Modular Reinforced Structural Beam and Connecting Member System

a beam system and beam technology, applied in the direction of girders, joists, building roofs, etc., can solve the problems of reducing the service life of the beam,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

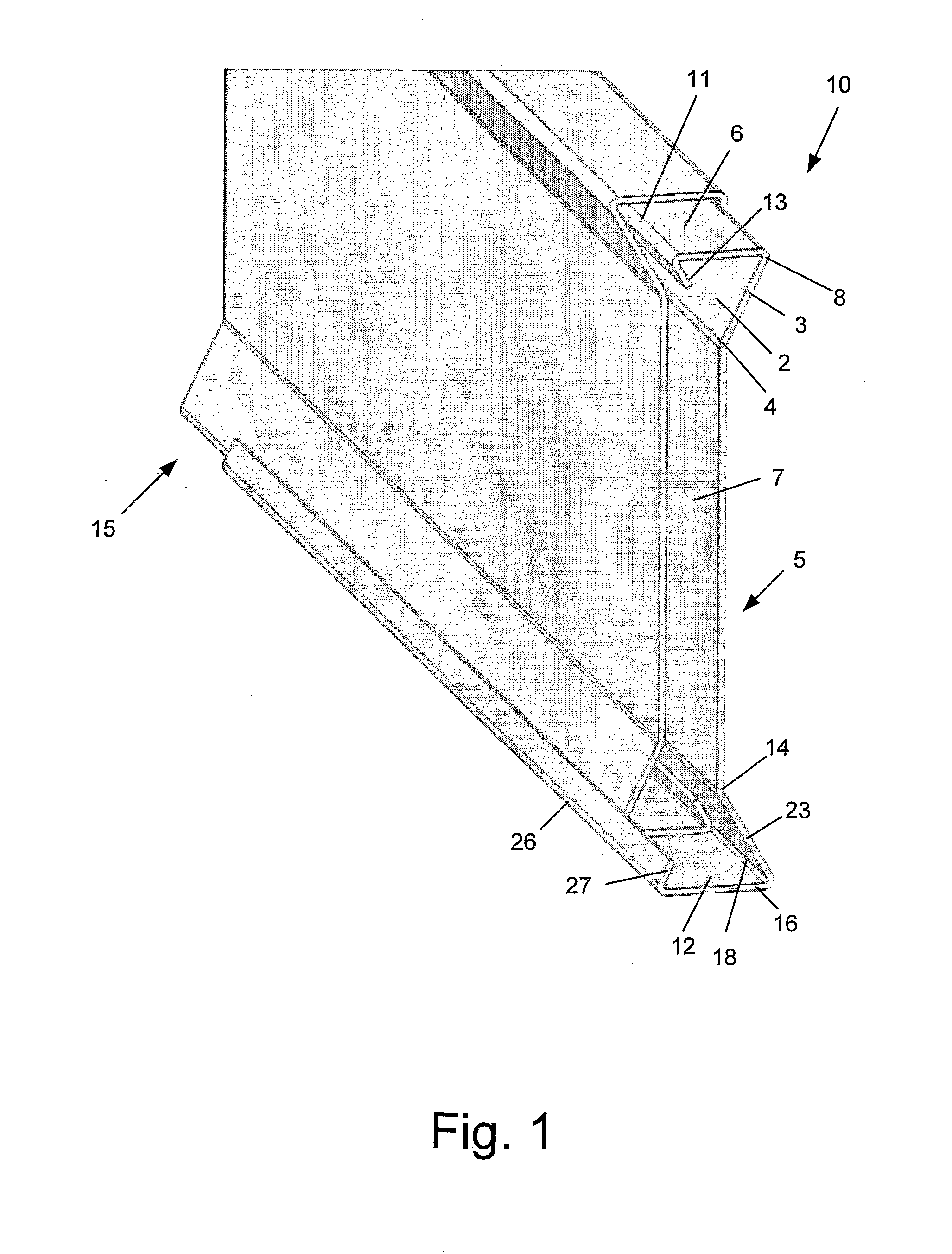

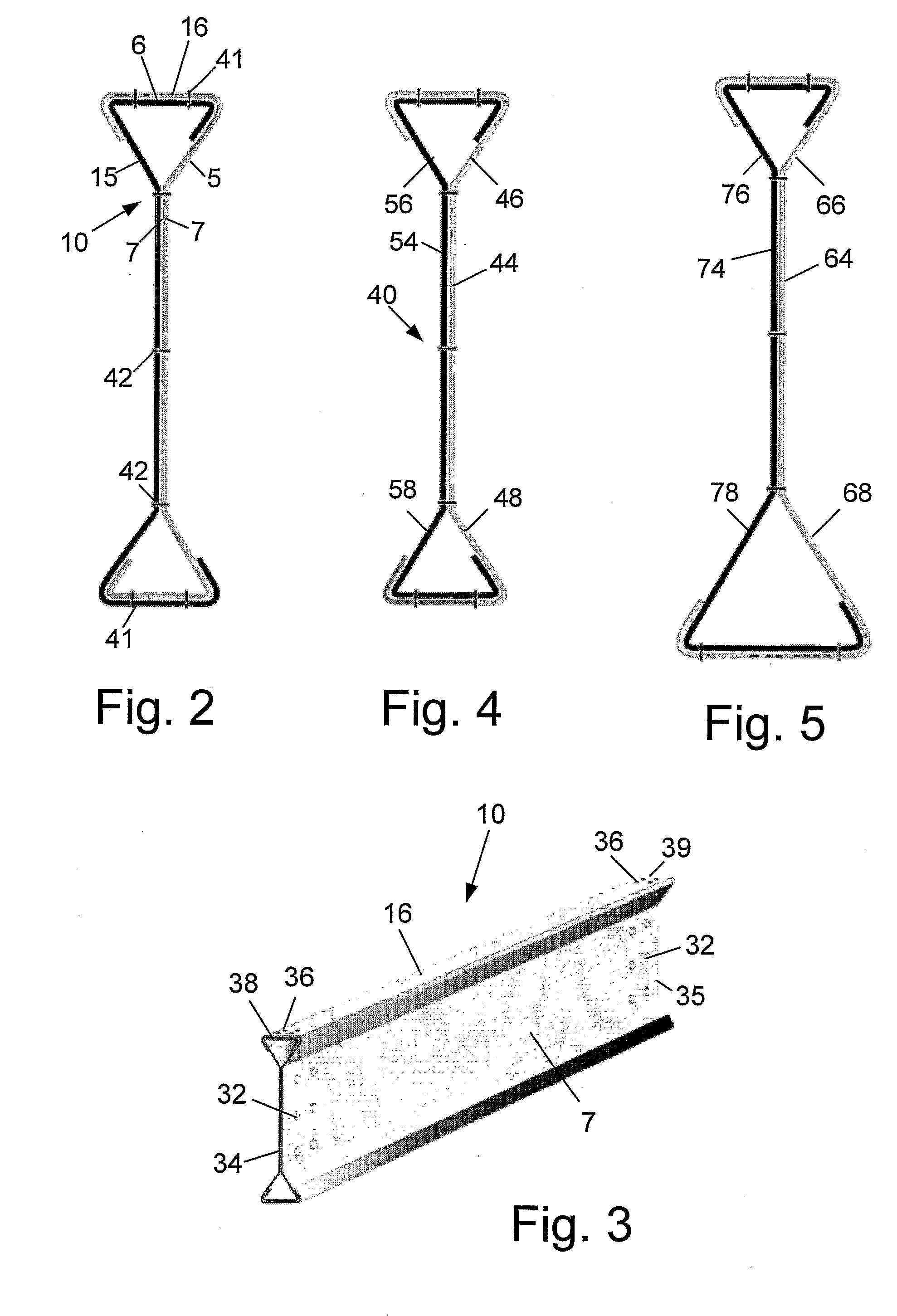

[0085]The present invention is a novel lightweight structural beam having two triangularly shaped head portions which provide an increased lateral stability and strength to weight ratio with respect to conventional I-beams. While some prior art beams have been configured with triangularly shaped head portions produced by a cold rolling process, these head portions are closed triangles and the third side thereof cannot be quickly and automatically shaped due to its inaccessibility and the inability of rollers to support the fed sheet metal as it is bent to form a closed triangle. In contrast, the beam of the present invention is a composite beam made of two separate and oppositely oriented members arranged such that corresponding head portions of the two members are nested one within the other. Each head portion is an incomplete triangle, so that the lip, i.e. an extremity, of a member is sufficiently accessible to rollers to allow the desired configuration of the member to be shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com