Patents

Literature

389results about How to "Structure more" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

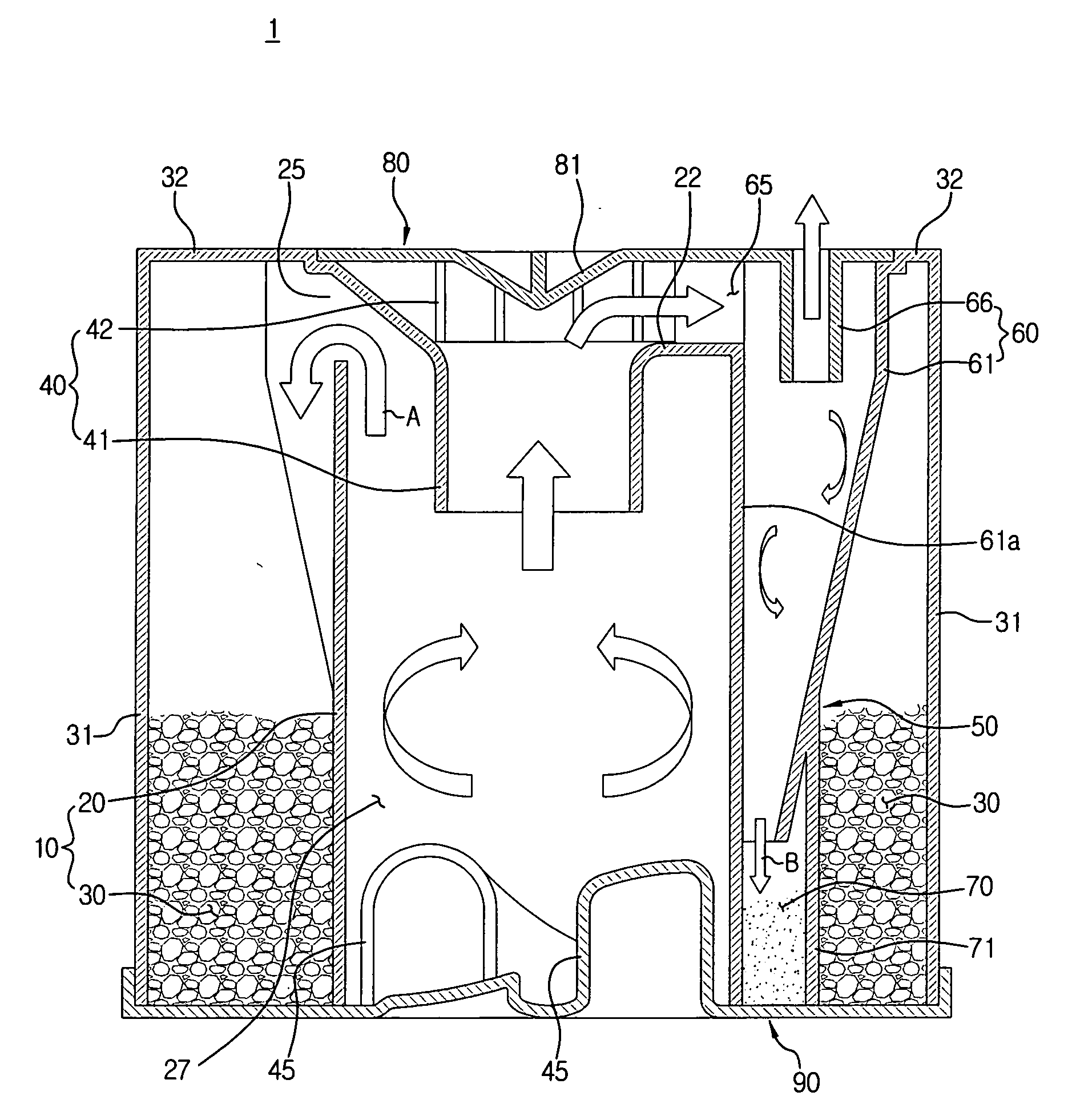

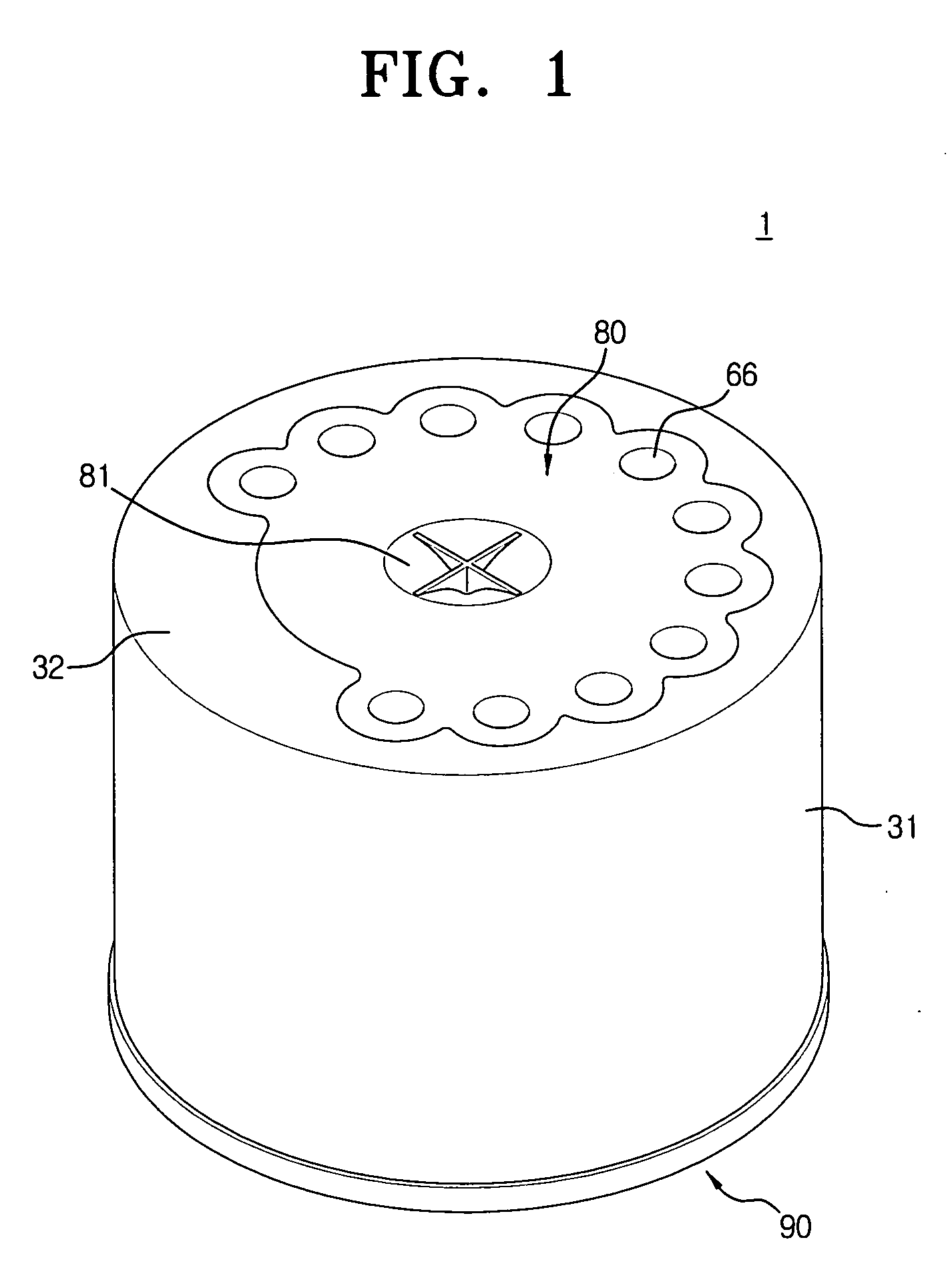

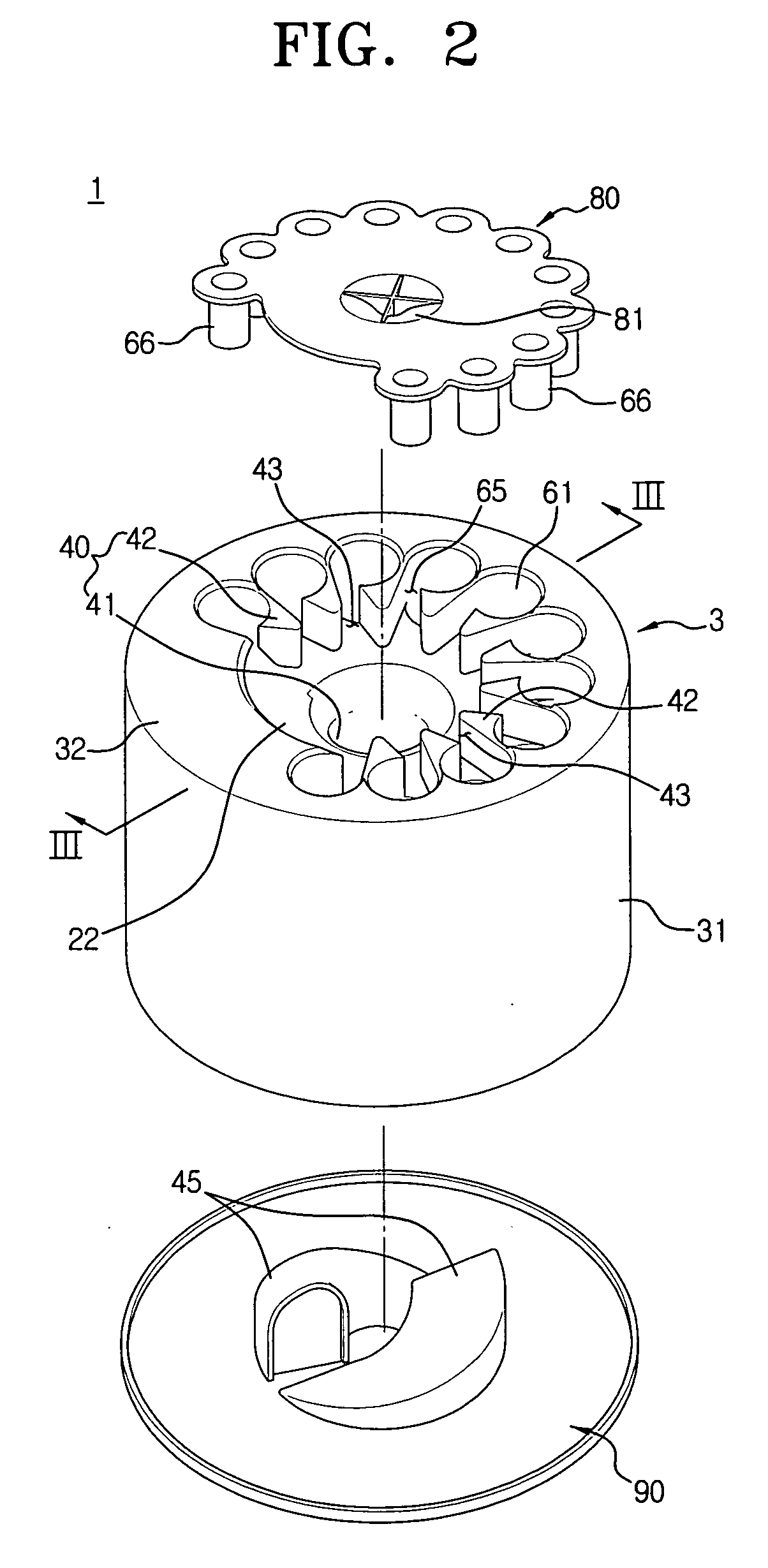

Multi-cyclone dust collector for vacuum cleaner

InactiveUS20070084160A1High contaminant collecting efficiencyMore compact structureSuction filtersDispersed particle separationCycloneEngineering

The present invention relates to a multi-cyclone dust collector for a vacuum cleaner. The multi-cyclone dust collector includes a first cyclone forcing contaminants-laden air that is drawn-in at a lower portion of the first cyclone to form an upwardly whirling air current so as to centrifugally separate contaminants therefrom air, a first contaminants chamber wrapping around a first part of the first cyclone and collecting contaminants discharged from the first cyclone, and a second cyclone unit wrapping around a second part of the first cyclone and having a plurality of second cyclones, each of the plurality of second cyclones drawing-in semi-clean air discharged from the first cyclone at an upper portion of each of the plurality of second cyclones so as to centrifugally separate fine contaminants from the semi-clean air.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

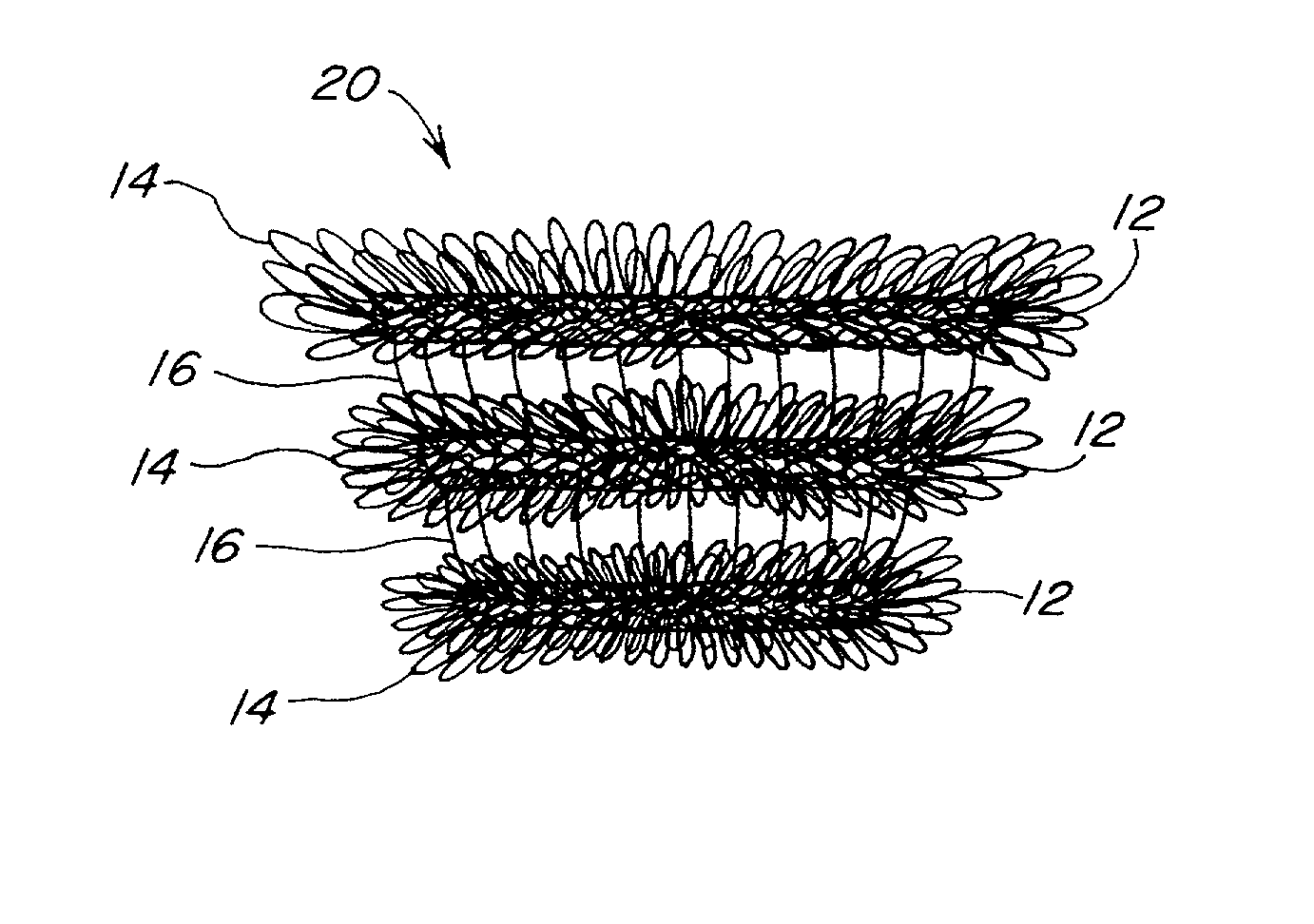

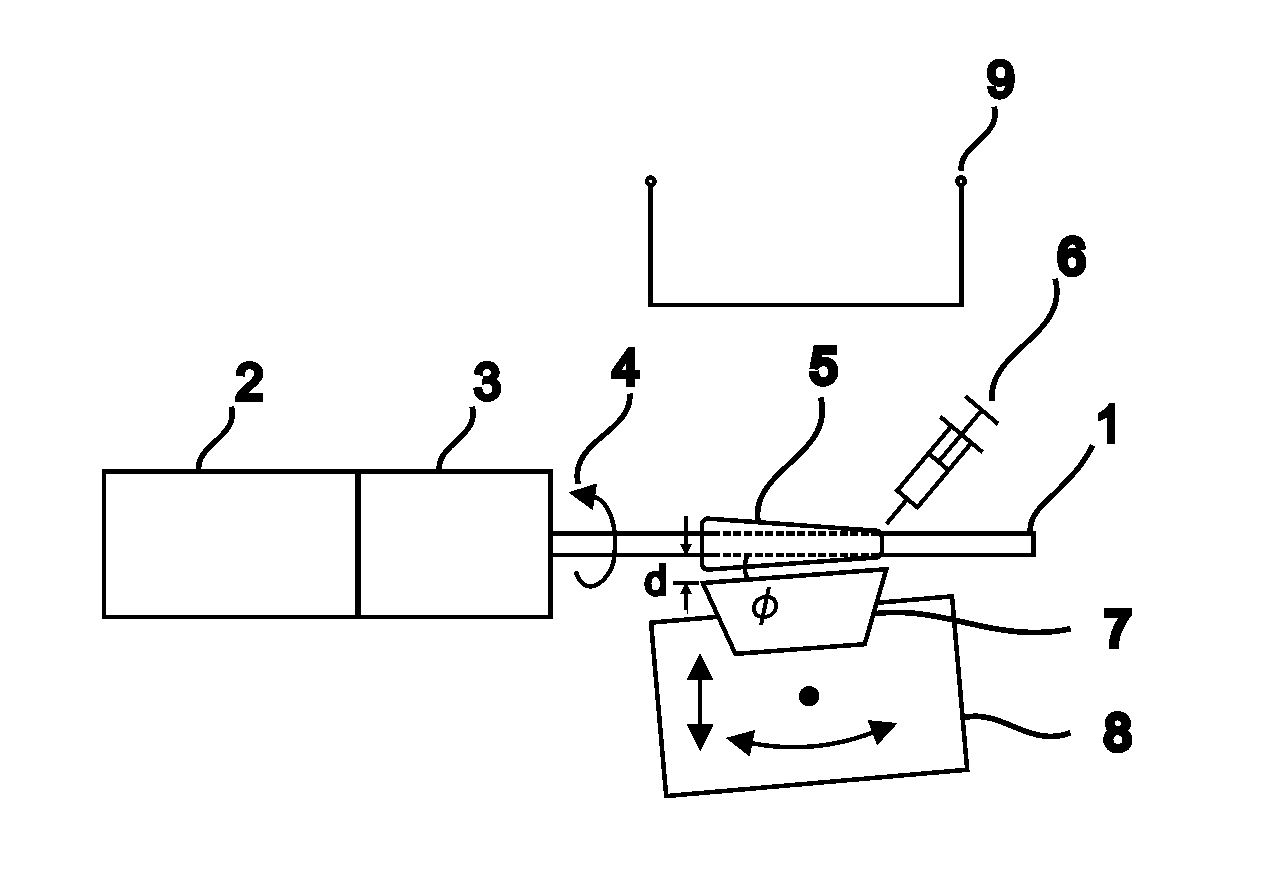

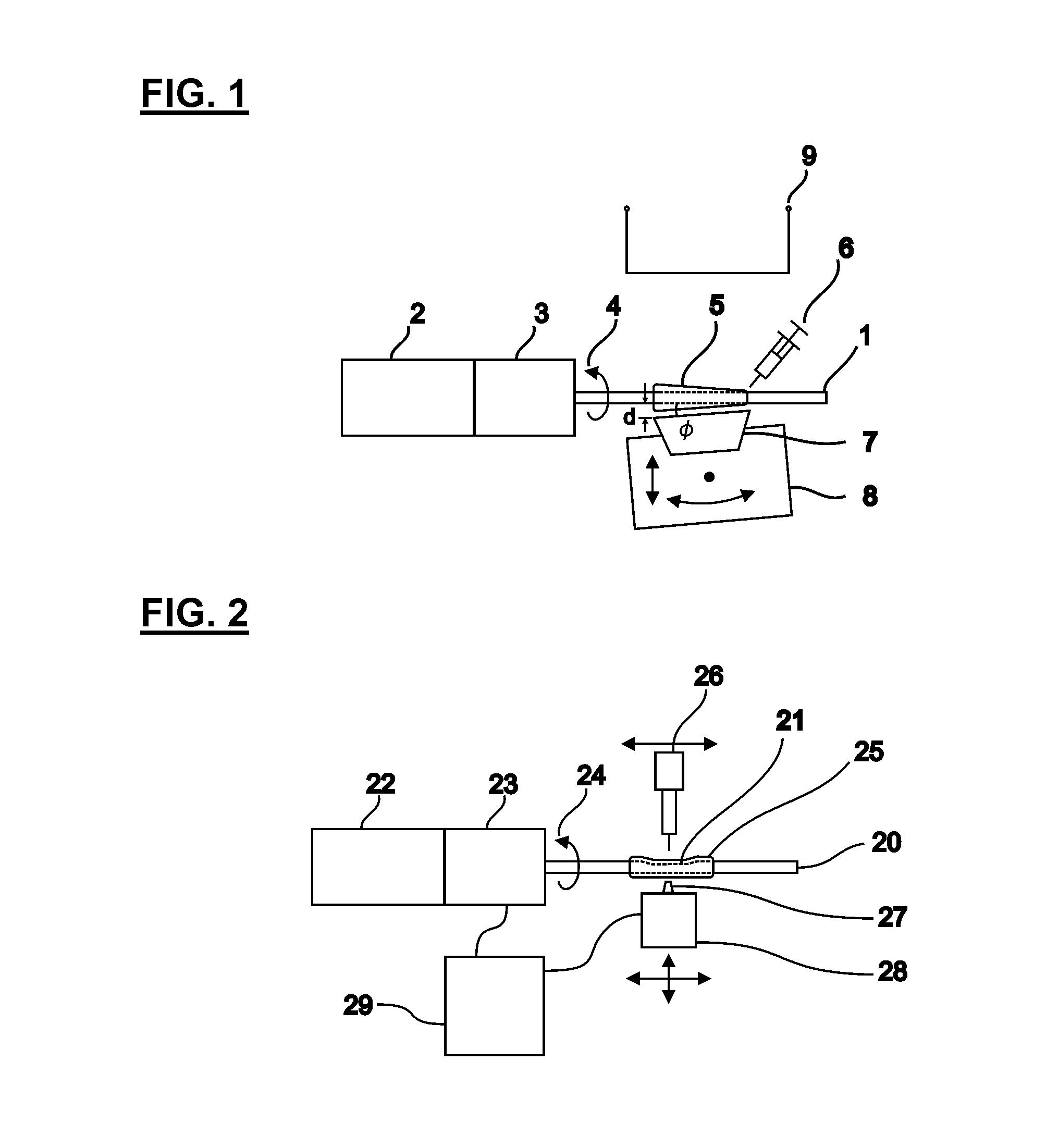

Nanostructures formed of branched nanowhiskers and methods of producing the same

InactiveUS20060057360A1Structure moreMaterial nanotechnologyLiquid surface applicatorsHeterojunctionEngineering

A method of forming a nanostructure having the form of a tree, comprises a first stage and a second stage. The first stage includes providing one or more catalytic particles on a substrate surface, and growing a first nanowhisker via each catalytic particle. The second stage includes providing, on the periphery of each first nanowhisker, one or more second catalytic particles, and growing, from each second catalytic particle, a second nanowhisker extending transversely from the periphery of the respective first nanowhisker. Further stages may be included to grow one or more further nanowhiskers extending from the nanowhisker(s) of the preceding stage. Heterostructures may be created within the nanowhiskers. Such nanostructures may form the components of a solar cell array or a light emitting flat panel, where the nanowhiskers are formed of a photosensitive material. A neural network may be formed by positioning the first nanowhiskers close together so that adjacent trees contact one another through nanowhiskers grown in a subsequent stage, and heterojunctions within the nanowhiskers create tunnel barriers to current flow.

Owner:QUNANO

Al-Cu-Li-Mg-Ag-Mn-Zr alloy for use as structural members requiring high strength and high fracture toughness

An improved aluminum lithium alloy comprising 0.1 to 2.5 wt. % Li, 2.5 to 5.5 wt. % Cu, 0.2 to 1.0 wt. % Mg, 0.2 to 0.8 wt. % Ag, 0.2 to 0.8 wt. % Mn, up to 0.4 wt. % Zr or other grain refiner such as chromium, titanium, hafnium, scandium or vanadium, the balance aluminum. The present alloy exhibits an improved combination of strength and fracture toughness, over any thickness range. The present invention is further directed to methods for preparing and using Al—Li alloys as well as to products comprising the same.

Owner:CONSTELLIUM ROLLED PROD RAVENSWOOD

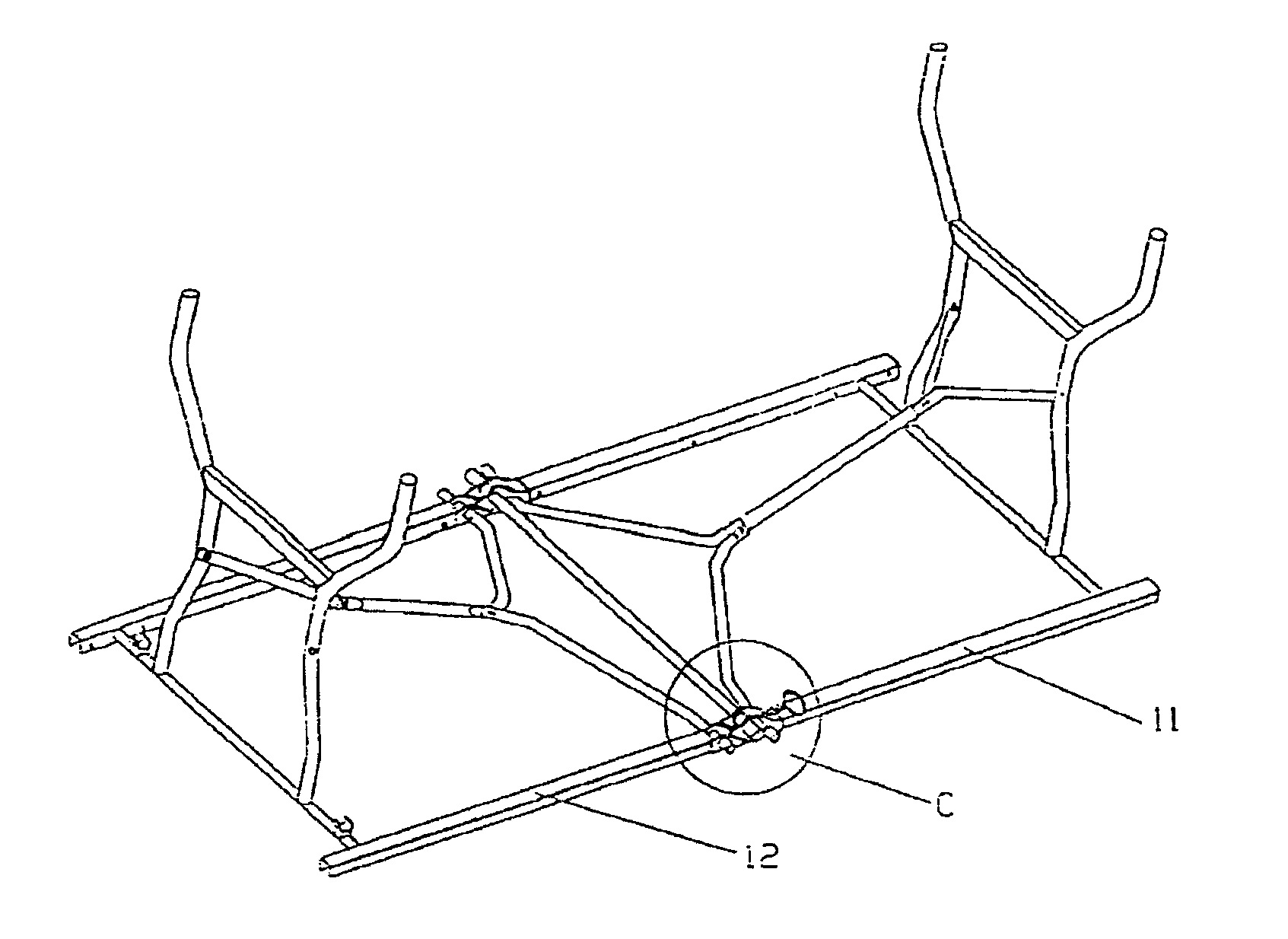

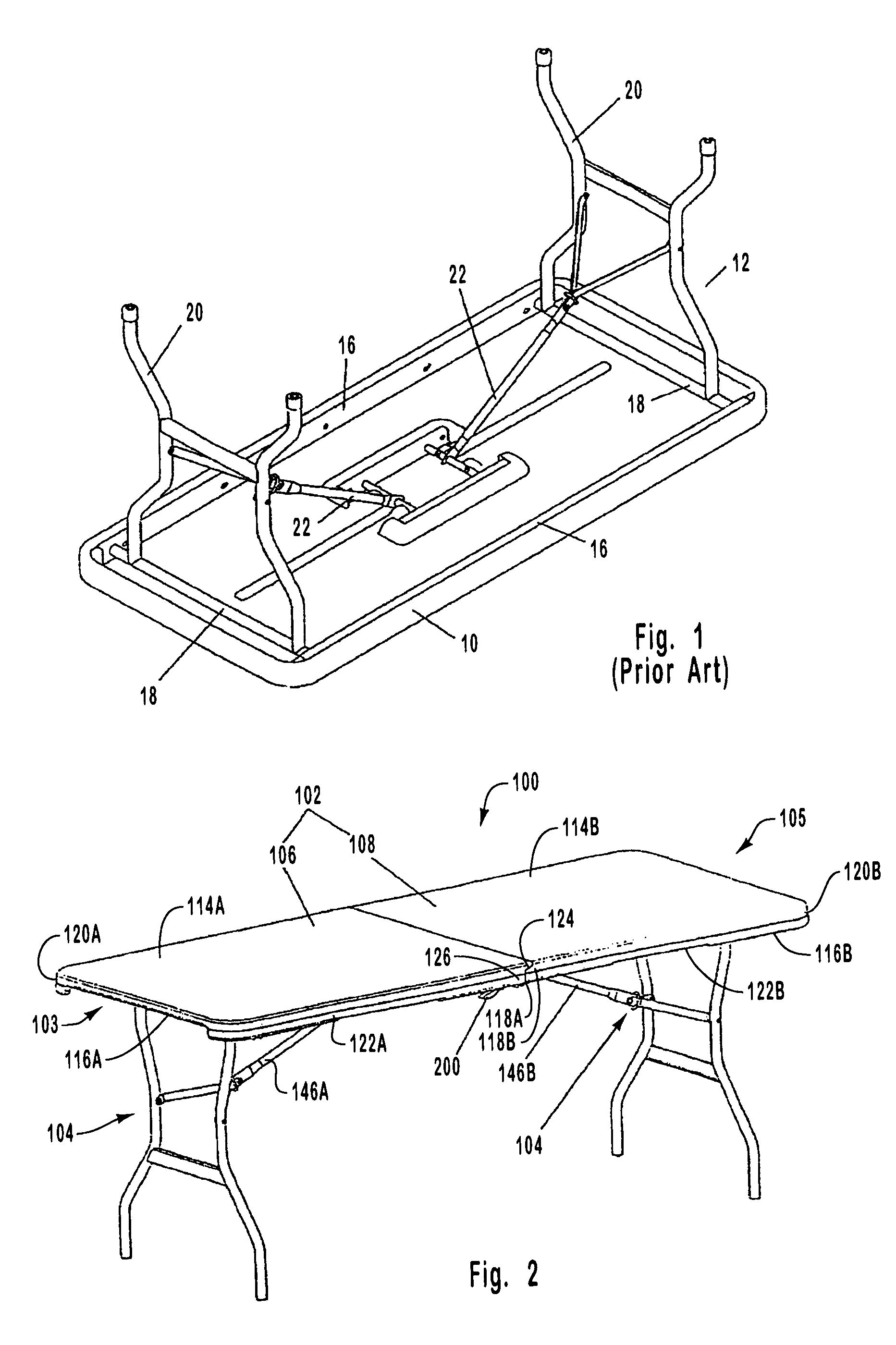

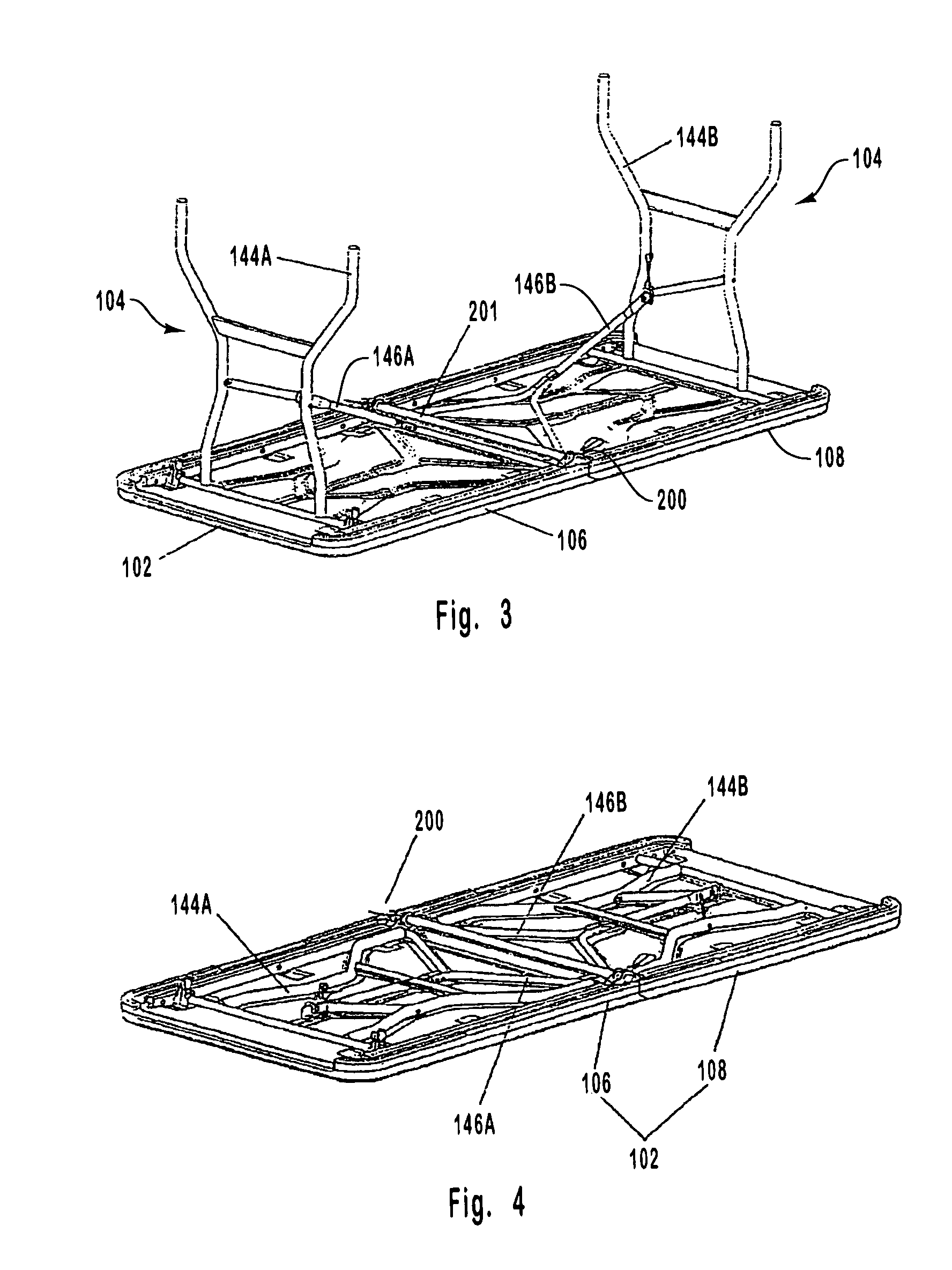

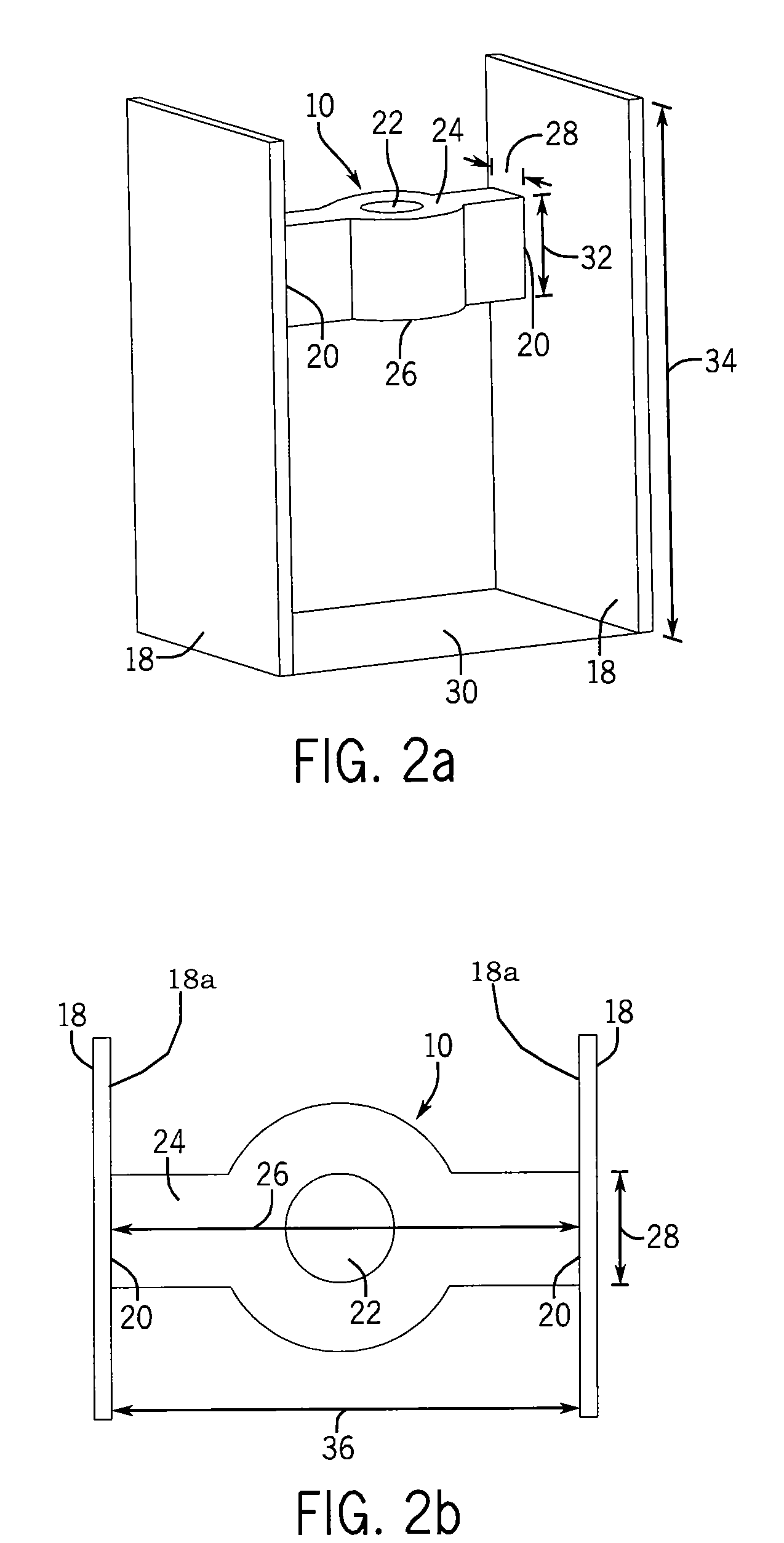

Folding table

A folding table is disclosed having a two-stage folding mechanism. The folding table includes a table top divided into a first planar portion and a second planar portion. A pair of side rails is connected to each planar portion. A foldable leg and support brace is connected to each planar portion. A hinge assembly is provided disposed between the first planar portion and the second planar portion. The hinge assembly includes a hinge pin, a first hinge connector and a second hinge connector. The first hinge connector has a cam portion. A locking pin is disposed through a slot in the second hinge connector. A lock actuating mechanism may be used to move the locking pin in the slot between the locked and unlocked position. In one embodiment, the lock actuating mechanism includes a handle coupled to the locking pin and a spring biased against the locking pin.

Owner:LIFETIME HONG KONG

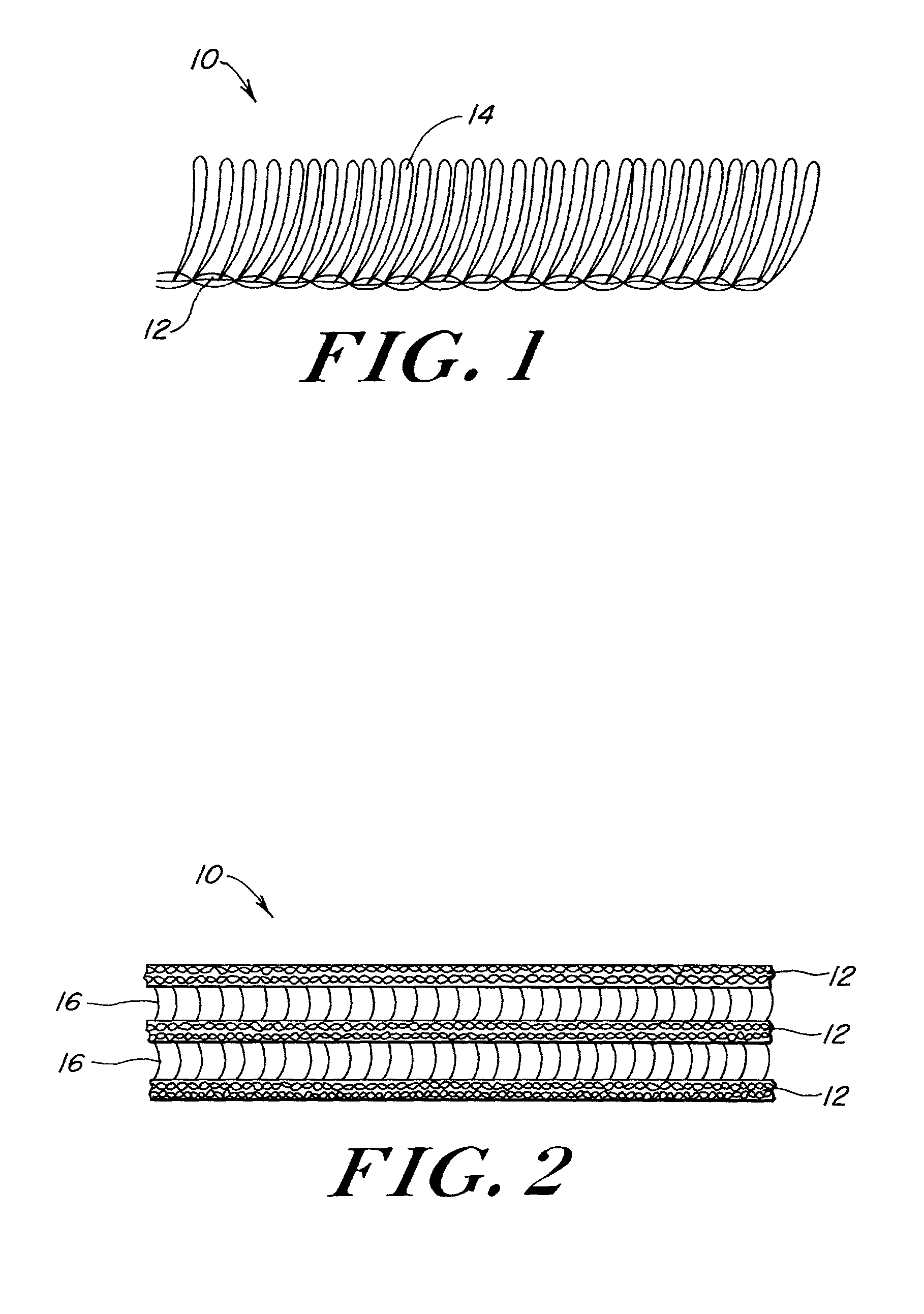

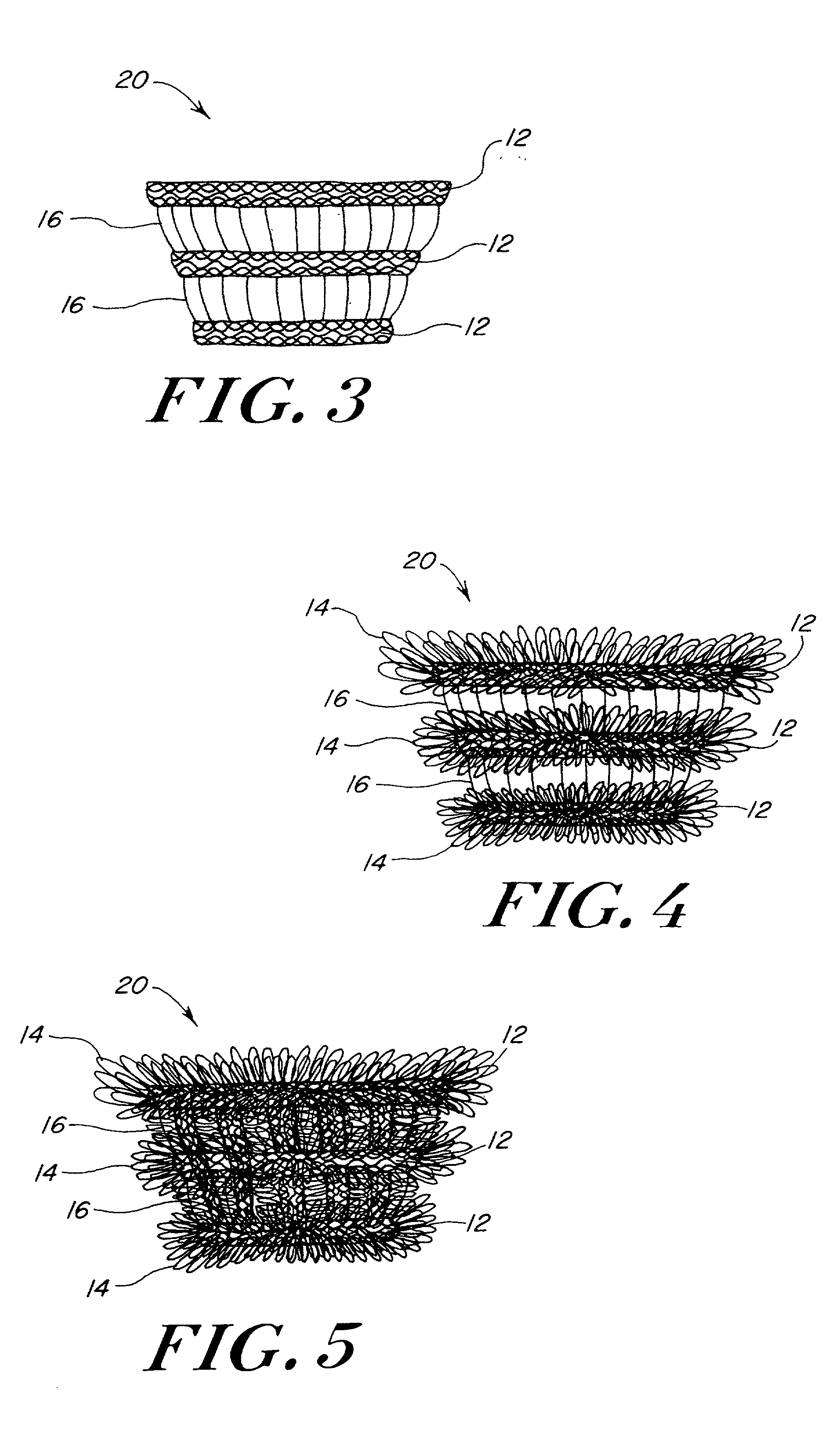

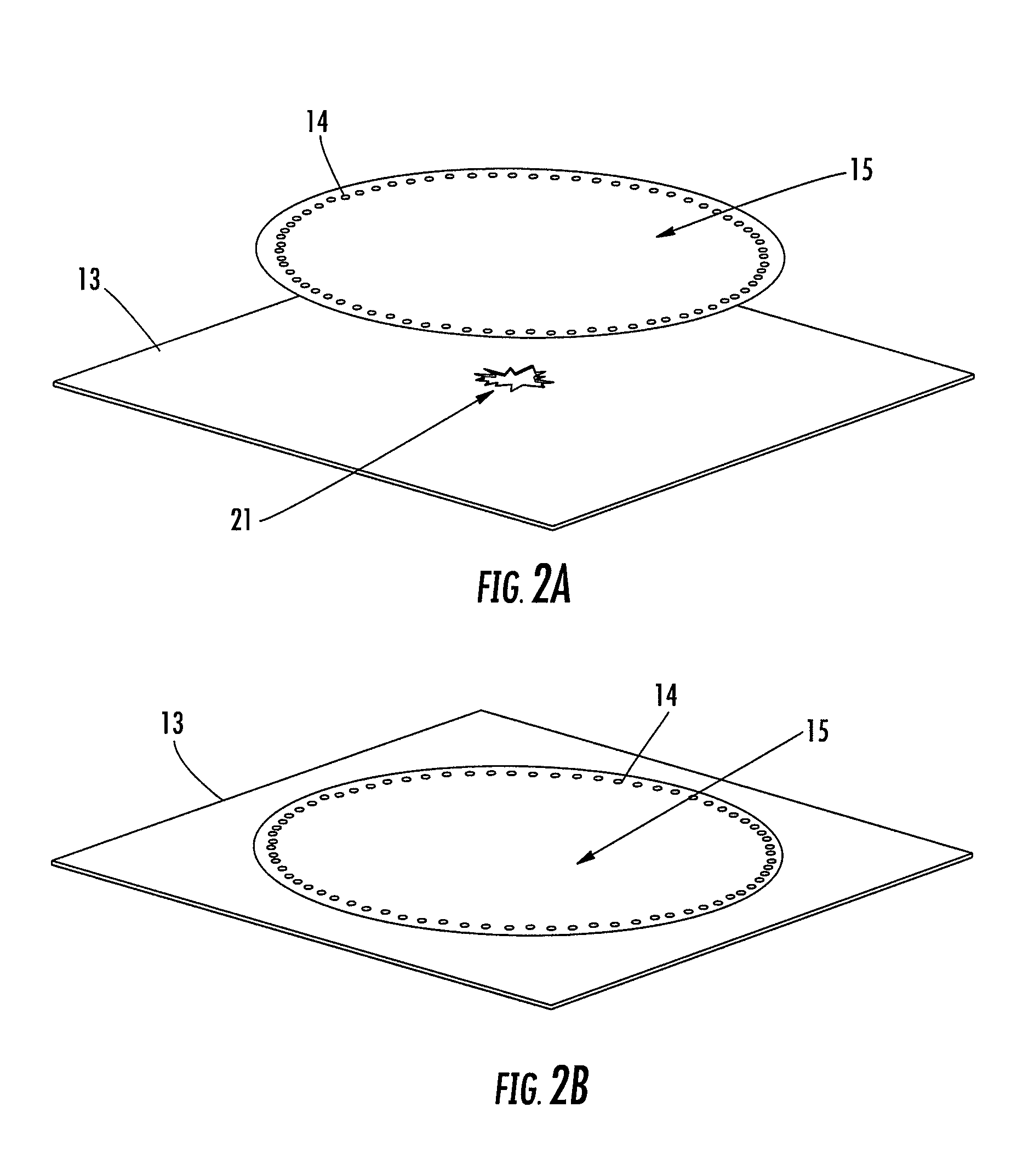

Pile mesh prosthesis

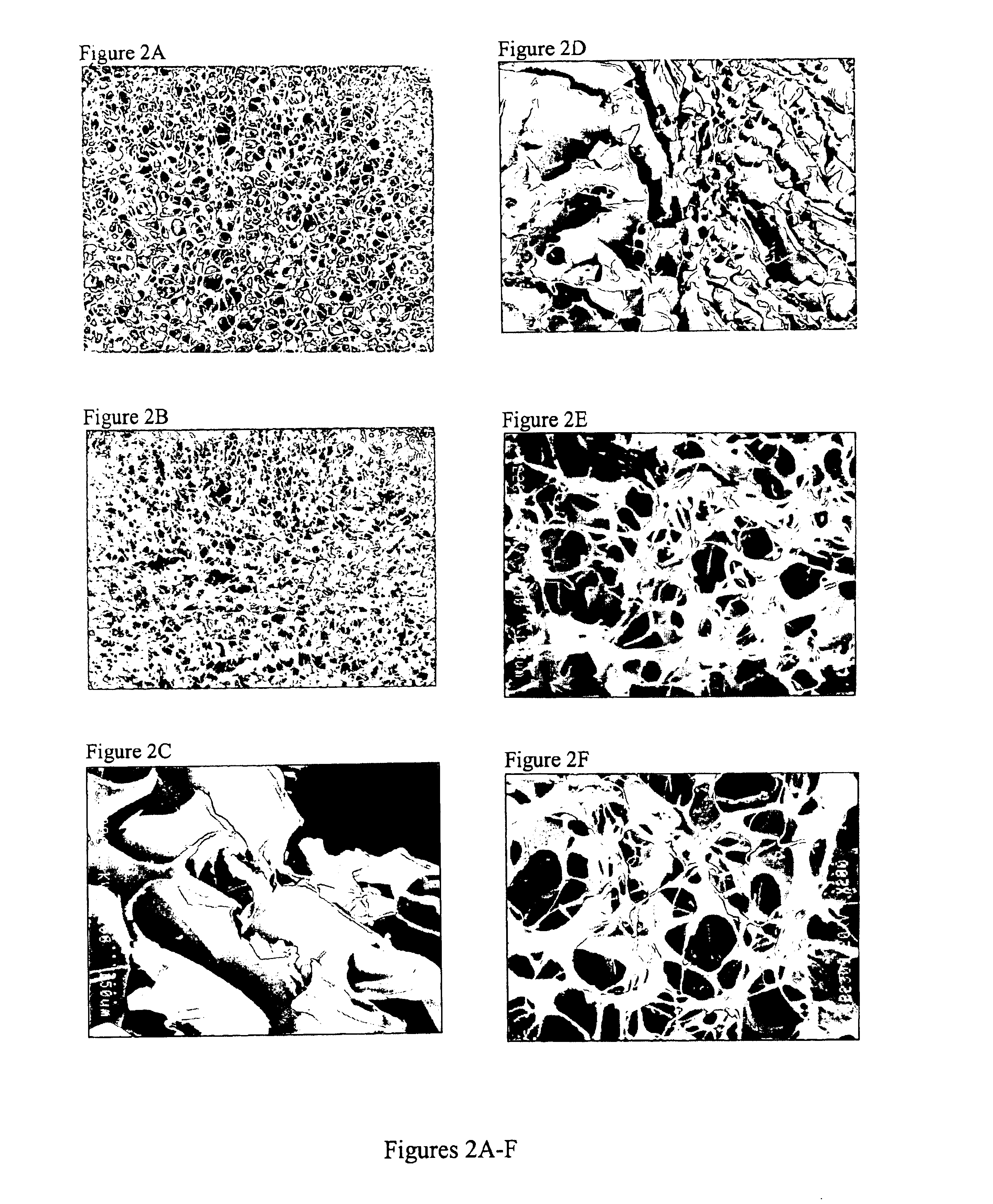

InactiveUS20020116070A1Add support structurePromoting rapid tissue in-growthWeft knittingWarp knittingRepair tissueProsthesis

A method and apparatus relating to a biocompatible soft tissue implant is disclosed. The implant, in the form of a prosthesis, is constructed of a knitted pile mesh material arranged into either a 3-dimensional structure or a planar shape or structure. The material or fabric includes a plurality of filament extensions projecting outwardly therefrom. The filament extensions can be radially projecting looping filaments from one or more rows of the knitted pile mesh material. The combination of the filament extensions with the 3-dimensional structure results in the biocompatible implant having a structural resistance to hinder anticipated crushing forces applied to the implant, and also provide a suitable 3-dimensional structure for promoting rapid tissue in-growth to anchor such implant without migration and strengthen the repaired tissue area.

Owner:ATRIUM MEDICAL

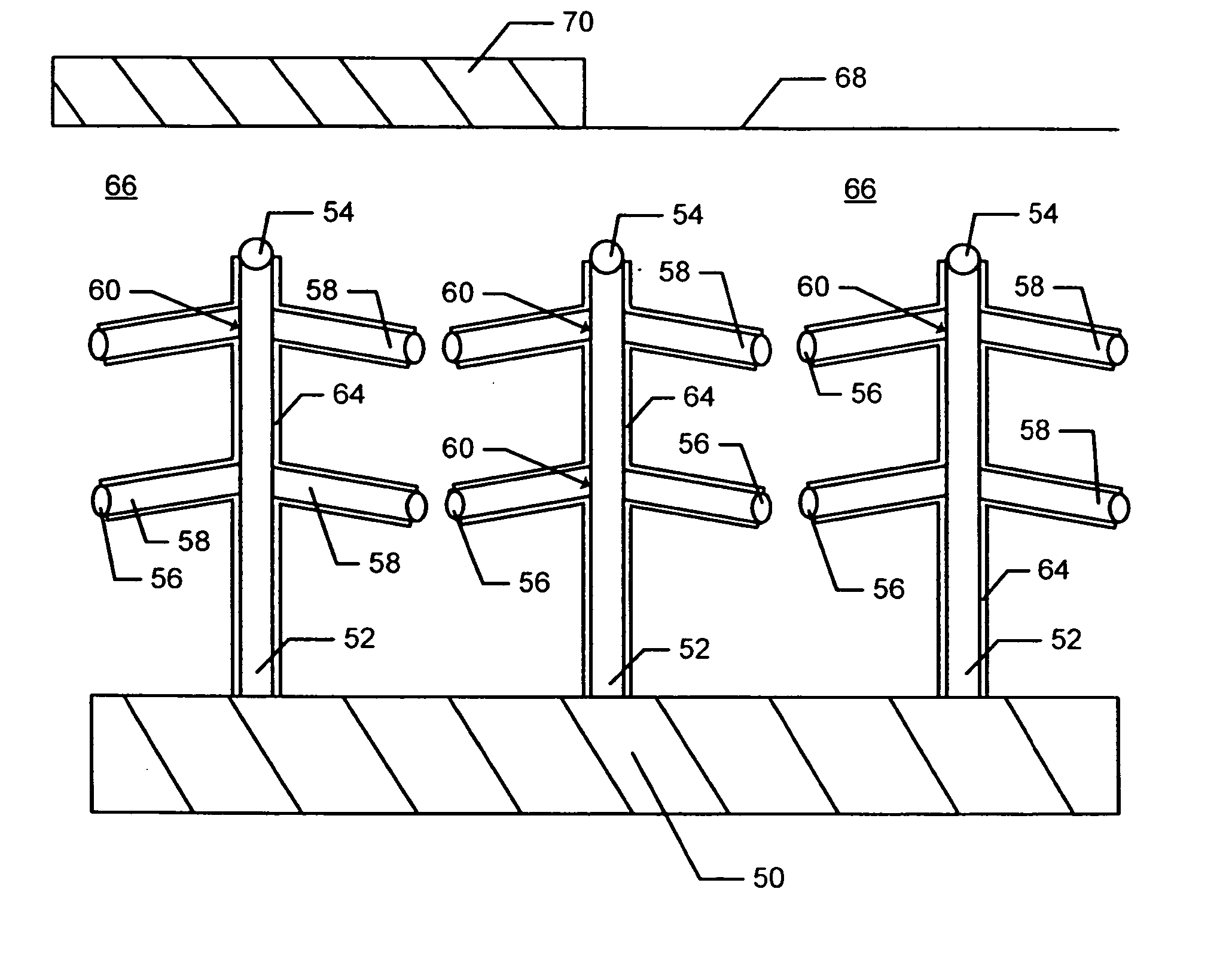

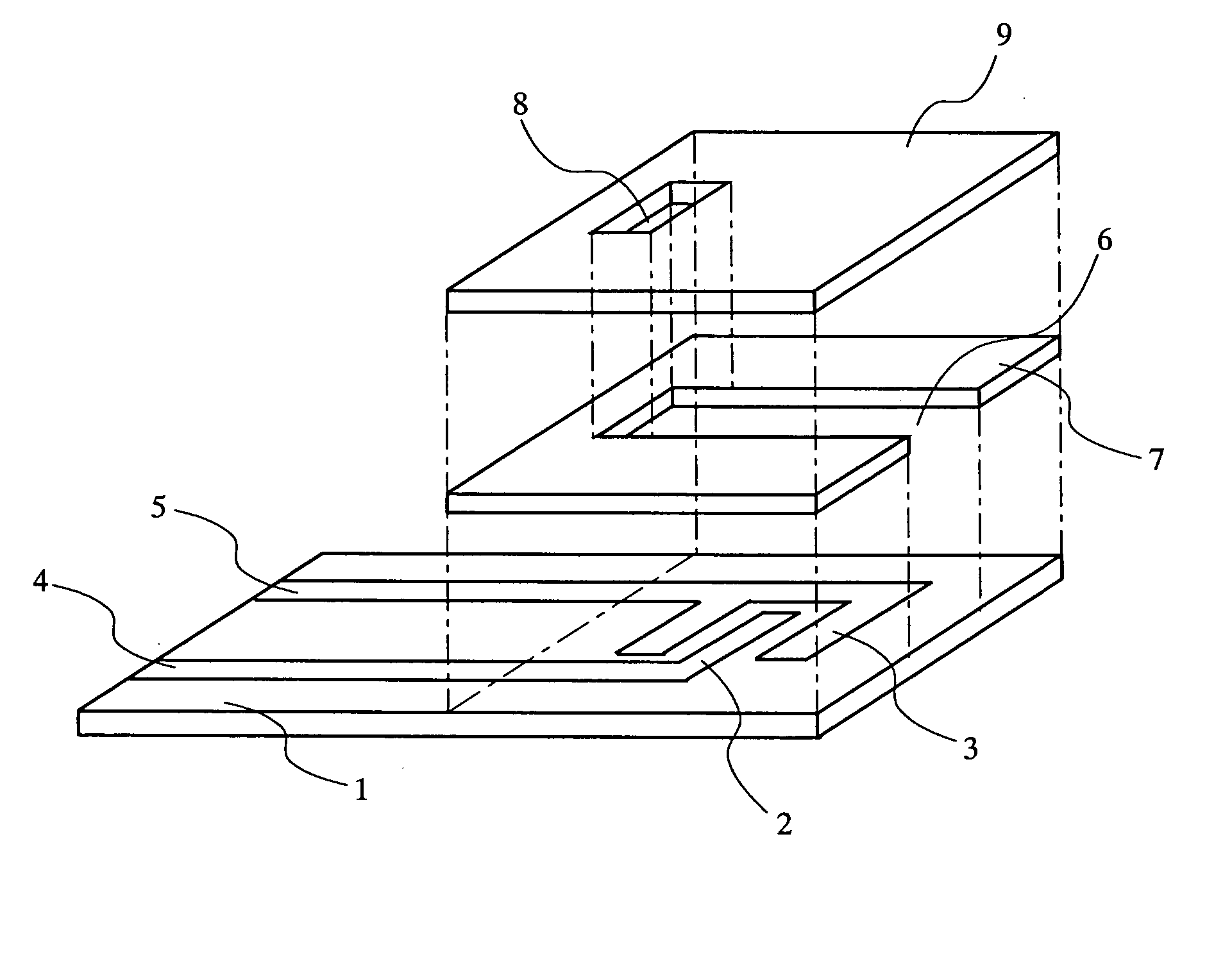

Structures and methods of manufacture for gas diffusion electrodes and electrode components

InactiveUS6103077AReduce in quantityStructure moreMachining electrodesSolid electrolytesAlkaline fuel cellFluid electrolytes

Gas Diffusion Electrodes (GDES) play a pivotal role in clean energy production as well as in electrochemical processes and sensors. These gas-consuming electrodes are typically designed for liquid electrolyte systems such as phosphoric acid and alkaline fuel cells, and are commercially manufactured by hand or in a batch process. However, GDEs using the new electrolytes such as conductive polymer membranes demand improved electrode structures. This invention pertains to GDEs and gas diffusion media with new structures for systems using membrane electrode assemblies (MEAs), and automated methods of manufacture that lend themselves to continuous mass production Unexpected improvements in gas and vapor transport through the electrode are realized by incorporating a new dispersion process in the construction, reformulating the applied mix with solution additives, and creating a novel coating structure on a conductive web. Furthermore, combining these changes with a judicious choice in coating methodology allows one to produce these materials in a continuous, automated fashion.

Owner:IND DE NORA SPA

Biosensor

InactiveUS20050175509A1Eliminate measurement errorsHigh precisionMicrobiological testing/measurementBiological material analysisCompound (substance)Organic compound

The present invention relates to a biosensor which comprises an electrode system including at least one pair of electrodes, at least one insulating base plate for supporting the electrode system, a first reaction layer provided at least on a working electrode of the electrode system, including an organic compound having a functional group capable of bonding or being adsorbed to an electrode and a hydrophobic hydrocarbon group, a second reaction layer provided on the first reaction layer, including an amphiphilic lipid capable of bonding or being adsorbed to a hydrophobic portion of the first reaction layer, and a reagent system carried in a two-component membrane composed of the first and second reaction layers, including at least membrane-binding type pyrroquinoline quinone-dependent glucose dehydrogenase and an electron mediator.

Owner:PANASONIC CORP

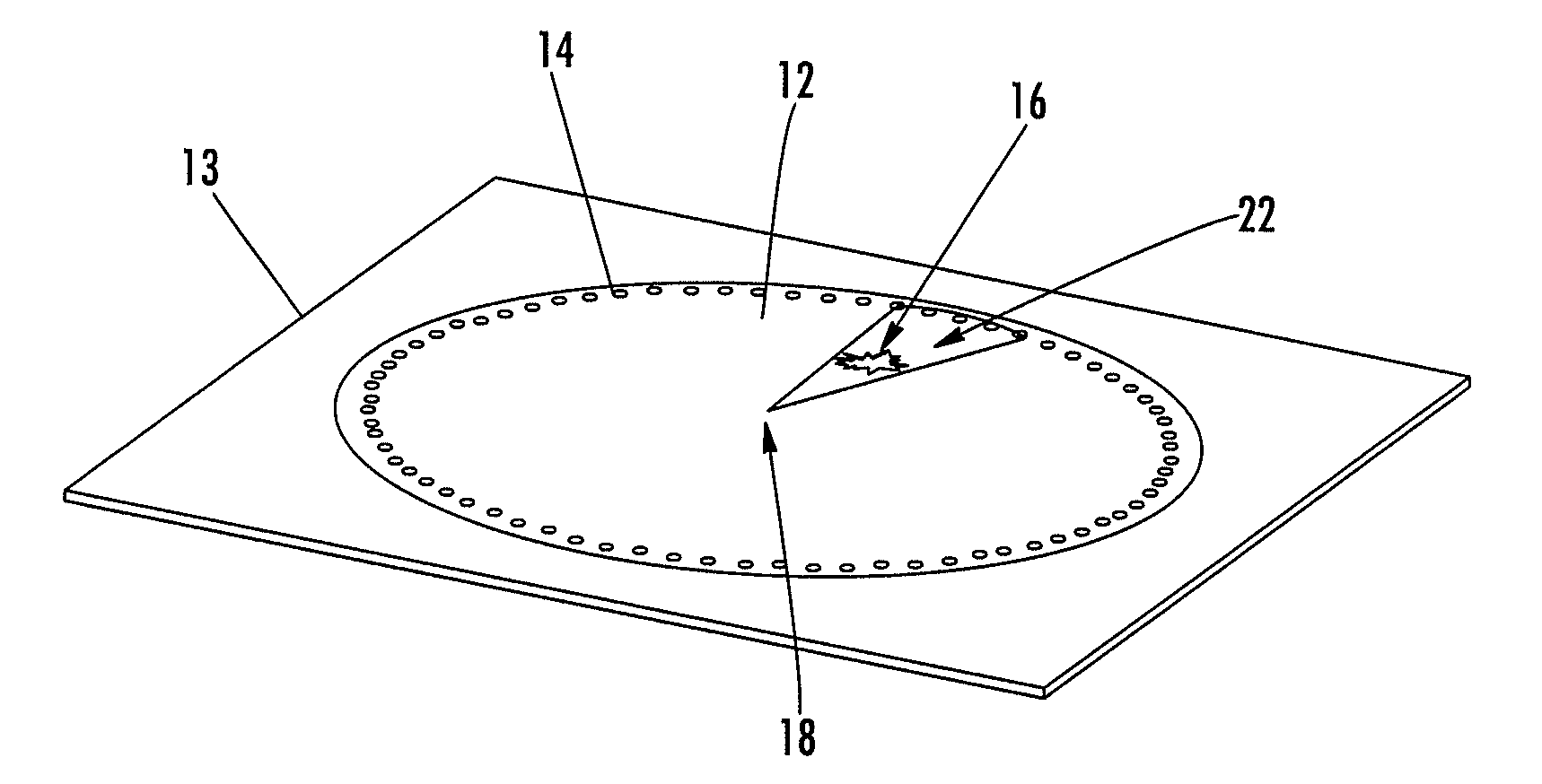

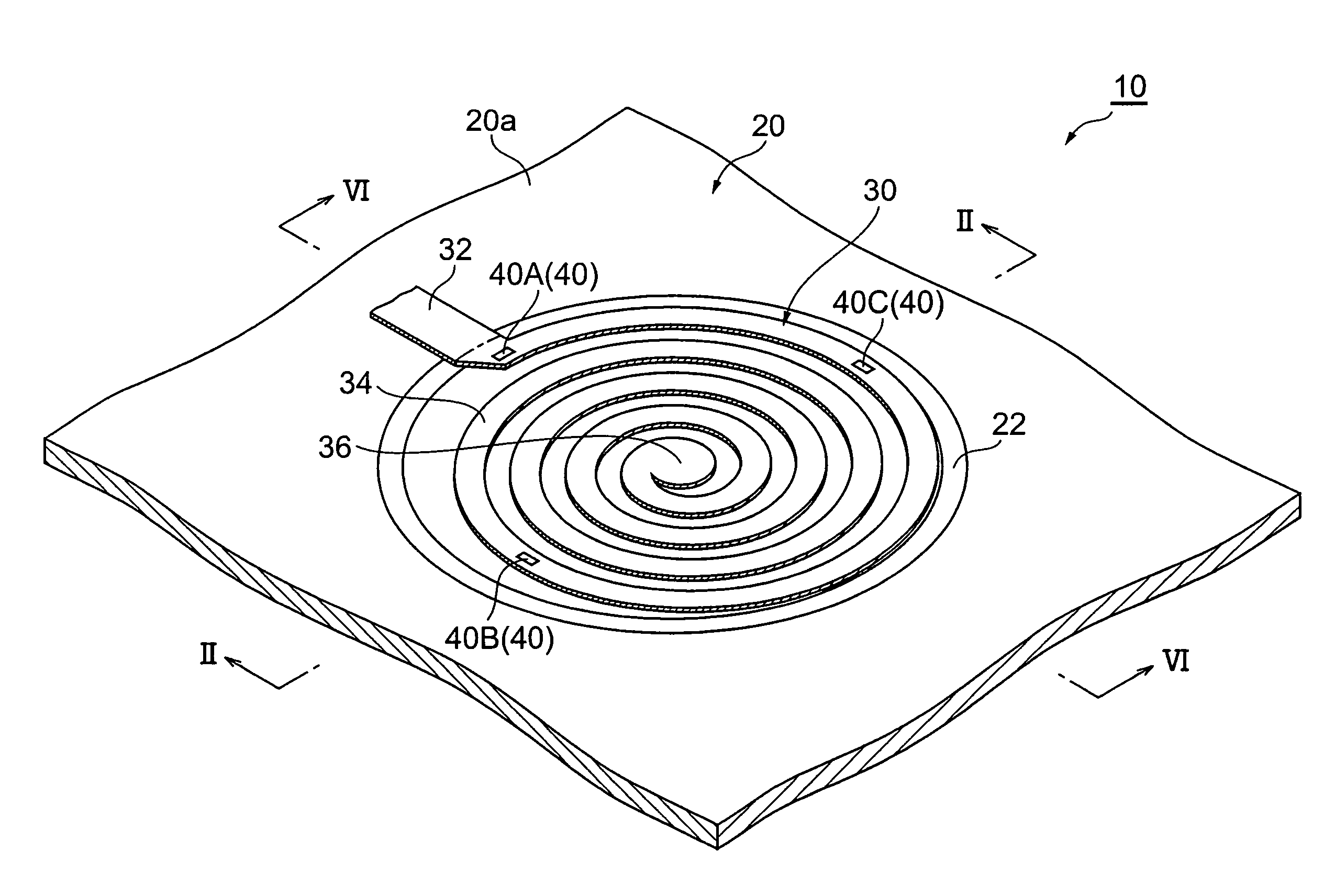

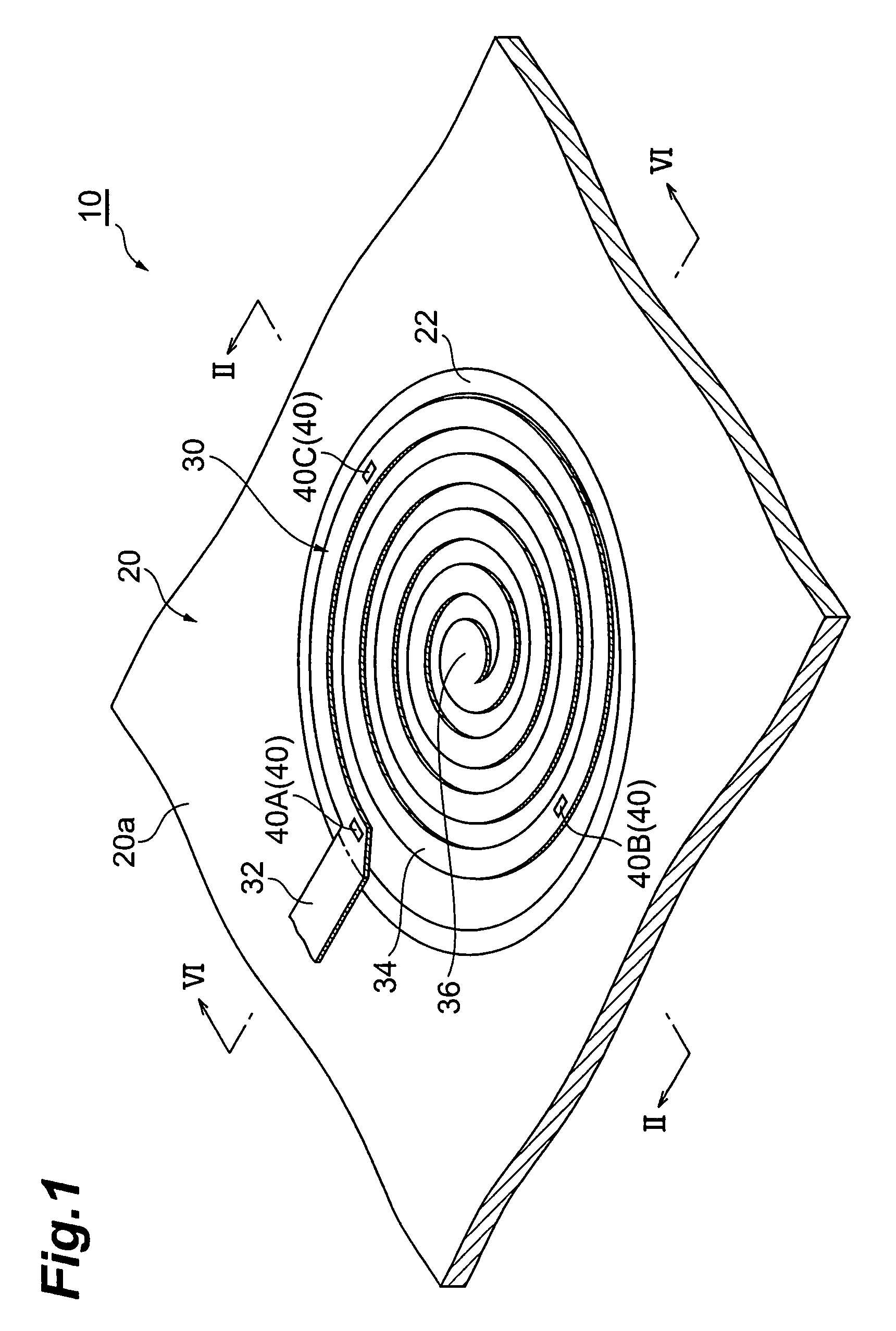

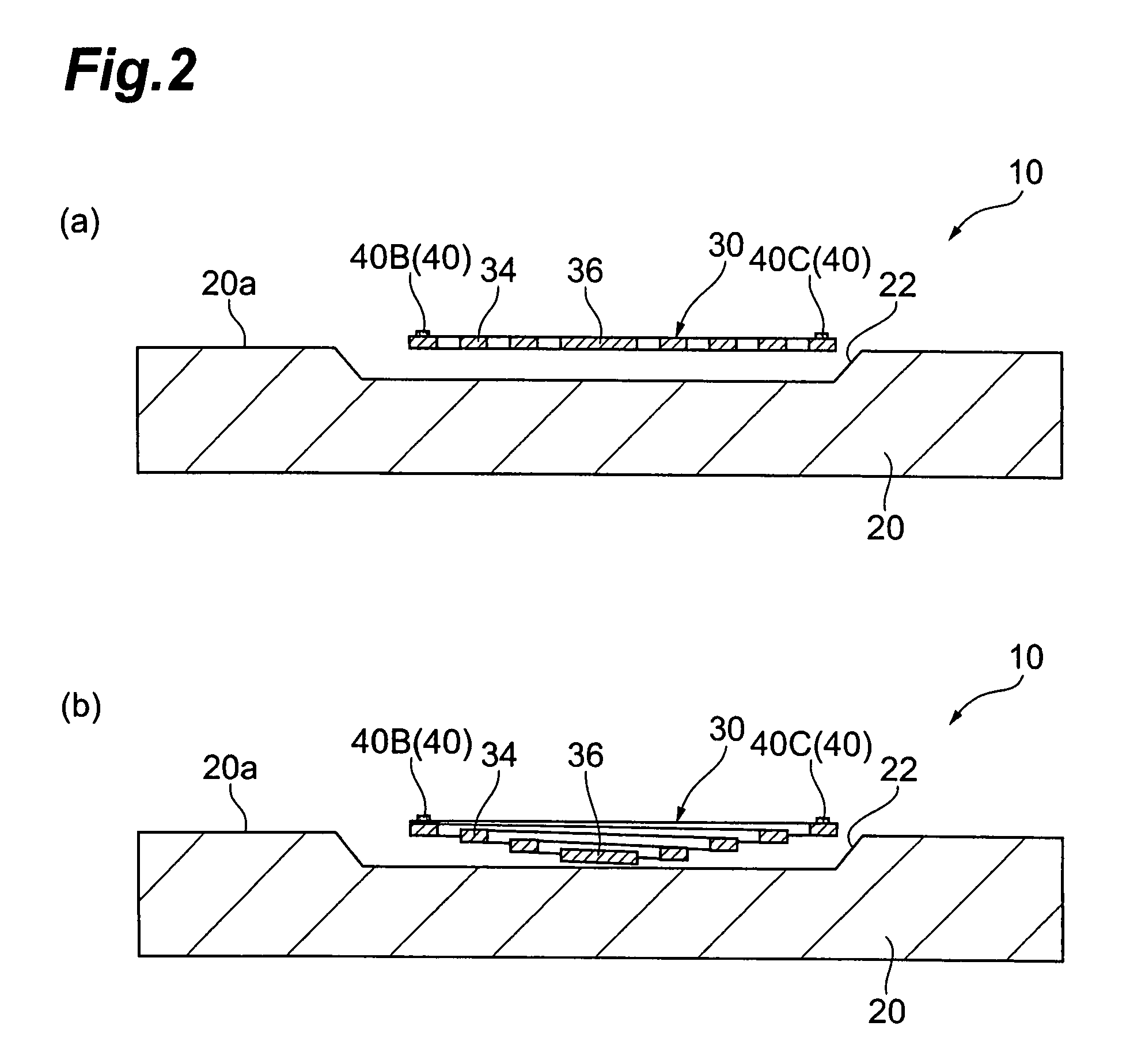

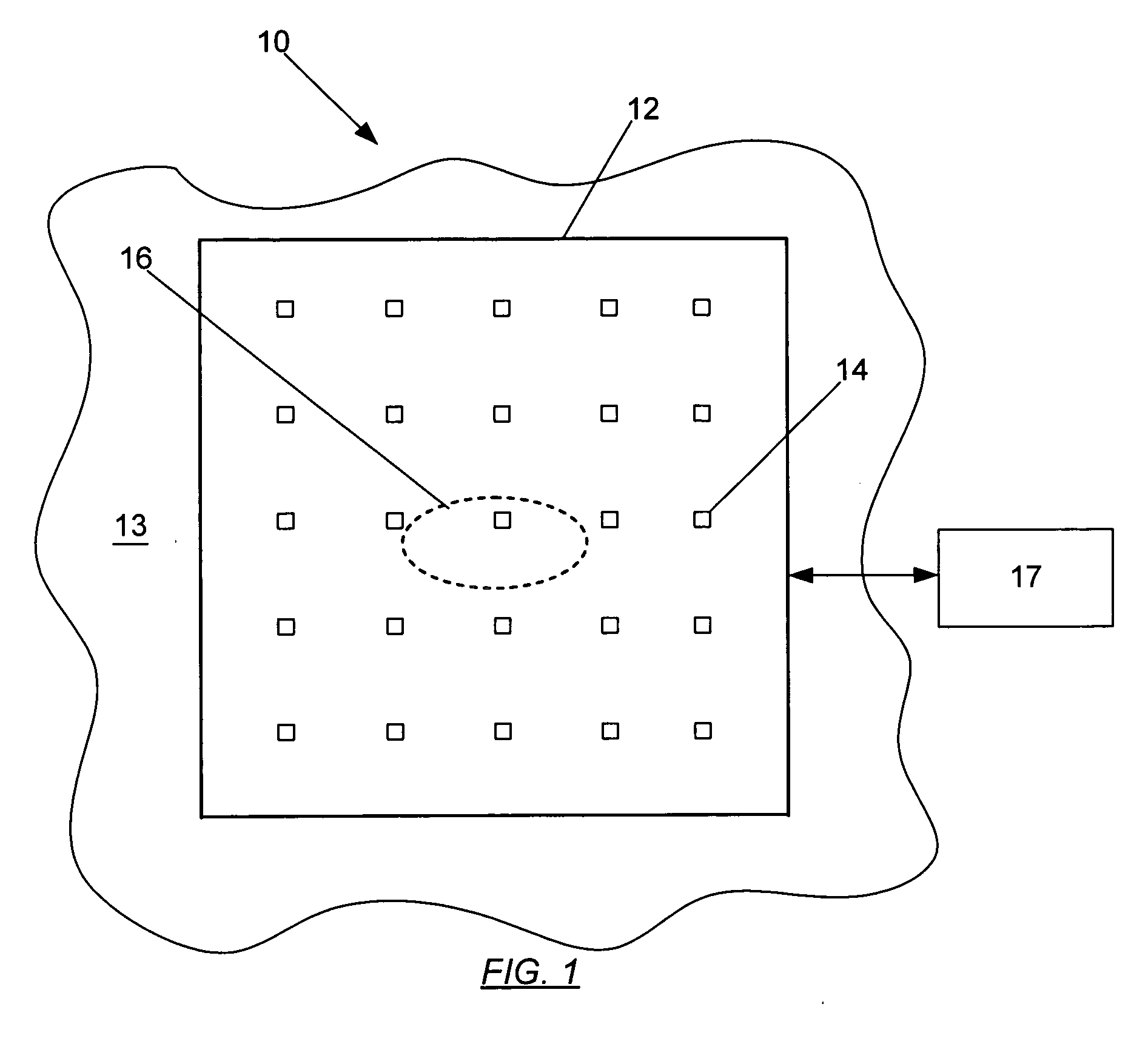

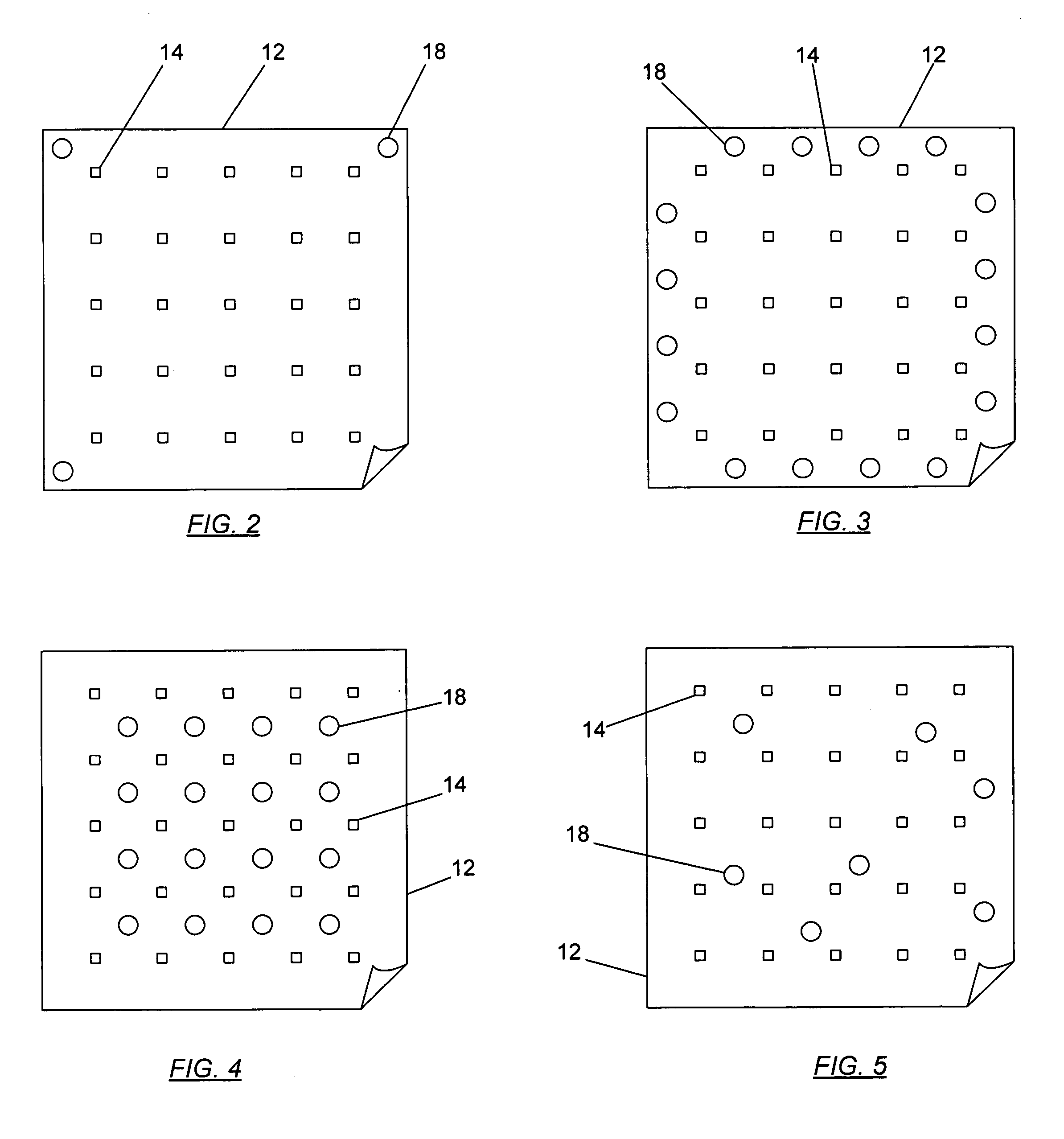

Smart repair patch and associated method

ActiveUS7398698B2Structure moreLow costAnalysing solids using sonic/ultrasonic/infrasonic wavesNuclear monitoringNon destructiveData acquisition

A system and method for identifying defects in a repair patch applied to a structure are provided. The system includes a sheet of material configured to be attached to the structure, and a mechanism operable to generate stress waves within and along the sheet of material. The system also includes a plurality of non-destructive sensors carried by the sheet of material. Each sensor is capable of detecting the stress waves. The system further includes a data acquisition system capable of communicating with the sensors such that the data acquisition system is also capable of generating information indicative of at least a portion of the sheet of material based on the data detected by the sensors.

Owner:THE BOEING CO

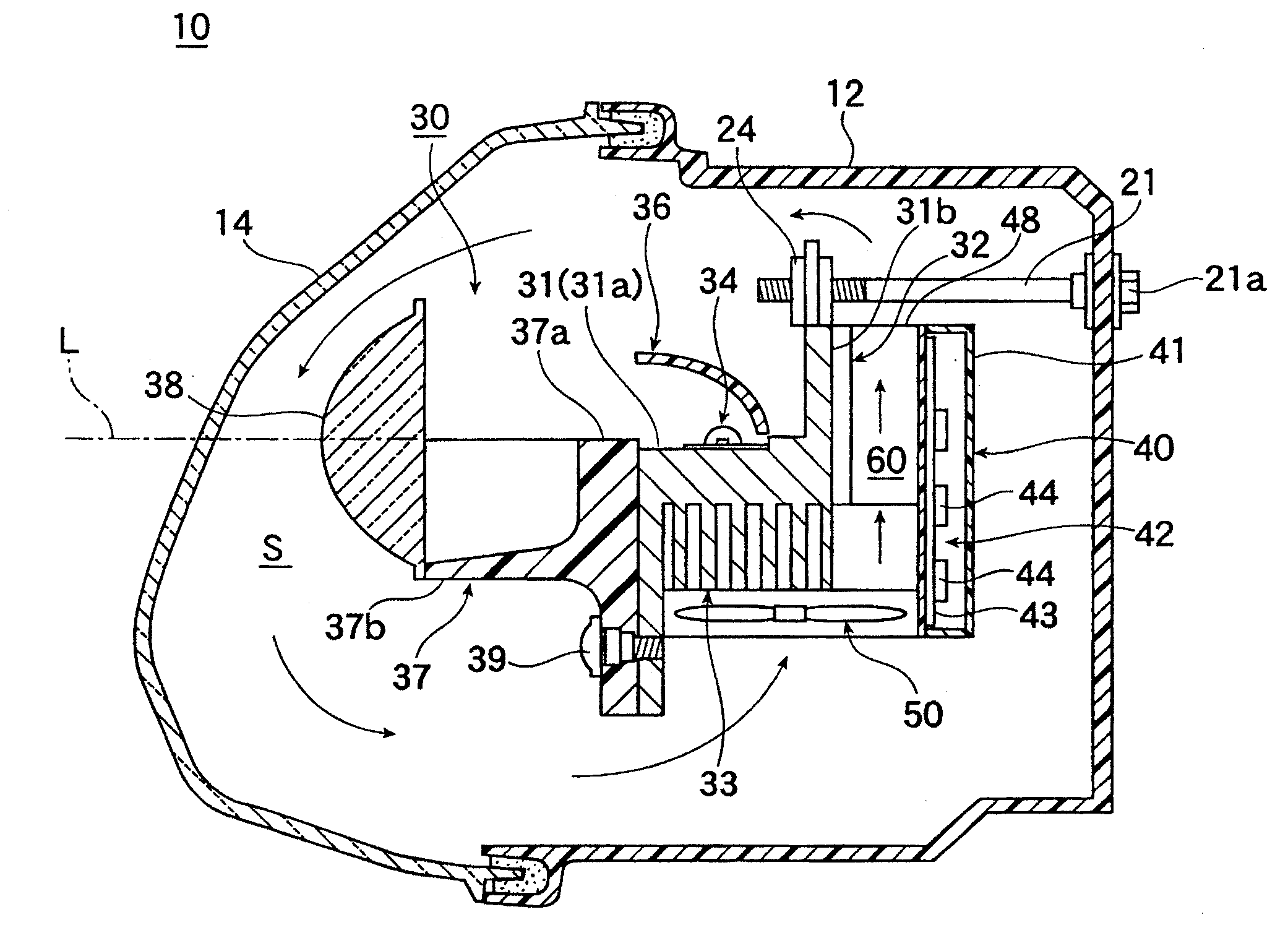

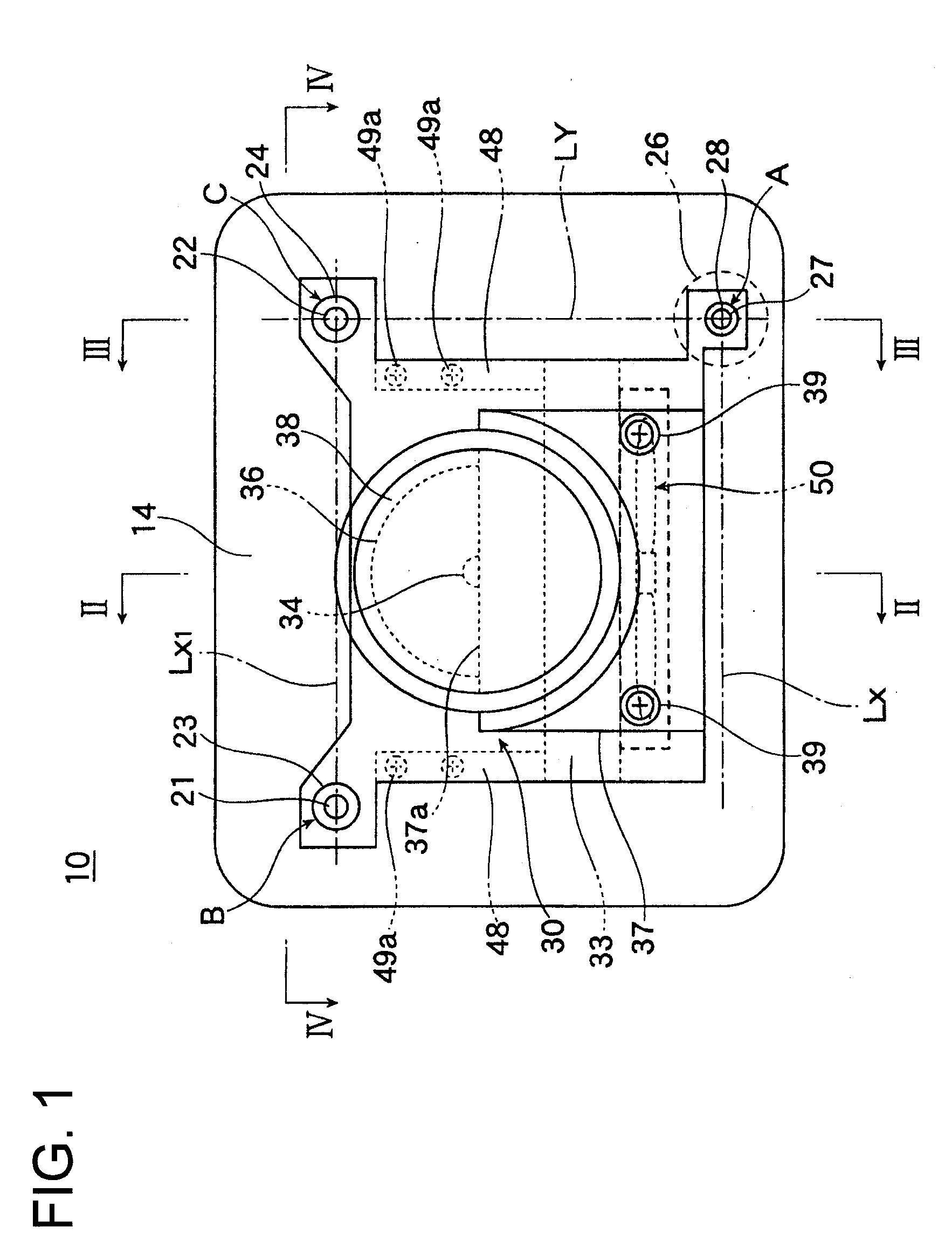

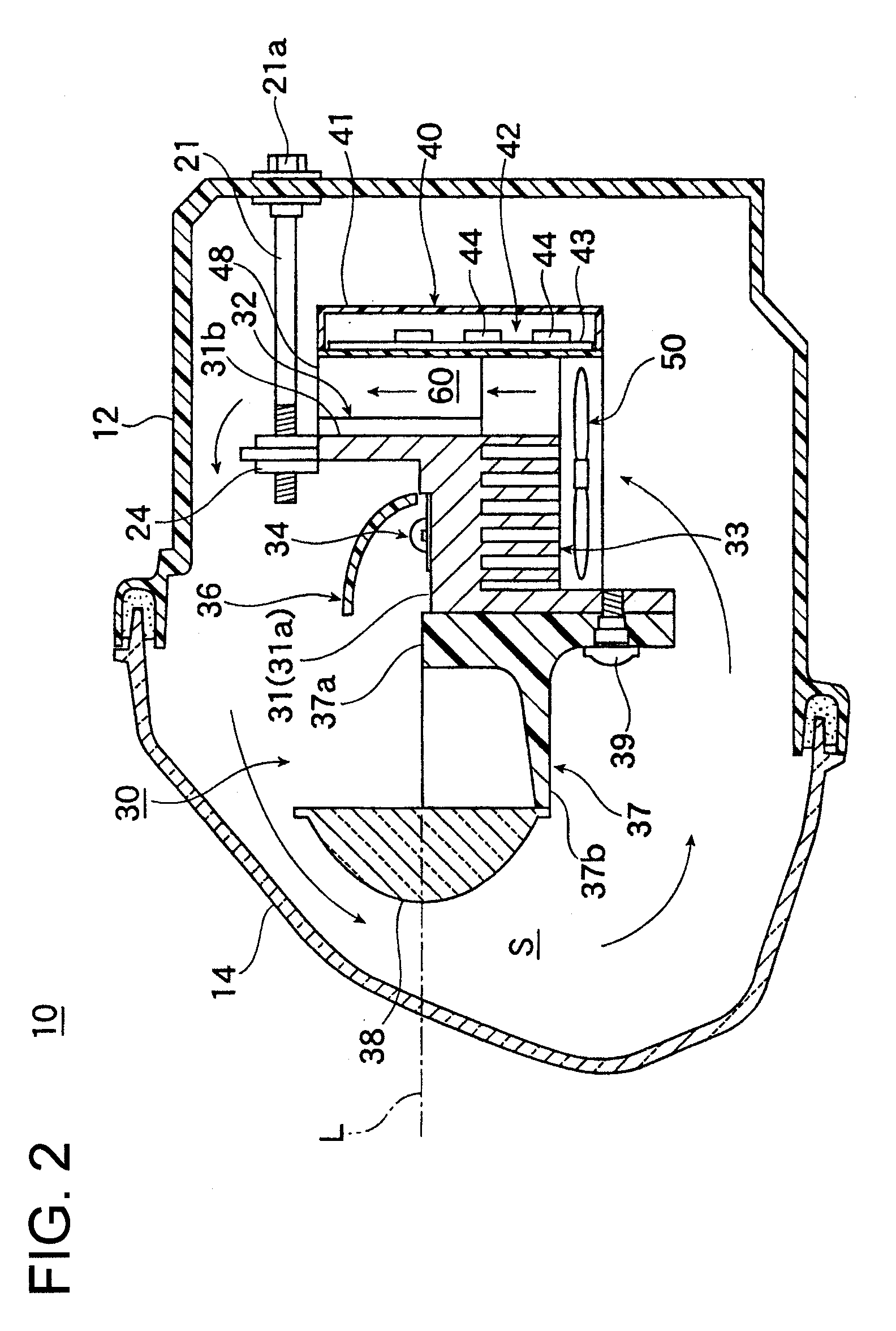

Vehicular headlamp

InactiveUS20100253223A1Simple internal lamp chamber structureReduced luminous efficiencyVehicle headlampsVehicle interior lightingEffect lightEngineering

A vehicular headlamp, wherein a light source unit for light distribution formation is accommodated inside a lamp chamber defined by a lamp body and a front cover, includes a metal heat transfer member that serves as a light source unit structural member; a light-emitting element that serves as a light source; a fan for cooling the light-emitting element provided inside the lamp chamber; and a lighting circuit that controls lighting of the light-emitting element. The light-emitting element, the fan, and the lighting circuit are each attached to the metal heat transfer member.

Owner:KOITO MFG CO LTD

Sensing unit and method of making same

ActiveUS7698941B2Increase the number ofStructure moreAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsEngineeringElectric wire

Owner:HEADWAY TECH INC +1

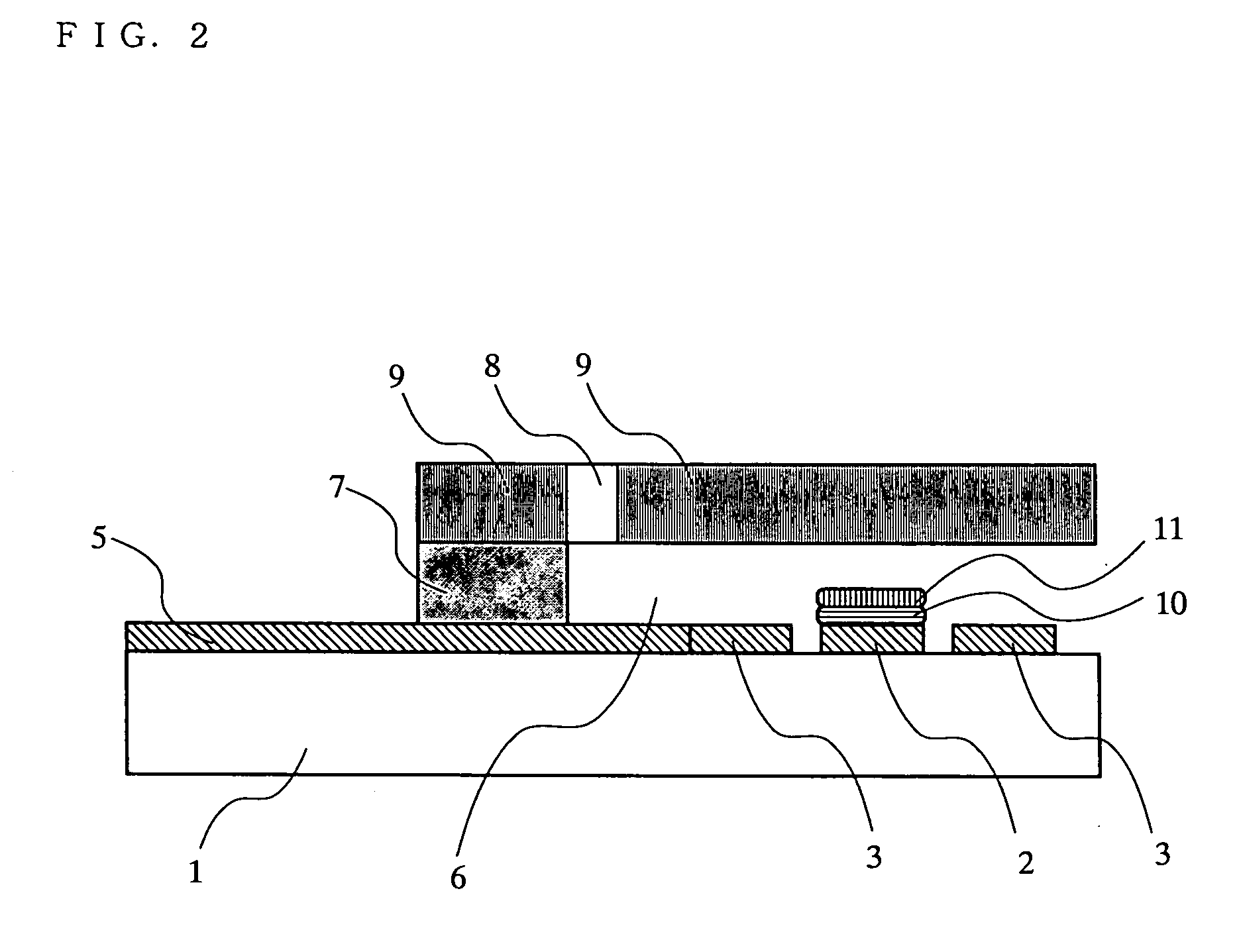

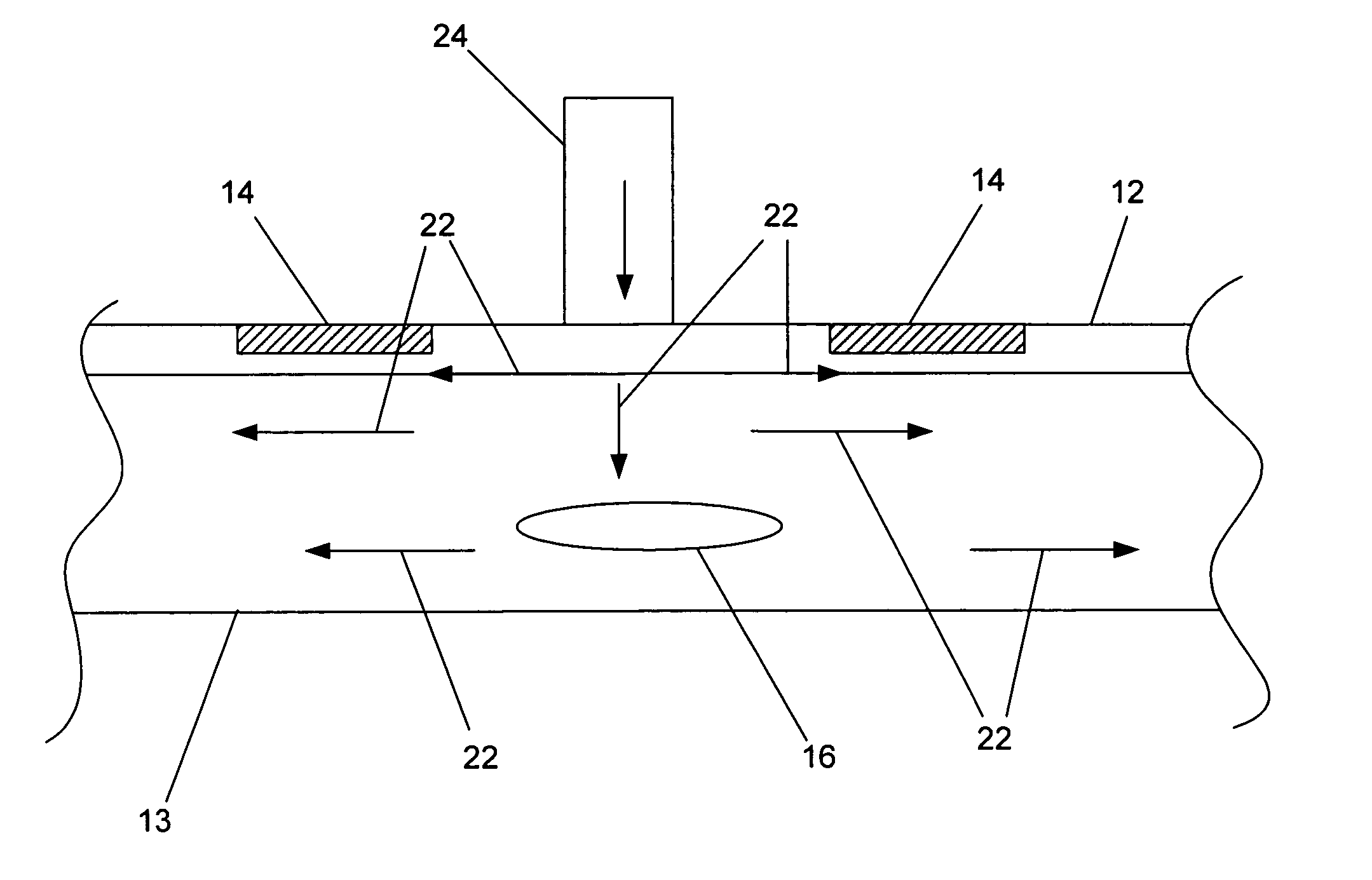

Non-destructive inspection system and associated method

ActiveUS20070017297A1Low costStructure moreAnalysing solids using sonic/ultrasonic/infrasonic wavesElasticity measurementNon destructiveProximate

An assembly, system, and method for identifying defects in a structure are provided. The assembly includes a structure of a metallic or composite material, and a flexible sheet of material positioned adjacent to the structure. The assembly also includes a plurality of non-destructive sensors secured to the flexible sheet, and a mechanism operable to impact the flexible sheet or proximate to the flexible sheet to generate stress waves within and along a surface of the structure. The system further provides a data acquisition system capable of communicating with the sensors such that the data acquisition system generates feedback indicative of at least a portion of the structure based on data from the stress waves acquired by the sensors.

Owner:THE BOEING CO

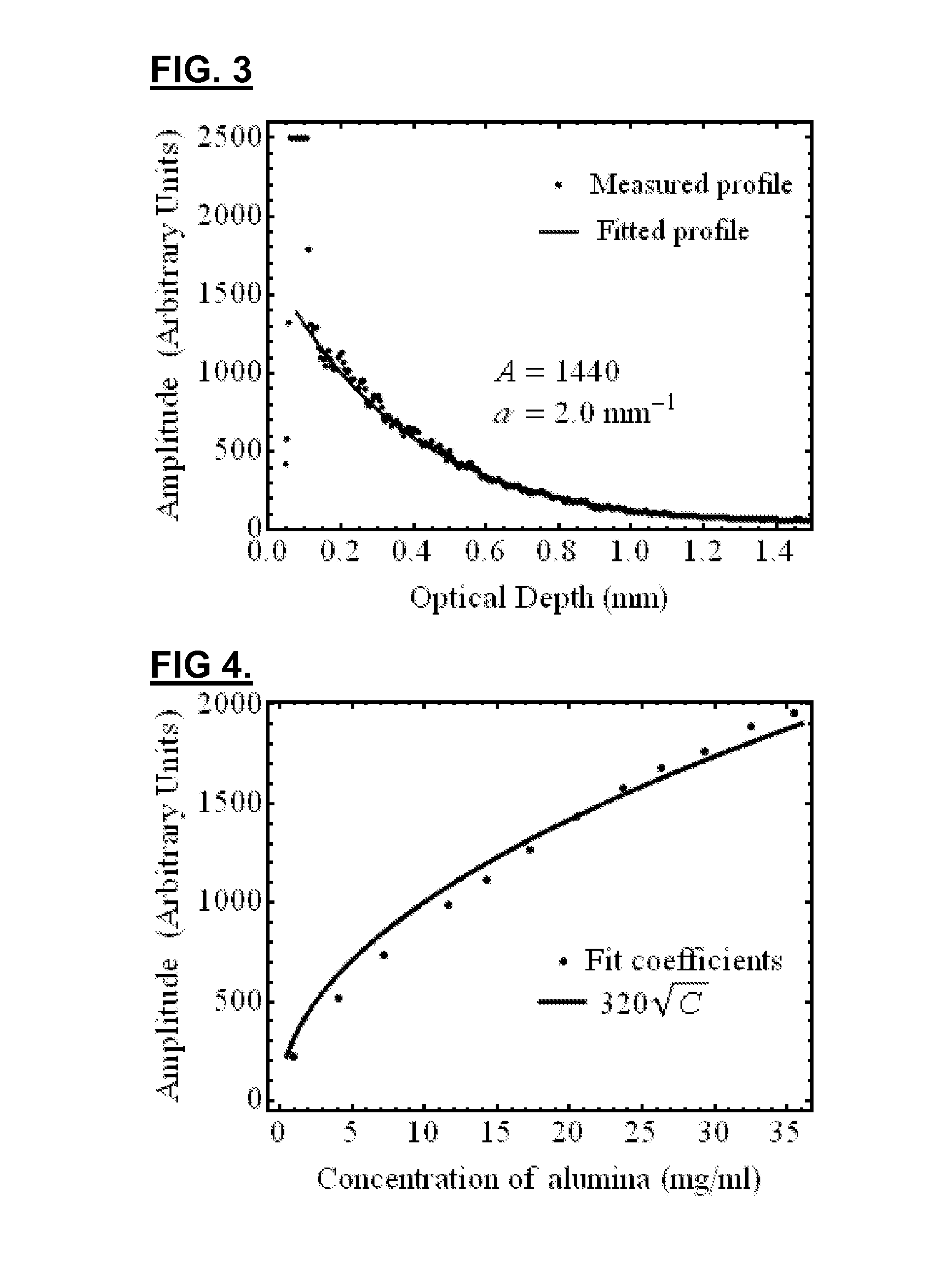

Multilayered tissue phantoms, fabrication methods, and use

InactiveUS8888498B2Efficiently formedStructure morePreparing sample for investigationPretreated surfacesOptical propertyEngineering

A method for producing a multilayer tissue phantom involves successively forming at least two layers, each layer formed by depositing a viscous flowable material over a supporting element or over a previously formed layer of the phantom supported by the supporting element, selectively redistributing the material while material is solidifying to control a thickness distribution of the layer, and allowing the material to solidify sufficiently to apply a next layer. The supporting element supports the material in 2 or 3 directions and effectively molds a lumen of the tissue. The neighboring layers are of different composition and of chosen thickness to provide desired optical properties and mechanical properties of the phantom. The phantom may have selected attenuation and backscattering properties to mimic tissues for optical coherence tomography imaging.

Owner:NAT RES COUNCIL OF CANADA

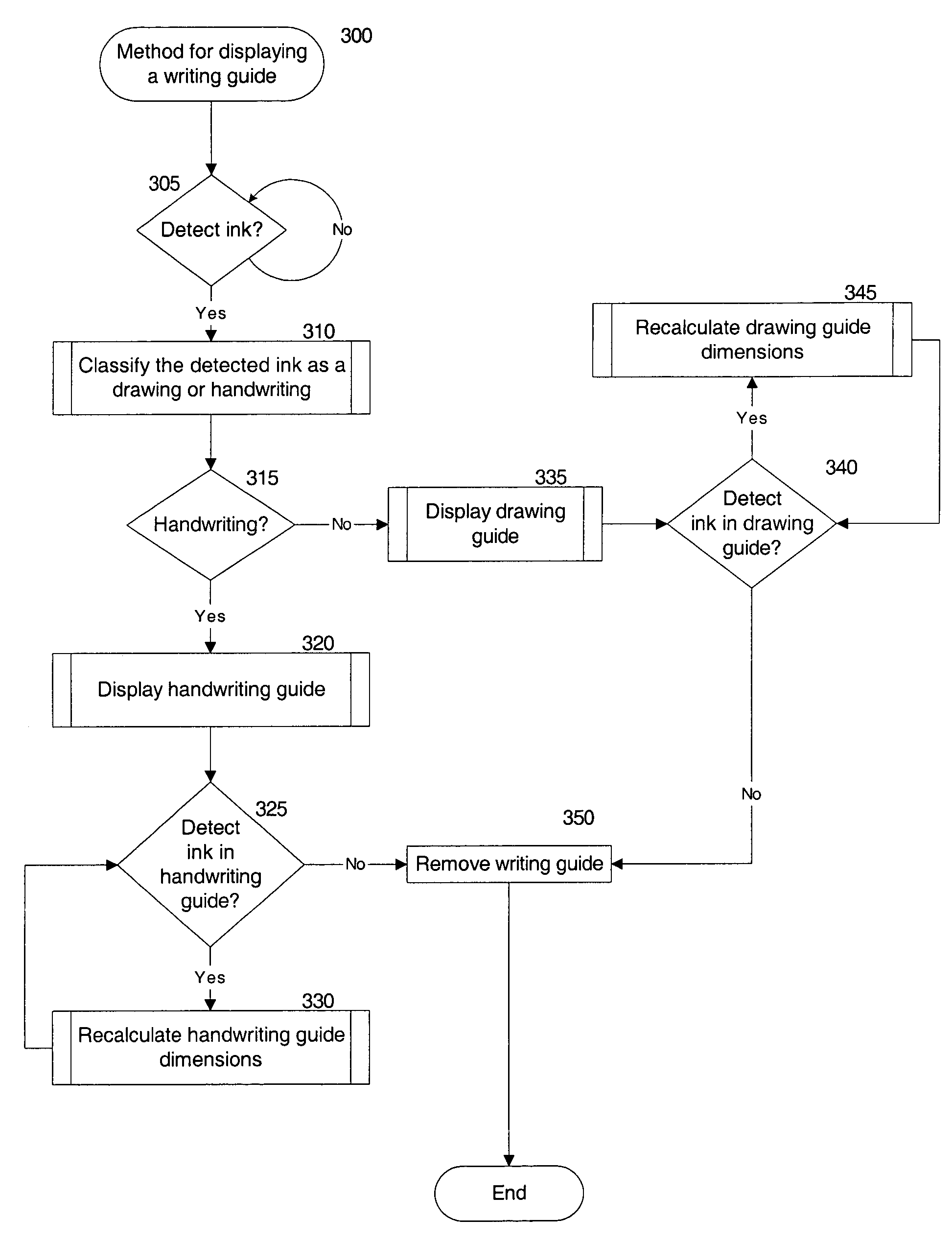

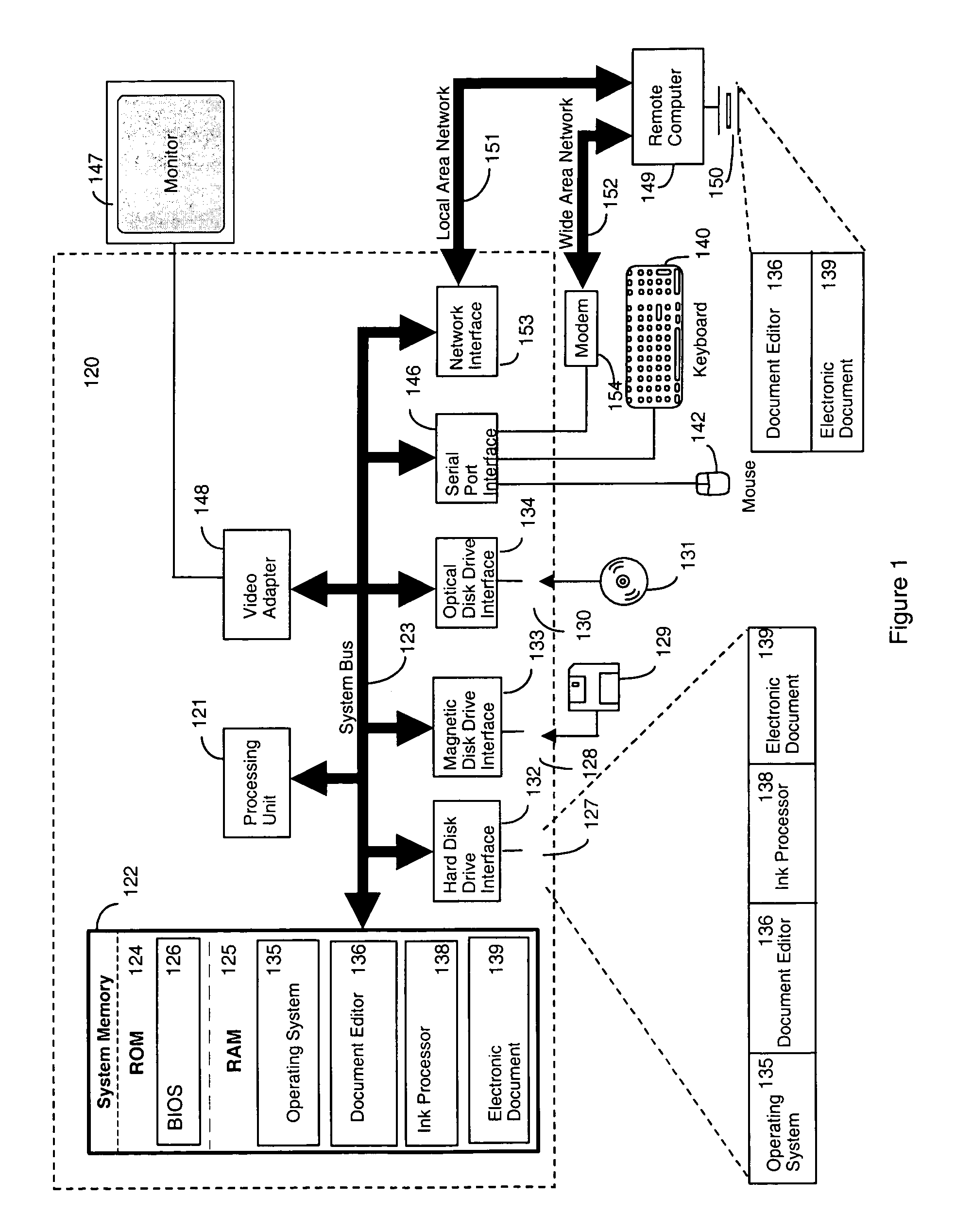

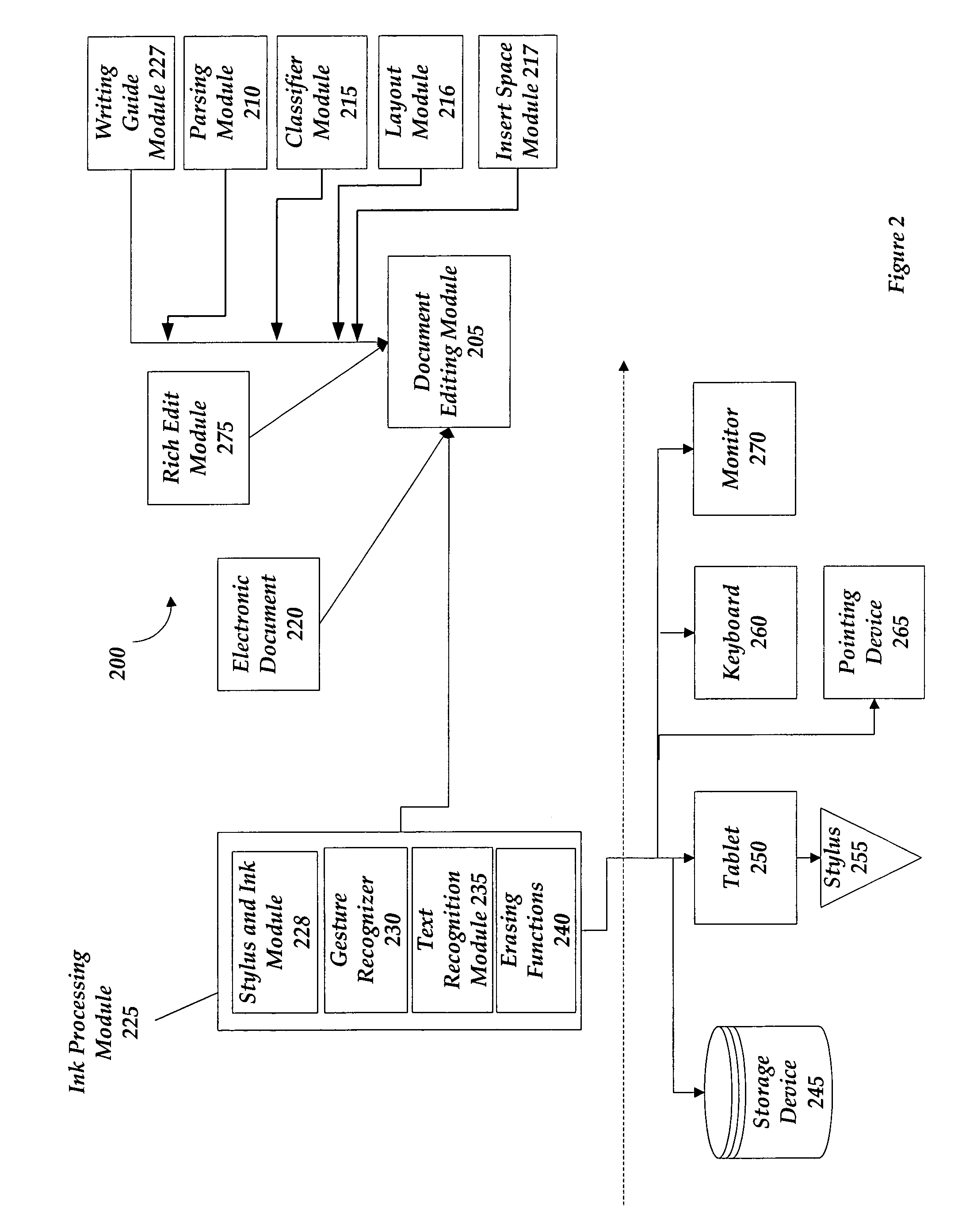

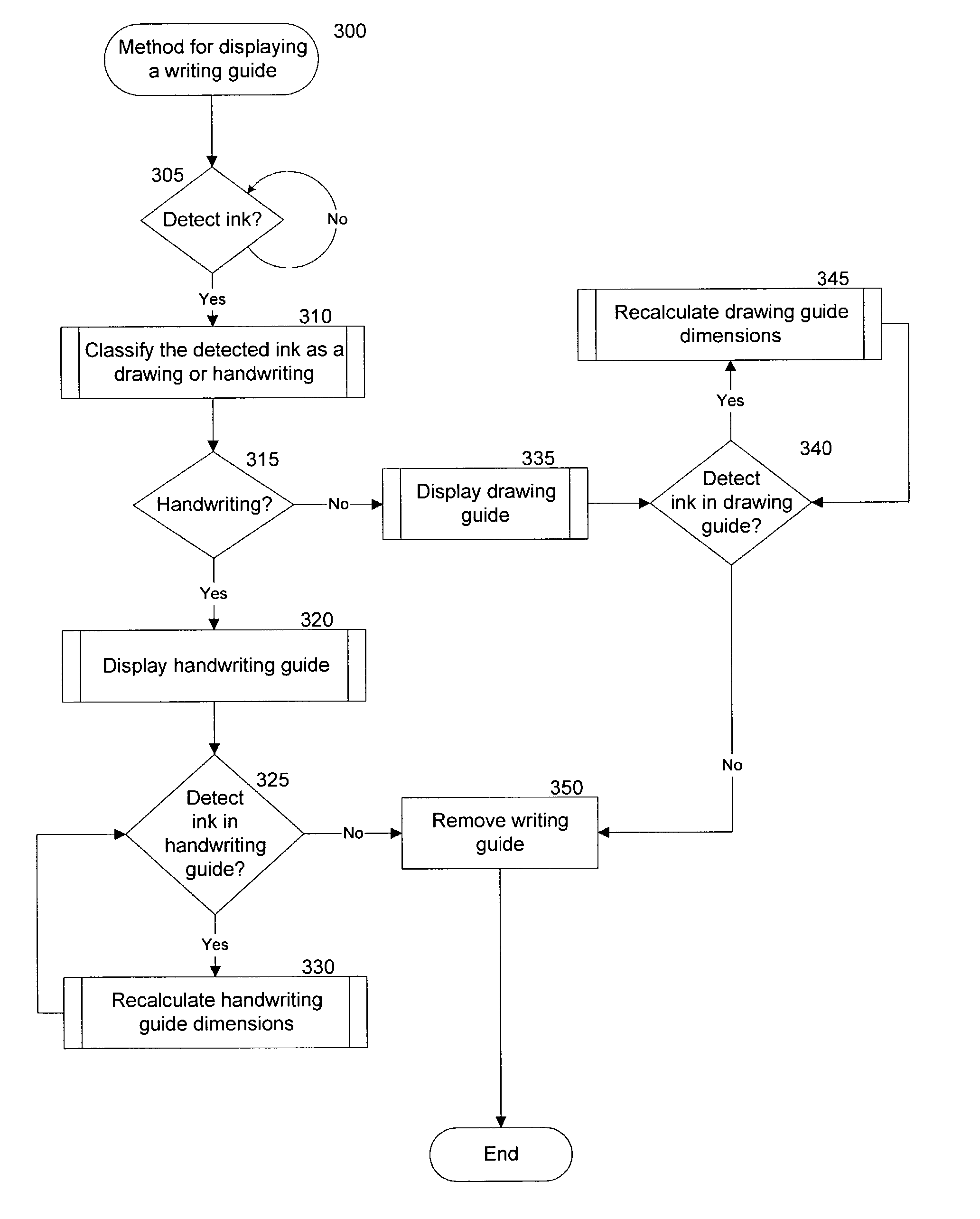

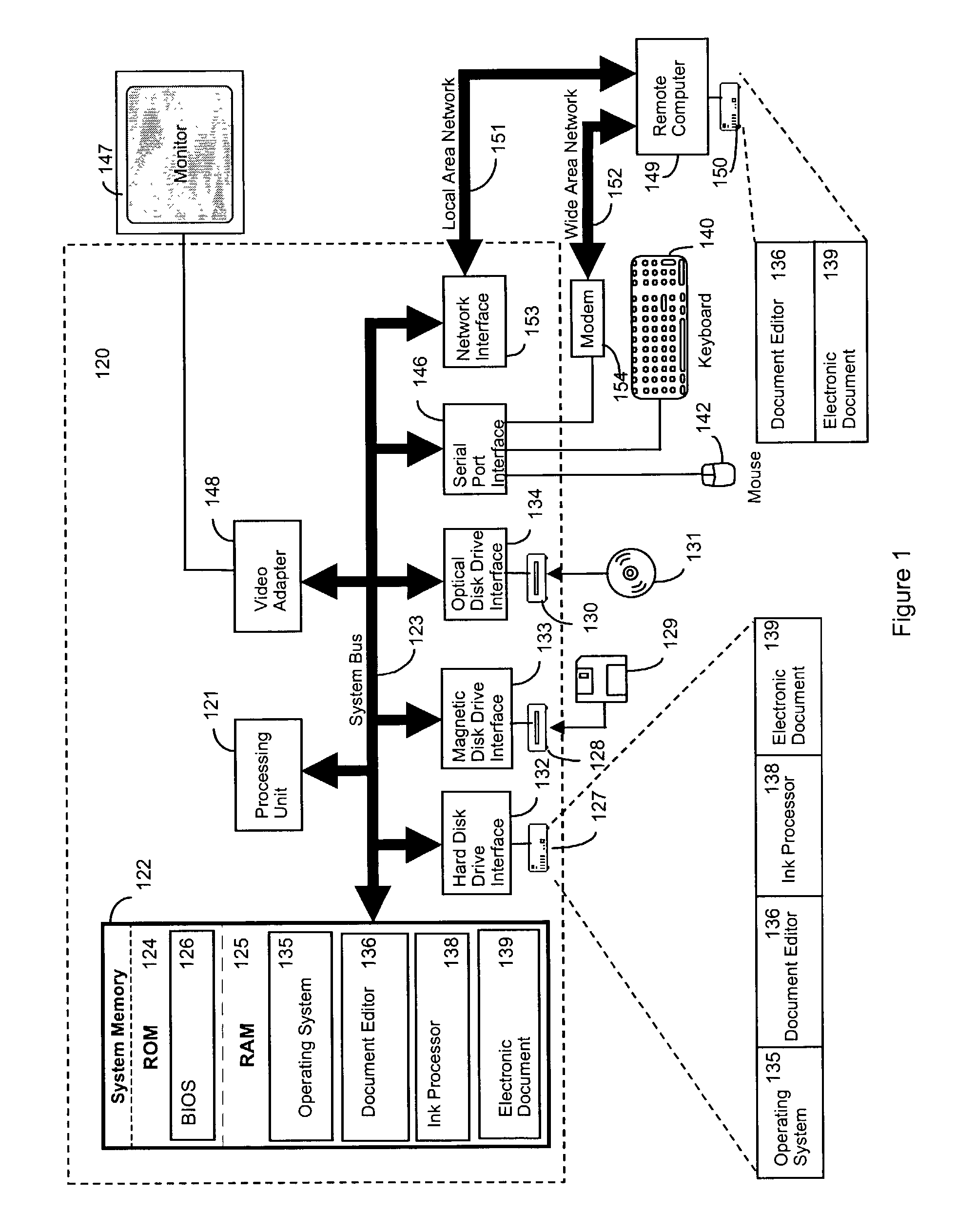

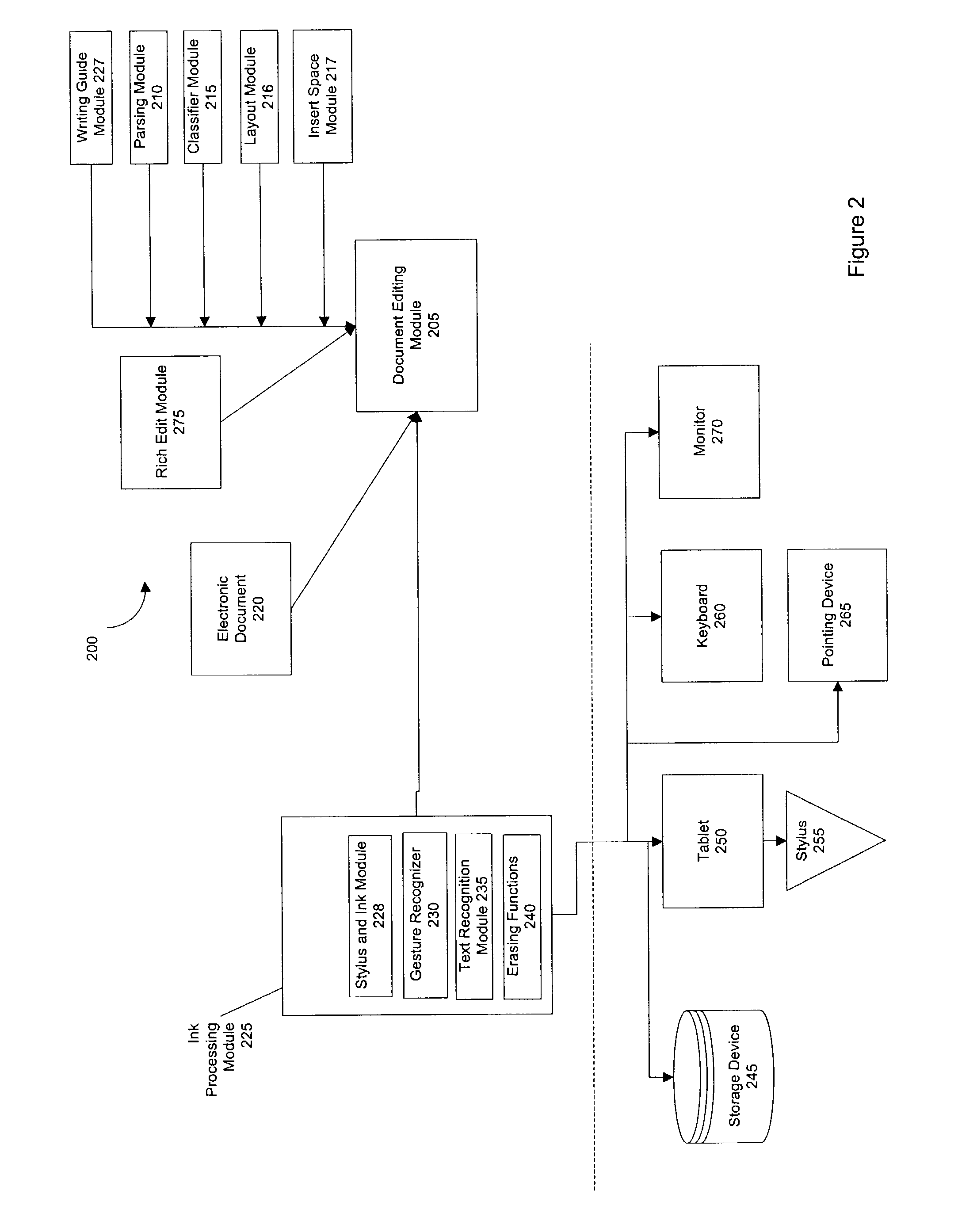

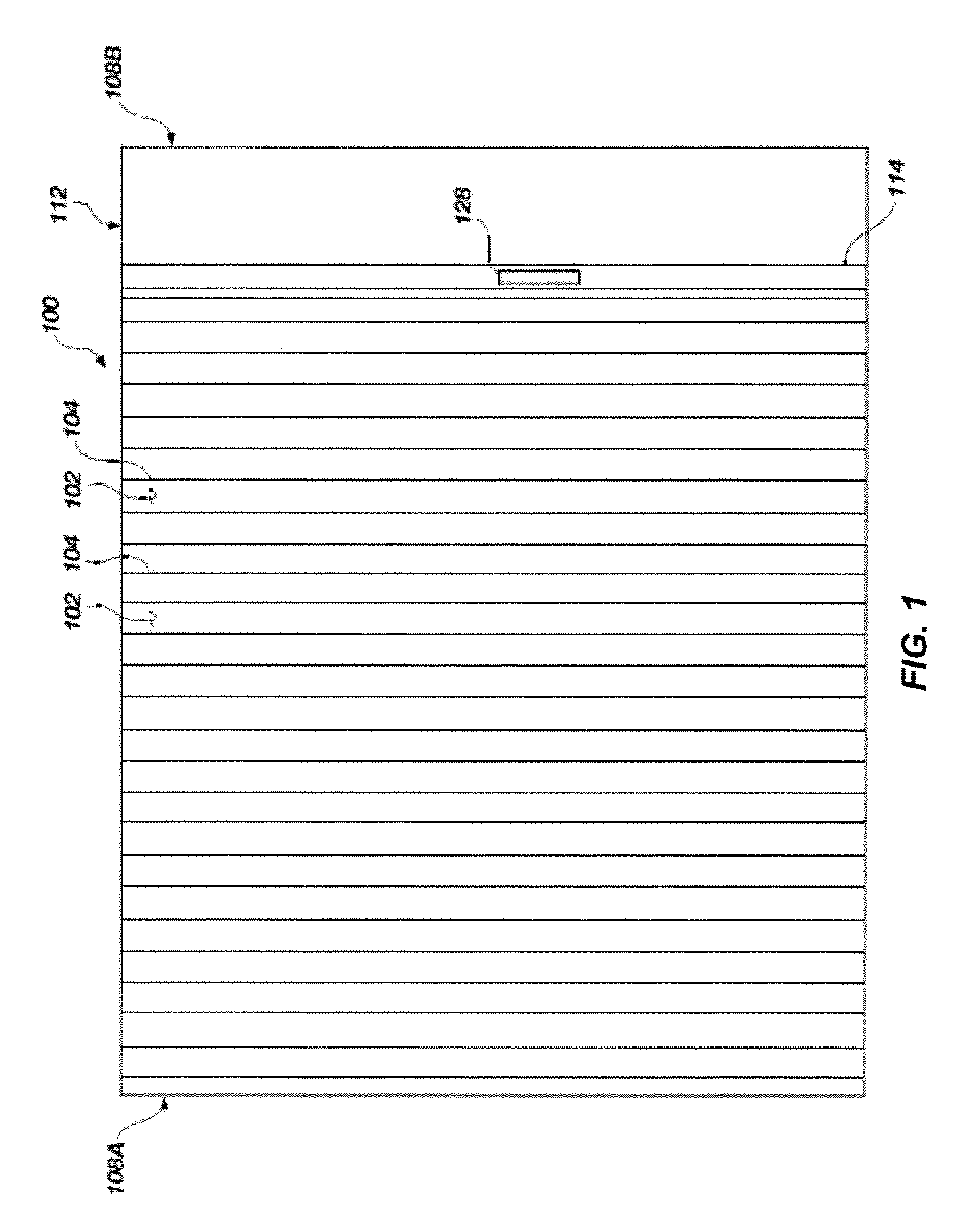

Writing guide for a free-form document editor

InactiveUS7751623B1Improve accuracyHigh degree of recognitionNatural language data processingDigital ink recognitionHandwritingText mode

A handwriting guide including an active and / or inactive writing guide is rendered by displaying a shaded outline object having a line for receiving electronic ink, displaying the active writing guide thereby indicating a location of a current active context, and expanding the active and / or inactive writing guide up to a maximum width of the outline object in response to receiving more electronic ink within a line. The active writing guide can comprise a bracket displayed on each corner of a writing area distinguished on a line and can correspond to an insertion point upon switching to text mode. A drawing guide that includes an active and / or inactive drawing guide is rendered by displaying a shaded drawing guide and the active drawing guide in response to detecting ink strokes within the drawing guide. The active drawing guide can comprise a bounding rectangle encompassing a drawing area that receives ink strokes.

Owner:MICROSOFT TECH LICENSING LLC

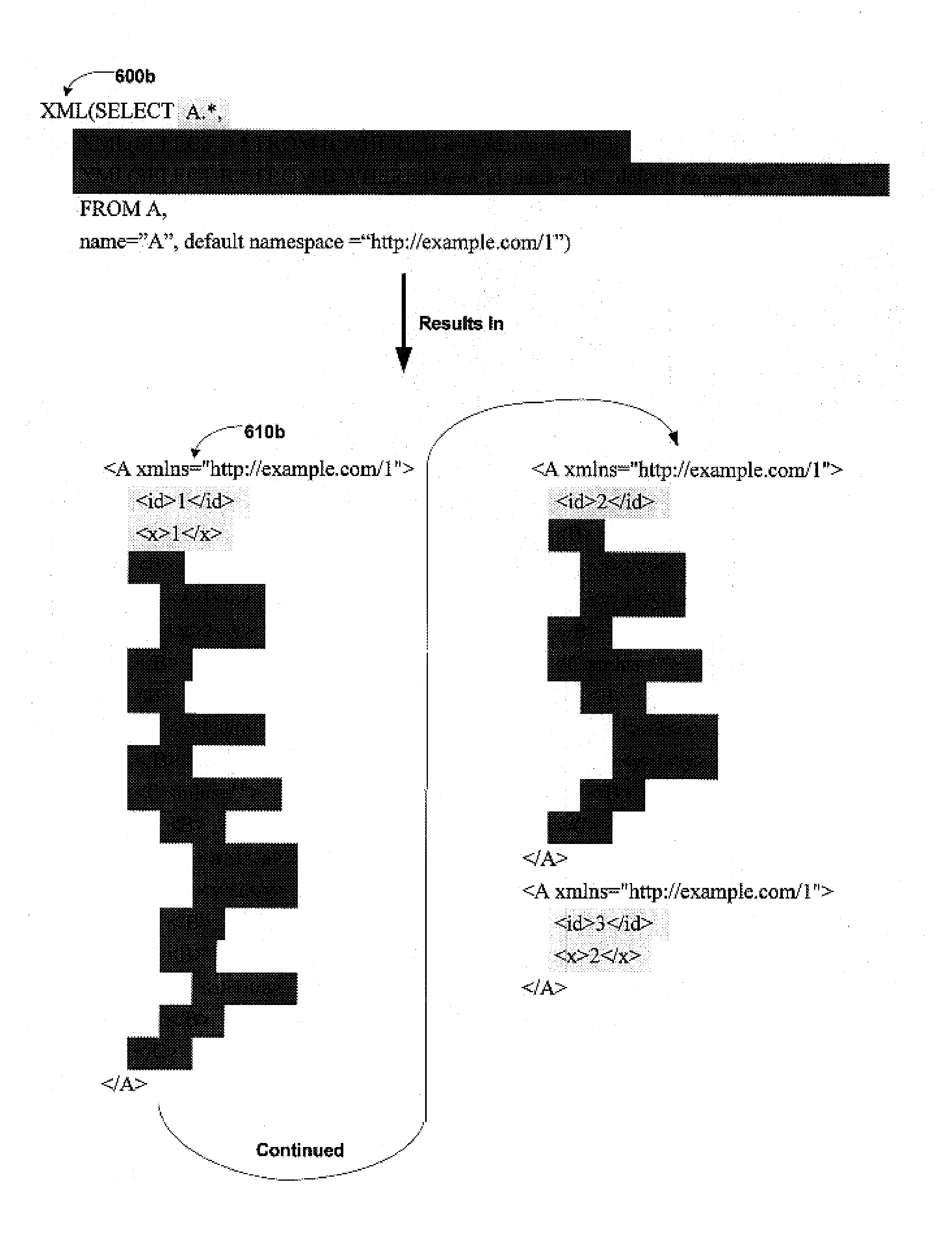

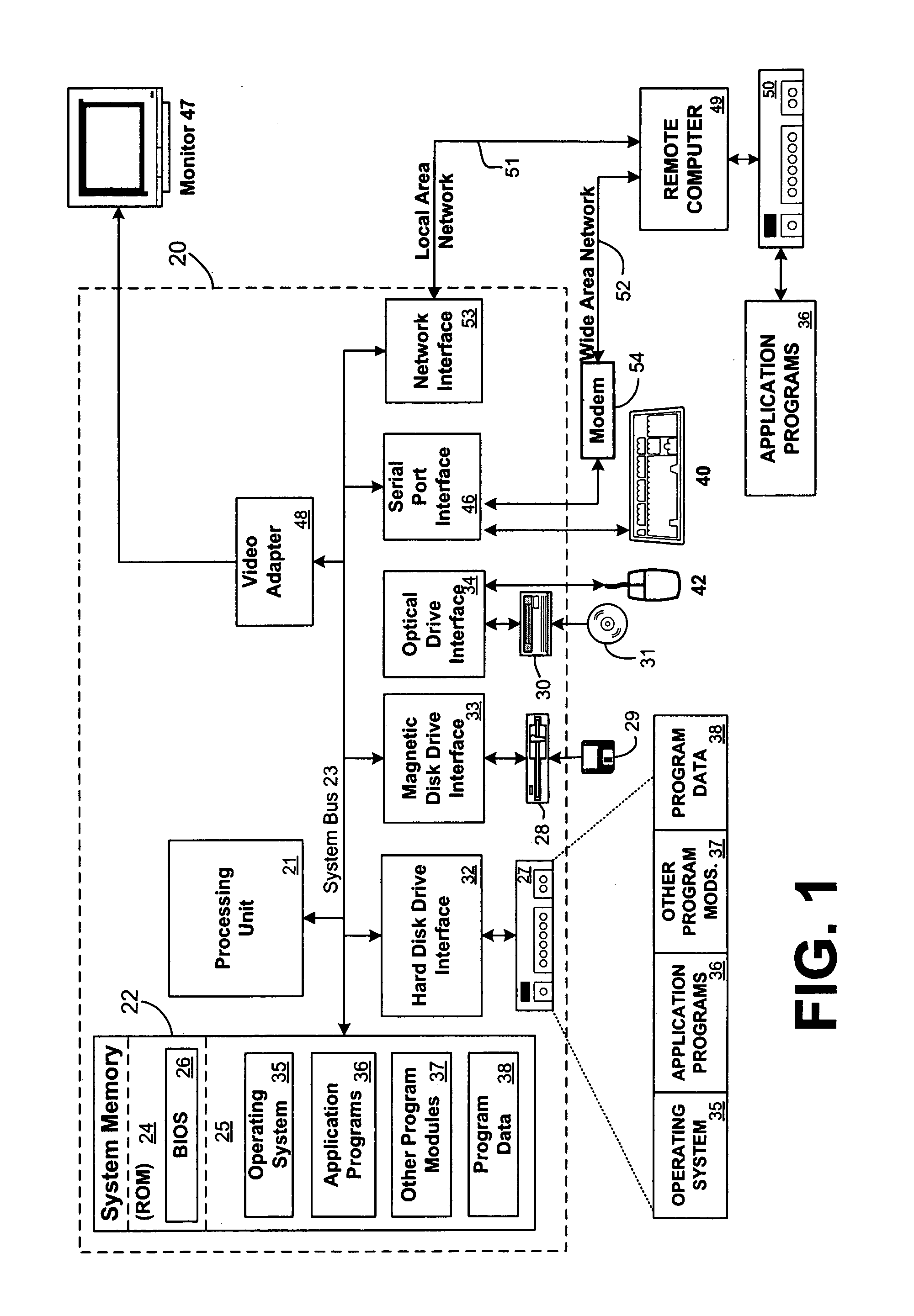

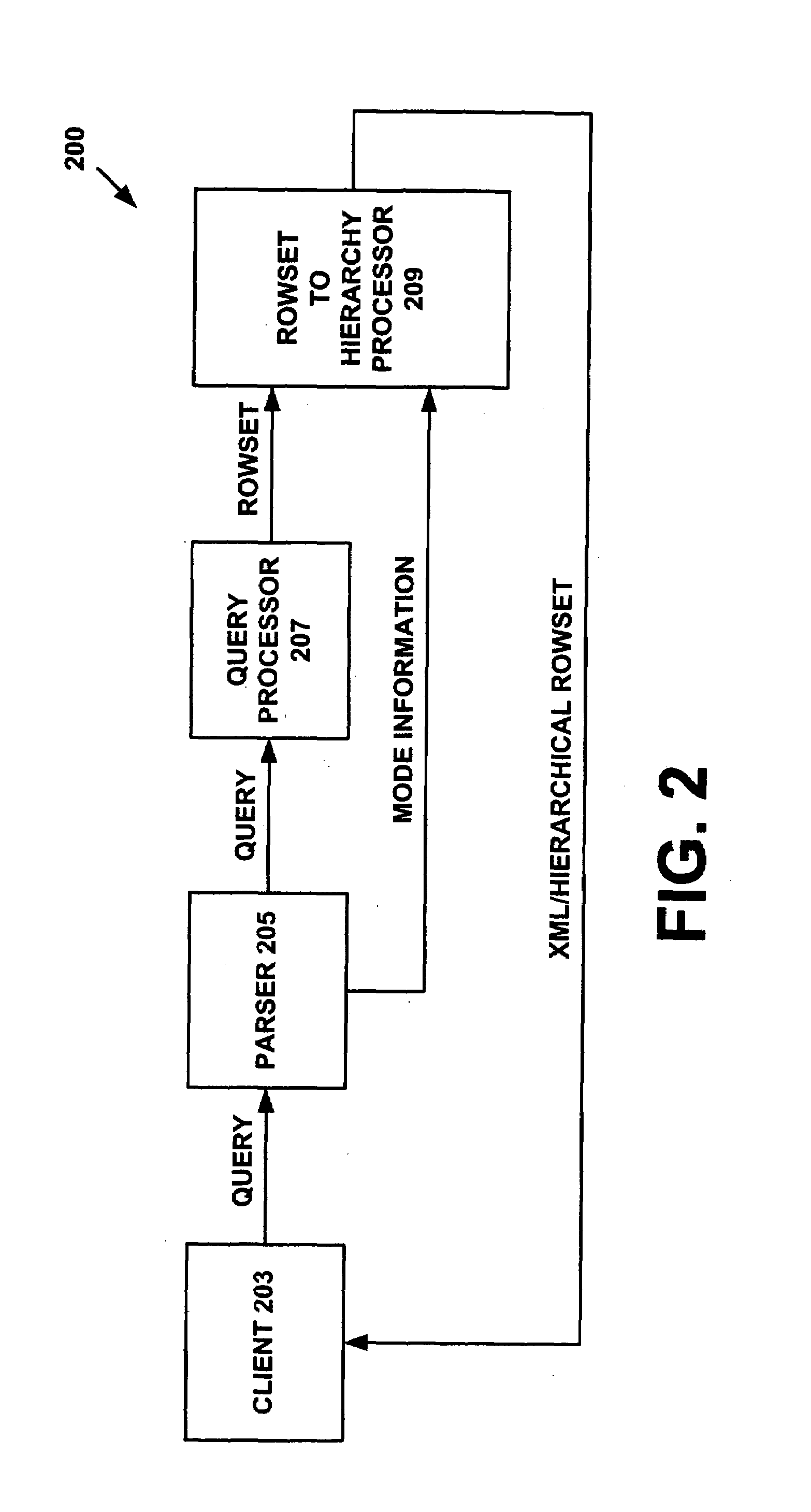

Systems and methods for transforming query results into hierarchical information

InactiveUS7213017B2Facilitate compositionStructure moreData processing applicationsDigital computer detailsData streamExtensible markup

A computerized system and method for transforming (formatting or aggregating) the results of a query into a hierarchical information stream, such as an extensible Markup Language (XML) data stream is disclosed. A database server receives a query and generates a rowset. A rowset processor, using the mode specified in the query, processes the rowset and query to generate the XML data stream. For the “auto1” mode, the rowset processor transforms a rowset into an XML data stream using primary-foreign key information specified in the query to determine nesting. For the “auto2” mode, the rowset processor transforms a rowset into an XML data stream using table ordering information included in the query to determine nesting. For the “explicit” mode, the rowset processor transforms a rowset into an XML data stream using the explicit organizational information specified in the query. In one embodiment, it is easier for a developer to compose expressions to generate nested hierarchical structures than previous formulations and simpler semantics are provided without implicit hierarchy inference. The syntax of an embodiment of the hierarchical formatting function includes optional arguments including a name option, a root option, map option, namespace options and a null option.

Owner:MICROSOFT TECH LICENSING LLC

Writing guide for a free-form document editor

InactiveUS7062090B2High accuracyImprove accuracyNatural language data processingModifying/creating image using manual inputElectronic documentHandwriting

Displaying a writing guide for a free-form document editor by detecting electronic ink, classifying the detected ink as corresponding to handwriting or a drawing, and displaying a handwriting guide or a drawing guide in response to classifying the detected ink as handwriting or a drawing, respectively. The writing guides can provide feedback regarding the classification of the detected ink and can be resized as additional ink is detected. The handwriting guide can comprise a writing area, writing guide portion, bullet guide, indent marker, character notches, gesture guide, or sacrificial guide to create meaningful structure within an outline object of an electronic document.

Owner:MICROSOFT TECH LICENSING LLC

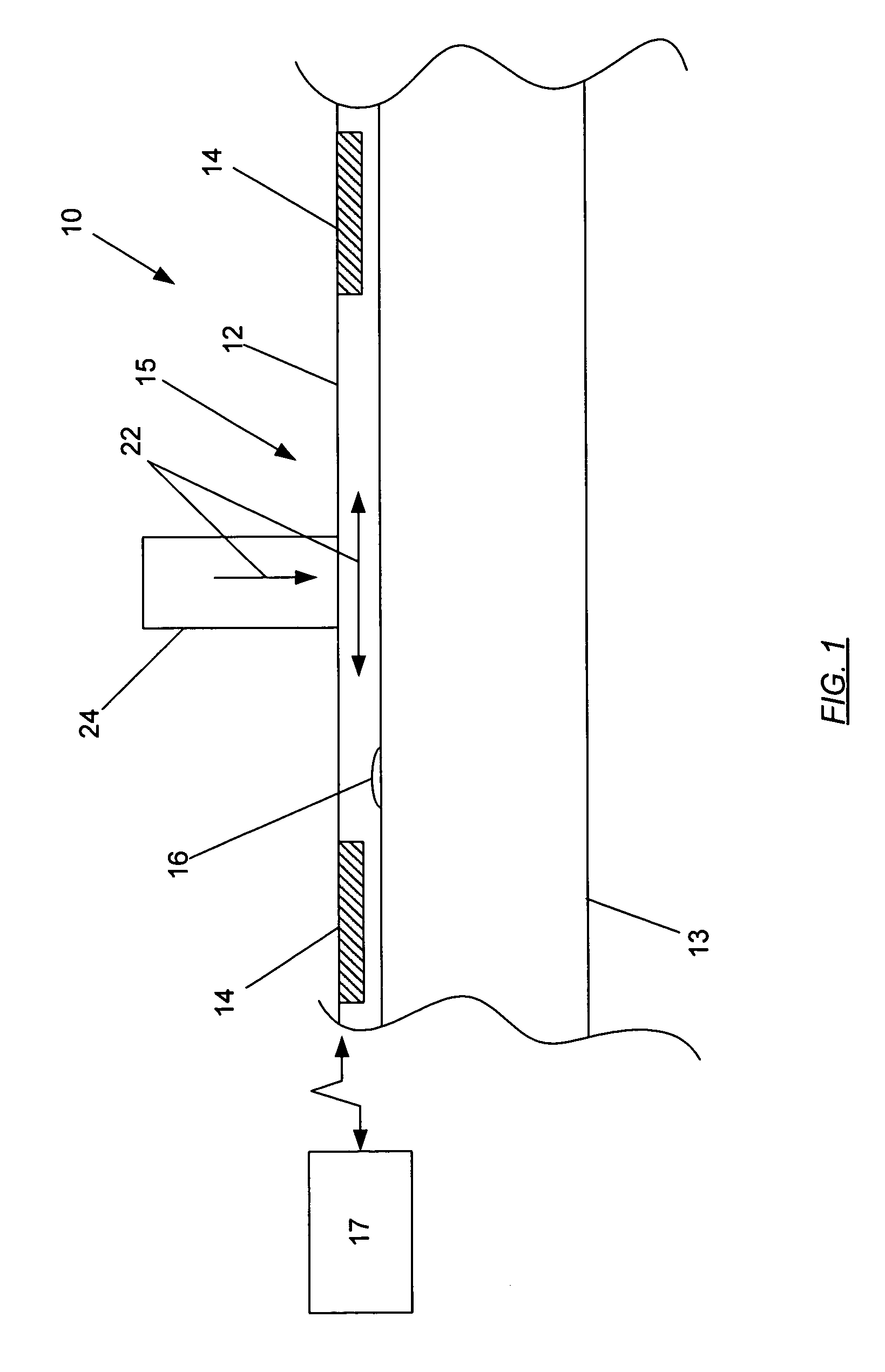

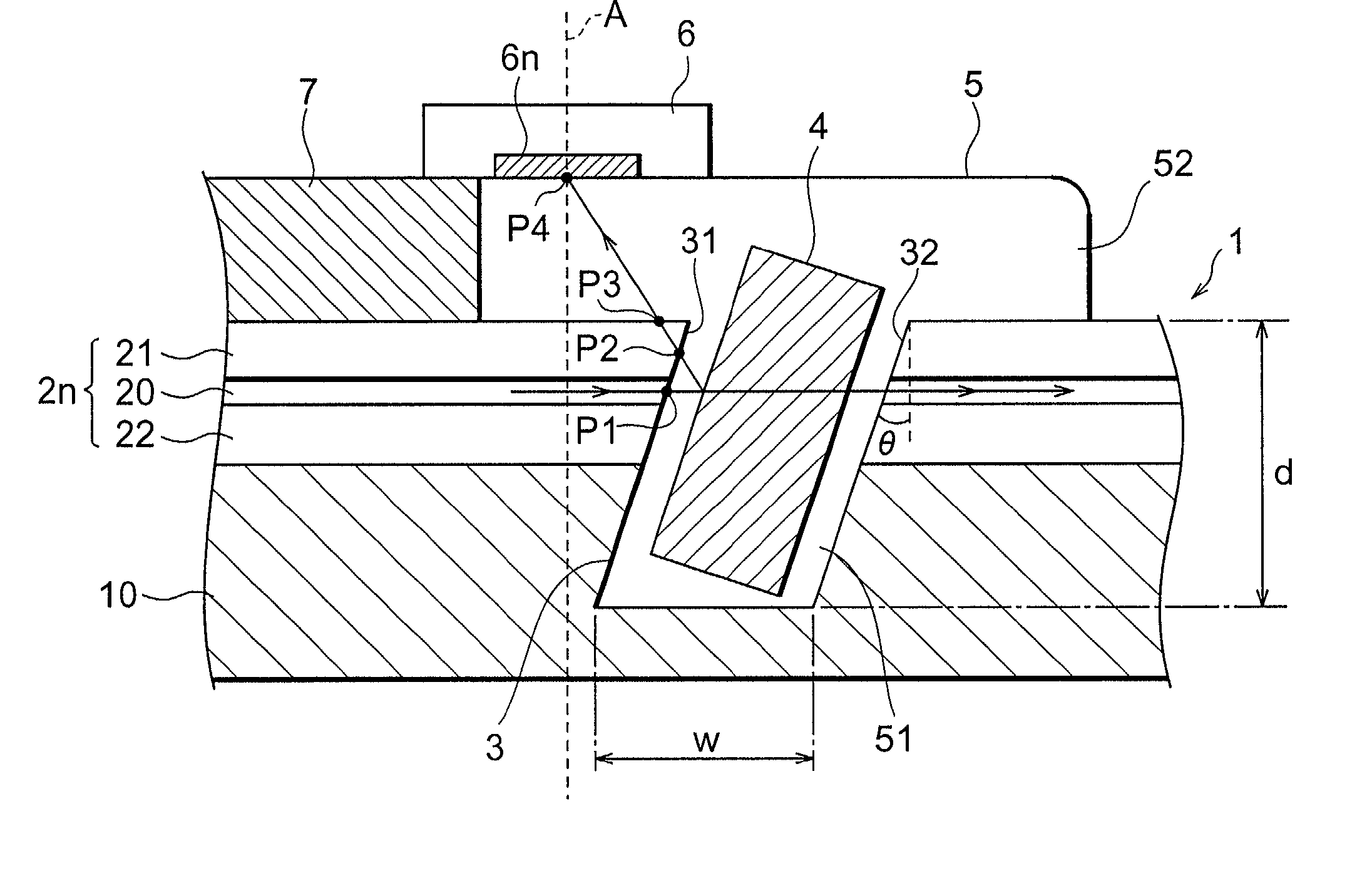

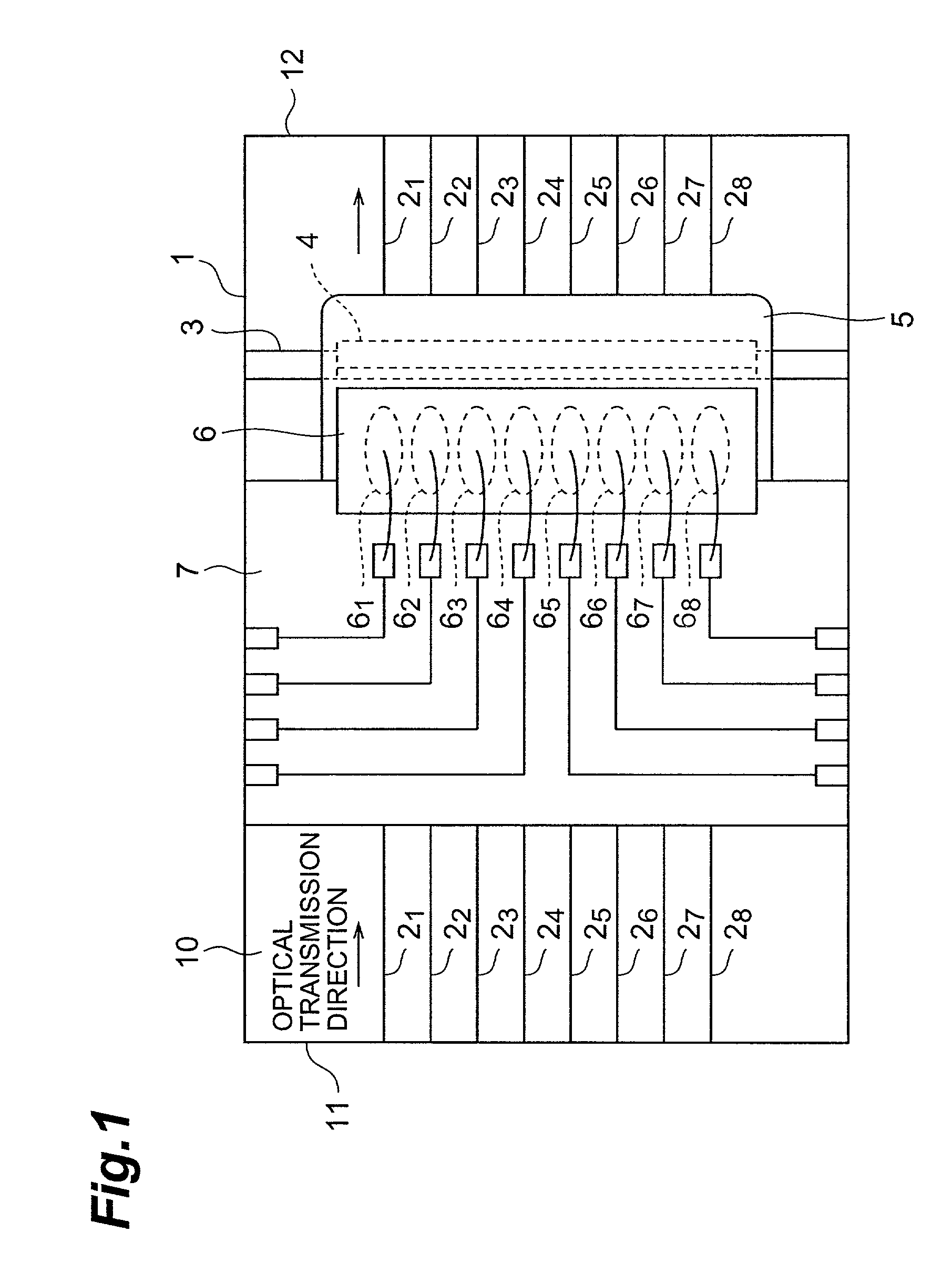

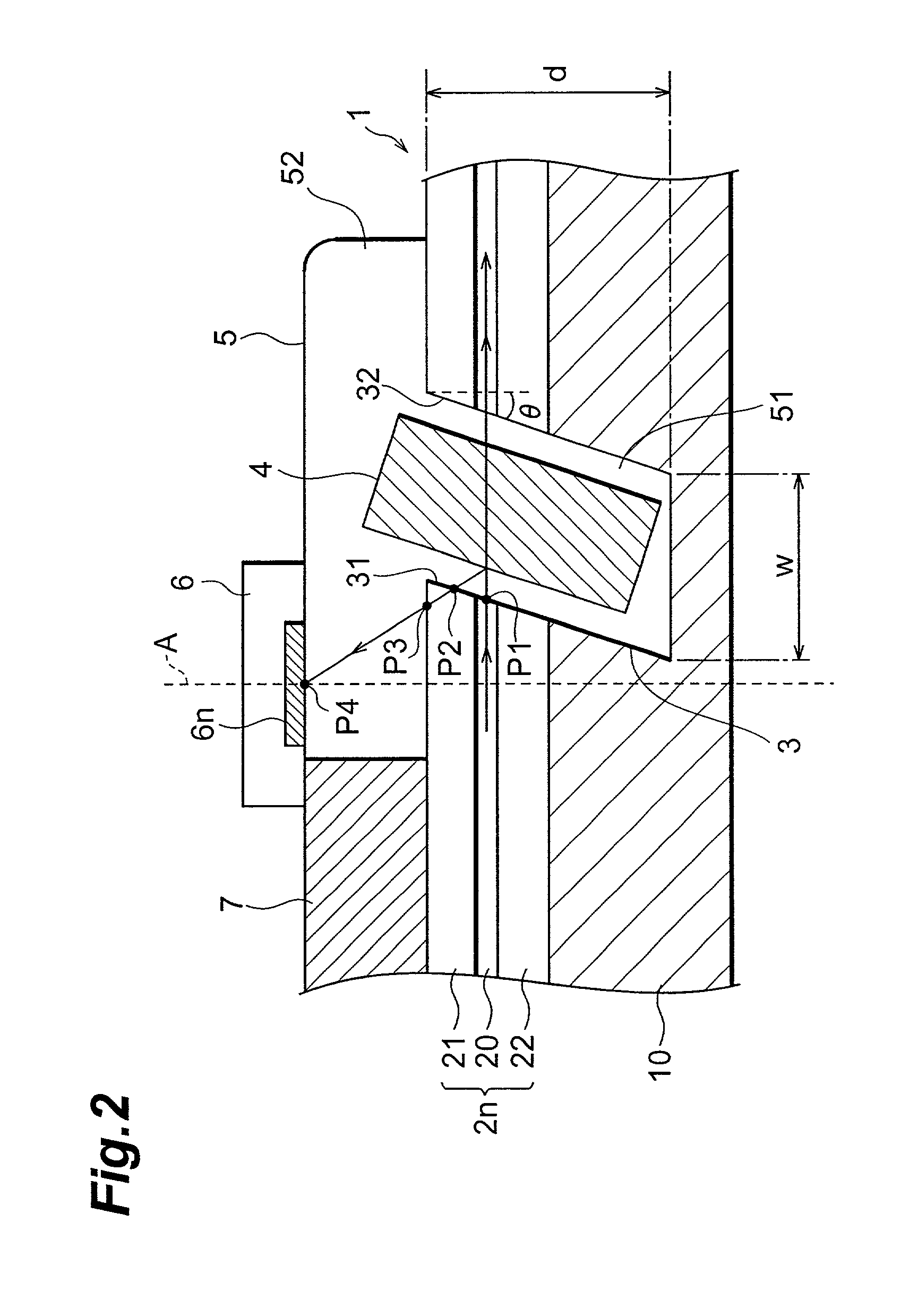

Optical waveguide module

InactiveUS20030044119A1Increase the number ofMore processedSolid-state devicesCoupling light guidesSignal lightWaveguide

In a planar waveguide optical circuit 1, a inclined groove 3 is formed at an inclination angle .theta. with respect to the vertical axis so as to cross optical waveguides 2.sub.n. A reflection filter 4 structured such that the difference in reflectivity between orthogonal polarization is compensated for with respect to signal light is installed inside the groove 3, the reflected light from the reflection filter 4 is detected by the photodetectors 6.sub.n, and the optical intensity of the signal light is monitored. This makes it possible to accurately monitor the optical intensity regardless of the polarization state of the signal light. Also, since the inside of the groove 3 including the reflection filter 4 is sealed with a filler resin 5, any deterioration in long-term stability that would otherwise be caused by contamination of these components is prevented. Thus, the optical waveguide module with which the structure of the optical circuit is simpler, and the optical intensity can be correctly monitored regardless of the state of polarization of the signal light is realized.

Owner:SUMITOMO ELECTRIC IND LTD

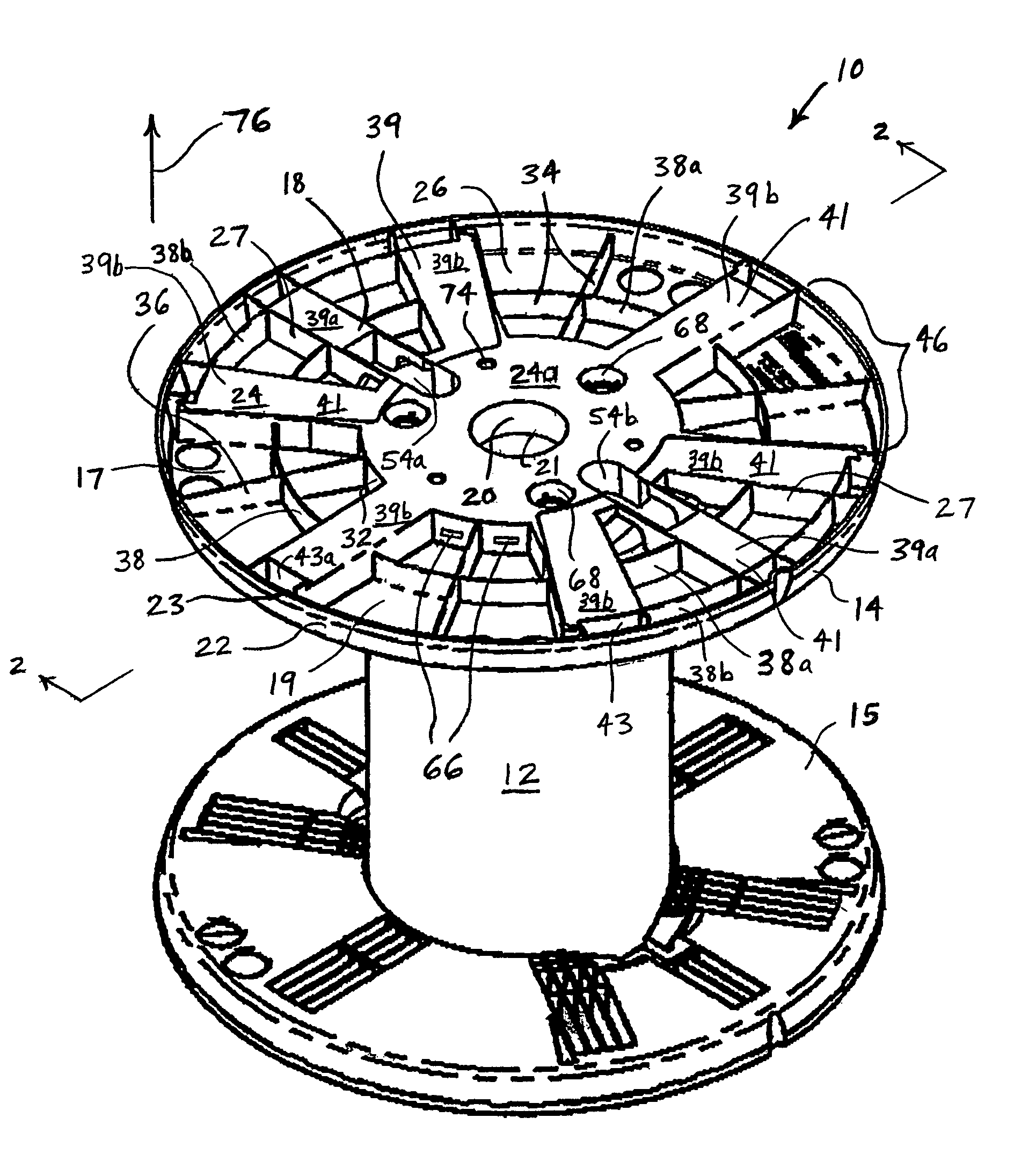

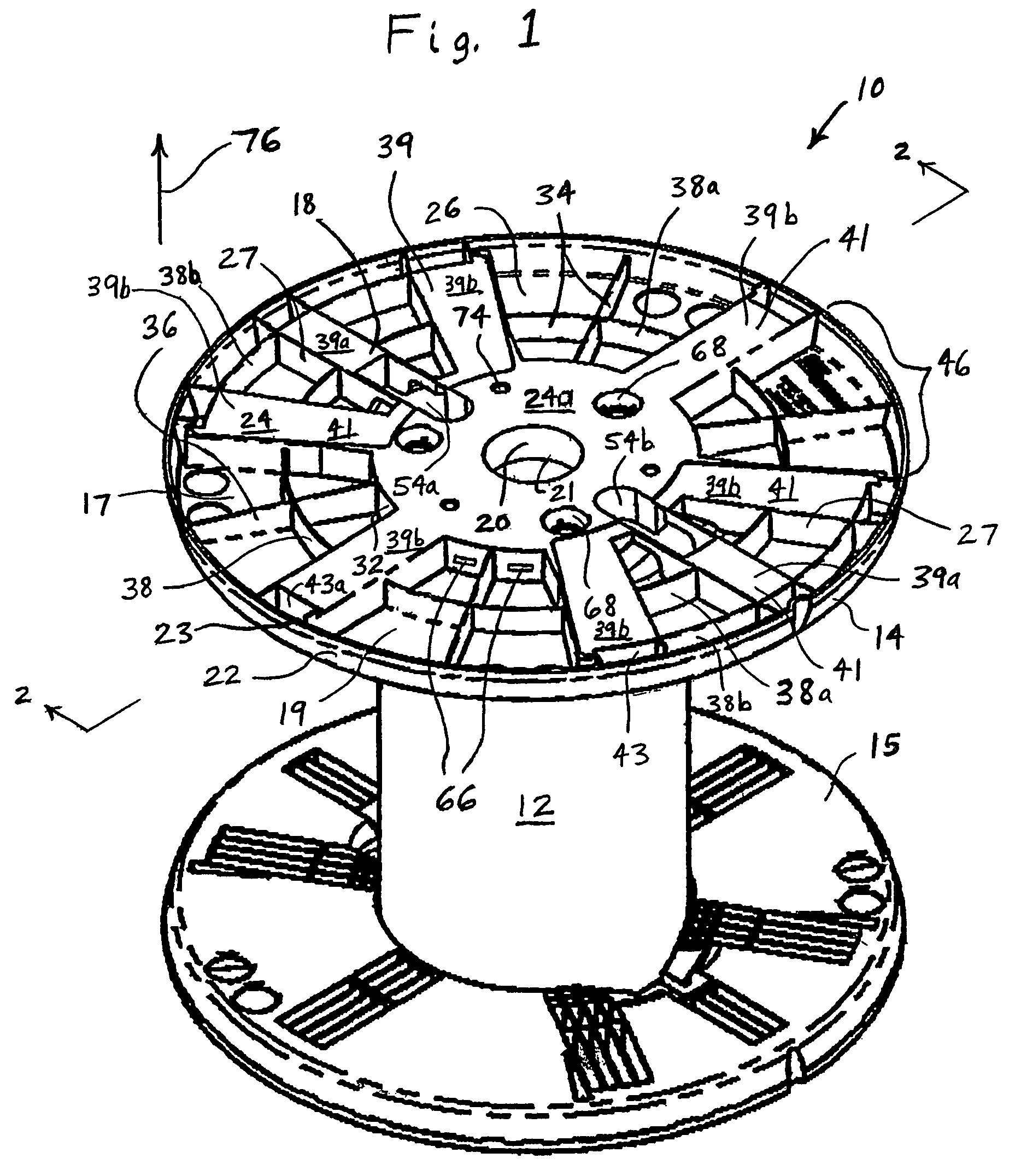

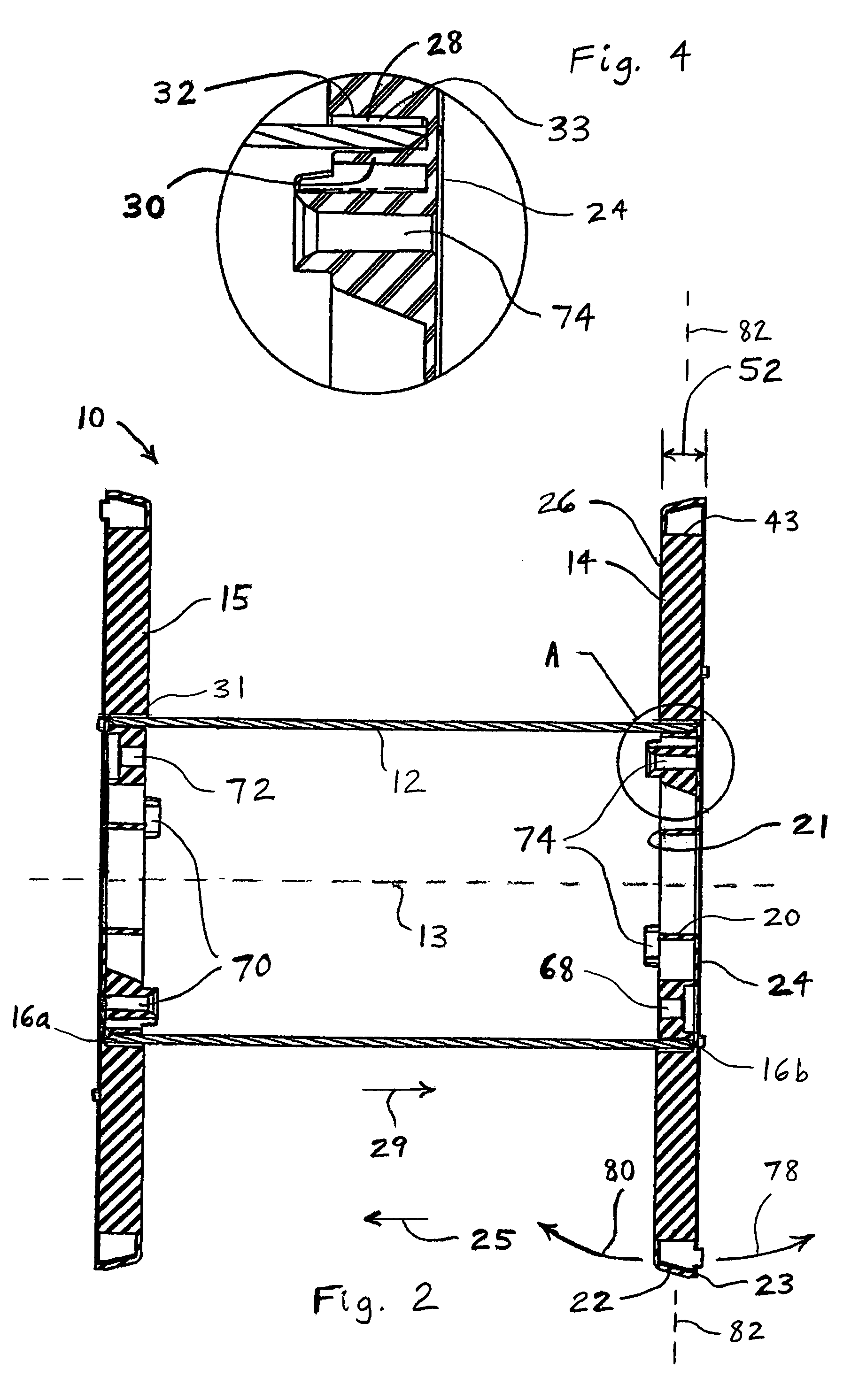

Webbed flange for a reel

A flange is for use in a reel for supporting a wound flexible medium. The reel includes an elongated core defining a longitudinal core axis. The flange includes a first annular wall oriented substantially perpendicular to the axis and engaging the core. A second annular wall is oriented substantially perpendicular to the axis and is offset in an axial direction from the first annular wall. At least one connecting wall interconnects the second annular wall and the first annular wall. A first annular rim is attached to the first annular wall or the second annular wall and is oriented substantially parallel to the axis.

Owner:VANDOR CORP

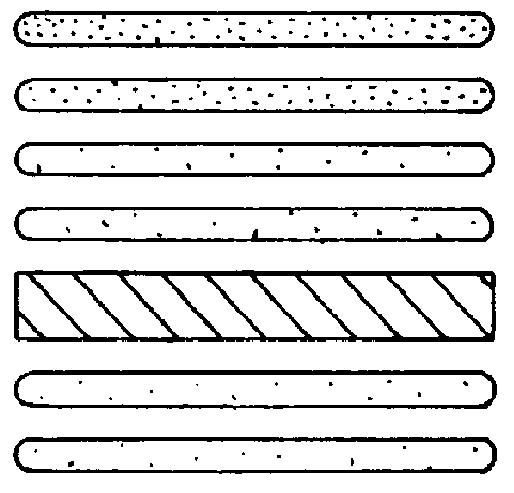

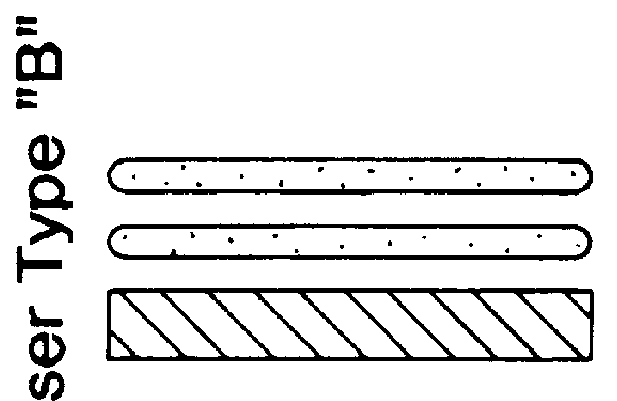

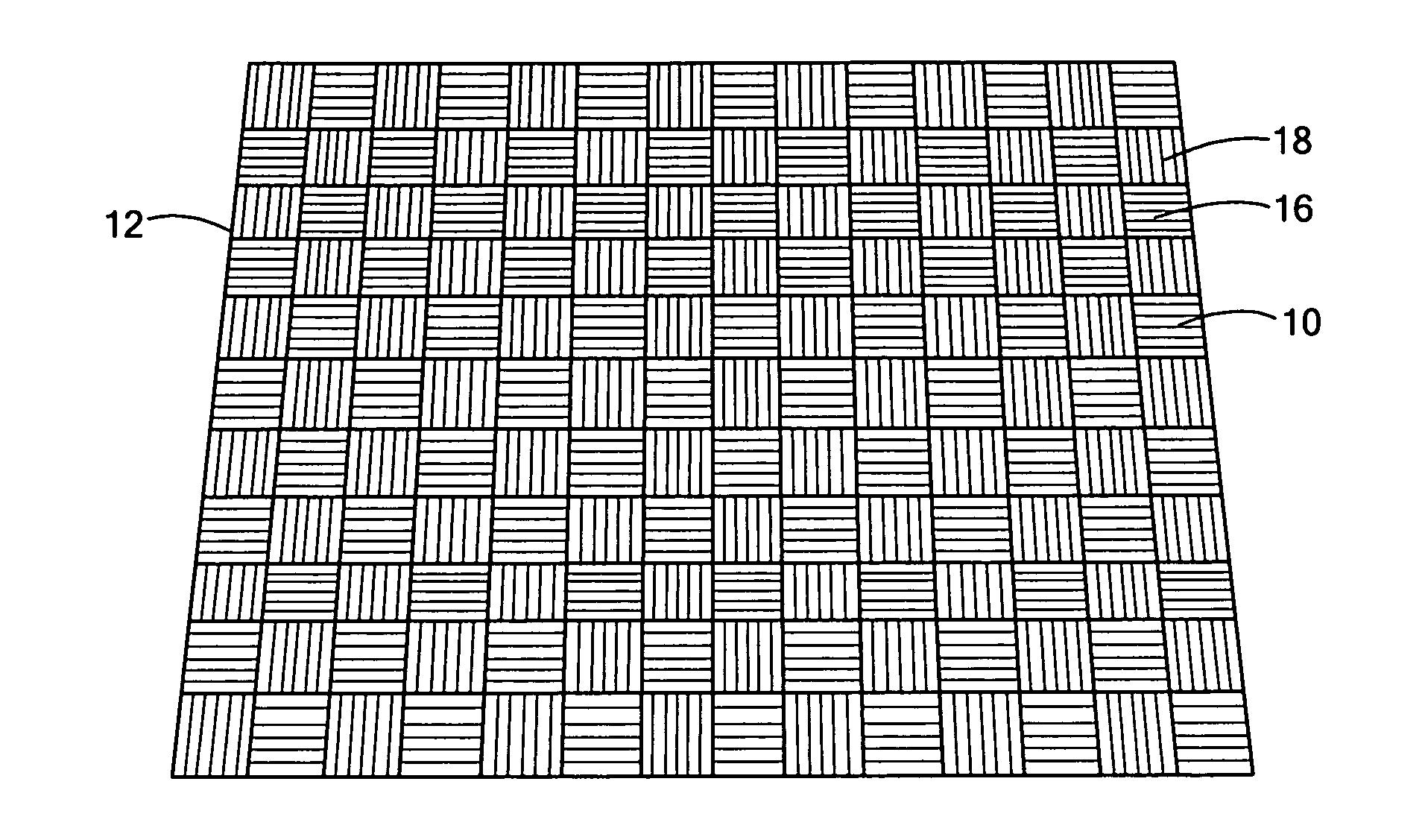

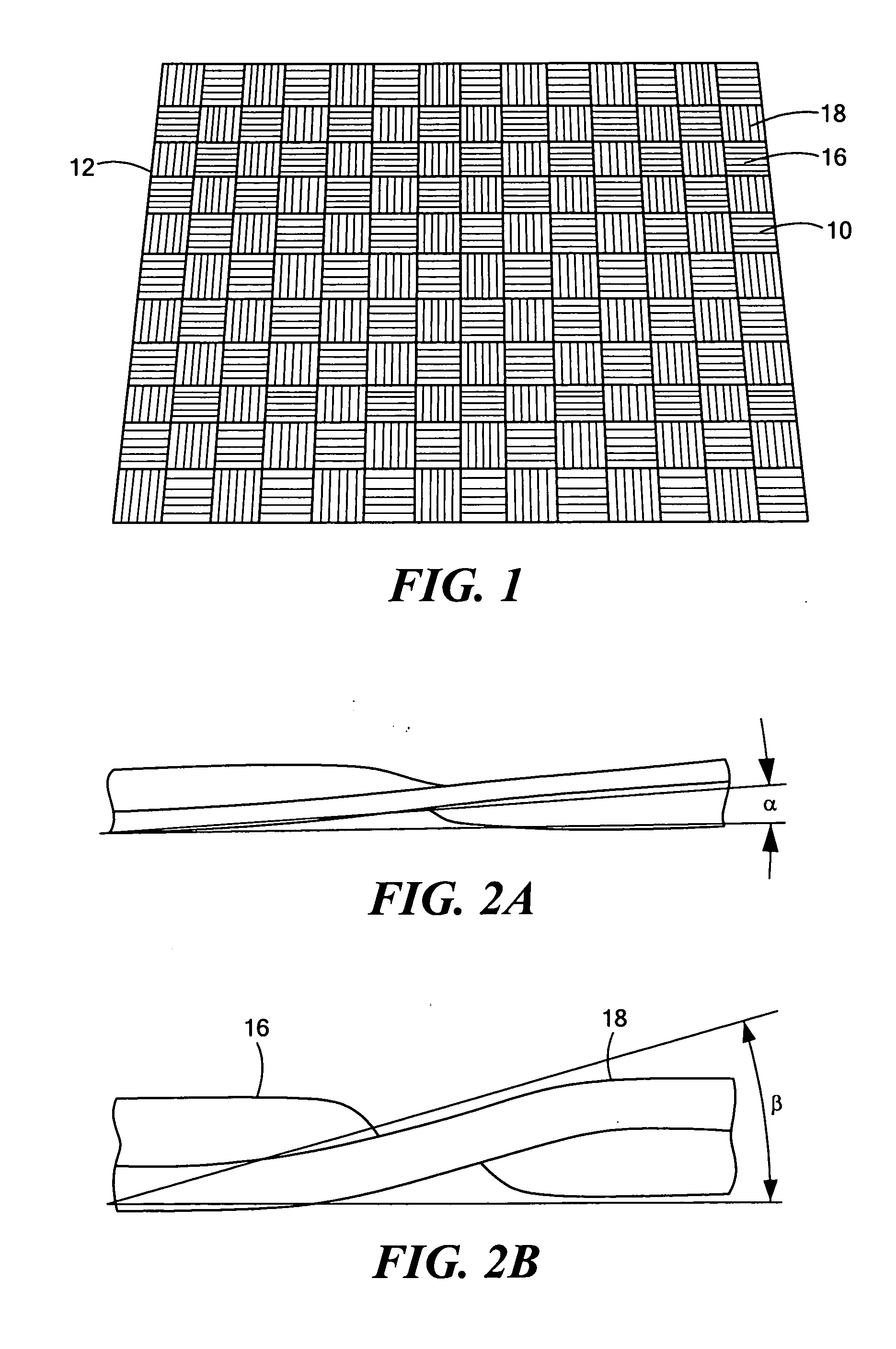

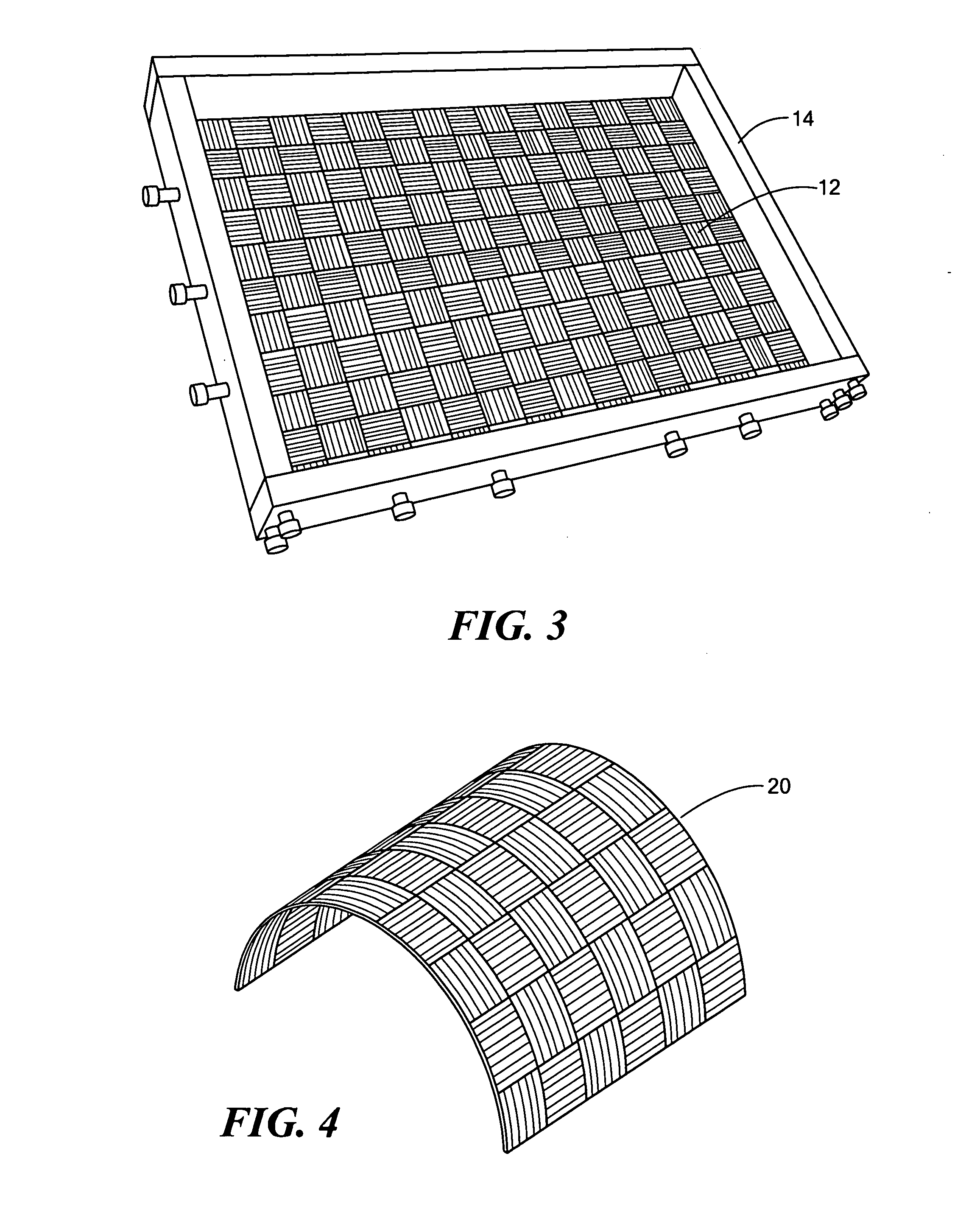

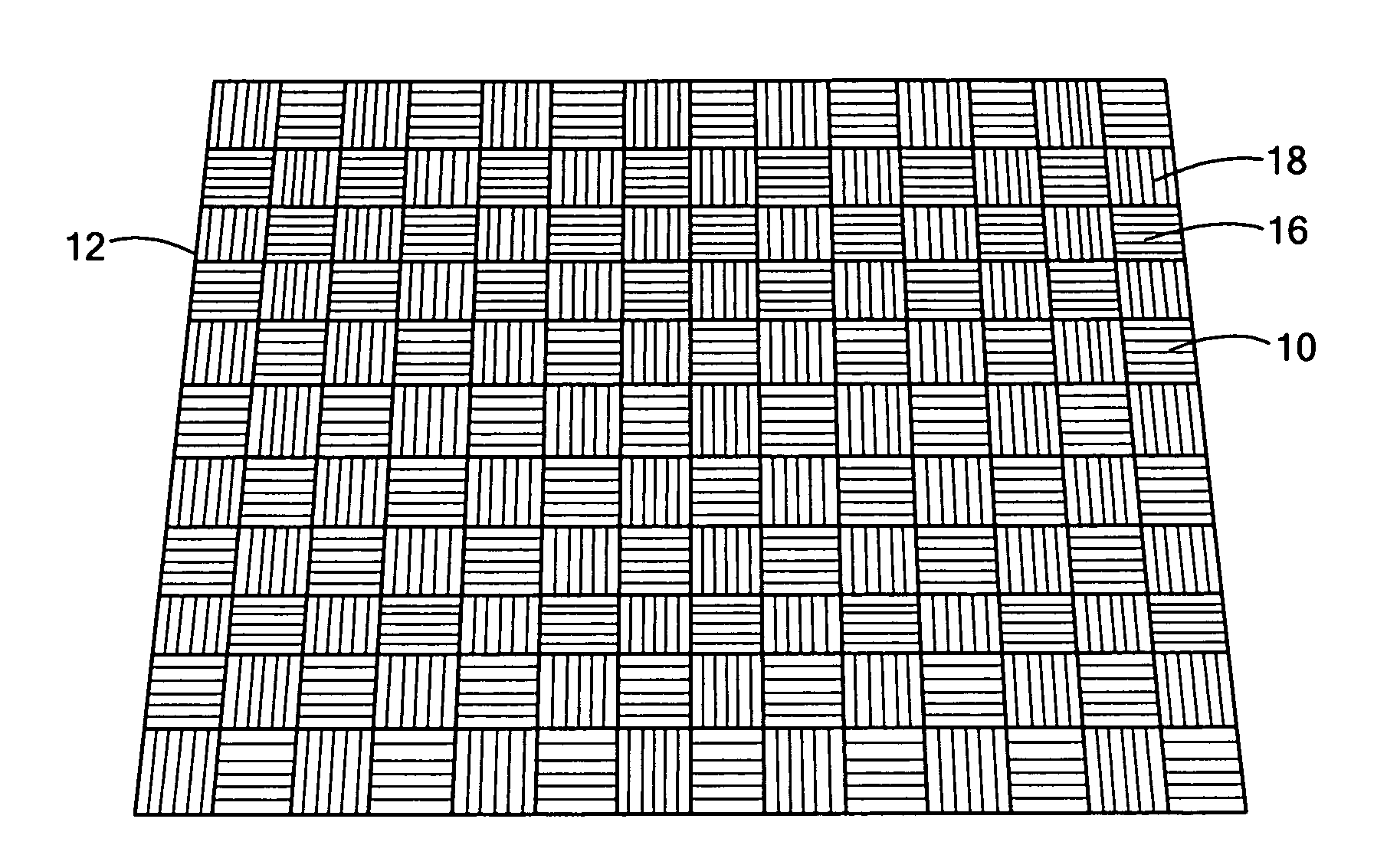

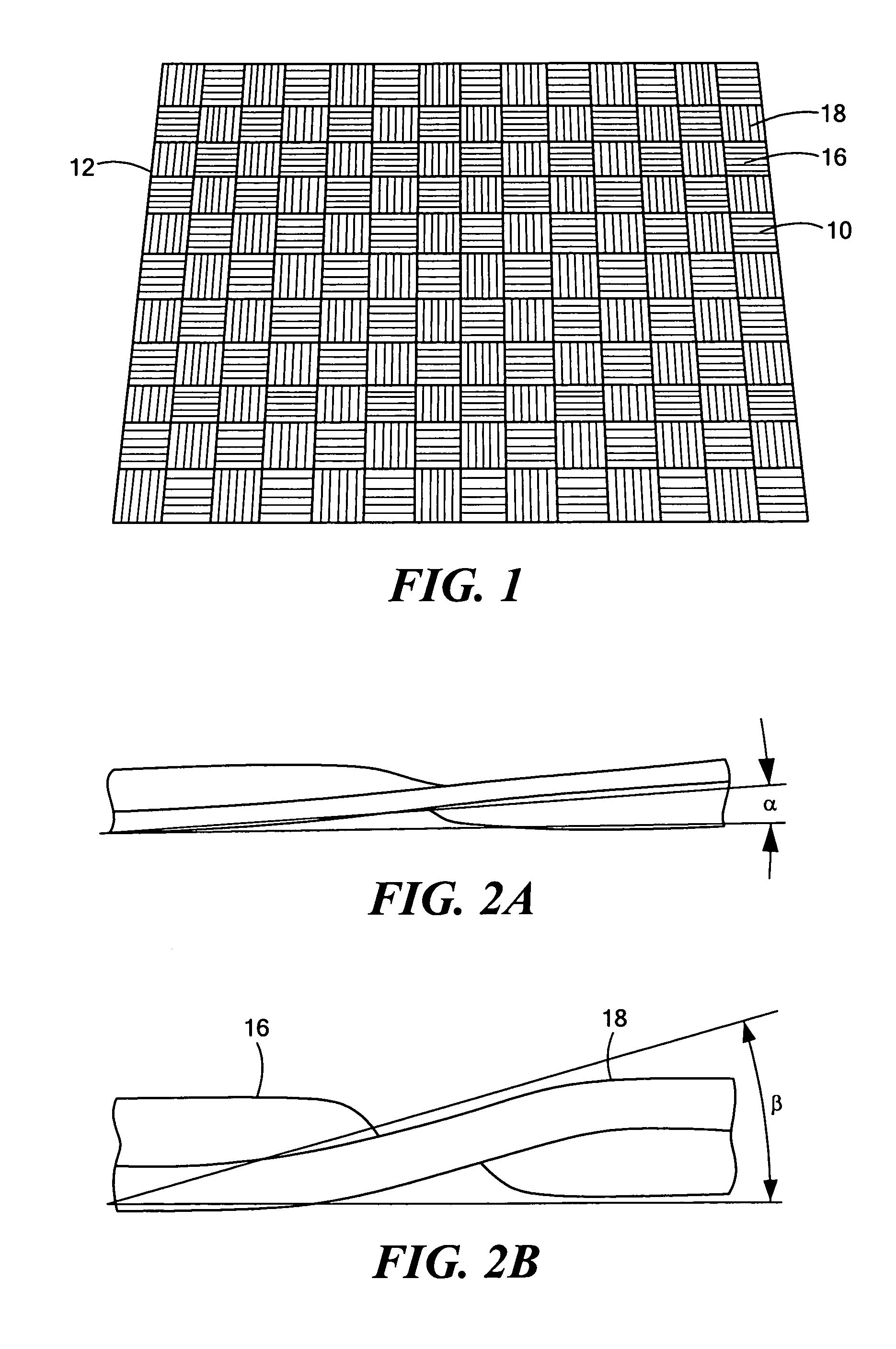

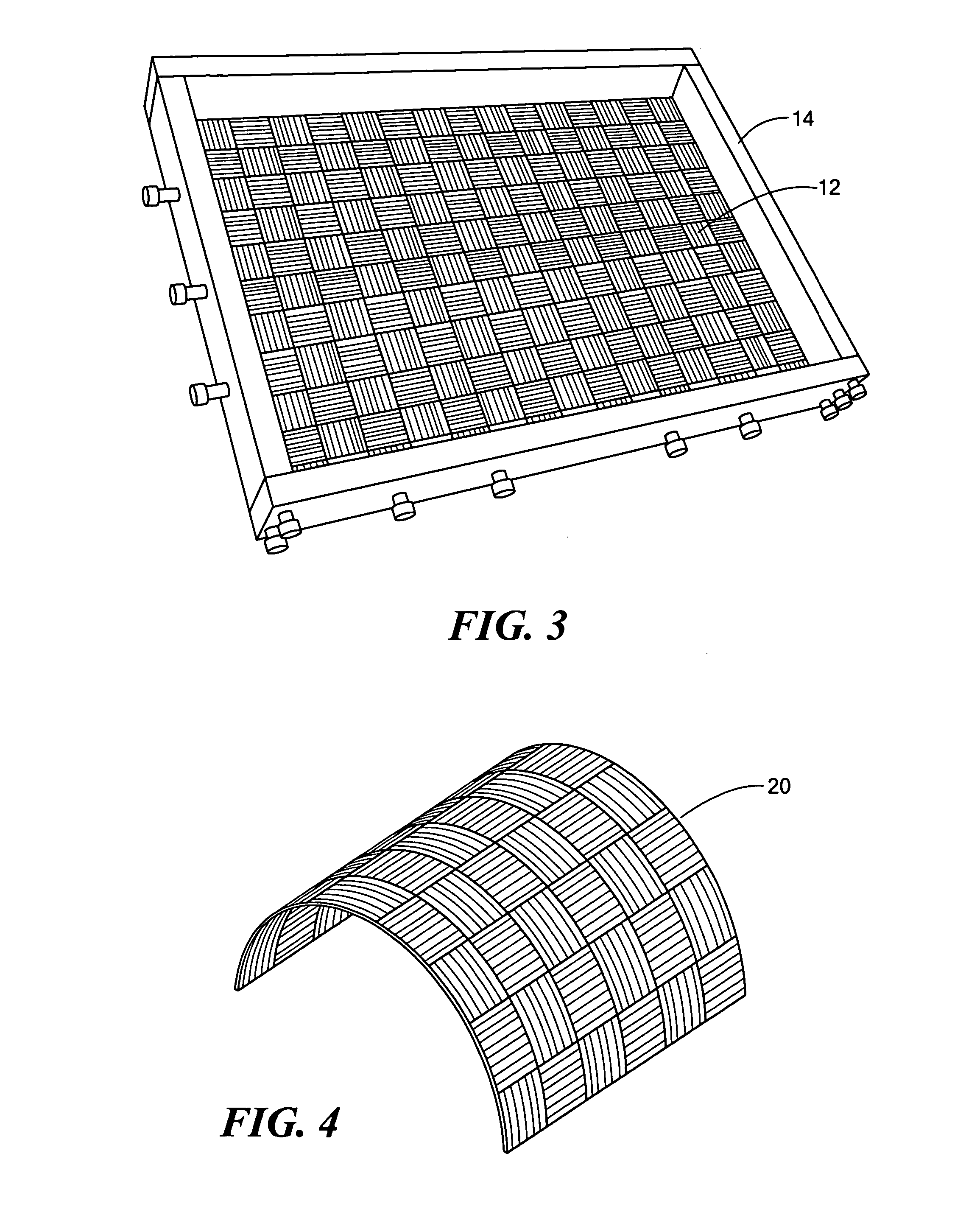

Impact resistant, thin ply composite structures and method of manufacturing same

InactiveUS20070066171A1Improve impact resistanceStructure moreMaterial nanotechnologySynthetic resin layered productsCarbon fibersReinforced carbon–carbon

A reinforced carbon-carbon (RCC) composite material has improved impact resistance. The RCC composite material is formed from a fiber reinforcement of layers or plies of thin ply carbon fiber fabric impregnated with a carbon matrix. Carbon nanotube reinforcement in the matrix further improves impact resistance. The stacking arrangement of the plies of the thin ply fabric also further improves impact resistance.

Owner:KAZAK COMPOSITES

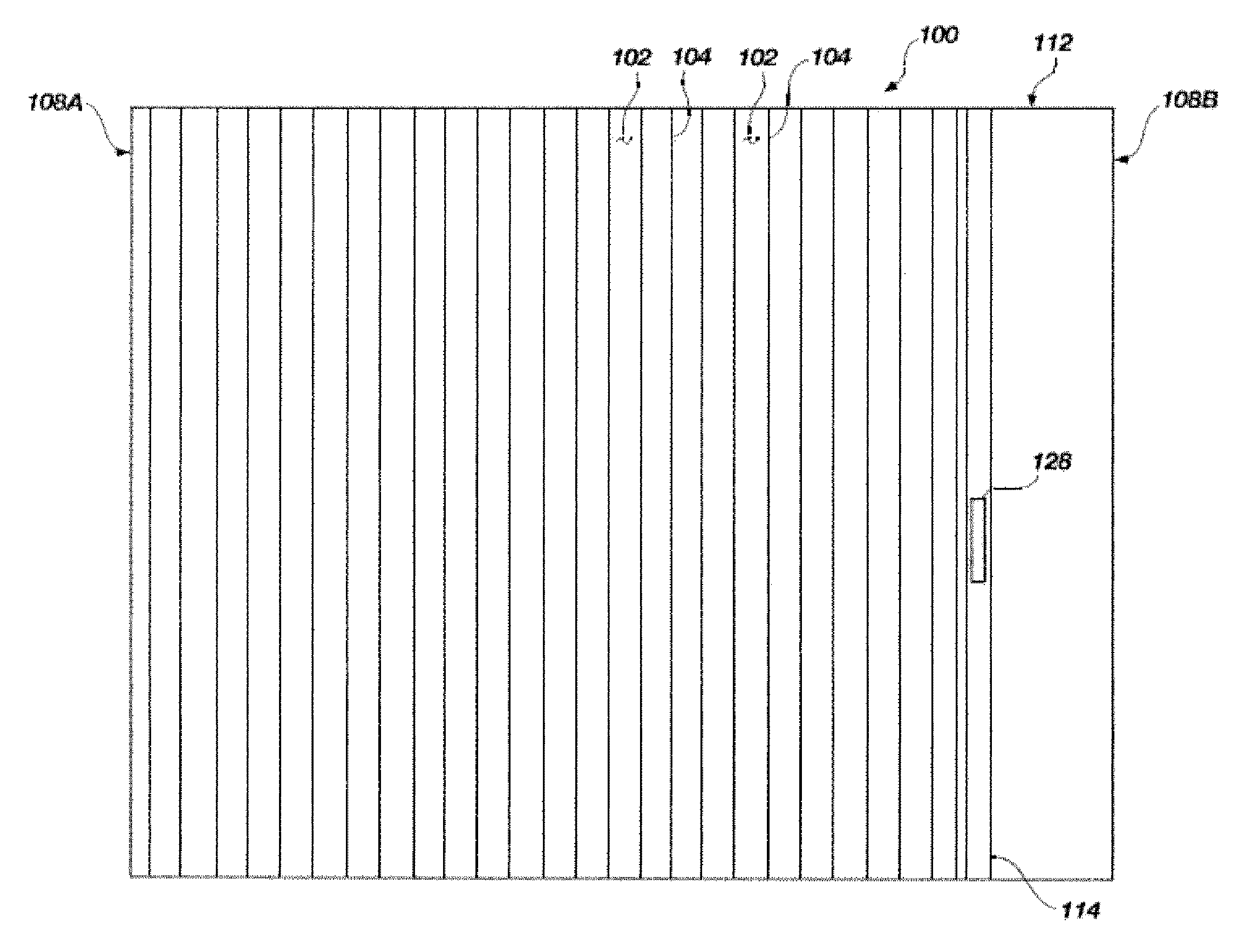

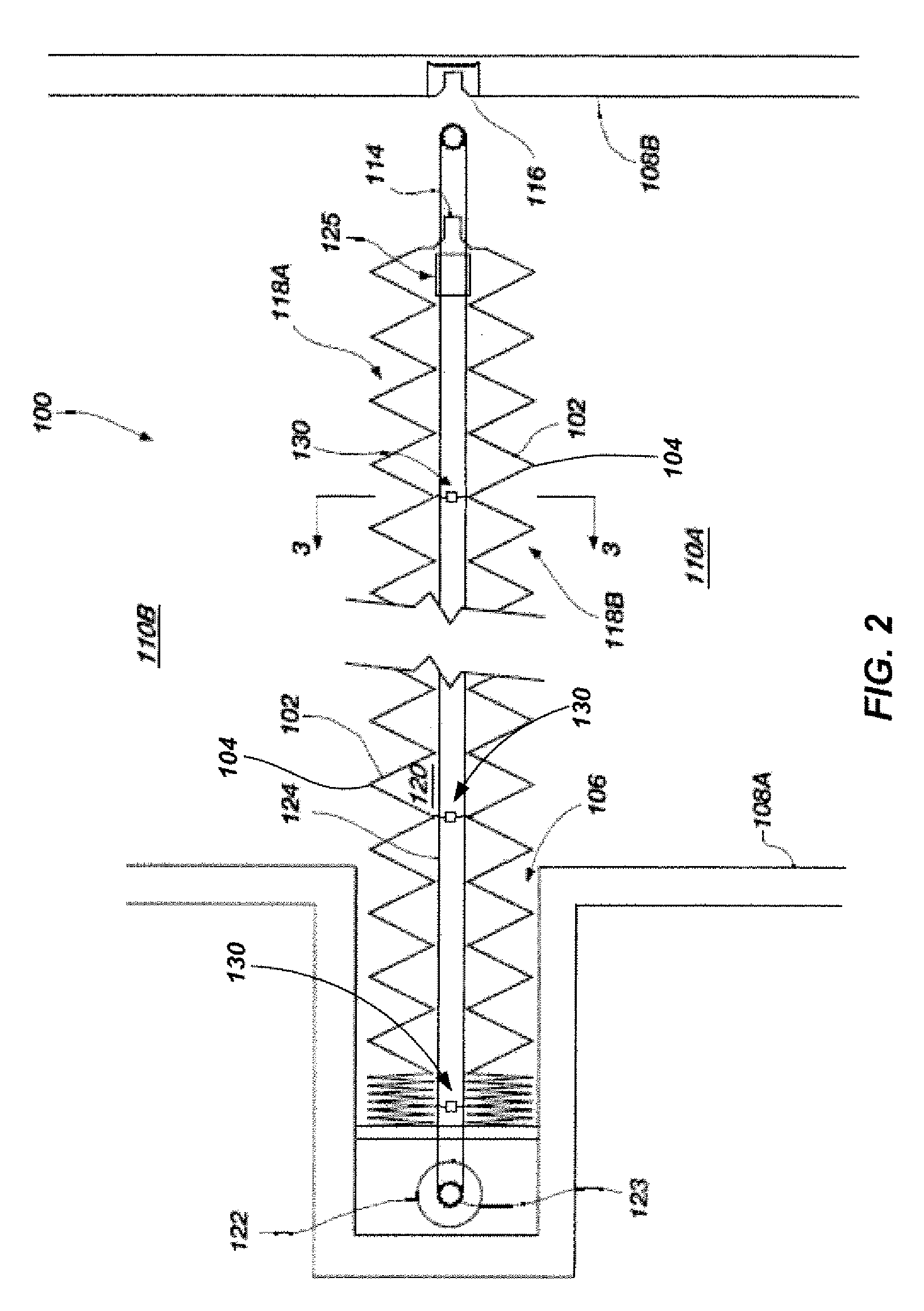

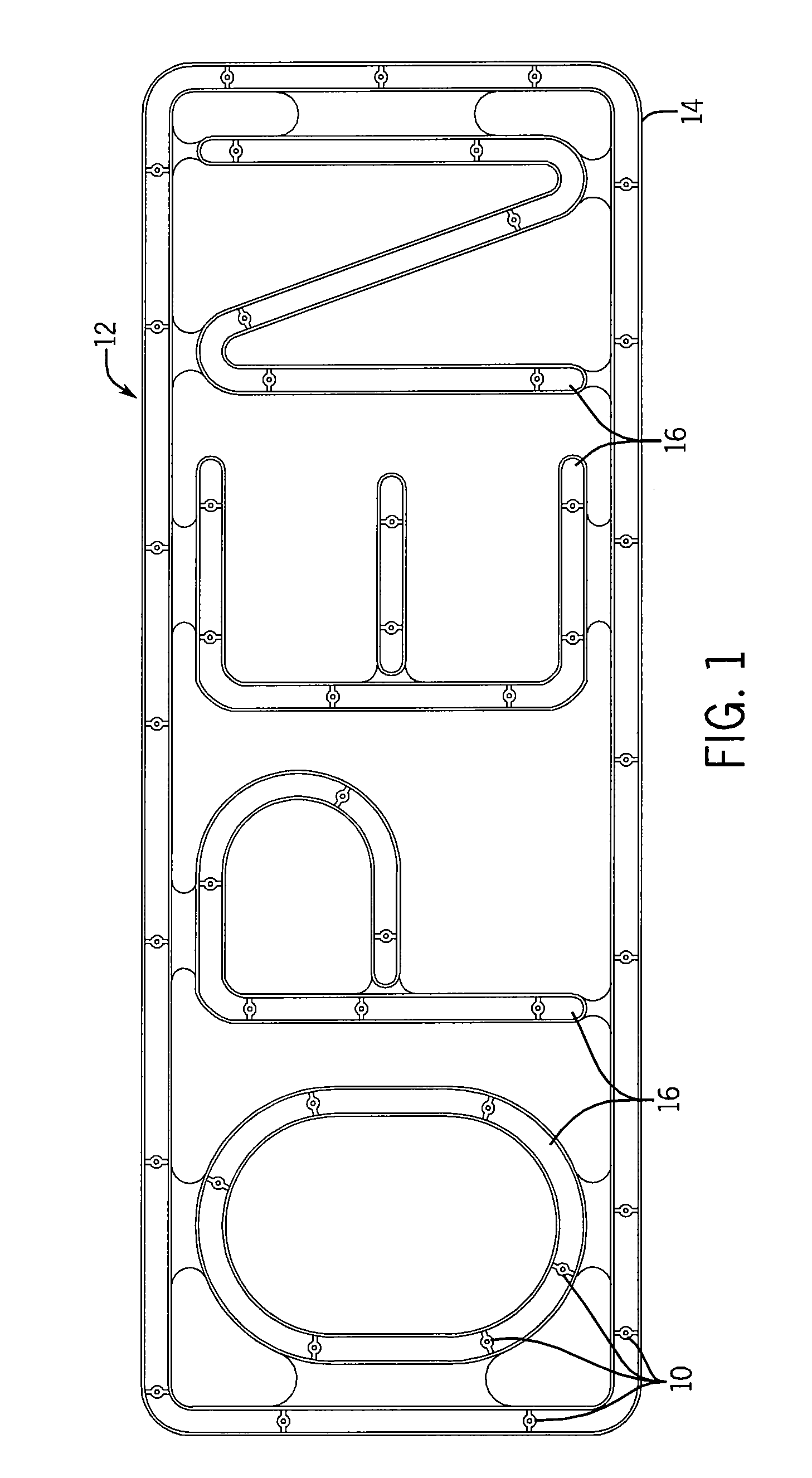

Movable partitions with lateral restraint devices and related methods

ActiveUS20080115896A1Prevent lateral movementDisplacement of moreExtensible doors/windowsCurtain accessoriesEngineeringFace sheet

Embodiments of the present invention include movable partitions and devices, methods and systems that help to limit or prevent lateral displacement of movable partitions. In accordance with one embodiment of the present invention, a movable partition includes two structures, each structure having a first plurality of panels, and each panel being hingedly coupled to an adjacent panel. The two panels are each supported from an overhead track at laterally spaced locations. One or more lateral restraint devices are supported from the overhead track at a location between the two laterally spaced structures. The lateral restraint device may include a trolley disposed in a channel of the overhead track and an elongated member coupled with the trolley and extending away from the trolley to a location proximate a lower edge of the first structure and a lower edge of the second structure.

Owner:WOW DOOR CORP

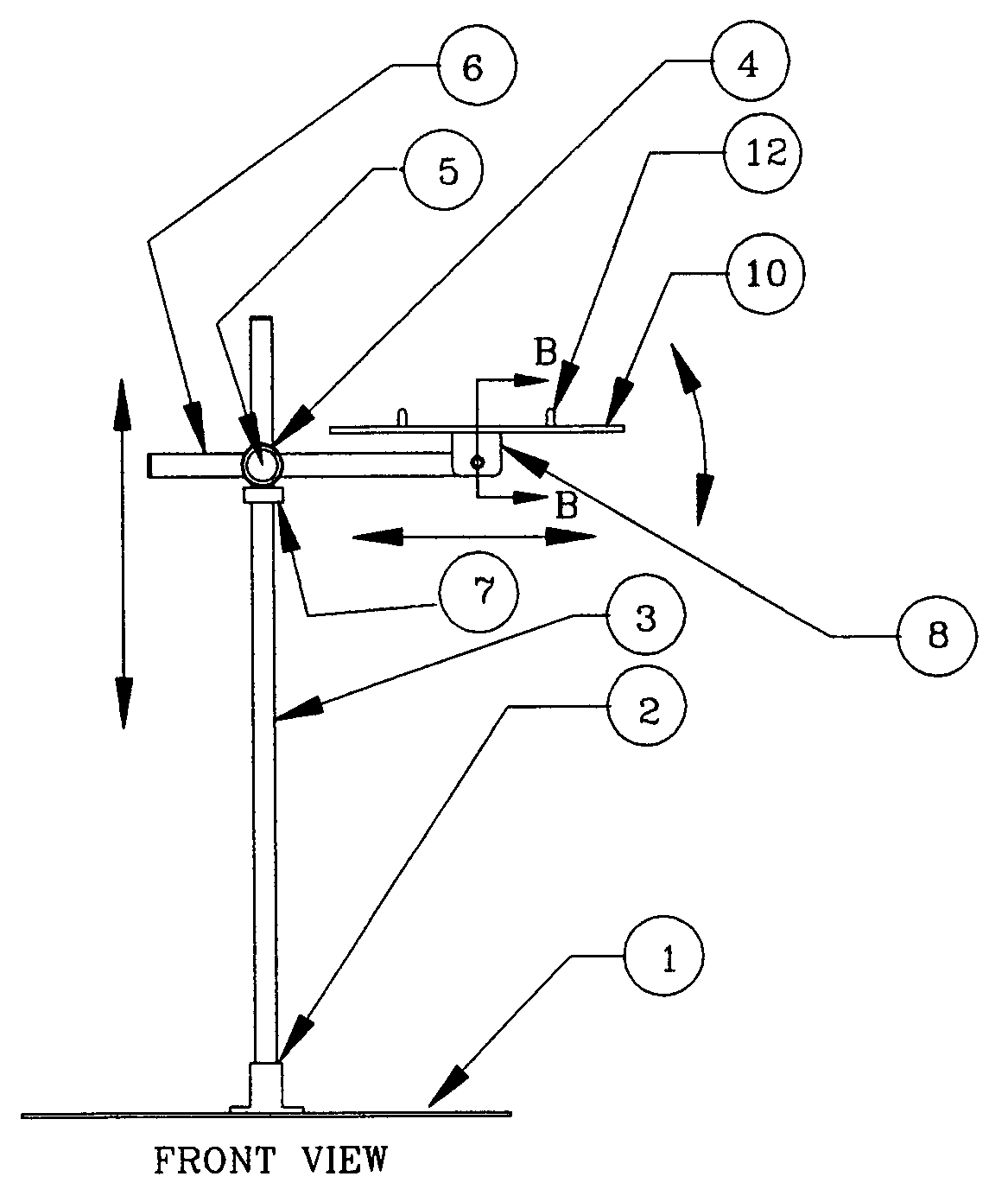

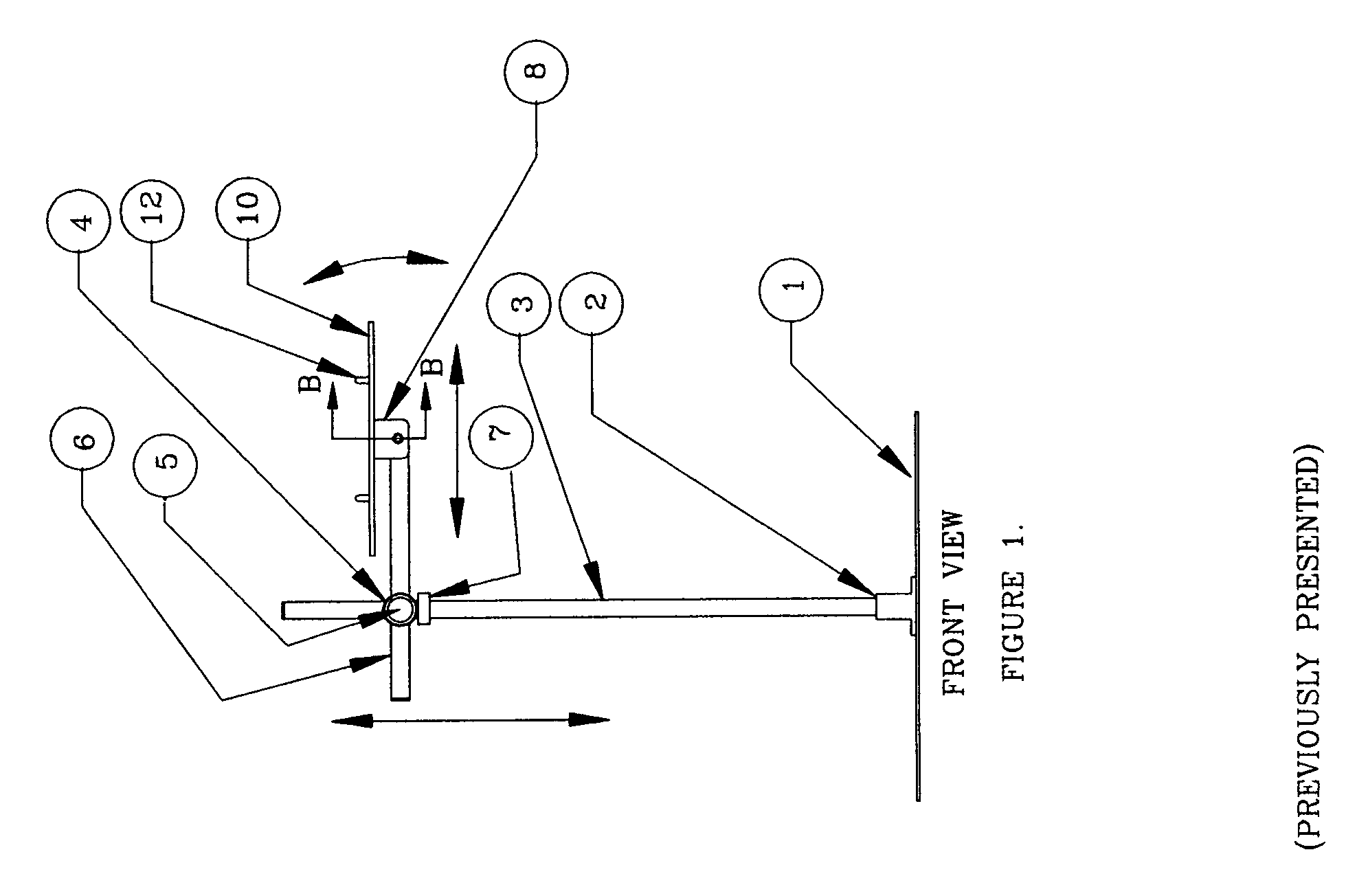

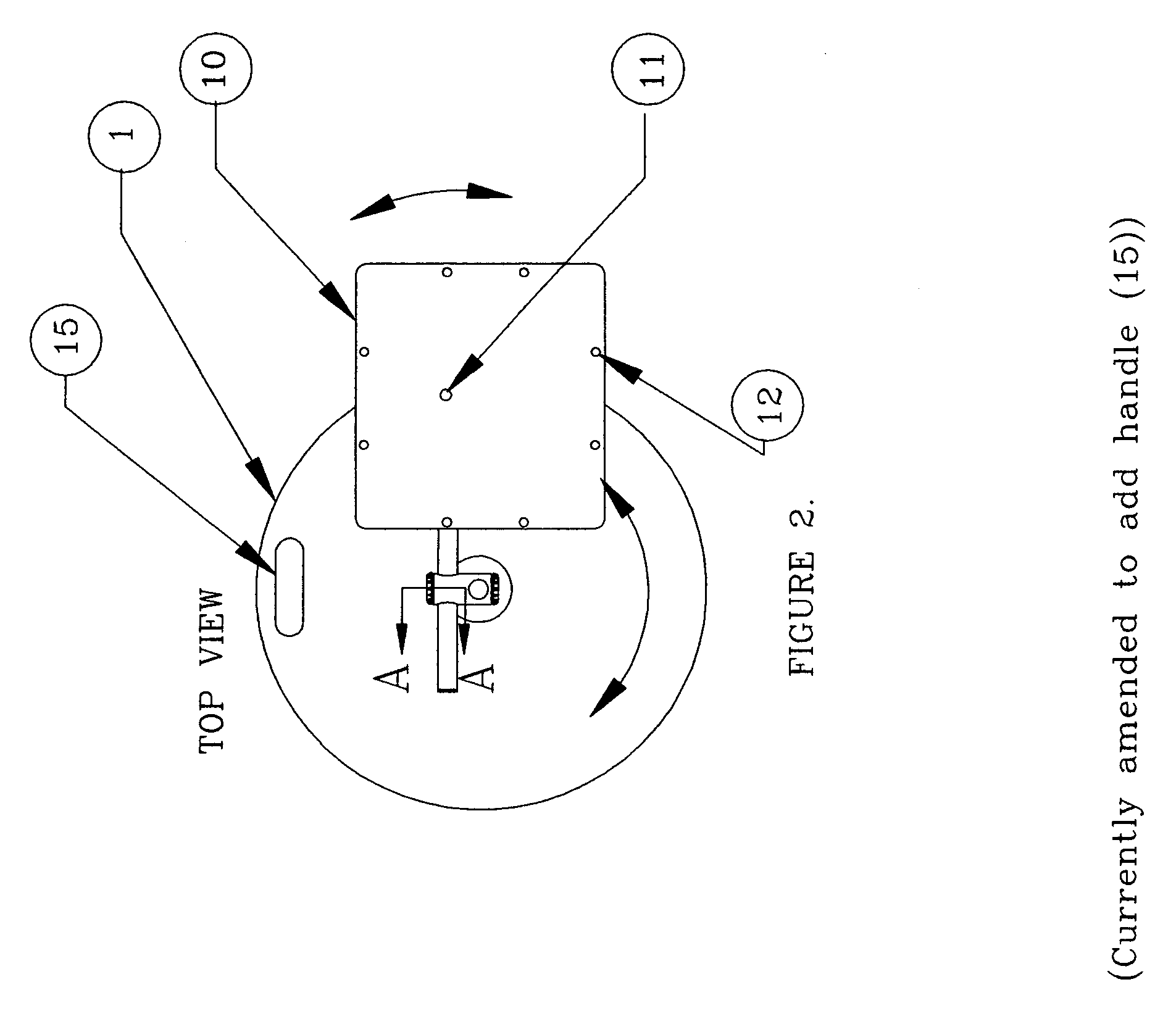

AirDesk free standing and vehicle mounted 6-axis positionable tray, positionable shelf, cup-holder, stanchion apparatus and related systems

InactiveUS20060278770A1Precise positioningImprove comfortOffice tablesFurniture partsCrowd controlRange of motion

An apparent need exists for compact devices to ergonomically support such items as laptop computers and keyboards. The AirDesk® desk / stand design positions such items with full 3D positioning using all 6 directions of adjustment. Each direction of motion has the correct friction and range of motion for easy and secure re-positioning. Unique accessory shelves and cup holder may be attached to the device frame. A unique, flat, very thin, trip-free base provides unparalleled positioning flexibility of the unit, furniture legs may be placed directly on the base sheet. Additionally, a unique universal and quickly installed folding frame for an automobile or truck seat is provided for supporting the AirDesk positionable tray in a vehicle. AirDesks allow computing from any chair, recliner, sofa, bed, while standing or in a vehicle. The unique trip-free base may also be used for such applications as supporting medical equipment and crowd control stanchions.

Owner:MTI RES CORP

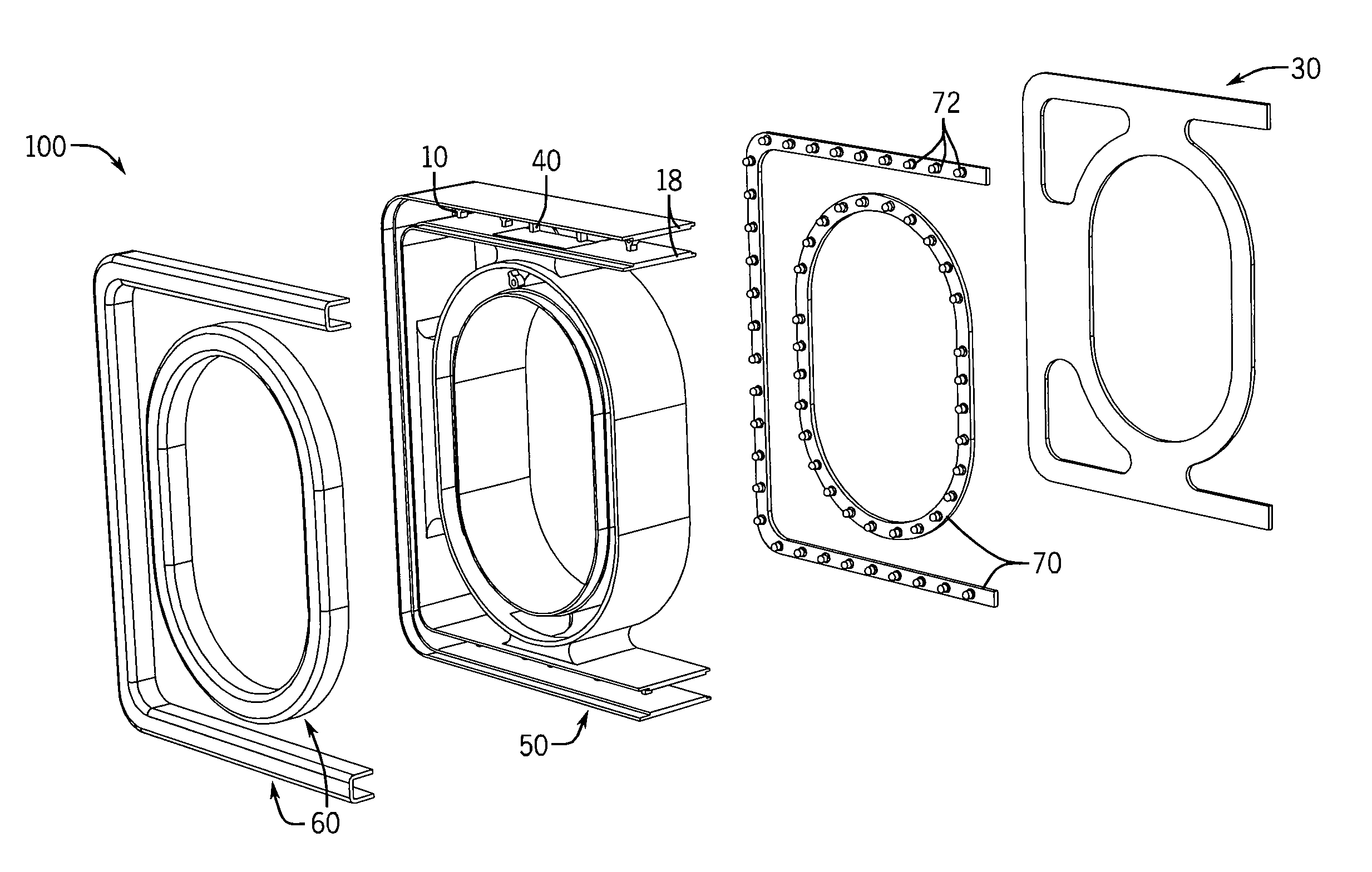

Reinforced housing structure for a lighted sign or lighting fixture

ActiveUS8449142B1Reduce material usageMaintaining and improving structural integrityNon-electric lightingLighting support devicesEffect lightElectrical and Electronics engineering

Owner:C M GLO

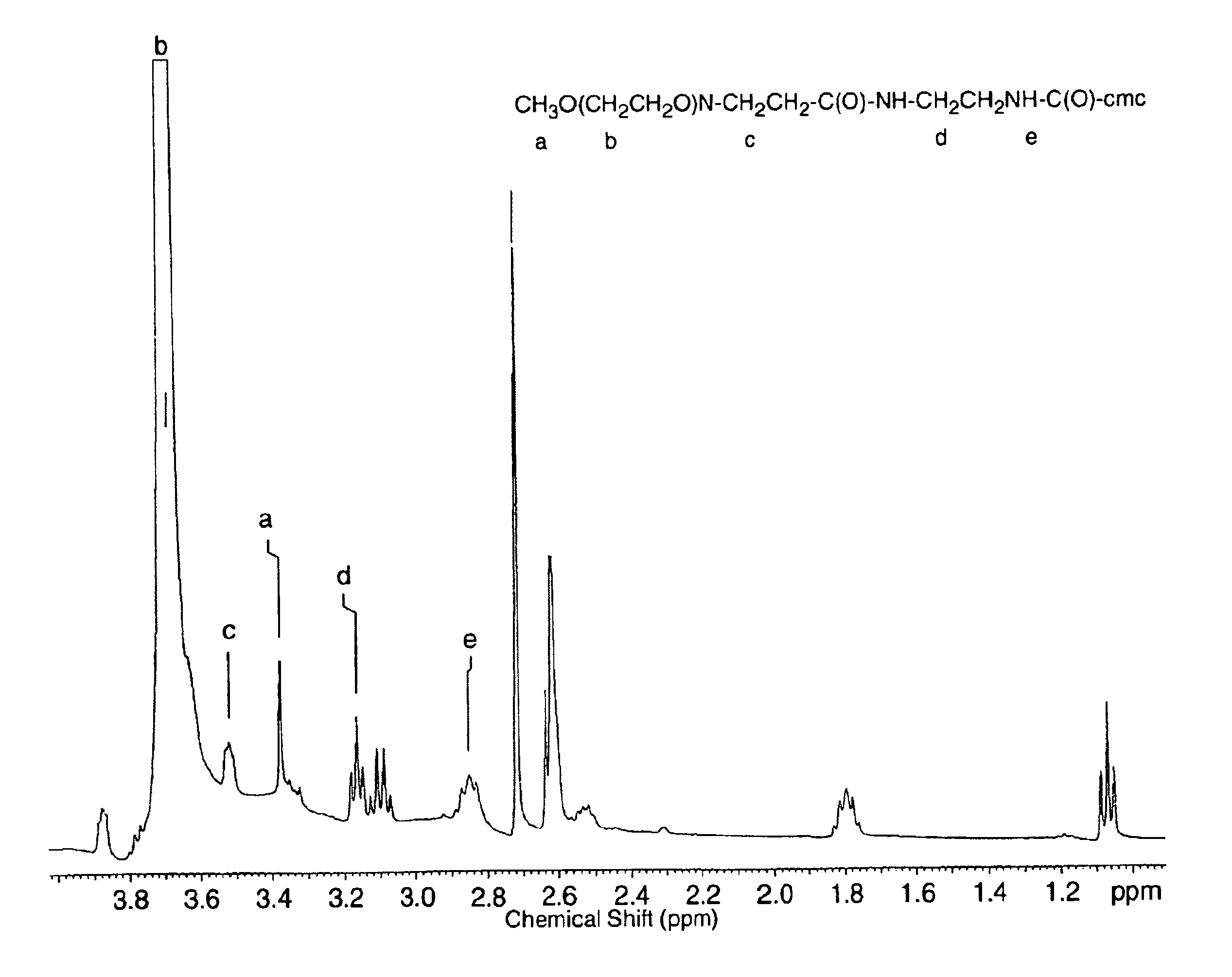

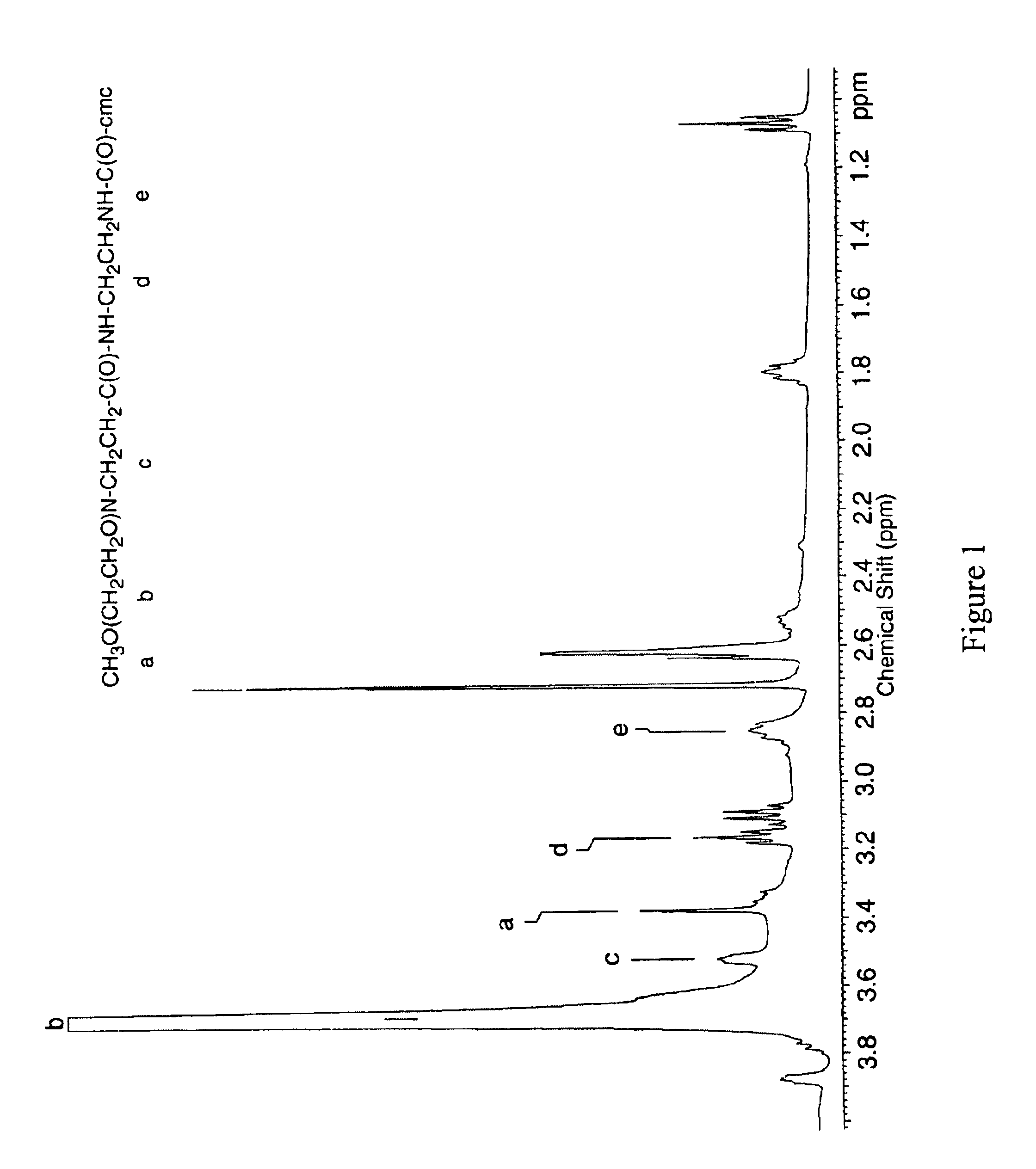

Chemically activated carboxypolysaccharides and methods for use to inhibit adhesion formation and promote hemostasis

InactiveUS6923961B2Trend downReduce adverse effectsAntibacterial agentsOrganic active ingredientsParticulatesThrombus

Carboxypolysaccharides (CPS) including carboxymethyl cellulose and their derivatives are provided that can be made into sponges, gels, membranes, particulates and other forms, for a variety of antiadhesion, antithrombogenic, drug delivery and / or hemostatic applications during surgery and pharmacological therapeutics. CPSs derivatized with primary amines can be used alone or in combination with poly(ethylene glycol) and poly(ethylene oxides) and other poly(alkylene oxides) to form materials having improved drug delivery, antiadhesion, and hemostatic uses. Applications include other types of chemical modifications of CPS to provide hydrogen, ionic, Van der Walls interactions and / or covalent bonding with drugs, biologicals and other therapeutic or diagnostic purposes.

Owner:FZIOMED

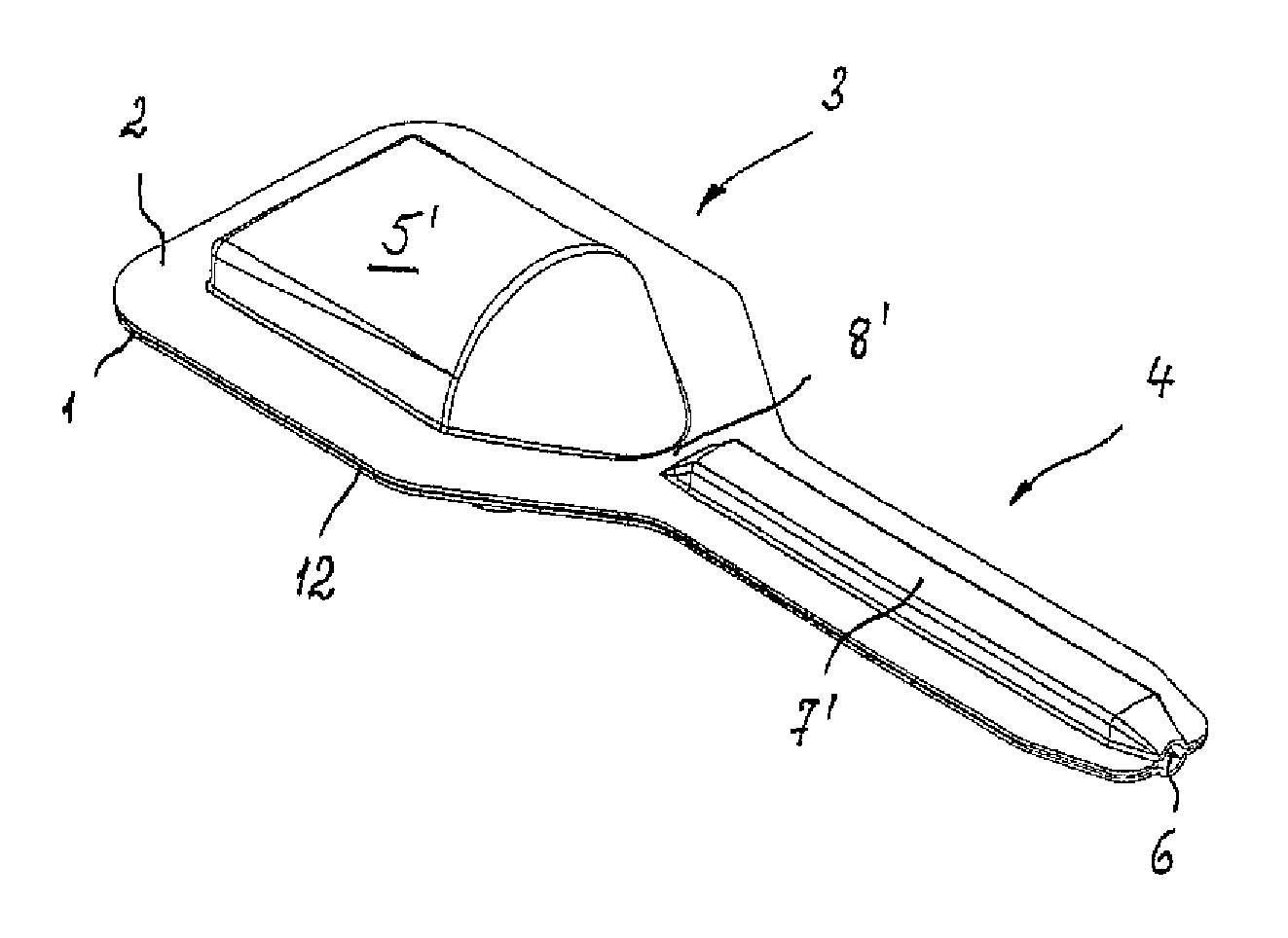

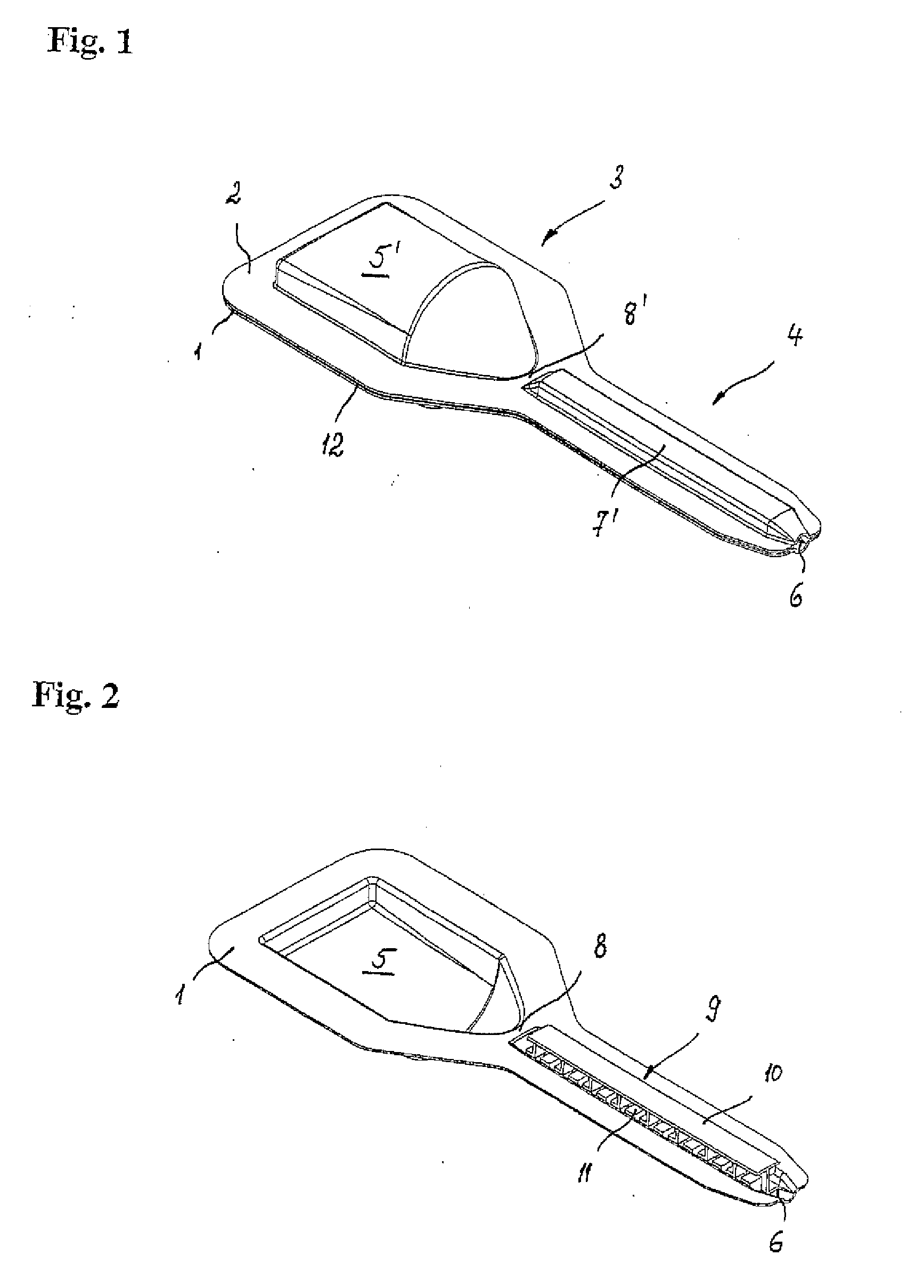

Multicomponent Foil-Type Container

InactiveUS20080123465A1Efficient mixingWell mixedSmall article dispensingFlow mixersEngineeringMechanical engineering

The invention relates to a multicomponent foil-type container comprising a first chamber (5) for accommodating a first component, at least one second chamber (5′) for accommodating a second component, a discharge duct (6) that can be connected to said chambers (5, 5′), deflection elements (11) for mixing the components within the discharge duct (6), and a seal (12; 12′; 21; 25, 25′; 36, 36′) which prevents the components from being mixed before being used and can be opened for discharging the components. The deflection elements (11) of the inventive multicomponent foil-type container are disposed on a separate mixing element (9) that is located in the discharge duct (6) such that the multicomponent foil-type container is easy to produce while allowing different components to be mixed in a particularly effectively manner. The invention further relates to a device for squeezing a multicomponent foil-type container in a particularly effective fashion. The disclosed squeezing device is provided with a holding element (61; 77) for accommodating a multicomponent foil-type container. At least one leg (68, 69; 88) that can be moved towards the chambers (5, 5′) of the multicomponent foil-type container in order to squeeze the multicomponent foil-type container is hingedly connected to the end of the holding element (61; 77) which faces the rear end of an inserted multicomponent foil-type container, resulting in the components being effectively mixed.

Owner:SULZER MIXPAC AG

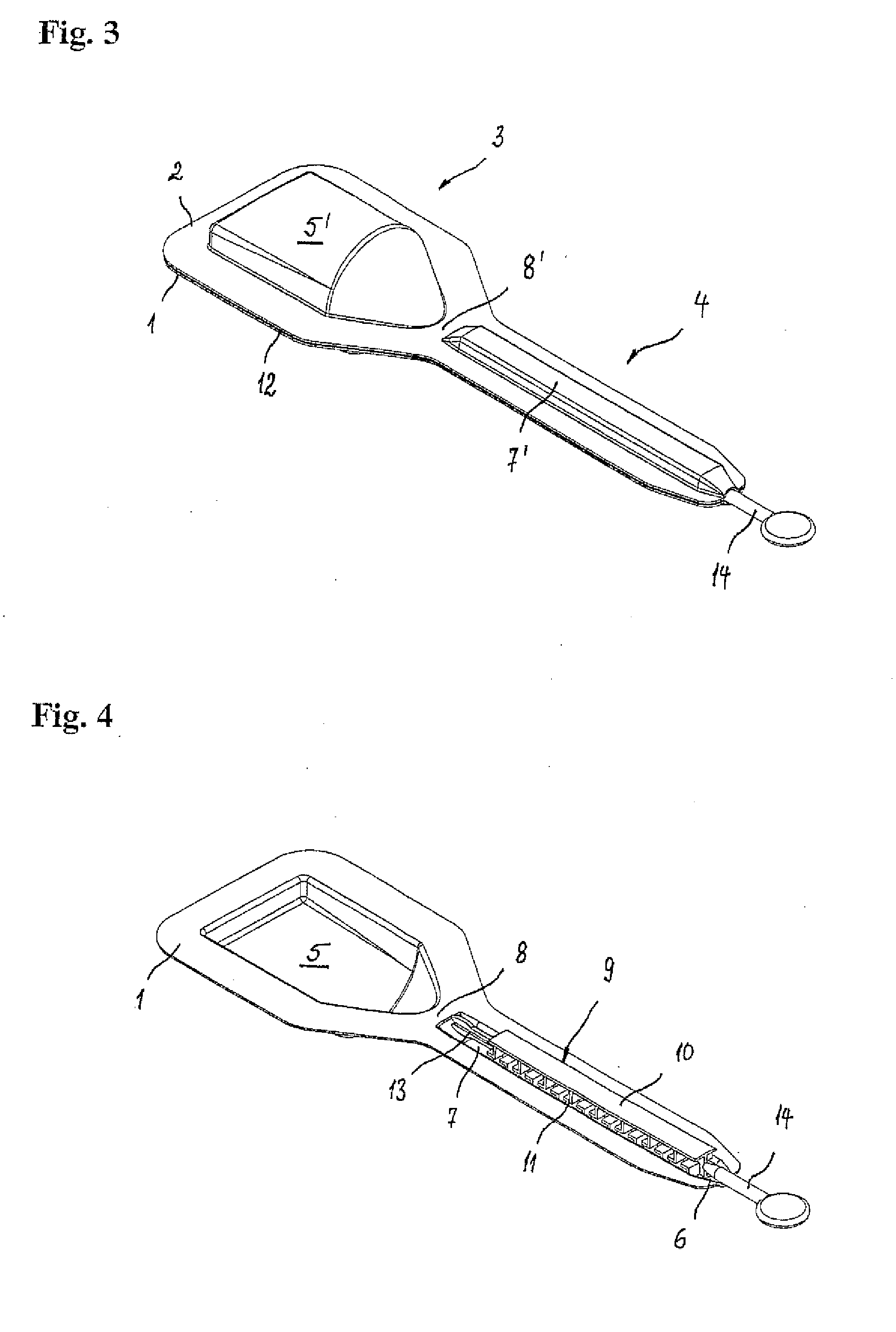

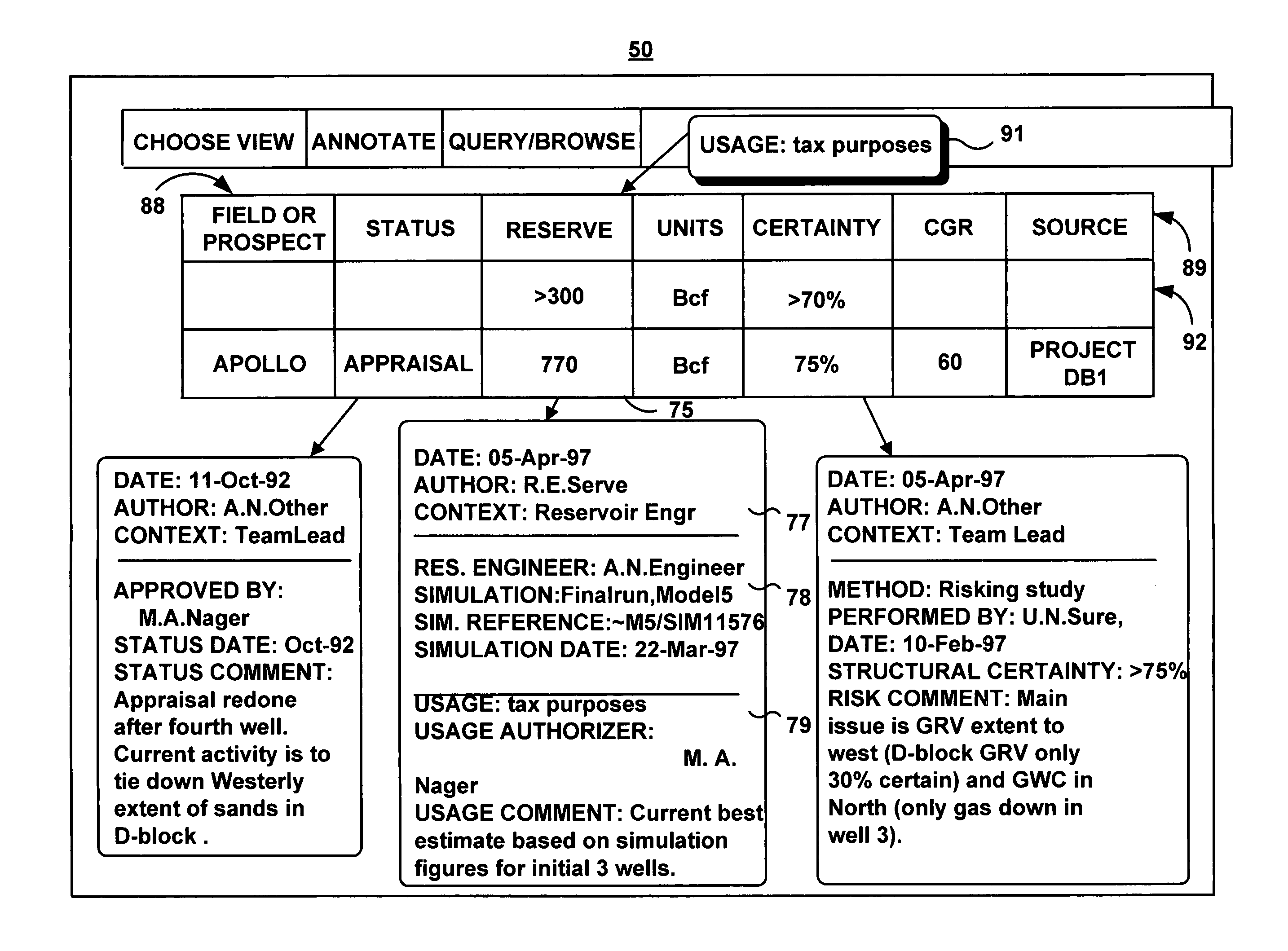

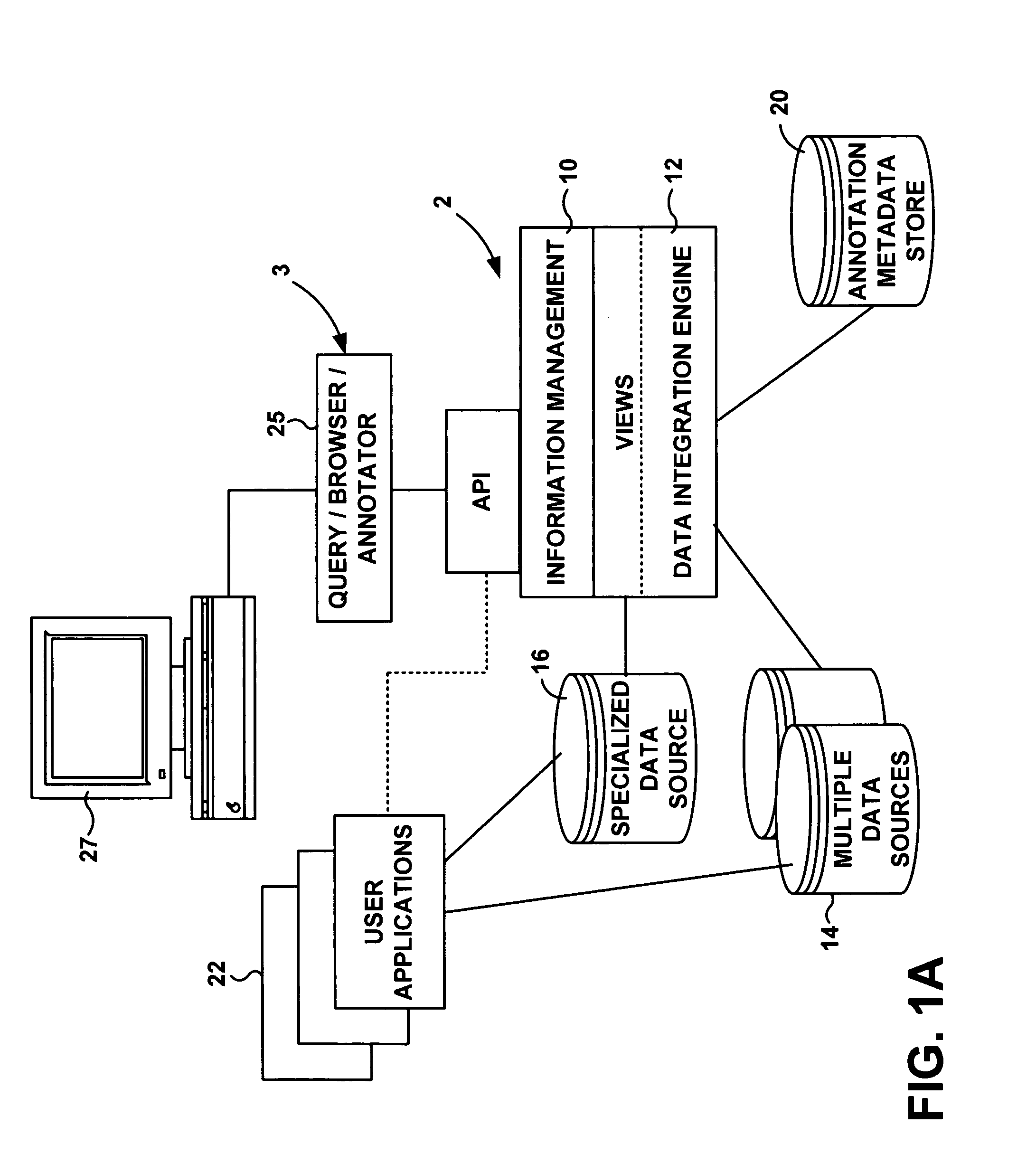

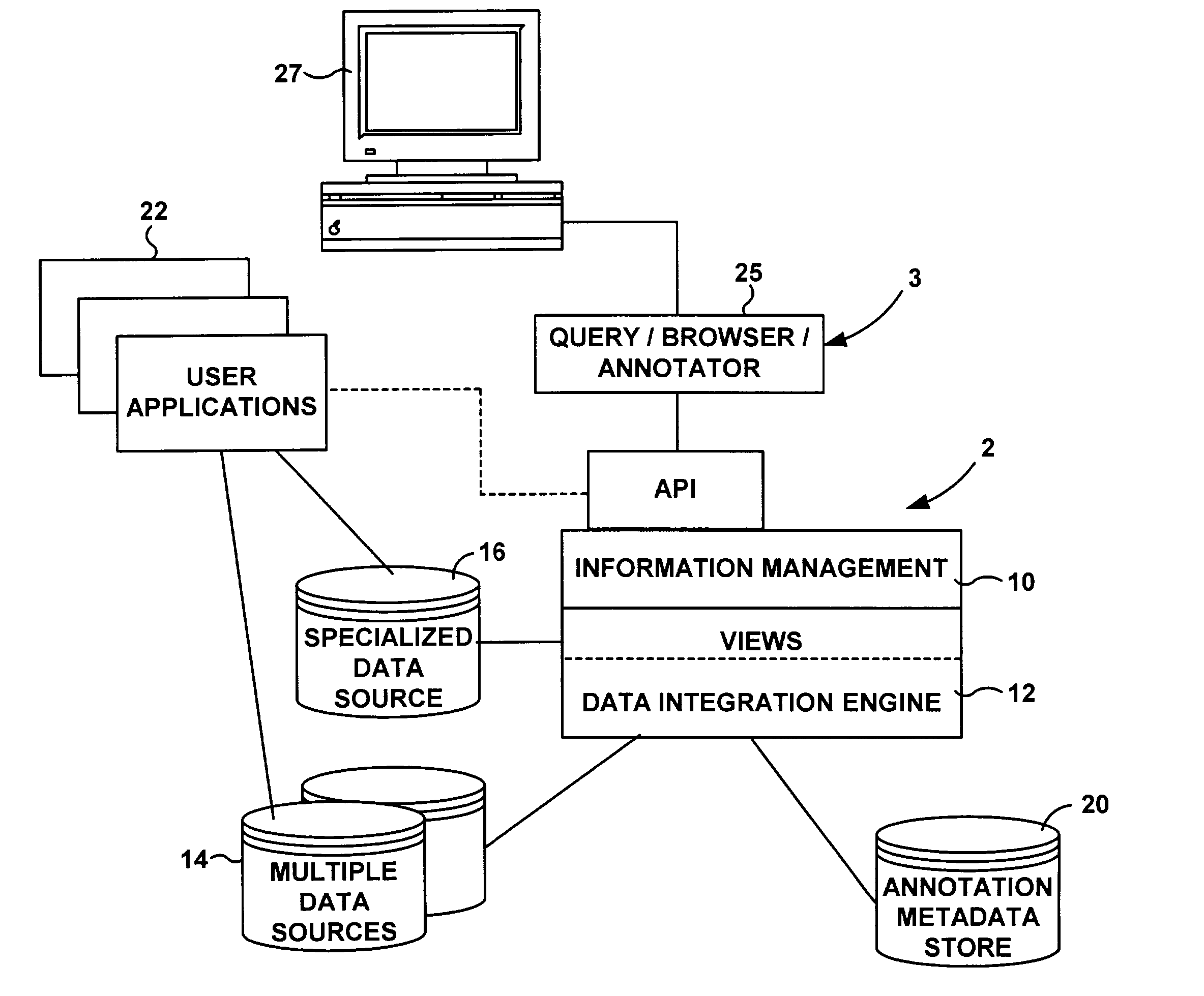

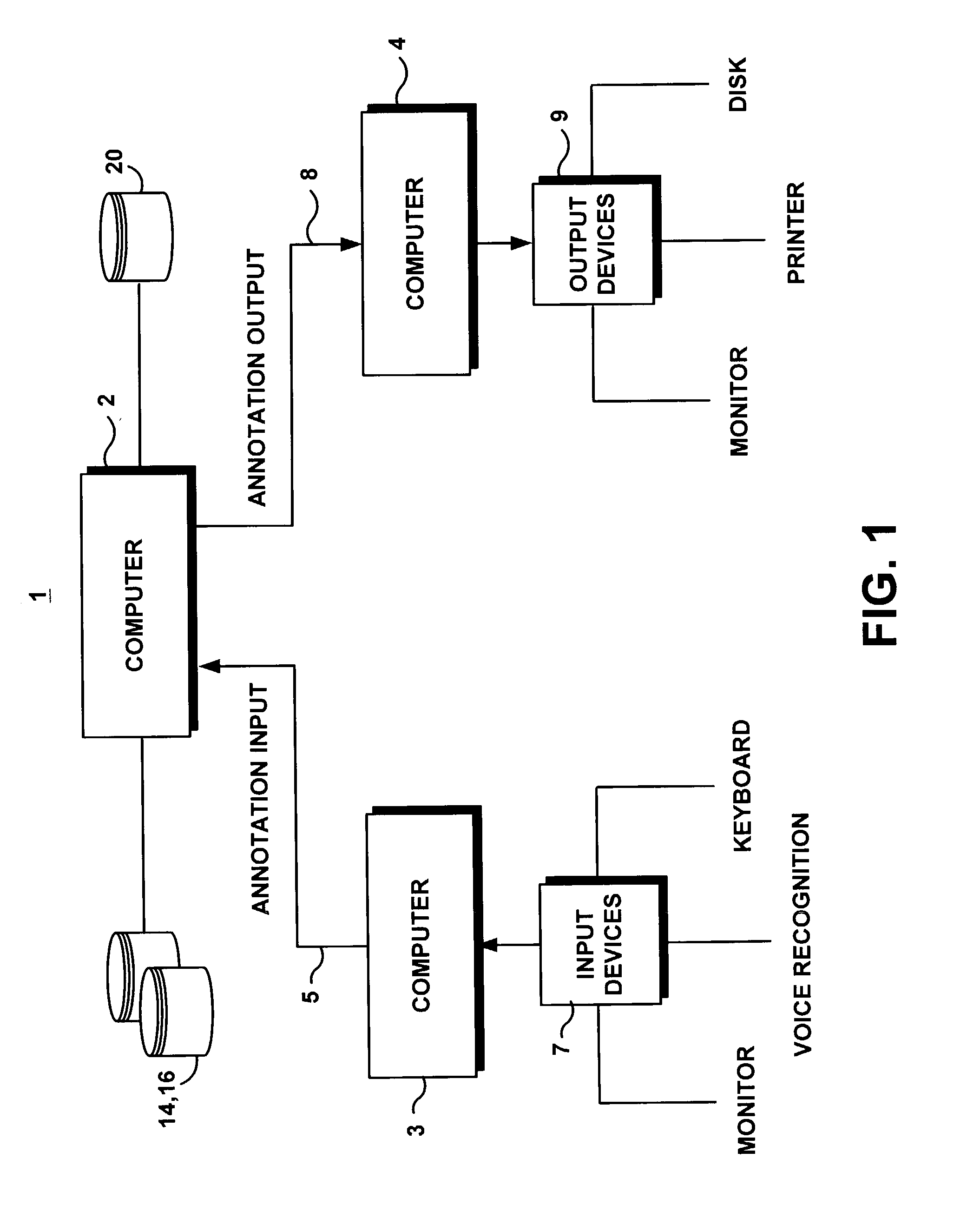

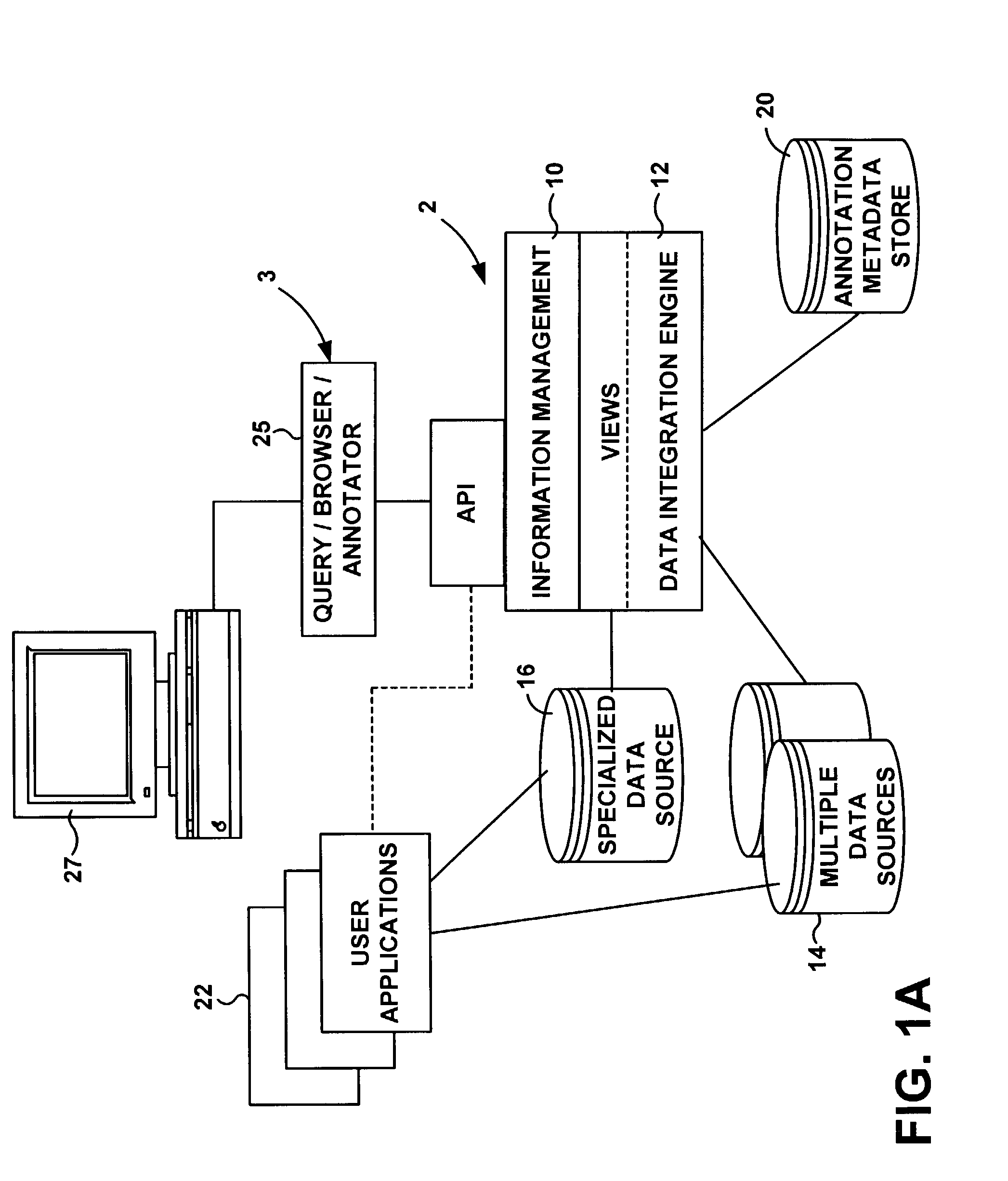

System for annotating a data object by creating an interface based on a selected annotation structure

InactiveUS20060129596A1More consistencyStructure moreData processing applicationsDigital data processing detailsGraphicsSemantic interpretation

A method and apparatus for capturing annotations about database material in a way that allows queries with conditions or predicates on both the database material and the annotations. Database material may be text, computer programs, graphics, audio, spreadsheets, or any other material which may be stored and indexed. Database material may be in one or multiple sources, and annotations may be stored together with the original material or in a separate store. Annotations can be used to capture information such as additional facts about the database material, the opinions and judgments of experts about the database material, and / or links to other related material. Annotations may be captured in a structured form to enhance queryability and semantic interpretation.

Owner:INT BUSINESS MASCH CORP

New Al-Cu-Li-Mg-Ag-Mn-Zr alloy for use as structural members requiring high strength and high fracture toughness

An improved aluminum lithium alloy comprising 0.1 to 2.5 wt. % Li, 2.5 to 5.5 wt. % Cu, 0.2 to 1.0 wt. % Mg, 0.2 to 0.8 wt. % Ag, 0.2 to 0.8 wt. % Mn, up to 0.4 wt. % Zr or other grain refiner such as chromium, titanium, hafnium, scandium or vanadium, the balance aluminum. The present alloy exhibits an improved combination of strength and fracture toughness, over any thickness range. The present invention is further directed to methods for preparing and using Al—Li alloys as well as to products comprising the same.

Owner:CONSTELLIUM ROLLED PROD RAVENSWOOD

Impact resistant, thin ply composite structures and method of manufacturing same

InactiveUS7407901B2Structure moreMaterial nanotechnologySynthetic resin layered productsCarbon fibersReinforced carbon–carbon

A reinforced carbon-carbon (RCC) composite material has improved impact resistance. The RCC composite material is formed from a fiber reinforcement of layers or plies of thin ply carbon fiber fabric impregnated with a carbon matrix. Carbon nanotube reinforcement in the matrix further improves impact resistance. The stacking arrangement of the plies of the thin ply fabric also further improves impact resistance.

Owner:KAZAK COMPOSITES

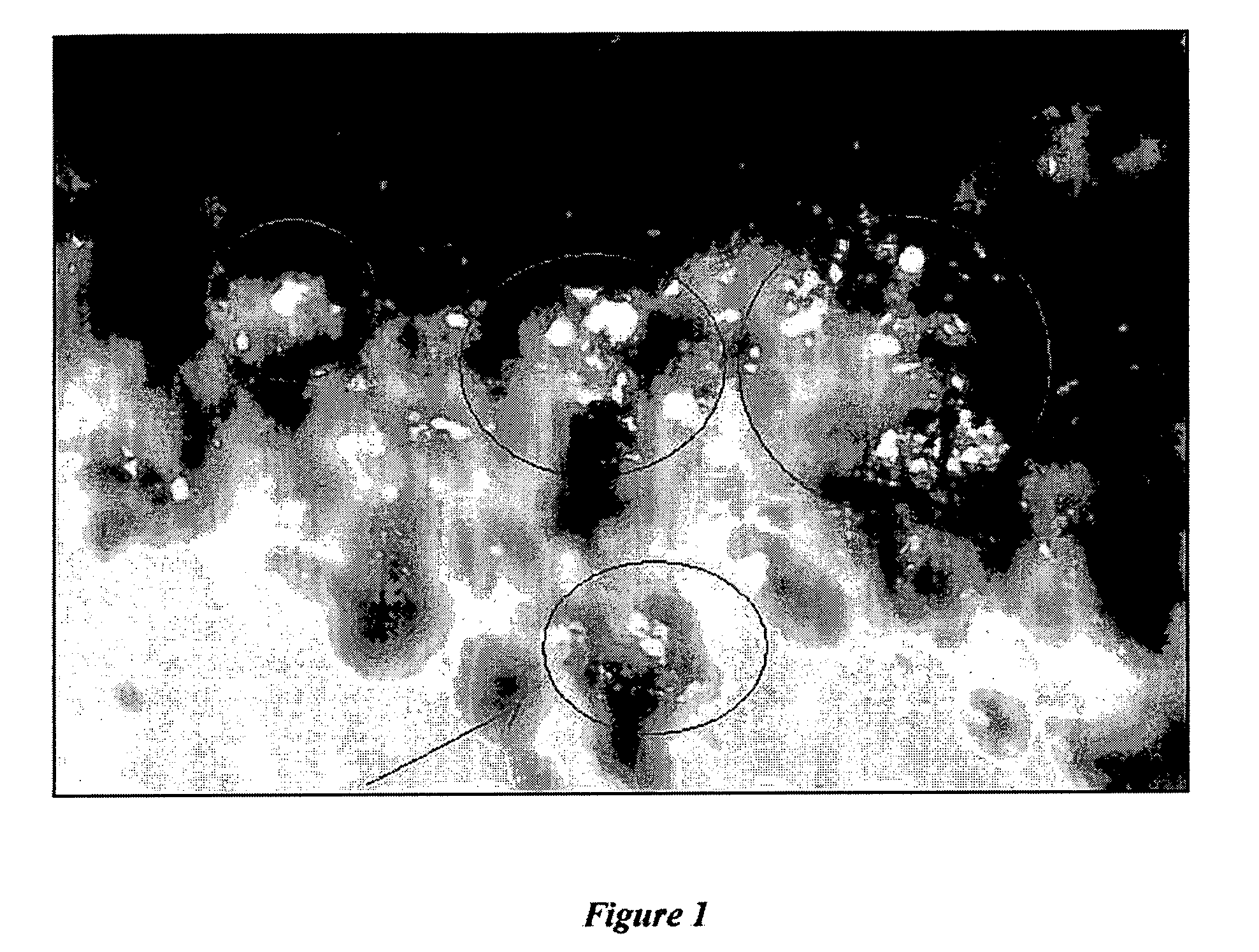

Manufacturing process for high performance lignocellulosic fibre composite materials

InactiveUS20090065975A1Structure moreStrict requirementsRotary stirring mixersLaminationDecompositionFlexural strength

The present invention relates to a process for the manufacture of composite materials having lignocellulosic fibres dispersed in a thermoplastic matrix, while generally maintaining an average fibre length not below 0.2 mm. The process comprises defibrillation of the lignocellulosic fibres using a mixer and at a temperature less than the decomposition temperature of the fibres in order to separate the fibres and generate microfibres, crofÊbres, followed by dispersion of the fibres in the thermoplastic matrix by mechanical mixing to get the moldable thermoplastic composition, followed by injection, compression, extrusion or compression injection molding of said composition. The process produces high performance composite materials having a tensile strength not less than about 55 MPa, a flexural strength not less than about 80 MPa, a stiffness not less than about 2 GPa, notched impact strength not less than about 20 J / m, and un-notched impact strength not less than about 100 J / m. The composite materials of the present invention are well-suited for use in automotive, aerospace, electronic, furniture, sports articles, upholstery and other structural applications.

Owner:SAIN MOHINI M +2

System for organizing an annotation structure and for querying data and annotations

InactiveUS7013307B2Achieve queryabilityEnhance semantic interpretationData processing applicationsDigital data processing detailsGraphicsElectronic form

A method and apparatus for capturing annotations about database material in a way that allows queries with conditions or predicates on both the database material and the annotations. Database material may be text, computer programs, graphics, audio, spreadsheets, or any other material which may be stored and indexed. Database material may be in one or multiple sources, and annotations may be stored together with the original material or in a separate store. Annotations can be used to capture information such as additional facts about the database material, the opinions and judgments of experts about the database material, and / or links to other related material. Annotations may be captured in a structured form to enhance queryability and semantic interpretation.

Owner:IBM CORP

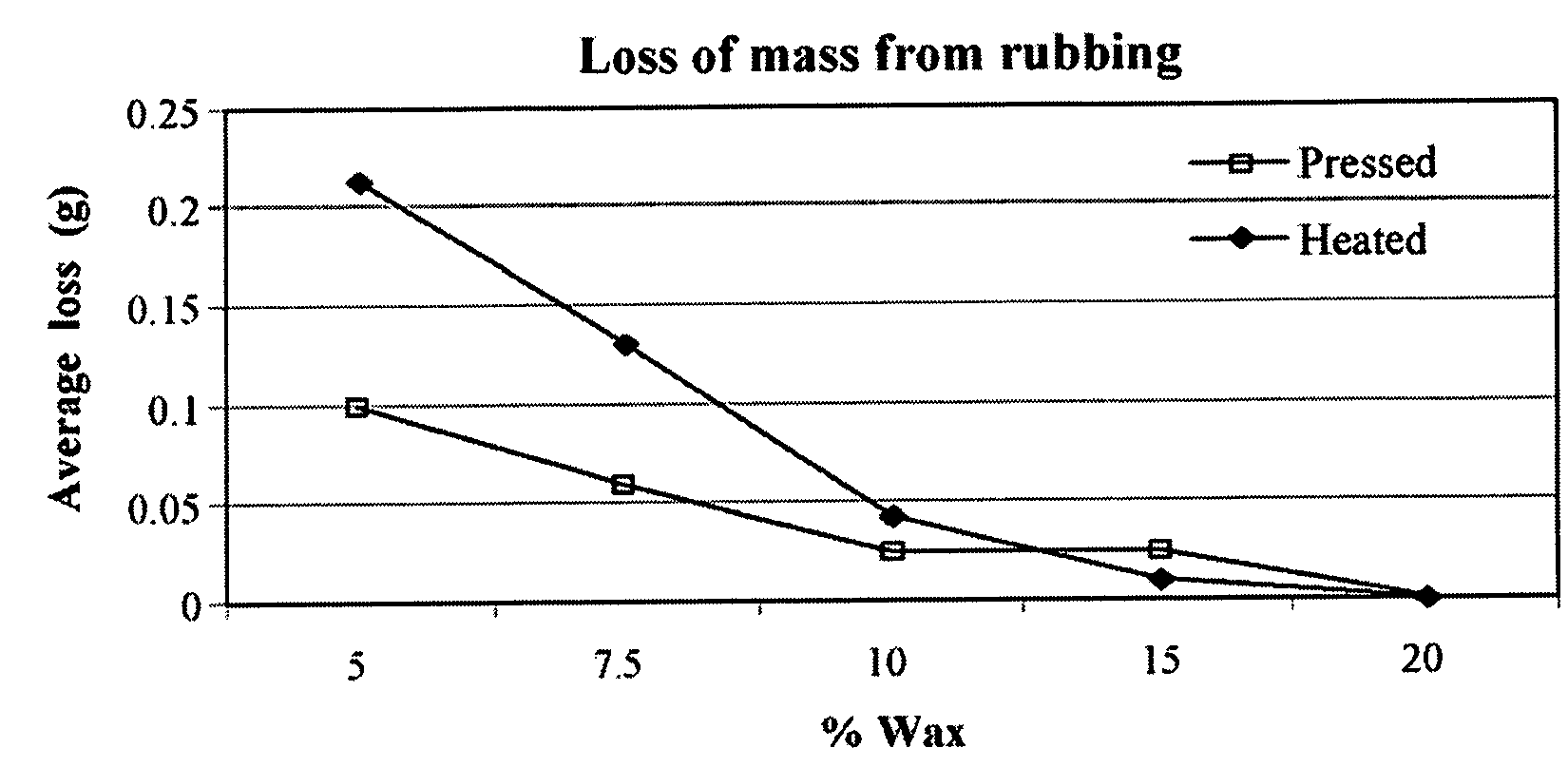

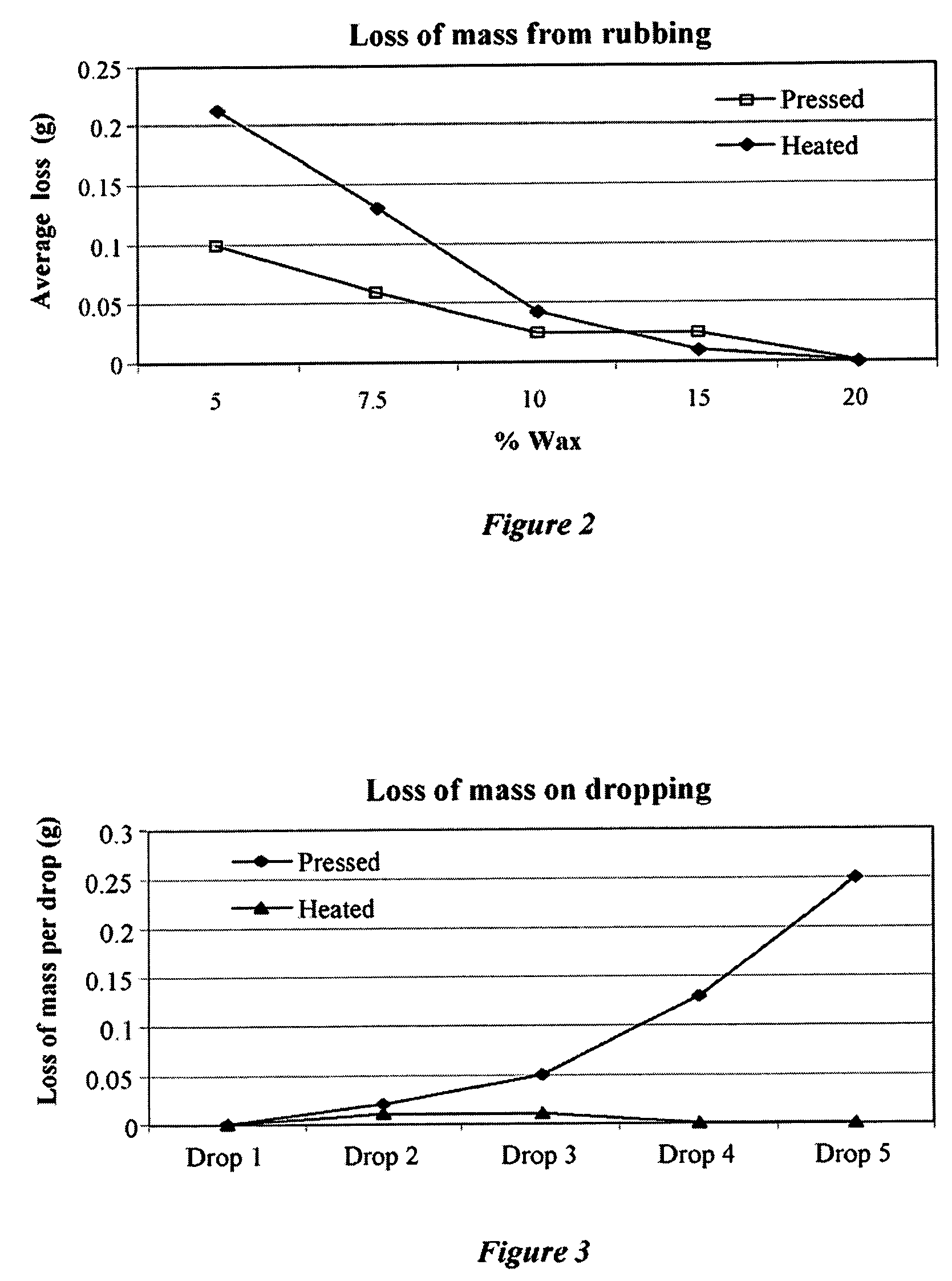

Powder Cosmetic Composition

ActiveUS20090142382A1Overcome deficienciesDesirable transferabilityCosmetic preparationsBody powdersParticulatesPolymer chemistry

Methods for preparing a solid powder cosmetic composition comprise heating a wax component and one or more cosmetic powders at a temperature sufficient to melt the wax, and subsequently cooling the mixture to provide a solid composition comprising a wax matrix having particulate materials homogenously dispersed therein.

Owner:AVON PROD INC

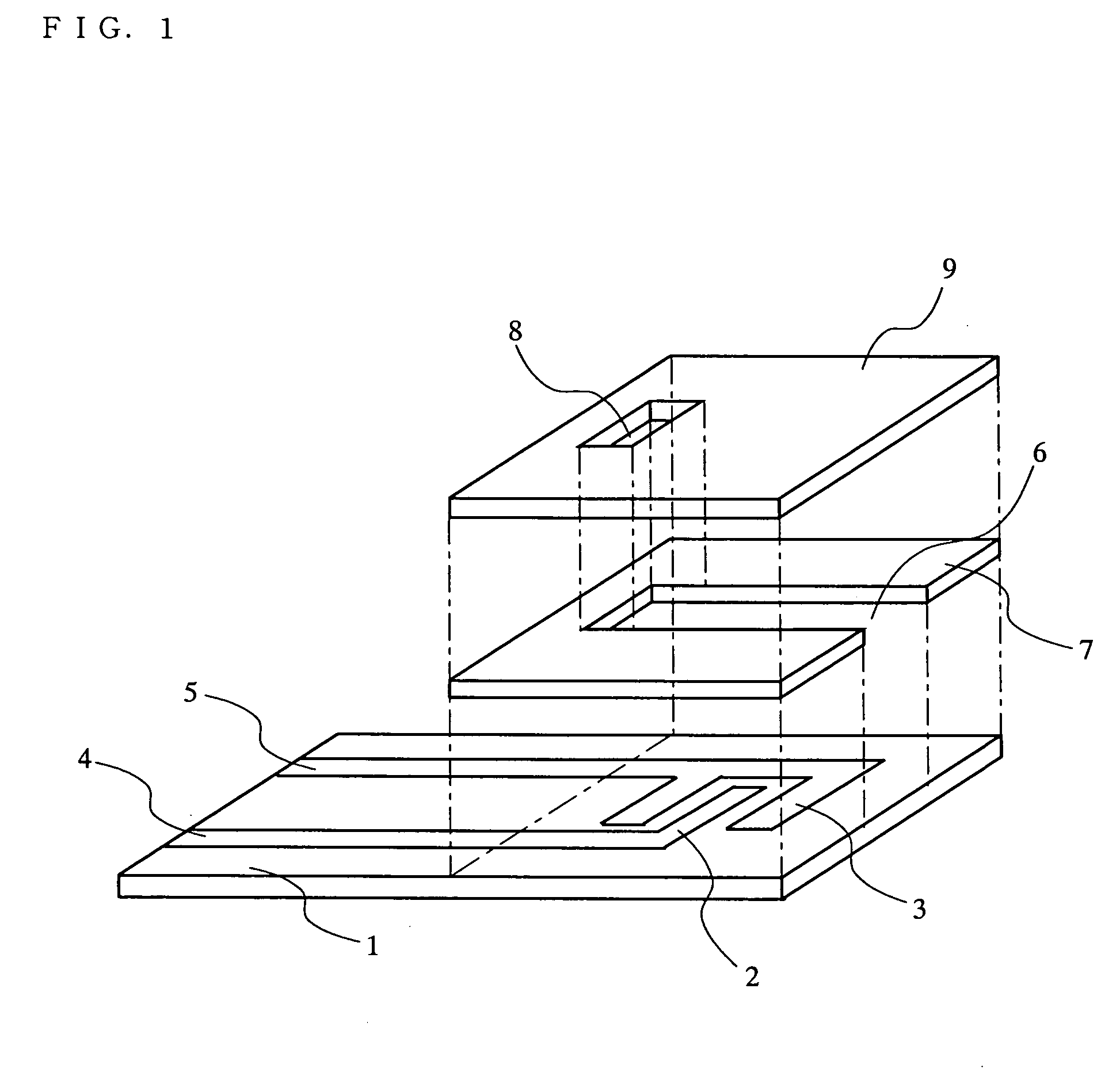

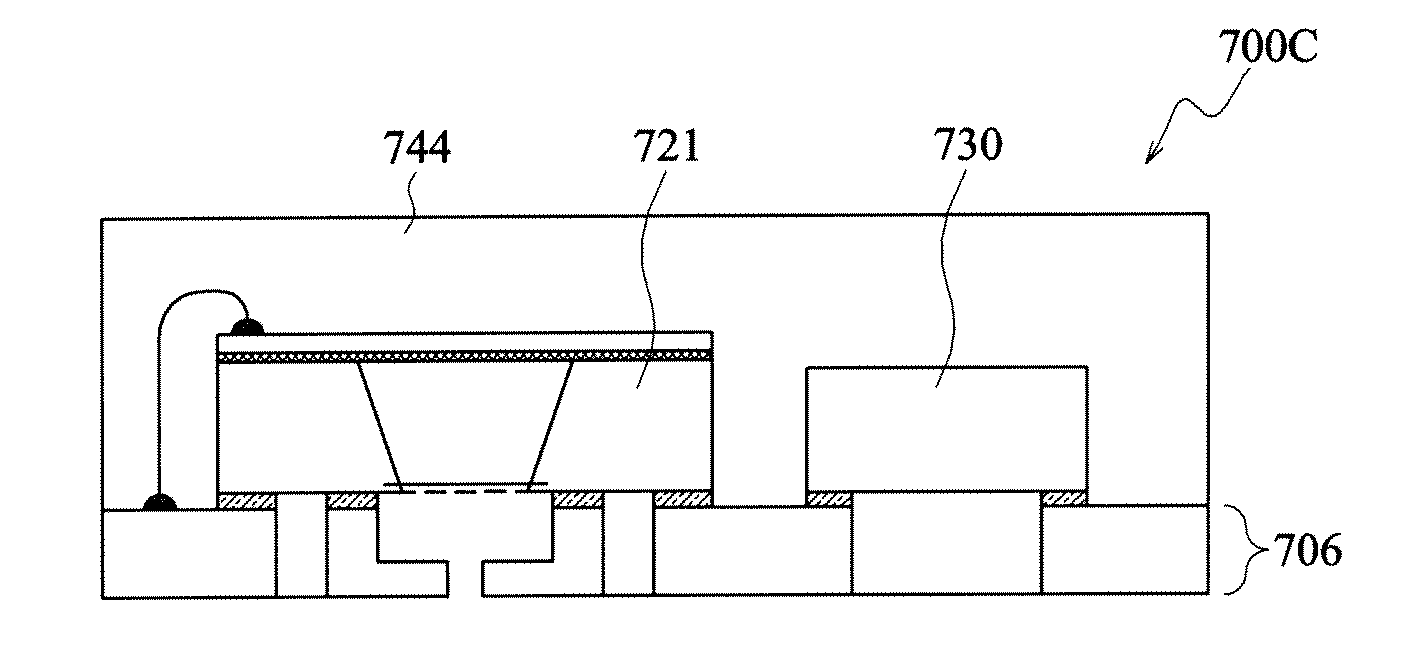

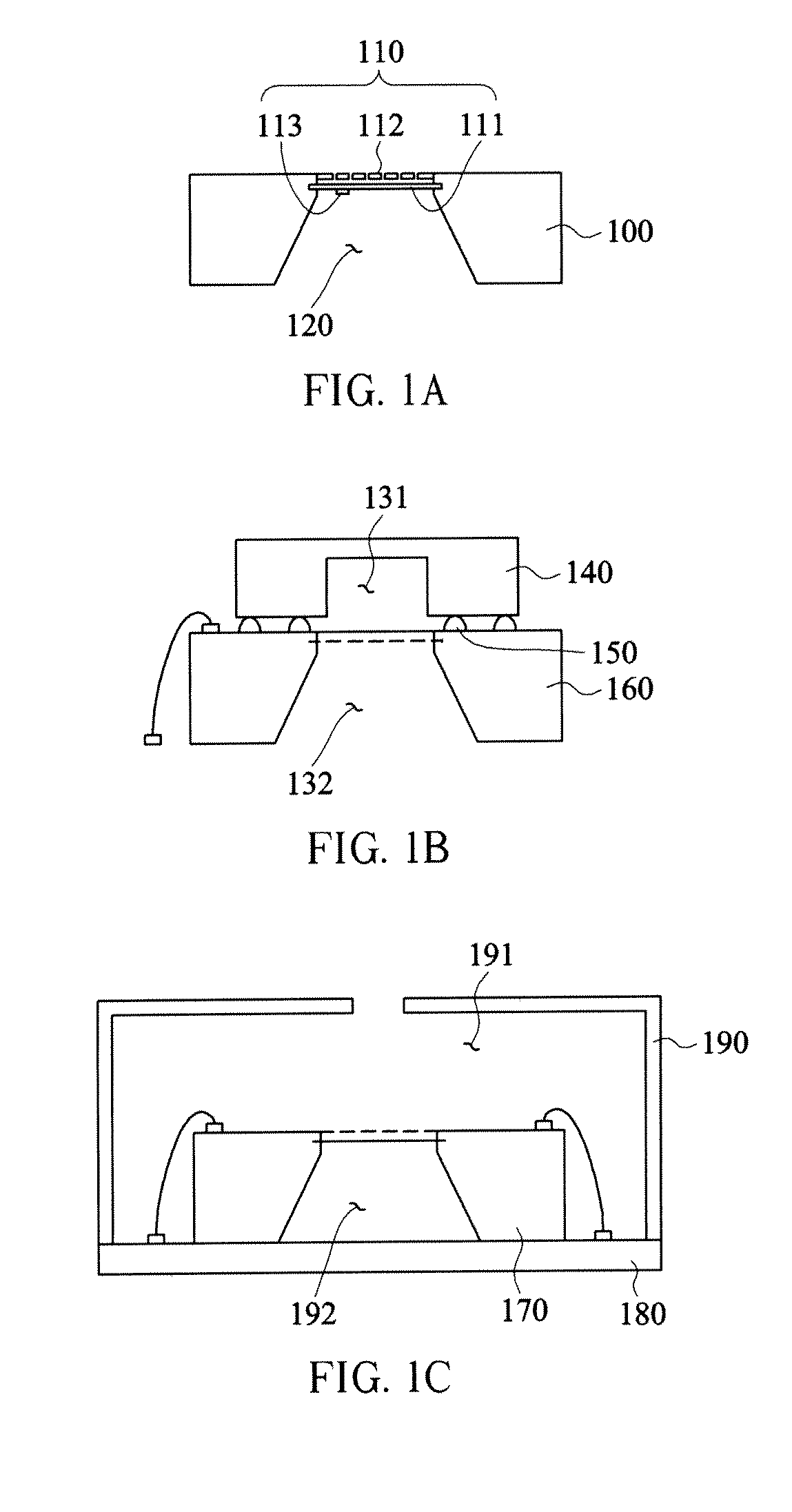

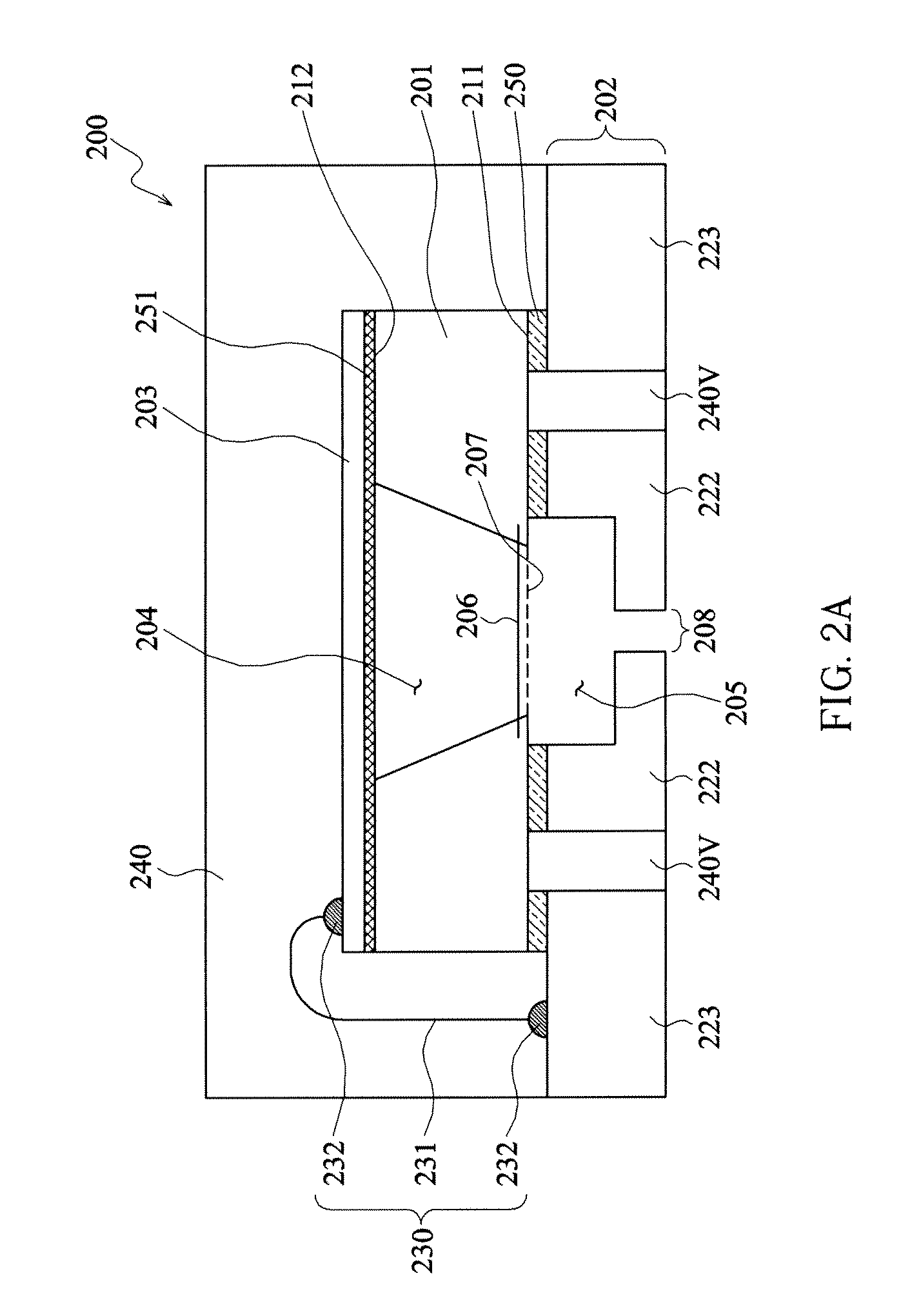

MEMS package

InactiveUS20100109103A1High frequency responseStructure moreTransducer detailsSemiconductor/solid-state device detailsElectromagnetic shieldingSealant

The invention provides a MEMS package including: a MEMS chip including a first surface, a second surface, a first cavity, and a sensing device, the sensing device defining a first end of the first cavity; a leadframe including a second cavity and being electrically connected to the first surface of the MEMS chip, the second cavity being adjacent to the sensing device of the MEMS chip; a conductive layer disposed on the second surface of the MEMS chip to define a second end of the first cavity and grounded via the leadframe that is electrically connected to the conductive layer so as to provide electromagnetic shielding to the MEMS chip; and an encapsulant covering the MEMS chip, the leadframe, and the conductive layer to define an shape of the MEMS package and allowing outer surfaces of the leadframe to emerge from the MEMS package.

Owner:WINDTOP TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com