Technology for machining lens cone plastic mould precise assembly of digital camera

A technology for digital cameras and plastic molds, which is applied in the field of processing technology for precision assembly of plastic molds for digital camera lens barrels, can solve the problems of thin outer wall structure and low strength of 6-piece core sliders, save processing costs and time, and improve Production efficiency, innovative design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

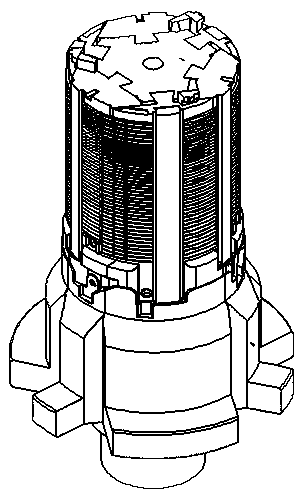

[0032] refer to figure 1 As shown, the digital camera barrel plastic mold precision assembly process includes the following steps:

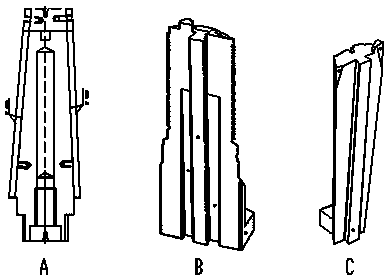

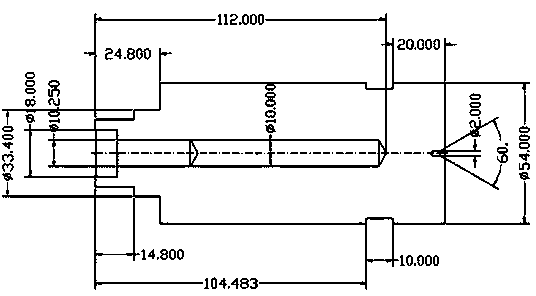

[0033] Step 1) Refer to image 3 , Figure 4 As shown, 1 piece of core seat blank and 2 pieces of core slider blank are processed by CNC turning, and the top, bottom, and inside of the core seat blank are drilled and drilled; the two ends of the core slide blank are processed with process holes ;

[0034] Step 2) Refer to Figure 5 , Image 6 As shown, milling and tapping, drill 12 holes on the circumference of each blank and tap M3.0 teeth, and tap M12 teeth at the bottom of the core seat blank;

[0035] Step 3) heat treatment, the blank is tempered at high temperature;

[0036] Step 4) Refer to Figure 7 As shown, the outer surface is ground, and the outer surface of the workpiece after gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com