Patents

Literature

249results about How to "Precise Dimensions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

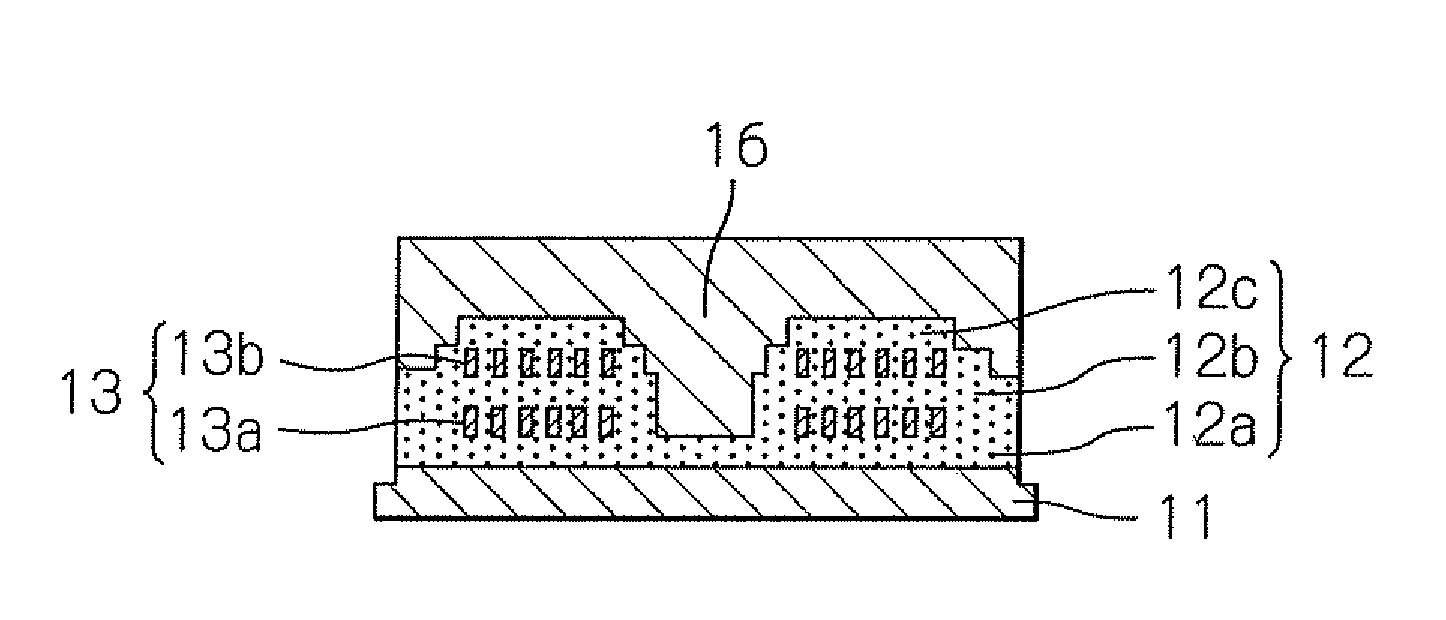

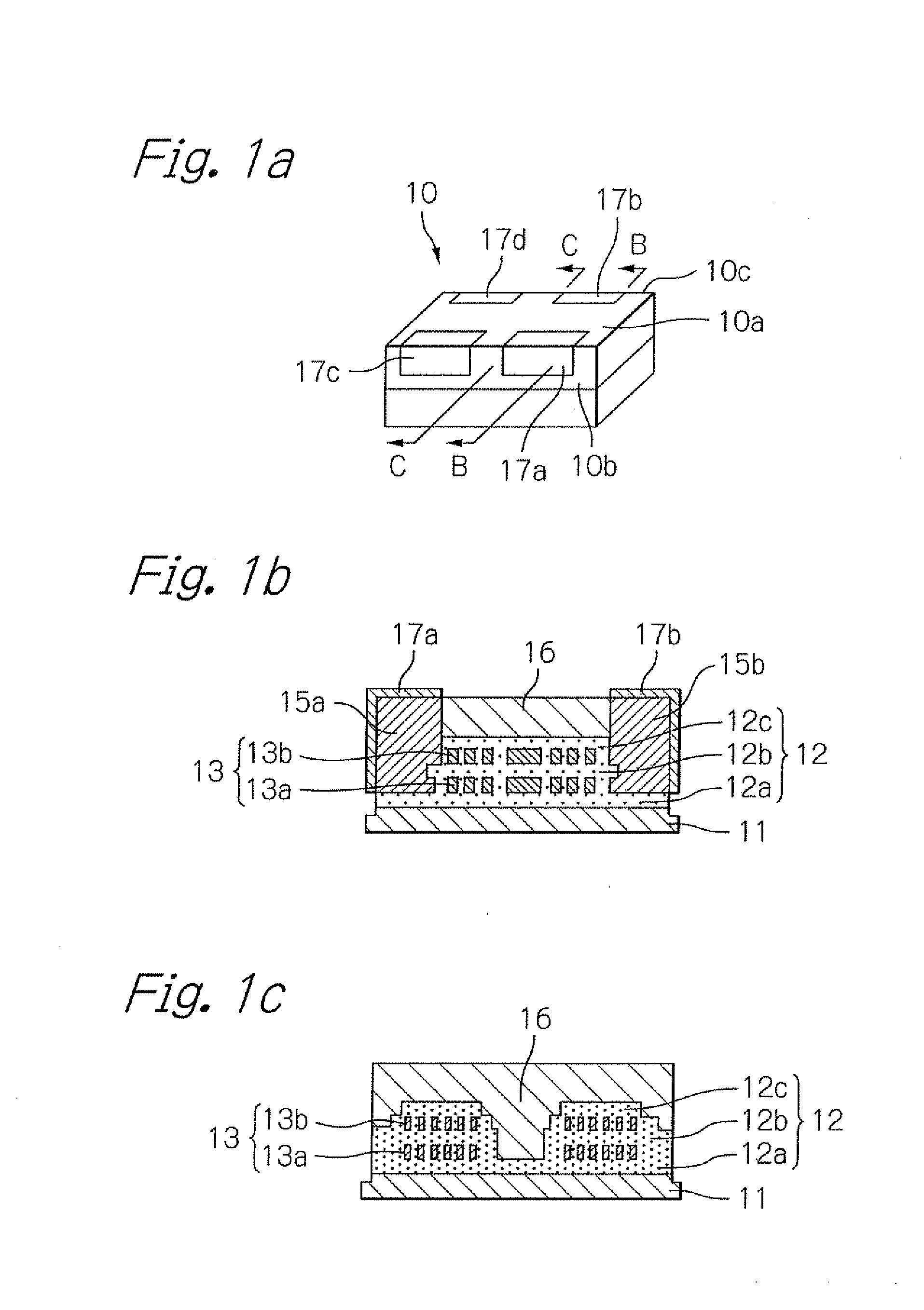

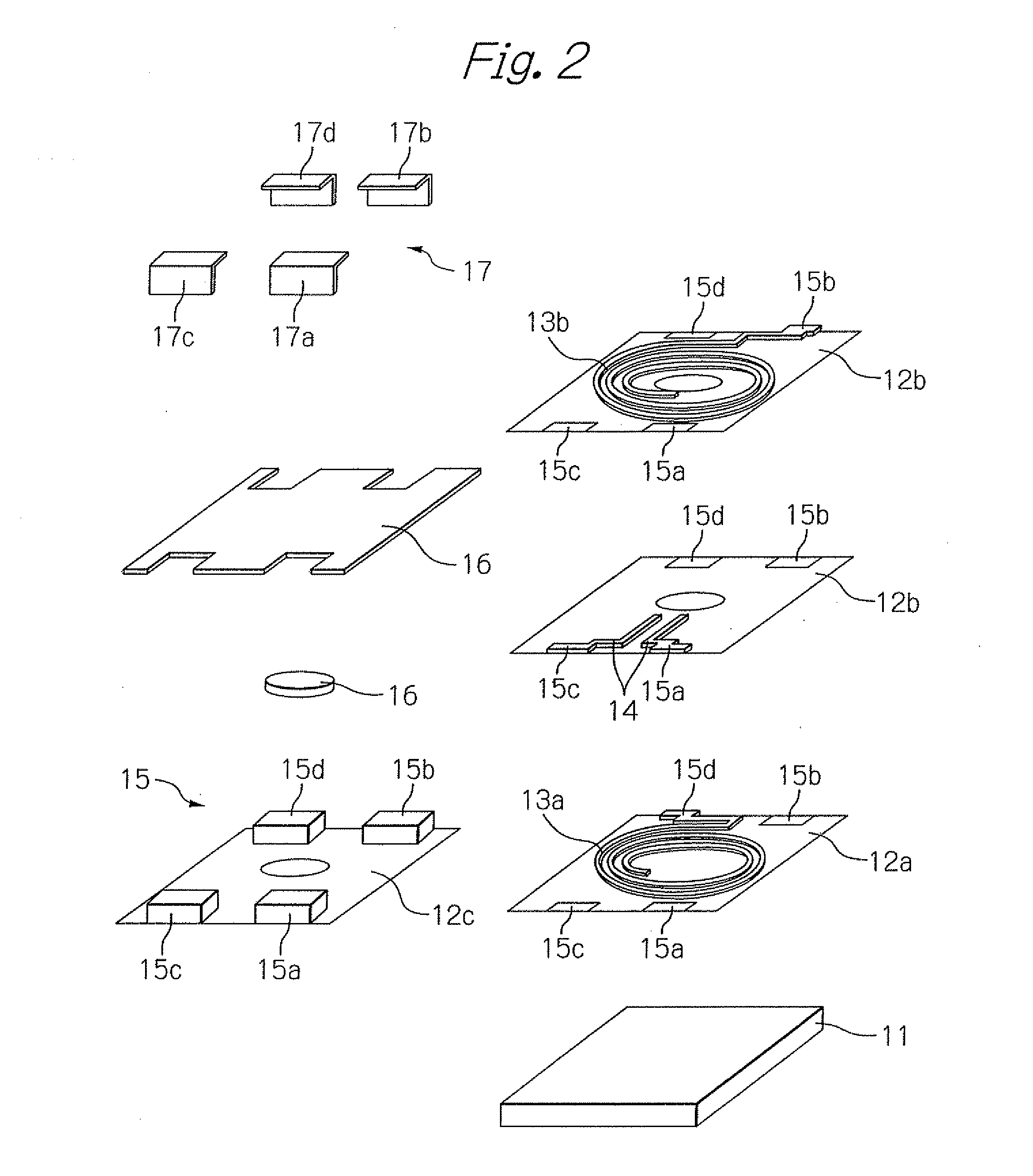

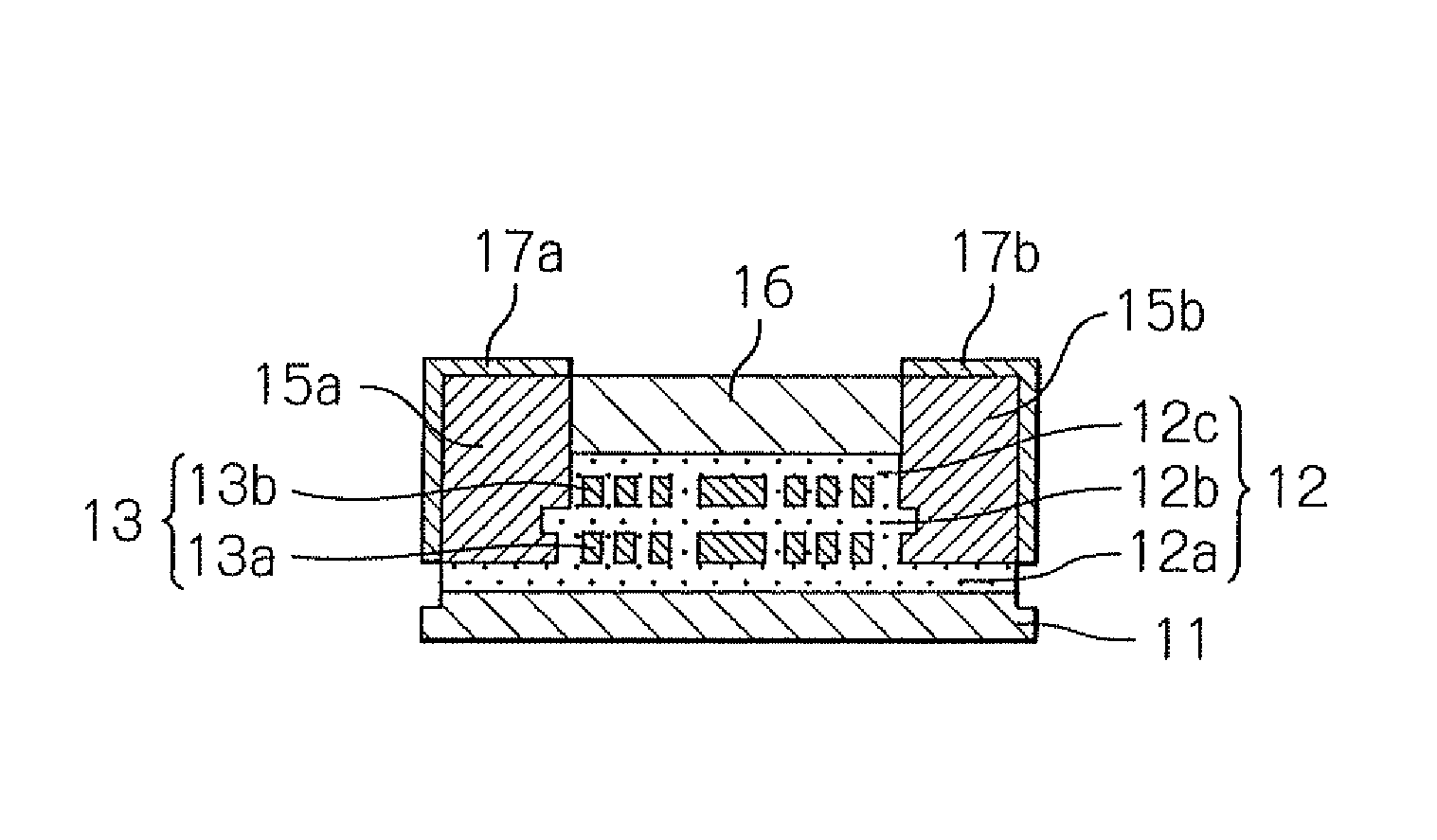

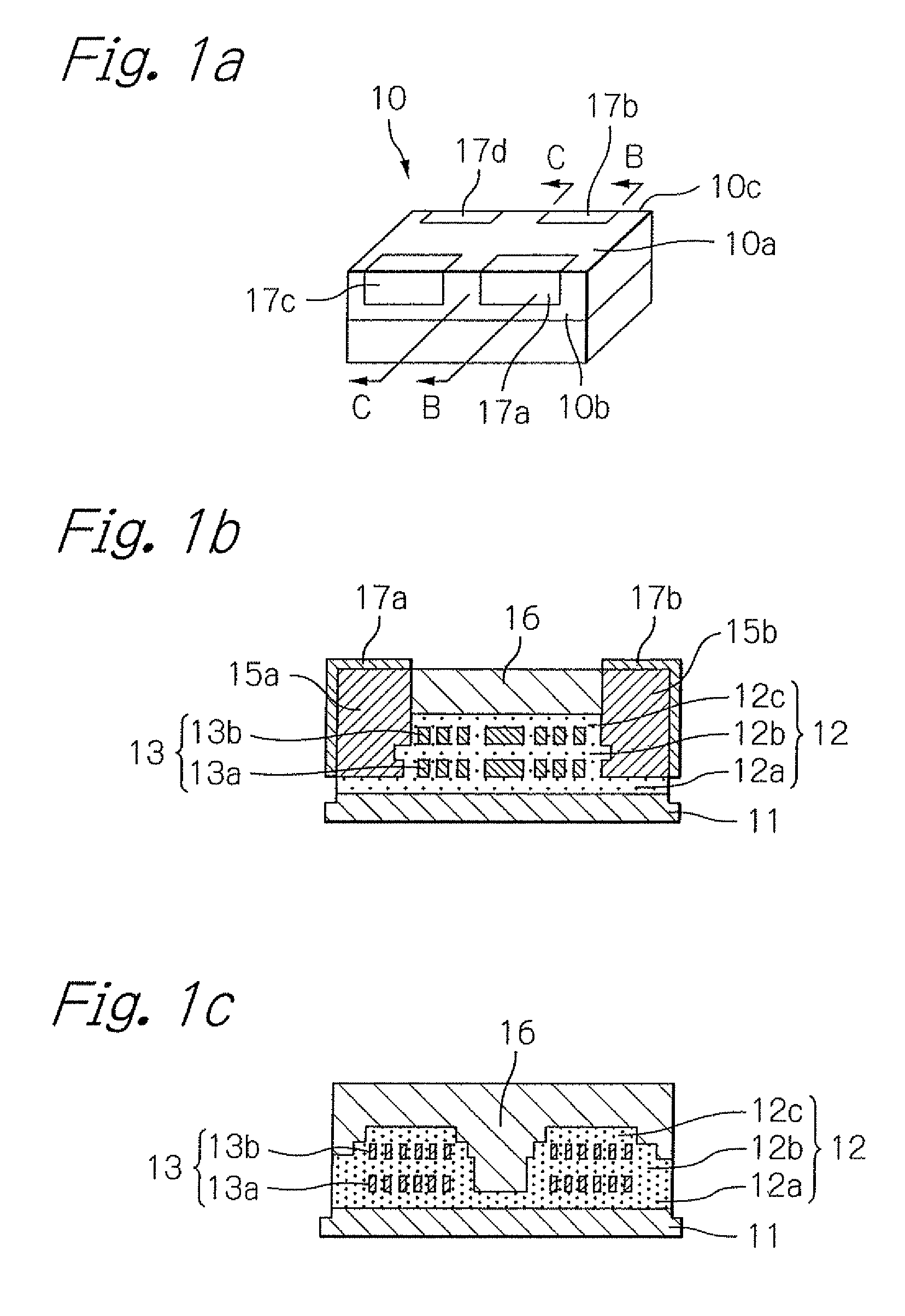

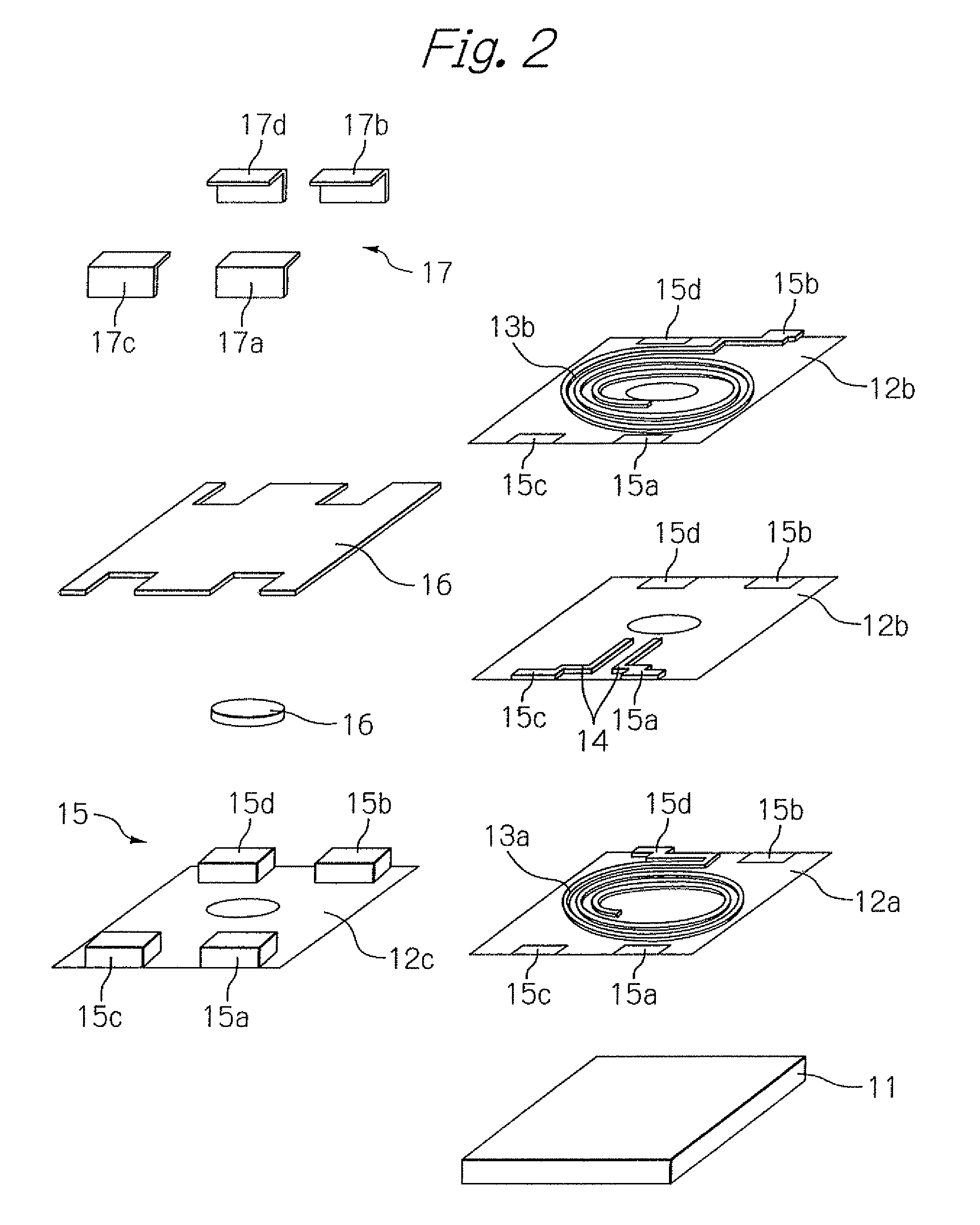

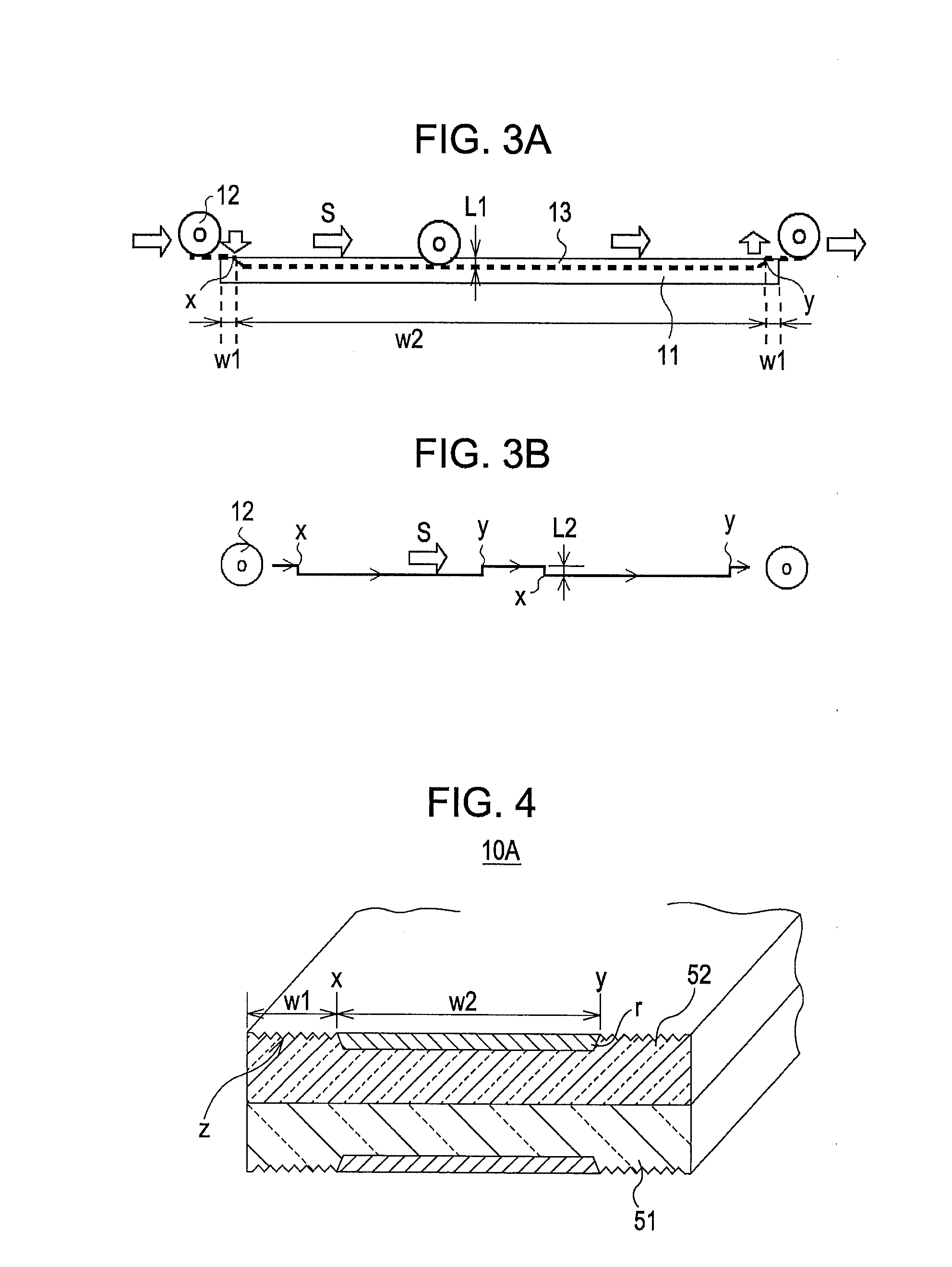

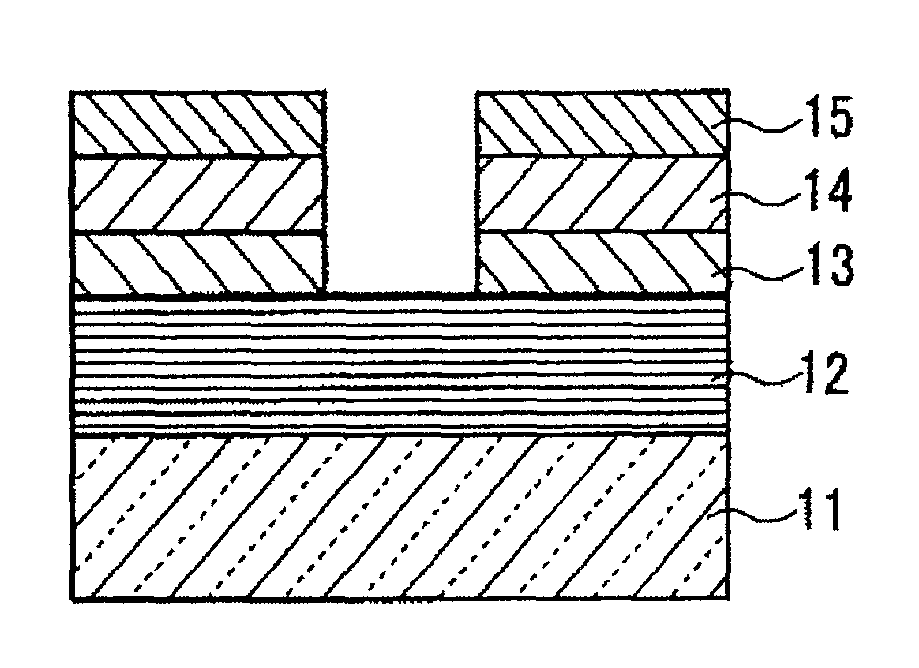

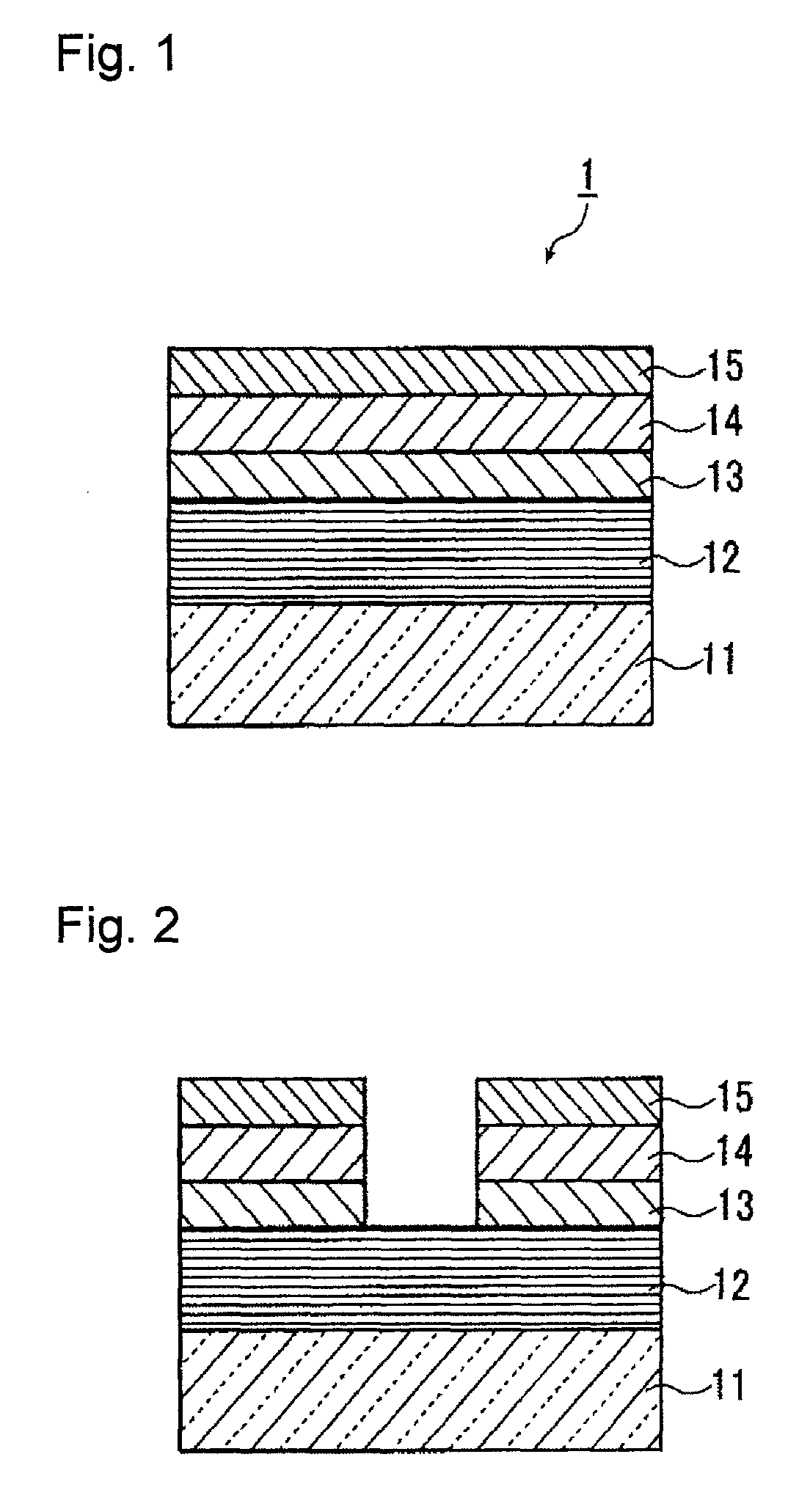

Electronic component and manufacturing method of electronic component

ActiveUS20100157565A1Sufficient soldering strengthIncrease electrode areaSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsInsulation layerElectrical conductor

A manufacturing method of electronic components includes forming a first insulation layer on a substrate, forming a plurality of passive elements on the first insulation layer, forming a second insulation layer on the passive elements, forming a plurality of conductor layers electrically connected to the respective passive elements, on the outer side of the second insulation layer to be exposed to an upper surface of each electronic component, and forming grooves between the electronic components including the respective passive elements to expose side surfaces of each electronic component and parts of the conductor layers from the side surfaces of each electronic component. The manufacturing method further including plating a plurality of external electrodes on the respective conductor layers exposed to the upper surface and the side surfaces of each electronic component, and cutting the substrate to completely separate into individual electronic components.

Owner:TDK CORPARATION

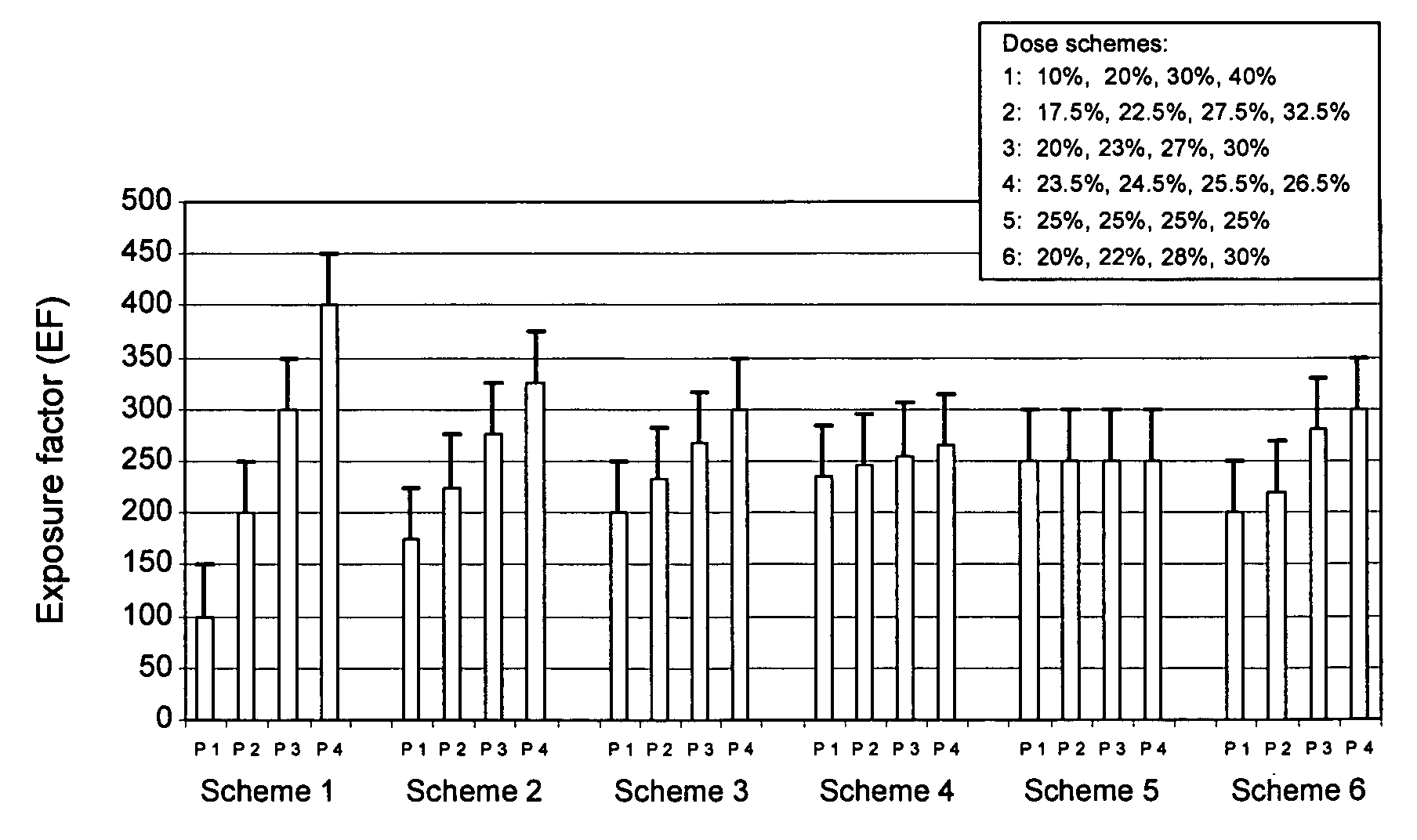

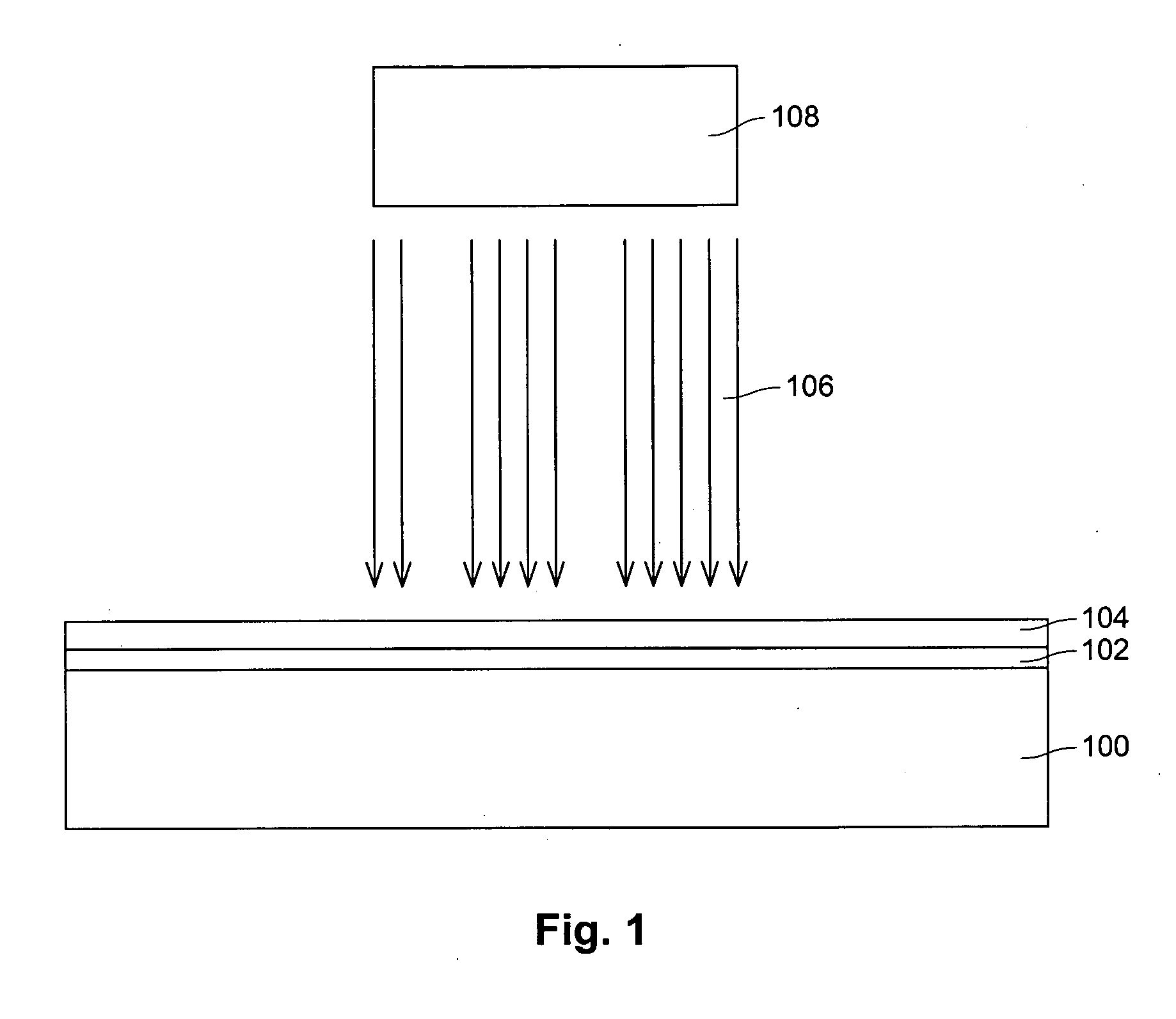

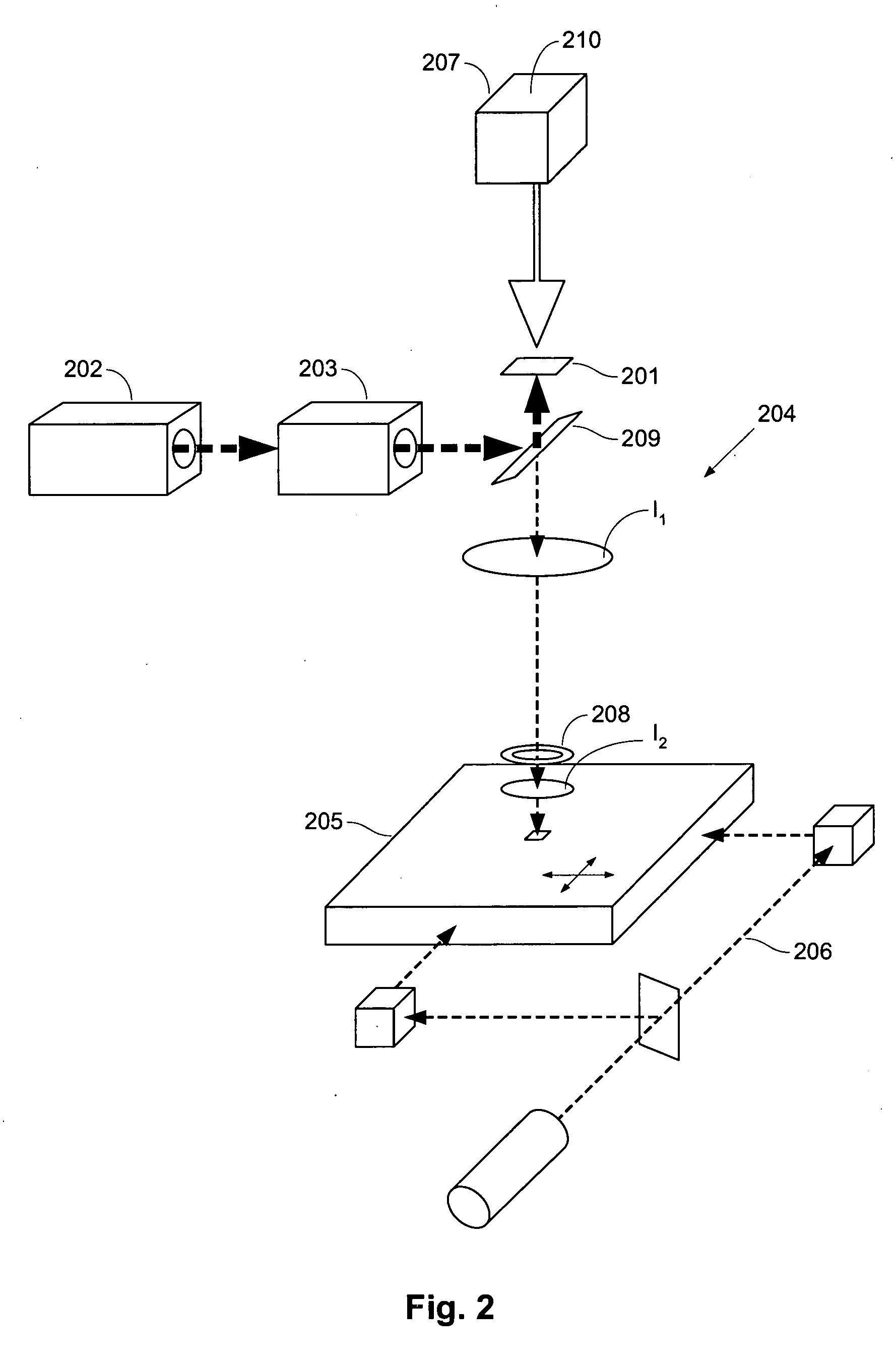

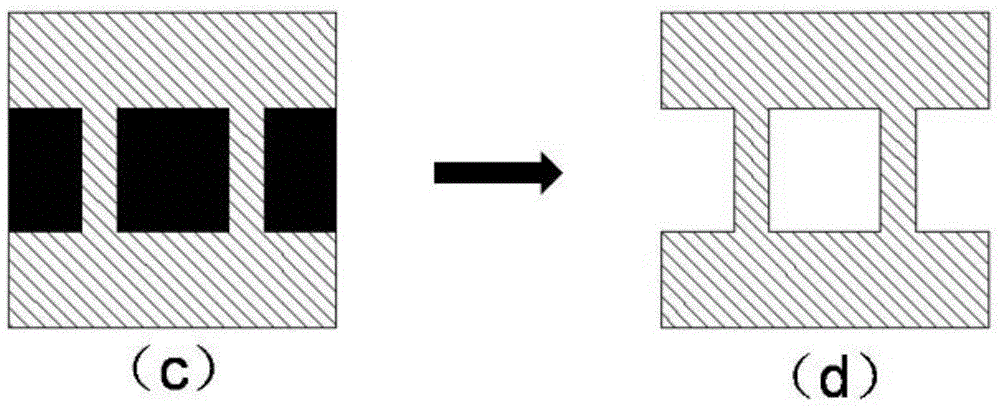

Further method to pattern a substrate

InactiveUS20050053850A1Precise DimensionsElectric discharge tubesSemiconductor/solid-state device manufacturingResistCritical dimension

The present invention relates to methods for patterning substrates, such as reticles, masks or wafers, which reduce critical dimension variations, improving CD uniformity. In particular, it relates to tuning doses applied in passes of a multipass writing strategy to measurable characteristics of resists or radiation sensitive layers applied to the substrates. Particular writing strategies are described. Aspects of the present invention are described in the claims, specification and drawings.

Owner:MICRONIC LASER SYST AB

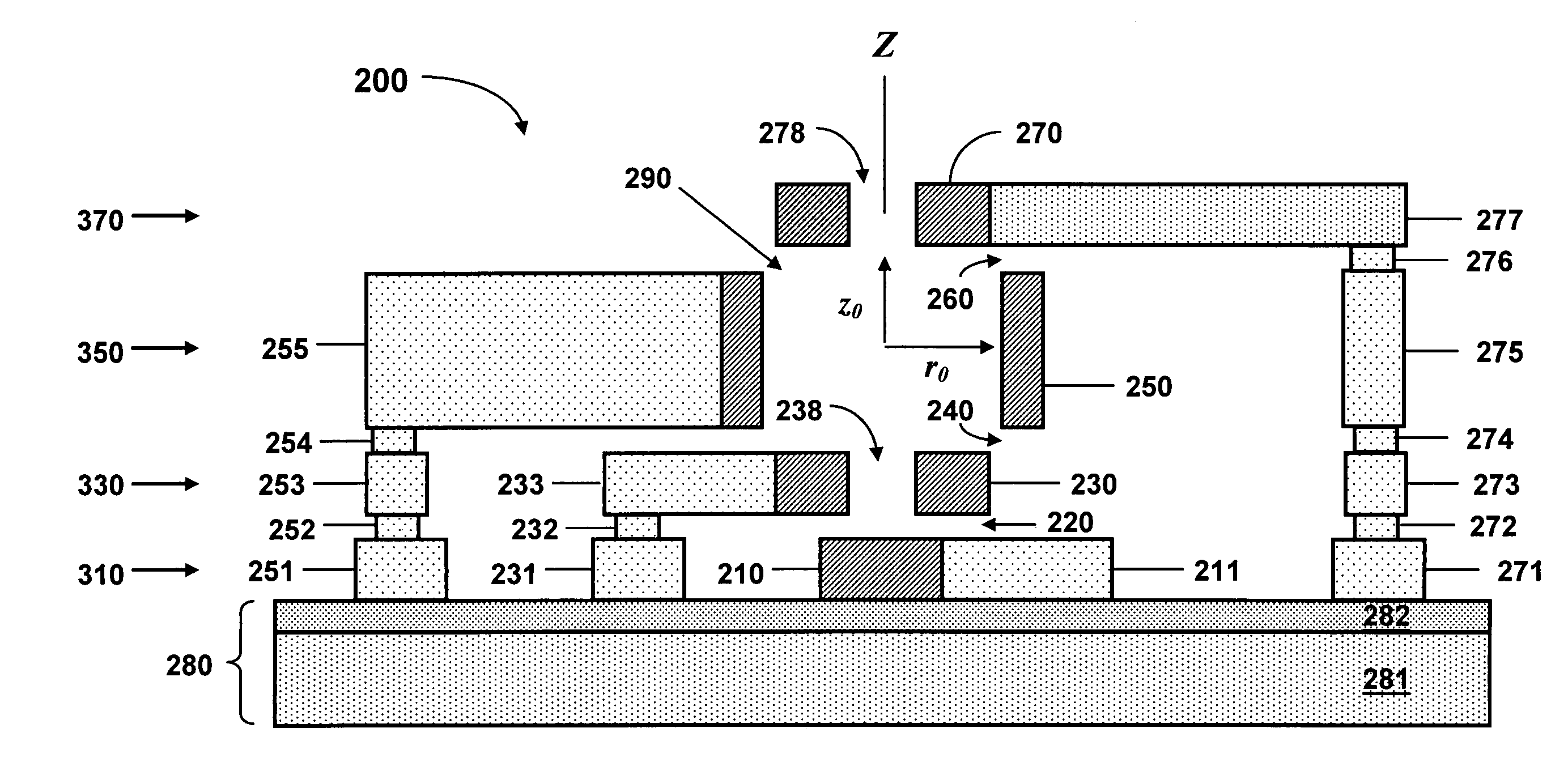

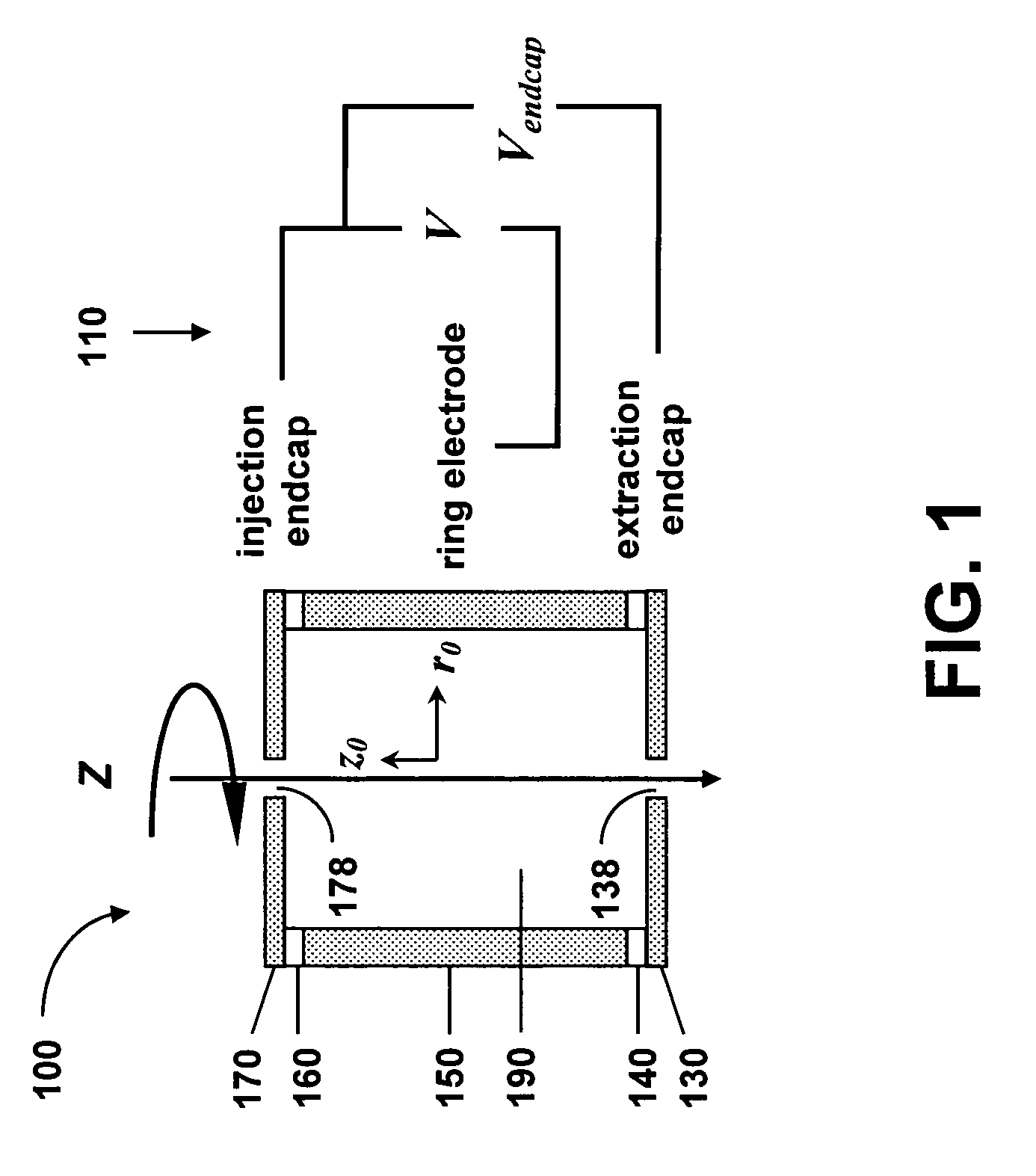

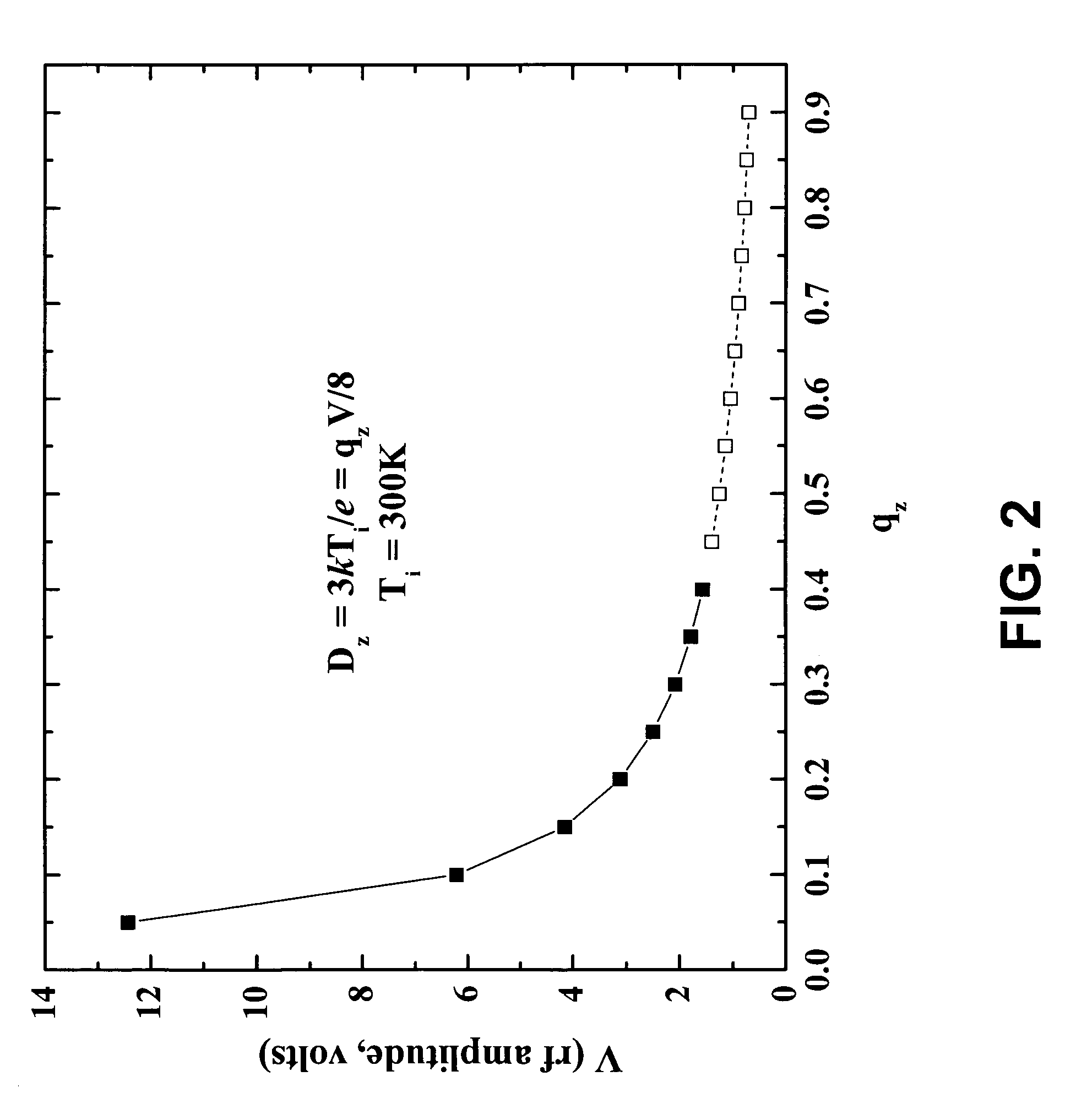

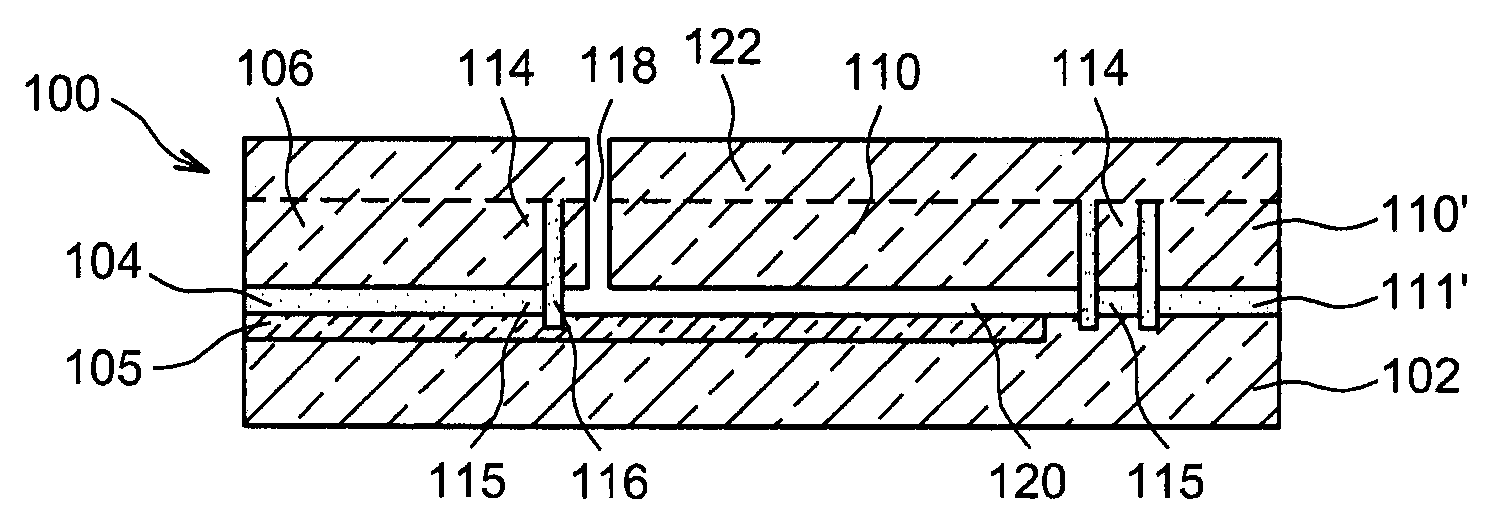

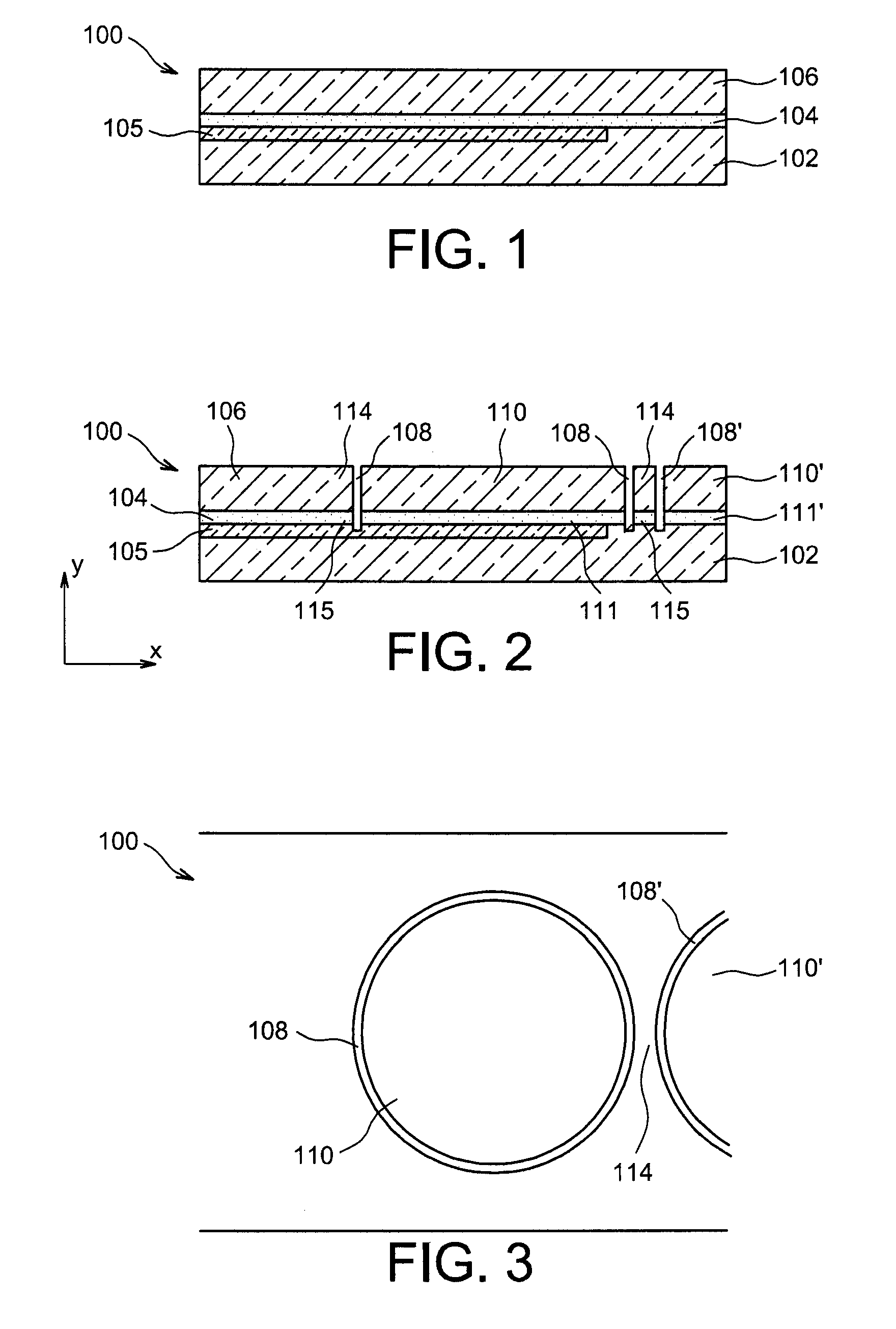

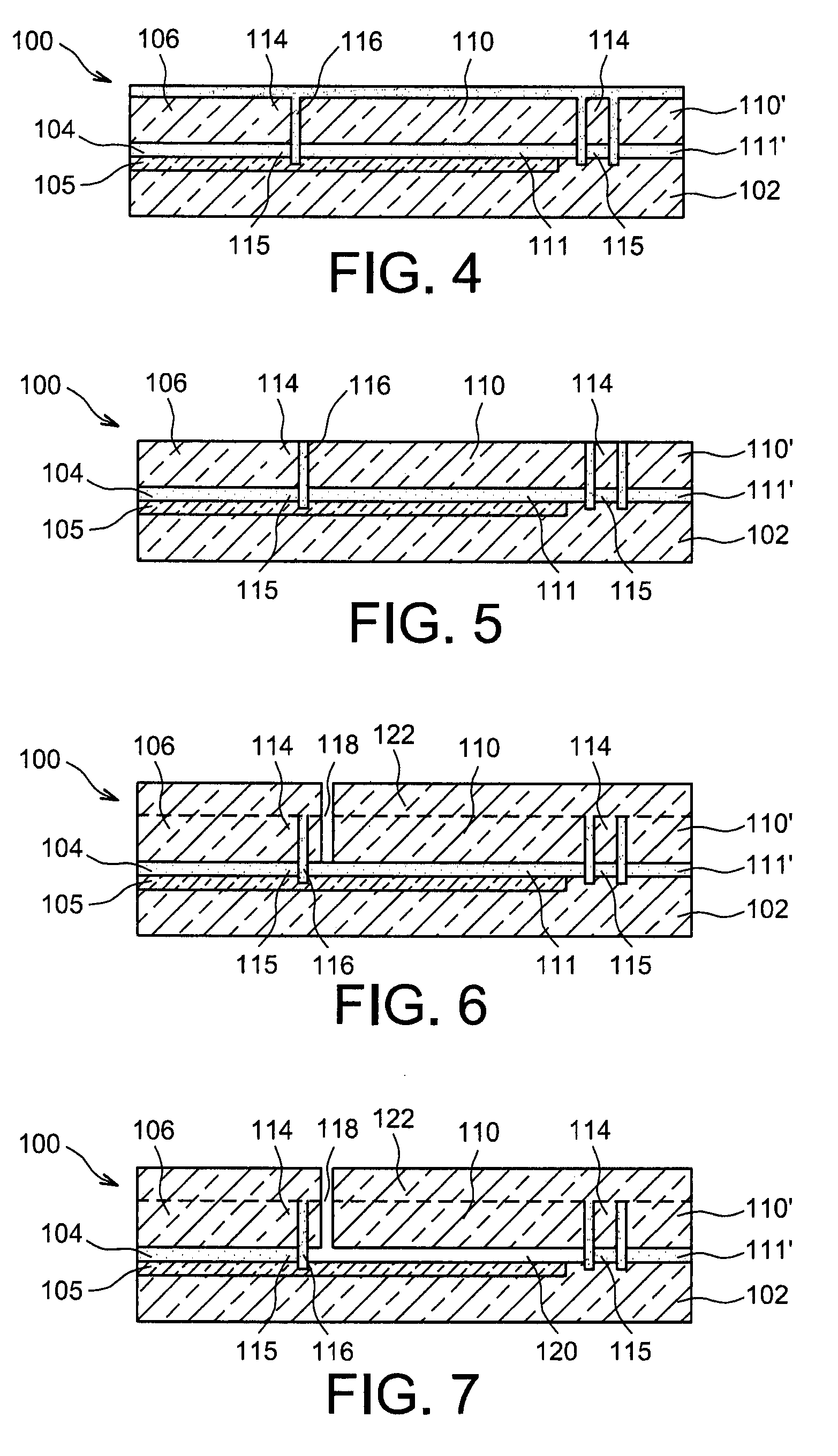

Microfabricated ion trap array

ActiveUS7154088B1High chemical selectivityResolution advantageStability-of-path spectrometersIsotope separationPhysicsIntegrated circuit

A microfabricated ion trap array, comprising a plurality of ion traps having an inner radius of order one micron, can be fabricated using surface micromachining techniques and materials known to the integrated circuits manufacturing and microelectromechanical systems industries. Micromachining methods enable batch fabrication, reduced manufacturing costs, dimensional and positional precision, and monolithic integration of massive arrays of ion traps with microscale ion generation and detection devices. Massive arraying enables the microscale ion traps to retain the resolution, sensitivity, and mass range advantages necessary for high chemical selectivity. The reduced electrode voltage enables integration of the microfabricated ion trap array with on-chip circuit-based rf operation and detection electronics (i.e., cell phone electronics). Therefore, the full performance advantages of the microfabricated ion trap array can be realized in truly field portable, handheld microanalysis systems.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Polymer powder with polyamide, use in a shaping process, and moldings produced from this polymer powder

ActiveUS20060202395A1Maximal dimensional precisionImprove surface qualityAnimal watering devicesAnimal feeding devicesPolymer scienceSusceptor

The present invention relates to a polymer powder which comprises polyamide, and to the use of this powder for shaping processes, and also to moldings produced from this polymer powder. The shaping processes are layer-by-layer processes which use powders, where regions of the respective layer are selectively melted via introduction of electromagnetic energy. The selectivity may be achieved, with no intention of restricting the invention thereto, be achieved via masks, application of inhibitors, of absorbers, or of susceptors, or via focusing of the energy introduced. After cooling, the regions then solidified can be removed in the form of moldings from the powder bed.

Owner:EVONIK OPERATIONS GMBH

Electronic component and manufacturing method of electronic component

ActiveUS8174349B2High strengthIncrease the areaSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsElectrical conductorInsulation layer

A manufacturing method of electronic components includes forming a first insulation layer on a substrate, forming a plurality of passive elements on the first insulation layer, forming a second insulation layer on the passive elements, forming a plurality of conductor layers electrically connected to the respective passive elements, on the outer side of the second insulation layer to be exposed to an upper surface of each electronic component, and forming grooves between the electronic components including the respective passive elements to expose side surfaces of each electronic component and parts of the conductor layers from the side surfaces of each electronic component. The manufacturing method further including plating a plurality of external electrodes on the respective conductor layers exposed to the upper surface and the side surfaces of each electronic component, and cutting the substrate to completely separate into individual electronic components.

Owner:TDK CORPARATION

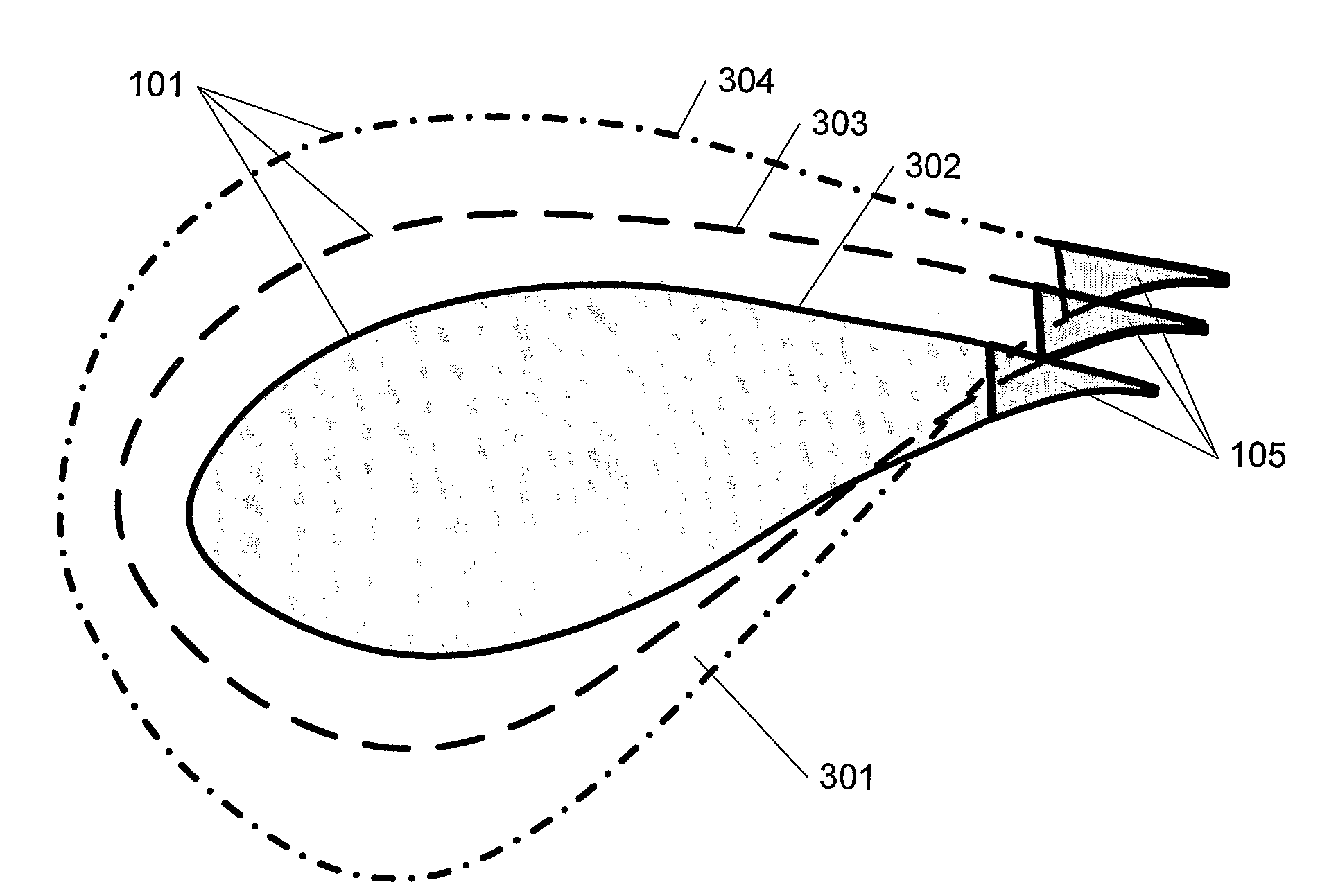

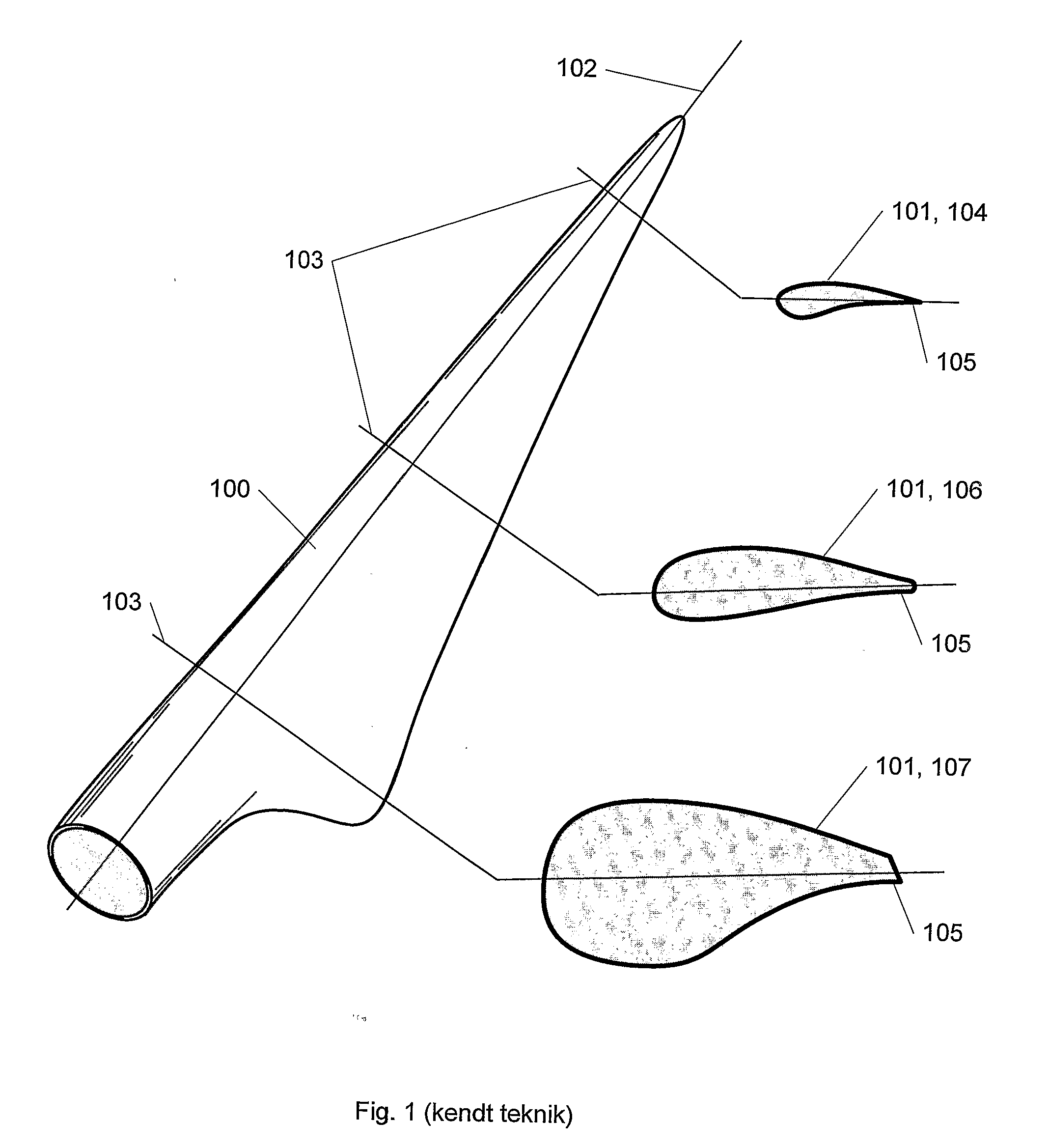

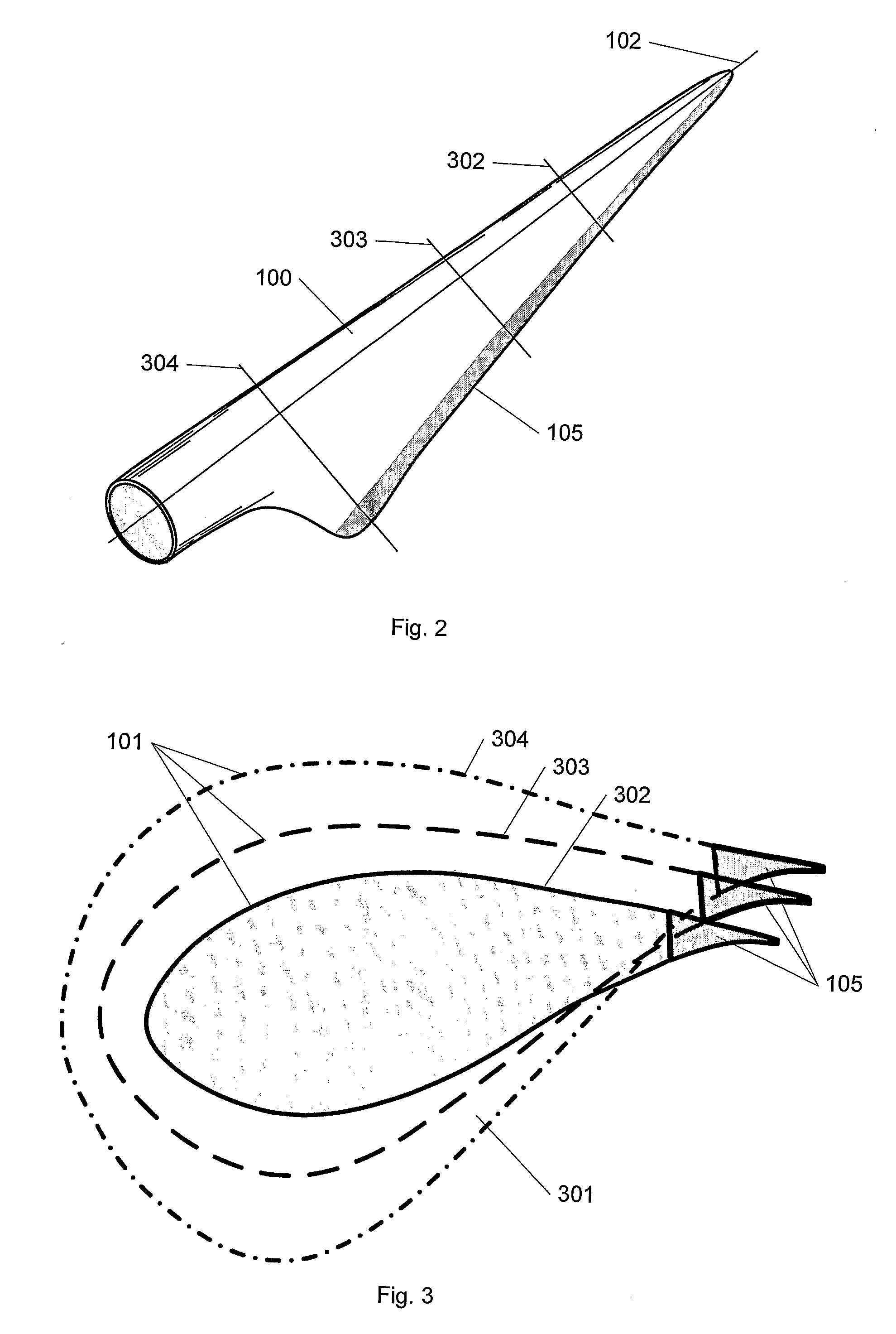

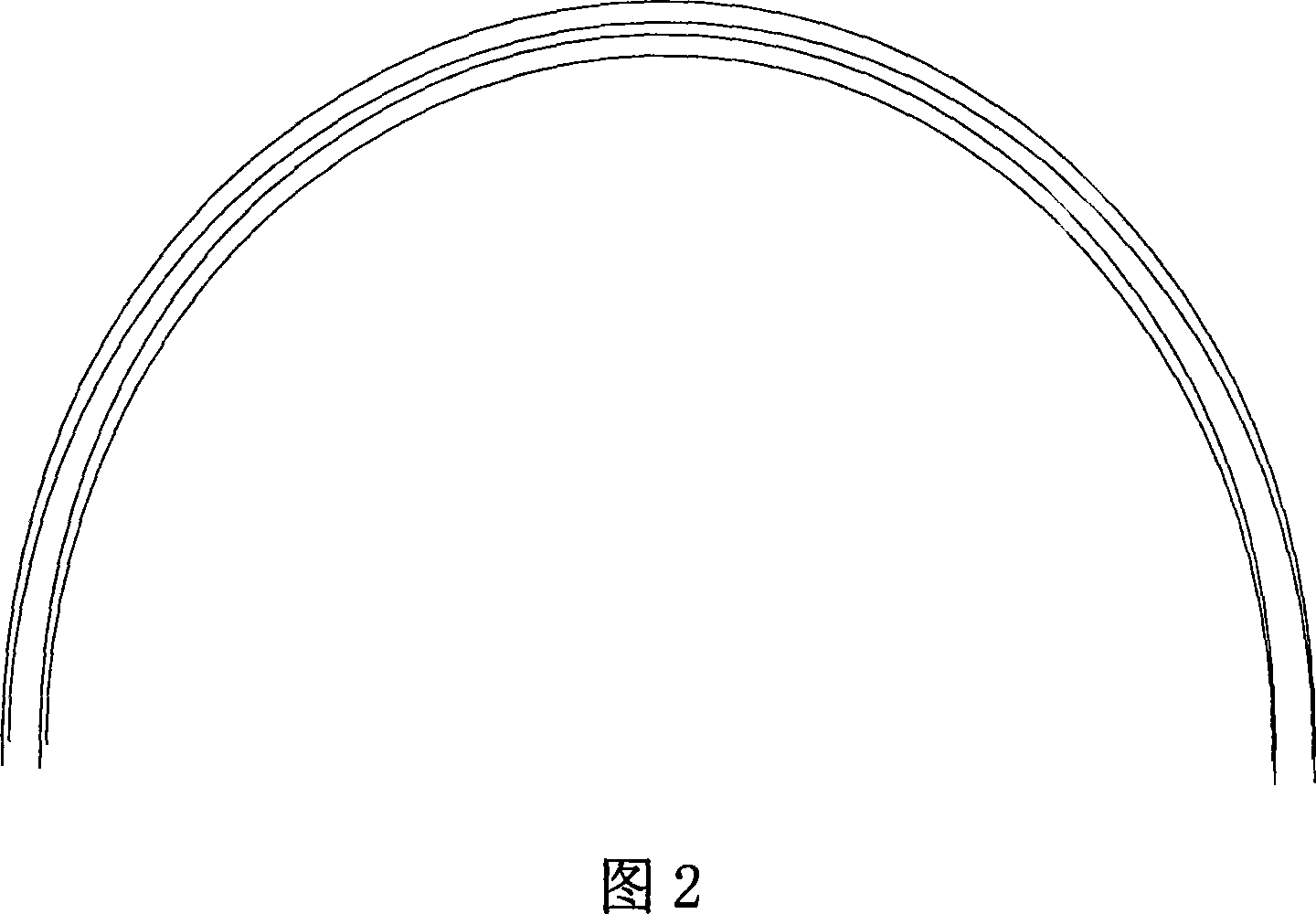

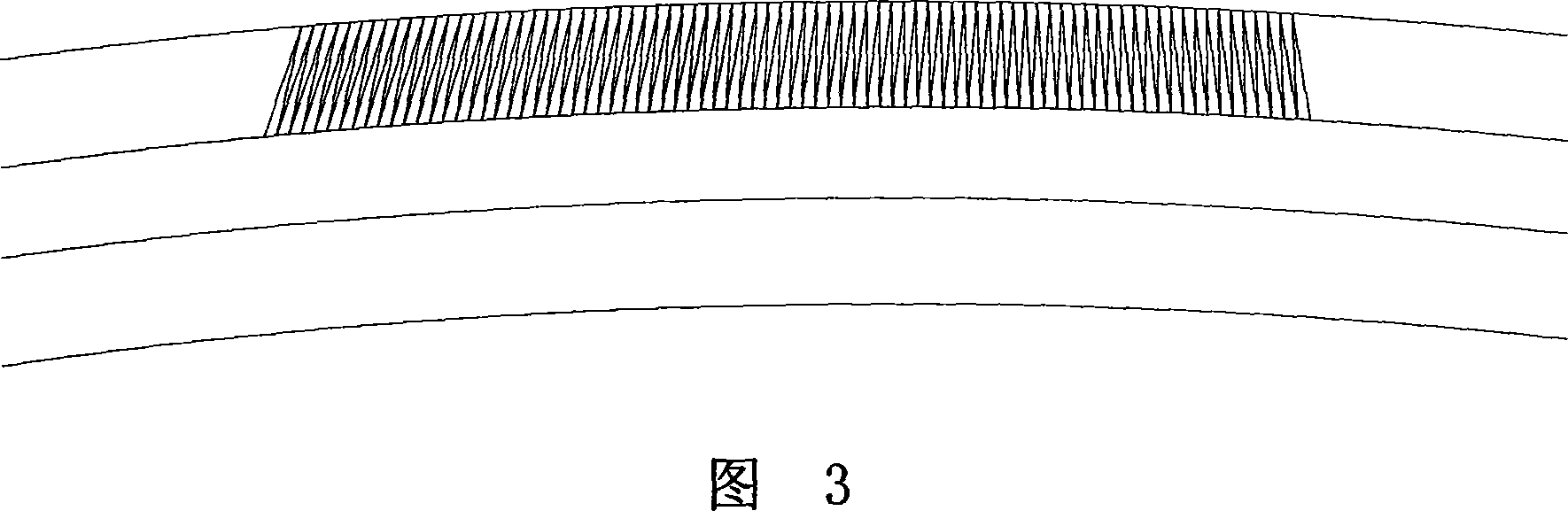

Airfoil Family for a Blade of a Wind Turbine

InactiveUS20090104038A1Improve aerodynamic performanceReduce weightPropellersRotary propellersTurbine rotorClassical mechanics

A wind turbine rotor blade comprising a series of profiles is presented, which series of profiles comprises a number of profiles describing the outline of the blade transversally of its longitudinal axis, wherein some of the profiles of the series of profiles comprise approximately the same profile rear edge which describes at least a portion of the rear edge of the blade. The rear edge of the blade is configured in one piece and / or of a flexible material. Moreover a method of designing a series of profiles for a wind turbine rotor blade is presented.

Owner:LM GLASSFIBER

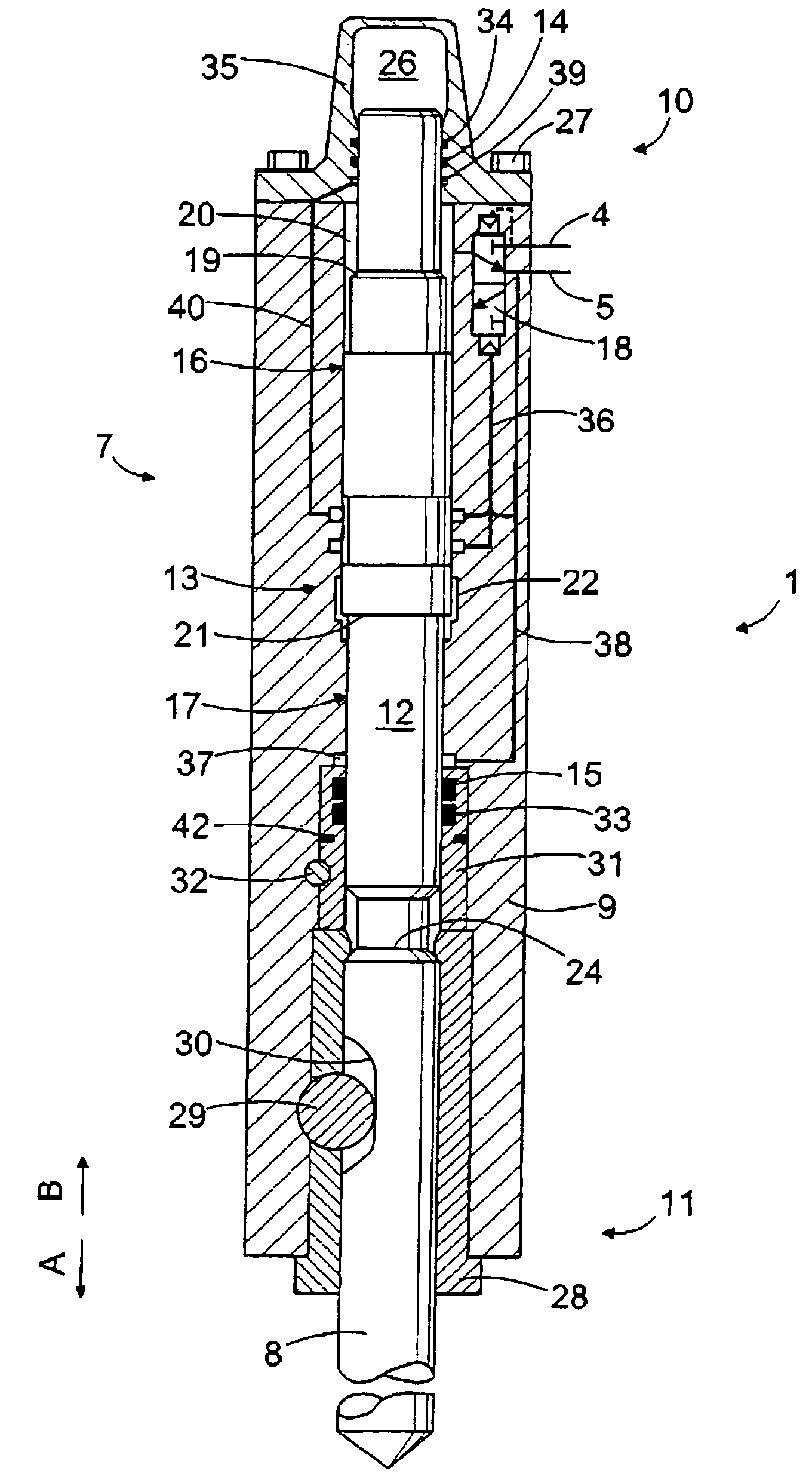

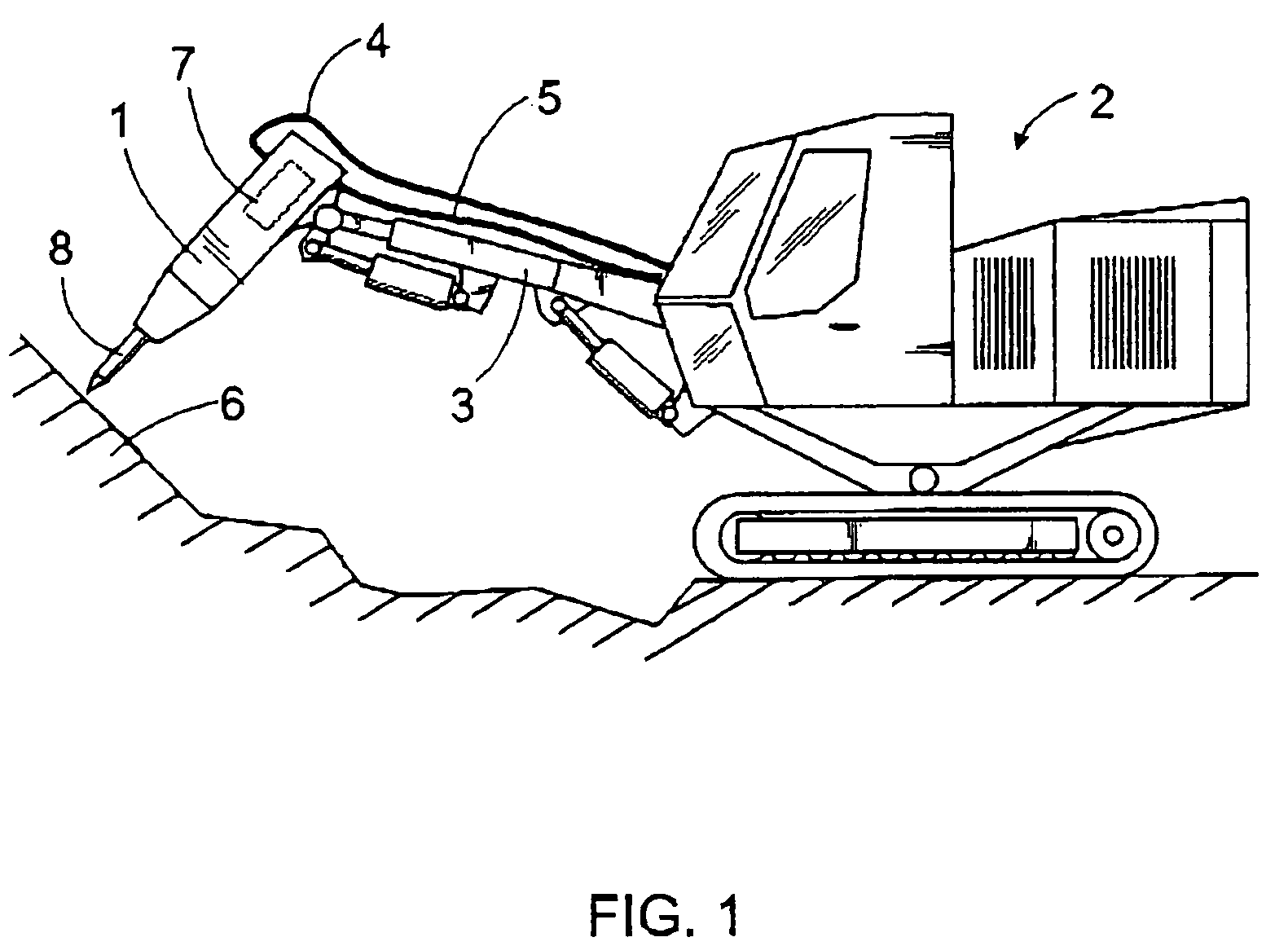

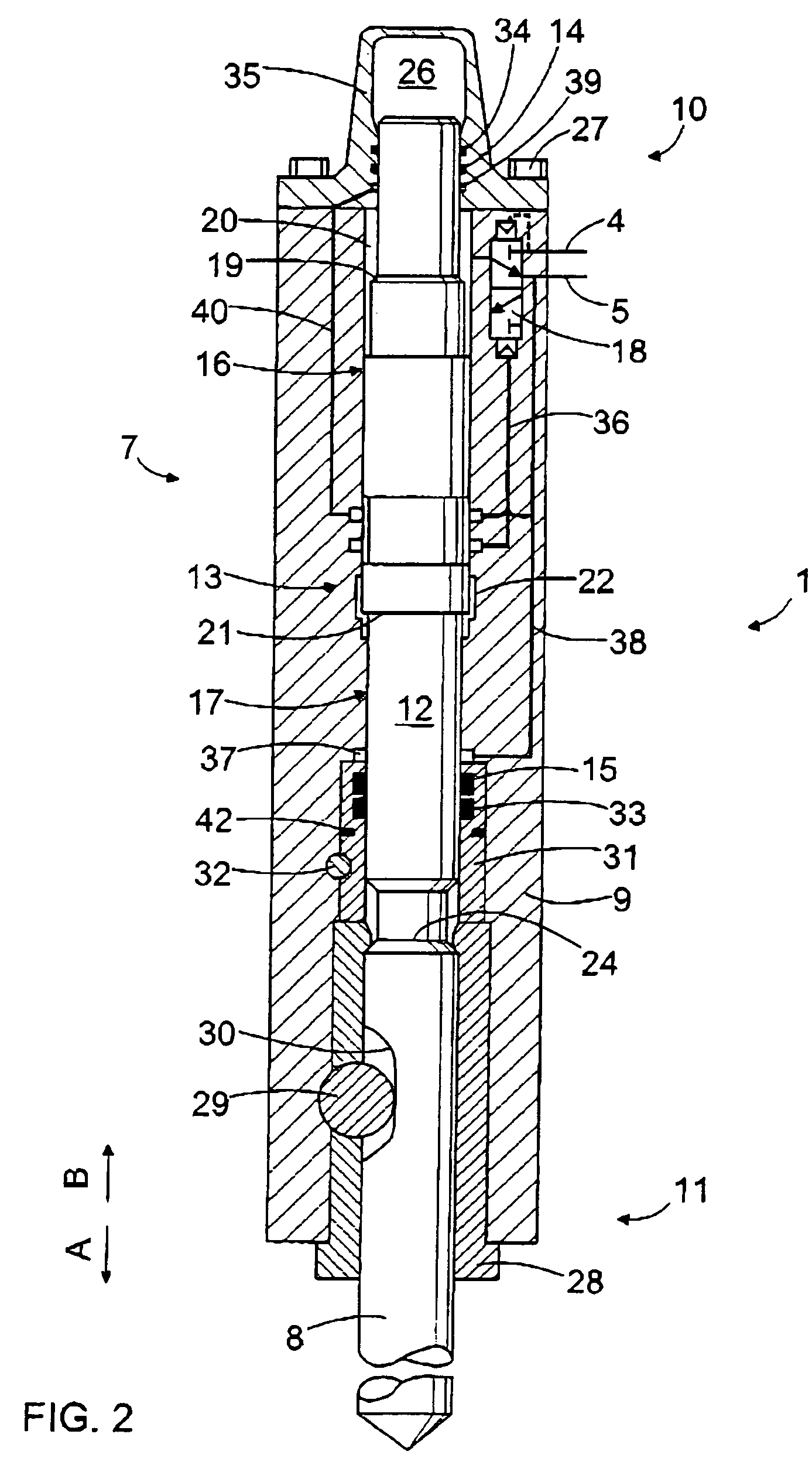

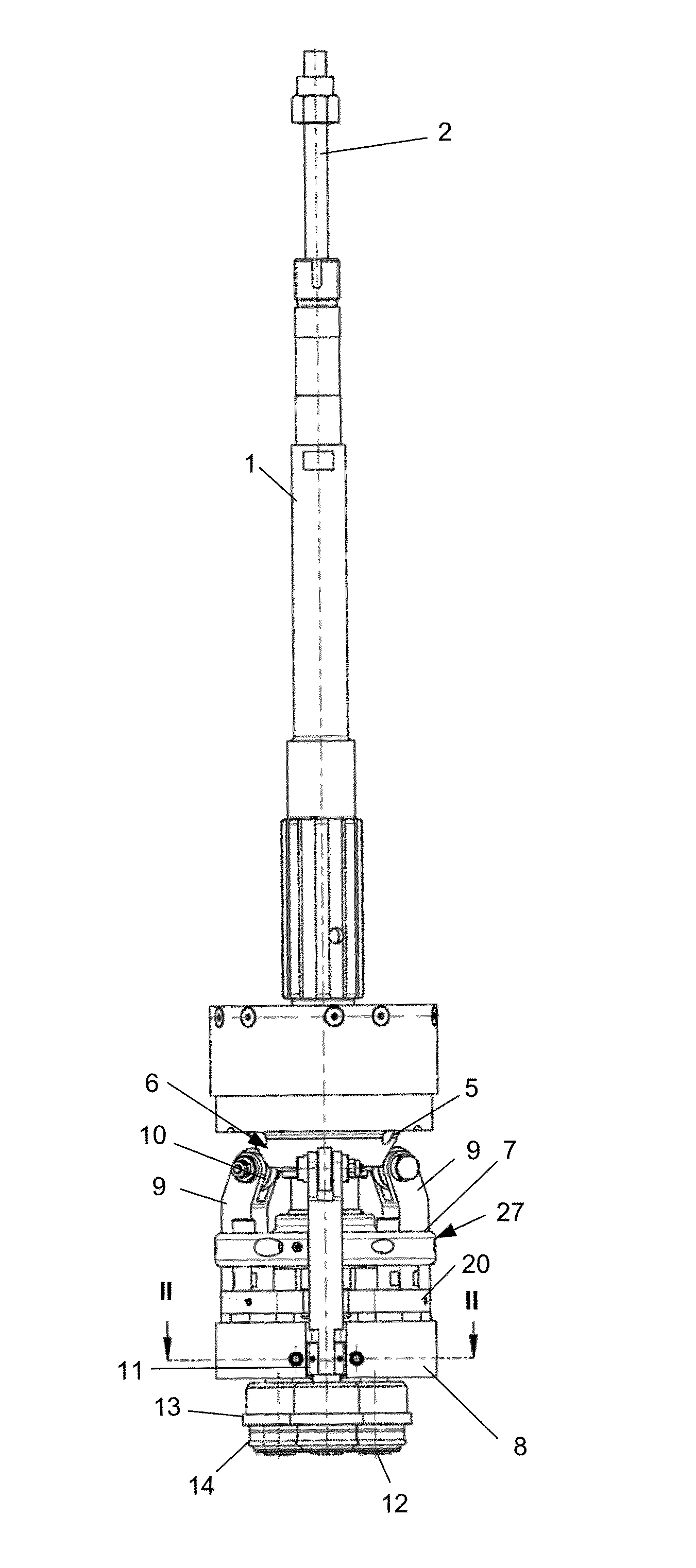

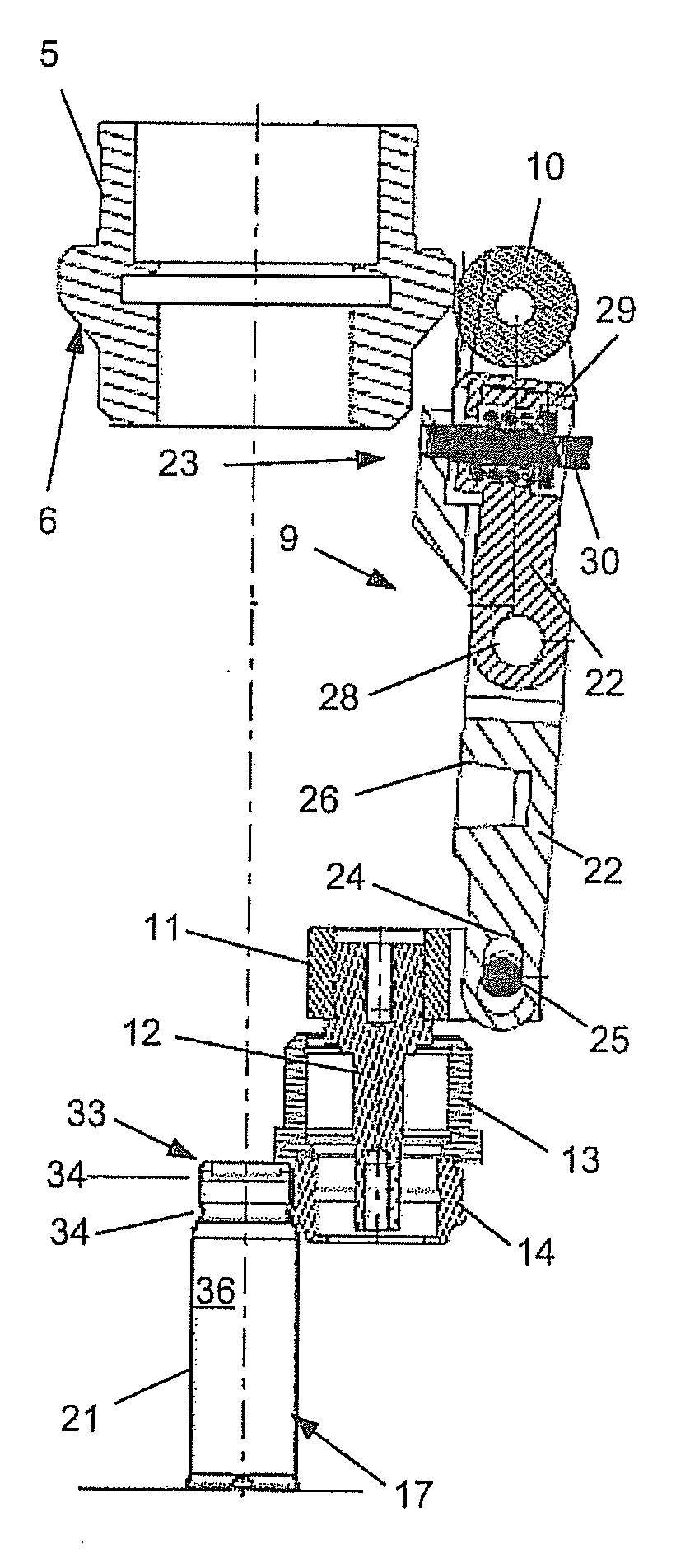

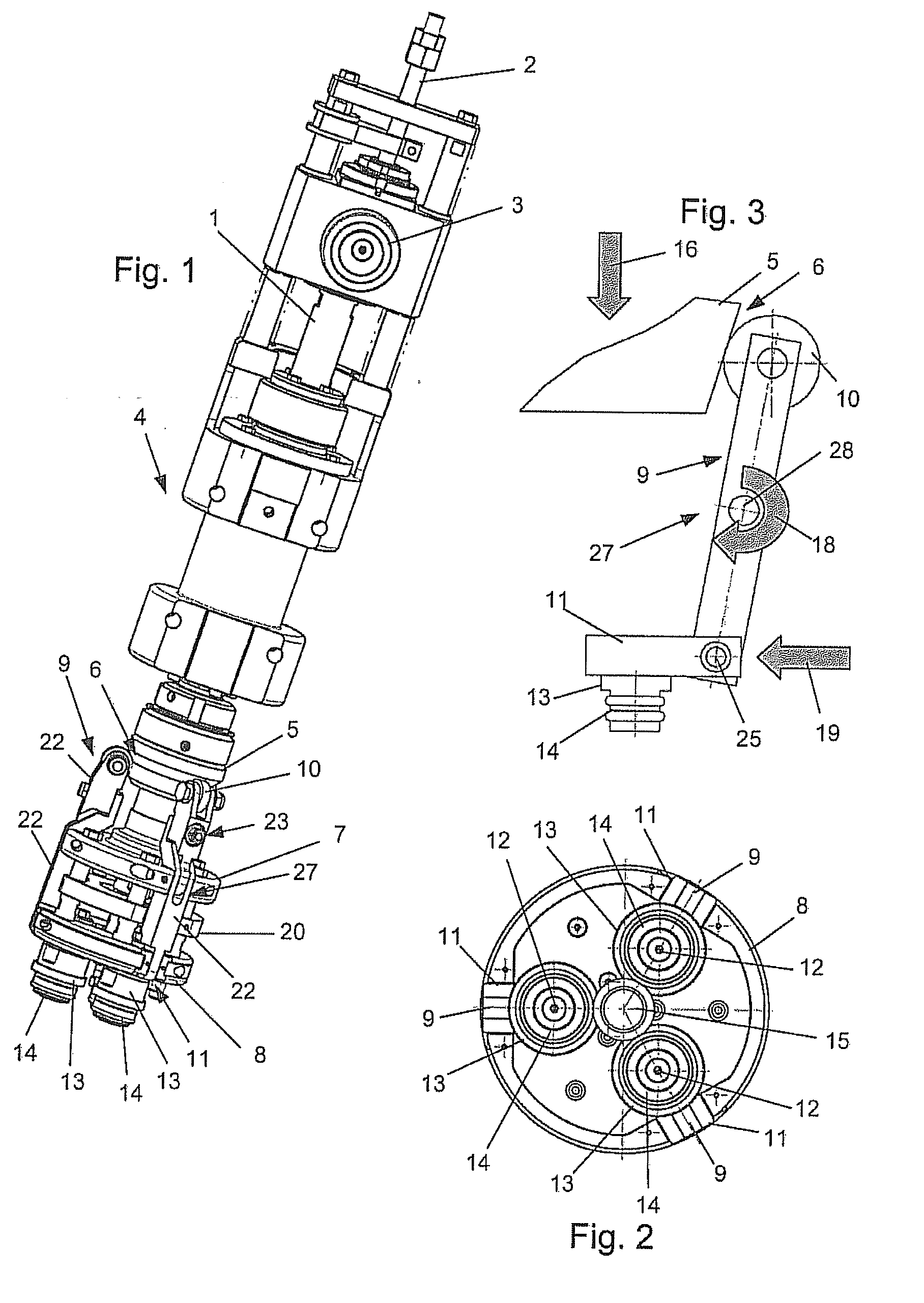

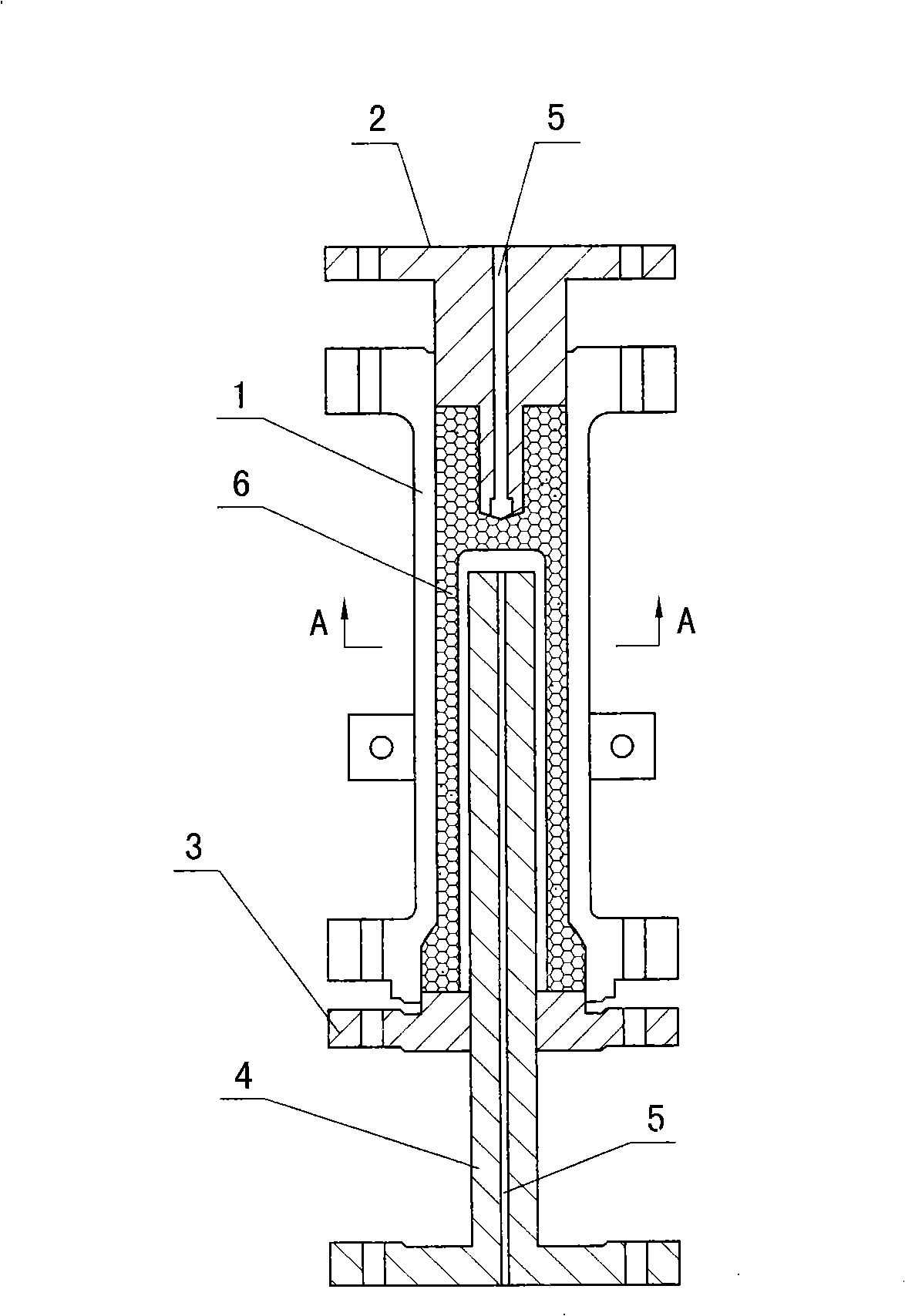

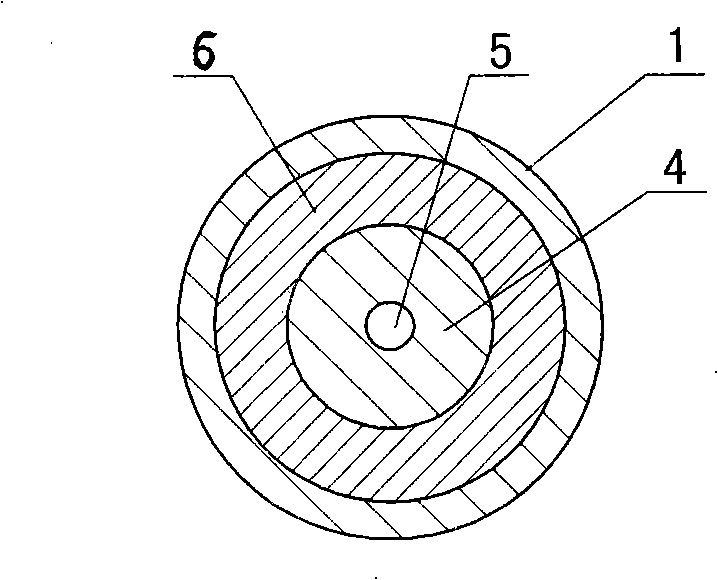

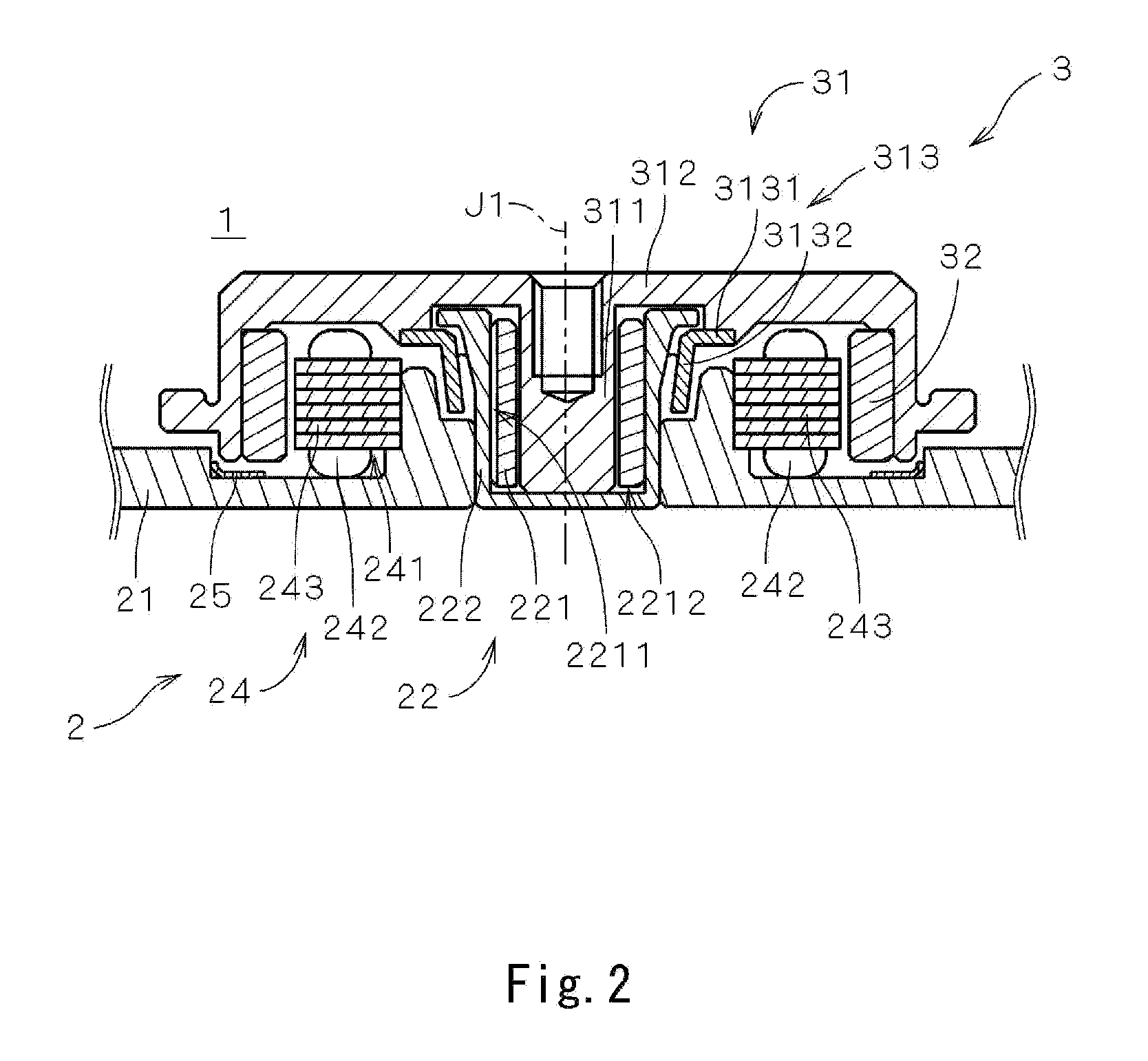

Hydraulic hammer having a sealing bushing

ActiveUS7152692B2Rapid and less maintenanceManufactured with lessReciprocating drilling machinesSoil-shifting machines/dredgersEngineeringMechanical engineering

A hydraulic hammer having a sealing bushing includes a percussion piston that delivers strokes to a tool. A lower part of the percussion piston is sealed with respect to a frame by the sealing bushing, which includes one or more lower seals. The sealing bushing does not contribute to the bearing of the percussion piston and it is arranged in place through the lower end of the hydraulic hammer.

Owner:SANDVIK TAMROCK

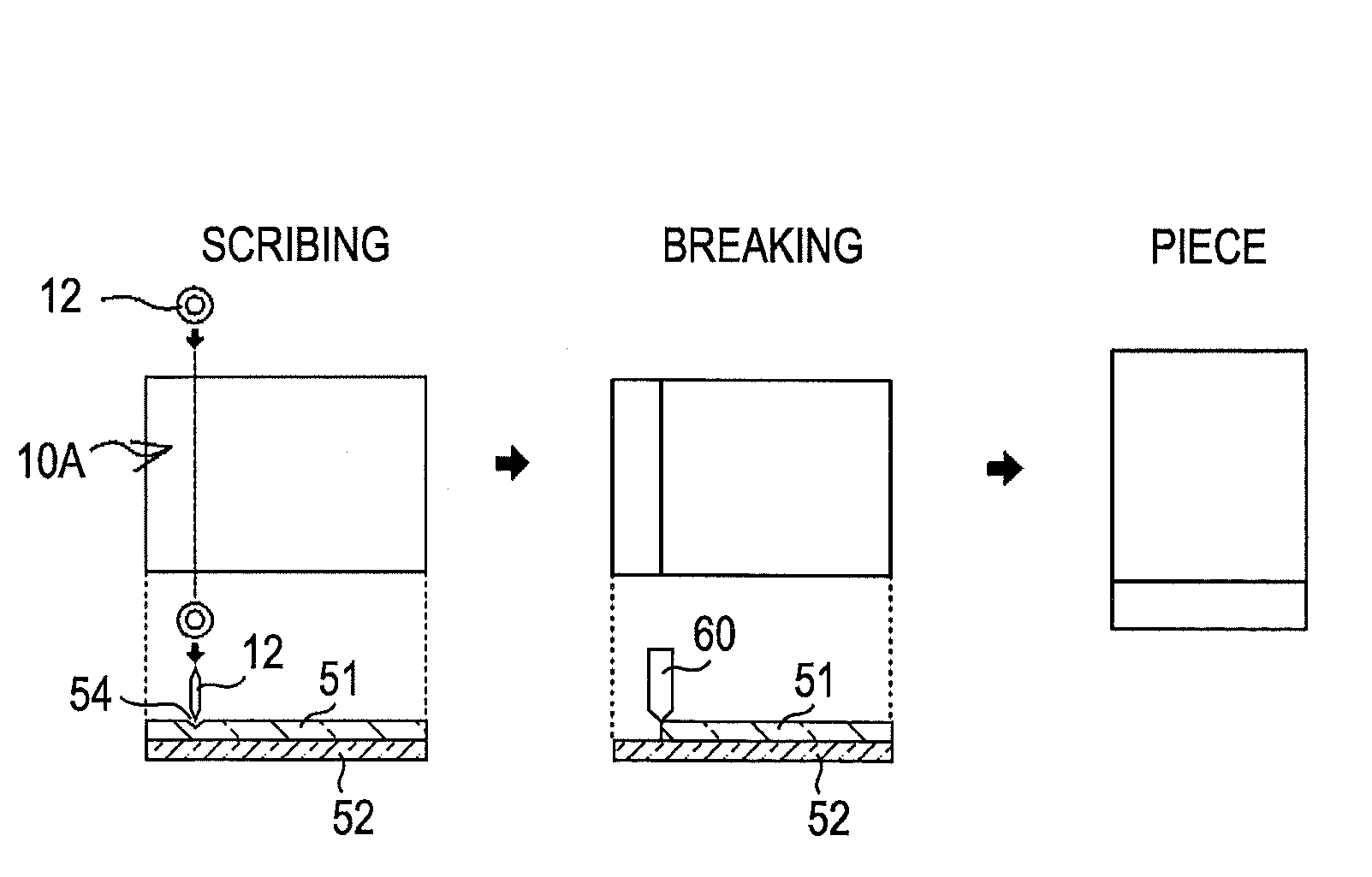

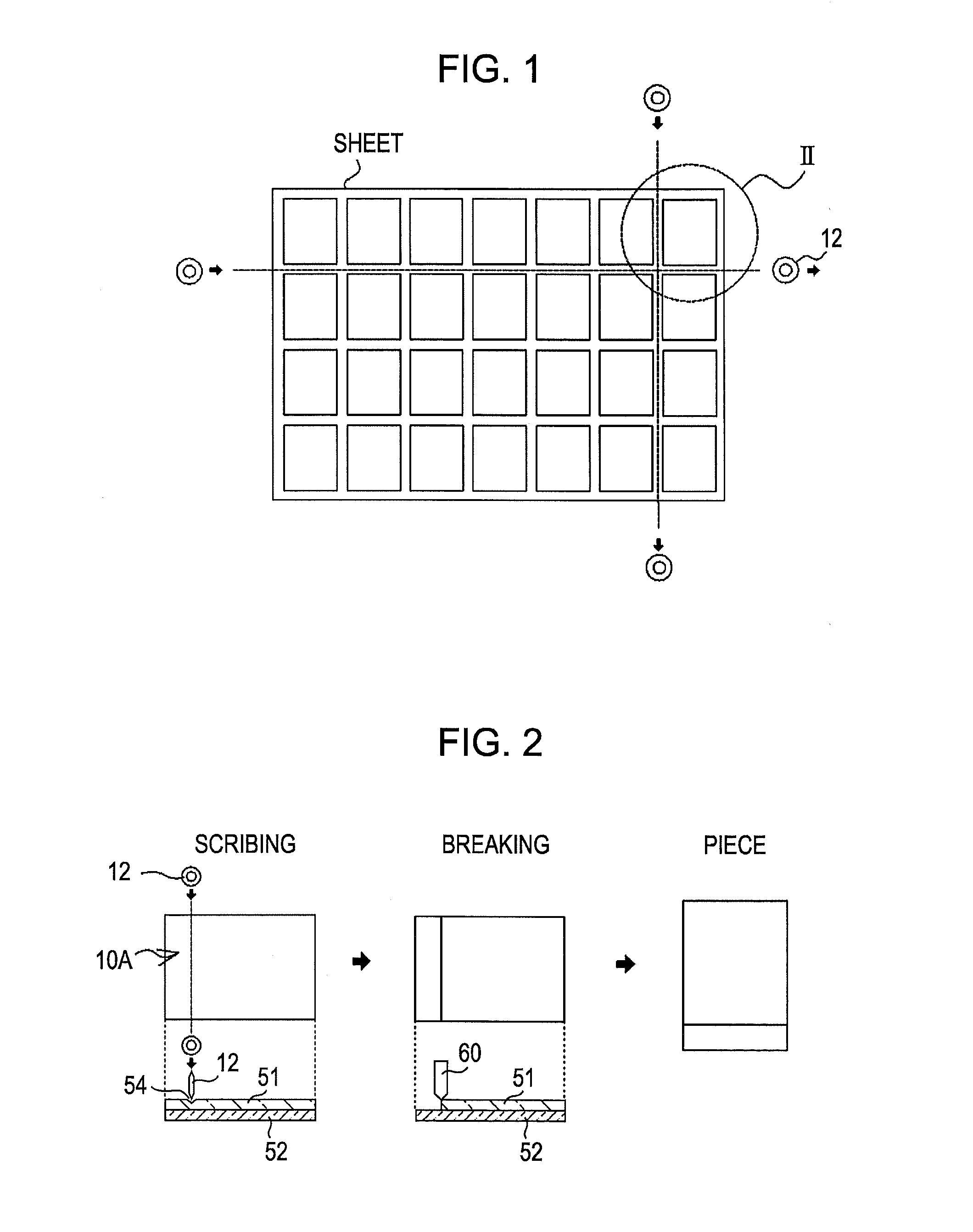

Display device having pair of glass substrates and method for cutting it

InactiveUS20080311817A1Out dimension of accurateOuter dimension can be preventedStampsWrappersDisplay deviceEngineering

Owner:JAPAN DISPLAY WEST

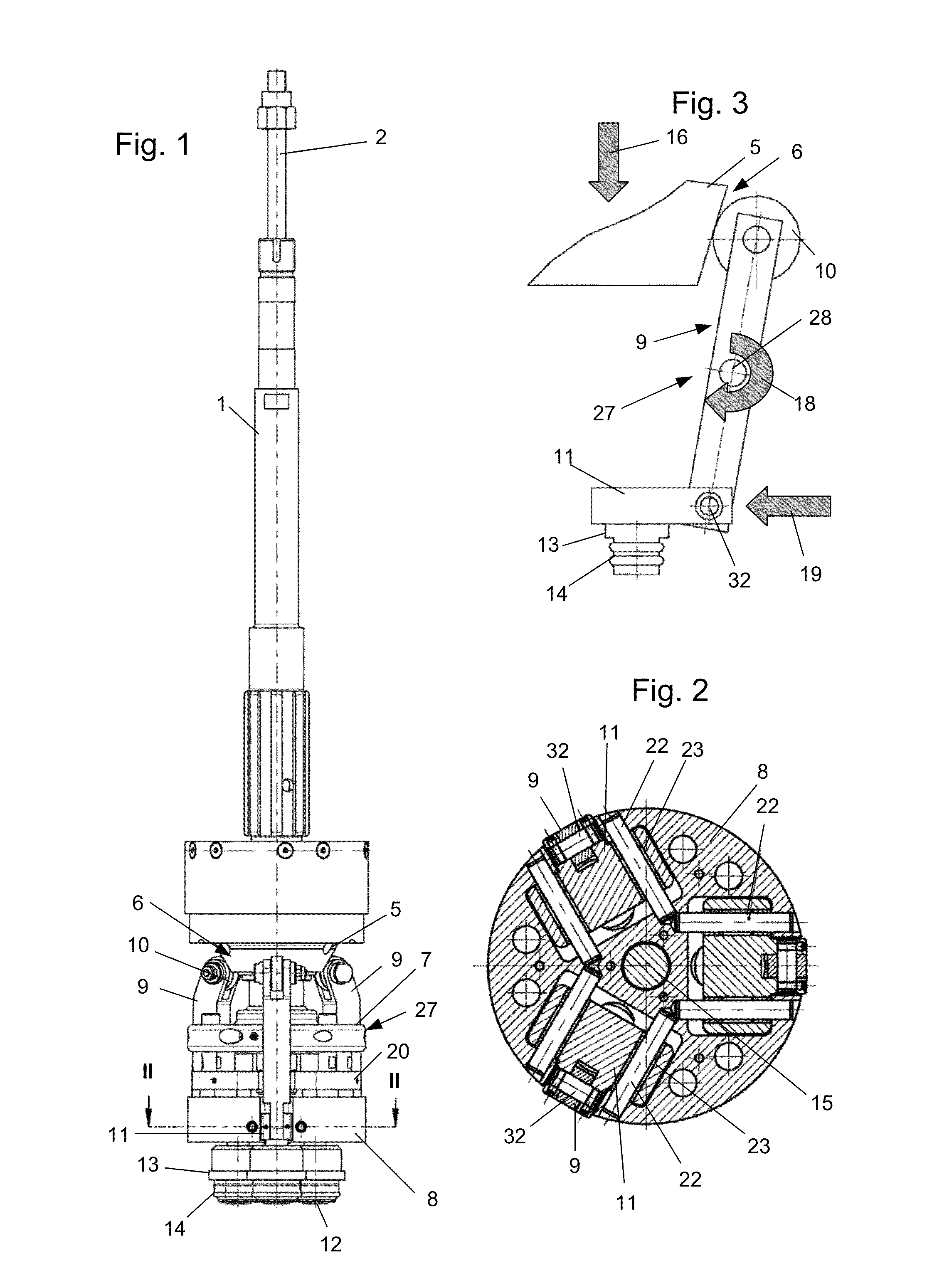

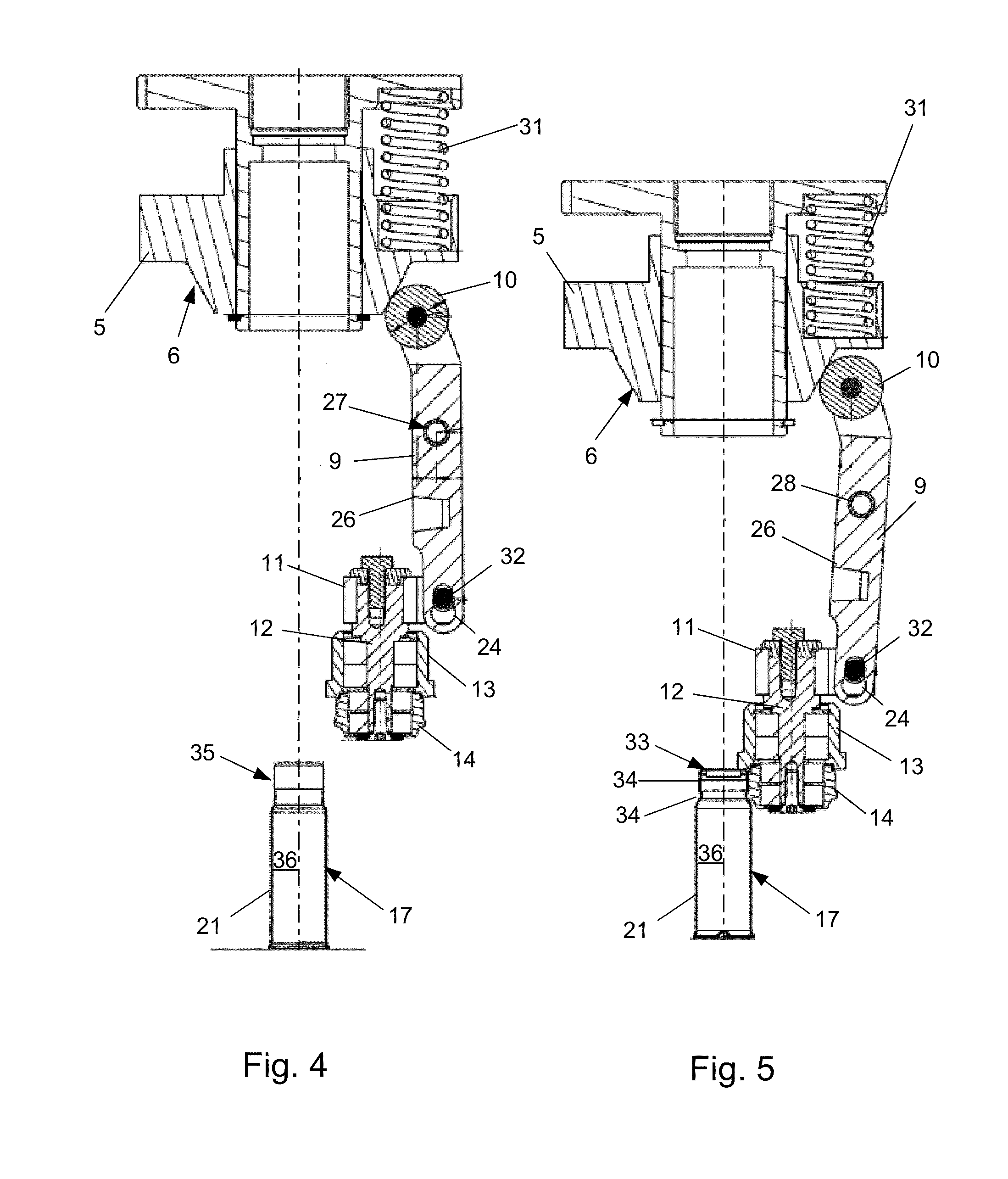

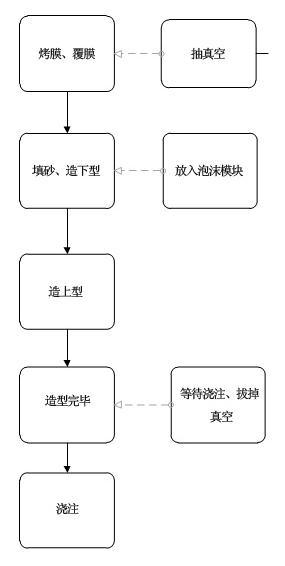

Shaping tool having a rotatable base member

ActiveUS8495901B2Guaranteed uptimeAvoid foamingForging press detailsSingle-unit apparatusRotational axisEngineering

Owner:BOEHRINGER INGELHEIM INT GMBH

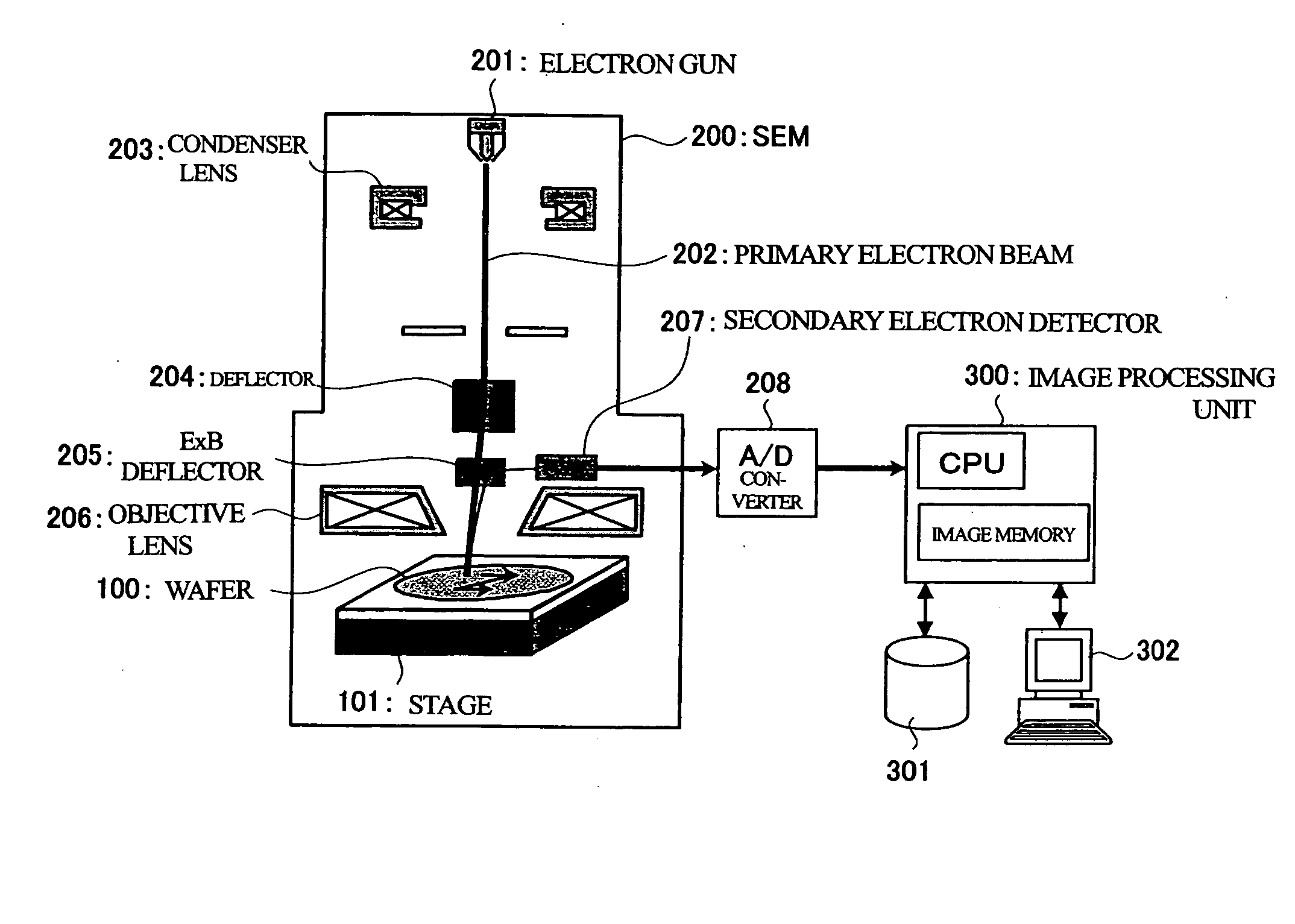

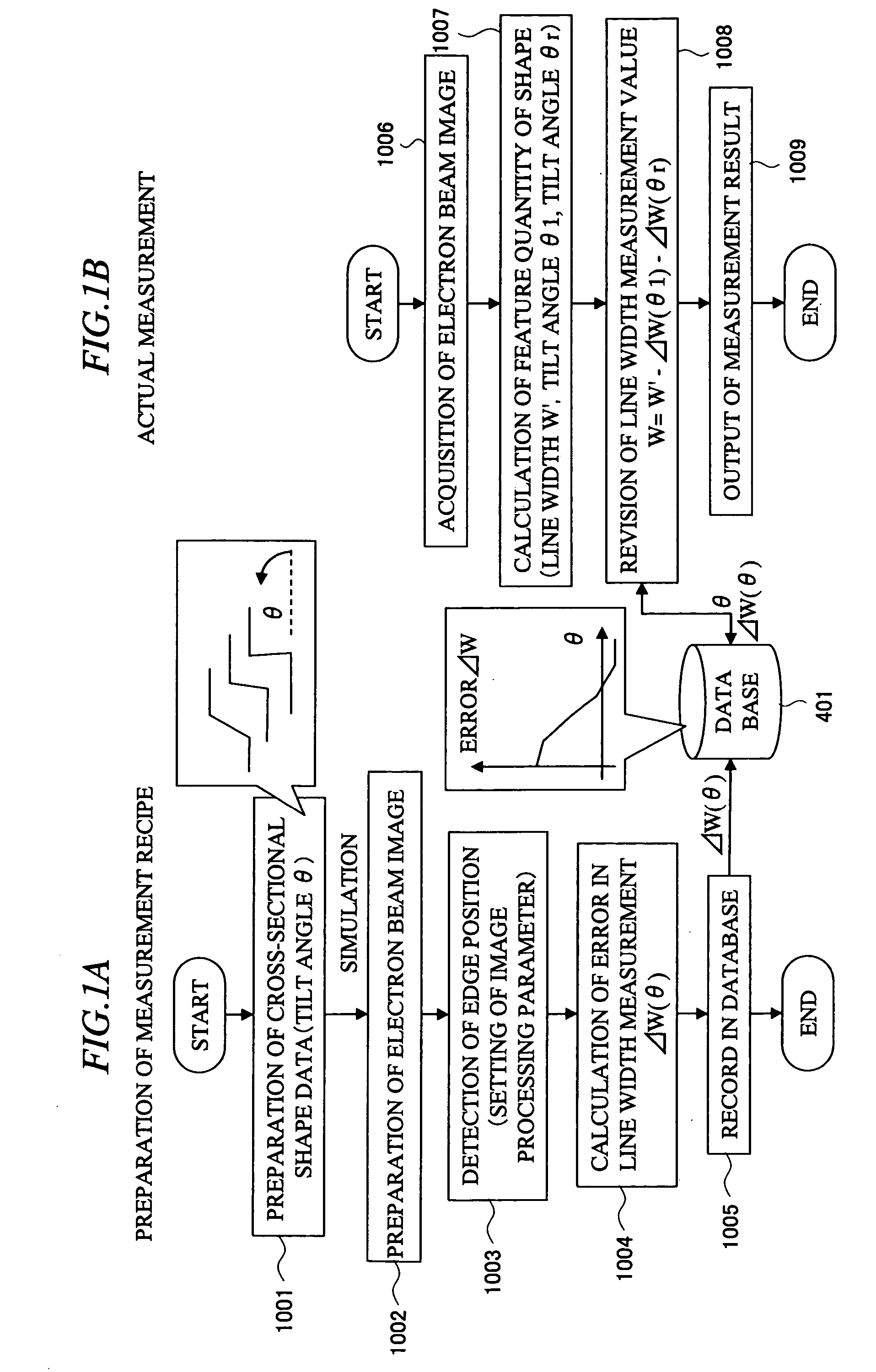

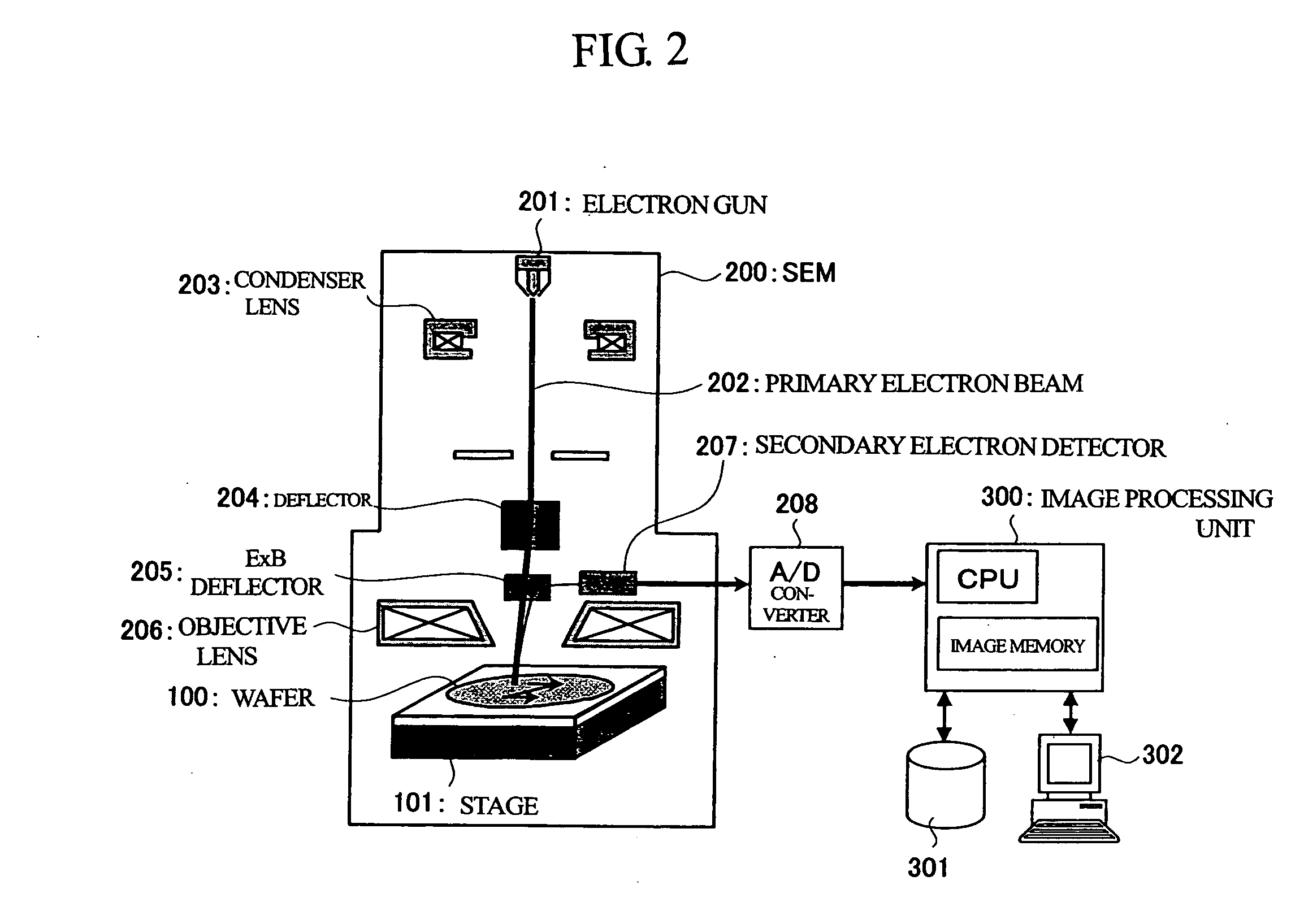

Method of measuring pattern dimension and method of controlling semiconductor device process

ActiveUS20050116182A1Precise DimensionsReduce the amount of calculationMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementDevice materialDimension measurement

This invention provides a method of measuring semiconductor pattern dimensions capable of realizing a stable and highly precise pattern dimension measurement technique even when the pattern cross-sectional shapes are changed and making the calculation amount relatively small to reduce the calculation time. More specifically, the relationship between cross-sectional shapes of a pattern and measurement errors in a specified image processing technique is evaluated in advance by the electron beam simulation in a pattern measurement system in a length measuring SEM, and in the actual dimension measurement, dimensions of an evaluation objective pattern are measured from image signals of a scanning electron microscope, and errors of the dimensional measurement of the evaluation objective pattern are estimated and revised based on the relationship between cross-sectional shapes of a pattern and measurement errors evaluated in advance, thereby realizing highly precise measurement where dimensional errors depending on pattern solid shapes are eliminated.

Owner:HITACHI HIGH-TECH CORP

Shaping tool having a rotatable base member

ActiveUS20100242557A1Guaranteed uptimeAvoid foamingSingle-unit apparatusMedical atomisersEngineeringMechanical engineering

Owner:BOEHRINGER INGELHEIM INT GMBH

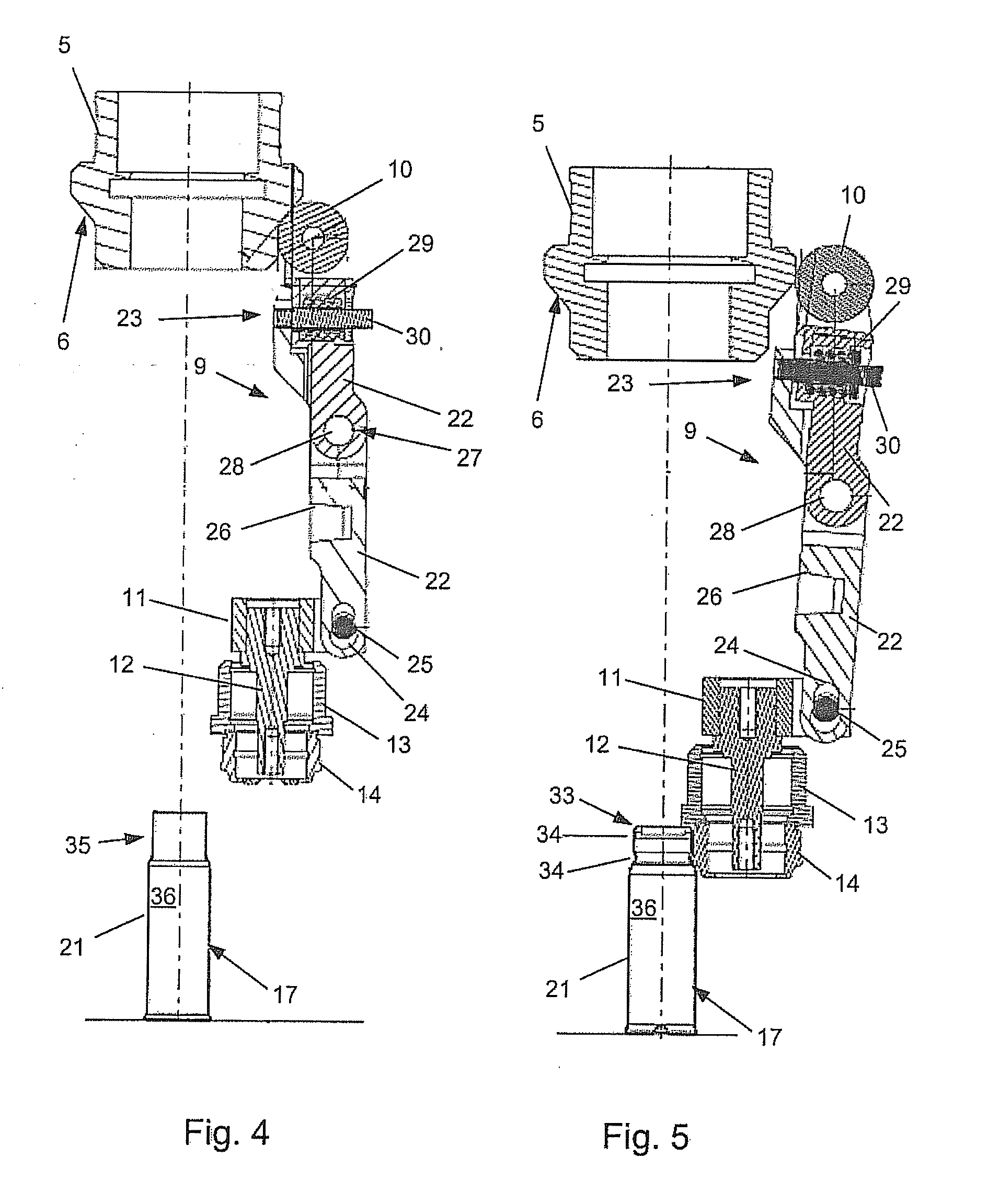

Precise casting technology for green sand vacuum sealing model

InactiveCN102218505ALow costReduce energy consumptionFoundry mouldsFoundry coresSmooth surfaceVacuum pumping

The present invention provides a precise casting technology for a green sand vacuum sealing model, which belongs the vacuum casting technical field. The invention is characterized in that the green sand is taken as a molding material, quantity of the sand core can be minimized through an effective usage of foamed materials, which is suitable for producing medium and small sized comparative precision castings. The problems of serious dust pollution, long vacuum-pumping time and production efficiency affected by using paint in a present V method can be solved. When a complex cavity is casted, the foamed material is provided at the position unsuitable for drafting to form a portion of the cavity, the foamed material is melted when casting, therefore the purposes of minimizing sand core quantity and weight can be reached, so that the production technology can be simplified as well as cost can be saved. The produced casting has the advantages of high dimensional precision, clear contour and smooth surface.

Owner:JIAHE ZHONGHE CASTING +1

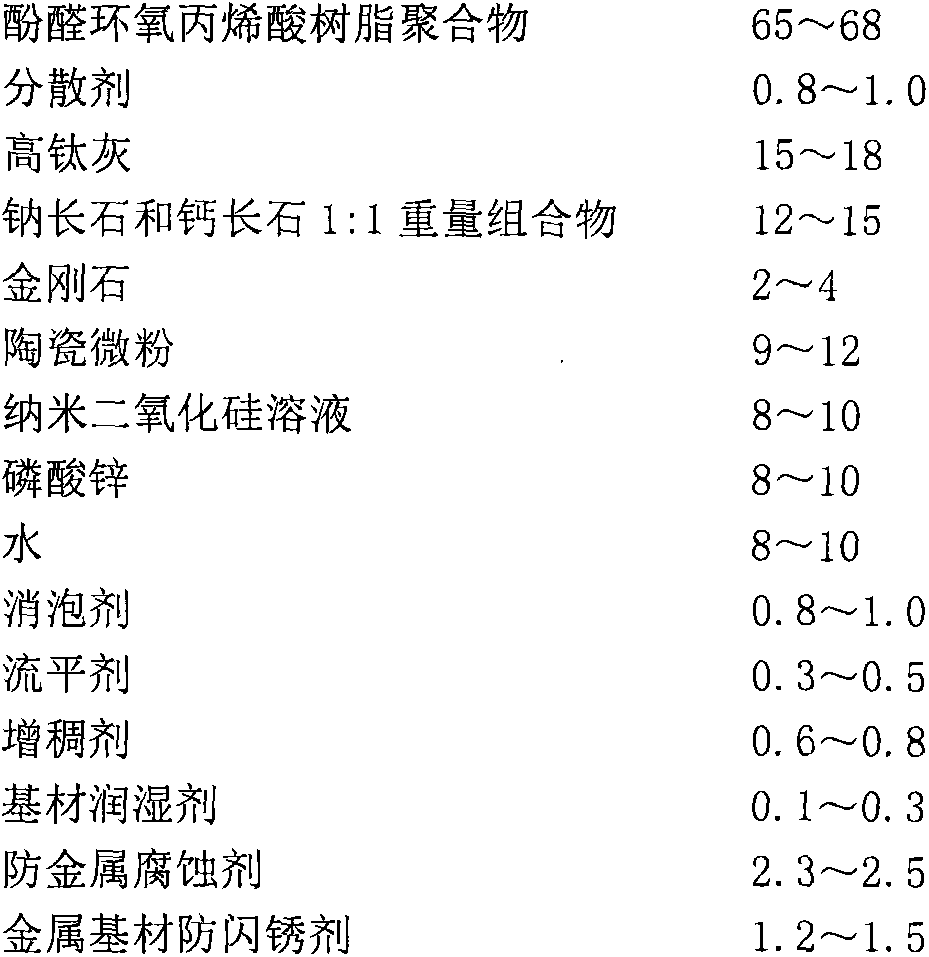

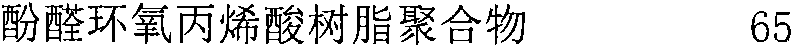

Manufacturing method of steel structure box girder

ActiveCN103639671AEasy to produceImprove quality and efficiencyArc welding apparatusWear resistantSpot welding

A manufacturing method of a steel structure box girder comprises steps as follows: 1), a computer is used for controlling sizes of a cover plate, webs, lining plates of the webs, a baffle and a lining plate of the baffle for blanking; 2), spot welding lining plates are assembled on back surfaces of grooves of the webs and the baffle respectively; 3), a bottom plate and the two webs are assembled into a U shape and welded on a box girder mould; 4), the baffle is placed and welded in a U-shaped groove; 5), the cover plate is assembled and welded on the U-shaped groove; and 6), the steel box girder is subjected to shot blasting and paint spraying, and paint adopts anticorrosive paint and comprises a component A and a component B. According to the steel structure box girder manufactured with the method, materials are saved, the production efficiency is improved, the integrally formed anticorrosive paint is corrosion-resistant and wear-resistant, and the requirement for inner wall coating of the steel structure box girder is met.

Owner:GUIZHOU LIHONG STEEL STRUCTURE

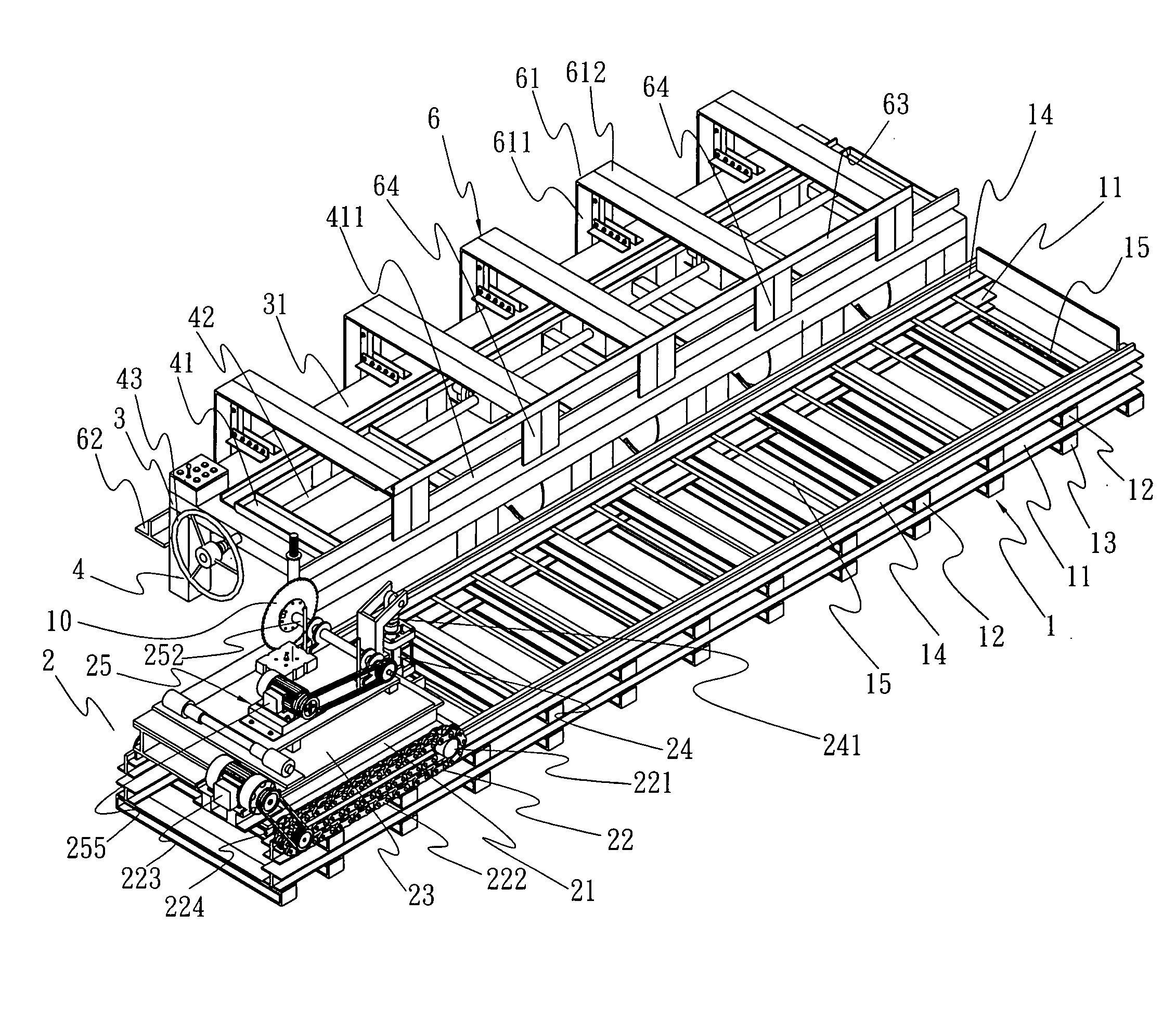

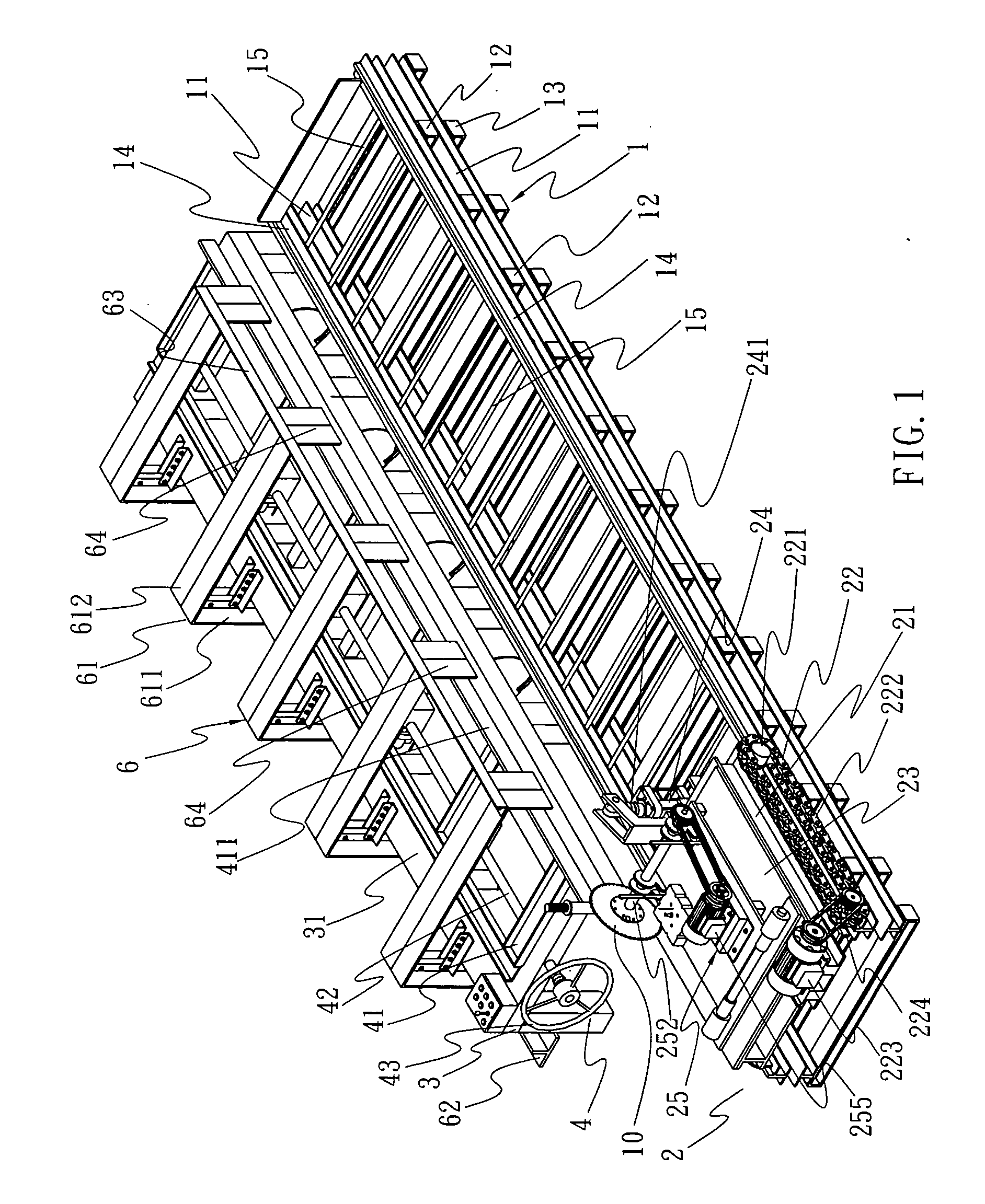

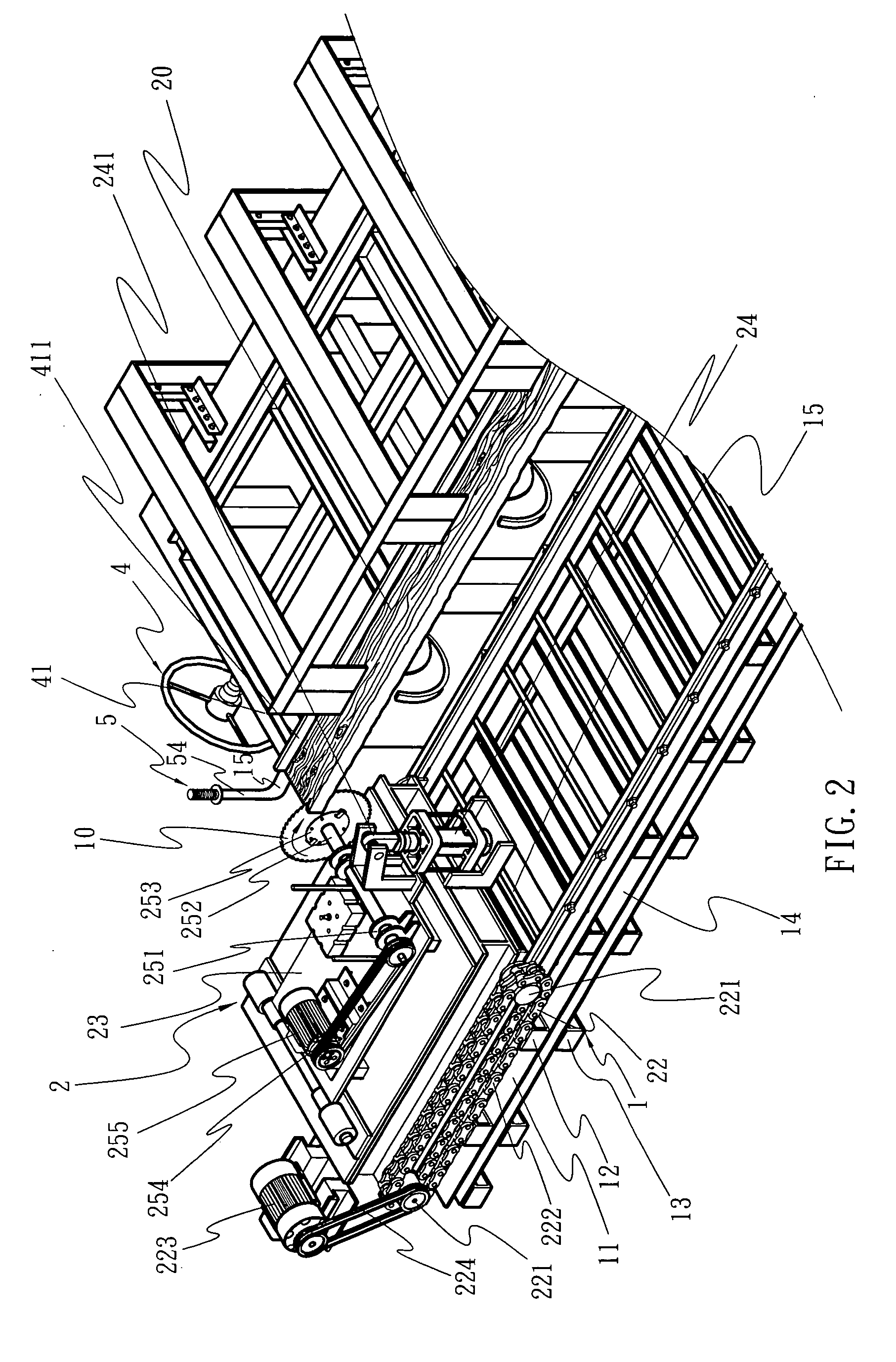

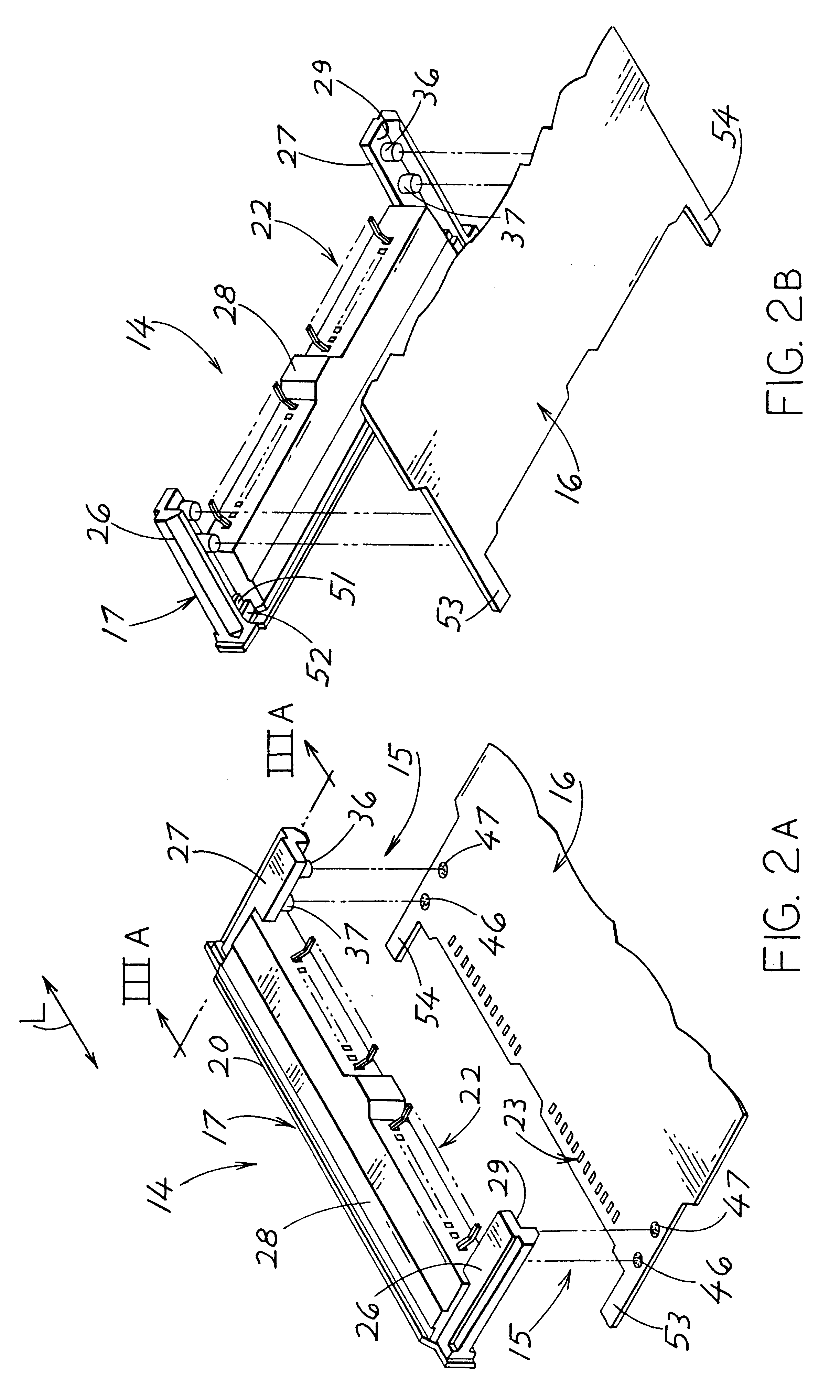

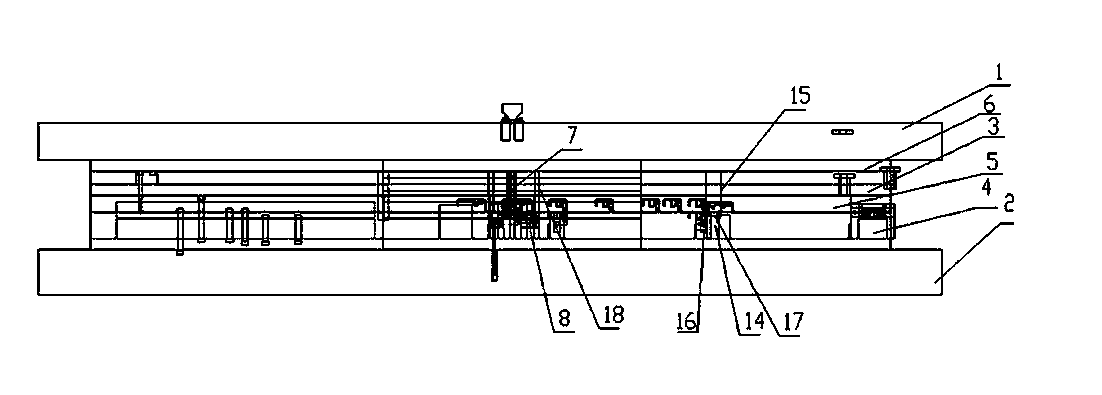

Reciprocal bi-directional table saw

InactiveUS20050268765A1Easy and convenient operationPrecise DimensionsMetal sawing devicesShearing machinesProduction rateCircular saw

A reciprocal bi-directional table saw including a cutting table and a deck to secure a work piece in place; the table including a horizontally provided runway and a cutting process unit that automatically travels back and forth on the runway; an automatic travel device being each provided on both sides of a seat plate provided to the cutting process unit; a saw blade elevates as controlled by a plunger having one side pivoted to the seat plate; a circular saw blade and a device to drive the circular saw blade being provided on the saw blade holder for the table saw to reciprocally execute the cutting on the work piece to achieve precise process of the work piece and upgrade the production rate.

Owner:CHIEN CHUN JEN

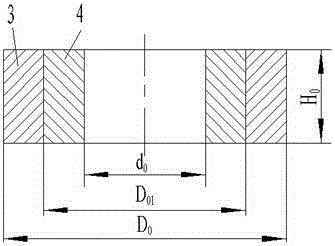

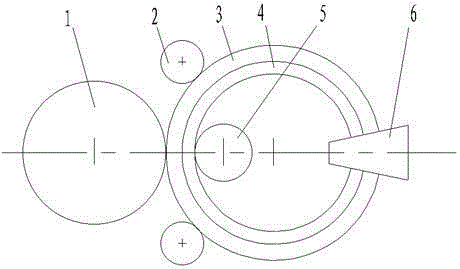

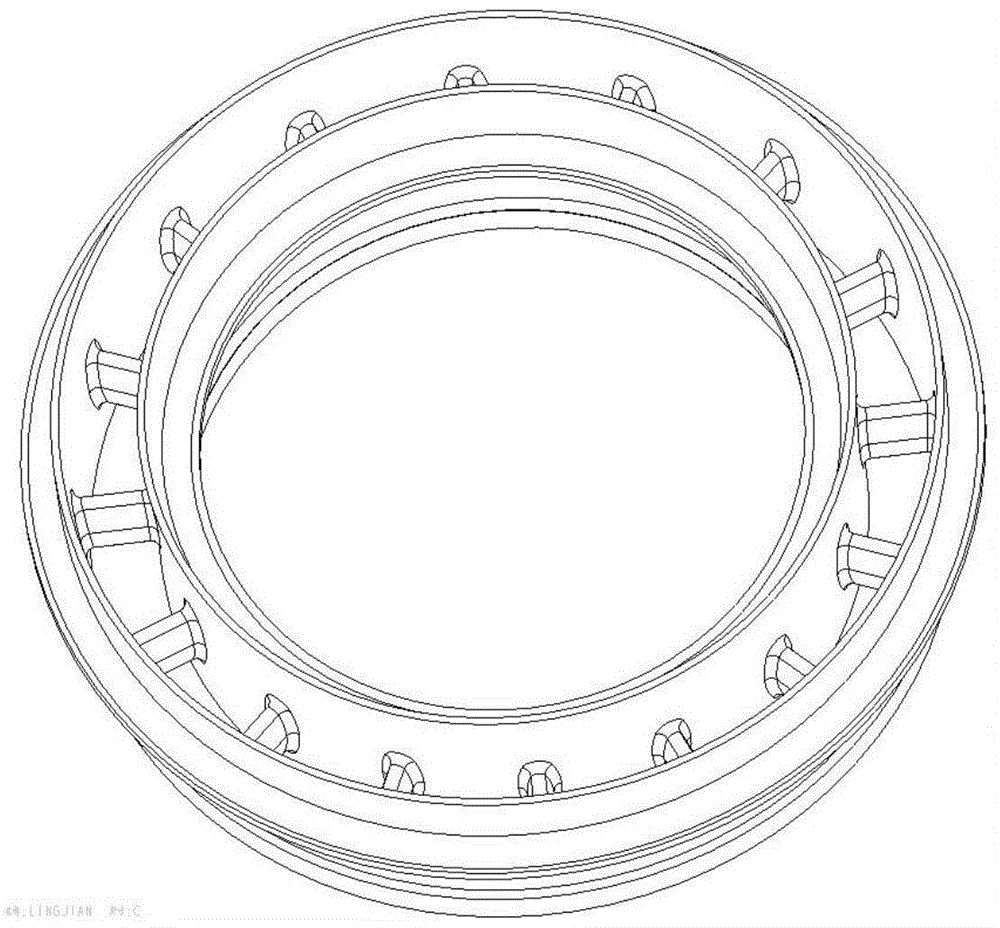

Centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology

InactiveCN105170850AImprove surface qualityPrecise DimensionsMetal rollingUltimate tensile strengthMechanical property

The invention relates to a centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology, and belongs to the technical field of ring part rolling expansion machining. The centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology is characterized by comprising the following steps: (1) isothermal heating is carried out; (2) a heated duplex-metal composite ring blank is placed on a radial and axial direction ring rolling machine; (3) the contact relation between a forming roller and the ring blank is determined; (4) a driving roller drives the duplex-metal composite ring blank and a core roller to perform rotation motion, meanwhile, the core roller does straight line feeding motion in the radial direction of the ring blank, an end face taper roller only keeps the rotary motion rather than conducting axial feeding, and continuous local plastic deformation of wall thickness reduction, diameter enlarging and cross section layout shaping is continuously carried out on the duplex-metal composite ring blank; and (5) when a preset value of the outer diameter of a duplex-metal composite ring part is obtained, a guide roller gives out a signal, the core roller stops feeding, and extend-rolling is finished. The centrifugal casting duplex-metal composite ring part hot extend-rolling forming technology has the beneficial effects that the process procedure is shortened, the device investment is reduced, and energy and materials are saved; and meanwhile, the composite ring part interface plastic deformation is sufficient, the bonding strength is high, the mechanical property is good, and the service life is long.

Owner:定州市金华蓝天汽车零部件有限公司 +1

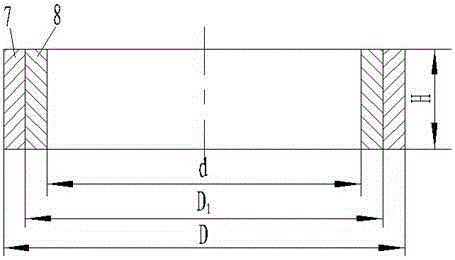

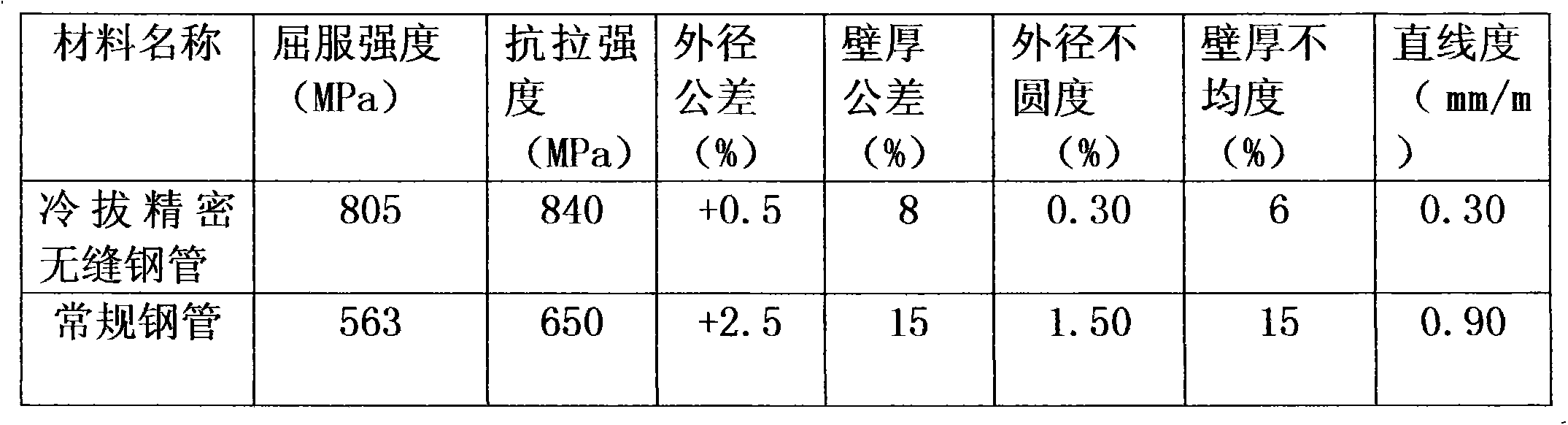

Production method of cold-drawn precision seamless steel pipes

InactiveCN104338777AImprove performanceImprove low temperature impact toughnessAcid washingLubrication

The invention relates to a production method of cold-drawn precision seamless steel pipes. The production method comprises the steps of: heating: pipe blanks are heated in an annular furnace; perforation: the heat pipe blanks are perforated by a perforation machine; annealing: the pipe blanks are annealed; cold rolling: the annealed pipe blanks are leaded into a pipe rolling machine for cold rolling to obtain rolled pipes; stress relieving: the rolled pipes are leaded into a heating furnace for heating to obtain annealed pipe blanks; acid washing treatment: the acid washing is performed for the annealed pipe blanks to remove scales on the surfaces; phosphating treatment: zinc phosphate chemical generation films are formed on the surfaces of the pipe blanks; saponification treatment: such lubrication films as metallic soaps are formed on the films; cold drawing: the cold drawing is performed for the pipe blanks to be cold drawn to obtain cold-drawn pipes; normalization air-cooling treatment; first straightening treatment; induction furnace quenching treatment; box furnace tempering treatment; honing; thermal straightening treatment; and obtaining of the cold-drawn precision seamless steel pipes. The production method obtains the cold-drawn precision seamless steel pipes with high yield strength, high tensile strength, precise sizes and smooth surfaces.

Owner:WUXI DAJIN HIGH PRECISION COLD DRAWN STEEL TUBE

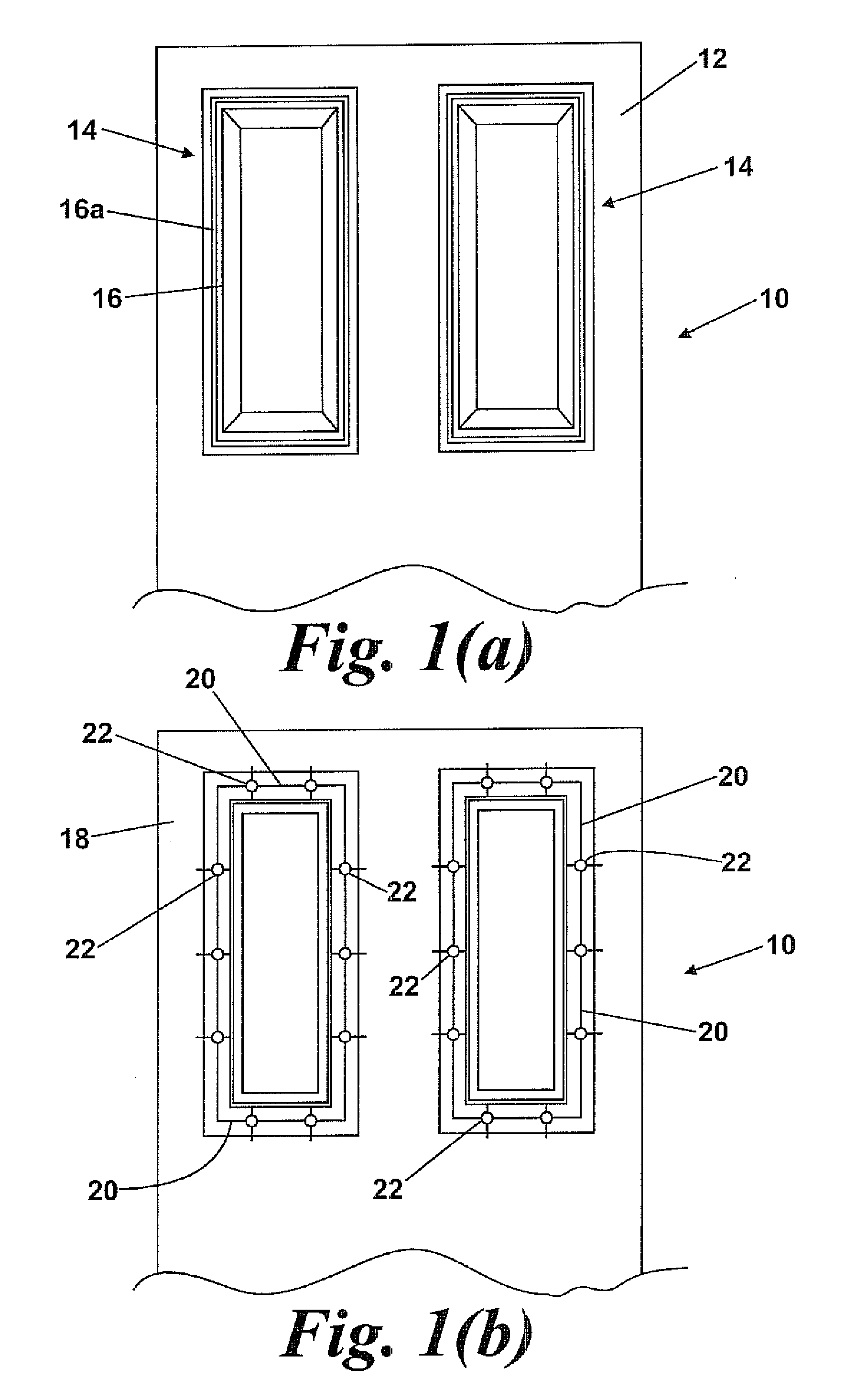

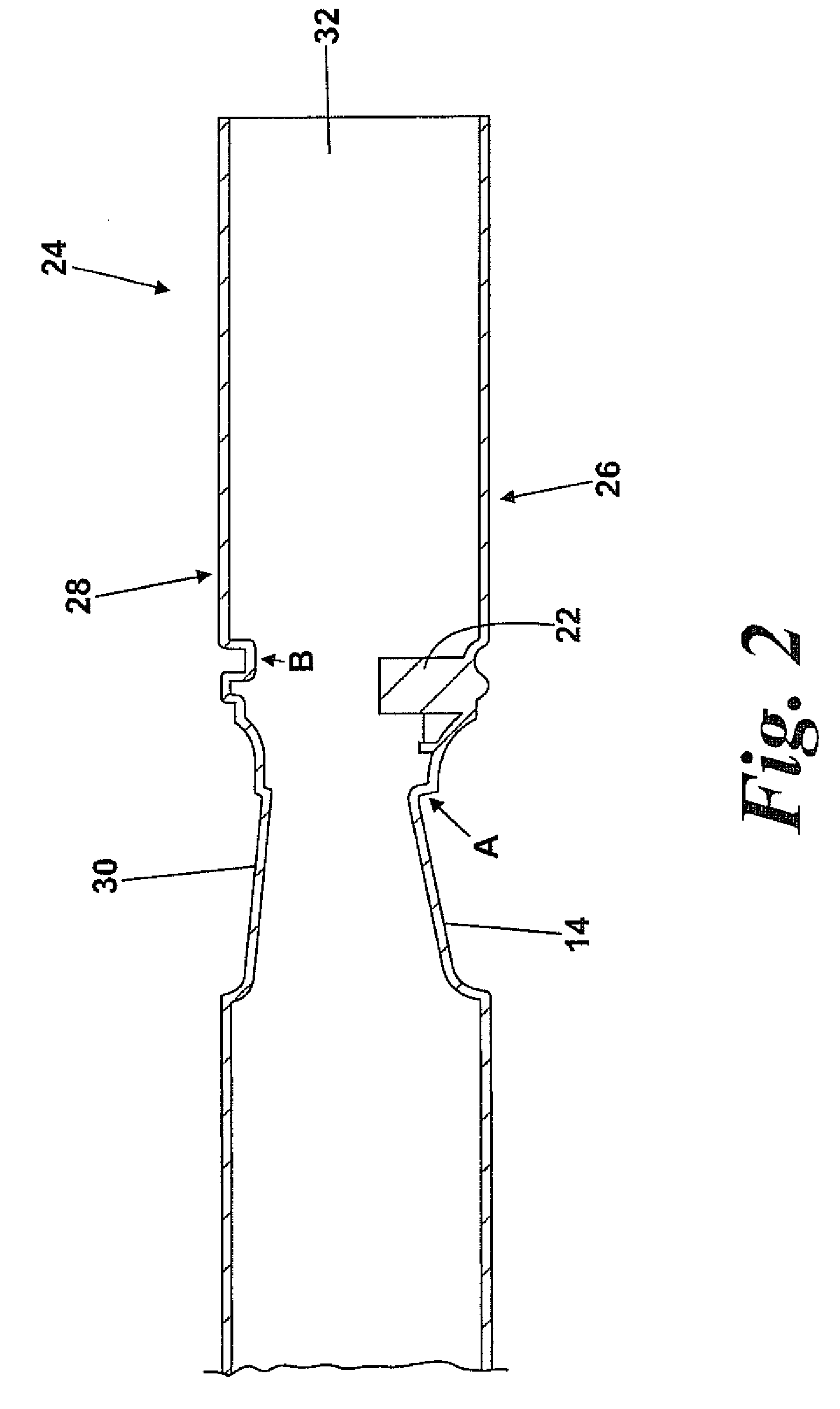

Composite doors

InactiveUS20080209826A1Low production costConveniently producedWing framesDoor leavesEngineeringElectrical and Electronics engineering

Owner:LSSD UK

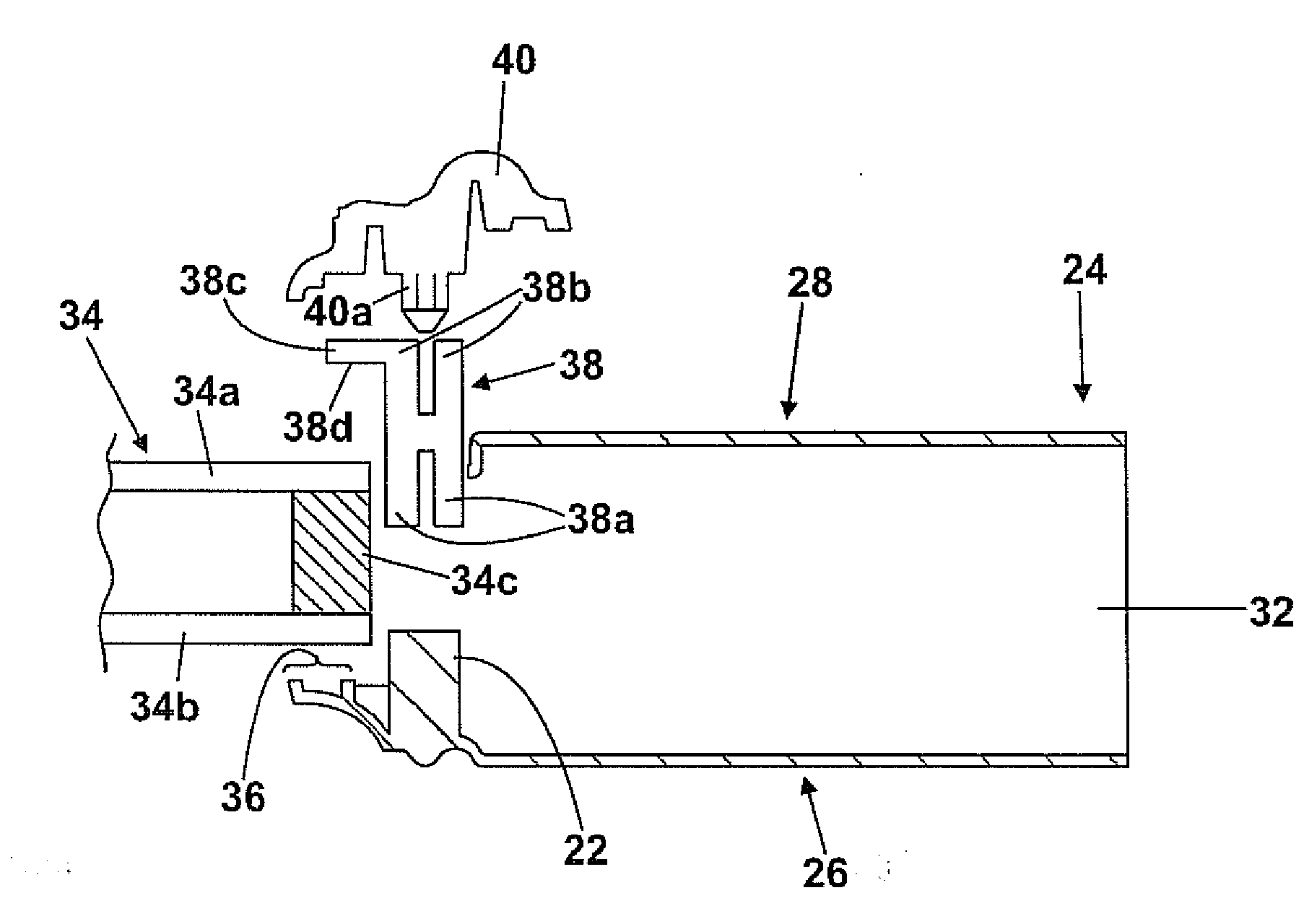

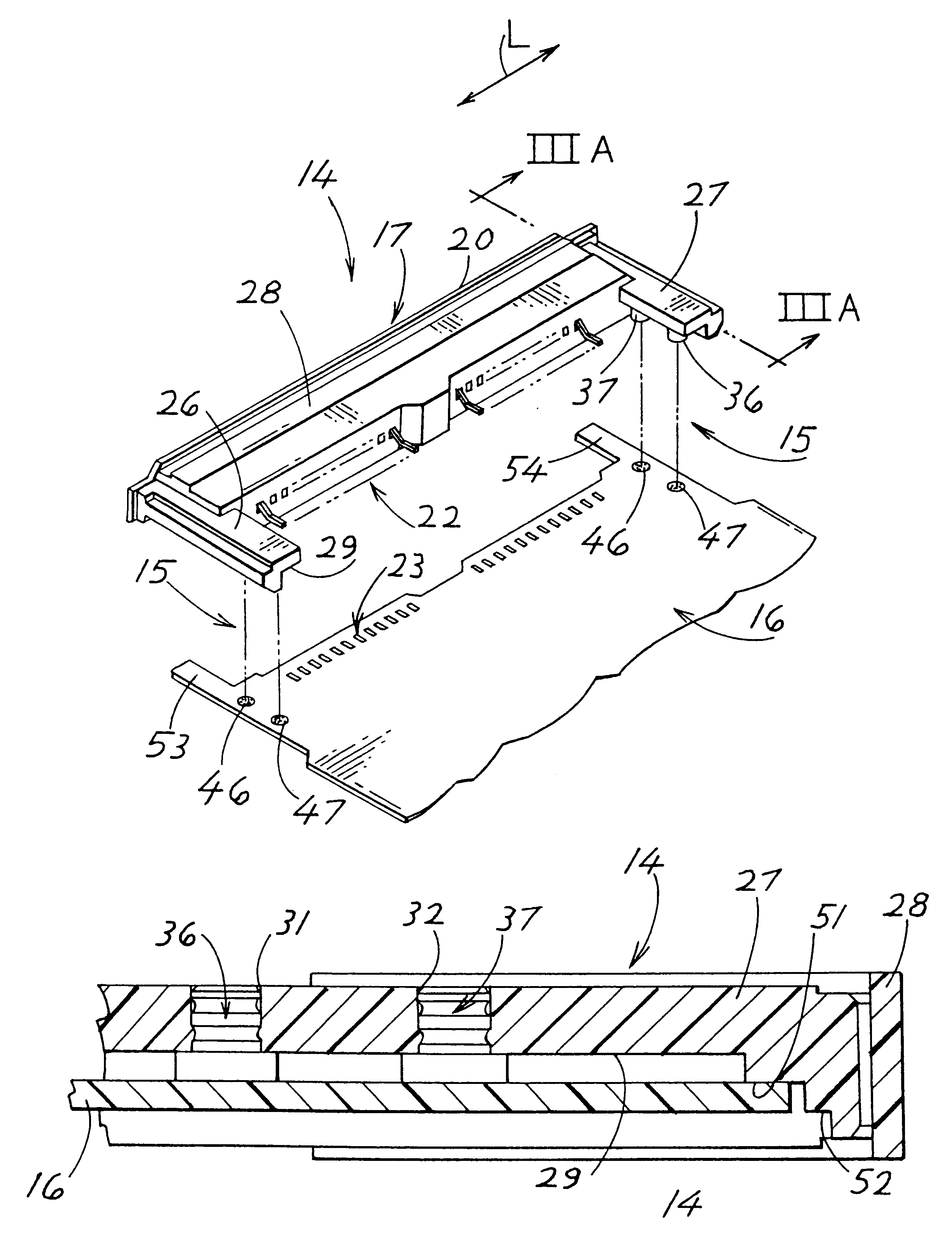

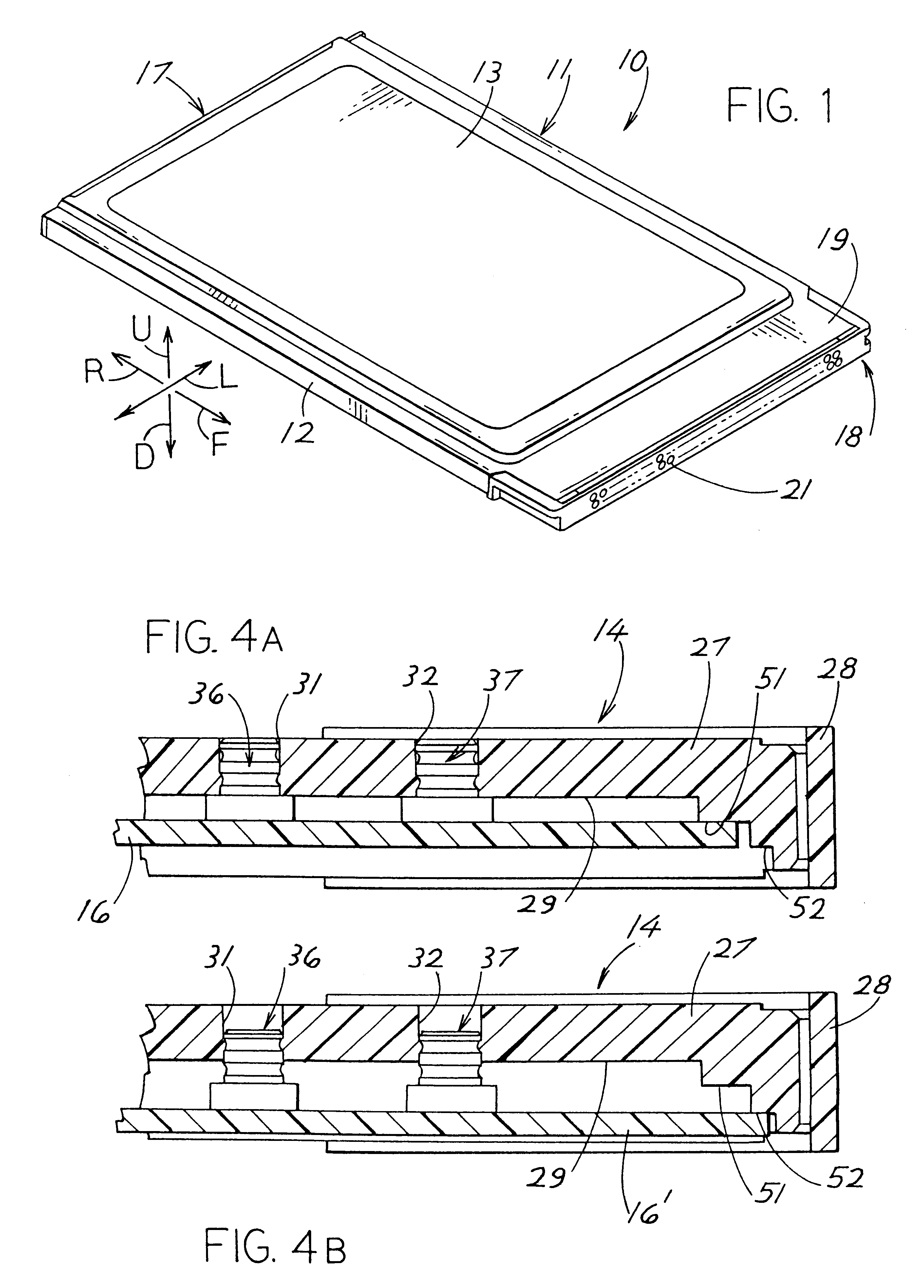

Connection assembly of printed-circuit board and connector and an electronic-equipment plug-in card provided with same

InactiveUS6307753B1Easy to produceAssembly precisionPrinted circuit assemblingIncadescent body mountings/supportSolderingPrinted circuit board

In a connection assembly (15) of printed-circuit board and connector, a printed-circuit board (16) and a connector (17) can be fixed positionally accurately in relation to one another by means of position holders (36, 37) provided on the connector (17). The position holders are constituted of soldering pins (36, 37) and the printed-circuit board (16) is provided with soldering pads (46, 47) which can be connected to the opposing soldering pins (36, 37) by soldering. There is provided in this manner a connection assembly (15) of printed-circuit board and connector in which the positionally accurate fixing of a printed-circuit board (16) and a connector (17) is more easily produced and more precisely assembled than has been possible to date.

Owner:ITT CANNON

Method of producing a suspended membrane device

ActiveUS20090124035A1High precisionPrevent degradationSemiconductor/solid-state device manufacturingCable/conductor manufactureEtchingEngineering

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

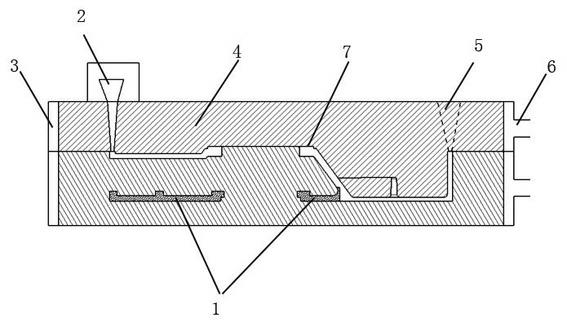

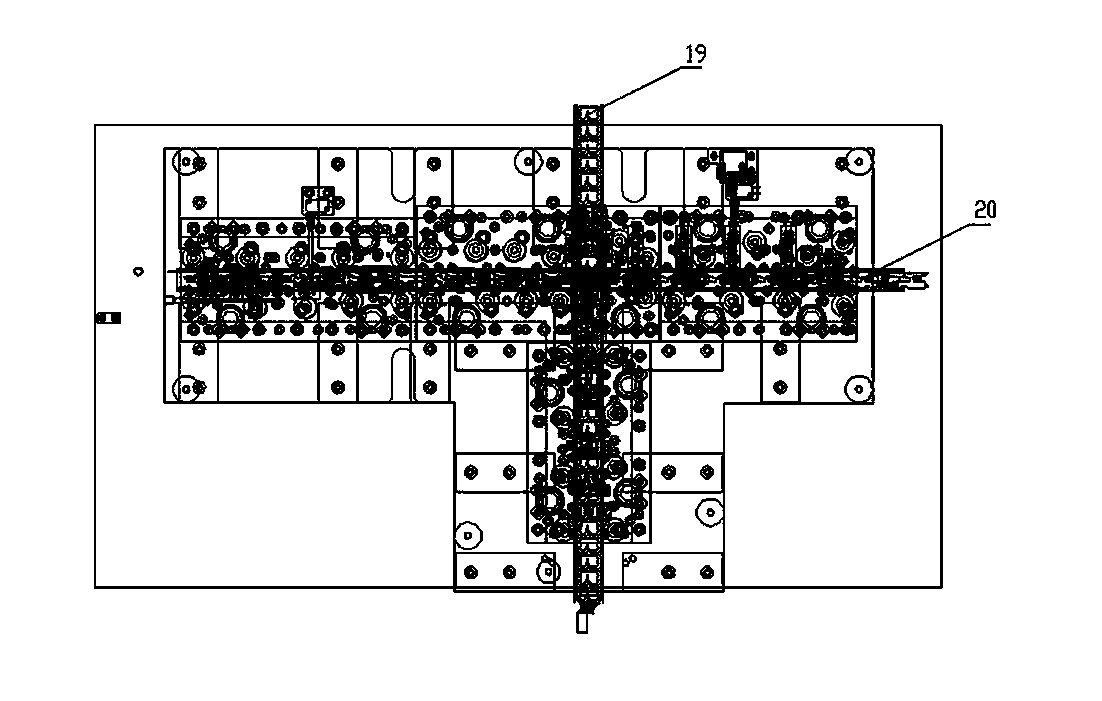

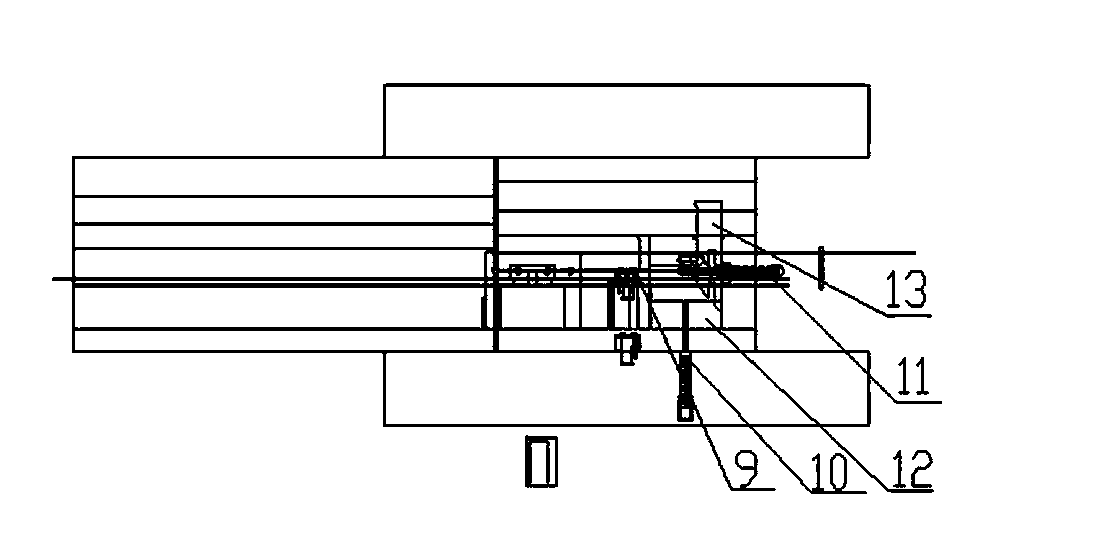

In-die riveting die of multi-position high-accuracy hardware bending piece

InactiveCN103480729AAvoid continuous processingIncrease productivityShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention discloses an in-die riveting die of a multi-position high-accuracy hardware bending piece. The in-die riveting die comprises an upper die base, a base plate, an upper die plate, a lower die base, a stripper plate, a lower die plate, a first in-die feeding mechanism, a second in-die feeding mechanism, a first feed inlet, a second feed inlet, a first forming mechanism, a second forming mechanism, a riveting mechanism and a blanking mechanism, wherein the upper die base, the base plate and the upper die plate are sequentially and fixedly connected from top to bottom; the lower die base, the stripper plate and the lower die plate are sequentially and fixedly connected from bottom to top; material belts in the first feed inlet and the second feed inlet are respectively driven to carry out straight feed by the first in-die feeding mechanism and the second in-die feeding mechanism; the first forming mechanism and the second forming mechanism can be respectively used for carrying out punch forming on products on a main material belt and an auxiliary material belt which are vertical to each other; the riveting mechanism which is exactly positioned in a crossing and overlapping position of the main material belt and the auxiliary material belt comprises a riveting punch on the upper die plate, a riveting female die on the lower die plate and a main material belt cut-off tool, the separating between the product on the main material belt and the main material belt can be realized by the main material belt cut-off tool, and the riveting punch on the upper die plate is matched with a riveting position of a to-be-riveted product; the blanking of the auxiliary material belt can be realized by the blanking mechanism. According to the in-die riveting die disclosed by the invention, all processes of forming, riveting and blanking can be completed in one step, the production efficiency and the product accuracy are high, and the production cost and the follow-up detection cost are reduced.

Owner:昆山德盛精密模具有限公司

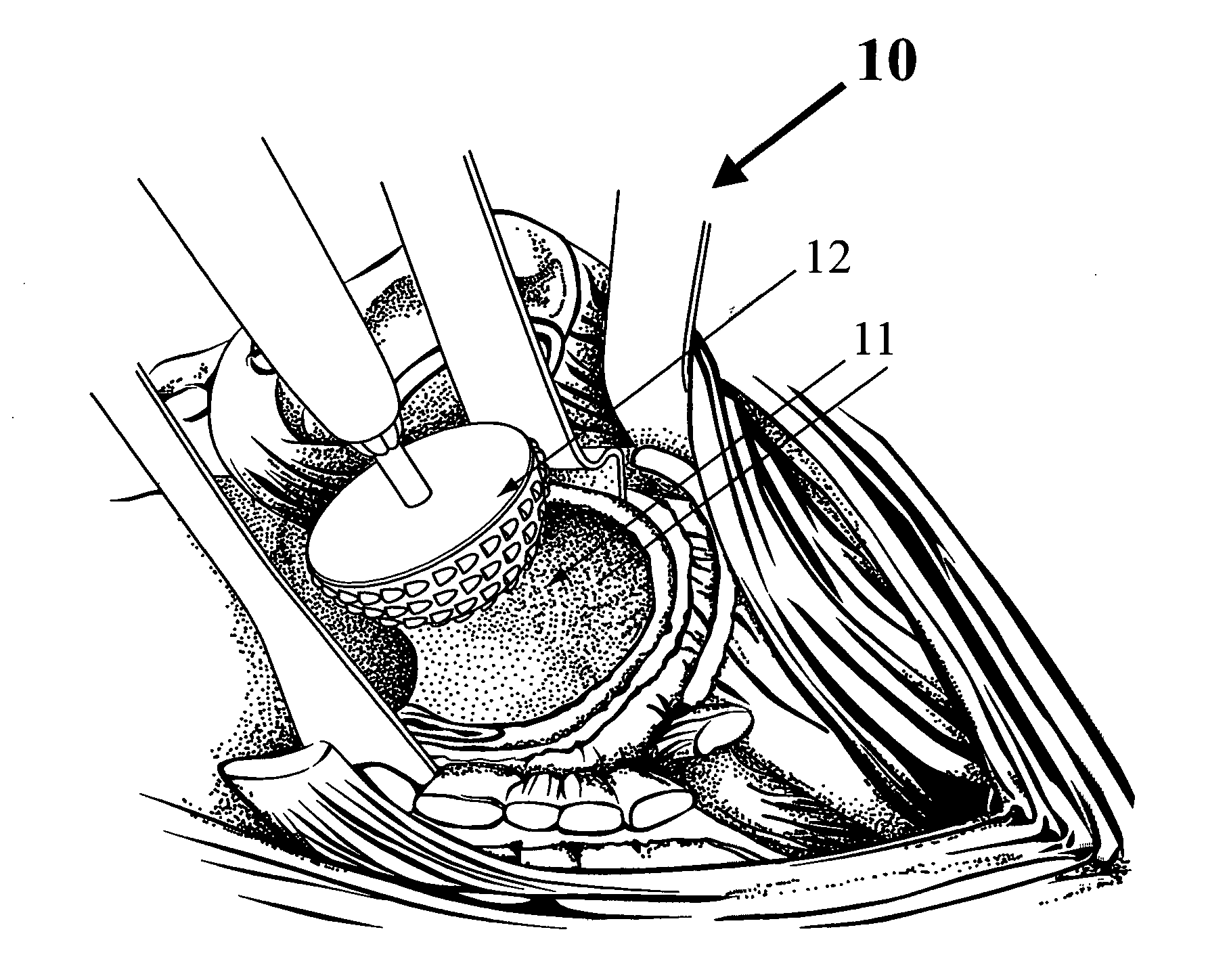

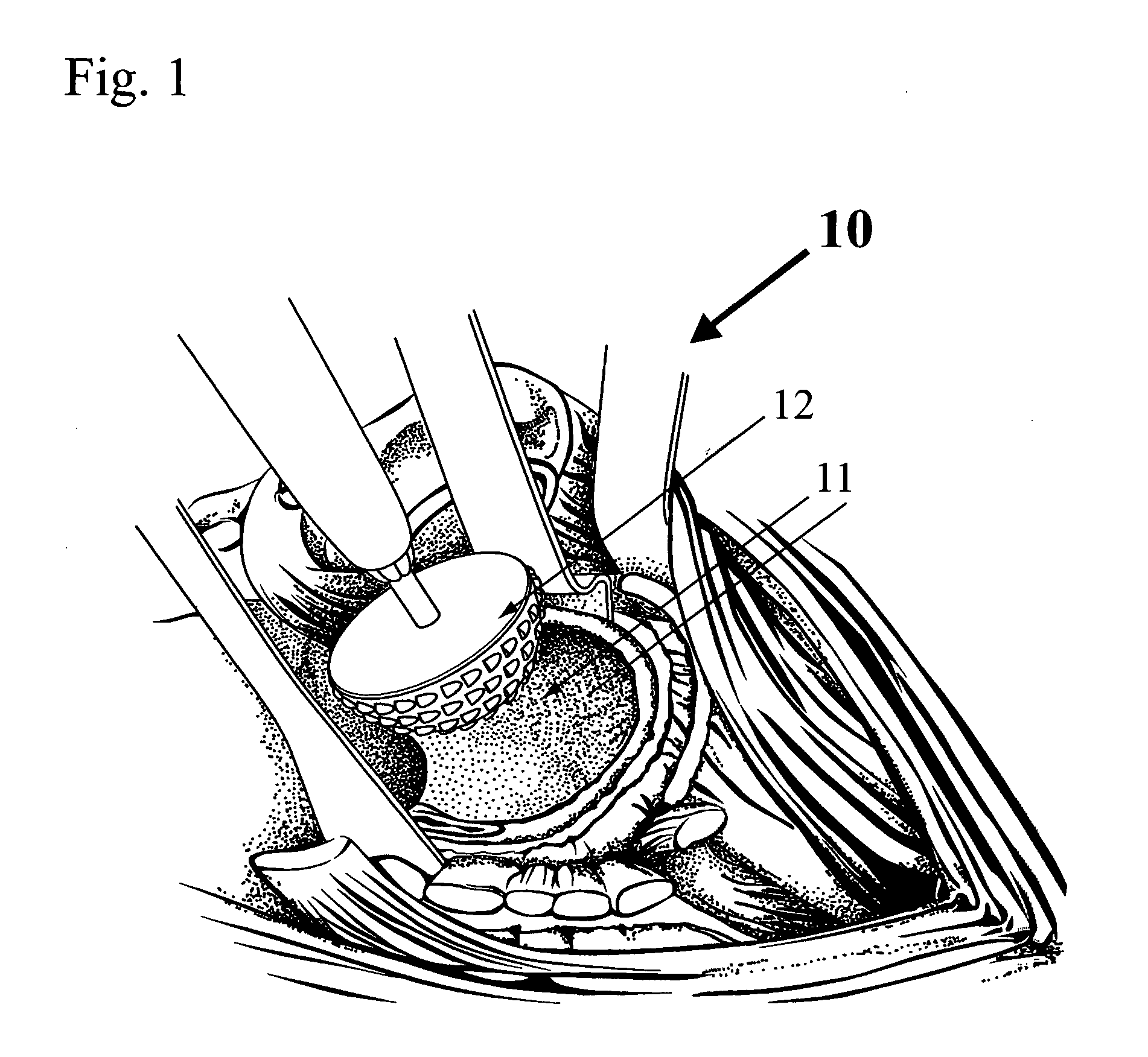

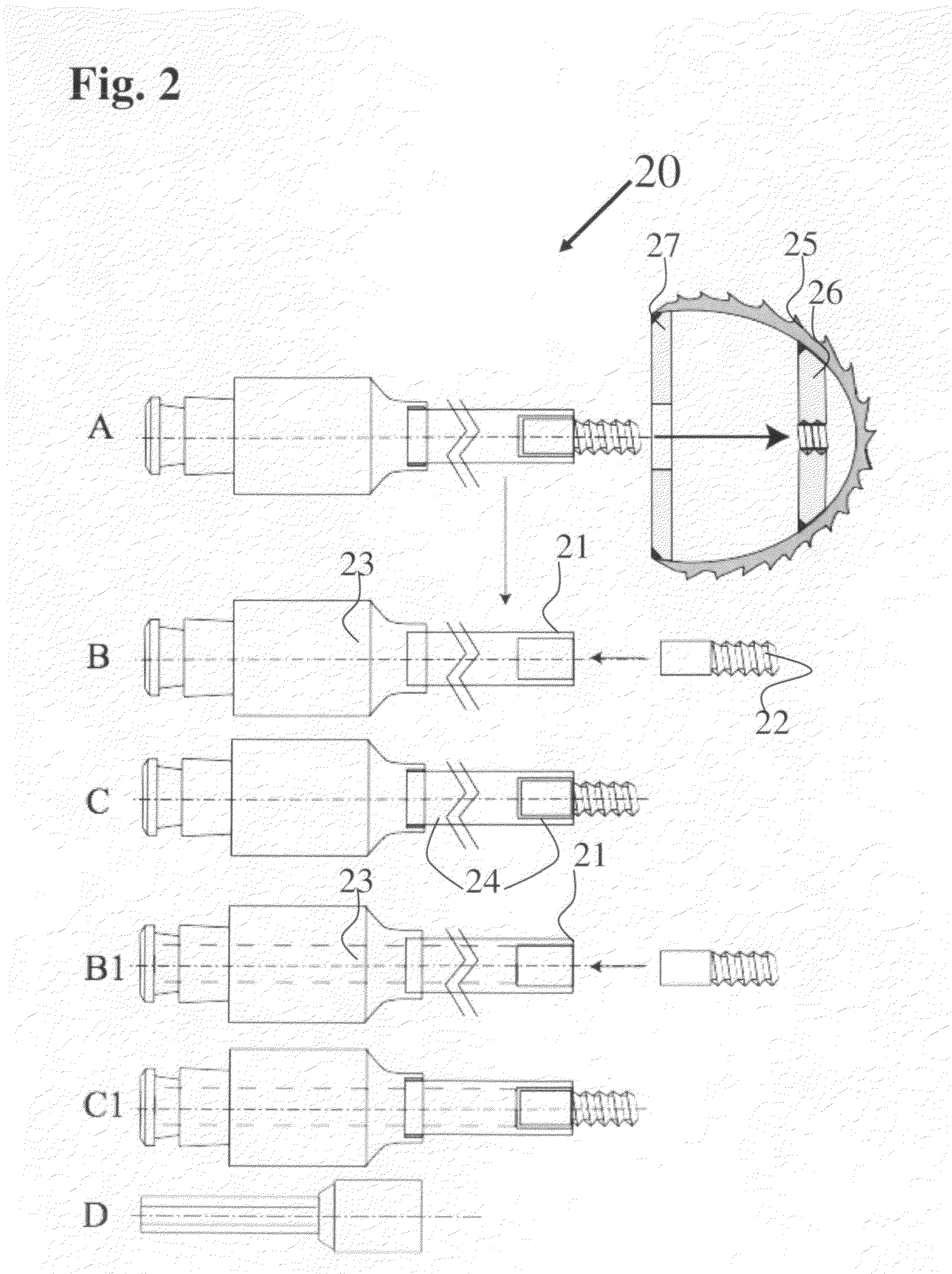

Disposable reamer shaft or modular spherical or tapered hollow reamer assembly for medical applications

ActiveUS20100168749A1Reduce manufacturing costPrecise processingMetal-working drilling toolsSurgeryFiberEpoxy

A low cost disposable reamer shaft is made from a rod or tube stock of stainless steel, Nitinol or fiber reinforced polymer having a precise outer diameter in the range of 4 to 14 millimeter and is cut to a shaft length of 250 to 400 millimeters. An attachment piece with male or female thread matching a spherical hollow or tapered hollow reamer is machined and glued with epoxy on one end of the rod of tube stock using a precision centerline aligning jig. An attachment piece for connecting to a drive power unit is machined and glued with epoxy to the other end of the rod or tube stock thus forming a low cost disposable reamer shaft that aligns the centerline of the shaft with that of the reamer. The shaft contacts the reamer at two attachment locations that are displaced from each other, providing precise centerline alignment.

Owner:LRS SCI & TECH LLC

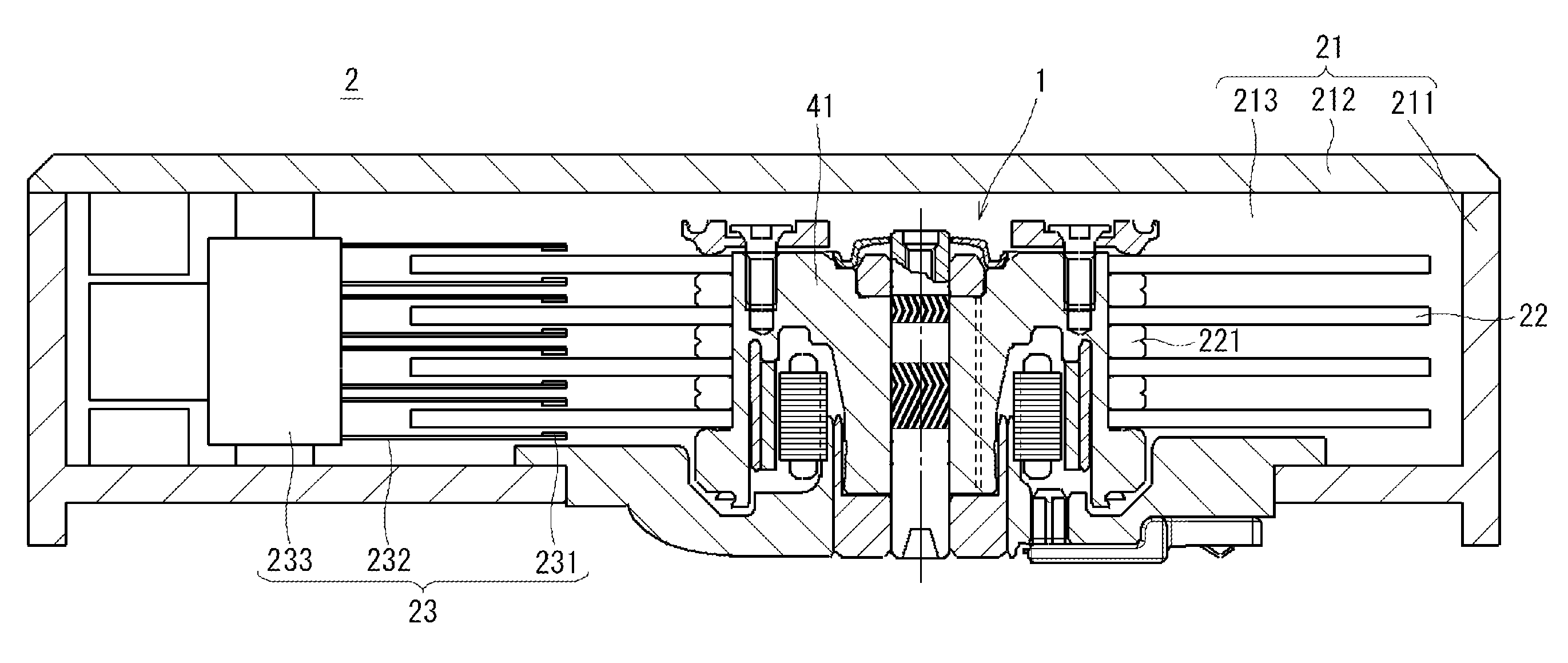

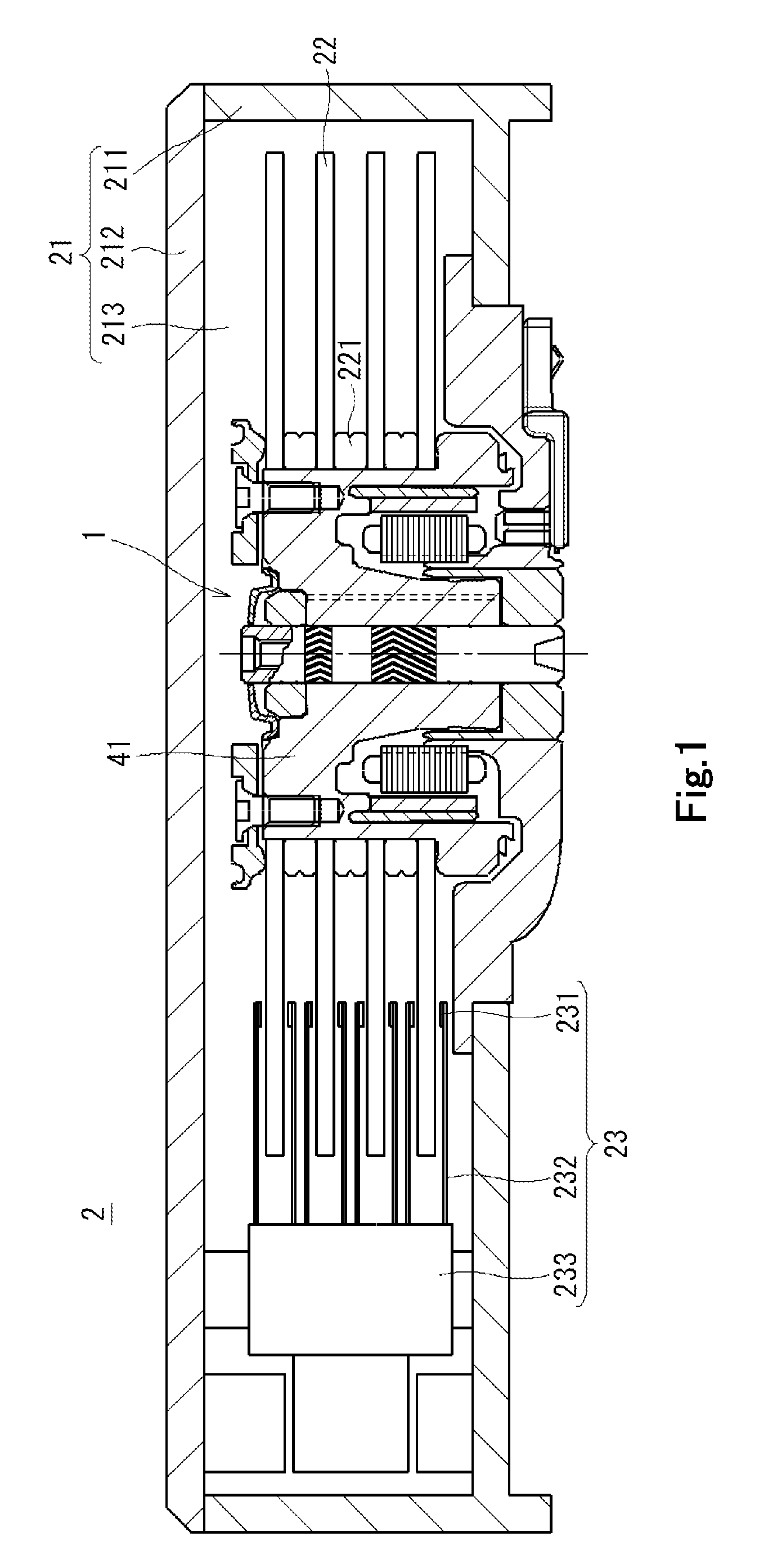

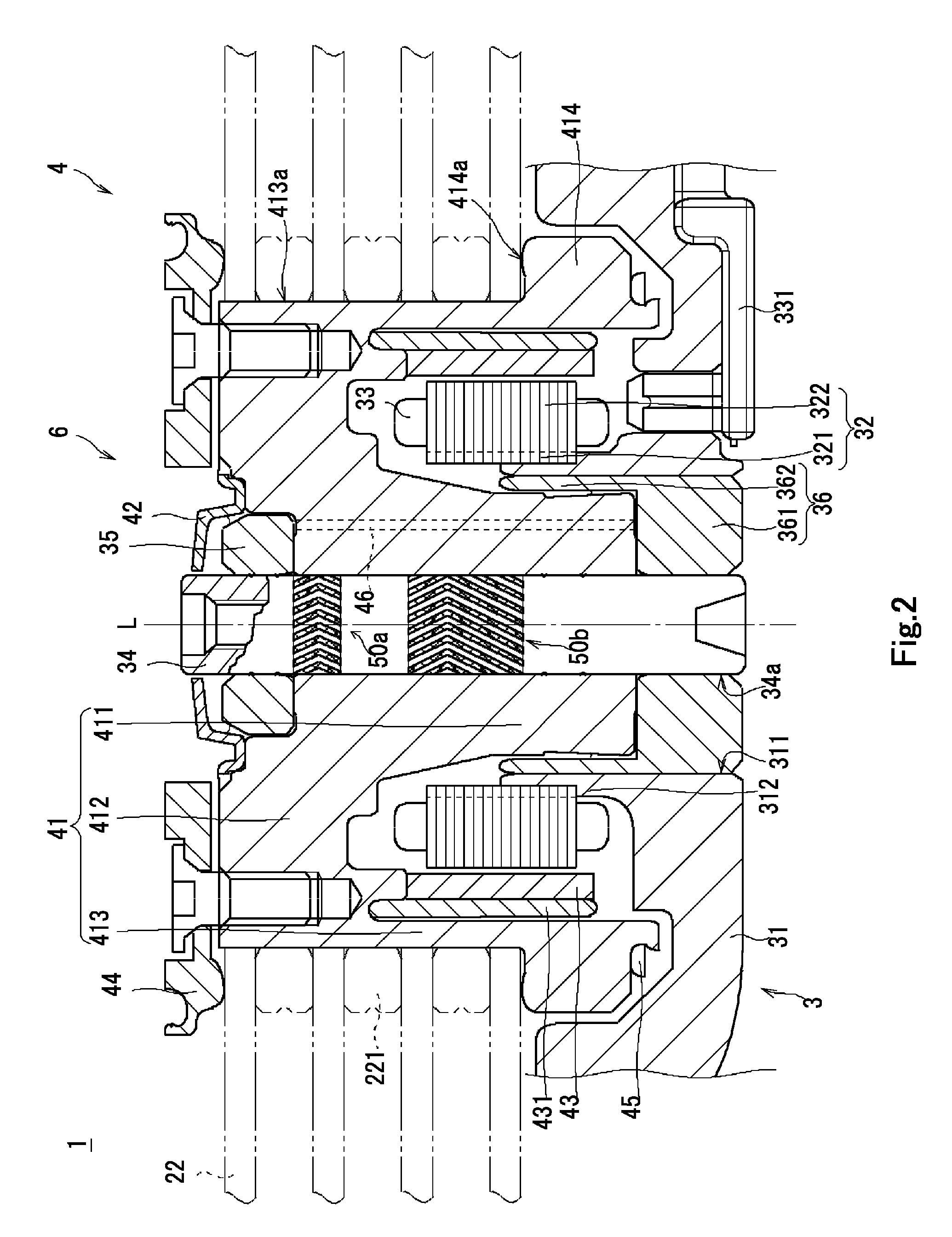

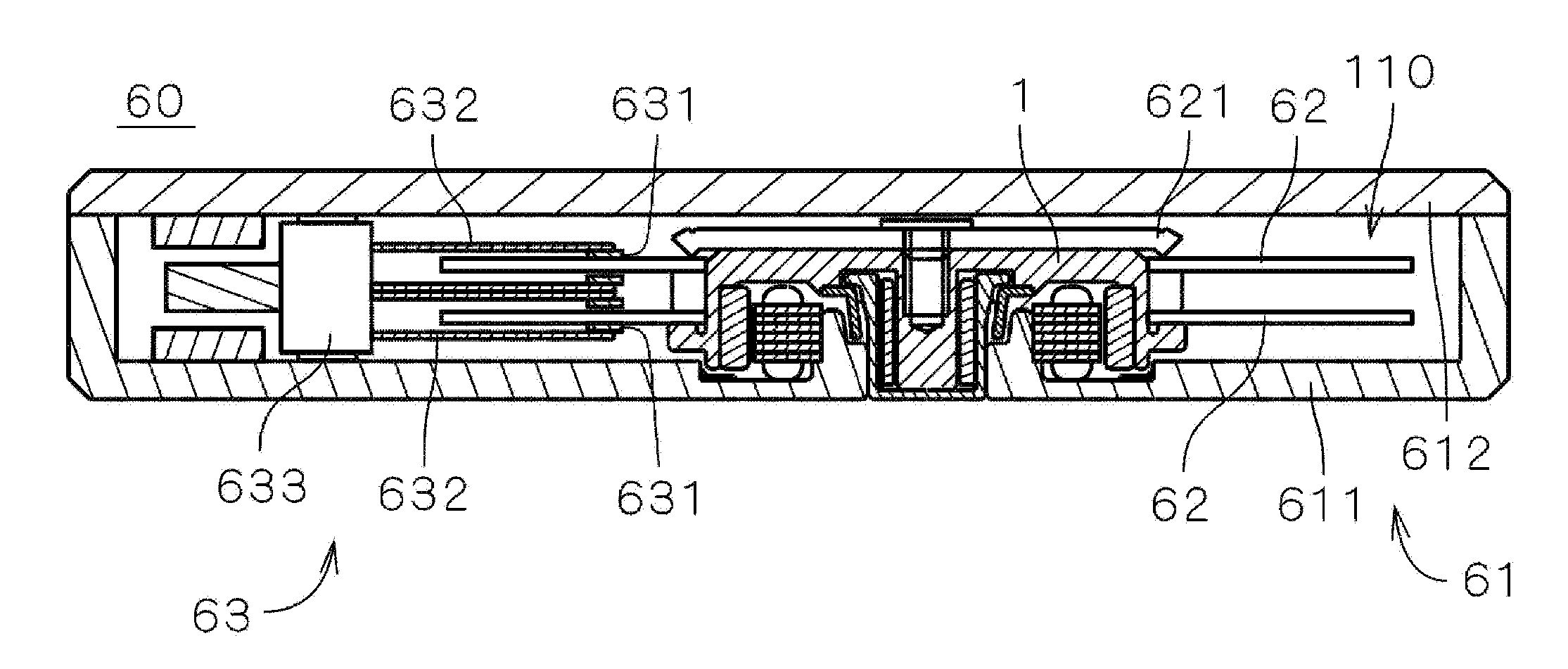

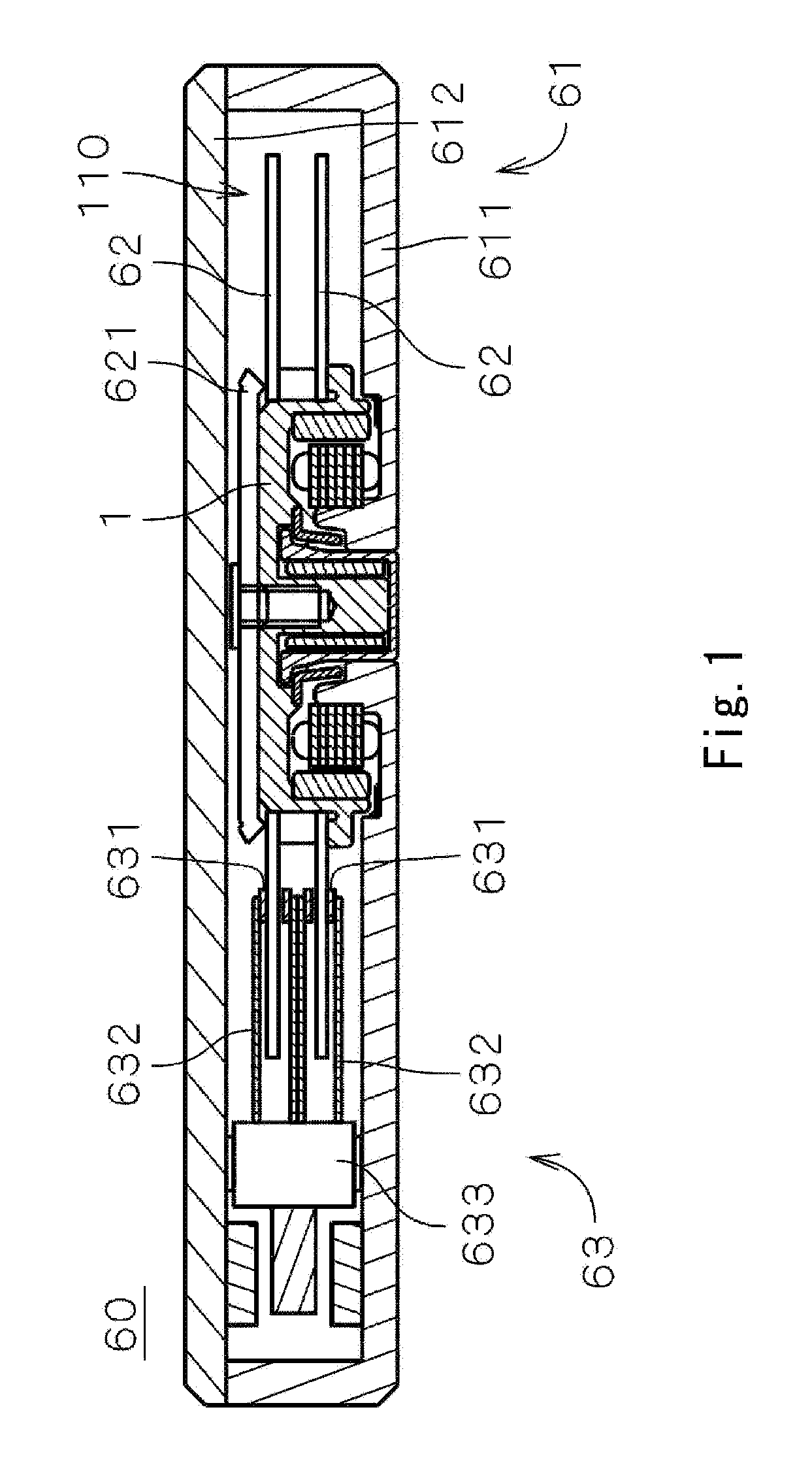

Fluid dynamic bearing apparatus, spindle motor, and disk drive apparatus

InactiveUS20110019303A1Reducing and preventing evaporationEasy to guaranteeShaftsRecord information storageCapillaria obsignataEvaporation

In a spindle motor, a capillary seal portion having a radial dimension that decreases in an axially downward direction, and a labyrinth seal portion arranged above the capillary seal portion are defined between an outer circumferential surface of a rotating member and an inner circumferential surface of a tubular portion. The capillary seal portion includes a liquid surface of a lubricating oil positioned therewithin. The radial dimension of the labyrinth seal portion is smaller than the radial dimension of an upper end portion of the capillary seal portion, so that the labyrinth seal portion contributes to reducing evaporation of the lubricating oil.

Owner:NIPPON DENSAN CORP +1

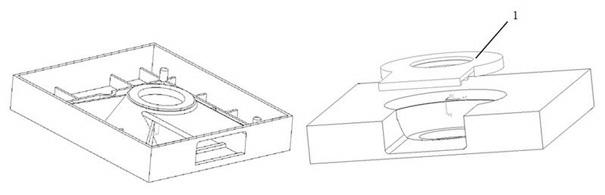

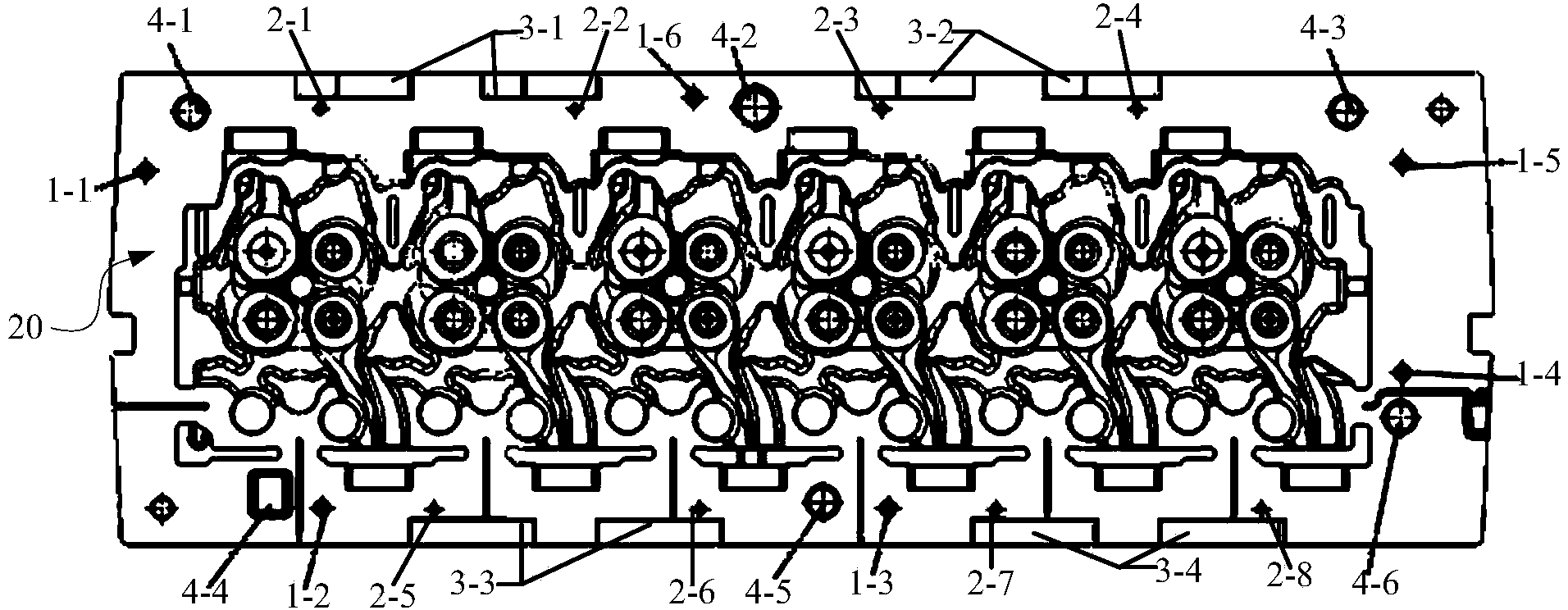

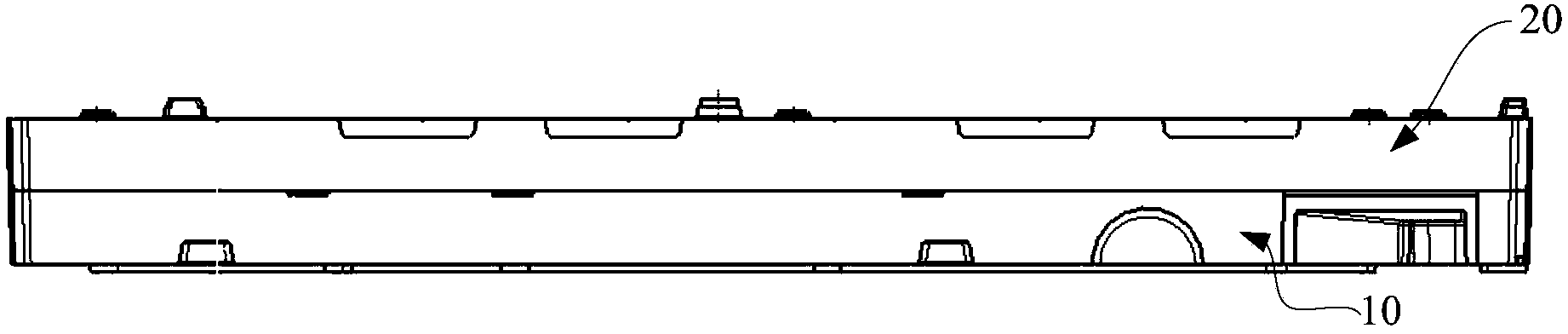

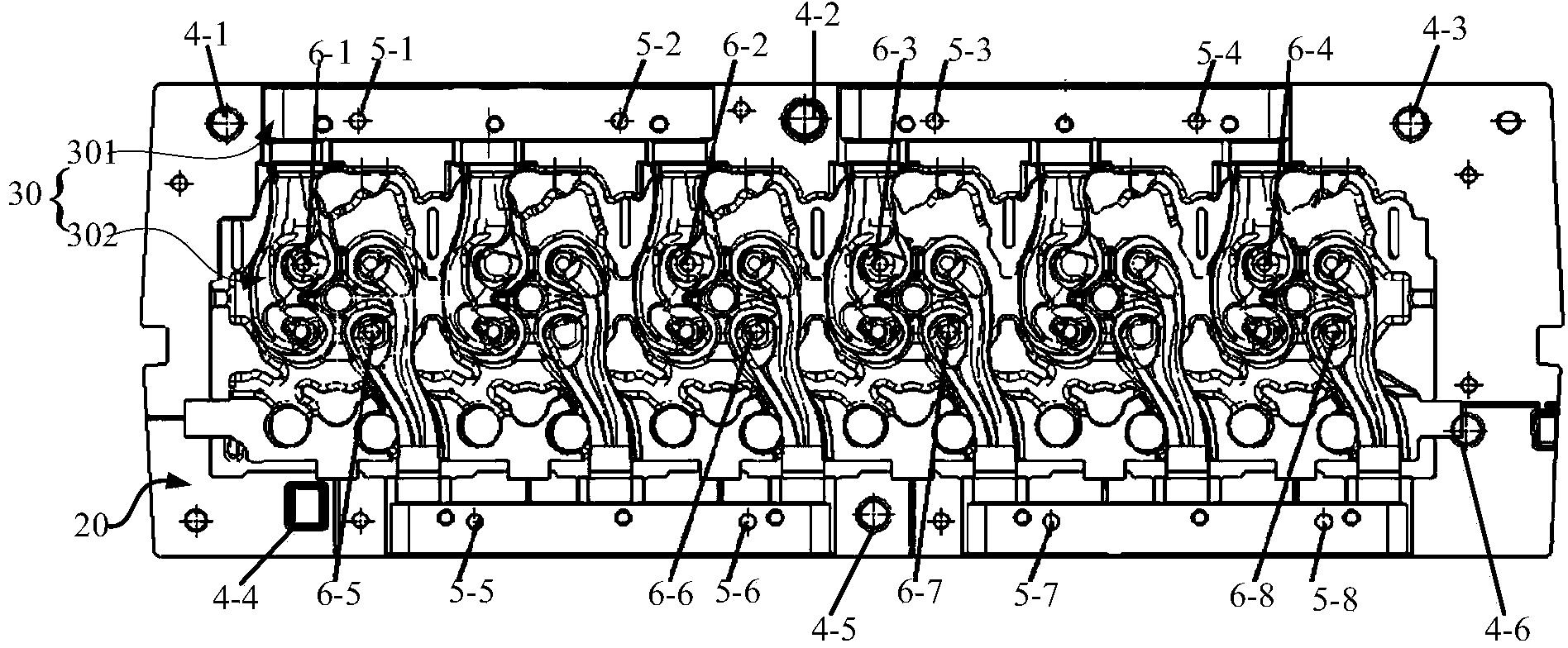

Cylinder head sand core group and assembling method

The invention discloses a cylinder head sand core group and an assembling method. The cylinder head sand core group comprises a chassis sand core, a lower main body sand core, an air channel sand core and an upper main body sand core, wherein the lower main body sand core is locked with the chassis sand core through a first screw, a frame of the lower main body sand core is provided with an adhesive convex platform, an adhesive groove is formed in a frame of the upper main body sand core, the adhesive groove is buckled with the adhesive convex platform to form a chamber, the chamber is communicated with the outer side of the upper main body sand core through an injection hole, and a hot melt adhesive enters the chamber through the injection hole and is solidified to enable the upper main body sand core and the lower main body sand core to be bonded together. The invention also discloses an assembling method of a cylinder head sand core. The cylinder head sand core group is high in production speed, firm in structure and low in cost.

Owner:GUANGXI YUCHAI MASCH CO LTD

Technology for machining lens cone plastic mould precise assembly of digital camera

The invention discloses a technology for machining a lens cone plastic-mould precise assembly of a digital camera. The technology comprises the following steps of numerical control turning, milling machining and tapping, thermal treatment, outer surface grinding, linear cutting, grinding matching, excircle grinding, machining of a numerical control machining center, electric spark forming and machining, linear cutting and electric spark machining and ejection and product detection. The technology for machining the lens cone plastic-mould precise assembly of the digital camera is novel in design, convenient to implement and precise in part size, the machining cost and the time are saved, and the production efficiency is improved.

Owner:SUZHOU UNIV

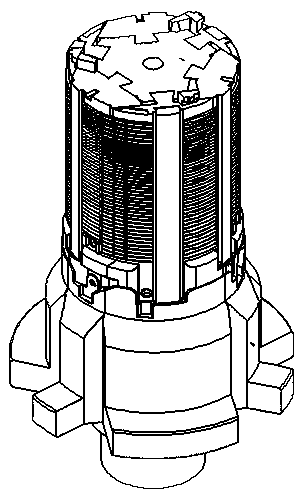

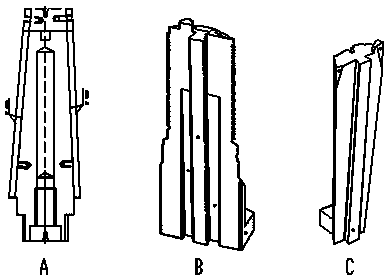

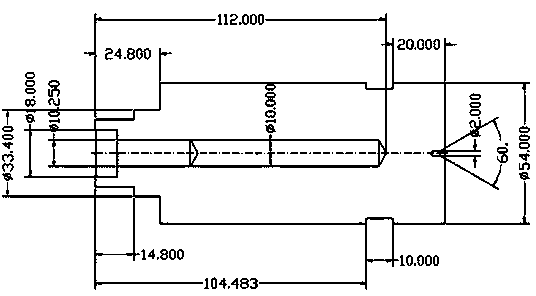

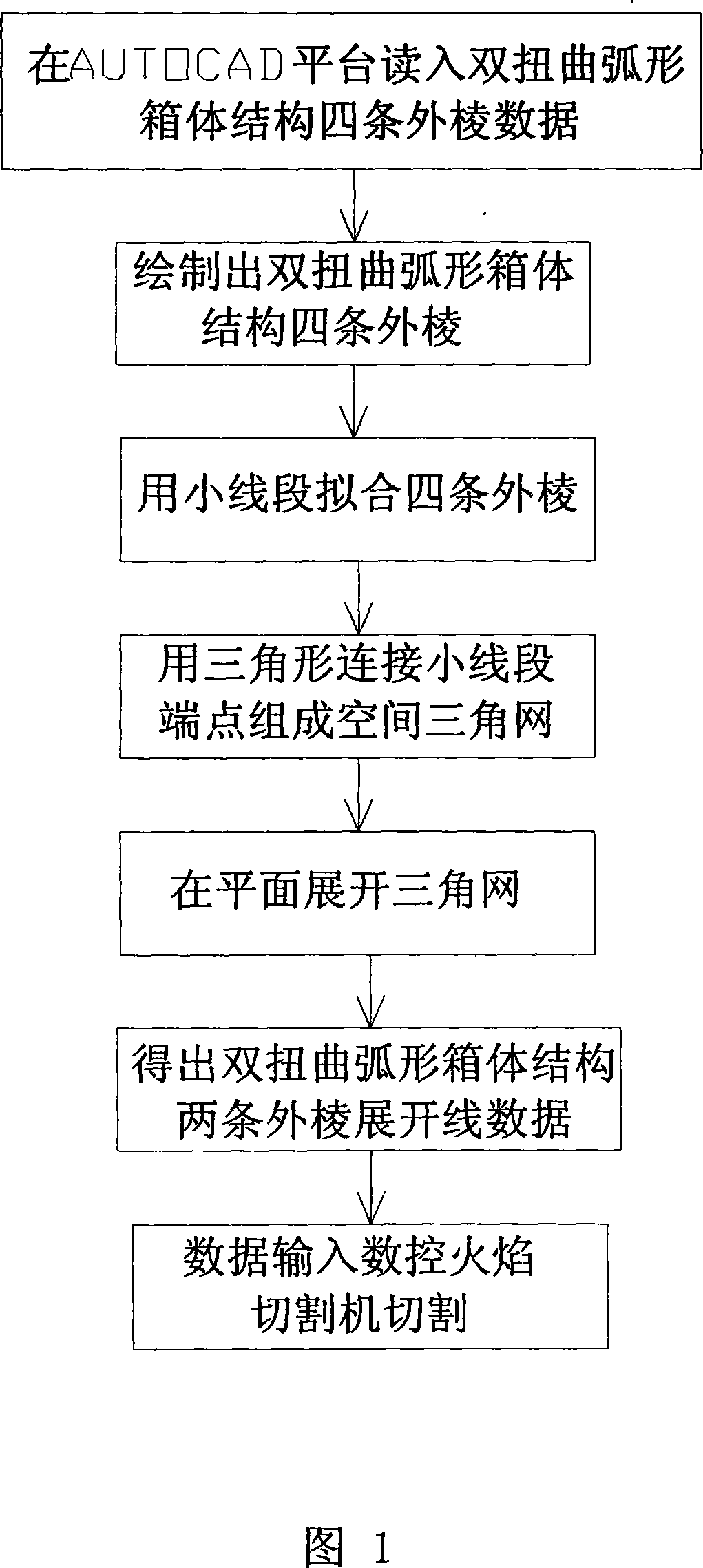

Method of manufacturing double-distortion arc box body structure

The invention relates to a manufacturing method for double-twist arc box structure, belonging to the steel structure field, comprising material cutting aided by computer, cutting, fabricating for clamping fixture of box-sectioned beam and assembly of box-sectioned beam so on. The method makes use of computer to assisted lofting, cutting, designing for space clamping fixture and assembling for space clamping fixture. It can solve the problem very well that when material cutting of complicated-component spiral box structure is carried out in fabrication of metal structure, the dimension of material cutting is not accurate and assembly is not easy. Component with relative accurate figuration dimension is fabricated. It takes a higher guiding role for fabrication of similar engineering in future.

Owner:CHINA 22MCC GROUP CORP

Method for producing silicon carbide porous ceramic filtering element and extrusion apparatus

InactiveCN101406782ARich macropore structureImprove filtration efficiencyCeramic shaping apparatusFiltration separationGranularitySlurry

The invention discloses a method for preparing a silicon carbide porous ceramics filtering element and squeezing equipment. The method comprises slurry preparing, forming, drying and baking, and the method is characterized by comprising the following steps: mixing silicon carbide powder of which the granularity is smaller than 200 mu m, ceramics binding agent, pore forming agent and plasticity agent according to certain proportion into a pug mill to prepare porous ceramics plasticity slurry; squeezing the porous ceramics plasticity slurry to obtain a silicon carbide porous ceramics plastic tube; filling the tube in the squeezing equipment; pressurizing two ends of the tube to form a flange at one end of the silicon carbide porous ceramics plastic tube, and to form an end enclosure at the other end; removing the die, drying to obtain silicon carbide porous ceramics filtering unit blank; and baking at certain temperature to obtain the silicon carbide porous ceramics filtering element. The silicon carbide porous ceramics filtering element has the advantages of high intensity, uniform pore diameter, high porosity, higher filtering precision and filtering efficiency, high temperature resistance, easy regeneration and repeated use, and is suitable for industrial bulk production.

Owner:SHANDONG UNIV OF TECH

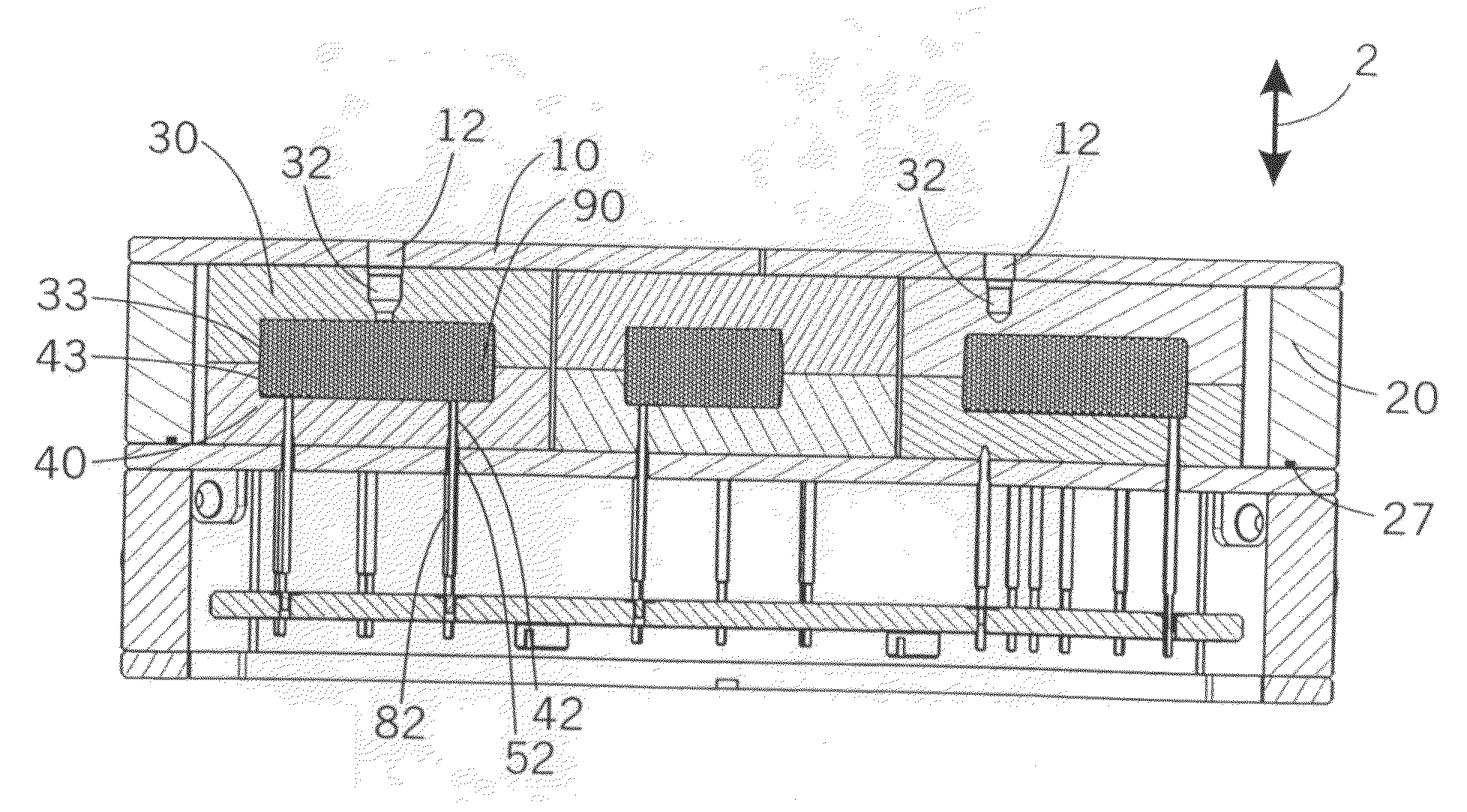

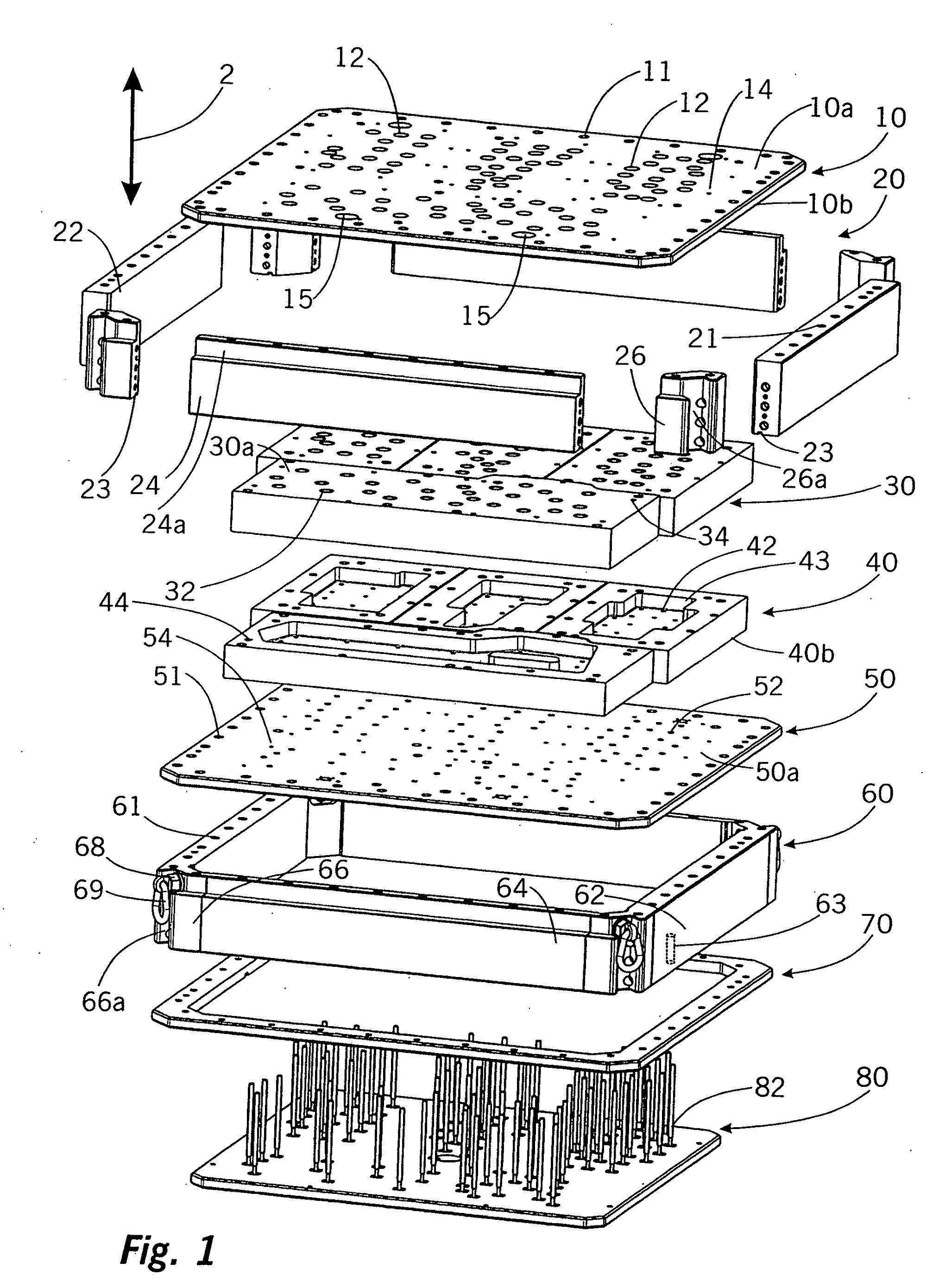

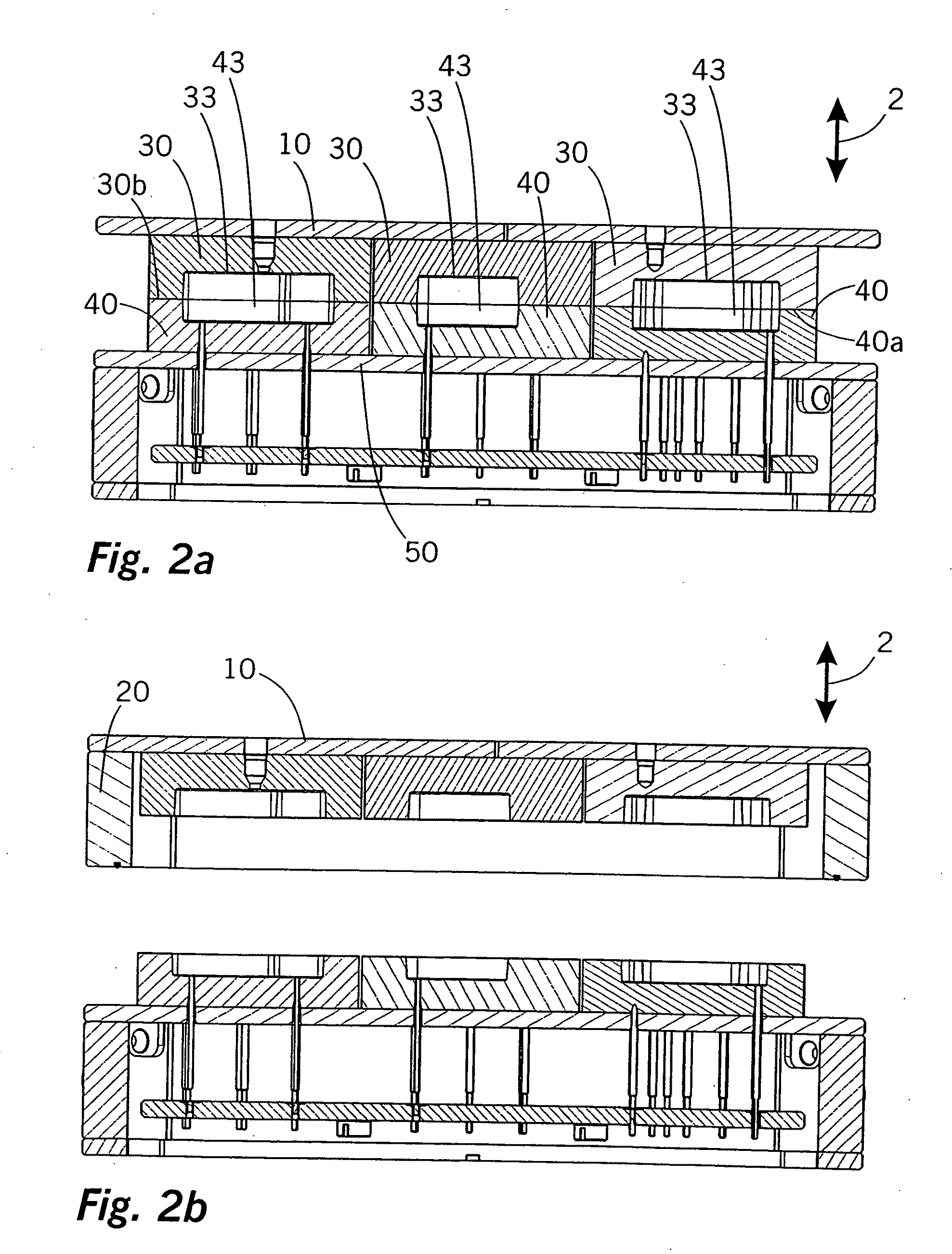

Casting tool and core-making machine

InactiveUS20100122790A1Eliminate disadvantagesPrecise DimensionsMoulding machinesSand castingMulti segment

The invention relates to a casting tool for the production of castings, particularly for the production of cores (90) for sand castings, comprising a supporting device consisting of a first and a second supporting unit (10, 20, 50, 60) capable of being moved in a joining direction (2) toward each other, and comprising at least two mold elements (30, 40), of which a first mold element (30) is attached to the first supporting unit (10, 20) and a second mold element (40) is secured to the second supporting unit (50, 60), which mold elements (30, 40) each have a mold recess (33, 43), which mold recesses (33, 43) in the mold elements (30, 40) together define the shape of at least one casting core to be produced (90) when the first and second mold elements (30, 40) bear against each other.According to the present invention, one of the supporting units (10, 20) has a first peripheral frame (20) that surrounds the mold element (30) attached to said supporting unit (10, 20), and the frame (20), as multi-segment frame, is composed of at least two frame segments (22, 24, 26) joined together by positively effective securing means.The use thereof as a very simply and quickly produced core-casting tool.

Owner:HERZOG & HERZOG HLDG & SERVICE

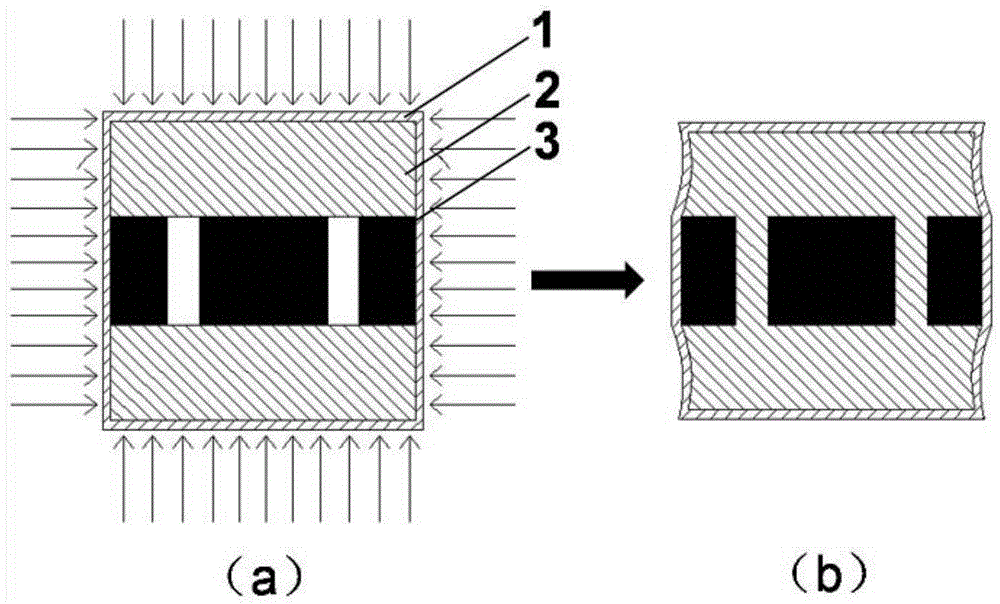

Hot isostatic pressure near-net forming method for semi-solid complex difficult-machining compact piece

InactiveCN105772726ASmall and uniform tissueGuaranteed forming accuracyHigh pressureTemperature and pressure

The invention discloses a hot isostatic pressure near-net forming method for a semi-solid complex difficult-machining compact piece. The hot isostatic pressure near-net forming method comprises the steps that a semi-solid material is used as a forming material, graphite is used as an internal form control core, the hot isostatic pressure temperature is selected as the solid-liquid two-phase interval temperature, and the compact piece in a complex shape is directly formed under coupling of temperature and pressure. According to the hot isostatic pressure near-net forming method for the semi-solid complex difficult-machining compact piece, performance defects caused by powder surface pollutants in traditional methods can be effectively overcome, and the part forming precision can be effectively ensured through high pressure at the high temperature; in addition, the temperature close to the melting point of an alloy material is adopted, and a solid-liquid coexisting phase occurs in a ladle sleeve at the temperature; due to the fact that liquid phase components exist among crystal grains or solid phase particles, the solid phase particles almost have no binding force and are very low in flow deformation resistance, and a complex runner in the form control core is filled with parent metal advantageously; and moreover, the solid phase particles are easy to separate on specification portions, and while, due to the fact that the liquid phase components exist, the separated portions are very easy to connect integrally.

Owner:HUAZHONG UNIV OF SCI & TECH

Manufacturing method of bearing member and manufacturing method of sleeve unit

A sleeve housing for a motor includes a bearing member, which includes a cylindrical portion and a collar portion and is formed by press working or by forging. The bearing member is retained by a retaining portion which is a portion of a cutting tool and which relatively rotates with respect to the cutting tool in a concentric manner with a predetermined rotation axis in order to execute a cutting process on a lower portion of the collar portion with reference to an upper portion thereof, so as to effectively form the sleeve housing with very high precision.

Owner:NIDEC CORP

Reflective mask blank for EUV lithography

ActiveUS8029950B2Improve smoothnessIncrease roughnessNanoinformaticsSemiconductor/solid-state device manufacturingLithographic artistHydrogen

A reflective mask blank for EUV lithography is provided which has an absorber layer wherein stress and crystal structure can be easily controlled.A reflective mask blank for EUV lithography, which comprises a substrate, and at least a reflective layer for reflecting EUV light and an absorber layer for absorbing EUV light formed in this order on the substrate, wherein the absorber layer contains tantalum (Ta), nitrogen (N) and hydrogen (H); and in the absorber layer, the total content of Ta and N is from 50 to 99.9 at %, and the content of H is from 0.1 to 50 at %.

Owner:ASAHI GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com