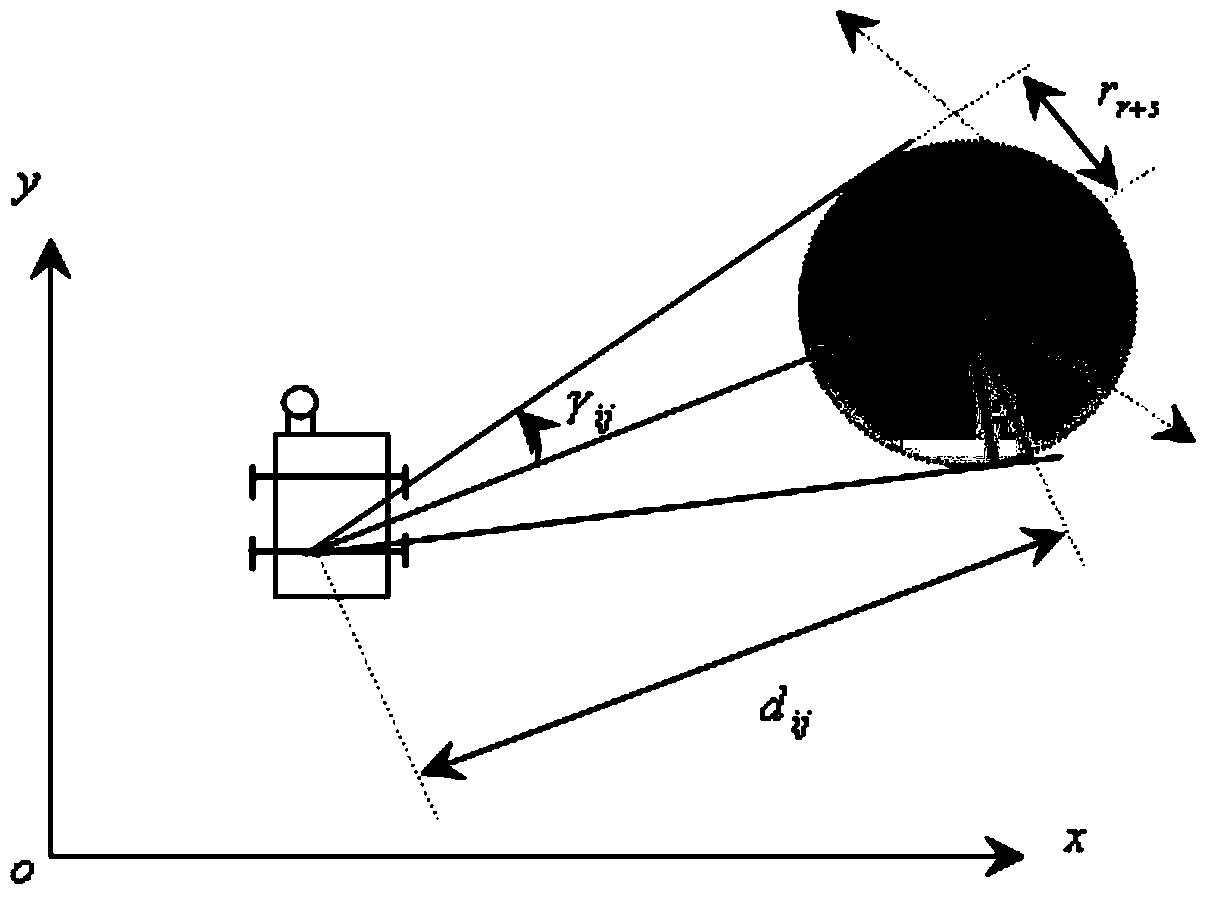

Improved VFH algorithm-based positioning and obstacle avoidance method and robot

ActiveCN103926925ASolve the obstacle avoidance path planning problemPosition/course control in two dimensionsLaser rangingHome environment

The invention provides an improved VFH algorithm-based positioning and obstacle avoidance method and robot. According to the improved VFH algorithm-based positioning and obstacle avoidance method and robot, on the basis of an improved vector field histogram method and a scan matching algorithm, environmental information is acquired by the adoption of a laser range-finder sensor, and the pose error brought by speedometer is amended by the adoption of the polar coordinate scan matching algorithm. After robot positioning is finished, environmental information is rasterized, an obstacle is expanded according to the relationship between the robot and the obstacle and considering the sensing uncertainty of a movable robot and the real size of the robot, an original polar coordinate histogram is built, the free walking area and the obstacle avoidance area are acquired, a binary polar coordinate histogram is acquired through the definition of two threshold values, a shielding polar coordinate histogram is built through estimating the movement trail of the movable robot, and finally, the cost function is introduced to determine the best movement direction of the robot so as to solve the problem of shielding route planning of the movable robot in a home environment.

Owner:江苏久祥汽车电器集团有限公司

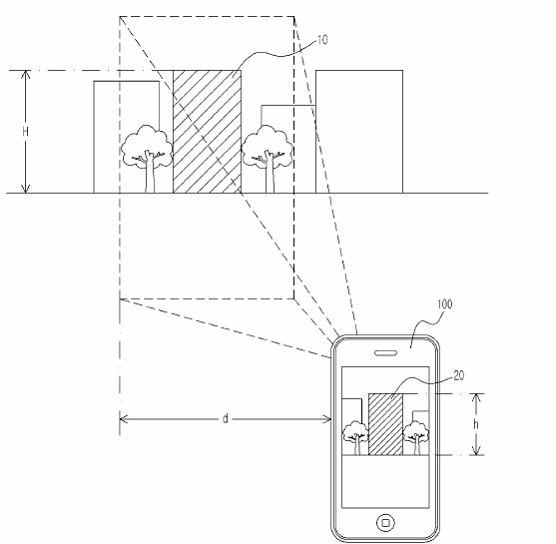

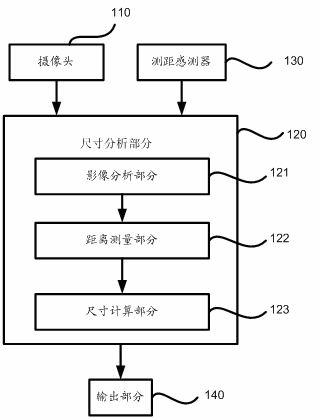

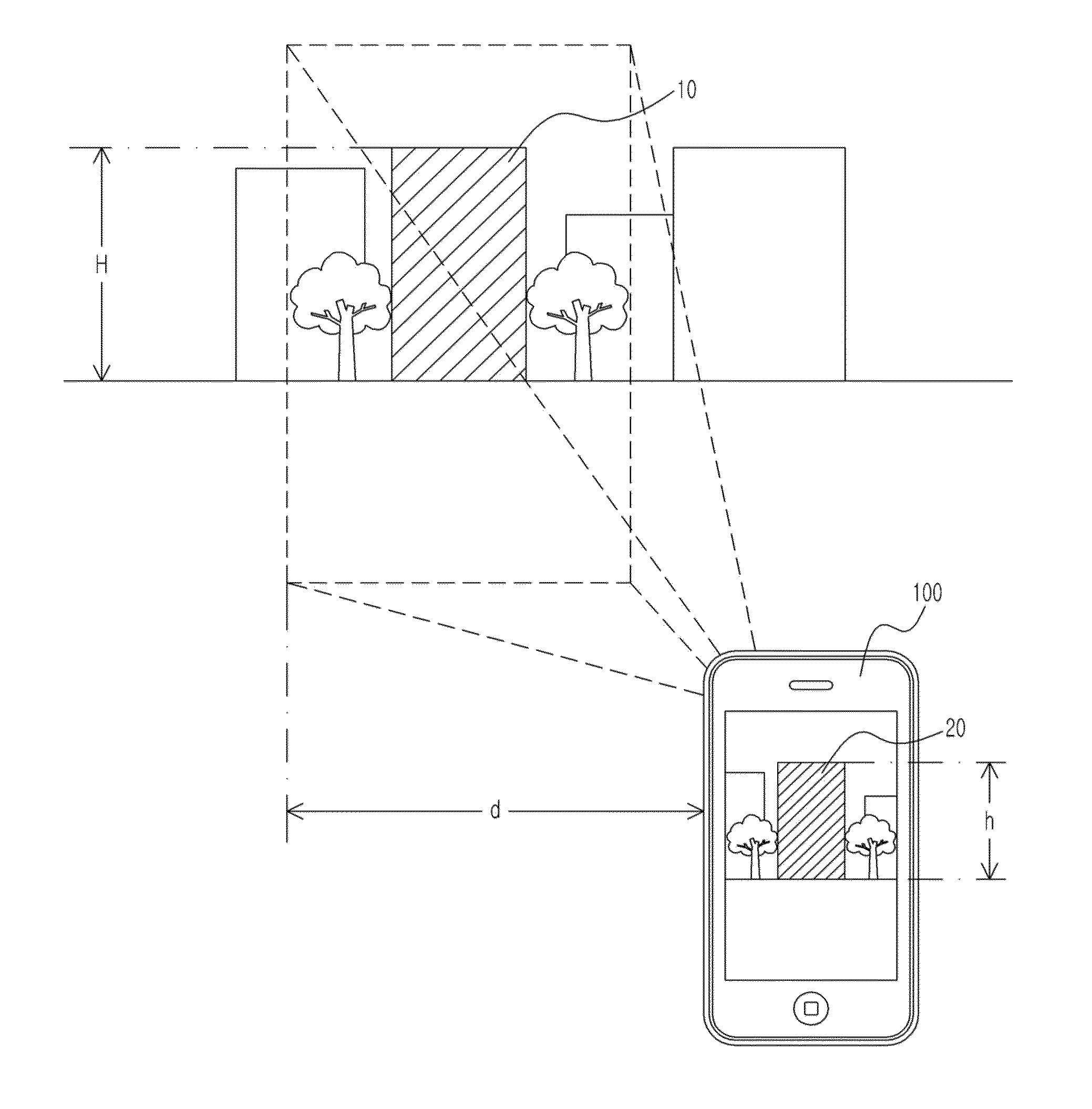

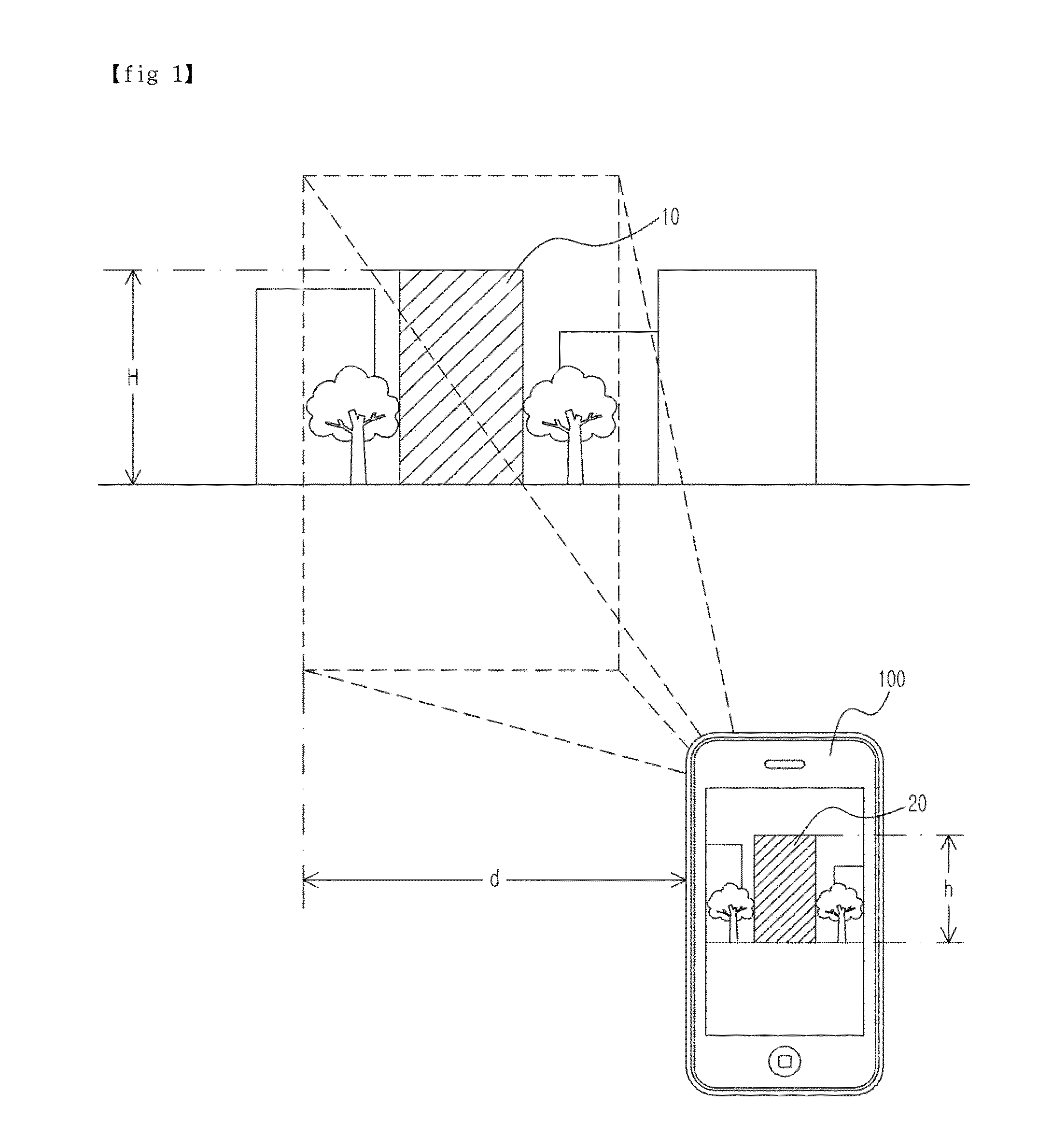

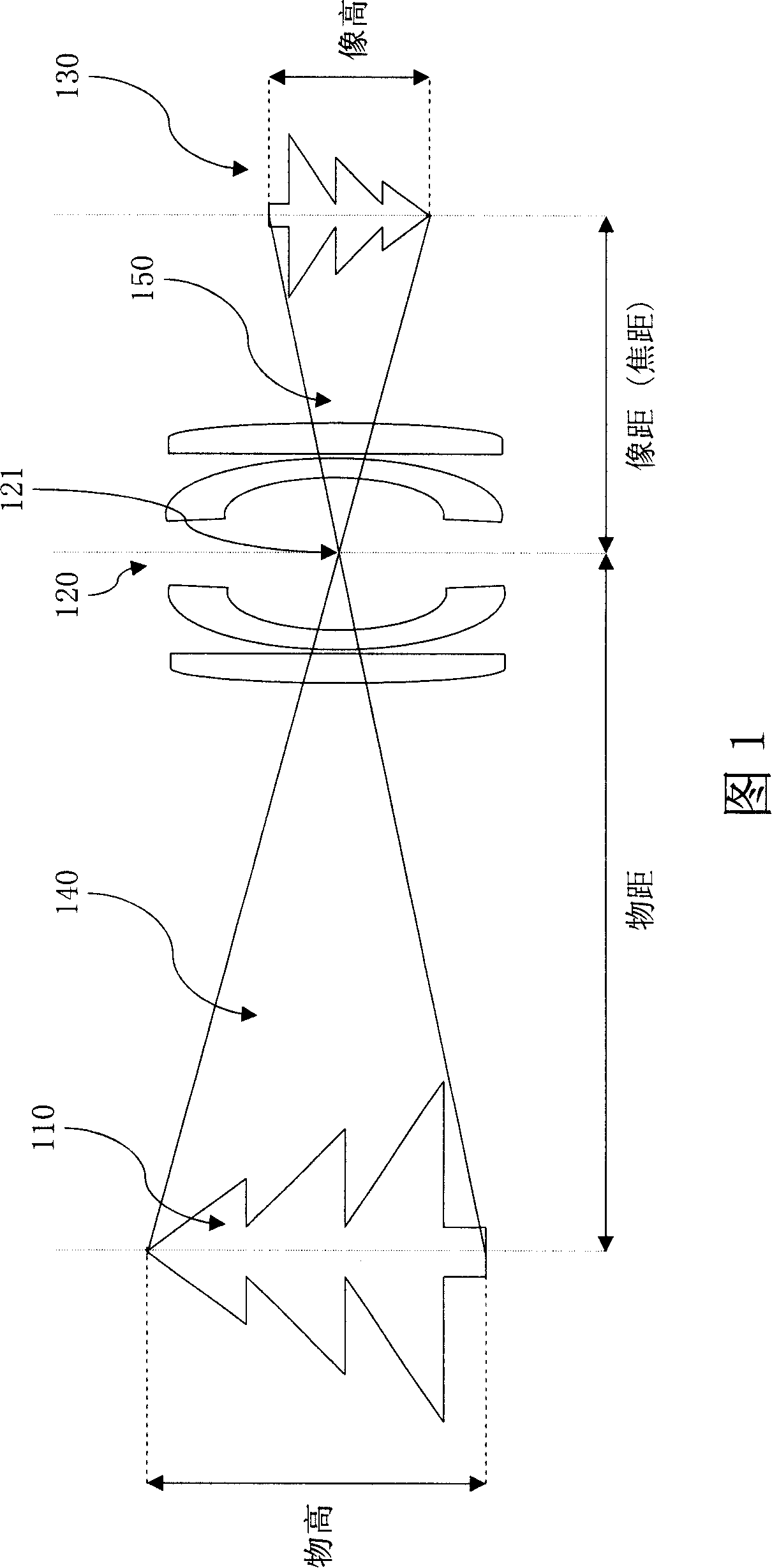

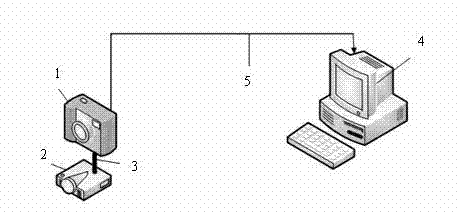

Method for measuring real size of object using camera of mobile terminal

A method for measuring a real size of an object using a camera of a mobile terminal, includes the steps (1) recognizing an object image taken using a camera of a mobile terminal; (2) measuring a size of an object image recognized in step (1); (3) measuring a distance between the object and the camera; and (4) computing a real size of the object using the characteristic of the camera, the size of the object image measured in step (2), and the distance between the object measured in step (3) and the camera. In a method of measuring a real size of an object by using a camera of a mobile terminal, it is possible to measure an accurate real size of an object by using a simpler, faster method like a scale method. The size of the object is measured by using the camera of the mobile terminal and the distance between the camera and the object and the real size of the object is calculated by utilizing the characteristics of the camera like camera of focal lengths and measured values.

Owner:裵相模

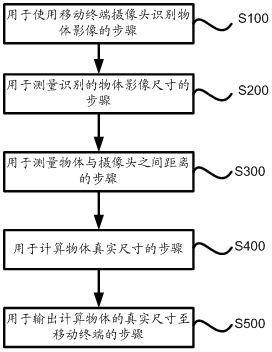

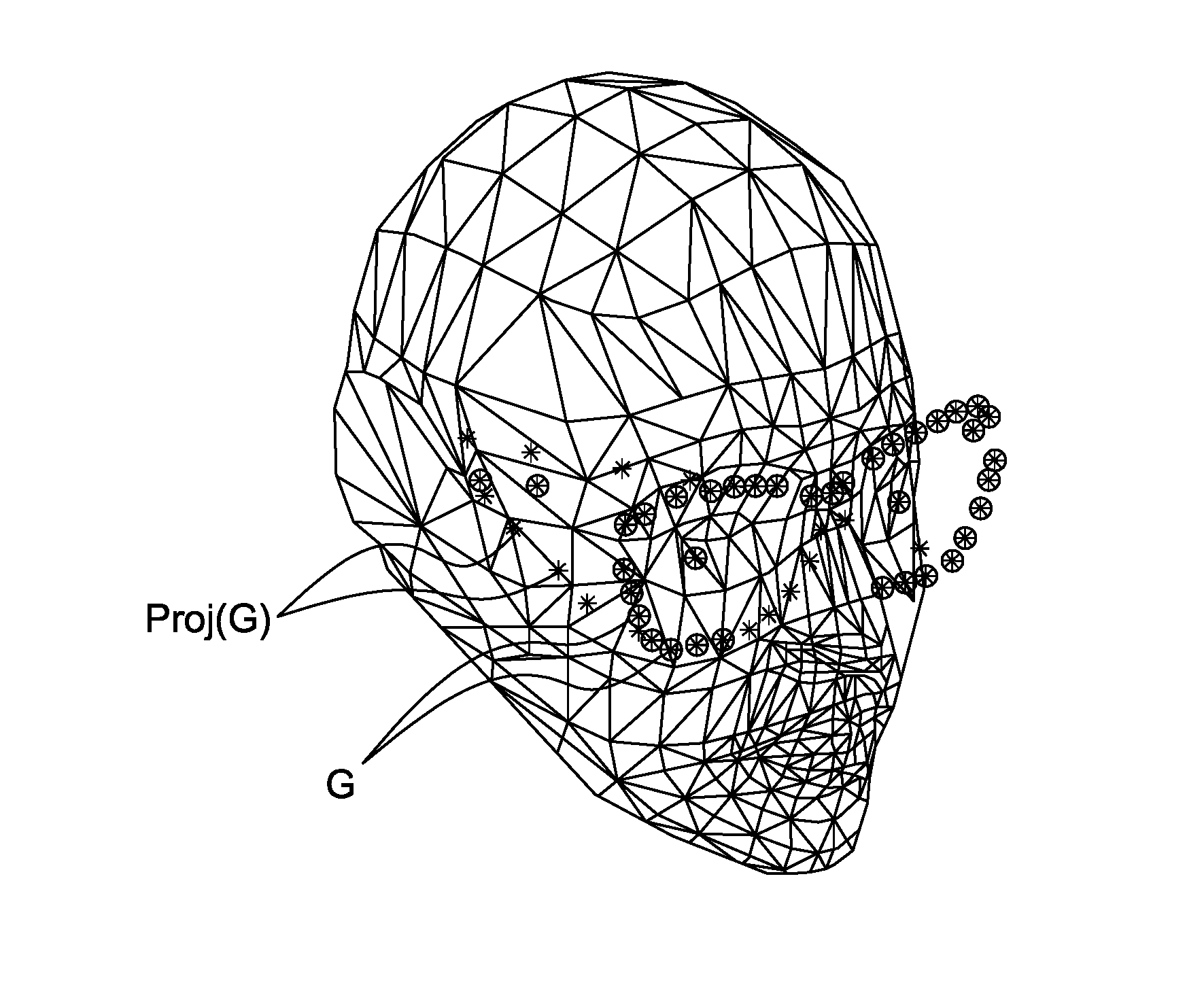

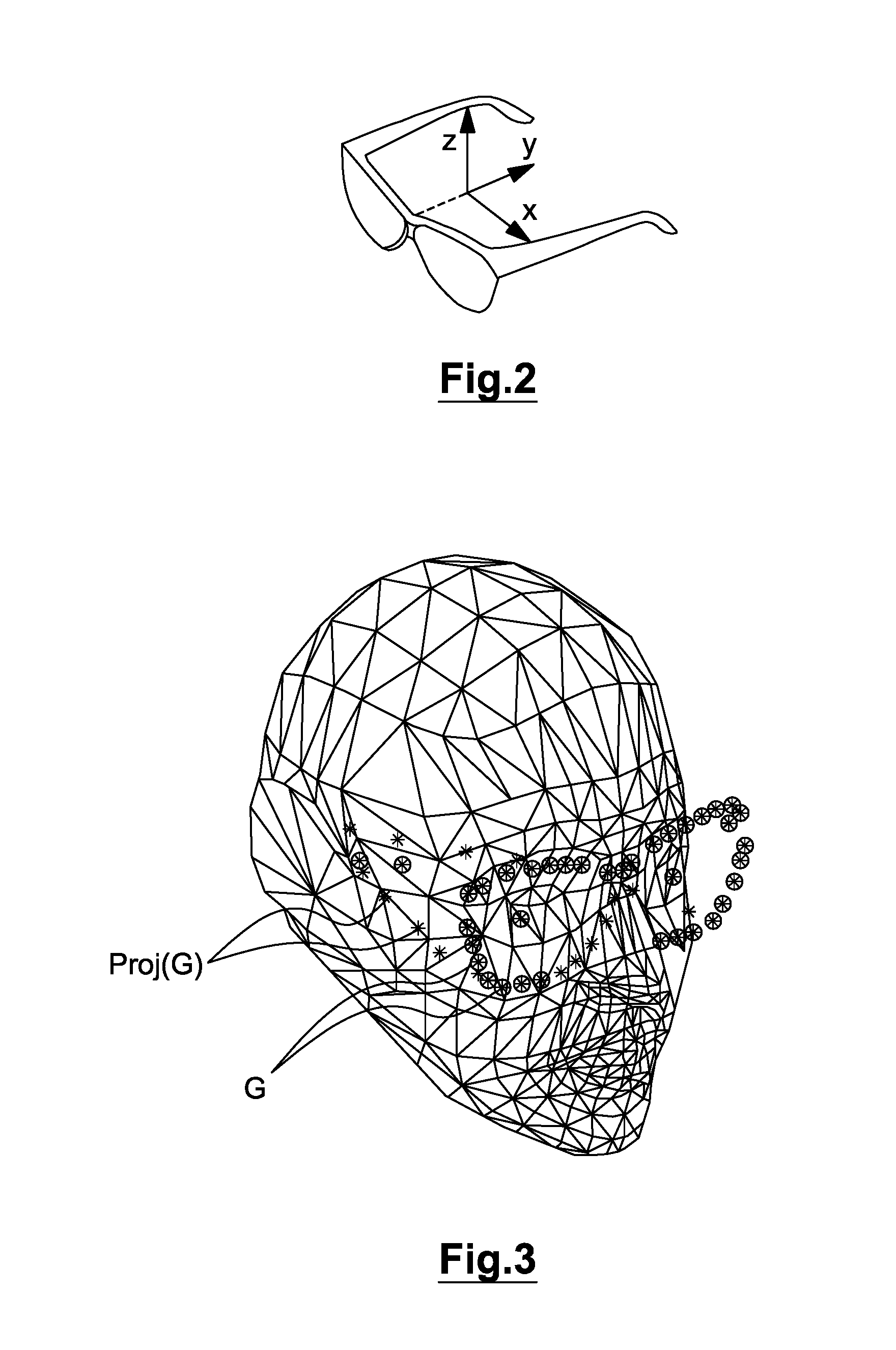

Process and method for real-time physically accurate and realistic-looking glasses try-on

A method for generating a real-time realistic-looking image of a pair of virtual glasses positioned on a real user face image issued from a single image, a bundle of pictures, a video clip or a real-time camera streams. A face analysis element estimates the 3D rotation matrix, the 3D translation vector, morphology parameters of the user's face. A glasses positioning element associated with a try-on mode for look or real-size simulation estimates the 3D rotation matrix, the 3D translation vector, global and local deformation parameters of the virtual glasses, and arms articulation, adapted to the morphology parameters computed by the face analysis element. A realistic rendering element mixes the real user face image with the virtual glasses positioned by the glasses positioning element.

Owner:FITTINGBOX

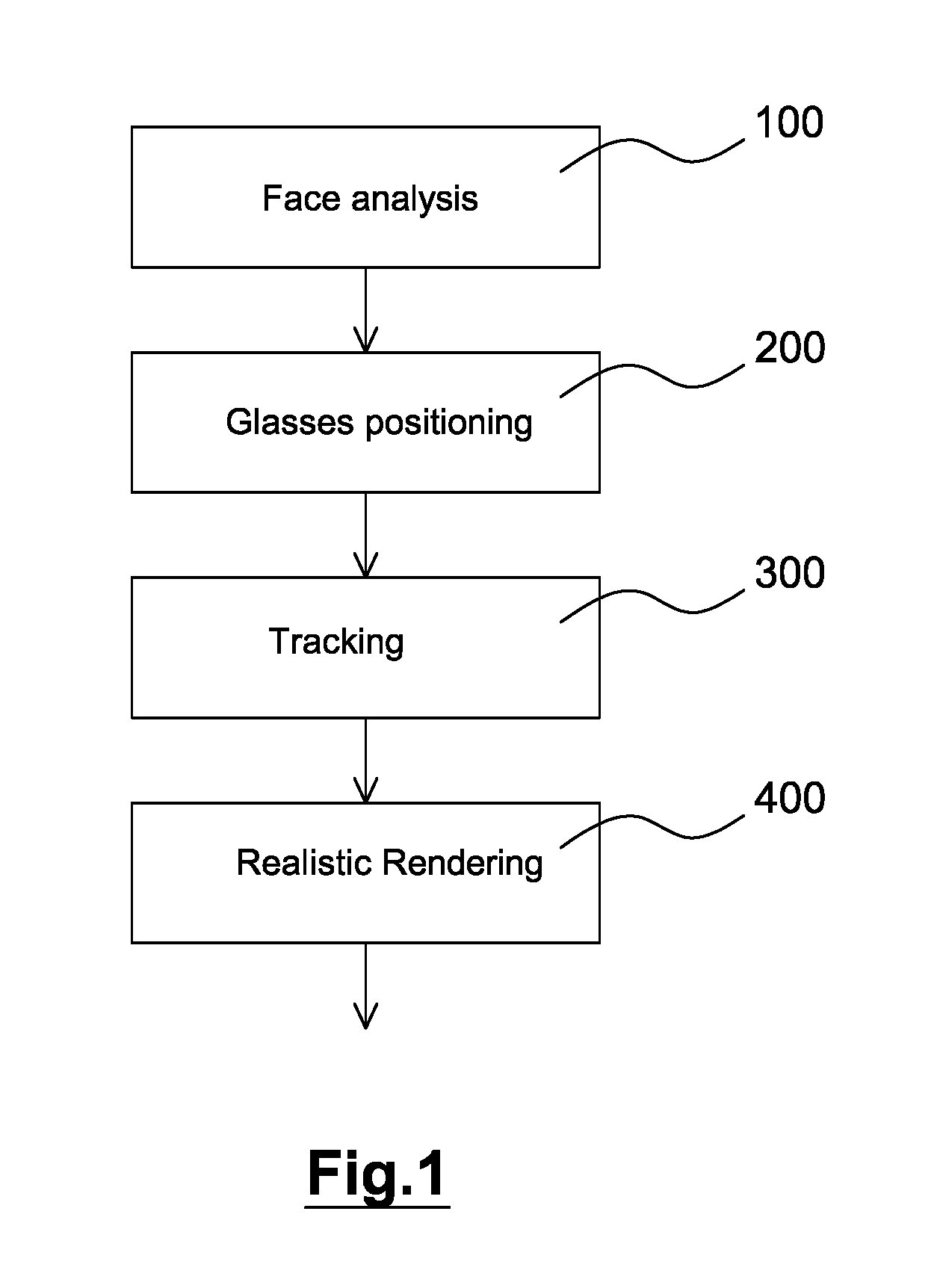

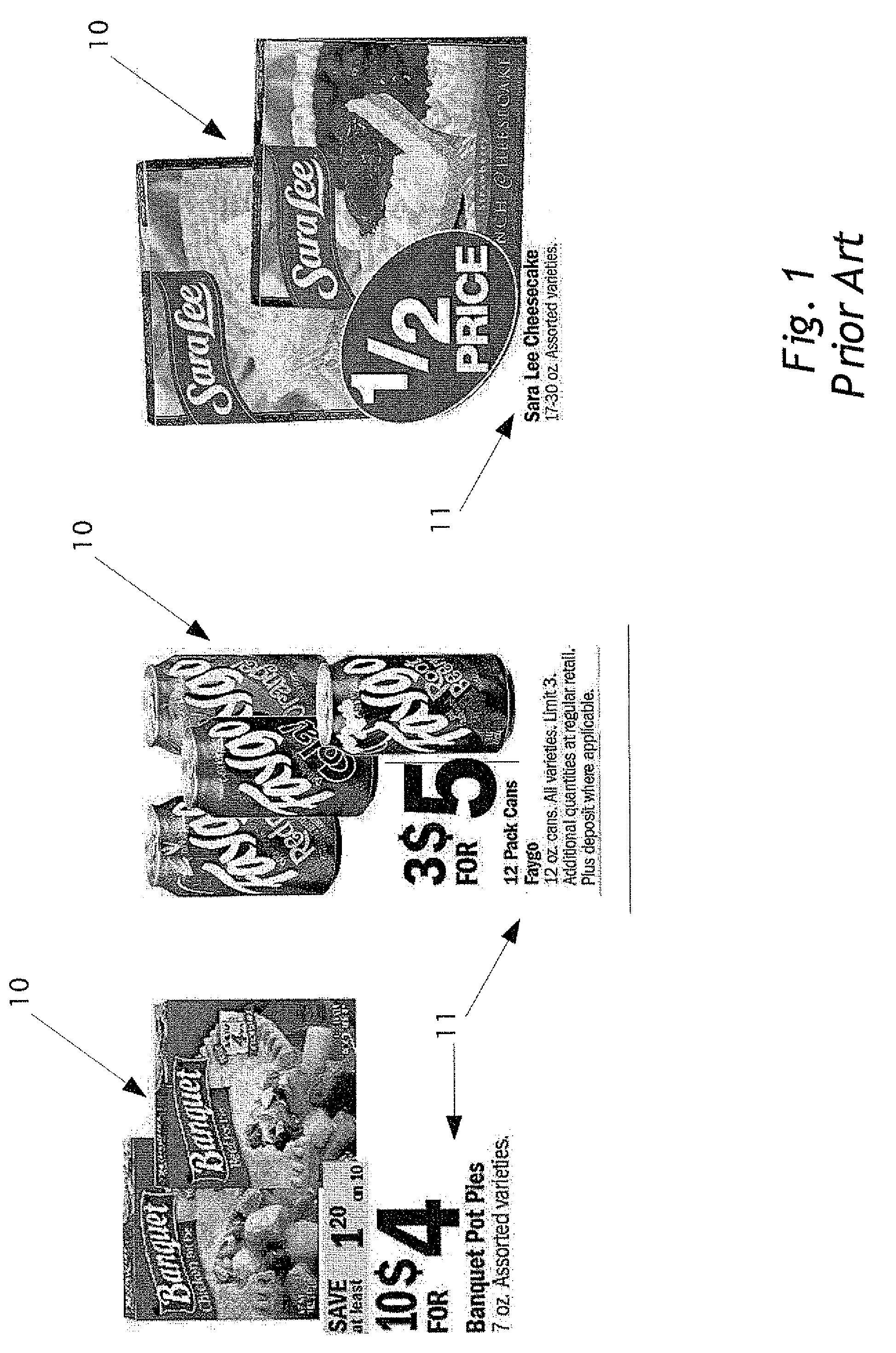

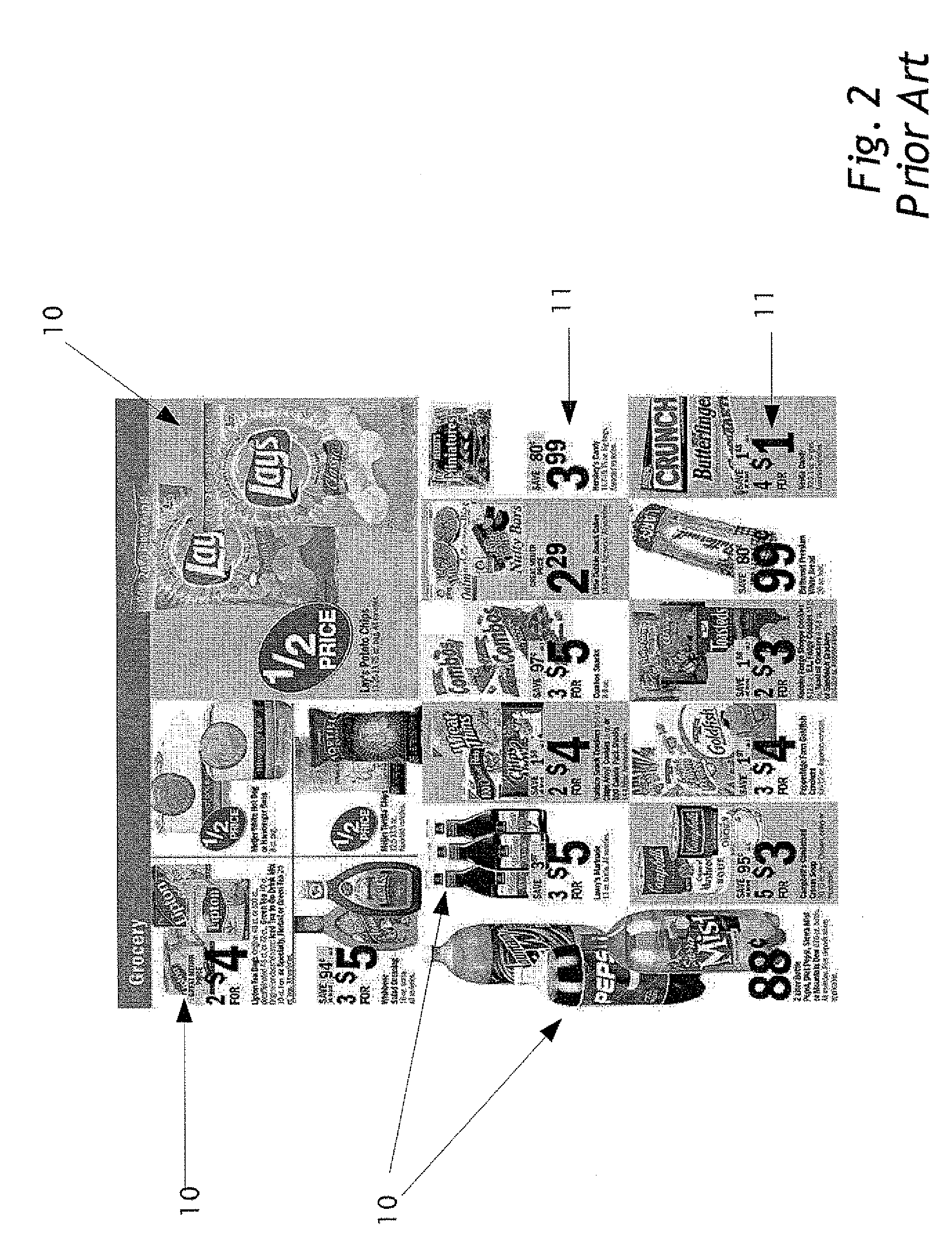

Creation Of Visual Composition Of Product Images

InactiveUS20090013268A1Input/output processes for data processingEditing/combining figures or textComputer graphics (images)Computerized system

A computerized method for creating in a computer system a visual composition. One or more photographs are provided, including respectively images of products for presenting in the visual composition. The images are outlined producing outlines of the product images. Based on the outlines, an arrangement is selected from multiple previously defined arrangements. The arrangement becomes the selected arrangement for presenting the images in the visual composition. The images are positioned in the selected arrangement based on at least one previously defined rule. A set of metadata is preferably associated with each photograph and / or with each product; and the selection of the selected arrangement is performed based on the metadata and / or on extractable features. Scaling of the images is preferably based on the metadata or on extractable features. Features of the products in the images are preferably extracted based on the outline or from a database. Extractable features include: orientation of the product in the image, lighting at time of capture, camera position at time of capture, faces showing of the product in the image, a rotation angle of the product in the image, a line of symmetry of the product, a scale ratio of product dimension to image dimension, a diagonal of the outline, product meta data, product category, product orientation, product real dimensions, and product colors.

Owner:REVIONICS

Method for Measuring Real Size of Object Using Camera of Mobile Terminal

InactiveUS20120224052A1Faster and easy wayImage analysisColor television detailsComputer terminalReal size

A method for measuring a real size of an object using a camera of a mobile terminal, includes the steps (1) recognizing an object image taken using a camera of a mobile terminal; (2) measuring a size of an object image recognized in step (1); (3) measuring a distance between the object and the camera; and (4) computing a real size of the object using the characteristic of the camera, the size of the object image measured in step (2), and the distance between the object measured in step (3) and the camera.

Owner:BAE SANG MO

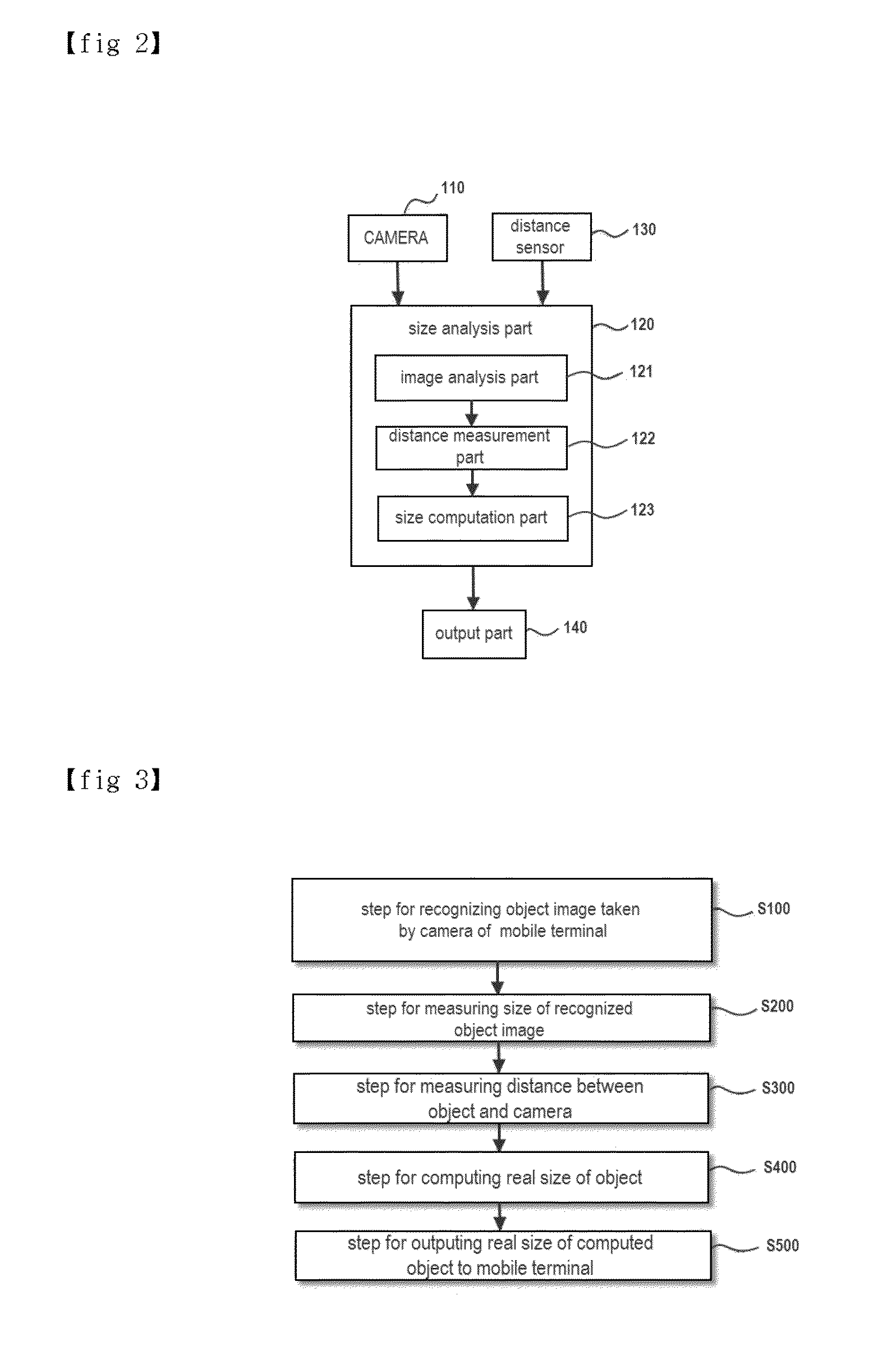

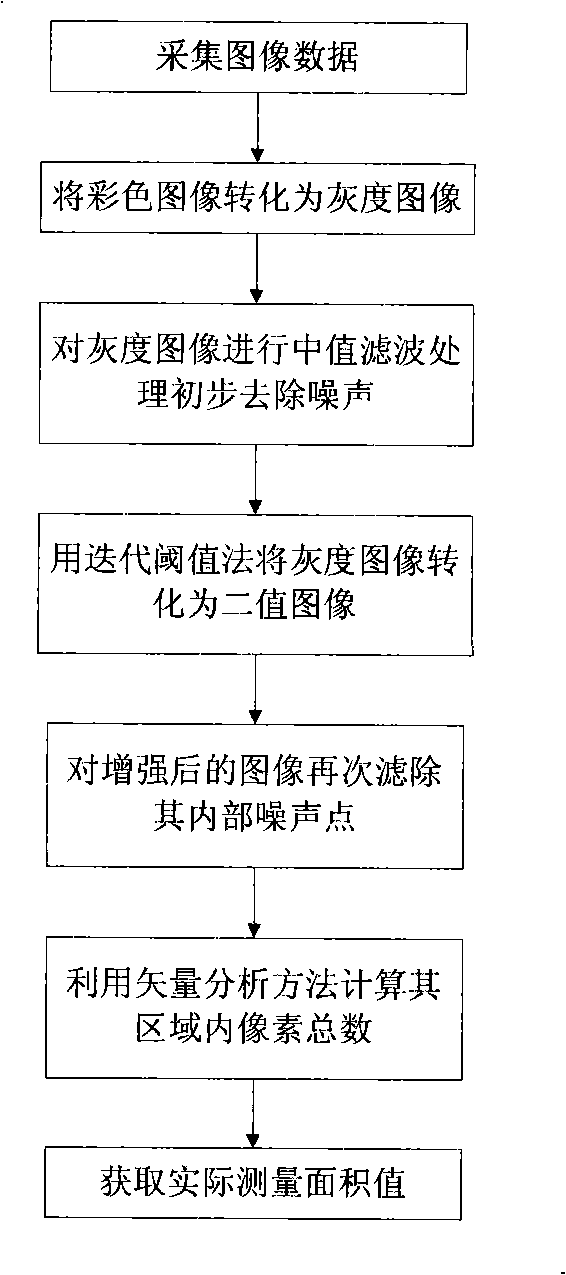

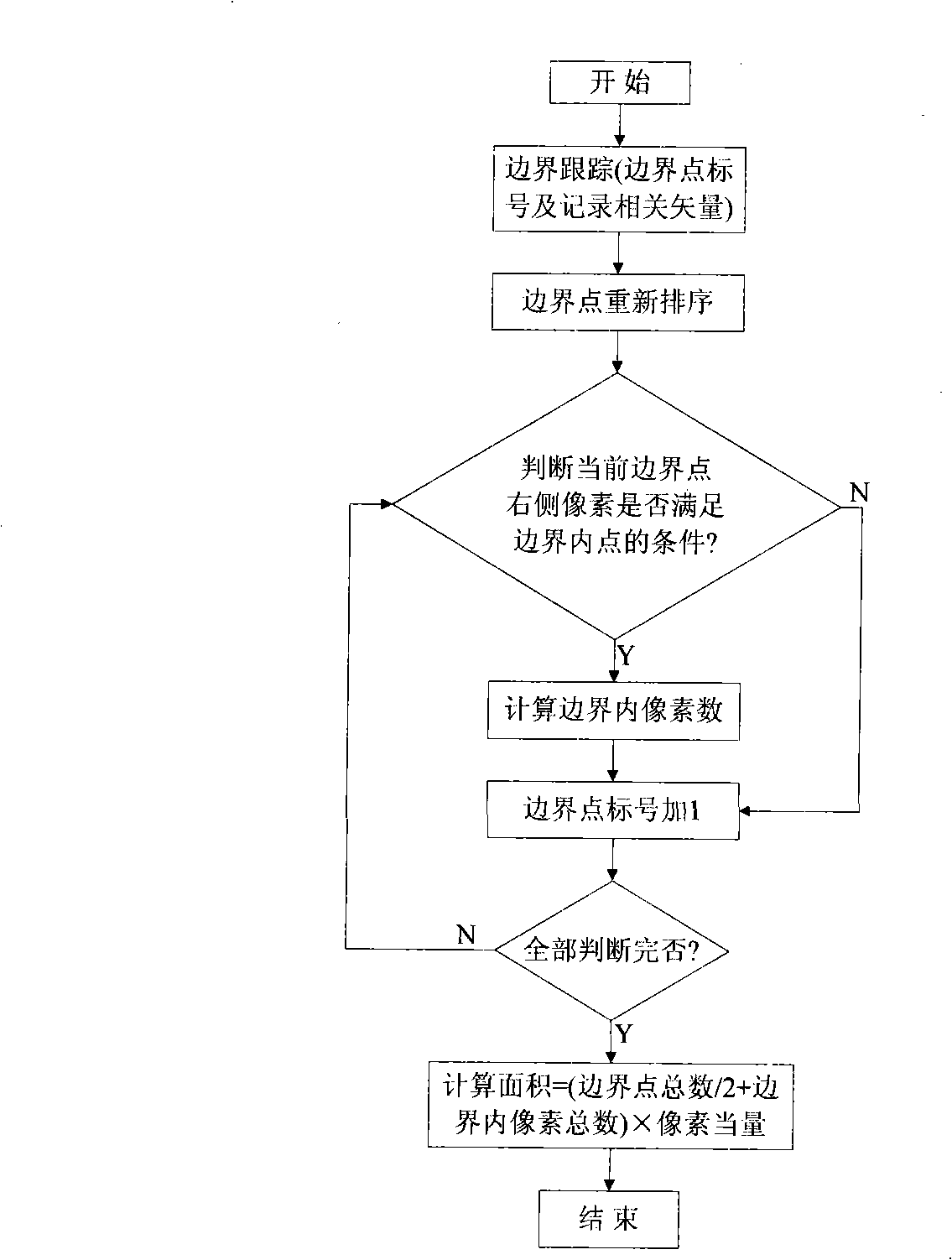

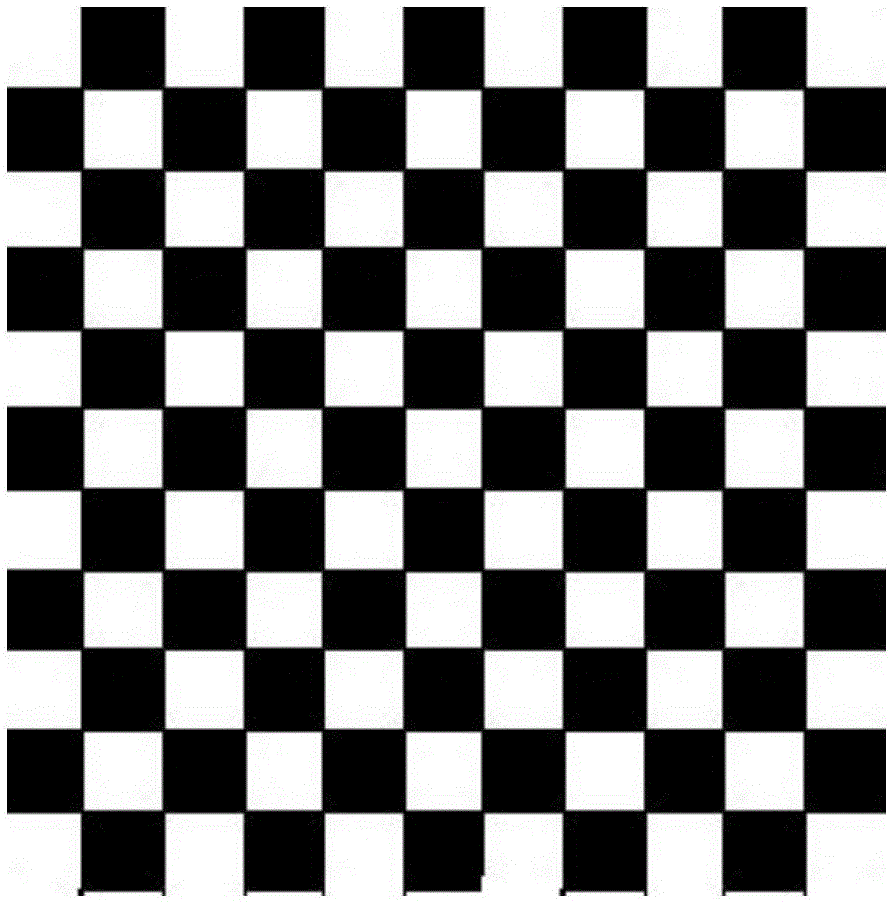

System and method for measuring leather area based on digital image method

InactiveCN101403610ALow costHigh measurement accuracyImage analysisUsing optical meansCamera lensDigital image

The invention provides a leather area measuring system and a method based on a digital image method, which comprises a CCD video camera connected with an image acquisition device lens, the CCD video camera is connected with an image collection card and a computer; the measurement steps comprise: first, calibrating the system to gain the system pixel equivalent Epsilon, and the practical dimension represented by unit pixel, second, obtaining the gray image of the leather to be measured, third, denoising the gray image, fourth, converting the gray image to a binary image using an iterative threshold method, and separating the object from the background area, fifth, denoising the image for a second time, sixth, processing a leather image by a vector analysis method, and obtaining the edge outline and the pixel number of the object area, and seventh, calculating the leather area to be measured. The invention has the advantages of low cost, non-contact, high measuring precision, and convenient industrial use.

Owner:SHAANXI UNIV OF SCI & TECH

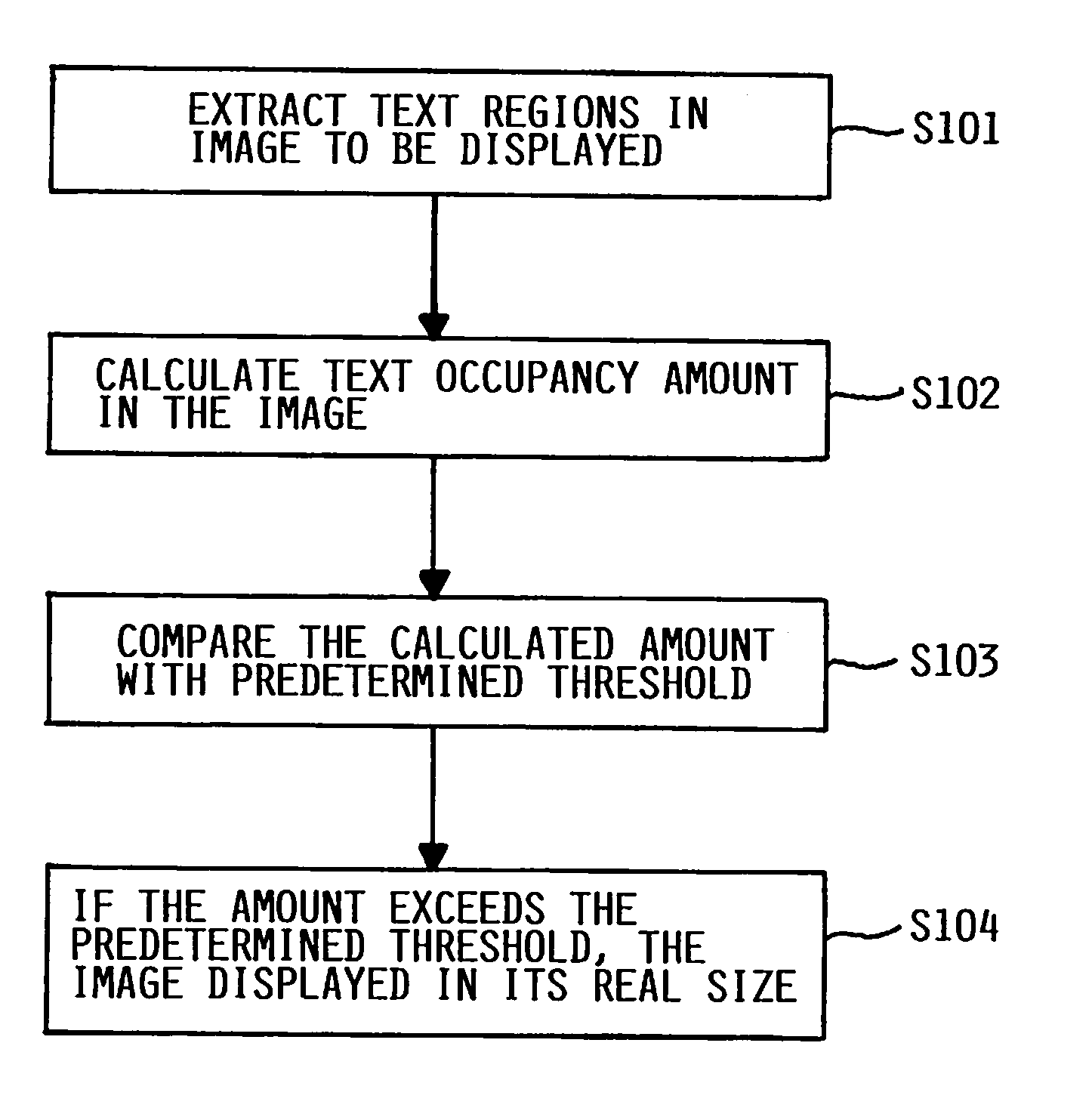

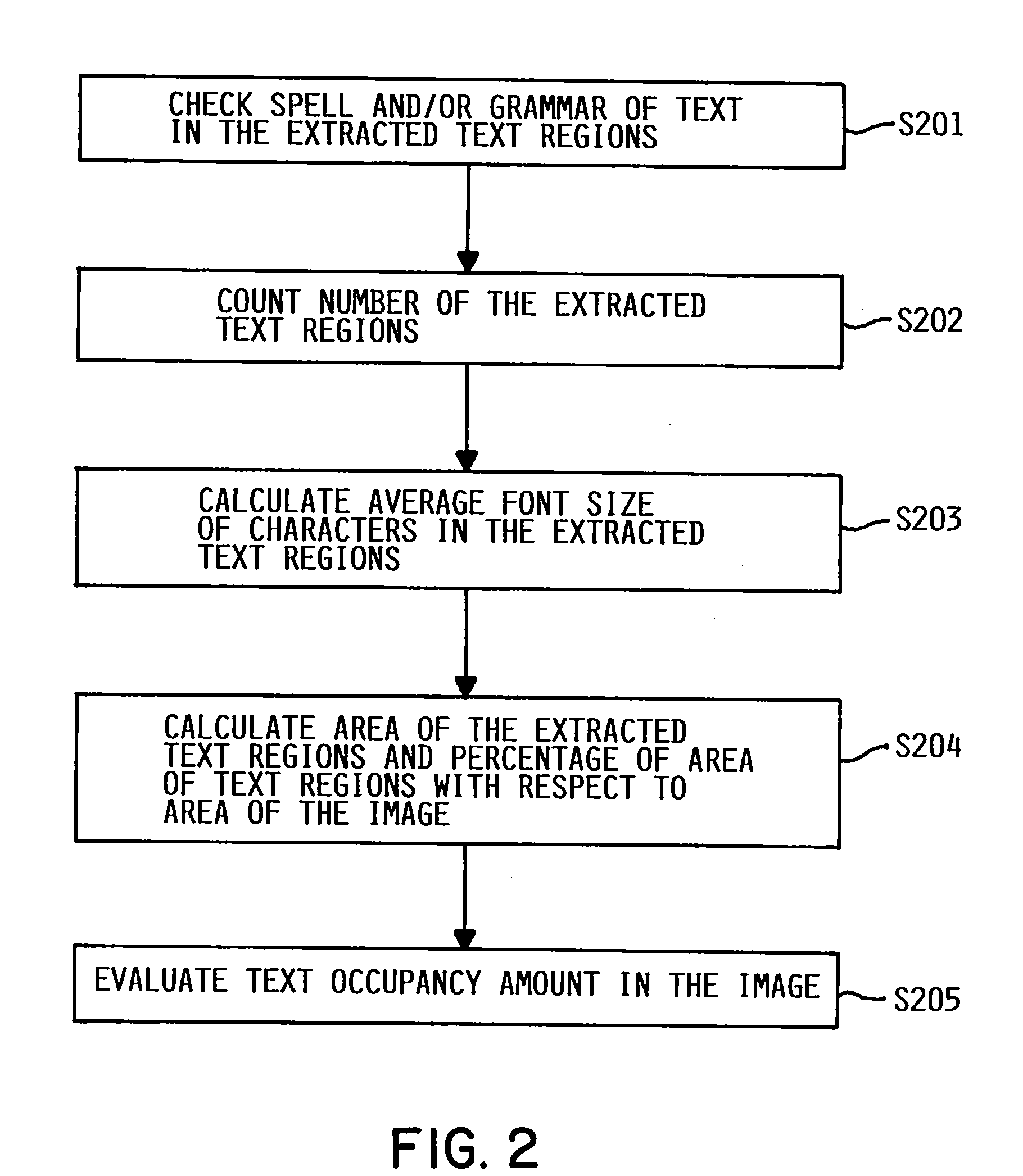

Method and system for displaying image based on text in image

InactiveUS20090110287A1Save operationsShorten the timeCathode-ray tube indicatorsCharacter recognitionComputer graphics (images)Computerized system

A method and a system for displaying an image based on texts in the image are provided. The method of the invention for displaying the image includes: a text extracting step, extracting text regions in the image to be displayed; a text occupancy amount calculating step, calculating occupancy amount of the text in said image; a comparing step, comparing the calculated occupancy amount with a predetermined threshold; a display step, displaying the image in real size of the image if said occupancy amount exceeds said predetermined threshold. It is achieved to display the image to the user in a manner of satisfying the viewing aim of the user, and unnecessary load of the computer system is avoided.

Owner:IBM CORP

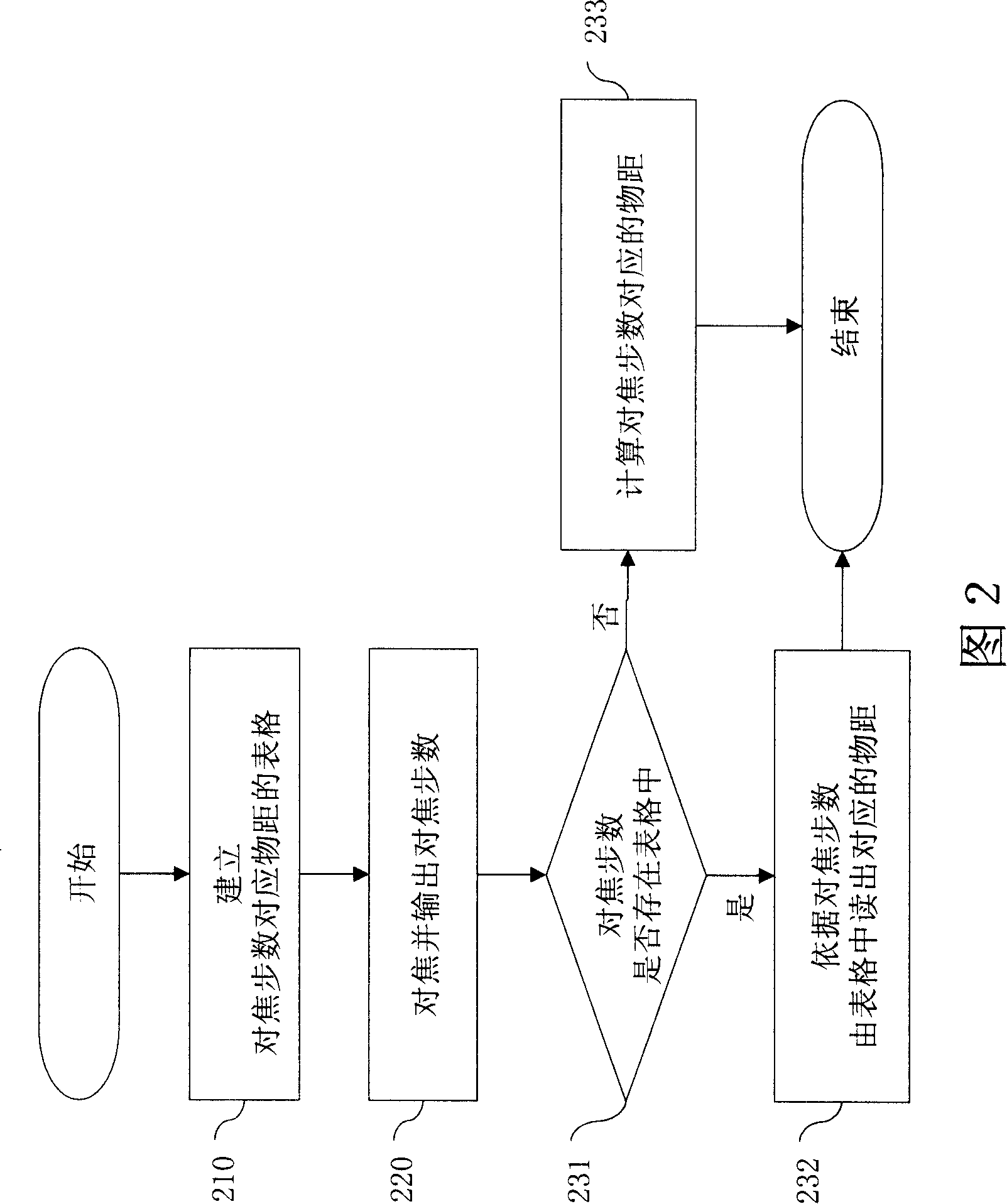

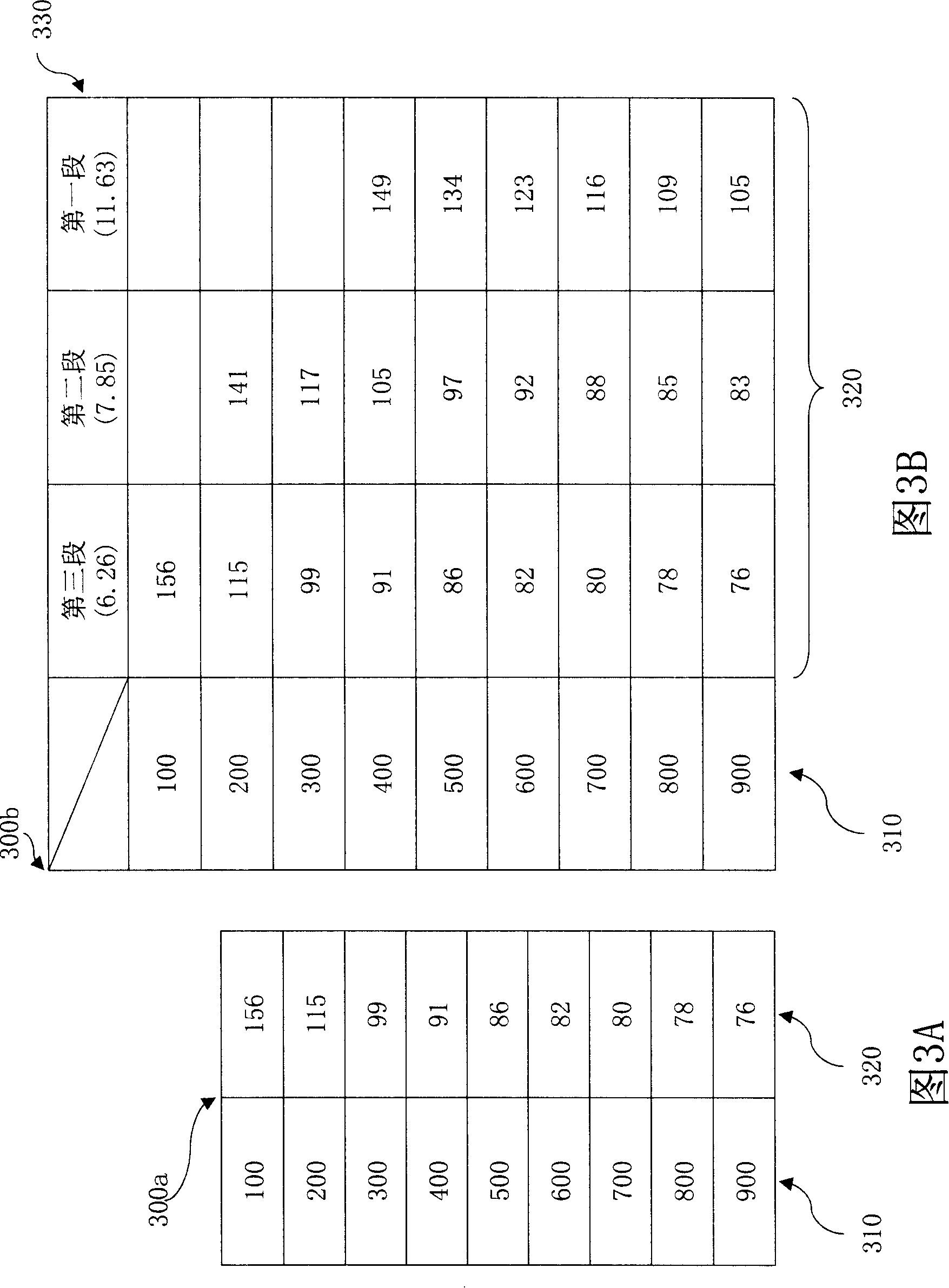

Method for calculating distance and actuate size of shot object

InactiveCN101183206AThe actual size is knownTelevision system detailsPicture taking arrangementsPattern recognitionComputer graphics (images)

The present invention provides a calculating method for distance between a photographed object and a real scale, which can be applied to a picture searching device. First of all, a relation-corresponded table is established, which is provided with focal step numbers and object distances (the distance between the picture searching device and the photographed object); next, the real scale can be gained by directly looking up the table after focusing. On the condition that the object distance and an image distance are known, an object height (the real scale of the photographed object) can be easily worked out by using a calculating formula ''an object distance / an object height equals to an image distance / an image height''; because the image height of the photographed object can be gained by the size of the corresponded pixel of the picture searching device and calculating.

Owner:ALTEK CORP

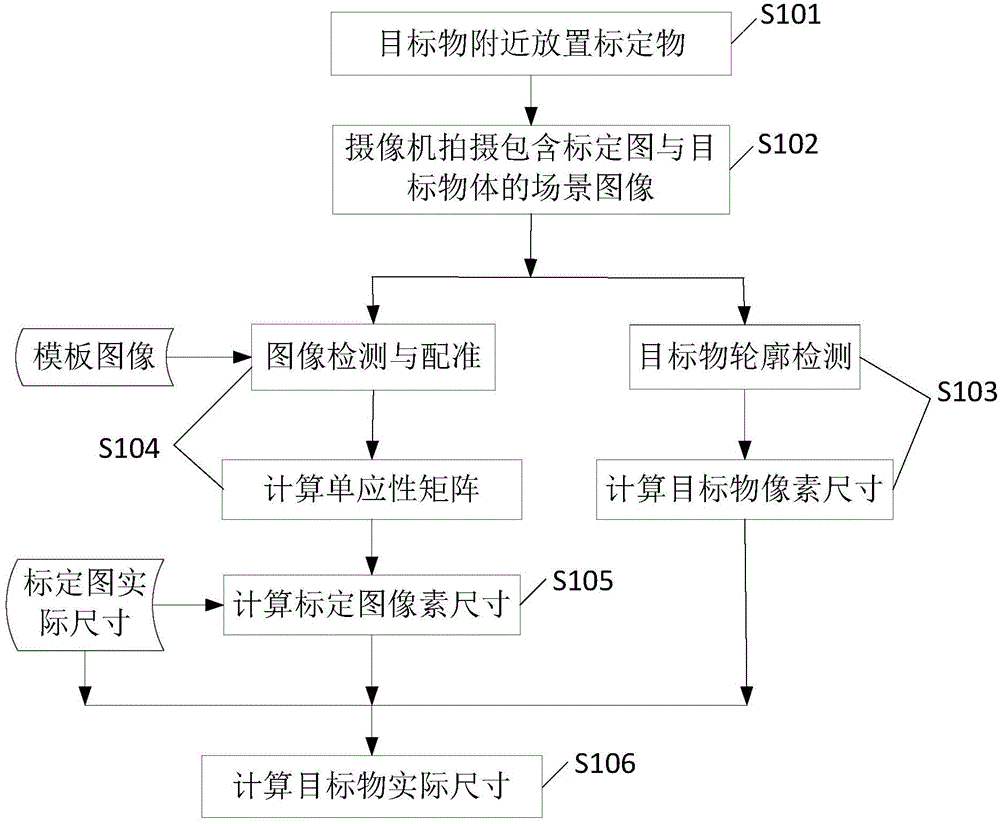

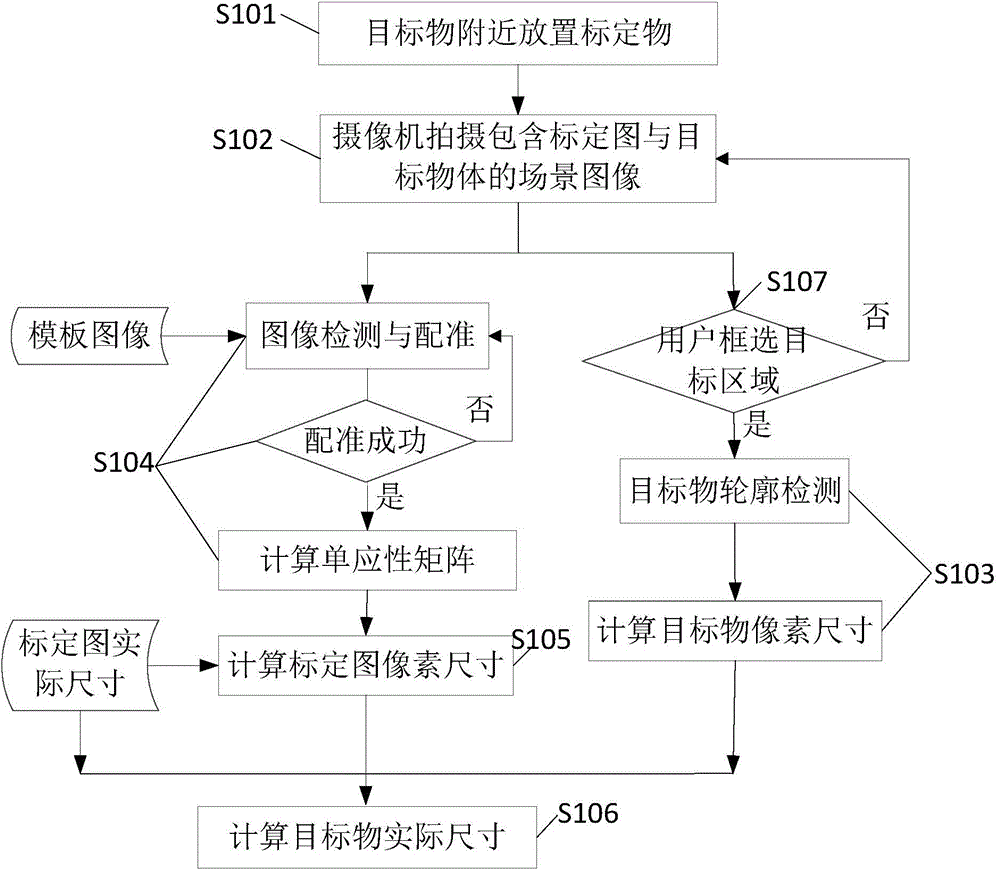

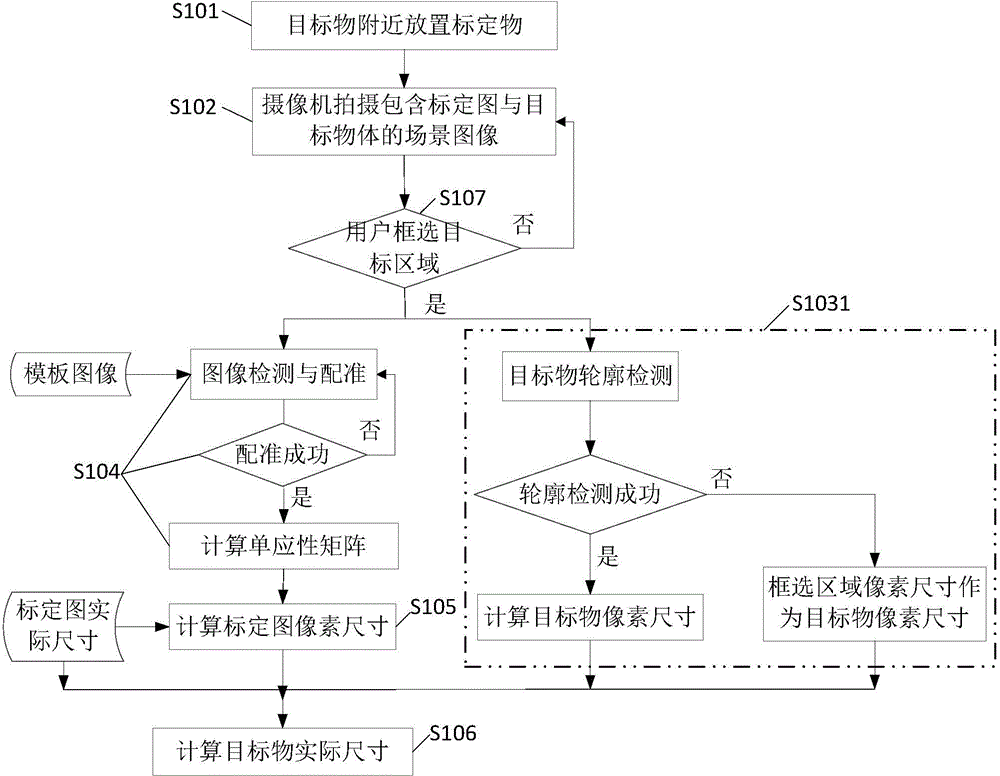

Object size measurement method and image database data acquisition method

InactiveCN105865326AQuick measurementAccurate measurementUsing optical meansSpecial data processing applicationsSize measurementData acquisition

Owner:CHENGDU IDEALSEE TECH

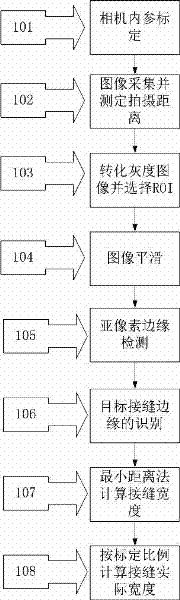

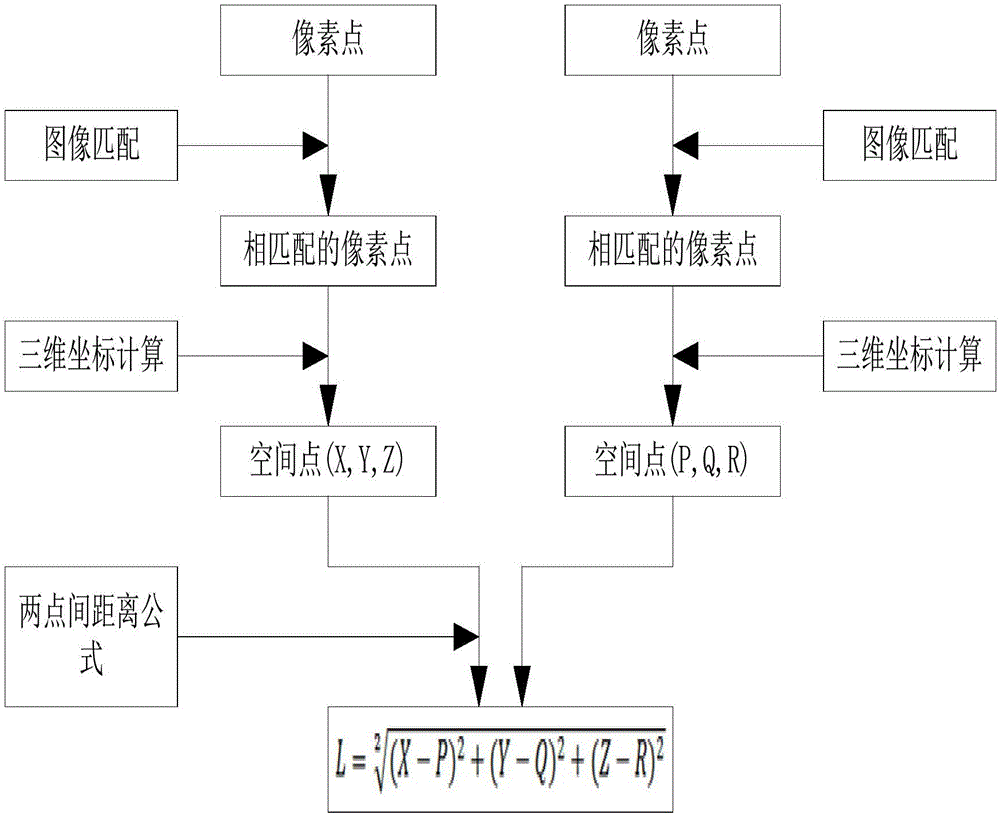

A method and device for measuring the opening width of a shield tunnel lining segment joint

InactiveCN102297660ALow costHigh precisionUsing optical meansNeural learning methodsLaser rangingLag

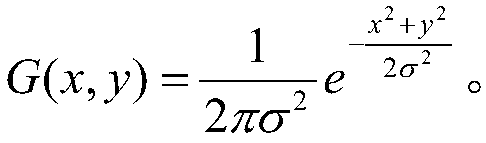

The invention relates to a measuring method of a shield tunnel lining segment seam open width and an apparatus thereof. The method comprises the following steps: using a computer vision kit to demarcate cameras, collecting segment seam images through the digital cameras and determining a shooting distance through a laser range finder; converting the collected images into grayscale images, selecting an appropriate filtering parameter and using a Gauss filter to smooth the images in a selected region of interest (ROI); determining a maximum threshold and a minimum threshold after the images aresmoothed and carrying out Canny lag threshold segmentation so as to obtain a sub-pixel linear characteristic of the images and a segment seam edge; screening needed sub-pixel segment seam edge imagesfrom the sub-pixel linear characteristic; using a normal vertical minimum distance method to respectively calculate a largest width and a mean width according to the obtained two sub-pixel segment seam edge images; determining a conversion proportion between a pixel dimension and an actual dimension according to a predetermined internal parameter of the cameras and calculating so as to obtain an actual width of the segment seam. The method and the apparatus have advantages of low costs and high precision. The method can be used rapidly and conveniently.

Owner:TONGJI UNIV

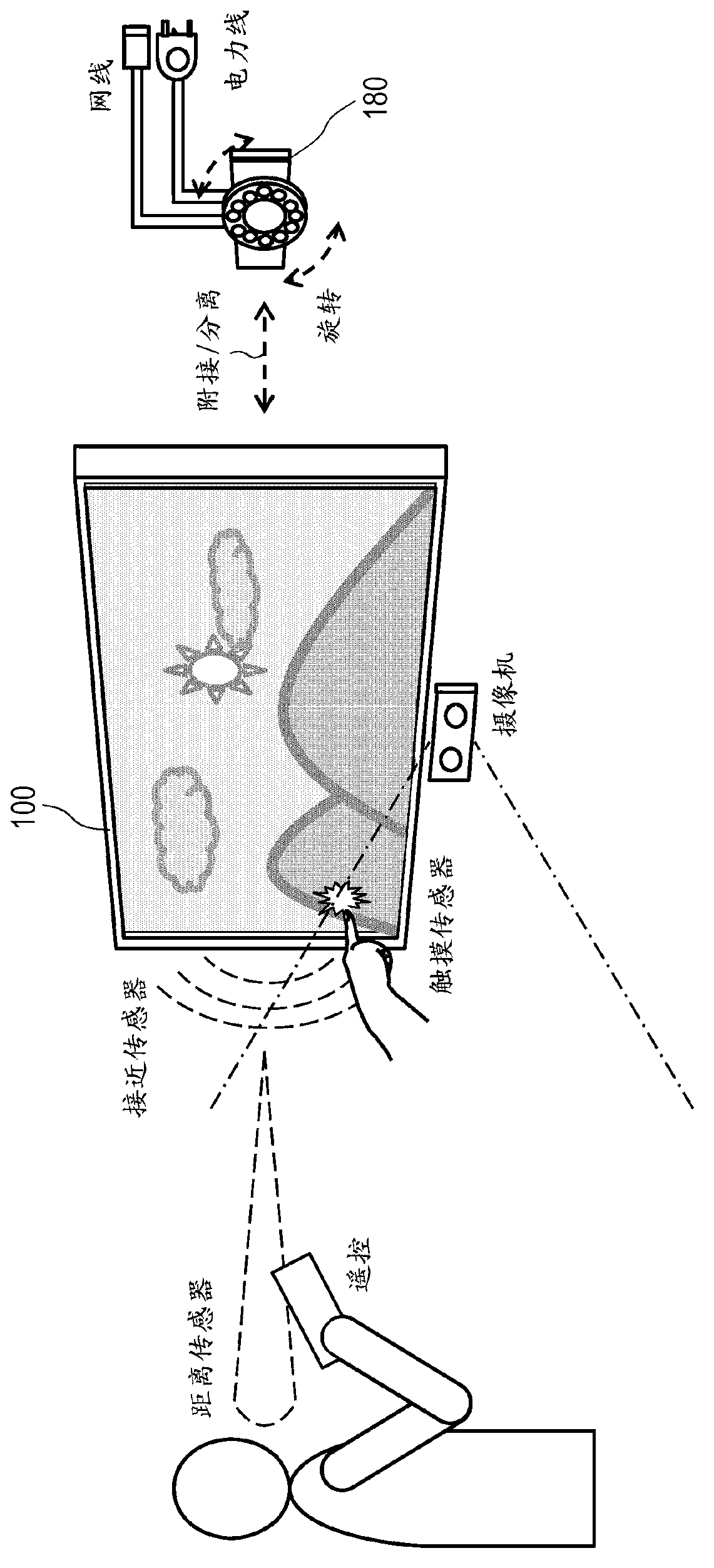

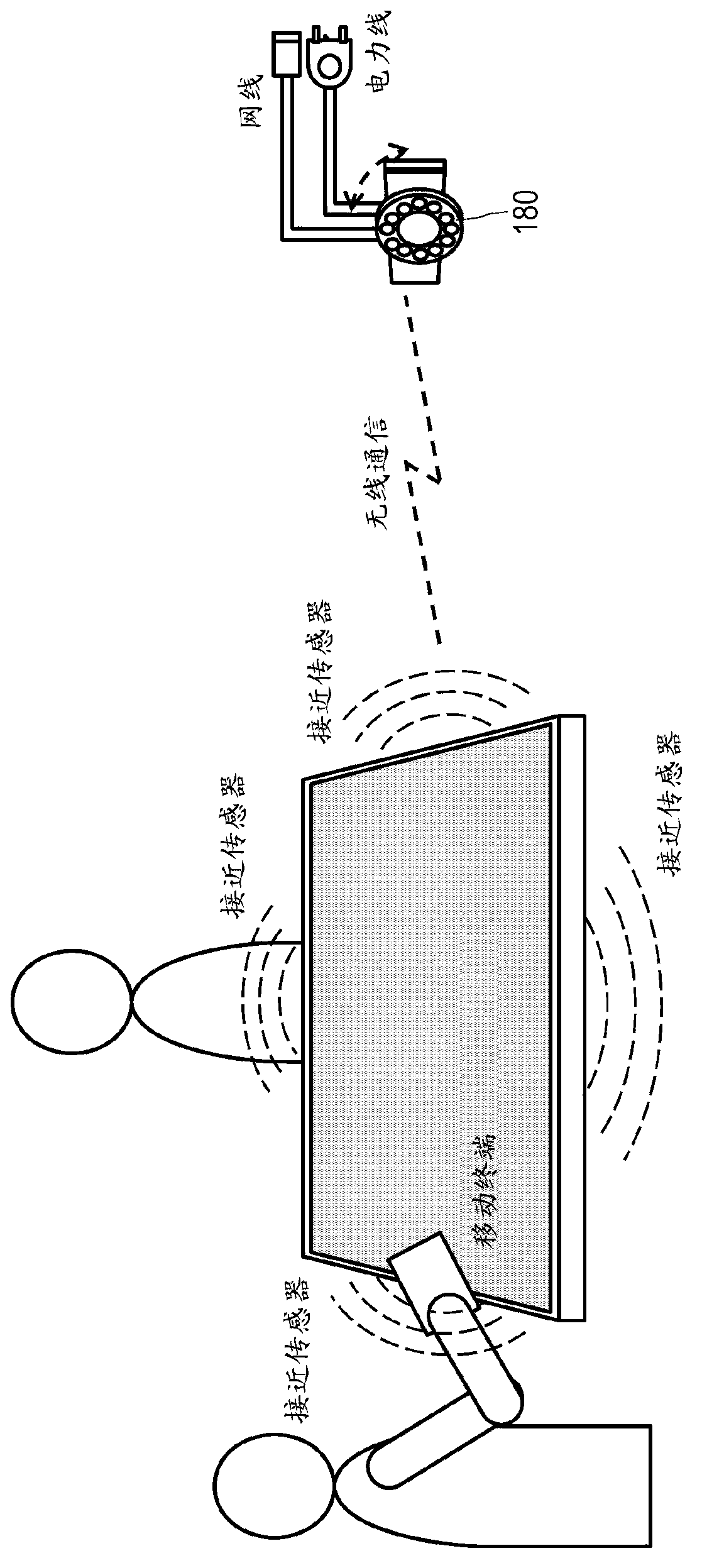

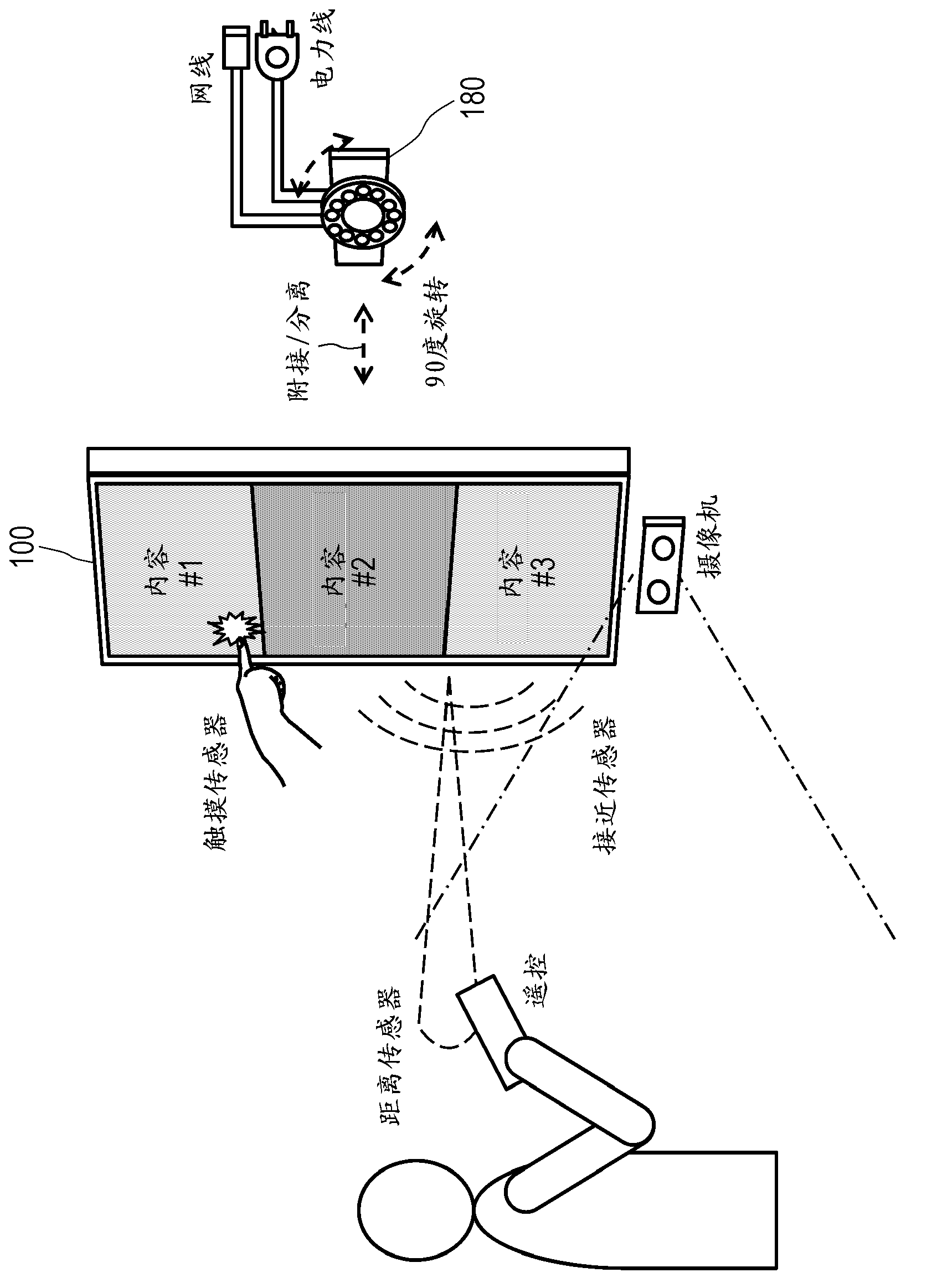

Information processing device, information processing method and computer program

ActiveCN103207668ASuitable for collaborative workSimple methodInput/output for user-computer interactionTelevision system detailsInformation processingComputer graphics (images)

Provided are an information processing device and an information processing method. The information processing device includes a display unit; an object image obtaining unit configured to obtain images of objects to be displayed on the screen of the display unit; a real size obtaining unit configured to obtain information related to the real size of the objects to be displayed on the screen of the display unit; and a calculating unit configured to process the images of the objects, based on the real size of the objects obtained by the real size obtaining unit.

Owner:SONY CORP

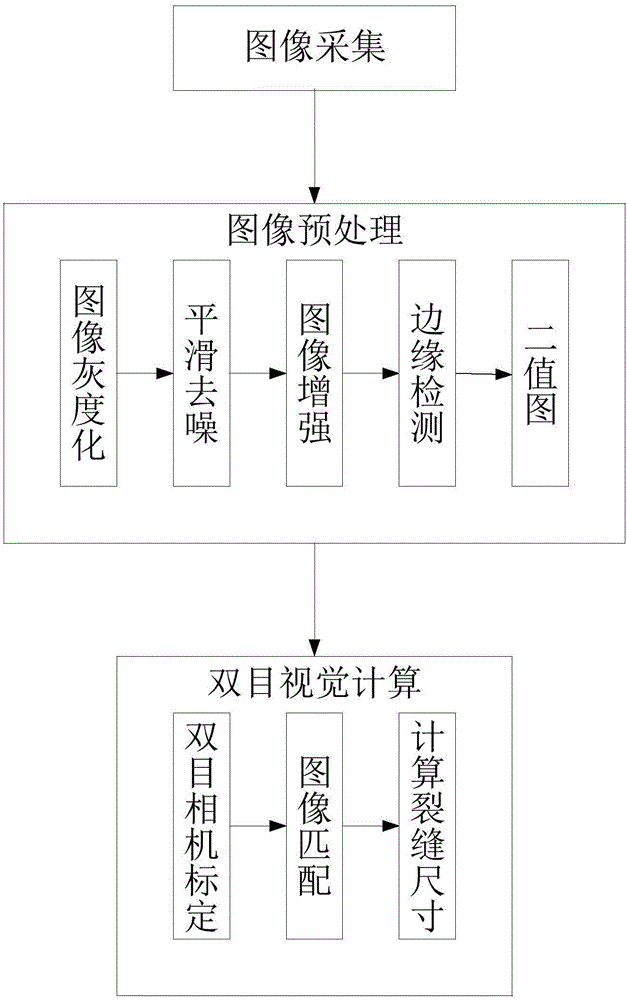

Bridge bottom surface crack detecting method based on binocular vision

InactiveCN107179322AKeep detailsAvoid excessive smoothingOptically investigating flaws/contaminationImaging processingCalculation error

The invention discloses a bridge bottom surface crack detecting method. The real size of cracks is reduced by binocular vision; the errors are greatly avoided; the condition that in the monocular vision, the shooting plane of a camera in the monocular vision is not parallel to the bridge bottom surface, so that a shot crack image in only the projection of the crack on the shooting plane of a monocular camera is avoided; in the monocular vision, the crack picture is subjected to simple image processing, so that the calculation error is great; only the projection size of the crack on the shooting plane of the monocular camera is obtained; the size is not the real size of the crack; in the image processing aspect, improved median filter is used. Compared with the traditional median filter, the method has the advantages that the condition that all pixel points in the image need to perform median replacement is avoided; only detected noise points need to perform median replacement; by the method, the detail information of the crack in the image is greatly preserved; the excessive smoothing of the crack image after wave filtering is avoided.

Owner:CHANGAN UNIV

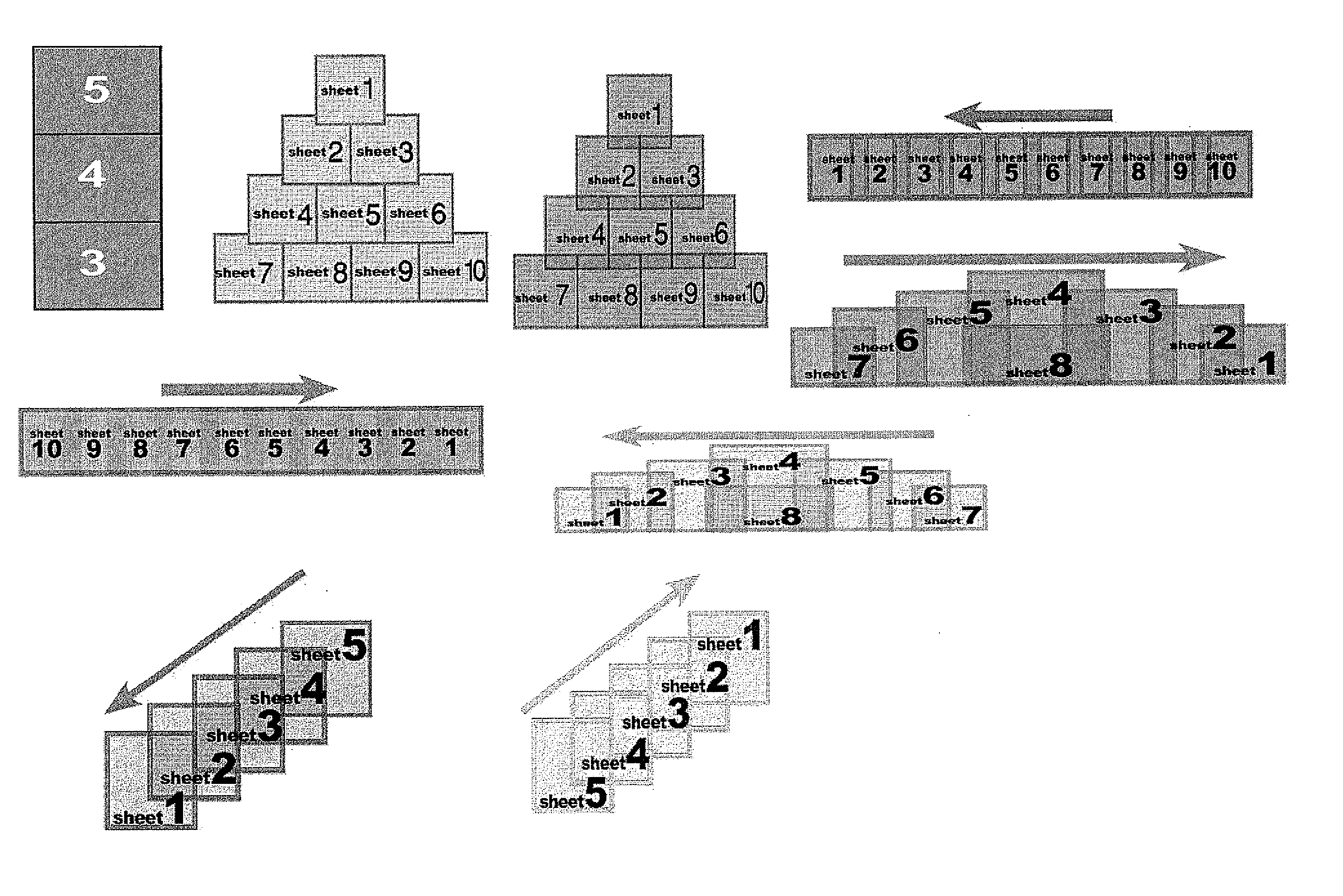

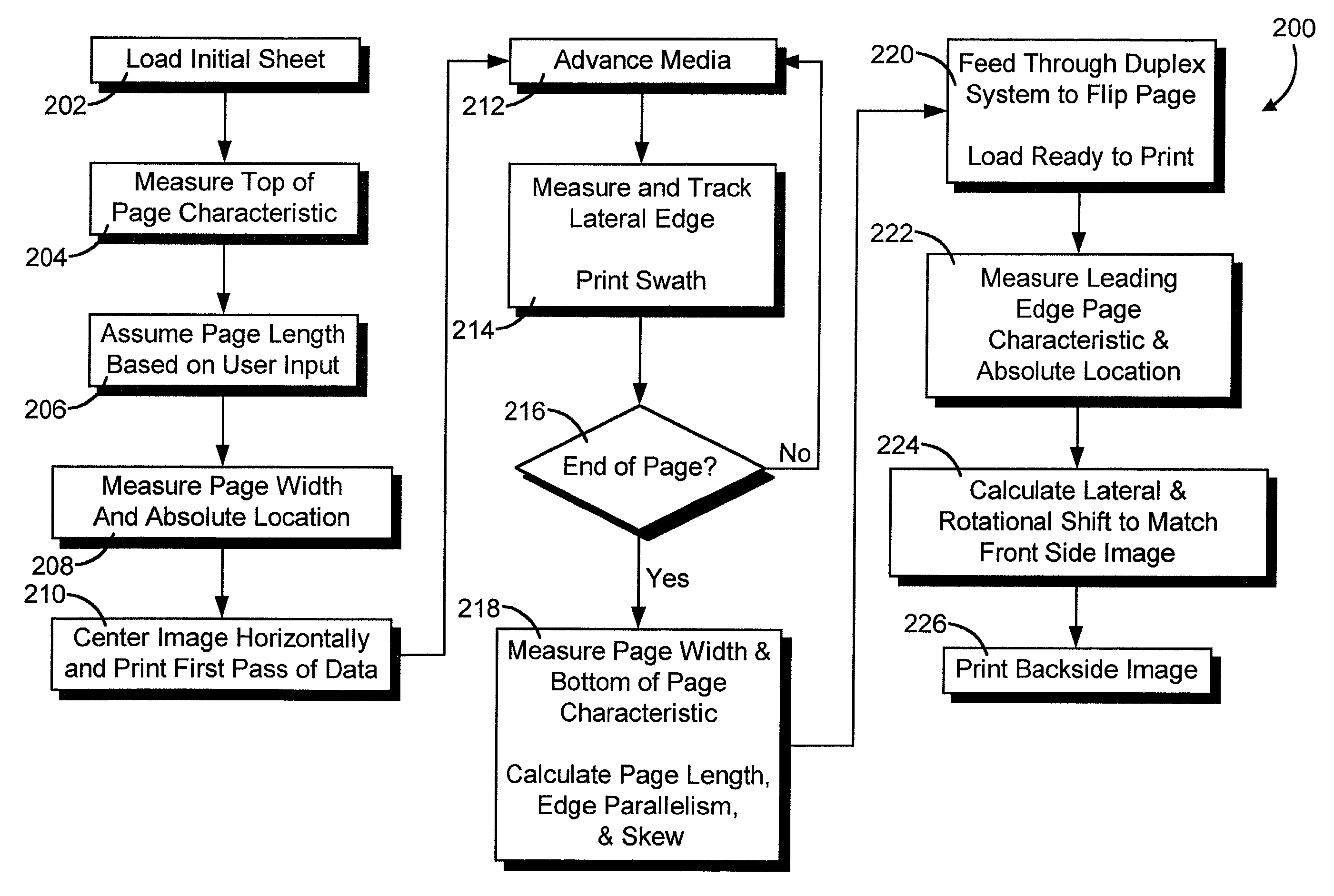

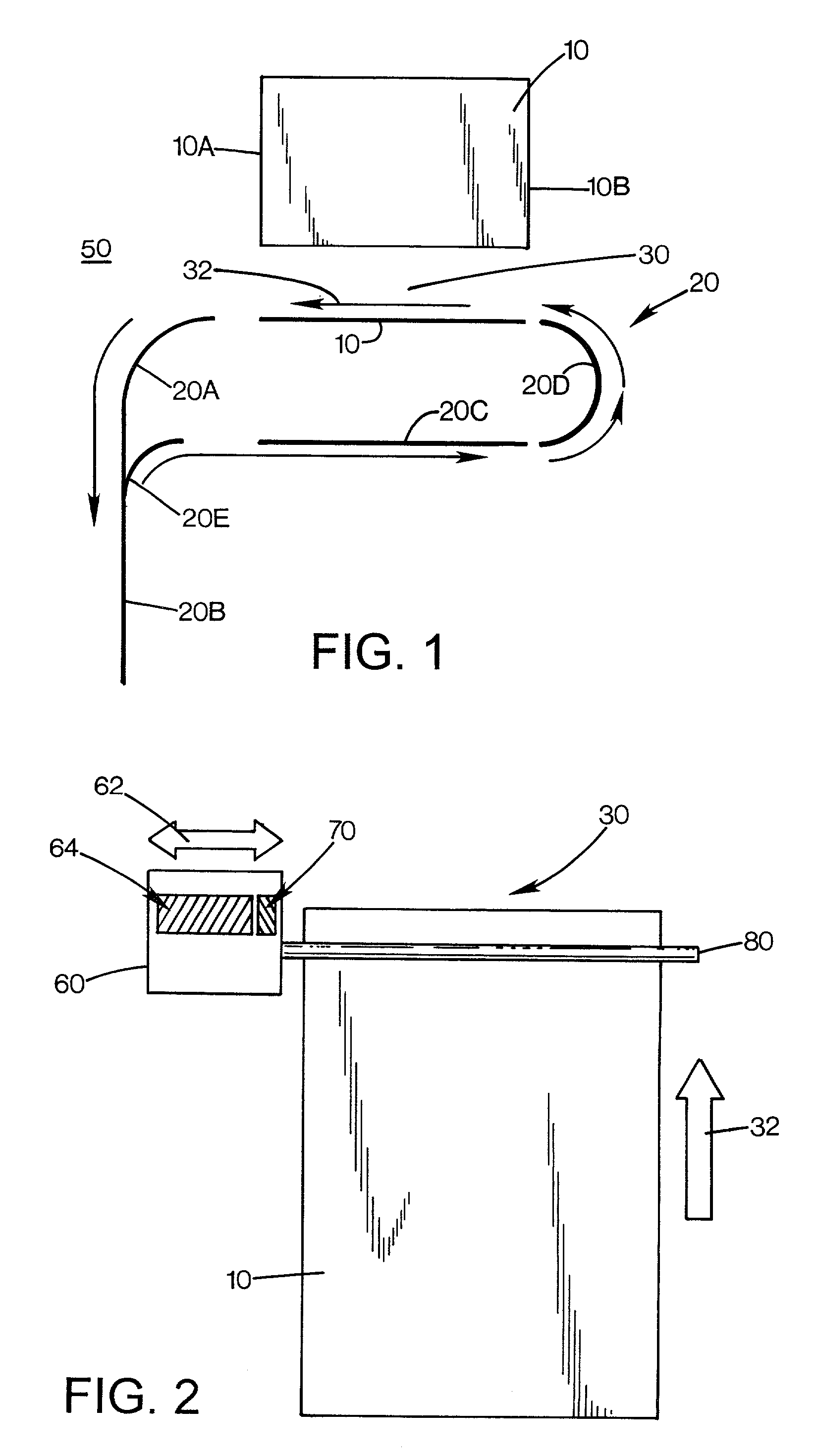

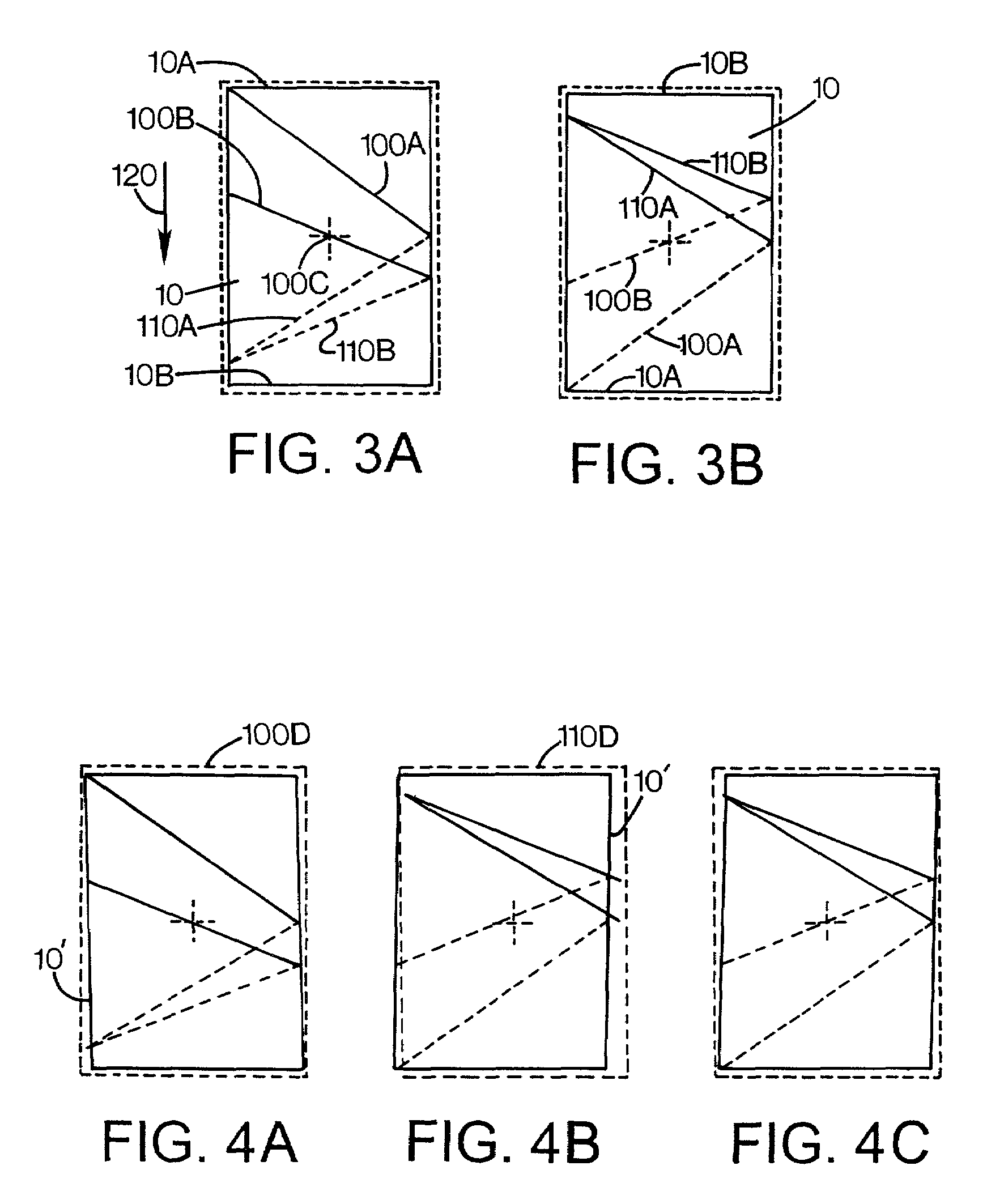

Techniques for aligning images using page characteristics and image shifting

InactiveUS7456995B2Digitally marking record carriersDigital computer detailsComputer graphics (images)Real size

Owner:HEWLETT PACKARD DEV CO LP

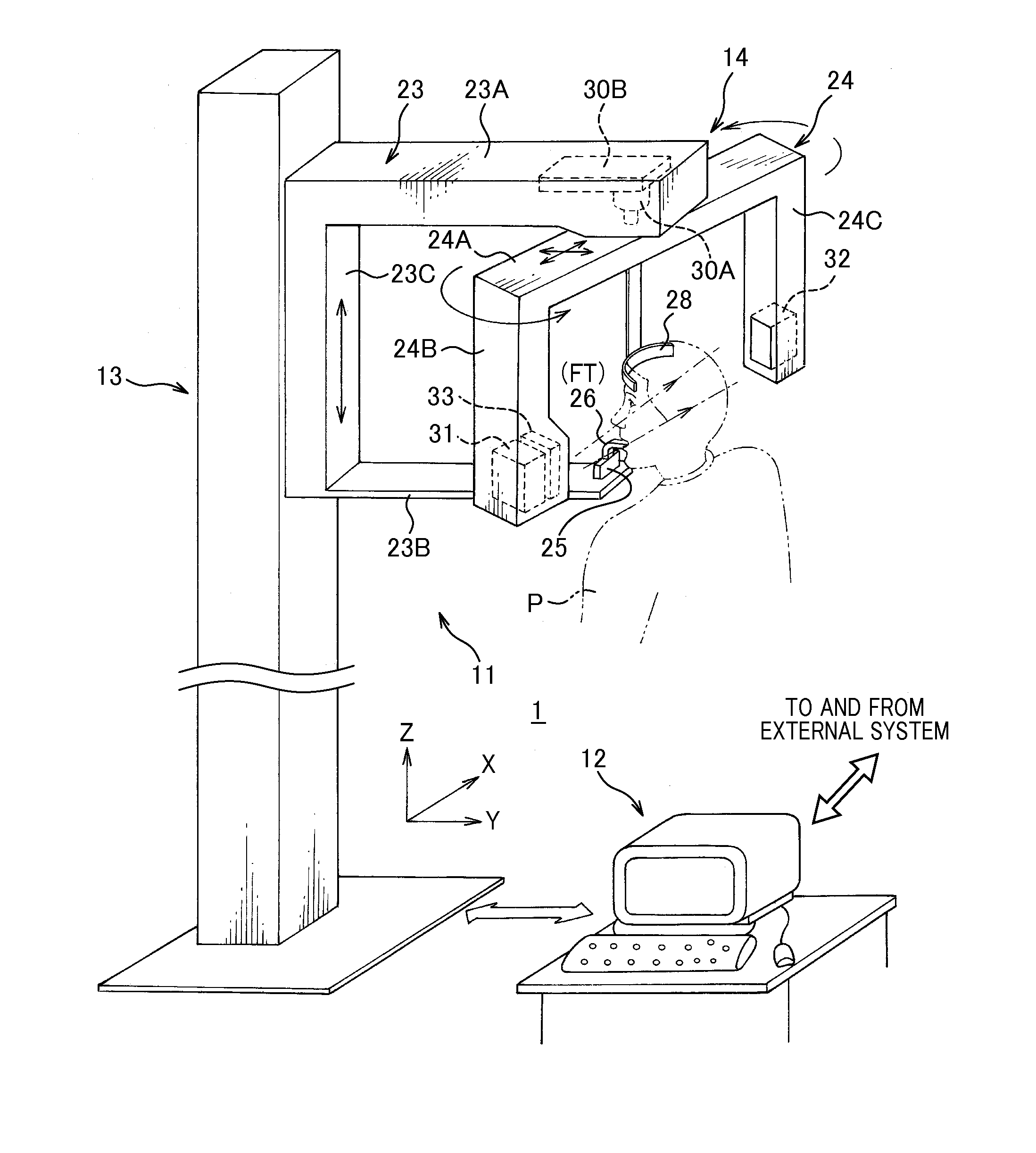

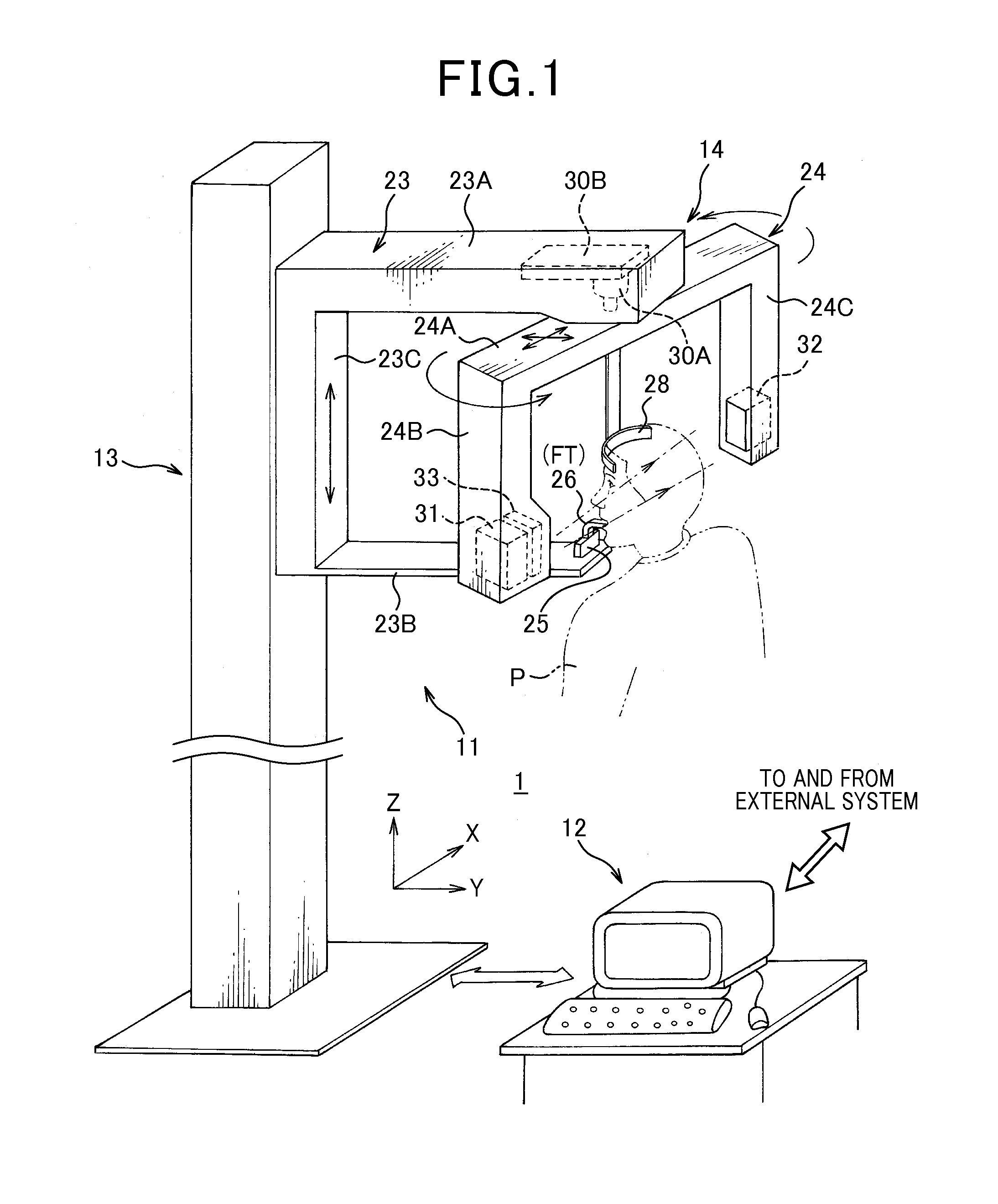

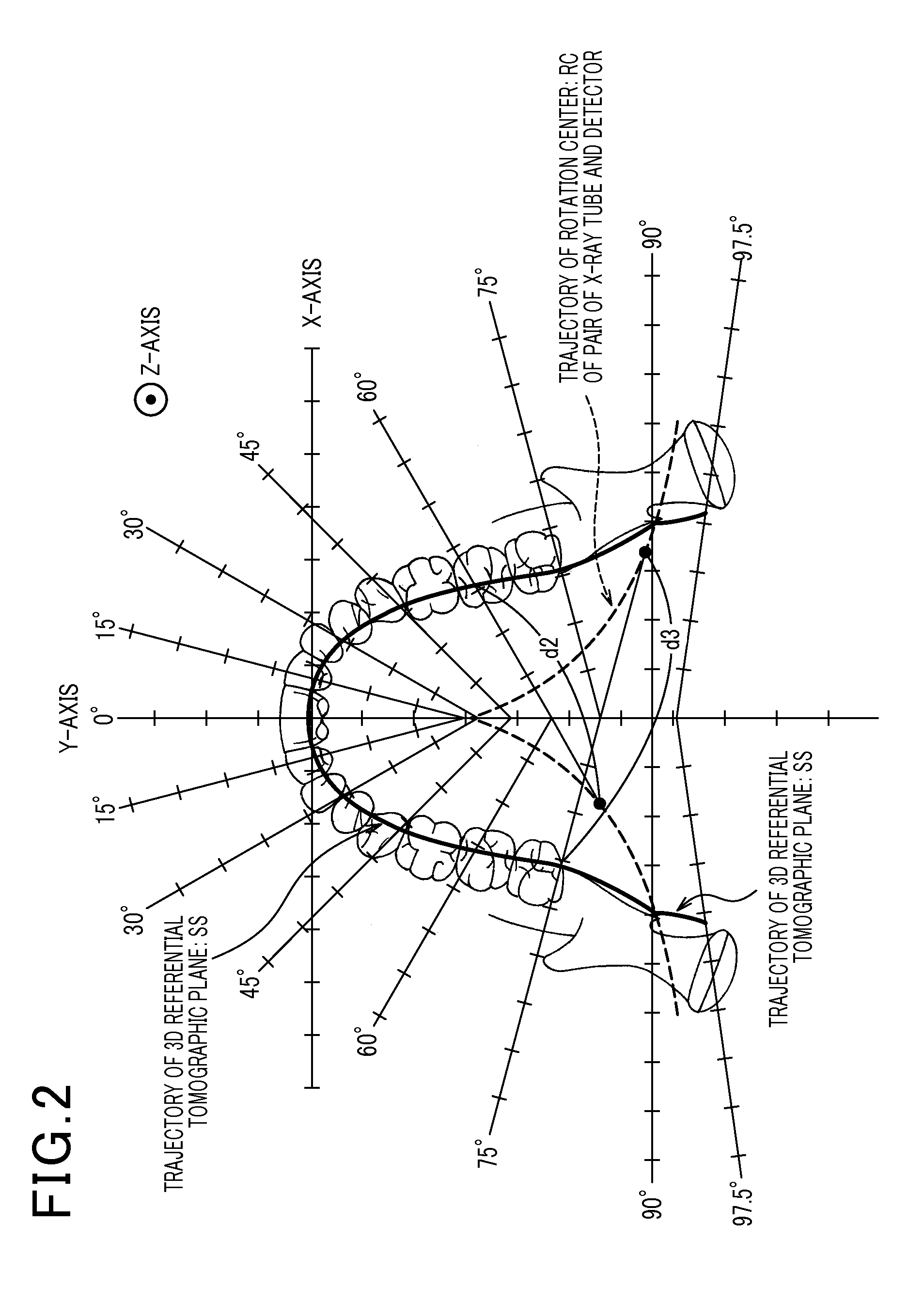

Radiation imaging apparatus and imaging method using radiation

ActiveUS20120230467A1Reduce removalFocusMaterial analysis using wave/particle radiationRadiation/particle handlingRadiation imagingX-ray

There is provided a panoramic imaging apparatus which serves as a radiation imaging apparatus. The panoramic imaging apparatus includes an X-ray tube radiating an X-ray as a radiation, a detector outputting digital-quantity frame data corresponding to an incident X-ray, and moving means moving the pair of X-ray tube and the detector relatively to an object. The apparatus further includes means for acquiring the frame data from the detector during movement of the X-ray tube and the detector, and means for optimally focusing a portion being imaged of the object using the acquired data and producing a three-dimensional optimally focused image in which the real size and shape of the portion being imaged are reflected.

Owner:TAKARA TELESYST

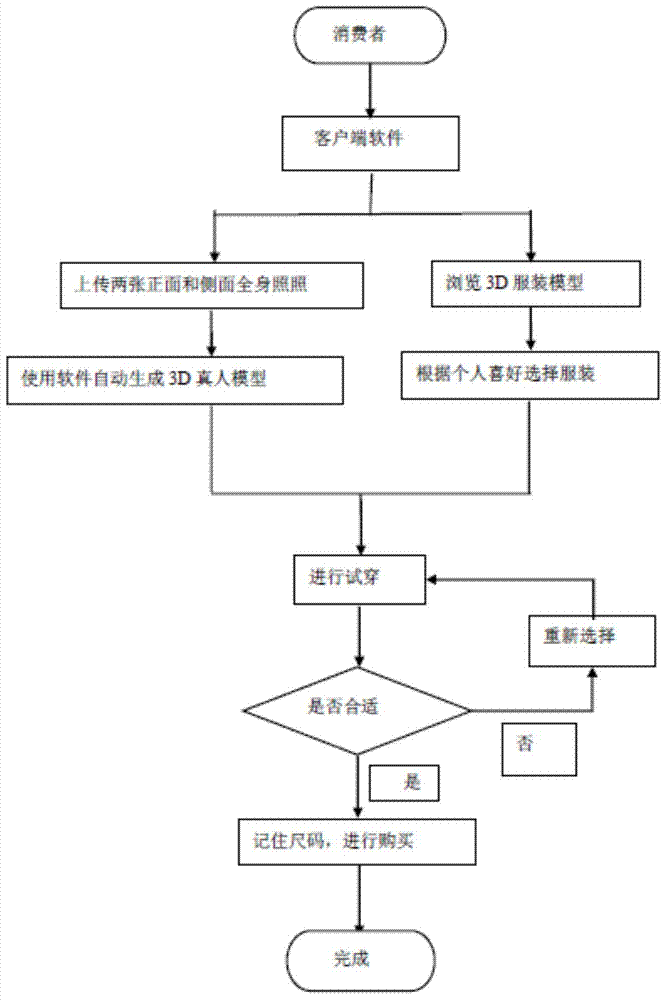

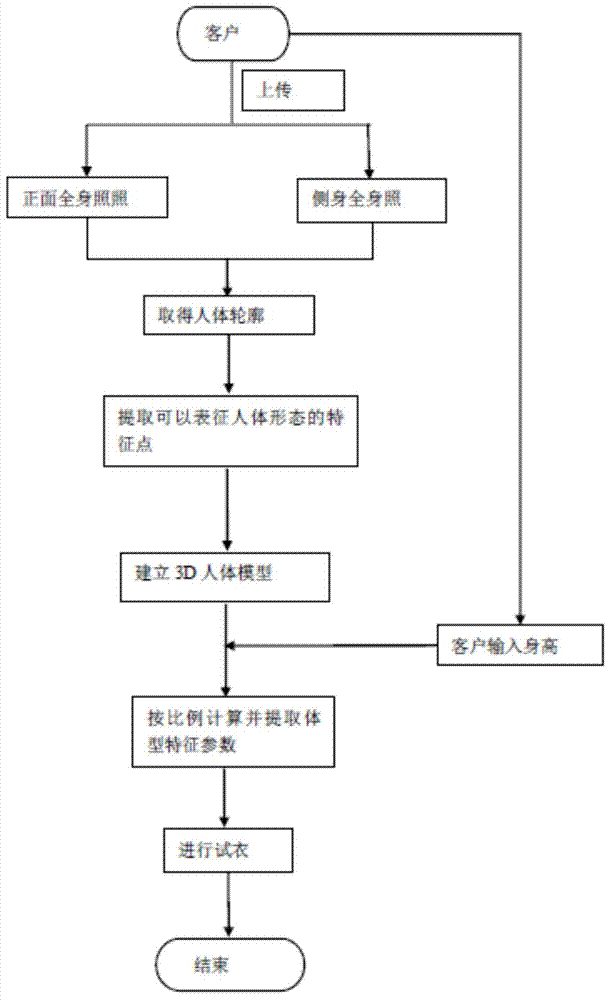

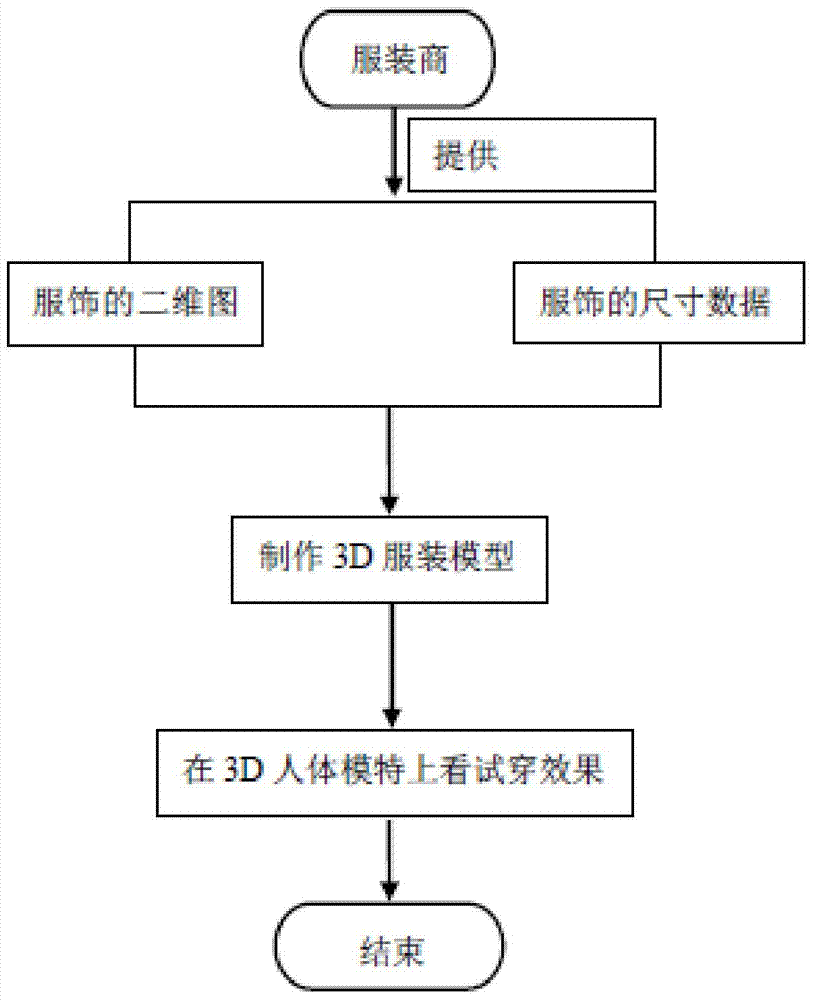

Taobao virtual fitting system

The invention relates to a taobao virtual fitting system; a customer uses client software on a computer to visit 3D virtual clothes and decorations of various brands provided by the system on internet, thus carrying out clothes fitting; the 3D clothes provided by the system can be visited for fitting online, and are set up according to standard data of clothes images and sizes provided by a clothes provider; the customer can use a camera head to take two body photos including a front photo and a side photo, so a real person 3D model can be automatically generated by the software of the system; the system generates figure size data of the customer in a real proportion according to the height inputted by the customer, thus realizing 3D virtual clothes trying on. 3D body model virtual clothes fitting can be realized according to customer figure size data and real sizes of various clothes under various sizes, so wearing effect on the model can be presented under each clothes size, and the customer can determine a suitable size.

Owner:NANJING ZHUANCHUANG INTPROP SERVICES

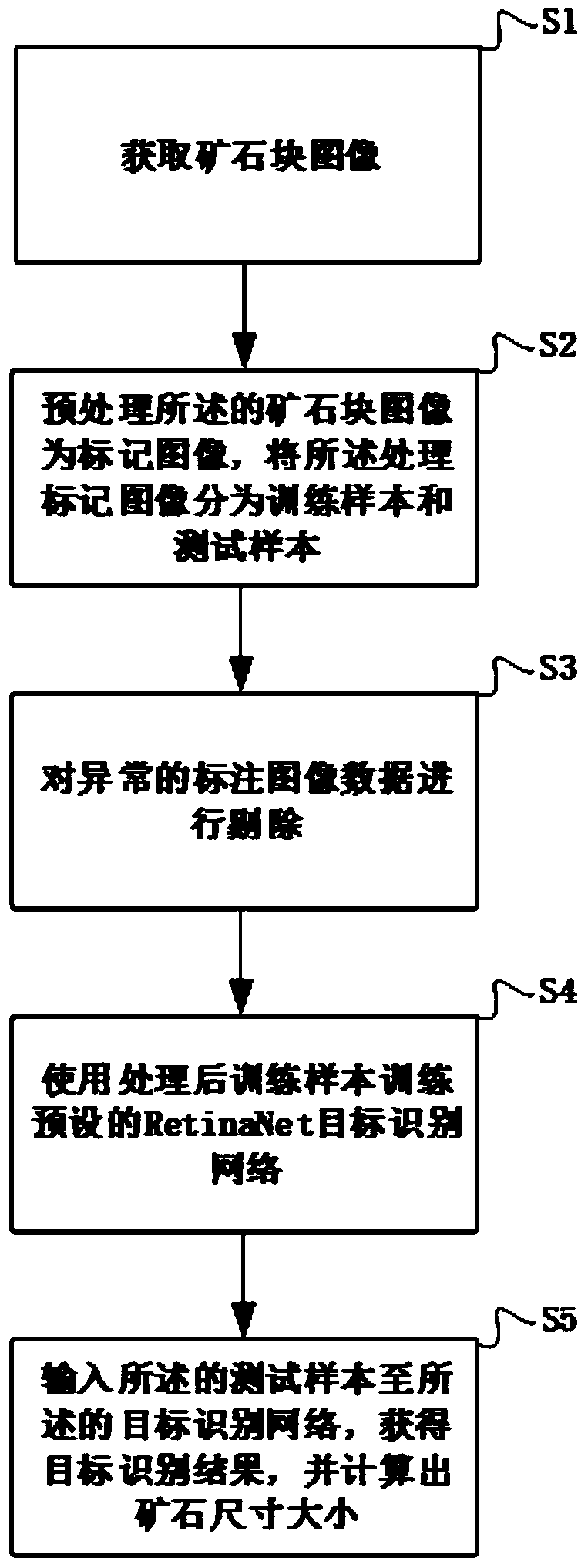

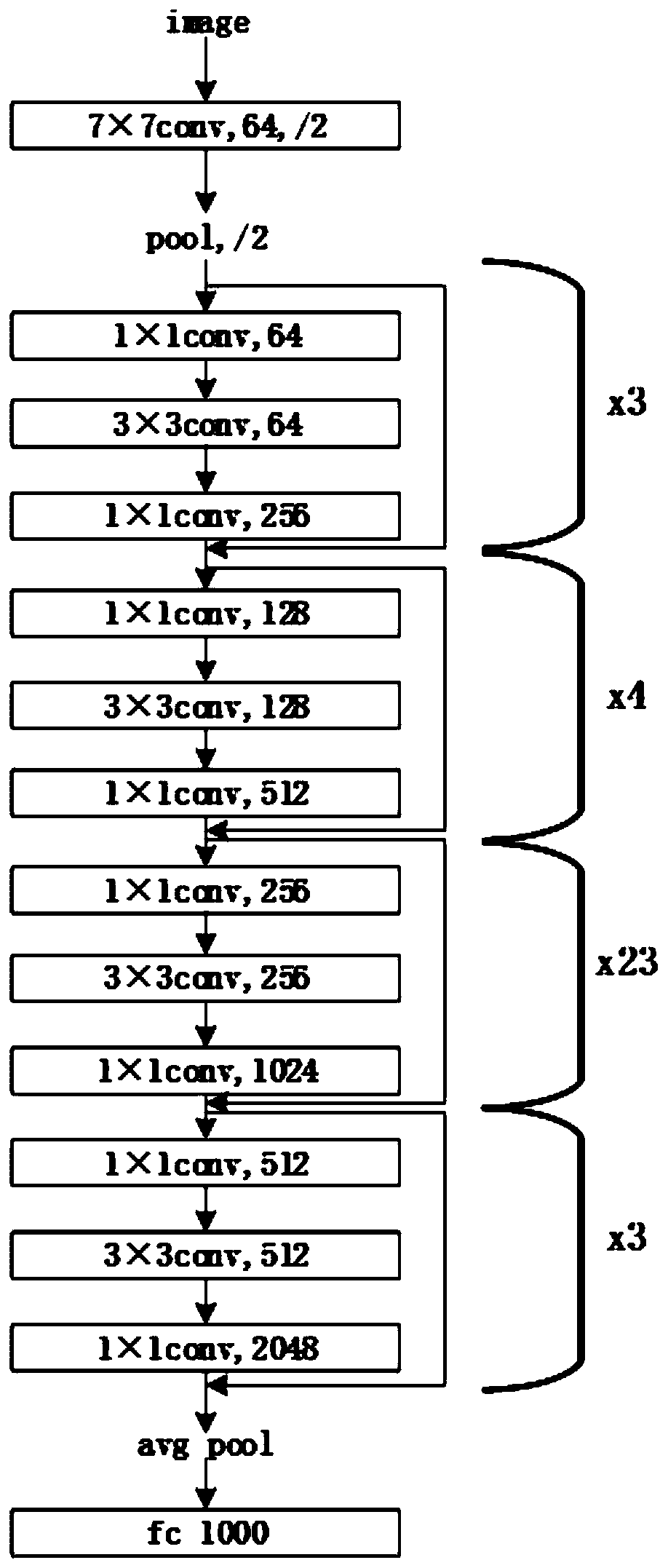

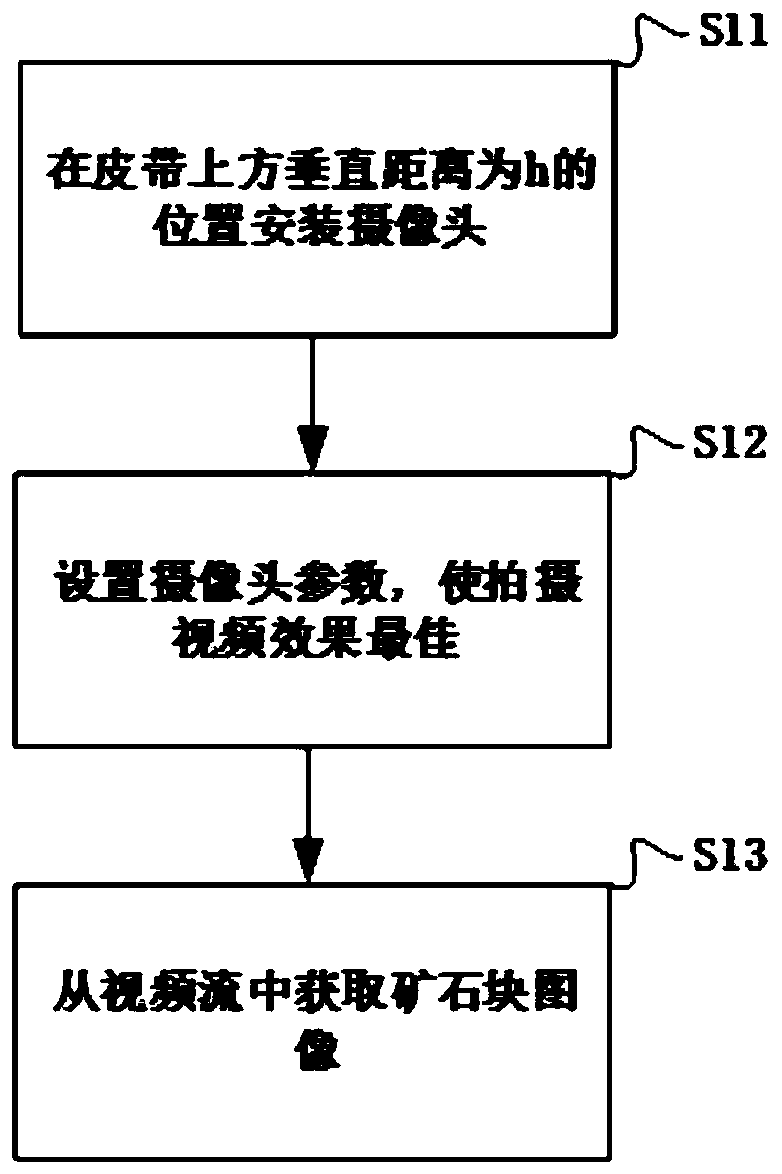

Ore scale measurement method based on deep learning and application system

InactiveCN110390691AImprove accuracyEasy to useImage enhancementImage analysisTest sampleNetwork model

The invention discloses an ore scale measurement method based on deep learning and an application system. The method comprises the following steps: obtaining an ore block image; image preprocessing: processing the implemented ore block image into a marked image, and dividing the marked image subjected to processing into training sample boxes and test samples; removing the abnormal marked image data; training a preset RetinaNet target recognition network by using the processed training sample; inputting the test sample to a target identification network to obtain a target identification result,and calculating the size of the ore; the invention discloses an ore scale measurement method based on deep learning and an application system. The RetinaNet target recognition network is trained by adopting a labeled ore image sample; the trained network model is obtained to be used for classifying and positioning the ore blocks, the real sizes of the ore blocks are calculated, complex features do not need to be extracted manually, the detection efficiency is high, and the problem that efficiency is low in traditional ore scale measurement is solved.

Owner:合肥合工安驰智能科技有限公司

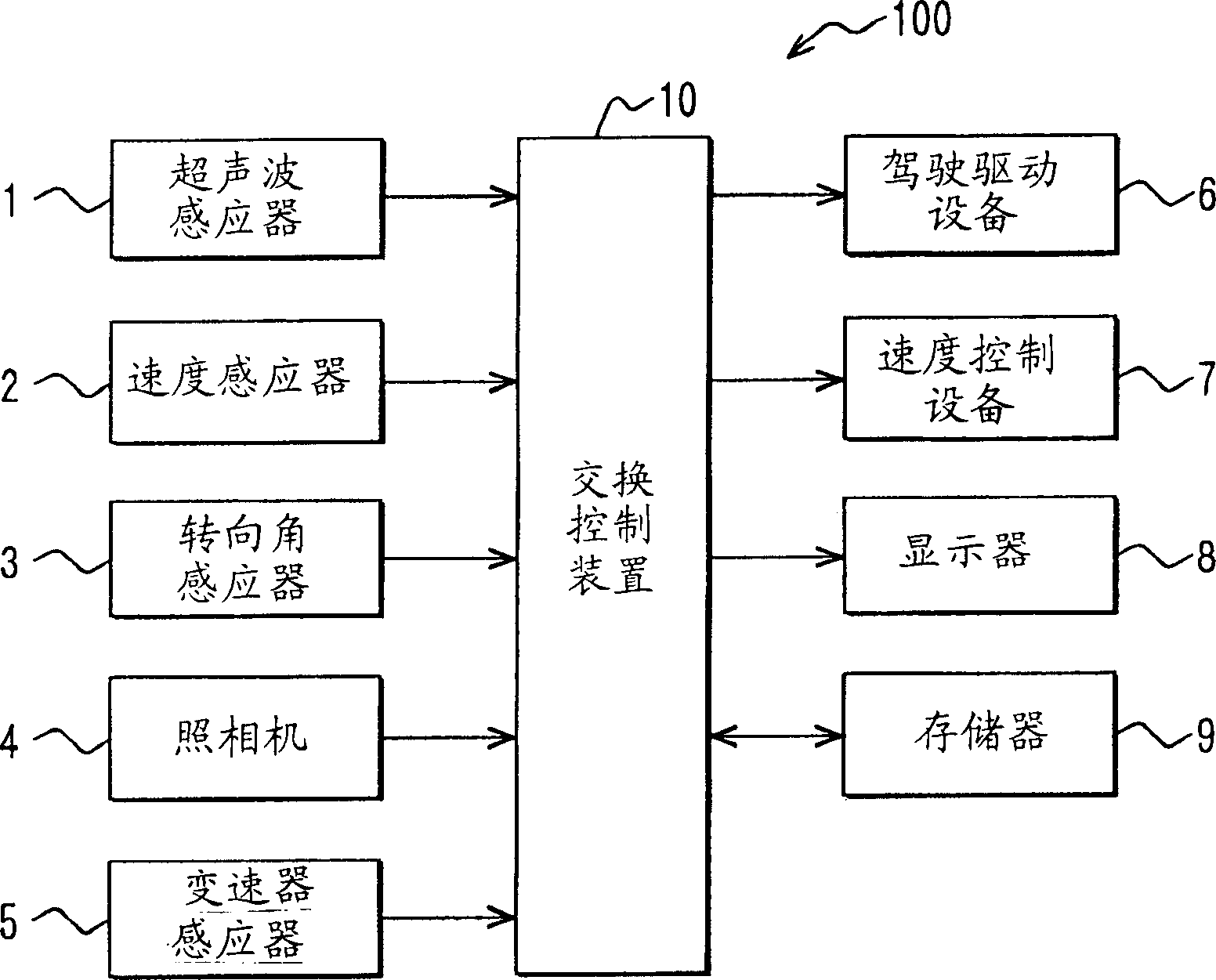

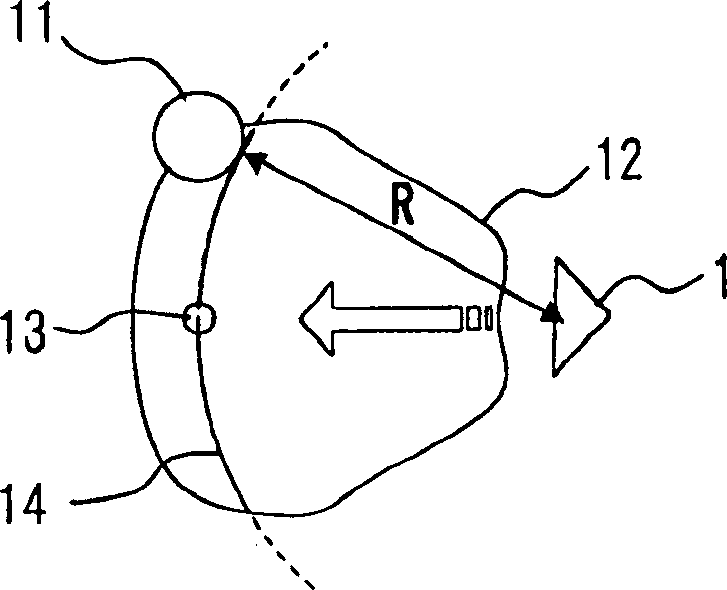

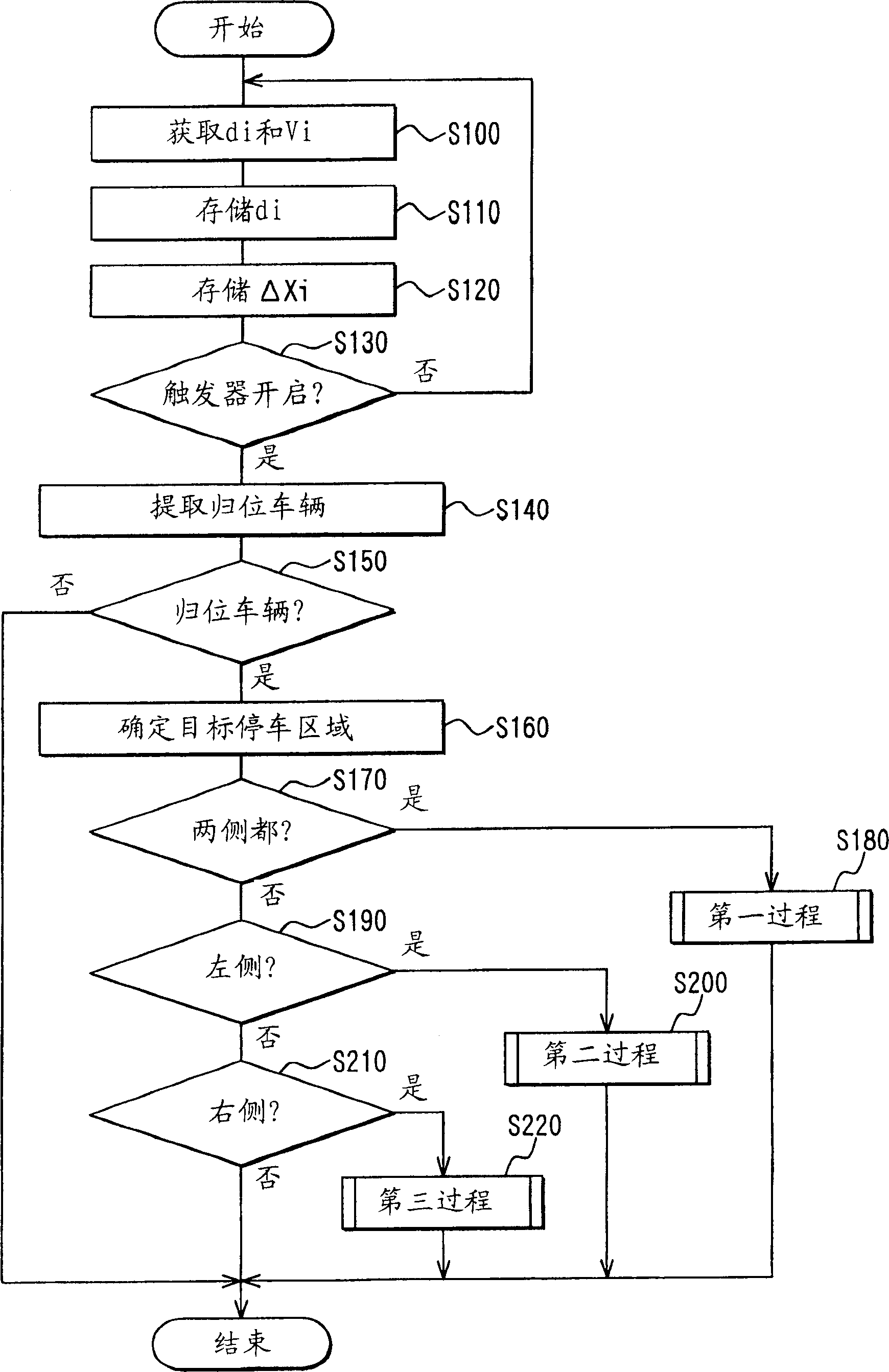

Parking assistance system

ActiveCN1713099AHigh precisionIndication of parksing free spacesAnti-collision systemsUltrasonic sensorReal size

By using the ultrasonic sensor (1) and the speed sensor (2) while the subject vehicle is stopped and moved backwards, the detection distance data item (di) and the forward distance data item (ΔXi) are obtained. These data items are stored together with data items related to each other. The detection distance data item indicates the distance to the home vehicle adjacent to the target vehicle and the forward distance data item indicates the distance forward of the target vehicle. When the size of the home vehicle is calculated from the forward distance data item, the size of the home vehicle is determined to be smaller than the total distance corresponding to the forward distance data item. This makes it possible for the determined dimensions of the home vehicle to be close to the true dimensions of the home vehicle.

Owner:DENSO CORP

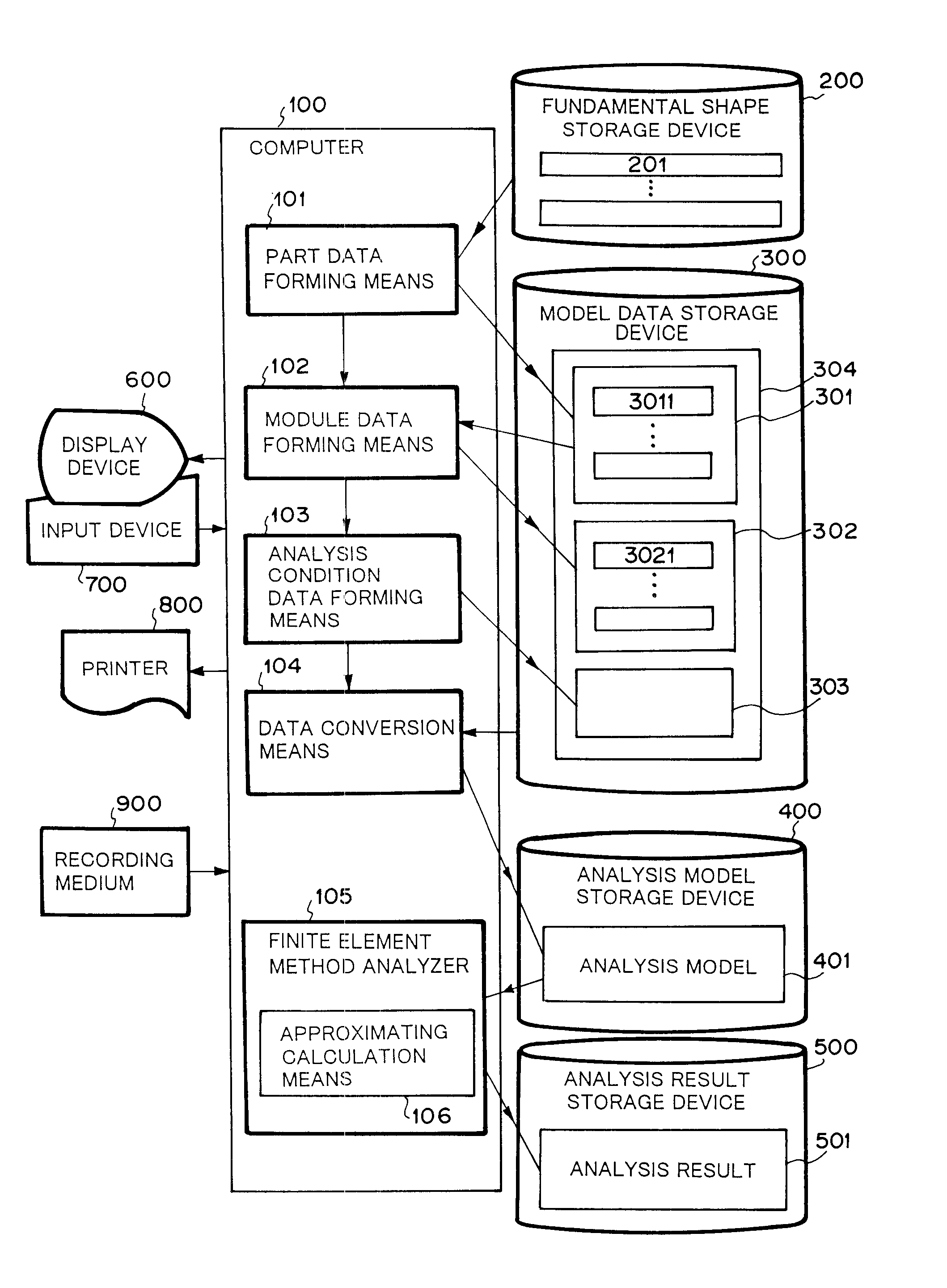

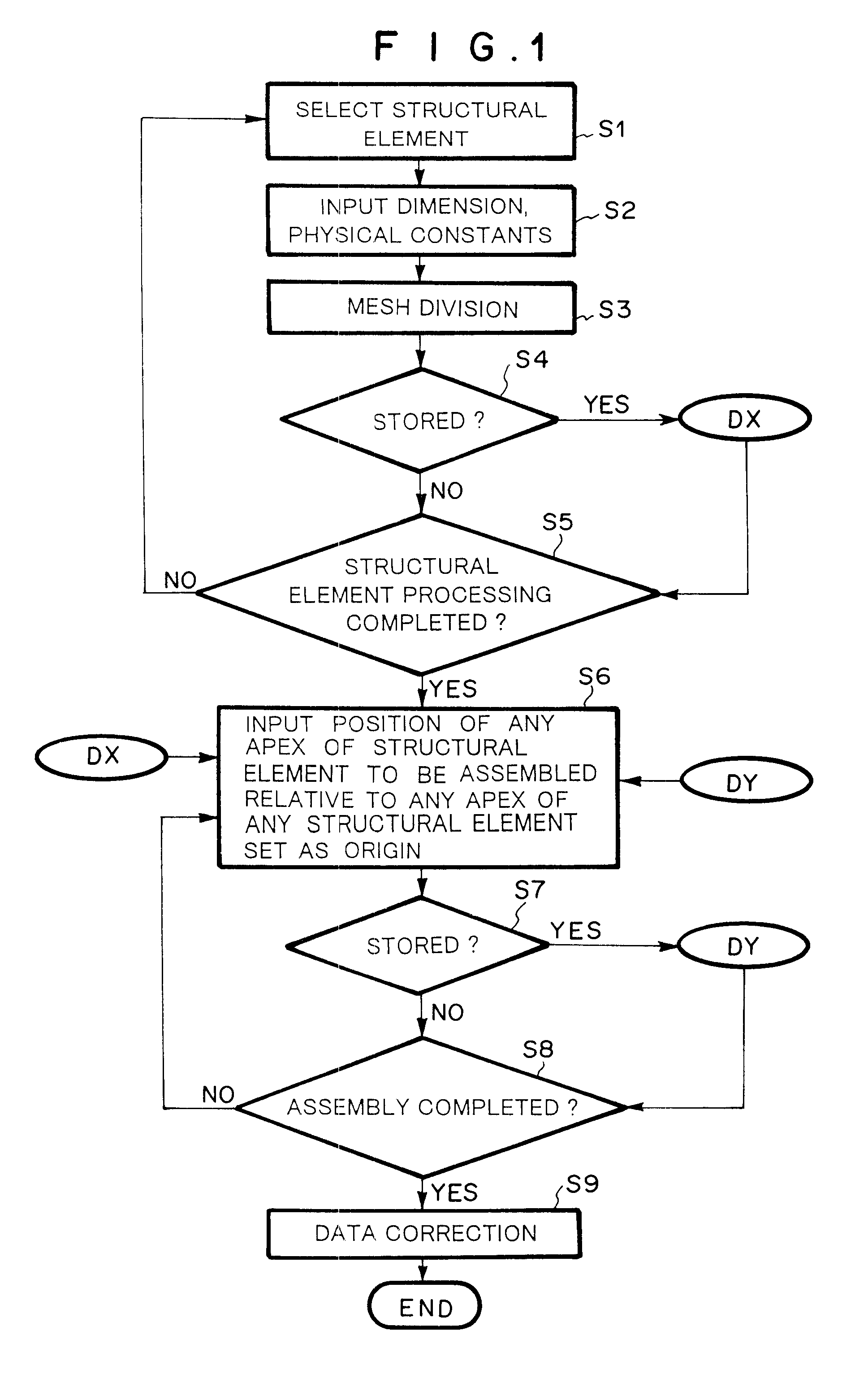

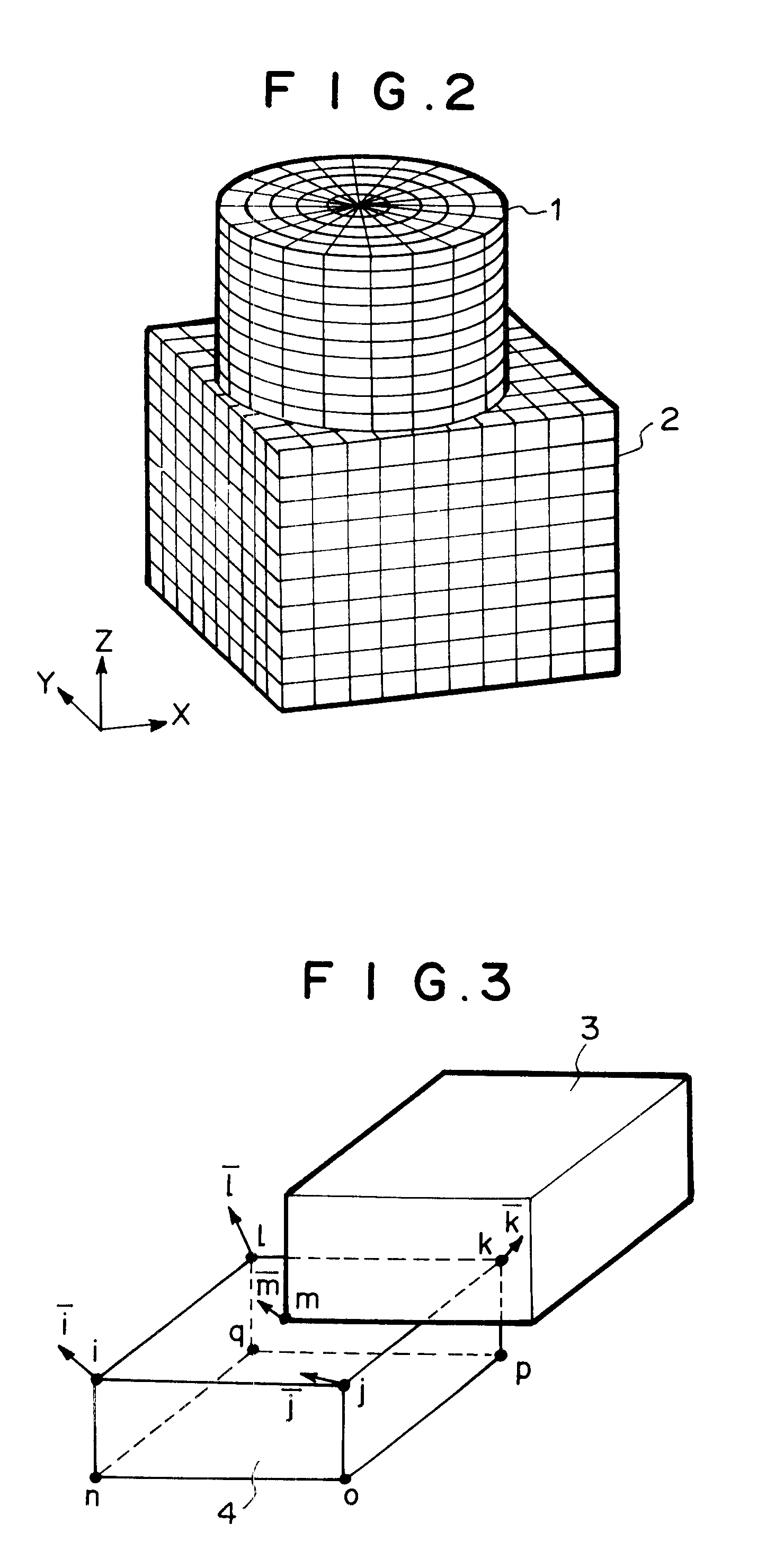

Method, apparatus and computer program product for forming data to be analyzed by finite element method and calculation method based on finite element method

InactiveUS6618694B1Computation using non-denominational number representationDesign optimisation/simulationAnalysis dataMixed finite element method

A user uses part data forming means 101 and module data forming means 102 to input the actual dimension, physical constants and mesh dividing number for fundamental shapes which are registered in advance, thereby forming parts, and then indicates the relative position between the parts to form the entire shape of an assembly of plural parts without paying attention to coincidence or non-coincidence of nodal points. Data converting means 104 divides the shape of each part thus assembled according to the indicated mesh divisional number to generate element data and nodal point data. Further, it generates a constraint equation for connecting nodal points which are non-connected between neighboring parts, and forms an analysis model 401. A finite element method analyzer 105 uses approximate calculation means 106 to approximate a non-connected nodal point displacement from a nodal point displacement of neighboring structural elements on the basis of the constraint equation.

Owner:NEC CORP

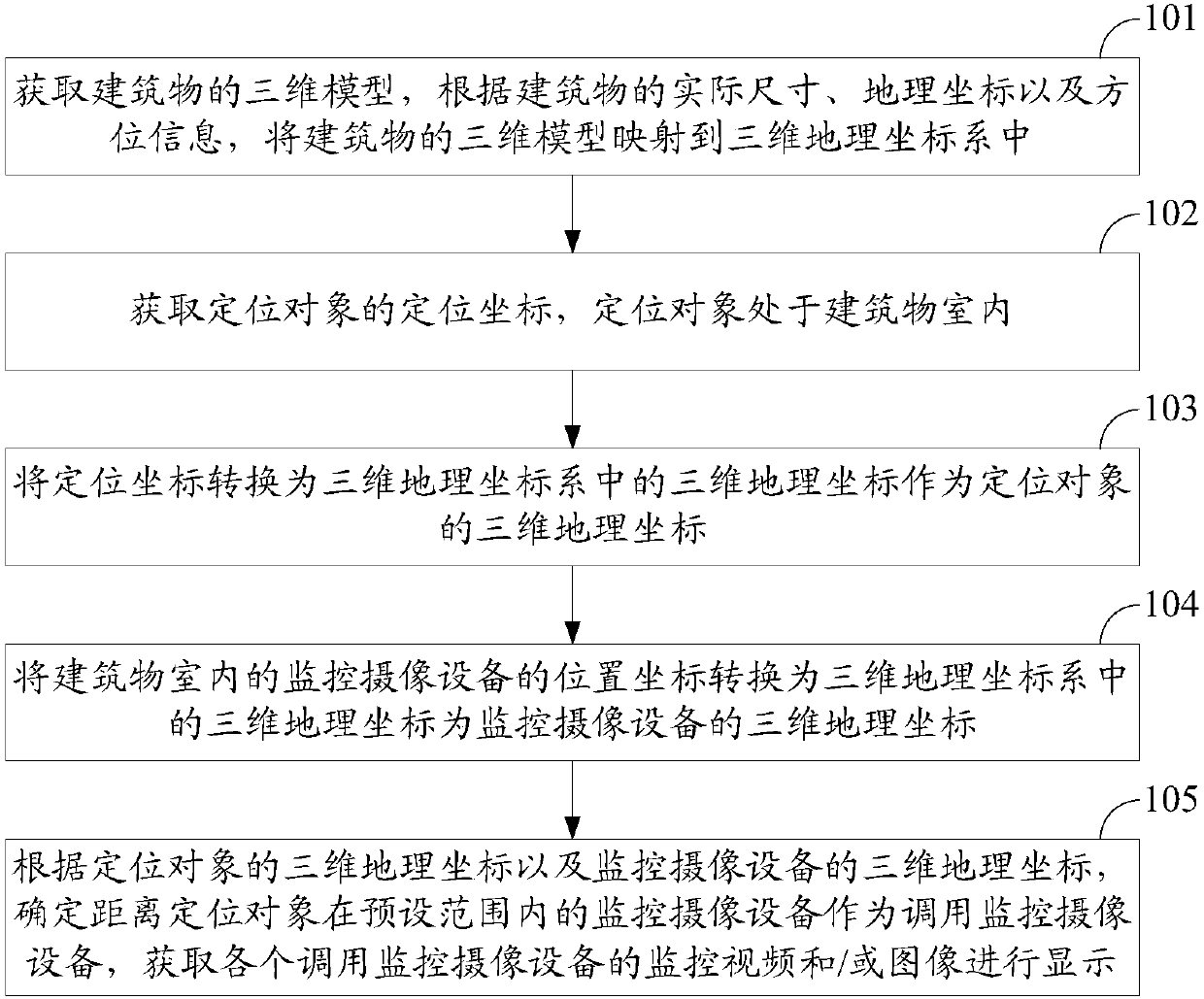

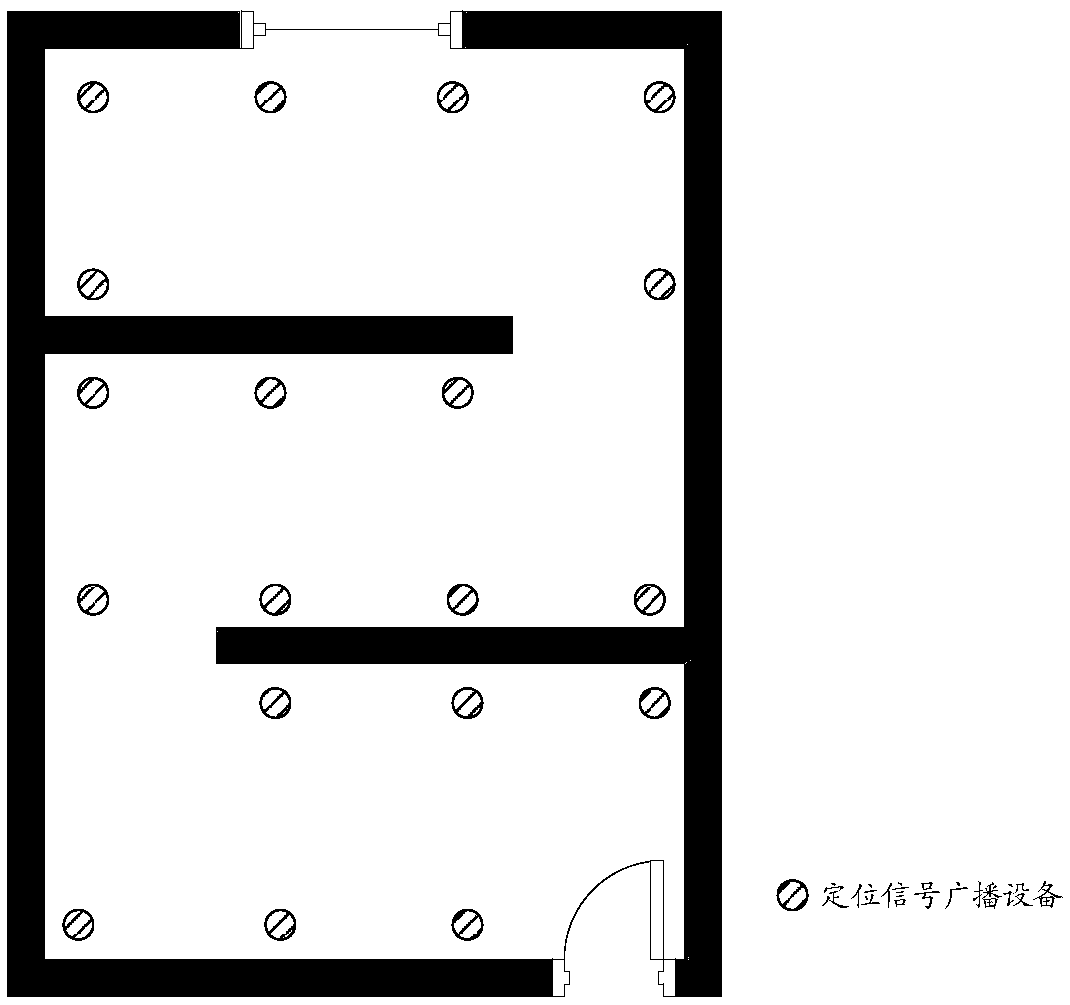

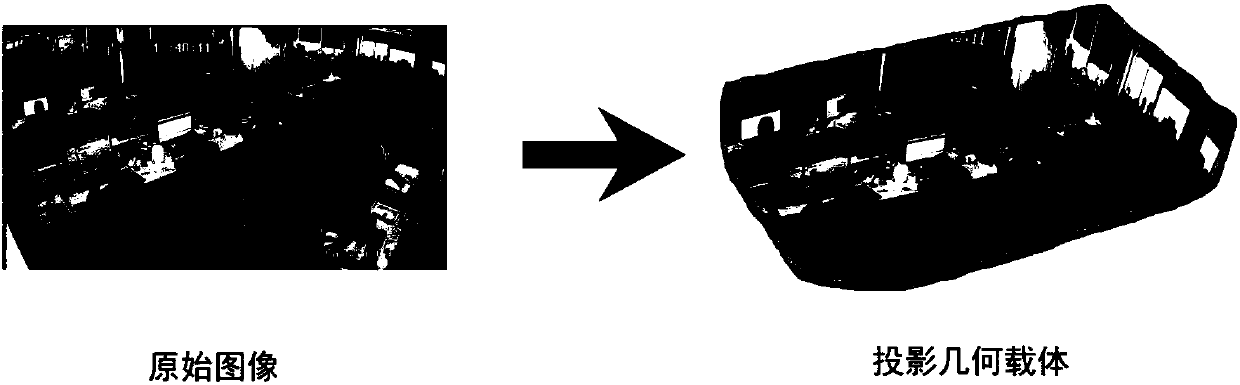

Method and device for realizing monitored video display

InactiveCN107197200AReduce in quantityIncrease spatial awarenessClosed circuit television systemsUsing reradiationGeographic coordinate systemReal size

The invention discloses a method and a device for realizing monitored video display, so as to realize monitored video display based on positioning and tracking. The method comprises steps: a three-dimensional model of a building is acquired, and according to the actual size, the geographic coordinates and the azimuth information of the building, the three-dimensional model of the building is mapped to a three-dimensional geographic coordinate system; the positioning coordinates of a positioned object are acquired; the positioning coordinates of the positioned object are converted to three-dimensional geographic coordinates in the three-dimensional geographic coordinate system as three-dimensional geographic coordinates of the positioned object; the position coordinates of a monitoring and photographing device in the building are converted to three-dimensional geographic coordinates in the three-dimensional geographic coordinate system as the three-dimensional geographic coordinates of the monitoring and photographing device; and according to the three-dimensional geographic coordinates of the positioned object and the three-dimensional geographic coordinates of the monitoring and photographing device, a monitoring and photographing device with a distance with the positioned object in a preset range is determined as a called monitoring and photographing device, and a monitored video and / or an image of each called monitoring and photographing device are / is acquired to be displayed.

Owner:北斗智图科技(北京)有限公司

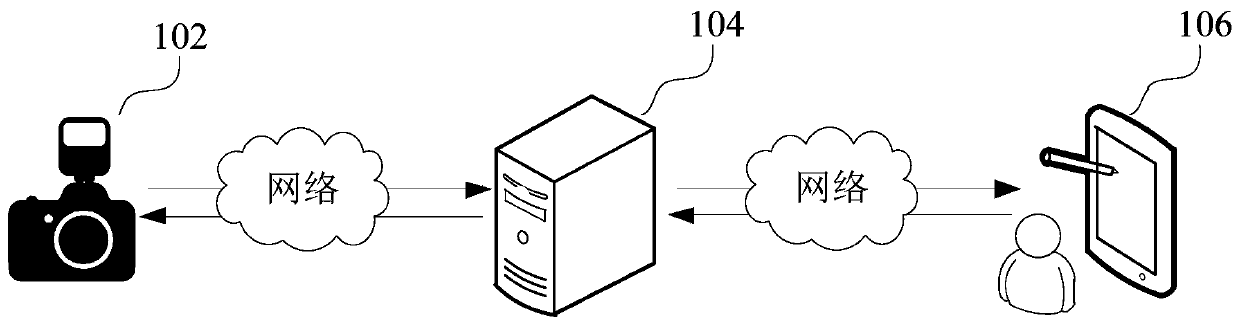

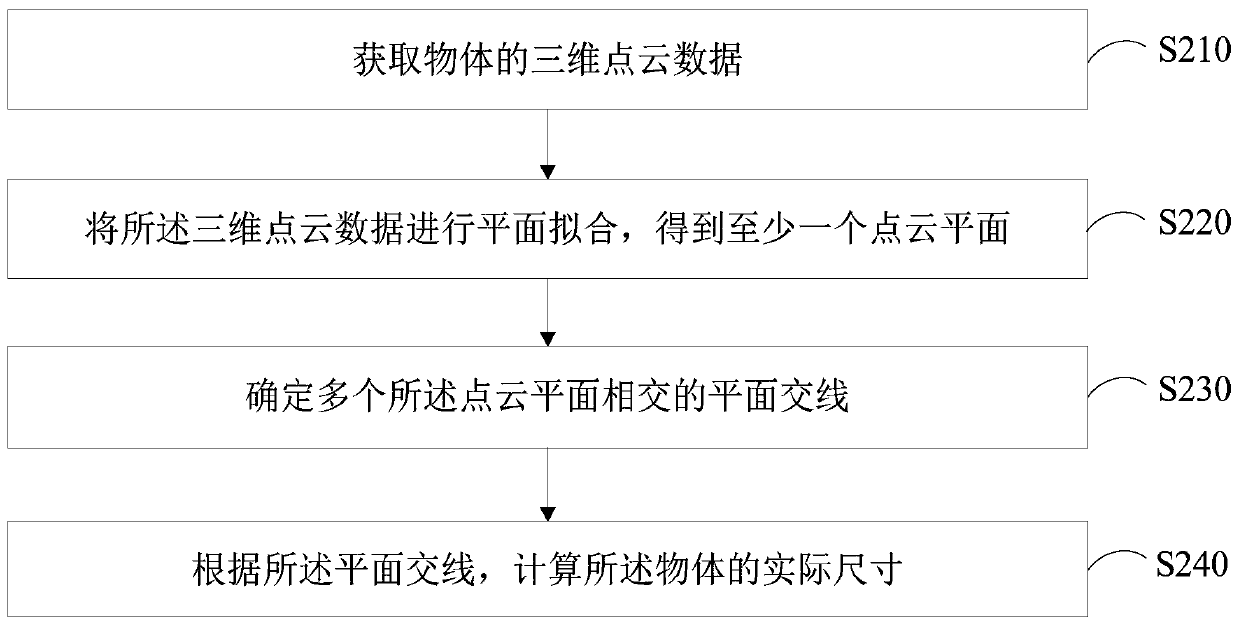

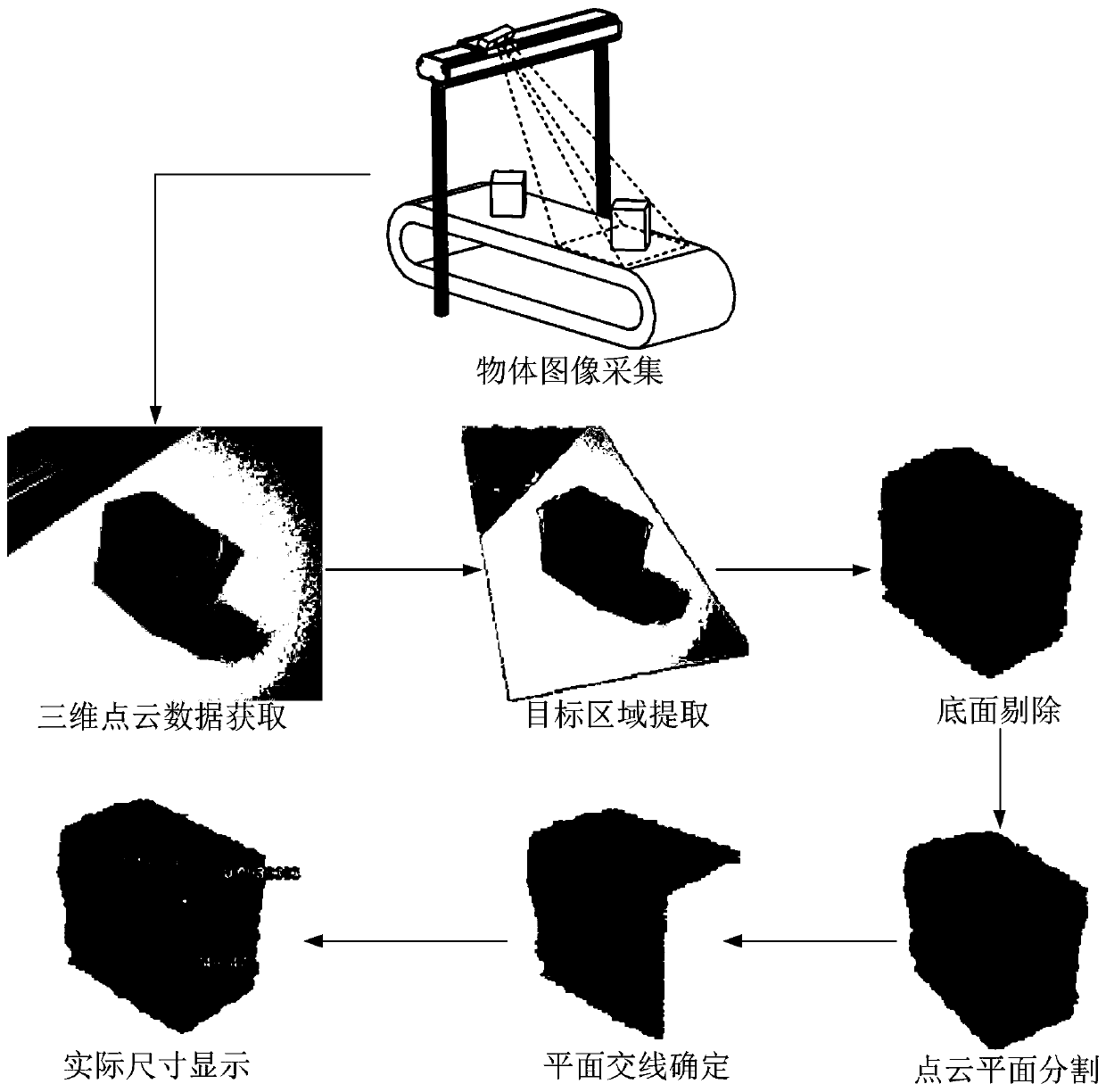

Object size measuring method and device based on three-dimensional vision technology

ActiveCN109737874AImprove the efficiency of dimension measurementImprove reliabilityUsing optical meansSize measurementLogistics management

The application relates to an object size measuring method and device based on three-dimensional vision technology. The method comprises the following steps: acquiring three-dimensional point cloud data of the object; performing plane fitting on the three-dimensional point cloud data to obtain at least one point cloud plane; determining a plane intersection line at which the plurality of point cloud planes intersect; and calculating the actual size of the object according to the plane intersection line. The method can not only enhance the reliability of the size measurement result, but also improve the efficiency of measuring the size of the object, thereby realizing the rapid measurement of the shape and structure of the packaging box by the object measuring system in the logistics application scenario.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

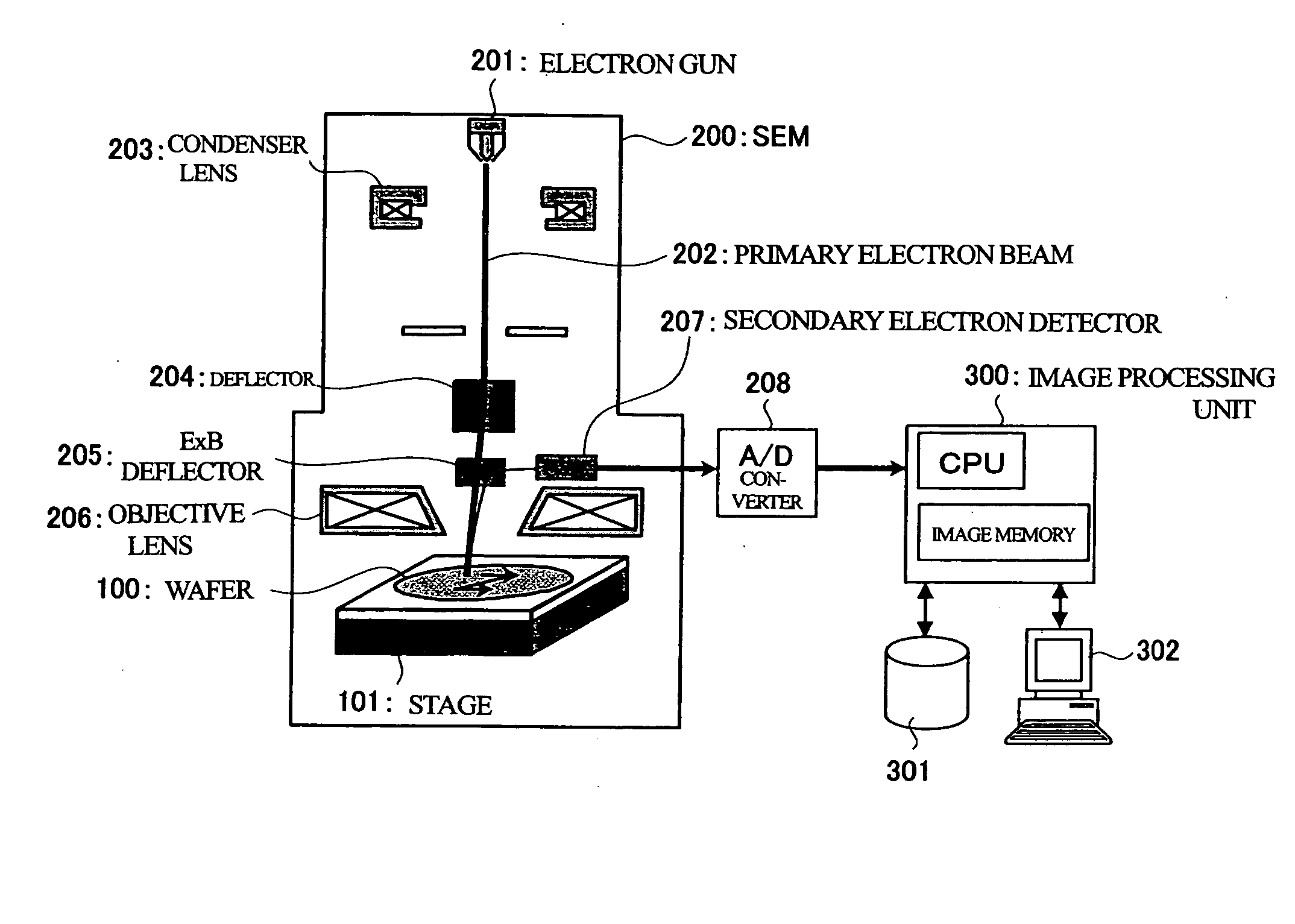

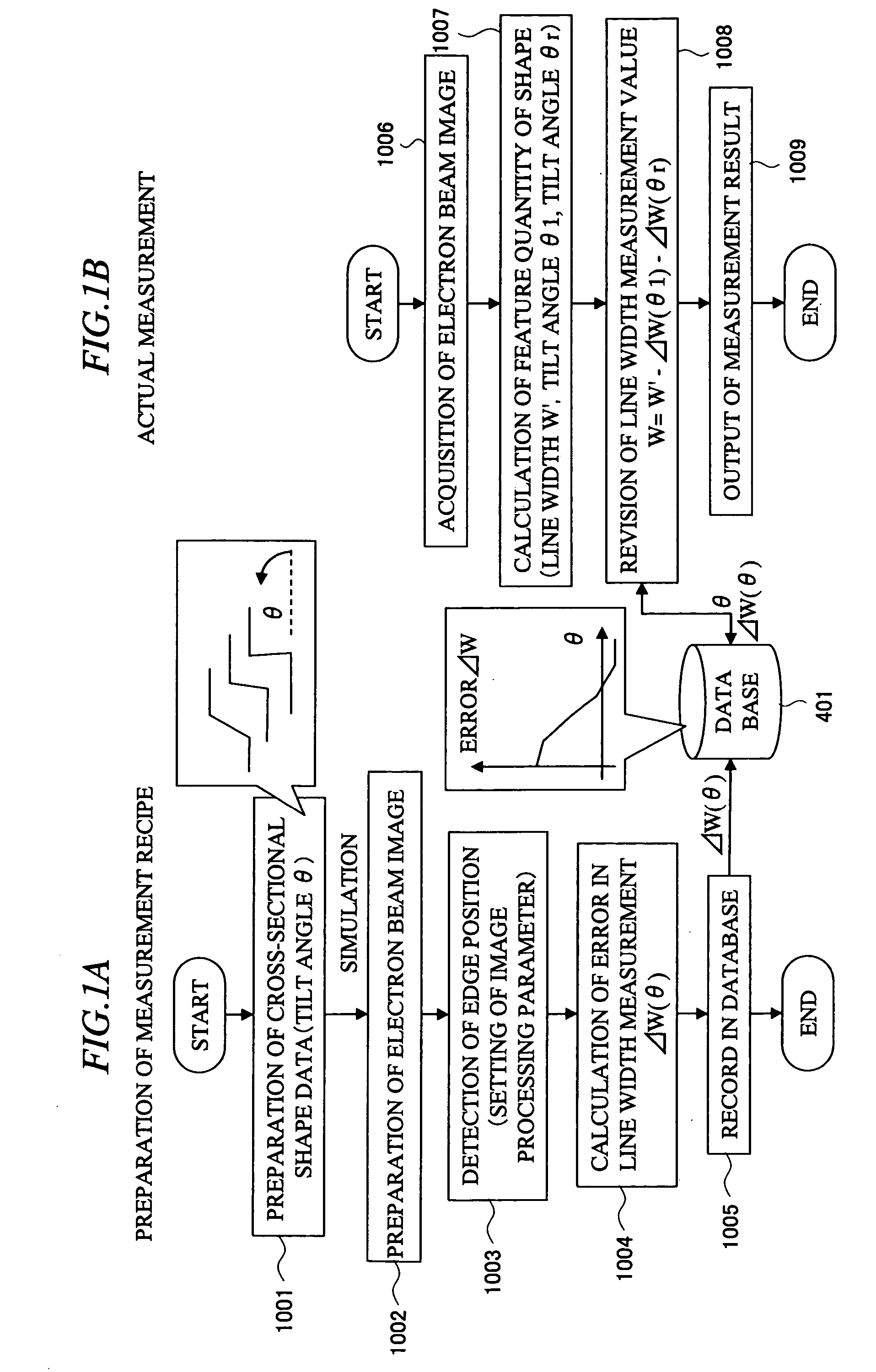

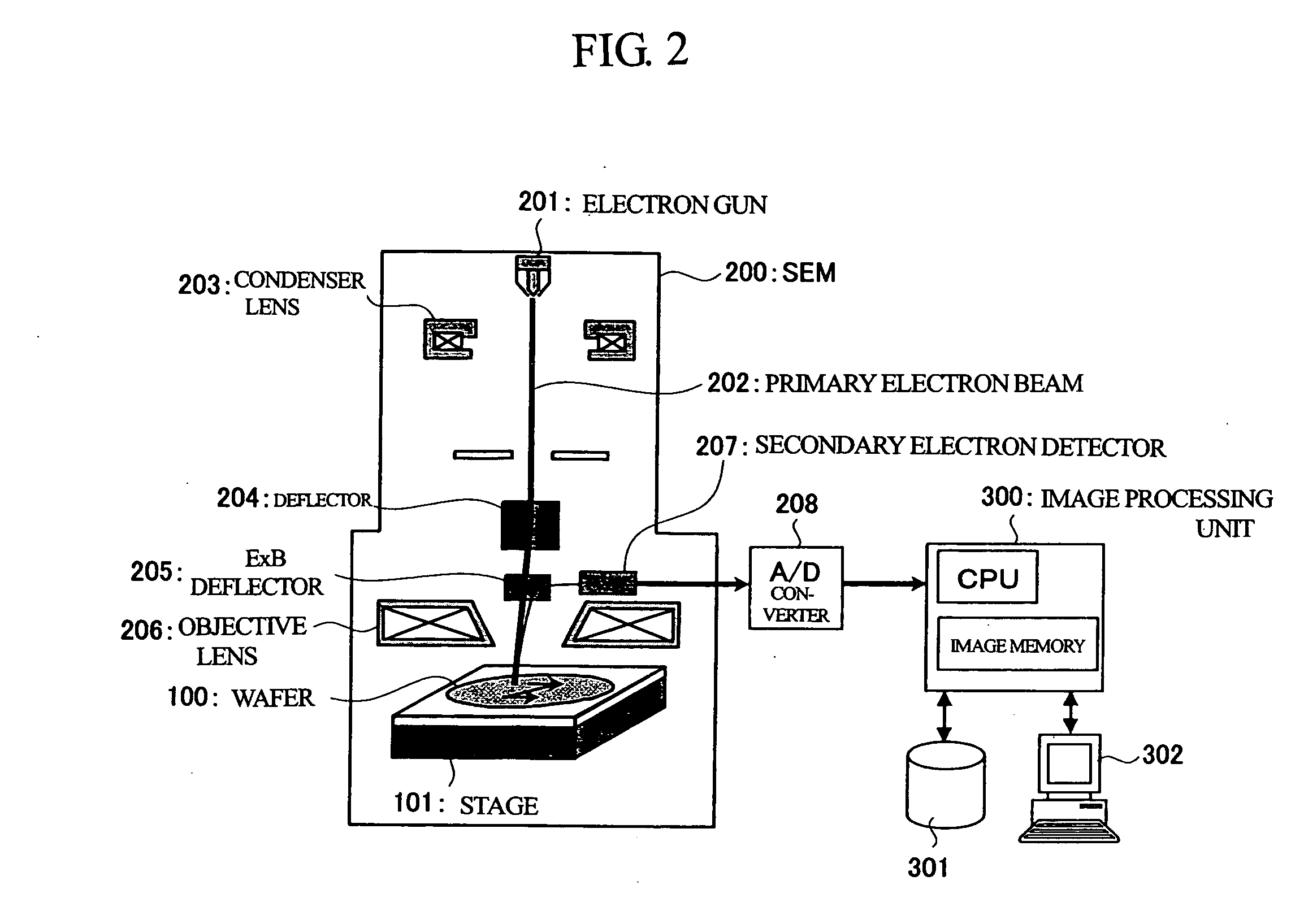

Method of measuring pattern dimension and method of controlling semiconductor device process

ActiveUS20050116182A1Precise DimensionsReduce the amount of calculationMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementDevice materialDimension measurement

This invention provides a method of measuring semiconductor pattern dimensions capable of realizing a stable and highly precise pattern dimension measurement technique even when the pattern cross-sectional shapes are changed and making the calculation amount relatively small to reduce the calculation time. More specifically, the relationship between cross-sectional shapes of a pattern and measurement errors in a specified image processing technique is evaluated in advance by the electron beam simulation in a pattern measurement system in a length measuring SEM, and in the actual dimension measurement, dimensions of an evaluation objective pattern are measured from image signals of a scanning electron microscope, and errors of the dimensional measurement of the evaluation objective pattern are estimated and revised based on the relationship between cross-sectional shapes of a pattern and measurement errors evaluated in advance, thereby realizing highly precise measurement where dimensional errors depending on pattern solid shapes are eliminated.

Owner:HITACHI HIGH-TECH CORP

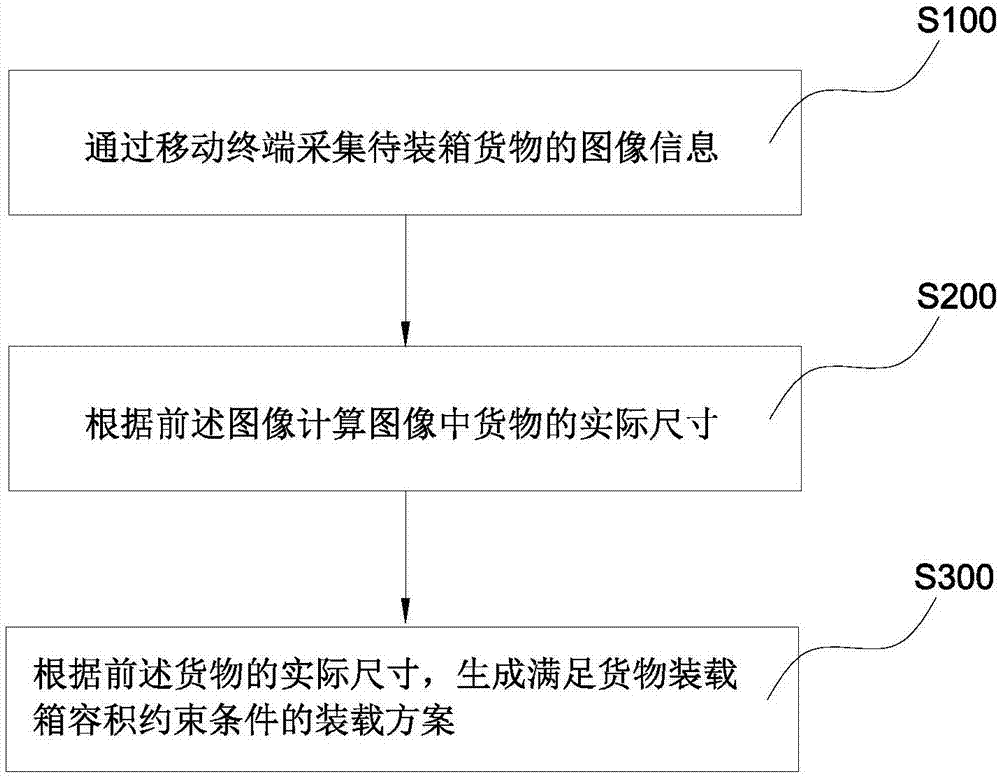

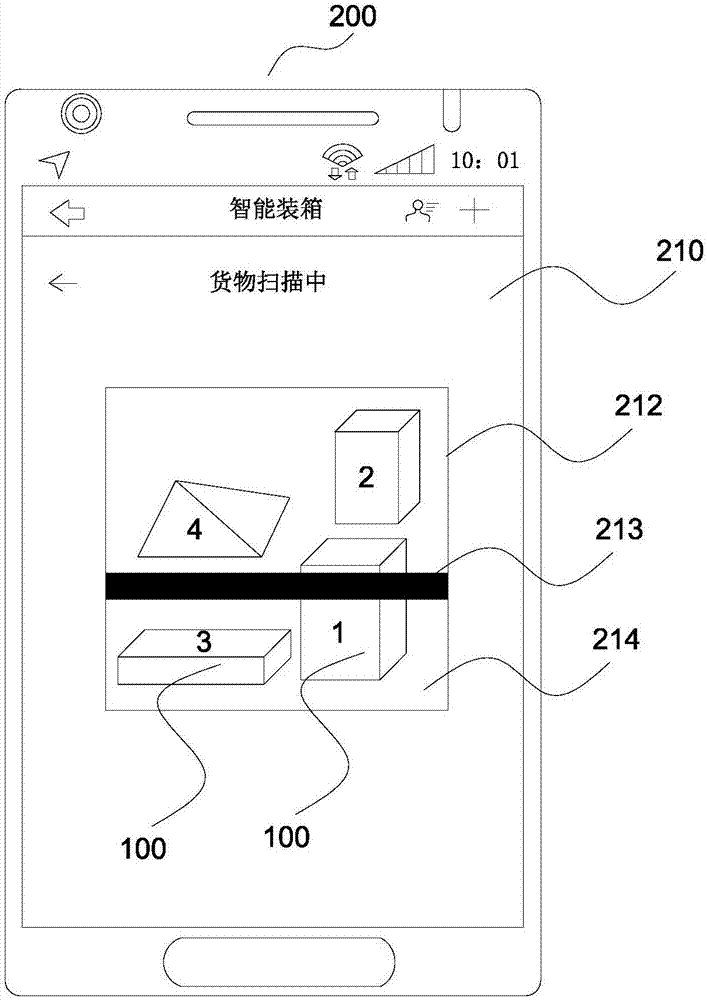

Cargo boxing method, apparatus and system

ActiveCN108009675AImprove packaging efficiencyReduce manual measurementsForecastingLogisticsWorkloadReal size

The invention provides a cargo boxing method, apparatus and system, and relates to the technical field of container loading layout optimization. The cargo boxing method comprises the following steps of collecting image information of a to-be-boxed cargo through a mobile terminal; according to an image, calculating an actual size of the cargo in the image; and according to the actual size of the cargo, generating a loading scheme meeting a cargo loading box capacity constraint condition. The actual size of the cargo in the image is calculated through the mobile terminal; and the loading schememeeting the cargo loading box capacity constraint condition is generated according to the actual size of the cargo, so that the workload of manual measurement and manual input during boxing is reducedand the cargo boxing efficiency can be further improved.

Owner:上海维祥信息技术有限公司

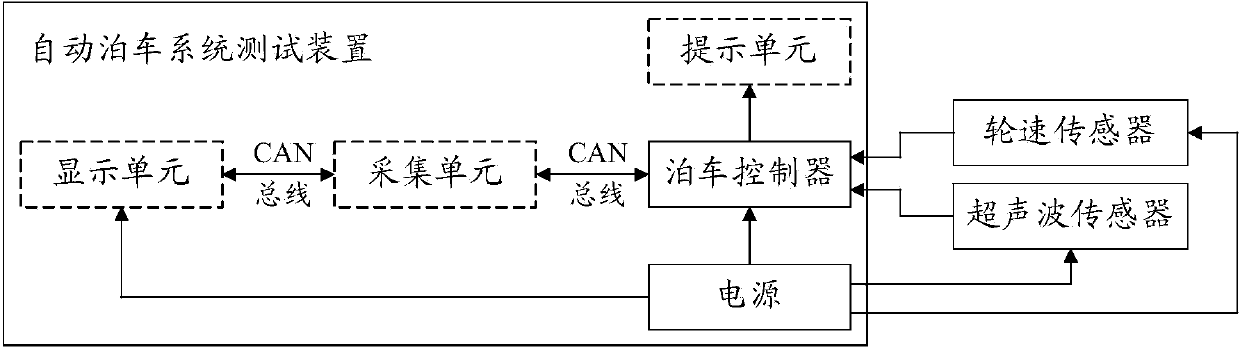

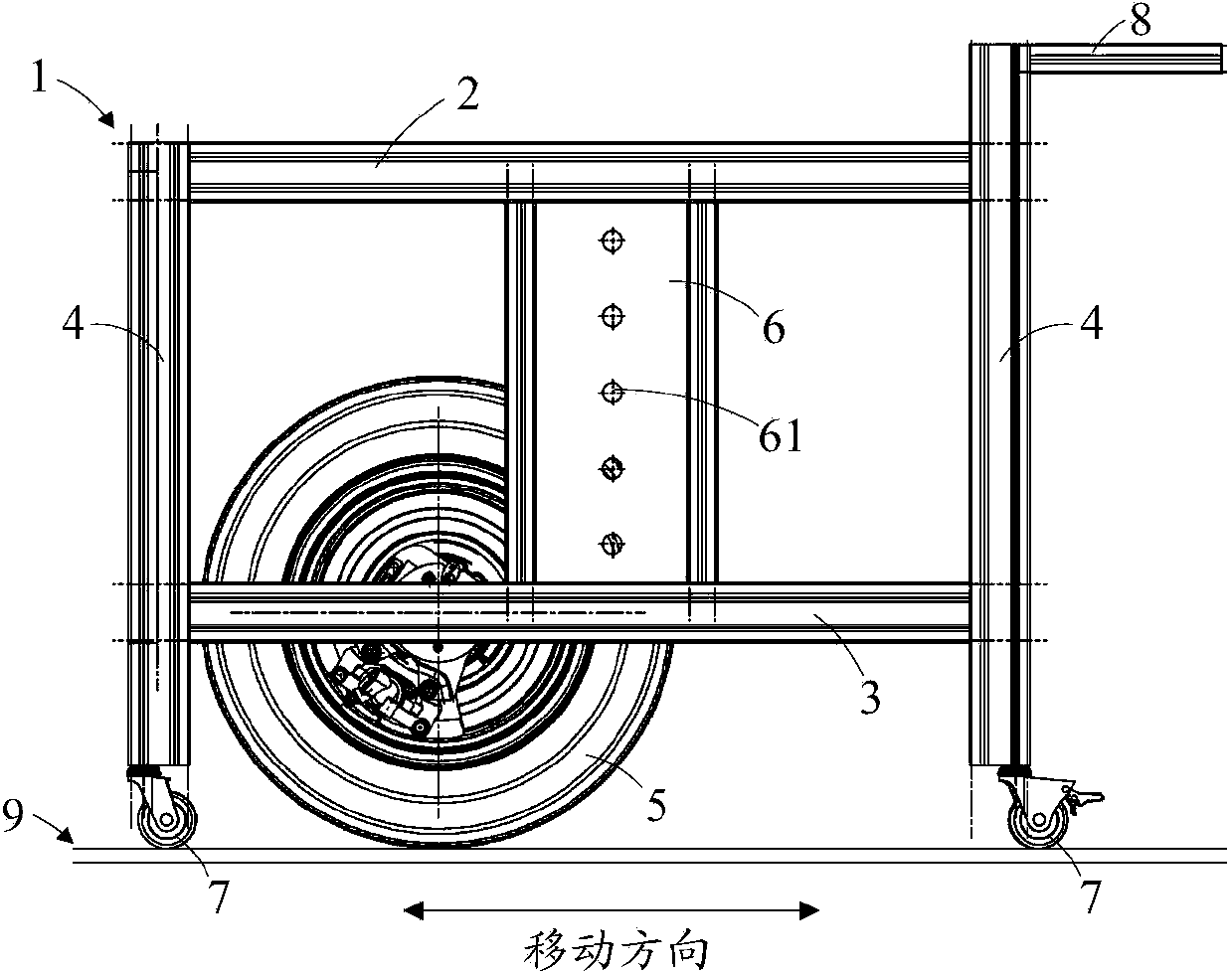

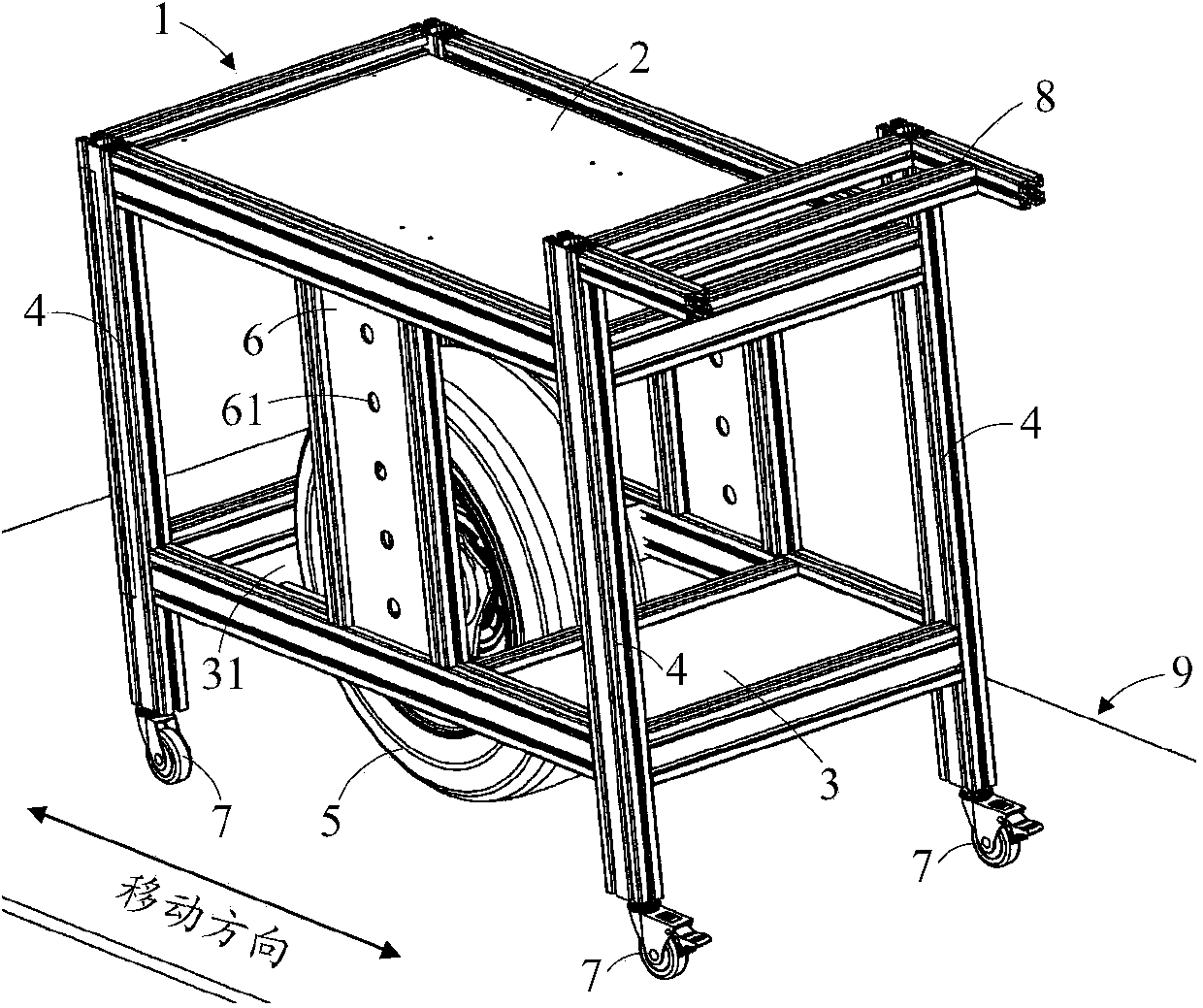

Testing device and method for automatic parking system

ActiveCN104176051AMeet the needs of finding calibrationVehicle testingWheel speed sensorSystem testing

The invention provides a testing device for an automatic parking system. The testing device comprises a parking controller and a test-bench, wherein the parking controller as the main controller of the automatic parking system is placed on the test-bench; a wheel is arranged at the lower part of the test-bench; a wheel speed sensor is arranged on the wheel shaft of the wheel; an ultrasonic wave sensor is arranged on at least one side surface parallel to the test-bench in the moving direction of the test-bench; the wheel speed sensor and the ultrasonic wave sensor are electrically connected with the parking controller; a parking space recognition algorithm, a parking space compensation algorithm, a parking space actual size and various working condition patterns are built in the parking controller used for verifying the accuracy of the parking space recognition algorithm and standardizing the parking space compensation algorithm when the test-bench simulates various parking working condition patterns of automobiles. Correspondingly, the invention provides a testing method applied in the testing device. According to the invention, the testing device for the automatic parking system and the testing method applied in the testing device are low in cost and short in testing time, and can simulate various parking working condition patterns.

Owner:WUHU LION AUTOMOTIVE TECH CO LTD

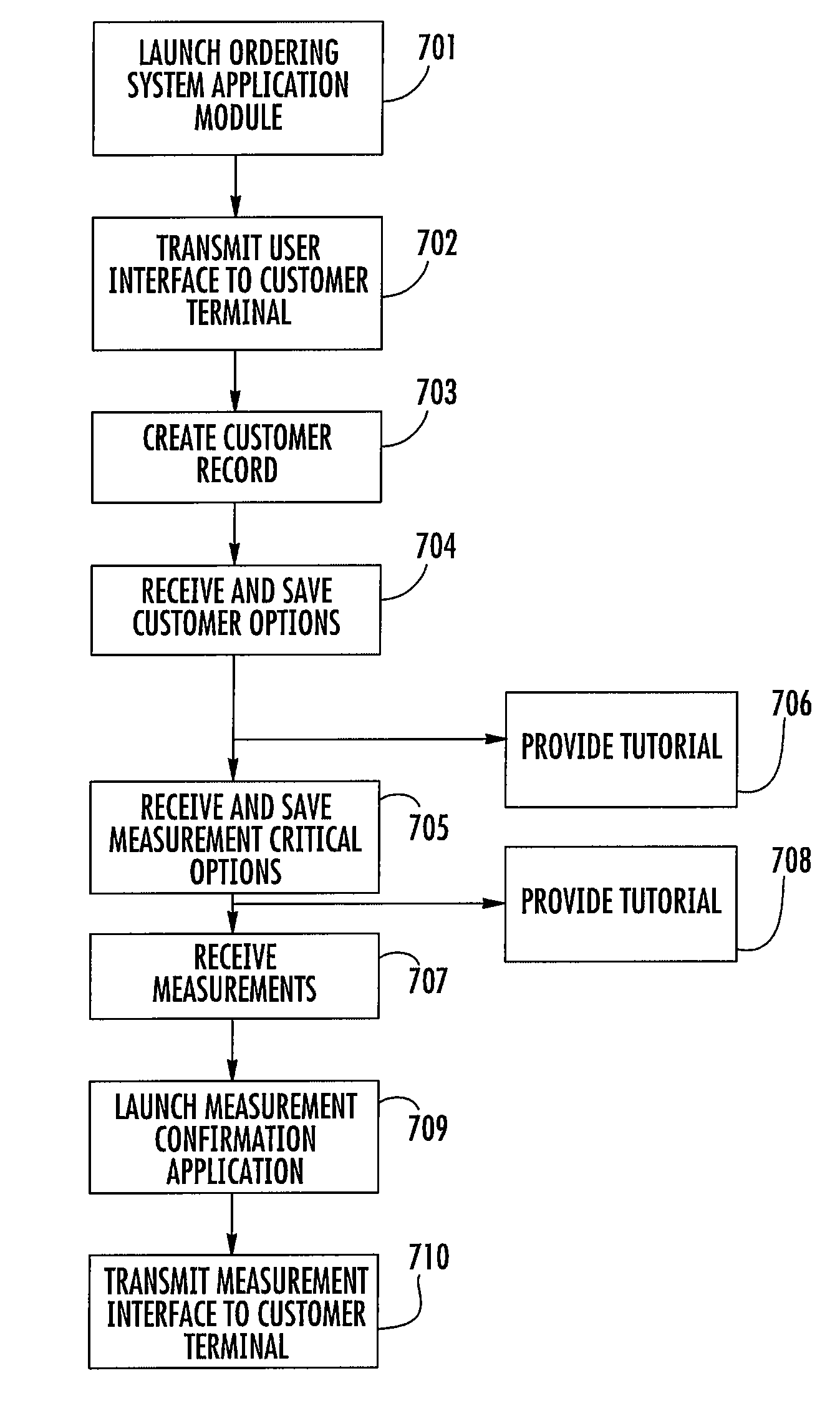

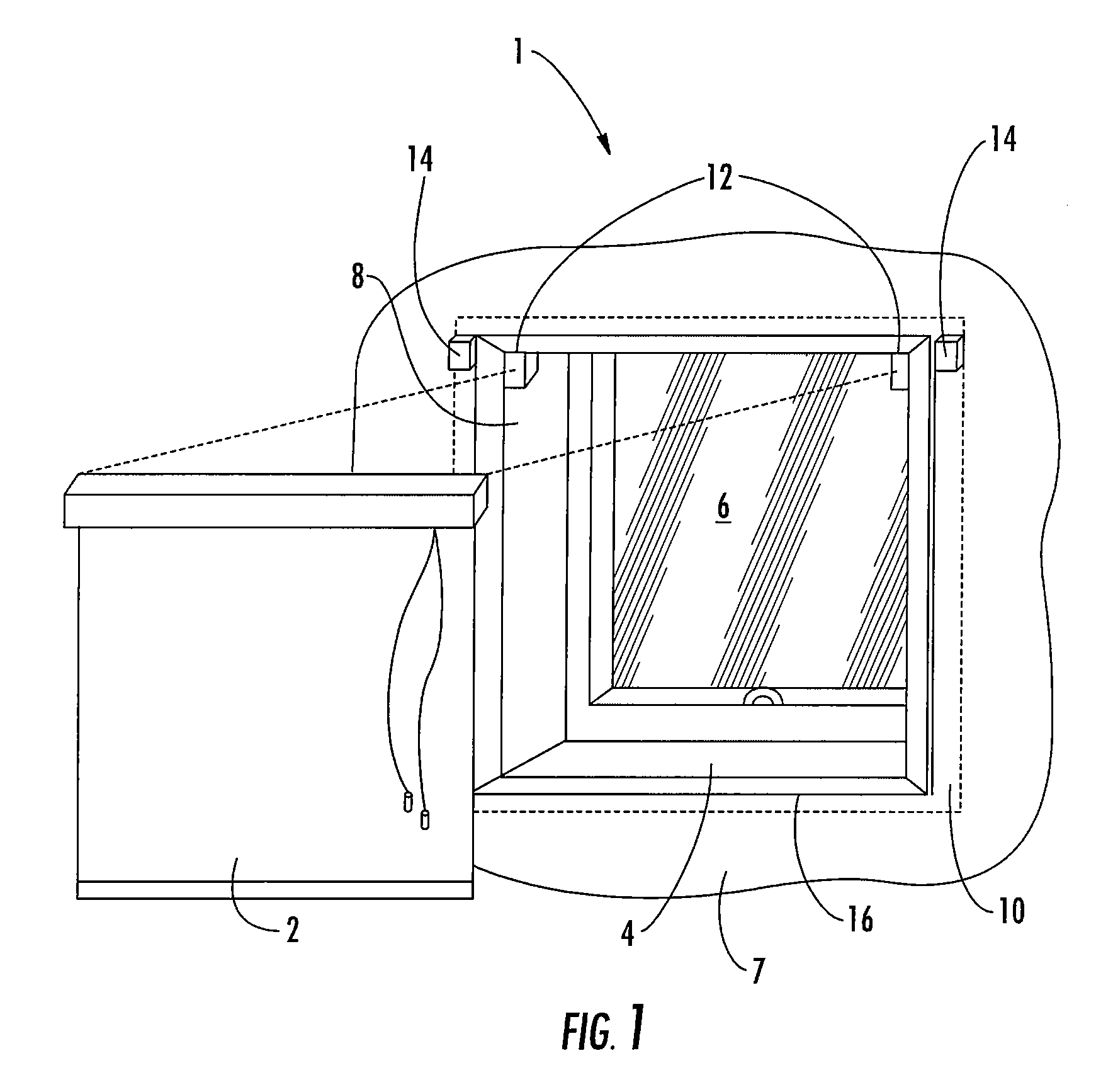

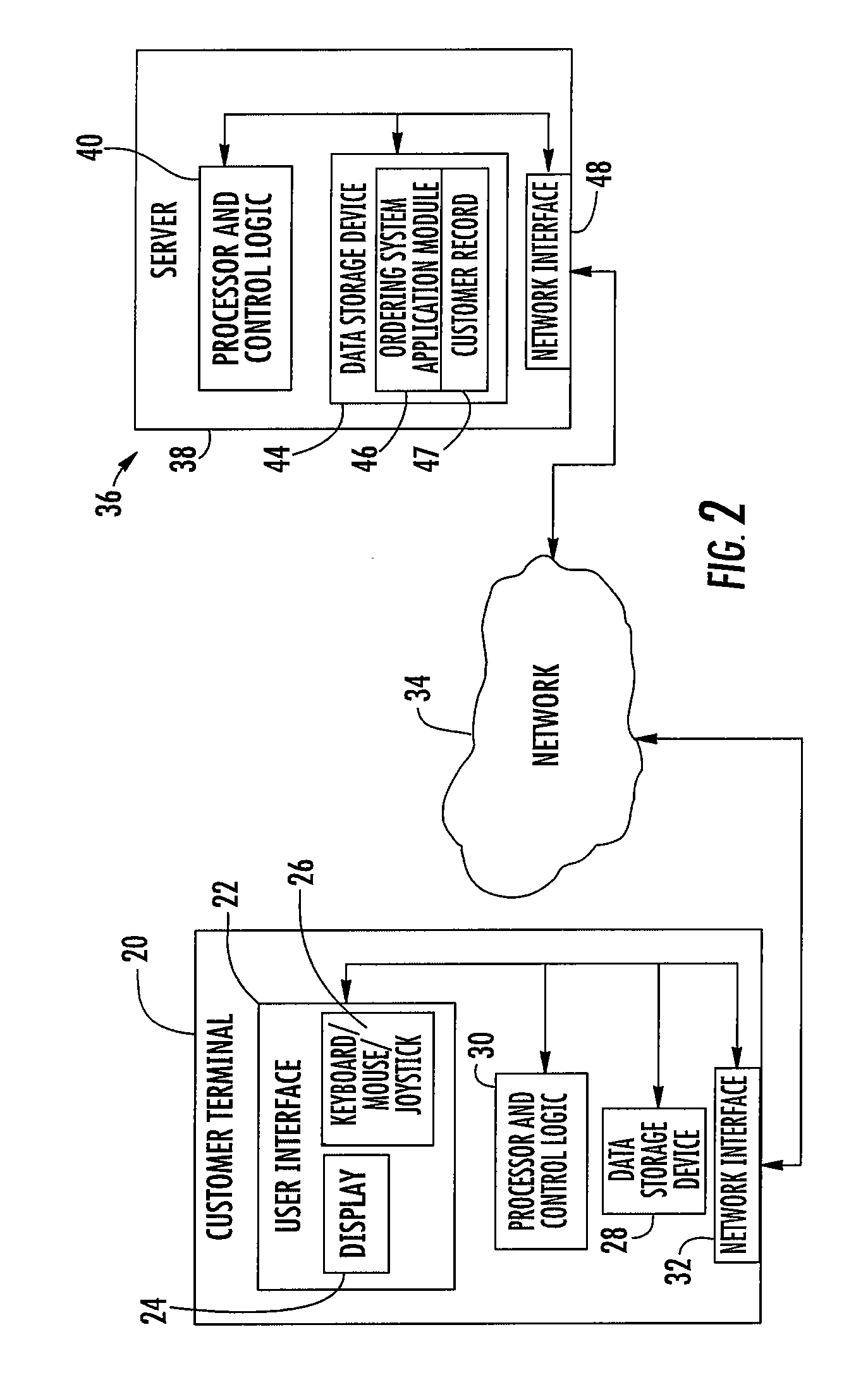

Method and apparatus for a product ordering system

InactiveUS20070239551A1Minimize measurement errorAccurate measurementBuying/selling/leasing transactionsProduct orderProduct characteristics

A customer is presented with a product ordering interface for a size dependent product such as a window covering. The customer is presented with ordering options. Once the customer has selected the desired product, the user is presented with a measurement confirmation interface. The customer is directed to enter at least one first measurement and one second measurement. The measurement(s) are entered into the customer ordering interface. From these measurements the system calculates a theoretical dimension for a product feature. The customer also measures the actual dimension of the product feature. The ordering system compares the calculated dimension to the customer measured dimension. If the calculated dimension matches the customer measured dimension, the measurement is confirmed.

Owner:HUNTER DOUGLAS INDS SWITZERLAND

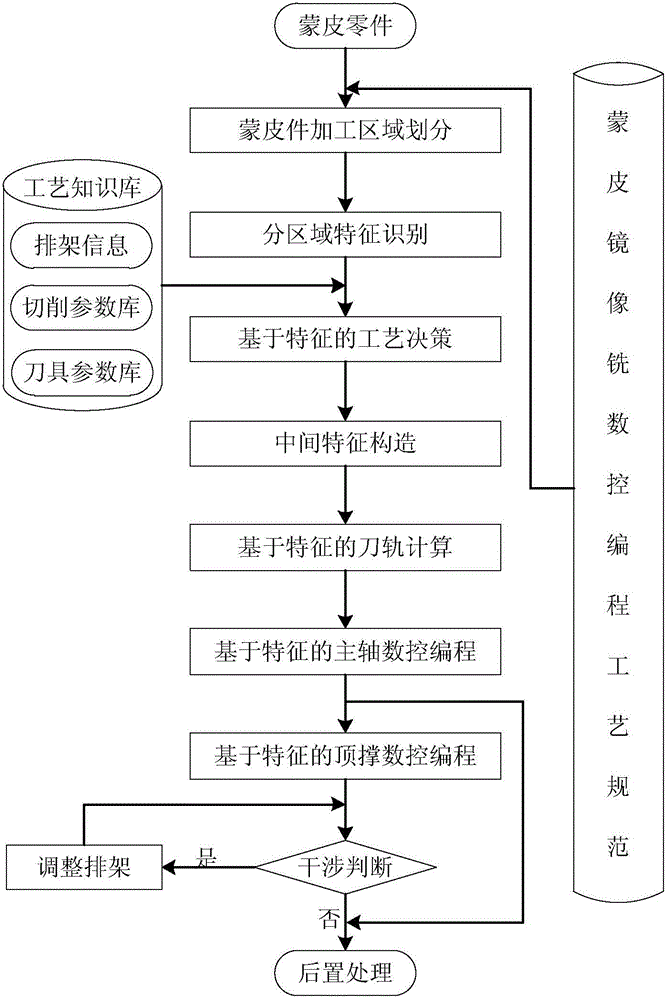

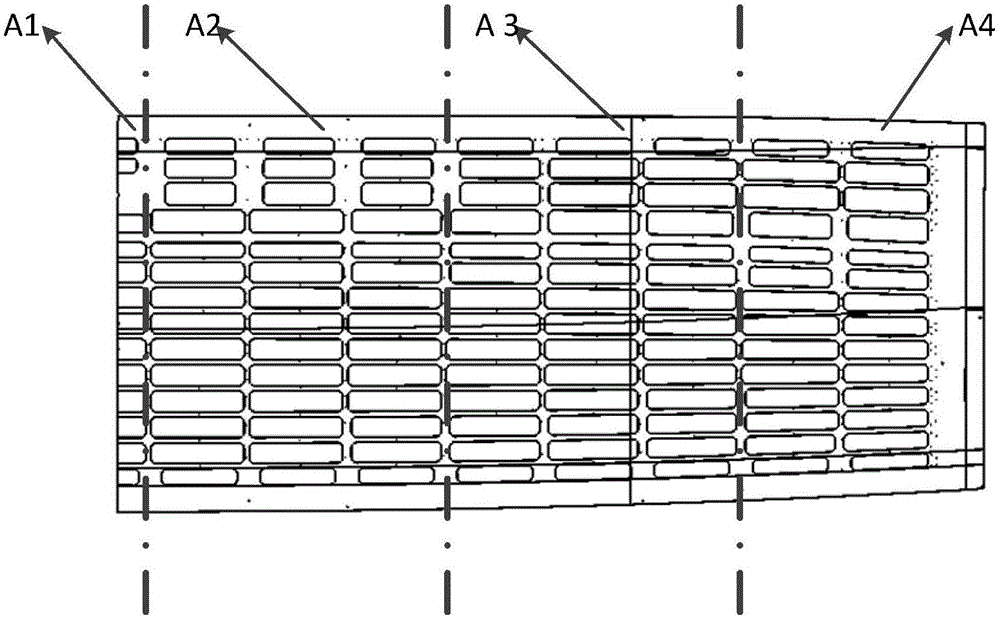

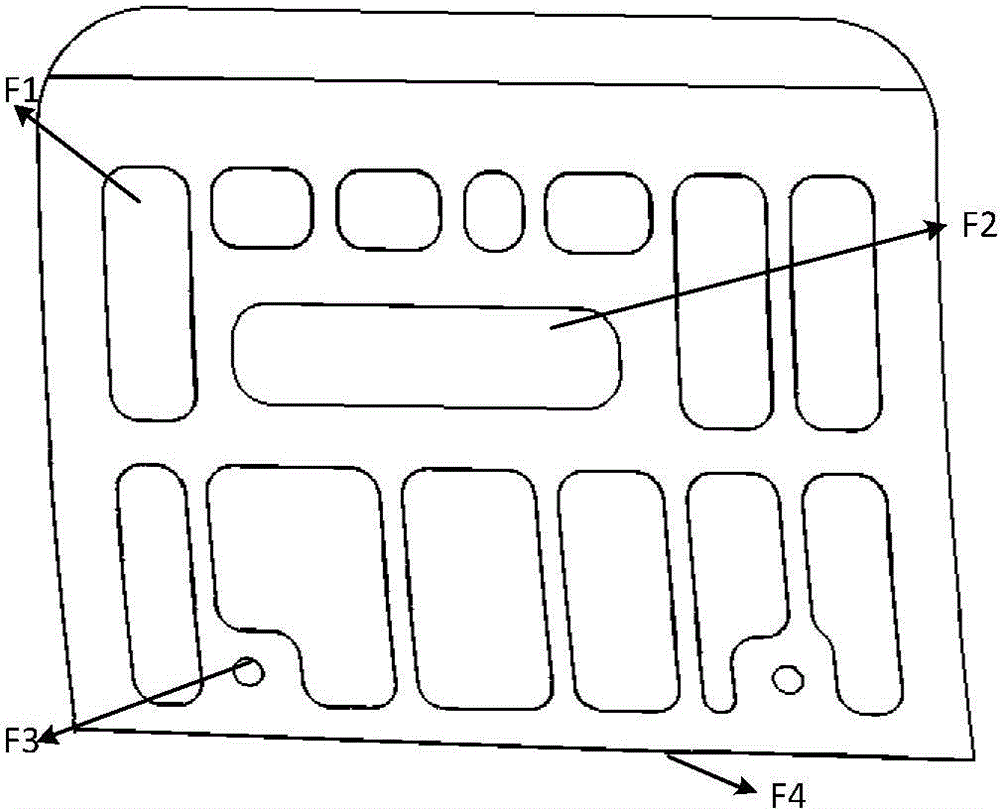

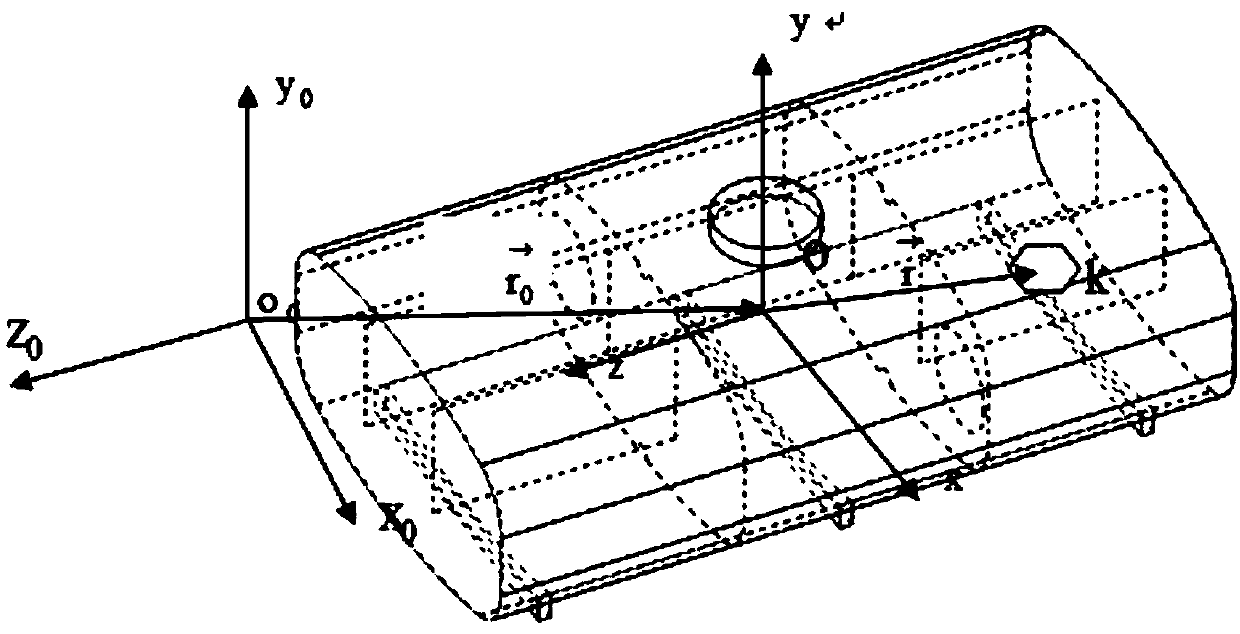

Skin mirror image milling numerical control program fast generating method based on features

ActiveCN104360634AFully automatedRealize intelligenceNumerical controlNumerical controlRapid processing

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

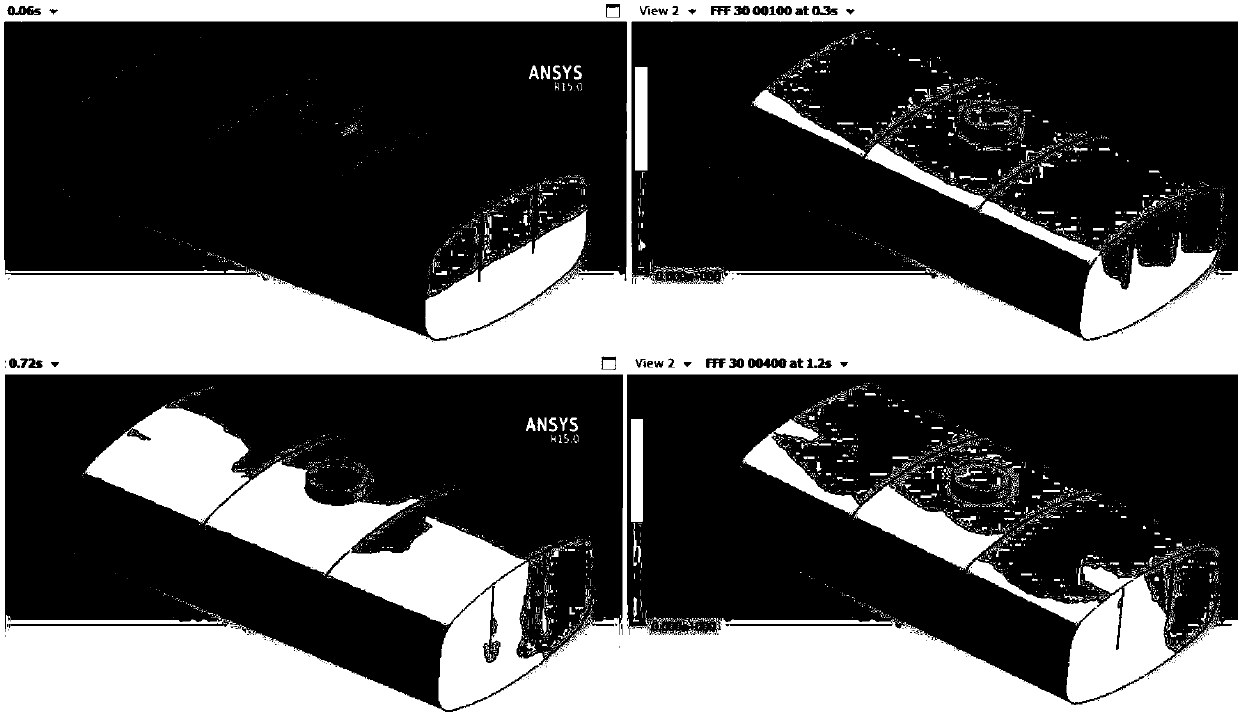

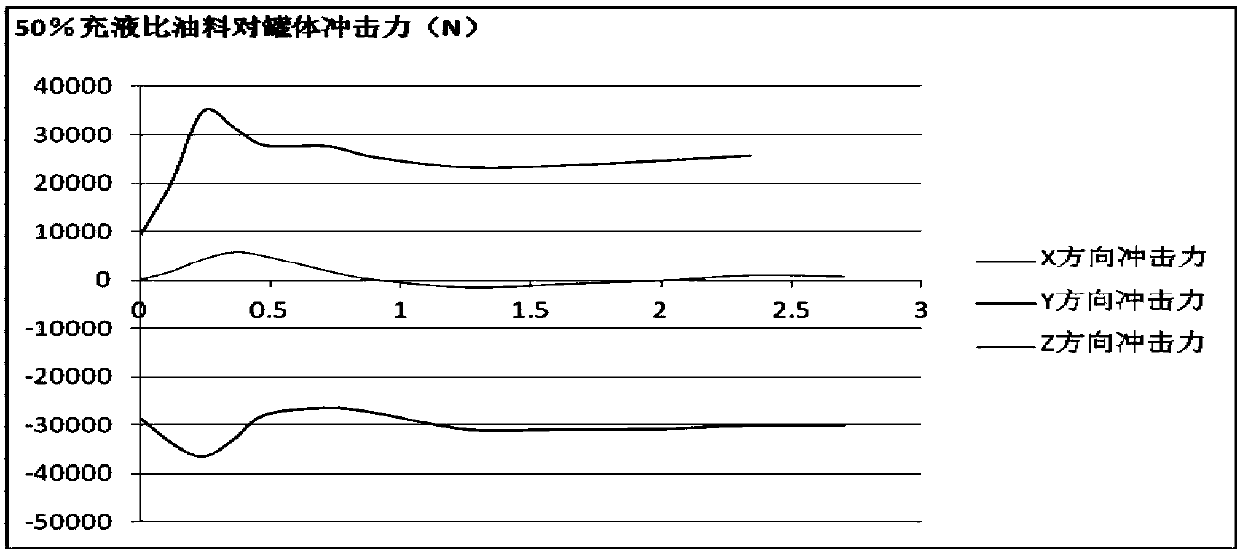

Method for establishing sloshing numerical model of oil in vehicle-mounted metal oil tank

InactiveCN107436981AImprove structural strengthImproved rollover stabilityGeometric CADDesign optimisation/simulationThree dimensional simulationTank truck

The invention discloses a method for establishing a sloshing numerical model of oil in a vehicle-mounted metal oil tank. The method comprises the steps of building an oil sloshing basic equation, determining boundary conditions of oil sloshing, carrying out stress analysis on a solid structure region and the like. A VOF method and a dynamic coordinate system are used for establishing a three-dimensional simulation model for sloshing of the oil in the vehicle-mounted metal oil tank, wherein the three-dimensional model is established according to actual sizes of a tank body, an internal medium and a swash plate, and coupling analysis of stress and deformation of a solid tank wall region can be achieved. An inertia force function corresponding to the change of braking deceleration in the braking process of a tank truck is loaded into a momentum equation to be solved, the calculation time is saved, and the higher precision is guaranteed. The method can be mainly used for researching the side turning stability during emergency turning of the off-road metal oil tank truck and the structural strength of the tank body during emergency braking.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

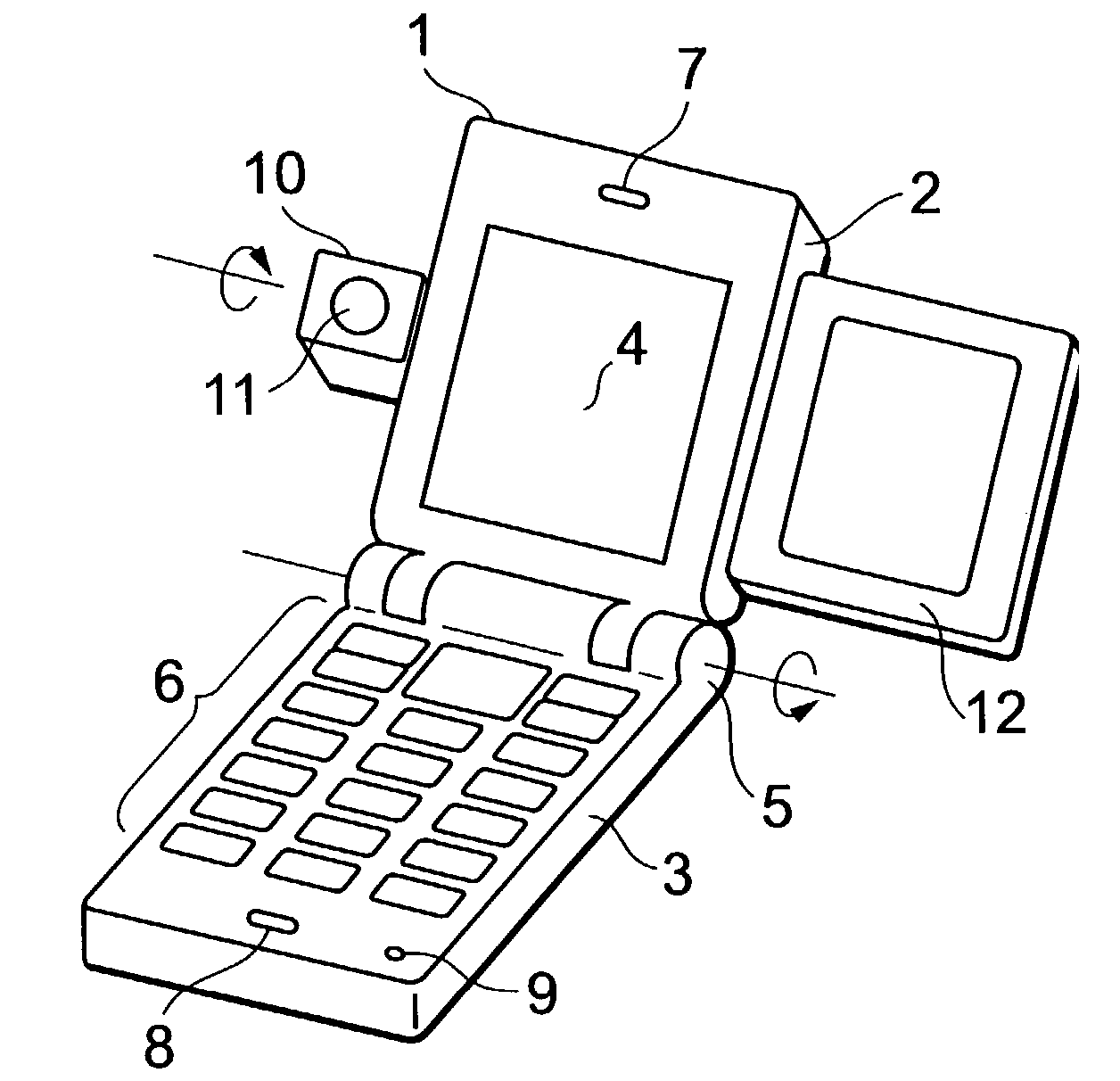

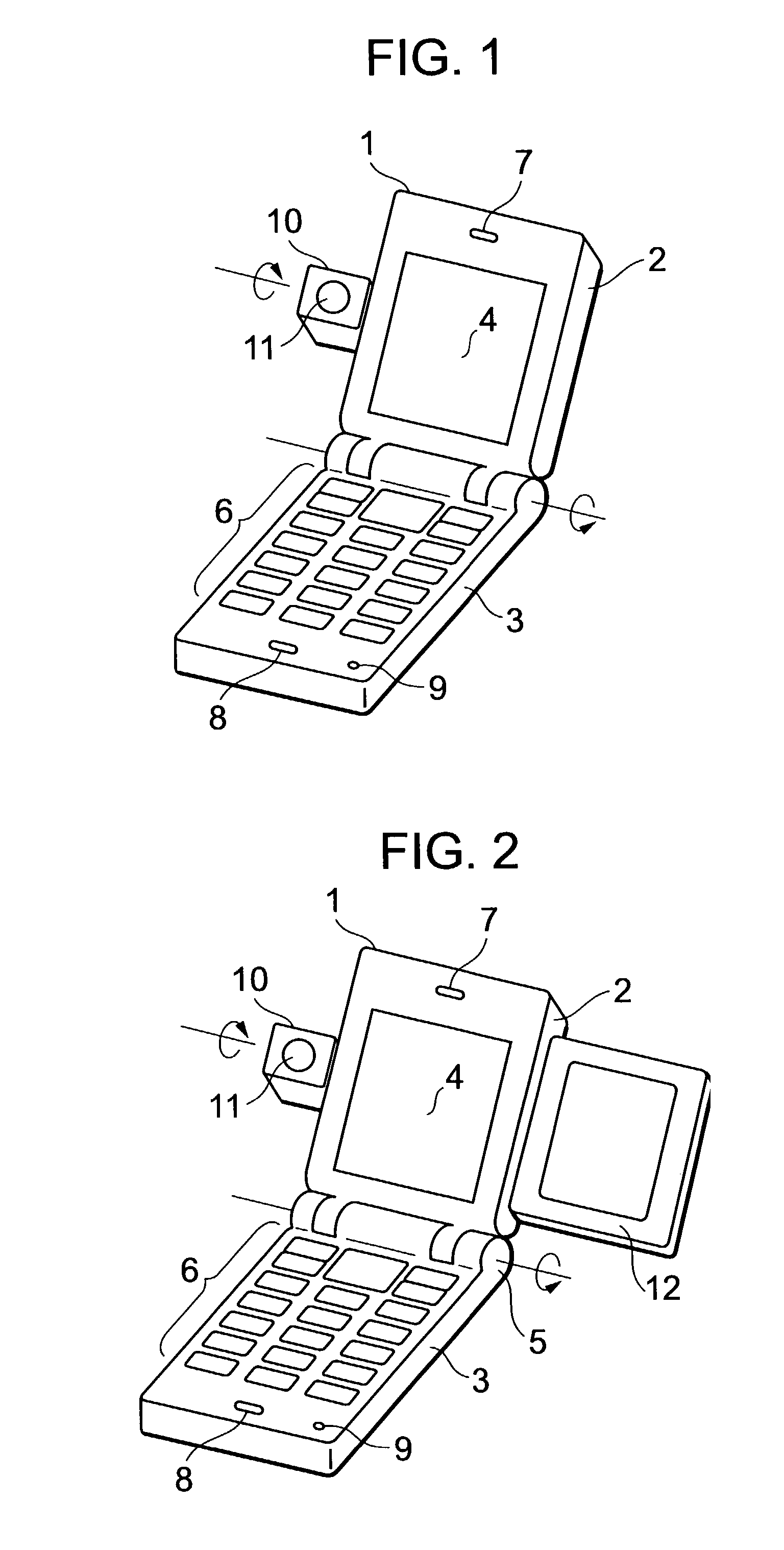

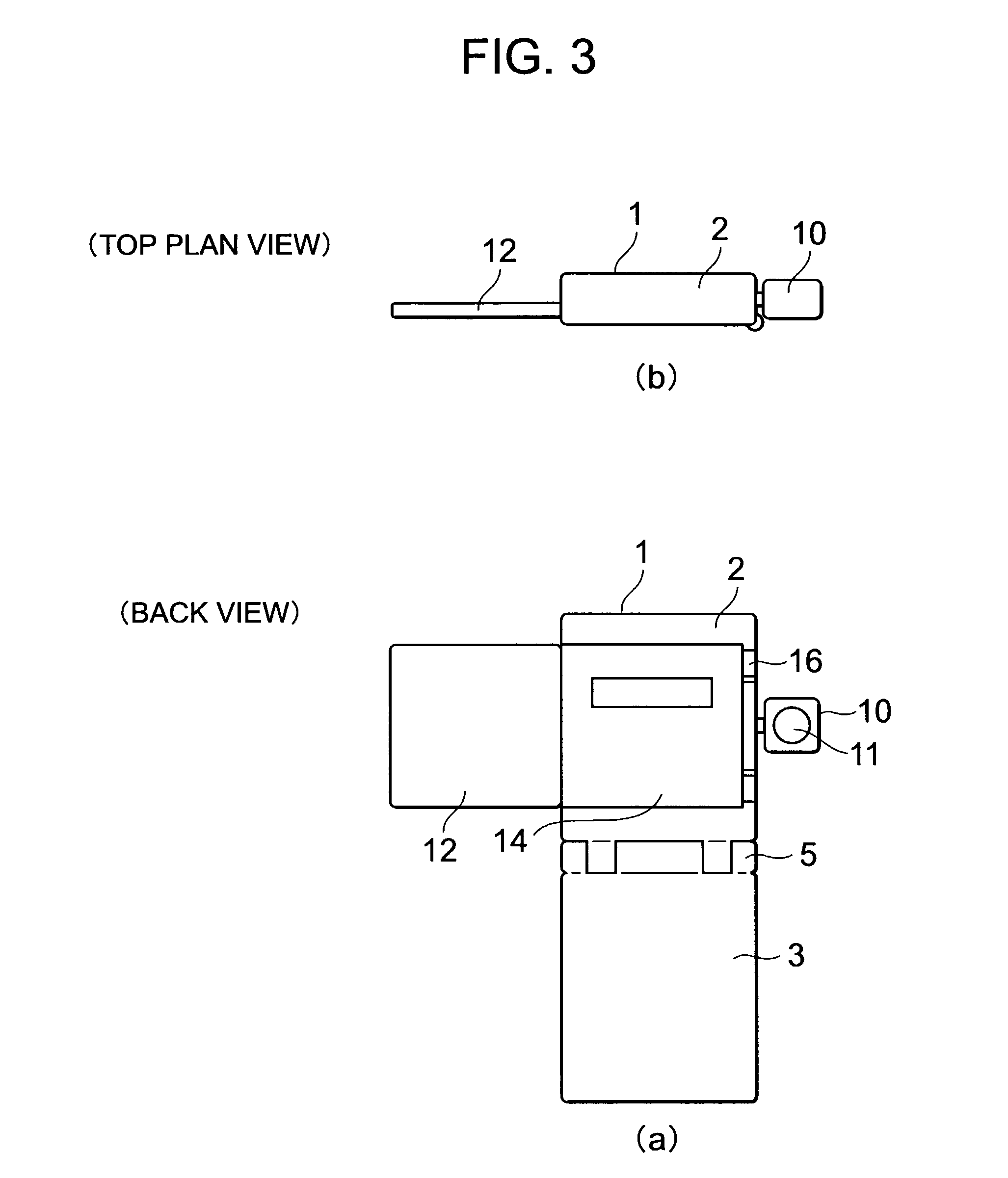

Portable information terminal comprising a camera with a fixed and movable display

InactiveUS7496378B2Improve the display effectDevices with multiple display unitsDigital data processing detailsComputer graphics (images)Computer terminal

Owner:NEC CORP

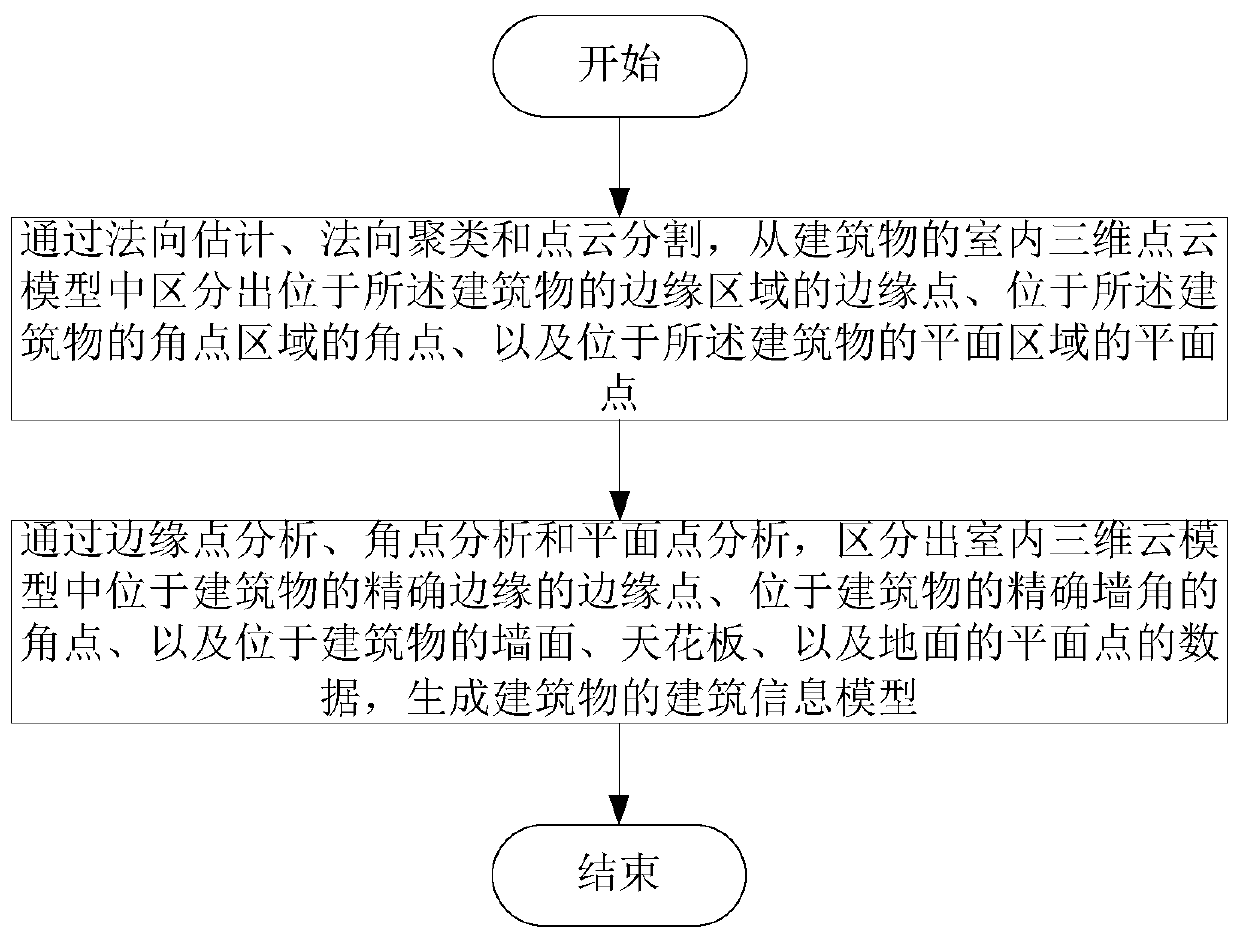

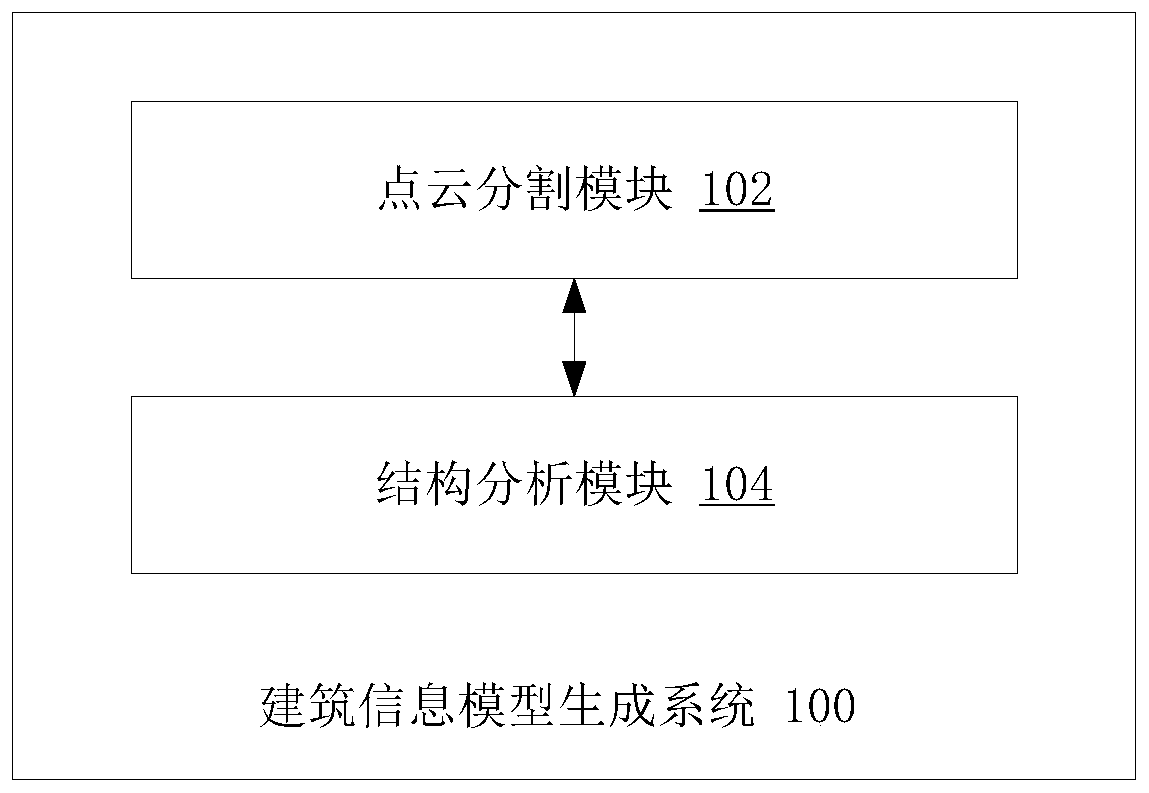

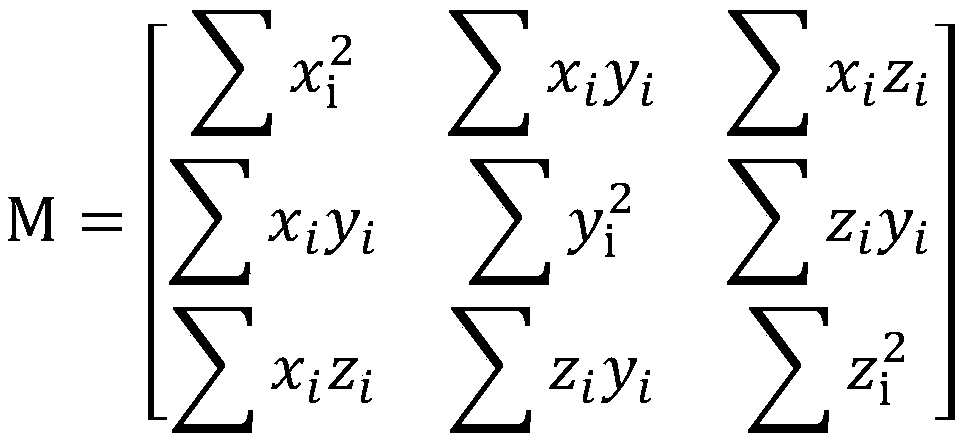

Building information model generation method and system

The invention provides a building information model generation method and system. The building information model generation method comprises the steps that through normal estimation, normal clusteringand point cloud segmentation, edge points located in an edge area of a building, corner points located in the corner point area of the building and plane points located in the plane area of the building are distinguished from the indoor three-dimensional point cloud model of the building; and through edge point analysis, corner point analysis and plane point analysis, the data of edge points located at the accurate edge of the building, corner points located at the accurate wall corners of the building and plane points located on the wall surface, the ceiling and the ground of the building inthe indoor three-dimensional cloud model are distinguished, and the building information model of the building is generated. According to the building information model generation method and system,the high-precision BIM with the real size information of the building can be generated, so that a high-precision map can be provided for indoor navigation, and accurate multi-machine scheduling of different robots is realized.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

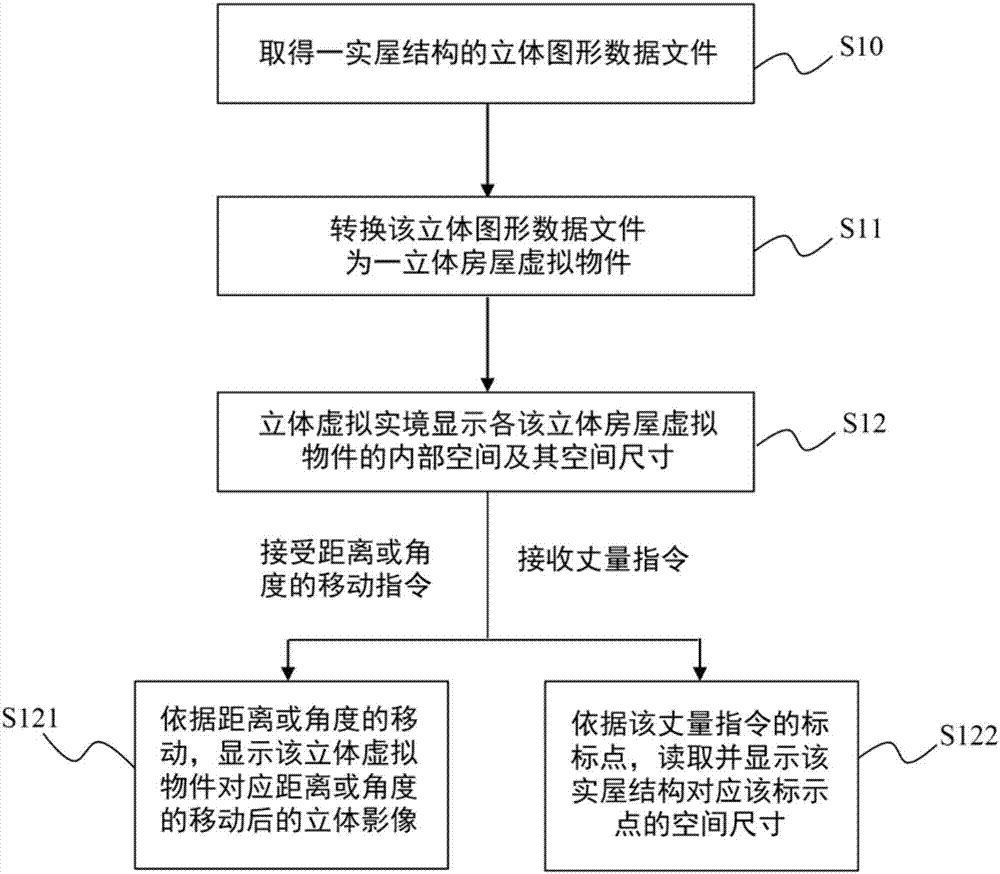

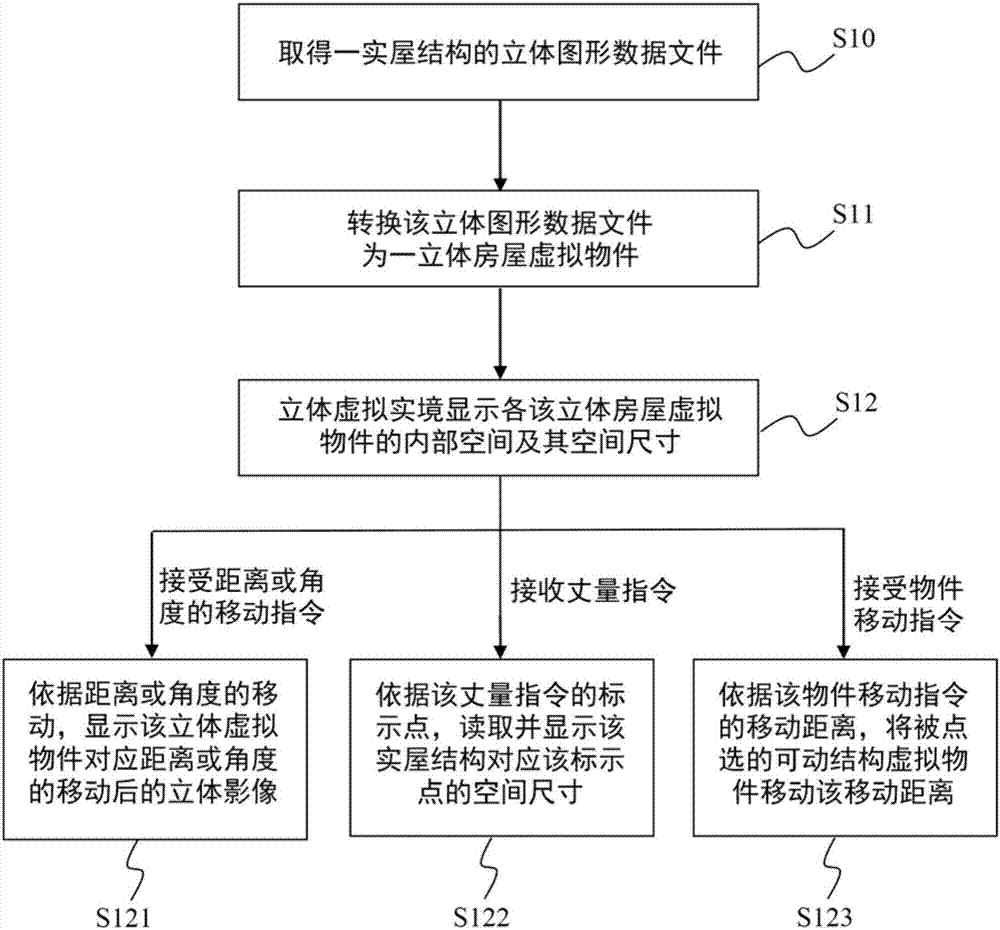

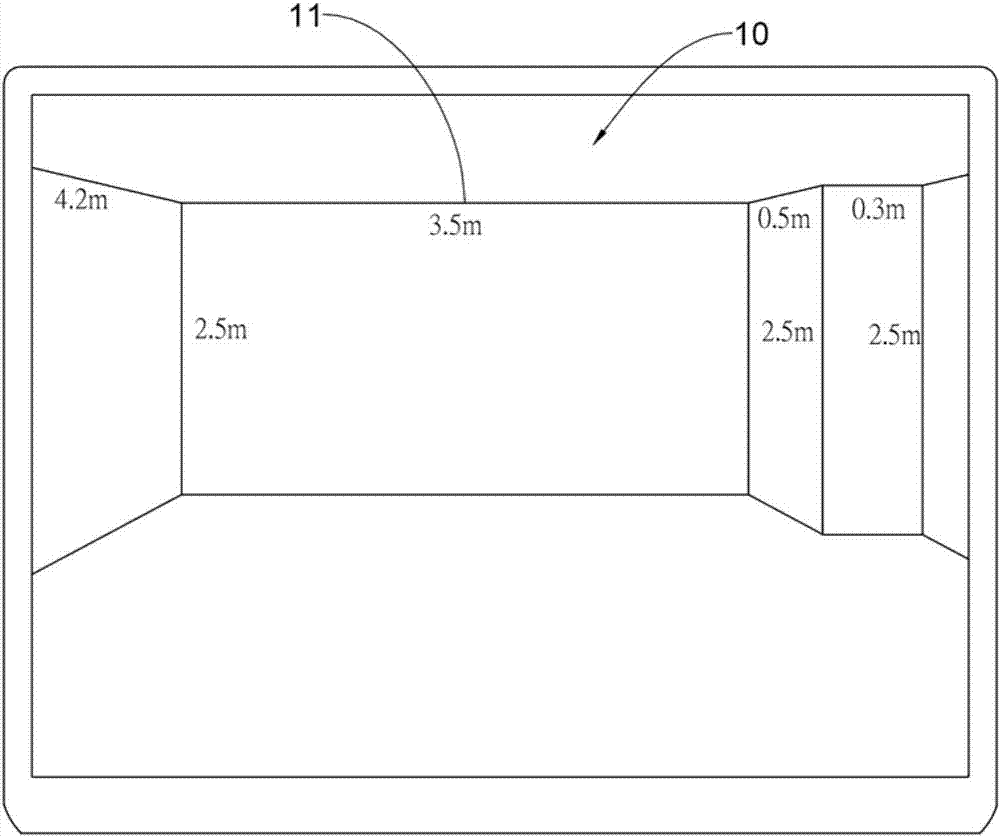

Method for browsing house interactively in 3D virtual reality and system for the same

InactiveCN106991723AReduce construction costsHardware costs can be controlledInput/output for user-computer interactionImage data processingGraphicsInterior space

The present invention relates to a method for browsing house interactively in 3D virtual reality and system for the same. The method has steps of: (a) acquiring a 3D graph and data file of a real house structure; (b) converting the 3D graph and data file to a 3D house virtual object; and (c) browsing an inside space and space size of the 3D house virtual object in 3D virtual reality, wherein a new 3D image of the moved 3D house virtual object is displayed according to a distance or angle moving command, and a real dimension between two measured positions of the real house is provided according to a measurement command. In addition, the method of the present invention also verifies whether a size of a selected 3D household virtual object matches that of a selected position in the 3D house virtual object, where the selected 3D household virtual object is going to be placed. Accordingly, a user can quickly determine whether the real house corresponding to the 3D house virtual object is qualified.

Owner:莲嚮科技有限公司

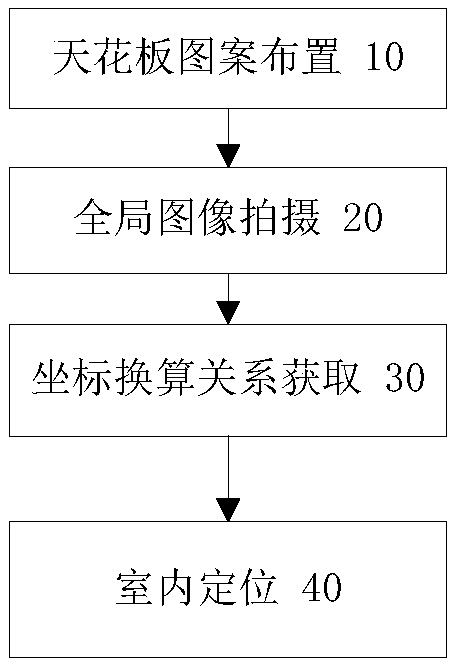

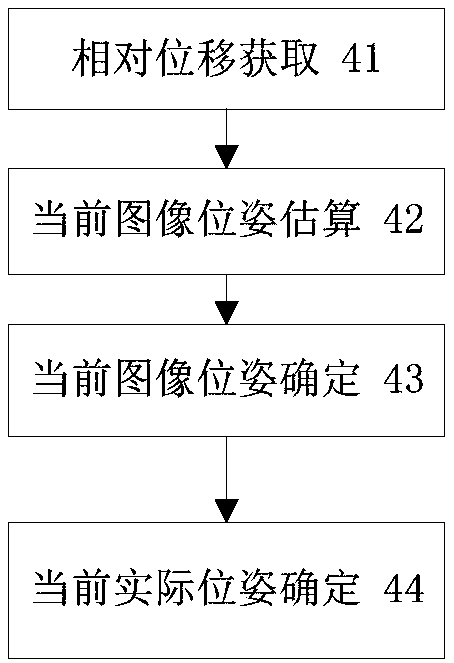

Robot indoor positioning method based on ceiling images

InactiveCN107689063AAdaptableReduce distractionsImage enhancementImage analysisOptical flowImage matching

The invention provides a robot indoor positioning method based on ceiling images. The method comprises the following steps of arranging a pattern obviously different from an image in an adjacent vision field on a ceiling; programming to make a robot traverse indoor positions, shooting pictures through a camera on the top, and splicing collected images to obtain a global image; comparing the actualindoor size with the pixel size of the global image, and obtaining coordinate conversion relationsbetween image coordinates and actual coordinates; calculating the pose of the robot in the global image through an optical flow method and image matching, and according to the coordinate conversion relations, determining the current actual pose of the robot. The robot indoor positioning method basedon the ceiling images calculates the pose of the robot in the global image through the optical flow method and image matching, and determines the current actual pose of the robot according to the coordinate conversion relations. The robot indoor positioning method based on the ceiling images is high in adoptability and good in stability.

Owner:THE NORTHERN RES INST OF NJUST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com