Skin mirror image milling numerical control program fast generating method based on features

A technology of mirror image milling and NC program, applied in the direction of digital control, electrical program control, etc., can solve the problems of long NC machining program programming cycle, affecting the machining efficiency of NC machine tools, reading process regulations, etc., to solve the problem of heavy workload and erroneous Effects of operation, improvement of programming efficiency, and improvement of programming efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

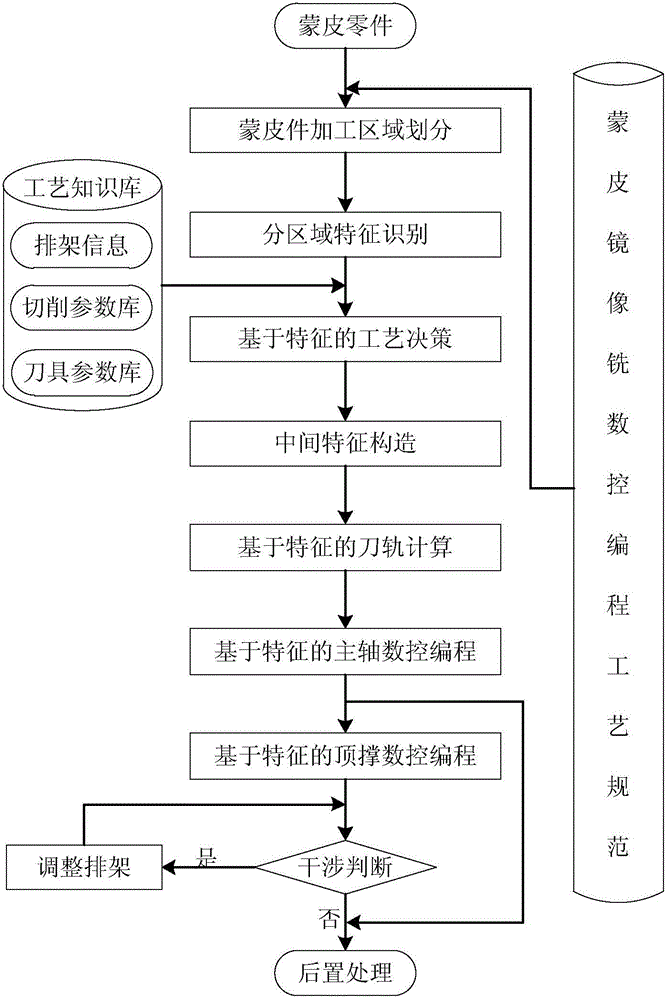

[0045] A feature-based method for quickly generating NC programs for skin mirror milling, the flow chart is as follows figure 1 As shown, the method is implemented through the following steps:

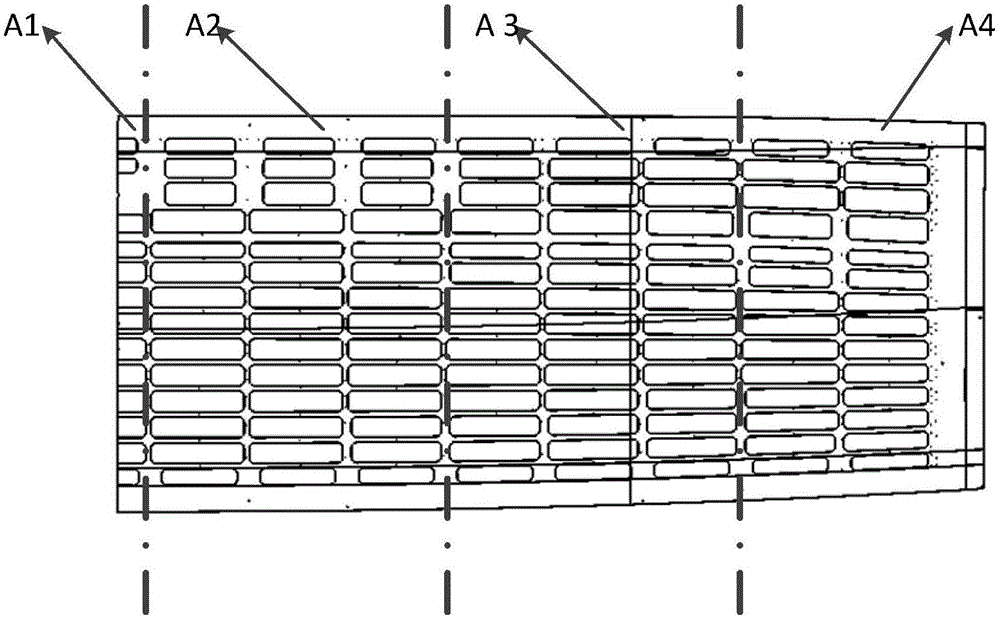

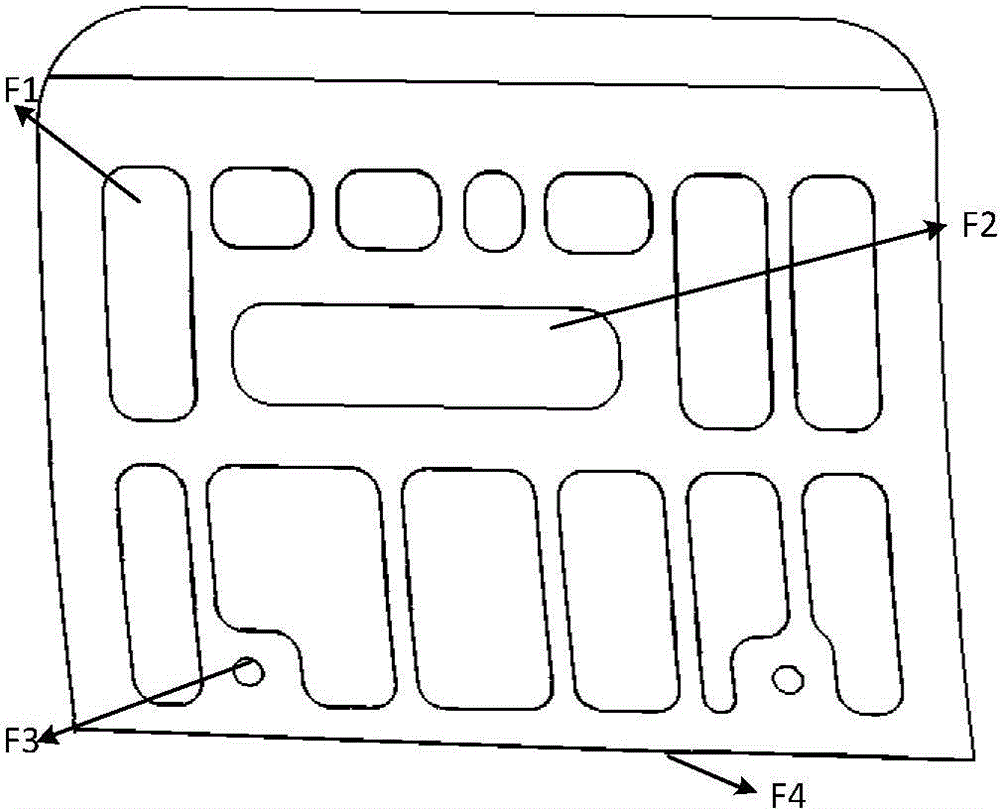

[0046] 1. Division of processing areas

[0047] The skin mirror milling adopts rack-type vacuum adsorption, and at the same time, the supporting device on the back and the processing spindle follow up to form a mirror image processing. In order to avoid the interference between the supporting and the rack, it is necessary to divide the processing area of the skin during NC programming. The process of dividing the area mainly includes:

[0048] 1) Since the Y-direction stroke of the skin mirror image milling machine is only 1200mm, and the Z-direction adsorption and clamping stroke is less than 700mm, it is necessary to consider the Y-direction and Z-directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com