Concrete truss

a technology of concrete trusses and beams, which is applied in the direction of bridges, building components, structural elements, etc., can solve the problems of increasing the cost and time of production, requiring significantly more steel and concrete, and no concrete truss is considered. to achieve the effect of conserving the position of design steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

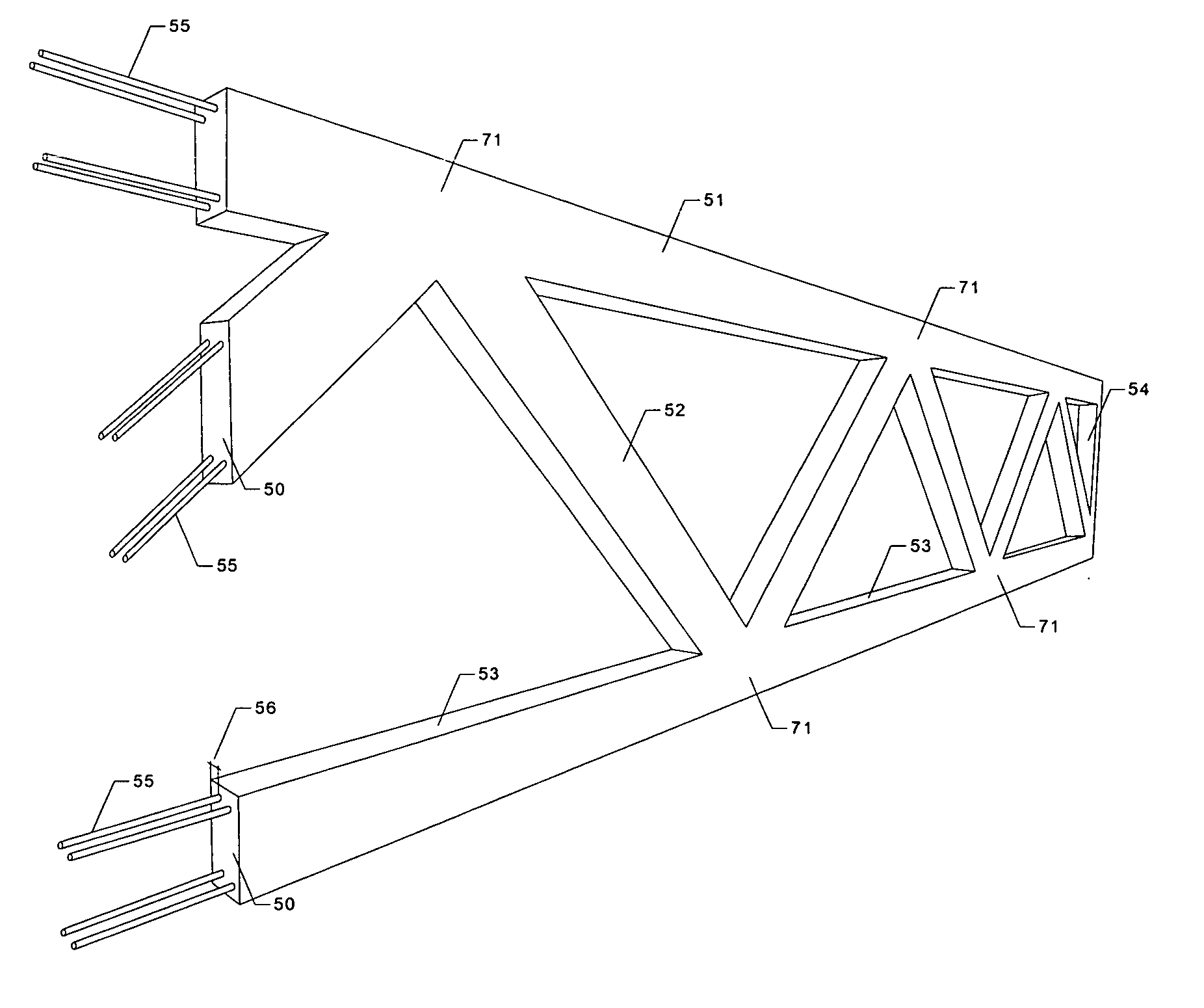

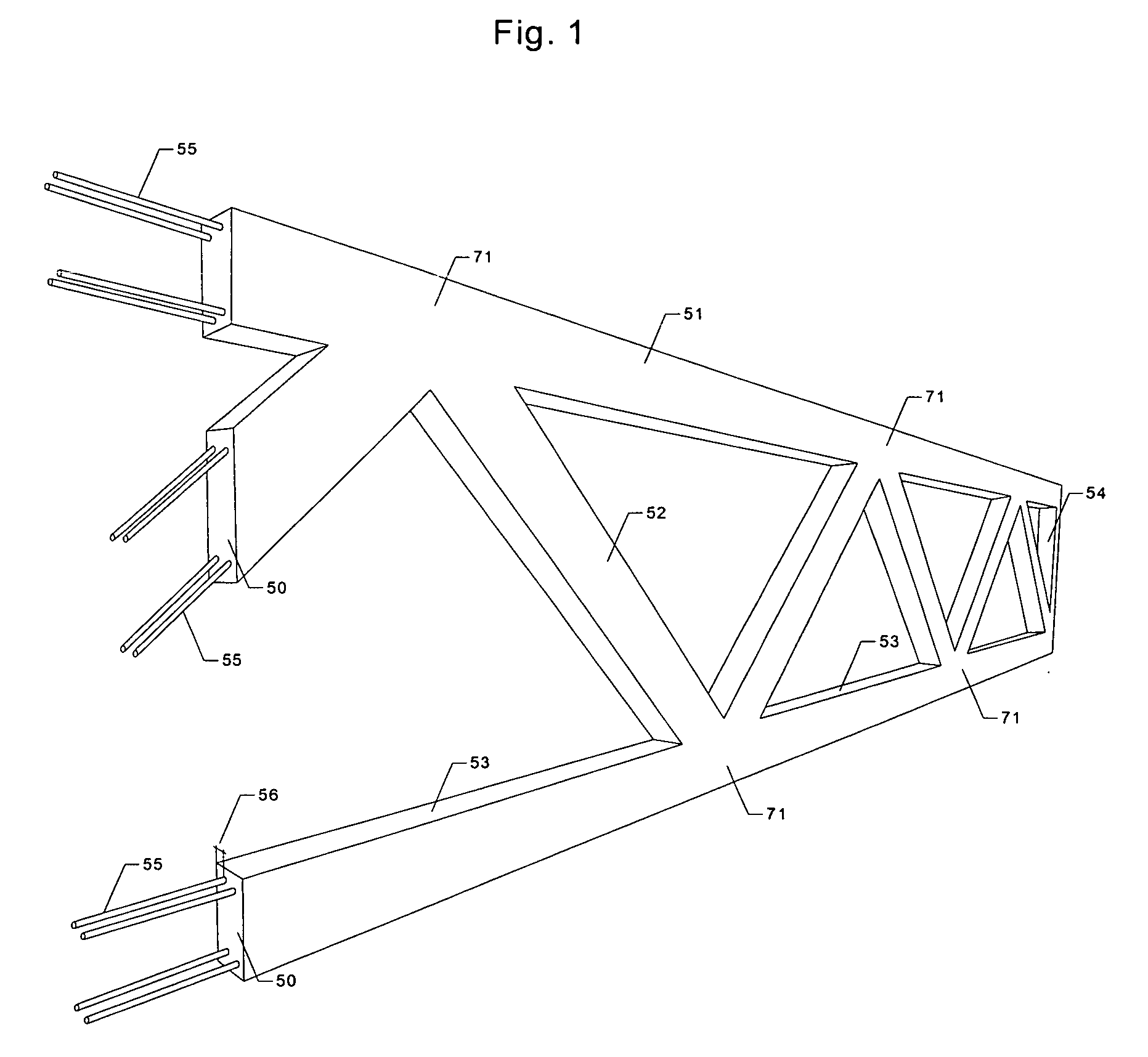

[0073]FIG. 1 depicts the perferred embodiment of the present invention denominated Concrete Truss in which the right pieces are observed (top chord 51, diagonals webs 52, bottom chord 53, vertical web 54), manufactured of concrete 50, reinforced steel 55, and the corresponding cover 56, according to the applicable norms. The present invention contemplates that reinforced steel 55 can also be pretressed or post-tensioned. The pieces are joined together monolithically 71, so that the external loads applied where they are joined produce stress directly on these pieces. The preferred embodiment contemplates that the basic geometric form of a triangle is used in the disposition of the elements, since it is the only geometric figure that is not deformed.

[0074] The elements that are shown in FIG. 1 have a disposition type Warren, they have a rectangular section as shown in FIG. 22, the steel reinforce concrete as shown in FIG. 19, and the union is monolithic as shown in FIG. 15. Important...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com