Device for compositely catalytic oxidation treatment of organic wastewater and preparation method of catalytic anode

A technology of organic wastewater and catalytic oxidation, applied in catalyst activation/preparation, oxidized water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high operating cost, inability to achieve industrial-scale application, and poor complete mineralization ability. To achieve the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

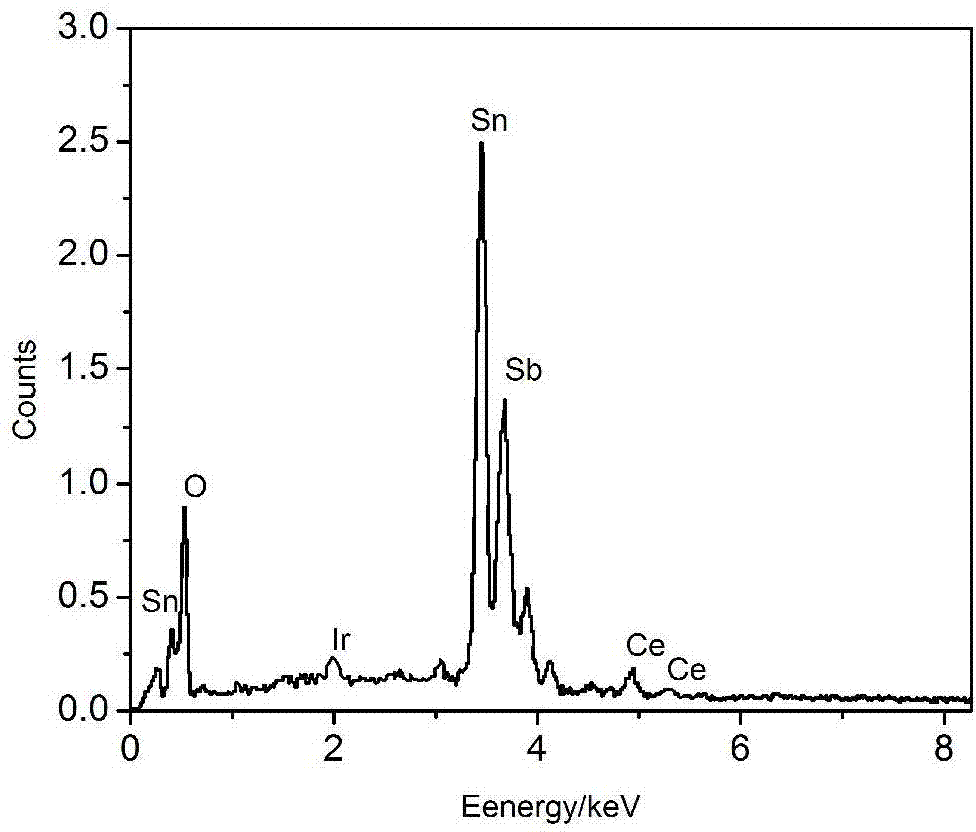

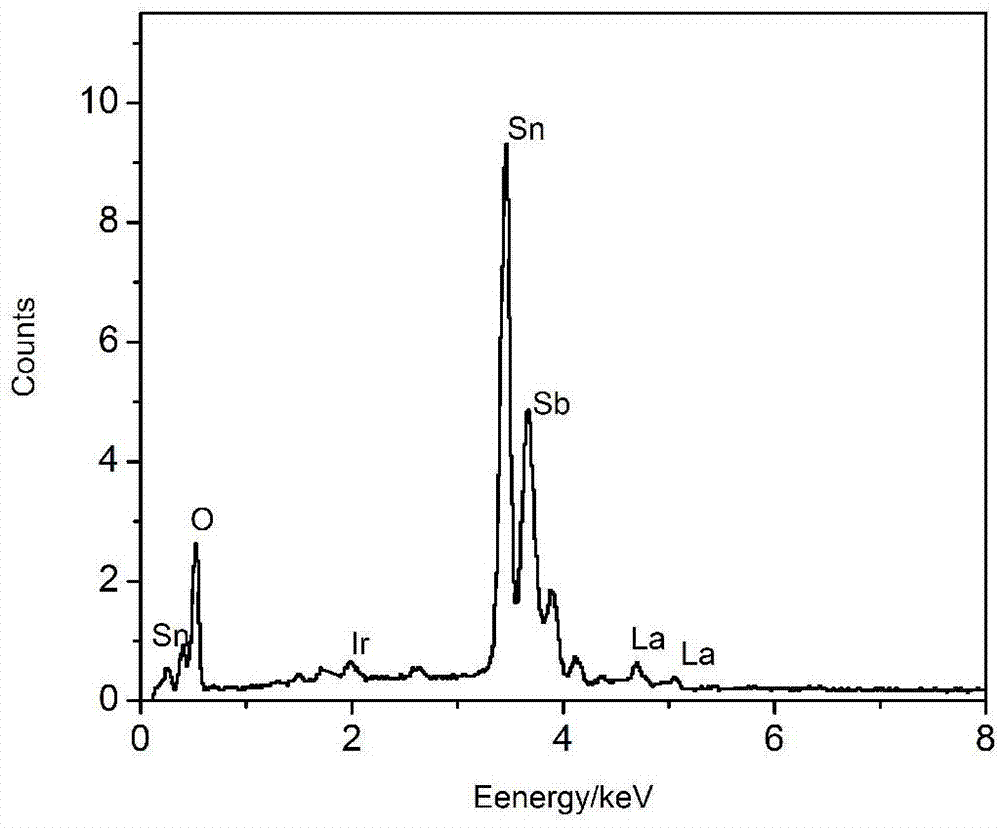

[0050] Ce, La, Ir doped Ti / SnO 2 -Sb electrode preparation:

[0051] The surface of the titanium metal plate substrate is sanded with abrasive cloth and pretreated with acid and alkali to remove the oil stain on the surface, and the surface is etched to increase the adhesion of the active coating on the titanium substrate. Take a certain amount of SnCl with a molar ratio of Sn:Sb:Ir=100:10:24 ·5H 2 O, SbCl 3 , IrCl 3 ·3H 2 O metal salt mixture, add citric acid to it, its molar ratio to the sum of each metal is citric acid: the sum of each metal = 1:1, to obtain a solid mixture, add absolute ethanol and polyethylene glycol to the solid mixture (400), the volume addition of absolute ethanol is 8-12 times the volume addition of polyethylene glycol (400), the mass content of the metal salt in the mixture is 2-4%, and the mixture is magnetically stirred at 60°C After 3h, a uniform inner layer precursor mixed solution was obtained. Apply the prepared mixed solution of the inne...

Embodiment 2

[0054] Preparation of particle electrodes: ①Carrier pretreatment, the ceramic particles were placed in 0.1mol / l hydrochloric acid and 0.1mol / l sodium hydroxide solution and boiled for 30min, then rinsed and soaked repeatedly to remove the impurities adsorbed on the surface, and washed Drain the carrier and dry it at 105°C for 10 hours; 3 ) 2 , Ce(NO 3 ) 3 and RuCl 3 The molar ratio is 100:10:1 to prepare the mixture, and then add absolute ethanol to the mixture to form a mixed solution. The mass content of the metal salt in the mixed solution is 5-10%, and then add 5% of the mixed solution to the mixed solution. % of 0.1mol / l hydrochloric acid solution to obtain the impregnation solution; ③ impregnation, the pretreated ceramic particles are placed in the impregnation solution, dynamically soaked on a shaker for 3 hours, and the particles are filtered out to impregnate the impregnated active components on the ceramic particles. ; ④ drying and roasting activation. The ceram...

Embodiment 3

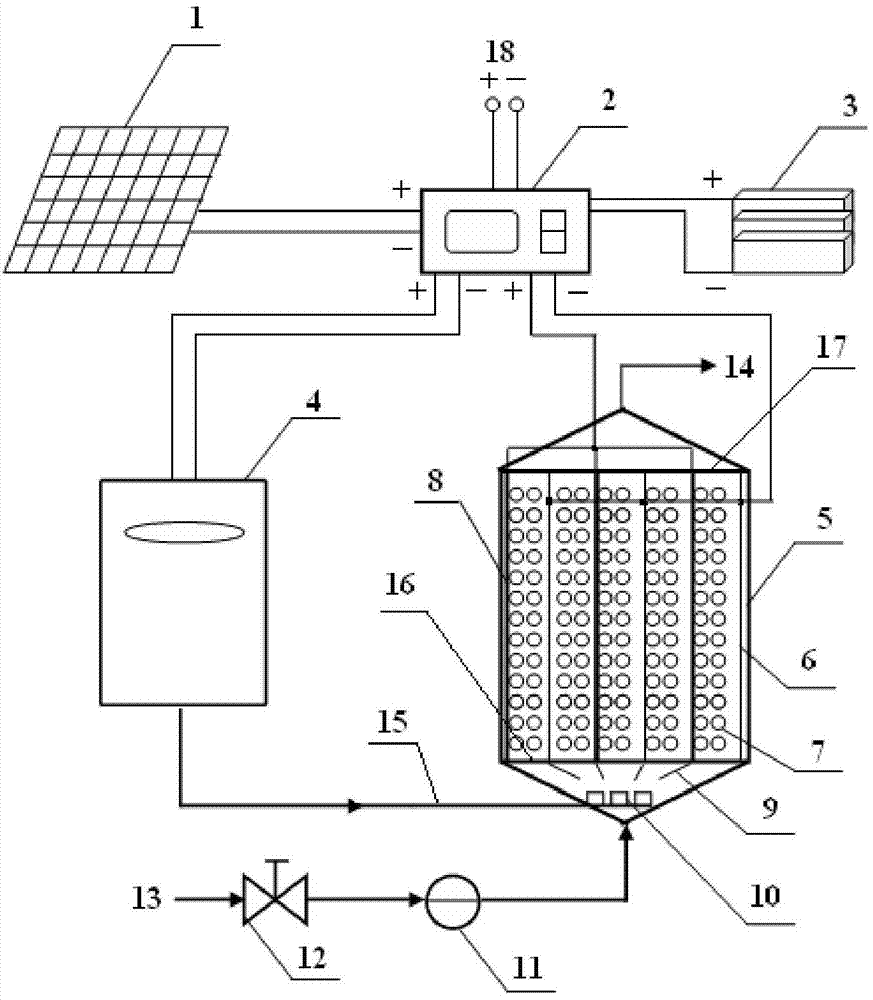

[0056] The initial concentration of aniline wastewater is 2150mg / L, using three Ti / SnO 2 -Sb-Ir-Ce anode and three titanium plate cathodes are connected in parallel, the electrode spacing is 1.5cm, and ceramic particles / MnO are filled between the positive and negative electrodes 2 -Ce-Ru electrodes, solar photovoltaic cells to charge the battery, adjust the control system to output electrocatalytic initial voltage of 6V and ozone generator electrolytic working voltage of 5V, ozone flow rate of 20L / H, circulating wastewater flow rate of 200L / H, ozone recombination by electric field Catalytic oxidation treatment for 2 hours. The conversion rate of aniline was 99.6%, and the removal rate of COD was 86.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com