Impact resistant, thin ply composite structures and method of manufacturing same

a composite structure and thin ply technology, applied in the field of impact resistance, thin ply composite structure and method of manufacturing same, can solve the problems of brittle nature of rcc, limited performance and range of applications of these materials, and difficulty in using carbon nanotubes (cnts) alone as reinforcement to enhance the mechanical properties of a material, and achieve the effect of greater impact resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

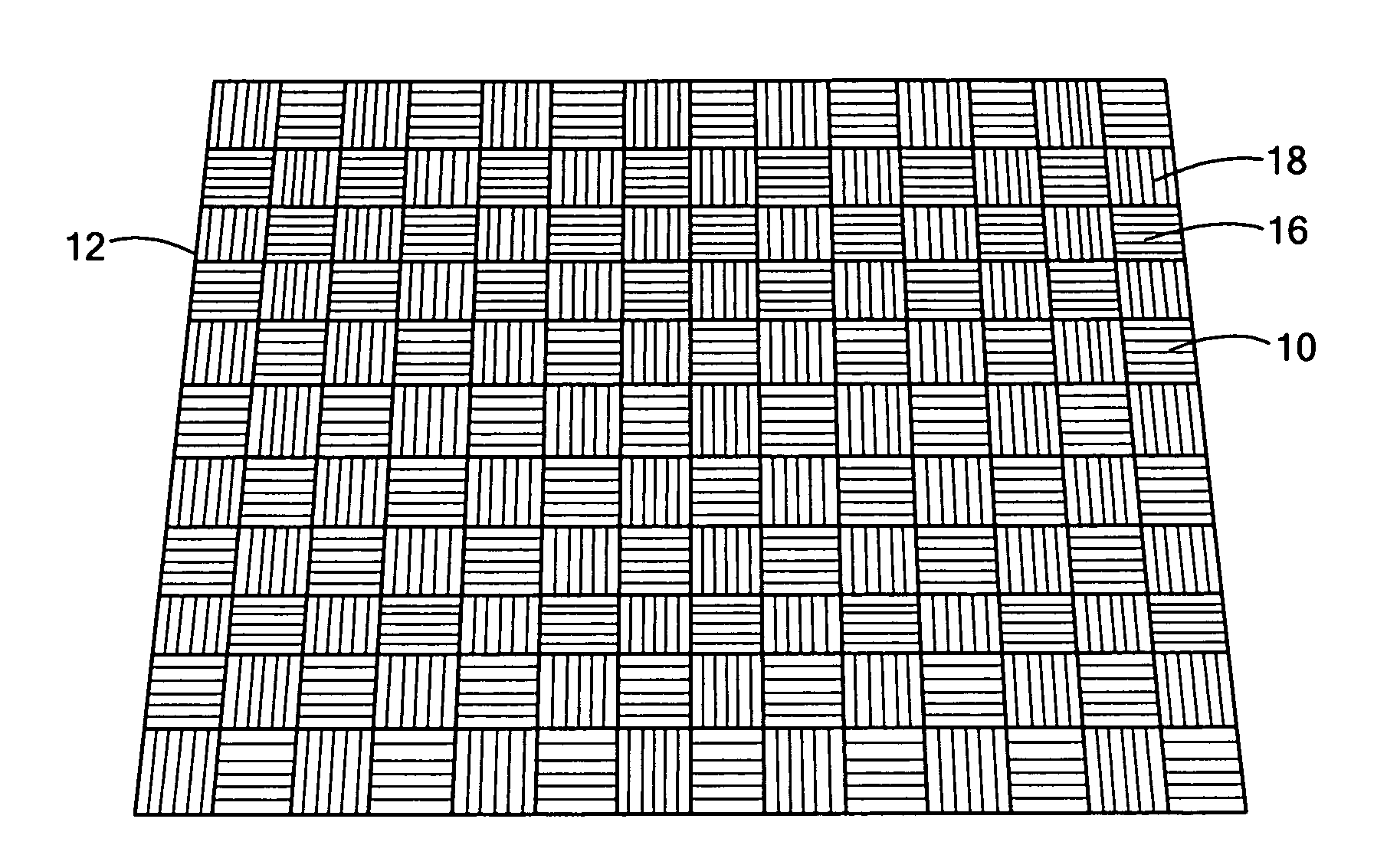

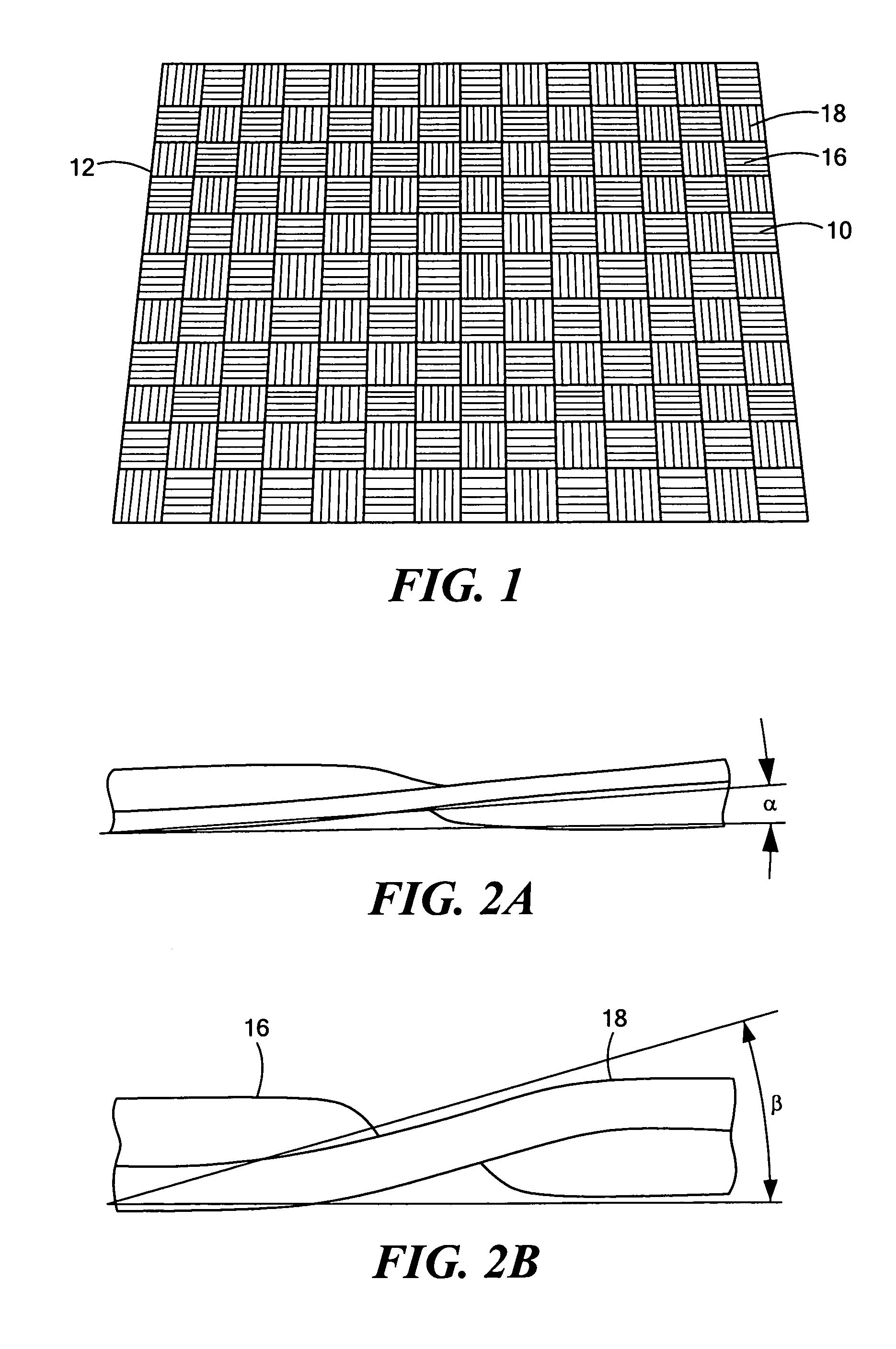

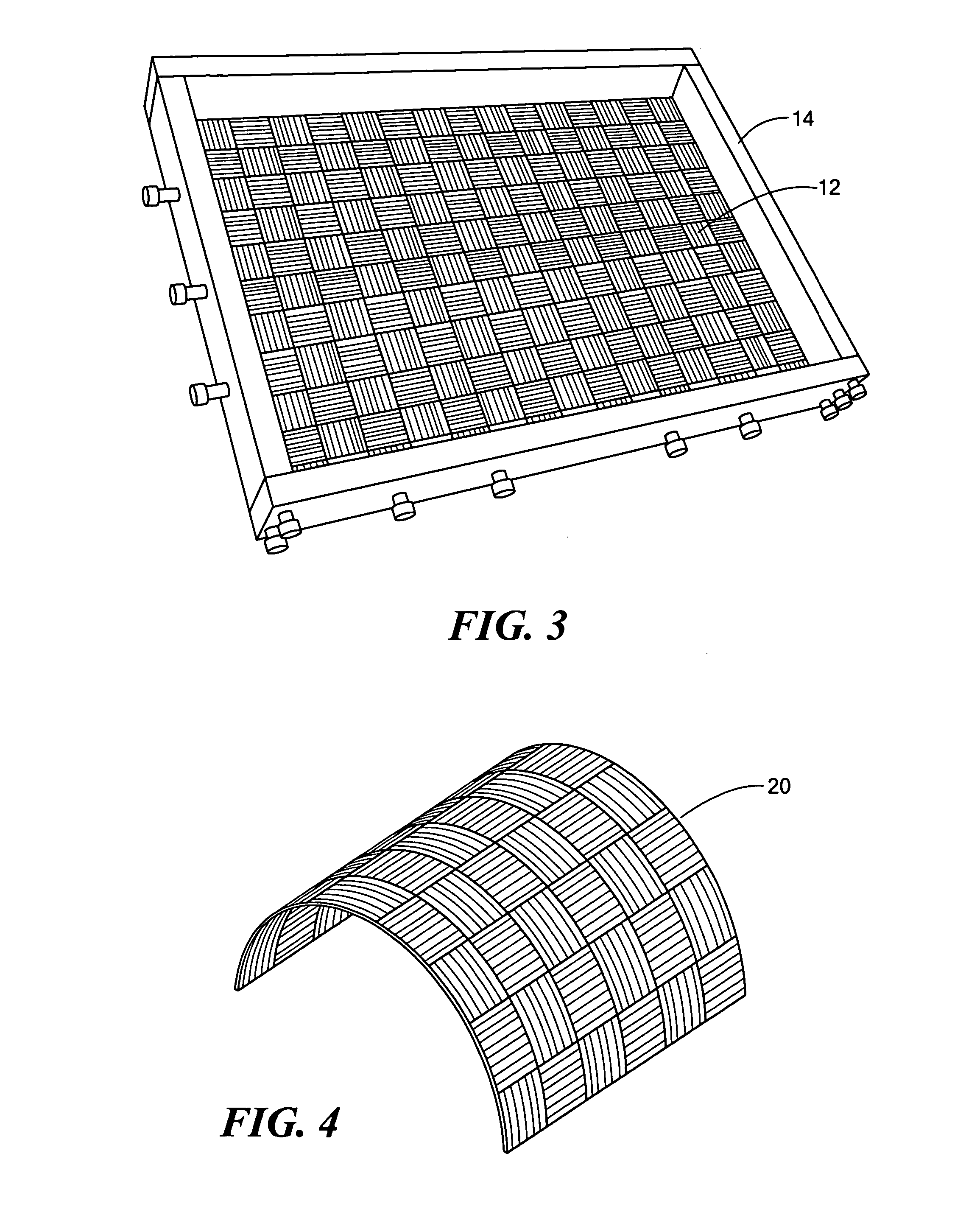

[0018]In the present invention, a reinforced carbon-carbon (RCC) composite material is provided having improved impact resistance. The composite material is formed from a fiber reinforcement of layers or plies of thin ply carbon fiber fabric impregnated with a carbon matrix and preferably further reinforced with carbon nanotubes. The fabrication of the RCC composite begins with a preform 12 of dry or preimpregnated thin ply carbon fiber fabric layers. See FIG. 1. The preform is infiltrated with a carbon precursor matrix material and cured to form a precursor composite material. Various processes, such as vacuum assisted resin transfer matrix molding (VARTM), hot press molding, and pultrusion, can be used to form and cure the precursor composite material. Thereafter, the precursor composite material undergoes a carbonization process to convert the precursor matrix material to carbon through thermal degradation and a densification process to achieve a desired bulk density.

[0019]The th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com