Hot isostatic pressure near-net forming method for semi-solid complex difficult-machining compact piece

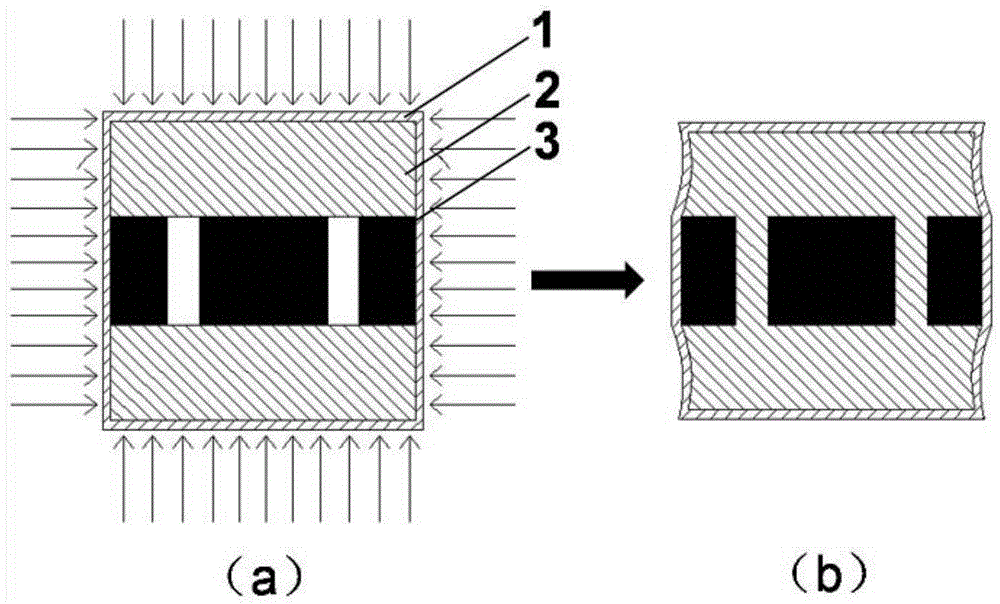

A hot isostatic pressing and near-net-shaping technology, which is applied in the manufacture of aerospace parts with complex structures, and in the field of parts with difficult-to-process and complex-shaped static-pressed materials, which can solve the problems of easy-to-produce pores, excessive sheath deformation, and microstructure Coarse and other problems, to achieve the effect of easy deformation and flow, avoid performance defects, fine and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

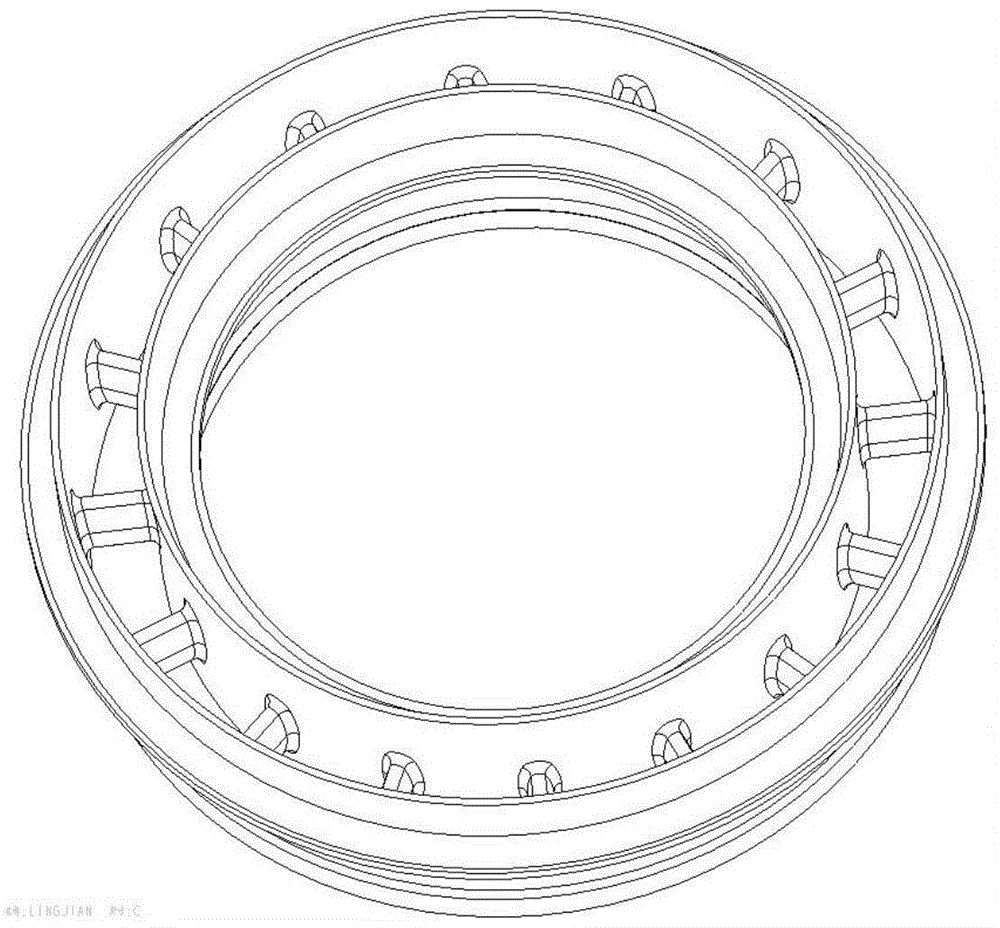

[0039] This is to utilize the present invention to make nickel alloy (inconel625) blisk ( image 3 ) instance:

[0040] The melting point of Inconel625 is 1290°C to 1350°C, so the thermal isostatic process parameters this time are temperature 1300°C and pressure 120MPa; increasing the temperature first and then boosting the pressure is more accurate in size and mechanical properties than the simultaneous temperature increase and pressure increase. Therefore, this hot isostatic pressing chooses the process method of raising the temperature first and then raising the pressure.

[0041] Against this background, the above-mentioned problems can be solved by using the present invention. Specific steps are as follows:

[0042] (1) According to the structure of the blisk, the hot isostatic pressing forming sheath and the shape-controlling core are designed. The sheath is mainly composed of a cylinder, a lower cover and an upper The distance is arranged in a ring shape and consists...

example 2

[0053] This is to use the present invention to adopt titanium alloy semi-solid material (Ti6Al4V) to manufacture long straight structural parts ( Image 6 ) instance:

[0054] The melting point of Ti6Al4V is about 1660°C, so the process parameters of this hot isostatic process are temperature 1600°C and pressure 120MPa.

[0055] Against this background, the above-mentioned problems can be solved by using the present invention. Specific steps are as follows:

[0056] (1) According to the design of the parts, the hot isostatic pressing forming jacket and graphite core are selected as the jacket material of No. 45 steel;

[0057] (2) Design the semi-solid CAD model of the prefabricated Ti6Al4V alloy according to the remaining dimensions in the sheath after the sheath and the shape-controlled core are assembled;

[0058] (3) Machining methods are used to process the sheath, graphite, and semi-solid Ti6Al4V models respectively, and assemble them;

[0059] (4) Weld the sheath, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com