Resin composition and use of the same

A resin composition, thermoplastic resin technology, applied in the field of molded products, can solve the problems of thermal conductivity anisotropy, insufficient heat radiation of components, etc., and achieve the effect of small thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0102] The invention is illustrated by using the following examples, but the invention is not limited to these examples.

[0103] The alumina fine particles as component (B) used here are as follows.

[0104] Alumina fine particles (Low Soda Sumitomo fine particles ALM-41-01 produced by Sumitomo Chemical Co., Ltd.).

[0105] Volume-average particle size: 1.7μm

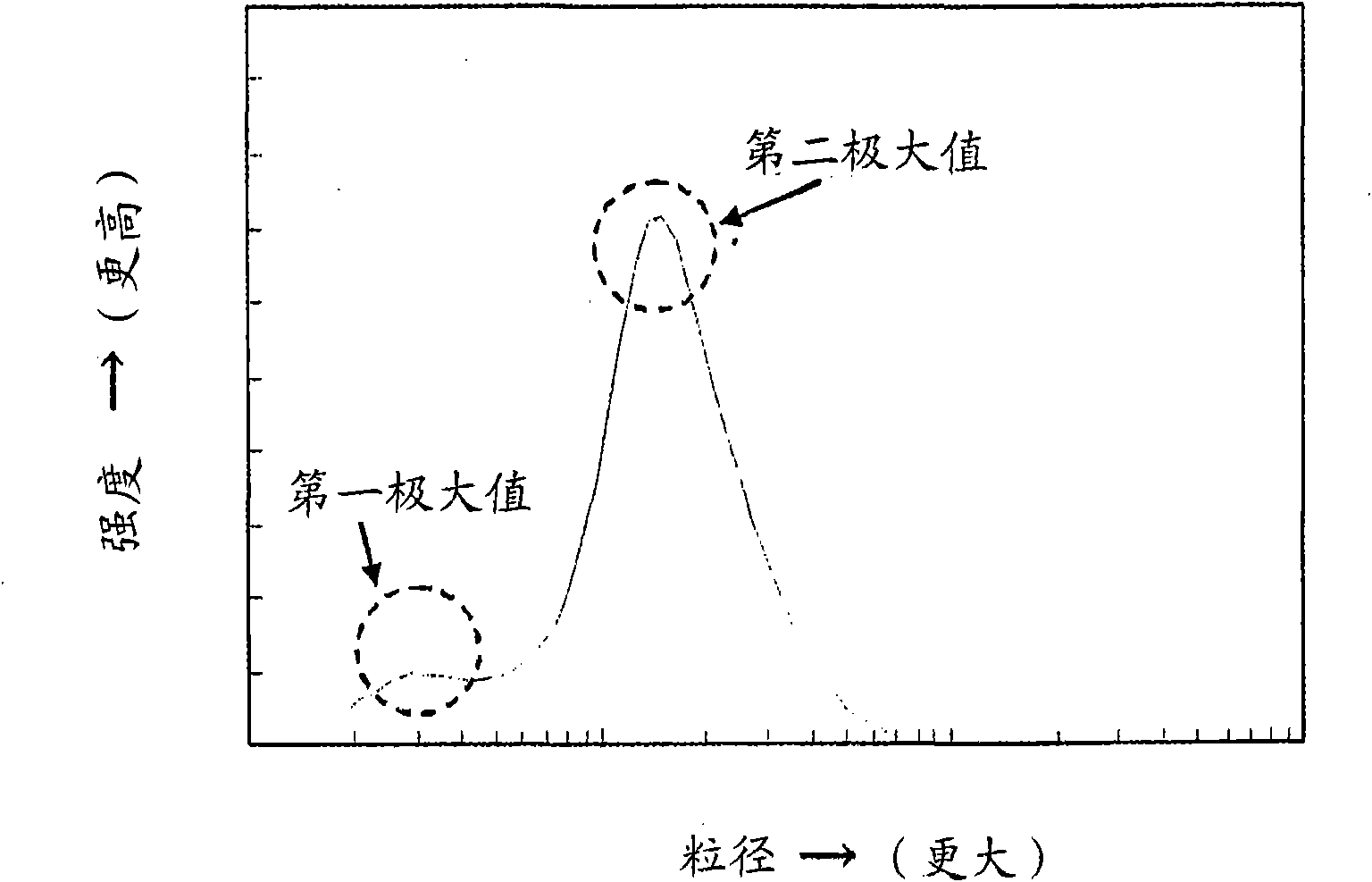

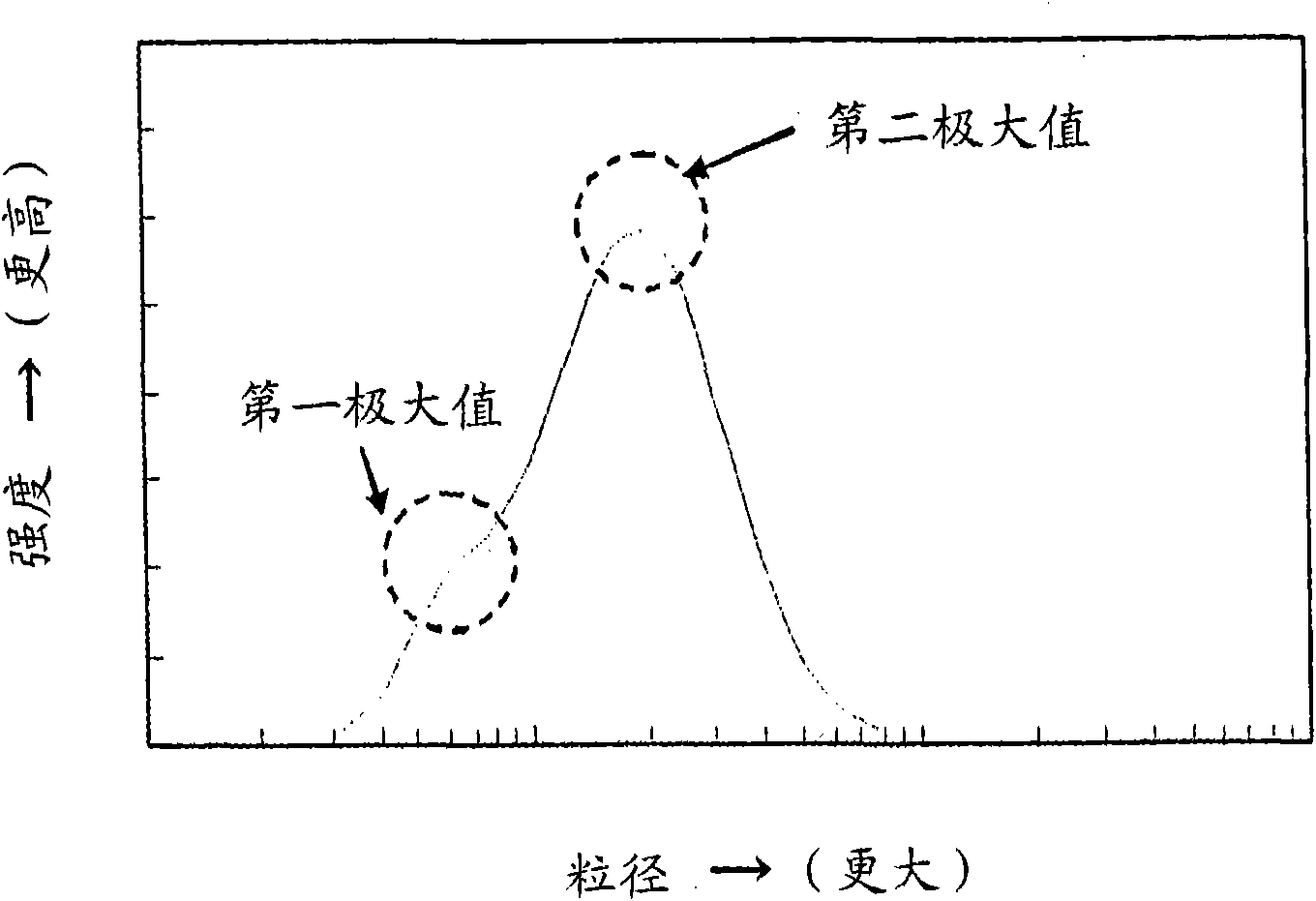

[0106] (It has a bimodal particle size distribution with two maxima in the range of 1.0-2.0 μm in terms of volume-average particle size and in the range of 0.2-0.4 μm in terms of volume-average particle size maximum value within ).

[0107] BET specific surface area 1.2m 2 / g.

[0108] The platy filler used here as component (C) is as follows.

[0109] Talc (Talc X50 manufactured by Nippon Talc Co., Ltd.; volume-average particle diameter of major axis: 17.4 μm, BET specific surface area: 2.64 m 2 / g).

[0110] The glass fibers used here as component (D) are as follows.

[0111] Glass fiber 1 (chopped glass fibe...

preparation Embodiment 1

[0113] In a reactor equipped with a stirrer, torque meter, nitrogen introduction tube, thermometer and reflux condenser, add 994.5g (7.2mol) of p-hydroxybenzoic acid, 446.9g (2.4mol) of 4,4'-dihydroxybiphenyl , 299.0 g (1.8 mol) terephthalic acid, 99.7 g (0.6 mol) isophthalic acid and 1347.6 g (13.2 mol) acetic anhydride. After the gas in the reactor was completely replaced with nitrogen, the temperature inside the reactor was raised to 150° C. during 30 minutes under a nitrogen atmosphere, and then the mixture was refluxed for 1 hour while maintaining the same temperature.

[0114] The temperature was raised to 320° C. during 2 hours and 50 minutes while distilling off acetic acid and unreacted acetic anhydride produced as by-products. After the reaction was complete, an increase in torque was observed, resulting in a prepolymer.

[0115] The prepolymer thus obtained was cooled to room temperature, ground with a coarse grinder, and then heated by raising the temperature from...

Embodiment 1-9

[0116] Embodiment 1-9, comparative example 1-4

[0117] According to the composition shown in Table 1, LCP1 obtained in Preparation Example 1, and the above components (B), (C) and (D) were obtained by using a unidirectional twin-screw extruder (by Ikegai Iron PCM-30HS manufactured by Works Ltd.) was granulated by melt-kneading at 330°C. The obtained pellets were molded at a cylinder temperature of 350°C and a molding temperature of 130°C with an injection molding machine (type PS40E5ASE manufactured by Nissei Plastic Industrial Ltd.) at a distance of 30 cm. 3 / s injection rate for injection molding. Two kinds of molded articles each having a different shape were obtained, and then evaluated.

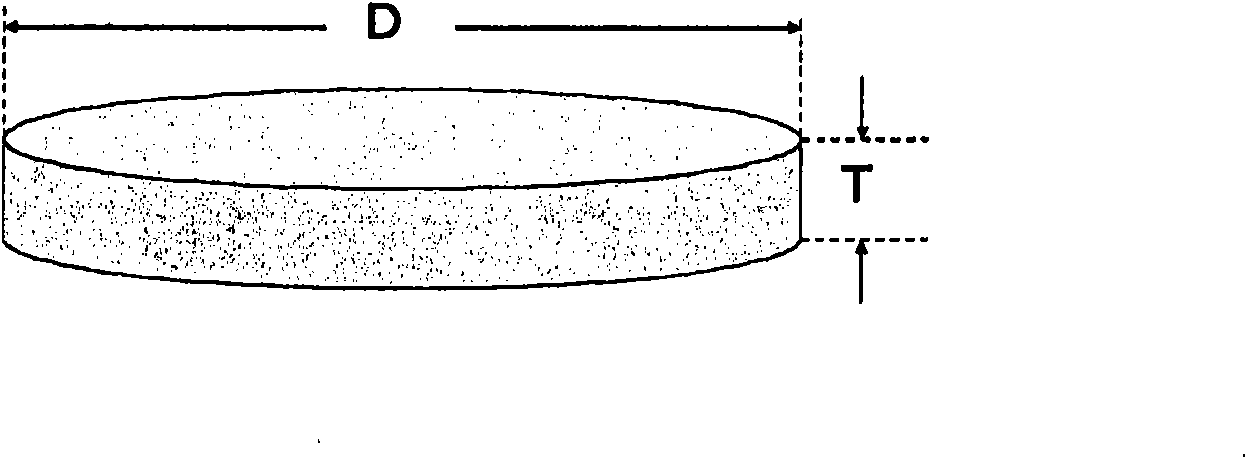

[0118] Molded product 1: 126mm×12mm×6mm;

[0119] Molded product 2: ASTM No.4 dumbbell shape

[0120] Regarding the molded article thus obtained, its specific gravity, thermal conductivity, tensile strength and bending strength were evaluated. The results are given in Table 1. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com