Method for producing silicon carbide porous ceramic filtering element and extrusion apparatus

A technology for porous ceramics and filter elements, applied in ceramic products, chemical instruments and methods, filtration and separation, etc., can solve the problems of uneven pore size distribution, low strength of filter elements, difficult backflushing and cleaning, etc. The effect of high temperature and wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Preparation of vitrified bond:

[0023] Alumina and kaolin are evenly mixed at a weight percentage of 10% and 90%, and the obtained mixed powder is dry-milled in a ball mill until the particle size is less than 2 μm powder.

[0024] 2. Forming of silicon carbide porous ceramic filter element:

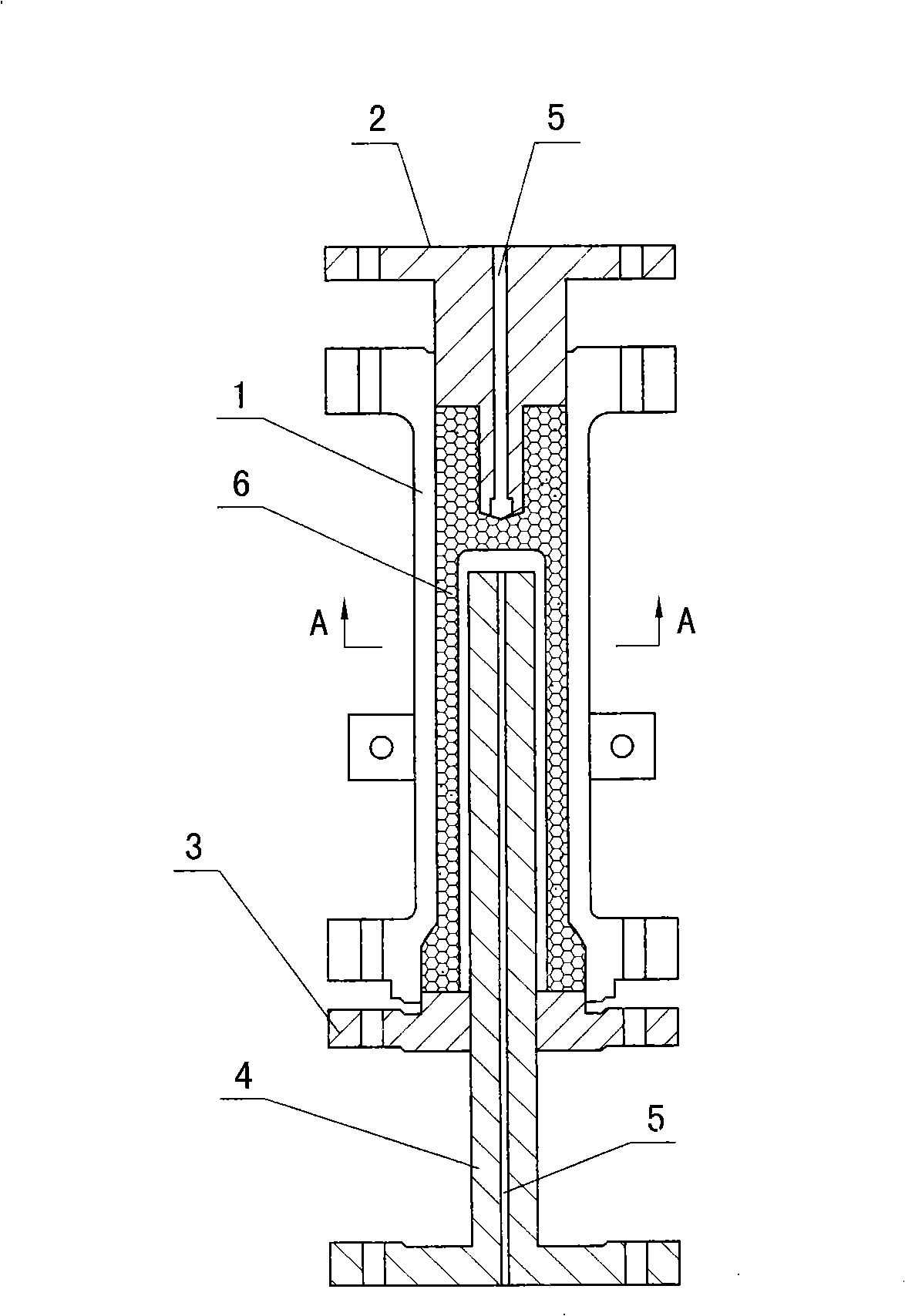

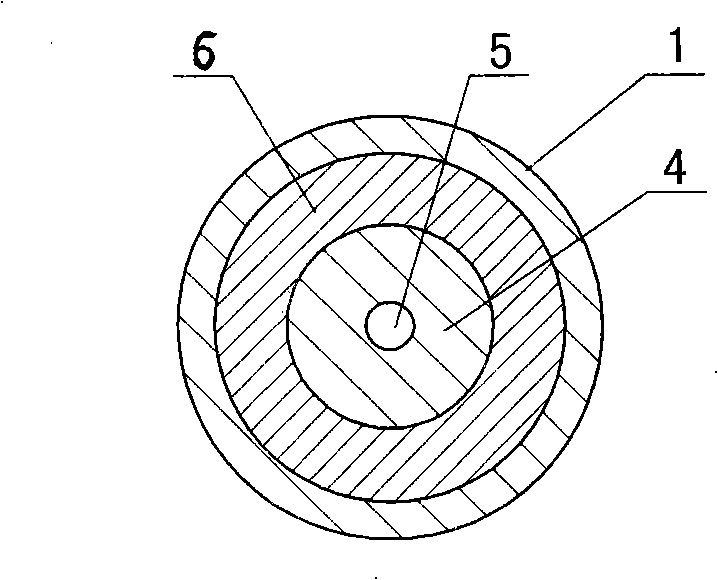

[0025] Mix 150μm silicon carbide powder, ceramic bond, carbon powder, carboxymethyl cellulose and water at a weight percentage of 58%, 15%, 5%, 2%, and 20%, and then knead in a mud mixer Uniformly make silicon carbide porous ceramic plastic mud, and then extrude the above silicon carbide porous ceramic plastic mud to form The silicon carbide porous ceramic plastic tube 6 is set on the mold core 4 and supported on the lower movable mold 3, and is pressed into the fixed mold 1 from the bottom of the fixed mold 1, and the upper movable mold 2 is pressed into the fixed mold 1 from the top of the fixed mold 1 1. Extrude the silicon carbide porous ceramic plastic tube 6 from both...

Embodiment 2

[0033] 1. Forming of silicon carbide porous ceramic filter element:

[0034] Mix 90μm silicon carbide powder, mullite, carbon powder, polyvinyl alcohol and water at a weight percentage of 70%, 5%, 8%, 7% and 10%, and then knead them evenly in a mud mixer Silicon carbide porous ceramic plastic mud, and then the above-mentioned silicon carbide porous ceramic plastic mud is extruded to form The silicon carbide porous ceramic plastic tube 6 is extruded from both ends of the silicon carbide porous ceramic plastic tube 6 as in Example 1, so that the lower end is flange-shaped and the upper end is a seal with a concave hole. head, and then unmold.

[0035] 3. Dry

[0036] Dry the silicon carbide porous ceramic plastic tube 6 after demoulding at 60°C for 5 hours, then at 90°C for 5 hours, and at 120°C until the water content is less than 1.5%. Silicon carbide porous ceramic filter element body.

[0037] 4. Firing

[0038] The dried silicon carbide porous ceramic filter element b...

Embodiment 3

[0042] 1. Forming of silicon carbide porous ceramic filter element

[0043] Mix 200μm silicon carbide powder, vanadium pentoxide, wood chips, oil and water at a weight percentage of 45%, 5%, 10%, 10%, and 30%, and then knead them evenly in a mud mixer to make carbonization Silicon porous ceramic plastic mud, and then the above-mentioned silicon carbide porous ceramic plastic mud is extruded to form The silicon carbide porous ceramic plastic tube 6 is extruded from both ends of the silicon carbide porous ceramic plastic tube 6 as in Example 1, so that the lower end is flange-shaped and the upper end is a seal with a concave hole. head, and then unmold.

[0044] 3. Dry

[0045] Dry the silicon carbide porous ceramic plastic tube after demoulding at a temperature of 60°C for 5 hours, then at a temperature of 90°C for 5 hours, and at a temperature of 120°C until the water content is less than 1.5%. Silicon carbide porous ceramic filter element body.

[0046] 4. Firing

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com