Patents

Literature

265 results about "Catalytic particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanostructures formed of branched nanowhiskers and methods of producing the same

InactiveUS20060057360A1Structure moreMaterial nanotechnologyLiquid surface applicatorsHeterojunctionEngineering

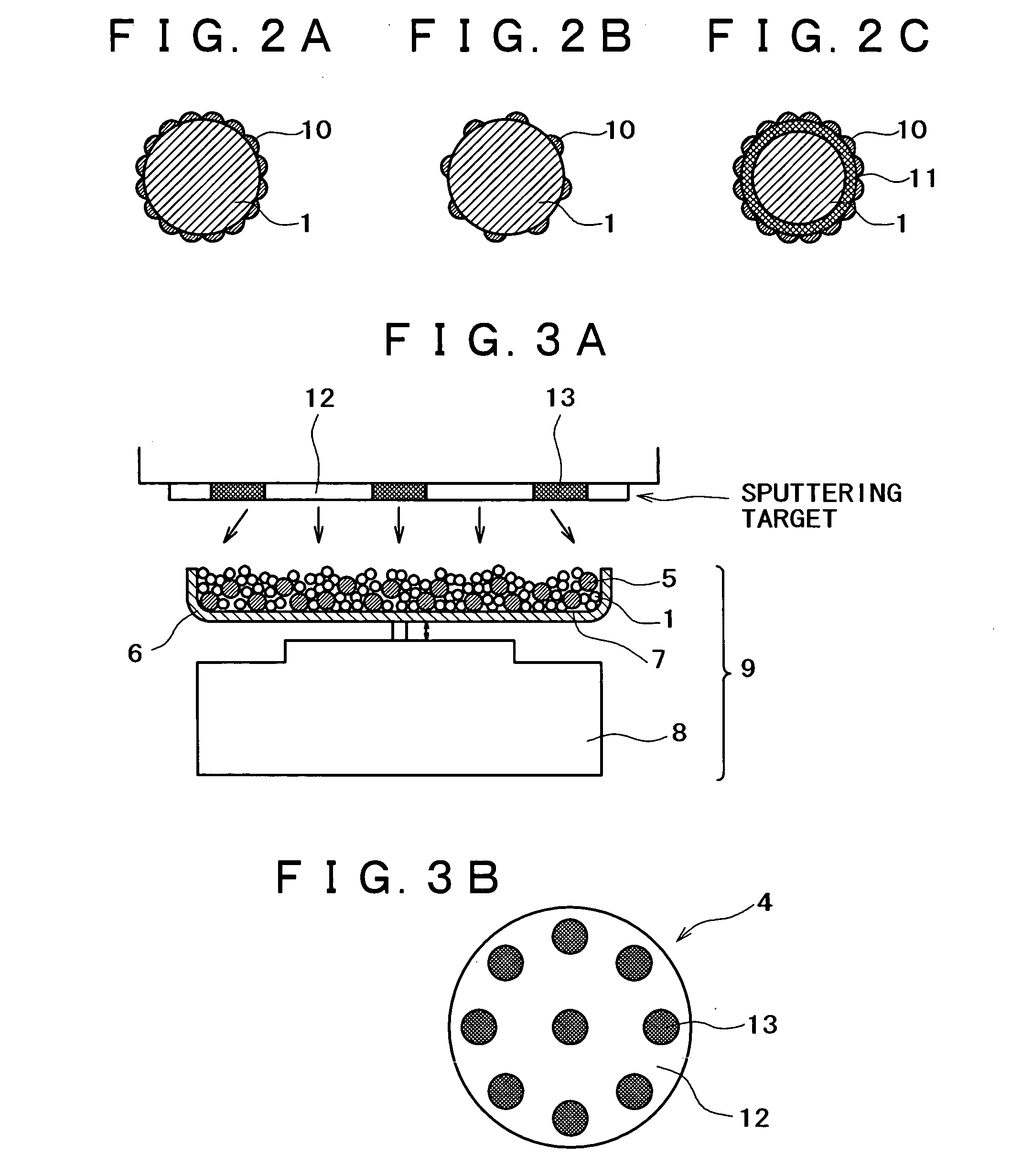

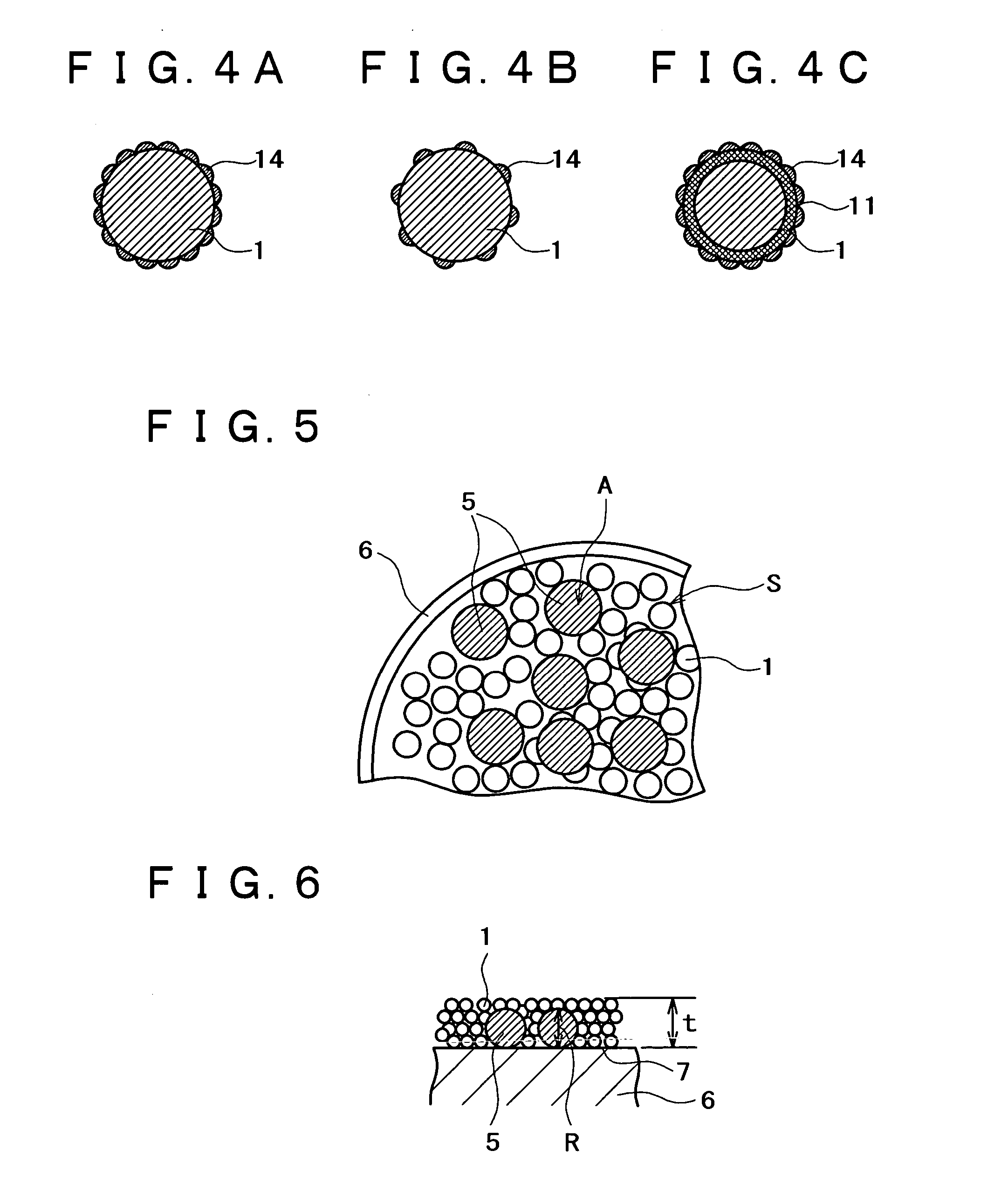

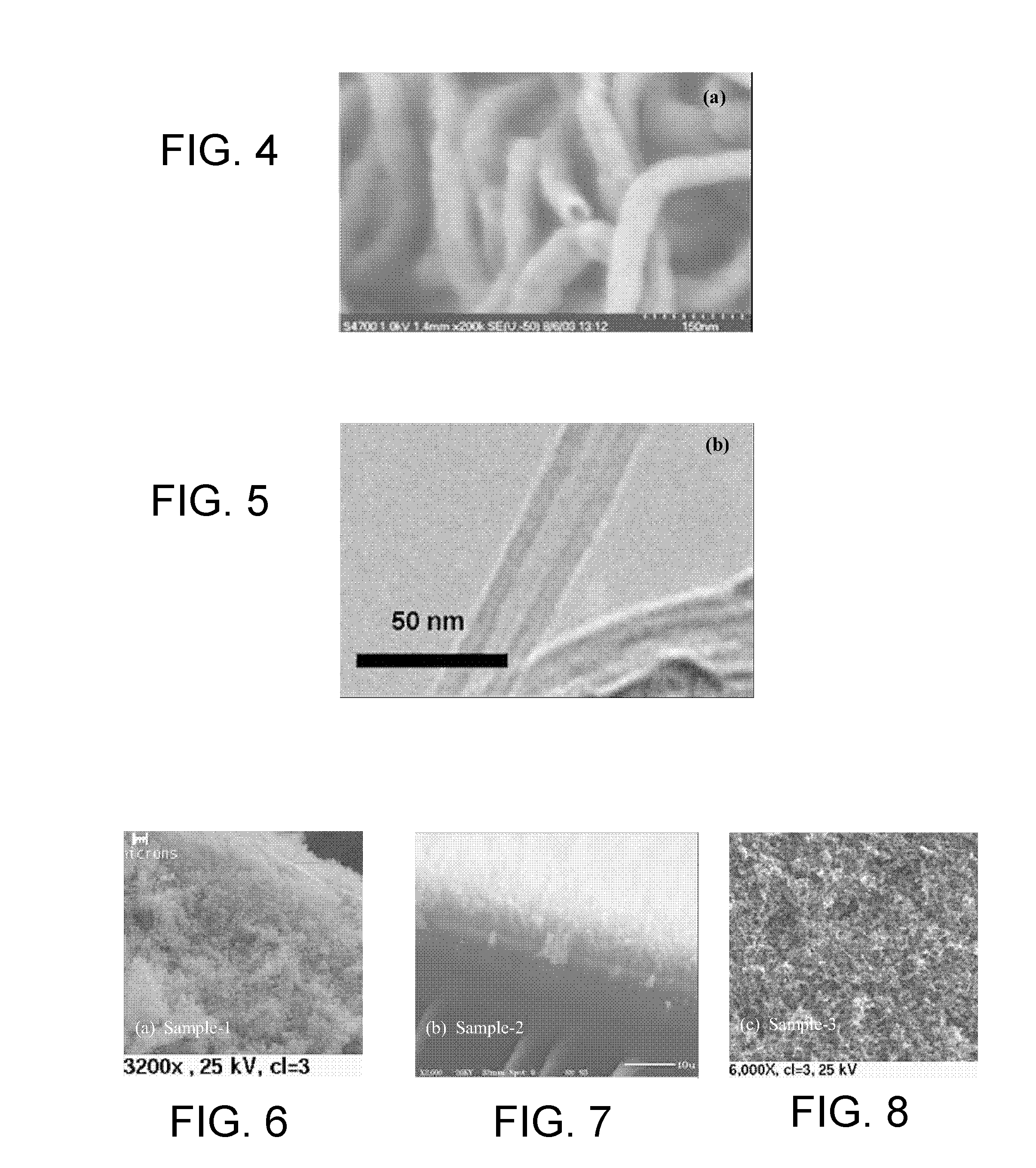

A method of forming a nanostructure having the form of a tree, comprises a first stage and a second stage. The first stage includes providing one or more catalytic particles on a substrate surface, and growing a first nanowhisker via each catalytic particle. The second stage includes providing, on the periphery of each first nanowhisker, one or more second catalytic particles, and growing, from each second catalytic particle, a second nanowhisker extending transversely from the periphery of the respective first nanowhisker. Further stages may be included to grow one or more further nanowhiskers extending from the nanowhisker(s) of the preceding stage. Heterostructures may be created within the nanowhiskers. Such nanostructures may form the components of a solar cell array or a light emitting flat panel, where the nanowhiskers are formed of a photosensitive material. A neural network may be formed by positioning the first nanowhiskers close together so that adjacent trees contact one another through nanowhiskers grown in a subsequent stage, and heterojunctions within the nanowhiskers create tunnel barriers to current flow.

Owner:QUNANO

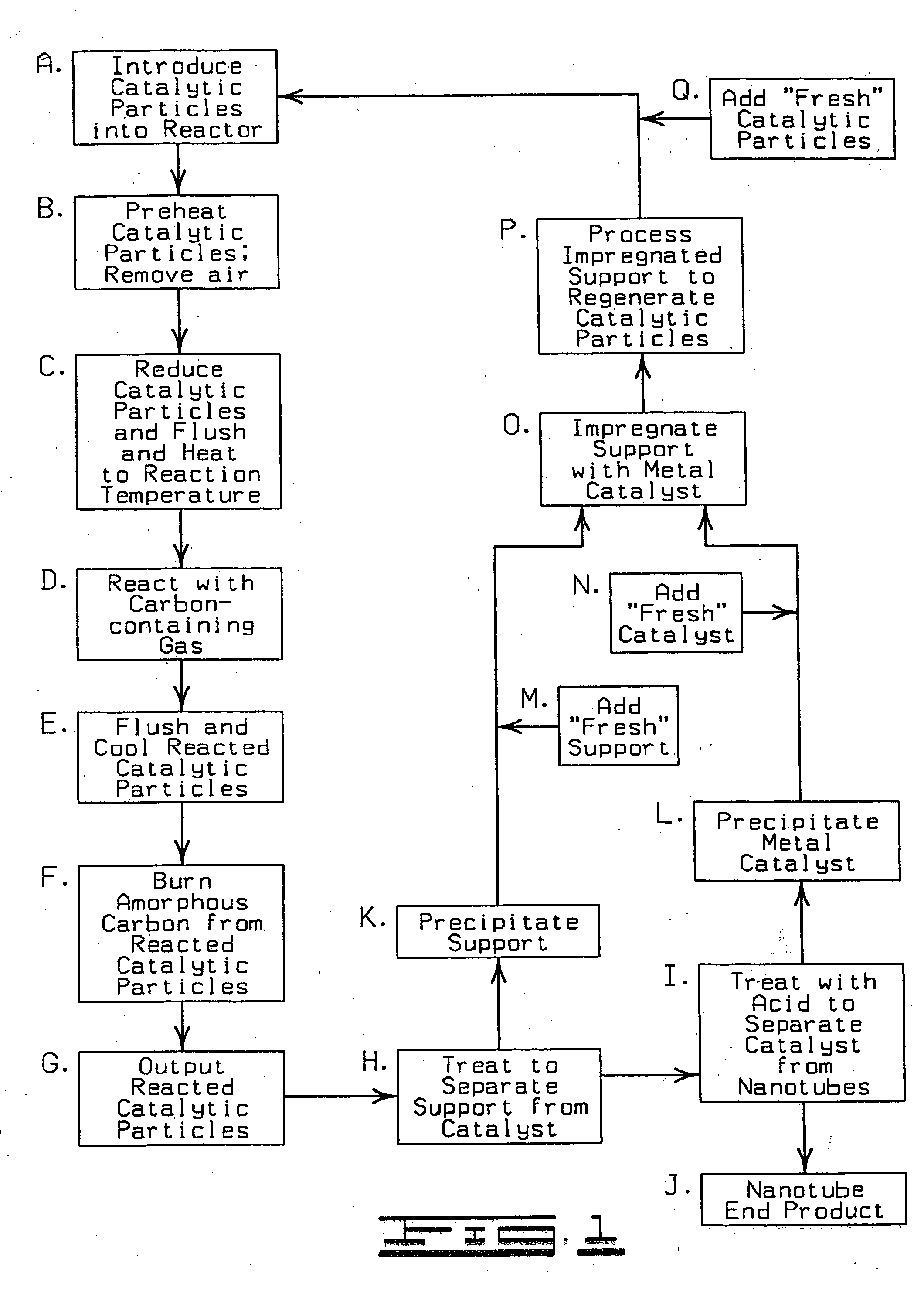

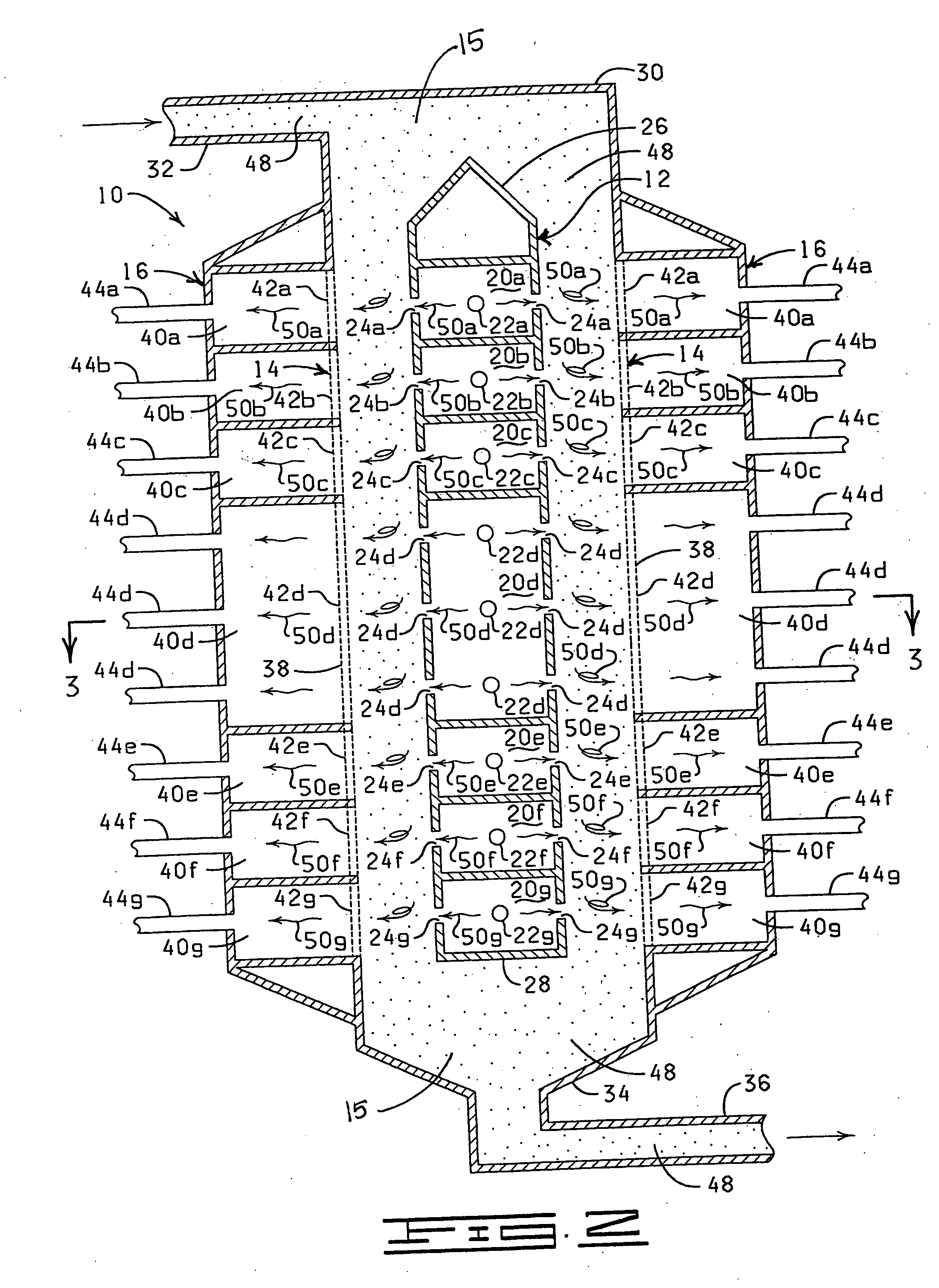

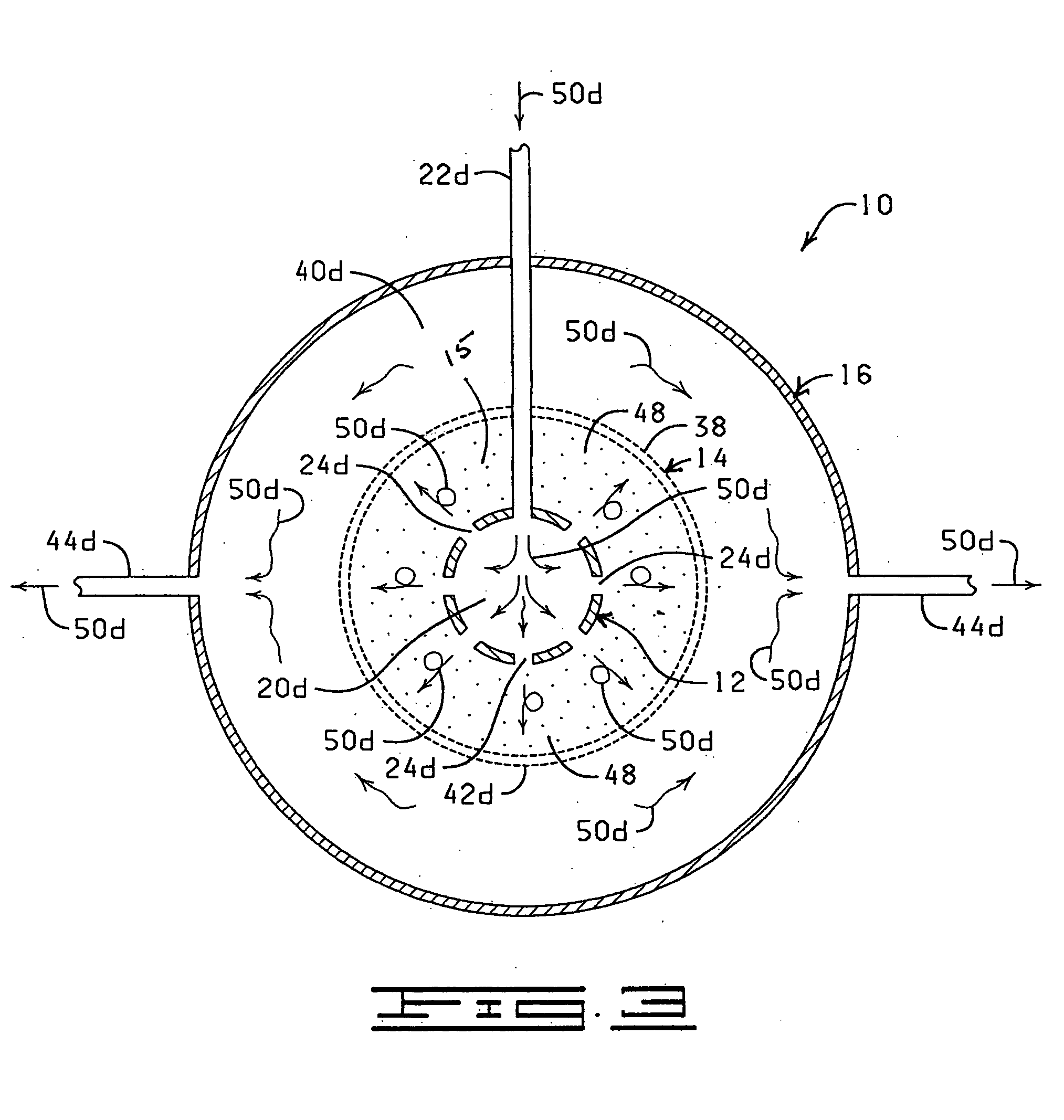

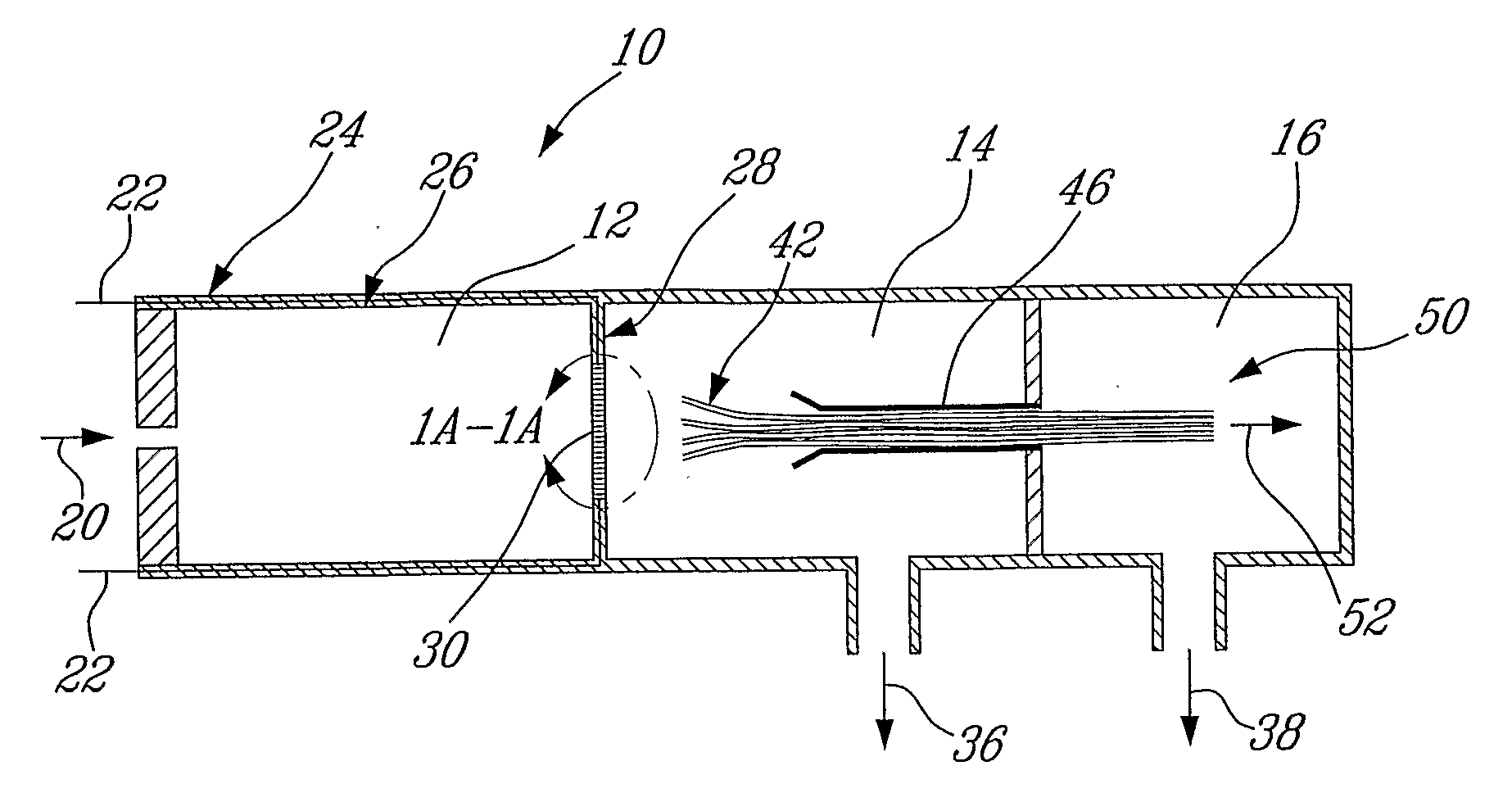

Method and apparatus for producing carbon nanotubes

InactiveUS6955800B2Avoid disadvantagesAvoid defectsMaterial nanotechnologyCatalyst regeneration/reactivationParticulatesCarbon nanotube

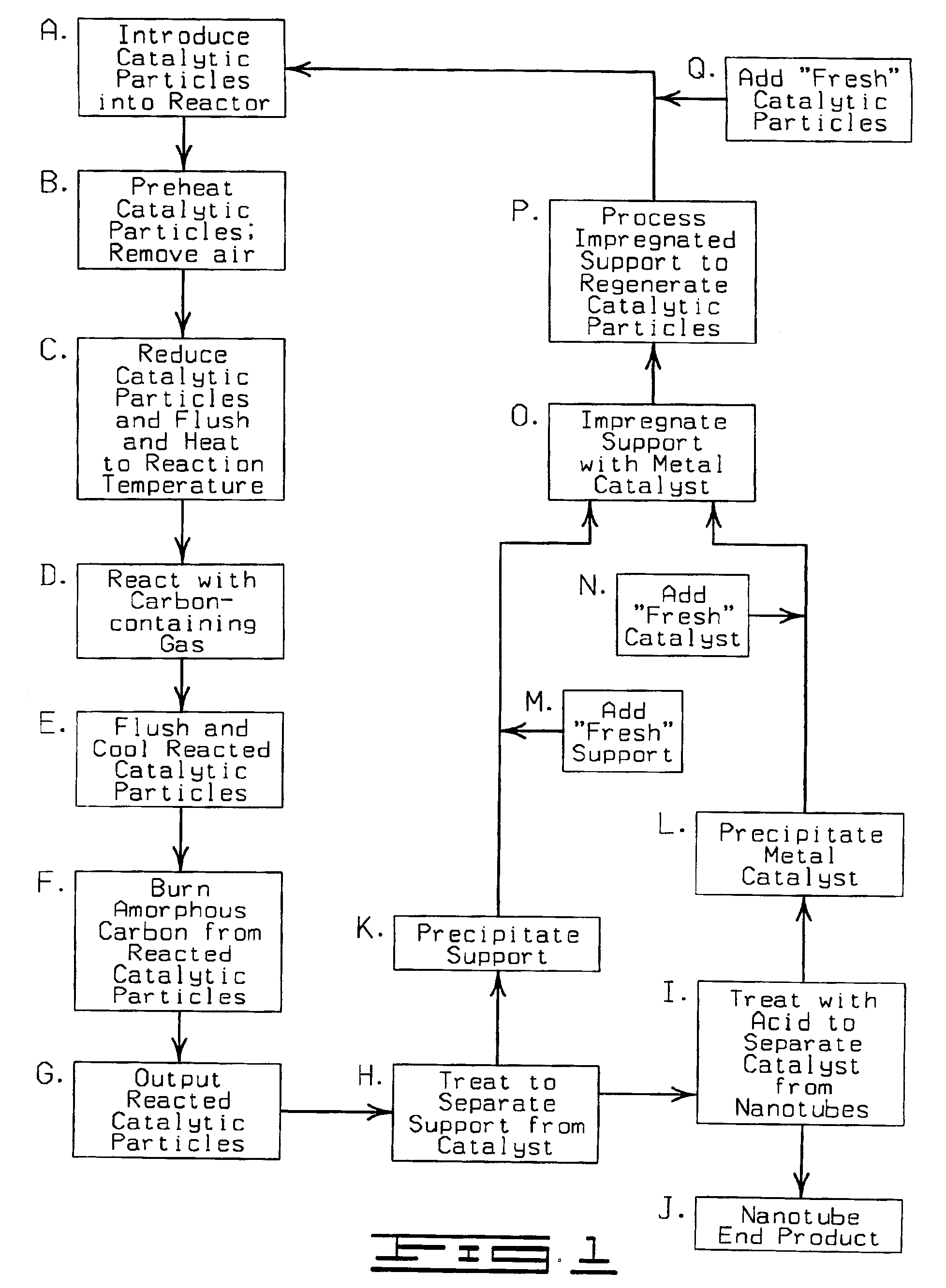

A method and apparatus for catalytic production of carbon nanotubes. Catalytic particles are exposed to different process conditions at successive stages wherein the catalytic particles do not come in contact with reactive (catalytic) gases until preferred process conditions have been attained, thereby controlling the quantity and form of carbon nanotubes produced. The method also contemplates methods and apparatus which recycle and reuse the gases and catalytic particulate materials, thereby maximizing cost efficiency, reducing wastes, reducing the need for additional raw materials, and producing the carbon nanotubes, especially SWNTs, in greater quantities and for lower costs.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

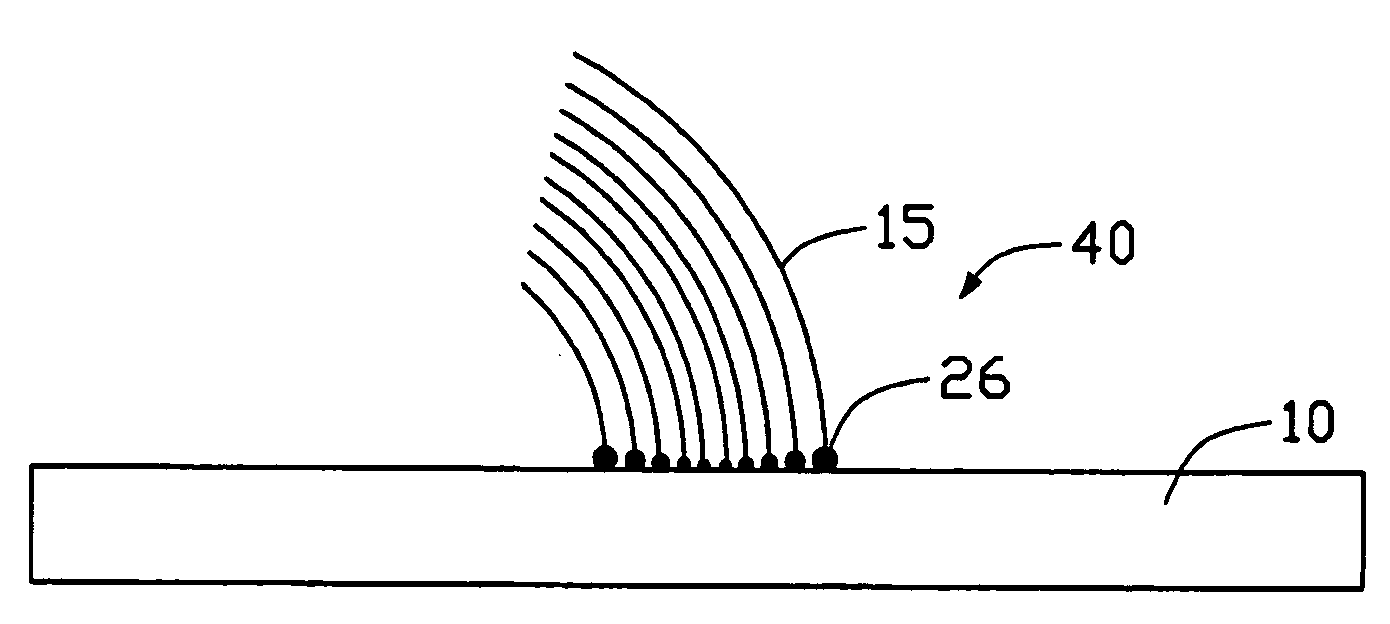

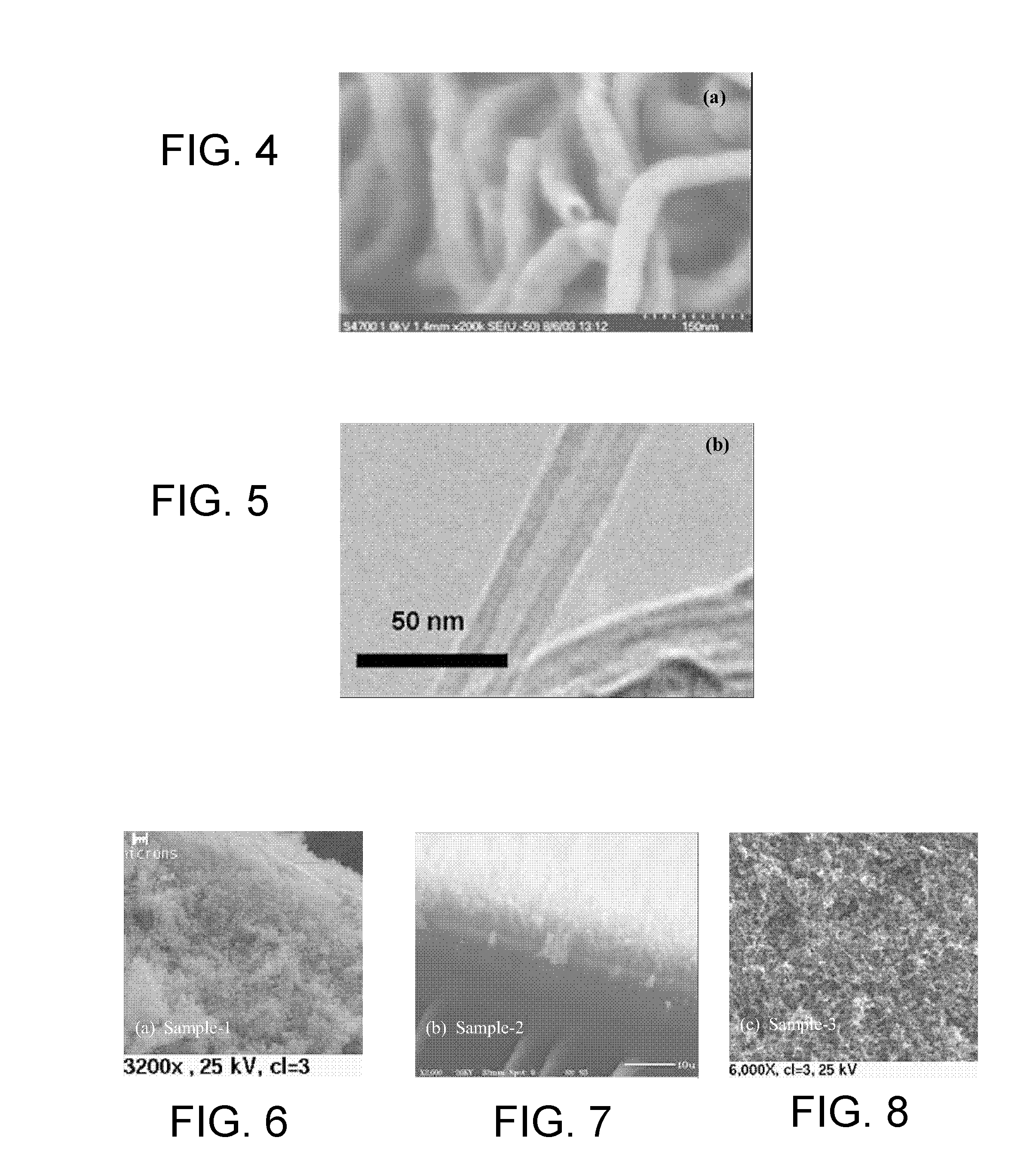

Carbon annotate-based device and method for making carbon nanotube based device

ActiveUS20040136896A1Easy to controlWide applicationMaterial nanotechnologyLayered productsGas phaseAlloy

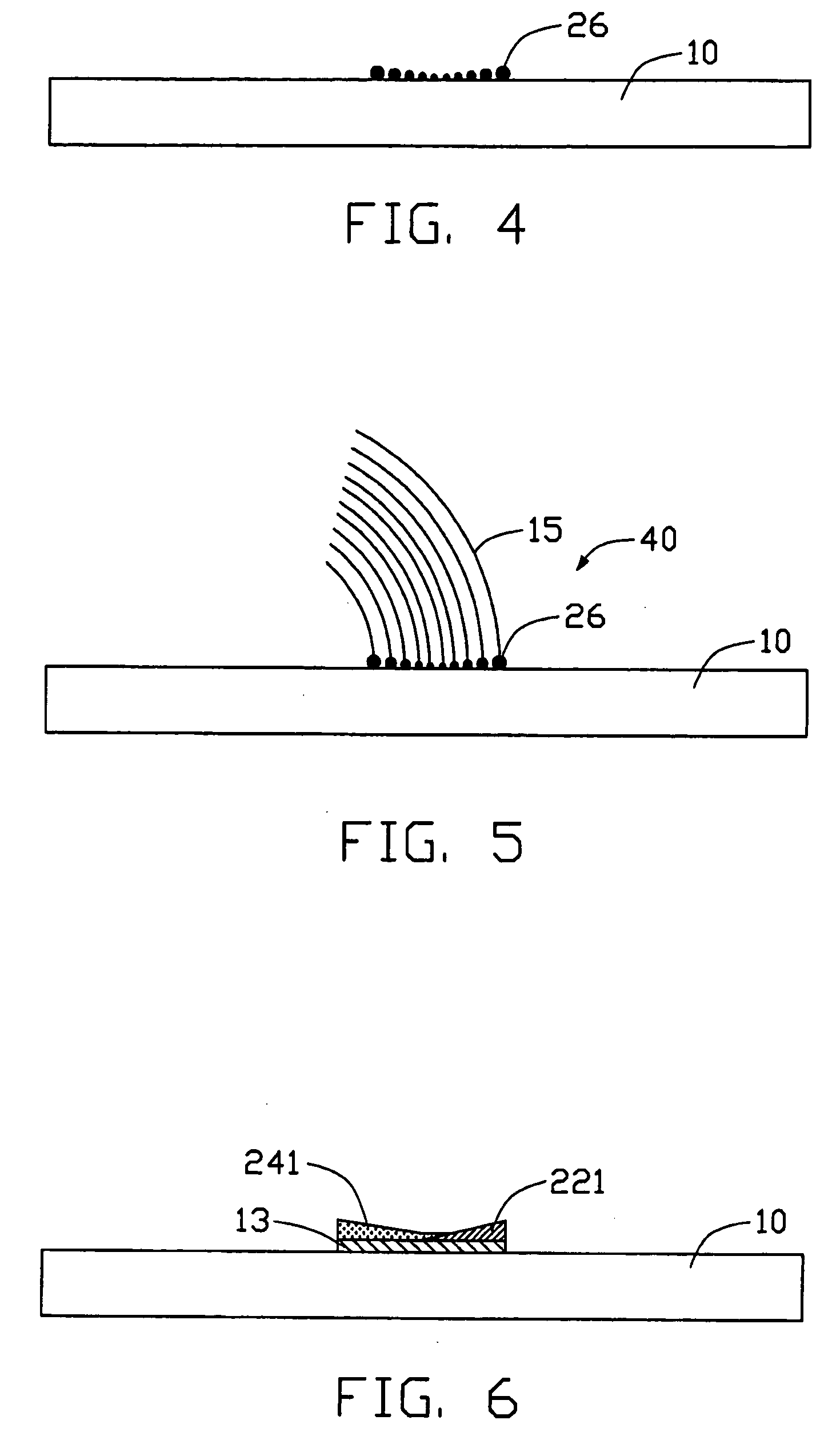

A carbon nanotube-based device (40) includes a substrate (10), a number of alloyed, nano-sized catalytic particles (26) formed on the substrate, and an array of aligned carbon nanotubes (15) extending from the alloyed, nano-sized catalytic particles. The nanotube array bends in an arcuate configuation. A method for making the carbon nanotube-based device includes the steps of: providing a substrate; depositing a catalyst layer on the substrate; depositing two different layers of catalyst-doped materials on different areas of the catalyst layer for accelerating or decelerating the rate of synthesis of the aligned carbon nanotube array; annealing the catalyst and the catalyst-doped materials in an oxygen-containing gas at a low temperature; introducing a carbon source gas; and forming an array of aligned carbon nanotubes extending from the alloyed, nano-sized catalytic particles using a chemical vapor deposition method.

Owner:TSINGHUA UNIV +1

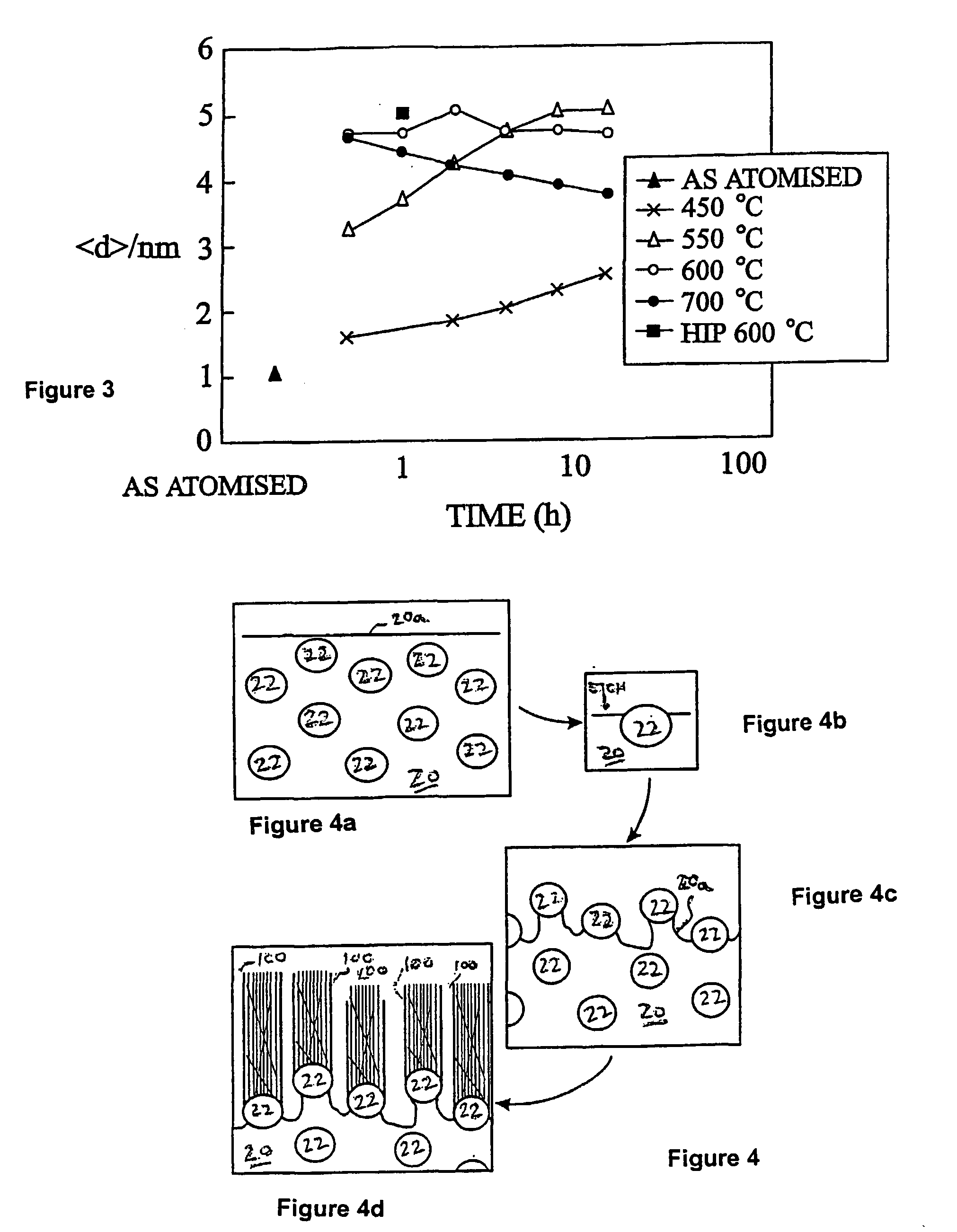

Probe structures incorporating nanowhiskers, production methods thereof and methods of forming nanowhiskers

InactiveUS20050017171A1Small sizeReduce the overall diameterMaterial analysis using wave/particle radiationInorganic material artificial filamentsEtchingWhiskers

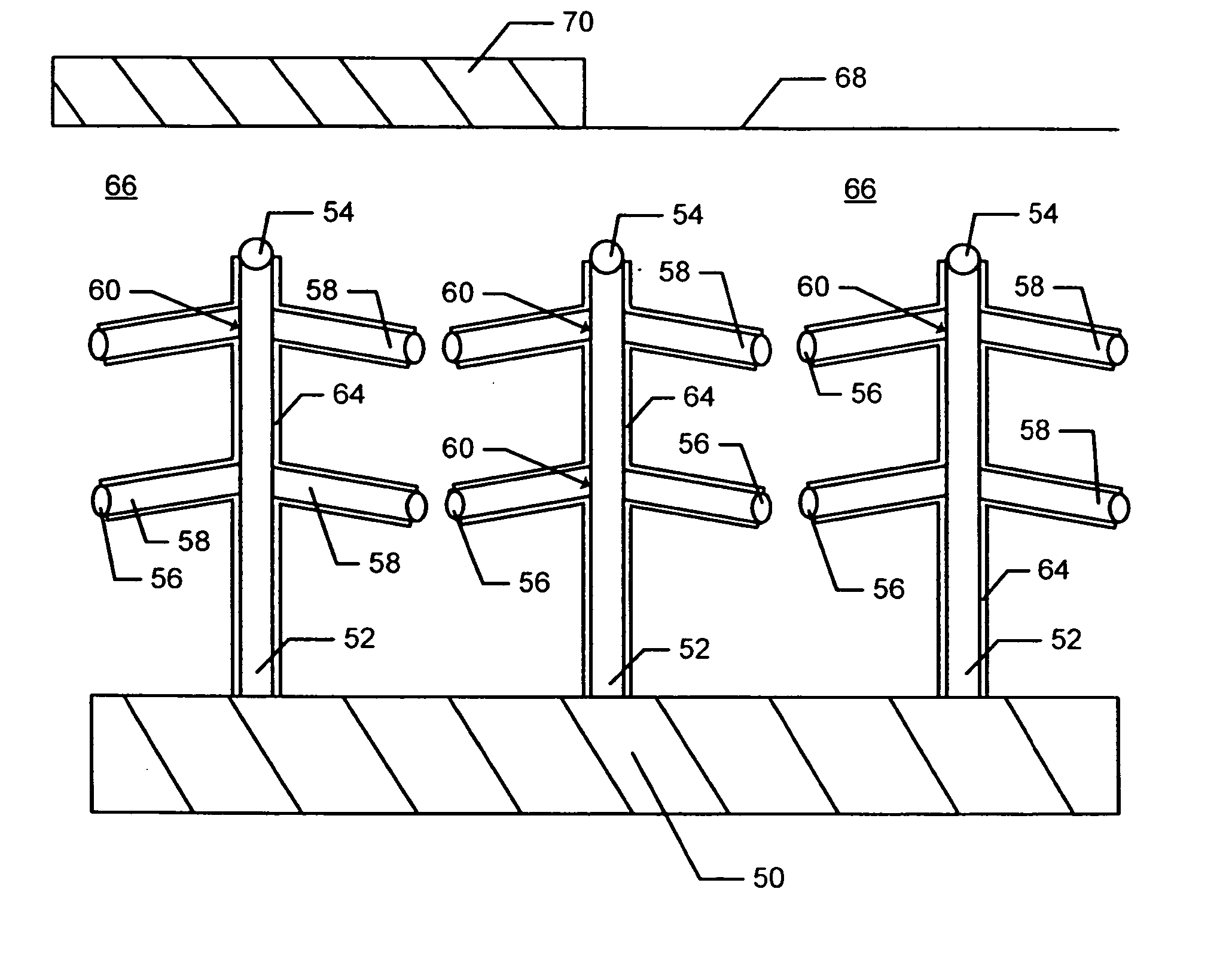

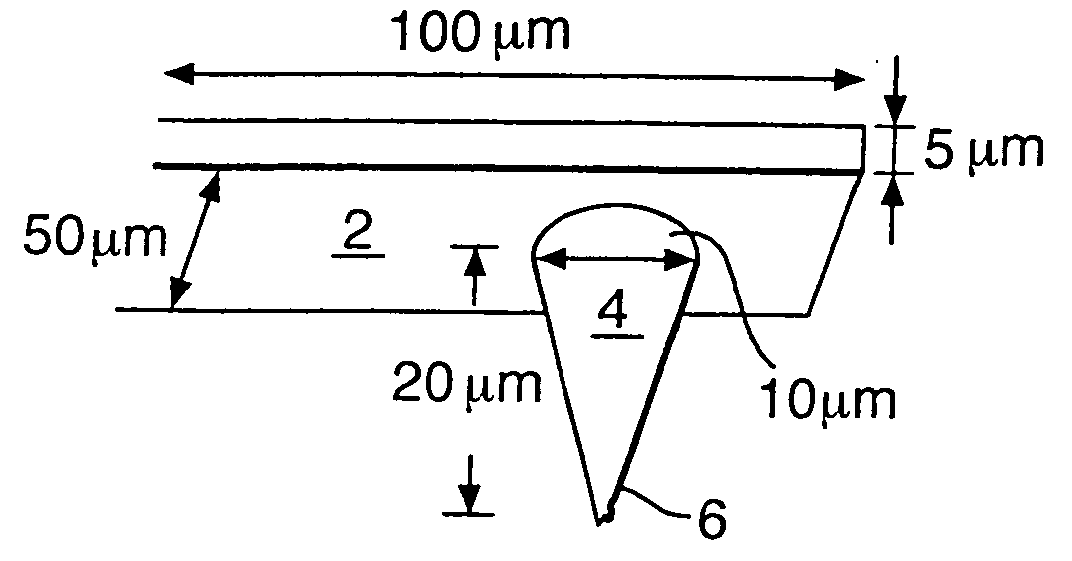

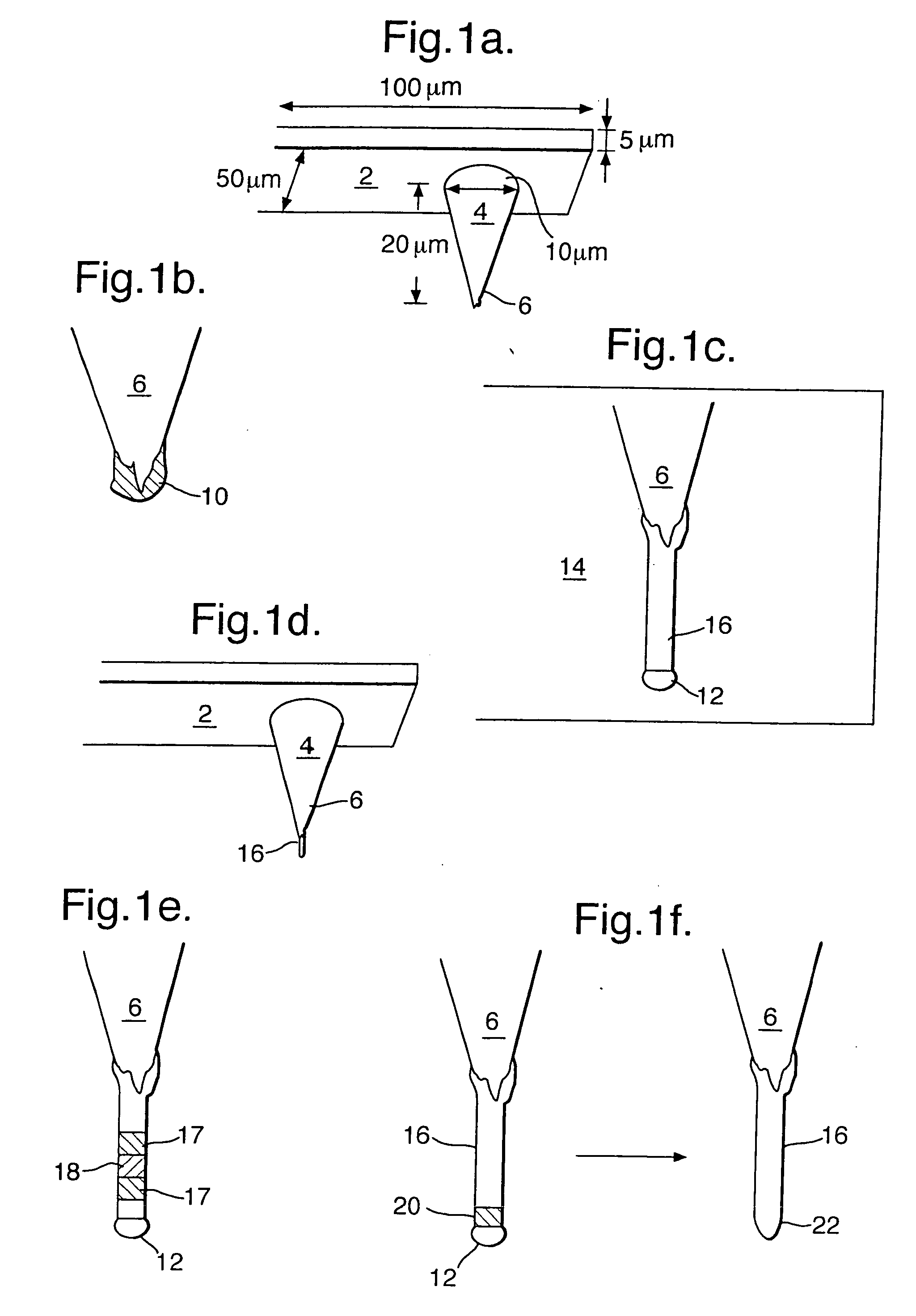

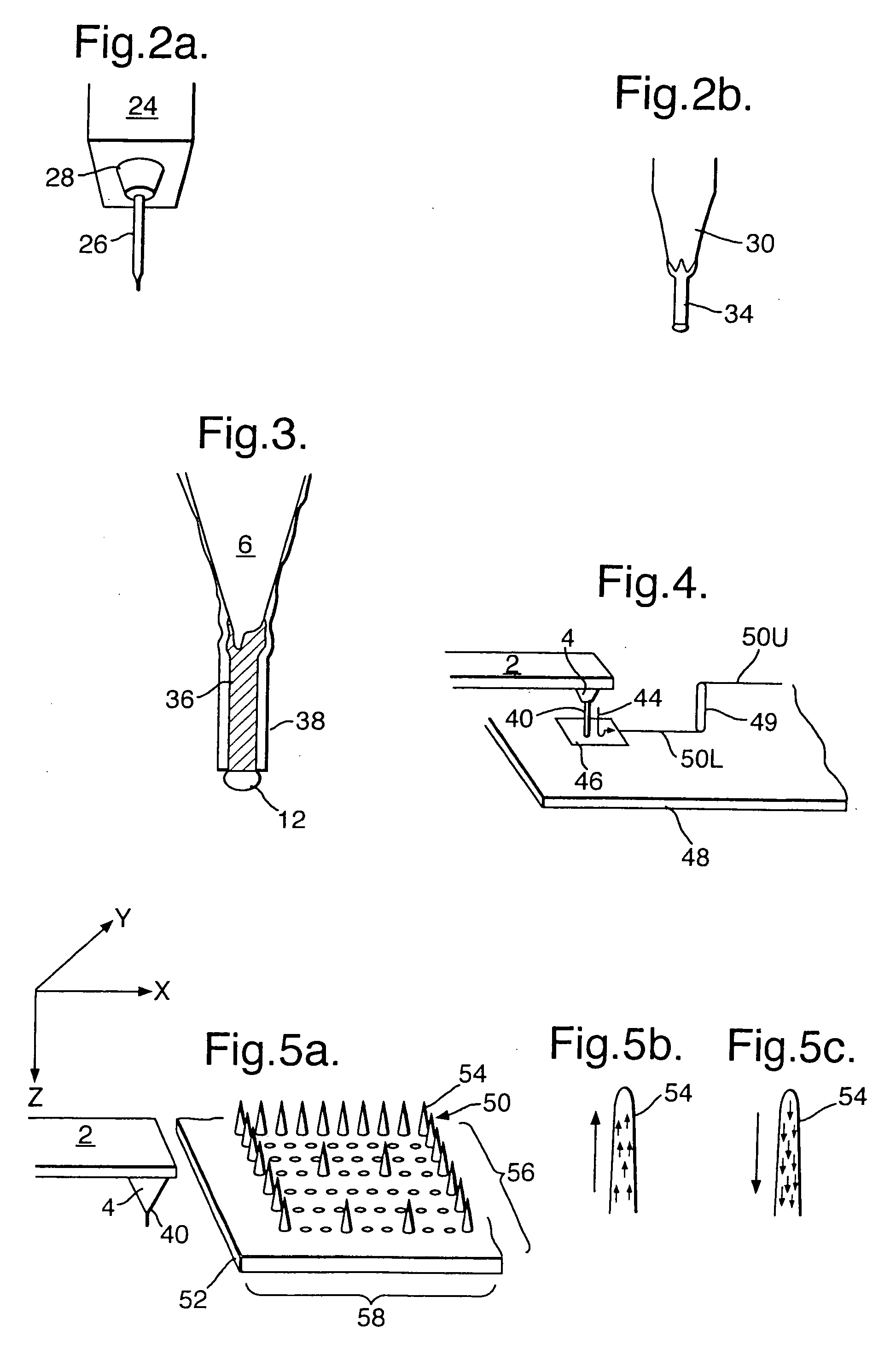

A probe structure for a scanning probe microscope comprises a nanowhisker (16,34) projecting from a free end of an upstanding tip member (4,26), and being formed integrally with the tip member. In another embodiment, a data storage medium comprises an array of nanowhiskers (54), each nanowhisker being formed from magnetic material, the diameter of the nanowhisker being such that a single ferromagnetic domain exists within the nanowhisker, preferably having a diameter not greater than about 25 nm and more preferably not greater than about 10 nm, and a read / write structure comprising the probe structure for injecting a stream of spin-polarised electrons into a selected nanowhisker of the array, either for sensing the direction of magnetisation in the nanowhisker, or for forcing the nanowhisker into a desired direction of magnetisation. When the probe nanowhisker is formed by a VLS process using a catalytic particle melt, the whisker may be formed with a sacrificial segment to allow for removal of the catalytic material by selective etching of the segment.

Owner:QUNANO

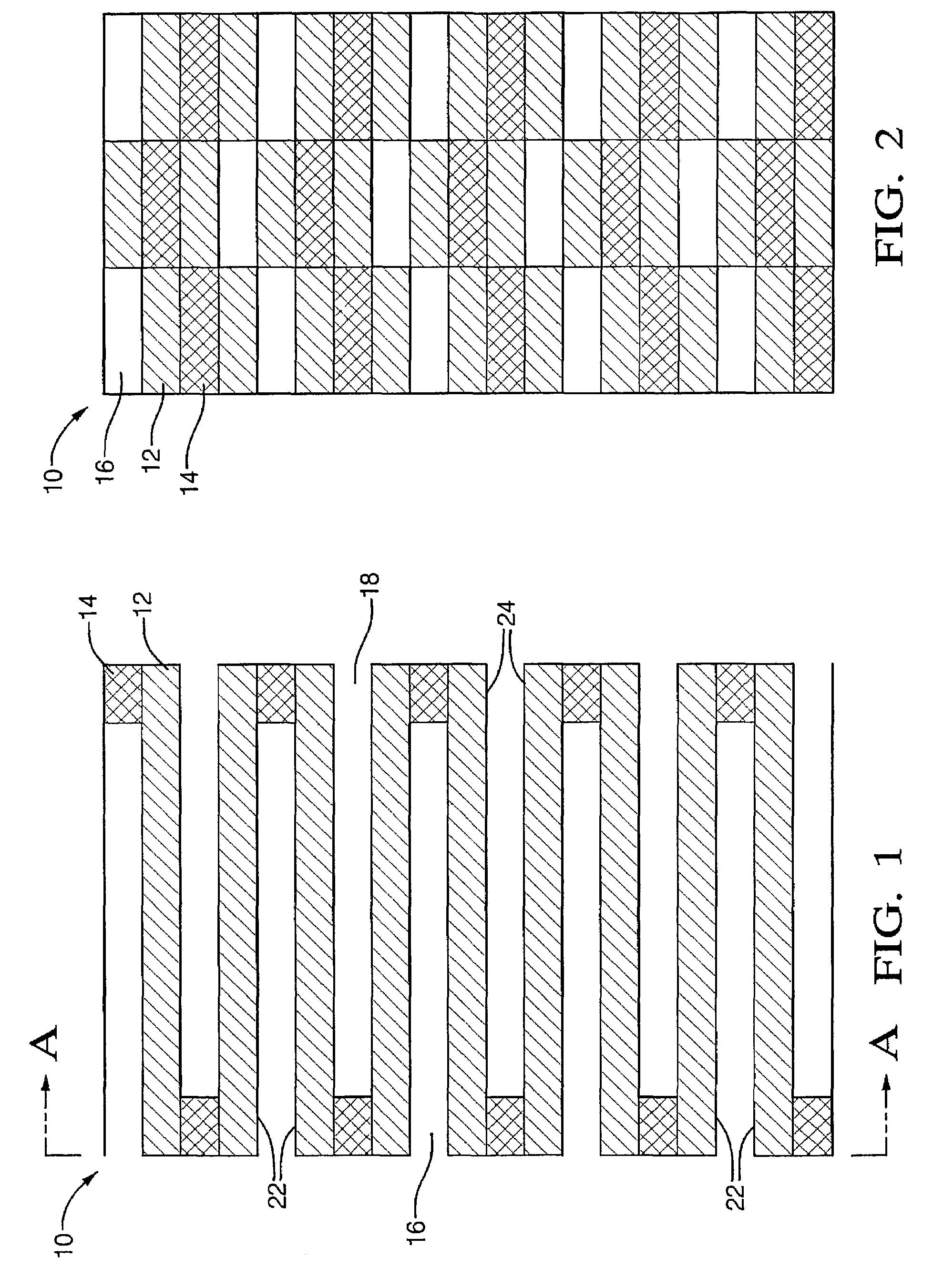

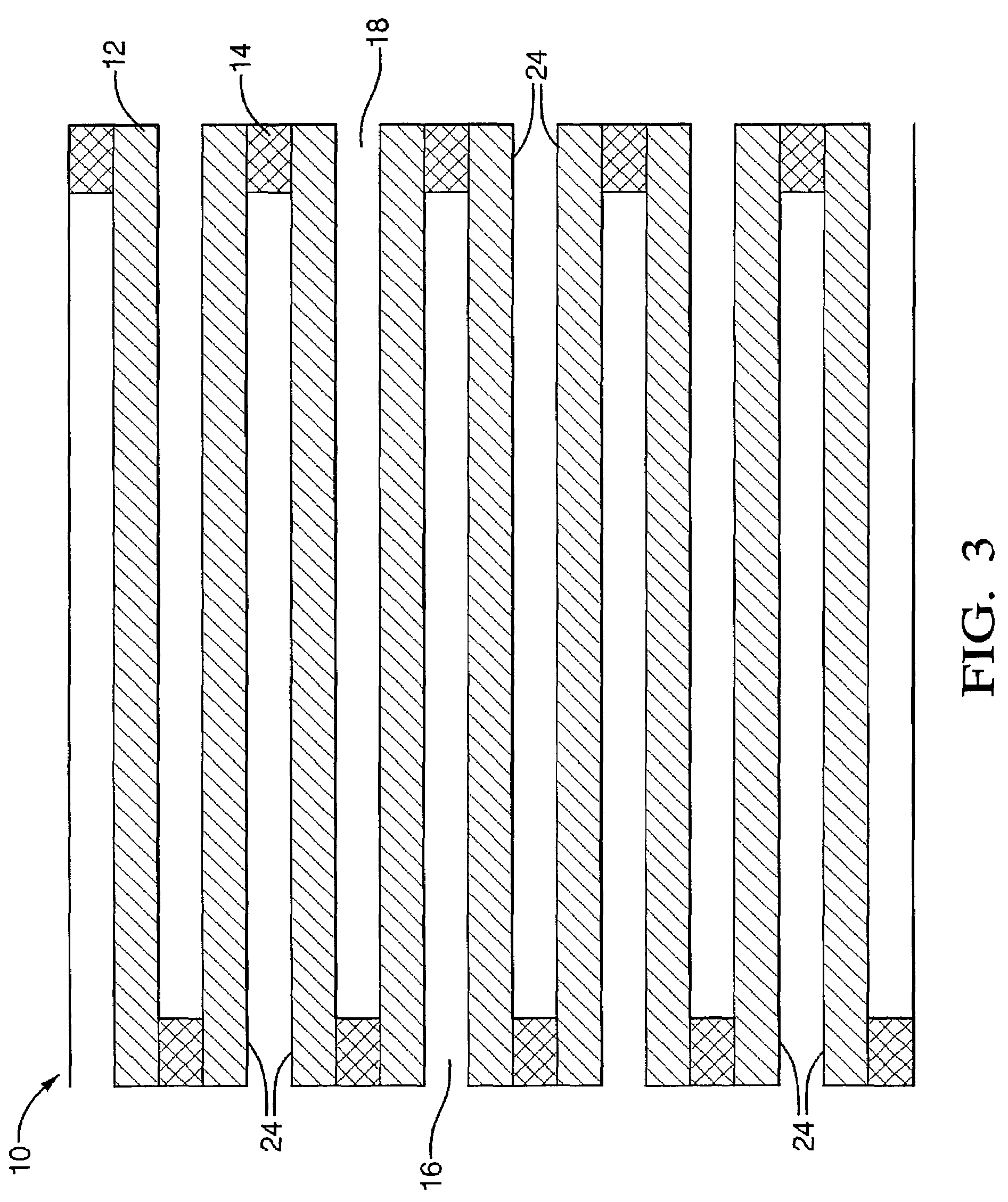

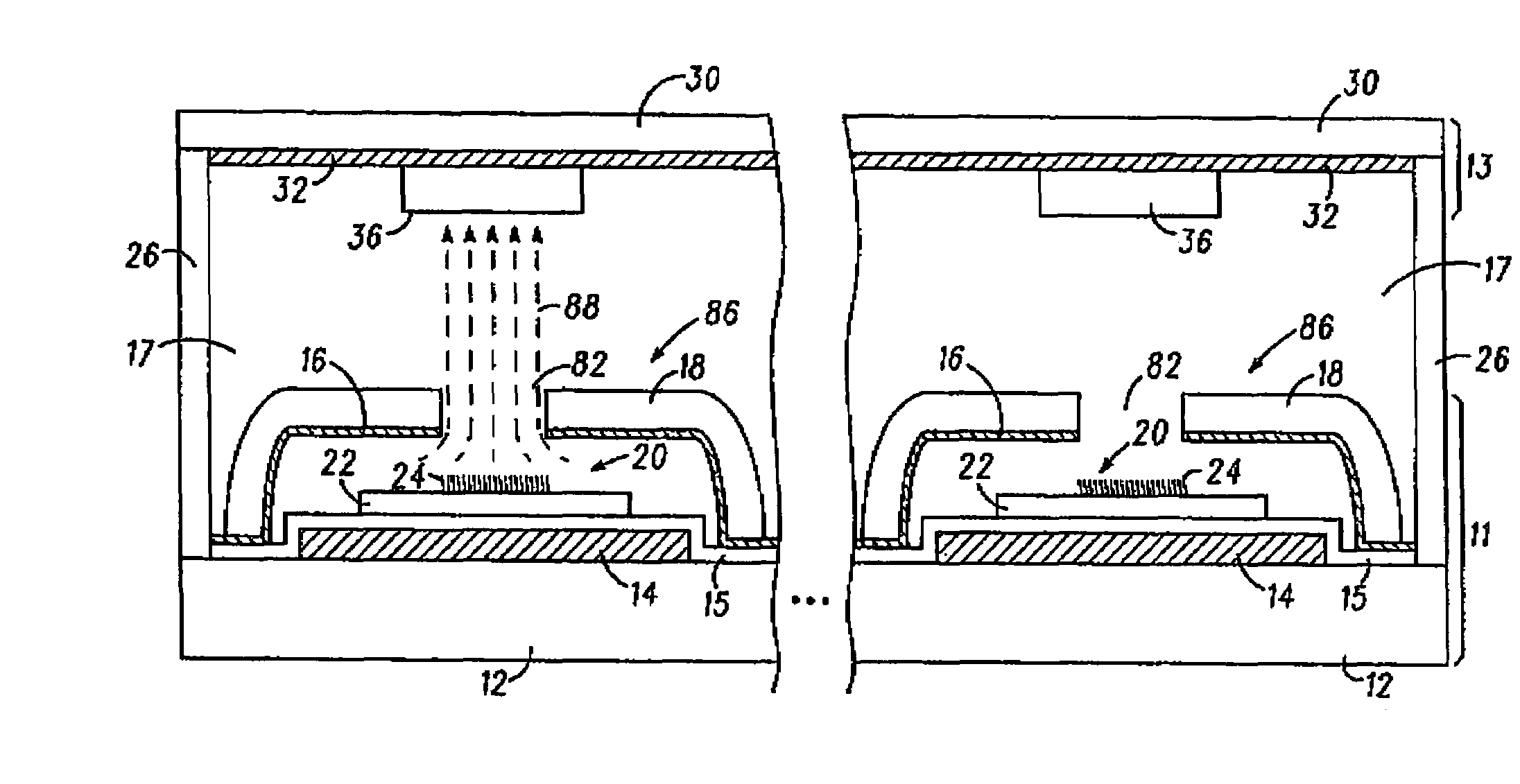

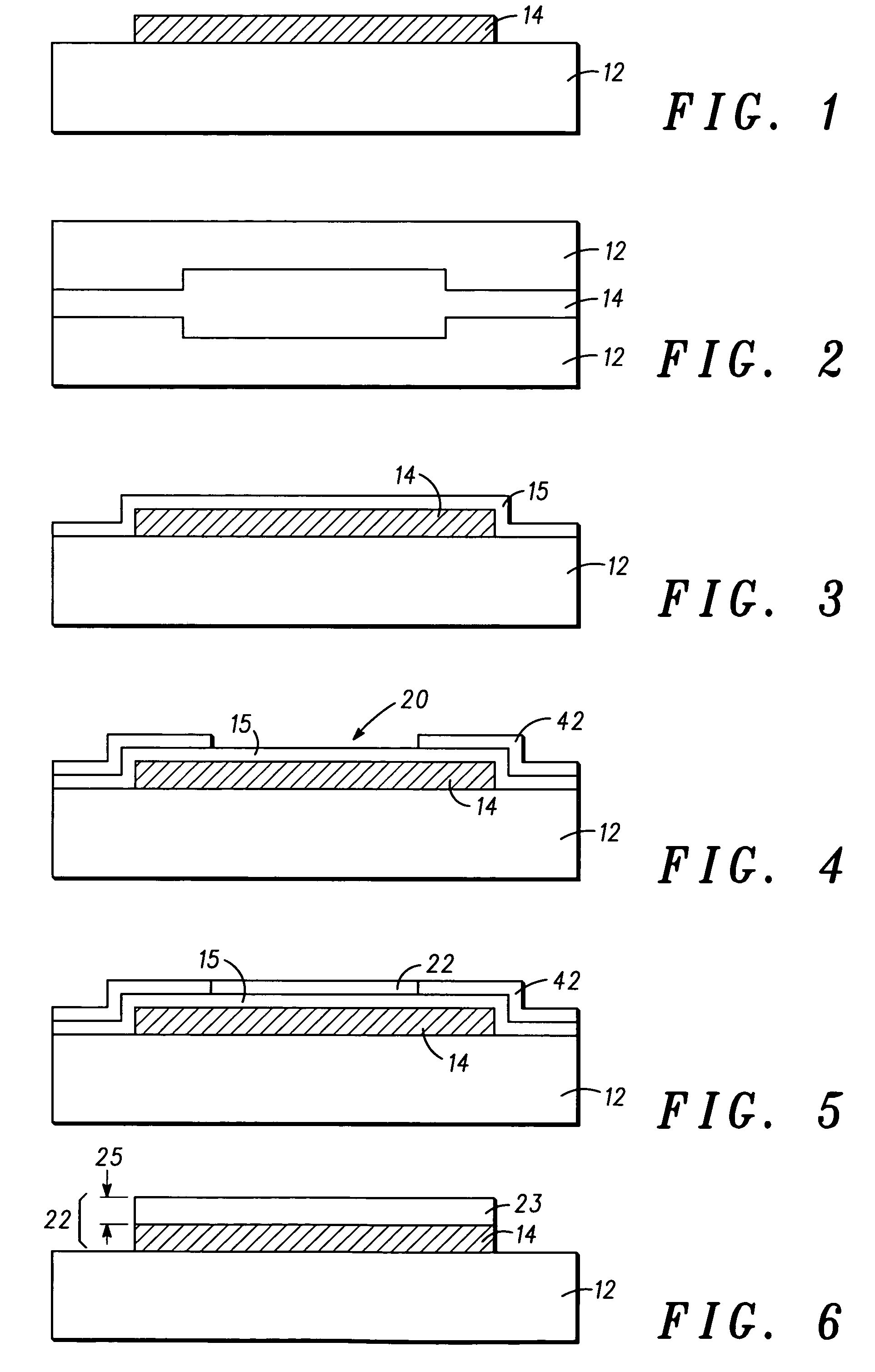

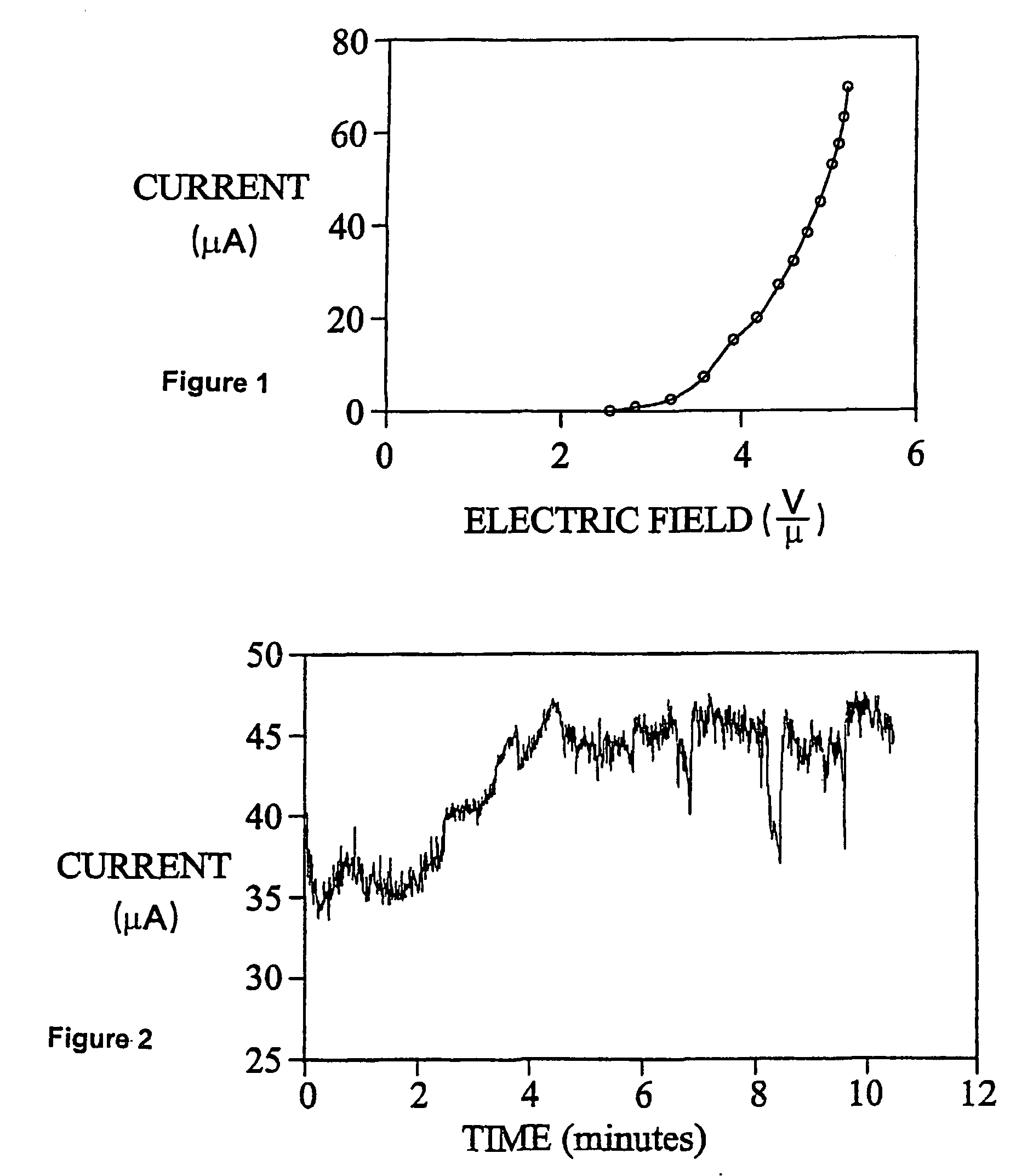

Field emission display and methods of forming a field emission display

A field emission device and method of forming a field emission device are provided in accordance with the present invention. The field emission device is comprised of a substrate (12) having a deformation temperature that is less than about six hundred and fifty degrees Celsius and a nano-supported catalyst (22) formed on the substrate (12) that has active catalytic particles that are less than about five hundred nanometers. The field emission device is also comprised of a nanotube (24) that is catalytically formed in situ on the nano-supported catalyst (22), which has a diameter that is less than about twenty nanometers.

Owner:MOTOROLA SOLUTIONS INC

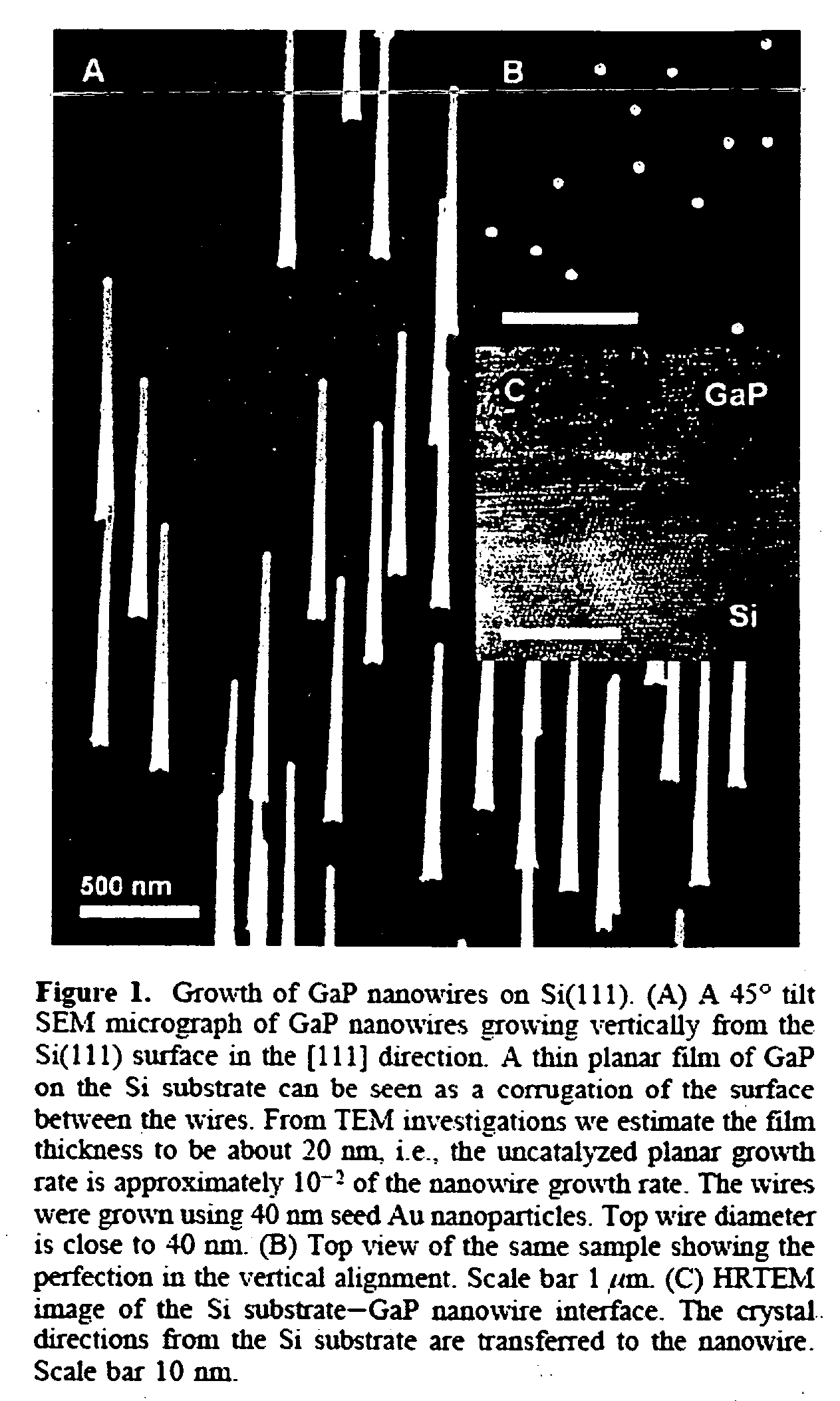

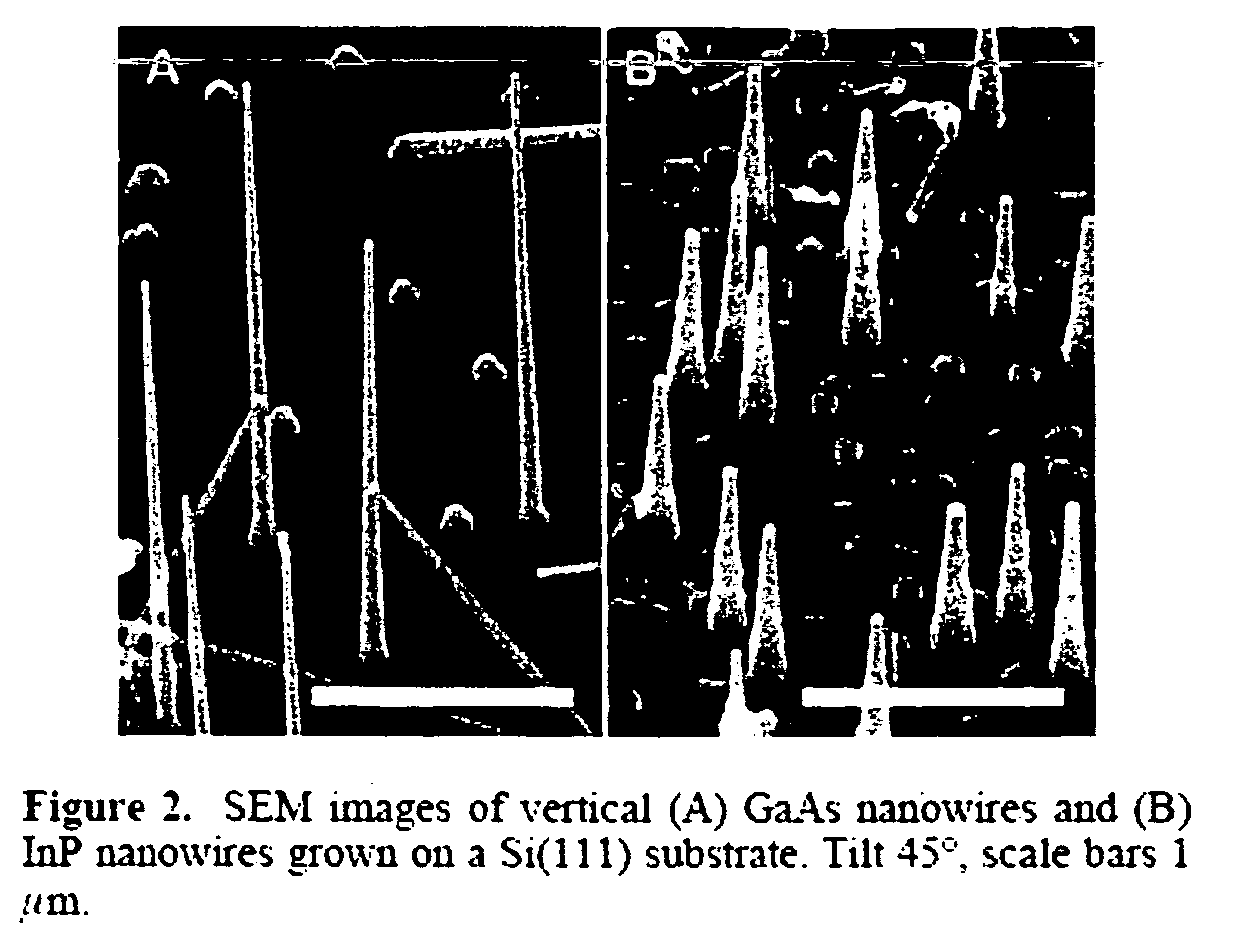

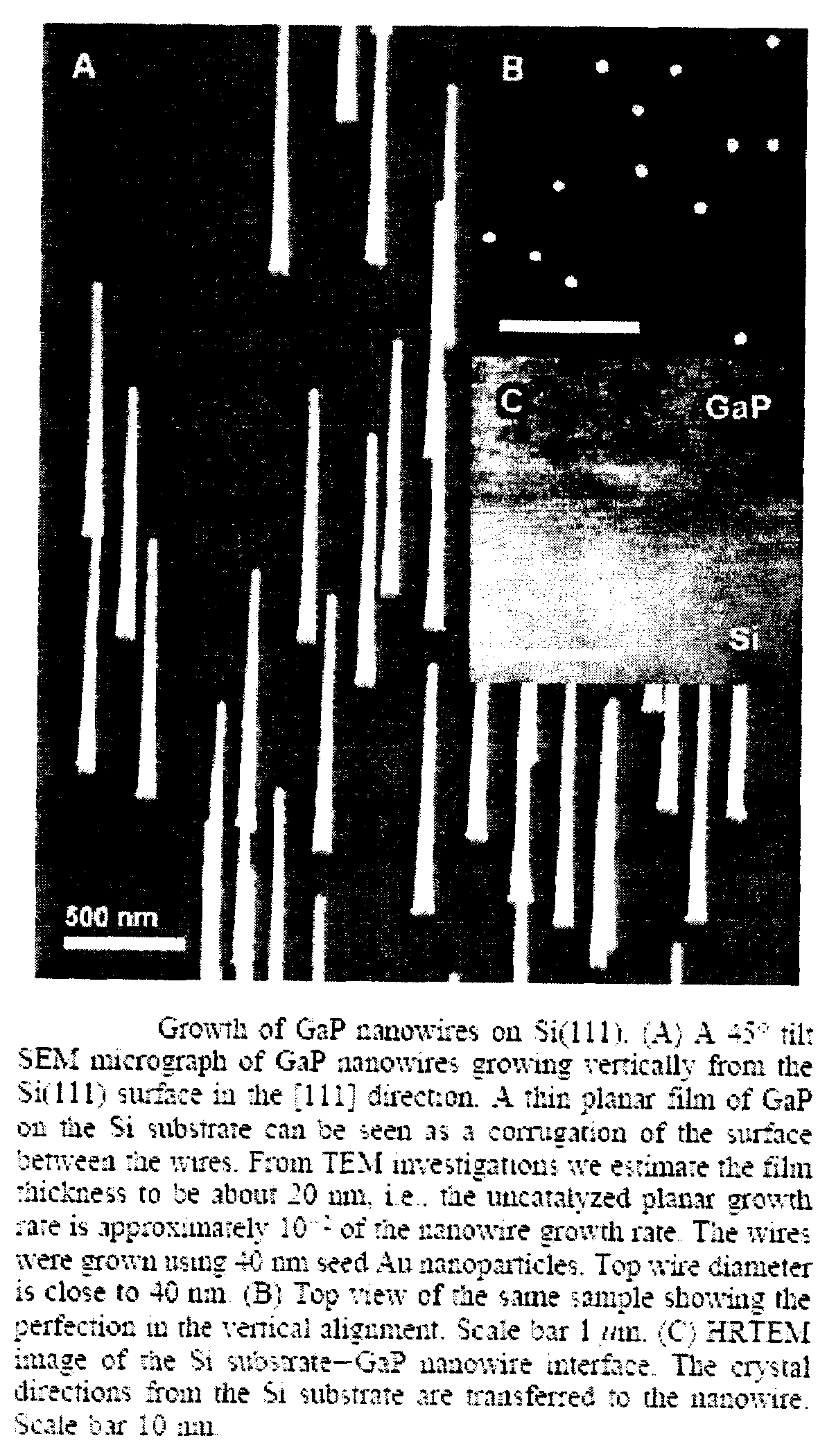

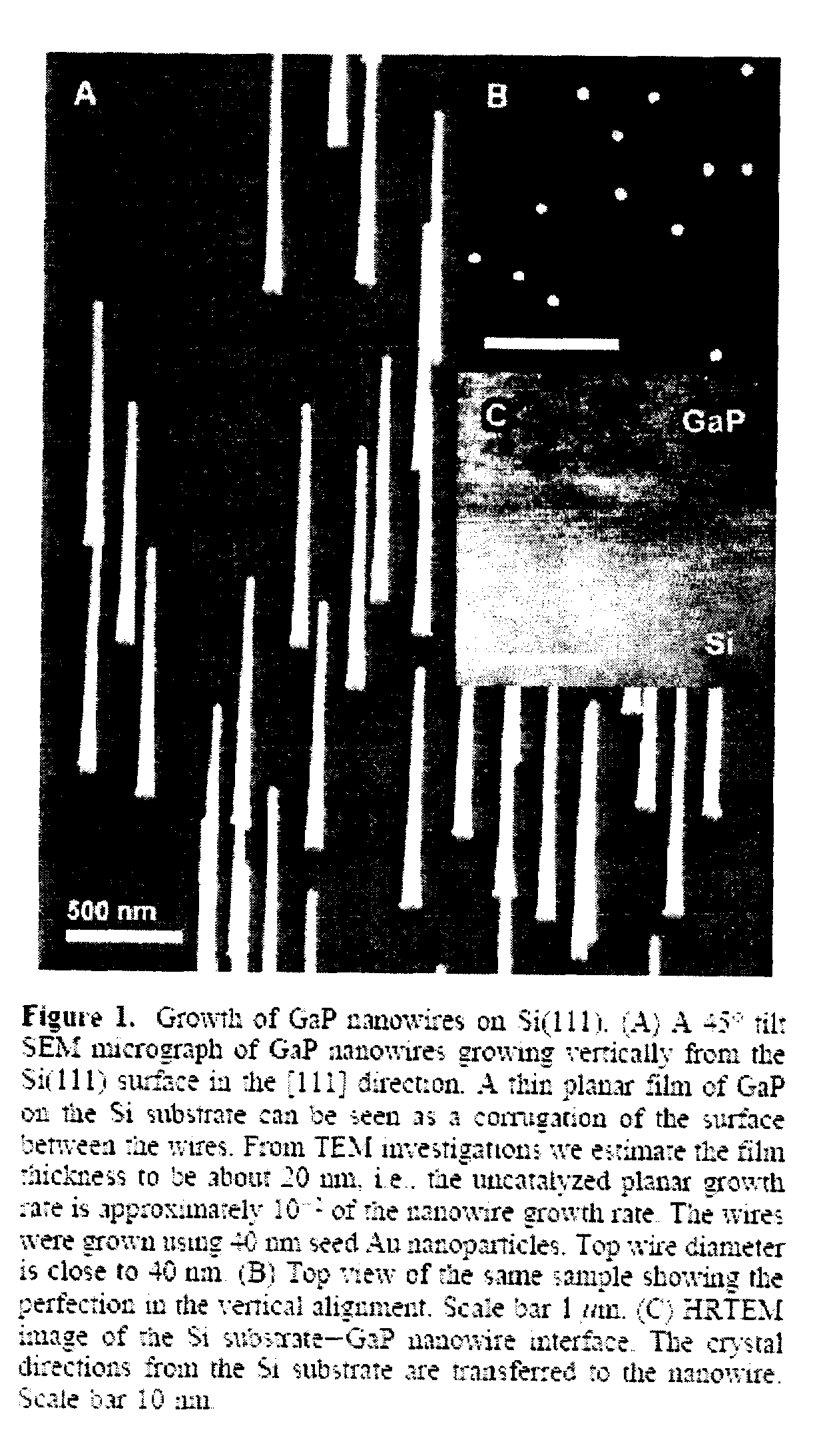

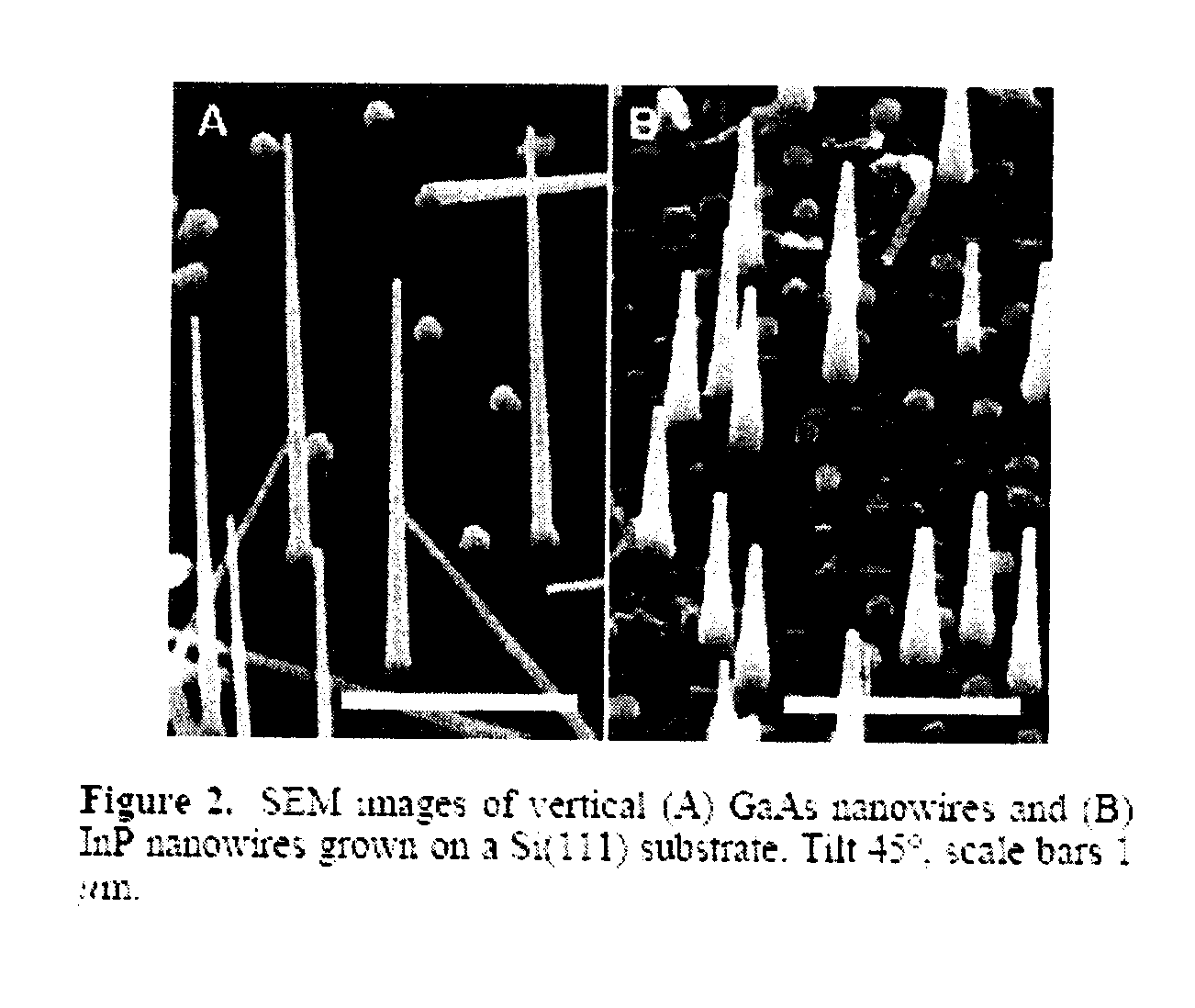

Formation of nanowhiskers on a substrate of dissimilar material

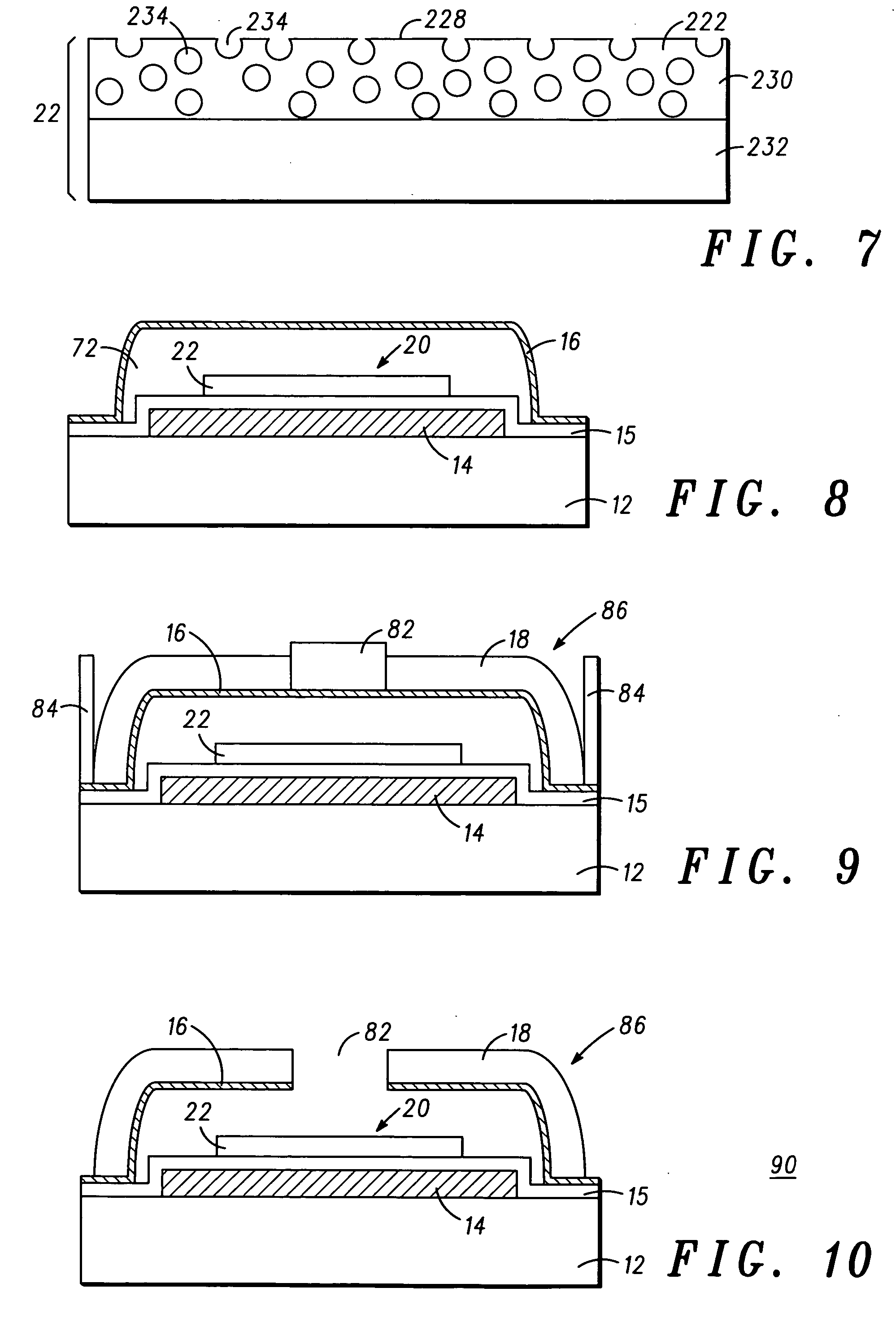

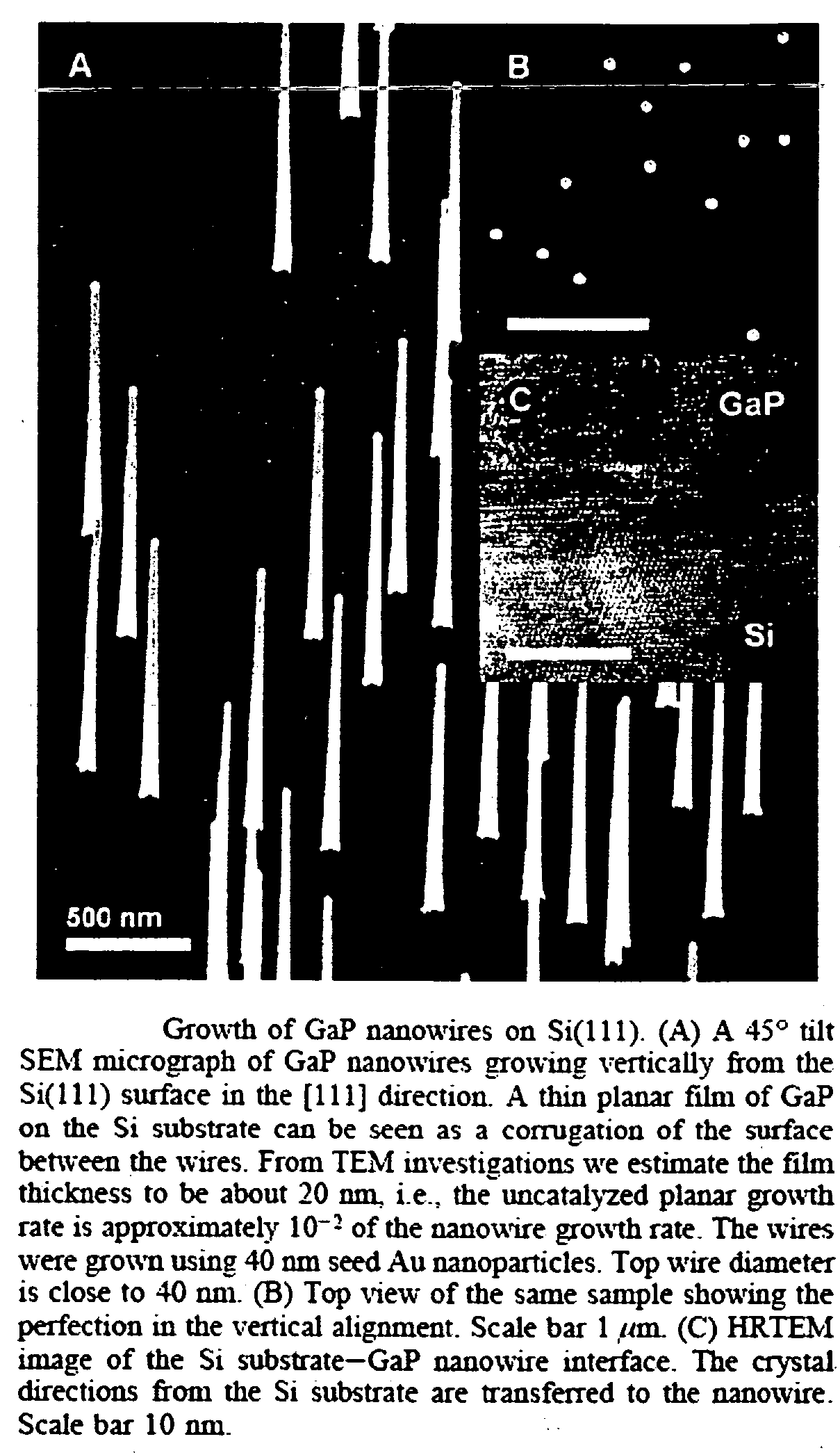

InactiveUS20060125056A1Improve reliabilityEfficient implementationMaterial nanotechnologyPolycrystalline material growthHeterojunctionThermal energy

A method for forming a nanowhisker of, e.g., a III-V semiconductor material on a silicon substrate, comprises: preparing a surface of the silicon substrate with measures including passivating the substrate surface by HF etching, so that the substrate surface is essentially atomically flat. Catalytic particles on the substrate surface are deposited from an aerosol; the substrate is annealed; and gases for a MOVPE process are introduced into the atmosphere surrounding the substrate, so that nanowhiskers are grown by the VLS mechanism. In the grown nanowhisker, the crystal directions of the substrate are transferred to the epitaxial crystal planes at the base of the nanowhisker and adjacent the substrate surface. A segment of an optically active material may be formed within the nanowhisker and bounded by heterojunctions so as to create a quantum well wherein the height of the quantum well is much greater than the thermal energy at room temperature, whereby the luminescence properties of the segment remain constant without quenching from cryogenic temperatures up to room temperature.

Owner:QUNANO

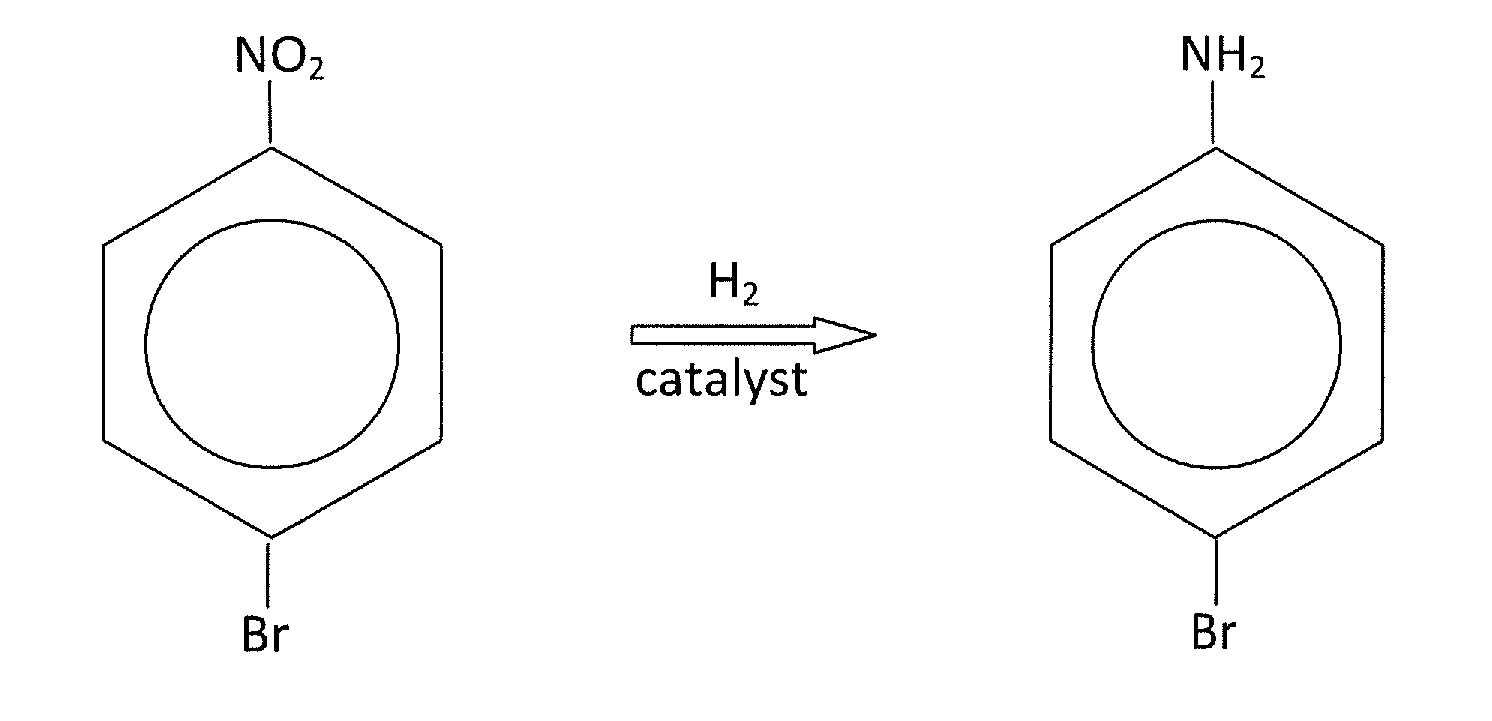

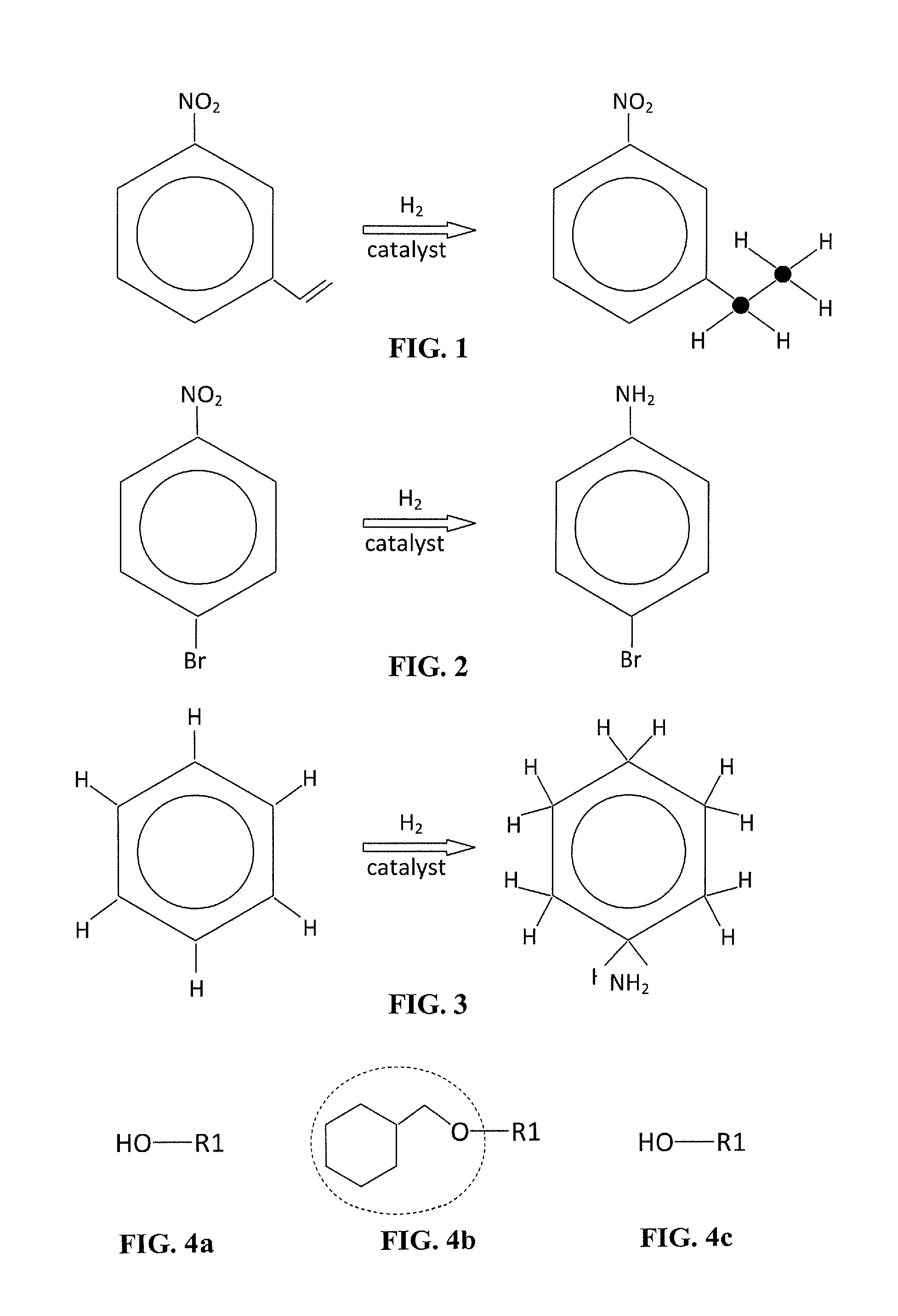

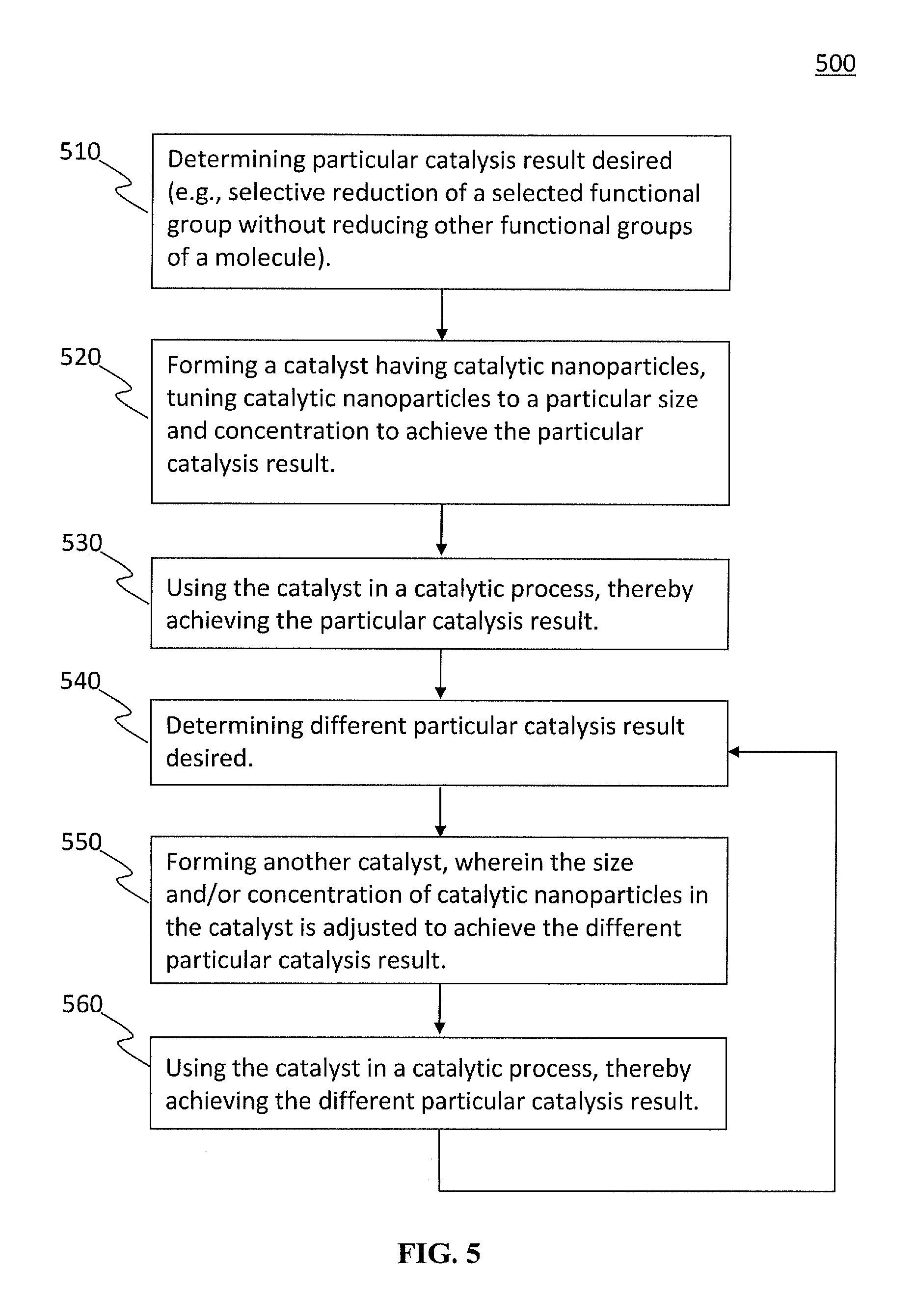

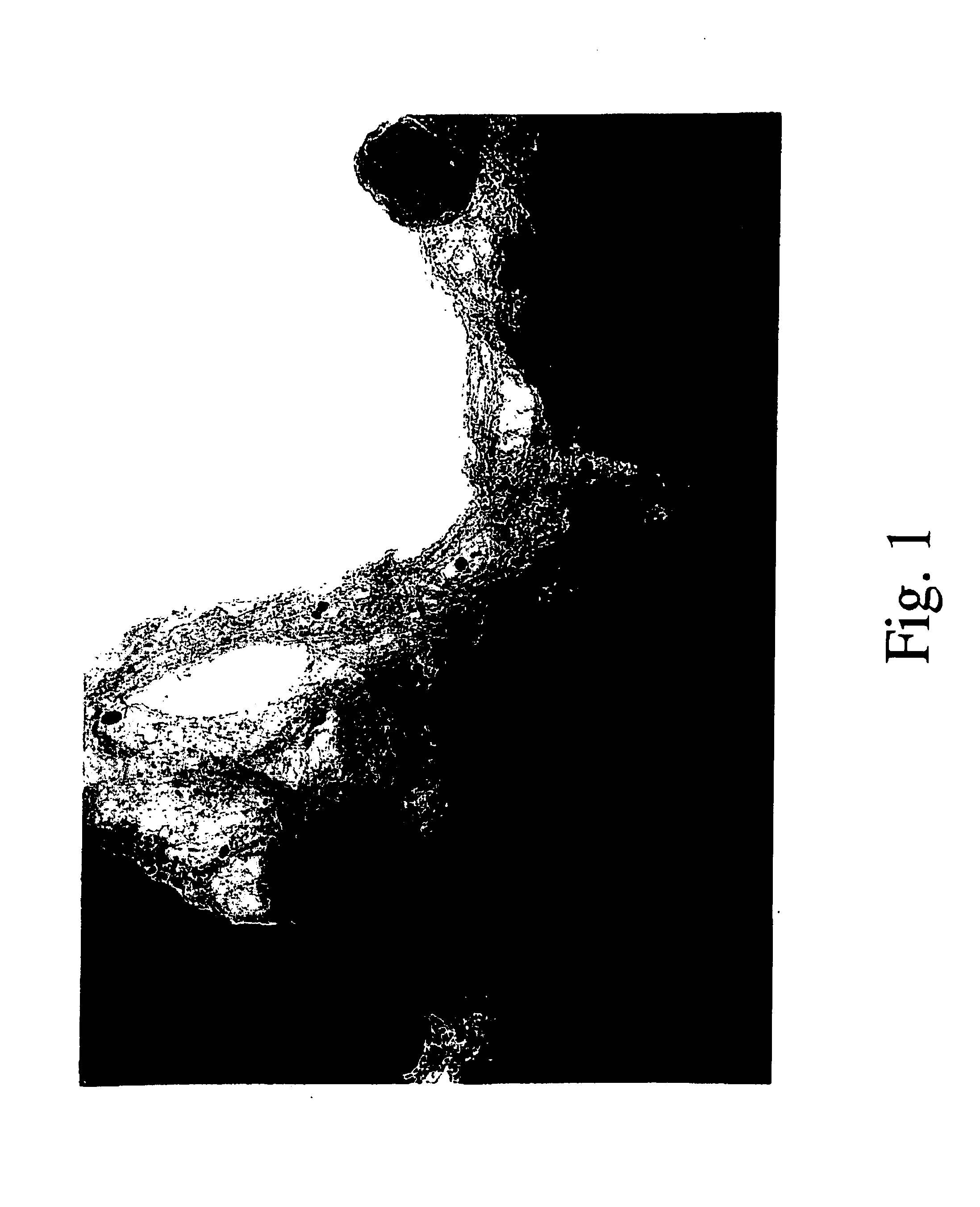

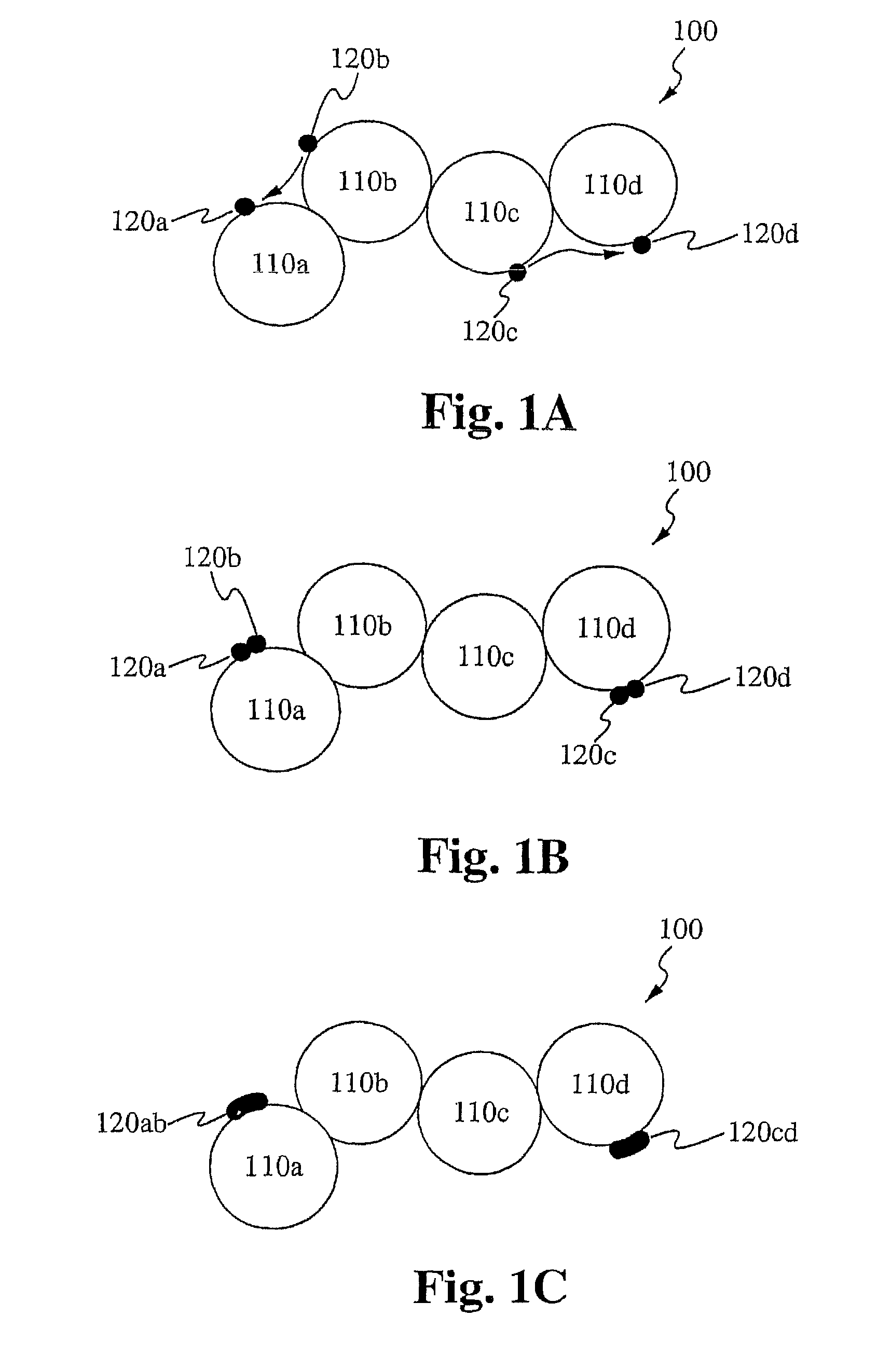

Advanced catalysts for fine chemical and pharmaceutical applications

A catalyst comprising a plurality of support nanoparticles and a plurality of catalytic nanoparticles. At least one catalytic nanoparticle is bonded to each support nanoparticle. The catalytic particles have a size and a concentration, wherein a first configuration of the size and the concentration of the catalytic nanoparticles enables a first catalysis result and a second configuration of the size and the concentration of the catalytic nanoparticles enables a second catalysis result, with the first and second configurations having a different size or concentration, and the first and second catalysis results being different. In some embodiments, the first catalysis result is a selective reduction of a first selected functional group without reducing one or more other functional groups, and the second catalysis result is a selective reduction of a second selected functional group without reducing one or more other functional groups.

Owner:SDC MATERIALS

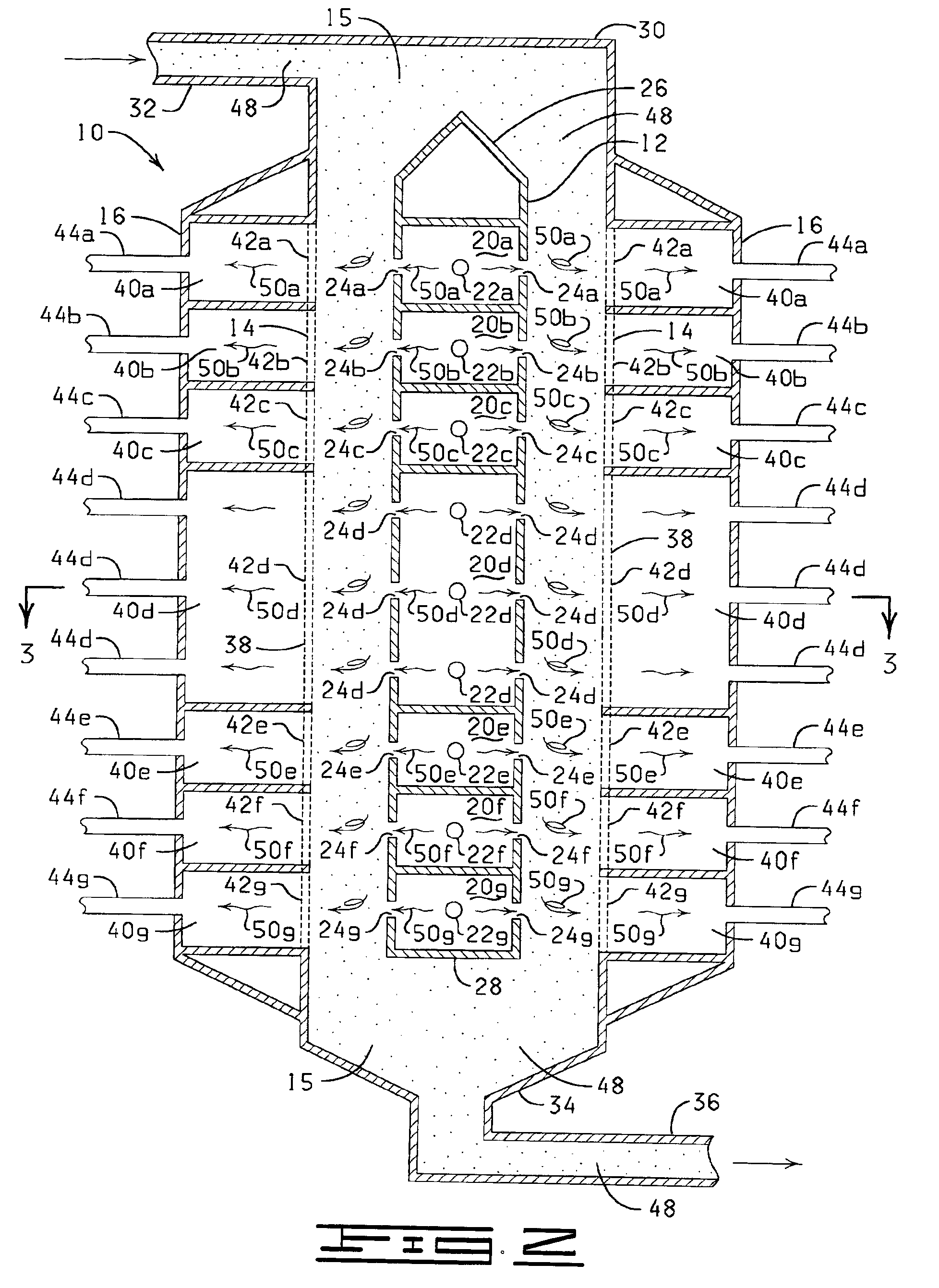

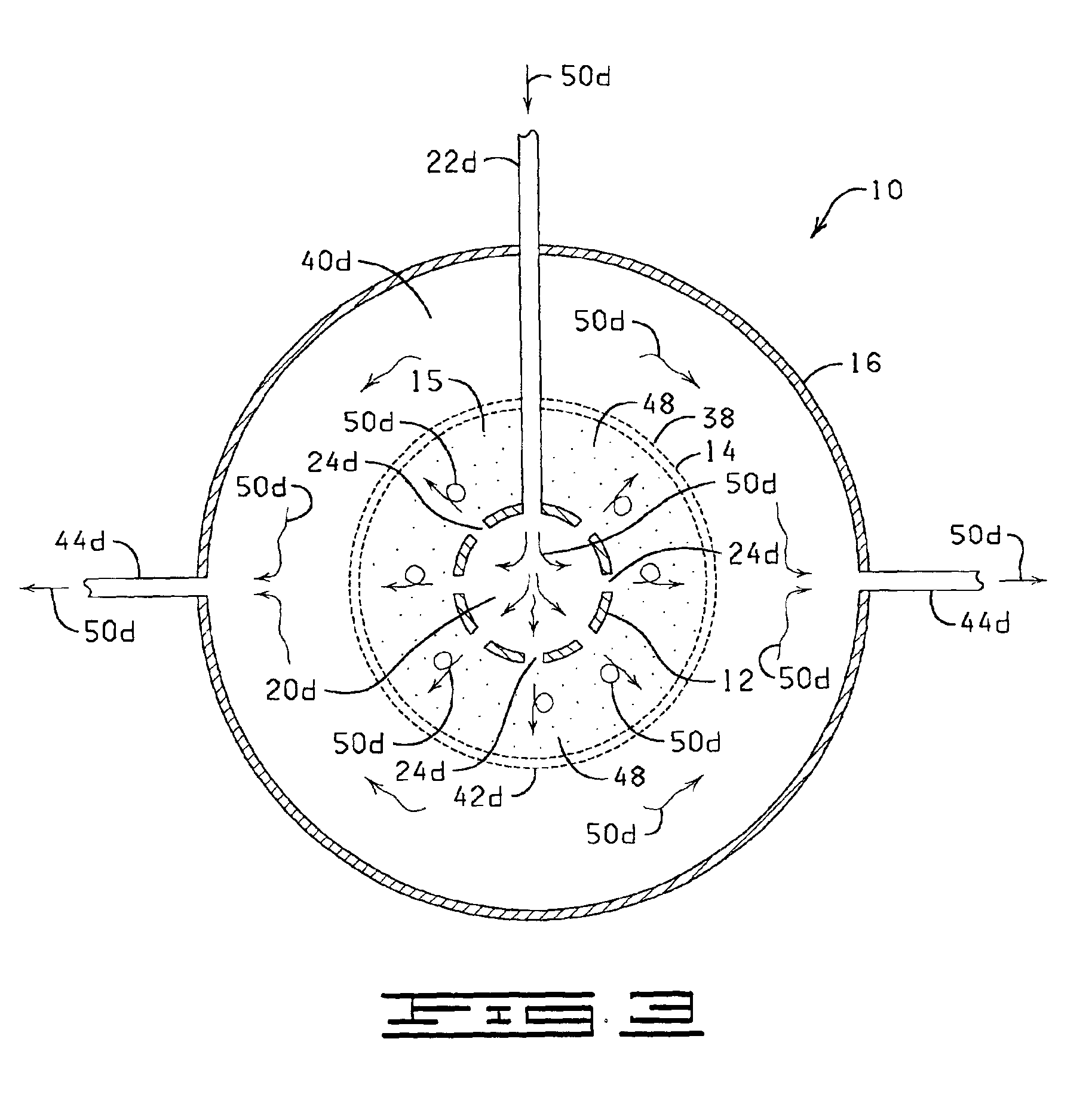

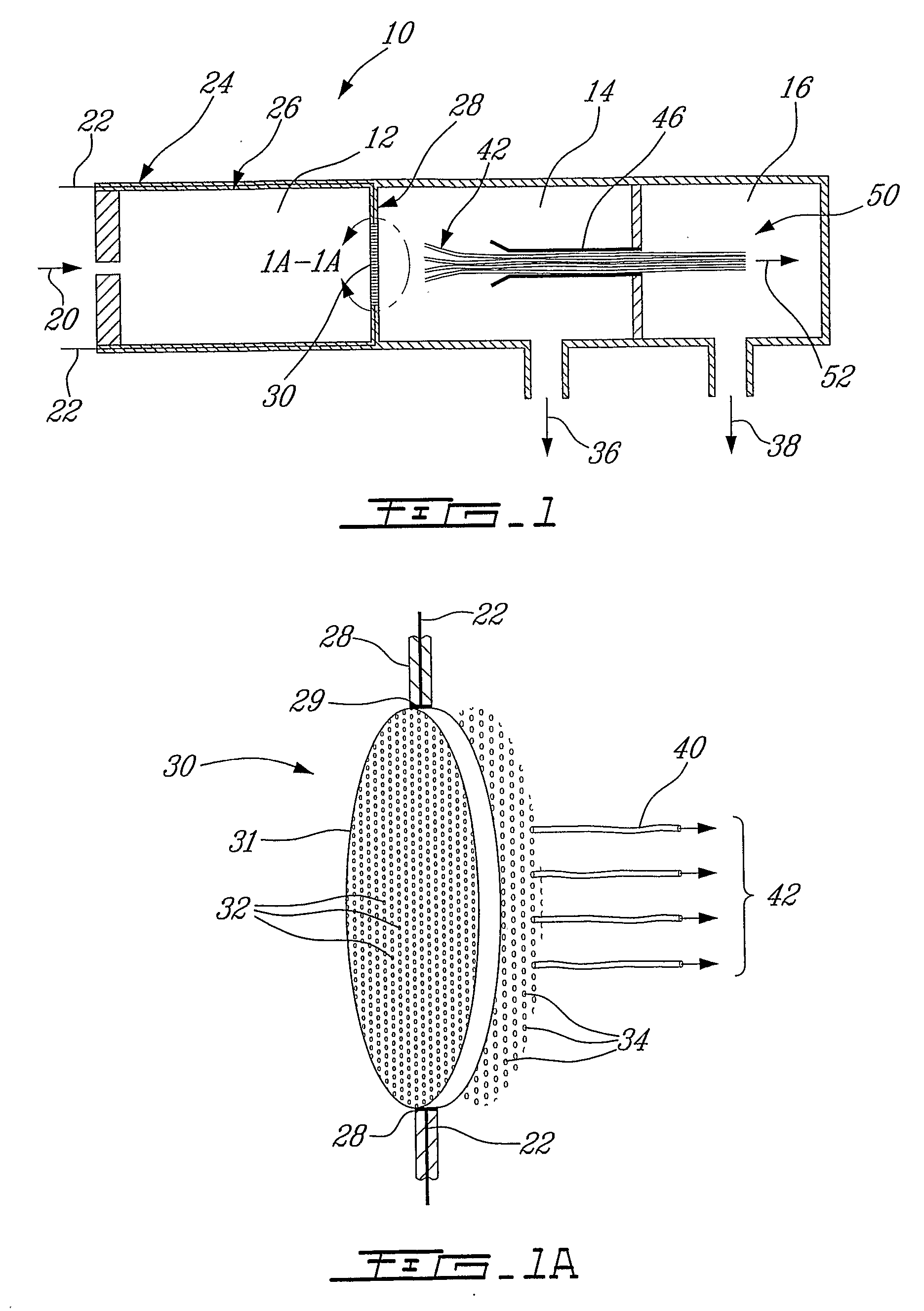

Process and apparatus for producing single-walled carbon nanotubes

InactiveUS20050042162A1Avoid disadvantagesOptimize quantityMaterial nanotechnologyCatalyst regeneration/reactivationParticulatesCarbon nanotube

A process and apparatus for catalytic production of single walled carbon nanotubes. Catalytic particles are exposed to different process conditions at successive stages wherein the catalytic particles do not come in contact with reactive (catalytic) gases until preferred process conditions have been attained, thereby controlling the quantity and form of carbon nanotubes produced. The process also contemplates processes and apparatus which recycle and reuse-the gases and catalytic particulate materials, thereby maximizing cost efficiency, reducing wastes, reducing the need for additional raw materials, and producing the carbon nanotubes, especially SWNTs, in greater quantities and for lower costs.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

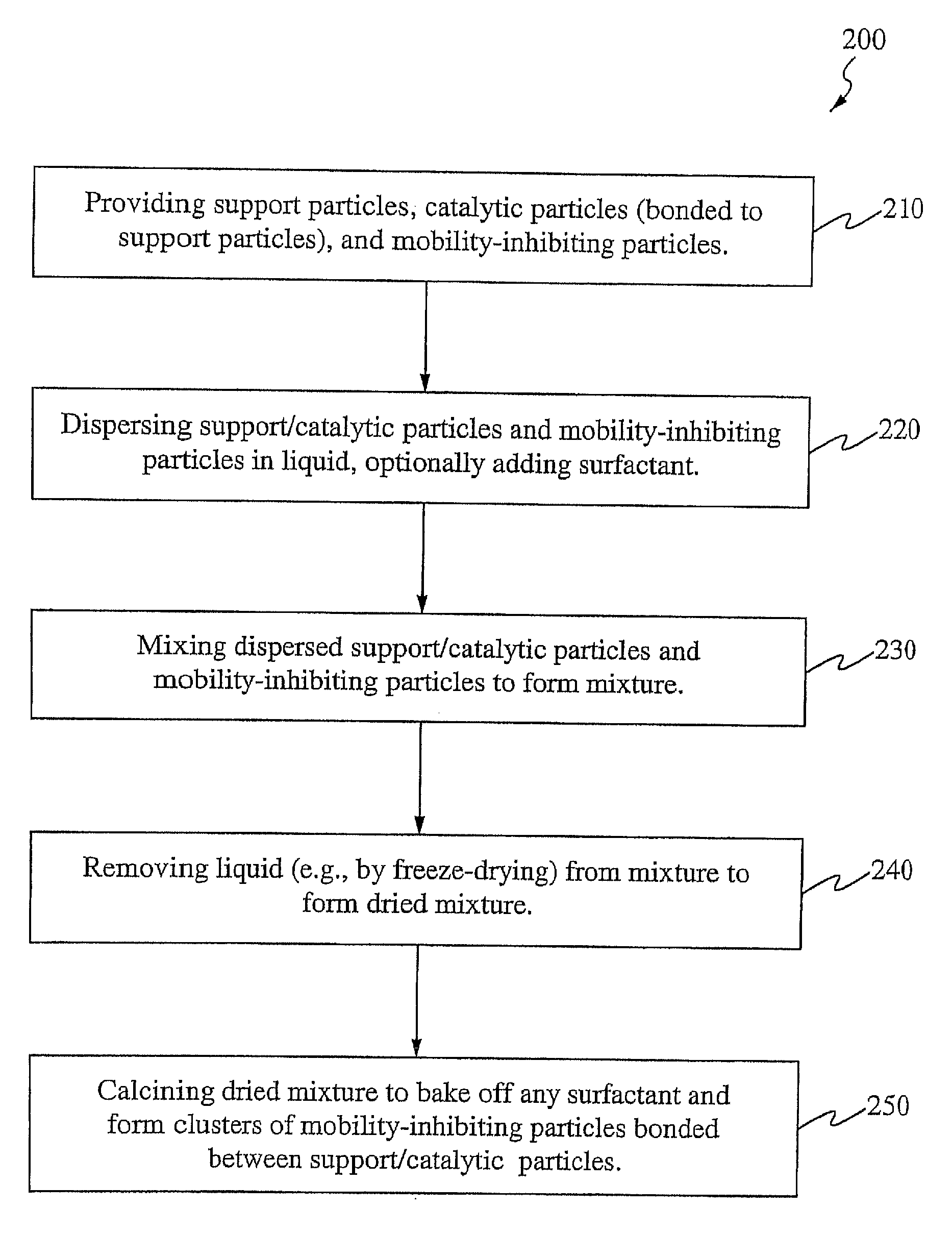

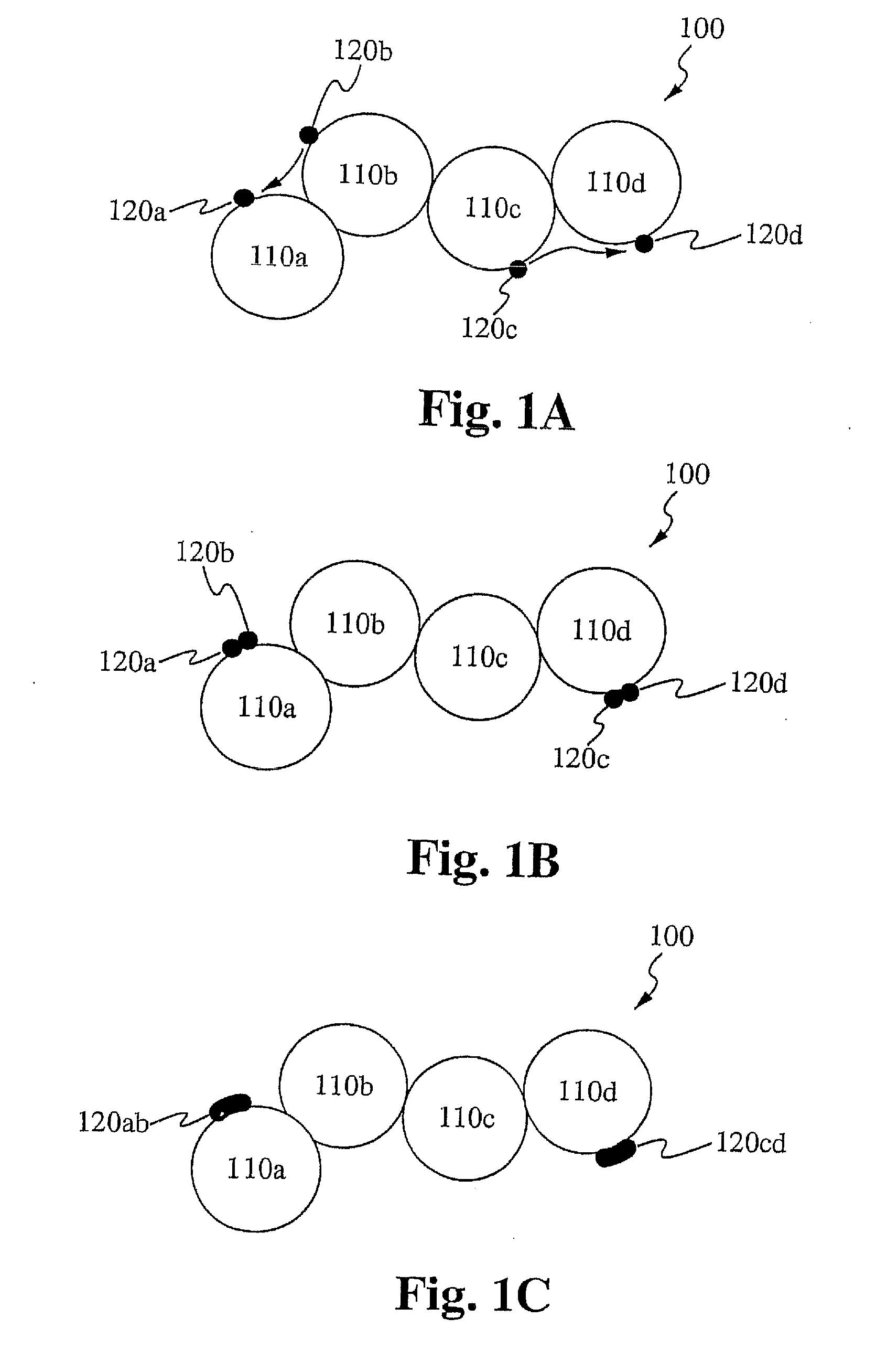

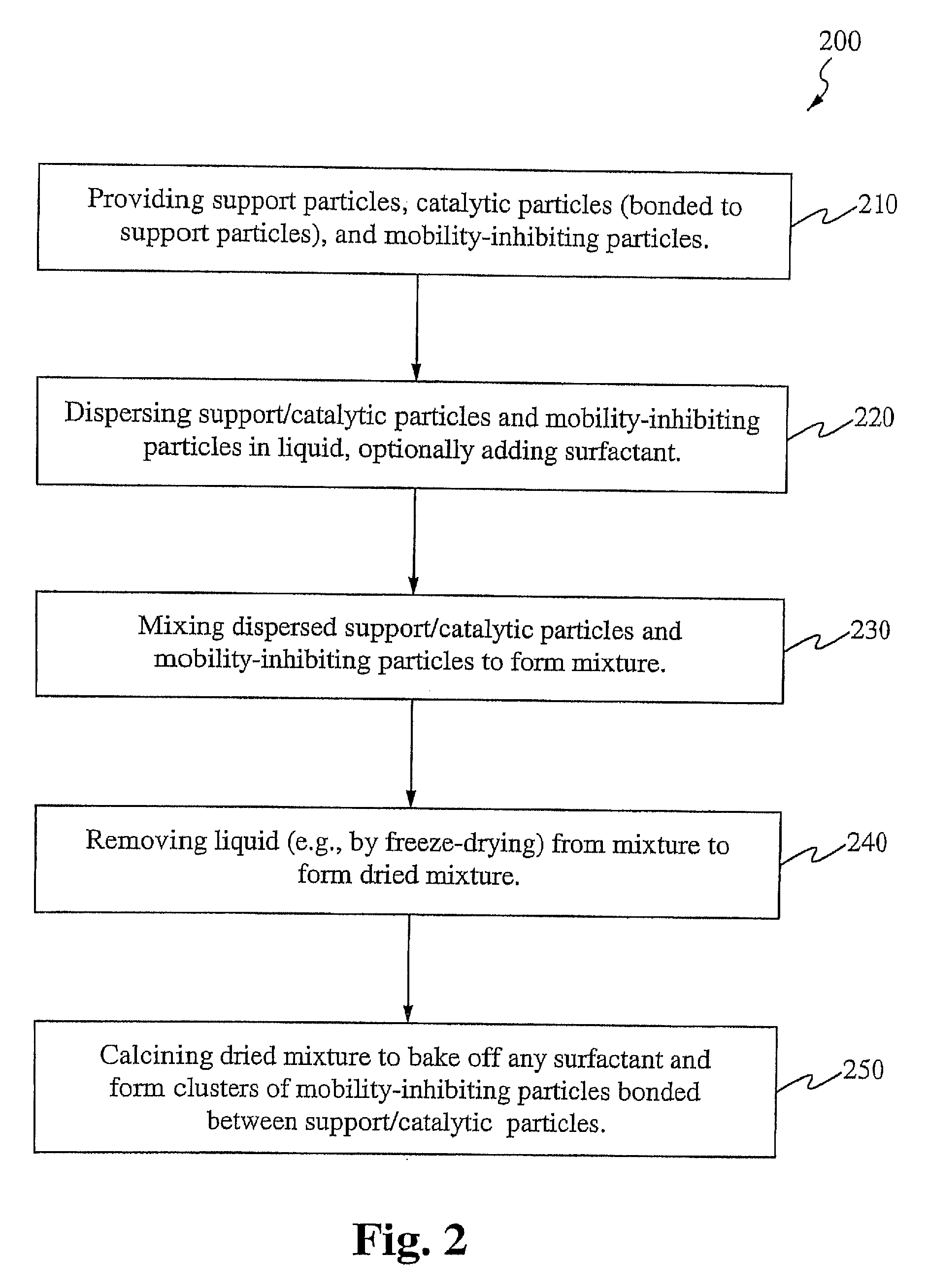

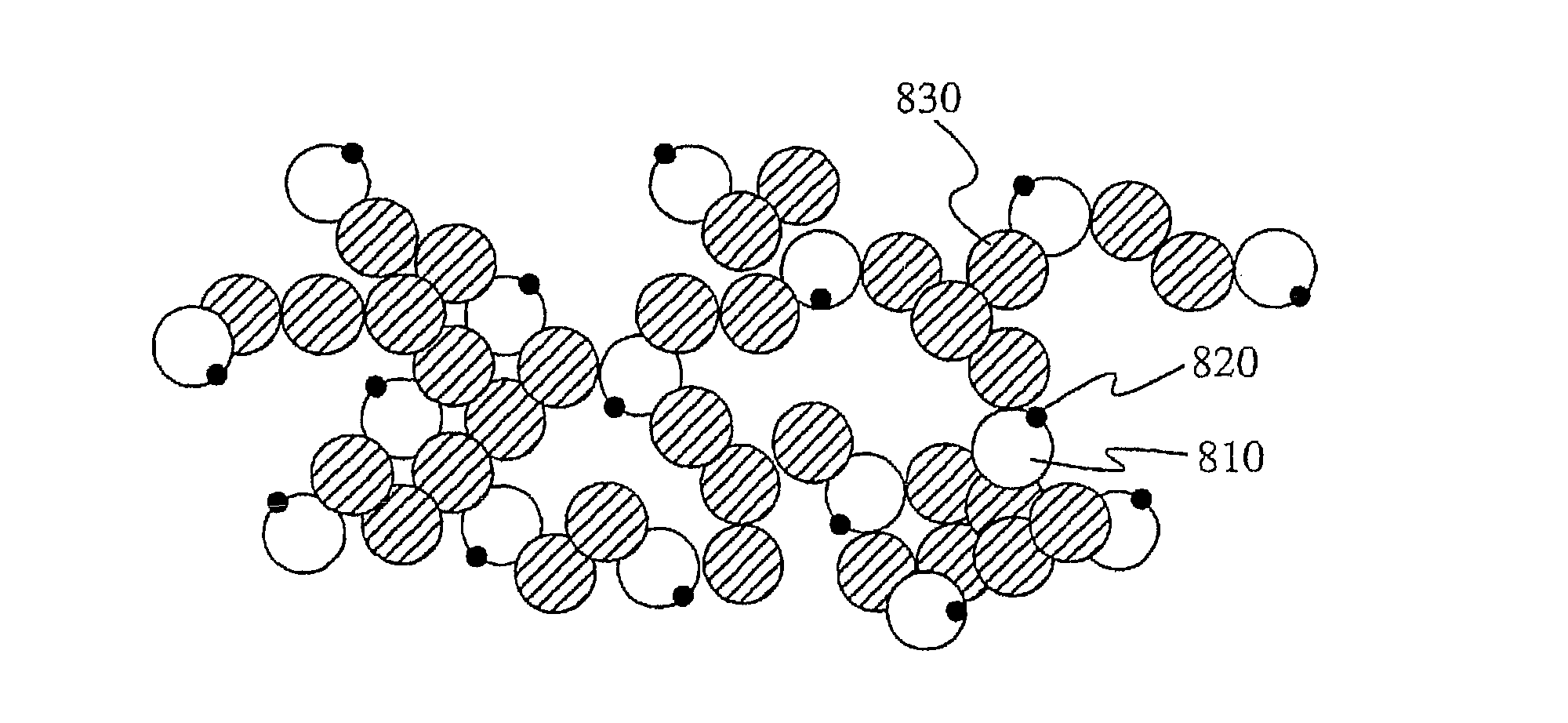

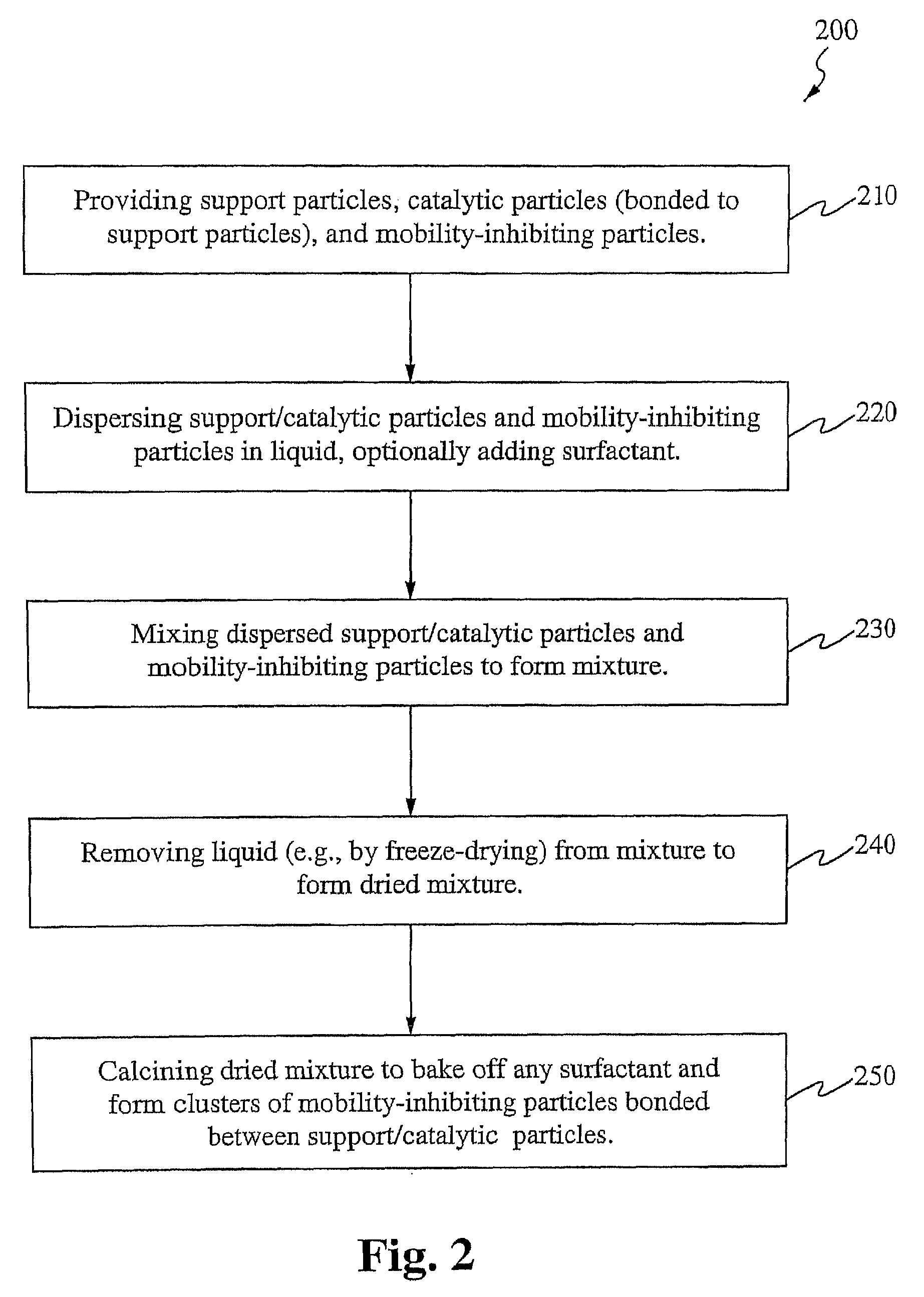

Method of forming a catalyst with inhibited mobility of nano-active material

InactiveUS20110143926A1Reduce coalescenceMinimized in sizeMaterial nanotechnologyInorganic chemistryEngineeringNanometre

A method of forming a catalyst, comprising: providing a plurality of support particles and a plurality of mobility-inhibiting particles, wherein each support particle in the plurality of support particles is bonded with its own catalytic particle; and bonding the plurality of mobility-inhibiting particles to the plurality of support particles, wherein each support particle is separated from every other support particle in the plurality of support particles by at least one of the mobility-inhibiting particles, and wherein the mobility-inhibiting particles are configured to prevent the catalytic particles from moving from one support particle to another support particle.

Owner:SDC MATERIALS +1

Metallic catalytic particle for producing single-walled carbon nanotubes

InactiveUS6962892B2Avoid defectsOptimize quantityMaterial nanotechnologyMolecular sieve catalystsCarbon nanotubeSilicon dioxide

A metallic catalytic particle for producing single-walled carbon nanotubes. The catalytic particles contain at least one metal from Group VIII, including for example Co, Ni, Ru, Rh, Pd, Ir, and Pt, and at least one metal from Group VIb including for example Mo, W and Cr. The metal component is on a support such as silica.

Owner:THE BOARD OF RGT UNIV OF OKLAHOMA

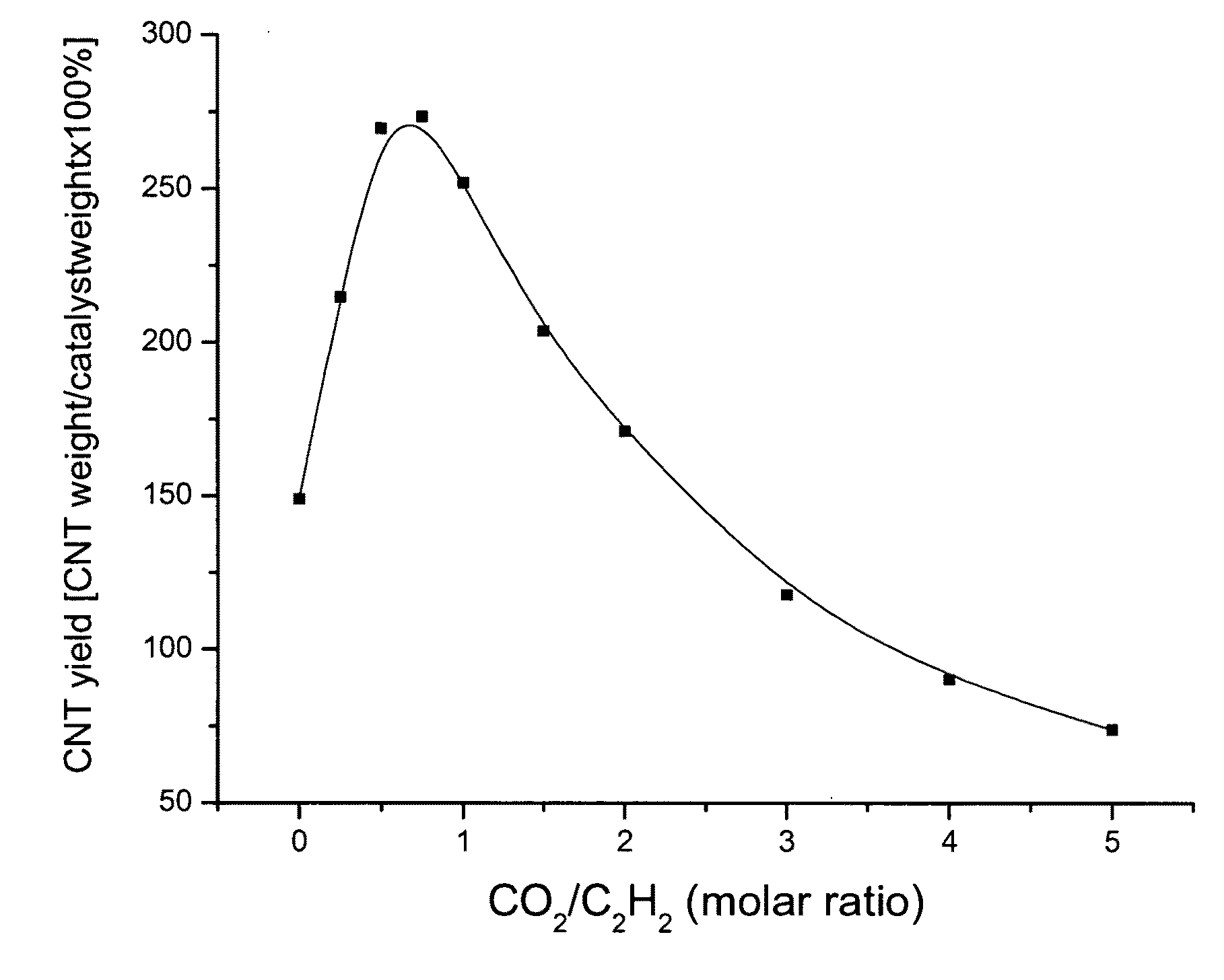

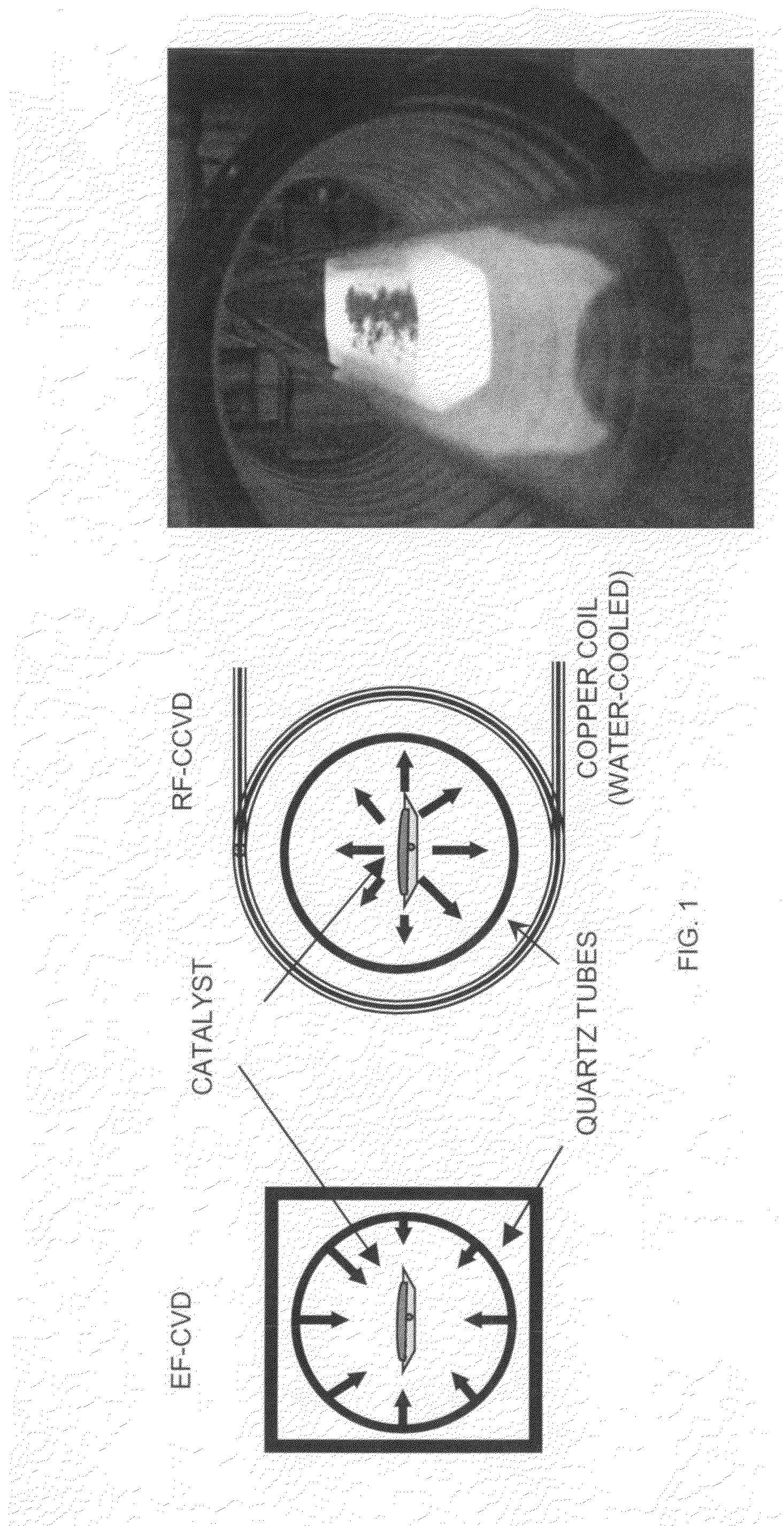

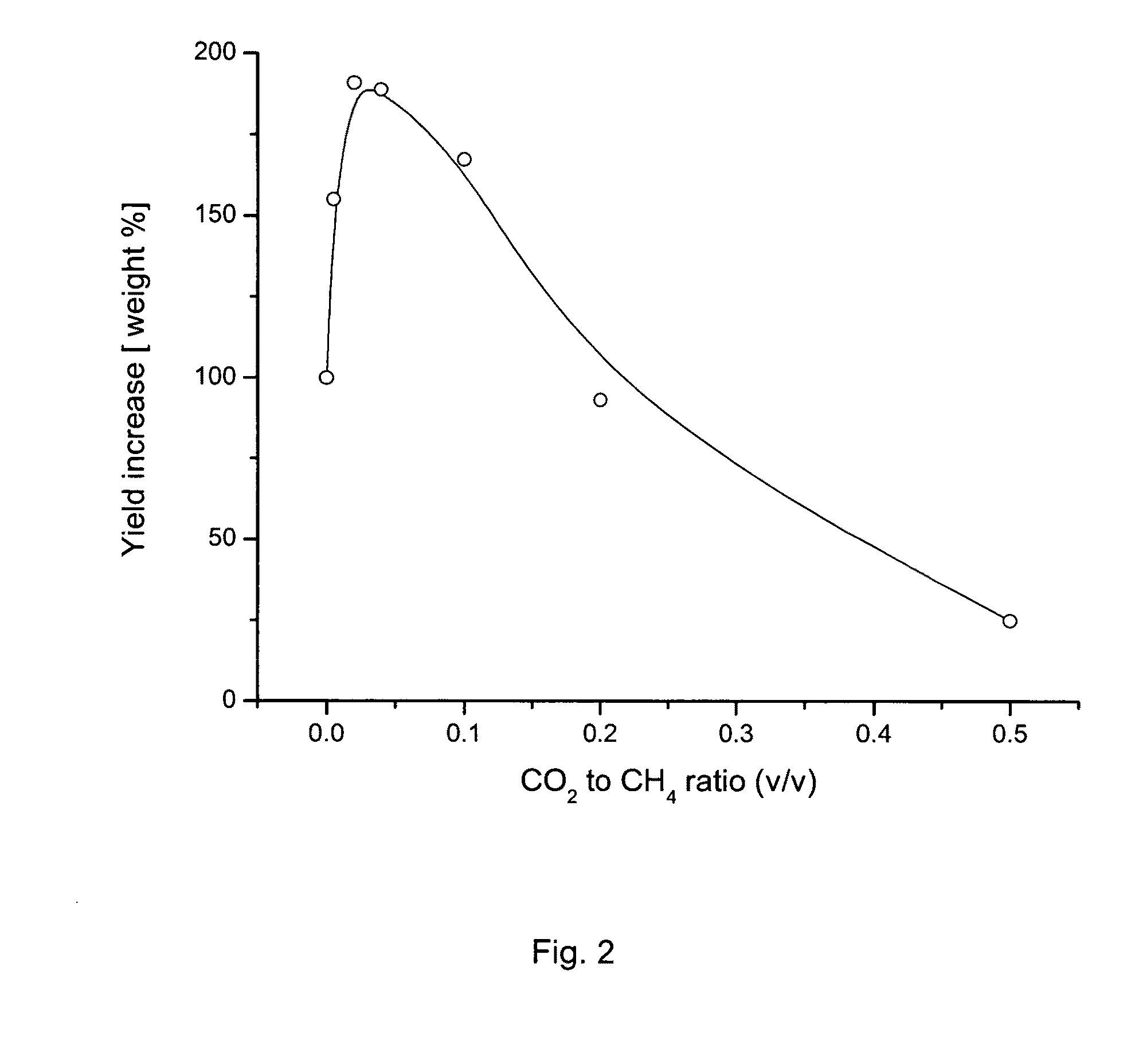

Method for enhanced synthesis of carbon nanostructures

A method of significantly improving carbon nanotube or carbon nanofiber yield from catalytic chemical vapor deposition of a carbon-containing gas comprising at least one hydrocarbon with the assistance of a proper amount of carbon dioxide (CO2). The catalytic particles preferably contain at least one metal from Group VIII (Fe, Co, Ni or the like) or / and one metal from Group VIb, including Mo, W, and Cr. The catalytic particles are preferably supported on oxide powders such as MgO, Al2O3, SiO, CaO, TiO, and ZrO, or a flat substrate such as, but not limited to, a Si wafer. The carbon nanotube or nanofiber product is preferably formed by exposing the catalyst to a mixture of a carbon-containing gas comprising at least one hydrocarbon with a proper amount of CO2 at a sufficiently high temperature. In an alternative embodiment, other oxygen-containing gases, such as alcohols, may be included in the mixture in addition to carbon dioxide.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

Method of forming a catalyst with inhibited mobility of nano-active material

InactiveUS8557727B2Reduce coalescenceMinimized in sizeMaterial nanotechnologyInorganic chemistryEngineeringNanometre

A method of forming a catalyst, comprising: providing a plurality of support particles and a plurality of mobility-inhibiting particles, wherein each support particle in the plurality of support particles is bonded with its own catalytic particle; and bonding the plurality of mobility-inhibiting particles to the plurality of support particles, wherein each support particle is separated from every other support particle in the plurality of support particles by at least one of the mobility-inhibiting particles, and wherein the mobility-inhibiting particles are configured to prevent the catalytic particles from moving from one support particle to another support particle.

Owner:SDC MATERIALS +1

Continuous production of carbon nanotubes

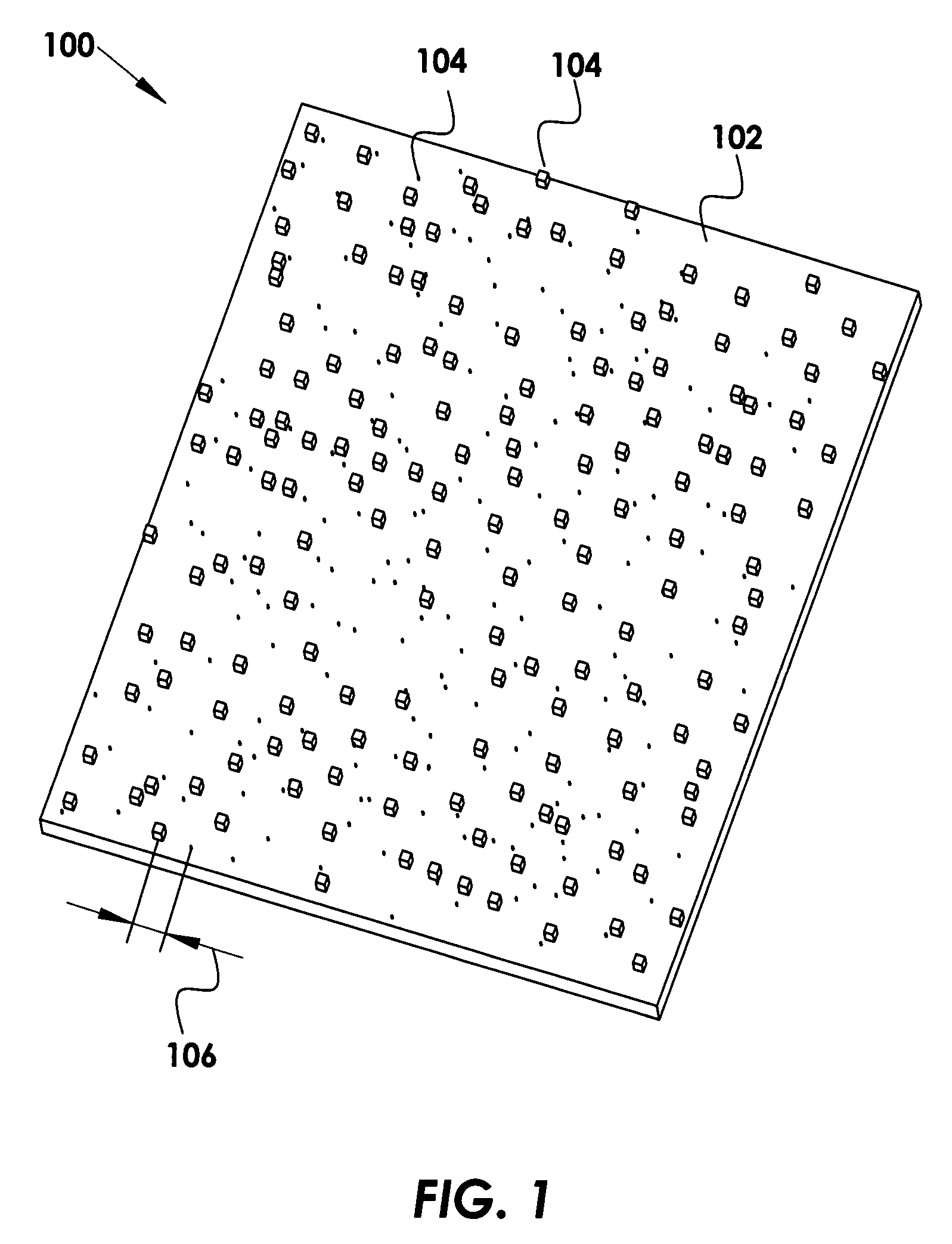

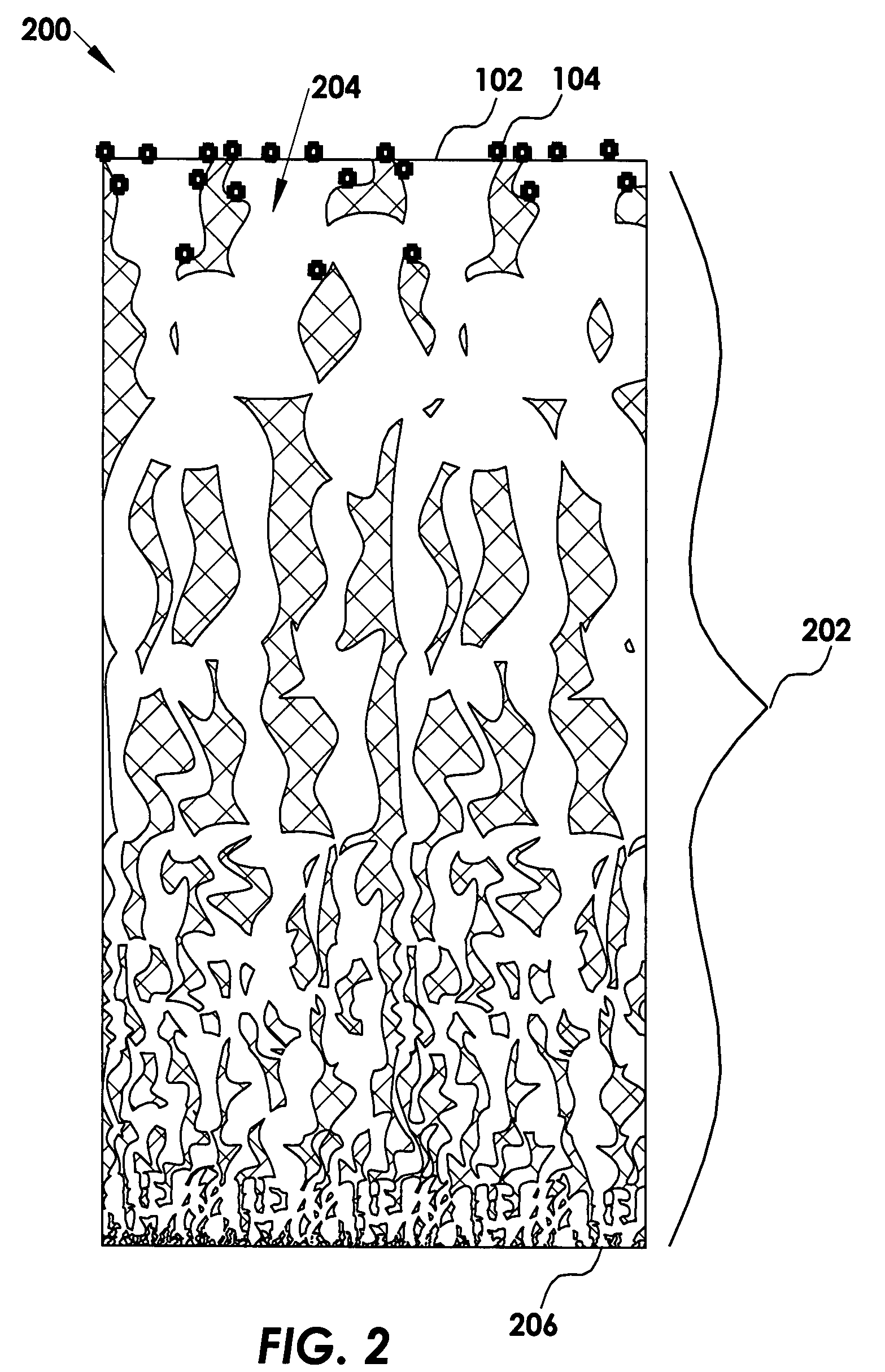

InactiveUS20070140947A1Promote growthMaterial nanotechnologyNanostructure manufactureNanoparticleOrder form

The invention relates to a nanoparticle growing mat (30), a method of manufacturing the mat, and a method for the continuous production of organized nanotubes using the mat. The mat (30) comprising a substrate including carbon, on which is deposited in a predetermined pattern of nanosized catalytic particles whose pattern produces nanotubes in a highly ordered form. The mat (30) is activated in the presence of a carrier gas, by passing current through the mat (30) which raises the temperature to the level where, nanotubes are: formed; gathered; withdrawn as nanotube bundles (42); and collected.

Owner:VERSATILIS

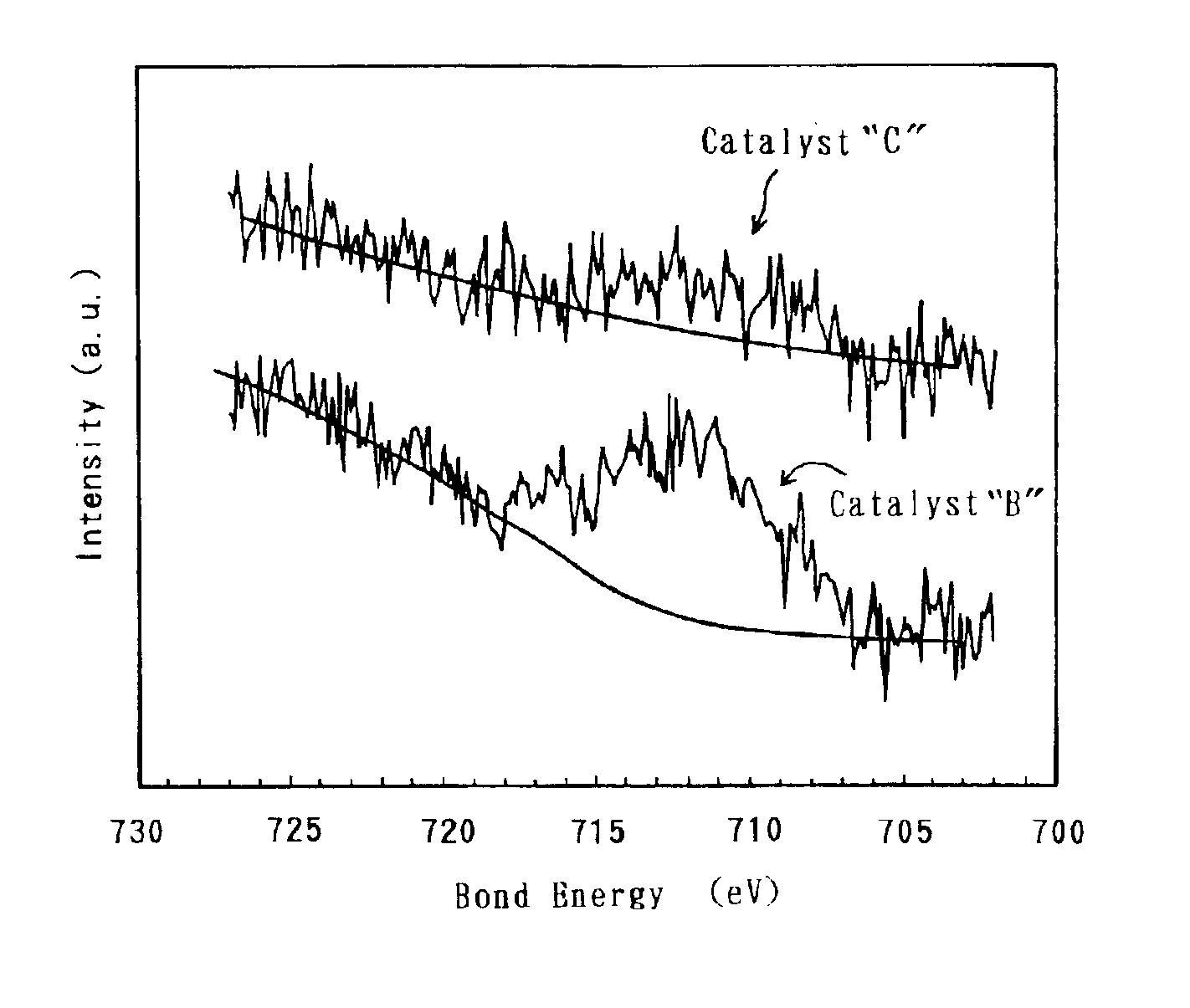

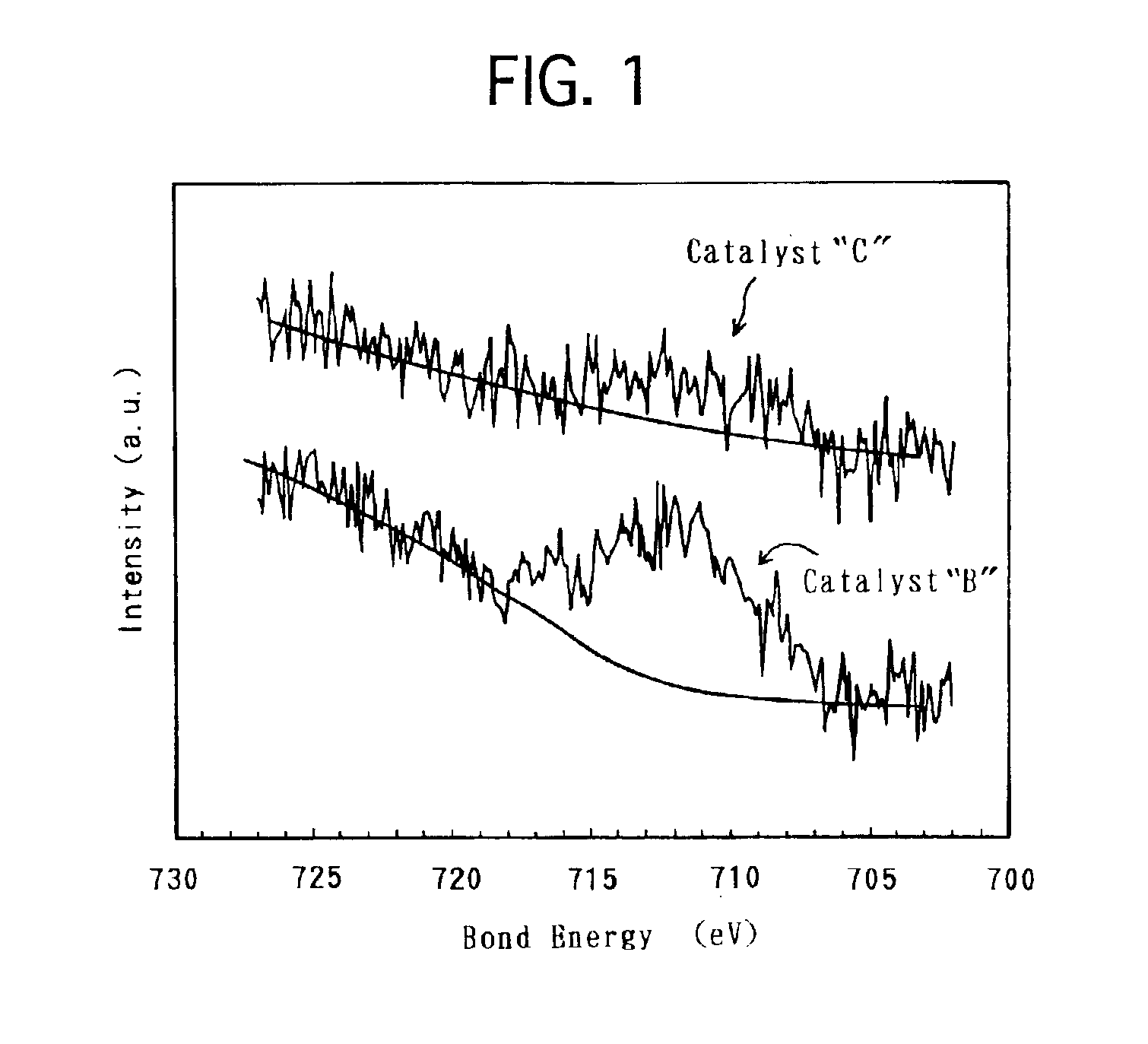

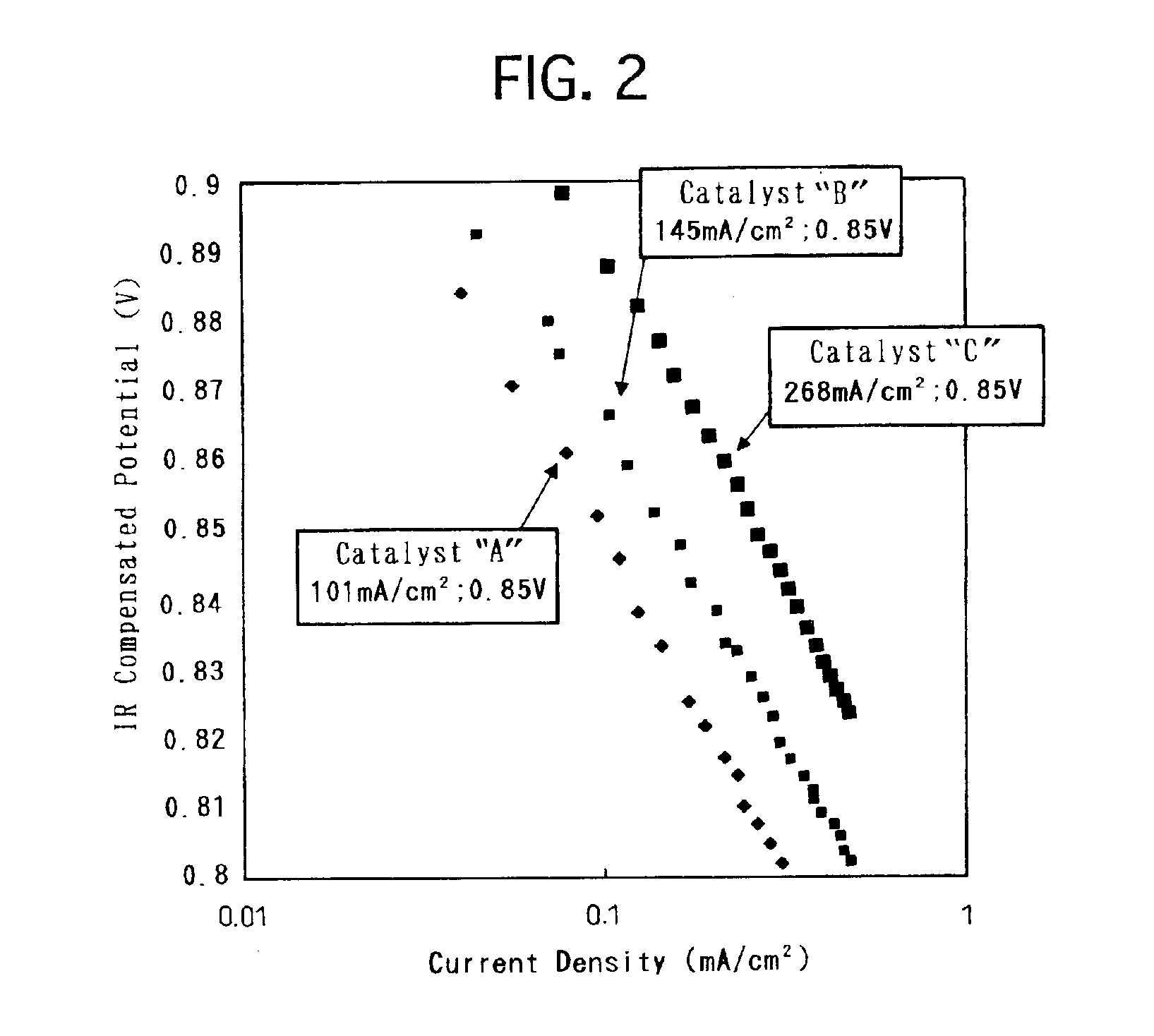

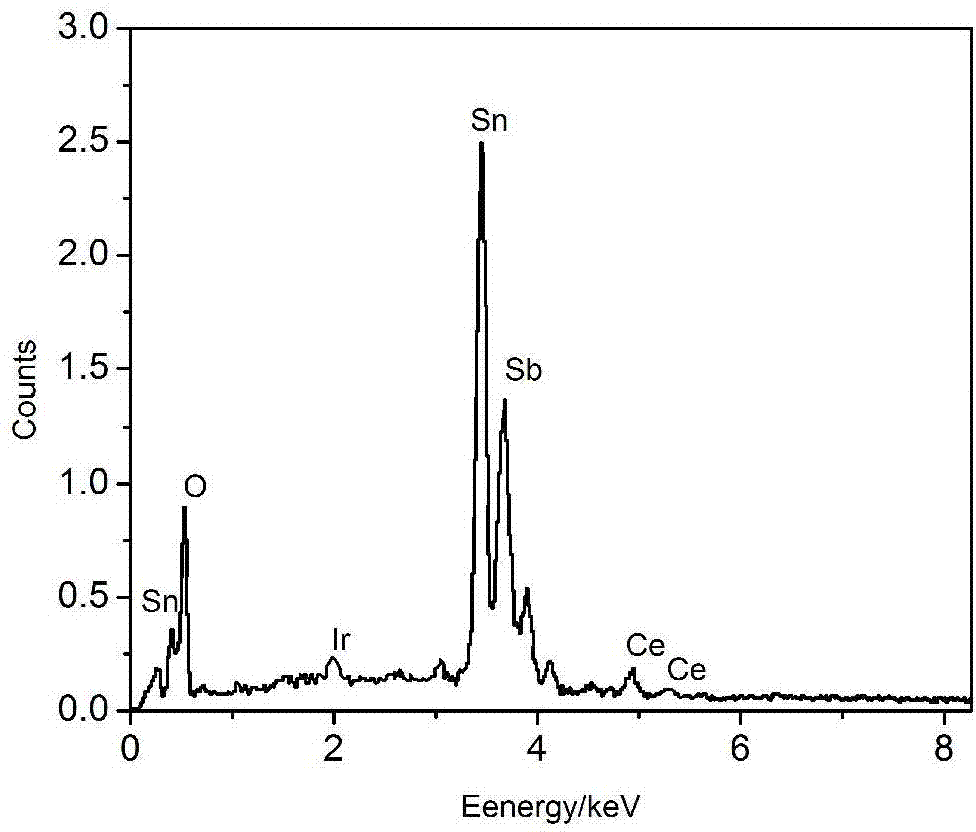

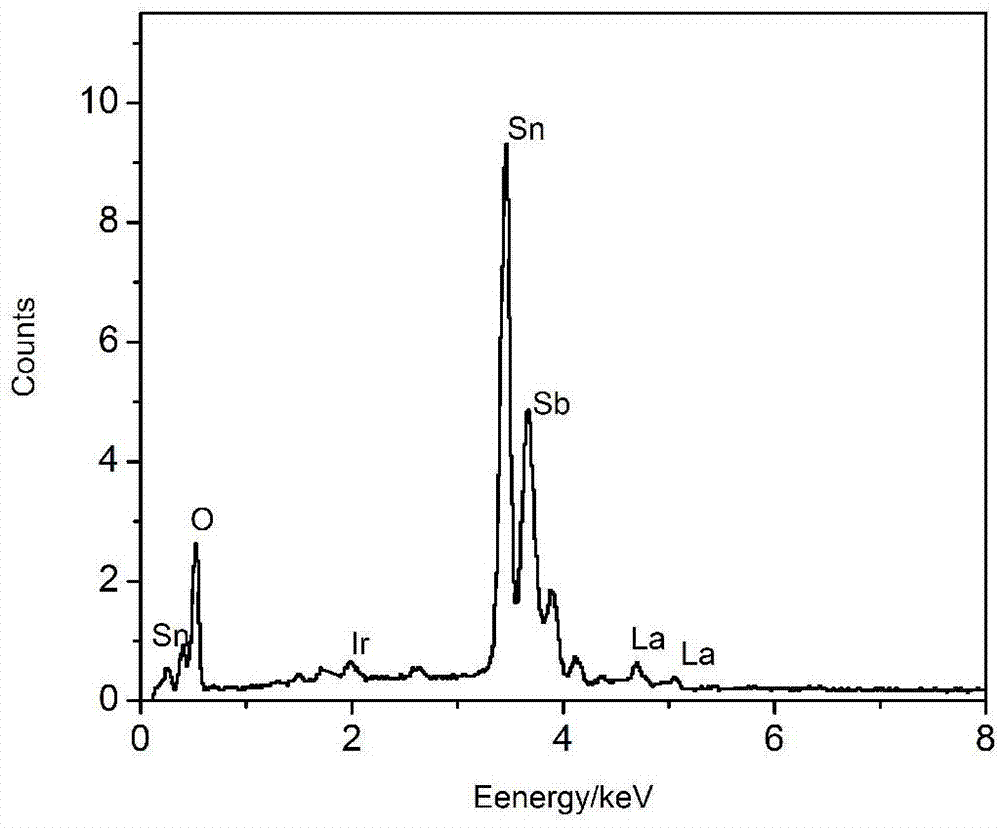

Conductive catalyst particle and its manufacturing method, gas-diffusing catalyst electrode, and electrochemical device

InactiveUS20040142230A1Internal self-diffusion can be avoidedHigh catalytic activityCatalyst carriersTransportation and packagingRare-earth elementAlloy

Conductive catalytic particles which are composed of a conductive powder and a catalytic material adhering to the surface thereof. The catalytic material is an alloy of a noble metal material with an additive material which is thermally solid-insoluble in said noble metal material, or an alloy of MI and MII (where MI denotes at least one species selected from noble metal elements, and MII denotes at least one specifies selected from Fe, Co, Ni, Cr, Al, Cu, Hf, Zr, Ti, V, Nb, Ta, W, Ga, Sn, Ge, Si, Re, Os, Pb, Bi, Sb, Mo, Mn, O, N, C, Zn, In, and rare earth elements). The conductive catalytic particles are produced by causing the noble metal material and the additive material or MI and MII to adhere at the same time to the surface of a conductive powder by physical vapor deposition. The conductive catalytic particles are not liable to sintering and are used for a gas-diffusing catalytic electrode and an electrochemical device provided therewith.

Owner:SONY CORP

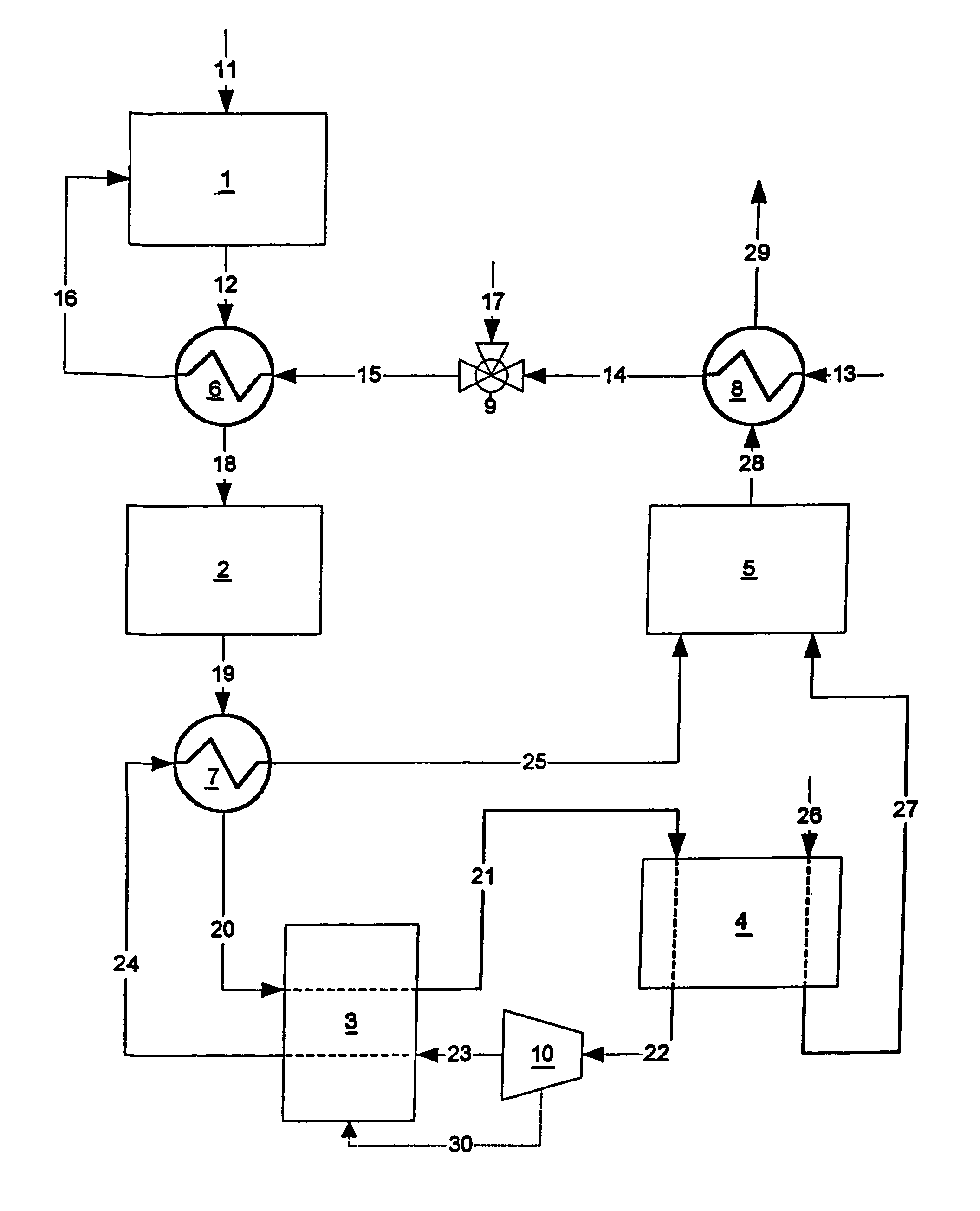

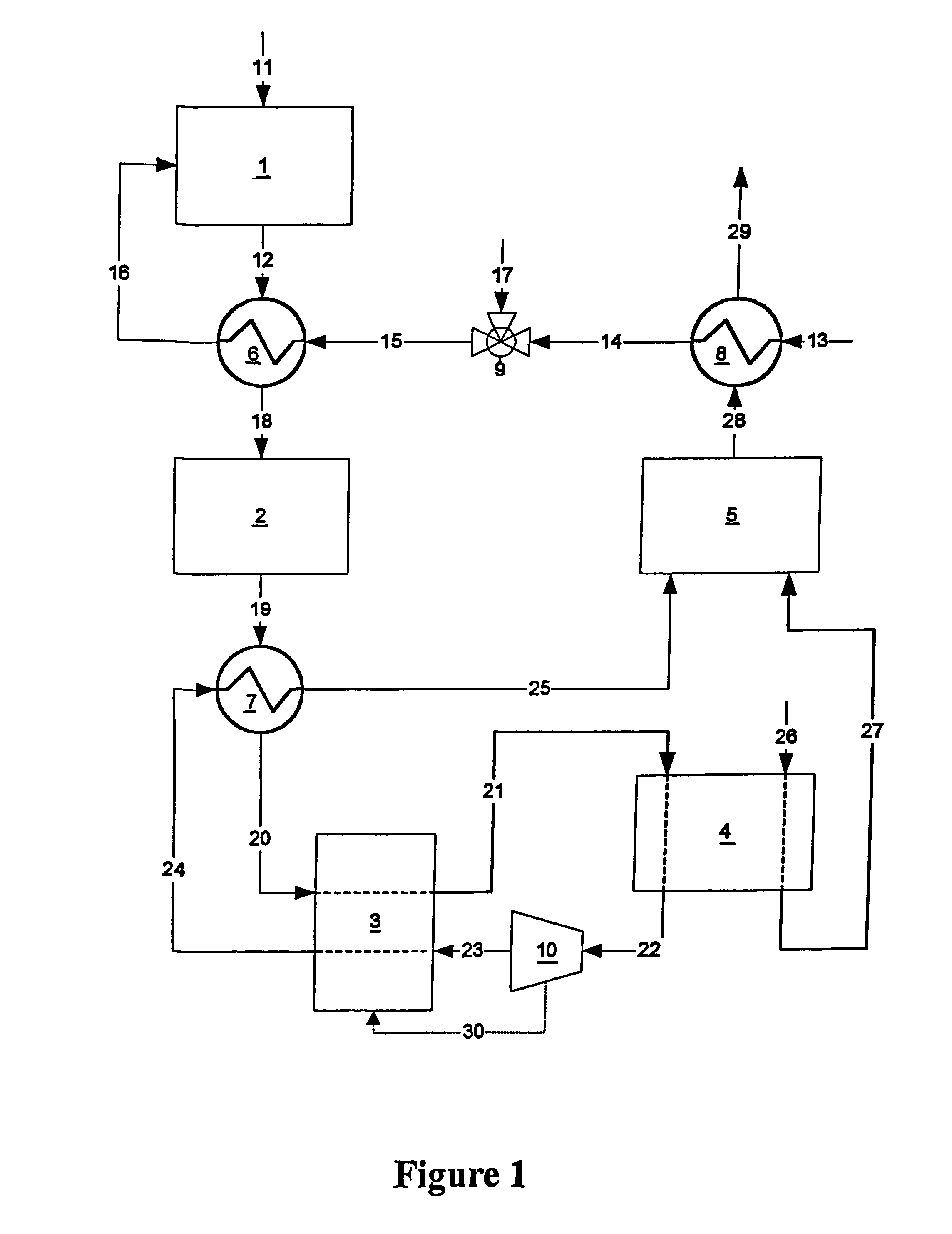

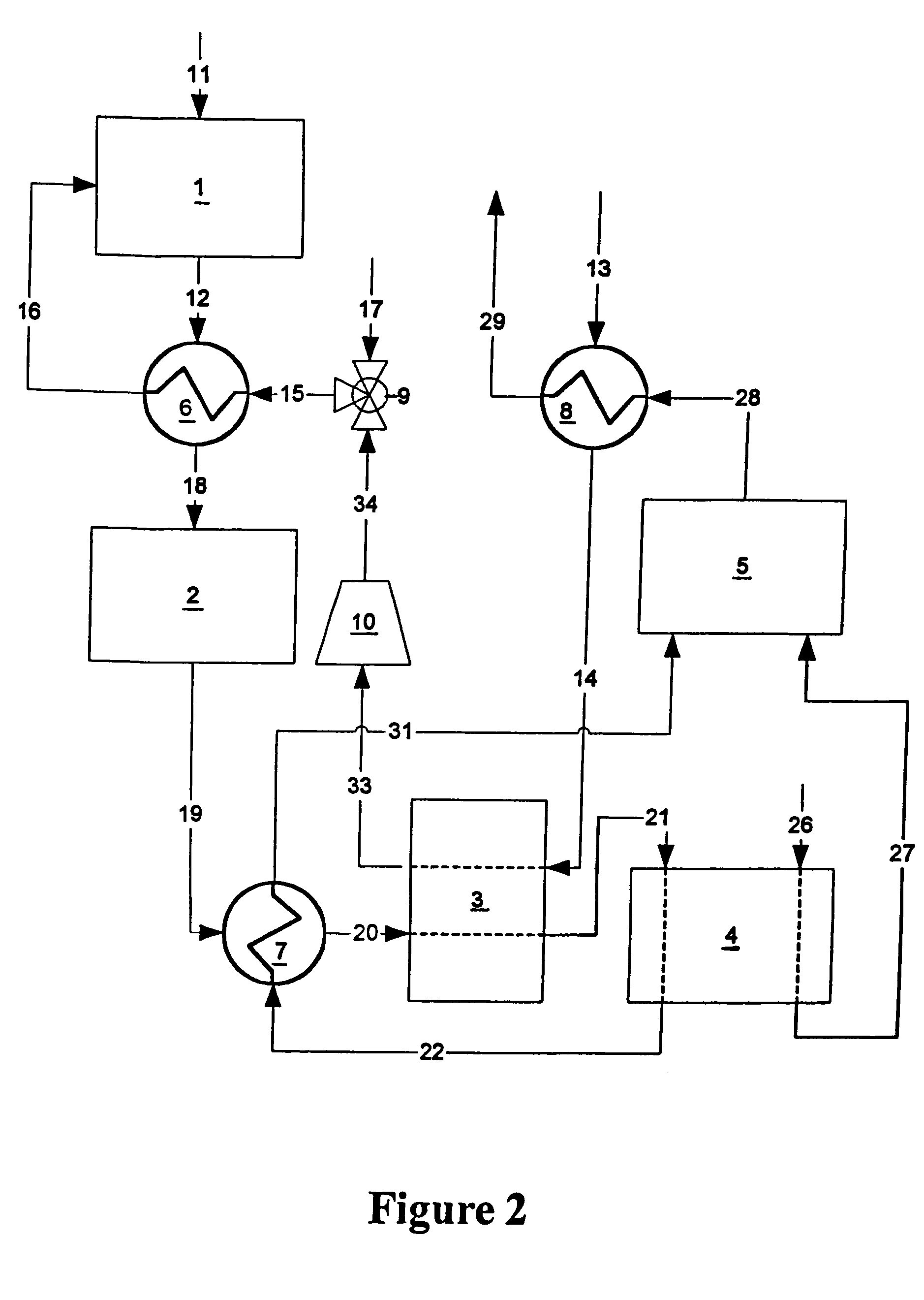

Carbon monoxide adsorption for carbon monoxide clean-up in a fuel cell system

InactiveUS6964692B2Eliminate useReduce carbon monoxide contentThermal non-catalytic crackingCombination devicesSorbentHydrogen fuel cell

An apparatus removes carbon monoxide (CO) from a hydrogen-rich gas stream in a hydrogen fuel cell system. CO fouls costly catalytic particles in the membrane electrode assemblies of proton exchange membrane (PEM) fuel cells. A vessel houses a carbon monoxide adsorbent. The vessel may be a rotating pressure swing adsorber. A water gas shift reactor is upstream of the rotating pressure swing adsorber. The water gas shift reactor may include a second adsorbent adapted to adsorb carbon monoxide at low temperatures and to desorb carbon monoxide at high temperatures. The apparatus advantageously eliminates the use of a preferential oxidation (PROX) reactor, by providing an apparatus which incorporates CO adsorption in the place of the PROX reactor. This cleans up carbon monoxide without hydrogen consumption and the concomitant, undesirable excess low grade heat generation. The present invention reduces start-up duration, and improves overall fuel processor efficiency during normal operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

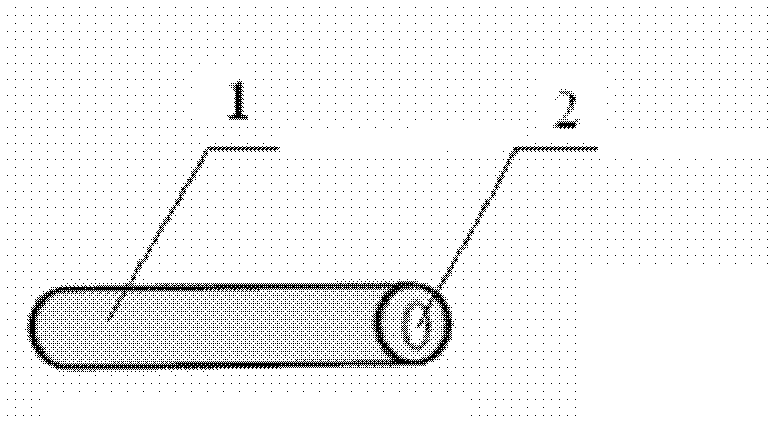

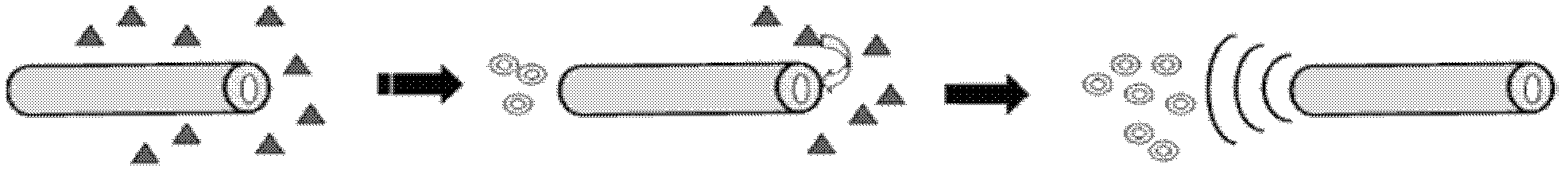

Preparation method of artificial nanometer pipes and application of utilizing artificial nanometer pipes as nanometer motors

ActiveCN102530853AAchieve swimmingEasy to operateIndividual molecule manipulationNanosensorsPolyelectrolyteElectricity

The invention relates to a preparation method of artificial nanometer pipes and application thereof, in particular to a preparation method of artificial nanometer pipes and application of utilizing the artificial nanometer pipes as nanometer motors, which aim to solve the technical problem that an existing method of synthetizing micro-nanometer motors by means of electrochemical deposition is high in cost, small in one-time synthetizing number and high in required difficulty of particle beam spraying method. The preparation method includes: firstly, preparing metal catalytic particles; secondly, assembling a polyelectrolyte layer into a hole of a template; thirdly, assembling metal catalytic particles; and fourthly, removing the template to obtain an artificial nanometer pipe. The application of utilizing the artificial nanometer pipes as the nanometer motors includes that the artificial nanometer pipes are placed into hydrogen peroxide solution, hydrogen peroxide is catalyzed to generate oxygen gas, air bubbles are used as driving force, and moving of the motor is realized. The preparation method is simple in operation, low in cost and large in one-time synthetizing number, and the size of the artificial nanometer pipes is controllable. Besides, the artificial nanometer pipes can be used as nanometer motors in the medical field.

Owner:HARBIN INST OF TECH

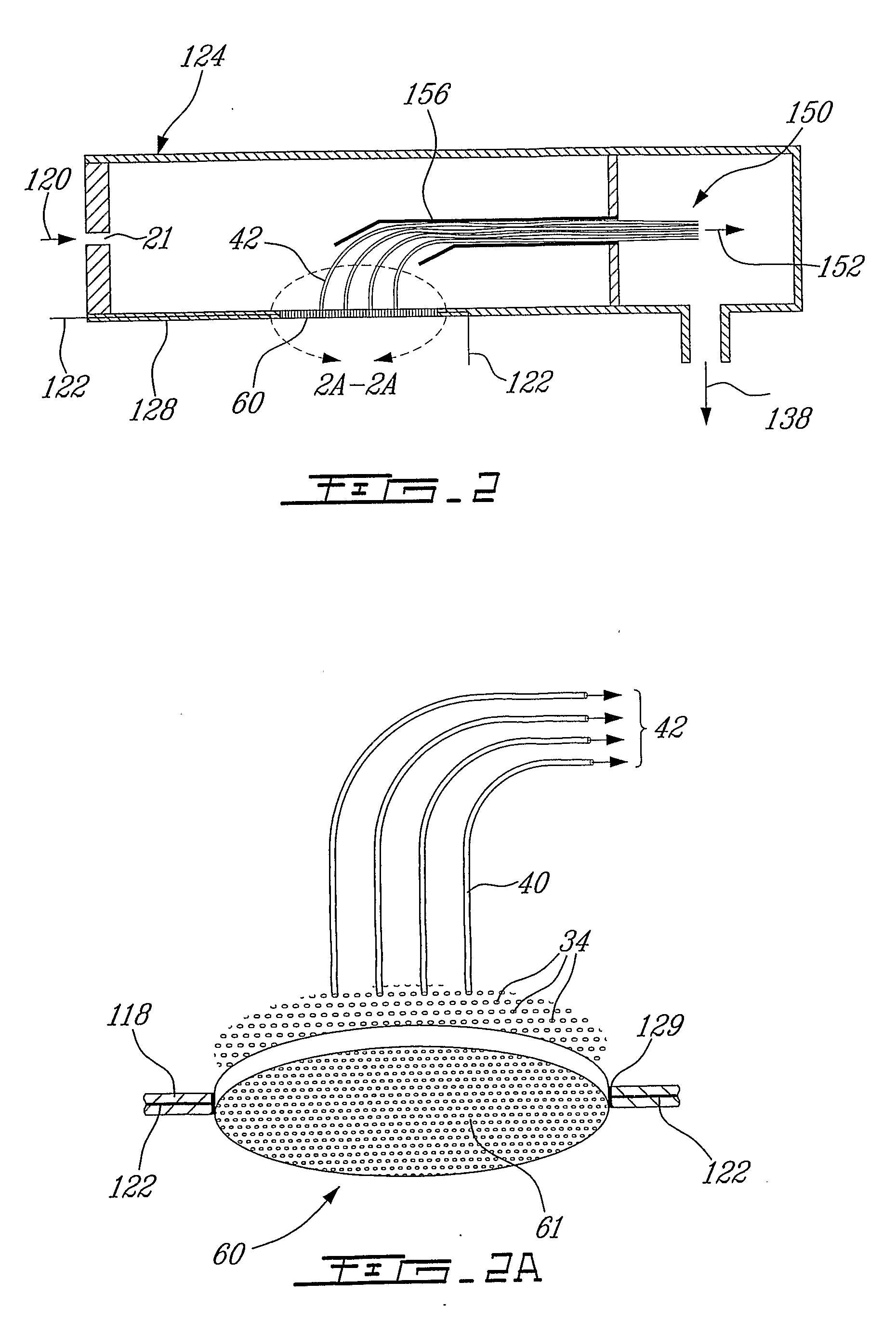

Electrode catalyst for fuel cell and process for producing the same

InactiveUS6911278B2High catalytic activityImprove performanceOrganic-compounds/hydrides/coordination-complexes catalystsActive material electrodesPlatinumFuel cells

An electrode catalyst for a fuel cell includes a conductive support, and catalytic particles loaded on the conductive support. The catalytic particles include platinum and a base metal being on the lower end of the electrochemical series with respect to platinum. The number of the atoms of the base metal, forming metallic oxides without alloying with the platinum, is less than 5 atomic % of the number of the atoms of the platinum on a surface of the catalytic particles. The electrode catalyst is produced by loading the platinum and base metal on the conductive support, alloying the platinum and base metal thereon by a heat treatment, thereby making the catalytic particles, and removing metallic oxides from a surface of the catalytic particles. The electrode catalyst is less expensive comparatively, exhibits high catalytic activities, and hardly lowers the battery performance of fuel cells.

Owner:TOYOTA JIDOSHA KK

Exhaust treatment device

An exhaust treatment device for treating an exhaust gas stream combines the functionalities of a catalytic particulate filter and a NOx absorber catalyst into a single integral device and is disposed in an exhaust conduit. By combining the functionalities of the catalytic particulate filter and a NOx absorber catalyst into a single integral device, the exhaust treatment device eliminates the temperature losses inherent to the heat capacity of one catalytic device placed in front of the other.

Owner:UMICORE AG & CO KG

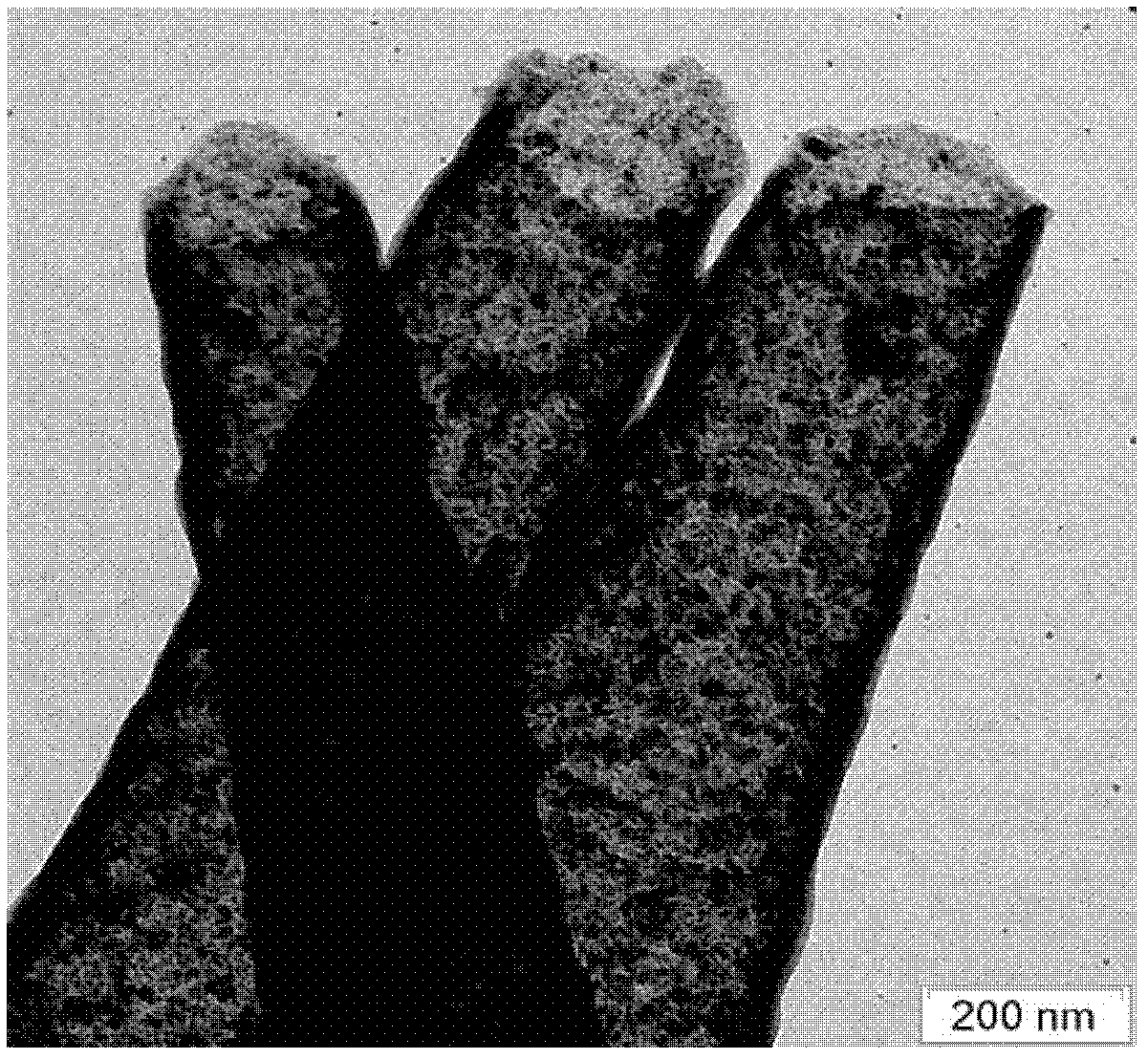

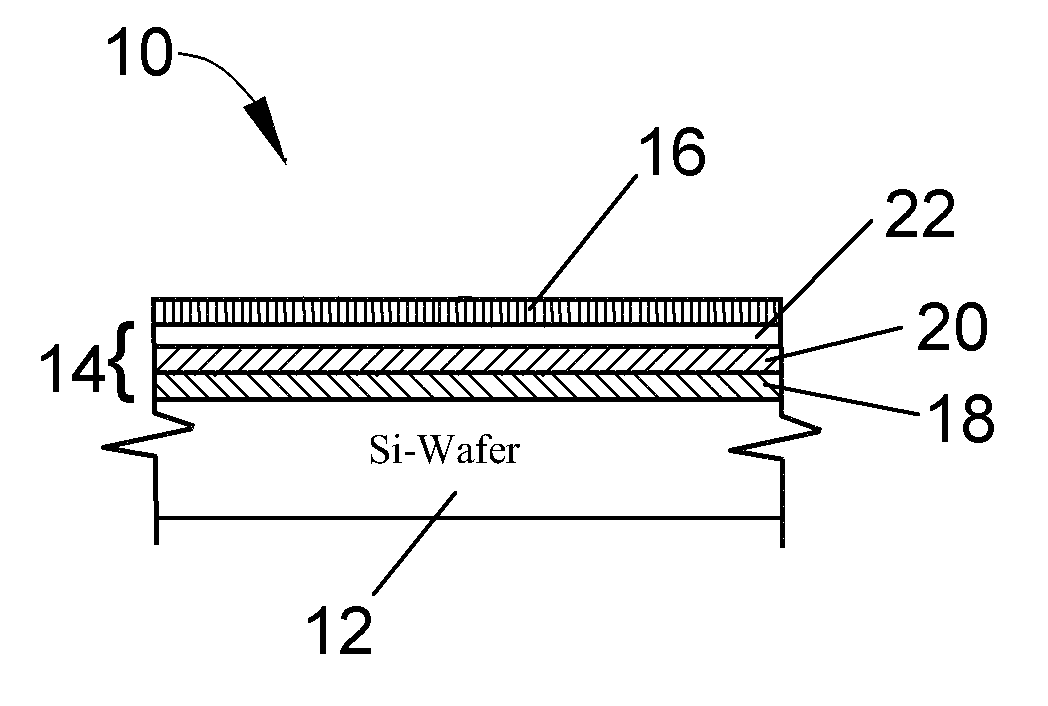

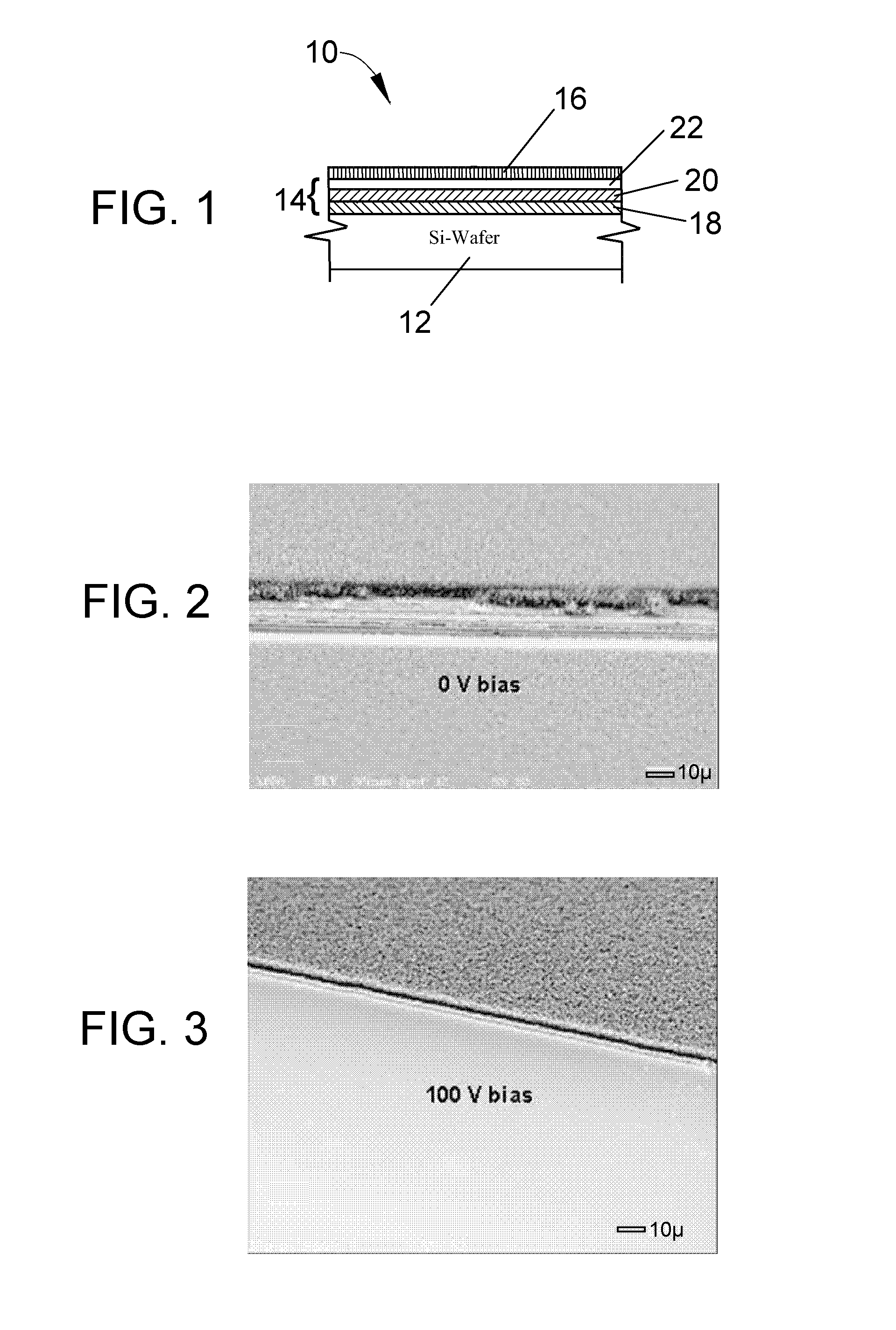

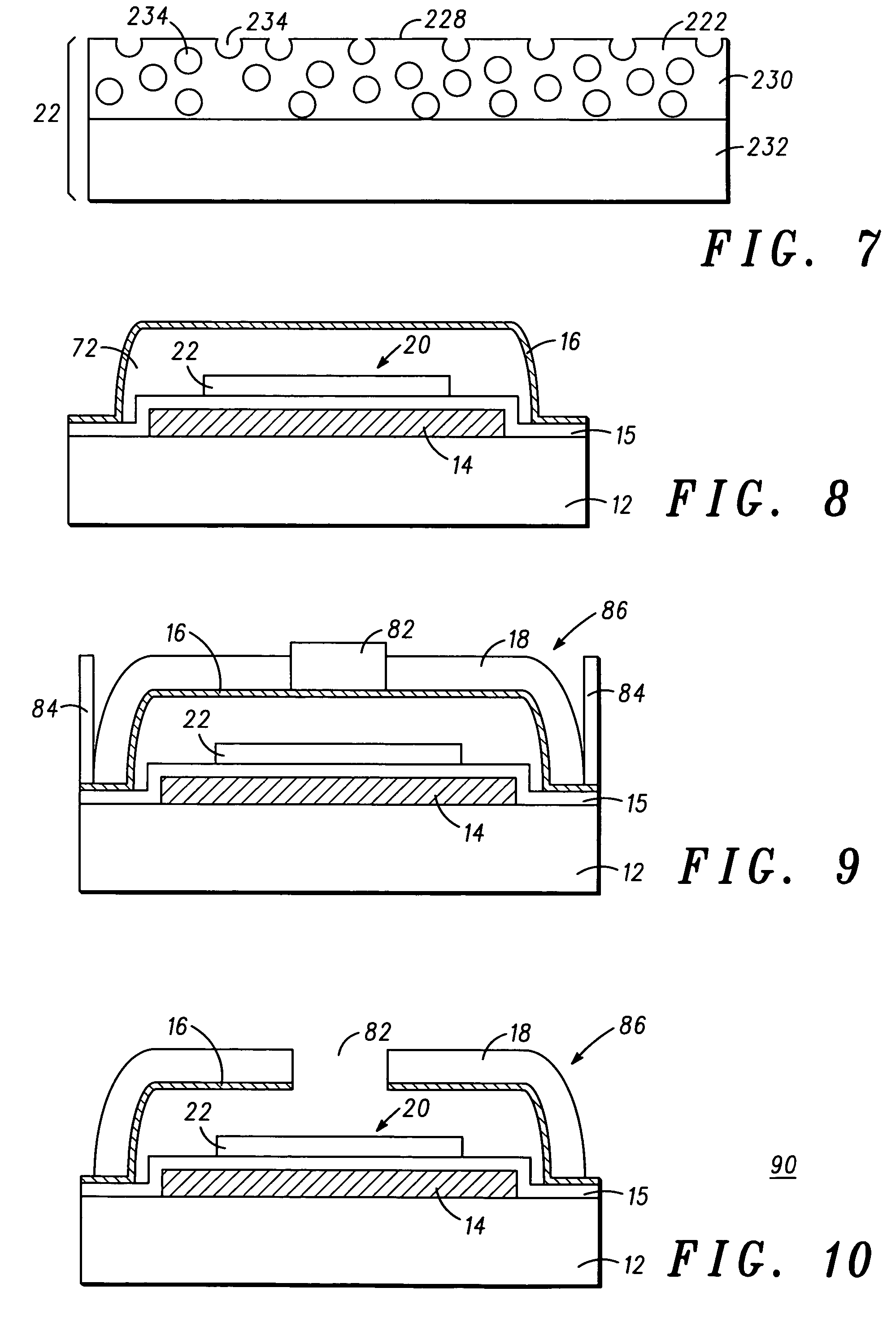

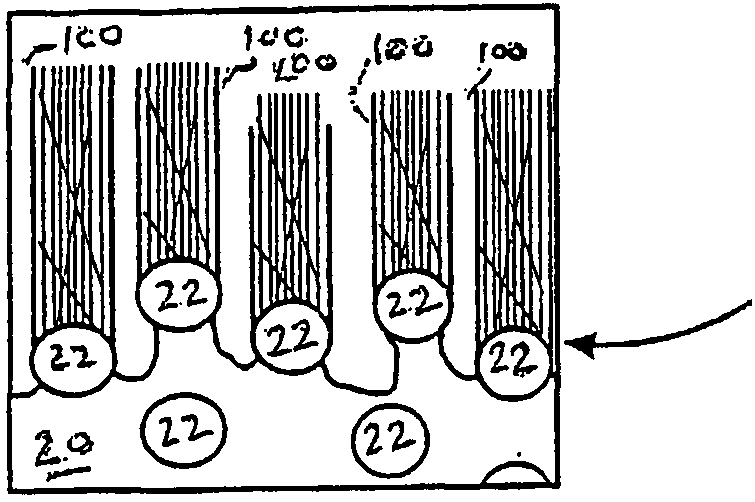

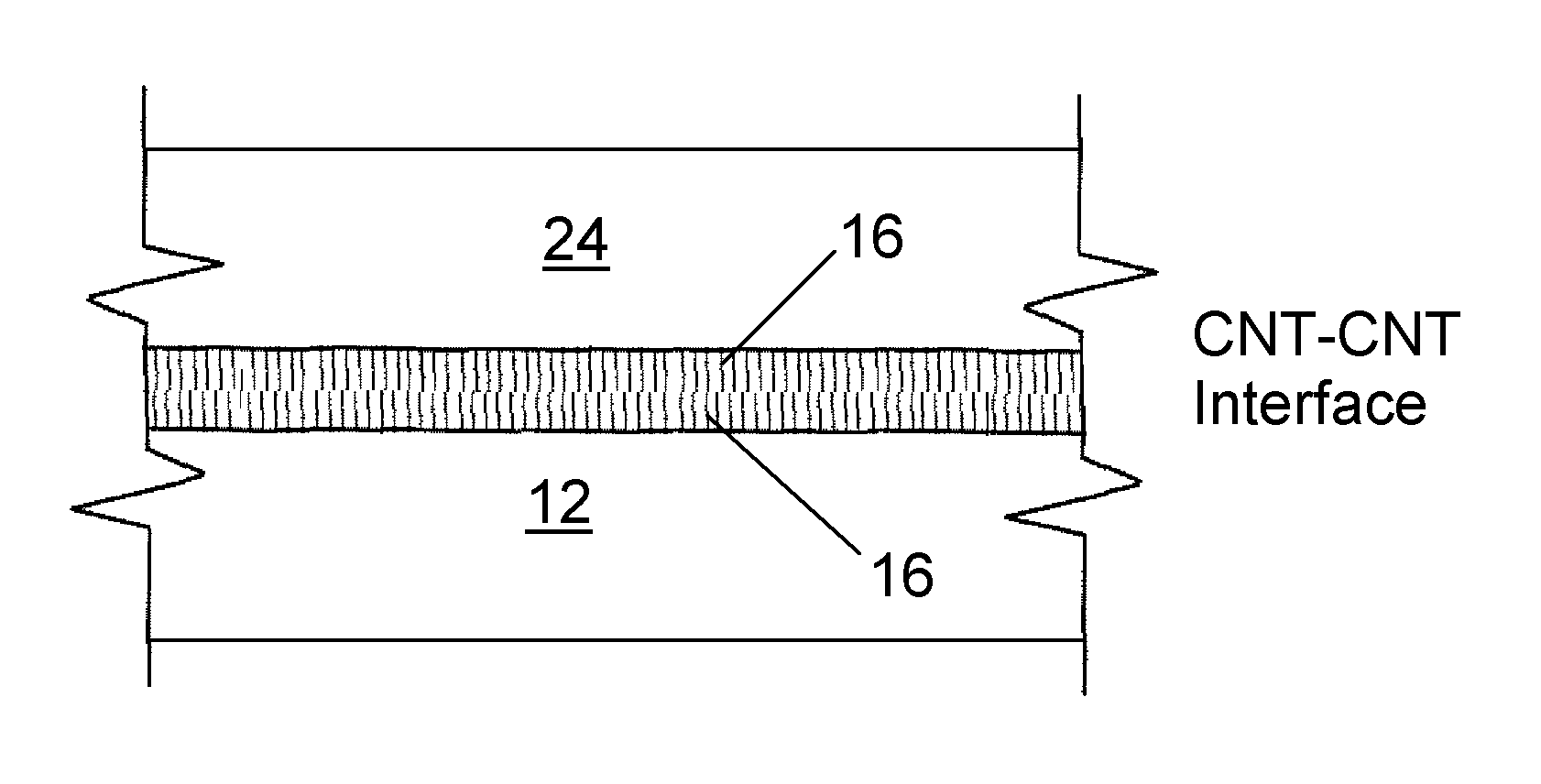

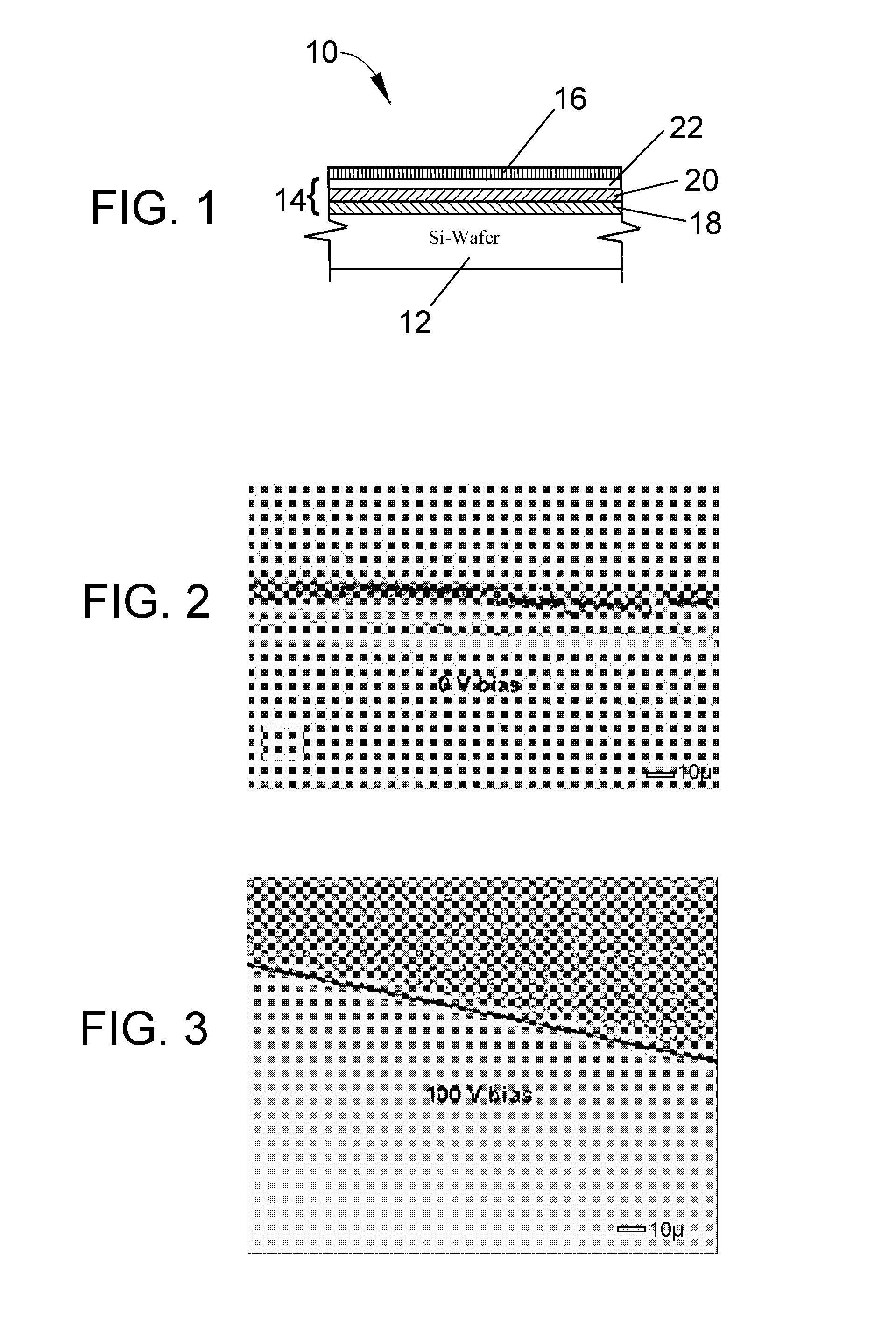

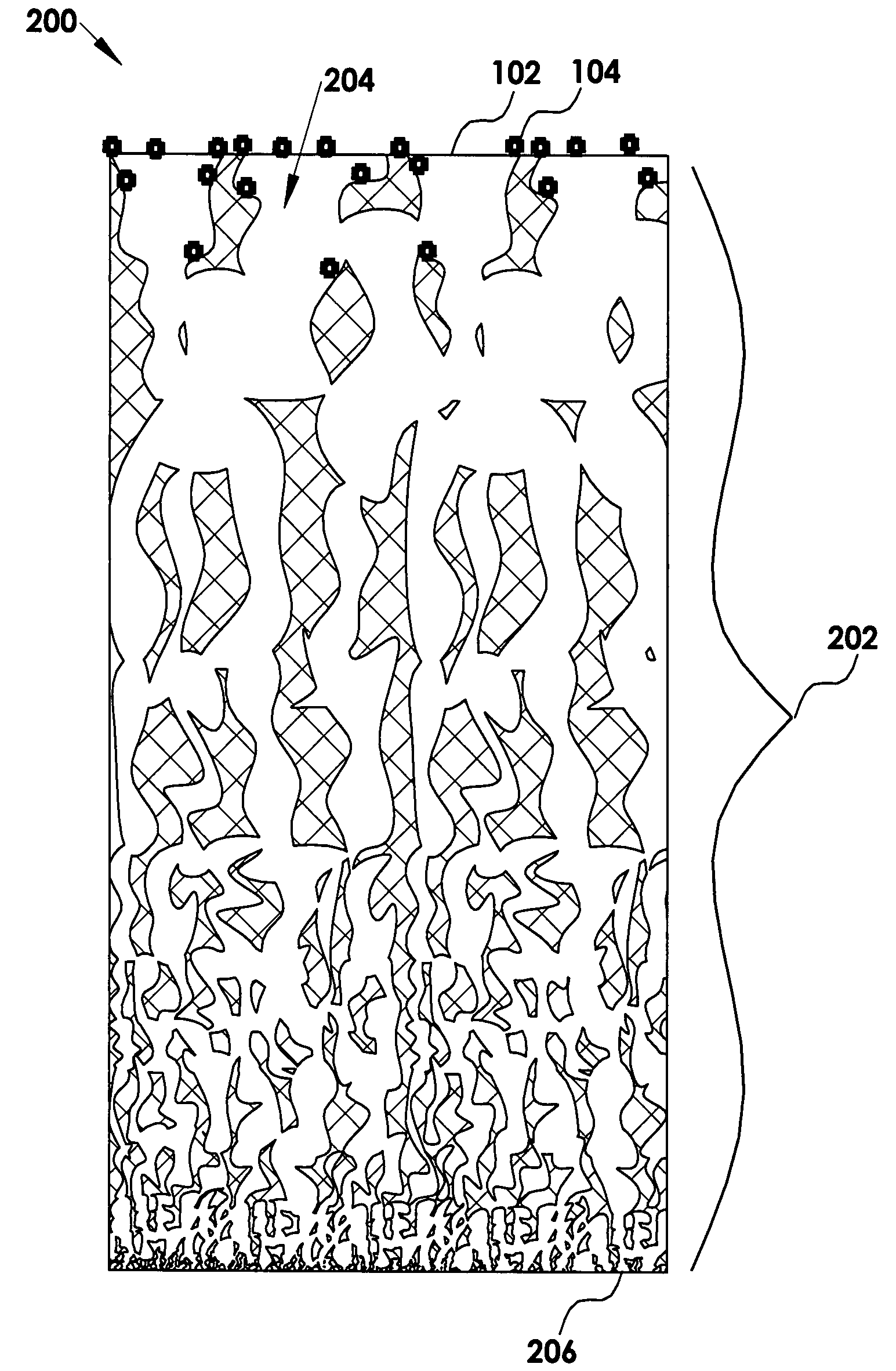

Enhancement of thermal interface conductivities with carbon nanotube arrays

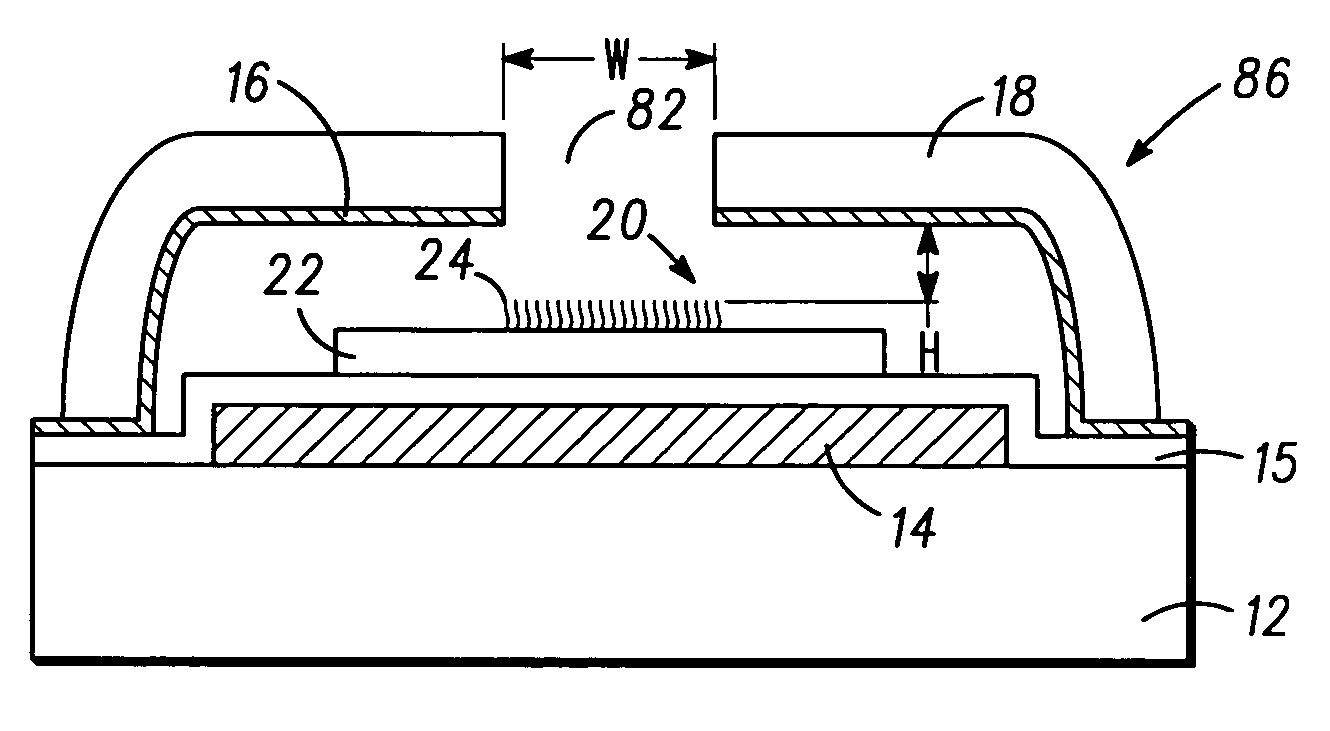

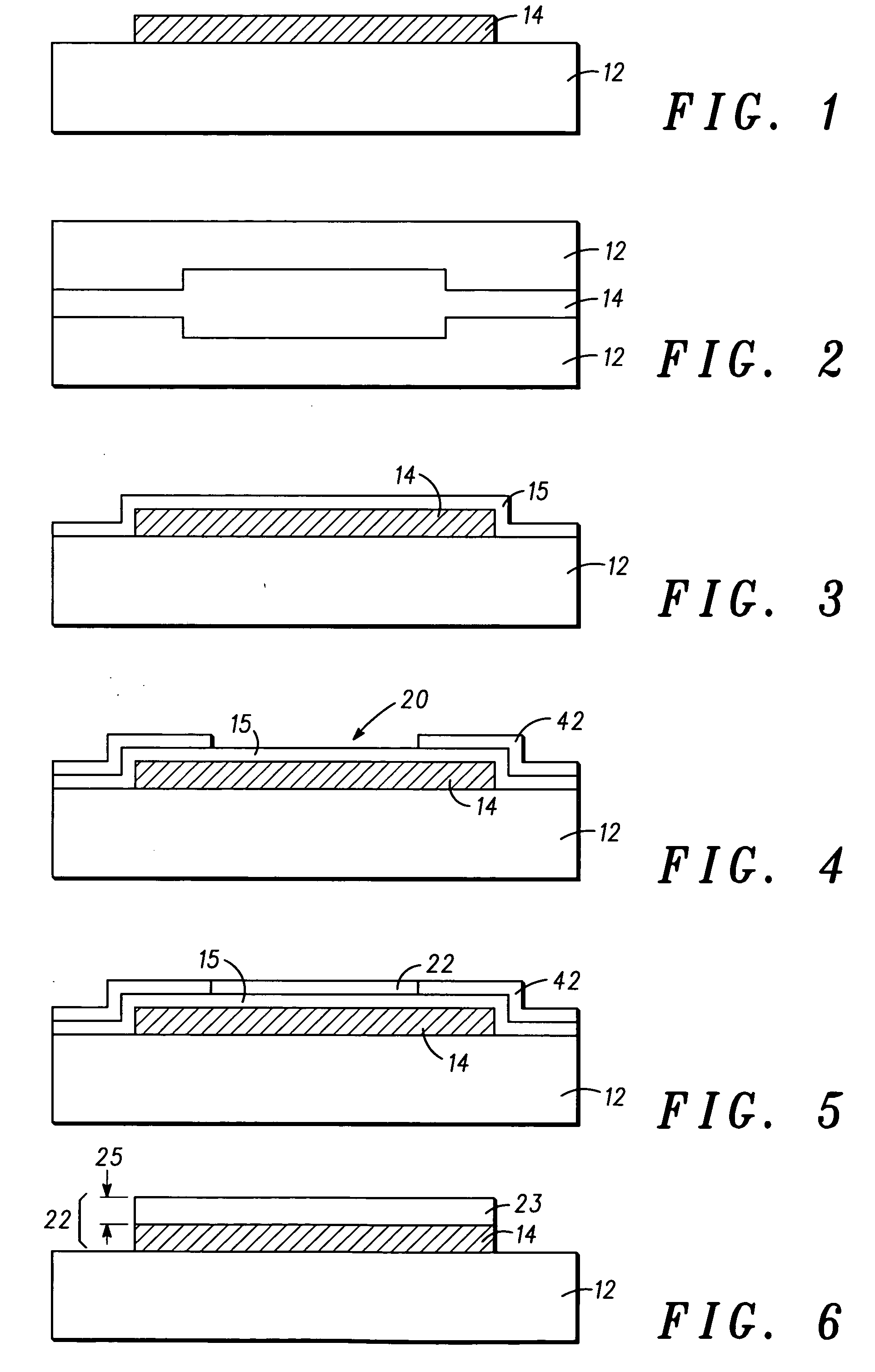

ActiveUS20110007477A1High thermal contact conductanceImprove interface performanceNanotechSemiconductor/solid-state device detailsCarbon nanotubeCombined use

A method of forming a well-anchored carbon nanotube (CNT) array, as well as thermal interfaces that make use of CNT arrays to provide very high thermal contact conductance. A thermal interface is formed between two bodies by depositing a continuous array of carbon nanotubes on a first of the bodies so that, on mating the bodies, the continuous array is between surface portions of the first and second bodies. The thermal interface preferably includes a multilayer anchoring structure that promotes anchoring of the continuous array of carbon nanotubes to the first body. The anchoring structure includes a titanium bond layer contacting the surface portion of the first body, and an outermost layer with nickel or iron catalytic particles from which the continuous array of carbon nanotubes are nucleated and grown. Additional thermal interface materials (TIM's) can be used in combination with the continuous array of carbon nanotubes.

Owner:PURDUE RES FOUND INC

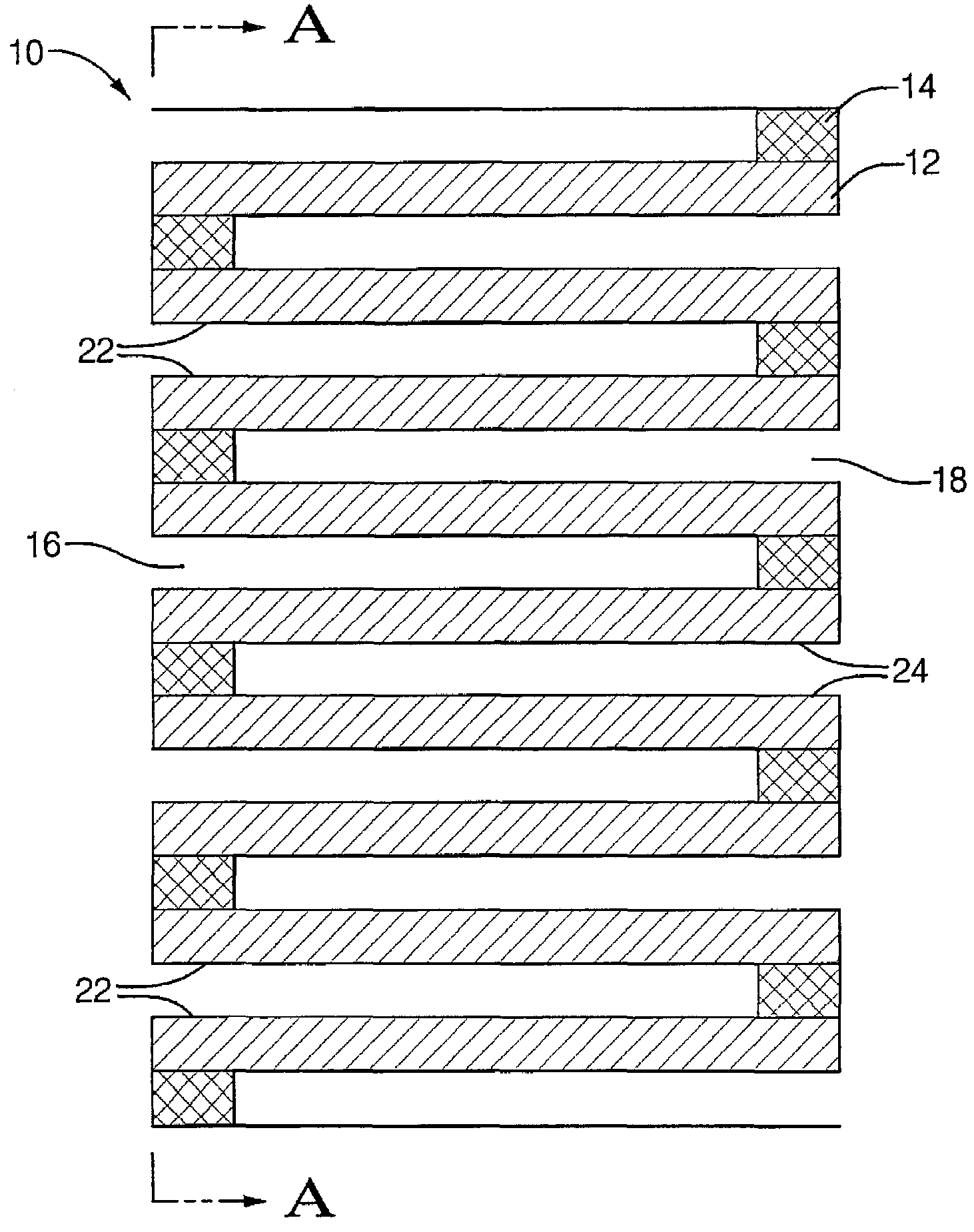

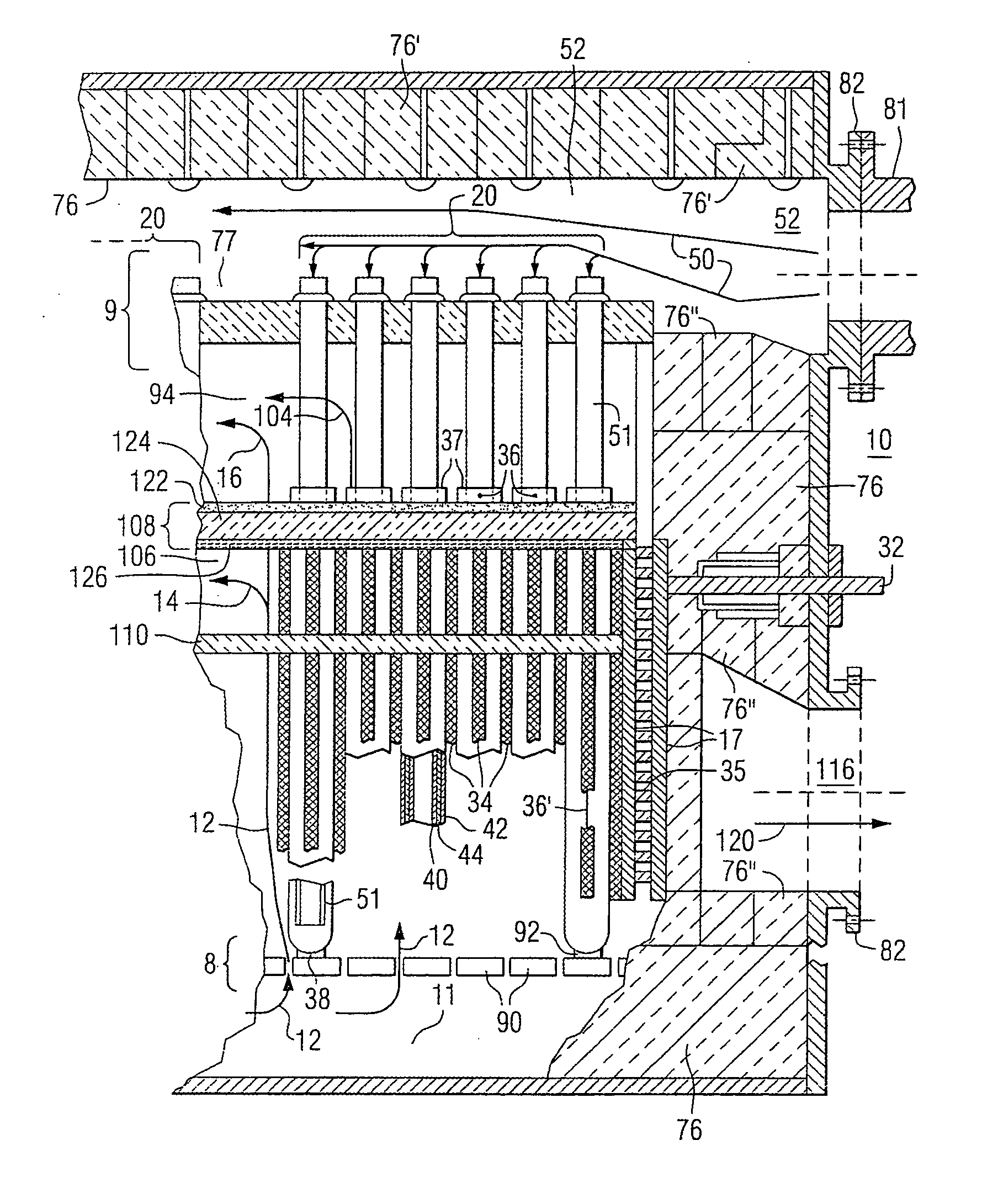

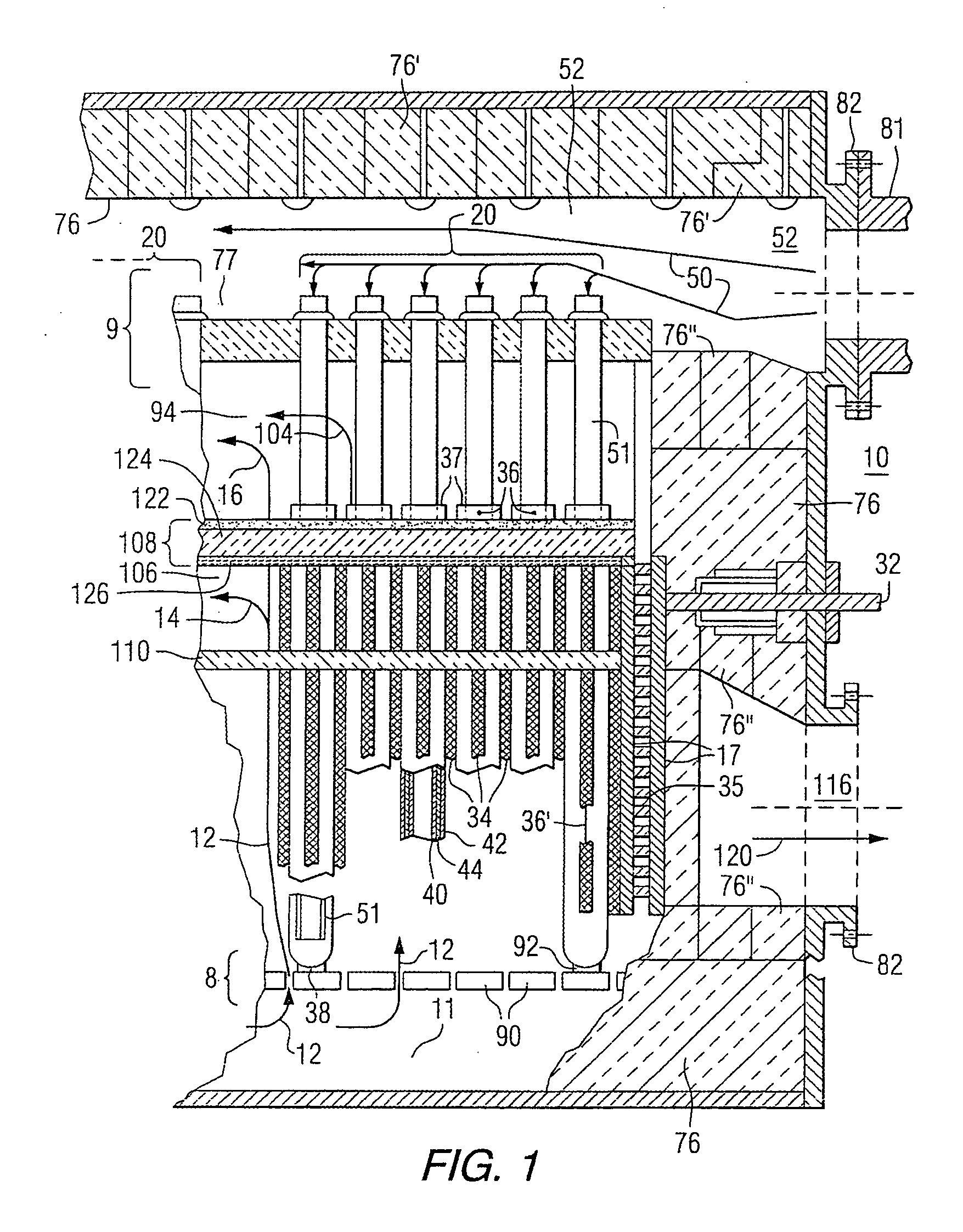

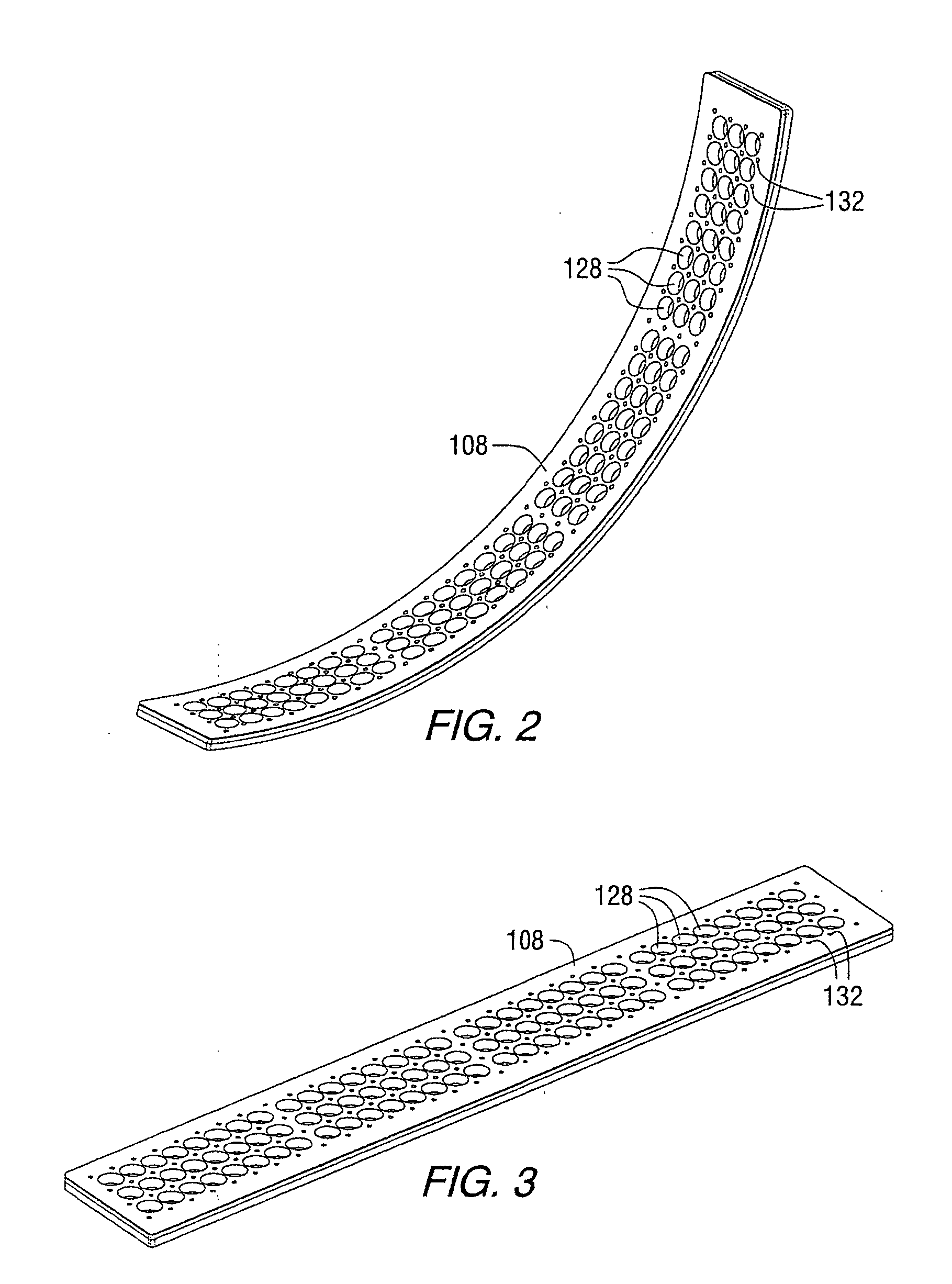

Flexible ceramic gasket for SOFC generator

InactiveUS20050266288A1Effective absorptionLow cost productionFuel cells groupingFinal product manufactureFuel cellsCombustion chamber

A solid oxide fuel cell generator (10) contains stacks of hollow axially elongated fuel cells (36) having an open top end (37), an oxidant inlet plenum (52), a feed fuel plenum (11), a combustion chamber (94) for combusting reacted oxidant / spent fuel; and, optionally, a fuel recirculation chamber (106) below the combustion chamber (94), where the fuel recirculation chamber (94) is in part defined by semi-porous fuel cell positioning gasket (108), all within an outer generator enclosure (8), wherein the fuel cell gasket (108) has a laminate structure comprising at least a compliant fibrous mat support layer and a strong, yet flexible woven layer, which may contain catalytic particles facing the combustion chamber, where the catalyst, if used, is effective to further oxidize exhaust fuel and protect the open top end (37) of the fuel cells.

Owner:SIEMENS ENERGY INC

Composite air purifying filter paper material and filter element using same

InactiveCN106334373AImprove fast purification adsorption performanceImprove removal rateGas treatmentDispersed particle filtrationFiberEnvironmental engineering

The invention relates to a composite air purifying filter paper material and a filter element using the same. The composite air purifying filter paper material comprises an active carbon fiber pre-filtering layer, an adsorption catalytic particle layer, a particulate matter filtering layer and a sterilizing supporting layer which are superposed according to any sequence. Compared with the existing filter paper material, the composite air purifying filter paper material is provided with the active carbon fiber pre-filtering layer; an air purifying filter element prepared from the composite air purifying filter paper material can significantly improve quick purification and adsorption performance on pollutant molecules, such as peculiar smell and the like, in the environment, and the removal rate of the whole filter element on gas-state pollutant molecules is increased.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD +1

Formation of nanowhiskers on a substrate of dissimilar material

InactiveUS7528002B2Reduce riskAccurately and reliably implementedMaterial nanotechnologyPolycrystalline material growthHeterojunctionThermal energy

A method for forming a nanowhisker of, e.g., a III-V semiconductor material on a silicon substrate, comprises: preparing a surface of the silicon substrate with measures including passivating the substrate surface by HF etching, so that the substrate surface is essentially atomically flat. Catalytic particles on the substrate surface are deposited from an aerosol; the substrate is annealed; and gases for a MOVPE process are introduced into the atmosphere surrounding the substrate, so that nanowhiskers are grown by the VLS mechanism. In the grown nanowhisker, the crystal directions of the substrate are transferred to the epitaxial crystal planes at the base of the nanowhisker and adjacent the substrate surface. A segment of an optically active material may be formed within the nanowhisker and bounded by heterojunctions so as to create a quantum well wherein the height of the quantum well is much greater than the thermal energy at room temperature, whereby the luminescence properties of the segment remain constant without quenching from cryogenic temperatures up to room temperature.

Owner:QUNANO

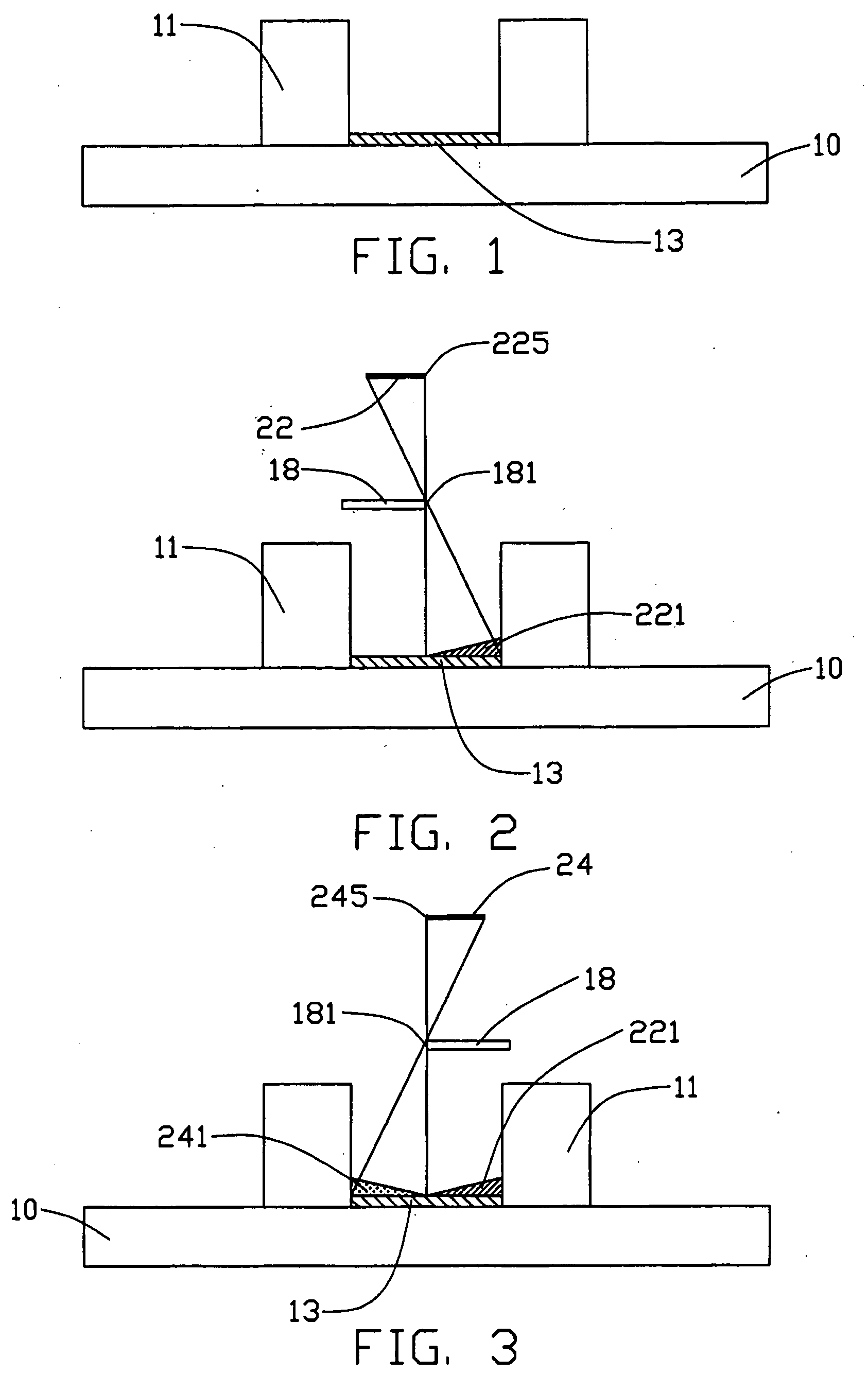

Field emission display and methods of forming a field emission display

A field emission device and method of forming a field emission device are provided in accordance with the present invention. The field emission device is comprised of a substrate (12) having a deformation temperature that is less than about six hundred and fifty degrees Celsius and a nano-supported catalyst (22) formed on the substrate (12) that has active catalytic particles that are less than about five hundred nanometers. The field emission device is also comprised of a nanotube (24) that is catalytically formed in situ on the nano-supported catalyst (22), which has a diameter that is less than about twenty nanometers.

Owner:MOTOROLA SOLUTIONS INC

Methods of direct growth of carbon nanotubes on catalytic surfaces

The present invention uses a conductor as a catalytic support for carbon nanotube growth. The use of conductive catalytic support will provide a contact to the nanotubes with low resistance. Carbon nanotubes grown on insulators must be modified to allow good connections. Second, creation of catalytic particles has been largely accomplished by precipitation of transition metals from salt solutions or thermal decomposition of thin films, while the present method uses precipitation from a solid solution. This will allow better control of the size distribution of catalysts. The precipitates will be coherent with the support allowing good anchoring of the catalysts for base growth of carbon nanotubes. Third, the approach is amenable to patterning by photolithography or other means of applying copper / transition metal thin films.

Owner:VANDERBILT UNIV

Antibacterial fiber and preparation method thereof

ActiveCN103774265AEasy to weave and shapeEasy to weave into shapeFilament/thread formingMonocomponent polyolefin artificial filamentFiberAntioxidant

The invention relates to an antibacterial fiber and a preparation method thereof. The antibacterial fiber prepared by the invention comprises the following components of characteristic matters in parts by weight: 100 parts of a polymer, 10-50 parts of ZnO catalytic particles, 0.2-1.5 parts of coupling agent, 0.1-0.5 parts of antioxidant and 0-50 parts of plasticizer. The antibacterial fiber provided by the invention is not treated by toxic organic matters and is free from secondary pollution. The catalyst used is rich minerals, so that the antibacterial fiber is convenient for industrial production, low in cost and simple in preparation process. The utilization efficiency of an antibacterial agent is improved, the degerming rate is fast and the removal rate is high due to the antibacterial fiber. The antibacterial fiber is easy to weave and form and high in soaping degree and can be repeatedly used.

Owner:无锡国纳超纤科技有限公司

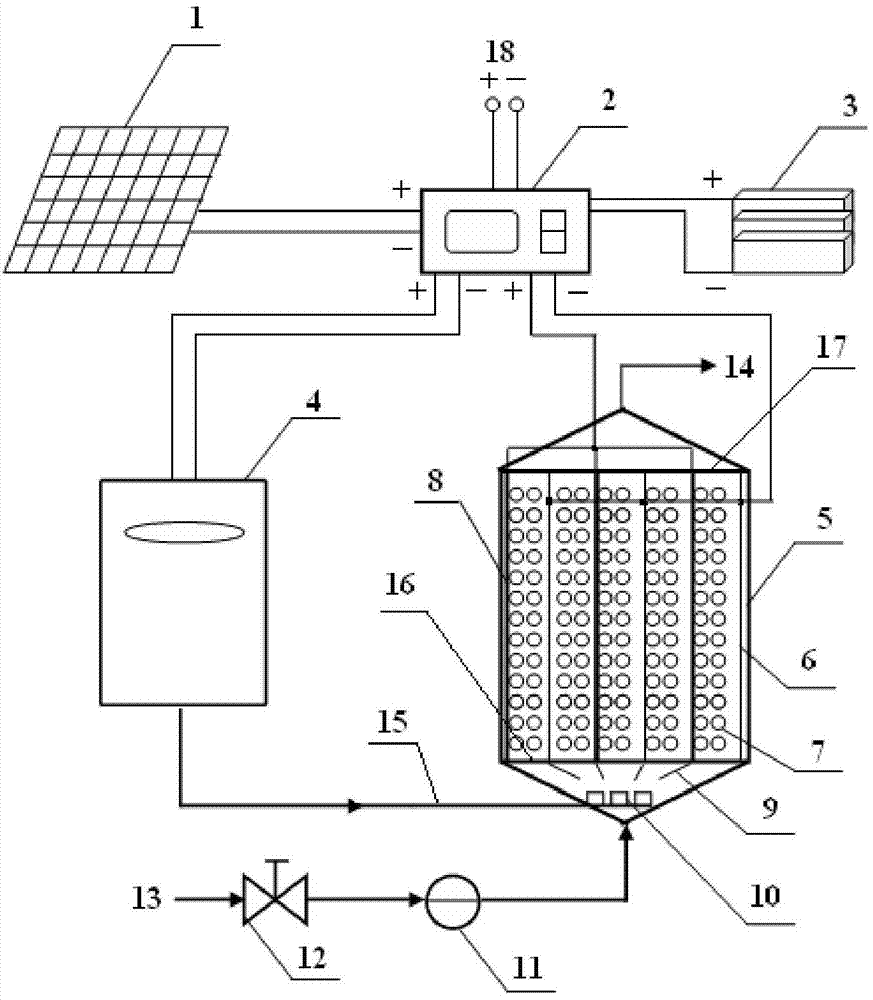

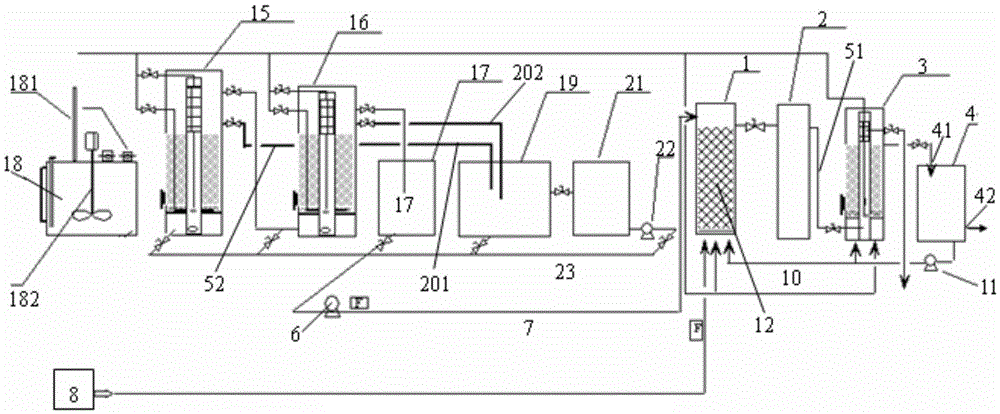

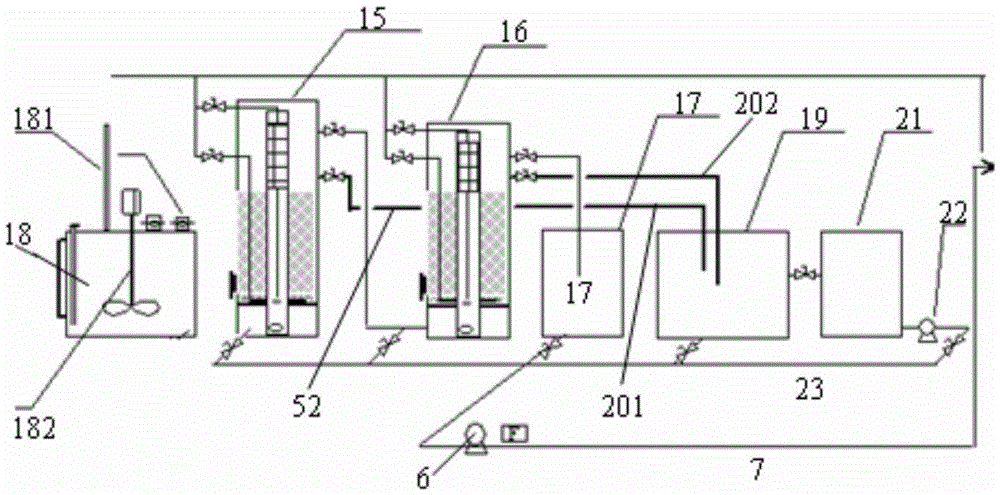

Device for compositely catalytic oxidation treatment of organic wastewater and preparation method of catalytic anode

InactiveCN102923826ALow running costComplies with low voltageWater contaminantsWater/sewage treatment by electrochemical methodsCatalytic oxidationTitanium plate

The invention discloses a device for compositely catalytic oxidation treatment of organic wastewater and a preparation method of a catalytic anode. The device comprises a solar photovoltaic power system, a control system, a storage battery pack, an ozone generator and an electric field ozone catalytic composite reactor, wherein the electric field ozone catalytic composite reactor comprises a shell, a wastewater inlet is formed on the lower end of the shell, and a wastewater outlet is formed on the upper end of the shell; a lower septal pore plate and an upper septal pore plate are arranged in the shell; a catalytic anode and a catalytic cathode are arranged between the lower septal pore plate and the upper septal pore plate; catalytic particles are filled between the catalytic anode and the catalytic cathode; and a gas-water mixer is arranged between the lower septal pore plate and the wastewater inlet. The preparation method comprises the following steps: taking a titanium plate and using the titanium plate as a substrate; uniformly coating mixed precursor solution of an inner layer onto the titanium plate and forming a film on the titanium plate, drying, thermally oxidizing and annealing to form an inner layer; and coating the mixed precursor solution of an outer layer onto the inner layer, drying, thermally oxidizing and annealing to a room temperature.

Owner:SOUTHEAST UNIV

Enhancement of thermal interface conductivities with carbon nanotube arrays

ActiveUS8093715B2Increase effective thermal contact conductance of thermalHigh thermal contactNanotechSemiconductor/solid-state device detailsCarbon nanotubeCombined use

A method of forming a well-anchored carbon nanotube (CNT) array, as well as thermal interfaces that make use of CNT arrays to provide very high thermal contact conductance. A thermal interface is formed between two bodies by depositing a continuous array of carbon nanotubes on a first of the bodies so that, on mating the bodies, the continuous array is between surface portions of the first and second bodies. The thermal interface preferably includes a multilayer anchoring structure that promotes anchoring of the continuous array of carbon nanotubes to the first body. The anchoring structure includes a titanium bond layer contacting the surface portion of the first body, and an outermost layer with nickel or iron catalytic particles from which the continuous array of carbon nanotubes are nucleated and grown. Additional thermal interface materials (TIM's) can be used in combination with the continuous array of carbon nanotubes.

Owner:PURDUE RES FOUND INC

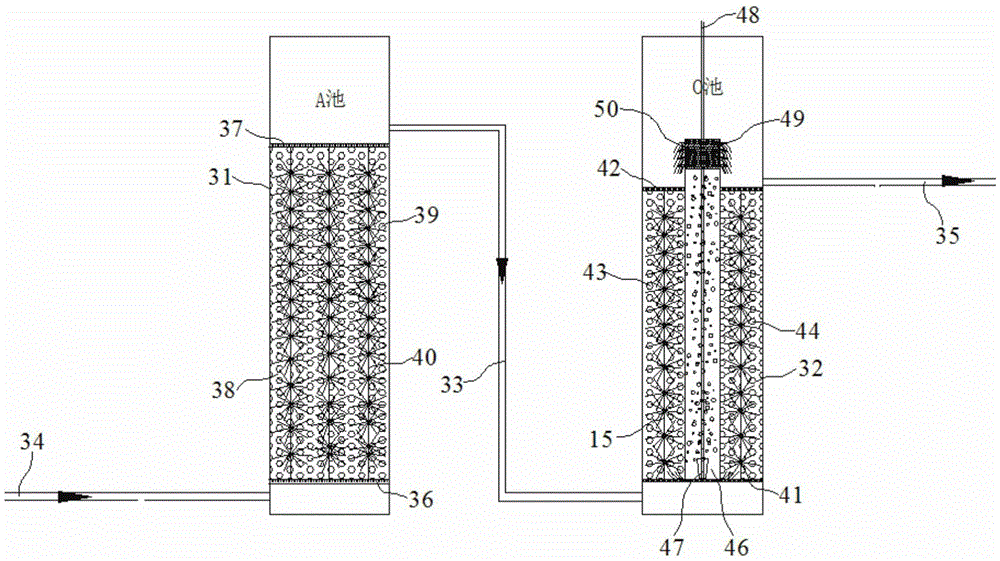

Low-consumption nitrification and denitrification coal chemical wastewater advanced treatment device

InactiveCN105481177AIncrease reaction rateImprove biodegradabilityWater treatment compoundsHeterogenous catalyst chemical elementsActivated sludgeCellulose

The invention discloses a low-consumption nitrification and denitrification coal chemical wastewater advanced treatment device, comprising a catalytic oxidation pond, an oxidation stabilization pond and a rear biochemical BAF pond, wherein the catalytic oxidation pond is filled with ozone-catalytic particles in a static bed form, and a comprehensive dilution tank is provided with a charging hole and a stirrer; the ozone-catalytic particles are prepared from 88.7-91.3 parts of activated aluminium oxide particles, 1.2-1.5 parts of copper oxide, 4-7 parts of polyethylene glycol, 1.5-2 parts of polyvinyl alcohol, 0.8-1 part of titanium dioxide, 0.3-0.5 part of hydroxyl propyl cellulose and 0.2-0.4 part of manganese dioxide; the lower part and the upper part of an aerobic tank in the rear biochemical BAF pond are respectively provided with a lower sieve plate and an upper sieve plate, the lower sieve plate, the upper sieve plate and the side wall of the aerobic tank form an aerobic cavity, and a plurality of aerobic activated sludge particles and a plurality of second masson pines as a filler are arranged in the aerobic cavity. The low-consumption nitrification and denitrification coal chemical wastewater advanced treatment device oxidizes a macromolecular organic matter hard to degrade into a micromolecular organic matter easy to biochemically treat, and the biochemical property of effluent is further improved.

Owner:KOOVINE ENVIRONMENTAL PROTECTION TECH CO LTD

Monoalkylated Aromatic Compound Production

ActiveUS20090306446A1Simple processHydrocarbon by isomerisationMolecular sieve catalystsAlkyl transferReaction zone

A process for producing a monoalkylated aromatic compound in an alkylation reaction zone, said process comprising the steps of:(a) providing a first catalytic particulate material having a ratio of surface area over surface volume ratio greater than about 79 cm−1,(b) providing said alkylation reaction zone with an alkylatable aromatic compound, an alkylating agent, and said first catalytic particulate material; and(c) contacting said alkylatable aromatic compound and said alkylating agent with said catalytic particulate material in said alkylation reaction zone maintained under alkylation conditions, to form a product comprised of said monoalkylated aromatic compound and polyalkylated aromatic compound(s). The molar ratio of said polyalkylated aromatic compound(s) over said monoalkylated aromatic compound produced by said first catalytic particulate material is less than the molar ratio of polyalkylated aromatic compound(s) over monoalkylated aromatic compound produced by a second catalytic particulate material and said alkylation reaction zone is operated under the same alkylation conditions, wherein at least 51 wt. % of said second catalytic particulate material having a ratio of surface area over surface volume between 78 and 79 cm−1.

Owner:EXXONMOBIL CHEM PAT INC

Multi-functional cermet anodes for high temperature fuel cells

An anode in a Direct Carbon Fuel Cell (DCFC) is provided. The anode includes a cermet anode that can be made of nickel-copper / yttria-stabilized zirconia oxide (Ni—Cu / YSZ) or nickel-copper / gadolina-doped ceria (Ni—Cu / GDC). The surface of the cermet anode is functionalized by decorating it with dispersed catalytic particles. The particles can be made of various materials such as ruthenium (Ru), rhodium (Rh), palladium (Pd), rhenium (Re), osmium, (Os), iridium (Ir), platinum (Pt), gold (Au), or any combination of the particles' alloys and mixtures. Decorating is a process where discrete particles are deposited to the anode surface. In general the particles are not able to contact each other and have a well-defined separation. The cermet anode has a graded porous microstructure spanning from a macropore outer region to a submicron inner region, where the pore span is from tens of microns to hundreds of nanometers.

Owner:DIRECT CARBON TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com