Patents

Literature

63 results about "Catalytic chemical vapor deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

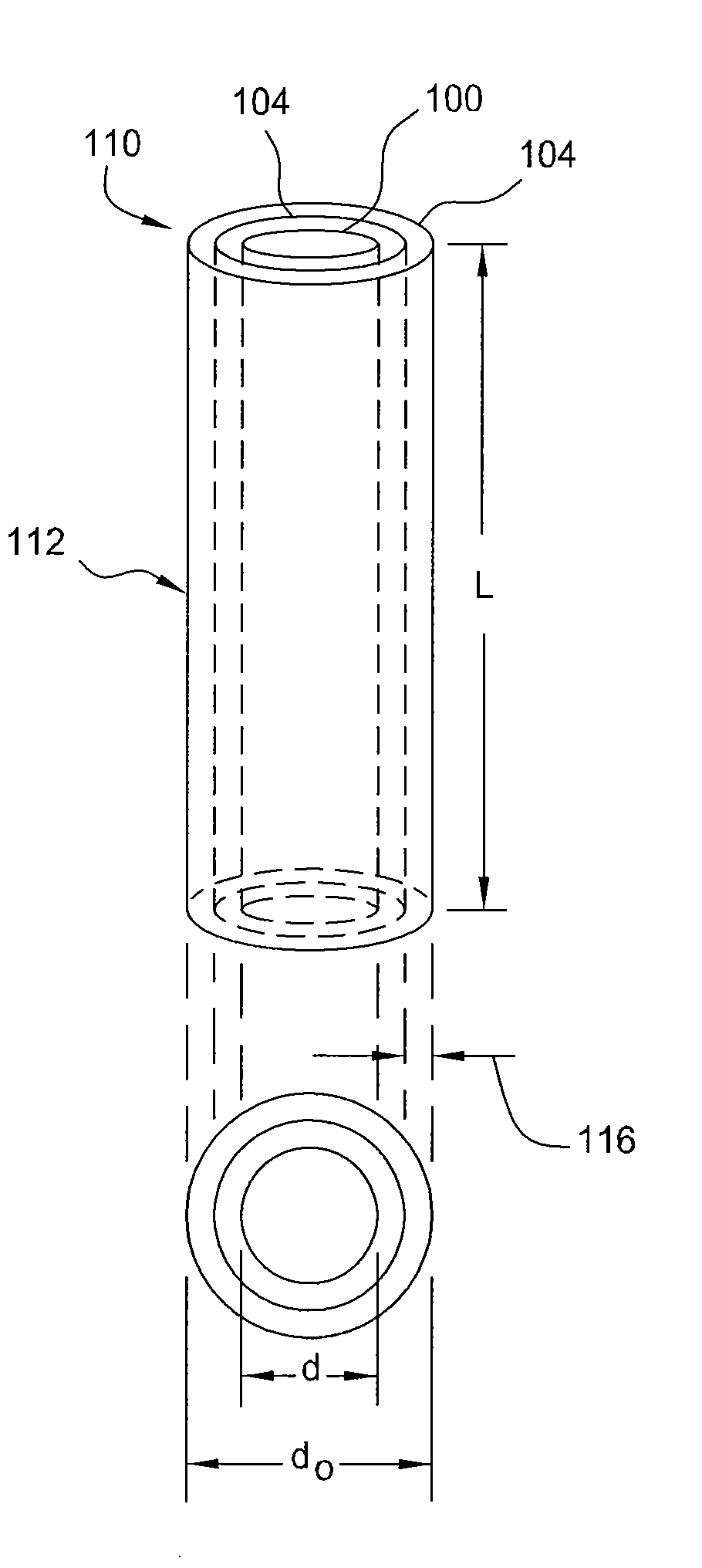

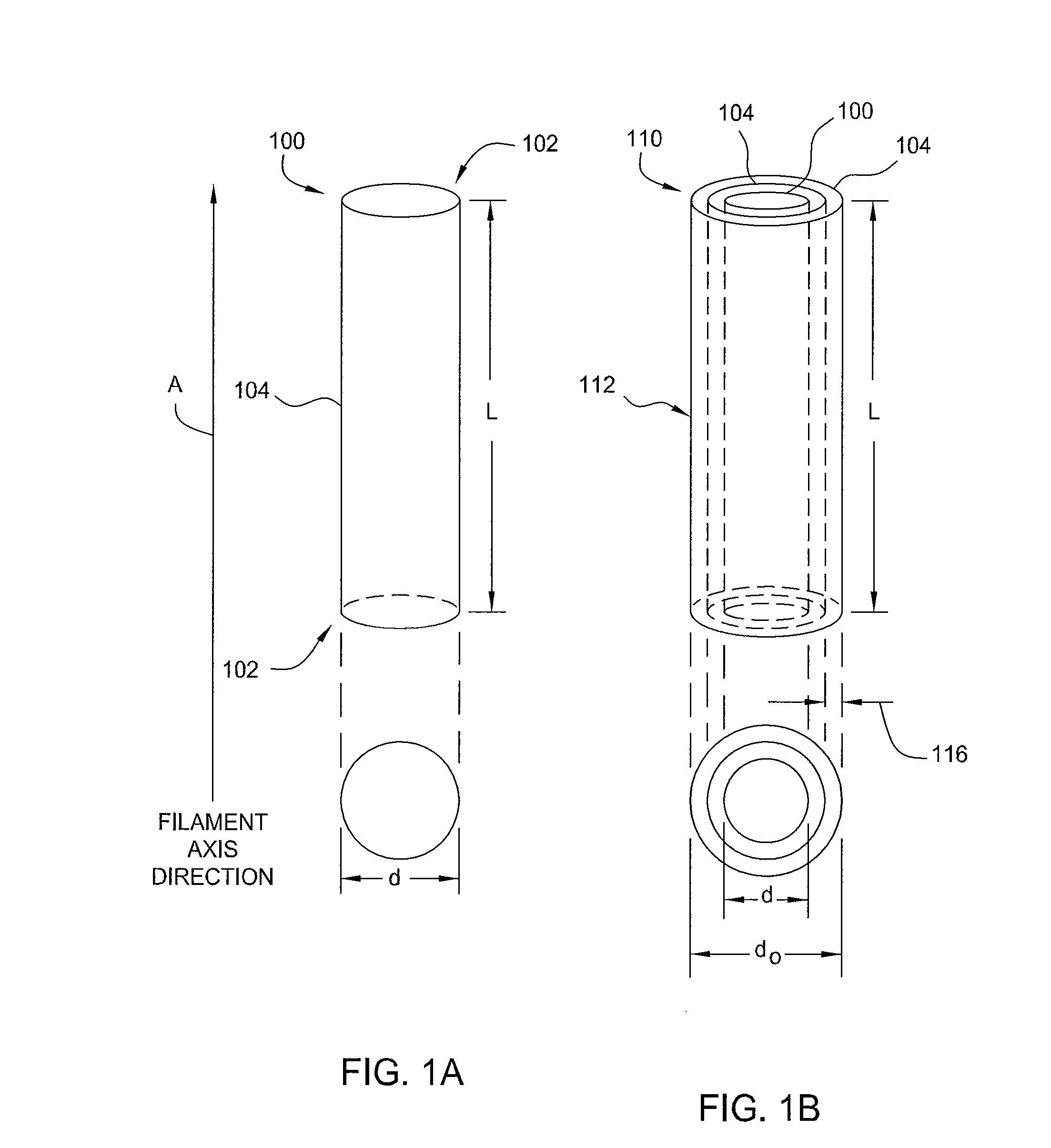

Composite materials containing metallized carbon nanotubes and nanofibers

A method and apparatus are provided for the cost effective formation of a composite material which includes metallized carbon nanotubes and / or nanofibers that can be used to form portions of an energy storage device, such as a lithium ion battery. In one embodiment, carbon nanotubes are formed on a host substrate using a catalytic chemical vapor deposition process. An initiation-adhesion layer is formed over the carbon nanotubes and a metallic layer is then deposited on the initiation-adhesion layer and each layer is formed using a wet deposition process. In one embodiment, portions of the host substrate are used to form an electrochemical storage device that may be integrated with other formed electrochemical storage devices to create an interconnected battery array. The battery array may be formed as a woven sheet, panel, or other flexible structure depending upon the type of host substrate material. In one case, the host substrate material may be a flexible fibrous material that has multiple layers formed thereon to form a fiber battery, such as a lithium ion battery.

Owner:APPLIED MATERIALS INC

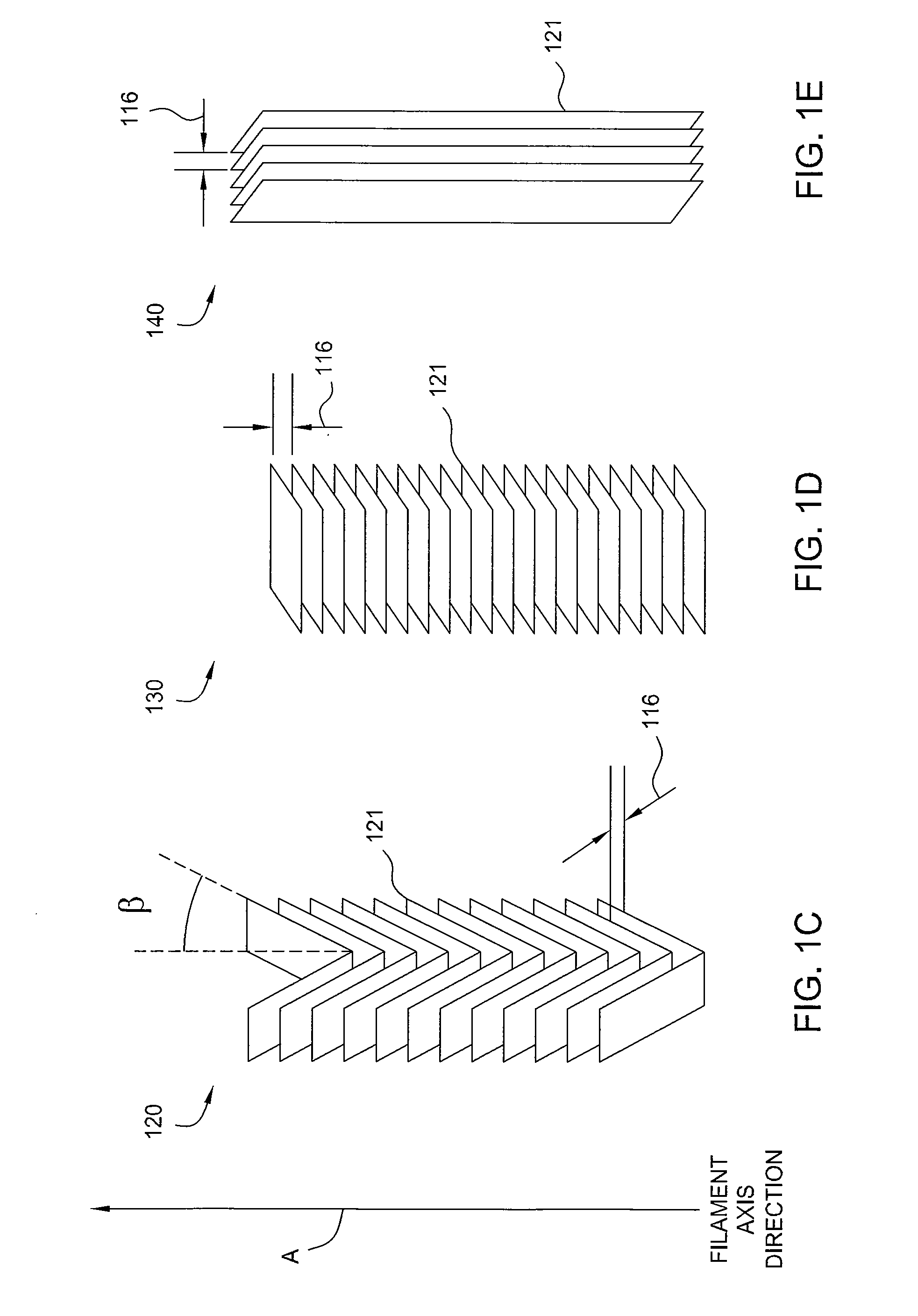

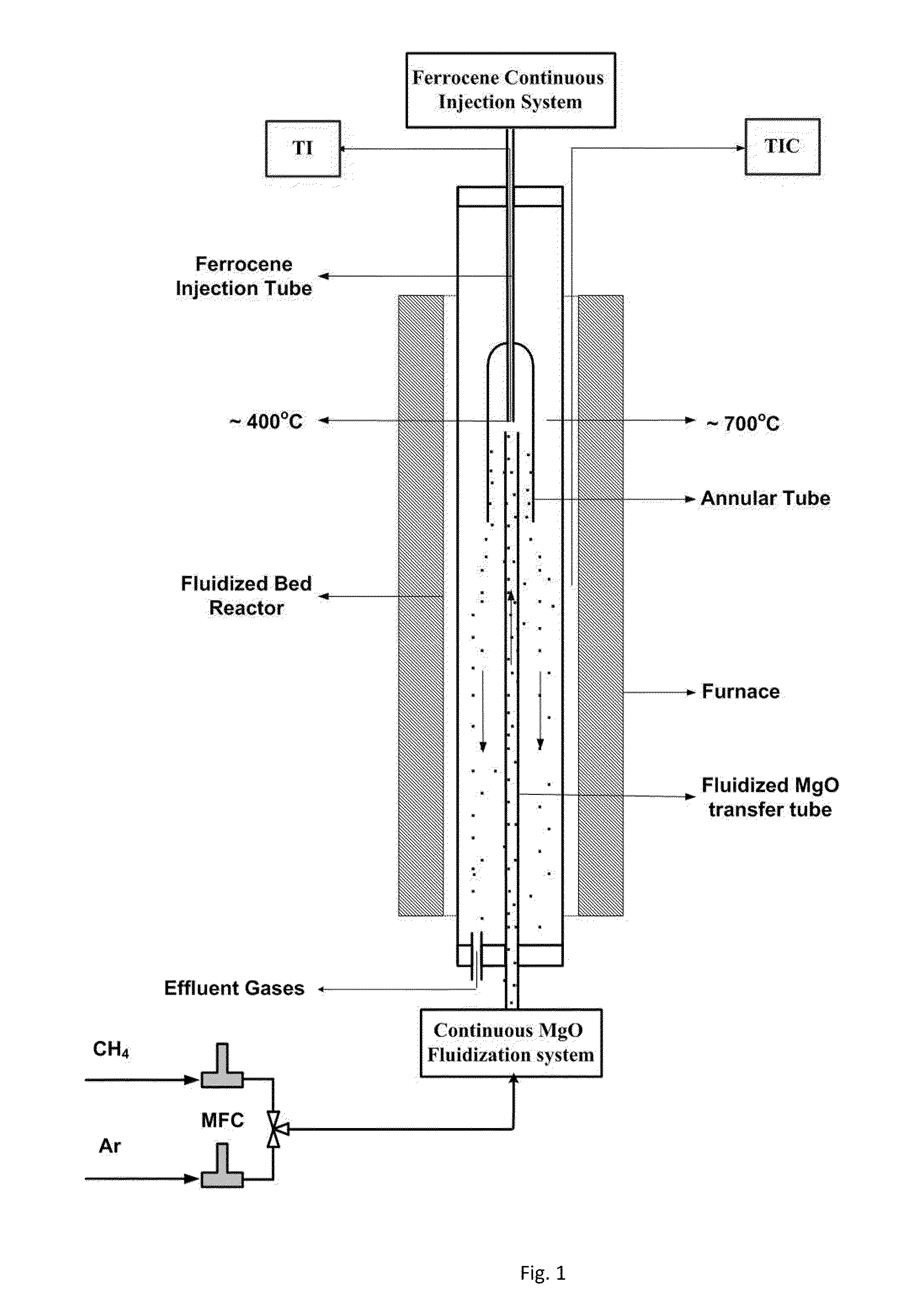

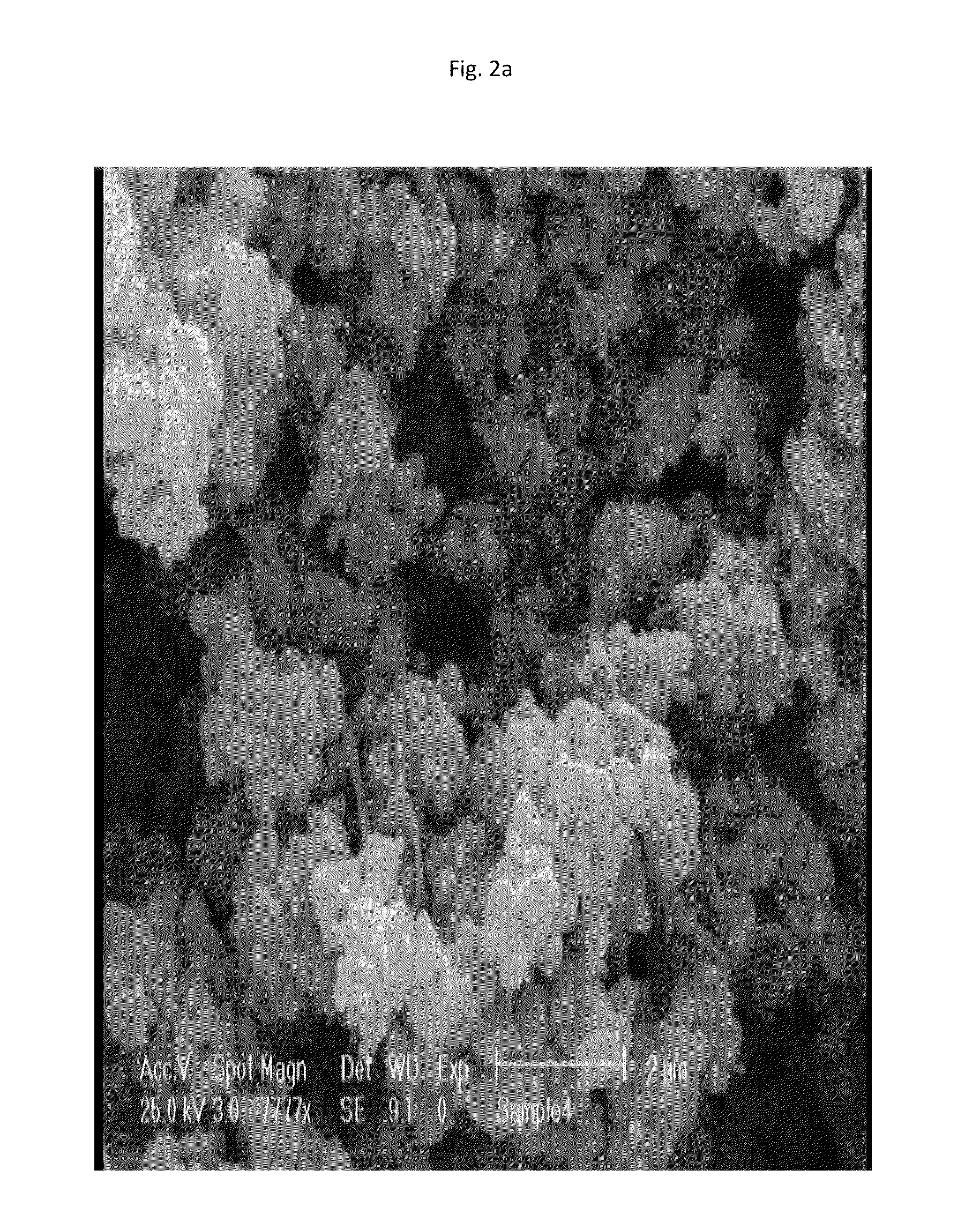

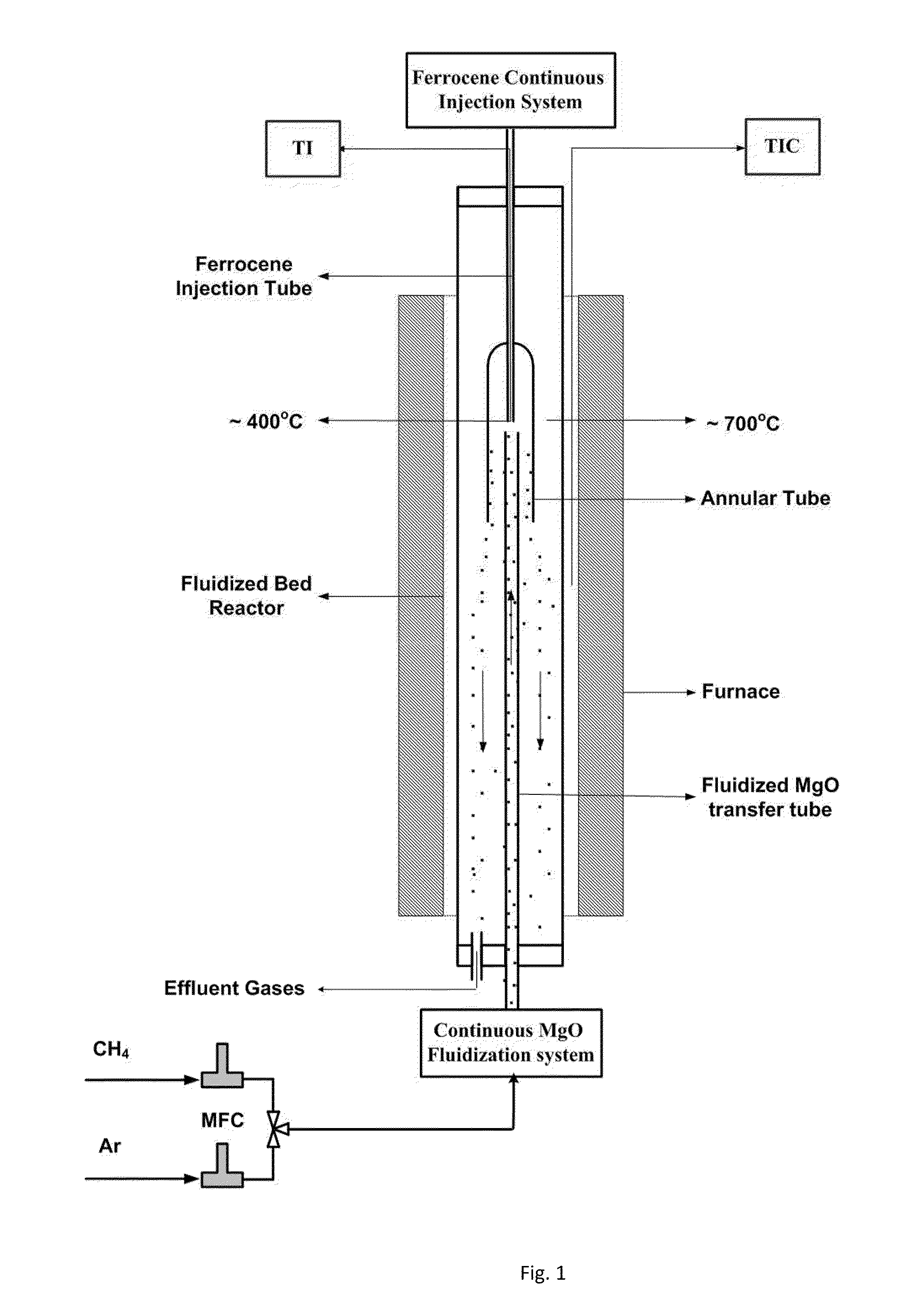

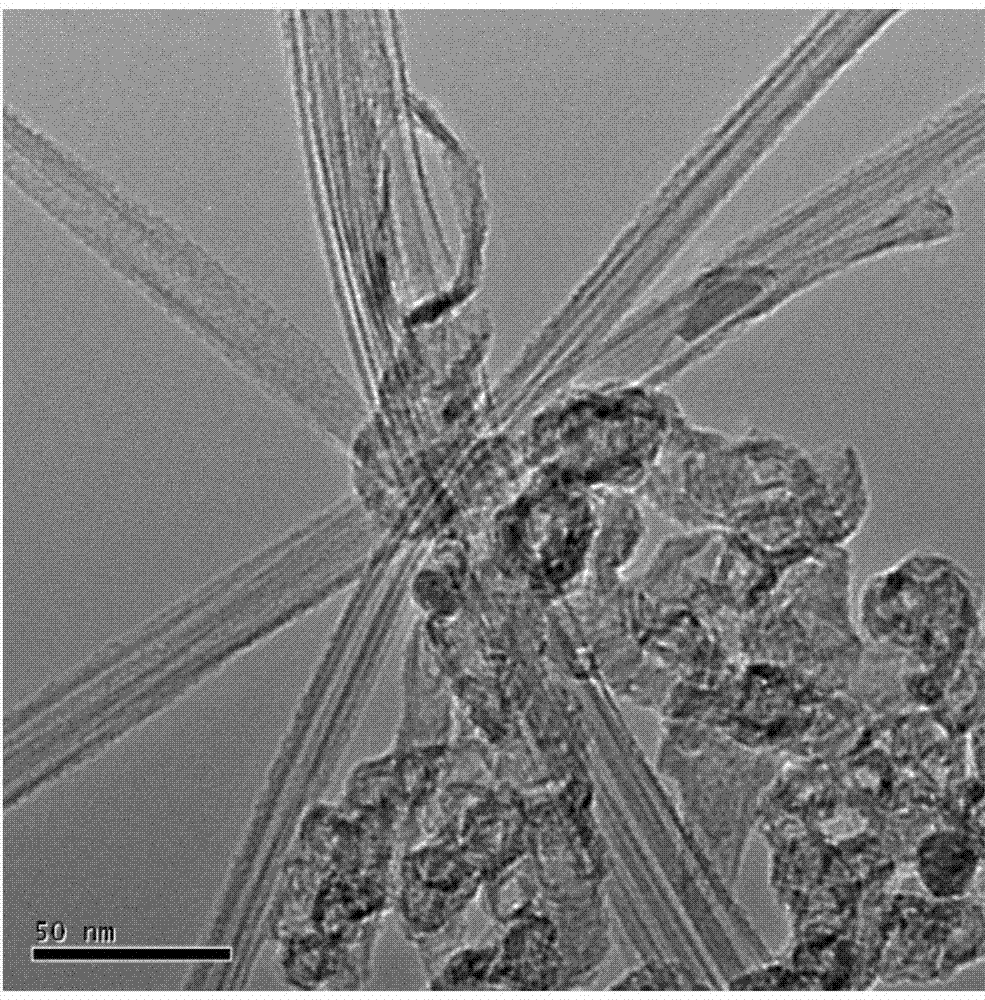

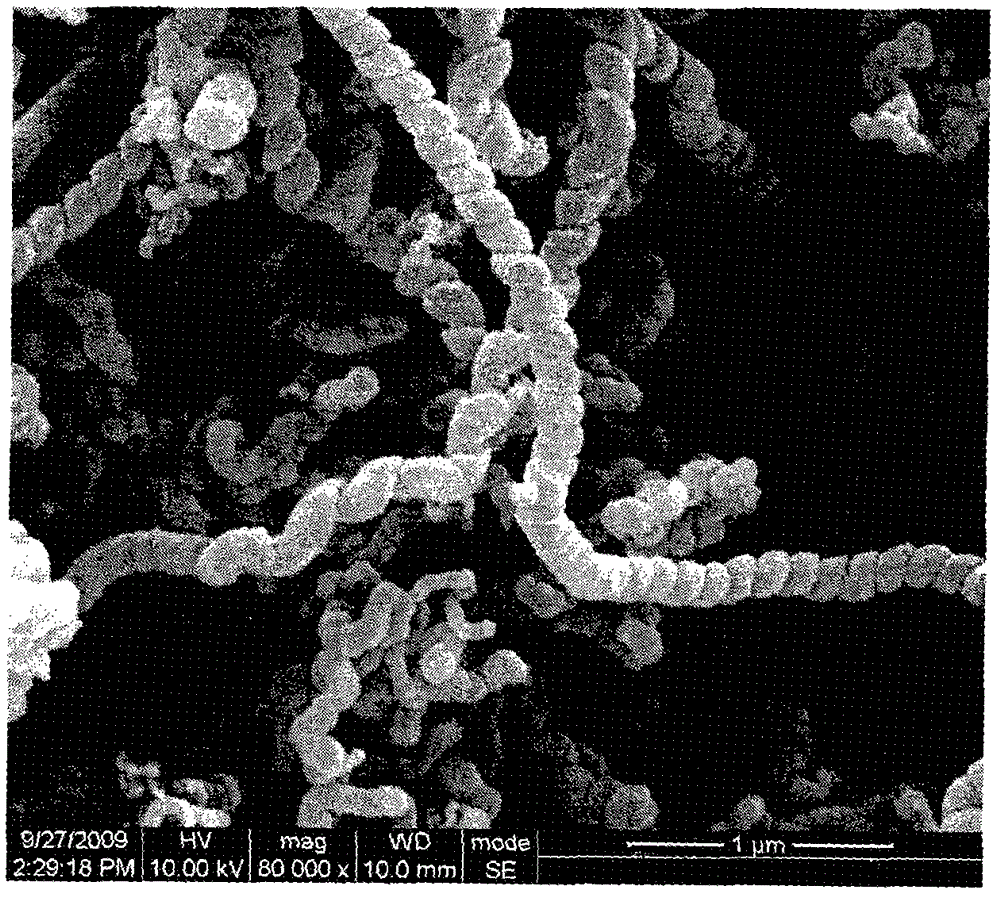

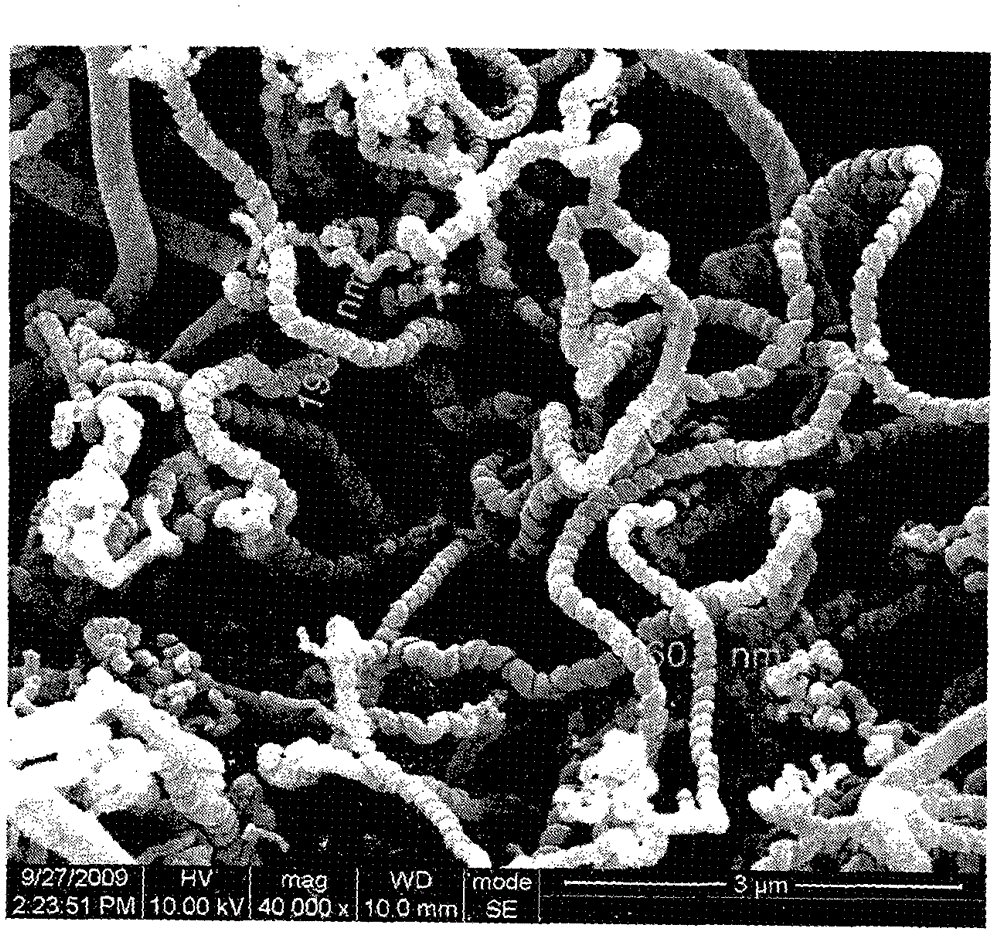

Novel carbon nanotubes synthesis continuous process using iron floating catalysts and MgO particles for CVD of methane in a fluidized bed reactor

InactiveUS20110150746A1Increase surface areaWastingMaterial nanotechnologyCatalytic crackingHot zoneFluidized bed

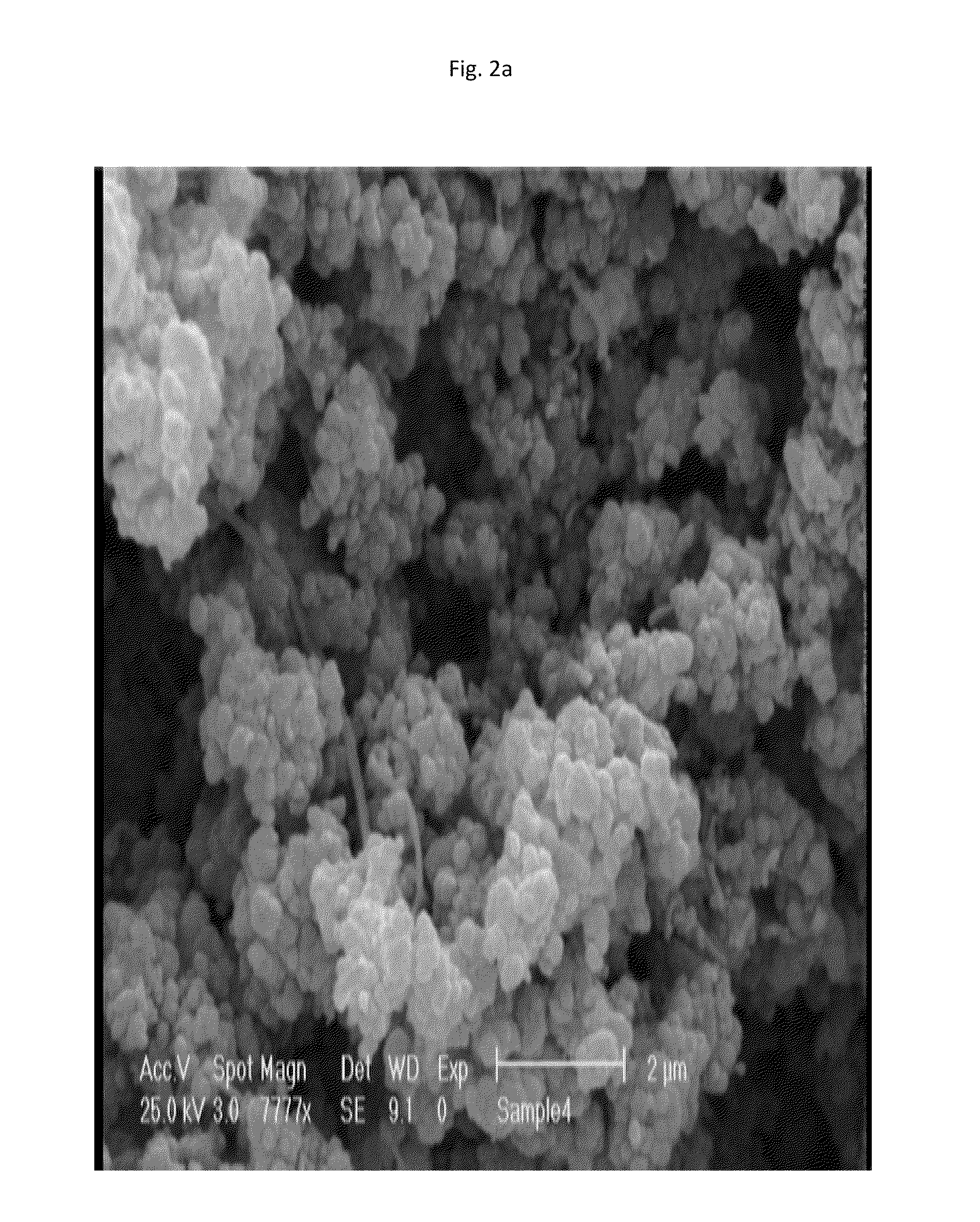

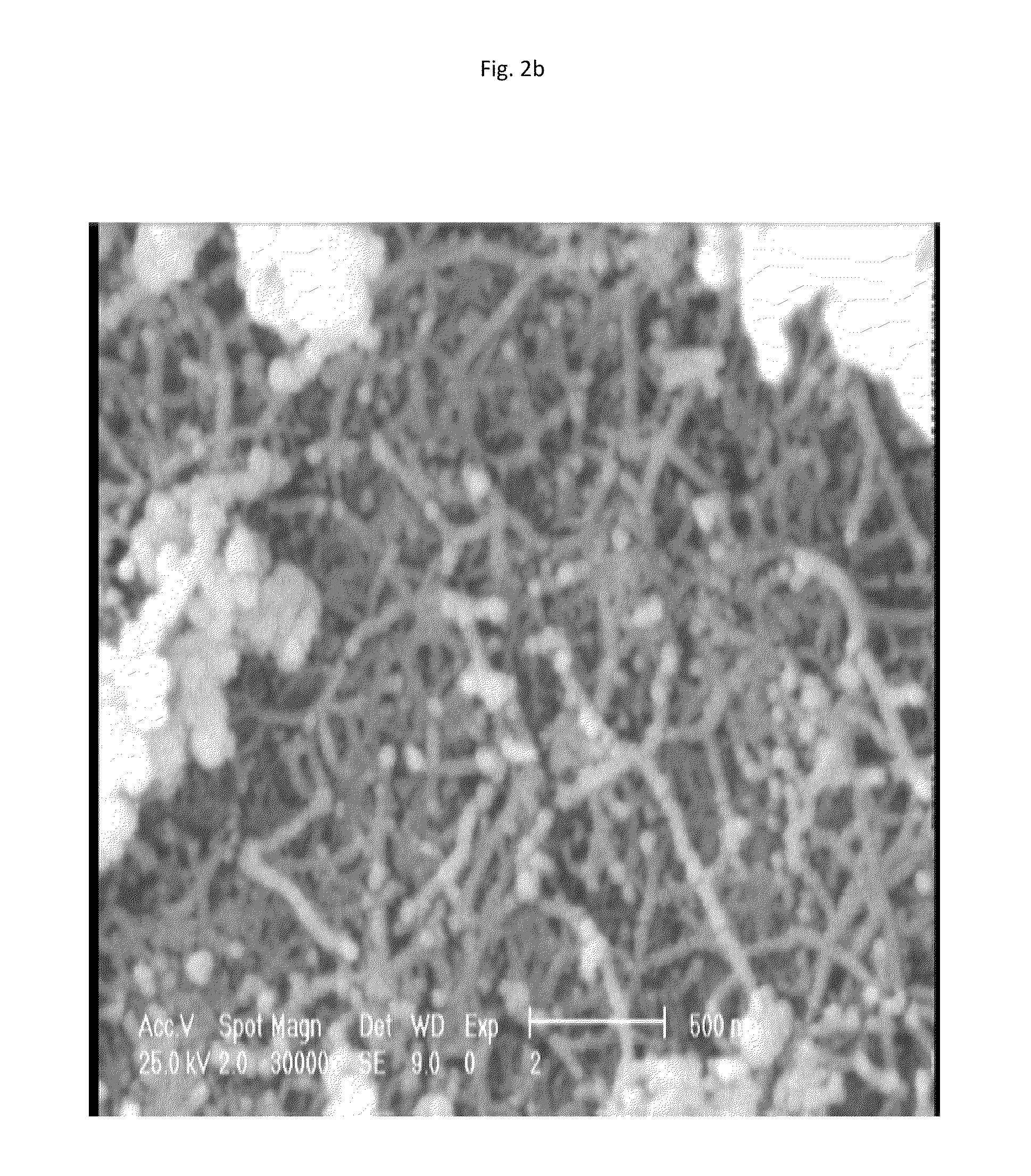

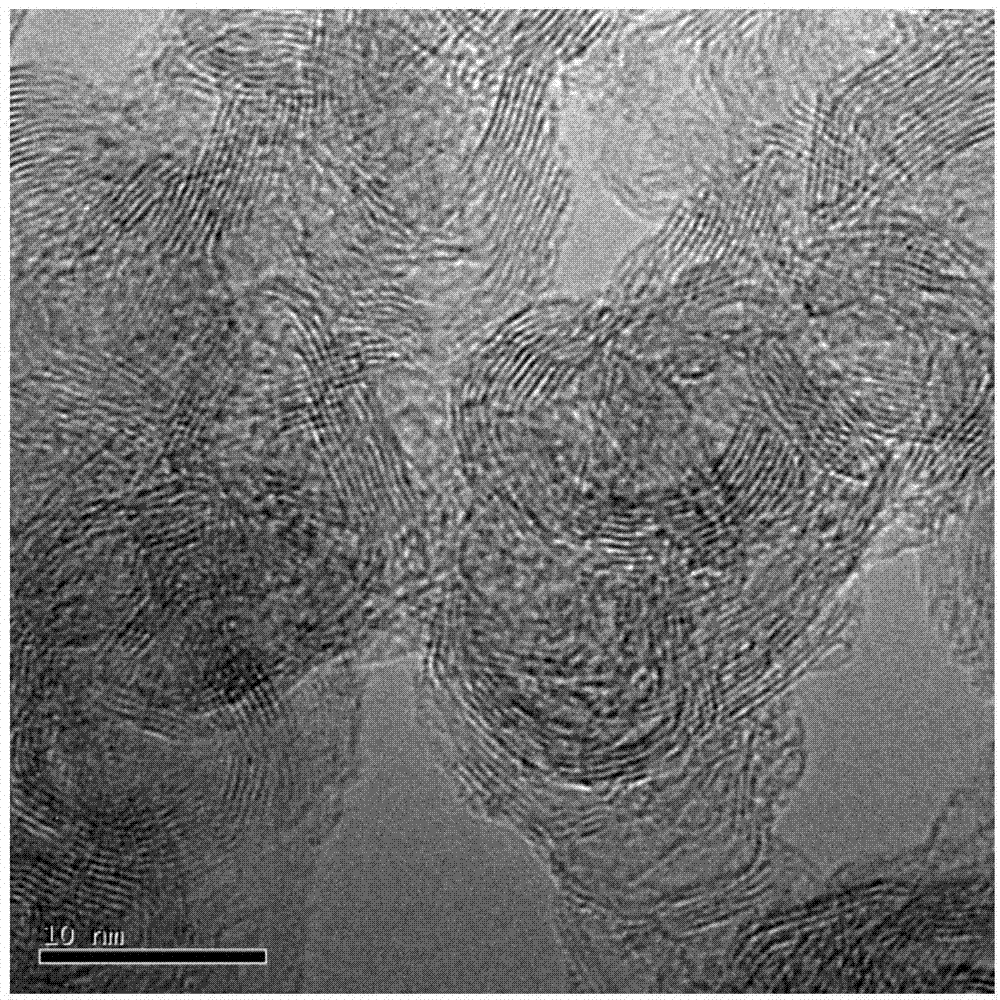

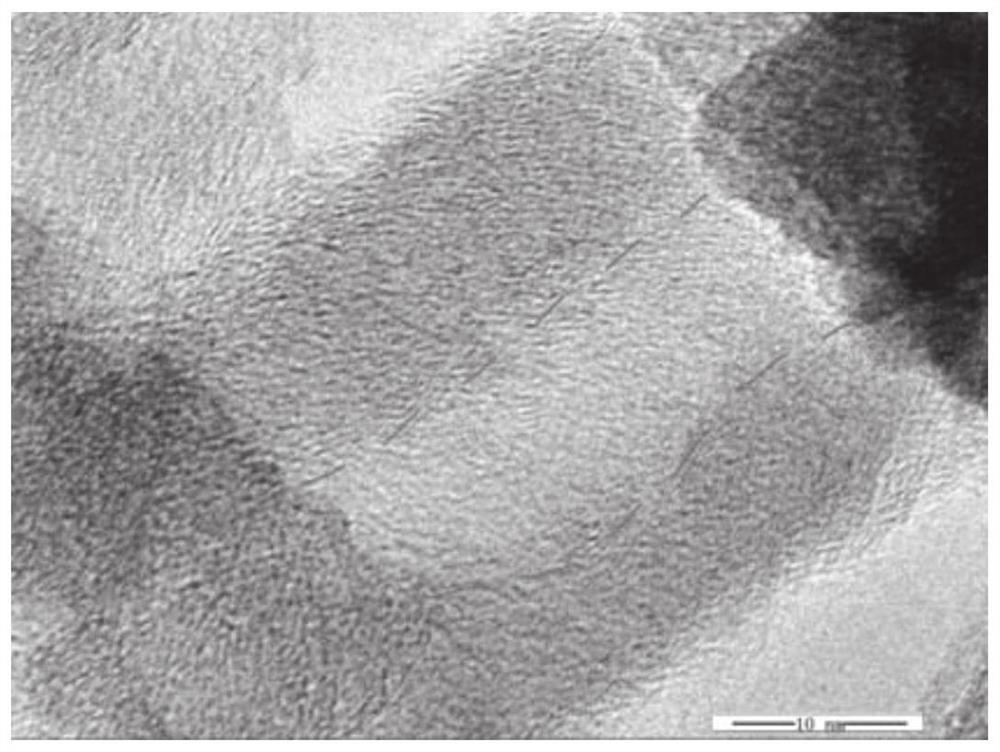

A novel continuous process is used for production of carbon nanotubes (CNTs) by catalytic chemical vapor deposition (CCVD) of methane on iron floating catalyst in-situ deposited on MgO in a fluidized bed reactor. In the hot zone of the reactor, sublimed ferrocene vapors were contacted with MgO powder fluidized by methane feed to produce Fe / MgO catalyst in-situ. An annular tube was used to enhance the ferrocene and MgO contacting efficiency. Multi-wall as well as single-wall CNTs were grown on the Fe / MgO catalyst while falling down the reactor. The CNTs were continuously collected at the bottom of the reactor, only when MgO powder was used. The annular tube enhanced the contacting efficiency and improved both the quality and quantity of CNTs. The SEM and TEM micrographs of the products reveal that the CNTs are mostly entangled bundles with diameters of about 20 nm. Raman spectra show that the CNTs have low amount of amorphous carbon with IG / ID ratios as high as 10.2 for synthesis at 900° C. The RBM Raman peaks indicate formation of single-walled carbon nanotubes (SWNTs) of 1.0-1.2 nm diameter.

Owner:KHODADADI ABBAS ALI +1

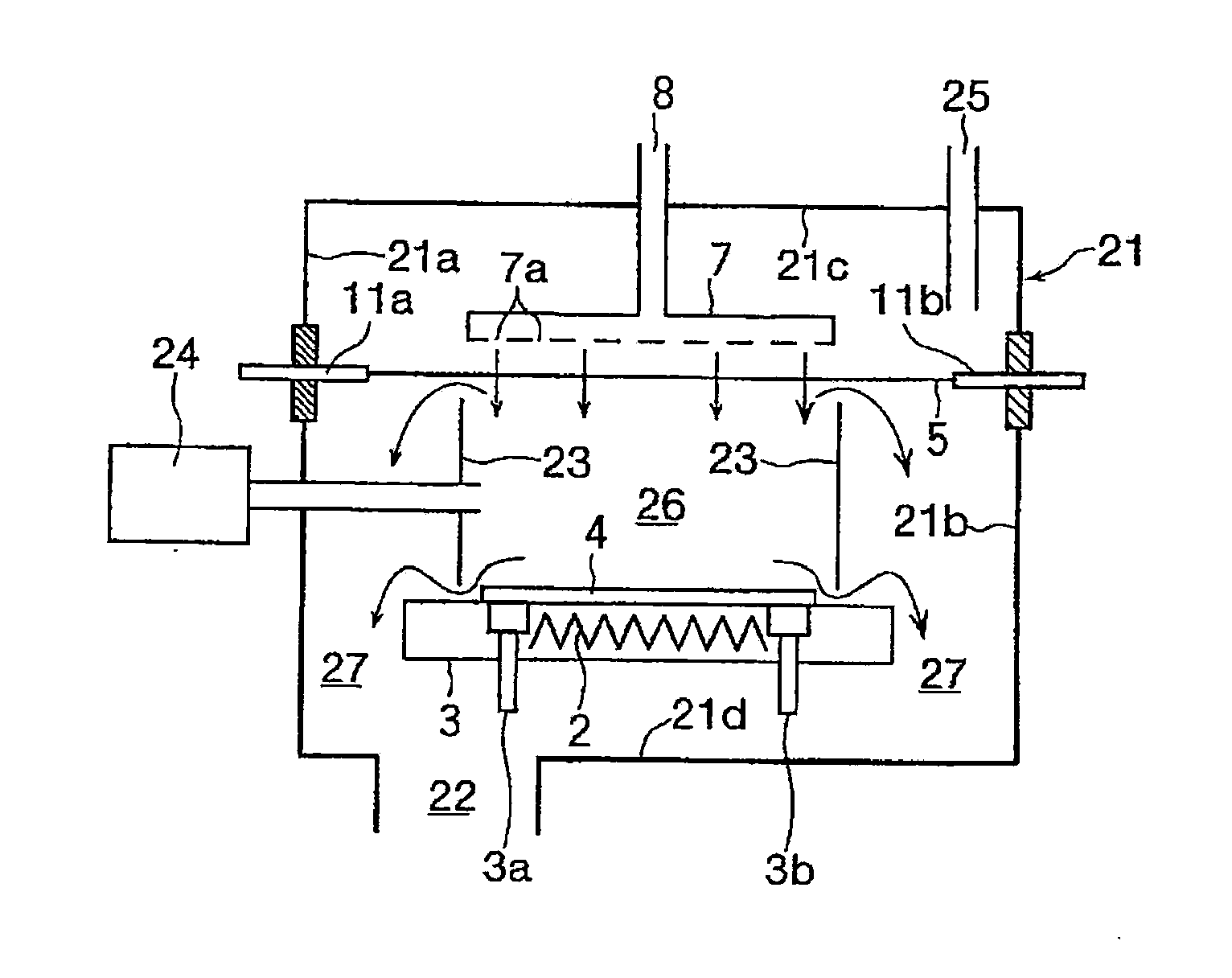

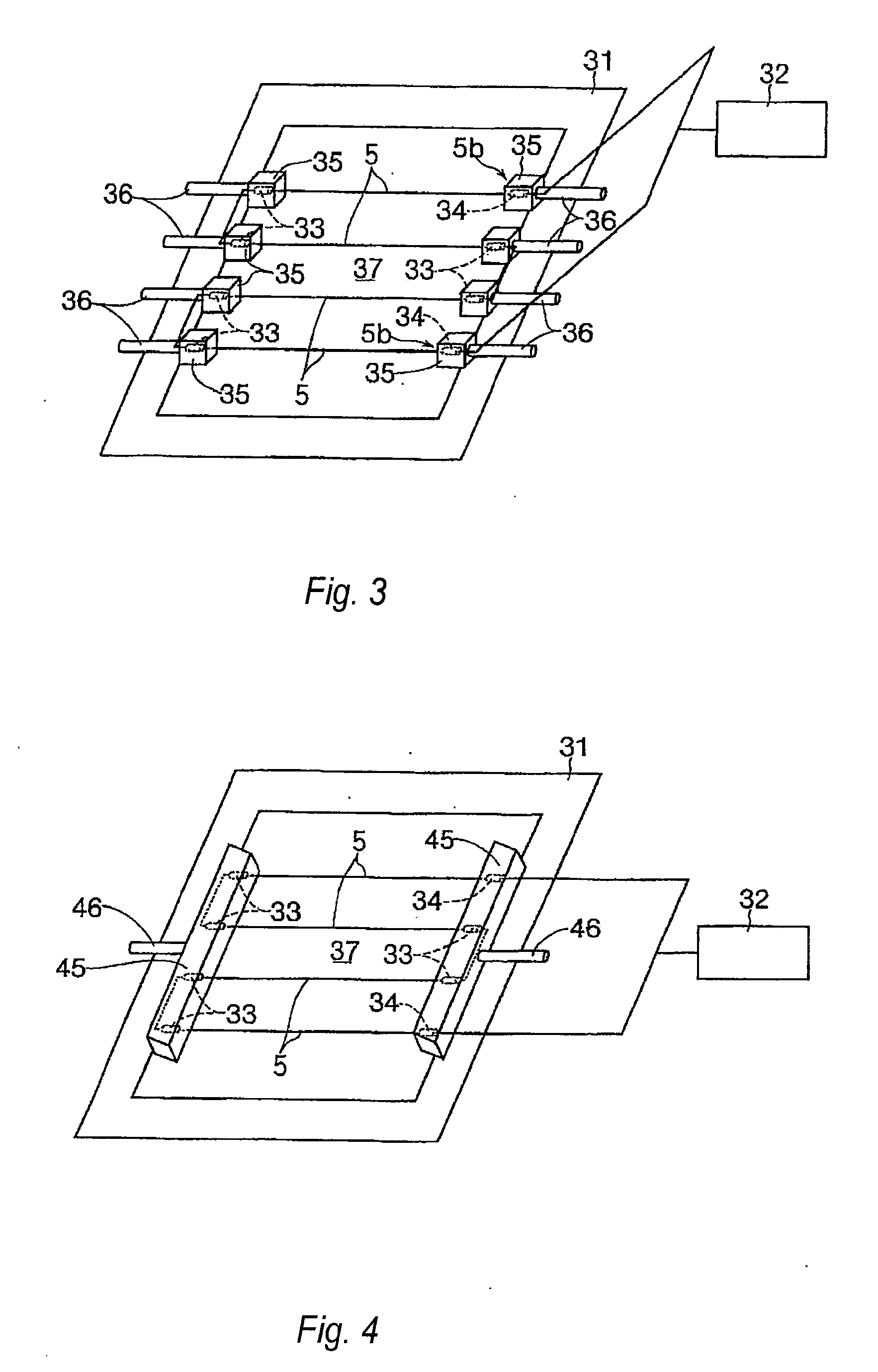

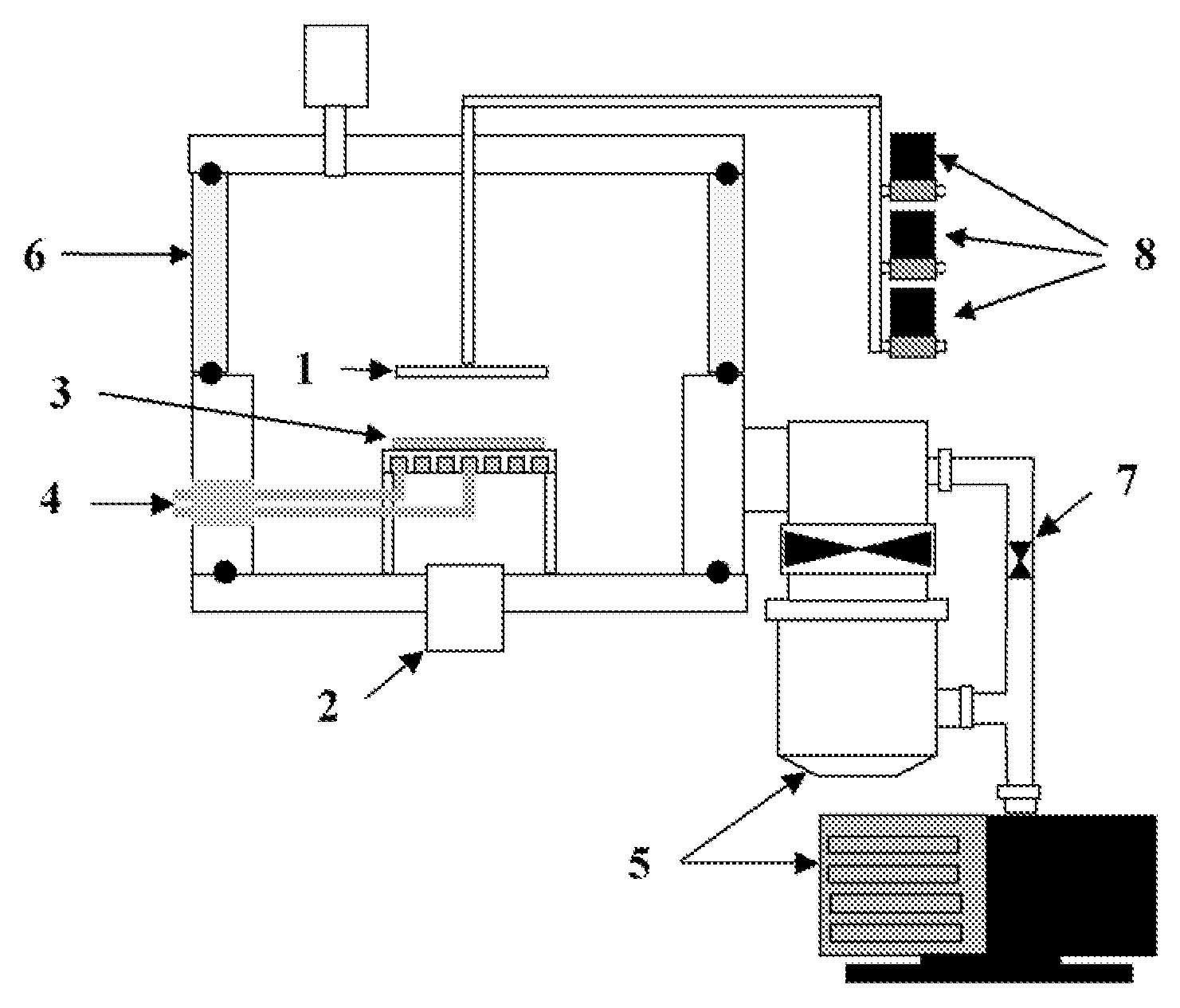

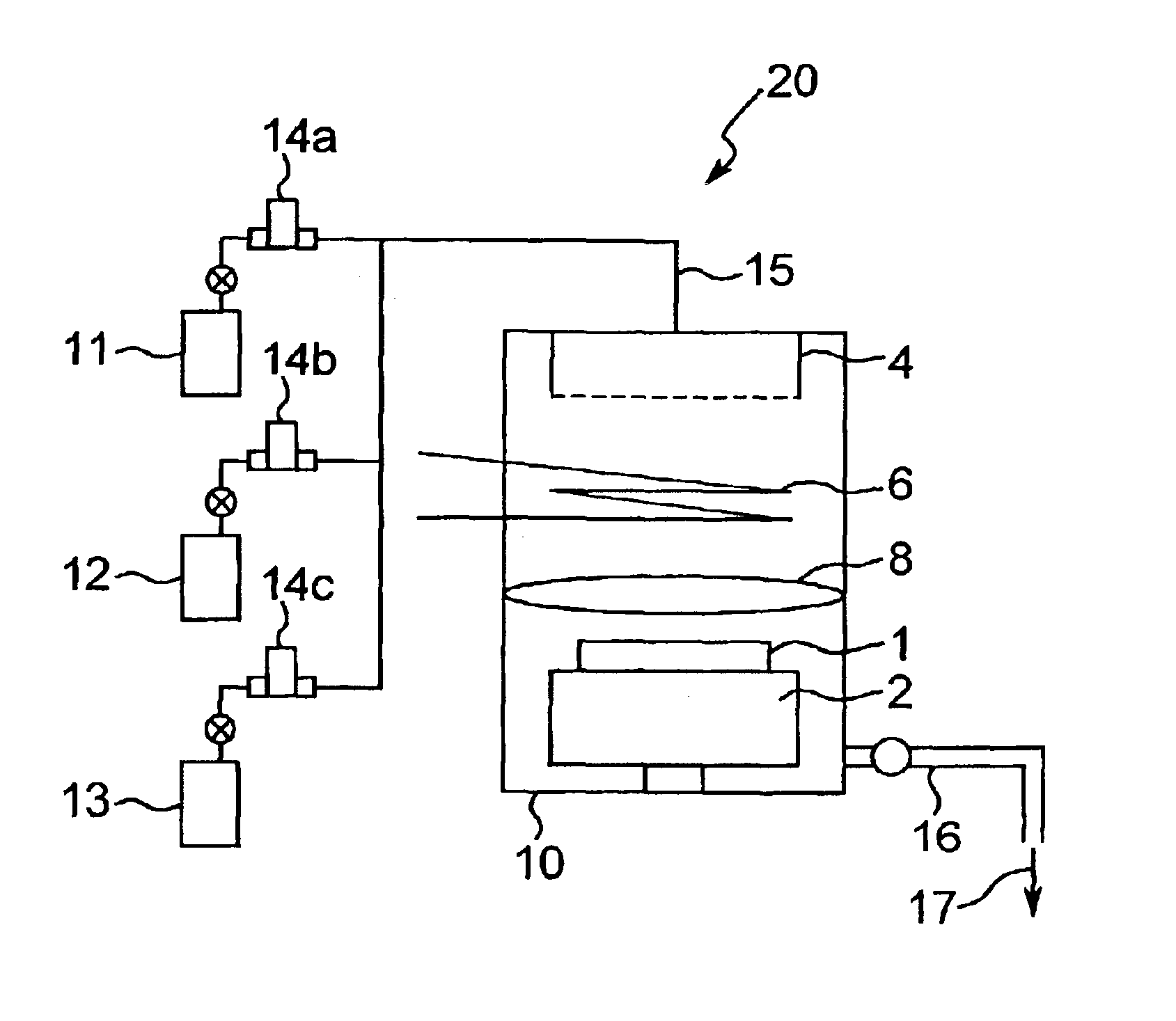

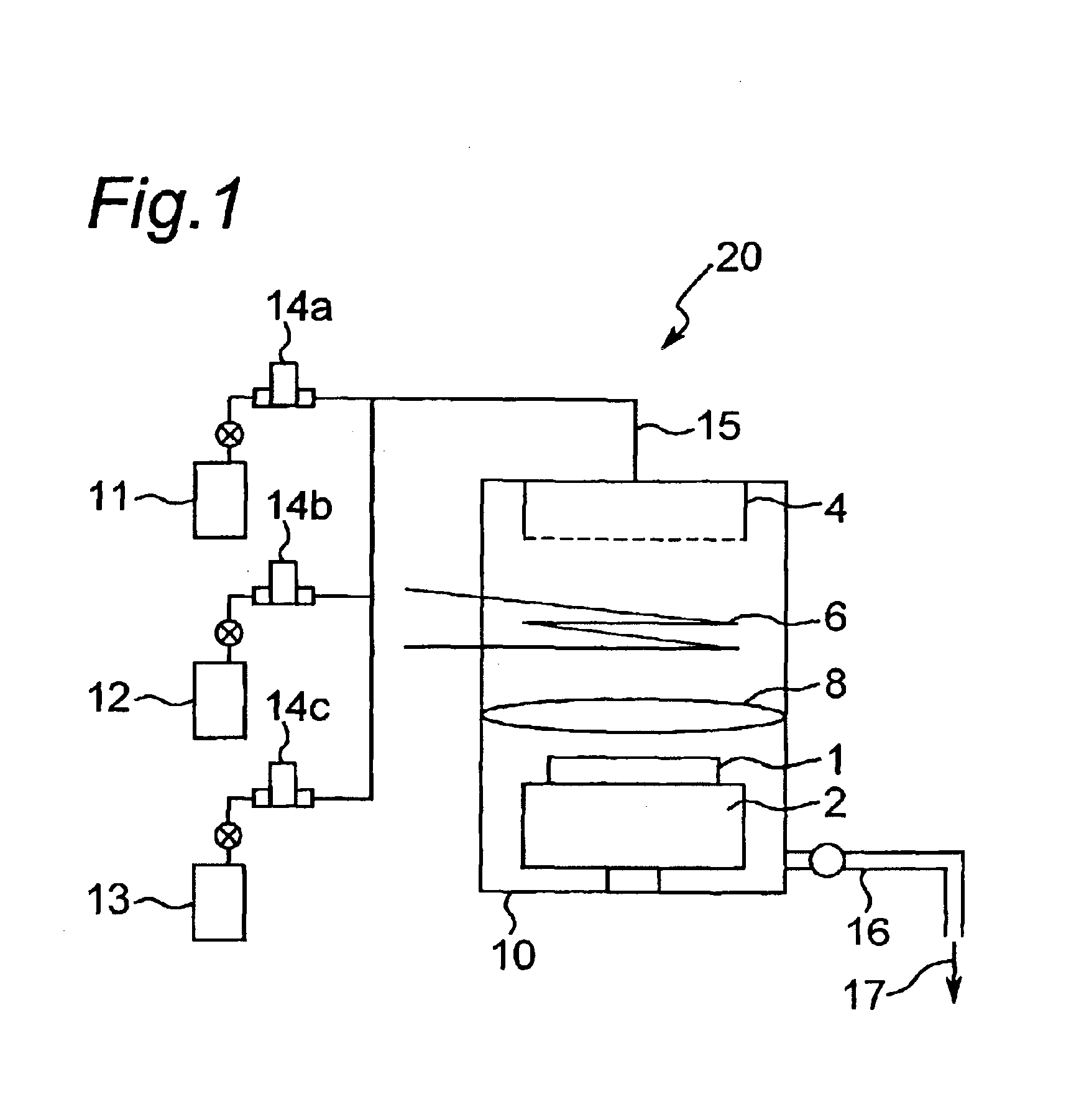

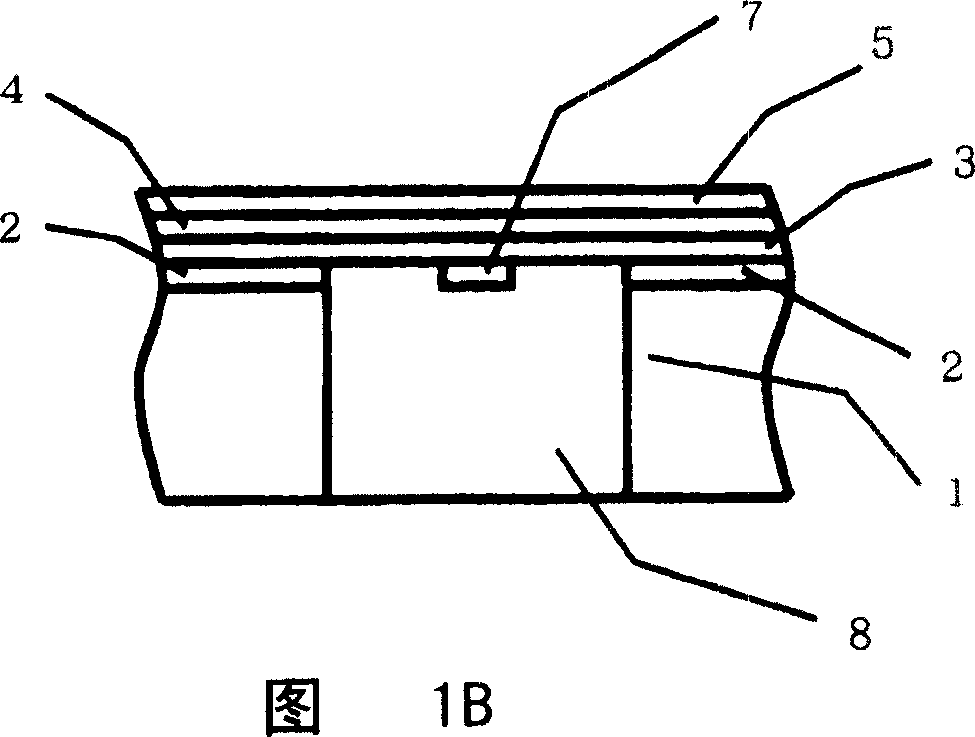

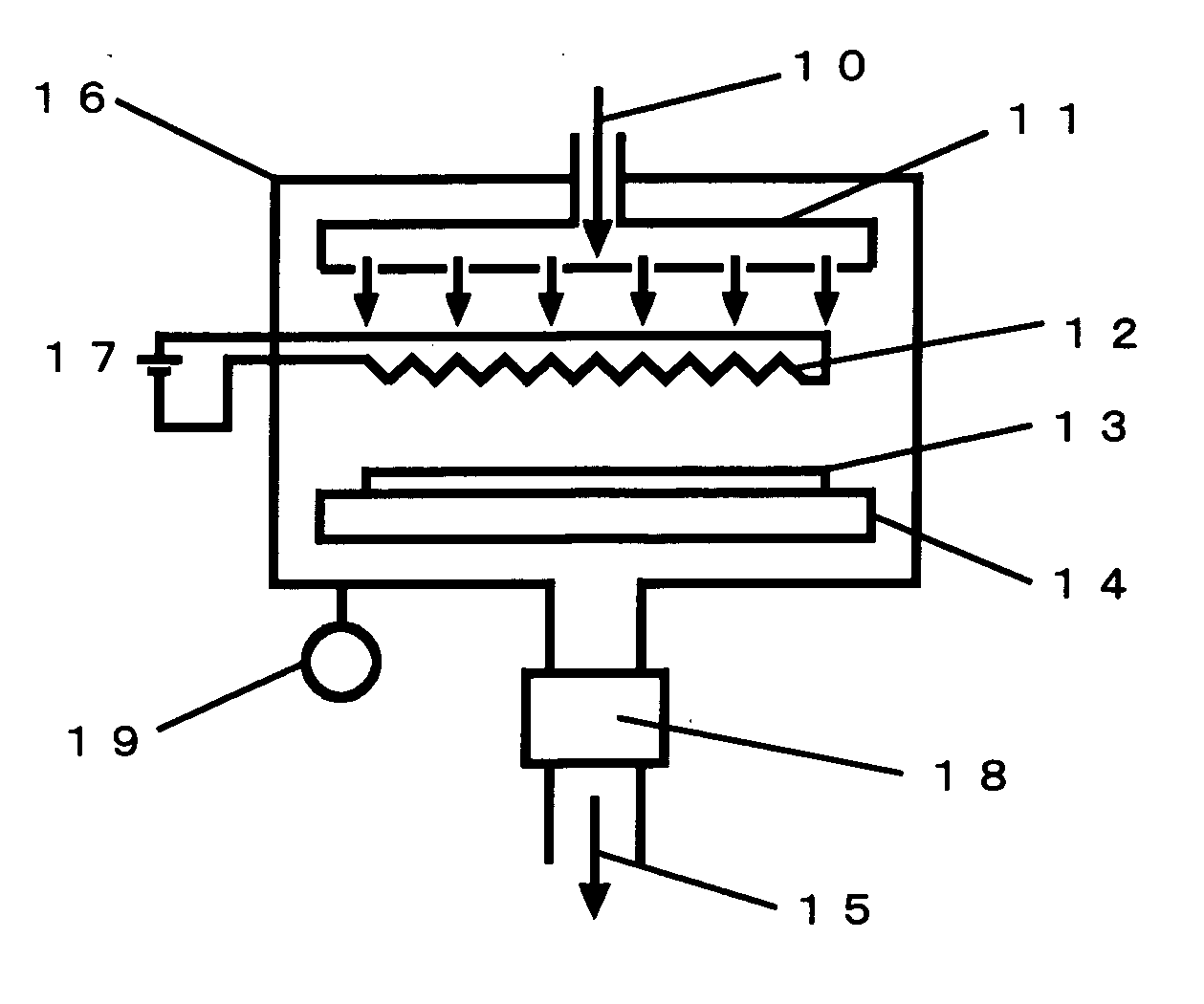

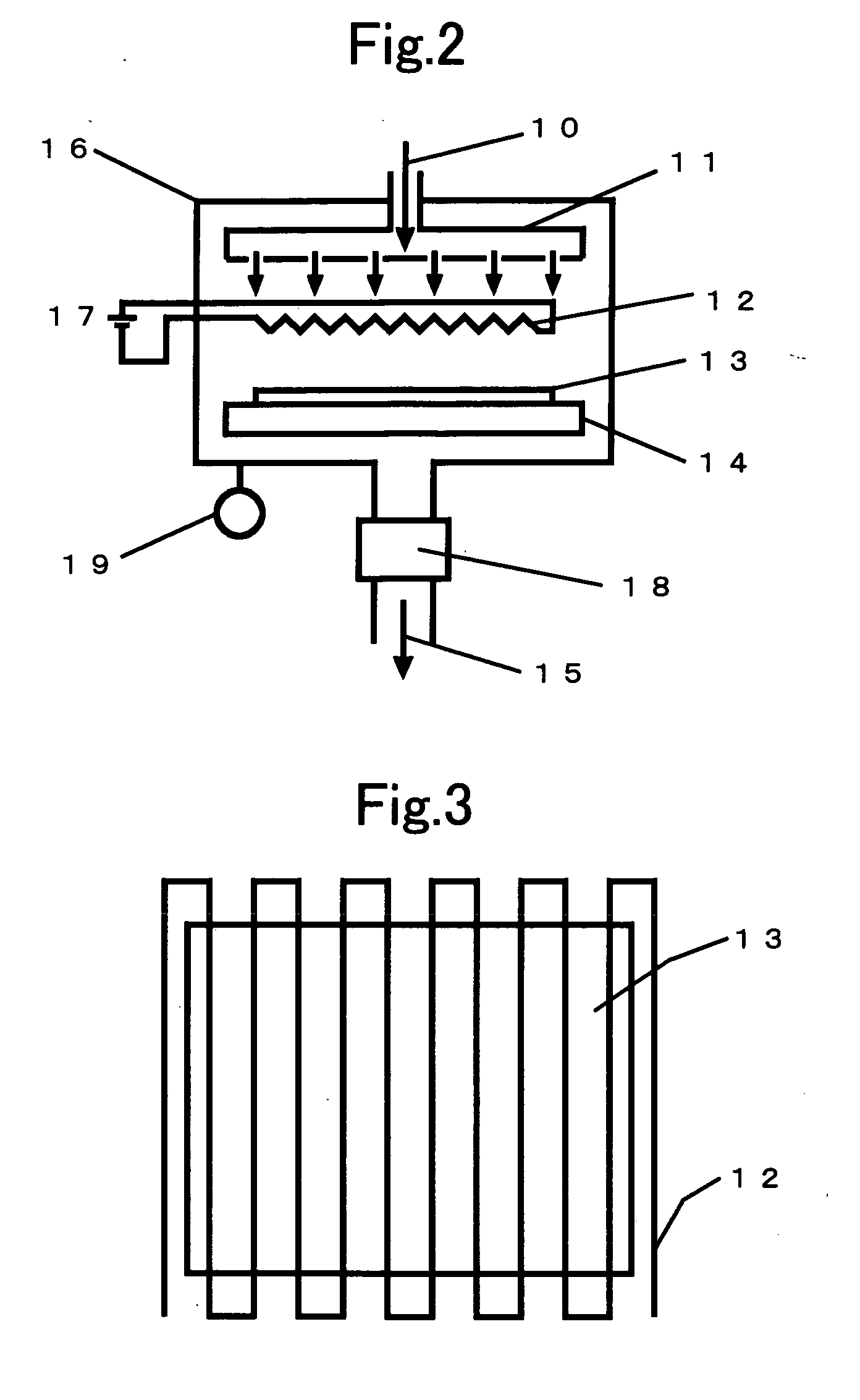

Catalytic chemical vapor deposition apparatus

InactiveUS20090277386A1Reduce pressureInhibit temperature riseSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCountermeasureTungsten

A catalytic chemical vapor deposition apparatus is provided for producing a thin film of desired film quality, by making a particle countermeasure against the release gas such as H2O and deposit materials from or on members composing the structure of the inside of the processing chamber and the inner wall of the processing chamber.A catalytic chemical vapor deposition apparatus comprising a substrate 4 arranged in a processing chamber 1, a shower plate 7 facing the substrate 4, and a catalyst 5 comprising metal tungsten wire activating a raw material gas from the shower plate 7, where the catalyst 5 is interposed between the substrate 4 and the shower plate 7 and where a cylindrical peripheral wall 23 encloses the space where the substrate 4 and the shower plate 7 face each other in the processing chamber 1, and additionally comprising a vacuum gas discharge unit so as to make the pressure inside the cylindrical peripheral wall 23, namely the pressure in the film formation region 26 higher than that in the other region.

Owner:ULVAC INC

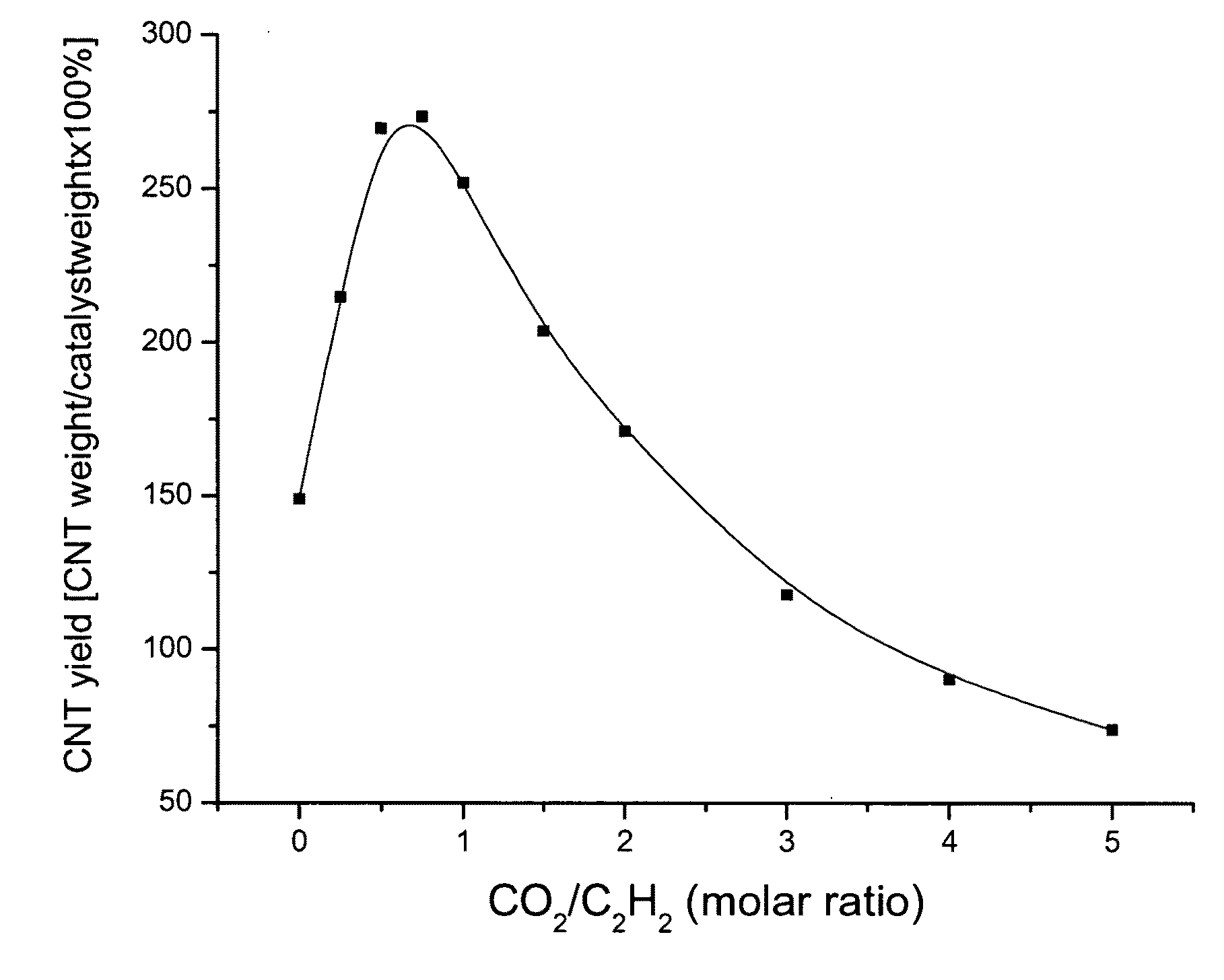

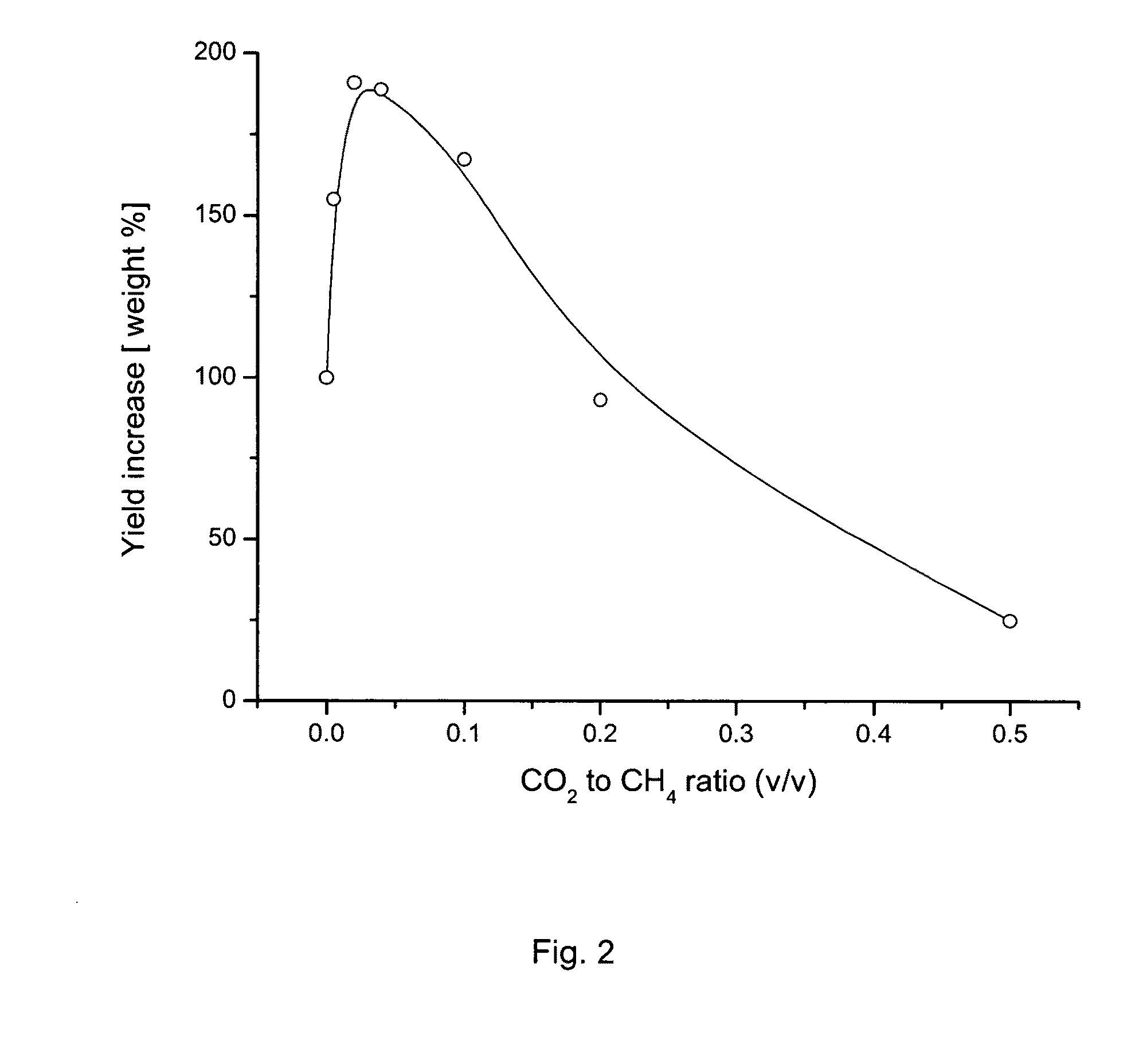

Method for enhanced synthesis of carbon nanostructures

A method of significantly improving carbon nanotube or carbon nanofiber yield from catalytic chemical vapor deposition of a carbon-containing gas comprising at least one hydrocarbon with the assistance of a proper amount of carbon dioxide (CO2). The catalytic particles preferably contain at least one metal from Group VIII (Fe, Co, Ni or the like) or / and one metal from Group VIb, including Mo, W, and Cr. The catalytic particles are preferably supported on oxide powders such as MgO, Al2O3, SiO, CaO, TiO, and ZrO, or a flat substrate such as, but not limited to, a Si wafer. The carbon nanotube or nanofiber product is preferably formed by exposing the catalyst to a mixture of a carbon-containing gas comprising at least one hydrocarbon with a proper amount of CO2 at a sufficiently high temperature. In an alternative embodiment, other oxygen-containing gases, such as alcohols, may be included in the mixture in addition to carbon dioxide.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

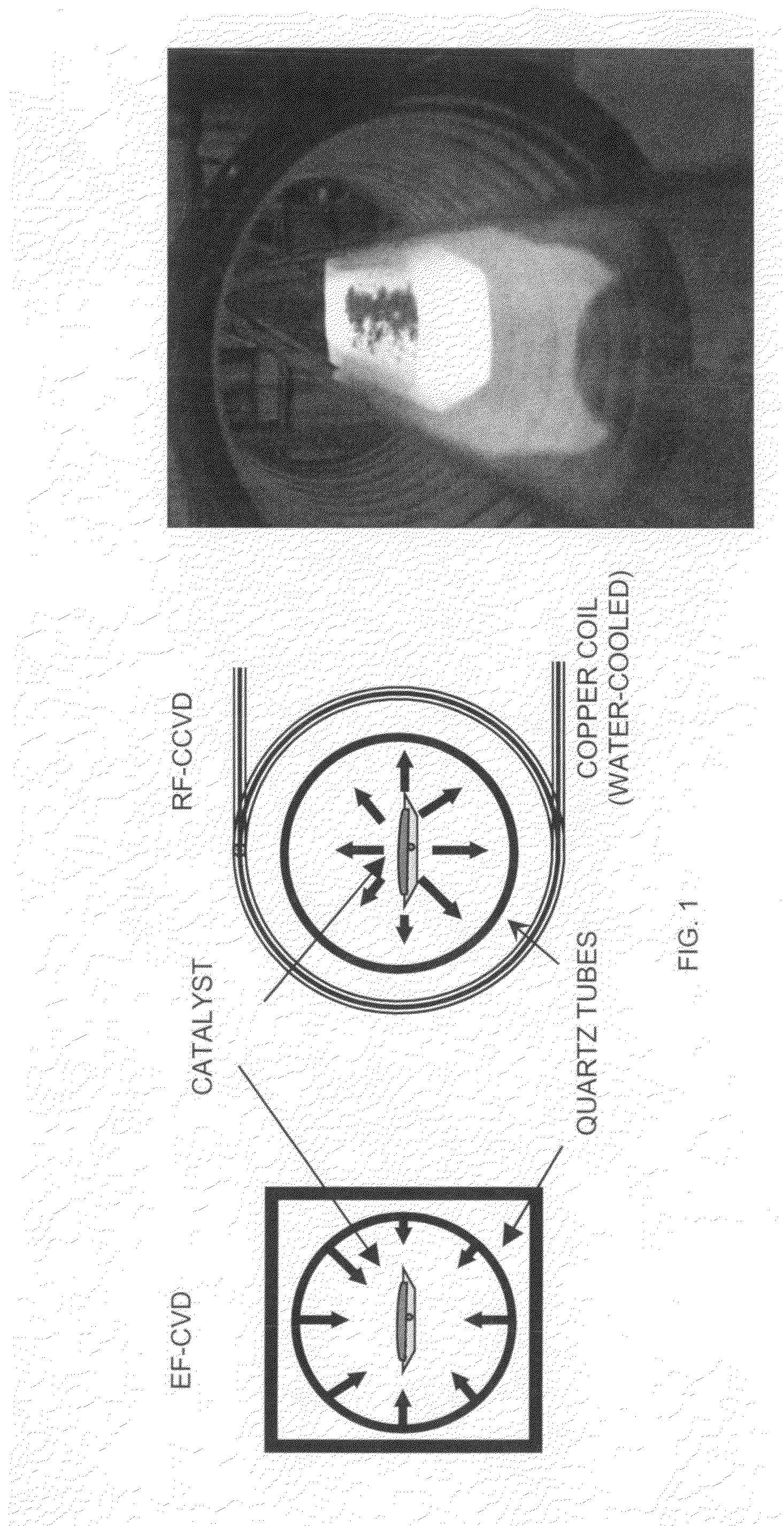

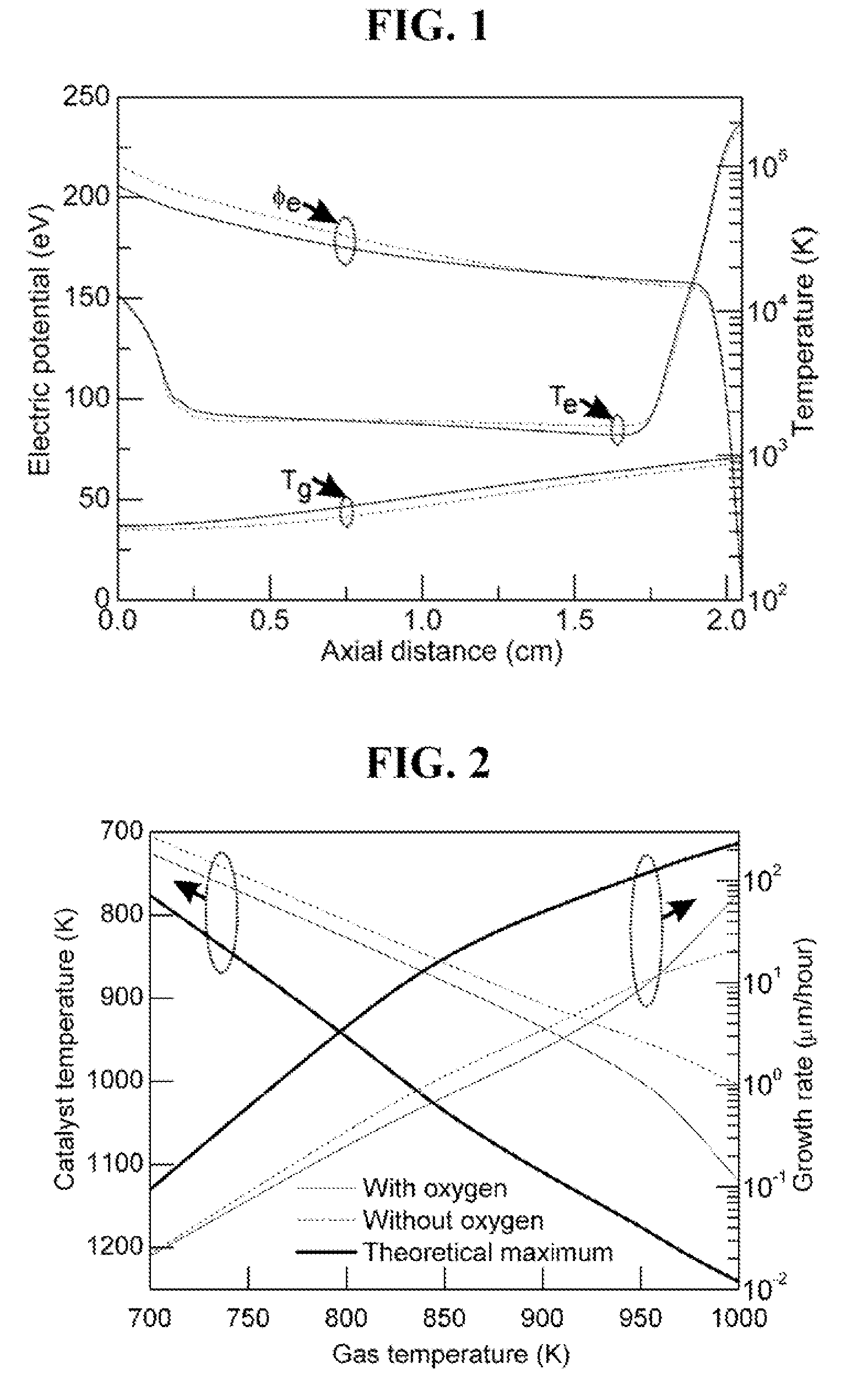

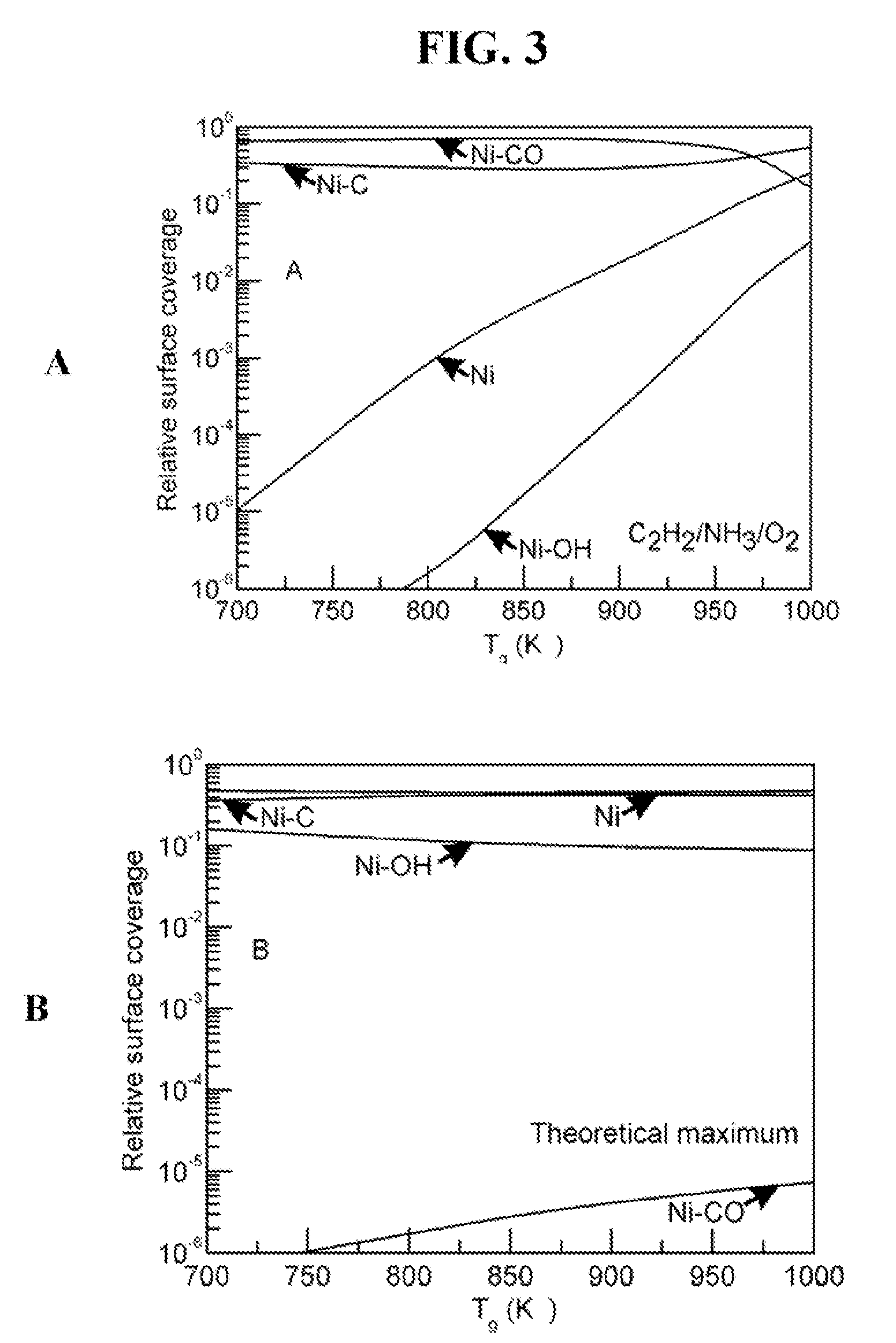

Synthesis of carbon nanotubes by selectively heating catalyst

The present invention is a catalytic chemical vapor deposition method and apparatus for synthesizing carbon nanotubes and / or carbon nanofibers (CNTs) on a substrate by selectively heating a catalyst for CNT synthesis on or near the surface of the substrate. Selective heating of the catalyst is achieved using an exothermic oxidation reaction on the surface of the catalyst. Selective heating of the catalyst prevents heating of the substrate and enables the synthesis of CNTs on temperature sensitive substrates.

Owner:CFD RES CORP

Chemical vapor deposition of carbon nanotubes on structures and substrates

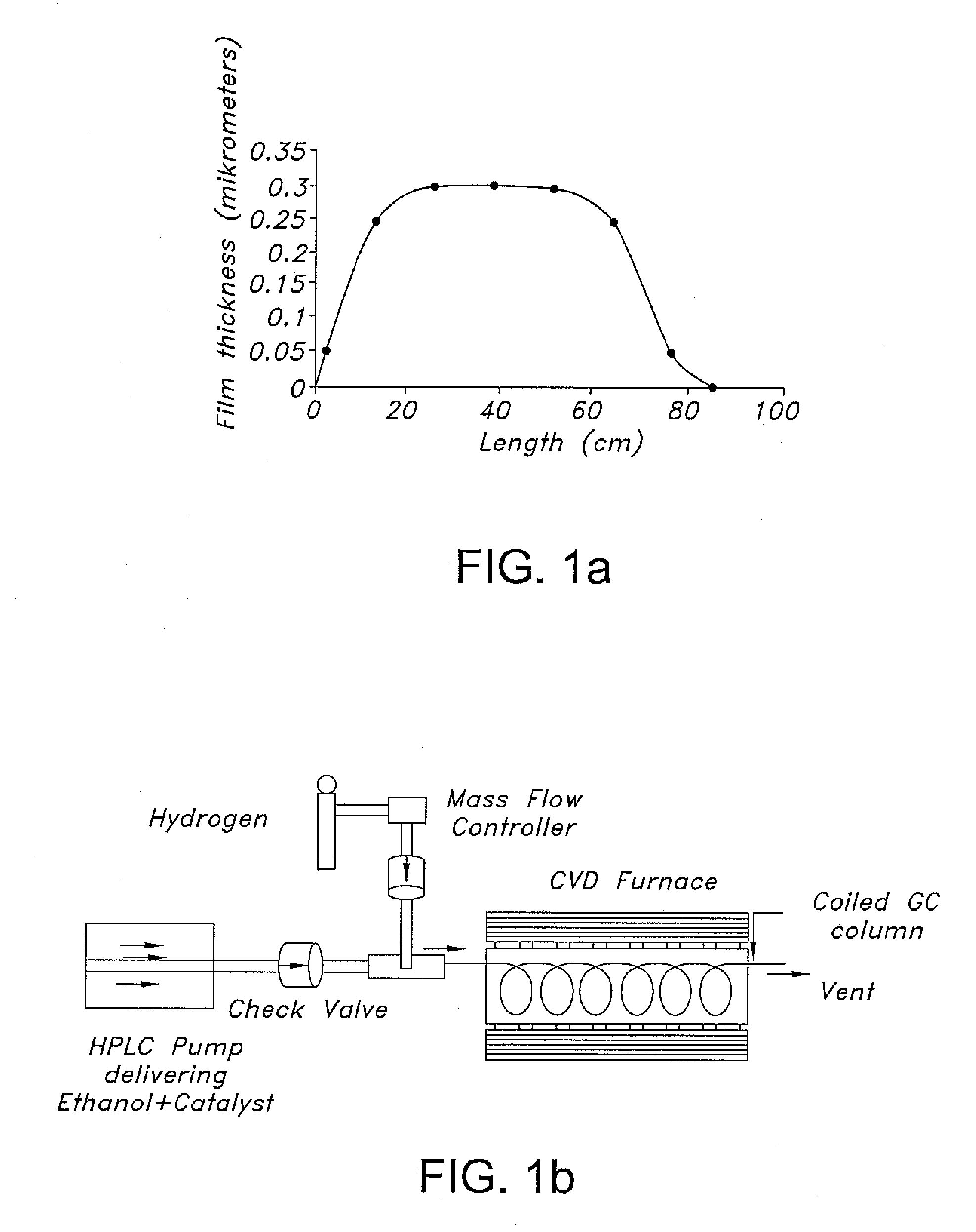

InactiveUS20080175785A1Thicker and smoother and uniformIncrease flow rateMaterial nanotechnologyMulti-walled nanotubesStationary phaseGas phase

Apparatus, systems, and methods are provided for the production and application of carbon nanotubes (CNTs) on structures. Disclosed embodiments relate to apparatus, systems, and methods for the production of CNTs in an open tubular configuration on the inside surface of a steel capillary tubing. Disclosed embodiments of means for the production of CNTs include, self-assembly through a catalytic chemical vapor deposition (CVD) process. Applications of the apparatus, systems, and methods disclosed generally relate to sorbency, and more particularly, include adsorption, separation, and chromatographical application. Disclosed embodiments include apparatus, systems, and methods, for the production of high performance stationary phases of CNTs with advantageous temperate stability for high resolution chromatographical applications.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

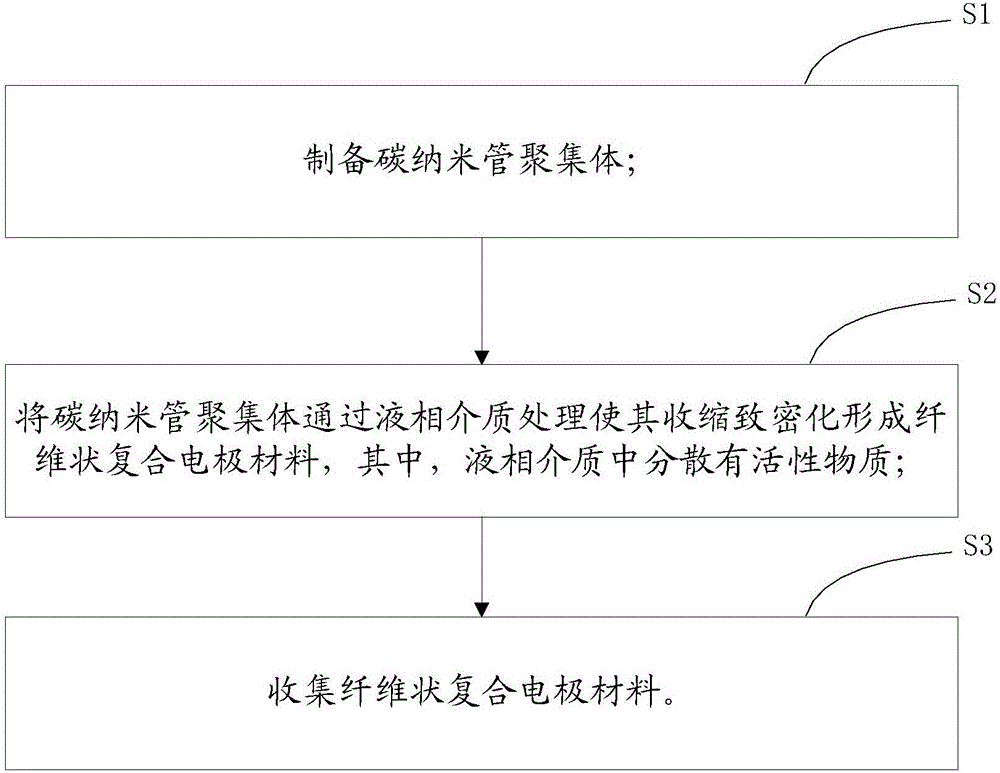

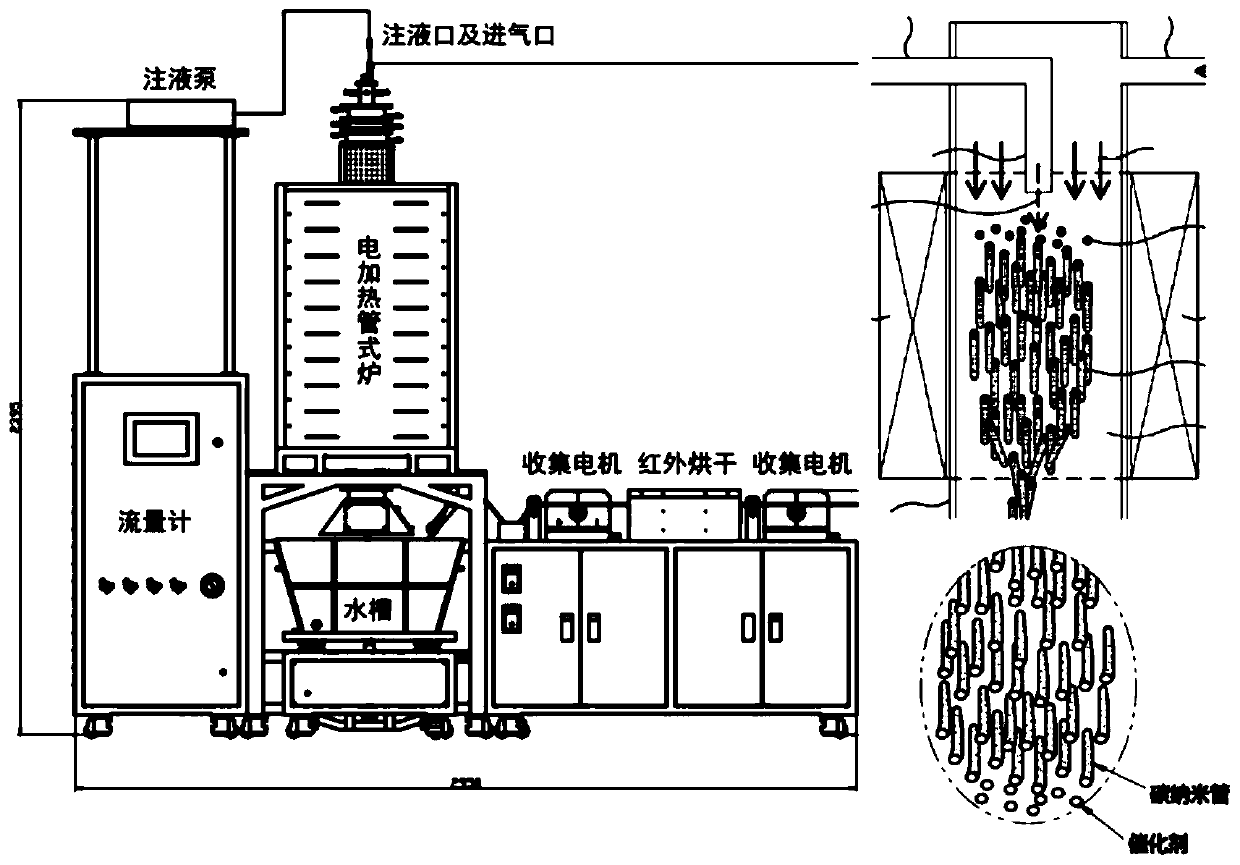

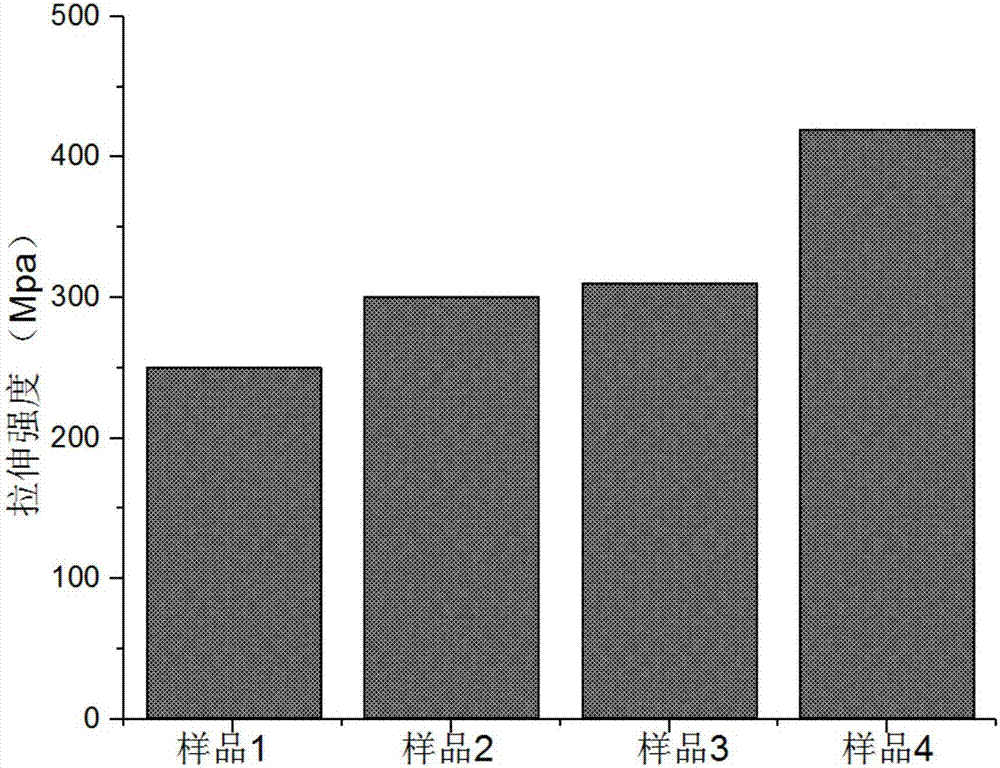

Fibrous composite electrode material and preparation method thereof

InactiveCN106340395AImprove conductivitySimple processHybrid capacitor electrodesCell electrodesState of artEnergy device

The invention provides a fibrous composite electrode material and a preparation method thereof. The preparation method comprises the following steps: S1, preparing carbon nanotube aggregates; S2, compacting the carbon nanotube aggregates by a liquid phase medium to form a fibrous composite electrode material, wherein active substances are dispersed in the liquid phase medium; and S3, collecting the fibrous composite electrode material. Compared with the prior art, the method is characterized in that the carbon nanotube aggregates are synthesized by a floating catalytic chemical vapor deposition method, and the liquid phase medium employs active substance solution or suspending liquid, and the carbon nanotube aggregates are compacted by the liquid phase medium to obtain the carbon nanotube fiber. In the process of compact, the active substances are effectively compounded to the surface and the internal of the carbon nanotube fiber to obtain a fibrous composite electrode material. The method has the advantages of simple process, low cost, high fiber conductivity and easy batch preparation, which is of great significance to the development of fibrous energy devices.

Owner:SUZHOU CREATIVE CARBON NANOTECH

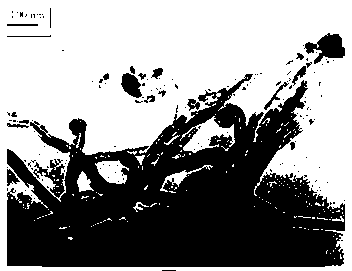

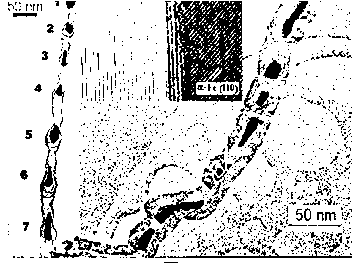

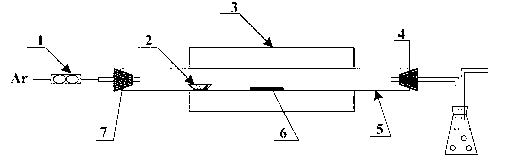

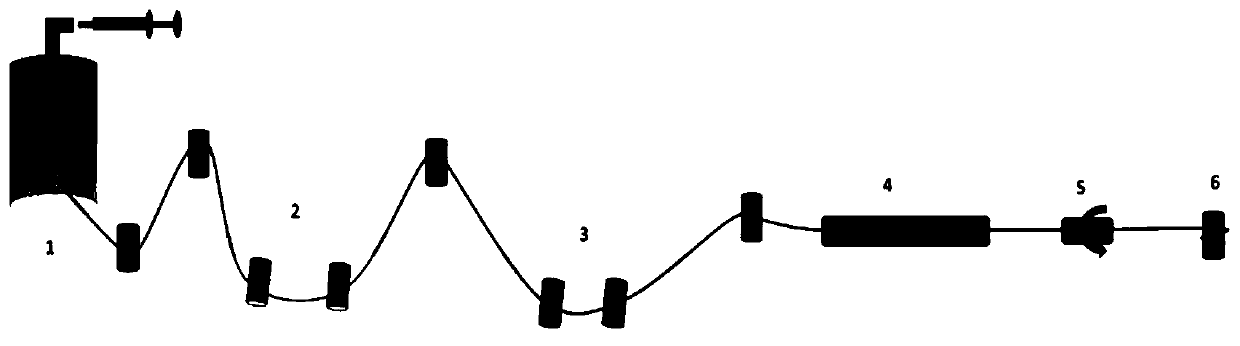

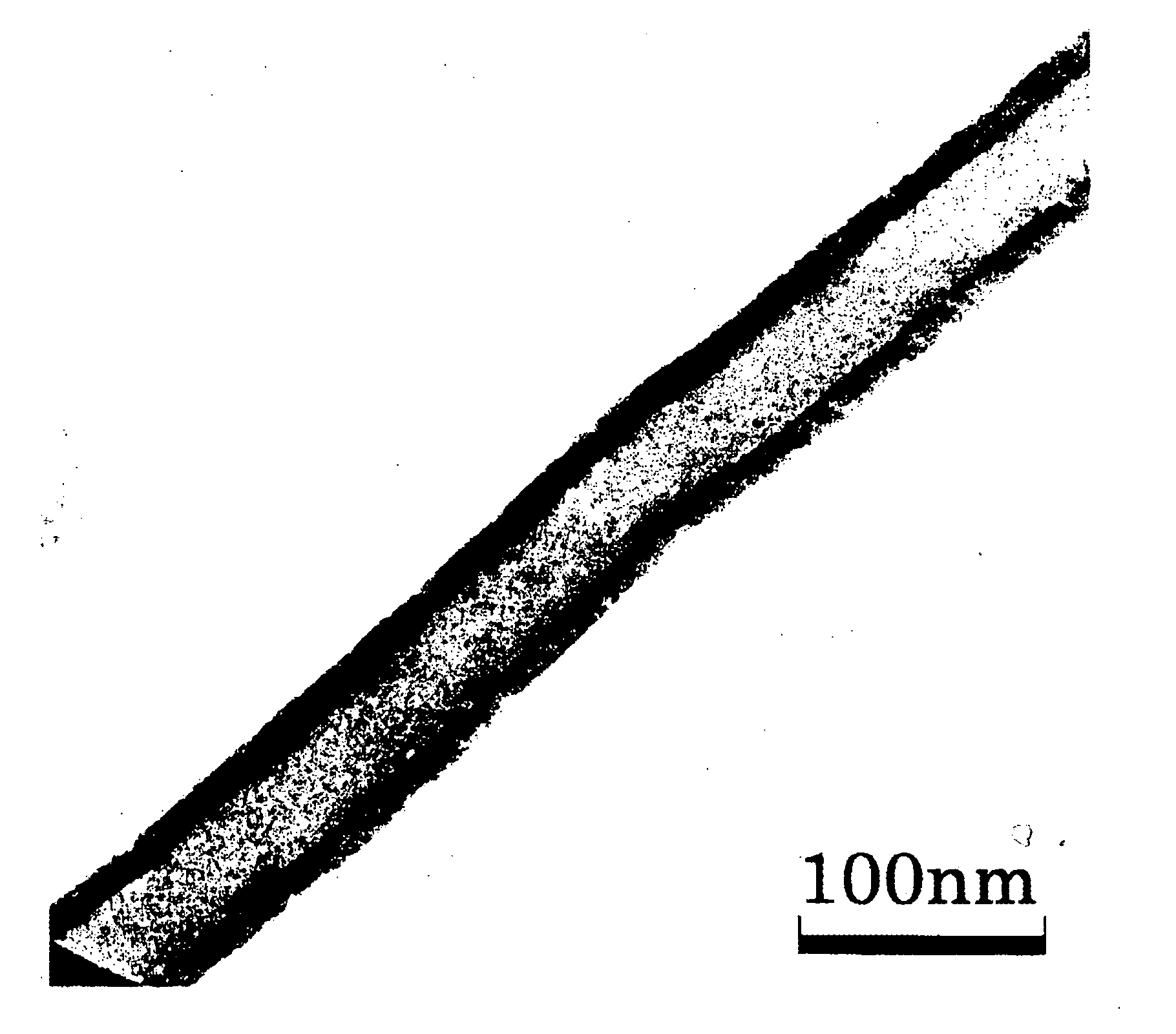

Preparation method of iron filled carbon nano tube and reaction device

InactiveCN103288072AImprove fill rateIncrease filling volumeMaterial nanotechnologyCarbon compoundsPtru catalystIron(III) chloride

The invention provides a preparation method of an iron filled carbon nano tube and a reaction device. The preparation method of the iron filled carbon nano tube comprises the following steps of: preparing the iron filled carbon nano tube by adopting an inorganic covalent compound of iron namely ferric chloride anhydrous as a catalyst precursor and selecting different carbon sources through floating catalysis chemical vapor deposition method, wherein the iron filled carbon nano tube comprises a non-nitrogen-doped iron filled carbon nano tube or a nitrogen-doped iron filled carbon nano tube. The preparation method of the iron filled carbon nano tube disclosed by the invention is simple and scientific in steps and can prepare a high-iron filled carbon nano tube. The invention further discloses a reaction device of the preparation method of the iron filled carbon nano tube. According to the preparation method of the iron filled carbon nano tube and the reaction device, a plurality of disadvantages in the prior art can be overcome; and the advantages that the preparation method is simple and the obtained iron filled carbon nano tube has high iron filling rate are realized.

Owner:DALIAN UNIV OF TECH

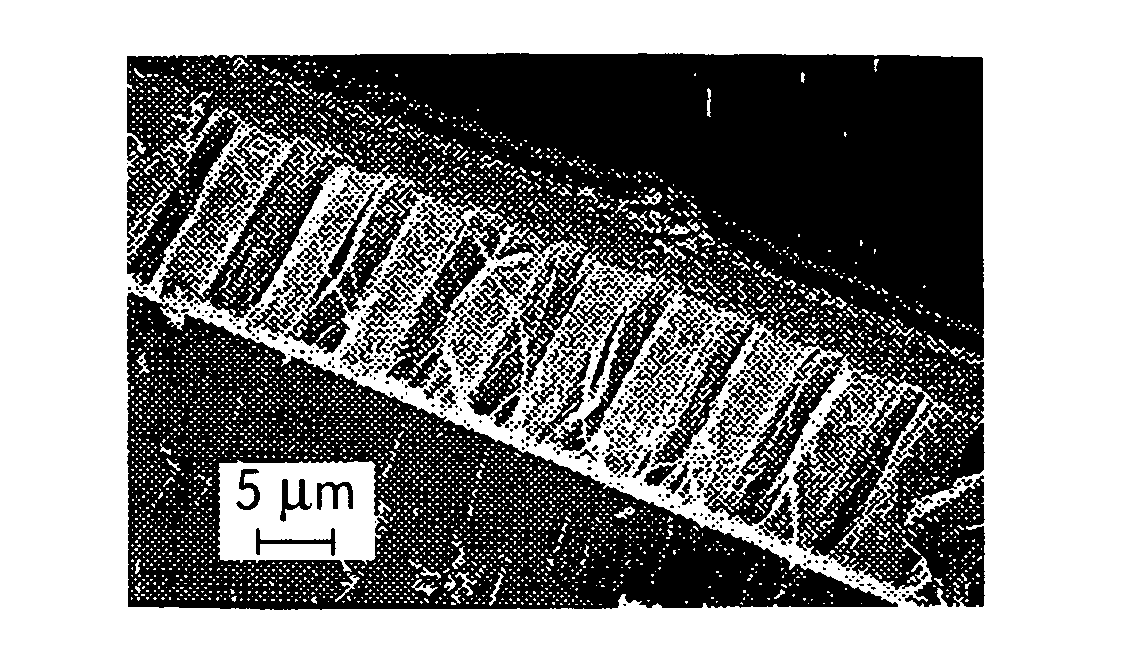

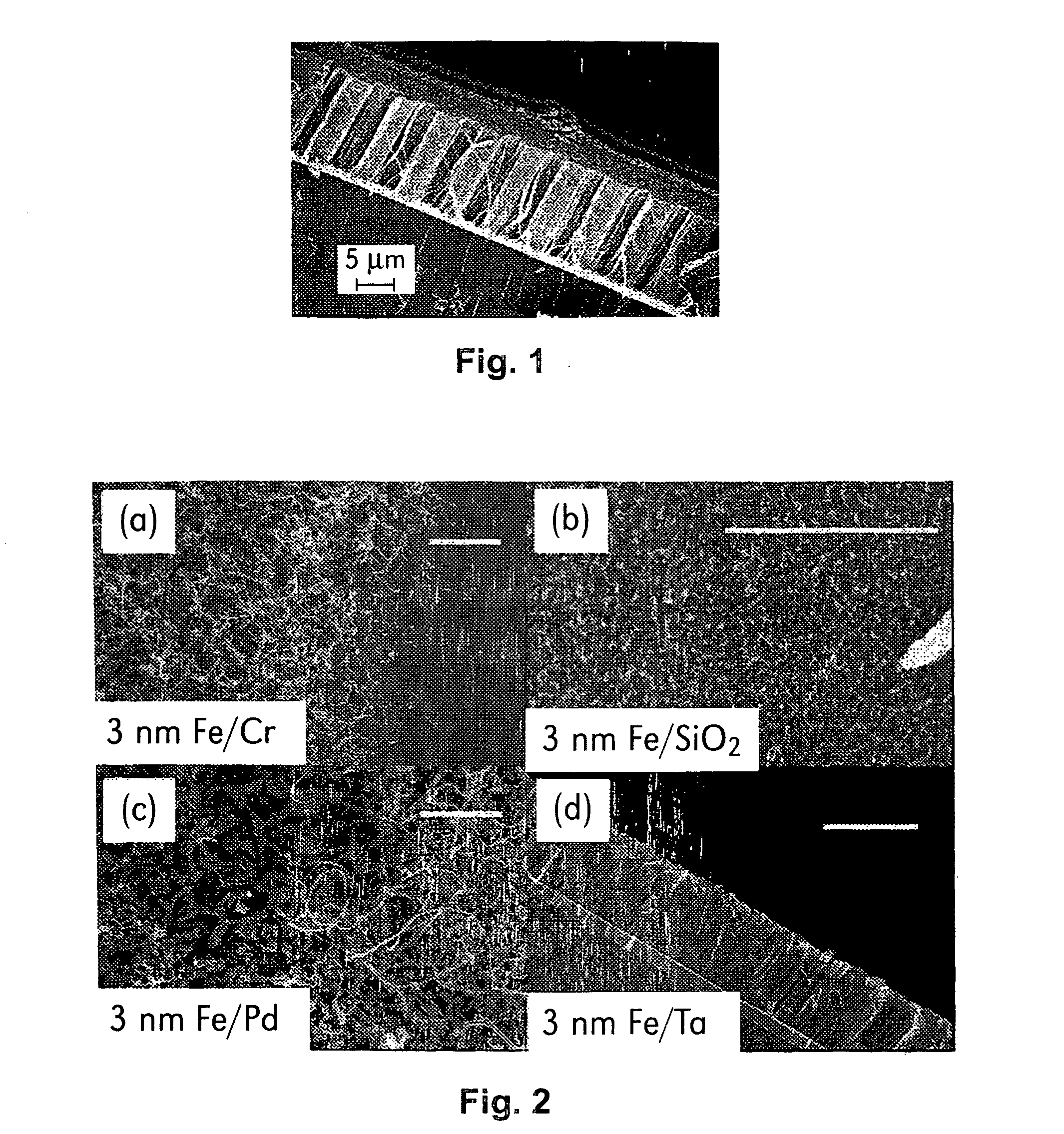

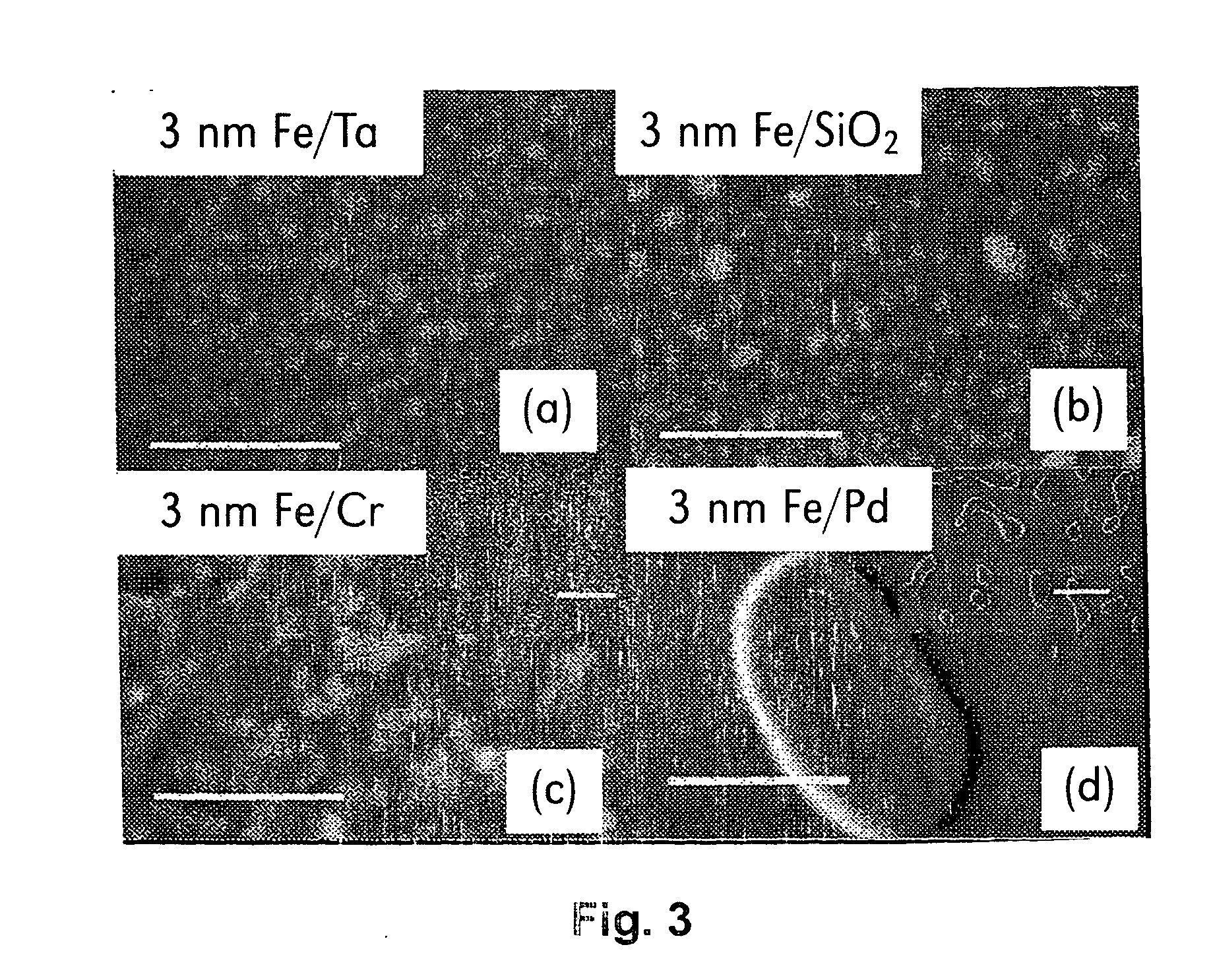

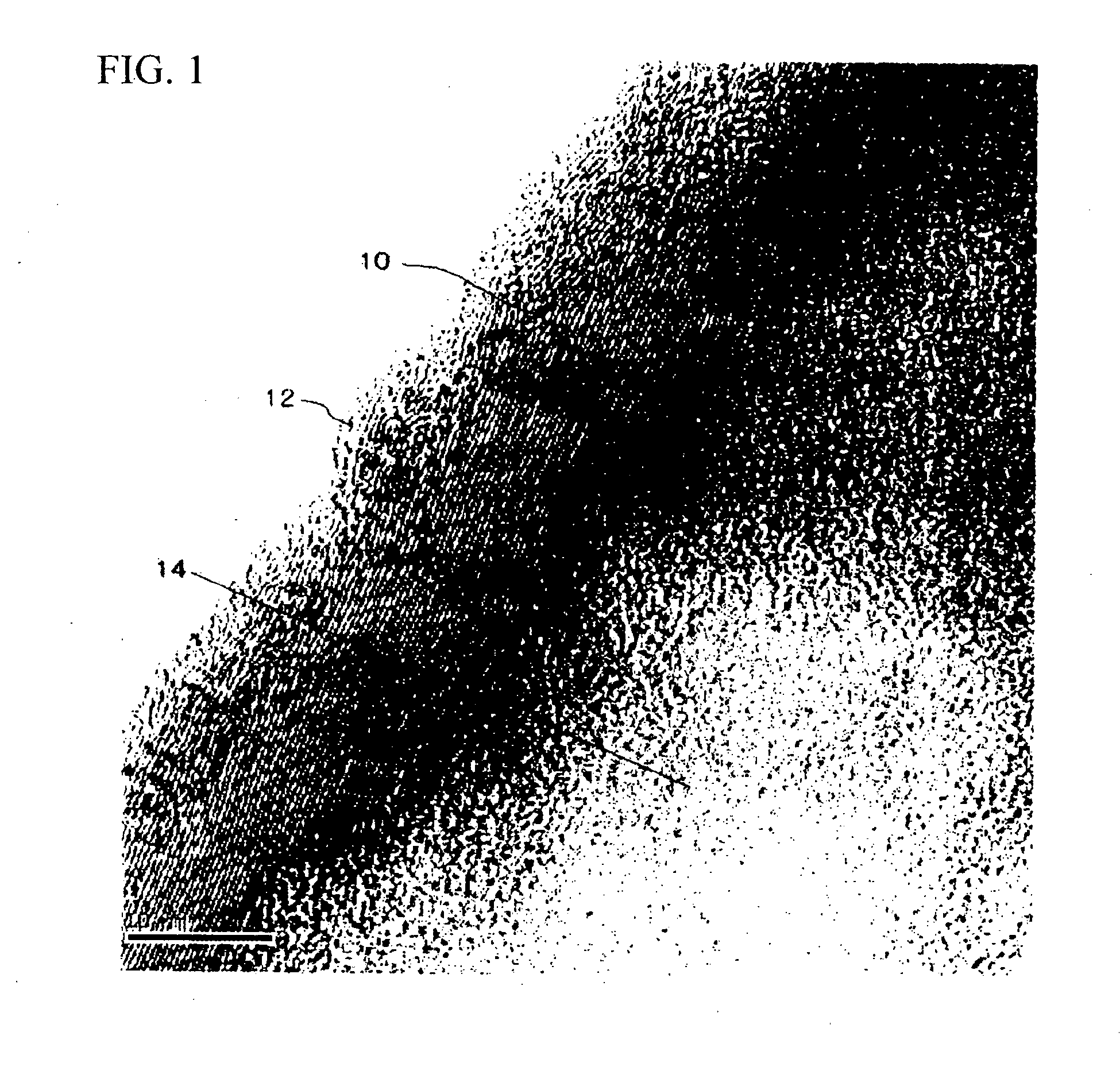

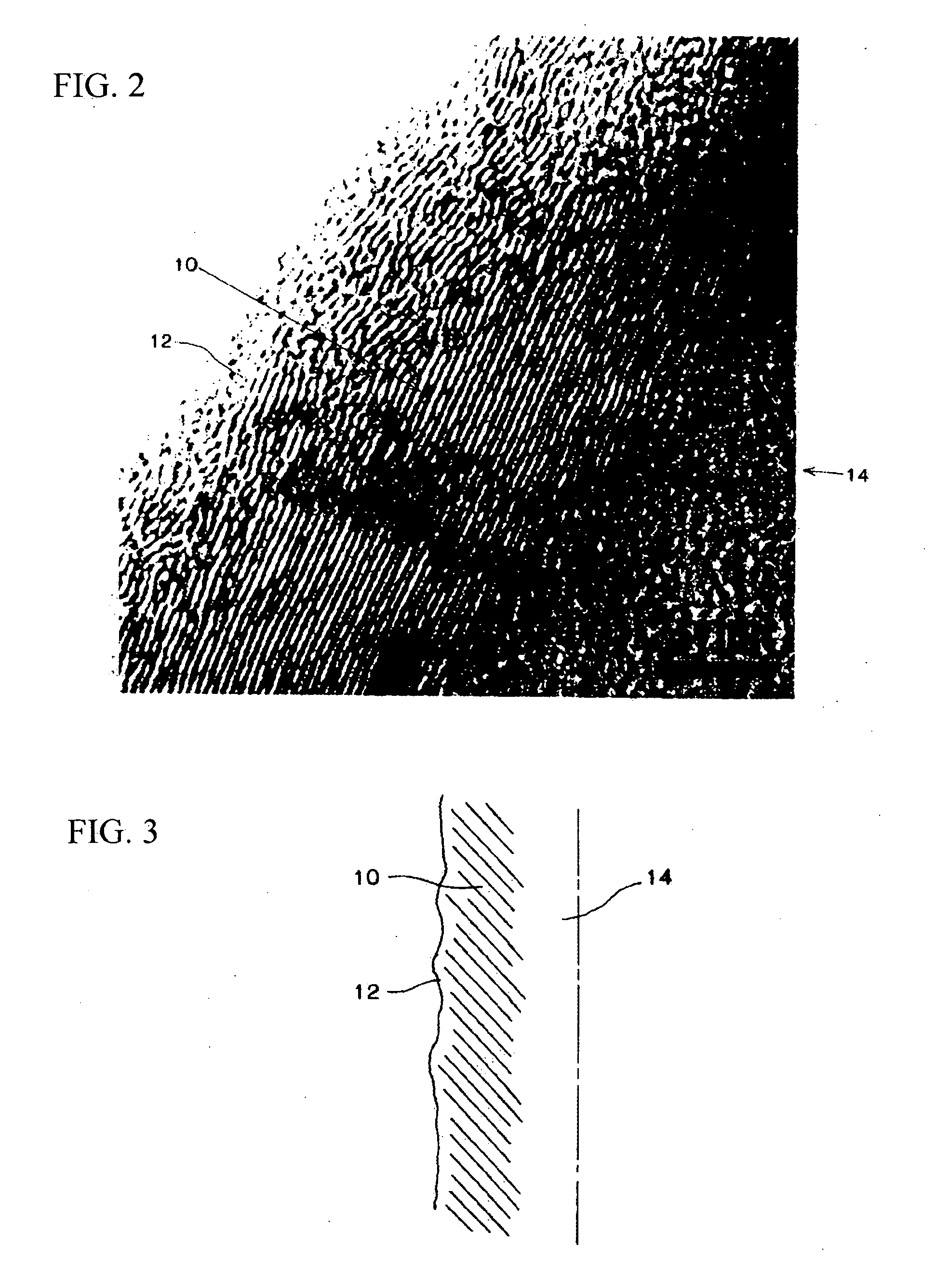

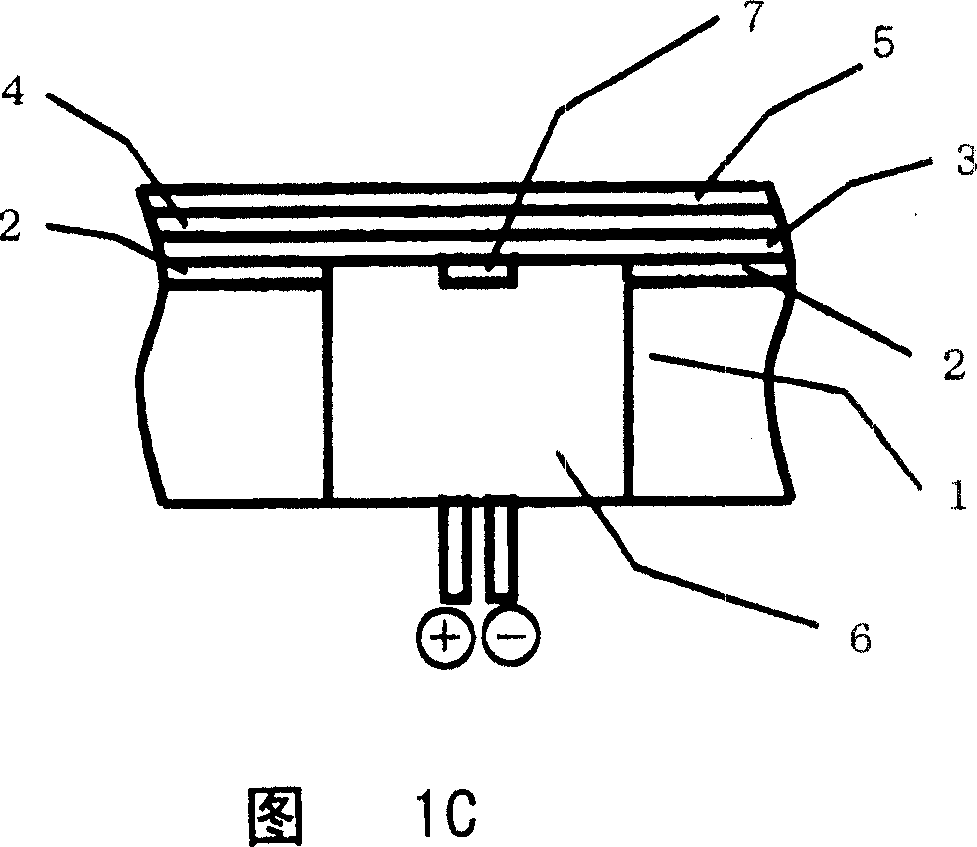

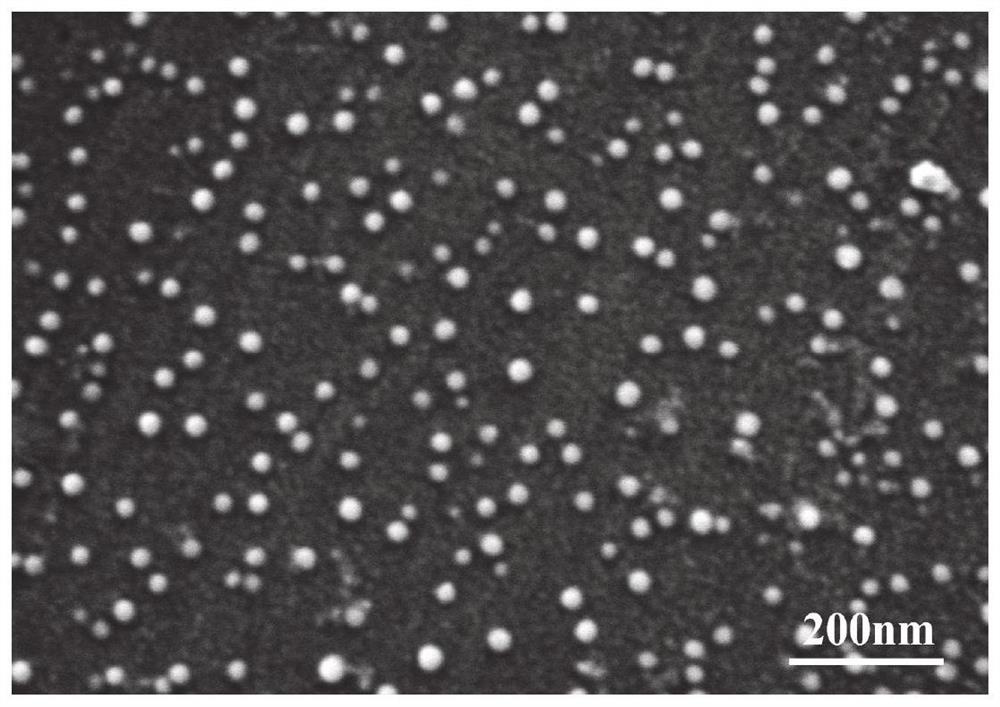

Assisted selective growth of highly dense and vertically aligned carbon nanotubes

InactiveUS20100117764A1Increased film coverageImprove uniformityMaterial nanotechnologyChemical vapor deposition coatingMethod selectionElectron

The selective growth of vertically aligned, highly dense carbon nanotube (CNT) arrays using a thermal catalytic chemical vapor deposition (CCVD) method via selection of the supporting layer where the thin catalyst layer is deposited on. A thin iron (Fe) catalyst deposited on a supporting layer of tantalum (Ta) yielded CCVD growth of the vertical dense CNT arrays. Cross-sectional transmission electron microscopy revealed a Vollmer-Weber mode of Fe island growth on Ta, with a small contact angle of the islands controlled by the relative surface energies of the supporting layer, the catalyst and their interface. The as-formed Fe island morphology promoted surface diffusion of carbon atoms seeding the growth of the CNTs from the catalyst surface.

Owner:INTELLECTUAL VENTURES HLDG 40

Carbon nanotubes continuous synthesis process using iron floating catalysts and MgO particles for CVD of methane in a fluidized bed reactor

InactiveUS8293204B2Increase surface areaWastingMaterial nanotechnologyNanostructure manufactureHot zoneFluidized bed

A novel continuous process is used for production of carbon nanotubes (CNTs) by catalytic chemical vapor deposition (CCVD) of methane on iron floating catalyst in-situ deposited on MgO in a fluidized bed reactor. In the hot zone of the reactor, sublimed ferrocene vapors were contacted with MgO powder fluidized by methane feed to produce Fe / MgO catalyst in-situ. An annular tube was used to enhance the ferrocene and MgO contacting efficiency. Multi-wall as well as single-wall CNTs were grown on the Fe / MgO catalyst while falling down the reactor. The CNTs were continuously collected at the bottom of the reactor, only when MgO powder was used. The annular tube enhanced the contacting efficiency and improved both the quality and quantity of CNTs. The SEM and TEM micrographs of the products reveal that the CNTs are mostly entangled bundles with diameters of about 20 nm. Raman spectra show that the CNTs have low amount of amorphous carbon with IG / ID ratios as high as 10.2 for synthesis at 900° C. The RBM Raman peaks indicate formation of single-walled carbon nanotubes (SWNTs) of 1.0-1.2 nm diameter.

Owner:KHODADADI ABBAS ALI +1

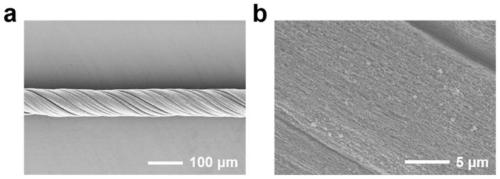

Method for improving orientation degree and conductivity of carbon nanotube fiber

InactiveCN111155217AGood orientationImprove compactnessCarbon fibresLiquid/gas/vapor removalFiberSpinning

The invention discloses a method for improving the orientation degree and conductivity of a carbon nanotube fiber. The method comprises the steps of preparing a continuous carbon nanotube fiber by a floating catalytic chemical vapor deposition method; then, immersing the carbon nanotube fiber into a solvent to fully expand; performing proper stretching, so that the carbon nanotube fiber is rearranged to improve the axial orientation; next, immersing the carbon nanotube fiber into a coagulating bath; driving phase separation through solubility differences; extruding the solvent from the carbonnanotube fiber; then, performing online washing and drying to form a compact carbon nanotube fiber; and finally, twisting the carbon nanotube fiber to form a multistage spiral structure. The method has the advantages that the primary carbon nanotube fiber prepared by a direct spinning method is swelled and shrunk, and the orientation degree and compactness of the fiber are well improved, so that the electrical conductivity and the mechanical strength of the fiber are greatly improved; the preparation process is simple; the preparation conditions are mild; the cost is low; the production efficiency is high; and the method is suitable for industrial production.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

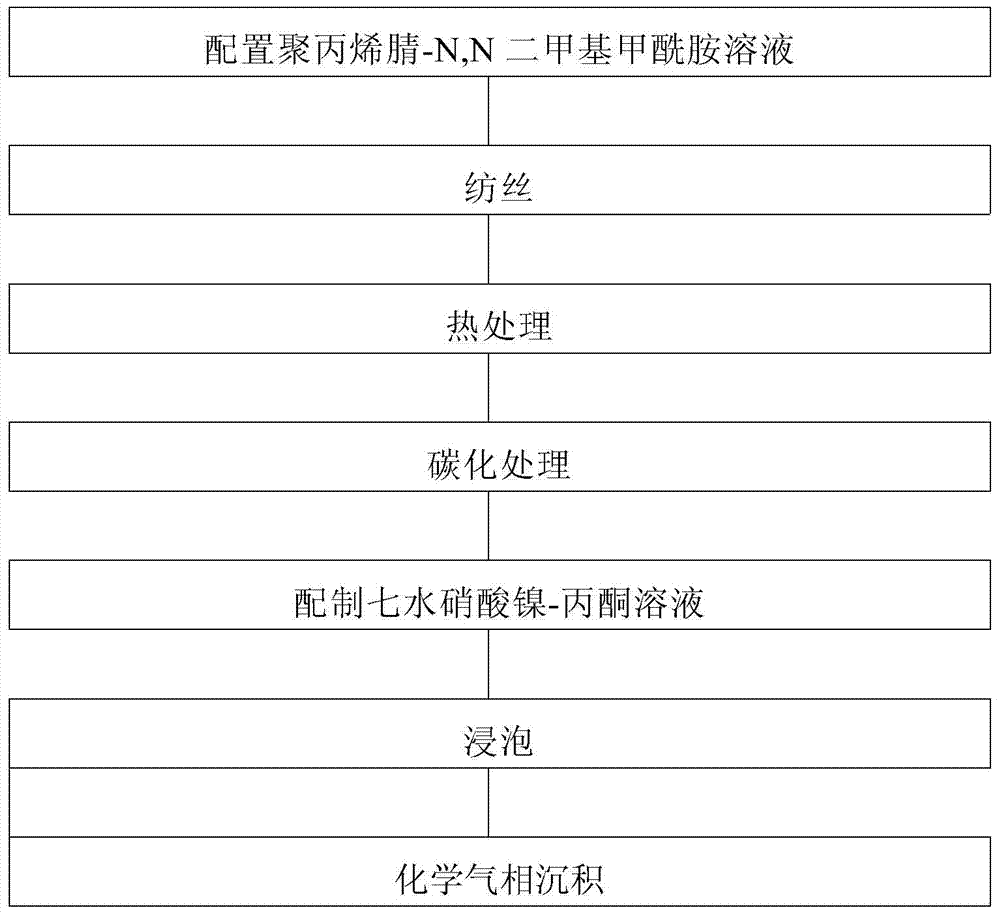

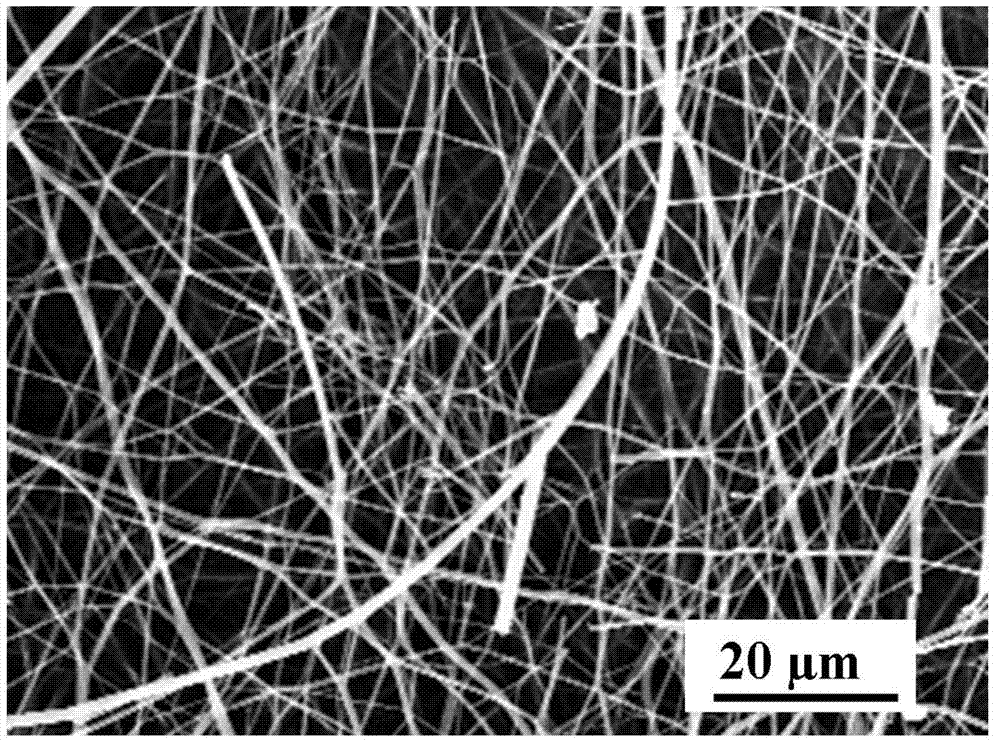

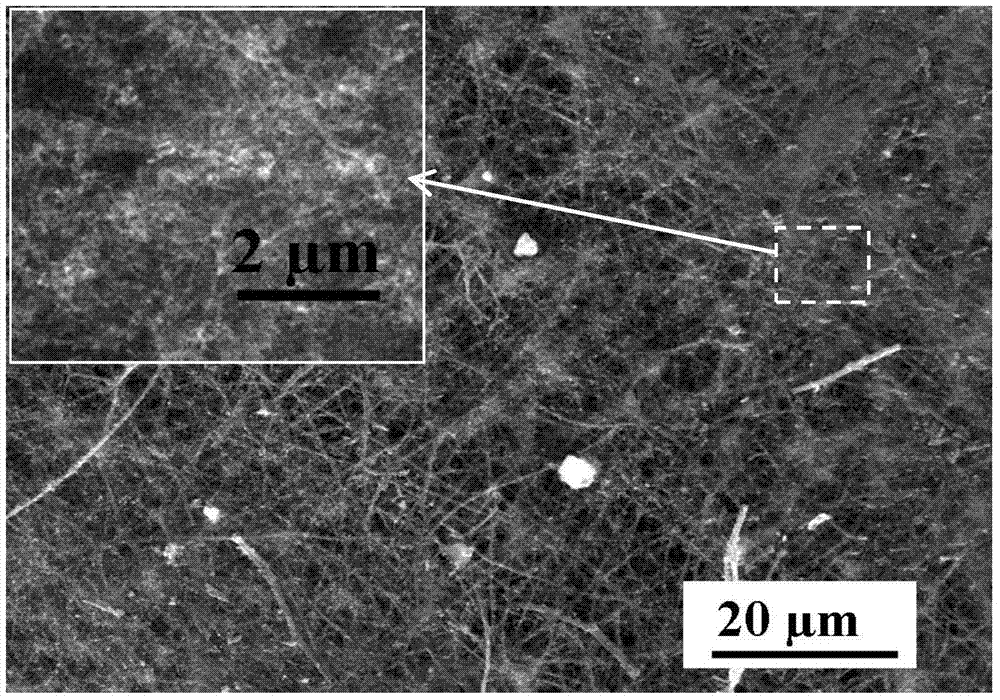

Preparation method of carbon nano-fiber film

ActiveCN103696239AHigh strengthHigh temperature carbonization produces good flexibility and flexibilityCarbon fibresFilament/thread formingIn planeGas phase

The invention discloses a preparation method of a carbon nano-fiber film, and particularly discloses a method for preparing a high-strength polyacrylonitrile-based carbon nano-fiber film by using electrostatic spinning-high temperature carbonization in combination with a catalytic chemical vapor deposition process. The method comprises the following steps: preparing a polyacrylonitrile-based carbon nano-fiber porous reinforcement with high flexibility but low strength by using electrostatic spinning and high temperature carbonization; and further filling vapor growth carbon nano-fibers into the polyacrylonitrile-based carbon nano-fiber porous reinforcement by using a chemical vapor deposition technology to obtain the carbon nano-fiber film with high flexibility and high strength. Compared with a polyacrylonitrile-based carbon nano-fiber film prepared by merely using an "electrostatic spinning-high temperature carbonization" technology, the carbon nano-fiber film prepared with the method disclosed by the invention has the advantage that the in-plane tensile strength is increased by 80-120 percent.

Owner:XIAN AVIATION BRAKE TECH

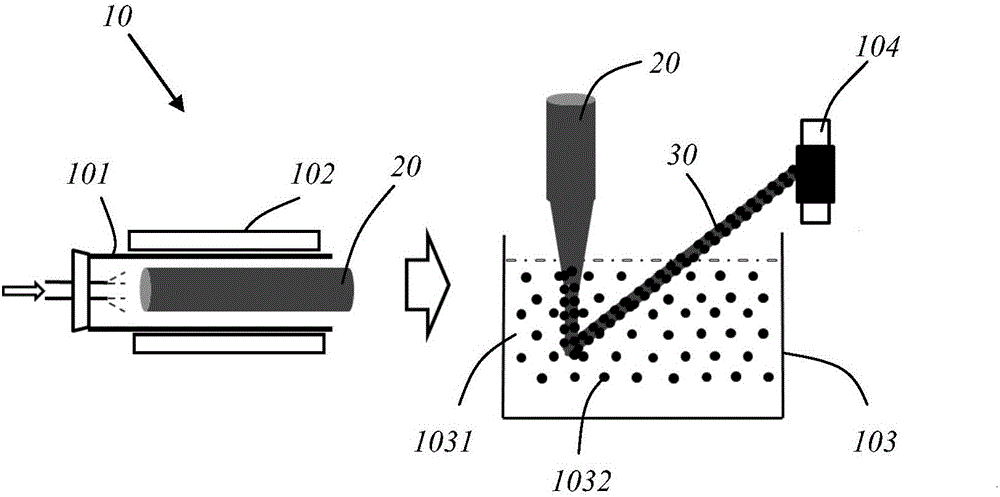

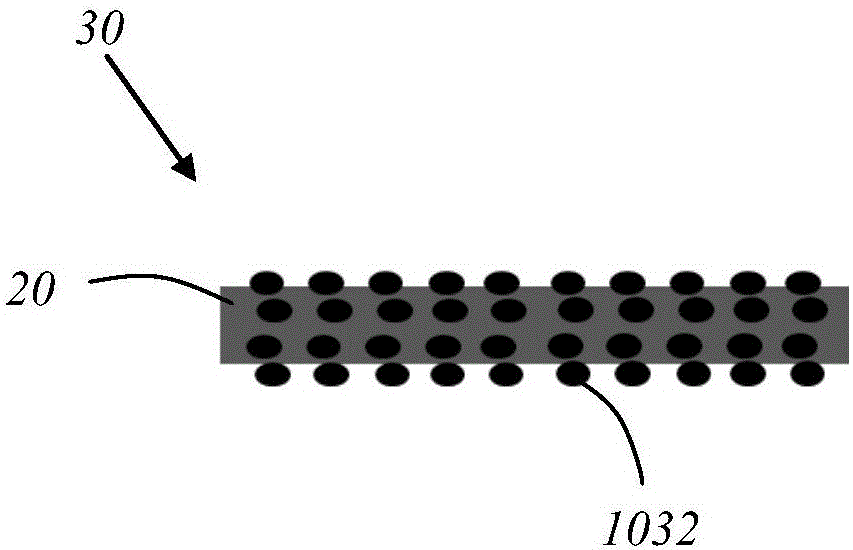

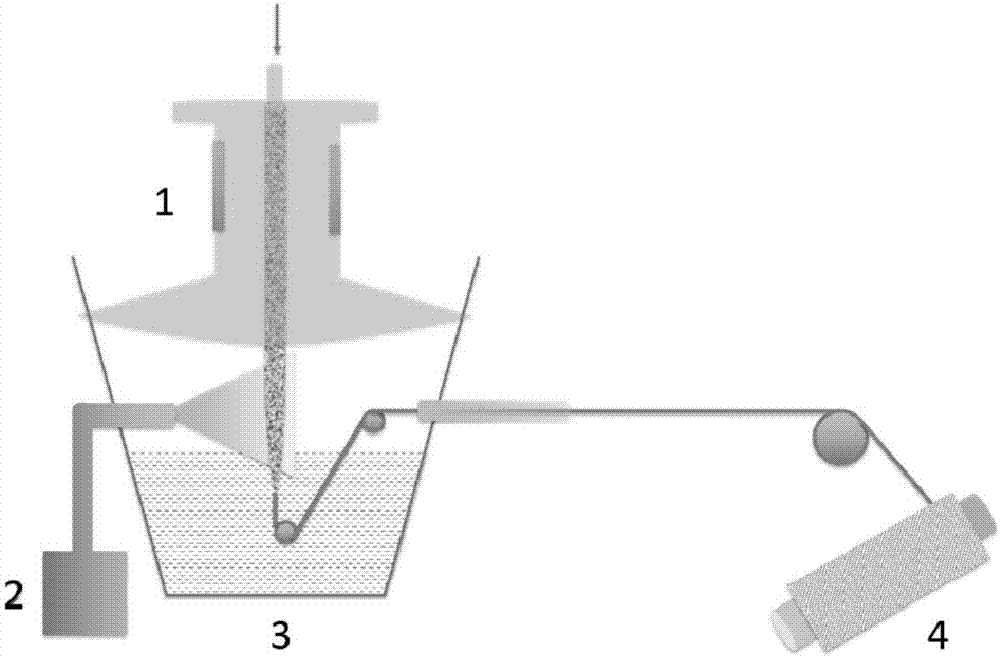

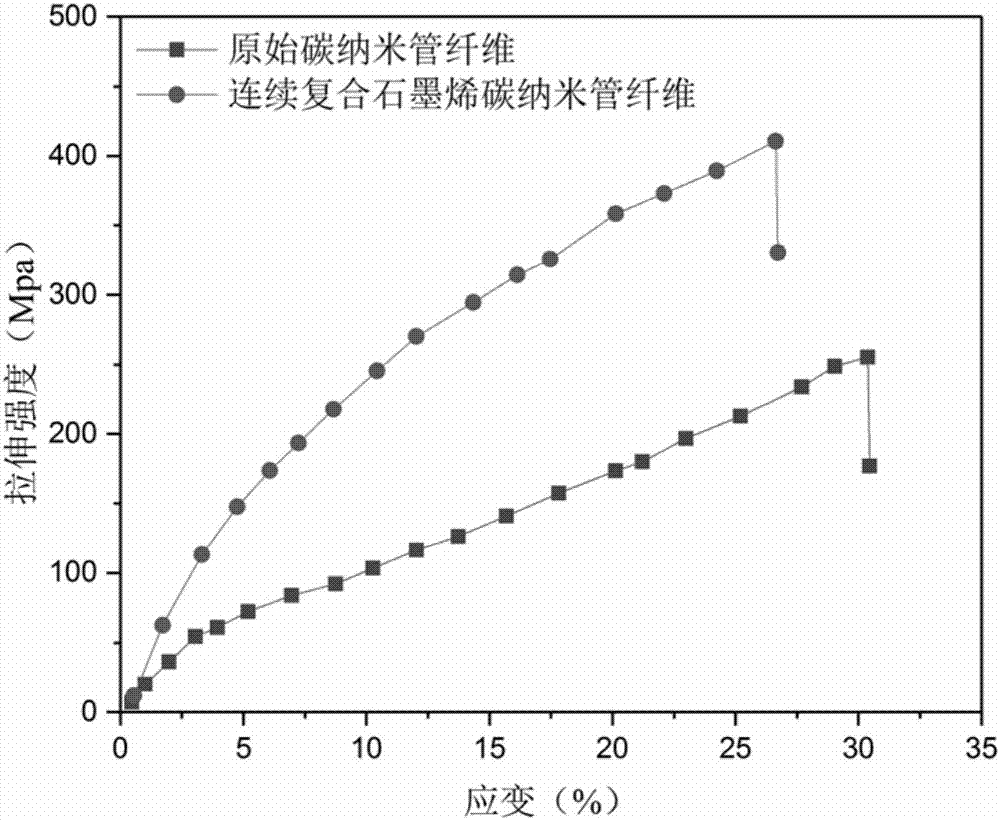

Method and device for continuously preparing carbon nano-tube composite thin film or fiber

ActiveCN107473203AHigh degree of compoundUniform structureGrapheneCarbon nanotubesFiberComposite film

The invention discloses a method and a device for continuously preparing a carbon nano-tube composite thin film or fiber. The method comprises the following steps: preparing a continuous and un-contracted carbon nano-tube aggregate by utilizing a floating catalytic chemical vapor deposition method; continuously or intermittently spraying at least one selected material or a fluid containing at least one selected material to the carbon nano-tube aggregate, so that the selected material is fully in contact with and compounded with a plurality of carbon nano-tubes forming the carbon nano-tube aggregate to form a carbon nano-tube composite aggregate; collecting after the carbon nano-tube composite aggregate is contracted to obtain the continuous carbon nano-tube composite thin film or fiber. The method and the device disclosed by the invention have the benefit that as the carbon nano-tube aggregate is compounded with the selected material before contraction, the compound concentration and the contact area of the selected material and the carbon nano-tubes can be greatly improved, so that the controllable online continuous preparation of the carbon nano-tube composite thin film or fiber with high compound degree and uniform structure is realized.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

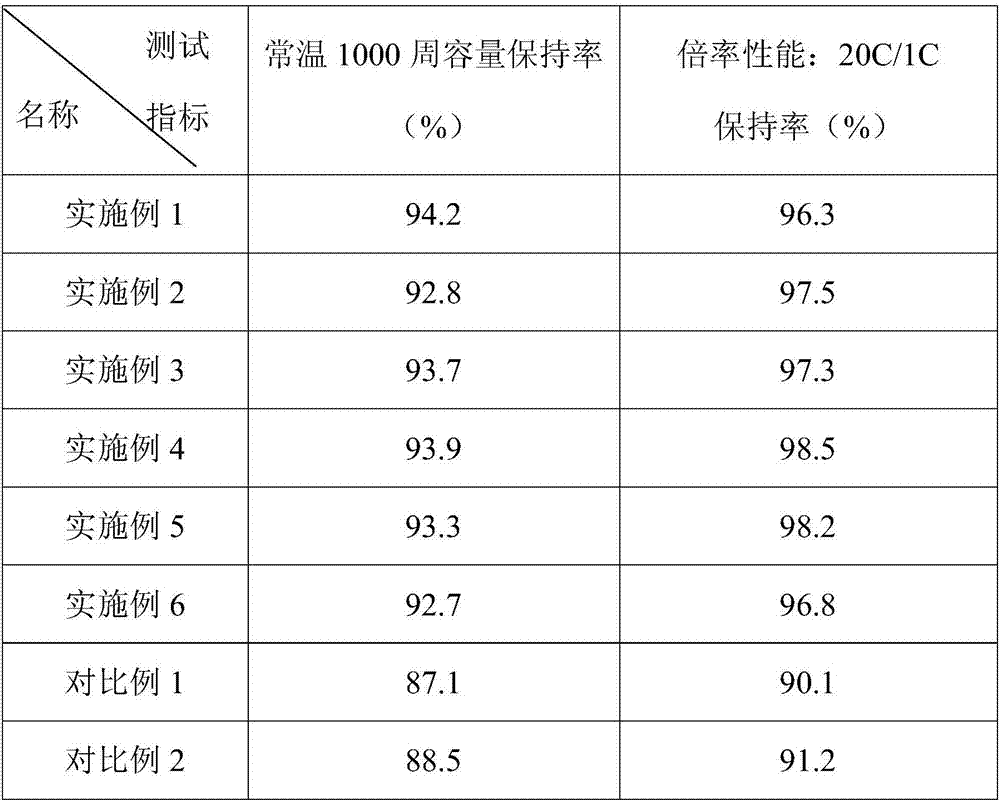

Heteroatom doped graphene coated composite electrode material and preparation method thereof

InactiveCN107221666AImprove conductivityImprove cycle lifeVapour deposition manufacturingDoped grapheneCatalytic chemical vapor deposition

The invention discloses a heteroatom doped graphene coated composite electrode material and a preparation method thereof, firstly an electrode material and a catalyst are mixed to obtain a mixed precursor for catalytic chemical vapor deposition in the presence of both a compound containing a carbon source and a compound containing a doping source to obtain the heteroatom doped graphene coated composite electrode material. The composite electrode material comprises the electrode material and doped graphene coating the surface of the electrode material, and the doped atom is any one or a combination of at least two of boron, sulfur or phosphorus, in the heteroatom doped graphene coated composite electrode material, a heteroatom doped graphene coating layer has good uniformity and less lamination, the heteroatom doped graphene coating layer is uniformly and tightly combined with an electrode material matrix, is not easy to fall off, not easy to agglomerate and wrinkle, and conducive to improvement of the performance of electrical contact with the electrode material matrix, can protect the surface of the electrode material from erosion, can significantly improve the properties of the electrode material, and enhances the electrical conductivity and the cycle life of the electrode material.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Synthesis of Carbon Nanotubes by Selectively Heating Catalyst

ActiveUS20080182027A1Material nanotechnologyPolycrystalline material growthGas phaseCarbon nanofiber

Owner:CFD RES CORP

Preparation method of nitrogen-doped carbon nanotube thin film having high electrochemical properties

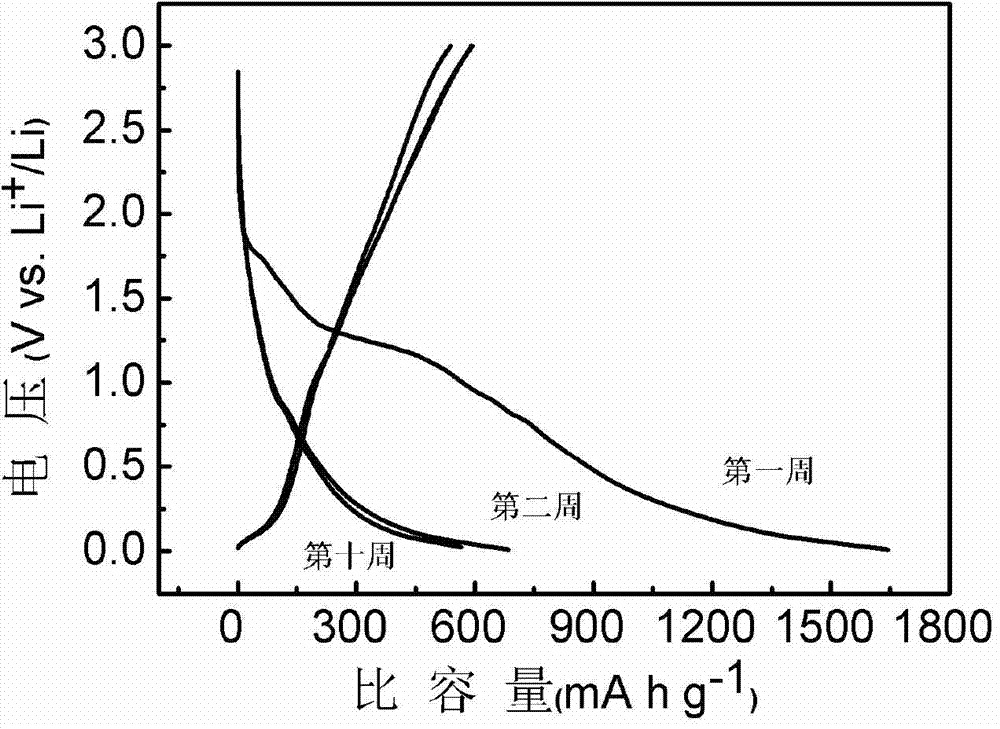

The invention provides a preparation method of a nitrogen-doped carbon nanotube thin film having high electrochemical properties and discloses a preparation method of an anode material of a nitrogen-doped carbon nanotube lithium-ion battery. The following floating catalytic chemical vapor deposition method is adopted: a liquid-phase carbon source, a nitrogen source, a catalyst and an accelerant are mixed and then ultrasonically dispersed to obtain an even precursor solution; a reactor is heated to the range of 900-1200 DEG C in an argon environment and kept at a constant temperature, under the driving of a carrier gas (hydrogen or hydrogen and argon mixed gas), and the precursor solution is injected into the reactor at the rate of 2-12mL / h, then a uniform and continuous thin film can be obtained; the thin film is thermally treated for 1-4 hours under the air condition of 300-600 DEG C, and finally, the anode material of the nitrogen-doped carbon nanotube lithium-ion battery is obtained. The preparation method is simple in process, relatively low in energy consumption, and capable of further improving the properties of the material; under the current density of 30mAg<-1>, the initial charge capacity and the initial discharge capacity of the material are 591.1mAhg<-1> and 1644.4mAhg<-1>, respectively; after 100 charge-discharge cycles under the current density of 3000mAg<-1>, the charge capacity and the discharge capacity are stabilized at 293.2mAhg<-1> and 305.1mAhg<-1>; in short, the preparation method can be widely applied to the electrode materials of the lithium ion batteries.

Owner:TIANJIN UNIV

Method for controlled growth of carbon nanotubes in a vertically aligned array

InactiveUS20170342550A1Prevent surfaceReduce carbon nanotube nucleation siteMaterial nanotechnologyAnodisationVolumetric Mass DensityBCN nanotube

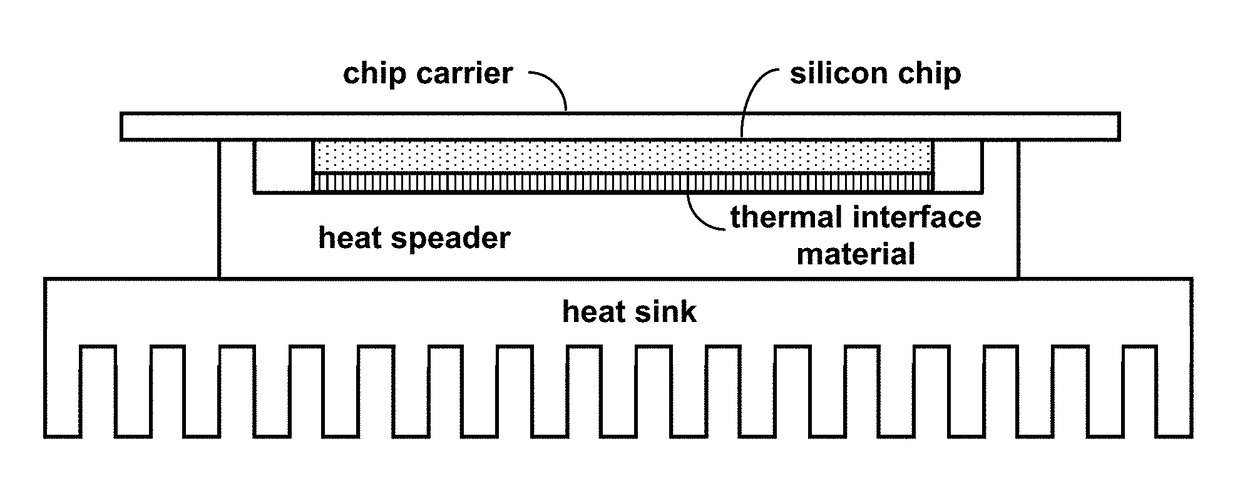

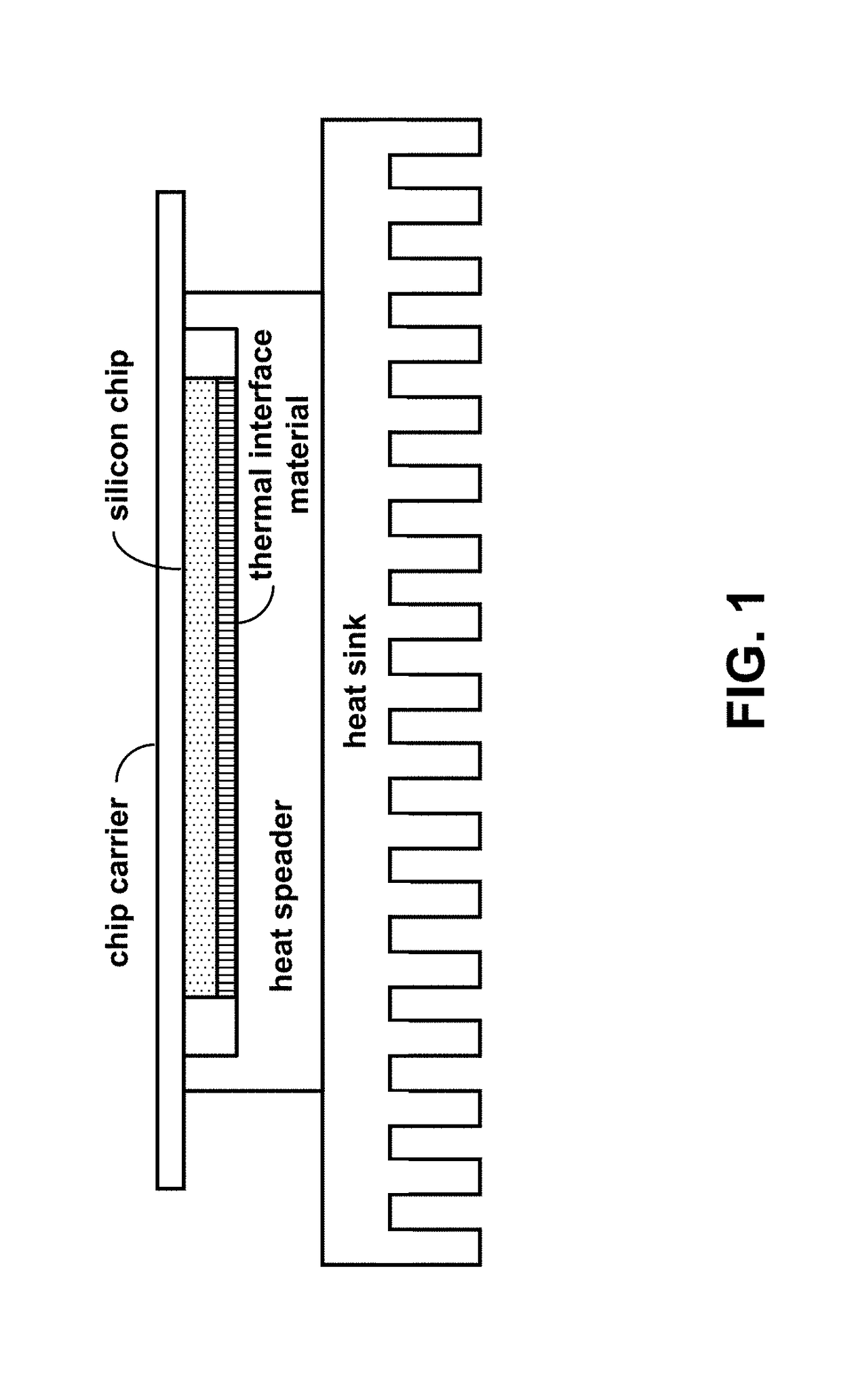

Template-guided growth of carbon nanotubes using anodized aluminum oxide nanopore templates provides vertically aligned, untangled planarized arrays of multiwall carbon nanotubes with Ohmic back contacts. Growth by catalytic chemical vapor deposition results in multiwall carbon nanotubes with uniform diameters and crystalline quality, but varying lengths. The nanotube lengths can be trimmed to uniform heights above the template surface using ultrasonic cutting, for example. The carbon nanotube site density can be controlled by controlling the catalyst site density. Control of the carbon nanotube site density enables various applications. For example, the highest possible site density is preferred for thermal interface materials, whereas, for field emission, significantly lower site densities are preferable.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

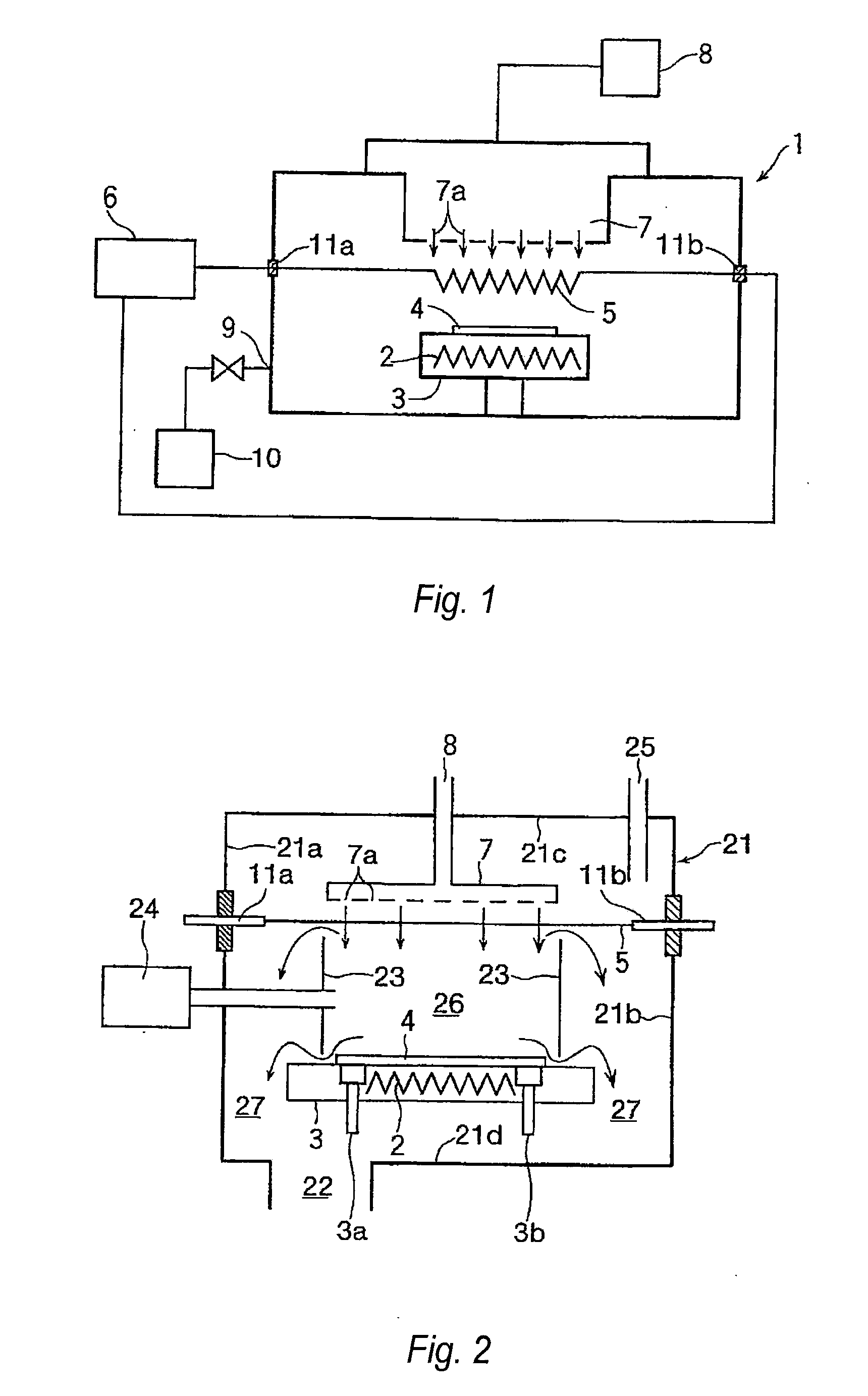

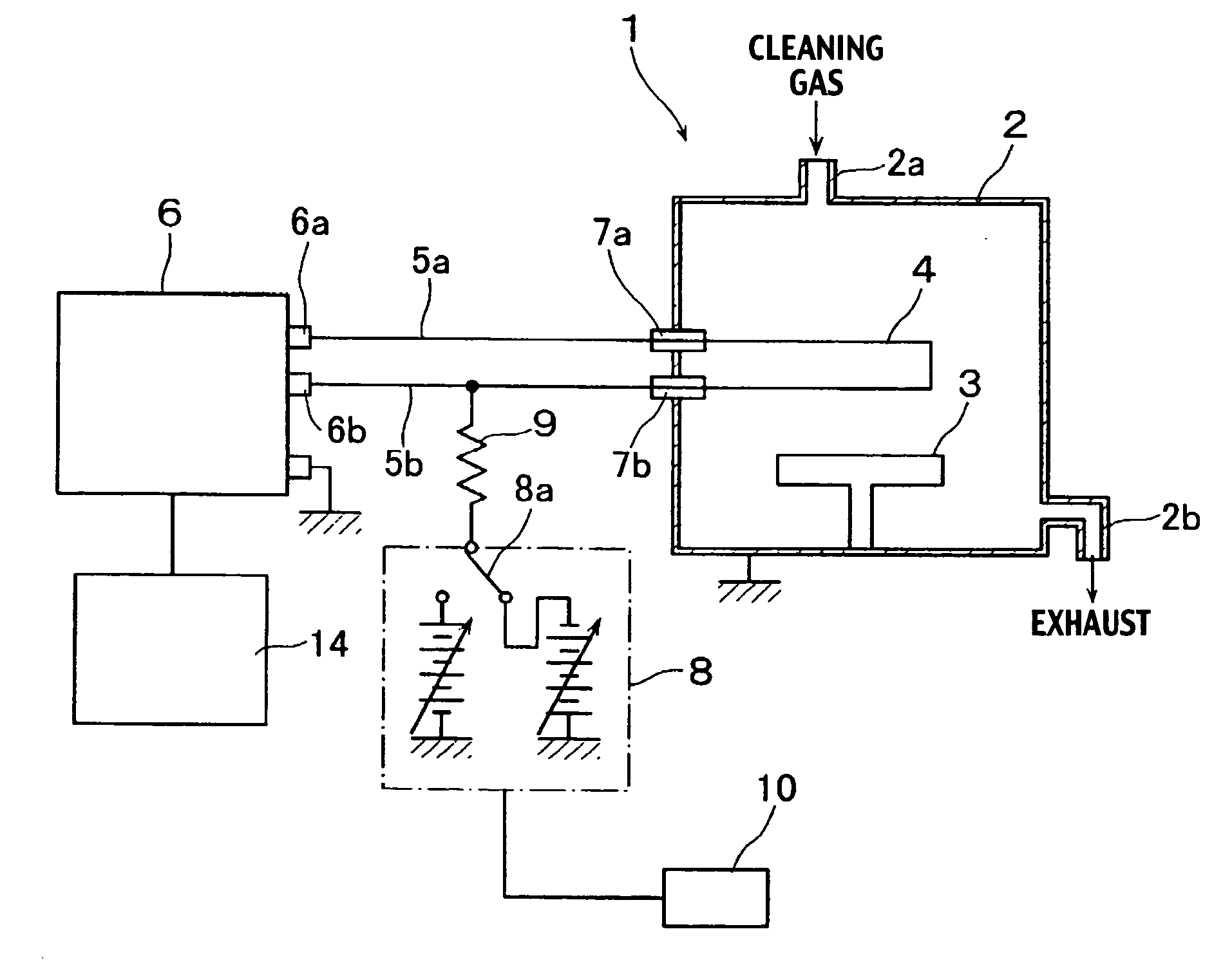

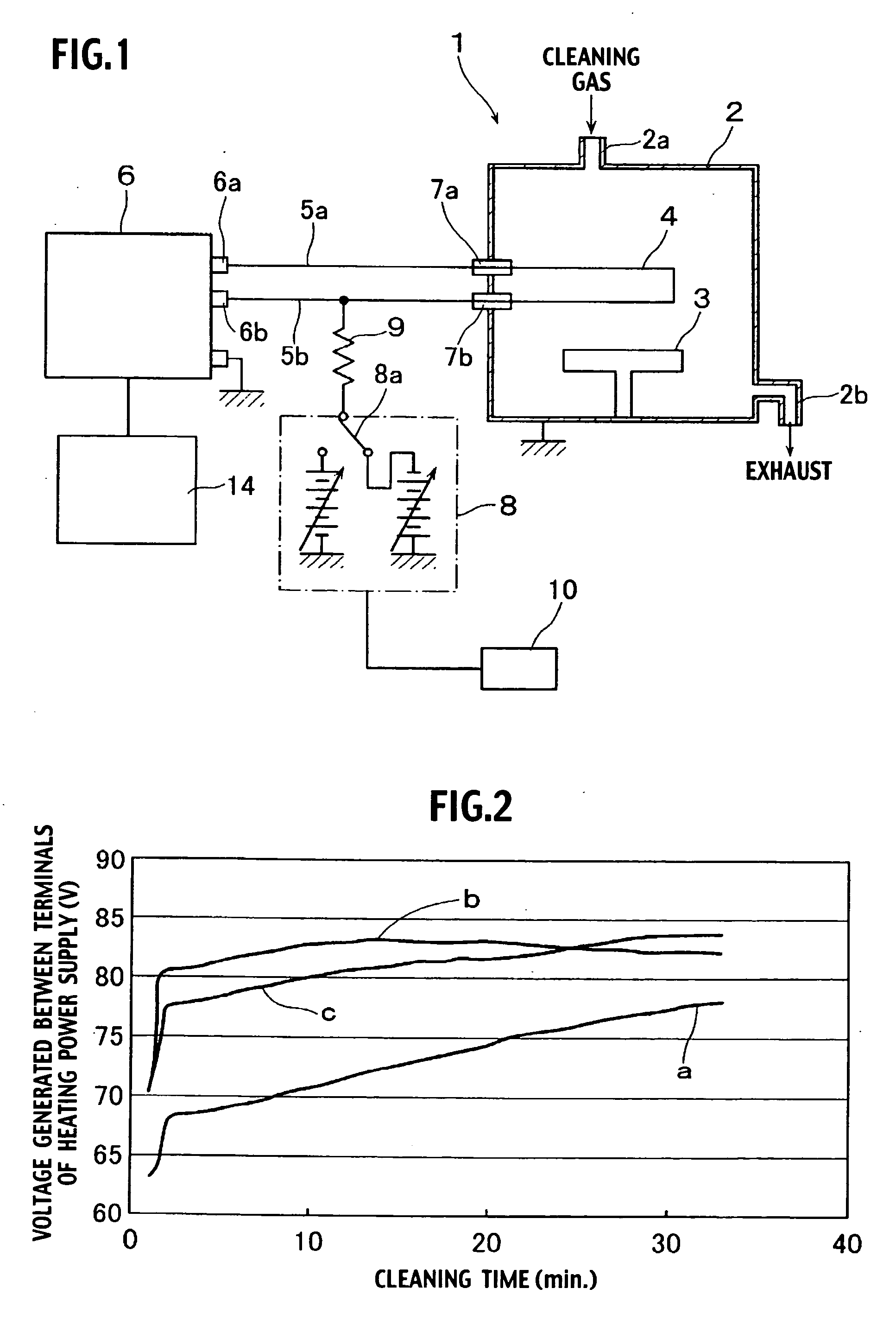

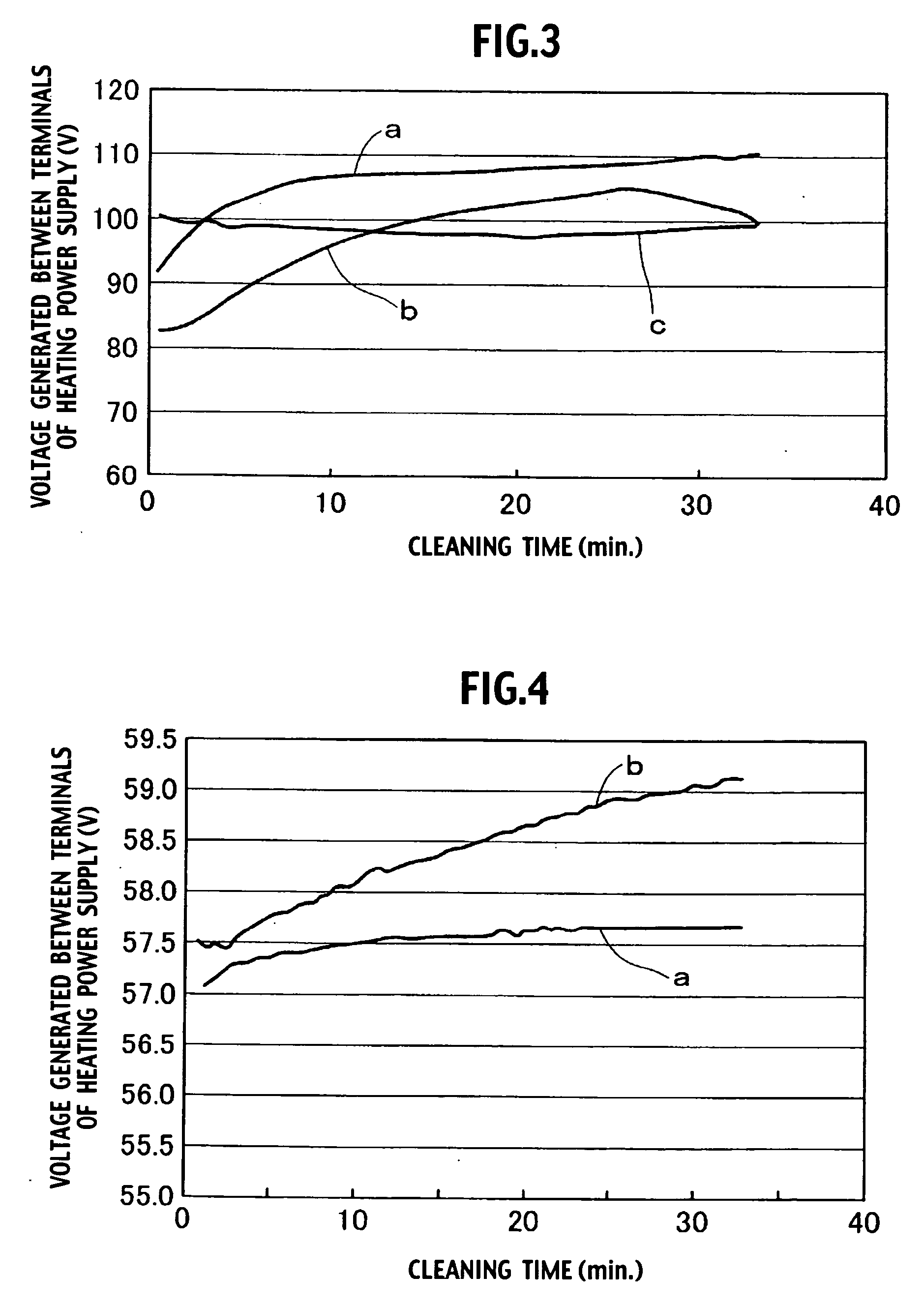

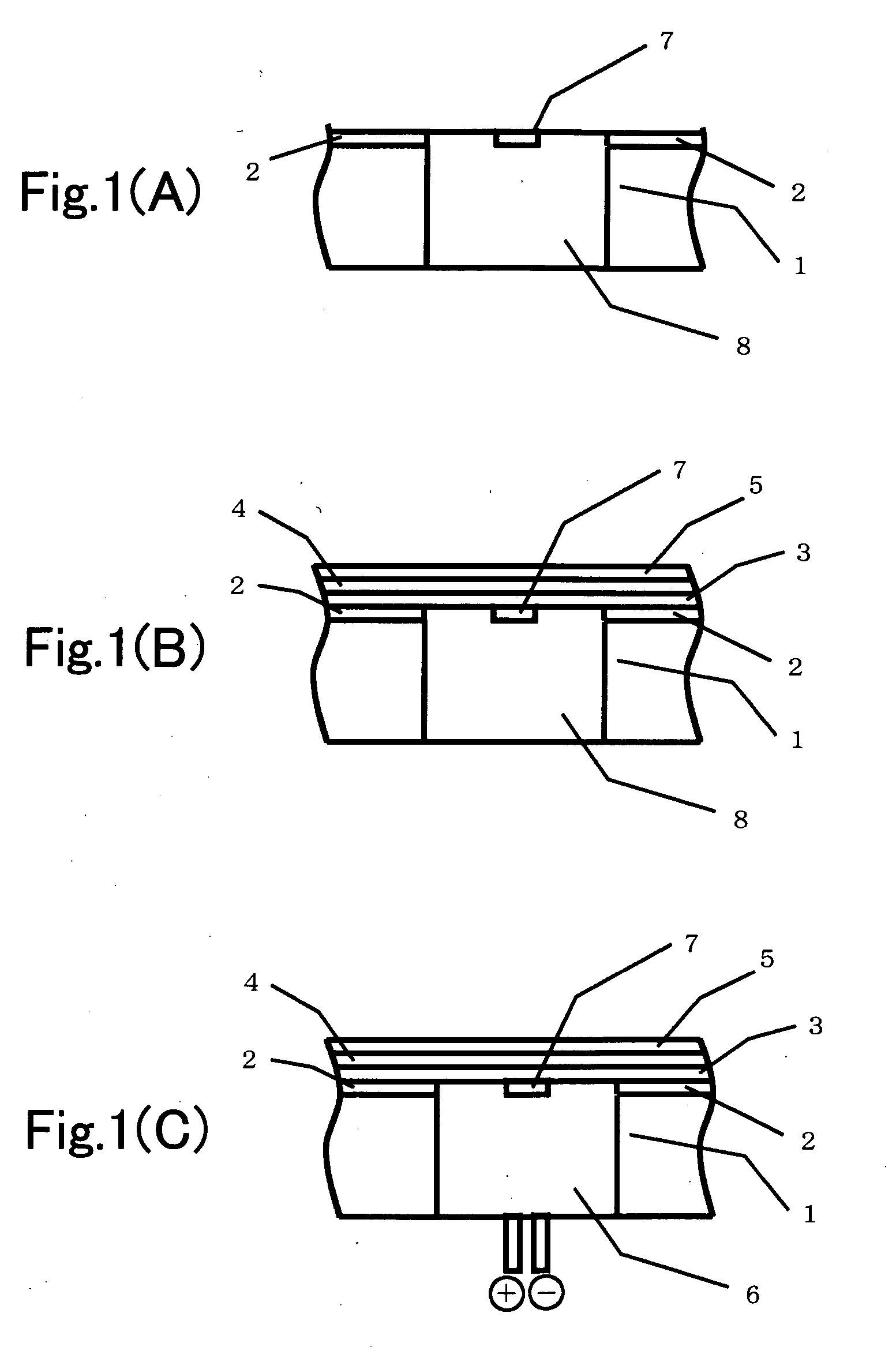

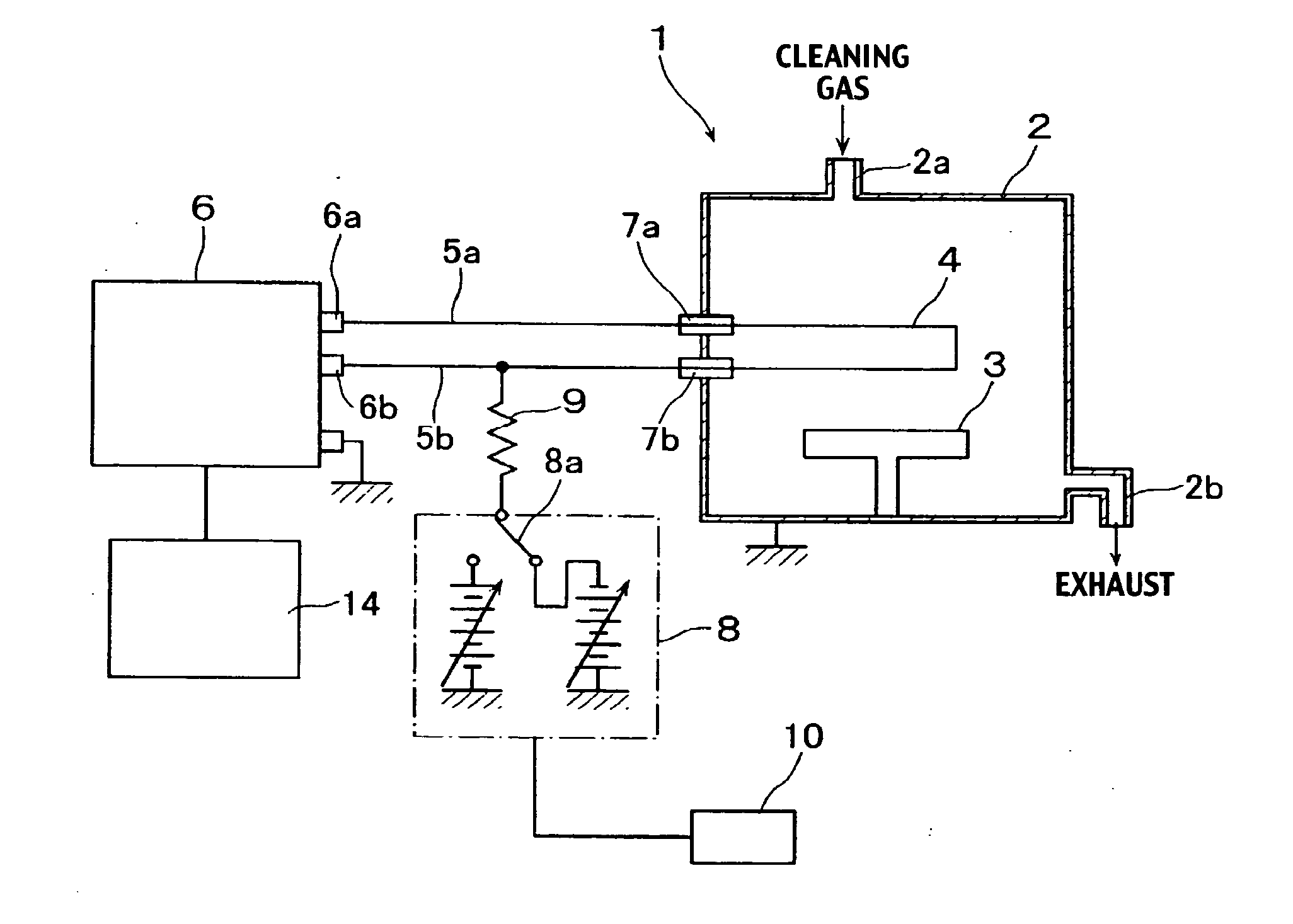

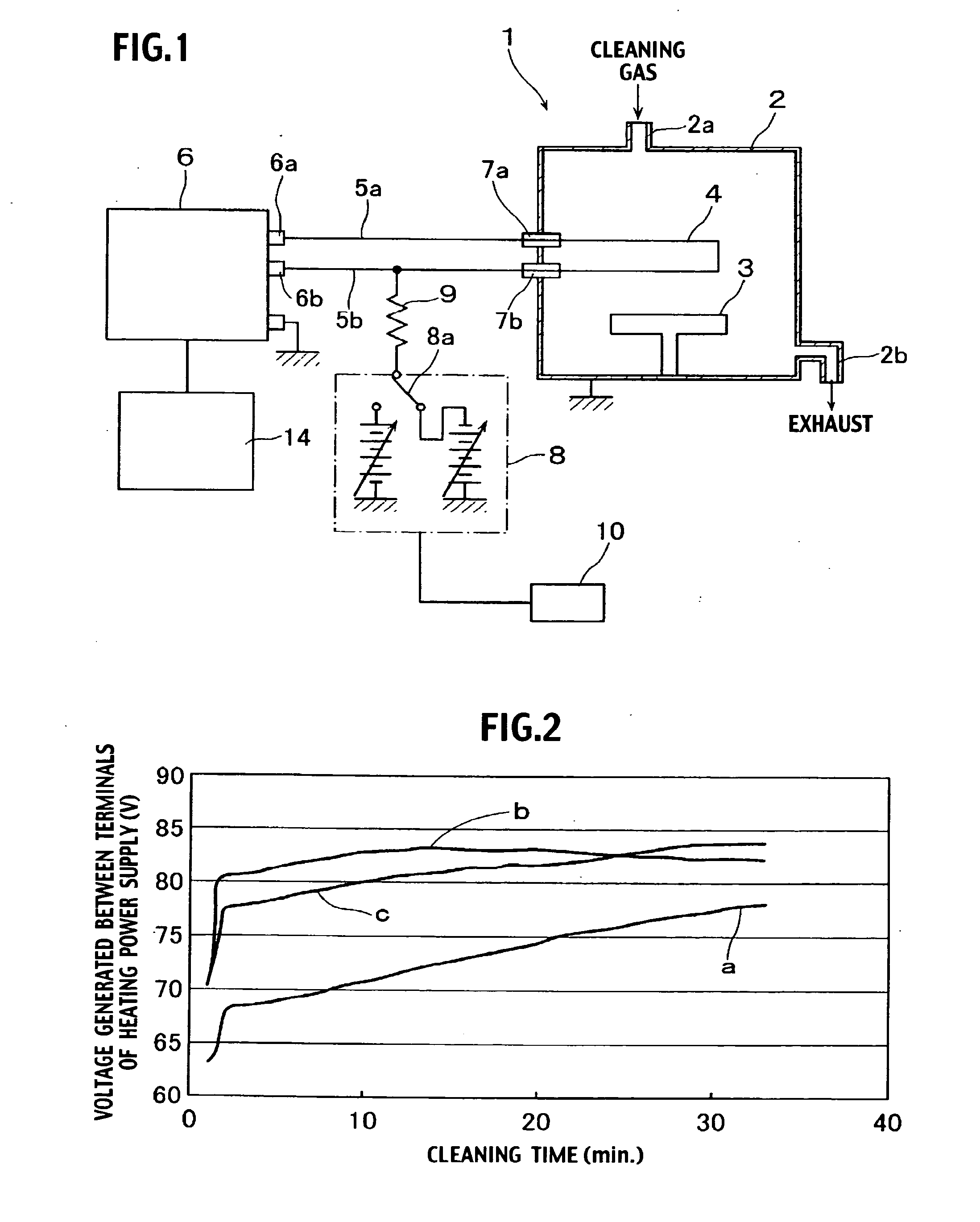

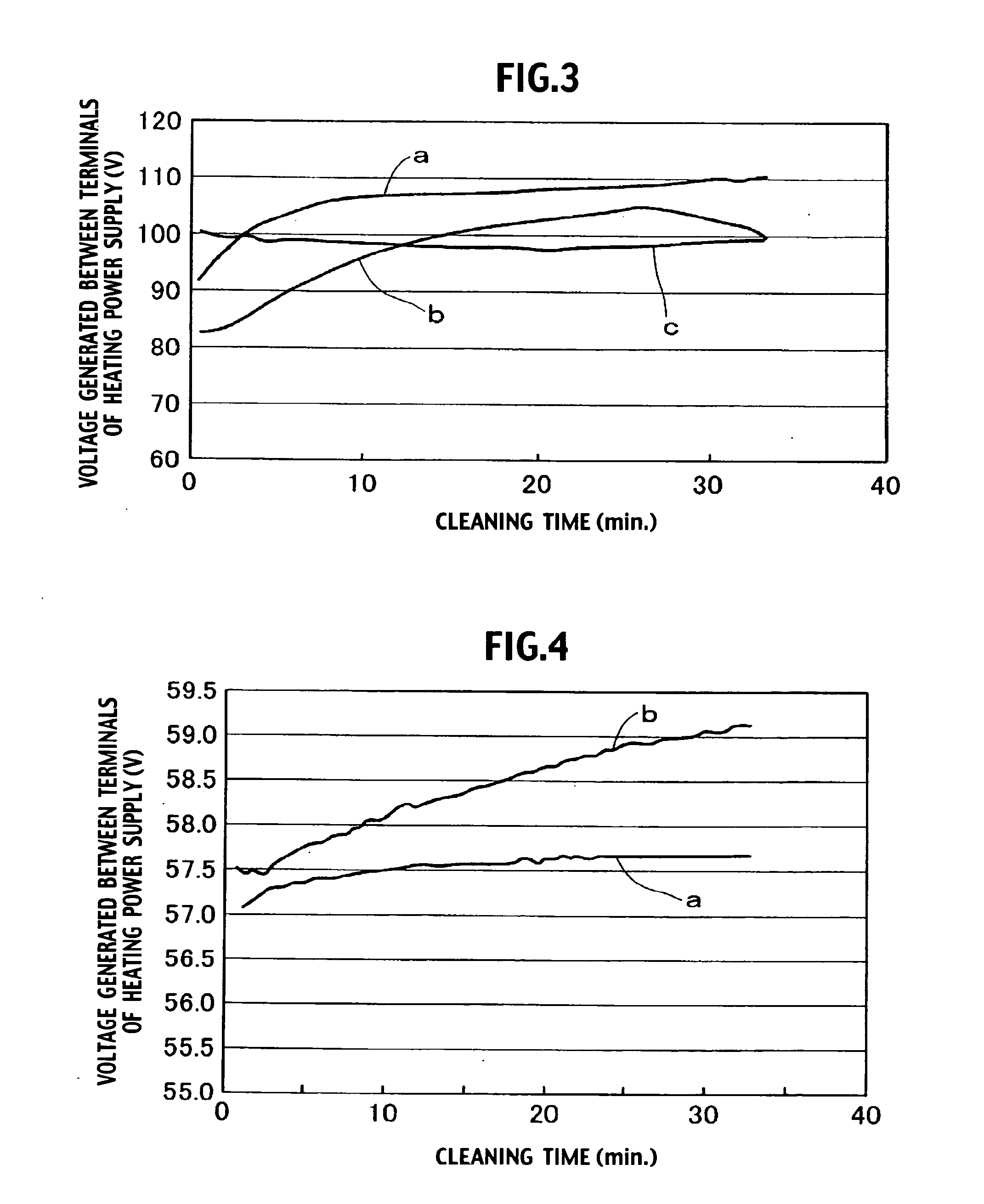

Self-Cleaning Catalytic Chemical Vapor Deposition Apparatus And Cleaning Method Thereof

InactiveUS20070209677A1Stable and good filmLow costSemiconductor/solid-state device manufacturingElectrostatic cleaningElectrical conductorGas phase

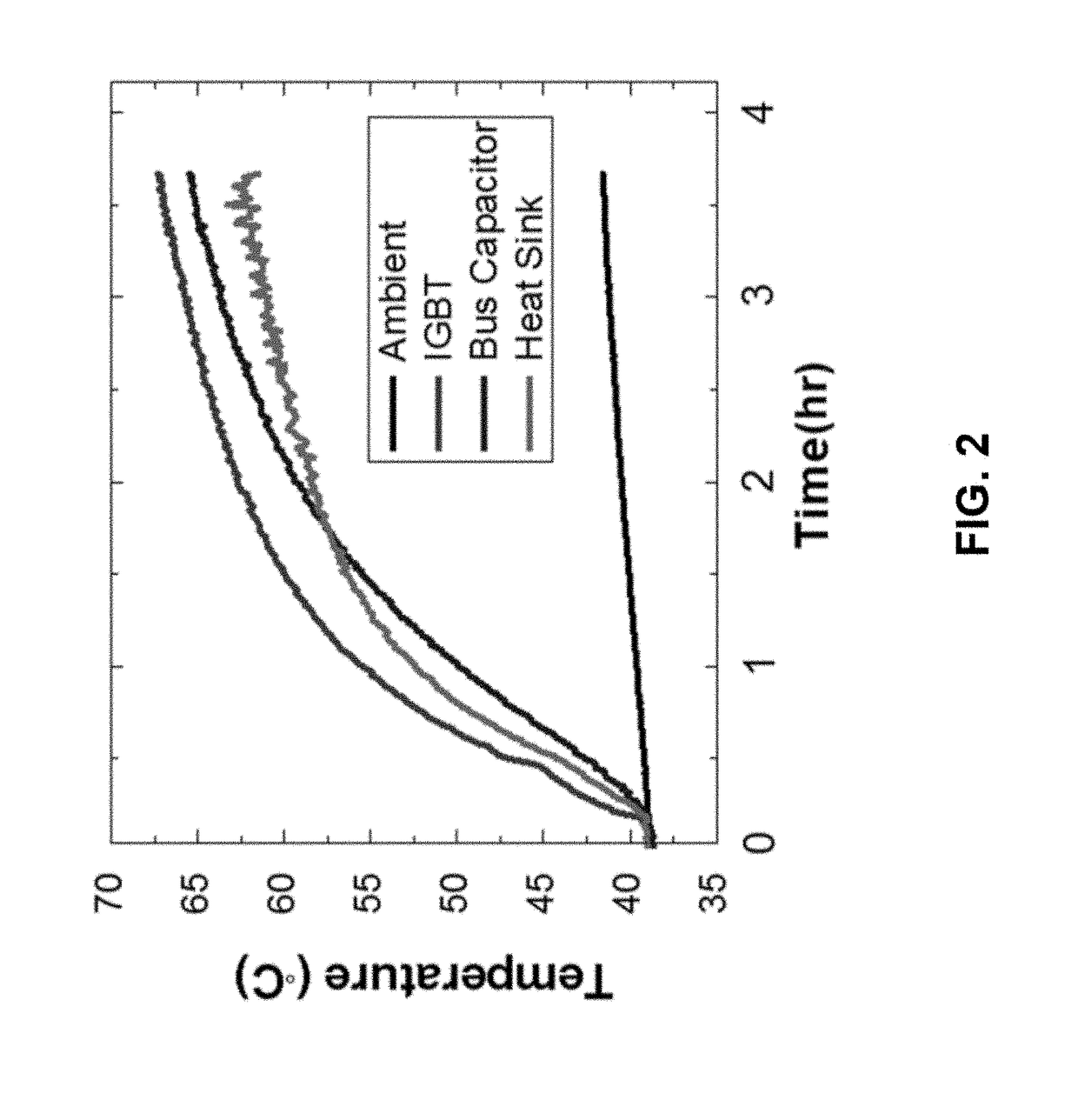

Provided is a self-cleaning catalytic chemical vapor deposition apparatus which suppresses the corrosion-induced degradation of a catalytic body by a cleaning gas without heating a catalytic body to not less than 2000° C. and permits practical cleaning rates and good cleaning at low cost. With conductors 5a, 5b which supply a constant current to a catalytic body 4 within a reaction chamber 2 from a heating power supply 6 and terminals 6a, 6b of the heating power supply 6 kept electrically insulated from the reaction chamber 2, a cleaning gas containing halogen elements is introduced into the reaction chamber 2 which has been evacuated, and the catalytic body 4 is heated by the energization from the heating power supply 6. An active species generated by this heating is caused to react with an adhering film which adheres to the interior of the reaction chamber 2, whereby the adhering film is removed. During this removal of the adhering film, a DC bias voltage having an appropriate polarity and an appropriate value is applied from a constant-voltage power supply 8 to the conductor 5b of the heating power supply 6.

Owner:ULVAC INC

Preparation method of carbon nanotube fiber/polydimethylsiloxane composite electro-conductive elastomer

ActiveCN109929248AIncrease elasticityImprove flexibilityCarbon fibresFibre chemical featuresFiberElastomer

The invention discloses a preparation method of a carbon nanotube fiber / polydimethylsiloxane composite conductive elastomer. The method comprises the following steps: 1) ultrasonically mixing ethanol,ferrocene, thiophene and deionized water to obtain a reaction solution, preparing a hollow cylindrical object of the carbon nano tube by a floating catalytic chemical vapor deposition method, performing bundling, filament collecting and air exhaustion, performing twisting operation to obtain carbon nano tube fibers, and drying the carbon nano tube fibers for later use; 2) fully stirring and uniformly mixing polydimethylsiloxane and a curing agent to obtain a mixed solution, vacuumizing the solution, pouring the mixed solution into a culture dish, and drying and preheating the mixed solution;3) dipping the dried carbon nanotube fiber into the preheated mixed solution, adding the mixed solution before preheating, and curing and molding the carbon nanotube fibers in a drying oven to obtaina carbon nanotube fiber / polydimethylsiloxane compound; and 4) performing cutting operation to obtain the carbon nanotube fiber / polydimethylsiloxane composite conductive elastomer. The preparation method is controllable in process and easy to operate, and the prepared finished product has high elasticity and flexibility and also has good electrical conductivity.

Owner:ZHEJIANG SCI-TECH UNIV

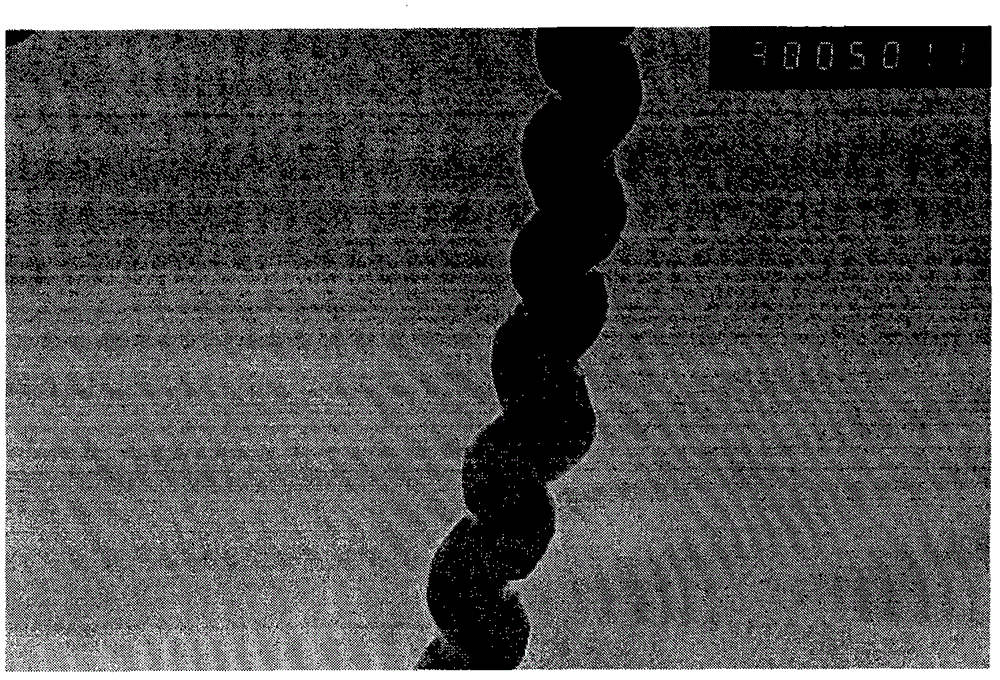

Method for preparing helical structure carbon nanotubes

The present invention discloses a method for preparing helical structure carbon nanotubes. According to the helical structure carbon nanotubes, a copper-nickel-aluminum composite oxide is adopted as a catalyst, acetylene is adopted as carbon source gas, a mixed gas of hydrogen and nitrogen is adopted as carrier gas, and the helical structure carbon nanotubes are prepared at a temperature of 500-800 DEG C by using a fixed bed catalytic chemical vapor deposition method. The prepared helical structure carbon nanotubes are twisted shape, and have characteristics of regular morphology, uniformity, tube diameter of 100-200 nm, length of 2-10 mum, and purity more than 80%, wherein the yield of the prepared helical structure carbon nanotubes can be 25 times the weight of the catalyst.

Owner:CHENGDU ZHONGKE PURUI PURIFYING EQUIP

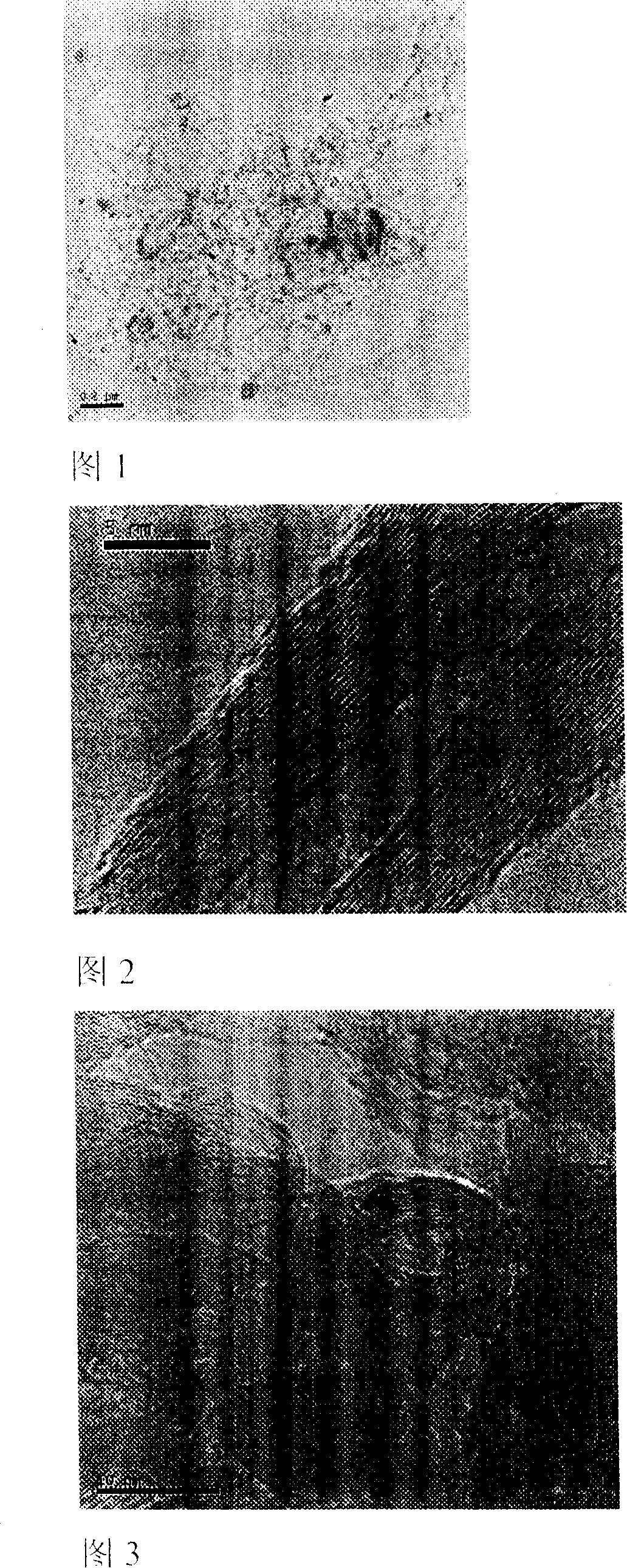

Process for preparing carbon nano tube and carbon onion by Ni/Al catalyst chemical gas phase deposition

InactiveCN100368080CEasy to makeIncrease productionPolycrystalline material growthFrom chemically reactive gasesGas phaseCracking reaction

The present invention discloses Ni / Al catalytic chemical vapor deposition (DVD) process of preparing carbon nanotube and carbon onion. The preparation process can obtain carbon nanotube and carbon onion of high quality and high purity in high yield. Firstly, nickel nitrate hexahydrate and aluminum powder in certain weight ratio are prepared Ni / Al catalyst precursor in corresponding weight ratio in the presence of sodium hydroxide or ammonia water as precipitant. Hydrogen is introduced to reduce the Ni / Al catalyst precursor into Ni / Al catalyst, and methane, acetylene or other gas as carbon source is then introduced to perform catalytic cracking reaction of 1-4 hr.

Owner:TIANJIN UNIV

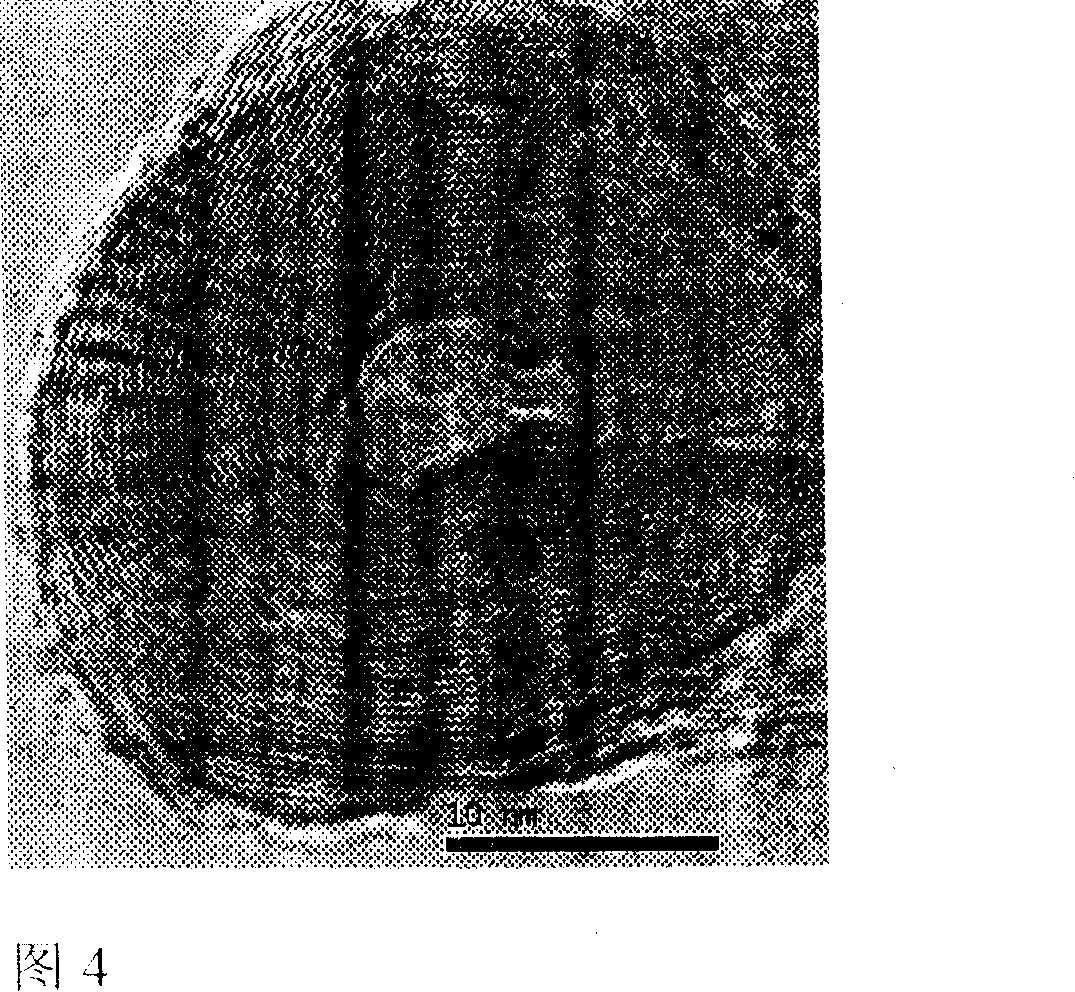

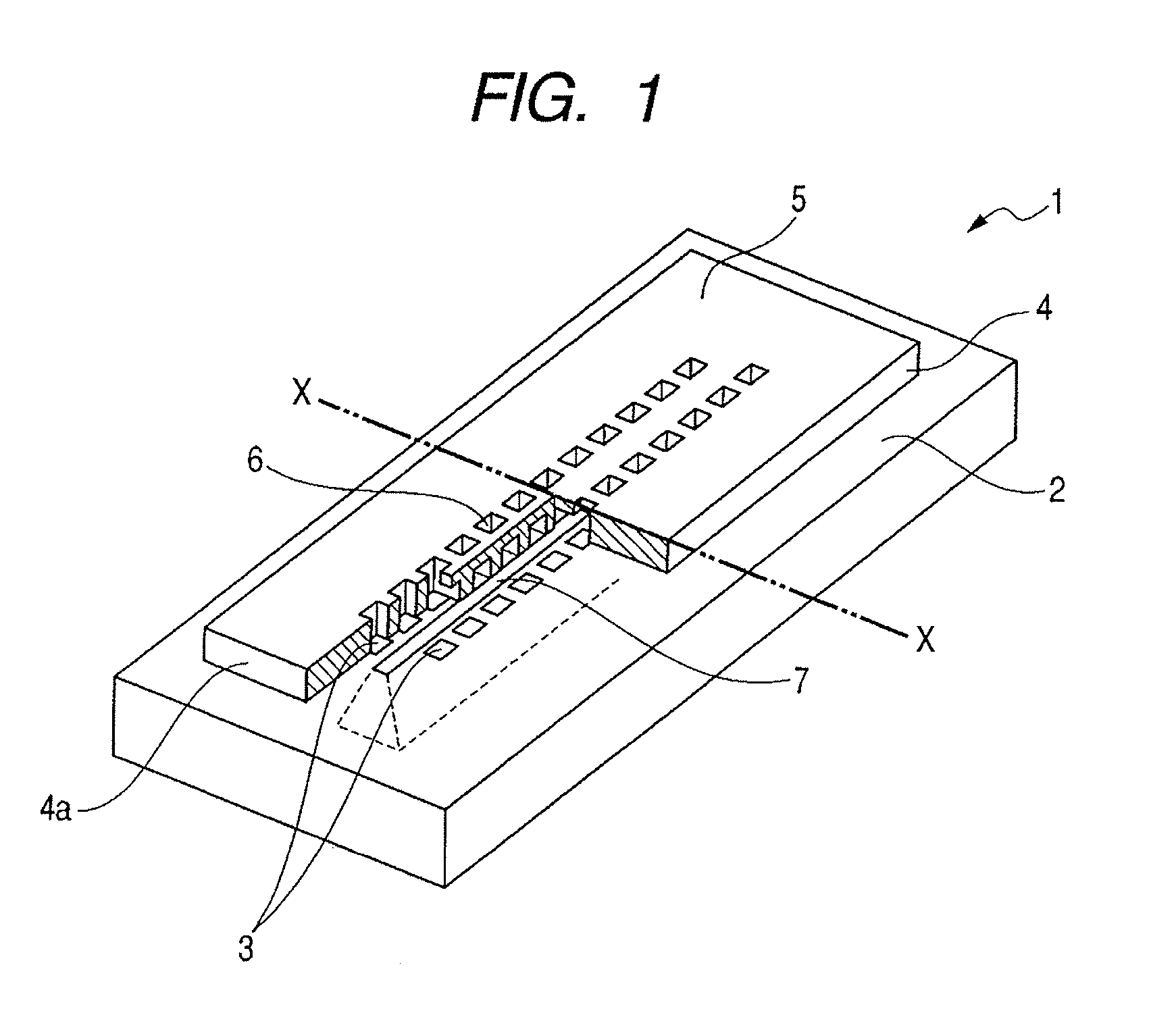

Cell culture carrier and jig for cell culture

InactiveUS20060014275A1High densityMaterial nanotechnologyBioreactor/fermenter combinationsCarbon layerHigh density

The present invention provides a cell culture carrier and a method for cell culture, which are capable of growing multi-layered cells or stably growing cells with a high density. To solve the above described disadvantage, the cell culture carrier of the present invention comprises cup-stacked type carbon nano tubes produced by a catalytic chemical vapor deposition method, a plurality of bottomless cup-shaped carbon layers (graphene sheet) are stacked in each of the cup-stacked type carbon nano tubes, and edges of the stacked carbon layers are exposed.

Owner:GSI CREOS CORP

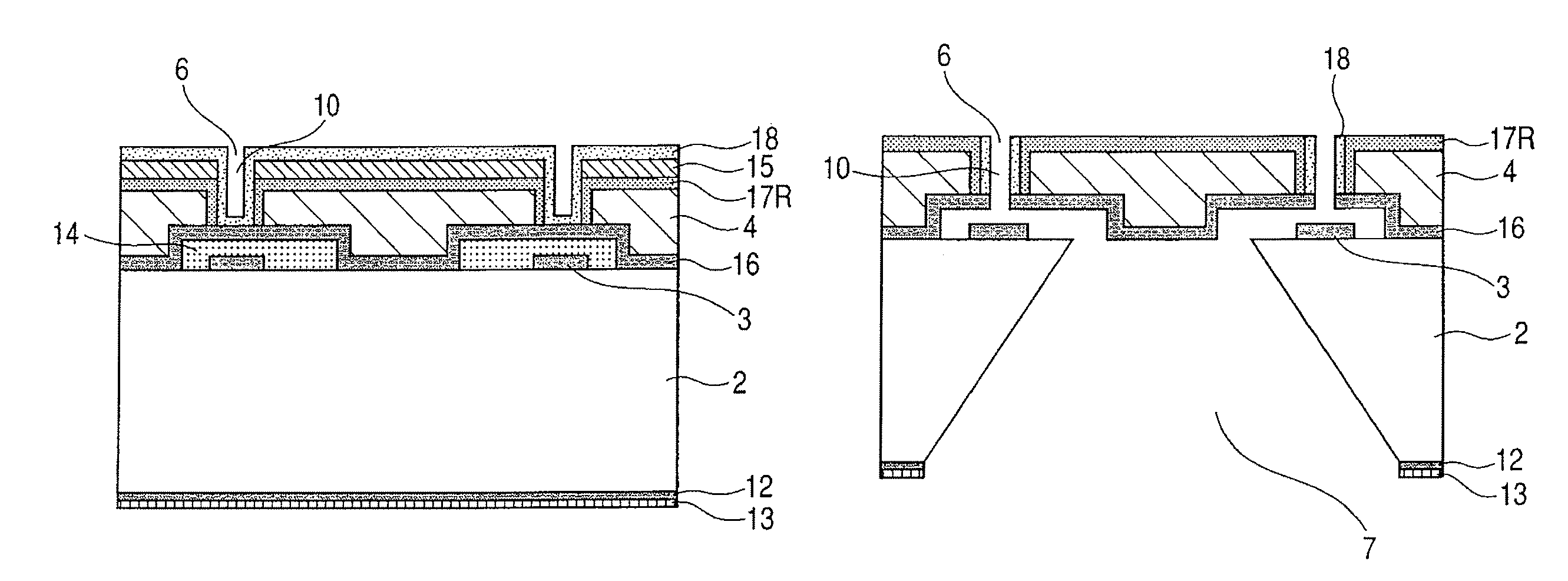

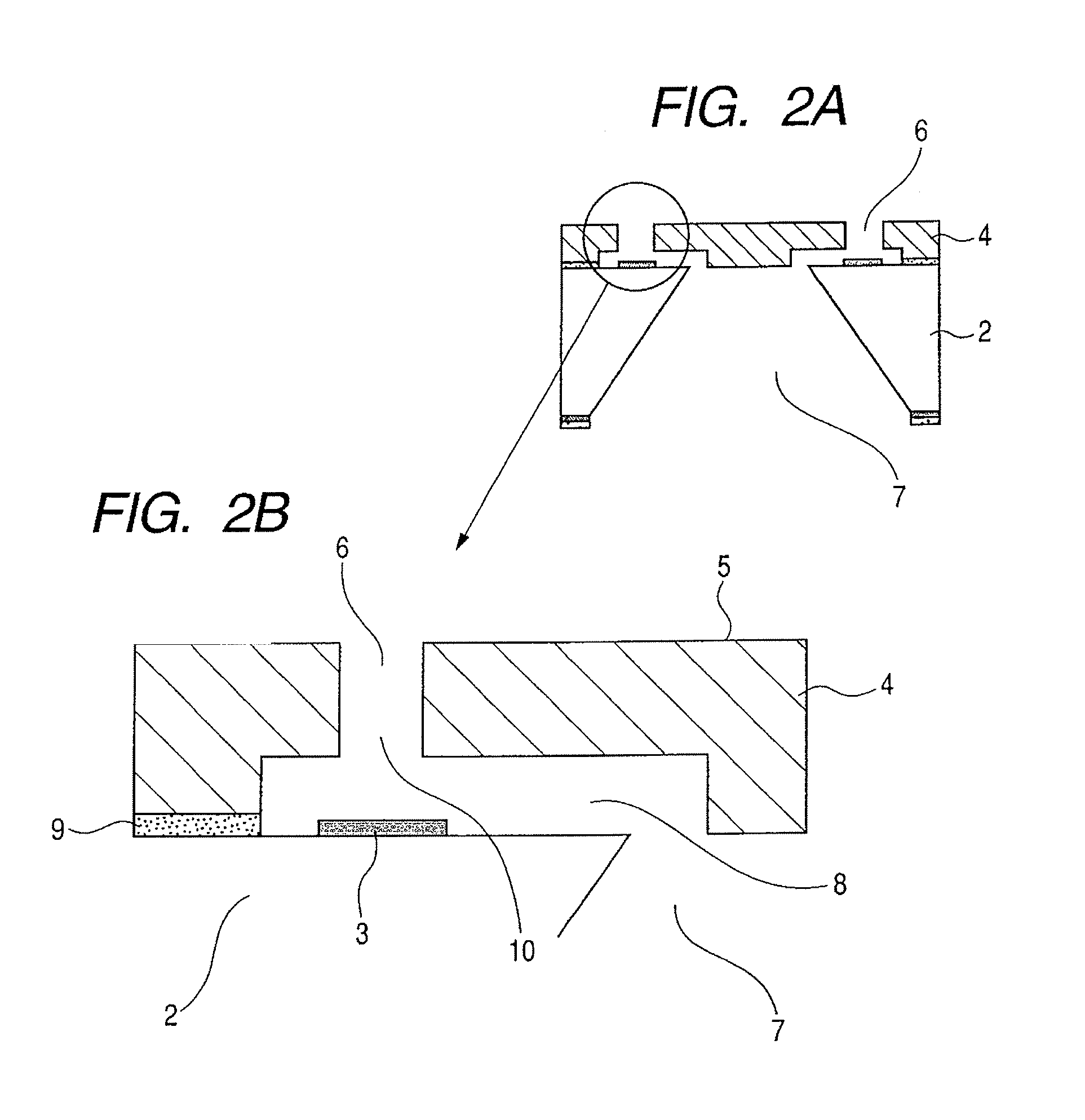

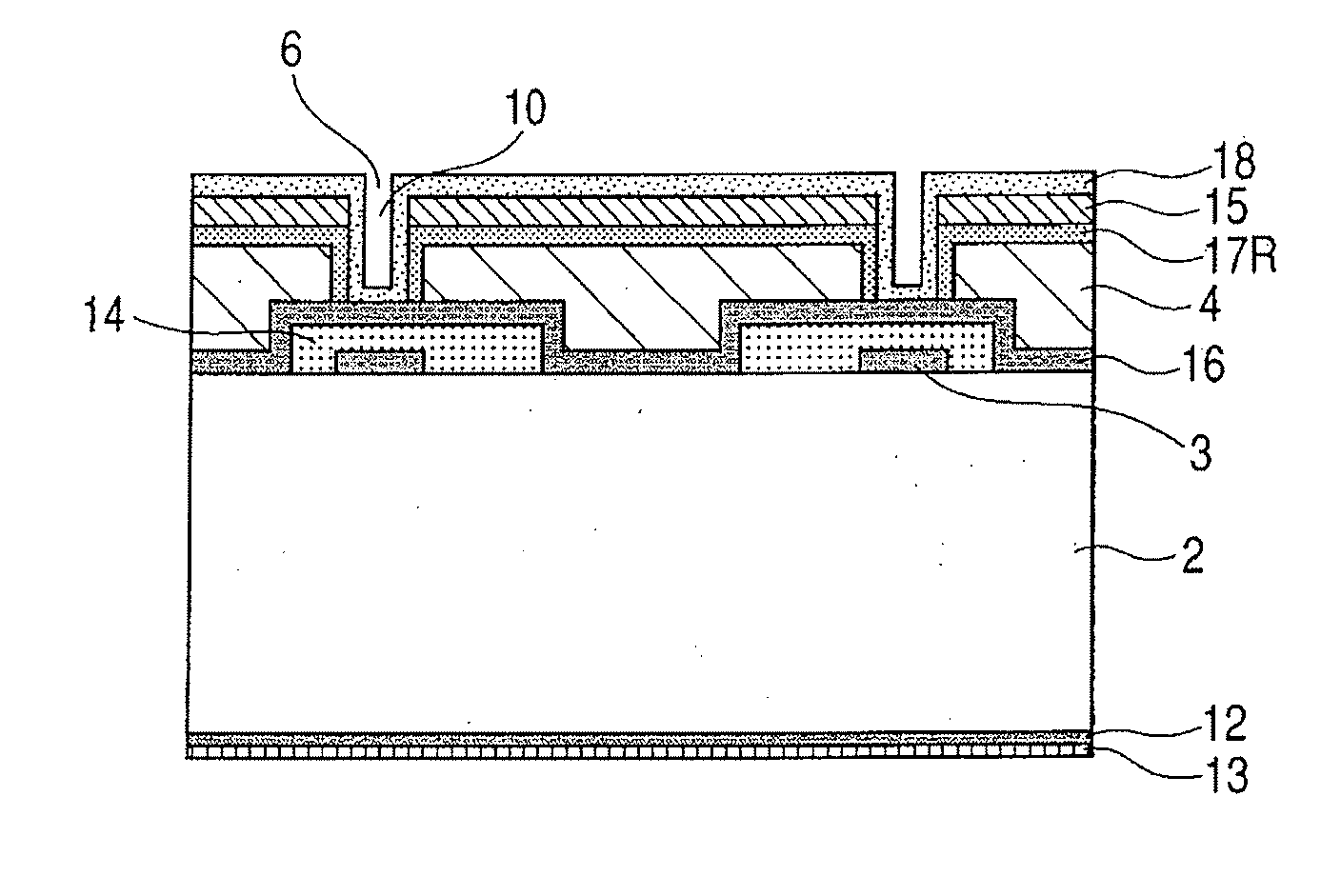

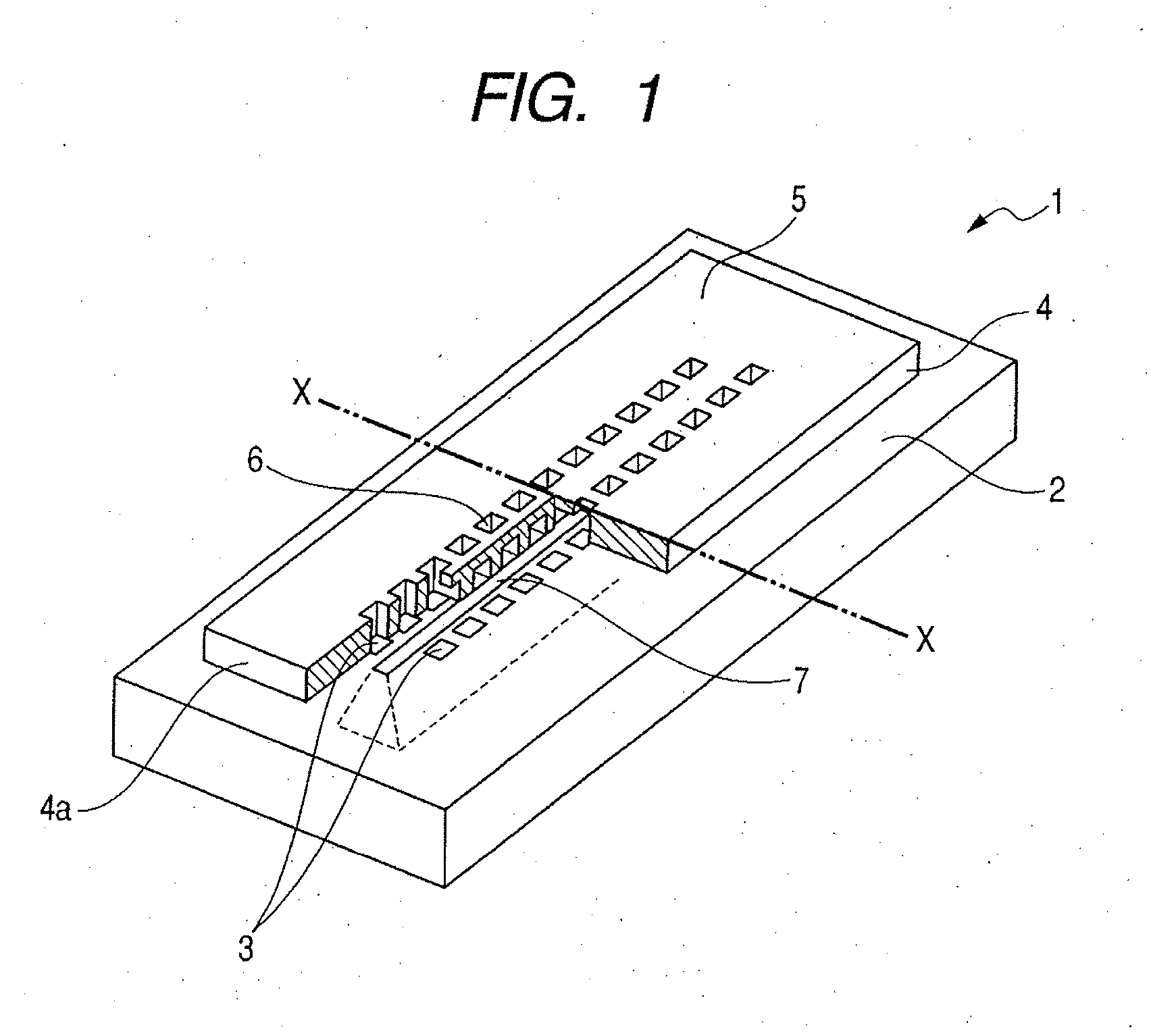

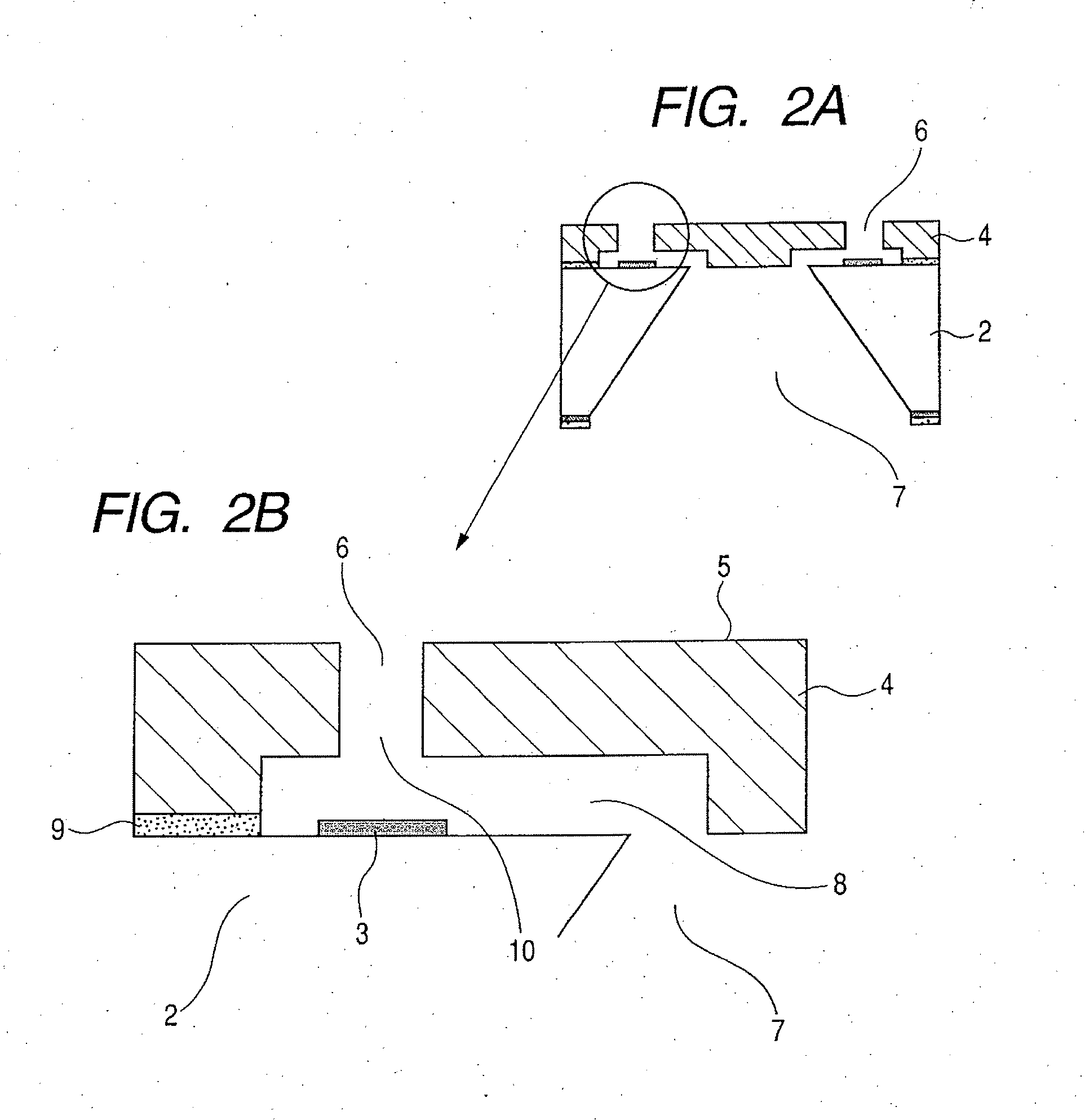

Base member for liquid discharge head, liquid discharge head utilizing the same, and producing method therefor

For providing a base for a liquid discharge head having an internal surface of a liquid flow path and a discharge port, suppressed in swelling by liquid and having high precision and high reliability, the base including a base member, an energy generating element for discharging a liquid, formed on the base member, and a resin structure having a liquid discharge port for discharging the liquid and disposed on the base member so as to cover the energy generating element, is provided with a protective layer. The protective layer is formed by a catalytic chemical vapor deposition on a surface of the resin structure in which the liquid discharge port is opened.

Owner:CANON KK

Base member for liquid discharge head, liquid discharge head utilizing the same, and producing method therefor

InactiveUS20070242106A1Improve accuracyImprove reliabilityPrintingElectrical and Electronics engineeringCatalytic chemical vapor deposition

For providing a base member for liquid discharge head having internal surface of liquid flow path and discharge port, suppressed in swelling by liquid and having high precision and high reliability, the invention provides a base member including a base member, an energy generating element for discharging a liquid, formed on the base member, and a resin structure having a liquid discharge port for discharging the liquid and disposed on the base member so as to cover the energy generating element, wherein a protective layer formed by a catalytic chemical vapor deposition is formed on a surface of the resin structure in which the liquid discharge port is opened.

Owner:CANON KK

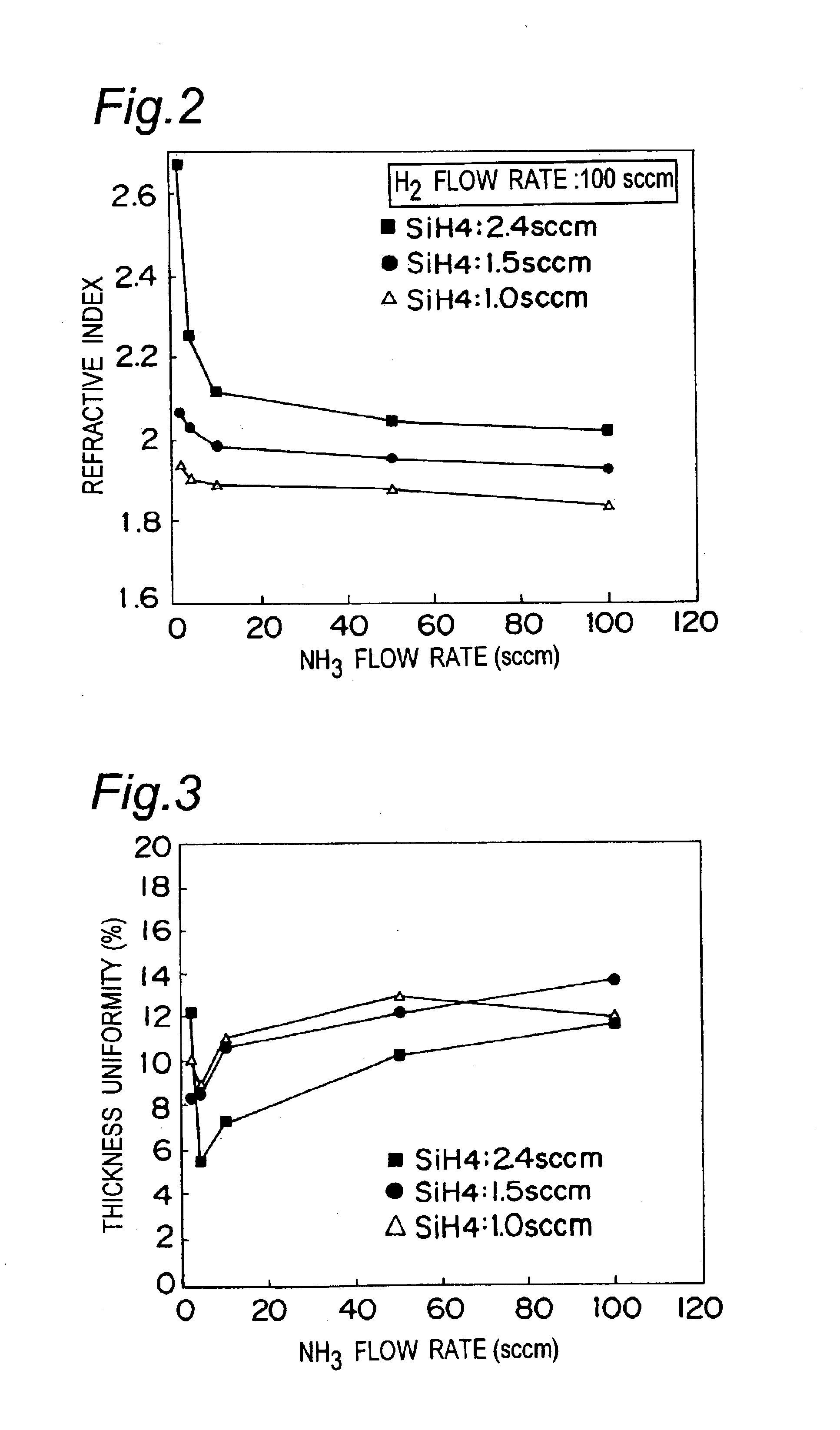

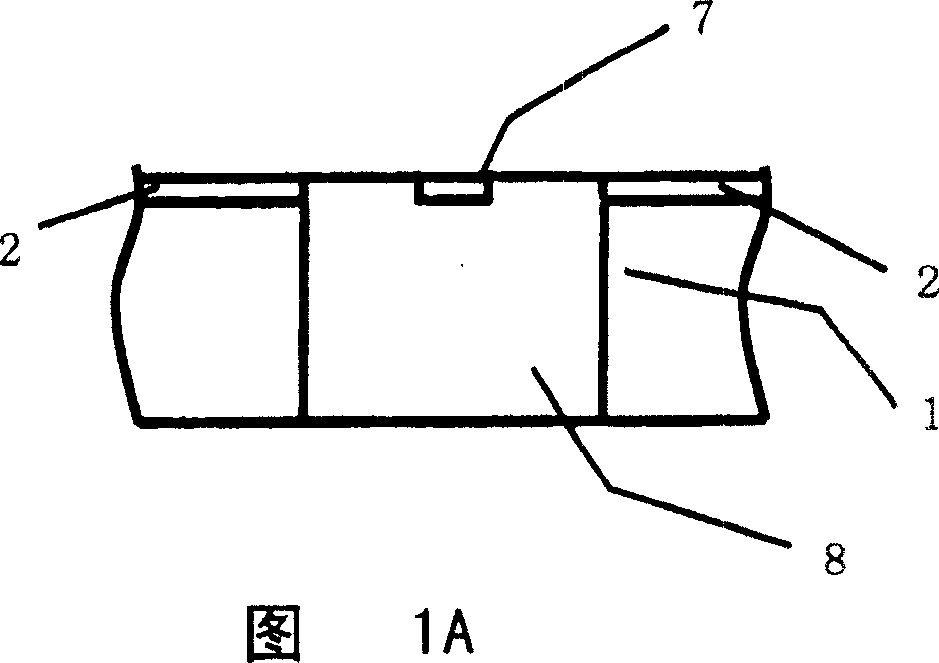

Process for manufacturing a semiconductor device

InactiveUS6933250B2High film forming rateSuppression problemSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesHydrogen supply

A process of manufacturing a semiconductor device uses catalytic chemical vapor deposition. In the process, a reaction chamber containing a catalyzer and a substrate has gasses, including silane, ammonia, and hydrogen supplied to the reaction chamber. The gases are brought into contact with the catalyzer and then with the substrate to deposit a silicon nitride film.

Owner:MITSUBISHI ELECTRIC CORP

Electrostatic chuck, thin film manufacturing apparatus having the same, thin film manufacturing method, and substrate surface treatment method

InactiveCN1932074ASemiconductor/solid-state device manufacturingChemical vapor deposition coatingManufactured apparatusSilicon membrane

A difficulty has been given, that is, in a condition that an electrostatic chuck having an oxide layer as a dielectric layer is set in catalytic chemical vapor deposition apparatus, as a silicon thin film is repeatedly deposited on a workpiece held by the electrostatic chuck, adsorbing power of the electrostatic chuck is gradually decreased, and finally the chuck does not adsorb a substrate at all. Thus, a dielectric layer on a surface of the electrostatic chuck is covered with an insulating film containing silicon nitride or silicon oxide. Thus, since damage to a chuck surface can be prevented, the damage being due to hydrogen radicals generated during depositing the silicon film by the catalytic chemical vapor deposition apparatus, even if the silicon film is repeatedly deposited, power for adsorbing the substrate is not decreased, and consequently substrate temperature is stabilized during depositing the silicon film.

Owner:SEIKO INSTR INC

Graphene carbon nanotube composite high-thermal-conductivity film and preparation method thereof

InactiveCN111908452AImprove thermal conductivityImprove conductivitySemiconductor/solid-state device detailsSolid-state devicesGraphene nanoplateletNanotube

The invention discloses a preparation method of a graphene / carbon nanotube composite heat-conducting film, which mainly comprises the following steps: preparing graphene oxide (GO) nanosheet powder byan improved hummers method, reducing the GO, growing carbon nanotubes by a catalytic chemical vapor deposition method, carrying out high-pressure homogeneous mixing on reduced graphene oxide (rGO) and carbon nanotubes (CNTs), adding an adhesive for coating the film, performing drying film forming, and calendering the film. The preparation process of the graphene / carbon nanotube composite high-thermal-conductivity film is simple, the film thickness is controllable, the in-plane thermal conductivity is up to 1900 w / k.m at 323k, and the thermal conductivity in the vertical direction is 76 w / k.m.

Owner:深圳市展旺新材料科技有限公司

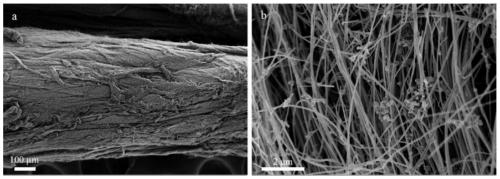

Carbon nanotube-carbon fiber multi-scale reinforcement as well as preparation method and application thereof

The invention discloses a process scheme for growing a carbon nanotube on the surface of a continuous carbon fiber tow through a catalytic chemical vapor deposition method by using a multi-element catalytic system containing a copper component. An implementation method disclosed by the invention comprises the following steps of preparing a catalyst precursor solution taking absolute ethyl alcoholas a solvent by taking copper nitrate and ferric nitrate as necessary options and cobalt nitrate and nickel nitrate as optional options, then feeding surface-activated carbon fibers into the solution,performing dipping for 10-15 minutes, and then performing drying in a drying oven; and feeding the carbon fiber tow with the surface loaded with a catalyst precursor into a tubular furnace, and respectively carrying out reduction of a catalyst and CCVD growth of the carbon nanotube to obtain carbon nanotube-carbon fiber multi-scale reinforcement. According to the method, the carbon nanotube-carbon fiber multi-scale reinforcement with more uniform carbon nanotube distribution and more regular carbon atom arrangement can be obtained, and the interface bonding capability of a carbon fiber composite material can be significantly improved.

Owner:SHANDONG UNIV

Electrostatic chuck, thin film manufacturing apparatus having the same, thin film manufacturing method, and substrate surface treatment method

InactiveUS20070062648A1Increase powerSemiconductor/solid-state device manufacturingChemical vapor deposition coatingManufactured apparatusSilicon oxide

A difficulty has been given, that is, in a condition that an electrostatic chuck having an oxide layer as a dielectric layer is set in catalytic chemical vapor deposition apparatus, as a silicon thin film is repeatedly deposited on a workpiece held by the electrostatic chuck, adsorbing power of the electrostatic chuck is gradually decreased, and finally the chuck does not adsorb a substrate at all. Thus, a dielectric layer on a surface of the electrostatic chuck is covered with an insulating film containing silicon nitride or silicon oxide. Thus, since damage to a chuck surface can be prevented, the damage being due to hydrogen radicals generated during depositing the silicon film by the catalytic chemical vapor deposition apparatus, even if the silicon film is repeatedly deposited, power for adsorbing the substrate is not decreased, and consequently substrate temperature is stabilized during depositing the silicon film.

Owner:SEIKO INSTR INC

Self-cleaning catalytic chemical vapor deposition apparatus and cleaning method thereof

InactiveUS20120145184A1Suppresses the corrosion-induced degradationLow costSemiconductor/solid-state device manufacturingElectrostatic cleaningElectrical conductorGas phase

A self-cleaning catalytic chemical vapor deposition apparatus which suppresses the corrosion-induced degradation of a catalytic body by a cleaning gas without heating a catalytic body to not less than 2000° C. and permits practical cleaning rates and good cleaning at low cost. Conductors supply a constant current to a catalytic body within a reaction chamber from a heating power supply. Terminals of the heating power supply are electrically insulated from the reaction chamber. A cleaning gas containing halogen elements is introduced into the evacuated reaction chamber. The catalytic body is heated by the heating power supply. An active species generated by this heating reacts with an adhering film adhered to the interior of the reaction chamber, which is removed. During this removal, a DC bias voltage with appropriate polarity and appropriate value is applied from a constant-voltage power supply to the conductor of the heating power supply.

Owner:ULVAC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com