Patents

Literature

396results about "Portal frames" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

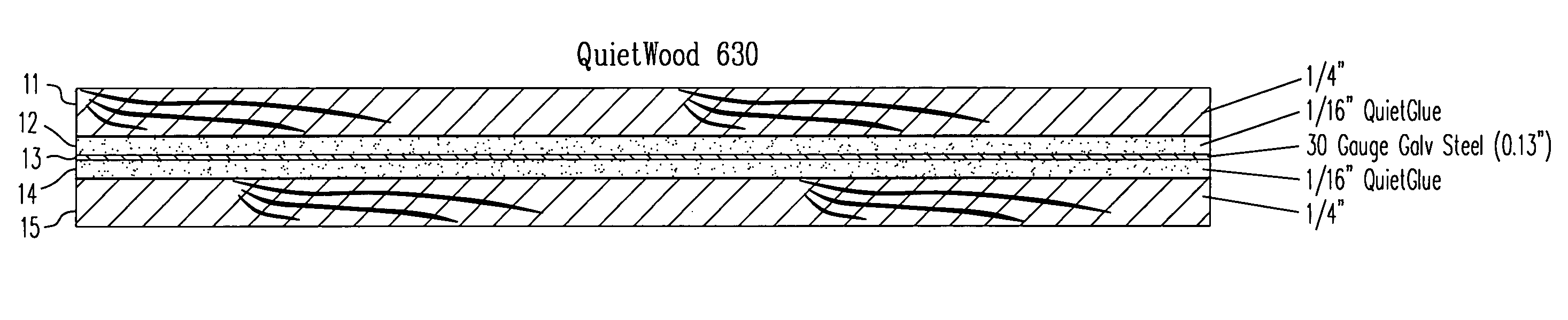

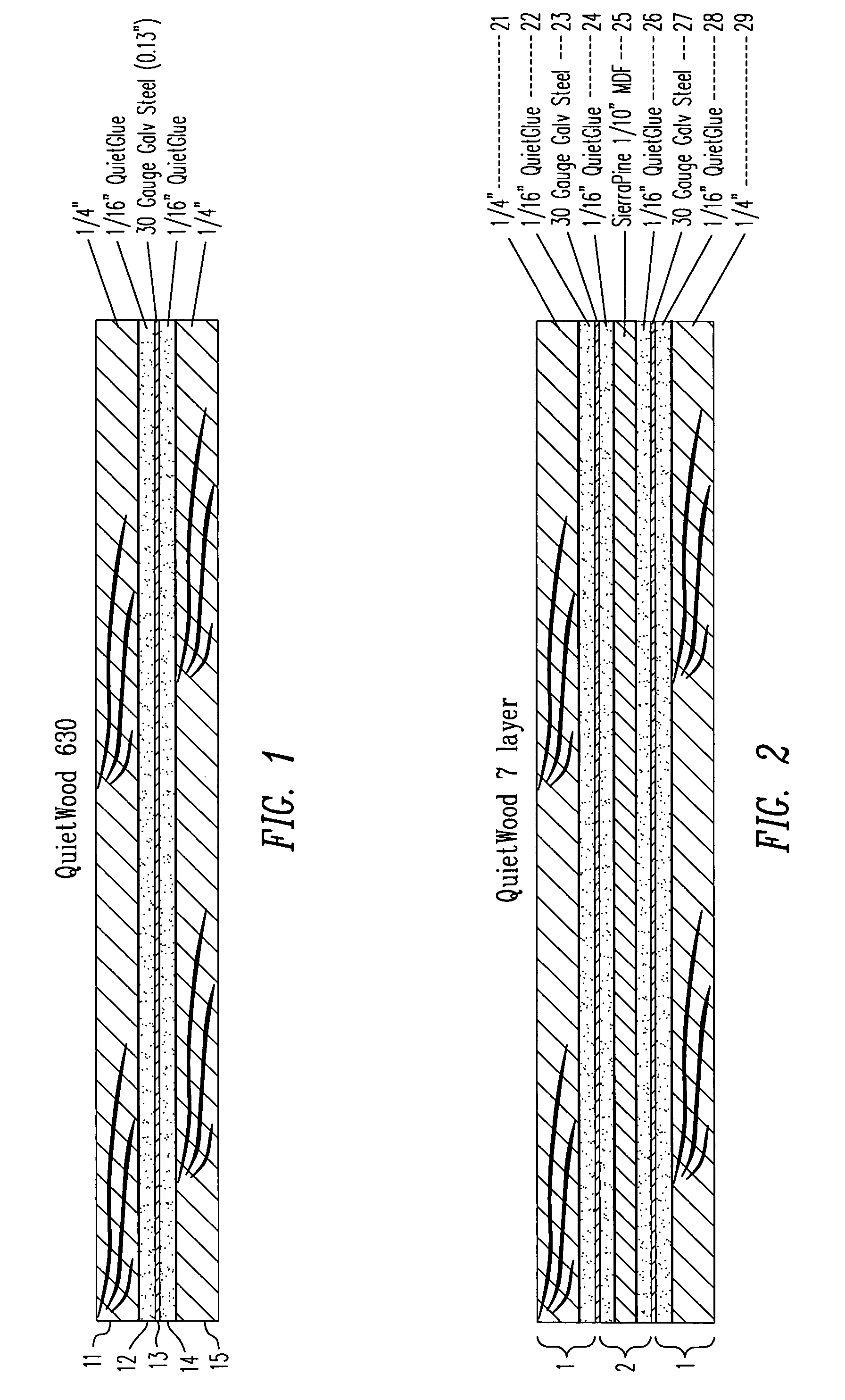

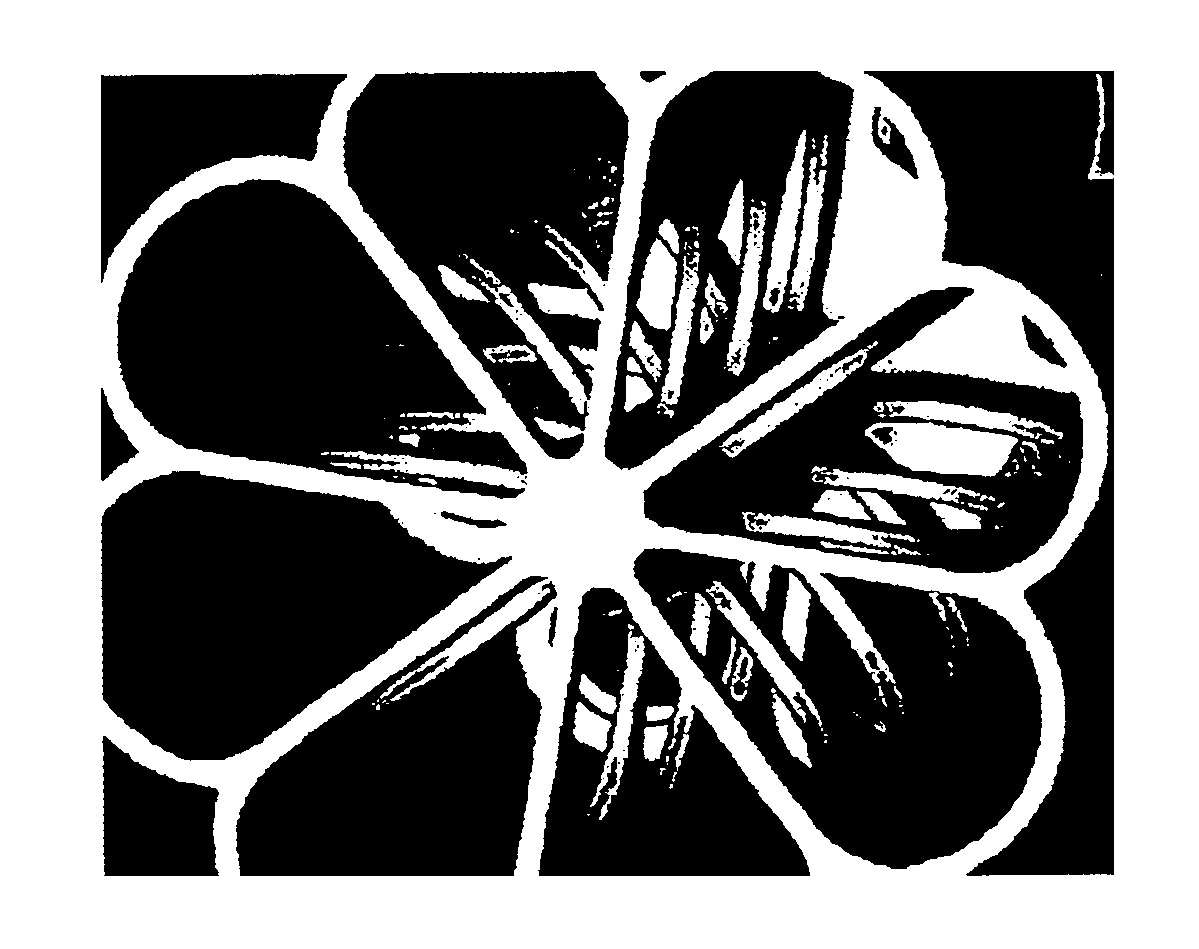

Acoustical sound proofing material and methods for manufacturing same

ActiveUS7181891B2Improve abilitiesReduce sound transmissionBuilding roofsCeilingsUltrasound attenuationCellulose

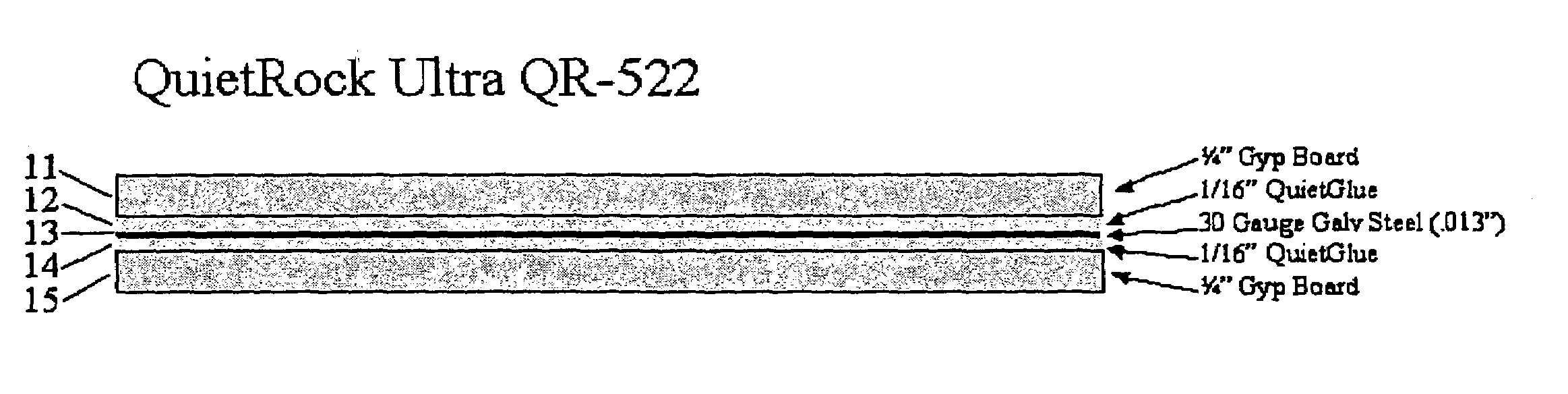

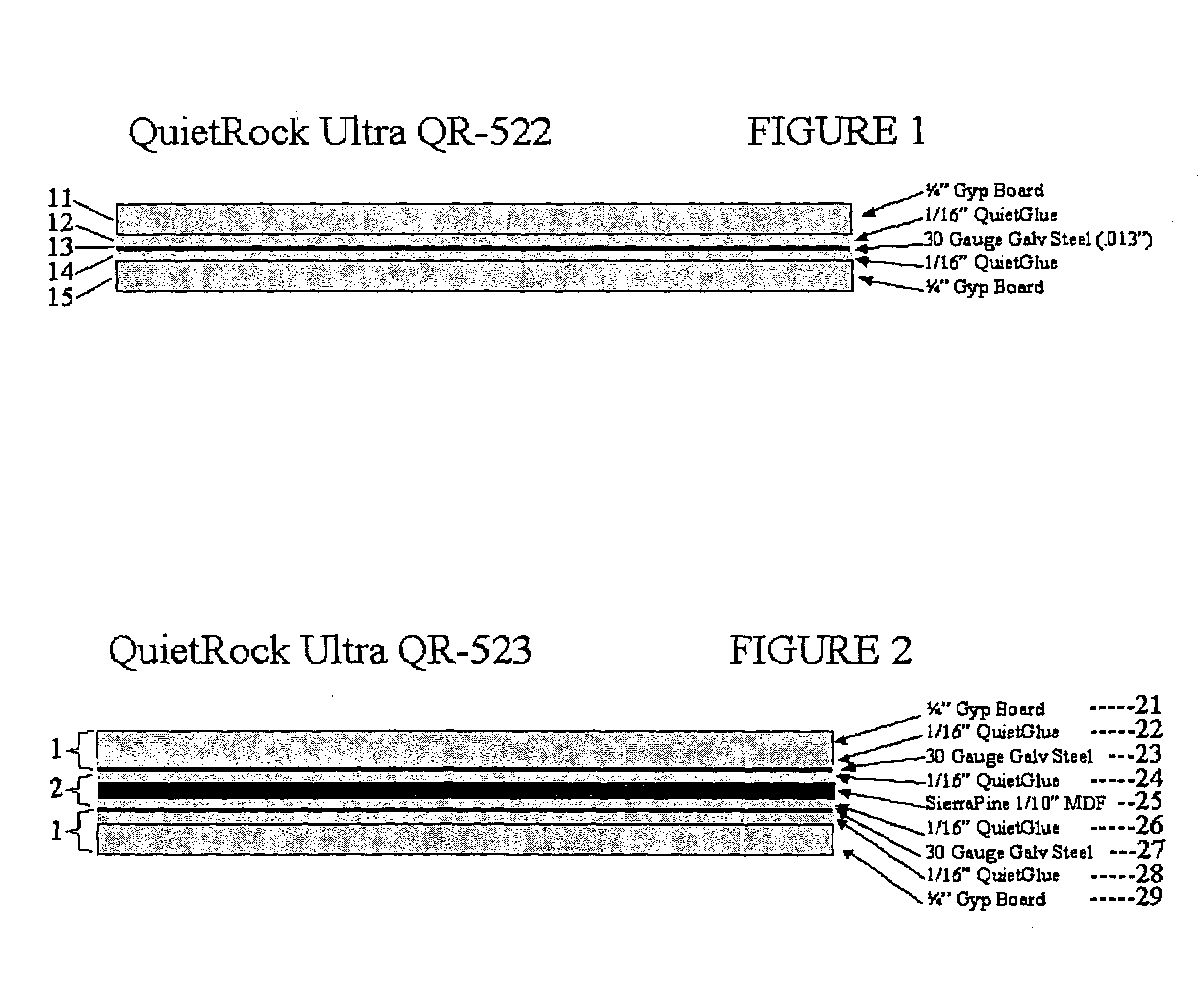

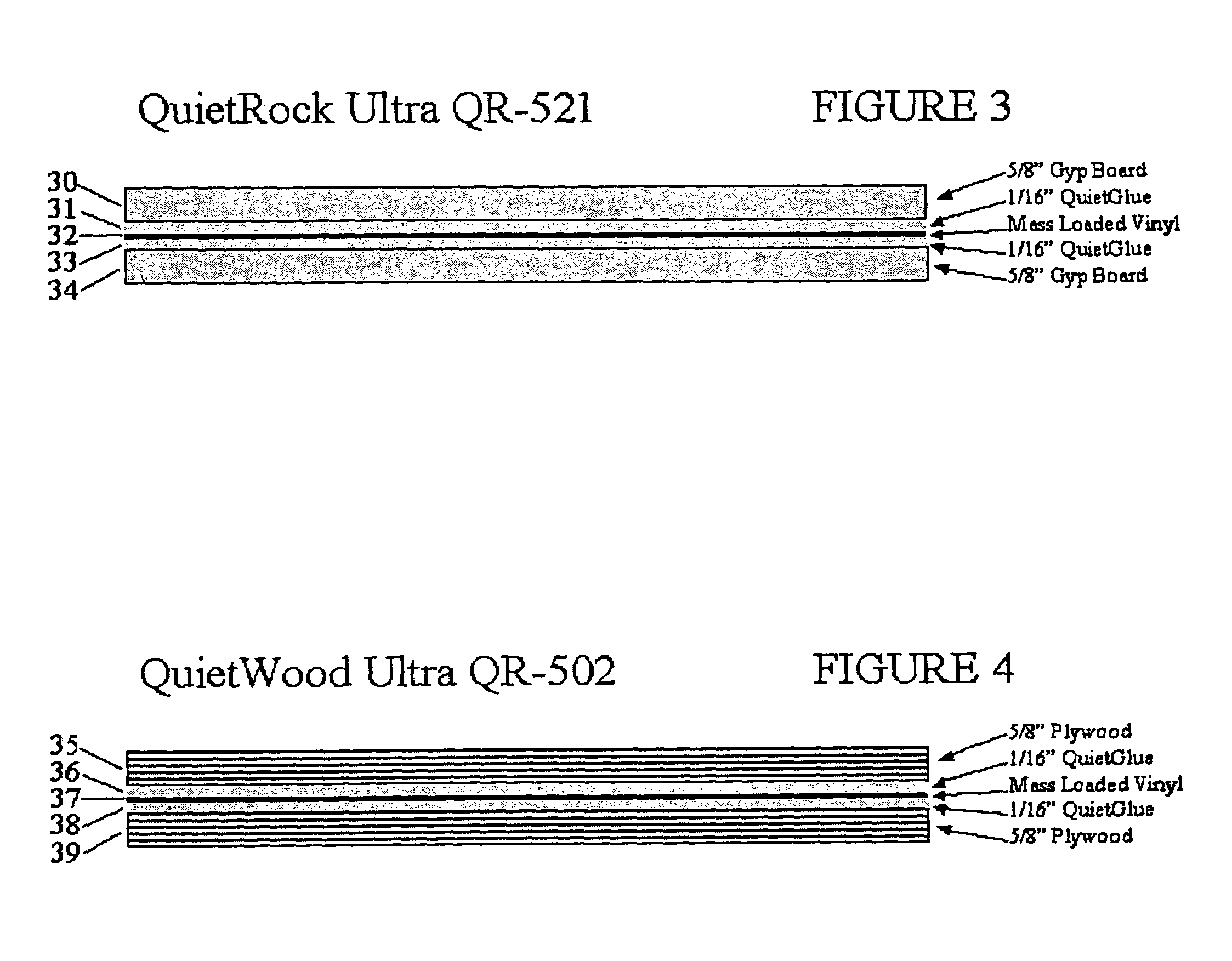

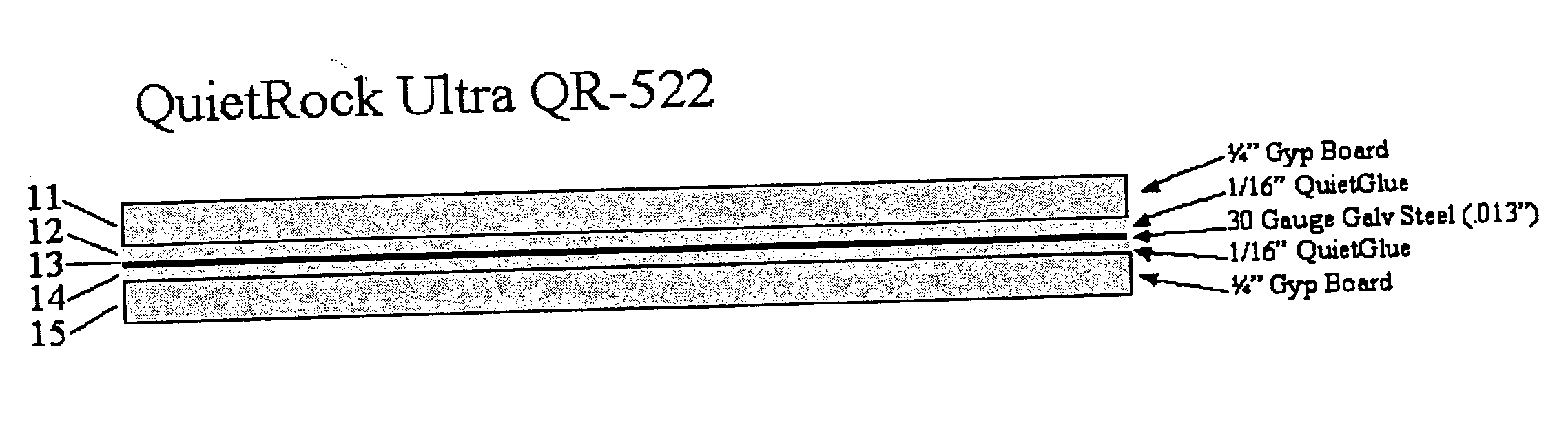

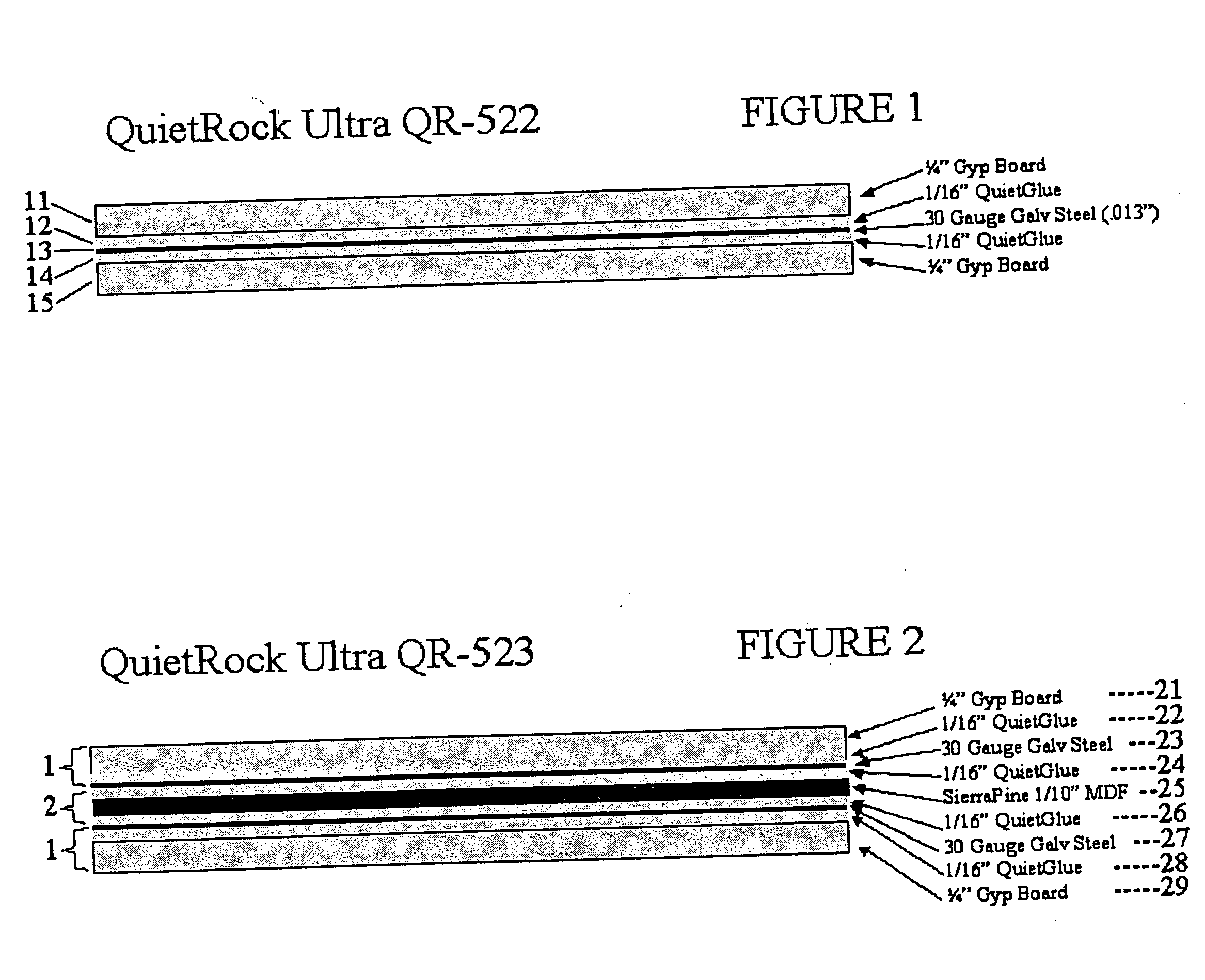

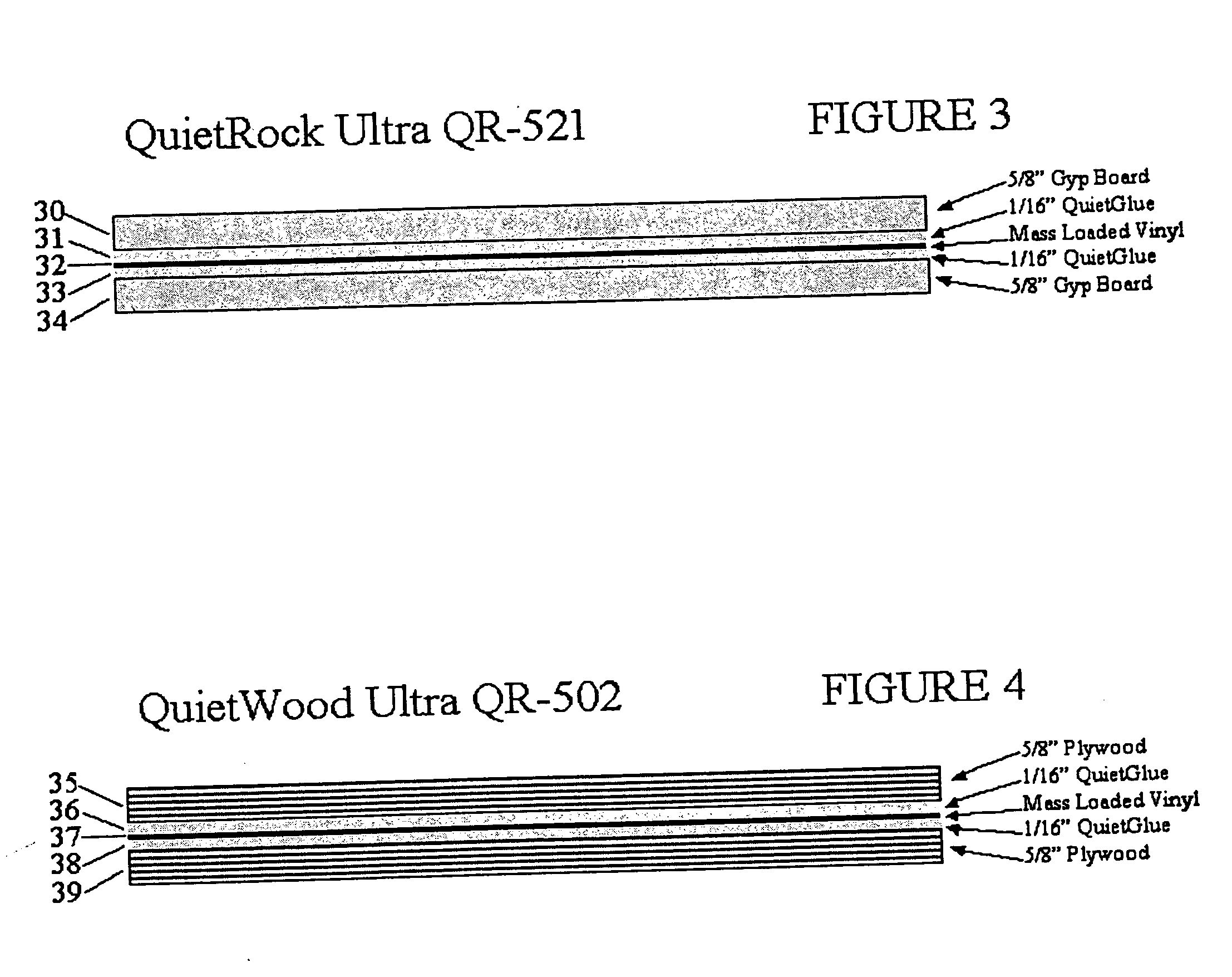

An improved acoustical damping wall (ceiling or floor) or door material comprises a laminar structure having as an integral part thereof one or more layers of viscoelastic material which also functions as a glue and one or more constraining layers, such as metal, cellulose, wood, or petroleum-based products such as plastic, vinyl, plastic or rubber. In one embodiment, standard wallboard, typically gypsum, comprises the external surfaces of the laminar structure; and one or more constraining layers are fabricated between the gypsum exterior. The resulting structure improves the attenuation of sound transmitted through the structure.

Owner:PACIFIC COAST BUILDING PRODS

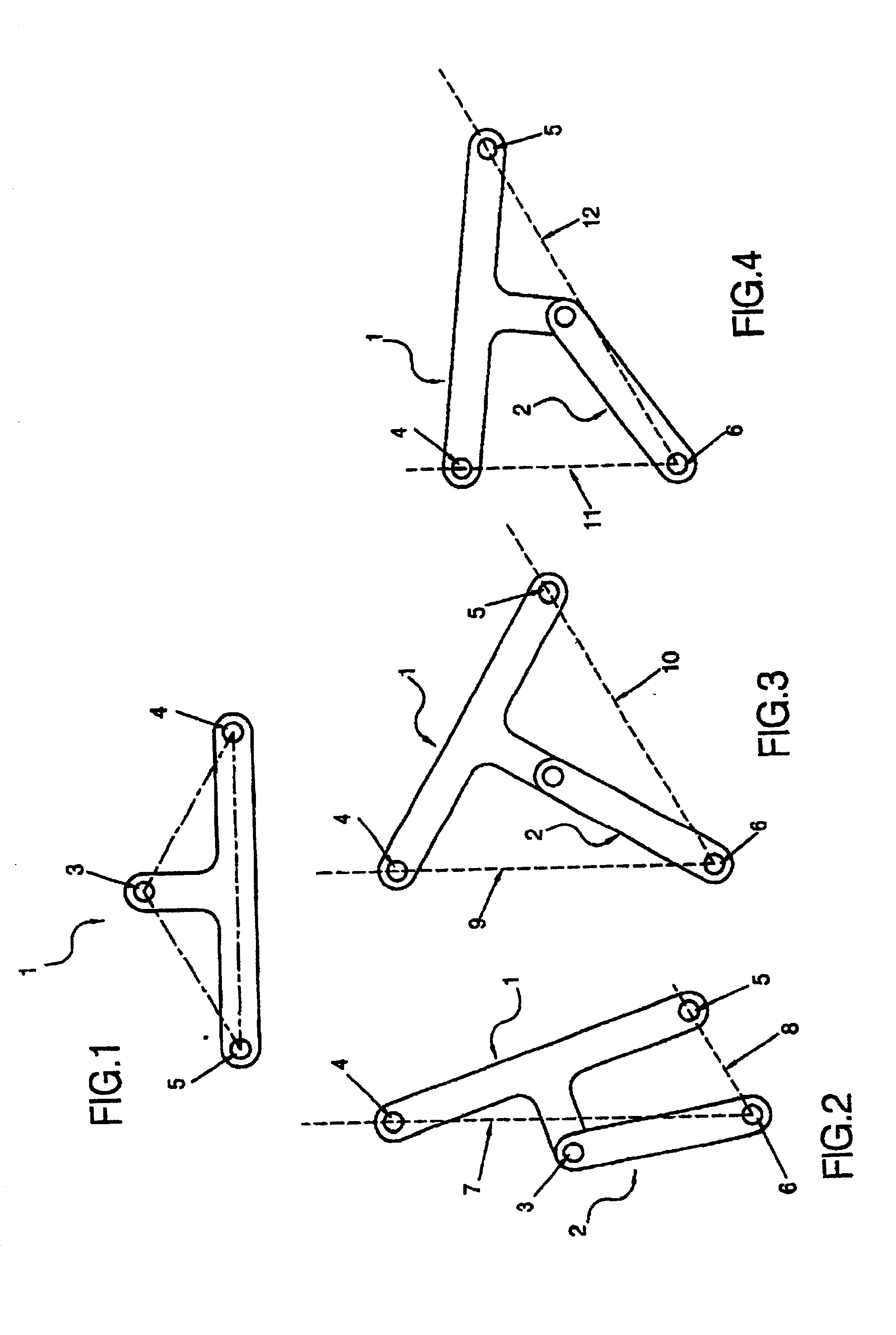

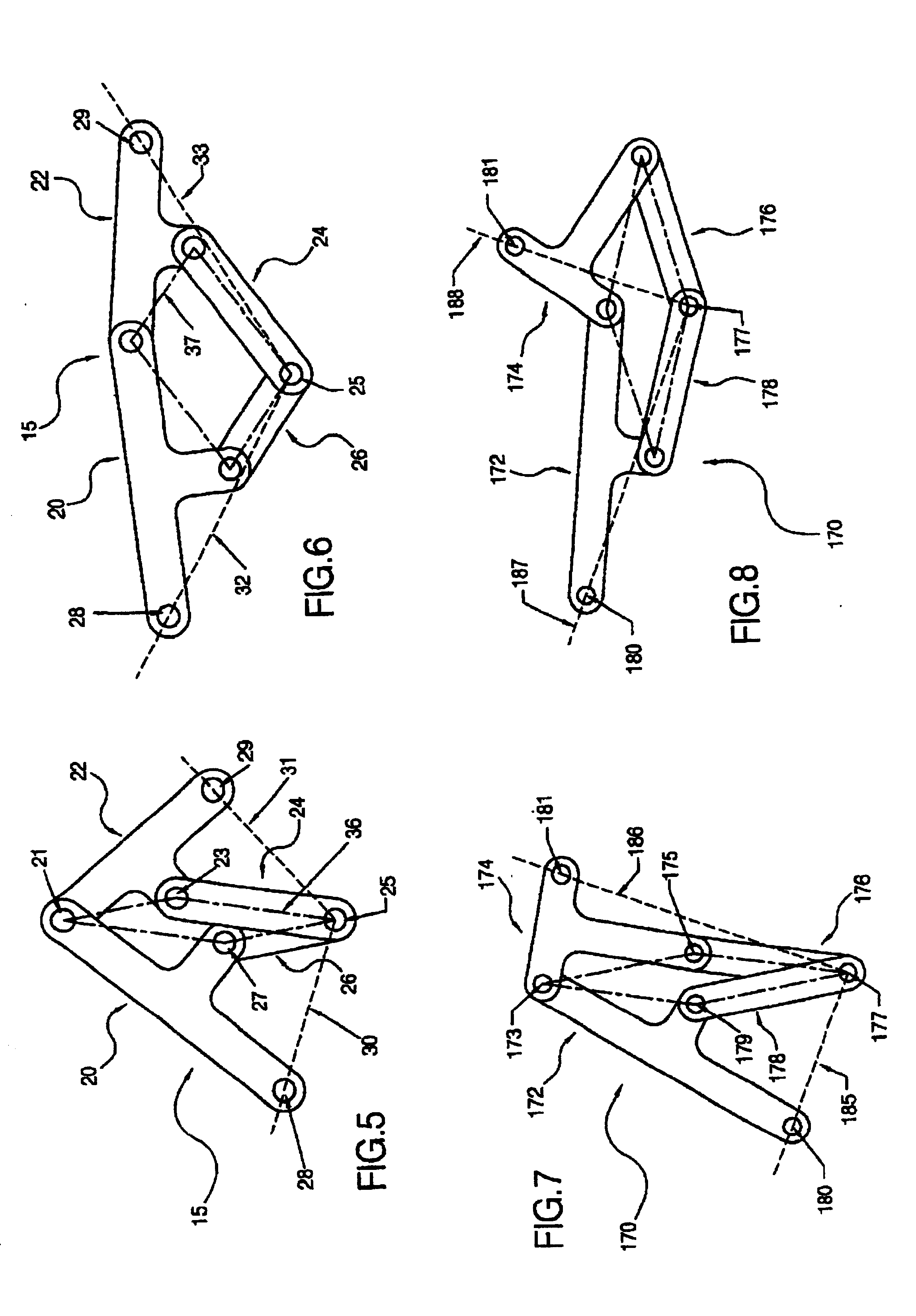

Foldable member

InactiveUS6374565B1Weight increaseDimensional instabilityBuilding roofsCosmonautic vehiclesMechanical engineeringEngineering

Owner:FOSTER-MILLER

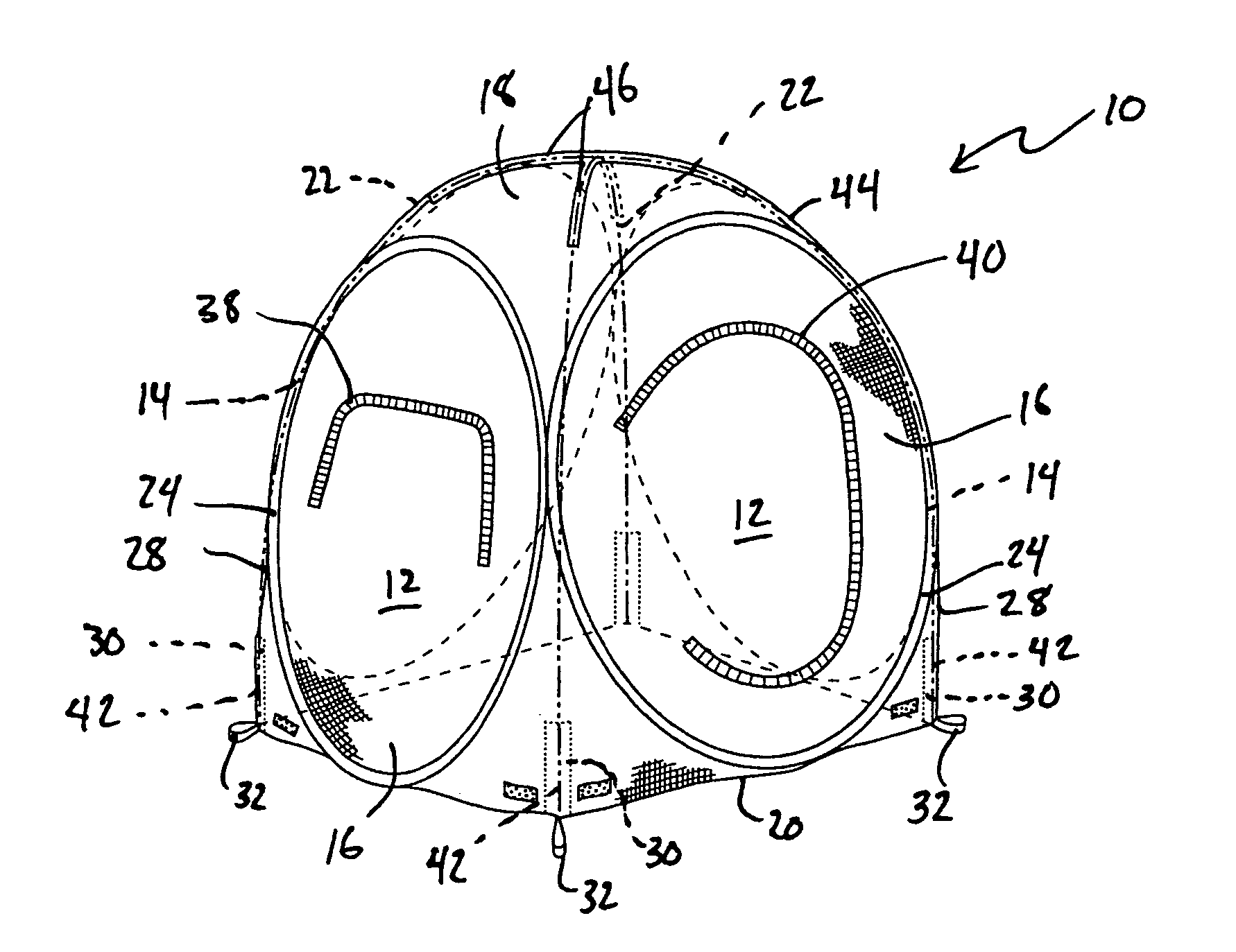

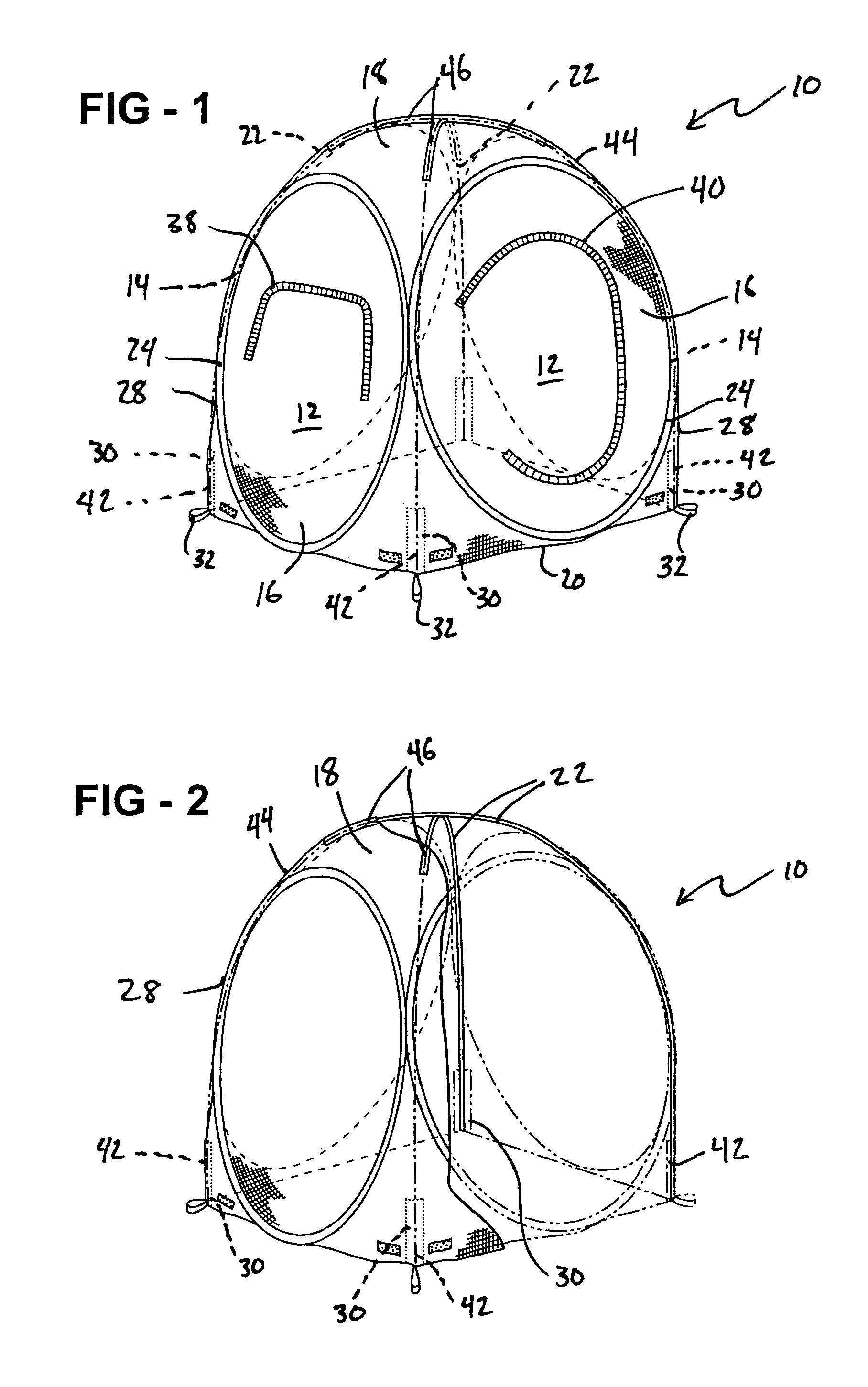

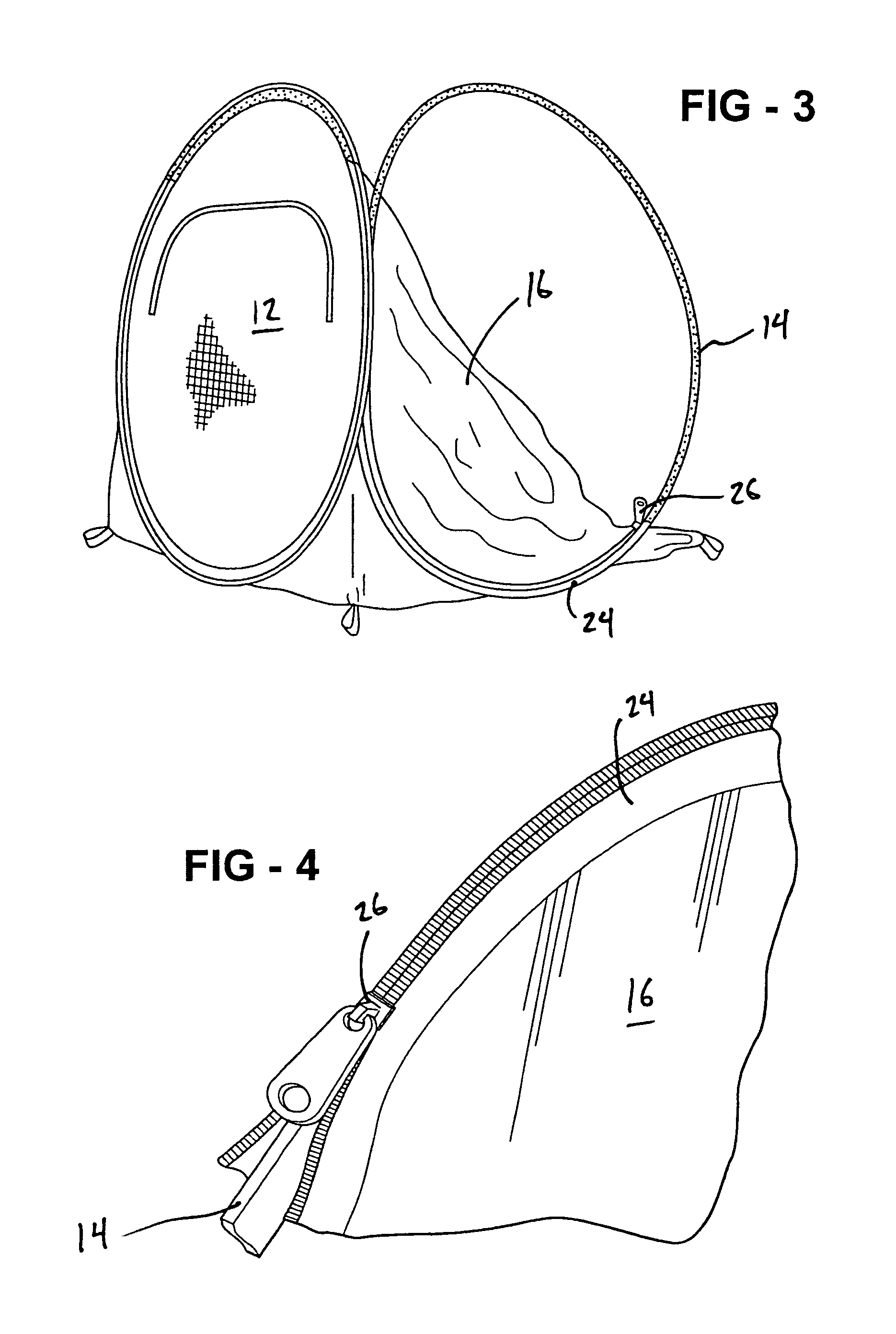

Collapsible structure with top supporting elements

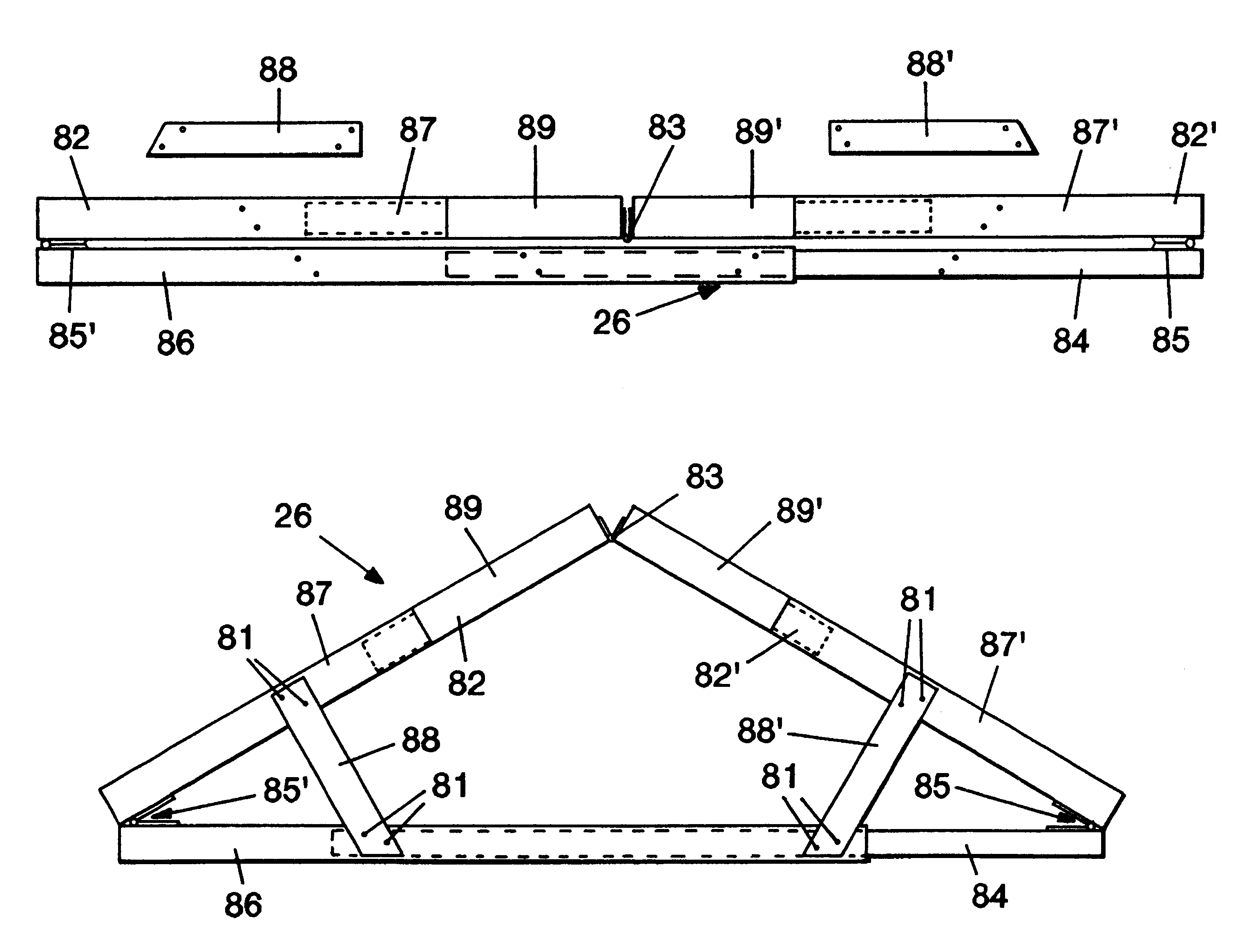

The invention is a collapsible structure comprising a plurality of panel elements, each having a coilable frame element and flexible material attached to the frame element. The panel elements are joined to define an enclosure having a roof portion and a bottom perimeter. The bottom perimeter rests on a supporting surface. The structure has at least one roof support rod having a first end and a second end. The first end of the at least one roof support rod is attached to a first location on the bottom perimeter, and the second end of the at least one roof support rod is attached to a second location on the bottom perimeter. The at least one roof support rod is in supporting contact with the roof portion of the enclosure.

Owner:EVOLVED INGENUITY

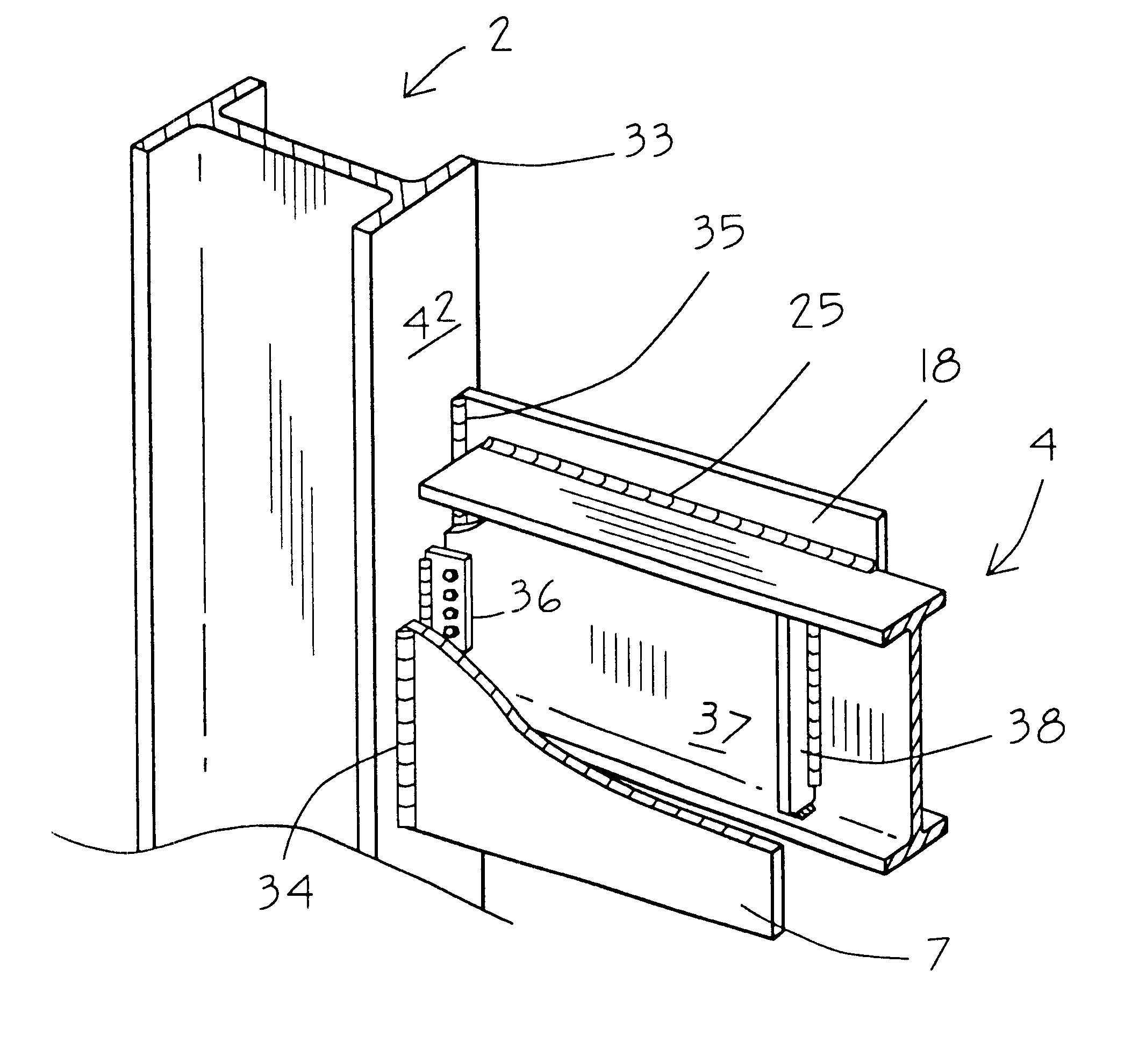

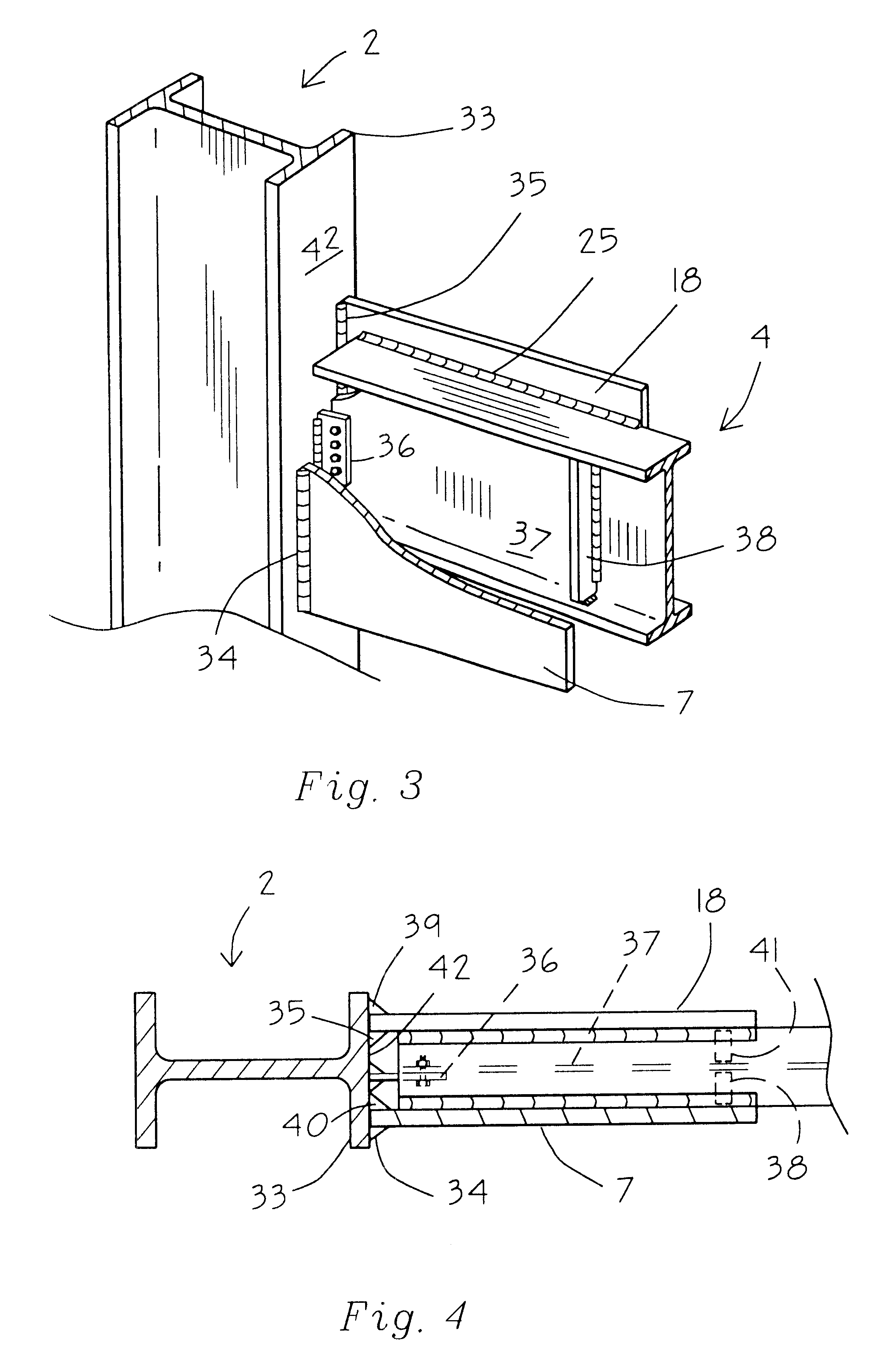

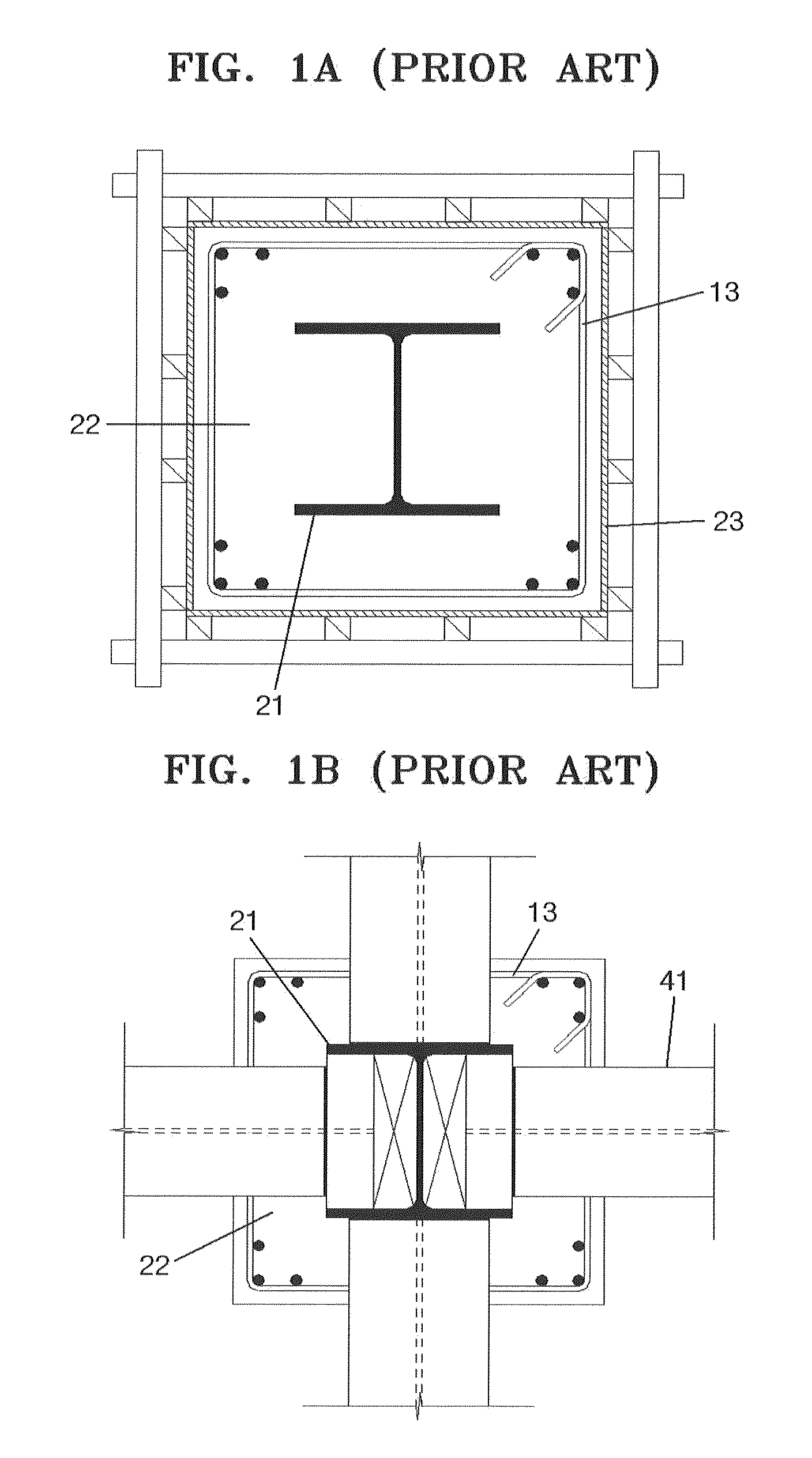

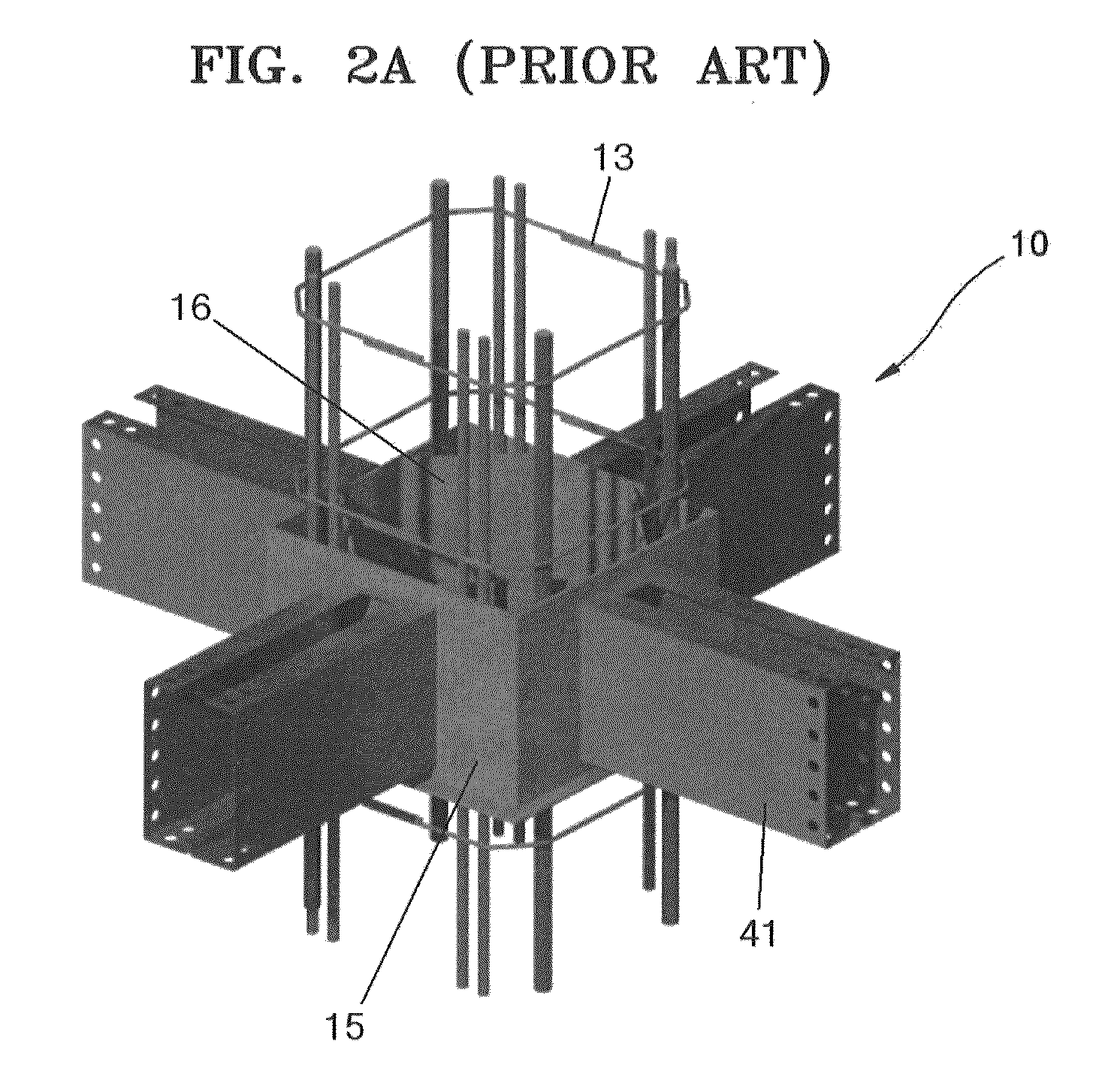

Gusset plates connection of beam to column

InactiveUS6591573B2Improve rendering capabilitiesImprove stabilityBuilding roofsArched girdersGusset plateEngineering

This invention relates to columnar, "primary support" for a building or other heavy structure, in which a beam is connected to a column in a strong, moment-resisting connection comprised of two gusset plates welded to a flange or the face of the flange of the column and welded to the beam or attached to cover plates fixedly attached to the beam.

Owner:MITEK HLDG INC

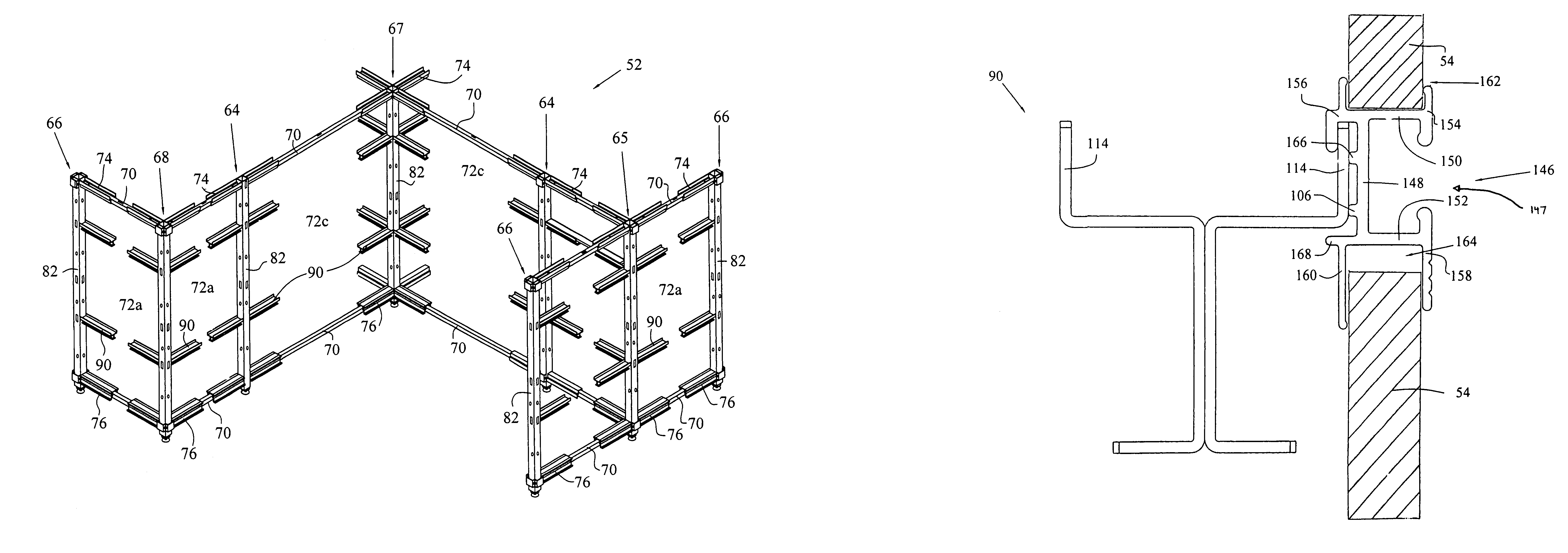

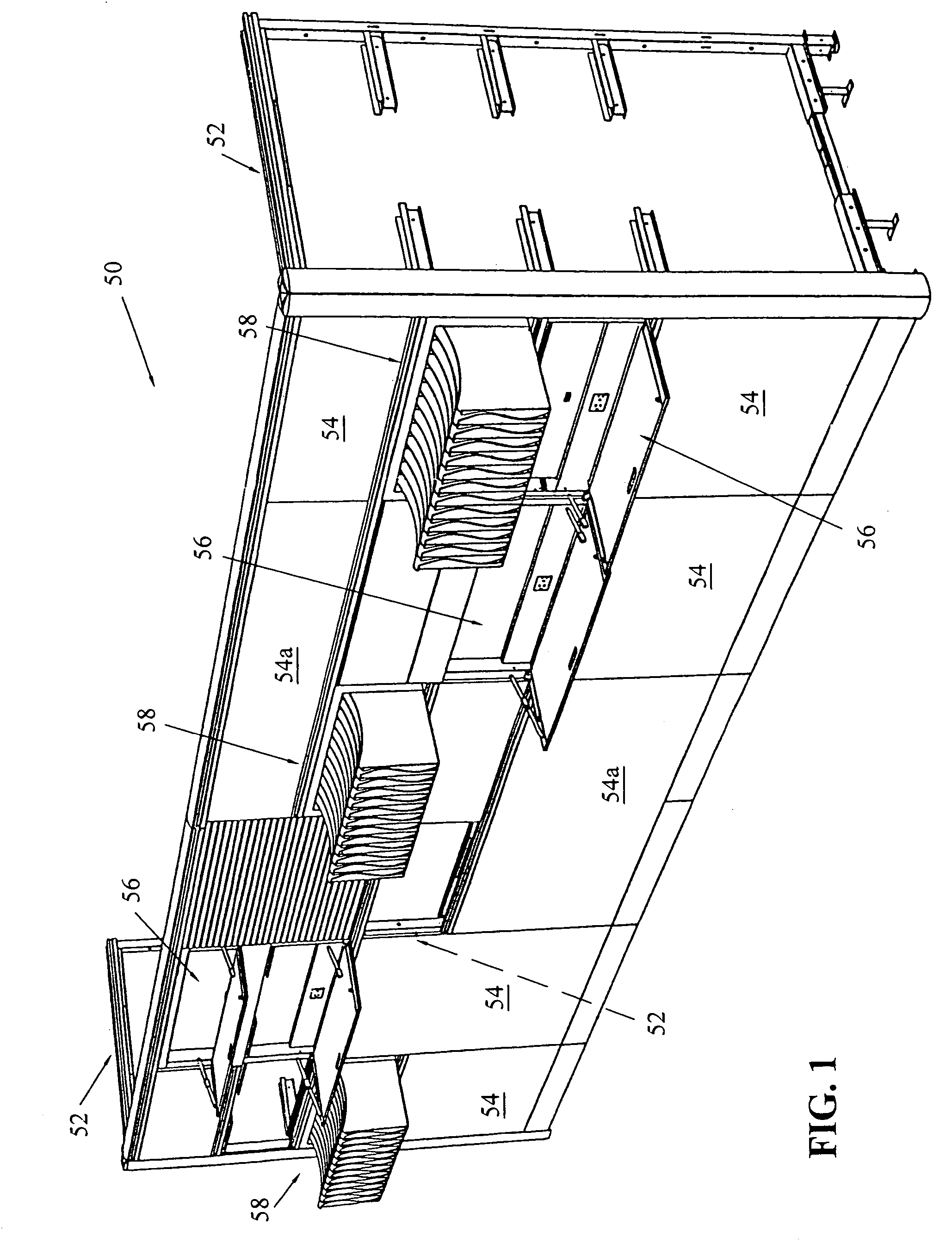

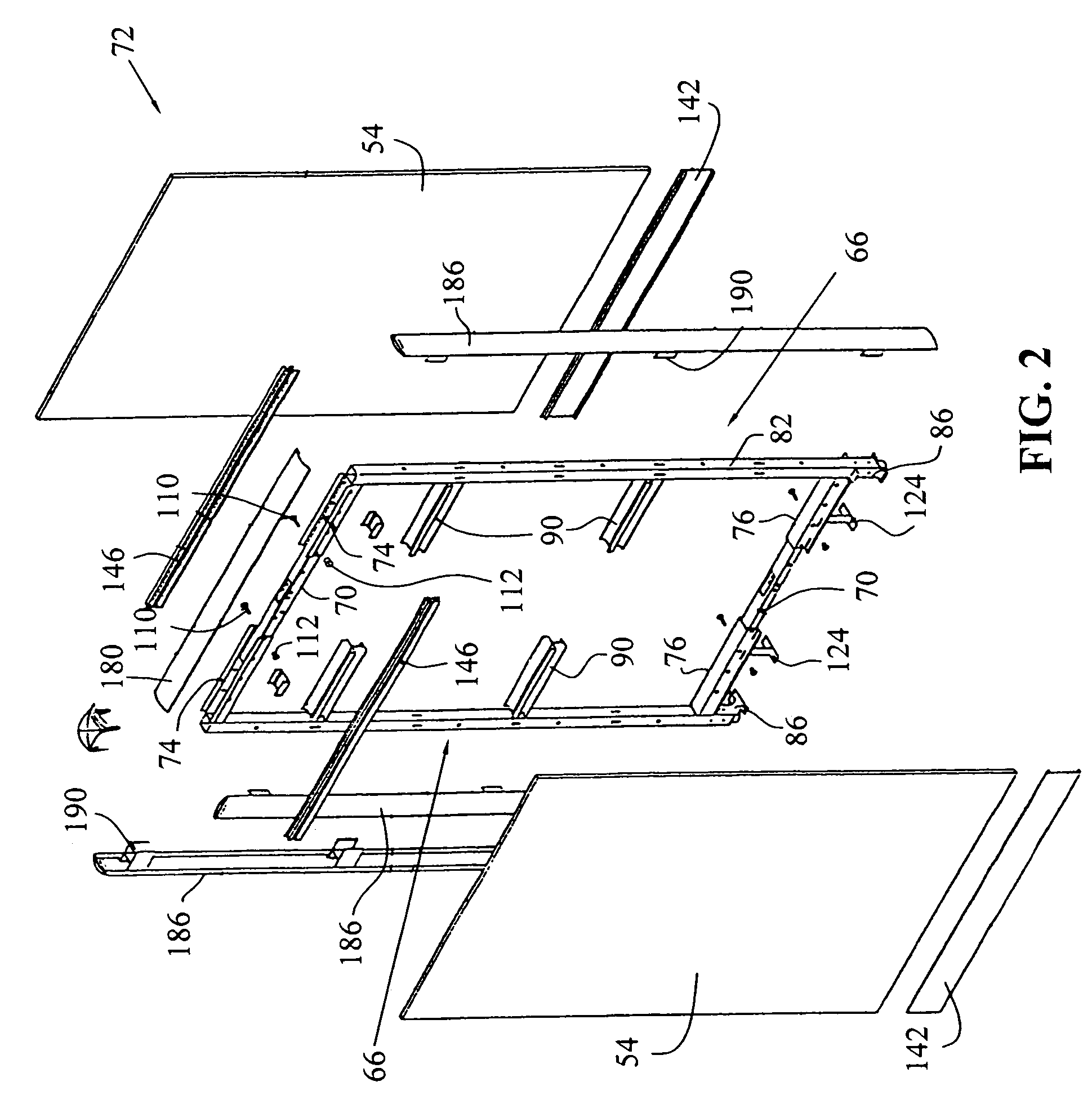

Partition system

InactiveUS7150127B2Easily attachable to the frameworkEasy to changeCorner/edge jointsLight protection screensBrickEngineering

Owner:KIMBALL INTERNATIONAL

Acoustical sound proofing material and methods for manufacturing same

ActiveUS20060057345A1Reduce sound transmissionImprove abilitiesBuilding roofsCoatingsCelluloseEngineering

An improved acoustical damping wall (ceiling or floor) or door material comprises a laminar structure having as an integral part thereof one or more layers of viscoelastic material which also functions as a glue and one or more constraining layers, such as metal, ceramics, composites, cellulose, wood, or petroleum-based products such as plastic, vinyl, plastic or rubber.

Owner:PACIFIC COAST BUILDING PRODS

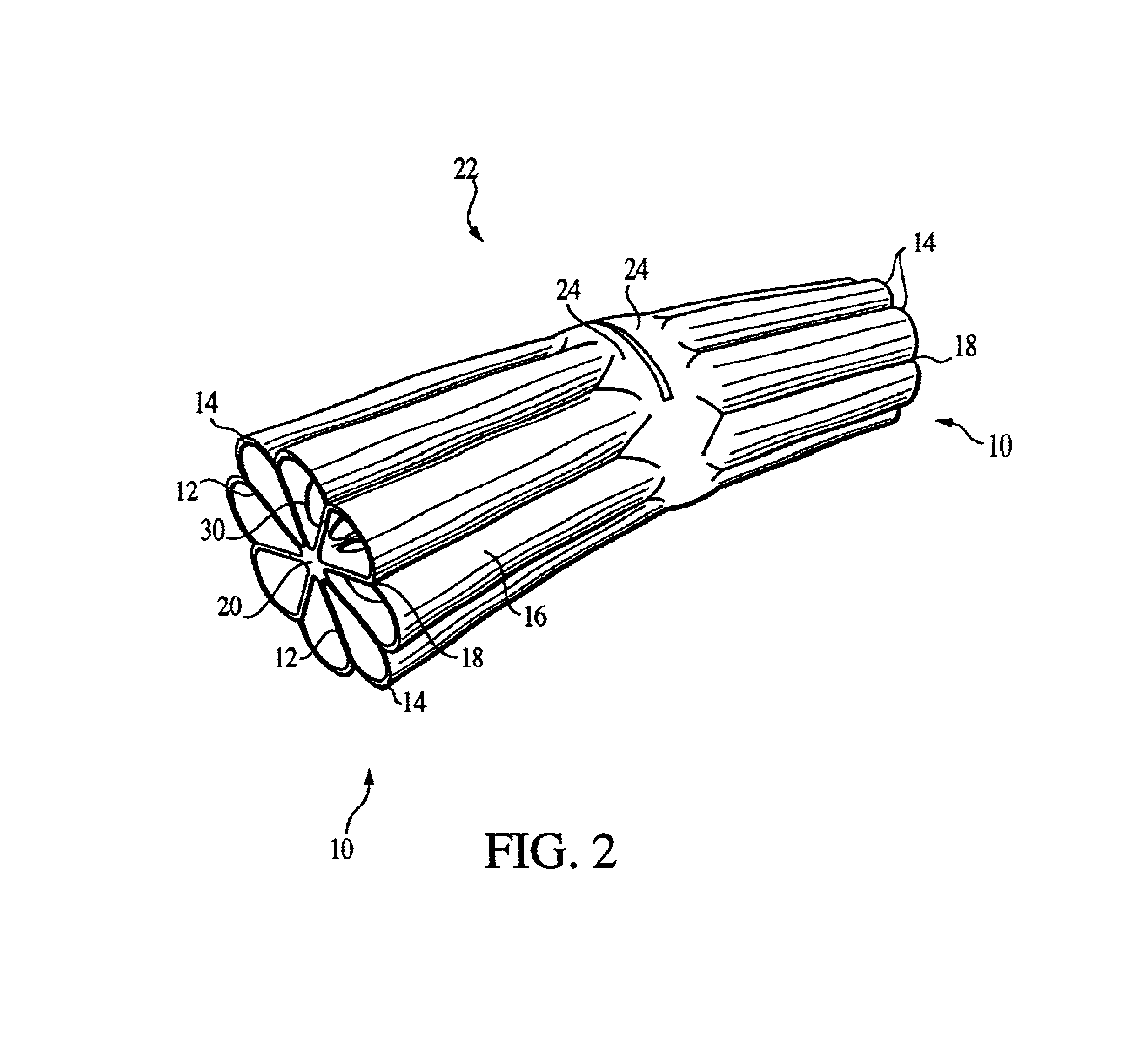

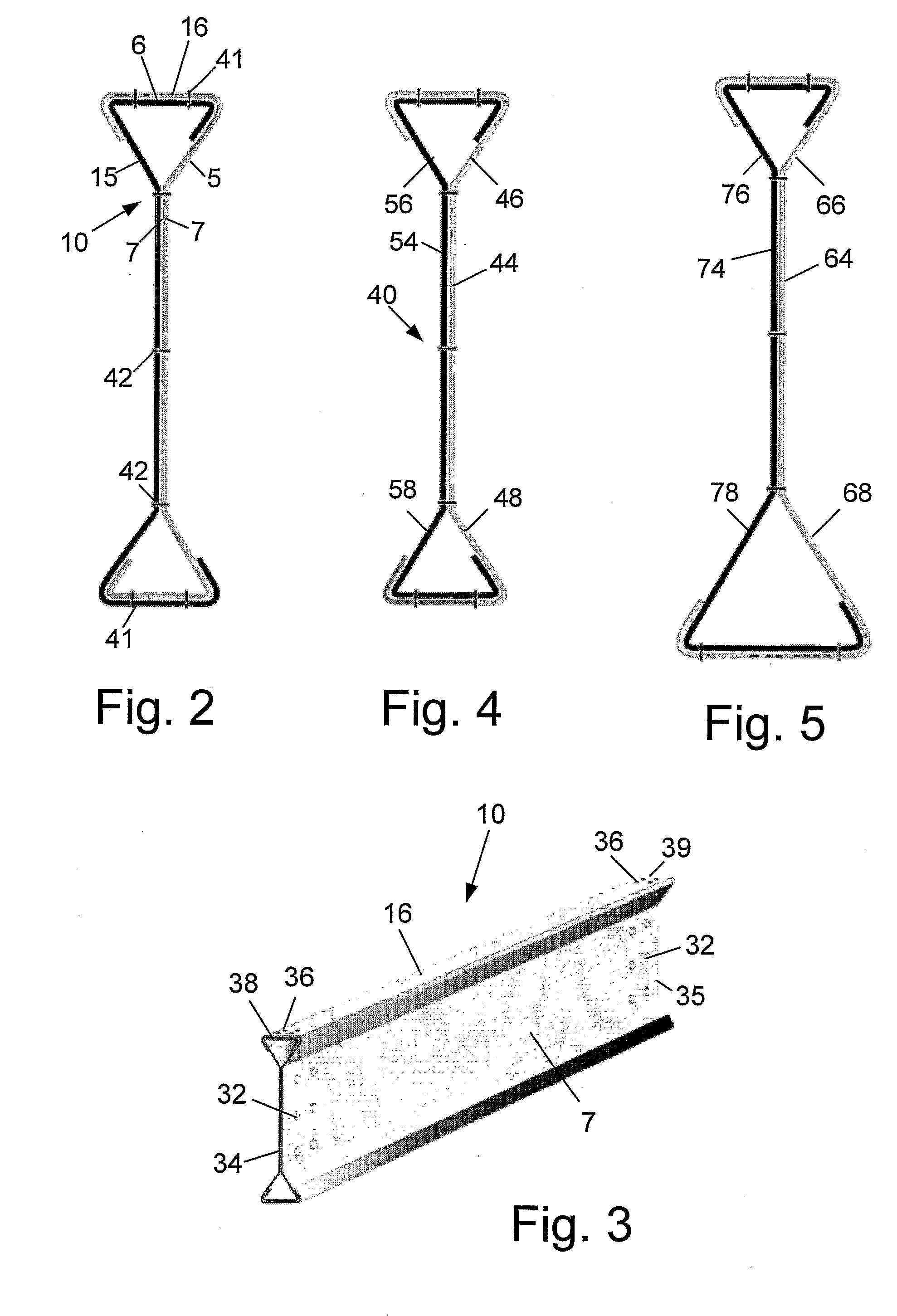

Unitary metal structural member with internal reinforcement

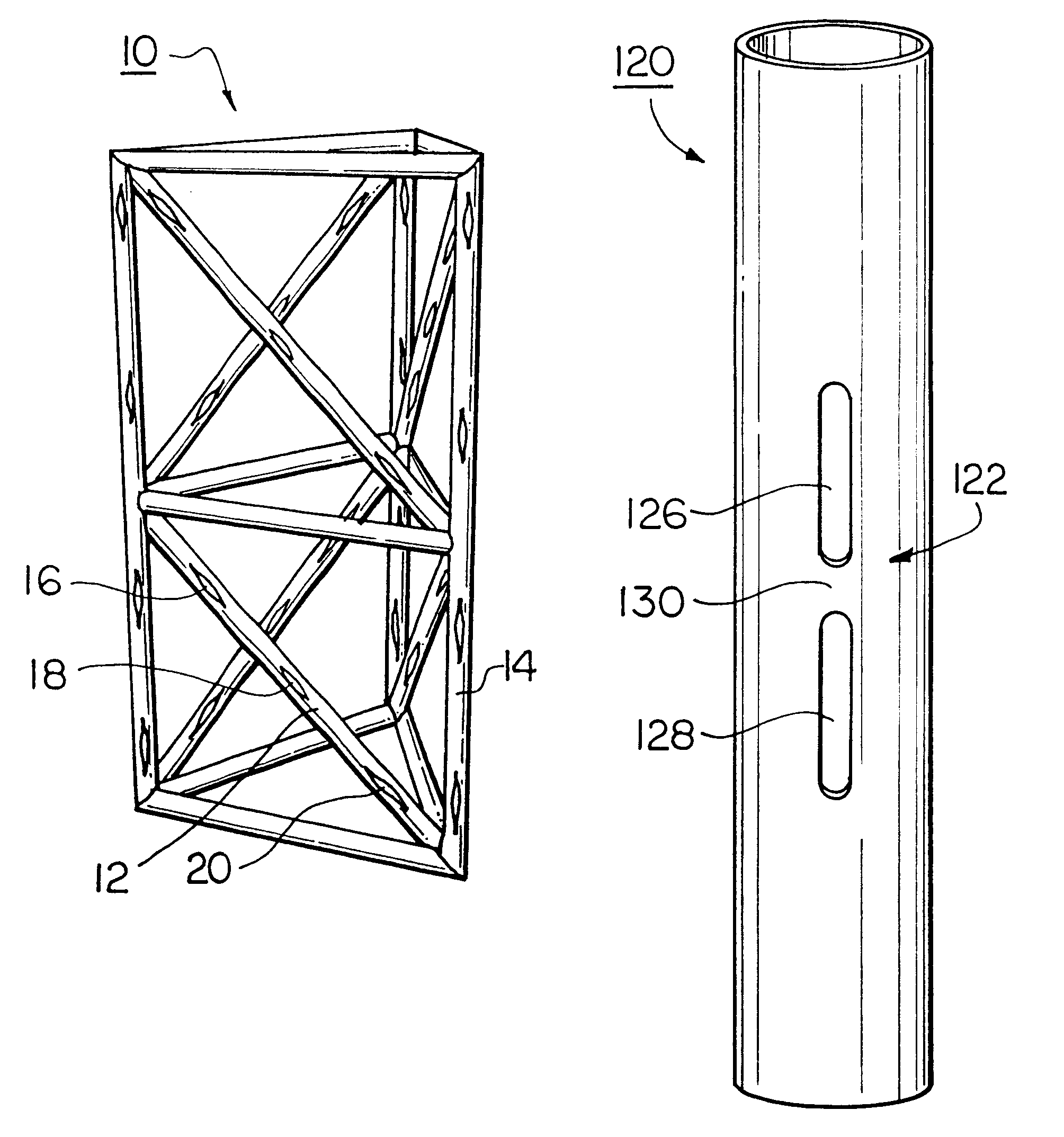

A metal unitary structural member for structural support. The member includes a plurality of web portions extending radially from each other and extending with each other in an axial direction, and a plurality of outer portions extending in an axial direction with the web portions and between the web portions in cross-section. The plurality of outer portions defines an outer surface of the member. The web portions may extend from a substantially central portion. The plurality of web portions may include perforations.

Owner:ROTHEROE KEVIN CHAITE

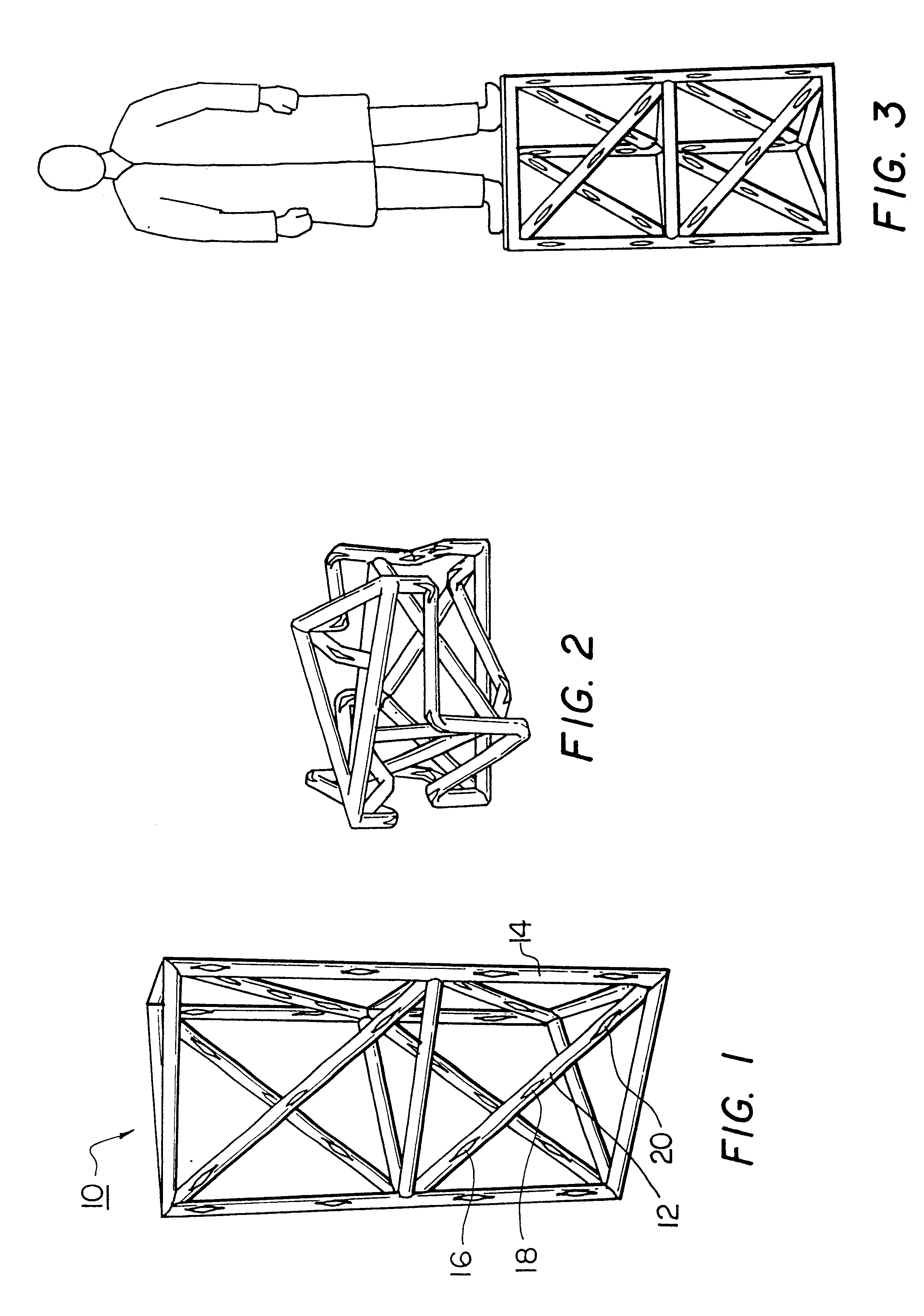

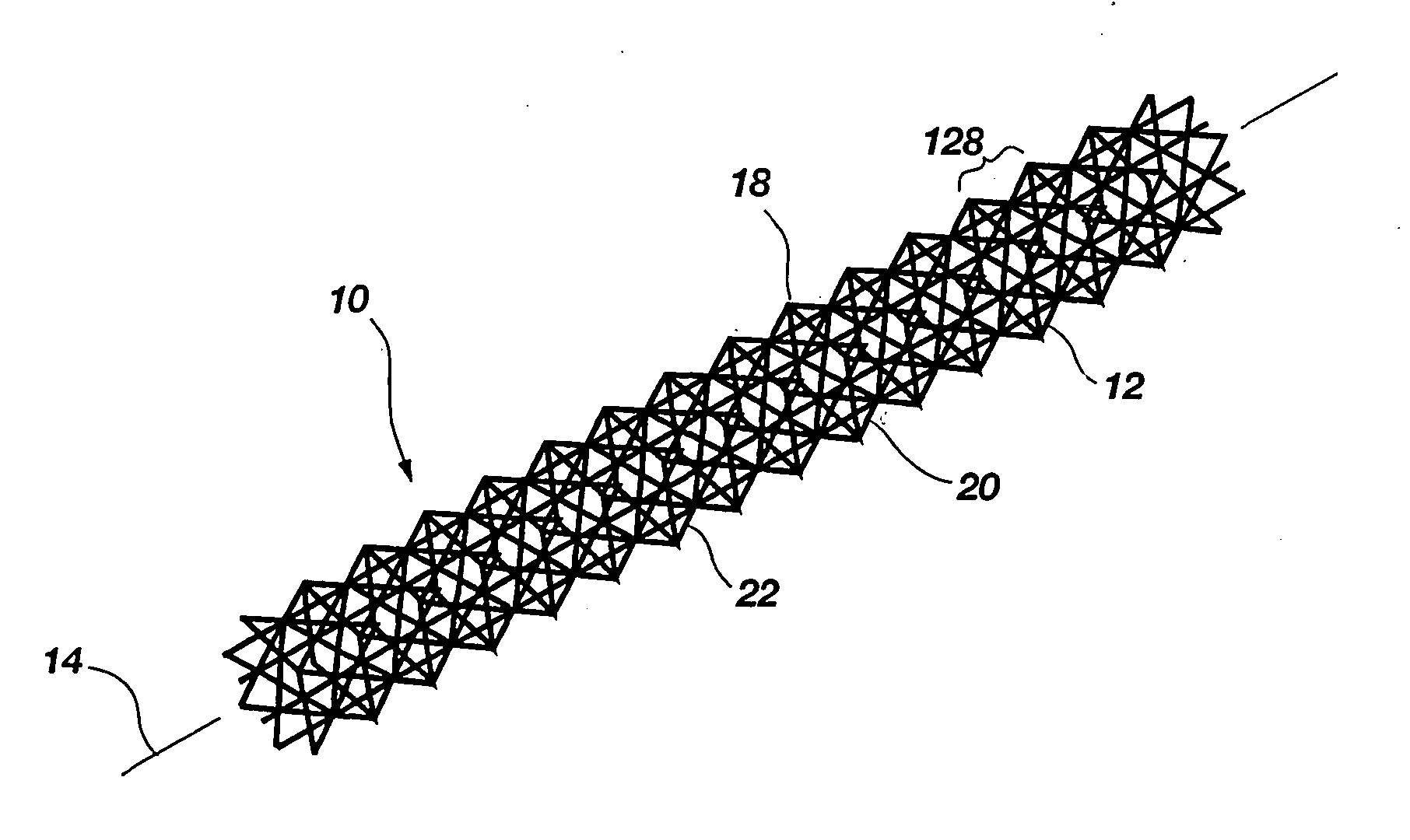

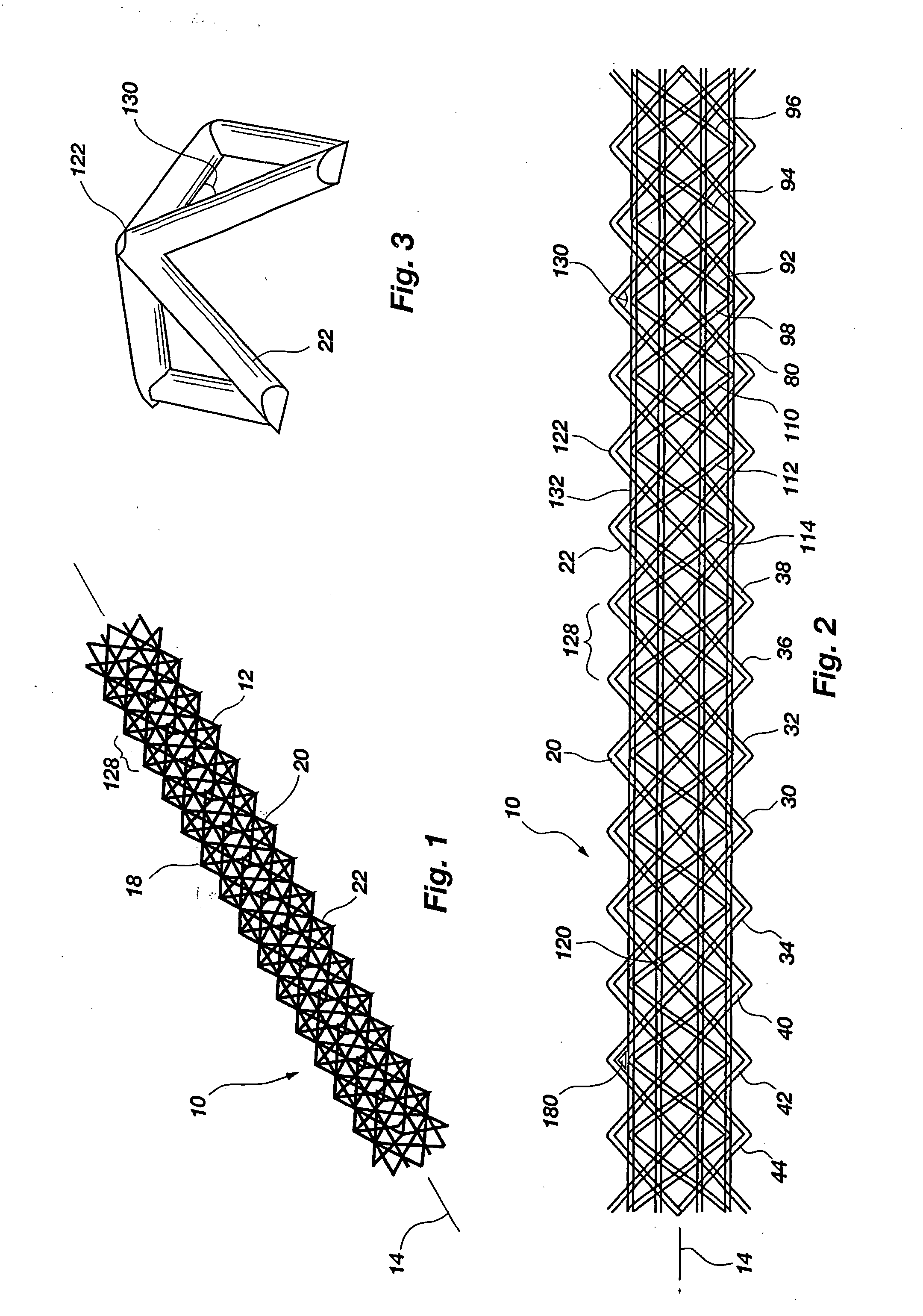

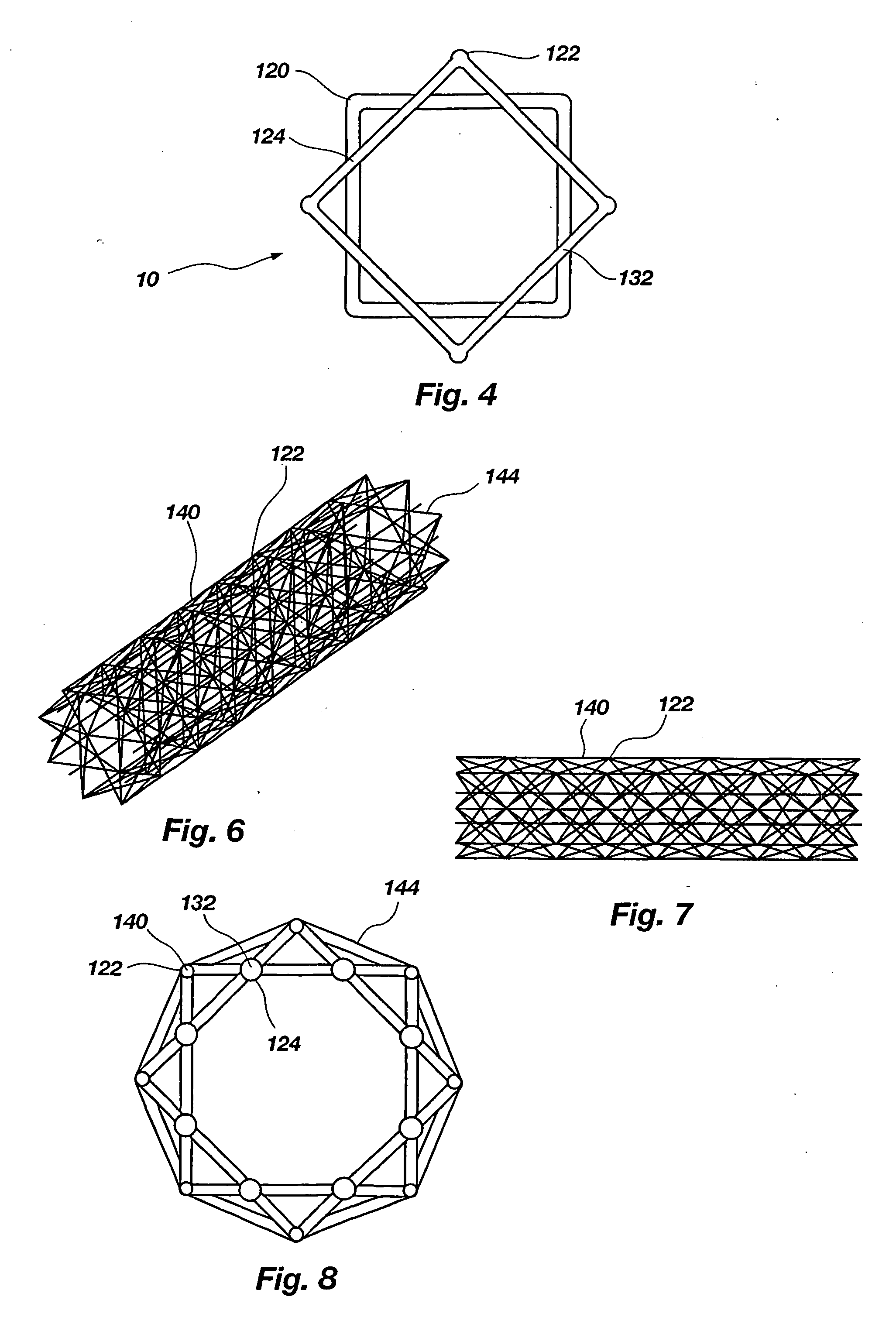

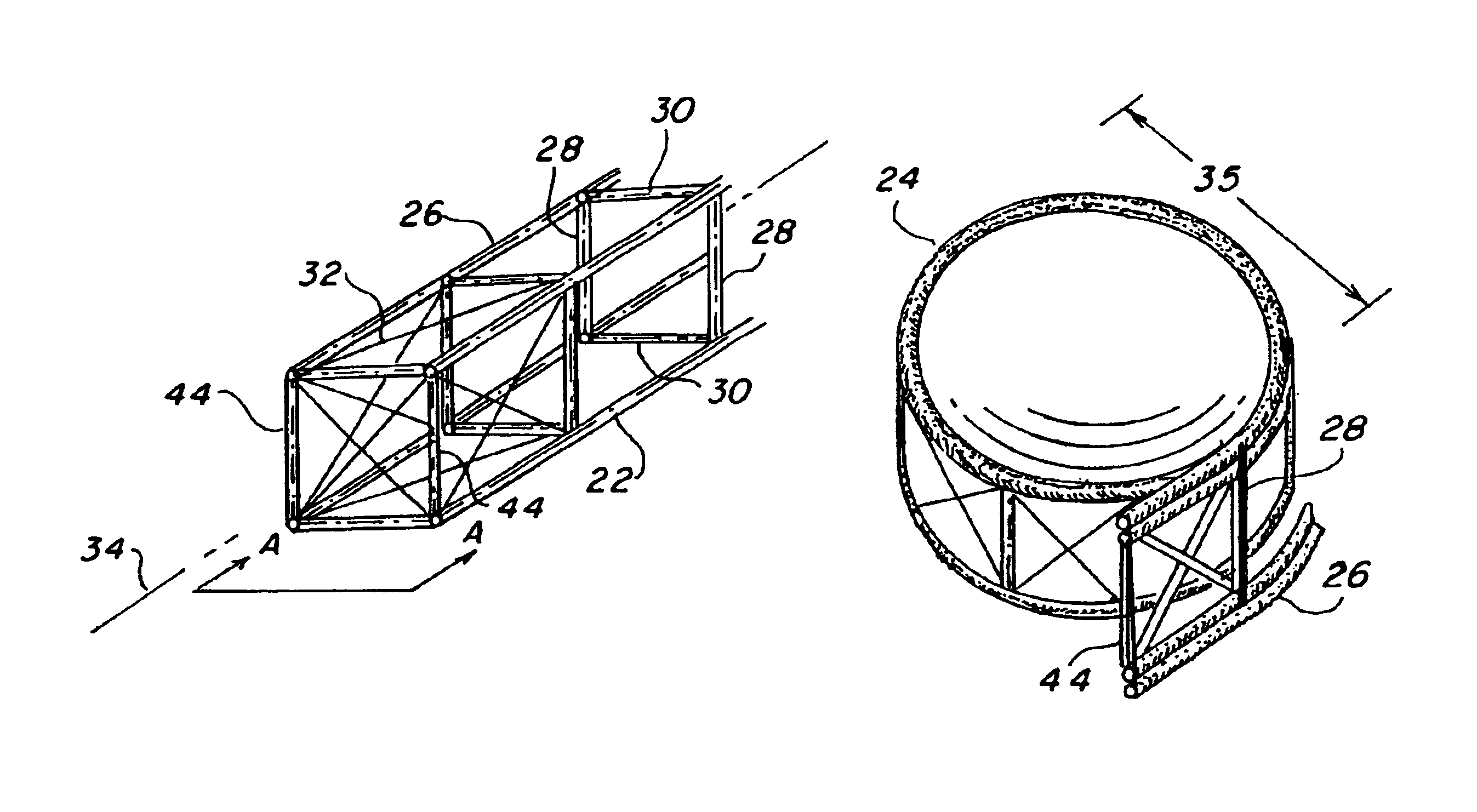

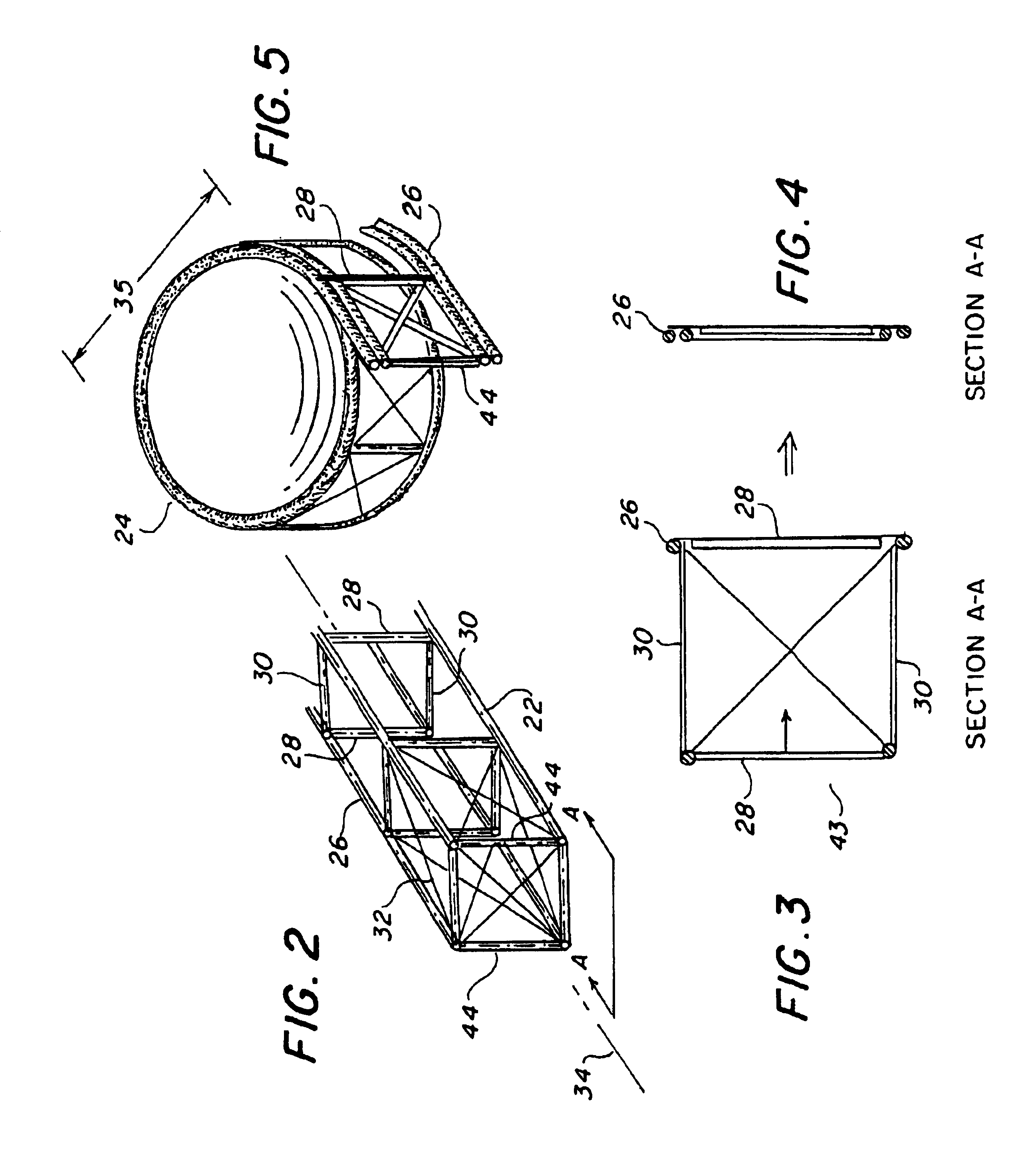

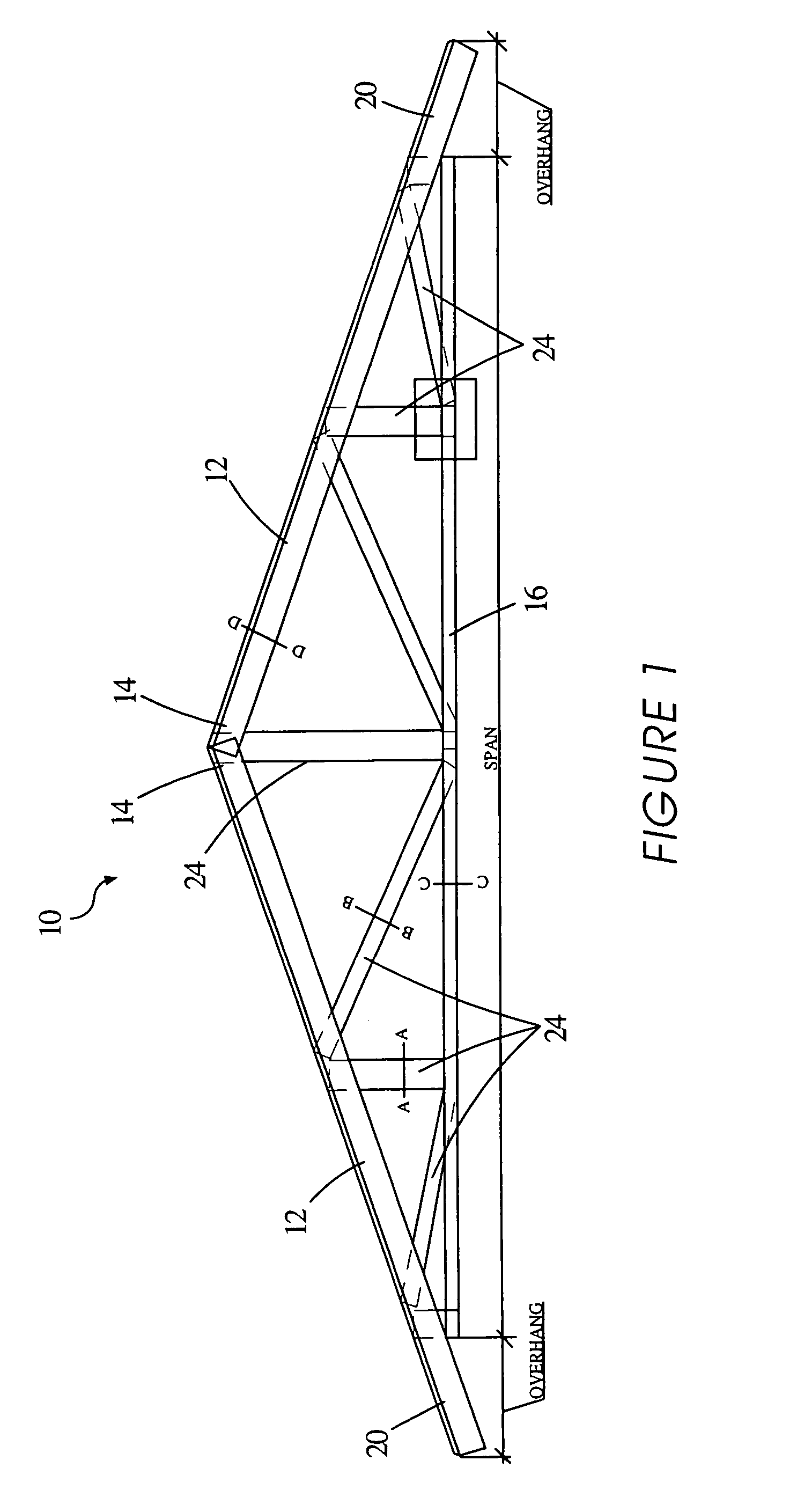

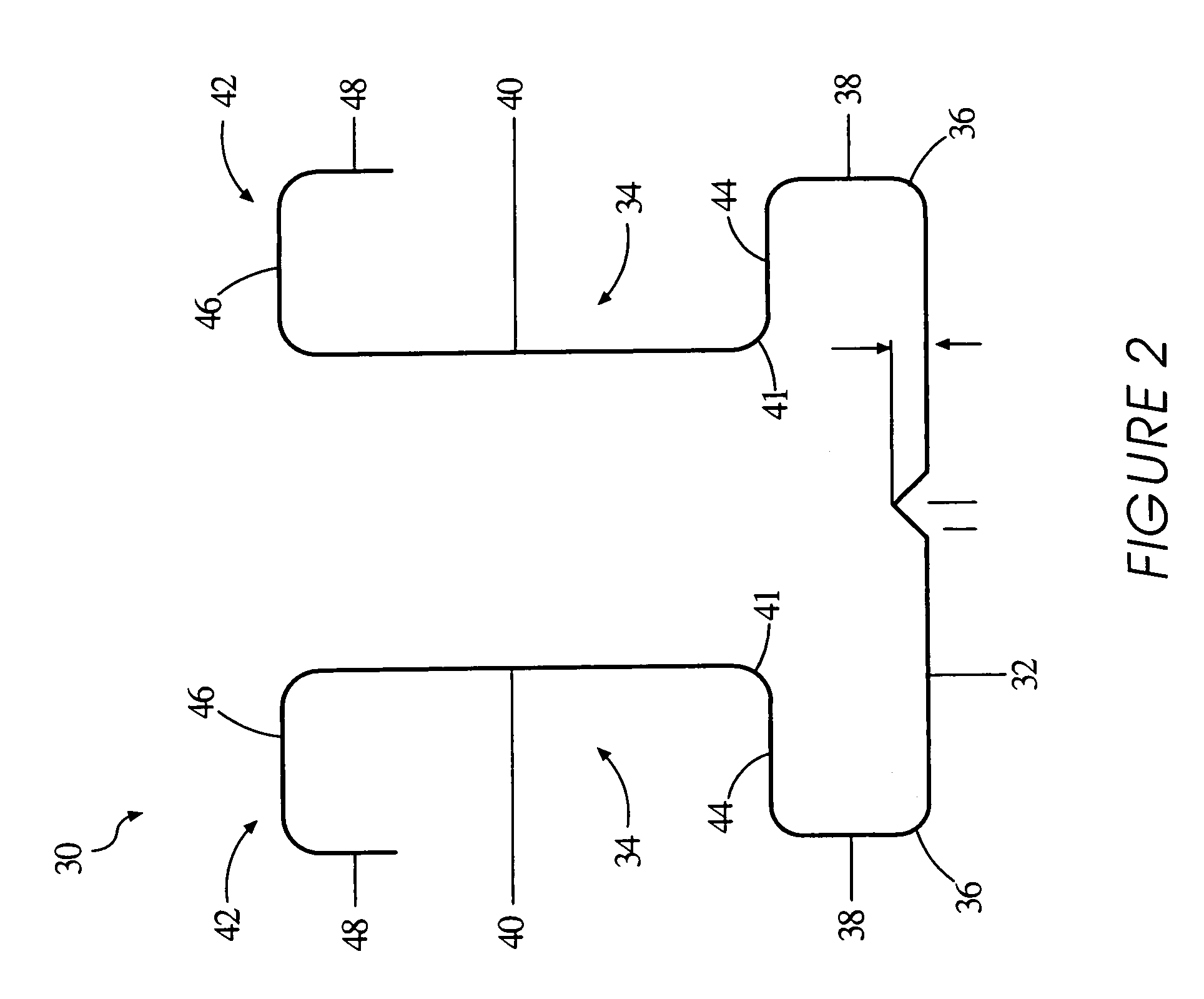

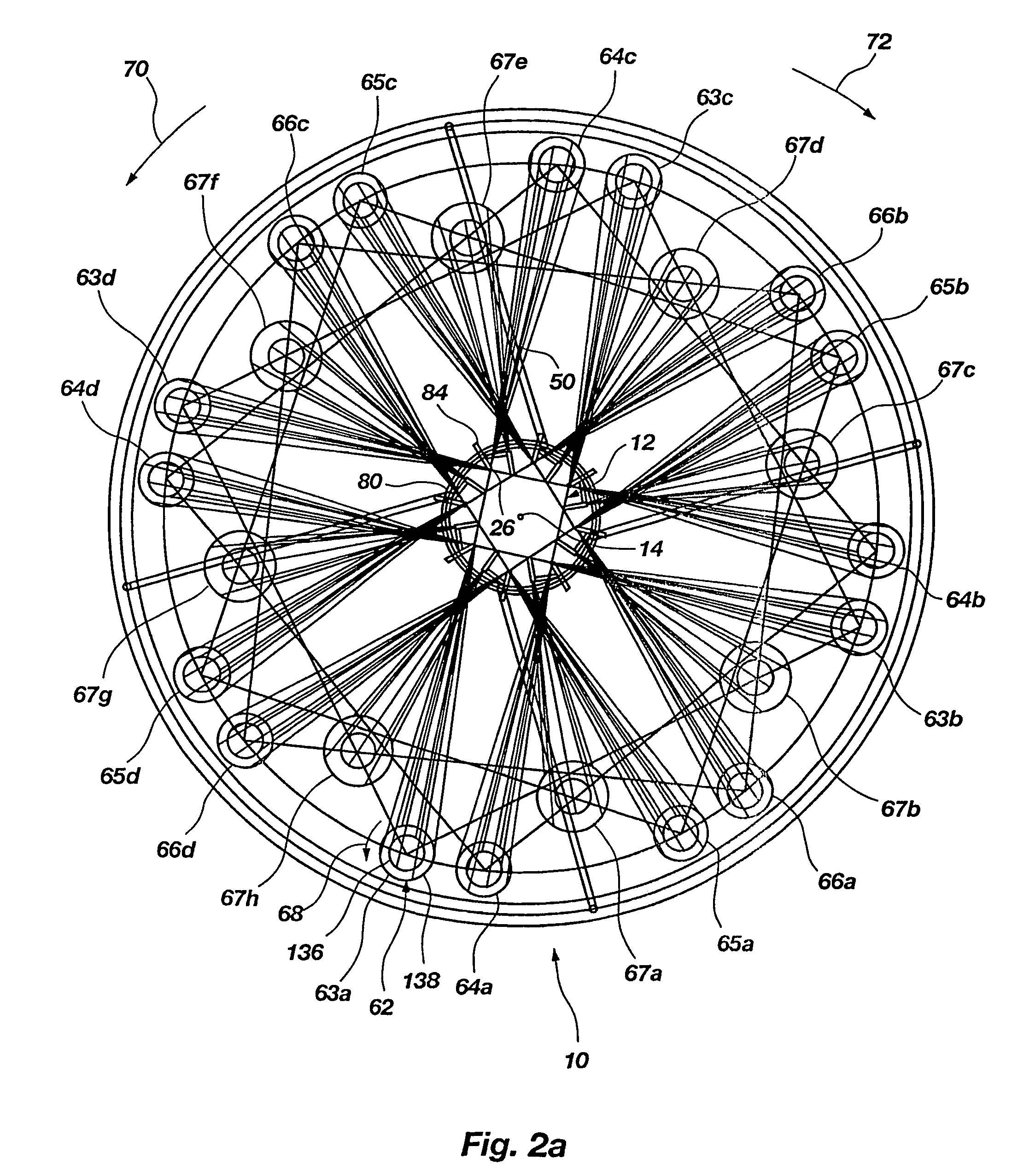

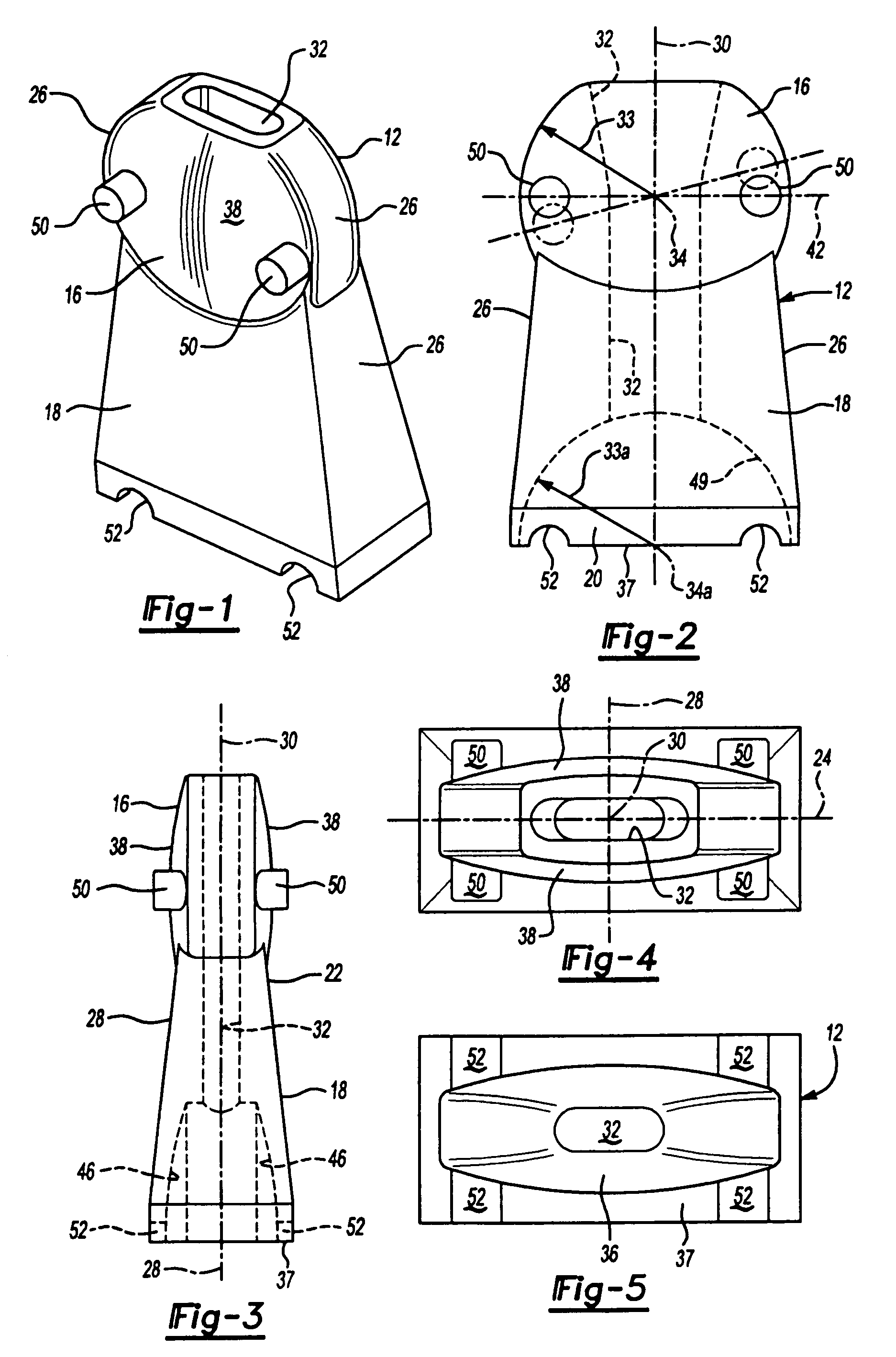

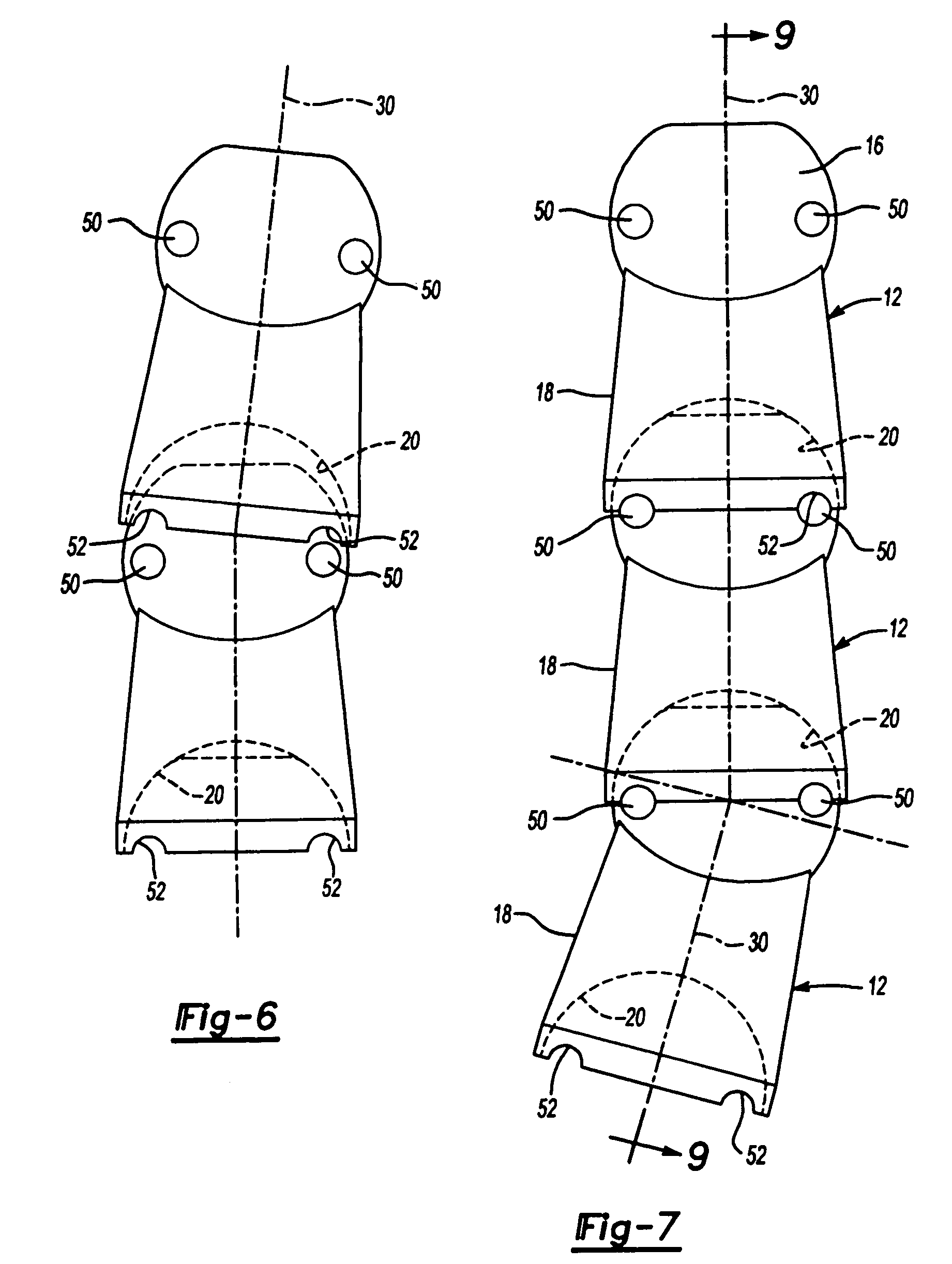

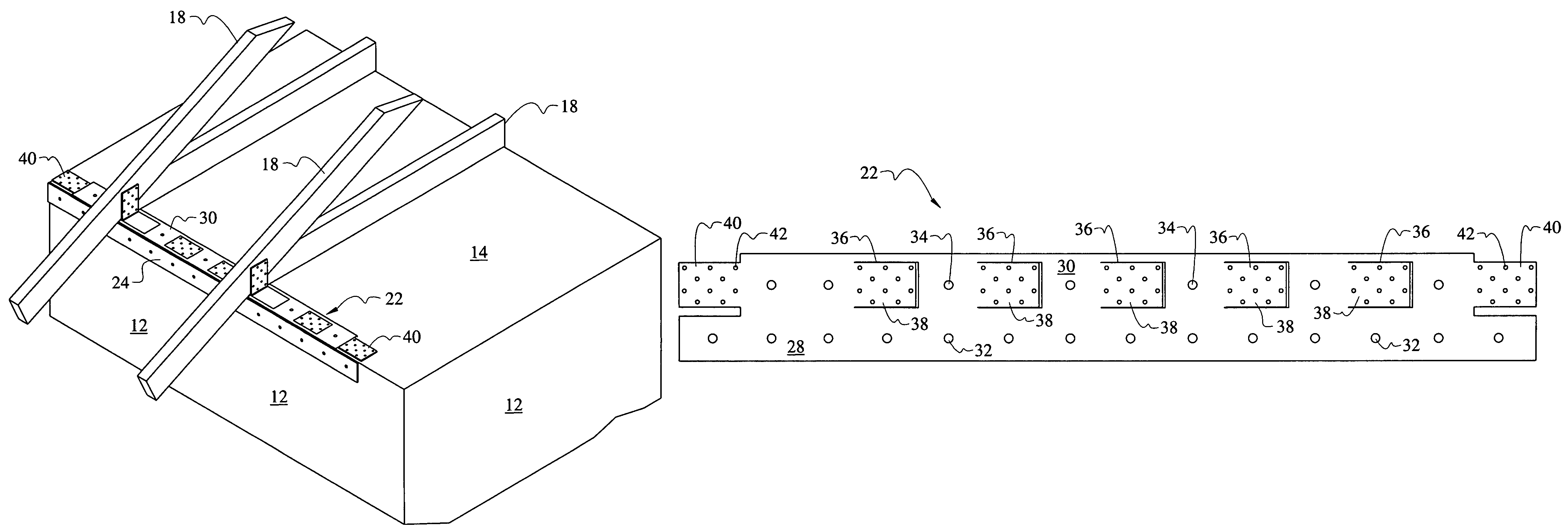

Iso-truss structure

InactiveUS20050115186A1Improved performance characteristicsReduced strengthTravelling sacksTruss-type bridgeSquare cross sectionAngular orientation

An iso-truss structure (10) includes at least two helical components (30, 32) and at least one reverse helical component (34) attached thereto with opposing angular orientations. Each helical and reverse helical component preferably includes at least four elongate, straight segments (22) rigidly connected end to end in a helical configuration forming a single, substantially complete rotation about a common axis (14) forming a first square cross section. The structure may further include at least two rotated helical components (80, 92) and at least one rotated reverse helical component (98) which are rotated with respect to the helical and reverse helical components forming a second square cross section, rotated with respect to the first. The structure may be straight, curved, flexible, or form angles.

Owner:ISOTRUSS IND LLC

Acoustical sound proofing material and methods for manufacturing same

ActiveUS20050050846A1Reduce transmission rateImprove abilitiesBuilding roofsCeilingsCelluloseUltrasound attenuation

An improved acoustical damping wall (ceiling or floor) or door material comprises a laminar structure having as an integral part thereof one or more layers of viscoelastic material which also functions as a glue and one or more constraining layers, such as metal, cellulose, wood, or petroleum-based products such as plastic, vinyl, plastic or rubber. In one embodiment, standard wallboard, typically gypsum, comprises the external surfaces of the laminar structure; and one or more constraining layers are fabricated between the gypsum exterior. The resulting structure improves the attenuation of sound transmitted through the structure.

Owner:PACIFIC COAST BUILDING PRODS

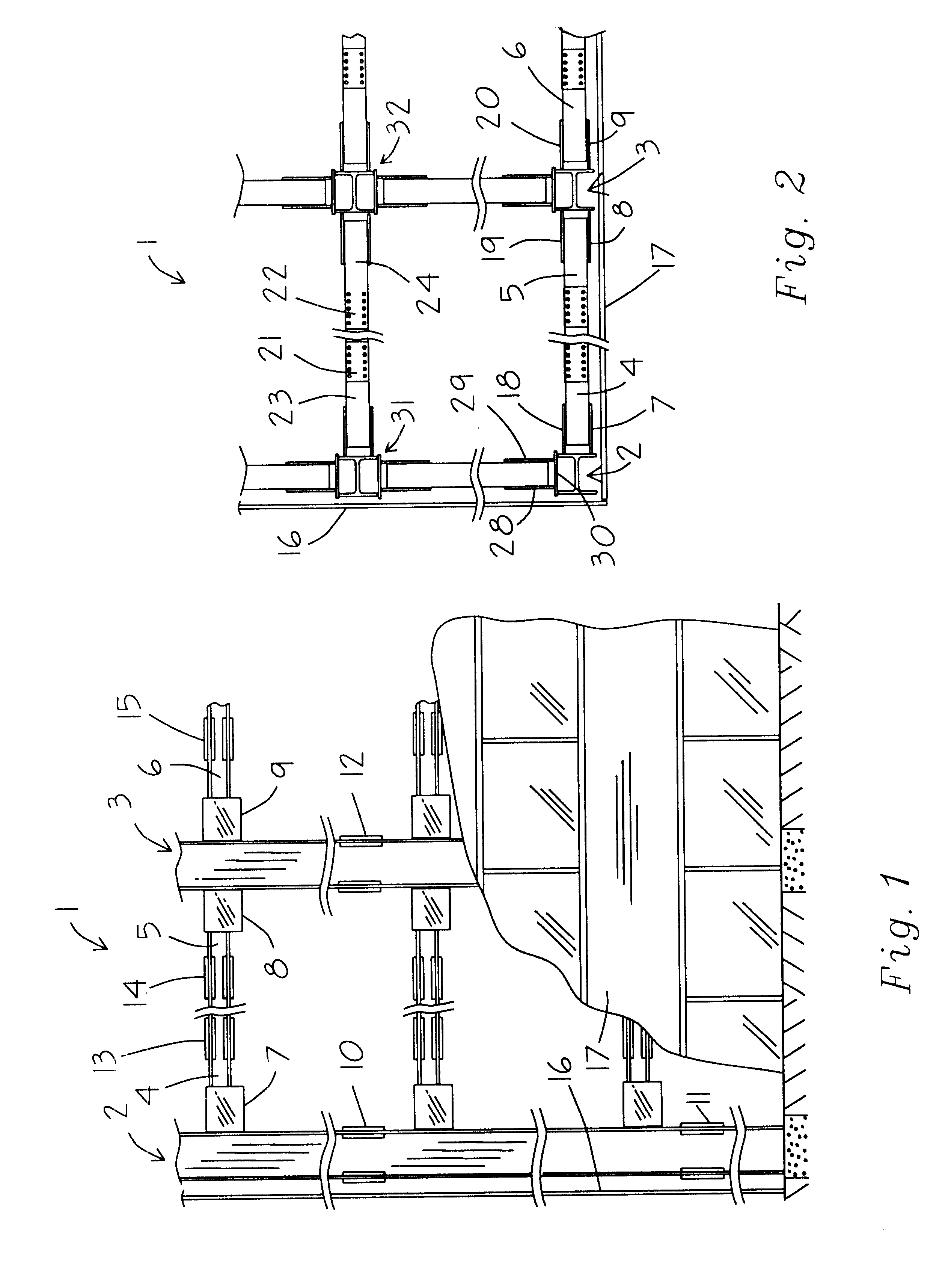

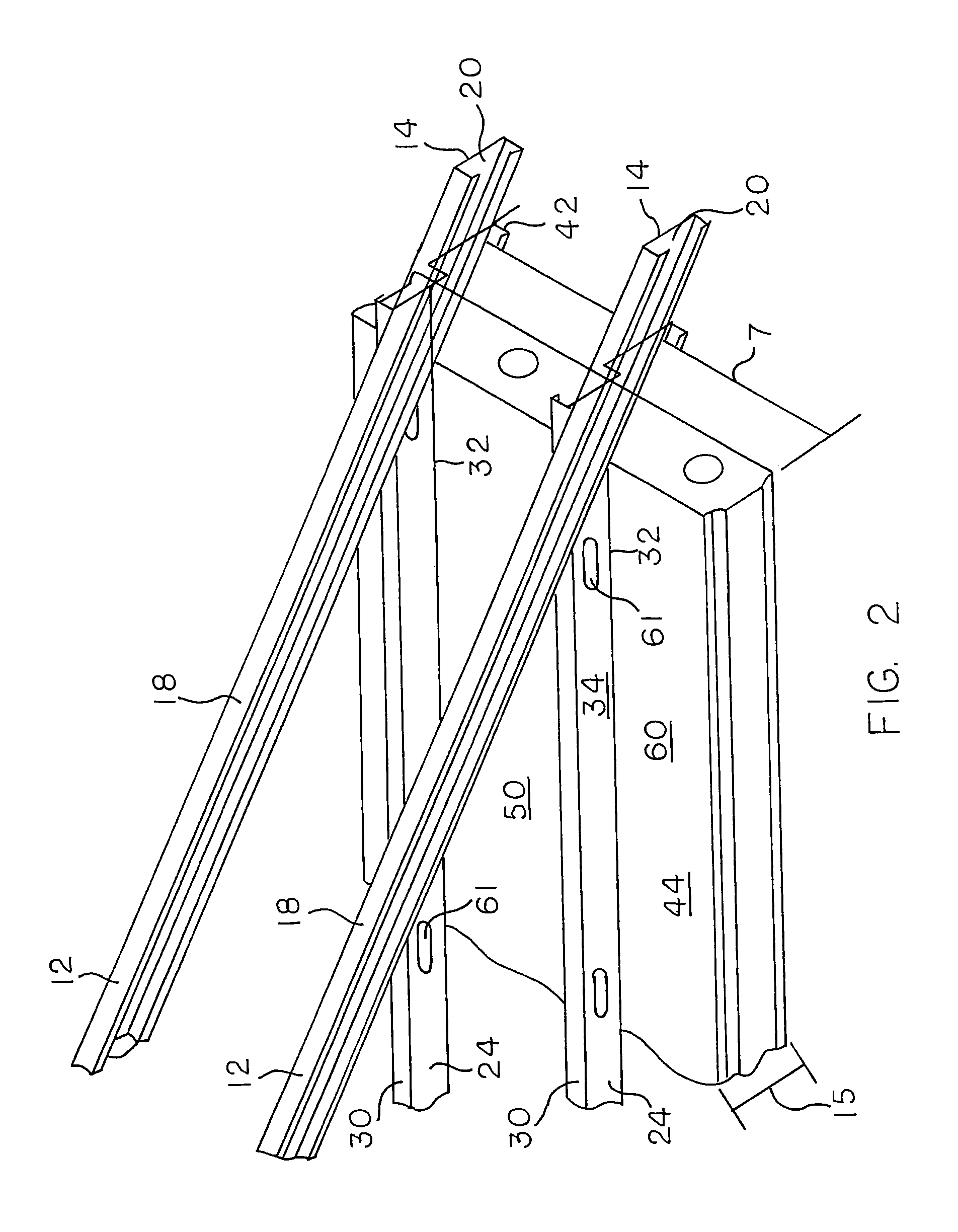

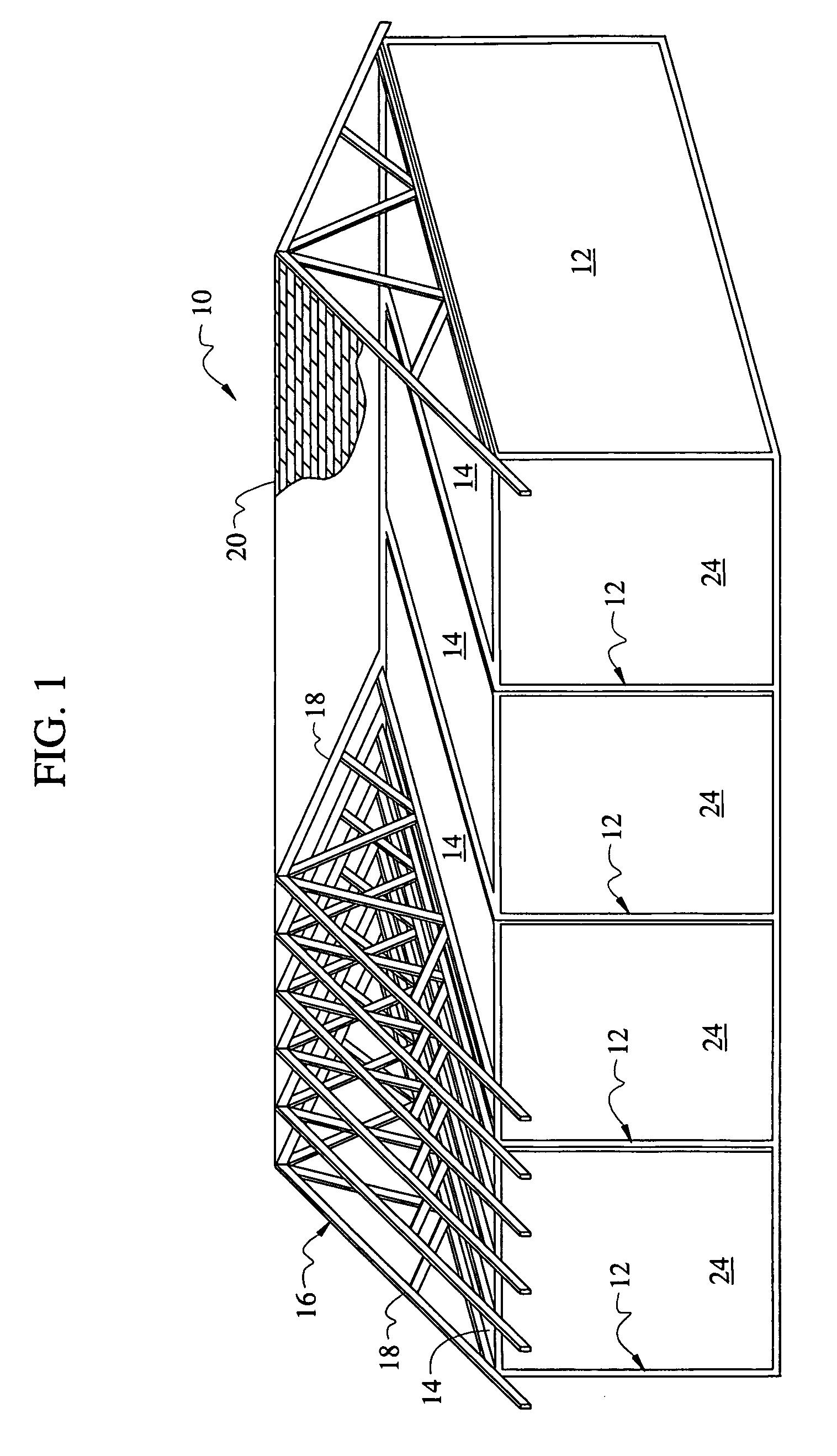

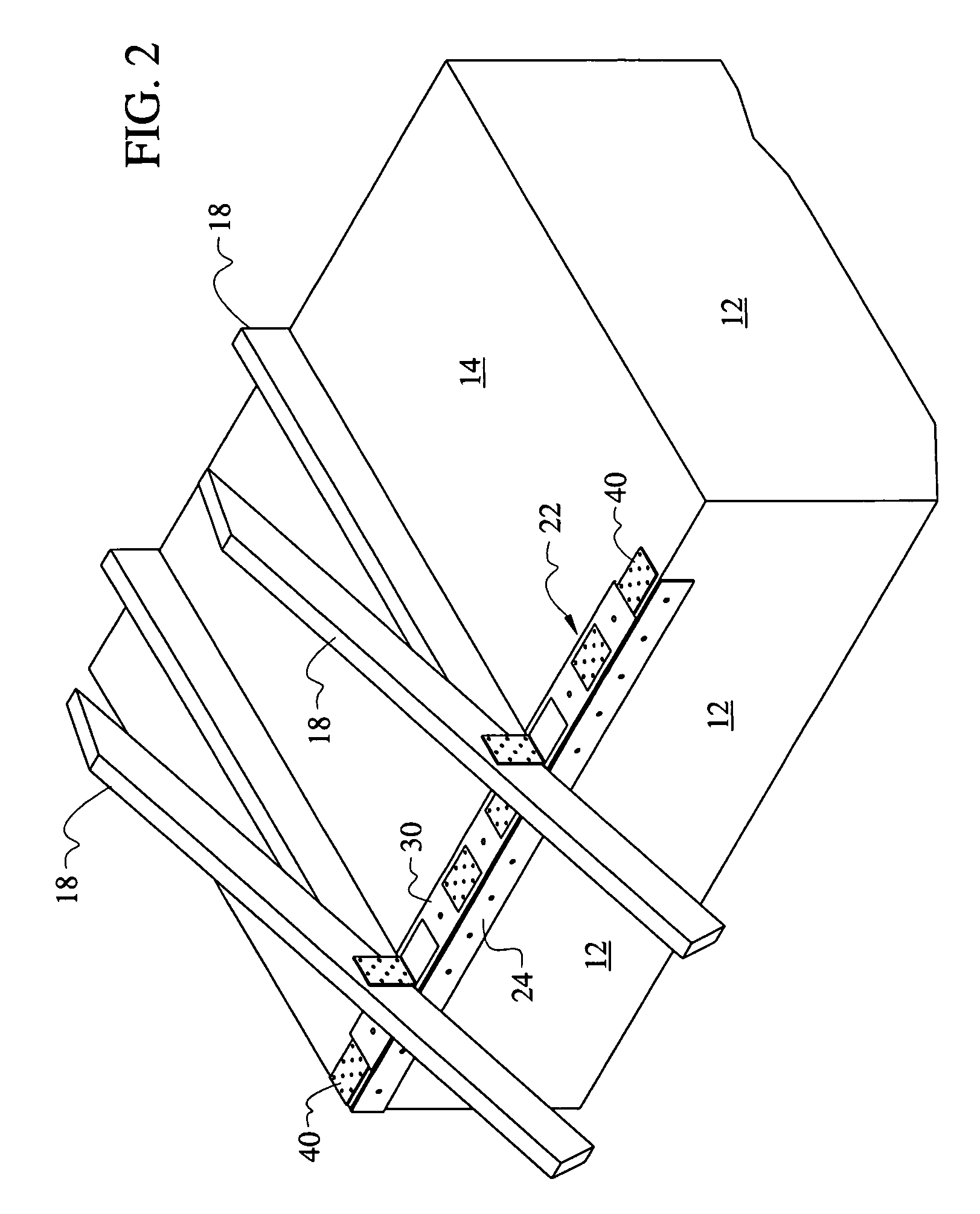

Framing system for building construction

According to existing methods of frame building construction, a concrete foundation is formed on which wooden floor joists are laid. Walls are constructed on the foundation and floor using wooden wall studs, and a roof is constructed on the walls using wooden rafters, beams and trusses. These methods require skilled carpenters and high quality wood materials, both of which are increasingly expensive. There is therefore a need for a system for framing houses or other buildings which uses prefabricated steel framing and which is quick and easy to construct. The invention provides a prefabricated system for framing a complete building on a foundation. Folding telescopic framing units are used for vertical partitions and horizontal floor panels. The invention therefore provides a prefabricated system of framing units forconstructing a building comprising: a) proving a foundation; b) securing vertical beams having open upper ends to the foundation at spaced locations; c) securing horizontal beams between the upper ends of the vertical beams; d) erecting and securing folding, telescopic floor joists on the foundation; and e) erecting and securing folding, telescopic roof trusts at spaced locations on the horizontal beams. The invention also provides a framed building comprising: a) a foundation; b) vertical beams having open upper ends secured to the foundation at spaced locations; c) horizontal beams secured between the upper ends of the vertical beams; d) erected folding, telescopic floor joists secured on the foundation; and e) erected folding, telescopic roof trusts secured at spaced locations on the horizontal beams.

Owner:CAMPBELL RONALD W

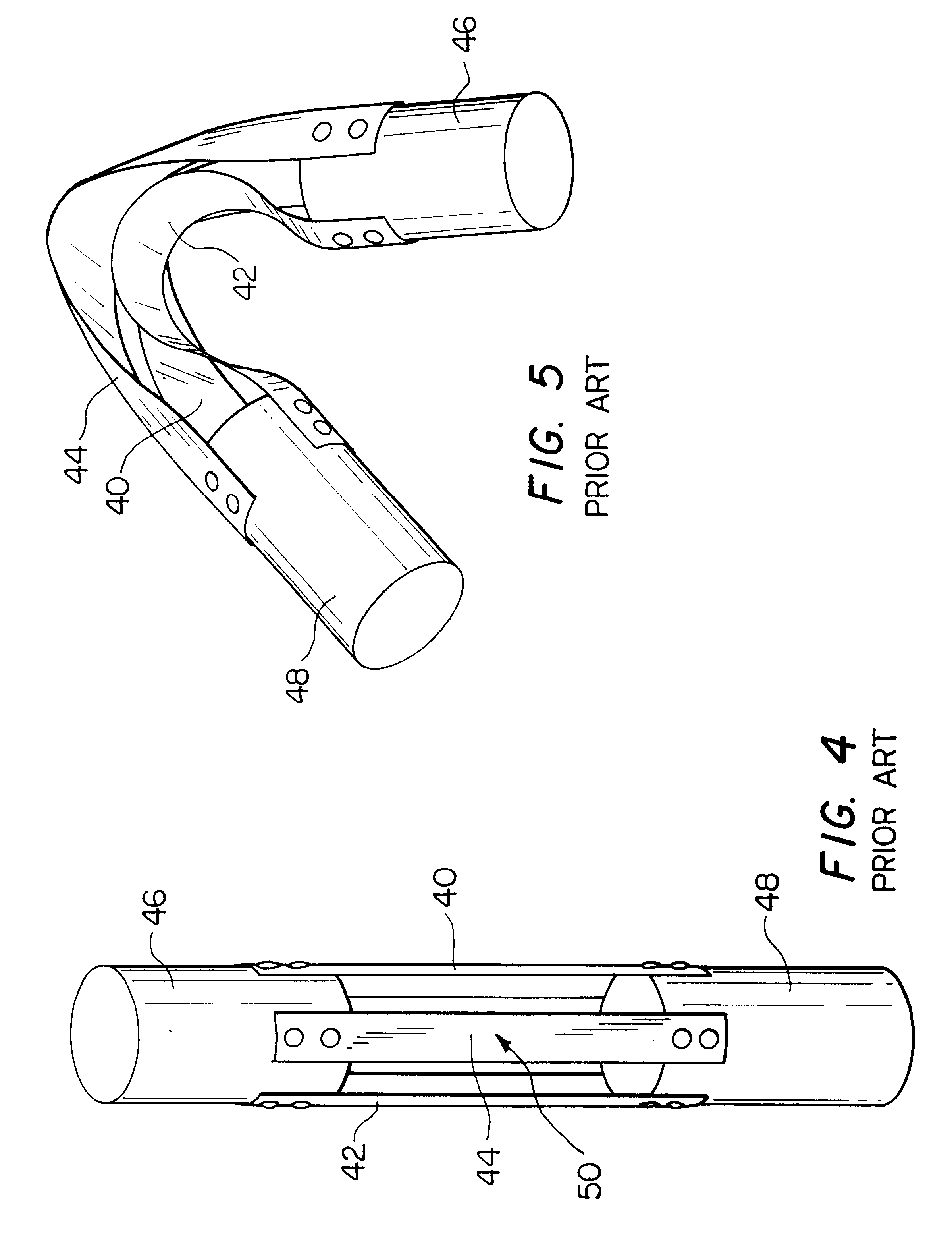

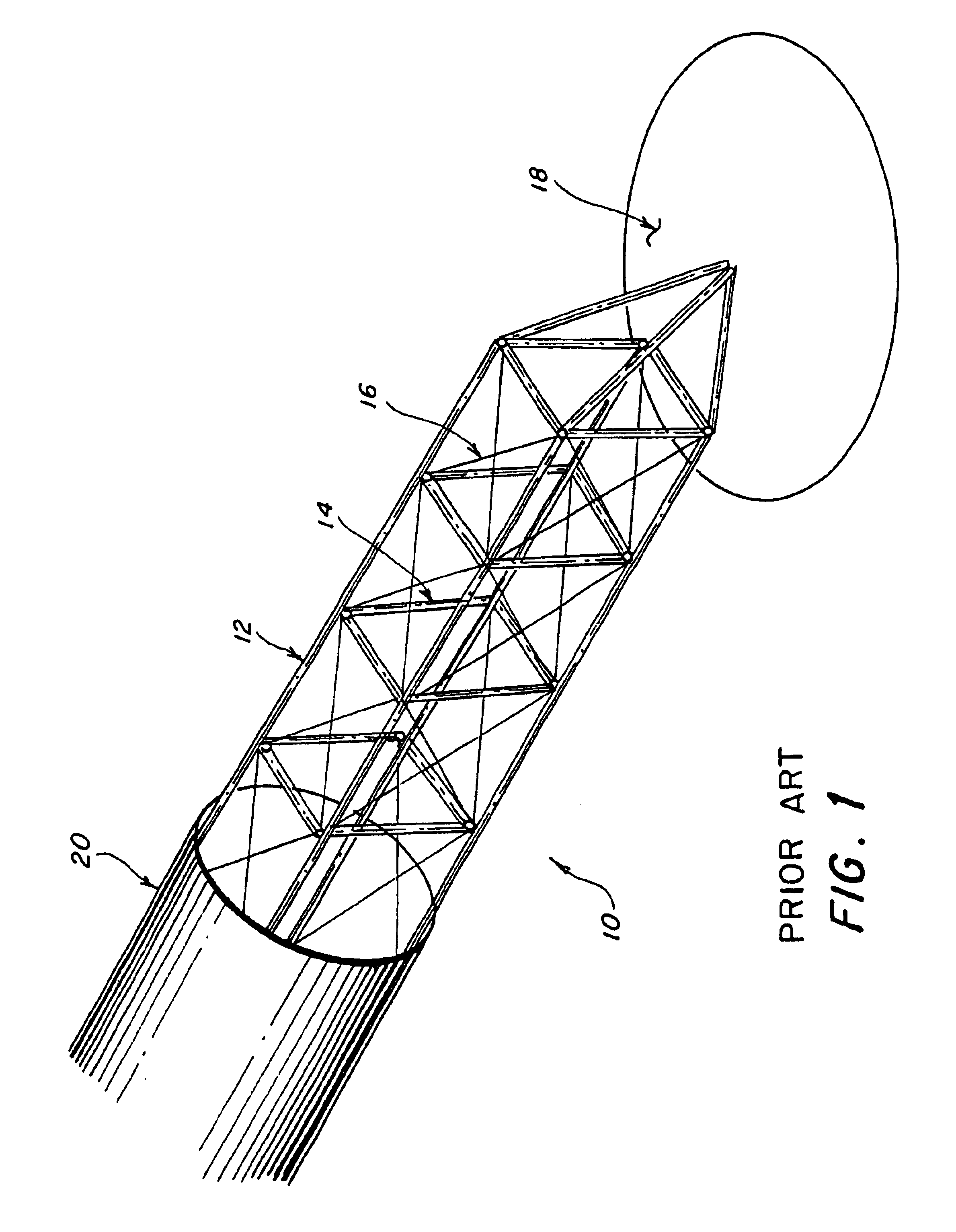

Elongated truss boom structures for space applications

An elongated truss boom structure is adapted to be flattened and coiled to a stowed configuration. The truss boom includes longerons, battens, and diagonals. A fixed ladder shaped structure is formed by a plurality of fixedly coupled battens which interconnect two adjacent longerons. The truss boom is flattened for stowage by arranging all of the longerons coplanar to the plane of the fixed ladder shaped structure. The longerons preferably have a corrugated cross section. For stowage the longeron is heated and compressed into a ribbon shaped cross section, and upon deployment the longeron is heated to restore its corrugated cross section. A mechanical assembly machine includes a drum, a stowed flattened truss boom rolled into a coil around the drum, a device for unrolling the coil, an actuating and locking mechanism, and a control arm which connects the actuating and locking mechanism to the drum.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

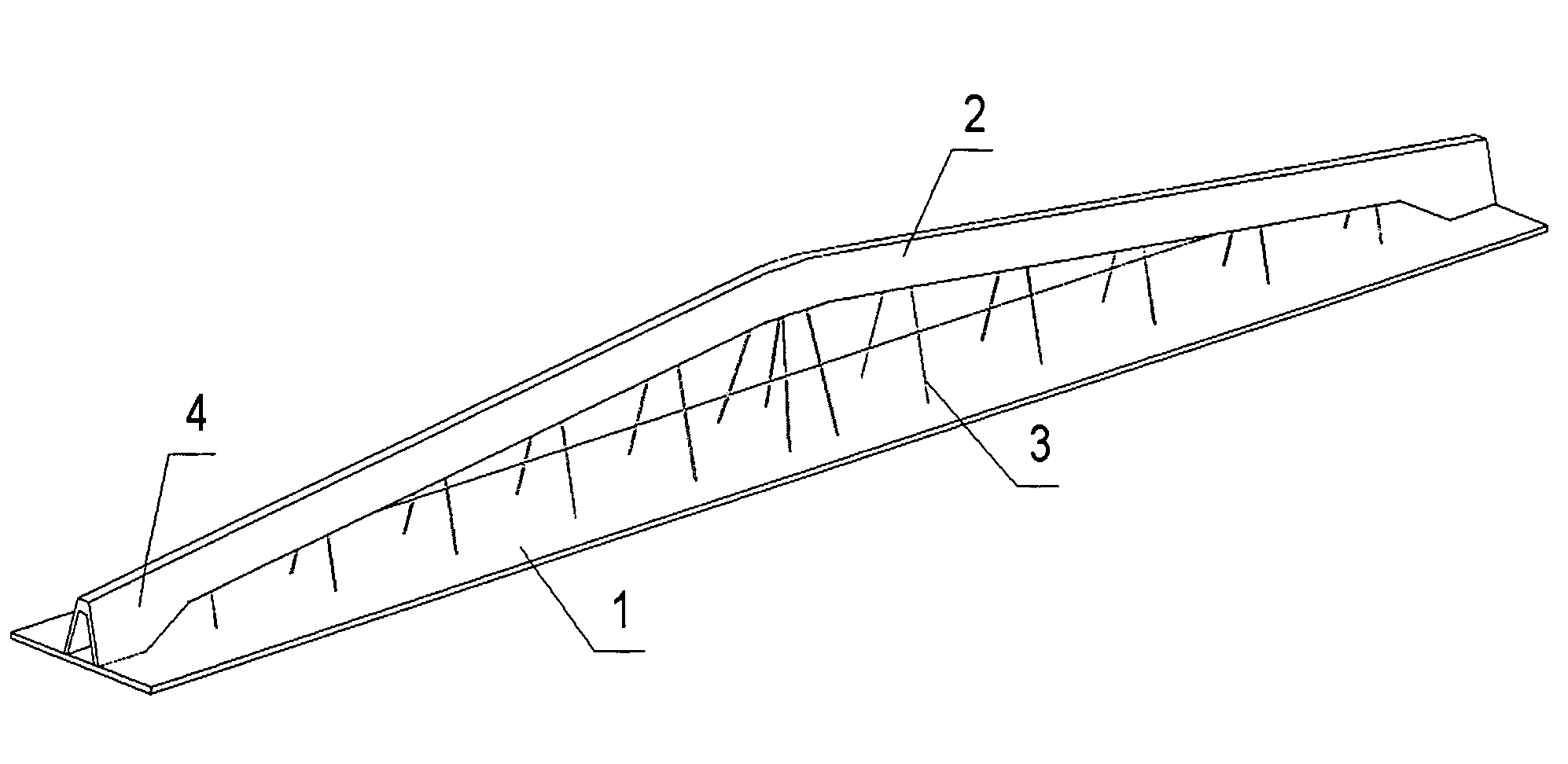

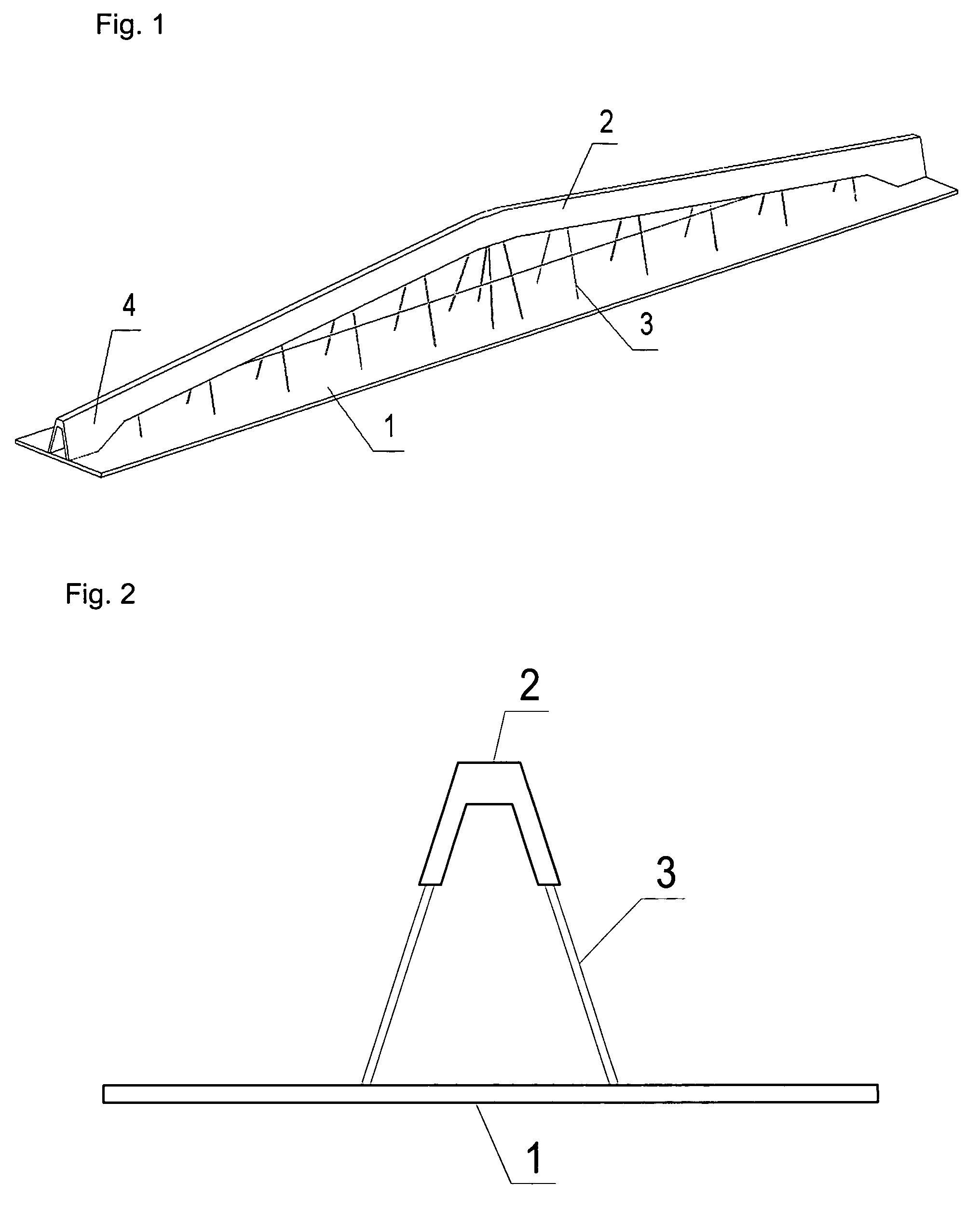

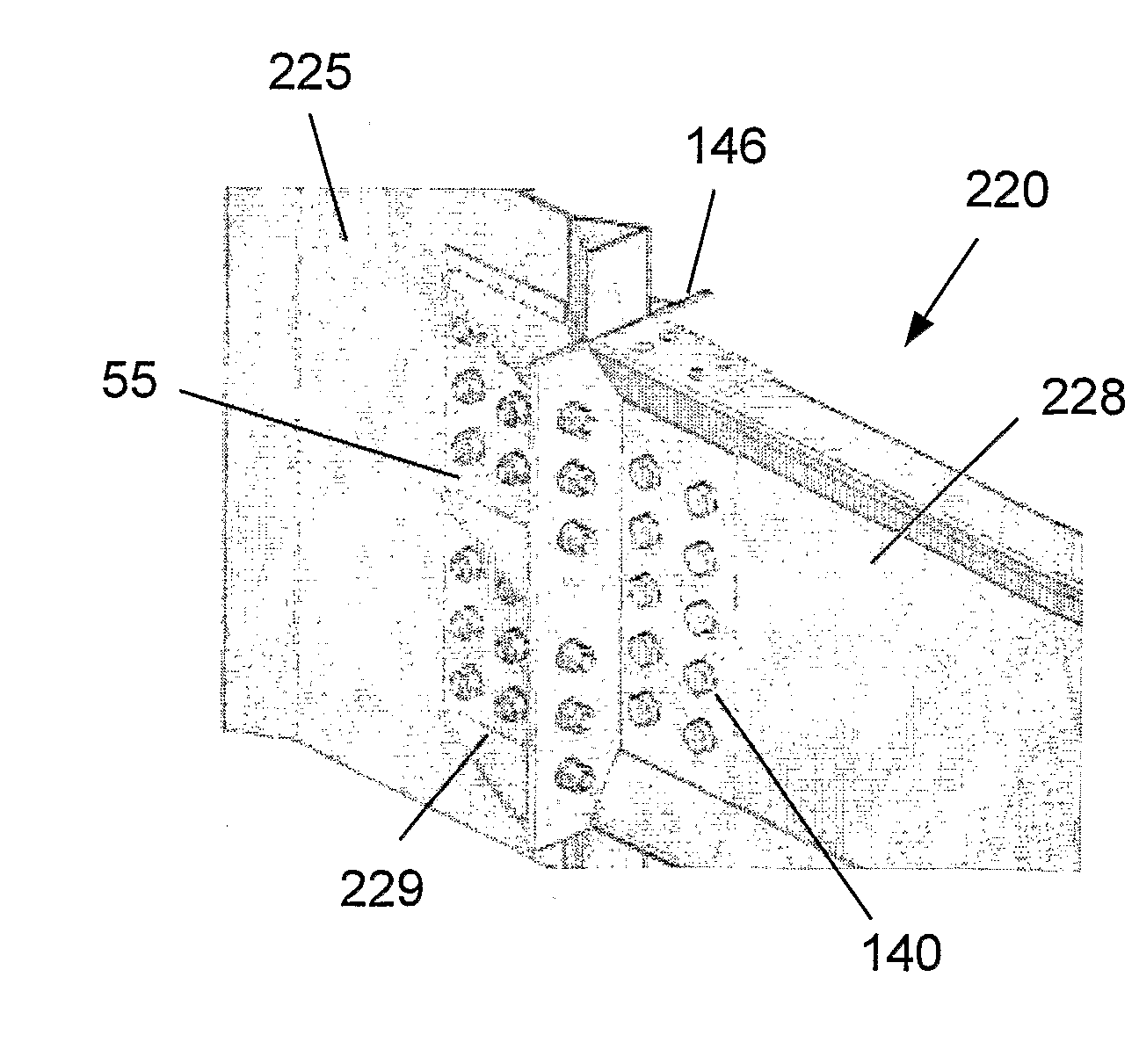

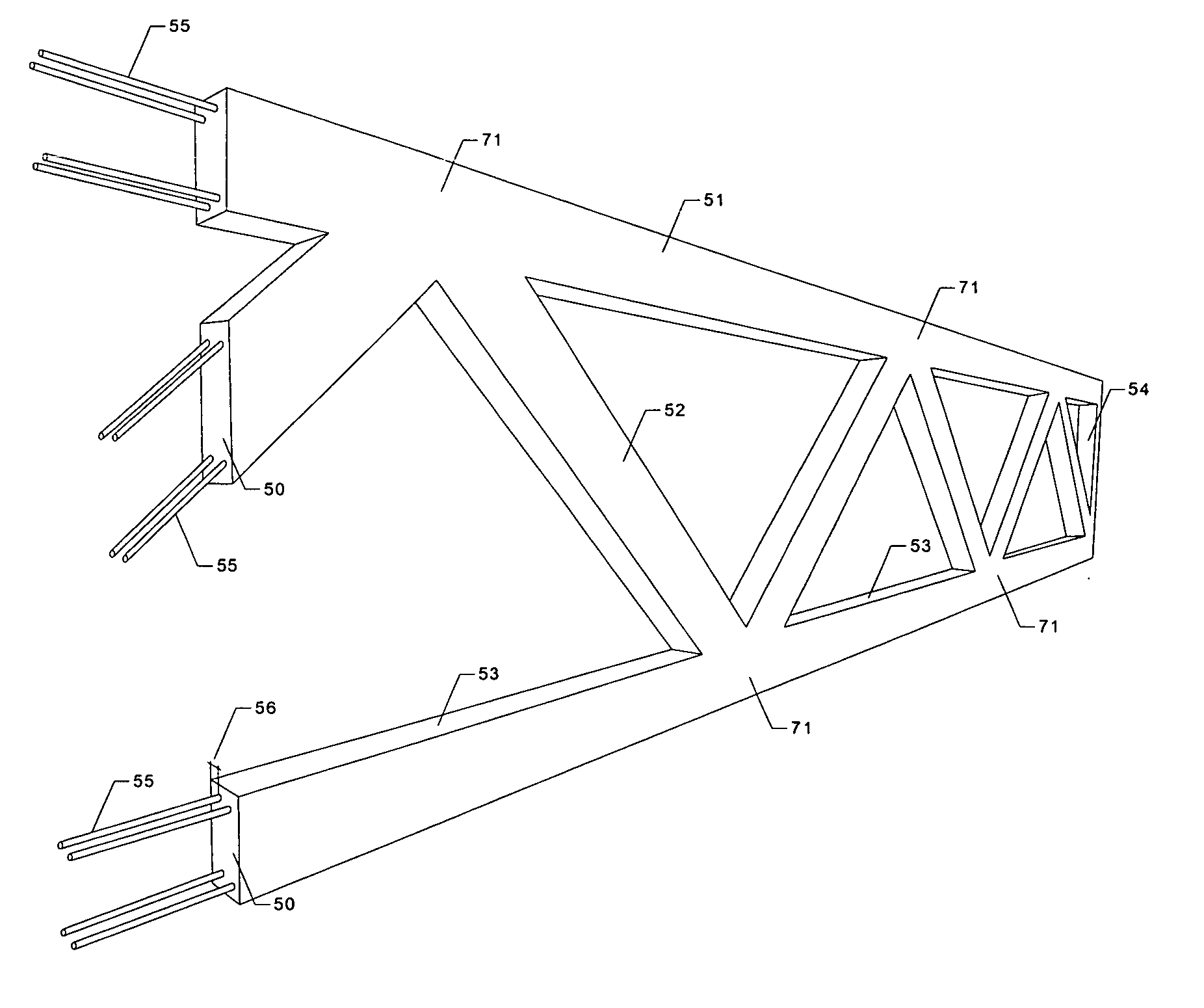

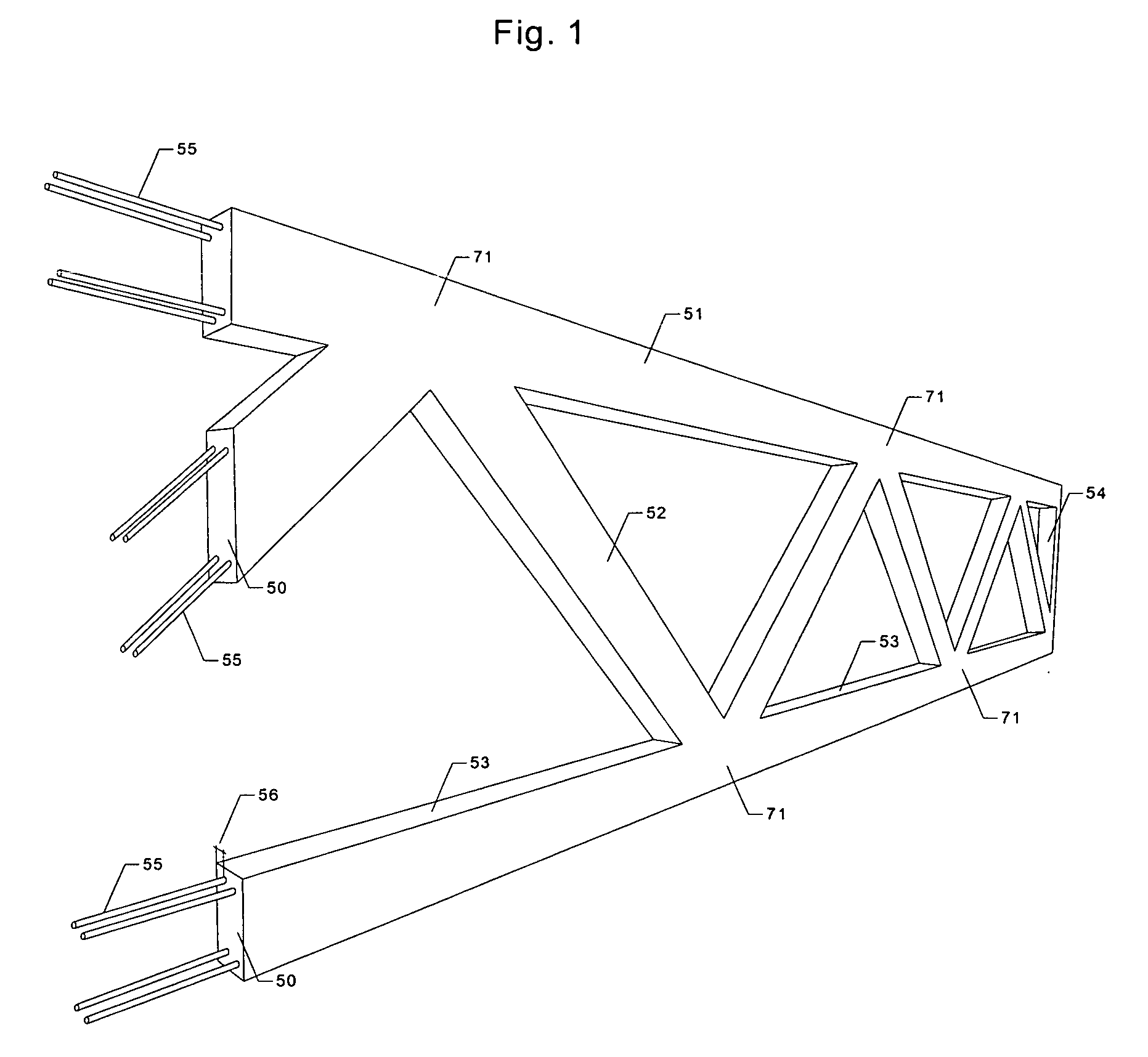

Indirectly prestressed, concrete, roof-ceiling construction with flat soffit

An indirectly prestressed concrete roof-ceiling construction is a prefabricated element for constructing large-span industrial buildings. The construction includes a distinctly wide and thin concrete soffit plate and an upper concrete girder of an inverse “V”-shaped cross section, interconnected by slender steel pipe-rods that are used to stabilize the upper girder against lateral buckling and to prevent the plate and the girder from getting closer or further away from each other. Prestressing of the soffit plate causes compression in the upper girder which passively (indirectly) pushes the ends of the construction, acting on some eccentricity over the center of gravity of the cross section, causing rotation of its ends, bending in that way the soffit plate upwards. There are two efficient methods of prestressing these constructions.

Owner:MARA INST D O O

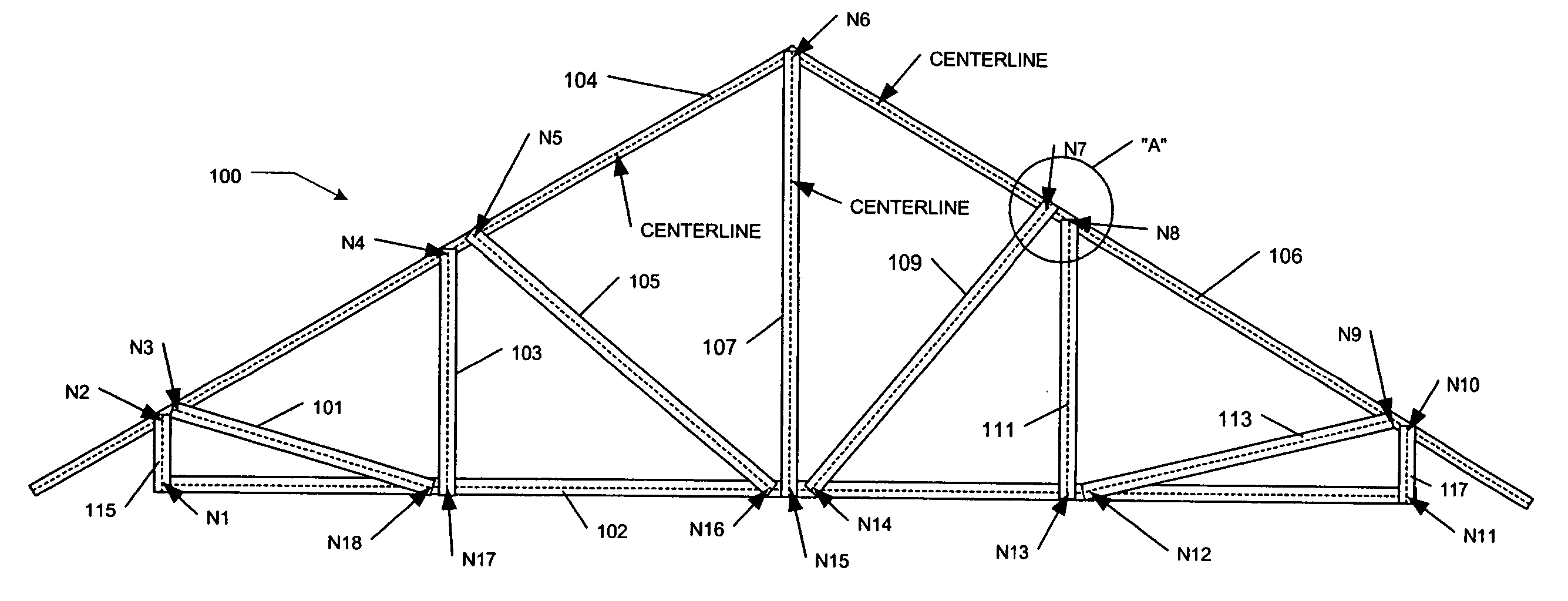

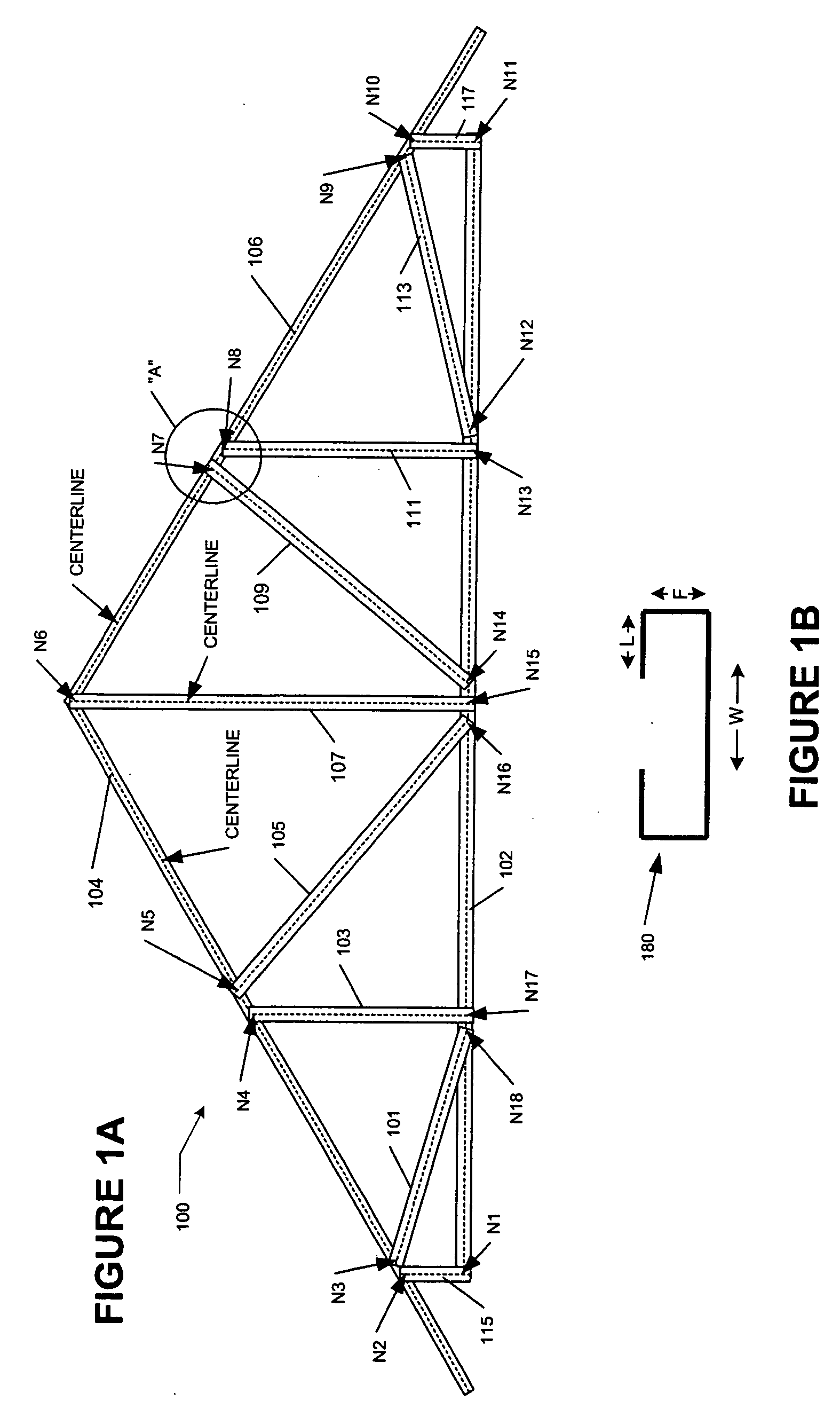

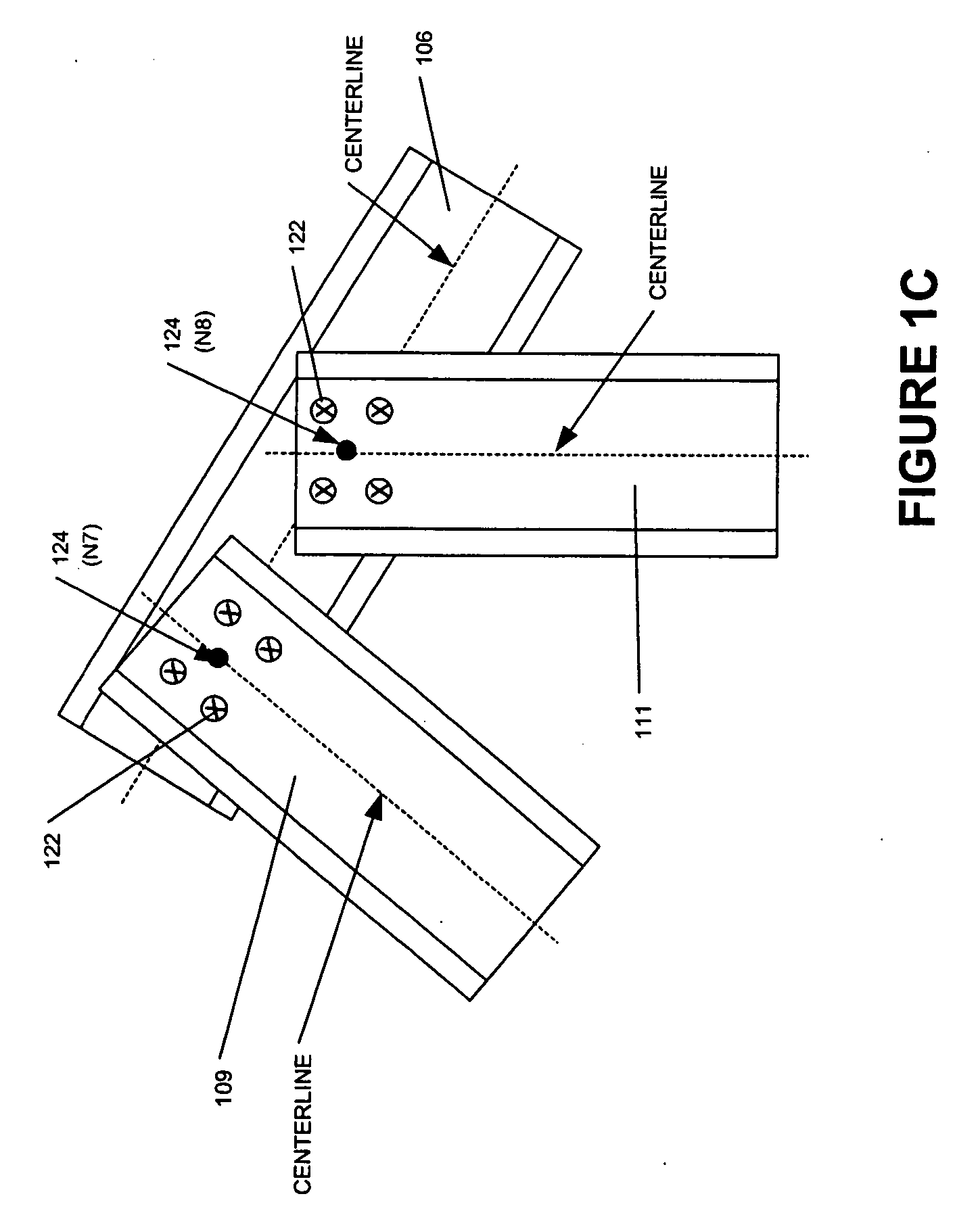

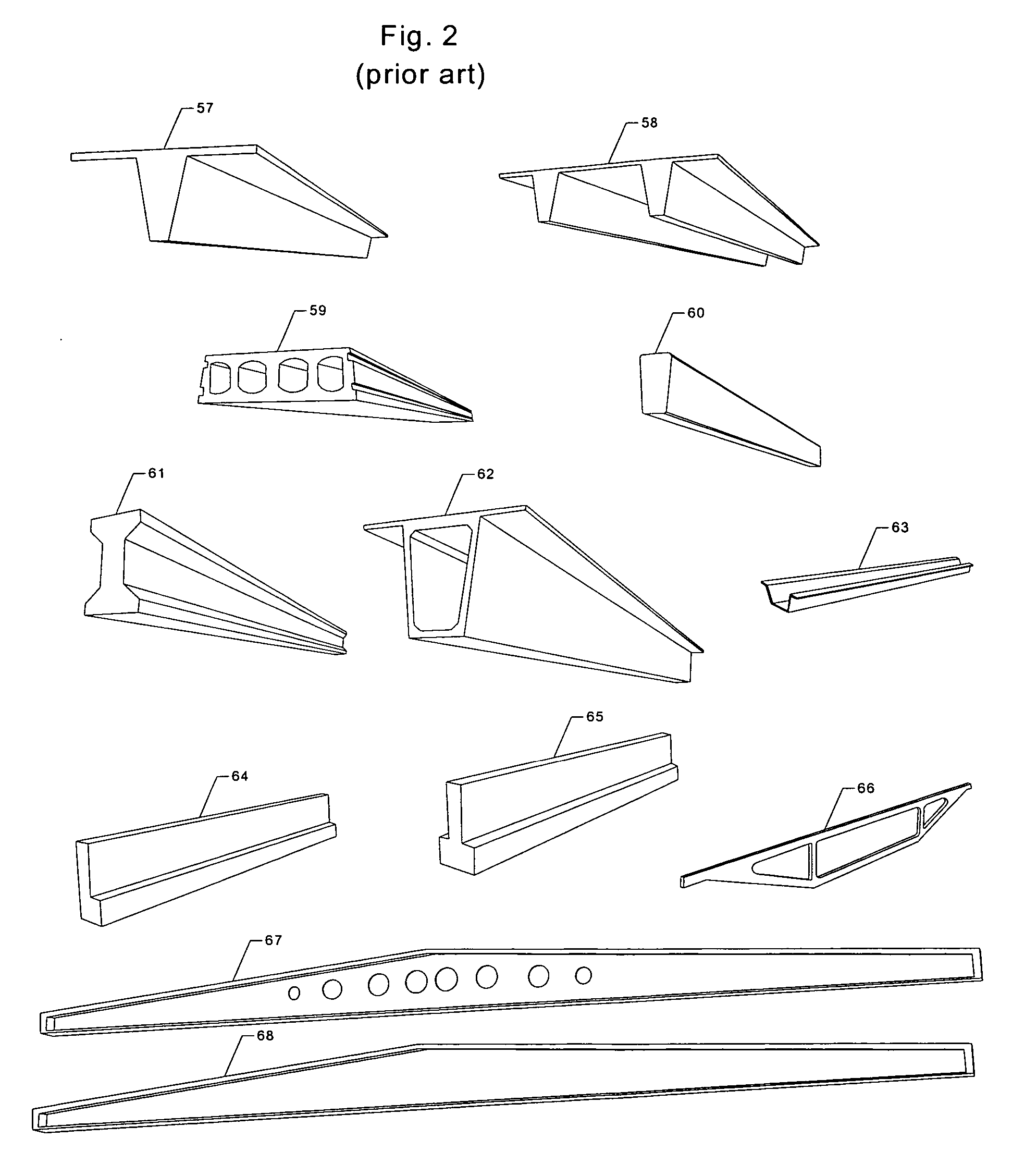

Light gauge metal truss system and method

InactiveUS7093401B2Easy to engageConvenient nestingBuilding roofsLayered productsEngineeringUltimate tensile strength

A truss system wherein the structural components and fixtures are formed from light gauge metal. The trusses are fabricated from roll formed truss chord members and truss web members. The truss chord members are roll formed to have a generally U-shaped cross-section with a base and two substantially parallel legs with recessed web attachment faces and outwardly extending stiffening flanges to improve structural capacity thus improving the strength-to-weight ratio of the chord member and minimizing costs. The truss web members are formed by nesting two roll formed C-shaped members to form a web member which is box-shaped in cross section. The web members provide the structural advantages of a box-shaped member and the ease and flexibility of a roll formed member. The truss system and method provides improved means and methods for positioning and attaching the web members to the chord members as well as improved truss clips for resistance to uplifting forces and improved truss jack clips for forming hip connections.

Owner:INNOVATIVE STEEL TECH

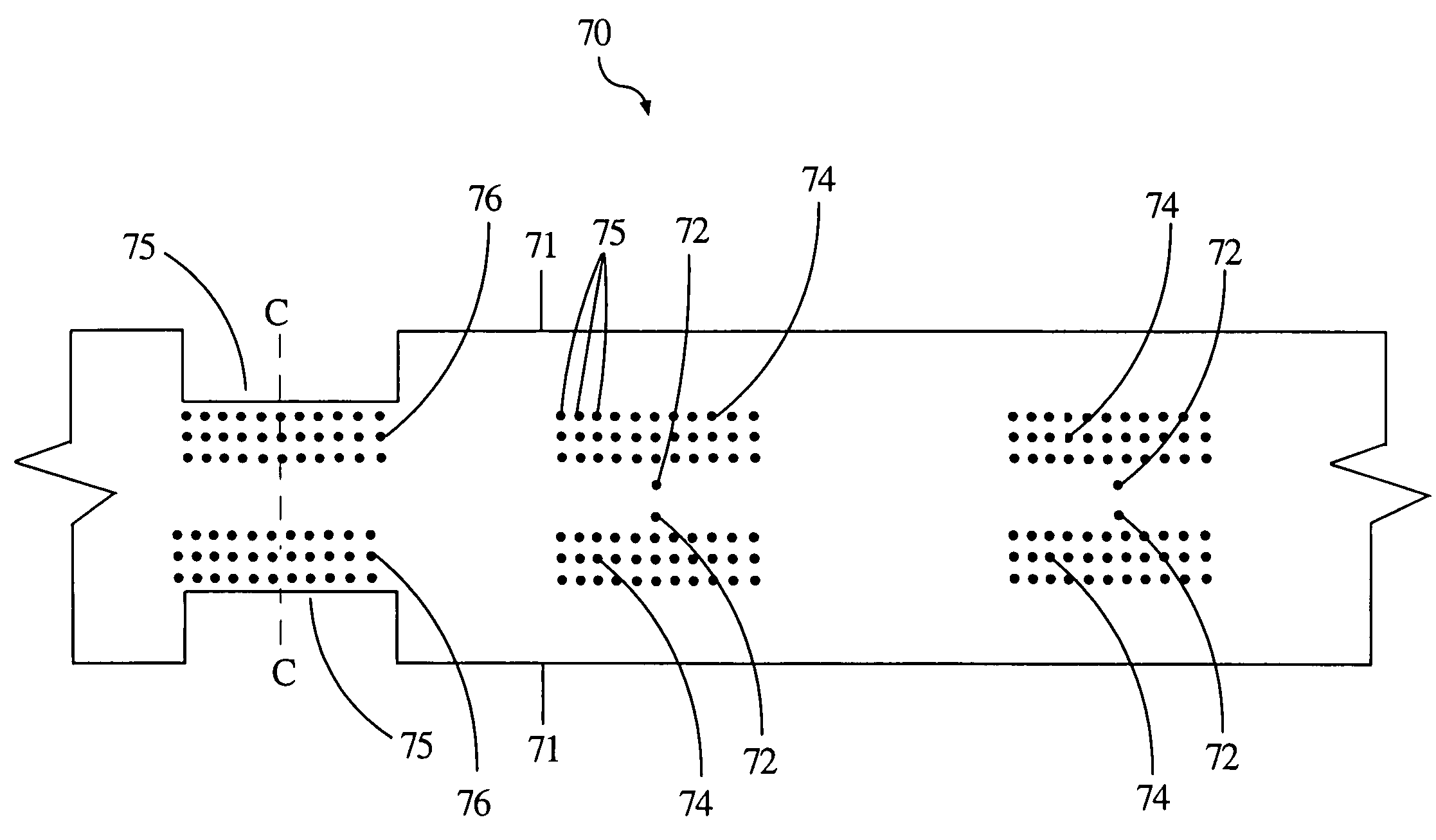

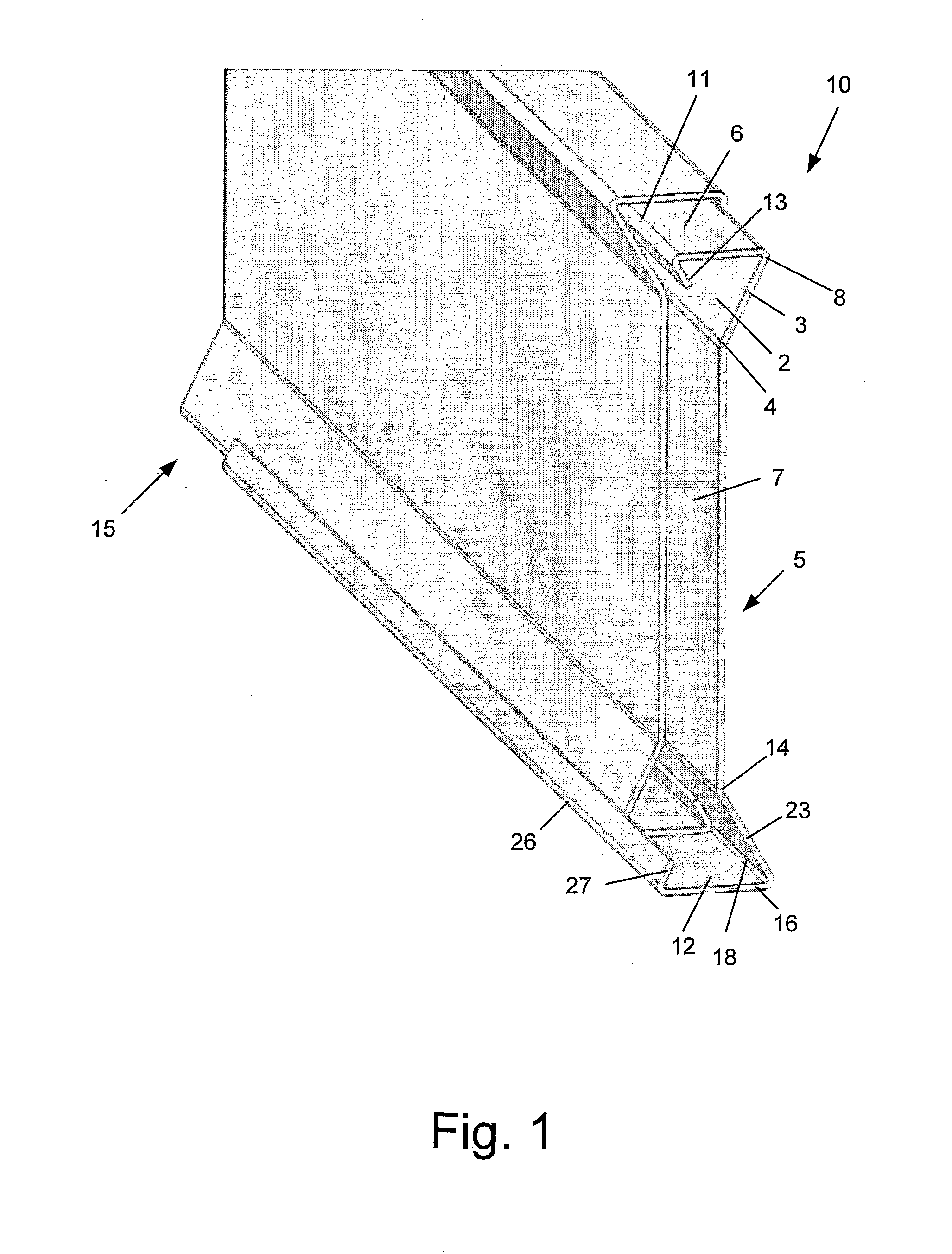

Modular Reinforced Structural Beam and Connecting Member System

InactiveUS20090007520A1Avoid displacementArched girdersBuilding roofsComposite beamsComposite girder

A modular reinforced structural beam and connecting member system that includes at least one composite beam having two oppositely oriented triangular closed head portions and a transversally extending web interposed between said two closed head portions, each of said beams consisting of two separate members arranged such that corresponding head portions of said two members are nested one within the other and adjacent elements of the two members are in mutual stabilizing contact. A plurality of connecting members are connected to, and are in force transmitting contact with, one of the composite beams and another structural element.

Owner:NAVON RAM

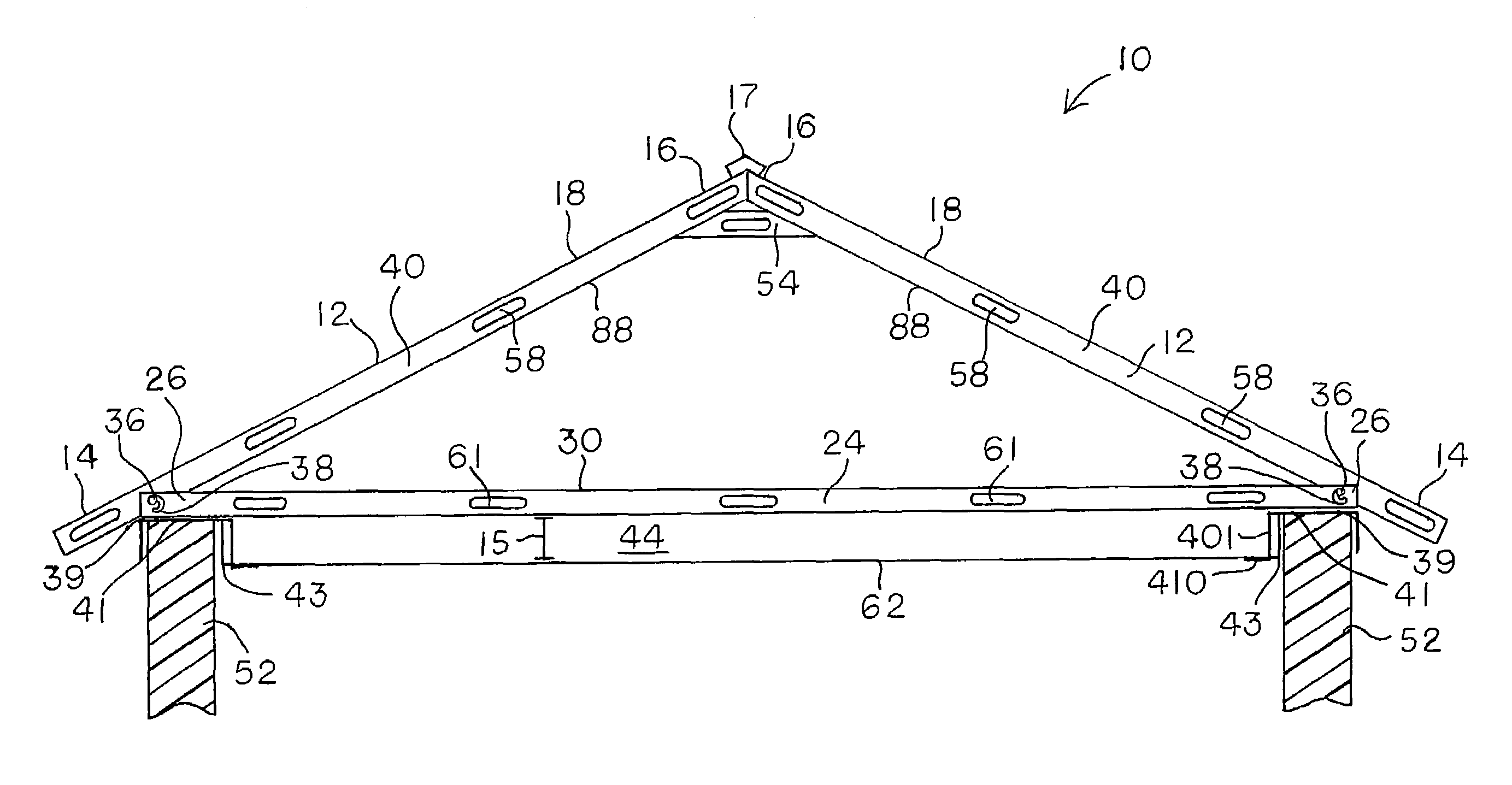

Roof truss system

An adjustable roof truss that includes roof truss members, roof base members and a central body containing a polymer matrix. The roof truss members include a pivot end, a connection end, a roof facing edge, an inside edge, and a pivot surface. The roof base members include a receiving end, a connecting end, a top edge, a bottom edge, and a contact surface. The roof truss members are pivotally connected to the roof base members by a pivot fastener inserted through a pivot opening on the roof base members and a stator opening on the roof truss members. One or both of the roof truss members and the roof base members include an embedded portion extending from the roof facing edge or the bottom edge respectively into the central body. Expansion hole(s) are positioned along the embedded portion such that the polymer matrix expands through the expansion holes.

Owner:SYNTHEON HLDG SPA

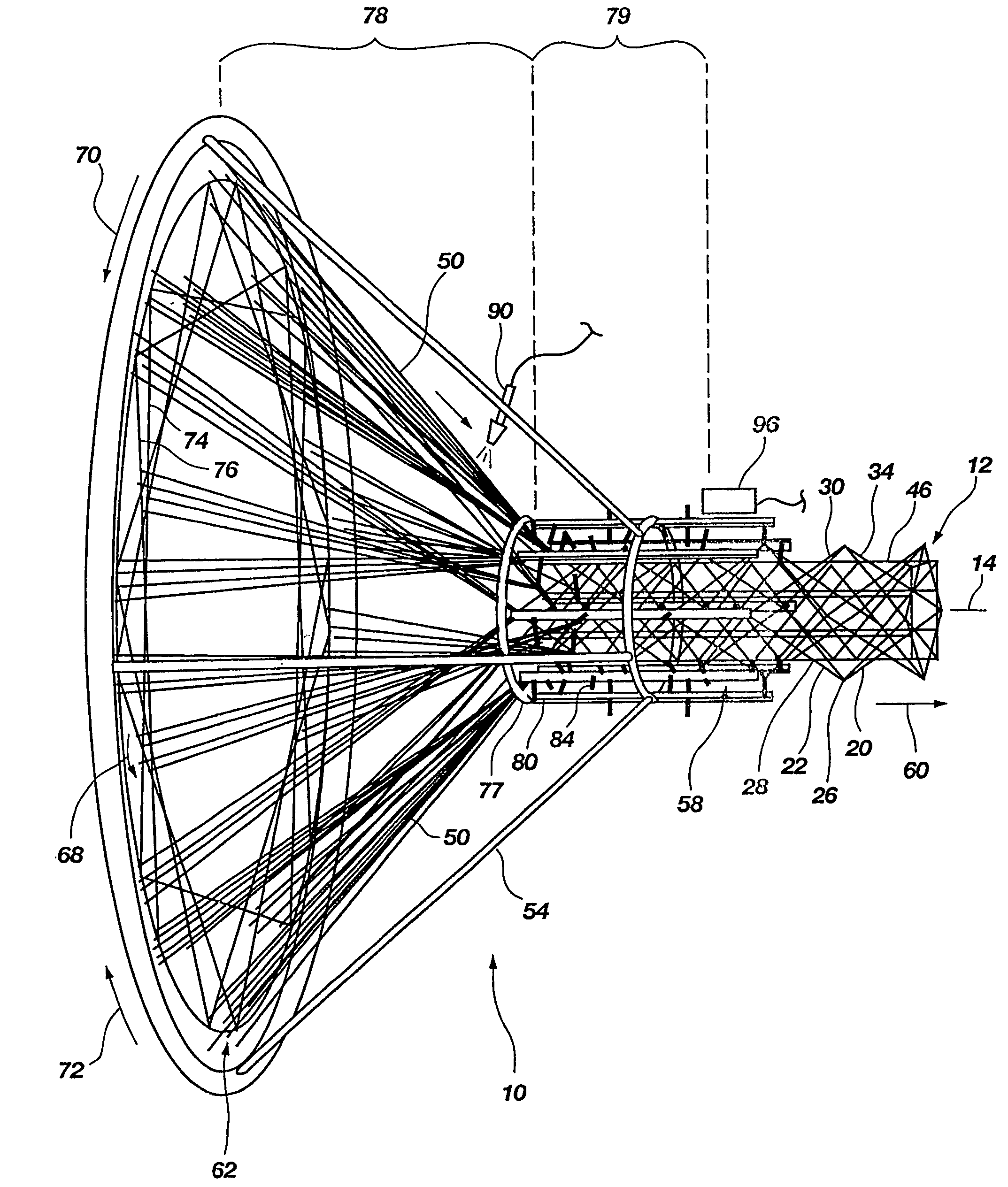

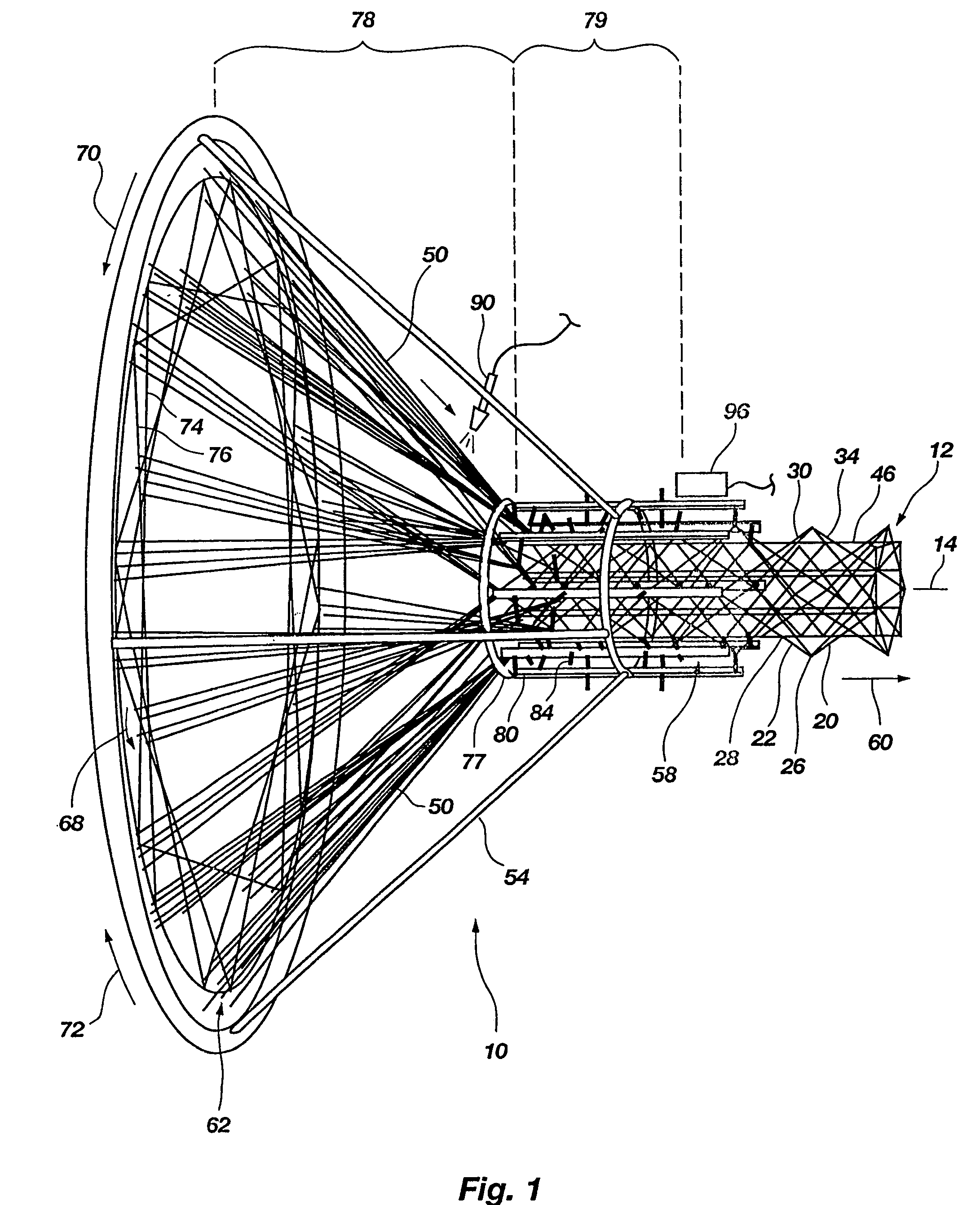

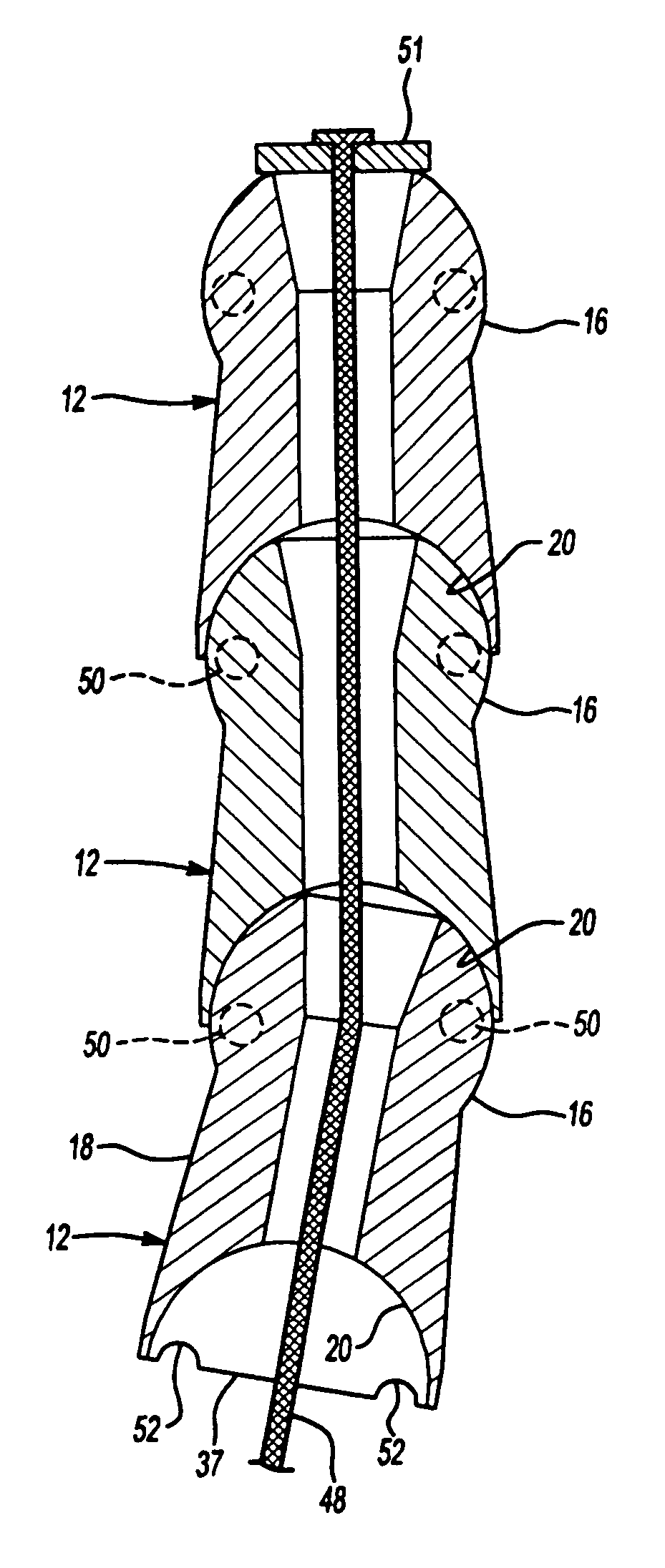

Complex composite structures and method and apparatus for fabricating same from continuous fibers

A method and apparatus for fabricating a complex, three-dimensional structure (12), such as a truss, from composite fiber / resin includes pulling a plurality of continuous fibers (50) from a feed source (62) along a processing path (58) about a longitudinal axis (14). At least some of the fibers are wound around the longitudinal axis in opposite directions (70,72) by rotational elements to form helical and reverse helical components (30, 34) that intersect at nodes (26,28). Select nodes are engaged by engagement members (84) and are maintained radially outwardly from the longitudinal axis by a support frame (80) to create sequential discrete segments (22) in the helical and reverse helical components. The select nodes can be engaged and maintained from outside the helical and reverse helical components. Resin can be applied to the fibers by resin applicator (90) and cured. A three-dimensional structure (200) can be formed with one or more continuous fibers forming two or more different components (204, 206) of the structure and transitioning at transition nodes (207). A three-dimensional structure can be formed with the components including a sleeve (162) of braided fibers surrounding a core (163) of elongated fibers to reduce gaps.

Owner:ISOTRUSS IND LLC

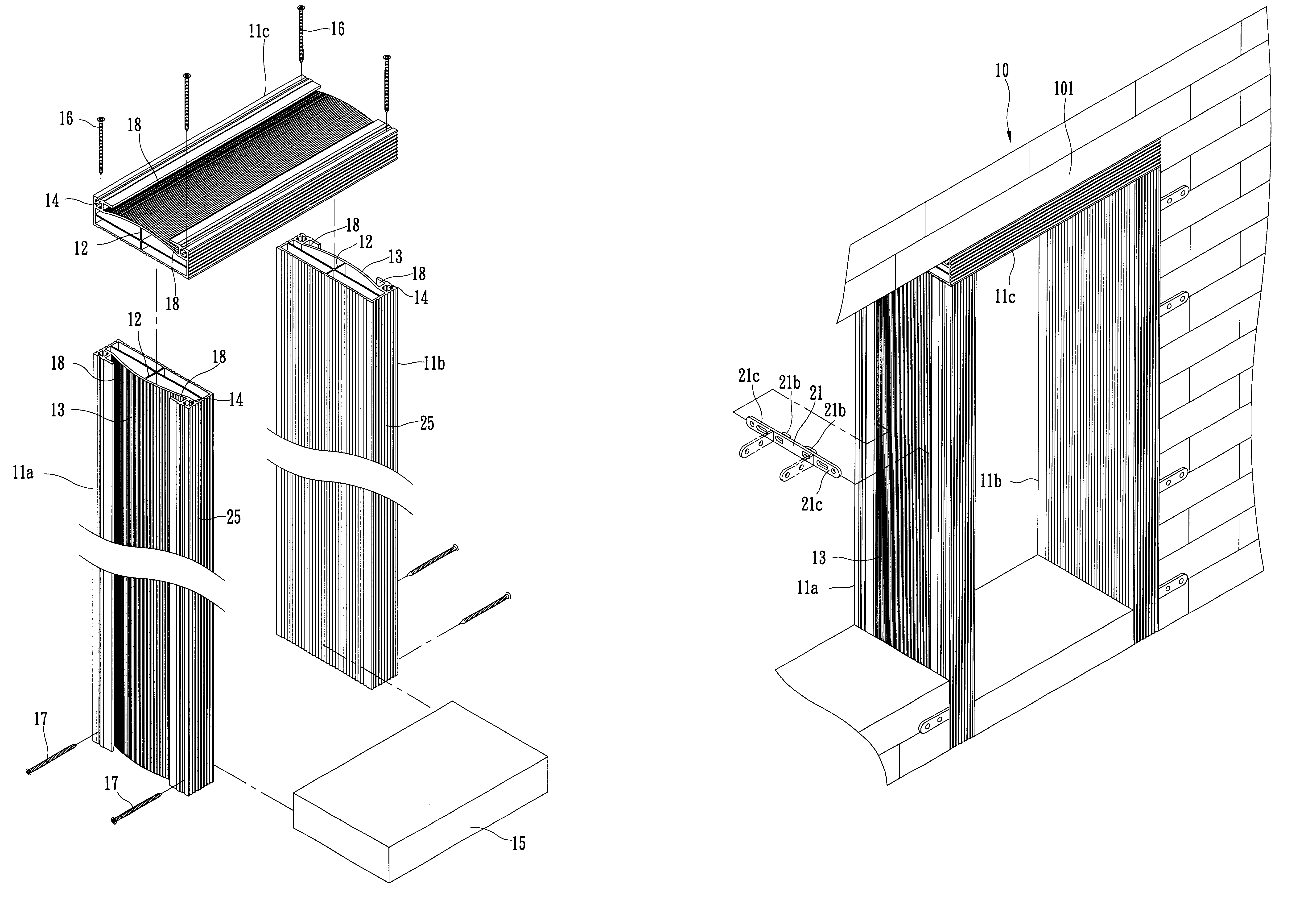

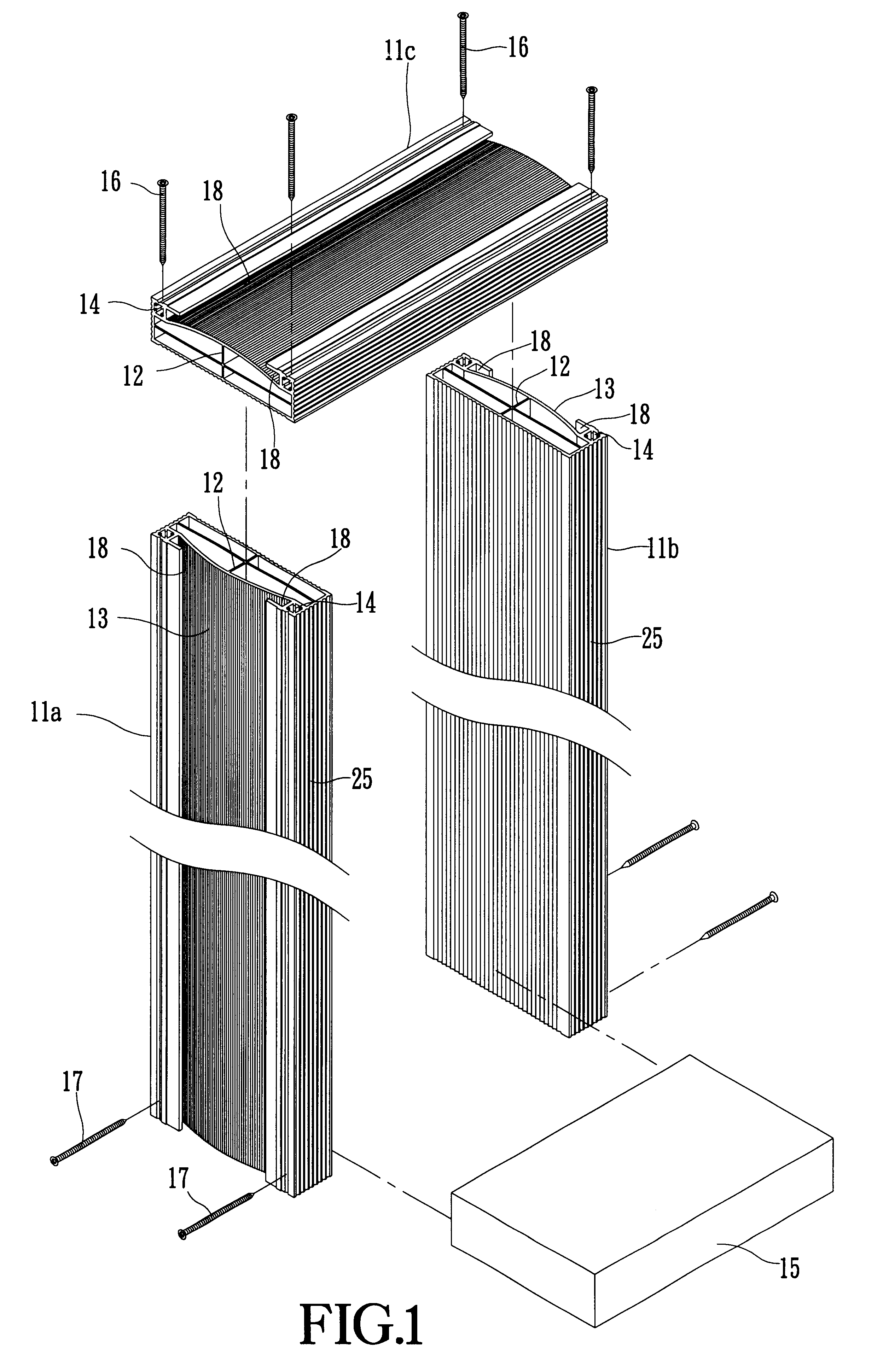

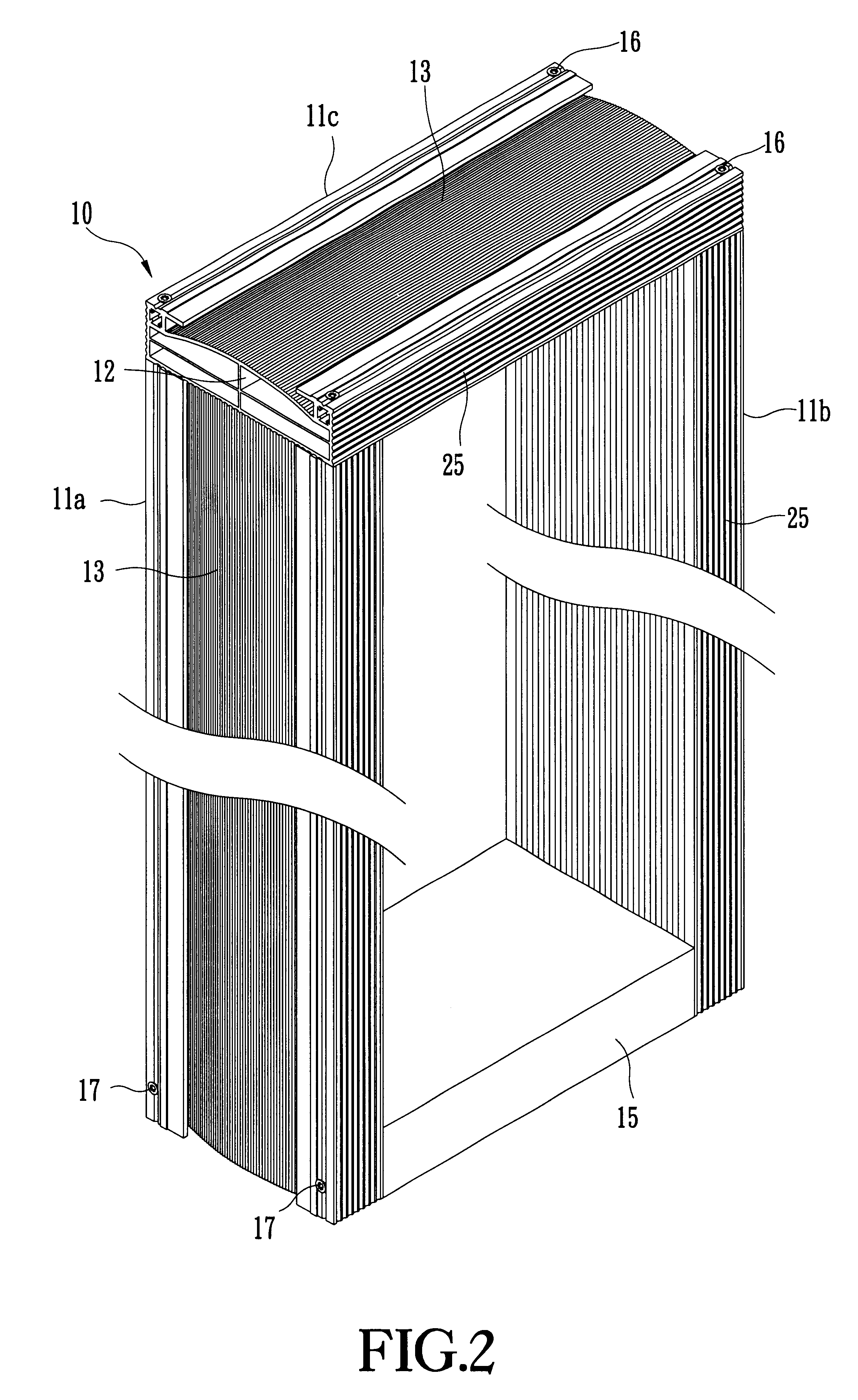

Auxiliary frame for improving conventional frame and method for working the same

InactiveUS6343448B1Easily rottedHigh strengthArched girdersBuilding roofsMetallic materialsEngineering

Owner:LIN CHUN CHEN

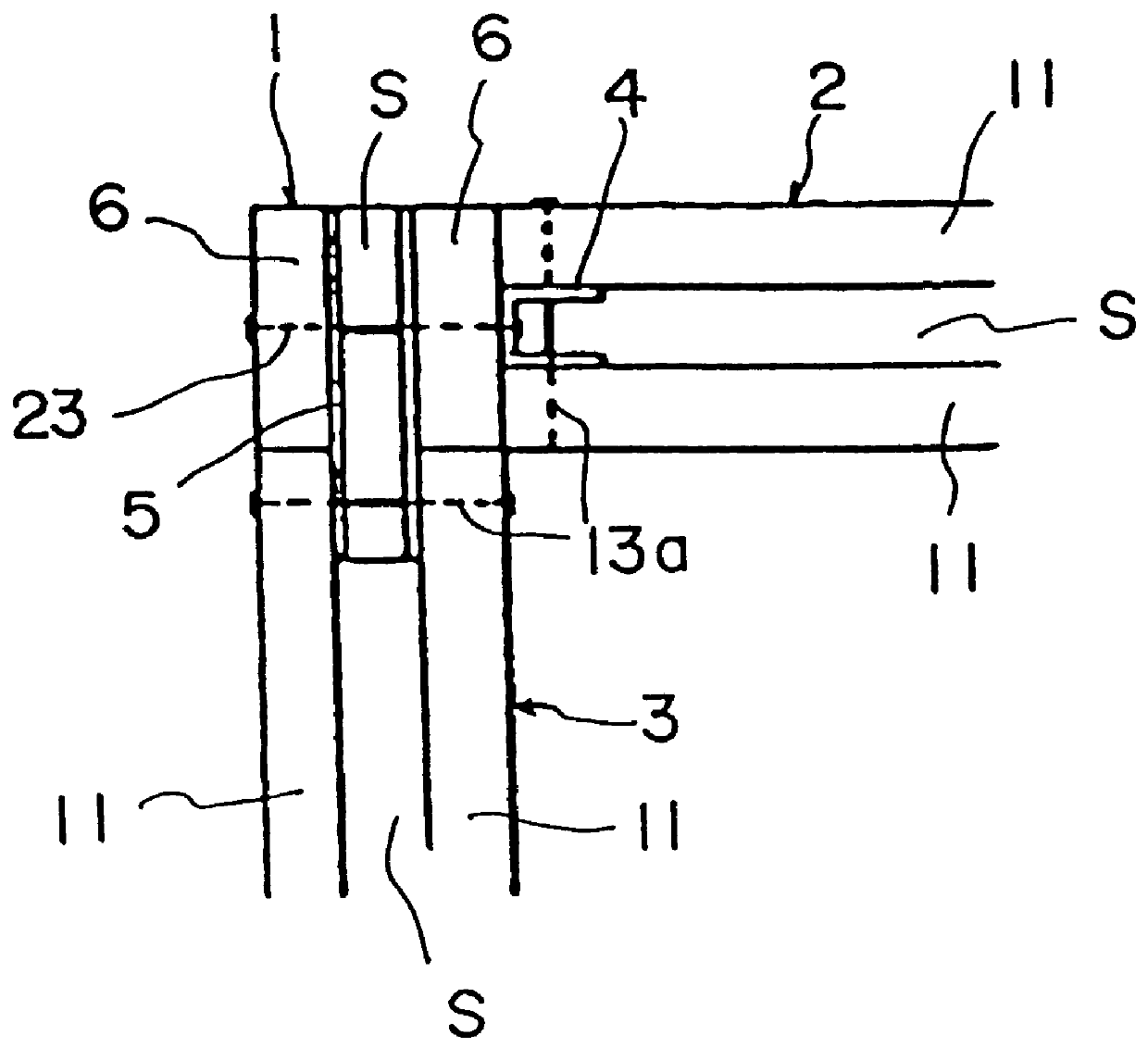

Framing member

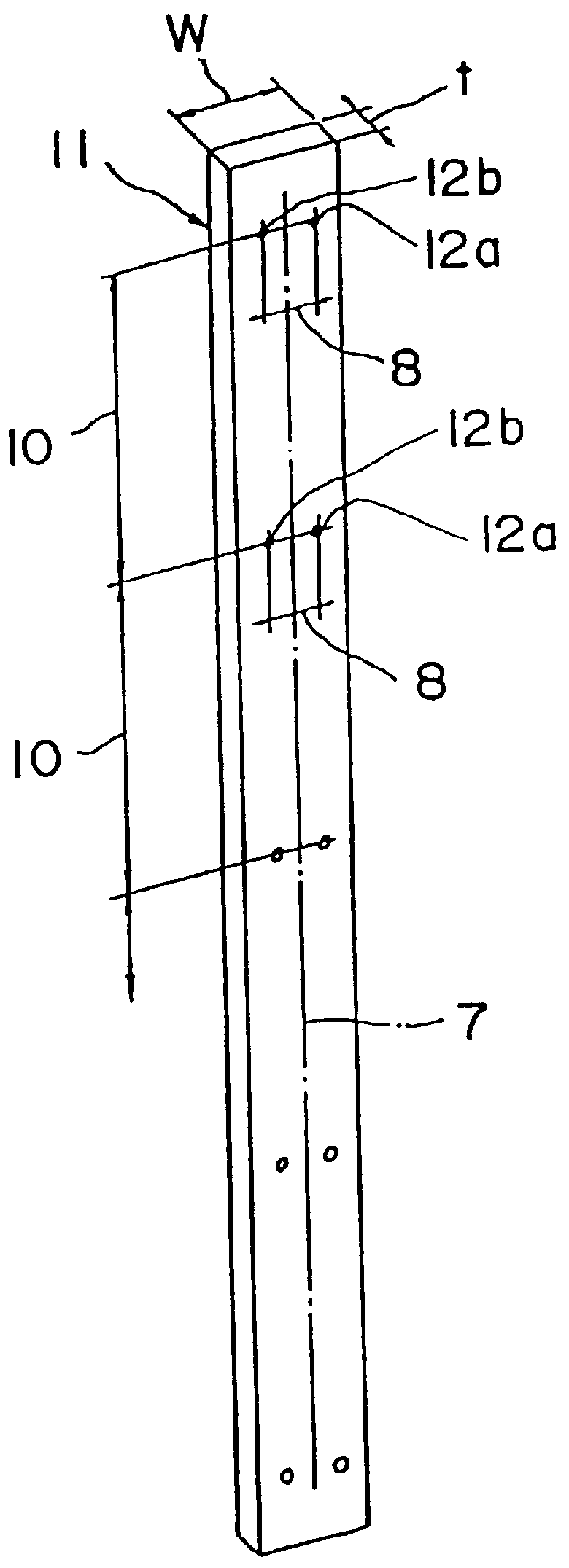

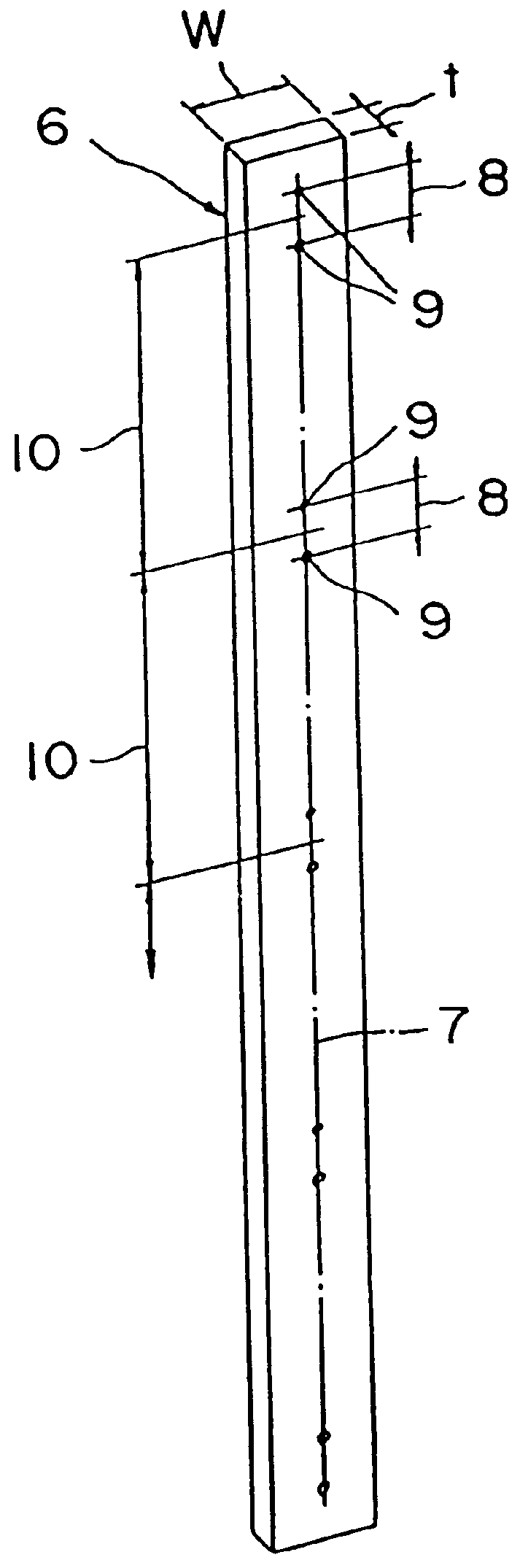

PCT No. PCT / JP96 / 03640 Sec. 371 Date Sep. 25, 1998 Sec. 102(e) Date Sep. 25, 1998 PCT Filed Dec. 12, 1996 PCT Pub. No. WO97 / 22766 PCT Pub. Date Jun. 26, 1997A frame material that can be easily formed as a pillar or beam by appropriately adjusting the length and / or strength thereof, a joint portion of which is uniform and smooth, a residual portion of which can be used as a joint, and which can easily be combined with other building materials. The frame material is formed into an elongate shape, and a cross section crossing at right angles a longitudinal axis thereof is formed into a rectangular shape with the length of a shorter side of the rectangular cross section being made one-third of the length of a longer side. The frame material comprises in combination a frame material in which a pair of through holes (5,5) are provided at a predetermined pitch on a center line (4) of a front side whose lateral width (w) is constituted by the longer side of the cross section, the hole pitch of the pair of through holes being a half of the lateral width, and a frame material in which a pair of through holes (5, 5) are provided on a line crossing at right angles the center lines at a hole pitch of a half of the lateral width in such a manner as to be symmetric with respect to the center line, and pairs of through holes are provided along the center line (4) at the predetermined pitch. In this case, the pitch of the through holes (5, 5) on the center line may be provided so as to be equal to a module dimension of a building material.

Owner:ADO SUPESU

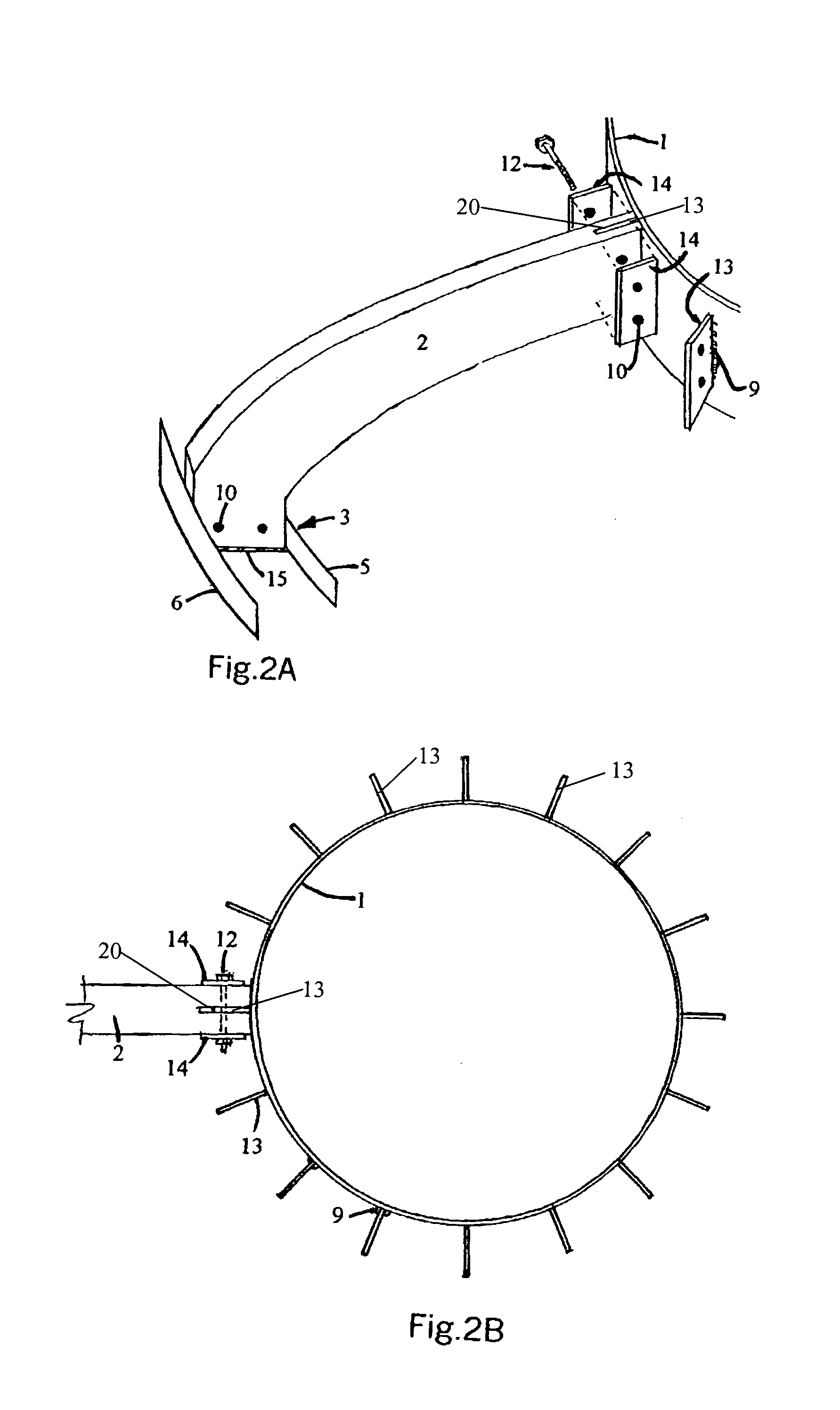

Dome kit, structure and method

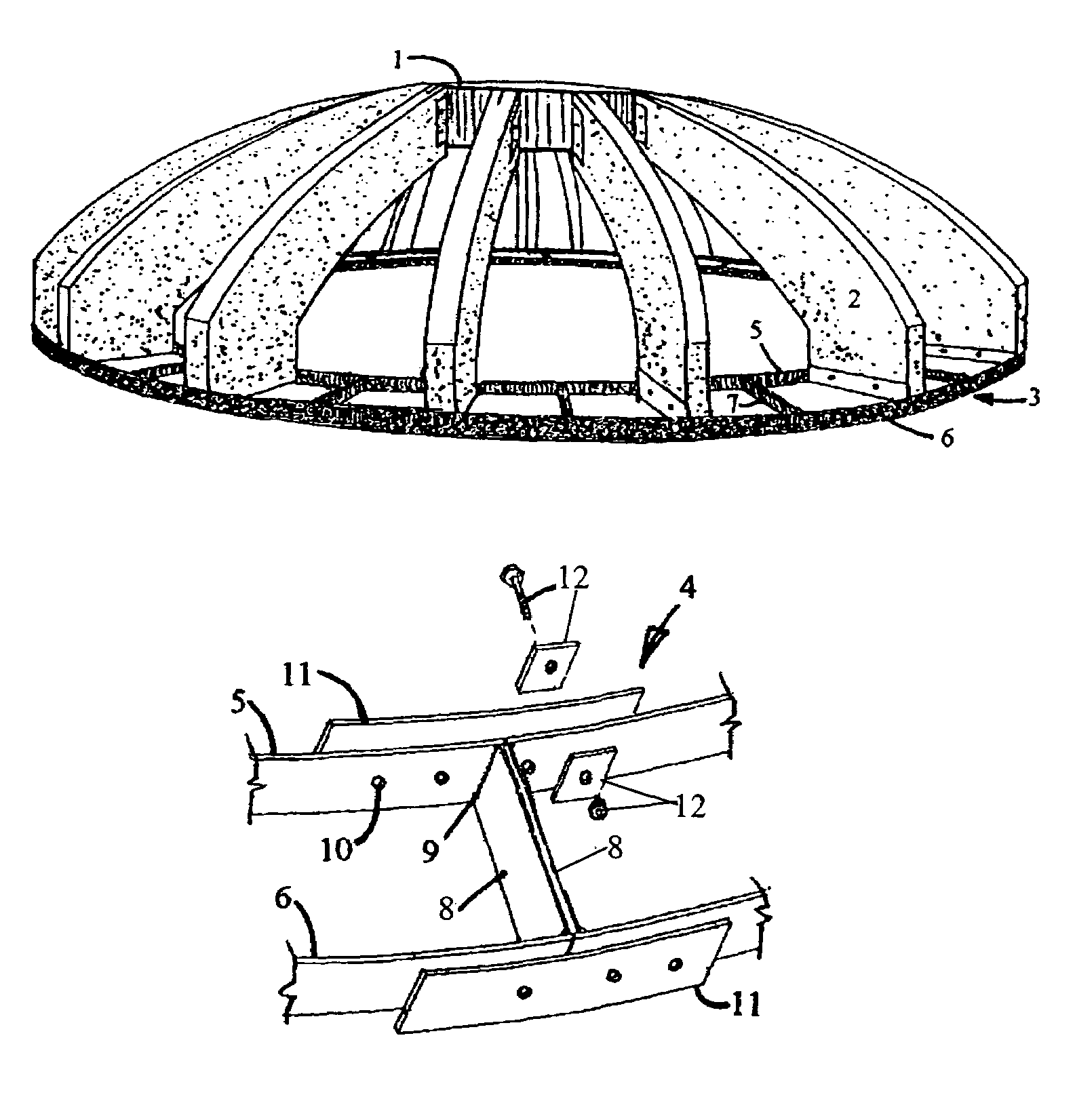

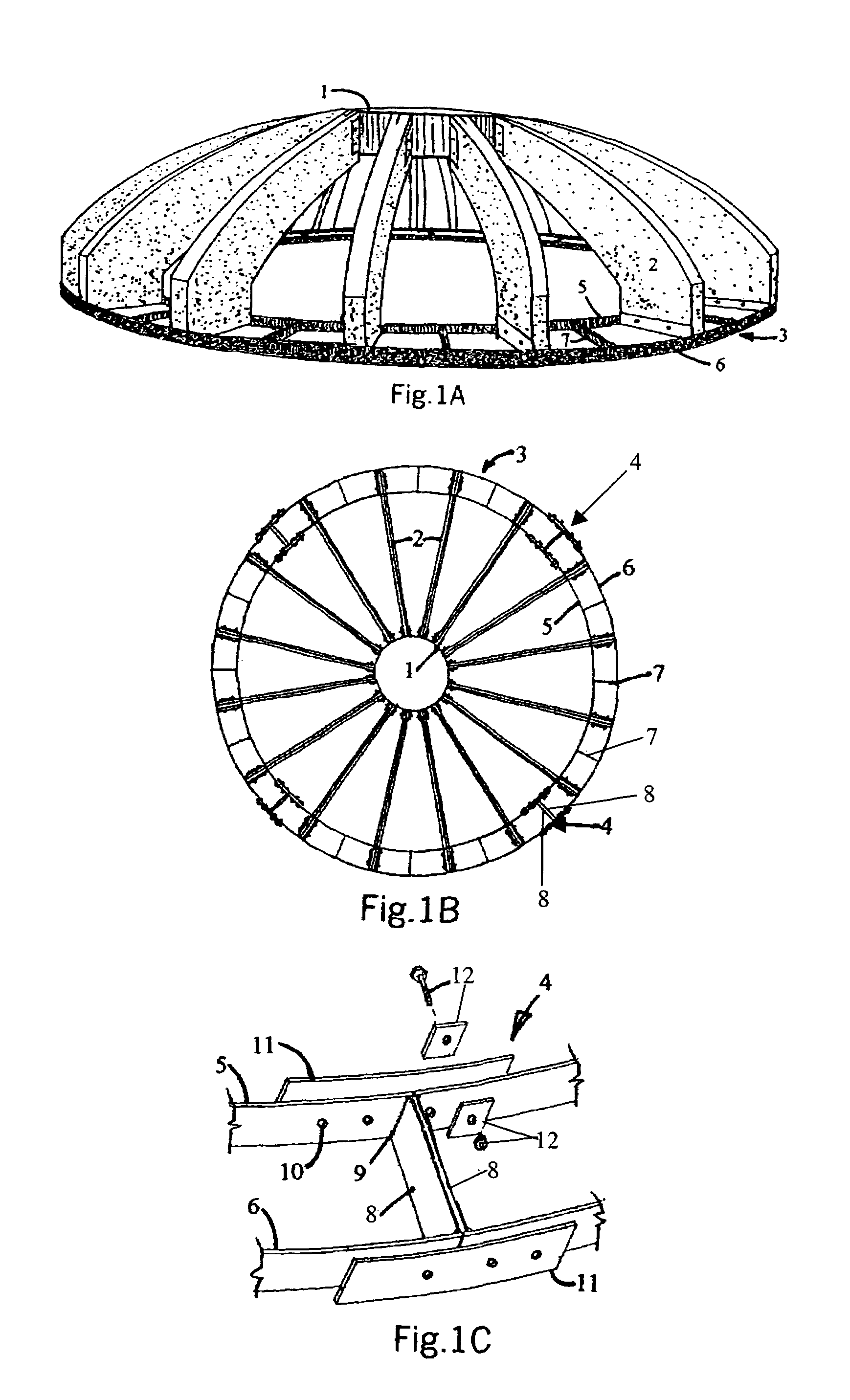

InactiveUS7152384B1Predict costFirmly connectedBuilding roofsArched girdersDome shapeBiomedical engineering

A new and useful Dome Kit, dome shaped structural system and method of assembling a dome shaped structural system are provided. The Dome Kit and method are used to form a dome shaped structural system comprising a compression ring, a lower ring that is larger than the compression ring and spaced below the compression ring, and a plurality of ribs connected with the compression ring. The lower ring, the compression ring, lower ring and connected ribs form a dome shaped structural system; i.e. a structural system with a dome shaped appearance.

Owner:MCCARTY GERALD JOSEPH

Collapsible structural members

A collapsible structural member has been provided in which substantially identical modules made up of metal or plastic are threaded on a tensioning member such as a cable and are movable relative to each other in the collapsed condition of the beam and are brought together into a condition where adjacent modules are locked together to form a rigid construction when the beam is in its erected operating condition. The beam is changed from its erected condition to its collapsed condition by relaxing the tensioning member or cable.

Owner:LUCO ED ENTERPRISES

Truss manufacturing method and system

Methods and systems are provided for making one or more structural stud trusses without the need for using a jig when the truss is assembled. In one embodiment, data identifying a plurality of structural stud members for making the truss is generated. The data includes data for each stud including physical stud parameters and one or more locations for an alignment guide where another member is to connect with it. A roll forming machine is controlled with the generated data to produce the plurality of stud members whereby the roll forming machine applies one or more alignment guides onto each member based on locations identified in the generated data. Finally, after all or some of the stud members are formed, the members are assembled to form the truss using the alignment guides to align connecting members with each other in order to fasten them together.

Owner:KARDOSZ TIMOTHY J +1

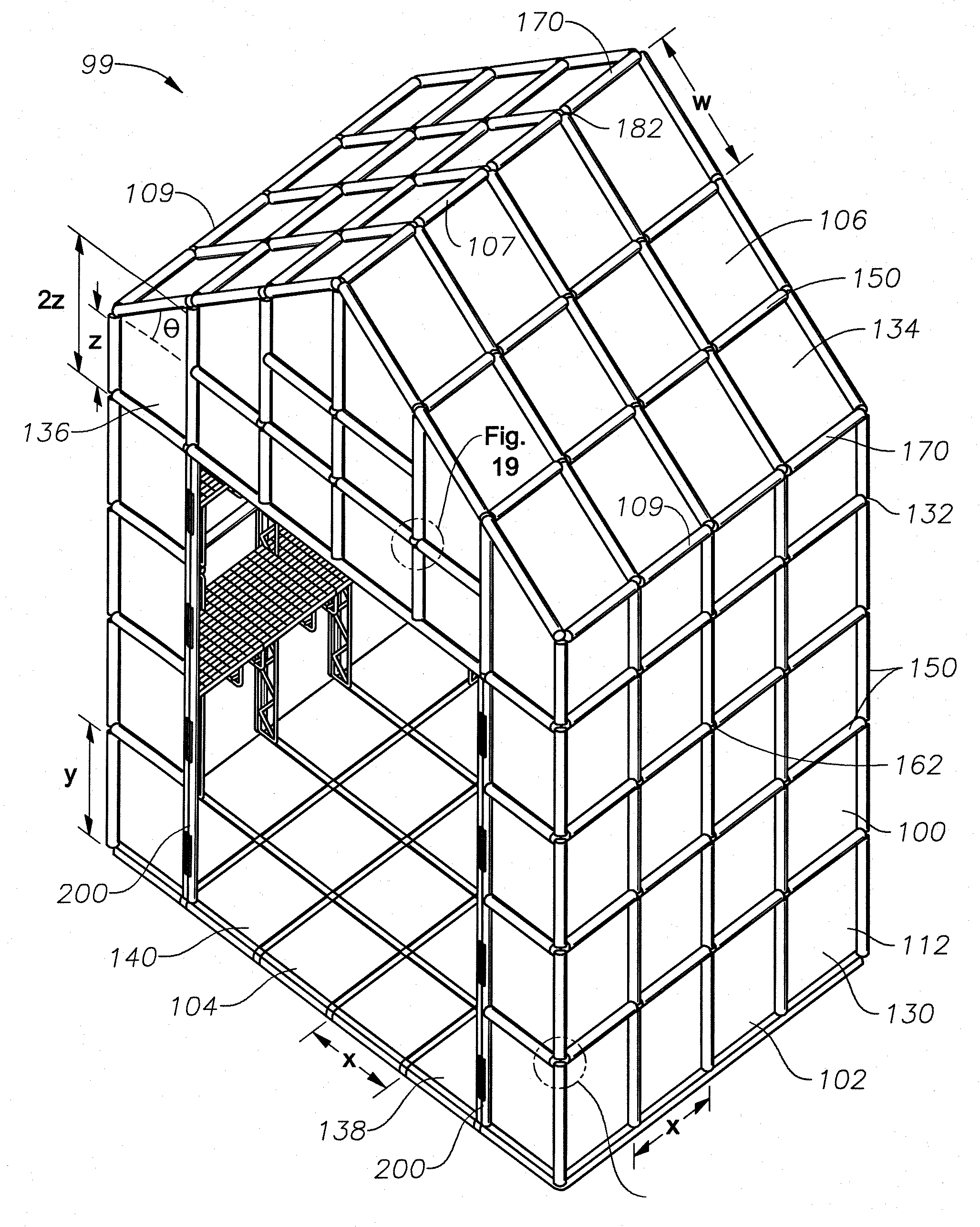

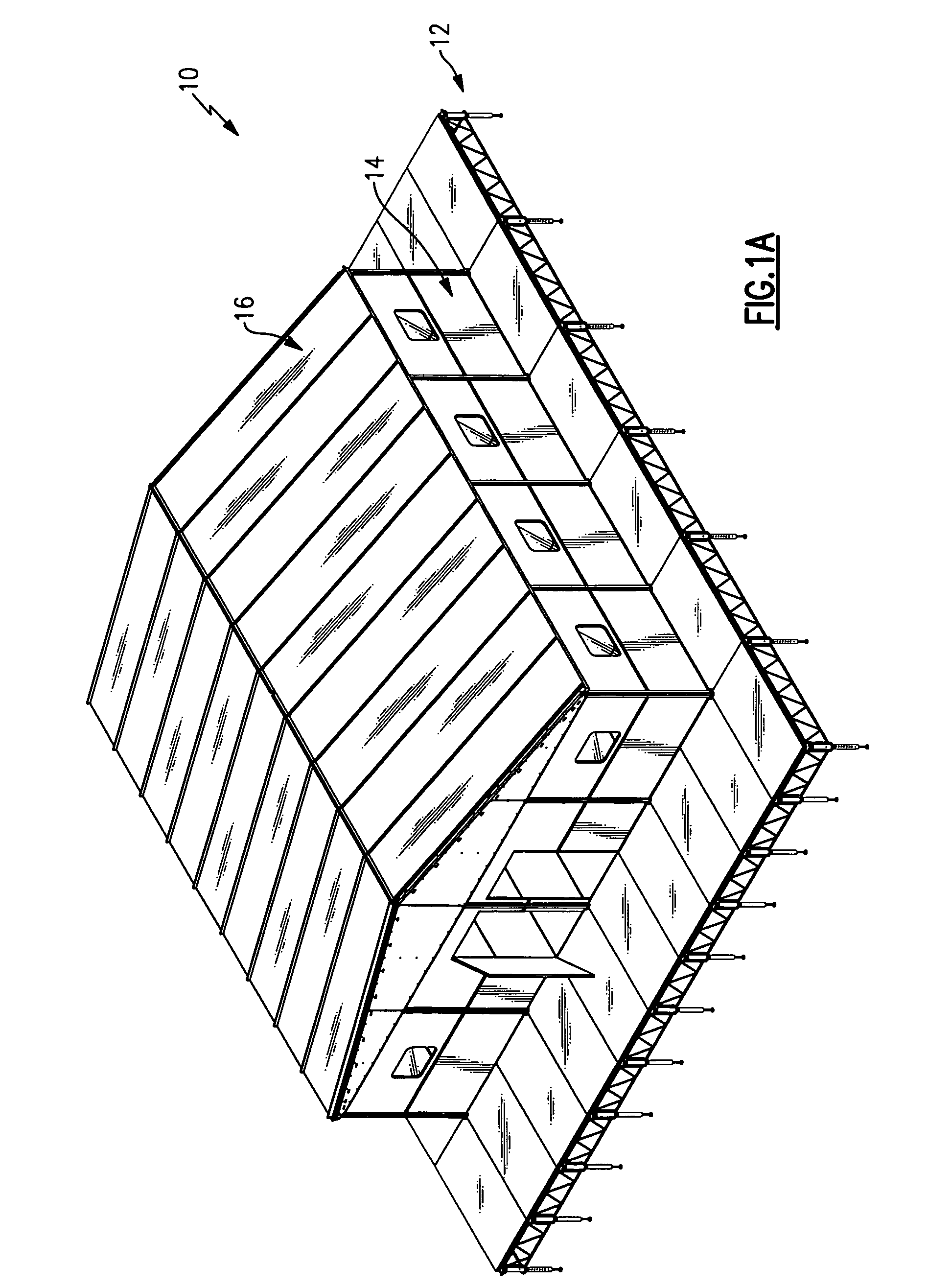

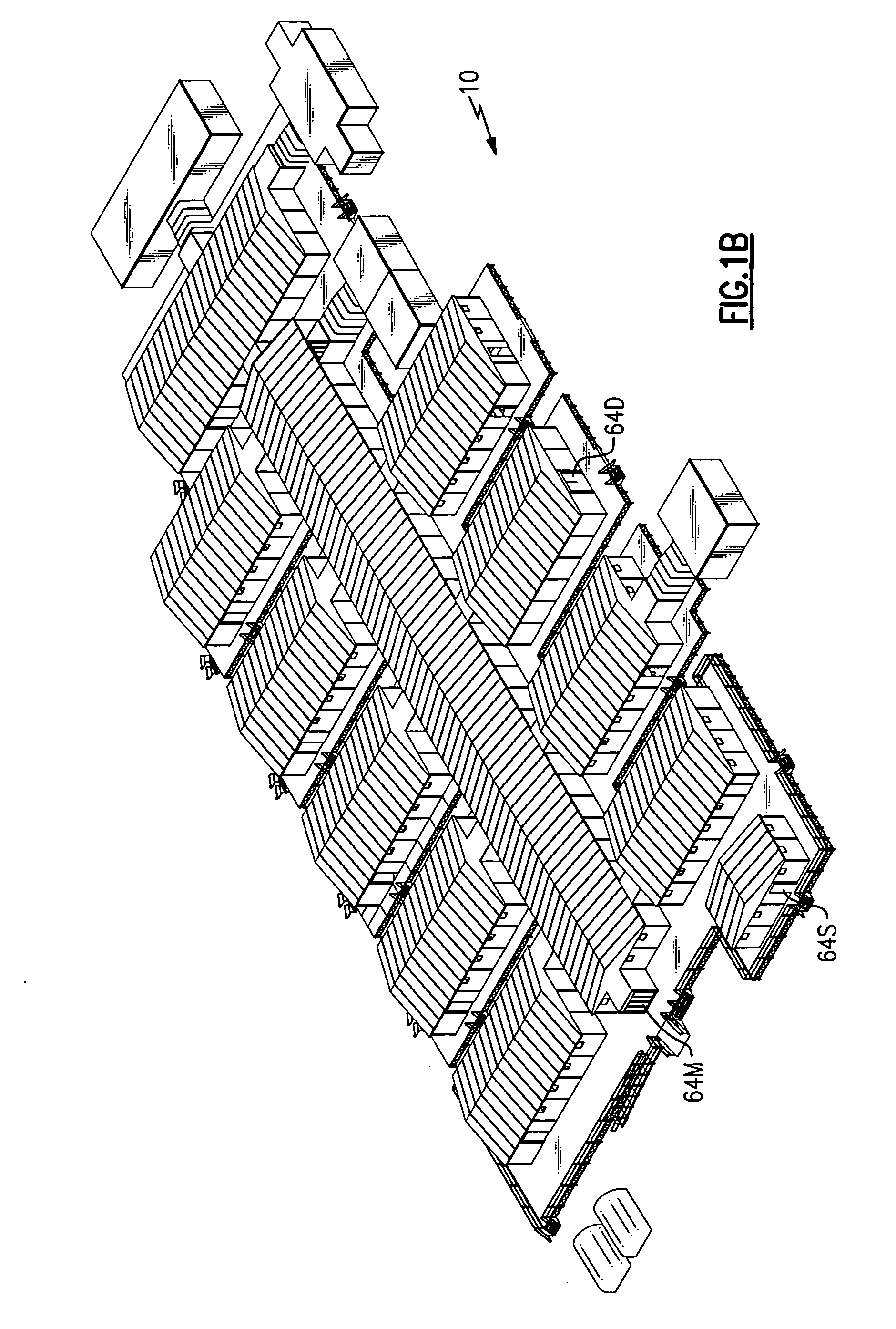

Method and system for a modular building structure

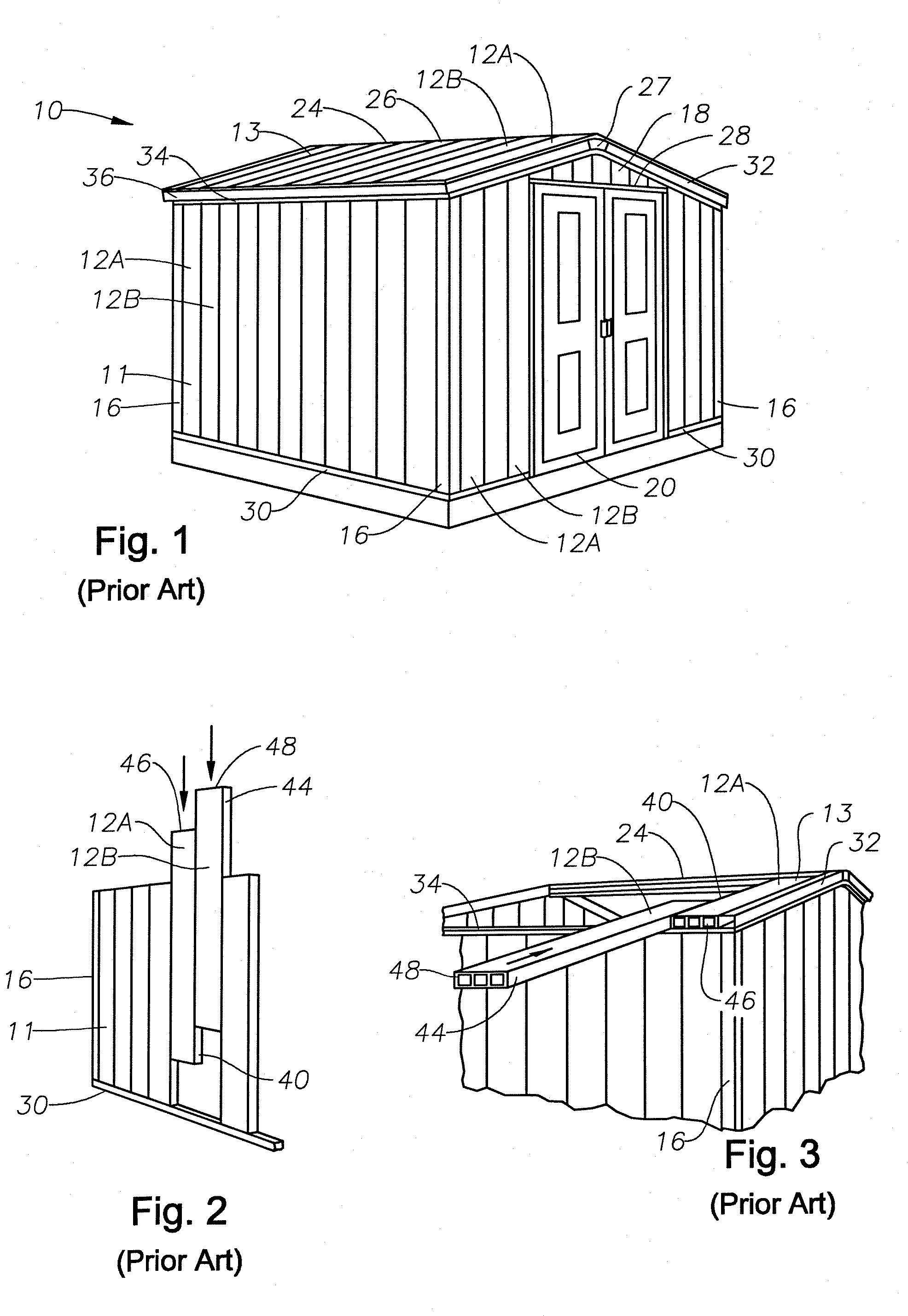

InactiveUS20090165401A1Low-cost factory manufactureRapid and efficient mannerArched girdersBuilding roofsGreenhousePlanar array

A method and system for construction of building structures from a variety of standard size panels having integral dovetail tenons on all four edges and a variety of connectors with corresponding mortises for interlocking the panels. The panels may be horizontally disposed to form floors, ceilings or roofs or may be vertically disposed to form walls. The panels are produced from blow-molded plastic. Panels are interlocked in columns and rows of a planar array to form walls, floors, roofs, etc. Panels can also be interlocked edge to edge in a non-planar orthogonal manner, allowing the panels to be interconnected in virtually unlimited ways. Plastic frame members with trussing interconnect to the panels to provide rigidity and strength to the assembled building structure. The panels may be formed of opaque material for ordinary sheds or of transparent or translucent material for greenhouses.

Owner:SMALLEY III ARTHUR L

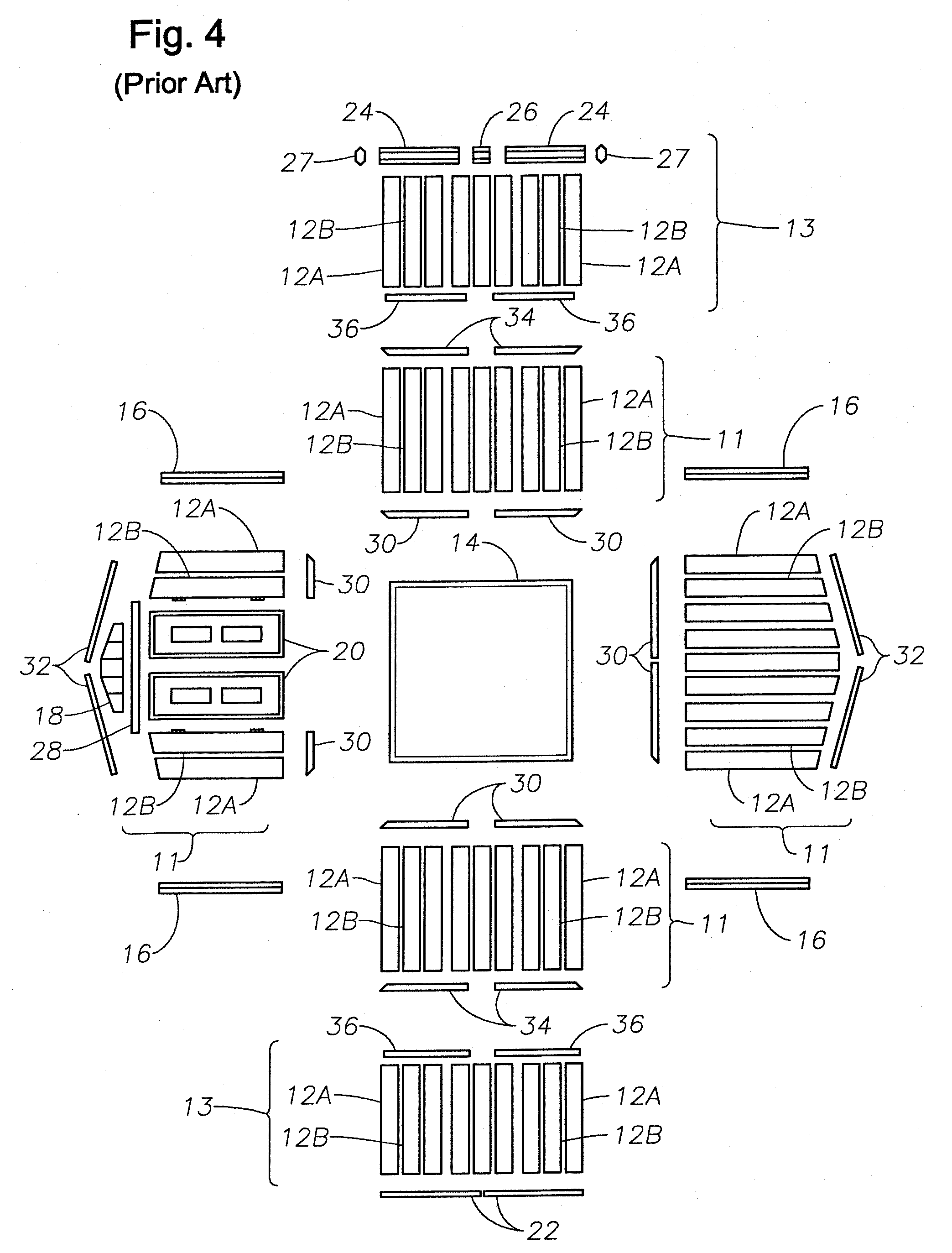

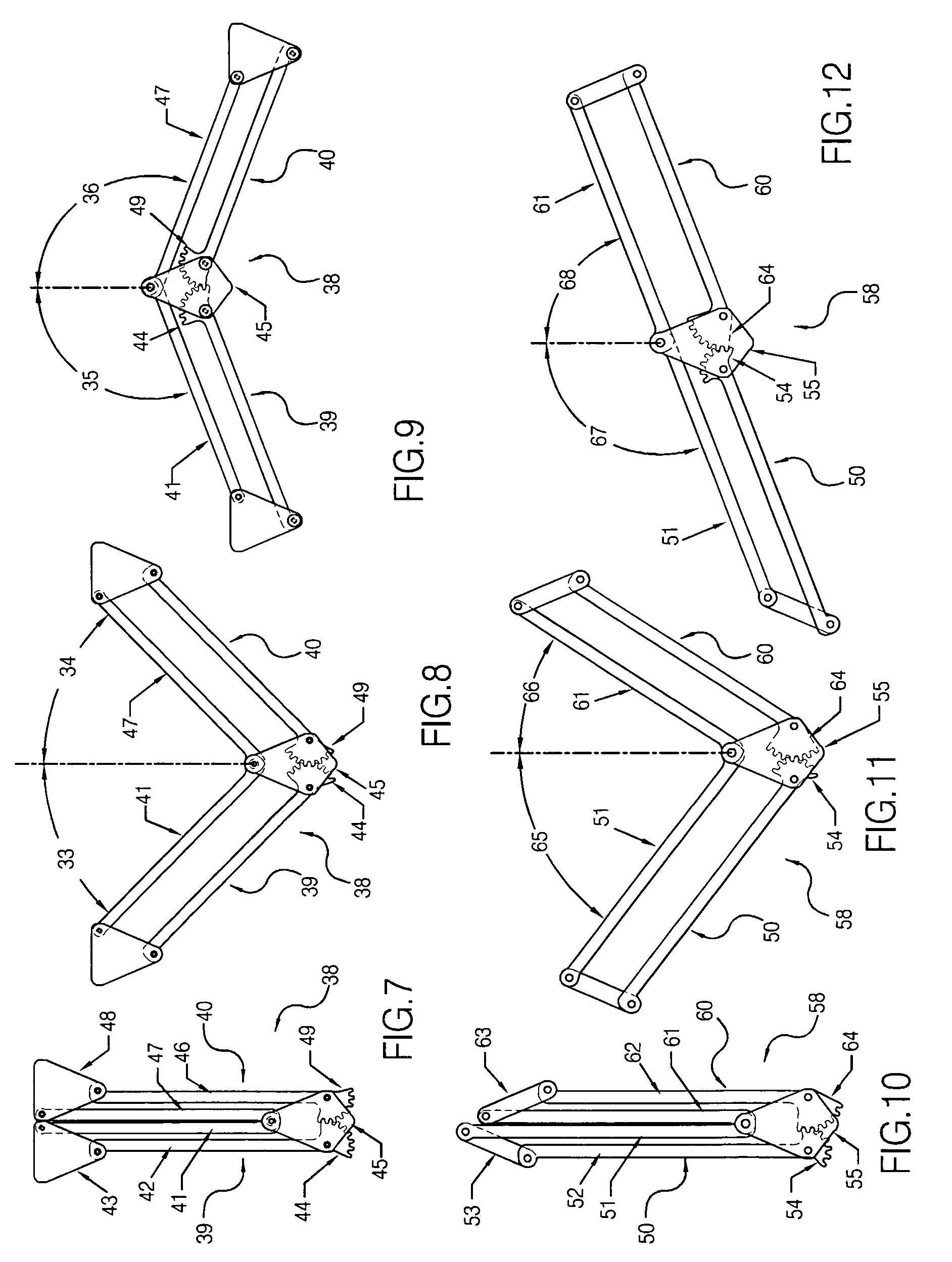

Synchronized four-bar linkages

ActiveUS7644721B2Rapidly deployableEasy to deployBuilding roofsPaper/cardboard articlesEngineeringLinkage concept

Owner:RAPID DEPLOYABLE SYST LLC

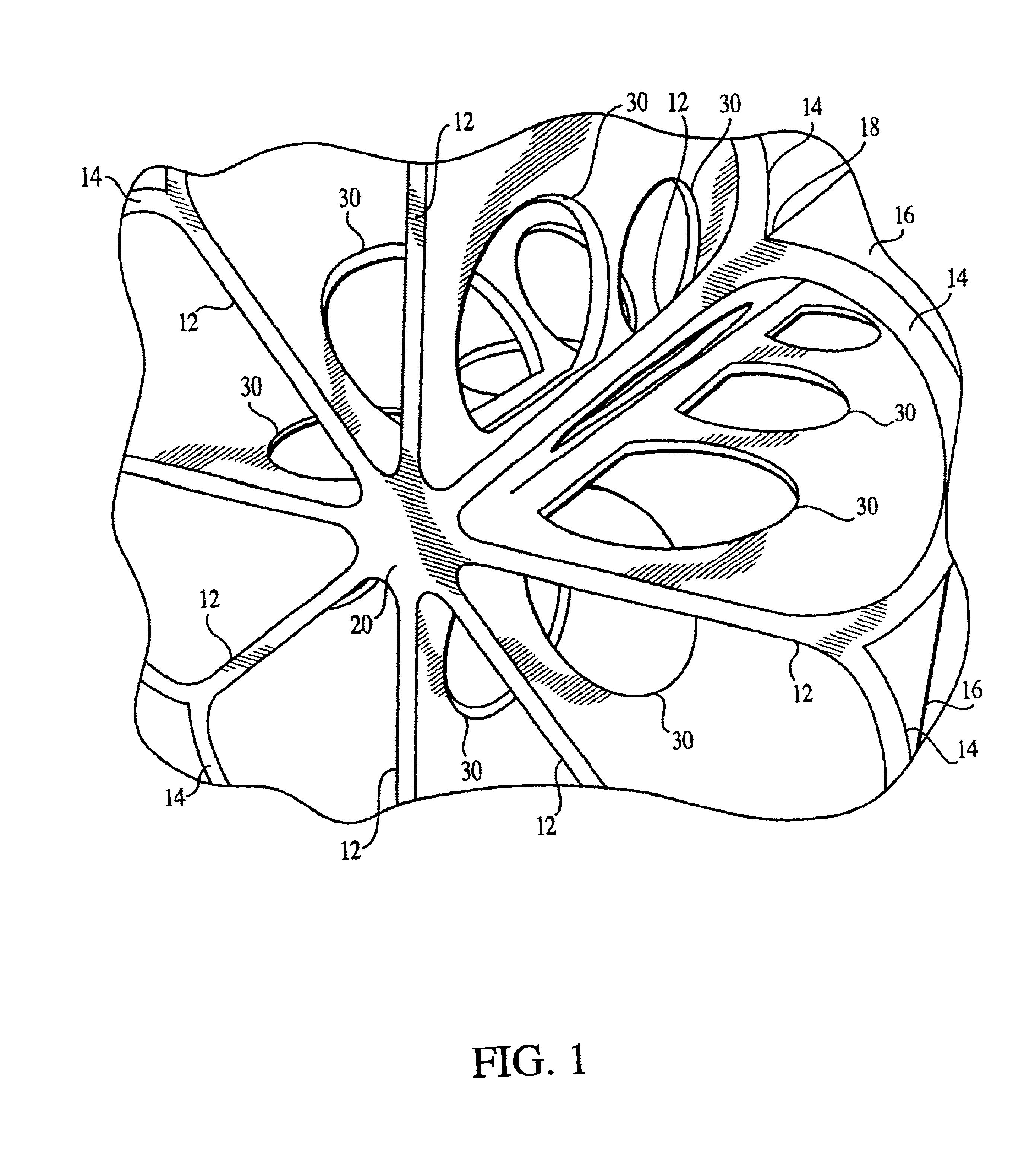

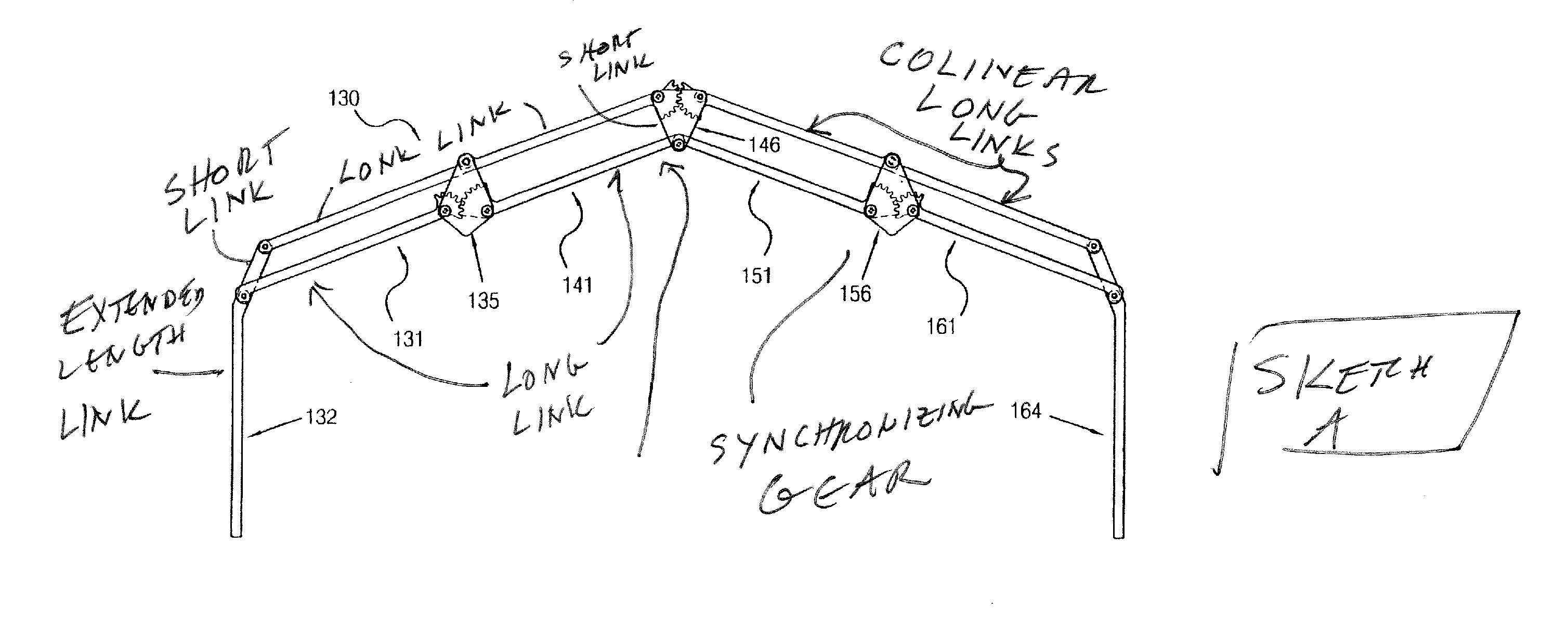

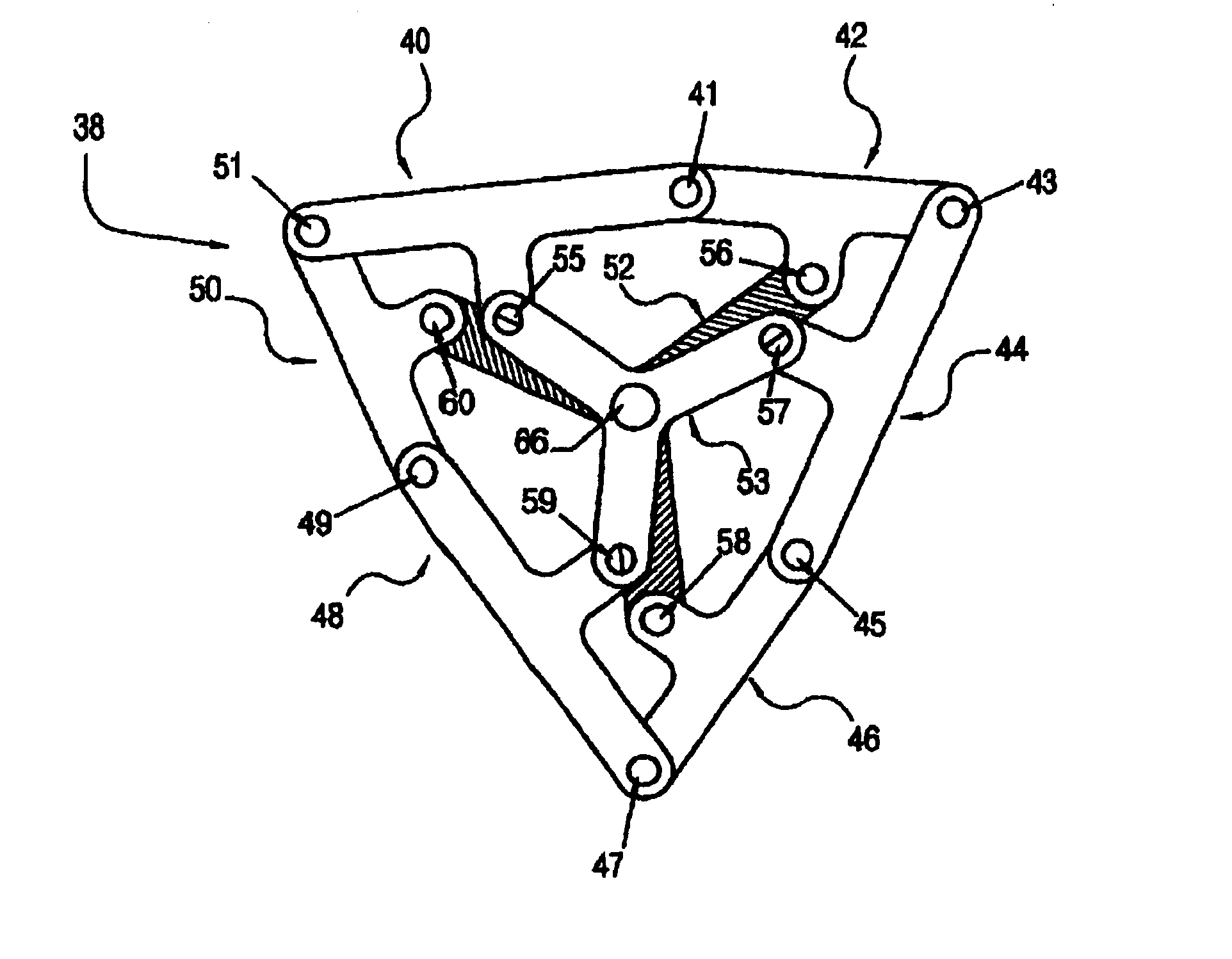

Loop assemblies having a central link

InactiveUS7100333B2Maintain good propertiesAbility to useWalking sticksArched girdersEngineeringPivot joint

Improved reversibly expandable structures are formed from novel loop assemblies comprising a plurality of links, each of said links having at least one center pivot joint and a plurality of end pivot joints, each of at least two of said plurality of end pivot joints proximate to the outer edge of said loop assembly and connected to another link; each of said plurality of links being connected to another one of said plurality of links by at least two end pivot joints thereby forming a link pair, said loop assembly comprising at least three link pairs, each of said at least three link pairs connected to at least two other link pairs through at least one of said end pivot joints; each of said at least three link pairs connected to a central piece that is central to the loop assembly, said central piece being rotatable around a central axis, wherein the rotation of the central piece reversibly expands said loop assembly.

Owner:HOBERMAN CHARLES

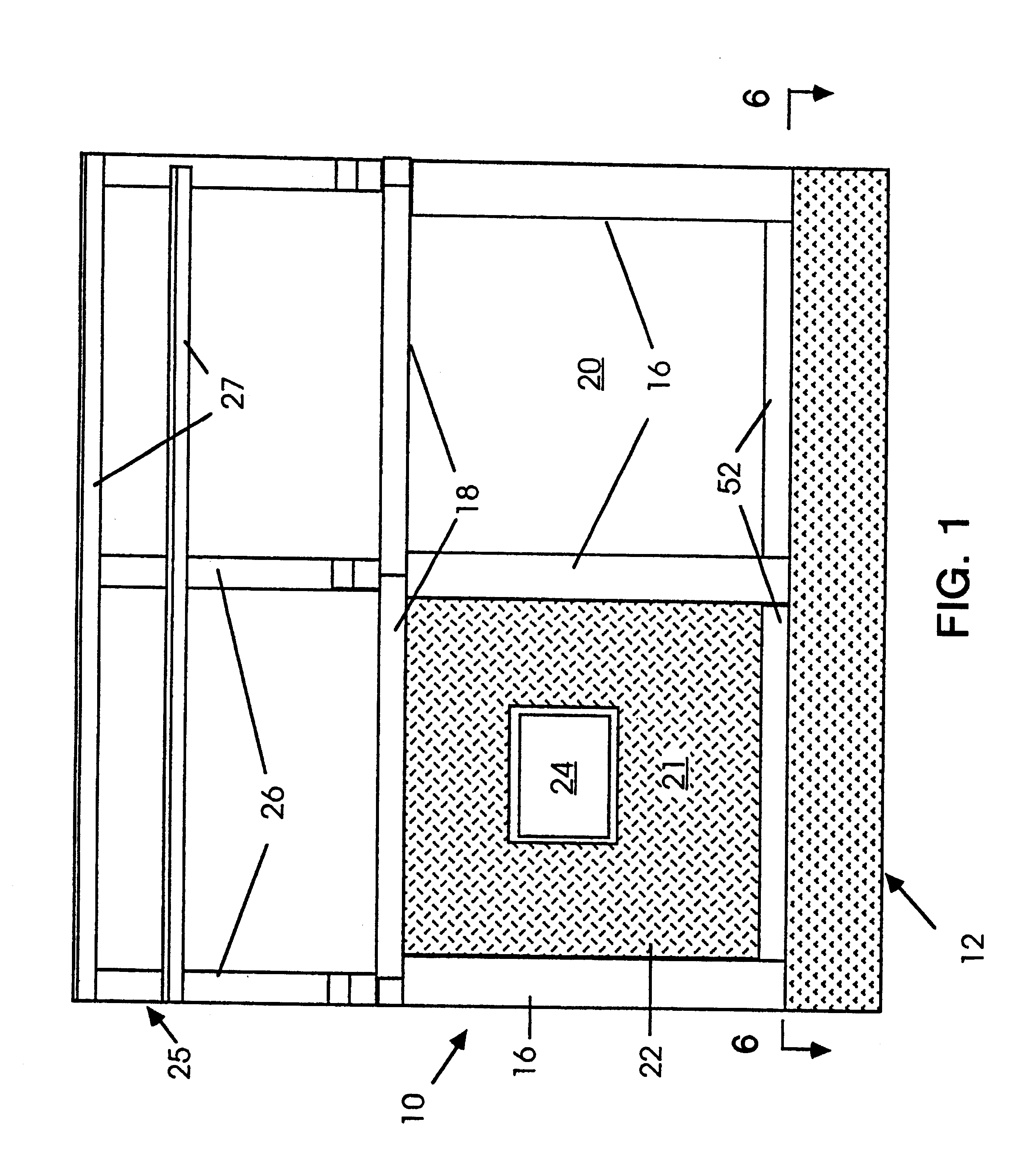

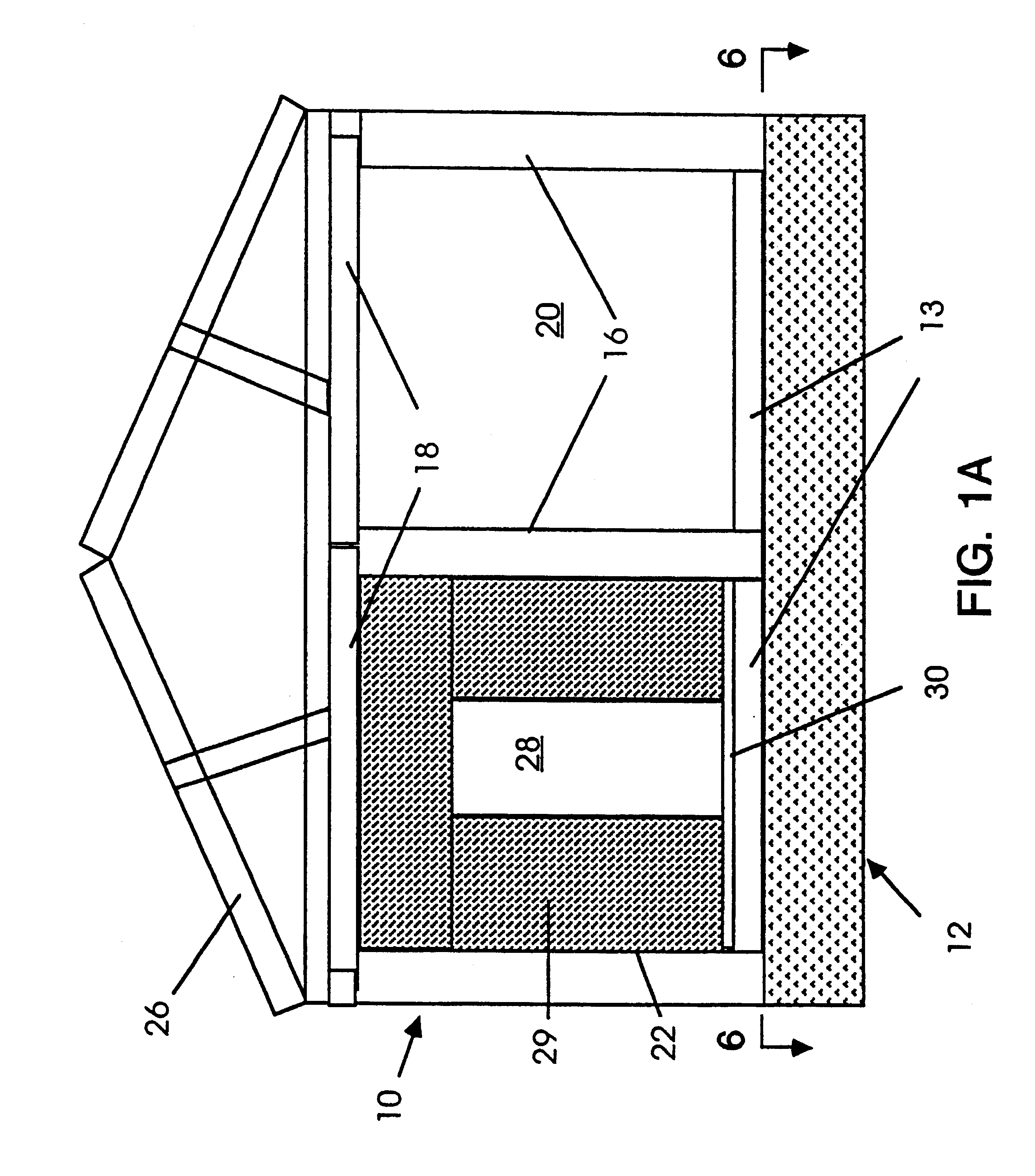

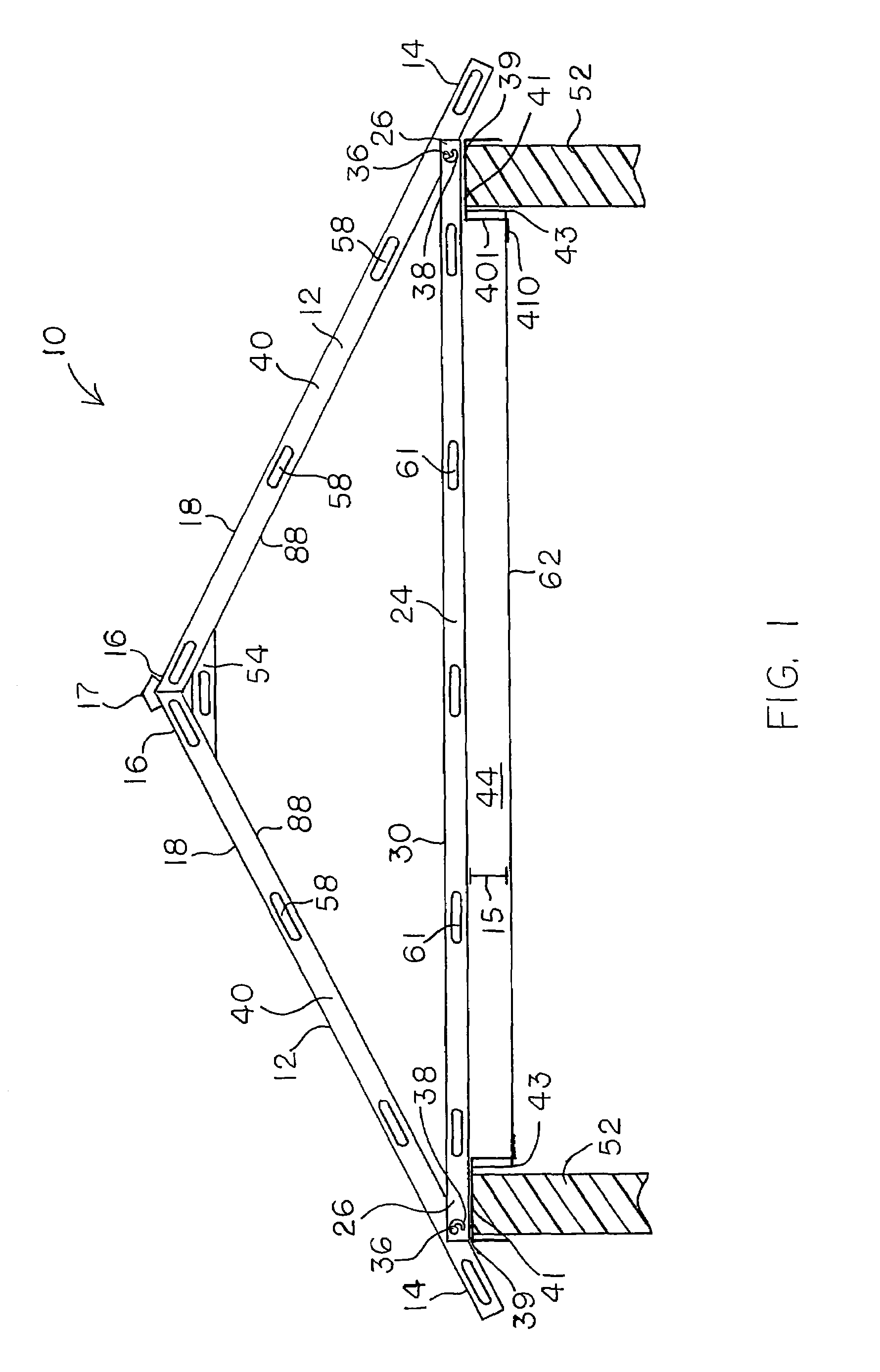

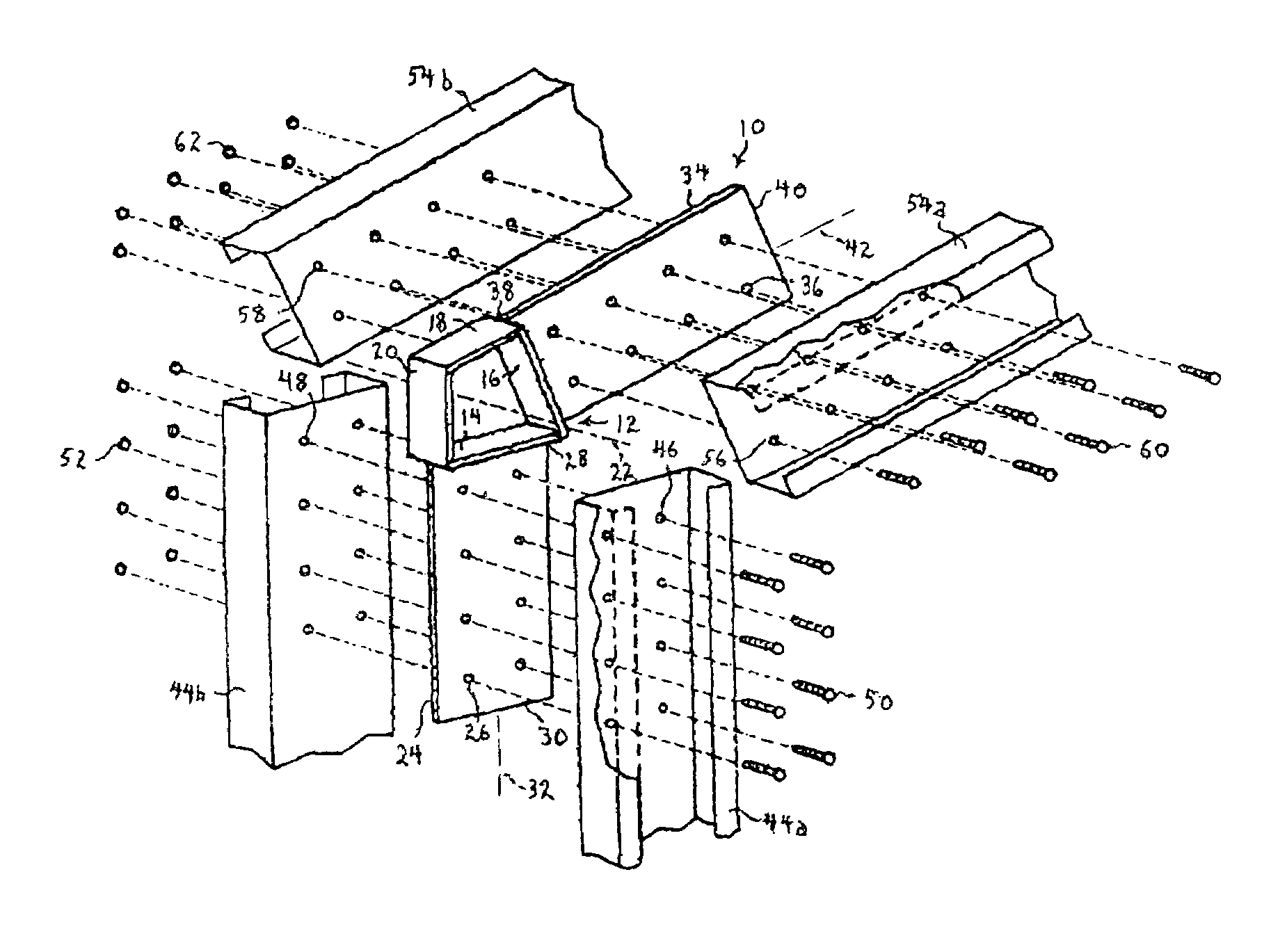

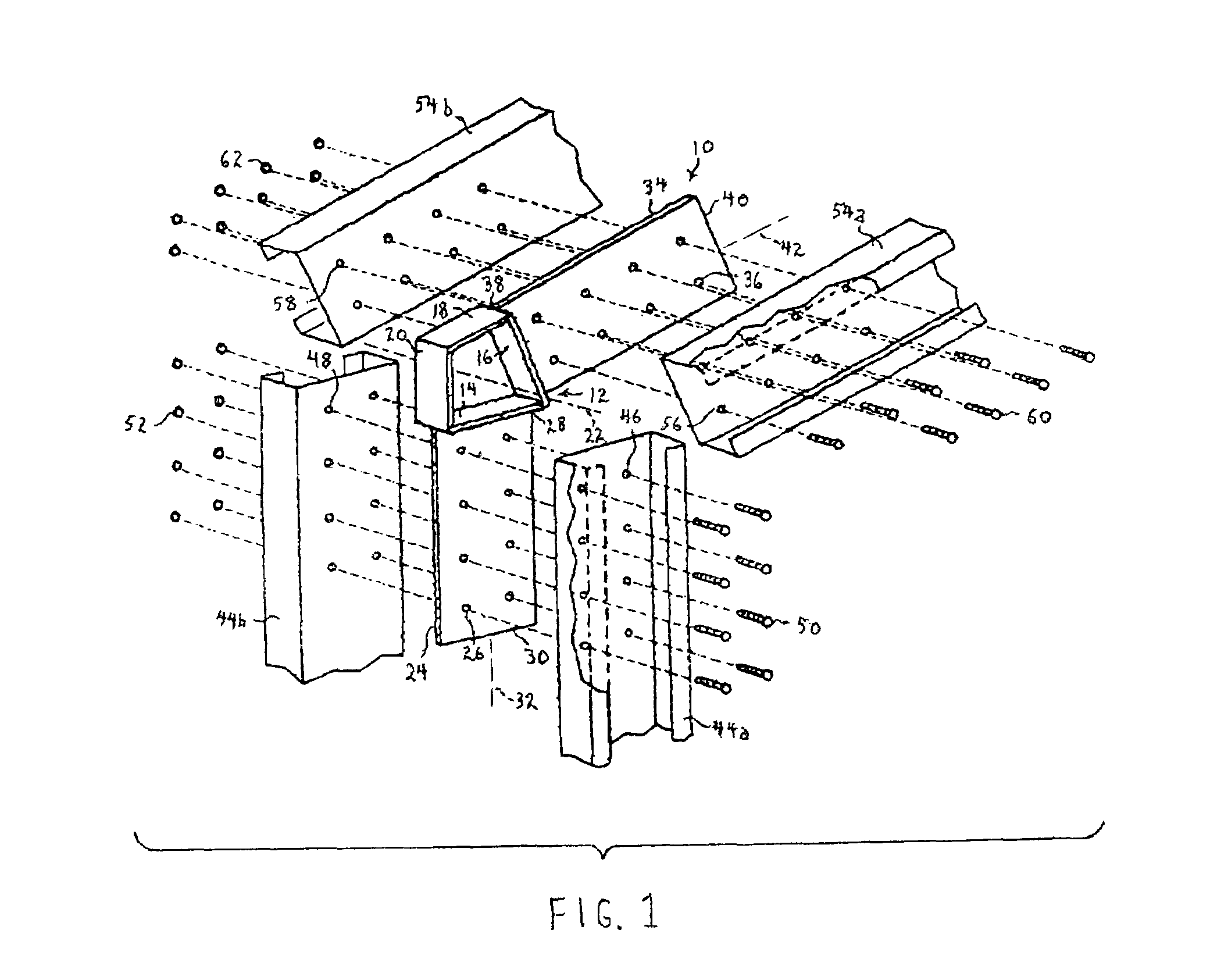

Framing in a building assembly

InactiveUS7739841B1Firmly connectedMaximize available spaceBuilding roofsArched girdersAcute angleEngineering

The invention relates to framing for a ready to assemble building, which employs a novel connector for connection of a column to a rafter (“knee connector”) or a rafter to another rafter (“peak connector”). The connector includes a hub comprising multiple substantially planar hub portions. The hub portions include a first hub portion, a second hub portion integrally connected to the first hub portion so as to define an acute angle with respect thereto, and at least one other hub portion integrally connected between the first and second hub portions. The connector further includes first and second legs comprised of elongated plates. The first leg perpendicularly extends outwardly from the first hub portion, and the second leg perpendicularly extends outwardly from the second hub portion. Each leg has a plurality of holes therethrough for alignment with corresponding holes in a structural member, preferably light gauge C-channel. Suitable fasteners are receivable through holes in a leg as aligned with corresponding holes in a structural member.

Owner:EXCEL METAL BUILDING SYST

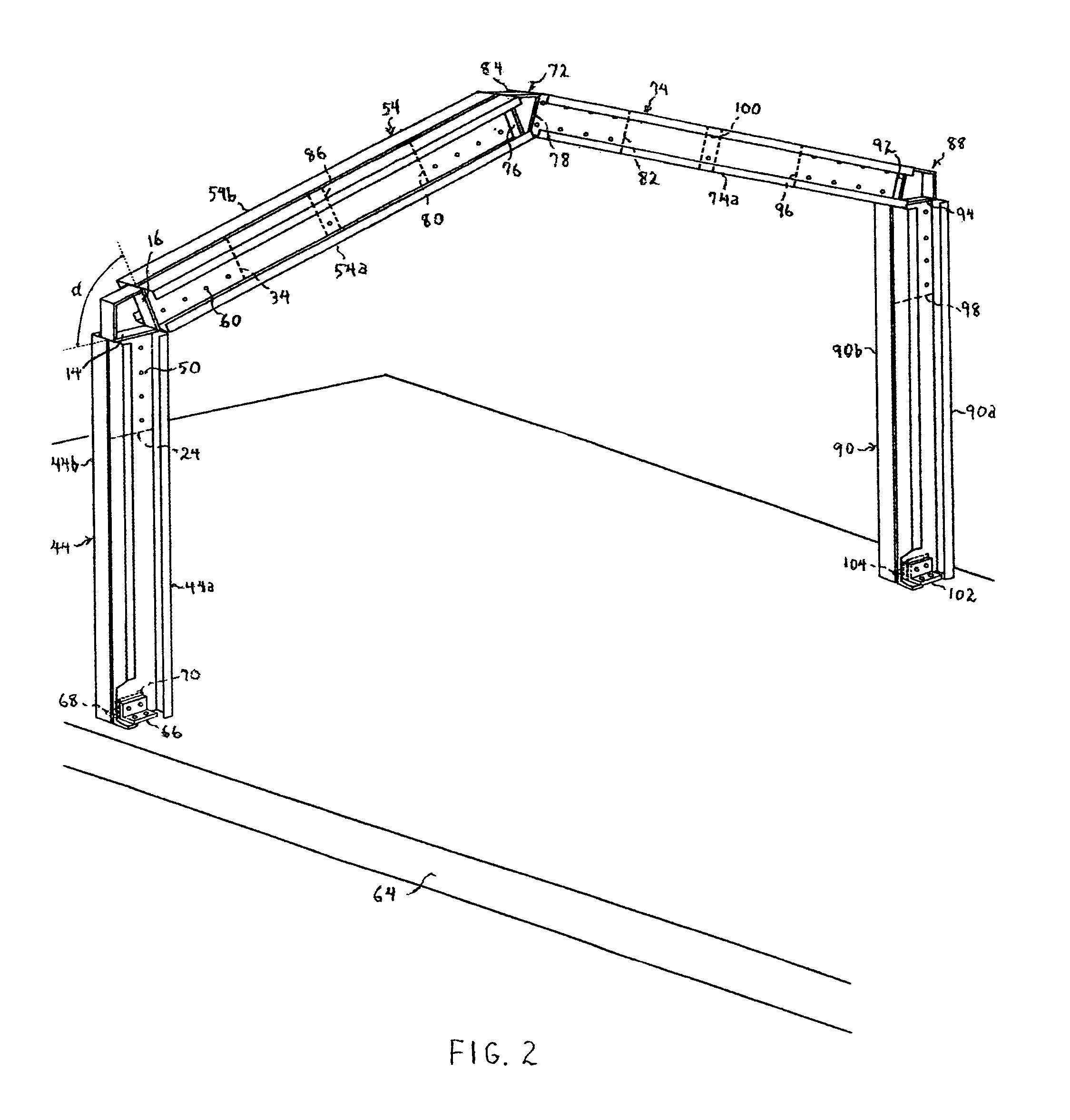

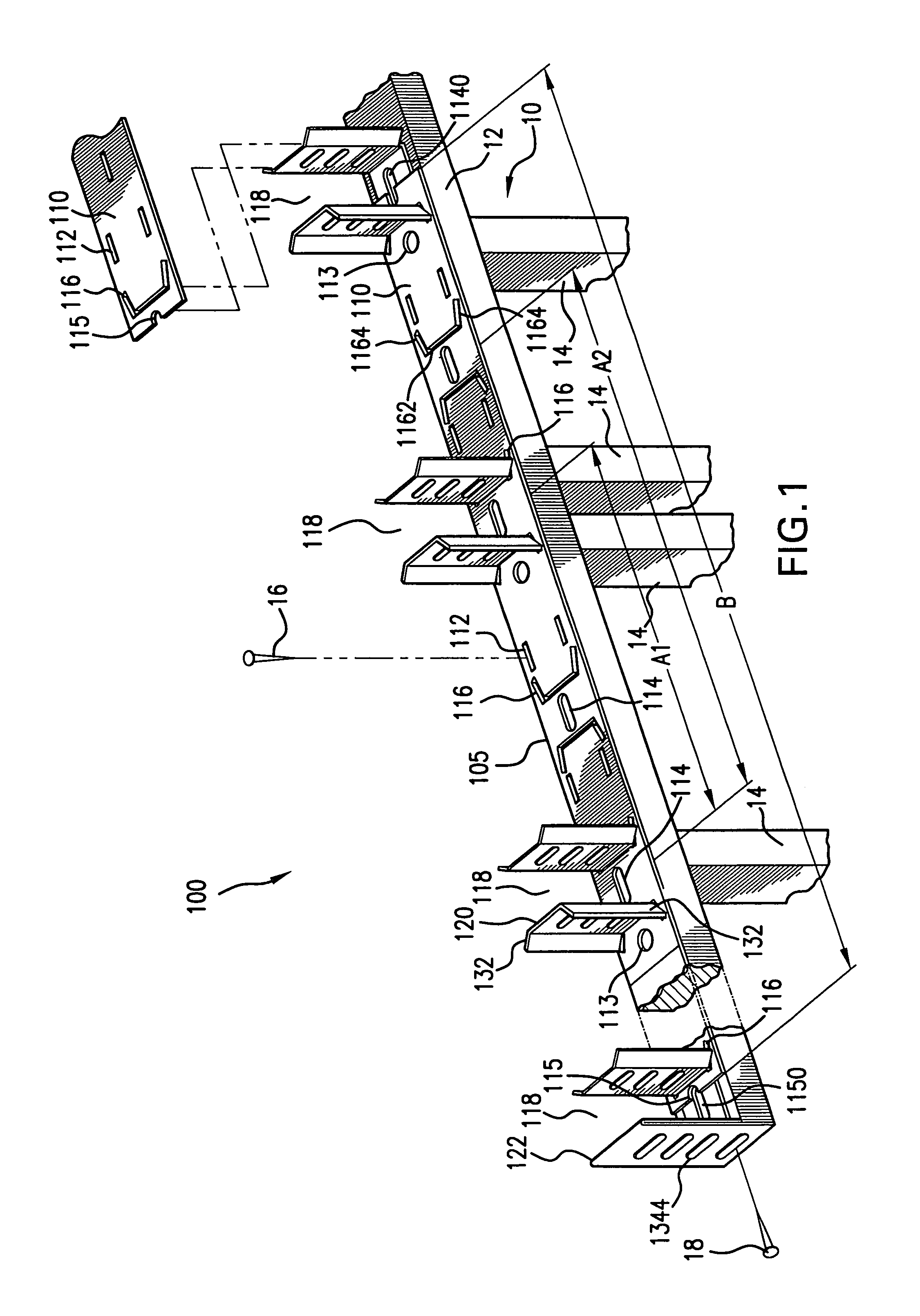

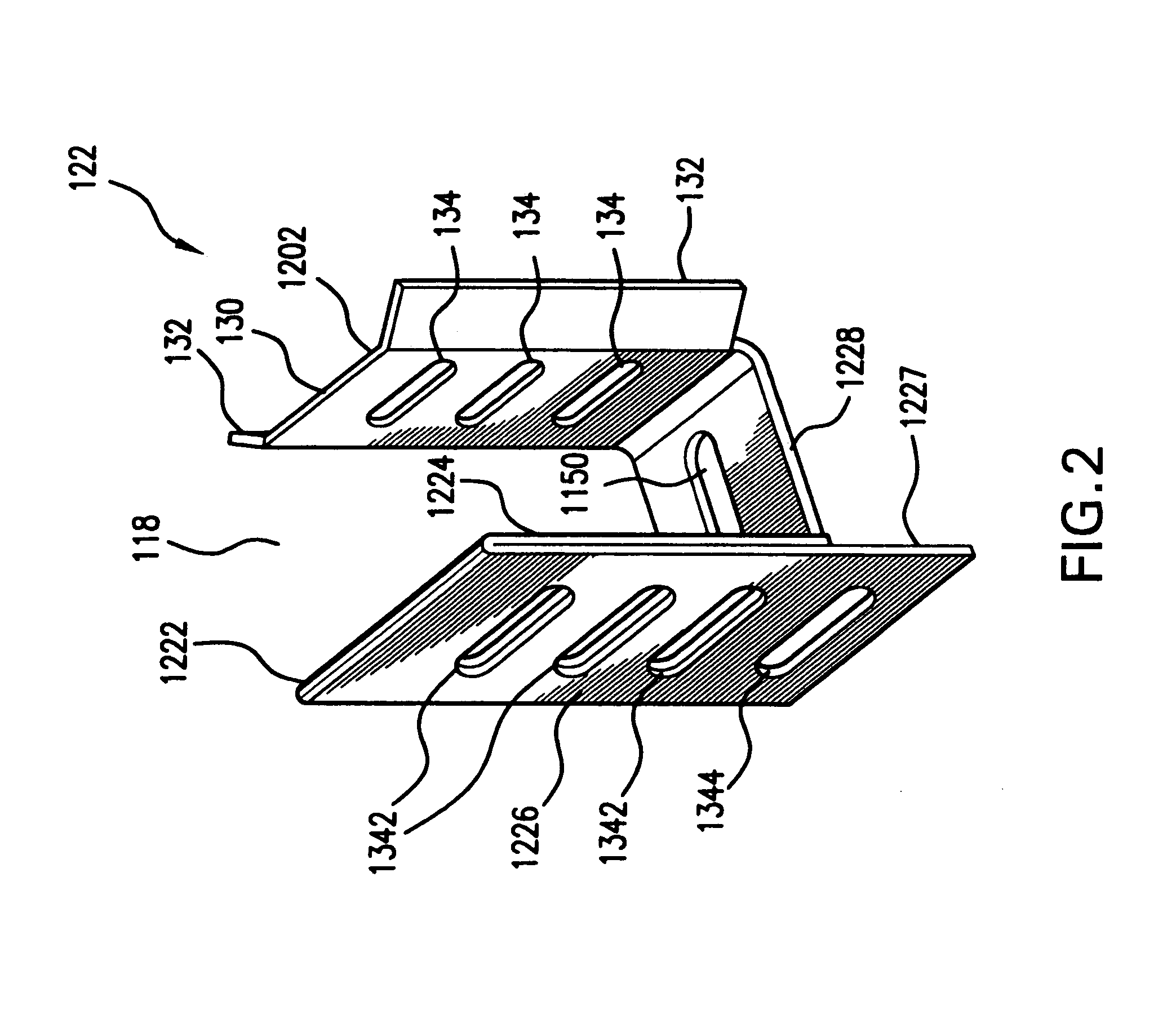

Universal structural member support and positioning system

A universal system (100) for support and positioning of building structural support members (20, 30) includes at least one longitudinally extended base plate (110) and at least one fixing member (120, 122). The base plate (110) has a plurality of slotted openings (116) formed therethrough. The fixing member (120, 122) has a pair of longitudinally spaced upstanding support members (1202, 1222) defining a structural member receiving space (118) therebetween. At least one of the upstanding support members (1202) is formed with a pair angularly extending flanges (132) that are elastically angularly displaceable to pass through a respective slotted opening (116) having corresponding portions (1164) at a different angle (C), and then return to their original angle (D) to prevent reversibly passing back through the slot (116).

Owner:JONES TERRY V

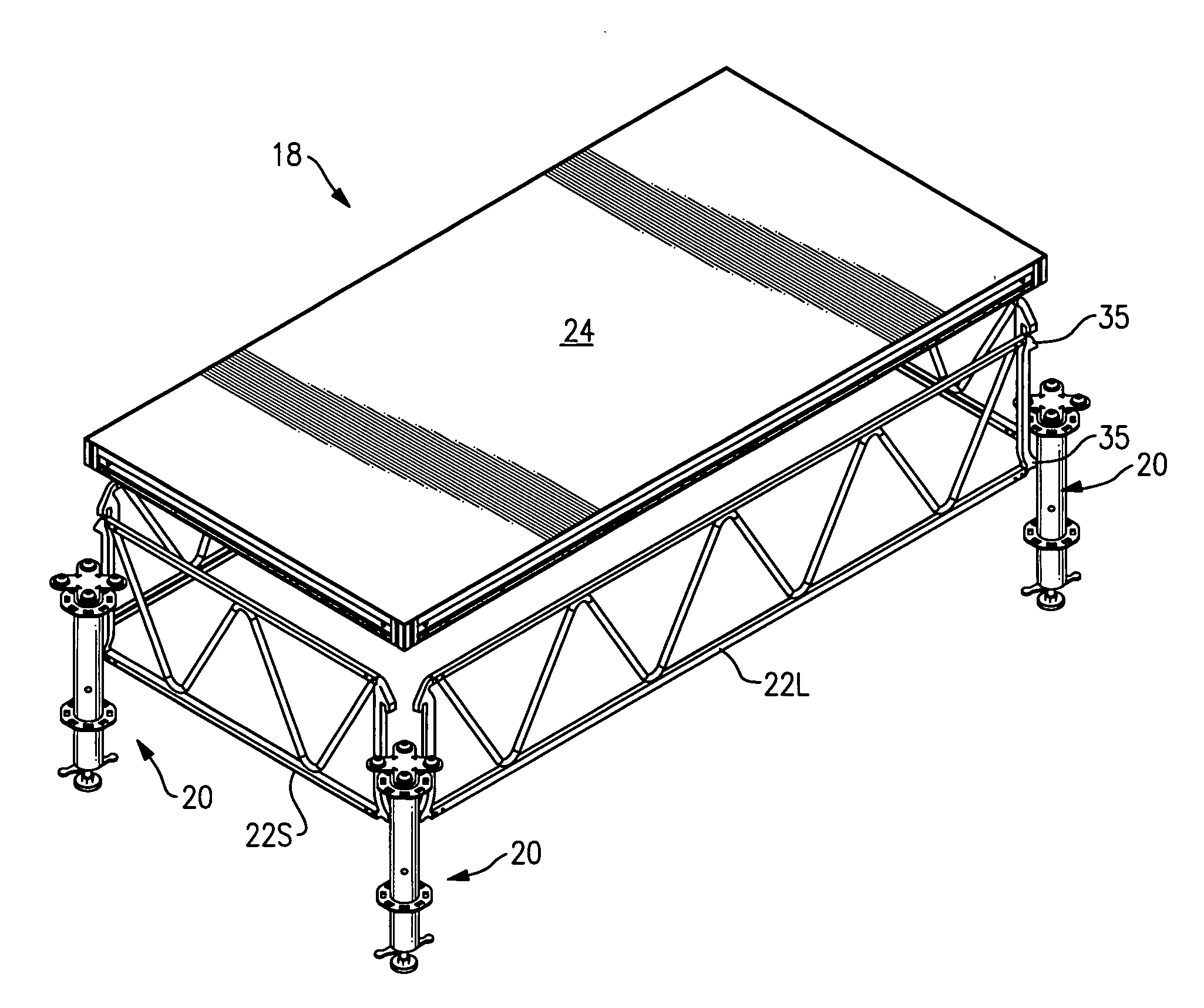

Support column system for emergency isolation and treatment shelter (EITS)

InactiveUS20080053032A1Convenient to accommodateEasy to assembleArched girdersBuilding roofsSwitch boxRigid wall

An Emergency Isolation and Treatment Shelter (EITS) rigid wall system is modular and includes two support columns and a rigid wall assembly therebetween. Each support column is a tubular generally rectilinear member in cross-section having a center opening and a wall receipt slot on each side thereof. Intermediate each wall receipt slot is an auxiliary area which permits running of conduits for electrical wiring, plumbing conduits as well as junction boxes, switch boxes or the like.

Owner:SERENUS JOHNSON PORTABLES

Concrete truss

A concrete structural framework comprised of a combination of reinforced steel, including pre-stressed and post-tensioned, with high performance concrete (HPC), for use in construction and other industries. This framework provides a highly fire resistant structure that is also resistant to the forces of nature and maintains a high level of structural integrity. The members of this concrete truss are joined or otherwise secured together by monolithic means, welded with badges, rivets, screws, or the like, in a triangular weblike configuration which provides the ultimate support against forces of compression and tension.

Owner:MENTADO DURAN JAVIER

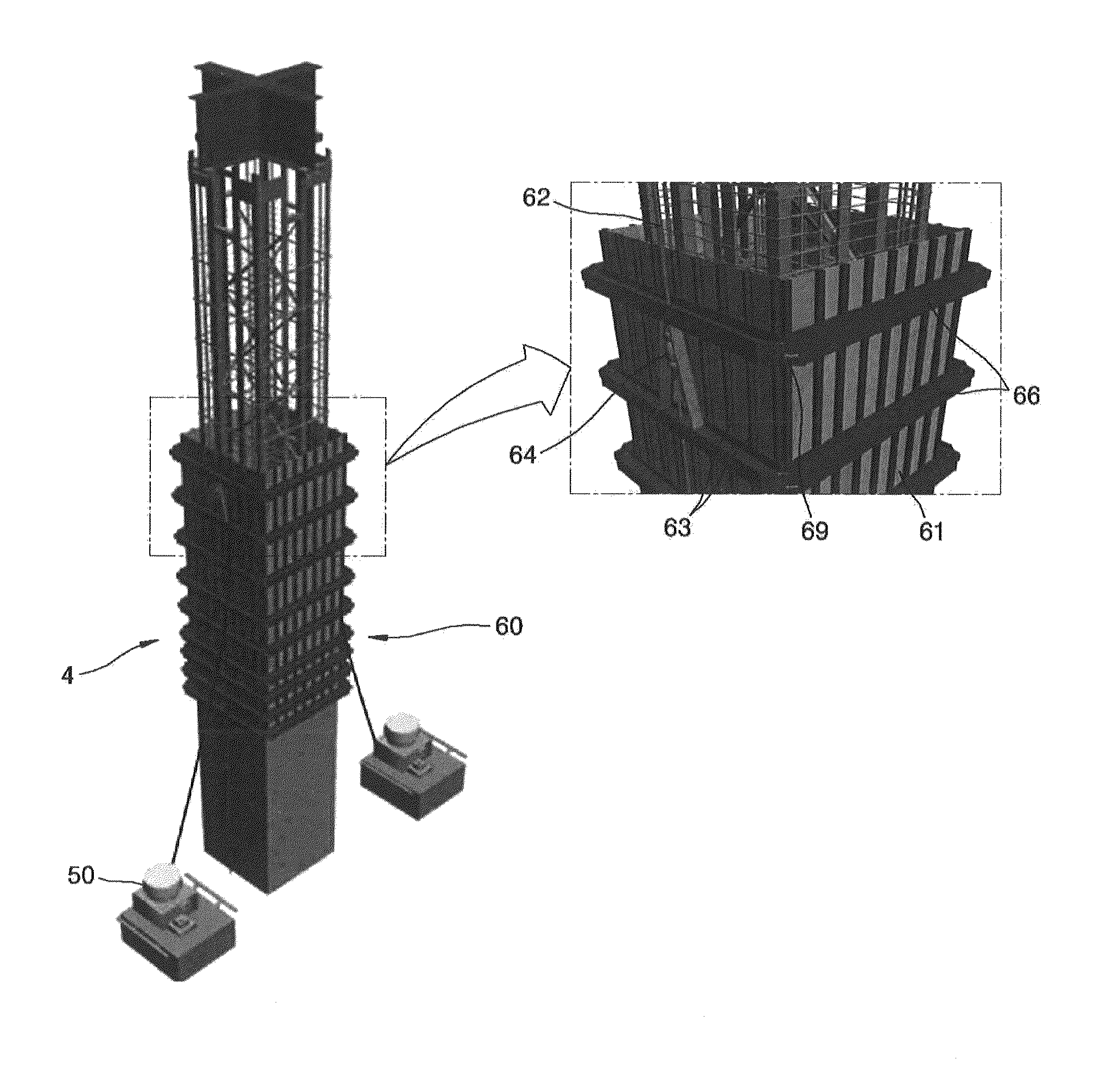

Method of constructing prefabricated steel reinforced concrete (PSRC) column using angle steels and psrc column using angle steels

InactiveUS20120210669A1Easy to useImprove efficiencyArched girdersPortal framesReinforced concreteEngineering

A steel reinforced concrete (PSRC) column is prefabricated with angle steels at the corners. The column has auxiliary reinforcement bars between the angle steels and tie bars surround the angle steels and auxiliary reinforcement bars. Column capital steel plates are fixed to the structure, outside the angle steels and the auxiliary reinforcement bars. Column capital reinforcing steel plates are diagonally attached inside the PSRC column. A mold is used to fill the column with cement.

Owner:SENVEX

Truss bracket for shipping container construction

InactiveUS7310914B1Assembly safetyProtect the occupantsArched girdersBuilding roofsEngineeringFlange

A truss bracket for connecting a roof to a shipping container includes an initially flat rectangular sheet of material in which is formed a longitudinally extending fold line that divides the sheet of material into a first part and a second part that are disposed at a predetermined angle relative to one another when a fold is formed in the fold line. The first part is adapted to be secured to a vertical wall of a shipping container and the second part is adapted to be engaged to a roof. A plurality of flanges are stamped from the second part and are folded out at a ninety degree angle relative to the plane of the second part to enable connection of the second part to the roof. A house is made by joining plural shipping containers together and securing a roof to the shipping container by using the truss bracket.

Owner:MOORE MARSHALL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com