In-die riveting die of multi-position high-accuracy hardware bending piece

A high-precision, bending technology, applied in the direction of forming tools, positioning devices, manufacturing tools, etc., can solve the problems of low yield of finished products, low production efficiency, high labor intensity, etc., to achieve high production efficiency, accurate dimensions, The effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

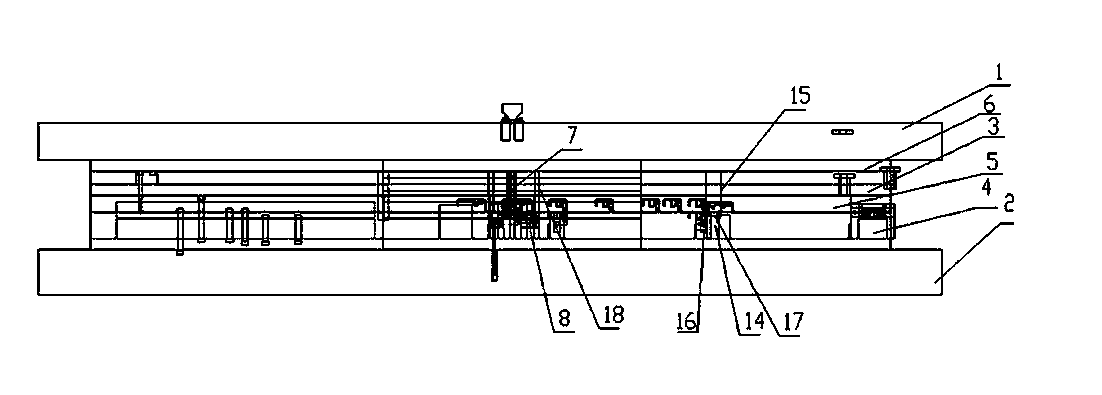

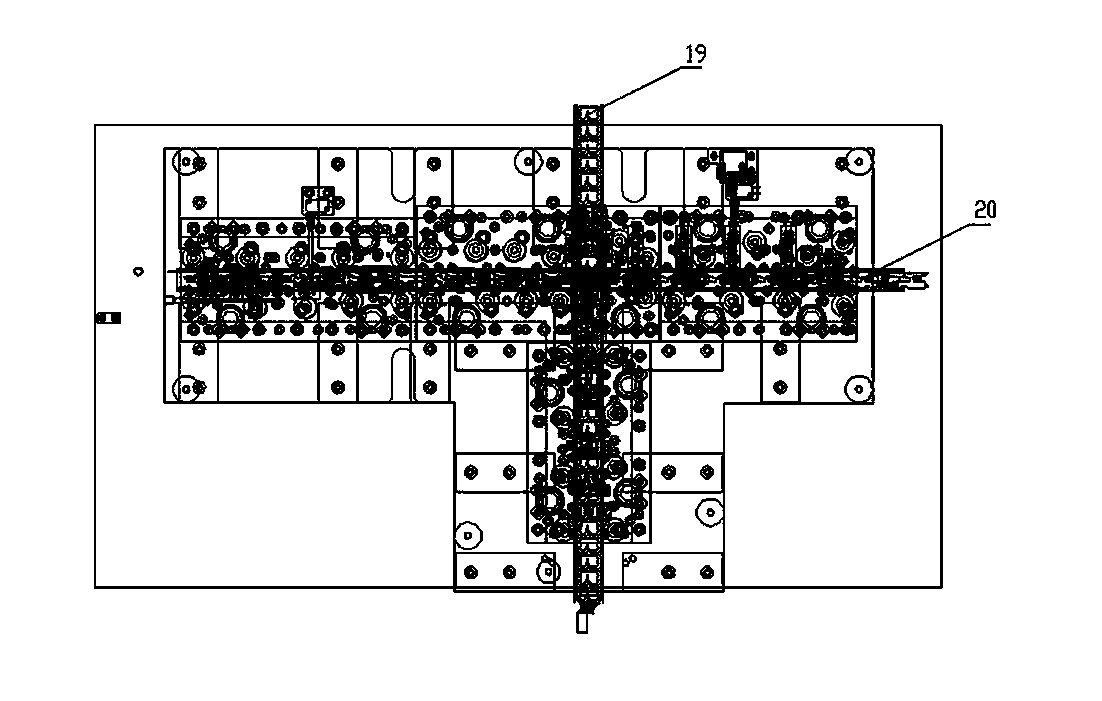

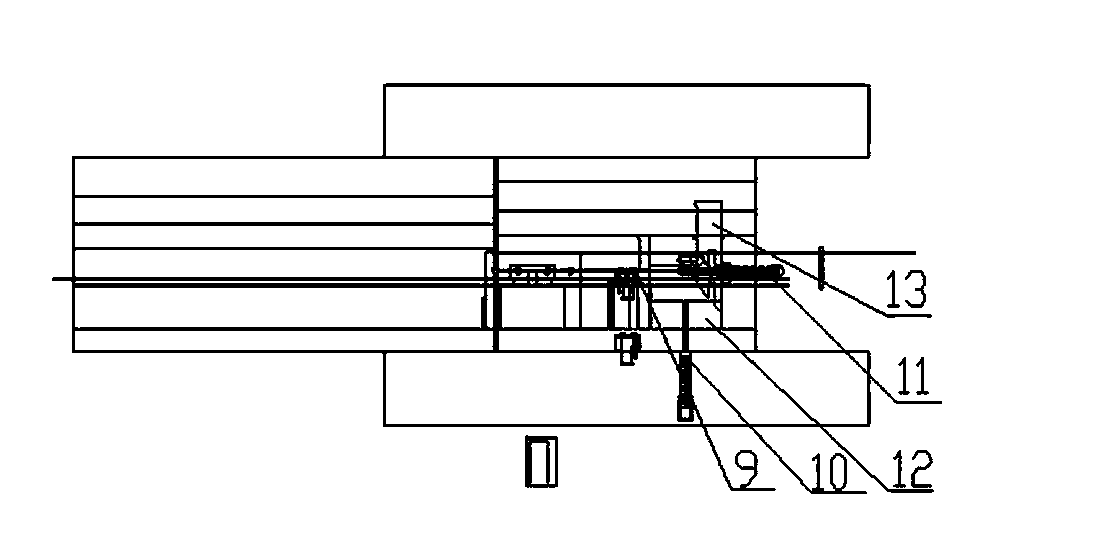

[0013] Embodiment: A multi-station high-precision metal bending part in-mold riveting mold, including an upper mold base 1, a lower mold base 2, an upper mold plate 3, a lower mold plate 4, a stripper plate 5, a backing plate 6, and a mutual The first and second in-mold feeding mechanisms for vertical feeding, the first and second feeding ports perpendicular to each other, the first and second forming mechanisms, riveting mechanism and blanking mechanism, based on the use direction, under the upper mold base 1 A backing plate 6 is provided, an upper formwork 3 is provided under the backing plate 6, a lower formwork 4 is arranged above the lower mold base 2, and a stripping plate 5 that can slide longitudinally elastically is provided on the lower formwork 4, respectively driving the first and second feeders. The material belt in the material port is fed and fed in a straight line, and the first and second forming mechanisms can punch and form the products on the mutually perpen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com