High-strength Al-Cr-SC alloy through 3D printing

An al-cr-sc, 3D printing technology, applied in the direction of improving energy efficiency, process efficiency, additive manufacturing, etc., can solve the problems of low mechanical properties, thermal cracks, poor mechanical properties, etc., and achieve the increase of precipitated phases, The effect of fine and uniform tissue and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

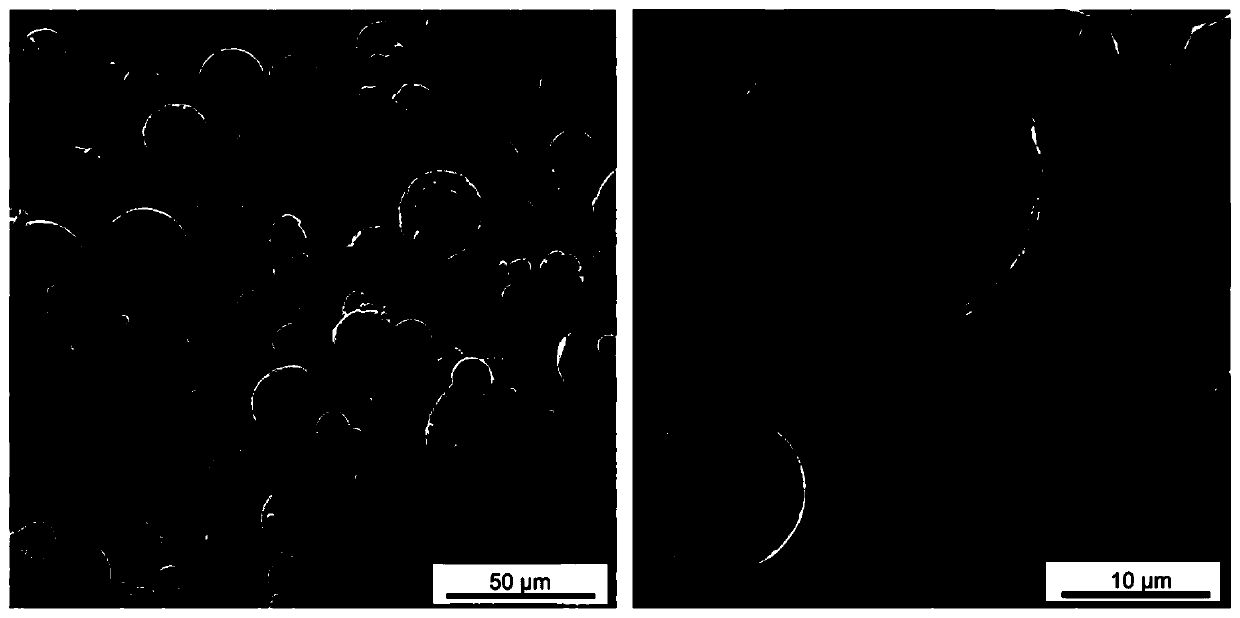

Image

Examples

Embodiment 1

[0035] The composition of the high-strength aluminum-chromium alloy specially used for 3D printing according to the present invention is prepared, and the composition includes the following components in terms of mass percentage: Cr: 4.5%, Mg: 1.5%, Sc: 0.65%, Zr: 0.2%, Si: 0.2% %, Mn: 0.25%, Fe: 0.2%, Ti: 0.15%, AlCl 3 Powder: 0.14%; CaCl 2 +NaCl: 0.16%, the balance is Al.

[0036] The above-mentioned aluminum alloy powder preparation method:

[0037] (1) Raw material smelting: except AlCl 3 , CaCl 2 And except for NaCl powder, other elements are weighed in proportion to the raw material of the intermediate compound metal block and placed in a vacuum induction furnace for heating and melting. The pressure in the vacuum induction furnace is 0.8MPa, and the melting temperature is 850°C.

[0038] (2) Atomized powder production: transfer the above-mentioned smelted pre-alloyed metal into an atomization tank, and use helium gas to conduct atomization powder production, and the...

Embodiment 2

[0045] The composition of the high-strength aluminum-chromium alloy specially used for 3D printing in the present invention is prepared, and the composition includes the following components in terms of mass percentage: Cr: 5%, Mg: 1.7%, Sc: 0.75%, Zr: 0.25%, Si: 0.24 %, Mn: 0.28%, Fe: 0.24%, Ti: 0.17%, AlCl 3 Powder: 0.18%, CaCl 2 +NaCl: 0.17% and the balance is Al.

[0046] The above-mentioned aluminum alloy powder preparation method:

[0047] (1) Raw material smelting: except AlCl 3 , CaCl 2 In addition to NaCl powder, other elements are weighed in proportion to the raw material of the intermediate compound metal block and placed in a vacuum induction furnace for heating and melting.

[0048] (2) Atomized powder making: transfer the above-mentioned smelted pre-alloyed metal into an atomizing tank, and use helium gas to carry out atomized powder making.

[0049] (3) Powder sieving: the above-mentioned pre-alloyed metal powder was sieved through a mesh to obtain a metal ...

Embodiment 3

[0055] The composition of the high-strength aluminum-chromium alloy specially used for 3D printing in the present invention is prepared, and the composition includes the following components in terms of mass percentage: Cr: 6%, Mg: 1.9%, Sc: 0.80%, Zr: 0.28%, Si: 0.27 %, Mn: 0.3%, Fe: 0.27%, Ti: 0.19%, AlCl3 powder: 0.22%, CaCl2+NaCl: 0.18%, and the balance is Al.

[0056] The above-mentioned aluminum alloy powder preparation method:

[0057] (1) Raw material smelting: except AlCl 3 , CaCl 2 In addition to NaCl powder, other elements are weighed in proportion to the raw material of the intermediate compound metal block and placed in a vacuum induction furnace for heating and melting.

[0058] (2) Atomized powder making: transfer the above-mentioned smelted pre-alloyed metal into an atomizing tank, and use helium gas to carry out atomized powder making.

[0059] (3) Powder sieving: the above-mentioned pre-alloyed metal powder is screened through a mesh to obtain a metal powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com